Page 1

DB-209

SERVICE HANDBOOK

2000.02

Ver. 1.0

KONICA CORPORATION

TECHNOLOGY SUPPORT CENTER

TOKYO JAPAN

Page 2

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS .............

Refer to the 7020 service handbook on page C-1

1. OUTLINE

DB-209 PRODUCT SPECIFICATIONS .................1-1

[1] Type........................................................1-1

[2] Functions ................................................1-1

[3] Machine data ..........................................1-1

[4] Maintenance ...........................................1-1

[5] Machine environment .............................1-1

CENTRE CROSS-SECTIONAL DRAWING...........1-2

DRIVE SYSTEM DIAGRAM...................................1-3

2. UNIT EXPLANATION

PAPER FEED SECTION........................................2-1

[1] Composition............................................2-1

[2] Mechanisms ........................................... 2-1

[3] Paper feed and no paper detection

control .....................................................2-2

[4] Tray up and down control .......................2-4

[5] Paper size detection control ...................2-5

[6] Control of paper-level detection..............2-6

[7] Jam detection control ............................. 2-6

3. DISASSEMBLY/ASSEMBLY

DISASSEMBLY/ASSEMBLY..................................3-1

[1] Removing and reinstalling paper

feed tray..................................................3-1

[2] Removing and reinstalling the paper

feed unit ..................................................3-1

[3] Replacing the feed roller rubber and

double feed prevention rubber/upper .......3-2

[4] Repacing the double feed prevention

rubber/lower............................................ 3-3

1 OUTLINE

2 UNIT EXPLANA TION

3 DIS./ASSEMBLY

Page 3

1

OUTLINE

1 OUTLINE

2 UNIT EXPLANA TION

3 DIS./ASSEMBLY

Page 4

DB-209 PRODUCT SPECIFICATIONS

DB-209

[1] Type

Type: Tray paper feed

(Front loading)

[2] Functions

Paper size: A3, B4, A4, A4R, B5, B5R

A5R, 8.5 x 11, 8.5 x 11R,

8.5 x 14, 11 x 17

Paper type: 60g/m

Maximum

Paper capacity: 500 Sheets x 2 Trays

2

to 90g/m2 high quality

paper

2

(80g/m

)

[3] Machine data

Power: DC24V/5V (supplied from

main body)

Power consumption: Max.30VA

Weight: Approx. 25.5kg

Machine

Dimensions: Length 580mm

Depth 595mm

Height 304mm

1 OUTLINE

2 UNIT EXPLANA TION

3 DIS./ASSEMBLY

[4] Maintenance

Maintenance: Same as main body

Machine Life: Same as main body

[5] Machine operation environment

Temperature: 10 to 30˚C

Humidity: 10 to 80%RH

(below condensation-forming

conditions)

Caution: The contents of this Handbook may be

revised for the purposes of improvement

without notice.

1-1

Page 5

DB-209

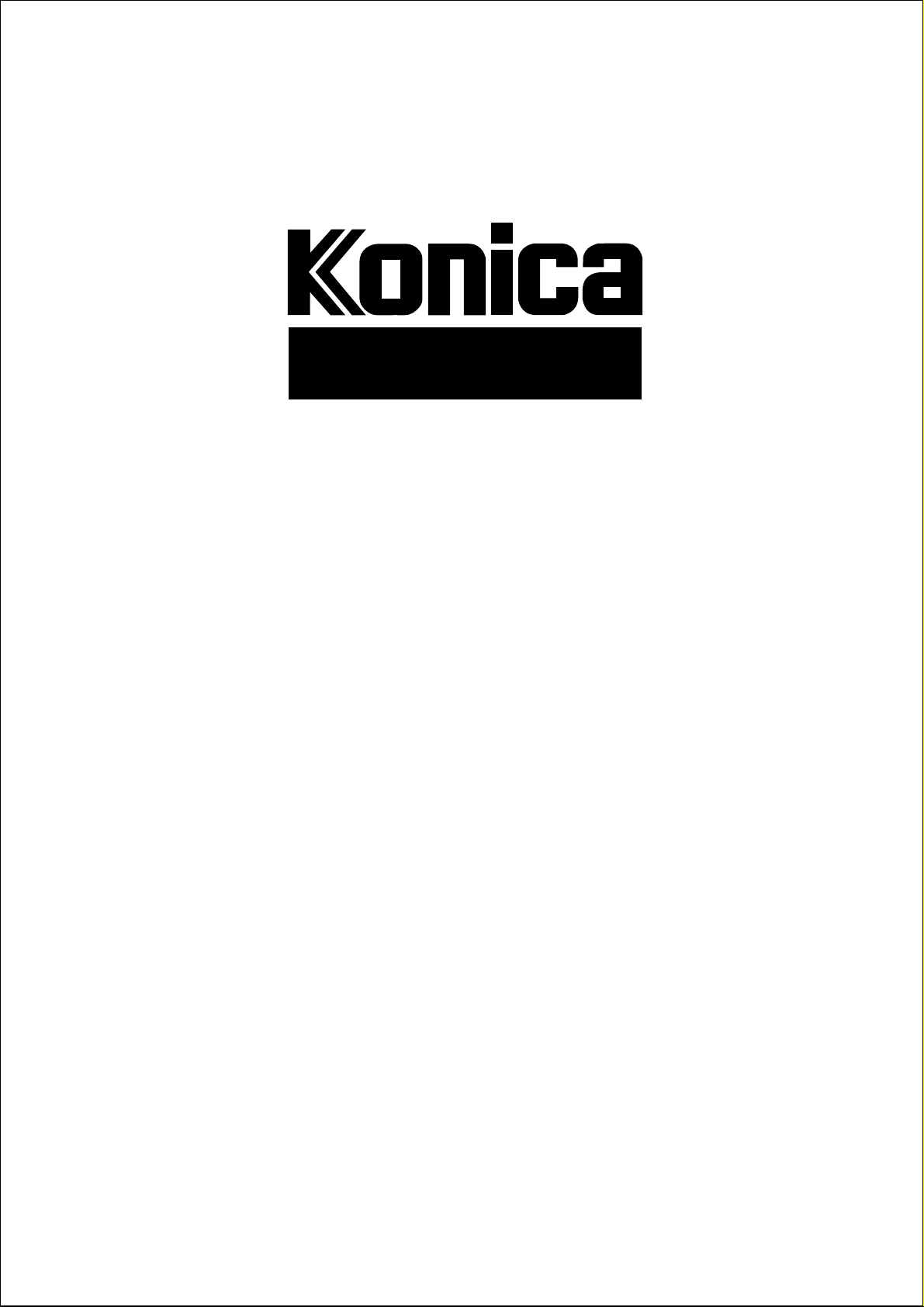

CENTRE CROSS-SECTIONAL DRAWING

1 OUTLINE2 UNIT EXPLANA TION3 DIS./ASSEMBLY

Paper lift-up plates

Feed rollers

Paper lowering levers

Double feed prevention

rollers/upper

Double feed prevention

roller/lower

Conveyance

rollers

1-2

Page 6

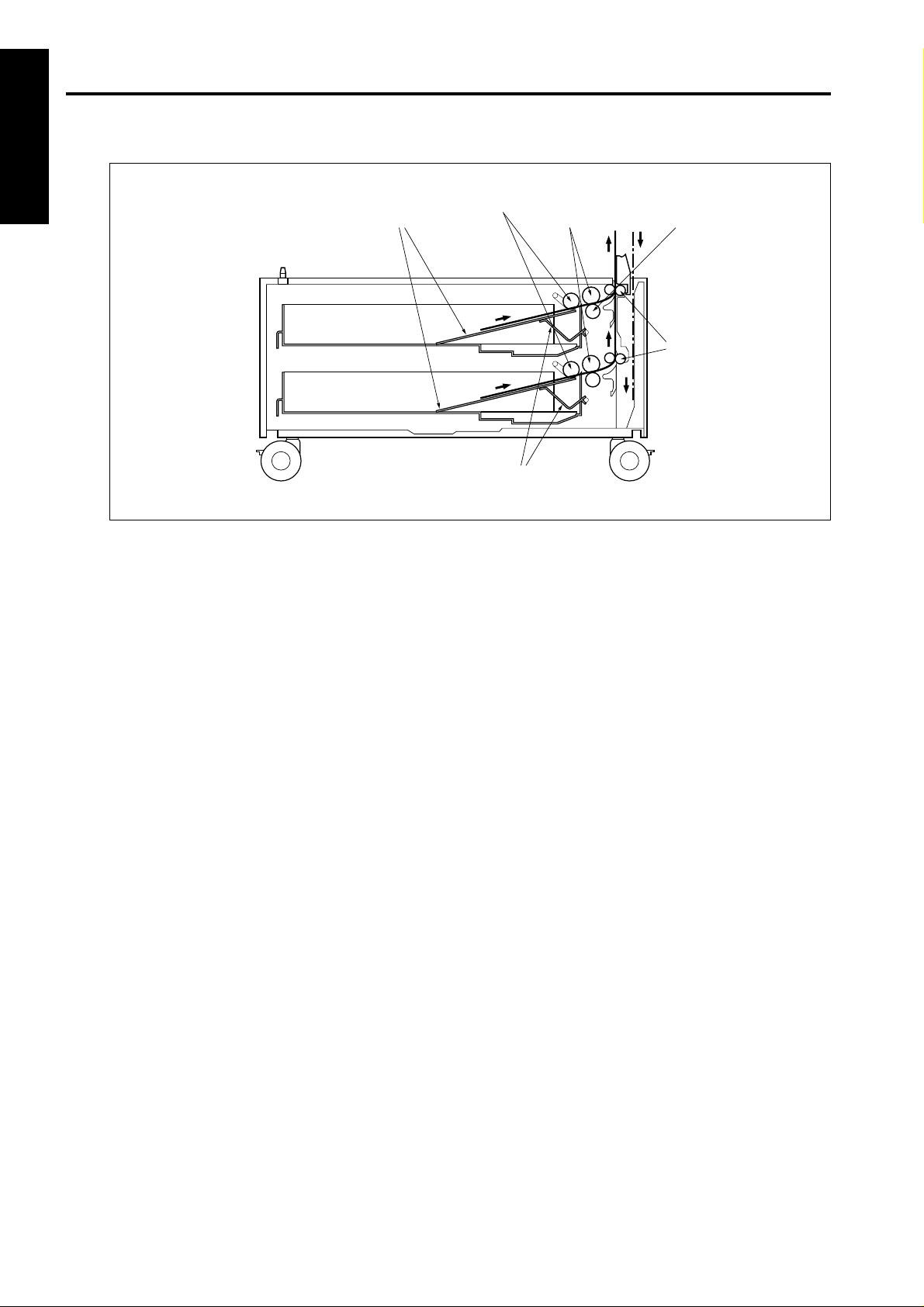

DRIVE SYSTEM DIAGRAM

Conveyance roller

DB-209

1 OUTLINE

Double feed prevention roller/upper

2 UNIT EXPLANA TION

1st paper feed SD (upper) (SD101)

Conveyance roller

DB drive motor (M101)

3 DIS./ASSEMBLY

Double feed prevention roller/lower

1st paper feed SD (lower) (SD102)

1-3

Page 7

2

UNIT EXPLANATION

1 OUTLINE

2 UNIT EXPLANA TION

3 DIS./ASSEMBLY

Page 8

PAPER FEED UNIT

DB-209

[1] Composition

Paper size indicator units

[2] Mechanisms

Mechanism Method

Paper feed Paper feed roller

Paper lifting Paper lift-up plate

Double feed Torque limiter

prevention

Tray loading Front loading

1st paper feed Paper feed SD

Feed roller

Jam processing Release of pressure on

double feed prevention roller

No paper detect Photosensor

Paper size detect Paper size indicator unit

Paper conveyance Roller conveyance

Conveyance drive Gears

1 OUTLINE2 UNIT EXPLANA TION3 DIS./ASSEMBL Y

Double feed prevention roller/upper

Double feed prevention roller/lower

Feed roller

Paper feed door

2-1

Page 9

DB-209

1 OUTLINE2 UNIT EXPLANA TION3 DIS./ASSEMBLY

[3] Paper feed and no paper detection

control

M100 CONT

SD101 CONT

SD102 CONT

DB SELECT1

DB SELECT2

MAIN BODY

24VDC

24VDC

PGND

PGND

5VDC

SGND

PS103

PS108

M100 CONT

SD101 DRIVE

SD102 DRIVE

PFUDB

24VDC

PGND

24VDC

24VDC

SGND

PS103

5VDC

SGND

PS108

5VDC

EM

M100

SD101

SD102

PS103

PS108

1. Operation

a. Paper feed operation timing (upper tray)

(1) 1st. sheet start

A specified time after start-button is turned ON

(2) 2nd. sheet start

A specified time after 1st. sheet SD101 is turned ON

(3) OFF timing

A specified time after SD101 is turned ON

b. Paper feed operation timing (lower tray)

(1) 1st. sheet start

A specified time after start-button is turned ON

(2) 2nd. sheet start

A specified time after 1st. sheet SD102 is turned ON

(3) OFF timing

A specified time after SD102 is turned ON

Paper feed is achieved by transmitting the drive of the

M100 (DB drive motor) to the upper and lower paper feed

rollers and to the feed rollers. When feed starts, SD101

(1st. paper feed SD (upper)) or SD102 (1st. paper feed SD

(lower)) raises and lowers the feed roller and contacts the

paper.

Drive of the M100, SD101 and SD102 is achieved by

PFUDB (PFU drive board)and controlled by the main

body.

No paper detection is achieved with PS103 (No paper

detect PS (upper)) and PS108 (No paper detect PS

(lower)) and controlled by the main body via the PFUDB.

c. No paper detection

If paper in the tray is used up, PS103 or PS 108 go [L]

and the no paper detection of each tray is sent to the

main body via the PFUDB.

2-2

Page 10

DB-209

DB DB-SELECT 1 DB-SELECT 0

DB-209 H L

DB-409 L H

No contact H H

Uncertain L L

Signal

2. Signals

a. Input signals

(1) PS103 (PS103 → PFUDB)

Upper tray paper/no paper detection signal

[H] :with paper

[L] :no paper

(2) PS108 (PS108 → PFUDB)

Lower tray paper/no paper detection signal

[H] :with paper

[L] :no paper

(3) M100 CONT (MAIN BODY → PFUDB)

M100 ON/OFF control signal from main body

(4) SD101 CONT (MAIN BODY → PFUDB)

SD101 ON/OFF control signal from main body

(5) SD102 CONT (MAIN BODY → PFUDB)

SD102 ON/OFF control signal from main body

b. Output signals

(1) M100 CONT (PFUDB → M100)

M100 drive control signal

[H] :M100 OFF

[L] :M100 ON

(2) M100 CLK (PFUDB → M100)

M100 revolution control board clock signal

(3) SD101 (PFUDB → SD101)

SD101 drive control signal

[H] :OFF

[L] :ON

(4) SD102 DRIVE (PFUDB → SD102)

SD102 drive control signal

[H] :OFF

[L] :ON

(5) PS103 (PFUDB → MAIN BODY)

Upper tray paper/no paper detection signal sent to

main body

1 OUTLINE2 UNIT EXPLANA TION3 DIS./ASSEMBL Y

(6) PS108 (PFUDB → MAIN BODY)

Lower tray paper/no paper detection signal sent to

main body

(7) DB SELECT (PFUDB → MAIN BODY)

DB Type identification signal sent to main body

2-3

Page 11

DB-209

1 OUTLINE2 UNIT EXPLANA TION3 DIS./ASSEMBLY

[4] Tray up and down control

24VDC

24VDC

PGND

PGND

5VDC

SGND

M101 CONT

M102 CONT

PS101

PS102

PS106

PS107

MAIN BODY PFUDB

M101 DRIVE

24VDC

SGND

PS101

5VDC

SGND

PS102

5VDC

M102 DRIVE

24VDC

SGND

PS106

5VDC

SGND

PS107

5VDC

M101

PS101

PS102

M102

PS106

PS107

2. Signals

a. Input signals

(1) PS101 (PS101 → PFUDB)

Upper tray detect signal

By turning ON with [L] showing, M101 raises the

paper in the upper tray.

(2) PS106 (PS106 → PFUDB)

Lower tray detect signal

By turning on with [L] showing, M102 raises the paper

in the lower tray.

(3) PS102 (PS102 → PFUDB)

Upper tray paper upper limit detect signal

When the upper tray paper is raised and arrives at the

upper limit position, the signal becomes [H] and

M101 is turned off.

(4) PS107 (PS107 → PFUDB)

Lower tray paper upper limit detect sensor

When the lower tray paper is raised and arrives at the

upper limit position, the signal becomes [H] and

M102 is turned off.

1. Operation

When the paper feed tray of each level is set, PS101

(Tray detect PS (upper)) and PS106 (Tray detect PS

(lower)) detect the tray, M101 (Paper feed motor 1)

and M102 (Paper feed motor 2) turn on and lift the

base plate in the tray. When the tray is lifted, PS102

(Upper limit detect PS (upper)) and PS 107 (Upper

limit detect PS (lower)) detect the paper upper limit

and turn ON, M101 and M102 turn off and the raising

of the tray is completed.

The down operation of the trays is performed

mechanically.

(5) M101 CONT (MAIN BODY → PFUDB)

M101 ON/OFF control signal from main body

(6) M102 CONT (MAIN BODY → PFUDB)

M102 ON/OFF control signal from main body

b. Output signals

(1) M101 DRIVE (PFUDB → M101)

M101 drive control signal

[L] :M101 ON

[H] :M101 OFF

(2) M102 DRIVE (PFUDB → M102)

M102 drive control signal

[L] :M102 ON

[H] :M102 OFF

(3) PS101 (PFUDB → MAIN BODY)

Upper tray detect signal sent to main body

(4) PS102 (PFUDB → MAIN BODY)

Upper tray paper upper limit detect signal sent to

main body

(5) PS106 (PFUDB → MAIN BODY)

Lower tray detect signal sent to main body

(6) PS107 (PFUDB → MAIN BODY)

Lower tray paper upper limit detect signal sent to

main body

2-4

Page 12

DB-209

[5] Paper size detection control

24VDC

24VDC

PGND

PGND

5VDC

SGND

SIZE D

SIZE C

SIZE B

SIZE A

MAIN BODY

Tray paper size is detected in the main body by a signal

sent from SDB1(size detection board1) and SDB2 (size

detection board2) via the PFUDB (PFU drive board).

1. Operation

a. Tray paper size detection

Paper size for either tray is set by SW1 above SDB1

and SDB2 and the PFUDB detects the switch signal

corresponding to the position of SW1.

The relation between switch signal and paper size is

as follows.

U SIZE D

U SIZE C

U SIZE B

U SIZE A

U SIZE SELECT

L SIZE D

L SIZE C

L SIZE B

L SIZE A

L SIZE SELECT

PFUDB

SW1

SDB1

SW1

SDB2

For U.S.A.

Paper size

(Label display

order)

11 x 17

A5R

A4

A4R

A3

F4

5.5 x 8.5

8.5 x 11

8.5 x 11R

8.5 x 14

For Europe

Paper size

(Label display

order)

11 x 17

B5

B4

A5R

A4

A4R

A3

F4

11

11R

1 OUTLINE2 UNIT EXPLANA TION3 DIS./ASSEMBL Y

Switch signal

SIZE A SIZE B SIZE C SIZE D

Switch signal

SIZE A SIZE B SIZE C SIZE D

2. Signals

a. Input signals

(1) U SIZE A - D (SDB1 → PFUDB)

Upper tray paper size detect signal

(2) U SIZE A - D (SDB2 → PFUDB)

Lower tray paper size detect signal

b. Output signal

(1) SIZE A - D (PFUDB → MAIN BODY)

Paper size detection signal sent to main body

2-5

Page 13

DB-209

1 OUTLINE2 UNIT EXPLANA TION3 DIS./ASSEMBLY

[6] Control of paper-level detection

[7] Jam detection control

NAIN BODY

SGND

5VDC

PFUDB

SGND

PS101

5VDC

SGND

PS106

5VDC

PS101

PS106

After the trays have been set in the machine, paper level is

detected by PS101 (tray detect sensor PS (upper)) and

PS106 (tray detect sensor PS (lower)).

As the paper level in tray runs low, the actuator at the rear

part of the tray gradually rotates as illustrated below. The

level is detected by the number of times the sensor goes

ON/OFF (the number of slits detected).

Rotation direction

(when moving up)

Tray detect

sensor

Slit 1

Slit 2

Actuator

MAIN BODY

5VDC

SGND

PS104

PS105

PFUDB

SGND

PS104

5VDC

SGND

PS105

5VDC

1. Operation

The ADU jam detect control is performed by the main

body when it has judged the changes in the PS104

(jam detect PS1) and PS105 (Jam detect PS2)

detection signals. If the ON detection signal of each

sensor does not change after a specified time, it is

judged that there is a paper jam.

2. Signals

a. Input signals

(1) PS104 (PS104 → PFUDB)

Turns on when [H] is showing, and notifies the main

body of the presence or absence of paper in the

upper part of the DB.

(2) PS105 (PS105→PFUDB)

Turns on when [H] is showing, and notifies the main

body of the presence or absence of paper in the

lower part of the DB.

PS104

PS105

1. Operation

a. Detection of paper level in tray

The following shows the relation between the paper

level and the number of slit detections by the sensor

(PS101 or PS106).

0 slits : Full

1 slit : Medium

2 slits : Low

b. Output signals

(1) PS104 (PFUDB→MAIN BODY)

PS104 detect signal sent to main body

(2) PS 105 (PFUDB→MAIN BODY)

PS105 detect signal sent to main body

2-6

Page 14

3

DISASSEMBLY/ASSEMBLY

1 OUTLINE

2 UNIT EXPLANA TION

3 DIS./ASSEMBLY

Page 15

1 OUTLINE2 UNIT EXPLANA TION3 DIS./ASSEMBLY

This section explains how to disassemble and reassemble the

machine.

Observe the following precautions when performing disassembly

and assembly work.

1. Be sure to unplug the power cord before working on the

machine.

2. Perform all reassembly work by reversing the order in which the

component was disassembled, unless otherwise specified.

3. Do not lose small parts (screws, etc.) or insert them in the

wrong place.

4. Install all parts completely before operating the machine.

5. Do not loosen the screws indicated as disallowed for removal.

Page 16

DISASSEMBLY/ASSEMBLY

DB-209

Caution: Make sure the power plug is taken

out of the socket.

[1] Removing and reinstalling paper

feed tray

(1) Pull out the paper feed tray and take out the 2 set

screws on the right hand side.

(2) Remove the paper tray from the guide rails.

Set screws

Paper feed trays

Guide rails

[2] Removing and reinstalling the

paper feed unit

(1) Remove the paper feed tray and the tray cover.

Tray cover

(2) Opening the paper feed door, take out the 3 set

screws and remove the each paper size indicator

units.

1 OUTLINE

2 UNIT EXPLANATION3 DIS./ASSEMBLY

(3) Install by reversing the removal procedure.

Paper size

indicator units

(3) Remove the 3 set screws and remove the cover.

Cover

Set screws

(4) Remove the paper feed unit connector.

Paper feed door

Set screws

3-1

Page 17

DB-209

(5) Remove the 2 screws indicated by the engraved

1 OUTLINE2 UNIT EXPLANATION

3 DIS./ASSEMBLY

arrows and remove by drawing the paper feed unit

forward.

Paper feed units

Set screws

(6) Install by reversing the removal procedure.

Caution: Immediately after installing the paper feed

unit, as the swing gear and the paper feed

solenoid are not in the correct position, it

sometimes happens that paper is not fed.

For this reason, always make a copy to

confirm that operation is normal.

[3]

Replacing of the feed roller rubber

and double feed prevention rubber/

upper

(1) Remove the paper feed unit.

(2) Remove the fixing rings and bearings.

(3) While withdrawing the paper feed shaft, remove the

double feed prevention roller/upper from the paper

feed roller unit.

Double feed prevention roller/upper

Paper feed roller unit

Fixing rings

Feed shaft

(4) Removing the fixing ring and remove the feed roller

by withdrawing the guide shaft in the direction

shown by the arrow.

(5) Remove the feed rubber from the feed roller.

(6) Remove the double feed prevention rubber/upper

from the swivel roller.

Feed rubber

Guide shaft

Fixing

ring

Feed roller

Feed shaft

Swivel roller

Double feed

prevention

rubber/upper

Paint mark

(7) Install by reversing the removal procedure.

Caution: Pay attention to the direction in which you

install each roller rubber. Install so that the

swing-gear shaft enters the paper feed

roller unit.

3-2

Page 18

DB-209

[4] Replacing the double feed

prevention rubber/lower

(1) Remove the paper feed unit.

(2) Remove the set screw.

(3) Pushing the knobs on either side of the double feed

prevention unit, then remove by drawing it forward.

Double feed

prevention unit

Set screw

(4) While pushing the projection of the lever click shaft,

withdraw it and remove the double feed prevention

roller.

1 OUTLINE

2 UNIT EXPLANATION3 DIS./ASSEMBLY

Double feed prevention

Paint mark

(5) Remove the double feed prevention rubber/lower

from the double feed prevention roller.

(6) Install by reversing the removal procedure.

Caution : Pay attention to the direction in which

rubber/lower

Double feed prevention

roller

Lever click shaft

you install each roller rubber.

When installing the double-feed

prevention unit into the main body, be

sure to align it with the center of the

mark engraved on the main-body

plate.

3-3

Loading...

Loading...