Page 1

DF-315

SERVICE HANDBOOK

Sep. 2000

Ver. 1.0

KONICA CORPORATION

TECHNOLOGY SUPPORT CENTER

TOKYO JAPAN

Page 2

KONICA CORPORATION

COPYRIGHT ©2000

CN55YF1300

Page 3

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS .............

Refer to the 7045 service handbook on page C-1

1. OUTLINE

DF-315 PRODUCT SPECIFICATIONS .................. 1-1

CENTER CROSS-SECTIONAL VIEW ................... 1-2

DRIVE SYSTEM DIAGRAM ................................... 1-2

ORIGINAL CONVEYANCE PROCESS ................. 1-3

[1] Single Side Original Copy Mode ................ 1-3

[2] Double Side Original Copy Mode ............... 1-4

[3] Mixed Original/Z-Fold Original Mode ......... 1-5

2. UNIT EXPLANATION

EXTERNAL SECTION ........................................... 2-1

[1] Composition ............................................... 2-1

[2] Mechanisms ...............................................2-1

PAPER FEED/PAPER EXIT SECTION ................. 2-3

[1] Composition ............................................... 2-3

[2] Mechanisms ...............................................2-3

[3] Paper Feed/Conveyance/Scan Control ..... 2-5

[4] Paper Exit/Reverse Conveyance Control ....2-8

[5] Original Size Detection Control ...............2-10

3. DISASSEMBLY/ASSEMBLY

DISASSEMBLY AND REASSEMBLY .................... 3-1

[1] Removing and Reinstalling

the Paper Dust Removing Pad .................. 3-1

[2] Removing the RADF .................................. 3-1

[3] Reinstalling the RADF ................................ 3-3

[4] Removing and Reinstalling

the Paper Feed Roller/Separation Roller ... 3-5

[5] Removing and Reinstalling the Double Feed

Prevention Pad .......................................... 3-6

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Page 4

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 5

1

OUTLINE

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Page 6

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 7

DF-315 PRODUCT SPECIFICATIONS

DF-315

1. Type

Type: Sheet-through type

reversible DF

2. Functions

Originals size: A3, B4, A4, A4R, A5, A5R,

B5, B5R, 8.5 x 11, 8 x 13,

(for Europe), 11 x 17, 8.5 x

14, 8.5 x 11, 8.5 x 11R, 5.5 x

8.5, 5.5 x 8.5R, A4R (for

U.S.A)

• Double sided copy of A5

originals is not possible.

• All sizes are detected

automatically.

• Mixing of original sizes

possible.

Kinds of originals

Ordinary paper: 50 - 130 g/m

paper

Special paper: Paper feed and conveyance

ability may sometimes be

inferior to those of 50 to 130

2

g/m

fine quality paper.

The following kinds of paper

cannot be used:

• OHP film

• Blueprint masters

• Label paper

• Offset masters

• Pasted originals

2

fine quality

Original read speed (copies per minute)

Mode

Single-sided

original to Single-

sided copy

Dual-sided original

to duplex copy

Original image

read position: At the slit glass section

Original size

A4

A4

Feed speed

45

28

3. Particulars of Machine

Power source: 24 V DC / 5 V

(supplied from main body)

Max. power

consumption: Less than 120VA

Weight: Approx. 14 kg

Machine dimensions : Width 590mm

Depth 570mm

Height 150mm

4. Maintenance and Life

Maintenance: Same as the main body

Machine life: Same as the main body

5. Operating Environment

Temperature: 10°C to 30°C

Humidity: 10% to 80%RH

Note: The contents of this manual may be changed

without prior notice.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

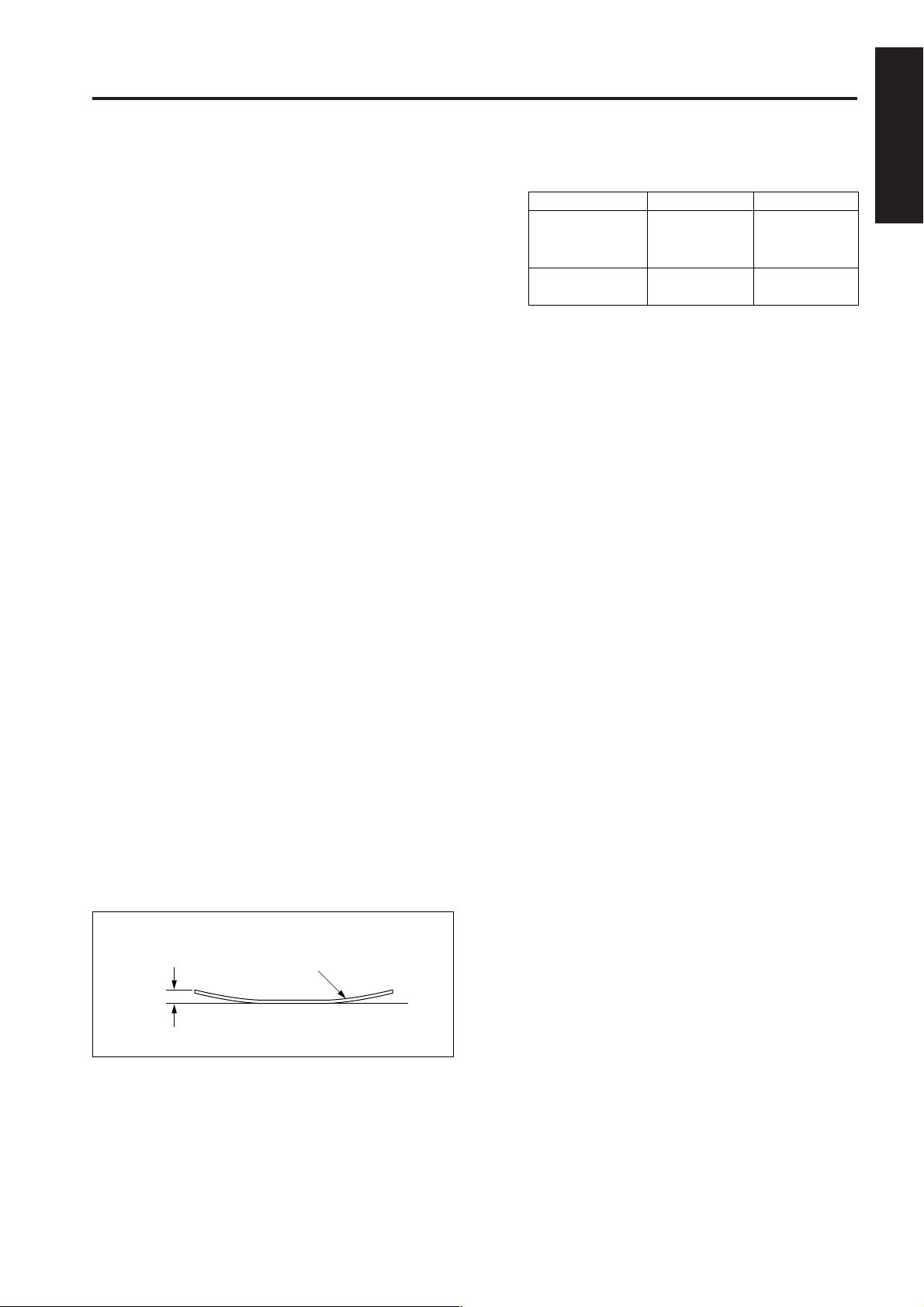

Maximum number

of stacked originals: 50 sheets (80g/m

Original curling: 10 mm Max.

Curling

Original

2

)

1-1

Page 8

DF-315

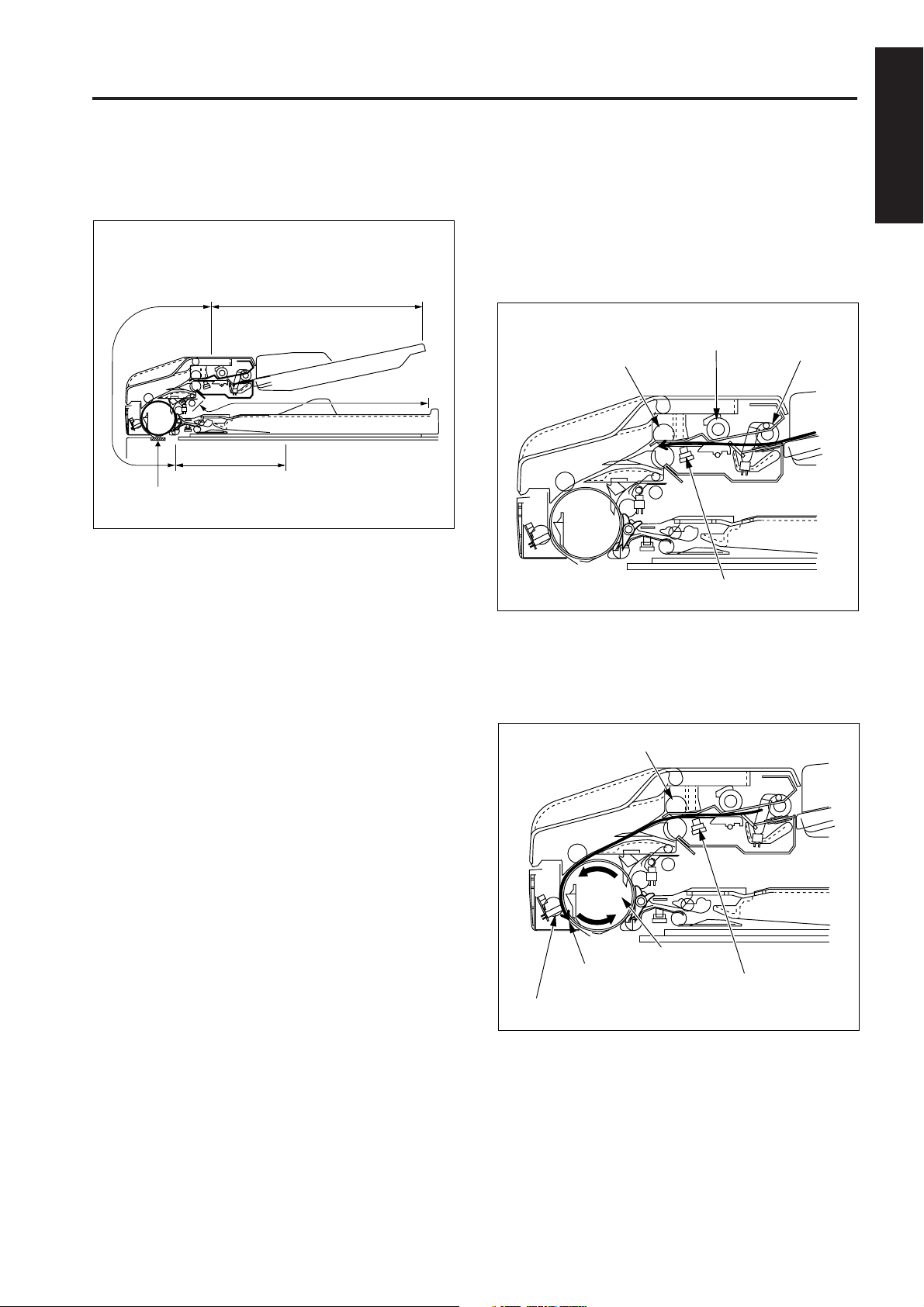

CENTER CROSS-SECTIONAL VIEW

1 OUTLINE

2

Separation roller

Registration roller

Conveyance roller

2 UNIT EXPLANATION

Double feed prevention pad

Pressure pulley

Reversal roller

Paper exit roller

Slit glass

Original

image read

position

3 DIS./ASSEMBLY

DRIVE SYSTEM DIAGRAM

Paper feed roller

Paper feed tray

Original conveyance

motor (M301)

Original feed motor

(M302)

Separation roller

Original feed CL (CL302)

Paper feed roller

Original pick-up CL (CL301)

Registration roller

Conveyance roller

Paper exit roller

1-2

Page 9

ORIGINAL CONVEYANCE PROCESS

DF-315

As the figure below shows, the DF-315 is composed of the

paper feed section, conveyance section, reversal section

and paper exit section.

Conveyance

section

Reversal section

Slit glass

(Read section)

The originals, which have been placed in the paper feed

tray with the front side facing up, are fed starting with the

topmost original. Originals that are fed are not conveyed

to the original glass. Reading is carried out as the original

passes by the slit glass section set midway through the

conveyance path.

The operational modes of the DF-315 include three

modes: (a) single side original copy mode, (b) double side

original copy mode, (c) mixed original copy mode. The

conveyance path is different for each mode.

Paper feed section

Paper exit section

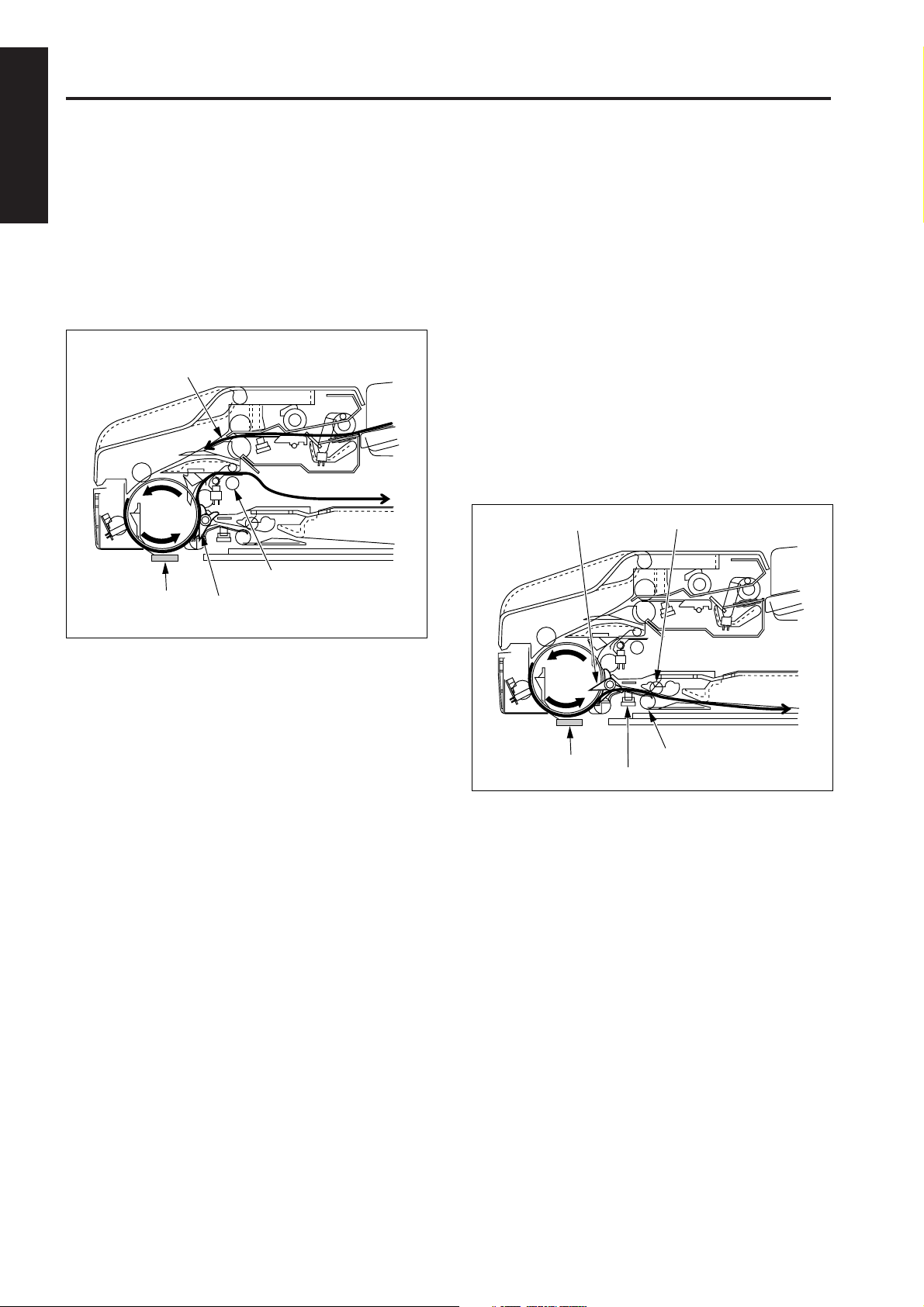

[1] Single Side Original Copy Mode

(single side to single side copy, single side to

double side copy)

The originals set in the paper feed tray are fed by means of

the paper feed roller and separation roller to the position

where original registration PS (PS306) goes on.

Separation roller

Registration roller

Original registration PS

When original registration PS goes on, pre-feed is carried out

by the registration roller and the original is conveyed to the

conveyance roller. The conveyance roller conveys the

original to the position where original feed detect PS (PS308)

goes on. The original stops at the scanning standby position.

Registration roller

Paper feed roller

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

1-3

Conveyancec roller

Scanning standby

position

Original feed detect PS

Original registration PS

Page 10

1 OUTLINE

2

2 UNIT EXPLANATION

DF-315

When scan is started, the conveyance roller rotates again

in the forward direction to convey the original. If there is

another original at this time, pre-feed is carried out.

Reading of the original is carried out when the original

passes over the slit glass. Originals which have been read

are conveyed around the circumference of the

conveyance roller by closing of the flapper and are ejected

to the paper exit section via the paper exit roller.

Next original

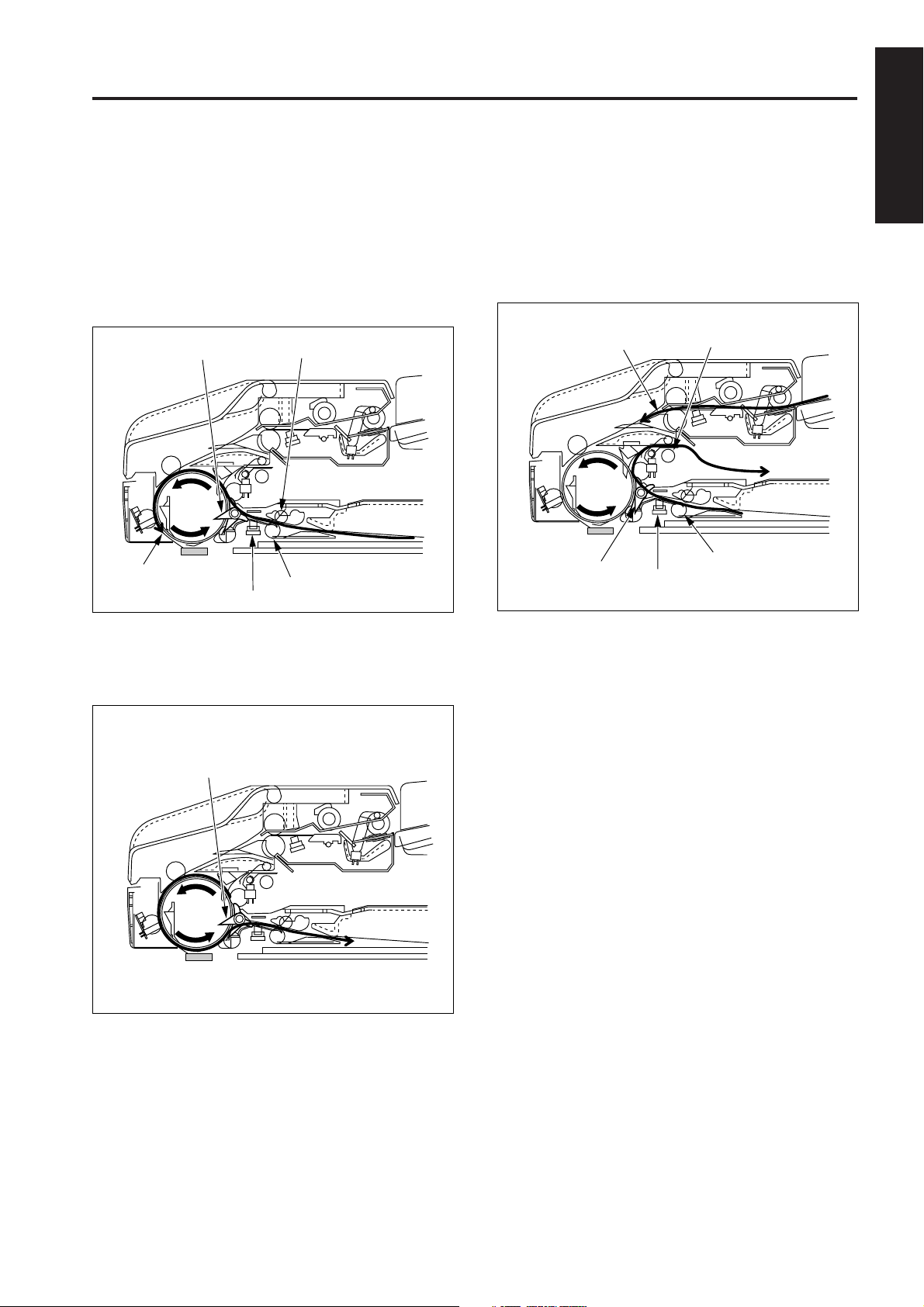

[2] Double Side Original Copy Mode

(double side to single side copy, double side to

double side copy)

The conveyance operation from feeding of the double

sided original to the front side scanning standby position is

the same as that for the single side original copy mode.

When scanning starts and reading of the front side is

completed, the original is conveyed to the reversal section

when the flapper opens and the paper exit path is blocked.

When original reverse detect PS (PS309) detects the

leading edge of the original that has been conveyed to the

reversal section and goes ON, pressure is applied to the

pressure pulley. As a result, the reversal roller and

pressure pulley clasp the original on both sides and

convey it to the inside of the reversal section.

Flapper

Paper exit roller

3 DIS./ASSEMBLY

Slit glass

Flapper

Slit glass

Pressure pulley

Reversal roller

Original reverse detect PS

1-4

Page 11

DF-315

When original reverse detect PS (PS309) detects the trailing

edge of the original and goes OFF, the reversal roller rotates in

the reverse direction to feed the original from the reversal

section to the conveyance roller. Since the original passes

over the top of the flapper at this time, the front and back sides

are reversed and the original is sent to the conveyance roller.

The conveyance roller conveys the original to the

scanning standby position.

Flapper Pressure pulley

Scanning

standby position

Original reverse detect PS

Reversal roller

When original reverse detect PS detects the trailing edge of

the original and goes OFF, the reversal roller rotates in the

reverse direction to feed the original from the reversal

section to the conveyance roller. Since the flapper is

closed at this time, the original is conveyed along the

flapper and is ejected to the paper exit section via the

paper exit roller.

Next original

Flapper

Original reverse detect PS

Paper exit roller

Reversal roller

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

When scanning of the back side starts, the flapper is

opened. As a result, the original which has been read is

conveyed to the inside of the reversal section again.

Flapper

[3] Mixed Original/Z-Fold Original Mode

In the mixed original mode (can handle both same

series and different series of originals) and the Z-fold

original mode, the original size in the sub-scanning

direction is determined by to the ON time of original

registration PS (PS306), hence size detection takes

place before the scanning operation. This operation

takes place for all originals in the mixed original

mode, and only for the first original in the Z-fold

original mode.

After size detection is completed, the original stops at

the scanning standby position. The subsequent

operations are the same for all copy modes. For

details of the size detection process, refer to [5]

"Original Size Detection Control" in "PAPER FEED/

PAPER EXIT SECTION".

1-5

Page 12

1 OUTLINE

2

2 UNIT EXPLANATION

DF-315

3 DIS./ASSEMBLY

Blank page

1-6

Page 13

2

UNIT EXPLANATION

1 OUT LINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Page 14

1 OUT LINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 15

EXTERNAL SECTION

DF-315

[1] Composition

1 OUT LINE

Open/close cover

Paper feed tray

2 UNIT EXPLANATION

Paper exit section

3 DIS./ASSEMBLY

[2] Mechanisms

Mechanisms

Jam clearance

1*: Jam clearance

If a paper jam occurs during the feed process, open

the open/close cover, raise the conveyance guide

open/close lever, and rotate the release knob to

remove the jammed original.

Open/close cover *1

Release knob

Conveyance guide open/close

lever

Pressure release lever

Platen guide

Methods

Open/close cover

Release knob

Conveyance

guide open/close

lever

Conveyance guide

2-1

Page 16

1 OUT LINE

2

2 UNIT EXPLANATION

DF-315

If the jammed original is hard to remove, operate the

pressure release lever to remove the pressure of the

separation roller, and then remove the original.

Separation roller

Pressure release lever

If a paper jam occurs during the reversal process, the

jammed sheet can be removed by opening the platen guide.

3 DIS./ASSEMBLY

Platen

guide

Lock

2-2

Page 17

PAPER FEED/PAPER EXIT SECTION

DF-315

[1] Composition

[2] Mechanism

Open/close cover

Original press SD

Flapper SD

Paper feed tray

Paper exit tray

Paper feed roller

Original feed motor

Original feed CL

1 OUT LINE

Registration roller

Separation roller

2 UNIT EXPLANATION

Conveyance roller

Original conveyance motor

Original pick-up CL

3 DIS./ASSEMBLY

Mechanisms

Paper feed

Double feed prevention

Conveyance

Conveyance path switching

Reversal feed *2

*1

Methods

Paper feed roller

Double feed prevention pad

Separation roller

Conveyance roller

Flapper

Reversal roller pressure

Reversal roller turn-back

2-3

Page 18

DF-315

1 OUT LINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

*1: Conveyance path switching

In the double side original copying, the conveyance

path after the end of reading operations differs for

front side copies and back side copies. Change of

the conveyance path is carried out by the flapper.

Turning flapper SD (SD301) ON and OFF switches

between the reversal section and the paper exit

section.

Conveyance roller

Flapper

Flapper SD

*2: Reversal feed

During double side original copy operation, the

original conveyed to the reversal section is held in the

standby mode on the reversal roller. Reversal feed is

activated by bringing the pressure pulleys into

contact with the reversal roller. Pressure of the

pressure pulleys is conducted by original press SD

(SD302).

Pressure pulley

Reversal roller

Pressure pulleys

Flapper

Original press SD

2-4

Page 19

DF-315

[3] Paper Feed/Conveyance/Scan Control

PS302

PS303

5VDC

SGND

PS302

5VDC

SGND

PS303

PTBD

24VDC

PGND

PGND

SGND

DF RXD

DSR

RTS

5VDC

PGND

24VDC

24VDC

MAIN BODY

5VDC

PS303

PS302

SGND

VR301

DF TXD

CTS

DTR

VALID

DFCB

24VDC

24VDC

M301 DRIVE A

M301 DRIVE A

M301 DRIVE B

M301 DRIVE B

M302 DRIVE 1

M302 DRIVE 2

24VDC

CL301 DRIVE

24VDC

CL302 DRIVE

24VDC

SD301 DRIVE

24VDC

SD302 DRIVE

5VDC

PS304

SGND

5VDC

SGND

PS306

5VDC

PS309

SGND

PS305

SGND

5VDC

M301

M302

CL301

CL302

SD301

SD302

PS304

PS307

PS309

PS305

1 OUT LINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Paper feed takes place by transmitting the drive force of

motor M302 (original feed) to the paper feed roller and

separation roller. Conveyance takes place by transmitting

the drive force of motor M301 (original conveyance) to the

conveyance roller.

M301 and M302 are controlled by the DFCB (RADF control

board).

1. Operation

a. Sensor adjustment when the power is ON.

When SW2 (sub power) is ON, a sensitivity PS306

(original registration) and PS308 (original feed detect)

is adjusted automatically. However, if the RADF open/

close cover is open or an original is inside of the

RADF, there will be no automatic adjustment.

b. Original pressure operation

When a control signal from the main body is received,

CL301 (original pick-up) goes ON, and after the

specified time M302 starts to rotate in the forward

direction. This causes the paper feed roller to be

lowered, applying pressure to the original.

After the specified time, M302 and CL301 go OFF,

but the pressure on the original is maintained.

2-5

Page 20

DF-315

1 OUT LINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

c. Paper feed operation

When CL302 (original feed) goes ON, the driving

force of M302 (original feed) is transmitted to the

paper feed roller and the separation roller.

CL302 goes ON at the same time as M302 performs

forward rotation. When M302 switches from forward

to reverse rotation, paper feed starts.

When PS306 (original registration) goes ON, the

reverse rotation of M302 is switched OFF after the

specified time.

d. Pre-feed of first sheet

When the reverse rotation of M302 stops, the motor

starts again to rotate in forward direction after the

specified time.

This causes the original to be moved to the

conveyance roller.

At the specified time after forward rotation of M302

has started, M301 (original conveyance) goes ON

and moves the original from the conveyance roller

to the scanning standby position.

When PS308 (original feed detect) detects the

leading edge of the original and turns ON, CL302 and

M302 go OFF. After the specified time, M301 slows

down and then goes OFF. At this point, the original

still moves a small distance further due to the inertia

of the conveyance roller and then stops. This is the

scanning standby position.

h. Original pressure release

When M301 completes the scanning operation for

the last original and goes OFF, CL301 and M302 go

ON which causes the original pressure to be

released. After the specified time, CL301 and M302

go OFF.

e. Pre-feed of second and further sheets

The forward rotation of M302 starts the pre-feed

process of the following original, but because the

motor immediately goes OFF, the original temporarily

stops before reaching the conveyance roller. When

M301 begins the scanning operation, the forward

rotation of M302 starts again. Pre-feed of the original

then is carried out while the preceding original is

being scanned.

f. Scanning operation (except last original)

At the specified time after M301 goes OFF, it goes

ON again and conveys the original over the slit glass

area of the main body, where scanning is performed.

When PS306 detects the trailing edge of the original that

is being scanned and goes OFF, CL302 again goes ON

g. Scanning operation (last original)

During scanning, when M301 is ON and one of the

sensors PS302 (original size detect 1), PS303

(original size detect 2), or PS305 (no original detect)

goes OFF, the original currently being scanned is the

last one.

A sensor that is used to judge the last original differs

depending on the original size.

When PS307 (original exit detect) goes OFF, M301

also is switched OFF after the specified time.

2-6

Page 21

DF-315

24V

0V

2. Signals

a. Input signals

(1) PS302 (PS302 to PTDB to DFCB)

Original sub-scanning direction signal

[L]: Original is detected

[H]: Original is not detected

(2) PS303 (PS303 to PTDB to DFCB)

Original sub-scanning direction signal

[L]: Original is detected

[H]: Original is not detected

(3) PS304 (PS304 to DFCB)

M301 (original conveyance) encoder surface slit

detection signal

[L]: Slit is not detected

[H]: Slit is detected

(4) PS305 (PS305 to DFCB)

No original detection signal at the paper feed tray

[L]: Original is detected

[H]: Original is not detected

(5) PS306 (PS306 to DFCB)

Original detection signal at the conveyance roller en

trance section

[L]: Original is detected

[H]: Original is not detected

(6) PS307 (PS307 to DFCB)

Original detection signal at the paper exit section

[L]: Original is detected

[H]: Original is not detected

(7) PS308 A, B (PS308 to DFCB)

Original detection signal at the pre-scanning standby

position

[L]: Original is detected

[H]: Original is not detected

(8) DF RXD (MAIN BODY to DFCB)

Serial data line for transmitting operation status

informa tion from control board in main body to

RADF.

b. Output signals

(1) M301 DRIVE A, A, B, B (DFCB to M301)

M301 ON/OFF drive signal

(2) M302 DRIVE 1, 2 (DFCB to M302)

M302 (original conveyance) drive signal.

M302 rotation direction is controlled by switching the

current direction of these two signals.

State

Forward rotation

Reverse rotation

Stop

(3) CL301 DRIVE (DFCB to CL301)

CL301 (original pick-up) ON/OFF drive signal

[L]: CL301 ON

[H]: CL301 OFF

(4) CL302 DRIVE (DFCB to CL302)

CL302 (original feed) ON/OFF drive signal

[L]: CL302 ON

[H]: CL302 OFF

(5) DF TXD (DFCB to MAIN BODY)

Serial data line for transmitting operation status

informa- tion from RADF to main body CB (control

board).

(6) DTR (DFCB to MAIN BODY)

Send request from RADF to main body.

(7) CTS (DFCB to MAIN BODY)

Send enable from RADF to main body.

(8) VALID (DFCB to MAIN BODY)

Image forming start signal.

M302 DRIVE 1

H

L

L

M302 DRIVE 2

1 OUT LINE

L

H

L

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(9) DSR (MAIN BODY to DFCB)

Send enable from main body to RADF.

(10) RTS (MAIN BODY to DFCB)

Send request from main body to RADF.

2-7

Page 22

DF-315

1 OUT LINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[4] Paper Exit/Reverse Conveyance

Control

24VDC

24VDC

M301 DRIVE A

M301 DRIVE A

M301 DRIVE B

M301 DRIVE B

M302 DRIVE 1

M302 DRIVE 2

5VDC

PS304

SGND

SGND

PS306

5VDC

5VDC

SGND

PS307

5VDC

PS308 A

PS308 B

SGND

24VDC

PGND

PGND

SGND

DF RXD

5VDC

PGND

24VDC

24VDC

MAIN BODY

DSR

RTS

DF TXD

CTS

DTR

VALID

DFCB

Paper path switching in the exit area is carried out by

solenoid SD301 (flapper) which operates a flapper. In

duplex copy mode, the pressure pulley in the reversal

section is operated by the SD302 (original press).

SD301 and SD302 are controlled by the DFCB (RADF

control board).

M301

M302

PS304

PS306

PS307

PS308

1. Operation

a. Sensor adjustment when the power is ON.

When SW2 (sub power) is ON, a sensitivity of PS309

(original reverse detect) is adjusted automatically.

However, if the RADF open/close cover is open or an

original is in the inside of the RADF, there will be no

automatic adjustment.

b. Paper exit operation

In single-sided copy mode and when copying the

reverse side of a sheet in duplex copy mode, SD301

is OFF and the flapper is closed. The original is

therefore conveyed to the paper exit section after

scanning.

c. Reversal paper exit operation

When copying the first side of a sheet in duplex copy

mode, at the specified time after M301 (original

conveyance) goes ON and scanning starts, SD301

goes ON and the flapper opens. This causes the

original to be sent to the reversal section after

scanning.

At the same time as SD301 goes ON, M302 (original

feed) starts reverse rotation and the drive force is

transmitted to the reversal roller.

When PS309 detects the leading edge of the original

and goes ON, the SD302 goes ON after the specified

time and applies pressure to the pressure pulley. As

a result, the original which has been conveyed to the

reversal section is caught between the reversal roller

and pressure pulley, and conveyed to the inside of

the reversal section.

d. Reversal feed operation

When PS309 detects the trailing edge of the original

and goes OFF, both the M301 and M302 go OFF

after the specified time, and conveyance operation of

the original is stopped.

After a predetermined OFF interval, M302 starts

reverse rotation and feeds the original to the

conveyance roller side of the reversal section. At this

time, PS309 again goes ON and SD302 goes OFF

after the specified time. M302 goes OFF after the

specified time from PS309 goes OFF.

e. Pre-feed operation of next original when reading

back side of original

When PS309 goes OFF, M301 and M302 start

forward rotation after the specified time, and next

original pre-feed is carried out.

2-8

Page 23

DF-315

2. Signals

a. Input signal

(1) PS309 (PS309 to DFCB)

Original detection signal at the reversal section

[L]: Original is detected

[H]: Original is not detected

b. Output signals

(1) SD301 DRIVE (DFCB to CL301)

SD301 (flapper) ON/OFF drive signal

[L]: SD301 ON

[H]: SD301 OFF

(2) SD302 DRIVE (DFCB to SD302)

SD302 (original pressure) drive signal

[L]: SD301 ON

[H]: SD302 OFF

1 OUT LINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

2-9

Page 24

DF-315

1 OUT LINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[5] Original Size Detection Control

5VDC

SGND

PS302

5VDC

SGND

PS303

5VDC

VR301

SGND

PTDB

PS303

PS302

VR-301

24VDC

PGND

PGND

SGND

DF RXD

5VDC

PGND

24VDC

24VDC

MAIN BODY

DSR

RTS

5VDC

DF TXD

CTS

DTR

DFCB

SGND

PS302

PS303

VR301

1. Operation

a. Normal copy mode

The DFCB detects the original size from the

combination of the following signals.

(1) Detection of size in the main scanning direction

The guide plate is connected to VR301. The

resistance of VR301 varies according to the position

of the guide plate, enabling the size of the original in

the main scanning direction to be detected.

(2) Detection of size in the sub-scanning direction

The size of the original in the sub-scanning direction

is detected according to the combination of the ON/

OFF status of PS302 and PS303.

b. Original size detection in the mixed original/Z-

fold original mode

(1) Detection of size in the main scanning direction

The size of the largest original of mixed size originals

in the main scanning direction is detected according

to the position of the guide plate.

(2) Detection of size in the sub-scanning direction

The size of the original in the sub-scanning direction

is detected according to the time at which PS306

(original registration) goes ON after the original is fed

from the registration roller.

(3) Size detection process in the sub-scanning direction

When original pre-feed is started by the registration

roller, M301 (original conveyance) rotates in the

forward direction after the specified time from when

PS306 goes ON, causing the original to be conveyed

to the paper exit section. M301 continues to rotate in

the forward direction until PS306 detects the trailing

edge of the original and goes OFF. The size of the

original in the sub-scanning direction is detected

according to the ON time of PS306.

The size of the original placed in the paper feed tray is

detected by PS302 (original size detect 1), PS303 (original

size detect 2), and VR301 (original size detect).

PS302, PS303, and VR301 are controlled by the DFCB

(RADF control board) via the PTBD (Paper tray board).

Inside the DFCB is a non-volatile memory for recording

the timing data and original size detection threshold

values.

2-10

Registration roller

PS308

(Original feed detect)

PS306

(Original registration)

Conveyance roller

Page 25

DF-315

Standard original (maximum original size that is detected with the guide plate).

Other originals

11×17

8.5×11

8.5

×

14

8.5

×

11R

8.5

×

5.5

8.5×5.5R

11×17 8.5×11 8.5×14 8.5×11R 8.5×5.5 8.5×5.5R

–

–

–

–

–

–

–

–

–

–

–

✕✕✕✕ ✕

M301 (original conveyance) rotates in the reversal

direction after the specified time from PS306 (original

registration) goes OFF and returns the leading edge

of the original that has been conveyed to the paper

exit section to the scanning standby position. The

trailing edge of the original which has been returned

is conveyed to the exit section due to the

configuration of the conveyance section. The

reversal rotation of the M301 stops after the specified

time from PS308 (original feed detect) detects the

leading edge of the original and goes ON.

Scanning standby

position

PS308

(Original feed detect)

Conveyance roller

Following this, there is the same reading as in the

normal mode (scanning operation).

The process of detecting the size of the original in the

sub-scanning direction takes place only for in the all

originals in the mixed original mode, and for the first

original in the Z-fold original mode.

(4) The original size detection operation with the second

original and subsequent originals has a different start

timing for the single side mode and double side mode.

Single side mode: At time of starting scanning opera-

tion of former original.

Double side mode: At time of starting scanning opera-

tion of former original back side.

2nd original

1st original

c. List of the possible mixing of sizes.

(

: Same size : Same series : Different series

× : Mixing not possible – : Setting not possible.)

(1) AB series

Standard original (maximum original size that is detected with the guide plate).

A3 A4 B4 B5 A4R A5R B5R A5

A3

A4

B4

B5

A4R

A5

Other originals

B5R

A5R

✕✕✕

–––––

✕✕✕✕

✕

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

1 OUT LINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(2) Inch series

2. Signals

a. Input signal

(1) VR301 (VR301 to PTBD to DFCB)

Original main scanning direction signal

2-11

Page 26

1 OUT LINE

2

2 UNIT EXPLANATION

DF-315

3 DIS./ASSEMBLY

Blank page

2-12

Page 27

3

DISASSEMBLY/ASSEMBLY

1 OUT LINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Page 28

1 OUT LINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

This section covers the structure, functions, operation and method of

disassembling and assembling the machine.

Observe the following precautions when performing disassembly and

assembly work.

1. Be sure to unplug the power cord before working on the machine.

2. Perform all reassembly work by reversing the order in which the

componet was disassembled, unless otherwise specified.

3. Do not lose small parts (screws, etc.) or insert them in the wrong

place.

4. Install all parts completely before operating the machine.

5. Do not loosen the screws indicated as disallowed for removal.

Page 29

DISASSEMBLY AND REASSEMBLY

DF-315

Caution: Be sure that the power cord has

been unplugged from the power

outlet.

[1] Removing and Reinstalling the Paper

Dust Removing Pad

a. Procedure

(1) Open the open/close cover.

(2) Remove the set screw, then remove the paper dust

removing pad.

Paper dust removing pad

Set screw

[2] Removing the RADF

a. Procedure

(1) Remove the rear cover from the main body.

(2) Remove the two connectors (CN100, CN102).

(3) Remove the set screw, then withdraw the cable from

the main body.

Cable

Set screw

Connector

(CN102)

Connector

(CN100)

1 OUT LINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(3) Reinstall the paper dust removing pad in the opposite

sequence to removal.

3-1

Page 30

DF-315

1 OUT LINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(4) Remove the set screw from each, then remove the two

stoppers.

(5) Remove the two set screws from each, then remove the

two fixing plates/R.

Set screw

Stopper

Fixing

plate/R

Set

screws

(6) Open the RADF.

(7) Remove the set screw from each while supporting the

RADF, then remove the two fixing plates/F.

(8) Remove the RADF from the main body.

Fixing plate/F

Set

screw

3-2

Caution: Be sure to support the RADF during

this process as it may fall to the rear

side when the fixing plate/F has been

removed.

Page 31

DF-315

[3] Reinstalling the RADF

a. Procedure

(1) Remove the two set screws, then remove the original

stopper plate of the main body.

Set screw

Original stopper plate

Set screw

(2) Install the two RADF positioning jigs in the hole of the

original stopper plate.

(3) After installing the RADF, temporarily fix the two fixing

plates /F using one set screw each.

Caution: Set each fixing plate/F with the long

hole over the guide screw.

(4) Close the RADF, and match the reference hole with the

RADF positioning jig.

Guide screw

Set screw

Reference

hole

(round hole)

Reference

hole

(long hole)

Fixing plate/F

1 OUT LINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

RADF

positioning jigs

3-3

Page 32

DF-315

1 OUT LINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(5) When the positions are matched, tighten the two set

screws of each fixing plate /R.

(6) Open the RADF, then tighten the set screw of each

fixing plate /F.

Set screws

Fixing plate/R

(9) Adjust the adjustment screws A and B alternately so

that both stoppers contact with the slit glass.

Caution: Repeat Step (8) to (9) until both stoppers

make contact with the slit glass

simultaneously.

Adjustment

screw B

(10) Reinstalling hereafter is performed in the opposite

sequence to removal.

Adjustment

screw A

(7) Remove the two RADF positioning jigs, then install the

original stopper plate.

(8) Close the RADF, and check whether or not the stoppers

of the read section at the two locations contact with the

slit glass.

Stopper

Projection

Projection

Slit glass

Stopper

3-4

Page 33

DF-315

[4] Removing and Reinstalling the Paper

Feed Roller/Separation Roller

a. Procedure

(1) Remove the four set screws to remove the rear cover.

Set screws

Set screws

Rear cover

(2) Open the open/close cover.

(3) Rotate the gear until the two pressure pins on the pick-

up shaft point up.

Gear

(4) Remove the two springs.

(5) Remove the stop ring and slide the bearing to the side.

(6) Slide the paper feed roller assembly towards the front

side, then remove it.

Bearing

Front

Stop ring

Springs

Paper feed

roller assembly

(7) Remove the bearing.

(8) Remove the two stop rings, then remove the guide

lever.

Separation roller

Pick-up clutch

Stop rings

Bearing

1 OUT LINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Pressure

pin

Pick-up shaft

Caution: The pick-up shaft cannot be turned

directly. Be sure to rotate it via the gear.

Paper

feed

drive

belt

Paper feed roller

Spring

Guide lever

Side shape of roller

(9) Remove the separation roller and paper feed roller.

Caution: When reinstalling the separation roller,

pay attention to correct roller orientation.

(The correct orientation can be determined

by looking at the side shape of the roller.)

(10) Reinstall the paper feed roller and separation roller in

the opposite sequence to removal.

3-5

Page 34

DF-315

1 OUT LINE

[5] Removing and Reinstalling the

Double Feed Prevention Pad

2

a. Procedure

(1) Remove the paper feed roller assembly.

(2) Push the pressure release lever so that on the double

feed prevention pad is released.

Double feed

prevention pad

Pressure

release lever

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(3) Push the double feed prevention pad down, slide it

towards the paper feed tray, and then remove it.

Double feed prevention pad

(4) Reinstall the double feed prevention pad in the opposite

sequence to removal.

Paper feed tray

3-6

Loading...

Loading...