Page 1

3

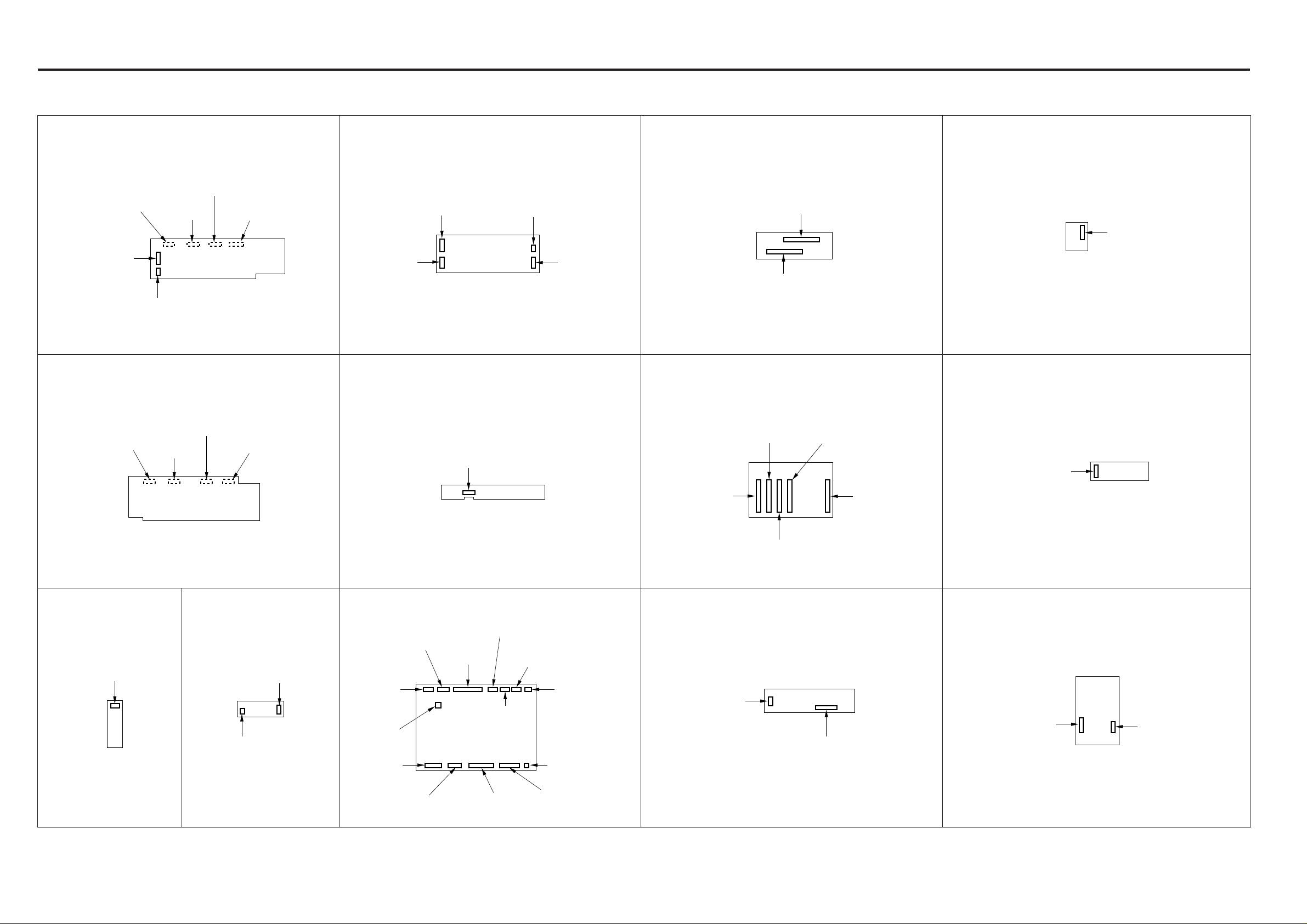

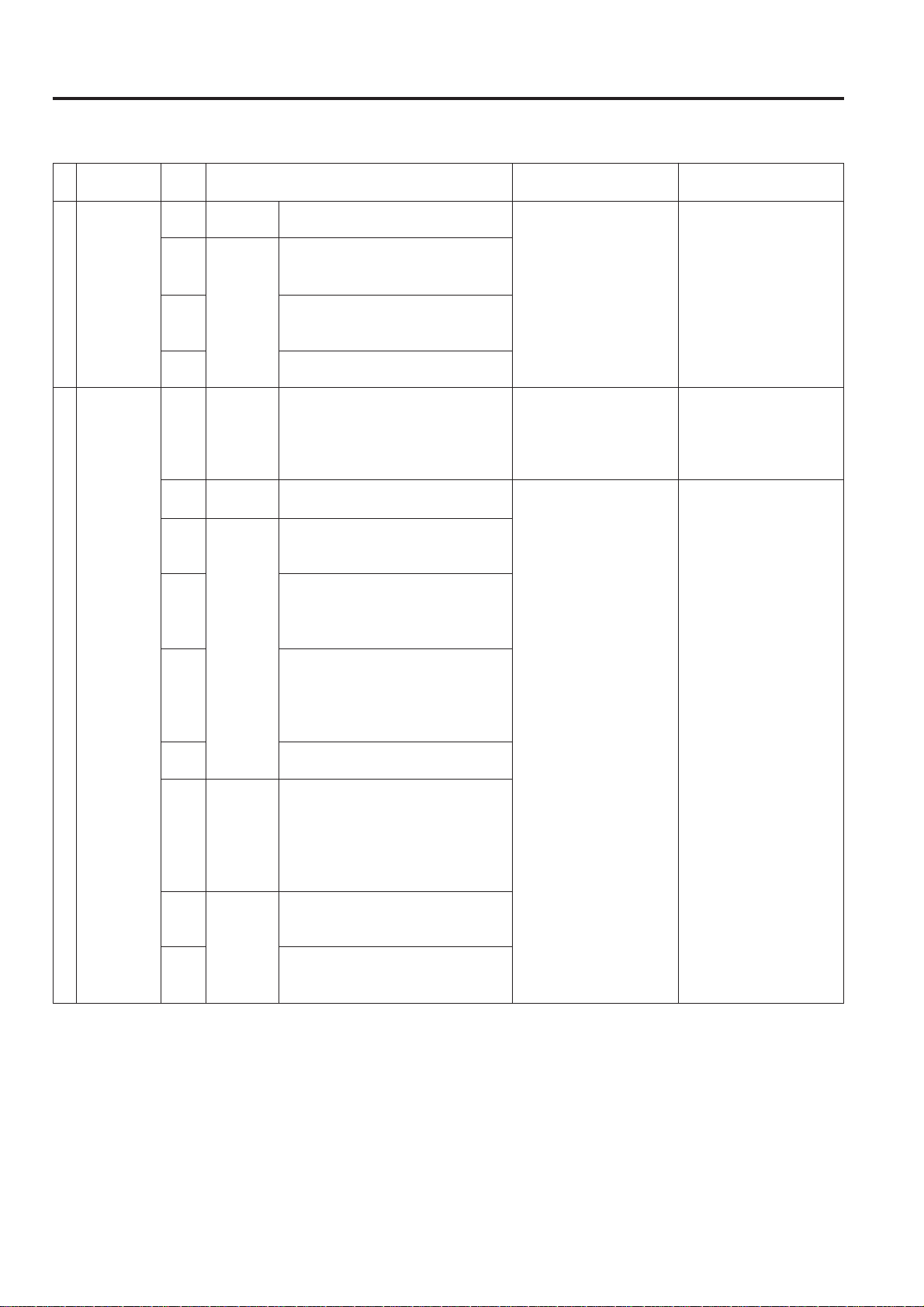

DIAGRAMS

Page 2

14

29

56

18 21 25 62

23

19

27

20

222824

16

15

13

51

50

48

49

47

52

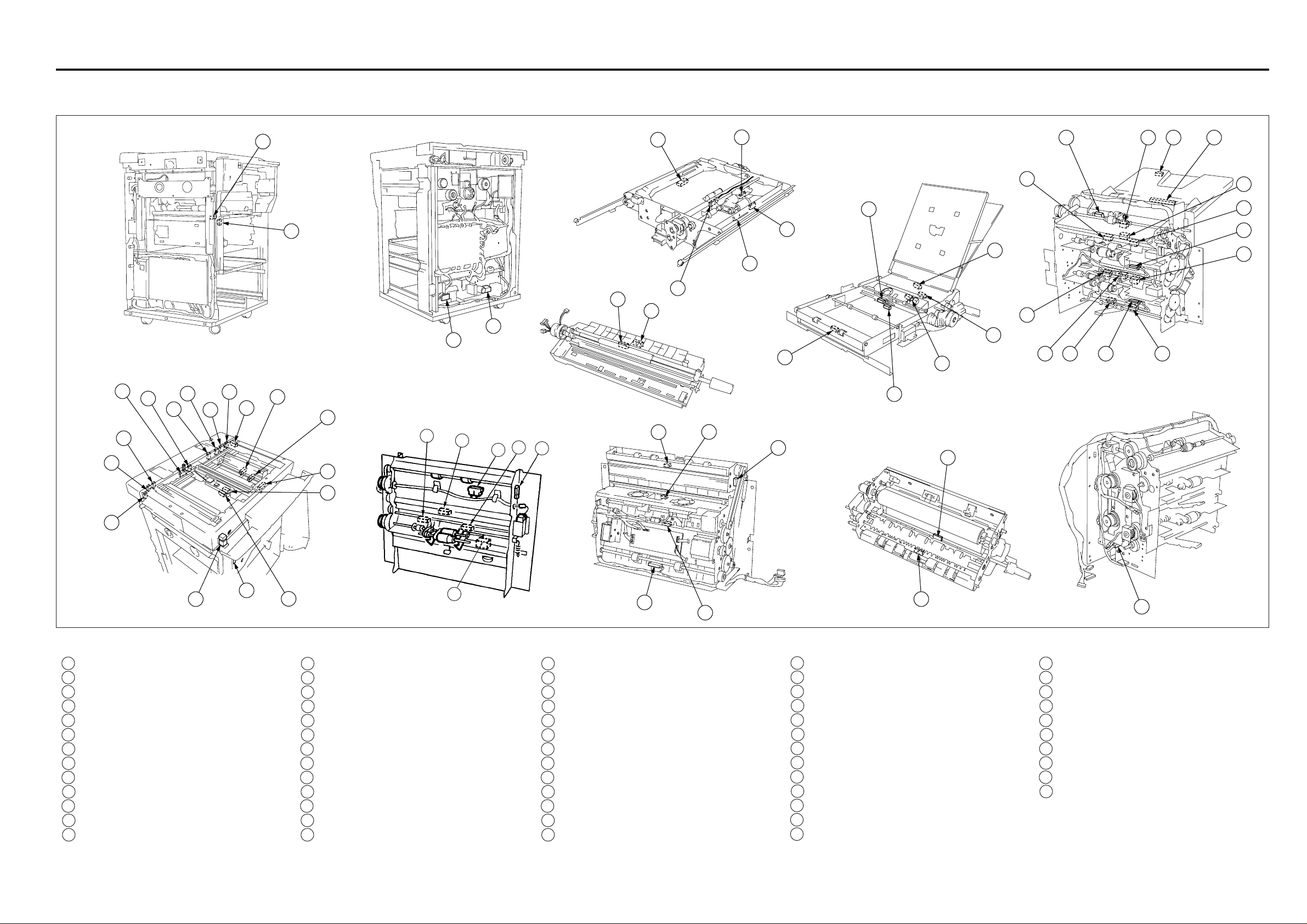

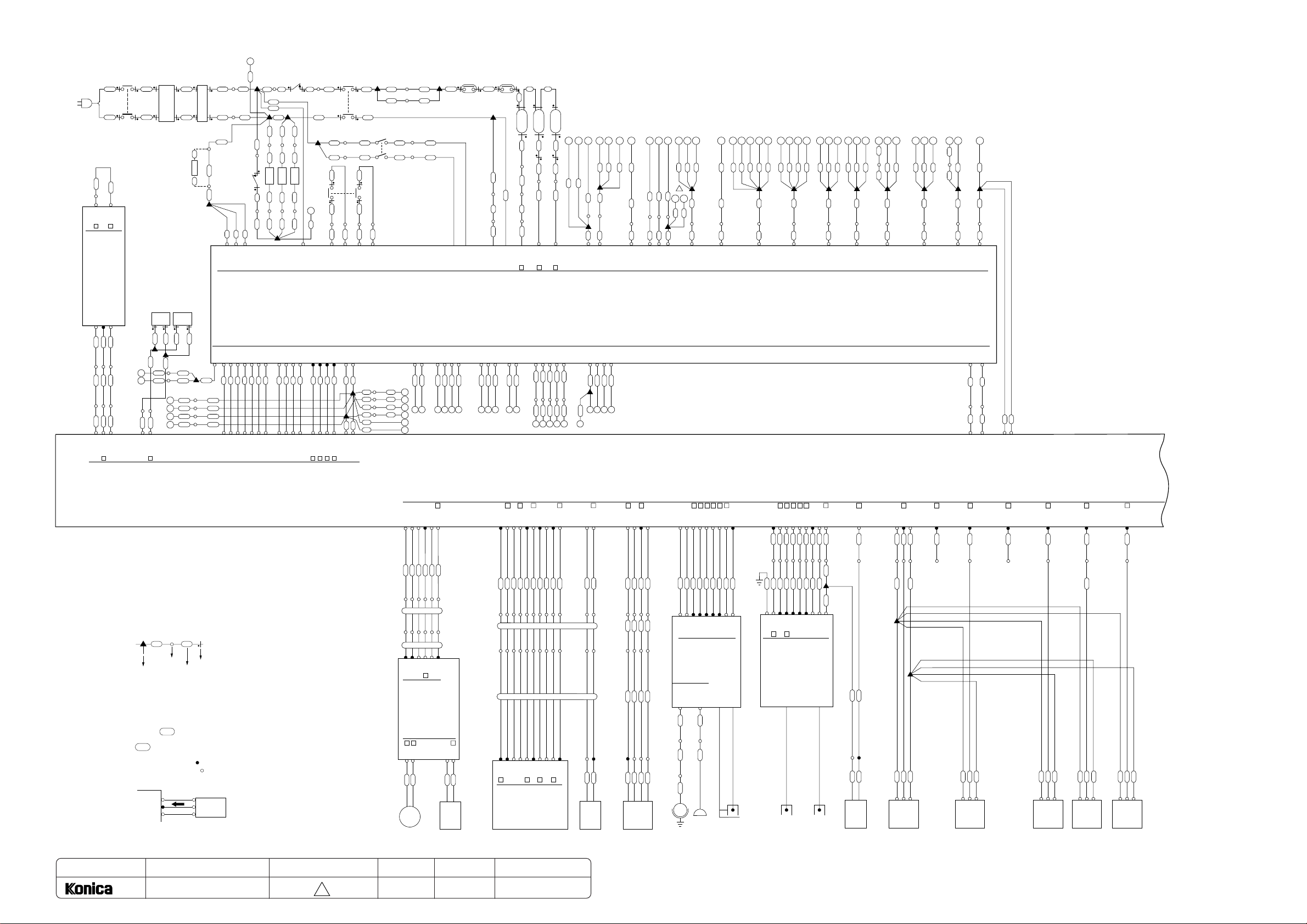

7065 ELECTRICAL PARTS LAYOUT DRAWING

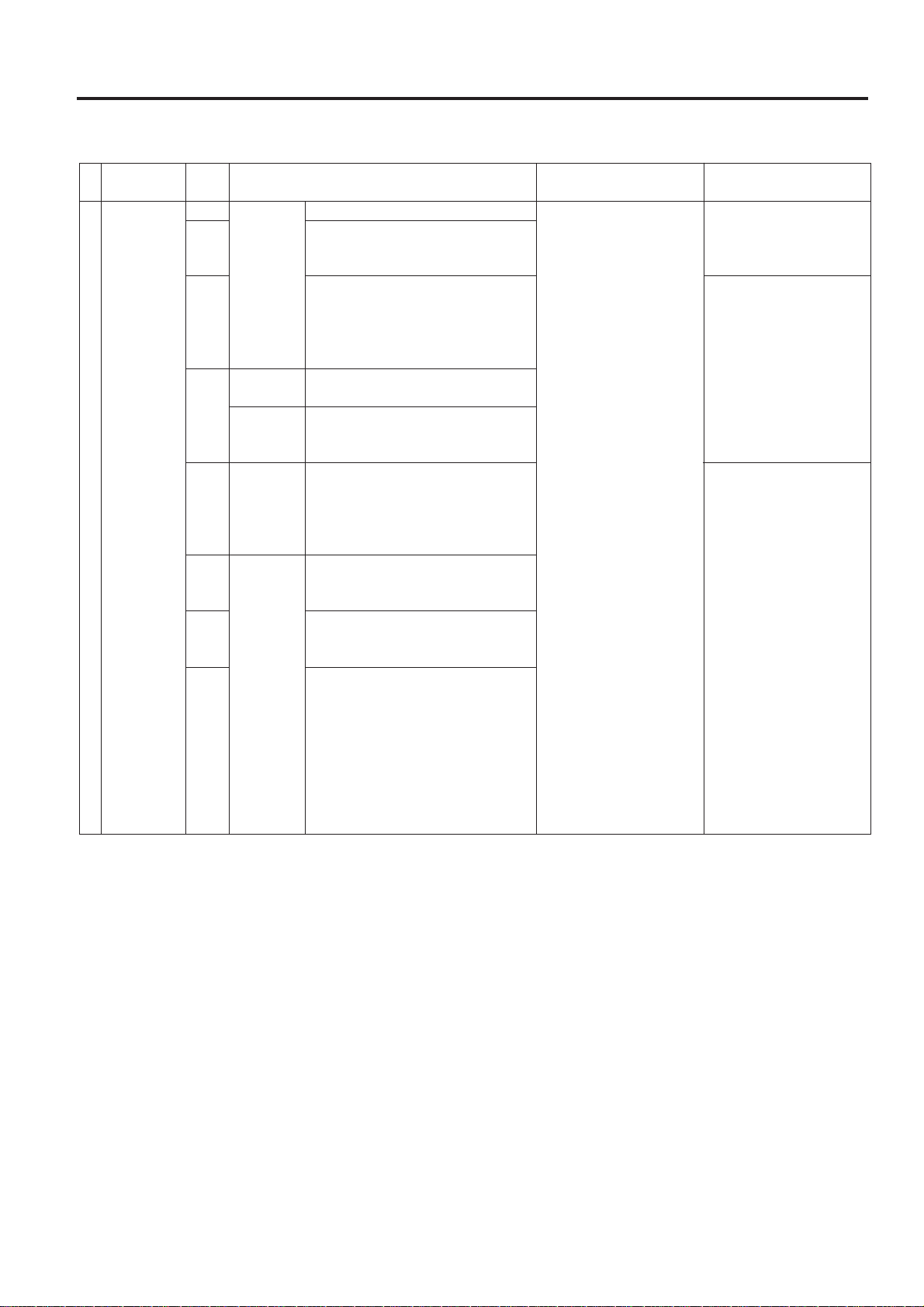

DIAGRAMS

31

37

3

26

17

4

5

30

7

8

6

10

9

11

38

35

36

40

55

43

42

53

45

54

32

60

44

41

39

57

61

12

1

1. Switch Sensor

1 SW1 Main switch

2 MS1 Interlock MS1

3 MS4 Fixing unit set interlock MS4

4 MS141 LCT interlock (1500)

5 MS142 LCT interlock (1000)

6 PS2 Scanner brake PS

7 PS3 Shading position PS

8 PS4 Paper feed restart PS

9 PS5 Optics return PS

10 PS7 Optics timing PS

11 PS8 Glass detection PS

12 PS9 ADF home position PS

13 PS10 Optic syncs PS 2

33

2

34

14 PS11 Paper conveyance door PS

15 PS12 Upper tray no paper PS

16 PS13 Lower tray no paper PS

17 PS14 Registration PS

18 PS15 By-pass no paper PS

19 PS16 Upper limit PS (upper)

20 PS17 Upper limit PS (lower)

21 PS18 No feed PS

22 PS19 Optics sync. PS 1

23 PS20 Pre try PS (upper)

24 PS21 Pre try PS (lower)

25 PS22 By-pass paper size PS

26 PS24 Fixing set PS

46

58

59

27 PS25 Prefeed PS (upper)

28 PS26 Prefeed PS (lower)

29 PS27 Fixing unit paper exit PS

30 PS28 Scan EE PS

31 PS29 ADF brake PS

32 PS30 By-pass PS

33 PS40 APS sensor 1

34 PS41 APS sensor 2

35 PS42 APS sensor 3

36 PS43 APS sensor 4

37 PS45 APS timing PS

38 PS48 APS sensor 7

39 PS140 LCT no paper PS (1500)

40 PS141 LCT no paper PS (1000)

41 PS142 LCT upper limit PS (1500)

42 PS143 LCT upper limit PS (1000)

43 PS144 LCT conveyance PS (1000)

44 PS145 LCT prefeed PS (1500)

45 PS146 LCT conveyance PS (1500)

46 PS147 LCT prefeed PS (1000)

47 PS151 ADU no paper PS

48 PS152 ADU paper feed PS

49 PS153 ADU reversal detection PS

50 PS154 ADU paper exit PS 1

51 PS155 ADU paper exit PS 2

52 PS156 ADU paper exit PS 3

53 PS160 LCT interlock PS

54 PS200 LCT pre try PS (1500)

55 PS210 LCT pre try PS (1000)

56 PS301 Reversal point PS

57 PS302 Reversal paper feed point PS

58 PS303 ADU gate PS

59 PS304 ADU paper feed PS

60 PS305 Reversal paper exit PS

61 PS306 Reversal paper exit interlock PS

62 VR1 By-pass tray paper size VR

3 - 1

Page 3

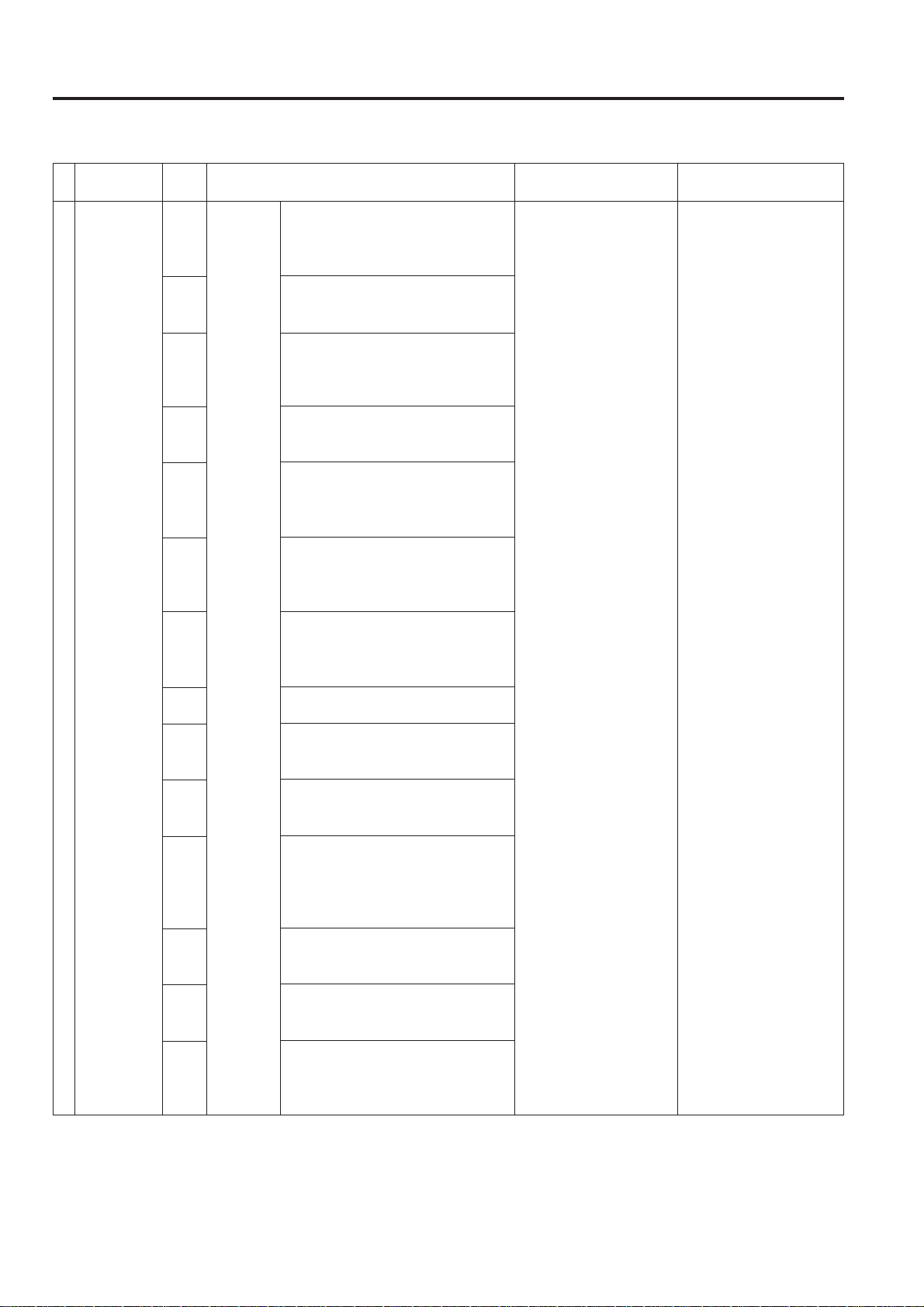

DIAGRAMS

55

50

32

33

51

56

6

17

16

39

5

4

42

62

45

43

44

46

47

52

18

19

60

40

41

28

61

53

14

10

12

9

8

11

26

31

57

24

34

25

15

13

48

59

54

49

2

35

36

3738

27

30

20

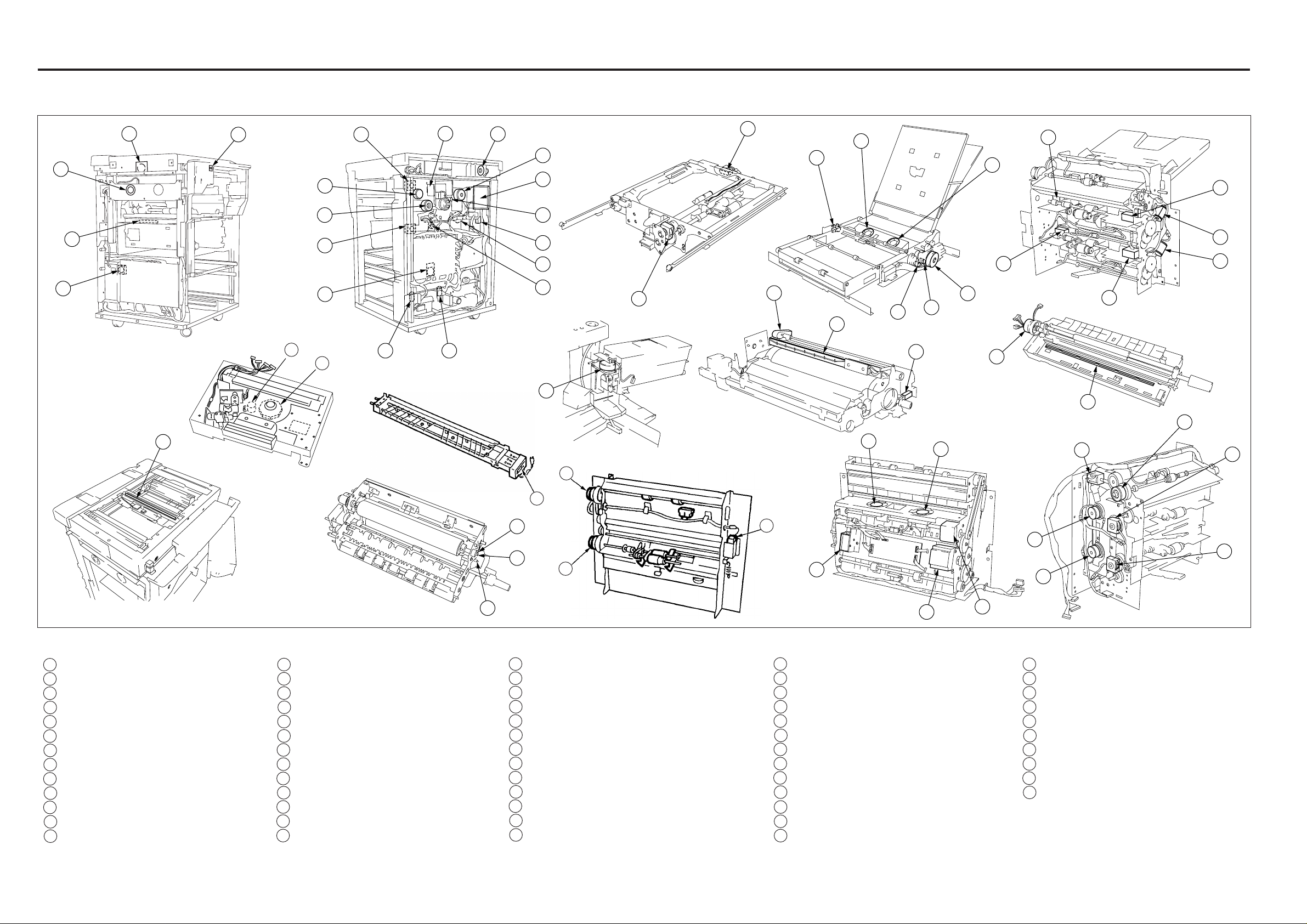

2. Load

1 CL1 LCT 1st paper feed CL (1000)

2 CL2 LCT 1st paper feed CL (1500)

3 CL3 LCT conveyance CL

4 CL151 ADU paper feed CL

5 CL152 ADU reversal CL

6 CL153 ADU timing CL

7 C(K) Key counter

8 C(T) Total counter

9 FM2 Optics cooling fan

10 FM3 DCPS cooling fan

11 FM11 Polygon cooling fan

12 FM14 Conveyance suction fan

13 FM16 Main body cooling fan

14 FM22 E-RDH cooling fan

15 FM30 Developing suction fan

16 FM153 ADU cooling fan 1

17 FM154 ADU cooling fan 2

18 FM203 Paper exit fan 1

19 FM204 Paper exit fan 2

20 L1 Exposure lamp

21 L2 Fixing heater lamp 1

22 L3 Fixing heater lamp 2

23 L4 Fixing heater lamp 3

24 M1 Main motor

25 M3 Developing drive motor

26 M4 Drum motor

3

29

22

21

1

23

27 M5 Polygon motor

28 M7 Charger cleaning motor

29 M8 Transfer/separation cleaning motor

30 M10 Toner supply motor

31 M12 Optics drive motor

32 M17 Upper tray motor

33 M18 Lower tray motor

34 M35 Agitator screw motor

35 M40 Laser correction motor

36 M140 LCT paper feed motor

37 M141 LCT tray motor (1500)

38 M142 LCT tray motor (1000)

39 M151 ADU paper feed motor

58

40 M201 Reversal paper exit motor

41 M202 Paper exit motor

42 MC3 2nd paper feed MC

43 MC5 Paper feed MC (upper)

44 MC6 Paper feed MC (lower)

45 MC7 Paper feed MC (by-pass)

46 MC8 Middle conveyance MC1

47 MC9 Middle conveyance MC2

48 MC10 Cleaner MC

49 MC11 Assist drive MC

50 SD1 1st paper feed SD (upper)

51 SD2 1st paper feed SD (lower)

52 SD3 1st paper feed SD (by-pass)

53 SD4 Separation claw SD

54 SD5 Conveyance SD

55 SD6 Upper tray SD

56 SD7 Lower tray SD

57 SD140 LCT paper feed SD (1500)

58 SD141 LCT paper feed SD (1000)

59 SD153 Paper exit gate SD

60 SD160 Reversal gate SD

61 PCL Pre-charging lamp

62 TSL Transfer Synchronization lamp

3 - 2

Page 4

8

14

32

6

26

DIAGRAMS

13

10

2

27

5

11

33

12

7

19

29

18

16

15

4

22

30

24

17

20

3

37

35 34 38

9

1

23

25

21

28

36 39

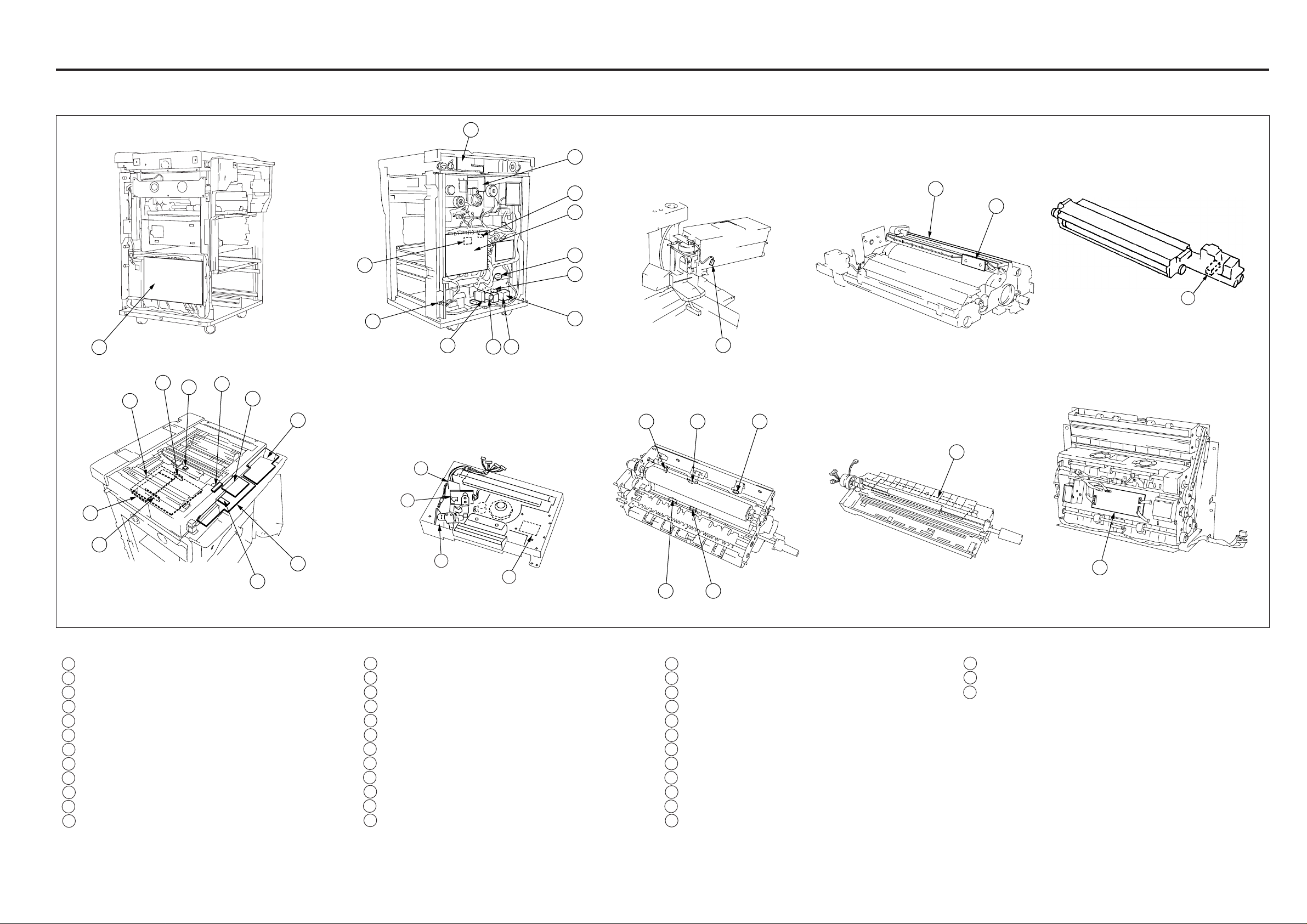

3. Others

1 ADB AD conversion board

2 CB Control board

3 CBR Circuit breaker

4 COIL1 Coil 1

5 COIL2 Coil 2

6 DB Drum board

7 DCPS DC power supply unit

8 EPFDB Paper exit drive board

9 E-RDH Electronic RDH processing board

10 HTR1 Internal heater 1

11 HTR2 Internal heater 2

12 HTR3 Internal heater 3

3 - 3

13 HV1 High voltage unit 1

14 HV2 High voltage unit 2

15 INDICATING BOARD

16 INDICATING STARTER

17 INDEXSB Index sensor board

18 INVB Inverter board

19 IPB Image processing board

20 LDB1 Laser driver board 1

21 LDB2 Laser driver board 2

22 NF Noise filter

23 OB1 Operation board 1

24 OB2 Operation board 2

25 OB3 Operation board 3

26 OPMDB Optics motor drive board

27

–

Paper size detection board

28 PMDB Polygon drive board

29 RDH IFB E-RDH I/F board

30 RL1 Main relay

31

––

32 TCSB Toner control sensor board

33 TDS Toner density sensor

34 TH1 Fixing temperature sensor 1

35 TH2 Fixing temperature sensor 2

36 TH3 Fixing temperature sensor 3

37 TLD Toner level detection sensor

38 TS1 Thermostat 1 (upper)

39 TS2 Thermostat 2 (lower)

Page 5

DIAGRAMS

383

(W:4PIN)

41

(BK:2PIN)

134

(W:3PIN)

133

(W:3PIN)

232(BK:3PIN)

138(W:3PIN)

219(W:10PIN)

222(BK:7PIN)

137(BK:3PIN)

110(BK:3PIN)

72(BK:3PIN)

111(BK:3PIN)

75(BK:3PIN)

113(BK:4PIN)

236(W:3PIN)

130(W:3PIN)

235(W:3PIN)

239

(W:3PIN)

74

(W:3PIN)

67

(W:3PIN)

73

(W:3PIN)

66

(W:3PIN)

76

(W:3PIN)

)

)

)

)

)

392(B:19PIN)

40(W:3PIN)

90(W:3PIN) 610(W:3PIN)

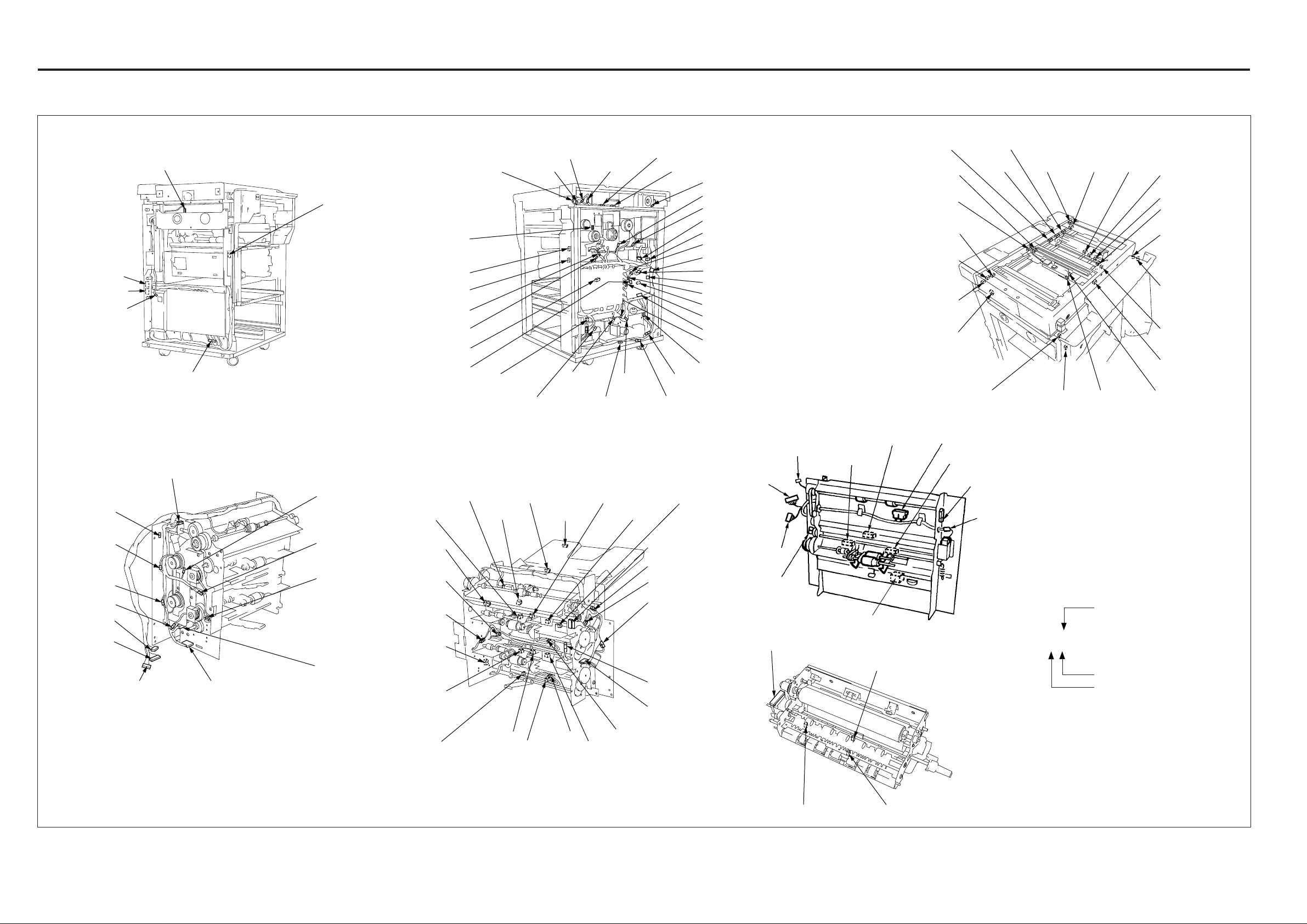

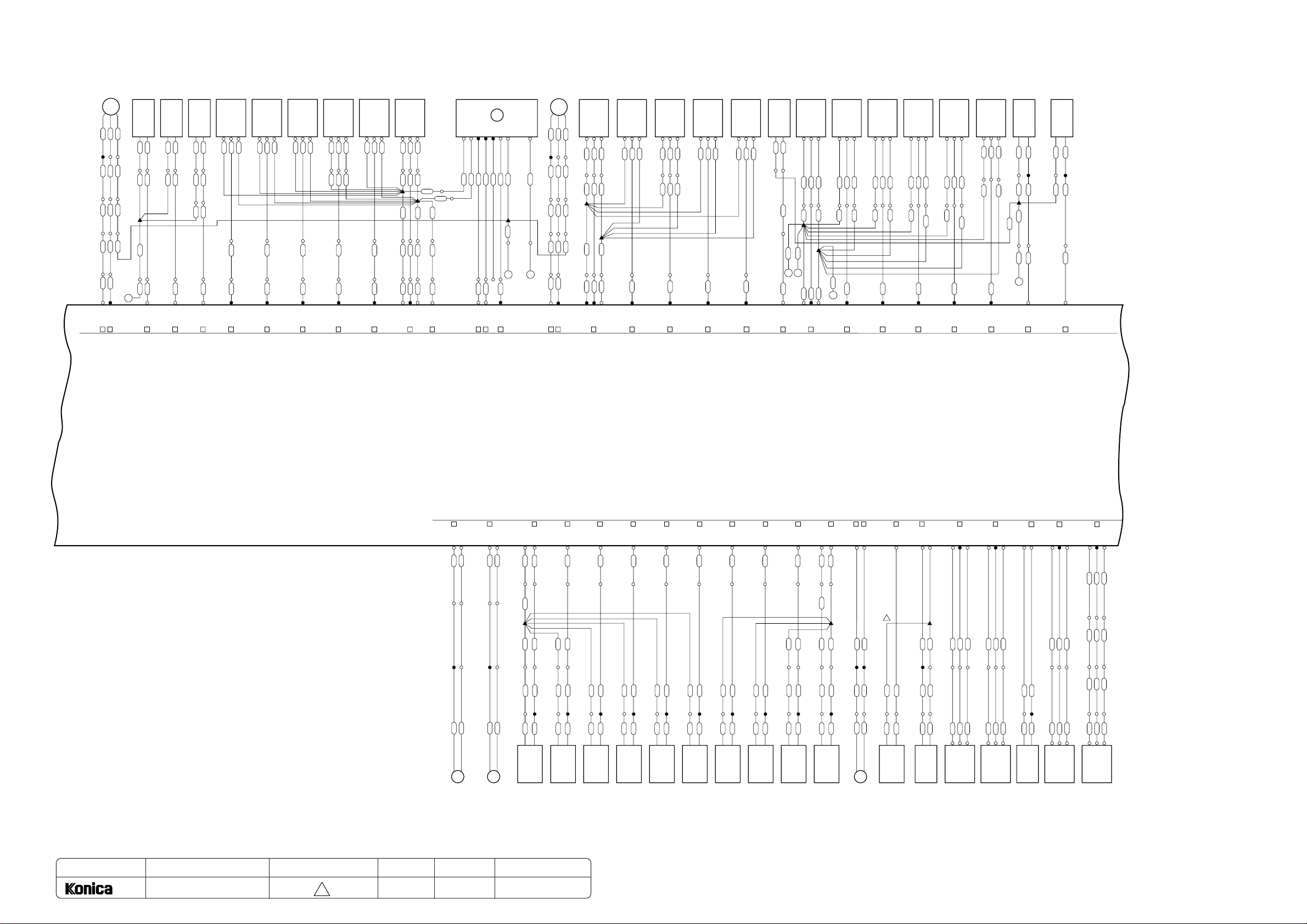

7065 CONNECTOR LAYOUT DRAWING

49(BK:4PIN)

37(W:3PIN)

125(BK:8PIN)

101(W:6PIN)

119(W:12PIN)

237(BK:4PIN)

399(W:2PIN)

53(W:2PIN)

233(W:2PIN)

463(W:4PIN)

48(BK:4PIN)

326(BK:4PIN)

11(BK:4PIN)

169(W:2PIN)

56(W:6PIN)

44(R:8PIN)

44(W:3PIN)

92(W:8PIN) 142(W:7PIN)

163(W:9PIN) 92(W:8PIN) 102(BK:7PIN)

731

(W:2PIN)

734

(W:2PIN)

462

(W:3PIN)

735

(BK:2PIN)

753

(W:2PIN)

327

(W:3PIN)

47

(W:3PIN)

13

(W:3PIN)

732

(W:2PIN)

465

(W:3PIN)

122

(BK:2PIN)

58

(W:3PIN)

152(W:3PIN)

752(W:4PIN)

750

(BK:2PIN)

97(BK:4PIN)

167(BK:2PIN

16(BK:4PIN)

98(BK:4PIN)

91(W:2PIN)

121(BK:8PIN

3(R:8PIN)

123(BK:5PIN

1(R:8PIN)

128(BK:4PIN

387(W:2PIN)

96(BK:4PIN)

475(W:3PIN)

733(BK:4PIN

753(BK:2PIN)

727

(W: 12 PIN)

730 (W: 2 PIN)

723

(W: 3 PIN)

726

(W: 3 PIN)

727 (W: 3 PIN)

724 (W: 3 PIN)

725 (W: 3 PIN)

721 (BK: 3 PIN)

111(BK:12PIN)

234(W:2PIN)

464(W:2PIN)

231(R:2PIN)

110(W:9PIN)

68(BK:8PIN)112(W:13PIN)

230(W:2PIN)

209(BK:5PIN)

52(W:3PIN)

206(W:2PIN)

38(BK:8PIN)

728 (BK: 10 PIN)

23(W:2PIN)

202(W:3PIN)

79(BK:7PIN)

720 (W: 2 PIN)

24(W:2PIN)

207(W:2PIN)

729 (W: 3 PIN)

203(W:3PIN)

123(BK:2PIN)

45(W:3PIN)

328

(W:3PIN)

147

(W:3PIN)

69

(W:3PIN)

141

(W:3PIN)

59

(W:3PIN)

25(BK:7PIN)

54

(W:3PIN)

[How to read connector numbers]

1. Inscribed contents

Connector No.

100

(W: 3 PIN)

Number of pins

Connector color

2. Color code

BN: Brown

R: Red

O: Orange

Y: Yellow

GN: Green

LB: Light blue

S: Silver

B: Blue

V: Violet

GY: Gray

W: White

BK: Black

P: Pink

As an example, (B/W) indicates that the male side of the

connector is blue and the female side white.

3 - 4

Page 6

DIAGRAMS

3

(W: 20 pin)

6

(W: 24 pin)

223

(B: 11 pin)

62

(W: 22 pin)

5

(W: 24 pin)

489

(W: 16 pin)

402

(W: 18 pin)

481

(BK: 24 pin)

61

(W: 9 pin)

30

(W: 24 pin)

65

(W: 22 pin)

83

(W: 24 pin)

200

(W: 20 pin)

120

(BK: 24 pin)

1

(W: 5 pin)

106

(W: 8 pin)

114

(W: 7 pin)

60

(W: 20 pin)

800

(W: 24 pin)

801

(W: 16 pin)

36

(W: 10 pin)

135

(W: 11 pin)

57

(B: 16 pin)

322

(W: 8 pin)

144

(W: 16 pin)

7

(W: 24 pin)

140

(BK: 20 pin)

208

(NC)

4

(W: 8 pin)

9

(W: 18 pin)

22

(W: 16 pin)

35

(W: 5 pin)

78

(W: 7 pin)

88(W: 5 pin)

99

(W: 5 pin)

28

(W: 5 pin)

2

(W: 10 pin)

401

(W: 4 pin)

400

(W: 9 pin)

382

(W: 5 pin)

398

(W: 4 pin)

397

(W: 6 pin)

395

(W: 4 pin)

396

(W: 5 pin)

8

(W: 10 pin)

709(BK:18PIN) 716(BK:2PIN)

532(W:3PIN)

553(W:2PIN)

534(W:3PIN)

712(W:3PIN)715(W:3PIN) 714(BK:2PIN) 713(W:3PIN)

711(W:3PIN)

710(W:3PIN)

523(W:3PIN) 526(W:4PIN) 557(W:3PIN) 556(W:3PIN)

550(W:3PIN)

Control Board

51(BK:5PIN) 34(BK:2PIN)

50

(W: 4 PIN)

17(W:3PIN)

12(W:5PIN)

559(R:3PIN)

524

(R:RPIN)

616(BK:4PIN)

619(W:6PIN)

600(W:6PIN)

618(W:2PIN)

601

(W:12PIN)

617(BK:4PIN)

558

(R:3PIN)

(W:8PIN)

555

(W:3PIN)

614(W:3PIN)

522

(W:8PIN)

505

(BK:24PIN)

611(W:3PIN)

622(W:7PIN)612(W:3PIN)602

525(BK:4PIN)

551(R:2PIN)

552(W:2PIN)

531

(W:13PIN)

613(W:3PIN)

615(W:3PIN)

604(W:6PIN)

603(W:7PIN)

620(BK:6PIN)

621(W:12PIN)

85

(W:11PIN)

42

(R:10PIN)

DCPS

86

(W:2PIN)89(BK:2PIN)46(W:3PIN)32(W:3PIN)

168

(BK: 2 PIN)

3 - 5

Page 7

DIAGRAMS

Operation Board/1

210

(BK: 24 pin)

212

(W: 8 pin)

Operation Board/2

221

(W: 5 pin)

(W: 10 pin)

213

(W: 14 pin)

215

(W: 4 pin)

225

(NC)

10

214

(BK: 24 pin)

217

(W: 10 pin)

216

(W: 3 pin)

Optics Drive Board E-RDH I/F Board

226

(W: 5 pin)

224

(W: 11 pin)

Toner Control Board

19

(W: 10 pin)

225

(W: 3 pin)

228

(W: 10 pin)

RDH Processing Board

454

(W: 144 pin)

(W: 100 pin)

450

(W: 100 pin)

453

(W: 144 pin)

Index Detection Board

428

442

(W: 11 pin)

LD Drive Board

451

(W: 144 pin)

440

(W: 12 pin)

450

(W: 100 pin)

Operation Board/3 Image Processing Board

220 (W: 10 pin)

INDICATING STARTER

77 (W: 4 pin)

71 (W: 3 pin)

430

(W: 4 pin)

431

(N.C.)

427

(N.C.)

425

(W: 24 pin)

426

(N.C.)

428

(W: 100 pin)

422

(W: 12 pin)

421

(W: 12 pin)

420

(W: 34 pin)

423

(W: 12 pin)

465

(W: 50 pin)

424

(W: 8 pin)

467

(W: 16 pin)

452

(W: 144 pin)

AD Converter Board Polygon Driver Board

410

(W: 5 pin)

432

411

(W: 40 pin)

(W: 12 pin)

320

(W: 8 pin)

3 - 6

Page 8

7065 OVERALL WIRING DIAGRAM (1/5)

1

MAIN RELAY

AC POWER

CBR

BK BK

WW

L1

∗

385-4

385-1

∗

LV

HV

INVB

752-1 752-3 752-4

COIL2

BK BK

752-2

W

W W W W

∗

NF

∗

∗

∗

∗

COIL1

COIL1

(KBE ONLY)

∗

390-2 390-1

∗

∗

398-3

AC(C)

RL2

(KBJ ONLY)

SUB RELAY

753-2 753-1

∗

∗

397-5

397-6

AC(H)

AC(C)

BK

∗

BK

BK

W

∗

387-2

750-2

WWW

HTR3

∗

BK

387-1

750-1

BKBKBK

W

W

HTR2

BK

RL1

∗

W

751-2

HTR1

BK

2

751-1

BK

398-1

AC(H)

MS4

BK BK BK BK

BK BK

MAIN SWITCH

BK

395-1

AC(H)

381-3

BK

BK

W W

W

396-3

AC(C)

381-4

SW1

W

395-2

AC(C)

383-1

BK

383-2

BK

MS1

BK BK

∗

381-1

381-2

BK

396-1

AC(H)

BK

BK

392-9

392-10

383-3

383-4

∗∗∗

BK

BK

397-1

AC(H)

TS-2 TS-1

BK

W

394-2

∗

399-2

W

397-2

AC(H)

AC(H)

W

382-1

AC(C)

∗

L2

W

392-18

GY

394-1

∗

399-1

V

∗

L2 DRIVE

L3

W

392-19

BN BNBNBN

382-2

∗

L3 DRIVE

L4

W

392-20

382-4

∗

L4 DRIVE

4036 37 41 42 43 44 45 46 47 48 49 50 52 53 54

∗∗∗

∗∗

∗

∗

∗

∗

122-1

122-2

122-3

∗

∗

∗

78-1

78-2

78-3

24V DC

24V DC

24V DC

∗

122-4

122-5

∗∗∗

78-4

24V DC

∗

78-5

24V DC

122-6

∗

38 39

78-6

PGND

∗∗∗

2

∗

∗

∗

121-1

∗

78-7

PGND

51

∗∗∗∗∗

∗

121-3

∗

99-2

24V DC

57 58 59 60

55 64 66

∗∗∗

∗

∗

121-4

∗

99-3

24V DC

121-5

∗

∗

99-4

PGND

61 63

6256

∗

∗∗∗∗∗

121-6

65 67 69

∗

123-2

∗

99-5

PGND

∗

∗

∗

88-2

PGND

68 70 72

∗

∗

128-2

∗∗

∗

123-3

∗

88-3

PGND

71 73

∗∗∗

∗

123-4

∗

88-4

40V DC (1)

∗∗

∗

128-1

∗

123-574121-2

∗

88-5

40V DC (1)

75

∗

∗

∗

99-1

24V DC

29-3

29-2

29-1

∗∗∗∗

232-2

232-1

∗∗∗

470-1 232-3

470-2

470-3

∗∗∗

60-B8

60-A9

60-A10

H

PGND

24V DC

L1 CONT

[How to see the diagram]

1. The signals shown reflect levels present

under normal idleing conditions with

the main switch turned ON.

2. Wiring symbols in the figure are

as follows.

(1) [Symbol]

(2) [Color code]

Example: represents

green yellow striped pattern.

(3) is ribbon cable.

(4) Signal flow

The solid black circle ( ) among

the connector symbols ( )

indicates the direction of signal flow.

Example)

RL1 RL2

BBR

∗∗

3

∗∗∗

4

81-1

81-2

∗

60-B9

60-B10

L

24V DC

RL DRIVE

Connector

PGC

BN - Brown

R - Red

O - Orange

Y - Yellow

GN - Green

LB - Light blue

Y/GN

RC

CB

5VDC

PS1

SGND

∗

96-1

96-3

∗∗

5

∗

6

∗

7

∗

8

∗

50-1

VV

Wire (Violet)

B - Blue

V - Violet

GY- Gray

W - White

BK- Black

P - Pink

Direction of

signal flow

R

24V DC (2)

24V DC (2)

PGND

12V DC

SGND

SGND

5V DC

8V DC

5V DC (For control board)

2-2

2-1

2-3

2-4

2-5

2-6

2-8

2-10

8-10

∗∗∗∗∗∗∗∗∗∗∗∗∗∗∗∗∗

96-4

∗

96-5

∗

96-6

∗

96-7

∗

4-1

61-5

61-7

61-9

Faston

61-1

61-2

61-3

61-4

PS1

5V DC (For control board)

SGND

SGND

8-9

8-7

8-6

8-4

8-3

4-2

4-4

4-5

60-B7

60-A6

L

L

L2 CONT

RL1 CONT

8-2

8-1

60-A7

60-A8

H

H

L3 CONT

L4 CONT

SGND

2-7

∗

61-6

5V DC

2-9

∗

61-8

DCPS

5V DC

5V DC

11V DC (For KRDS)

SGND

SGND

SGND

PGND

PGND

PGND

24V DC

24V DC

5V DC

-5V DC

SGND

SGND

12V DC

40V DC

PGND

12V DC

SGND

401-1

401-2

8-8

8-5

401-3

401-4

28-1

28-2

28-3

28-5

28-6

400-6

400-8

400-7

400-9

400-5

400-1

400-2

400-3

400-4

412-3

412-5

26

27 28 29 30

412-2

412-4

412-1

∗∗∗∗∗

∗∗∗∗∗

35

∗

31 32 33 34

∗

∗∗∗

∗

100-1

∗

100-2

∗

101-2

∗

101-3

∗

∗

∗

∗

9

∗

10

∗

11

∗

12

∗

13

14

∗∗∗

∗

∗

∗

∗∗∗

2524232221201918171615

121-7

99-6 PGND

∗

∗

1-4

123-1

88-1 PGND

∗

∗

1-3

∗

∗

1-2

1-1

CB (1/5)

TDS CONT

12VDC

TDS ANG

SGND

24VDC

PGND

B CONT

C CONT

C SHIFT

B SHIFT

G SHIFT

M7 DRIVE 1

30-B7

∗∗∗∗∗

63—3

63—4

50—3

50—4

21—1

21—2

M7 DRIVE 1

∗

39—1

R

M7

CHARGER

CLEANING

MOTOR

5VDC

M7 DRIVE 2

5-A1

5-A2

30-B8

63—5

63—6

RC

50—5

50—6

RC

21—3

21—4

∗

TH2 ANG

M7 DRIVE 2

∗

39—2

BK

24VDC

PCL CONT

L

5-A3

5-A4

∗

63—7

63—8

50—7

50—8

21—5

21—6

CHARGING

DB

PRE-

LAMP

24VDC

PCL CONT

L

20—1

20—2

R

W

γ / Dmax LED V ref

12VDC

∗

5-A12

5-A11

5-B1

Y

∗

∗

324—1

324—2

324—3

325—1

325—2

325—3

19—1

19—2

19—10

∗

γ sig / MONI

Dmax LED CONT

DRUM JAM CONT

L

L

5-B2

5-B3

5-B4

∗

324—4

324—5

324—6

325—4

325—5

325—6

19—3

19—4

19—5

∗

Dmax MONI

TCBS

TONER

CONTROL

SENSOR

5-B5

∗∗∗

324—7

324—8

RC

325—7

325—8

RC

19—6

∗

Dmax sig

SGND

5-B6

5-B7

B

324—9

325—9

19—7

19—8

DRUM JAM

LED CONT

L

5-B8

∗

∗

324—10

325—10

19—9

∗

24VDC

SD 4 DRIVE

L

5-B9

5-B10

O

∗

324—11

324—12

325—11

325—12

34—1

34—2

B

R

SD4PCL

SEPARATION

CLAW

SOLENOID

∗

5-A5

5-A6

Y

∗

63—9

63—10

∗∗∗

50—12

50—13

∗∗∗

51—1

51—2

R

BN

DENSITY

SENSOR

∗

5-A7

∗

63—11

50—14

51—3

O

5-A8

B

63—12

∗

50—15

∗

51—4

Y

GP CONT

L

L

L

∗∗∗

62-A11

62-A2

62-A3

62-A4

62-A5

62-A6

62-A7

62-A8

62-A9

B

O

∗∗∗

∗

∗∗∗

84—1

84—2

84—3

84—4

84—5

84—6

84—7

84—8

84—9

L

F SIG

GP

71—1

GUIDE

PLATE

HV1

31—2

BN

∗

CHARGING

31—1 BIAS

GY

GY

50—20 70—1

GY

BIASTONER

S SHIFT (DC)

S SHIFT (AC)

S CONT

T SHIFT

T CONT

PGND

62-B5

85—5

24VDC

L

L

∗

62-B4

62-B3

62-B2

62-B1

O

B

85—4

85—3

85—2

85—1

L

∗

∗

62-B10

62-B8

62-B7

62-B6

∗∗∗∗∗∗∗

85—10

85—8

85—7

85—6

∗

∗∗∗

∗

∗∗∗

∗

∗

∗

87—1

87—3

87—5

87—6

87—7

87—8

87—9

87—10

87—11

T SIG

HV2

HV2

87—12

SYNCHRONIZATION

∗

∗

F.G

S SIG

SEPARATE TRANSFER TRANSFER

89—1

LAMP

85—9

∗

89—2

R

PSL CONT

∗

62-B11

∗

∗

W

5VDC

PS40

L

22-A5

22-A6

R

∗

163-1

163-2

∗

133-3

133-2

PS40TSLTDS

APS

SENSOR 1

163-3

SGND

22-A7

B

∗

∗∗∗

133-1

∗∗∗

134-1

PS47

L

22-A2

∗

163—8

NC

PS42

L

22-B1

∗

163—5

130-3

130-2

APS

SENSOR 3

∗∗∗

130-1

PS46

H

22-A1

163—7

NC

PS41

L

22-AB

∗

∗

163—4

134-3

134-2

PS41 PS42 PS43

APS

SENSOR 2

PS48

L

22-A3

∗∗

163—9

239-3

239-2

PS48

APS

SENSOR 7

∗∗∗

239-1

PS43

L

22-B2

∗

163—6

138-3

138-2

APS

SENSOR 4

∗∗∗

138-1

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

3 - 7

2

DATE

Jan.2000

PAGE

3-7

METHOD

REPLACEMENT

Page 9

7065 OVERALL WIRING DIAGRAM (2/5)

DEVELOPING

CLEANER

CLUTCH

MC10

∗

167-1

∗

30-B1 30-B2

24VDC

DEVELOPING

SCREW

MOTOR

161-1

∗

167-2

∗

54

H

MC 10 DRIVE

161-5

161-3

∗

∗

O

30-A6

30-A7

∗∗

P

M35 PLL

M35 DRIVE

161-2

61

SUCTION

FAN

Y

R

11-1

11-2

∗

∗

B

65-A1

65-A2

H

H

FM30 LD

FM30 DRIVE

CONVEYANCE

SUCTION

FAN

Y

R

BK

BN

15-1

15-2

11-3

11-4

∗

∗

∗

B

49

59

65-A3

65-A10

65-A11

H

H

FM14 LD

FM30 H/L

FM14 DRIVE

BK

15-3

B

POLYGON

COOLING

FAN

Y

R

BN

48-1

48-2

48-3

∗

∗

O

53

65-A4

65-A5

∗

H

FM11 LD

FM11 H/L

48-4

58

BK

B

DCPS

COOLING

FAN

FM3

Y

R

237-1

237-2

237-3

∗

55

30-B5

H

FM3 LD

BK

BN

2

237-4

∗

∗∗

∗

48

56 63

30-B4

∗

FM3 H/L

TONER

SUPPLY

MOTOR

14-1

14-5

14-3

∗ ∗

12-4

12-5

12-6

∗

O

30-B11

30-B12

P

L

M10 PLL

M10 DRIVE

14-2

∗∗

12-7

∗

B

E-RDH

COOLING

FAN 2

Y

R

BN

49-1

49-2

49-3

∗

∗

O

3

65-A6

65-A7

∗

H

FM22 LD

FM22 H/L

FAN

OPTICS

COOLING

FAN

MAIN BODY

COOLING

FM2M10 FM16FM11FM14FM30 FM22M35

R

Y

R

BK

49-4

B

57 52 50 60

16-1

2

16-2

O

65-B9

FM16 LD

BN

16-3

∗

∗

65-B10

∗

H

FM16 H/L

BK

16-4

B

113-1

113-2

97-1

97-2

∗

128-3

128-4

∗∗

83-A1

H

FM2 DRIVE

Y

BK

113-4

∗∗ ∗

97-4

∗

B

83-B1

H

FM2 LD

2

204-1

∗∗∗∗∗∗∗

74

69

MAIN

MOTOR

DRUM

MOTOR

M1 M4 M3

2

204-2

205-1

30-A1

5VDC

205-3

205-4

30-A3

30-A4

H

H

M1PLL

M1 CONT

205-5

30-A5

SGND

205-2

30-A2

P

M1 CLK

62

51

201-8

201-10

201-1

201-2

201-3

∗∗∗∗∗∗∗

125-8

125-7

125-1

125-2

125-3

∗∗∗∗∗∗∗

124-8

124-7

124-1

124-2

124-3

∗∗∗∗∗∗∗

30-A8

30-A9

30-A10

H

5VDC

SGND

M4 CONT

201-5

125-5

124-5

30-B6

∗

M4 H/L

201-4

125-4

124-4

30-A11

P

M4 CLK

201-6

217-1

217-2

∗

∗∗∗∗∗∗∗∗∗∗∗

125-6

∗

124-6

∗

65-B3

65-B4

30-A12

H

5VDC

SGND

M4 PLL

DEVELOPING

DRIVE

MOTOR

217-3

217-4

217-5

217-6

65-B5

65-B6

65-B7

P

H

∗

M3 H/L

M3 CLK

M3 CONT

217-7

65-B8M3 LD

H

NC

217-8

65

217-9

66

217-10

70

217-11

71

321-1

321-2

321-3

PPPPP

M5 DRIVE A

M5 DRIVE B

M5 DRIVE C

320-1

320-2

320-3

∗

∗

95-1

95-2

95-3

322-1

322-2

322-3

P

H

SGND

M5 CLK

M5 CONT

POLYGON

MOTOR

M5

321-5

321-6

321-7

PPP

M5 MAG A

M5 MAG A’

M5 MAG B’

PMDB

M5 RDY

∗

320-4

320-5

320-6

∗∗∗

95-4

95-5

95-6

∗∗∗∗∗

322-4

322-6

∗

M5 RDY

M5 BREAK

321-8

321-9

M5 MAG B

M5 MAG C’

320-8

320-7

∗∗∗

95-7

95-8

321-10

321-11

P

P

V MAG-

M5 MAG C

4 35 68

326-3

326-2

∗∗∗

326-1

∗∗∗

12VDC

22-B3

Y

12-1

∗∗∗

TLD

∗

22-B4

∗

12-2

SGND

22-B5

B

12-3

22-B7

∗

L

22-B8

∗

SGND

9-A1

B

92-1

∗

92-2

PS2

L

9-A2

∗

5VDC

9-A3

R

92-3

CB(2/5)

L

9-A9 PS8

∗

92-4

∗

92-5

9-A5 PS4

L

∗

92-6

L

9-A6 PS5

∗

92-7

L

9-A7 PS7

∗

9-B3 PS28L65-B1 24V DC

∗

∗

92-8

H

65-B2 MC11 DRIVE

∗

142-3

∗

L

9-B9 PS29

∗

∗

L

9-B2 PS9

∗

142-1

∗

∗∗∗

L

2

9-A4 PS3

∗

142-2

2

∗

∗

9-B6 SGND

142-4

∗

L

9-B7 PS45

∗∗∗

142-5

142-6

9-B8 5VDC

∗

∗

144-A1 PS22

∗

110-1

∗

∗∗∗

152-2

152-1

152-3

463-3

∗

∗

∗∗∗

∗

∗∗∗

∗

463-2

∗∗∗

∗

144-A3 VR1

∗

110-2

∗

463-1

∗

463-4

111-1

79-1

L

7-B1 PS12

7-B11 SGND

∗

∗

111-1

∗

∗

∗∗∗

79-2

∗

∗∗∗

79-3

7-A11 5VDC

∗

111-12

∗

∗

∗

L

7-B3 PS16

∗

111-3

∗

79-4

∗∗∗

L

7-B9 PS20

∗

111-9

∗

79-5

∗∗∗

L

7-B6 PS19

∗

111-6

∗∗∗

2

68-2

68-1

∗∗∗

68-3

209-3202-1

144-A7 PS25

∗

110-4

∗∗∗

209-4

∗

∗

202-2

∗∗∗

209-5

∗

202-3

203-1

144-B7 PS26

∗

110-5

∗

68-5

∗∗∗

203-2

∗∗∗

144-A5 PS10

∗

110-3

∗

68-4

203-3

∗∗∗

111-2

∗

25-1

∗

∗∗∗

25-2

L

7-B2 PS13

∗

∗

25-3

L

7-B4 PS17

∗

111-4

∗

∗

25-4

L

7-B10 PS21

∗

111-10

∗

25-5

38-6

∗

L

7-B5 PS18

111-5

38-7

L

7-B7 PS15

∗

∗

∗

111-7

∗

38-8

L

7-B8 PS11

∗

111-8

∗

∗∗∗

∗∗∗

∗∗∗

∗∗∗

∗∗∗

17-1

17-2

17-3

∗∗∗

TONER

LEVEL

DETECTION

41-1

41-2

R

BK

TOTAL

COUNTER

∗∗∗

76-1

76-2

PS2 PS8 PS4 PS7PS5C (T)TLD

SCANNER

BRAKE

SENSOR

76-3

∗∗∗

67-1

67-2

GLASS

SENSOR

67-3

PAPER FEED

∗∗∗

73-1

73-2

RESTART

SENSOR

73-3

∗∗∗

66-1

66-2

OPTICS

RETURN

SENSOR

66-3

∗∗∗

74-1

74-2

OPTICS

TIMING

SENSOR

74-3

∗∗∗

110-1

110-2

PS28

SCAN

EE

SENSOR

110-3

169-1

169-2

∗

MC11

ASSIST

DRIVE

CLUTCH

∗

111-1

111-2

111-3

PS29

ADF-BRK

SENSOR

75-1

75-2

PS9

OPTICS

ADF-HP

SENSOR

75-3

72-1

72-2

72-3

PS3

OPTICS

SHADING

DETECTOR

137-1

137-2

PS45

APS

TIMING

SENSOR

137-3

462-1

462-2

PS22

BY-PUS

PAPER

SIZE

SENSOR

462-3

465-3

VR1

BY-PUS

PAPER

SIZE

DETECTING

VR

MODEL

465-2

465-1

NO PAPER

7065

58-1

58-2

44-1

44-2

44-3

PS12

UPPER

TRAY

SENSOR

58-3

PS16

UPPER

LIMIT

SENSOR

(UPPER)

327-1

327-2

PS20

PRE W

TRY

SENSOR

(UPPER)

MANUAL

SERVICE HANDBOOK

327-3

141-1

141-2

141-3

PS19

OPTICS

SYNC

SENSOR 1

54-1

54-2

54-3

69-1

69-2

69-3

147-1

PS25

PRE-FEED

SENSOR

(UPPER)

PS26

PRE-FEED

SENSOR

(UPPER)

PS10

OPTICS

SYNC

SENSOR 2

REVISED EDITION

3 - 8

2

147-2

147-3

45-1

45-2

45-3

PS13

LOWER

TRAY

NO PAPER

SENSOR

DATE

Jan.2000

59-1

59-2

59-3

PS17

UPPER

LIMIT

SENSOR

(LOWER)

328-1

328-2

PS21

PRE W

TRY

SENSOR

(LOWER)

PAGE

3-8

13-1

13-2

328-3

13-3

PS18

NO FEED

SENSOR

REPLACEMENT

47-1

47-2

47-3

PS15

BY-PASS

NO PAPER

SENSOR

METHOD

52-1

52-2

52-3

PS11

PAPER

CONVEYANCE

DOOR

SENSOR

Page 10

7065 OVERALL WIRING DIAGRAM (3/5)

ADU

COOLING

FAN 1

FM153

∗

∗

∗

525-4

525-2

∗∗∗

523-1

523-2

523-4

∗∗∗

522-2

522-4

522-1

∗

∗

∗

505-11

505-9 525-1

∗

∗

83-B10

83-B11

∗

H

FM153 LD

FM153 DRIVE

ADU

PAPER

FEED

CLUTCH

CL151

∗

∗

551-1

551-2

∗

∗

∗

505-1

505-2

∗

∗

44

83-A4CL151 DRIVEH83-A5CL152 DRIVE

H

ADU

REVERSAL

CLUTCH

CL152

∗

∗

552-1

552-2

∗

∗

505-3

∗

ADU

TIMING

CLUTCH

CL153

∗

553-1

553-2

∗

531-1

531-2

∗

505-4

83-A6CL153 DRIVE

H

∗

∗

∗

∗

ADU

NO PAPER

SENSOR

PS151

550-3

550-2

550-1

∗∗∗

531-4

∗

505-18

∗

57-B3PS151

H

ADU

PAPER

FEED

SENSOR

PS152

555-3

555-2

∗∗∗

531-5

∗

505-5

∗

57-A1PS152

H

REVERSAL

DETECTION

555-1

ADU

SENSOR

PS153

556-3

556-2

556-1

∗∗∗

531-6

∗

505-6

∗

57-A2PS153H57-A3PS154

H

ADU

PAPER

EXIT

SENSOR 1

PS154

557-3

557-2

557-1

∗∗∗

532-3

532-1

532-2

∗∗∗

531-7

∗

505-7

∗

ADU

PAPER

EXIT

SENSOR 2

PS155

558-3

558-2

558-1

∗∗∗

531-8

∗

505-8

∗

57-A4PS155

H

ADU

PAPER

EXIT

SENSOR 3

PS156

559-3

559-2

559-1

∗∗∗

534-1

534-2

∗∗∗

∗

∗

531-11

531-9

531-10

∗∗∗

505-13 534-3

505-12

505-10

∗∗∗

57-B45VDC

57-A5PS156

57-B6SGND

H

554-1

554-2

554-3

∗∗∗∗∗

∗

531-13

∗

531-12

∗

531-3

∗∗

505-23

505-14

∗

57-A8ADU SW

L

ADU

PAPER

FEED

MOTOR

M151

554-4

554-5

554-6

505-15

505-16

505-17

∗∗∗

83-A8M151 DRIVE

83-A9M151 CLOCK

83-A11M151 LD

P

H

H

554-8

∗

∗

505-20

47 40

554-11

∗

505-22

ADU

COOLING

FAN 2

FM154

∗∗∗

526-4

526-2

∗∗∗

524-2

524-4

524-1

∗∗∗

522-6

522-8

522-5

∗

∗

∗

505-21

505-19 526-1

∗∗

∗

83-B12

83-A12

H

FM154 LD

FM154 DRIVE

REV-FEED

POINT

SENSOR

PS302

611-1

611-3

611-2

∗∗∗

619-1

619-2

619-3

∗∗∗

∗

∗

622-1

622-2

622-7

∗∗∗

200-A4

200-A1

200-A10

H

5V DC

PS302

S GND

ADU

GETE

SENSOR

PS303

612-3

612-2

∗∗∗

622-3

∗

200-A5

H

PS303

612-1

AUD

PAPER

FEED

SENSOR

PS304

613-3

613-2

∗∗∗

619-4

619-5

619-6

∗∗∗

622-4

∗

200-A6

H

PS304

613-1

REV-PAPER

EXIT

SENSOR

PS305

614-3

614-2

614-1

∗∗∗

622-5

∗

200-A7

H

PS305

INTER

LOCK

SENSOR

PS306

615-3

615-2

615-1

∗∗∗

622-6

∗

200-A8

H

PS306

LCT 1ST

NO PAPER

PAPER FEED

SOLENID

(10)

SD141

∗

∗∗

721-1

721-2

728-4

∗

777876

∗

120-B11SD141 DRIVE

H

LCT PAPER

LCT

UPPER LIMIT

(10)

723-1

723-2

∗∗∗

728-6

∗

723-3

728-7

∗

SENSOR

(10)

PS143

724-1

724-2

∗∗∗

728-8

728-9

728-10

∗

SENSOR

PS141

728-5

∗

∗

∗

∗∗∗

83-B3SGNDH83-B4PS141

83-B55VDCL83-B6PS143L83-B7PS160

INTERLOCK

SENSOR

PS160

724-3

∗

LCT

725-1

∗∗∗

722-1

∗

722-2

CONVEYANCE

725-3

725-2

722-3

∗

∗

LCT

SENSOR

(10)

PS144

727-1

727-2

∗

∗

722-6

722-4

722-5

∗

∗

83-B8PS144

H

727-3

∗∗

LCT

PRE W

SENSOR

(10)

PS210

726-1

726-2

726-3

∗∗∗∗

722-7

722-8

722-9

∗

83-B9PS210

∗

∗

LCT

PRE-FEED

SENSOR

(10)

PS147

729-1

729-2

729-3

∗∗∗

722-10

722-11

722-12

∗

∗

∗

83-A10PS147

H

LCT

CNVEYANCE

CLUTCH

CL3

∗

∗

730-1728-1

730-2

∗∗∗∗

728-3

∗

∗

41

120-B9CL3 DRIVE

H

LCT 1ST

PAPER FEED

CLUTCH

(10)

CL1

∗

∗

720-1

720-2

∗

∗

728-2

∗

120-B10CL1 DRIVE

H

CB(3/5)

H

7-A1 M17 DRIVE

7-A2 24VDCH7-A3 M18 DRIVE

∗

∗

110-6

110-7

110-8

23-1

24-1

23-2

∗

∗

∗

24-2

∗

7-A4 24VDC

∗

110-9

∗

24V DC

7-A5

∗∗

112-1

∗

79-6

∗

122-1

∗

SD1 DRIVE

H

7-A6

∗

112-2

∗∗∗

79-7

∗

122-2

∗

24V DC

∗

∗

∗

∗

112-10

∗

38-5

∗

206-2

∗

114-B3

∗∗

112-11

∗

209-1

∗

207-1

∗

7-A7 SD2 DRIVEH7-A8 SD3 DRIVEH7-A12 MC7 DRIVEH7-A9 MC5 DRIVEH7-A10 MC6 DRIVEH7-B12 MC8 DRIVEH114-A4 MC9 DRIVEH114-B2 SD6 DRIVEH114-B4 SD7 DRIVE

∗

25-6

∗

123-1

∗

112-3

25-7

∗

123-2

∗

53-1

∗

112-4

∗

∗

53-2

∗

∗

∗

233-1

∗

∗

112-7

∗

233-2

∗

∗

230-1

∗

∗

112-5

∗

230-2

∗

∗

231-1

∗

∗

112-6

∗

231-2

∗

234-1

∗

112-8

∗

∗

234-2

∗

∗

∗

464-1

∗

∗

112-9

∗

464-2

∗

38-4

206-1

H

∗

112-12

∗

209-2

∗

207-2

∗

∗

∗

30-B9 M8 DRIVE 1

30-B10 M8 DRIVE 2

∗

∗

42-4

42-5

∗

∗

168-1

168-2

∗

∗

2

91-1

∗

91-2

∗

H

6-A10 SD153 DRIVE

40-3

∗

64-2

∗

H

6-B11 SD5 DRIVE

6-B10 24V DC

∗

∗

40-1

∗

∗

64-1

∗

∗

6-A1 SGND

∗∗∗

42-1

42-2

∗∗∗

H

6-A2 PS14

43-3

6-A3 5VDC

6-A4 SGND

42-8

H

6-A5 PS30

∗∗∗

42-9

∗∗∗

5V DC

6-A6

42-10

H

6-A7 24VDC

6-A8 MC3 DRIVEL6-B8 PS24

∗

∗

86-1

86-2

∗

∗

6-A9 SGND

∗∗∗

82-1

∗∗∗

82-2

82-3

6-B9 5VDC

3-B1 5V DC

∗∗∗

98-11

98-10

∗∗∗

392-7

392-15

∗∗∗

90-2

90-1

∗∗∗

H

6-A11 PS301

98-12

392-16

90-3

3-B3 SGND

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

3 - 9

2

DATE

Jan.2000

M17

UPPER

TRAY

MOTOR

PAGE

3-9

SD1

M18

LOWER

TRAY

MOTOR

1ST

PAPER

FEED

SOLENOID

(UPPER)

METHOD

REPLACEMENT

SD2

1ST

PAPER

FEED

SOLENOID

(LOWER)

SD3

1ST

PAPER

FEED

SOLENOID

(BY-PASS)

MC7

PAPER

FEED

CLUTCH

(BY-PASS)

MC5

PAPER

FEED

CLUTCH

(UPPER)

MC6

PAPER

FEED

CLUTCH

(LOWER)

MC8

MIDDLE

CNVEYANCE

CLUTCH

1

MC9

MIDDLE

CNVEYANCE

CLUTCH

2

SD6

UP

TRAY

SOLENOID

SD7

LOU

TRAY

SOLENOID

M8

TRANSFER

/SEPARATE

CLEANING

MOTOR

SD153

EXIT GATE

SOLENOID

SD5

CNVEYANCE

SOLENOID

46-1

46-2

46-3

PS14

REGIST.

SENSOR

32-1

32-2

32-3

PS30

BY-PASS

SENSOR

MC3

2ND

PAPER

FEED

CLUTCH

37-1

37-2

PS24

FUSER

DETECT

SENSOR

37-3

610-1

610-2

610-3

PS301

REV

POINT

SENSOR

Page 11

7065 OVERALL WIRING DIAGRAM (4/5)

LCT 1ST

PAPER FEED

CLUTCH (15)

CL2

∗

∗

716-1

716-2

∗

∗

709-1

709-2

43

∗

120-B1

H

CL2 DRIVE

LCT 1ST

PAPER FEED

SOLENID (15)

SD140

∗

714-1

714-2

∗

∗

709-9

709-4

42

∗

120-B2

H

SD140 DRIVE

LCT

710-1

∗

710-2

710-3

∗

LCT PAPER

UPPER LIMIT

SENSOR (15)

711-1

∗

NO PAPER

SENSOR (15)

PS140 PS142 PS146 PS200

∗

∗∗∗

709-5

709-6

709-7

711-2

∗∗

709-8

SENSOR (15)

711-3

∗

LCT

PRE-FEED

PS145

715-1

715-2

∗∗∗

∗∗

709-16

CONVEYANCE

SENSOR (15)

715-3

2

∗∗∗

120-B3

SGND

120-B4

H

PS140

120-B5

5VDC

120-B6

L

PS142

120-B12

H

PS145

LCT

713-1

∗

709-3

713-2

∗

∗

120-B7

H

PS146

713-3

∗

LCT

PRE W

SENSOR (15)

712-1

712-2

∗

∗

∗

709-10

709-12

709-11

77 78

∗

120-B8

∗

PS200

712-3

∗

∗

LCT PAPER

FEED MOTOR

703-3

703-1

∗

709-15

73 76

40VDC

703-2

67

204-1

PGND

M140

2

204-2

204-3

∗∗∗∗∗∗∗∗∗

120-A1

5VDC

204-4

204-5

204-6

120-A2

120-A3

120-A4

P

∗

SGND

M140 PLL

M140 CONT

CB (4/5)

LCT

TRAY

MOTOR (15)

M141 M142

∗

∗

731-1

731-2

∗

∗

46

120-A5

120-A6

L

P

M140 CLOK

M141 DRIVE

LCT

TRAY

MOTOR (10)

∗

∗

732-1

732-2

∗

∗

45

120-A7

L

M142 DRIVE

LCT TRAY

DETECTOR (15)

MS141 MS142

∗∗

735-2

709-14

709-13

∗

733-2

∗

∗

2

735-1

∗

∗

733-1

∗

120-A9

120-A8

P

P

TMP4

TRAY (15) ADD

LCT TRAY

DETECTOR (10)

∗

∗

734-1

734-2

∗

∗

120-A10

120-A11

P

P

TMP4

TRAY (10) ADD

DCPS

30

29 26 28 27

∗∗∗∗∗

410-1

410-2

410-3

410-4

410-5

5VDC

SGND

TCK2

ACKTGCLAMP

411-2

411-3

420-33

420-32

411-4

420-31

411-5

420-30

GND

411-6

420-29

SGND

S CK

411-7

420-28

S IN

411-8

420-27

—5VDC

S LD

MD 0

411-9

411-10

420-26

420-25

MD 1

411-11

420-24

MD 2

411-12

420-23

GND

411-13

420-22

OD 0

411-14

420-21

OD 1

411-15

420-20

OD 2

411-16

420-19

OD 3

411-17

420-18

12VDC

TCK1

PPPPPPPPPPPPPPPPPPPPPPPPPPPPP

411-1

420-34

OD 4

411-18

420-17

OD 5

411-19

RC

420-16

OD 6

411-20

420-15

OD 7

411-21

420-14

ADB

OD 8

411-22

420-13

GND

411-23

420-12

ED 0

411-24

420-11

ED 1

411-25

420-10

ED 2

411-26

420-9

ED 3

411-27

420-8

ED 4

411-28

420-7

ED 5

411-29

420-6

ED 6

411-30

420-5

IPB (1/2)

ED 7

411-31

420-4

ED 8

411-32

420-3

APR

P

411-33

420-2

GND

411-34

420-1

LASER

REVISE MOTOR

M40

Y

O

W

BK

GY

443-1

443-2

443-3

443-4

443-6

∗∗∗∗∗∗∗

424-1

424-2

424-3

424-4

424-5

PPPPP

M40 PWR A

M40 PWR B

M40 DRIVE A

M40 DRIVE B

M40 DRIVE A’

IP REQ

INDEX

TXA 1

∗

425-A1

425-A2

425-A3

425-A4

425-A5

∗∗∗∗∗∗∗

442-1

442-2

442-3

BN

443-5

424-6

424-7

424-8

423-1

423-2

∗

SMPR

425-A9

425-A10

425-A11

5VDC

425-A12

423-3

PPP

SGND

M INDEX 1

MPR

425-B1

P

∗

HLVL

M40 DRIVE B’

425-A6

425-A7

∗∗∗∗∗∗∗∗∗∗∗∗∗

INDXSB LDB1 LDB2

442-4

442-5

442-6

442-7

442-8

423-4

SGND

425-B2

RC

423-5

M INDEX 2

TXA 0

425-B3

425-B4

423-6

SGND

425-B5

442-9

423-7

423-8

423-9

P

SGND

S INDEX 1

S INDEX 2

425-B6

425-B7

442-10

423-10

SGND

425-B8

∗

423-11

∗

HLVL

425-B9

423-12

∗

IPR

O YOBI 1

425-B10

425-B11

∗

∗

∗

425-B12

∗

440-1

421-1

5VDC

440-2

421-2

SGND

440-3

440-4

440-5

440-6

RC

421-3

421-4

421-5

421-6

∗

∗

H

SGND

LD1 VIDEO

LD1 APC CONT 1

LD1 APC CONT 2

440-7

421-7

H

LD1 ALM

440-8

440-9

421-8

421-9

P

∗∗∗

LD1 INC

LD1 IRCLK

440-10

421-10

LD1 U/D

440-11

421-11

LD1 C/S

440-12

421-12

∗

LD1 LPR

441-1

422-1

5VDC

441-2

422-2

SGND

441-3

441-4

441-5

441-6

RC

422-3

422-4

422-5

422-6

∗

∗

H

SGND

LD2 VIDEO

LD2 APC CONT 1

LD2 APC CONT 2

441-7

422-7

H

LD2 ALM

441-8

441-9

422-8

422-9

P

∗∗∗

LD2 INC

LD2 IRCLK

441-10

422-10

LD2 U/D

441-11

441-12

422-11

422-12

∗

LD2 C/S

LD2 LPR

DCPS

17 18 19 20

∗∗∗

430-1

430-2

430-3

5VDC

5VDC

SGND

∗

430-4

SGND

TH1 ANG 1

TH1 ANG 2

∗

∗

6-B1

6-B2

∗

∗

98-1

98-2

98-3

∗

∗

392-1

392-2

392-3

∗∗∗

TH1

FIXING

TEMPERATURE

SENSOR 1, 2

TH2 ANG 1

TH2 ANG 2

TH3 ANG 1

∗

∗∗∗

6-B3

6-B4

6-A12

∗∗∗

98-4

98-5

∗∗∗

392-5

392-4

∗

∗

TH2

TH3 ANG 2

6-B12

∗∗

98-6

392-6

∗

TH3

SENSOR

SGND

6-B5

∗∗∗

98-7

98-8

∗∗∗

392-12

392-13

∗∗∗

40-1

PS27

FIXING

EXIT

PS27

L

6-B6

40-2

5VDC

6-B7

98-9

392-14

40-3

M12 H/L

M12 CLK

M12 STOP

M12 MODE 0

M12 MODE 1

M12 MODE 2

M12 F/R

M12 CONT

∗

223-4

∗

223-5

∗

223-6

HHH

223-7

223-8

M12 BRAKE

223-9

P

223-1

∗

223-2

∗

223-3

∗∗∗∗∗∗∗∗∗∗∗

224-1

224-2

224-3

224-4

224-5

224-6

224-7

224-8

224-9

M12 DRIVE C

M12 DRIVE A

M12 DRIVE B

M12 MAG A’

M12 MAG A

M12 MAG B’

M12 MAG B

M12 MAG C’

PPPPPPPPP

225-1

225-2

225-3

WWW

M12 MAG C

228-1

228-2

228-3

228-4

228-5

228-6

BKBKBKBKBKBKBKBKBK

M12

OPTICS DRIVE MOTOR

M12 NCR

M12 PLLL

∗

223-10

223-11

224-10

224-11M12 PLL

∗

SGND

5VDC

228-7

228-8

M12 FG

∗

228-9

OPMDB

2

40VDC

PGND

12VDC

226-1

226-2

226-3

∗∗∗ ∗

31 32 33

DCPS

481-A1

481-A2

481-A3

481-A4

481-A5

481-A6

481-A7

481-A9

481-B1

481-B2

481-B3

481-B4

481-B5

481-B6

481-B7

481-B8

P

RXA 1

SGND

MTN V/V

MAPC CAL

481-B9

481-B10

∗

∗∗∗

∗

CORR

MIND CHG

481-B11

481-B12

SV

GND

3-A7

∗

SD LE DRIVE

WT LE DRIVE

∗

∗

3-A8

3-A9

∗

∗

SGND

3-A10

∗

SGND

3-B5

∗

8VDC

3-B6

∗

5VDC

3-B7

∗

OB1 TXD

P

3-A1

∗

219-1

∗

10-1

3-A2

∗

219-2

∗

10-2

P

OB1 RXD

OB1 RTS

P

3-A3

∗

219-3

∗

10-3

219-4

3-A4

∗

219-5

∗

10-4

P

OB1 CTS

OB1 DTR

P

3-A5

∗

219-6

∗

10-5

3-A6

5678

∗

∗∗∗

219-7

219-8

∗

10-6

10-7

P

5VDC

OB1 DSR

∗

10-8

5VDC

219-9

∗

∗

10-9

SGND

219-10

∗

∗

10-10

SGND

P

P

∗∗∗∗∗

SGND

RESET

M V/V

MEE V/V

481-A10

DCORR

I YOBI 1

481-A11

481-A12

GND

8VDC

P

P

∗

RXA 0

OB1

5VDC

S LE

G LE

SS LE

EXT LE

JSD 0

JSD 5

JSD 6

JSL 14

217-8

220-8

217-9

220-9

NC

217-10

220-10

Y1 CONT

X1 CONT

Y2 CONT

X2 CONT

FL HOTNCNC

FL GND

LCD Vajd

24VDC

LD3

LD2

LD1

LD0

24VDC

PGND

5VDCCPLP

213-9

82-9

∗

213-10

82-10

∗

213-11

82-11

FLMNCDISP OFF

∗

∗

212-12

213-13

213-14

82-12

82-13

82-14

217-1

220-1

217-2

220-2

217-3

220-3

217-4

220-4

217-5

217-6

217-7

RC

220-5

220-6

220-7

SGND

226-5

222-4

∗

221-1

222-5

221-2

P

P

P

213-3

82-3

213-4

82-4

213-5

82-5

P

213-6

82-6

213-7

82-7

213-8

RC

82-8

222-6

222-7

222-3

222-2

222-1

210-1

210-2

210-3

210-4

210-5

210-6

210-7

210-8

210-9

210-10

210-11

210-12

210-13

210-14

210-15

210-16

210-17

210-18

210-19

210-20

210-21

210-22

210-23

210-24

∗

∗

∗

221-3

221-4

∗

215-1

∗

215-2

∗

215-4

214-1

214-2

214-3

214-4

214-5

214-6

214-7

214-8

RC RC

214-9

214-10

214-11

214-12

214-13

214-14

214-15

214-16

214-17

214-18

214-19

214-20

214-21

214-22

214-23

214-24

∗∗∗∗∗

212-1

212-2

212-3

212-4

83-1

83-2

83-3

83-4

212-5

212-6

-1

-2

∗∗∗∗∗∗

212-7

-3

212-8

-4

∗∗

∗

213-1

82-1

213-2

82-2

∗

34

WT SW

OB2

LMP ADJ

SGND

216-1

216-2

RC

71-1

71-2

5VDC

216-3

71-3

INDICATING BOARD

FL

FL GND

R

BK

77-1

77-4

OB3

INDICATING STARTER

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

3 - 10

2

DATE

Jan.2000

PAGE

3-10

METHOD

REPLACEMENT

Page 12

7065 OVERALL WIRING DIAGRAM (5/5)

1

MAIN RELAY

AC POWER

CBR

BK BK

WW

L1

∗

385-4

385-1

∗

LV

HV

INVB

752-1 752-3 752-4

COIL2

BK BK

752-2

W

W W W W

∗

NF

∗

∗

∗

∗

COIL1

COIL1

(KBE ONLY)

∗

390-2 390-1

∗

∗

398-3

AC(C)

RL2

(KBJ ONLY)

SUB RELAY

753-2 753-1

∗

∗

397-5

397-6

AC(H)

AC(C)

BK

∗

BK

BK

W

∗

387-2

750-2

WWW

HTR3

∗

BK

387-1

750-1

BKBKBK

W

W

HTR2

BK

RL1

∗

W

751-2

HTR1

BK

2

751-1

BK

398-1

AC(H)

MS4

BK BK BK BK

BK BK

MAIN SWITCH

BK

395-1

AC(H)

381-3

BK

BK

W W

W

396-3

AC(C)

381-4

SW1

W

395-2

AC(C)

383-1

BK

383-2

BK

MS1

BK BK

∗

381-1

381-2

BK

396-1

AC(H)

392-9

392-10

383-3

BK

383-4

BK

TS-2 TS-1

397-1

AC(H)

397-2

AC(H)

BK

394-2

399-2

W

∗

W

AC(H)

W

382-1

AC(C)

∗

L2

W

392-18

GY

394-1

∗

399-1

V

∗

L2 DRIVE

L3

W

392-19

BN BNBNBN

382-2

∗

L3 DRIVE

L4

W

392-20

382-4

∗

L4 DRIVE

∗

∗∗∗

BK

BK

4036 37 41 42 43 44 45 46 47 48 49 50 52 53 54

∗∗∗

∗∗

∗

∗

∗

122-1

122-2

122-3

∗

∗

∗

78-1

78-2

78-3

24V DC

24V DC

24V DC

∗

122-4

122-5

∗∗∗

78-4

24V DC

∗

78-5

24V DC

122-6

∗

78-6

PGND

∗∗∗

2

38 39

∗

51

∗∗∗∗∗

∗

121-1

∗

78-7

PGND

∗

121-3

∗

99-2

24V DC

∗

57 58 59 60

55 64 66

∗∗∗

∗

∗

121-4

∗

99-3

24V DC

121-5

∗

∗

99-4

PGND

61 63

6256

∗

∗∗∗∗∗

121-6

65 67 69

∗

123-2

∗

99-5

PGND

∗

∗

∗

88-2

PGND

68 70 72

∗

∗

128-2

∗∗

∗

123-3

∗

88-3

PGND

71 73

∗∗∗

∗

123-4

∗

88-4

40V DC (1)

∗∗

128-1

123-574121-2

88-5

40V DC (1)

75

∗

∗

∗

∗

∗

∗

99-1

24V DC

3

4

81-1

60-B10

24V DC

∗∗

81-2

∗

60-B9

L

RL DRIVE

RL1 RL2

BBR

∗

96-1

∗∗∗

96-3

5

6

7

8

R

24V DC (2)

2-2

∗∗

96-4

∗

∗

96-5

∗

∗

96-6

∗

∗

96-7

∗

∗

24V DC (2)

PGND

12V DC

SGND

SGND

5V DC

8V DC

5V DC (For control board)

2-1

2-3

2-4

2-5

2-6

2-8

2-10

8-10

∗∗∗∗∗∗∗∗∗∗∗∗∗∗∗∗∗

61-1

61-2

61-3

4-1

61-4

61-5

61-7

61-9

29-3

29-2

29-1

∗∗∗∗

232-2

232-1

∗∗∗

470-1 232-3

470-2

470-3

∗∗∗

60-B8

60-A9

60-A10

H

PGND

24V DC

L1 CONT

5V DC (For control board)

SGND

SGND

8-9

8-7

8-6

8-4

8-3

4-2

4-4

4-5

60-B7

60-A6

L

L

L2 CONT

RL1 CONT

8-2

8-1

60-A7

60-A8

H

H

L3 CONT

L4 CONT

SGND

2-7

∗

61-6

5V DC

2-9

∗

61-8

DCPS

5V DC

5V DC

11V DC (For KRDS)

SGND

SGND

SGND

PGND

PGND

PGND

24V DC

24V DC

5V DC

-5V DC

SGND

SGND

12V DC

40V DC

PGND

12V DC

SGND

401-1

401-2

8-8

8-5

401-3

401-4

28-1

28-2

28-3

28-5

28-6

400-6

400-8

400-7

400-9

400-5

400-1

400-2

400-3

400-4

412-3

412-5

27 28 29 30

26

412-2

412-4

412-1

∗∗∗∗∗

∗∗∗∗∗

35

∗

31 32 33 34

∗

∗∗∗

∗

100-1

∗

100-2

∗

101-2

∗

101-3

∗

∗

∗

∗

9

∗

10

∗

11

∗

12

∗

13

14

∗∗∗

∗

∗

∗

∗∗∗

2524232221201918171615

121-7

99-6 PGND

∗

∗

1-4

123-1

88-1 PGND

∗

∗

1-3

∗

∗

1-2

1-1

CB (1/5)

TDS CONT

12VDC

TDS ANG

SGND

24VDC

PGND

B CONT

C CONT

C SHIFT

B SHIFT

G SHIFT

M7 DRIVE 1

30-B7

∗∗∗∗∗

63—3

63—4

50—3

50—4

21—1

M7 DRIVE 1

∗

39—1

R

M7

CHARGER

CLEANING

MOTOR

5VDC

M7 DRIVE 2

5-A1

5-A2

30-B8

63—5

63—6

RC

50—5

50—6

RC

21—2

21—3

21—4

∗

TH2 ANG

M7 DRIVE 2

∗

39—2

BK

24VDC

PCL CONT

L

5-A3

5-A4

∗

63—7

63—8

50—7

50—8

21—5

21—6

CHARGING

DB

PRE-

LAMP

24VDC

20—1

R

PCL CONT

L

20—2

W

γ / Dmax LED V ref

∗

5-A12

5-A11

∗

324—1

324—2

324—3

325—1

325—2

325—3

19—1

19—10

∗

γ sig / MONI

12VDC

Dmax LED CONT

L

5-B1

5-B2

5-B3

Y

324—4

324—5

324—6

325—4

325—5

325—6

19—2

19—3

19—4

∗

Dmax MONI

TCBS

TONER

CONTROL

SENSOR

DRUM JAM CONT

SGND

L

5-B4

5-B5

5-B6

5-B7

B

∗

∗∗∗∗∗

324—7

324—8

324—9

324—10

RC

325—7

325—8

325—9

325—10

RC

19—5

19—6

19—7

19—8

∗

∗

Dmax sig

DRUM JAM

LED CONT

L

5-B8

∗

19—9

SEPARATION

24VDC

5-B9

O

324—11

324—12

325—11

325—12

34—1

34—2

R

SD4PCL

CLAW

SOLENOID

SD 4 DRIVE

L

5-B10

∗

B

∗

5-A5

5-A6

Y

∗

63—9

63—10

∗∗∗

50—12

50—13

∗∗∗

51—1

51—2

R

BN

DENSITY

SENSOR

∗

5-A7

∗

63—11

50—14

51—3

O

5-A8

B

63—12

∗

50—15

∗

51—4

Y

GP CONT

L

L

L

∗∗∗

62-A11

62-A2

62-A3

62-A4

62-A5

62-A6

62-A7

62-A8

62-A9

B

O

∗∗∗

∗

∗∗∗

84—1

84—2

84—3

84—4

84—5

84—6

84—7

84—8

84—9

L

F SIG

GP

GUIDE

PLATE

HV1

31—2

BN

71—1

∗

CHARGING

31—1 BIAS

GY

GY

50—20 70—1

GY

BIASTONER

S SHIFT (DC)

S SHIFT (AC)

S CONT

T SHIFT

T CONT

PGND

24VDC

L

L

62-B5

85—5

L

∗

62-B4

62-B3

62-B2

62-B1

O

B

85—4

85—3

85—2

85—1

∗

∗

62-B10

62-B8

62-B7

62-B6

∗∗∗∗∗∗∗

85—10

85—8

85—7

85—6

∗

∗∗∗

∗

∗∗∗

∗

∗

∗

87—1

87—3

87—5

87—6

87—7

87—8

87—9

87—10

87—11

T SIG

HV2

HV2

87—12

SYNCHRONIZATION

∗

∗

F.G

S SIG

SEPARATE TRANSFER TRANSFER

89—1

LAMP

85—9

∗

89—2

R

PSL CONT

∗

62-B11

∗

∗

W

5VDC

PS40

L

22-A5

22-A6

R

163-1

163-2

∗

133-3

133-2

PS40TSLTDS

APS

SENSOR 1

PS46

H

22-A1

∗

NC

PS41

L

22-AB

∗

163—4

PS47

L

22-A2

∗

163—8

NC

SGND

22-A7

B

∗

163—7

163-3

PS42

L

22-B1

∗

163—5

PS48

L

22-A3

∗∗

163—9

PS43

L

22-B2

∗

163—6

∗

138-3

138-2

APS

SENSOR 4

∗∗∗

138-1

∗∗∗

133-1

130-3

130-2

APS

SENSOR 3

∗∗∗

130-1

∗∗∗

134-3

134-2

134-1

PS41 PS42 PS43

APS

SENSOR 2

239-3

239-2

PS48

APS

SENSOR 7

∗∗∗

239-1

MODEL

7065

MANUAL

SERVICE HANDBOOK

REVISED EDITION

3 - 11

2

DATE

Jan.2000

PAGE

3-11

METHOD

REPLACEMENT

Page 13

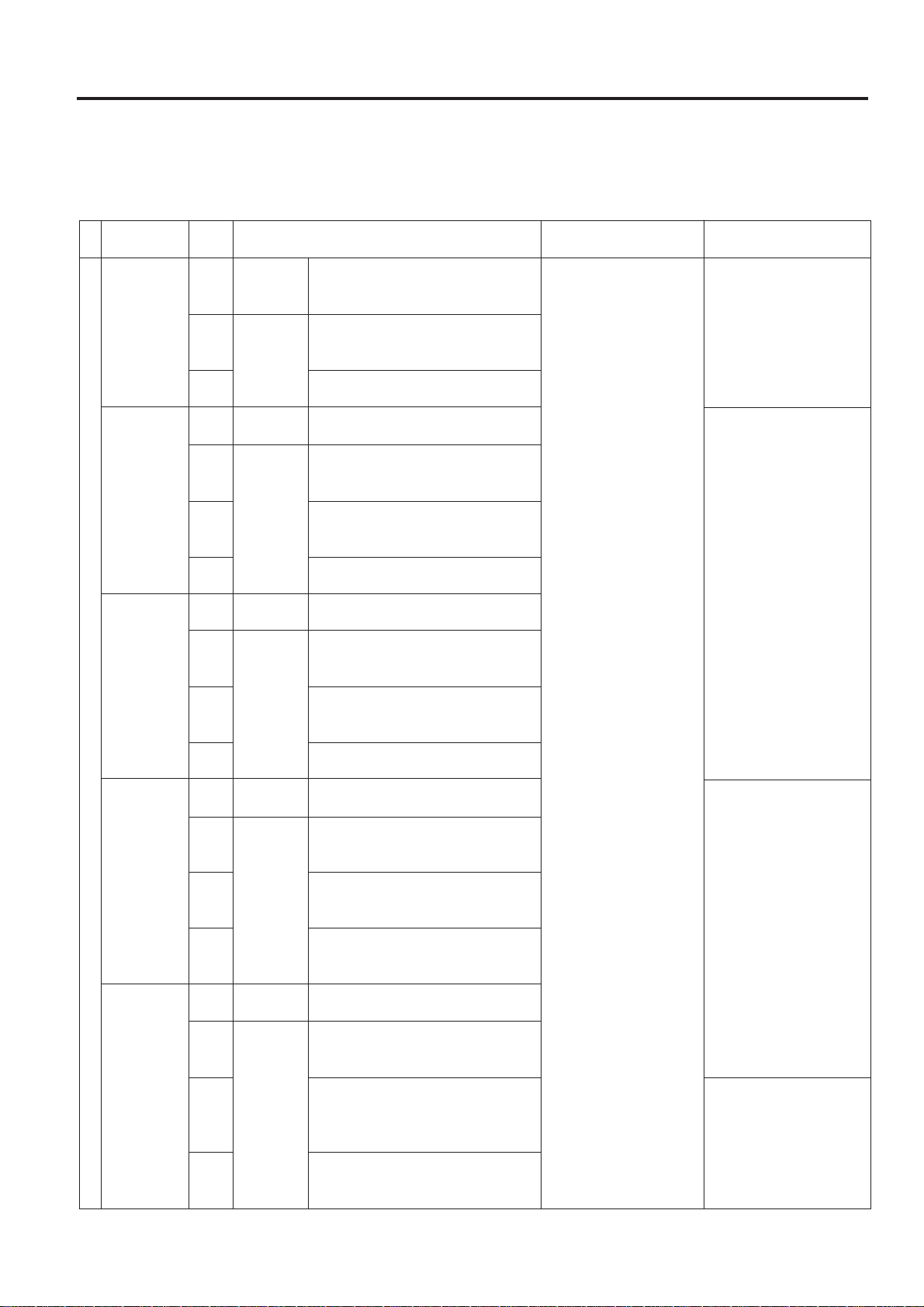

JAM LIST

Following jam detection is carried out in this machine.

[1] Paper Jam

Classifica-

tion

By-pass

feed tray

Tray 1

Tray 2

Tray 3

Main body and LCT

Tray 4

Jam

code

J10-1

J10-2

J10-4

J11-1

J11-2

J11-3

J11-4

J12-1

J12-2

J12-3

J12-4

J13-1

J13-2

J13-3

J13-4

J14-1

J14-2

J14-3

J14-4

When

stationary

When

operating

When

stationary

When

operating

When

stationary

When

operating

When

stationary

When

operating

When

stationary

When

operating

Causes

PS18 (no feed) and PS14 (registration) are OFF during idling but PS30

(by-pass feed) is ON.

PS14 (registration) or PS30 (by-pass

feed) is not turned ON within 4 seconds from ON of SD3 (by-pass feed).

PS30 (by-pass) is ON at the time of

ON of SD3 (by-pass feed).

PS20 (pre try (upper)) is ON during

idling.

PS20 (pre try (upper)) is not turned

ON within 400 msec from ON of SD1

(1st paper feed (upper)).

PS18 (no feed) is not turned ON

within 650 msec from ON of SD1

(1st paper feed (upper)).

PS20 (pre try (upper)) is ON when SD1

(1st paper feed (upper)) goes ON.

PS21 (pre try (lower)) is ON during

idling.

PS21 (pre try (lower)) is not turned

ON within 400 msec from ON of SD2

(1st paper feed (lower)).

PS18 (no feed) is not turned ON

within 820 msec from ON of SD2

(1st paper feed (lower)).

PS21 (pre try (lower)) is ON when SD2

(1st paper feed (lower)) goes ON.

PS210 (LCT pre try (1000)) is ON

during idling.

PS210 (LCT pre try (1000)) is not

turned ON within 420 msec from ON

of SD141 (LCT paper feed (1000)).

PS144 (LCT conveyance (1000)) is

not turned ON within 2 seconds from

ON of SD141 (LCT paper feed (1000)).

PS210 (LCT pre try (1000)) is ON

when SD141 (LCT paper feed

(1000)) is ON.

PS200 (LCT pre try (1500)) is ON

during idling.

PS200 (LCT pre try (1500)) is not

turned ON within 370 msec from ON

of SD140 (LCT paper feed (1500)).

PS146 (LCT conveyance (1500)) is

not turned ON within 2.4 seconds

from ON of SD140 (LCT paper feed

(1500)).

PS200 (LCT pre try (1500)) is ON

when SD140 (LCT paper feed

(1500)) is ON.

Operation when jam

occurs

If a copy is being

made when a jam

occurs, copy operation

is stopped after

completion of exit of

the copy.

DIAGRAMS

Method of clearing jam

Remove the original

paper from by-pass tray

then remove the jammed

paper.

Open the main body

conveyance door and

remove the jammed

paper and close it.

Open the tray and

remove the jammed

paper and close it.

Open the LCT conveyance door and remove

the jammed paper and

close it.

Open the tray and

remove the jammed

paper and close it.

Open the LCT upper

cover and remove the

jammed paper and close

it.

Open the tray and

remove the jammed

paper and close it.

3 - 13

Page 14

DIAGRAMS

Classifica-

tion

LTC-352

paper feed

jam

LT-352

Conveyance

jam

Main body and LCT

Jam

code

J15-1

J15-2

J15-3

J15-4

J16-0

J17-1

J17-3

J17-4

J17-5

J17-6

J19-0

J19-1

J19-2

When

stationary

When

operating

When

stationary

When

stationary

When

operating

When

operating

When

stationary

Causes

PS802 (LT pre try) is ON during idling.

PS802 (LT pre try) is not turned ON

within 400 msec from ON of MC800

(LT 1st paper feed).

PS18 (no feed) is not turned ON

within 800 msec from ON of PS802

(LT pre tray).

PS802 (LT pre try) is ON when

MC800 (LT 1st paper feed) is ON.

PS14 (register) is ON during idling.

PS18 (no feed) or PS19 (optics sync

1) is ON during idling.

PS19 (optics sync 1) is not turned

ON within 560 msec from ON of

PS156 (ADU paper exit 3).

PS19 (optics sync 1) is not turned

ON within 430 msec from the start of

reconveyance in right lengthwise

conveyance in LCT paper feed.

PS18 (no feed) is not turned ON

within 560 msec from the start of

reconveyance in right lengthwise

conveyance in LCT/ADU reverse

side.

A loop is not completed within 400

msec from ON of PS18 (no feed).

PS144 (LCT conveyance (1000)) is

not turned ON within 2 sec. from ON

of PS147 (LCT prefeed (1000)).

PS146 (LCT conveyance (1500)) is

not turned ON within 2 sec. from ON

of PS145 (LCT prefeed (1500)).

PS144 (LCT conveyance (1000)) or

PS146 (LCT conveyance (1500)) is

ON during idling.

PS147 (LCT prefeed (1000)) or

PS145 (LCT prefeed (1500)) is ON

during idling.

Operation when jam

occurs

If a copy is being made

when a jam occurs,

copy operation is

stopped after completion of exit of the copy.

If a copy is being made

when a jam occurs,

copy operation is

stopped after completion of exit of the copy.

If a copy is being made

when a jam occurs,

copy operation is

stopped after completion of exit of the copy.

Method of clearing jam

Open the LCT conveyance door and remove

the jammed paper and

close it.

Pull the LCT out and

remove the jammed

paper.

Open the front door and

remove the jammed

paper and close it.

Open the conveyance

door and remove the

jammed paper and close

it.

3 - 14

Page 15

DIAGRAMS

Classifica-

tion

Conveyance

jam

Main body and LCT

Jam

code

J21

J30

J31

J32

J33-1

J33-2

J33-3

J33-4

When

stationary

When

operating

When

stationary

When

operating

Causes

TCSB (drum wrapping sensor) is ON.

PS14 (registration) is not turned OFF

within paper size length + 40 mm

from ON of MC3 (2nd paper feed).

PS27 (fixing paper exit) is not turned

ON within 2000 msec from ON of

MC3 (2nd paper feed).

PS27 (fixing paper exit) was turned

ON within 280 msec from copy start.

PS27 (fixing paper exit) is ON during idling.

PS27 (fixing paper exit) does not go

OFF within 2000 msec after PS27

(fixing paper exit) goes ON.

PS301 (reversal point), PS302 (reversal paper feed point), PS303

(ADU gate), PS304 (ADU paper feed)

or PS305 (reversal paper exit) is ON

during idling.

PS301 (reversal point) is not turned

ON within 800 msec from ON of

PS27 (fixing paper exit).

PS301 (reversal point) is not turned

OFF within 2.4 sec. from ON of

PS301 (reversal point).

PS305 (reversal paper exit) is not

turned OFF within 1 sec. from ON of

PS27 (fixing paper exit) at the

straight paper exit.

PS305 (reversal paper exit) is not

turned OFF within 1 sec. from start

of M201’s (reversal paper exit) reversing operation at the reversal

paper exit.

Operation when jam

occurs

The main body is

stopped immediately.

Method of clearing jam

Open the front door and

remove the jammed

paper and close it.

Open the paper exit and

the front door and

remove the jammed

paper and close them.

Open the main body left

plate, remove the jammed

paper, then close it.

3 - 15

Page 16

DIAGRAMS

Classification

DF-312

RADF

Jam

code

J61-0

J61-1

J62-1

J62-2

J62-3

J62-4

J62-5

J63-0

J63-1

J63-2

J63-3

When

stationary

When

operating

When

stationary

When

operating

Causes

MS301 (cover open/close detect) is

ON during idling.

MS301 (cover open and close detect)

was turned ON during RADF operating.

PS301 (DF open and close detect) is

OFF during idling.

PS301 (DF open/close detect) was

turned OFF during RADF operation.

PS306 (original registration) is not

turned OFF within a certain period

after it has been turned ON.

PS308 (original conveyance) is not

turned ON within a certain period

after the pre-feed of the duplex

original front side (include the

simplex original) has been started.

PS308 (original conveyance) is not

turned ON within a certain period

after the pre-feed of the duplex

original back side has been started.

PS308 (original conveyance) is not

turned OFF within a certain period

after the scanning of the duplex

original front side (include the

simplex original) has been started.

PS308 (original conveyance) is not

turned OFF within a certain period

after the scanning of the duplex