Page 1

4

ADJUSTMENT

Page 2

ADJUSTMENT

HOW T O USE THE ADJUSTMENT SECTION

[1] Composition

This section details adjusting items and procedures. Use this

section for making adjustments and as a checklist before implementing corrective measures in the field.

1. Does the power supply meet the requirements?

2. Is the power supply properly grounded?

3. Is the machine sharing its power source with another high

current consumption machine that draws large currents

intermittently? (e.g. an elevator, air conditioner, or other

source of electrical consumption)

4. Is the installation environment suitable?

a. The machine must be installed in a well-ventilated place

free from high temperature, high humidity and direct

sunlight.

b. The machine must be installed on a level floor.

5. Does the cause of a defective image lie in the original itself?

6. Is the density adjusting control at the proper position?

7. Are the platen glass and RADF platen guide clean?

8. Is the correct paper being used for the copy?

9. Are the copying materials and parts replaced when they

reach the end of their usable life? (de veloper , drum, cleaning blade, etc.)

10.Is there toner in the machine?

The following items should also be observed when repairing

the machine.

1. Only one side of the AC power line is disconnected when

the main switch of this machine is turned off. Always unplug the machine before beginning work. If absolutely necessary to work with the power on, exercise care to avoid

being caught in the scanning rear of the exposure unit.

2. Special care should be taken when handling the fixing unit

since it operates at extremely high temperatures.

3. The developing unit is surrounded by a strong magnetic

field. Keep watches and metering equipment away from it.

4. Avoid scarring the drum with tools or similar objects.

5. Do not touch IC pins with your bare hands.

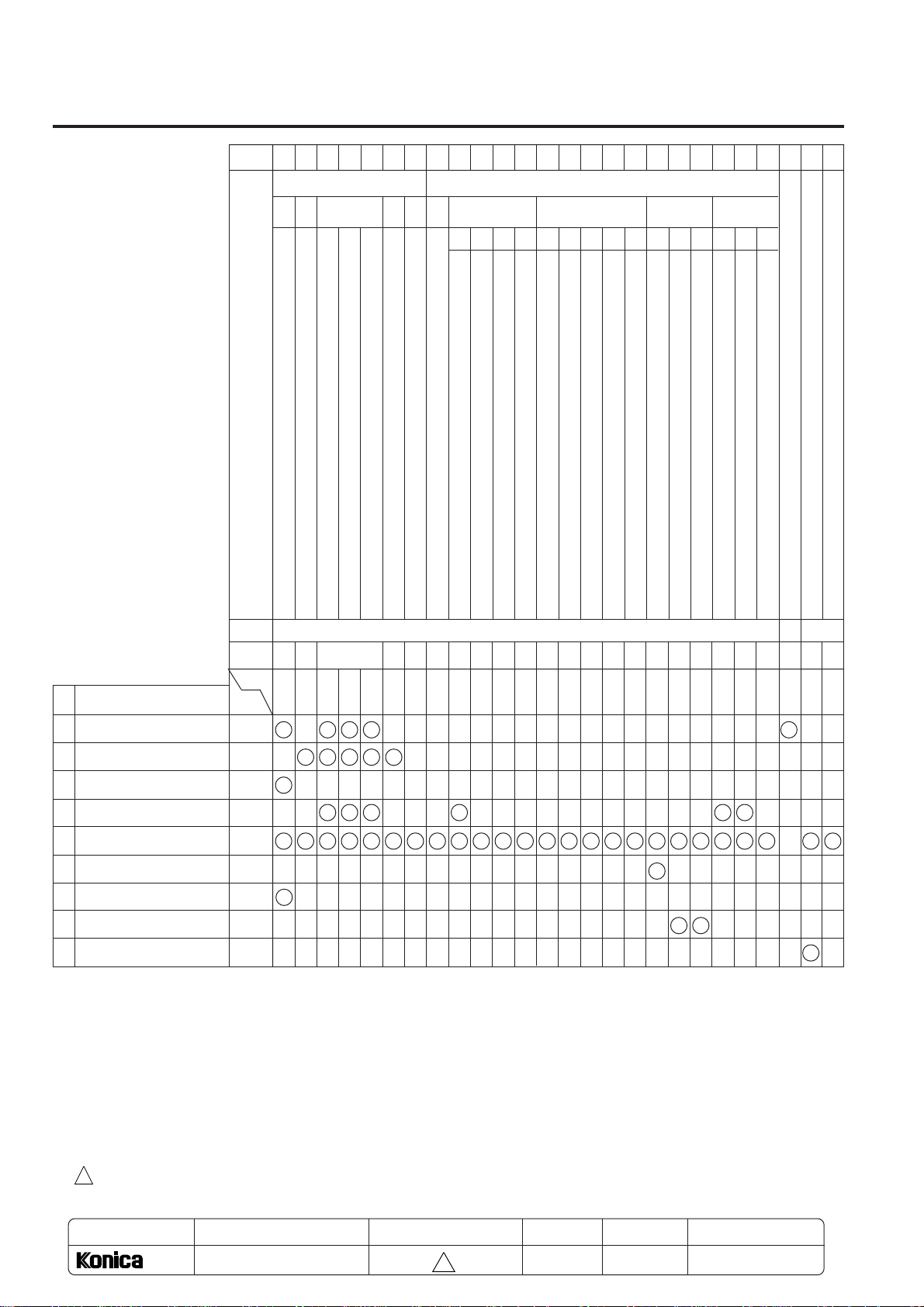

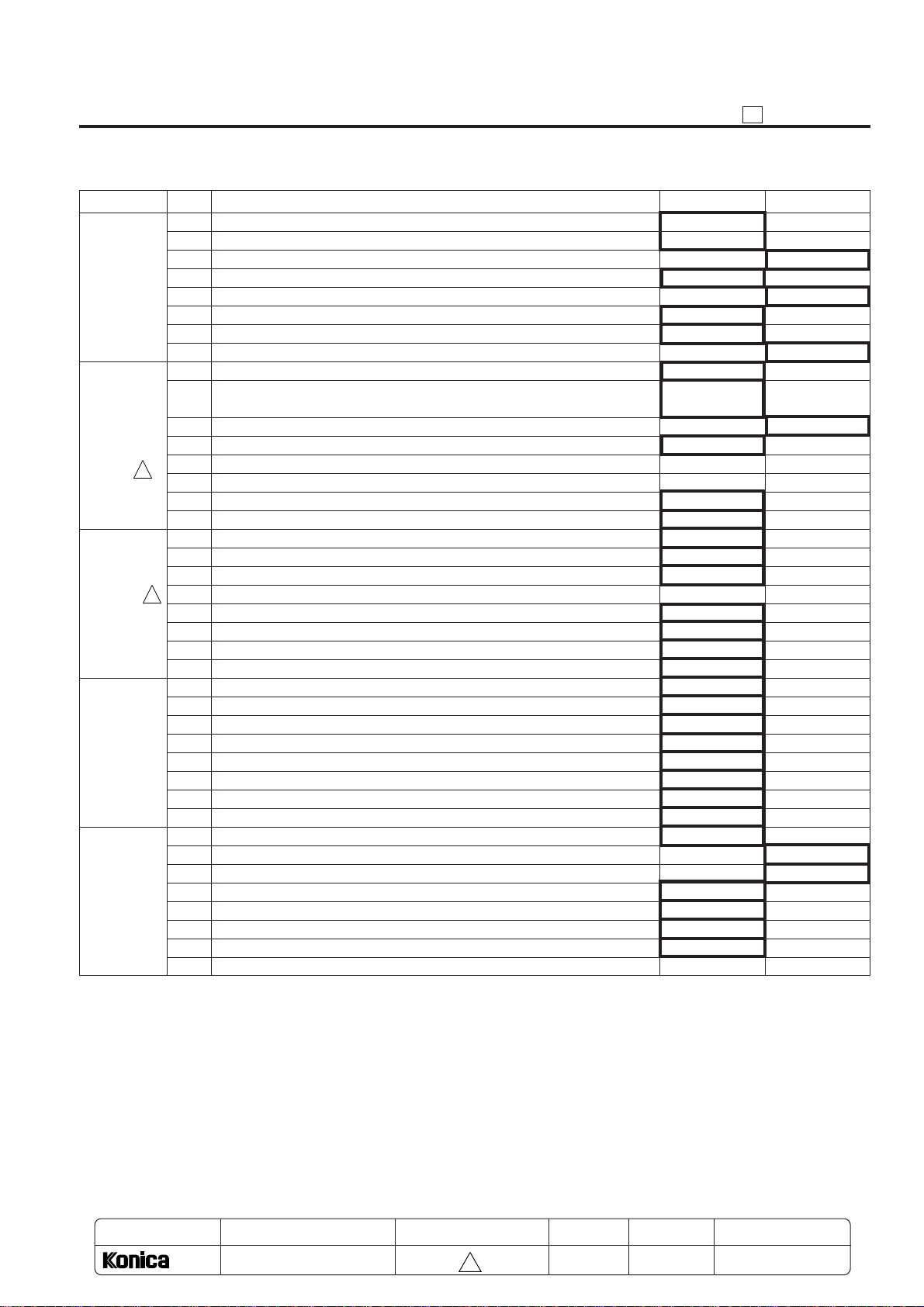

ADJUSTMENTS WHEN REPLACING PARTS

Adjustments (including checks) and settings are not only required when a defective copy image occurs, but also after replacing or reinstalling certain parts.

[How to Use the Table]

The following items are used in the table throughout this section.

1. Mode

Indicates the adjustment mode.

[“P”] : P mode

[“25”] : 25 mode

[“36”] : 36 mode

[“47”] : 47 mode

2. Codes

Indicates the applicable code and/or Copy Quantity Setting

button for each mode.

3. Page

Indicates the page to refer to in the Adjustment section.

4. Conditions

New: Indicates adjustment (including check) is re-

quired when replacing a new part.

Reinstall: Indicates adjustment (including check) is re-

quired when a part has been re-installed.

5. Symbols used in the table

1 2 ·················: Indicates there is a priority sequence

for adjustments (including checks) and

settings.

(Empty circle): Indicates adjustments (including

checks) and settings that can be carried

out independently.

4 - 1

Page 3

ADJUSTMENT

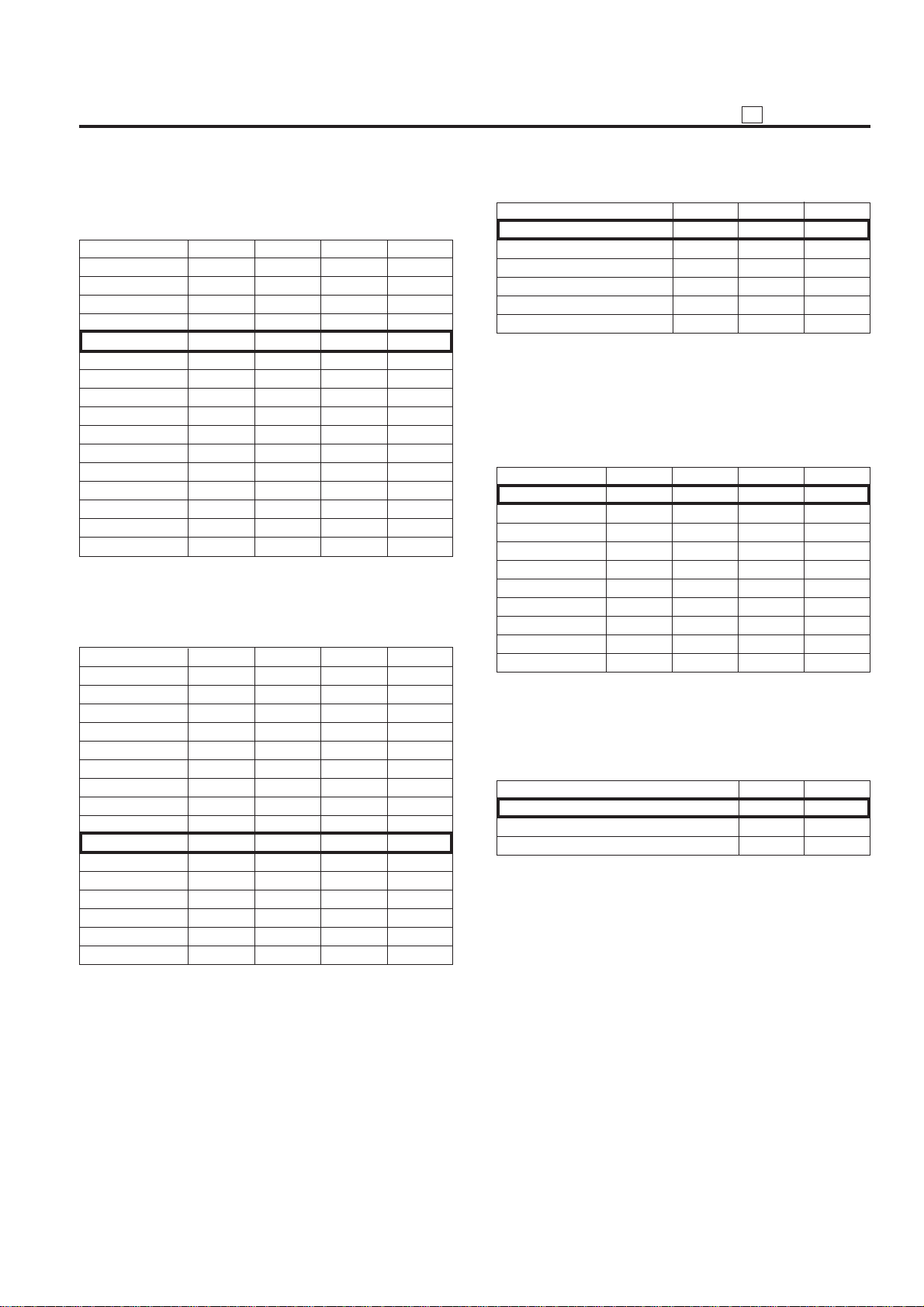

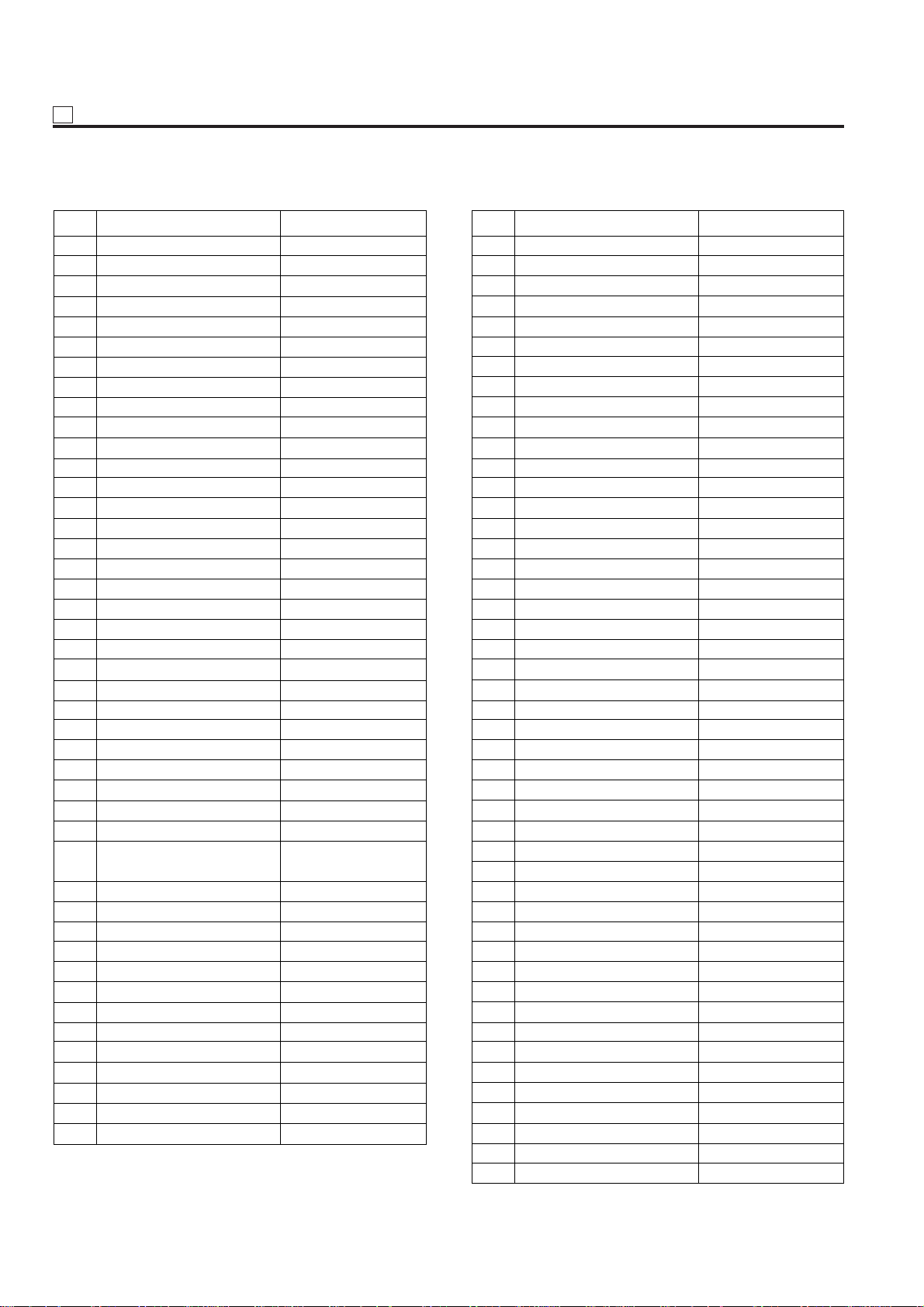

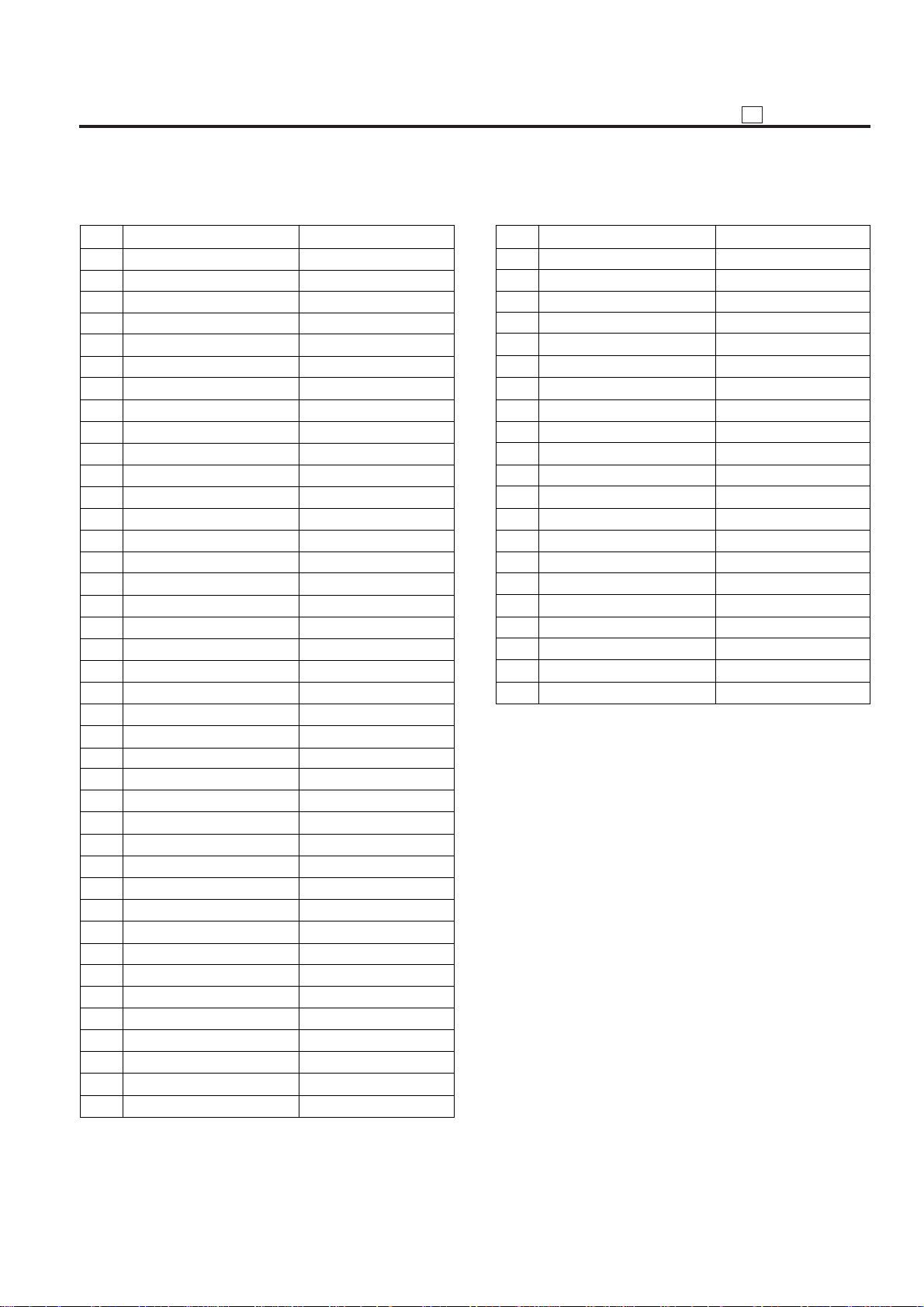

No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

1 Process adjustment 2 Image adjustment

12 451

3 Laser

adjustment

2 Magnification

adjustment

3 Timing adjustment

4 RADF

adjustment

5 Centering

adjustment

123412378123123

Adjustment and setting item

High voltage adjustment - Charging grid voltage adjustment

L-detecting adjustment

Gradation adjustment (LD1/LD2 offset adjustment 400 dpi)

Gradation adjustment (LD1/LD2 offset adjustment 600 dpi)

Sub pitch offset adjustment

Maximum density adjustment (Dmax adjustment)

Gamma adjustment

Scale plate position auto adjustment

Drum clock adjustment (Printer)

Drum clock adjustment (Platen copy)

Horizontal adjustment (Platen copy)

Drum clock adjustment (RADF copy)

Restart timing adjustment

Paper feed loop adjustment

Lead edge timing adjustment

RADF registration loop adjustment

RADF lead edge timing adjustment

Density adjustment

Original size adjustment

Sensor sensitivity adjustment

Centering adjustment (Front) - for each tray

Mode

1-1

1-2

1-3

1-4

1-5

2-1

4-59

4-60

2-2

-1

4-62

1

4-63

Code

Page

4-55

4-56

4-57

4-57

4-58

4-59

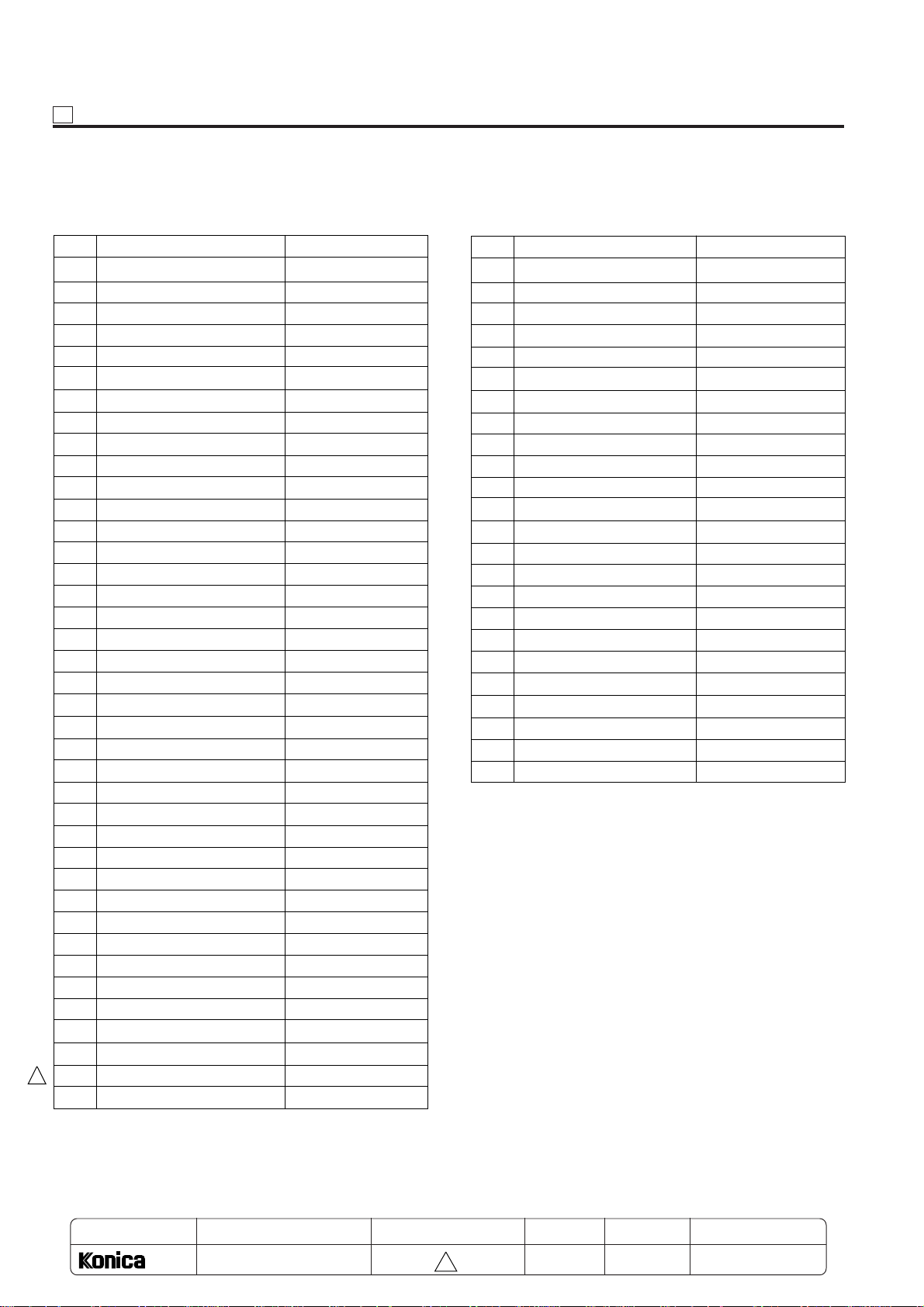

No. Part Name

1 Drum New

2 Developer New

3 High voltage unit New

4 Writing unit

5 Memory IC <Note> New

6 Slit glass New

7 Charging control plate New

8 RADF control board New

9

Change of paper size for tray 2,3and4

• New means replace with a new part and Reinstall means to reinstall the part.

• The circles will have a number when there is an adjustment priority.

Condition

New

Reinstall

—

2

3

4

5

1

3

4

5

2

2

3

4

36 47

2-2

2-2

2-2

2-3

2-3

2-3

2-3

2-3

2-4

2-4

-2

-3

-4

-1

-2

-3

-7

-8

4-64

4-65

4-66

4-67

4-68

4-69

4-70

-1

4-71

-2

4-72

2-4

4-73

2-5

2-5

-3

-1

-2

4-74

4-75

5

6

Note:

• When replacing a damaged control board, the memory IC on the damaged control board, in principle, is to be used on

the new control board.

A new memory IC can be used on the new control board only when the memory IC is assumed to be damaged.

In this case, the above adjustment items must be set as adjustment data is not supplied in the new memory IC. Furthermore, 47-92 must be perform prior to performing the above adjustment items in order to make the new memory IC itself

effective.

• Be sure to perform 47-96 when performing the adjustment items. By performing 47-96, the adjustment value will

recover to the 47-96 performing value by performing 47-93 even upon readjustment.

• See the section "ADJUSTMENT" in each service handbook when adjusting the stapler stopper PS or the folding stopper

2

PS for FNS (FS-108BM) and when doing the cover sheet tray size for PPI (PI-108).

Centering adjustment (Back) - for ADU

RADF centering adjustment

Drum count reset

Tray paper size setting

Serial number setting

25

2-5

-3

4-76

091

4-9824-16

7

4-30

1

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

4 - 2

2

DATE

Jan.2000

PAGE

4-2

METHOD

REPLACEMENT

Page 4

SETTING AND CHECKING WITH P FUNCTION

Copy quantity

setting button

Start Print button

Operation panel

Step

1

2

3

Operation (Indication)

Entry Terminal

Press 2 from the copy quantity

setting button.

Press the Start Print button.

Check the PM count displayed in

the message area.

Copy quantity

setting button

Start Print button

Operation panel

Step

1

2

3

Operation (Indication)

Entry Terminal

Press 3 from the copy quantity

setting button.

Press the Start Print button.

Check the drum count displayed

in the message area.

Copy quantity

setting button

Start Print button

Operation panel

Step

1

2

3

Operation (Indication)

Entry Terminal

Press 4 from the copy quantity

setting button.

Press the Start Print button.

Check the drum count displayed

in the message area.

Copy quantity

setting button

Start Print button

Operation panel

Step

1

2

3

Operation (Indication)

Entry Terminal

Press 5 from the copy quantity

setting button.

Press the Start Print button.

Check the density shift (text/photo)

displayed in the message area.

Copy quantity

setting button

Start Print button

Operation panel

Step

1

2

3

Operation (Indication)

Entry Terminal

Press 1 from the copy quantity

setting button.

Press the Start Print button.

Check the total count displayed in

the message area.

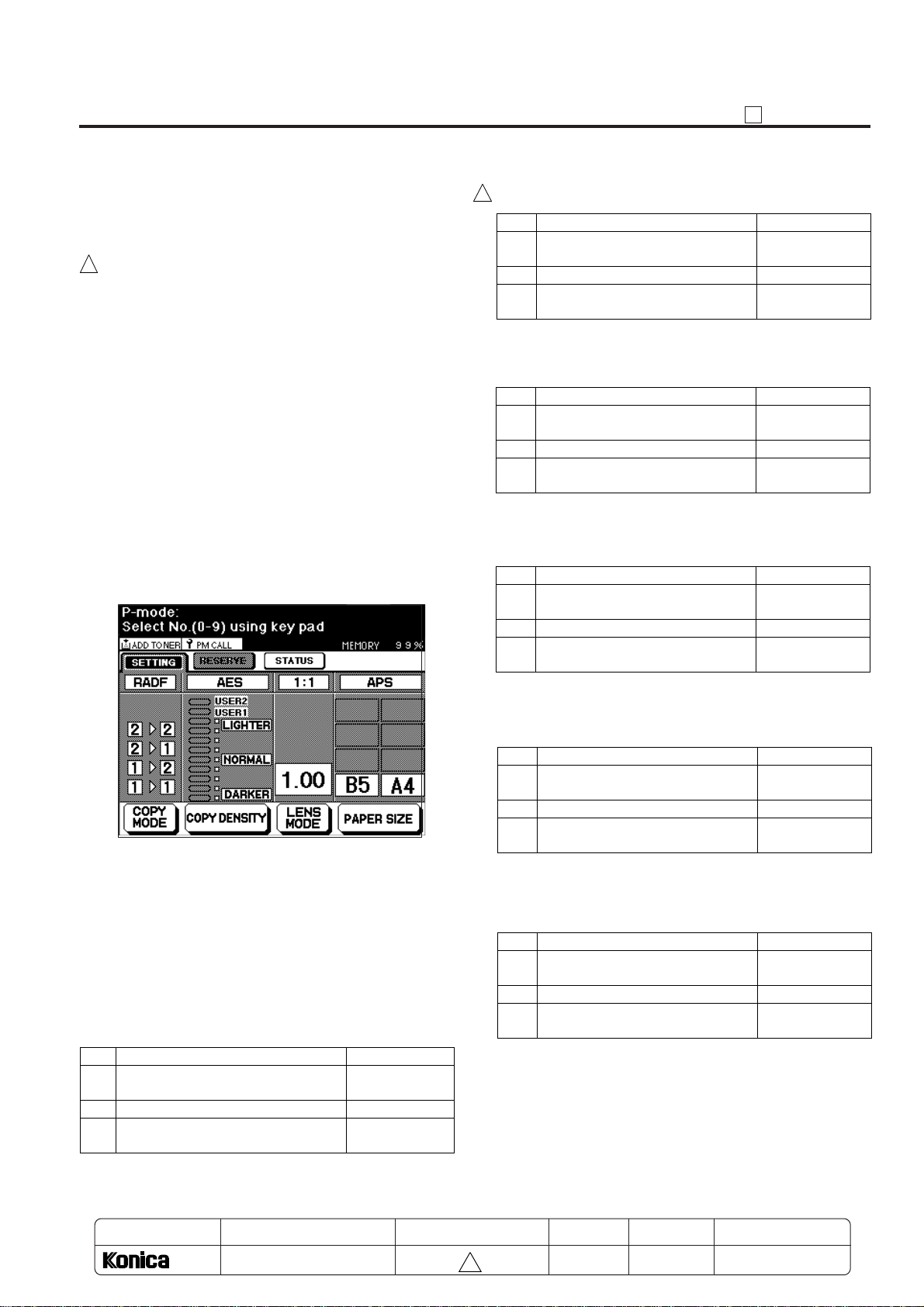

P ADJUSTMENT

P function enables to display the following parameters with

the P button.

0. Checking the Printer Count

1. Checking the Total Count / Set-up Date

2

2. Checking the PM Count/Starting Date

3. Checking the Drum Count

4. Checking the Developing Count

5. Checking the Density Shift (text/photo)

6. Checking the Density Shift (text)

7. Checking the Density Shift (photo)

8. Checking the Density Shift (Increase contrast)

9. Printing User Data

This section explains the various functions which is exclusive

for the service technician.

For those used by the users, refer to "Operation section".

[1] Setting Method of P Function

a. Tur n on the main switch.

b. Press P button.

c. P Mode Screen will appear.

[3] Checking the Total Count / Set-up Date

2

[4] Checking the PM Count/Starting Date

[5] Checking the Drum Count

d. Use the copy quantity setting button to enter the de-

sired number, following the message on the operation

panel.

e. Press the Start Print button to confirm the various data

displayed in the message area, or output user data.

f. Press Stop/Clear button.

g. Turn off the main switch.

[2] Checking the Printer Count

Step

1

2

3

Operation (Indication)

Press 0 from the copy quantity

setting button.

Press the Start Print button.

Check the printer count (IP output

only) displayed in the message area.

Entry Terminal

Copy quantity

setting button

Start Print button

Operation panel

[6] Checking the Developing Count

[7] Checking the Density Shift (text/photo)

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

4 - 3

2

DATE

Jan.2000

PAGE

4-3

METHOD

REPLACEMENT

Page 5

P ADJUSTMENT

[8] Checking the Density Shift (text)

Step

1

2

3

Operation (Indication)

Press 6 from the copy quantity

setting button.

Press the Start Print button.

Check the density shift (text)

displayed in the message area.

Entry Terminal

Copy quantity

setting button

Start Print button

Operation panel

[9] Checking the Density Shift (photo)

Step

1

2

3

Operation (Indication)

Press 7 from the copy quantity

setting button.

Press the Start Print button.

Check the density shift (photo)

displayed in the message area.

Entry Terminal

Copy quantity

setting button

Start Print button

Operation panel

[10] Checking the Density Shift

(INCREASE CONTRAST)

Reference: Each copy count data number describe paper

size as follows.

No. KBJ Europe USA

001 — — —

002 A3 A3 11x17

003 B4 B4 8.5x14

004 A4 A4 8.5x11

005 B5 B5 5.5x8.5

006 A5 A5 —

007 B6 F4 —

008 8.5x14 — —

009 8.5x11 — —

010

Non-standard Non-standard Non-standard

Step

1

2

3

Operation (Indication)

Press 8 from the copy quantity

setting button.

Press the Start Print button.

Check the density shift (increase contrast)

displayed in the message area.

[11] Printing User Data

Step

1

2

3

4

5

6

7

8

Operation (Indication)

Press 9 from the copy quantity

setting button.

Press the Start Print button.

Enter the EKC master key code.

(8-digit)

Press the Start Print button.

Select the number (1 to 3) that

you wish to output. *1

Press the Start Print button.

The user data starts to be output.

To output a different user data,

repeat steps 5 and 6.

Turn off the main switch to cancel

the user data output mode.

Entry Terminal

Copy quantity

setting button

Start Print

button

Operation panel

Entry Terminal

Copy quantity

setting button

Start Print button

Copy quantity

setting button

Start Print button

Copy quantity

setting button

Start Print button

Main switch

*1: The selection items are as follows.

1 Copy count for each password (256 items)

2 Limit quantity for each password (256 items)

3 Copy count for each size (10 items)

4 - 4

Page 6

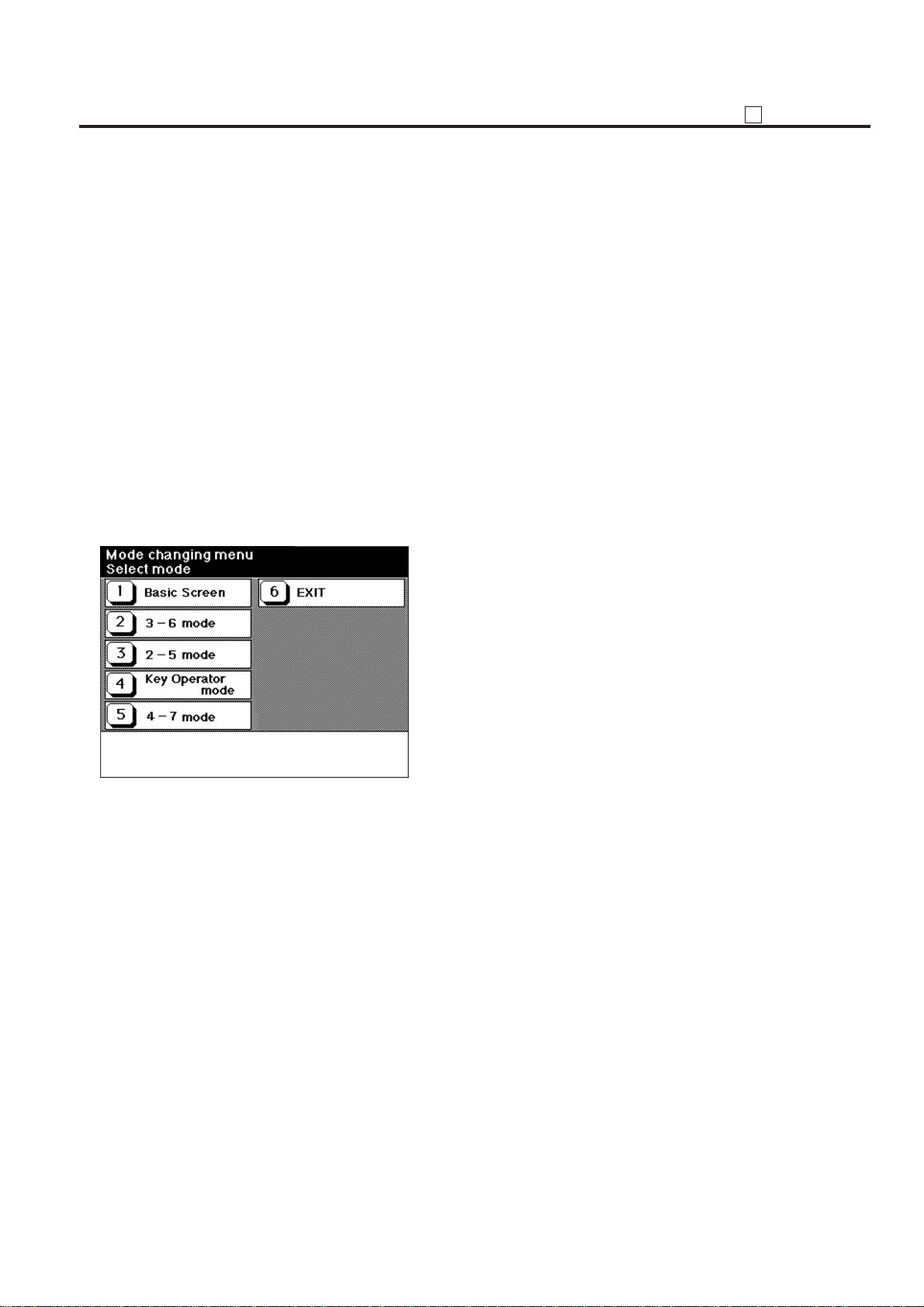

MODE CHANGING MENU SELECT

[1] Setting Method

The 7065 includes a new adjustment screen called the "Mode

Changing Menu Select" which allows the following modes to

be selected without the need to repeatedly turn the machine

on and off.

— Basic Screen

— 36 mode

— 25 mode

— Key Operator mode

— 47 mode

1. Turn the main switch on and wait for the "Ready to copy"

message.

2. Hold the P button down until the message "Enter 4-digit

password to change" is displayed.

3. Enter the password 9272 and press the start print button.

(This is a fixed password and it cannot be changed.)

[Mode Changing Menu Screen]

P ADJUSTMENT

4. Press the desired number key of the item to set.

5. To return to the Mode Changing Menu Screen, hold down

the P button until the Mode Changing Menu Screen reappears.

6. When adjustment has been completed, press the "Basic

Screen" button to return to the Basic Copy Screen.

7. Turn off the main switch and then turn back on.

4 - 5

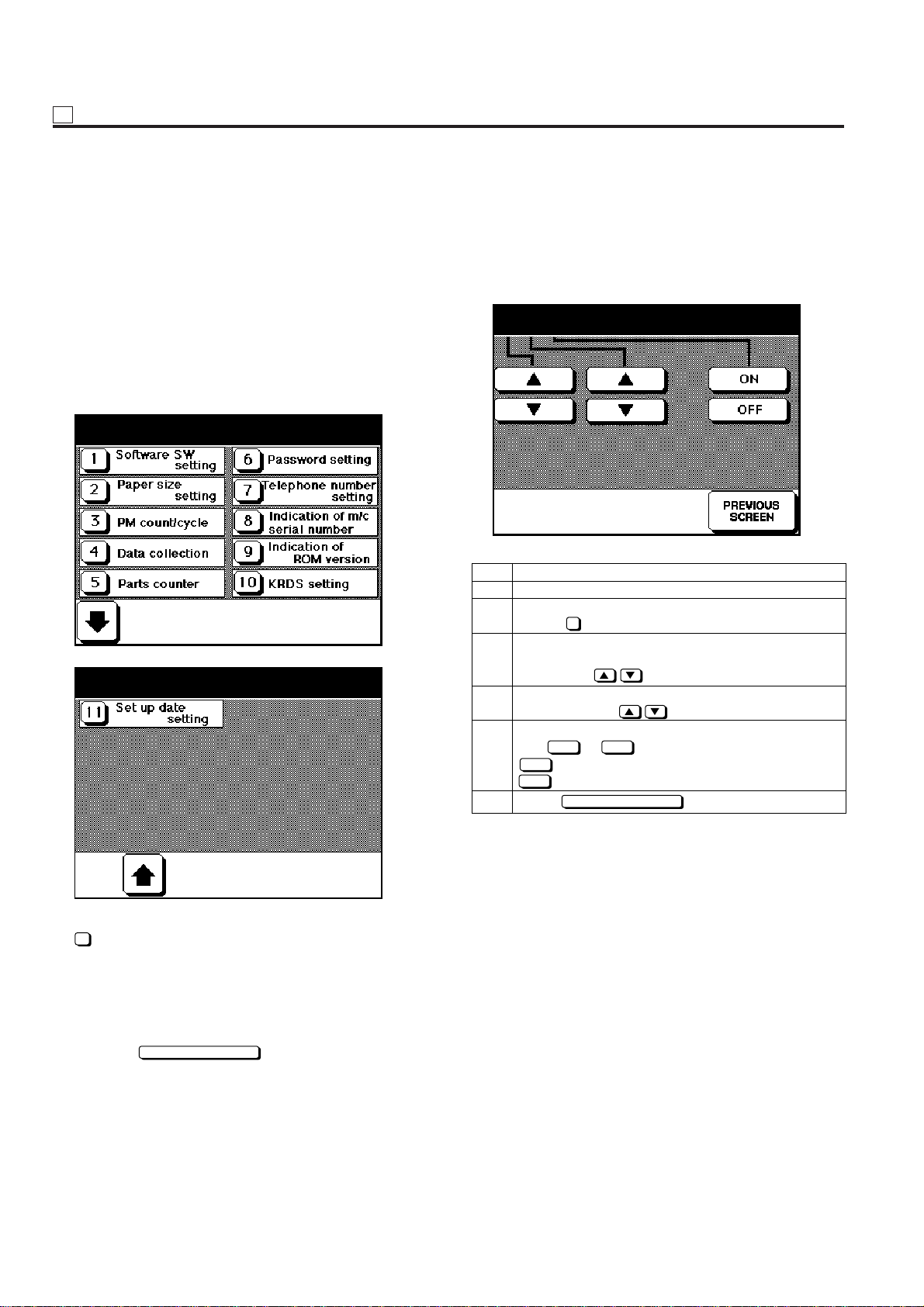

Page 7

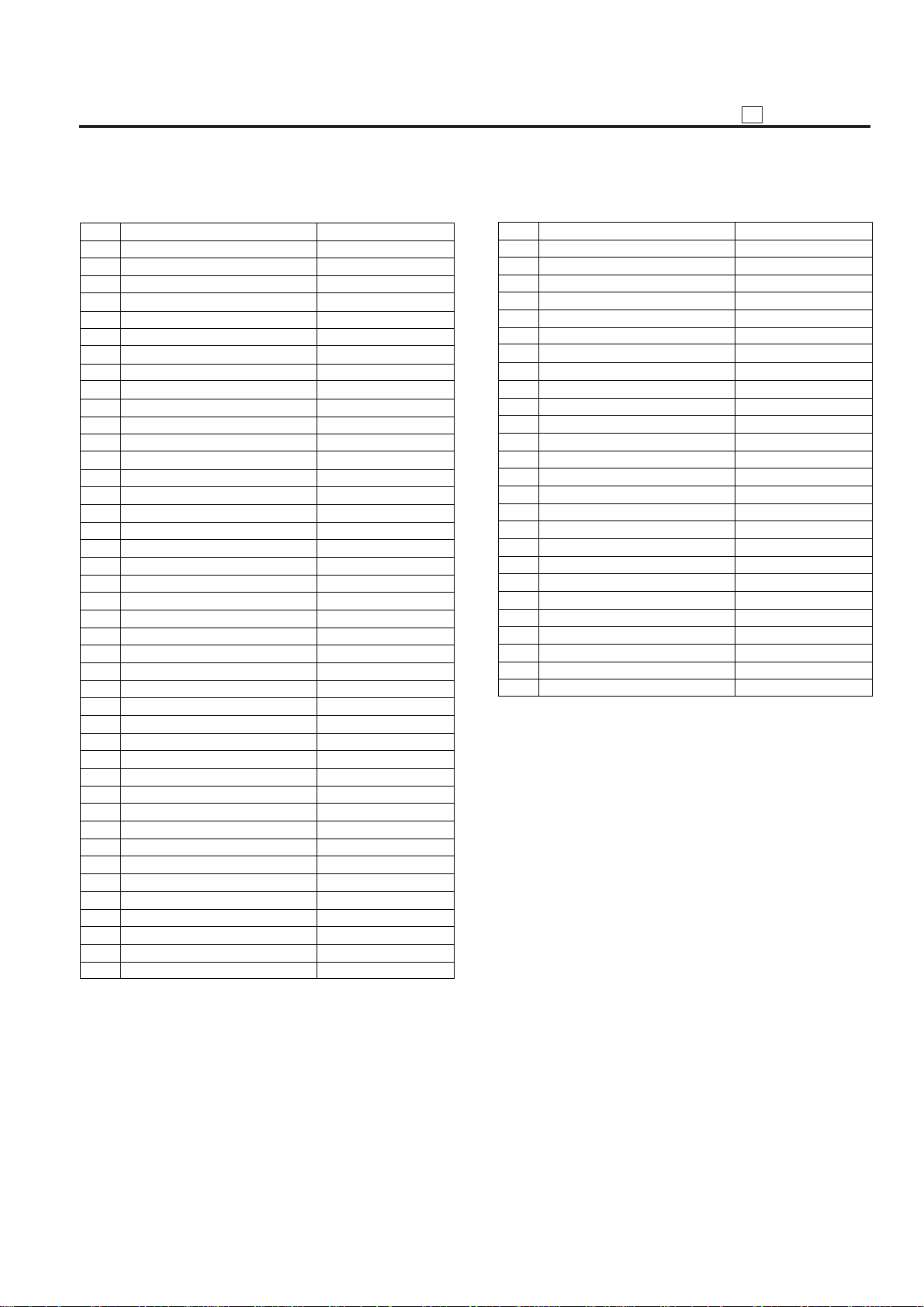

25 ADJUSTMENT

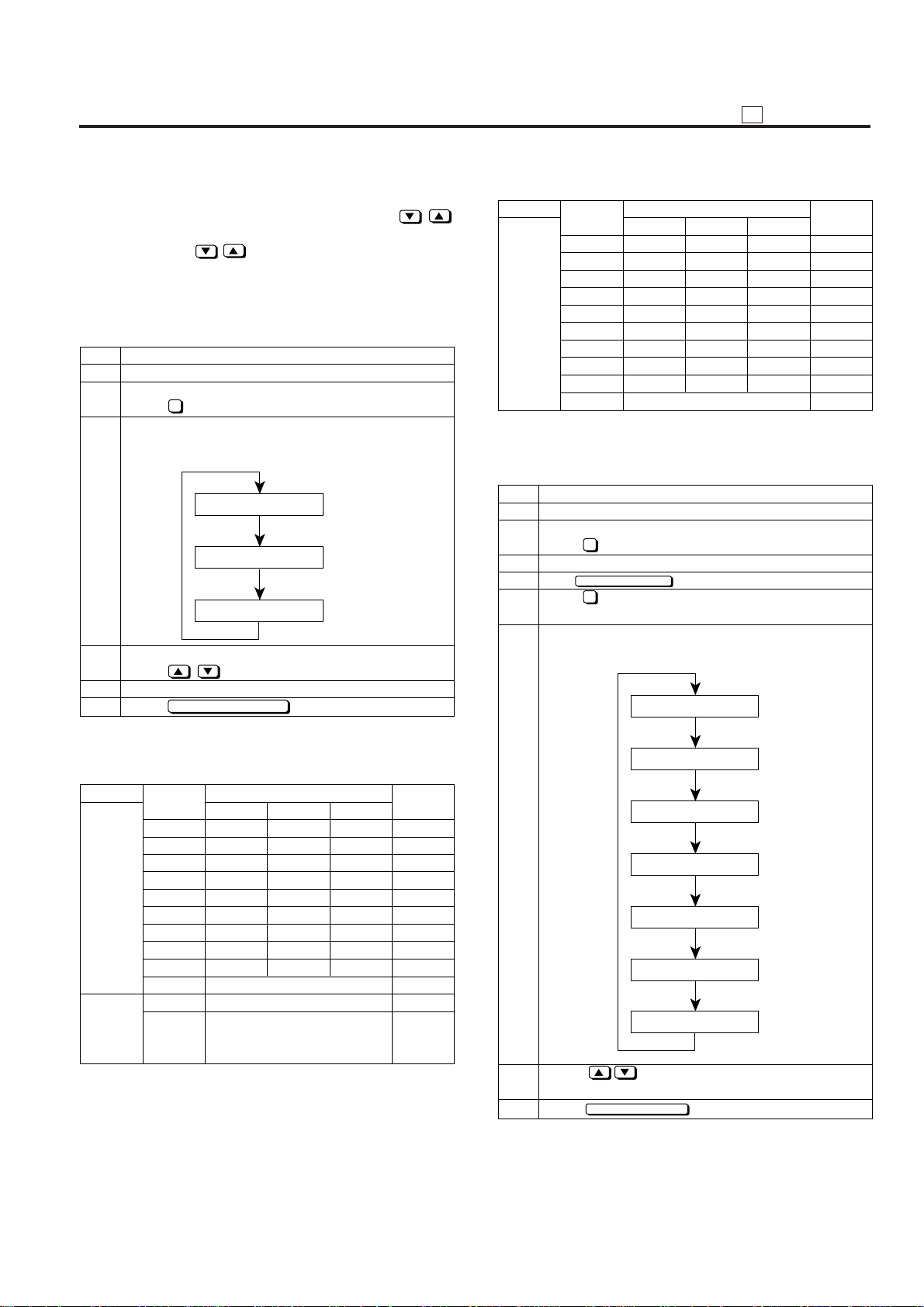

Step

1

2

3

4

5

6

Operation

Enter the 25 mode.

[25 Mode Menu Screen]

Press Software SW setting.

[Software DIP SW Setting Screen]

Select DIP switch number.

Use the left key.

Select bit number of the switch.

Use the middle key.

Select ON(=1) or OFF(=0) of switch.

Use or key.

: "1" is set (Set bit).

: "0" is set (Clear bit).

Press key to end setting.

1

ON

ON OFF

OFF

PREVIOUS SCREEN

25 MODE

[1] Setting Method

A special operating mode called "25 Mode" has been provided

with this machine. This mode enables to rewrite the non-volatile storage and specify other various settings.

1. Turn off the main switch.

2. Turn the main switch back on while holding down 2 and 5

of the copy quantity setting buttons.

25 Mode Menu Screen will appear.

In the 25 mode normal copy operation becomes unavailable.

[25 Mode Menu Screen]

Memory setting mode

Select one of following items

[2] Setting Software DIP SW

1. Setting method

This setting specifies the software DIP SW on the software DIP SW Setting Screen. (Refer to "*1" on next page.)

[Software DIP SW Setting Screen]

Software Switch set mode

12 - 0 : 1 FF

Memory setting mode

Select one of following items

10

KRDS setting will be shaded and unavailable if the op-

*

tional KRDS or Memory Card Adapter Kit is not equipped.

3. Press the desired number key of the item to set.

Each setting screen will appear.

4. Enter data in each selected screen.

5. Press the

has been entered.

6. Turn the main switch off to cancel the 25 mode.

7. New data will be effective after restarting.

PREVIOUS SCREEN

key to check the data that

4 - 6

Page 8

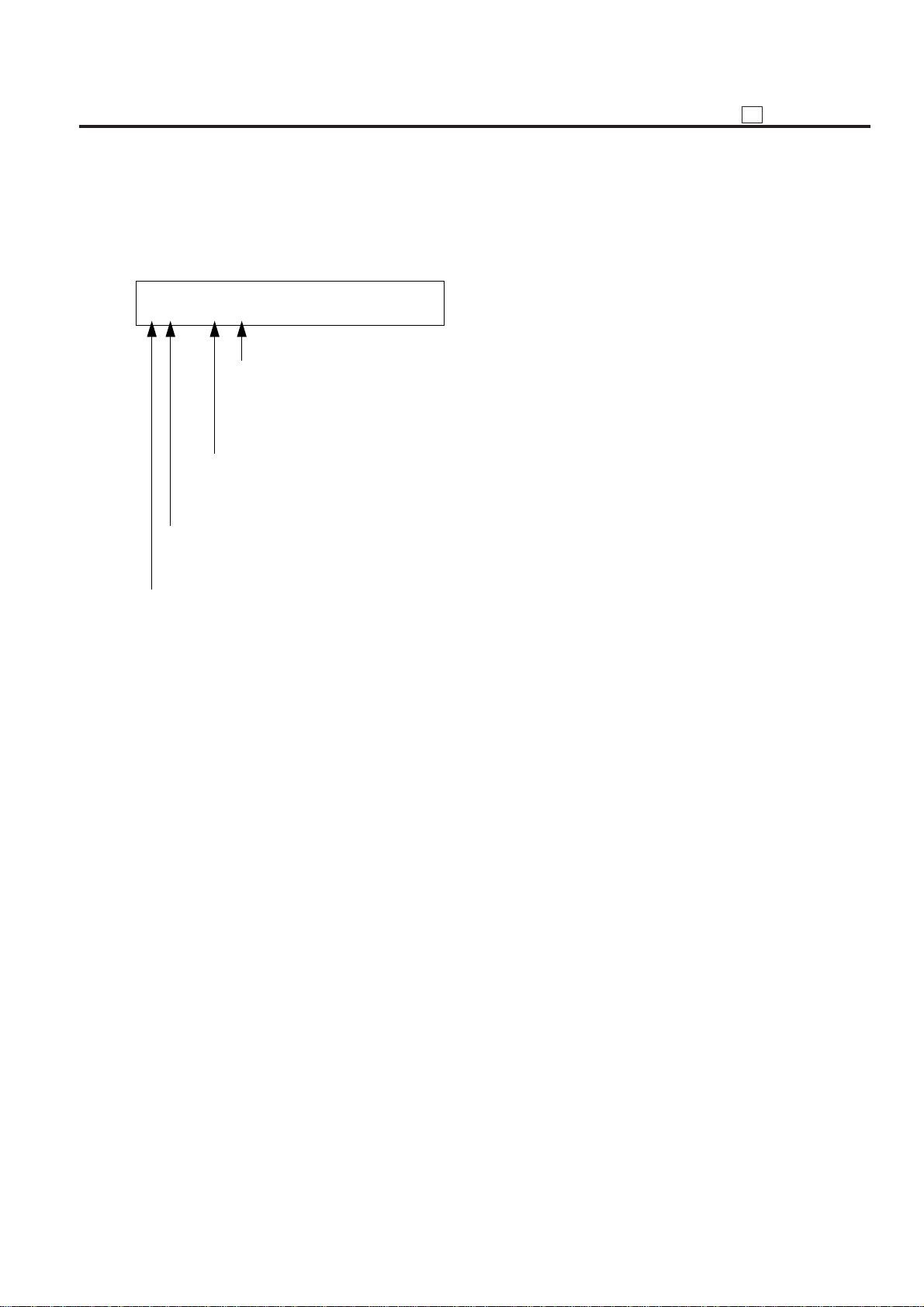

*1:

• The bit of the switch is written in the non-volatile RAM

every time it is changed.

• The numbers shown in the message area are defined as

follows:

Software Switch set mode

4 - 7 : 1 F3

8-bit switch value is indicated in

hexadecimal from 00 to FF.

Bit Data

1: ON

0: OFF

Bit Number(0~7)

25

ADJUSTMENT

Switch Number

For each switch function, refer to "List of Software SW".

4 - 7

Page 9

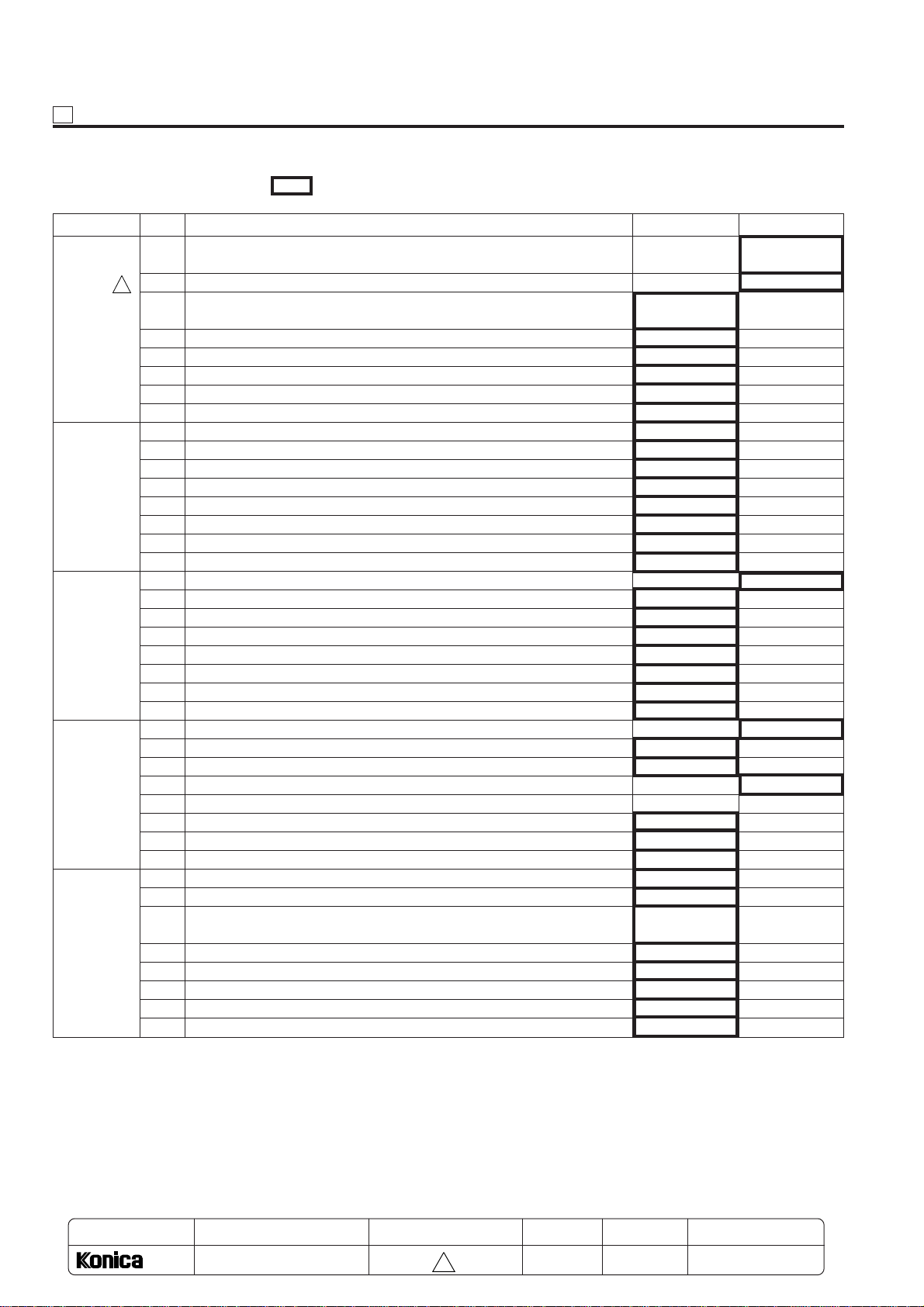

25 ADJUSTMENT

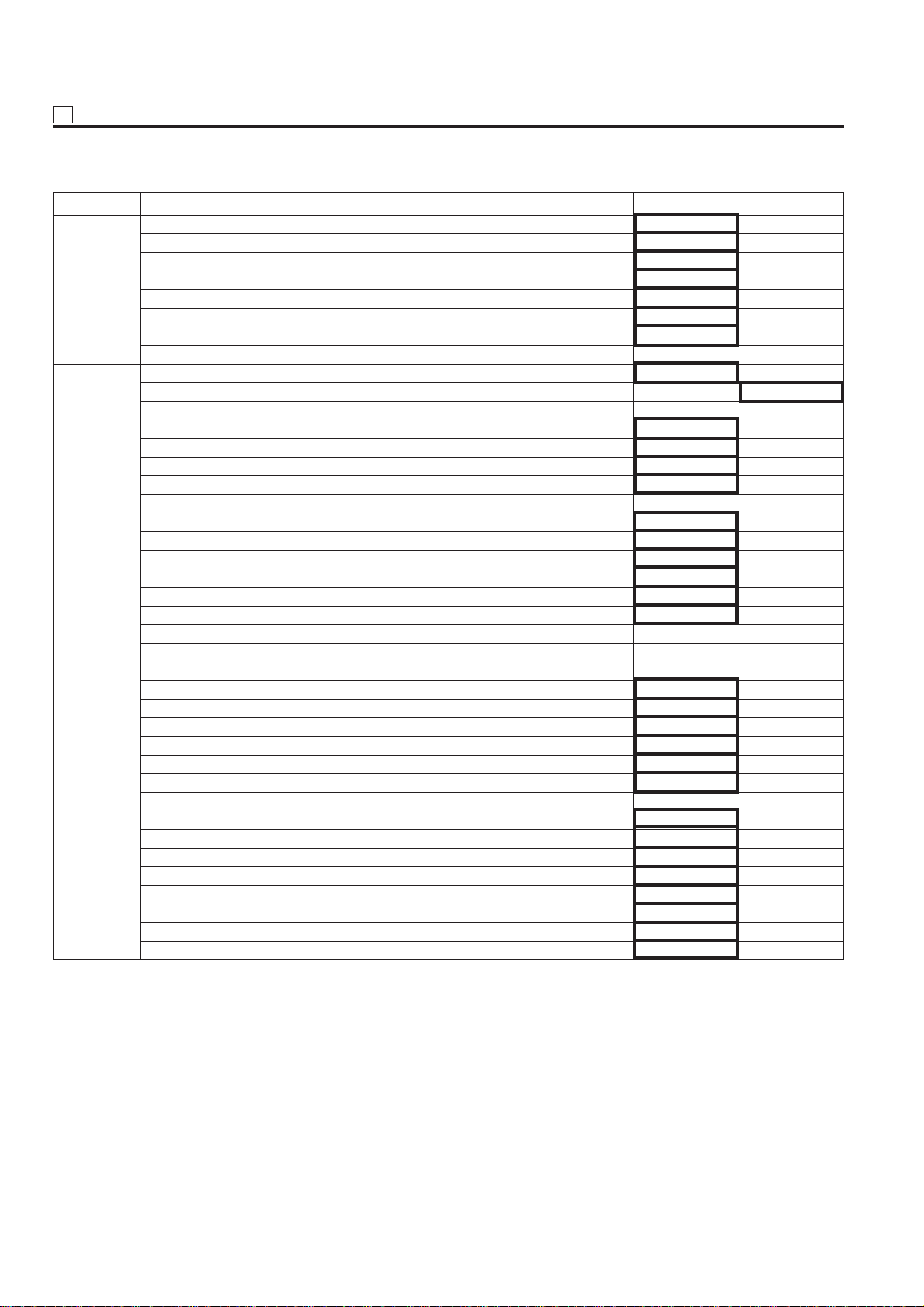

<List of Software Switch> : The boxes with thick lines indicate factory settings.

DIPSW No. Bit Function 0 1

0 Operation when key counter is removed (when using as a copier) Ignore Instantaneous

stop jam

1 A3 (11 x 17) count method 1 count 2 count

2

2 FNS number of stapled sheets upper limit stop select

DIPSW 1 3 FNS maximum number of stapled sheets * 1 * 1

4

5 FNS sensor failure sensing * 2 * 2

6

7

F/E code screen select (all other than fixing unit F code can be replaced with E code)

0 FNS sub-tray select for service check * 3 * 3

1

2 Jam code display No Yes

DIPSW 2 3 Auto Charge electrode cleaning Yes No

4 Auto Transfer/Separation electrode cleaning Yes No

5 FNS over-stacking sensing Sense Ignore

6 25, 36, 47 mode password request. Password: 9272 (fixed) No request Request

7 Select A-series papers only (for Europe) No Yes

0– – –

1 F34 latch No Yes

2 F35 latch No Yes

DIPSW 3 3 F36 latch No Yes

4 F37 latch No Yes

5 Operation when a key counter is removed (when using as a printer) Ignore

6 Confirmation message when the Clear button is on Display No display

7 Status screen No Yes

0 Toner level sensing (replenish toner display) * 5 * 5

1

2 Destination select * 6 * 6

DIPSW 4 3

4– – –

5 Reserve page memory at job start (Refer to "Note 4" on page 4-11) No Yes

6 Polygon motor low-speed timing * 7 * 7

7

0 F4 size setting * 8 * 8

1

2 Select paper line (Vertical line/Horizontal line) (for Japan only) All horizontal.

DIPSW 5 3 Polygon motor low-speed select (when idling) * 9 * 9

4

5

6 Image lead edge erasure amount during RADF copy * 10 * 10

7

″

″

″

″

″

″

″

″

″

″

Immediate stop

* 1 * 1

* 2 * 2

No Yes

* 3 * 3

* 5 * 5

* 6 * 6

* 7 * 7

* 8 * 8

* 9 * 9

* 9 * 9

* 10 * 10

Stop at an interval

of copy set

Same as copier

Horizontal for

A4/B5/by-pass feed.

(Note)

Note: For Europe / 2 count

other than Europe / 1 count

MODEL

7065

SERVICE HANDBOOK

MANUAL

REVISED EDITION

4 - 8

2

DATE

Jan.2000

PAGE

4-8

METHOD

REPLACEMENT

Page 10

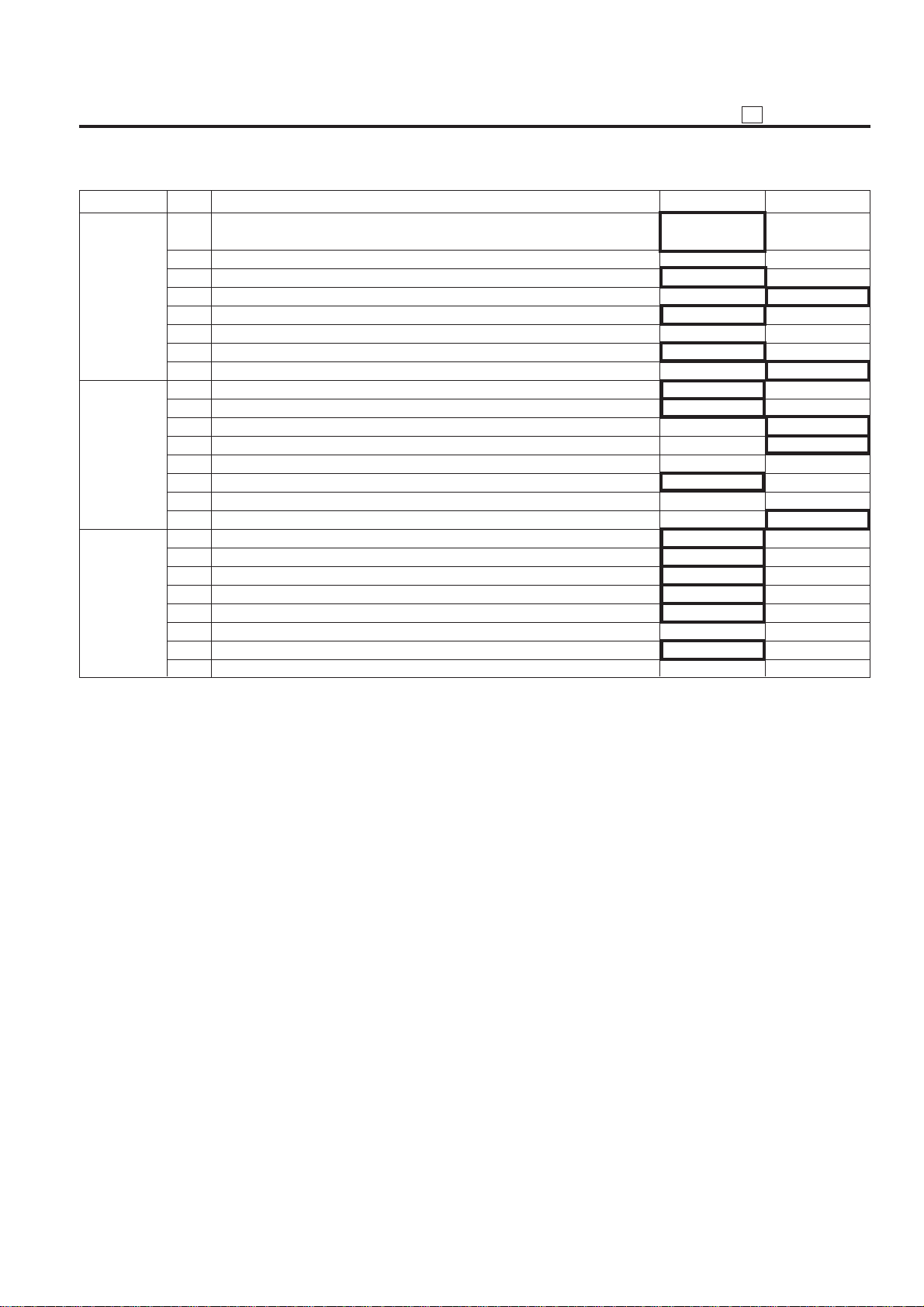

25

ADJUSTMENT

DIPSW No. Bit Function 0 1

0 Separation claw on timing * 11 * 11

1

2

DIPSW 6 3

4 Separation claw off timing * 11 * 11

5

6

7

0 Toner replenish stop function No Yes

1 Toner replenish stop timing (Refer to "Note 1" on page 4-11) When copying

DIPSW 7 2 Number of copies available after toner replenishment display * 19 * 19

3

4— — —

2

{

5— — —

6 LCD contrast adjustment in help screen No Yes

7 Full auto screen setting Yes No

0 Selects erasure area in Auto Non-image Area Erasure Mode * 26 * 26

1 Fixed mag. ratio change Enable Disable

DIPSW 8 2 Prevents copying at PM display No Yes

3— — —

2

4 Preferential tray select when APS is canceled * 12 * 12

5

6

7 For data collection (For checking collection data 4 to 7 in the 25 mode) No Yes

0 Number of copies limit * 13 * 13

1

2

DIPSW 9 3

4 Normal/Fine select * 14 * 14

5

6 Japanese P81 MSG (MSG for Grocery store use)

7

0 Sets the WT daylight saving time * 16 * 16

1

2

DIPSW 10 3

4 Switches the [-A-] display -A- 1.00

5 Message on setting screen

6 Displays icons on the third line No Yes

7— — —

″

″

″

″

″

″

″

″

″

″

″

″

″

″

″

″

″

* 11 * 11

* 11 * 11

* 11 * 11

* 11 * 11

* 11 * 11

* 11 * 11

Interval between

ends

* 19 * 19

* 12 * 12

* 12 * 12

* 13 * 13

* 13 * 13

* 13 * 13

* 14 * 14

* 16 * 16

* 16 * 16

* 16 * 16

Guidance display

copy set

Machine status display.

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

4 - 9

2

DATE

Jan.2000

PAGE

4-9

METHOD

REPLACEMENT

Page 11

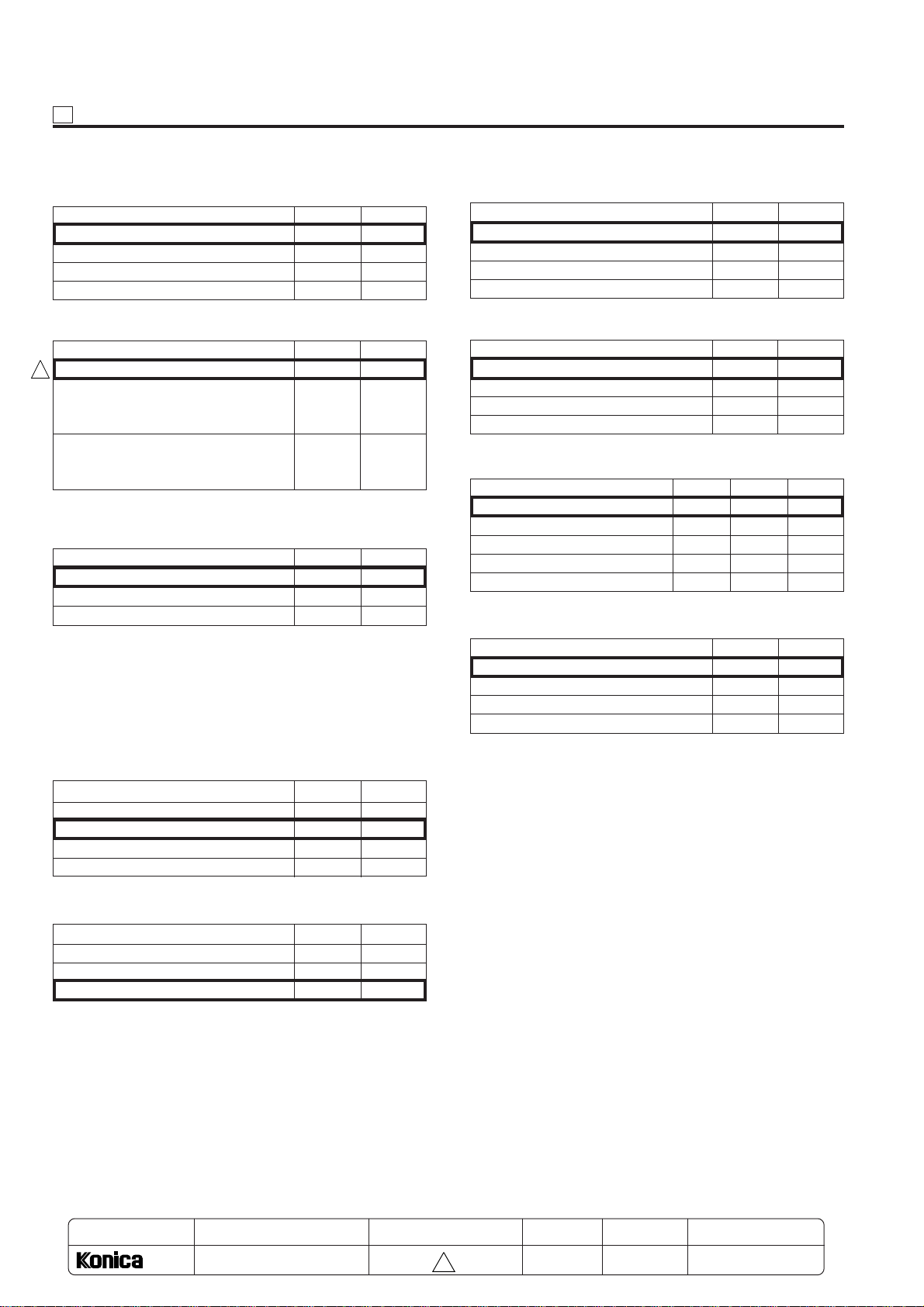

25 ADJUSTMENT

DIPSW No. Bit Function 0 1

0

Tray screen OK key display (Effective when layer type menu screen is selected.)

1

Magnification screen OK key display (Effective when layer type menu screen is selected.)

2

Density screen OK key display (Effective when layer type menu screen is selected.)

DIPSW 11 3

DIPSW 12 3 Sets number of copies for copy disable (at PM display) * 18 * 18

DIPSW 13 3 Isolates Tray 4 as provisional measure Normal Unusable

DIPSW 14 3 Selects consolidated operation during printer mode Disable Enable

DIPSW 15 3 Displays universal tray Display size Special

Copy mode OK key display (Effective when layer type menu screen is selected.)

4

Select time without OK (Effective when layer type menu screen is selected.)

5 Operation screen select

6

Tray icon display (Effective when direct selection menu screen is selected.)

7– – –

0 Sets number of print for 24-hour processing * 20 * 20

1

2– – –

4

5

6 Recognizes KRDS connection Not connected Connected

7

—

0 Isolates Tray 1 as provisional measure Normal Unusable

1 Isolates Tray 2 as provisional measure Normal Unusable

2 Isolates Tray 3 as provisional measure Normal Unusable

4 Isolates Tray 5 as provisional measure Normal Unusable

5 Isolates ADU as provisional measure Normal Unusable

6– – –

7– – –

0– – –

1 Exit to Subtray in non-sort No Yes

2 Variable magnification APS disable No Yes

4 Selects arbitrary tray operation during printer mode Disable Enable

5–

6–

7– – –

0 Selects first selected tray in auto tray selection * 22 * 22

1

2

4 Changes Platen memory read order N to 1 1 to N

5 Sets Taiwan A series 25 mode tray size B series size K series size

6 Detects Taiwan K series size B series size K series size

7 Dual prohibition Not prohibited Prohibited

″

″

″

″

″

Yes No

Yes No

Yes No

Yes No

Short Long

Layer type menu screen Direct selection menu screen

No Yes

* 20 * 20

* 18 * 18

* 18 * 18

——

Must not be changed Must not be used

Must not be changed Must not be used

* 22 * 22

* 22 * 22

4 - 10

Page 12

25

ADJUSTMENT

DIPSW No. Bit Function 0 1

0 Platen original size detection AB/inch Destination Both AB & inch

series only

1– – –

2 Platen original size minimum detection * 23 * 23

DIPSW 16 3

4

5– – –

6 Stop method when toner empty (Refer to "Note 1" below) No

7 Thin line reproducibility (Refer to "Note 2" below) Normal Smoothing

0 Displays total count starting date Disable Enable

1 Sets trailing edge erase amount * 24 * 24

2

3 47-15-01 data collection counter clear protect Enable Prohibit

DIPSW 17 4 – – –

5 Job offset (Refer to "Note 3" below) No Yes

6– – –

7 Recovery operation when key counter is removed Yes No

0 Sets tandem mode with auto button No Yes

1 Displays 47-94 data No Yes

2 Selects threshold value in Auto Non-image Area Erasure Mode * 26 * 26

DIPSW 18 3

4 Counts C(K) drive during printer mode Yes No

5– – –

6 RADF book copy No Yes

7– – –

″

″

″

″

* 23 * 23

* 23 * 23

Stop after paper exit

* 24 * 24

* 26 * 26

Note 1: DIP SW related to the stop method during toner empty are DIP SW7-1 and 16-6, and are related as indicated below:

• 16-6 becomes the toner empty stop method if it is set in “1” (Stop after paper exit).

• 7-1 becomes the toner empty stop method if 16-6 is set at “0” (No).

Note 2: The smoothing selection becomes effective when the lines break during thin line copying. The resolution, however,

will decrease.

Note 3: A setting which performs offset output between jobs for devices equipped with a finisher.

Note 4: After the original is read, page memory for output operation during output should be used in the following operations:

<Rotation, Thick paper mode, Overlay, Shift, Aggregating function>

Therefore, memory overflow may occur during output even after the read operation if the memory is narrowly sufficient when the original is read. This setting is to secure page memory in advance in order to avoid such problems.

When securing this page memory, however, the absolute amount of memory is decreased for outputs which do not

apply page memory, thus care must be taken when using this setting.

4 - 11

Page 13

25 ADJUSTMENT

* 1: FNS maximum number of stapled sheets

Mode 1-4 1-3

50 sheets 0 0

45 sheets 0 1

40 sheets 1 0

35 sheets 1 1

* 2: FNS sensor failure sensing

Mode 1-6 1-5

Lower limit sensor sensing 0 0

2

Lower limit sensor sensing 0 1

Abnormal drop sensing

Upper limit sensing

Lower limit sensor sensing 1 0

Abnormal drop sensing

Upper limit sensing

Number of copies overrun sensing

* 3: FNS sub-tray select for service check

Mode 2-1 2-0

Does not 0 0

Sub-tray (Exits sheets face down) 0 1

Sub-tray (Exits sheets face up) 1 0

* 5: Toner level sensing (toner replenish display)

Note: When increasing the set value (number of copies), the

amount of toner may become insufficient before the

toner supply indication, and the density may decrease

when copying a large amount of high dark rate originals continuously.

* 7: Polygon motor low-speed timing select

Mode 4-7 4-6

15 sec. after job end 0 0

30 sec. after job end 0 1

60 sec. after job end 1 0

120 sec. after job end 1 1

* 8: F4 size setting

Mode 5-1 5-0

8.5 × 13 0 0

8.25 × 13 0 1

8.125 × 13.25 1 0

8 × 13 1 1

* 9: Polygon motor low-speed select (when idling)

Mode 5-5 5-4 5-3

No low-speed rotation 0 0 0

Low-speed rotation 14,000rpm 0 0 1

Low-speed rotation 11,024rpm 0 1 0

Low-speed rotation 8,000rpm 0 1 1

Stop 1 0 0

* 10: Image lead edge erasure amount during RADF copy

Mode 5-7 5-6

2 mm 0 0

3 mm 0 1

4 mm 1 0

5 mm 1 1

Mode 4-1 4-0

After 100 copies 0 0

After 1000 copies 0 1

After 2000 copies 1 0

After 3000 copies 1 1

* 6: Destination select

Mode 4-3 4-2

Japan 0 0

USA 0 1

Europe/others 1 0

MODEL

7065

SERVICE HANDBOOK

MANUAL

REVISED EDITION

4 - 12

2

DATE

Jan.2000

PAGE

4-12

METHOD

REPLACEMENT

Page 14

25

ADJUSTMENT

* 11: Separator claw ON setting

Note: Separator jams occur in some cases when the setting

is changed.

Mode 6-3 6-2 6-1 6-0

0 mm 0 0 0 0

5 mm 0 0 0 1

10 mm 0 0 1 0

15 mm 0 0 1 1

20 mm 0 1 0 0

25 mm 0 1 0 1

30 mm 0 1 1 0

35 mm 0 1 1 1

40 mm 1 0 0 0

45 mm 1 0 0 1

50 mm 1 0 1 0

55 mm 1 0 1 1

60 mm 1 1 0 0

65 mm 1 1 0 1

70 mm 1 1 1 0

75 mm 1 1 1 1

* 11: Separator claw OFF setting

Note: Separator jams occur in some cases when the setting

is changed.

Mode 6-7 6-6 6-5 6-4

50 mm 0 0 0 0

55 mm 0 0 0 1

60 mm 0 0 1 0

65 mm 0 0 1 1

70 mm 0 1 0 0

75 mm 0 1 0 1

80 mm 0 1 1 0

85 mm 0 1 1 1

90 mm 1 0 0 0

95 mm 1 0 0 1

100 mm 1 0 1 0

105 mm 1 0 1 1

110 mm 1 1 0 0

115 mm 1 1 0 1

120 mm 1 1 1 0

125 mm 1 1 1 1

* 12: Preferential tray when APS is canceled.

Mode 8-6 8-5 8-4

Select by destination 0 0 0

Tray 1 0 0 1

Tray 2 0 1 0

Tray 3 0 1 1

Tray 4 1 0 0

Tray 5 1 0 1

Tray selection according to the destinations

Japan: Tray 1

USA: Tray 2

Europe/others: Tray 3

* 13: Number of copies limit

Mode 9-3 9-2 9-1 9-0

No 0000

1 copy 0001

3 copies 0010

5 copies 0011

9 copies 0100

10 copies 0101

20 copies 0110

30 copies 0111

50 copies 1000

99 copies 1001

* 14: Normal/fine select

Note: 4ED select tends to cause memory overflow . Also , se-

lection of many functions such as rotation, etc., will not

be possible.

Mode 9-5 9-4

1ED + 2ED 0 0

1ED + 4ED 0 1

2ED + 4ED 1 0

4 - 13

Page 15

25 ADJUSTMENT

* 16: Set the WT daylight saving time

Mode 10-3 10-2 10-1 10-0

0 min. 0000

10 min.0001

20 min.0010

30 min.0011

40 min.0100

50 min.0101

60 min.0110

70 min.0111

80 min.1000

90 min.1001

100 min. 1010

110 min. 1011

120 min. 1100

130 min. 1101

140 min. 1110

150 min. 1111

* 18: Sets number of copies for copy disable upon PM arrival.

Note: This set value is effectiv e only when DIP SW 8-2 is set

at “1” (Yes).

Mode 12-5 12-4 12-3

1000 copies 0 0 0

2000 copies 0 0 1

3000 copies 0 1 0

4000 copies 0 1 1

5000 copies 1 0 0

* 19: Number of copies available after toner replenishment

Note: When DIP SW 7-0 is set at “1” (Yes) , it will stop when

copying the set value in accordance with the toner

empty stop method which has been set, and further

copying will be disabled until toner is supplied.

Mode 7-3 7-2

100 copies 0 0

1000 copies 0 1

2000 copies 1 0

3000 copies 1 1

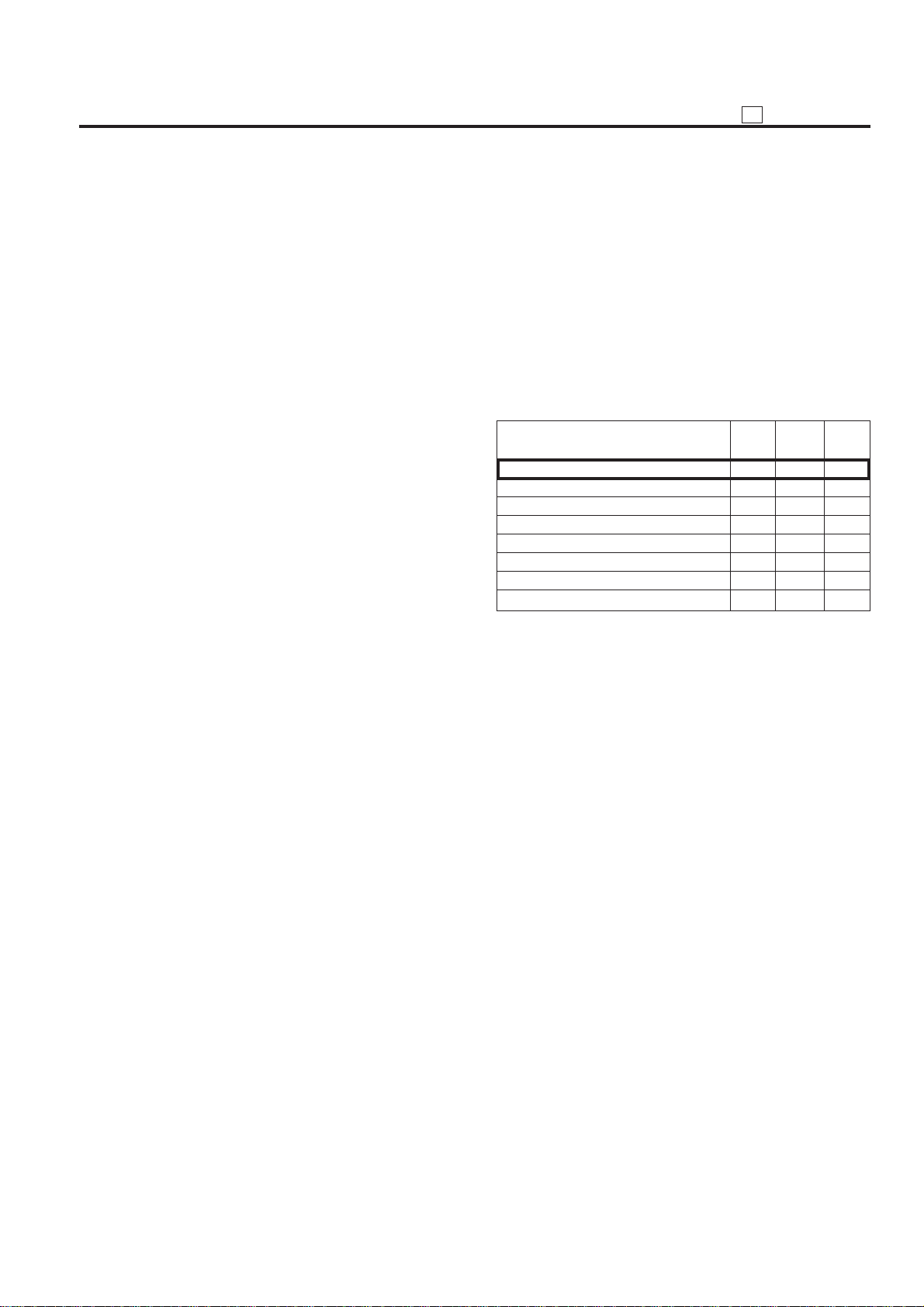

* 22: Selects first selected tray in auto tray selection

Note: Trays are searched as shown in the figure below, and

selection of the first tray to be used is made.

Tray 1

Tray 2 Tray 5

Tray 3 Tray 4

Mode 15-2 15-1 15-0

Search sequence

by destination

Search from tray 1 0 0 1

Search from tray 2 0 1 0

Search from tray 3 0 1 1

Search from tray 4 1 0 0

Search from tray 5 1 0 1

Search sequence by destination

Japan : tray 1

USA : tray 2

Europe/others : tray 3

* 23: Platen original size minimum detection.

Mode 16-4 16-3 16-2

A3 0 0 0

B6R 0 0 1

2

2

A5R 0 1 0

5.5 x 8.5R 0 1 1

11 x 17 1 0 0

8.5 x 11 1 0 1

Note: For USA : 5.5 X 8.5R

* 24: Sets trailing edge erase amount.

Mode 17-2 17-1

Does not 0 0

2 mm 0 1

3 mm 1 0

5 mm 1 1

000

(Note)

* 20: Sets number of print for 24-hour processing

Note:

Assuming a device which is energized continuously, the

process automatic adjustment applied for image level

stabilization is performed per number of prints for the setting indicated below. (Process automatic adjustment is

being performed when the power (main switch) is ON.)

Mode 12-1 12-0

2000 times 0 0

4000 times 0 1

3000 times 1 0

5000 times 1 1

* 21: Delete

2

MODEL

7065

SERVICE HANDBOOK

MANUAL

REVISED EDITION

4 - 14

2

DATE

Jan.2000

PAGE

4-14

METHOD

REPLACEMENT

Page 16

25

ADJUSTMENT

* 26: Selects erasure area in Auto Non-image Area Erasure

Mode.

This setting is related to the non-image area automatic erase

mode of the application function.

1. Selecting the erasure area

"Rectangle erasure" and "Skewed original compensation"

are the two options in selecting an area to be erased, and

are used as indicated below:

• When the shape of the original is not rectangle (circular,

etc.) → Select "Skewed original compensation"

• When the original is rectangle and in standard size →

Select "Rectangle erasure"

In the rectangle erase selection, however, black streaks

may appear even for a rectangle shape original if it is set

skewed. Furthermore, if there are black areas on the outer

rim of the original, it may mistakenly be judged as an nonimage, and non-image erase may not be perf ormed accurately . Rectangle erasing becomes effectiv e is such a case.

2. Selecting the Discrimination level (threshold value)

Discrimination of the original and the outer-original areas

(Non-image Area) may not be performed accurately for

dark originals, or when miscellaneous lights (light from a

fluorescent lamp or the sun) break into the copier. For

such case, the threshold value can be changed.

• To correspond to dark originals → Select 80, 96, 101

(The smaller value, the more it conforms to darker originals.)

• To correspond to miscellaneous lights → Select 176

Remarks:

There is a non-image area erasure function setting in the key

operator mode memory switch. When the copy paper is selected by manual, the copy area can be selected as follows:

• When copying only the image size area determined by the

APS sensor → Select "erase the outer-original (non-image area) area"

• When copying the entire area of the selected copy paper

→ Select "will not erase the outer-original (non-image area)

area"

(Note: The APS sensor will be in effect even when selecting

the copy paper by manual.)

Erasure area/Discrimination level 8-0 18-3 18-2

(Threshold value)

Rectangle erasure/128 0 0 0

Rectangle erasure/96 0 0 1

Rectangle erasure/80 0 1 0

Rectangle erasure/176 0 1 1

Skewed original compensation/128 1 0 0

Skewed original compensation/101 1 0 1

Skewed original compensation/176 1 1 0

Skewed original compensation/176 1 1 1

4 - 15

Page 17

25 ADJUSTMENT

Japan

Europe

U.S.A.

A4, B5, A4R, B5R, 8.5 × 11, 8.5 × 11R

A4, B5, A4R, B5R, 8.5 × 11, 8.5 × 11R

8.5 × 11, 8.5 × 11R, A4, B5, A4R, B5R

Japan

Europe

U.S.A.

A4, B5, 8.5 × 11

A4, B5, 8.5 × 11

8.5 × 11, A4, B5

Step

1

2

3

4

5

Operation

Enter the 25 mode.

[25 Mode Menu Screen]

Press Paper size setting.

[Paper Size Setting Screen]

Press the tray key to be changed.

Press or key to select the paper size.

Press key to end setting.

2

PREVIOUS SCREEN

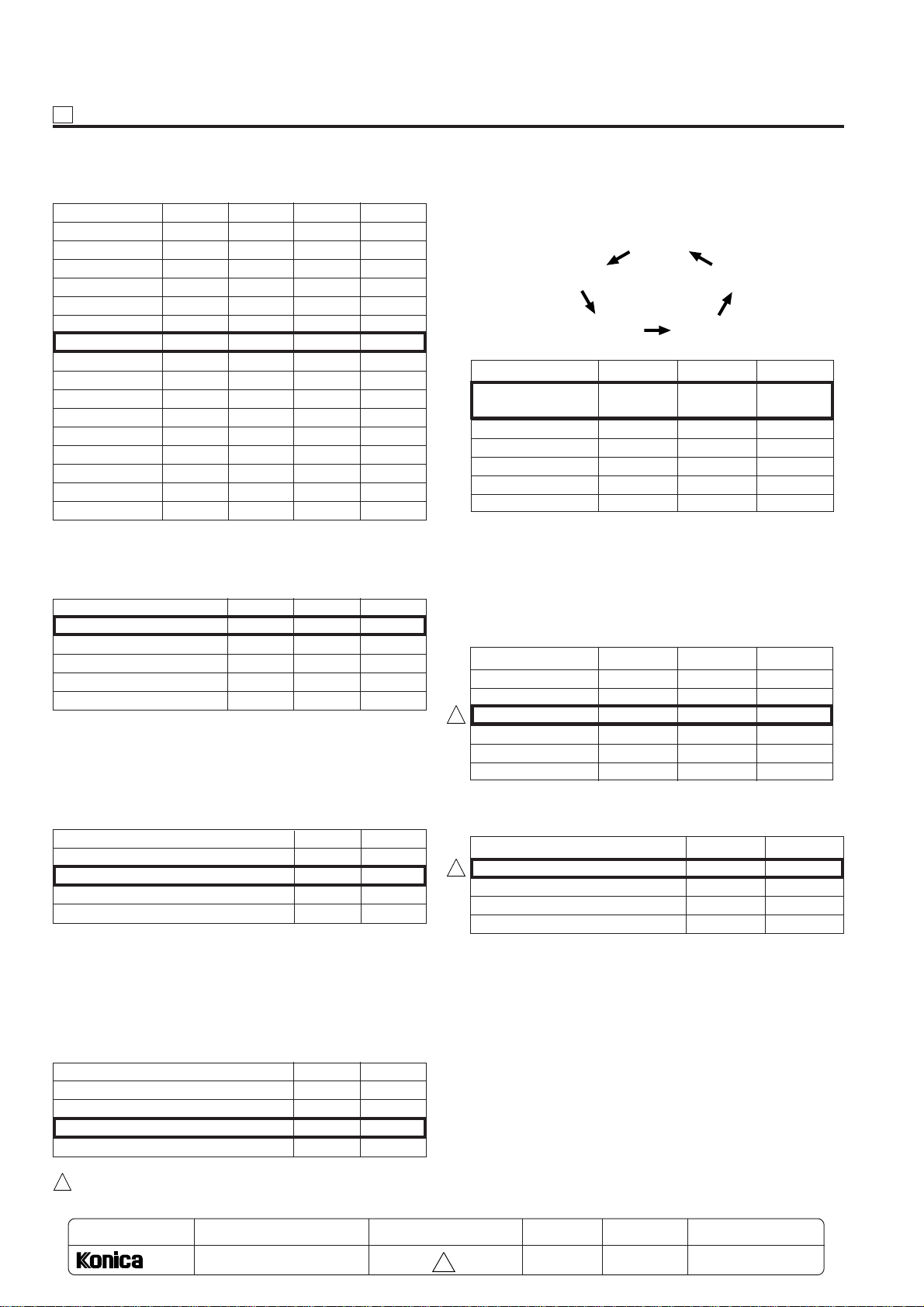

[3] Tray Paper Size Setting

This function stores the paper size into memory if the tray size

has been changed.

[Tray Size Setting Screen]

a. When you do not use any optional tray:

Paper size setting mode

b. When you use the optional tray, LT-352:

Paper size setting mode

Reference:

• The upper tra y of the main body is Tray 1, the lower tra y

Tray 2, the LCT 1000 tr ay Tray 3, and the LCT 1500 tr a y

Tray 4. The option tray will be Tray 5. For the tray 2, 3,

4, and 5 only service personnel can perform size setting.

• A v ailability of paper size depends on the selected tr ay.

The unavailable paper sizes will be skipped and not

displayed.

• New data on tra y size will be written in non-volatile RAM

every time it is changed in this screen.

• The paper size that can be used in the tray 2 as follows.

A3, B4, A4, A4R, A5R, B5, B5R, B6, 11 x 17, 8.5 x 14,

8 x 13, 8.5 x 11, 5.5 x 8.5, 8.5 x 11R

• The following table shows the paper sizes that can be

used in the tray 3.

• The following table shows the paper sizes that can be

used in the tray 4.

Note:

• F or tra y 1 and the b ypass f eed tra y, settings cannot be

performed in the non-volatile RAM.

Both tray 1 and the bypass feed tray can read the paper size using sensors.

• The screen is automatically changed from the optional

tray according to the type of trays.

4 - 16

Page 18

25

ADJUSTMENT

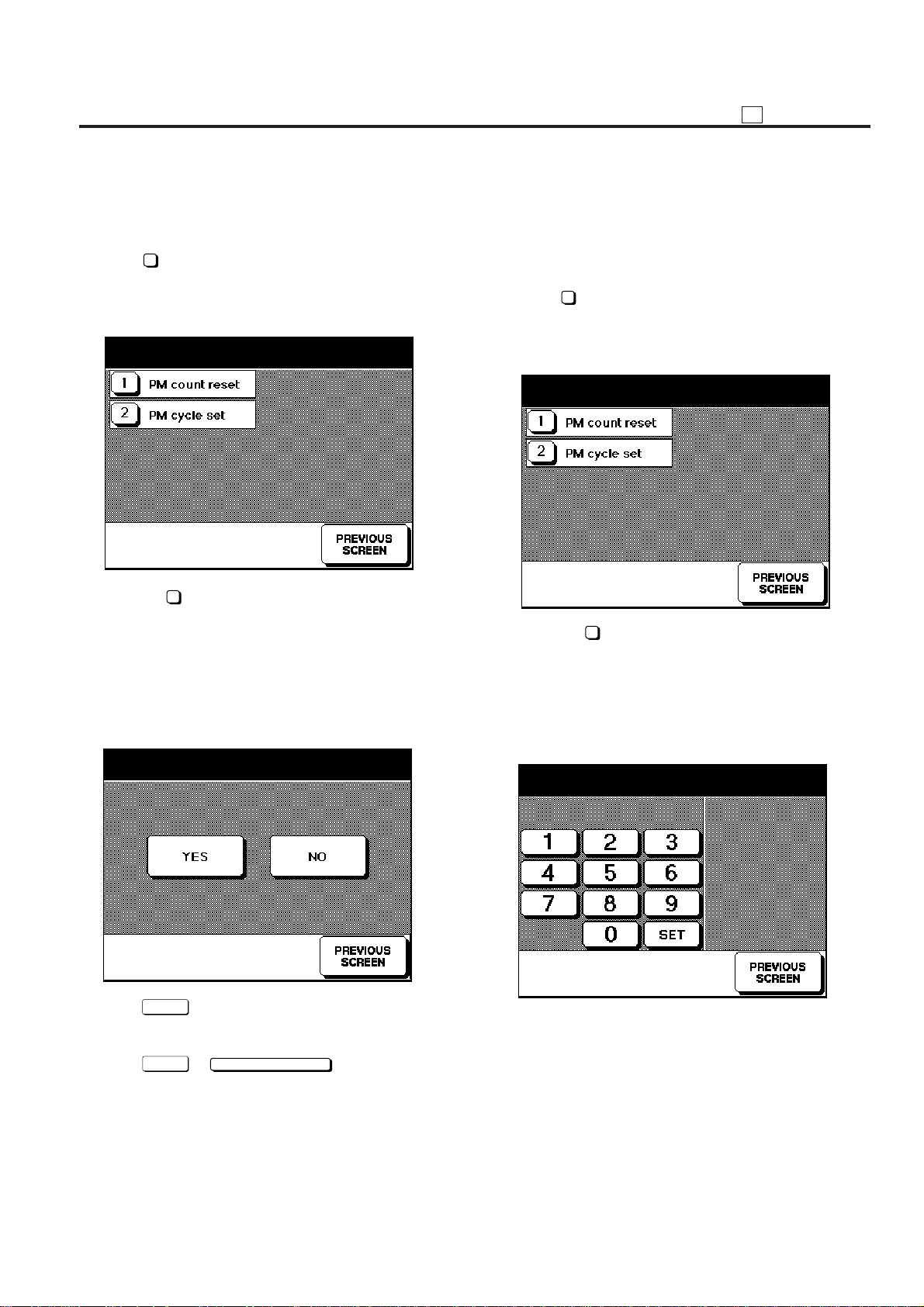

[4] PM Count Reset

Care should be taken to reset PM count properly.

1. Screen selection

Select 3 PM count/cycle in the 25 Mode Menu Screen to

display PM Count/Cycle Menu Screen as an initial screen.

[PM Count/Cycle Menu Screen]

PM count/cycle

PM/CYCLE 1562/15000 START:12/06/97

Select

Screen.

2. PM count reset

Select whether to reset the count in the PM Count Reset

Screen.

[PM Count Reset Screen]

PM count reset? YES / NO ?

1

PM count reset to display PM Count Reset

[5] Setting PM Cycle

This function sets the PM cycle.

Note: PM cycle is set in advance. This is used when chang-

ing the cycle.

1. Screen selection

Select 3 PM count/cycle in the 25 Mode Menu Screen to

display PM Count/Cycle Menu Screen as an initial screen.

[PM Count/Cycle Menu Screen]

PM count/cycle

PM/CYCLE 1562/15000 START:12/06/97

Select 2 PM cycle set to display PM Cycle Setting

Screen.

2. Setting method

Enter PM cycle in the PM Cycle Setting Screen.

[PM Cycle Setting Screen]

PM cycle set mode

150000 => 150000

:

(1) Select

PM count and PM count start date will be set automatically.

(2) Select

Count/Cycle Menu Screen.

YES

in the PM Count Reset Screen to reset the

NO

PREVIOUS SCREEN

or

key to return to PM

(1) On the second row of the message area, the current PM

cycle value (on the left side) and the newly entered value

(on the right side) are displayed.

(2) Enter the first three digits of the value (number of hundred

thousands, ten thousands and thousands) using the numeric key on the screen.

(3) The first entered number will be shifted to the left end.

4 - 17

Page 19

25 ADJUSTMENT

No.

1

2

3

4

5

6

7

Data collection

-1

Data collection

-2

Data collection

-3

Data collection

-4

Data collection

-5

Data collection

-6

Data collection

-7

Contents

Count number of

copies by each

size (Printer

mode and Copy

mode)

Count ADF

original feed

quantities

Count number

of copies by

each size

(Printer mode)

Count number

of copies by

each size (Copy

mode)

Count number

of JAM

occurrence by

each Jam code

Count number

of copies by

each mode

Count number

of SC

occurrence

(F code)

Count number

of SC

occurrence

(E code)

Pre-operationClassification

–

–

–

Enter the 25

mode.

Select

Software SW

setting.

Set the address

to 8-7 : 1

*1

*1: It is possible to view only data collection -1 to 3 if DIP

SW8-7 is set to 0.

1

Step

Enter the 25 mode.

1

[25 Mode Menu Screen]

2

3

4

3

Press PM count/cycle.

[PM Count/Cycle Menu Screen]

2

Press PM cycle set.

[PM Cycle Setting Screen]

Operation

Enter the first three digits of the PM cycle value

(number of hundred thousands, ten thousands and

thousands) using the numeric keys on the screen.

Press key to enter the PM cycle that has

5

SET

been entered.

PREVIOUS SCREEN

Press key to end setting and

6

return to PM Count/Cycle Menu Screen.

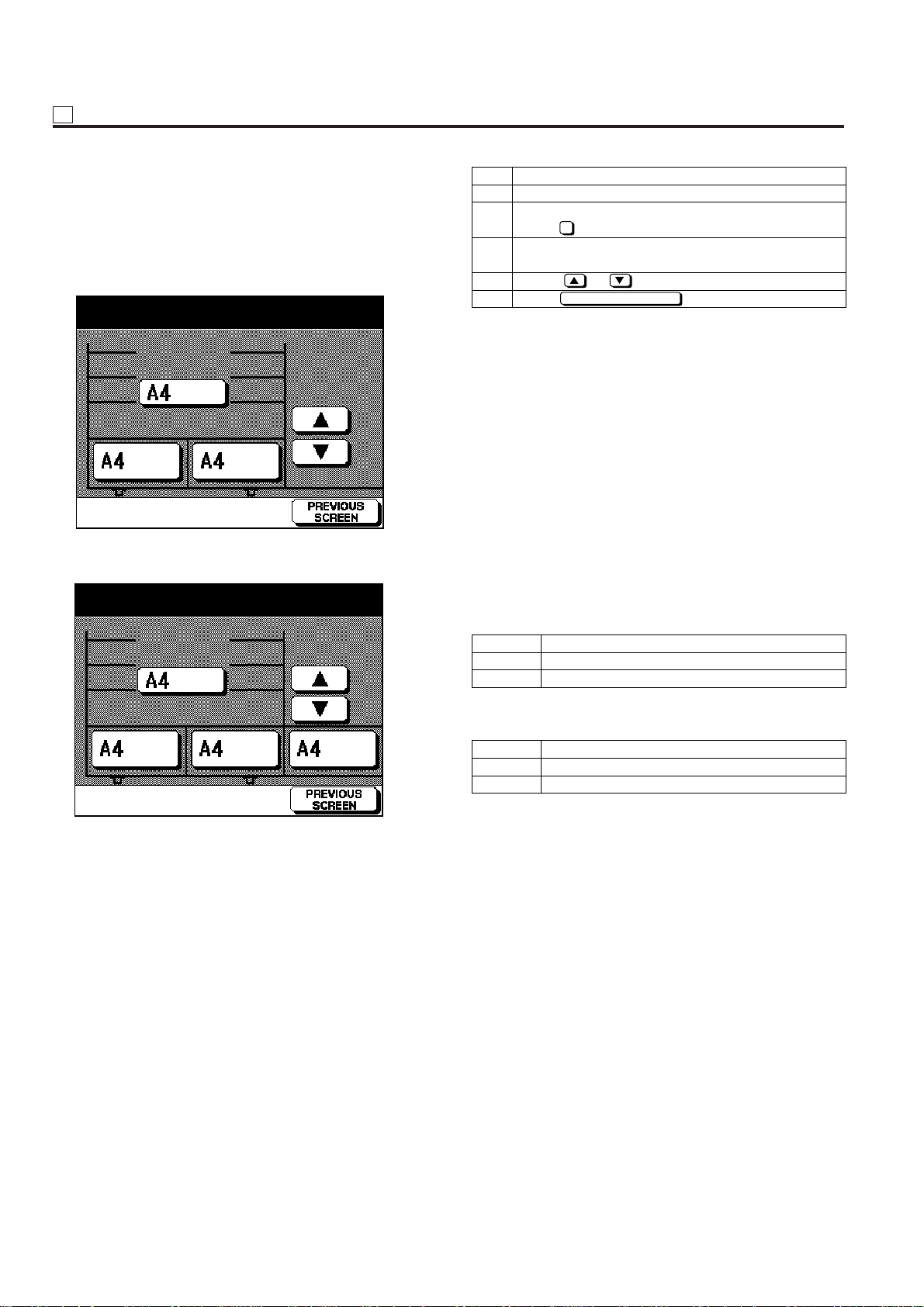

[6] Data Collection

This function enables to view the various data recorded in the

machine.

1. Data view method

Select 4 Data collection in the 25 Mode Menu Screen.

[Data Collection Screen]

Collecting data - 1

No.2 = 107

<List of Available Data>

4 - 18

Page 20

25

ADJUSTMENT

(1) The data is displayed at the second row of the message

area as "Data number (No.) : Count value (000000)".

(2) The data number can be changed by pressing

key.

(3) Press and hold

key to display the next items con-

tinuously .

2. Data view procedure (data collection 1-3)

a. Operation procedure

Step

Enter the 25 mode.

1

[25 Mode Menu Screen]

2

3

4

Press Data collection.

[Data Collection Screen]

Press "Auto Reset" button and select Data

Collection 1 to 3.

Data collection - 1

Data collection - 2

Data collection - 3

Change the data number.

4

Press key.

Repeat steps 3 - 4 to check the various data.

5

PREVIOUS SCREEN

Press key to end checking.

6

Operation

(2) Data Collection 2, 3

Type

Count

number

of copies

by each

size (at

printer

mode or

copy

mode).

Size No.

1

2

3

4

5

6

7

8

9

10

Paper Size for Destination

Japan

—

A3

B4

A4

B5

A5

B6

8.5x14

8.5x11

U.S.A.

—

11x17

8.5x14

8.5x11

5.5x8.5

—

—

—

—

Europe

—

A3

B4

A4

B5

A5

F4

—

—

Non-standard size

Maximum

Count No.

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

3. Data view procedure (data collection 4 - 7)

a. Operation procedure

Step

Enter the 25 mode.

1

[25 Mode Menu Screen]

2

3

4

5

1

Press Software SW setting.

Set the DIP switch No. 8-7 to 1.

PREVIOUS SCREEN

Press key to return to 25 Mode Menu Screen.

4

Press Data collection to display the Data

Collection -1 Screen.

Pressing "Auto Reset" button enables to display

6

next data collection screen.

Operation

Data collection - 1

b. Data details

(1) Data collection 1

Type

Count

number

of copies

by each

size

(Printer

mode

and Copy

mode)

Count ADF

original

feed

quantities

Size No.

1

2

3

4

5

6

7

8

9

10

11

12

Paper Size for Destination

Japan

A3

B4

A4

B5

A5

B6

8.5x14

8.5x11

—

U.S.A.

—

11x17

8.5x14

8.5x11

5.5x8.5

—

—

—

—

Europe

—

A3

B4

A4

B5

A5

F4

—

—

Non-standard size

ADF (1-1 or 1-2)

RADF (2-1 or 2-2)

Maximum

Count No.

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

Data collection - 2

Data collection - 3

Data collection - 4

Data collection - 5

Data collection - 6

Data collection - 7

Using key, select the desired data

7

number.

PREVIOUS SCREEN

Press key to end the operation.

8

4 - 19

Page 21

25 ADJUSTMENT

b. Data details

(1) Data collection -4

Count number of JAM occurrence by each Jam code

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

1

39

Jam code

–

–

–

–

–

–

–

–

J19

J21

J31

J32

J61

J62

J63

J72

–

J92

J93

J94

–

J11-2

J11-3

J11-4

–

J12-2

J12-3

J12-4

–

J13-2

J13-3

J13-4

–

J14-2

J14-3

J14-4

J30

J95

–

Maximum count No.

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

No.

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

Jam code

J96

J10-2

J10-4

–

–

J17-3

J17-4

J17-5

J17-6

–

–

–

–

–

–

–

–

–

J15-2

J15-3

J15-4

J33-2

J33-3

J33-4

Maximum count No.

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

4 - 20

1

DATE

Sep.1999

PAGE

4-20

METHOD

REPLACEMENT

Page 22

(2) Data collection -5

Count number of copies by each mode

25

ADJUSTMENT

No.

1

Platen 1-1 mode

2

Platen 1-2 mode

3

RADF2-1 mode

4

RADF2-2 mode

5

RADF1-1 mode

6

RADF1-2 mode

7

Staple sort

8

Sort

9

Group

10

No. of stapling time

11

1.0 magnification mode

12

RE1

13

RE2

14

RE3

15

RE4

16

RE5

17

RE6

18

Arbitray magnification

19

Zoom

20

4.00 magnification

21

0.33 magnification

22

AMS

23

APS

24

AE

25

Interrupt

26

Bypass feed

27

Book copy

28

Frame erase

29

Fold erase

30

Shift

31

Reduction shift

32

Thick paper

33

Thin paper

Sheet/Cover interleave

34

–

35

OHP (blank paper interleave)

36

Mixed Original

37

Job memory

38

Pre-heat

39

Copy quantity is set to 1.

40

Copy quantity is set between 2 and 5.

41

Copy quantity is set between 6 and 10.

42

Contents

(except for thick paper)

Maximum Count No.

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

No.

Copy quantity is set to 11 or above.

43

Sheet/Cover interleave start

44

—

45

Text/Photo Enhance (Photo)

46

—

47

Verti./Horiz. zoom

48

Booklet

49

Single step

50

Un-select Text/Photo Enhance

51

Text/Photo Enhance (Text)

52

Copy density (user set)

53

OHP(copy paper)

54

Sheet/Cover interleave (thick paper)

55

—

56

Image insert

57

Chapter

58

Combination

59

Repeat

60

Reverse image

61

Non-image area erase

62

—

63

—

64

—

65

—

66

—

67

Print mode

68

Contents

Maximum Count No.

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

99,999,999

4 - 21

Page 23

25 ADJUSTMENT

(3) Data collection -6

Count number of SC occurrence (F code)

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

SC Code

F18-1

F18-2

F18-3

F18-4

F28-1

F28-2

F34-1

F34-2

F35-1

F35-2

F36-1

F36-2

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

F22-1

F22-2

–

F28-3

–

–

–

–

F49-0

F49-1

F49-2

Maximum count No.

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

No.

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

SC Code

F49-3

F49-4

F49-5

F51-1

F51-2

F51-3

F51-4

F51-5

F51-6

F51-7

–

F51-9

F52-1

F52-2

F52-3

F52-4

F52-5

F52-6

–

–

–

–

–

–

–

–

–

F18-5

–

–

–

–

–

–

–

–

–

–

–

–

–

F37-1

F52-8

F52-9

F52-10

F52-11

F52-12

Maximum count No.

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

4 - 22

Page 24

(4) Data collection -7

No.

E46-20

E77-9

E77-11

E77-12

E77-15

E77-21

E77-22

E77-23

E77-24

E77-25

E77-26

E77-31

E77-32

E77-33

E77-34

E77-35

E77-41

E77-91

E77-92

E46-24

E46-25

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

E Code

Maximam count No.

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

Count number of SC occurrence (E code)

25

ADJUSTMENT

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

E Code

–

E48

E46-0

–

E46-2

E46-6

E46-8

E46-9

E60

E67

E70

E77-1

E77-2

E77-3

E77-4

E77-5

E77-6

E77-7

E77-8

–

E46-3

E46-11

E46-12

E41-1

E41-2

E41-3

E41-4

E47-1

E47-2

E47-3

E47-4

E47-5

E41-5

E47-6

E46-5

E46-7

E46-10

E46-15

E46-16

E46-17

Maximam count No.

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

9,999

4 - 23

Page 25

25 ADJUSTMENT

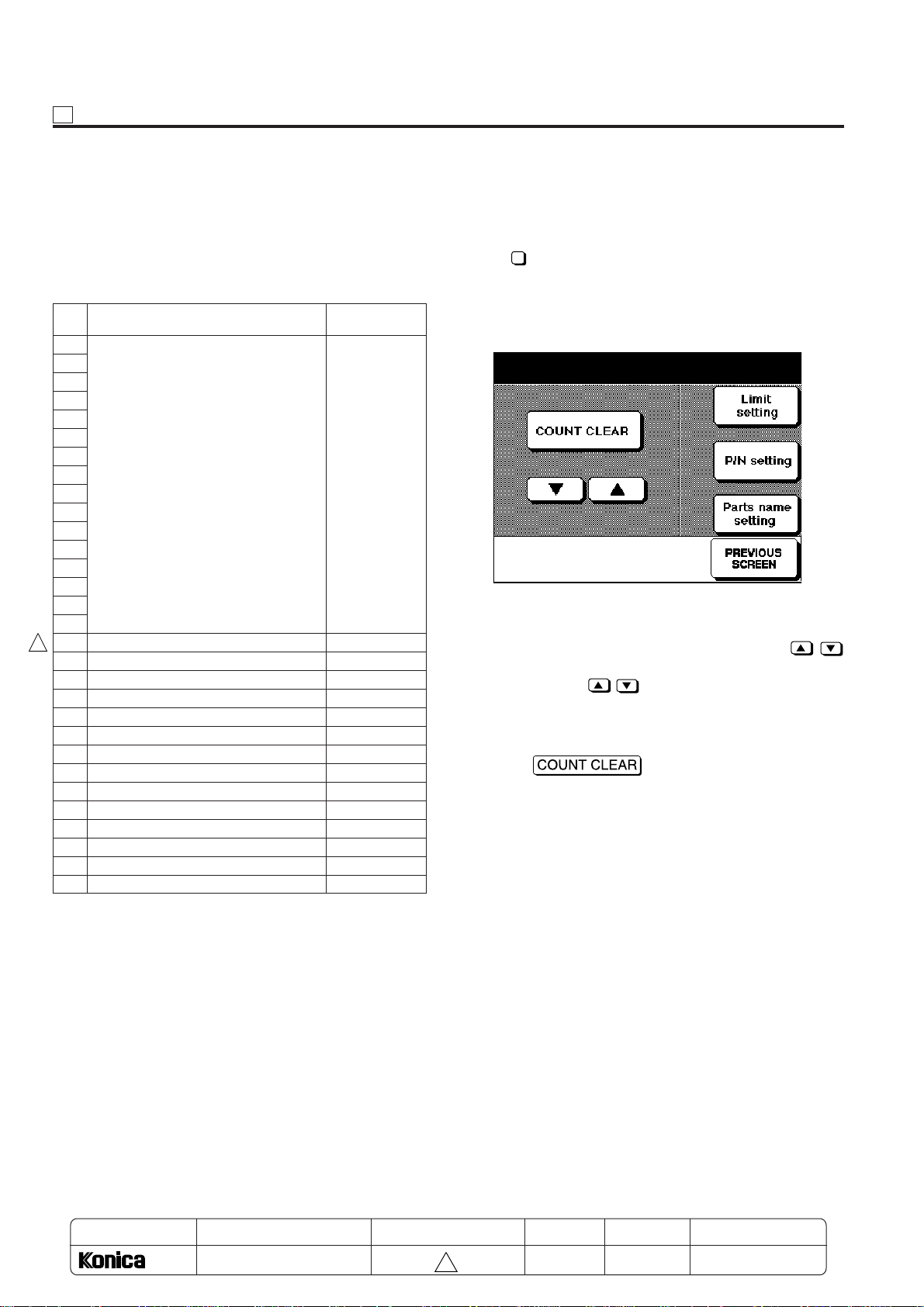

[7] Copy Count by Parts to be Replaced

The following settings are used for arbitrary parts or data.

1. Copy count reset

2. Limit value setting

3. Part number setting

4. Part name setting

Data

No. initial status

1

When copy count (paper exit and ADU)

2 (Setting is

3 available)

4

5

6

7

8

9

10

11

12

13

14

15

16

17 When PI-108 feed <PI>

2

18 When stapling select (at rear) <STAPLER/R>

19 When stapling select (at front) <STAPLER/F>

20 When LT-352 paper feed <TRAY 5>

21 When by-pass paper feed <BY-PASS>

22 When tray 1 select <TRAY 1>

23 When tray 2 select <TRAY 2>

24 When tray 3 select <TRAY 3>

25 When tray 4 select <TRAY 4>

26 When ADU paper feed <ADU>

27 When main unit paper exit <MB-EXIT>

28 When ADF feed <ADF 1>

29 When ADF feed <ADF 2>

30 When ADF feed <ADF 3>

Count timing

Part name

Not set

1. Copy count reset by parts to be replaced

This function resets the copy count by parts to be replaced.

<Count Reset Selection>

Select 5 Parts counter in the 25 Mode Menu Screen to display

Copy Count Screen by Parts to be Replaced as an initial screen.

Select the count reset here.

[Copy Count Screen by Parts to be Replaced]

Copy count of each part

Copy count of each part EX-LAMP

No.1 1565/5000

No.15 P/N xxxxxxxxx 000300/050000

(1) Data number, count value then limit value are displayed

on the second row of the message area.

(2) The data number can be changed by pressing

key.

(3) Press and hold

ously.

The count/limit value for the selected data No. will be displayed.

(4) Press

set Screen by Parts to be Replaced.

key to display next items continu-

key to return to Copy Count Re-

<Initial Status>

* Part numbers 1~30 are not set.

* Part names No. 1~17 are not set.

* Refer to the part names of No. 18~30 in the table above.

MODEL

7065

SERVICE HANDBOOK

MANUAL

REVISED EDITION

4 - 24

2

DATE

Jan.2000

PAGE

4-24

METHOD

REPLACEMENT

Page 26

25

ADJUSTMENT

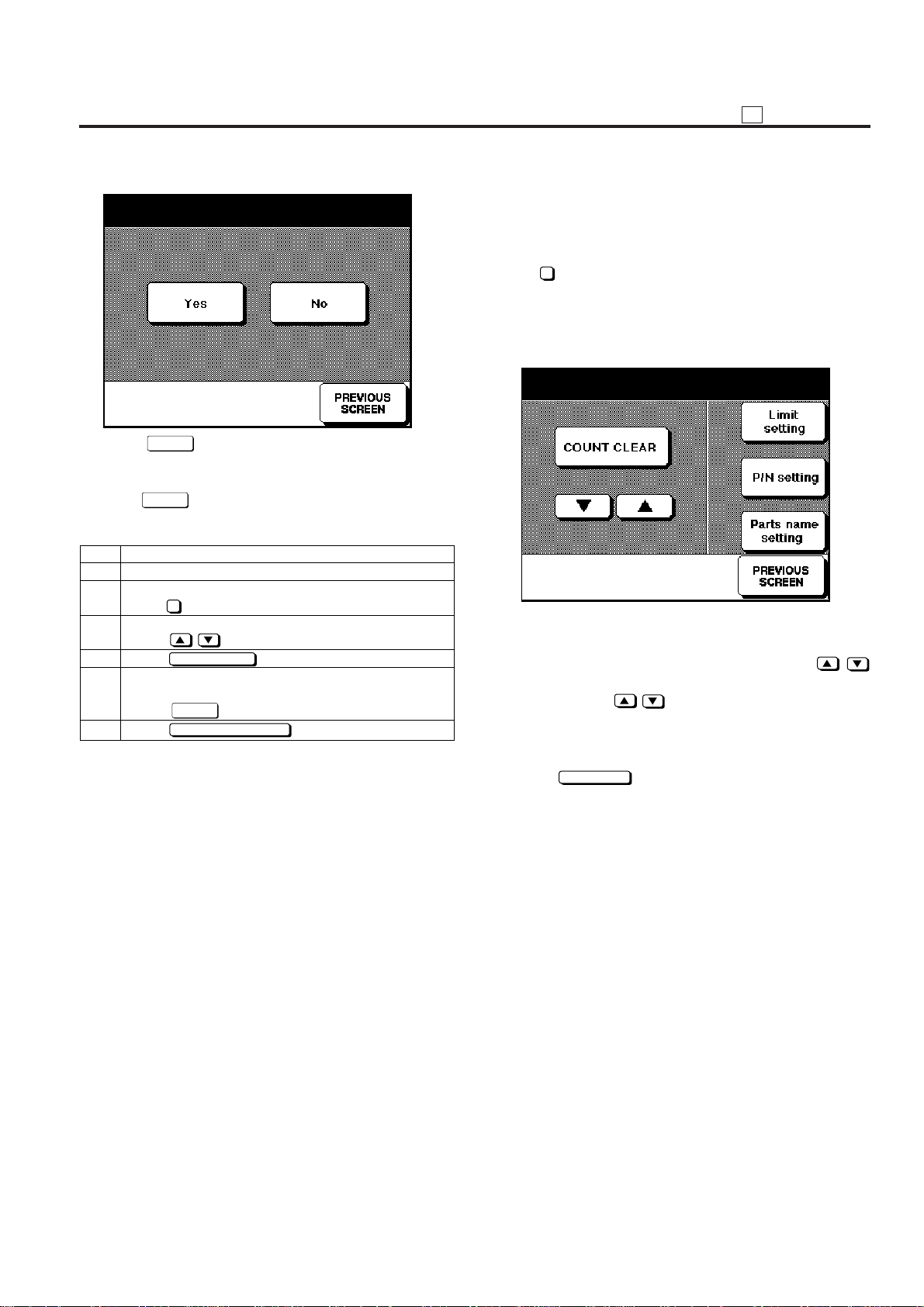

[Copy Count Reset Screen by Parts to be Replaced]

Each part counter clear YES / NO?

No.1 1565/5000

(5) Select

YES

key to reset the copy count. The screen

returns to Copy Count Screen by Parts to be Replaced

after the count is cleared.

(6) Select

NO

key to return to Copy Count Screen by Parts

to be Replaced without resetting any count.

Step

1

Enter the 25 mode.

2

[25 Mode Menu Screen]

5

Press

3

[Copy Count Screen by Parts to be Replaced]

Press

4

Press key.

5

[Copy Count Reset Screen by Parts to be

Parts counter.

COUNT CLEAR

Operation

key to select the data number.

Replaced]

Press key to reset the count.

6

Press key to end setting.

Yes

PREVIOUS SCREEN

Note:

The right side of the limit value will be marked as "*" if the

copy count exceeds its limit value.

2. Copy count limit setting by parts to be replaced

Set new limit value for the copy count by parts to be replaced.

<Count Limit Selection>

Select 5 Parts counter in the 25 Mode Menu Screen to display Copy Count Screen by Parts to be Replaced as an initial

screen. Select the limit setting here.

[Copy Count Screen by Parts to be Replaced]

Copy count of each part EX-LAMP

No.15 P/N xxxxxxxxx 000300/050000

(1) Data number, count value then limit value are displayed

on the second row of the message area.

(2) The data number can be changed by pressing

key.

(3) Press and hold

key to display next items continuously .

The count/limit value for the selected data No. will be displayed.

(4) Press

Limit setting

key to set the limit value.

Copy Count Limit Setting Screen by P arts to be Replaced

will appear.

4 - 25

Page 27

25 ADJUSTMENT

Step

1

2

3

4

5

6

7

Operation

Enter the 25 mode.

[25 Mode Menu Screen]

Press

Parts counter.

[Copy Count Screen by Parts to be Replaced]

Press key to select the data number.

Press key.

[Part Number Setting Screen]

Use the numeric and alphabet keys to input the new

part number (P/N).

Press

key to enter the input part number.

Press key to end setting.

5

P/N Setting

SET

PREVIOUS SCREEN

3. Count Limit Setting Method

[Copy Count Limit Setting Screen by Parts to be Replaced]

Each part counter limit setting

No.1 1565/5000

(1) Using the numeric keys on the screen, enter new limit value.

• Ne wly entered data will be display ed on the second row of

the message area.

• The firstly entered number will be shifted to the left end.

(2) Press

Note:

Step

1

2

3

4

5

6

7

SET

key to return to Copy Count Screen by Parts

to be Replaced.

The screen will also return to Copy Count Screen by Parts

to be Replaced if

out pressing

PREVIOUS SCREEN

SET

key. In this case, no limit value will be

key is pressed with-

changed.

Operation

Enter the 25 mode.

[25 Mode Menu Screen]

5

Press

Parts counter.

[Copy Count Screen by Parts to be Replaced]

Press key to select the data number.

Limit setting

Press key.

[Copy Count Limit Setting Screen by Parts to be

Replaced]

Enter new limit value using the numeric keys.

SET

Press key to execute.

Press key to end setting.

PREVIOUS SCREEN

4. Part Number Setting Method

[Part Number Setting Screen]

Each part counter P/N setting

No.15 P/N xxxxxxxxx 000300/050000

(1) Using the numeric and alphabet keys on the screen, enter

new parts number (P/N).

• The input characters are displa y ed in the part number display area on the second row of the message display area.

• The display shifts one space from right to left each time a

character is input.

• When 9 characters have been input, the character on the

farthest left will be deleted each time an additional character is input.

(2) Press

Note:

SET

key to return to Copy Count Screen by Parts

to be Replaced.

The screen will also return to Copy Count Screen by Parts

to be Replaced if

out pressing

PREVIOUS SCREEN

SET

key. In this case, no parts number will

key is pressed with-

be changed.

Note:

The right side of the limit value will be marked as "*" if the

copy count exceeds its limit value.

4 - 26

Page 28

25

ADJUSTMENT

5. Part Name Setting Method

[Part Name Setting Screen]

Parts name setting EX-LAMP

No.15 P/N xxxxxxxxx 000300/050000

(1) Using the numeric and alphabet keys on the screen, enter

new parts name.

• The input characters are displayed in the part name display area on the first row of the message display area.

• The displa y shifts one space from right to left each time a

character is input.

• When 8 characters have been input, the character on the

farthest left will be deleted each time an additional character is input.

(2) Press

Note:

SET

key to return to Copy Count Screen by Parts

to be Replaced.

The screen will also return to Copy Count Screen by Parts

to be Replaced if

out pressing

PREVIOUS SCREEN

SET

key. In this case , no parts name will be

key is pressed with-

changed.

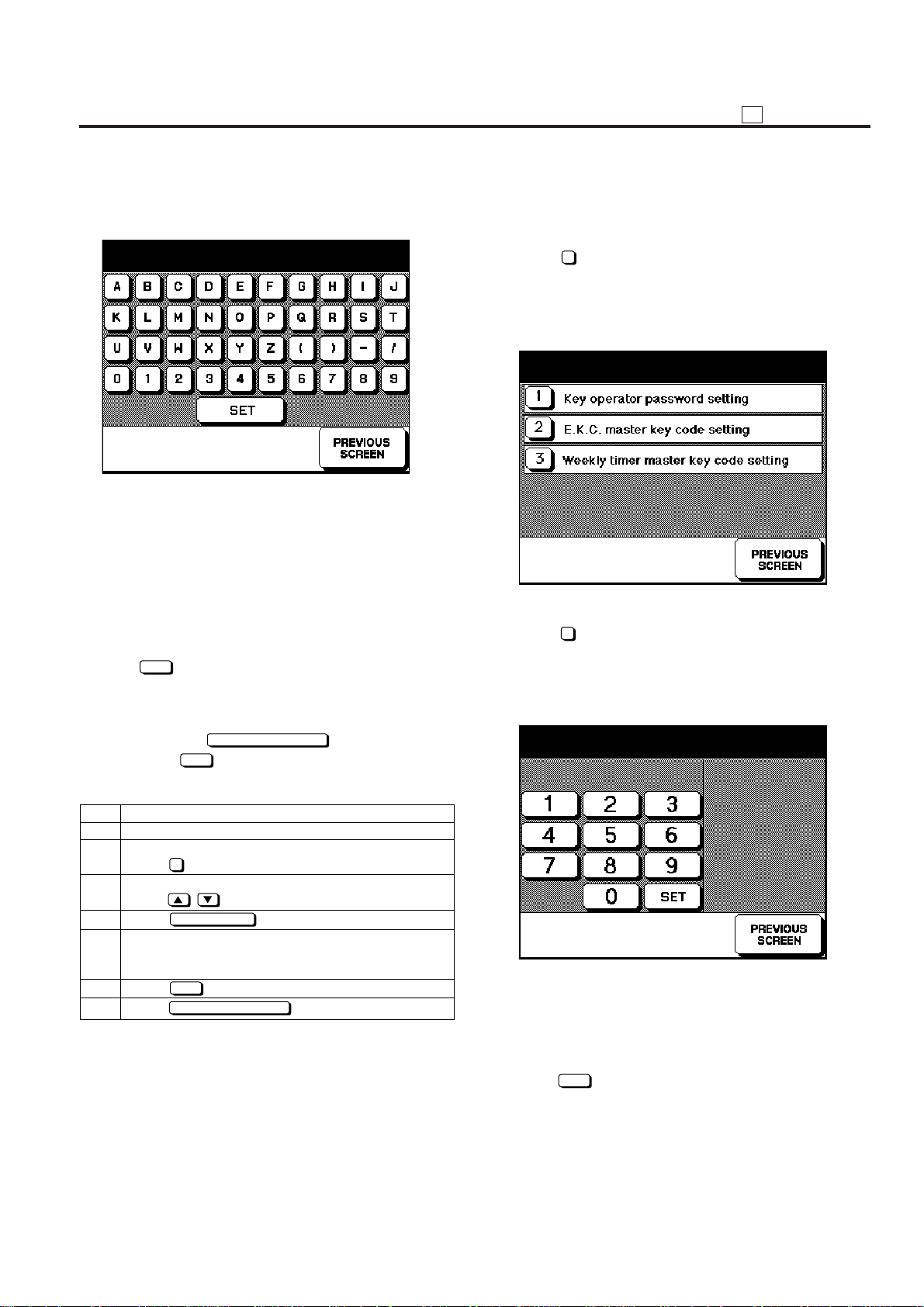

[8] Setting Key Operator Password

This function sets the password to enter the k ey operator mode.

1. Password setting screen selection

Select 6 Password setting in the 25 Mode Menu Screen

to display Password Setting Menu Screen as an initial screen.

In this screen, select the password to be set.

[Password Setting Menu Screen]

Password setting mode

Select one of following item

2. Setting method

Select 1 Key operator password setting in Password Setting Menu Screen.

Key Operator Password Setting Screen will appear.

[Key Operator Password Setting Screen]

Key operator password setting

1111

Step

1

Enter the 25 mode.

2

[25 Mode Menu Screen]

5

Press

3

[Copy Count Screen by Parts to be Replaced]

Parts counter.

Operation

Press key to select the data number.

4

5

Part Name Setting

Press key.

[Part Name Setting Screen]

Use the numerical keys to input the new part

name.

SET

key

Press

6

Press key to end setting.

7

PREVIOUS SCREEN

to enter the input part name.

(1) Using the numeric keys on the screen, enter 4-digit new

password.

• Newly entered number will be displayed on the second

row of the message area.

• The firstly entered number will be shifted to the left end.

(2) Press

SET

key to execute.

4 - 27

Page 29

25 ADJUSTMENT

Step

1

2

3

4

5

6

Operation

Enter the 25 mode.

[25 Mode Menu Screen]

Press Password setting.

[Password Setting Menu Screen]

Press EKC master key code setting.

[EKC Master Key Code Setting Screen]

Using the numeric keys on the screen, enter 8-digit

new EKC master key code.

Press key to execute.

Press key to end setting.

6

2

SET

PREVIOUS SCREEN

(3) The screen will return to Password Setting Menu Screen if

PREVIOUS SCREEN

key is pressed without pressing

SET

key. In this case, no password will be changed.

Step

1

Enter the 25 mode.

2

[25 Mode Menu Screen]

6

Press Password setting.

3

[Password Setting Menu Screen]

1

Press Key operator password setting.

4

[Key Operator Password Setting Screen]

Operation

Using the numeric keys on the screen, enter 4-digit

new password.

5

6

SET

Press key to execute.

Press key to end setting.

PREVIOUS SCREEN

Note:

Set the password to "0000" to enter the key operator mode

without any password. In other words, without displaying the

field for entering password, Key Operator Screen will appear

when the key operator mode is started.

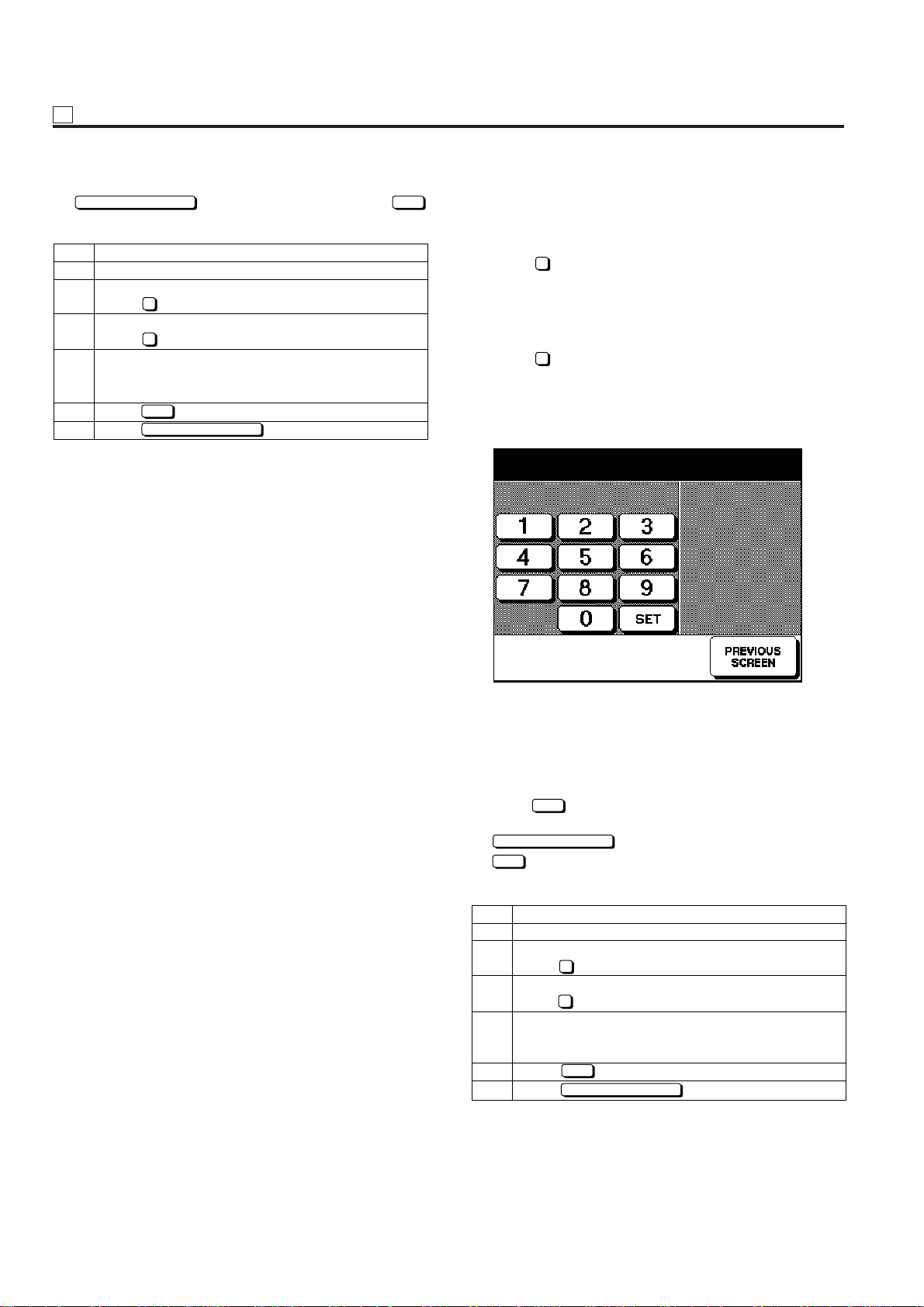

[9] Setting EKC Master Key Code

This function sets EKC master key code.

1. Password setting screen selection

Select 6 Password setting in the 25 Mode Menu Screen

to display Password Setting Menu Screen as an initial screen.

In this screen, select the password to be set.

2. Setting method

Select 2 EKC master key code setting in Password Setting Menu Screen.

EKC Master Key Code Setting Screen will appear.

[EKC Master Key Code Setting Screen]

E.K.C. master key code setting

11111111

(1) Using the numeric keys on the screen, enter 8-digit new

EKC master key code.

• Newly entered number will be displayed on the second

row of the message area.

• The firstly entered number will be shifted to the left end.

(2) Press

SET

key to execute.

(3) The screen will return to Password Setting Menu Screen if

PREVIOUS SCREEN

SET

key. In this case, no EKC master key code will be

key is pressed without pressing

changed.

4 - 28

Page 30

25

ADJUSTMENT

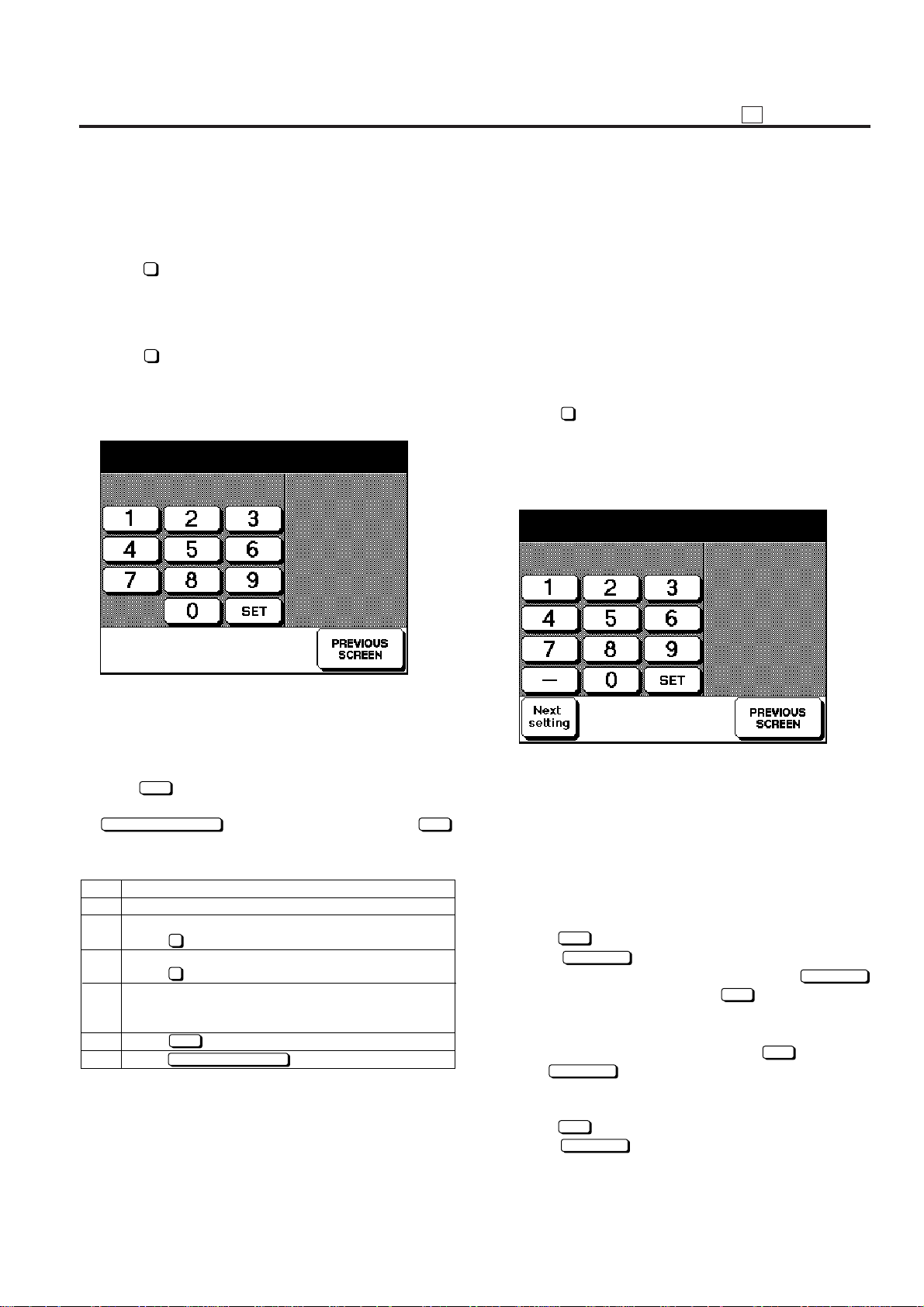

[10]

Setting Weekly Timer Master Key Code

This function sets the weekly timer master key code required

for entering the various weekly timer set mode.

1. Password setting screen selection

Select 6 Password setting in the 25 Mode Menu Screen

to display Password Setting Menu Screen as an initial screen.

In this screen, select the password to be set.

2. Setting weekly timer master key code

Select 3 Weekly timer master key code setting in Password Setting Menu Screen.

Weekly Timer Master Ke y Code Setting Screen will appear .

[Weekly Timer Master Key Code Setting Screen]

Weekly timer master key code setting

1111

[11] Specifying Phone Number of Service

Center

This function specifies the phone and fax numbers of the service center which is indicated in the screen if the service call is

issued.

These numbers are also indicated as "Contact Number of

Service Center" of the basic help screen in the user's display.

This function is not related with KRDS functions. It is designed

only for indicating the data on the screen.

1. Specifying phone and fax n umber of service

center

Select 7 Telephone number setting in the 25 Mode Menu

Screen. Service Center Number Setting Screen will appear.

[Service Center Number Setting Screen]

Customer support (Telephone) 1/2

0000000000000000

(1) Using the numeric keys on the screen, enter 4-digit new

weekly timer master key code.

• Newly entered number will be displayed on the second

row of the message area.

• The firstly entered number will be shifted to the left end.

SET

(2) Press

(3) The screen will return to Pass word Setting Menu Screen if

PREVIOUS SCREEN

key. In this case, no weekly timer master key code will be

changed.

Step

1

2

3

4

5

6

key to execute.

key is pressed without pressing

Operation

Enter the 25 mode.

[25 Mode Menu Screen]

6

Press Password setting.

[Password Setting Menu Screen]

3

Press Weekly timer master key code setting.

[Weekly Timer Master Key Code Setting Screen]

Using the numeric keys on the screen, enter 4-digit

new weekly timer master key code.

SET

key

Press

PREVIOUS SCREEN

Press key to end setting.

to execute.

SET

Note:

Set the password to "0000" to enter the weekly timer mode

without any password.

In other words, without displaying Weekly Timer Master Key

Code Entry Screen, Weekly Timer Setting Screen will appear

when the weekly timer mode is started.

(1) Specifying phone number of service center

a. Using the numeric keys on the screen, enter 16-digit

number.

b. This number must be 16 digits. Arrange the number with

hyphenation if it is less than 16 digits.

c. Newly entered number and hyphen (if any) will be displayed

on the second row of the message area.

d. The firstly entered number will be shifted to the left end.

e. Press

f. Select

g. The new phone number will not be effective if

SET

key to execute.

Next setting

key is pressed without pressing

key to specify the fax number.

SET

Next setting

key.

(2) Specifying fax number of service center

a. After entering the phone number, press

Next setting

lect

screen. Enter new fax number according to the same pro-

cedure as that for the phone number.

b. Press

SET

Next setting

Select

entry screen.

key to move to the fax number entry

key to execute.

key again to return to the phone number

SET

key and se-

4 - 29

Page 31

25 ADJUSTMENT

Select

PREVIOUS SCREEN

key to end setting the phone

number and return to the 25 Mode Menu Screen.

Step

1

Enter the 25 mode.

2

[25 Mode Menu Screen]

Press Phone number of service center setting.

3

[Service Center Number Setting Screen]

7

Operation

Using the numeric keys on the screen, enter 16-digit

new phone number and hyphen (if necessary) and

SET

press key.

4

Next Setting

Press key to move to the fax number

entry screen.

5

Using the numeric keys on the screen, enter 16digit new fax number and hyphen (if necessary) and

SET

press key.

6

PREVIOUS SCREEN

Press key to end setting.

[12] Setting and Displaying Serial Number

This function is used to display, set and change the serial

number of the main machine or optional machines.

The serial number can be read from KRDS.

1. Serial number display procedure

Select 8 Indication of m/c serial number in the 25 Mode

Menu Screen. Serial Number Display Screen will appear.

The name of the main machine or optional machine will be

displayed on the first row of the message area.

On the second row, the corresponding serial number for

each machine will be displayed.

Pressing

item such as main machine → Option tray → RADF →

Finisher.

[Serial Number Display Screen]

Next indication

key enables to proceed to the next

Indication of m/c serial number 1/4

Main body : 55FF00002

2. Setting and changing serial number

Input No.

4 - 30

Press

move to Serial Number Setting Screen.

Using the numeric and alphabet keys on the screen, enter

9-digit number and alphabet.

The firstly entered number or alphabet will be shifted to

the left end.

SET

Press

Display Screen.

The screen also returns to Serial Number Display Screen

SET

if

key is pressed without entering any number or

alphabet. In this case, no data will be changed.

PREVIOUS SCREEN

Select

Menu Screen.

key in Serial Number Display Screen to

key to execute and return to Serial Number

key to simply return to 25 Mode

Page 32

25

ADJUSTMENT

Step

1

Enter the 25 mode.

2

[25 Mode Menu Screen]

8

Press Indication of m/c serial number

3

[Serial Number Display Screen]

Operation

Check the number shown in the message area.

Next indication

Press key to move to the next item.

4

5

6

Input No.

Press key to change the number.

Using the numeric keys on the screen, enter 9-digit

serial number and press key.

Press key to end setting.

PREVIOUS SCREEN

SET

[13] Displaying ROM Version

This function is used to display ROM version mounted to the

machine.

1. ROM version view method

Select 9 Indication of ROM version in the 25 Mode Menu

Screen. ROM Version Display Screen will appear.

The ROM version of each of the main body control board

(CB), the operation panel (OB1), the image processing

board (IPB), and the RADF control board (DFCB) is displayed on the second row of the message display area.

[ROM Version Display Screen]

Indication of ROM version

Select

PREVIOUS SCREEN

key to end this screen and re-

turn to 25 Mode Menu Screen.

4 - 31

Page 33

25 ADJUSTMENT

Step

1

2

3

4

5

6

7

8

9

10

Operation

Setting the KRDS connection recognition

(25 mode → Software SW setting)

Set copier software DIPSW 12-6 (KRDS connection

recognition) to "1".

Turn off the modem to connect the copier using a

modem cable and wall jack using a modular cable

to the modem. (See *5)

Initialize KRDS memory.

(47 mode → → Copy button ON)

Set KRDS software SW.

(25 mode → KRDS setting → KRDS software

switch setting)

(Select type of modem and dial mode.)

Select type of modem from the bit pattern 0 to 6 of

KRDS software SW No.1 and dial mode from the bit

pattern 7.

Host Password Setting.

(25 mode → KRDS setting → Host password

setting)

(See *2, *3)

KRDS Phone Number Setting.

(25 mode → KRDS setting → KRDS

telephone number setting)

(See *4.)

Turn off the main switch of the copier.

Plug the outlet in and out.

Turn on the modem.

Turn on the main switch of the copier.

115

410

10

10

2

3

P 9 8 P

[14] Setting KRDS

This function selects whether to set KRDS or store data in the

memory card. This selection is not available unless the machine is equipped with either KRDS or memory card.

KRDS enables to call the host computer from the copier regularly or when any error occurs; query the various data on the

copier; and change the data from the host computer.

KRDS can execute the above functions for the following data:

a. Data on the copier's status such as total and PM count.

b. Data on the frequency of the partial copier such as