Page 1

4

SERVICE

1 OUTLINE

2 ISW

3 SERVICE

4 SERVICE

Page 2

1 OUTLINE

2 ISW

Main Precautions for Maintenance

1. Points to be confirmed before maintenance

Before starting maintenance, ask a user

and collect information about troubles occurred on the machine before the maintenance and the conditions of the machine to

grasp key points for the maintenance.

2. Copy sample

3 SERVICE

4 SERVICE

Be sure to make copy samples at the start

and the end of maintenance for checking

images.

3. Drum

1) Never expose the drum to the sunlight.

2) When replacing a drum or a cleaning

Blank page

Be also careful not to expose a drum to

indoor light as far as possible.

When a drum unit or a drum is out of the

machine, never fail to cover it with a

drum cover.

blade, refer to item of mounting/dismounting of a cleaning blade for doing a

replacement work.

4. After replacing the drum or the developer,

refer to the list of adjustment items, and

carry out the necessary adjustments.

5. When maintenance is completed, be sure

to reset the PM counter (25 mode). Incidentally, a development counter is reset automatically in the course of L detection adjustment.

6. When replacing a toner bottle, wait until the

toner supply message on the operation

panel displays before the replacement.

Caution: Turn the main switch off and

pull out the power plug without fail before the work of

maintenance.

Page 3

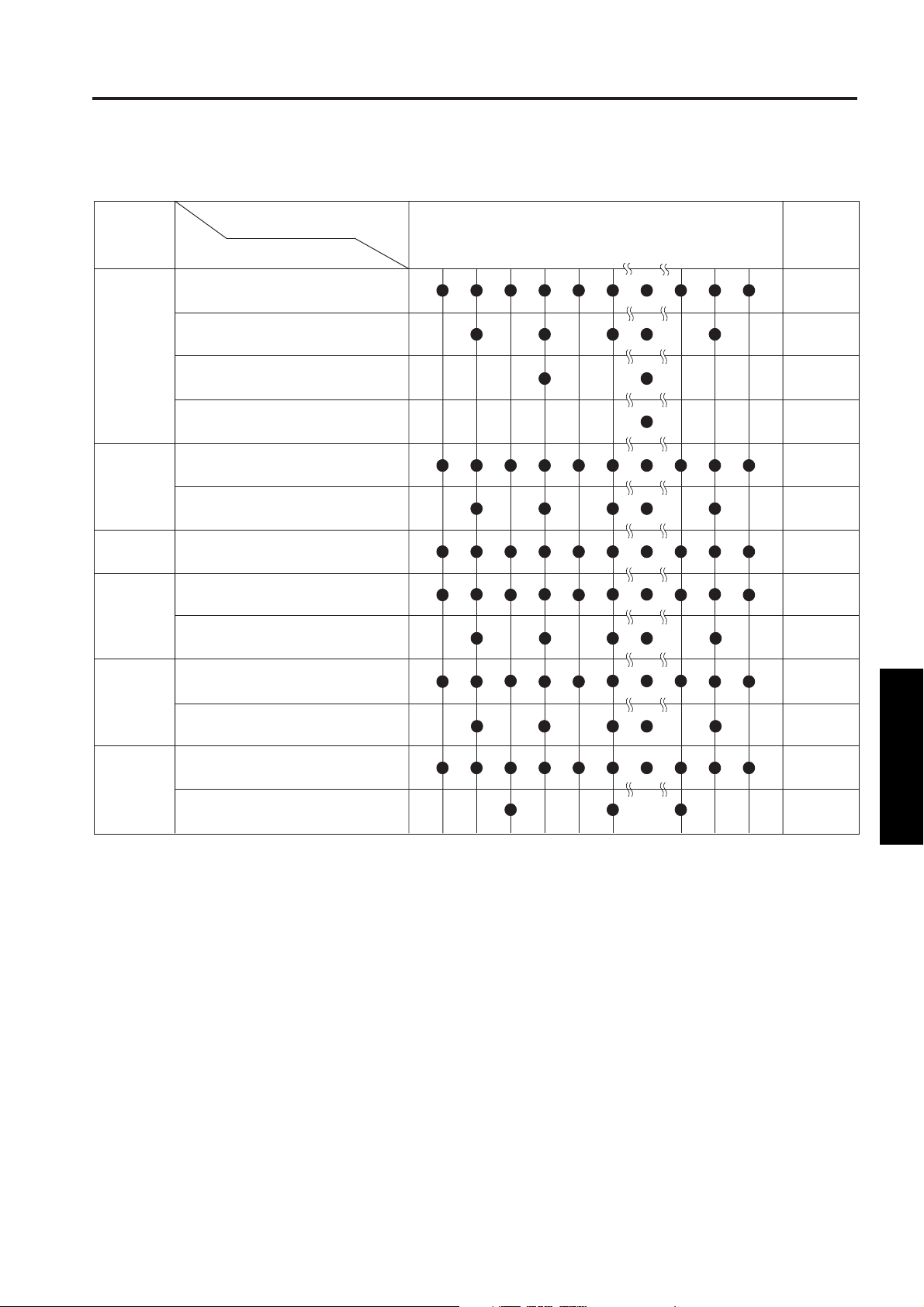

SERVICE SCHEDULE

Number of copies (unit: 10,000)

Service item (cycles)

Maintenance

(Every 100,000 copies or prints)

Periodic check (I)

(Every 200,000 copies or prints)

Periodic check (II)

(Every 400,000 copies or prints)

Periodic check (III)

(Every 800,000 copies or prints)

Maintenance

(Every 100,000 copies or prints)

Periodic check

(Every 200,000 copies or prints)

Periodic check

(Every 100,000 copies or prints)

Periodic check

(Every 200,000 copies or prints)

Maintenance

(Every 200,000 copies or prints)

Maintenance

(Every 100,000 copies or prints)

MaintenanceMaintenance

(Every 100,000 copies or prints)

Maintenance

(Every 100,000 copies or prints)

Periodic check

(Every 300,000 copies or prints)

Classifica-

tion

Main body

RADF

(DF-315)

DB-608

(1 tray + LCT)

DB-208

(3 trays)

DB-208A

(1 tray)

FNS

(FS-109)

10 20 30 40 50 60 90 100 110

Service

times

11 times

5 times

2 times

1 time

11 times

5 times

11 times

11 times

5 times

11 times

5 times

11 times

3 times

Guarantee period (5 years or 1,200,000 copies)

SERVICE

[1] Service Schedule

1 OUTLINE

2 ISW

3 SERVICE

4-1

4 SERVICE

Page 4

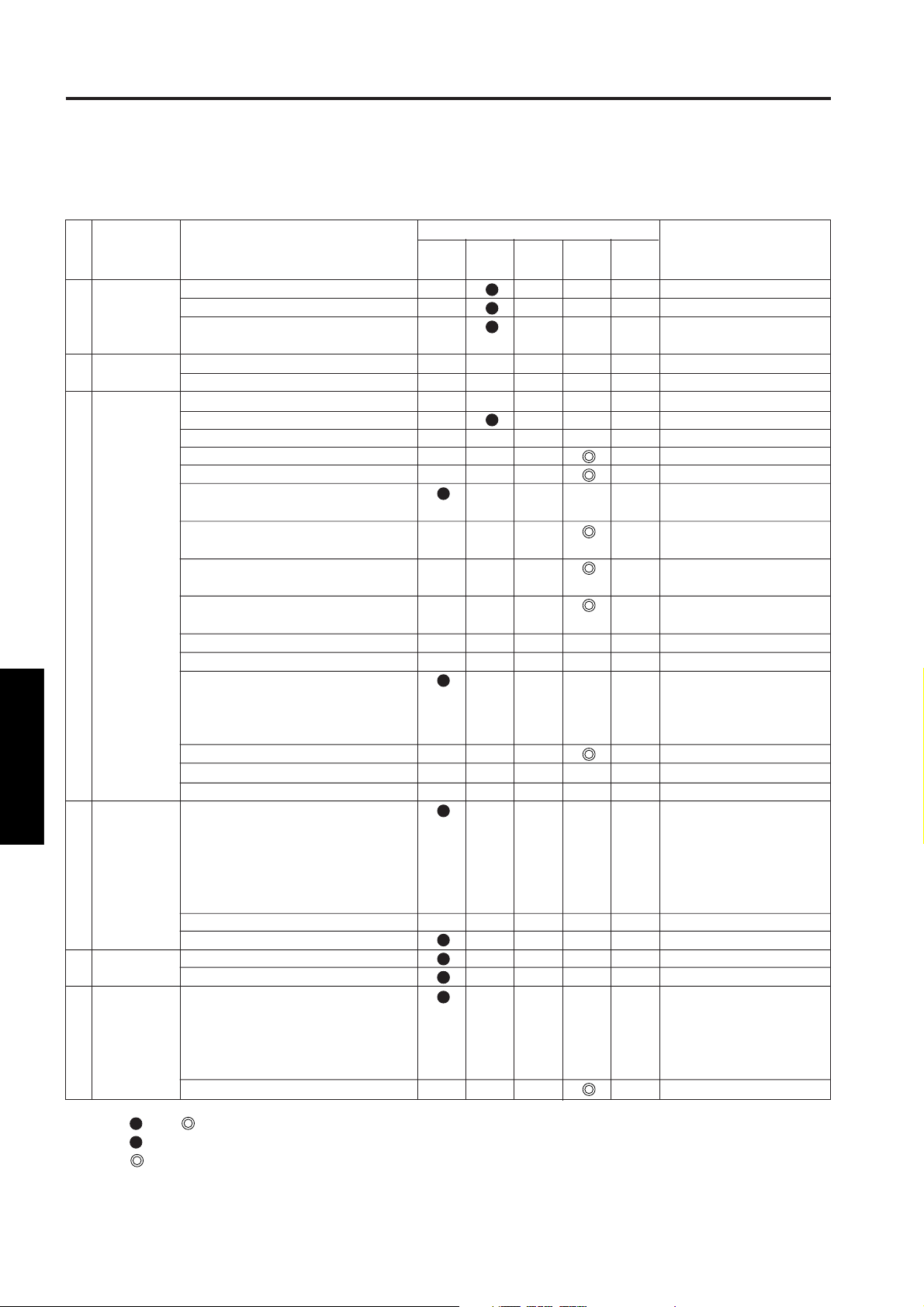

SERVICE

[2] Maintenance Items

1 OUTLINE

1. Main body (Every 100,000 copies or prints)

Classification Service itemNo.

Preparation

1

Fixing unit

2

2 ISW

Drum unit

3

3 SERVICE

4 SERVICE

Developing

4

unit

Write unit

5

6

Transfer/

Separation

corona unit

(1) Image check

(2) External parts

(3) Check of adjustment value,

Dmax and correction error

(1) Fixing unit removing

(2) Upper cover removing

(1) Drum unit removing

(2) Drum unit check

(3) Charging corona unit removing

(4) Charging control plate

(5) Charging wire 55FA2501*

(6) Charging corona unit cleaning

(Back plate and its around, and PCL)

(7) Cleaner mount assembly

(8) Charging wire cleaning block (C)

(9) Charging wire cleaning block (D)

(10) Developing unit removing

(11) Drum removing

(12) Drum cartridge/Developing unit bot-

tom plate/Toner control sensor/Sepa-

rating claw/Developing bias intercept/

Clean with each

(13) Cleaning blade 55GA5601*

(14) Drum installing

(15) Charging corona unit installing

(1) Developing unit lower rib (inside &

outside)/upper cover (back side of

the urethane sheet)

(2) Developing unit installation

(3)

Toner supply opening and its around

(1)

Mirror

(2)

Dust-proof glass

(1) Transfer/Separation corona unit

cleaning (Front and rear block/Guide

rail/Separating bridge/Entrance guide

plate/Back plate) and include remov-

ing and installing

(2) Discharging wire 55GA2607*

55GA2507*

55GA-252*

55GA-253*

55GA-255*

Implementation classification

Cleaning

Lubrication

Replacement

Material used

SupplyCheck

Drum cleaner / Waste rag /

Blower brush

Blower brush / Cleaning pad /

Drum cleaner (Drum cleaner:

only when using the toner con-

trol sensor cleaning.)

Waste rag / Blower brush

(When cleaning the back

side of the urethane sheet,

the back side should be

cleaned, particularly the

urethane sheet section.)

Waste rag

Cleanig pad

Cleanig pad

Blower brush / Cleaning pad

Tools used

Remarks: ( ) and ( ) indicate the following in the classification of implementation.

( ) indicates items that must always be implemented.

( ) indicates items for checking whether they have reached the substantial resistance count listed in the fixed replacement part list and judge

whether to replace them or not.

4-2

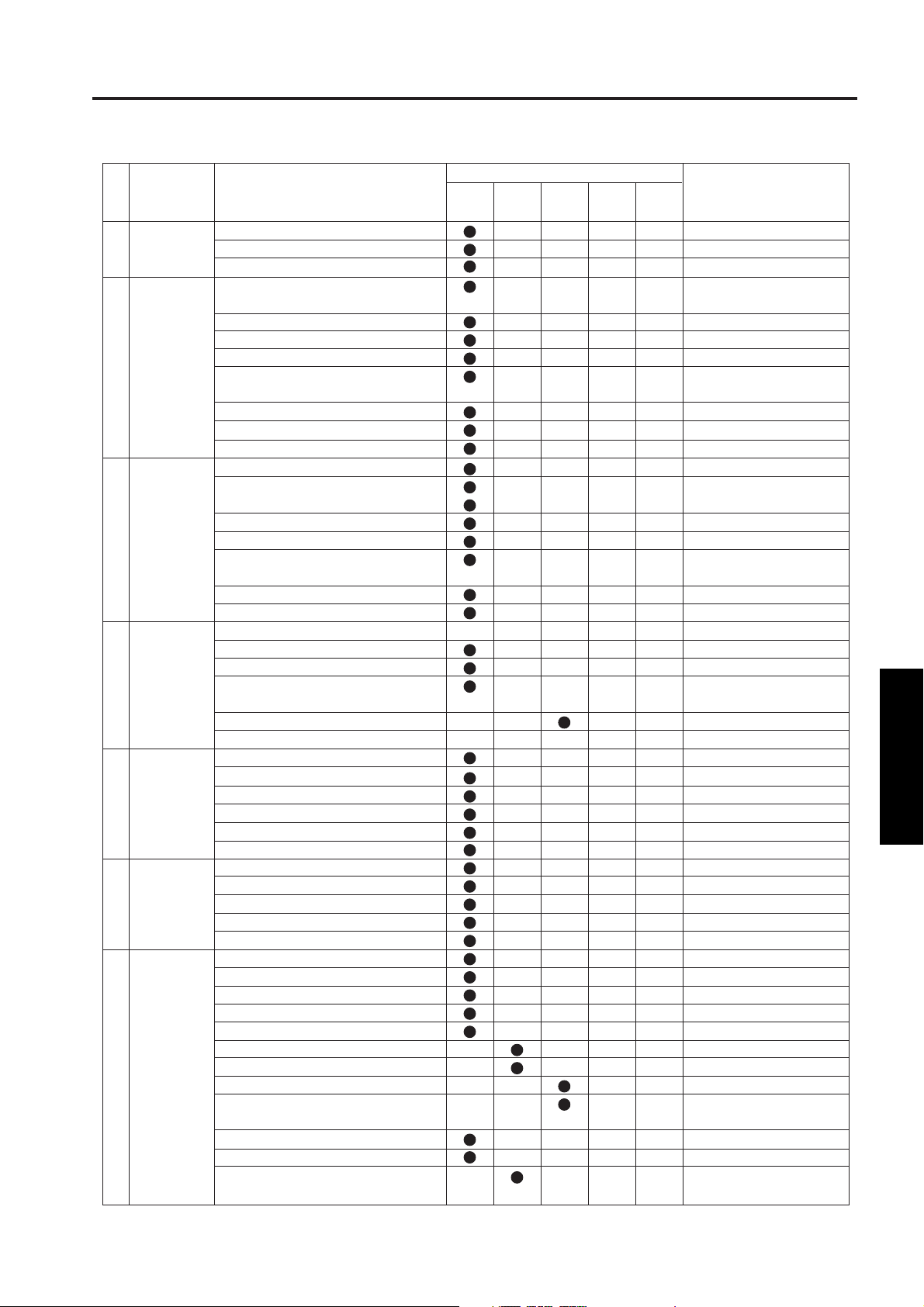

Page 5

SERVICE

Classification Service itemNo.

Machine

7

inside

2nd paper

8

feed unit

By-pass unit

9

Paper feed

10

unit

ADU

11

Reversal

12

paper exit

section

Reading

13

section

(1) Conveyance unit 55GA4501*

Conveyance guide plate

(2)

Conveyance belt 55GA4506*

(3)

Registration guide plate (B) assembly

(1)

Registration unit 55GA4301*

(2)

Registration roller (lower)

(3)

Registration roller (upper)

(4)

Registration paper feed roller

(5)

P

aper conveyance roller

(6)

Photo sensors 55208551*

(7)

Paper feed door 55GA-408*

(8)

By-pass tray 55GA-428*

(1)

Double feed prevention roller

(2)

Separation roller 54004056*

(3)

Paper feed roller 25BA4032*

(4)

Double feed prevention plate

(5)

Photo sensor/2 55WA8552*

(6)

Photo sensor 55208551*

(7)

Paper feed unit removing

(1)

Paper feed roller 25BA4032*

(2)

Separation roller 54004056*

(3)

Double feed prevention roller

(4)

Gears

(5)

Paper feed unit installing

(6)

Registration roller (lower)

(1)

Conveyance roller (A) 55HA5025*

(2)

Conveyance roller (B) 55HA5026*

(3)

Conveyance roller (C) 55HA5087*

(4)

Photo sensor 25AA8551*

(5)

Photo sensor 55208551*

(6)

Paper exit reversal roller

(1)

Reversal roller 40BA4825*

(2)

Conveyance roller 55GA4806*

(3)

Paper exit roller 55GA4805*

(4)

Photo sensors 25AA8552*

(5)

Original glass 55YA6150*

(1)

Lens 55GA6001*

(2)

1st mirror 55GA6106*

(3)

2nd mirror 55GA6115*

(4)

Original glass (1) 55GA6139*

(5)

Optics drive wire (front)

(6)

Optics drive wire (rear)

(7)

Optics driven sheet 25BA6189*

(8)

Optics driven sheet (upper)

(9)

APS sensors 25SA8552*

(10)

Photo sensors 55208551*

(11)

Lamp power supply relay cord

(12)

55GA4502*

55GA-431*

55GA4311*

55GA4312*

55GA4322*

55GA4323*

54004056*

54004235*

54004056*

55GA6132*

55YA9012*

Implementation classification

Cleaning

Lubrication

Replacement

Material used

SupplyCheck

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Blower brush

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Blower brush

Blower brush

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Plus guard No. 2

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Blower brush

Blower brush

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Blower brush

Drum cleaner / Cleaning pad

Blower brush

Blower brush / Cleaning pad

Blower brush / Cleaning pad

Drum cleaner / Cleaning pad

Multi oil / Cotton tips

Multi oil / Cotton tips

Blower brush

Blower brush

Tools used

1 OUTLINE

2 ISW

3 SERVICE

4 SERVICE

4-3

Page 6

SERVICE

1 OUTLINE

Classification Service itemNo.

1415Fixing unit

2 ISW

3 SERVICE

Final check

4 SERVICE

(1) Fixing cleaning roller 55GA5312*

(2) Fixing roller (A) 55GA5311*

(3) Fixing cleaning pad 55GA5350*

(4) Fixing roller (upper) 55GA5303*

(5) Paper exit guide (lower) removing

(6) Fixing roller (lower) 55GA5304*

(7) Fixing claw (upper) 25SA5315*

(8) Fixing claw (lower) 54005310*

(9) Fixing paper exit roller (lower)

55GA5329*

(10) Paper exit pulley 54005322*

(11) Fixing entrance plate (lower)

55GA5320*

(12) Fixing entrance plate (upper)

55GA5337*

(13) Fixing temperature sensor 2

55GA8842*

(14) Photo sensor 55208551*

(15) Paper exit guide (lower) installing

(16) Fixing upper cover installing

(17) Fixing unit installing

(1) Toner cartridge supply

(2) W.U.T measure and check

(3) Image check after changing

consumables

(Necessary operation when replac-

ing the 200,000 copy materials).

(4) Copy sample check

(5) PM counter reset (25 mode)

(6) Leakage breaker reset

(7) Machine surroundings, Externals

Implementation classification

Cleaning

Lubrication

Replacement

SupplyCheck

()

Material used

Tools used

Roller cleaner / Cleaning pad

Roller cleaner / Cleaning pad

Roller cleaner / Cleaning pad

Roller cleaner / Cotton tips

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Roller cleaner / Cleaning pad

Roller cleaner / Cleaning pad

Roller cleaner / Cleaning pad

Blower brush

Drum cleaner / Cleaning pad

4-4

Page 7

SERVICE

2. RADF [DF-315] (Every 100,000 copies or prints)

Implementation classification

Classification Service itemNo.

Machine

1 (1) Registration sensor mirror

inside

(2) Registration sensor

(3) Read sensor reflection element

(4) Read sensor

(5) Switchback sensor mirror

(6) Switchback sensor

(7) Paper dust removing pad

(8) Paper feed roller

(9) Separation roller

(10) Double feed prevention roller

Cleaning

3. DB [DB-208/DB-208A/DB608] (Every 100,000 copies or prints)

Implementation classification

Classification Service itemNo.

Externals

1

Paper feed

2

section Note

Externals

3

(1) Externals

(1) Paper feed unit removing

(2) Paper feed roller 25BA4032*

(3) Separation roller 54004056*

Note

(4) Double feed prevention roller

Note

(5) Gears

(6) Paper feed unit installing

(1) Externals

54004056*

Cleaning

Lubrication

Replacement

SupplyCheck

Material used

Tools used

Blower brush

Blower brush

Blower brush

Blower brush

Blower brush

Blower brush

Blower brush

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

DB-208: Operational manhours of 1 unit X 3

DB-208A: Operational manhours of 1 unit X 1

DB-608: Operational manhours of 1 unit X 2

Lubrication

Replacement

( )

( )

( )

SupplyCheck

Material used

Tools used

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Plus guard No. 2

Drum cleaner / Cleaning pad

1 OUTLINE

2 ISW

3 SERVICE

Note : For the DB-208A alone, replace after 100,000 copies.

4. FNS [FS-109] (Every 100,000 copies or prints)

Classification Service itemNo.

Conveyance

1 (1) Conveyance drive roller (A)

section

(2) Paper exit drive roller

Implementation classification

Cleaning

Lubrication

Replacement

4 SERVICE

Material used

SupplyCheck

Drum cleaner / Cleaning pad

Drum cleaner / Cleaning pad

Tools used

4-5

Page 8

SERVICE

[3] Main Body Periodic Check

1 OUTLINE

1. Periodic check (I) (Every 200,000 copies or prints)

Classification Service itemNo.

(1) Fixing claw (upper) 25SA5315*

(2) Heat insulating sleeve 45405339*

(3) Fixing roller (upper) 55GA5303*

(1) Drum

(2) Separation claw 55GA-206*

(3) Drum counter reset (47 mode)

(1) Developer (include the developing

unit installing)

(2) L detection adjustment (36 mode)

(1) Separation roller

(2) Paper feed roller

Double feed prevention roller

(3)

(1) Ozone filter 55YA7350*

(2) Fixing filter 55GA7337*

54004056*

25BA4032*

54004056*

2 ISW

Fixing unit

1

Drum unit

2

Developing

3

unit

Paper feed4

unit

Ozone filter

5

Implementation classification

Cleaning

Lubrication

Replacement

Material used

SupplyCheck

Tri-flow

Setting powder

Tools used

3 SERVICE

2. Periodic check (II) (Every 400,000 copies or prints)

Classification Service itemNo.

By-pass

1

(paper feed

section)

Fixing unit

2

4 SERVICE

(1) Double feed prevention roller

54004056*

(2) Separation roller 54004056*

(3) Paper feed roller 25BA4032*

(1) Fixing claw (lower) 54005310*

(2) Fixing roller (lower) 55GA5304*

(3) Fixing bearing (upper) 55GA7502*

(4) Bearing 55GA7503*

(5) Fixing bearing (lower) 55GA7504*

3. Periodic check (III) (Every 800,000 copies or prints)

Classification Service itemNo.

Fixing unit1 (1) Fixing heater lamp 1 55HF8302*

(2) Fixing heater lamp 2 55HF8303*

Implementation classification

Cleaning

Implementation classification

Cleaning

Lubrication

Lubrication

Replacement

Replacement

Material used

SupplyCheck

SupplyCheck

Tools used

Material used

Tools used

4-6

Page 9

SERVICE

[4] RADF [DF-315]

1. Periodic check (Every 200,000 copies or prints)

Classification Service itemNo.

Paper feed

1 (1) Paper feed roller 120A4582*

section

(2) Separation roller 120A4582*

(3)

Double feed prevention pad

(4) Paper dust removing pad 129H-472*

120A-458*

Cleaning

[5] DB [DB-208]

1. Periodic check (Every 300,000 copies or prints)

Classification Service itemNo.

Paper feed

1 (1) Separation roller 54004056*

section

( three units)

(2) Paper feed roller 25BA4032*

(3) Double feed prevention roller

54004056*

Cleaning

[6] DB [DB-608]

Implementation classification

Lubrication

Implementation classification

Lubrication

Replacement

Replacement

1 OUTLINE

Material used

SupplyCheck

Tools used

2 ISW

Material used

SupplyCheck

Tools used

3 SERVICE

1. Periodic check (Every 200,000 copies or prints)

Classification Service itemNo.

Paper feed

1 (1) Separation roller 54004056*

section

( two units)

(2) Paper feed roller 25BA4032*

(3) Double feed prevention roller

54004056*

Cleaning

[7] FNS [FS-109]

1. Periodic check (Every 300,000 copies or prints)

Classification Service itemNo.

Paper exit

1 (1) Paper exit drive roller / A (Tray 2)

section

(2) Paper exit drive roller / A (Tray 3)

13LP-498*

13LP-498*

Cleaning

Implementation classification

Lubrication

Implementation classification

Lubrication

Replacement

Replacement

Material used

SupplyCheck

Tools used

4 SERVICE

Material used

SupplyCheck

Tools used

4-7

Page 10

SERVICE

[8] Actual Count Replacement Parts

1 OUTLINE

Classification

Drum cartridge

(include charging

corona unit)

2 ISW

Developing unit

Paper feed unit

3 SERVICE

By-pass paper feed

unit

4 SERVICE

Fixing unit

Parts name

Cleaning blade

Charging wire

Charging control plate

Cleaner mount assembly

Charging wire cleaning block (C)

Charging wire cleaning block (D)

Transfer/Separation charging wire

OPC drum

Separation claw

Developer

(Tray: 1) Separation rubber

(Tray: 1) Paper feed rubber

(Tray: 1) Double feed prevention rubber

(Tray: 2) Separation rubber

(Tray: 2) Paper feed rubber

(Tray: 2) Double feed prevention rubber

(Tray: 3) Separation rubber

(Tray: 3) Paper feed rubber

(Tray: 3) Double feed prevention rubber

(Tray: 4) Separation rubber

(Tray: 4) Paper feed rubber

(Tray: 4) Double feed prevention rubber

(By-pass) Separation rubber

(By-pass) Paper feed rubber

(By-pass) Double feed prevention rubber

Fixing cleaning roller

Fixing roller (A)

Fixing cleaning pad

Fixing roller (upper)

Fixing claw (upper)

Heat insulating sleeve

Fixing roller (lower)

Fixing claw (lower)

Fixing bearing (upper)

Bearing

Fixing bearing (lower)

Fixing heater lamp / 1

Fixing heater lamp / 2

Part number Actual count

55GA5601* 100,000

55FA2501* 100,000

55GA2507* 100,000

55GA-252* 100,000

55GA-253* 100,000

55GA-255* 100,000

55GA2607* 100,000

– 200,000

55GA-206* 200,000

– 200,000

54004056* 100,000

25BA4032* 100,000

54004056* 100,000

54004056* 100,000

25BA4032* 100,000

54004056* 100,000

54004056* 100,000

25BA4032* 100,000

54004056* 100,000

54004056* 100,000

25BA4032* 100,000

54004056* 100,000

54004056* 100,000

25BA4032* 100,000

54004056* 100,000

55GA5312* 100,000

55GA5311* 100,000

55GA5350* 100,000

55GA5303* 200,000

25SA5315* 200,000

45405339* 200,000

55GA5304* 400,000

54005310* 400,000

55GA7502* 400,000

55GA7503* 400,000

55GA7504* 400,000

55HF8302* 800,000

55HF8303* 800,000

4-8

Page 11

SERVICE

Classification

Rear of main body

DF-315

FS-109

Part number Actual count

55GA7337*

55YA7350*

200,000

200,000

120A4582* 90,000

120A4582*

120A-458*

129H-474*

129H-472*

90,000

90,000

450,000

90,000

13LP-498* 200,000

13LP-498* 200,000

120H5040* 500,000

120H5040* 500,000

Parts name

Fixing filter

Ozone filter

Paper feed roller

Separation roller

Double feed prevention pad

Pick-up clutch ass'y

Paper dust removal pad

(Tray 2) Paper exit drive roller / A

(Tray 3) Paper exit drive roller / A

* Staple unit (front)

* Staple unit (rear)

Note: Regarding usage frequency, 1 staple of the 3-sheets sort is the condition for assuming a main body count 1.5

million resistance when using the system.

1 OUTLINE

2 ISW

4-9

3 SERVICE

4 SERVICE

Page 12

SERVICE

COPY MATERIALS

[1] PM Parts Kit Composition

1 OUTLINE

1. Composition (100,000 copies/kit)

Cleaning blade

2 ISW

Fixing cleaning roller

Fixing cleaning pad

3 SERVICE

Name

Quantity

1

1

1

Name

Cleaner mount assembly

Charging wire cleaning block (C)

Charging wire cleaning block (D)

Charging corona wire

Quantity

1

1

1

1

Fixing roller / A

4 SERVICE

Charging control plate

1

Charging wire (Transfer/Separation corona)

1

Toner filter (Note)

Note: Unnecessary in the case of the 7045.

2

1

4-10

Page 13

SERVICE

Name

Cleaning pad (10 sheets)

Vanity bag for collection

Dust bag (rubber band)

Developer collecting sheet (rubber band)

Quantity

3

1

1

1

1 OUTLINE

2 ISW

3 SERVICE

Cotton tips (4 pcs.)

1

4 SERVICE

4-11

Page 14

SERVICE

SERVICE MATERIALS LIST

1 OUTLINE

Material No.

2 ISW

00GR00020

3 SERVICE

00GR00170

000V-16-0

000V-17-0

Description Shape

Drum cleaner

Roller cleaner

Plus guard No. 2

Multi-oil

Remark

200 ml

200 ml

25 g

000V-19-0

4 SERVICE

000V-18-1

200 ml

Setting powder

25 g

Cleaning pad

10 pcs

1 pack

4-12

Page 15

SPECIAL TOOLS LIST

SERVICE

Tool No. Description Shape

Temperature sensor

55GAJG01*

120A1052*

7050K002*

00M6-2-00

position adjusting jig

(for fixing)

RADF position adjusting jig

Optics position

adjusting jig

Door switch jig

Quantity

1

1 set

2

1

Remark

2 pieces/set

1 OUTLINE

2 ISW

3 SERVICE

00VD-5000

55GA2025*

120A9711*

120A9712*

Note: The 55GA2025* drum support tool is screwed to the inside of the main body (front panel/left).

Application: Makes it possible to rotate the drum with the drum cartridge removed from the main body.

New pyramid chart

Drum support tool

(Note)

ADJ chart

White chart

1

1

1

1

Instelled below

the total

counter in the

front door

4 SERVICE

4-13

Page 16

SERVICE

1 OUTLINE

2 ISW

3 SERVICE

Tool No.

00VC-2-00

00VD-1000

00VE-1004

Description Shape Remark

Drum cover

Blower brush

Tester

(00VE-1004)

Quantity

1

1

1

4 SERVICE

4-14

Loading...

Loading...