Page 1

5

DIAGRAMS

5 DIAGRAMS

Page 2

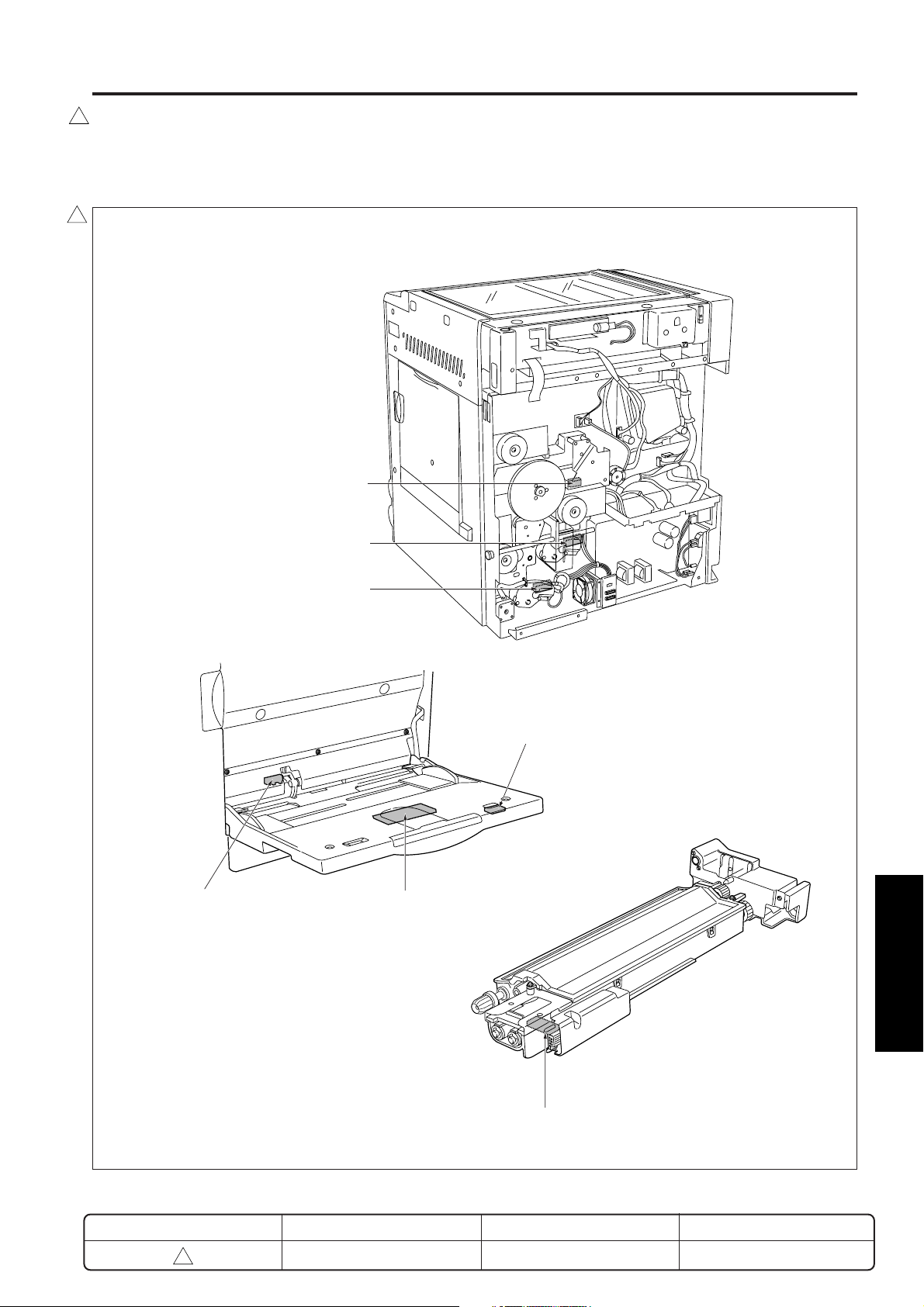

MAIN BODY ELECTRICAL PARTS LAYOUT DRAWING

1

MAIN BODY ELECTRICAL PARTS LAYOUT DRAWING

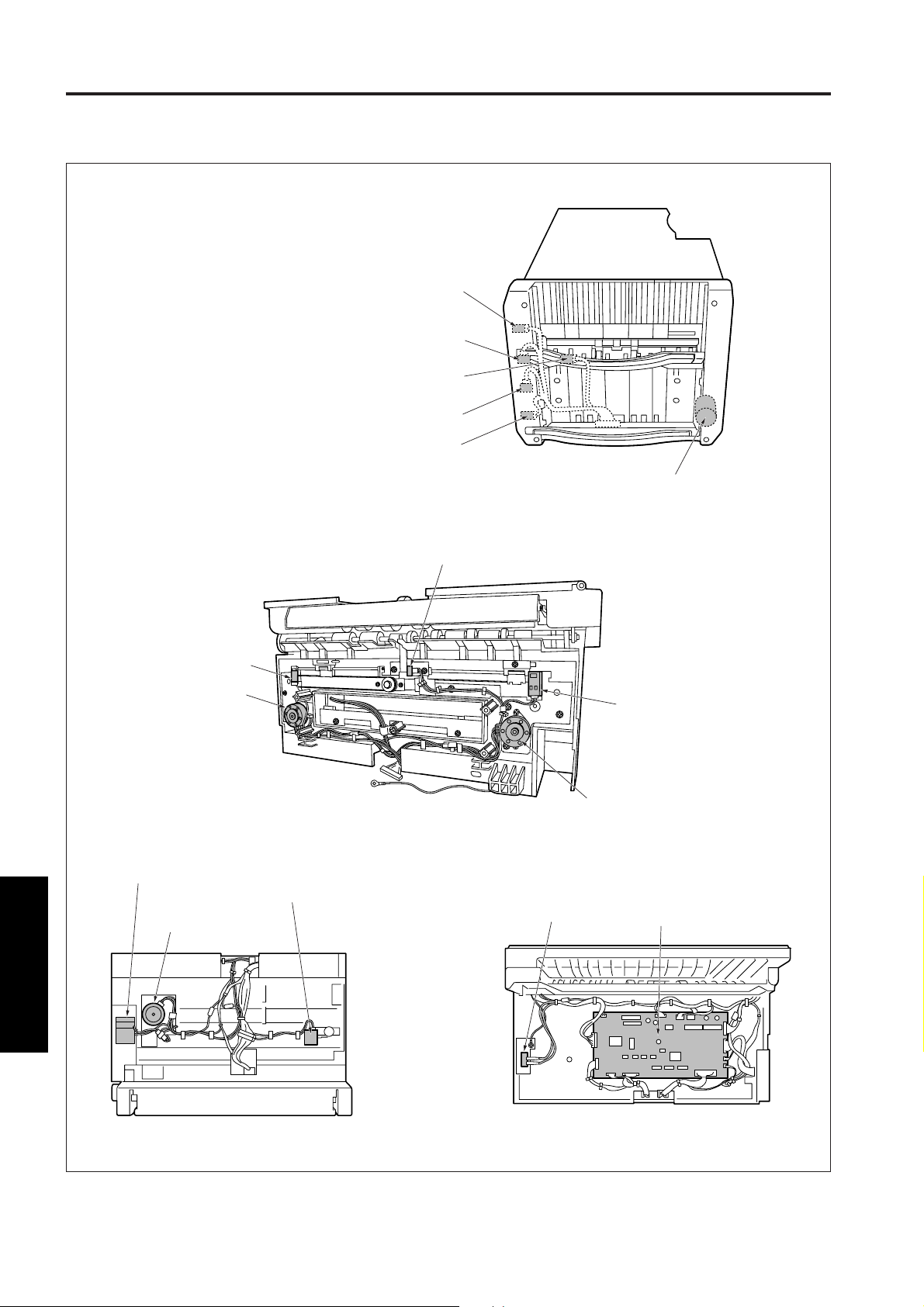

[1] Switches and sensors

1

TLD Toner level detector

PS9 Tray detect PS (upper)

PS12 Tray detect PS (lower)

PS13 By-pass no paper detect PS

PS20 By-pass tray paper size detect PS

VR1 By-pass tray paper size VR

REVISED EDITION

1

DATE

May 2000

TDS Toner density sensor

PAGE

5-1

5-1

5 DIAGRAMS

METHOD

REPLACEMENT

Page 3

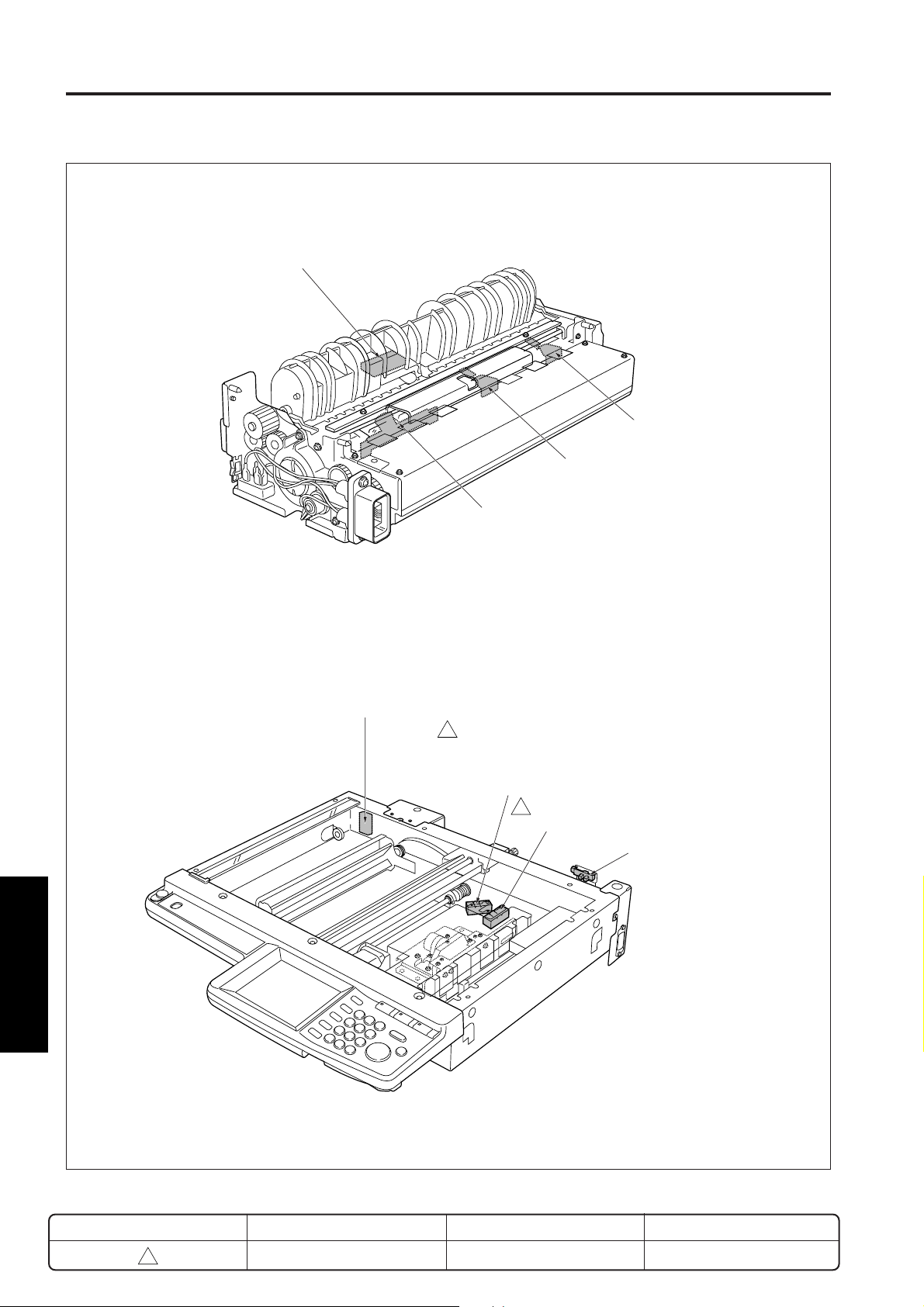

MAIN BODY ELECTRICAL PARTS LAYOUT DRAWING

PS2 Fixing exit PS

TH2 Fixing temperature sensor 2

TH1 Fixing temperature sensor 1

TS Thermostat

5 DIAGRAMS

PS14 Optics home position PS

3

PS17 APS sensor 1

*

Exclusivery for the 7020/25/30/35

PS18 APS sensor 2

*

Exclusivery for machines other than 7020/25/30/35

PS18 APS sensor 2

3

*

Exclusivery for the 7020/25/30/35

PS15 APS timing PS

REVISED EDITION

3

DATE

Jan. 2002

5-2

PAGE

5-2

METHOD

REPLACEMENT

Page 4

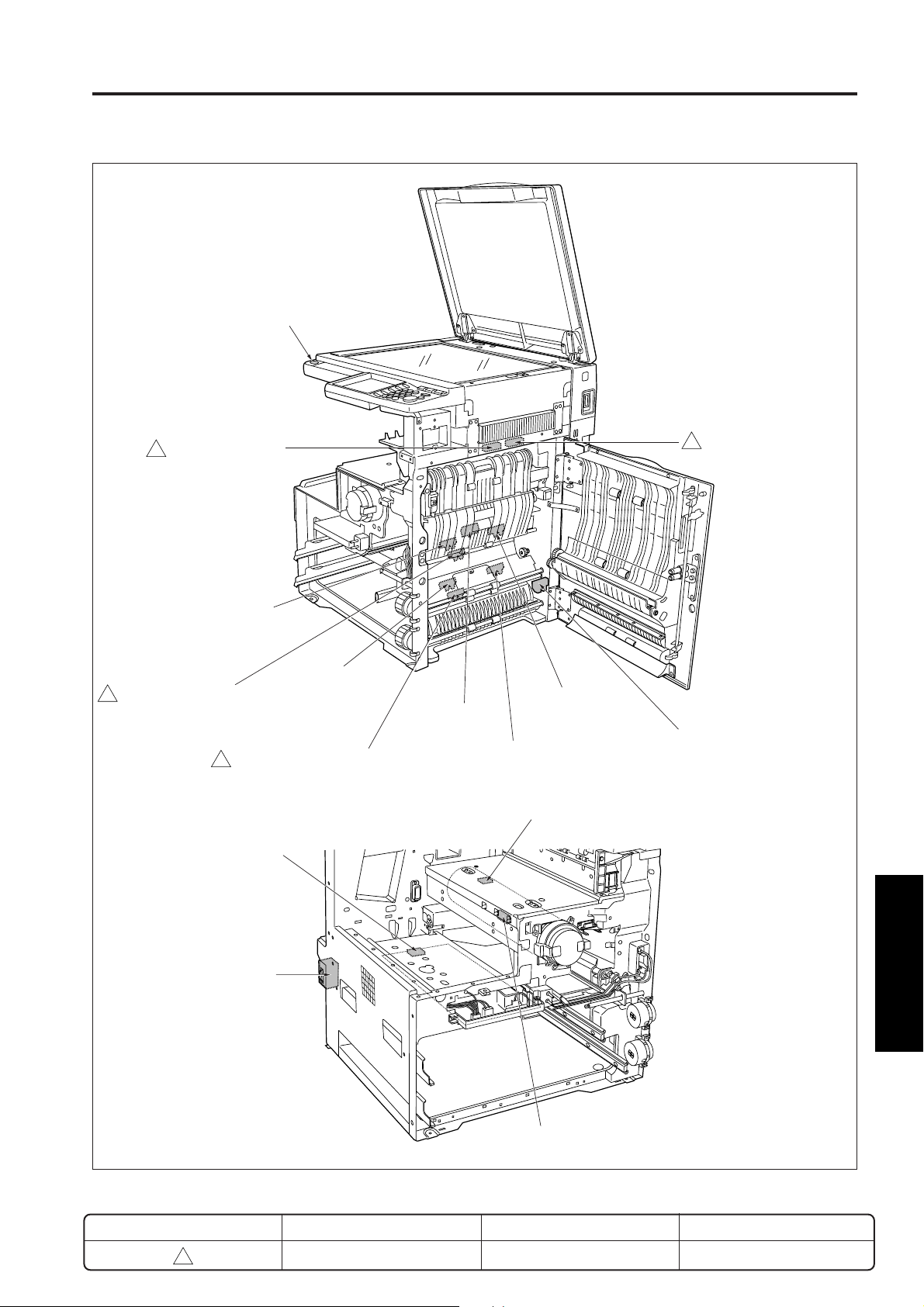

SW2 Sub power switch

PS3 Paper exit PS

3

*

Exclusivery for the

7020/25/30/35

MAIN BODY ELECTRICAL PARTS LAYOUT DRAWING

PS19 Exit limit detect PS

3

* Installed only on old type

7020/25/30/35

PS7 Upper limit

detect PS (upper)

PS21 Intermediate conveyance

3

PS (upper)

* Exclusively for the 7030/7130/7035

PS22 Intermediate conveyance PS

3

HUM1 Humidity sensor

SW1 Main power switch

PS10 Upper

limit detect PS

(lower)

(lower)

* Exclusively for the 7030

PS1 Registration PS

PS8 No paper

detect PS (upper)

PS4 ADU PS

PS11 No paper detect PS (lower)

/7130/7035

PS5 Toner bottle PS

5 DIAGRAMS

REVISED EDITION

3

DATE

Jan. 2002

5-3

SW3 Interlock switch

PAGE

5-3

METHOD

REPLACEMENT

Page 5

MAIN BODY ELECTRICAL PARTS LAYOUT DRAWING

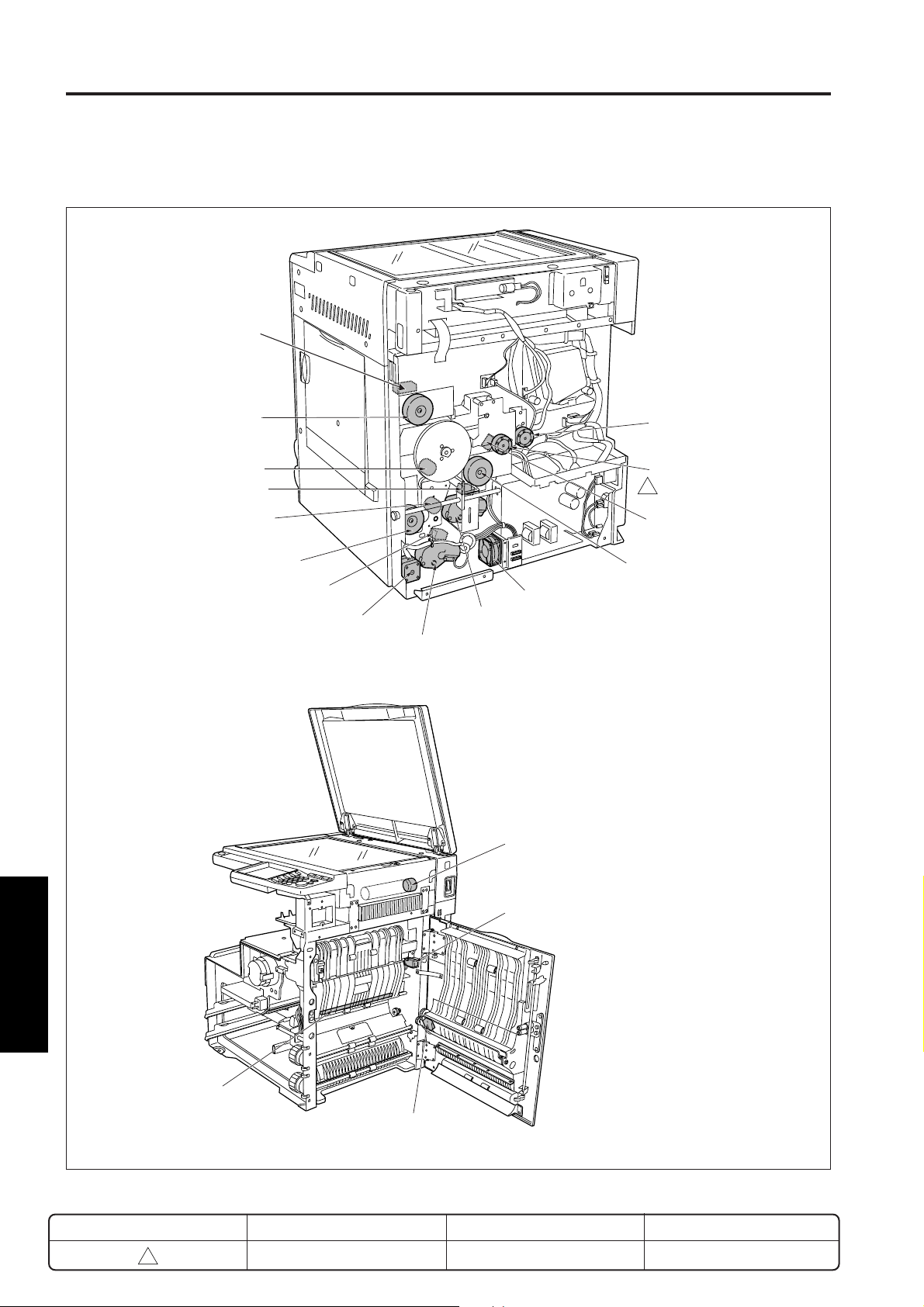

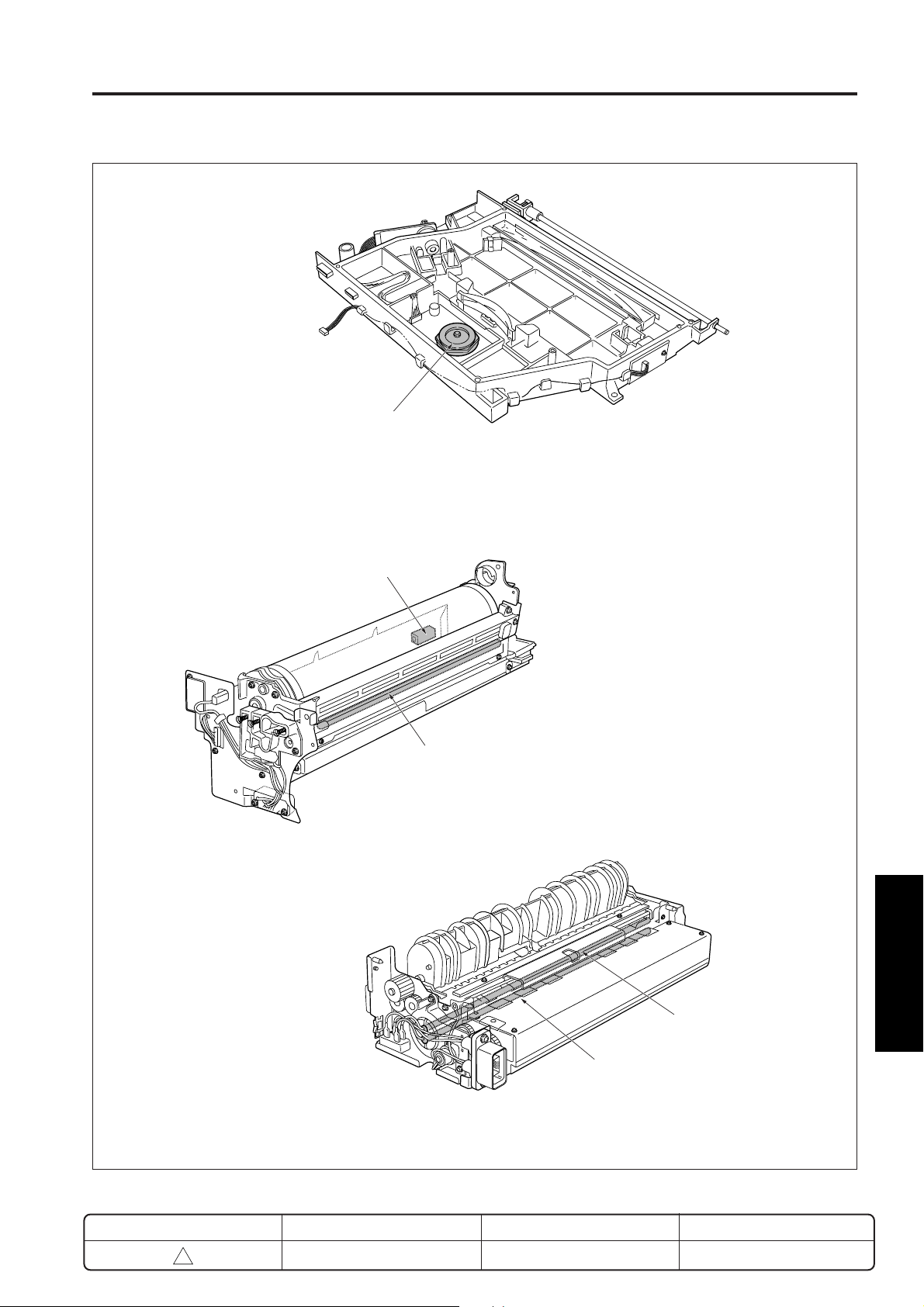

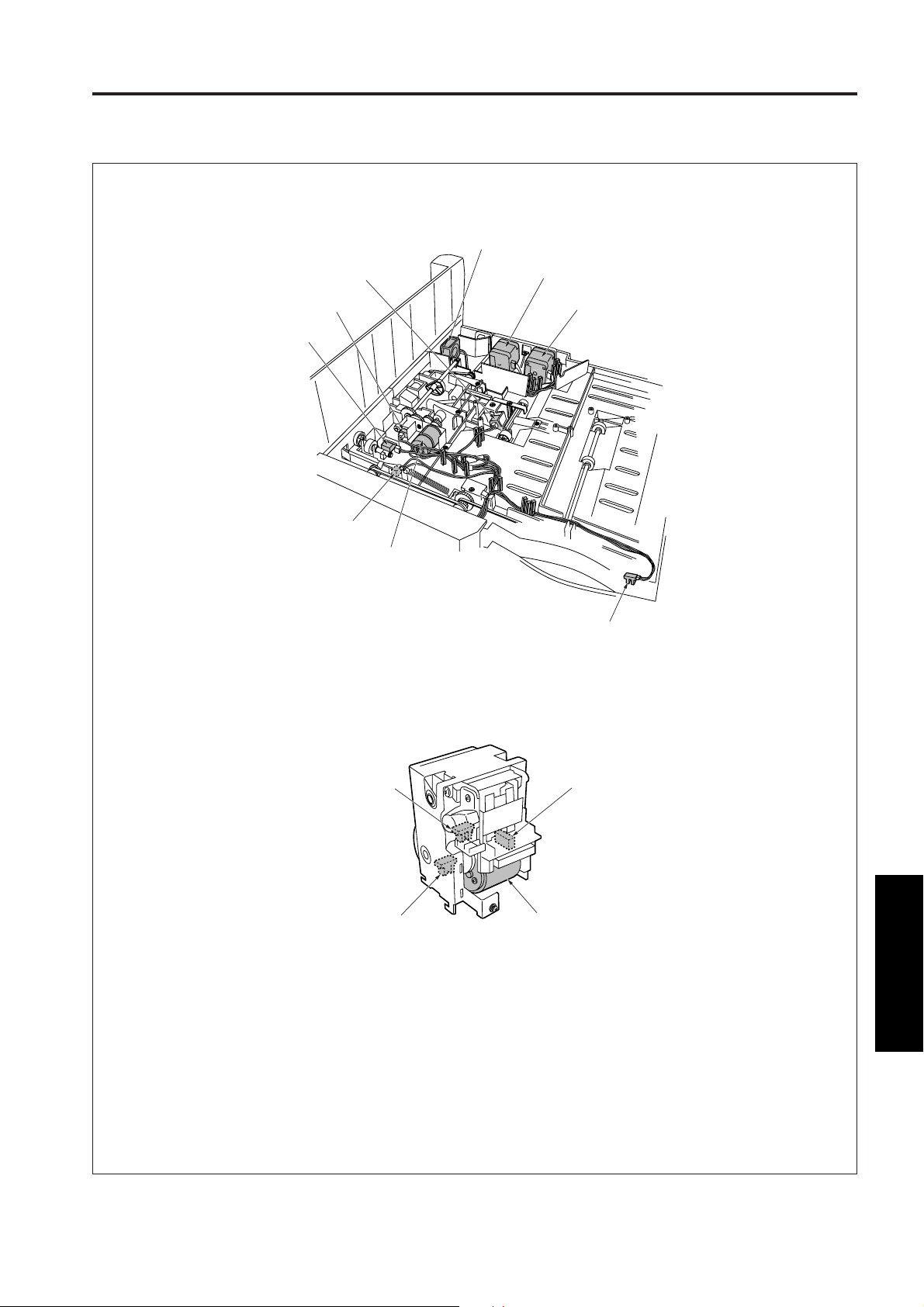

[2] Loads

SD5 ADU gate SD

M1 Main motor

MC1 Registration clutch

SD1 1st paper feed SD (upper)

MC2 Loop clutch

M9 Paper feed motor

SD2 1st paper feed SD (lower)

M6 ADU motor

M7 Tray motor (upper)

M8 Tray motor (lower)

M4 Toner supply motor 1

M10 Toner supply motor 2

*

Exclusivery for machines

3

other than 7020/25/30

SD6 Toner bottle SD

*

Exclusively for the 7020/25/30

M3 Developing motor

FM1 DCPS cooling fan

FM3 Internal dehumidifying fan

5 DIAGRAMS

TSL Transfer synchronisation lamp

REVISED EDITION

3

SD3 By-pass paper feed SD

DATE

5-4

Jan. 2002

SD4 Cleaning web SD

PAGE

5-4

METHOD

REPLACEMENT

Page 6

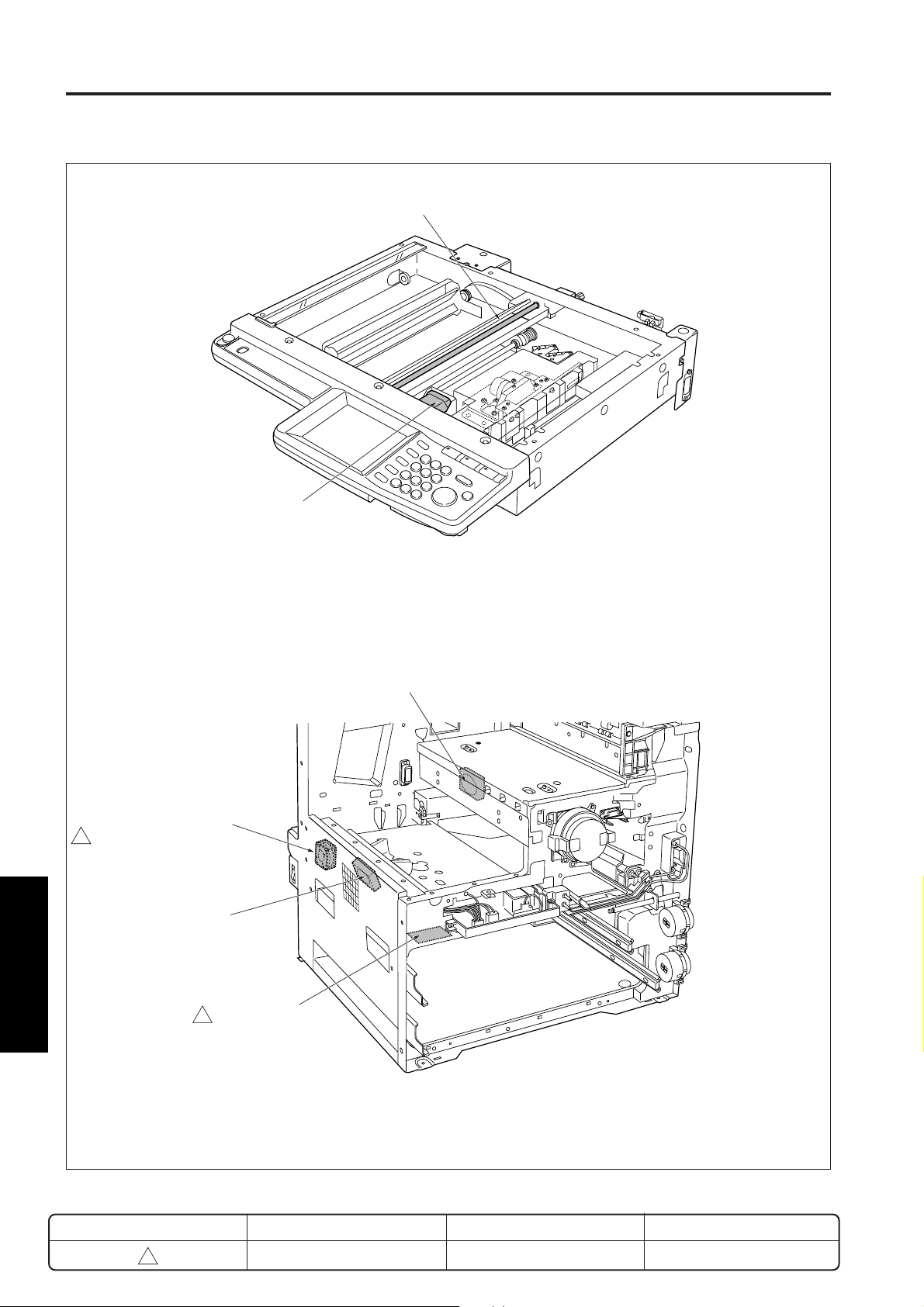

M5 Polygon motor

MAIN BODY ELECTRICAL PARTS LAYOUT DRAWING

SD7 Separation claw SD

PCL Pre-charging lamp

REVISED EDITION

1

DATE

May 2000

5-5

L2 Fixing heater lamp1

L3 Fixing heater lamp2

PAGE

5-5

5 DIAGRAMS

METHOD

REPLACEMENT

Page 7

MAIN BODY ELECTRICAL PARTS LAYOUT DRAWING

L1 Exposure lamp

M2 Optical drive motor

FM5 Developing suction fan

*

Exclusively for machines

3

other than 7020/25/30

FM4 Internal cooling fan

5 DIAGRAMS

PTC PTC heater

3

*

Treated as spare parts

in the case of a

machine other than the

7020/25/30/35.

FM2 Fixing cooling fan

REVISED EDITION

3

DATE

Jan. 2002

5-6

PAGE

5-6

METHOD

REPLACEMENT

Page 8

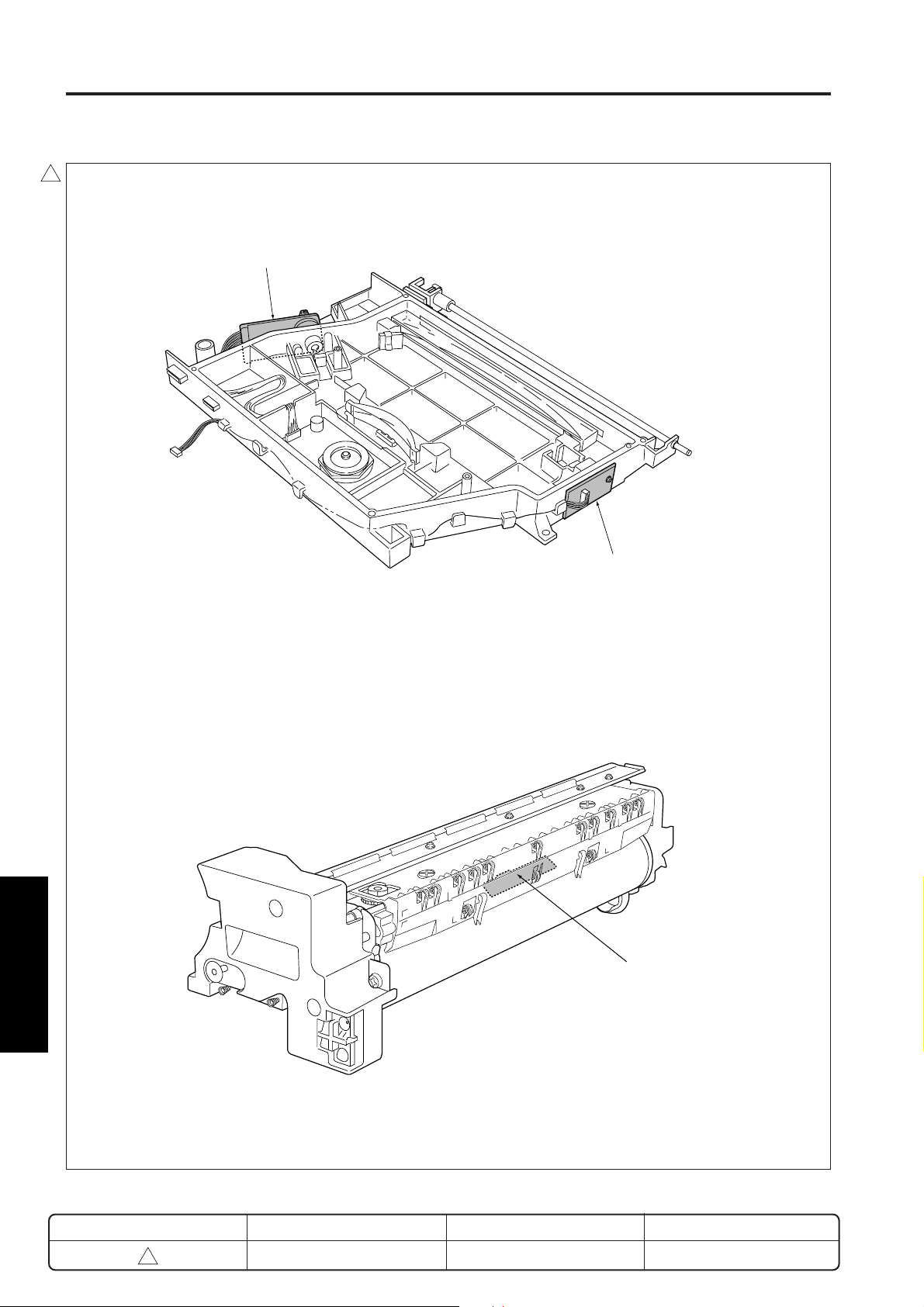

[3] PCBs and others

1

MAIN BODY ELECTRICAL PARTS LAYOUT DRAWING

HV High voltage unit

PRMB Parameter memory board

PFDB (UPPER)

Paper feed detection

board (upper)

PFDB (LOWER)

Paper feed detection

board (lower)

INV1 Exposure lamp inverter

PRDB Printer drive board

CBR2 Circuit breaker 2

CBR1 Circuit breaker 1

CB Overall control board

PSWB Power SW board

PAKB Panel key board

REVISED EDITION

1

DCPS DC power supply unit

LCD display board

INV2 display inverter

DATE

May 2000

OB operation board

5-7

PAGE

5-7

L1INVB Exposure lamp

power supply board

5 DIAGRAMS

ADB A/D conversion

board

SCDB scanner drive board

METHOD

REPLACEMENT

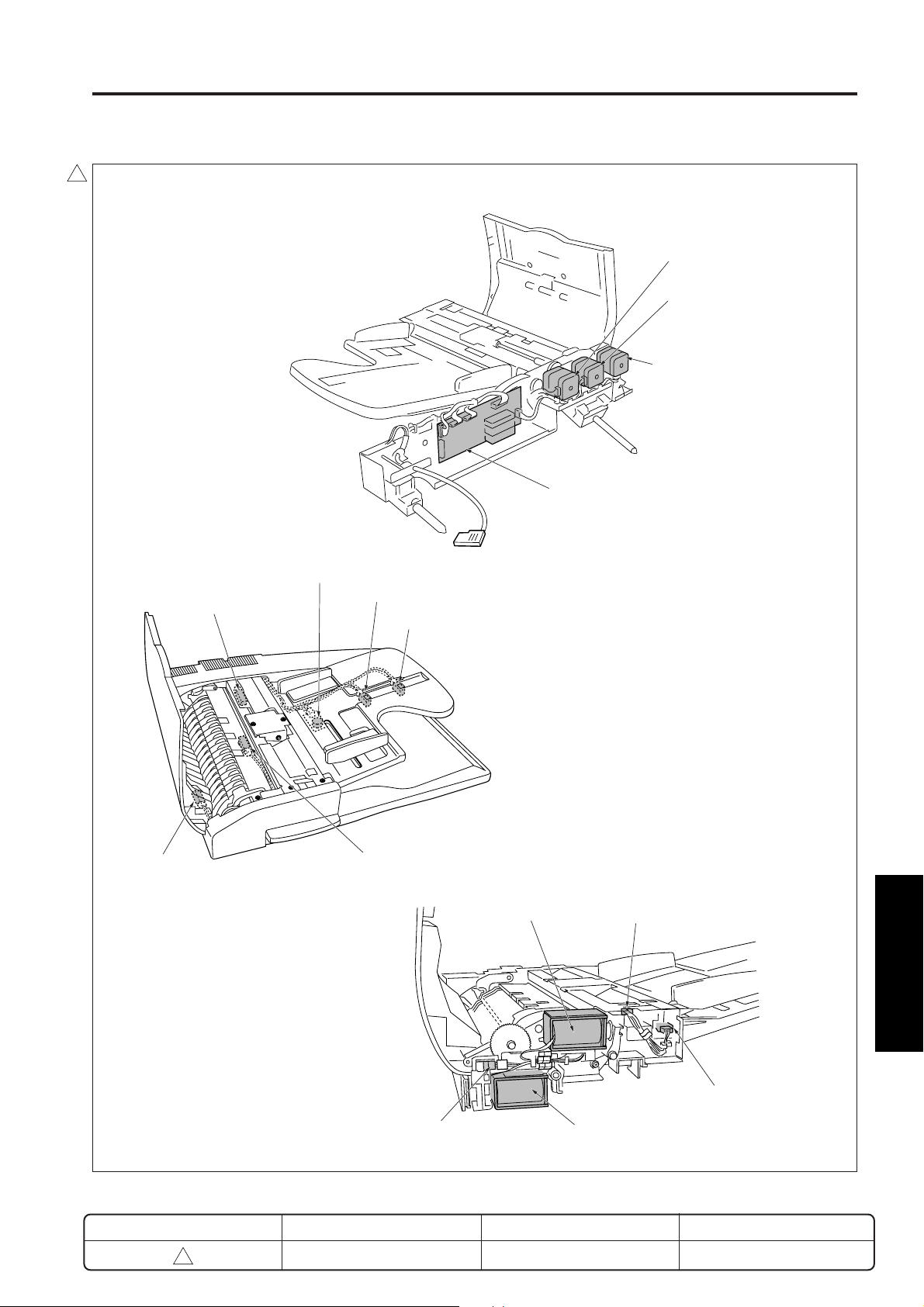

Page 9

MAIN BODY ELECTRICAL PARTS LAYOUT DRAWING

1

LDB LD drive board

INDEX Index sensor board

TCSB Toner control sensor board

5 DIAGRAMS

REVISED EDITION

1

DATE

May 2000

5-8

PAGE

5-8

METHOD

REPLACEMENT

Page 10

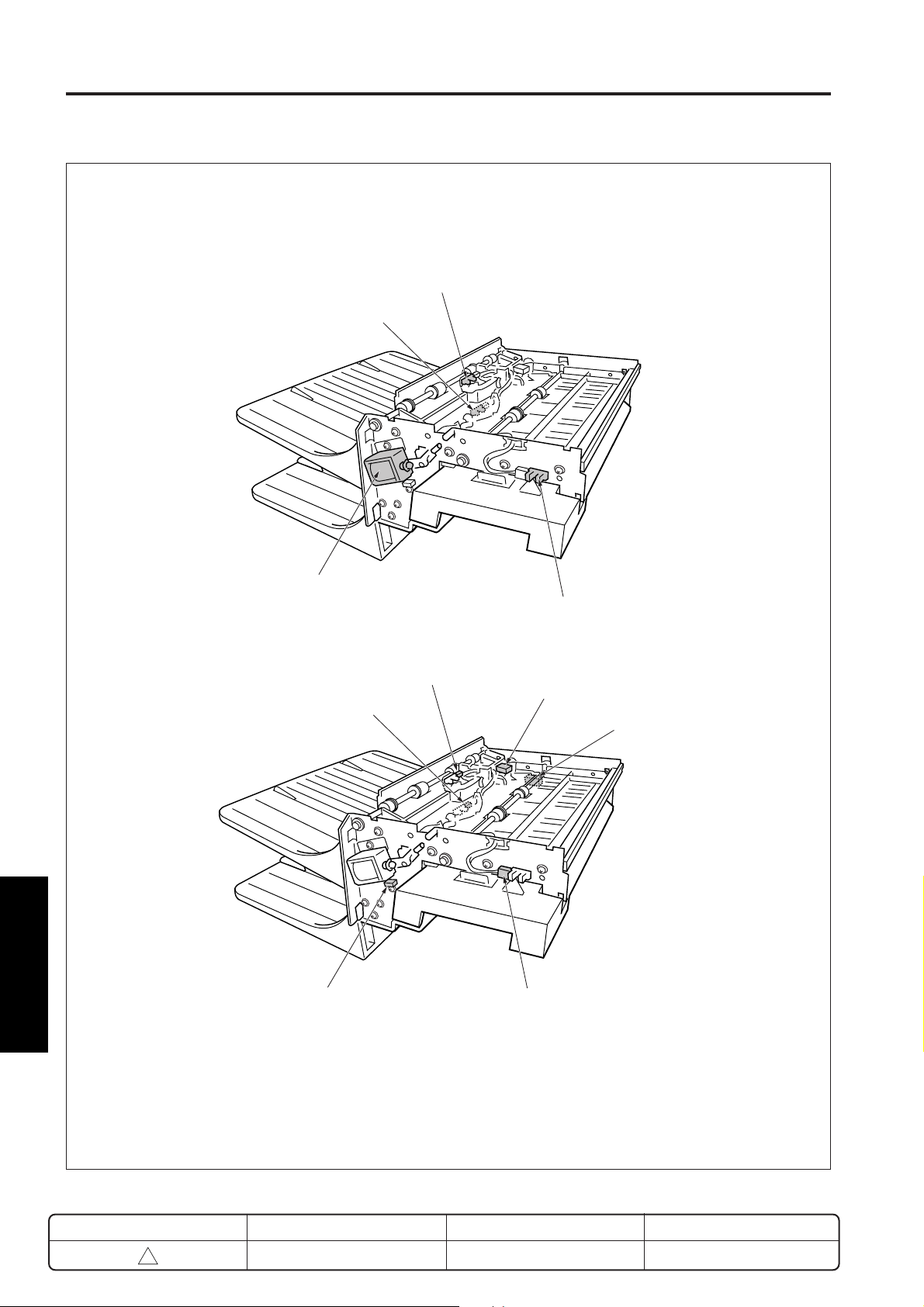

DF-314 ELECTRICAL PARTS LAYOUT DRAWING

DF-314 ELECTRICAL PARTS LAYOUT DRAWING

1

M301 Original feed motor

M303 Original reversal motor

M302 Original conveyance motor

DFCB RADF control board

PS303 Original exit PS

PS312 Original feed PS

VR301 Size detect VR

PS306 Original detect PS1

PS311 Original registration PS

PS307 Original detect PS2

SD302 Rollar pressure SD

PS305 Cover open/close detect PS

5 DIAGRAMS

REVISED EDITION

1

PS304 RADF open/close detect PS

DATE

5-9

May 2000

SD303 Exit SD

PAGE

5-9

PS301 No original detect PS

METHOD

REPLACEMENT

Page 11

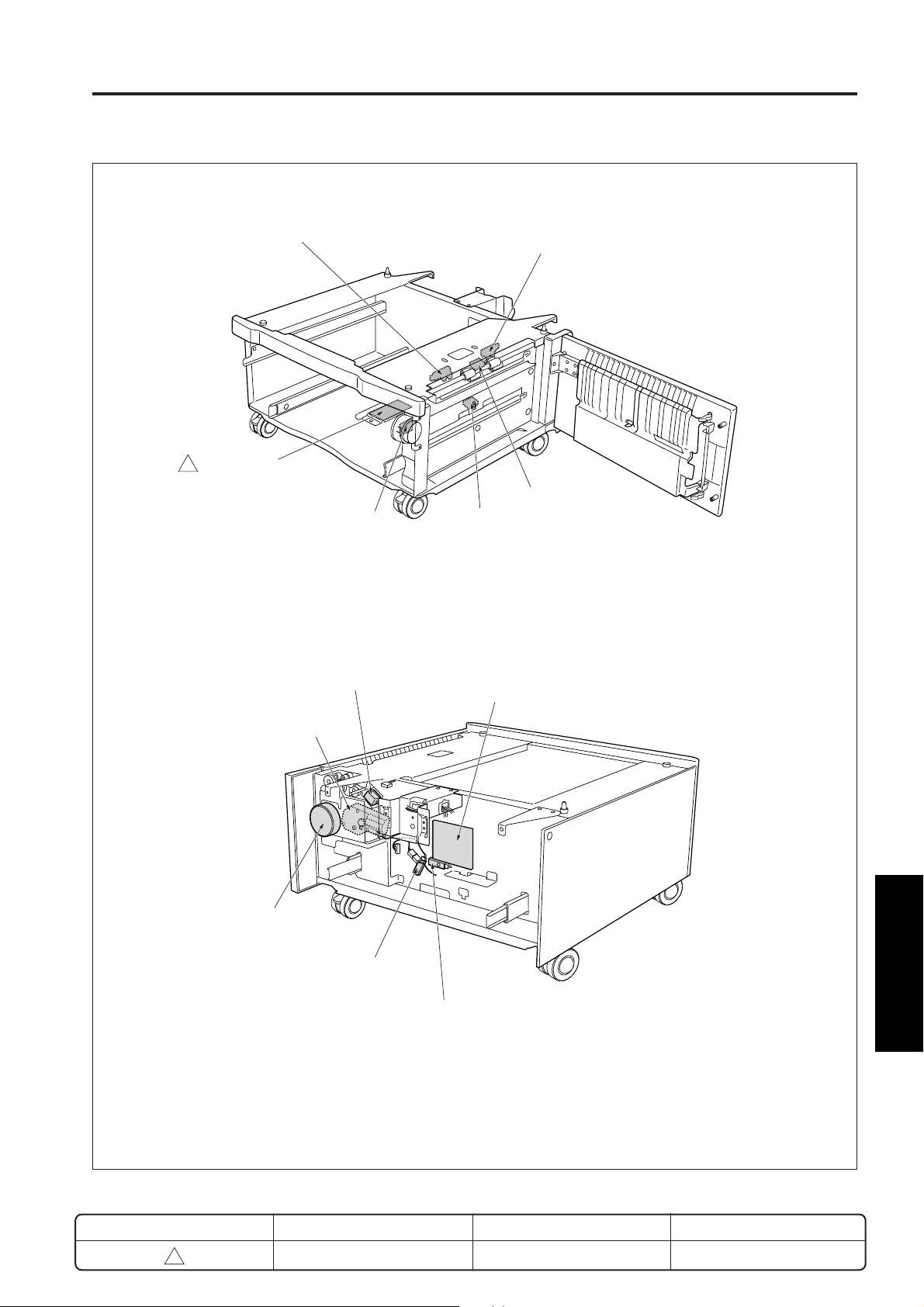

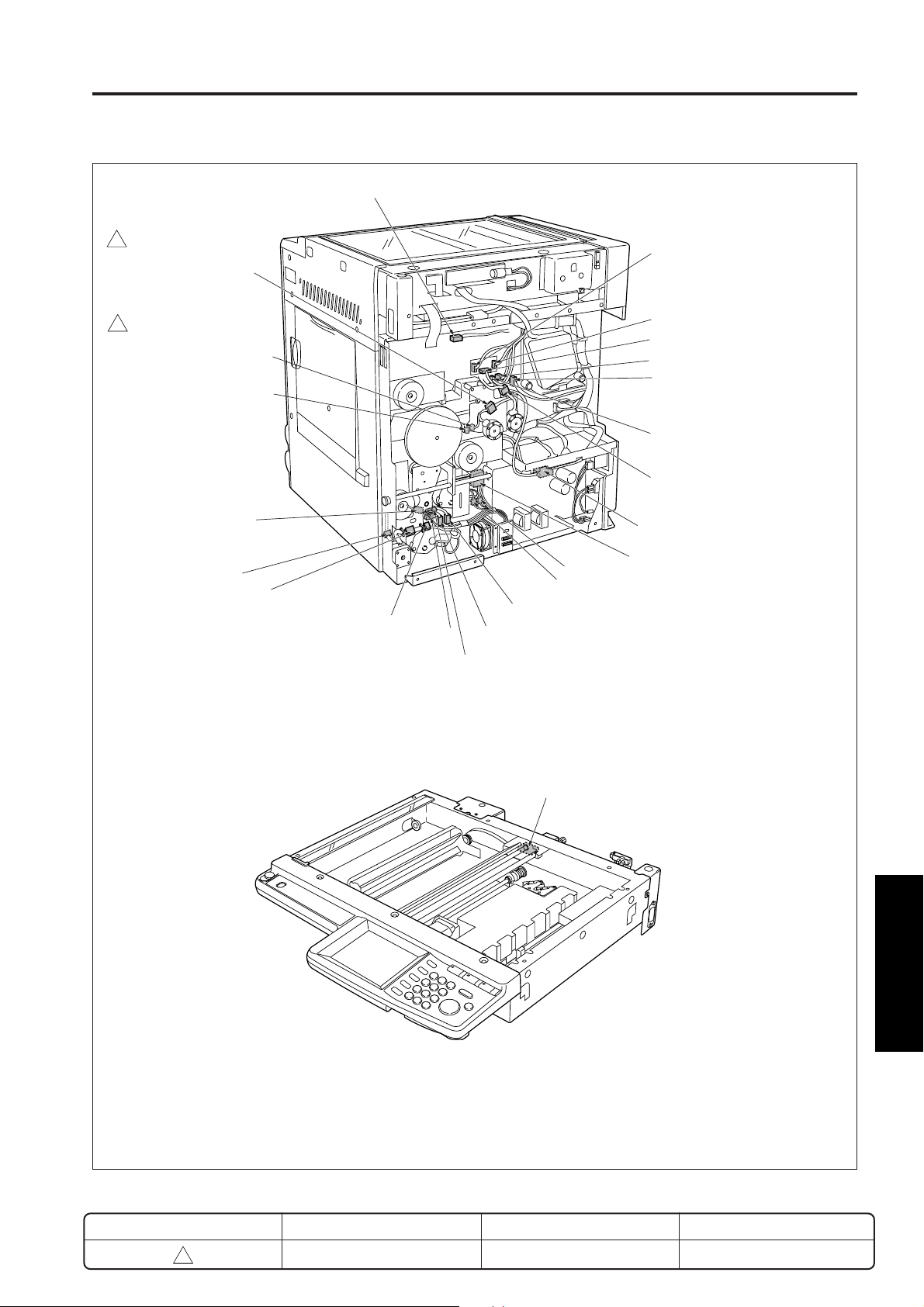

FS-107 ELECTRICAL PARTS LAYOUT DRAWING

FS-107 ELECTRICAL PARTS LAYOUT DRAWING

PS711 Tray upper limit detect PS

PS704 Tray full-stack detect PS

PS703 Paper exit detect PS

PS716 Tray count PS

PS706 Tray lower limit detect PS

M706 Tray up/down motor

PS709 Alignment plate

detect PS (rear)

M703 Alignment motor (rear)

M706 Tray up/down motor

M705 Stapler shift motor

PS707 No paper detect PS

PS708 Stapler unit HP detect PS

M704 Alignment motor (front)

MS701 Front door switch

PS710 Alignment plate

detect PS (front)

FSCB FS control board

5 DIAGRAMS

5-10

Page 12

FS-107 ELECTRICAL PARTS LAYOUT DRAWING

M709 Cooling fan motor

PS702 Paper entrance detect PS

PS701 Paper pressure PS

PS705 Shutter PS

MS702 Shutter switch

M707 Paper pressure motor

M702 Paper exit motor

M701 Paper conveyance motor

PS717 Conveyance cover open/close detect PS

PS714 Stapler ready detect PS

PS712 Stapler HP detect PS

M708 Stapler motorPS713 No-staple PS

5 DIAGRAMS

5-11

Page 13

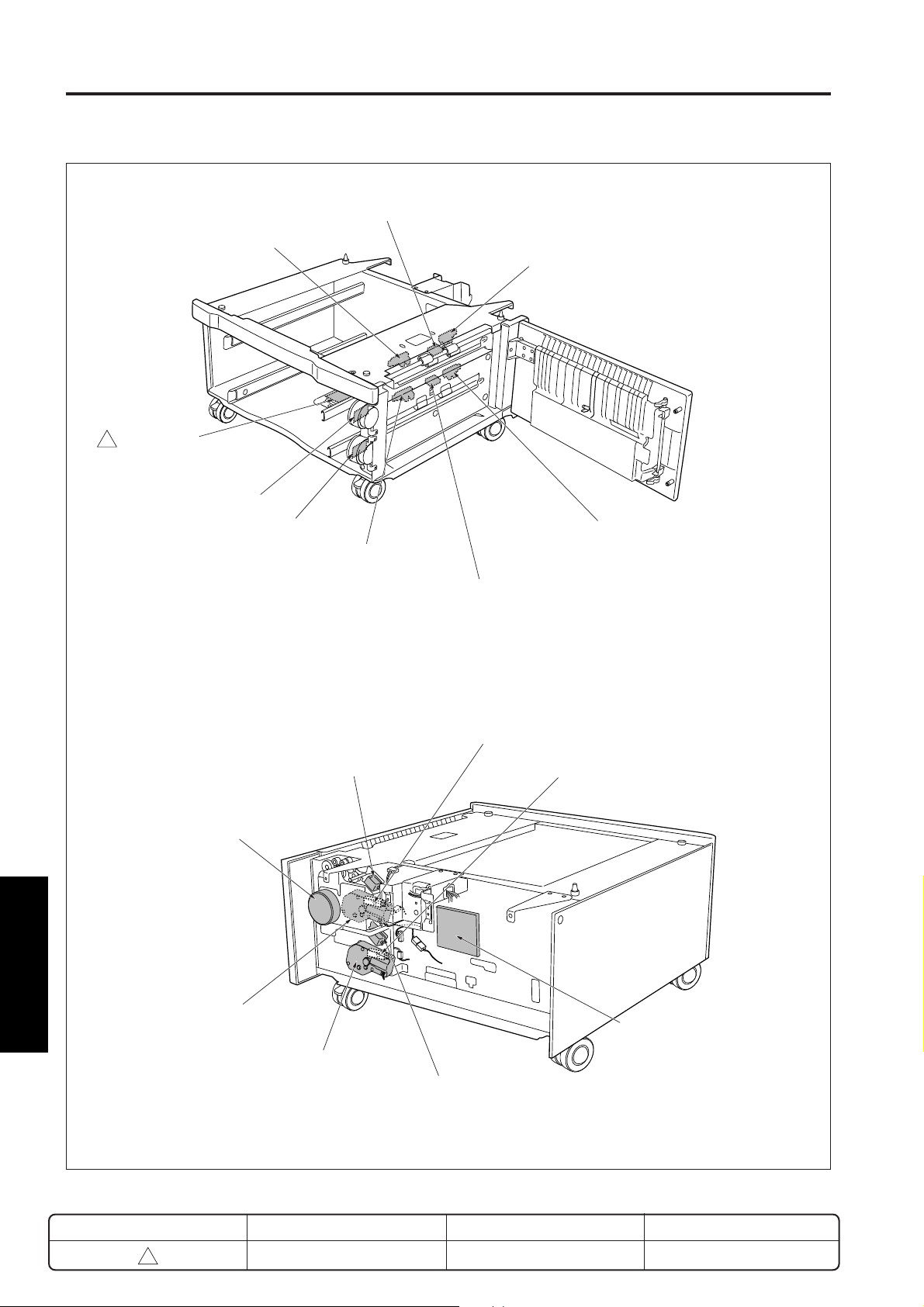

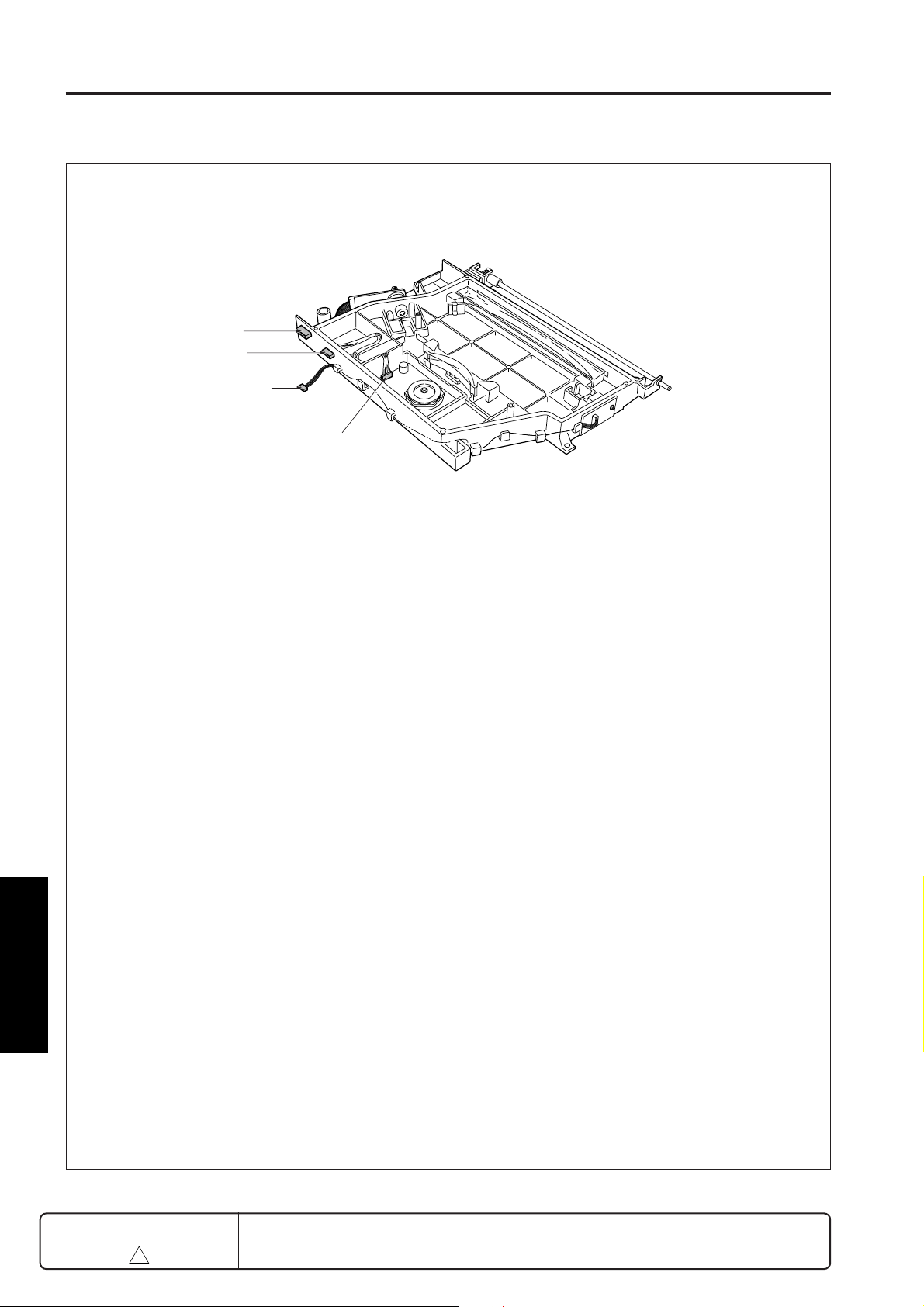

DB-209/210 ELECTRICAL PARTS LAYOUT DRAWING

DB-209/210 ELECTRICAL PARTS LAYOUT DRAWING

PS104 Jam detect PS1

PS102 Upper limit detect PS (upper)

PS103 No paper detect PS (upper)

PTC heater

3

*

Treated as a spare parts in

the case of new type DB

SDB1 Size detection board 1

SDB1 Size detection board 2

PS107 Upper limit detect PS (lower)

SD101 1st paper feed SD (upper)

M100 Paper feed motor

PS108 No paper detect PS (lower)

PS105 Jam detect PS2

PS101 Tray detect PS (upper)

PS106 Tray detect PS (lower)

5 DIAGRAMS

REVISED EDITION

3

M101 Tray motor1

M102 Tray motor2

SD102 1st paper feed SD (lower)

DATE

5-12

Jan. 2002

PAGE

5-12

PFUDB PFU drive board

METHOD

REPLACEMENT

Page 14

DB-409/410 ELECTRICAL PARTS LAYOUT DRAWING

DB-409/410 ELECTRICAL PARTS LAYOUT DRAWING

PS102 Paper level detect PS1

PTC Heater

3

*

Treated as a spare parts in

the case of new type DB

SDB 1 Size detection board 1

SD101 1st paper feed SD

PS103 No paper detect PS

PS104 Jam detect PS1

PS105 Jam detect PS2

LCTDB LCT drive board

M101 Tray motor

M100 Paper feed motor

PS101 Tray detect PS

PS109 Paper level detect PS2

5 DIAGRAMS

REVISED EDITION

3

DATE

Jan. 2002

5-13

PAGE

5-13

METHOD

REPLACEMENT

Page 15

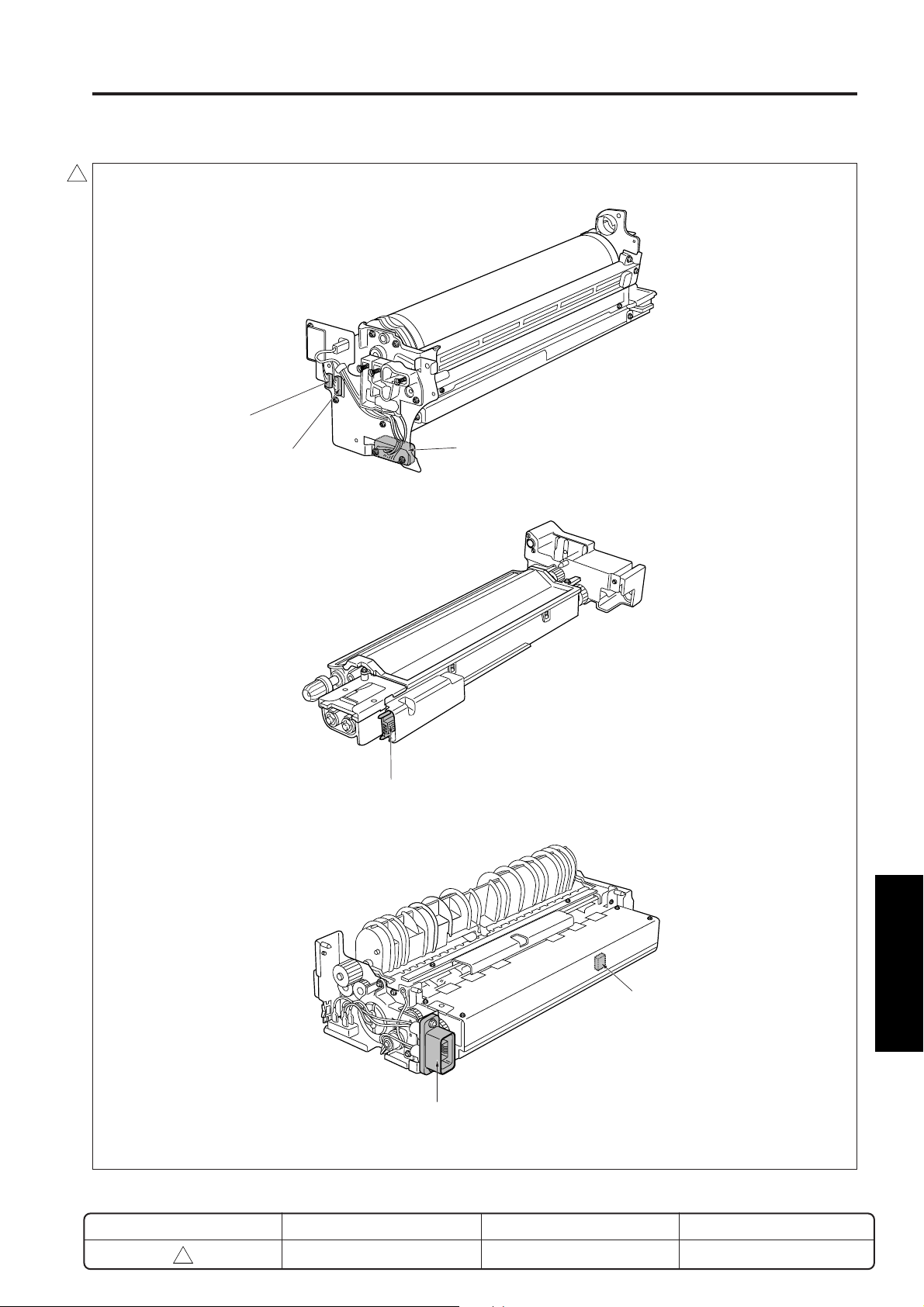

IT-101 ELECTRICAL PARTS/CONNECTOR LAYOUT DRWING

IT-101 ELECTRICAL PARTS/CONNECTOR LAYOUT DRAWING

PS23 IT exit PS (upper)

PS24 IT exit PS (lower)

5 DIAGRAMS

SD8 IT gate SD

PS25 IT door PS

CN972 (W:3pin)

J43 (W:8pin)

CN973 (W:3pin)

J42 (BK:12pin)

CN292 (W:2pin) CN974 (W:3pin)

REVISED EDITION

2

DATE

Feb. 2001

5-14

PAGE

5-14

METHOD

ADDITION

Page 16

MAIN BODY CONNECTOR LAYOUT DRAWING

MAIN BODY CONNECTOR LAYOUT DRAWING

J42 (BK:12pin)

3

J915 (W:6pin)

* Exclusively for machines

other than 7020/25/30

3

CN927 (W:2pin)

*

Exclusively for the 7020/25/30

J05 (W:3pin)

CN921 (B:2pin)

J30 (W:3pin)

J04 (W:11pin)

CN905 (W:6pin)

J03 (W:11pin)

J12 (W:9pin)

J28 (B:3pin)

J21 (W:3pin)

J23 (W:4pin)

CN903 (W:8pin)

J06 (W:3pin)

J 903 (W:6pin)

CN9 (W:3pin)

J14 (W:6pin)

J31 (W:3pin)

CN922 (W:2pin)

J32 (W:3pin)

CN923 (W:2pin)

J02 (W:7pin)

REVISED EDITION

3

DATE

Jan. 2002

5-15

CN930 (W:2pin)

PAGE

5-15

5 DIAGRAMS

METHOD

REPLACEMENT

Page 17

MAIN BODY CONNECTOR LAYOUT DRAWING

J50 (W:12pin)

J51 (W:5pin)

J52 (W:5pin)

CN904 (5pin)

5 DIAGRAMS

REVISED EDITION

1

DATE

May 2000

5-16

PAGE

5-16

METHOD

REPLACEMENT

Page 18

MAIN BODY CONNECTOR LAYOUT DRAWING

1

J928 (W:2pin)

J11 (W:7pin)

J16 (BK:18pin)

J17 (BK:10pin)

REVISED EDITION

1

DATE

May 2000

J13 (BK:8pin)

5-17

PAGE

5-17

J13 (W:4pin)

5 DIAGRAMS

METHOD

REPLACEMENT

Page 19

MAIN BODY CONNECTOR LAYOUT DRAWING

Overall control board

CN39

(25pin)

CN40

(36pin)

CN32

(20pin)

CN46

(50pin)

CN800

(68pin)

CN37

(120pin)

CN33

(24pin)

CN48

(20pin)

CN801

(68pin)

CN47

(22pin)

CN34

(24pin)

CN803

(6pin)

CN500

CN30

(6pin)

CN431

(5pin)

(4pin)

CN432

(12pin)

CN45

(11pin)

CN44

(19pin)

CN42

(9pin)

CN38

(100pin)

3

CN31

(8pin)

High voltage unit Printer drive board

CN70

(9pin)

CN72

(3pin)

5 DIAGRAMS

CN71

(12pin)

CN28

(

38 pin

(

CN37

(

)

8 pin

CN38

(

)

4 pin

CN35

(

)

5 pin

CN36

(

)

10 pin

CN601

3

(

10 pin

*

Exclusively for the machines

other than 7020/25/30

CN19

(

24 pin

)

)

CN29

36 pin

CN25

(

34 pin

)

CN23

(

22 pin

)

)

CN26

(

26 pin

3

CN79

(6

)

pin

)

*

Exclusively for the

CN27

(

)

8 pin

CN24

(

)

40

pin

)

7030/7130/7035

CN20

(

)

4 pin

CN21

(

)

6 pin

CN22

(

)

5 pin

REVISED EDITION

3

DATE

Jan. 2002

5-18

PAGE

5-18

METHOD

REPLACEMENT

Page 20

MAIN BODY CONNECTOR LAYOUT DRAWING

DC power supply unit A/D conversion board

CN1

(5pin)

CN2

(14pin)

CN3

(5pin)

CN7

(26pin)

CN8

(4pin)

CN5

(4pin)

CN6

(20pin)

CN10

(3pin)

CN60

(50pin)

Scanner drive board Operation board

<Other than 7035>

3

CN62

(

3 pin

CN66

(

7 pin

CN65

(

8 pin

<7035>

CN62

(

3 pin

CN66

(

7 pin

CN65

(

8 pin

)

)

)

CN60

(

10 pin

)

)

)

CN60

(

10 pin

)

CN63

(

4 pin

)

CN63

(

4 pin

CN64

(

15 pin

)

CN64

(

7 pin

)

CN68

(

)

8 pin

Exclusively for the

*

CN61

(

)

11 pin

)

CN61

(

)

11 pin

CN67

(

)

6 pin

)

3

<Other than 7020/25/30/35>

CN81

(13pin)

<7020/25/30/35>

CN81

(13pin)

CN87

(2pin)

CN86

(14pin)

CN86

(14pin)

(12pin)

(12pin)

CN80

CN80

CN82

(5pin)

CN82

(5pin)

CN84

(18pin)

CN84

(18pin)

CN83

(4pin)

5 DIAGRAMS

CN83

(4pin)

REVISED EDITION

3

DATE

Jan. 2002

5-19

PAGE

5-19

METHOD

REPLACEMENT

Page 21

MAIN BODY CONNECTOR LAYOUT DRAWING

LD drive board Index senser board

CN50

(12pin)

Toner control sensor board Power SW board

CN1

(7pin)

CN51

(5pin)

CN1

(3pin)

Paper feed detection board (upper, lower) Parameter memory board

5 DIAGRAMS

REVISED EDITION

1

CN1

(5pin)

DATE

May 2000

5-20

PAGE

5-20

CN2

(24pin)

CN1

(20pin)

METHOD

REPLACEMENT

Page 22

Exposure lamp power supply board

MAIN BODY CONNECTOR LAYOUT DRAWING

CN97 (2pin)

Display inverter

CN77

(4pin)

CN96 (2pin)

CN71

(3pin)

Exposure lamp inverter

CN931

(4pin)

REVISED EDITION

1

CN930

(3pin)

DATE

May 2000

5-21

PAGE

5-21

5 DIAGRAMS

METHOD

REPLACEMENT

Page 23

DF-314 CONNECTOR LAYOUT DRAWING

DF-314 CONNECTOR LAYOUT DRAWING

1

CN130 (W:6pin)

CN132 (W:6pin)

CN131 (W:6pin)

CN200 (GY:18pin)

CN123 (W:3pin)

CN113 (W:3pin)

CN117 (W:3pin)

CN116 (W:3pin)

CN1 (18pin)

CN3 (7pin)

CN6 (15pin)

CN5 (8pin)

CN4 (9pin)

DFCB

CN7 (30pin)

CN2 (22pin)

CN122 (W:3pin)

5 DIAGRAMS

REVISED EDITION

1

CN121 (W:3pin)

May 2000

DATE

CN114 (W:3pin)

5-22

CN136 (BK:2pin)

CN137 (W:2pin)

PAGE

5-22

CN115 (W:3pin)

CN111 (W:3pin)

CN105 (W:3pin)

METHOD

REPLACEMENT

Page 24

FS-107 CONNECTOR LAYOUT DRAWING

FS-107 CONNECTOR LAYOUT DRAWING

CN736 (B:3pin)

CN735 (W:3pin)

CN734 (W:3pin)

CN744 (W:3pin)

CN737 (B:3pin)

CN756 (W:15pin)

CN741 (W:3pin)

CN724 (W:6pin)

CN756 (W:15pin)

CN738 (W:3pin)

CN723 (B:6pin)

CN725 (W:6pin)

CN740 (B:3pin)

CN756 (W:15pin)

CN739 (W:3pin)

CN726 (BK:2pin)

5 DIAGRAMS

CN751 (W:1pin)

5-23

Page 25

FS-107 CONNECTOR LAYOUT DRAWING

CN753 (W:2pin) CN752 (W:3pin)

CN709 (12pin)

CN715 (30pin)

CN706 (2pin)

CN714 (15pin)

CN701 (10pin)

CN712 (2pin)

FS CB

CN711 (2pin)

CN704 (12pin)

CN702 (11pin)

CN713 (3pin)

CN710 (2pin)

CN733 (W:3pin)

CN732 (W:3pin)

CN300 (BK:24pin)

CN708 (8pin)

CN731 (W:3pin)

CN703 (12pin)

CN705 (W:6pin)

CN722 (W:6pin)

CN721 (W:6pin)

CN707 (30pin)

5 DIAGRAMS

CN734 (W:3pin)

CN730 (BK:2pin)

CN745 (W:3pin)

5-24

Page 26

DB-209/210 CONNECTOR LAYOUT DRAWING

2

DB-209/210 CONNECTOR LAYOUT DRAWING

CN102

2

(DB-209:6pin)

(DB-210:11pin)

PFU drive board

CN100

(6pin)

CN103

(24pin)

CN101

(26pin)

CN104

(19pin)

J70 (W:6pin)

J69 (W:6pin)

CN1

(5pin)

Size detection board 2Size detection board 1

CN1

(5pin)

J68 (W:7pin)

CN113 (W:12pin)

J64 (W:8pin)

J66 (W:3pin)

5 DIAGRAMS

J67 (W:3pin)

J63 (W:6pin)

J65 (W:11pin)

REVISED EDITION

2

DATE

Feb. 2001

5-25

PAGE

5-25

METHOD

REPLACEMENT

Page 27

DB-409/410 CONNECTOR LAYOUT DRAWING

2

DB-409/410 CONNECTOR LAYOUT DRAWING

CN102

2

(DB-409:6pin)

(DB-410:11pin)

LCT drive board

CN100

(6pin)

CN103

(24pin)

CN101

(26pin)

CN105

(DB-410:3pin)

Size detection board 1

CN1

(5pin)

CN105

(DB-409:3pin)

J69 (W:6pin)

CN113 (W:2pin)

5 DIAGRAMS

J68 (W:3pin)

J64 (W:8pin)

J66 (W:3pin)

J63 (W:6pin)

REVISED EDITION

2

DATE

Feb. 2001

5-26

PAGE

5-26

METHOD

REPLACEMENT

Page 28

LIST OF JAM CODES

During operation

LIST OF JAM CODES

Classification

By-pass

Upper tray

Lower tray

DB tray

Conveyance

Fixing/exit

ADU

conveyance

FS-107

3

7020/25/30/

35 only

3

7020/25/30/

35 only

J72-16

J72-17

J72-19

Code

J10

J11

J12

J13

J14

J16

J30

J31

J32

J32-2

J33

J92

J97-1

J97-2

Causes

PS1 (registration) failed to turn ON within a

predetermined time after start of by-pass feed

(after SD3 (by-pass) ON).

PS1 (registration) failed to turn ON within a

predetermined time after start of upper-tray

feed (after SD1 (first paper-feed (upper)) ON).

PS1 (registration) failed to turn ON within a

predetermined time after start of upper-tray

feed (after SD2 (first paper-feed (lower)) ON).

PS104 (jam detect 1) failed to turn ON within a

predetermined time after start of feed from DB

upper tray (after SD101 (first paper-feed

(upper)) ON).

PS104 (jam detect 1) failed to turn ON within a

predetermined time after start of feed from DB

lower tray.

PS1 (registration) failed to turn ON within a

predetermined time after paper passed PS104

(jam detect 1).

• DB upper tray feed

• DB lower tray feed

PS1 (registration) failed to turn OFF within a

predetermined time after MC1 (registration) ON.

PS2 (fixing exit) failed to turn OFF within a

predetermined time after MC1 (registration) ON.

PS3 (paper exit) failed to turn ON within a

predetermined time after PS2 (fixing exit) ON.

(At the single side copy mode)

PS2 (fixing exit) failed to turn OFF within a

predetermined time after turning ON.

PS3 (paper exit) failed to turn OFF within a

predetermined time after turning ON.

PS1 (registration) failed to turn ON within a

predetermined time after start of ADU reversal.

PS4 (ADU) failed to turn ON within a

predetermined time after PS2 (fixing exit) ON.

PS4 (ADU) failed to turn OFF within a

predetermined time after turning ON.

PS702 (paper entrance detect) failed to turn ON within

a predetermined time after PS3 (paper exit) ON.

PS702 (paper entrance detect) failed to turn ON within a

predetermined time after PS707 (no paper detect) ON.

(Straight, sort/group mode for other than small size)

PS702 (paper entrance detect) failed to turn OFF

within a predetermined time after turning ON.

(Staple, sort/group, and small size straight modes)

Resulting

If copying is in

progress at time

of jam, the

copier

completes

ejection and

then stops.

The main body

stops

immediately.

The FS-107 and

main body stop

immediately.

operation

Correction

Take out the paper from the

bypass tray, and remove

any jammed paper.

Open the ADU door,

remove any jammed paper,

and close the door.

Pull out the tray, and

remove any jammed paper.

Open the DB conveyance

door, remove any jammed

paper, and close the door.

Pull out the tray, and

remove any jammed paper.

Open the ADU door and/or

DB conveyance door,

remove any jammed paper,

and close the door.

Open the ADU door,

remove any jammed paper,

and close the door.

Open the finisher front door,

and conveyance cover

remove any jammed paper,

and close the door.

5 DIAGRAMS

REVISED EDITION

3

DATE

Jan. 2002

5-27

PAGE

5-27

METHOD

REPLACEMENT

Page 29

LIST OF JAM CODES

Classification

FS-107

IT-101

DF-314

5 DIAGRAMS

Code

J72-21

J72-23

J72-81

J75-10

J75-11

3

J75-12

J75-13

PS707 (No paper detect) failed to turn OFF within a

predetermined time after M702 (Paper exit) turning ON.

(Staple, sort/group, and small size straight modes)

PS707 (No paper detect) failed to turn OFF within

a predetermined time after turning ON. (Straight,

sort/group mode for other than small size)

Staple jam: M708 (stapler) failed to turn OFF

within a predetermined time after turning ON.

(Forward operation not completed.) (Staple mode)

PS23 (IT paper exit (upper)) does not go ON within a

predetermined time after PS3 (paper exit) (in the case of a

machine other than 7020/25/30/35, PS2 (fixing exit)) goes ON.

PS24 (IT exit (lower)) is not turned ON within a

predetermined time after PS3 (paper exit) (in the case

of the 7020/25/30/35, PS2 (fixing exit)) is turned ON.

PS3 (paper exit) (in the case of machines other

than the 7020/25/30/35, PS2 (fixing exit)) does

not go OFF within a predetermined time after

PS23 (IT paper exit (upper)) or PS24 (IT paper

exit (lower)) goes ON.

The IT door of the IT-101 opened while the main

body was operating.

J61-0

PS305 (cover open/close detect) turned ON.

(The paper feed cover is opened.)

J61-1

PS304 (RADF open/close detect) turned ON.

J62-0

Original did not feed.

J62-2

PS312 (original feed) failed to turn ON within a

predetermined time after start of refeed for

single sided original.

J62-3

PS312 (original feed) failed to turn ON within a

predetermined time after start of reverse exit for

double sided original.

J62-4

PS312 (original feed) did not go OFF within the

specified period after it went ON, during paper exit.

J62-5

PS312 (original feed) did not go OFF within the

specified period after it went ON, during reversal.

J63-0

PS303 (original exit) did not go ON during

paper exit.

J63-2

PS303 (original exit) did not go OFF within the

specified period after it went ON, during paper

exit.

J63-4

PS311 (original registration) failed to turn OFF

within a predetermined time after start of refeed

of single sided original.

J63-5

PS311 (original registration) failed to turn OFF within

a predetermined time after start of reverse feed.

Causes

Resulting

operation

The FS-107

and main body

stop

immediately.

The main body

stops

immediately.

The DF-314

stops

immediately.

Correction

Open the finisher front

door, and conveyance

cover remove any jammed

paper, and close the door.

Remove the jammed

staple.

Open the IT door, and

remove the jammed paper,

then close the door.

Open the RADF, remove

any jammed paper, and

then close.

Remove any jammed

paper from the main body's

conveyance section.

REVISED EDITION

3

DATE

Jan. 2002

5-28

PAGE

5-28

METHOD

REPLACEMENT

Page 30

LIST OF JAM CODES

Others

J20-2

J20-3

J20-4

J20-5

J20-6

J50-1

J50-2

J50-3

ADU door open jam

SW3 (Interlock switch) went OFF during printing.

FNS front door open jam

MS701 (front door) went OFF during printing.

System emergency stop jam

FNS conveyance door open jam

PS717 (conveyance cover open/close detect)

went OFF during printing.

FNS shutter switch operation jam

MS702 (shutter) went ON during printing.

Failed to receive print request from system within

a predetermined time after PS1 (registration) ON.

“Valid” signal failed to turn ON within a

predetermined time after start of printing.

MC1 (registration) failed to turn ON within a

predetermined time after start of printing.

Printer section

stops

immediately.

Machine stops

immediately.

Remove jammed paper

according to message.

Opne the ADU door,

remove any jammed paper,

and close the door.

Classification

Code

Causes

Resulting

operation

Correction

3

REVISED EDITION

3

DATE

Jan. 2002

5-29

PAGE

5-28-1

5 DIAGRAMS

METHOD

REPLACEMENT

Page 31

When idling

LIST OF JAM CODES

Classification

Paper feed

Exit

ADU

FS-107

DF-314

IT-101

3

Code

J81

J82

J90

J91

J100

J72-1

J72-2

J65-1

J65-2

J65-3

J65-8

J65-9

J65-10

J65-11

J75-10

Causes Correction

PS1 (registration) ON during idling state.

PS105 (Jam detect 2) ON during idling state.

PS2 (fixing exit) ON during idling state.

PS3 (paper exit) ON during idling state.

(7020/25/30/35 only)

PS4 (ADU) ON during idling state.

PS702 (paper entrance detect) ON during

idling state.

PS707 (no paper detect) ON during idling

state.

PS311 (original registration) ON during idling

state.

PS312 (original feed) ON during idling state.

PS311 (original registration), PS312 (original

feed) ON during idling state.

PS303 (original exit) ON during idling state.

PS311 (original registration), PS303 (original

exit) ON during idling state.

PS312 (original feed), PS303 (original exit) ON

during idling state.

PS311 (original registration), PS312 (original

feed), PS303 (original exit) ON during idling

state.

PS23 (IT exit (upper)) or PS24 (IT exit (lower))

went ON during idling.

Open the ADU door, remove jammed paper,

and close the door.

Open the DB feed door, remove jammed

paper, and close the door.

If paper is jammed in the main body: open

the ADU door, remove the jammed paper,

and close the door.

Open the ADU door, remove jammed paper,

and close the door.

Open the ADU door, remove jammed paper,

and close the door.

Open the finisher door, remove jammed

paper, and close the door.

Open the RADF, remove jammed paper,

and then close.

Open the IT door, remove jammed paper,

then close the door.

REVISED EDITION

3

DATE

Jan. 2002

5-31

PAGE

5-29

METHOD

REPLACEMENT

Page 32

LIST OF WARNING (ERROR) CODES

LIST OF WARNING (ERROR) CODES

Classification

Communication

abnormalities

Feed-tray and

drum-area

abnormalities

5 DIAGRAMS

Warning

code

F10-1

F10-2

F10-9

F18-1

F18-2

F18-3

F18-4

F22-1

F23-1

Causes

Failure in serial

communication between the

PRDB (printer drive board)

and CB (overall control board).

Two consecutive failures to

respond to PRDB (printer drive

board) A/D conversion request.

Communication error at PRDB

(printer drive board)

SRGA (serial gate array) error.

(Error in protocol for receive

control signals SREC, SACK.)

Error in main body upper tray

PS7 (tray upper limit detect

(upper)) failed to turn ON

within 26 seconds after M7

(tray (upper)) ON.

Error in main body lower tray

PS10 (tray upper limit detect

(lower)) failed to turn ON

within 26 seconds after M8

(tray (lower)) ON.

Error in DB upper tray

PS102 (upper limit detect

(upper)) failed to turn ON

within 26 seconds after M101

(tray 1) ON.

Error in DB lower tray

PS107 (upper limit detect

(lower)) failed to turn ON

within 26 seconds after M102

(tray 2) ON.

Internal overheating

The temperature at the

outside of the drum reached or

exceeded 47˚C.

PCL connector detached

With 24V ON and PCL OFF,

the PCL EM signal (pcl_em)

was detected as "H" (software

logic).

Resulting

operation

If copying is in

progress, the

main body

stops

immediately,

and the main

relay and 24V

power turn

OFF.

Correction Estimated abnormal parts

Switch SW2 (sub

power switch)

OFF and then

back ON.

Switch SW2 (sub

power switch) OFF,

connect the PCL

connector, and then

set SW2 ON.

PRDB (printer drive board)

CB (overall control board)

PRDB (printer drive board)

PRDB (printer drive board)

CB (overall control board)

PRDB (printer drive board)

M7 (tray (upper))

PS7 (tray upper limit detect

(upper))

PRDB (printer drive board),

M8 (tray (lower))

PS10 (tray upper limit detect

(lower))

PFU DB (PFU drive board)

or LCT DB (LCT drive board)

M101 (tray 1)

PS102 (upper limit detect

(upper))

PFU DB (PFU drive board)

M102 (tray 2)

PS107 (upper limit detect

(lower))

TCSB (toner-control sensor

1

board)

FM4 (internal cooling)

PCL connector

PRDB (printer drive board)

REVISED EDITION

1

DATE

May 2000

5-30

PAGE

5-30

METHOD

REPLACEMENT

Page 33

LIST OF WARNING (ERROR) CODES

Classification

High voltage

unit abnormalities

3

Fixing high

temperature

abnormalities

Warning

code

F26-1

F26-2

F26-3

F28-1

F28-2

F28-3

F34-1

F34-2

Causes Correction Estimated abnormal parts

L detection data error

If L detection power exceeds 26V

prior to toner out detection by the

TLD (toner level detect), the

automatic toner supply feature

should restore the toner density.

This error occurs if this feature

fails to restore the density.

Abnormal output from TDS

(toner density sensor)

Maximum TDS output voltage

failed to exceed 1.0V.

Abnormal output from TDS

(toner density sensor)

TDS output ripple voltage

failed to reach 0.5V

Charging error

EM detect signal

(charge_em1) was read 3

times at 100msec intervals.

Abnormal transfer spark (trans_em)

detected 3 times at 20msec

intervals, 5 times in succession for

the same job.

Abnormal separation spark

(separate_em) detected 5 times

at 20msec intervals, 5 times in

succession for the same job.

TH1 (fixing temperature sensor

1) detected abnormally high

temperature.

Temperature detected by TH1

remained at or above 231˚C for

0.4 seconds.

TH2 (fixing temperature sensor

2) detected abnormally high

temperature.

Temperature detected by TH2

remained at or above 231˚C for

0.4 seconds.

If copying is in

progress, the

main body

stops

immediately,

and the main

relay and 24V

power turn

OFF.

Main relay and 24

V power supply

go OFF at the

end of the job.

If copying is in

progress, the

main body

stops

immediately,

and the main

relay and 24V

power turn

OFF.

Main relay

turns OFF and

acceptance of

all keys is

disabled.

Resulting

operation

Set SW2 (sub

power switch)

OFF and then

back ON.

Set SW2 (sub

power switch)

OFF and then

back ON after set

to "0" the bit 1 in

DIP SW3 in 25

mode. (If you

switch power back

on without

releasing the

latch, the error will

recur.)

TDS (toner density sensor)

TLD (toner level detect

sensor)

PRDB (printer drive board)

Toner supply unit

TDS (toner density sensor)

PRDB (printer drive board)

Developer

TDS (toner density sensor)

PRDB (printer drive board)

M1 (main)

Developer agitating screw

Developing unit connector

Charging corona unit

HV (high voltage unit)

PRDB (printer drive board)

Transfer corona unit

HV (high voltage unit)

PRDB (printer drive board)

Separation corona unit

HV (high voltage unit)

PRDB (printer drive board)

TH1 (fixing temperature sensor 1)

TH2 (fixing temperature sensor 2)

L2 (fixing heater lamp 1)

L3 (fixing heater lamp 2)

PRDB (printer drive board)

DCPS (DC power supply)

5 DIAGRAMS

REVISED EDITION

3

DATE

Jan. 2002

5-31

PAGE

5-31

METHOD

REPLACEMENT

Page 34

LIST OF WARNING (ERROR) CODES

1

Classification

Fixing low

temperature

abnormalities

Warning

code

F35-1

F35-2

F35-3

F35-4

F35-5

Causes Correction Estimated abnormal parts

T

H1 (fixing temperature sensor 1)

detected abnormally low temperature.

Occurs if main motor remains

energized for longer than 10

seconds during idling state.

T

H1 (fixing temperature sensor 1)

detected abnormally low temperature.

During idling or copying, TH1

detected that temperature remained

at or below 165˚C for 10 seconds.

TH1 (fixing temperature sensor 1)

detected abnormally low temperature

(during warmup)

If TH1 detects that temperature is

below 170˚C at the time that L2

(fixing heater lamp 1) is started, it

records the temperature reading and

compares this with the temperature

reading obtained 10 seconds later.

This error occurs if the difference

between these temperature readings

is less than a predetermined level.

If TH1 detects that temperature is at

or above 170˚C at the time that L2

starts, this error occurs if TH1 fails to

detect warm-up completion temperature

within 10 seconds thereafter.

TH2 (fixing temperature sensor 2)

detected abnormally low

temperature.

Occurs if L3 (fixing heater lamp 2)

remains energized for longer than

10 seconds during idling state.

TH2 (fixing temperature sensor 2)

detected abnormally low

temperature.

During idling or copying, TH2

detected that temperature remained

at or below 165˚C for 10 seconds.

Resulting

operation

Main relay

turns OFF and

acceptance of

all keys is

disabled.

Set SW2 (sub

power switch)

OFF and then

back ON, after set

to "0" the bit 1 in

DIP SW3 in 25

mode. (If you

switch power back

on without

releasing the

latch, the error will

recur.)

TH1 (fixing temperature sensor

1)

TH2 (fixing temperature sensor

2)

L2 (fixing heater lamp 1)

L3 (fixing heater lamp 2)

PRDB (printer drive board)

DCPS (DC power supply)

5 DIAGRAMS

REVISED EDITION

1

DATE

May 2000

5-32

PAGE

5-32

METHOD

REPLACEMENT

Page 35

LIST OF WARNING (ERROR) CODES

Classification

Fixing low

temperature

abnormalities

Warning

code

F35-6

F35-7

F35-8

Causes

T

H2 (fixing temperature sensor 2)

detected abnormally low temperature.

At warm-up, if TH2 detects that

temperature is less than 170˚C at

the time when L3 (fixing heater lamp

2) is first energized, it stores the

temperature reading, then

compares it with the temperature

reading obtained 10 seconds later.

This error occurs if the difference

between the two reads is less than a

predetermined value.

If TH2 detects that temperature is

170˚C or higher at the time when

power is first supplied to L3, this

error occurs if the TH2 fails to detect

warm-up completion temperature

within 10 seconds.

Fixing heat roller wrapping jam failure

This error occurs during print state if

the temperature detected by TH1

(fixing temperature sensor 1) is

more than 10 data readings above

the temperature data reading

obtained 1 second earlier (i.e.,

temperature is low), and this

condition continues for 0.2 seconds.

Fixing heat roller wrapping jam failure

This error occurs during print state if

the temperature detected by TH2

(fixing temperature sensor 2) is

more than 10 data readings above

the temperature data reading

obtained 1 second earlier (i.e.,

temperature is low), and this

condition continues for 0.2 seconds.

Resulting

operation

Main relay

turns OFF and

acceptance of

all keys is

disabled.

Correction Estimated abnormal parts

Set SW2 (sub

power switch)

OFF and then

back ON. Set to

"0" the bit 1 in DIP

SW3 in 25 mode.

(If you switch

power back on

without releasing

the latch, the error

will recur.)

TH1 (fixing temp detector 1)

TH2 (fixing temp detector 2)

L2 (fixing heater lamp 1)

L3 (fixing heater lamp 2)

PRDB (printer drive board)

DCPS (DC power supply)

5-33

5 DIAGRAMS

Page 36

LIST OF WARNING (ERROR) CODES

Classification

Fixing low

temperature

abnormalities

Warning

code

F35-9

1

F35-10

1

TH1 (fixing temperature sensor

1) bad contact

This error occurs during

warm-up if TH1 fails to make

its first detection of "Ready"

temperature within 11

seconds after TH2 (fixing

temperature sensor 2) first

makes this detection.

TH2 (fixing temperature sensor

2) bad contact

This error occurs during

warm-up if TH2 fails to make

its first detection of "Ready"

temperature within 11

seconds after TH1 (fixing

temperature sensor 1) first

makes this detection.

Resulting

operation

Main relay

turns OFF and

acceptance of

all keys is

disabled.

Correction Estimated abnormal partsCauses

Set SW2 (sub

power switch)

OFF and then

back ON. Set to

"0" the bit 1 in DIP

SW3 in 25 mode.

TH1 (fixing temperature sensor 1)

TH2 (fixing temperature sensor 2)

L2 (fixing heater lamp 1)

L3 (fixing heater lamp 2)

PRDB (printer drive board)

DCPS (DC power supply)

(If you switch

power back on

without releasing

the latch, the error

will recur.)

Broken fixing

sensor

(open circuit)

5 DIAGRAMS

TH1 (fixing temperature sensor 1)

F36-1

high temperature error

This error occurs if TH1 high

temperature error signal is detected

continuously for at least 1 second.

1

TH1 (fixing temperature sensor 1)

F36-2

open error

Occurs if TH1 open signal is

detected.

1

TH2 (fixing temperature sensor 1)

F36-3

high temperature error

This error occurs if TH2 high temp

error signal is detected continuously

for at least 1 seconds.

1

"TH2 (fixing temperature

F36-4

sensor 2) open" error

"TH2 open" signal is detected.

REVISED EDITION

1

DATE

May 2000

5-34

PAGE

5-34

METHOD

REPLACEMENT

Page 37

LIST OF WARNING (ERROR) CODES

1

Classification

Scanner

abnormalities

Image

processing

abnormalities

Warning

code

F40-1

F40-9

F41-1

F43-1

F46-1

F46-8

F46-10

Causes

Communication error at optics CPU

SRGA error (bad parity, overrun, or

framing error in received data) or by

transmission timeout [100ms].

Communication error at optics CPU

SRGA error (protocol error in

receive control signal [SREQ,

SACK]).

M2 (optical drive) drive error

Occurs at exposure unit initial

search or at exposure unit return

scan if PS14 (optics home-position)

fails to turn ON within a

predetermined time.

L1 (exposure lamp) error

Occurs if L1 error signal is detected

continuously for 500msec

first 500msec after L1 ON).

Laser-driver error

Caused by overcurrent in laser

output.

Laser index error

Occurs if index period is different

from expected value.

AOC error

AOC counter overflow

(excluding

If copying is in

progress, the

main body

stops

immediately,

and the main

relay and 24V

power turn

OFF.

Scanner stops

immediately.

Resulting

operation

Correction Estimated abnormal parts

Switch SW2

(sub power

switch)

OFF/ON.

SCDB (scanner drive board)

M2 (optical drive)

SCDB (scanner drive board)

L1 (exposure lamp)

Laser diode

LDB (laser drive board)

CB (overall control board)

INDEX (index sensor board)

M5 (polygon)

Laser route

CB (overall control board)

ADB (A/D conversion board)

L1 (exposure lamp)

INV1 (exposure lamp inverter)

Exposure unit stop position

CB (overall control board)

REVISED EDITION

1

DATE

May 2000

5-35

PAGE

5-35

5 DIAGRAMS

METHOD

REPLACEMENT

Page 38

LIST OF WARNING (ERROR) CODES

Classification

Image

processing

abnormalities

Motor speed

abnormalities

Fan lock

abnormalities

5 DIAGRAMS

3

3

Warning

code

F46-11

F49-2

F49-4

F49-6

F51-4

F51-5

F51-6

F52-1

F52-2

F52-3

F52-4

(Other

than

7020/

25/30)

F52-6

Causes

AGC error

AGC counter overflow

LDB (laser drive board) connection

error

INDEX (index sensor board)

connection error

ADB (A/D conversion board)

connection error

M3 (developing) speed error

EM detect signal

(developing_motor_em) detected 5

times at 100msec intervals.

M1 (main) speed error

EM detect signal (drum_motor_em)

detected 5 times at 100msec

intervals.

M5 (polygon) speed error

M5 was not locked 5 sec. after

starting to run.

FM3 (

Internal dehumidifying fan

error

EM detect signal detected 5 times

at 100msec intervals.

FM2 (fixing cooling fan) error

EM detect signal detected 5 times

at 100msec intervals. (Clear if

detection counter is not EM).

FM4 (internal cooling) error

EM detect signal detected 5 times

at 100msec intervals. (Clear if

detection counter is not EM).

FM5 (developing suction) error

EM detection signal detected

5 times at 100 msec intervals.

(Clear if detection counter is

not EM.)

IP CPU fan abnormal

Scanner stops

immediately.

If copying is in

progress, the

main body stops

immediately, and

the main relay

and 24V power

turn OFF.

Scanner stops

immediately

If copying is in

progress, the

main body stops

immediately, and

the main relay

and 24V power

turn OFF.

)

Resulting

operation

Correction Estimated abnormal parts

Switch SW2

(sub power

switch)

OFF/ON.

.

ADB (A/D conversion board)

L1 (exposure lamp)

INV1 (exposure lamp inverter)

exposure unit stop position

CB (overall control board)

LDB (laser drive board)

CB (overall control board)

INDEX (index sensor board)

CB (overall control board)

ADB (A/D conversion board)

CB (overall control board)

flex wire bundle

M3 (developing)

PRDB (printer drive board)

M1 (main)

PRDB (printer drive board)

M5 (polygon)

PRDB (printer drive board)

FM3 (internal dehumidifying)

PRDB (printer drive board)

FM2 (fixing cooling)

PRDB (printer drive board)

FM4 (internal cooling)

PRDB (printer drive board)

FM5 (developing suction)

PRDB (printer drive board)

Printer controller (IP-421/422)

REVISED EDITION

3

DATE

Jan. 2002

5-36

PAGE

5-36

METHOD

REPLACEMENT

Page 39

LIST OF WARNING (ERROR) CODES

Classification

Image control

communication

abnormalities

Operations

unit control

abnormalities

2

Main body

abnormalities

Warning

code

E56-1

E56-2

E56-3

E56-4

E56-5

E56-6

E56-7

E56-8

E56-9

E56-10

F56-11

Causes

Communication error between

system-control and engine-control

sections of the CB (overall control

board).

Occurs if CB fails to responds

when SW2 (sub power) turns ON.

(10sec.)

Communication error between

system-control and engine-control

sections of the CB (overall control

board).

Process READY signal not detected

for 30sec. during standby.

Communication error between

system-control and engine-control

sections of the CB (overall control

board).

Scanner READY signal is not

detected for 30sec. during standby.

Communication error between

system-control and engine-control

sections of the CB (overall control

board).

Finisher READY signal is not

detected for 30sec. during standby.

Communication error between

system-control and engine-control

sections of the CB (overall control

board).

Platen-original size notification

timeout (5sec.).

Operation status error

Memory access error at copy

insertion.

Control error at panel manager

Operation drawing error

Screen-data drawing mismatch

Operation drawing error

Drawing-component data error

Operation panel communication

error

Main-body identification error

Detected CB (overall control board)

(ROM) for different machine.

Engine power

supply OFF

Machine cannot

be used.

Resulting

operation

Correction Estimated abnormal parts

Switch SW2

(sub power

switch)

OFF/ON. (CB

reset)

Switch SW2 (sub

power switch)

OFF/ON, then

overwrite the

overall control

ROM-ISW.

CB (overall control board)

CB (overall control board)

CB (overall control board)

CB (overall control board)

FSCB (FS control board)

CB (overall control board)

CB (overall control board)

CB (overall control board)

OB (operation board)

CB (overall control board)

5 DIAGRAMS

REVISED EDITION

2

DATE

Feb. 2001

5-37

PAGE

5-37

METHOD

REPLACEMENT

Page 40

LIST OF WARNING (ERROR) CODES

Classification

DF-314

FS-107

5 DIAGRAMS

3

Warning

code

F60-1

F60-11

F67-3

F70-1

F70-9

F70-11

F77-2

Causes

RADF communication error

•

Caused by SRGA error detection

(bad parity, overrun, or framing

error in received data) or by

transmission timeout [100ms]).

•

Caused by SRGA error detection

(protocol error in receive control

signal [SREQ, SACK]).

RADF flash-ROM error

Detected checksum error in RADF

flash ROM.

Error in RADF nonvolatile memory

Error in reading or writing the

nonvolatile memory.

FNS communication error

Caused by SRGA error detection

(bad parity, overrun, or framing

error in received data) or by

transmission timeout [100ms]).

FNS communication error

Caused by SRGA error detection

(protocol error in receive control

signal [SREQ, SACK]).

FNS flash-ROM error

Detected checksum error in FNS

flash ROM.

M706 (tray up/down) drive error

1. Following removal of paper, tray

failed to reach PS711 (tray upper

limit detect) or PS706 (tray lower

limit detect) within 10 sec. after start

of tray up.

2. During copying, tray failed to

reach PS711 (tray upper limit

detect) or PS706 (tray lower limit

detect) within 10 sec. after start of

tray up.

RADF cannot

be used.

If copying is in

progress, the

main body stops

immediately, and

the main relay

and 24V power

turn OFF.

FNS cannot be

used.

If copying is in

progress, the

main body stops

immediately, and

the main relay

and 24V power

turn OFF.

Resulting

operation

Correction Estimated abnormal parts

Switch SW2

(sub power

switch)

OFF/ON.

Switch SW2 (sub

power switch)

OFF/ON, then

overwrite the RADF

ROM-ISW.

Switch SW2 (sub

power switch)

OFF/ON.

Switch SW2 (sub

power switch)

OFF/ON, then

overwrite the FNS

ROM-ISW.

Switch SW2

(sub power

switch)

OFF/ON.

DFCB (RADF control board)

CB (overall control board)

DFCB (RADF control board)

DFCB (RADF control board)

CB (overall control board)

CB (overall control board)

FSCB (FS control board)

FSCB (FS control board)

M706 (tray up/down),

FSCB (FS control board)

PS711 (tray upper limit detect)

PS706 (tray lower limit detect)

REVISED EDITION

3

DATE

Jan. 2002

5-38

PAGE

5-38

METHOD

REPLACEMENT

Page 41

LIST OF WARNING (ERROR) CODES

Classification

FS-107

Nonvolatile

memory

2

Warning

code

F77-3

F77-5

F77-6

F77-11

F77-16

F77-18

F80-1

F80-2

F80-3

F80-4

F80-5

Causes

M704 (alignment (front)) drive error

1. Failed to reach HP within 1

second after start of alignment-plate

HP search.

2. PS710 (alignment-plate HP detect

(front)) failed to turn OFF within 1

seconds after start of alignmentplate size position shift.

M707 (paper-pressure) drive error

M707 failed to complete 1 rotation

within 500msec after starting to run.

M705 (stapler shift) drive error

1. Stapler unit failed to reach PS708

(stapler unit HP detect) within 1

seconds after the commencement of

a stapler home search.

2. PS708 (stapler unit HP detect)

failed to turn OFF within 1 second

after start of double stapling standby

position shifting.

Stapler reversal error

Stapler failed to read PS712 (stapler

HP detect) within 500msec after

start of M708 (stapler) reverse drive.

M703 (alignment (rear)) drive error

1. Failed to reach HP within 1

second after start of alignment-plate

HP search.

2. PS709 (alignment-plate detect

(rear)) failed to turn OFF within 1

seconds after start of alignmentplate size position shift.

M709 (cooling fan) drive error

Lock condition (lasting more than 10

seconds) was detected any time from

10 seconds after operation start

following operation stop.

Error in main body's nonvolatile memory

Detected abnormal function parameter.

Error in main body's nonvolatile memory

Detected error in stored factory data.

Error in main body's nonvolatile memory

Detected abnormal function parameter,

error in stored factory data.

Error in main body's nonvolatile memory

Unable to access function parameter.

Error in main body's nonvolatile memory

Unable to access stored factory data.

Resulting

operation

If copying is in

progress, the

main body

stops

immediately,

and the main

relay and 24V

power turn

OFF.

Factory settings

are copied.

Correction Estimated abnormal parts

Switch SW2

(sub power

switch)

OFF/ON.

Switch SW2

(sub power

switch)

OFF/ON. (CB

reset)

–

M704 (alignment (front))

PS710 (alignment-plate HP

detect (front))

FSCB (FS control board)

M707 (paper-pressure)

FSCB (FS control board)

FSCB (FS control board)

M705 (stapler shift)

PS708 (stapler-unit HP detect)

FSCB (FS control board)

M708 (stapler)

M703 (alignment (rear))

PS709 (alignment-plate

detect (rear))

FSCB (FS control board)

M709 (cooling fan)

FSCB (FS control board)

PRMB (Parameter memory

board)

5 DIAGRAMS

REVISED EDITION

2

DATE

Feb. 2001

5-39

PAGE

5-39

METHOD

REPLACEMENT

Page 42

LIST OF WARNING (ERROR) CODES

Classification

Flash ROM

Printer

board

Image

processing

CB (overall

control board)

communication

abnormalities

5 DIAGRAMS

Warning

code

F81-1

F81-2

F81-3

E87-1

F87-2

F87-3

E88-1

E89-1

E89-2

E89-3

E89-4

E89-5

Causes

Error in image-control flash ROM

Detected checksum error in CB's

image-control ROM.

Software error

Overall control and image control

have non-matching software device

types.

OEM compatibility error

Printer controller not identified.

Printer controller did not respond.

(But copier and fax can be used.)

Printer-controller error

Error F87-1 occurred 3 times in

succession.

Printer board HDD error

HDD cannot be accessed.

Image error

Error detected in image processing

at overall control side.

Copy sequence error

Error in job object pointer. (Could

not get page-control object for some

reason.)

Copy sequence error

Error in memory copy sequence.

(Cause unknown)

Copy sequence error

Error in through copy sequence

(FCOT). (Cause unknown)

Copy sequence error

Memory scanner did not complete

stop. (Notification of stop completion

not received from engine.)

Copy sequence error

Memory printer did not complete stop.

(Notification of stop completion not

received from engine.)

Resulting

operation

Engine power

supply OFF

Only the printer

cannot be used.

Engine power

supply OFF

Main relay and

24 V power

supply go OFF at

the end of

copying.

Engine power

supply OFF

Correction Estimated abnormal parts

Switch SW2 (sub

power switch)

OFF/ON, then

overwrite the

image-processing

flash ROM.

Switch SW2 (sub

power switch)

OFF/ON, then

overwrite the flash

ROM.

Switch SW1 (main

power switch)

3

OFF/ON.

Switch SW2 (sub

power switch)

OFF/ON. (CB

reset)

3

CB (overall control board)

Optional printer controller

CB (overall control board)

REVISED EDITION

3

DATE

Jan. 2002

5-40

PAGE

5-40

METHOD

REPLACEMENT

Page 43

LIST OF WARNING (ERROR) CODES

Classification

Warning

code

Correction Estimated abnormal partsCauses

Resulting

operation

CB (overall

control board)

communication

abnormalities

E89-6

Main relay and 24 V

power supply go

OFF at the end of

copying.

All indicators on the

operation panel

light.

Switch SW2 (sub

power switch)

OFF/ON. (CB

reset)

CB (overall control board)

Sub power switch OFF processing

wait timeout

Note: For details of E86-xx and other FAX-related error codes, refer to the FK service handbook.

About abnormal units isolation

The following table shows how defective units are cut off (by software) in accordance with the error type.

Error code

18-1

18-2

18-3

18-4

60-1, -9, 67-1, -3

70-1, -9, -11

77-2

77-3, -16

77-5

3

77-6, -11

77-18

3

86-2, -3

87-2, -3

Unit isolation Method

Upon the occurrence of any of the error codes shown above, the defective unit will be cut off from the system (by

software) when you press the [AUTO RESET] key and then switching SW2 (sub power) OFF/ON. Other functions will

remain available. Note that if you don't clear the problem in the defective unit, the error will be detected again (and the

error code displayed again) the next time you turn SW2 OFF/ON. (This cutoff feature is effective one time only.)

Error Unit to be cut off Remarks

Error in main body upper tray

Error in main body lower tray

Error in DB upper tray

Error in DB lower tray (LCT)

RADF error

FNS error (Note)

Error in FNS tray up/down drive (Note)

Error in FNS alignment-plate,

pressure motor

Error in FNS paper-pressure motor

FNS stapler error

Error in FNS cooling fan motor

Fax-board error

Printer-board error

Main body upper tray

Main body lower tray

DB upper tray

DB lower tray, LCT

RADF

FNS

FNS

FNS alignment unit

FNS

FNS alignment unit

FNS

Fax

Printer

Tray can not be selected.

Tray can not be selected.

Tray can not be selected.

Tray can not be selected.

RADF can not be used.

FNS can not be used; FNS must be removed.

FNS can not be used; FNS must be removed.

Only straight exit remains available.

FNS can not be used; FNS must be removed.

Only straight exit remains available.

FNS can not be used; FNS must be removed.

Copying and printing remain enabled.

Copying and faxing remain enabled.

5 DIAGRAMS

Note: If F70-1, -9, -11 or 77-2, -5, -18 occurs, you cannot separate the unit concerned using the above procedure. In this

3

REVISED EDITION

case, you must either remove the cause of the error code or remove the FNS, otherwise printing will not take place.

3

DATE

Jan. 2002

5-41

PAGE

5-41

METHOD

REPLACEMENT

Page 44

LIST OF WARNING (ERROR) CODES

L detection error code list

Code Cause Clearance method Suspected defective part

0003

0004

0005

0006

2

The TDS (toner density sensor) output ripple at the

end of L detection was 0.5 V or less.

The TDS (toner density sensor) output ripple while

the developer is being agitated during L detection

adjustment was 0.02 V or less (there is almost no

change in output).

TDS (toner density sensor) control voltage cannot

be adjusted to within the range 5.76~7.46 V.

TCSB (toner control sensor board) output signal

D/A conversion error

SW2 (sub power switch)

OFF/ON

SW2 (sub power switch)

OFF/ON

SW2 (sub power switch)

OFF/ON

SW2 (sub power switch)

OFF/ON

• Developing unit connector

TDS (toner density sensor)

•

•

PRDB (printer drive board)

M1 (main motor)

•

•

Developing agitator screw

Developing unit connector

•

•

TDS (toner density sensor)

PRDB (printer drive board)

•

•

Developer

•

TDS (toner density sensor)

•

PRDB (printer drive board)

•

PRDB (printer drive board)

•

TCSB (toner control sensor

board)

5 DIAGRAMS

REVISED EDITION

2

DATE

Feb. 2001

5-42

PAGE

5-42

METHOD

REPLACEMENT

Page 45

Symbol

Item

Time

(

sec

)

Registration clutch

MC2 Loop clutch

MC1

1st paper feed SD (upper)SD1

Registration PSPS1

V-Valid

Paper feed motor

PS3

Fixing exit PSPS2

Exit PS

Main motor

M9

Developing motor

M1

Separation claw SD

M3

Cleaning web SD

SD7

Charge

SD4

Developing bias

HV

Transfer

HV

Separation

HV

HV

Transfer synchronization lamp

Guide-plate voltage

TSL

GTP

Pre-charging lamp

PCL

0

1234 5

6

7

8

9

10

Start ON

: Does not come ON for some copy counts.

100ms

100ms

100ms

100ms

2880ms

1

7020 TIME CHART (A4, LIFE SIZE, 2 COPIES, FEED FROM TRAY 1)

DIAGRAMS

REVISED EDITION

1

DATE

May 2000

5-43

5 DIAGRAMS

PAGE

5-43

METHOD

REPLACEMENT

Page 46

DIAGRAMS

Symbol

Item

Time

(

sec

)

Registration clutch

MC2 Loop clutch

MC1

1st paper feed SD (upper)SD1

Registration PSPS1

Intermediate conveyance sensor/upper

PS21

V-Valid

Paper feed motor

PS3

Fixing exit PSPS2

Exit PS

Main motor

M9

Developing motor

M1

Separation claw SD

M3

Cleaning web SD

SD7

Charge

SD4

Developing bias

HV

Transfer

HV

Separation

HV

HV

Transfer synchronization lamp

Guide-plate voltage

TSL

GTP

Pre-charging lamp

PCL

0

1234 5

6

7

8

9

10

Start ON

: Does not come ON for some copy counts.

: If the intermediate conveyance sensor ON (paper leading edge detection)

timing is early, the loop clutch stops momentarily.

100ms

100ms

100ms

100ms

1980ms

1

7030 TIME CHART (A4, LIFE SIZE, 2 COPIES, FEED FROM TRAY 1)

5 DIAGRAMS

REVISED EDITION

1

DATE

May 2000

5-44

PAGE

5-44

METHOD

REPLACEMENT

Page 47

2

Symbol

Item

Time (sec)

Registration MC

MC2

Loop clutch

MC1

1st paper feed SD (upper)

SD1

Registration PS

Intermediate conveyance

sensor / upper

PS1

PS21

V-Valid

paper feed motor

PS3

Fixing exit PS

PS2

Paper exit PS

Main motor

M9

Developing motor

M1

Separation claw SD

M3

Cleaning web SD

SD7

Charge

SD4

Developing bias

HV

Transfer

HV

Separation

HV

HV

Transfer synchronization lamp

Guide-plate voltage

TSL

GTP

Pre-charging lamp

PCL

0

1234 5

6

7

8

9

10

PS23

IT exit PS (upper)

Start ON

: Does not come ON for some copy counts.

: If the intermediate conveyance sensor ON (paper leading edge detection)

timing is early, the loop clutch stops momentarily.

100ms

1695ms

340ms

100ms

100ms

100ms

7035 TIME CHART (A4, LIFE SIZE, 2 COPIES, FEED FROM TRAY 1)

DIAGRAMS

REVISED EDITION

DATE

PAGE

METHOD

5 DIAGRAMS

5-45

2

Feb. 2001

5-45

ADDITION

Page 48

DIAGRAMS

100ms

1 2 3 4 5 6 7 9 10 11 12 13 14 15 16 17 188

182ms

125ms

1543ms

20ms

20ms

20ms

1543ms

1543ms

20ms

131ms

2800ms

2800ms

75ms

182ms

243ms

125ms

75ms

182ms

200ms

182ms

293ms

75ms

1614ms

1543ms

20ms

243ms

125ms

243ms

125ms

182ms

182ms

293ms

75ms

1543ms

243ms

125ms

125ms

293ms

75ms

1543ms

243ms

293ms

293ms

Symbol

Item

Time

(

sec

)

Registration clutchMC1

Loop clutchMC2

1st paper feed SD (upper)SD1

Registration PSPS1

V-Valid

Fixing exit PSPS2

Main motor

M1

Exit PSPS3

ADU motorM6

F

R

140mm/s

350mm/s

140mm/s

Start ON

ADU gate SD

ADU PS

SD5

PS4

0

7020ADU TIME CHART (A4, LIFE SIZE, 3 COPIES, FEED FROM TRAY 1)

5 DIAGRAMS

REVISED EDITION

2

DATE

Feb. 2001

5-46

PAGE

5-46

METHOD

REPLACEMENT

Page 49

Symbol

Item

Time (sec)

Registration MC

MC1

PS21

Loop clutch

MC2

1st paper feed SD (upper)

SD1

Registration PS

PS1

V-Valid

Fixing exit PS

PS2

Main motor

M1

Paper exit PS

PS3

ADU motor

M6

F

R

450mm/s

180mm/s

180mm/s

Start ON

Gate SD

ADU PS

SD5

PS4

01234567 91011121314151617188

IT exit PS (lower)

PS24

Intermediate conveyance

sensor / upper

100ms

2150ms

2150ms

154ms

154ms

154ms

154ms

154ms

154ms

110ms

130ms

377ms

340ms

100ms

100ms

110ms

110ms

110ms

446ms

980ms

980ms 980ms980ms980ms980ms

110ms

110ms

377ms

377ms

340ms

340ms

130ms

130ms

2

7035ADU TIME CHART (A4, LIFE SIZE, 3 COPIES, FEED FROM TRAY 1)

DIAGRAMS

5 DIAGRAMS

REVISED EDITION

2

DATE

Feb. 2001

5-47

PAGE

5-47

METHOD

ADDITION

Page 50

DIAGRAMS

01234567

Symbol

Item

Time

(

sec

)

Valid (Scan)

Original feed

motor

M301

Original

reversal motor

M303

Original

conveyance

motor

M302

Roller pressure SD

SD302

Original exit PS

PS303

F

140mm/s

F

260mm/s

R

140mm/s

R

260mm/s

F

250mm/s

No original detect PSPS301

Original registration PSPS311

PS312

Original feed PS

Exit SD

SD303

R

F

DF-314 TIME CHART (A4, SINGLE SIDE ORIGINAL, 3 SHEETS)

5 DIAGRAMS

REVISED EDITION

DATE

PAGE

METHOD

5-48

2

Feb. 2001

5-48

REPLACEMENT

Page 51

Symbol

Item

Time (sec)

Valid (Scan)

Original feed

motor

M301

Original reversal

motor

M303

Original

conveyance

motor

M302

Roller pressure SD

SD302

Original exit PS

PS303

F

180mm/s

F

277mm/s

R

180mm/s

R

277mm/s

F

250mm/s

No original detect PS

PS301

Original registration PS

PS311

PS312

Original feed PS

Exit SD

SD303

01234567

F

180mm/s

R

180mm/s

2

7035/DF-314 TIME CHART (A4, SINGLE SIDE ORIGINAL, 3 SHEETS)

DIAGRAMS

5-49

5 DIAGRAMS

Page 52

DIAGRAMS

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14

Symbol

Item

Time

(

sec

)

Valid (Scan)

Original feed

motor

M301

Original

reversal

motor

M303

Original

conveyance

motor

M302

Roller pressure SD

SD302

Original exit PS

PS303

F

140mm/s

F

260mm/s

R

140mm/s

R

260mm/s

F

250mm/s

No original detect PSPS301

Original registration PSPS311

PS312

Original feed PS

Exit SD

SD303

R

F

DF-314 TIME CHART (A4, DOUBLE SIDE ORIGINALS, 2 SHEETS)

5 DIAGRAMS

REVISED EDITION

DATE

PAGE

METHOD

5-50

2

Feb. 2001

5-50

REPLACEMENT

Page 53

Symbol

Item

Time (sec)

Valid (Scan)

Original feed

motor

M301

Original

reversal motor

M303

Original

conveyance

motor

M302

Roller pressure SD

SD302

Original exit PS

PS303

F

180mm/s

F

180mm/s

R

180mm/s

F

277mm/s

R

180mm/s

R

277mm/s

F

250mm/s

No original detect PS

PS301

Original registration PS

PS311

PS312

Original feed PS

Exit SD

SD303

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14

2

7035/DF-314 TIME CHART (A4, DOUBLE SIDE ORIGINALS, 2 SHEETS)

DIAGRAMS

REVISED EDITION

2

DATE

Feb. 2001

5-51

PAGE

5-51

5 DIAGRAMS

METHOD

ADDITION

Page 54

DIAGRAMS

01 2 3 4 567 9108

Symbol

Item

Time

(

sec

)

Paper

conveyance

motor

M701

Paper exit

motor

M702

140mm/s

600mm/s

Alignment

motor

M703,704

Stapler shift

motor

M705

Paper

pressure PS

Open

Pressure

Lower

Raise

PS701

140mm/s

Stop

Reverse

Alignment

Shift

600mm/s

Exit PSPS3

Paper entrance detect PSPS702

PS707

No paper detect PS

Tray up/down

motor

M706

R

F

FS-107 TIME CHART (A4, SORT MODE, 2 SHEETS, 2 SETS)

5 DIAGRAMS

REVISED EDITION

DATE

PAGE

METHOD

5-52

2

Feb. 2001

5-52

REPLACEMENT

Page 55

01 2 3 4 567 9108

Symbol

Item

Time

(

sec

)

Paper

conveyance

motor

M701

Paper exit

motor

M702

180mm/s

600mm/s

Alignment

motor

M703,704

Stapler shift

motor

M705

Paper

pressure PS

Open

Pressure

Lower

Raise

PS701

180mm/s

Stop

Reverse

Alignment

Shift

600mm/s

Exit PSPS3

Paper entrance detect PSPS702

PS707

No paper detect PS

Tray up/down

motor

M706

R

F

2

7035/FS-107 TIME CHART (A4, SORT MODE, 2 SHEETS, 2 SETS)

DIAGRAMS

REVISED EDITION

2

DATE

Feb. 2001

5-53

PAGE

5-53

5 DIAGRAMS

METHOD

ADDITION

Page 56

DIAGRAMS

01 2 34 56 7 9108

Symbol

Item

Time

(

sec

)

Paper

conveyance

motor

M701

Paper exit

motor

M702

140mm/s

600mm/s

Alignment

motor

M703,704

Stapler shift

motor

M705

Stapler motor

M708

Paper

pressure PS

Open

Pressure

Lower

Raise

PS701

140mm/s

Stop

Reverse

Alignment

Shift

600mm/s

Exit PSPS3

Paper entrance detect PSPS702

PS707

No paper detect PS

Tray up/down

motor

M706

R

F

FS-107 TIME CHART (A4, STAPLE MODE, 2 SHEETS, 1 POSITION)

5 DIAGRAMS

REVISED EDITION

DATE

PAGE

METHOD

5-54

2

Feb. 2001

5-54

REPLACEMENT

Page 57

01 2 34 56 7 9108

Symbol

Item

Time

(

sec

)

Paper

conveyance

motor

M701

Paper exit

motor

M702

180mm/s

600mm/s

Alignment

motor

M703,704

Stapler shift

motor

M705

Stapler motor

M708

Paper

pressure PS

Open

Pressure

Lower

Raise

PS701

180mm/s

Stop

Reverse

Alignment

Shift

600mm/s

Exit PSPS3

Paper entrance detect PSPS702

PS707

No paper detect PS

Tray up/down

motor

M706

R

F

2

7035/FS-107 TIME CHART (A4, STAPLE MODE, 2 SHEETS, 1 POSITION)

DIAGRAMS

REVISED EDITION

2

DATE

Feb. 2001

5-55

PAGE

5-55

5 DIAGRAMS

METHOD

ADDITION

Page 58

DIAGRAMS

01234567 910118

3000ms

3000ms

1543ms75ms

293ms

243ms125ms

182ms

1543ms75ms

293ms

243ms125ms

182ms

1543ms75ms

293ms

243ms125ms

182ms

Symbol

Item

Time

(

sec

)

Registration clutchMC1

Loop clutchMC2

1st paper feed SD (upper)SD101

Registration PSPS1

V-Valid

Fixing exit PSPS2

Copy ON

Exit PS

DB Paper feed motor

PS3

M100

DB-209/DB409 TIME CHART (A4, LIFE SIZE, 3 COPIES, FEED FROM TRAY 3)

5 DIAGRAMS

REVISED EDITION

DATE

PAGE

METHOD

5-56

2

Feb. 2001

5-56

REPLACEMENT

Page 59

PRINTED IN JAPAN

CS26XF1270

Loading...

Loading...