Page 1

FS-108

FS-108BM

SERVICE HANDBOOK

Sep.1999

Ver.1.0

KONICA CORPORATION

TECHNOLOGY SUPPORT CENTER

TOKYO JAPAN

Page 2

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the 7065 service handbook on page C-1

1. FS-108/FS-108BM

FS-108/FS-108BM PRODUCT SPECIFICATIONS

CENTER CROSS-SECTION.................................1-3

DRIVE SYSTEM DIAGRAM ..................................1-4

[1] Paper Conveyance Drive ........................1-4

[2] Stacker Drive...........................................1-5

[3] Folding Drive (FS-108BM only) ..............1-5

PAPER CONVEYANCE PATH ............................... 1-6

[1] Paper Conveyance Path .........................1-6

[2] Non-Sort Mode ........................................1-7

[3] Sort,Group Mode.....................................1-8

[4] Sub-tray Mode.........................................1-9

[5] Staple Mode ..........................................1-10

[6] Booklet Mode (FS-108BM only)............1-12

EXTERNAL SECTION.........................................1-13

[1] Composition(FS-108/FS-108BM) .........1-13

[2] Disassembly and Reassembly.............1-13

CONVEYANCE SECTION...................................1-18

[1] Composition ..........................................1-18

[2] Mechanisms ..........................................1-19

[3] Disassembly and Reassembly..............1-22

[4] M1 (FNS Conveyance) Control.............1-28

[5] Gate Control ..........................................1-30

[6] M13 (Stacker Entrance) Control ...........1-33

M5 (Alignment Plate/Upper ) Control.....

[7]

[8] M15 (Alignment Plate/Lower)

(FS-108BM only)

[9] M2 (Roller Shift)

[10] M7 (Paper Exit Roller)

[11] SD4 (Paper Exit Opening)

[12] M8 (Paper Exit Opening)

STAPLER UNIT ...................................................1-44

[1] Composition .......................................... 1-44

[2] Mechanism ............................................1-45

[3] Disassembly and Reassembly..............1-49

[4] Stapler Control ......................................1-52

MAIN TRA Y SECTION ........................................1-55

[1] Composition ..........................................1-55

[2] Mechanism ............................................1-55

[3] Disassembly and Reassembly..............1-55

[4] Main-Tray Up/Down Control ................. 1-58

FOLDING UNIT (FS-108BM ONLY)....................1-60

[1] Composition ..........................................1-60

[2] Mechanism ............................................1-61

....................................

Control........................

Control

Control ..............

Control .......

Control..........

................

1-1

1-35

1-36

1-38

1-39

1-41

1-43

[3] Disassembly and Reassembly..............1-62

[4] Folding-Unit Control ..............................1-64

FS-108/FS-108BM ADJUSTMENTS...................1-66

[1] Adjusting the Magnets on Conveyance

Guide Plate B ........................................1-66

[2] Adjusting the Magnets on Conveyance

Guide Plate C ........................................1-67

[3] Adjusting the Sub-tray Paper Exit Guide.1-68

[4] Adjusting the Paper-Path Switching

Guide .....................................................1-69

[5] Adjusting the By-pass Guide ................1-70

[6] Adjusting the Shift Position ...................1-72

[7] Adjusting Opening/Closing at

the Paper Exit........................................1-73

[8] Adjusting the Paper Exit-Opening

Solenoid ................................................1-74

[9] Adjusting the Paper Exit-Opening Lower

Guide Plate............................................1-75

[10] Adjusting the Tension Of the Stacker

Paper exit Belt.......................................1-76

[11] Adjusting the Mount Location Of the

Upper Alignment Plates ........................1-76

[12] Adjusting the Tension of the Upper Align-

ment-Plates Drive Timing Belt ..............1-77

[13] Adjusting the Mount Location of the Lower

Alignment Plates(FS-108BM only)........ 1-78

[14] Adjusting the Tension of the Lower-

ALignment-Plate Drive Timing Belt.......1-79

[15] Adjusting the Stapling Position

(Flat Stapling)........................................1-79

[16] Adjusting the Stapler Vertical Positioning . 1-80

[17] Adjusting the Staple Orientation(Stapling-

and-Folding)(FS-108BM only) ..............1-82

[18] Adjusting the Staple Position(Stapling-and-

Folding)(FS-108BM only)......................1-83

[19] Adjusting the Angle Of The Folding

Stopper(FS-108BM only) ......................1-84

[20] Adjusting the Folding-Stopper Positions

(FS-108BM only) ...................................1-85

[21] Adjusting the Tension of the Stapler-

Movement Timing Belt ..........................1-86

[22] Adjusting the Tension of the Stapler-Rotaion

Timing Belt.............................................1-86

[23] Adjusting the Folding Force

(FS-108BM only) ...................................1-87

This section covers the structure,functions,operation and method of disassembling and assembling the machine.

Observe the following precautions when performing disassembly and assembly work.

1. Be sure to unplug the power cord before working on the machine.

2. Perform all reassembly work by reversing the order in which the component was disassembled,unless otherwise specified.

3. Do not lose small parts (screws,etc.) or insert them in the wrong place.

4. Install all parts completely before operating the machine.

5. Do not loosen the screws indicated as disallowed for removal.

Page 3

CONTENTS

2. DIAGRAM

FS-108/FS-108BM ELECTRICAL PARTS LAYOUT

DRAWING....................................................................... 2-1

FS-108/FS-108BM CONNECTOR LA YOUT DRAWING ......2-4

FS-108/FS-108BM OVERALL WIRING DIAGRAM (1/3) ....... 2-7

FS-108/FS-108BM OVERALL WIRING DIAGRAM (2/3) ....... 2-8

FS-108/FS-108BM OVERALL WIRING DIAGRAM (3/3) ....... 2-9

FS-108/FS-108BM CONTROL-BOARD CIRCUIT

DIAGRAM (1/9).................................................... 2-10

FS-108/FS-108BM CONTROL-BOARD CIRCUIT

DIAGRAM (2/9).....................................................

FS-108/FS-108BM CONTROL-BOARD CIRCUIT

DIAGRAM (3/9).................................................... 2-12

FS-108/FS-108BM CONTROL-BOARD CIRCUIT

DIAGRAM (4/9).................................................... 2-13

FS-108/FS-108BM CONTROL-BOARD CIRCUIT

DIAGRAM (5/9).................................................... 2-14

FS-108/FS-108BM CONTROL-BOARD CIRCUIT

DIAGRAM (6/9).................................................... 2-15

FS-108/FS-108BM CONTROL-BOARD CIRCUIT

DIAGRAM (7/9).................................................... 2-16

FS-108/FS-108BM CONTROL-BOARD CIRCUIT

DIAGRAM (8/9).................................................... 2-17

FS-108/FS-108BM CONTROL-BOARD CIRCUIT

DIAGRAM (9

FS-108/FS-108BM CONNECTOR-BOARD CIRCUIT

DIAGRAM ............................................................2-19

FS-108/FS-108BM TIMING CHART (SORT MODE,

A4, 2-PAGE ORIGINAL, 5 COPIES, 1:1 RATIO) ......2-20

FS-108/FS-108BM TIMING CHART (2-STAPLE

MODE, A4, 2-PAGE ORIGINAL, 3 COPIES,

1:1 RATIO) ........................................................... 2-21

FS-108/FS-108BM TIMING CHART (STAPLING

AND FOLDING, A4R, 3-PAGE ORIGINAL, 2

COPIES, 1:1 RATIO, 1-1 MODE)........................ 2-22

/9)............................................................ 2-18

2-11

Page 4

1

FS-108BM FS-108BM

Page 5

FS-108/FS-108BM

Amount of Curll

Copy paper (5 sheets)

Fold height

Original Pages

A3R, 11x17R

0 to 5

11 to 16

6 to 10

25mm or less

Not specified*

50mm or less

A4R, 8.5x11R

25mm or less

Not specified*

B4, 8.5x14R

25mm or less

50mm or less

Not specified*

Not specified*

FS-108/FS-108BM PRODUCT SPECIFICATIONS

1. Type

FS-108: Finishing device implementing offset colla-

tion, stapling, and sub-tray eject

FS-108BM: Finishing device implementing offset colla-

tion, stapling, sub-tray eject, stapling-andfolding, and folding

2. Functions

Type of Paper: Same as for the main body.

Paper Size: A3R, B4R, F4R, A4R, A4, B5R, B5, A5R,

B6R.

B6R is not possible in off-set mode;

B5R, A5R, B6R are not possible in staple

mode. F4R, A4, B5R, B5, A5R, A5, B6R

are not available in booklet mode.

Paper Stacking Capacity:

Sub-tray exit mode:

Maximum 200 sheets (same-size sheets

only)

Non-Staple, Group, and Offset modes:

Maximum 1500 sheets (A3R, B4R, F4R)

Maximum 3000 sheets (B5R, B5, A4R, A4)

Maximum 500 sheets (B6R, A5R, A5)

Staple Mode: Maximum 1000 sheets

Main-Tray Capacity (same-size sheets only)

Original Pages

2 to 9

10 to 20

21 to 30

31 to 40

41 to 50

Other than A3R, 11x17R

100 stacks

50 stacks

30 stacks

25 stacks

20 stacks

A3R, 11x17R

50 stacks

50 stacks

30 stacks

25 stacks

20 stacks

Paper curling: Maximum 10mm

Booklet-mode folding level (FS-108BM only)

(For 80g/m

2

paper or equivalent, same-size sheets only)

* May be unf olded after e xit, pro vided that fold state can

be easily restored.

Amount of sort

off-setting: 30mm (when off-setting/grouping)

Tray: Main tray

Sub-tray

Booklet tray (FS-108BM only)

Booklet Mode (FS-108BM only):

• Stapling-and-folding + folding

20 booklets of 5 folded sheets each (20 pages/booklet; eq. to 400 pages)

• Folding

33 booklets of 3 folded sheets each (12 pages/booklet; eq. to 396 pages)

1-1

Page 6

FS-108/FS-108BM

3. Staple Mode

Number of pages

which may be stapled:

50 sheets maximum* (80g/m

quality paper, 5mm and below)

* Maximum sheets can be set to 45, 40, or 35 in accor-

dance with paper quality and thickness.

Staple position: A = 8.5mm±3mm

(adjustment possible)

B = 8.5mm±3mm

C = 82.5mm±3mm

D = 8.5mm±3mm

(adjustment possible)

E = 14mm±3mm)

2

high-

6. Machine Data

Power Source:

24 VDC, 5 VDC (supplied from the

main body)

Maximum Power

Consumption: 100VA

Weight:

FS-108: Approximately 55kg

FS-108BM: Approximately 80kg

External Dimensions:

85

367

781656

1151

1095

Single staple (rear) Two staples Single staple

Booklet mode (stapling and folding)

(FS-108BM only)

@@@(front)

Staple capacity: 5000 staples/cartridge

4. Booklet Mode (FS-108BM only)

Stapling-and-folding:

Maximum 16 sheets (80g/m2 high-quality paper)

Maximum 15 sheets (80g/m

+ 1 sheet (200g/m

2

high-quality paper)

Folding: Maximum 3 sheets (80g/m2 high-quality paper)

2

high-quality paper)

7. Maintenance

Maintenance: Same as the main body.

Service Life: Same as main body.

8. Machine Operating Environment

Temperature: 10 to 30˚C

Humidity: 10 to 80% RH

These specifications are subject to change without notice.

5. Option

PI-108 (Sheet feeder)

1-2

Page 7

CENTER CROSS-SECTION

Sub-tray

Shift Unit

Main Tray Paper Exit Unit

FS-108/FS-108BM

Gate

Sub-tray Gate

Stacker Unit

Booklet T ra y

Folding Stopper

By-pass Gate

Flat-Stapling Stopper

Stapler Unit

Area within dotted lines:

FS-108BM only

Stapling and

Folding Stopper

Folding Unit

1-3

Page 8

FS-108/FS-108BM

DRIVE SYSTEM DIAGRAM

[1] Paper Conveyance Drive

Sub-tray Paper Exit Roller B

Conveyance Slide Shaft

Sub-tray Paper Exit Roller C

Sub-tray Paper Exit Roller A

Nip Paper Exit Roller

Conveyance Roller D

Conveyance Roller C

Conveyance Roller B

Conveyance Roller A

M1 (FNS Conveyance)

Paper Exit Roller

M7 (Paper Exit

Roller)

Intermediate Conveyance Roller

1-4

Page 9

[2] Stacker Drive

FS-108/FS-108BM

Paper Exit Roller

Paper Exit Belts

Stacker Entrance Roller

Swivel Roller

Paper Exit Arms

[3] Folding Drive (FS-108BM only)

M7 (Paper Exit Roller)

Pulley

M13 (Stacker Entrance)

Folding Roller B

Folding Roller A

Folding Conveyance Roller

Folding Knife

M19 (Folding Knife)

Pressure Roller A

Pressure Roller B

Folding Conveyance Belts

M20 (Folding Conveyance)

1-5

Page 10

FS-108/FS-108BM

PAPER CONVEYANCE PATH

[1] Paper Conveyance Path

The FNS (finisher) provides four paper paths, as shown in the diagram below.

Face-up and face-down inversion is handled by at the main-body side by the main body’s exit page inverter.

Sub-tray

Main T ra y

Booklet T ra y

Finishing

Sort, Group, Non-sort mode

Sub-tray mode

Staple mode

Booklet mode (FS-108BM only)

Paper Conveyance Paths

1-6

Page 11

[2] Non-Sort Mode

Exit to main tray

A paper exited from the main body is conveyed and exited to the main tray.

FS-108/FS-108BM

Sub-tray Gate

Gate

Main T ra y

Paper Exit Roller

Conveyance Roller B

Conveyance Roller A

Conveyance Roller D

Conveyance Roller C

1-7

Page 12

FS-108/FS-108BM

[3] Sort, Group Mode

Exit to the main tray

Paper exited from the main body is conveyed and exited to the main tray. This mode has an off-set function that allows each

page of the even-numbered sets to be exited with the paper shifted 30mm to the rear.

Off-set Function

(1) The odd-numbered pages are exited to the main tray with the image side face down.

(2) The even-numbered pages are shifted 30mm to the rear by the conveyance slide shaft of the shift unit and

then exited to the main tray.

Main T ra y

Paper Exit Roller

Shift Unit

Conveyance Slide Shaft

Conveyance Roller D

Gate

Sub-tray Gate

Conveyance Roller B

Conveyance Roller A

Conveyance Roller C

1-8

Page 13

[4] Sub-tray Mode

The sub-tray gate opens. Paper exited from the main body is conveyed and exited to the sub-tray.

Sub-tray Paper Exit Roller C

Sub-tray

Sub-tray Paper Exit Roller B

Sub-tray Paper Exit Roller A

FS-108/FS-108BM

Sub-tray Gate

Conveyance Roller B

Conveyance Roller A

1-9

Page 14

FS-108/FS-108BM

[5] Staple Mode

(1) The gate switches to the staple mode.

(2) For A4R paper and above, the paper exit opening opens.

(3) The first set of paper is conveyed and stacked.

1) The stacker section roller sends the paper to the flat-stapling stopper and the paper is lined up in the

lengthwise direction.

2) The upper alignment plate lines up paper in the widthwise direction.

3) Paper is stapled.

4) The first set is conveyed by the paper exit arm and exited to the main tray.

Paper Exit Opening

Conveyance Roller C

Main Tray

First Stapled Set

Paper Exit Belt

Stapler Unit

Intermediate Conveyance

Roller

Alignment Plate

/Upper

Gate

Sub-tray Gate

Conveyance Roller B

Conveyance Roller A

By-pass

Gate

Stacker Entrance

Roller

Swivel Roller

Flat-Stapling Stopper

Paper Exit Arm

1-10

Page 15

FS-108/FS-108BM

(4) The second and subsequent sets of paper are conveyed and stacked.

1) The first page stops in the stack er entrance with the by-pass gate opened. The stack er entrance roller stops

to wait for the previous stack to be exited.

2) The by-pass gate is closed and the second page is stacked on top of the first.

3) Once the previous stack has exited, the stack entrance roller rotates and the first and second pages are

simultaneously sent to the stacker.

* The above steps (1) to (3) are for paper to a maximum of A4 size.

4) The stacker section roller sends the paper to the flat-stapling stopper and the paper is lined up in the

lengthwise direction.

5) The upper alignment plate lines up paper in the widthwise direction.

6) When all paper is conveyed to the stacker, the paper is stapled.

7) The second and subsequent sets are conveyed by the paper exit arm and the paper is exited to the main

tray.

Paper Exit Opening

Conveyance Roller C

Second Stapled Set

Main Tray

Intermediate

Conveyance Roller

Paper Exit Belt

Stapler Unit

Alignment Plate/Upper

Second Sheet

Sub-tray Gate

Gate

Conveyance Roller B

Conveyance Roller A

By-pass

Gate

First Sheet

Stacker Entrance Roller

Swivel Roller

Flat-Stapling Stopper

Paper Exit Arm

1-11

Page 16

FS-108/FS-108BM

[6] Booklet Mode (FS-108BM only)

(1) The gate switches to the staple mode.

(2) The paper exit opening opens.

(3) The paper is conveyed and stacked.

(4) The stacker section roller sends the paper to the stapling-and-folding stopper and the paper is lined up in the

lengthwise direction.

(5) The upper and lower alignment plate lines up paper in the widthwise direction.

(6) If stapling-and-folding has been selected, staple the stack.

(7) Release the stapling-and-folding stopper and convey the stack to the folding unit by the paper exit belt.

(8) Convey the stack up to the folding stopper, fold it with the folding knife, and eject to the booklet tray.

Conveyance Roller C

Booklet Tray

Intermediate Conveyance Roller

Paper Exit Belt

Stapler Unit

Upper

Alignment Plate

Pressure Roller A

Folding Roller A

Gate

Sub-tray Gate

Conveyance Roller B

Conveyance Roller A

Stacker Entrance Roller

Swivel Roller

Alignment Plate/Lower

Stapling and Folding stopper

Folding Conveyance Roller

Pressure

Roller B

Folding Stopper

Folding Conveyance Belt

Folding

Roller B

Folding Knife

1-12

Page 17

EXTERNAL SECTION

Screws

Hinge

Front Cover

[1] Composition (FS-108/FS-108BM)

FS-108/FS-108BM

Paper Exit Cover

Sub-tray

Main T ra y

Rear Cover

Paper Exit Stopper Plate

Booklet T ra y

[2] Disassembly and Reassembly

CAUTION: Be sure that the power cord has been un-

plugged from the outlet.

1. Removing and Reinstalling the Rear Cover

a. Procedure

(1) Remove the 5 set screws holding the rear cover

in place, and take off the cover.

Top Cover

Front Cover

Front Side Cover

2. Removing and Reinstalling the Front Cover

a. Procedure

(1) Open the front cover.

(2) Remove the 2 set screws holding the bottom

hinge in place, and take off the front cover.

Screws

Screws

Rear Cover

(2) Reinstall the rear cover in the opposite sequence

to removal.

(3) Reinstall the front cover in the opposite sequence

to removal.

1-13

Page 18

FS-108/FS-108BM

Screw

Paper Exit Cover

Screw

3. Removing and Reinstalling the Top Cover

a. Procedure

(1) Remove the sub-tray.

(2) Open the paper exit cover.

(3) Remove the two caps.

(4) Open the front cover.

(5) Remove the 6 set screws holding the top cover

in place, and take off the cover.

Screws

Cap

4 Removing and Reinstalling the Paper Exit Co ver

a. Procedure

(1) Remove the top cover.

(2) Remove the 2 set screws holding the paper exit

cover in place, and tak e off the paper e xit cover.

Screws

(3) Reinstall the paper cover in the opposite se-

quence to removal.

(6) Reinstall the top cover in the opposite sequence

to removal.

1-14

Page 19

FS-108/FS-108BM

Front Side

Cover

Screws

5. Removing and Reinstalling the Main Tray

a. Procedure

(1) Remove the rear cover.

(2) Detach the connector and remove the 2 set

screws holding motor M3 (tray up-down motor)

in place. Remove M3.

CAUTION: Support the main tray with your hand when

removing M3.

M3 (Tray Up-Down)

Screws

Connector

(3) Remove the 2 set screws holding the main tray

in place, and lift the main tray up and off.

Screws

6. Removing and Reattaching the Front Side Cover

a. Procedure

(1) Remove the 2 set screws holding the front side

cover in place, and take off the front side co ver.

(2) Reinstall the front side cover in the opposite se-

quence to removal.

Main Tray

(4) Reinstall the main tray in the opposite sequence

to removal.

1-15

Page 20

FS-108/FS-108BM

Screws

Screws

Up-Down Stay

Wire Bracket

Wire Bracket

Screws

Screws

Screws

Rear Auxiliary

Side-Up-Down

Plate

Front Auxiliary

Side-Up-Down

Plate

7. Removing and Reinstalling the Paper Exit

Stopper Plate

a. Procedure

(1) Remove the following parts.

• Rear cover

• Main tray

• Booklet tray

• Front cover

• Front side cover

(2) Remove the 4 set screws holding the left and

right up-down covers in place, and remove these

two covers.

Screws

Screws

(3) Remove the 4 set screws from the front and rear

wire brackets (two screws at each bracket), and

then remove the up-down stay.

(4) Remove 8 set screws and tak e off the front and

rear auxiliary side-up-down plates.

Up-Down Covers

1-16

Page 21

FS-108/FS-108BM

Press down

Wire Bracket

Wire Bracket

Screws

Screws

Up-Down Stay

(5) Remove the two plates (front and back plates)

at the booklet exit.

Plate

Screw

Plate

(6) Remove 13 more set screws, and take off the

paper exit stopper.

(7) Remove the up-down sta y . (See “Removing and

reattaching the up-down stay”.)

(8) Reinstall the stopper in the opposite sequence

to removal. But note the following caution.

CAUTION: Be sure to press down on the up-down stay

while tightening the 4 screws for the wire

brackets.

Paper Exit

Stopper Plate

Screws

Screws

Screws

Up-Down Stay

Screws

Screws

1-17

Page 22

FS-108/FS-108BM

Conveyance Section

[1] Composition

Sub-tray Paper Exit Roller C

Sub-tray Paper Exit Roller B

FS-108/FS-108BM Rear

Sub-tray Paper Exit Roller A

Conveyance Roller B

Conveyance Roller A

Conveyance Roller C

Intermediate Conveyance Roller

M1 (FNS Conveyance)

Conveyance Slide Shaft

M7 (Paper Exit Roller)

Nip Paper Exit Roller

Paper Exit Roller

(Sponge Roller)

Conveyance Roller D

M13 (Stacker Entrance)

Stacker Entrance Roller

Paper Exit Belt

Area within dotted lines: FM-108BM only

Folding Conveyance Roller

Folding Conveyance Belt

M20 (Folding Conveyance)

Folding Roller A

Pressure Roller A

Pressure Roller B

Folding Roller B

1-18

Page 23

FS-108/FS-108BM

Link Mechanism

M2 (Roller Shift)

M2 (Roller Shift)

Paper exit direction

Slide Shaft

Link Mechanism

Slide Shaft

30mm towards the direction

of the back side

[2] Mechanisms

1. Paper Conveyance

Paper conveyance is carried out by conveyance rollers A,

B, C, and D; the intermediate conveyance roller; the conveyance slide shaft; and sub-tray paper exit rollers A, B,

and C. These components are driven b y M1 (FNS conv eyance) by means of a timing belt.

Stacking is implemented by the stacker entrance roller and

the swivel roller. These rollers are driven by the M13

(stacker entrance) by means of a timing belt.

Ejection to the main tray (following staple processing) is

implemented by the stacker paper exit belt arm and the

paper exit roller. These components are driven by the M7

(paper exit).

Ejection to the booklet tray is implemented by the folding

convey ance roller, the folding conve yance belt, the f olding

knife, f olding rollers A and B, and pressure rollers A and B.

The folding knife is driven by M19 (folding knife). The conveyance belt, folding rollers, and pressure rollers are driven

by the M20 (folding conveyance) by means of a timing

belt.

2. Paper Path Switching

Gate

Sub-tray Gate

SD2

(Sub-tray Paper Exit)

By-pass Gate

SD5 (By-pass)

SD1 (Gate)

Path switching is carried out b y the gate, the sub-tray gate ,

and the by-pass gate. Each of these is controlled by the

ON/OFF action of a corresponding solenoid: SD1 (gate),

SD2 (sub-tray paper exit), and SD5 (b y-pass), respectively .

3. Shift Unit Sort Shift Operation

(1) Paper entering the shift unit is fed toward the

paper exit direction by the action of the slide

shaft.

(2) Driving by M2 (roller shift) causes the linkage to

shift the slide shaft and paper 30mm toward the

rear.

1-19

Page 24

FS-108/FS-108BM

4. Stacker Unit

Alignment Plate/

Upper

Paper Exit

Belts

FS-108BM Only

M17 (Stapling and Folding Stopper Release)

Paper Exit Arms

Alignment Plate/Upper

M14

(Stapling and Folding Stopper)

M5

(Alignment

Plate/Upper)

Paper Alignment (Staple Mode (Flat Stapling))

Sheets conveyed into the stacker are aligned by the oscillation of the (front and rear) alignment plates/upper. The

alignment plates/upper are driven by M5 (alignment plate/

upper).

Paper Alignment (Booklet Mode (FS-108BM only))

Sheets conveyed into the stacker are aligned by the movement of the (front and rear) alignment plates/upper and

the (front and rear) alignment plates/lower . The alignment

plates/upper are driven by M5 (alignment plate/upper); the

alignment plates/lower are driven by M15 (alignment plate/

lower). The stapling-and-folding stopper is moved b y M14

(stapling-and-folding stopper) and is released by M17 (stapling-and-folding stopper release).

Paper Exiting

Stapled paper is sent to the paper exit by the paper exit

arm. The paper exit belt is driven b y M7 ( paper exit-roller).

Feeding to the Folding Unit (FS-108BM only)

M17 (stapling-and-folding stopper release) releases the

stapling-and-folding stopper and feeds the paper into the

folding unit.

Alignment Plate/

Lower

Alignment

Plate/Lower

M15

(Alignment Plate/

Lower)

Stapling and Folding Stopper

1-20

Page 25

FS-108/FS-108BM

Conveyance

Roller B

Conveyance Roller A

Conveyance

Roller C

Conveyance Roller D

Paper Exit Rolle

r

Main T ra y

Paper Exit Opening

SD4 (Paper Exit Opening)

Nip Roller

Paper Exit Roller

SD4 (Paper Exit

Opening)

5. Paper Exit Opening Unit

M8

SD4 (Paper Exit Opening)

Paper Exit Opening

Nip Roller

(Paper Exit Opening)

a. Staple Mode and Booklet Mode Operation for

Paper Sizes A4R and Above

Because paper of this size juts out from the stacker, the

paper exit opening is held open from the start of copying

until the completion of stapling.

c. Pressure of the Paper Exit Roller

The paper exit roller turns more slowly than the conveyance rollers (A, B, C, and D), and remains unengaged by

the nip roller except during ejection.

When paper reaches the paper exit opening, the paper

exit roller is engaged by the nip roller and the paper is

ejected to the main tray. Engagement and release is controlled by SD4 (paper exit opening).

b. Paper Exit of the Staple Mode (Flat Stapling)

Upon completion of stapling, the paperr exit closes, and

the paper is grasped and ejected to the main tray. The

opening and closing of the paper exit is controlled by M8

(paper exit opening).

M8 (Paper Exit Opening)

Paper Exit Opening

Open

Close

1-21

Page 26

FS-108/FS-108BM

Sponge Roller

Match

Match

6. Folding by the Folding Unit (FS-108BM only)

Paper is conveyed to the folding stopper by the action of

the folding conveyance roller and the folding conveyance

belts, and is then folded by the action of the folding knife

and the folding rollers. The folding conveyance roller, the

folding conveyance belts, the folding rollers, and the pressure roller are driven by M20 (folding conveyance). M18

(folding stopper) drives the folding stopper. M19 (folding

knife) drives the folding knife.

M20

(Folding Conveyance)

Folding Rollers

M18

(Folding

Stopper)

Folding Conveyance Belts

[3] Disassembly and Reassembly

CAUTION: Be sure that the power cord has been un-

plugged from the outlet.

1. Replacing a Paper Exit Roller (Sponge Roller)

a. Procedure

(1) Run the copier in mode 47 (code 75-06) to lower

the main tray.

Sponge Roller

Main Tray

Folding

Paper-End Stopper

Paper

Folding Knife

Folding Knife

Folding Knife

M19 (Folding Knife)

(2) Insert the end of a screwdriver into the slot in

the sponge roller, and twist the screwdriver to

pry the roller off.

(3) Take the two halves of the new sponge roller

and align their indentations with the indentations

on the roller shaft.

(4) Press the two halves of the roller together until

the click into place.

1-22

Page 27

FS-108/FS-108BM

Clamps

Wirings

M2 (Roller Shift) Connector

PS18 (Roller Shift HP)

Connector

Clamp Screw

Screws

Ground Wire

Fixing Screw

Shift Unit

Screws

2. Replacing an Intermediate Conveyance

Roller (Sponge Roller)

a. Procedure

(1) Open the front cover and pull out the stacker/

stapler unit.

(2) Insert the end of a screwdriver into the slot in

the sponge roller, and twist the screwdriver to

pry the roller off.

Sponge Rollers

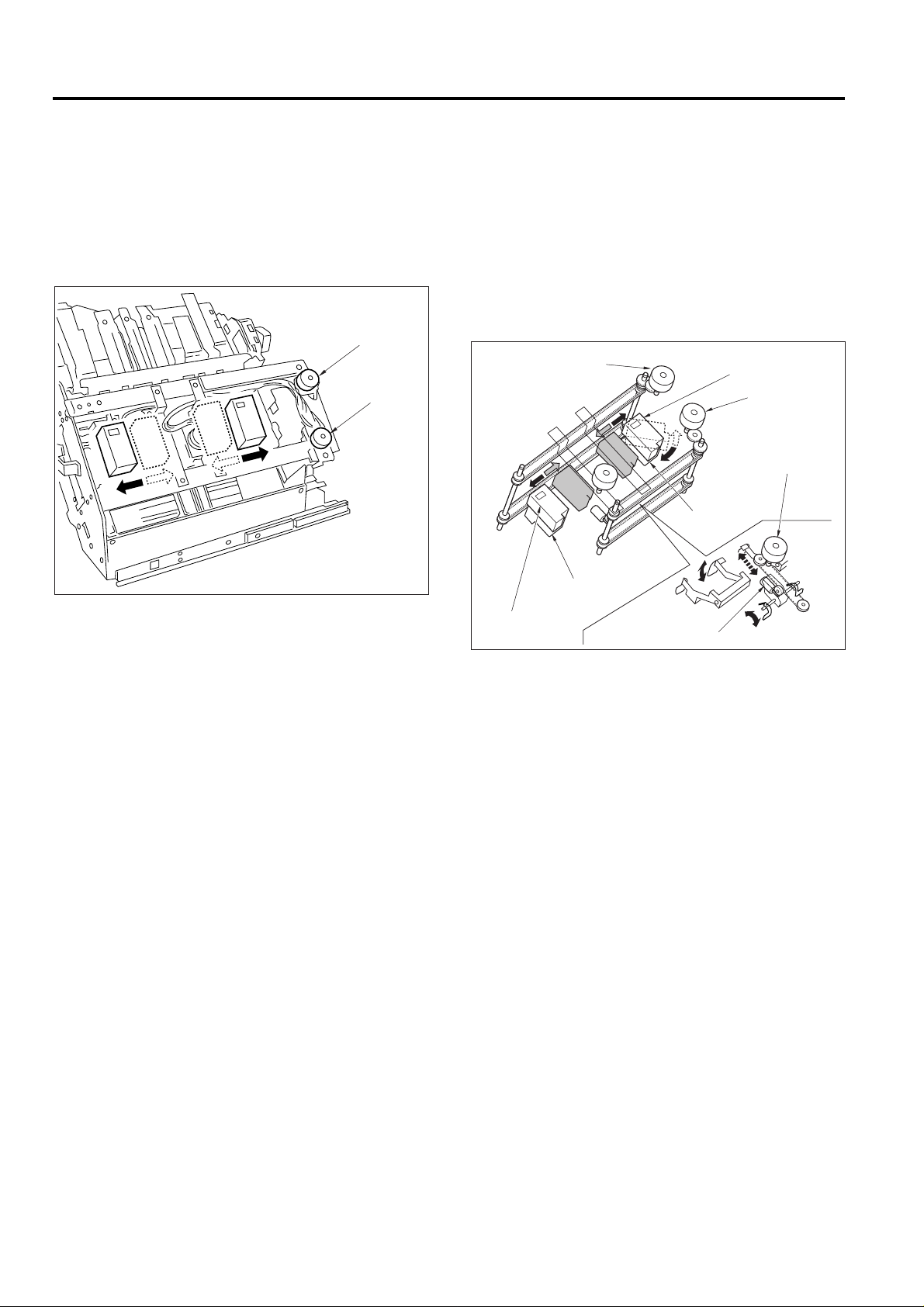

3. Removing and Reinstalling the Shift Unit

a. Procedure

(1) Remove the following parts.

• Rear cover

• Top cover

• PI-108 (if installed)

(2) Detach the M2 (roller shift) and PS18 (roller shift

HP) connectors.

(3) Remove the wiring from the three clamps.

Sponge Roller

(3) Take the two halves of the new sponge roller

and align their indentations with the indentations

on the roller shaft.

(4) Press the two halves of the roller together so

that they click into place.

Match

Match

(4) Remove the ground wire fixing screw.

(5) Remove the clamp set screw.

(6) Remove 4 more set screws (see illustration).

1-23

Page 28

FS-108/FS-108BM

Drive Belt

Pulley

Belt

Collar

E-ring

Gear

E-ring

Collar

Shaft Holder

(7) Remove 3 more set screws and remo ve the shift

pulley .

(8) Slide the conveyance slide shaft and take out

the shift unit.

Screws

Conveyance

Slide Shaft

Screw

Shift Pulley

(9) Reinstall the shift unit in the opposite sequence

to removal.

CAUTION: When reinstalling the shift unit, be sure to

align the conveyance slide shaft with the hole

in the shift pulley.

4. Removing and Reinstalling the Paper Exit-Opening

Unit

a. Procedure

(1) Remove the following parts.

• Rear cover

• Top cover

• Front side cover

• PI-108 (if installed)

• Shift unit

(2) Remove the pulley and its belt.

(3) Remove the E-ring, and then remove the collar,

the gear, and the drive belt.

(4) Remove the collar, E-ring, and shaft holder.

1-24

Page 29

FS-108/FS-108BM

Spring

(5) Remove the clamp set screw and the ground

wire screw.

(6) Detach the SD4 (paper exit opening) and PS6

(paper exit-1) connectors.

(7) Remove the screw holding PS10 (paper exit-2)

to the unit. Remove PS10 and detach the connector.

CAUTION: When withdrawing the PS10, ensure that

needless force is not applied to the lever

below the PS10.

Clamp Screw

SD4 (Paper Exit

Opening) Connector

Ground Wire Screw

PS6 (Paper Exit-1)

Connector

(9) Open the front cover. Remove the front side E-

ring and the shaft holder.

E-ring

Shaft Holder

(10)Remove the spring.

PS10 (Paper Exit-2)

PS10 (Paper Exit-2)

Screw

(8) Remove the paper exit opening open-shut link

screw.

Paper Exit Opening

Open-Shut Link

Screw

1-25

Page 30

FS-108/FS-108BM

Stacker/Stapler Unit

Rail Stopper Screw

Rail Stopper Screw

Screws

Screws

Cover

(11)Remove the 4 set screws holding the paper e xit-

opening cover in place, and take off the cover.

(12)Lift the paper exit-opening unit up and out.

Paper Exit-Opening Cover

Screws

Screws

Paper Exit-Opening Unit

(13)Reinstall the unit in the opposite sequence to

removal.

5. Removing and Reinstalling the Stacker/Stapler

Unit

a. Procedure

(1) Open the front cover and pull the stacker/sta-

pler unit part of the way out..

(2) Remove the 2 rail-stopper set screws . Then pull

the stacker/stapler unit all of the way out.

(3) Remove 4 set screws holding the cov er in place,

and remove the cover.

1-26

Page 31

FS-108/FS-108BM

Cartridge Rails

Screws

Screws

Screws

Screw

Screw

Stacker/

Stapler Unit

(4) Remove the 2 set screws holding the bundle

guide arm to the stacker/stapler unit.

Screws

Bundle Guide Arm

(5) Detach the two connectors from the connector

board at the rear of the stacker/stapler unit.

(6) Remove the 4 set screws holding the cartridge

rails in place, and take out the cartridge rails.

(7) Remove the final 4 set screws holding the

stacker/stapler unit in place. Remove the

stacker/stapler unit.

Connector

Connector

(8) Reinstall the stacker/stapler unit in the opposite

sequence to removal.

1-27

Page 32

FS-108/FS-108BM

Sub-tray

Sub-tray Paper Exit Roller C

PS1 (Sub-tray

Paper Exit)

Sub-tray Paper

Exit Roller A

Sub-tray

Paper Exit Roller B

M1 (FNS

Conveyance)

PS4

(FIN Entrance

Path)

Sub-tray

Conveyance

Roller A

Conveyance Roller B

[4] M1 (FNS Conveyance) Control

24V

24V

PGND

PGND

PS1IN

GND

PS4IN

GND

GND

GND

1-B6

5V

1-B1

1-B2

1-B3

1-B4

1-B5

1-B19

1-B20

1-B13

1-B14

5V

1-A12

1-A30

1-A21

1-A11

5V

1-A29

1-A20

5V

1-A13

5V

1-B18

1-A22

24V-IN

24V

5V

SGND

PGND

PGND

TXD

NC

DTR

NC

CTS

NC

RXD

NC

DSR

NC

RTS

NC

MAIN BODY

MS1

28-6

28-3

28-1

114-1

114-2

114-5

114-3

114-7

114-6

6-1

2-9

2-7

6-3

6-4

6-5

6-6

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

5V

SGND

PGND

PGND

RXD

SGND

CTS

SGND

DTR

SGND

TXD

SGND

RTS

SGND

DSR

SGND

M1BRK

M1CONT

M1CLK

M1PLL

M1F/R

PS10IN

PS207IN

FNS CB

M1 (finisher convey ance) drives paper conve yance (if maintray exit) and paper exit (if sub-tray exit) by means of conveyance rollers A, B , C , D, convey ance slide shaft and the

sub-tray paper paper exit roller A, B , C . M1 is controlled by

the FNS CB (FNS control board).

M1

PS1

PS4

PS207

1. Operation

a. Interlock

FNS paper-conveyance drive control is initiated by the ON

signal from the main body START button. If MS1 (interlock) is OFF at this time, however, the finisher transmits

an error signal to the main body CB and does not begin

control.

b. PS207 (paper exit cover open/close detection)

control

As mentioned above, FNS paper-conveyance drive control is initiated by the ON signal from the main body ST AR T

button. But if PS207 (paper exit cover open/close detector) is [H] at this time (paper exit cover is open), the FNS

transmits an error signal to the main body CB and does

not begin control.

c. M1 (FNS conveyance) control

(1) Main tray paper exit operation

M1 (FNS conveyance) is set ON by the ON signal of the START button and goes OFF a preset

time interval after PS4 (FIN entrance passage)

detects the trailing edge of the final copy paper.

(2) Sub-tray paper exit operation

M1 is set ON by the START button ON signal,

and begins with rapid rotation. M1 then switches

to slow rotation a preset time period after PS4

detects the trailing edge of the paper. M1 then

returns to rapid rotation to prepare for transport

of the next paper. M1 goes OFF a preset time

period after PS4 detects the trailing edge of the

final paper.

1-28

Page 33

2. Signals

a. Input signals

(1) TXD (Main-Body CB → FNS CB)

Serial data line; transmits operating status of the

main body’s CB to the FNS CB.

(2) DTR (Main-Body CB → FNS CB)

Request to send signal from the main body to

the FNS.

(3) RTS (Main-Body CB → FNS CB)

Transmission acknowledgment signal from the

main body to the FNS.

(4) 24V IN (MS1 → FNS CB)

Outputs +24V if MS1 (interlock) is ON. The

power is supplied to all loads on the FNS side.

(5) PS207 IN (PS207 → FNS CB)

Inputs [L] when the sub-tray paper paper exit

cover is closed.

(6) PS4 IN (PS4 → FNS CB)

Comes ON and inputs [L] when paper passes

through the FNS inlet.

(7) MI PLL (M1 → FNS CB)

Monitors rotation status of M1 (FNS conveyance).

[L] is input when M1 reaches the specified speed.

FS-108/FS-108BM

b. Output signals

(1) TXD (FNS CB → Main-Body CB)

Serial data line; transmits FNS operating status

to the main body’s CB.

(2) RTS (FNS CB → Main-Body CB)

Request to send signal from the FNS to the main

body .

(3) DTR (FNS CB → Main-Body CB)

Transmission acknowledgment signal from the

FNS to the main body.

(4) M1 CONT (FNS CB → M1)

M1 (FNS conveyance) drive control signal.

[H]: OFF

[L]: ON

(5) M1 BRK (FNS CB → M1)

M1 (FNS conveyance) brake signal.

[H]: OFF

[L]: ON

(6) M1 CLK (FNS CB → M1)

Reference clock signal for controlling the speed

of M1 (FNS conveyance).

(7) M1 F/R (FNS CB → M1)

M1 (FNS conveyance) direction signal.

[H]: Counterclockwise

[L]: Clockwise

1-29

Page 34

FS-108/FS-108BM

PS1

(Sub-tray

Paper Exit)

PS4

(FIN Entrance

Passage)

PS5 (Stacker Conveyance Passage)

PS6 (Paper Exit-1)

SD1 (Gate)

SD5

(By-pass)

Stacker Entrance Roller

SD2

(Sub-tray

Paper Exit)

[5] Gate Control

DRV

1-B26

24V

1-B27

DRV

24V

DRV

24V

PS4IN

GND

PS5IN

GND

PS6IN

GND

1-B24

1-B28

1-B23

1-A3

5V

1-A11

1-A29

1-A20

5V

1-A11

1-A28

1-A19

5V

1-A9

1-A27

1-A18

24V-IN

MS1

24V

5V

SGND

PGND

PGND

TXD

NC

DTR

NC

CTS

NC

RXD

NC

DSR

NC

RTS

NC

MAIN BODY

28-6

28-3

28-1

114-1

114-2

114-5

114-3

114-7

114-6

2-9

2-7

6-1

6-3

6-4

6-5

6-6

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

5V

SGND

PGND

PGND

RXD

SGND

CTS

SGND

DTR

SGND

TXD

SGND

RTS

SGND

DSR

SGND

FNS CB

The paper conveyance path is switched by the ON/OFF

switching of SD1 (gate), SD2 (sub-tray paper exit), and

SD5 (by-pass), which are switched ON/OFF by the FNS

CB (FNS control board).

1. Operation

SD1

SD2

SD5

PS4

PS5

PS6

a. Main-tray Paper Exit Operation (Sort, Group, and

Non-Sort modes)

Paper moves through the shift unit and paper exits to the

main tray, passing through the sub-tray gate and the gate.

As both these gates direct the paper toward the shift-unit

side by default, SD2 (sub-tray paper exit) and SD1 (gate)

remain off.

1-30

Page 35

FS-108/FS-108BM

Finishing

SD1

Sort, Group, and Non-Sort modes

Sub-tray mode

ON

SD5

ON

(OFF)

OFF

SD2

Staple mode, sizes A4,

B5 ( ) is for sizes other

than A4, B5

First paper of

2nd or

subsequent set

Others

Booklet mode (FS-108BM only)

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

b. Stacker conveyance operation (Staple mode)

Paper moves through the stacker unit to the main tray,

passing the sub-tray gate, the gate, and the by-pass gate.

As the sub-tray gate is already set to the stacker side, SD2

(sub-tray paper paper exit) remains off.

(1) ON timing for SD1 (gate)

SD1 comes on when the START button ON signal is received, setting the gate to the stacker

side. The FNS stands by for paper conveyance

to begin.

(2) Conveyance of paper sizes other than A4 and

B5

The gates direct the paper into the stacker . SD5

remains OFF, as paper moves without by-pass

toward the stacker entrance roller.

(3) Conveyance of A4 and B5 paper (first paper of

second and subsequent sets)

SD5 comes ON a preset time period after PS4

(FIN entrance passage) detects the trailing edge

of the final paper of the preceding set. This

switches the by-pass gate to the by-pass side,

so that the first paper of the new set is carried to

that side.

(4) Conveyance of A4 and B5 paper (second and

subsequent papers of second and subsequent

sets)

SD5 goes OFF a preset time period after PS4

detects the trailing edge of the first sheet of the

current set, closing the by-pass gate. The second sheet moves directly (without by-pass), together with the first paper, to the stac ker entrance

roller.

SD5 remains off for the third and subsequent

sheets of the set, which move without by-pass

to the stacker.

(5) OFF timing for SD1 (gate)

SD1 goes OFF a preset time period after PS6

(paper exit-1) detects the final stapled set.

c. Stacker conveyance operation (Booklet mode)

(FS-108BM only)

Paper moves through the stacker unit to the folding unit,

passing the sub-tray gate, the gate, and the by-pass gate.

As the sub-tray gate is already set to the stacker side, SD2

remains off.

(1) ON timing for SD1 (gate)

SD1 comes on when the START button ON signal is received, setting the gate to the stacker

side. The FNS stands by for paper conveyance

to begin.

(2) The gates direct the paper to the stacker. SD5

remains OFF, as paper moves without by-pass

toward the stacker entrance roller.

(3) OFF timing for SD1 (gate)

SD1 goes OFF a preset time period after PS6

(paper exit-1) detects the final stapled set.

d. Sub-tray paper exit operation

SD2 (sub-tray paper exit) comes on when the START button ON signal is received, setting the sub-tray gate to the

sub-tray side. SD2 goes OFF a preset time period after

PS4 (FIN entrance passage) detects the final sheet.

1-31

Page 36

FS-108/FS-108BM

2. Signals

a. Input signals

(1) TXD (Main-Body CB → FNS CB)

Serial data line; transmits operating status of the

main body’s CB to the FNS CB.

(2) DTR (Main-Body CB → FNS CB)

Request to send signal from the main body to

the FNS.

(3) RTS (Main-Body CB → FNS CB)

Transmission acknowledgment signal from the

main body to the FNS.

(4) PS1 IN (PS1 → FNS CB)

Comes ON ([L]) when paper passage is detected

at the sub-tray paper paper exit.

(5) PS4 IN (PS4 → FNS CB)

Comes ON ([L]) when paper passage is detected

at the FNS entrance.

(6) PS5 IN (PS5 → FNS CB)

Comes ON ([L]) when paper passage is detected

at the stacker entrance.

(7) PS6 IN (PS6 → FNS CB)

Comes ON ([L]) when paper passage is detected

at the main-tray paper paper exit.

b. Output signals

(1) TXD (FNS CB → Main-Body CB)

Serial data line; transmits FNS operating status

to the main body CB.

(2) RTS (FNS CB → Main-Body CB)

Request to send signal from the FNS to the main

body .

(3) DTR (FNS CB → Main-Body CB)

Transmission acknowledgment signal from the

FNS to the main body.

(4) SD1 DRV (FNS CB → SD1)

SD1 (gate) drive control signal.

[H]: OFF

[L]: ON

(5) SD2 DRV (FNS CB → SD2)

SD2 (sub-tray) drive control signal.

[H]: OFF

[L]: ON

(6) SD5 DRV (FNS CB → SD5)

SD5 (by-pass) drive control signal.

[H]: OFF

[L]: ON

1-32

Page 37

[6] M13 (Stacker Entrance) Control

PS4

(FIN Entrance

Passage)

PS5 (Stacker Conveyance Passage)

PS6 (Paper Exit-1)

Stacker Entrance Roller

M13 (Stacker Entrance)

Swivel Roller

Flat-Stapling Stopper

Stapling and

Folding Stopper

FS-108/FS-108BM

24V

24V

24V

24V

21-A1

21-A2

21-A3

21-A4

21-A5

21-A6

25-A11

25-A7

25-A8

25-A9

25-A10

25-A12

M13

M13DRVA

M13DRVA

M13DRVB

M13DRVB

M13DRVA

M13DRVA

M13DRVB

M13DRVB

MS1

28-6

24V

2-9

5V

SGND

PGND

PGND

TXD

DTR

CTS

RXD

DSR

RTS

2-7

28-3

28-1

114-1

NC

114-2

NC

114-5

NC

114-3

NC

114-7

NC

114-6

NC

MAIN BODY

M13 (stacker entrance) drives the stacker entrance roller

and the swivel roller , thereby carrying out the following functions: conveyance of paper to the stacker; paper alignment;

and adjustment of staple waiting time. M13 is controlled

by the FNS CB (FNS control board) via the RB (relay

board).

4-A1

4-A2

4-A3

4-A4

4-A5

4-A6

6-1

6-3

6-4

6-5

6-6

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

M13DRVA

M13DRVA

M13DRVB

M13DRVB

24V

24V

24V-IN

5V

SGND

PGND

PGND

RXD

SGND

CTS

SGND

DTR

SGND

TXD

SGND

RTS

SGND

DSR

SGND

5V

1-A11

PS4IN

GND

PS5IN

GND

1-A29

1-A20

5V

1-A11

1-A28

1-A19

PS4

PS5

FNS CBRB

1. Operation

Conveyance to the stacker varies according to paper size:

one method is used for A4 and B5, another is used for all

other sizes.

1-33

Page 38

FS-108/FS-108BM

a. Conveyance to the stacker (sizes other than A4

or B5)

(1) M13 ON timing

M13 (stacker entrance) is set ON b y the START

button ON signal, and begins with rapid rotation. M13 then switches to slow rotation a preset time period after PS4 (FIN entrance passage)

detects the trailing edge of the first paper. M13

then returns to rapid rotation a preset period after PS5 (stacker conveyance passage) detects

the trailing edge of the paper. This action is repeated as necessary to transport all papers to

be stacked into the stacker.

(2) M13 OFF timing

M13 goes OFF a preset time period after PS5

(stacker conveyance passage) detects the trailing edge of the final paper set.

b. Conveyance to the stacker (A4 and B5 sizes)

(1) First set

Paper for the first set to be stapled is conveyed

in the same way as other paper sizes.

(2) First paper of second and subsequent sets

M13 goes OFF a preset time period after PS4

(FIN entrance passage) detects the trailing edge

of the first paper for the second or subsequent

set, and the paper moves into the by-pass . This

prevents paper from moving into the stacker

while stapling of the previous set is still in

progress.

(3) Second and subsequent papers of second and

subsequent sets

M13 resumes slow rotation a preset time period

after PS4 detects the trailing edge of the second paper of the set. This causes the first and

second papers to move together (one atop the

other) into the stacker. M13 switches to rapid

rotation a preset time period after PS5 (stacker

conveyance passage) detects the trailing edge

of the first and second papers, so that it is ready

to handle the third paper of the set when it arrives from the main body. Third and subsequent

papers for the set are then conveyed in the same

way as the papers in the first set.

c. Paper alignment (trailing-edge alignment)

For operation in staple mode:

The swivel roller adjusts the position of each paper (one

paper at a time) within the stacker.

For operation in booklet mode (FS-108BM only): The stapling & folding stopper is moved and set into appropriate

position. The swivel roller adjusts the position of each paper (one paper at a time).

2. Signals

a. Input signals

(1) TXD (Main-Body CB → FNS CB)

Serial data line; transmits operating status of the

main body’s CB to the FNS CB.

(2) DTR (Main-Body CB → FNS CB)

Request to send signal from the main body to

the FNS.

(3) RTS (Main-Body CB → FNS CB)

Transmission acknowledgment signal from the

main body to the FNS.

(4) PS4 IN (PS4 → FNS CB)

Comes ON ([L]) when paper passage is detected

at the FNS entrance.

(5) PS5 IN (PS5 → FNS CB)

Comes ON ([L]) when paper passage is detected

at the stacker entrance.

(6) PS6 IN (PS6 → FNS CB)

Comes ON ([L]) when paper is detected at the

main-tray paper paper exit.

b. Output signals

(1) TXD (FNS CB → Main-Body CB)

Serial data line; transmits FNS operating status

to the main body’s CB.

(2) RTS (FNS CB → Main-Body CB)

Request to send signal from the FNS to the main

body .

(3) DTR (FNS CB → Main-Body CB)

Transmission acknowledgment signal from the

FNS to the main body.

(4) M13 DRV A,A / M13 DR V B ,B (FNS CB → RB

→ M13)

M13 (stacker entrance) drive control signals.

1-34

Page 39

[7] M5 (Alignment Plate/Upper) Control

Alignment

Plate/Upper

PS5

(Stacker Conveyance

Passage)

M5 (Alignment Plate/Upper)

FS-108/FS-108BM

M5DRVA

M5DRVA

M5DRVB

M5DRVB

PS 8IN

PS8IN

GND

24V

24V

M5DRVA

M5DRVA

M5DRVB

M5DRVB

21-A15

21-A16

21-A17

21-A18

21-B26

5V

25-A5

25-A3

25-A1

25-B2

25-B1

25-B6

25-B5

25-B4

25-B3

M5

PS8

24V

5V

SGND

PGND

PGND

TXD

NC

DTR

NC

CTS

NC

RXD

NC

DSR

NC

RTS

NC

MAIN BODY

PS5

MS1

28-6

28-3

28-1

114-1

114-2

114-5

114-3

114-7

114-6

2-9

2-7

4-A15

4-A16

4-A17

4-A18

4-B26

1-A10

1-A28

1-A19

6-1

6-3

6-4

6-5

6-6

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

FNS CBRB

M5DRVA

M5DRVA

M5DRVB

M5DRVB

PS 8IN

M5 (alignment plate/upper) aligns the paper widthwise in

the stacker by opening and closing the alignment plates/

upper. M5 is controlled by the FNS CB (FNS control board)

via the RB (relay board).

1. Operation

At start-up, the alignment plates/upper are stationary at

the ON position of PS8 (alignment-plate/upper HP). A specified time period after PS5 (stacker conveyance passage)

detects the paper trailing edge, M5 begins rotation so as

to close the plates. After another specified interval it opens

the plates. This cycle repeats for each paper.

5V

PS5IN

GND

24V-IN

5V

SGND

PGND

PGND

RXD

SGND

CTS

SGND

DTR

SGND

TXD

SGND

RTS

SGND

DSR

SGND

2. Signals

a. Input signals

(1) TXD (Main-Body CB → FNS CB)

Serial data line; transmits operating status of the

main body’s CB to the FNS CB.

(2) DTR (Main-Body CB → FNS CB)

Request to send signal from the main body to

the FNS.

(3) RTS (Main-Body CB → FNS CB)

Transmission acknowledgment signal from the

main body to the FNS.

(4) PS5 IN (PS5 → FNS CB)

Comes ON ([L]) when paper passage is detected

at the stacker entrance.

(5) PS8 IN (PS8 → RB → FNS CB)

Detects the position of the upper alignment

plates. [L] when the plates are at home position.

b. Output signals

(1) TXD (FNS CB → Main-Body CB)

Serial data line; transmits FNS operating status

to the main body’s CB.

(2) RTS (FNS CB → Main-Body CB)

Request to send signal from the FNS to the main

body .

(3) DTR (FNS CB → Main-Body CB)

Transmission acknowledgment signal from the

FNS to the main body.

(4) M5 DRV A ,A, B,B (FNS CB → RB → M5)

M5 (alignment plate/upper) drive control signals.

1-35

Page 40

FS-108/FS-108BM

Alignment

Plate/Upper

PS5

(Stacker Conveyance

Passage)

Alignment Plate/

Lower

M5 (Alignment Plate/Upper)

M15 (Alignment Plate/Lower)

[8] M15 (Alignment Plate/Lower) Control (FS-108BM only)

PS24

M15

27-3

27-2

27-1

27-4

27-5

27-6

27-7

27-8

27-9

PS24IN

GND

24V

24V

M15DRVA

M15DRVA

M15DRVB

M15DRVB

M15DRVA

M15DRVA

M15DRVB

M15DRVB

PS24IN

22-A5

22-A6

22-A7

22-A8

22-B5

5V

M15 (alignment plate/lower) aligns the stapling-and-folding position by opening and closing the alignment plates/

lower. M15 is controlled by the FNS CB (finisher control

board) via the RB (relay board).

MS1

24V

5V

SGND

PGND

PGND

TXD

NC

DTR

NC

CTS

NC

RXD

NC

DSR

NC

RTS

NC

MAIN BODY

1-A10

PS5IN

GND

5V

1-A28

1-A19

PS5

28-6

28-3

28-1

114-1

114-2

114-5

114-3

114-7

114-6

M15DRVA

5-A5

M15DRVA

5-A6

M15DRVB

5-A7

M15DRVB

5-A8

PS24IN

5-B5

24V-IN

6-1

6-3

2-9

2-7

6-4

6-5

6-6

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

5V

SGND

PGND

PGND

RXD

SGND

CTS

SGND

DTR

SGND

TXD

SGND

RTS

SGND

DSR

SGND

FNS CBRB

1. Operation

At start-up, the alignment plates/lower are stationary at

the ON position of PS24 (alignment-plate/lower HP). A

specified time period after PS5 (stacker conveyance passage) detects the paper trailing edge, M15 begins rotation

so as to close the plates. After another specified interval it

opens the plates. This cycle repeats for each paper.

1-36

Page 41

2. Signals

a. Input signals

(1) TXD (Main-Body CB → FNS CB)

Serial data line; transmits operating status of the

main body’s CB to the FNS CB.

(2) DTR (Main-Body CB → FNS CB)

Request to send signal from the main body to

the FNS.

(3) RTS (Main-Body CB → FNS CB)

Transmission acknowledgment signal from the

main body to the FNS.

(4) PS5 IN (PS5 → FNS CB)

Comes ON ( [L]) when paper passage is detected at the stacker entrance.

(5) PS24 IN (PS24 → connector board → FNS CB)

Detects the position of the lower alignment

plates. [L] when the plates are at home position.

b. Output signals

(1) TXD (FNS CB → Main-Body CB)

Serial data line; transmits FNS operating status

to the main body’s CB.

(2) RTS (FNS CB → Main-Body CB)

Request to send signal from the FNS to the main

body .

(3) DTR (FNS CB → Main-Body CB)

Transmission acknowledgment signal from the

FNS to the main body.

(4) M15 DRV A,A,B,B (FNS CB → RB → M15)

M15 (alignment plate/lower) drive signals.

FS-108/FS-108BM

1-37

Page 42

FS-108/FS-108BM

PS4

(FIN Entrance

Passage)

PS18 (Roller Shift HP)

M2 (Roller Shift)

Conveyance Slide Shaft

Paper Exit Roller

[9] M2 (Roller Shift) Control

24V-IN

6-1

6-3

6-4

6-5

6-6

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

5V

SGND

PGND

PGND

RXD

SGND

CTS

SGND

DTR

SGND

TXD

SGND

RTS

SGND

DSR

SGND

M2DRV

PS18IN

FNS CB

24V

5V

SGND

PGND

PGND

TXD

NC

DTR

NC

CTS

NC

RXD

NC

DSR

NC

RTS

NC

MAIN BODY

MS1

28-6

28-3

28-1

114-1

114-2

114-5

114-3

114-7

114-6

2-9

2-7

When running in Sort or Group mode, the FNS carries out

shifting of paper. Shifting is driven b y M2 (roller shift), which

is controlled by the FNS CB (FNS control board).

1. Operation

If operation is in Sort or Group mode, M2 (roller shift) comes

ON a predetermined time period after PS4 (FIN entrance

passage) detects the trailing edge of a paper that needs to

be shifted.

Rotation of M2 starts shifting of the conveyance slide shaft,

while rotation of M1 (FNS conveyance) causes the shaft

to turn, so that shifting and conveyance occur simultaneously. PS18 (roller-shift HP) comes ON when the shaft

has been fully shifted, causing M2 to go OFF.

A specified time period after PS4 goes off, M2 comes back

ON and returns the conveyance slide shaft to its original

position. PS18 (roller-shift HP) goes OFF when the shaft

has returned all the way, causing M2 to go OFF again.

This operation is repeated as necessary to shift paper as it

moves toward the exit roller.

PS4IN

GND

GND

24V

5V

5V

1-A2

1-B29

1-A11

1-A29

1-A20

1-A5

1-A23

1-A14

M2

PS4

PS18

2. Signals

a. Input signals

(1) TXD (Main-Body CB → FNS CB)

Serial data line; transmits operating status of the

main body’s CB to the FNS CB.

(2) DTR (Main-Body CB → FNS CB)

Request to send signal from the main body to

the FNS.

(3) RTS (Main-Body CB → FNS CB)

Transmission acknowledgment signal from the

main body to the FNS.

(4) PS4 IN (PS4 → FNS CB)

Comes ON ([L]) when paper passage is detected

at the FNS entrance.

(5) PS18 IN (PS18 → FNS CB)

Roller-shift position detection signal.

[L]→[H]: Forward position

[H]→[L]: Back position

b. Output signals

(1) TXD (FNS CB → Main-Body CB)

Serial data line; transmits FNS operating status

to the main body’s CB.

(2) RTS (FNS CB → Main-Body CB)

Request to send signal from the FNS to the main

body .

(3 DTR (FNS CB → Main-Body CB)

Transmission acknowledgment signal from the

FNS to the main body.

(4) M2 DRV (FNS CB → M2)

M2 (roller-shift motor) drive control signal.

[H]: ON

[L]: OFF

1-38

Page 43

[10] M7 (Paper Exit Roller) Control

Paper Exit Roller

(Sponge Roller)

PS6 (Paper Exit-1)

M7 (Paper Exit Roller)

PS10 (Paper Exit-2)

PS9 (Paper Exit-Belt HP)

Paper Exit Belt

Paper Exit

Arm

FS-108/FS-108BM

PS9IN

GND

21-B27

5V

25-A6

25-A4

25-A2

PS9

PS 9IN

MS1

28-6

24V

SGND

PGND

PGND

TXD

DTR

CTS

RXD

DSR

RTS

2-9

5V

2-7

28-3

28-1

114-1

NC

114-2

NC

114-5

NC

114-3

NC

114-7

NC

114-6

NC

MAIN BODY

The paper exit belt ejects paper from the stacker , while the

paper exit roller ejects the paper from the FNS. M7 (paper

exit roller) drives both the belt and the roller. M7 is controlled by the FNS CB (FNS control board).

4-B27

6-1

6-3

6-4

6-5

6-6

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

PS 9IN

24V-IN

5V

SGND

PGND

PGND

RXD

SGND

CTS

SGND

DTR

SGND

TXD

SGND

RTS

SGND

DSR

SGND

1-B7

5V

1-B8

M7P/S

M7H/L

M7LD

PGND

PGND

24V

24V

M7F/R

PS4IN

GND

GND

1-B9

1-B10

1-B11

1-B16

1-B17

1-B21

1-B22

1-B12

5V

1-A11

1-A29

1-A20

5V

1-A8

1-A26

1-A17

M7

PS4

PS10

M7CLK

PS10IN

FNS CBRB

1. Operation

a. Sort, Group, and Non-Sort modes

b. Staple mode (flat stapling)

c. Booklet mode

M7 (paper exit roller) starts turning when PS4 (FIN entrance passage) detects the leading edge of a paper. M7

goes off when PS10 (paper exit-2) detects paper exit of

the paper, unless an FNS start signal has already been

received from the main body.

M7 starts running when stapling is finished, and stops when

PS9 (paper exit-belt HP) comes ON.

M7 starts running in reverse when stapling is finished, and

stops when PS9 (paper exit-belt HP) comes ON.

1-39

Page 44

FS-108/FS-108BM

2. Signals

a. Input signals

(1) TXD (Main-Body CB → FNS CB)

Serial data line; transmits operating status of the

main body’s CB to the FNS CB.

(2) DTR (Main-Body CB → FNS CB)

Request to send signal from the main body to

the FNS.

(3) RTS (Main-Body CB → FNS CB)

Transmission acknowledgment signal from the

main body to the FNS.

(4) PS4 IN (PS4 → FNS CB)

Comes ON ([L]) when paper passage is detected

at the FNS entrance.

(5) PS9 IN (PS9 → RB → FNS CB)

Comes ON ([L]) when the paper exit belt is in

home position.

(6) PS10 IN (PS10 → FNS CB)

Comes ON ( [L]) when paper is detected at the

FNS paper exit.

(7) M7 LD (M7 → FNS CB)

M7 rotational status detection signal. This signal becomes [L] when M7 reaches the set speed.

b. Output signals

(1) TXD (FNS CB → Main-Body CB)

Serial data line; transmits FNS operating status

to the main body’s CB.

(2) RTS (FNS CB → Main-Body CB)

Request to send signal from the FNS to the main

body .

(3) DTR (FNS CB → Main-Body CB)

Transmission acknowledgment signal from the

FNS to the main body.

(4) M7 P/S (FNS CB→ M7)

M7 (paper exit roller) drive control signal.

[H]: OFF

[L]: ON

(5) M7 CLK (FNS CB → M7)

M7 (paper exit roller) speed-adjustment clock

signal.

(6) M7 H/L (FNS CB → M7)

Reference clock signal for controlling the speed

of M7 (paper exit roller).

[H]: Slow

[L]: Fast

(7) M7 F/R (FNS CB → M7)

M7 (paper exit roller) rotation direction control

signal.

[H]: Counterclockwise

[L]: Clockwise

1-40

Page 45

[11] SD4 (Paper Exit Opening) Control

Nip Paper

Exit Roller

PS6 (Paper Exit-1)

SD4

(Paper Exit

Opening)

PS10 (Paper

Exit-2)

PS4 (FIN Entrance Roller)

Conveyance Roller C

Conveyance Roller A

Conveyance Roller B

Conveyance Roller D

Paper Exit Roller

(Sponge Roller)

SD4

MS1

28-6

24V

SGND

PGND

PGND

2-9

5V

2-7

28-3

28-1

1-B25

1-A4

6-1

6-3

6-4

6-5

6-6

SD4 DRV

24V

24V-IN

5V

SGND

PGND

PGND

PS6IN

GND

PS10IN

GND

PS12IN

GND

FS-108/FS-108BM

5V

1-A9

1-A27

1-A18

5V

1-A8

1-A26

1-A17

5V

1-A7

1-A25

1-A16

PS6

PS10

PS12

114-1

TXD

NC

114-2

DTR

NC

114-5

CTS

NC

114-3

RXD

NC

114-7

DSR

NC

114-6

RTS

NC

MAIN BODY

SD4 (paper exit opening) controls engagement by the nip

paper exit roller. SD4 is controlled by the FNS CB (FNS

control board).

1. Operation

When ejection is not in progress, a gap is maintained between the nip paper exit roller and the paper exit roller so

as to prevent paper jams at the paper e xit. At time of ejection, howev er, SD4 comes ON, inclining the nip paper exit

roller against the paper exit roller so that the gap is closed.

a. SD4 ON timing

(1) Sort, Group, and Non-Sort modes

SD4 comes ON a preset time period after PS10

(paper exit-2) detects the leading edge of the

sheet.

(2) Staple mode

SD4 comes ON a preset time period following

completion of stapling.

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

RXD

SGND

CTS

SGND

DTR

SGND

TXD

SGND

RTS

SGND

DSR

SGND

FNS CB

b. SD4 OFF timing

(1) Sort, Group, and Non-Sort modes

(2) Staple mode

SD4 goes OFF a preset time period after PS10

(paper exit-2) detects the trailing edge of the

paper.

SD4 goes OFF a preset time period after PS6

(paper exit-1) detects the trailing edge of the

paper set.

1-41

Page 46

FS-108/FS-108BM

2. Signals

a. Input signals

(1) TXD (Main-Body CB → FNS CB)

Serial data line; transmits operating status of the

main body’s CB to the FNS CB.

(2) DTR (Main-Body CB → FNS CB)

Request to send signal from the main body to

the FNS.

(3) RTS (Main-Body CB → FNS CB)

Transmission acknowledgment signal from the

main body to the FNS.

(4) PS6 IN (PS6 → FNS CB)

Comes ON ([L]) when paper passage is detected

at the FNS paper exit.

(5) PS10 IN (PS10 → FNS CB)

Comes ON ([L]) when paper passage is detected

at the FNS paper exit.

(6) PS12 IN (PS12 → FNS CB)

Detects open/closed state of the paper exit opening.

[H]→[L]: Closed

[L]→[H]: Open

b. Output signals

(1) RXD (FNS CB → Main-Body CB)

Serial data line; transmits FNS operating status

to the main body’s CB.

(2) RTS (FNS CB → Main-Body CB)

Request to send signal from the FNS to the main

body .

(3) DTR (FNS CB → Main-Body CB)

Transmission acknowledgment signal from the

FNS to the main body.

(4) SD4 DRV (FNS CB → SD4)

SD4 (paper exit opening) drive control signal.

[H]: OFF

[L]: ON

1-42

Page 47

FS-108/FS-108BM

[12] M8 (Paper Exit Opening) Control

24V-IN

24V

5V

SGND

PGND

PGND

TXD

NC

DTR

NC

CTS

NC

RXD

NC

DSR

NC

RTS

NC

MAIN BODY

MS1

28-6

28-3

28-1

114-1

114-2

114-5

114-3

114-7

114-6

6-1

2-9

2-7

6-3

6-4

6-5

6-6

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

5V

SGND

PGND

PGND

RXD

SGND

CTS

SGND

DTR

SGND

TXD

SGND

RTS

SGND

DSR

SGND

M8DRV

PS12IN

FNS CB

M8 (paper exit opening) controls opening and closing of

the paper exit by means of a linkage mechanism. M8 is

controlled by the FNS CB (FNS control board).

1. Operation

If large paper is being stapled, M8 comes on when the

START button ON signal is received, causing the paper

exit to open. Upon completion of stapling, the stapling-completed signal from the FNS CB causes the paper exit to

close, and the stapled set is exited. The status of the paper exit opening is detected by PS12 (paper exit opening).

M8 (Paper Exit Opening)

Paper Exit Opening

24V

GND

1-A1

1-B30

5V

1-A7

1-A25

1-A16

PS12

(Paper Exit

Opening)

M8

PS12

When paper conveying to Stacker

Open

Closed

Open

Staple (not A4 or B5)

Staple (A4, B5)

Of-fset

Booklet

When Copy

Starts

Open

Closed

Closed

Open

2. Signals

a. Input signals

(1) TXD (Main-Body CB → FNS CB)

Serial data line; transmits operating status of the

main body’s CB to the FNS CB.

(2) DTR (Main-Body CB → FNS CB)

Request to send signal from the main body to

the FNS.

(3) RTS (Main-Body CB → FNS CB)

Transmission acknowledgment signal from the

main body to the FNS.

(4) PS12 IN (PS12 → FNS CB)

Detects open/closed state of the paper exit opening.

[H]→[L]: Closed

[L]→[H]: Open

b. Output signals

(1) TXD (FNS CB → Main-Body CB)

Serial data line; transmits FNS operating status

to the main body’s CB.

(2) RTS (FNS CB → Main-Body CB)

Request to send signal from the FNS to the main

body .

(3) DTR (FNS CB → Main-Body CB)

Transmission acknowledgment signal from the

FNS to the main body.

(4) M8 DRV (FNS CB → M8)

M8 (paper exit opening) drive control signal.

[H]: ON

[L]: OFF

When paper

exit to the tray

Closed

Closed

Closed

Open

1-43

Page 48

FS-108/FS-108BM

Stapler UNIT

[1] Composition

PS23 (Stapling and Folding Stopper HP)

M14

(Stapling and

Folding Stopper)

Clincher-F

Flat-Stapling Stopper

M11 (Stapler Movement)

Cincher-R

Flat-Stapling Stopper

M4 (Stapler Rotation)

M17

(Stapling and Folding Stopper)

Stapling and Folding Stopper

Stapler-R

PS14 (Stapler Rotation HP)

PS11 (Stapler Movement)

Stapler-F

1-44

Page 49

FS-108/FS-108BM

M11 (Stapler Movement)

M4

(Stapler Rotation)

[2] Mechanism

1. Single staple (front)

Stapler-F and clincher-F move to the staple position, driven

by M11 (stapler movement). After mo ving into position, thy

staple the stacked paper.

M11 (Stapler Movement)

2. Single staple (rear)

Stapler-R and clincher-R slide into the staple position. M11

(stapler movement) and M4 (stapler rotation) control the

motion.

Stapler-R and clincher-R rotate and move to the staple

position.

Rotation is driven by M4 (stapler rotation).

Stapler-R and clincher-R staple the stacked paper.

1-45

Page 50

FS-108/FS-108BM

Clincher-R

M4

(Stapler Rotation)

Stapler-R

Stapler-F

Clincher-F

M11 (Stapler Movement)

M17 (Stapling and Folding Stopper release)

M14

(Stapling and Folding

Stopper)

3. Two staples (flat)

Stapler-F, stapler-R, clincher-F, and clincher-R move into

position and staple the stacked paper in two locations.

Stapler-F and clincher-F are driven by M11 (stapler mov ement). Stapler-R and clincher-R are driven by M11 and

M4 (stapler rotation).

M11 (Stapler Movement)

M4

(Stapler Rotation)

4. Two staples (staple & fold) (FS-108BM only)

Stapler F, stapler R, clincher F, and clincher R move into

position.

Paper is transported to the stapling-and-folding stopper,

and then aligned by the action of the upper and lower alignment plates. The paper is then stapled in two locations.

Stapler-F and clincher-F are driven by M11 (stapler movement). Stapler-R and clincher-R are driven by M11 and

M4 (stapler rotation).

1-46

Page 51

FS-108/FS-108BM

5. Operation of the flat-stapling and stapling-andfolding stopper (FS-108BM only)

The flat-stapling stopper is held set while the stapling-andfolding stopper unit is at home position. The flat-stapling

stopper is released by a spring when the stapling-and-folding stopper unit is moved out of home position by the action of M14 (stapling-and-folding stopper).

M14

Spring

PS23

(Stapling and

Folding Stopper

HP)

Flat-Stapling Stopper

Staple position

(Stapling and Folding

Stopper)

Stapling and

Folding Stopper Unit

Stapling and

Folding Stopper

For stapling-and-folding oper ation: P aper is transported up

to the stapling-and-folding stopper for stapling. When stapling is completed, M17 releases the stopper and the paper set moves to the folding unit. Setting and releasing of

the stopper is repeated for each paper set.

Return of the staple paper-end stopper to home position