Page 1

3

DISASSEMBLY/ASSEMBLY

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Page 2

1 MAIN BODY

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

This section explains how to disassemble and reassemble the machine.

When disassembling and reassembling the machine, follow the precautions given below.

1. Be sure the power cord has been unplugged from the wall outlet.

2. The disassembled parts must be reassembled following the disassembly procedure in reverse unless otherwise specified.

3. Care should be taken not to lose small parts. Care should also be

taken not to install machine parts in wrong places.

4. Do not operate the machine before installing all the disassembled

parts completely.

5. Removal of some screws is prohibited in this section. Never loosen

them.

Page 3

EXTERNAL SECTION

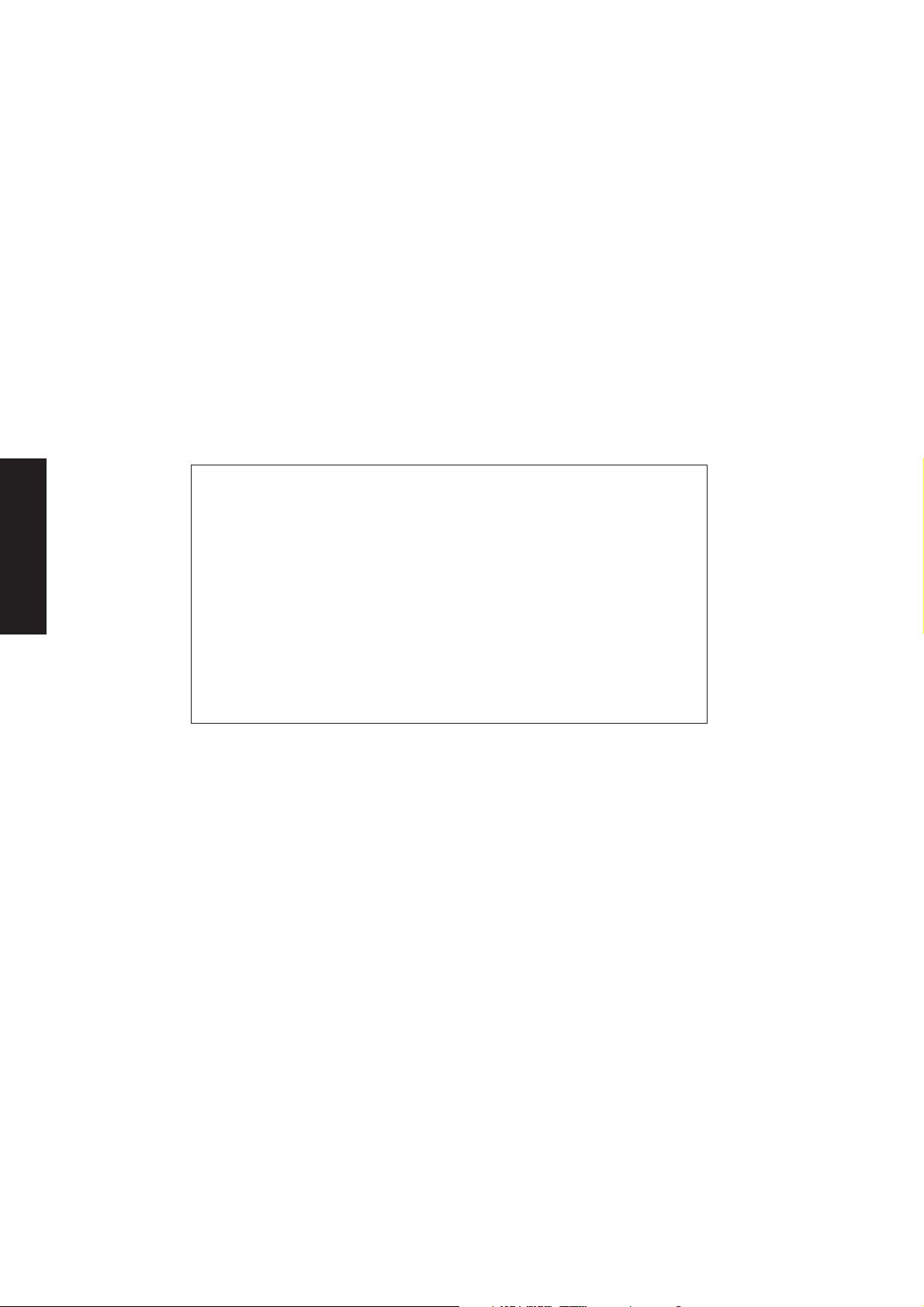

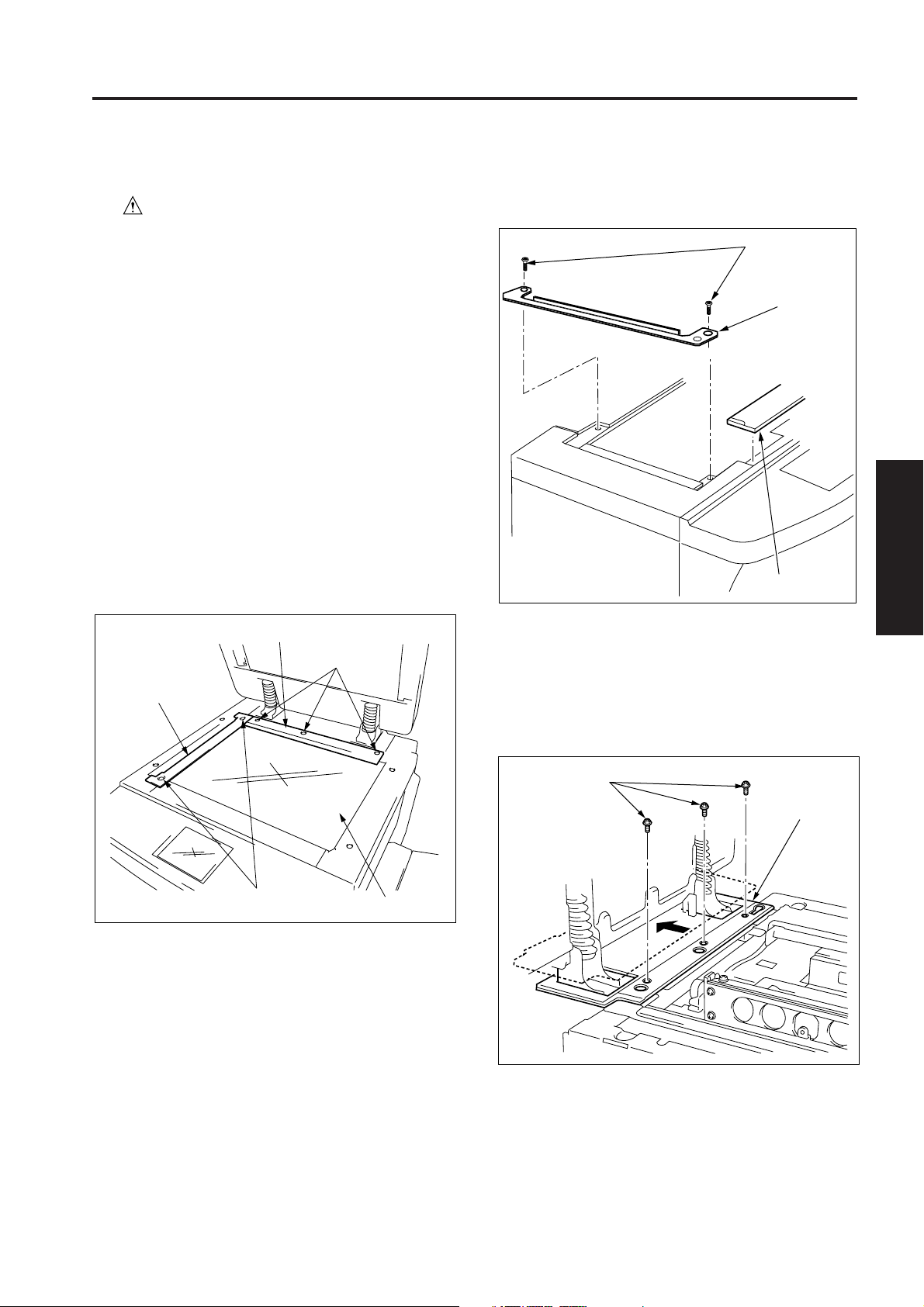

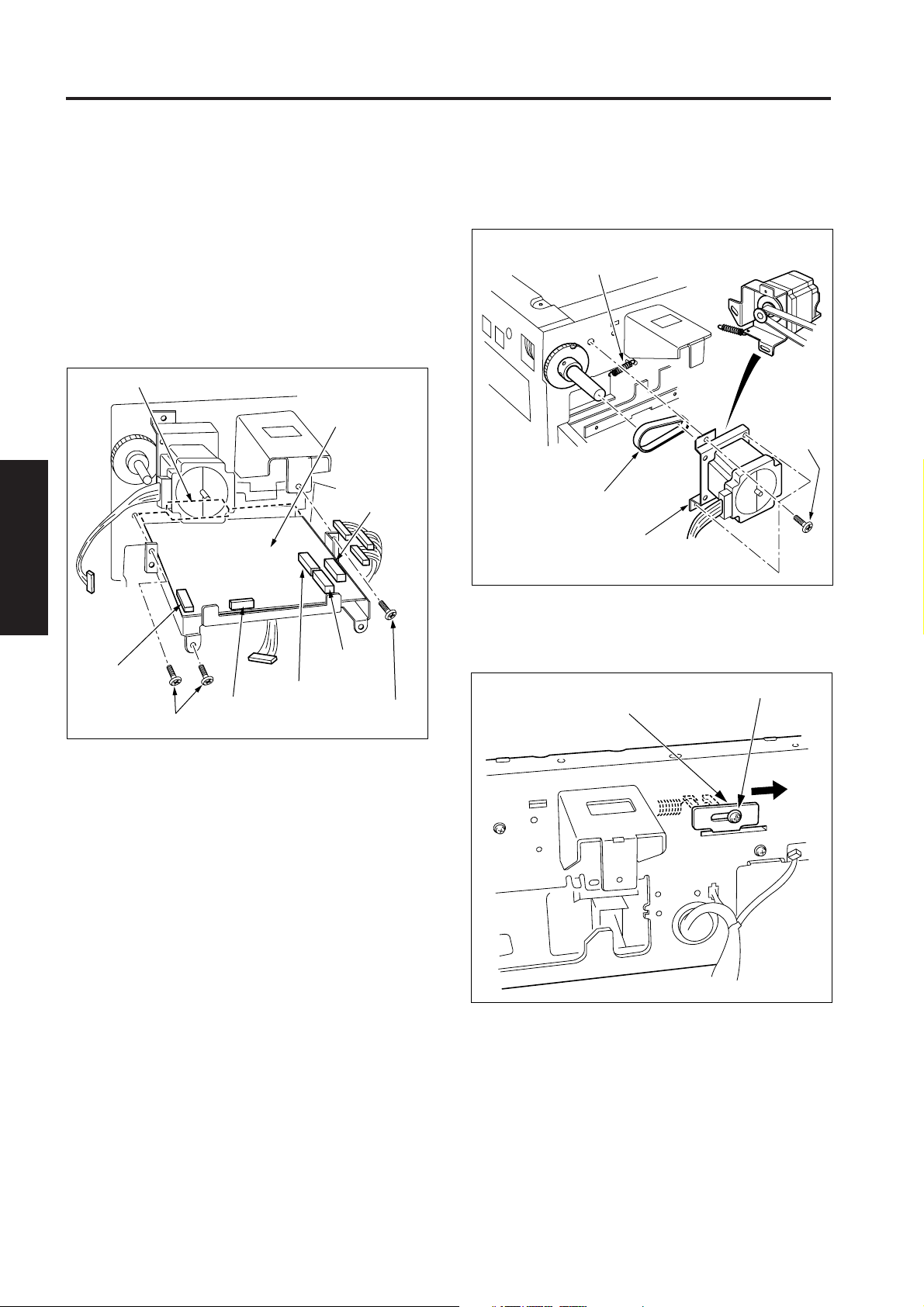

[1] Replacing the Ozone Filter

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

a. Procedure

(1) Remove the one set screw, then remove the rear cover

(2).

(2) Remove the two set screws holding the conveyance

suction (FM4).

EXTERNAL SECTION

(5)

Reinstall the ozone filter in the opposite sequence to removal.

Filter retainer

Ozone filter

Hook

Caution 1: When installing the ozone filter, ensure

that the hook is at the front, as shown

in the figure.

FM4

1 MAIN BODY

2 UNIT EXPLANATION

Set screws

Conveyance

suction

Rear cover (2)

(3) Pull out the conveyance suction towards you. Do not

strain the wires during this process.

(4) Replacing the ozone filter.

Hook

Hook

Set screw

Filter retainer

Caution 2: Be sure to install the filter retainer.

3 DIS./ASSEMBLY

When reinstall

the toner filter,

place the label

on the outside.

Ozone filter

Conveyance suction

3-A-1

Page 4

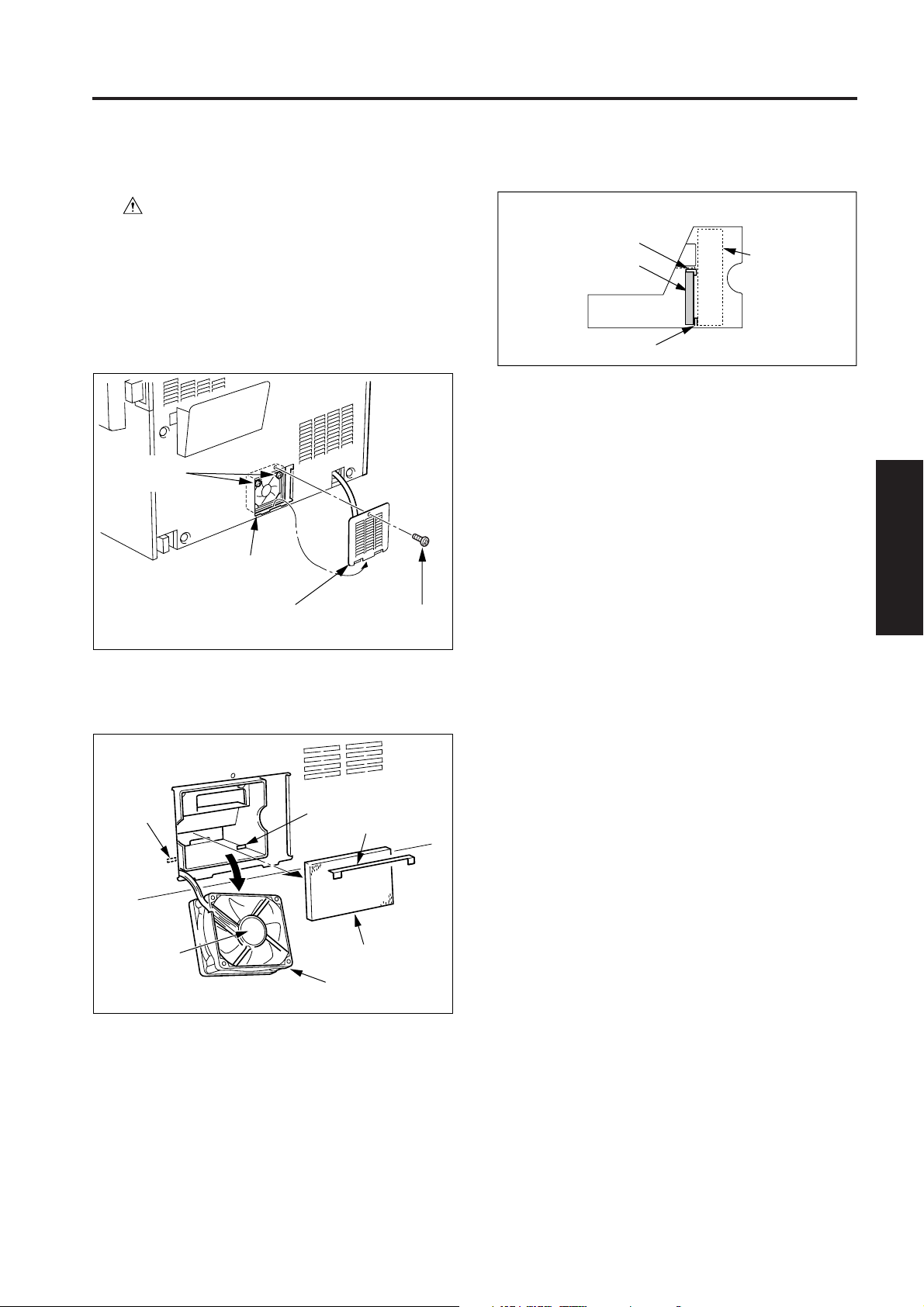

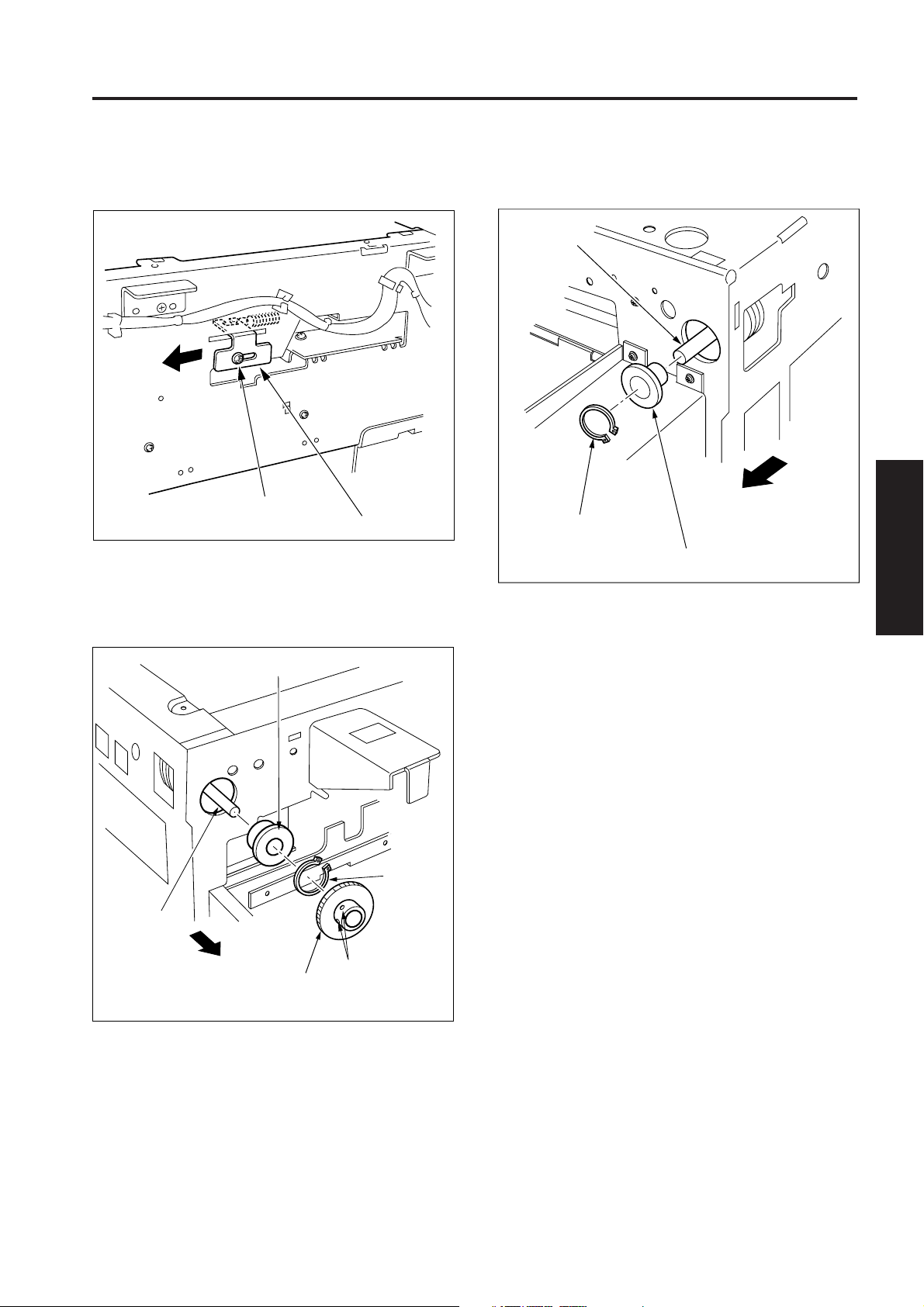

EXTERNAL SECTION

[2] Removing and Reinstalling the Rear

1 MAIN BODY

a. Procedure

2

(1) Remove the ten set screws, then remove the rear

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Cover

cover.

Rear cover

Set screws

Set screws

Set screws

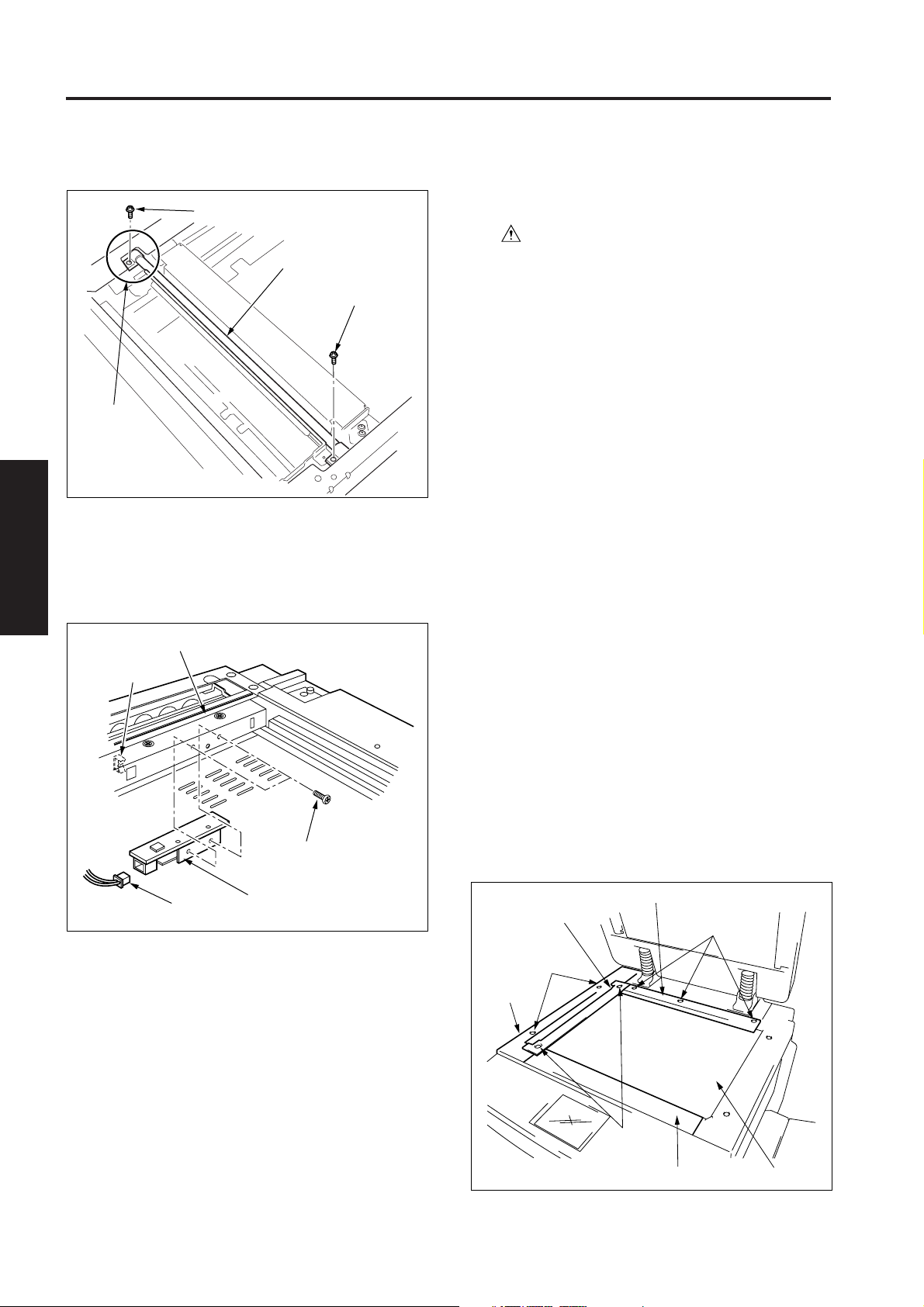

[4] Removing and Reinstalling the Side

Cover (right)

a. Procedure

(1) Pull out the ADU and tray1, and open the front door.

(2) Open the by-pass tray.

(3) Loosen the four set screws, then remove the side cover

(right).

By-pass tray

Side cover (right)

Set screws

(2) Reinstall the rear cover in the opposite sequence to

removal.

[3] Replacing the Fixing Filter

a. Procedure

(1) Remove the rear cover.

(2) Replacing the fixing filter.

Fixing filter

(4) Reinstall the side cover (right) in the opposite sequence

to removal.

(3) Reinstall the fixing filter in the opposite sequence to

removal.

3-A-2

Page 5

DRIVE SECTION

DRIVE SECTION

[1] Disassembly and Reassembly

Caution : Disassembly and reassembly of the drive

section is not made in the normal service.

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

3-B-1

Page 6

1 MAIN BODY

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 7

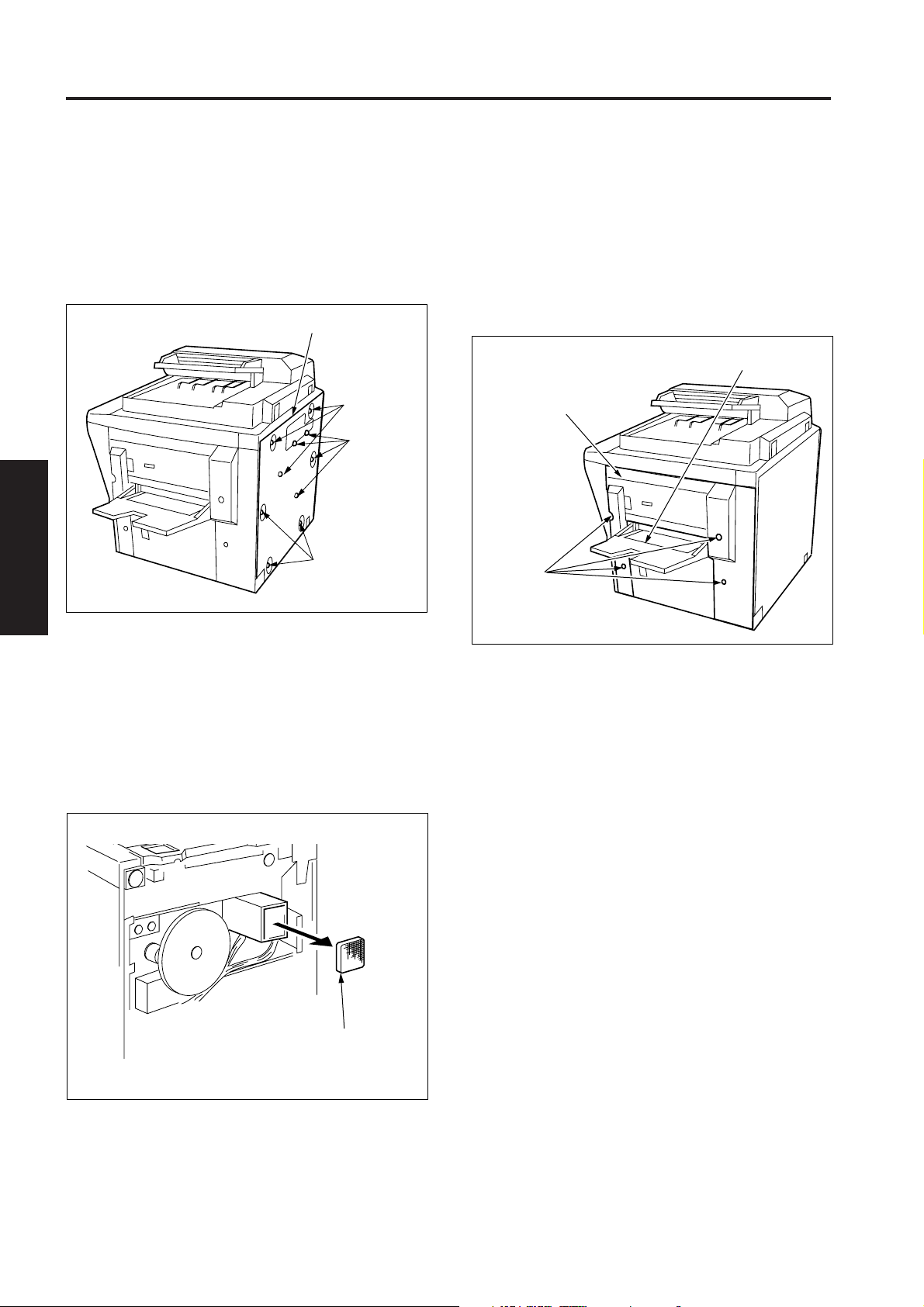

READ SECTION

READ SECTION

[1] Screws That Must Not Be Removed

a. The 16 set screws of the CCD unit

Screw that must

not be removed

Screws that must

not be removed

Screws that must

not be removed

Screws that must

not be removed

Screws that must not be

removed (on the (CCD)

CCD sensor board side)

Screws that must

not be removed

Screws that must

not be removed

Screws that

must not be

removed

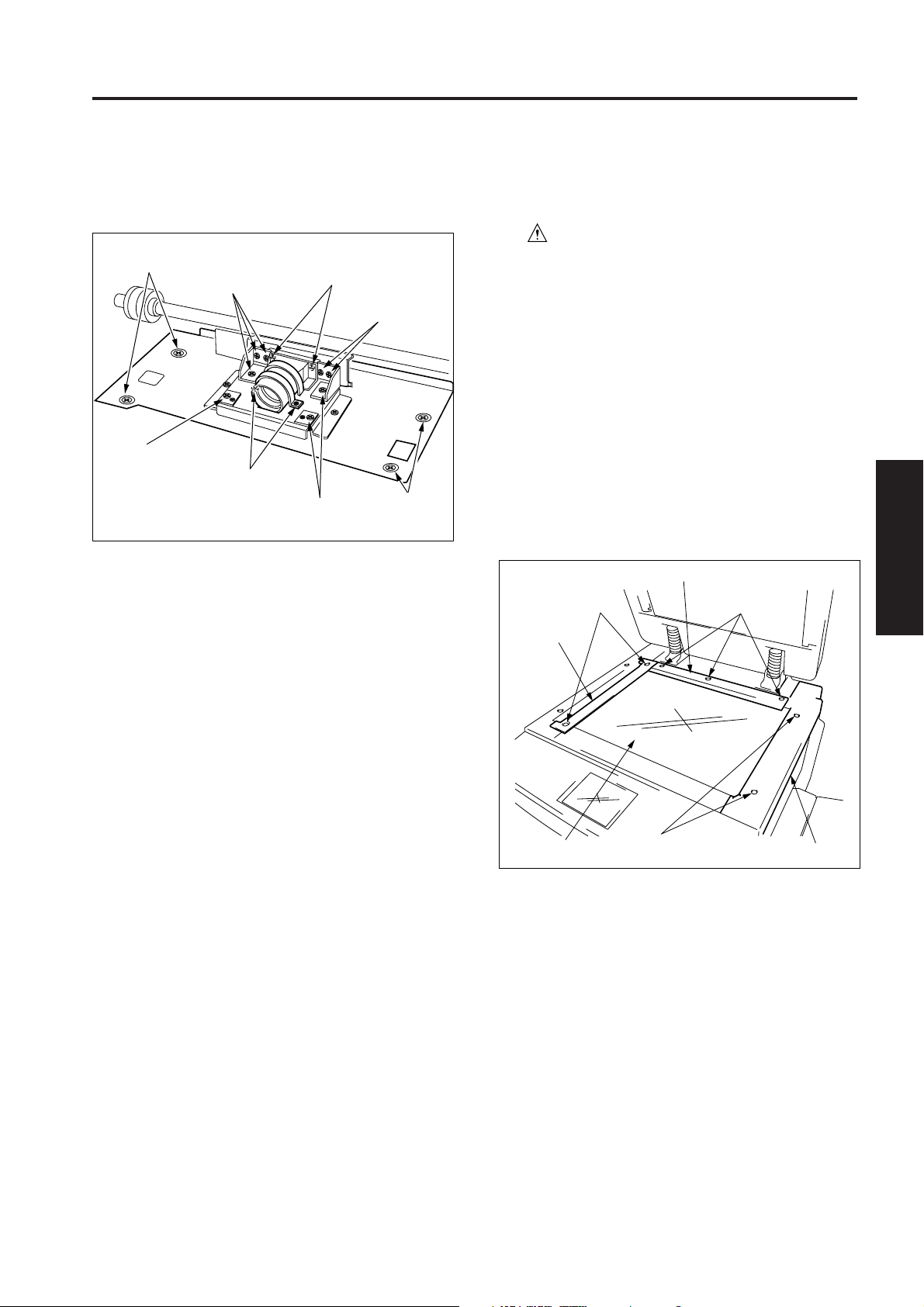

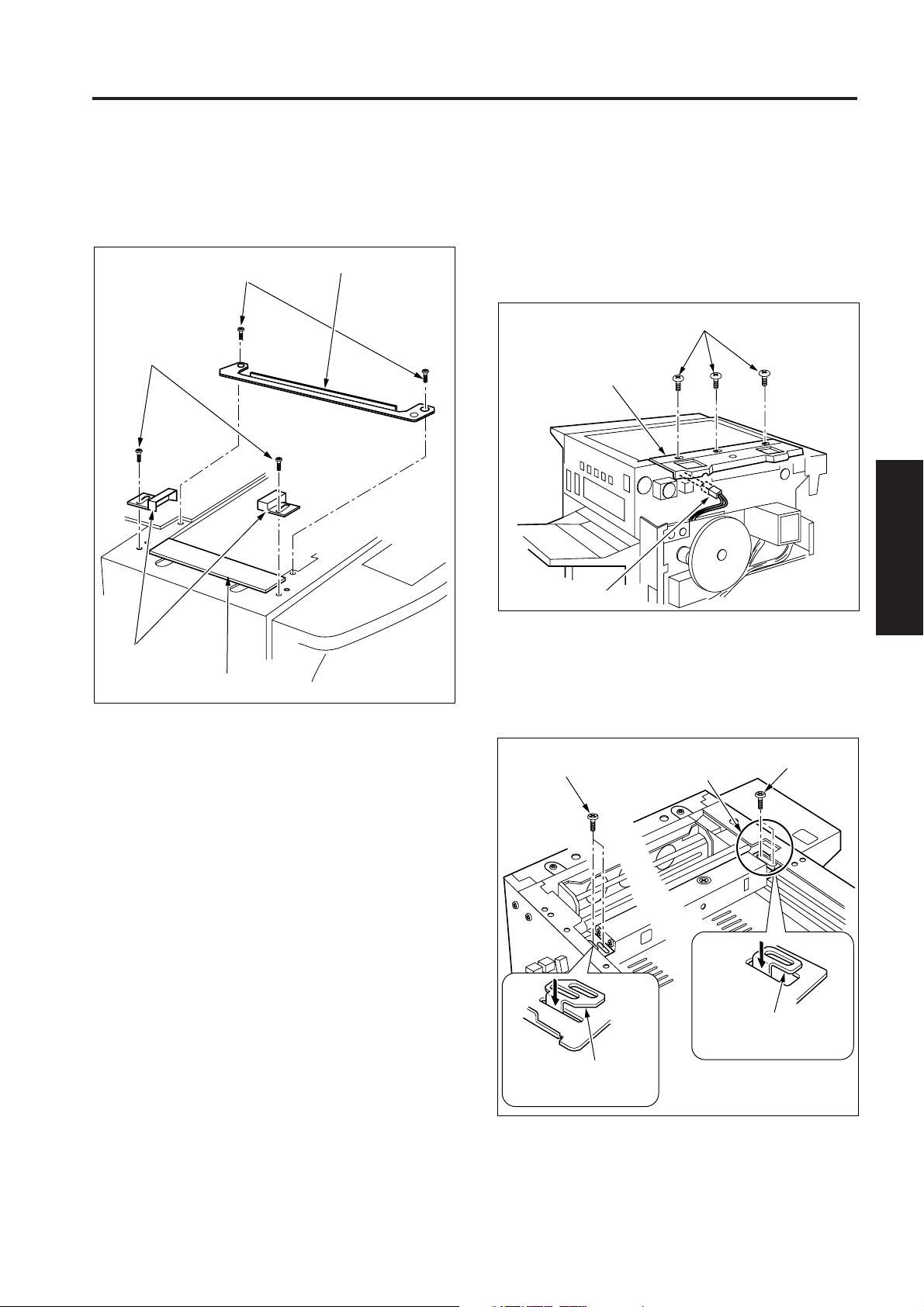

[2] Removing and Reinstalling the CCD

Unit

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

Caution: Be sure to perform image quality adjustment

after installing the CCD unit. (For details,

refer to “Adjustment section” in Field

Service.)

a. Procedure

(1) Remove the two set screws (with step), then remove

the original stopper plate.

(2) Remove the two set screws, then remove the read

cover (right).

(3) Remove the three set screws (with step), then remove

the original stopper plate (rear).

(4) Remove the original glass.

Original stopper plate (rear)

Set screws

(with step)

Original stopper

plate

Set screws

(with step)

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

3-C-1

Original glass

Set screws

Read cover (right)

Page 8

READ SECTION

(5) Loosen the three set screws and remove the nine set

1 MAIN BODY

2

2 UNIT EXPLANATION

(6) Remove the side cover (right).

(7) Loosen the three lower set screws and remove the

3 DIS./ASSEMBLY

screws, then remove the lens light shield cover.

Set screws

Loosen the

set screws

Lens light

shield cover

Set screws

(Refer to “External section”)

three upper set screws, then remove the cover plate.

Loosen the three set screws

(8) Disconnect the two connectors (CN12,13) from the

image control board.

Image control board

Connector

(CN13)

Connector

(CN12)

(9) Remove the two set screws and loosen ground plate

fixed screw, then remove the CCD unit.

CCD unit

Set screws

Ground plate fixed screw

Set screws

Cover plate

(10) Reinstall the CCD unit in the opposite sequence to

removal.

3-C-2

Page 9

READ SECTION

[3] Replacing the Exposure Lamp (L1)

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

Caution 1: When removing the lamp terminals, be

sure to hold the contact terminal.

Caution 2: Never pull the cord.

Caution 3: Do not touch the glass of the L1 with

bare hands.

Caution 4: Check to ensure that you have not

forgotten to insert a connector or install

a screw, and also that a cord is not

crushed.

a. Procedure

(1) Remove the two set screws (with step), then remove

the original stopper plate.

(2) Remove the three set screws (with step), then remove

the original stopper plate (rear).

(3) Remove the original glass.

Original stopper plate (rear)

Set screws

(with step)

Original stopper

plate

(4) Remove the read cover (front).

(5) Remove the two set screws, then remove the glass

stopper plate.

Set screws

Glass

stopper

plate

Read cover (front)

Caution: When re-installing the original stopper

plate ensure that the film attached to the

original glass (1) is on top of the glass

stopper plate.

(6) Remove the three set screws, and move the read cover

(rear) to the rear.

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Set screws

(with step)

Set screws

Read cover (rear)

Original glass

(7) Move the exposure unit to the position of the notch in the

main body frame at the rear.

3-C-3

Page 10

READ SECTION

(8) Remove the two set screws from the exposure lamp (L1).

1 MAIN BODY

2

2 UNIT EXPLANATION

(9) Remove the two set screws, then remove the L1 in-

(10) Disconnect the connector (CN29) from the L1 inverter.

(11) Remove the set screw holding the exposure lamp on

3 DIS./ASSEMBLY

Set screw

Exposure lamp

Set screw

notch

verter (L1 INVB).

the rear side, then remove the exposure lamp.

Exposure lamp

Cord clamp

[4] Removing and Reinstalling the

Exposure Unit

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

Caution 1: Never pull the cord.

Caution 2: Check to ensure that you have not

forgotten to insert a connector or install

a screw, and also that a cord is not

crushed.

Caution 3: Use a optics position adjusting jig

when installing the exposure unit.

Caution 4: Be sure to perform image quality

adjustment after installing the

exposure unit. (For details, refer to

“Adjustment section” in Field Service.)

Caution 5: When reinstalling the original stopper

plate ensure that the film attached to

the original glass (1) is on top of the

glass stopper plate.

Caution 6: Before installing the original glass (1),

be sure to clean it. (To prevent the

image defect)

Set screws

L1 inverter

Connector (CN29)

(12) Reinstall the exposure lamp in the opposite sequence

to removal.

Caution: Be sure to check the image after installing

the exposure lamp. (For details, refer to

“Adjustment section” in Field Service.)

a. Removal procedure

(1) Remove the two set screws (with step), then remove

the original stopper plate.

(2) Remove the three set screws (with step), then remove

the original stopper plate (rear).

(3) Remove the original glass.

(4) Remove the two set screws, then remove the read

cover (left).

(5) Remove the read cover (front).

Original stopper plate (rear)

Original stopper plate

Set screws

Read cover

(left)

Set screws

(with step)

Read cover (front)

Set screws

(with step)

Original glass

3-C-4

Page 11

READ SECTION

(6) Remove the two set screws, then remove the two glass

holders and original glass (1).

(7) Remove the two set screws, then remove the glass

stopper plate.

Set screws

Set screws

Glass stopper plate

(8) Remove the ten set screws, then remove the rear

cover.

(Refer to “External section”)

(9) Remove the RADF.

(Refer to the service handbook of the DF-315)

(10) Remove the three set screws, disconnect the relay

connector (CN91), then remove the read cover (rear).

Set screws

Read cover (rear)

Relay connector (CN91)

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Glass holders

Original glass (1)

(11) Move the exposure unit to the position of the notch in the

main body frame at the rear.

(12) Remove the four set screws each, then remove the two

exposure unit mounting pieces (front and rear) from the

exposure unit.

Set screws

Exposure unit mounting

piece (front)

notch

Exposure unit mounting

piece (rear)

Set screws

3-C-5

Page 12

READ SECTION

(13) Remove the exposure unit from the main body frame

1 MAIN BODY

(14) Disconnect the connector (CN28) from the L1 inverter

2

(15) Remove the one set screw, then remove the lamp cord

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

while rotating it to the left.

(L1 INVB).

from the exposure unit.

Connector (CN28)

Set screw

Lamp cord

Exposure unit

b. Reinstallation procedure

(1) Open the front door and open the toner supply unit.

(2) Remove the one set screw holding the front door belt on

the left side.

(3) Remove the six set screws and disconnect the three

connectors (CN59, CN210, CN211), then remove the

operation panel.

Set screw

Connector (CN210)

Connector

(CN211)

Connector

(CN59)

Front door belt

Operation

panel

Set screws

Set screw

(4) Install the exposure unit to the main body.

(5) Install the front and rear mounting pieces of the expo-

sure unit in the slit of the exposure unit, then temporarily

fix them with four set screws each.

Set screws Set screws

Exposure unit mounting

Exposure unit mounting

piece (front)

piece (rear)

3-C-6

Page 13

READ SECTION

(6) Move the V-mirror unit to the paper exit side, then insert

the two optics position adjusting jigs into the exposure

unit mounting position from the front.

At this time, pass through the optics position adjusting

jigs into each unit and fasten the exposure unit and Vmirror unit.

V-mirror unit

Paper exit side

Exposure unit

Optics position adjusting jigs

(7) Fasten the exposure unit mounting pieces (front and

rear) with the four set screws.

(8) Remove the optics position adjusting jigs and install the

operation panel.

(9) The reminder of the installation procedure is in the

opposite sequence to removal.

[5] Removing the Optics Wire

Caution: Be sure to perform image quality adjustment

after replacing or re-installing the wire.

(For details, refer to “Adjustment section”

in Field Service.)

a. Procedure

(1) Remove the exposure unit.

(2) Remove the operation panel.

(3) Move the V-mirror unit to the paper exit side, then insert

the optics position adjusting jig into the V-mirror unit

mounting position from the front.

At this time, pass through the optics position adjusting

jig into the V-mirror unit and fasten the V-mirror unit.

V-mirror unit

Paper exit side

Optics position adjusting jig

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

3-C-7

Page 14

READ SECTION

(4) Remove the rear cover, then free the wiring from the two

1 MAIN BODY

(5) Remove the five connectors (CN20 to CN24) and the

2

(6) Pull out the scanner drive board and disconnect the

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

cord clamps on the rear side of the scanner drive board

(SCDB).

three set screws from the scanner drive board.

connector (CN11) on the image control board, then

remove the scanner drive board.

Caution: Be careful not to drop screws etc. between

the boards at the rear of the main body.

Connector (CN11)

Scanner drive board

Connector

(CN22)

Connector

Connector

(CN23)

Set screws

Connector

(CN20)

(CN24)

Connector

(CN21)

Set screw

(7) Remove the three set screws and the belt tension

spring, then remove the scanner motor (M2) and timing

belt.

Belt tension spring

Set screws

Timing belt

Scanner moter

(8) Loosen the set screw holding the spring retainer (rear),

slide it to the paper exit side while pressing it with a flat-

blade screwdriver etc. to fix it again with the set screw.

Set screw

Spring retainer (rear)

3-C-8

Page 15

READ SECTION

(9) Slide the spring retainer (front) to the paper exit side to

fix it in the same way.

Set screw

Spring retainer (front)

(10) Remove the two set screws, then remove the read

driven pulley.

(11) Remove the C-ring and bearing on the rear side of the

machine. Be careful not to scratch the pulley shaft.

Bearing

(12) Remove the one C-ring and bearing on the front side of

the machine from the pulley shaft in the same way.

Pulley shaft

Front side of

C-ring

Bearing

the machine

(13) Remove the two optics wires (front and rear).

(14) Remove the pulley shaft from the main body. At this

time, if the leading edge of the set screw holding the

optics rail contacts with the shaft, loosen the set screw.

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Pulley shaft

Rear side of

the machine

C-ring

Set screws

Read driven

pulley

3-C-9

Page 16

READ SECTION

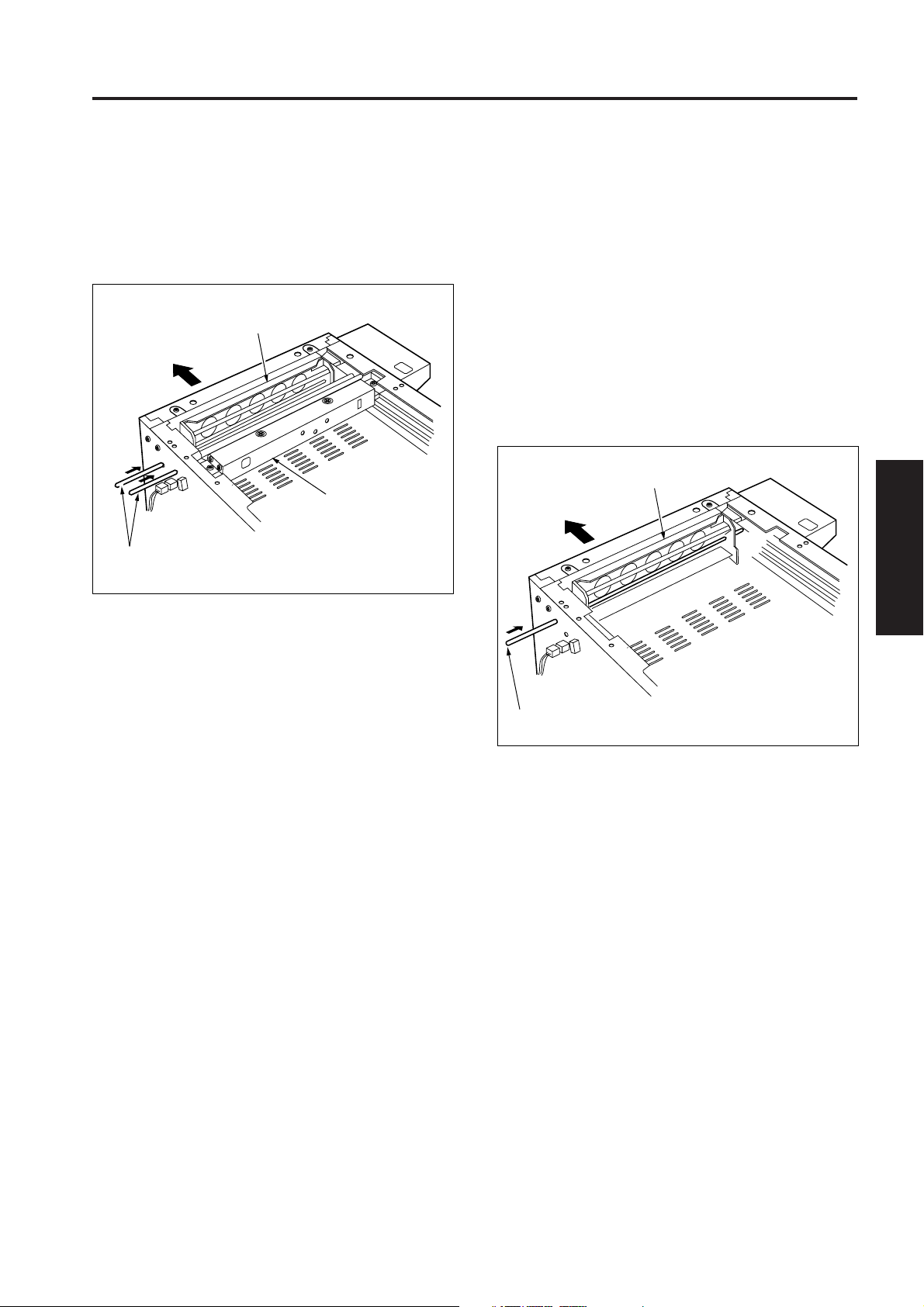

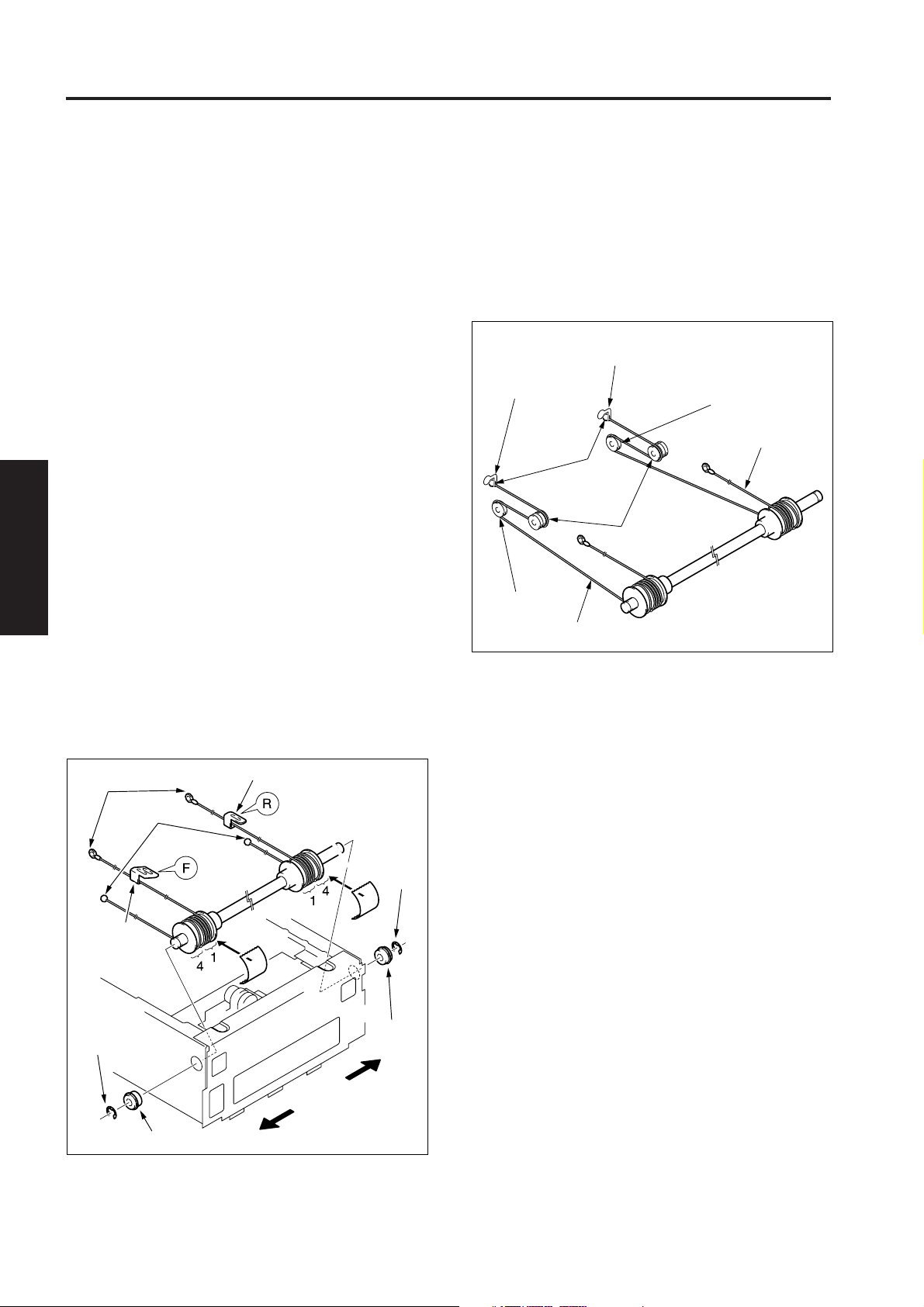

[6] Installing the Optics Wire

1 MAIN BODY

2

2 UNIT EXPLANATION

(1) Insert the metal bead at the mid-point of the optics wire

3 DIS./ASSEMBLY

(2) Provisionary fasten the wire to the drive pulley with a

Caution 1: When winding the wire around the

pulley, be sure to run the wire tightly to

ensure that it does not ride up the side

of the pulley.

Caution 2: When reinstalling or replacing the

optics wire, be sure to use the optics

position adjusting jig.

Caution 3: Be sure to perform image quality

adjustment after replacing or reinstalling

the wire. (For details, refer to “Adjustment

section” on Field Service.)

(front) into the mounting hole of the drive pulley, then

wind four turns around the pulley to the outside, and one

turn to the inside, starting this position.

(a) Use the optics wire marked “F” on the exposure unit

mounting piece to the front side and “R” to the rear

side.

(b) Wind the optics wire so that the side with the metal

bead at the leading edge is outside (front/rear) of the

pulley shaft.

(c) Wind the optics wire so that the side with the metal

bead at the leading edge passes under the drive

pulley.

gummed tape so that the wire winding is not lost, after

that, fix the pulley shaft to the frame with the bearings

and E-rings.

(3) Pass the optics wire (front) of the metal bead side

around the pulley 1 (V-mirror unit) then pass it around

the inside slit of the pulley 2 (exposure unit). Pass

around the optics wire (rear) at the same procedure.

(4) Remove the optics position adjusting jig.

(5) Fasten each metal bead at the leading edge of the

optics wire (front and rear) to the slits of the main body

frame on the paper exit side.

Slit

Slit

(front side of

the machine)

Pulley 1

Optics wire (front)

(rear side of the machine)

Pulley 1

Optics wire (rear)

Metal bead

Pulleys 2

Round

terminals

Metal

beads

Exposure unit

mounting piece

(front)

E-ring

Bearing

Exposure unit mounting piece (rear)

Gummed tape

(for provision)

E-ring

Bearing

Rear side of

the machine

Front side of

the machine

3-C-10

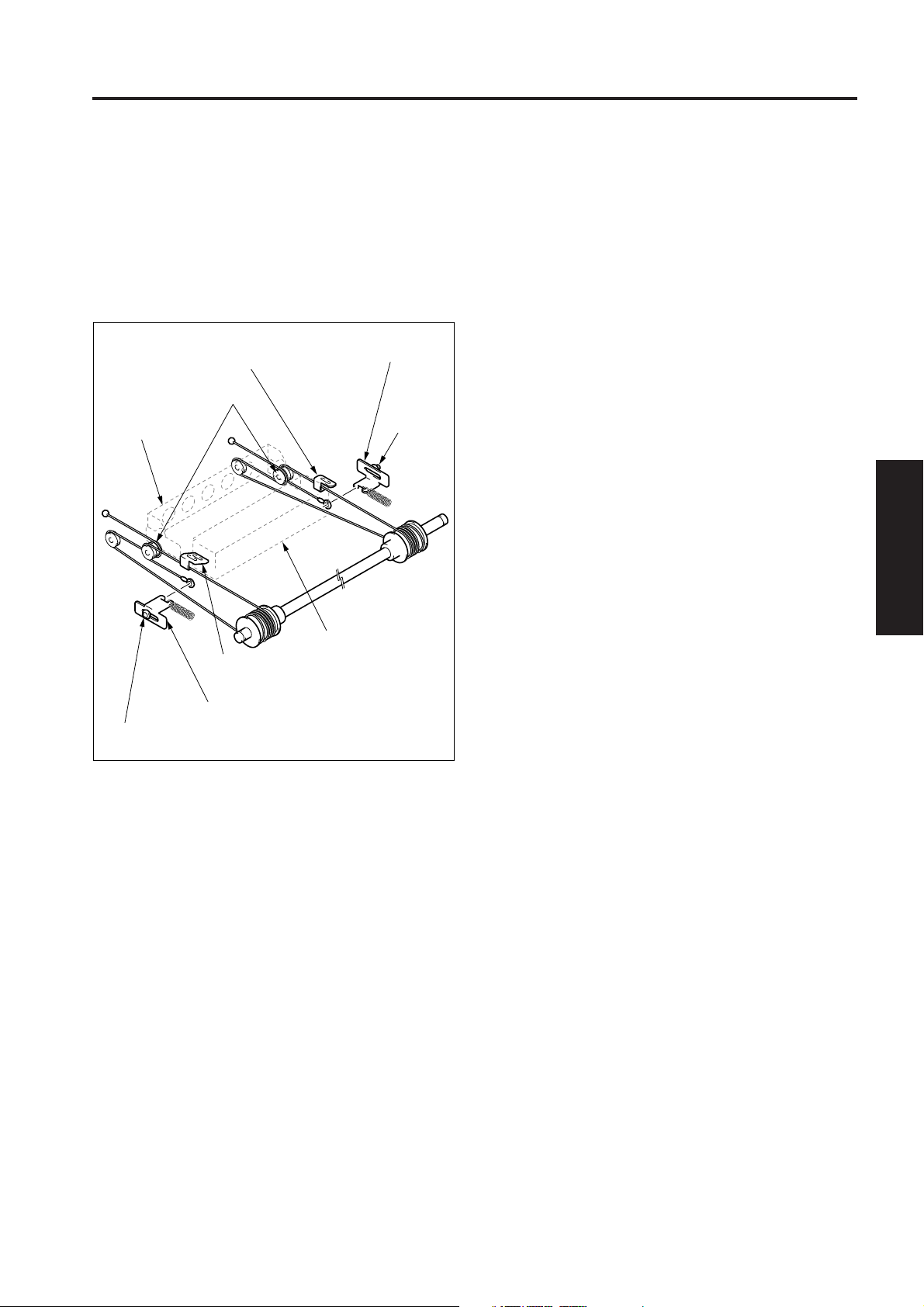

Page 17

READ SECTION

(6) Pass the side with the round terminal of the optics wire

(front) to the outside of the pulley 2 and hook the round

terminal on the spring retainer. Hook the optics wire

(rear) in the same way.

(7) Install the exposure unit to the main body.

(8) Loosen each set screw fasting the spring retainers.

(9) Fasten each set screw of the spring retainers after

moving the exposure unit two or three times.

Exposure unit mounting

piece (rear)

Pulleys 2

V-mirror unit

Spring ratainer

(rear)

Set screw

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Exposure unit

Exposure unit mounting

piece (front)

Spring ratainer (front)

Set screw

(10) The reminder of the installation procedureis in the

opposite sequence to removal.

3-C-11

Page 18

1 MAIN BODY

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 19

WRITE UNIT

WRITE UNIT

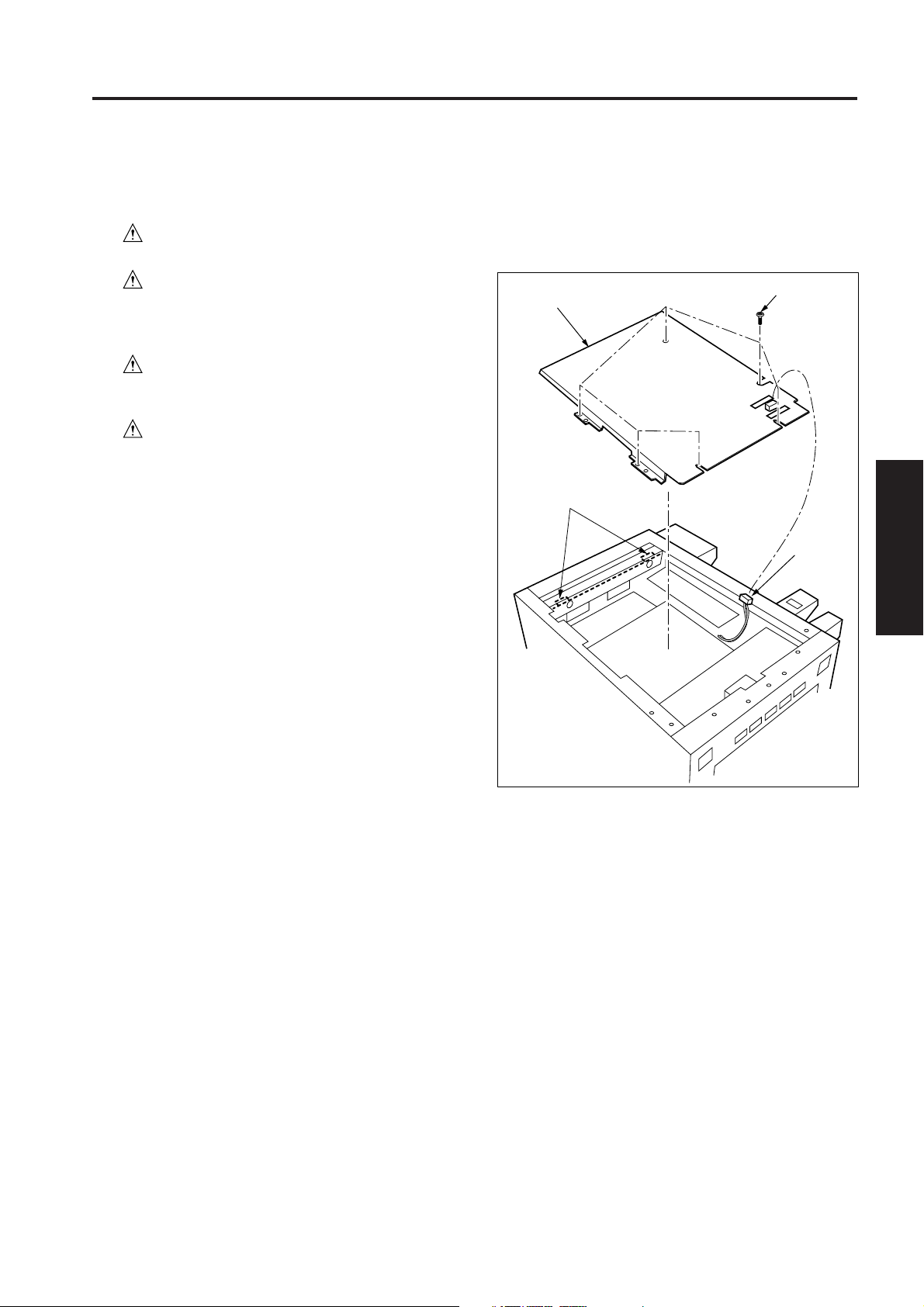

[1] Removing and Reinstalling the Write

Unit

Warning1:

Warning2:

Warning3:

Caution: Be sure that the power cord has

Caution 1: When removing the write unit, do not

Caution 2: When installing the write cover, check

Do not energize the write unit when

it is not installed in the machine.

Never remove the cover from the write

unit with the circuit being energized.

(If the laser beam gets into your eyes,

you may lose your sight.)

Never remove the write unit for at

least two minutes after turning OFF

the main switch.

been unplugged from the power

outlet.

make contact with the write mirror and

dust-proof glass. (prevention of the

scratch and stain for the mirror.)

that the write cover is got caught in

the ground spring.

a. Procedure

(1) Remove the original glass.

(Refer to “Read section”)

(2) Remove the six set screws and disconnect the connec-

tor (CN93), then remove the write cover.

Write cover

Ground springs

Set screws

Connector

(CN93)

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

3-D-1

Page 20

WRITE UNIT

(3) Remove the rear cover.

1 MAIN BODY

(4) Remove the three set screws holding the scanner drive

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(5) Remove the side cover (right).

(6) Remove the cover plate.

(7) Disconnect two connectors (CN12,13) from the image

(8) Pull out the scanner drive board into the rear side of the

(9) Remove the two set screws and pull out the image

(Refer to “External section”)

board (SCDB).

Caution: Be careful not to drop screws etc. between

the boards at the rear of the main body.

Scanner drive board

Set screws

Set screw

(Refer to “External section”)

(Refer to “Read section”)

control board (ICB).

(Refer to “Read section”)

machine and disconnect the connector (CN11) on the

image control board from the scanner drive board.

control board.

(10) Remove the five set screws, then remove the printer

side cover.

Printer side cover

Set screws

Set screws

(11) Disconnect the seven connectors (CN1, CN2, CN5,

CN6, CN7, CN200, CN505) and free the wiring from the

six cord clamps.

(12) Remove the nine set screws, then remove the board

stay assembly .

Connector

(CN200)

Connector

(CN1)

Connector

(CN2)

Set screws

Connector (CN7)

Cord

clamp

Connector

(CN505)

Connector

(CN5)

Set screws

Image control board

Set screw

Connector

(CN13)

Connector

(CN12)

Connector

(CN11)

Scanner drive board

Set screw

3-D-2

Cord clamps

Connector

(CN6)

Board stay

assembly

Set screws

Page 21

WRITE UNIT

(13) Disconnect the connector (CN44).

(14) Remove the four set screws, then remove the write unit

Write unit

Connector (CN44)

Set screws

[2] Cleaning the Dust-proof Glass

1 MAIN BODY

a. Procedure

(1) Remove the drum unit.

(Refer to “Drum unit”)

(2) Reach inside the main body and using a soft cloth wipe

the dirt from the dust-proof glass.

Dust-proof glass

2 UNIT EXPLANATION

.

Drum shaft

3 DIS./ASSEMBLY

Dust-proof glass

Set screws

(15) Reinstall the write unit in the opposite sequence to removal.

Write

unit

Dust-proof glass

Mirror

Mirror

Insert hand from here

Drum shaft

3-D-3

Page 22

1 MAIN BODY

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

3-C-4

Page 23

DRUM UNIT

DRUM UNIT

[1] Removing and Reinstalling the Drum

Unit

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

Caution 1: Do not shake the drum unit up and

down, side to side, or repeatedly move

back and forth when removing or

installing and handle it slowly keeping

it horizontal to its axis.

Caution 2: When removing or installing the drum

unit, pull out the drum coupling shaft

that is on your side and work with the

lock mechanism fixed in place.

Caution 3: When installing the drum unit, clean

the drawer connector on the back side

of the drum unit with the blower brush.

Caution 4: After installing the drum unit back into

the main unit, rotate the charge

cleaning knob back and forth about 2

times.

Caution 5: When removing the drum unit, be sure

to place the drum cover over it and

store the drum carriage in a dark place.

(2) Release the conveyance lever.

(3) Remove the Transfer/separation corona unit from the

main body.

(Refer to “Corona unit”)

(4) Remove the one set screw holding the drum unit.

Set screw

Drum coupling shaft

Transfer/separation

corona unit

Conveyance lever

: Screws that must not be removed

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Caution 6: Be careful not to rotate the drum when

installing or removing the drum unit. If

you rotate the drum in the direction

opposite to the direction in which it

rotates during a copy operation, you

risk damaging the cleaning blade.

a. Removal procedure

(1) Open the front door, loosen the one set screw, release

the lock plate of the toner supply unit, then open the

toner supply unit to the paper feed side.

Lock plate

Toner supply unit

Set screw

(5) Slowly pull the drum unit out careflly to the front.

b. Reinstallation procedure

(1) Make sure that the drum coupling shaft and the drum

flange are correctly meshed.

(2) Slowly insert the drum unit into the main body until the

drum coupling shaft hit the drum shaft and it is pushed

out slightly toward you. (When the drum coupling shaft

and the drum flange are not correctly meshed, the drum

coupling shaft hit the drum shaft and it is pushed out

toward you.)

Caution: At this time, do not squeeze the drum unit

into the main body by force. Also, do not

rotate the drum coupling shaft with the

drum unit is squeezed into the main body.

(3) With the drum coupling shaft is pushed out slightly

toward you, rotate the drum coupling shaft in the

forwarding direction, and mesh the drum coupling shaft

and the drum shaft correctly.

(4) Securely reinstall the drum unit to the main body and fix

it with the set screw.

(5) Reinstall the drum unit in the opposite sequence to

removal.

3-E-1

Page 24

DRUM UNIT

[2] Removing and Reinstalling the Drum

1 MAIN BODY

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Caution 1: Be careful not to touch the drum or the

cleaning blade with bare hands, or

damage these parts.

Caution 2: When removing and re-installing the

drum, be careful not to hit the drum on

the metal plate section of the cleaning

blade.

Caution 3: When leaving the drum to stand, be

sure to place the drum cover over it

and store it in a dark place.

Caution 4: When installing the drum and cleaning

blade, regardless of the new or old

parts, apply setting powder to all of the

drum surface and the both ends of the

cleaning blade.

Caution 5: After applying setting powder to the

drum, carry out the following work

before installing the drum unit into the

main body.

• To obtain the correct toner density,

clean setting powder leakage on the

surface of the sensor on the toner

control sensor board with an alcohol

damped cloth.

Caution 6: When installing the drum, be careful of

the orientation of the drum. The gear

side of the drum is rear the side.

Caution 7: When installing a new drum, be sure to

enter code 91-1 of the 47 mode and

reset the drum counter. Then, be sure

to preform the charging grid voltage

adjustment and PWM gamma (patch)

adjustment. (For details, refer to

“Adjustment section” in Field Service.)

a. Removal procedure

(1) Pull out the drum coupling shaft, then fasten it with the

lock lever.

(2) Remove the drum unit from the main body.

(3) Remove the charging corona unit and developing unit

from the drum unit. (For the sequence of removing

these parts, refer to “Corona unit” and “Developing

unit”.)

(4) Holding the both ends of the drum and lower the

cleaning unit, then shake the drum unit few times.

(5) Check that the toner is not left between cleaning blade

and toner collection sheet.

Fasten

Release

Drum coupling shaft

(6) Gently lift out the drum while holding it at both ends to

ensure that you do not damage the photosensitive

surface.

Lock lever

3-E-2

Drum

Page 25

DRUM UNIT

b. Reinstallation procedure

Caution: Push down both ends of the toner

collection sheet towards you and confirm

that the entire drum is in contact without

any space.

(1) Remove the cleaning blade.

(Refer to “Cleaning / toner recycle section”.)

(2) Apply setting powder into the entire surface of the drum.

(3) Install the drum to the drum casing and release the lock

lever, then lock the drum coupling to the drum flange.

(4) Remove the drum support tool from the main body and

insert it into the drum (gear side).

Drum support

tool

Set screw

Fixing unit

Drum support

tool

(5) Rotate the drum counterclockwise once.

(6) Rotate the drum clockwise a bit.

(7) Check that setting powder collected by the toner collec-

tion sheet remains on the surface of the drum to the both

ends of the drum without a clearance.

Reverse direction

Toner collection sheet

Drum

Forward direction

Setting powder

(8) Remove the drum support tool from the drum.

(9) Pull out the drum coupling shaft, then fasten it with the

lock lever.

(10) Remove the drum from the drum casing.

(11) Gently wipe setting powder on the surface of the drum

with a cleaning pad.

(12) Apply setting powder to the entire surface of the drum.

(13) Apply toner to both ends of the cleaning blade edge and

setting powder to the middle of the drum.

(14) Install the drum to the drum casing, release the lock

lever, lock the drum coupling to the drum flange and

install the drum support tool to the drum.

(15) Rotate the drum in the forward direction and check that

there is no setting powder falling and curling of the

cleaning blade.

(16) The reminder of the installation procedure is in the

opposite sequence to removal.

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

3-E-3

Page 26

DRUM UNIT

[3] Removing and Reinstalling the

1 MAIN BODY

2

a. Procedure

(1) Remove the drum unit from the main body.

2 UNIT EXPLANATION

(2) Remove the drum from the drum unit.

(3) Disconnect the relay connector (CN62) and free the

(4) Remove the Separation swing spring and the two

3 DIS./ASSEMBLY

Separation Claws

Caution 1: Take care not to damage the drum

when removing the separation claws.

Caution 2: Be careful of the orientation and

position of the separation claws when

re-installing the claws.

Caution 3: Do not touch the cleaning blade or the

drum with the bare hands.

(Refer to “Drum unit section”)

wiring from the cord clamps.

positioning screws, then remove the separation claws

unit.

Separation claws unit

(5) Remove the separation press spring from each of the

separation claws.

(6) While pressing down the separation fulcrum shaft,

remove the separation claw (two).

Separation press spring

Separation

claw

Separation fulcrum shaft

Cord clamps

Relay connector

(CN62)

Caution: Take care not to lose the collar of the

positioning screw.

Positioning

screws

Separation

swing spring

(7) Reinstall the separation claws in the opposite sequence

to removal.

3-E-4

Page 27

CORONA UNIT SECTION

CORONA UNIT SECTION

[1] Removing and Reinstalling the

Charging Corona Unit and PCL

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

Caution: If you installed the PCL, ensure that it is

securely tightened.

a. Procedure

(1) Remove the drum unit from the main body.

(Refer to “Drum unit section”)

(2) Disconnect the relay connector (CN62) from the drum

unit.

(3) Lift up the charging corona unit at the rear side first then

while moving it to the rear raise the front side.

(4) Remove the PCL from the hooks of the charging corona

unit.

Hook

Charging corona unit

Hook

[2] Removing and Reinstalling the

Transfer and Separation Corona Unit

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

a. Procedure

(1) Open the front door, and release the conveyance lever.

(2) Remove the one set screw, then pull the transfer and

separation corona unit forward to remove it.

Caution: Take care not to drop the set screws into

the main body.

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

PCL

Relay connector (CN62)

(5) Reinstall the charging corona unit and PCL in the

opposite sequence to removal.

Set screw

Conveyance lever

(3) Reinstall the transfer and separation corona unit in the

opposite sequence to removal.

Transfer and separation corona unit

3-F-1

Page 28

CORONA UNIT SECTION

[3] Removing and Reinstalling the

1 MAIN BODY

2

a. Procedure

(1) Remove the drum unit from the main body.

(2) Remove the charging corona unit.

(3) Remove the two charging control springs, then remove

2 UNIT EXPLANATION

(4) Remove dirt from the charging control plate by gently

3 DIS./ASSEMBLY

Charging Control Plate

Caution: Install the charging control plate so that

the end with the round holes has the

springs hooking it to the rear of the

charging corona unit.

(Refer to “Drum unit section”)

the charging control plate.

dabbing it with a cloth moistened with drum cleaner,

then remove any remaining dirt with a blower brush.

Charging control springs

Charging control plate

(5) Reinstall the charging control plate in the opposite

sequence to removal.

Caution: When installing the charging control

springs, be careful of the attachment

direction.

Charging

control spring

Charging

control spring

3-F-2

Page 29

CORONA UNIT SECTION

[4] Replacing the Charging Wire

a. Procedure

(1) Remove the drum unit from the main body.

(Refer to “Drum unit section”)

(2) Remove the charging corona unit.

(3) Remove the charging control plate.

(4) Remove the charging cover (front and rear) each.

(5) Remove the charging wire cleaning block (C).

(6) Remove the charging wire cleaning block (D).

(7) Remove the one spring, then remove the charging wire.

Charging cover (rear)

Charging wire cleaning block (C)

Charging cover

(front)

Charging wire

cleaning block (D)

[5] Replacing the Transfer and

Separation Wires

a. Procedure

(1) Remove the transfer and separation corona unit from

the main body.

(2) While lifting the transfer entrance plate, remove the two

springs.

(3) Remove the one set screw, then remove the transfer

entrance plate.

Transfer entrance plate

Set screw

Spring

Spring

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Spring

Charging wires

(8) Reinstall the charging wire in the opposite sequence to

removal.

(4) Remove the five hooks from the transfer and separation

corona unit with tweezers, then remove the plunging

prevention plate.

Plunging prevention

plate

Hooks

Hooks

3-F-3

Page 30

CORONA UNIT SECTION

(5) Remove the spark arrestor plates (front and rear).

1 MAIN BODY

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Spark arrestor

plate (rear)

Spark arrestor plate (front)

[6] Replacing the Charging Wire

Cleaning Blocks (C) and (D)

a. Procedure

(1) Remove the drum unit from the main body.

(Refer to “Drum unit section”)

(2) Remove the charging corona unit.

(3) Remove the charging control plate.

(4) Remove the charging wire cleaning block (C).

Changing control spring

Changing control plate

Charging wire

cleaning block (C)

(6) Remove the springs (one spring) for each wire, then

remove the transfer wire and separation wire.

(7) Remove the support rubber from each wire.

Separation wire

Support rubbers

Springs

(8) Reinstall the transfer and separation wires in the oppo-

site sequence to removal.

Support rubbers

Transfer wire

Caution: When installing the charging control

spring, be careful of the attachment

direction of the spring.

Charging

control spring

Charging

control spring

3-F-4

Page 31

CORONA UNIT SECTION

(5) Remove the charging cover (rear).

(6) Remove the charging wire from the spring.

(7) Remove the charging wire cleaning block (D) and

cleaner mount assembly.

Charging cover (rear)

Charging wire

cleaning block

(D)

Cleaner

mount assembly

Charging wire

Spring

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(8) Reinstall the charging wire cleaning block (C) and (D) in

the opposite sequence to removal.

3-F-5

Page 32

1 MAIN BODY

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 33

DEVELOPING UNIT

DEVELOPING UNIT

[1] Screws That Must Not Be Removed

Caution: Never do any adjustments, remove set

screws, or any similar task at the market in

regards to the items below.

(1) The two set screws of the developing regulating plate.

(2) The one set screw of the magnet angle adjustment

plate.

Screw that must

not be removed

Screw that must

not be removed

Screw that must

not be removed

[2] Removing and Reinstalling the

Developing Unit

a. Procedure

(1) Remove the drum unit from the main body.

(Refer to “Drum unit section”)

(2) Tap the recycle pipe a few times around the discharge

opening to drop recycled toner into the developing unit.

Tap this part few times

(3) Disconnect the relay connector (CN65).

(4) Loosen the two set screws, then remove the developing

unit from the drum unit.

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Set screw

Relay connector (CN65)

Developing unit

Set screw

3-G-1

Page 34

DEVELOPING UNIT

(5) Place paper under the toner exit of the toner recycle

1 MAIN BODY

2

2 UNIT EXPLANATION

(6) Reinstall the developing unit in the opposite sequence

3 DIS./ASSEMBLY

pipe (for catching remaining toner).

Place paper

to removal.

[3] Replacing the Developer

Caution 1: When replacing the developer, take

care that dirt does not become mixed

with it.

Caution 2: After supplying new developer, never

rotate the developing drive input gear

(2) in the clockwise (reverse direction)

direction.

Caution 3: After supplying new developer, make

sure to perform 36 mode L detection

adjustment (For details, refer to

"Adjustment section" in Field Service).

Reverse

direction

Developing drive

input gear (2)

a. Procedure

(1) Remove the drum unit from the main body.

(Refer to “Drum unit section”)

(2) Remove the developing unit from the drum unit.

(3) Release the hooks on the developing unit cover, then lift

up and remove the cover.

Hooks

Developing unit cover

3-G-2

Page 35

DEVELOPING UNIT

(4) Tilt the developing unit so that the agitator screw side is

downward, then rotate the developing drive input gear

(2) in the counterclockwise direction until all of the

developer adhering to the inside of the developing unit

and the developing sleeve is discharged.

(5) Wipe the developer remaining on the developing regu-

lation plate.

Developing regulating plate

Agitator screws

Rotate

Developing drive

input gear(2)

(6) Supply fresh developer evenly from the top of the

agitator screw.

(7) Rotate the developing drive input gear (1) in the

counterclockwise direction until all of the developer

enters the inside of the developing unit.

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Developing drive

input gear (1)

Toner leakage

prevention sheets

(8) Repeat steps (6) and (7) until all of the developer has

been supplied to the developing unit.

(9) Rotate the developing drive input gear (2) in the

counterclockwise direction, and check that the developer bristles along the entire length of the developing

sleeve.

(10) Install the developing cover

(11) Check that the toner leakage prevention sheet is not

caught by the developing unit cover.

(12) Install the developing unit on the drum unit.

3-G-3

Page 36

1 MAIN BODY

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 37

TONER SUPPLY UNIT

TONER SUPPLY UNIT

[1] Removing and Reinstalling the Toner

Cartridge

a. Procedure

(1) Open the front door, then swing out the toner supply

unit.

(2) Pull the pressure lever, then remove the toner cartridge.

Toner cartridge

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Pressure lever

(3) Reinstall the toner cartridge in the opposite sequence to

removal.

3-H-1

Page 38

1 MAIN BODY

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 39

CLEANING/TONER RECYCLE UNIT

CLEANING/TONER RECYCLE UNIT

[1] Removing and Reinstalling the

Cleaning Blade

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

Caution 1: Do not touch the edge of the cleaning

blade with bare hands.

Caution 2: Push down both ends of the toner

collection sheet towards you and

confirm that the entire drum is in

contact without any space.

Caution 3: When installing the drum and cleaning

blade, apply setting powder to the

entire surface of the drum and also the

cleaning blade, regardless of whether

the drum and cleaning blade are new

or old type parts.

Caution 4: Once the drum has been applied with

setting powder, carry out the following

work before installing the drum unit to

the main body.

• To obtain the correct toner density,

clean setting powder leakage on the

surface of the sensor on the toner

control sensor board with an alcohol

damped cloth.

a. Procedure

(1) Remove the drum unit from the main body.

(Refer to “Drum unit section”)

(2) Remove the charging corona unit.

(Refer to “Corona unit section”)

(3) Remove the developing unit and drum from the drum

casing.

(4) Remove the two set screws, then remove the cleaning

blade.

Cleaning blade

Set screw

Set screw

Drum casing

(5) Reinstall the cleaning blade in the opposite sequence to

removal.

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

3-I-1

Page 40

1 MAIN BODY

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 41

PAPER FEED UNIT

PAPER FEED UNIT

[1] Removing and Reinstalling the By-

pass Paper Feed Unit

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

a. Procedure

(1) Remove the side cover (right).

(2) Remove the two relay connectors (CN80, CN81) of the

by-pass paper feed unit.

(3) Remove the one set screw, then remove the paper feed

door.

Relay connector (CN81)

Relay connector (CN80)

[2] Removing and Reinstalling the Paper

Feed Unit

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

a. Procedure

(1) Pull out ADU and the paper feed tray in the forward

direction.

(2) Remove the one set screw, then pull out the paper feed

unit with the rail as guide of the paper feed tray toward

you.

ADU

Set screw

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Set screw

Paper feed

door

(4) Remove the four set screws, then remove the by-pass

paper feed unit.

Set screws

By-pass paper feed unit

Set screws

Paper feed

unit

Paper feed tray

(3) Reinstall the paper feed unit in the opposite sequence

to removal.

Caution: Be sure to make a copy after installing the

paper feed unit and check that paper is fed

normally.

If the rocking gear is not held by the 1st

paper feed solenoid, the paper feed is not

made normally.

(5) Reinstall the by-pass paper feed unit in the opposite

sequence to removal.

3-J-1

Page 42

PAPER FEED UNIT

[3] Replacing the By-pass Paper Feed

1 MAIN BODY

a. Procedure

2

(1) Remove the by-pass paper feed unit.

(2) Remove the one stop ring and bearing.

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Rubber

Bearing

Stop ring

(3) Press the plunger of the by-pass SD (SD4) until claw of

the by-pass solenoid releases from the gear of the

torque limiter.

(4) Pull out the by-pass drive shaft while pressing the

plunger of the by-pass SD, then remove the by-pass

paper feed roller.

(5) Remove the by-pass paper feed rubber from the by-

pass paper feed roller.

By-pass paper feed rubber

By-pass paper

feed roller

By-pass drive shaft

Claw

Torque limiter

Plunger

By-pass SD

(6) Reinstall the by-pass paper feed rubber in the opposite

sequence to removal.

3-J-2

Page 43

PAPER FEED UNIT

[4] Replacing the By-pass Separation

Rubber

a. Procedure

(1) Remove the by-pass paper feed unit.

(2) Remove the two stop rings.

(3) Pull out the by-pass conveyance shaft, then remove the

by-pass separation roller.

(4) Remove the by-pass separation rubber from the by-

pass separation roller.

By-pass separation rubber

Paint mark

By-pass

separation roller

Stop ring

By-pass conveyance shaft

Stop ring

[5] Replacing the By-pass Double Feed

Prevention Rubber

a. Procedure

(1) Remove the by-pass paper feed unit.

(2) Remove the double feed pressure spring from the

double feed prevention unit, then open the double feed

prevention unit.

(3) While pressing the lever section of the lever click shaft,

then pull out the lever click shaft.

(4) Remove the by-pass double feed prevention roller.

(5) Remove the by-pass double feed prevention rubber

from the by-pass double feed prevention roller.

Lever section

Lever click shaft

By-pass double feed prevention rubber

By-pass double feed

prevention roller

Double feed

pressure spring

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(5) Reinstall the by-pass separation rubber in the opposite

sequence to removal.

Caution: Check that the mounting orientation of the

by-pass separation rubber is correct.

Paint mark

Double feed prevention unit

(6) Reinstall the by-pass double feed prevention rubber in

the opposite sequence to removal.

Caution: Check that the mounting orientation of the

by-pass double feed prevention rubber is

correct.

3-J-3

Page 44

PAPER FEED UNIT

[6] Replacing the Feed Rubber and

1 MAIN BODY

a. Procedure

2

(1) Remove the paper feed unit.

(2) Remove the one stop ring and bearing.

(3) While pulling out the paper feed shaft, remove the

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Paper Feed Rubber

separation roller from the paper feed roller unit.

Feed rubber

Separation roller

Paper feed shaft

Paint mark

Bearing

(5) Remove the feed rubber from the feed rubber.

(6) Remove the paper feed roller from the paper feed

rubber.

(7) Reinstall the above parts in the sequence to remobval.

Caution 1: Check that the mounting orientation of

each roller rubber is correct.

Caution 2: Install each roller rubber so that the

swing shaft gets under the paper feed

roller unit.

Stop ring

Swing shaft

(4) Remove the stop ring, then pull out the guide shaft in the

direction of the arrow and remove the paper feed roller.

Paper feed rubber

Guide shaft

Paper feed roller unit

Paper feed roller

Stop ring

3-J-4

Page 45

PAPER FEED UNIT

[7] Removing and Reinstalling the

Double Feed Prevention Roller

a. Procedure

(1) Remove the paper feed unit.

(2) Remove the double feed pressure spring from the

double feed prevention unit.

(3) While pressing the shaft, remove the double feed

prevention unit from the paper unit.

Double feed

prevention unit

[8] Removing and Reinstalling the 2nd

Paper Feed Unit

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

a. Removal procedure

(1) Remove the rear cover. (Refer to “External section”)

(2) Remove the three set screws, then remove the two

flywheels.

Caution: When installing the flywheel, be careful of

the direction of the stamped mark. Install

the flywheel in such a way that the mark on

the first faces the main body side, and the

mark on the second faces the rear.

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Double feed pressure spring

(4) Remove the stop ring, then pull out the lever click shaft

while pushing the lever of the shaft, and remove the

double feed prevention roller.

Double feed prevention roller

Stop ring

Double feed prevention unit

(5) Reinstall the double feed prevention roller in the oppo-

site sequence to removal.

Caution: After reinstallation, check that the double

feed pressure spring smoothly moves the

double feed prevention roller.

Shaft

Lever click shaft

Flywheels

(3) Disconnect the three connectors (CN66, CN3, CN4) on

the rear of the 2nd paper feed unit and relay connector

(CN86).

Connector (CN66)

Set screws

3-J-5

Connector (CN4)

Relay connector

Connector (CN3)

(CN86)

Page 46

PAPER FEED UNIT

(4) Remove the by-pass paper feed unit from the main

1 MAIN BODY

(5) Remove the drum unit from the main body.

(6) Remove the two set screws, then remove the 2nd paper

2

2 UNIT EXPLANATION

b. Reinstallation procedure

3 DIS./ASSEMBLY

(1) Insert the 2nd paper feed unit into the inside of the main

(2) Install the 2nd paper feed unit so that the metal plate in

body.

feed unit.

2nd paper feed unit

Set screws

body.

the bottom of the 2nd paper feed unit gets under the

receive section of the main body.

[9] Replacing the Registration Rollers

(upper/lower)

a. Procedure

(1) Remove the 2nd paper feed unit.

(2) Loosen the one set screw, then remove the registration

guide plate (B).

Caution 1: Be careful not to fold PET sheet

(upper/lower).

Caution 2: When installing the registration guide

plate (B), make sure that PET sheets

(upper/lower) goes between the axes

of the registration rollers (upper/lower).

PET sheets (upper)

Registration

guide plate (B)

Set screw

PET sheets (lower)

2nd paper feed unit

Receive section of

Metal plate in the bottom

of the 2nd paper feed unit

(3) The reminder of the installation procedure is in the

opposite sequence to removal.

the main body

(3) Remove the two set screws, then remove the clutch

retainer.

(4) Remove the one E-ring, then remove the registration

MC (MC1).

Clutch retainer

Set screw

Registration MC

E-ring

3-J-6

Page 47

PAPER FEED UNIT

(5) Pull up the registration springs (front and rear) and

expand its, then remove the registration springs from

the flange of each registration bearing (upper).

Registration bearing (upper)

Registration spring

Registration bearing (upper)

Registration spring

(6) Remove the two E-rings and two registration bearings

(upper), then remove the registration roller (upper).

(7) Remove the set screw, then remove the roller knob.

(8) Remove the E ring, then remove the registration bear-

ing (lower) and the registration spring.

E-ring

Set screw

Registration spring

Roller knob

Registration

bearing (lower)

(9) Remove the one E-ring, then remove the registration

bearing (lower) and registration spring.

(10) Remove the registration roller (lower) from the 2nd

paper feed unit.

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Registration bearing (upper)

Registration roller (upper)

Registration

bearing (upper)

E-ring

E-ring

Registration

roller (lower)

Registration bearing

(lower)

Registration spring

E-ring

3-J-7

Page 48

PAPER FEED UNIT

(11) Reinstall the registration rollers (upper/lower) in the

1 MAIN BODY

2

opposite sequence to removal.

Caution 1: When installing the registration

bearing (lower), flange section is

directed downwards.

Caution 2: Removing and reinstalling the registration

spring with hooked the both ends of the

spring.

Caution 3: When installing the registration spring,

the hook section is between the

registration bearing (upper) and

registration bearing (lower).

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Caution 4: When installing the registration clutch,

insert the clutch retainer into the

groove of the stopper section.

3-J-8

Page 49

FIXING UNIT

FIXING UNIT

[1] Removing and Reinstalling the

Fixing Unit

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

Caution: Because the fixing unit is extremely

hot soon after its switch is turned

OFF, ensure that the fixing unit has

cooled down sufficiently before

working on it.

Caution: After uninstalling the fixing unit, make

sure to screw the set screw.

a. Procedure

(1) Open the front door, then remove the one set screw

holding the fixing unit.

(2) Hold the fixing knob and pull out. If it will not pull out in

the horizontal direction, lift it up a little while pulling it out.

[2] Replacing the Fixing Heater Lamps 1

and 2 (L2 and L3)

Caution: Do not touch the fixing heater lamp

with the bare hands.

Caution 1: Install the fixing heater lamp with the

manufacture mark facing the drive

gear side.

Caution 2: Avoid touching the inside of roller with

the fixing heater lamp .

Caution 3: Install the fixing heater lamp so that

small rated power consumption is in

the paper exit side and large is paper

feed side.

Caution 4: Be careful of the installation orientation

of the faston terminal at the rear side.

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Remove the two set screws, then remove the fixing

cover (front).

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Set screw Fixing knob

Fixing unit

(3) Reinstall the fixing unit in the opposite sequence to

removal.

Fixing cover (front)

Set screws

3-K-1

Page 50

FIXING UNIT

(3) Disconnect the faston terminal at the front side of each

1 MAIN BODY

(4) Remove the two set screws, then remove the heater

2

2 UNIT EXPLANATION

(5) Free the two wires from the cord clamp at the rear of the

3 DIS./ASSEMBLY

(6) Disconnect the faston terminal at the rear side of each

(7) Stretch the wire of the faston terminal at the rear side

fixing heater lamp.

mount plate (front).

Faston

terminals

Set screws

fixing heater lamp.

fixing heater lamp.

and pull out each fixing heater lamp towards you.

Heater mount plate (front)

[3] Replacing the Fixing Cleaning Roller,

Fixing Roller (A) and Fixing Cleaning

Pad

Caution: When installing the oil supply unit, hit it

downward to fix it with the set screws.

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Open the paper exit roller unit (upper).

(3) Remove the four set screws, then open the oil supply

unit in the upward direction and remove it in the direction of the arrow.

Set screws

Oil supply unit

Fixing heater

lamps

Cord clamp

Faston

terminals

(8) Reinstall the fixing heater lamps in the opposite se-

quence to removal.

Paper exit roller unit (upper)

3-K-2

Page 51

FIXING UNIT

(4) Remove the two E-rings (front and rear), then remove

the fixing cleaning roller.

(5) Remove the two pressure springs (front and rear).

(6) Remove the two E-rings and fixing cleaning bearings

(front and rear), then remove the fixing roller (A).

Caution: When installing the fixing roller (A), be

careful of the mounting direction.

E-rings

Pressure

spring

Serial No.

side

E-ring

Bearing

E-ring

Fixing cleaning roller

Pressure spring

Fixing cleaning

bearing

Fixing cleaning bearing

Bearing

Fixing roller (A)

Marking side

[4] Removing and Reinstalling the

Fixing Roller (upper)

Caution: When replacing the heat insulation sleeve,

apply tri-fluorocarbon to the inside of the

heat insulation sleeve, and insert it into the

fixing roller (upper).

a. Procedure

(1) Remove the fixing unit from the main body and remove

the oil supply unit from the fixing unit.

(2) Remove the two fixing heater lamps.

(3) Remove the four set screws, then remove the heater

mount plate (rear) from the fixing unit.

At this time, place the fixing unit on a stable platform the

extent to which is 5 cm and do not strain the bind wiring

from the fixing unit.

Heater mount

plate (rear)

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(7) Remove the three set screws, then remove the fixing

cleaning pad.

Set screws

Fixing cleaning pad

(8) Reinstall the above parts in the opposite sequence to

removal.

Set screws

(4) Move the pressure release lever at the front side to the

release position with a pair of pliers.

Pressure

release

lever

Pressure

Release

3-K-3

Page 52

FIXING UNIT

(5) Move the pressure release lever at the rear side to the

1 MAIN BODY

2

2 UNIT EXPLANATION

(6) Remove the one C-ring, fixing gear and C-ring on the

(7) Remove the C-ring on the front side.

(8) Remove the two heat insulation sleeves (front and rear)

3 DIS./ASSEMBLY

(9) Remove the fixing roller (upper).

release side in the same way.

Pressure

release

lever

Pressure

Release

rear side.

and bearing on the front and rear side.

Heat

insulation

sleeve

Fixing gear

Fixing roller (upper)

Bearing

C-ring

Heat

insulation

sleeve

[5] Removing and Reinstalling the

Fixing Claw (upper)

Caution 1: When installing the fixing claw (upper),

be careful of the installation orientation.

Caution 2: The fixing claw (upper) should be firmly

caught in the claw spring.

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Open the paper exit roller unit (upper).

(3) Remove the two set screws, then remove the paper exit

roller unit (upper).

Set screw

Set screw

(4) Remove the four claw springs from the fixing claws

(upper).

(5) Pull out the shaft holding the fixing claws (upper), then

remove the four fixing claws (upper).

Paper exit

roller unit (upper)

C-ring

C-ring

Bearing

Rear side

Front side

(10) Reinstall the fixing roller (upper) in the opposite se-

quence to removal.

Fixing

claw (upper)

Claw spring

Shaft

(6) Reinstall the fixing claw (upper) in the opposite se-

quence to removal.

3-K-4

Page 53

FIXING UNIT

[6] Removing and Reinstalling the Paper

Exit Roller Unit (lower)

Caution: When installing the paper exit roller unit

(lower), be sure not to damage the roller

by the claw.

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Open the paper exit roller unit (upper), then remove the

oil supply unit.

(3) Remove the five set screws (with step) holding the

paper exit roller unit (lower).

(4) Be careful so that the fixing claw (lower) does not

damage the fixing roller and remove the paper exit roller

unit (lower) from the fixing unit.

Set screws (with step)

Paper exit

roller unit

(lower)

[7] Removing and Reinstalling the

Fixing Claw (lower)

Caution: The fixing claw (lower) should be firmly

caught in the claw spring.

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Remove the paper exit roller unit (lower).

(3) Remove the four separation springs (lower) from the

fixing claws (lower).

(4) Remove the one set screw each, then remove the four

paper exit auxiliary plates.

(5) Remove the four fixing claws (lower).

Set screw

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(5) Reinstall the paper exit roller unit (lower) in the opposite

sequence to removal.

Fixing claw

(lower)

Paper exit auxiliary

plate

(6) Reinstall the fixing claw (lower) in the opposite se-

quence to removal.

Separation

spring (lower)

3-K-5

Page 54

FIXING UNIT

[8] Removing and Reinstalling the

1 MAIN BODY

a. Procedure

2

(1) Remove the fixing unit from the main body.

(2) Remove the fixing roller (upper) from the fixing unit.

(3) Remove the two set screws (with step), then remove

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Fixing Roller (lower)

the fixing entrance plate (lower).

Fixing entrance

plate (lower)

Set screws

(with step)

(6) Remove the paper exit roller unit (lower).

(7) Remove the fixing roller (lower) from the fixing unit.

(8) Remove the one set screw, then remove the fixing knob

from the fixing roller (lower).

(9) Remove the two C-rings (front and rear), then remove

the bearings (front/rear) from the fixing roller (lower).

Set screw

Fixing knob

C-ring

Bearing

Fixing roller (lower)

Bearing

U-groove

C-ring

U-groove

(4) Remove the two set screws, then remove the guide

unit.

(5) Remove the two set screws, then remove the fixing

entrance plate (upper).

Fixing entrance

plate (upper)

Set screws

Guide unit

Set screws

(10) Reinstall the fixing roller (lower) in the opposite se-

quence to removal.

Caution: When installing the bearing, make sure

that the flange of the bearing set into the

U-groove of the fixing unit securely.

3-K-6

Page 55

FIXING UNIT

[9] Removing and Reinstalling the

Fixing Temperature Sensor 1 and 2

(TH1 and TH2)

Caution: After reinstalling fixing temperature

sensor 2 and check that the sensor

wires are not touching with the fixing

roller (upper).

Caution: After installing the fixing tempera-

ture sensor 2, check that sensor

section of the fixing temperature sensor 2 contact with the fixing roller

(upper).

Caution: Be sure to apply paint lock to the set

screw of the installed sensor.

a. Removal procedure

(1) Remove the fixing unit from the main body.

(2) Remove the oil supply unit from the fixing unit.

(3) Remove the two set screws, then release the fastening

of the connector (CN390).

(4) Cut the two wiring bands, then remove the pins 10 to 13

of connector (CN390) with tweezers.

(5) Remove the two set screws, then remove the fixing

temperature sensor 1.

(6) Remove the two set screws, then remove the fixing

temperature sensor 2.

Set screwsSet screws

Fixing temperature sensor 2 Fixing temperature sensor 1

b. Reinstallation procedure

(1) Fix the fixing temperature sensor 2 with the two set screws,

then contact the sensor surface to the fixing roller (upper).

Set screws

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Wiring bands

Set screw

Connector

(CN390)

Pin 10

Pin 11

Pin 12

Fixing

temperature sensor 2

Set screw

Pin 13

3-K-7

Page 56

FIXING UNIT

(2) Fix the fixing temperature sensor 1 (TH1) with the two

1 MAIN BODY

(3) Set the fixing temperature sensor positioning jig be-

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

set screws.

tween the fixing temperature sensor 1 and fixing roller

(upper), then adjust the clearance between the sensor

and the fixing roller (upper) is within the standard value

with the two set screws.

Set screws

Fixing

temperature

sensor 1

Fixing temperature

sensor positioning jig

[10] Removing and Reinstalling the

Thermostat (TS)

Caution: After reinstalling the thermostat,

check that the wiring is not touching

with the fixing roller (upper).

Caution: Be sure to coat the set screw of the

thermostat with screw lock agent after reinstalling the thermostat .

a. Removal procedure

(1) Remove the fixing unit from the main body.

(2) Remove the oil supply unit from the fixing unit.

(3) Disconnect the two faston terminals connected to the

thermostat.

(4) Remove the one set screw, then remove the thermostat.

Set screw

Faston terminal

Faston terminal

(a) Set the distance ‘a’ between the fixing roller (up-

per) and fixing temperature sensor 1 so that it is

equal to the thickness of the fixing temperature

sensor positioning jig.

Fixing temperature sensor 1

a

Fixing roller (upper)

Standard: a =0.9±0.15mm

(4) Coat the set screws of each sensor with paint

(5) Insert the connector pins of each sensor into applicable

position of the connector (CN390).

(6) The reminder of the installation procedure is in the

opposite sequence to removal.

Thermostat

3-K-8

Page 57

FIXING UNIT

b. Reinstallation procedure

(1) Set the fixing temperature sensor positioning jig be-

tween the thermostat (TS) and the fixing roller (upper),

then fix the thermostat with the set screw so that the

clearance between the thermostat and the fixing roller

(upper) is the standard value.

Faston terminal

Set screw

Thermostat

Fixing temperature

sensor positioning

jig

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(a) Set the distance ‘a’ between the fixing roller (upper) and

the thermostat so that it is equal to the thickness of the

fixing temperature sensor positioning jig.

Thermostat

a

Fixing roller (upper)

Standard: a =0.9±0.15mm

(2) Coat the set screw of the thermostat with paint lock agent.

(3) Connect the two faston terminals.

(4) The reminder of the installation procedure is in the

opposite sequence to removal.

3-K-9

Page 58

1 MAIN BODY

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 59

REVERSAL AND PAPER EXIT SECTION

REVERSAL AND PAPER EXIT SECTION

[1] Removing and Reinstalling the

Reversal and Paper Exit Unit

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

a. Procedure

(1) Remove the side cover (left) and rear cover of the main

body.

(Refa to “Exterval section”)

(2) Open the paper exit cover (upper).

(3) Remove the two set screws for the stay of the reversal

and paper exit unit, then slowly open the paper exit

cover (lower).

Stays

Set screw

Set screw

(4) While holding the reversal and paper exit unit, remove

the six set screws, then remove the reversal and paper

exit unit.

Set screw

Set screws

Set screws

(5) Reinstall the reversal and paper exit unit in the opposite

sequence to removal.

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Paper exit

cover (lower)

Paper exit cover (upper)

3-L-1

Page 60

1 MAIN BODY

1 MAIN BODY

2

2

2 UNIT EXPLANATION

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

3 DIS./ASSEMBLY

Blank page

Page 61

ADU SECTION

ADU SECTION

[1] Removing and Reinstalling the ADU

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

a. Procedure

(1) Pull out the ADU, then remove the four set screws (two

screws for right/left respectively).

(2) Lift up the ADU, then remove it.

Set screws

ADU

Set screws

1 MAIN BODY

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(3) Reinstall the ADU in the opposite sequence to removal.

3-M-1

Page 62

1 MAIN BODY

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Loading...

Loading...