Page 1

2

MAIN BODY

Page 2

This section covers the structure, functions, operation and method of

disassembling and assembling the machine.

Observe the following precautions when performing disassembly and

assembly work.

1. Be sure to unplug the power cord before working on the machine.

2. Perform all reassembly work by reversing the order in which the

component was disassembled, unless otherwise specified.

3. Do not lose small parts (screws, etc.) or insert them in the wrong

place.

4. Install all parts completely before operating the machine.

5. Do not loosen the screws indicated as disallowed for removal.

Page 3

OUTLINE OF THE SYSTEM

2

MAIN BODY

Expansion memory unit

[MU-103]

Post Inserter

[PI-108]

Finisher

[FS-106]

Finisher

[FS-108 BM]

Memory card

Memory card

adapter kit

Tamdem kit 7065

[TD-101]

Key counter

3500-sheet LCT [LT-352]

KRDS (TYPE 5)

Printer controller

[IP-303]

Network card

[KN-301]

PS UG KIT TYPE 2

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

2 - A - 1

2

DATE

Jan.2000

PAGE

2-A-1

METHOD

REPLACEMENT

Page 4

MAIN BODY

7065 PRODUCT SPECIFICATIONS

1. Type

Type: Console type

(floor-mounted type)

Copying method: Indirect electrostatic method

Original table method: Fixed

Photosensitive

material: OPC

Sensitizing method: Laser writing method

Paper feed method: Two stacked trays (500 sheets,

2

80 g/m

Multi by-pass tray (100 sheets,

80 g/m

LCT (1000/1500 sheets, 80 g/m

LCT (3500 sheets, 80 g/m

x 2)

2

)

*1: Optional

2. Functions

Originals: Sheets, books, solid objects

Original size: Max. A3

Copy size: A3 to A5R

F4/8 x 13

Magnification

Fixed magnifications: x1.00, x1.41, x1.22, x1.15, x0.86,

x0.82, x0.71

Special ratio

magnifications: 3 modes

Zoom magnification: x0.33 to 4.00 (1% steps)

Vertical magnification: x0.33 to 4.00 (1% steps)

Horizontal

magnification: x0.33 to 4.00 (1% steps)

Warm-up time: Less than 6.5 minutes*

(20°C, rated voltage)

First copy time (seconds)

Size

Manual

EE

APS

Continuous copy speed (life size, copies/minute)

Size

A4

Number of

continuous copies: 1 to 9999

Copy density selection:

AE, manual

Arbitrarily set density (2 modes)

A4

3.9

3.9

3.9

A4

65

Special functions: Sheet/Cover Interleave, Chapter,

Combination (2-in-1, 4-in-1, 8-in1, overlay), Booklet, Transparency Interleave, Image Insert,

Book Copy, Different Series Mixed

Original, Text/Photo Enhance

(text/photo/pencil), Reverse Image, Repeat, Frame/Fold Erasure, AUTO Layout, Thin/Thick

Paper, Shift/Reduction Shift, Nonimage Area Erase, memory function, density monitor, single step,

2

) *1

2

)

density shift, printing function,

copy reservation, image rotation,

weekly timer, job memory

3. Copy Paper

Plain paper High quality paper (60 g/m2 to 90 g/m2)

Special paper * Label paper

(By-pass feed

only)

* OHP film

* Blueprint master paper

* Recycled paper

* High quality paper (50 g/m

91 g/m

2

to 170 g/m2)

2

to 59 g/m2,

4. Options

Finisher: FS-106, FS-108BM

2

3500-sheets LCT: LT-352

Expansion memory unit: MU-103

Post Inserter: PI-108

1

2

Memory card

Memory card adapter kit

Tamdem Kit 7065: TD-101

2

Key counter

Printer controller: IP-303

Network card: KN-301

PS UG KIT TYPE 2

2

KRDS: KRDS TYPE 5

5. Particulars of Machine

Power source: 230 VAC -14% to +10.6%,

50 Hz/60 Hz

120 VAC ±10%, 60 Hz

Power consumption: Max 2,300 W (when all options

are connected)

Weight: Approx. 231 kg

MODEL

7065

MANUAL

SERVICE HANDBOOK

*1: 6.5 minutes is the machine for the 230 VAC specification.

Warm-up time differs depend on the power source (voltage).

REVISED EDITION

2 - A - 2

2

DATE

Jan.2000

PAGE

2-A-2

METHOD

REPLACEMENT

Page 5

Machine dimensions

1164mm

756mm 710mm

6. Maintenance

Maintenance interval: Every 150,000 copies

Machine service life: 5,000,000 copies or 5 years

MAIN BODY

7. Copy Materials

Developer: Common with 7060

Toner: Exclusively for 7065

Drum: OPC drum (φ 80)

Common with 7060

8. Machine Operating Environment

Temperature:10 to 30°C

Humidity: 10 to 80%RH

These specifications are subject to change without notice.

2 - A - 3

Page 6

MAIN BODY

CENTER CROSS-SECTION

Image processing unit

Fixing unit

Reversal/

paper exit unit

Exposure lamp

Cleaning section

Charging

corona unit

RADF

PCL

Image read unit

Image write unit

Developing unit

Paper feed unit

Upper tray

Conveyance unit

Lower tray

ADU paper feed/

conveyance unit

LCT-1500 tray

2nd paper feed unit

Transfer corona unit

TSL

Separation corona unit

LCT-1000 tray

2 - A - 4

Page 7

DRIVE SYSTEM DIAGRAM

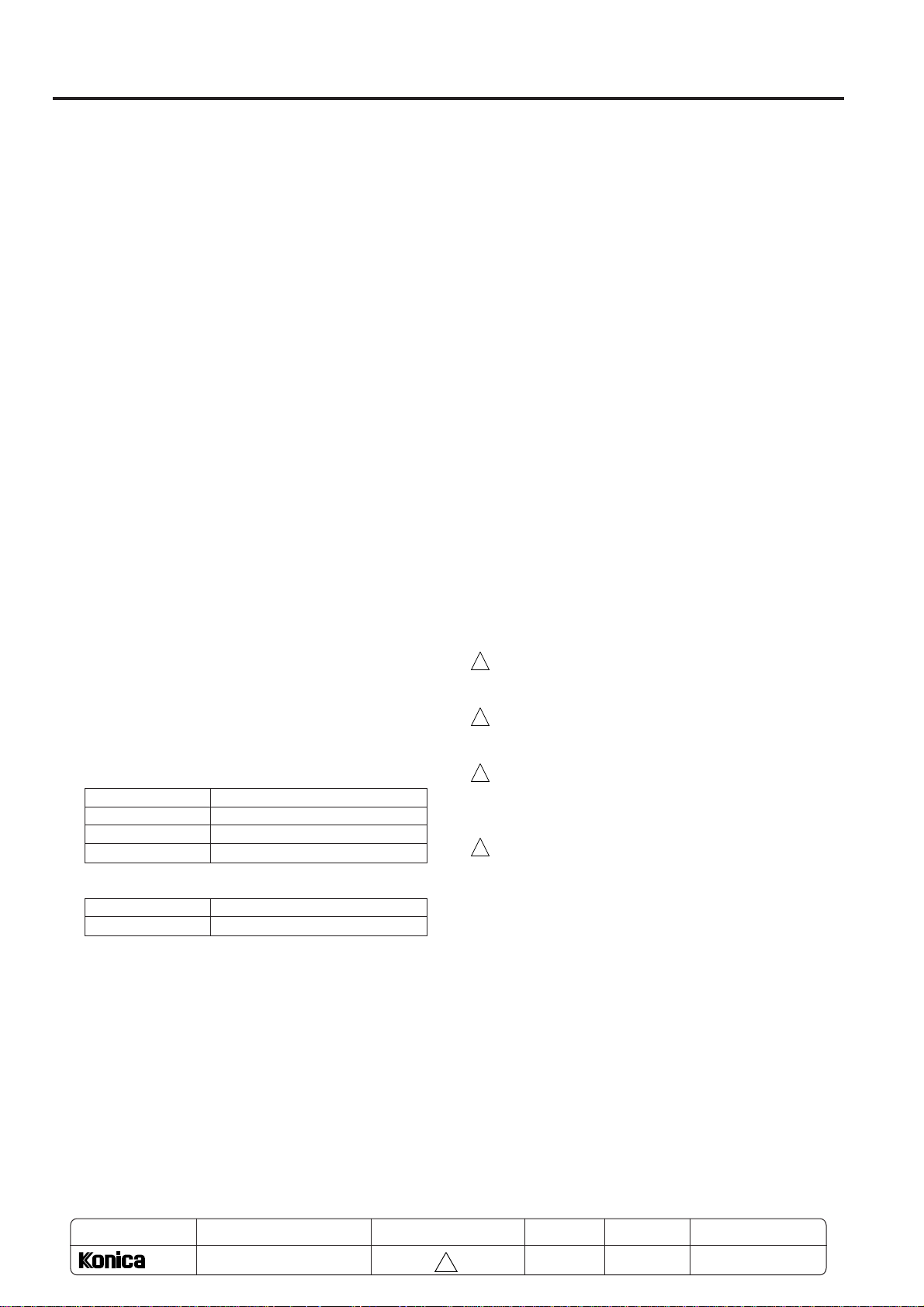

[1] Main Drive

Conveyance belt

Toner conveyance screw

DRIVE SYSTEM DIAGRAM

Decurler unit

2nd paper feed roller

Main Motor

(M1)

Cleaner MC

(MC 10)

A

Timing belt

2nd paper feed MC (MC3)

2 - B - 1

Page 8

DRIVE SYSTEM DIAGRAM

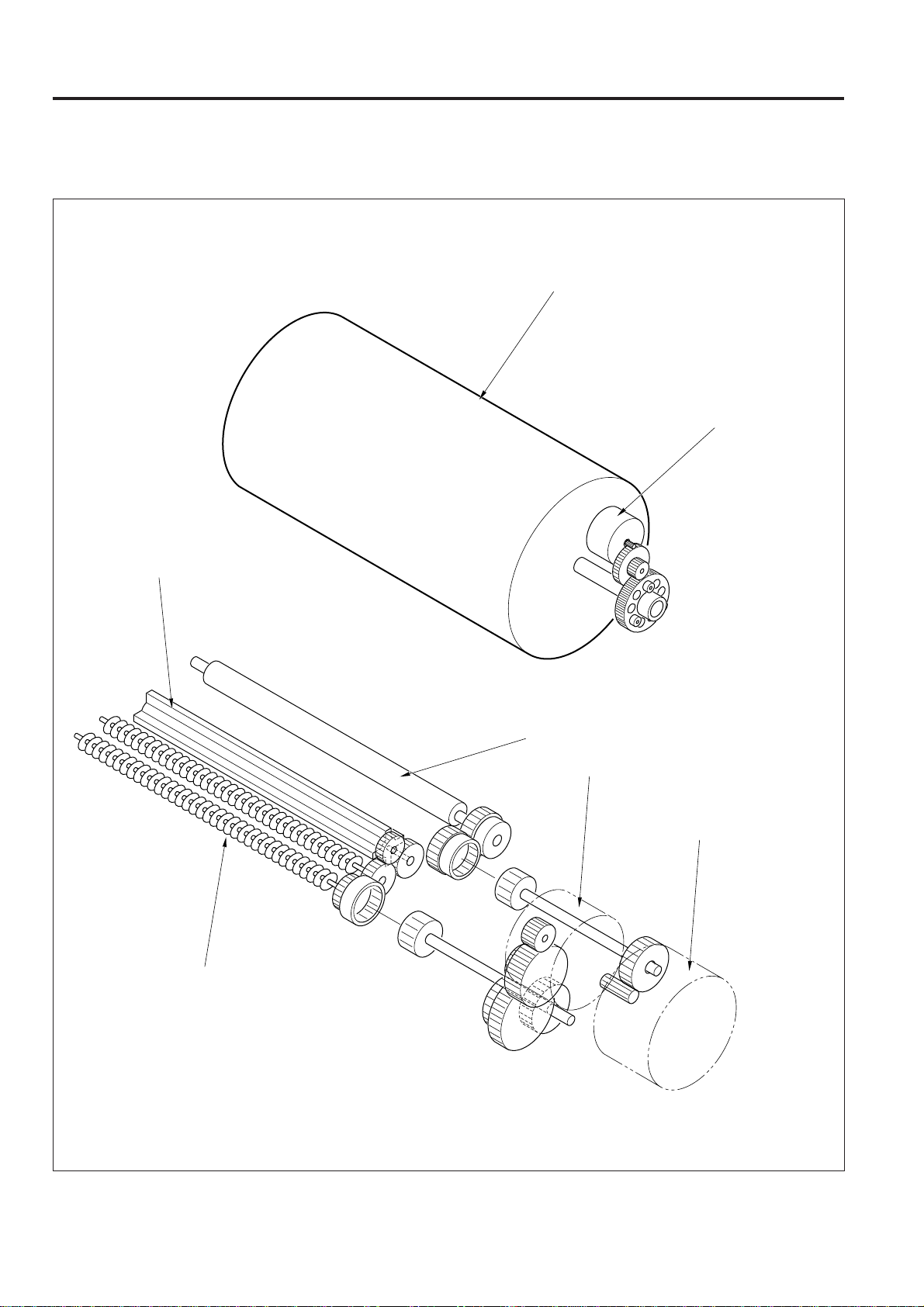

[2] Drum/Developing Drive

Drum

Drum motor (M4)

Agitator wheel

Agitator screw

Developing sleeve

Agitator screw motor (M35)

Developing drive

motor (M3)

2 - B - 2

Page 9

B

A

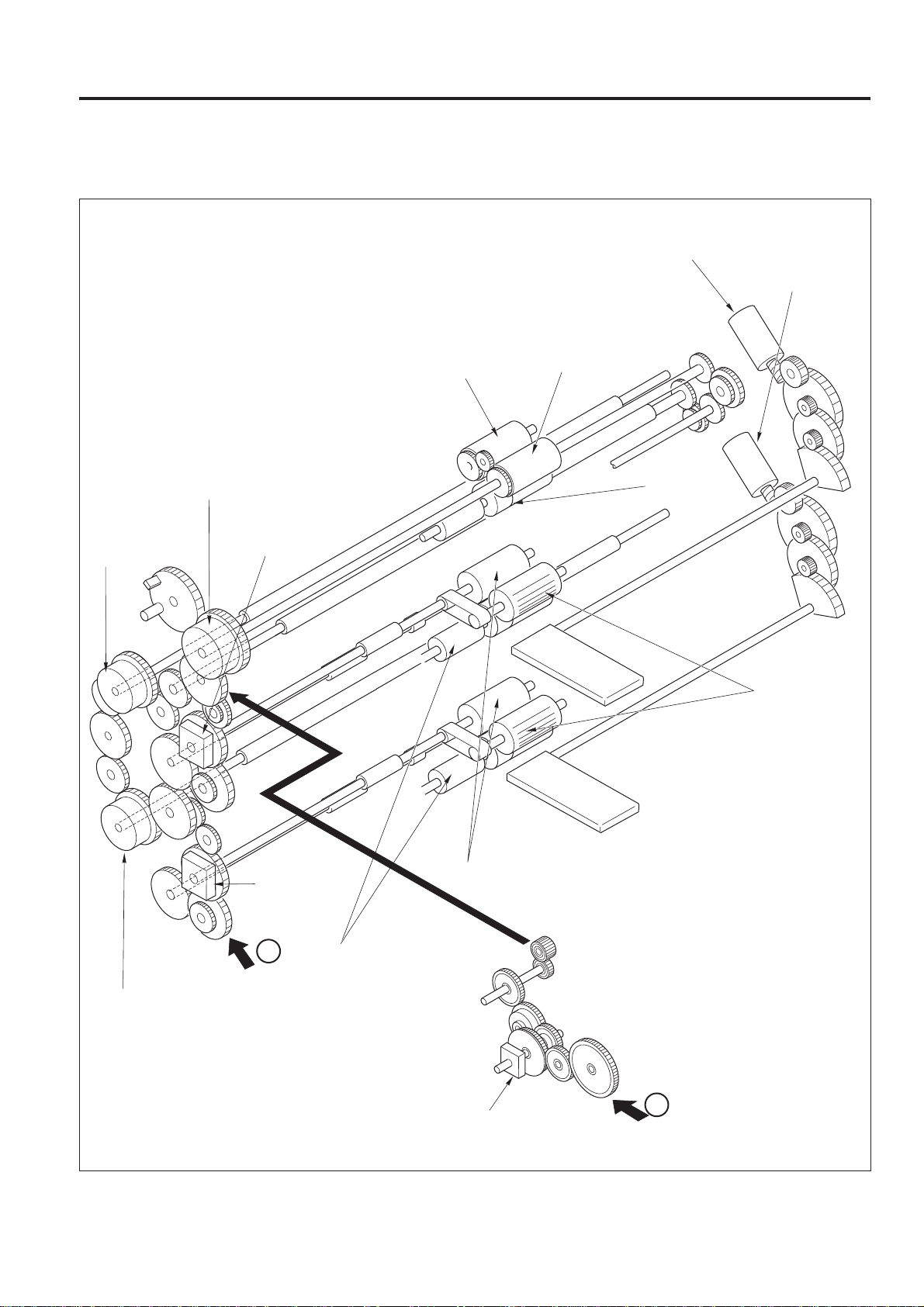

[3] Paper Feed Drive

DRIVE SYSTEM DIAGRAM

Upper tray motor (M17)

Lower tray motor

(M18)

By-pass paper feed MC

(MC7)

Middle conveyance

MC1 (MC8)

Paper feed MC

(Upper tray) (MC5)

By-pass paper feed roller

By-pass roller

Double feed

prevention roller

Paper feed rollers

Middle conveyance MC2

(MC9)

Paper feed MC

(Lower tray)

(MC6)

Double feed

prevention rollers

Feed rollers

Assist drive MC (MC11)

2 - B - 3

Page 10

DRIVE SYSTEM DIAGRAM

[4] ADU Paper Feed/Conveyance Drive

Timing belt

Paper exit rollers

ADU paper feed motor

(M151)

Timing belt

ADU timing CL (CL153)

Timing belt

Timing belt

Paper exit rollers

ADU reversal MC (CL152)

Conveyance roller

ADU paper feed MC (CL151)

2 - B - 4

Reversal roller

Page 11

[5] 1000-Tray Paper Feed/Conveyance Unit

Conveyance roller (upper)

LCT conveyance CL (CL3)

DRIVE SYSTEM DIAGRAM

Conveyance roller (lower)

LCT 1st paper feed CL (1000)

(CL1)

Feed roller

Paper feed roller

Double feed prevention roller

2 - B - 5

Page 12

DRIVE SYSTEM DIAGRAM

[6] 1500-Tray Paper Feed/Conveyance Unit

B

Timing belt

Horizontal conveyance

rollers

Feed roller

C

Paper

feed roller

Timing belt

Double feed prevention roller

LCT 1st paper feed CL

(1500) (CL2)

LCT paper feed motor (M140)

2 - B - 6

Page 13

[7] Reversal/Paper Exit Unit

DRIVE SYSTEM DIAGRAM

Paper exit conveyance roller (upper)

Paper exit conveyance roller (middle)

Paper exit conveyance roller (lower)

Paper exit motor

(M202)

Timing belt

Reversal paper exit motor

(M201)

2 - B - 7

Page 14

EXTERNAL SECTION

[1] Composition

EXTERNAL SECTION

Left side

upper

cover

Left side

lower cover

Lower tray

Main switch

ADU

LCT-1500

tray

Front door

Operation panel

Upper tray

Paper feed and

conveyance door

LCT-1000

tray

By-pass feed

table

LCT conveyance

door

Right side

upper cover

RADF

Outer I/F

connectors

Rear cover

Right side lower cover

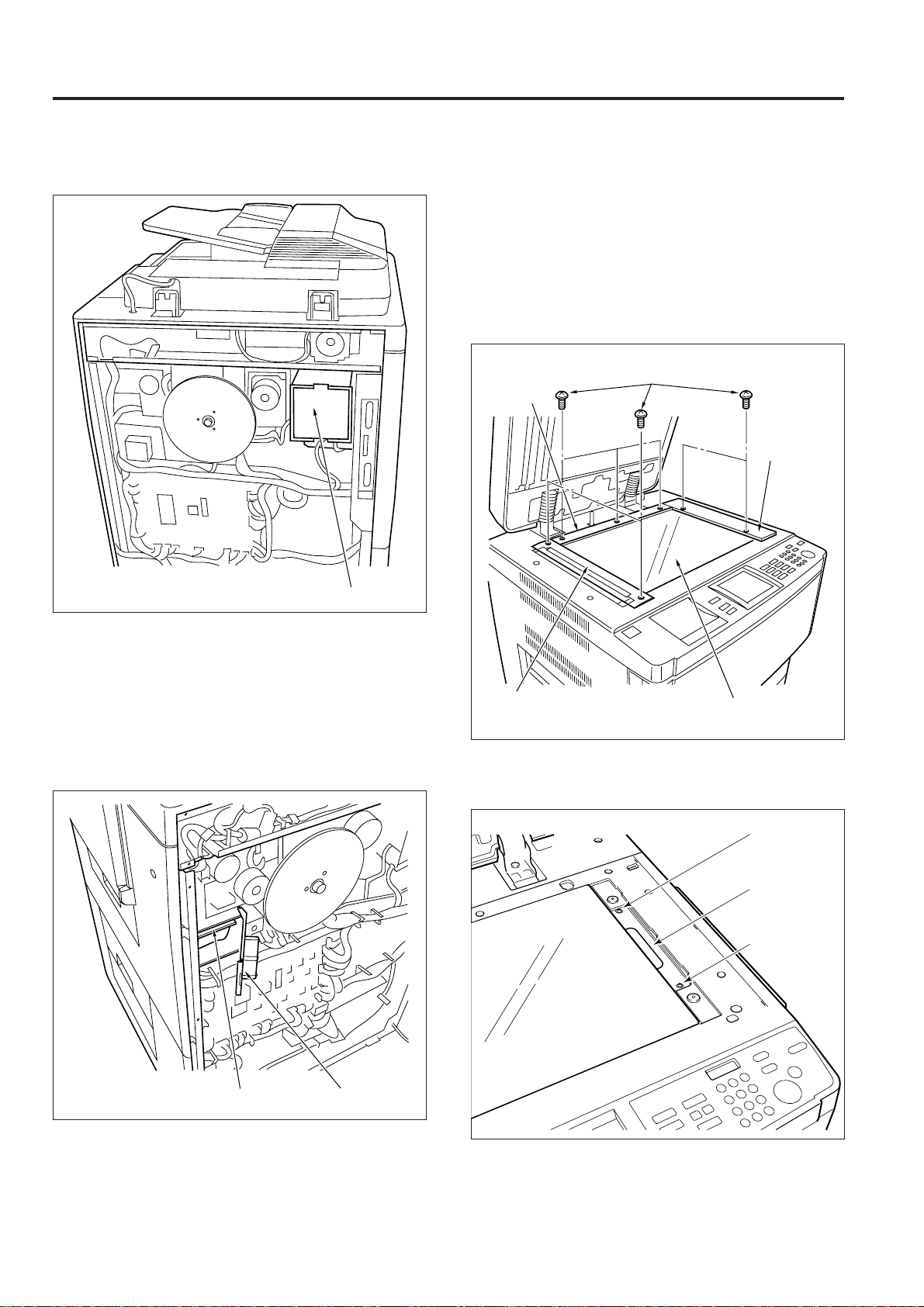

[2] Disassembly and Re-assembly

1. Replacing the Ozone Filter (K)

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Caution: When replacing the ozone filter (K), ensure the new

filter is fitted securely inside the main body.

a. Procedure

(1) Remove the nine set screws, then remove the rear

cover.

Set

screws

Set

screws

Rear cover

Set screws

2 - C - 1

Page 15

EXTERNAL SECTION

(2) Pull the ozone filter (K) forward and remove it.

Ozone filter (K)

3. Replacing the Dust Proof Filter Assembly

Caution: Be sure to install the dust proof filter so that the filter

material is on the finisher side of the assembly.

a. Procedure

(1) Open the RADF.

(2) Remove the two set screws, then remove the original

stopper plate (rear/right).

(3) Remove the five set screws, then remove the original

stopper plate (rear/right).

Original

stopper plate

(rear)

Set screws

Original

stopper plate

(right)

(3) Re-install the ozone filter in the opposite sequence to

removal.

2. Replacing the Developing Suction Filter

a. Procedure

(1) Remove the rear cover.

(2) Release the lock, open the filter box, and remove the

developing suction filter.

Original stopper plate

Platen glass

(4) Loosen the two set screws, and remove the glass fixing

plate/right.

Set screw

Glass fixing

plate/right

Set screw

Filter boxDeveloping suction filter

(3) Re-install the suction filter in the opposite sequence to

removal.

(5) Remove the platen glass.

2 - C - 2

Page 16

(6) Remove the four set screws to open the bypass table,

and remove the upper cover (middle).

Set screws

Set screws

EXTERNAL SECTION

Upper cover (middle)

(7) Remove the dust proof filter ass’y, then install the new

dust proof filter ass’y.

Dust proof filter ass'y

(8) Re-install the removed parts in the reverse sequence

to removal.

2 - C - 3

Page 17

DRIVE SECTION

[1] Composition

DRIVE SECTION

Drum motor (M4)

Agitator screw motor (M35)

Developing drive motor (M3)

Assist drive clutch (MC11)

Main motor (M1)Drum drive unit

[2] Mechanisms

Mechanism Method

*1

Drum drive Gear drive (dedicated motor)

*1

Developing sleeve drive Gear drive (dedicated motor)

*1

Developing agitator drive Gear drive (dedicated motor)

2nd paper feed drive Timing belt + gear drive

Conveyance drive Timing belt + gear drive

Fixing and paper exit drive Timing belt + gear drive

ADU lead-in drive Timing belt + gear drive

Toner recycle Timing belt + gear drive

*2

Loop assist drive Clutch + gear drive

*1: Separation of the different parts of the drive system

The drum, developing sleeve and developing agitator of

this machine are driven by separate motors in order to

improve the serviceability of the drum unit and also to

improve the developing performance.

*2: Loop assist drive

Drive which is supplied to the 2nd paper feed roller is also

transmitted to the middle conveyance roller in order to

stabilize the loop formation before the 2nd paper feed

roller. This drive is transmitted from the drive section via the

assist drive clutch (MC11) during loop formation.

Loop

Middle conveyance

roller

Drive section

2nd

paper feed roller

Assist drive clutch

(MC11)

2 - D - 1

Page 18

DRIVE SECTION

[3] Disassembly and Re-assembly

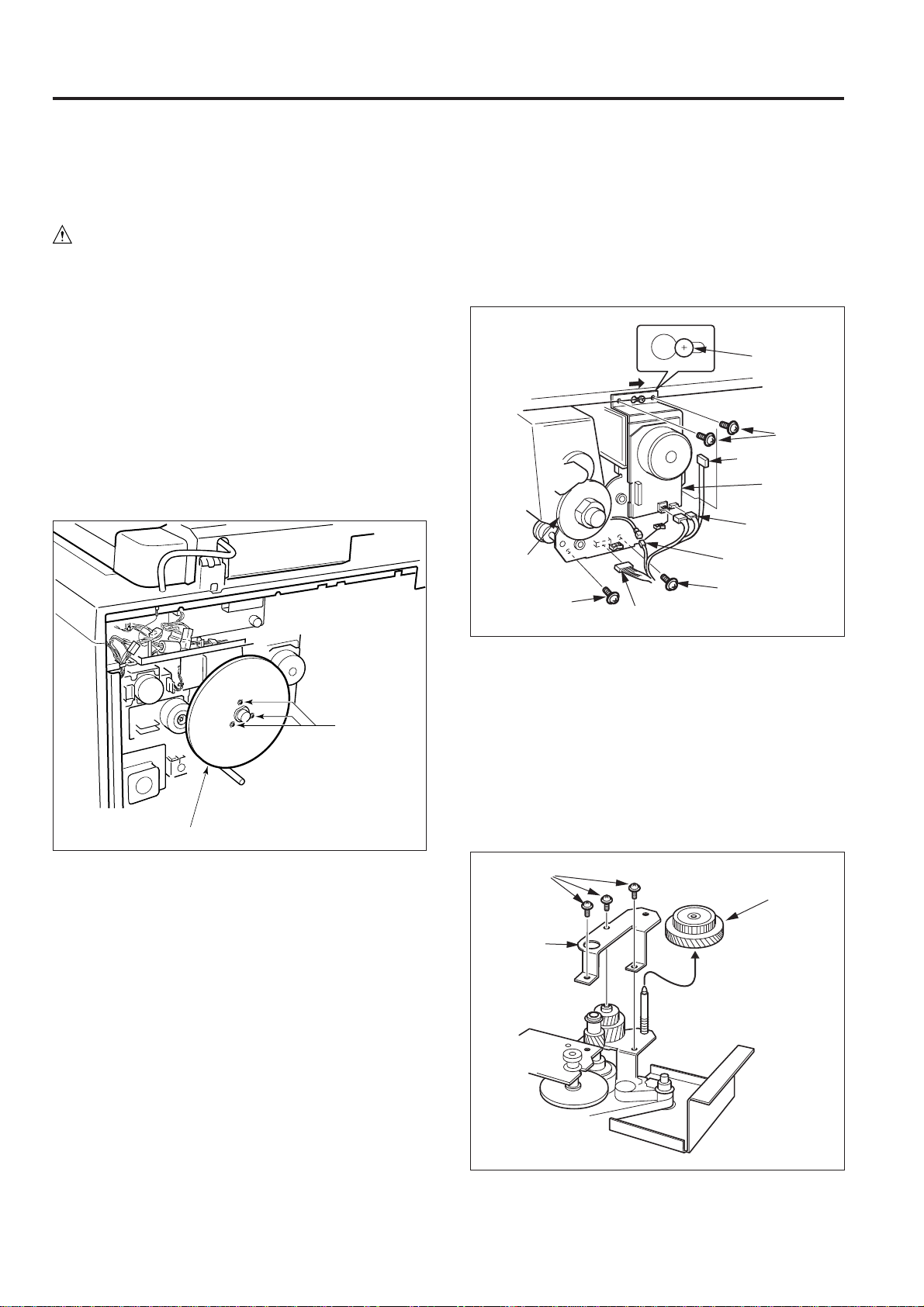

1. Removing and Re-installing the Main Motor

Unit

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Caution: Be sure to remove the drum unit before removing or

re-installing the main motor unit.

If you leave the drum unit installed, the cleaning

blade is likely to be damaged because the drum will

turn when you remove or re-install the flywheel.

a. Procedure

(1) Remove the drum unit from the main body. (Refer to

"Drum unit section".)

(2) Remove the nine set screws, then remove the rear

cover.

(3) Remove the three set screws, then remove the fly-

wheels (three).

(4) Disconnect the relay connector and the four connec-

tors (CN16, 204, 205 and 324), then remove the cable

from the wiring clamp.

(5) Remove the four set screws, slide the main motor unit

to the right, then pull it forward and remove it.

Caution: DO NOT strike the main motor unit against the drum

drive gear when removing or re-installing it.

Slotted hole

Guide screw

Set screws

Connector (CN16)

Main motor

unit

Connectors

(CN204, 205)

Drum

drive gear

Set screw

Connector (CN324)

Relay

connector

Set screw

Flywheels

Set

screws

(6) Re-install the main motor unit in the opposite sequence

to removal.

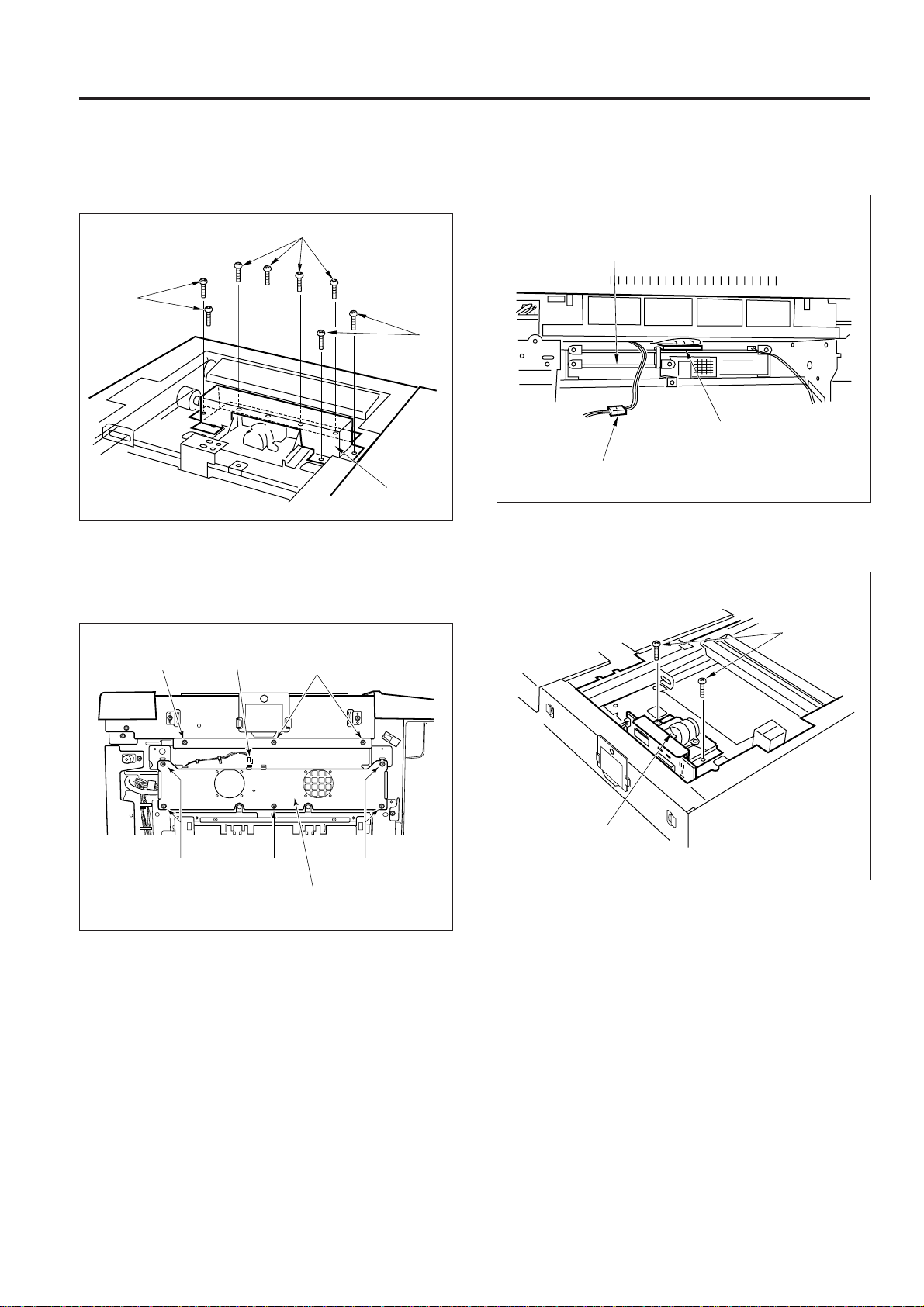

2. Replacing the Paper Feed Drive Shaft and

Fixing Input Gear

a. Procedure

(1) Remove the main motor unit.

(2) Remove the three set screws, then remove the fixing

drive plate.

(3) Remove the fixing input gear.

Set screws

Fixing input

gear

Fixing drive

plate

2 - D - 2

Page 19

DRIVE SECTION

(4) Remove the four set screws, then remove the paper

feed drive plate.

Set screws

Paper feed drive plate

Set screw

(5) Remove the drive spacer and the paper feed input gear.

Caution: Do not forget to re-install the drive spacer when re-

installing the paper feed input gear.

(6) Remove the bearing and developing drive gear, then

pull out the pin remaining in the paper feed drive shaft.

(7) Remove the main body drive belt from the drive pulley.

(8) Remove the E ring from the paper feed drive shaft, then

remove the drive pulley.

(9) Remove the paper feed drive shaft, then pull out the pin

remaining in the paper feed drive shaft.

3. Replacing the Assist Drive Clutch (MC11)

a. Procedure

(1) Remove the nine set screws, then remove the rear

cover.

(2) Remove the three set screws, then remove the fly

wheels (3 wheels).

(3) Remove the set screw and the connector (CN86), then

remove the wiring support element. (Refer to the 2nd

paper feed unit removing/re-installing of the paper

feed section.)

(4) Remove the two set screws, then remove the convey-

ance clutch shaft ass’y.

(5) Remove the connector (CN169).

(6) Remove the E ring, then remove the drive shaft bearing.

(7) Loosen the set screw, then remove the assist drive

clutch (MC11).

Setting screw

Assist drive

clutch (MC11)

Drive shaft

bearing

E ring

Connector

(CN169)

Set screw

Bearing

Paper feed drive shaft

Pins

Drive spacer

Paper feed

input gear

Developing

drive gear

E ring

Drive pulley

Main body drive belt

(10)Re-install the above parts in the opposite sequence to

removal.

Set screw

(8) Re-install the above parts in the opposite sequence to

removal.

2 - D - 3

Page 20

DRIVE SECTION

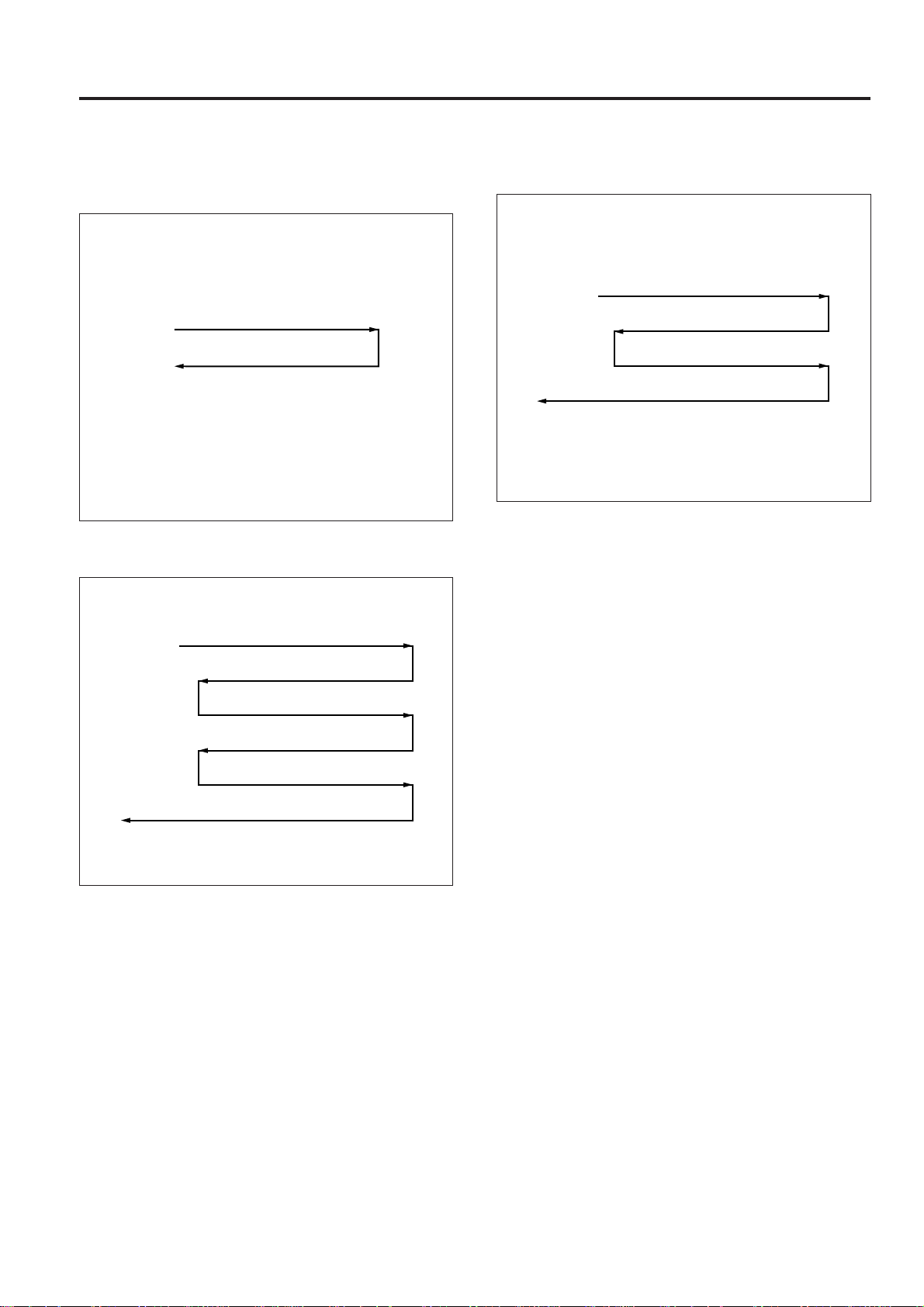

[4] M1 (main) Control [5] M4 (drum) Control

40VDC

DCPS

CB

PGND

5VDC

M1 CONT

M1 PLL

SGND

M1 CLK

88-5

88-3

M1

30-A1

30-A3

30-A4

30-A5

30-A2

24VDC

PGND

DCPS

5VDC

SGND

M4 CONT

M4 H/L

M4 CLK

M4 PLL

CB

99-2

99-5

30-A8

30-A9

30-A10

30-B6

30-A11

30-A12

M4

M1 (main) is controlled by the CB (control board).

1. Operation

M1 is a 40 V drive DC motor which drives the toner recycle,

conveyance, 2nd paper feed and fixing sections. M1 is

PLL-controlled by feedback signals from a speed sensor

installed inside M1 itself, maintaining it at a constant speed.

M1 goes ON when the Start button is pressed, and goes

OFF again when the final copy has been exited.

During warm-up, M1 rotates, causing the fixing roller to

rotate.

2. Signals

a. Input signal

(1) M1 PLL (M1 → CB)

M1 rotation monitoring signal

[H]: Stop or abnormal or rotation

[L]: Normal rotation

b. Output signals

(1) M1 CONT (CB → M1)

M1 drive control signal

[L]: M1 ON

[H]: M1 OFF

(2) M1 CLK (CB → M1)

M1 rotational speed control reference clock signal

M4 (drum) is controlled by the CB (control board).

1. Operation

M4 is a 24 V drive DC motor which drives the drum and the

cleaning guide roller. M4 is PLL-controlled by feedback

signal from a speed sensor installed inside M4 itself,

maintaining it at a constant speed.

M4 goes ON when the start button is pressed, and goes

OFF again when the final copy has been exited.

2. Signals

a. Input signal

(1) M4 PLL (M4 → CB)

[L] is output when M4 reaches the specified speed.

b. Output signals

(1) M4 CONT (CB → M4)

M4 drive control signal

[L]: M4 ON

[H]: M4 OFF

(2) M4 H/L (CB → M4)

M4 rotational speed control gain switchover signal

Normally [H]: 370 mm/sec

[L]: 185 mm/sec

(3) M4 CLK (CB→M4)

M4 rotational speed control reference clock signal

2 - D - 4

Page 21

READ SECTION

[1] Composition

READ SECTION

CCD unit

Optics cooling fan (FM2)

Optics drive wire

Optics rail (R)

Exposure unit

V mirror unit (2nd and 3rd mirrors)

A/D converter board (ADB)

[2] Mechanisms [3] Disassembly and Re-assembly

1. Screws that must not be removed

Mechanism Method

Light source Xenon lamp

Exposure Light source shift slit exposure

Scanning Platen original scanning:

1st, 2nd, 3rd mirror shift

RADF original scanning:

Fixed light source/Original moving

Lamp power supply Lamp cord

Cooling of optics Cooling of intake air using a fan

a. The 14 set screws of the CCD unit

Screws that must

not be removed

Screws that must

not be removed

2 - E - 1

Screws that must

not be removed

Screws that must

not be removed

Page 22

READ SECTION

b. The read positioning plate set screw and the two

glass stopper plate (right) set screws.

Read positioning

plate

Screw that must

not be removed

Screws that must

not be removed

Glass stopper

plate (right)

2. Removing and Re-installing the CCD Unit

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Caution: Be sure to perform image adjustment after installing

the CCD unit. (For details, refer to "Adjustment

section".)

a. Procedure

(1) Remove the original stopper plate, original stopper

plate (right/rear), platen glass and upper cover (middle).

(2) Remove the two set screws, then remove the glass

stopper plate.

Set screws

Glass stopper plate

(3) Remove the two set screws, then remove the lens light

blocking cover 2.

Set screws

Lens light

blocking cover 2

2 - E - 2

Page 23

READ SECTION

(4) Remove the eight set screws, then remove the lens

light blocking cover 1.

Set screws

Set

screws

Set

screws

Lens light

blocking

cover 1

(5) Remove the left side upper cover.

(6) Disconnect the connector (CN49).

(7) Remove the eight set screws, then remove the fan

mounting plate.

(8) Disconnect the two connectors (CN420 and 412).

Electronic RDH processing

board (E-RDH)

Connector (CN420)

Connector (CN412)

(9) Remove the two set screws, then remove the CCD

unit.

Set screw

Set screws

Connector (CN49)

Set screw Set screws

Fan mounting plate

Set screws

Set screws

CCD unit

(10) Re-install the CCD unit in the opposite sequence to

removal.

2 - E - 3

Page 24

READ SECTION

3. Replacing the Exposure Lamp

Caution:

1. Be sure that the power cord has been unplugged

from the power outlet.

2. DO NOT touch the glass of the exposure lamp with

bare hands.

Caution:

Be sure to check the image after installing the exposure lamp. (For details, refer to "Adjustment section".)

a. Procedure

(1) Remove the original stopper plate, original stopper

plate (right/rear), platen glass and the upper cover

(middle).

(2) Move the exposure unit to the notch of the main body

frame on the paper exit side.

(3) Disconnect the connector and remove the two set

screws, then remove the exposure lamp.

Set screws

Exposure lamp

Connector

4. Removing and Re-installing the Exposure Unit

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Caution:

1. Use the optics positioning jig when installing the exposure unit.

2. Be sure to perform image adjustment after installing

the exposure unit. (For details, refer to "Adjustment

section".)

a. Removal procedure

(1) Remove the original stopper plate, original stopper

plate (right/rear), platen glass and upper cover (middle).

(2) Remove the seven set screws, then remove the opera-

tion panel and disconnect the three connectors (CN219,

222 and 383).

Connector (CN383)

Set screws

Connector

(CN222)

Connector

(CN219)

(4) Re-install the exposure lamp in the opposite sequence

to removal.

2 - E - 4

Operation

panel

Set screws

(3) Move the exposure unit to the notch of the main body

frame on the paper exit side.

(4) Remove the set screw, then remove the cord retaining

material (B) and disconnect the connector (CN29).

(5) Remove the four set screws, then remove the expo-

sure unit.

Page 25

Set screws

Connector

(CN29)

Exposure unit

Set screws

Set screw

READ SECTION

5. Installing the Optics Wire

Caution:

1. When winding the wire around the pulley, be sure to

run the wire tightly to ensure that it does not ride up the

side of the pulley.

2. When re-tensioning or replacing the optics wire, be

sure to use the optics positioning jig.

3. Be sure to perform image adjustment after replacing or

re-installing the wire. (For details, refer to "Adjustment

section".)

a. Procedure

(1) Remove the exposure unit.

(2) Remove the glass stopper plate.

(3) Remove the two set screws, then remove the belt of the

front door from the main body.

(4) Disconnect the two connectors (CN381 and 41).

(5) Remove the five set screws, then remove the right side

upper cover.

(6) Remove the five set screws, then remove the front

cover/lower.

Cord retaining

material (B)

b. Re-installation procedure

(1) Insert the Optics positioning jig into the exposure unit

mounting position from the front.

(2) Slide the exposure unit to the paper feed side until it

touches the Optics positioning jig.

Exposure unit

Connector (CN381)

Set

screw

Set screws

Set screws

Connector (CN41)

Front cover/lower

Set

screw

Front door

Optics positioning jig

(3) Install the exposure unit on the optics wire mounting

piece using the four set screws.

2 - E - 5

Page 26

READ SECTION

(7) Move the V mirror unit to the paper feed side, then

insert the optics positioning jigs from the front so as to

fix the V mirror unit. Ensure that the jigs pass through

the V mirror unit.

(8) Insert the Optics positioning jigs to the exposure unit

mounting position from the front.

Exposure unit

V mirror unit

Optics positioning jigs

(9) The exposure unit mounting piece is installed on the

optics wire in advance. The position of the mounting

piece differs depending upon whether it is on the front

or the rear wire. Use the wire that has the shorter length

from the metal bead at the end to the mounting piece,

at the rear.

(10)Place the metal bead at the mid-point of each optics

wire in the mounting hole of the drive pulley, then wind

five turns around the pulley to the outside, and four

turns to the inside, starting from this point.

Caution:

1. Ensure that there is a metal bead at the end of the outer

wire, and a wire terminal at the end of the inner wire.

2. Pull out the outer wire from the top of the drive pulley

in the paper exit direction, and pull out the inner wire

from the bottom of the drive pulley in the paper feed

direction.

(11)After winding the outer wire, fix it to the wire stopper via

the outer side of pulley 1 and the V mirror pulley.

2 - E - 6

Page 27

READ SECTION

Five

10 10 11

Front

turns

Four

turns

Four

turns

Five

turns

Rear

Wire stopper

Metal bead

Metal bead

Drive pulley

Optics wire (front)

Wire stopper

11

Pulley 1

Exposure unit

mounting piece

Metal bead

Wire

stopper

Metal bead

Optics wire (rear)

Metal bead

Spring

V mirror unit

Spring fixing plate

V mirror unit

12 13

Set screws

Pulley 1

Rear

Pulley 3

Pulley 2

Spring fixing plate

Metal bead

Wire stopper

Pulley 1

V mirror unit

9

Optics wire (rear)

Optics wire (front)

Note: There are two grooves in the wire stopper. Ensure that

the outer groove is at the rear and the inner groove at

the front.

(12)Pass the inner wire through the notch in the wire

stopper, reverse it at pulley 2, then pass it around the

inside of the V mirror pulley and also around pulley 3,

in that sequence, and attach the wire terminal to the

spring fixing plate. At this time, temporarily fix the

spring fixing plate with the set screw.

Exposure unit

Metal bead

mounting piece

Metal bead

Wire terminal

(13)Install the other wire using the same procedure.

(14) Slacken each screw that was temporarily fixed, then

install the spring on the spring fixing plate and fix the

each screw once again.

2 - E - 7

Page 28

READ SECTION

[4] M12 (optics drive) Control

M12 H/L

M12 CLK

M12 M STOP

M12 MODE 0

M12 MODE 1

M12 MODE 2

M12 F/R

M12 CONT

M12

BRAKE

M12 NCR

M12 PLL

SGND

PS2

5VDC

PS4

PS5

PS7

PS8

PS28

SGND

PS3

5VDC

PS9

PS29

CB

223-1

223-2

223-3

223-4

223-5

223-6

223-7

223-8

223-9

223-10

223-11

9-A1

9-A2

9-A3

9-A5

9-A6

9-A7

9-A9

9-B3

9-B6

9-B5

9-B8

9-B2

9-B9

224-1

224-2

224-3

224-4

224-5

224-6

224-7

224-8

224-9

224-10

224-11 M12 PLL

OPMDB

76-1

76-2

76-3

73-1

73-2

73-3

66-1

66-2

66-3

74-1

74-2

74-3

67-1

67-2

67-3

110-1

110-2

110-3

72-1

72-2

72-3

75-1

75-2

75-3

111-1

111-2

111-3

M12 DRIVE C

M12 DRIVE A

M12 DRIVE B

M12 MAG A'

M12 MAG A

M12 MAG B'

M12 MAG B

M12 MAG C'

M12 MAG C

SGND

5VDC

M12 FG

PS2

PS4

PS5

PS7

PS8

PS28

PS3

PS9

PS29

225-1

225-2

225-3

228-1

228-2

228-3

228-4

228-5

228-6

228-7

228-8

228-9

226-5

226-1

226-2

226-3

400-4

400-1

400-2

400-3

M12

SGND

40VDC

PGND

12VDC

DCPS

1. Operation

a. Operation of M12

M12 is a 3-phase brushless DC motor which is driven using

a 3-phase bipolar method. The current flowing through the

windings is switched according to the position of the rotor

which is detected by a sensor (magnetic sensor) inside the

motor.

b. Moving speed of the exposure unit

Moving speed

Magnification Moving speed

During scanning 370 mm/sec (life size)

Forward 1520 mm/sec

Home position search 70 mm/sec

Shading correction read 70 mm/sec

c. Position of each sensor

Paper feed side

PS9 PS29 PS3

d. Home position search of the exposure unit

The return operation is executed at low speed when the

exposure unit is not at the home position during the main

switch ON and the start button is pressed, and detects the

home position of the exposure unit when PS9 (ADF home

position) is OFF and PS29 (ADF brake) is ON.

e. Shading correction read operation

At the position where PS3 (shading position) goes ON, the

light reflected from the white reference plate installed

under- neath the glass stopper plate is read.

Home position

(PS9 OFF, PS29 ON

PS3 OFF)

White correction data collecting

PS28 PS2 PS4

PS9 ON,

PS29 OFF,

PS3 OFF

PS5 PS7

PS9 OFF,

PS29 OFF,

PS3 ON

L1 ON

M12 (optics drive) is driven by the OPMDB (optics motor drive

board), and is controlled by the CB (control board).

Related signals are PS2 (scanner brake), PS3 (shading position), PS4 (paper feed restart), PS5 (optical return), PS7

(optical timing), PS8 (glass detection), PS9 (ADF home position), PS28 (scan EE), and PS29 (ADF brake).

Black correction

data collecting

L1 OFF

2 - E - 8

Page 29

READ SECTION

f. Other operations

(1) During copying (manual, EE)

Start button

pressed

EE scan

Exposure scan

(2) Non-image area erase (+ Book copy)

(3) Book copy (EE)

Start button

pressed

EE scan

Exposure scan (page 1)

Exposure scan (page 2)

Start button

pressed

EE, Size detection scan

Exposure scan (page 1)

Exposure scan (page 2)

2 - E - 9

Page 30

READ SECTION

2. Signals

a. Input signals

(1) PS2 (PS2 → CB)

The brake is applied to M12 after the specified period

from when PS2 goes ON during the forward scan of the

exposure unit

[L]: Exposure unit detected

[H]: Exposure unit not detected

(2) PS3 (PS3 → CB)

White reference plate read position detection signal of

the exposure unit

[L]: The exposure unit is in the white reference plate

read position.

[H]: The exposure unit is not in the white reference

plate read position.

(3) PS4 (PS4 → CB)

Original leading edge detection signal during platen

mode

The timer that determines the 2nd paper feed start

timing starts when PS4 goes ON during the exposure

unit

[L]: Exposure unit detected

[H]: Exposure unit not detected

(4) PS5 (PS5 → CB)

Return position detection signal of the exposure unit on

the leading edge of the original during platen mode

[L]: Exposure unit detected

[H]: Exposure unit not detected

(5) PS7 (PS7 → CB)

Return position detection signal of the exposure unit on

the leading edge of the original during platen mode

[L]: Exposure unit detected

[H]: Exposure unit not detected

(6) PS8 (PS8 → CB)

Signals to detect the setting of the original glass

[L]: Original glass detected

[H]: Original glass not detected

(7) PS9 (PS9 → CB)

Signals to detect the home position of the exposure

unit

[L]: Exposure unit detected

[H]: Exposure unit not detected

(8) PS28 (PS28 → CB)

Signals to detect the EE scan (exclude photo mode,

non-image area erase mode) starting position of the

exposure unit

[L]: Exposure unit detected

[H]: Exposure unit not detected

(9) PS29 (PS29 → CB)

Signals to detect the home position and the M12 brake

starting position during return of the home position of

the exposure unit

[L]: Exposure unit detected

[H]: Exposure unit not detected

(10)M12 PLL (OPMDB → CB)

[L] is output when M4 reaches the specified speed.

(11)M12 MAG A/A' (M12 → OPMDB)

M12 MAG B/B' (M12 → OPMDB)

M12 MAG C/C' (M12 → OPMDB)

These are the output signals from the sensors (magnetic sensors) contained in M12. OPMDB detects the

position of the rotor of the motor by means of these

signals, and switches over the M12 DRIVE A to C

output.

(12)M12 FG (M12 → OPMDB)

This is a feedback signal from the rotational speed

sensor contained in M12. It is compared with the M12

CLK signal from the CB, and the output voltage adjusted so that the feedback signal becomes the same

as the M12 CLK signal, thus controlling the rotational

speed of M12.

2 - E - 10

Page 31

READ SECTION

2-1

2-3

61-1

61-2

DCPS1

PGND

L1 CONT

24VDC

60-B8

60-A9

60-A10

24VDC

PGND

CB

INVB

L1

LVHV385-1

385-4

29-3

29-2

29-1

b. Output signals

(1) M12 DRIVE A, B, C (OPMDB → M12)

This is the M12 drive signal. While M12 is rotating,

voltages are output sequentially from M12 DRIVE A to

C, and applied to M12.

The voltage from each output that is applied to M12

consists of the pulses shown below. The pulse width

of this output changes according to the rotation condition of M12, as shown in the figure, and as a result the

RMS value of the voltage applied to M12 changes,

causing the speed to be regulated.

M12 DRIVE A

M12 DRIVE B

M12 DRIVE C

(2) M12 CONT (CB → OPMDB)

M12 ON/OFF control signal

[L]: M12 ON

[H]: M12 OFF

(3) M12 CLK (CB → OPMDB)

M12 rotational speed control reference clock signal

(4) M12 F/R (CB → OPMDB)

Signal used to control the rotational direction of M12

[L]: Forward operation

[H]: Return operation

(5) M12 BRAKE (CB → OPMDB)

M12 brake control signal

(6) M12 NCR (CB → OPMDB)

M12 brake control signal

(7) M12 MODE 0, 1, 2 (CB → OPMDB)

M12 rotational speed control signal

Eight rotational speed modes are activated by combinations of these three signals.

[5] Exposure control

Power is supplied to L1 (exposure lamp) from the INVB

(inverter board) and is controlled by the CB (control board).

1. Operation

L1 is a xenon lamp which is driven by an inverter circuit. A

xenon lamp provides a stable light intensity and also generates

relatively little heat, hence it does not require a light intensity

control circuit that is used in conventional copying machines,

and also protective control that is normally required due to heat

generation from the lamp is no longer used.

2. Signal

a. Output signal

(1) L1 CONT (CB → INVB)

L1 ON/OFF control signal

[L]: L1 ON

[H]: L1 OFF

2 - E - 11

Page 32

READ SECTION

[6] Original Read Control

425-A1 481-A1

425-A12 481-A12

425-B1 481-B1

425-B12 481-B12

CB

The original is read by the ADB (A/D converter board) and the

CCD image sensor installed on the ADB.

1. Operation

The light reflected off the exposed original passes through a

lens to the CCD image sensor. The analog voltages that

correspond to the input light intensity are A/D-converted in the

ADB, and output to the IPB (image processing board).

a. Original read operation

The original read timing is as follows.

(1) During a platen copy operation

When PS4 (paper feed restart) goes ON.

(2) During a DF copy operation

After the specified time from the ON of PS308 (original

conveyance) by original leading edge.

IPB

420-40

420-1

411-1

CCD

ADB

411-40

[7] APS Control

SGND

9-B6

PS45

9-B7

5VDC

9-B8

SGND

22-A7

PS40

22-A6

5VDC

22-A5

PS41

22-A8

PS42

22-B1

PS43

22-B2

PS48

22-A3

CB

The APS differs depending upon whether the platen mode or

the DF mode is used. The APS control is carried out by

processing the signal of the RADF original size detection

sensor read by CB (control board).

1. Operation

a. APS detection operation

(1) During a DF copy operation

A paper size is detected by ON or OFF of PS302 (original

size detect 1) and PS303 (original size detect 2) of the

paper feed tray of RADF, and resistance value of VR301

(original size detect).

(2) During a platen copy operation

APS detection is an operation that detects the paper

size according to the particular ON/OFF combination

of PS40 (APS 1), PS41 (APS2), PS42 (APS 3), PS43

(APS 4) and PS48 (APS 7).

The APS sensor consists of LEDs and photosensors.

APS detection takes place as a result of the light

emitted from each LED being reflected off the original

and received by the photosensor.

137-1

137-2

137-3

133-1

133-2

133-3

134-1

134-2

134-3

130-1

130-2

130-3

138-1

138-2

138-3

239-1

239-2

239-3

PS45

PS40

PS41

PS42

PS43

PS48

2 - E - 12

Paper exit side

PS41

PS40

Photosensor

LED

PS48

PS42

PS43

Page 33

READ SECTION

The relation between each sensor and the paper size is

shown below.

Sensor

Paper size

A3

B4

A4R

B5R

A4

B5

Minimum size

b. APS detection timing

The APS detection timing differs depending upon whether the

platen mode or the DF mode is used.

(1) During a DF copy operation

When either the DF mode is selected or an original is

placed in the RADF paper feed tray, the original size is

detected by PS302 (original size detect 1), PS303

(original size detect 2) and VR301 (original size detect).

(2) During a platen copy operation

APS detection takes place when PS45 (APS timing)

goes ON.

APS detection stops when PS45 goes OFF.

PS40

PS302

ON

ON

ON

OFF

OFF

OFF

OFF

PS41

PS303

PS42

ON

ON

OFF

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

PS43

ON

OFF

OFF

OFF

ON

OFF

OFF

PS48

ON

ON

ON

ON

ON

ON

OFF

(5) PS45 (PS45 → CB)

RADF opening/closing detection signal

Activates or deactivates the APS function during a

platen copy operation.

[L]: ON (APS function activated)

[H]: OFF (APS function deactivated)

RADF(DF-312)

PS45 goes ON

(6) PS48 (PS48 → CB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

2. Signals

a. Input signals

(1) PS40 (PS40 → CB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

(2) PS41 (PS41 → CB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

(3) PS42 (PS42 → CB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

(4) PS43 (PS43 → CB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

2 - E - 13

Page 34

READ SECTION

[8] EE Control

425-A1 481-A1

425-A12 481-A12

425-B1 481-B1

425-B12 481-B12

CB

EE control takes place during an EE scan as a result of the CCD

image sensor reading the original density and selecting the

most suitable copy γ correction curve.

EE processing is performed by the IPB (image processing

board).

1. Operation

a. EE detection operation

(1) During Platen mode (normal)

Density is measured in the following range with PS28

(scan EE) being the starting point when the exposure

unit moves from the home position to the leading edge

of the original by turning the start button ON.

<EE sampling area>

Main scanning direction: 182mm from rear side of an

Sub scanning direction: 182mm from when PS28

IPB

420-40

420-1

original

goes ON

411-1

CCD

ADB

411-40

(2) During Platen Copy (during photo mode, non-image

area erase mode)

Density is measured in the following range by executing EE scan as PS4 (paper feed restart) being the

starting point when the exposure unit moves from the

home position to the leading edge of the original by

turning the start button ON.

<EE sampling range>

Photo mode:

Main scanning direction: 182mm from rear side of an

original

Sub scanning direction: 182mm from when PS4

goes ON

Non-image area erase mode:

Entire size detected by size detection scan

(3) During a DF copy mode

The image at the leading edge of the original is read by

the original feed operation that takes place when the

start button is pressed, and the read data is used to

perform density measurement.

<EE sampling area>

1) Main scanning direction

• An area of 20 mm inward of the original size

detected by the APS

• If the original size cannot be determined by the

APS, an area of 20 mm inward of the minimum

original size set for the particular shipping destination of the machine.

2) Sub scanning direction

An area between 1 mm and 4 mm from the leading

edge of the original

2 - E - 14

Page 35

WRITE UNIT

[1] Composition

WRITE UNIT

Index mirror

Index sensor board

Laser driver board 1

Laser driver board 2

Collimator lens unit 2

[2] Mechanisms

Mechanism Method

*1

Scan Polygon mirror

(Rotational speed: 21850.4 rpm)

(400 dpi standard mode)

Light source Laser diodes (two)

(Output: Max. 35 mW)

*2

Positioning Index sensor

Fine adjustment prism

*3

Laser beam combining Beam combining prism

*1: Path of laser beam

The light output to each semiconductor laser is sent to the

OPC drum via the collimator lens, compression prism, fine

adjustment prism, beam combining prism, cylindrical lens

1, polygon mirror, fθ lens, 2nd mirror, cylindrical lens 2, and

the 3rd mirror.

Collimator lens unit 1

2nd mirror

Beam combining prism

Polygon mirror

3rd mirror

Stepping

motor

Compression

prism

Semiconductor

laser LD1

Glass cover

Index mirror

Index sensor

OPC drum

Cylindrical lens 2

3rd mirror

Polygon mirror

Polygon driver board

CY2 lens

Cylindrical lens 1

fθ lens

fθ lens unit

Fine

adjustment

prism

2nd mirror

CY1 lens

Beam

combining prism

Compression

prism

Collimator

lens unit

Semiconductor

laser LD2

2 - F - 1

Page 36

WRITE UNIT

*2: Positioning

Each laser beam is positioned by the compression prism

and the fine adjustment prism.

*3: Combining the laser beams

The two laser beams are output at right angles with respect

to each other. The beam combining prism causes them to

be output in the same direction.

Semiconductor laser 1

Beam combining prism

Semiconductor laser 2

[3] Disassembly and Re-assembly

1. Removing and Re-installing the Write Unit

Warning:

(1) DO NOT energize the write unit when it is not in the

correct position.

(2) DO NOT remove the cover from the write unit and

the polygon unit cover.

If the laser beam gets into your eyes, you may lose

your sight.

(3) DO NOT remove the write unit for at least two

minutes after turning OFF the main switch.

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

a. Procedure

(1) Remove the original stopper plate, original stopper

plate (right/rear) and platen glass.

(2) Remove the two set screws, then remove the board

cover.

Set screws

Board cover

(3) Remove the 11 set screws, then remove the board

protection cover.

Set screws

Set screw

Board protection

cover

Set screws

2 - F - 2

Set screws

Set screws

Page 37

WRITE UNIT

(4) Disconnect the four connectors (CN421, 422, 423 and

424) from the image processing board (IPB).

Image processing board (IPB)

Connector

(CN424)

Connector

(CN421)

Connector

(CN423)

Connector

(CN422)

(5) Slacken the five set screws, then remove the right side

upper cover.

(6) Remove the relay connector and the two set screws,

then remove the bypass-feed table.

(7) Remove the eight set screws, then remove the write

unit cover.

Write unit cover

Set

screws

Set screws

Set screw

(8) Disconnect the connector (CN95).

(9) Slacken the two set screws, then pull out the write unit.

Set screw

Bypass-feed table

Relay

connector

Set screw

Write unit

Set screws

Connector

(CN95)

(10) Re-install the write unit in the opposite sequence to

removal.

2 - F - 3

Page 38

WRITE UNIT

2. Removing and Re-installing the Electronic RDH

Board

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

a. Procedure

(1) Remove the left side upper cover. (four set screws)

(2) Disconnect the connector (CN49).

(3) Remove the eight set screws, then remove the fan

mounting plate.

Set screw

Set screws

Connector (CN49)

Set screw

Set screws

Set screws

[4] M5 (polygon) Control

M5 CONT

M5 CLK

M5 BREAK

322-2

322-3

322-4

322-6

320-2

320-3

320-4

320-5

M5 RDY

M5 DRIVE A

M5 DRIVE B

M5 DRIVE C

CB

PGND

40VDC

24VDC

DCPS

88-3

88-5

99-2

320-6

320-7

320-8

PMDB

M5 (polygon) is driven by the PMDB (polygon driver board),

and is controlled by the CB (control board).

M5 MAG A'

M5 MAG A

M5 MAG B'

M5 MAG B

M5 MAG C'

M5 MAG C

V MAG -

321-1

321-2

321-3

321-5

321-6

321-7

321-8

321-9

321-10

321-11

M5

Fan mounting plate

(4) Remove the set screw, then remove the board support

material 1.

(5) Remove the two set screws, then pull out the Electronic

RDH processing board.

Electronic RDH

processing board

Set screws

Board support material 1

Set screw

(6) Re-install the electronic RDH board in the opposite

sequence to removal.

1. Operation

a. M5 is a 3-phase brushless DC motor which is driven using

a 3-phase bipolar method. The current flowing through the

windings is switched according to the position of the rotor

which is detected by a sensor (magnetic sensor) inside the

motor.

This motor rotates the polygon mirror, causing the laser

beams from LDB1 and 2 (laser driver boards 1 and 2) to be

scanned in the axial direction of the drum. The speed of the

motor is maintained constant by PLL control.

b. M5 is powered by 40 VDC. The rotational speed is as

follows.

State of the machine

During copy

During idling

* If the item marked * is selected, the rotational speed of

M5 switches over after the lapse of the specified time

from the end of the copy process or warm up completion.

The specified time can be selected using the "25" mode

from the selection below.

(15 sec, 30 sec, 60 sec, 120 sec)

Rotational speed

High speed (21,850 rpm)

One of the following four speeds can

be selected using the "25" mode.

• 21,850 rpm *

• 14,000 rpm *

• 11,024 rpm *

• 8,000 rpm *

• Stop *

2 - F - 4

Page 39

2. Signals

a. CB output signals

(1) M5 CONT (CB → PMDB)

This signal controls the ON/OFF state of M5.

L: M5 ON

H: M5 OFF

(2) M5 CLK (CB → PMDB)

This is a reference clock signal for PLL-controlling M5

in the PMDB.

(3) M5 BREAK (CB → PMDB)

Signal which brakes M5

L: Brake OFF

H: Brake ON

b. CB input signal

(1) M5 RDY (PMDB → CB)

This signal indicates the rotation condition of M5.

L: Specified rotational speed

H: If the specified speed has not been reached

c. PMDB input signals

(1) M5 MAG A/A' (M5 → PMDB)

M5 MAG B/B' (M5 → PMDB)

M5 MAG C/C' (M5 → PMDB)

These are output signals from the position sensors

(magnetic sensors) contained in M5. The PMDB

detects the position of the rotor of the motor by means

of these signals, and switches over the M5 DRIVE A to

C output.

d. PMDB output signals

(1) V MAG- (PMDB → M5)

GND line to the rotor position sensors (magnetic sensors) contained in M5

(2) M5 DRIVE A to C (PMDB → M5)

This is the drive output signal for M5. While M5 is

rotating, voltages are output sequentially from M5

DRIVE A to C, and applied to M5.

The voltage from each output that is applied to M5

consists of the pulses shown below. The pulse width

of this output changes according to the rotation condition of M5, as shown in the figure, and as a result the

RMS value of the voltage applied to M5 changes,

causing the speed to be regulated.

WRITE UNIT

M5 DRIVE A

M5 DRIVE B

M5 DRIVE C

2 - F - 5

Page 40

WRITE UNIT

[5] Image Write Control

E-RDH

450-A1

450-A50

450-B1

450-B50

MEE V/V

I YOBI 1

CB

MTN V/V

MAPC CAL

MIND CHG

INDXSB

RESET

M V/V

DCORR

RXA 0

RXA 1

CORR

RDH IFB

481-A2

481-A3

481-A4

481-A5

481-A6

481-A7

481-A9

481-A10

481-B1

481-B2

481-B3

481-B4

481-B6

481-B7

481-B8

481-B9

481-B10

442-3

442-5

442-7

442-9

425-A2

425-A3

425-A4

425-A5

425-A6

425-A7

425-A9

425-A10

425-B1

425-B2

425-B3

425-B4

425-B6

425-B7

425-B8

425-B9

425-B10

423-3

423-5

423-7

423-9

423-11

423-12

428-B1

428-B50

428-A1

428-A50

IP REQ

INDEX

TXA 1

MPR

TXA 0

O YOBI 1

M INDEX 1

M INDEX 2

S INDEX 1

S INDEX 2

HLVL

IPR

LD1 APC CONT 1

LD1 APC CONT 2

LD2 APC CONT 1

LD2 APC CONT 2

IPB

M40 PWR A

M40 PWR B

M40 DRIVE A

M40 DRIVE A’

M40 DRIVE B

M40 DRIVE B’

LD1 VIDEO

LD1 ALM

LD1 IRCLK

LD1 INC

LD1 U/D

LD1 C/S

LD1 LPR

LD2 VIDEO

LD2 ALM

LD2 IRCLK

LD2 INC

LD2 U/D

LD2 C/S

LD2 LPR

424-1

424-2

424-3

424-4

424-5

424-6

421-3

421-4

421-5

421-7

421-8

421-9

421-10

421-11

421-12

422-3

422-4

422-5

422-7

422-8

422-9

422-10

422-11

422-12

420-40

420-1

440-3

440-4

440-5

440-7

440-8

440-9

440-10

440-11

440-12

441-3

441-4

441-5

441-7

441-8

441-9

441-10

441-11

441-12

411-1

411-40

M40

LDB1

LDB2

ADB

The analog image data from the CCD sensor is A/D-converted

by the ADB (A/D converter board), then sent to the IPB (image

processing board) where it is data-processed. The processed

image data is converted into laser beam and applied to the

drum with the control signals from the CB (control board).

There are two lasers which are used to write two lines of image

data in a single scan. The write start position of each laser is

detected by the INDXSB (index sensor board). The E-RDH

(Electronic RDH board) can store digitized image data. Various editing functions can be carried out based on this data.

1. Operation

a. Image processing

The following processing is done by the IPB (image processing board).

(1) Shading correction

<Implementation timing>

* When the machine is switched ON

* At 500 copies

* At 1000 copies

* Every 5000 copies

(2) Brightness/density conversion

(3) EE processing

(4) Text/dot pattern judgement

(5) Filtering

(6) Magnification change processing

(7) Copy γ correction

(8) Write density control

The following processing is performed by the E-RDH

(electronic RDH processing board).

a) Error diffusion processing

b) Data compression

The write operation takes place under instructions from the

CB after the above processing has been completed.

2 - F - 6

Page 41

WRITE UNIT

b. Write

The IPB (image processing board) sends image data one

pixel at a time to LDB1 and LDB2 in accordance with control

signals from the CB (control board).

LDB1 and LDB2 cause the lasers to emit at a time period

corresponding to the image data. This laser light is applied

to the drum.

(1) APC (automatic adjustment of laser beam intensity)

The CB monitors the laser drive current at fixed intervals, and maintains the light intensity at the correct

value.

APC takes place at the following timing.

a) Before Dmax/gradation correction

b) When the Start button is pressed

c) After each two copies during a continuous copy

operation

d) When the front door is opened and closed.

(2) Write Timing

a) Axial direction of drum

In this machine, the INDEX signal from INDXSB

determines the laser write start timing for each

scan in the axial direction of the drum.

INDEX

Laser output

1

Laser output

2

Symbol

a

b

b–c

c–d

d–e

abc de

When laser goes ON during 1st scan

When index sensor goes ON

The timing at left is controlled by counting the

LD1 IRCLK and LD2 IRCLK signals. It differs

depending upon the paper size.

Image area

1st scan

Description

2nd scan

b) Direction of rotation of drum

When data is output from the E-RDH memory

When the copy paper reaches the specified position

* In the case of paper feed from the tray, LCT or

ADU:

After the specified period from when PS18 (no

feed) goes ON

* In the case of by-pass paper feed:

After the specified period from the start of bypass paper feed

(3) Laser beam position correction

a) Axial direction of drum

The index sensor detects the deviation of the

positions of the 2 beams. This error is corrected by

changing the timing of the light emission from the

laser.

b) Direction of rotation of drum

The index sensor detects the deviation of the

positions of the 2 beams, and M40 (laser correction) changes the angle of the fine adjustment

prism of laser LD1, thus adjusting the beam in the

up-down direction.

2. Signals

a. CB output signals

(1) MEE V/V (CB → IPB)

This signal determines the scanning area in the sub

scanning direction during the pre-scanning operation

(EE control). The period during which this signal is [L]

is judged as the scanning area.

(2) M V/V (CB → IPB)

This signal determines the scanning area in the sub

scanning direction during the exposure scan. The

period over which this signal is [L] is judged as the

scanning range.

(3) DCORR (CB → IPB)

Black data collection trigger signal used when shading

correction is taking place.

(4) I YOBI 1 (CB → IPB)

Spare input port

(5) RXA 0, 1 (CB → IPB)

Data that is transferred serially from the CB to the IPB

(6) MTN V/V (CB → IPB)

This signal determines the patch output area in the sub

scanning direction while Dmax is being measured.

The period during which this signal is [L] is judged as

the patch output area.

(7) MAPC CAL (CB → IPB)

APC and PWM calibration trigger signal

(8) MIND CHG (CB → IPB)

This signal selects the index signal.

[H]: External index signal

[L]: Internal index signal

(9) CORR (CB → IPB)

White data collection trigger signal used when shading

correction is taking place

(10)RESET (CB → IPB)

Processing CPU reset signal (not used)

b. CB input signals

(1) IP REQ (IPB → CB)

Processing board communications enable signal

(2) INDEX (IPB → CB)

Write system index signal

2 - F - 7

Page 42

WRITE UNIT

(3) TXA 0, 1 (IPB → CB)

Data that is transferred serially from the IPB to the CB

(4) MPR (IPB → CB)

Image processing board power supply monitoring signal (connector check)

(5) O YOBI 1 (IPB → CB)

Spare output port

c. IPB output signals

(1) M40 PWR A (IPB → M40)

M40 A phase drive signal

(2) M40 PWR B (IPB → M40)

M40 B phase drive signal

(3) M40 DRIVE A/A' (IPB → M40)

M40 A phase drive pulse signal

(4) M40 DRIVE B/B' (IPB → M40)

M40 B phase drive pulse signal

(5) LD1 APC CONT 1, 2 (IPB → LDB1)

APC (laser light intensity automatic adjustment) of

LD1 takes place according to the combination of

these two signals.

(6) LD1 VIDEO (IPB → LDB1)

LD1 laser image data signal

(7) LD1 IRCLK (IPB → LDB1)

LD1 APC clock signal

(8) LD1 INC (IPB → LDB1)

LD1 MPC signal

(9) LD1 U/D (IPB → LDB1)

LD1 MPC signal

(10)LD1 C/S (IPB → LDB1)

LD1 MPC signal

(11)LD2 APC CONT 1, 2 (IPB → LDB2)

APC (laser light intensity automatic adjustment) of

LD2 takes place according to the combination of

these two signals.

(12)LD2 VIDEO (IPB → LDB2)

LD2 laser image data signal

(13)LD2 IRCLK (IPB → LDB2)

LD2 APC clock signal

(14)LD2 INC (IPB → LDB2)

LD2 MPC signal

(15)LD2 U/D (IPB → LDB2)

LD2 MPC signal

(16)LD2 C/S (IPB → LDB2)

LD2 MPC signal

(17)HLVL (IPB → INDXSB)

5 VDC for monitoring power supply

d. IPB input signals

(1) LD1 ALM (LDB1 → IPB)

Signal which indicates an abnormality in the laser drive

current

[H]: Normal

[L]: Abnormal

(2) LD2 ALM (LDB2 → IPB)

Signal which indicates an abnormality in the laser drive

current

[H]: Normal

[L]: Abnormal

(3) M INDEX 1, 2 (INDXSB → IPB)

Index signal for detection of main scanning deviation

(4) S INDEX 1, 2 (INDXSB → IPB)

Index signal for detection of sub scanning deviation

(5) IPR (INDXSB → IPB)

INDXSB power supply monitoring signal (connector

check)

[H]: Normal

[L]: Abnormal

(6) LD1 LPR (LDB1 → IPB)

LD1 power supply monitoring signal (connector check)

[H]: Normal

[L]: Abnormal

(7) LD2 LPR (LDB2 → IPB)

LD2 power supply monitoring signal (connector check)

[H]: Normal

[L]: Abnormal

2 - F - 8

Page 43

DRUM UNIT

[1] Composition

DRUM UNIT

PCL

Charging corona unit

Cleaning unit

Cleaning unit

Developing unit

PCL

TSL

Charging corona unit

Transfer and separation corona unit

Drum

Separation claws

Developing unit

Drum

Separation claw solenoid

[2] Mechanisms

Mechanism

Carriage supply

PCL

Auxiliary separation

*1

Conveyance auxiliary

*2

Fixed rail

LED

Separation claws

Ratchet wheel

The drum unit of this machine is an integral assembly consisting of the drum, charging corona unit, developing unit, cleaning

unit, toner recycle unit and the PCL which are installed around

the drum.

*1: Auxiliary separation

Three separation claws separate the paper from the drum

and prevent paper jamming. These claws are operated via

the claw operation lever by the ON/OFF operation of the

separation claw solenoid (SD4).

Also, while the swing clutch installed in the swing block is

turning one revolution, the separation claws slide about 7

mm, preventing a specific part of the paper from becoming

dirty and also preventing the drum from being scratched.

*2: Ratchets

The thick paper conveyance ability has been improved by

the use of five ratchets on the board cover.

Method

Separation claw

Ratchets

Board cover

Drum

Swing clutch

Swing block

Separation claw

solenoid (SD4)

2 - G - 1

Page 44

DRUM UNIT

[3] Disassembly and Re-assembly

1. Removing and Re-installing the Drum Unit

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Caution:

1. When pulling out the drum unit, be sure to place the

drum cover over it and store the drum carriage in a dark

place.

2. Be careful not to rotate the drum when installing or

removing the drum unit. If you rotate the drum in the

direction opposite to the direction in which it rotates

during a copy operation, you risk damaging the cleaning blade.

3. Do not touch the separation claw when installing or

removing the drum unit.

a. Procedure

(1) Open the front door, slacken the set screw, release the

lock plate of the toner supply unit, then pull forward the

toner supply unit.

Toner supply unit

Set screw

(2) Release the conveyance lever.

(3) Remove the two set screws, then remove the drum

cover.

Drum cover

Conveyance lever

Set screws

(4) Remove the three set screws, then slowly pull the drum

unit forward. (Raise the toner recycle unit, then remove

the set screw at the center of the drum.)

Caution: There is a possibility of the drum rotating in reverse,

so retain the cleaner idler gear to prevent the drum

from rotating.

Lock plate

Set screws

Cleaner idler gear

Toner recycle unit

Drum unit

(5) Re-install the drum unit in the opposite sequence to

removal.

2 - G - 2

Page 45

2. Removing and Re-installing the Drum

Caution:

1. Be careful not to touch the drum or the cleaning blade

with bare hands, or damage these parts.

2. When leaving the drum to stand, be sure to place the

drum cover over it and store it in a dark place.

3. When re-installing the drum, cleaning blade and guide

roller, apply setting powder to the entire surface of the

drum and also to the cleaning blade regardless of

whether or not the parts are new or old. In addition,

apply toner to both ends of the cleaning blade.

4. After applying setting powder to the drum, carry out the

following work before installing the drum unit on the

main body.

1) To ensure that the toner density is correct, before

installing the drum to the drum unit, discharge the

surface of γ detection sensor and the Dmax sensor

on the control board by using a piece of cloth

moistened with alcohol, thus preventing toner from

adhering to the sensors.

2) With the charging corona unit and the developing

unit removed, insert the centering jigs into both

sides of the drum, then turn the drum one revolution. This prevents setting powder from scattering

onto the charging corona unit, and other parts, and

also prevents image defects.

5. When installing the drum, be careful of the orientation

of the drum. The end of the drum with the wider nonimage area is the front.

6. When installing a new drum, be sure to enter code 091

of the 47 mode and reset the process counter (drum

counter). (For details, refer to "Adjustment section".)

a. Procedure

(1) Remove the drum unit from the main body.

(2) Remove the charging corona unit, developing unit and

cleaning blade from the drum unit. (For the sequence

of removing these parts, refer to "Charging corona unit,

Developing unit and cleaning/recycle unit section".)

(3) Remove the cleaner idler gear and the drum fixing

coupling.

(4) Gently lift out the drum while holding it at both ends to

ensure that you do not damage the photosensitive

surface.

DRUM UNIT

Drum fixing coupling

Cleaner idler gear

Drum

(5) Re-install the drum in the opposite sequence to re-

moval.

3. Removing and Re-installing the Separation

Claws

Caution:

1. Take care not to damage the drum when removing the

separation claws.

2. Be careful of the direction and position of the separa-

tion claws when re-installing the claws.

3. Do not touch the cleaning blade or the drum with the

bare hands.

a. Procedure

(1) Remove the drum unit from the main body.

(2) Remove the drum from the drum unit.

(3) Remove the spring.

(4) Remove the three set screws, then remove the swing

block and swing clutch.

(5) Remove the separation claw unit.

Separation claw unit

Swing clutch

2 - G - 3

Spring

Set screws

Swing block

Page 46

DRUM UNIT

(6) Remove the spring and the E ring from the separation

claw unit.

(7) Remove the three set screws of the claws (one screw

each), then remove the three claws.

Set screws

E ring

Separation claws

Spring

(8) Re-install the separation claws in the opposite se-

quence to removal.

5. Removing and Re-installing the PCL

a. Procedure

(1) Remove the charging corona unit. (Refer to "Corona

unit section" for the method of removing the PCL.)

(2) Disconnect the connector (CN20) from the drum board.

(3) Push the front and rear hooks of the PCL cover inward,

then lift out the PCL.

Connector (CN20)

Charging corona unit

Charging wire

cleaning motor (M7)

PCL

4. Removing and Re-installing the Separation

Claw Solenoid Press-fit Ass'y

a. Procedure

(1) Remove the drum unit from the main body.

(2) Remove the drum and separation claw unit from the

drum unit.

(3) Disconnect the connector (CN34).

(4) Remove the two set screws, then remove the separa-

tion claw solenoid press-fit ass'y.

Connector (CN34)

Separation claw

solenoid press-fit

ass'y

Set screws

(4) Re-install the PCL in the opposite sequence to re-

moval.

(5) Re-install the separation claw solenoid press-fit ass'y

in the opposite sequence to removal.

2 - G - 4

Page 47

DRUM UNIT

[4] PCL/TSL Control

24VDC

PCL CONT

24VDC

TSL CONT

5-A3

5-A4

62-B1

62-B11

21-5

21-6

CB

The PCL (precharging exposure lamp) and TSL (transfer synchronization exposure lamp) consist of LEDs which are controlled by the CB (control board).

1. Operation

PCL goes ON and OFF in synchronism with M1 (main), and

TSL goes ON and OFF in synchronism with M4 (drum).

TSL

PCL CONT

DB

24VDC

20-1

20-2

PCL

[5] Separation Claw Control

24VDC

5-B9

SD4 DRIVE

5-B10

CB

The separation claws are operated by SD4 (separation claws),

and are controlled by the CB (control board).

1. Operation

During the separation discharge, SD4 goes ON, causing

the separation claws to touch the drum in order to help

separate the paper from the drum.

SD4

2. Signals

a. Output signals

(1) PCL CONT (CB → DB → PCL)

PCL ON/OFF control signal

[L]: PCL ON

[H]: PCL OFF

(2) TSL CONT (CB → TSL)

TSL ON/OFF control signal

[L]: TSL ON

[H]: TSL OFF

2. Signal

a. Output signal

(1) SD4 DRIVE (CB → SD4)

SD4 drive control signal

[L]: SD4 ON

[H]: SD4 OFF

2 - G - 5

Page 48

DRUM UNIT

[6] Paper Guide Plate Control

24VDC

PGND

GP CONT

62-A11

62-A2

62-A8

84-1

84-2

84-8

GP

CB

HV1

A constant voltage is applied to the paper guide plate in order

to prevent toner from adhering to it.

1. Operation

a. ON/OFF timing

ON and OFF in synchronism with M4 (drum).

b. Applied voltage

-500 VDC

2. Signal

a. Output signal

(1) GP CONT (CB → HV1)

Controlling ON/OFF of the voltage applied to the

paper guide plate

[L]: Voltage applied.

[H]: Voltage not applied.

2 - G - 6

Page 49

CORONA UNIT SECTION

[1] Composition

CORONA UNIT SECTION

<Charging corona unit>

Drum board

<Transfer and separation corona unit>

Transfer entrance guide plate

Charging wire cleaning motor (M7)

Charging corona unit

Charging wire cleaning material

PCL

Guide pulleys

Plunging prevention plate

Separation corona unit

[2] Mechanisms

Mechanism

Charging

*1

Transfer

*2

Separation

*1: Cleaning of the charging wires and grid

The charging corona unit has a wire cleaner. The charging

wire cleaning motor causes the charging wire cleaning

block to move back and forth, removing dirt from the wires

and grid.

Scorotron (DC negative corona discharge)

Discharge wire: Tungsten ø0.06 mm

Grid control: Stainless steel plate

With automatically wire grid cleaner

DC positive corona discharge

Discharge wires: Tungsten ø0.06 mm

With automatically wire cleaner

AC/DC corona discharge

Discharge wires: Tungsten ø0.06 mm

With automatically wire cleaner

Method

(gold-plated skin path)

Transfer corona unit

Transfer and separation

wire cleaning motor (M8)

Charging wire

cleaning motor (M7)

Charging wire

cleaning block

Charging wires

2 - H - 1

Page 50

CORONA UNIT SECTION

*2: Cleaning of the transfer and separation wires

The transfer and separation corona unit has a wire cleaner.

The transfer and separation wire cleaning motor causes

the transfer and separation wire cleaning blocks to move

back and forth, removing dirt from the wires.

Transfer and separation

wire cleaning motor (M8)

Transfer wire

cleaning block

Transfer wire

Separation wire

cleaning block

Separation wires

[3] Disassembly and Re-assembly

1. Screws that must not be Removed

a. Nine set screws of the transfer enter guide plate

Transfer entrance guide plate

2. Removing and Re-installing the Charging

Corona Unit

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

a. Procedure

(1) Remove the drum unit from the main body.

(2) Disconnect the connector (CN21).

(3) Lift out the charging corona unit, then remove it.

Charging corona unit

Connector (CN21)

(4) Re-install the charging corona unit in the opposite

sequence to removal.

3. Removing and Re-installing the Transfer and

Separation Corona Unit

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

a. Procedure

(1) Open the front door, and release the conveyance

lever.

(2) Remove the set screw, then remove the transfer and

separation corona unit cover.

Screws that

must not be

removed

Screws that must

not be removed

Screws that must

not be removed

Caution:

1. Be careful not to apply pressure on the transfer entrance guide plate and the guide pulley.

2. Be careful when handling the transfer entrance guide

plate, as its leading edge deforms easily.

Set screw

Transfer and separation

corona unit cover

Conveyance lever

2 - H - 2

Page 51

CORONA UNIT SECTION

(3) Disconnect the connector (CN168).

(4) Slacken the set screw, then pull forward and remove

the transfer and separation corona unit.

Connector (CN168)

Set screw

Transfer and separation

corona unit

(5) Re-install the transfer and separation corona unit in the

opposite sequence to removal.

4. Removing and Re-installing the Plunging

Prevention Plate

a. Procedure

(1) Remove the transfer and separation corona unit

(2) Push in the six hooks at the rear of the back plate while

grasping them with a pair of tweezers, and remove the

plunging prevention plate.

Plunging prevention plate

Narrow

Wide

Charging control plate

Charging electrode

Springs

(3) Remove dirt from the charging control plate by first

using a blower brush then gently dabbing it with a piece

of cloth moistened with drum cleaner.

(4) Re-install the charging control plate in the opposite

sequence to removal.

6. Replacing Charging Wire Cleaning Block B

a. Procedure

(1) Remove the charging corona unit.

(2) Remove the charging control plate.

(3) Remove the two set screws of the charging electrode

(front).

(4) Remove the grounding plate in the direction of the arrow.

(5) Lift out and remove charging wire cleaning block B

together with the spark arrestor plate (front).

Hooks

Hooks

(3) Re-install the plunging prevention plate in the opposite

sequence to removal.

5. Cleaning the Charging Control Plate

a. Procedure

(1) Remove the charging electrode.

(2) Remove the two springs, then slide the charging con-

trol plate toward the charging wire cleaning motor and

remove it.

2 - H - 3

Spark arrestor plate (front)

Charging wire

cleaning block B

Charging electrode (front)

Set screw

Grounding

plate

Set screw