Page 1

FS-106

SERVICE HANDBOOK

Jan. 2000

Ver. 2.0

KONICA CORPORATION

TECHNOLOGY SUPPORT CENTER

TOKYO JAPAN

Page 2

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS ................

Refer to the 7065 service handbook on page C-1

1. FS-106

FS-106 PRODUCT SPECIFICATIONS ............ 1-1

CENTER CROSS SECTION ............................ 1-2

DRIVE SYSTEM DIAGRAM............................. 1-3

[1] Paper Conveyance Drive ..................... 1-3

[2] Stacker Drive ....................................... 1-4

PAPER CONVEYANCE PATH......................... 1-5

[1] Paper Conveyance Path ...................... 1-5

[2] Non-Sort mode..................................... 1-6

[3] Sort/Group mode ................................. 1-7

[4] Sub-tray mode ..................................... 1-8

[5] Staple mode......................................... 1-9

EXTERNAL SECTION.................................... 1-10

[1] Composition ....................................... 1-10

[2] Disassembly and Assembly ............... 1-10

CONVEYANCE SECTION.............................. 1-13

[1] Composition ....................................... 1-13

[2] Mechanism......................................... 1-13

[3] Disassembly and Assembly ............... 1-16

[4] M1 (1st conveyance) Control ............. 1-23

[5] M4 (2nd conveyance) Control ............ 1-24

[6] Gate Control....................................... 1-26

[7] M14 (Stacker Entrance) Control ........ 1-28

[8] M5 (Alignment Plate) Control ............. 1-29

[9] M2 (Roller Shift) Control .................... 1-30

[10] M7 (Paper Exit Roller) Control ........... 1-31

[11] SD4 (Paper Exit Opening) Control..... 1-32

[12] M8 (Paper Exit Opening) Control....... 1-34

STAPLER UNIT .............................................. 1-35

[1] Composition ....................................... 1-35

[2] Mechanism......................................... 1-35

[3] Disassembly and Assembly ............... 1-36

[4] Stapler Control ................................... 1-38

MAIN TRAY SECTION ................................... 1-40

[1] Composition ....................................... 1-40

[2] Mechanism......................................... 1-40

[3] Disassembly and Assembly ............... 1-40

[4] Main Tray Up-Down Control ............... 1-42

FS-106 ADJUSTMENTS ................................ 1-44

[1] Sub-tray Gate Adjustment.................. 1-44

[2]

Adjusting the Paper Route Switching Gate ..

[3] Adjusting the By-Pass Gate ............... 1-46

[4] Adjusting the Shift Position ................ 1-47

[5] Adjusting the Open/Close Section of

the Paper Exit Opening...................... 1-48

[6]

Adjusting the Paper Exit Opening Solenoid..

[7] Adjusting the Paper Exit Opening

Lower Guide Plate ............................. 1-50

[8]

Adjusting the Stacker Paper Exit Belt Tension ..

[9] Adjusting the Alignment Plate Installation

Position .............................................. 1-51

[10] Adjusting the Alignment Plate Drive

Timing Belt Tension............................ 1-52

[11] Adjusting the Stapler Rotation Drive

Section Installation............................. 1-52

[12] Adjusting the Staple Position for

2 Position Stapling ............................. 1-53

[13] Adjusting the Staple Slant for

2 Position Stapling ............................. 1-53

[14] Adjusting the Staple Position for

1 Position Stapling ............................. 1-54

[15] Adjusting the Tension of the Stapler

Move Timing Belt ............................... 1-54

2. DIAGRAMS

FS-106 ELECTRICAL PARTS LAYOUT DRAWING...

FS-106 CONNECTOR LAYOUT DIAGRAM..... 2-3

FS-106 OVERALL WIRING DIAGRAM ............ 2-5

FS-106 CONTROL BOARD CIRCUIT DIAGRAM (1/7) .....

FS-106 CONTROL BOARD CIRCUIT DIAGRAM (2/7) .....

FS-106 CONTROL BOARD CIRCUIT DIAGRAM (3/7) .....

FS-106 CONTROL BOARD CIRCUIT DIAGRAM (4/7) .....

FS-106 CONTROL BOARD CIRCUIT DIAGRAM (5/7) ..

FS-106 CONTROL BOARD CIRCUIT DIAGRAM (6/7) ...

FS-106 CONTROL BOARD CIRCUIT DIAGRAM (7/7) ..

FS-106 TIMING CHART (Sort mode, A4, 2 page

originals, 5 copies, 1:1 ratio) ..............................

FS-106 TIMING CHART (2 position staple mode,

A4, 2 page originals, 3 copies)...........................

1-45

1-49

1-51

2-1

2-6

2-7

2-8

2-9

2-10

2-11

2-12

2-13

2-14

This section covers the structure, functions, operation and method of

disassembling and assembling the machine.

Observe the following precautions when performing disassembly and

assembly work.

1. Be sure to unplug the power cord before working on the machine.

2. Perform all reassembly work by reversing the order in which the

component was disassembled, unless otherwise specified.

3. Do not lose small parts (screws, etc.) or insert them in the wrong

place.

4. Install all parts completely before operating the machine.

5. Do not loosen the screws indicated as disallowed for removal.

Page 3

1

FS-106

Page 4

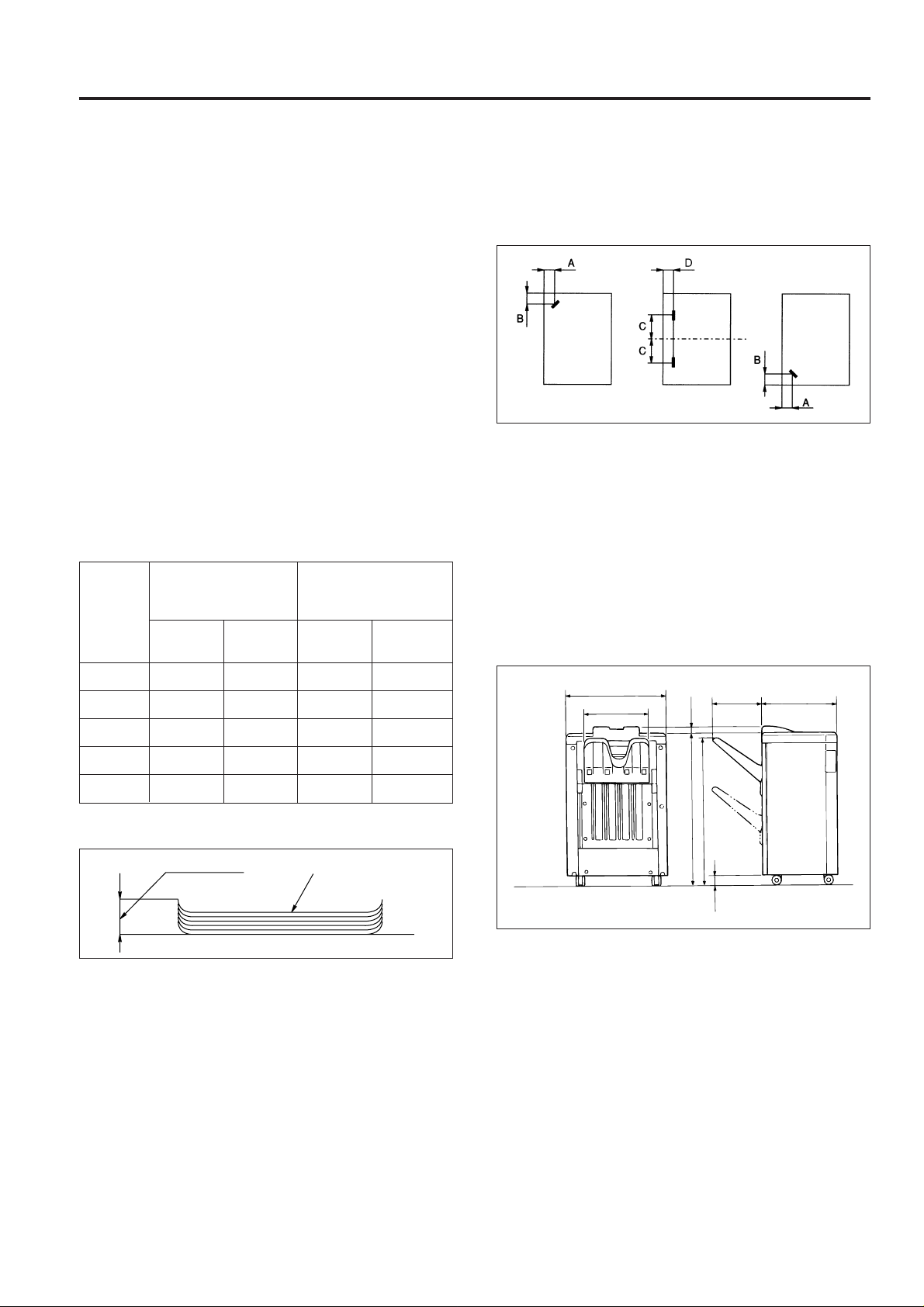

FS-106 PRODUCT SPECIFICATIONS

616

367

324 460

915

945

35

63

FS-106

1. Type

Type: Off-set sorting and stapling equipment

with printer outlet function.

2. Functions

Types of paper: Same as the main body.

Paper size: A3R, B4R, F4R, A4R, A4, B5, B5R,

A5R, B6R; however

B6R is not possible in off-set mode;

B5R, A5R and B6R are not possible in

staple mode.

Paper stacking capacity:

Sub-tray exit mode: Maximum 200 sheets

Non-staple/Group/

Off-set mode: Maximum 1,500 sheets (B4R/F4R/

A3R)

Maximum 2,000 sheets (B5R/B5/

A4R/A4)

Maximum 500 sheets (B6R/A5R)

Staple mode: Maximum 1,000 sheets

Other than

Number of

original

pages Staple in Staple in Staple in Staple in

2 to 9 100 stacks 100 stacks 50 stacks 50 stacks

A3R, 11X17R

2 places 1 place 2 places 1 place

A3R, 11x17R

Staple position: A = 8.8 mm (±3 mm adjustment possible)

B = 8.8 mm (±3 mm adjustment possible)

C = 89.1 mm (±3 mm adjustment possible)

D = 8.0 mm (±3 mm adjustment possible)

Staple capacity: 5,000 staples/cartridge

(Same as FS-103/FS-103A/FS-106)

4. Machine Data

Power source: 24 V/5 VDC (supplied from the main

body).

Maximum power

consumption: Max. 100 VA (FS-106 only)

Weight: Approximately 50 kg

External dimensions:

Units: mm

10 to 20 50 stacks 50 stacks 50 stacks 50 stacks

21 to 30 30 stacks 30 stacks 30 stacks 30 stacks

31 to 40 25 stacks 25 stacks 25 stacks 25 stacks

41 to 50 20 stacks 20 stacks 20 stac ks 20 stacks

Paper curling: Max. 10 mm

5 sheets of copy paperAmount of curl

Amount of sort

off-setting: 30 mm (when off-setting/grouping)

Tray: Main tray

Sub-tray

3. Stapler Kit

Number of pages

which may be

stapled: 50 sheets maximum (80 g/m

paper, 5 mm and below)

2

high-quality

5. Maintenance

Maintenance: Same as the main body

Service life: Same as the main body

6. Machine Operating Environment

Temperature: 10 to 30°C

Humidity: 10 to 80% RH

These specifications are subject to change without notice.

1 - 1

Page 5

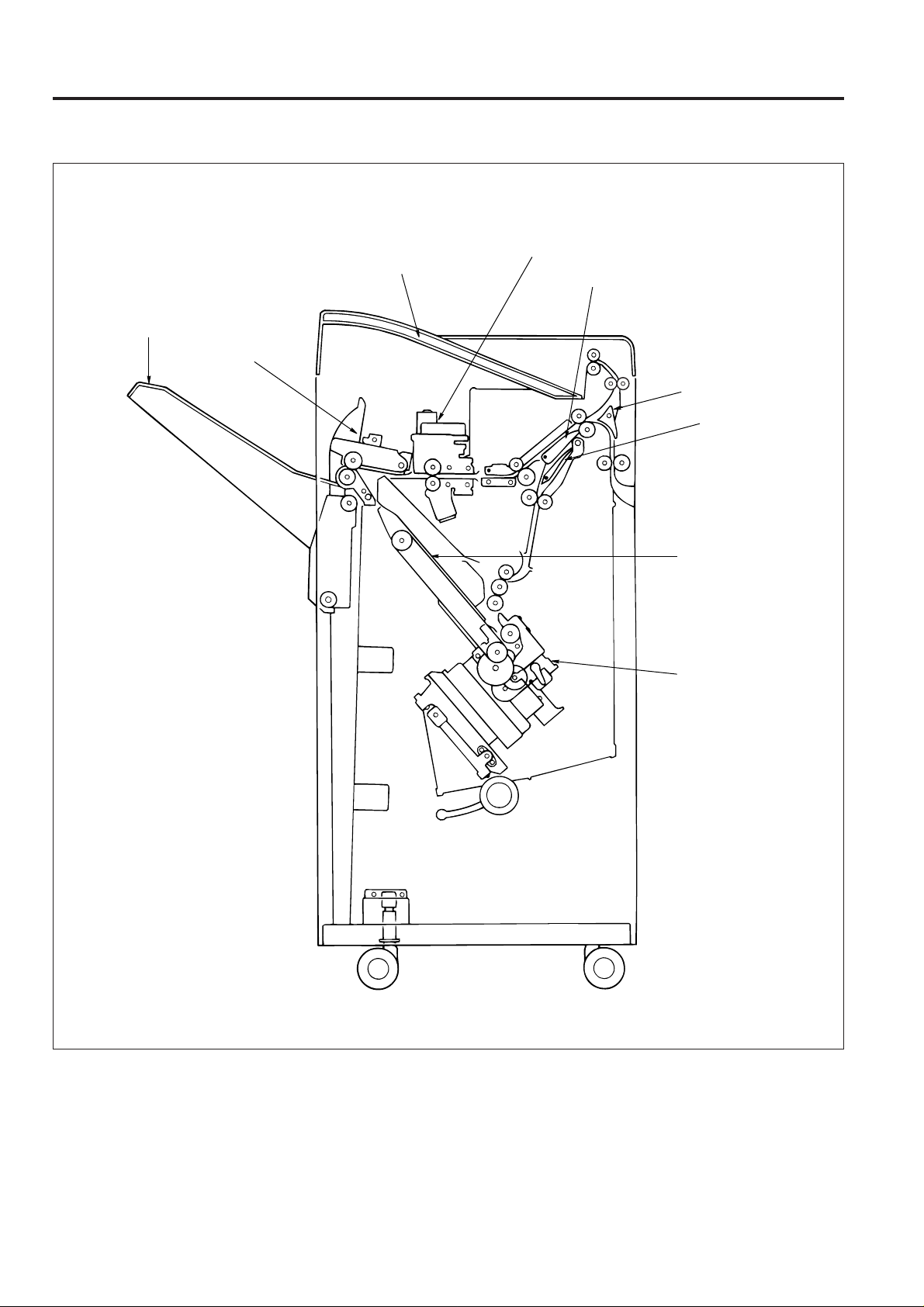

FS-106

CENTER CROSS SECTION

Sub-tray

Main tray

Paper exit unit

Shift unit

Gate

Sub-tray gate

By-pass gate

Stacker unit

Stapler unit

1 - 2

Page 6

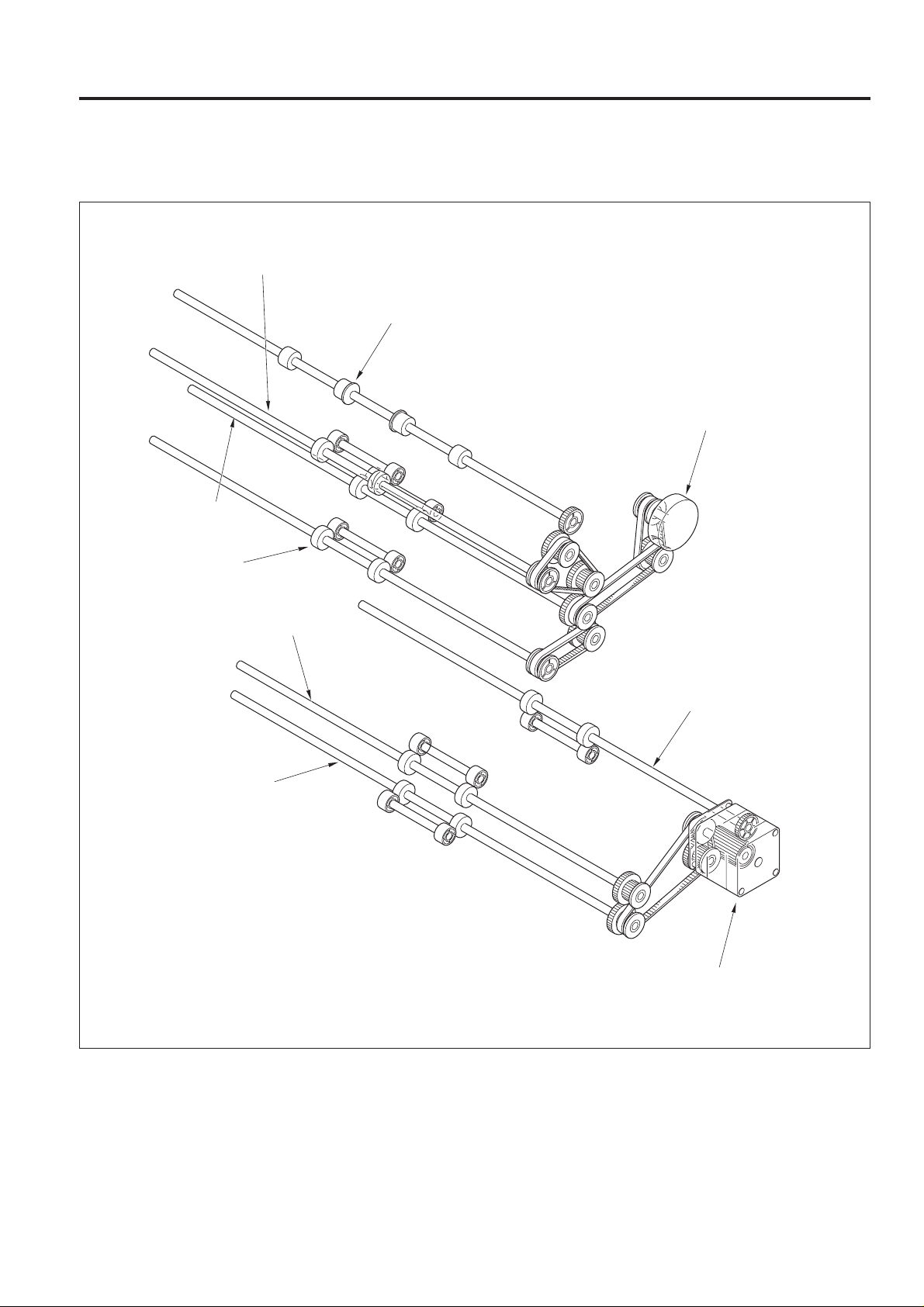

DRIVE SYSTEM DIAGRAM

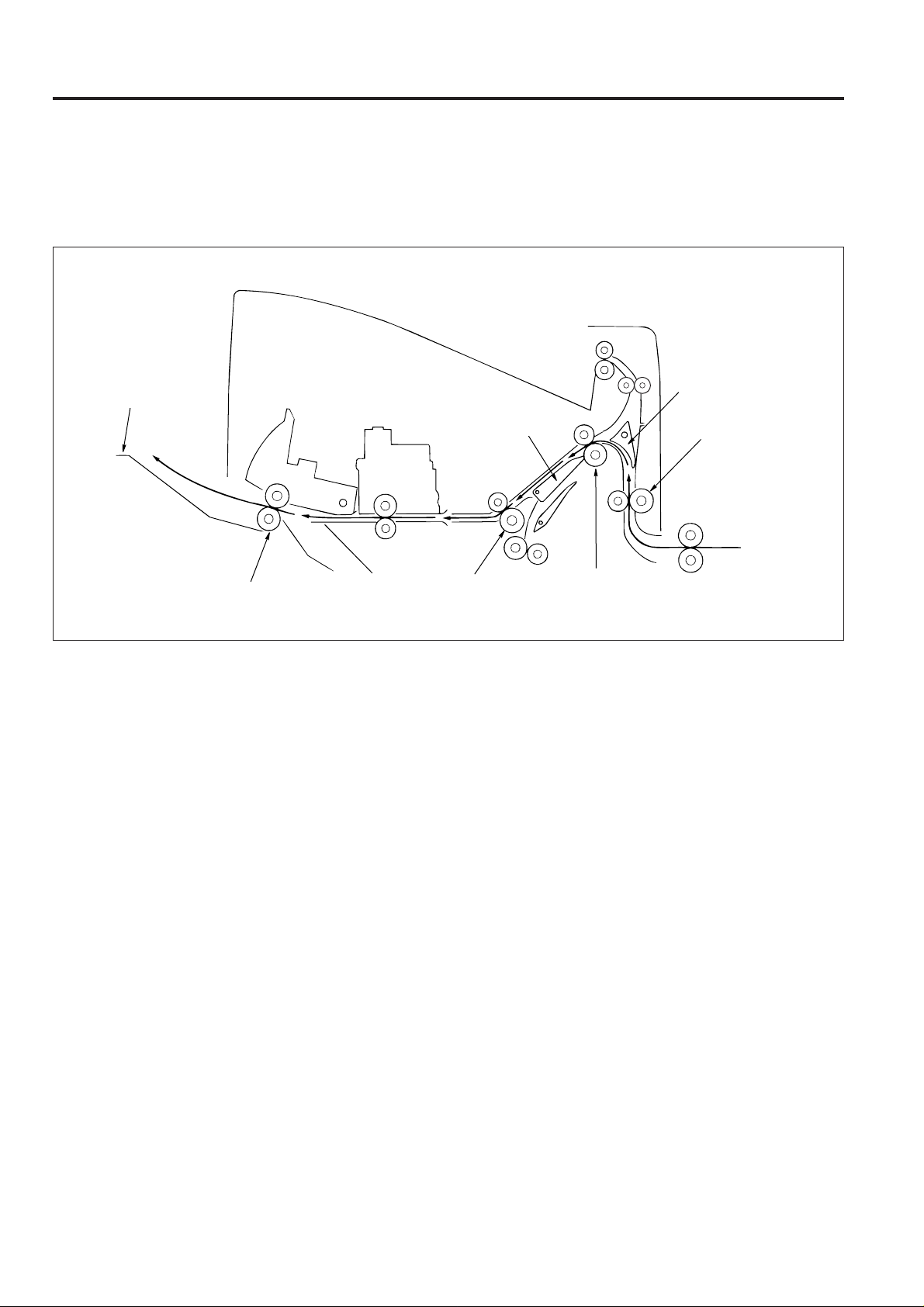

[1] Paper Conveyance Drive

Conveyance roller D

Sub-tray printer paper exit roller

Conveyance roller B

FS-106

1st conveyance motor (M1)

Conveyance roller A

Conveyance roller C

Intermediate roller

Conveyance slide shaft

2nd conveyance motor (M4)

1 - 3

Page 7

FS-106

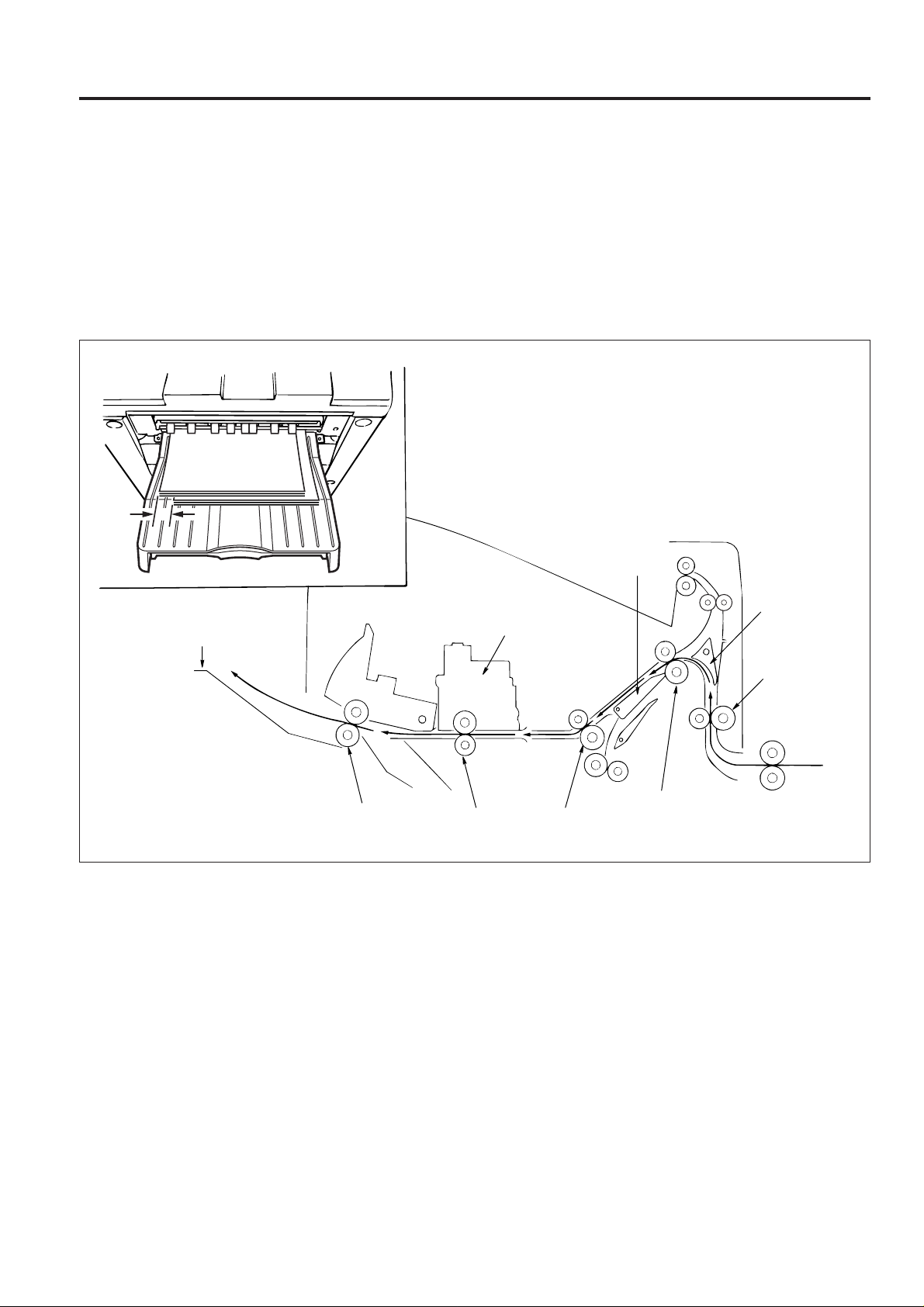

[2] Stacker Drive

Paper exit roller

Paper exit roller motor (M7)

Paper exit belt

Stacker entrance roller

Sponge roller

Paper exit arm

Stacker entrance motor (M14)

1 - 4

Page 8

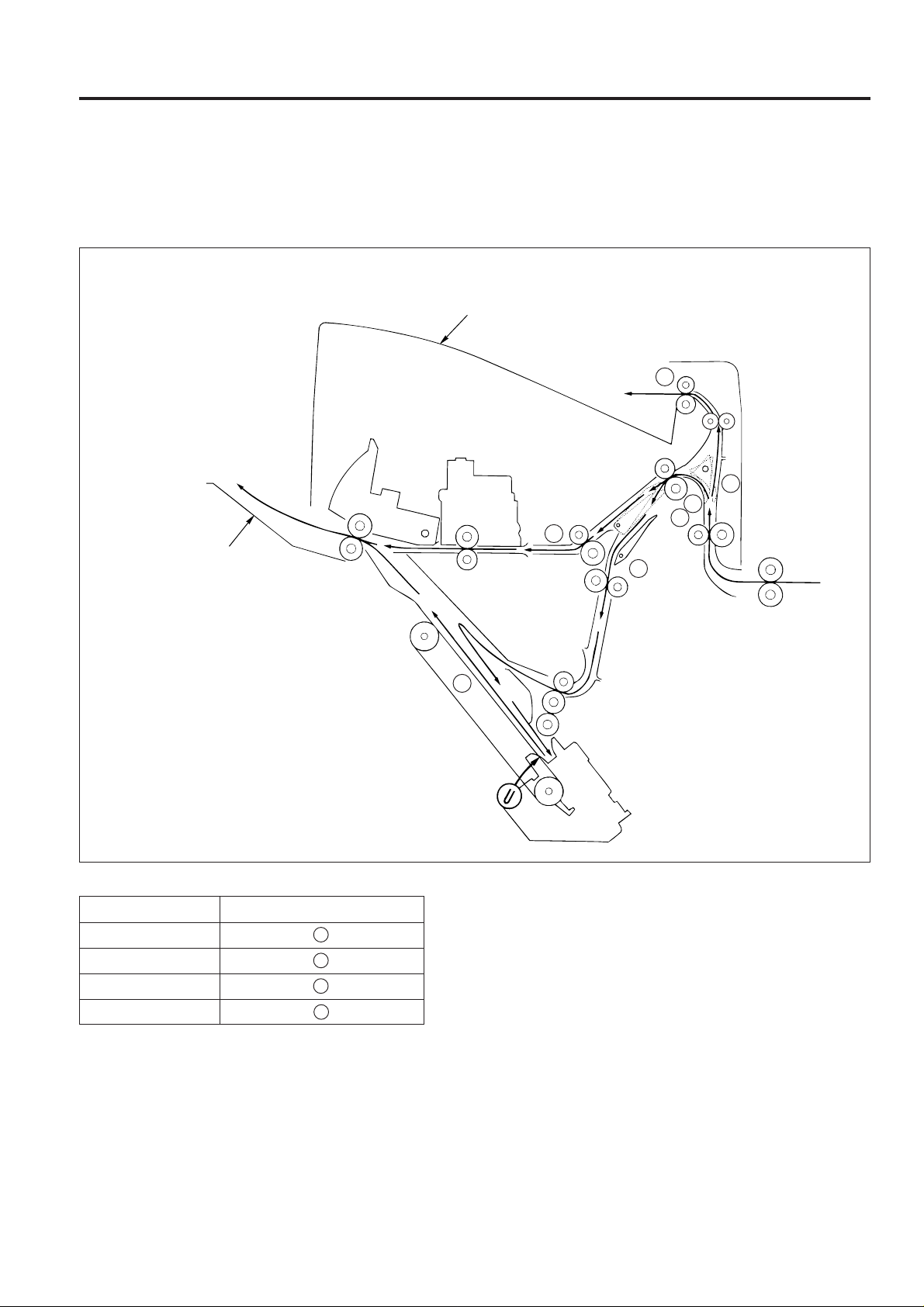

PAPER CONVEYANCE PATH

[1] Paper Conveyance Path

The FNS (Finisher) has three paper conveyance paths as shown in the diagram below.

Face up and face down operations are performed in the reversal paper exit section of the main body.

Sub-tray

2

1

1

Main tray

3

FS-106

2

3

Finishing Paper conveyance paths

Non-Sort mode 1

Sort/Group mode 1

Sub-tray mode 2

Staple mode 3

3

1 - 5

Page 9

FS-106

[2] Non-Sort mode

Exit to main tray

A paper exited from the main body is conveyed and exited to the main tray.

Main tray

Paper exit roller

Gate

Shift unit

Conveyance roller C

Sub-tray gate

Conveyance roller A

Conveyance roller B

1 - 6

Page 10

[3] Sort/Group mode

Exit to main tray

Paper exited from the main body is conveyed and exited to the main tray. This mode has an off-set function that allows each page

of the even-numbered sets to be exited with the paper shifted 30mm to the rear.

off-set function

(1) The odd-numbered pages are exited to the main tray with the image side face down.

(2) The even-numbered pages are shifted 30mm to the rear by the conveyance slide shaft of the shift unit and then

exited to the main tray.

30mm

FS-106

Main tray

Paper exit roller

Shift unit

Conveyance

slide shaft

Gate

Sub-tray gate

Conveyance roller A

Conveyance roller B

Conveyance roller C

1 - 7

Page 11

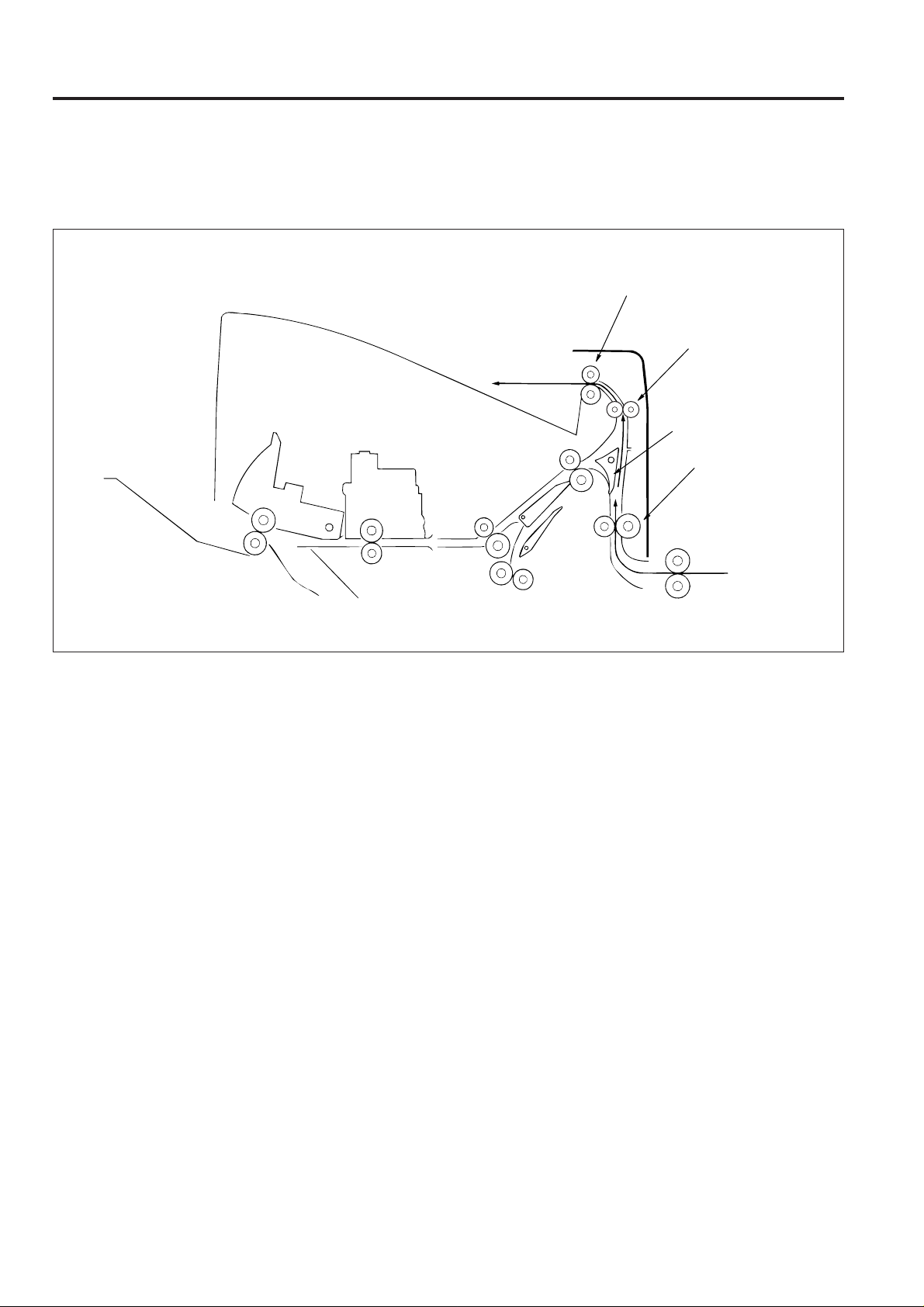

FS-106

[4] Sub-tray mode

The sub-tray gate opens. Paper exited from the main body is conveyed and exited to the sub-tray.

Paper exit roller

Sub-tray

Conveyance roller D

Sub-tray gate

Conveyance roller A

1 - 8

Page 12

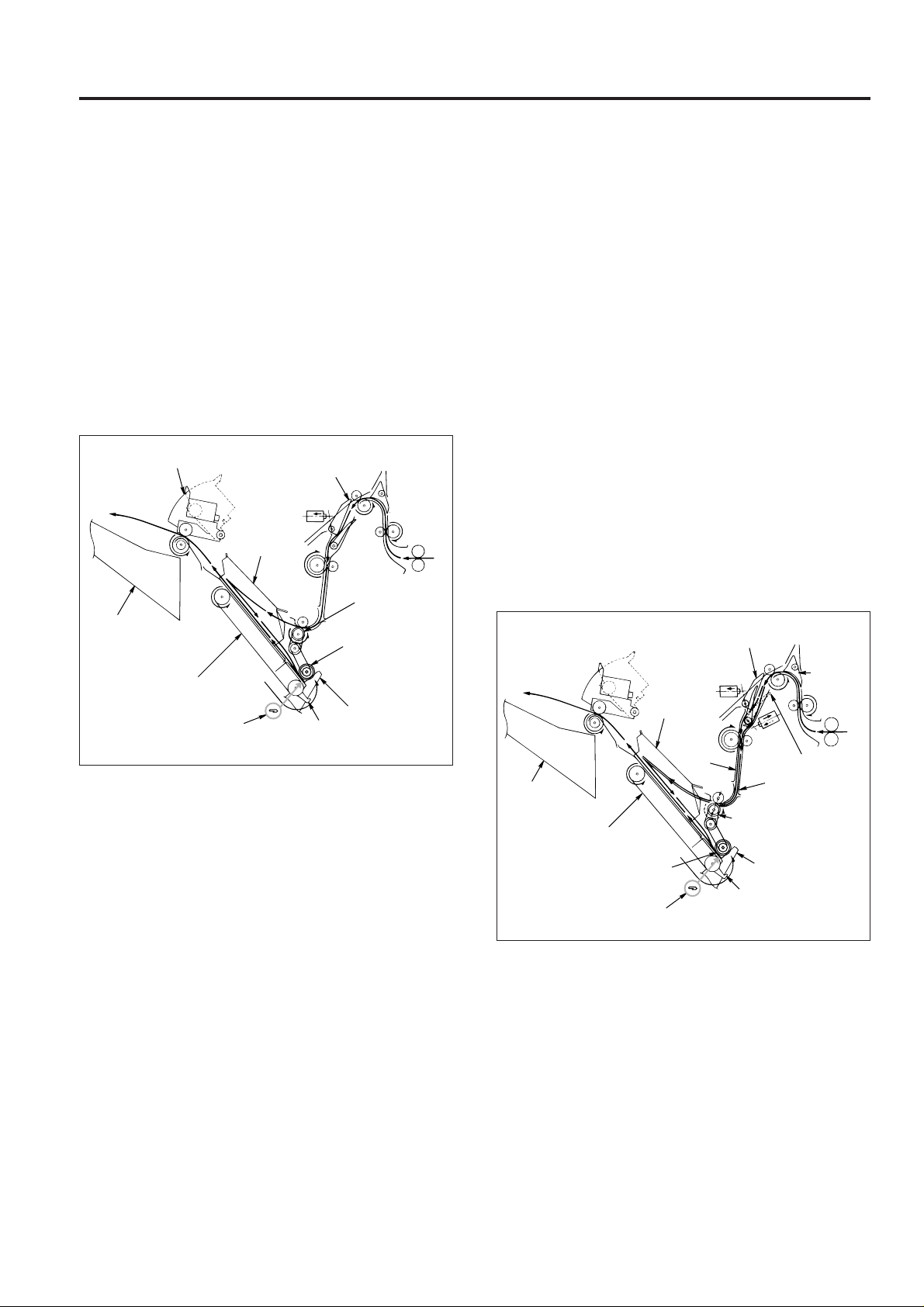

FS-106

[5] Staple mode

(1) The gate switches to the staple mode.

(2) For A4R paper and above, the paper exit opening

opens.

(3) The first stack of paper is conveyed and stacked.

(a) The sponge roller of the stac ker section sends the

paper to the stopper and the paper is lined up in

the lengthwise direction.

(b) The alignment plate unit lines up paper in the width-

wise direction.

(c) Paper is stapled.

(d) The first stack is conveyed by the paper exit arm

and exited to the main tray.

Paper exit opening

1st stack

Alignment

plate unit

Main tray

Stacker

Stapler

Gate

Stacker

entrance roller

Sponge roller

Stopper

Paper

exit arm

(4) The second and subsequent stacks of paper are con-

veyed and stacked.

(a) The first page stops in the stacker entrance with

the by-pass gate opened. The stacker entrance

roller stops to wait for the previous stack to be

exited.

(b) The by-pass gate is closed and the second page

is stacked on top of the first.

(c) Once the previous stack has e xited, the stac k en-

trance roller rotates and the first and second pages

are simultaneously sent to the stacker.

• The above steps (a) to (c) are for paper to a maximum of A4 size.

(d) The sponge roller of the stack er section sends the

paper to the stopper and the paper is lined up in

the lengthwise direction.

(e) The alignment plate unit lines up paper in the width-

wise direction.

(f) When all paper is conv e yed to the stac k er, the pa-

per is stapled.

(g) The second and subsequent sets are conveyed

by the paper exit arm and the paper is exited to

the main tray.

2nd and

subsequent

stacks

Main tray

Alignment

plate unit

2nd

page

Gate

By-pass gate

1st page

Sub-tray

gate

1 - 9

Stacker

Sponge roller

Stacker entrance roller

Stopper

Paper exit arm

Stapler

Page 13

FS-106

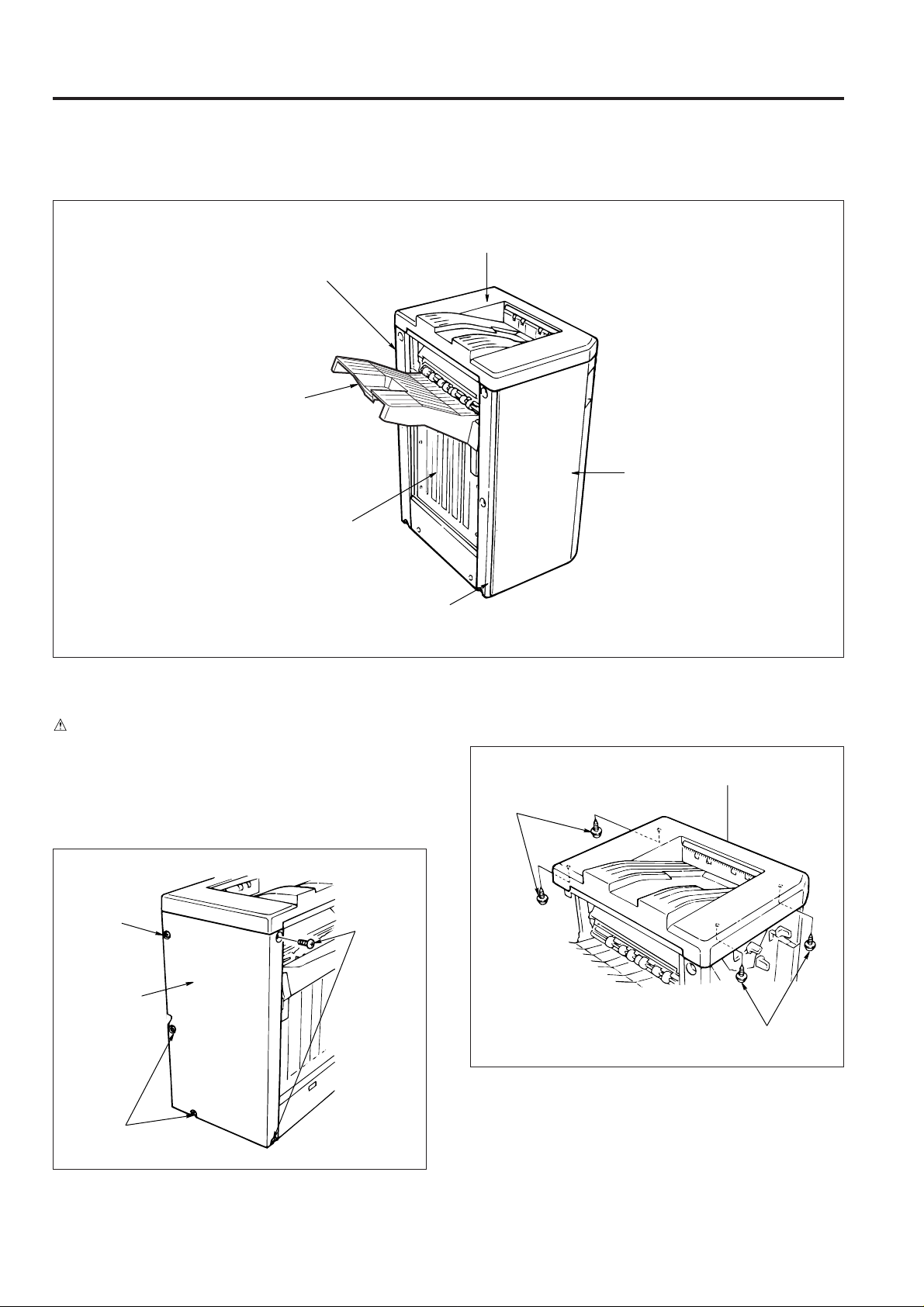

EXTERNAL SECTION

[1] Composition

Rear cover

Main tray

Paper exit

stopper plate

Top cover

Front cover

[2] Disassembly and Assembly

CAUTION

Be sure that the power cord has been unplugged from

the outlet.

1. Removing/installing the rear and top covers

a. Procedure

(1) Remove the 5 screws and remove the rear cover.

Screw

Rear cover

Screws

Front side cover

(2) Open the front cover.

(3) Remove the 4 screws and remove the top cover.

Top cover

Screws

Screws

Screws

(4) Reinstall the rear and top covers in the opposite se-

quence to removal.

1 - 10

Page 14

FS-106

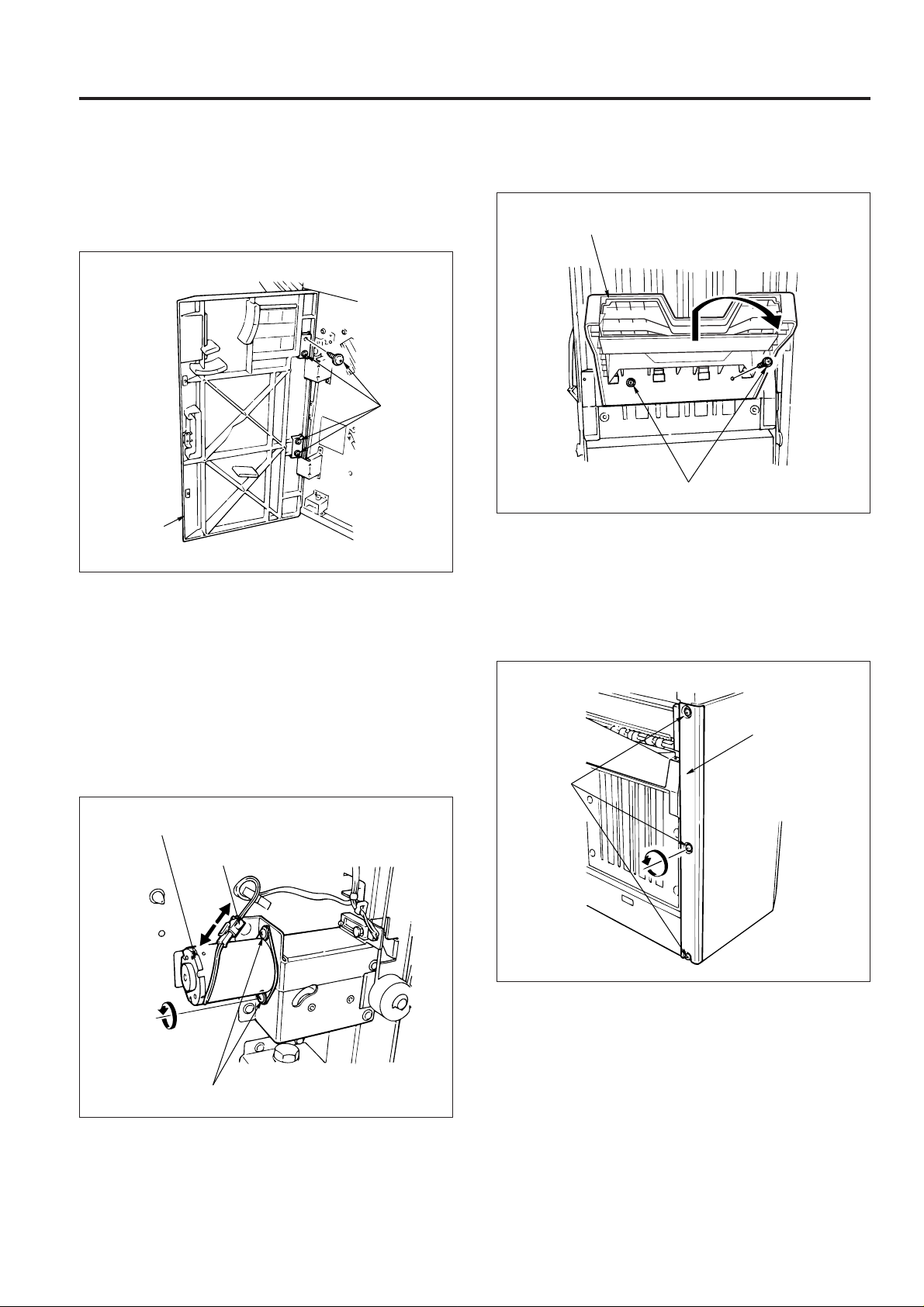

2. Removing and installing the front cover

a. Procedure

(1) Open the front cover.

(2) Remove the 4 screws and remove the front cover.

Screws

Front cover

(3) Reinstall the front cover in the opposite sequence to

removal.

3. Removing and installing the main tray

a. Procedure

(1) Remove the rear cover.

(2) Remove the connector and the 2 screws, then remov e

the tray up-down motor (M3).

CAUTION: Take out the tray up-down motor while sup-

porting the main tray with your hand.

(3) Remove the 2 screws, lift up and remove the main tray.

Main tray

Screws

(4) Reinstall the shift tray in the opposite sequence to re-

moval.

4. Removing and installing the front side cover

a. Procedure

(1) Remove the 3 screws and remov e the front side cover .

Front side cover

Screws

Tray up-down motor (M3)

Connector

Screws

(2) Reinstall the front side cover in the opposite sequence

to removal.

1 - 11

Page 15

FS-106

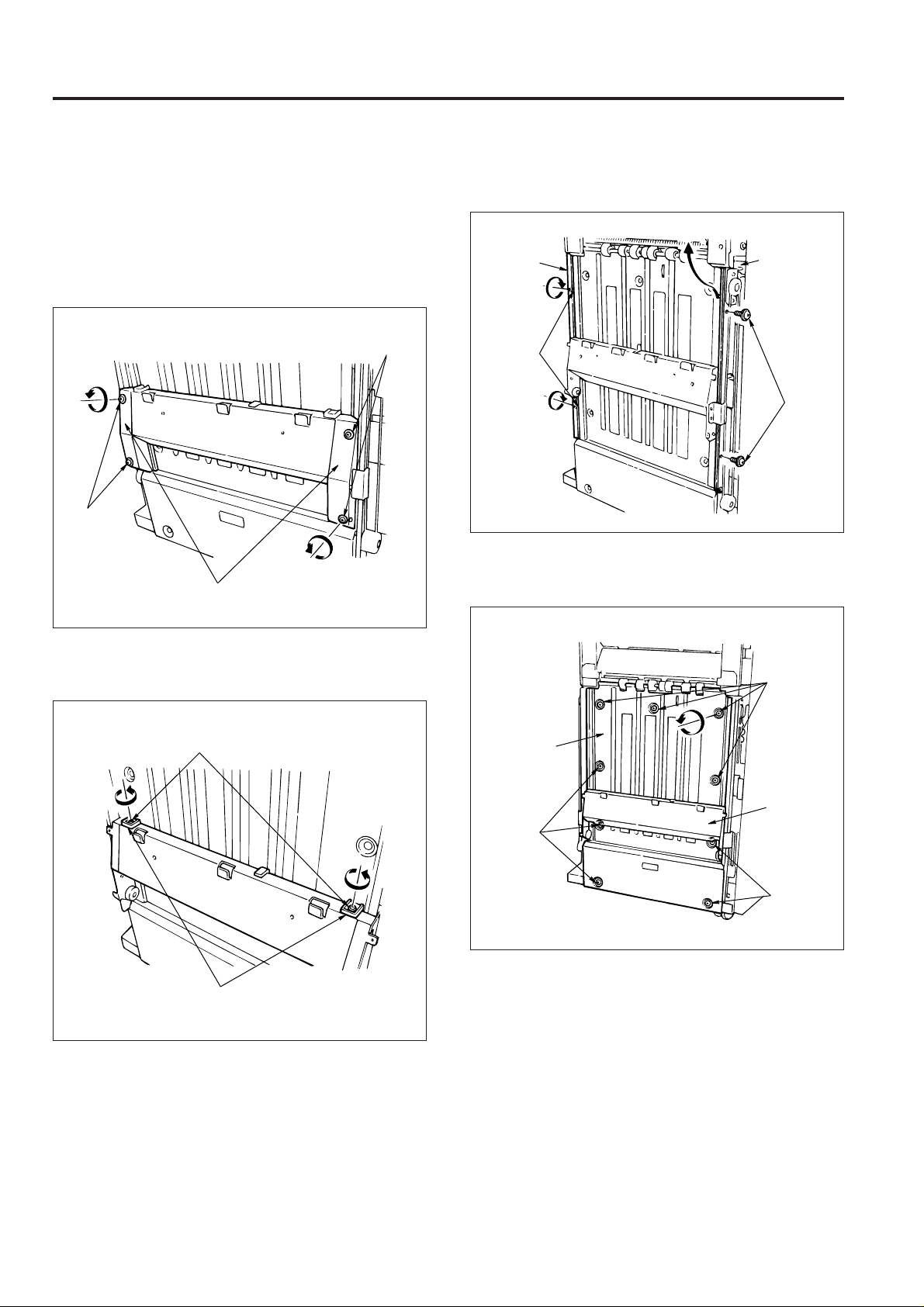

5. Removing and installing the paper exit stopper

plate

a. Procedure

(1) Remove the rear cover, main tray and the front side

cover.

(2) Remove the 4 screws and remove the left and right

up-down covers.

Screws

Screws

Up-down cover

(4) Remove the 2 screws and take out the up-down sup-

port plate (front and rear).

Up-down

support

plate (rear)

Screws

Up-down

support

plate (front)

Screws

(5) Remove the 9 screws, lift the up-down stay and take

out the paper exit stopper plate to the lower side.

(3) Remove the 2 screws and remove the 2 slide stop-

pers.

Screws

Slide stoppers

Screws

Paper exit

stopper plate

Up-down

stay

Screws

Screws

(6) Reinstall the paper exit stopper plate in the opposite

sequence to removal.

1 - 12

Page 16

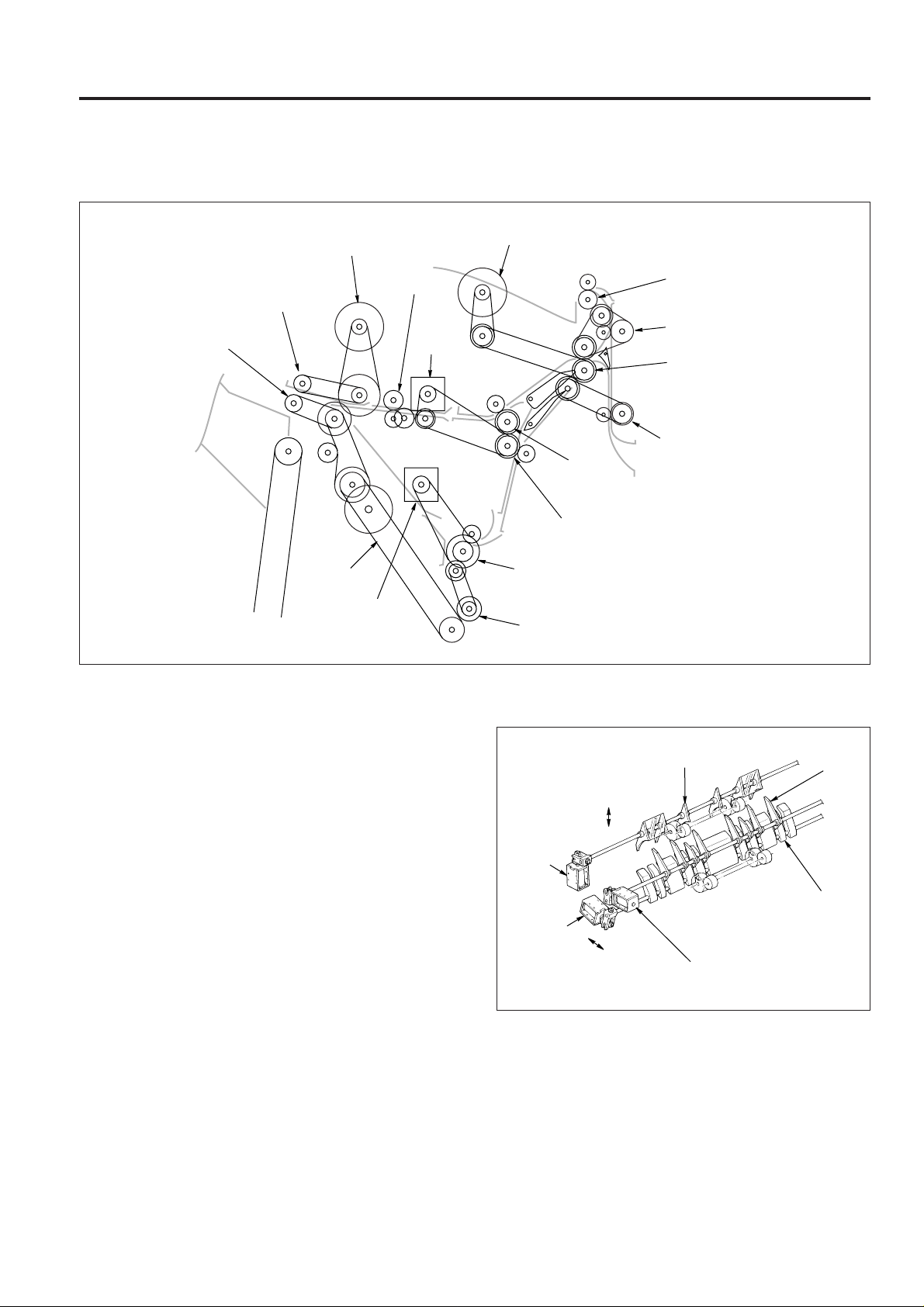

CONVEYANCE SECTION

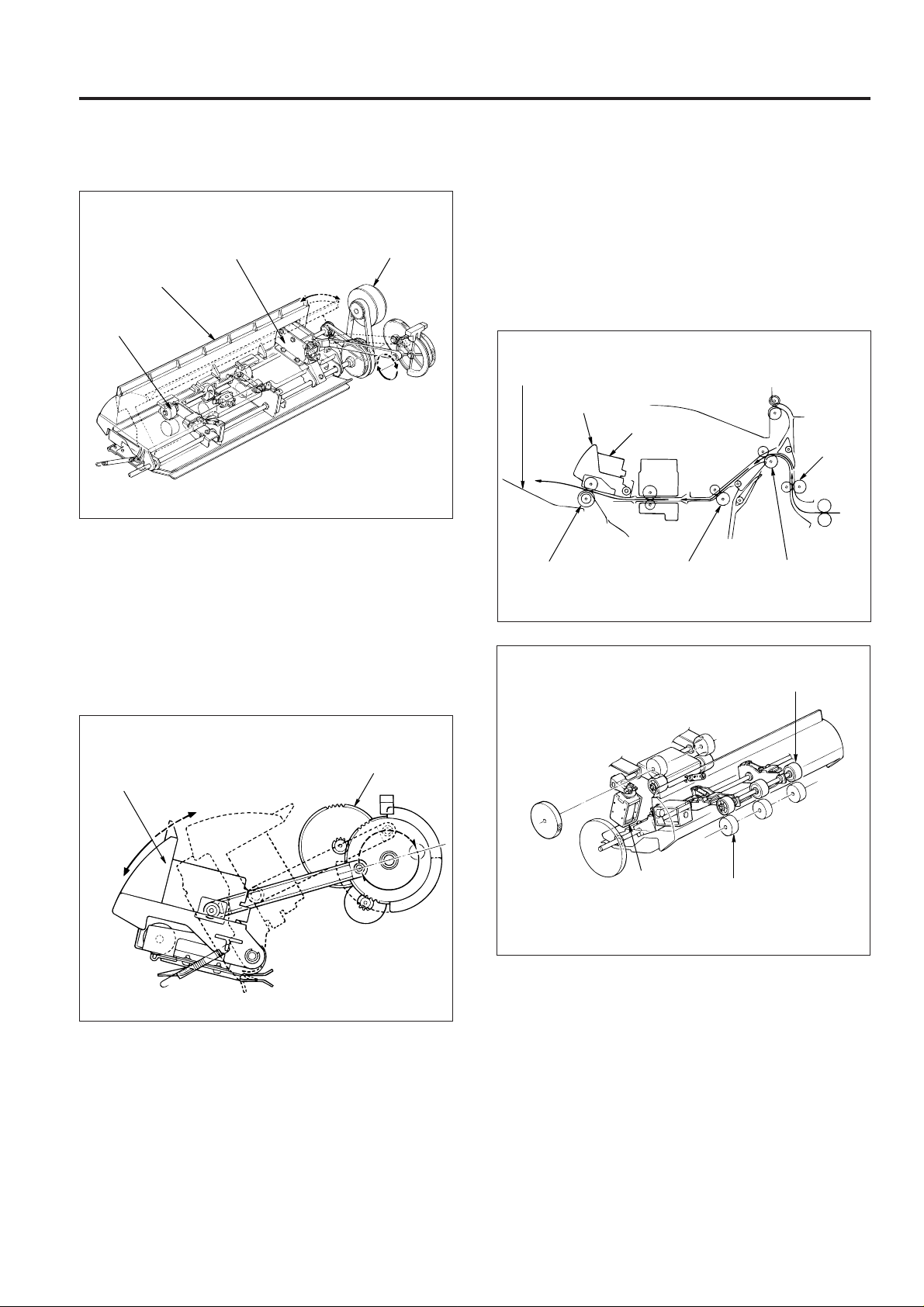

[1] Composition

FS-106

Paper exit roller

(sponge roller)

Paper exit roller motor (M7)

Nip paper exit roller

Paper exit belt

Stacker entrance

Conveyance

motor (M14)

slide shaft

2nd

conveyance

motor (M4)

1st conveyance motor (M1)

Sub-tray paper exit roller

Conveyance roller D

Conveyance roller B

Conveyance roller A

Conveyance

roller C

Intermediate roller

Stacker entrance roller

Sponge roller

[2] Mechanism

1. Paper conveyance

Paper conveyance is performed by the conveyance rollers A,

B, C and D , the intermediate roller, conveyance slide shaft and

sub-tray paper exit roller . These components are driven b y the

1st conveyance motor (M1) and the 2nd conveyance motor

(M4) through the timing belt.

Stacking to the paper stacker is performed by the stacker

entrance roller and sponge roller. These are driven by the

stacker entrance motor (M14) via the timing belt.

Paper exiting is perfor med by the stacker paper exit belt arm

and the paper exit rollers. These are driven by the paper exit

motor (M7) via the timing belt.

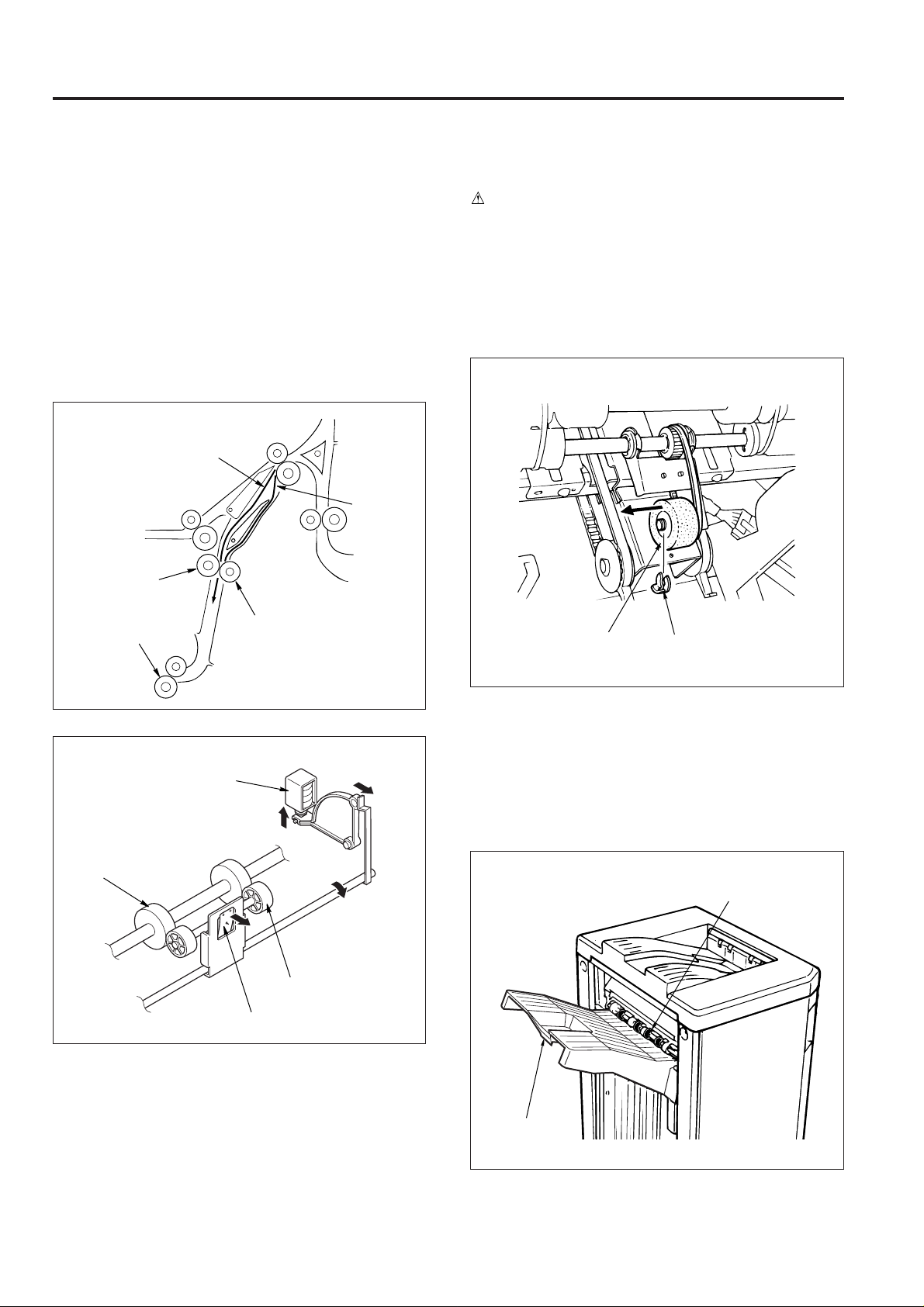

2. Paper path switching

Sub-tray gate

Sub-tray

paper

exit

solenoid

(SD2)

By-pass

solenoid

(SD5)

OFF

ON

ON

OFF

Gate solenoid

(SD1)

The paper route switches using the gate, sub-tray gate and

by-pass gate. Each gate oper ates with the ON/OFF s witching

of the gate solenoid (SD1), sub-tray paper e xit solenoid (SD2)

and by-pass solenoid (SD5).

Gate

By-pass

gate

1 - 13

Page 17

FS-106

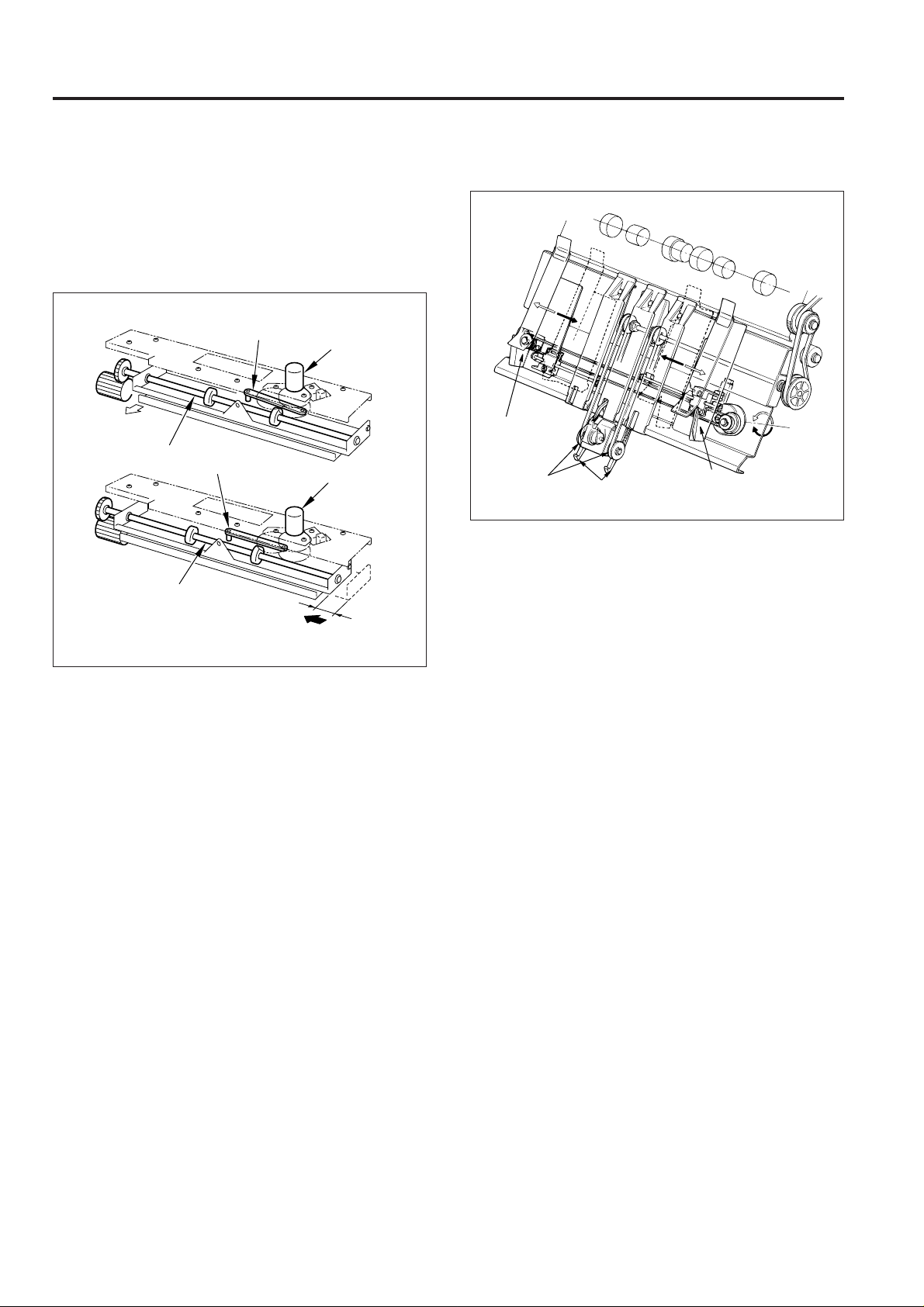

3. Shift unit sort shift operation

(1) The paper in the shift unit is fed in the exit direction by

the slide shaft.

(2) When the roller shift motor (M2) rotates, the link mecha-

nism shifts the paper along with the slide shaft, 30mm

towards the direction of the back side.

Shift unit

Exit direction

Slide shaft

Slide shaft

Link mechanism

Link mechanism

30mm towards the direction

of the back side

Roller shift

motor (M2)

Roller shift motor (M2)

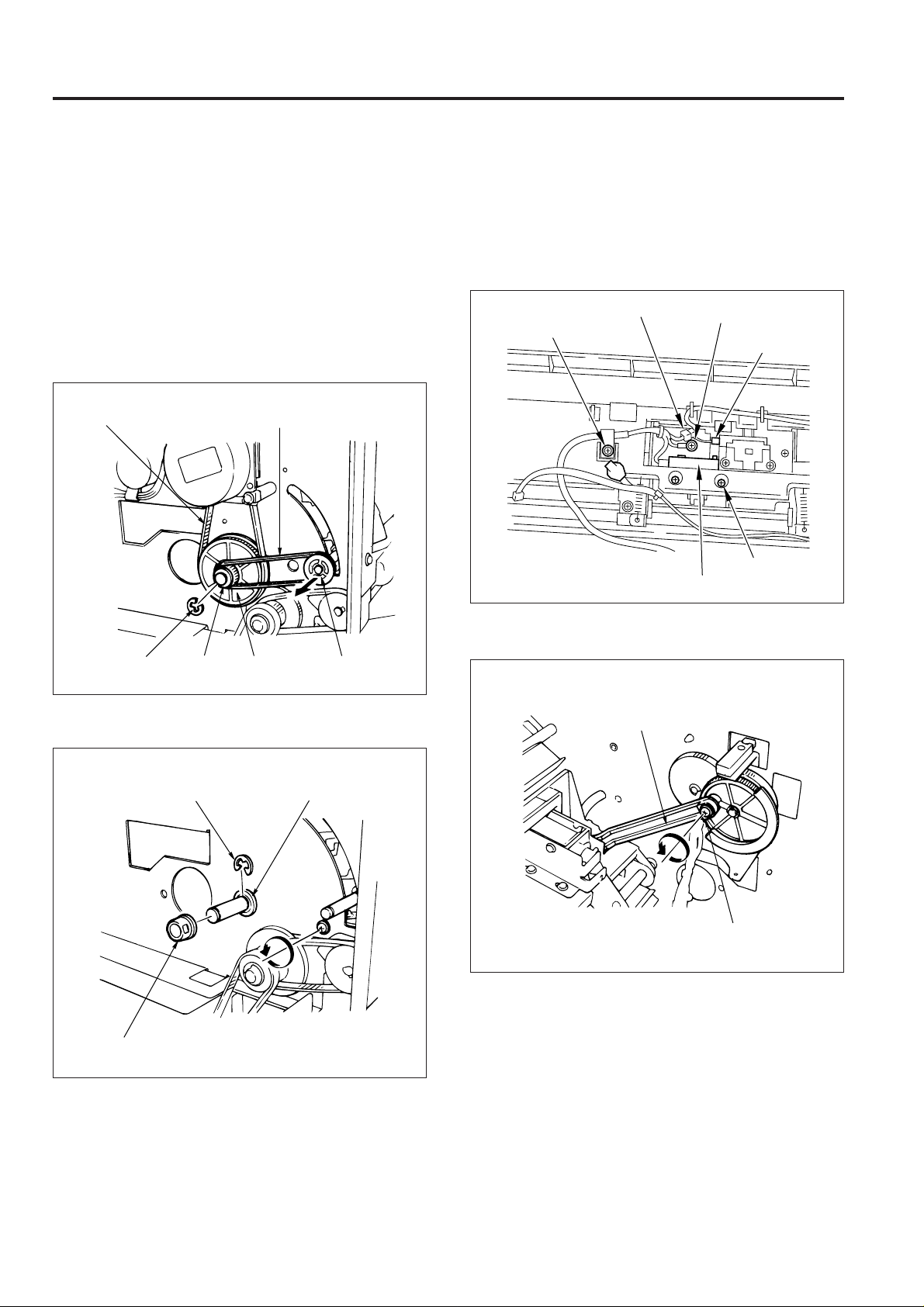

4. Stacker unit

Alignment

plate

Paper exit belt

Paper exit arm

Alignment plate

Alignment

plate

motor

(M5)

Paper alignment

Paper in the stacker is lined up by the forward and reverse

movement of the alignment plates. The forward/re verse motion

of the alignment plates is performed by the alignment plate

motor (M5).

Paper exiting

The paper exit arm sends the stapled paper out to the paper

exit opening.

The paper exit belt is rotated by the paper exit roller motor

(M7).

1 - 14

Page 18

FS-106

5. Paper exit opening unit

Paper exit opening

Paper exit

opening

Nip roller

solenoid (SD4)

Close Open

(1) Stapling mode for paper sized A4R and above

The paper exit opening is opened from the time copying commences to the time stapling is complete.

(2) Paper exit of the staple mode

When the stapling has finished, the paper exit opening is closed, the paper gripped and exited to the main

tray. The opening and closing of the paper exit opening is performed by the paper exit opening motor (M8).

Paper exit

opening motor

(M8)

(3) Pressure of the paper exit roller

The paper exit roller rotation is slower than the conveyance rollers A, B and C. Therefore pressure is released at times other than when paper is exiting.

When the paper reaches the paper exit opening the

paper exit roller applies pressure and paper is exited

to the main tray. The pressing and releasing of paper is

performed by the paper exit opening solenoid (SD4).

Main tray

Paper exit roller

Paper exit

opening

Paper exit

opening solenoid

(SD4)

Conveyance

roller C

Conveyance

roller B

Nip roller

Conveyance

roller A

Paper exit

opening

Close

Open

Paper exit

opening motor (M8)

Paper exit

opening

solenoid

(SD4)

Paper exit

roller

1 - 15

Page 19

FS-106

6. Intermediate conveyance roller

In this machine, in order to be compatible with thick paper ,

it has its pressure of the intermediate conveyance roller

set at a slightly higher level.

While in conve yance collectively of the 1st and 2nd copies

of the 2nd set and later to the stacker in staple copy mode

for small-sized paper, the decompression solenoid (SD3)

is operated to lower the pressure of the intermediate conveyance roller.

This is to prevent dirt from the roller from sticking to the

paper and wrinkles from taking place on paper in conveyance.

2nd copy

1st copy

Intermediate roller

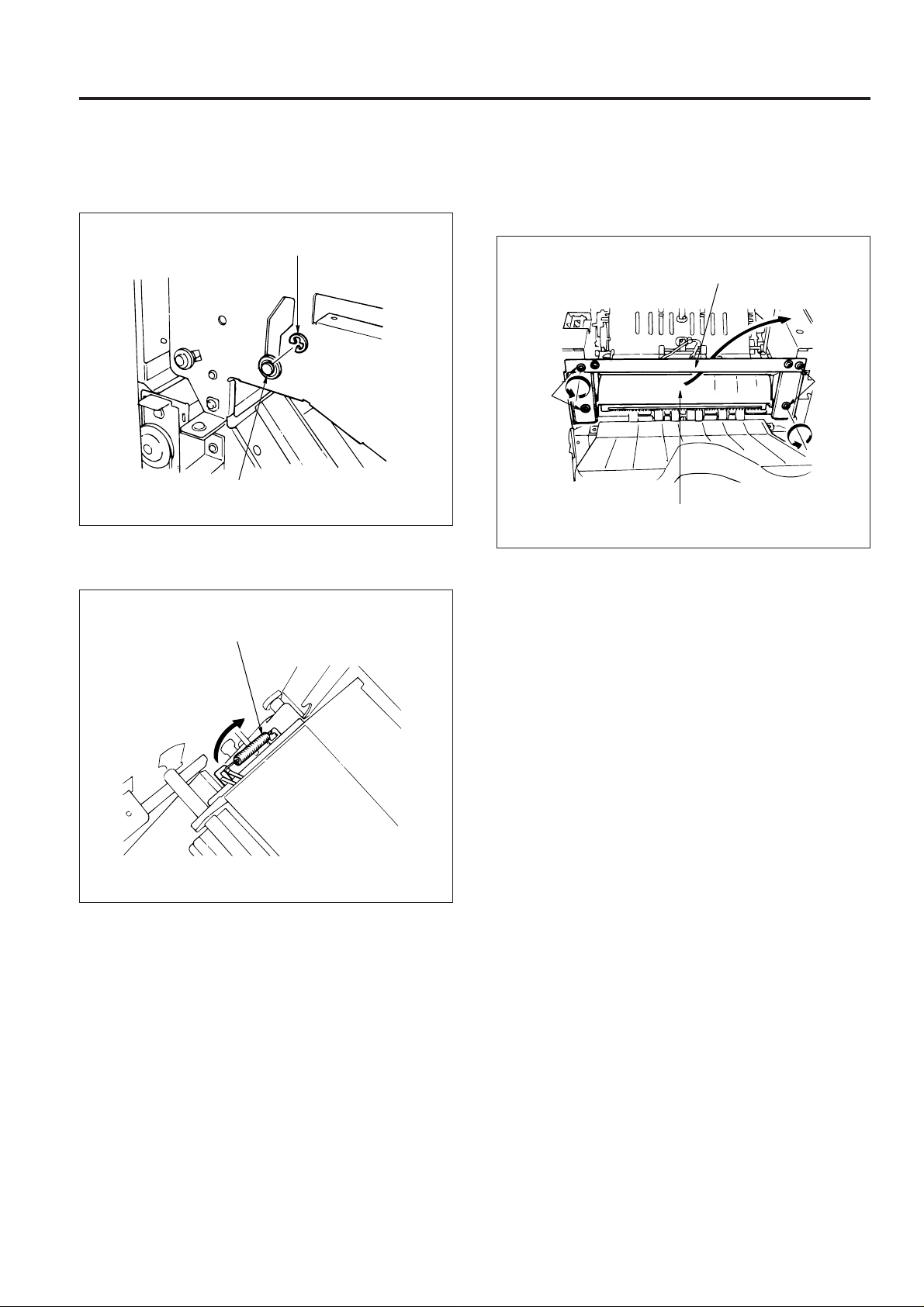

[3] Disassembly and Assembly

CAUTION

Be sure to remove the power cord from the power

outlet.

1. Exchanging the stacker unit section sponge

roller

a. Procedure

(1) Open the front cover, remove the fixing ring of the

stacker unit section and then remov e the sponge roller.

Stacker entrance roller

Decompression

solenoid (SD3)

Intermediate roller

Backup roller

Backup roller

Tension spring

Sponge roller

Fixing ring

(2) Reinstall the sponge roller in the opposite sequence

to removal.

2. Exchanging the paper exit roller (sponge roller)

a. Procedure

(1) Move the main tray down by using the 47 mode func-

tion (75-06 code).

Sponge rollers

1 - 16

Main tray

Page 20

FS-106

(2) Insert a screwdriver into the slot of the sponge roller,

then pry the roller open.

Sponge roller

(3) Align the grooves of the new sponge rollers with the

shaft.

(4) Press the sponge rollers until a click sounds, so that

they are properly installed.

3. Removing and reinstalling the shift unit

a. Procedure

(1) Remove the following parts:

• rear cover

• top cover

(2) Remove the connector of M2 and PS18.

(3) Remove the wiring from the three clamp positions.

Clamps

Wiring

M2 connector

(4) Remove the ground wire fixing screw.

(5) Remove the clamp screw.

(6) Remove the 4 screws, then remove the shift unit.

PS18

connector

Align

Align

Clamp screw

Screws

Ground wire

fixing screw

Shift unit

(7) Reinstall the shift unit in the opposite sequence to re-

moval.

Screws

1 - 17

Page 21

FS-106

4. Removing and installing the paper exit

opening unit

a. Procedure

(1) Remove the following parts:

• rear cover

• top cover

• front side cover

• shift unit

(2) Remove the pulley and belt.

(3) Remove the E-ring and then remove the collar, gear

and drive belt.

Drive belt

Belt

(5) Remove the clamp screw and the ground wire screw.

(6) Remove the connector of SD4 and PS6.

(7) Remove a set screw and withdraw the PS23 from the

unit, then remove the connector.

Note: When withdrawing the PS23, ensure that needless

force is not applied to the lever below the PS23.

SD4 connector

Clamp screw

Ground wire screw

PS6 connector

Screw for PS23

SD23

E-ring

Collar

Gear

Pulley

(4) Remove the collar, E-ring and shaft holder.

E-ring

Collar

Shaft holder

(8) Remove the paper exit opening open-shut link screw.

Paper exit opening

open-shut link

Screw

1 - 18

Page 22

FS-106

(9) Open the front cover and remove the front side E-ring

and shaft holder.

E-ring

Shaft holder

(10)Remove the spring.

(11)Remove the 4 screws and then remove the paper exit

opening cover.

(12)Take the paper exit opening unit out to the top.

Paper exit

opening cover

Screws

Screws

Paper exit

opening unit

(13) Reinstall the paper exit opening unit in the opposite

sequence to removal.

Spring

1 - 19

Page 23

FS-106

5. Removing/installing the stacker unit

a. Procedure

(1) Remove the following parts:

• rear cover

• top cover

• front side cover

(2) Take out the E-ring and flange, then remove the belt

and the two pulleys.

(3) Remove the shaft with a screwdriver and remove the

belt detection gear.

Belt

Belt detection

gear

Pulley E-ring Flange

Shaft

Pulley

(4) Remove the four connectors (CN1, CN5, CN11, CN12)

on the FNS control board.

CN5

CN11

CN1

FNS control

board

CN12

(5) Remove the four set screws , then remove the con vey-

ance unit.

Note: When placing the conveyance unit on the floor, etc.,

ensure that it is placed upside down.

Set screws

Set screw

Set screw

Conveyance unit

1 - 20

Page 24

FS-106

(6) Remove the E-ring and then shift the shaft holder.

Shaft

holder

E-ring

(7) Shift the shaft holder and then remove the shaft.

(8) Remove the connector of PS9 and then remove the

wiring from the clamp.

PS9 connector

Clamp

(9) Remove the screw and then remove PS9.

Shaft

Shaft holder

Screw

Clamp

PS9

1 - 21

Page 25

FS-106

(10)Remove CN6 and CN3 on the FNS control board and

the stapler F and R connectors. Then remove the

wiring from the clamp.

FIN control board

CN6

CN3

Clamps

Stapler F

connector

Stapler R connector

(11) Remove the 4 screws and then remove the stacker

unit.

Screws

CAUTION:

1. When the stacker paper exit arm is in the position as

that of the diagram, engage the gear so that the notch

of the detection gear actuator meets with the edge of

PS9 as per the diagram below.

Belt detection gear

Stacker paper

exit arm

Actuator

PS9

Actuator notch

2. When reinstalling the stacker unit, be careful not to

damage the conveyance guide sheets on the stacker

unit guide plate.

Screws

Stacker unit

(12)Reinstall the stacker unit in the opposite sequence to

removal.

Conveyance guide sheet

Conveyance

unit

Stacker unit guide plate

1 - 22

Page 26

FS-106

[4] M1 (1st conveyance) Control

P.GND

101-4

P.GND

101-5

S.GND

101-3

5V

101-2

114-1

TXD

114-2

DTR

114-6

RTS

114-3

RXD

114-7

DSR

114-5

CTS

101-1

24V

MAIN BODY

MS1

The 1st conveyance control during main tray paper exit and the

paper exit control during sub-tray paper exit are done by

transmitting the rotation of M1 (1st conveyance) to conveyance

rollers (A), (B), (D), and to the sub-tray paper exit roller.

FNS CB (FNS control board) controls M1.

1. Operation

a. Interlock

Paper 1st conveyance control commences with the ON

signal from the main body start button. However, if MS1

(interlock) is OFF, error data will be output to the main body

CB and control will not commence.

9-3

9-4

9-5

9-7

10-1

10-2

10-3

10-4

10-5

10-6

9-1

RXD

CTS

DSR

TXD

RTS

DTR

24V-IN

M1 BLK

M1 CONT

M1 CLK

M1DIR

24V GND

24V GND

PS4 IN

PS1 IN

FNS CB

VCC

24V

24V

24V

VCC

GND

GND

5-A1

5-B10

5-B9

5-B8

5-B11

1-A1

1-A2

1-A3

1-A5

1-A6

5-A3

5-A8

5-B4

5V

5-A5

5-B6

5-A7

M1

PS4

PS1

b. M1 (1st conveyance) Control

(1) Main tray paper exit operation

M1 (1st conveyance) turns ON by the ON signal of the

start button and goes OFF after the specified time

when PS4 (FIN entrance path) detects the trailing edge

of the final copy.

(2) Sub-tray paper exit operation

M1 turns ON by the ON signal of the start button, and

rotates at high speed. When PS4 (FIN entrance path)

detects the trailing edge of the paper, rotation switches

to low speed after the specified time. Then, rotation

once again returns to high speed to be ready for

conveyance of the next copy. On detection of the

trailing edge of the final copy by PS4, it turns OFF in the

specified time.

M1 (1st convenyance)

PS1 (sub-tray upper limit)

Sub-tray

paper exit roller

Conveyance

roller D

Conveyance

roller B

PS4

(FIN entrance path)

Conveyance roller A

c. Sub-tray Upper Limit Detection Control

PS1 (sub-tray upper limit) is fitted in the sub-tray, and when

PS1 turns ON by detecting paper during sub-tray paper

exit, the main body and the FNS stop after ejecting the

paper being copied at that time.

2. Signals

a. Input signals

(1) TXD (main body CB FNS CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) DTR (main body CB

FNS CB)

Transmission acknowledgement signal from the main

body to FNS.

(3) RTS (main body CB

FNS CB)

Request-to-send signal from the main body to FNS.

(4) 24 V IN (MS1

FNS CB)

When MS1 (interlock) goes ON, +24 V is output. This

power supply is supplied to each electrical load of FNS.

1 - 23

Page 27

FS-106

(5) PS1 IN (PS1 FNS CB)

When the sub-tray is full, PS1 (sub-tray upper limit)

goes ON and inputs [L].

(6) PS4 IN (PS4

FNS CB)

When paper passes through the FNS entrance, this

signal turns ON and [L] is input.

b. Output signals

(1) TXD (FNS CB main body CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) RTS (FNS CB

Transmission acknowledgement signal from the main

body to FNS.

(3) DTR (FNS CB

Request-to-send signal from the main body to FNS.

(4) M1 CONT (FNS CB

Operational signal used by M1 (1st conveyance). M1

turns ON at the same time as the finisher operation

start signal.

[H]: OFF

[L]: ON

(5) M1 BLK (FNS CB

M1 (1st conveyance) brake signal.

[H]: OFF

[L]: ON

(6) M1 CLK (FNS CB

M1 (1st conveyance) speed adjustment clock.

(7) M1 DIR (FNS CB

M1 (1st conveyance) rotation direction signal.

[H]: Forward rotation (CW)

[L]: Reverse rotation (CCW)

main body CB)

main body CB)

M1)

M1)

M1)

M1)

[5] M4 (2nd conveyance) Control

P.GND

101-4

P.GND

101-5

S.GND

101-3

5V

101-2

TXD

114-1

DTR

114-2

RTS

114-6

RXD

114-3

DSR

114-7

CTS

114-5

24V

101-1

MAIN BODY

MS1

The 2nd convey ance control during main tray paper exit is done

by transmitting the rotation of M4 (2nd conveyance) to the

intermediate roller, conve yance roller (C), and the conv eyance

slide shaft.

FNS CB (FNS control board) controls M4 only when the main

tray paper exit is operated in the sort/group/non-sort/staple

mode.

1. Operation

Nip paper exit roller

9-3

9-4

9-5

9-7

10-1

10-2

10-3

10-4

10-5

10-6

9-1

RXD

CTS

DSR

TXD

RTS

DTR

24V-IN

M4 DRV A

M4 DRV A

M4 DRV B

M4 DRV B

PS4-IN

SD3 DRV

PS6-IN

FNS CB

24V

24V

VCC

GND

24V

GND

Conveyance slide roller

M4 (2nd conveyance)

12-1

12-6

12-2

12-3

12-4

12-5

5-A3

5-A8

5-B4

1-A9

1-A8

5V

5-A6

5-B7

5-A10

M4

PS4

SD3

PS6

Stacker entrance roller

a. During Sort/Group/Non-Sort Mode

M4 (2nd conveyance) turns ON by the ON signal of the start

button, and rotates at high speed. When PS4 (FIN entrance path) detects the trailing edge of the paper fed from

the main body, rotation switches to low speed after the

specified time.

Then, rotation once again returns to high speed to be ready

for conveyance of the next copy. On detection of the trailing

edge of the final copy by PS4, it turns OFF in the specified

time.

1 - 24

Conveyance

roller (C)

Intermediate roller

PS4 (FIN entrance

path)

Page 28

FS-106

b. During Staple Mode

(1) ON timing of M4 (2nd conveyance)

M4 (2nd conveyance) goes ON by the ON signal of

the start button, and rotates at high speed. When PS4

(FIN entrance path) detects the trailing edge of the

paper fed from the main body, rotation switches to low

speed after the specified time.

Then, rotation once again returns to high speed to be

ready for conveyance of the next copy.

(2) Paper conveyance of the 1st copy of the 2nd and later

sets

When PS4 (FIN entrance path) detects the trailing edge

of the 1st copy fed from the main body, it goes OFF

after the specified time, and enters a standby mode to

convey the 2nd copy.

As a result, the 1st copy is conveyed to the stacker

entrance.

(3) Paper conveyance of the 2nd copy of the 2nd and later

sets

When PS4 detects the trailing edge of the 2nd copy,

M4 starts to rotate at high speed after the specified

time. Then, in the specified time from detection of the

trailing edge of the 2nd copy by PS4, M4 is switched

over into low speed rotation.

Further, in the specified time, it once again returns to

high speed rotation which is the standby state for conveyance of the 3rd copy and later.

For the 3rd copy and later, rotation is switched over

into low speed in the specified time after the trailing

edge of the copy is detected by PS4, and is returned

to high speed in the specified time.

(4) OFF timing of M4 (2nd conveyance)

M4 turns OFF in the specified time after PS6 (paper

exit 1) detects the final set stapled.

c. Pressing Release Operation of Intermediate

Roller

The intermediate roller, when conveying the 1st and 2nd

copies of the 2nd set on collectively in staple copy mode

for A4/B5 paper, operates SD3 (decompression) and release its pressing, reducing pressing force of the roller.

SD3 turns ON after PS4 detects the trailing edge of the 1st

copy of the 2nd and later sets, and then goes OFF in the

specified time after the trailing edge of the 2nd copy of the

2nd and later sets is detected by PS4.

2. Signal

a. Input signals

(1) TXD (main body CB FNS CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) DTR (main body CB

Transmission acknowledgement signal from the main

body to FNS.

(3) RTS (main body CB

Request-to-send signal from the main body to FNS.

(4) 24V IN (main body CB

+24V is output when MS1 (interlock) is turned ON.

This power is supplied to each load of FNS.

(5) PS4 IN (main body CB

When paper passes through the FNS entrance, this

signal turns ON and [L] is input.

(6) PS6 IN (PS6

When paper passes through the paper exit opening

to the main tray, this signal turns ON and [L] is input.

FNS CB)

FNS CB)

FNS CB)

b. Output signals

(1) TXD (FNS CB main body CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) RTS (FNS CB

Transmission acknowledgement signal from the main

body to FNS.

(3) DTR (FNS CB

Request-to-send signal from the main body to FNS.

(4) M4 DRV A/M4 DRV B (FNS CB

M4 (2nd conveyance) drive signal.

(5) SD3 DRV (FNS CB

SD3 (decompression) drive use signal.

[H]: SD3 OFF

[L]: SD3 ON

main body CB)

main body CB)

SD3)

FNS CB)

FNS CB)

M4)

1 - 25

Page 29

FS-106

[6] Gate Control

P.GND

101-4

P.GND

101-5

S.GND

101-3

5V

101-2

TXD

114-1

DTR

114-2

RTS

114-6

RXD

114-3

DSR

114-7

CTS

114-5

24V

101-1

MAIN BODY

MS1

The paper conveyance path is switched by the ON/OFF

switching of SD1 (gate), SD2 (sub-tray paper exit) and SD5

(by-pass). The FNS CB (FNS control board) controls the ON/

OFF switching of SD1, SD2 and SD5.

1. Operation

PS6

(paper exit 1)

9-3

9-4

9-5

9-7

SD1 DRV

1-B5

24V

SD2 DRV

24V

SD5 DRV

24V

VCC 5-A3

PS4-IN 5-A8

GND 5-B4

VCC 5-A4

PS5-IN

GND

5V

GND

PS6-IN

1-B6

1-B7

1-B8

1-B11

1-B12

5-A9

5-B5

5-A6

5-B7

5-A10

10-1

10-2

10-3

10-4

10-5

10-6

9-1

RXD

CTS

DSR

TXD

RTS

DTR

24V-IN

FNS CB

SD2 (sub-tray paper exit)

Sub-tray paper exit roller

SD1 (gate)

PS5 (stacker

conveyance

path)

SD5 (by-pass)

SD1

SD2

SD5

PS4

PS5

PS6

b. Main tray paper exit operation (during staple

mode)

Paper is fed to the main tray via the stacker. At this time,

the paper passes the sub-tray gate, gate, and the b y-pass

gate as its convey ance path. Among these gates, the subtray gate is installed so that the stack er side becomes the

convey ance path beforehand, thus SD2 does not oper ate.

(1) SD1 (gate) ON timing

SD1 goes ON by the ON signal of the start button,

switches the gate to the stacker side, and enter a

standby mode for paper conveyance.

(2)

Paper conv ey ance f or paper in sizes other than A4/B5

Paper in sizes other than A4/B5 is conveyed to the

stacker side by the gate. At this time, SD5 does not

operate and the paper is fed to the stacker entrance

roller.

(3) A4/B5 sized paper conveyance (Conveyance of the

1st copy of the 2nd and later batches)

For conve y ance of A4 or B5 sized paper, in the specified time after the trailing edge of the final copy of the

preceding set is detected by PS4 (FIN entrance path),

SD5 is turned ON, switching the bypass gate into Bypass. The 1st copy of the following set is, therefore,

guided into the bypass track.

(4) A4/B5 sized paper conveyance (Conveyance of the

2nd copy of the 2nd and later sets)

In the specified time after the trailing edge of the 1st

copy is detected by PS4, SD5 turns OFF, closing the

bypass gate.

The 2nd copy, therefore, follows the normal course,

which is conveyed to the stacker entrance roller together with the 1st copy held in the bypass track.

The 3rd copy and later are conv e y ed to the stacker in

the normal course, where SD5 never turns ON.

(5) OFF timing of SD1 (gate)

SD1 turns OFF in the specified time after PS6 (paper

exit 1) detects the final set stapled.

PS4 (FIN entrance

path)

Stacker entrance

roller

a.

Main tray paper exit operation (during sort/group/

non-sort mode)

Paper is fed to the main tr a y via the shift unit. At this time,

the paper passes the sub-tray gate and the gate as its

conveyance path. These gates, however, are installed so

that the shift unit side becomes the conve yance path during idling state, so SD2 (sub-tray paper exit) and SD1 (gate)

which drive each gate do not operate.

1 - 26

Page 30

FS-106

c. Operation to exit to sub-tray

SD2 (sub-tray paper exit) turns ON with the start button ON

signal and the sub-tray gate to the sub-tray side.

When PS4 (FIN entrance path) detects the trailing edge of

the final copy, SD2 goes OFF after the specified time.

Finishing

Sort / Group / Non-sort

First page of

Staple-A4 • B5

(Other)

Sub-tray paper exit

second and

subsequent sets

Other

SD1

OFF

ON

ON

OFF

SD2

OFF

OFF

OFF

ON

2. Signals

a. Input signals

(1) TXD (main body CB FNS CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) DTR (main body CB

Transmission acknowledgement signal from the main

body to FNS.

(3) RTS (main body CB

Request-to-send signal from the main body to FNS.

(4) PS4 IN (PS4

This signal turns ON when the paper passes the FNS

entrance and [L] is input.

(5) PS5 IN (PS5

This goes ON when the paper passes the stacker entrance and [L] is input.

(6) PS6 IN (PS6

This signal turns ON when the paper passes the main

tray paper exit opening and [L] is input.

FNS CB)

FNS CB)

FNS CB)

FNS CB)

FNS CB)

SD5

OFF

ON

(OFF)

OFF

OFF

b. Output signals

(1) TXD (FNS CB main body CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) RTS (FNS CB

Transmission acknowledgement signal from the main

body to FNS.

(3) DTR (FNS CB

Request-to-send signal from the main body to FNS.

(4) SD1 DRV (FNS CB

SD1 (gate) drive use signal.

[H]: OFF

[L]: ON

(5) SD2 DRV (FNS CB

SD2 (sub-tray) drive use signal.

[H]: OFF

[L]: ON

(6) SD5 DRV (FNS CB

SD5 (by-pass) drive use signal.

[H]: OFF

[L]: ON

main body CB)

main body CB)

SD1)

SD2)

SD5)

1 - 27

Page 31

FS-106

[7] M14 (Stacker Entrance) Control

P.GND

101-4

P.GND

101-5

S.GND

101-3

5V

101-2

TXD

114-1

DTR

114-2

RTS

114-6

RXD

114-3

DSR

114-7

CTS

114-5

24V

101-1

MAIN BODY

MS1

M14 (stacker entrance) drives the stacker entrance roller and

the sponge roller. These rollers allow paper conveyance to

the stacker , aligning the tr ailing ends of pages, and adjust the

timing of staple standby.

FNS CB (FNS control board) controls M14.

1. Operation

The operation to convey paper to the stacker differs between paper of A4/B5 sizes and other sizes.

PS6 (paper exit 1)

M14 (stacker entrance)

9-3

9-4

9-5

9-7

10-1

10-2

10-3

10-4

10-5

10-6

9-1

RXD

CTS

M14 DRV A

DSR

M14 DRV A

TXD

M14 DRV B

RTS

M14 DRV B

DTR

24V-IN

FNS CB

PS5

(stacker

conveyance

path)

VCC

PS4 IN

GND

VCC

PS5 IN

GND

GND

PS6-IN

7-1

24V

7-6

24V

7-2

7-3

7-4

7-5

5-A3

5-A8

5-B4

5-A4

5-A9

5-B5

5V

5-A6

5-B7

5-A10

Stacker entrance

roller

Sponge roller

M14

PS4

PS5

PS6

PS4 (FIN entrance

path)

Then, in the specified time after the trailing edge of

paper is detected by PS5 (stacker conveyance path),

it returns to high speed rotation once again, entering

standby state for conveyance of the following copy.

Through repetition of these operations, sheets of paper are carried successively to the stacker section.

(2) OFF timing of M14

M14 turns OFF in the specified time after PS6 (paper

exit 1) detects the final batch stapled.

b. Conveyance operation to the stacker (A4/B5

sizes)

(1) Paper conveyance for the 1st set

A4/B5 sized sheets of paper for the 1st batch to staple

are fed in the same way as those other than A4/B5

sized.

(2) Paper conveyance of the 1st copy of the 2nd and later

sets

M14 turns OFF in the specified time after the trailing

edge of this paper is detected by PS4 (FIN entrance

path). The 1st copy, therefore, is held in standby in

the by-pass track so that paper of the 2nd set is not

conveyed to the stacker section before completing to

staple the first set.

(3) Paper conveyance of the 2nd copy of the 2nd and later

sets

M14 turns ON again in low speed in the specified time

after the trailing edge of this paper is detected by PS4.

Therefore, the 1st and 2nd copies are collectively conveyed to the stacker section as being piled up. In the

specified time after PS5 (stacker conveyance path)

detects the trailing edges of the 1st/2nd copies, M14

changes into high speed rotation, entering standby

state for conveyance of the following copy.

The 3rd and later copies are conveyed to the stacker

section in the same manner as that for the 1st.

c. Operation for justifying the trailing edge of the

paper

The trailing edge of the paper conveyed to the stacker are

aligned by the sponge roller one at a time.

a. Conveyance operation to the stacker (sizes

other than A4/B5)

(1) M14 (stacker entrance) ON timing

M14 (stacker entrance) turns ON with input of ON signal by the start button and, rotates at high speed.

Rotation switches into low speed in the specified time

after the trailing edge of paper is detected by PS4 (FIN

entrance path).

1 - 28

Page 32

FS-106

2. Signals

a. Input signals

(1) TXD (main body CB FNS CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) DTR (main body CB

FNS CB)

Transmission acknowledgement signal from the main

body to FNS.

(3) RTS (main body CB

FNS CB)

Request-to-send signal from the main body to FNS.

(4) PS4 IN (PS4

FNS CB)

This signal turns ON when paper passes the FNS

entrance and [L] is output.

(5) PS5 IN (PS5

FNS CB)

This signal turns ON when paper passes the stacker

entrance and [L] is output.

(6) PS6 IN (PS6

FNS CB)

This signal turns ON when the paper passes the main

tray paper exit opening and [L] is input.

b. Output signals

(1) TXD (FNS CB main body CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) RTS (FNS CB

Transmission acknowledgement signal from the main

body to FNS.

(3) DTR (FNS CB

Request-to-send signal from the main body to FNS.

(4) M14 DRV A, A

M14 (stacker entrance) drive use signal.

main body CB)

main body CB)

/M14 DRV B, B¯ (FNS CB M14)

¯

[8] M5 (Alignment Plate) Control

P.GND

101-4

P.GND

101-5

S.GND

101-3

5V

101-2

TXD

114-1

DTR

114-2

RTS

114-6

RXD

114-3

DSR

114-7

CTS

114-5

24V

101-1

MAIN BODY

MS1

The alignment of the widthwise direction of paper conveyed

to the stacker is performed by the opening and closing of

the alignment plate by M5 (alignment plate). M5 is controlled

by FNS CB (FNS control board).

1. Operation

In the initial operation, the alignment plate is stopped in the

position where PS8 (alignment plate HP) is ON. After the

specified time from when PS5 (stacker conveyance path)

detected the trailing edge of the paper, M5 (alignment

plate) rotates, and closes the alignment plate which opens

after the specified time. This operation is performed for

each page.

9-3

9-4

9-5

9-7

10-1

10-2

10-3

10-4

10-5

10-6

9-1

RXD

CTS

DSR

TXD

RTS

DTR

24V-IN

M5 DRV A

M5 DRV A

M5 DRV B

M5 DRV B

PS5 IN

PS8 IN

FNS CB

24V

24V

VCC

GND

VCC

GND

6-A12

6-B12

3-5

3-6

3-7

3-8

5-A4

5-A9

5-B5

6-A1

6-A8

6-B4

M5

PS5

PS8

1 - 29

Alignment

plate

PS5 (stacker

conveyance

path)

M5 (alignment plate)

Page 33

FS-106

2. Signals

a. Input signals

(1) TXD (main body CB FNS CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) DTR (main body CB

FNS CB)

Transmission acknowledgement signal from the main

body to FNS.

(3) RTS (main body CB

FNS CB)

Request-to-send signal from the main body to FNS.

(4) PS5 IN (PS5

FNS CB)

This signal turns ON when the paper passes the

stacker entrance and [L] is output.

(5) PS8 IN (PS8

FNS CB)

When this signal detects alignment plate home

position, [L] is output.

b. Output signals

(1) TXD (FNS CB main body CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) RTS (FNS CB

Transmission acknowledgement signal from the main

body to FNS.

(3) DTR (FNS CB

Request-to-send signal from the main body to FNS.

(4) M5 DRV A/M5 DRV B (FNS CB

M5 (alignment plate) drive use signal.

main body CB)

main body CB)

M5)

[9] M2 (Roller Shift) Control

P.GND

101-4

P.GND

101-5

S.GND

101-3

5V

101-2

TXD

114-1

DTR

114-2

RTS

114-6

RXD

114-3

DSR

114-7

CTS

114-5

24V

101-1

MAIN BODY

MS1

Paper shift for sort and group modes is performed by M2

(roller shift). The control of M2 is performed by the FNS CB

(FNS control board).

1. Operation

In the specified time after the trailing edge of the paper

subject to shifting is detected by PS4 (FIN entrance path)

in Sort/Group mode, M2 (roller shift) turns ON.

Rotation of M2 starts shifting of the conveyance slide shaft.

The conveyance slide shaft is rotated by M4 (2nd conveyance) driving, which shifts as conveying paper.

When PS18 (roller shift HP) turns ON and detects completion of shifting of the conveyance slide shaft, M2 turns OFF

and is brought to a stop.

In the specified time from turning OFF of PS4, M2 turns ON

once again, returning the conveyance slide shaft to the

original position. When PS18 turns OFF and the conveyance slide shaft returns fully to the original position, M2 is

brought to a stop, where it waits for the next paper subject

to shifting.

Through repetition of these operations, sheets of paper are

shifted and conveyed to the paper exit roller.

9-3

9-4

9-5

9-7

10-1

10-2

10-3

10-4

10-5

10-6

9-1

RXD

CTS

DSR

TXD

RTS

DTR

24V-IN

M2 DRV

PS18 IN

FNS CB

P.GND

VCC

PS4 IN

GND

GND

1-B1

1-B2

5-A3

5-A8

5-B4

5-A6

5V

5-B1

5-B7

M2

PS4

PS18

1 - 30

Page 34

[10] M7 (Paper Exit Roller) Control

FS-106

M2 (roller shift)

Conveyance slide shaft

Paper exit roller

2. Signals

a. Input signals

(1) TXD (main body CB FNS CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) DTR (main body CB

FNS CB)

Transmission acknowledgement signal from the main

body to FNS.

(3) RTS (main body CB

FNS CB)

Request-to-send signal from the main body to FNS.

(4) PS4 IN (PS4

FNS CB)

This signal turns ON once the paper passes the

FNS entrance and [L] is output.

(5) PS18 IN (PS18

FNS CB)

Roller shift position detection signal.

[L]

[H]: Front position

[H]

[L]: Rear position

b. Output signals

(1) TXD (FNS CB main body CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) RTS (FNS CB

Transmission acknowledgement signal from the main

body to FNS.

(3) DTR (FNS CB

Request-to-send signal from the main body to FNS.

(4) M2 DRV (FNS CB

M2 (roller shift) drive use signal.

[H]: M2 ON

[L]: M2 OFF

main body CB)

main body CB)

M2)

PS4 (FIN entrance path)

PS18 (roller shift HP)

P.GND

P.GND

S.GND

5V

TXD

DTR

RTS

RXD

DSR

CTS

24V

MAIN BODY

MS1

101-4

101-5

101-3

101-2

114-1

114-2

114-6

114-3

114-7

114-5

101-1

9-3

9-4

9-5

9-7

10-1

10-2

10-3

10-4

10-5

10-6

9-1

RXD

CTS

DSR

TXD

RTS

DTR

24V-IN

24V GND

M7 CONT

M7 CLK

M7 GAIN

PS23 IN

FNS CB

24V

VCC

GND

GND

PS9 IN

GND

1-A4

1-A7

5-A2

5-B2

1-A11

1-A10

1-A12

5V

11-1

11-2

11-3

5V

6-A2

6-A9

6-B5

M7

PS23

PS9

Paper exit from the stacker is performed by the paper exit

belt, and paper exit from FNS is performed by the paper exit

roller. They are driven by M7 (paper e xit roller). The control of

M7 is performed by the FNS CB (FNS control board).

1. Operation

a. Sort/Group/Non-sort mode

M7 (paper exit roller) rotates by the ON signal from the main

body start button.

PS23 (paper exit 2) detects the exiting of paper and if no

finisher start signal comes from the main body, it will stop.

b. Staple mode

The staple mode commences rotation with completion of

the stapling operation. It will stop when the PS9 (paper exit

belt HP) turns ON.

PS6 (paper exit 1)

Paper exit roller

(sponge roller)

M7 (paper exit roller)

PS23 (paper exit 2)

PS9 (paper exit

belt HP)

Paper exit belt

Paper exit

arm

1 - 31

Page 35

FS-106

2. Signals

a. Input signals

(1) TXD (main body CB FNS CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) DTR (main body CB

FNS CB)

Transmission acknowledgement signal from the main

body to FNS.

(3) RTS (main body CB

FNS CB)

Request-to-send signal from the main body to FNS.

(4) PS9 IN (PS9

FNS CB)

This turns ON when detecting the home position of

the paper exit belt and [L] is output.

(5) PS23 IN (PS23

FNS CB)

This turns ON when the paper passes the FNS

paper exit opening and [L] is output.

b. Output signals

(1) TXD (FNS CB main body CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) RTS (FNS CB

Transmission acknowledgement signal from the main

body to FNS.

(3) DTR (FNS CB

Request-to-send signal from the main body to FNS.

(4) M7 CONT (FNS CB

M7 (paper exit roller) drive use signal.

[H]: OFF

[L]: ON

(5) M7 CLK (FNS CB

M7 (paper exit roller) speed adjustment clock signal.

(6) M7 GAIN (FNS CB

M7 (paper exit roller) speed gain signal.

[H]: 500 to 600 rpm

[L]: 600 to 1,650rpm

main body CB)

main body CB)

M7)

M7)

M7)

[11] SD4 (Paper Exit Opening) Control

101-4

P.GND

101-5

P.GND

101-3

S.GND

101-2

5V

TXD

114-1

DTR

114-2

RTS

114-6

RXD

114-3

DSR

114-7

CTS

114-5

24V

101-1

MAIN BODY

MS1

Pressure between the exit rollers is done by SD4 (paper exit

opening). The control of SD4 (paper exit opening) is performed

by FNS CB (FNS control board).

1. Operation

Normally, a space is left between the paper exit rollers to

avoid papers being stuck.

During paper exit, SD4 (paper exit opening) goes ON and

tilts the paper exit roller, closing the space between the

paper exit rollers and exiting paper.

a. SD4 ON timing

(1) During sort/group/non-sort mode

After the specified time from when PS4 (FIN entrance

path) detects the trailing edge of the paper.

(2) During staple mode

After the specified time from when stapling is completed.

9-3

9-4

9-5

9-7

10-1

10-2

10-3

10-4

10-5

10-6

9-1

RXD

CTS

DSR

TXD

RTS

DTR

24V-IN

SD4 DRV

PS12 IN

FNS CB

24V

PS9 IN

GND

VCC

PS4 IN

GND

GND

PS6 IN

VCC

GND

1-B9

1-B10

5V

6-A2

6-A9

6-B5

5-A3

5-A8

5-B4

5V

5-A6

5-B7

5-A10

5-A6

5-A11

5-B7

SD4

PS9

PS4

PS6

PS12

1 - 32

Page 36

FS-106

b. SD4 OFF timing

(1) During sort/group/non-staple mode

After the specified time from when PS23 (paper exit 2)

detects the trailing edge of the paper.

(2) During staple mode

After the specified time from when PS6 (paper exit 1)

detects the trailing edge of the paper stack.

PS6

(paper exit 1)

SD4 (paper

Paper exit

roller

Paper exit roller

(sponge roller)

exit opening)

PS23

(paper exit 2)

Conveyance

roller C

PS4 (FIN

entrance path)

Conveyance

roller B

Conveyance

roller A

2. Signals

a. Input signals

(1) TXD (main body CB FNS CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) DTR (main body CB

Transmission acknowledgement signal from the main

body to FNS.

(3) RTS (main body CB

Request-to-send signal from the main body to FNS.

(4) PS4 IN (PS4

This signal turns ON when the paper has passed the

FNS entrance and [L] is output.

(5) PS6 IN (PS6

This signal turns ON when paper has passed through

the paper exit opening of FNS and [L] is output.

(6) PS9 IN (PS9

This turns ON when detecting the home position of

the paper exit belt and [L] is output.

(7) PS12 IN (PS12

This signal detects the opening and closing of the

paper exit opening.

[H]

[L]: Closed position

[L]

[H]: Open position

(8) PS23 IN (PS23

This turns ON when paper has passed through the

paper exit opening of FNS and [L] is output.

FNS CB)

FNS CB)

FNS CB)

FNS CB)

FNS CB)

FNS CB)

FNS CB)

b. Output signals

(1) TXD (FNS CB main body CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) RTS (FNS CB

Transmission acknowledgement signal from the main

body to FNS.

(3) DTR (FNS CB

Request-to-send signal from the main body to FNS.

(4) SD4 DRV (FNS CB

SD4 (paper exit opening) drive use signal.

[H]: OFF

[L]: ON

main body CB)

main body CB)

SD4)

1 - 33

Page 37

FS-106

[12] M8 (Paper Exit Opening) Control

P.GND

101-4

P.GND

101-5

S.GND

101-3

5V

101-2

114-1

TXD

114-2

DTR

114-6

RTS

114-3

RXD

DSR

114-7

CTS

114-5

24V

101-1

MAIN BODY

MS1

The opening and closing of the paper exit opening is performed

by M8 (paper exit opening) via the link mechanism. M8 (paper

exit opening) is controlled by FNS CB (FNS control board).

1. Operation

When stapling large sizes, M8 (paper exit opening) rotates

with the ON signal from the main body start button and the

paper exit opening is opened.

When stapling is finished, the paper exit opening is closed

once by the staple completion signal from the FNS CB and

the paper exited.

The opening and closing of the paper exit opening is

detected by PS12 (paper exit opening).

Paper exit opening

9-3

9-4

9-5

9-7

10-1

RXD

CTS

DSR

TXD

RTS

DTR

24V-IN

M8 DRV

PS12 IN

FNS CB

P.GND

VCC

GND

10-2

10-3

10-4

10-5

10-6

9-1

M8 (paper exit opening)

1-B3

1-B4

5-A6

5-A11

5-B7

PS12 (paper exit

opening)

M8

PS12

When paper When paper

conveying to exited to

the stacker the tray

Staple

(Other than A4/B5)

Staple

(A4/B5)

When

copy starts

Open Open Closed

Closed Closed Closed

Off-set Closed — Closed

2. Signals

a. Input signals

(1) TXD (main body CB FNS CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) DTR (main body CB

FNS CB)

Transmission acknowledgement signal from the main

body to FNS.

(3) RTS (main body CB

FNS CB)

Request-to-send signal from the main body to FNS.

(4) PS12 IN (PS12

FNS CB)

This signal detects the opening and closing of the

paper exit opening.

[H]

[L]: Closed position

[L]

[H]: Open position

b. Output signals

(1) TXD (FNS CB main body CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) RTS (FNS CB

Transmission acknowledgement signal from the main

body to FNS.

(3) DTR (FNS CB

Request-to-send signal from the main body to FNS.

(4) M8 DRV (FNS CB

M8 (paper exit opening) drive use signal.

[H]: M8 ON

[L]: M8 OFF

main body CB)

main body CB)

M8)

1 - 34

Page 38

STAPLER UNIT

[1] Composition

FS-106

[2] Mechanism

1. Stapling in one place

Stapler F

Stapler R

Stapler cartridges

2. Stapling in two places

Stapler moving

motor (M11)

Stapler F

Stapler R

The stapler F and R moves to the stapling position.

Movement of the stapler F and R is performed by the stapler

moving motor (M11).

Paper arranged within the stacker is stapled with either the

stapler F or R.

Stapler F

The stapler F and R is rotated so that it is parallel to the paper

and stapling made in two places.

Rotation of the stapler is performed by the stapler rotation motor

(M12).

Stapler rotation

motor (M12)

Stapler R

1 - 35

Page 39

FS-106

3. Staple operation

The staple operation is driven by the F and R stapler motors

(M9 and M10) and operated by the cam rotation.

The home position sensors (PS15 and PS17) detect that

one operation has been performed.

Whether there are staples or not is detected by the stapler

F and R no staple detection PS (PS14 and PS16).

Home position sensors

(PS15 and PS17)

Stapler F and R

no staple detection PS

(PS14 and PS16)

[3] Disassembly and Assembly

CAUTION:

Be sure that the power cord has been removed from the

power outlet.

1. Removeing and installing the stapler

a. Procedure

(1) Open the front cover.

(2) Pull the release shaft and open the stapler section.

Stapler F and R

ready PS

(PS24 and PS25)

Release shaft

(3) Lower the stapler unit, and remove the connector from

the stapler.

Stapler motors F and R

(M9 and M10)

Connector

1 - 36

Page 40

FS-106

(4) Remove the set screw from the stapler.

(5) Lift the stapler and remove.

Screw

Stapler

(6) Reinstall the stapler in the opposite sequence to re-

moval.

2. Cleaning staple jams in the stapler

a. Procedure

(1) Remove the stapler.

(2) Release the lever, and remove the cartridge from the

stapler.

(3) Lift the cartridge lever.

(4) Remove the jammed staples.

Cartridge lever

Release

Staple

(5) Set the stapler in the opposite sequence to removal.

3. Removing and installing the stapler unit

a. Procedure

(1) Remove the stapler.

(2) Close the stapler section.

(3) Remove connector CN2 from the finisher control board.

(4) Open the clamp in three places and then remove the

harness.

Lever

Cartridge

CN2

Finisher

control board

Clamps

(5) Remove the two springs.

Harness

1 - 37

Page 41

FS-106

(6) Remove the two E-rings and then remove the release

shaft.

E-rings

Release

shaft

Springs

(7) Remove the three E-rings from the shaft and remove

the stapler unit.

[4] Stapler Control

P.GND

P.GND

S.GND

5V

TXD

DTR

RTS

RXD

DSR

CTS

24V

MAIN BODY

PS14

PS15

PS24

PS16

PS17

PS25

PS11

101-4

101-5

101-3

101-2

114-1

114-2

114-6

114-3

114-7

114-5

101-1

MS1

9-3

9-4

9-5

9-7

10-1

10-2

10-3

10-4

10-5

10-6

9-1

6-A3

6-A11

6-A10

6-B6

6-B7

6-A6

6-A4

6-B2

6-B1

6-B8

6-B9

6-A7

2-B1

2-B2

2-B3

RXD

CTS

DSR

TXD

RTS

DTR

24V-IN

VCC

PS15 IN

PS14 IN

GND

GND

PS24 IN

VCC

PS17 IN

PS16 IN

GND

GND

PS25 IN

VCC

PS11 IN

GND

M11 DRVA

M11 DRVA

M11 DRVB

M11 DRVB

M10 DRVF

M10 DRVR

FNS CB

24V

24V

M12 DRV

P.GND

M9 DRVF

M9 DRVR

VCC

PS21 IN

GND

VCC

PS22 IN

GND

2-A1

2-A2

2-A3

2-A4

2-A5

2-A6

2-A7

2-A8

3-2

3-1

3-4

3-3

2-B4

2-B5

2-B6

2-B7

2-B8

2-B9

M11

M12

M9

M10

PS21

PS22

E-rings

Stapler unit

E-ring

(8) Reinstall the stapler unit in the opposite sequence to

removal.

M11 (stapler movement) and M12 (stapler rotation) move the

stapler to the fixed position corresponding to the stapler mode,

and paper is stapled by the rotation of M9/M10 (stapler R/F).

PS15 (stapler R HP) and PS17 (stapler F HP) switch ON-OFFON, and detect one cycle of the stapler movement. These are

controlled by the FNS CB (FNS control board).

1. Operation

a. Stapler one position movement control

Step motor M11 (stapler movement) turns ON by the ON

signal from the main body start button and the stapler is

moved to the fixed position that differs depending on paper

size and then stops. When the staple one position mode is

complete, M11 (stapler movement) moves the stapler and

it stops in the PS11 (stapler movement HP) ON position

(inside most).

1 - 38

Page 42

FS-106

b. Stapler two position movement control

Through the ON signal from the main body start button the

stapler is rotated by M12 (stapler rotation) so that the

stapler is parallel to the paper and then stops. At this time,

PS22 (stapler rotation HP2) is ON. When the stapler two

position mode is complete, M12 (stapler rotation) rotates

the stapler and it stops in the PS21 (stapler rotation HP1)

ON position (diagonal position).

c. Stapler movement control

Once the alignment plate is closed, M9 (stapler R)/M10

(stapler F) rotate and the staple push out plate drives the

staples in. When PS15 (stapler R HP) and PS17 (stapler F

HP) detects the home position (OFF-ON) and M9/M10

stop.

While the stapler is stapling, if within 500 ms from when

PS15/PS17 turn OFF they do not come ON again it is

judged as a staple jam. When the door is opened and

closed, M9/M10 rotate in reverse and return to the home

position (PS15/PS17 turn ON).

d. No staple detection control

PS14 (stapler R no staples) and PS16 (stapler F no staples)

detect that there are no staples in the staple cartridge.

After supplying the staples, M9/M10 rotates until PS24

(stapler R ready) / PS25 (stapler F ready) goes ON by the

staple, and prevents miss stapling.

2. Signals

a. Input signals

(1) TXD (main body CB FNS CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) DTR (main body CB

Transmission acknowledgement signal from the main

body to FNS.

(3) RTS (main body CB

Request-to-send signal from the main body to FNS.

(4) PS11 IN (PS11

This signal goes ON when the stapler movement position is in the home position and [L] is output.

(5) PS14 IN (PS14

If there are no staples detected in stapler R this signal

turns ON and [L] is output.

(6) PS15 IN (PS15

When stapler R is in the home position this signal turns

ON and [L] is output.

(7) PS16 IN (PS16

If there are no staples detected in stapler F, this signal

turns ON and [L] is output.

(8) PS21 IN (PS21

When both stapler F and R are in diagonal position,

[L] is output.

(9) PS22 IN (PS22

When both stapler F and R are in parallel position, [L]

is output.

FNS CB)

FNS CB)

FNS CB)

FNS CB)

FNS CB)

FNS CB)

FNS CB)

FNS CB)

(10)PS17 IN (PS17

This signal goes ON when stapler F is in the home

position and [L] is output.

(11)PS24 IN (PS24

When the stapler R has completed pre-feeding of staples and is held in ready state, [L] is output.

(12)PS25 IN (PS25

When the stapler F has completed pre-feeding of staples and is held in ready state, [L] is output.

FNS CB)

FNS CB)

FNS CB)

b. Output signals

(1) TXD (FNS CB main body CB)

This is a serial data line to transmit the operational

state of the main body CB to the FNS CB.

(2) RTS (FNS CB

Transmission acknowledgement signal from the main

body to FNS.

(3) DTR (FNS CB

Request-to-send signal from the main body to FNS.

(4) M9 DRV-F (FNS CB

M9 (stapler R) forward rotation drive use signal.

(5) M9 DRV-R (FNS CB

M9 (stapler R) reverse rotation drive use signal.

(6) M10 DRV-F (FNS CB

M10 (stapler F) forward rotation drive use signal.

(7) M10 DRV-R (FNS CB

M10 (stapler F) reverse rotation drive use signal.

(8) M11 DRVA/M11 DRVB (FNS CB

M11 (stapler movement) drive use signal.

(9) M12 DRV (FNS CB

M12 (stapler rotation) drive use signal.

[H]: ON

[L]: OFF

main body CB)

main body CB)

M9)

M9)

M12)

M10)

M10)

M11)

1 - 39

Page 43

FS-106

MAIN TRAY SECTION

[1] Composition

Main tray

Wire

Worm gear

Tray up-down

motor (M3)

Gearbox

Up-down shaft

Pulley

PS3

[2] Mechanism

1. Main tray up-down

The up-down shaft is rotated via the gearbox by the worm

gear on the tray up-down motor (M3). The main tray is

raised and lowered by the wire which is fixed by the front

and rear pulleys of the up-down shaft.

If the tray up-down motor (M3) rotates in the clockwise

direction (looking from the worm side), the main tray will

rise, and if the motor rotates in the anti-clockwise direction

it will lower.

Pulley

(2) Remove the 4 screws of the cable brackets (front and

rear) and remove the up-down stay.

Screws

Screws

Cable

bracket

(rear)

(3) Reinstall the up-down stay in the opposite sequence to

CAUTION: Be sure to tighten the 4 screws of cable bracket

Up-down stay

removal.

while the up-down stay is pressed down.

Push downwards

Cable bracket

(front)

[3] Disassembly and Assembly

CAUTION:

Be sure that the power cord has been removed from

the power outlet.

1. Removing and installing the up-down stay

a. Procedure

(1) Remove the following parts:

• rear cover

• front side cover

• main tray

• paper exit stopper plate

• up-down support plates (front and rear).

Screws

Up-down stay

Screws

1 - 40

Page 44

FS-106

2. Exchanging the up-down cables

a. Procedure

CAUTION: The following procedure uses the front cable

as an example. Fitting of the rear cable is

symmetrical to the front.

(1) Remove the following parts:

• rear cover

• front side cover

• main tray

• paper exit stopper plate

• up-down support plates (front and rear).

(2) Remove each of the 2 screws of the front and rear

cable bracket, then remove the up-down stay.

Screws

Up-down stay

(4) Move the up-down stay so that the inner cable which is

not removed (the shorter side from the cable bracket)

is wound around twice.

Shorter cable

Wrap

around

twice

(5) Wrap the short side of the cable (from the cable

bracket) being exchanged around the up-down pulley

twice.

(6) Line the cable bracket position up with another cable

bracket which was not removed and, after inserting the

pin, install the up-down pulley with the E-ring.

(7) Hook the cable onto the upper pulley.

Cable bracket

(front)

(3) Remove the E-ring, remove the lower up-down pulley

and then replace the cable.

CAUTION: Take care not to lose the pin which is used

inside the up-down pulley when removing the

pulley.

E-ring

Lower up-down pulley

Cable

2 winds

E-ring

Upper pulley

1 - 41

Page 45

FS-106

(8) Wrap the opposite side (long portion) of the cable

around the up-down pulley from the inside to the

outside and fix the cable end.

Cable (long portion)

Cable end

(9) When the up-down stay is pressed down, the 4 screws

of the cable bracket will tighten.

Push downwards

[4] Main Tray Up-Down Control

P.GND

101-4

P.GND

101-5

S.GND

101-3

5V

101-2

114-1

TXD

114-2

DTR

114-6

RTS

114-3

RXD

114-7

DSR

114-5

CTS

101-1

24V

MAIN BODY

MS1

M9

M10

The main tray up-down operation is performed by the clockwise

and anti-clockwise rotations of M3 (tray up-down).

M3 control is performed by FNS CB (FNS control board).

1. Operation

a. Sort/Group/Non-sort Mode

When paper passes PS23 (paper exit 2), M3 (tray up-down)

will lower the main tray until PS2 (tray upper limit) turns

OFF.

Next, M3 will raise the main tray until PS2 (tray upper limit)

turns ON and stops.

9-3

9-4

9-5

9-7

10-1

10-2

10-3

10-4

10-5

10-6

9-1

3-2

3-1

3-4

3-3

RXD

CTS

DSR

TXD

RTS

DTR

24V-IN

M9 DRVF

M9 DRVR

M10 DRVF

M10 DRVR

FNS CB

M3 DRVF

M3 DRVR

GND

PS6 IN

VCC

PS2 IN

GND

VCC

PS3 IN

GND

VCC

PS23 IN

GND

8-1

8-2

5-A6

5V

5-B7

5-A10

4-1

4-2

4-3

4-4

4-5

4-6

11-1