Page 1

FS-107

SERVICE HANDBOOK

2001.02

Ver. 3.0

KONICA CORPORATION

TECHNOLOGY SUPPORT CENTER

TOKYO JAPAN

Page 2

KONICA CORPORATION

COPYRIGHT ©2001

CN26NF1780

Page 3

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS ...........

Refer to the 7020/25/30/35 service handbook on page C-1

1. OUTLINE

FS-107 PRODUCT SPECIFICATIONS ..................1-1

[1] Type ........................................................ 1-1

[2] Functions ................................................ 1-1

[3] Stapler kit ................................................ 1-2

[4] Machine data .......................................... 1-2

[5] Maintenance ........................................... 1-2

[6] Machine environment ............................. 1-2

CENTER CROSS SECTION ..................................1-3

DRIVE SYSTEM DIAGRAM ................................... 1-4

[1] Paper conveyance drive ......................... 1-4

[2] Stapler unit drive ..................................... 1-5

PAPER CONVEYANCE PATH .............................. 1-6

[1] Straight mode ......................................... 1-6

[2] Offset mode/staple mode ....................... 1-7

2. UNIT EXPLANATION

EXTERNAL SECTION ........................................... 2-1

[1] Composition ............................................ 2-1

CONVEYANCE SECTION ..................................... 2-2

[1] Composition ............................................ 2-2

[2] Mechanisms ........................................... 2-2

[3] Conveyance control ................................ 2-3

[4] Tray up/down control .............................. 2-5

PAPER EXIT/STAPLER UNIT ............................... 2-7

[1] Composition ............................................ 2-7

[2] Mechanisms ........................................... 2-7

[3] Paper alignment control .......................... 2-9

[4] Paper exit control .................................. 2-10

[5] Paper stack control ............................... 2-11

[6] Stapler control ...................................... 2-12

[7] Staple control ........................................ 2-13

OTHER CONTROLS ............................................2-15

[1] Movement with power on ...................... 2-15

[2] Opening and closing motion of

the front door ........................................ 2-15

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

3. DISASSEMBLY/ASSEMBLY

DISASSEMBLY/ASSEMBLY .................................. 3-1

[1] Removing and reinstalling of the finisher

unit .......................................................... 3-1

[2] Removing and installing of the tray ........ 3-1

[3] Replacing the paper exit roller/A ............ 3-2

[4] Removing and installing of the up/down

wire ......................................................... 3-4

[5] Replacing the stapler cartridge ............... 3-5

[6] Removing and installing

the stapler unit........................................ 3-6

Page 4

1

OUTLINE

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Page 5

FS-107 PRODUCT SPECIFICATIONS

FS-107

[1] Type

Type: Built-in type compact finisher

(multiple trays type)

Option: Finisher tray [FT-107]

(Up to two trays can be

installed)

[2] Functions

Kinds of paper: Same as the main body

Modes: Normal exit mode (straight)

Offset mode (shift)

Staple mode

Paper size

2

Straight paper exit: A3, B4, A4, A4R, B5, B5R,

A5R, B6R, F4, 11 x 17, 8.5 x

14, 8.5 x 11, 8.5 x 11R, 5.5 x

8.5R

Offset: A3, B4, A4, A4R, B5, B5R,

F4, 11 x 17, 8.5 x 14, 8.5 x 11,

8.5 x 11R

1 position staple: A3, B4, A4, A4R, B5, B5R, A5R,

One point F4, 11 x 17, 8.5 x 14, 8.5 x 11,

8.5 x 11R, 5.5 x 8.5R

2 position staple: A3, B4, A4, A4R, B5, B5R, A5R,

Two points F4, 11 x 17, 8.5 x 14, 8.5 x 11,

8.5 x 11R, 5.5 x 8.5R

Maximum

Paper capacity: 2 trays:100 +1000 = 1,100

sheets

3 trays: 100 + 100 + 600 =

800 sheets

4 trays: 100 x 4 = 400 sheets

Copy

Paper weight: 50 to 200g/m

Stack capacity: (80g/m

With 2 standard trays

2

papers

2

high-quality paper)

Note 2: The number of stacked sheets in staple

mode must not exceed the stack sheet

capacity for non-staple mode.

Note 3: Small size: B6R, A5R, 5.5x8.5R

Medium size: Everything other than

small size, large size,

special paper.

Large size: A3, B4, F4, 8.5x14,

11x17

Special paper: Thin paper (60g/m

less), thick paper (over

128g/m

masters, OHP, etc.

Note 4: The stacking capacity of the option

conforms to the stacking capacity of tray

1.

Paper curling: 10mm max

Curl

Amount of sort

off-setting: 30mm

2

), blueprint

Five copy sheets

2

1 OUTLINE

or

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Small

Non-

Tray 1

Tray 2

Note 1: The above figures apply only to if

REVISED EDITION

staple

Staple

Nonstaple

Staple

stacked paper is all of the same size.

2

sheets

Medium

size

100

sheets

10

sets

1000

sheets

size

100

10

sets

50

sets

Large

size

100

sheets

10

sets

300

sheets

20

sets

DATE

Feb. 2001

Special

media

sheets

sheets

10

50

1-1

PA GE

1-1

METHOD

REPLACEMENT

Page 6

FS-107

1

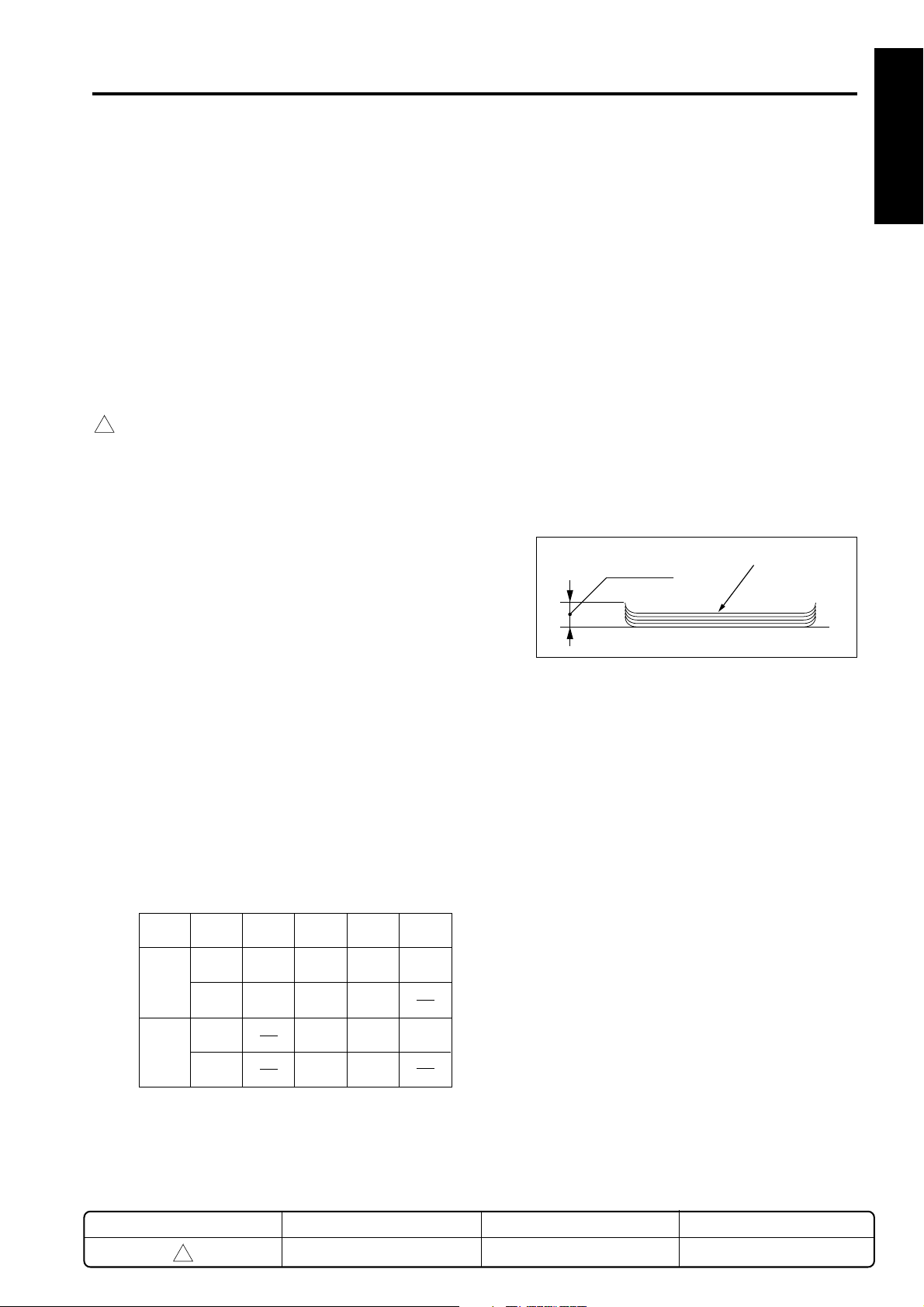

[3] Stapler kit

1 OUTLINE

Staple ability Maximum 50 sheets (with

Stapler capacity: 5,000 staples/cartridge

Staple position: A = 8.6mm ± 3mm

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Paper Size

A3/A4

B4/B5

A4R/A5

B5R

A5R

F4 (8 x 13)

F4 (8.125 x 13)

F4 (8.25 x 13)

F4 (8.5 x 13)

11 x 17/8.5 x 11

8.5 x 14/8.5 x 11R

5.5 x 8.5

5.5 x 8.5R

2

80g/m

ness less than 5mm)

B = 8.6mm ± 3mm

C = refer to following table

D = 10.5mm ± 3mm

1

E = 8.0mm ± 3mm

1

paper, paper thick-

C (mm)

60±4

53±4

90±4

80±4

63±4

90±4

91.5±4

93±4

95±4

52±4

95±4

95±4

60±4

[4] Machine data

Power source: DC24V/5V (supplied from the

main body)

Maximum power

Consumption: Max.70VA

Weight: 13kg

External

dimensions: Length 782mm

Depth 502mm

Height 392mm

[5] Maintenance

Maintenance: Same as the main unit

Machine life: Same as the main unit

[6] Machine environment

Temperature: 10 to 30˚C

Humidity: 20 to 80%RH

1

Note: Specifications are subject to change without

notice.

REVISED EDITION

1

DATE

May 2000

1-2

PA GE

1-2

METHOD

REPLACEMENT

Page 7

1

CENTER CROSS SECTION

FS-107

1 OUTLINE

Tray 2

Tray 1

Exit rolle/A

Conveyance roller

2 UNIT EXPLANATION

Conveyance rollers

Stapler unit

3 DIS./ASSEMBLY

Conveyance belt

REVISED EDITION

1

DATE

May 2000

1-3

PA GE

1-3

METHOD

REPLACEMENT

Page 8

FS-107

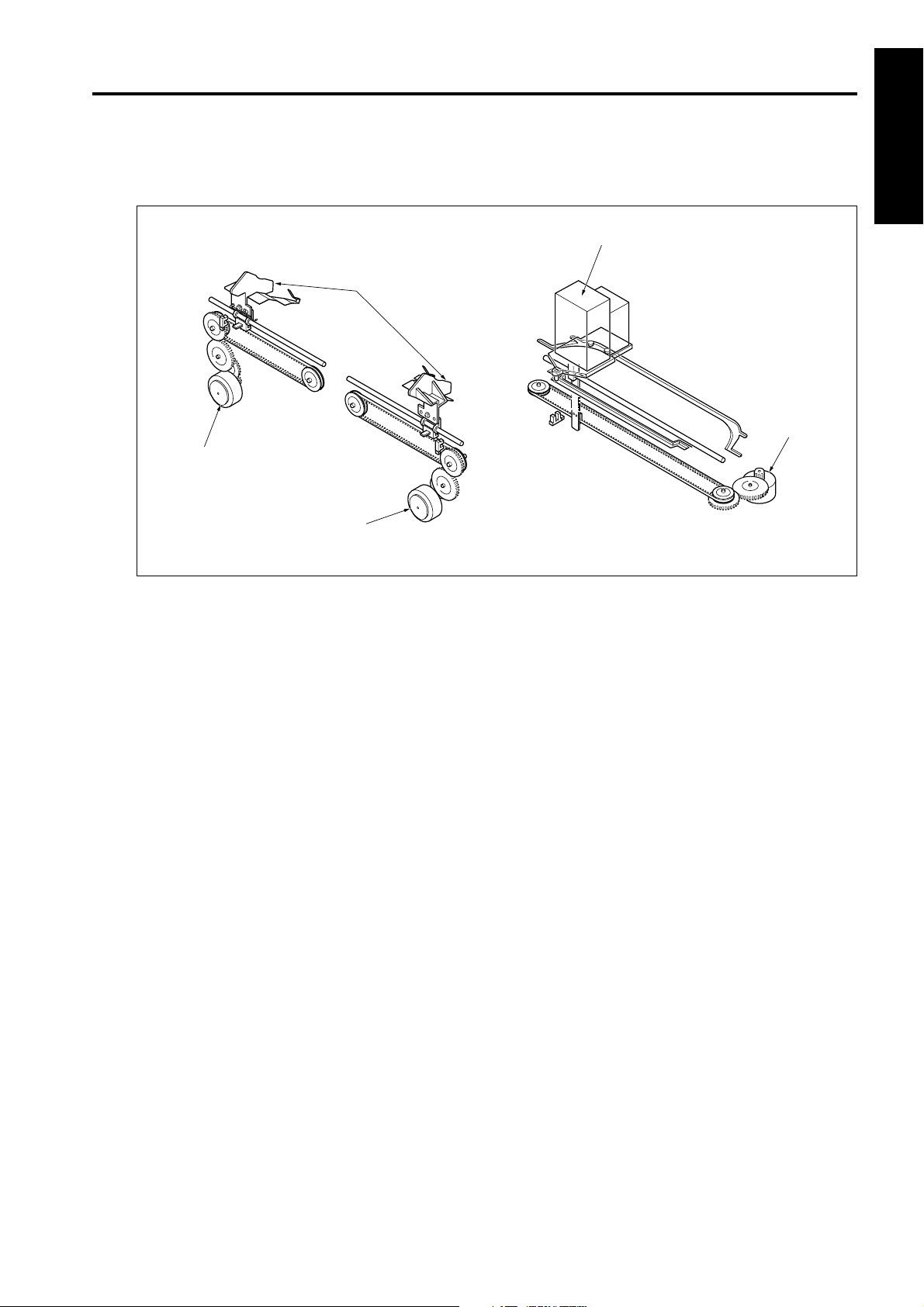

DRIVE SYSTEM DIAGRAM

1 OUTLINE

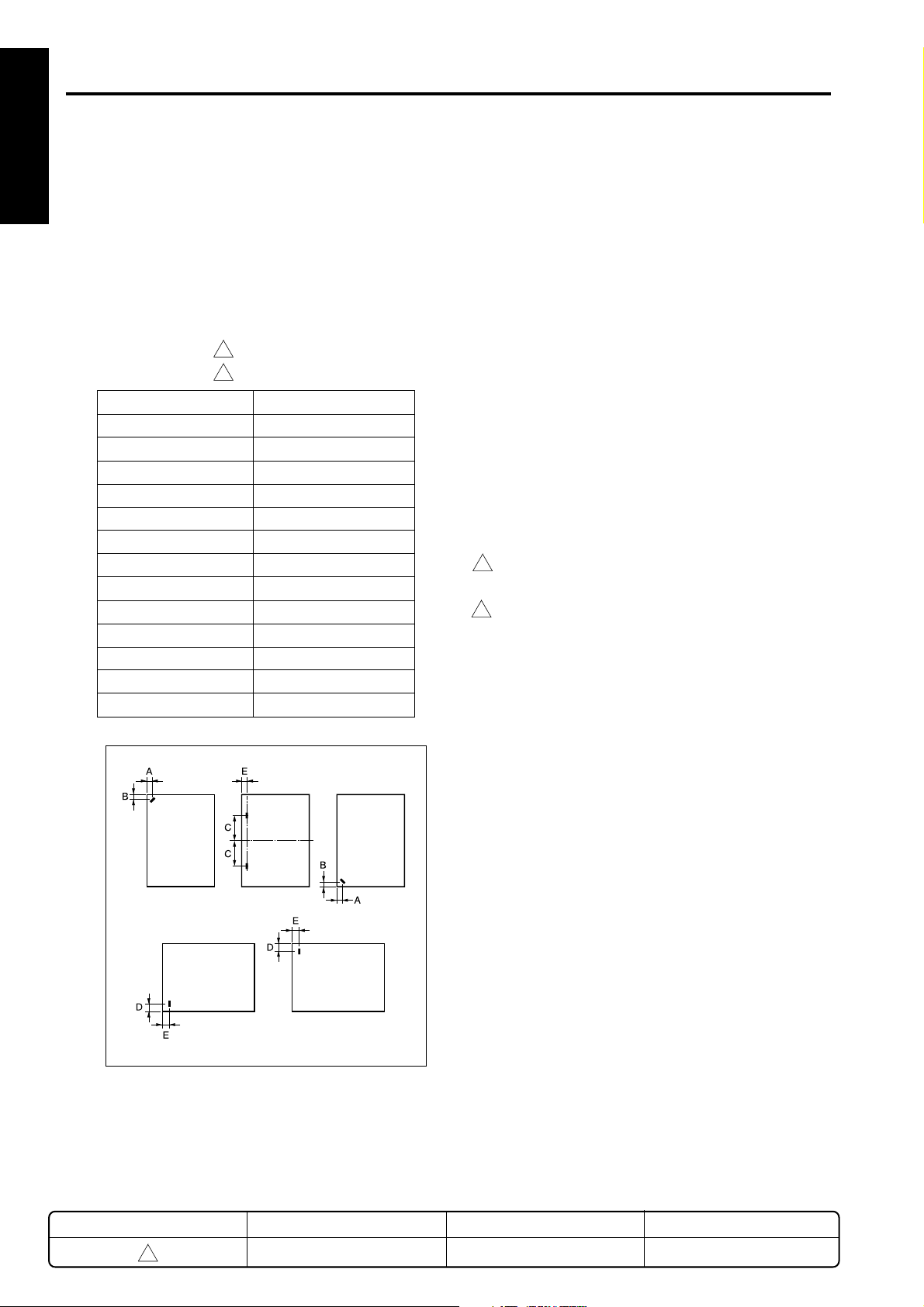

[1] Paper conveyance drive

Paper conveyance

motor (M701)

Paper exit motor (M702)

2 UNIT EXPLANATION

Conveyance roller

Conveyance roller

3 DIS./ASSEMBLY

Exit roller A

Conveyance belt

Paper jam release knob

Conveyance roller

Tray up/down wires

Trays

Tray up/down motor (M706)

1-4

Page 9

FS-107

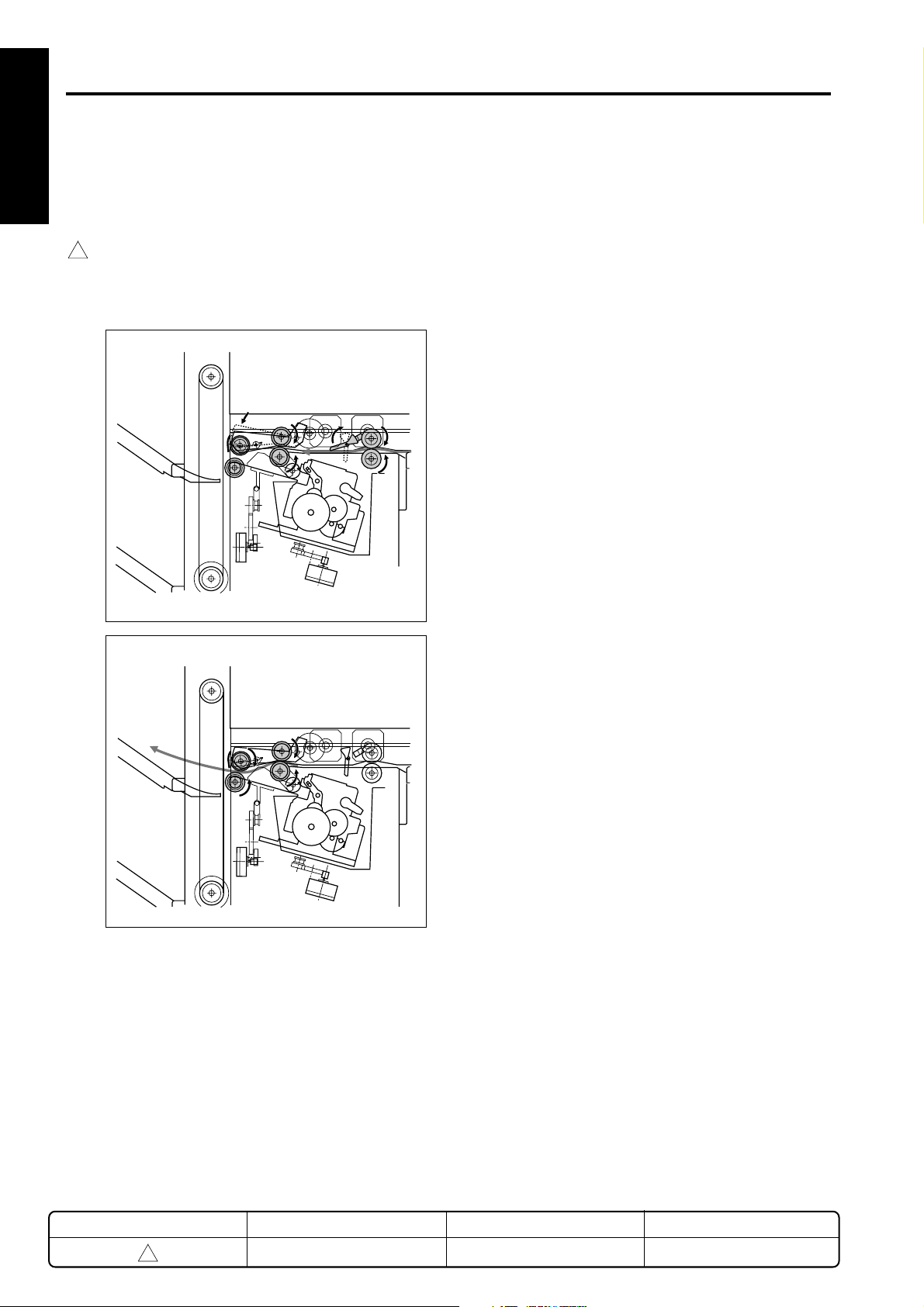

[2] Stapler unit drive

Alignment motor

(rear) (M703)

Alignment motor

(front) (M704)

Alignment plates

Stapler unit

Stapler shift

motor (M705)

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

1-5

Page 10

FS-107

PAPER CONVEYANCE PATH

In the finisher, two different paper conveyance paths are

1 OUTLINE

used, changing by the mode selected.

[1] Straight mode

1

In this mode, paper conveyed to the finisher is exited

straight into the tray. (For small size paper, the

operation of [2] Offset Mode/Stapling Mode takes

place, even in the straight paper exit mode.)

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

REVISED EDITION

1

DATE

May 2000

1-6

PA GE

1-6

METHOD

REPLACEMENT

Page 11

FS-107

[2] Offset mode/staple mode

In the offset mode or staple mode, paper conveyed

to the finisher is stacked once by the reverse rotation

of the exit roller. In the offset mode, this stacked

paper is offset by the paper alignment plates. In the

staple mode, the paper is stapled. When the respective

process is finished, the paper is exited to the tray by the

exit roller.

1

Paper exit roller

Alignment plate

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

REVISED EDITION

1

DATE

May 2000

1-7

PA GE

1-7

METHOD

REPLACEMENT

Page 12

2

1

1 OUTLINE

2 UNIT EXPLANATION

UNIT EXPLANATION

3 DIS./ASSEMBLY

Page 13

EXTERNAL SECTION

FS-107

[1] Composition

1

Front door

Conveyance door

Paper conveyance cover

Stapler unit

Tray 1

1 OUTLINE

Optional tray 1

[FT-107]

2 UNIT EXPLANATION

Optional tray 2

[FT-107]

Tray 2

3 DIS./ASSEMBLY

REVISED EDITION

1

DATE

May 2000

2-1

PA GE

2-1

METHOD

REPLACEMENT

Page 14

FS-107

1

CONVEYANCE SECTION

1 OUTLINE

[1] Composition

Tray 1

Paper conveyance motor (M701)

2 UNIT EXPLANATION

Tray up/down wire

Tray 2

3 DIS./ASSEMBLY

[2] Mechanisms

Mechanism System

Paper Conveyance Conveyance rollers

Tray Up/Down *1 Wire drive

Tray Up/Down Accident Shutter

Prevention *2

Conveyance rollers

Conveyance roller

Tray up/down motor (M706)

Tray up/down wires

*1 Tray up/down

The paper exit gate position is fixed; switching

between trays is accomplished by changing the

tray position up/down mechanism.

Tray up and down is done by the tray up/down

motor (M706), which the tray up/down wires to

drive the tray up or down.

REVISED EDITION

DATE

Trays

PA GE

Tray up/down

motor (M706)

METHOD

2-2

1

May 2000

2-2

REPLACEMENT

Page 15

FS-107

*2 Prevention of tray up/down accident

To prevent the accident insertion of the hand into

the paper exit gate during tray motion up or down,

the paper exit gate is equipped with a shutter. The

shutter is driven by the reverse motion of the paper

pressure motor (M707), closing the paper exit gate

when the tray is in motion.

Shutter

Paper pressure motor (M707)

[3] Conveyance control

5VDC

PS3

SGND

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

MAIN BODY

Conveyance is accomplished by the drive force of the

M701 (paper conveyance motor), which is transmitted to

the conveyance rollers. The M701 is linked with the main

body, so that rotation is set to low or high speed according

to the conveyance movement during copying.

The M701 is controlled by the FS CB (FS control board).

Related signals are provided by the PS702 (paper

entrance detect PS), PS717 (conveyance cover open/

close detect PS) and the MS701 (front door switch) and

PS3 (paper exit PS) of the main body.

PS3

M701 OUT A

M701 OUT A

M701 OUT B

M701 OUT B

FS CB

24VDC

24VDC

5VDC

PS702

SGND

5VDC

PS717

SGND

24VDC

MS701

M701

PS702

PS717

MS701

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

REVISED EDITION

1

DATE

May 2000

1. Operation

1

2-3

As paper passes by the PS3 of the main body, the

M701 conveys the paper at a low speed in relation

with the paper exit velocity of the main body. When

the end of the paper passes through the PS3, the

M701 then conveys the paper at high speed. The

M701 again changes to low speed after the specified

period of time when the end of the paper passes

through the PS702, ready to convey the next sheet of

paper.

PA GE

2-3

METHOD

REPLACEMENT

Page 16

FS-107

2. Signals

1 OUTLINE

a. Input signals

(1) PS3 (PS3 → PRDB)

When the main body paper exit section detection

signal detects paper, [H] is output.

(2) PS702 (PS702 → FS CB)

Conveyance section paper entrance detection signal

[L]: No paper is present

[H]: Paper is present

(3) PS717 (PS717 → FS CB)

2 UNIT EXPLANATION

Conveyance plate opening/closing detection signal

[L]: Conveyance plate open

[H]: Conveyance plate closed

(4) MS701 (MS701 → FS CB)

Power supply line for each load

When the finisher front door is closed, 24VDC is

supplied to each load.

3 DIS./ASSEMBLY

(5) S ACK (MAIN BODY → FS CB)

Transmission of OK signal from the main body to the

finisher.

b. Output signals

(1) M701 OUTA, M701 OUTA, M701 OUTB, M701

OUT B (FS CB → M701)

M701 drive control signal

24V

0V

(2) M ACK (FS CB → MAIN BODY)

Transmission of OK signal from the finisher to the

main body.

(3) S REQ (FS CB → MAIN BODY)

Transmission of request signal from the finisher to

the main body.

(4) M RXD (FS CB → MAIN BODY)

Serial data sign sending the movement condition of

the finisher to the main body CB.

(6) M TXD (MAIN BODY → FS CB)

Serial data sign sending the movement condition of

the main body to the finisher.

(7) M REQ (MAIN BODY → FS CB)

Transmission of request signal from the main body to

the finisher.

2-4

Page 17

FS-107

[4] Tray up/down control

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

MAIN BODY

The paper exit position of the FS is fixed, the selected tray

is elevated or lowered to the paper exit position. Control of

the tray up/down is by the M706 (tray up/down motor)

which drives wires which is connected to and moves the

trays up and down.

The M706 is controlled by the FS CB (FS control board).

Related signals are provided by the PS703 (paper exit

detect PS), PS706 (tray lower limit detect PS), PS716

(tray count PS) and the MS702 (shutter switch).

M706 DRIVE 1

M706 DRIVE 2

5VDC

PS706

SGND

5VDC

PS703

SGND

5VDC

PS716

SGND

24VDC

MS702

FS CB

M706

PS706

PS703

PS716

MS702

1. Operations

a. Tray lower limit detection operation

With the power swich turnd ON, and the PS706 OFF,

the M706 is reversed and the tray is lowered until the

PS706 is turned ON.

b. Tray count operation

One or two optional trays can be installed.

If PS716 goes OFF after the lower limit of the tray has

1

been detected, the machine judges that no optional

trays are installed.

When PS716 is ON, optional tray 1 is in place; in this

condition the M706 rotates normally, raising the tray

one step up until PS716’s detection position where

motion is stopped. Whether PS716 is ON or OFF at

this point determines whether optional tray 2 is in

place or not.

The number of trays is counted by means of a series

1

of operations.

After the tray count, the default tray that was set in

the key operator mode is set in the exit position.

c. Tray movement operation

If the exit tray has been selected at the LCD, then

1

when copying starts M706 turns ON and moves the

selected tray so that it sets into the exit position.

The number of times PS703 switches ON and OFF

sets the selected tray into the paper exit position.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

REVISED EDITION

1

DATE

May 2000

d. Shutter switch operation

While the tray is in motion, the shutter, which

prevents the fingers or foreign objects from entering

the paper exit gate, is closed, with MS702 in the ON

position supplying 24VDC to the various loads. While

the tray is being raised or lowered the shutter is

opened and MS702 is OFF, interrupting the flow of

electricity and halting the motion of the FS.

PAGE

2-5

2-5

METHOD

REPLACEMENT

Page 18

FS-107

2. Signals

1 OUTLINE

a. Input signals

(1) PS706 (PS706 → FS CB)

Tray lower limit detection signal

[L]: Not at lower limit

[H]: Lower limit

(2) PS703 (PS703 → FS CB)

Paper exit detection signal

[L]: Top face

2 UNIT EXPLANATION

[H]: Not at top face

(3) PS716 (PS716 → FS CB)

Tray installation detection signal

[L]: No tray

[H]: Tray in position

(4) PS702 (PS702 → FS CB)

The power supply line for each load.

3 DIS./ASSEMBLY

24VDC is supplied to each load when the shutter is

closed.

b. Output signal

(1) M706 DRIVE 1, 2 (FS CD → M706)

M706 drive control signal

The drive direction of the M706 is controlled by two

signals which change the direction of the electrical

current.

2-6

Page 19

PAPER EXIT/STAPLER UNIT

FS-107

[1] Composition

Trays

Exit roller/A

Alignment plates

Alignment motors

(M703, M704)

Stapler unit

Stapler shift motor (M705)

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[2] Mechanisms

Mechanism System

Paper Alignment *1 Separate plates for front

and rear

Paper Exit *2 Exit roller/A

Paper Stacking *3 Exit roller/A

Conveyance belt

Stapler Unit Shift *4 Stapler shift motor

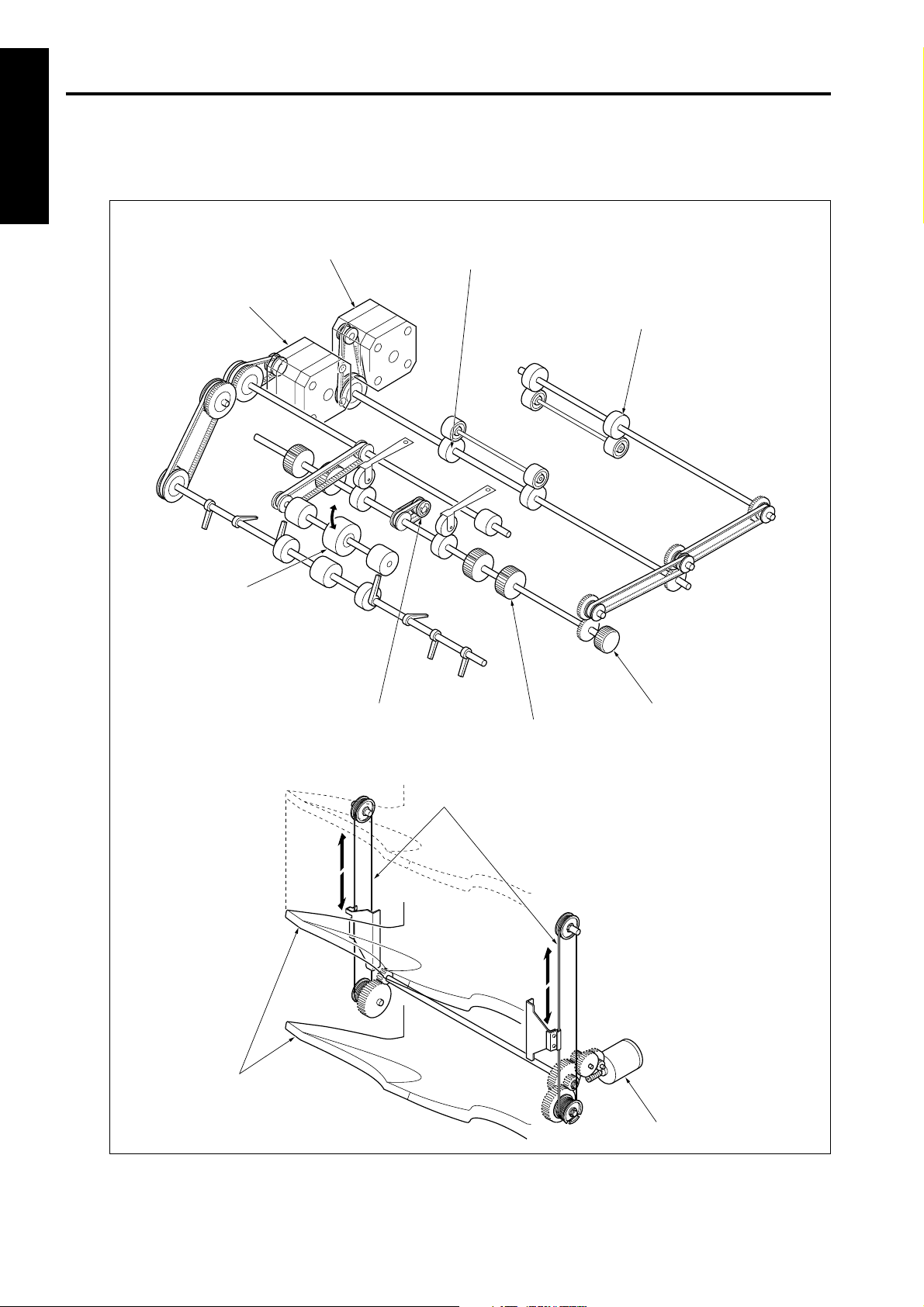

*1 Paper alignment

Paper conveyed to the paper exit gate by the conveyance roller is stacked by reverse rotation of the

paper exit roller/A. The stacked paper is aligned by

the alignment plates. Independently-driven alignment plates are set on both the front and rear

sides, allowing independent operation at the front

and rear during shift mode. The alignment plates

are driven by alignment motors M704 (front) and

M703 (rear).

Alignment plate (rear)

Alignment plate (front)

Alignment motor (rear)

(M703)

Alignment motor (front)

(M704)

2-7

Page 20

FS-107

1 OUTLINE

1

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

*2 Paper exit

In the straight mode, paper conveyed to the paper

exit gate by the conveyance rollers is conveyed to

the tray through paper pressure being applied to

paper exit roller/A by the paper pressure motor

(M707) and the roller being made to run forward.

(Does not apply to small paper sizes.)

In offset mode or staple mode, when the stacked

paper is conveyed, paper pressure being applied

to paper exit roller/A by the paper pressure motor

(M707) and the roller being made to run forward,

all the stacked paper is conveyed into the tray.

Straight mode

Paper exit roller/A

Offset mode/staple mode

*3 Paper stack

In the offset mode or staple mode, paper conveyed to the paper exit gate by the conveyance

rollers is then conveyed to the stack position by

paper exit roller/A running in reverse direction.

The conveyed paper is sent to the stopper by the

friction of the conveyance belt and stacked.

*4 Stapler unit shift

The stapler unit is driven by the stapler shift motor;

1

the stapler unit is fixed on the staple base and

moved by a belt along a rail. Owing to the shape of

the rail, when the stapler unit is moved to either the

forward or rear positions, the unit rotates and it is

possible to staple slantwise.When the stapler is

set to staple in two locations, it moves to the first

location, puts in the first staple, then moves to the

second location to put in the second staple.

REVISED EDITION

1

DATE

May 2000

2-8

Stapler unit

Belt

PA GE

2-8

Rails

Stapler shift motor

(M705)

METHOD

REPLACEMENT

Page 21

FS-107

[3] Paper alignment control

24VDC

24VDC

M702 OUT A

M702 OUT A

M702 OUT B

M702 OUT B

24VDC

24VDC

M703 OUT A

M703 OUT A

M703 OUT B

M703 OUT B

M704 OUT A

M704 OUT A

M704 OUT B

M704 OUT B

FS CB

24VDC

24VDC

5VDC

PS702

SGND

5VDC

PS709

SGND

5VDC

PS710

SGND

MAIN BODY

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

M702

M703

M704

PS702

PS709

PS710

1. Operations

a. Normal alignment operation

The front and rear alignment plates work in symmetry

to the front and rear based on the center of the

alignment section, alternately aligning and releasing.

To create this symmetrical movement the M703 and

M704 always rotate in opposite directions.

Every five sheets of the conveyed paper are aligned

and sent on to the paper exit section.

The timing of the M703 and M704 are set to the

starting point by the ON/OFF of the PS702 (paper

entrance detect PS).

b. Offset (shift alignment) operation

1

The sheets corresponding to odd sets of copies are fed

to the paper exit unit as soon as they have been aligned

normally. (up to 5 sheets are stacked and exited.)

During the alignment operation for even sets of

copies, M703 and M704 rotate in the same direction,

shifting the sheets forward from the center. The

aligned sheets are then sent to the paper exist

unit.(up to 5 sheets are stacked and exited.)

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

During sorting and stapling, paper exited by the

conveyance section is sent to the alignment section by the

M702 (paper exit motor) reverse direction, then aligned by

the alignment plates driven by the M703 (alignment motor,

(rear)) and the M704 (alignment motor, (front)).

The home position of the alignment plates is detected by

the PS709 (alignment plate detect PS (rear)) and the

PS710 (alignment plate detect PS (front)). The FS CB (FS

control board) controls the M702, M703 and M704. The

related signal are passed to the PS702 (paper entrance

detect PS).

c. Staple mode operation

In the staple mode, the M703 and M704 are released

after the stapling action is completed.

The ON/OFF timing of the M703 and M704 is set as

the M702 is turned from OFF to ON, and the PS702 is

turned OFF after the specified period of time.

REVISED EDITION

1

DATE

May 2000

2-9

PA GE

2-9

METHOD

REPLACEMENT

Page 22

FS-107

2. Signals

1 OUTLINE

a. Input signals

[4] Paper exit control

(1) PS709 (PS709 → FS CB)

Detection signal of the home position of the

alignment plate (rear)

[L]: Non-home position

[H]: Home position

(2) PS710 (PS710 → FS CB)

Detection signal of the home position of the

alignment plate (front)

2 UNIT EXPLANATION

[L]: Non-home position

[H]: Home position

b. Output signals

(1) M702 OUT A, M702 OUT A–, M702 OUT B,

M702 OUT B– (FS CB → M702)

Drive control signal for M702

3 DIS./ASSEMBLY

24V

0V

5VDC

MAIN BODY

PS3

SGND

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

PS3

FS CB

24VDC

24VDC

M702 OUT A

M702 OUT A

M702 OUT B

M702 OUT B

M707 DRIVE 1

M707 DRIVE 2

M708 DRIVE 1

M708 DRIVE 2

5VDC

PS701

SGND

5VDC

PS702

SGND

5VDC

PS703

SGND

5VDC

PS707

SGND

M702

M707

M708

PS701

PS702

PS703

PS707

Papers that have already been aligned or stapled are

exited by the paper exit roller.

(2) M703 OUT A, M703 OUT A–, M703 OUT B,

M703 OUT B– (FS CB → M703)

Drive control signal for M703

24V

0V

(3) M704 OUT A, M704 OUT A–, M704 OUT B,

M704 OUT B– (FS CB → M704)

Drive control signal for M704

24V

0V

A mechanical clutch is connected to M702 (paper exit

motor). A mechanical clutch can convey the forward

direction driving power to the exit roller with certain

movement.

The M702 is responsible for speed control for connection

with the mechanical clutch, for sending the alignment

section at the reversal rotation, and also during the usual

paper exit.

The M702 is controlled by the FS CB (FS control board).

The related signals are M707 (paper pressure motor),

M708 (stapler motor), PS701 (paper pressure PS), PS702

(paper entrance detect PS), PS703 (paper exit detect PS),

and PS707 (no paper detect PS).

2-10

Page 23

FS-107

1. Operation

During paper exit, both upper and lower exit rollers

are compressed as a consequence of the operation

performed by M707, and that condition is detected by

the ON/OFF state of PS701.

a. Non-staple mode operation

The ON/OFF timing of M702 is such that it turns ON

during the OFF of PS3, and turns OFF during the

OFF of PS702.

After the paper exit tray goes up until PS703 turns

ON, M706 moves the tray up and down in order to

keep the ON state of PS703 during paper exit.

b. Staple mode operation

M702 turns ON a certain time after M708 finishes the

stapling operation and turns OFF.

The subsequent operations are the same as for the

non-staple operation.

2. Signals

a. Input signal

(1) PS701 (PS701 → FS CB)

Pressure detection signal of the exit paper compressing plate

[L]: Pressure

[H]: Release

[5] Paper stack control

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

MAIN BODY

When the stack of the papers on the paper exit tray is full,

a message is put up on the LCD.

During the automatic switching mode of the tray, a

message is not put up on the LCD. The tray located 1 step

below is brought to the paper exit position by a vertical

movement of M706 (tray up/down motor).

The M706 is controlled by FS CB (FS control board).

The related signals are PS702 (paper entrance detect

PS), PS703 (paper exit detect PS), PS704 (tray full-stack

detect PS), PS706 (tray lower limit detect PS), and PS716

(tray count PS).

M706 DRIVE 1

M706 DRIVE 2

5VDC

PS702

SGND

5VDC

PS703

SGND

5VDC

PS704

SGND

5VDC

PS706

SGND

5VDC

PS716

SGND

FS CB

M706

PS702

PS703

PS704

PS706

PS716

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

b. Output signals

(1) M707 DRIVE 1,2 (FS CB → M707)

M707 drive control signal

The drive direction of the M707 is controlled by two

signals which change the direction of the electrical

current.

(2) M708 DRIVE 1,2 (FS CB → M708)

M708 drive control signal

The drive direction of the M708 is controlled by two

signals which change the direction of the electrical

current.

The automatic switching mode of the tray can be

controlled using the 25 modes of the main unit.

2-11

Page 24

FS-107

1. Operation

1 OUTLINE

a. Up/down operation

When the tip of the paper turns PS702 ON, the tray is

driven down by a certain amount. After the rear of the

paper turns PS702 OFF, M706 turns ON driving the

tray up until PS703 is turned ON.

b. Full-stack detection operation

When a tray other than tray 1 is selected and PS703

is turned ON when PS704 is ON, the paper-full

condition is detected. When tray 1 is selected and PS

2 UNIT EXPLANATION

703 is turned ON when PS706 is ON, the paper-full

condition is detected.

c. Automatic tray switching operation

When tray 1, optional tray 1, and optional tray 2 are

selected and the paper-full condition is detected,

M706 drives the tray up so that PS703 is turned OFF

and then ON again, and the immediately lower tray is

set at the paper exit position.

3 DIS./ASSEMBLY

When tray 2 is selected and the paper-full condition is

detected, M706 drives the tray down until PS716 is

turned ON, and then up until PS703 is turned ON, set

tray 1 at the paper exit position.

[6] Stapler control

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

MAIN BODY

M705 (staple shift motor) performs staple displacement

control by moving the stapler unit up to the stapler

operation position.

The home position of the stapler unit is detected by PS708

(stapler unit HP detect PS).

M705 is controlled by FS CB (FS control board).

M705 OUT A

M705 OUT A

M705 OUT B

M705 OUT B

FS CB

24VDC

24VDC

5VDC

PS708

SGND

M705

PS708

2. Signal

a. Input signal

(1) PS704 (PS704 → FS CB)

Paper-full detection signal

Goes [H] when paper-full condition is detected.

1. Operation

The stapler unit is usually at the home position of the

finisher.

When receiving a command signal from the main

unit, M705 moves the stapler unit to the stapling

position according to paper size and starts the

stapling operation.

After finishing the copy, M705 moves the stapler unit

to its home position.

The M705 OFF timing is controlled by the number of

driving steps after PS708 is turned OFF.

2-12

Page 25

FS-107

1

2. Signal

a. Input signal

(1) PS708 (PS708 → FS CB)

Detection signal of the home position of the stapler

unit

[L]: Non-home position

[H]: Home Position

b. Output signal

(1) M705 OUT A, M705 OUT A–, M705 OUT B,

M705 OUT B– (FS CB → M705)

Drive control signal for M705

24V

0V

[7] Staple control

24VDC

24VDC

M705 OUT A

M705 OUT A

M705 OUT B

M705 OUT B

M707 DRIVE 1

M707 DRIVE 2

M708 DRIVE 1

M708 DRIVE 2

5VDC

PS701

SGND

5VDC

PS708

SGND

5VDC

PS712

SGND

5VDC

PS713

SGND

FS CB

MAIN BODY

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

In staple mode, stapling is performed using the driving

force of the M708 (stapler motor).

M705

M707

M708

PS701

PS708

PS712

PS713

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

M708 is controlled by FS CB (FS control board).

The related signals are M705 (stapler shift motor), M707

(paper pressure motor), PS701 (paper pressure PS),

PS708 (stapler unit HP detect PS), PS712 (stapler HP

detect PS), PS713 (no-staple PS), and PS714 (stapler

ready PS).

The maximum number of sheets that can be stapled, and

the operation when stapling is not possible, can be chosen

in the 25 mode of the main body.

REVISED EDITION

DATE

PAGE

METHOD

2-13

1

May 2000

2-13

REPLACEMENT

Page 26

FS-107

1. Operation

1 OUTLINE

a. Stapler operation

After the aligning operation of the last paper, M707 is

turned ON and compresses the paper using the exit

rollers. Then, M708 is turned ON and stapling begins.

When PS701 is turned OFF, M707 is turned OFF,

PS712 is turned ON, and M708 is turned OFF.

For continuous stapling, M705 is not turned ON, and

the stapler unit waits for the next stapling at the same

position.

In the case of 2 stapling positions, the first staple is

2 UNIT EXPLANATION

executed and then M705 moves the stapler to the

specified position for the second staple. M708 then

turns ON and executes the second staple. At this

moment, if continuous stapling has been selected,

the stapler unit stops at the immediately previous

stapling position. When the first stapling operation of

the next paper is done, M705 moves the stapler unit

for the second stapling operation.

After the copy is finished, the stapler unit returns to its

home position.

3 DIS./ASSEMBLY

2. Signals

a. Input signals

(1) PS712 (PS712 → FS CB)

M708 home position detection signal

[L]: Home position

[H]: Non-home position

(2) PS713 (PS713 → FS CB)

No-staple detection signal of the stapler unit

[L]: With staple

[H]: No staple

(3) PS714 (PS714 → FS CB)

Detects whether staple is in position for stapling by

stapler unit (whether staple is present at point just

ahead of where it is actually driven from the stapler).

[L]: With staple

[H]: No staple

b. No-staple detection control

The PS713 is equipped to detect the no-staple

condition of the stapler unit. When the staple is not

present, the LCD (display board) of the main unit

shows a message indicating the no-staple condition.

c. Stapler Initial Operation

After replacing the stapler cartridge, M708 is driven

until staples are detected in the PS714, performing

up to a maximum of 16 blank stapling operations,

then the staples are positioned just in front of the

stapling position.

2-14

Page 27

1

OTHER CONTROLS

FS-107

[1] Movement with power on

When the power is turned ON, the finisher performs

1

the following initialization operations.

1. M707 turns ON and the paper exit gate pressure is

released.

2. PS708 (stapler unit HP detect PS) detects whether

the stapler unit is on stand-by in home position.

3. M703 (alignment motor (rear)) and M704 (alignment motor (front)) turn ON and perform a home

position search for the alignment plates (front and

rear).

1

4. The paper exit gate shutter closes, and the tray

count operation takes place.

[2] Opening and closing motion of the

front door

1. In case PS707 is ON, it makes M702 go through a

normal rotation and performs a paper exit operation.

2. M707 turns ON and the paper exit gate pressure is

released.

3. PS708 (stapler unit HP detect PS) detects whether

the stapler unit is on stand-by in home position.

4. M703 (alignment motor (rear)) and M704 (alignment motor (front)) turn on and perform a home

position search for the alignment plates (front and

rear).

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

REVISED EDITION

1

DATE

May 2000

2-15

PA GE

2-15

METHOD

REPLACEMENT

Page 28

3

DISASSEMBLY/ASSEMBLY

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Page 29

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

This section explains how to disassemble and reassemble the

machine.

Observe the following precautions when performing disassembly

and assembly work.

1. Be sure to unplug the power cord before working on the

machine.

2. Perform all reassembly work by reversing the order in which the

component was disassembled, unless otherwise specified.

3. Do not lose small parts (screws, etc.) or insert them in the

wrong place.

4. Install all parts completely before operating the machine.

5. Do not loosen the screws indicated as disallowed for removal.

Page 30

DISASSEMBLY/ASSEMBLY

FS-107

Caution: Make sure the power plug is taken

out of the socket.

[1] Removing and reinstalling of the

1

finisher.

(1) Open the front door, then insert a pen, or the like,

into the hole at the bottom of the finisher.

Caution: There is a risk of the internal lever becoming

1

deformed, so do not push it in hard.

(2) Take out each 2 sets of set screws from the wire

fittings on front and rear.

Set

screws

Wire fittings

(3) Pull out the tray downward from the frame that it is

installed.

Caution 1: Taking out the set screws from the fixed

fittings will make the tray frame fall out.

Caution 2: Take care not to drop the rollers installed

on the tray.

Set

screws

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(2) Pull the finisher forward and remove it.

[2] Removing and reinstalling of the tray

1

(1) Take out each 3 sets of set screws and remove the

cover’s front and rear.

Set screws

Set screws

1

Rollers

Cover (rear)

REVISED EDITION

1

Set screws

Cover (front)

DATE

May 2000

3-1

PA GE

3-1

METHOD

REPLACEMENT

Page 31

FS-107

(4) Install by reversing the removal procedure.

1 OUTLINE

Caution: In case of fixing the tray frame to the fixed

1

fittings, make sure the set screws are fastened so that the tray is horizontal.(Use

the 6 marks at each of the front and rear as

guides for horizontal adjustment.)

1

2 UNIT EXPLANATION

Rear

3 DIS./ASSEMBLY

Front

1

[3] Replacing the paper exit roller/A

(1) Remove the finisher from the main body.

(2) Take off 5 lids and 6 set screws and remove the

paper conveyance cover.

Lids

Set screws

Paper conveyance cover

(3) Take out each of the single springs and set screws

and remove the plate spring roller.

Set screws

Spring

Plate spring rollers

adjustment

plate

Caution: Do not remove the screws for the spring

adjustment plate.

REVISED EDITION

1

DATE

May 2000

3-2

PA GE

3-2

METHOD

REPLACEMENT

Page 32

FS-107

(4) Remove the E-ring and remove the cam shaft.

Shaft

E-ring

(5) Take out the 2 sets of set screws and remove the

set of 2 plate springs.

Set screws

Plate spring

(8) Remove the 5 E-rings and pull out the shaft from

1

the paper exit roller/A.

Caution: Be careful to not drop the pin inside the

paper exit roller/A.

Paper exit

roller/A

E-rings

Pin

E-rings

Shaft

Pin

(9) Replace the paper exit roller/A.

(10) Install by reversing the removal procedure.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(6) Take out 1 set screw and remove the plate.

(7) Remove the E-ring that affixes the belt gear, slide

the gear and remove the belt.

Caution: Be careful to not drop the pin inside the

gear.

1

REVISED EDITION

Set screw

Pin

1

Plate

E-ring

Belt

DATE

May 2000

3-3

PA GE

3-3

METHOD

REPLACEMENT

Page 33

FS-107

1 OUTLINE

[4] Removing and reinstalling of the

1

up/down wire

(1) Take out the 3 sets of set screws and remove the

front cover and rear cover.

(2) Remove the 2 set screws from each of the front and

1

rear wires, and then remove the tray unit.

Caution: Perform the removing/installing of the front

up/down wire before performing the

removing/installing of the rear up/down

wire.

(3) Loosen the 2 set screws and release the pulley

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

tension plate (front) from its fixed position.

(4) Remove the E-ring of the lower pulley (front).

(5) Remove the lower pulley (front) and remove the up/

down wire (front).

1

Pulley installation gear

Caution: Ensure that the pulley installation gear is

1

horizontal with respect to the casing.

(7) Wind the up/down wire once around the lower

pulley (front) counter-clockwise, and string it to the

upper pulley (front).

(8) Down the up/down wire strung to the upper pulley

(front) to the lower pulley and wind it around 4 times

counter-clockwise, and attach the metallic ball on

the end to the side of the lower pulley (front).

(9) Attach the E-ring and affix the lower pulley (front).

(10) Fasten the 2 set screws while pulling up the pulley

tension plate (front), applying 3kg tension.

Caution: Apply the required amount of tension at

the time of affixing the pulley tension plate

by using such devises as a tension gauge.

(6) Attach the metallic ball of the up/down wire on the

inner surface of the lower pulley (front), and insert

into the shaft. The metallic ball to be set is the one

longer from the wire fitting.

1

Also, check to see if the gear position at which the

pulley is installed is in line with the opposite side (rear).

Required value: 3kg

Set screws

Pulley tension

plate

REVISED EDITION

1

DATE

May 2000

3-4

PA GE

3-4

METHOD

REPLACEMENT

Page 34

FS-107

(11) Refer to procedures 3 to 6 and remove the up/down

1

1

wire on the rear.

(12) Wind the up/down wire once around the lower

pulley (rear) in the clockwise, and string it to the

upper pulley (rear).

(13) Down the up/down wire strung to the upper pulley

(rear) to the lower pulley and wind it around 4 times

clockwise, and attach the metallic ball on the end to

the side of the lower pulley (rear).

(14) Attach the E-ring and affix the lower pulley (rear).

(15) Fasten the 2 set screws while pulling up the pulley

tension plate (rear), applying 3kg tension.

[5] Replacing the stapler cartridge

1

(1) Operate the stapler cartridge replacing from the

operation panel. The stapler unit will move and

position itself to the front.

(2) Turn the stapler cartridge replace knob on the

stapler unit.

1

Cartridge

replace knob

Stapler unit

(3) Remove the old cartridge and push a new cartridge

firmly in place.

Stapler cartridge

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

REVISED EDITION

1

DATE

May 2000

3-5

PA GE

3-5

METHOD

REPLACEMENT

Page 35

FS-107

1

1 OUTLINE

[6] Removing and reinstalling the

stapler unit

(1) Remove the finisher from the main unit.

(2) Take out the fixing plates of the plate affixing the

stapler unit, from the rear of the finisher unit.

(3) Slide the plate and remove.

2 UNIT EXPLANATION

Plate

Hook

3 DIS./ASSEMBLY

Caution: When reinstalling the plate, be sure to

insert the plate into the insides of the

hooks.

Set screw

(5) Take out the set screw from the unit saddle, slide

out and remove the stapler unit.

Stapler units

(6) Install by reversing the removal procedure.

Set screw

(4) Take out the connector and 1 grounding screw

from the stapler unit.

Grounding screw

Ground

Connector

REVISED EDITION

1

DATE

May 2000

3-6

PA GE

3-6

METHOD

REPLACEMENT

Loading...

Loading...