Page 1

3

DISASSEMBLY/ASSEMBLY

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Page 2

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

This section explains how to disassemble and reassemble the machine.

When disassembling and reassembling the machine, follow the

precautions given below.

1. Be sure the power cord has been unplugged from the wall outlet.

2. The disassembled parts must be reassembled following the

disassembly procedure in reverse unless otherwise specified.

3. Care should be taken not to lose small parts. Care should also be

taken not to install small parts in wrong places.

4. Do not operate the machine before installing all the disassembled

parts completely.

5. Removal of some screws is prohibited in this section. Never loosen

them.

Page 3

EXTERNAL SECTION

EXTERNAL SECTION

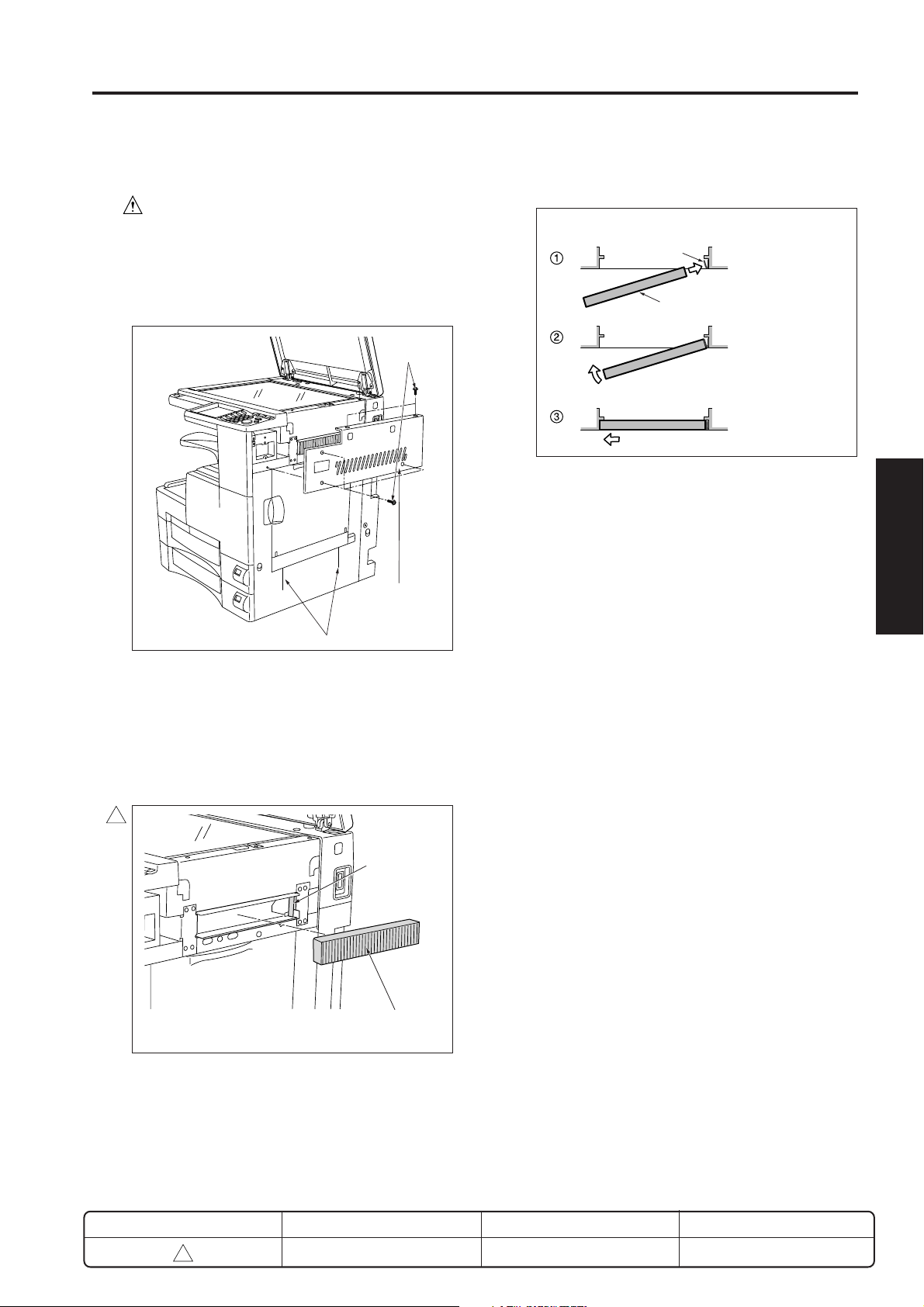

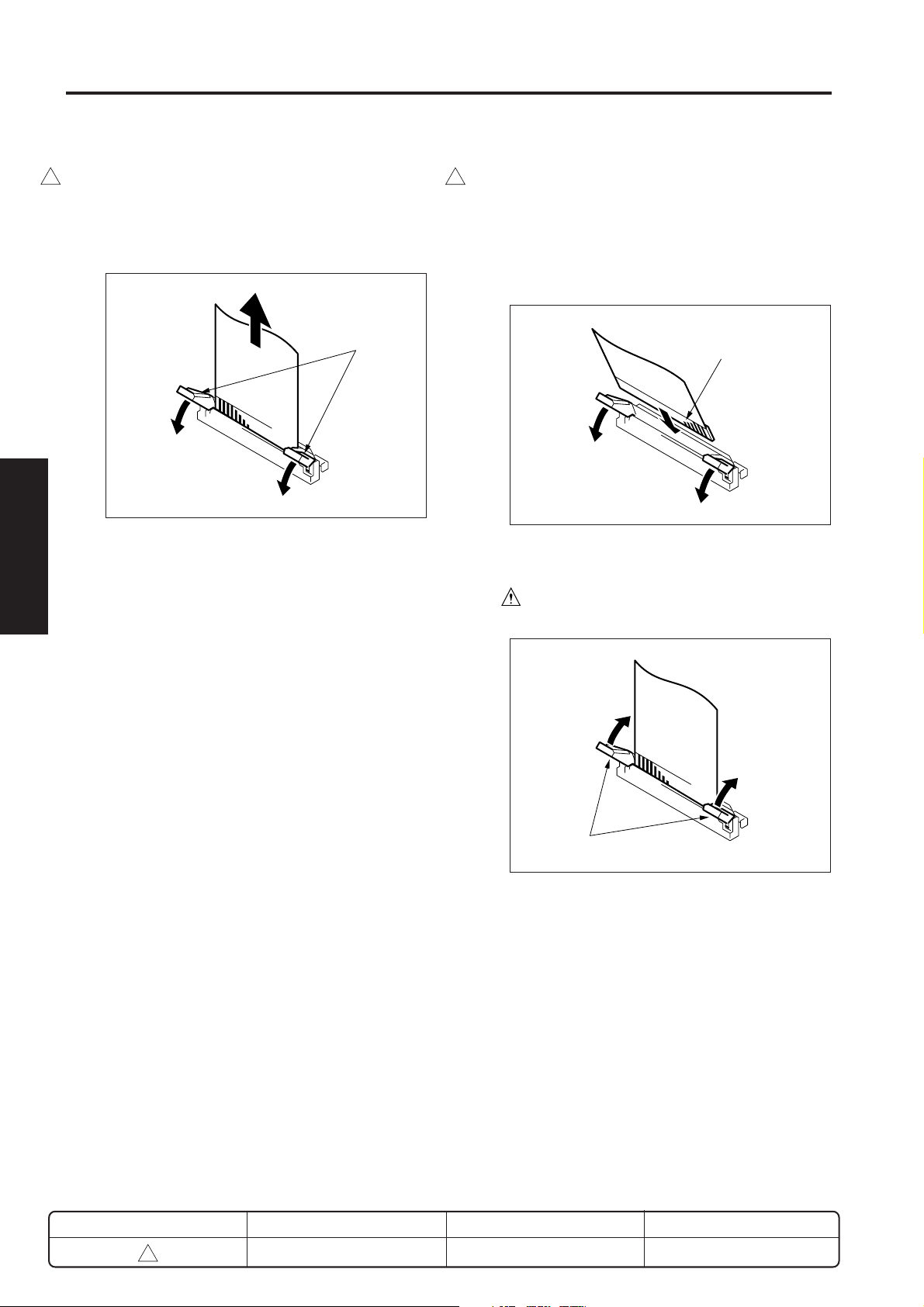

[1] Replacing the ozone filter

Caution: Be sure that the power cord has

been unplugged from the outlet.

a. Procedure

(1) Remove the five set screws, and remove the read

right cover.

Set screws

Read right

cover

(3) Reinstall the above parts following the removal

steps in reverse.

How to install the ozone filter

PET sheet

Ozone filter

Caution: When installing the ozone filter, take care

not to break it.

Push the PET sheet

firmly against the

rear.

Insert the front part.

Shift the front part to

eliminate clearance.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Rib

Note: If an unusual noise is emitted when you open

or close the by-pass tray, clean the ADU door

rib with alcohol.

(2) Remove the ozone filter.

2

PET sheet

<7020/25/30

only>

Ozone filter

REVISED EDITION

2

DATE

Feb. 2001

3-A-1

PAG E

3-A-1

METHOD

REPLACEMENT

Page 4

1 OUTLINE

2

2 UNIT EXPLANATION

EXTERNAL SECTION

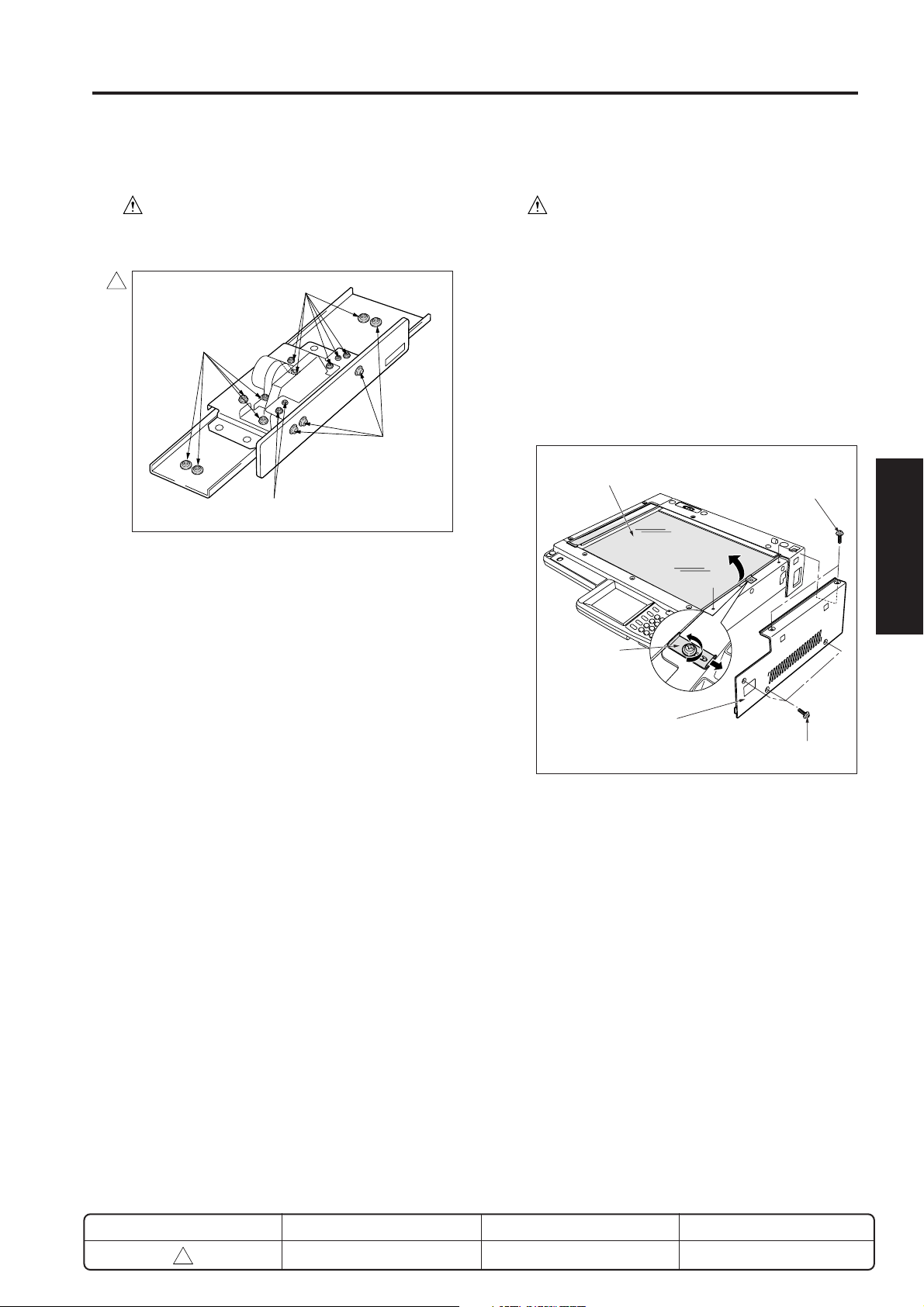

[2] Replacing the filter cover assembly

and suction filter/A

(other than 7020/25/30)

3

Caution: Be sure that the power cord has

been unplugged from the outlet.

a. Procedure

(1) Remove the set screw, then remove the filter cover

assembly.

(2) Remove the suction filter/A.

Set screw

3 DIS./ASSEMBLY

(3) Reinstall the above parts following the removal

steps in reverse.

Suction filter/A

Filter cover assembly

REVISED EDITION

3

DATE

Jan. 2002

3-A-2

PAG E

3-A-2

METHOD

REPLACEMENT

Page 5

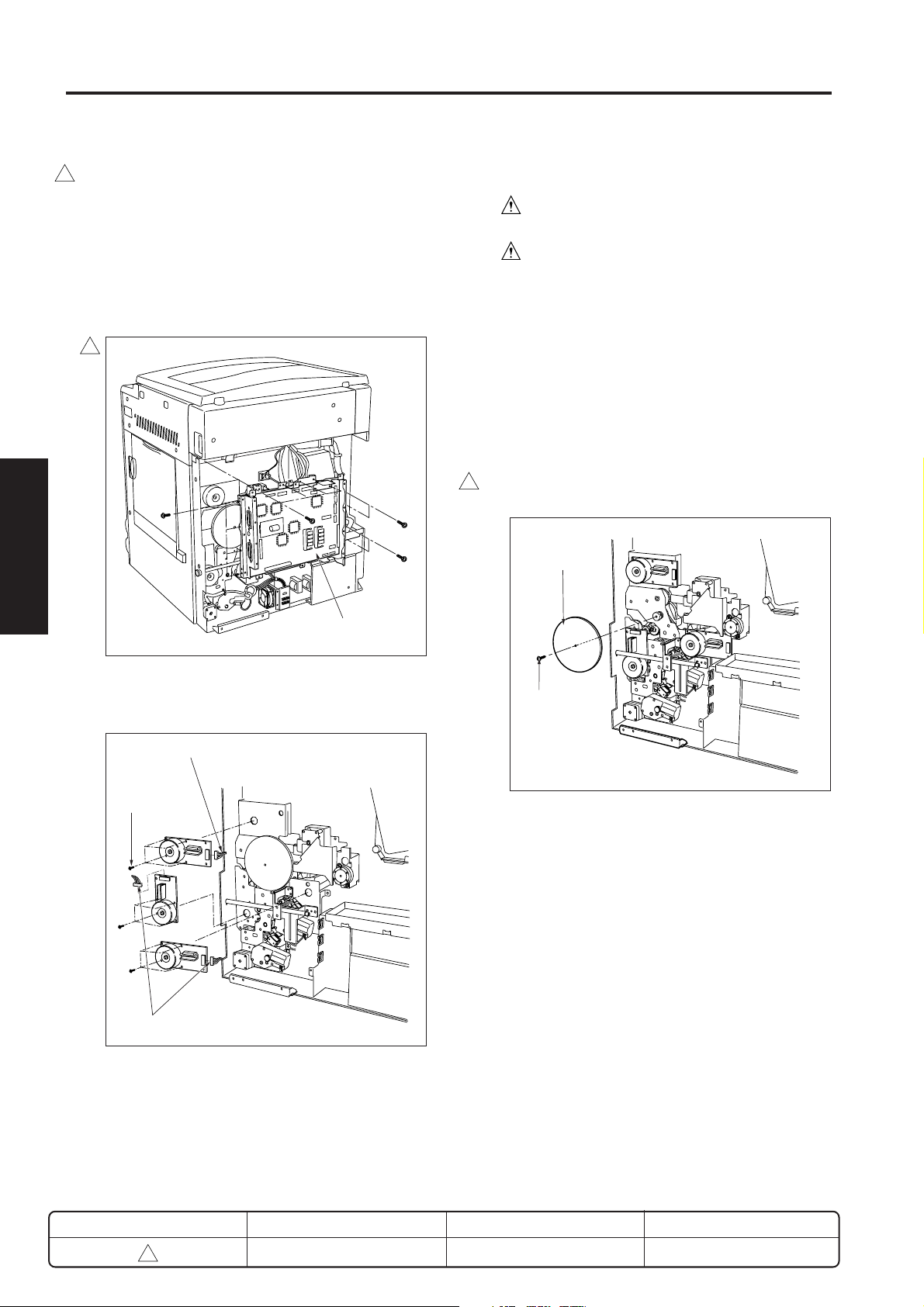

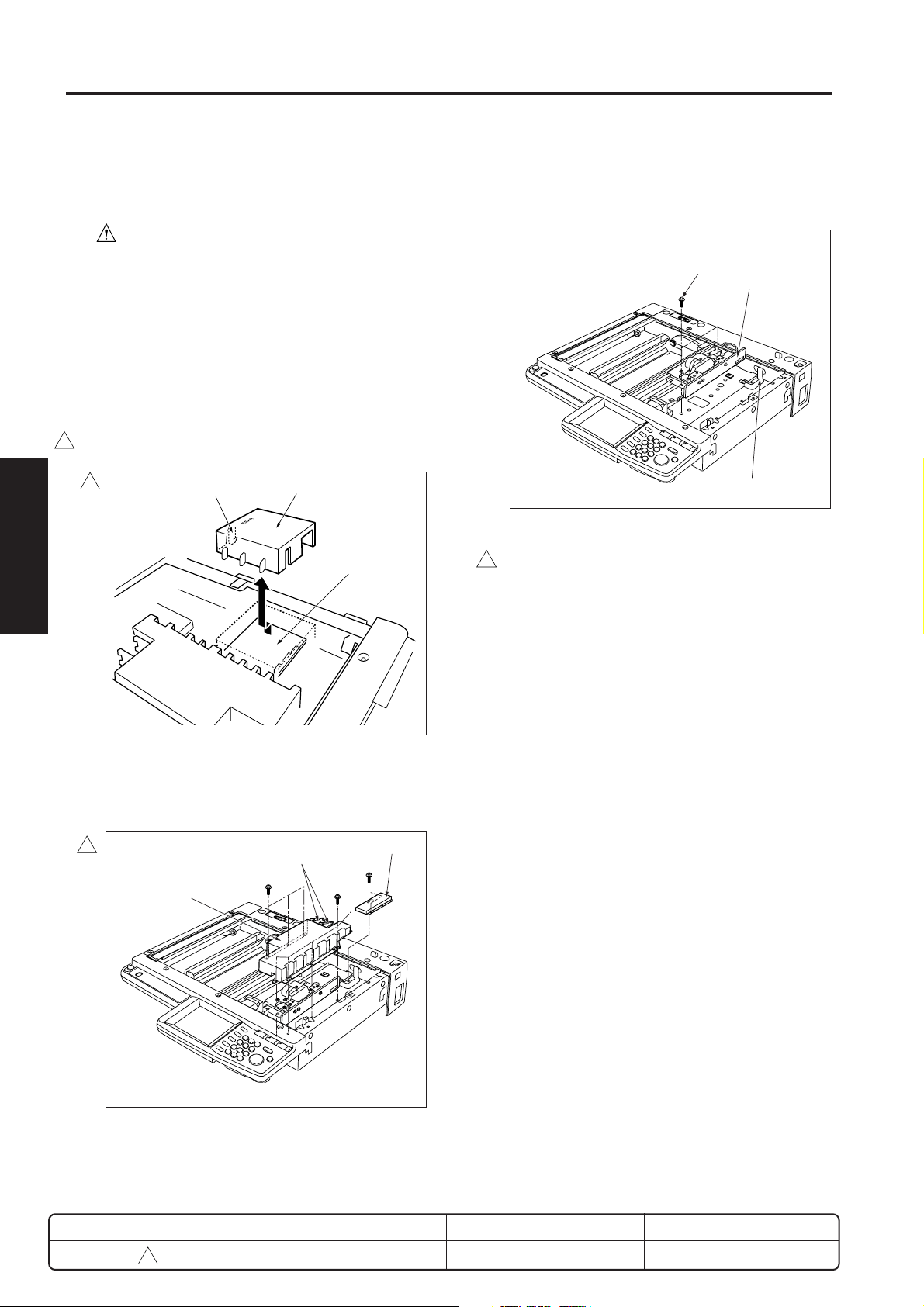

DRIVE SECTION

DRIVE SECTION

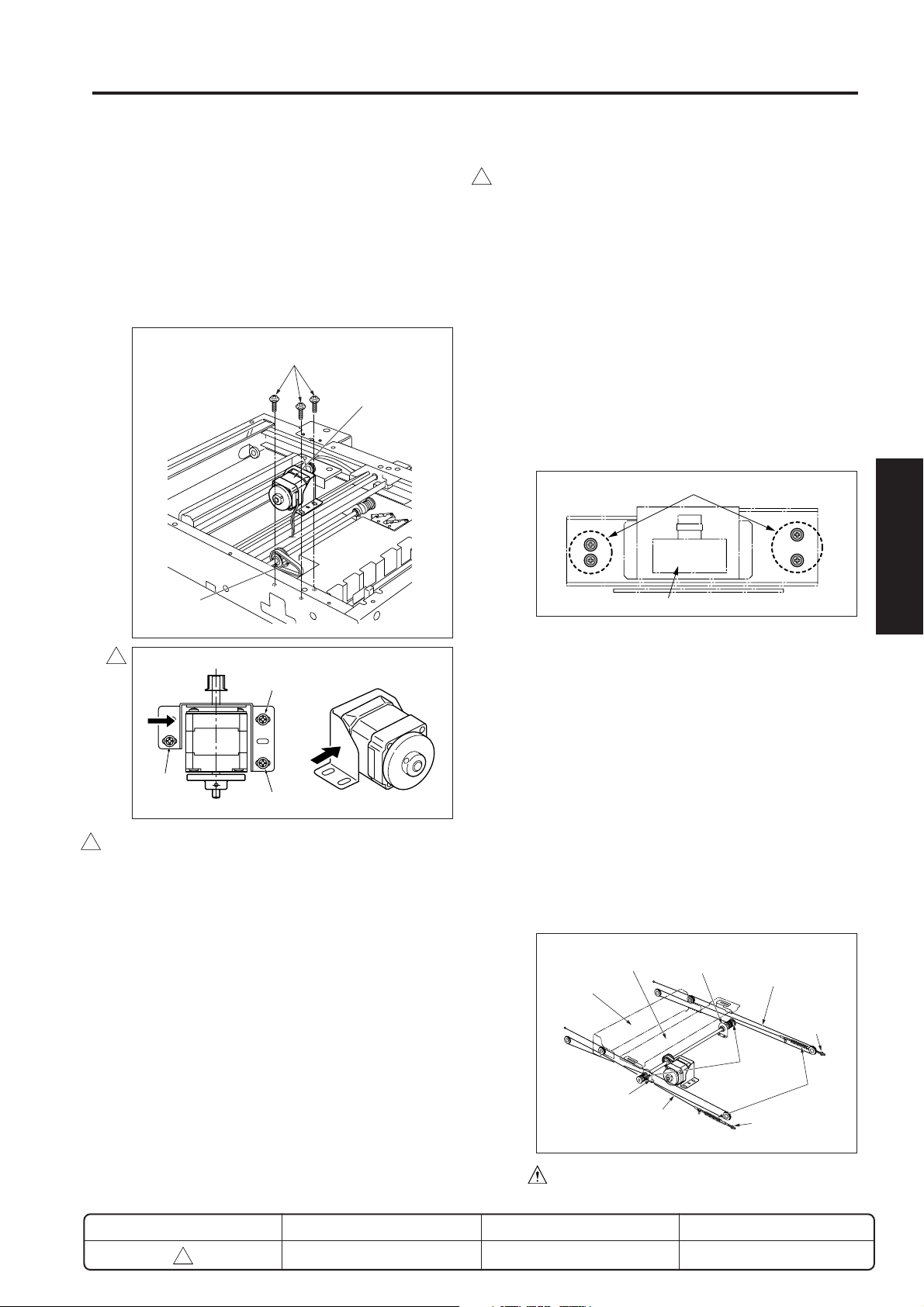

[1]

Removing and Reinstalling the motor

units (main, paper feed, developing)

Caution: Be sure that the power cord has

been unplugged from the outlet.

Caution: Be sure to remove the drum unit

from the main body before removing

or reinstalling the main motor unit. If

the drum unit is in place at this time,

the drum will rotate when you install

or remove the drum rotating plate,

resulting in possible damage to the

cleaning blade.

a. Procedure

(1) Remove the developing unit and drum unit from the

main body.

(2) Remove the 2 set screws, and remove the cord

cover A. Then remove the cord cover B.

(3) Remove the 9 set screws, and remove the rear

cover.

Rear cover

(4) Remove the 2 set screws holding the left and right

rear covers in place (2 screws each), and remove

the covers.

(5) Remove the 3 set screws, and remove the wire-

bundle guide plate.

2

Wire bundle

guide plate

Rear left cover

Rear right cover

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Cord cover B

Set screws

Cord cover A

(6) Remove the 16 set screws, and remove the board

cover D.

(7) Remove the 13 set screws, and remove the board

cover A.

2

Board cover A

Wire bundle

guide plate

Board cover D

REVISED EDITION

2

DATE

Feb. 2001

3-B-1

PAG E

3-B-1

METHOD

REPLACEMENT

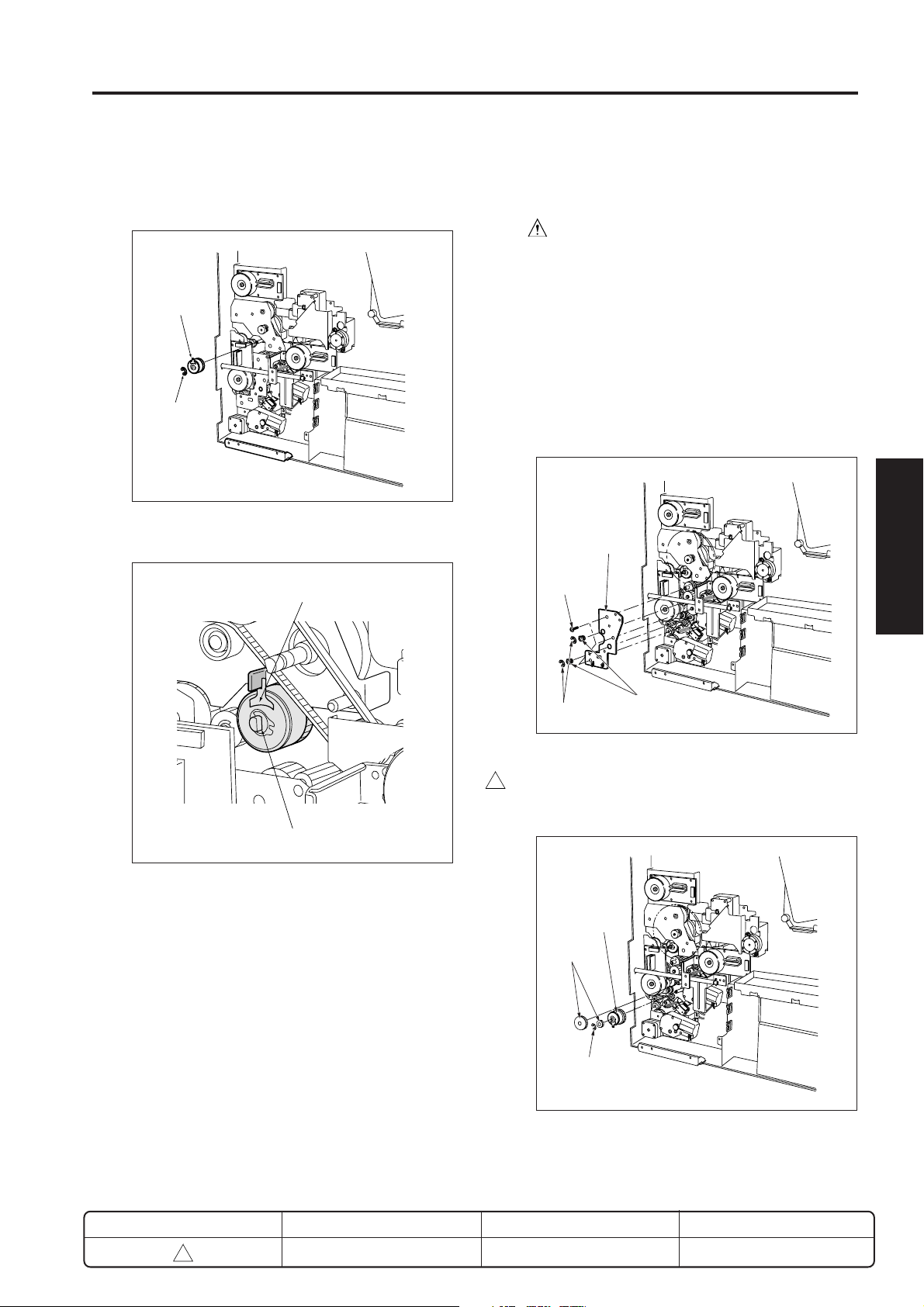

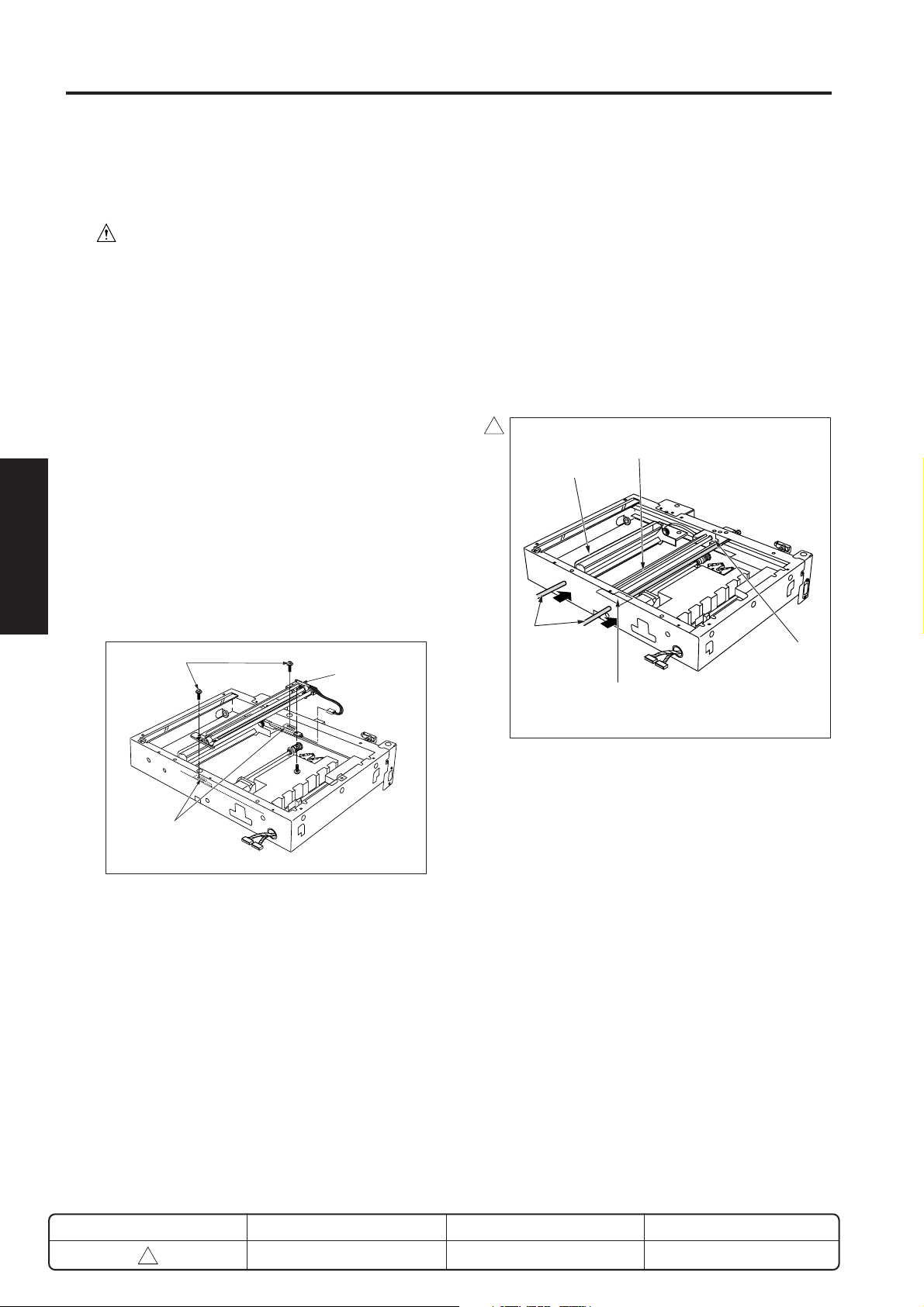

Page 6

1 OUTLINE

2

DRIVE SECTION

(8) Remove the various wiring connectors from the

2

overall control board.

Caution: Be very careful when handling the

ribbon cable connector from the CCD.

Refer to “[4] removing the ribbon cable” and “[5]

Installing the ribbon cable”.

(9) Remove the 12 set screws, and remove the overall

control board unit.

2

[2] Replacing the registration clutch

Caution: Be sure that the power cord has

been unplugged from the outlet.

Caution: Be sure to remove the drum unit

from the main body before carry out

the following procedure. If the drum

unit is in place at this time, the drum

will rotate when you install or

remove the drum rotating plate,

resulting in possible damage to the

cleaning blade.

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Overall control board

unit

(10) Disconnect the connectors from each motor unit.

Remove the 4 set screws, then remove each motor unit.

(11)

Connector

Set screws

a. Procedure

(1) Remove the rear panel and the overall control

board unit.

(2) Remove the set screw, and remove the drum rotating

2

plate.

Drum rotating

plate

Set screw

Connectors

(12) Reinstall in the opposite sequence to removal.

Caution: Be careful to avoid damaging the ribbon

cable connected to the overall control

board.

REVISED EDITION

2

DATE

Feb. 2001

PA GE

3-B-2

METHOD

REPLACEMENT

Page 7

DRIVE SECTION

(3) Remove the clutch connector.

(4) Remove the E-ring. Pull the registration clutch

toward you and rotate it to remove.

Registration

clutch

E-ring

(5) Reinstall in the opposite sequence to removal.

Turn-prevention groove

[3] Replacing the loop clutch

Caution: Be sure that the power cord has

been unplugged from the outlet.

a. Procedure

(1) Remove the rear panel and the overall control

board unit.

(2) Remove the wire bundle from the clamp on the

conveyance drive panel.

(3) Remove the 2 E-rings and 3 set screws, and

remove the conveyance drive panel. (Do not

remove the rotation prevention screws on the

clutch.

Conveyance

drive panel

Set screw

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Registration clutch

Caution: When installing the registration clutch, be

sure that the clutch's turn-prevention

groove is installed correctly.

E-rings

(4) Remove the E-ring, then remove the gear and the

1

Bearings

connector, remove the gear at the front, and then

remove the clutch.

Loop clutch

Gears

E-ring

(5) Reinstall in the opposite sequence to removal.

REVISED EDITION

1

DATE

May 2000

3-B-3

PAG E

3-B-3

METHOD

REPLACEMENT

Page 8

DRIVE SECTION

1 OUTLINE

[4]

2

Removing the ribbon cable

[5]

2

Reinstalling the ribbon cable

2

a. Procedure

(1) Move the lock levers forward to release the lock,

then pull out the ribbon cable.

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Lock levers

a. Procedure

(1) Move the lock levers forward, then, while ensuring

that the direction of the conductive face of the

ribbon cable is correct, push the connector firmly to

the rear.

Conductive face

(2) Firmly push both lock levers, and lock the ribbon

cable.

Caution: Be sure to push both lock levers

together.

REVISED EDITION

2

DATE

Feb. 2001

Lock levers

PAG E

3-B-4

METHOD

ADDITION

Page 9

READ SECTION

READ SECTION

[1] Screws that must not be removed

Caution: The paint-locked screws must not

be removed. Be sure that you do not

remove these screws.

2

Screws that must not be removed

Screws that must not

be removed

Screws that must not be

removed

Screws that must not be removed

[2] Removing the original glass

Caution: The white color reference plate on

the rear of the original glass must be

kept clean. If dirt gets on the board,

clean the board using a clean cloth.

a. Procedure

(1) Remove the platen cover or the RADF.

(2) Remove the 5 set screws, and remove the read

right cover.

(3) Loosen the set screw and slide the glass holding

plate toward the outer exterior.

(4) Raise the original glass and slide it off.

Original glass

Set screws

Glass

holding plate

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Read

right cover

Set screws

(5) Reinstall in the opposite sequence to removal.

Caution: Be sure that the original glass is pushed

flush left against the glass holding plate

when fastening into place.

REVISED EDITION

2

DATE

Feb. 2001

3-C-1

PAG E

3-C-1

METHOD

REPLACEMENT

Page 10

READ SECTION

2

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[3] Removing and Reinstalling the

CCD unit

Caution: Be sure that the power cord has

been unplugged from the outlet.

Caution: Be sure to perform image adjustment after

installing the CCD unit. (Refer to

the “Adjustment” section.)

a. Procedure

(1) Remove the original glass.

(2) Remove the 2 set screws, and remove the photo-

sensor.

(3) Remove the scanner drive board cover while being

2

careful not to strike the claw.

2

Claw

Scanner drive board cover

Scanner drive

board

(6) Remove the ribbon cable from the CCD unit board.

(7) Remove the 2 set screws, and remove the CCD

unit.

Set screws

(8) Reinstall in the opposite sequence to removal.

Caution: Be careful to avoid damage to the ribbon

cable when removing it. When reinstalling

it, be sure that it is securely in place.

Be sure to install the optics drive board cover

in the direction such that the word “REAR”

can be read from the front of the machine.

CCD unit

board

Ribbon cable

(4) Remove the 8 set screws, and remove the lens

shield cover.

(5) Remove the 3 set screws, and remove the ribbon

cable cover.

2

Lens shield cover

Photosensors

Ribbon cable

cover

REVISED EDITION

DATE

PAG E

METHOD

3-C-2

2

Feb. 2001

3-C-2

REPLACEMENT

Page 11

READ SECTION

[4] Replacing the exposure lamp

Caution: Be sure that the power cord has

been unplugged from the outlet.

Do not touch the exposure lamp's

lamp area with bare hands.

Caution: Be sure to clean original glass before

reinstalling it.

a. Procedure

(1) Remove the read right cover and the original glass.

(2) Remove the operation panel, the read left cover,

and the read rear cover.

(3) Remove the 2 set screws, and remove the read

front cover.

2

(3) Read left cover

(6) Read

front cover

(2) Original glass

(4) Read rear cover

(4) Shift the exposure unit to the cutout location at the

center of the main body frame.

(5) Remove the 2 set screws (through the holes in the

frame), and remove the auxiliary reflecting mirror.

Auxiliary

reflecting mirrorSet screws

(6) Remove the 1 connector and 2 set screws. Tilt and

remove the exposure lamp.

Set screws

Exposure lamp

Connector

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(5) Operation panel

* Remove above parts in

order of numbers.

(1) Read right cover

Cutout

Exposure unit

(7) Reinstall in the opposite sequence to removal.

Caution: Be careful when reinstalling the original

glass. To install: push the glass against

the left rear of the readout rear exterior,

then hold the readout front cover against

with glass hold plate.

And further, hold the glass plate, while

pressing the cut portion of the read left

cover.

REVISED EDITION

2

DATE

Feb. 2001

3-C-3

PAG E

3-C-3

METHOD

REPLACEMENT

Page 12

READ SECTION

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[5] Removing and Reinstalling the

exposure unit

Caution: Be sure that the power cord has

been unplugged from the outlet.

Caution: Be sure to the use optics positioning jig

when reinstalling the exposure unit.

Be sure to clean the original glass before

reinstalling it (to prevent degradation of

image quality).

a. Removal procedure

(1) Remove the read right cover and the original glass.

(2) Remove the operation panel, read left cover, and

read rear cover.

(3) Remove the 2 set screws, and remove the read

front cover.

(4) Shift the exposure unit to the cutout location at the

center of the main body frame.

(5) The exposure unit is fixed in place by set screws

fastened to the front and rear exposure unit mount

fittings (1 screw in each fitting). Remove the 2

screws.

Set screws

Exposure unit

b. Installation procedure

(1) Fit the exposure unit into the main body.

(2) Insert the front exposure unit mount fitting and rear

exposure unit mount fitting into the corresponding

slits in the exposure unit.

(3) Shift the V mirror unit to the exit side. Through the

front, insert the two optics positioning jigs so that

they are at the installation location for the exposure

unit. Pass the jig through the V mirror unit to fasten

it in place.

Position the exposure unit by pushing it against the

frame on the right side of the unit.

1

V mirror unit

Optics

positioning

jigs

Exposure unit

Exposure unit

mount fitting

(front)

Exposure unit

mount fitting

(rear)

Exposure unit

mount fittings

(6) Tilt and slide the exposure unit to remove it from

the frame.

(7) Disconnect the exposure lamp connector.

(4) Fasten the front and rear exposure unit mount

fittings into place (1 screw in each fitting).

(5) Remove the optics positioning jigs.

(6) Finish installation by reversing the sequence of the

removal procedure.

REVISED EDITION

1

DATE

May 2000

3-C-4

PAG E

3-C-4

METHOD

REPLACEMENT

Page 13

READ SECTION

2

[6] Removing and Reinstalling the

optics drive motor

a. Procedure

(1) Remove the original glass.

(2) Remove the 3 set screws, and remove the optical

motor.

Set screws

Optical motor

Belt

2

(1)

(2)

(3)

(3) When reinstalling the optics drive motor, tighten the

2

screws in sequence while gently applying a load

(approximately 1 kg) to the arrow direction.

[7] Removing the optics wire

Caution1: There are two types of optics wire in

existence (the old type: with a spring, and

the new type: without a spring), so when

removing them, reference should be made

to the removal method for each type.

Caution2: When removing or reinstalling optics wires,

be sure to the use optics positioning jig.

Be sure to perform image adjustment

after replacing or reinstalling the wire.

(For details, refer to “Adjustment section”.)

Caution3: When removing optics wires, the screws

shown in the figure below should absolutely

not be removed.

Screws that must not be removed

CCD unit

a. Procedure (Old Type: With a spring)

(1) Unfasten and remove all externals from the read unit.

(2) Shift the V mirror unit to the left side. Through the

front, insert the optics positioning jig so that it is at

the V mirror attachment location. Pass the jig

through the V mirror unit to fasten the it in place.

(3) Remove the exposure unit.

(4) Detach the springs and spring axes from the ends

of the front and rear optics wires (1 spring on each

wire), and remove the wires.

(5) Remove the set screws holding the two drive pulley

bearings in place (two screws on each pulley), and

remove the bearings.

(6) Remove the front and rear optics wires from the

drive pulleys.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Exposure unit

V mirror unit

Bearing

Optics wire (front)

Bearing

Optics wire (rear)

Nut

Drive

pulleys

Springs

/Spring axis

Nut

Caution: Do not change the position of the paint-

locked nut on the spring shaft.

REVISED EDITION

DATE

PAG E

METHOD

3-C-5

2

Feb. 2001

3-C-5

REPLACEMENT

Page 14

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

READ SECTION

a. Procedure (New Type: Without a spring)

2

(1) Unfasten and remove all externals from the read unit.

(2) Shift the V mirror unit to the left side. Through the

front, insert the optics positioning jig so that it is at

the V mirror attachment location. Pass the jig

through the V mirror unit to fasten the it in place.

(3) Remove the exposure unit.

(4) Detach the nuts and washers from the ends of the

front and rear optics wires, and remove the wires.

(5) Remove the set screws holding the two drive pulley

bearings in place (two screws on each pulley), and

remove the bearings.

(6) Remove the front and rear optics wires from the

drive pulleys.

Exposure unit

V mirror unit

Bearing

Optics wire (front)

Bearing

Optics wire (rear)

Drive pulleys

Nut

Nut

[8] Installing the optics wire

Caution 1: When winding wire around pulleys, be

sure that the winds are close. Be

careful to avoid overlap.

Caution 2: When changing the wire, be sure to

use the optics positioning jigs.

Caution 3: Be sure to perform image adjustment after

installing the CCD unit. (Refer to the

“Adjustment” section.)

a. Procedure (Old Type: With a spring)

2

(1) Fit the metal ball (midway along each optics wire)

into the mount opening on the drive pulley. Starting

from this position, wind 6 times around the outside

and 5 times around the inside.

• After winding the wires, fasten them in place (with

tape, etc.) so that they cannot come off.

• Use the “F” exposure unit mount fitting (the fitting

with the “F” printed on it) at the front, and use the

“R” fitting at the rear.

• The end with the metal ball at the tip winds around

the inside of the pulley shaft.

• Wind so that the two ends of the wire come off the

top of the pulley.

Tape

(Rear)

5 winds

6 winds

6 winds 5 winds

Front

Rear

(Front)

Tape

Drive

pulleys

REVISED EDITION

2

DATE

Feb. 2001

3-C-6

PAG E

3-C-6

METHOD

REPLACEMENT

Page 15

READ SECTION

2

(2) On the metal ball side, pass the optics wire so that

it passes under the V mirror unit, through the left

side pulley, and through the inside pulley on the V

mirror unit. Hook the end of the wire onto the cutout

on the frame.

(3) On the round-end side, pass the wire so that it

passes through the right side pulley, passes over

the pulley on the outside of the V mirror unit, and

passes under the V mirror unit. Fasten the end to

the right side frame with the spring.

(4) Fasten the drive pulley bearings into place with the

attachment screws (2 screws each).

(5) Using the optics positioning jigs to install the

exposure unit.

(6) Remove the jigs.

(7) Slide the exposure unit two or three times to make

sure that it works correctly.

Pulley

Metal ball

V mirror unit

a. Procedure (New Type: Without a spring)

(1) Fit the metal ball (midway along each optics wire)

into the mount opening on the drive pulley. Starting

from this position, wind 6 times around the outside

and 5 times around the inside.

• After winding the wires, fasten them in place (with

tape, etc.) so that they cannot come off.

• Use the “F” exposure unit mount fitting (the fitting

with the “F” printed on it) at the front, and use the

“R” fitting at the rear.

• The end with the metal ball at the tip winds around

the inside of the pulley shaft.

• Wind so that the two ends of the wire come off the

top of the pulley.

(Rear)

6 winds

5 winds

Rear

Tape

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

To metal

ball

Pulley

V mirror unit

Optics positioning jigs

To metal

ball

Spring shaft Spring

Tape

Drive

pulleys

(Front)

6 winds 5 winds

Front

(2) On the metal ball side, pass the optics wire so that

it passes under the V mirror unit, through the left

side pulley, and through the inside pulley on the V

mirror unit. Hook the end of the wire onto the cutout

on the frame.

(3) On the right side, pass the wire so that it passes

through the right side pulley, passes over the pulley

on the outside of the V mirror unit, and passes

under the V mirror unit. Fasten the end to the right

side frame with the spring.

REVISED EDITION

DATE

PAG E

METHOD

3-C-7

2

Feb. 2001

3-C-7

ADDITION

Page 16

1 OUTLINE

2

READ SECTION

(4) After temporary fastening, use a spring balancer to

apply 0.5 ~ 0.8 kg of tension to the front and rear

optics wires in the arrow direction, then fully tighten

the nuts.

Nut

2 UNIT EXPLANATION

(5) Fasten the drive pulley bearings into place with the

attachment screws (2 screws each).

(6) Using the optics positioning jigs to install the

exposure unit.

(7) Remove the jigs.

(8) Slide the exposure unit two or three times to make

sure that it works correctly.

Nut

3 DIS./ASSEMBLY

Metal ball

V mirror unit

To metal

ball

Pulley

To metal

ball

V mirror unit

Optics positioning jigs

REVISED EDITION

2

Pulley

DATE

Feb. 2001

3-C-8

PAG E

3-C-8

METHOD

ADDITION

Page 17

WRITE UNIT

WRITE UNIT

[1] Removing and Reinstalling the

write unit

Warning:

(1) Never supply power while the write unit is

out of its proper installed position.

(2) Do not open the cover of the write unit

while power is being supplied. Shining of

the laser beam on the eye may cause

blindness.

(3) After turning the main power switch OFF,

wait at least two minutes before removing

the write unit.

Caution: Be sure that the power cord has

been unplugged from the outlet.

Caution: (1) When removing the write unit, take

care to avoid touching with the write

mirror and the dust proof glass. (Touching these

areas may leave scratches and smudges.)

(2) When installing the write unit, confirm that the

PET sheet at the end is seated correctly in the

duct.

a. Procedure

(1) Open the front door and remove the drum unit and

the developing unit.

(2) Remove the exit tray, open the ADU door, and

remove the main body front cover. Remove the side

rear cover, the main-body upper cover, and the

main-body auxiliary cover.

(3) Remove the write cleaning knob from the dust

proof glass cleaning rod and then puch the rod to

inside of main body.

Cleaning knob

(4) Remove the 11 set screws, and remove the write

cover.

Set screws

Write unit cover

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

3

Filter cover assembly

(other than 7020/25/30)

(4) Main body auxiliary cover

(2) Side rear cover

(1) Main body front cover

(3) Main body upper cover

*Remove above parts in order of numbers.

REVISED EDITION

3

Front door

DATE

Jan. 2002

3-D-1

PA GE

3-D-1

METHOD

REPLACEMENT

Page 18

WRITE UNIT

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(5) Remove the two write unit mount pieces (each is

held in place by set screw).

Write unit mount pieces

Set

screws

(6) Disconnect the 3 connectors.

(7) Remove the 3 set screws (SEMS II: long screws),

and remove the write unit by pulling it to the left.

Also, remove the air duct connected to the fan.

2

Set screws

Connectors

Write unit

(8) Reinstall in the opposite sequence to removal.

Cooling air guide PET

Note: Reinstall the write unit while inserting the front

edge of the cooling air guide PET into the

specified position.

Airduct

REVISED EDITION

2

Printer drive board

Connector

DATE

Feb. 2001

3-D-2

PA GE

3-D-2

METHOD

REPLACEMENT

Page 19

DRUM UNIT

DRUM UNIT

[1] Removing and Reinstalling the

drum unit

Caution: Be sure that the power cord has

been unplugged from the outlet.

Caution 1: After removing the drum unit, close the

drum cover and store the unit in a dark

place.

Caution 2: During removal and reinstallation work,

never rotate the drum in the wrong

direction (in the direction opposite to

the direction it moves during normal

copying). Rotating the drum in the

reverse direction may cause scratches

to the cleaning blade.

a. Procedure

(1) Open the front door, loosen the set screw, and

gently pull the developing unit out toward you.

(2) Open the ADU door, and open the conveyance

unit.

(3) Loosen the set screw, and gently pull the drum unit

out toward you until it stops. Then tilt it slightly and

remove it.

2

ADU door

Conveyance unit

[2] Removing and Reinstalling the

drum

Caution 1: Take care to avoid scratching the

drum's light sensitive areas and the

cleaning blade. Do not touch these

areas with bare hands.

Caution 2: When removing or installing, never

allow the drum to bump against the

plate-metal part of the cleaning blade.

Caution 3: If you are going to place the drum in

storage, be sure to place a cover on

the drum (to cut off light to it) and store

it in a dark place.

Caution 4: Before installing the drum and cleaning

blade (regardless of whether new or

used), be sure to coat these with

setting powder. Apply the powder

around the entire drum, and on both

sides of the blade.

Caution 5: If you have coated setting powder onto

the drum: Before installing the drum

unit back into the main body, use an

alcohol-soaked cloth to remove stray

powder from the sensor surface on the

toner control sensor board. This is

necessary to ensure that accurate

toner density readings are obtained.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Front door

Drum unit

<Handling the drum unit>

Do not touch the separation claw unit.

*

(4) Reinstall in the opposite sequence to removal.

Caution 6: Be sure that the drum is oriented

correctly before installing it. The

convex end (bulging end) should be

facing the rear.

Caution 7: After installing a new drum, be sure to reset

the drum-related counters in the 36 mode.

Caution 8: When removing the drum unit, do not place

2

your hand on the separation claw unit.

REVISED EDITION

2

DATE

Feb. 2001

3-E-1

PA GE

3-E-1

METHOD

REPLACEMENT

Page 20

DRUM UNIT

2

2

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

a. Removing procedure

(1) Remove the drum unit from the main body.

(2) Set the unit so the drum is to the top.

(3) Remove the cleaning rod's shaft stopper fitting, and

2

pull out the cleaning rod.

(4) Disconnect the connector from the drum unit.

(5) Remove the two set screws, then disengage the rear

of the charging corona unit in the direction of 햲, and

remove the charging corona unit in the direction of 햳.

2

Charging corona unit

Set screw

Connector

Clearning rod

(6) Remove the stopper ring, and pull out the drum

shaft.

Drum shaft

Stopper ring

Stopper

fitting

(8) Remove the 2 semicircular seal blocks (one on

each end of the drum).

(9) To remove the drum, push it back toward the rear

and lift it up and out from the front.

Scerw that must

*

Seal blocks

not be removed

Drum bearing

b. Installing procedure

Caution: Be sure that the toner collection sheet

makes contact with the entire span of the

drum, with no gaps.

(1) Coat the entire surface of the drum with setting

powder.

(2) Fit the convex end of the drum into the rear side of

the unit, then set the drum down into the unit.

Reattach the two seal blocks (one at each end of

the drum).

Seal block 2 (rear)

Seal block 1 (front)

Drum

(7) Remove the 2 set screws holding the drum bearing

in place, and remove the bearing.

(3) Reattach the drum bearing. Fasten it into place with

the 2 set screws.

(4) Insert the drum shaft and reattach the stopper.

REVISED EDITION

DATE

PAG E

METHOD

3-E-2

2

Feb. 2001

3-E-2

REPLACEMENT

Page 21

DRUM UNIT

2

(5) Using the jig included on the drum unit cover, rotate

the drum clockwise and confirm that there are no

gaps in the setting powder coat, and that the toner

collection sheet and cleaning blade are smooth,

etc.

Jig

(6) Install the charging corona unit. Fasten it into place

with 2 set screws.

[3] Removing and Reinstalling the

separation claw

Caution 1: While removing or installing the claw,

be careful to avoid damage to the

drum.

Caution 2: When installing the claw, be sure that it

is correctly oriented and positioned.

Caution 3: Do not touch the cleaning blade or the

drum's light sensitive areas with bare

hands.

a. Procedure

(1) Remove the drum unit from the main body.

(2) Remove the drum from the drum unit.

(3) Disconnect the relay connector.

(4) Remove the separation rock spring.

(5) Remove the 2 positioning screws and the 2 collars,

2

and then remove the separation claw unit.

2

Relay Connector

Positioning screws

Separation

rock spring

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Collars

Separation claw unit

(6) Pull out the separation fulcrum shaft while pressing

down the claw and remove the 2 separation claws.

2

Separation claw

Separation

fulcrum shaft

Claw

(7) Reinstall in the opposite sequence to removal.

REVISED EDITION

DATE

PA GE

METHOD

3-E-3

2

Feb. 2001

3-E-3

REPLACEMENT

Page 22

CORONA UNIT SECTION

CORONA UNIT SECTION

[1] Removing and Reinstalling the

charging corona unit

Caution: Be sure that the power cord has

been unplugged from the outlet.

a. Procedure

(1) Remove the drum unit from the main body.

(2) Remove the cleaning rod's shaft stopper fitting, and

pull out the cleaning rod.

(3) Disconnect the connector from the drum unit.

(4) Remove the 2 set screws, and remove the charging

corona unit by pulling it out from the rear.

1

Charging corona unit

Connector

Stopper

fitting

Set screw

[2] Removing and Reinstalling the

charge control plate

Caution: When reinstalling, be sure to set the

charge control plate so that the

spring held end is toward the front

of the charging corona unit.

a. Procedure

(1) Remove the drum unit from the main body.

(2) Remove the charging corona unit. Move the

charging cleaning block to its home position (at the

right side).

(3) Remove the 2 charge control springs, and remove

the charge control plate.

(4) To clean, use: Tap lightly with a cloth soaked in

drum cleaner, then use a blower brush to remove

remaining debris.

Charge control plate

Charge control

springs

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Cleaning rod

(5) Reinstall in the opposite sequence to removal.

(5) Reinstall in the opposite sequence to removal.

REVISED EDITION

1

DATE

May 2000

3-F-1

PA GE

3-F-1

METHOD

REPLACEMENT

Page 23

CORONA UNIT SECTION

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[3] Replacing the charging wire

a. Procedure

(1) Remove the drum unit from the main body.

(2) Remove the charging corona unit. Move the

charging cleaning block to its home position (at the

right side).

(3) Remove the charge control plate.

(4) Remove the 2 charging covers (charging rear

cover, and charging front cover).

(5) Remove the spring, and remove the charging wire.

Charging rear cover

Charging wire

Charging front cover

Spring

[4] Removing and Reinstalling the

transfer and separation corona unit

Caution: Be sure that the power cord has

been unplugged from the outlet.

a. Procedure

(1) Open the ADU door.

(2) Pull the conveyance unit toward you to open.

(3) Push the left catch of the transfer/separation corona

1

unit, then remove the unit.

1

Transfer/Separation

corona unit

(6) To install the replacement wire: first fasten the rear

end of the wire to the unit, then pass the wire

through the charging cleaning block and fix it in

place with the spring. Then complete the

installation by reversing the steps above.

Conveyance unit

(4) Reinstall in the opposite sequence to removal.

Caution: When installing the Transfer/Separation

corona unit, be sure that the cleaning

material is in home position at the right side.

REVISED EDITION

1

DATE

May 2000

3-F-2

PAG E

3-F-2

METHOD

REPLACEMENT

Page 24

CORONA UNIT SECTION

[5] Replacing the transfer and

separation wires

Caution: Do not remove the paper entrance guide

plate.

2

Paper entrance guide plate

Screws that must not

be removed

a. Procedure

(1) Remove the transfer and separation corona unit

from the main body.

(2) Use a tweezers to remove the hook from the

transfer and separation corona unit. Then remove

the plunging prevention plate.

(3) Remove the front and rear spark arrestor plates.

Spark arrestor plate

(rear)

Spark arrestor plate

(front)

(4) Move the cleaning block to home position, and

remove the top covers from the cleaning block.

(5) Remove the spring from each wire, and remove the

wires.

V holder

Top covers

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Plunging prevention

plate

Springs

V holder

(6) Reinstall in the opposite sequence to removal.

Caution: When installing the wire, be sure that the

cleaning block is in home position at the

right side. Stretch the wire so that it fits into

the V holders.

REVISED EDITION

2

DATE

Feb. 2001

3-F-3

PA GE

3-F-3

METHOD

REPLACEMENT

Page 25

DEVELOPING UNIT

DEVELOPING UNIT

[1] Screws that must not be removed

Caution: The 4 set screws below must not be

removed or adjusted in the field. Please do

not interfere with these screws.

2

Screw that must not be removed

Screw that must not

be removed

Screws that must not

be removed

[2] Removing and Reinstalling the

developing unit

a. Procedure

(1) Remove the set screw fastening the developing

unit in place.

(2) Pull the developing unit outward to remove.

Developing unit

Set screw

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(3) To reinstall: Fit the rails on the bottom of the

developing unit onto the grooves on the main body,

and slide the unit into place. Then fasten into place

with the attachment screw.

REVISED EDITION

2

DATE

Feb. 2001

3-G-1

PA GE

3-G-1

METHOD

REPLACEMENT

Page 26

DEVELOPING UNIT

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[3] Replacing the developer

Caution 1: When carrying out replacement, take

care to prevent dirt and debris from

entering the system.

Caution 2: After installing new developer, do not

turn the developer-input gear or

agitator input gear in the clockwise

(reverse) direction.

Caution 3: After replacing developer, carry out L

detection adjustment before making

copies.

Agitator input gear

Developing input gear

(3) Release the hooks. Lift the developing cover, and

remove it.

Developing cover

Hook

(4) Tilt the developing unit so that the agitator screws

are toward the bottom, and rotate the agitator input

gear counterclockwise as necessary to discharge

all developer from within the developing unit and

from the developing sleeve.

(5) Wipe away any toner remaining on the developing

regulator plate.

Agitator screws

a. Procedure

(1) Remove the developing unit from the main body.

(2) Remove the 2 set screws holding the developing

cover in place.

Set screw

Developing cover

Caution : The 2 set screws of the developing

3

cover are used only in an old type

machines (7020/25/30/35).

Developing

regulator plate

(6)

Pour new developer evenly over the agitator screws.

REVISED EDITION

3

DATE

Jan. 2002

3-G-2

PAG E

3-G-2

METHOD

REPLACEMENT

Page 27

DEVELOPING UNIT

(7) Rotate the agitator input gear 1 counterclockwise

so that the developer moves into the inside of the

developing unit.

Developing input gear 1

(8) Repeat steps (6) and (7) as necessary to load all of

the developer.

(9) Rotate the developing input gear counterclockwise

and check the bristle height along the entire

surface of the developing sleeve.

(10) Reinstall the developing cover, and fasten it in

place with the 2 set screws. Be careful to keep the

cover clear of the scatter prevention sheet.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

2

Scatter prevention sheet

REVISED EDITION

2

DATE

Feb. 2001

3-G-3

PA GE

3-G-3

METHOD

REPLACEMENT

Page 28

TONER SUPPLY UNIT

TONER SUPPLY UNIT

[1] Removing and Reinstalling the

toner bottle

a. Procedure

(1) Open the front cover, and then open the toner-

supply cover.

(2) Pull the toner bottle slightly out, and turn it

clockwise so that the upper part of the cartridge

aligns with the cutout.

(3) Withdraw the toner bottle.

Front door

Toner supply cover

Toner bottle

[2] Removing and Reinstalling the

toner supply unit

a. Procedure

(1) Remove the toner bottle.

(2) Remove the rear cover.

(3) Remove the overall control board unit.

Caution: Note that there are numerous connectors

connected to the overall control board. You

can either disconnect the connectors, or keep

the board close to its present location.

(4) Remove the set screw, and remove the drum

2

rotating plate.

(5) Remove the 3 connectors.

(6) Remove the 4 set screws, and remove the toner-

supply unit by pulling it toward you.

Toner supply unit

Connector

Set screws

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(4) Reinstall in the opposite sequence to removal.

(7) Reinstall in the opposite sequence to removal.

REVISED EDITION

2

DATE

Feb. 2001

3-H-1

PA GE

3-H-1

METHOD

REPLACEMENT

Page 29

CLEANING/TONER RECYCLE UNIT

CLEANING/TONER RECYCLE UNIT

[1] Removing and Reinstalling the

cleaning blade

Caution: Be sure that the power cord has

been unplugged from the outlet.

Caution 1: Be careful of the cleaning blade edge.

Do not touch the edge with bare hands,

and take care to avoid scratching it.

Caution 2: Before installing the drum and cleaning

blade (regardless of whether new or

used), be sure to coat these with setting powder. Apply the powder around

the entire drum, and on both sides of

the blade.

Caution 3: If you have coated setting powder onto

the drum: Before installing the drum

unit rear into the main body, use an

drum cleaner cloth to remove stray

powder from the sensor surface on the

toner control sensor board. This is necessary to ensure that accurate toner

density readings are obtained.

a. Procedure

(1) Remove the drum unit from the main body.

(2) Remove the charging corona unit.

(3) Remove the drum from the drum unit.

(4) Remove the 2 set screws, and remove the fitting

(suppressor piece) holding the cleaning blade in

place.

(5) Remove the cleaning blade.

1

Cleaning blade

(6) Reinstall in the opposite sequence to removal.

Caution: When installing the cleaning blade, install

so that the unit's transparent sheet is oriented as shown in the diagram.

Collected toner

conveyance screw Transparent sheet

Cleaning

blade

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

1

REVISED EDITION

1

Set screws

Suppressor

piece

DATE

May 2000

3-I-1

PA GE

3-I-1

METHOD

REPLACEMENT

Page 30

PAPER FEED UNIT

PAPER FEED UNIT

[1] Replacing the by-pass pickup

roller/by-pass conveyance roller

a. Procedure

(1) Open the by-pass tray.

(2) Remove the 3 set screws and remove the plate.

Plate

Set screws

(3) Remove the 2 set screws and the connector, then

remove the by-pass sensor.

(4) Remove the stopper ring and the bearing.

(5) Remove the 2 set screws, and slide the by-pass

paper feed unit left to remove it from the by-pass

drive shaft, so that the by-pass pickup roller comes

off.

By-pass paper feed unit

Stopper ring

(6) Remove the 2 stopper rings.

(7) Pull out the by-pass conveyance shaft, and

remove the by-pass conveyance roller.

1

Bearing

By-pass drive shaft

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

By-pass sensor

Set screws

Stopper ring

By-pass

conveyance

roller

Painting mark

By-pass

pickup roller

Stopper ring

By-pass

conveyance

shaft

(8) Reinstall in the opposite sequence to removal.

Caution: When reinstalling rollers, pay attention to

their orientation.

Painting mark

REVISED EDITION

1

DATE

May 2000

3-J-1

PAG E

3-J-1

METHOD

REPLACEMENT

Page 31

PAPER FEED UNIT

2

1 OUTLINE

[2] Replacing the by-pass reversal

[3] Replacing the feed rubber and the

2

roller

a. Procedure

(1) Remove the by-pass feed roller unit.

(2) Remove the 2 set screws, and remove the unit.

By-pass feed roller unit

2 UNIT EXPLANATION

(3) Remove the 2 stopper rings, and pull out the shaft.

3 DIS./ASSEMBLY

(4) Remove the 2 stop rings and the E ring, then pull

out the shaft to the side where there is no E ring.

2

Paint mark

Shaft

Set screws

double feed prevention upper

rubber (upper tray)

a. Procedure

(1) Open the ADU door, and then open the conveyance

unit.

(2) Remove the developing unit and the drum unit.

(3) Slide the upper tray out. Remove the 2 set screws

holding the tray in place, and take the tray off.

Upper tray

Set screws

(4) Remove the paper feed roller cover in the direction of

2

arrow 햳 while pushing it in the direction of arrow 햲.

By-pass

reversal roller

Spring

E-ring

(5) Reinstall in the opposite sequence to removal.

Pulley

Spring

Stopper

rings

Paper feed roller cover

REVISED EDITION

DATE

PAG E

METHOD

3-J-2

2

Feb. 2001

3-J-2

REPLACEMENT

Page 32

PAPER FEED UNIT

(5) Remove the 2 stopper rings, and remove the

bearings from the plate.

(6) Lift the left shaft and remove the feed roller unit.

(7) Pull out the feed shaft, and remove the double feed

prevention roller (upper).

2

Feed roller

Stopper

rings

Double-feed prevention roller (upper)

Feed roller unit

Feed shaft

Bearings

Stopper rings

Swing shaft

(8) Remove the stopper ring, pull the guide shaft out of

the feed roller unit, and remove the feed roller.

(9) Remove the feed rubber from the feed roller.

(10) Remove the feed shaft and then remove the double

2

feed prevention roller (upper).

(11) Remove the double feed prevention upper rubber

(upper) from the double feed prevention roller (upper).

[4] Replacing the double feed

prevention lower rubber (upper

tray)

a. Procedure

(1) Open the ADU door, and then open the conveyance

unit.

(2) Remove the developing unit and the drum unit.

(3) Slide the upper tray out. Remove the 2 set screws

holding the tray in place, and take the tray off.

Upper tray

Set screws

(4) Remove the set screw, and remove the plate. Then

remove the set screw fastening the double feed

prevention roller unit in place.

Double feed prevention unit

Set screw

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Feed rubber

Paint mark

Stopper ring

Feed roller

Guide shaft

Feed shaft

Double feed prevention

upper rubber (upper)

Double feed prevention

roller (upper)

(12) Reinstall in the opposite sequence to removal.

Caution: Be sure to install the roller rubbers in the

correct direction.

Install so that the swing shaft goes to the

inside of the feed roller unit.

REVISED EDITION

2

DATE

Feb. 2001

3-J-3

Plate

Set screw

(5) From the inside of the main body, press on the two

ends of the roller unit and remove it.

PAG E

3-J-3

METHOD

REPLACEMENT

Page 33

1 OUTLINE

1

2

2 UNIT EXPLANATION

PAPER FEED UNIT

(6) While pressing on the lever on the lever click shaft,

pull out the shaft and then remove the double feed

prevention roller.

1

Paint mark

Double feed

prevention

lower rubber

Double feed

prevention roller

Lever click shaft

[5] Replacing the feed rubber and

double feed prevention upper

rubber (lower tray)

a. Procedure

(1) Open the ADU door, and then open the conveyance

unit.

(2) Remove the developing unit and the drum unit.

(3) Slide the lower tray out. Remove the 2 set screws

holding the tray in place, and take the tray off.

Set screws

Lower tray

(7) Remove the double feed prevention lower rubber

from the roller.

(8) Reinstall in the opposite sequence to removal.

3 DIS./ASSEMBLY

Caution: Be sure to install the roller rubbers in the

correct orientation.

:

When installing the double feed prevention

unit into the main body, align the unit with

the center of the marking stamped on the

main-body plate.

(4) Remove the set screw, and remove the plate.

Set screw

Plate

REVISED EDITION

DATE

PAG E

METHOD

3-J-4

1

May 2000

3-J-4

REPLACEMENT

Page 34

PAPER FEED UNIT

(5) Remove the 2 stopper rings, and remove the

bearings from the plate.

(6) Lift the left shaft and remove the feed roller unit.

(7) Pull out the feed shaft and remove the double feed

prevention roller (upper).

2

Feed roller unit

Bearings

Stopper rings

(8) Remove the 1 stopper ring, pull the guide shaft out

of the feed roller unit, and remove the feed roller.

(9) Remove the feed rubber from the feed roller.

(10) Remove the feed shaft and then remove the double

2

feed prevention roller (upper).

(11) Remove the double feed prevention upper rubber

(upper) from the double feed prevention roller (upper).

Swing

shaft

Feed

shaft

(12) Reinstall in the opposite sequence to removal.

Caution: Be sure to install the roller rubbers in the

correct direction.

Install so that the swing shaft goes to the

inside of the feed roller unit.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Paint mark

Feed rubber

Stopper ring

Double feed

prevention

roller (upper)

Feed roller

Guide shaft

Feed shaft

Double feed

prevention upper

rubber (upper)

REVISED EDITION

2

DATE

Feb. 2001

3-J-5

PAG E

3-J-5

METHOD

REPLACEMENT

Page 35

PAPER FEED UNIT

1

1 OUTLINE

[6]

Replacing the double feed prevention

[7] Replacing the registration rollers

2

lower rubber (lower tray)

a. Procedure

(1) Open the ADU door, and then open the conveyance

unit.

(2) Remove the developing unit and the drum unit.

(3) Slide the lower tray out. Remove the 2 set screws

holding the tray in place, and take the tray off.

(4) Open the guide plate, and remove the set screw

fastening the double feed prevention roller unit in

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

place.

1

Set screw

1 and 2

a. Procedure

(1) Open the ADU door, and then open the conveyance

unit.

(2) Remove the developing unit and the drum unit.

(3) Slide the upper tray out. Remove the 2 set screws

holding the tray in place, and take the tray off.

(4) Slide the lower tray out. Remove the 2 set screws

holding the tray in place, and take the tray off.

(5) Remove the registration clutch.

(6) Remove the all external cover from the front.

Registration

roller (1)

Guide plate

Double feed prevention

roller unit

(5) From the inside of the main body, press on the two

ends of the roller unit and remove it.

(6) While pressing on the lever on the lever click shaft,

pull out the shaft and then remove the double feed

prevention roller.

1

Paint mark

(7) Remove the double feed prevention lower rubber

from the roller.

(8) Reinstall in the opposite sequence to removal.

Double feed prevention

lower rubber

Lever click shaft

Double feed

prevention roller

Registration roller (2)

(7) Stretch the 2 registration springs (front and rear)

upward and remove them from the flanges on the

registration bearings.

Registration bearings

E-rings

Registration

bearings

E-rings

Registration spring

Registration spring

REVISED EDITION

DATE

PAG E

METHOD

3-J-6

1

May 2000

3-J-6

REPLACEMENT

Page 36

PAPER FEED UNIT

3

(8) Remove the E-ring and registration bearing at each

end of each shaft (4 E-rings and 4 bearings in

total).

Caution: Be careful to avoid dropping E-rings and

bearings into the main unit.

(9) Remove the registration rollers from the interior of

the main body.

Registration spring

Registration roller (1)

Registration

bearings

E-rings

Registration spring

Registration bearings

Registration roller (2)

E-rings

(10) Reinstall in the opposite sequence to removal.

Caution: Install each registration bearing so that the

flat part is flush on the inside.

[8]

Cleaning the paper dust removing brush

a. Removal procedure

(1) Open the ADU door, and open the conveyance unit.

(2) Remove the developing unit and the drum unit.

(3) Remove the paper dust removing brush.

To remove the brush, raise the

A part and

disengage the claw, then pull out the brush in the

direction of the arrow.

Caution: Do not bend the metal plate of the paper

dust removing brush.

Paper dust removing brush

Claw

A

(4) Clean the PET sheet and the plastic part using a

cleaning pad and a blower brush.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Leave the registration springs hooked (do

not unhook them) when removing and

reinstalling them. Install the springs so that

the hook part is located at the top between

the two shafts.

PET sheet

Plastic part

b. Installation procedure

(1) Insert the paper dust removing brush from the B

(rear) side, and confirm that the hole in the brush is

engaged with the claw.

B

Hole

Claw

(2) After this, install the brush using the reverse

procedure to removal.

REVISED EDITION

DATE

PAG E

METHOD

3-J-7

3

Jan. 2002

3-J-7

REPLACEMENT

Page 37

FIXING UNIT

FIXING UNIT

[1] Removing and Reinstalling the

fixing unit

Caution: Be sure that the power cord has

been unplugged from the outlet.

The fixing unit remains extremely hot

immediately after power is switched

OFF. To avoid injury from burns, do

not begin work until the fixing unit

has cooled down sufficiently.

Caution: When installing the fixing unit, be

sure to firmly tighten the unit's 2 set

screws.

a. Procedure

(1) Open the ADU door and the conveyance unit, and

loosen the 2 set screws holding the fixing unit in

place.

(2) Pull the fixing unit out toward you and remove it.

2

Set screws

[2] Replacing the fixing heater lamps

(main lamp and sub lamp)

Caution: Do not touch the lamp area with

bare hands.

Caution 1: When installing, be sure that manufac-

turer's mark is mounted on the front

side.

Caution 2: Do not allow the heater lamps to make

contact with the inside of the roller.

Caution 3: Install so that the main lamp is at the

top, and the sub lamp is at the bottom.

Heater cords are color-coded as

follows.

Color

Positions

Lamp

Main

Sub

Caution 4: When installing the faston terminal on

JAPAN

Front Rear Front Rear Front Rear

White

White

Black

White

the drive gear side, be sure that the installation position is correct.

U.S.A.

Red

Red

Black

Red

EUROPE

OTHERS

Blue

Blue

Black

Blue

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Conveyance

unit

<Handling the fixing unit>

Caution: Do not touch the areas shown in the

diagram above when attaching or

removing the fixing unit. Observe care,

as force applied to the fixing web may

result in the rollers being scratched.

Fixing unit

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Remove the set screws, and remove the two

covers (fixing front cover, and fixing rear cover).

Fixing front cover

Set screws

Fixing rear cover

(3) Reinstall in the opposite sequence to removal.

REVISED EDITION

2

DATE

Feb. 2001

3-K-1

PAG E

3-K-1

METHOD

REPLACEMENT

Page 38

FIXING UNIT

(3) Detach the faston terminal at the rear of each lamp.

1 OUTLINE

[3] Removing and Reinstalling the

fixing claw

2

Fasten

terminals

2 UNIT EXPLANATION

(4) Remove the 2 set screws, and remove the lamp

support piece (front).

(5) Detach the faston terminal at the front of each

lamp.

(6) Keeping all cord faston terminal wiring straight, pull

each fixing heater lamp toward you to remove.

3 DIS./ASSEMBLY

Fasten terminals

Lamp support piece

(front)

Set screws

Caution 1: When installing the fixing claw, be sure

that it is oriented correctly.

Caution 2: Be sure that the claw is securely at-

tached to the claw spring.

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Remove the 2 set screws, and remove the fixing

exit plate.

(3) Remove the 4 set screws, and remove the fixing

claw unit.

Fixing exit plate

Set screw

(4) Unhook the spring, and remove the fixing claw.

Set screws

Fixing claw unit

Set screw

Main

Fixing heater lamps

Sub

(7) Reinstall in the opposite sequence to removal.

REVISED EDITION

3

DATE

Jan. 2002

3-K-2

Spring

Fixing claw

Caution: The number of fixing claws installed

3

differs according to the particular

model.

7020/25/30/35 : 6 claws

7022/7130 : 4 claws

(5) Reinstall in the opposite sequence to removal.

PAG E

3-K-2

METHOD

REPLACEMENT

Page 39

FIXING UNIT

[4] Replacing the fixing web/Fixing

cleaning roller

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Remove the fixing claw unit.

(3) Detach the connectors, remove the set screw at the

bottom and the 2 set screws (Note 1) on the

cleaning unit, and then remove the cleaning unit by

pulling it out from the fixing unit.

Connectors

Set screws

Cleaning unit

(5) Detach the springs from the bearings for the fixing

cleaning roller, and remove the E-ring from the

shaft. Move the shaft and take off the bearings. You

can then remove the fixing cleaning roller.

Fixing cleaning roller

Bearings

Springs

(6) Reinstall in the opposite sequence to removal.

Note 1: Tighten the setscrews of the cleaning unit

while pressing down on the cleaning unit.

Note 2: After replacing the fixing web, wind it up

3

until the end with the green line is within

0~10 mm of the nip of the fixing heat roller

and the fixing cleaning roller.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(4) Remove the 3 set screws and remove the 3 fixing-

web bearings. Remove the web together with the

entire shaft.

Bearing

Bearings

0~10mm

Nip

Fixing heat

roller

Fixing cleaning roller

Fixing web

Green line

REVISED EDITION

3

DATE

Jan. 2002

3-K-3

PAG E

3-K-3

METHOD

REPLACEMENT

Page 40

FIXING UNIT

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[5] Removing and Reinstalling the

fixing heat roller/fixing pressure

roller

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Remove the fixing claw unit.

(3) Remove the fixing cleaning unit.

(4) Remove the two fixing heater lamps

(5) Remove the 2 set screws and 2 collars for the

connector that was connected to the faston

terminal. Remove the connector.

(6) Remove the 2 set screws, and remove the lamp

support piece (rear).

1

Set screws

Connector

(10) Remove the 2 fixing bearings (one at the front, one

at the rear) from the unit.

Heat insulating

sleeve A

Fixing bearings

(11) Remove the pressure roller.

Fasten terminals

Lamp support piece

Set screws

(rear)

(7) Open the fixing guide to release the pressure.

(8) Remove the ring at the rear of the heat roller, and

then remove the gear and heat insulating sleeve A,

B.

1

Heat insulating

sleeve A

Heat roller

Ring

Gear

Heat

insulating

sleeve B

Heat insulating

sleeve B

Heat insulating

sleeve A

solvest 240

Gear

Fixing pressure

roller

(12) Reinstall in the opposite sequence to removal.

Caution: Be sure that heat insulating sleeves A and

B are oriented and positioned correctly.

When replacing the heating insulating

1

sleve/A, apply solvest 240 to the inside

and outside surfaces of the heat insulation

sleeve/A and then instal it.

(9) Remove another ring, then remove the heat

insulating sleeve A (the sleeve toward the front).

Then remove the heat roller.

REVISED EDITION

1

DATE

May 2000

3-K-4

PAG E

3-K-4

METHOD

REPLACEMENT

Page 41

FIXING UNIT

[6] Removing and Reinstalling the

fixing temperature sensors

Caution: After installing the fixing temperature

sensors:

Make sure that the wire bundles are

not in contact with the fixing heat

roller.

Make sure that the sensors themselves (the sensor areas) are in

contact with the fixing heat roller.

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Remove the fixing claw unit.

(3) Remove the fixing cleaning unit.

(4) Remove the 2 set screws, and remove the fixing

temperature sensors.

Set screws

Fixing

temperature

sensors

[7] Removing and Reinstalling the

3

Fuse mounting plate assembly

Caution: This is an important safety part. (P/

N:SP00-0110) Be sure to observe

the following cautions and steps

when removing or reinstalling.

Caution: After installing the thermostat:

Make sure that the wire bundle is

not in contact with the fixing heat

roller.

Make sure that the thermostat itself

is in contact with the fixing heat

roller.

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Remove the fixing front and rear cover.

(3) Remove the fixing exit plate.

(4) Remove the fixing claw unit.

(5) Remove the fixing cleaning unit.

(6) Remove the heat roller.

(7) Detach the thermostat 2 Faston terminals.

(8) Remove the 2 set screws, and remove the Fuse

mounting plate assembly.

Faston terminals

Thermostat

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(5) Reinstall in the opposite sequence to removal.

Caution: When installing the sensors, attach the

longer wire bundle to the center of the unit.

Make sure that the sensors are in contact

with the heat roller.

REVISED EDITION

3

DATE

Jan. 2002

3-K-5

Set screws

Fuse mounting plate

assenbly

(9) Reinstall in the opposite sequence to removal.

Caution: When installing the Fuse mounting plate

assembly, install so that the base plate fits

between the unit's sheet metal.

Make sure that the thermostat is in contact

with the heat roller.

PAG E

3-K-5

METHOD

REPLACEMENT

Page 42

ADU/PAPER EXIT SECTION

ADU/PAPER EXIT SECTION

[1] Removing and Reinstalling the exit

3

sensor unit (7020/25/30/35 only)

a. Procedure

(1) Remove the read right cover.

(2) Remove the 2 set screws, and remove the right

side cover (upper).

(3) Remove the 2 set screws, and remove the cover.

Cover

(4) Remove the 2 set screws (by inserting the screw-

driver through the holes in the sheet metal). Detach

the connector at the side of the sheet metal, and

remove the exit sensor unit/1.

Set screws

(5) Remove the set screw (again, by inserting the

3

screwdriver through the hole), and remove the exit

limit detection actuator.(Old type 7020/25/30/35

only)

Set screw

Exit limit detection actuator

(6) Reinstall in the opposite sequence to removal.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Connector

REVISED EDITION

3

Exit sensor unit/1

DATE

Jun. 2002

Set

screws

Connector

3-L-1

PAG E

3-L-1

METHOD

REPLACEMENT

Loading...

Loading...