Page 1

1

PROCESS

Page 2

PROCESS

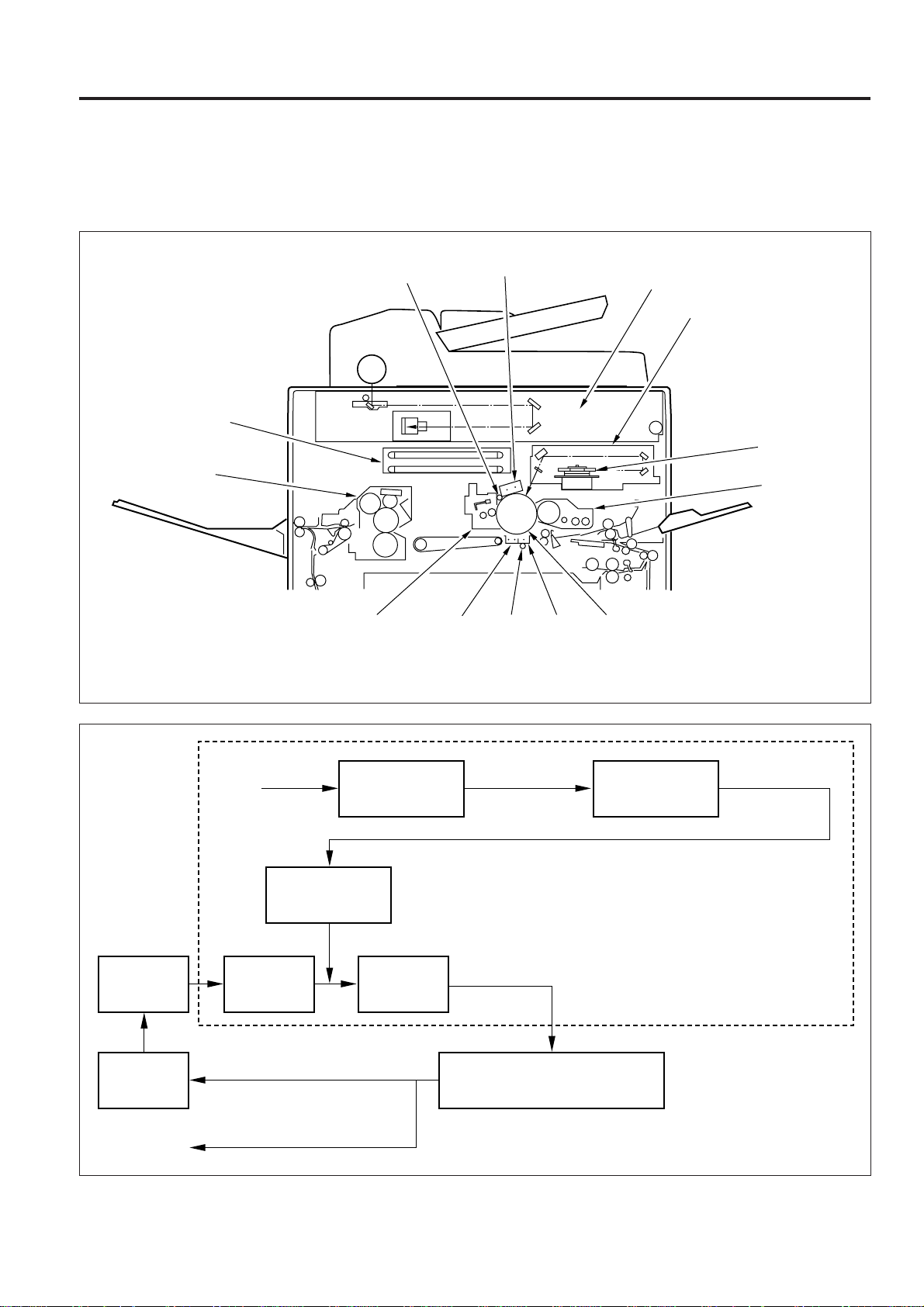

OUTLINE AND COMPOSITION

In this digital copying machine, optical data (light beam) reflected from the original is converted into electrical signals, subjected to

image processing, then converted back into optical data (light beam) and directed onto the drum.

Figure 1 shows the composition of the machine, and Fig.2 an outline of the digital copying process.

Image processing unit

Fixing unit

Cleaning

unit

PCL

PCL

Charging corona unit

Separation

corona unit

TSL

Fig.1

Transfer

corona unit

Image read unit

Image write unit

Polygon mirror

Developing unit

OPC drum

PCL

Cleaning

Fixing

Original

Charging

Optical data

Image write

Image read

Optical data

Developing

Electrical data

Image processing

Separation ← Transfer corona

(Transfer simultaneous

exposure)

Fig.2

Electrical signal

1 - 1

Page 3

PROCESS

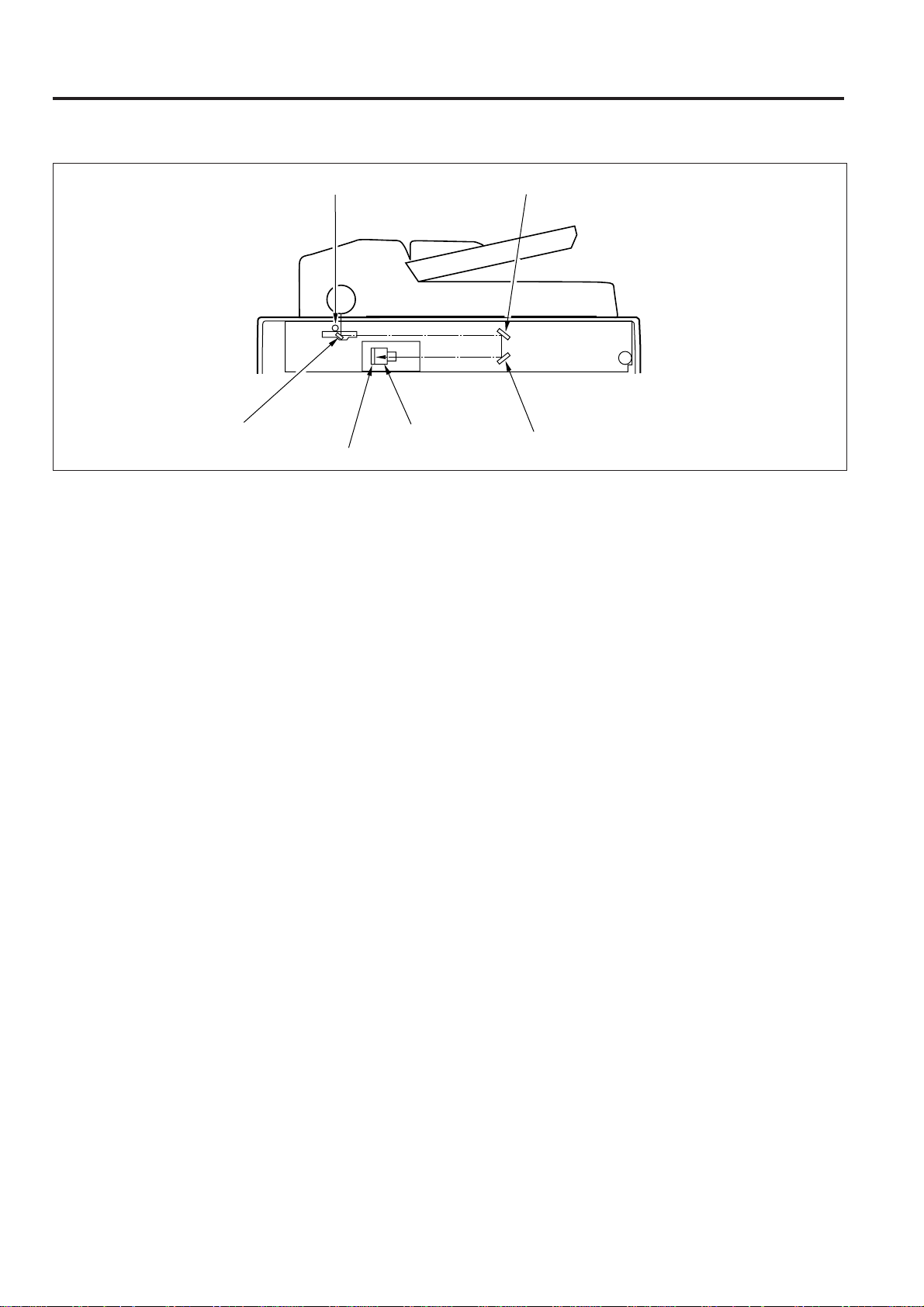

IMAGE READ MECHANISM

Light source (xenon lamp)

Lens1st mirror

CCD image sensor

[1] Outline

A xenon lamp is used as the light source, and the light from the

lamp is directed onto the original.

The light reflected off the original is reflected by the 1st, 2nd and

3rd mirrors shown in Fig.1, then passed through the lens and

directed onto the CCD image sensor.

The CCD image sensor consists of 5000 pixels. One pixel is

7 µm in length, and the length on the original that can be read

by one pixel is 63.5 µm.

2nd mirror

3rd mirror

Fig.3

1 - 2

Page 4

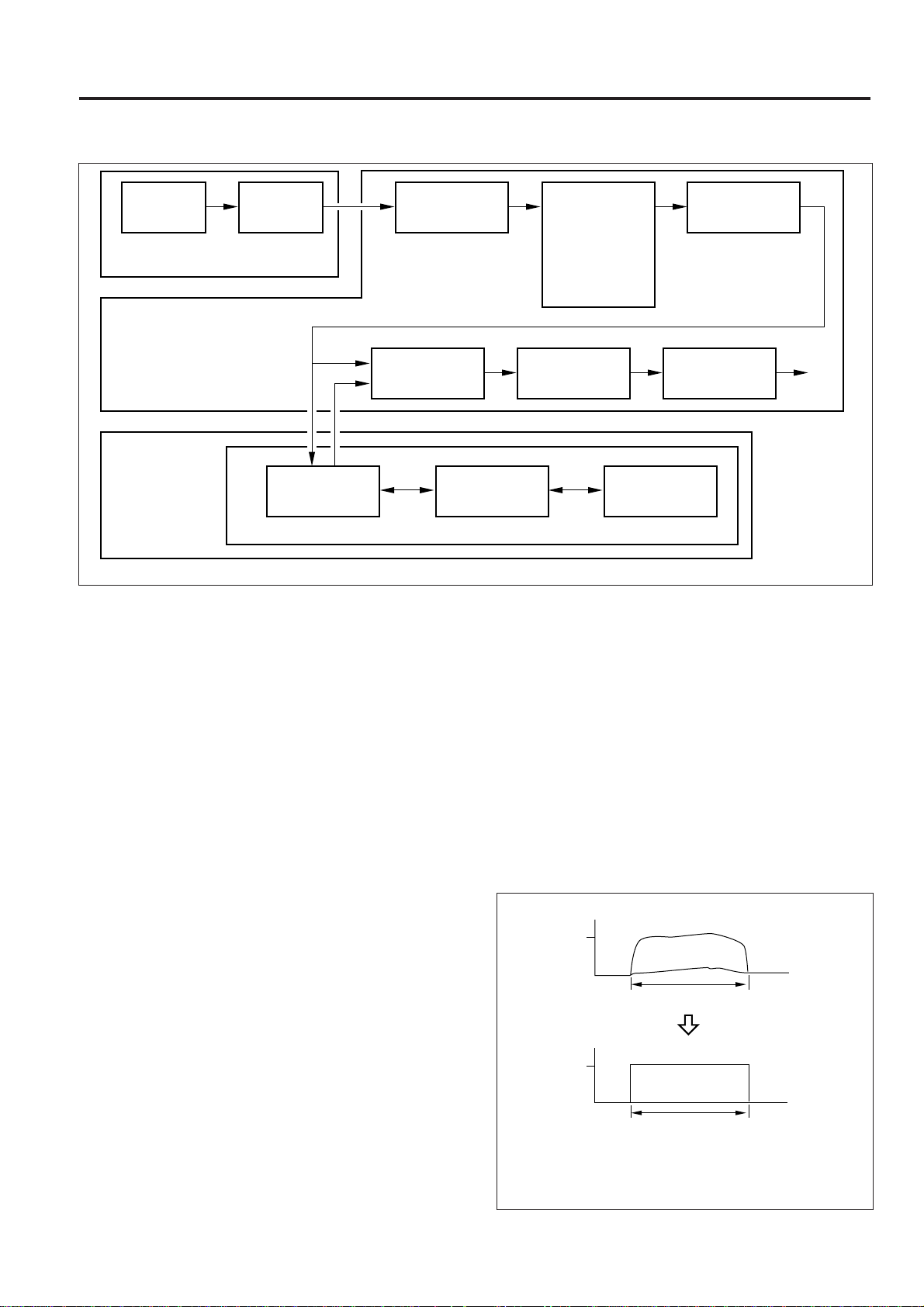

IMAGE PROCESSING

PROCESS

CCD image

sensor

A/D Board

Image Processing Board

Electronic RDH

Processing Board

A/D

conversion

Error diffusion

processing

Shading correction

Selector/SGU

[1] Outline

The analog signal produced by opto-electric conversion by the

CCD image sensor on the A/D board is subjected to analog

processing, then A/D-converted, and transmitted to image

processing board.

Image processing consists of shading correction, brightness/

density conversion, EE processing, text/dot pattern judgement, filter/magnification change processing, copy γ correction, write density control, and 2-beam control. In addition,

Error diffusion processing and image compression are carried out within Electronic RDH.

[2] Analog Processing

In the analog processing board, the minute image signals from

the CCD image sensor are amplified and also level-shifted into

the A/D conversion range.

Amplification and level-shifting take place automatically at the

shading correction timing by an electronic variable resistor,

hence there is no need to perform manual adjustment.

[3] A/D Conversion

The image signals from the analog processing board are

converted one pixel at a time into 9-bit digital signals.

[4] Shading Correction

Shading correction is done to even out the light distribution of

the CCD image sensor. The following correction takes place

at the specified timing.

Brightness/density

conversion,

EE processing, Text/

dot pattern

judgement, Filter/

magnification

processing

Reversal processing

Write density

Image

compression

Fig.4

1. White correction

The voltage output from each pixel of the CCD image

sensor when the white reference plate is exposed to the

light from the exposure lamp is memorized as the maximum output value for that pixel.

2. Black correction

The output voltage from each pixel of the CCD image

sensor when the exposure lamp is out is memorized as the

minimum output voltage for that pixel.

* Based on the difference between the white and black

data for each pixel memorized in 1 and 2 above, the

calculated result that indicates the number of the step

corresponding to the image data read from the original is

output to an accuracy of 10 bits.

(1)

(2)

(1)····Output before shading correction

(2)····Output after shading correction

control

512

0

1024

0

Copy γ correction

2-beam control

Memory

Before shading correction

Read width

After shading correction

Read width

Fig.5

White

Black

White

Black

1 - 3

Page 5

PROCESS

[5] Brightness/Density Conversion

The signal resulting from shading correction corresponds to

the light reflected off the original, hence it is generally called a

brightness signal. The brightness/density conversion section

converts the brightness signal into a 8 bit density data, as

shown below.

255

Density

0

Brightness

Fig.6

1024

[7] Text/Dot Pattern Judgement

In order to copy an original under the optimum conditions, the

text/dot pattern judgement section judges whether the read

part is text, dot pattern or a photograph, and uses the results in

the subsequent filtering section.

[8] Filtering

Appropriate filtering takes place according to the kind of original

and the selected magnification.

(1) Text filter................ Highlights the light and dark parts

of the original.

(2) Dot pattern filter ..... Reduces moire.

(3) Photograph filter .... Improves the gray scale repro-

duction.

[6] EE Processing

A density that is suitable for the density of the original is

automatically selected by EE processing, and a suitable copy

made.

1 - 4

Page 6

PROCESS

[9] Magnification Processing

In an analog copying machine, the horizontal magnification is

changed by changing the scanning speed of the exposure unit,

and the vertical magnification by changing the position of the

lens. In this machine, the horizontal magnification is changed

by changing the scanning speed of the exposure unit, and the

vertical magnification by means of electrical image processing.

The read unit of the CCD (63.5 µm) and the write unit of the

laser (63.5 µm) are equal to each other, and remain unchanged

when the copy image is enlarged or reduced in the vertical

direction. As a result, write data that corresponds exactly to the

write position when the image is enlarged or reduced in the

vertical direction sometimes fails to exist.

1. Vertical magnification change processing

during enlargement

As shown in the example of Fig.10, if the pixel data obtained

when the original is read by the CCD is D

positions of the read data when the image is enlarged are

E

1 to E5. However, the following problems will occur if the

write data consists of this read data alone.

(a) There will be a gap between one data and the next,

resulting in gaps in the image.

(b) The data position and write position will not coincide

exactly.

Consequently, if read data that corresponds exactly to the

write position fails to exist, as indicated by the dotted lines

of Fig.10, the write density is determined as shown below.

Original read position

Data position when

image is enlarged

D1 D2 D3 D4 D5

E1 E2 E4 E5

E3

1 to D5, the

2. Vertical magnification change processing

during reduction

As shown in the example of Fig.11, if the pixel data obtained

when the original is read by the CCD is D1 to D5, the

positions of the read data when the image is reduced

overlap each other as indicated by R1 to R5, hence the

write positions fail to coincide with the write

positions.Therefore, the write density is determined as

shown below.

Original read position

Data position when

image is reduced

Write position

D1 D2 D3 D4 D5

R1 R2 R4 R5

W1 W2 W3 W4 W5

Fig.11

R3

3. Density correction

Figure 12 is a graph the vertical axis of which represents

density (256 steps) and the horizontal axis of which represents position: Here, the distance between E

Fig.10 is set out on the horizontal axis and divided into 16

steps. If the position with respect to write data W

the density S can be obtained using the following equation.

S = E1 + ( ) x

E2 – E1

16

2 and E1 of

2 is “ ”,

Write position

W1 W2 W3 W4 W5 W6 W7 W8

Fig.10

1 - 5

255

S

Density

E1

0

0

Position

Fig.12

E2

W2

15

Page 7

PROCESS

[10] Reversal Processing

This function reverses the input brightness data in order to

reverse black and white when the reverse copy mode is

selected.

[11] Copy γ Correction

The copy γ correction function selects the density curve

corresponding to the density selected by the density button

on the operation panel.

Suitable density curves are provided for the text, photo and text

photo modes.

[12] Selector, SGU

Selector is a function that switches between the image signal

from the Electronic RDH, and the read time image processed

signal.

SGU is a function that generates various test patterns.

[13] Write Density Control

The write density control function converts image data to the

optimum laser exposure based on the characteristics related to

the drum such as drum potential, toner density, etc.

[15] Image Compression Processing

This processing function stores compressed image data in

the memory to enable a large quantity of image data to be

stored when Electronic RDH is used.

[16] Memory

The memory can hold about 180 pages of A4 sized originals

consisting of average word processor text. The number of

pages will be less than this, if the originals include many

photographs and dot pattern images. Expansion memory

units MU-103 are available as an option.

[17] 2-beam Control

This function is used to adjust the timing of the laser data from

the two beams and also to detect and correct any deviation

between the two beams.

1.5

Copy density

0

Laser exposure level

Fig.13

255

[14] Error Diffusion Processing

Error diffusion processing is intended to make efficient use of

the installed memory and also to obtain a satisfactory copy

image.

1 - 6

Page 8

IMAGE WRITE

PROCESS

CY2 lens

Polygon mirror

3rd mirror

Stepping motor

Compression prism 1

Collimator lens unit 1

Semiconductor laser LD1

Glass cover

Index mirror

3rd mirror

Index senser

Fine adjustment

prism 1

Fig.14

fθ lens unit

1st mirror

2nd mirror

CY1 lens

Beam combining prism

Compression prism 2

Collimator lens unit 2

Semiconductor laser LD2

2nd mirror

1st mirror

[1] Outline

Figure 14 shows the layout of the various parts of the write unit.

The processed image data is output by semiconductor lasers.

The light output from these lasers is sent via the path shown in

Fig.15 to the OPC drum.

Semiconductor laser 1

(LD1)

Collimator lens unit 1

Compression prism 1

Fine adjustment prism

1 (sub scanning)

Beam combining

Cylindrical lens 1 (cy1)

fθ lens

unit

3rd mirror

Index mirror

1st mirror

2nd mirror

OPC drum

Semiconductor laser 2

(LD2)

Collimator lens unit 2

Compression prism 2

prism

Polygon mirror

Cylindrical lens 2

(Cy2)

Index sensor

1 - 7

Fig.15

Page 9

PROCESS

[2] Collimator lens

Figure 16 shows the function of the collimator lens. This lens

is used to form the light which diverges from a point source into

a parallel beam.

Semiconductor

laser

Collimator

lens

Fig.16

Parallel

beam

[3] Beam combining prism

This prism causes the beams from the two semiconductor

lasers mounted at right angles to each other to be output in the

same direction.

[6] Polygon mirror

This is a multi-sided mirror which converts the laser beam into

a scanning beam. An octagonal mirror is used in this machine.

Figure 18 shows the appearance of the polygon mirror.

Fig.18

[7] fθ lens

The polygon mirror rotates at a constant angular speed.

Consequently, if a general image forming lens were to be used,

the speed at which the laser beam scans the surface of the

drum would vary at the center and at the both edges of the

drum, as shown in Fig.19.

Laser beam

Semiconductor laser 1

Beam combining prism

Semiconductor laser 2

Fig.17

[4] Compression Prism

This prism shapes the beam radiated from each semiconductor laser, and adjusts the height in the up-down direction.

[5] Fine Adjustment Prism

This prism performs fine adjustment of the beam radiated from

each semiconductor laser in the left-right and up-down directions.

Drum;

Scanning

speed falls as

beam

approaches

center of

Polygon

mirror

Image forming lens

Fig.19

drum.

An fθ lens is used to maintain the scanning speed constant

over the entire length of the drum.

Laser beam

Drum;

Scanning

speed is

constant.

Polygon

mirror

fθ lens

Cylindrical

lens

Fig.20

1 - 8

Page 10

[8] Cylindrical Lenses

Two lenses, cylindrical lens 1 (Cy1) and cylindrical lens 2

(Cy2), are used to eliminate the tilt error of the polygon mirror.

Cylindrical lenses 1 and 2 are installed before and after the

polygon mirror, as shown in Fig.21. The laser beam is focused

on the polygon mirror by means of cylindrical lens 1, and the

light reflected off the polygon mirror is once again focused on

the drum by means of cylindrical lens 2.

The optical relationship between the polygon mirror and the

drum face with respect to cylindrical lens 2 is that of image and

object. Consequently, even if the polygon mirror is tilted, the

light path is corrected by cylindrical lens 2, ensuring that the

beam is scanned along the same line.

PROCESS

Semiconductor

laser

Collimator lens

Cylindrical lens

1 (Cy1)

Polygon

mirror

Fig.21

fθ lens

Cylindrical lens

2 (Cy2)

Mirror

Drum

[9] Index Sensor

This sensor is intended to determine the leading edge write

position for each scan in the axial direction of the drum, and

also to determine the positions of the two beams.

1 - 9

Page 11

PROCESS

IMAGE FORMATION

[1] Charging

Charging corona unit

Fig.22

A negative charging method using a Scorotron is employed. A

constant negative voltage is applied to the charging plate and

back plate in order to maintain the potential of the drum

constant.

[3] Developing

Fig.24

Negatively charged toner adheres to the parts of the surface

of the drum where charge was erased during the exposure

process.

[2] Exposure

Fig.23

Exposure is performed by means of the laser beams, causing

the charge on the drum to be erased. Two laser beams are

used to write (exposure) two lines of image data at a time.

[4]

Transfer/Transfer Synchronization Exposure

Drum

Transfer

corona unit

TSL

Fig.25

The transfer corona unit causes the toner on the drum to be

transferred to the paper by means of a discharge from the back

of the paper.

The TSL improves the transfer of the toner and the separation

of the paper.

1 - 10

Page 12

PROCESS

[5] Separation

Separation corona unit

Fig.26

The separation corona unit erases the charge on the paper by

applying an AC discharge from the back of the paper, thus

enabling the paper to separate from the drum under its own

weight.

[7] PCL

PCL

Drum

Fig.28

The PCL erases the potential remaining on the surface of the

drum.

[6] Cleaning

Cleaning blade

Toner collecting roller

Drum

Fig.27

Toner remaining on the drum is removed by the cleaning blade.

1 - 11

Loading...

Loading...