Page 1

LT-352

SERVICE HANDBOOK

Jul. 1999

Ver. 1.0

KONICA CORPORATION

TECHNOLOGY SUPPORT CENTER

TOKYO JAPAN

Page 2

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS................

Refer to the 7065 service handbook on page C-1

1. LT-352

LT-352 PRODUCT SPECIFICATIONS ...................... 1-1

CENTER CROSS-SECTIONAL DRAWING............... 1-2

DRIVE SECTION ....................................................... 1-3

PAPER FEED SECTION............................................ 1-5

[1] Composition ................................................... 1-5

[2] Mechanisms ................................................... 1-5

[3] Disassembly and Reassembly ....................... 1-6

[4] Centering adjustment of LT-352 .................. 1-10

2. DIAGRAMS

LT-352 ELECTRICAL PARTS LAYOUT DRAWING .. 2-1

LT-352 CONNECTOR LAYOUT DRAWING .............. 2-2

LT-352 OVERALL WIRING DIAGRAM ...................... 2-3

CONTENTS

This section covers the structure, functions, operation and method of

disassembling and assembling the machine.

Observe the following precautions when performing disassembly and

assembly work.

1. Be sure to unplug the power cord before working on the machine.

2. Perform all reassembly work by reversing the order in which the

component was disassembled, unless otherwise specified.

3. Do not lose small parts (screws, etc.) or insert them in the wrong

place.

4. Install all parts completely before operating the machine.

5. Do not loosen the screws indicated as disallowed for removal.

Page 3

1

LT-352

Page 4

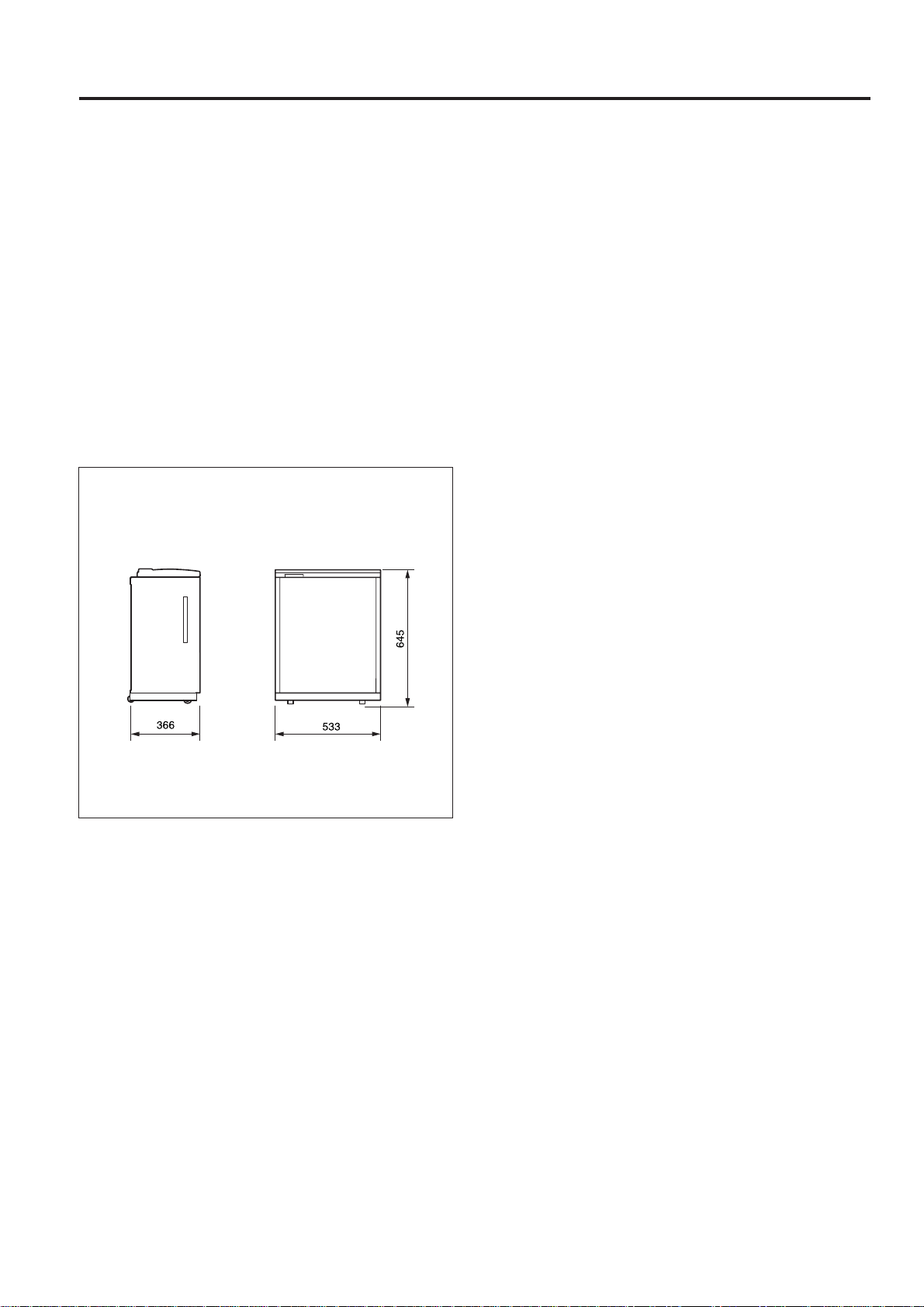

LT-352 PRODUCT SPECIFICATIONS

LT-352

1. Type

Type: Large capacity paper feed tray mounted on side of

the main body.

2. Functions

Paper size: A4, 8.5" x 11"

Kind of paper: High quality paper (60 g/m

Maximum capacity: 3500 sheets (80 g/m

2

)

2

- 90 g/m2)

3. Machine Data

Power supply: 5, 24 and 40 VDC (Supplied from the

main body.)

Maximum power consumption

Weight: Approx. 26.6 kg

Machine dimensions

: 82 VA

: W 366 x D 553 x H 645

(Unit = mm)

4. Maintenance

Maintenance: Same as the main body

Machine life: Same as the main body

5. Operating Environment

Temperature: 10 to 33°C

Humidity: 10 to 80%RH

Note: The contents of this manual may be changed without

prior notice for the sake of improvement.

1 - 1

Page 5

LT-352

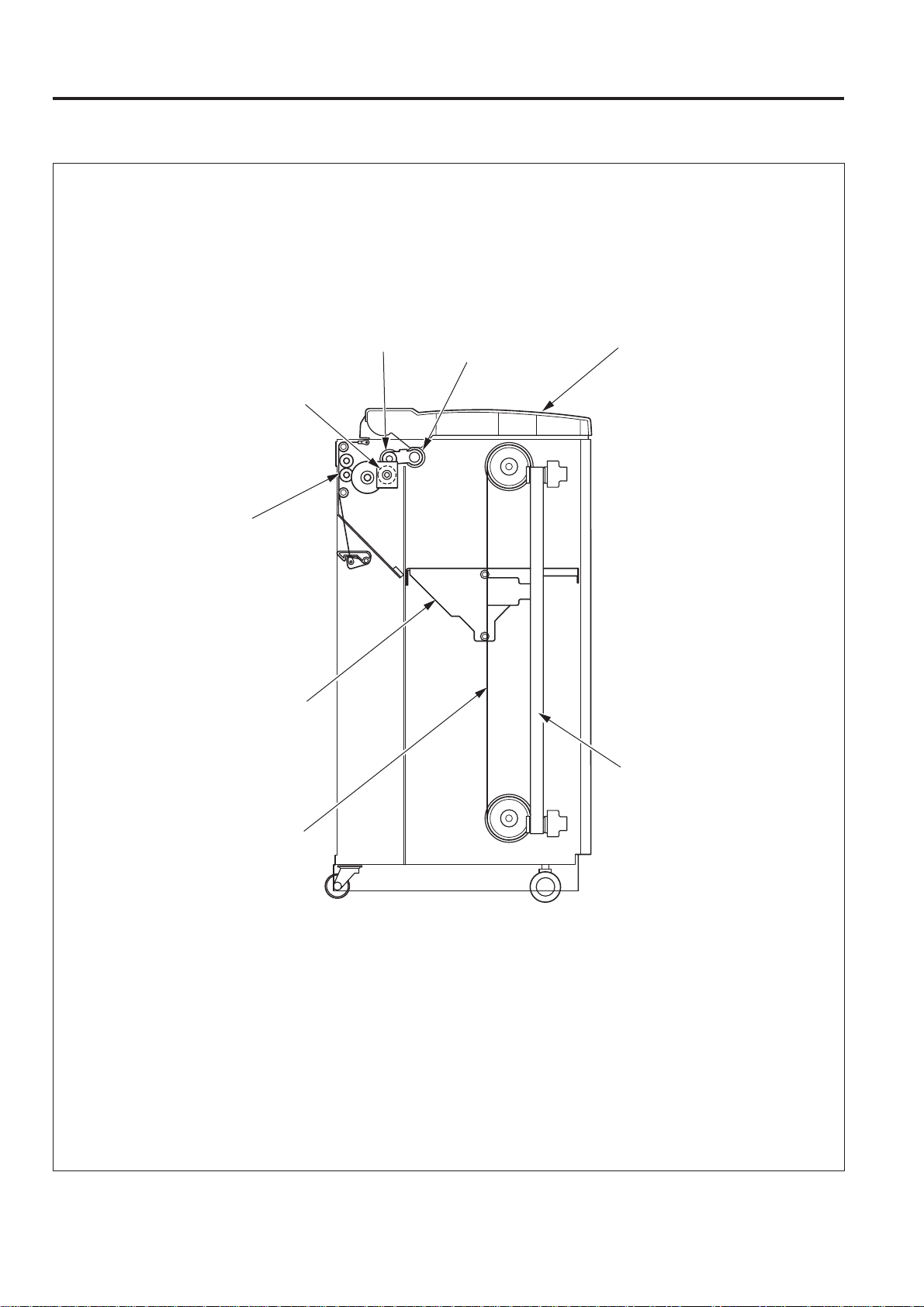

CENTER CROSS-SECTIONAL DRAWING

Double feed

prevention roller

Conveyance roller

Up/down plate

Feed roller

Paper feed roller

Upper cover

Remaining paper

indication belt

Up/down belt

1 - 2

Page 6

DRIVE SECTION

<Conveyance drive section>

Conveyance roller

LT-352

Paper feed motor

(M800)

Double feed prevention roller

Paper feed clutch

(MC800)

Feed roller

Paper feed roller

1 - 3

Page 7

LT-352

<Stacker drive section>

Up/down belt

Up/down plate

Remaining paper

indication belt

Up/down motor

Up/down shaft

1 - 4

Page 8

PAPER FEED SECTION

[1] Composition

Down button

LT-352

LT upper limit detection PS (PS801)

Paper feed roller unit

Up/down plate (Tray)

[2] Mechanisms

Mechanism Method

Paper lifting Belt drive

*1

Paper feed 1st paper feed roller

No paper detection PS800

Paper size detection None

Remaining paper indicator

*2

Paper conveyance Roller conveyance

Paper size A4, 8.5" x 11"

*1: Paper lifting

a. Lifting operation of the up/down plate

The up/down plate is lifted by belt drive.

When the upper cover is closed, the up/down plate

drive motor (M801) rotates, causing the up/down plate

coupled to the up/down drive belt to raise.

Linked to up/down plate

LT no paper detection PS (PS800)

b. Lowering operation of the up/down plate

When the upper cover is opened, the up/down plate

automatically falls 100 mm.

Subsequently, each time the down button is pressed,

the up/down plate falls a distance equal to the height of

the loaded paper.

*2: Remaining paper indicator

The amount of paper remaining in the paper tray can

be judged from the state of the indicator belt that is

visible from the front slit.

The indicator belt is directly linked to the up/down

motion of the up/down plate.

1 - 5

Page 9

LT-352

[3] Disassembly and Reassembly

1. Removing and Re-installing the Paper Feed roller

Unit

a. Procedure

(1) Open the upper cover.

(2) Remove the spring from the paper feed roller unit.

Upper cover

Spring

Paper feed

roller unit

2. Replacing the paper feed roller Rubber and the Feed

roller Rubber

a. Procedure

(1) Remove the paper feed roller unit.

(2) Remove the three stop rings and the three bearings on

the paper feed roller unit, and also the paper feed

reference actuator and the two shafts, then remove

each roller.

(3) Remove the rubber (feed rubber/A and double feed

prevention rubber) from each roller.

Paper feed

drive belt

Bearing

Feed rubber/A

Double feed

prevention

rubber

Paint mark

Feed roller

Blue mark

Stop ring

Bearing

Stop ring

(3) Remove the two stop rings and the two bearings, then

remove the paper feed roller unit.

Paper feed

roller unit

Bearing

Stop ring

Bearing

Stop ring

(4) Re-install the paper feed roller in the opposite se-

quence to removal.

Paper feed roller

Blue mark

Bearing

Stop ring

Paper feed

reference actuator

(4) Re-install the above parts in the opposite sequence to

removal.

Caution: Ensure that the mounting direction of the rubber and

rollers are correct.

1 - 6

Page 10

LT-352

3. Replacing the Double feed prevention roller rubber

a. Procedure

(1) Remove the three set screws, then remove the paper

feed cover (left).

Paper feed

cover (left)

Set screws

(2) Remove the two set screws, then remove the double

feed prevention roller unit. (When re-installing the unit,

align the drive coupling pin, then insert the two projections on the unit into the square holes before fixing the

two set screws.

(3) Remove the two stop rings, then pull out the shaft and

remove the double feed prevention roller together with

the paper feed reversal gear.

Paint mark

Double feed

prevention roller

(rubber)

Paper feed

Stop ring

Shaft

reversal gear

Stop ring

(4) Remove the double feed prevention rubber from the

double feed prevention roller.

(5) Re-install the above parts in the opposite sequence to

removal.

Caution: Ensure that the mounting direction of the rubber is

correct.

Double feed prevention

roller unit

Set screw

Set screw

1 - 7

Page 11

LT-352

4. Replacing the LT Clutch

a. Procedure

(1) Remove the four set screws, then remove the right

side cover.

Set screw

Set

screw

Right side cover

Set screw

Set screw

(2) Remove the four set screws, then remove the front

cover.

(3) Remove the two set screws, then remove the upper

cover.

Set screw

<Front>

Set screw

<Rear>

(4) Remove the four set screws, then remove the paper

feed cover (upper).

(5) Remove the three set screws, then remove the paper

feed cover (left).

Set screw

Set screw

Set screw

Front cover

Set screw

Paper feed cover

(upper)

Set screws

Set screws

Paper feed

cover (left)

1 - 8

Page 12

LT-352

(6) Disconnect the three relay connectors. (8) Remove the two set screws fixing the clutch cover from

the rear.

Relay connector (Large)

Relay

connector

(White)

Relay

connector

(Black)

(7) Remove the two E rings, then remove the two bear-

ings.

Set screw

Set screw

(9) Remove the hex socket screw, then remove LT clutch/2.

LT clutch/2 projection

Bearing

Bearing

Hex socket

screw

E rings

C ring

(10)Re-install the above parts in the opposite sequence to

removal.

Note: When re-installing the LT clutch, ensure that the projec-

tion is at the top.

1 - 9

Page 13

LT-352

[4] Centering adjustment of LT-352

Upper cover

Step

1

2

3

4

5

Set screws

Operation

Open the upper cover.

Slacken the side guide set screws (four each) at the

front and rear of the tray.

Move each side guide back and forth until the miscentering of the paper is within the standard value

range. (Move both guides by the same amount,

using the stamped marks on the guide reinforcing

plates (front/rear) and the LCT base plate below

them as a rough guide.)

Tighten the eight adjustment screws firmly, and

perform the centering adjustment for the 36 mode.

Repeat 1~4 until the miscentering value is within

the standard.

Set screws

1 - 10

Page 14

2

DIAGRAMS

Page 15

LT-352 ELECTRICAL PARTS LAYOUT DRAWING

LT-352

12

3

9

8

14

11

2

1

7

10

5

4

13

6

1. Switch/Sensor

1 PS800 LT no paper detection PS

2 PS801 LT upper limit detection PS

3 PS802 LT pre try PS

4 PS803 LT conveyance PS

5 PS804 LT release PS

6 PS805 LT lower limit detection PS

7 PS806 LT pre feed PS

8 SW800 LT down SW

9 SW801 LT cover open/close SW

2. Load

10 M800 LT paper feed Motor

11 M801 LT up/down Motor

12 MC800 LT 1st paper feed MC

3. Others

13 LT CB LT control board

14 HTR Heater

2 - 1

Page 16

LT-352

LT-352 CONNECTOR LAYOUT DRAWING

821(W:6 PIN)

811(B:3 PIN)

822(W:2 PIN)

823(BK:2 PIN)

812(R:3 PIN)

824(BK:2 PIN)

813(W:3 PIN)

826(BK:2 PIN)

816(BK:3 PIN)

816(W:3 PIN)

830(W:2 PIN)

810(W:3 PIN)

815(W:3 PIN)

820(W:11 PIN)

827(W:11 PIN)

814(W:3 PIN)

802(W:13 PIN)

803(W:18 PIN)

804(W:5 PIN)

800(W:5 PIN)

801(W:16 PIN)

391(W:2 PIN)

391(W:2 PIN)

127(BK:10 PIN)

126(BK:10 PIN)

2 - 2

831(W:2 PIN)

Page 17

LT-352 OVERALL WIRING DIAGRAM

LT DB

5V DC

SGND

M800 LD

M800 CONT

M800 MODE

M800 CLK

M800 FG

PGND

PGND

40V DC

40V DC

24V DC1

MC800 DRIVE

SGND

PS800

5V DC

PS801

PS802

SGND

PS803

5V DC

827-1803-A1

803-A2

803-A3

H

803-A4

H

803-A5

803-A6

P

803-A7

803-A8

803-A9

803-B8

803-B9

803-B1

803-B2

H

802-1

802-2

L

802-3

802-4

802-5

H

802-6

H

802-7

802-8

820-8 821-3 823-1

820-9

820-1

820-2

820-3

820-4

820-5

821-4 823-2

827-2

827-6

827-3

827-5

827-4

827-7

827-8

827-9

827-10

827-11

810-1

810-2

810-3

811-1

811-2

811-3

812-1

812-2

812-3

813-1

813-2

813-3

M800

MC800

PS800

PS801

PS802

PS803

LCT

PAPER

FEED

MOTOR

LCT 1st

PAPER FEED

CLUTCH

LCT

NO PAPER

SENSOR

LCT PAPER

UPPER LIMIT

SENSOR

LCT

PRE W

SENSOR

LCT

CONVEYANCE

SENSOR

40V DC

24V DC

PGND

5V DC

SGND

M800 CLK

M800 CONT

M801 CONT

PS806

MC800 CONT

M801 F/R

AC (H)

AC (N)

MAIN BODY

814-1

814-2

PS804

814-3

SW801

R

B

LCT

RELEASE

SENSOR

LCT COVER

DETECTOR

LCT TRAY

UP/DOWN

M801

MOTOR

816-1

816-2

816-3

PS805

SW800

LCT TRAY

LOWER LIMIT

SENSOR

LCT TRAY

DOWN

SWITCH

815-1

815-2

815-3

PS806

LCT

PRE-FEED

SENSOR

HRT

802-9

802-10

802-11

803-B3

803-B7

H

804-4

804-5

804-1

804-2

804-3

802-12

802-13

H

820-10 821-5 824-1

820-11 821-6 824-2

826-1

826-2

820-6 821-1 822-1

820-7 821-2 822-2

816-1

816-2

816-3

LCT

HEATER

126-1

88-4

126-2

99-1

126-3

88-2

126-4

140-A1

126-5

140-A2

126-6

140-A3

P

H

L

H

H

140-A4

140-A5

140-A6

140-A8

140-A9

140-B1

140-B2

140-B3

140-B4

140-B5

140-B6

140-B7

140-B8

140-B9

752-1

752-2

126-7

126-8

126-9

126-10

127-1

127-2

127-3

127-4

127-5

127-6

127-7

127-8

127-9

127-10

127-11

391-1

391-2

BK

W

391-1

391-2

800-1

800-2

800-3

800-4

800-5

801-A1

801-A2

801-A3

801-A4

801-A5 NC140-B10

801-A6

801-A7

801-A8

801-B1

801-B2

801-B3

801-B4

801-B5

801-B6

801-B7

801-B8

BK

W

M800 PLL

H

PS800

L

PS801

L

L

PS802

H

PS803

L

LT352 ADD (NC)

SW801

L

PS804

L

H

SW800

PS805

H

830-1

830-2

831-1

831-2

SGND

PS804

5V DC

24V DC

SW801

M801 DRIVE 1

M801 DRIVE 2

SGND

PS805

5V DC

SGND

SW800

2 - 3

Loading...

Loading...