Page 1

DF-314

SERVICE HANDBOOK

2001.02

Ver. 3.0

KONICA CORPORATION

TECHNOLOGY SUPPORT CENTER

TOKYO JAPAN

Page 2

KONICA CORPORATION

COPYRIGHT ©2001

CN26NF1780

Page 3

CONTENTS

1

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS .............

Refer to the 7020/25/30/35 service handbook on page C-1

2

1. OUTLINE

DF-314 PRODUCT SPECIFICATIONS .................. 1-1

[1] Type ........................................................ 1-1

[2] Functions ................................................ 1-1

[3] Machine data .......................................... 1-1

[4] Maintenance ........................................... 1-1

[5] Machine environment ............................. 1-1

CENTER CROSS SECTION ..................................1-2

DRIVE SYSTEM DIAGRAM ................................... 1-3

ORIGINAL CONVEYANCE PROCESS ................. 1-4

[1] Single-side original copy mode ............... 1-4

[2] Double-side original copy mode ............. 1-5

[3] Mixed original copy mode ....................... 1-5

2. UNIT EXPLANATION

EXTERNAL SECTION ........................................... 2-1

[1] Composition ............................................ 2-1

[2] Mechanisms ........................................... 2-1

ORIGINAL FEED/REVERSAL/ORIGINAL EXIT

SECTION ............................................................... 2-2

[1] Composition ............................................ 2-2

[2] Mechanisms ........................................... 2-2

[3] Original feed/conveyance/scan control ... 2-3

[4] Original exit/reversal and conveyance

control ..................................................... 2-5

[5] Original size detection control ................ 2-7

1 OUTLINE

2 UNIT EXPLANATION

3

Assembly

3 DIS./ASSEMBLY

3. DISASSEMBLY/ASSEMBLY

DISASSEMBLY/ASSEMBLY .................................. 3-1

[1] Replacing feed roller/A ........................... 3-1

[2] Replacing the double-feed prevention

roller/A assy ............................................ 3-1

[3] Replacing the read roller ........................ 3-2

[4] Removing and attaching the paper dust

2

removing brush ....................................... 3-3

REVISED EDITION

2

DATE

Feb. 2001

PA GE

–

METHOD

REPLACEMENT

Page 4

1

1 OUTLINE

2

Unit

2 UNIT EXPLANATION

3

Assembly

3 DIS./ASSEMBLY

Blank page

Page 5

1

OUTLINE

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Page 6

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 7

DF-314 PRODUCT SPECIFICATIONS

DF-314

[1] Type

Type:

Sheet-through Type reversible

DF

[2] Functions

Originals Size:

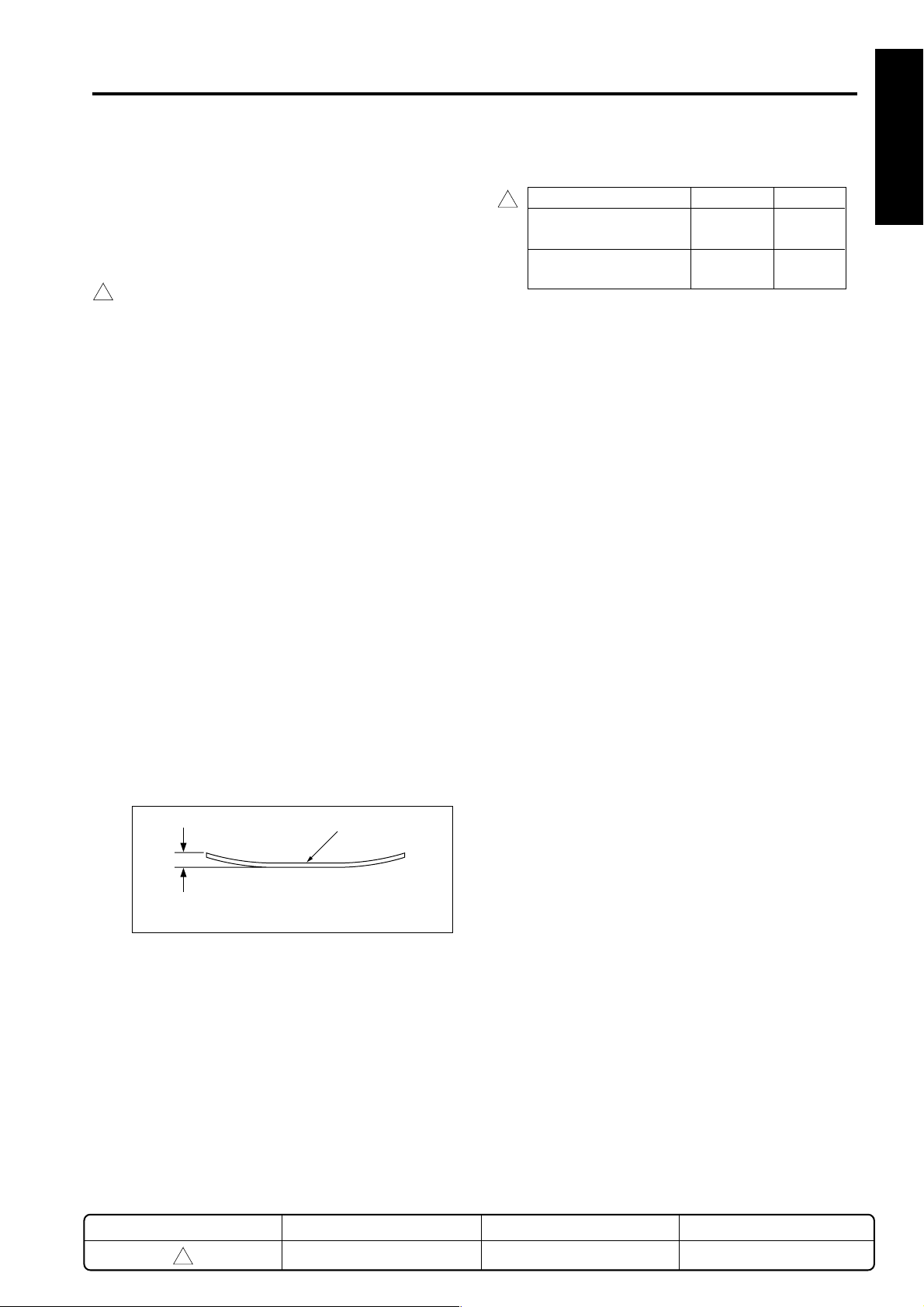

2

Original Type

Plain Original: 35g/m

Special Original: Original feed and convey-

Original Curling: 10mm maximum (35g/m

A3, B4, A4, A4R, B5, A5,

A5R, B5R, B6R, 11x17,

8.5x14, F4, 8.5x11, 8.5x11R,

5.5x8.5, 5.5x8.5R

• Only single-side mode is

available with B6R

• All sizes are detected

automatically.

• Mixing of original size

possible.

2

- 130g/m2 fine quality

original

ance ability may be inferior

those of 35g/m

fine quality original.

The following types of original

cannot be used:

• OHP film

• Blueprint masters

• Offset masters

• Bonded original

130g/m

2

high-quality paper)

Original

2

to 130g/m

2

to

Original scan speed (copies per minute)

Mode 7020/25/30 7035

2

Single sided Original → 30 35

Single sided Copy

Double sided Original → 18 18

Double sided Copy

Original Feed Layout:

Face-up placement, centre

standard

Original image read Position:

At the slit glass section

1 OUTLINE

2 UNIT EXPLANATION

[3] Machine data

Power Source: DC24V/5V (supplied from the

main body)

Max. Power Consumption:

Max.100VA

Weight: Approximately 10.7kg

2

Machine Dimensions: Length 576mm

(including about 1.1kg for

platen)

Depth 498mm

Height 100mm

(Excluding the original feed tray)

3 DIS./ASSEMBLY

[4] Maintenance

Maintenance: Same as the main unit

Machine Life: Same as the main unit

Curling

Maximum number of stacked originals:

50 sheets Maximum (80g/m2)

REVISED EDITION

2

DATE

Feb. 2001

[5] Machine environment

Temperature: 10 to 30˚C

Humidity: 20 to 80%RH

Note: Specifications are subject to change without

notice.

PA GE

1-1

1-1

METHOD

REPLACEMENT

Page 8

DF-314

1

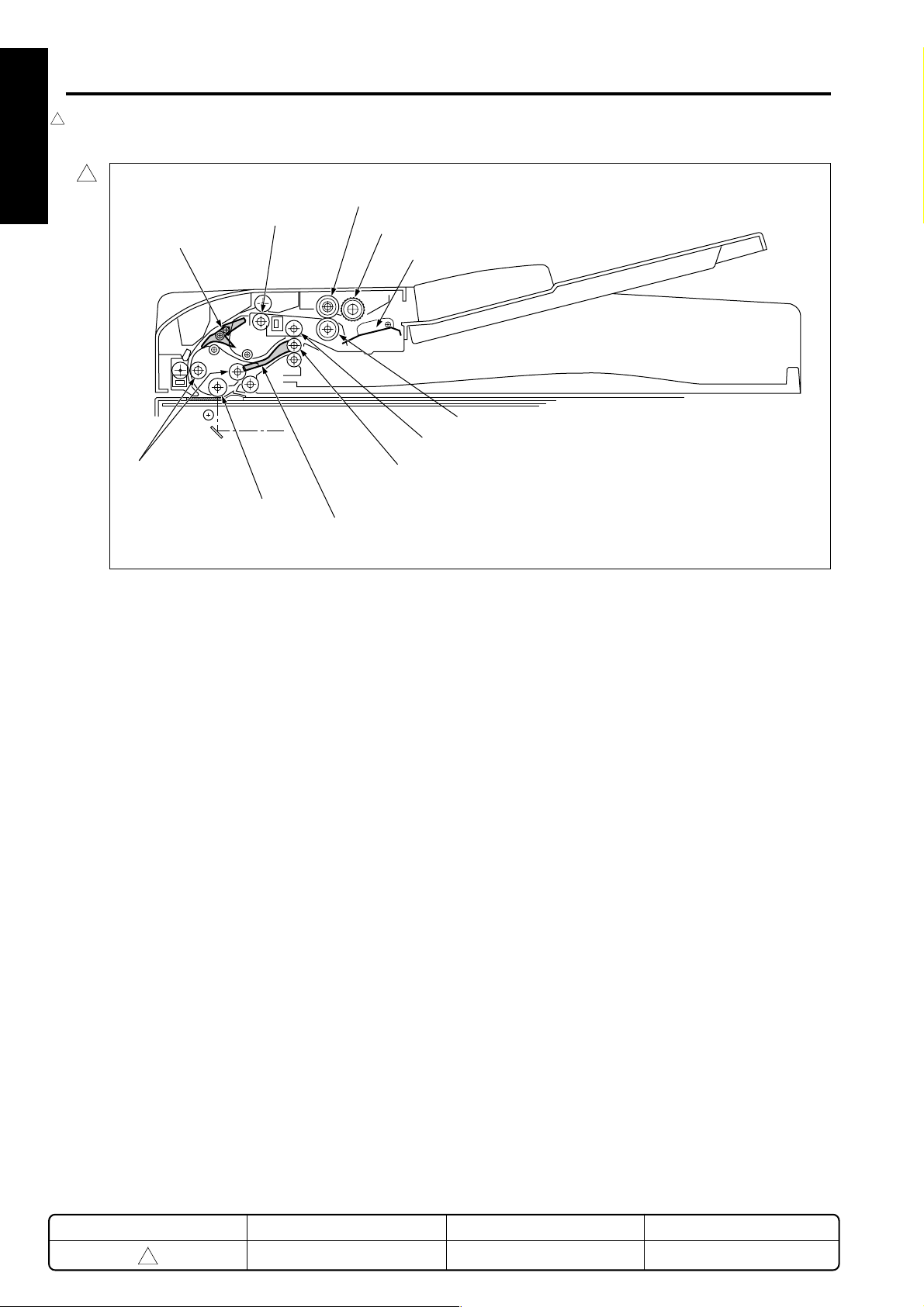

CENTER CROSS SECTION

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

1

Reversal guide

Original conveyance

rollers

Registration roller

Read-out roller

Separation roller

Original feed roller

Paper lift-up plate

Double feed prevention roller

Reversal roller

Original exit roller

Exit guide

REVISED EDITION

1

DATE

May 2000

1-2

PA GE

1-2

METHOD

REPLACEMENT

Page 9

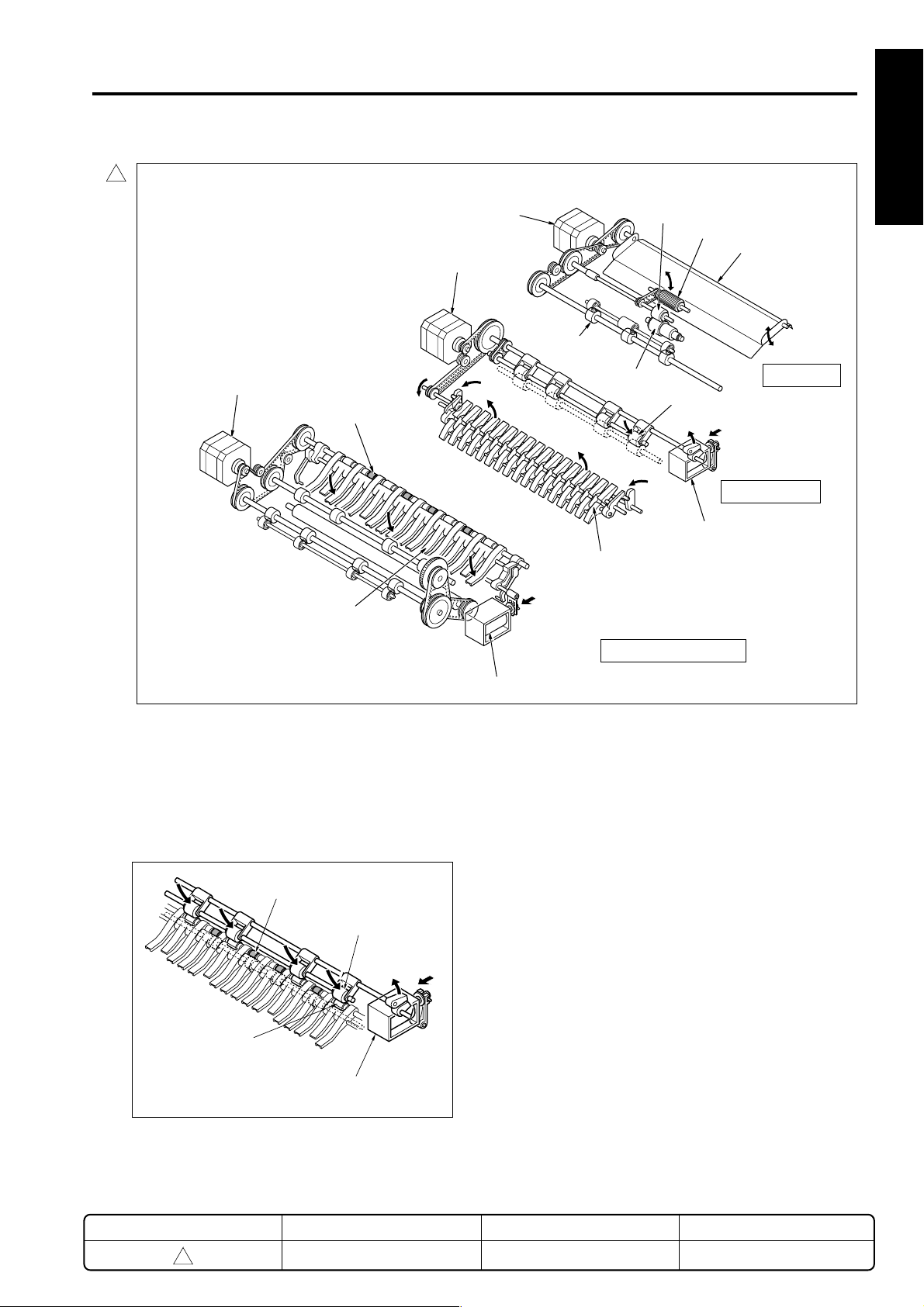

DRIVE SYSTEM DIAGRAM

DF-314

1

Original conveyance motor (M302)

Original feed motor (M301)

Original reversal motor (M303)

Original exit roller

Exit guide

Registration

roller

Double feed

prevention roller

Reversal guide

1 OUTLINE

Separation roller

Original feed roller

Paper lift-up plate

Feed drive

Reversal roller

2 UNIT EXPLANATION

Reversal drive

Roller pressure SD (SD302)

3 DIS./ASSEMBLY

*Reversal and Exit Rollers

A reversal roller pulley is attached to the original

exit roller shaft. The reversal roller conveys the

original through pressure being applied on the

pulley by the roller pressure SD.

Original exit roller

Reversal roller

Pulley

Roller pressure SD (SD302)

Conveyance/exit drive

Exit SD (SD303)

REVISED EDITION

1

DATE

May 2000

1-3

PA GE

1-3

METHOD

REPLACEMENT

Page 10

DF-314

ORIGINAL CONVEYANCE PROCESS

As illustrated below, the DF-314 is made up of a original

1 OUTLINE

feed section, conveyance section, original exit section and

reversal section.

Original feed section

Reversal section

Original exit section

Platen glass

2 UNIT EXPLANATION

1

Conveyance

section

Slit glass

(Read section)

With the originals set face-up on the original feed tray,

they are fed from the topmost original. Rather than being

conveyed to an original glass surface, the originals that

are fed in and read when they pass a slit glass placed in

the conveyance path.

The operation mode of the DF-314 consists of 3 modes,

3 DIS./ASSEMBLY

the one-side original copy mode, the two-side original

copy mode and the mixed original copy mode.The

conveyance method differs for each mode.

[1] Single-side original copy mode

When PS311 turns ON, the original is re-fed by the

registration roller and conveyed to the original conveyance

roller. The original conveyance roller conveys the original

to the position where PS312 (original feed PS) turns ON.

Conveyance rollers

Original feed PS

(PS312)

Registration roller

Original registration

PS (PS311)

The conveyance roller turns, and scanning starts. If there

is another original waiting, it is pre-fed at this point.

The scanning of the original is conveyed out when the

original passes over the slit glass. The original which has

been read is exited to the original exit tray by the original

exit roller with the exit SD OFF (i.e. with the exit guide

raised).

Next original

(Single-side→single-side copy, single-side→doubleside copy)

The original that has been set in the paper feed tray is

lifted by the paper lift-up plate so it comes into contact with

the original feed roller. The original feed roller and the

separation roller pre-feed to the position where P311

(original registration PS) turns on.

Separation roller

Registration roller

Original registration PS (PS311)

Original feed roller

Paper lift-up plate

Slit glass

Original exit roller

Exit guide

REVISED EDITION

1

DATE

May 2000

1-4

PA GE

1-4

METHOD

REPLACEMENT

Page 11

DF-314

[2] Double-side original copy mode

(Double-side→single-side copy, double-side→

double-side copy)

The original set in the original feed tray is pre-fed to the

position where PS311 (original registration PS) turns ON

by the original feed roller and the separation roller. When

PS311 turns ON, the reversal guide opens, the

registration roller conveys the original to the reversal

section, and the reversal roller conveys the original into

the interior of the reversal section.

Reversal guide

Original registration PS (PS311)

After the specified period from when PS311 detects the

1

trailing edge of the original and goes OFF, the original is

conveyed to the stop position at the front edge of the

reversal guide. As the original has been reversed at this

point, the reversal roller is made to rotate in reverse and it

conveys the original to the original conveyance roller. If

there is another original waiting, it is pre-fed at this timing.

Registration roller

Reversal roller

The exit SD comes ON (the exit guide is lowered) when

scanning of the rear side of the original begins, and the

original is again conveyed to the reversal roller. When

PS312 detects the rear edge of the original and turns OFF,

the original is conveyed as far as the stop position in front

of the reversal gate by the timer. The original has been

reversed once again by this point so is conveyed to the

original conveyance roller. The original conveyance roller

conveys the original and reading of the oliginal face side

starts.

Flapper

Original conveyance

PS (PS312)

Next original

Reversal roller

Exit guide

Slit glass

The original which has been read is exited to the original

exit tray by the original exit roller with the exit SD OFF (i.e.

with the paper exit guide raised). If there is another

original, it is conveyed to the reversal section at this point.

Next original

Reversal roller

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

The original conveyance roller conveys the original to the

position where PS312 turns ON and the reading of the

original back side starts.

1

Reversal guide

Flapper

Conveyance roller

Next original

Reversal roller

Exit roller

Slit glass Exit guide

[3] Mixed original copy mode

The mixed original copy mode supports both same-series

originals and different series originals, but as size

detection is performed in PS311 ON time, size detection is

performed before reading.

After the size of the original is detected, the original stops

1

at the reversal position. Subsequently, operation is the

same as that of the two-sided copy mode.

Refer to "ORIGINAL FEED/REVERSAL/ORIGINAL EXIT

SECTION [5] Original size detection control" for size

detection operation.

REVISED EDITION

1

DATE

May 2000

1-5

PA GE

1-5

METHOD

REPLACEMENT

Page 12

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 13

2

1

1 OUTLINE

2 UNIT EXPLANATION

3

Assembly

UNIT EXPLANATION

3 DIS./ASSEMBLY

Page 14

1

1 OUTLINE

2

Unit

2 UNIT EXPLANATION

3

Assembly

3 DIS./ASSEMBLY

Blank page

Page 15

EXTERNAL SECTION

DF-314

[1] Composition

1

Jam access cover

[2] Mechanisms

Mechanism System

Jam release* Jam access cover

Reversal guide open/close lever

RADF Main body open/close

Knob

Exit-guide open/close lever

Platen separation lever

Original feed tray

Original exit tray

If a jam occurs in the reversal section, open the

reversal guide with the reversal guide open/close

lever and withdraw the sheet.

1

Reversal guide open/close lever

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

* Jam removal

If a jam occurs at the original feed, open the Jam

access cover and turning the knob closer to you

withdraw the sheet.

1

Jam

access

cover

Knob

Reversal

guide

If a jam occurs in the conveyance section, open

the exit tray (using the platen separation lever)

and the exit guide (using the exit-guide open/close

lever) and withdraw the sheet.

Exit guide

Exit guide open/close lever

Platen separation lever

Original exit tray

REVISED EDITION

1

DATE

May 2000

2-1

PA GE

2-1

METHOD

REPLACEMENT

Page 16

DF-314

1

ORIGINAL FEED/REVERSAL/ORIGINAL EXIT SECTION

1 OUTLINE

[1] Composition

1

Original feed unit

2 UNIT EXPLANATION

Jam access cover

Exit SD (SD303)

Roller pressure SD (SD302)

3 DIS./ASSEMBLY

[2] Mechanisms

Mechanism System

Original feed Feed roller

Double feed prevention Separation roller

Double feed prevention

Roller

Original conveyance Original conveyance rollers

Original reverse and Reversal guide

feed *1

Original exit path Original exit guide

section *2

Original feed tray

Original exit tray

Original

reversal

motor

(M303)

Original conveyance

motor (M302)

Original reversal motor (M303)

Original feed motor (M301)

Reversal guide

Reversal guide

*1: Reversed original feed

During double-side copying, in order to reverse the

original the paper feed path is switched by the

reversal guide, the paper is conveyed to the

reverse mechanism and is reversed.

REVISED EDITION

1

DATE

May 2000

2-2

PA GE

2-2

METHOD

REPLACEMENT

Page 17

DF-314

*2: Original exit path switching

In the case of a two-sided copy, the paper exit guide

1

changes over the paper feed path so as to either exit

the original directly, or feed the original to the

reversal section in order to read it once again.

Exit guide

Exit guide

Exit SD (SD303)

[3] Original feed/conveyance/scan

control

24VDC

24VDC

M301 OUT A

M301 OUT A

M301 OUT B

M301 OUT B

24VDC

24VDC

M302 OUT A

M302 OUT A

M302 OUT B

M302 OUT B

MAIN BODY

M TXD

M REQ

S ACK

M ACK

S TXD

S REQ

24VDC

24VDC

PGND

PGND

5VDC

SGND

SGND

5VDC

VV

DF CB

5VDC

PS301

SGND

5VDC

PS303

SGND

5VDC

PS311

SGND

5VDC

PS312

SGND

M301

M302

PS301

PS303

PS311

PS312

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Original feed is achieved by the transmission of the

M301(original feed motor) drive power to the original feed

roller, separation roller and registration roller. Original

conveyance is achieved by the transmission of the M302

(original conveyance motor) drive power to the original

conveyance roller.

The M301 and M302 are controlled by the DFCB (RADF

control board).

REVISED EDITION

1

DATE

May 2000

2-3

PA GE

2-3

METHOD

REPLACEMENT

Page 18

DF-314

1. Operation

1 OUTLINE

a. Original feed

Original feed is started by the transmission of the

M301 drive power to the original feed roller,

separation roller and paper lift-up plate.

b. 1st original pre-feed

When the copy button is pressed, the M301 starts

original pre-feed, and when the conveyed original

arrives at PS311, M301 stops temporarily after a

specified time. M301 then rotates in reverse, turning

2 UNIT EXPLANATION

the registration roller so that feeding starts again. The

original passes PS311, so that PS311 turns OFF. A

predetermined time interval after PS311 turns OFF,

M301 also turns OFF.

c. 2nd original pre-feed

When there is still an original in the original feed tray,

M301 starts after a specified time after PS311 has

3 DIS./ASSEMBLY

turned OFF, and starts the pre-feed from after the

second sheet. The original is conveyed in the same

way as in the 1st. original pre-feed.

2. Signals

a. Input signals

(1) PS301(PS301 → DF CB)

Original feed tray no-paper detection signal

[L] : Original

[H]: No original

(2) PS303(PS303 → DF CB)

Original exit section original detection signal

[L] : No original

[H]: Original

(3) PS311(PS311 → DF CB)

Original conveyance roller entrance original

detection signal

[L] : No original

[H]: Original

(4) PS312(PS312 → DF CB)

Original detection signal from detector in front of scan

position

[L] : No original

d. Scanning operation (except last original)

When the original arrives at PS311, M302 starts after

a specified time has elapsed and the original is

conveyed to the read section.

Scanning of the original is achieved when the original

passes over the surface of the slit glass of the main

body optical section.

When the original arrives at PS312, scanning is

started after a specified time has elapsed, and when

PS312 turns OFF after the original has passed,

scanning is stopped after the lapse of a fixed period

of time.

e. Scanning operation (last original)

During the scanning operation, when PS301(no

original detect PS) turns OFF, the original currently

being scanned is judged to be the last original. When

the last original has passed PS311, M301 turns OFF

after the lapse of a fixed period of time, and when the

original has passed PS303 (original exit PS), M302

turns OFF after a specified time.

[H]: Original

(5) M TXD (MAIN BODY → DF CB)

Serial data line; informs RADF of the operating state

of the main body's CB

(6) M REQ (MAIN BODY → DF CB)

Transmission request signal from main body to

RADF

(7) S ACK (MAIN BODY → DF CB)

Transmission OK signal from main body to RADF

2-4

Page 19

DF-314

b. Output signals

–

(1) M301 OUT A, M301 OUT A

, M301 OUT B,

M301 OUT B– (DF CB → M301)

M301 drive control signal

24V

0V

–

(2) M302 OUT A, M302 OUT A

, M302 OUT B,

M302 OUT B– (DF CB → M302)

M302 drive control signal

24V

0V

(3) M ACK (DF CB → MAIN BODY)

Transmission OK signal from RADF to main body

(4) S TXD (DF CB → MAIN BODY)

Serial data line; informs the main body's CB of the

RADF operating state

(5) S REQ (DF CB → MAIN BODY)

Transmission request signal from RADF to main

body.

[4] Original exit/reversal and

conveyance control

24VDC

24VDC

M301 OUT A

M301 OUT A

M301 OUT B

M301 OUT B

24VDC

24VDC

M302 OUT A

M302 OUT A

M302 OUT B

M302 OUT B

24VDC

24VDC

M303 OUT A

M303 OUT A

M303 OUT B

M303 OUT B

MAIN BODY

M TXD

M REQ

S ACK

M ACK

S TXD

S REQ

24VDC

24VDC

PGND

PGND

5VDC

SGND

SGND

5VDC

VV

DF CB

24VDC

SD302

24VDC

SD303

5VDC

PS311

SGND

5VDC

PS312

SGND

The exit guide used in exit path switching is driven by the

SD303 (exit SD).

M301

M302

M303

SD302

SD303

PS311

PS312

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Reversal conveyance drive in double-side copy mode is

performed by the M303 (original reversal motor). The

reversal roller pressure/freeing used in reversal original

feed is performed by the SD 302 (roller pressure SD).

M303, SD302 and SD303 are controlled by the DF CB

(RADF control board).

2-5

Page 20

DF-314

1. Operation

1 OUTLINE

a. Original exit operation

During single side copying and face side copying in

double-side copying, the exit guide is raised because

SD303 is OFF. For this reason, an original which has

been read is conveyed to the exit section.

b. Reversal original exit operation

During back side copying in double side copying, the

original is conveyed to the scanning section by

reverse rotation of M303 and nomal rotation of M302.

2 UNIT EXPLANATION

When PS312 turns ON, SD302 turns OFF, and

reversal roller paper pressure conveys the freed

original to the reversal section.

c. Reversal original feed operation

After PS312 has detected the rear edge of the

original, SD302 turns ON after a specified time has

elapsed and the reversal roller applies pressure

3 DIS./ASSEMBLY

(seizes, pinches) to the original. After that, M303

stops, but then immediately reverses and starts the

original feed operation of the original face side scan.

2. Signals

a. Output signals

(1) M301 OUT A, M301 OUT A

M301 OUT B– (DF CB → M301)

M301 drive control signal

24V

0V

(2) SD302 (DF CB → SD302)

SD302 drive control signal

[L] : ON

[H]: OFF

(3) SD303 (DF CB → SD303)

SD303 drive control signal

[L] : ON

[H]: OFF

–

, M301 OUT B,

d. Pre-feed operation of next original when

reading back side of original

PS311 turns OFF once the first original has passed,

and after a specified period of time has elapsed,

starts the pre-feed operation for the 2nd. original.

After the elapse of a specified time after the 2nd.

original has arrived at PS311, M301 (original feed

motor) stops.

e. Overlap control

When scanning of the back side of the first original

1

sheet has been completed and the leading edge of

the original fed from the reversal section reaches

PS312, M301 turns ON and feeding of the second

original starts. At this time, the SD302 goes OFF,

causing the pressure on the reversal roller and the

paper exit roller to be released. This enables the first

and second originals to pass over each other in

opposite directions in the reversal unit.

REVISED EDITION

1

DATE

May 2000

2-6

PA GE

2-6

METHOD

REPLACEMENT

Page 21

DF-314

[5] Original size detection control

DF CB

5VDC

PS306

SGND

5VDC

PS307

SGND

5VDC

PS311

SGND

5VDC

VR301

SGND

PS306

PS307

PS311

VR301

M TXD

M REQ

S ACK

M ACK

S TXD

S REQ

VV

24VDC

24VDC

PGND

PGND

5VDC

SGND

SGND

5VDC

MAIN BODY

Size detection on an original set in the original feed tray is

performed by PS306 (original size detect PS1), PS307

(original size detect PS2), and VR301 (size detect VR).

Note that the DF CB includes internal nonvolatile memory

that stores timing data, size-detection reference values,

and other such data.

b. Original size detection in mixed-original

modes and Z-fold-original modes (1st sheet)

(1) Drum axis direction size detection

The width of the maximum sized original being

mixed-loaded is detected by the position of the

VR301 guide plate.

(2) Size detection in original feed direction

Original feed direction size is detected during PS311

ON time (the time taken by the original to pass

PS311).

(3) Operation of size detection in original feed

direction

When original re-feed is started by the registration

roller, when a specified time has elapsed after PS311

turning ON, M303 (original reversal motor) turns ON

and conveys the original to the reversal section.

PS311 (Original registration PS)

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

1. Operation

a. Normal copy mode

The DF CB detects the original size when the signals

described below combine.

(1) Drum axis direction size detection

VR301 resistance value changes in the position

where the guide plate contacts VR301. The width of

the original is detected by the resistance value.

(2) Size detection in original feed direction

The length of the original is detected by the ON/OFF

states of PS306 and PS307.

Conveyance to the scanning section is performed by

M303 reverse rotation.

Conveyance or scanning thereafter for both single

and double-sided originals is performed by the same

operation as for double-side copy mode. However in

single-side copying, the back side of the original

passes the scanning section without being scanned

and is conveyed to the reverse section.

Original size detection operation after the 2nd.

original starts after the completion of the exit of the

first original.

2-7

Page 22

DF-314

c. Allowed size combination

1 OUTLINE

( : same size, : same series, : different series,

: no mixed loading, : not supported)

(1) AB series

1

Other originals A3 A4 B4 B5 A4R A5 B5R A5R

A3

A4

B4

B5

2 UNIT EXPLANATION

A4R

A5

B5R

A5R

Standard originals (the maximum original size detected

by the guide plate)

(2) Inch series

1

3 DIS./ASSEMBLY

Other originals 11x17 8.5x11 8.5x14 8.5x11R 8.5x5.5 8.5x5.5R

11 x 17

8.5 x 11

8.5 x 14

8.5 x 11R

8.5 x 5.5

8.5 x 5.5R

Standard originals (the maximum original size

detected by the guide plate)

2. Signals

a. Input signals

(1) PS306 (PS306 → DF CB)

Detection of original's length

[1] : Original

[2] : No original

(2) PS307 (PS307 → DF CB)

Detection of original's length

[1] : Original

[2] : No original

(3) VR301 (VR301 → DF CB)

Detection of original's width

REVISED EDITION

1

DATE

May 2000

2-8

PA GE

2-8

METHOD

REPLACEMENT

Page 23

3

DISASSEMBLY/ASSEMBLY

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Page 24

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

This section explains how to disassemble and reassemble the machine.

Observe the following precautions when performing disassembly and

assembly work.

1. Be sure the power cord has been unplugged from the wall outlet.

2. The disassembled parts must be reassembled following the

disassembly procedure in reverse unless otherwise specified.

3. Care should be taken not to lose small parts. Care should also be

taken not to install small parts in wrong places.

4. Do not operate the machine before installing all the disassembled

parts completely.

5. Removal of some screws is prohibited in this section. Never loosen

them.

Page 25

DISASSEMBLY/ASSEMBLY

1

DF-314

Caution: Make sure the power plug is taken

out of the socket.

[1] Replacing feed roller/A

(1) Open jam access cover.

(2) Take out the 2 fixed screws and lifting the feed unit

lightly draw it forwards towards yourself and

remove it.

1

Feed unit

(3) Remove the E-rings on the ends of the paper-feed

unit (one E-ring on each end), and remove the feed

roller/A assy.

(4) Remove feed roller/A from the bearing of the feed

roller/A assy.

Set screws

Feed unit

Feed roller/A

[2] Replacing the double-feed

prevention roller/A assy

(1) Open jam access cover.

(2) Remove feed unit.

1

(6) Remove double feed prevention roller.

1

Jam access cover

Feed unit

Double feed prevention roller

1 OUTLINE

2 UNIT EXPLANATION

3

Assembly

3 DIS./ASSEMBLY

E-ring

Feed roller/A assy

E-ring

E-ring

(5) Install by reversing the removal procedure.

Caution: When installing the feed unit, insert the

unit in order to fit the D cut side on the

drive shaft in the coupling.

E-ring

Double-feed prevention

roller/A assy

Double feed prevention roller

REVISED EDITION

1

DATE

May 2000

3-1

PAG E

3-1

METHOD

REPLACEMENT

Page 26

1

DF-314

(4) Remove the E-ring from the double-feed prevention

1 OUTLINE

(5) Pull out the double-feed prevention roller/A assy.

2

Unit

2 UNIT EXPLANATION

3

Assembly

(6) Install by reversing the removal procedure.

Caution: When installing the double-feed prevention

3 DIS./ASSEMBLY

roller/A assy.

E-ring

Double-feed prevention

roller/A assy

roller, make sure you install it in the correct

direction.

E-ring

Paint mark

1

[3] Replacing the read roller

(1) Remove the 3 set screws, and remove the cover.

Set screws

Cover

Set screw

(2) Remove the set screw, and remove the guide.

Next, remove the E ring at the top of the read roller

and also the bearing at the bottom together with the

E ring fixing it.

Set screws

Guide

E-ring

E-ring

REVISED EDITION

1

DATE

May 2000

3-2

PA GE

3-2

METHOD

REPLACEMENT

Page 27

DF-314

1

(3) Move the read roller upward, then take out the pin

and remove the gear. Move the lower bearing,

then pull out the shaft of the read roller.

Gear

Pin

Read

roller

Read

roller

Bearing

(4) Reinstall the read roller in the opposite sequence to

removal.

Caution: Use glass cleaner to clean the roller if it is

dirty.

[4] Removing and attaching the paper

2

dust removing brush

( 1 ) Open the cover.

( 2 ) Remove the set screw, and then remove the paper

dust removing brush.

Paper dust removing brush

Set screw

(3) Attach the paper dust removing brush in the

opposite sequence to removal.

1 OUTLINE

2 UNIT EXPLANATION

3

Assembly

3 DIS./ASSEMBLY

REVISED EDITION

2

DATE

Feb. 2001

3-3

PAG E

3-3

METHOD

REPLACEMENT

Page 28

1

1 OUTLINE

2

Unit

2 UNIT EXPLANATION

3

Assembly

3 DIS./ASSEMBLY

Blank page

Loading...

Loading...