Page 1

SERVICE MANUAL

MODEL

7045

NOVEMBER 2000

CSM-7045

Page 2

7045

SERVICE MANUAL

NOVEMBER 2000

Page 3

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Business Technologies strongly recommends that all servicing be performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Business Technologies,

Inc., makes no representations or warranties, either

expressed or implied, that the information contained in

this service manual is complete or accurate. It is understood that the user of this manual must assume all risks

or personal injury and/or damage to the equipment while

servicing the equipment for which this service manual

is intended.

Corporate Publications Department

© 2000, KONICA BUSINESS TECHNOLOGIES, INC.

All rights reserved.

Printed in U.S.A.

Page 4

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS ........... vii

IMPORTANT NOTICE ................................................... vii

DESCRIPTION ITEMS FOR DANGER, WARNING

AND CAUTION............................................................... vii

SAFETY WARNINGS ................................................... viii

SAFETY INFORMATION................................................. x

IMPORTANT INFORMATION ......................................... x

SAFETY CIRCUITS ........................................................ xi

INDICATION OF WARNING ON THE MACHINE........ xii

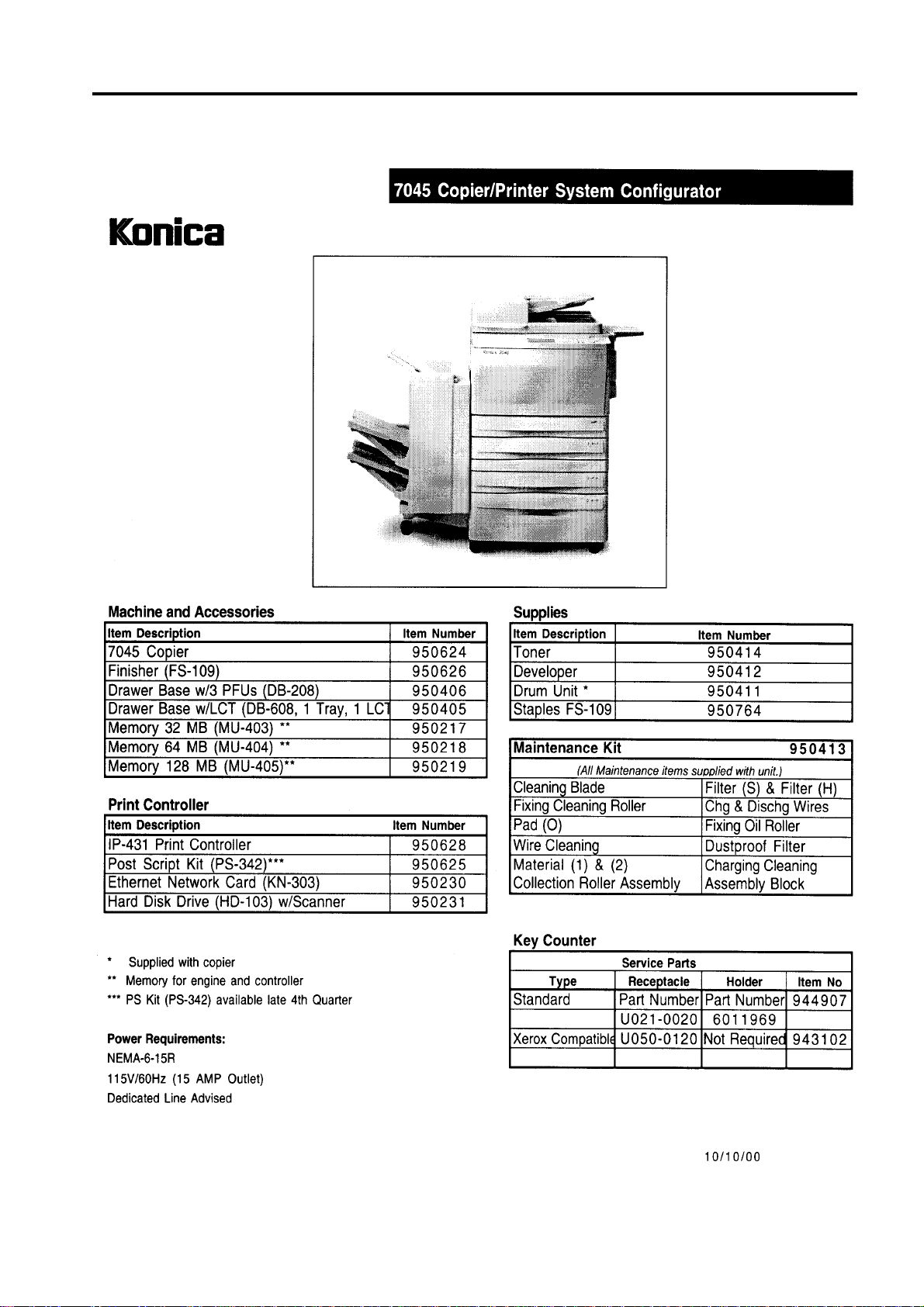

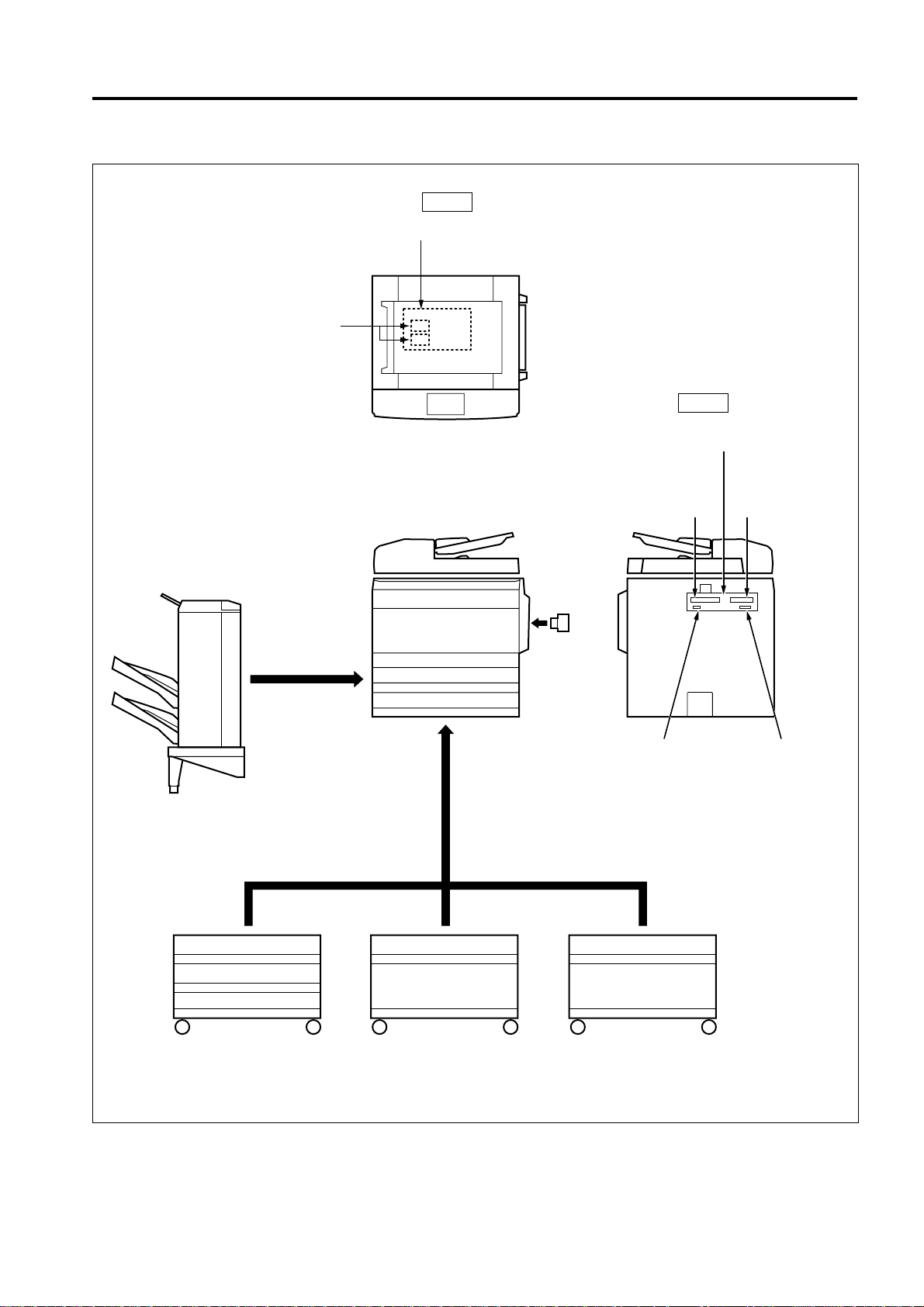

7045 SYSTEM CONFIGURATOR ................................ xv

MAINBODY SECTION

1. OUTLINE

OUTLINE OF SYSTEM ........................................1-A-1

7045 PRODUCT SPECIFICATIONS...................1-A-2

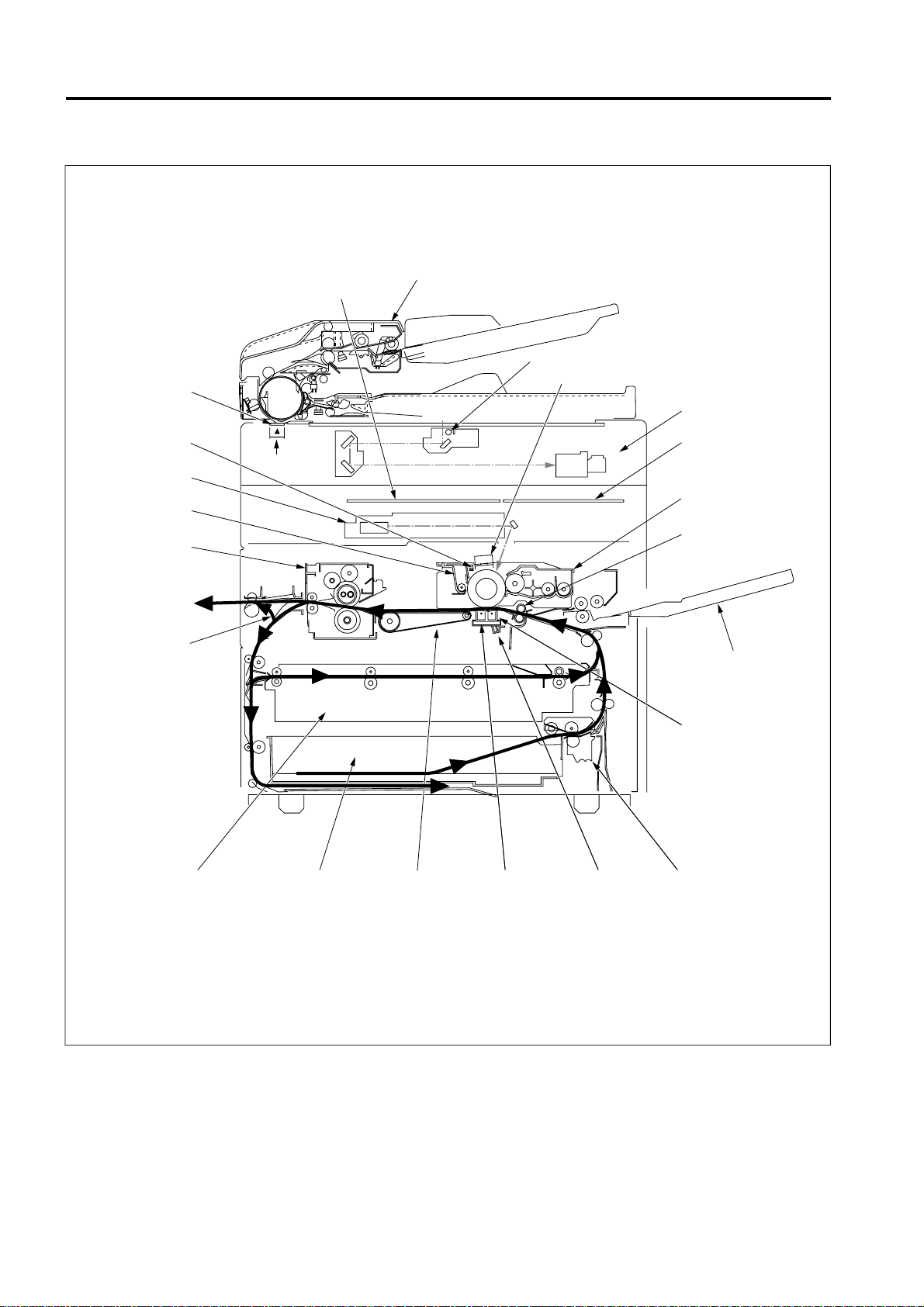

CENTER CROSS-SECTIONAL VIEW ................1-A-4

DRIVE SYSTEM DIAGRAM.................................1-B-1

[1] Main Drive ............................................1-B-1

[2] Drum / Toner Recycle Drive................1-B-2

[3] Developing Drive..................................1-B-3

[4] By-pass Paper Feed / 1st Paper

Feed Drive ............................................1-B-4

[5] ADU Drive.............................................1-B-5

[6] Reversal / Paper Exit Drive .................1-B-6

[7] Read Unit Drive....................................1-B-7

[8] Toner Supply Drive ..............................1-B-8

2. UNIT EXPLANATION

EXTERNAL SECTION..........................................2-A-1

[1] Composition..........................................2-A-1

DRIVE SECTION..................................................2-B-1

[1] Composition..........................................2-B-1

[2] Mechanisms .........................................2-B-1

[3] M1 (Main) Control ................................2-B-2

[4] M4 (Drum) Control ...............................2-B-3

READ SECTION .................................................. 2-C-1

[1] Composition......................................... 2-C-1

[2] Mechanisms ........................................ 2-C-1

[3] M2 (Scanner) Control ......................... 2-C-2

[4] Exposure Control ................................ 2-C-4

[5] Original Read Control ......................... 2-C-5

[6] APS Control......................................... 2-C-5

[7] AE Control ........................................... 2-C-7

WRITE UNIT ........................................................ 2-D-1

[1] Composition......................................... 2-D-1

[2] Mechanisms ........................................ 2-D-1

[3] M5 (Polygon) Control.......................... 2-D-2

[4] Image Write Control............................ 2-D-3

DRUM UNIT..........................................................2-E-1

[1] Composition..........................................2-E-1

[2] Mechanisms .........................................2-E-1

[3] PCL/TSL Control ..................................2-E-2

[4] Separation Claw Control......................2-E-2

[5] Transfer Entrance Guide Plate Control ..2-E-3

CORONA UNIT SECTION ...................................2-F-1

[1] Composition..........................................2-F-1

[2] Mechanisms .........................................2-F-1

[3] Charging Control..................................2-F-2

[4] Transfer/Separation Control................2-F-3

DEVELOPING UNIT............................................ 2-G-1

[1] Composition.........................................2-G-1

[2] Mechanisms ........................................ 2-G-1

[3] M3 (Developing) Control.....................2-G-2

iii

Page 5

CONTENTS

[4] Developing Bias Control.....................2-G-3

[5] Toner Density Control ........................2-G-4

[6] Dmax Control ..................................... 2-G-6

[7] Gradation Correction Control .............2-G-7

TONER SUPPLY UNIT ...................................... 2-H-1

[1] Composition ....................................... 2-H-1

[2] Mechanisms ....................................... 2-H-1

[3] Toner Level Detection Control ........... 2-H-3

CLEANING/TONER RECYCLE UNIT ................. 2-I-1

[1] Composition ........................................ 2-I-1

[2] Mechanisms ........................................ 2-I-1

PAPER FEED UNIT ............................................ 2-J-1

[1] Composition ........................................ 2-J-1

[2] Mechanisms ........................................2-J-2

[3] Paper Feed Control.............................2-J-3

[4] Paper Up-down Control.......................2-J-5

[5] Paper Size Detection Control..............2-J-6

[6] No Paper Detection Control ................2-J-7

FIXING UNIT ...................................................... 2-K-1

[1] Composition ....................................... 2-K-1

[2] Mechanisms ....................................... 2-K-1

[3] Fixing Temperature Control ............... 2-K-2

REVERSAL AND PAPER EXIT SECTION......... 2-L-1

[1] Composition ....................................... 2-L-1

[2] Mechanisms ....................................... 2-L-1

[3] Reversal Paper Exit Control............... 2-L-3

ADU SECTION .................................................. 2-M-1

[1] Composition ...................................... 2-M-1

[2] Mechanisms ...................................... 2-M-1

[3] Conveyance Control.......................... 2 -M-3

OTHER KINDS OF CONTROL .......................... 2-N-1

[1] Parts Through Which Current Flows

When the Main Switch is

Turned OFF........................................ 2-N-1

[2] Parts That Operate When the Power

Switch is Turned ON .......................... 2-N-2

[3] Fan Control ......................................... 2-N-4

[4] Operation Panel Control..................... 2-N-5

[5] Counter Control.................................. 2-N-7

[6] Option Control .................................... 2-N-8

3. DISASSEMBLY/ASSEMBLY

EXTERNAL SECTION ....................................... 3-A-1

[1] Replacing the Ozone Filter................. 3-A-1

[2] Removing and Reinstalling the

Rear Cover ......................................... 3-A-2

[3] Replacing the Fixing Filter.................. 3-A-2

[4] Removing and Reinstalling the

Side Cover (right) ............................... 3-A-2

DRIVE SECTION ............................................... 3-B-1

[1] Disassembly and Reassembly ........... 3-B-1

READ SECTION ................................................ 3-C-1

[1] Screws That Must Not Be Removed ... 3-C-1

[2] Removing and Reinstalling the

CCD Unit ............................................3-C-1

[3] Replacing the Exposure Lamp (L1).... 3-C-3

[4] Removing and Reinstalling the

Exposure Unit ..................................... 3-C-4

[5] Removing the Optics Wire.................. 3-C-7

[6] Installing the Optics Wire.................. 3-C-10

WRITE UNIT ......................................................3-D-1

[1] Removing and Reinstalling the

Write Unit............................................ 3-D-1

[2] Cleaning the Dust-proof Glass ...........3-D-3

DRUM UNIT ....................................................... 3-E-1

[1] Removing and Reinstalling the

Drum Unit ........................................... 3-E-1

[2] Removing and Reinstalling

the Drum............................................. 3-E-2

[3] Removing and Reinstalling the

Separation Claws ............................... 3-E-4

CORONA UNIT SECTION ................................. 3-F-1

[1] Removing and Reinstalling the

Charging Corona Unit and PCL ......... 3-F-1

[2] Removing and Reinstalling the

Transfer and Separation Corona Unit 3-F-1

[3] Removing and Reinstalling the

Charging the Control Plate ................. 3-F-2

[4] Replacing the Charging Wire ............. 3-F-3

[5] Replacing the Transfer and

Separation Wires................................ 3-F-3

[6] Replacing the Charging Wire

Cleaning Block (C) and (D) ................ 3-F-4

DEVELOPING UNIT........................................... 3-G-1

[1] Screws That Must Not Be Removed ... 3-G-1

[2] Removing and Reinstalling the

Developing Unit ..................................3-G-1

[3] Replacing the Developer....................3-G-2

TONER SUPPLY UNIT ...................................... 3-H-1

[1] Removing and Reinstalling the

Toner Cartridge .................................. 3-H-1

CLEANING/TONER RECYCLE UNIT ................. 3-I-1

[1] Removing and Reinstalling the

Cleaning Blade .................................... 3-I-1

PAPER FEED UNIT ............................................ 3-J-1

[1] Removing and Reinstalling the

By-pass Paper Feed Unit ....................3-J-1

[2] Removing and Reinstalling the

Paper Feed Unit ..................................3-J-1

[3] Replacing the By-pass Paper

Feed Rubber .......................................3-J-2

[4] Replacing the By-pass Separation

Rubber.................................................3-J-3

[5] Replacing the By-pass Double Feed

Prevention Rubber ..............................3-J-3

[6] Replacing the Feed Rubber and

Paper Feed Rubber.............................3-J-4

[7] Removing and Reinstalling the

Double Feed Prevention Roller ...........3-J-5

iv

Page 6

CONTENTS

[8] Removing and Reinstalling the

2nd Paper Feed Unit ...........................3-J-5

[9] Replacing the Registration Rollers

(upper/lower) .......................................3-J-6

FIXING UNIT ...................................................... 3-K-1

[1] Removing and Reinstalling the

Fixing Unit .......................................... 3-K-1

[2] Replacing the Fixing Heater

Lamps 1 and 2 (L2 and L3) ................ 3-K-1

[3] Replacing the Fixing Cleaning Roller,

Fixing Roller (A) and Fixing

Cleaning Pad ...................................... 3-K-2

[4] Removing and Reinstalling the

Fixing Roller (upper)........................... 3-K-3

[5] Removing and Reinstalling the

Fixing Claw (upper) ............................ 3-K-4

[6] Removing and Reinstalling the

Paper Exit Roller Unit (lower) ............. 3-K-5

[7] Removing and Reinstalling the

Fixing Claw (lower)............................. 3-K-5

[8] Removing and Reinstalling the

Fixing Roller (lower) ........................... 3-K-6

[9] Removing and Reinstalling the

Fixing Temperature Sensor 1 and 2

(TH1 and TH2) ................................... 3-K-7

[10] Removing and Reinstalling the

Thermostat (TS) ................................. 3-K-8

REVERSAL AND PAPER EXIT SECTION......... 3-L-1

[1] Removing and Reinstalling the

Reversal and Paper Exit Unit ............. 3-L-1

ADU SECTION ................................................... 3-M-1

[1] Removing and Reinstalling the ADU ... 3-M-1

SERVICE SECTION

1. ADJUSTMENT

HOW TO USE THE ADJUSTMENT SECTION......1-1

[1] Construction ...........................................1-1

ADJUSTMENTS WHEN REPLACING PARTS ......1-1

LIST OF ADJUSTMENT ITEMS ............................1-2

MODE SELECT MENU ..........................................1-3

[1] Setting Method .......................................1-3

CHECK OF COUNT VALUE WITH P MODE ......... 1-4

[1] How to Use P Mode ............................... 1 -4

25 MODE................................................................ 1 - 5

[1] Setting Method .......................................1-6

[2] Setting Software SW ..............................1-6

[3] Paper Size Setting................................1-17

[4] PM Count Setting .................................1-18

[5] Collecting Data ..................................... 1-19

[6] Parts Counter .......................................1-24

[7] Password Setting .................................1-28

[8] Setting Phone Number of the

Service Center......................................1-29

[9] Setting the Serial Number ....................1-30

[10] Displaying the ROM Version ................1-31

[11] KRDS Setting .......................................1-31

[12] ISW Setting...........................................1-31

[13] Root Counter Display ...........................1-31

[14] Setting Date.......................................... 1-31

36 MODE.............................................................. 1-32

[1] Setting Method .....................................1-36

[2] High Voltage Adjustment...................... 1-36

[3] Timing Adjustment ................................1-38

[4] Running Test Mode..............................1-48

[5] Test Pattern Output..............................1-49

[6] Density Adjustment .............................. 1-56

[7] Image Quality Adjustment ....................1-56

[8] List Print ................................................ 1-63

[9] Adjustment of RADF.............................1-64

47 MODE.............................................................. 1-78

[1] 47 Mode Setting Method ......................1-78

[2] Initial Setting in the Field ......................1-79

[3] Drum Count Reset................................1-79

[4] RADF Original Size Detection

Adjustment ...........................................1-79

[5] E-RDH Memory Check.........................1-80

[6] RADF Sensor Adjustment ....................1-80

[7] Input Check (code) List ........................1-81

[8] Output Check (code) List ...................... 1-83

OTHER ADJUSTMENTS .....................................1-87

[1] Centering Adjustment........................... 1-87

[2] Adjusting the Inclination of the

Paper Tray (DB-608) ............................ 1-88

[3] Image Distortion Adjustment ................1-89

v

Page 7

CONTENTS

[4] Paper Skew Adjustment .......................1-90

[5] RADF Skew Adjsutment (DF-315) .......1-91

[6] RADF

[7]

Paper Skew Adjustment (DF-315) ...

Tray 2/3 Belt Tension Adjustmentt (FS-109)

2. ISW

ISW.........................................................................2-1

[1] Boards that Support ISW........................2-2

[2] Operating Method ...................................2-2

3. KRDS

KRDS .....................................................................3-1

[1] Specifications .........................................3-1

[2] KRDS Setting ......................................... 3-1

[3] KRDS Set up ..........................................3-2

[4]

Calling Time Set Menu Mode (Arbitrary)....

[5] A Point to Notice for Operation.............3-16

[6] ASCII Code Table ................................ 3-17

[7] Error Code Table.................................. 3-18

4. SERVICE

SERVICE SCHEDULE ...........................................4-1

[1] Service Schedule ................................... 4 -1

[2] Maintenance Items ................................. 4- 2

[3] Main Body Periodic Check .....................4-6

[4] RADF [DF-315] ....................................... 4 -7

[5] DB [DB-208] ...........................................4-7

[6] DB [DB-608] ...........................................4-7

[7] FNS [FS-109] ......................................... 4 -7

[8] Actual Count Replacement Parts ...........4 -8

COPY MATERIALS .............................................. 4-10

[1] PM Parts Kit Composition .................... 4-10

SERVICE MATERIALS LIST................................4-12

SPECIAL TOOLS LIST ........................................4-13

1-92

1-93

3-13

5. DIAGRAMS/TIMING CHARTS

7045 ELECTRICAL PARTS LAYOUT DRAWING...5-1

7045 CONNECTOR LAYOUT DRAWING .............5-4

7045 TIMING CHART (8.5X11, LIFE SIZE,

MANUAL DENSITY, TWO COPIES,

DB MIDDLE TRAY PAPER FEED) ...................... 5-11

7045 TIMING CHART (ADF ORIGINAL, 8.5X11,

LIFE SIZE, AES, TWO COPIES, TRAY 1

PAPER FEED) ......................................................5-12

ADU TIMING CHART (8.5X11, LIFE SIZE,

THREE COPIES) .................................................5-13

6. JAM/ERROR CODES

JAM CODE LIST ....................................................6-1

ERROR CODE LIST ..............................................6-5

7. APPENDIX

7045 OVERALL WIRING DIAGRAM (1/4).. Appendix-1

7045 OVERALL WIRING DIAGRAM (2/4).. Appendix-2

7045 OVERALL WIRING DIAGRAM (3/4).. Appendix-3

7045 OVERALL WIRING DIAGRAM (4/4).. Appendix-4

vi

Page 8

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY AND IMPORTANT WARNING ITEMS

Read carefully the Safety and Important Warning Items described below to understand them before

doing service work.

IMPORTANT NOTICE

Because of possible hazards to an inexperienced person servicing this copier, as well as the risk of

damage to the copier, Konica Corporation, strongly recommends that all servicing be performed only

by Konica-trained service technicians.

Changes may have been made to this copier to improve its performance after this Service Handbook

was printed. Accordingly, Konica Corporation, makes no representations or warranties, either expressed or implied, that the information contained in this Service Handbook is complete or accurate.

It is understood that the user of this Service Handbook must assume all risks or personal injury and/

or damage to the copier while servicing the copier for which this Service Handbook is intended.

Therefore, this Service Handbook must be read carefully before doing service work both in the

course of the technical training and even after that, for keeping the correct maintenance and control

of the copier. Keep this Service Handbook also for the future service. When it is impossible to read

the description about safety and warning (due to contamination or tear), the relevant page should be

replaced.

DESCRIPTION ITEMS FOR DANGER, WARNING AND CAUTION

In this Service Handbook, each of three expressions, “ DANGER”, “ WARNING” and “ CAUTION” is defined as follows together with a symbol mark to be used in a limited meaning.

When servicing, the relevant works (disassembling, assembling, adjustment, repair and maintenance) need to be conducted with utmost care.

DANGER: Actions having a high possibility of suffering death or seri-

ous wound

WARNING: Actions having a possibility of suffering death or serious

wound

CAUTION: Actions having a possibility of suffering a slight wound,

medium trouble and material damage

vii

Page 9

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY WARNINGS

[1] Modifications Not Authorized by

Konica

Konica copiers are renowned for their high reliability. This

reliability is achieved through high-quality design and a solid

service network.

Photocopier design is a highly complicated and delicate

process where numerous mechanical, physical, and electrical aspects have to be taken into consideration, with the aim

of arriving at proper tolerances and safety factors. For this

reason, unauthorized modifications involve a high risk of

degrading performance and safety. Such modifications are

therefore strictly prohibited. The points listed below are not

exhaustive, but they illustrate the reasoning behind this

policy.

PROHIBITED ACTIONS :

(1) Using extension cables or a different power cord

than specified by Konica.

(2) Using other fuses than specified by Konica. Safety

will not be assured, leading to a risk of fire and

injury.

(3) Disabling fuses or bridging fuse terminals with wire,

metal clips, solder or similar. (This applies also to

thermal fuses.)

(4) Removing air filters (except for replacement).

(5) Disabling relay functions (such as wedging paper

between relay contacts, etc.).

(6) Disabling safety functions (interlocks, safety cir-

cuits, etc.). Safety will not be assured, leading to a

risk of fire and injury.

(7) Performing actions to copier not described in the

instruction manual or the service handbook.

(8) Using parts other than specified by Konica.

1. Advance Preparation for Safety Checks

CAUTION:

(1) Wear clothing that facilitates work and is designed

for safety.

(2) Carry out all procedures carefully to prevent injury.

(3) Be sure to disconnect the power cord of the copier

and all optional equipment from the AC outlet.

Simply turning off the power switch is not sufficient,

because paper feed units or other electrical equip-

ment may be powered also when the power switch

is turned off.

(4) Proceed with special care when performing opera-

tion checks or adjustment while the unit is powered.

When carrying out operation checks or adjustment

while external covers are removed, the risk of elec-

trical shock exists when touching parts which carry

high voltage or electrical charge. The risk of injury

exists when touching moving parts such as gears or

chains.

2. Safety Checkpoints

The following list is not exhaustive, but it includes actions

which must be carried out at every on-site service.

CAUTION:

(1) Check external covers and the frame for sharp

edges, burrs, or nicks.

(2) Check external covers and hinges for loosening or

damage.

(3) Check wiring for squeezing or damage.

(4) Check power cord for insulation problems (conduc-

tor must not be exposed).

(5) Check power cord and cable ties etc. for loosening

from frame.

[2] Checkpoints When Performing On-site

Service

Konica copiers are extensively tested before shipping, to

ensure that all applicable safety standards are met, in order

to protect the customer and customer engineer from the risk

of injury. However, in daily use, any electrical equipment may

be subject to parts wear and eventual failure. In order to

maintain safety and reliability, the customer engineer must

perform regular safety checks.

WARNING:

(1) Verify that the copier is properly grounded. If a

problem is detected, establish a proper ground

connection.

(2) Connecting the ground lead to an improper point

such as listed below results in a risk of explosion

and electric shock.

Unsuitable ground points:

- Gas pipe

- Lightning rod

- Telephone line ground

- Plastic water pipe or water pipe or faucet that has

not been approved by authorities for grounding

use

viii

Page 10

3. Description of Safety Checks

CAUTION:

(1) Before performing safety check work, read all rel-

evant documentation (service handbook, technical

notices, etc.) and proceed according to the prescribed procedure, using only the prescribed tools.

Do not carry out any adjustments not described in

the documentation.

(2) If the power cord is damaged, replace it only with the

specified power cord. If the power cord insulation

has been damaged and there are exposed sections,

short- circuits and overheating may occur, leading to

a serious fire risk.

(3) Do not route the power cord so that it can be stepped

on or pinched. Otherwise overheating may occur,

leading to a serious fire risk.

(4) When disconnecting any cables, always grasp the

connector and not the cable (especially in the case of

AC and high-voltage leads).

(5) Carefully remove all toner remnants from electrical

parts, electrodes, etc.

(6) Make sure that wiring cannot come into contact with

sharp edges, burrs, or other pointed parts.

(7) Double-check to make sure that all screws, compo-

nents, wiring, connectors, etc. that were removed for

safety check maintenance have been reinstalled in

the original location. (Pay special attention to forgotten connectors, pinched cables, forgotten screws,

etc.)

(8) When installation and preventive maintenance, verify

that the power cord has been securely plugged into

the AC outlet. Contact problems may lead to increased resistance, overheating, and the risk of fire.

WARNING:

(1) Before disassembling or adjusting the write unit or

any parts that use a laser, make sure that the power

cord has been disconnected.

(2) Do not remove the main cover of the write unit. Direct

exposure of the eye to laser beams may lead to

blindness.

(3) Do not turn the copier on while the write unit is not

installed in its normal position.

(4) Danger of explosion if battery is incorrectly replaced,

replace only with the same or equivalent recommended by the manufacturer. Discard used batteries according to the manufacture's instructions.

VORSICHT:

Expiosionsgefahr dei unsachegemäßem Austausch

der Battetie. Ersatz nur durch denselben oder einen

vom. Hersteller empfohlenen gleichwertigen Typ.

Entsorgung gebrauchter Batterien nach Angaben

des Herstellers.

SAFETY AND IMPORTANT WARNING ITEMS

[3]

Handling of Materials for Servicing

CAUTION: Drum cleaner (alcohol-based) and roller

cleaner (acetone- based) are highly flammable and must be handled with care.

When using these materials for cleaning of copier parts, observe the follow-

ing precautions.

(1) Disconnect the power cord from the AC outlet.

(2) Use only a small amount of cleaner at a time and take

care not to spill any liquid. If this happens, immediately wipe it off.

(3) Perform cleaning only in an environment where

sufficient ventilation is assured. Breathing large

quantities of organic solvents can lead to discomfort.

(4) Do not replace the cover or turn the unit on before

any solvent remnants on the cleaned parts have

fully evaporated.

CAUTION: Toner and developer are not harmful

substances, but care must be taken not

to breathe excessive amounts or let the

substances come into contact with eyes

etc. It may be stimulative. If the sub-

stances get in the eye, rinse it with

plenty of water immediately. When

symptoms are noticeable, consult a

physician.

[4] Measures to Take in Case of an

Accident

(1) If an accident has occurred, the distributor who has been

notified first must immediately take emergency measures to provide relief to affected persons and to prevent

further damage.

(2) If a report of a serious accident has been received from

a customer, an on-site evaluation must be carried out

quickly and Konica Corporation must be notified.

(3) To determine the cause of the accident, conditions and

materials must be recorded through direct on-site checks,

in accordance with instructions issued by Konica Corporation.

(4) For reports and measures concerning accidents, con-

sult your superior, and follow the regulations set in

"Standards for the Control Program for Measures Against

Electrical Equipment Accidents".

[5] Conclusion

(1) Safety of users and customer engineers depends highly

on accurate maintenance and administration. Therefore, safety can be maintained by the appropriate by the

proper daily service work conducted by the customer

engineer.

(2) When performing service, each copier on the site must

be tested for safety. The customer engineer must verify

the safety of parts and ensure appropriate management

of the equipment.

ix

Page 11

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY INFORMATION

IMPORTANT INFORMATION

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration

implemented regulations for laser products manufactured since August 1, 1976. Compliance is mandatory for products marketed in the United States.

This copier is certified as a "Class 1" laser product under the U.S.

Department of Health and Human Services (DHHS) Radiation Performance Standard according to

the Radiation Control for Health and Safety Act of 1968. Since radiation emitted inside this copier is

completely confined within protective housings and external covers, the laser beam cannot escape

during any phase of normal user operation.

x

Page 12

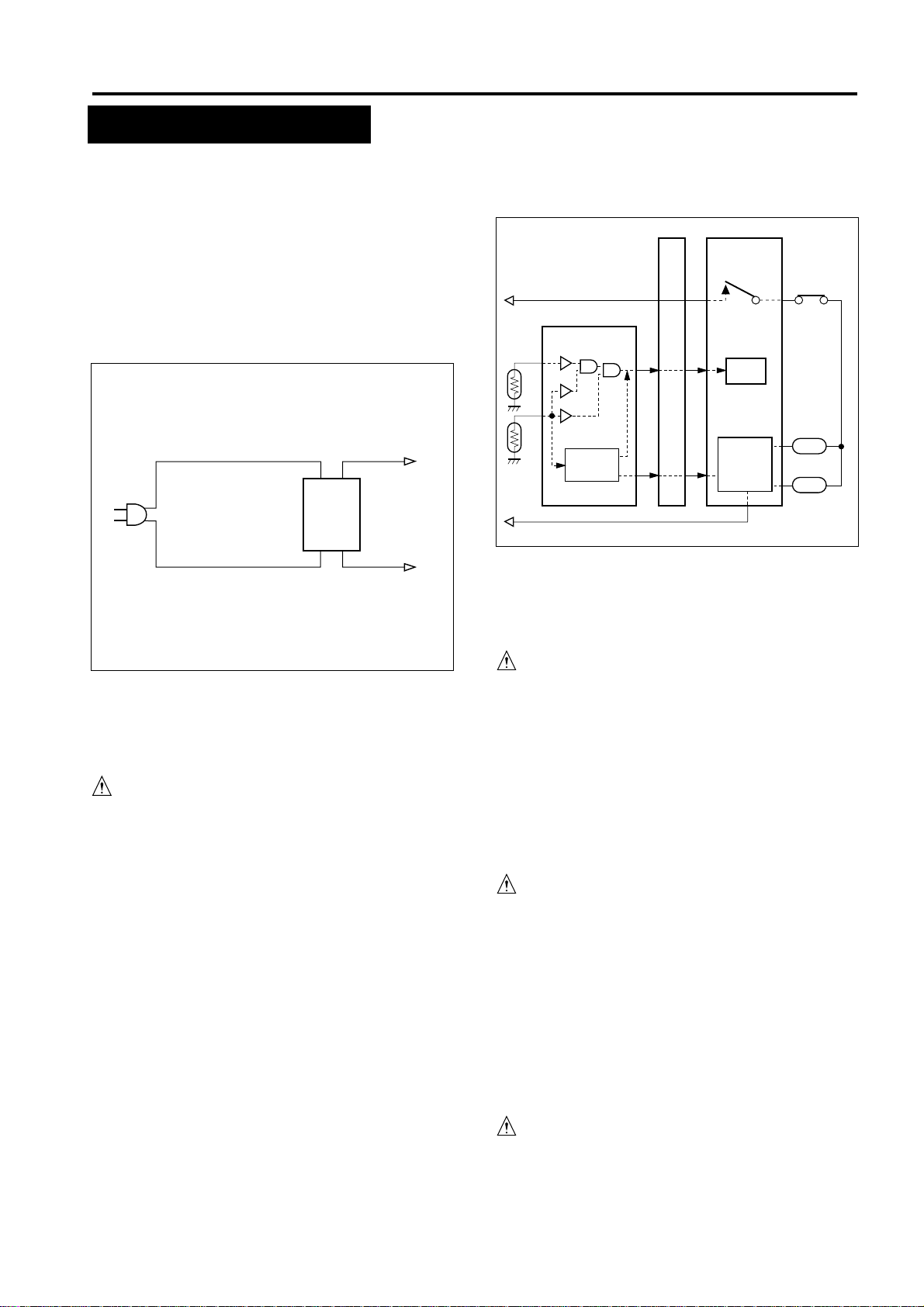

SAFETY CIRCUITS

SAFETY AND IMPORTANT WARNING ITEMS

This unit incorporates the following electrical safety circuits

to guard against the risk of accidents in case of any

malfunction.

[1] Overall protection circuit

[2] L2/L3 (fixer heater lamps) overheat protection circuit

Operation principles of these safety circuits are described

below. It is necessary to understand this information fully, in

order to prevent mistakes during servicing.

[1] Overall protection circuit

LBR

1. LBR (line breaker) protection

When an excessively large current flows due to a short-

circuit in the AC line, the AC line itself is instantly cut off

due to the action of this circuit breaker.

[2] L2/L3 (fixer heater lamps) overheat

protection circuit

DCPS1CB

RL1

PRDB

RL1

TH2TH1

Control

section

1. Software protection

The output voltage of TH1 (fixer temperature sensor 1) is

constantly read by the CPU. If the voltage becomes

abnormal, L2 (fixer heater lamp 1), L3 (fixer heater lamp

2), and RL1 (main relay) are set to OFF.

CAUTION: The clearance between the roller and

TH1 may not be altered.

After replacement, verify that dimensions

correspond to specifications.

RL1 may not be disabled under any circumstances.

AC driver

section

TS

L2

L3

CAUTION: The line breaker must not be disabled

under any circumstances.

2. Hardware protection

The output voltages of TH1 and TH2 (fixer temperature

sensors) are compared to a reference voltage in the

comparator circuit. If the voltage exceeds the threshold,

L2, L3, and RL1 are set to OFF in hardware.

CAUTION: Periodically check the roller contact area

of TH2 and replace the sensor if any

problem is detected.

Since the TH1 is non-contact, check the

distance from the roller and installing

orientation of the sensor when an abnormality has occurred.

RL1 may not be disabled under any circumstances.

3. TS (thermostat) protection

If the fixer roller temperature exceeds the threshold, TS

goes OFF and directly cuts power to L2 and L3.

CAUTION: TS may not be replaced by any other

conductor.

Do not change the distance between the

TS and roller.

xi

Page 13

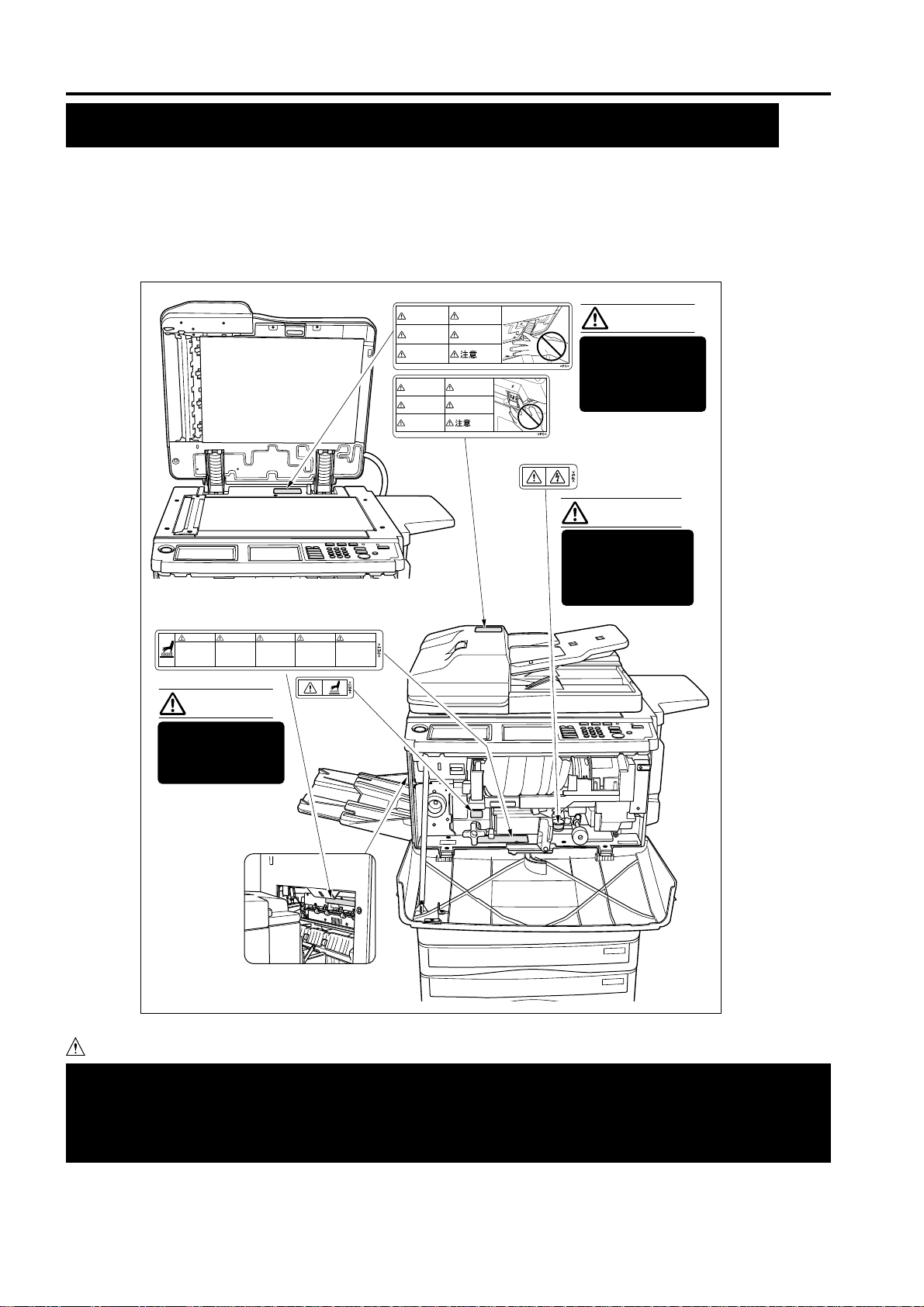

SAFETY AND IMPORTANT WARNING ITEMS

INDICATION OF WARNING ON THE MACHINE

The caution labels are attached to the machine areas, as shown below, where you are advised

to pay special attention to avoid any dangerous situations or serious injury.

ATTENTION

CAUTION

High temperature!

Do not touch.

Use care when

clearing paper.

Température élevée!

Risque de brûlure.

Soyez prudent en

retirant la feuille

coincée.

VORSICHT

Heiße Oberfläche!

Brandverletzungsgefahr.

Bei Beseitigung von

Papierstaus vorsichtig

vorgehen.

CAUTION

This internal area is

very hot. To avoid

getting burned DO

NOT TOUCH.

PRECAUCION

¡Temperatura alta!

No tocar. Tener

cuidado al

remover el papel.

ATTENZIONE

Alta temperatura!

Non toccare. Agire

con prudenza nel

rimuovere la carta.

CAUTION

ATTENTION

VORSICHT

CAUTION

ATTENTION

VORSICHT

PRECAUCION

ATTENZIONE

PRECAUCION

ATTENZIONE

CAUTION

DO NOT INSERT

your finger into the

two RADF hinge

portions, otherwise

you may be injured.

WARNING

This area generates

high voltage. If

touched, electrical

shock may occur. DO

NOT TOUCH!

CAUTION:

If you carry out work on the machine without reading these warning labels, an unexpected accident may

occur, resulting in possible blindness. DO NOT REMOVE these warning labels.

Do not remove caution labels. If any caution label or caution indicator is soiled, clean the label.

If you cannot make it legible or if the caution label is removed, please contact your Service Centre.

xii

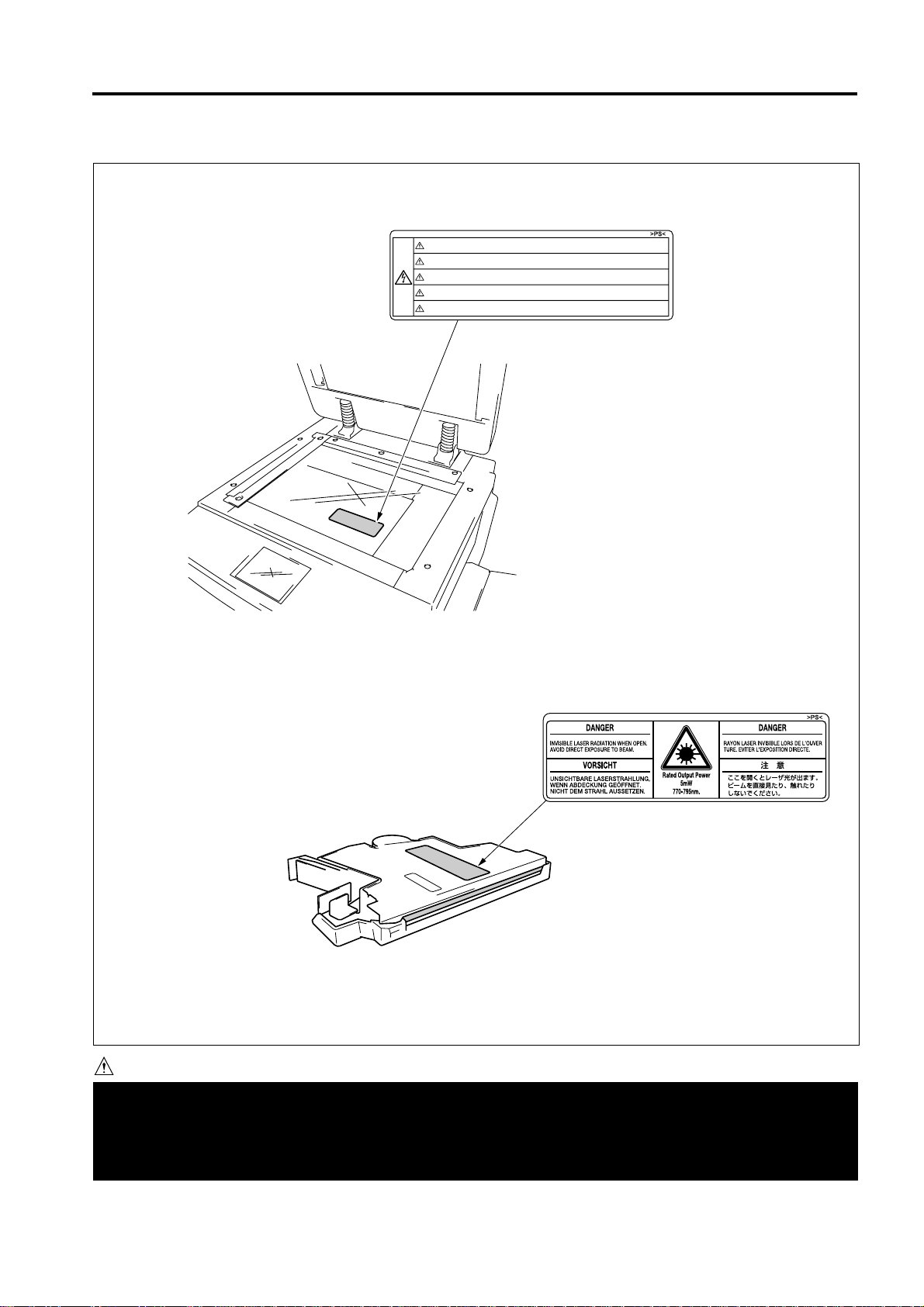

Page 14

WARNING

WARNUNG

ADVERTENCIA

AVVERTIMENTO

DANGER

Unplug the machine before removing platen glass.

Vor Entfernen des Vorlagenglases Netzstecker ziehen.

Desenchufe la máquina antes de quitar el vidrio.

Estrarre la spina dalla presa prima di rimuovere il vetro di esposizione.

Débrancher le copieur abant de retirer la vitre d’exposition.

<Read section>

SAFETY AND IMPORTANT WARNING ITEMS

<Write unit>

CAUTION:

You may be burned or injured if you touch any area that you are advised by any caution label to keep

yourself away from.

Do not remove caution labels. If any caution label or caution indicator is soiled, clean the label.

If you cannot make it legible or if the caution label is removed, please contact your Service Centre.

xiii

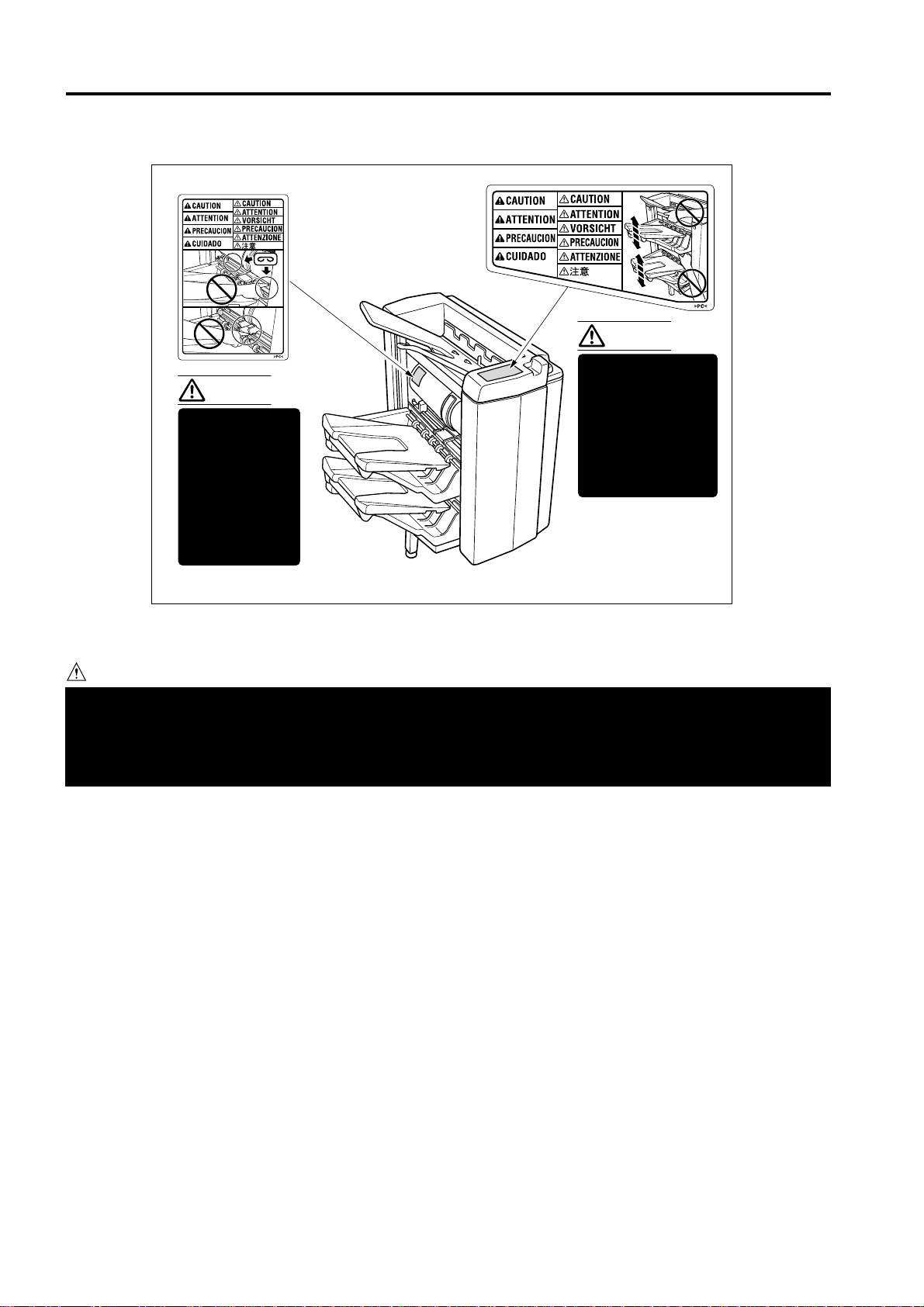

Page 15

SAFETY AND IMPORTANT WARNING ITEMS

CAUTION:

DO NOT INSERT

your finger into

the two staple

driving portions

or into the

grooves of the

paper exit lever,

otherwise you

may be injured.

CAUTION:

To avoid injury

when the Finisher

middle exit tray

moves up and

down, DO NOT

PUT your hand into

the two portions of

the closing area.

FS-109 Finisher

CAUTION:

If you carry out work on the machine without reading these warning labels, an unexpected accident may

occur, resulting in possible blindness. DO NOT REMOVE these warning labels.

Do not remove caution labels. If any caution label or caution indicator is soiled, clean the label.

If you cannot make it legible or if the caution label is removed, please contact your Service Centre.

xiv

Page 16

SAFETY AND IMPORTANT WARNING ITEMS

xv

Page 17

7045

MAINBODY

SECTION

Page 18

1

OUTLINE

Page 19

OUTLINE OF SYSTEM

CB(Control board)

Expansion memory unit

[MU-403/404/405]

OUTLINE OF SYSTEM

Top

Back

Printer controller [IP-431]

Finisher [FS-109]

Main body [7045]

Key counter

Hard disk

[HD-103]

PostScript

[PS-342]

Network board

[KN-303]

Expansion memory

unit for printer

[MU-403/404]

PFU 3 trays

[DB-208]

PFU 1 tray

[DB-208A]

1-A-1

PFU 1 tray + LCT

[DB-608]

Page 20

7045 PRODUCT SPECIFICATIONS

7045 PRODUCT SPECIFICATIONS

1. Type

Type: Semi-console type

Copying method: Indirect electrostatic method

Original table method:

Fixed

Photosensitive material:

OPC

Sensitizing method: Laser writing

Paper feed trays: One stacked tray

(500 sheets; 21 lb)

Multisheet by-pass tray

(100 sheets; 21 lb)

PFU (500 sheets/tray, 21 lb

x 1 tray, or 3 trays)*1

LCT (1500 sheets; 21 lb)*1

*1: Option

2. Functions

Originals: Sheets; book; solid object

Original size: A3 max.

Copy sizes: 11 x 17, 8.5 x 14,

8.5 x 11, 5.5 x 8.5

ADU usable paper size:

11 x 17, 8.5 x 14,

8.5 x 11, 8.5 x 11R,

Magnification:

Fixed magnifications:

x0.50, x0.65, x0.77, x1.00,

x1.29, x1.55, x2.00

Special ratio: Three kinds.

Zoom magnifications:

x0.25 to x4.00 (1% steps)

Vertical magnifications:

x0.25 to x4.00 (1% steps)

Horizontal magnifications:

x0.25 to x4.00 (1% steps)

Warm-up time: Within 90 seconds (at 20½C,

at rated voltage)*1

*1 Warm-up time differs de-

pending on the Power

Source (Voltage).

First copy out time: Approx. 3.9 seconds

* When using face-up paper

exit, manual mode, platen

mode and tray 1 are in

use.

Continuous copy speed (life size copies/min):

Size CPM

8.5x11 45

Continuous copy count:

1 to 999

Copy density selections:

manual (9 steps), AES

Arbitrary density (2 modes)

Resolution: 600 dpi x 600 dpi

E-RDH memory: Standard 32 MB

Maximum 288 MB

Application functions:

Sheet/Cover Insertion, Chapter, Combination (2-in-1, 4-in-1,

8-in-1), Booklet, Special paper,

Image Insert, Dual page, Special Original, Text/Photo Enhance (text/photo/Increase),

Reverse Image, Repeat,

Frame/Fold Erasure, Auto Layout, Image Shift, Non-image

Area Erase, memory function,

density monitor, single step

copy, density shift, printing

function, copy reservation, original rotation, weekly timer, job

memory, KRDS

3. Applicable copy paper

Plain paper: 16 to 24 lb high-quality paper

Special paper: Label paper

(by-pass feed only) OHP film

Blueprint-master paper

13 to 16 lb high-quality paper

24 to 35 lb high-quality paper

1-A-2

Page 21

4. Options

Finisher: FS-109

Drawer base unit: DB-208 (500 x 3 trays)

DB-208A (500 x 1 tray)

DB-608 (500 X 1 tray + 1500 LCT)

Key counter

Expansion memory unit

Printer controller: IP-431

Hard disk: HD-103

Network board: KN-303

PostScript: PS-342

: MU-403 (32MB DIMM)

MU-404 (64MB DIMM)

MU-405 (128MB DIMM)

5. Particulars of machine

Power supply: 120 VAC ±10.0%

Power consumption: Max. 1500W

(Full option)

Weight: Approx. 229 lbs.

Machine dimensions: Width: 25.5 in.

Depth: 27.75 in.

Height: 29.3 in.

7045 PRODUCT SPECIFICATIONS

6. Maintenance and Life

Maintenance: Every 100,000 copies

7. Consumables

Developer: Common with Konica 7033/7040

Toner: Common with Konica 7040

Drum: Common with Konica 7033/7040 (φ60)

8. Environmental conditions

Temperature: 50°C to 86°C

Humidity: 10% to 80%RH

Note: Specifications are subject to change without notice.

1-A-3

Page 22

CENTER CROSS-SECTIONAL VIEW

CENTER CROSS-SECTIONAL VIEW

DF-315 (standard)

CB (control board)

Exposure lamp

Charging corona section

Slit glass

PCL

Image write section

Cleaning unit

Fixing unit

Original

image read

position

Image read section

ICB (image control board)

Developing section

2nd paper feed section

Reversal/Paper

exit unit

ADU section

Tray 1

Conveyance

section

Separation corona

section

TSL

By-pass tray

Transfer corona section

Paper feed section

1-A-4

Page 23

DRIVE SYSTEM DIAGRAM

[1] Main Drive

Registration MC (MC1)

DRIVE SYSTEM DIAGRAM

Main motor (M1)

Registration roller (upper)

Registration roller

(lower)

Conveyance belt

Fixing roller (upper)

Fixing roller (lower)

1-B-1

Page 24

DRIVE SYSTEM DIAGRAM

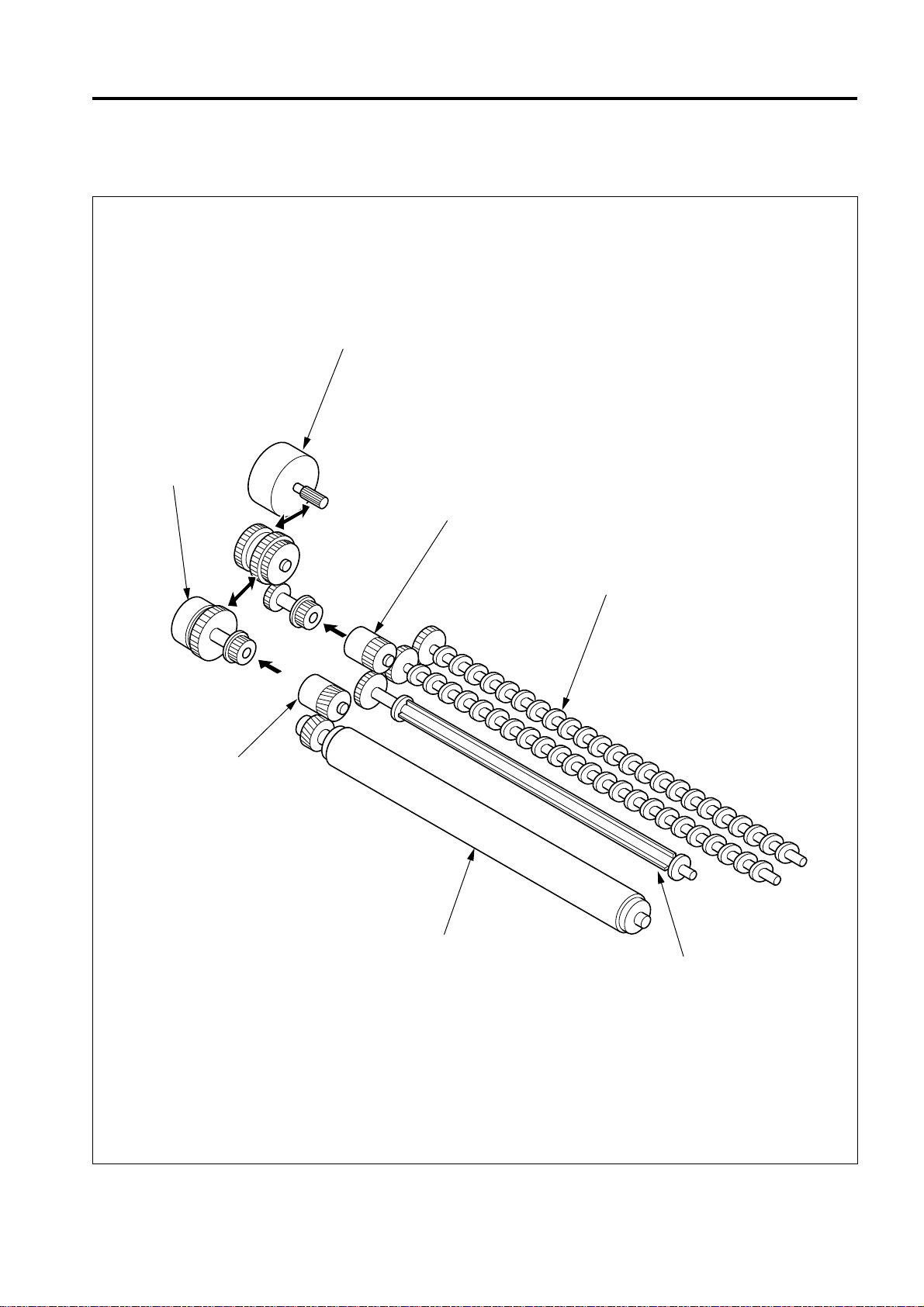

[2] Drum / Toner Recycle Drive

Drum motor (M4)

Drum

Separation claw swing gear

Toner conveyance screw

Toner recycle screw

1-B-2

Page 25

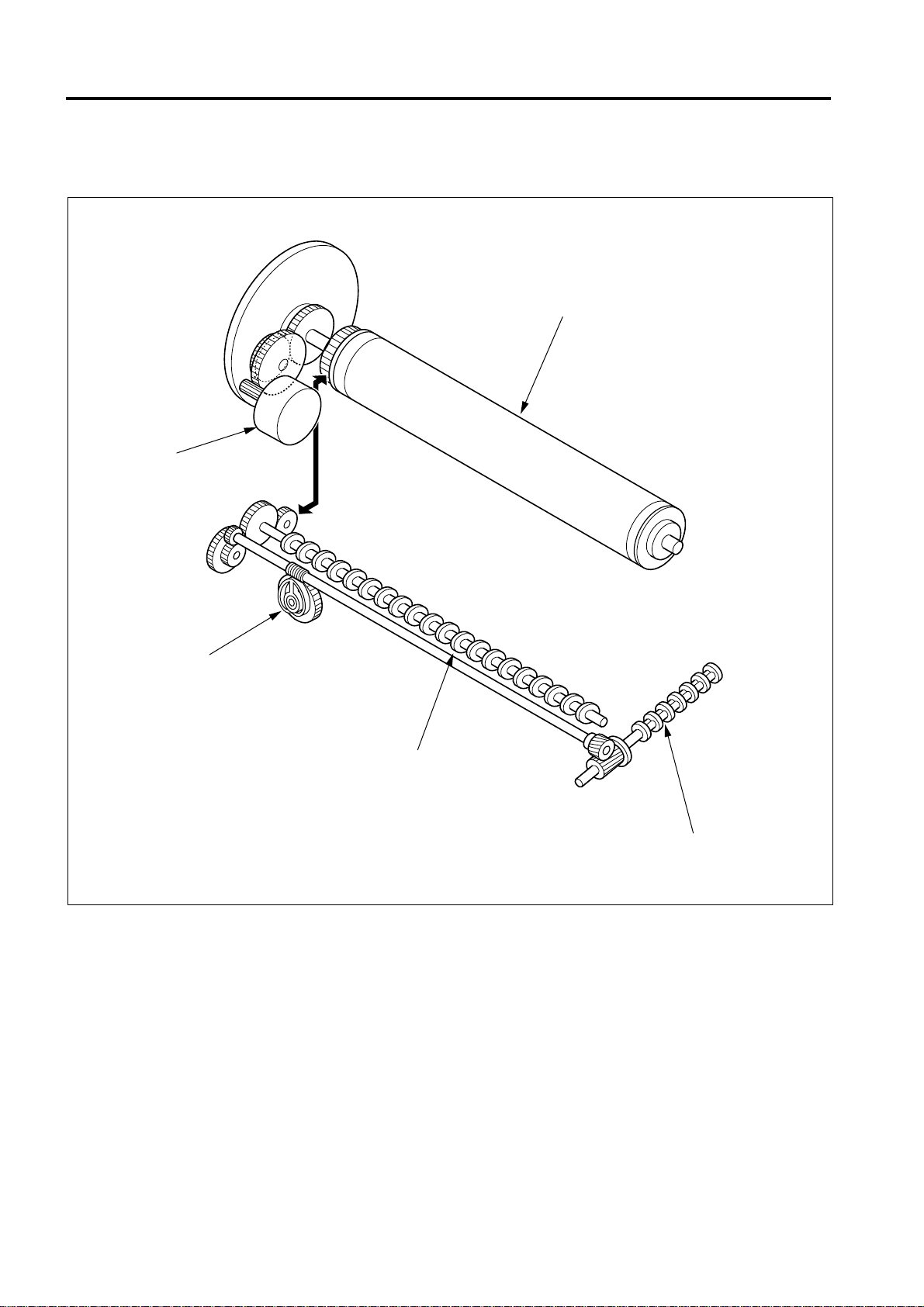

[3] Developing Drive

Developing motor (M3)

Developing MC

(MC2)

DRIVE SYSTEM DIAGRAM

Developing drive input gear (1)

Developing drive

input gear (2)

Agitator screw

Developing sleeve

Agitator wheel

1-B-3

Page 26

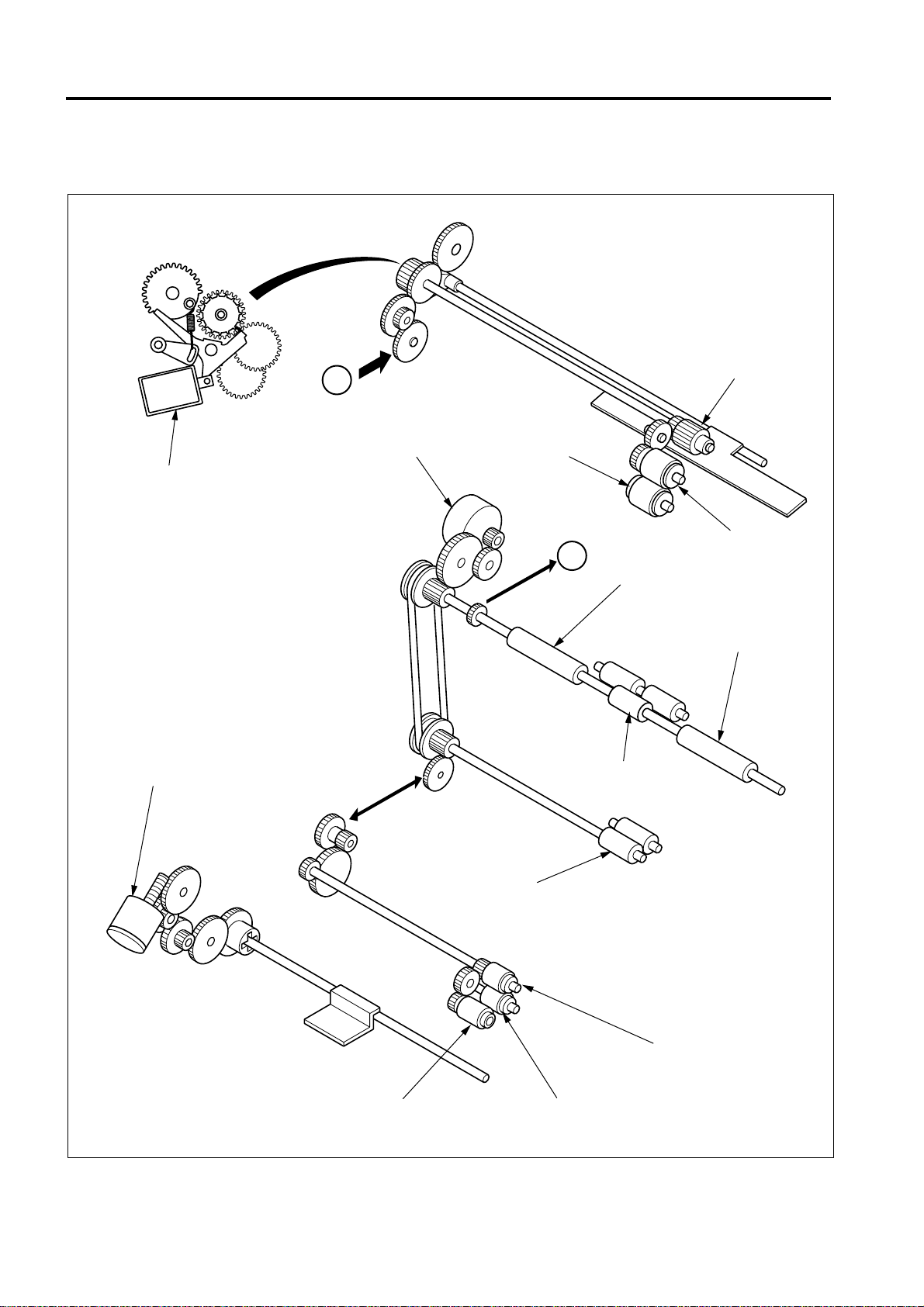

DRIVE SYSTEM DIAGRAM

[4] By-pass Paper Feed / 1st Paper Feed Drive

A

1st paper feed motor (M6)

By-pass SD (SD4)

By-pass paper feed roller

By-pass double feed

prevention roller

By-pass separation roller

A

Paper feed pulley

Tray motor (M8)

Paper feed pulley

Registration paper feed

roller

Paper conveyance pulleys

Separation roller

Paper feed roller

Double feed prevention roller

1-B-4

Page 27

[5] ADU Drive

DRIVE SYSTEM DIAGRAM

Conveyance roller (B)

Conveyance roller (C)

Registration roller (upper)

Registration

roller (lower)

ADU paper feed

motor (M501)

ADU restart

MC (MC501)

ADU loop MC (MC502)

Conveyance roller (A)

ADU feed MC (MC503)

1-B-5

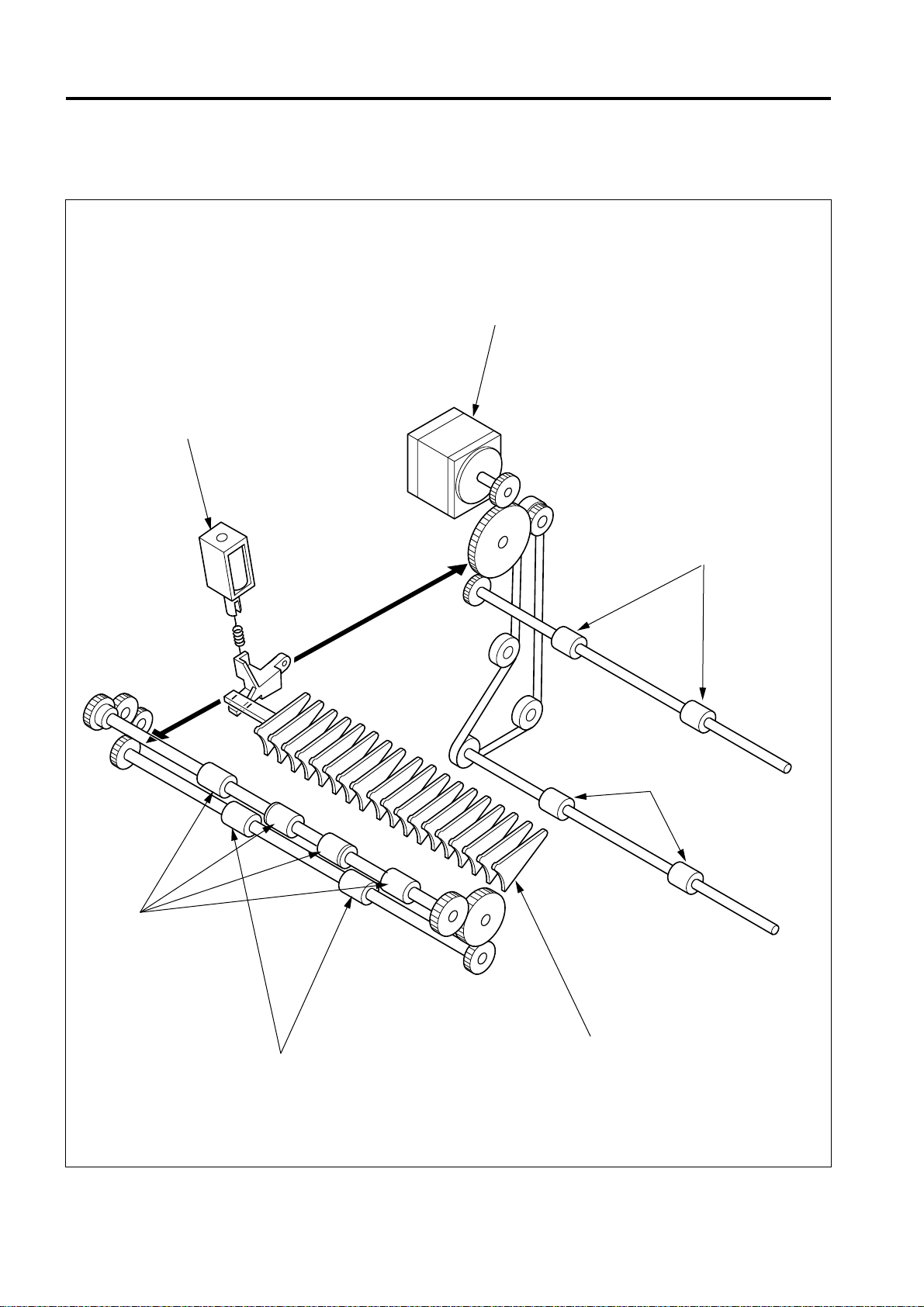

Page 28

DRIVE SYSTEM DIAGRAM

[6] Reversal / Paper Exit Drive

Gate SD (SD5)

Reversal/paper exit motor (M12)

Paper exit rollers

Paper exit reversal rollers

Reversal rollers

Conveyance rollers

Switching guide

1-B-6

Page 29

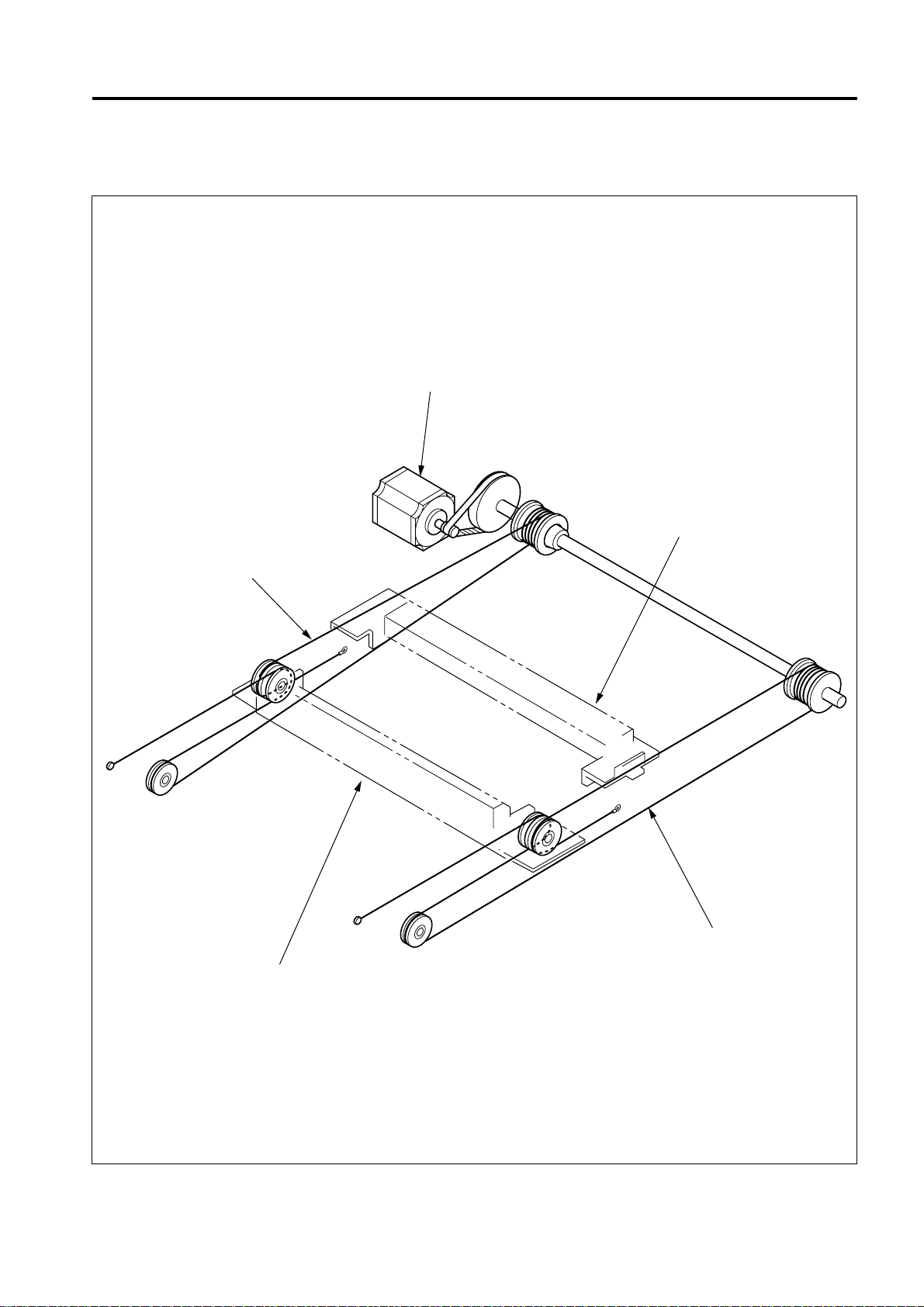

[7] Read Unit Drive

DRIVE SYSTEM DIAGRAM

Scanner motor (M2)

Exposure unit

Optics wire (rear)

V-mirror unit

Optics wire (front)

1-B-7

Page 30

DRIVE SYSTEM DIAGRAM

[8] Toner Supply Drive

Toner supply motor 1 (M10)

Toner supply motor 2 (M11)

Toner cartridge drive

coupling

Agitator plate

Toner conveyance screw

1-B-8

Page 31

2

UNIT EXPLANATION

Page 32

EXTERNAL SECTION

[1] Composition

EXTERNAL SECTION

Main power switch

Left side

cover

Paper exit cover

Sub power swicth

Operation panel

Front door

ADU

Tray 1

RADF

Right side cover

Rear cover

By-pass

tray

Paper feed door

2-A-1

Page 33

DRIVE SECTION

[1] Composition

DRIVE SECTION

Scanner motor

Developing motor

1st paper feed motor

[2] Mechanisms

Mechanisms

Drum drive *1

Developing drive *1

1st paper feed drive

2nd paper feed, conveyance and fixing drive

ADU drive

Reversal/paper exit drive

Drum motor

Reversal paper exit motor

Main motor

Methods

Gear drive

Gear drive

Timing belt + gear drive

Gear drive

Timing belt + gear drive

Timing belt + gear drive

*1: Separation of the different parts of the drive

system

The drum and developing agitator of this machine are

driven by separate motors in order to improve the

serviceability of the drum unit and also to improve the

developing performance.

2-B-1

Page 34

DRIVE SECTION

[3] M1 (Main) Control

5VDC

SGND

DCPS2

ICBCB

M1 (main) is controlled by the PRDB (printer drive

board).

1. Operation

M1 is a 24 V drive DC motor which drives the

conveyance section, 2nd paper feed section, fixing

section and conveyance belt. M1 is PLL-controlled

by feedback signals from a speed sensor installed

inside M1 itself, maintaining it at a constant speed.

M1 goes ON after the specified time from when the

Start print button is pressed, and goes OFF again

after the specified time from PS16 (registration)

going OFF at the final copy exit.

SCDB

28VDC

PGND

24VDC

PGND

PGND

DCPS1

M1

5VDC

SGND

PRDB

5VDC

CONT

LOCK SIG

SGND

M1 CLK

SGND

PS16 SIG

5VDC

PS16

2. Signals

a. Input signals

(1) LOCK SIG (M1 to PRDB)

M1 rotational status detection signal

This signal becomes [L] when M1 reaches the set

speed.

(2) PS16 SIG (PS16 to PRDB)

Paper detection signal used for detecting the paper

feed temporary stop position.

PS16 goes ON and outputs [H] when paper is

detected at the paper feed temporary stop position.

b. Output signals

(1) CONT (PRDB to M1)

M1 drive control signal

[L]: M1 ON

[H]: M1 OFF

(2) M1 CLK (PRDB to M1)

Reference clock signal for controlling the speed of M1

2-B-2

Page 35

[4] M4 (Drum) Control

DRIVE SECTION

5VDC

SGND

DCPS2

ICBCB

SCDB

M4 (drum) is controlled by the PRDB (printer drive board).

1. Operation

M4 is a 24 V drive DC motor which drives the drum,

toner conveyance screw, toner recycle screw and

separation claw swing section.

M4 is PLL-controlled by feedback signal from a

speed sensor installed inside M4 itself, maintaining it

at a constant speed.

M4 goes ON when the Start button is pressed, and

goes OFF again when the final copy has been exited.

28VDC

PGND

24VDC

PGND

DCPS1

M4

5VDC

SGND

5VDC

CONT

LOCK SIG

SGND

M4 CLK

PRDB

2. Signals

a. Input signal

(1) LOCK SIG (M4 to PRDB)

M4 rotational status detection signal

This signal becomes [L] when M4 reaches the set

speed.

b. Output signals

(1) CONT (PRDB to M4)

M4 drive control signal

[L]: M4 ON

[H]: M4 OFF

(2) M4 CLK (PRDB to M4)

Reference clock signal for controlling the speed of M4

2-B-3

Page 36

READ SECTION

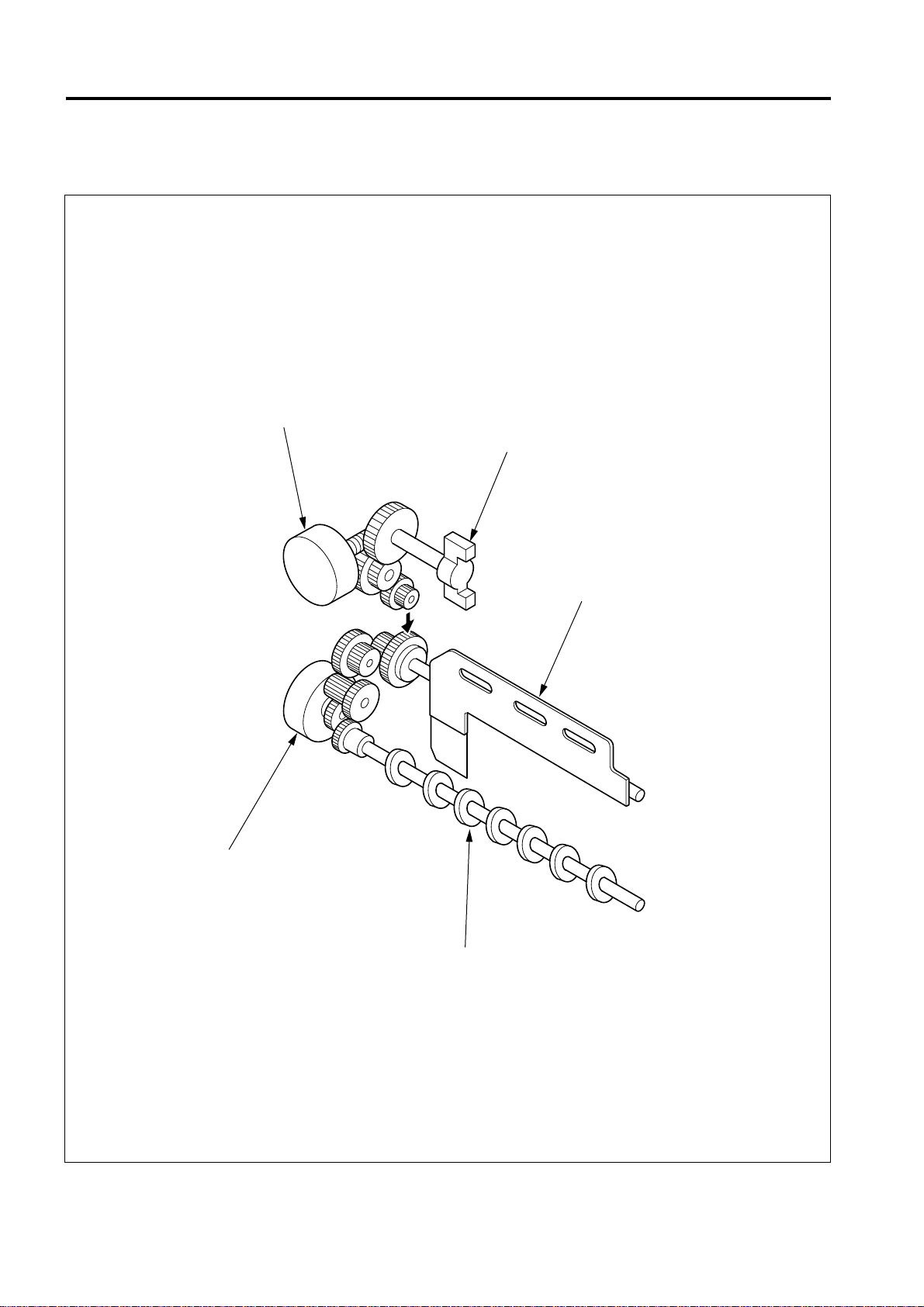

[1] Composition

APS 1 sensor

APS 2 sensor

Exposure unit

Optics rail (rear)

2nd mirror

CCD unit

Optics rail (front)

Optics driven sheet (lower)

READ SECTION

Optics driven sheet (lower)

V-mirror unit

CCD unit

V-mirror unit

3rd mirror

1st mirror

[2] Mechanisms

Mechanisms

Light source

Exposure

Scanning *1

Xenon lamp

Slit exposure

Platen original scanning:

1st, 2nd and 3rd mirror shift

RADF original scanning:

Fixed light source / Original moving

Lamp power supply

Cooling of optics

Lamp cord

Cooling of intake air using a fan

*1: Platen original scanning and RADF original

scanning

Methods

Optics driven sheet

(upper)

Original glass (1)

V-mirror unit

RADF original

Exposure unit

Platen original

Optics driven

sheet (upper)

Exposure unit

CCD unit

a. An original on the original glass is read while

moving the exposure unit and V mirror unit.

b. When reading a RADF original, the exposure unit

and V mirror unit shift to under the original glass (1).

Original reading takes place with the original

passing over the stationary exposure unit.

2-C-1

Page 37

READ SECTION

[3] M2 (Scanner) Control

5VDC

5VDC

SGND

SGND

CB

DCPS2

ICB

28VDC

PGND

DCPS1

SCDB

M2 (scanner) is driven by the SCDB (scanner drive board),

and is controlled by the ICB (image control board).

Related signal is PS3 (optics HP).

1. Operation

a. Operation of M2

M2 is a stepping motor which drives the exposure

unit. It rotates in the forward or reverse direction and

also changes speed according to the particular

scanning control operation.

The position of the exposure unit is controlled and

monitored by PS3 alone. The drive period and

direction of rotation of M2 are controlled by the

number of count pulses from when PS3 goes ON or

OFF.

The ICB continuously monitor the state of motion of

M2. It acquires the control timing related to paper

feed from the number of drive count pulses.

The ICB continuously monitors the motion of M2. It

acquires the control timing related to paper feed from

the number of drive count pulses.

b. Scanning speed of the exposure unit

Scanning speed

Magnification

Forward

Return

210 mm/sec (1:1)

862 mm/sec (Max.)

PGND

PGND

24VDC

24VDC

28VDC

PGND

24VDC

A

A

B

B

24VDC

SGND

OPT HOME

5VDC

Scanning speed

M2

PS3

c. Initial operation when power is turned ON

When SW2 (sub power) is turned ON, the exposure

unit performs a home position search. The home

position search operation differs depending upon

whether PS3 is ON or OFF. After the home position

search, the exposure unit waits in the platen mode

APS read position.

(1) When PS3 is ON

Shading correction read position

Platen APS read

position

Reference point

PS3

(2) When PS3 is OFF

Shading correction read position

Platen APS read

position

Reference point

d. Shading correction read operation

The white reference plate is glued at the back of the

original glass and the shading correction is carried out

when the SW2 is turned on and every scanning job.

e. Exposure scan mode

There are two exposure scanning modes, a platen

mode and a DF mode.

In the platen mode, the exposure unit scans and

reads the original in the same way as in a

conventional copying machine. In the DF mode,

however, the exposure unit remains fixed in the

specified position, and instead the RADF conveys the

original, causing it to be read.

PS3

2-C-2

Page 38

READ SECTION

f. Scanning operation during DF mode

The read position in the DF mode is on the paper exit

side of PS3 (optics HP). While the exposure unit is

moving from the standby position (platen APS read

position) to the DF read position, the shading

correction read operation takes place.

Upon reaching the DF read position, the exposure

unit remains there until the original has been read,

upon completion of reading, then once again moves

to the platen APS read position and goes into a

standby status.

DF original

read position

Shading correction read position

Platen APS read

position

Reference

point

PS3

g. Scanning operation during platen copy mode

In the platen mode, the motion of the exposure unit

differs depending upon whether the copy density

mode is set to AE or Manual. In both cases, a

shading correction read operation takes place before

the exposure scanning operation starts. After

completion of the exposure scanning, then the

exposure unit moves to the APS read position and

goes into a standby status.

(2) When manual density has been selected

Shading correction read position

PS3

Exposure scan

Platen APS read position

Reference point

(3) Booklet mode (Output 1 to N, AE mode)

Shading correction read position

PS3

AE scan

Exposure scan (rear half)

Exposure scan (front half)

(1) AE mode

Shading correction read position

PS3

Reference point

AE scan

Exposure scan

Platen APS read

position

Platen APS read position

Reference point

(4) Booklet mode (Output 1 to N, When manual

density has been selected)

Shading correction read position

PS3

Exposure scan (rear half)

Exposure scan (front half)

Platen APS read position

Reference point

2-C-3

Page 39

READ SECTION

2. Signals

a. Input signal

(1) OPT HOME (PS3 to SCDB to ICB)

Exposure unit home position detection signal

[L]: Exposure unit is in the home position.

[H]: Exposure unit is not in the home position.

b. Output signal

(1) A, A, B, B (SCDB to M2)

M2 (scanner) ON/OFF drive signal

24V

0V

[4] Exposure Control

PGND

LAMP ON/OFF

24VDC

L1 INVB

SCDB

DCPS1

L1 CONT

ICB

28VDC

PGND

24VDC

24VDC

PGND

PGND

Power is supplied to L1 (exposure lamp) from the L1 INVB

(L1 inverter) and is controlled by the ICB (image control

board) via the SCDB (scanner drive board).

LV

L1

HV

1. Operation

L1 is a xenon lamp which is driven by an inverter

circuit.

A xenon lamp provides a stable light intensity and

also generates relatively little heat, hence it does not

require a light intensity control circuit that is used in

conventional copying machines, and also protective

control that is normally required due to heat

generation from the lamp is no longer used.

2. Signals

a. Output signal

(1) LAMP ON/OFF (ICB to SCDB to L1 INVB)

L1 ON/OFF control signal

[L]: L1 ON

[H]: L1 OFF

2-C-4

Page 40

READ SECTION

[5] Original Read Control

5VDC

SGND

12VDC

SGND

DCPS2

CB

28VDC

PGND

DCPS1

ICB

GND

SD0

SD1

/SEN

RCK

GND

TCK

GND

CCD

ADB

[6] APS Control

CB DCPS2 DCPS1

ICB

5VDC

SGND

12VDC

SGND

PS3

PS25

PS26

PS4

APS BOOK

SCDB

SGND

OPT HOME

5VDC

5VDC

APS TIMING

SGND

SGND

APS DATA2

5VDC

SGND

APS DATA3

5VDC

28VDC

PGND

ADB

PS3

PS4

PS25

PS26

The original is read by the CCD sensor installed on

the ADB (A/D converter board).

1. Operation

The light from the exposure lamp reflects back from

the original, passes through a lens, and hits the CCD

sensor. The CCD sensor generates an anolog

electrical signal corresponding to the light intensity.

The ADB then converts this signal into a digital

signal.

a. Original read operation

The original read timing is as follows.

(1) During a platen copy operation

PS3 (optics HP) goes OFF after the specified time

from when the Start button is pressed, and then the

exposure unit moves 2 mm to the paper feed side.

(2) During a DF copy operation

After the specified time from the ON of PS308

(original feed detect) by original leading edge.

APS takes place as a result of the signals read by the

APS sensors and CCD sensor being sent to the ICB

(image control board) when the RADF is opened and

closed.

Related signals are PS3, PS4 (APS timing) and PS301

(DF open/close detect).

1. Operation

a. APS detection operation

The APS detection operation differs depending upon

whether the platen mode or DF mode is used.

(1) During a DF copy operation

An original size is detected by ON or OFF of PS302

(original size detect 1) and PS303 (original size detect

2) on the paper feed tray of RADF, and resistance

value of VR301 (original size detect).

(2) During a platen copy operation

APS detection is used to detect the original size. This

is done by combining the ON/OFF signals from PS25

(APS 1) and PS26 (APS 2) with the detection signal

from the CCD sensor mounted on ADB.

2-C-5

Page 41

READ SECTION

PS25 (APS 1) and PS26 (APS 2) detect the original

size in the sub-scanning direction, and the CCD

sensor detects the original size in the main scanning

direction.

During APS detection, when L1 (exposure lamp)

lights, gradations of light intensity occur in the main

scanning direction due to the presence of an original.

The CCD sensor detects these gradations of light

intensity along one line, and the ICB (image control

board) judges the size of the original in the main

scanning direction from the positional relationship

between the two points where the light intensity level

switches from black generated by a sky shot to white

generated by the edge of the original.

Close RADF, then detection of the original size in the

main scanning direction takes place once again at

the instant PS301 (DF open/close detect) goes ON,

and the original size is confirmed.

PS25 and PS26 each consist of an LED and a

photosensor. Light emitted from each LED is

reflected off the original, and received by the

photosensor, thus enabling the size of the original to

be detected.

The PS25 and PS26 consist of LEDs and

photosensors. APS detection takes place as a result

of the light emitted from each LED being reflected off

the original and received by the photosensor.

Paper size

A3

B4

A4R

B5R

A4

B5

Sensor

PS302

PS25

●

●

●

×

×

×

PS303

PS26

: Paper is detected (ON).

✕ : Paper is not detected (OFF).

b. APS detection timing

The APS detection timing differs depending upon

whether the platen mode or the DF mode is used.

(1) During a DF copy operation

When either the DF mode is selected or an original is

placed in the RADF paper feed tray, the original size

is detected by PS302 (original size detect 1), PS303

(original size detect 2) and VR301 (original size

detect).

(2) During a platen copy operation

• When PS4 (APS timing) is ON and PS301 is ON

• If RADF is open, the original size is detected when

the Start button is pressed.

●

●

×

×

×

×

Paper exit side

: Photosensor

: LED

The relation between each sensor and the paper size

is shown below.

2-C-6

Page 42

READ SECTION

2. Signals

a. Input signals

(1) OPT HOME (PS3 to SCDB to ICB)

Exposure unit home position detection signal

[L]: Exposure unit is in the home position.

[H]: Exposure unit is not in the home position.

(2) APS TIMING (PS4 to SCDB to ICB)

RADF opening/closing detection signal

Activates or deactivates the APS function at a platen

copy operation.

[L]: OFF (APS function deactivated)

[H]: ON (APS function activated)

(3) APS DATA 2 (PS25 to SCDB to ICB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

(4) APS DATA 3 (PS26 to SCDB to ICB)

Paper size detection signal

[L]: Paper is detected.

[H]: Paper is not detected.

[7] AES Control

5VDC

SGND

12VDC

SGND

DCPS2

CB

28VDC

PGND

ICB

DCPS1

GND

SD0

SD1

/SEN

RCK

GND

TCK

GND

CCD

ADB

When an AE scanning takes place, the CCD sensor

installed on the ADB (A/D converter board) reads the

original density, and the ICB (image control board)

performs processing corresponding to the read

results and selects the optimum γ correction curve for

the original reproduction. This operation is called AE

control. The selection of this γ correction curve is

done by the CPU on the ICB.

2-C-7

Page 43

READ SECTION

1. Operation

a. AES detection operation

(1) During a platen copy operation

When the Start button is pressed, an AE scanning

takes place, and the density of the original is read

over the following range.

<AES sampling range>

1) When RADF is open

Range of non-image area erace mode, or the

inside of the area detected by the APS

2) When RADF is closed

• Range of 20 mm inward of the original size

detected by the APS

• If the original size cannot be determined by the

APS, a range of 20 mm inward of the minimum

original size set for the particular shipping

destination of the machine.

(2) During a DF copy operation

The image at the leading edge of the original is read

by the original feed operation that takes place when

the Start button is pressed, and the read data is used

to perform density measurement.

<AES sampling range>

1) Main scanning direction

• A range of 20 mm inward of the original size

detected by the APS

• If the original size cannot be determined by the

APS, a range of 20 mm inward of the minimum

original size set for the particular shipping

destination of the machine.

2) Sub scanning direction

Range between 1.5 mm and 2.9 mm from the

leading edge of the original

2-C-8

Page 44

WRITE UNIT

[1] Composition

WRITE UNIT

Dust-proof glass

fθ lens

Polygon mirror

[2] Mechanisms

Mechanisms Methods

Scan *1 Polygon mirror

Rotational speed:

· 49606.3 rpm

Light source Laser diode (1)

· Output : Max. 5 mW

· Wavelength : 780 nm

Positioning Index sensor

Write mirror

Cylindrical lens 2

Collimator lens unit

Cylindrical lens 1

Cylindrical

lens 1

Polygon mirror

Index mirror

Cylindrical lens 2

fθ lens

Index sensor board

Laser drive board

Write mirror

Dust-proof

glass

*1: Path of laser beam

The light output from the semiconductor laser is sent

to the OPC drum via the collimator lens, cylindrical

lens 1, polygon mirror, f

θ

lens, cylindrical lens 2, and

write mirror.

2-D-1

Collimator lens unit

Polygon mirror

fθ lens

Index mirror

Laser diode

Index sensor board

Write mirror

Cylindrical lens 2

OPC drum

Dust-proof

glass

Page 45

WRITE UNIT

[3] M5 (Polygon) Control

POLY CONT

POLY PLL LOCK

POLY CLK

SCDB

24VDC

PGND

DCPS1

M5 (polygon) is driven by the PMDB (Polygon motor

drive board), and is controlled by the SCDB (scanner

drive board).

1. Operation

a. M5 is a 3-phase brushless DC motor which is driven

using a 3-phase bipolar method. The current flowing

through the windings is switched according to the

position of the rotor which is detected by a sensor

(magnetic sensor) inside the motor.

This motor rotates the polygon mirror, causing the

laser beam from LDB (lazer drive board) to be

scanned in the axial direction of the drum. The

speed of the motor is maintained constant by PLL

control.

b. M5 is powered by 24 VDC. The rotational speed is

as follows.

PMDB

M5 DRIVE A

M5 DRIVE B

M5 DRIVE C

M5 MAG C

M5 MAG C'

M5 MAG B

M5 MAG B'

M5 MAG A

M5 MAG A'

12VDC

SGND

M5

2. Signals

a. Input signals

(1) POLY PULL LOCK (PMDB to SCDB)

M5 rotation speed monitoring signal

[L]: Normal rotation

[H]: Stop or rotation abnormality

(2) M5 MAG A/A' (M5 to PMDB)

M5 MAG B/B' (M5 to PMDB)

M5 MAG C/C' (M5 to PMDB)

These are output signals from the position sensors

(magnetic sensors) installed inside M5. The PMDB

detects the position of the rotor of the motor by

means of these signals, and switches over the M5

DRIVE A to C output.

b. Output signals

(1) POLY CONT (SCDB to PMDB)

This signal controls the ON/OFF state of M5.

[L]: M5 ON

[H]: M5 OFF

(2) POLY CLK (SCDB to PMDB)

This is a reference clock signal for PLL-controlling M5

in the PMDB.

(3) M5 DRIVE A to C (PMDB to M5)

This is the drive output signal for M5. While M5 is

rotating, voltages are output sequentially from M5

DRIVE A to C, and applied to M5.

The voltage from each output that is applied to M5

consists of the pulses shown below. The pulse width

of this output changes according to the rotation

condition of M5, as shown in the figure, and as a

result the RMS value of the voltage applied to M5

changes, causing the speed to be regulated.

State of the machine

During copy

Rotational speed

49606.3 rpm

One of the following three

speeds can be selected

During idling

using the “25” mode.

• 49606.3 rpm

• 25000 rpm *

• Stop *

* If the item marked * is selected, the rotational

speed of M5 switches over after the lapse of the

specified time from the completion of the warm-up

or the end of the copy process.

The specified time can be selected using the “25”

mode among below.

· 15 sec, 30 sec, 60 sec, 120 sec

2-D-2

Page 46

WRITE UNIT

[4] Image Write Control

5VDC

SGND

/S/H

/ENB

/VIDEO

VIDEO

/ALM

N.C.

DACLK

DI

LD

5VDC

LDB

5VDC

SGND

/INX

SGND

IDPR 5VDC

INDEXSB

ADB

The analog image data from the CCD sensor is A/Dconverted and processed by the ADB (A/D converter

board). The processed image data is memorized by the CB

(control board), then returned to the ICB (image control

board) once again and converted into a laser record signal.

The laser record signal is transmitted via the CB to the LDB

(Laser drive board) by the control signal from the ICB, and

output as an optical signal from the laser installed on the

LDB. The write start position of the laser record signal is

detected by INDEXSB (index sensor board).

1. Operation

a. Image processing

The following processing is carried out by the ICB.

(1) AOC (Automatic Offset Correction)

IC on ADB automatically adjusts analog off set

voltage of CCD sensor output.

CB

ICB

(3) Shading correction

<Implementation timing>

White correction, Black correction

• When SW2 is ON

• Before job

(4) Brightness/density conversion

(5) AES processing

(6) Text/dot pattern judgement

(7) Filtering

(8) Magnification change processing

(9) Copy γ correction

(10) Write density control

b. Write

The ICB sends image data one pixel at a time to LDB

in accordance with control signals from the CB.

LDB cause the laser to emit at a time period

corresponding to the image data. This laser light is

applied to the drum.

(1) MPC (Maximum Power Control)

The ICB instructs the LDB to cause the laser to

output the maximum power output value, thus setting

the maximum output value. The LDB stores this

setting, and maintains the laser light intensity stored

by means of the APC (Automatic Power Control)

operation.

<MPC timing>

• When SW2 is turned ON.

(2) APC (Automatic Power Control)

The ICB outputs an APC start instruction to the LDB

at the following timing, after MPC is set.

<APC timing>

• When PLL lock of M5 (polygon) is detected.

After PLL lock is detected, the LDB automatically

monitors the laser drive current one line at a time,

and controls it so that the light intensity remains the

MPC value.

(3) Write Timing

In this machine, the INX signal from INDEXSB

determines the laser write start timing for each scan

in the axial direction of the drum.

(2) AGC (Automatic Gain Correction)

When SW2 (sub power) is turned ON, the white

reference plate is read, and the amplification of the

analog output from the CCD sensor is automatically

adjusted so that the resulting level is the upper limit of

the A/D converter.

2-D-3

Page 47

WRITE UNIT

2. Signals

a. Input signals

(1) INX (INDEXSB to CB to ICB)

Write system index signal

(2) IDPR (INDEXSB to CB to ICB)

5 VDC power monitoring signal for INDEXSB (index

sensor board)

(3) ALM (LDB to CB to ICB)

Signal which indicates an abnormality in the laser

drive current (APC operation).

[L]: Abnormal

[H]: Normal

b. Output signals

(1) VIDEO (ICB to CB to LDB)

Laser image data signal

(2) DA CLK (ICB to CB to LDB)

Data transfer clock signal for MPC setting value

(3) DI (ICB to CB to LDB)

Data signal of MPC setting value

(4) LD (ICB to CB to LDB)

Storage directive signal for MPC setting value

(5) S/H (ICB to CB to LDB)

APC sampling signal for one line scan

(6) ENB (ICB to CB to LDB)

Laser APC function ON/OFF control signal

While this signal is OFF then the laser beam output is

prohibited.

2-D-4

Page 48

DRUM UNIT

[1] Composition

DRUM UNIT

Developing unit

Cleaning unit

Charging corona unit

Cleaning unit

Transfer/separation

corona unit

Charge cleaning knob

PCL

Charging corona unit

TSL

Separation claws

Drum

Developing unit

Drum

[2] Mechanisms

Mechanisms

Carriage support

PCL

Auxiliary separation

The drum unit of this machine is an integral assembly

consisting of the drum, and also the charging corona unit,

developing unit, cleaning unit, toner recycle unit and the

PCL which are installed around the drum.

Methods

Fixed rail

LED

Separation claws

2-E-1

Page 49

DRUM UNIT

[3] PCL/TSL Control

PRDB

24VDC

PCL CONT

24VDC

TSL DRIVE

24VDC

MC1 DRIVE

SGND

PS16 SIG

5VDC

PCL

TSL

MC1

PS16

24VDC

PGND

DCPS1

The PCL (pre-charging lamp) and TSL (transfer

synchronization lamp) consist of LEDs which are

controlled by the PRDB (printer drive board).

1. Operation

PCL goes ON after the specified time from when the

Start print button is pressed, and goes OFF again

after the specified time from the turning OFF of PS16

(registration) upon the final copy exit.

TSL goes ON after the specified time from when MC1

(registration) goes ON, and goes OFF again after the

specified time from PS16 going OFF.

2. Signals

a. Output signals

(1) PCL CONT (PRDB to PCL)

PCL ON/OFF control signal

[L]: PCL ON

[H]: PCL OFF

[4] Separation Claw Control

MC1 DRIVE

PRDB

24VDC

SD1 DRIVE

24VDC

SD1

MC1

24VDC

PGND

DCPS1

The separation claws are driven by SD1 (separation claw),

and is controlled by the PRDB.

1. Operation

SD1 goes ON after the specified time from when MC1

goes ON, causing the separation claws to touch the

drum in order to help separate the paper from the drum.

2. Signals

a. Output signal

(1) SD1 DRIVE (PRDB to SD1)

SD1 drive control signal

[L]: SD1 ON

[H]: SD1 OFF

(2) TSL DRIVE (PRDB to TSL)

TSL drive control signal

[L]: TSL ON

[H]: TSL OFF

(3) MC1 DRIVE (PRDB to MC1)

MC1 drive control signal

[L]: MC1 ON

[H]: MC1 OFF

2-E-2

Page 50

[5] Transfer Entrance Guide Plate Control

DRUM UNIT

DCPS1

SCDB

24VDC

PGND

PGND

24VDC

PGND

24VDC

PGND

5VDC

SGND

CB

28VDC

PGND

DCPS2

ICB

A constant voltage is applied to the transfer guide plate in

order to prevent toner from adhering to it.

1. Operation

a. ON/OFF timing

Transfer guide plate control goes ON after the

specified time from when the Start button is pressed,

and goes OFF again after the specified time from

PS16 (registration) goes OFF.

SGND

5VDC

PRDB

5VDC

CONT

LOCK SIG

SGND

M1 CLK

GP CONT

SGND

PS16 SIG

5VDC

M1

GP

GP

HV2

PS16

b. Applied voltage

–500 VDC

2. Signals

a. Output signals

(1) GP CONT (PRDB to HV2)

Signal for controlling ON/OFF of the voltage applied

to the paper transfer guide plate.

[L]: Voltage is applied.

[H]: Voltage is not applied.

2-E-3

Page 51

CORONA UNIT SECTION

CORONA UNIT SECTION

[1] Composition

<Charging corona unit> <Transfer and separation corona unit>

Charging wire cleaning block

PCL

Transfer wire

Charging control plate

Charging

wires

Spark arrestor plate (front)

Plunging prevention plate

[2] Mechanisms

Mechanisms

Charging

Transfer

Separation

Scorotron (DC negative corona discharge)

Discharge wire: Tungsten 0.06 mm dia.

Grid control: Stainless steel plate

With manual wire cleaner

DC positive corona discharge

Discharge wires: Tungsten 0.06 mm dia.

(protection by a tough film of oxide)

AC/DC corona discharge

Discharge wires: Tungsten 0.06 mm dia.

(protection by a tough film of oxide)

Separation wire

Spark arrestor plate (rear)

Method

(gold-plated skin path)

2-F-1

Page 52

CORONA UNIT SECTION

[3] Charging Control

5VDC

SGND

DCPS2

CB

28VDC

PGND

ICB

24VDC

PGND

24VDC

PGND

24VDC

PGND

DCPS1

SCDB

HV1 (high voltage unit/1), which controls charging,

operates by means of control signals from the PRDB

(printer drive board), and outputs a high voltage to the

charging wires.

1. Operation

Charging control goes ON after the specified time

from when M4 (drum) goes ON, and goes OFF again

after the specified time from PS16 (registration) going

OFF.

a. Charging

A Scorotron charging method is used. 24 VDC input

from the DCPS1 (DC power supply 1) is raised to a

negative DC high voltage which is then discharged.

b. Charging correction by means of the grid

voltage

The grid voltage is output from HV1 to the charging

control plate.

5VDC

CONT

LOCK SIG

PGND

M4 CLK

C CONT

C SHIFT

SGND

5VDC

PRDB

G SHIFT

F(C) SIG

SGND

PS16 SIG

5VDC

2. Signals

a. Input signal

(1) F(C) SIG (HV1 to PRDB)

[L] is output when the spark detection circuit operates

and the charging output forcibly goes OFF.

b. Output signals

(1) C CONT (PRDB to HV1)

Charging and grid voltage ON/OFF control signal

[L]: Charging and grid voltage ON

[H]: Charging and grid voltage OFF

(2) C SHIFT (PRDB to HV1)

The charging corona unit output level is controlled by

means of analog signals from the PRDB.

C SHIFT output range 4 to 10 V

Charging output range –550 to –1200 µA

(3) G SHIFT (PRDB to HV1)

The charging grid voltage output level is controlled by