Page 1

5

DIAGRAM

1 ADJUSTMENT

2 ISW

3 KRDS

4 SERVICE

5 DIAGRAM

Page 2

1 OUTLINE

2 ISW

3 SERVICE

4 DIAGRAM

5 DIAGRAM

Blank page

Page 3

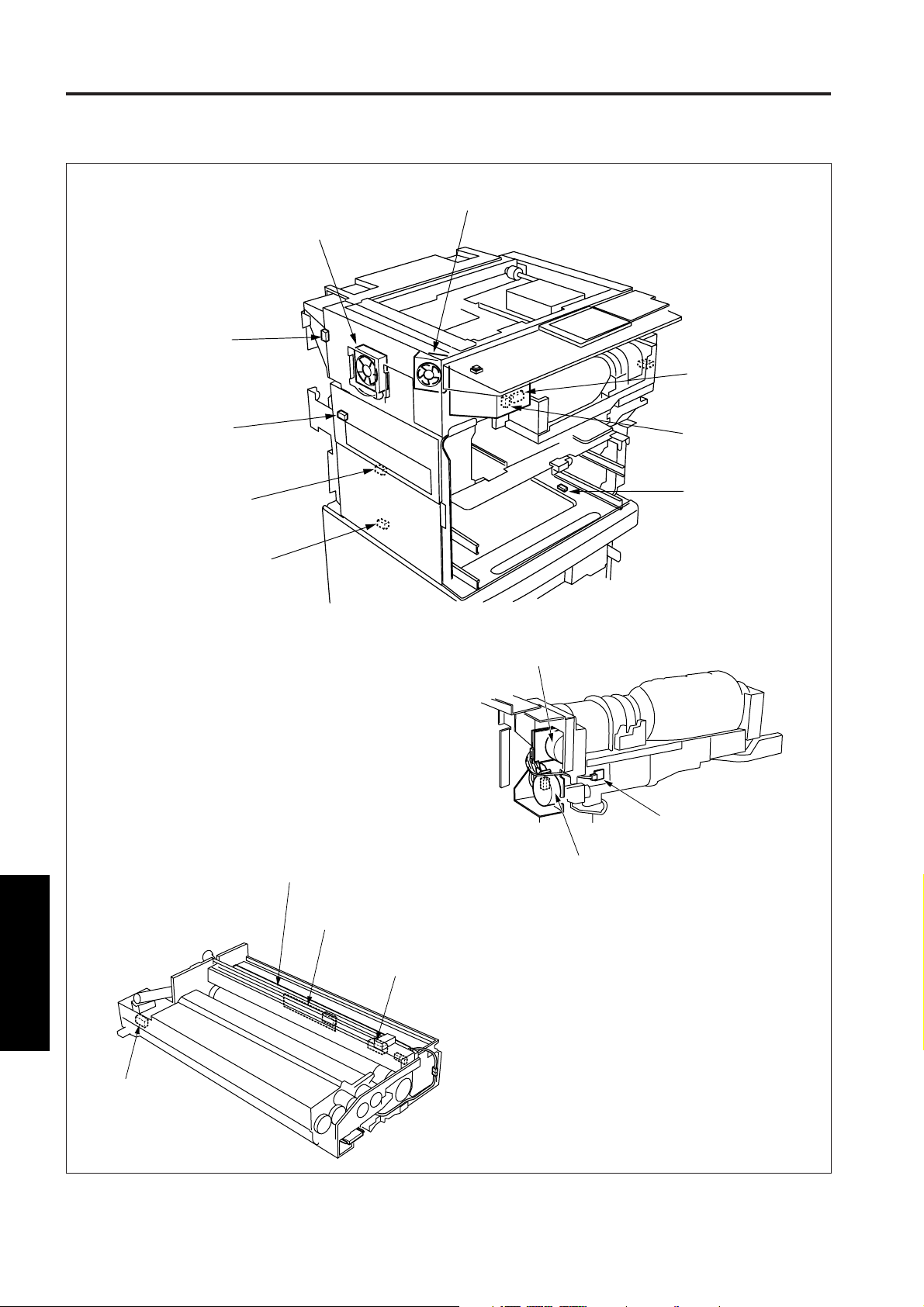

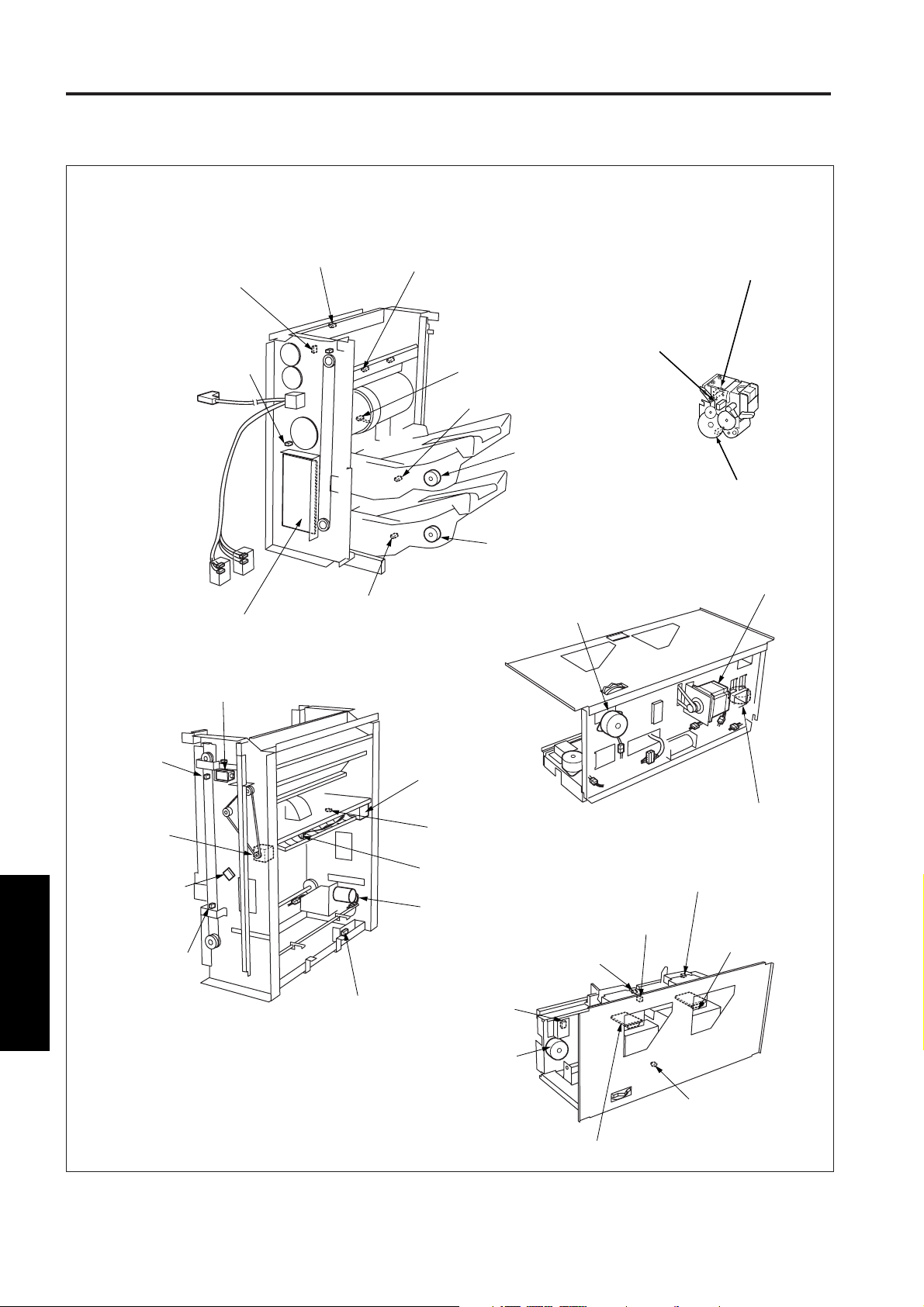

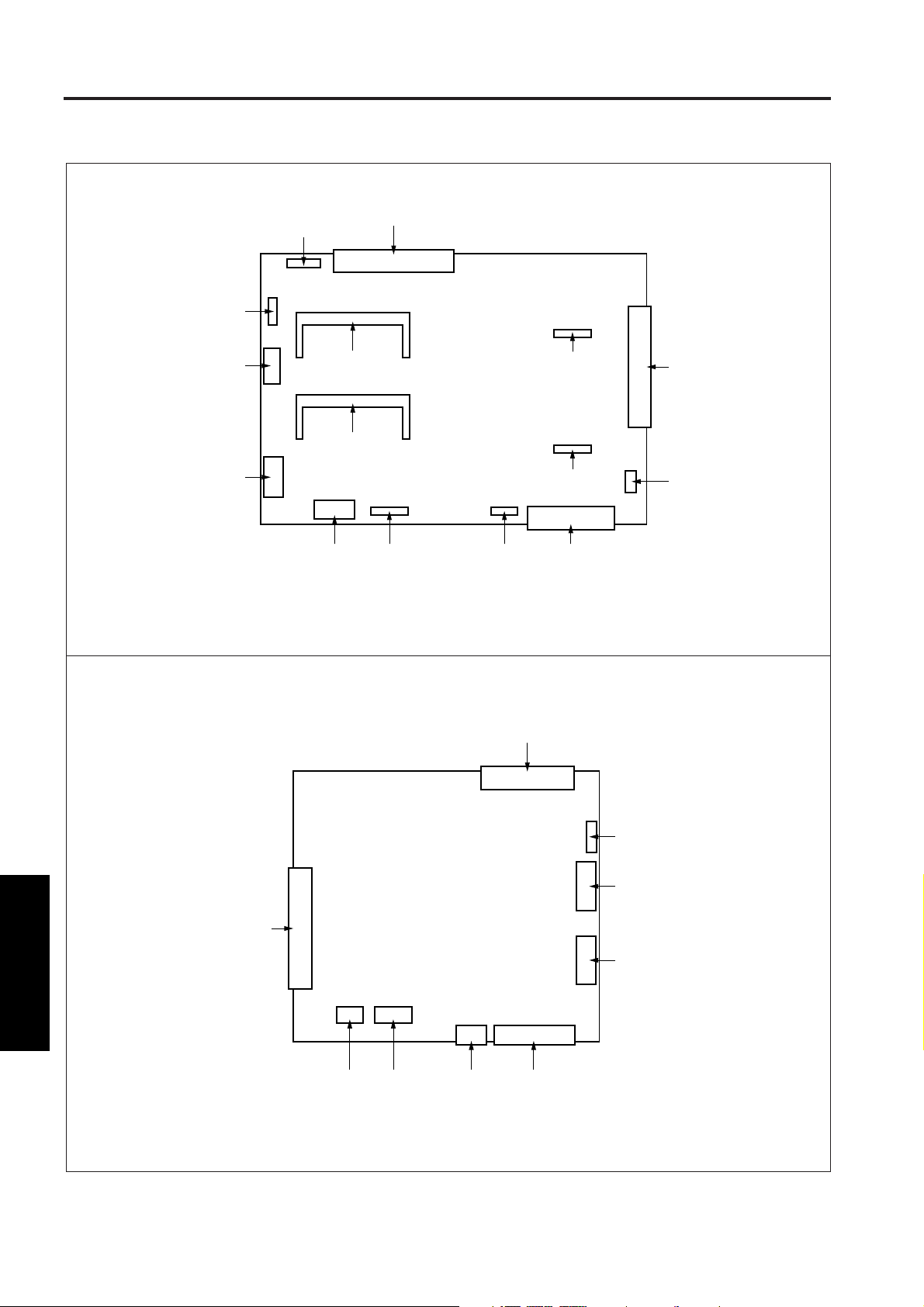

7045 ELECTRICAL PARTS LAYOUT DRAWING

DIAGRAMS

SCDB

Scanner drive board

M3

Developing motor

M6

1st paper feed motor

HV2

High voltage unit 2

SD2

1st paper feed SD

PS31

No paper detect PS

PS32

Upper limit detect PS

MC2

Developing MC

M2

Scanner motor

PFDB

Paper feed detect board

HV1

High voltage unit 1

M8

PRDB

Printer drive board

Tray motor

M4

Drum motor

M1

Main motor

PS1

Paper exit PS

SD5

Gate SD

FM3

Main body cooling fan

M12

Reversal paper exit motor

DCPS1

DC power supply unit 1

LBR

Leak breaker

FM5

DCPS cooling fan

FM4

Conveyance suction fan

LCD

Display board

OB

Operation board

INDEXSB

Index sensor board

ICB

Image control board

ADB

A/D converter board

PRMB

Parameter memory board

PS26

APS sensor 2

PS25

APS sensor 1

OB INV

OB Inverter

PS4

APS timing PS

SW2

Sub power switch

L1

Exposure lamp

L1 INVB

L1 Inverter board

CB

Control board

4 DIAGRAM

DCPS2

DC power supply unit 2

PMDB

Polygon motor drive board

PS3

Optics HP PS

5 DIAGRAM

M5

Polygon motor

LDB

Laser drive board

5-1

Page 4

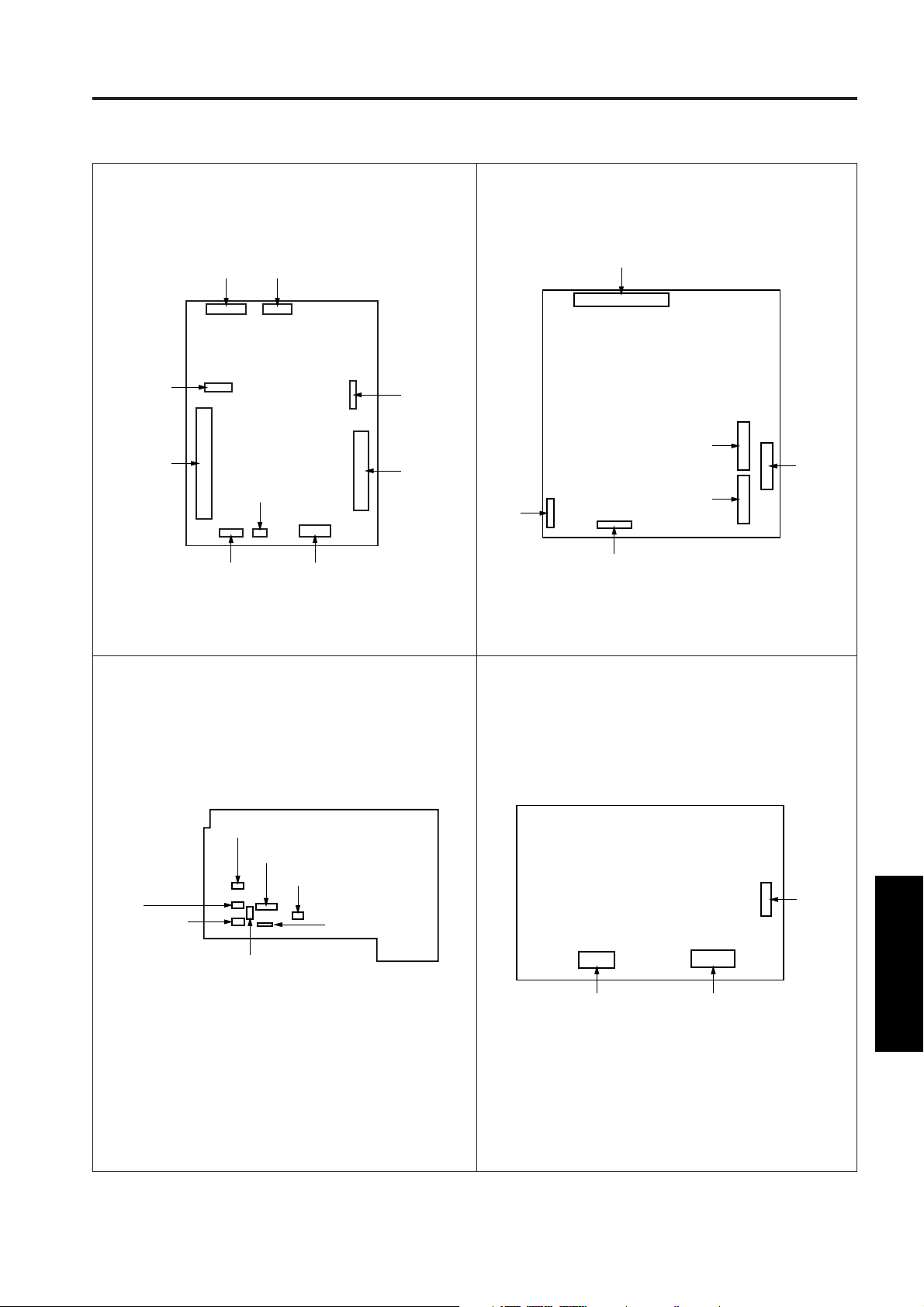

DIAGRAMS

SW1

Main power switch

MS2

Inter lock MS2

FM2

Scanner cooling fan 2

FM6

Polygon cooling fan

C(T)

Total counter

MS1

Inter lock MS1

4 DIAGRAM

PS28

Reversal detection PS 1

PS30

Reversal detection PS 2

PCL

Pre-charging lamp

TCSB

Toner control sensor board

PTC

PTC heater

M10

Toner supply motor 1

TLD

Toner level detection sensor

M11

Toner supply motor 2

5 DIAGRAM

TDS

Toner density

detection sensor

SD1

Separation claw SD

5-2

Page 5

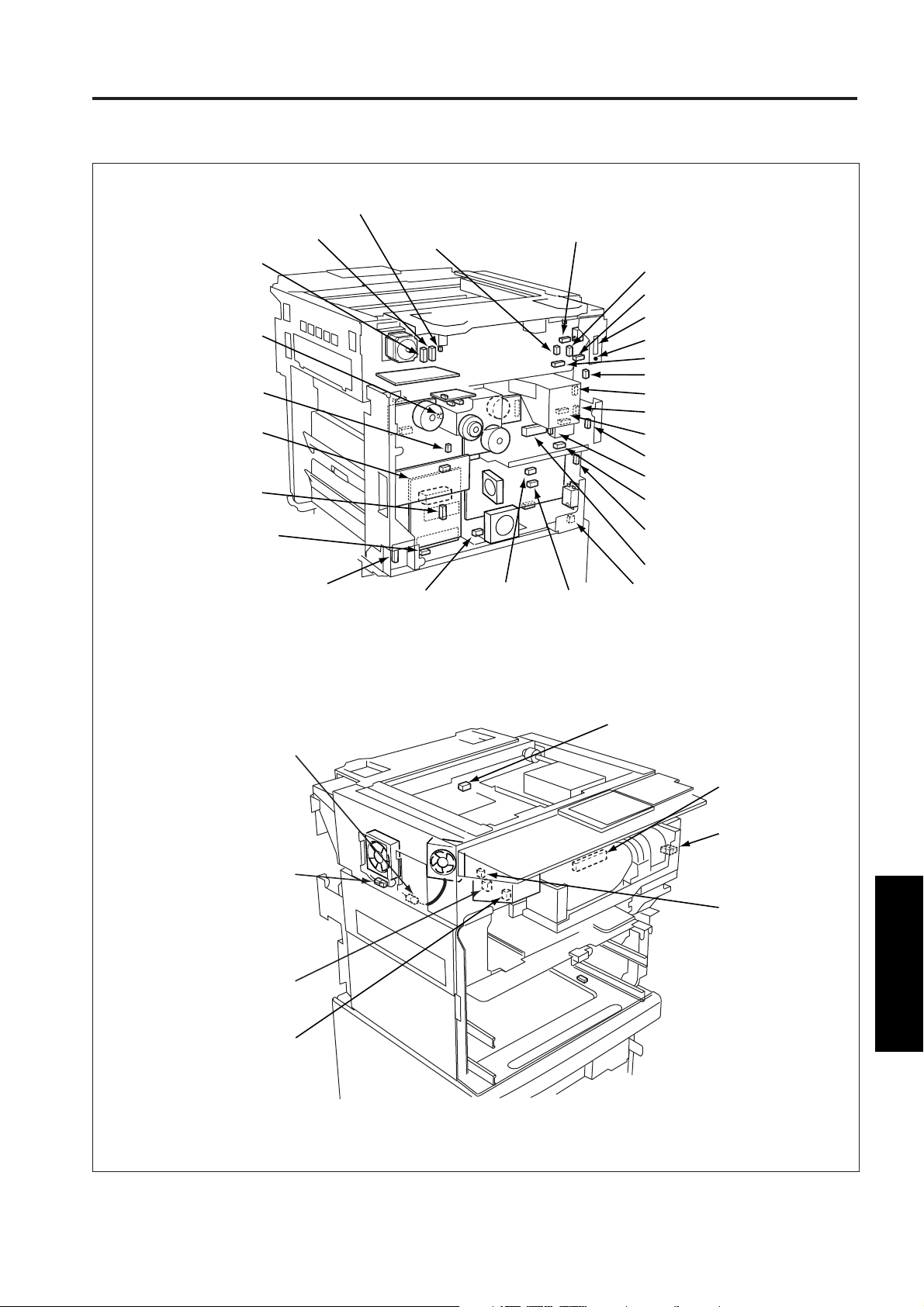

DIAGRAMS

HUM1

Humidity sensor

PS17

No feed PS

MC1

Registration MC

PS29

Fixing exit PS

TH2

Fixing temperature sensor 2

L2

Fixing heater lamp 1

PS16

Registration PS

TH1

Fixing temperature sensor 1

TS

Thermostat

TSL

Transfer synchronization lamp

MC503

ADU feed MC

MC501

ADU restart MC

MC502

M501

ADU paper feed motor

ADU loop MC

PS501

ADU no feed PS

PS502

ADU registration PS

L3

Fixing heater lamp 2

PS27

Paper size detection PS (by-pass)

4 DIAGRAM

PS14

Open/close detection PS

PS13

No feed PS (by-pass)

SD4

By-pass SD

5 DIAGRAM

VR1

Paper size detection VR (by-pass)

5-3

Page 6

DIAGRAMS

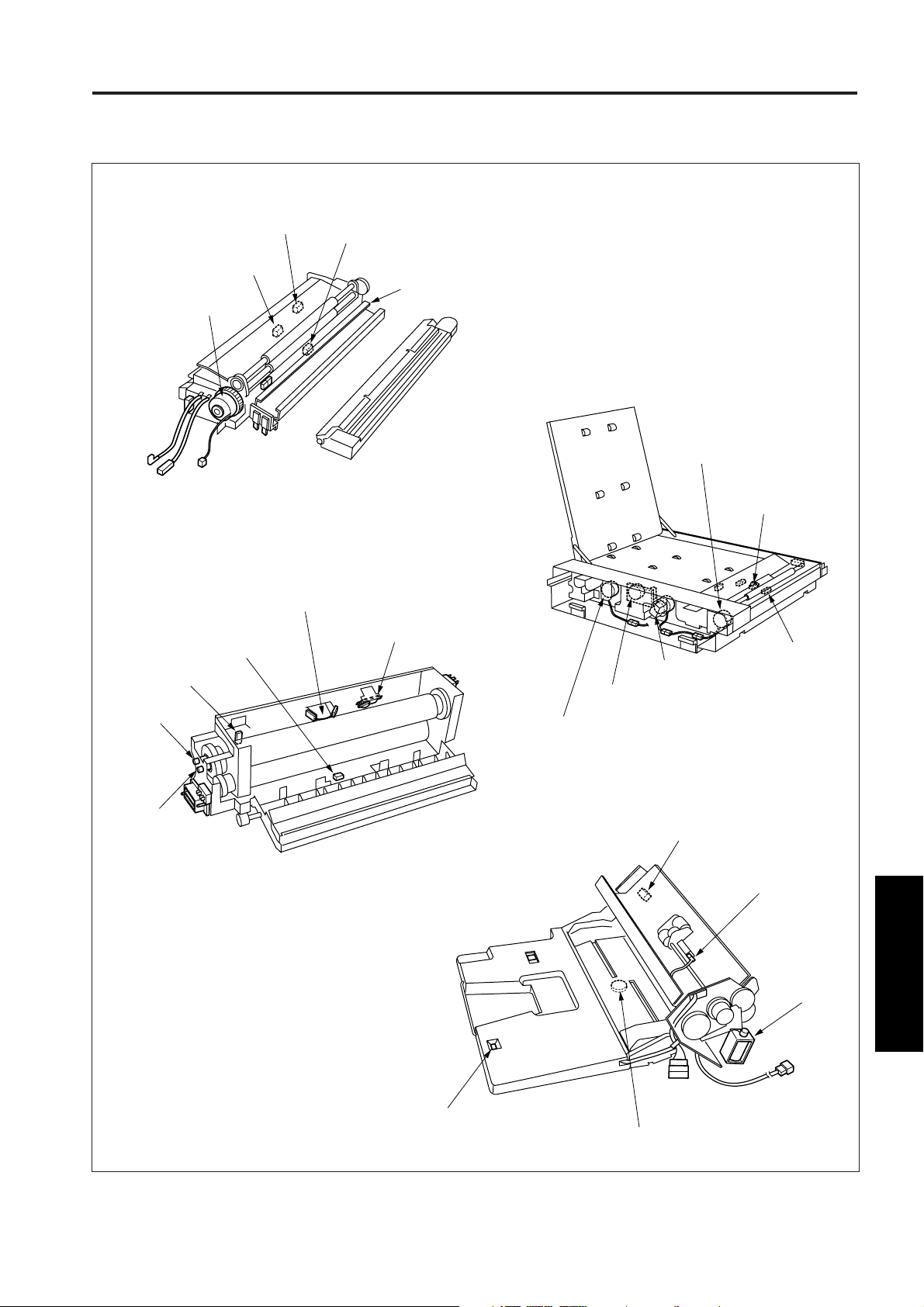

DF-315 ELECTRICAL PARTS LAYOUT DRAWING

PS308

Original feed detect PS

PS301

DF open/close detect PS

SD301

Flapper SD

PS307

Original exit detect PS

PS309

Original reverse detect PS

SD302

Original press SD

PS306

Original registration PS

PS305

No original detect PS

PS303

Original size detect PS2

VR301

Original size detect VR

PTBD

Paper tray board

PS302

Original size detect PS1

5 DIAGRAM

PS304

M302

Original feed motor

DFCB

RADF control board

Motor clock detect PS

MS301

Cover open/close detect MS

CL302

Original feed CL

CL301

Original pick-up CL

M301

Original conveyance motor

5-4

Page 7

DIAGRAMS

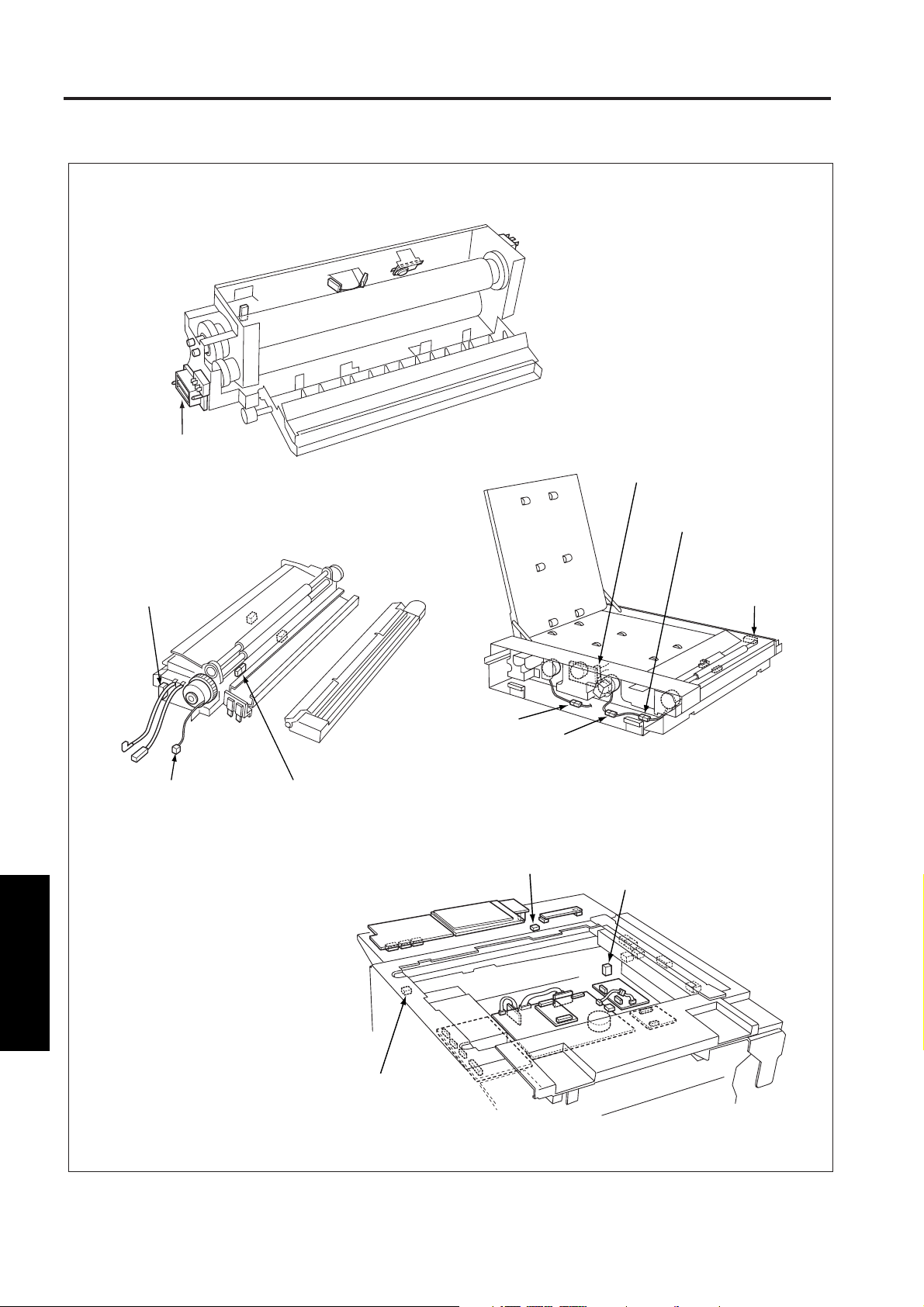

DB-208/208A ELECTRICAL PARTS LAYOUT DRAWING

PFUDB (upper)

PFU drive board (U)

PS402

PS403

Upper limit detect PS (U)

SD401

Paper feed SD (PFU) (U)

PS401

Paper feed detect PS

PS404

No paper detect PS (M)

(DB-208 only)

SD402

Paper feed SD (M)

(DB-208 only)

PS405

Upper limit detect PS (M)

(DB-208 only)

PS406

No paper detect PS (L)

(DB-208 only)

SD403

Paper feed SD (L)

(DB-208 only)

No paper detect PS (U)

M401

Paper feed motor

PFUDB (L)

PFU drive board (L) (DB-208 only)

PS407

Upper limit detect PS (L) (DB-208 only)

M402

Up/down motor (U)

M403

Up/down motor (M) (DB-208 only)

PFUDB (M)

PFU drive board (M)

(DB-208 only)

M404

Up/down motor (L)

(DB-208 only)

PTC

PTC heater

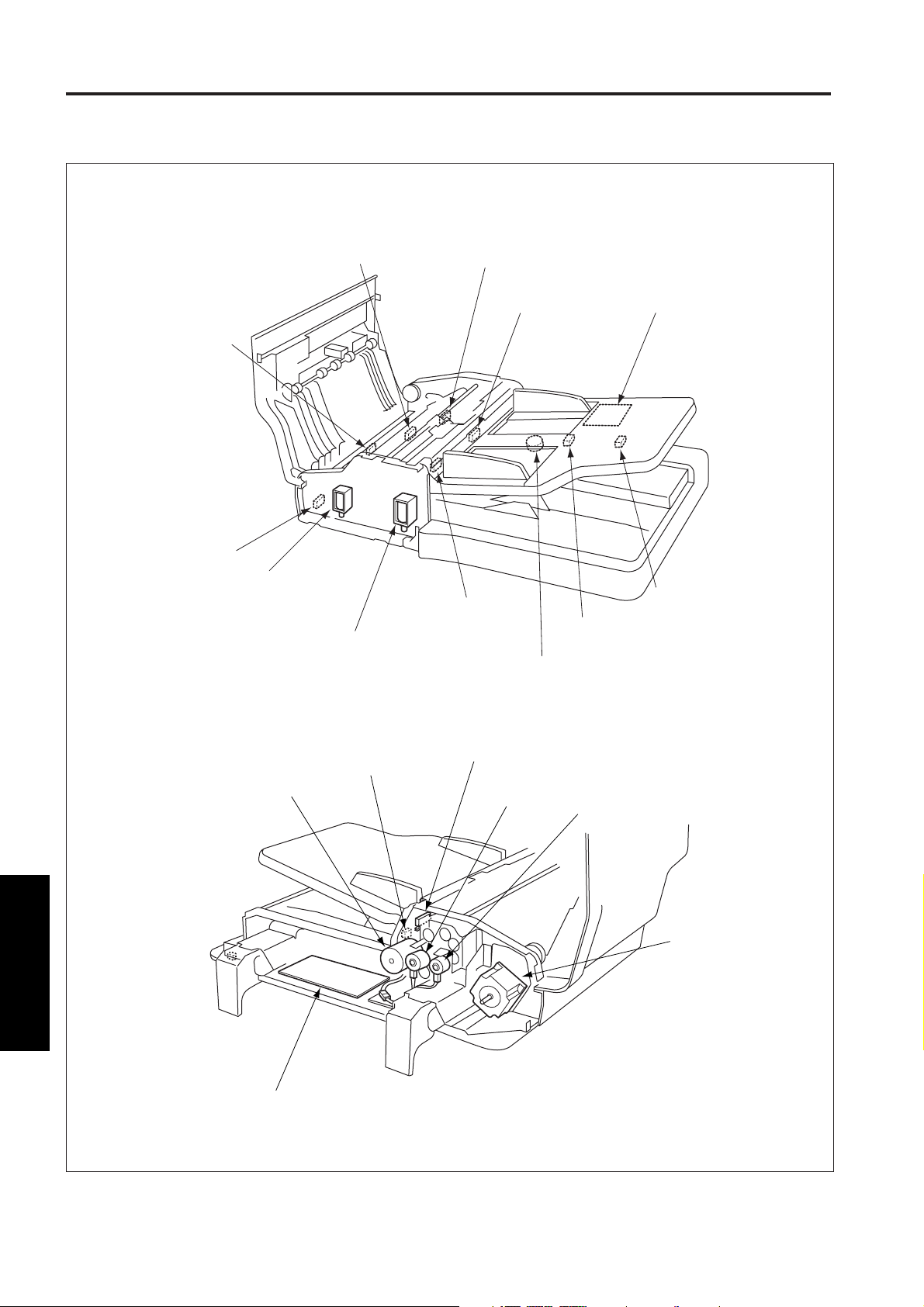

DB-608 ELECTRICAL PARTS LAYOUT DRAWING

PS402

No paper detect PS (PFU)

PS403

Upper limit detect PS (PFU)

PS401

Paper feed detect PS

SD401

Paper feed SD (PFU)

PS404

No paper detect PS (LCT)

SD402

Paper feed SD (LCT)

PS405

Upper limit detect PS (LCT)

PFUDB (PFU)

PFU drive board (PFU)

M401

Paper feed motor

PFUDB (LCT)

PFU drive board (LCT)

M402

Up/down motor (PFU)

M403

Up/down motor (LCT)

PTC

PTC heater

5 DIAGRAM

5-5

Page 8

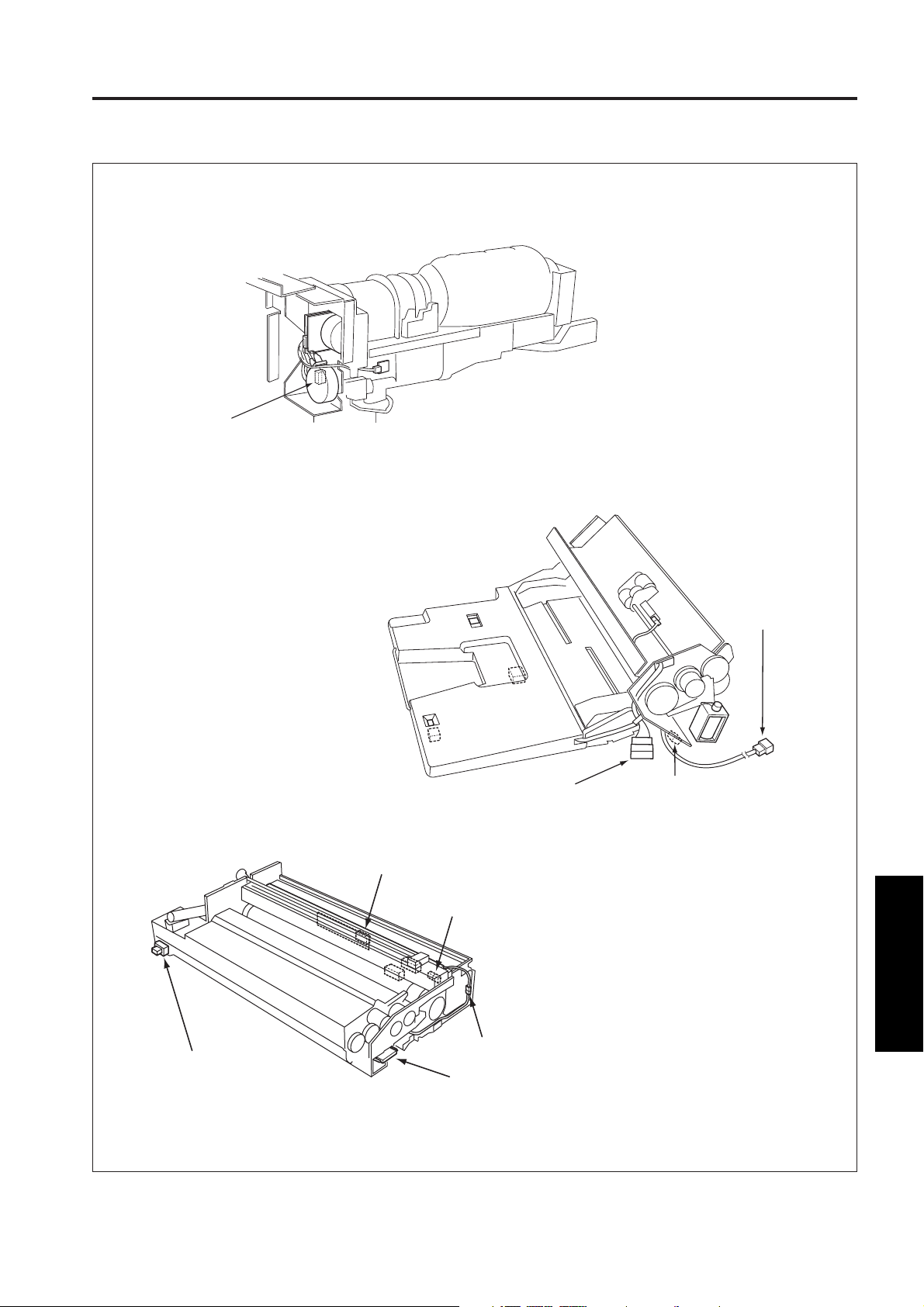

DIAGRAMS

FS-109 ELECTRICAL PARTS LAYOUT DRAWING

PS819

PS803

MS802

Up-down MS (upper)

PS801

Drum position detect PS

Tray 1 paper exit detect PS

FNSCB

FNS control board

PS802

Drum entrance PS

PS809

Tray 3 full-stack detect PS

PS817

Stapler HP (front) PS

PS820

Stapler HP (rear) PS

PS804

Paper through detect PS

PS807

Tray 2 full-stack detect PS

M810

Tray 2 motor

M811

Tray 3 motor

M806

Stapler movement motor

No-staple (front) (lead edge) PS

PS822

No-staple (rear) (lead edge) PS

PS818

No-staple (front) PS

PS821

No-staple (rear) PS

M805

Paper exit motor

PS805

Tray upper limit

PS

M801

Conveyance

motor

MS803

Up-down MS (lower)

PS806

Tray lower limit PS

5 DIAGRAM

SD801

Gate SD

MS801

Inter lock MS

M809 Alignment motor (front)

M807

Conveyance drum

motor

SD802

Shutter SD

MS804

Stapler safety MS

M804

Tray up/down motor

PS812

Stapler no paper

PS815

Alignment motor

(front) HP PS

PS

PS813

Paper exit motor

HP PS

M803

Stapler motor (front)

M808

Alignment motor (rear)

PS816

Alignment motor (rear) HP PS

M802

Stapler motor (rear)

PS814

Stapler unit HP PS

5-6

Page 9

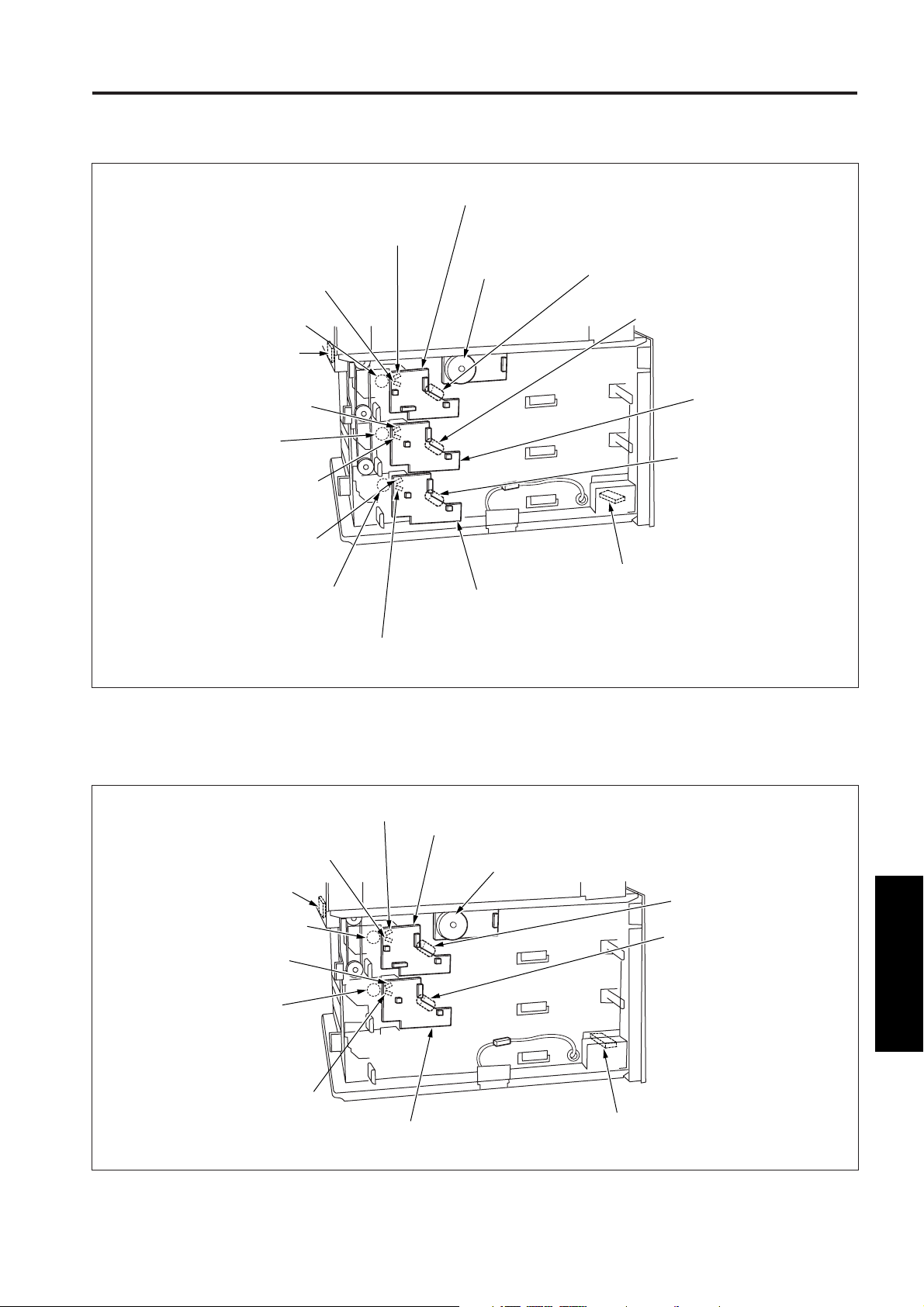

7045 CONNECTOR LAYOUT DRAWING

84 (BK: 3 PIN)

100 (BK: 8 PIN)

87 (W: 2 PIN)

86 (BK: 2 PIN)

152 (BK: 24 PIN)

399 (W: 2 PIN)

100A (BK: 7 PIN)

82 (W: 6 PIN)

85 (BK: 3 PIN)

DIAGRAMS

204 (W: 11 PIN)

205 (W: 2 PIN)

203 (BK: 25 PIN)

509 (BK: 2 PIN)

83 (BK: 8 PIN)

67 (BK: 2 PIN)

141 (W: 2 PIN)

140 (W: 6 PIN)

58 (BK: 4 PIN)

400 (GY: 16 PIN)

145 (W: 3 PIN)

142 (W: 3 PIN)

398 (W: 2 PIN)

300 (GY: 16 PIN)

97 (W: 3 PIN)

98 (BK: 4 PIN)

59 (W: 6 PIN)

57(W: 3 PIN)

392

(W: 3 PIN)

391

(W: 3 PIN)

156 (BK: 3 PIN)

390 (B: 16 PIN)

394 (W: 2 PIN)

92 (W: 6 PIN)

202

(BK: 36 PIN)

79

(BK: 9 PIN)

395

(BK: 2 PIN)

56 (W: 2 PIN)

5 DIAGRAM

5-7

Page 10

DIAGRAMS

390

(B: 16 PIN)

160 (W: 12 PIN)

166 (BK: 2 PIN)

(W: 8 PIN)

5 DIAGRAM

66

86

(BK: 2 PIN)

152 (BK: 24 PIN)

168 (BK: 2 PIN)

167 (BK: 2 PIN)

61

(BK: 2 PIN)

214 (W: 13 PIN)

59 (W: 6 PIN)

55 (W: 6 PIN)

5-8

Page 11

79 (BK: 9 PIN)

DIAGRAMS

65 (BK: 5 PIN)

64 (W: 7 PIN)

63 (BK: 2 PIN)

62 (BK: 2 PIN)

60 (BK: 20 PIN)

80 (BK: 8 PIN)

81 (BK: 5 PIN)

88 (W: 2 PIN)

5 DIAGRAM

5-9

Page 12

DIAGRAMS

Control Board

CN07

(6 pin)

CN01

(4 pin)

CN02

(24 pin)

CN505

(11 pin)

CN503

(144 pin)

CN504

(144 pin)

CN200

(22 pin)

CN500

(100 pin)

CN05

(12 pin)

CN06

(5 pin)

CN03

(20 pin)

CN04

(24 pin)

CN801

(22 pin)

CN10

(100 pin)

CN803

(6 pin)

Image control board

5 DIAGRAM

CN10

(100 pin)

CN17

(10 pin)

CN16

(24 pin)

CN10

(20 pin)

CN11

(80 pin)

CN14

(68 pin)

CN37

(8 pin)

CN12

(22 pin)

CN13

(24 pin)

5-10

Page 13

DIAGRAMS

Printer drive board

CN40

(15 pin)

CN31

(10 pin)

CN32

(60 pin)

CN36

(10 pin)

CN41

(11 pin)

CN35

(5 pin)

CN150

(26 pin)

CN30

(7 pin)

CN33

(50 pin)

Scanner drive board

CN23

(6 pin)

CN11

(80 pin)

CN20

(8 pin)

CN21

(22 pin)

CN24

(26 pin)

CN22

(28 pin)

DC power supply unit 1 DC power supply unit 2

FAN1

(3 pin)

CN387

(12 pin)

CN389

(10 pin)

CN380

(6 pin)

CN381

(7 pin)

CN386

(8 pin)

CN388

(14 pin)

CN1

(4 pin)

CN2

(5 pin)

CN3

(5 pin)

5 DIAGRAM

5-11

Page 14

DIAGRAMS

Polygon motor drive board

CN45

(11 pin)

CN44

(5 pin)

Paper feed detect board

CN317

High voltage unit 1 High voltage unit 2

(3 pin)

CN38

(5 pin)

CN318

(3 pin)

CN316

(13 pin)

CN47

(6 pin)

5 DIAGRAM

CN213

(14 pin)

(14 pin)

CN216

CN217

(5 pin)

CN211

(12 pin)

CN210

(13 pin)

CN48

(4 pin)

Parameter memory boardOperation board

CN1

(20 pin)

CN49

(10 pin)

CN2

(24 pin)

5-12

Page 15

DIAGRAMS

Index sensor board

CN9

(5 pin)

Toner control sensor board

CN64

(7 pin)

L1 Inverter board

CN28

(3 pin)

Laser drive board

CN8

(12 pin)

CN29

(4 pin)

A/D converter board

CN8

(12 pin)

5-13

OB inverter

CN71

(3 pin)

CN77

(4 pin)

5 DIAGRAM

Page 16

DIAGRAMS

DF-315 CONNECTOR LAYOUT DRAWING

46/47 (W:3 PIN)

10 (W:5 PIN)

51 (W:4 PIN)

33/38 (W:6 PIN)

49/50 (W:4 PIN)

45 (W:3 PIN)

52/53 (W:3 PIN)

55/56 (W:2 PIN)

28 (W:3 PIN)

44 (W:3 PIN)

46/47 (W:3 PIN)

12 (W:3 PIN)

11 (W:6 PIN)

43 (W:3 PIN)

57/58

(W:2 PIN)

40 (W:3 PIN)

41 (W:3 PIN)

54 (W:4 PIN)

30 (BK:8 PIN)

5 DIAGRAM

31 (BK:7 PIN)

34/35 (W:2 PIN)

36 (W:4 PIN)

37 (W:4 PIN)

1 (GY:10 PIN)

5-14

3 (W:10 PIN)

9 (W:7 PIN)

4 (W:4 PIN)

DFCB

10 (W:2 PIN)

5 (W:5 PIN)

6 (W:10 PIN)

7 (W:9 PIN)

2 (W:5 PIN)

8 (W:3 PIN)

11 (W:12 PIN)

Page 17

DB-208/208A CONNECTOR LAYOUT DRAWING

310 (GY:18 PIN)

DIAGRAMS

321 (W:12 PIN)

300 (GY:16 PIN)

305 (BK:9 PIN)

312 (W:3 PIN)

313 (W:3 PIN)

317A (W:3 PIN)

317B (W:3 PIN)

311 (GY:24 PIN)

316B (W:13 PIN)

316B (W:3 PIN)

306 (BK:8 PIN)

DB-608 CONNECTOR LAYOUT DRAWING

312 (W:3 PIN)

316A (W:13 PIN)

318A (W:3 PIN)

320 (W:2 PIN)

312 (W:3 PIN)

313 (W:3 PIN)

317 (W:3 PIN)

310 (GY:18 PIN)

311 (GY:24 PIN)

306 (BK:8 PIN)

321 (W:12 PIN)

312 (W:3 PIN)

316A (W:13 PIN)

318 (W:3 PIN)

320 (W:2 PIN)

5 DIAGRAM

300 (GY:16 PIN)

305 (BK:9 PIN)

5-15

Page 18

DIAGRAMS

FS-109 CONNECTOR LAYOUT DRAWING

757(BK:8 PIN)

730 (W:2 PIN)

756 (BK:8 PIN)

736 (W:3 PIN)

759 (W:3 PIN)

749 (W:9 PIN)

761 (BK:8 PIN)

737 (W:3 PIN)

401 (GY:16 PIN)

750

(W:12 PIN)

753

(W:6 PIN)

734 (W:3 PIN)

754 (W:2 PIN)

721 (W:6 PIN)

733 (W:3 PIN)

726

(BK:2 PIN)

724 (W:6 PIN)

763

(W:3 PIN)

724 (W:6 PIN)

744 (W:3 PIN)

760 (W:3 PIN)

751 (W:3 PIN)

723 (W:6 PIN)

727 (W:6 PIN)

725 (W:6 PIN)

743 (W:3 PIN)

741 (W:3 PIN)

740 (W:3 PIN)

746 (W:13 PIN)

742 (W:3 PIN)

745 (W:13 PIN)

722

(W:6 PIN)

5 DIAGRAM

729(W:6 PIN)

751 (BK:3 PIN)

728 (W:6 PIN)

752 (W:3 PIN)

(W:10 PIN)

752 (W:3 PIN)

5-16

702 (W:6 PIN)

701

711

(W:2 PIN)

709

(W:2 PIN)

FNSCB

704 (W:28 PIN)

703 (W:24 PIN)706 (W:15 PIN)

713

(GY:30 PIN)

712

(W:15 PIN)

710

(W:3 PIN)

707

(W:24 PIN)

705 (W:24 PIN)

Page 19

JAM CODE LIST

JAM CODE LIST

Classification

By-pass

feed tray

Tray 1

Main body

DB upper

tray

DB middle

tray or LCT

DB lower

DB

tray

Paper feed

conveyance

Others

Paper feed

conveyance

Fixing/

Paper exit/

Main body, ADU and FNS

ADU

Jam

code

J10

J12

J13

J14

J15

J16

J20-1

J20-2

J20-3

J30

J31

J32

J33

Causes

PS16 (registration) is not turned ON

within a certain period after SD4 (bypass paper feed) has been turned ON.

PS17 (no feed) is not turned ON within a

certain period after SD2 (1st paper feed)

has been turned ON.

PS401 (paper feed detect) is not turned

ON within a certain period after SD401

(paper feed (upper)) has been turned

ON.

PS401 (paper feed detect) is not turned

ON within a certain period after SD402

(paper feed (middle)) has been turned

ON.

PS401 (paper feed detect) is not turned

ON within a certain period after SD403

(paper feed (lower)) has been turned

ON.

PS16 (registration) is not turned ON

within a certain period after PS17 (no

Operating

feed) or PS401 (paper feed detect) has

been turned ON.

During copying, the front door or exit

door was opened.

During copying, the main body

conveyance door was opened.

During copying, the FNS was opened.

PS16 (registration) is not turned OFF

within a certain period after MC1

(registration) has been turned ON.

PS29 (fixing exit) is not turned ON within

a certain period after MC1 (registration)

has been turned ON.

PS1 (paper exit) is not turned ON within

a certain period after PS29 (fixing exit)

has been turned ON. (at the straight

eject mode)

PS1 (paper exit) is not turned OFF

within a certain period after it has been

turned ON. (at the straight eject mode)

Operation when jam

occurs

If a copy is being made

when a jam occurs, copy

operation is stopped

after completion of exit

of the copy.

The main body is

stopped immediately.

Jam clearing method

Remove the original

paper from by-pass

tray, then remove the

jammed paper.

Open the main body

conveyance door and

remove the jammed

paper and close it.

Open the tray and

remove the jammed

paper and close it.

Open the DB conveyance door and remove

the jammed paper and

close it.

Open the tray and

remove the jammed

paper and close it.

Open the main body

conveyance door, DB

conveyance door or

front door and remove

the jammed paper and

close it.

Remove the jammed

paper and close it.

Open the front door and

remove the jammed

paper and close it.

Open the exit door and

remove the jammed

paper and close it.

5 DIAGRAM

5-17

Page 20

JAM CODE LIST

Classification

Fixing/

Paper exit/

ADU

Main body, ADU and DB

Others

RADF

RADF

5 DIAGRAM

Jam

code

J34-1

J34-2

J34-3

J34-4

J34-5

J50-1

J50-2

J50-3

J61-0

J61-1

J62-0

J62-1

J62-2

J62-3

J62-4

Causes

PS28 (reversal detection 1) is not turned

ON within a certain period after PS29

(fixing exit) has been turned ON.

PS28 (reversal detection 1) is not turned

OFF within a certain period after it has

been turned ON.

PS1 (paper exit) is not turned ON within

a certain period after M501 (ADU paper

feed) has been turned ON. (when the

paper is reverse ejected.)

PS1 (paper exit) is not turned OFF

within a certain period after it has been

turned ON. (when the paper is reverse

ejected.)

PS30 (reversal detection 2) is not turned

OFF within a certain period after it has

been turned ON.

When PS16 (registration) is turned on,

print requirement signal is not sent

within the certain time.

When the start button is on, S-valid

does not turn on within the certain time.

When the start button is on, MC1

(registration) does not turn on within the

Operating

certain time.

MS301 (cover open/close detect) is OFF

white the RADF is operating.

PS301 (DF open/close detect) was

turned OFF during RADF operation.

PS306 (original registration) is not

turned ON within a certain period after

the original feed has been started.

PS306 (original registration) is not

turned OFF within a certain period after

it has been turned ON.

PS308 (original feed detect) is not

turned ON within a certain period after

the pre-feed of the duplex original front

side (include the simplex original) has

been started.

PS308 (original feed detect) is not

turned ON within a certain period after

the pre-feed of the duplex original back

side has been started.

PS308 (original feed detect) is not

turned OFF within a certain period after

the scanning of the duplex original front

side (include the simplex original) has

been started.

Operation when jam oc-

curs

The main body is stopped

immediately.

RADF is stopped

immediately.

If there is paper during or

after transfer, the main

body is stopped after exit

of the paper.

Jam clearing method

Open the exit door

and remove the

jammed paper and

close it.

Open the front door

and remove the

jammed paper and

close it.

Open the exit door

and remove the

jammed paper and

close it.

Open the main body

conveyance door, DB

conveyance door or

front door and remove

the jammed paper and

close it.

Open the RADF and

remove the jammed

paper and close it.

5-18

Page 21

JAM CODE LIST

Classification

RADF

RADF

Jam

code

J62-5

J63-0

J63-1

J63-2

J63-3

J63-4

J63-5

J63-6

J63-7

J65-1

J65-2

J65-4

J65-8

Causes

PS308 (original feed detect) is not

turned OFF within a certain period after

the scanning of the duplex original back

side has been started.

PS307 (original exit detect) is not

turned ON within a certain period after

the scanning of the simplex original has

been started.

PS307 (original exit detect) is not

turned ON within a certain period after

the scanning of the duplex original back

side has been started.

At the simplex original is exited, PS307

(original exit detect) is not turned OFF

within a certain period after it has been

turned ON.

At the duplex original is exited, PS307

(original exit detect) is not turned OFF

within a certain period after it has been

Operating

turned ON.

PS309 (original reverse detect) is not

turned ON within a certain period after

the scanning of the duplex original front

side has been started.

PS309 (original reverse detect) is not

turned ON within a certain period after

the reverse feed has been started.

At the start of the duplex original front

side scanning, PS309 (original reverse

detect) is not turned OFF within a

certain period after it has been turned

ON.

At the start of the reverse feed, PS309

(original reverse detect) is not turned

OFF within a certain period after it has

been turned ON.

PS306 (original registration) is ON

during idling.

PS308 (original feed detect) is ON

during idling.

PS309 (original reverse detect) is ON

during idling.

Stationary

PS307 (original exit detect) is ON

during idling.

Operation when jam

occurs

RADF is stopped

immediately.

If there is paper during or

after transfer, the main

body is stopped after exit

of the paper.

Jam clearing method

Open the RADF and

remove the jammed

paper and close it.

5 DIAGRAM

5-19

Page 22

JAM CODE LIST

Classification

FNS

FNS

Paper feed

conveyance

Fixing/

Paper exit/

ADU

Main body and ADU

5 DIAGRAM

Jam

code

J72-1

J72-4

J72-10

J72-11

J72-12

J72-13

J72-14

J72-15

J72-16

J72-21

J72-22

J80

J81

J82

J90

J91

J92

J93

J97-1

J100

Causes

PS802 (drum entrance) is ON during

idling.

PS803 (tray 1 paper exit detect) is ON

Staitionary

during idling.

PS803 (tray 1 paper exit detect) is not

turned ON within a certain period after

PS1 (paper exit) has been turned ON.

PS803 (tray 1 paper exit detect) is not

turned OFF within a certain period after

it has been turned ON.

PS802 (drum entrance) is not turned

ON within a certain period after PS1

(paper exit) has been turned ON.

PS802 (drum entrance) is not turned

OFF within a certain period after it has

been turned ON.

PS804 (paper through detect) is not

turned ON within a certain period after

Operating

PS802 (drum entrance) has been

turned ON.

PS804 (paper through detect) is not

turned OFF within a certain period after

it has been turned ON.

Paper detect sensor of the stapler unit

is not turned ON within a certain period

after M805 (paper exit) has been turned

ON.

Stapler (front) staple jam.

Stapler (rear) staple jam.

PS17 (no feed) is ON during idling.

PS16 (registration) is ON during idling.

PS401 (paper feed detect) is ON during

idling.

PS29 (fixing exit) is ON during idling.

Staitionary

PS1 (paper exit) is ON during idling.

PS28 (reverse detect 1) is ON during

idling.

PS30 (reverse detect 2) is ON during

idling.

PS501 (ADU no feed) is not turned ON

within a certain period after M501 (ADU

paper feed) has been turned ON.

Operating

PS502 (ADU registration) is ON during

idling.

Operation when jam oc-

curs

FNS and main body are

stoped immediately.

The main body are stoped

immediately.

Jam clearing method

Remove the jammed

paper of the FNS and

main body.

Open the main body

conveyance door, DB

conveyance door or

front door and remove

the jammed paper and

close it.

Open the exit door

and remove the

jammed paper and

close it.

Stationary

5-20

Page 23

ERROR CODE LIST

ERROR CODE LIST

Classification

Communication

abnormality

Paper feed

lifting

abnormality

High

voltage

power

supply

abnormality

Warning

code

F10-1

F10-2

F10-3

F18-2

F18-3

F18-4

F18-5

F28-1

F28-2

F28-3

Causes

Serial communication between the

PRDB (printer drive board) and

ICB (image control board) is discontinued.

The answer to the A/D

conversion is not replied two

times consecutively.

DB communication abnormality

signal is detected.

PS32 (upper limit) on the PFDB

(paper feed detect board) is not

turned ON within 26 seconds

from ON of M8 (tray).

PS403 (upper limit detect

(upper)) is not turned ON within

26 seconds from ON of M402

(up/down (upper)).

PS405 (upper limit detect

(middle)) is not turned ON within

26 seconds from ON of M403

(up/down (middle)).

PS407 (upper limit detect

(lower)) is not turned ON within

26 seconds from ON of M404

(up/down (lower)).

When charging output is judged

to be abnormal discharge.

When transfer output is judged to

be an abnormal discharge.

When separation output is

judged to be an abnormal

discharge.

Operation in case of

warning occurrence

The machine stops

immediately, and main relay

and 24VDC are turned OFF.

If a copy being made when

an error occurs, the machine

stops immediately after

completion of exit of the

copy, and main relay and

24VDC are turned OFF.

The machine stops

immediately, and main relay

and 24VDC are turned OFF.

Estimated abnormal parts

PRDB (printer drive board)

ICB (image control board)

SCDB (scanner drive board)

PRDB (printer drive board)

ICB (image control board)

SCDB (scanner drive board)

PFDB (paper feed detect board)

PRDB (printer drive board)

SCDB (scanner drive board)

PFDB (paper feed detect board)

M8 (tray)

M402(up/down (U))

M403(up/down (M))

M404 (up/down (L))

PS32 (upper limit)

PS403 (upper limit detect (U))

PS405 (upper limit detect (M))

PS407 (upper limit detect (L))

PRDB (printer drive board)

HV1 (high voltage unit 1)

Charging corona unit

PRDB (printer drive board)

HV2 (high voltage unit 2)

Transfer corona unit

PRDB (printer drive board)

HV2 (high voltage unit 2)

Separation corona unit

5-21

5 DIAGRAM

Page 24

ERROR CODE LIST

Classification

Fixing high

temperature

abnormality

Fixing low

temperature

Fixing sensor

abnormality

(open circuit)

Scanner

abnormality

5 DIAGRAM

Warning

code

F34-1

F34-2

F34-3

F34-4

F35-1

F35-2

F36-1

F36-2

F40-1

F41-1

Causes

TH1 (fixing temperature 1) detecting temperature (fixing temperature) exceeds approx. 225˚C. (Fixing high temperature abnormality

detection software operates.)

TH1 (fixing temperature 1) detecting temperature (fixing temperature) exceeds approx. 235˚C. (Fixing high temperature abnormality

detection circuit operates.)

TH2 (fixing temperature 2) detecting temperature (fixing temperature) exceeds approx. 235˚C. (Fixing high temperature abnormality

detection software operates.)

TH2 (fixing temperature 2) detecting temperature (fixing temperature) exceeds approx. 250˚C. (Fixing high temperature abnormality

detection circuit operates.)

Warm-up is not completed within

180 seconds from the start of the

warm-up. (Fixing low temperature

abnormality detection software operates.)

After completion of warm-up, fixing

temperature is lower than -30°C.

(Fixing law temperature abnormality software operates.)

Fixing temperature is not reached

30°C within 50 seconds from the

start of the warm-up. (Fixing senser

open circuit detection circuit operates.)

TH2 (fixing temperature 2) is broken (open circuit). (Fixing sensor

open circuit detection circuit operates.)

The errror of SRGA is detected.

At the start of optics initial search or

reverse scanning, PS3 (optics HP)

is not turned ON within a certain

period.

Operation in case of

warning occurrence

The machine stops

immediately, and main relay

and 24VDC are turned OFF.

Set to “1” the bit 1 in SW3.

Scanner stops immediately

and 24VDC is turned OFF.

Estimated abnormal parts

PRDB (printer drive board)

DCPS1 (DC power supply1)

TH1 (fixing temperature 1)

TH2 (fixing temperature 2)

L2 (fixing heater lamp 1)

L3 (fixing heater lamp 2)

ICB (image control board)

ICB (image control board)

SCDB (scanner drive board)

PS3 (optics HP)

5-22

Page 25

ERROR CODE LIST

Classification

Image

processing

abnormality

Motor

abnormality

Fan

abnormality

Warning

code

F46-1

F46-8

F46-10

F46-11

F49-2

F49-4

F49-6

F51-2

F51-3

F51-4

F51-5

F51-6

F51-7

F52-1

F52-2

F52-3

F52-4

F52-5

F52-6

Causes

The monitor value of the laser

light amount is low.

Index cycle differs from the

expectation.

AOC counter overflow

AGC counter overflow

LDB (laser diode board)

connection abnormality

INDEXSB (index sensor board)

connection abnormality

ADB (A/D converter board)

connection abnormality

Speed abnormality in the M1

(main)

Speed abnormality in the M10

(toner supply 1)

Speed abnormality in the M3

(developing)

Speed abnormality in the M4

(drum)

Speed abnormality in the M5

(polygon)

Speed abnormality in the M501

(ADU paper feed)

Locking abnormality in the FM3

(main body cooling).

Locking abnormality in the FM4

(conveyance suction).

Locking abnormality in the M5

(polygon).

Locking abnormality in the FM2

(scanner cooling).

IP-431 cooling fan locking

abnormality (printer kit)

IP-431 CPU cooling fan locking

abnormality .

Operation in case of

warning occurrence

The machine stops

immediately, and main relay

and 24VDC are turned OFF.

Scanner stops immediately.

The machine stops

immediately, and main relay

and 24VDC are turned OFF.

Scanner stops immediately.

The machine stops

immediately, and main relay

and 24VDC are turned OFF.

If a copy being made whenan

error occurs, the machine

stops immediately after

completion of exit of the

copy, and main relay and

24VDC are turned OFF.

The machine stops

immediately, and main relay

and 24VDC are turned OFF.

Estimated abnormal parts

ICB (image control board)

LDB (laser drive board)

ICB (image control board)

INDEXSB (index sensor board)

M5 (polygon)

ICB (image control board)

ADB (A/D converter board)

L1 INVB (L1 inverter board)

DCPS1 (DC power supply 1)

L1 (exposure lamp)

ICB (image control board)

LDB (laser drive board)

INDEXSB (index sensor board)

ICB (image control board)

ICB (image control board)

ADB (A/D converter board)

PRDB (printer drive board)

M1 (main)

PRDB (printer drive board)

M10 (toner supply 1)

PRDB (printer drive board)

M3 (developing)

PRDB (printer drive board)

M4 (drum)

ICB (image control board)

SCDB (scanner drive board)

M5 (polygon)

PRDB (printer drive board)

M501 (ADU paer feed)

PRDB (printer drive board)

FM3 (main body cooling)

PRDB (printer drive board)

FM4 (conveyance suction)

PRDB (printer drive board)

FM5 (polygon)

ICB (Image control board)

SCDB (scanner drive board)

FM2 (scanner cooling)

IP-431cooling fan

IP-431 CPU fan

5 DIAGRAM

5-23

Page 26

ERROR CODE LIST

Classification

Image

processing

communication

abnormality

Operation

unit

abnormality

Control

abnormality

RADF

abnormality

Warning

code

E56-01

E56-02

E56-03

E56-04

E56-05

E56-06

E56-07

E56-08

E56-09

E56-10

F56-11

F60-1

F60-11

Causes

When the SW2 (sub power) is

turned ON, the answer from the ICB

(Image control board) is not replied

to the CB (control board) within 10

seconds.

The CB (control board) is not

detected the process ready signal

60 seconds or more during idling.

The CB (control board) is not

detected the scanner ready

signal 60 seconds or more during

idling.

The CB (control board) is not

detected the finisher ready signal

60 seconds or more during idling.

The CB (control board) is not

detected the original size detect

signal within a certain period

during the platen copy operation.

Memory access abnormality is

occurred at the start of copy

process.

Control abnormality is occurred

at the panel manager.

Miss matching of the display data.

Display data abnormality.

Operation communication

abnormality.

The machine type of the software

version is different from that of

the image processing control

program.

RADF communication

abnormality.

RADF flash ROM abnormality.

Operation in case of

warning occurrence

The machine stops

immediately.

RADF can not be used.

The machine stops

immediately.

Estimated abnormal parts

CB (control borad)

ICB (image control board)

PRDB (printer drive board)

SCDB (scanner drive board)

CB (control borad)

ICB (image control board)

SCDB (scanner drive board)

FNS

CB (control borad)

ICB (image control board)

SCDB (scanner drive board)

CB (control borad)

OB (operation board)

LCD (display board)

ICB program

ICB (image control board)

SCDB (scanner drive board)

RADF

DFCB (RADF control borad)

RADF program

5 DIAGRAM

F67-1

F67-2

F67-3

F67-4

PS306 (original registration),

PS308 (original feed detect),

PS309 (original reverse detect)

adjustment faulty.

PS304 (motor clock detect) is not

detected clock pulse, when M301

(original conveyance) is turned

ON.

Writing and reading abnormality of

the nonvolatile memory (NVRAM).

Other abnormality

(RADF abnormality other than

F67-1 to 3).

RADF can not be used.

5-24

ICB (image control board)

SCDB (scanner drive board)

RADF

Page 27

ERROR CODE LIST

Classification

FNS

abnormality

FNS flash

ROM

abnormality

Warning

code

F70-1

F77-1

F77-2

F77-3

F77-4

F77-5

F77-6

F77-7

F77-8

F77-9

F77-10

F77-11

Causes

FNS communication abnormality

PS805 (tray upper limit) is not

turned ON within 8 seconds from

ON of M804 (up-down (upper)).

Or the MS802 (up-down (upper))

is turned OFF.

PS806 (tray lower limit detect) is

not turned ON within 8 seconds

from ON of M804 (up-down

(upper)).

PS801 (drum position) is not

turned ON within 4 seconds from

ON of M807 (conveyance drum ).

At the forward rotation, PS815

(alignment motor HP (front)) is

not turned OFF within 250 m

seconds from ON of M809

(alignment (front)).

At the reverse rotation, PS815

(alignment motor HP (front)) in

not turned ON within 2 seconds

from ON of M809 (alignment

(front)).

At the forward rotation, PS816

(alignment motor HP (rear) ) is not

turned OFF within 250 m seconds

from ON of M808 (alignment (rear)).

At the reverse rotation, PS816

(alignment motor HP (rear)) in

not turned ON within 2 seconds

from ON of M808 (alignment

(rear)).

At the forward rotation, PS814

(stapler unit HP) is not turned

OFF within 400 milliseconds from

ON of M806 (stapler movement).

At the reverse rotation, PS814

(stapler unit HP) is not turned ON

within 4 seconds from ON of

M806 (stapler movement).

PS813 (paper exit motor HP) is

not turned ON within 1.5 seconds

from ON of M805 (paper exit).

FNS flash ROM abnormality.

Operation in case of

warning occurrence

The machine stops

immediately.

The machine stops

immediately, and main relay

and 24VDC are turned OFF.

The machine stops

immediately.

Estimated abnormal parts

ICB (image control board)

SCDB (scanner drive board)

FNSCB (FNS control board)

FNSCB (FNS control board)

M804 (tray up/down)

MS802 (up/down (upper))

MS803 (up/down (lower))

FNSCB (FNS control board)

M807 (conveyance drum drive)

FNSCB (FNS control board)

M809 (alignment (front))

FNSCB (FNS control board)

M808 (alignment (rear))

FNSCB (FNS control board)

M806 (stapler movement)

FNSCB (FNS control board)

M805 (paper exit)

FNSCB (FNS control board)

FNS program

5 DIAGRAM

5-25

Page 28

ERROR CODE LIST

Classification

FNS

abnormality

Nonvolatile

memory

(NVRAM)

abnormality

Flash ROM

abnormality

IP-431

abnormality

Image

processing

abnormality

Control

board

communication

abnormality

5 DIAGRAM

Warning

code

F77-21

F77-22

F77-30

F80-1

F80-2

F80-3

F80-4

F80-5

F81-01

F81-02

F81-03

F87-02

F87-03

E88-01

E89-01

E89-02

E89-03

E89-04

E89-05

E89-06

Causes

Stapler HP is not turned ON

within a certain period after M803

(stapler (front)) is ON.

Stapler HP is not turned ON

within a certain period after M802

(stapler (rear)) is ON.

MS802 (up-down (upper)) or

MS803 (up-down (lower)) is

turned OFF.

MS804 (stapler safety) is turned

OFF during stapling.

Function parameter abnormality

is detected.

Factory saved data abnormality

is detected.

Function parameter and factory

saved data abnormality are

detected.

Can not be accessed to the

function parameter.

Can not be accessed to the

factory saved data.

The checksum error is detected on

the flash ROM (on the ICB (image

control board) ).

The machine type of software is

differed between CB (control

board) and ICB (image control

board).

The machine and CB (system) program model type do not match.

When SW1 (main power) is on,

there is no response to initialization

command within 5 minetes.

HDD access abnormality

Image processing abnormality is

detected on the CB (control

board).

Job object pointer abnormality

(The page management object is

not obtained with any causes.)

Memory copy sequence

abnormality.

Through copy sequence

abnormality (Cause can not be

determined.)

Memory scan signal stop is not

completed.

Memory printer signal stop is not

completed.

SW2 (sub power) OFF processing is not completed within a

certain period.

Operation in case of

warning occurrence

The machine stops

immediately, and main relay

and 24VDC are turned OFF.

Copy the factory saved data.

–

The machine stops

immediately.

If a copy being made when an

error occurs, the machine

stops immediately after

completion of exit of the copy,

and main relay and 24VDC

are turned OFF.

The machine stops

immediately.

The machine stops immediately and the all indicator are

gone out on operation panel.

Estimated abnormal parts

FNSCB (FNS control board)

M802 (stapler (front))

FNSCB (FNS control board)

M803 (stapler (rear))

FNSCB (FNS control board)

MS802 (up/down (upper)

MS803 (up/down (lower))

MS804 (stapler safety)

(parameter memory board)

PRMB

ICB (image control board)

ICB program

CB (control board)

ICB (image control board)

CB (system) program

ICB program

CB (control board)

CB (system) program

IP-431 control board

CB (control board)

IP-431 control board

CB (control board)

SCDB (scanner drive board)

CB (control board)

ICB (image control board)

PRDB (printer control board)

SCDB (scanner drive board)

CB (control board)

5-26

Page 29

ERROR CODE LIST

When any one of the following abnormality occurs, the user can disconnect the faulty unit temporarily.

When an error code is displayed, press the AUTO RESET button and turning the SW2 (sub power) OFF/ON according to the LCD

message allows you to use the mchine until you turn the SW2 OFF/ON again.

Warning code

10-3

18-2

18-3

18-4

18-5

51-7

60-0, 67-1 to 3

70-1

77-1 to 7, 77-10, 77-30

77-8 to 9, 77-21, 77-22

87-2, 87-3

Contents

DB communication abnormality

Tray (lower) lifting abnormality

DB tray (upper) lifting abnormality

DB tray (middle) lifting abnormality (LCT)

DB tray (lower) lifting abnormality

ADU feed motor abnormality

RADF abnormality

FNS communication abnormality

FNS tray (tray 2 and 3) abnormality

Stapler abnormality (FNS)

IP-431 communication abnormality

Separation subjects

DB unit (all tray)

Main body lower tray

DB upper tray

DB middle tray, LCT

DB lower tray

ADU

RADF

FNS

Tray 2 and 3 (FNS)

Stapler (FNS)

IP

Remarks

Tray can not be selected.

↑

↑

↑

↑

Duplex mode can not be selected.

RADF can not be used.

FNS can not be used.

Tray 2 and 3 (FNS) can not be used.

Stapler mode can not be selected.

Printer can not be used.

5-27

5 DIAGRAM

Page 30

TIMING CHART

7045 TIMING CHART

(A4, LIFE SIZE, MANUAL DENSITY, TWO COPIES, DB MIDDLE TRAY PAPER FEED)

5 DIAGRAM

5-28

Page 31

TIMING CHART

7045 TIMING CHART

(ADF ORIGINAL, A4, LIFE SIZE, AE, TWO COPIES, TRAY1 PAPER FEED)

5-29

5 DIAGRAM

Page 32

PS29

PS28

PS30

PS501

PS502

MC503

MC502

MC501

M501

M12

Fixing exit PS

Reversal detection PS 1

Reversal detection PS 2

ADU no feed PS

ADU registration PS

ADU feed MC

ADU loop MC

ADU restart MC

ADU paper feed motor

Reversal

paper

exit motor

F

R

630 mm/s

210 mm/s

630 mm/s

Symbol

Item

Time (sec)

012 45

(sec)

3

6

50 ms

200 ms

20 ms

20 ms

586 ms

340 ms

138+a ms

50 ms

200 ms

20 ms

20 ms

586 ms

340 ms

(Paper Lengrth +10) / 210 ms

226 ms

138+a ms

(Paper Lengrth +10) / 210 ms

226 ms

50 ms

200 ms

20 ms

20 ms

586 ms

340 ms

138+a ms

(Paper Lengrth +10) / 210 ms

226 ms

TIMING CHART

ADU TIMING CHART (A4, LIFE SIZE, THREE COPIES)

5 DIAGRAM

5-30

Page 33

DF-315 TIMING CHART

0

1

2

3

4

5

6

7

8

9

10

11

12

(sec)

R

F

0

1

2

3

4

5

6

7

8

9

10

11

12

(sec)

R

F

Start button ON

TIMING CHART

[1] A4, ONE SIDE ORIGINALS, FIVE

SHEETS

[2] A4, DUAL-SIDED ORIGINALS, TWO

SHEETS

5 DIAGRAM

5-31

Page 34

TIMING CHART

110ms

320ms

260ms

110ms

320ms

260ms

110ms

320ms

260ms

110ms

320ms

260ms

70ms

70ms

70ms

10ms

280ms

330ms

10ms

100ms

400ms

60ms

10ms

60ms

10ms

60ms

10ms

280ms

330ms

280ms

330ms

280ms

330ms

0

1

2

3

4

5

6

(sec)

70ms

70ms

200ms

250ms

240ms

190ms

60ms

10ms

70ms

70ms

250ms

210ms

200ms

250ms

200ms

250ms

60ms

10ms

60ms

10ms

110ms

320ms

260ms

110ms

320ms

260ms

110ms

320ms

260ms

110ms

320ms

260ms

110ms

260ms

FS-109 TIMING CHART

[1] A4, SORT MODE, THREE SHEETS,

THREE SETS

[2] A4, THREE SHEETS, TWO PLACES

STAPLING, THREE SETS

5 DIAGRAM

5-32

Page 35

0

1

2

3

4

5

6

7

8

9

(sec)

270ms 280ms

60ms

600ms

650ms

10ms

10ms

10ms

140ms

140ms

140ms

10ms

280ms

60ms

10ms

280ms

60ms

10ms

600ms

650ms

600ms

650ms

TIMING CHART

[3] A3, THREE SHEETS, TWO PLACES STAPLING, THREE SETS

5 DIAGRAM

5-33

Page 36

5 DIAGRAM

Blank page

Page 37

DF-315 OVERALL WIRING DIAGRAM

[How to see the diagram]

1.The signals shown reflect levels present

under normal idling conditions with

the main switch turned ON.

2.Wiring symbols in the figure are as follows.

(1) [Symbol]

(2)

Signal typs are as follows :

Active high

Active low

Analog signal

Pulse signal

(3) RC is ribbon cable.

(4) Signal flow

The solid black circle ( ) among

the connector symbols ( )

indicates the direction of signal flow.

Example)

(5) [Colour code]

BN - Brown B - Blue

R - Red V - Violet

O - Orange GY - Gray

Y - Yellow W - White

GN - Green BK - Black

LB - Light blue P - Pink

Example: Y/GN represents

green yellow striped pattern.

V

V

50-1

Crimp

Connector

Wire(Violet)

Faston

CB

5VDC

PS1

SGND

PS1

Direction of

signal flow

H

L

*

P

CN30-1

CN30-4

CN30-5

CN30-8

CN31-4

CN31-1

CN31-6

CN31-2

CN31-3

CN31-5

CN31-7

CN30-7

CN30-6

CN30-3

DFCB

5 DIAGRAM

CN30-2

MAIN BODY

5-35

Page 38

DB-208/208A OVERALL WIRING DIAGRAM

PTC HEATER

M 401

PFUDB (U)

312-1

312-3

313-1

313-3

300-15

300-2

300-14

300-1

300-3

300-4

300-5 P

300-6

300-7

300-8

300-10

300-9

300-13

300-12

24VDC

M402 DRIVE

24VDC

SD401 DRIVE

5VDC

S.GND

PS402

5VDC

S.GND

PS403

SD401

PS402

PS403

M 402

PFUDB (M)

318A-1

318A-3

317A-1

317A-3

24VDC

M403 DRIVE

24VDC

SD402 DRIVE

5VDC

S.GND

PS404

5VDC

S.GND

PS405

SD402

PS404

PS405

M 403

PFUDB (L)

318B-1

318B-3

317B-1

317B-3

24VDC

M404 DRIVE

24VDC

SD403 DRIVE

5VDC

S.GND

PS406

5VDC

S.GND

PS407

SD403

PS406

PS407

PS401

M 404

UP/DOWN

MOTOR

(L)

PAPER

FEED

SOLENOID

(L)

UP/DOWN

MOTOR

(M)

PAPER

FEED

SOLENOID

(M)

UP/DOWN

MOTOR

(U)

PAPER

FEED

MOTOR

PAPER FEED

DETECT

SENSOR

PAPER

FEED

SOLENOID

(U)

UPPER LIMIT

DETECT

SENSOR

(L)

NO PAPER

DETECT

SENSOR

(L)

UPPER LIMIT

DETECT

SENSOR

(M)

NO PAPER

DETECT

SENSOR

(M)

UPPER LIMIT

DETECT

SENSOR

(U)

NO PAPER

DETECT

SENSOR

(U)

311-B11

311-B12

311-B10

311-B9

311-A4

311-B8

311-B7

311-B6

311-B5

311-A11

311-A12

311-A10

311-A9

311-B3

311-A3

311-A8

311-A7

311-A6

311-A5

PS406

PS407

M404 DRIVE

SD403 DRIVE

SIZE SCN2

SIZE D

SIZE C

SIZE B

SIZE A

PS404

PS405

M403 DRIVE

SD402 DRIVE

SELECT

SIZE SCN1

SIZE D

SIZE C

SIZE B

SIZE A

316B-13

316B-7

316B-10

316B-1

316B-2

316B-3

316B-4

316B-5

316B-6

316B-8

361B-9

316B-11

361B-12

5VDC

S.GND

24VDC

SIZE A

SIZE B

SIZE C

SIZE D

SIZE SCN2

SD403 DRIVE

M404 DRIVE

PS407

PS406

316A-13

316A-7

316A-10

316A-1

316A-2

316A-3

316A-4

316A-5

316A-6

316A-8

361A-9

316A-11

361A-12

5VDC

S.GND

24VDC

SIZE A

SIZE B

SIZE C

SIZE D

SIZE SCN1

SELECT

SD402 DRIVE

M403 DRIVE

PS405

PS404

P.GND

(DCPS1)

P.GND

(DCPS1)

24VDC

(DCPS1)

24VDC

(DCPS1)

5VDC

(SCDB)

S.GND

(SCDB)

DB MTXD

(SCDB)

(SCDB)

DB SRXD

(SCDB)

(SCDB)

(PRDB)

X RESET

(PRDB)

28VDC

(DCPS1)

P.GND

(DCPS1)

310-B4

310-B3

310-A3

310-A2

310-A1

310-B1

310-A6

P 310-A5

P 310-A4

310-A7

P 310-A9

310-A8

DB MACK

DB SRXD

MPS DATA

311-A2

311-B1

311-A1

24VDC

S.GND

5VDC

311-B2 H

312-2

312-3

312-1

PS401

310-B6

310-B8

310-B7

310-B2

310-B9

310-B5

321-3

321-4

321-5

321-10

321-12

321-8

321-2

321-1

M401 CONT

M401 CLK

M401 H/L

24VDC

M401 CW/CCW

P.GND

SW401

SW402

SW403

SW404

SW401

SW402

SW403

SW404

SW401

SW402

SW403

SW404

MAIN BODY

320-2

320-1

PTC

P

R

BK

R

BK

R

BK

R

BK

R

BK

R

BK

P

P

H

H

H

H

H

H

H

H

H

H

H

H

H

H

P

P

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

[How to see the diagram]

1.The signals shown reflect levels present

under normal idling conditions with

the main switch turned ON.

2.Wiring symbols in the figure are as follows.

(1) [Symbol]

(2)

Signal typs are as follows :

Active high

Active low

Analog signal

Pulse signal

(3) RC is ribbon cable.

(4) Signal flow

The solid black circle ( ) among

the connector symbols ( )

indicates the direction of signal flow.

Example)

(5) [Colour code]

BN - Brown B - Blue

R - Red V - Violet

O - Orange GY - Gray

Y - Yellow W - White

GN - Green BK - Black

LB - Light blue P - Pink

Example: Y/GN represents

green yellow striped pattern.

V

V

50-1

Crimp

Connector

Wire(Violet)

Faston

CB

5VDC

PS1

SGND

PS1

Direction of

signal flow

H

L

*

P

DB-208

DB-208A

5 DIAGRAM

5-36

Page 39

DB-608 OVERALL WIRING DIAGRAM

R

BK

R

BK

R

BK

R

BK

PTC

PTC HEATER

320-2

320-1

O

O

O

O

O

O

O

O

O

O

M 401

SW405

SW401

SW402

SW403

SW404

MAIN BODY

PFUDB (PFU)

312-1

312-3

313-1

313-3

300-15

300-2

300-14

300-1

300-3

300-4

300-5 P

300-6

300-7

300-8 P

300-10

300-9

300-13

300-12

24VDC

M402 DRIVE

24VDC

SD401 DRIVE

5VDC

S.GND

PS402

5VDC

S.GND

PS403

SD401

PS402

PS403

M 402

PFUDB (LCT)

318A-1

318A-3

317A-1

317A-3

24VDC

M403 DRIVE

24VDC

SD402 DRIVE

5VDC

S.GND

PS404

5VDC

S.GND

PS405

SD402

PS404

PS405

M 403

PS401

UP/DOWN

MOTOR

(LCT)

PAPER

FEED

SOLENOID

(LCT)

UP/DOWN

MOTOR

(PFU)

PAPER

FEED

MOTOR

PAPER FEED

DETECT

SENSOR

PAPER

FEED

SOLENOID

(PFU)

UPPER LIMIT

DETECT

SENSOR

(LCT)

NO PAPER

DETECT

SENSOR

(LCT)

UPPER LIMIT

DETECT

SENSOR

(PFU)

NO PAPER

DETECT

SENSOR

(PFU)

311-A11

311-A12

311-A10 H

311-A9 H

311-B3

311-A3 P

311-A8

311-A7

311-A6

311-A5

PS404

PS405

M403 DRIVE

SD402 DRIVE

SELECT

SIZE SCN1

SIZE D

SIZE C

SIZE B

SIZE A

316A-13

316A-7

316A-10

316A-1

316A-2

316A-3

316A-4

316A-5

316A-6

316A-8

361A-9

316A-11

361A-12

5VDC

S.GND

24VDC

SIZE A

SIZE B

SIZE C

SIZE D

SIZE SCN1

SELECT

SD402 DRIVE

M403 DRIVE

PS405

PS404

P.GND(DCPS1)

P.GND(DCPS1)

24VDC(DCPS1)

24VDC(DCPS1)

5VDC(SCDB)

S.GND(SCDB)

DK MTXD(SCDB)

(SCDB)

(SCDB)

DB SACK(SCDB)

(PRDB)

X RESET(PRDB)

28VDC(DCPS1)

P.GND(DCPS1)

310-B4

310-B3

310-A3

310-A2

310-A1

310-B1

310-A6

310-A5

310-A4

310-A7

310-A9

310-A8

DB MACK

DB SRXD

MPS DATA

311-A2

311-B1

311-A1

24VDC

S.GND

5VDC

311-B2 H

312-2

312-3

312-1

PS401

310-B6

310-B8

310-B7

310-B2

310-B9

310-B5

321-3

321-4

321-5

321-10

321-12

321-8

321-2

321-1

M401 CONT

M401 CLK

M401 H/L

24VDC

M401 CW/CCW

P.GND

P

H

H

H

H

H

H

P

P

P

[How to see the diagram]

1.The signals shown reflect levels present

under normal idling conditions with

the main switch turned ON.

2.Wiring symbols in the figure are as follows.

(1) [Symbol]

(2)

Signal typs are as follows :

Active high

Active low

Analog signal

Pulse signal

(3) RC is ribbon cable.

(4) Signal flow

The solid black circle ( ) among

the connector symbols ( )

indicates the direction of signal flow.

Example)

(5) [Colour code]

BN - Brown B - Blue

R - Red V - Violet

O - Orange GY - Gray

Y - Yellow W - White

GN - Green BK - Black

LB - Light blue P - Pink

Example: Y/GN represents

green yellow striped pattern.

V

V

50-1

Crimp

Connector

Wire(Violet)

Faston

CB

5VDC

PS1

SGND

PS1

Direction of

signal flow

H

L

*

P

5 DIAGRAM

5-37

Page 40

FS-109 OVERALL WIRING DIAGRAM

[How to see the diagram]

1.The signals shown reflect levels present

under normal idling conditions with

the main switch turned ON.

2.Wiring symbols in the figure are as follows.

(1) [Symbol]

(2)

Signal typs are as follows :

Active high

Active low

Analog signal

Pulse signal

(3) RC is ribbon cable.

(4) Signal flow

The solid black circle ( ) among

the connector symbols ( )

indicates the direction of signal flow.

Example)

V

V

50-1

Crimp

Connector

Wire(Violet)

Faston

CB

5VDC

PS1

SGND

PS1

Direction of

signal flow

H

L

*

P

PAPER THROUGH

DETECTSENSOR

DRUM POSITION

DETECT SENSOR

DRUM ENTRANCE

SENSOR

TRAY 1

PAPER EXIT

DETECT SENSOR

TRAY

UPPER LIMIT

SENSOR

TRAY

LOWER LIMIT

SENSOR

TRAY 3

FULL–STACK

DETECT SENSOR

TRAY 2

FULL–STACK

DETECT SENSOR

STAPLER NO

PAPER SENSOR

PAPER EXIT

MOTOR HP SENSOR

STAPLER UNIT HP SENSOR

ALIGNMENT MOTOR

HP (FRONT) SENSOR

ALIGNMENT MOTOR

(REAR) HP

STAPLER (FRONT)

MOTOR

STAPLER HP (FRONT) SENSOR

NO STAPLE (FRONT) SENSOR

NO STAPLE (FRONT)

(LEAD EDGE) SENSOR

STAPLER (REAR)

MOTOR

STAPLER HP (REAR) SENSOR

NO STAPLE (REAR) SENSOR

NO STAPLE (REAR)

(LEAD EDGE) SENSOR

PAPER EXIT

CN727–4

CN727–2

CN727–5

25314

UL1007#24

UL1007#24

5253545556

CN705–B8 24V

CN705–B7 24V

PPP

CN704–B5 M801 DRVA

CN704–B7 M801 DRVB

CN704–B6 M801 DRVA

PPP

22

MOTOR

M805

CN727–6

CN727–3

UL1007#24

UL1007#24

UL1007#24

CN705–B10 M805 DRVA

CN705–B11 M805 DRVB

CN705–B9 M805 DRVA

CN704–B8 M801 DRVB

CN727–1

6

UL1007#24

57

CN705–B12 M805 DRVB

P

TRAY UP/DOWN

MOTOR

M804

CN726–1

CN726–2

UL1007#24

UL1007#24

23

24

CN707–A8 M804 DRV1

CN707–A9 M804 DRV2

H

H

CN704–B1 24V

CN704–B2 24V

P

1516192021

TRAY 2 MOTOR

M810

CN728–5

CN728–6

CN728–1

CN728–3

18

CN753–12

CN753–11

CN753–10

CN753–9

CN753–1

CN753–2

CN753–3

CN753–4

UL1007#26

UL1007#26

UL1007#26

34789

CN704–A7 M810 DRVA

CN704–A4 24V

CN704–A3 24V

PPP

CN704–B3 24V

CN704–B4 24V

PPP

1718232425

CN728–2

CN728–4

1314151617

CN753–8

CN753–7

CN753–5

CN753–6

UL1007#26

UL1007#26

UL1007#26

10

CN704–A9 M810 DRVB

CN704–A10 M810 DRVB

CN704–A8 M810 DRVA

P

CN704–B9 M807 DRVA

CN704–B10 M807 DRVA

CN704–B12 M807 DRVB

CN704–B11 M807 DRVB

P

26

CN729–5

12

CN753–6

CN753–7

56111213

UL1007#24

UL1007#24

UL1007#24

UL1007#24

UL1007#24

UL1007#24

UL1007#24

UL1007#24

UL1007#24

UL1007#24

UL1007#24

UL1007#24

5 DIAGRAM

25314

CN721–5

CN721–4

CN721–2

6

CN721–3

CN721–6

CN721–1

25314

CN722–2

CN722–5

CN722–6

CN722–4

6

CN722–3

CN722–1

M801

M807

ONVEYANCE MOTOR

CONVEYANCE

DRUM MOTOR

TRAY 3 MOTOR

M811

CN729–6

CN729–1

CN729–3

CN753–5

CN753–4

CN753–3

CN753–8

CN753–9

CN753–10

UL1007#26

UL1007#26

UL1007#26

UL1007#26

CN704–A12 M811 DRVA

CN704–A11 M811 DRVA

CN704–A6 24V

CN704–A5 24V

PPP

CN705–B1 24V

4647484950

UL1007#26

CN762–1

CN763–6

6

CN723–5

CN723–2

CN729–2

CN729–4

7891011

CN753–2

CN753–1

CN753–11

CN753–12

UL1007#26

UL1007#26

14

CN704–A14 M811 DRVB

CN704–A13 M811 DRVB

P

CN705–B2 24V

CN705–B3 M808 DRVA

CN705–B4 M808 DRVA

PPP

UL1007#26

UL1007#26

UL1007#26

CN762–4

CN762–5

CN762–3

CN762–2

CN763–5

CN763–4

CN763–3

CN763–2

CN723–6

CN723–1

CN723–3

CN723–2

CN723–5

CN723–4

CN723–6

CN723–1

M808

ALIGNMENT

MOTOR (REAR)

GATE SOLENOID

SD801

CN730–1

CN730–2

UL1007#26

2

1

CN704–A1 24V

CN705–B5 M808 DRVB

CN705–B6 M808 DRVB

P

51

UL1007#26

UL1007#26

CN762–6

CN763–1

12345

CN723–4

CN723–3

SHUTTER SOLENOID

SD802

CN731–2

CN731–1

1

2

CN748–1

CN748–2CN748–1

CN748–2

UL1007#26

UL1007#26

UL1007#26

27

28

CN704–A2 SD801 DRV

CN704–B14 24V

CN704–B13 SD802 DRV

H

H

CN705–A1 24V

CN705–A2 24V

PPP

3436373839

35

UL1007#26

UL1007#26

CN761–1

CN761–2

CN761–3

CN761–6

CN761–5

CN761–4

456

CN724–1

CN724–6

CN724–5

CN724–2

CN724–1

CN724–6

CN760–1

543

CN763–3

CN763–1

UL1007#26

424140

CN703–A12 VCC

CN705–A3 M809 DRVA

CN705–A4 M809 DRVA

CN705–A5 M809 DRVB

P

UL1007#26

UL1007#26

UL1007#26

CN761–4

CN761–5

CN761–6

CN761–3

CN761–2

CN761–1

132

CN724–4

CN724–2

CN724–3

CN724–4

CN724–5

CN724–3

M809

ALIGNMENT

MOTOR (FRONT)

PS804

CN760–2

CN760–3

CN760–2

CN763–1CN763–3

CN763–2

UL1007#26

UL1007#26

CN703–A11 PS804IN

CN703–A10 GND

CN705–A7 24V

CN705–A6 M809 DRVB

4042434445

UL1007#26

UL1007#26

CN725–6

CN725–1

CN705–A8 24V

CN705–A9 M806 DRVA

CN705–A10 M806 DRVA

PPP

41

UL1007#26

UL1007#26

UL1007#26

CN725–1

CN725–2

CN725–3

CN725–5

CN725–6

CN725–5

CN725–4

CN725–2

M806

STAPLER

MOVEMENT

MOTOR

PS801

CN732–3

CN732–2

CN732–1

UL1007#26

UL1007#26

UL1007#26

484746

CN703–B5 PS801IN

CN703–B4 GND

CN703–B6 VCC

CN705–A12 M806 DRVB

CN705–A11 M806 DRVB

P

UL1007#26

UL1007#26

CN725–4

CN725–3

PS802

CN733–1

CN733–2

CN733–3

UL1007#26

UL1007#26

UL1007#26

454344

CN703–B1 GND

CN703–B2 PS802IN

CN703–B3 VCC

L

T

OU

V

24

CN711–2

2

UL1015#18

CN734–1

CN734–2

UL1007#26

38

39

CN703–A9 VCC

IN

V

24

CN711–1

1

UL1015#18

MS801

INTER LOCK MS

PS803

PS805

CN734–3

CN736–1

CN736–2

CN736–3

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

37

3635343332

CN703–A4 GND

CN703–A5 PS805IN

CN703–A6 VCC

CN703–A8 PS803IN

CN703–A7 GND

L

L

FNSCB

T

OU

V

24

CN710–2

CN754–1

UL1015#18

MS (UPPER)

55

CN755–2

30

UL1007#22

CN754–2

UL1015#18

MS802

UP–DOWN

PS806

CN737–1

CN737–2

CN737–3

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

31

CN703–A1 GND

CN703–A3 VCC

CN703–A2 PS806IN

H

V IN

24

CN710–1

29

UL1007#22

UL1007#22

CN755–1

UL1015#18

UL1015#18

MS803

UP–DOWN

MS (LOWER)

PS809

CN752–1

CN752–2

CN752–3

456

CN750–4

CN750–5

CN750–6

CN750–1

CN750–2

CN750–3

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

545352

CN703–B10 GND

CN703–B11 PS809IN

CN703–B12 VCC

L

V IN

V OUT

24

24

CN709–1

CN709–2

1

2

UL1007#18

UL1015#18

MS804

STAPLER

SAFETY

MS

PS807

CN751–1

CN751–2

CN751–3

123

CN750–1

CN750–2

CN750–3

CN750–4

CN750–5

CN750–6

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

51

50

49

CN703–B8 PS817IN

CN703–B7 GND

CN703–B9 VCC

L

PS812

CN740–1

CN740–2

CN740–3

789

CN749–8

CN749–7

CN759–1 CN749–9

CN749–3

CN749–2

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

151413

CN706–13 GND

CN706–14 PS812IN

CN706–15 VCC

PS813

CN741–1

CN741–2

CN741–3

456

CN749–6

CN749–5

CN749–4

CN749–6

CN749–5

CN749–4

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

12

10

11

CN706–12 VCC

CN706–10 GND

CN706–11 PS813IN

H

PS814

CN742–1

CN742–2

CN742–3

123

CN749–3

CN749–2

CN759–1

CN749–9

CN749–8

CN749–7

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

789

CN706–7 GND

CN706–8 PS814IN

CN706–9 VCC

L

PS815

PS816

CN743–1

CN743–2

CN743–3

CN744–1

CN744–2

CN744–3

789

789

CN759–3

CN759–2

CN758–1

CN759–2

CN759–1

CN758–3

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

456

CN706–2 PS816IN

CN706–3 VCC

CN706–4 GND

H

GND

GND

GND

V

V

S.

5

5

P.

P.

CN701–6

CN701–2

CN701–3

CN701–4

CN701–5

UL1007#24

UL1007#24

UL1007#24

UL1007#24

UL1007#24

CN401–7 P.GND

CN402–5 P.GND

CN402–1 S.GND

CN401–8 5V

CN402–2 5V

CN759–1

CN759–3

UL1007#26

UL1007#26

123

CN706–1 GND

.GND

P

CN701–7

UL1007#24

CN402–3 P.GND

CN758–3

CN758–2

CN758–2

CN758–1

UL1007#26

UL1007#26

UL1007#26

CN706–5 PS815IN

CN706–6 VCC

H

GND

S.

CN701–1

123456789

UL1007#24

CN401–5 S.GND

M803

CN745–6

CN745–3

CN745–1

1234567

CN756–1

CN756–2

CN756–3

16171920212218

UL1007#24

UL1007#24

UL1007#26

CN707–A1 M803 DRV1

CN707–A4 VCC

CN707–A2 M803 DRV2

V

V

V

_TXD

_REQ

24

24

24

M

M

CN701–8

CN701–9

CN701–10

CN702–1

CN702–2

PPPPP

10111213141516

UL1007#24

UL1007#24

UL1007#26

UL1007#26

UL1007#24

CN401–4 M_TxD

CN401–3 M_REQ

CN401–8 24V

CN402–8 24V

CN402–4 24V

PS817

PS818

PS819

CN745–5

CN745–11

CN745–7

CN745–9

8

CN756–4

CN756–5

CN756–6

CN756–7

CN756–8

59

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#22

CN707–A3 GND

CN707–A7 PS819IN

CN707–A6 PS818IN

CN707–A5 PS817IN

LLL

_RXD

_ACK

_ACK

_REQ

S

M

M

S

CN702–4

CN702–3

CN702–5

CN702–6

P

UL1007#26

UL1007#26

UL1007#26

UL1007#26

CN402–7 S_ACK

CN401–1 S_RxD

CN402–8 S_REQ

CN401–2 M_ACK

CN746–1

1234567

CN757–1

33323029282831

17

UL1015#18

EARTH

CN100 –

MAIN BODY

M802

+5V

CN746–3

CN746–6

CN757–2

CN757–3

UL1007#24

UL1007#24

UL1007#24

CN707–B9 M802 DRV1

CN707–B8 M802 DRV2

CN707–B6 VCC

GND

PS820

PS821

PS822

CN746–9

CN746–7

CN746–11

CN746–5

8

CN757–4

CN757–5

CN757–6

CN757–7

CN757–8

58

UL1007#24UL1007#24

UL1007#24

UL1007#24

UL1007#24

UL1007#22

CN707–B7 GND

CN707–B3 PS822IN

CN707–B4 PS821IN

CN706–B5 PS820IN

LLL

5-38

Page 41

PRINTED IN JAPAN

CN55YF1300

Loading...

Loading...