Page 1

5

SERVICE

Page 2

Main Precautions for Maintenance

1. Points to be confirmed before maintenance

Before starting maintenance, ask a user and collect

information about troubles occurred on the machine

before the maintenance and the conditions of the machine to grasp key points for the maintenance.

2. Copy sample

Be sure to make copy samples at the start and the end

of maintenance for checking images.

3. Drum

1) Never expose the drum to the sunlight. Be also

careful not to expose a drum to indoor light as far as

possible.

When a drum unit or a drum is out of the machine,

never fail to cover it with a drum cover.

2) When replacing a drum or a cleaning blade, refer to

Item of mounting/dismounting of a cleaning blade

for doing a replacement work.

4. After replacing a drum, be sure to reset a drum counter

before image adjustment. After replacing developer, L

detection adjustment must be conducted also.

5. When maintenance is completed, be sure to reset the

PM counter. Incidentally, a development counter is reset

automatically in the course of L detection adjustment.

6. When replacing a toner cartridge, wait until the toner

supply LED on the operation panel flashes before the

replacement.

Caution: Turn the main switch off and pull out the

power plug without fail before the work of

maintenance.

Page 3

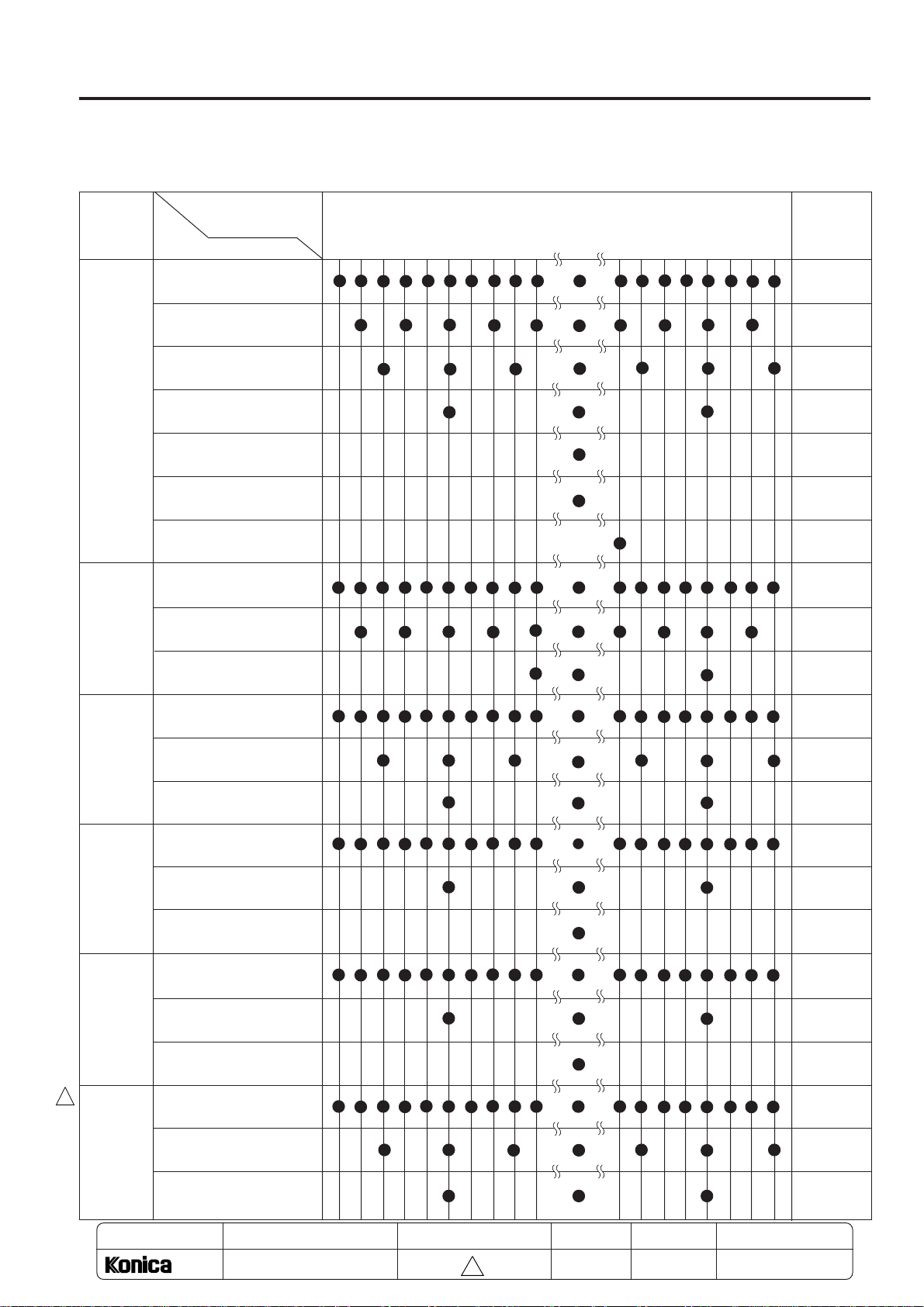

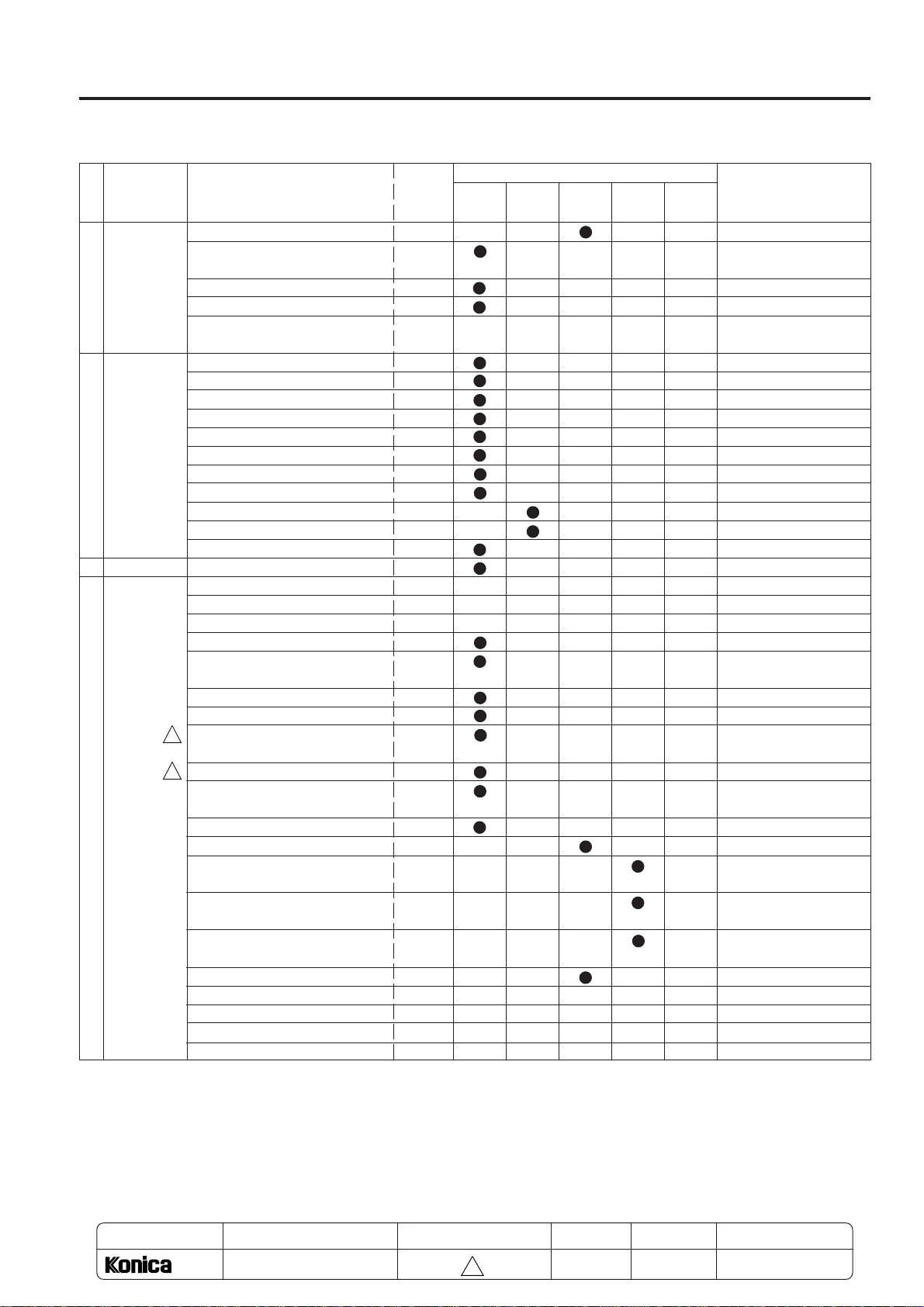

SERVICE SCHEDULE

[1] Service Schedule

SERVICE

Classifica-

Main body

(DF-312)

(LT-352)

(FS-106)

(FS-108BM)

2

(PI-108)

tion

RADF

LCT

FNS

FNS

PI

Number of copies

(unit: 10,000)

Service item (cycles)

Maintenance

(Every 150,000 copies)

Periodic check (I)

(Every 300,000 copies)

Periodic check (II)

(Every 450,000 copies)

Periodic check (III)

(Every 900,000 copies)

Periodic check (IV)

(Every 1,800,000 copies)

Periodic check (V)

(Every 3,000,000 copies)

Periodic check (VI)

(Every 3,900,000 copies)

Maintenance

(Every 150,000 copies)

Periodic check (I)

(Every 300,000 copies)

Periodic check (II)

(Every 1,500,000 copies)

Maintenance

(Every 150,000 copies)

Periodic check (I)

(Every 450,000 copies)

Periodic check (II)

(Every 900,000 copies)

Maintenance

(Every 150,000 copies)

Periodic check (I)

(Every 900,000 copies)

Periodic check (II)

(Every 2,550,000 copies)

Maintenance

(Every 150,000 copies)

Periodic check (I)

(Every 900,000 copies)

Periodic check (II)

(Every 2,550,000 copies)

Maintenance

(Every 150,000 copies)

Periodic check (I)

(Every 450,000 copies)

Periodic check (II)

(Every 900,000 copies)

Guarantee period (5 years or 5,000,000 copies)

15 30 45 60 75 90 105 120 135150 390 405 420 435 450 465 480 495

Service

times

33 times

16 times

11 times

5 times

2 times

1 time

1 time

33 times

16 times

3 times

33 times

11 times

5 times

33 times

5 times

1 time

33 times

5 times

1 time

33 times

11 times

5 times

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 1

2

DATE

Jan.2000

PAGE

5-1

METHOD

REPLACEMENT

Page 4

SERVICE

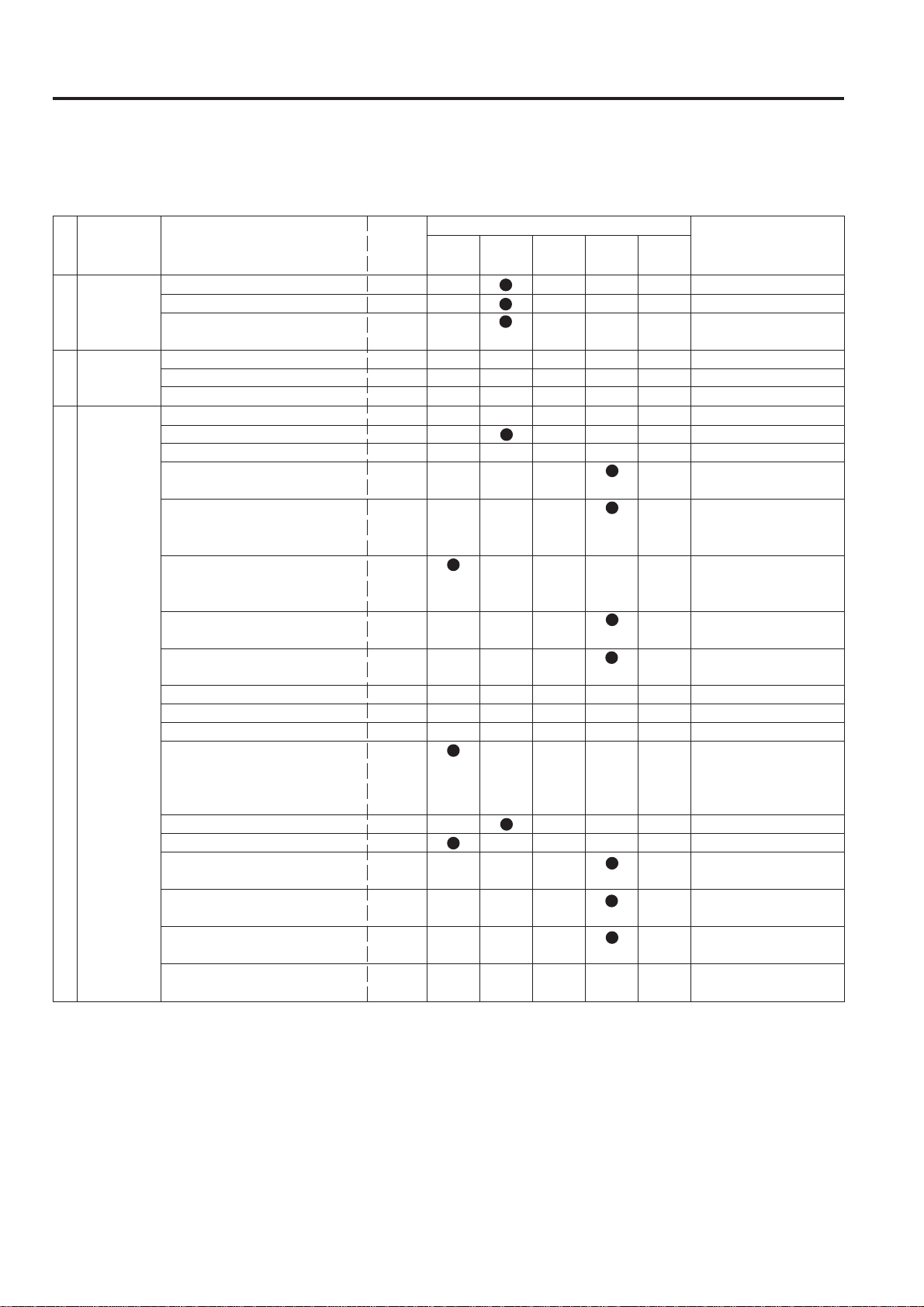

[2] Maintenance Items

1. Main body (Every 150,000 copies)

Classification

No.

Preparation

1

Fixing unit

2

Drum unit

3

Service item

(1) Image check

(2) Kit contents check

(3)

36 - 40 (Check of adjustment value,

Dmax and γ correction error)

(1) Fixing unit removing

(2) Jam clearance door removing

(3) Upper cover removing

(1) Drum unit removing

(2) Drum unit check

(3) Charging corona unit removing

(4)

Charging control plate replacement

25SA2508*

(5) Charging wire replacement

(Removing & installing)

55FA2501*

(6) Charging corona unit

(Back plate and its around, and

PCL)

(7) Charging wire cleaning block/B

(Upper) 25SA-254*

(8) Charging cleaning block/A

(Lower) 25SA-253*

(9) Developing unit removing

(10) Cleaning blade removing

(11) Drum removing

(12) Drum cartridge/Developing unit

bottom plate/Toner control sen-

sor/Separating claw

(13) Recycle pipe check

(14) Toner collecting screw/A

(15) Toner guide roller replacement

55TA-204*

(16) Cleaner idler gear replacement

55FA7707*

(17) Cleaning blade

25SA-206*

(18) Cleaning blade and upper plate

installing

Number

of parts

replaced

1

1

1

1

1

1

1

Cleaning

Implementation classification

Check

Lubrication

Replacement

Supply

Material used

Tools used

Drum cleaner & Waste rag

Blower brush

Blower brush & Cleaning pad

* Drum cleaner (used only

when cleaning the toner

control sensor)

Blower brush & Cleaning pad

5 - 2

Page 5

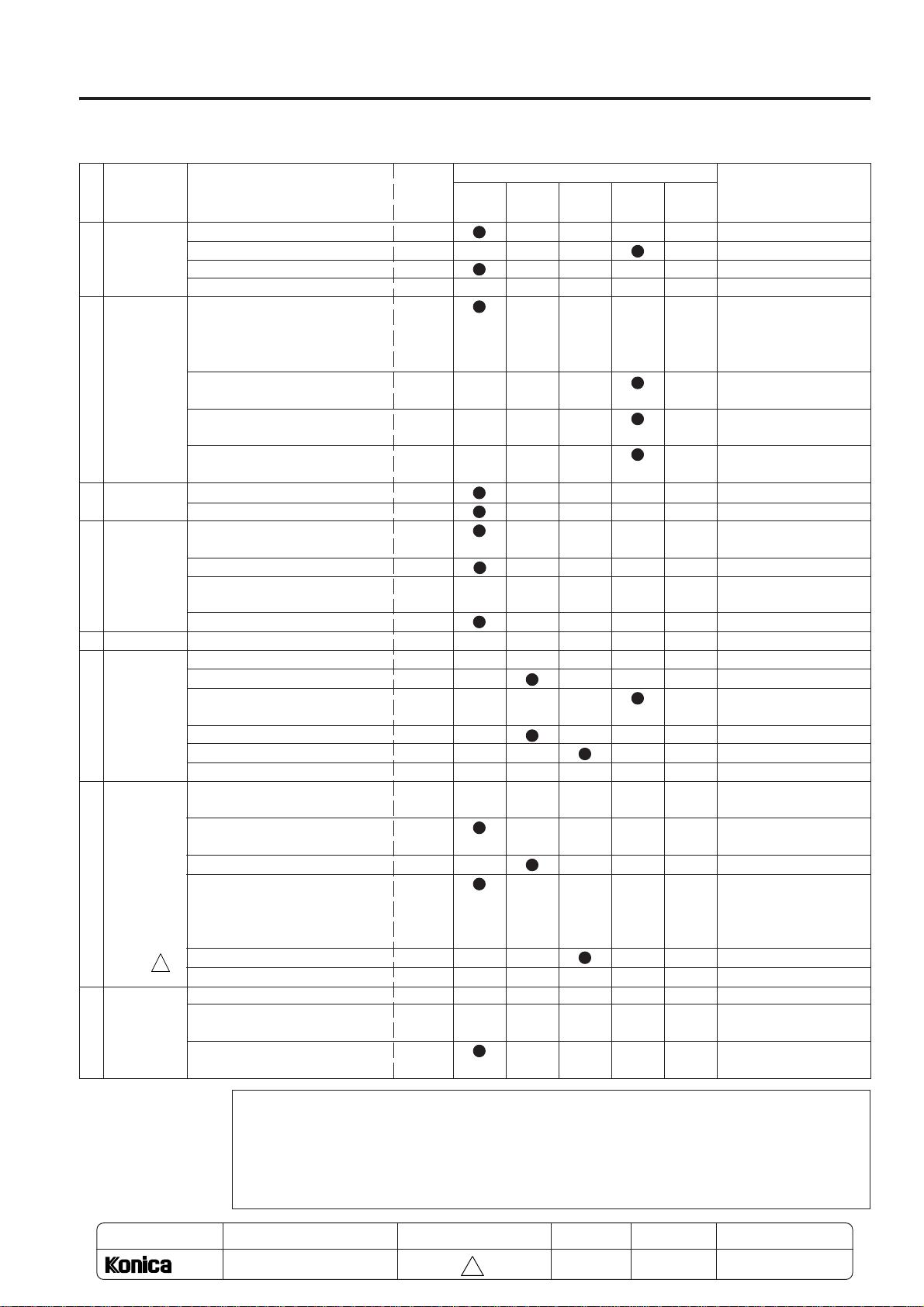

SERVICE

Classification

No.

Developing

4

unit

Transfer/

5

Separation

corona unit

(Note 1)

Machine

6

inside

2nd paper

7

feed unit

Drum unit

8

Drive unit &

9

Filter

Reversal

10

paper exit

& ADU

Paper feed

11

unit (Main

body/LCT)

Service item

(1) Developing bias intercept

(2) Developer

(3) Developing unit

(4) Developing unit installation

(1)

Transfer/Separation corona unit

(Front & rear block/Guide rail/Separating bridge/Enter guide plate/

Spark arrestor sheet/Back plate)

removing & installing

(2) Discharging wire

(3) Transfer cleaning block/upper

assembly 25SA-263*

(4) Separation cleaning block/upper

assembly 25SA-264*

(1) Upper part of conveyance unit

(2) Conveyance belt

(1) Paper dust removing brush

(Removing)

(2) 2nd paper feed roller

(3) Paper dust removing brush in-

stalling

(4)

Transfer synchronization lamp (TSL)

(1) Drum unit installing

(1) Back plate removing

(2) Developing suction filter check

(3) Filter K

(4) Timing belt check

(5) Drive gear oiling

(6) Back plate installing

(1) Left side external/reversal pa-

per exit unit removing

(2) Reversal paper exit rollers (Up-

per/Middle/Lower)

(3) Timing belt check

(4) Sensors cleaning

Reversal paper exit section (4

position) ADU horizontal con-

veyance section (6 position)

(5)

2

Gears oiling (drive / introduction section)

{

(6)

Reversal paper exit unit / Left side panel installing

Paper feed unit

(1) Upper right side plate and unit

removing

(2) Main body bottom plate and

around paper feed unit

25SA2612*

55FA7301*

Number

of parts

replaced

1

3

1

1

1

Cleaning

Implementation classification

Check

Lubrication

Replacement

Supply

Material used

Tools used

Blower brush & Cleaning pad

Blower brush & Cleaning pad

Blower brush & Cleaning pad

/Cotton swab/Drum cleaner

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Cleaning pad & Blower brush

Drum cleaner & Cleaning pad

Blower brush

Plus guard No. 2

Drum cleaner & Cleaning pad

Blower brush

Plus guard No. 2

Blower brush & Cleaning pad

MODEL

7065

(Note 1)

- Do not remove the entrance guide plate and rollers of transfer separation corona when cleaning them.

- Basically, use Blower brush to clean roller parts. Use cleaning pad and drum cleaner only when the foreign matters

or dust on the roller cannot be removed. In that case, do not press the roller hard. Wipe it gently.

- As to the cleaning of spark arrestor sheet, clean from the reverse side of the guide plate, using cotton swab.

Make sure to wipe gently, try not to press hard. It is possible to use drum cleaner when it is soiled heavily.

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 3

2

DATE

Jan.2000

PAGE

5-3

METHOD

REPLACEMENT

Page 6

SERVICE

Classification

No.

Paper feed

11

unit (Main

body/LCT)

Service item

(3)

Sensors(5 positions of upper tray)

2

(4) Gears (upper tray) oiling

(5) Conveyance/driven roller

(Upper tray)

(6) Swing/feed roller (3 positions in-

cluding by-pass tray)

(7) Double feed prevention roller (by-

pass tray)

(Removing & Cleaning & Installing)

(8) Double feed prevention roller (1st

tray of main body)

(Cassette guide rail removing/

Double feed prevention roller

cleaning)

(9) Cassette guide rail installing

(10) Double feed prevention roller

(2nd tray of main body)

(Cassette guide rail removing/

Double feed prevention roller

cleaning)

(11) Cassette guide rail installing

(12) Unit (cassette) and upper right

side plate installing

1000 LCT paper feed unit

(13) Lower right plate and unit re-

moving (LCT)

(14) Main body bottom plate & around

paper feed unit

(15) Sensors(4 positions of lower tray)

2

(16) Gears (lower)

(17) Conveyance Driven roller

(Lower)

(18) Swing/feed roller

(1 position)

(19) Double feed prevention roller

(Cleaning after opening open/

close cover)

(20) Unit (LCT) and lower right side

plate installing

LCT horizontal conveyance unit

(21) Horizontal conveyance unit re-

moving

(22) Sensors

Number

of parts

replaced

Cleaning

Implementation classification

Check

Lubrication

Replacement

Supply

Material used

Tools used

Blower brush

Plus guard No. 2

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Blower brush & Cleaning pad

Blower brush

Plus guard No. 2

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Blower brush

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 4

2

DATE

Jan.2000

PAGE

5-4

METHOD

REPLACEMENT

Page 7

SERVICE

Classification

No.

Paper feed

11

unit (Main

body/LCT)

Reading

12

section

Writing section

13

Fixing unit

14

Service item

(23) Gears

(24) Conveyance roller (Upper and

Lower)

(25) Swing/feed roller

(26) Double feed prevention roller

(27) Horizontal conveyance unit in-

stalling

(1) Platen glass/Slit glass

(2) Exposure lamp

(3) Reflection mirror

(4) Lens

(5) 1st, 2nd and 3rd mirror

(6) White reference cover glass

(7) APS sensor

(8) Photo interrupter

(9) Supply cord / Timing belt

(10) Wire tension

(11) Optics guide rail

(1) Dust proof glass (Outside)

(1) Oil pad removing

(2) Impregnated roller removing

(3) Fixing cleaning roller removing

(4) Fixing roller/Upper

(5) Fixing roller/Lower (Paper exit

guide plate removing)

(6) Fixing claw/Upper & Lower

(7) Paper exit roller

(8) Exit paper conveyance roller

2

(Right)/Guide rib

(9) Decurler belt

2

(10) Fixing entrance and exit guide

plate

(11) Fixing temperature sensor/2

(12) Fixing gear oiling

(13) Fixing cleaning roller

(+ installing) 25SA5320*

(14) Oil impregnated roller

(+ installing) 55FA5313*

(15) Oil pad (+ installing)

55FA-535*

(16) Insulating sleeve oiling

(17) Paper exit guide plate installing

(18) Fixing upper cover installing

(19) Jam clearance door installing

(20) Fixing unit installing

Number

of parts

replaced

1

1

1

Cleaning

Implementation classification

Check

Lubrication

Replacement

Supply

Material used

Tools used

Plus guard No. 2

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Blower brush

Cleaning pad

Blower brush & Cleaning pad

Blower brush & Cleaning pad

Drum cleaner & Cleaning pad

Blower brush

Blower brush

Cleaning pad

Blower brush & Cleaning pad

Roller cleaner & Cleaning pad

Roller cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Blower brush & Paper

Molytherm grease

Tri-flow

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 5

2

DATE

Jan.2000

PAGE

5-5

METHOD

REPLACEMENT

Page 8

SERVICE

Classification

No.

15

Final check

(1) Toner supply

(2) L detection (with new developer)

(3) W.U.T measure and check

(4)

(5) Copy sample check

(6) PM counter reset

(7) Drum counter reset

(8) Leakage breaker reset

(9)

Service item

47 - 95

Image check after changing

consumables

47 - 90

47 - 91

Machine surroundings, Externals

2. RADF [DF-312] (Every 150,000 copies)

Classification

No.

Paper feed

1

section

Conveyance

2

section

(1) Paper feed roller

(2) Separation roller

(3) Double feed prevention pad

(4) Paper dust removing pad

(1) Regist sensor

(2) Regist sensor mirror

(3) Original conveyance sensor

(4) Original conveyance sensor

(5) Original reversing sensor

(6) Original reversing sensor mirror

Service item

reflection part

Number

of parts

replaced

Number

of parts

replaced

Cleaning

Cleaning

Implementation classification

Check

Implementation classification

Check

Lubrication

Lubrication

Replacement

Replacement

Supply

( )

Supply

Material used

Tools used

Drum counter reset at 2PM

(300kc)

Drum cleaner & Cleaning pad

Material used

Tools used

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Blower brush

Cleaning pad & Blower brush

Cleaning pad & Blower brush

Cleaning pad & Blower brush

Cleaning pad & Blower brush

Cleaning pad & Blower brush

Cleaning pad & Blower brush

3. LCT [LT-352] (Every 150,000 copies)

No.

Classification

1

Preparation

2

Inside of

machine

3

Final check

(1) Paper feeding check

(1) Sensors

(2) Gears

(3) Conveyance roller/Driven roller

(4) Swing roller

(5) Feed roller

(6) Double feed prevention roller

(1) Paper feeding check

(2) Externals

Service item

Number

of parts

replaced

5 - 6

Implementation classification

Clean-

Check Lubrica-

ing

tion

Replace-

ment

Supply

Material used

Tools used

Blower brush

Plus guard No.2

Dram cleaner /

Cleaning Pad

Dram cleaner /

Cleaning Pad

Dram cleaner /

Cleaning Pad

Dram cleaner /

Cleaning Pad

Dram cleaner /

Cleaning Pad

Page 9

4. FNS [FS-106] (Every 150,000 copies)

2

Classification

No.

Preparation

1

Conveyance

2

unit

Paper exit unit

3

Drive unit

4

Stapler unit

5

Final check

6

Service item

(1) Paper through check

(1) Conveyance roller

(2) Swing roller

(1) Paper exit roller/A

(1) Main drive unit

(2) Tray up and down unit

(3) Shift drive unit

(4) Paper exit drive unit

(5) Staple unit

(1) Staple cartridge

(1) Paper through check

(2) Exterior

12QR5065*

122H4825*

*1

*1

*1

*1

*1

*2

12QRK001*

Number

of parts

replaced

1

10

2

Cleaning

Implementation classification

Check

*1: If abnormal sound is heard due to insufficient oil, apply oil (Plus guard No.2).

*2: This work confirms if the staple is exchanged by CE. (5,000 staples/1 cartridge)

Lubrication

( )

( )

( )

( )

( )

Replacement

( )

Supply

SERVICE

Material used

Tools used

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

5. FNS [FS-108BM] (Every 150,000 copies)

2

No.

Classification

1

Preparation

2

Conveyance

unit

Paper exit unit

3

Drive unit

4

Folding

5

section

Stapler unit

6

Final check

7

Service item

(1) Paper through check

(1) Conveyance roller

(2) roller

(1) Paper exit roller/A

(1) Main drive unit

(2) Tray up and down unit

(3) Shift drive unit

(4) Paper exit drive unit

(5) Staple unit

(6) Fold unit

(1) Flat belt

(2) Folding roller

(3) Pressurized roller

(1) Staple cartridge

Paper through and staple clinching condition check

(1)

(2) Exterior

122H4525*

122H4825*

12QRK001* *2

Number

of parts

replaced

1

10

*1

*1

*1

*1

*1

*1

2

Cleaning

Implementation classification

Check

*1: If abnormal sound is heard due to insufficient oil, apply oil (Plus guard No.2).

*2: This work confirms if the staple is exchanged by CE. (5,000 staples/1 cartridge)

6. PI [PI-108] (Every 150,000 copies)

2

Implementation classification

Check

Classification

No.

Conveyance

1

section

Paper feed

2

section

Final check

3

Service item

(1) Conveyance roller

(1) Paper feed roller *1

(2) Feed roller *1

(3) Double feed prevention roller *1

(1) Paper through check

(2) Exterior

Number

of parts

replaced

Cleaning

*1: If abnormal sound is heard due to insufficient oil, apply oil (Plus guard No.2).

Lubrication

( )

( )

( )

( )

( )

( )

Lubrication

( )

( )

( )

Replacement

( )

Replacement

Supply

Supply

Material used

Tools used

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Material used

Tools used

Drum cleaner & Cleaning pad

Drum cleaner & Cleaning pad

Cleaning pad & Blower brush

Cleaning pad & Blower brush

Cleaning pad & Blower brush

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 7

2

DATE

Jan.2000

PAGE

5-7

METHOD

REPLACEMENT

Page 10

SERVICE

[3] Periodic Check (Main Body)

1. Periodic check (I) (Every 300,000 copies)

No.

Classification

1

Fixing unit

2

Drum unit

3

Drive section

(Filter parts)

4

Reading

section

(1) Fixing roller/Upper

(2) Fixing claw/Upper

(3) Insulating sleeve / Upper

(1) Separating claw

(2) Drum

(1) Developing suction filter

(1) Dust proof filter

Service item

55FA5319*

25SA5315*

45405339*

55FA-203*

54007307*

55TA-694*

2. Periodic check (II) (Every 450,000 copies)

No.

Classification

1

Paper feed

unit

2

Fixing unit

3

2nd

paper feed unit

(1) Double feed prevention rubber

(2) Paper supply rubber (by-pass)

(3)

(1) Ball bearing

(2) Fixing roller/Lower

(3) Fixing claw/Lower

(4) Fixing rolling bearing

(1) Registration roller/lower

(2) Registration roller/upper

Service item

25SA4096*

54004056*

Double feed prevention rubber (by-pass)

55FA4234*

45407504*

55FA5320*

25BA5333*

25BA7603*

55TA4105*

55FA4106*

Number

of parts

replaced

1

6

2

3

1

1

1

Number

of parts

replaced

8

1

1

2

1

3

2

1

1

Cleaning

Cleaning

Implementation classification

Check

Implementation classification

Check

Lubrication

Lubrication

Replacement

Replacement

Supply

Supply

Material used

Tools used

Apply Tri - flow

at replacement

Material used

Tools used

Actual copy count:

100k copies

Actual copy count:

70k copies

Actual copy count:

70k copies

5 - 8

Page 11

3. Periodic check (III) (Every 900,000 copies)

SERVICE

Number

Classification

No.

Paper feed

1

unit

Fixing unit

2

Drive unit

3

Reversal pa-

4

per exit unit

(1) Feeding rubber/A

(2) Paper feeding rubber (by-pass)

(1) Fixing lamp/1

(2) Fixing lamp/2

2

(3) Fixing lamp/3

{

(4) Paper exit drive gear/1

(1) Fixing input gear

(1) Paper exit drive pulley/1

(2) Paper exit drive gear/1

Service item

of parts

replaced

25AA4001*

55FA4233*

55TF8303*

55TF8304*

55FF8305*

55TA7704*

25BA7726*

55TA7652*

55TA7704*

4. Periodic check (IV) (Every 1,800,000 copies)

Implementation classification

Cleaning

4

1

1

1

1

1

1

1

2

Check

Lubrication

Replacement

Supply

Material used

Tools used

Actual copy count:

800K copies

Actual copy count:

140K copies

Classification

No.

Drum unit

1

Paper feed

2

unit (main

unit/LCT)

2nd paper

3

feed unit

Transfer/

4

Separation

corona unit

Drive unit

5

Service item

(1) Solenoid press-in assembly

25SA-217*

(1) Middle conveyance clutch

55FA8204*

(1) 2nd paper feed clutch

55TA8201*

(1) Transfer/Separation corona

unit ass’y

55TA-260*

(1) Assist drive clutch

55FA8221*

Number

of parts

replaced

1

2

1

1

1

Cleaning

Implementation classification

Check

Lubrication

Replacement

Supply

Material used

Tools used

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 9

2

DATE

Jan.2000

PAGE

5-9

METHOD

REPLACEMENT

Page 12

SERVICE

5. Periodic check (V) (Every 3,000,000 copies)

No.

Classification

1

Drum unit

2

Paper feed

unit

3

Charging

corona unit

4

2nd paper

feed unit

5

Developing

unit

6

Fixing unit

7

ADU

8

Reversal

paper feed

unit

Service item

(1) Toner control board unit

25SA-910*

(1)

Paper feed regulation gear/Upper

25SA7726*

(1) Charging corona unit

(PCL included)

55FA-250*

(1) TSL ass’y

5400-913*

(1) Developing unit

55FA-300*

(1) Temperature sensor 2

25SA8844*

(1) Conveyance pulley/C

25SA7659*

(2) ADU conveyance roller/E

25SA5016*

(1) Paper exit conveyance roller/

Upper

55TA4315*

(2) Paper exit conveyance roller/

Middle

55TA4316*

(3) Paper exit conveyance roller/

Lower

55TA4317*

(4) Carriage idle gear/B

46207720*

(5) Gear/E

30007719*

Number

of parts

replaced

1

1

1

1

1

1

2

2

1

1

1

1

2

Cleaning

Implementation classification

Check

Lubrication

Replacement

Supply

Material used

Tools used

6. Periodic check (VI) (Every 3,900,000 copies)

Number

Classification

No.

1

Paper feed

unit

(1) Conveyance solenoid

(2) LCT Clutch/3

Service item

(Tray 1 – 4) 4 position for feeding

12EF8251*

(Tray 3/4 conveyance)

55FA8233*

of parts

replaced

Cleaning

Implementation classification

Check

Lubrication

Replacement

Supply

Material used

Tools used

Actual copy count:

1,000 k copies

4

Actual copy count :

2,000 K copies

1

5 - 10

Page 13

[4] Periodic Check (RADF [DF-312])

1. Periodic check (I) (Every 300,000 copies)

Classification

No.

Paper feed

1

unit

(1) Paper feed roller

(2) Forward rotation roller

(3) Separation pad

(4) Paper dust removing pad

2. Periodic check (II) (Every 1,500,000 copies)

Classification

No.

Paper feed

1

2

unit

(1) Pick-up clutch ass'y

Service item

120A4582*

120A4582*

120A-458*

129H-472*

Service item

129H-474*

Number

of parts

replaced

1

1

1

1

Number

of parts

replaced

1

Cleaning

Cleaning

Implementation classification

Check

Implementation classification

Check

Lubrication

Lubrication

Replacement

Replacement

Supply

Supply

SERVICE

Material used

Tools used

Original:

90K feeds

Original:

90K feeds

Original:

90K feeds

Original:

90K feeds

Material used

Tools used

Original:

450K feeds

[5] Periodic Check [LT-352]

1. Periodic check (I) (Every 450,000 copies)

Classification

No.

1

Paper feed

unit

(1) Double feed prevention rubber

Service item

25SA4096*

2. Periodic check (II) (Every 900,000 copies)

Classification

No.

1

Paper feed

unit

(1) Feeding rubber / A

Service item

25AA4001*

[6] Periodic Check [FS-106]

1. Periodic check (I) (Every 900,000 copies)

Classification

2

No.

1

Processing

unit

(1) Stapler unit

Service item

120H5040*

Number

of parts

replaced

2

Number

of parts

replaced

1

Number

of parts

replaced

2

Cleaning

Cleaning

Cleaning

Implementation classification

Check

Implementation classification

Check

Implementation classification

Check

Lubrication

Lubrication

Lubrication

Replacement

Replacement

Replacement

Supply

Supply

Supply

Material used

Tools used

Actual copy count:

100K copies

Material used

Tools used

Actual copy count:

800K copies

Material used

Tools used

Guarantee period of the

Stapler unit is 500k staples.

2. Periodic check (II) (Every 2,550,000 copies)

Number

Cleaning

1

2

Classification

No.

Drive unit

1

Service item

(1) Paper feed motor (Tray up/down

unit motor) *1 12QR-485*

of parts

replaced

*1: When the motor is removed by CE, please remove it holding the up-down tray to paper exit with hand.

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 11

Implementation classification

Check

Lubrication

DATE

2

Jan.2000

Replacement

Supply

PAGE

5-11

Material used

Tools used

Actual feed count:

2,500K feeds

METHOD

REPLACEMENT

Page 14

SERVICE

2

[7] FNS [FS-108BM]

1. Periodic check (I) (Every 900,000 copies)

Classification

No.

1

Stapler unit

(1) Stapler unit 129U4266*

Service item

2. Periodic check (II) (Every 2,550,000 copies)

Classification

No.

1

Drive unit

(1) Paper feed motor

Service item

(Tray up / down unit motor)

129U-108*

Number

of parts

replaced

2

Number

of parts

replaced

1

Cleaning

Cleaning

Implementation classification

Check

Implementation classification

Check

Lubrication

Lubrication

Replacement

Replacement

Supply

Supply

Material used

Tools used

Guarantee period of the

Stapler unit is 200K staples.

Material used

Tools used

Note:When the motors is

removed by CE,please

remove it holding the updown tray to paper exit with

hand.

Actual feed counts 2,500K

feeds.

2

[8] PI [PI-108]

1. Periodic check (I) (Every 450,000 copies)

Classification

No.

1

Paper feed

unit

(1) Feed roller unit/B

(2) Double feed prevention roller unit

Service item

50BA-575*

13FG-406*

2. Periodic check (II) (Every 900,000 copies)

Classification

No.

1

Paper feed

unit

(1) Feed roller unit/A 50BA-574*

Service item

Number

of parts

replaced

1

1

Number

of parts

replaced

1

Cleaning

Cleaning

Implementation classification

Check

Implementation classification

Check

Lubrication

Lubrication

Replacement

Replacement

Supply

Supply

Material used

Tools used

Actual feed count :

100K feeds

Actual feed count :

100K feeds

Material used

Tools used

Actual feed count :

200K feeds

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 12

2

DATE

Jan.2000

PAGE

5-11-1

METHOD

REPLACEMENT

Page 15

SERVICE

[9] Actual count replacement parts

Use frequency of the following parts differs depending on the use condition. Replace the parts in accordance with the each part counter in EKC

Unit Part number Parts name Q'ty Actual count Parts count No.

Paper feed unit

Tray-3 (1000LCT)

Tray-4 (1500LCT)

LT-352

12EF8251*

12EF8251*

55FA8203*

55FA8203*

09808253*

25SA8202*

25AA4001*

25SA4096*

55FA4233*

54004056*

55FA4234*

12EF8251*

12EF8251*

55FA8231*

55FA8232*

55FA8233*

55FA8232*

25AA4001*

25SA4096*

Conveyance solenoid (Tray-1 feed section)

Conveyance solenoid (Tray-2 feed section)

Paper feed clutch (Tray-1 feed section)

Paper feed clutch (Tray-2 feed section)

Original solenoid (By-pass feed)

Paper feed clutch/B (By-pass feed)

Feeding rubber/A (Tray1-4)

Double feed prevention rubber (Tray1-4)

Paper feed rubber (By-pass)

Paper supply rubber (By-pass)

Double feed prevention rubber (By-pass)

Conveyance solenoid (Tray-3, feed section)

Conveyance solenoid (Tray-4, feed section)

LCT clutch/1 (Tray-3, feed section)

LCT clutch/2 (Tray-4, feed section)

LCT clutch/3 (Tray-3/4, Conveyance)

LCT clutch/2 (Tray-5 feed section)

Feeding rubber/A

Double feed prevention rubber

1

1

1

1

1

1

4

8

1

1

1

1

1

1

1

1

1

1

2

1,000K copies

1,000K copies

2,000K copies

2,000K copies

1,000K copies

2,000K copies

800K copies

100K copies

140K copies

70K copies

70K copies

1,000K copies

1,000K copies

2,000K copies

2,000K copies

2,000K copies

2,000K copies

800K copies

100K copies

22

23

22

23

21

21

22,23,24,25

22,23,24,25

21

21

21

24

25

24

25

Total of 24 and 25

20

20

20

ADU

DF-312

FS-106

FS-108BM

2

PI-108

{

[Note]

1. Presuming from the use frequency durability of the parts with

(5,000,000 copies). However, check the counter at PM in case that the part is used frequently in particular.

2. Parts count No. is the No.displayed on the parts counter screen in the 25 mode

MODEL

7065

55FA8221*

25SA8222*

120A4582*

120A4582*

120A-458*

129H-472*

129H-474*

12QR-485*

120H5040*

129U-108*

129U4266*

50BA-575*

13FG-406*

50BA-574*

SERVICE HANDBOOK

ADU drive clutch (Conveyance section)

ADU drive clutch/B (Reversal section)

Paper feed roller

Forward rotation roller

Separation pad

Paper dust removing pad

Pick-up clutch ass'y

Paper feed motor

Stapler unit

Paper feed motor

Stapler unit

Feeding roller unit/B

Double feed prevention roller unit

Feeding roller unit/A

MANUAL

marks is considered as the same as that of the main body

REVISED EDITION

5 - 14

2

DATE

Jan.2000

1

2

1

1

1

1

1

1

2

1

2

1

1

1

5

2,000K copies

1,000K copies

Original 90K feeds

Original 90K feeds

Original 90K feeds

Original 90K feeds

Original 450K feeds

2,500K feeds

Each 500K staples

2,500K feeds

Each 200K staples

100K feeds

100K feeds

200K feeds

Parts counter.

PAGE

5-12

front/rear

front/rear

METHOD

REPLACEMENT

26

26

28

28

28

28

28

27

Front: 19

Rear: 18

27

Front:19

Rear:18

17

17

17

Page 16

COPY MATERIALS

[1] Maintenance Kit Construction

2

1. Construction (150,000 copies/kit)

SERVICE

Developer

Cleaning blade

Toner guide roller

Cleaner idler gear

Fixing cleaning roller

Name

Quantity

1

1

1

1

1

Name

Charging cover / Rear

Charging cleaning block / A assembly

Charging cleaning block / B assembly

Charging wire

Quantity

1

1

1

1

Oil impregnated roller

Oil pad assembly

Filter K

Discharging wire (transfer/separation corona unit)

1

Transfer unit cleaning block/upper assembly

1

Separation unit cleaning block/upper assembly

1

Charging control plate

3

1

1

1

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 13

2

DATE

Jan.2000

PAGE

5-13

METHOD

REPLACEMENT

Page 17

SERVICE

Name

Cleaning pad (10 sheets)

Polyethylene gloves

Dust bag (rubber band)

Developer collecting sheet (rubber band)

Quantity

3

1 set

1

1

Vanity bag for collection

Cotton swabs (4 pcs.)

1

1

5 - 14

Page 18

[2] PM Kit Construction

2

1. Construction (150,000 copies/kit)

SERVICE

Cleaning blade

Toner guide roller

Cleaner idler gear

Fixing cleaning roller

Name

Quantity

1

1

1

1

Name

Charging cover / Rear

Charging cleaning block / A assembly

Charging cleaning block / B assembly

Charging wire

Quantity

1

1

1

1

Oil impregnated roller

Oil pad assembly

Filter K

1

Discharging wire (transfer/Separation corona unit)

1

Transfer unit cleaning block/upper assembly

1

Separation unit cleaning block/upper assembly

Charging control plate

3

1

1

1

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 15

2

DATE

Jan.2000

PAGE

5-15

METHOD

REPLACEMENT

Page 19

SERVICE

Name

Cleaning pad (10 sheets)

Polyethylene gloves

Dust bag (rubber band)

Developer collecting sheet (rubber band)

Quantity

3

1 set

1

1

Vanity bag for collection

Cotton swabs (4 pcs.)

1

1

5 - 16

Page 20

SERVICE MATERIALS LIST

Material No. Description Shape Remark

SERVICE

000V-16-0

000V-17-0

00GR00020

00GR00150

Drum cleaner

200 ml

Roller cleaner

200 ml

Plus guard No. 2

25 g

Molytherm grease

25 g

000V-19-0

000V-18-0

Setting powder

25 g

Cleaning pad

10 pcs

1 pack

5 - 17

Page 21

SERVICE

SPECIAL TOOLS LIST

Tool No. Description Shape Remark

7050K0010

7050K0020

00M6-2-00

00M8-1-00

Temp. sensor PS

adjusting jig

Optics position

adjusting jig

Door switch jig

Thermostat PS

adjusting jig

(upper roller)

Quantity

1

2

1

1

00M8-2-00

00VD-5000

Thermostat PS

adjusting jig

(lower roller)

New pyramid chart

1

1

5 - 18

Page 22

SERVICE

Tool No. Description Shape Remark

00VC-2-00

00VD-1000

2

00VE-1004

120A1052*

Drum cover

Blower brush

Tester

(00VE-1004)

PS jig

Quantity

1

1

1

2pc/1set

DF-311/DF-312

120A9711*

2

2

120A9712*

129XJG011

ADJ chart

White chart

Stapler PS

jig

1

1

1

DF-311/DF-312

DF-311/DF-312

FS-108BM

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

5 - 19

2

DATE

Jan.2000

PAGE

5-19

METHOD

REPLACEMENT

Loading...

Loading...