Page 1

PI-108

SERVICE HANDBOOK

Sep.1999

Ver.1.0

KONICA CORPORATION

TECHNOLOGY SUPPORT CENTER

TOKYO JAPAN

Page 2

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the 7065 service handbook on page C-1

1. PI-108

PI-108 PRODUCT SPECIFICATIONS ..............1-1

CENTER CROSS SECTION.............................1-2

EXTERNAL SECTION.......................................1-3

[1] Composition.........................................1-3

[2] Disassembly and Reassembly.............1-3

DRIVE SYSTEM DIAGRAM..............................1-4

PAPER FEED UNIT...........................................1-5

[1] Composition.........................................1-5

[2] Mechanisms.........................................1-5

[3] Disassembly and Reassembly.............1-7

[4] Feed Control ........................................1-9

PI-108 ADJUSTMENTS ..................................1-12

[1] Adjusting the Size of the Coversheet-Tray

Width Regulation Plates ....................1-12

..............

2. DIAGRAM

PI-108 ELECTRICAL PARTS LAY OUT DRA WING ... 2-1

PI-108 CONNECTOR LAYOUT DRAWING ......2-3

PI-108 OVERALL WIRING DIAGRAM ..............2-5

PI-108 DRIVE BOARD CIRCUIT DIAGRAM.....2-6

PI-108

OPERATION BO ARD CIRCUIT DIA GRAM .....

PI-108 TIMING CHAR T (AUTO-FEED[ONLINE],

2 STAPLE,A4,2-PAGE ORIGINAL,2 COPIES) . ..2 -8

2-7

This section covers the structure,functions,operation and method of disassembling and assembling the machine.

Observe the following precautions when performing disassembly and assembly work.

1. Be sure to unplug the power cord before working on the machine.

2. Perform all reassembly work by reversing the order in which the component was disassembled,unless otherwise specified.

3. Do not lose small parts (screws,etc.) or insert them in the wrong place.

4. Install all parts completely before operating the machine.

5. Do not loosen the screws indicated as disallowed for removal.

Page 3

1

PI-108

Page 4

PI-108 PRODUCT SPECIFICATIONS

PI-108

1. Type

Sheet feeder employing torque-limiter separation

2. Functions

Automatic sheet feed (online operation)

The PI-108 automatically feeds sheets into the finisher

in accordance with instructions from the copier.

Manual sheet feed (offline operation)

User feeds sheets into finisher by operating the PI-108

controls.

User can select from three finishing modes.

• Booklet mode (available only if mounted to the FS108BM)

• Single-staple mode (staple at rear)

• Two-staple mode (flat stapling)

Copy paper

Plain paper

(high-quality paper, recycled paper, etc.)

(60g/m

Special paper

• OHP film

• Label paper

• Blueprint master paper

• 50 to 59g/m

• 91 to 200g/m

Printing paper

• Double-sided art paper

• Mat paper

• High-quality paper

2

to 90g/m2)

2

high-quality paper

2

high-quality paper

3. Power , Weight, Dimensions

Power Source: 24VDC, 5VDC (supplied from finisher)

Maximum power: Max. 25VA

Weight: PI-108: Approx. 7kg

External dimensions:

PI-108: Appro x. 330(W) x 120(H) x 456(D) (mm)

4. Maintenance

Maintenance: Same as for the main body.

Service life: Same as the main body.

5. Machine Operating Environment

Temperature: 10 to 30˚C

Humidity: 10 to 80% RH

These specifications are subject to change without notice.

Copy sizes: A3R, B4R, A4R, A4, B5, A5

Paper staking capacity: Up to 200 sheets (when using

130g/m

max. height of 40mm

Paper curling: Max. 10mm

Amount of curl

2

-equivalent paper), to

5 sheets of copy paper

1-1

Page 5

PI-108

CENTER CROSS SECTION

Paper Feed Roller

Width Regulation Plates

Feed Roller

M201 (Sheet Tray)

Sheet T ra y

Double-Feed prevention Roller

1-2

Page 6

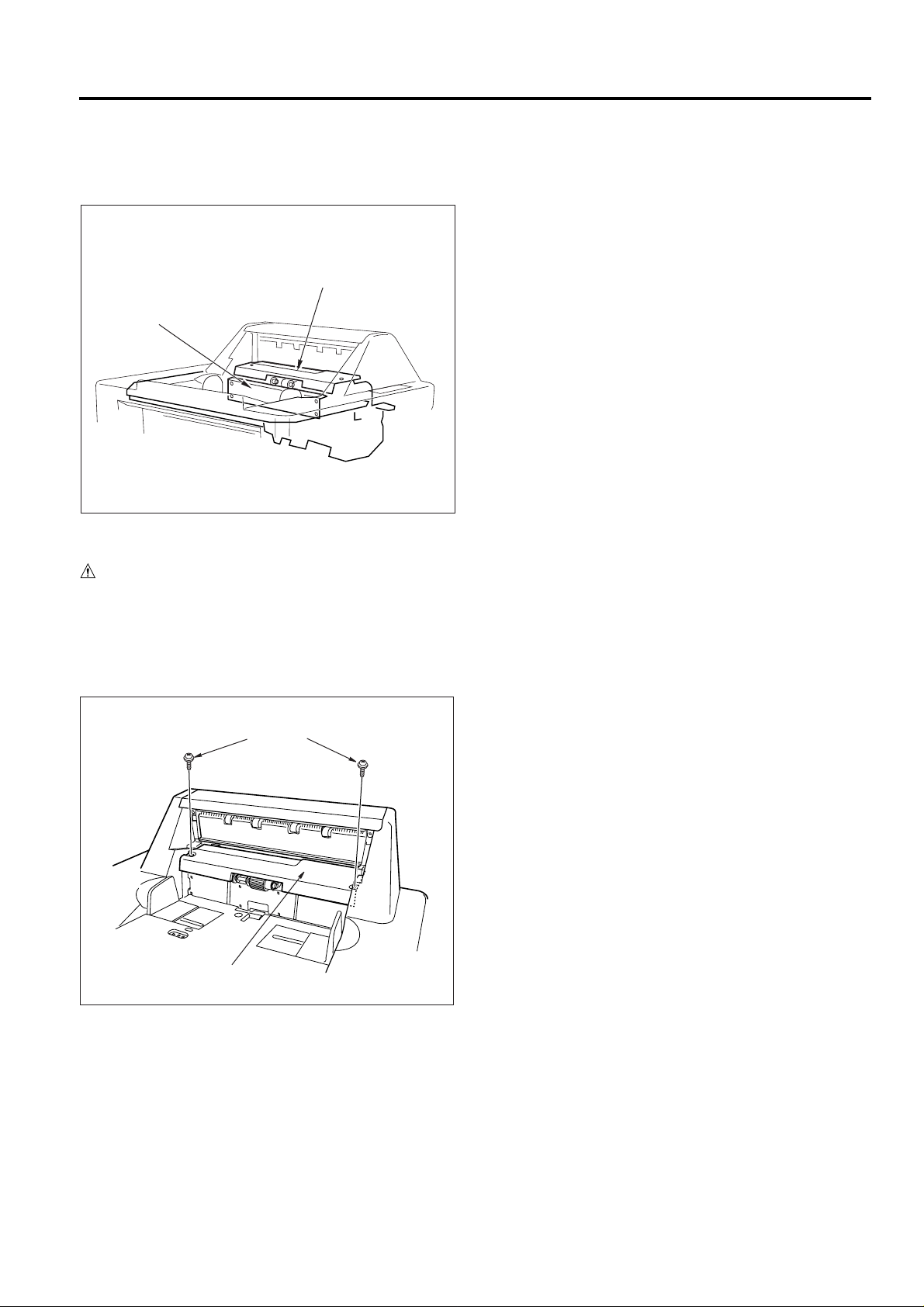

EXTERNAL SECTION

[1] Composition

Cover A

Plate

PI-108

[2] Disassembly and Reassembly

CAUTION: Be sure that the power cord has been un-

plugged from the outlet.

1. Removing and Installing the Cover A

a. Procedure

(1) Remove the sub-tray.

(2) Remove the 2 screws and remove the cover A.

Screws

Cover A

1-3

Page 7

PI-108

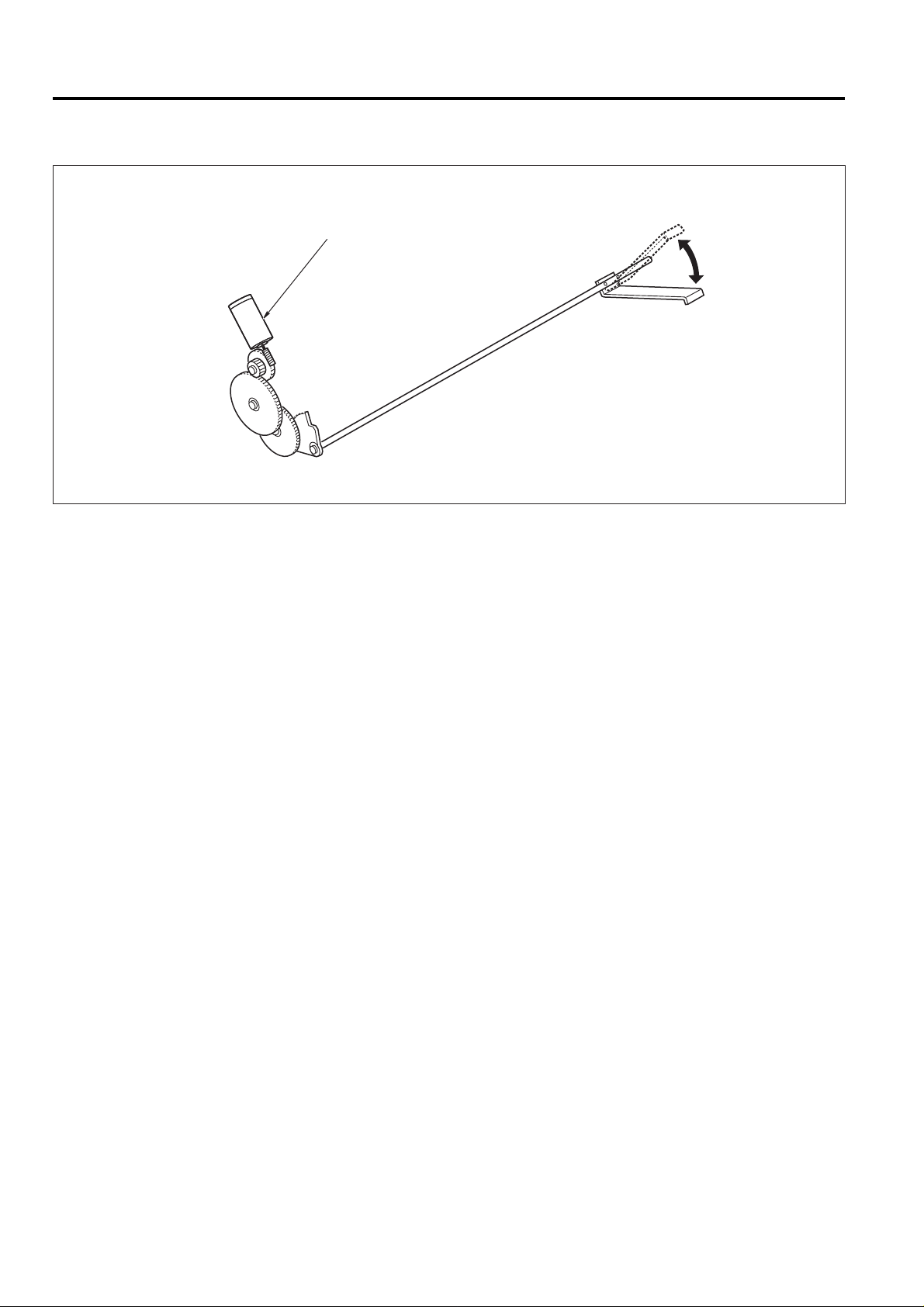

DRIVE SYSTEM DIAGRAM

M201 (Sheet Tray)

1-4

Page 8

PAPER FEED UNIT

[1] Composition

PI-108

M1 (FNS Conveyance motor)

Double-Feed prevention Roller

MC201 (Paper Feed Clutch)

Feed Roller

Paper Feed Roller

SD201 (Paper-Feed solenoid)

[2] Mechanisms

Mechanism

Paper Feed

Double-Feed Prevention

Sheet Width Detection

Method

Automatic Conveyance

(Top feeding)

Double-Feed prevention Roller

VRI

1-5

Page 9

PI-108

Paper Feed Roller

Feed Roller

M201 (Sheet Tray Motor)

Sheet T ra y

Double-Feed

prevention Roller

1. Automatic Sheet Feeding (online operation)

M201 (sheet tray motor) raises the sheet tray. SD201 (paper feed solenoid) and MC201 (paper-feed clutch) goes

on, causing the paper-feed, feed, and double-feed-prevention rollers to turn. This action feeds sheets, one by one,

into the stacker section. The rollers are driv en by FNS motor

M1 (FNS conveyance motor) via a timing belt.

Sheets are stacked as cover sheets onto paper from the

copier, and the results are then processed by the FNS

(single staple, double staple, or booklet generation).

Paper Feed Roller

Sheet T ra y

Double-Feed

prevention Roller

Feed Roller

M201 (Sheet Tray Motor)

2. Manual Sheet Feeding (offline operation)

M201 (sheet tray Motor) raises the sheet tray. SD201 (paper feed) and MC201 (paper-feed clutch) goes on, causing the paper-feed, feed, and double-feed-prevention rollers to turn. This action feeds all of the sheets from the

sheet tray into the stacker section. The FNS carries out

the required finishing (single stapling, double stapling, or

booklet generation).

1-6

Page 10

PI-108

Screws

Screws

Plate

[3] Disassembly and Reassembly

1. Replacing a Paper-Feed Roller and Feed Roller

a. Procedure

(1) Remove the sub-tray and the cover A.

(2) Remove the 2 Stop rings, Then shift the left and

right bearings outside, and remove the feedroller unit.

Stop ring

Stop ring

Bearing

Bearing

Feed Roller

Paper Feed Roller

(4) Re-install the paper-feed roller and feed roller in

the opposite sequence to removal.

CAUTION: Ensure that the mounting direction of the rubber

is correct.

2. Replacing the Rubber,Double-Feed-Prevention

Roller

a. Procedure

(1) Remove the cover A.

(2) Remove the feed-roller unit. Refer to the previ-

ous procedure for instructions on removing the

unit.

(3) Remove the 4 set screws, Then remove the plate.

(3) Pull out three stop rings,the three bearings,the

actactuator and two shaft of the feed-roller unit

then remove each roller .

Paint Mark

Rubber

Feed Drive Belt

Bearing

Rubber

Feed Roller

Feed Roller

Blue Mark

Blue Mark

Stop Ring

Bearing

Bearing

Stop Ring

Stop Ring

Actuator

1-7

Page 11

PI-108

(4) Remove the 3 stop rings, then pull out the shaft,

and remove the double-feed-prevention roller together with the feed-reverse gear.

Stop rings

Paint mark

Feed

Reverse Gear

Shaft

Double-Feed Prevention Roller

(5) Remove the rubber from the double-feed-pre-

vention roller.

(6) Re-install the removed parts in the reverse se-

quence to removal.

CAUTION: Ensure that the mounting direction of the rubber

is correct.

1-8

Page 12

[4] Feed Control

PI-108

M1

PS207

24V

SGND

PGND

PGND

TXD

DTR

CTS

RXD

DSR

RTS

MAIN BODY

MC201

SD201

M201

2-2

2-1

2-6

2-5

2-4

PS201

PS202

PS203

PS204

PS205

PS206

2-3

24V3

MC201CONT

24V2

DB

M201F/R

M201CONT

SD201CONT

8-1

5V

8-2

M1 BRK

8-3

M1 CONT

8-4

M1 CLK

8-5

M1 PLL

8-6

M1 F/R

8-7

24V

8-8

24V

8-9

PGND

8-10

PGND

1-A13

1-B18

1-A22

MS1

28-6

2-9

5V

2-7

28-3

28-1

114-1

NC

114-2

NC

114-5

NC

114-3

NC

114-7

NC

114-6

NC

6-3

6-4

6-5

6-6

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

5V

PS207IN

GND

24V-IN

6-1

5V

SGND

PGND

PGND

RX

SGND

CTS

SGND

DTR

SGND

TXD

SGND

RTS

SGND

DSR

SGND

M201CONT

M201F/R

MC201CONT

SD201CONT

SEETSET

PS201 IN

PS202 IN

PS203 IN

PS204 IN

PS205 IN

PS206 IN

24V

SGND

PGND

GND

GND

GND

GND

GND

GND

51-B2

51-B14

5V

51-A20

51-A21

51-A22

51-A23

51-A24

51-B1

51-B3

51-B25

5V

51-A1

51-B13

51-B24

5V

51-A2

51-B12

51-B23

5V

51-A3

51-B11

51-B22

5V

51-A4

51-B10

51-B21

5V

51-A5

51-B9

51-B20

5V

51-A6

51-B8

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

24V

5V

M201CONT

M201F/R

MC201CONT

SD201CONT

SEETSET

SGND

PGND

VR1

OB

1-7

1-8

51-A17

51-A18

51-B16

51-A10

51-B4

SW1

SW2

5V

VR1 IN

GND

FNS CB

M201 (sheet tray) raises the sheet tra y . SD201 (paper feed)

and MC201 (paper-feed clutch) operate in accordance with

the feed mode, thereby causing the feed, transmit, and

double-feed-prevention rollers to turn, feeding sheets into

the stacker section. The rollers are driven by FNS motor

M1 (FNS conveyance). M201 and MC201 are controlled

by the FNS CB (FNS control board) via the DB (drive

board).

PS208 IN

GND

PS209 IN

GND

5V

51-B18

51-A8

51-B6

5V

51-B17

51-A9

51-B5

PS208

PS209

1-9

Page 13

PI-108

Sheet T ra y

Operation Panel

SD201 (Paper Feed)

PS204 (Sheet Tray Upper Limit)

M201 (Sheet Tray)

MC201

(Paper-Feed Clutch)

1. Operation

a. Auto-sheet feeding (online)

(1) The ON signal from the copier’s START button

causes FNS motor M1 (FMS conveyance) to

come on. M201 (sheet tray) lifts the sheet tray

up to the position where the tray activates PS204

(sheet-tray upper limit).

(2) SD201 (paper-feed) and MC201 (paper-feed

clutch) come on in response to the CF feed request signal, feeding paper into the stacker.

M201 (Sheet Tray)

MC201

(Paper-Feed Clutch)

PS204 (Sheet-Tray Upper Limit)

SD201 (Paper Feed)

b. Manual sheet feeding (offline)

(1) The ON signal from the PI-108 operation panel’s

ST AR T button causes FNS motor M1 (FMS conveyance) to come on. M201 (sheet tray) lifts the

sheet tray to the position where the tray activates PS204 (sheet-tray upper limit).

(2) SD201 (paper-feed) and MC201 (paper-feed

clutch) come ON, feeding all paper from the

sheet tray into the stacker.

(3) The FNS carries out the required processing

(stapling or booklet generation).

Sheet T ra y

1-10

Page 14

PI-108

c. Detection of sheet size

VR1 (sheet width) detects the sheet width. Sheet length is

detected by the combination of PS205 (sheet size/small)

and PS206 (sheet size/large).

PS205 (Sheet-Size (Small))

PS206

(Sheet-Size (Large))

Width Regulation Plates

VR1 (Sheet Width)

d. Sheet tray up-down

M201 (sheet tray) drives the raising and lowering of the

tray . M201 is controlled b y the FNS CB (FNS control board)

via the DB (drive board).

2. Signals

a. Input signals

(1) TXD (Main-Body CB → FNS CB)

Serial data line; transmits operating status of the

Main-Body CB to the FNS CB.

(2) DTR (Main-Body CB → FNS CB)

Request to send signal from the main body to

the FNS.

(3) RTS (Main-Body CB → FNS CB)

Transmission acknowledgment signal from the

main body to the FNS.

(4) PS201 IN (PS201 → RB → FNS CB)

Comes ON [L] when paper passage is detected.

(5) PS202 IN (PS202 → RB → FNS CB)

Sheet-tray empty detection.

[H]: Tray is empty (no paper).

[L]: Tray has paper.

(6) PS203 IN (PS203 → RB → FNS CB)

Comes ON [L] when the sheet tray is at its lowerlimit position.

(7) PS204 IN (PS204 → RB → FNS CB)

Comes ON [L] when the sheet tray is at its upper-limit position.

(8) PS205 IN (PS205 → RB → FNS CB)

Paper-size detection.

[H]: Paper not detected

[L]: Paper detected

(9) PS206 IN (PS206 → RB → FNS CB)

Paper-size detection.

[H]: Paper not detected

[L]: Paper detected

(10)PS208 IN (PS208 → RB → FNS CB)

Paper-size detection.

[H]: Paper not detected

[L]: Paper detected

(11) PS209 IN (PS209 → RB → FNS CB)

Paper-size detection.

[H]: Paper not detected

[L]: Paper detected

(12)VRI IN (VR1 → RB → FNS CB)

Width detection (paper size in tray width direction).

b. Output signals

(1) TXD (FNS CB → Main-Body CB)

Serial data line; transmits FNS operating status

to the Main-Body CB.

(2) DTR (FNS CB → Main-Body CB)

Request to send signal from the FNS to the main

body .

(3) RTS (FNS CB → Main-Body CB)

Transmission acknowledgment signal from the

FNS to the main body.

(4) M201 CONT (FNS CB → RB → M201)

M201 (sheet-tray) drive control signal.

(5) MC201 CONT (FNS CB → RB → MC201)

MC201 (paper-feed clutch) drive control signal.

(6) SD201 CONT (FNS CB → RB → SD201)

SD201 (paper-feed solenoid) drive control signal

[H]: OFF

[L]: ON

1-11

Page 15

PI-108

PI-108 ADJUSTMENTS

[1] Adjusting the Size of the Coversheet-

Tray Width Regulation Plates

1. Preparation

(1) Install the coversheet tray (PI-108) on the fin-

isher.

(2) Connect the finisher to the copier.

(3) Check whether all paper sizes are correctly de-

tected.

(4) If one or more sizes are not correctly detected,

carry out adjustment as described below.

2. Adjustment procedure

(1) Hold down keys [3] and [6] on the copier’s nu-

meric keypad while setting the main switch ON.

The copier will enter finisher-adjustment mode.

(2) Select [[6] Finisher Adjust] at the copier display.

(3) Again at the copier display, select [[4] Adjust

coversheet tray size].

(4) Push the width regulation plates out to maximum

width.

Width

Regulation Plates

(5) At the screen, select [YES].

(6) Confirm that the following message is displayed,

indicating that adjustment is finished.

Adjust coversheet tray size

----Adjustment completed.----

1-12

Page 16

2

DIAGRAM

Page 17

PI-108 ELECTRICAL PARTS LAYOUT DRAWING

PI-108

1. Sensors

PS201 Sheet passage PS

PS202 No-sheet PS

PS203 Sheet-tray lower-limit PS

PS204 Sheet-tray upper-limit PS

PS205 Sheet-size PS (small)

PS206 Sheet-size PS (large)

PS208 Sheet set PS

PS209 Pre no-paper PS

VR1 Sheet-width VR

2-1

Page 18

PI-108

2. Motor, Clutch, Solenoid, Board

M201 Sheet-tray motor

MC201 Paper-feed clutch

SD201 Paper-feed solenoid

DB Drive board

OB Operation board

2-2

Page 19

PI-108 CONNECTOR LAYOUT DRAWING

503(W:6 PIN)

356(W:3 PIN)

356(W:3 PIN)

PI-108

54(W:9 PIN)

2(W:6 PIN)

DB

1(W:9 PIN)

355(W:3 PIN)

353(W:3 PIN)

359(W:3 PIN)

302(W:2 PIN)

501(W:9 PIN)

352(W:3 PIN)

351(W:3 PIN)

354(W:3 PIN)

303 (W:3 PIN)

358(W:3 PIN)

360(W:3 PIN)

2-3

Page 20

[Reading the Diagrams]

1. Signal states reflect condition in which system is in normal idling state with the main switch ON.

2. Symbols used in circuit diagrams are as follows.

(1) Symbols (3) RC denotes a ribbon cable.

(4) Signal Flow

Connectors are indicated by circle ( ) or ( ).

The dark circles indicate the direction of the signal flow.

(2) Color Codes

Example: Y/GN denotes a green wire with a yellow stripe.

BN : Brown

R : Red

O : Orange

Y : Yellow

GN : Green

LB : Light blue

B : Blue

V : Violet

GY : Gray

W : White

BK : Black

P : Pink

PGC Wire (Violet)

Connector Faston

VV

CB

Example:

Direction of signal flow:

PS1

5VDC

PS1

SGND

50-1

351-3

351-2

351-1

PS201

H

51-B25

51-A1

51-B13

M201

MC201

352-3

352-2

352-1

PS202

H

51-B24

51-A2

51-B12

353-3

353-2

353-1

PS203

L

51-B23

51-A3

51-B11

354-3

354-2

354-1

PS204

H

51-B22

51-A4

51-B10

355-3

355-2

355-1

PS205

L

51-B21

51-A5

51-B9

503-3

503-2

503-1

356-3

356-2

356-1

PS206

L

51-B20

51-A6

51-B8

5V

PS201 IN

GND

5V

PS202 IN

GND

5V

PS203 IN

GND

5V

PS204 IN

GND

358-3

358-2

358-1

PS208

L

51-B18

51-A8

51-B6

359-3

359-2

359-1

PS209

L

51-B17

51-A9

51-B5

360-3

360-2

360-1

VR1

OB

51-B16

51-A10

51-B4

5V

PS208 IN

GND

5V

PS209 IN

GND

5V

VR1 IN

GND

FNS CB

DB

5V

PS205 IN

GND

5V

PS206 IN

GND

51-B19

51-A7

51-B7

NCNCNC

51-A25

51-B15

NC

NC

503-6

503-5

503-4

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

24V5VM201CONT

M201F/R

MC201CONT

SD201CONT

SHEETSET

SGND

PGND

51-B2

51-B14

51-A20

51-A21

51-A22

51-A23

51-A24

51-B1

51-B3

2-2

2-1

2-6

2-5

2-4

2-3

53-2

53-1

53-6

53-5

53-4

53-3

M201F/R

M201CONT

SD201CONT

24V3

MC201CONT

24V2

24V

5V

M201CONT

M201F/R

MC201CONT

SD201CONT

SHEETSET

SGND

PGND

52-1

52-2

52-3

52-4

52-5

52-6

52-7

52-8

52-9

H

H

51-A11

51-A12

51-A13

51-A14

51-A15

51-A16

51-A17

51-A18

51-A19

5V

LED1

LED2

LED3

LED4

LED5

SW1

SW2

SGND

54-1

54-2

54-3

54-4

54-5

54-6

54-7

54-8

54-9

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

501-1

501-2

501-3

501-4

501-5

501-6

501-7

501-8

501-9

301-1

301-2

SD201

303-1

303-2

302-1

302-2

PAPER

FEED

CLUTCH

PAPER

FEED

SOLENOID

SHEET

TRAY

MOTOR

SHEET

PASSAGE

PS

NO SHEET

PS

SHEET

TRAY

LOWER LIMIT

PS

SHEET

TRAY

UPPER LIMIT

PS

SHEET

SIZE

PS

(SMALL)

SHEET

SIZE

PS

(LARGE)

SHEET

SET

PS

PRE

NO PAPER

PS

SHEET

SIZE

VR

PI-108 OVERALL WIRING DIAGRAM

2-5

Page 21

PI-108 DRIVE BOARD CIRCUIT DIAGRAM

By-pass condensers for IC1,IC2 IC3

2-6

Page 22

PI-108 OPERATION BOARD CIRCUIT DIAGRAM

2-7

Page 23

PI-108 TIMING CHAR T(AUTO-FEED [ONLINE],2-STAPLE,A4,2-PAGE ORIGINAL,2 COPIES)

Symbol

Item

Copier Exit PS

FIN Entrance Passage PSPS4

FNS Conveyance MotorM1

Paper Exit-Roller MotorM7

Paper Exit Opening SolenoidSD4

Paper Exit-1 PSPS6

Staple Paper Exit Upper-Limit PSPS7

Tray Up-Down MotorM3

CF Feed Request

CF Pre-Feed Request

Staple Request

Sheet Passage PSPS201

Stacker Conveyance Passage PSPS5

Paper Feed ClutchMC201

Paper-Feed SolenoidSD201

Alignment-Plate/Upper Motor M5

Stapler/RM21,M22

Stapler/FM23,M24

Stacker Entrance MotorM13

Time (seconds)

UP

DOWN

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 21 2220

2-8

Loading...

Loading...