Page 1

1

ADJUSTMENT

1 ADJUSTMENT

2 ISW

3 SERVICE

4 DIAGRAMS

Page 2

ADJUSTMENT

HOW TO USE THE ADJUSTMENT SECTION

[1] Construction

This section details adjusting items and procedures. Use

this section for making adjustments and as a checklist

before implementing corrective measures in the field.

1. Does the power supply meet the requirements?

2. Is the power supply properly grounded?

3. Is the machine sharing its power source with another

high current consumption machine that draws large

currents intermittently? (e.g. an elevator, air conditioner, or other source of electrical consumption)

4. Is the installation environment suitable?

a. The machine must be installed in a well-

ventilated place free from high temperature, high

humidity and direct sunlight.

b. The machine must be installed on a level floor.

5. Does the cause of a defective image lie in the original

itself?

6. Is the density adjusting control at the proper position?

7. Are the original glass and RADF platen guide clean?

8. Is the correct paper being used for the copy?

9. Are the copying materials and parts replaced when

they reach the end of their usable life? (developer,

drum, cleaning blade, etc.)

10. Is there toner in the toner cartridge?

The following items should also be observed when

repairing the machine.

1. Only one side of the AC power line is disconnected

when the main power of this machine is turned off.

Always unplug the machine before beginning work. If

absolutely necessary to work with the power on,

exercise care to avoid being caught in the scanning

rear of the exposure unit.

2. Special care should be taken when handling the

fixing unit since it operates at extremely high

temperatures.

3. The developing unit is surrounded by a strong

magnetic field. Keep watches and metering

equipment away from it.

4. Avoid scarring the drum with tools or similar objects.

5. Do not touch IC pins with your bare hands.

ADJUSTMENTS WHEN REPLACING PARTS

Adjustments (including checks) and settings are not only

required when a defective copy image occurs, but also

after replacing or reinstalling certain parts.

[How to use the tables]

The following items are used in the tables throughout this

section.

1. Mode

Indicates the adjustment mode.

[“25”] : 25 mode

[“36”] : 36 mode

[“47”] : 47 mode

2. Codes

Indicates the applicable code and/or Copy Quantity

Setting button for each mode.

3. Conditions

New: Indicates adjustment (including check) is

required when replacing a new part.

Reset: Indicates adjustment (including check) is

required when a part has been re-installed.

4. Symbols used in the tables

.................

1 2

(Empty circle) : Indicates adjustments (including

: Indicates there is a priority

sequence for adjustments

(including checks) and settings.

checks) and settings that can be

carried out independently.

1 ADJUSTMENT

2 ISW

3 SERVICE

4 DIAGRAMS

1-1

Page 3

ADJUSTMENT

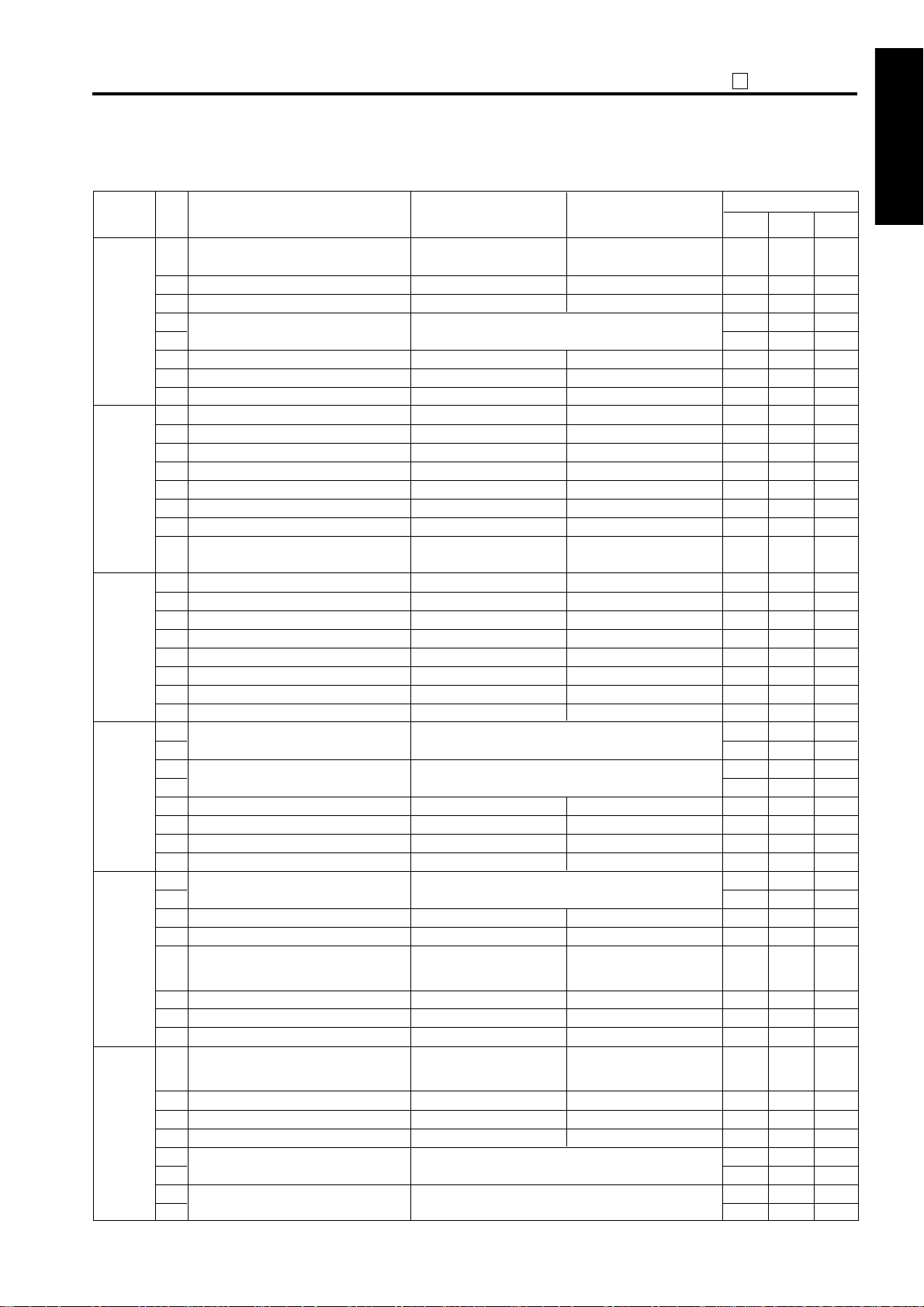

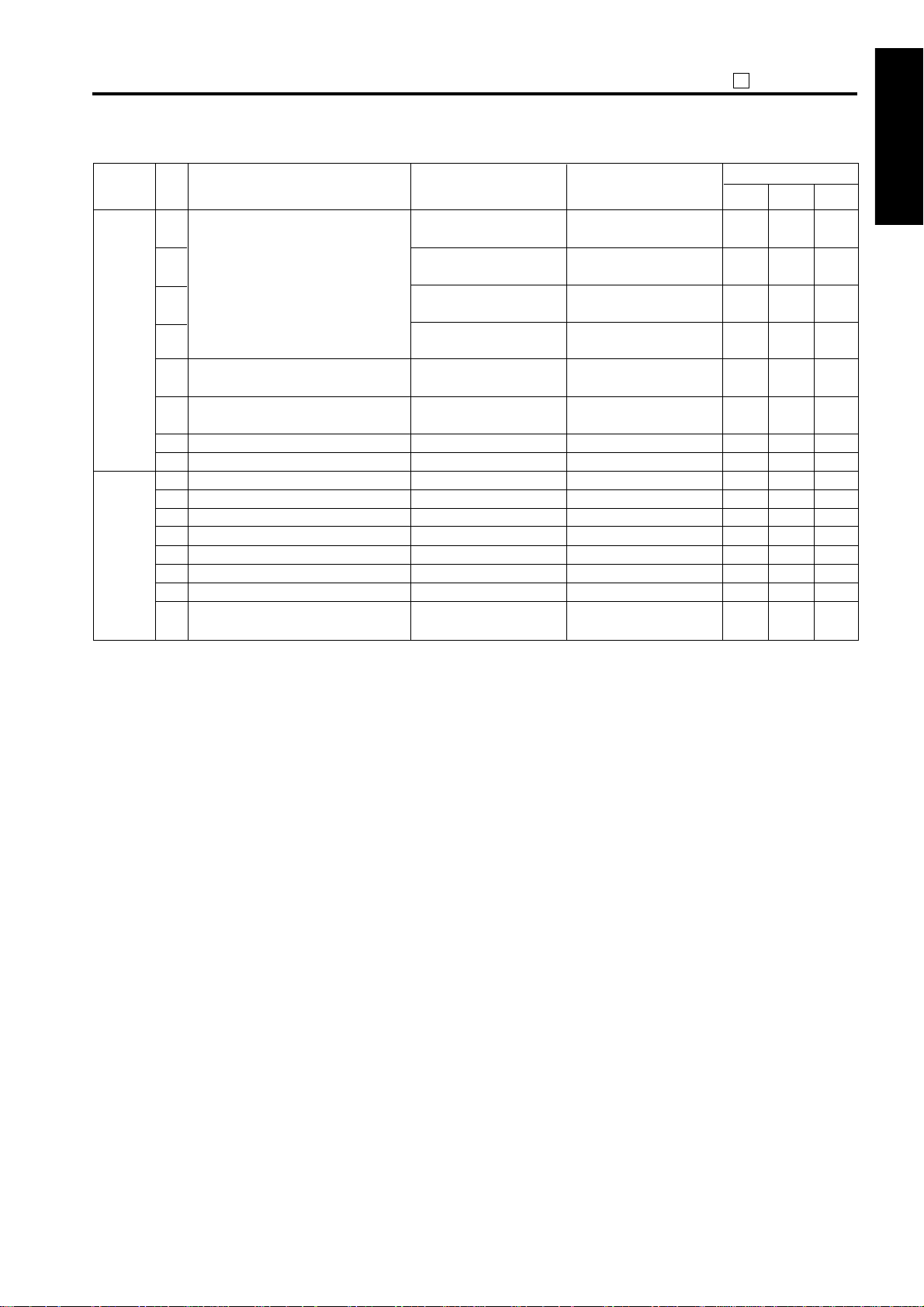

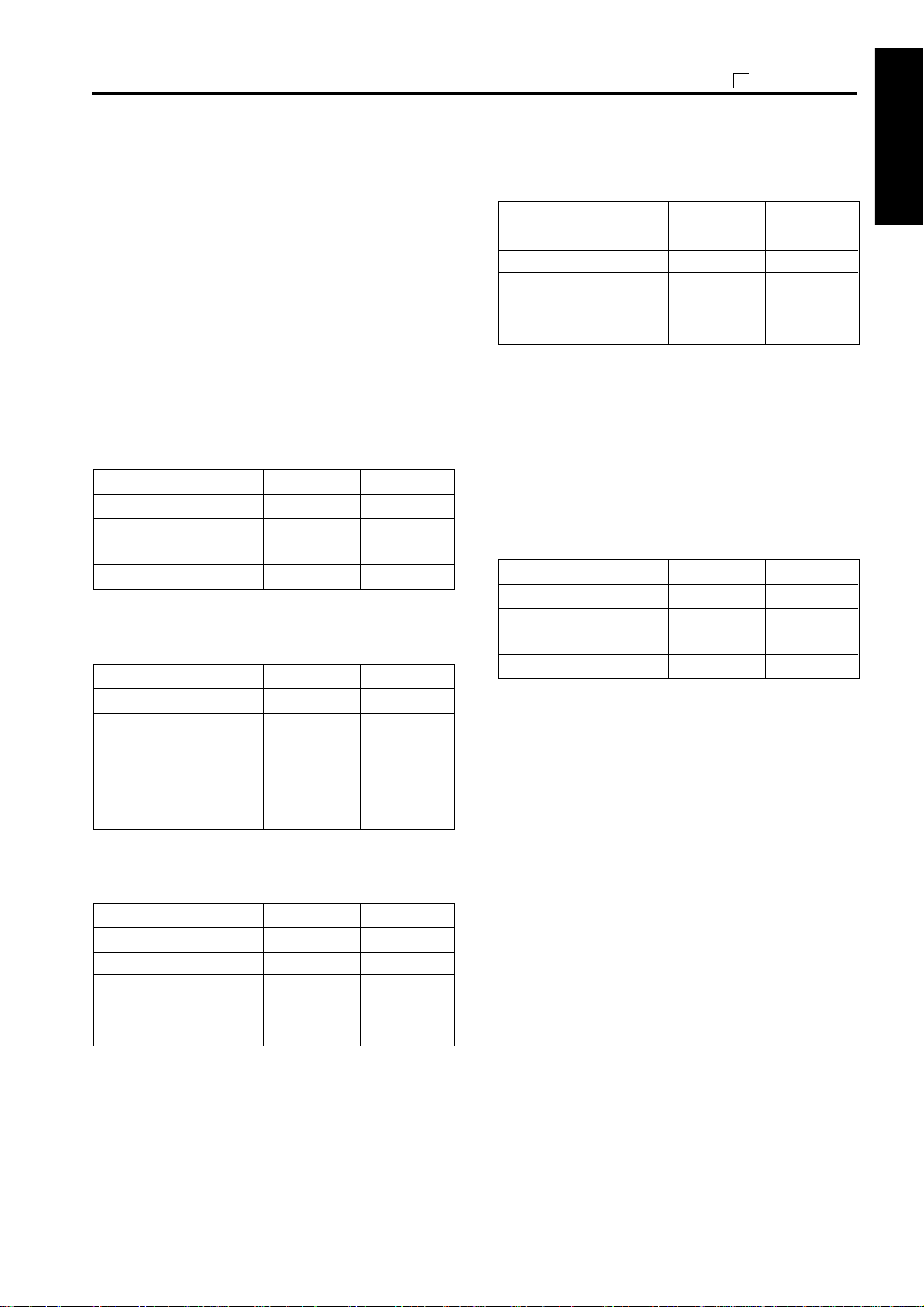

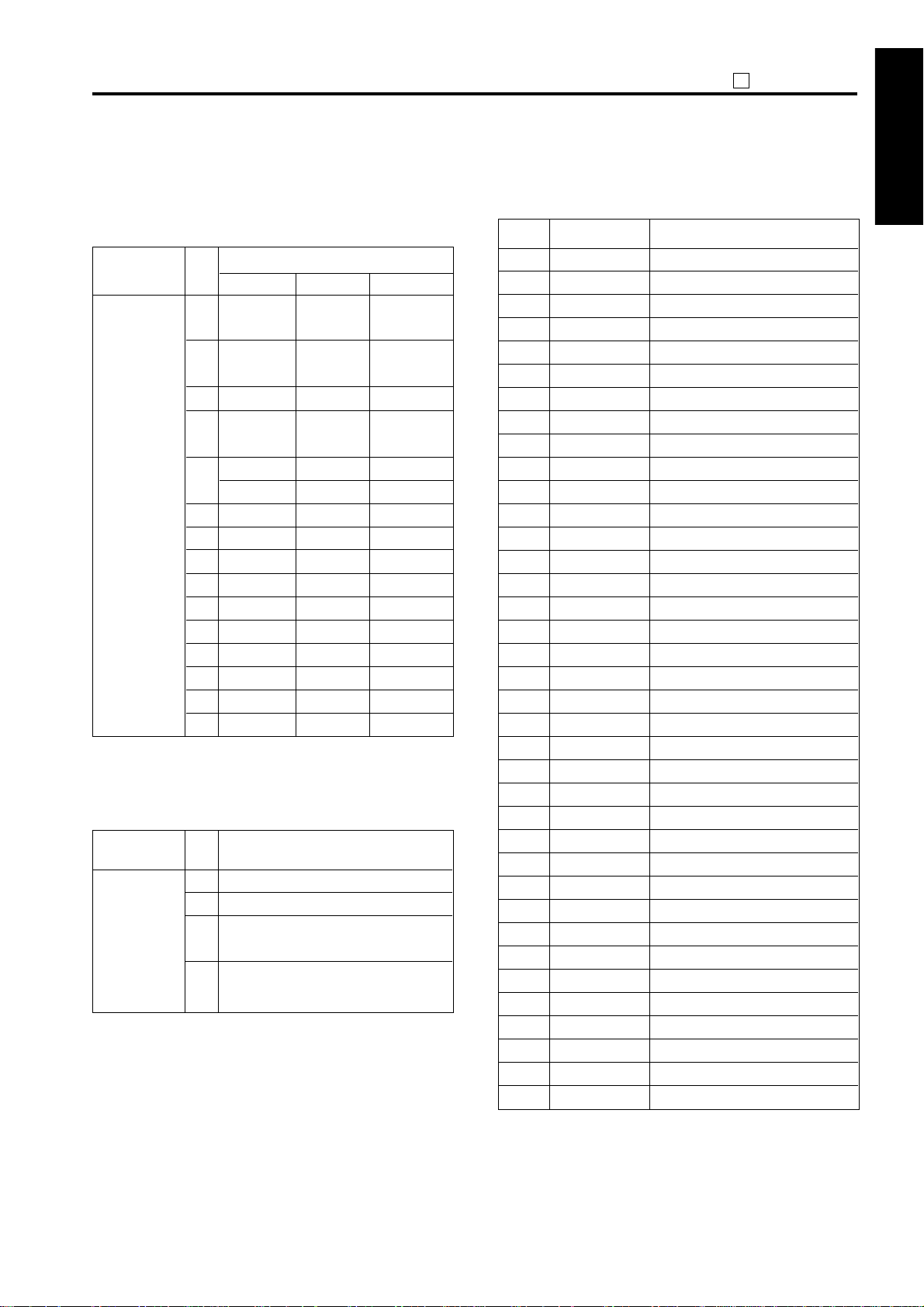

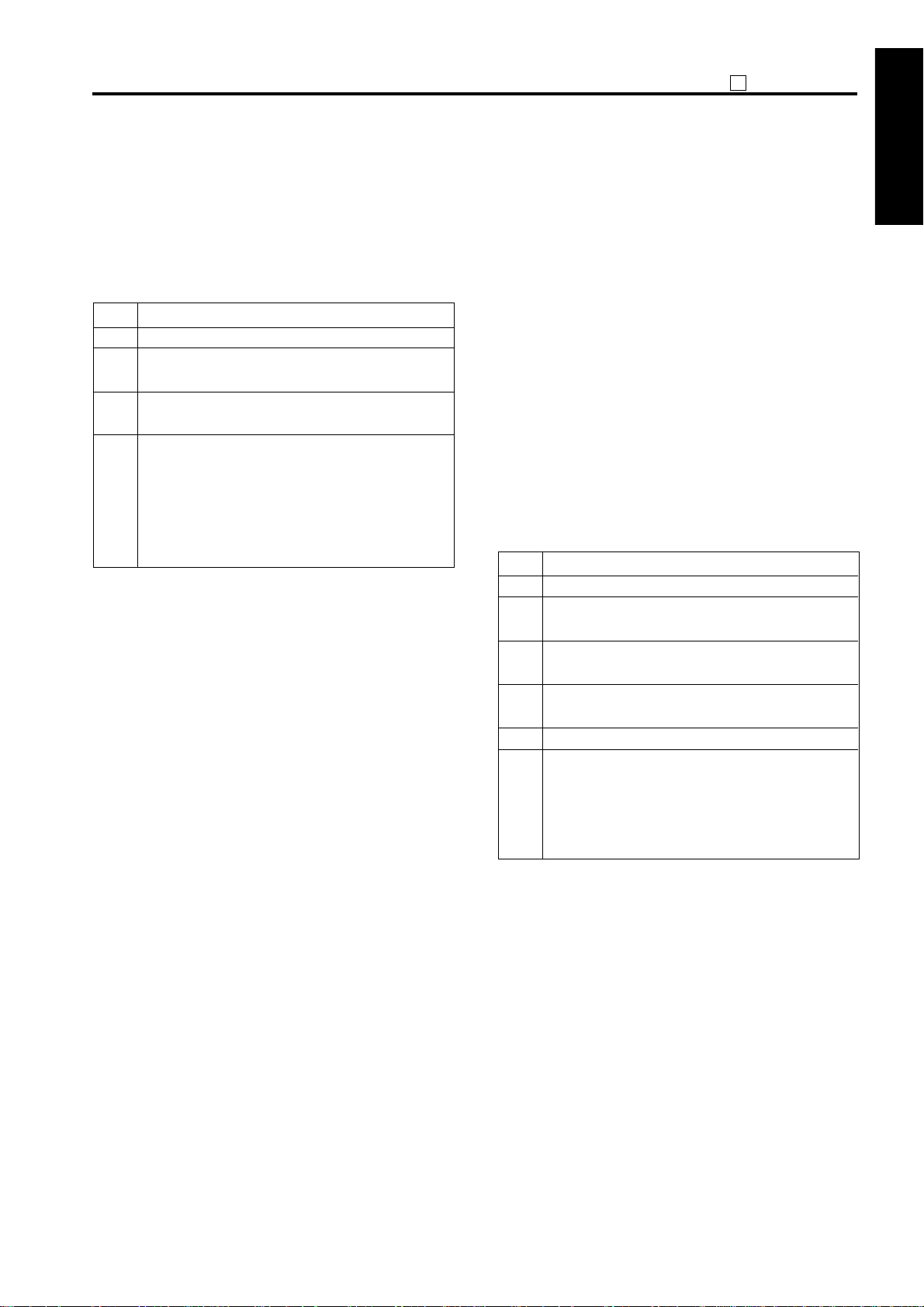

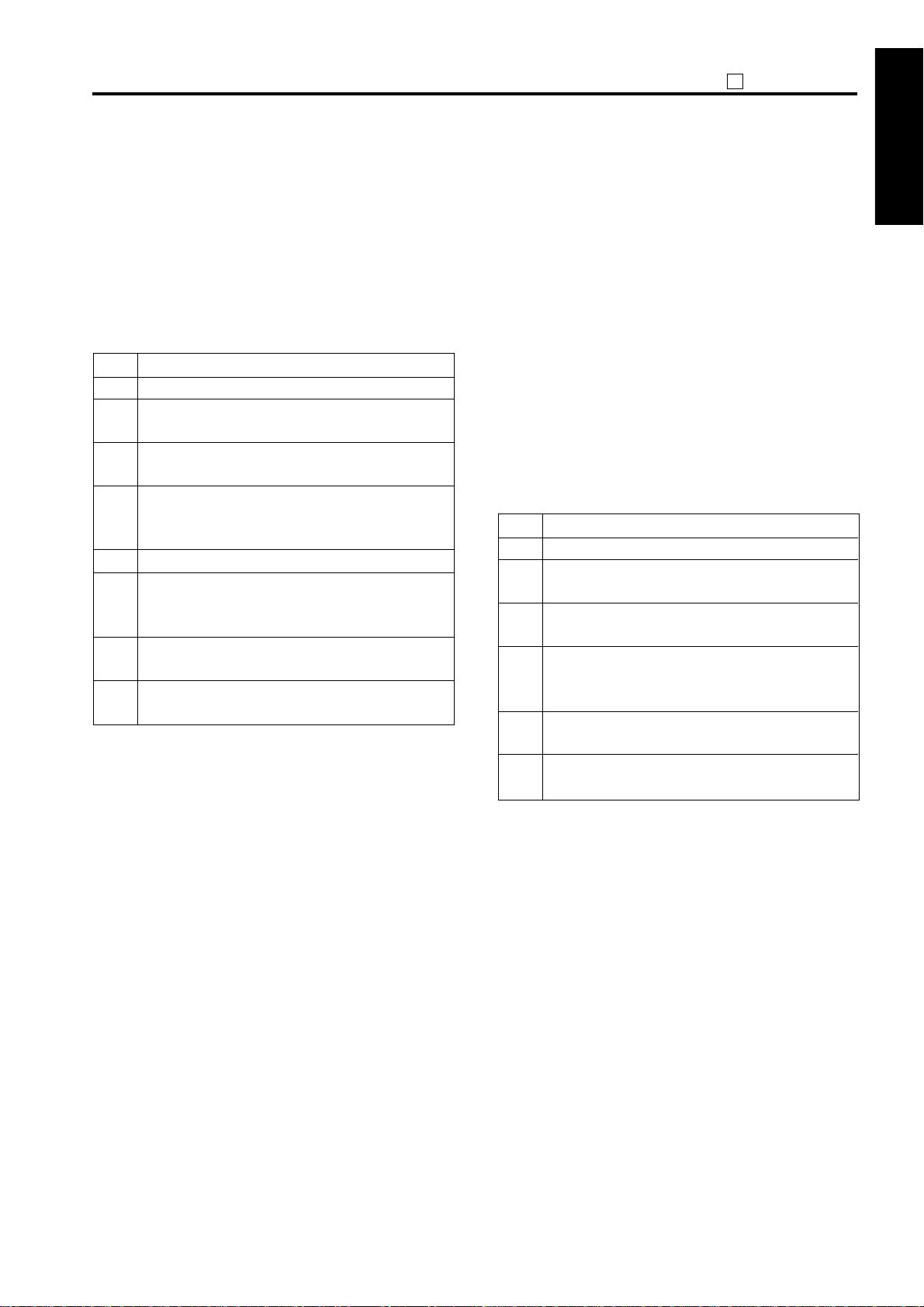

LIST OF ADJUSTMENT ITEMS

<List of adjustment items for 7020>

1 ADJUSTMENT

2 ISW

Adjustment setting items

PM counter reset

PM cycle set

L detection adjustment

Part name

3 SERVICE4 DIAGRAM

Drum

Developer

Fixing unit-related parts

Writing unit

Parameter memory substrate

Paper feeding-related rubber rollers

RADF

RADF slit glass

Electronic RDH

Mode

Code

New

New

New

New/Re

New

New

New/Re

New

New/Re

25

2-1252-2361

2

*

1

*

Vertical magnification adjustment (printer, platen)

Vertical magnification adjustment (RADF)

Horizontal magnification adjustment (platen)

Restart timing adjustment (copier system)

Restart timing adjustment (RADF)

Paper feed loop amount adjustment

Leading edge original erasure adjustment

Centering adjustment

Image read point adjustment

36

2-1362-1362-1362-2

1

2

334

1

2

1

2

1

2

4

3

36

36

2-3362-4362-5362-6366-2368-1368-247198

2-2

5

5

3

6

7

7

6

4

8 9

5

6

RADF scanning density adjustment

Sensor-related counter clearing

Fixing-related counter clearing

Electrical RDH memory check

7

• "New" means replace with a new part and "Re" means to reinstall the part.

• The circles will appear above a number when there is an adjustment priority.

*1: When the parameter memory board is replaced, remember to replaced the developer before conducting the L

deection adjustment.

*2: After replacing the developer, be sure that you do not make any copies until you have first carried out L detection

adjustment.

1-2

Page 4

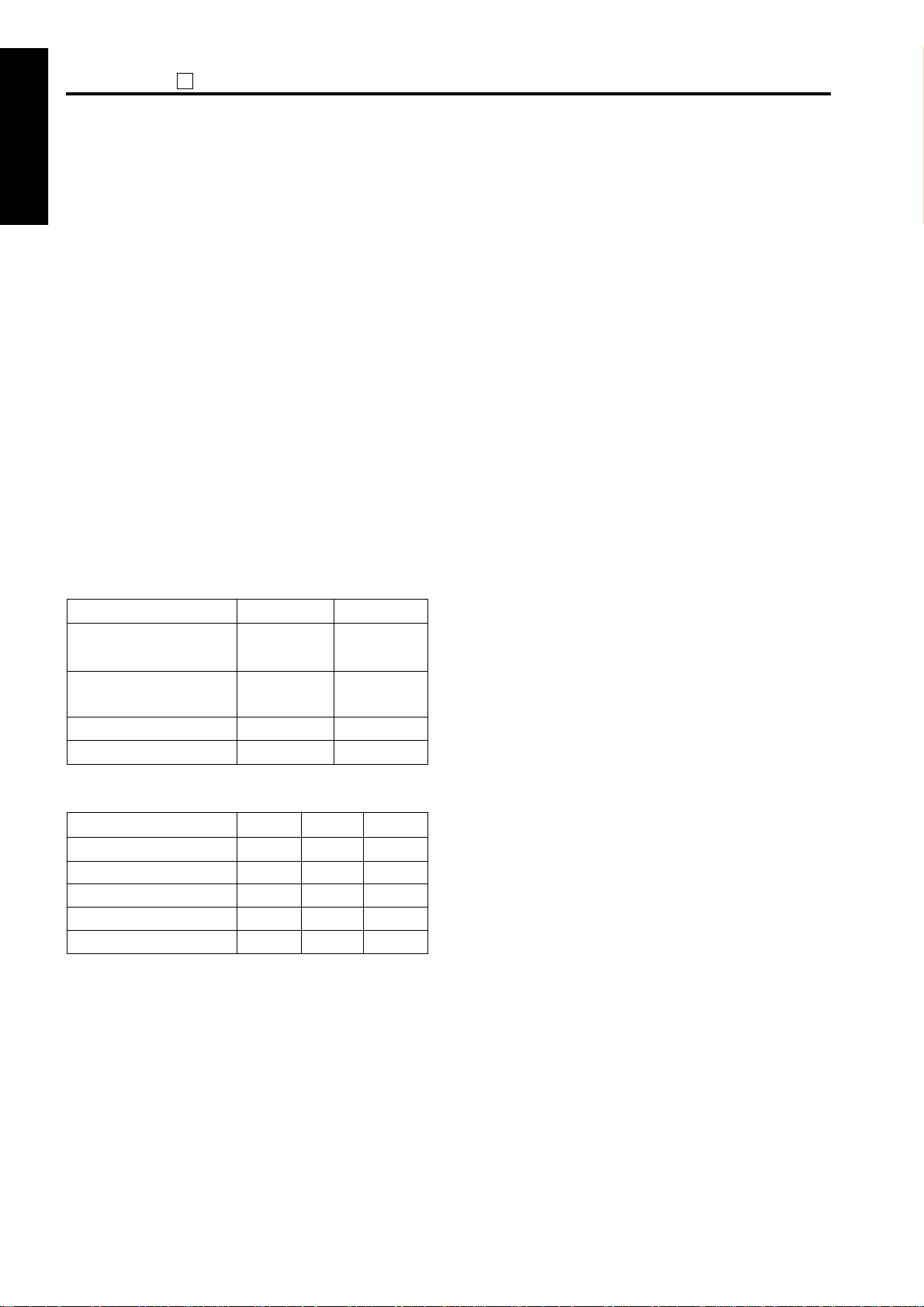

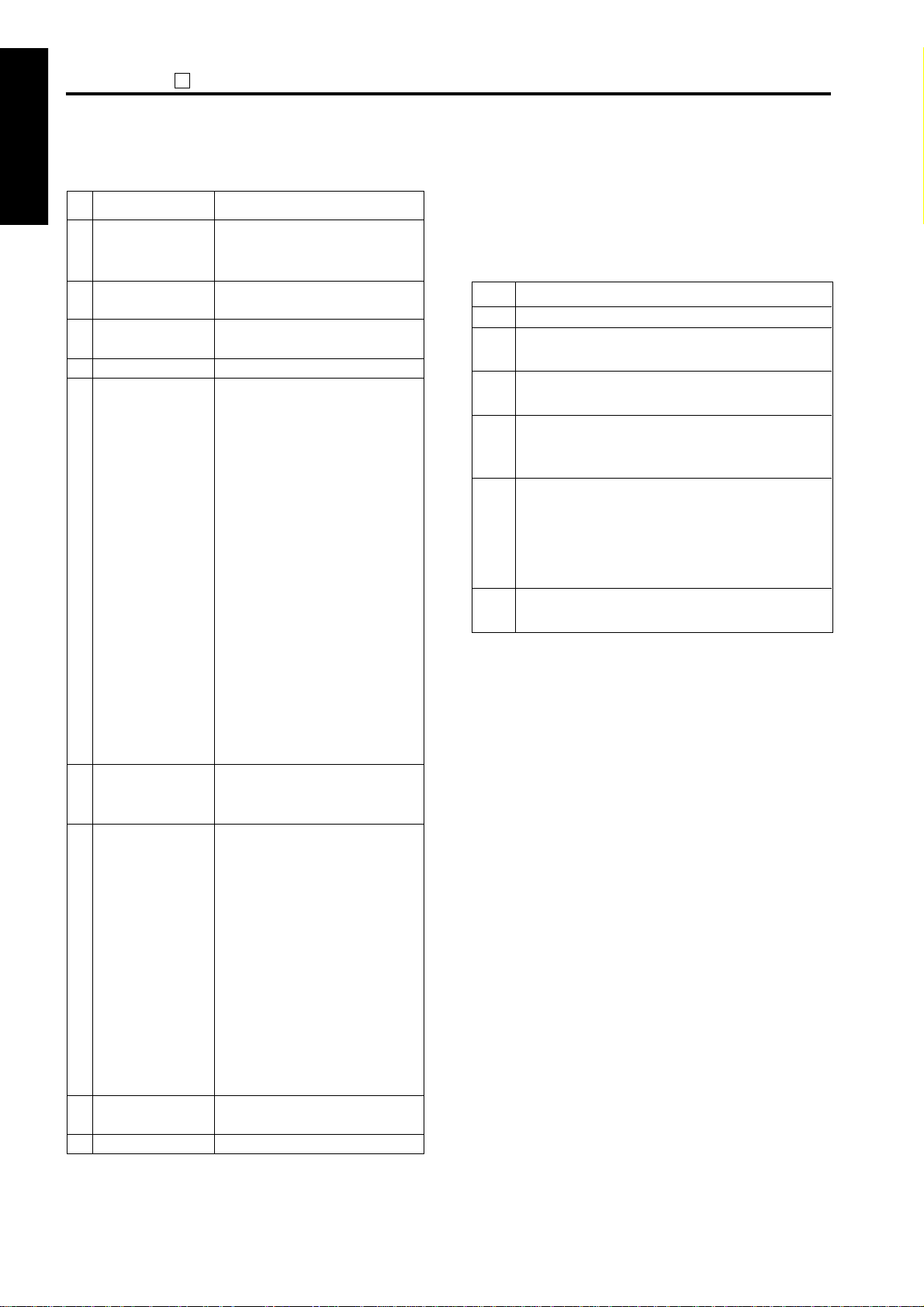

MODE CHANGE MENU

Each adjustment mode is selected by conducting special

operations:

[1] Setting method

The following modes can be selected on the screen

without turning OFF/ON the power supply:

1. Normal mode

2. Adjustment mode (36 mode)

3. Memory setting mode (25 mode)

4. Key ope mode (Key operator mode)

5. I/O check mode (47 mode)

6. Exit

ADJUSTMENT

1 ADJUSTMENT

2 ISW

Step

1

2

3

4

5

Operation procedure

Turn on the main and sub power switches.

Keep pressing the

“Please enter service password.” appears.

Input 9272 as the password and press the

[Start] key. (The password is fixed and cannot

be changed.)

[Mode Select Menu Screen]

Press the key of the mode to be selected on the

screen. To return to the Mode Change Menu

Screen, keep pressing the

screen appears.

When the adjustment ends, press

[1. Normal Mode] key and the basic screen will

appear.

button until the message

*

button until the

*

3 SERVICE

4 DIAGRAMS

1-3

Page 5

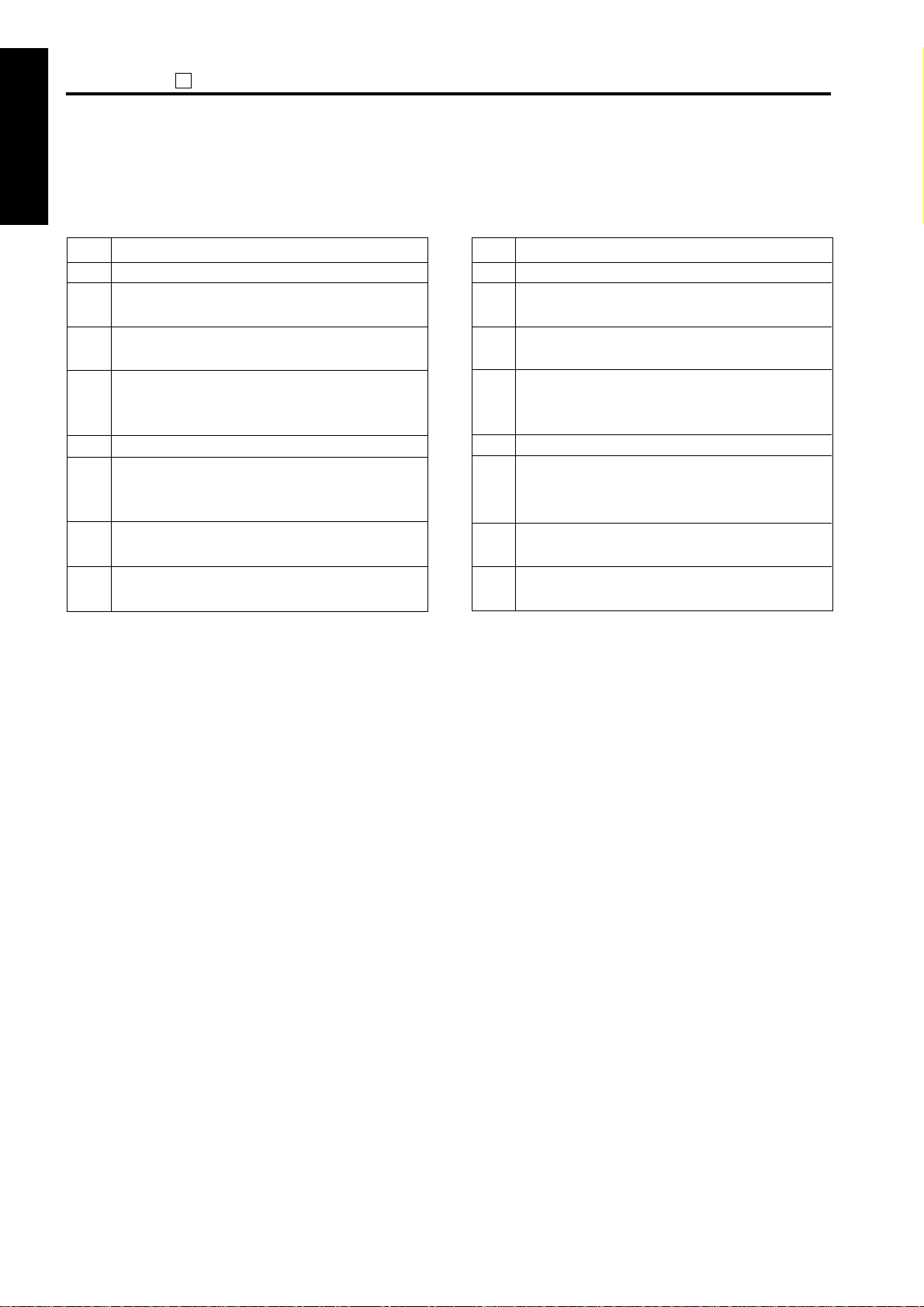

P ADJUSTMENT

ADJUSTMENT

CHECK OF COUNT VALUE WITH P FUNCTION

The P function enables to display of the following

parameters by using the

1 ADJUSTMENT

Total count

Total count start date

PM count/PM count limit

PM count start date

Fax send paper count*

Fax receive paper count*

2 ISW

Printer count*

Scanner count*

Drum count

Developing count

Fixing unit count

*: These values are displayed when the option is

mounted.

button:

*

3 SERVICE4 DIAGRAM

[1] How to use P function

1. Turn on the SW1 (main power) and SW2(sub

power) to display the basic screen.

2. Press the

3. The P mode Screen will appear and each count

value is displayed.

4. To display the count values on the next screen,

press the [ ↓ ] key on the screen. To return to the

previous screen, press the [ ↑ ] key.

5. To output the count value list, press the [PRINT]

key.

6. Press the [OK] key or the stop/clear button to return

to the basic screen.

button.

*

1-4

Page 6

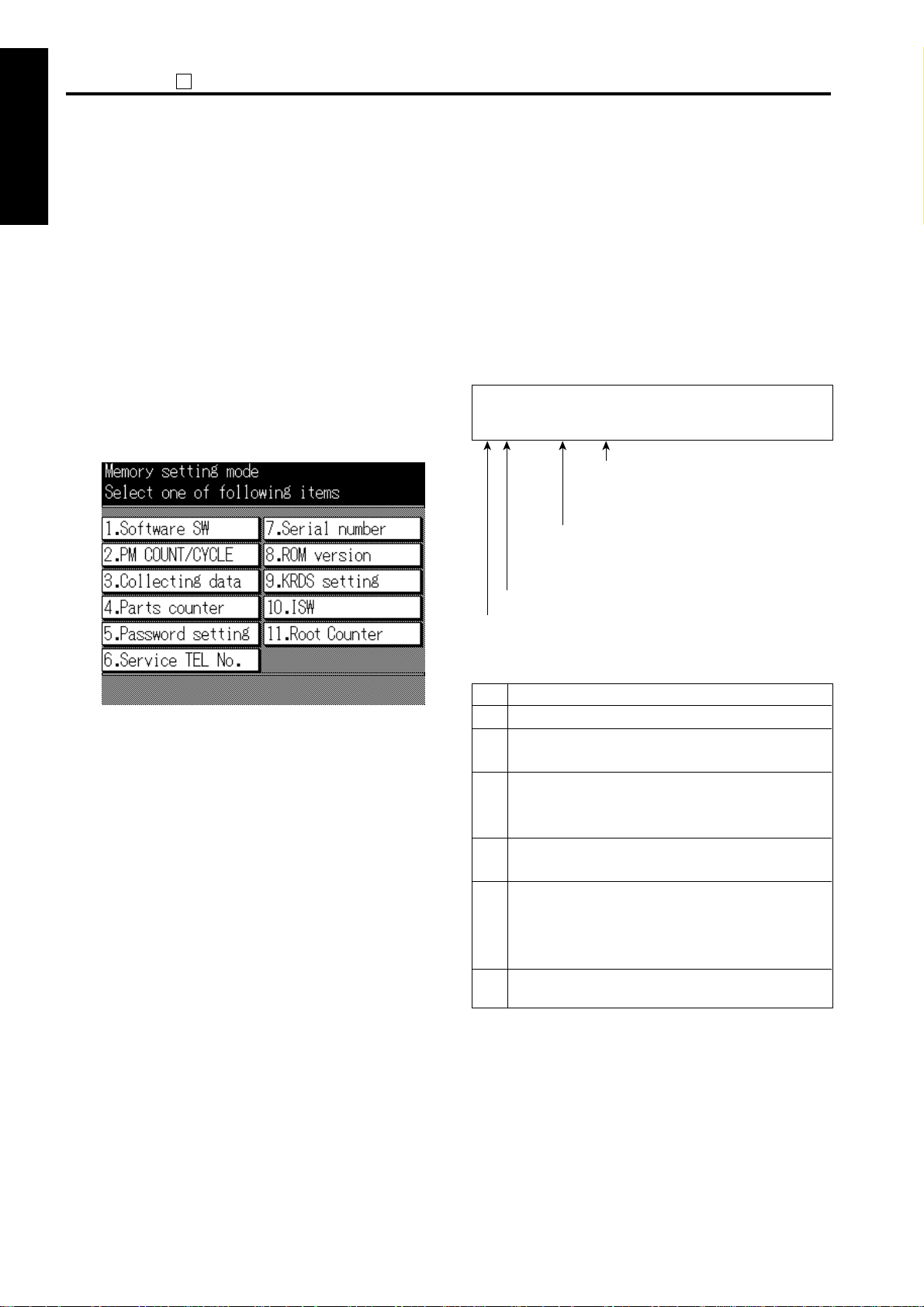

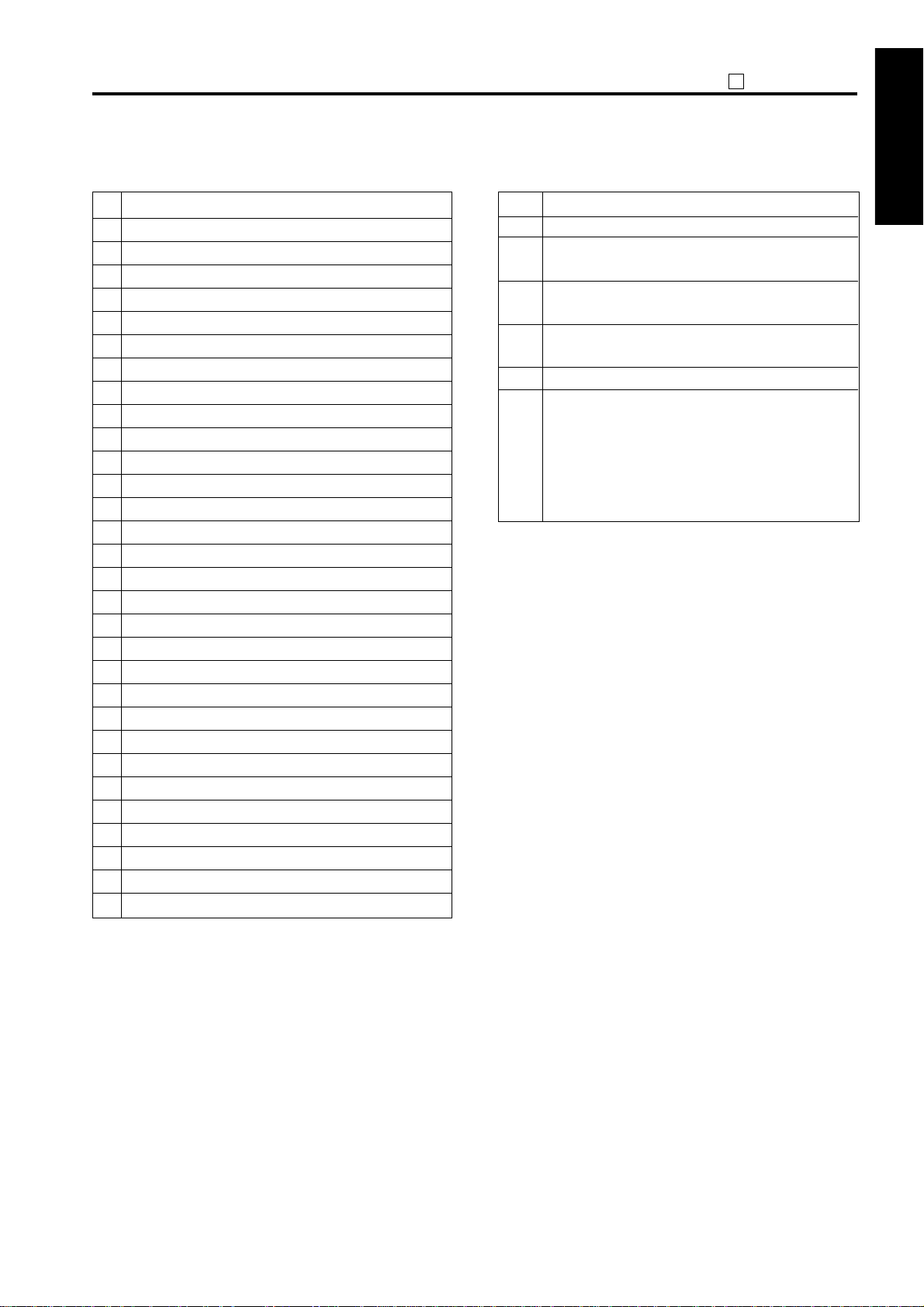

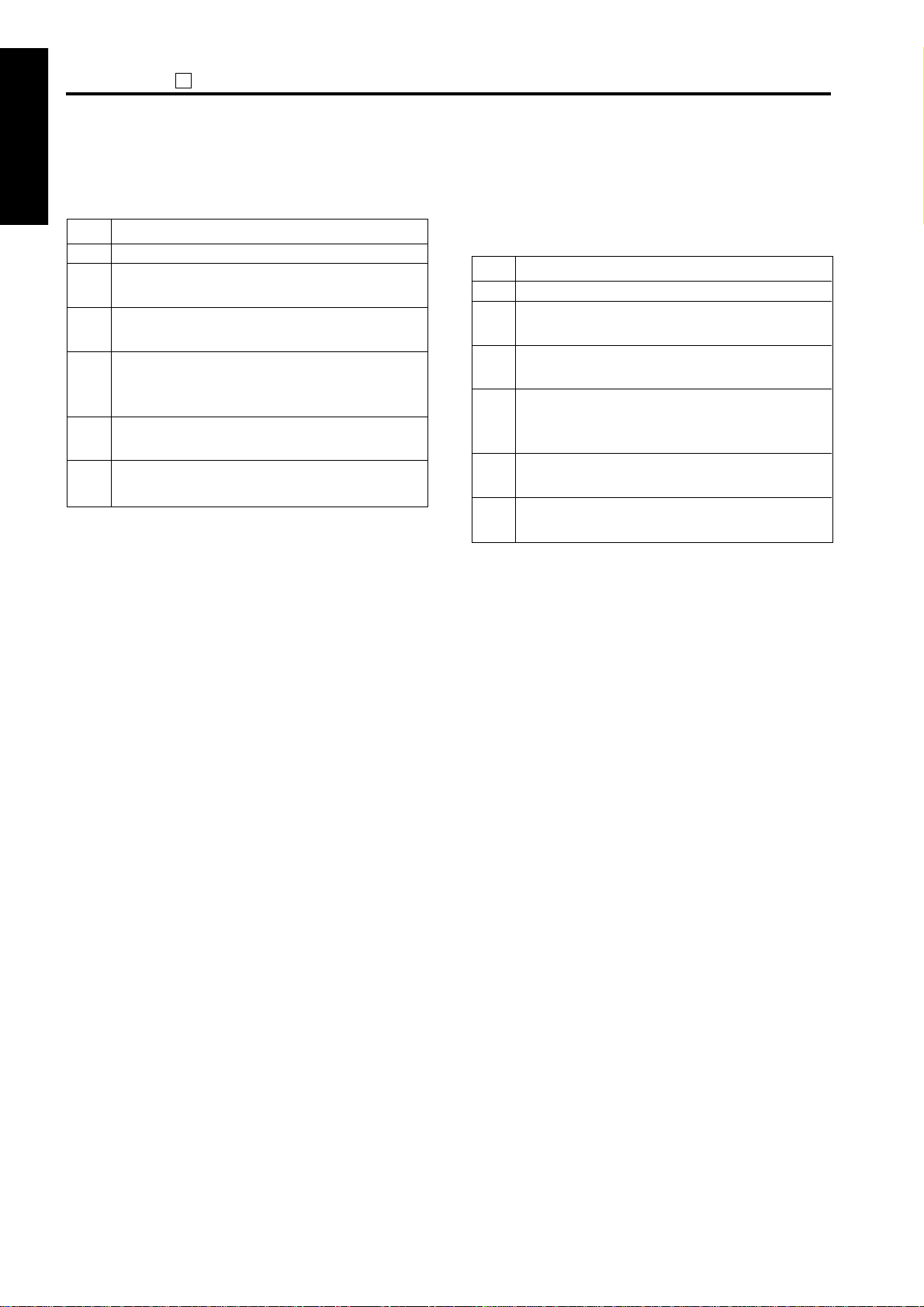

25 MODE

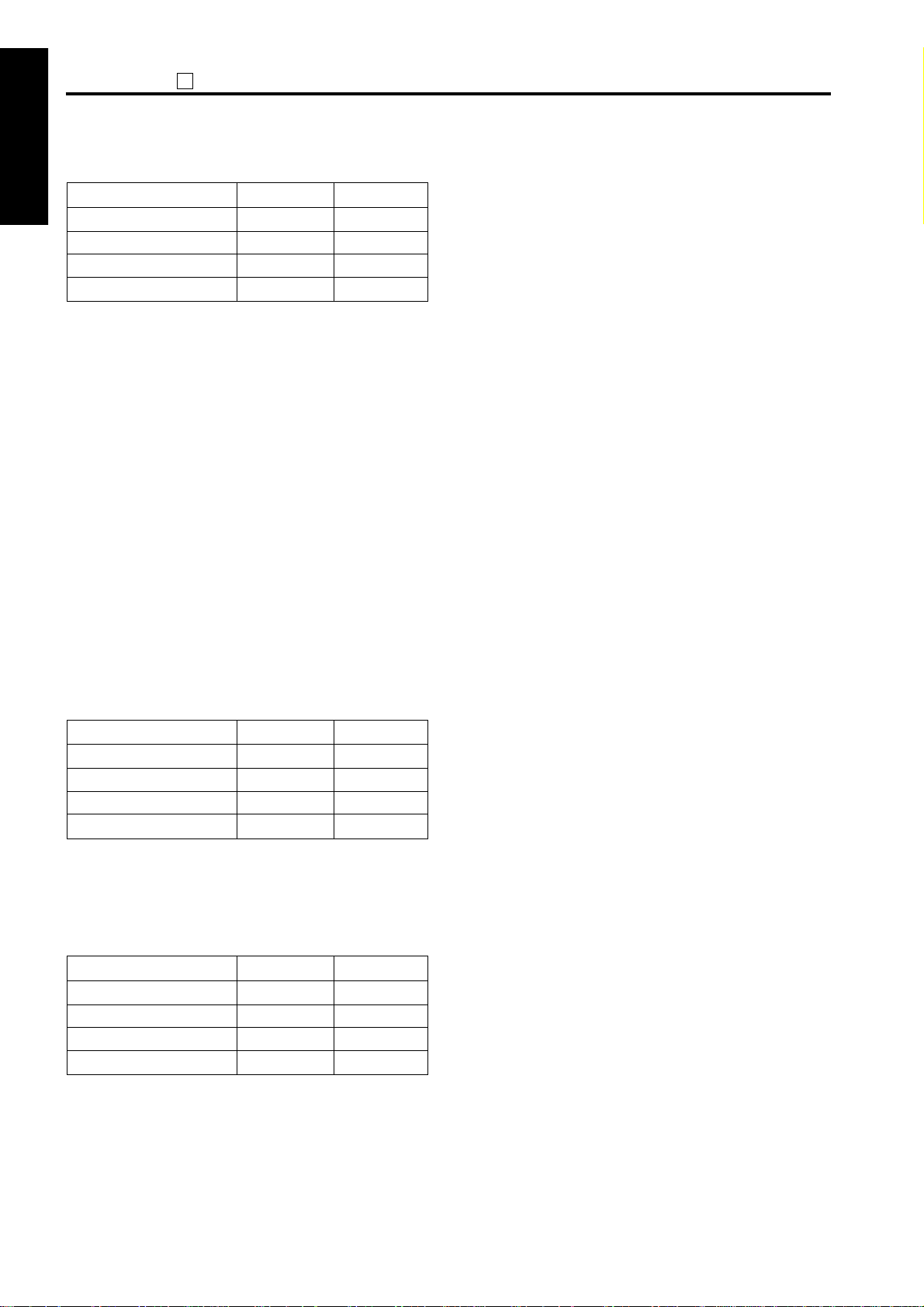

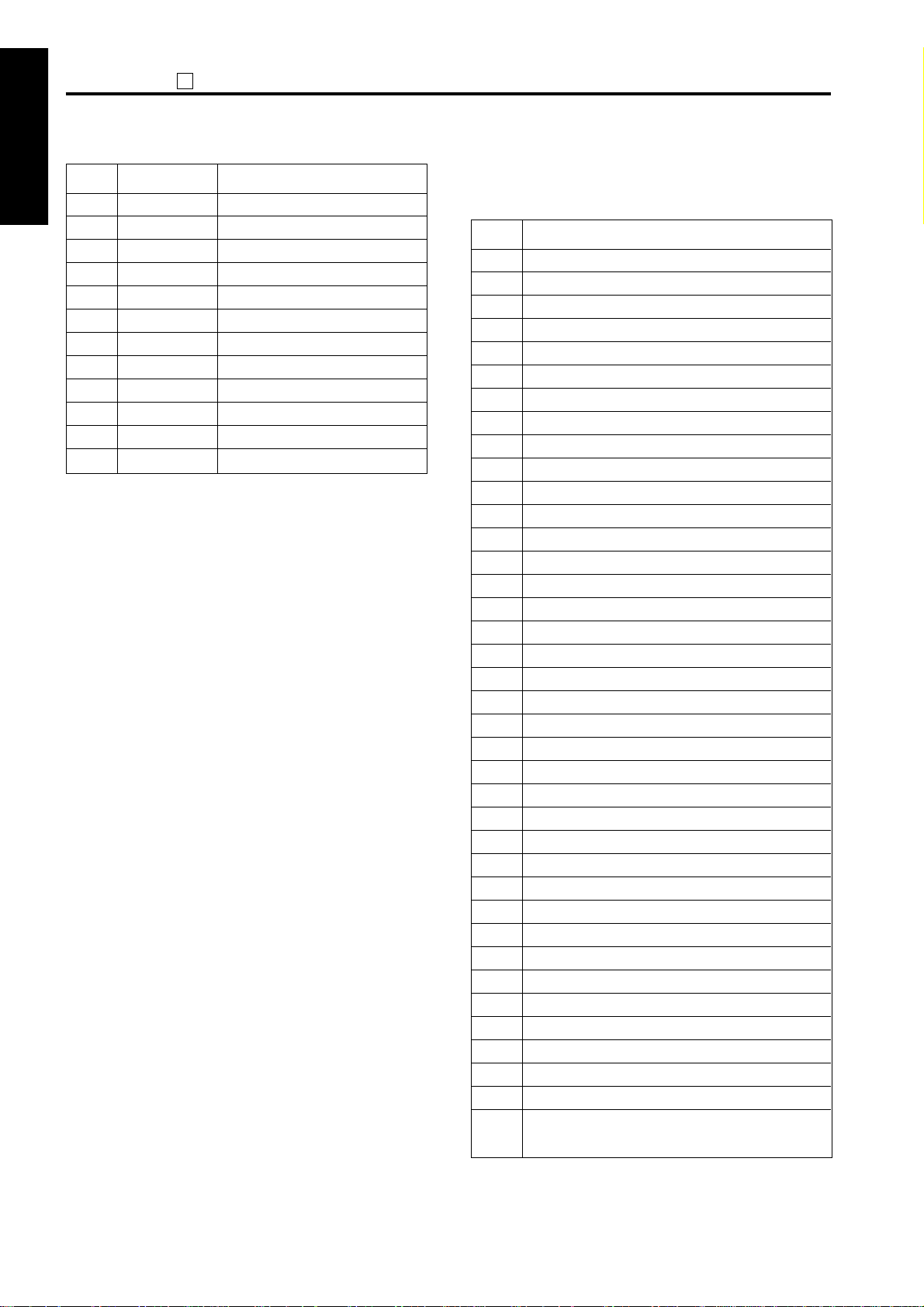

<List of adjustment items for 25 mode>

25

ADJUSTMENT

Software SW

1.

2. PM COUNT/CYCLE

3. Collecting data

4. Parts counter

5. Password setting

Service TEL No.

6.

Adjustment item menu

1. PM COUNT reset

2. PM CYCLE set

1. Count data

2. Date count data

1. Count of parts (Fixed)

2. Count of parts (Named)

1. Key operator password set

2. E.K.C. master key code set

3. Weekly timer master key set

Data Collection 1

(by each size)

(RADF paper passage count)

Data Collection 2

JAM occurrence count by each point)

(

Data Collection 3

(copy count by each mode)

Data Collection 4

(SC occurrence count : F code)

Remarks

Refer to “List of software DIP SW”.

39 items

30 items

4 digits

8 digits

4 digits

Telephone & Fax. No. of service

1 ADJUSTMENT

2 ISW

3 SERVICE

7.

Serial number

8.

ROM version

9. KRDS setting

10. ISW

11. Root counter

1. Calling time set

2. Host password set

3. KRDS TEL No. Setting

4. KRDS software SW set

5. KRDS Setup calling

center setting.

Indicates serial No. of main and each

optional unit.

Indicates each ROM version.

Refer to the chapter “ISW“.

Displays the root counter (total

counter).

4 DIAGRAMS

1-5

Page 7

ADJUSTMENT

25

[1] Setting method

1 ADJUSTMENT

A special operating mode called “25 Mode” has been

provided with this machine. This mode enables rewriting

of the non-volatile storage and specify other various

settings.

1. Turn OFF the SW2 (sub power) when the SW1

(main power) remains ON.

2. Turn the SW2 (sub power) ON while pressing 2 and

5 of the copy quantity setting buttons. The 25 mode

2 ISW

menu screen will appear.

In the 25 mode normal copy operation becomes

unavailable.

[25 MODE MENU SCREEN]

3 SERVICE4 DIAGRAM

[2] Setting software DIP SW

1. Setting method

This setting specifies the software DIP switch on the

software SW setting screen. (*1)

Caution 1: The bit of the DIP switch is written in

the non-volatile RAM every time it is

changed.

Caution 2: The numbers shown in the message

area are defined as follows:

Software SW

04-7 : 1 A8

8-bit switch values in indicated in

hexadecimals from 00 to FF.

Bit data

1 : ON

0 : OFF

Bit number (0 to 7)

3. Press the desired item key on the LCD screen.

Each setting screen will appear.

4. Enter data in each selected screen.

5. Press the [Return] key to check the data that has

been entered.

6. Turn the SW2 (sub power) off to cancel the 25

mode.

7. New data will be effective after restarting.

Switch number

2. Setting procedures

Step

Operation procedure

1

Enter the 25 Mode.

2

[25 mode menu screen]

Press the [1. Software SW] key.

3

[Software SW setting screen]

Select DIP switch number.

Use the left [ ▲ ] , [ ▼ ] key.

4

Select bit number of the DIP switch.

Use the center [ ▲ ] , [ ▼ ] key.

5

Select ON (=1) or OFF (=0) of the DIP switch.

Use [ON] or [OFF] key.

[ON] : Set bit.

[OFF] : Clear bit.

6

Press the [Return] key to return to the 25 mode

menu screen.

For each switch function, refer to “List of Software DIP

switches”.

1-6

Page 8

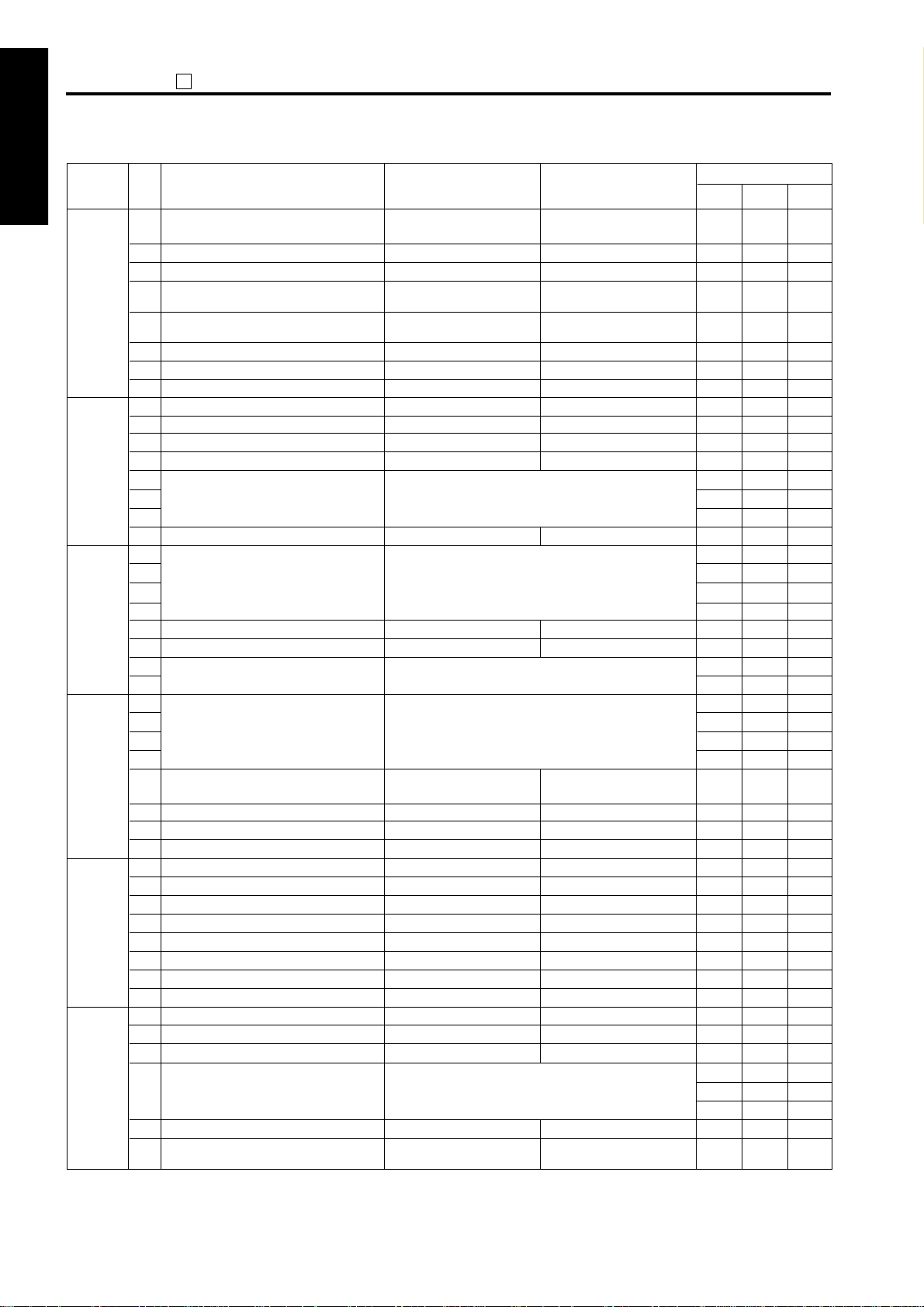

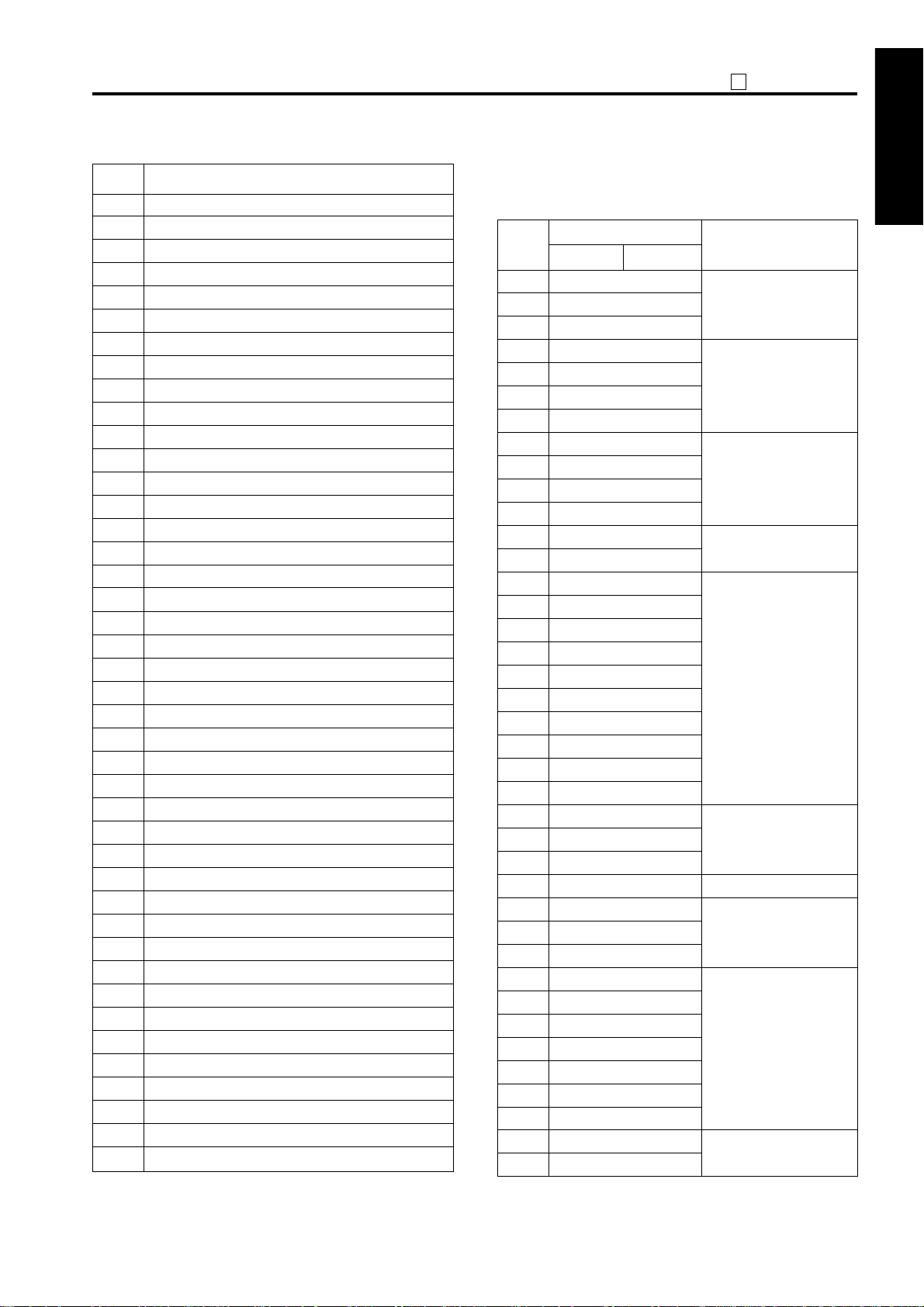

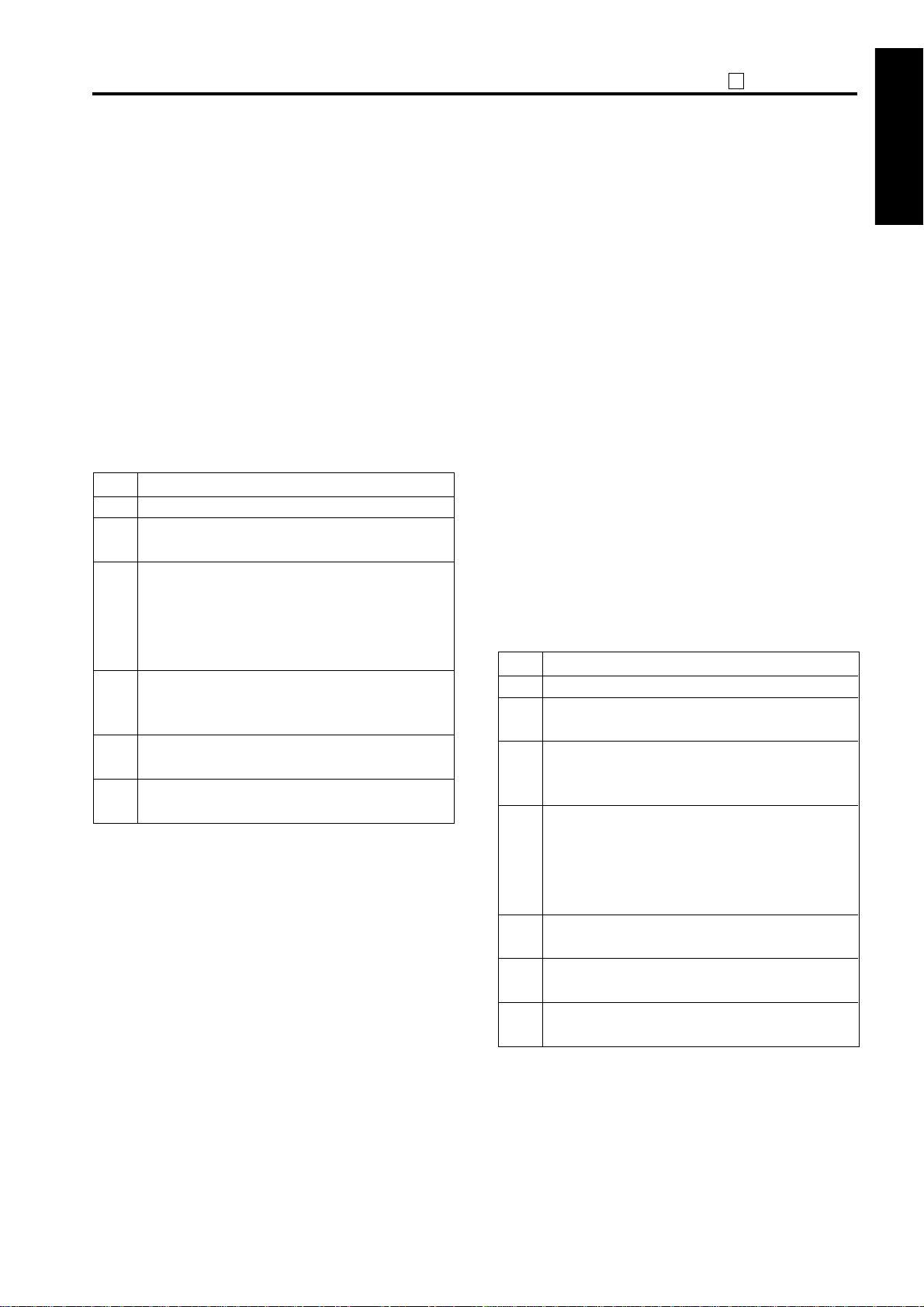

<List of software DIP switches>

25

ADJUSTMENT

DIP SW

No.

DIP-SW1

DIP-SW2

DIP-SW3

DIP-SW4

DIP-SW5

DIP-SW6

BIT Functions

0

Operation when key counter is removed

(when using as a copier)

1

A3 (11 x 17) counting method

2

3

Selection of maximum number of copies that

4

can be stapled by FS-107.

5

6

7

FS107 limit on number of stapled sets

0

Toner replenish stop timing

1

2

3

4

5

1-shot message display at automatic staple mode clearing

6

7

Prohibition of non-image area erases, repeat (auto)

and original position correction

0

Use of Latin specification F4

1

F34/F35/F36 latch

2

Toner replenish stop timing 2

3

Return to EKC screen after copying reservation

4

5

By-pass feed non-standard size selection

6

7

0

Toner level detection (”Supply toner” indication)

1

2

Number of copies allowed before machine stops

3

after “Supply Toner” indication.

4

Non-display of advance/delete buttons for job list

5

Job stop or nonstop at no toner

6

Impossibility of coping reservation to coin vender

7

0

Destination switchover

1

2

3

4

Detecting method of 8.5 x 11 size on RADF

5

6

7

0

Prevention of faulty image at high temperature

and high humidity. (When the machine is not

turned on for a long period.)

K size selection switch for Taiwan destination

1

2

3

Polygon motor low-speed rotation timing

4

5

Polygon motor pre-rotation selection

6

7

*3

*4

Ignore

Count as 1

*1

None

Decide with DIP SW 3-2

Yes

No

No

*5

No

*3

When copying ends

No

*6

*7

Size detection effective

*3

*3

0 : Display

*8

0 : Does not stop

*3

0 : Can reserve copying

*9

The size is detects as 8.5 x 11 even

if the original reaches to RADF’s

PS307 (original detect PS 2).

Yes

AB series sizes

*10

*11

10

Instantaneous stop Jam

Count as 2

Temporary stop after 25 sets of copy

Stop after paper exdit

No

Yes

Yes

Yes

Interval between copy set

Yes

Non-standard handling

1 : Do not display

1 : Stops

1 : Cannot reverse copying

If original reaches to RADF’s PS307

(original detect PS 2), the size is

detected as 8.5 x 14.

No

K size

Japan

*2

Default values

U.S.A.

0

0

0

0

0

0

0

0

0

0

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1 ADJUSTMENT

Europe

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

0

1

1

0

0

0

0

1

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

2 ISW

3 SERVICE

4 DIAGRAMS

1-7

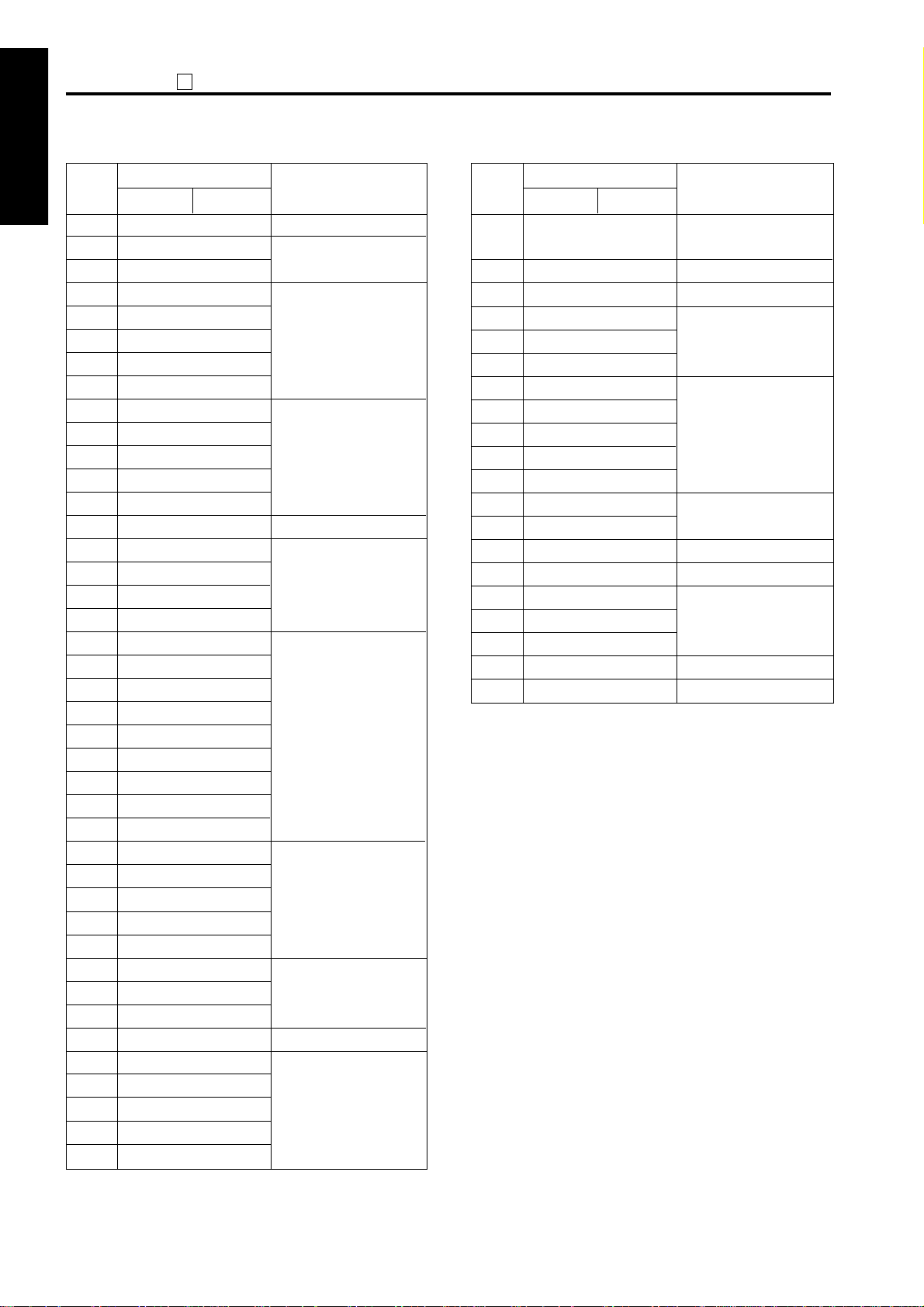

Page 9

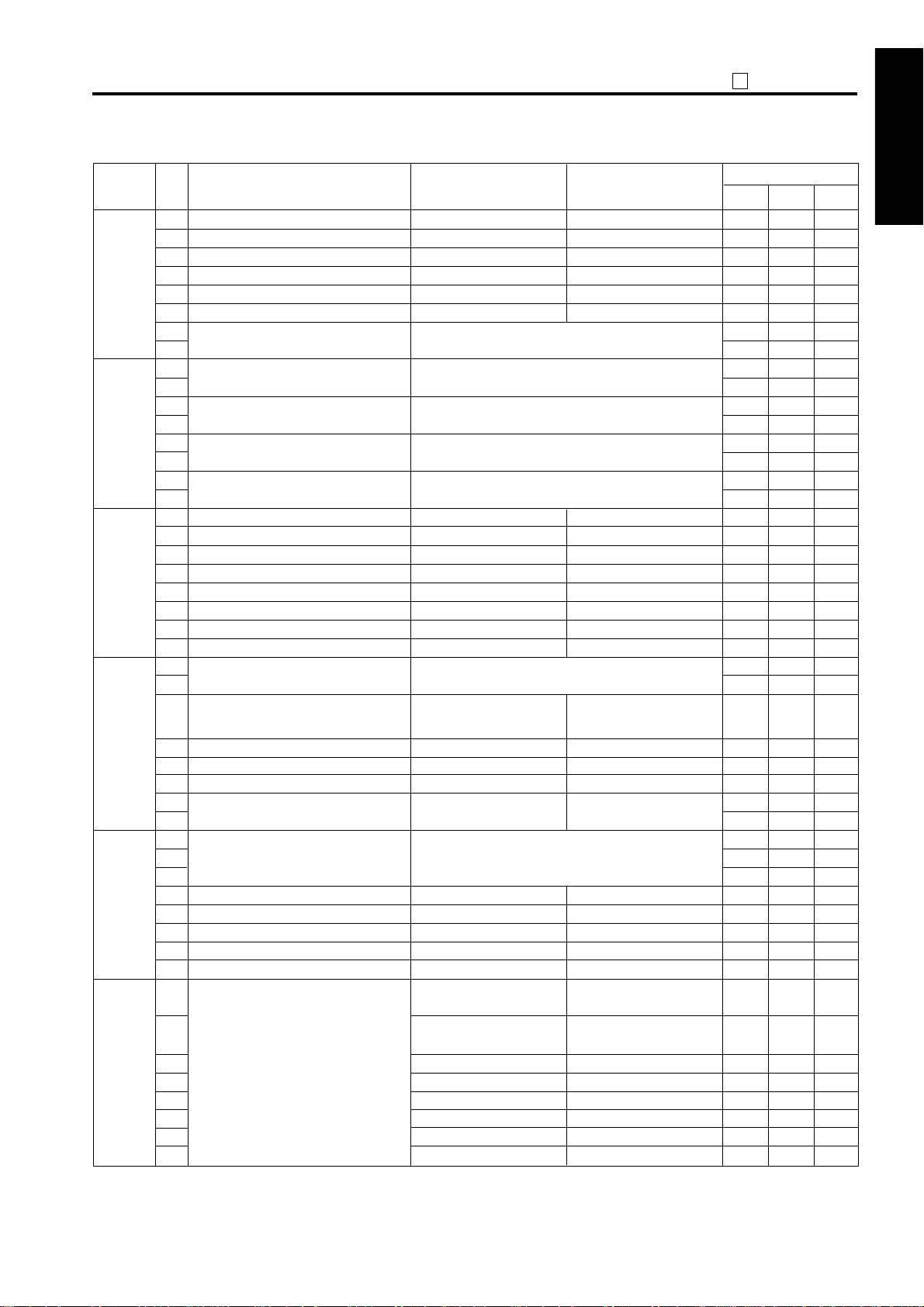

ADJUSTMENT

25

DIP SW

1 ADJUSTMENT

No.

DIP-SW7

2 ISW

DIP-SW8

3 SERVICE4 DIAGRAM

DIP-SW9

DIP-SW10

DIP-SW11

DIP-SW12

BIT

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

Functions

Transfer paper priority in image area

Automatic restart after feeding paper

8.5x11APS (Japan, Europe), A4APS (U.S.A.)

Nonstandard-size notification for platen APS B6

(Japan) / A5 (Europe) / 5.5 x 8.5 (U.S.A.) *15

Nonstandard-size notification for platen APS A4

(Japan, Europe) / 8.5x11 (U.S.A.)

Password request for 25/36/47 mode

Selection of A series size (European version)

Selection of automatic erasure outside manuscript

Changing of key operator fixed magnification setting

Disabling copying when PM count reached

Adjusting of LCD contrast to help screen

Priority tray when APS is released

Data collection (25 Mode)

Selection of copy quantity limit

Summer time setting for weekly timer

Selection of magnification mode when APS

function is cancelled.

Selection of setting screen message.

Displaying of icon to line 3

Displaying of JAM code

Tray icon display

Setting of PM count at which copying is

inhibited

KRDS connection recognition

F/E screen switchover (except for F34, F35 and F36)

*12

Area erasure outside manuscript

Does not restart

*13

Yes

*14

No

No

*15

No

*16

No

Rectangular erasure

Permit

*17

Permit

No

*18

*19

No

*20

Set time = Set value x 10 minutes

*21

Automatic

Guide display

No

No

No

*17

Not recognize

No

*22

10

Images on whole page in the

platen mode only

Restarts

No

Yes

Yes

Yes

Yes

For aslant manuscript

Prohibit

Prohibit

Yes

Yes

Life size

Display of machine state

Yes

Yes

Yes

Recognize

Yes

Default values

Japan

1

0

0

0

0

0

0

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

0

0

0

1

0

1

1

1

1

0

1

1

0

0

0

0

0

0

0

0

0

U.S.A.

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Europe

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1-8

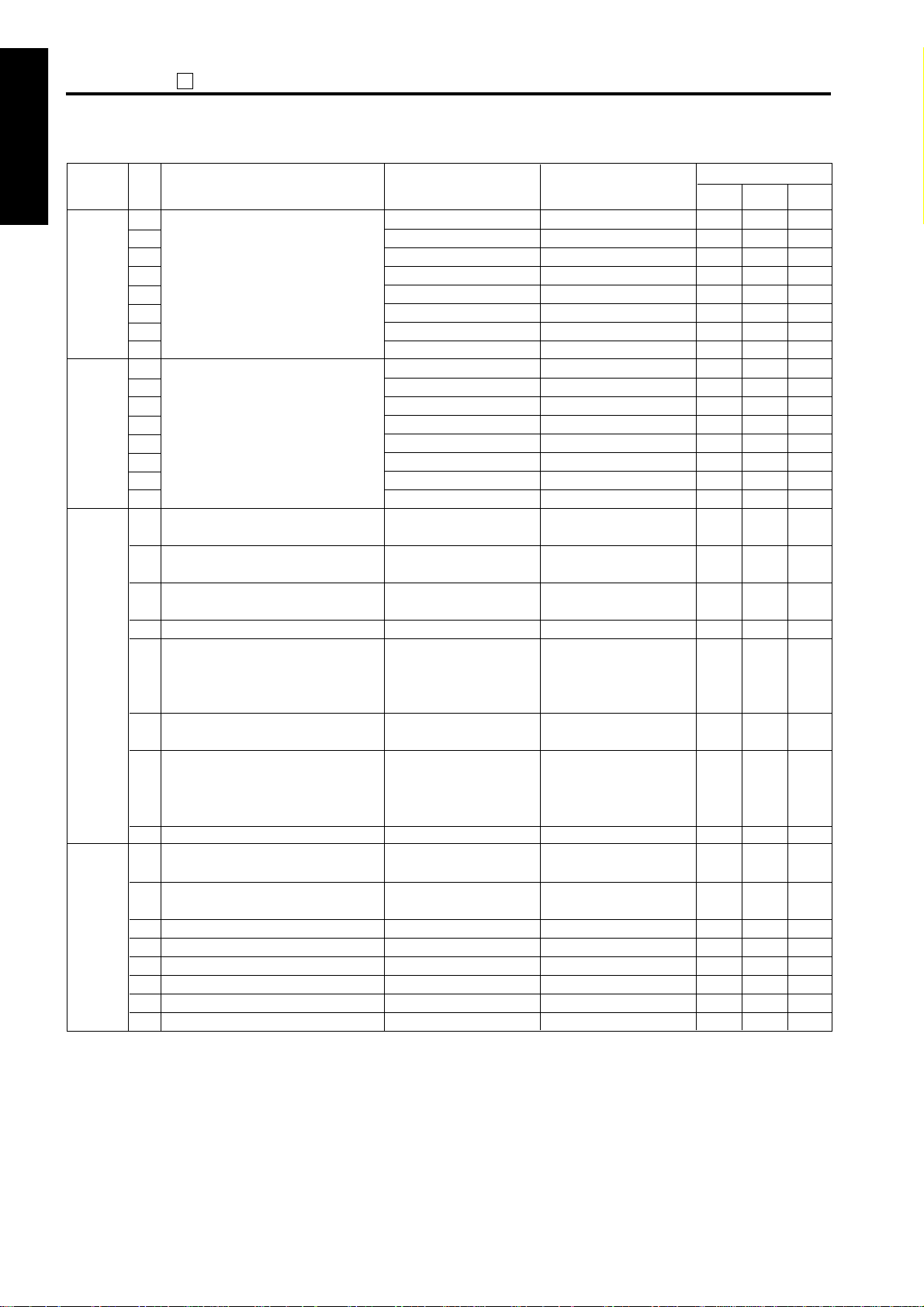

Page 10

25

ADJUSTMENT

DIP SW

No.

DIP-SW13

DIP-SW14

DIP-SW15

DIP-SW16

DIP-SW17

DIP-SW18

BIT Functions

0

1

2

3

4

5

6

Automatic erasure threshold outside original

7

0

Operation when stapling is not possible

1

Other than B6R, A5R, 5.5×8.5 nonstandard

2

3

4

Operation when 2 position stapling is not

5

available

6

Operation when one position stapling is not

7

available

0

1

2

3

4

5

6

Full stack stop when FNS not installed

7

0

Fixing temperature at low power mode

1

2

Operation of PTC

3

Indication to prepare toner bottle

4

5

Countermeasure for internal overheat

6

MPC correction control

7

0

F4 size setting

1

2

3

4

5

6

7

0

Unit isolation (1)

1

2

3

4

5

6

7

*24

*25

*26

*27

*28

No

*29

Always ON

No

Stop job

*30

*31

Tray 1 (upper part of main

*32

body) can be used

Tray 2 (lower part of main

body) can be used

Tray 3 (DB upper) can be used

Tray 4 (DB lower) can be used

DB can be used

10

Yes

PTC OFF if OFF mode, if SW2 (sub

power) is OFF, or if system is OFF

due to WT or auto shutoff.

Yes

Stop job, and turn fixing heater OFF

Tray 1 (upper part of main

body) is isolated

Tray 2 (lower part of main

body) is isolated

Tray 3 (DB upper) is isolated

Tray 4 (DB lower) is isolated

DB is isolated

Japan

Default values

U.S.A.

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

1

0

1

0

0

0

0

0

0

0

0

0

Europe

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

0

1

0

1

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

0

0

0

0

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

0

0

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1 ADJUSTMENT

2 ISW

3 SERVICE

4 DIAGRAMS

1-9

Page 11

ADJUSTMENT

25

DIP SW

1 ADJUSTMENT

No.

DIP-SW19

2 ISW

DIP-SW20

3 SERVICE4 DIAGRAM

DIP-SW21

DIP-SW22

BIT

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

Functions

Unit isolation (2)

Unit isolation (3)

Platen size recognition selector switch 1 for

Latin America (U.S.A. only)

Platen size recognition selector switch 2 for

Latin America (U.S.A. only)

Platen size recognition selector switch 3 for

Latin America (U.S.A. only)

Notice of nonstandard small platen size

Job suspension/end at pulling out key

counter

Notice of small size of platen mode

(8.5x11/A4 or smaller)

Total-counter/key-counter increment

operation

Sub power supply is turned ON when main

power is ON

Nonstandard size becomes effective at

automatic platen start

*31

*31

*15

*15

*32

Printer board can be used

Fax board can be used

Scanner can be used

RADF can be used

FNS can be used

8.5 x 11

8.5 x 11R

8.5 x 14

Notice of noticed size

If DIP SW1-0:0: Stop paper

feed and terminate

If DIP SW1-0:1 Immediatestop jam

Notice size detected by APS.

Normal operation

No

No

10

Printer board is isolated

Fax board is isolated

Scanner is isolated

RADF is isolated

FNS offset mode cannot be used

A4

A4R

F4

Notice as nonstandard size

If DIP SW1-0:0: Stop paper

feed and terminate

If DIP SW1-0:1 Immediatestop jam

Notice size as A4 (Japan, Europe)

or 8.5x11 (U.S.A.)

For copying: Increment both the

total counter and the key counter.

For printer/fax device: Increment

the total counter only.

Yes (WUT increase)

Yes (only by-pass tray)

Default values

Japan

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

U.S.A.

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Europe

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1-10

Page 12

25

ADJUSTMENT

DIP SW

No.

DIP-SW23

DIP-SW24

BIT

0

Automatic tray changeover when FNS tray

is full

1

2

3

4

100 sheets are discharged when FNS is

not stable, and tray is detected full

5

100 sheets are discharged when FNS is

stable, and tray is detected full

6

7

Fixing web count-over stop

0

1

2

3

4

5

6

7

Job start and changeover without print

process stop

Functions

No automatic changeover to

Tray 1

No automatic changeover

to optional Tray 1

No automatic changeover

to optional Tray 2

No automatic changeover to

Tray 2

No

No

Not stop

Process stop

10

Automatic changeover to

Tray 1

Automatic changeover to

optional Tray 1

Automatic changeover to

optional Tray 2

Automatic changeover to

Tray 2

Yes

Yes

Stops

Without process stop

Default values

Japan

1

1

1

1

0

1

0

0

0

0

0

0

0

0

0

0

U.S.A.

1

1

1

1

0

1

0

0

0

0

0

0

0

0

0

0

Europe

1

1

1

1

0

1

0

0

0

0

0

0

0

0

0

0

1 ADJUSTMENT

2 ISW

3 SERVICE

1-11

4 DIAGRAMS

Page 13

ADJUSTMENT

25

*1 : FS107 stapling upper limit

1 ADJUSTMENT

2 ISW

*2 : FS107 limit on number of stapled sets

*3 : Toner-replenish stop timing

3 SERVICE4 DIAGRAM

After 0 effective copies

After 100 effective copies

After 200 effective copies

After 500 effective copies

Mode 1-3 1-4

50 sheets

45 sheets

40 sheets

35 sheets

The following dipswitch settings are related:

• DIPSW 2 – 5

1-shot message display at automatic staple mode

clearing.

If this bit is set to "1", then if the user specifies more

than 25 stapled sets the copier automatically stops

after reaching the 25th set, and displays a message

instructing the user to remove the paper and press

the START button.

When the TLD (toner level detector) detects that the

toner-out condition has persisted for a fixed length of

time, the copier waits an additional number of copies

(as specified by DIPSW4 – 0, 4 – 1) and then displays

a message instructing the user to load new toner.

•

Toner-level detect (message requesting new toner)

Mode 4-0 4-1

Following the message display, the copier allows

printing of an additional number of copies as set by

DIPSW4 – 2, 4 – 3, and will then disable copying.

• Number of copies to copy-disable (following

message for new toner)

• The toner-low/toner-out condition is cleared by

insertion of a new toner bottle (toner-bottle detect

0

0

1

1

0

0

1

1

0

1

0

1

0

1

0

1

*4 : 1-shot message display at automatic staple mode

*5 : F34/F35/F36 latch

*6 : Return to EKC screen after copying reservation

*7 : By-pass feed nonstandard size selection

sensor OFF/ON).

• The toner-out stop conditions vary according to

the settings of DIPSW3 – 2 and DIPSW2 – 0.

clearing

If 1-shot display is enabled: If the copy limit is exceed

during staple-mode operation, a message indicating

this appears on the display, and copying continues in

sort mode.

Note that this setting is related to the “1-SHOT

DISPLAY TIME” setting available under key-operator

mode. For information about memory switches, refer

to the Instruction Manual.

In the event of a fixing-related error, the setting

changes to "1" so that power OFF/ON will not clear

the error condition. After correcting (repairing) the

problem, reset this to "0" to re-enable copying.

If EKC setup is enabled, then if this bit is set to "1"

(return to screen) the copier will immediately display

the EKC password-request screen following exit of

the final sheet for the reserved jobs. If copying is not

reserved, the copier will wait 1 minute following job

completion before displaying the EKC passwordrequest screen.

This setting determines whether the system detects

the size of the paper in the by-pass tray. If the setting

is "1" (handle as nonstandard), the size is not

detected and copying is based on the maximum

paper size.

Mode 4-2 4-3

After almost 100 copies

After almost 400 copies

After almost 700 copies

After almost 1000 copies

However, that the copier will stop only if DIPSW4 – 5

("Job stop or nonstop at no toner ") is set to "1".

0

0

1

1

0

1

0

1

*8 : Non-display of advance/delete buttons for job list

Under default conditions, the job list screen allows for

deletion or priority changing of jobs that have been

stoved in ERDH memory.

If this bit is set to "1"(non-display), however, the

advance and delete buttons will not appear on the

display so that it will not be possible to delete or

reorder the reserved jobs.

1-12

Page 14

25

ADJUSTMENT

*9 : Destination switch

Mode 5-0 5-1

Japan

U.S.A.

Europe

Taiwan

0

1

0

1

*10 : Polygon motor low-speed rotation timing

Use these bits to change the start timing of prerotation following copy completion.

Mode 6-4 6-5

15 seconds

30 seconds

60 seconds

120 seconds

0

0

1

1

*11 : Polygon motor pre-rotation selection

Use these bits to set the speed of polygon-motor

rotation during idling state.

Mode 6-6 6-7

No pre-rotation (33,070 rpm)

Pre-rotation (16,000 rpm)

Stopped

0

0

1

*12 : Copy-sheet size priority in image area

This setting determines how the copier handles

platen copying when the original size differs from the

copy-sheet size when the AMS setting is cleared. If

this bit is set to "1" (whole-page image in platen mode

only), then the copier will not erase the area outside

of the original (so that area outside of the APSdetected size is also copied).

If this bit is set to "0", then the copier does erase the

area outside of the original.

Note that in RADF copying, the copier will always

erase the area outside of the original regardless of

this setting.

Related settings are DIPSW8 – 0 (Selection of

automatic erasure outside original), key-operatormode and memory switch 4. For information about

memory switches, refer to the Instruction Manual.

*13 : Automatic restart after paper feed

This setting determines how copying is restarted if

0

0

1

1

0

1

0

1

0

1

0

the tray becomes empty while copying is in progress.

Under the default setting, the user (after adding

paper and setting the tray back in place) must press

the START button to resume copying. If this bit is set

to "1", however, copying restarts automatically when

the tray is set back in place.

*14 :

8.5x11 APS (Japan, Europe), A4 APS (U.S.A.)

If this bit is to "1" (No), the copier will forcibly copy as

A4 in Japan/Europe if it detects an original size of

8.5x11, and will forcibly copy as 8.5x11 in U.S.A. if it

detects an original size of A4). Under the default

setting, APS operates for both A4 and 8.5x11.

*15 : Settings related to nonstandard original sizes

• DIPSW21 – 5 "Notify of small size of platen mode"

This setting determines how the copier operates if

it detects that size of the original is smaller than A4

(Japan/Europe) or 8.5x11 (U.S.A.). If this bit is set

to "0", then according to the setting of DIPSW21 –

3 "Notify of nonstandard small size of platen

mode" the copier will either execute copy as

nonstandard size or will notify of the APS detected

size. If this bit is set to "1", then all originals are

reported as size A4/8.5x11.

• DIPSW21 – 3 "Notify of nonstandard small size of

platen mode"

This setting is effective only if DIPSW21 – 5 is set

to '0'. If this bit is set to "1", the copier will notify

that size is nonstandard if an original smaller than

A4 (Japan/Europe) or 8.5x11 (U.S.A.) is set on the

original glass.

• DIPSW7 – 4 "Nonstandard-size notification for

platen APS B6 (Japan) / A5 (Europe) / 5.5x8.5

(U.S.A.)"

This setting is effective only if DIPSW21 – 5,

DIPSW21 – 3, and DIPSW7 – 3 are all set to "0".

This setting determines how the copier notice the

original size when the platen APS detects that the

size is B6 (Japan), A5 (Europe), or 5.5x8.5

(U.S.A.). If this bit is set to "1", the copier notice the

minimum size.

If the bit is set to "0", the copier reports that the

size is nonstandard.

• DIPSW7 – 3 "Nonstandard-size notification for

platen APS A4 (Japan, Europe) / 8.5x11 (U.S.A.)"

This setting is effective only if DIPSW21 – 5,

DIPSW21 – 3, and DIPSW7 – 4 are all set to "0".

1 ADJUSTMENT

2 ISW

3 SERVICE

4 DIAGRAMS

1-13

Page 15

ADJUSTMENT

25

This setting determines how the copier notice the

1 ADJUSTMENT

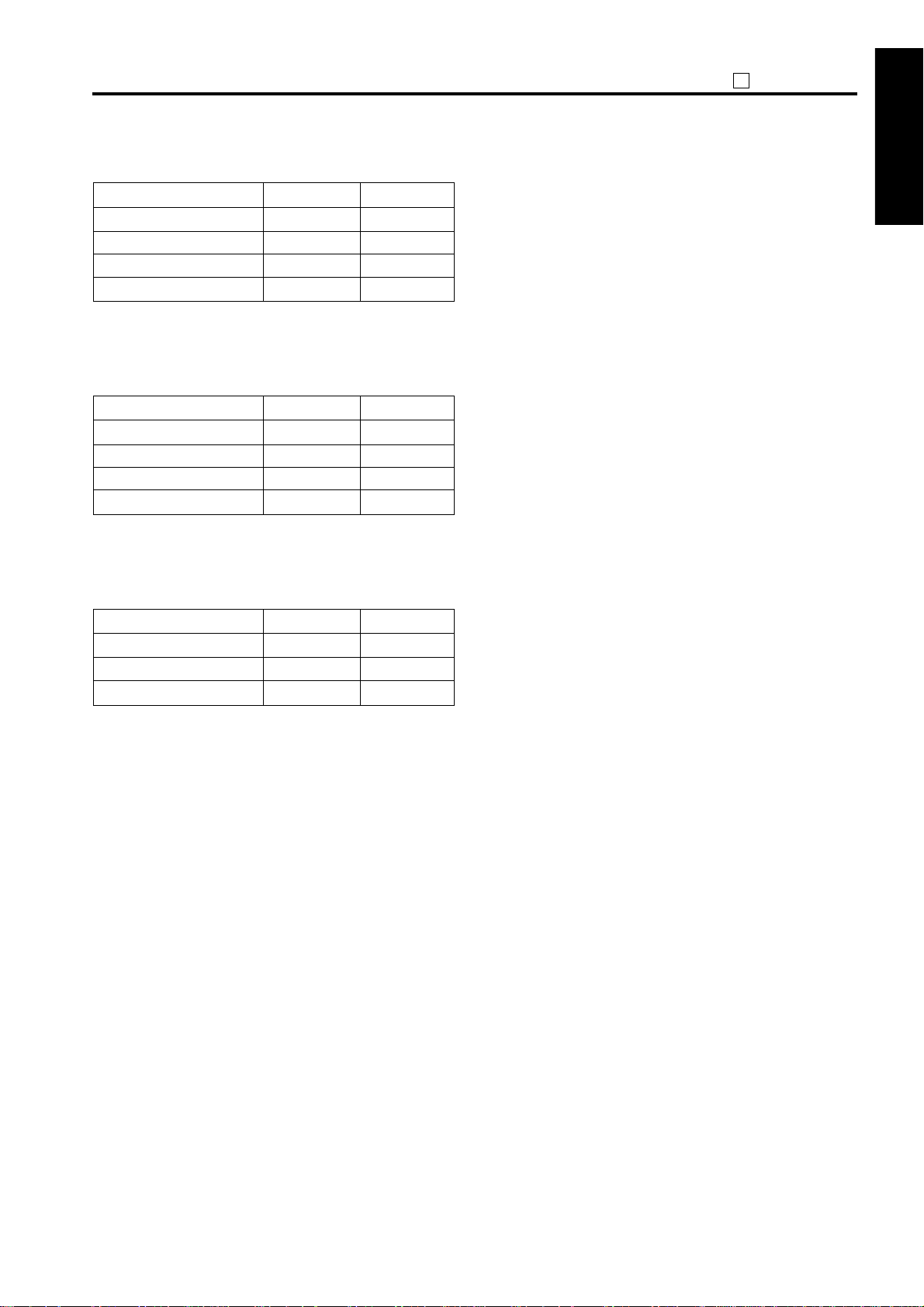

*16 : DIPSW8 – 0 "Selection of automatic erasure outside

2 ISW

original size for a platen copy when the size is

detected as being nonstandard. If this bit is set to

"1", the copier notice the size as A4 (Japan,

Europe) or 8.5x11 (U.S.A.). If the bit is set to "0",

the copier notice that the size is nonstandard.

• If DIPSW7 – 4 and 7 – 3 are both "1", operation is

according to 7 – 3 (A4/8.5x11).

original"

If this bit is set to "1" "Handling of slanted originals",

the copier will automatically erase area outside of the

original that have been placed a skew on the platen.

If this bit is set to "0" "Rectangular erasure", erasure

will always be in alignment with the copy paper.

(Example)

3 SERVICE4 DIAGRAM

BIT:0 BIT:1

*17 : Request password for 25, 36, 47 mode

If this bit is set to "1" ("Yes"), the copier will display a

password-request screen before entering service

mode. The password is "9272".

*18 : Disable of copying when PM count is reached

DIPSW12 – 3, 12 – 4, and 12 – 5 (Setting of PM count

at which copying is disabled) sets the number of

copies at which copying is disabled. Note that

copying will be disabled only if DIPSW8 – 2 (Disable

copying when PM count is reached) is set to "1".

Mode 12-3 12-5

1000 copies

2000 copies

3000 copies

4000 copies

5000 copies

0

0

0

0

1

12-4

0

0

1

1

0

*19 : Priority tray when APS is released

• This setting sets the tray selection used when APS

is set OFF from key-operator mode.

Priority tray when APS is released

Mode 8-4 8-6

No priority

Main-body upper tray

Main-body lower tray

DB upper tray

DB lower tray

0

0

0

0

1

8-5

0

0

1

1

0

0

1

0

1

0

*20 : Data collection (Mode 25)

If this bit is set to "1" (Yes), then all 25-mode collected

data 1 to 4 can be checked. If the setting is "0", then

only collected data 1 is available for checking.

*21 : Copy quantity limit

Mode 9-0 9-2

No limit

1 sheet

3 sheets

5 sheets

9 sheets

10 sheets

20 sheets

30 sheets

50 sheets

99 sheets

9-1

0

0

0

0

0

0

0

0

1

1

0

0

0

0

1

1

1

1

0

0

9-3

0

0

1

1

0

0

1

1

0

0

0

1

0

1

0

1

0

1

0

1

*22 : Summer time setting for WT (weekly timer)

Mode 10-0 10-2

0 minute

30 minutes

60 minutes

0

1

0

1

0

90 minutes

120 minutes

150 minutes

10-1

0

1

0

1

0

1

0

1

1

0

0

1

10-3

0

0

1

0

1

1

0

0

0

1

1

1

1-14

Page 16

25

ADJUSTMENT

*23 : F/E screen switch (except for F34, F35, F36)

If "1" (No), the display will show error codes for fixing

errors, but in all other cases will simply show a

message instructing the user to turn power OFF/ON.

If set to "0", all errors will be indicated by error codes.

*24 : Threshold for automatic erasure of area outside

original

Accurate detection of the outer boundary of the

original may become difficult if the original is light in

density or if extraneous light (sunlight, room

fluorescent light, etc.) has penetrated the copier.

Setting the threshold to lower values facilitates

detection for light-density originals but increases the

risk of incorrect detection due to extraneous light.

Mode 13-6 13-7

Threshold thr 80h

Threshold thr 60h

Threshold thr 50h

Threshold thr 50h

*25 :

Operation if stapling is not possible

Sizes other than B6R, A5R, 5.5x8.5R, nonstandard

Mode 14-0 14-1

Auto cancel

Auto switching to 1-position

stapling

Inhibit

Forced 2-position stapling

mode operation

0

0

1

1

0

1

0

1

0

1

0

1

0

0

1

1

*27 : Operation when 2 position stapling is not

available

Mode 14-6 14-7

Auto cancel

Auto cancel

Inhibit

Forced 2-position stapling

mode operation

0

1

0

1

0

0

1

1

*28 :Full stack stop when FNS not installed

If "1", then a copier will automatically stop copy

operation a predetermined number of copies after

PS20 (exit limit detect PS) turns ON, and will display

a message requesting the user to remove paper.

After removing the paper, the user can restart

copying by pressing the START button.

*29 :Fixing temperature at low power

Mode 16-0 16-1

160˚C

110˚C

85˚C

85˚C

0

1

0

1

0

0

1

1

1 ADJUSTMENT

2 ISW

3 SERVICE

4 DIAGRAMS

*26 : Operation when one position stapling is not

available

Mode 14-4 14-5

Auto cancel

Auto cancel

inhibit

Forced 1-position stapling

mode operation

0

1

0

1

0

0

1

1

1-15

Page 17

ADJUSTMENT

25

*30 : MPC correction control

1 ADJUSTMENT

2 ISW

These switches determine whether MPC correction is

carried out when sub power turns on.

MPC (laser maximum power correction) is designed

to optimize copy density (mainly to prevent excess

density), and is generally carried out every 20 copies.

In the copier is left off for a protracted period of time,

toner may begin to lose its charge, resulting in excess

density when copying restarts. To prevent this

problem, the default setting causes the copier to

automatically execute MPC when power turns ON

(from OFF mode or from main power OFF) if the

following two conditions hold: (1) the copier has been

off for a prolonged period (at least 8 hours), and (2)

the ambient humidity is 60% or higher.

If you set the switches to "01", then the copier will

execute MPC at power ON if either of the above two

conditions hold. If the switches are set to "10", then

MPC will always be carried out at power ON.

If "1", "1" is set to DIPSW16 – 6 and DIPSW16 – 7,

then MPC will never be carried out at power ON.

3 SERVICE4 DIAGRAM

Mode 16-6 16-7

Humidity over 60% and

First in the morning

Humidity over 60% or

First in the morning

Always

No control

*33 : SW2 (sub switch) turns ON with SW1

(main switch)

Setting this bit to "1" will increase the warm-up time.

Reason:

The CB (overall control board) houses both an

engine-control CPU and a system-control CPU.

Switching ON of the main power does not start the

engine CPU, but does start the power supply to the

system CPU. The system CPU is initialized, and then

the OS is initialized, and then memory and other

hardware checks are performed. This initialization

sequence takes about 6 seconds (until the fax,

printer/scanner, and copy LEDs have gone ON/OFF).

Normaly, pressing the SW2 during this time will not

cause the engine to start.

0

1

0

1

0

0

1

1

*31 : F4 size setting

Mode 12-3 12-5

8.5 x 13

8.25 x 13

8.125 x 13

8 x 13

8.5 x 13.5

0

1

0

1

0

12-4

0

0

1

1

0

*32 : Unit isolation

If a unit is malfunctioning and causing a problem, set

the corresponding bit to isolate the unit from the

system (software isolation). Copier operation can

then continue without problem until the unit can be

repaired, etc.

0

0

0

0

1

1-16

Page 18

25

ADJUSTMENT

[3] PM count setting

This function resets the PM count and sets the PM cycle.

Care should be taken to reset the PM count properly.

PM count / cycle menu

1. PM count resetting

2. PM cycle setting

1. PM count reset

Select whether to reset the count in the PM count

reset screen.

Step

Operation procedure

1

Enter the 25 Mode.

2

[25 mode menu screen]

Press the [2. PM COUNT/CYCLE] key.

3

[PM Count/Cycle Menu Screen]

Press the [1. PM count reset] key.

4

[PM Count Reset Screen]

Press the [YES] key to reset the PM count.

Press the [NO] or [RETURN] key, then the PM

count is not reset and returns to the PM count/

cycle setting menu screen.

3. Setting of PM cycle

Set PM Cycle as follows:

Step

Operation procedure

1

Enter the 25 mode.

2

[25 mode menu screen]

Press the [2. PM COUNT/CYCLE] key.

3

[PM Count/Cycle menu screen]

Press the [2. PM CYCLE Set] key.

4

[PM Cycle set screen]

Enter PM cycle from the numeric keys.

Enter upper 3-digit (hundred thousand, ten

thousand, thousand) only.

5

Press the [SET] key to enter a PM cycle that has

been entered.

6

Press the [RETURN] key to return to the PM

count/cycle setting menu screen.

1 ADJUSTMENT

2 ISW

3 SERVICE

2. Entering PM count start date

When resetting the PM count, it is necessary to input the start

date, and the screen below will appear automatically.

Step

Operation procedure

1

[PM Count Starting Date Input Screen]

Enter a PM count start date from the numeric

keys.

2

Press the [SET] key to enter the data that has

been entered.

3

Press the [RETURN] key to return to the PM

count/cycle menu screen.

Note: When pressing the [RETURN] key without

pressing the [SET] key, the PM count start

date is not changed. It is necessary to

reset the count again for inputting the

count.

4 DIAGRAMS

1-17

Page 19

ADJUSTMENT

25

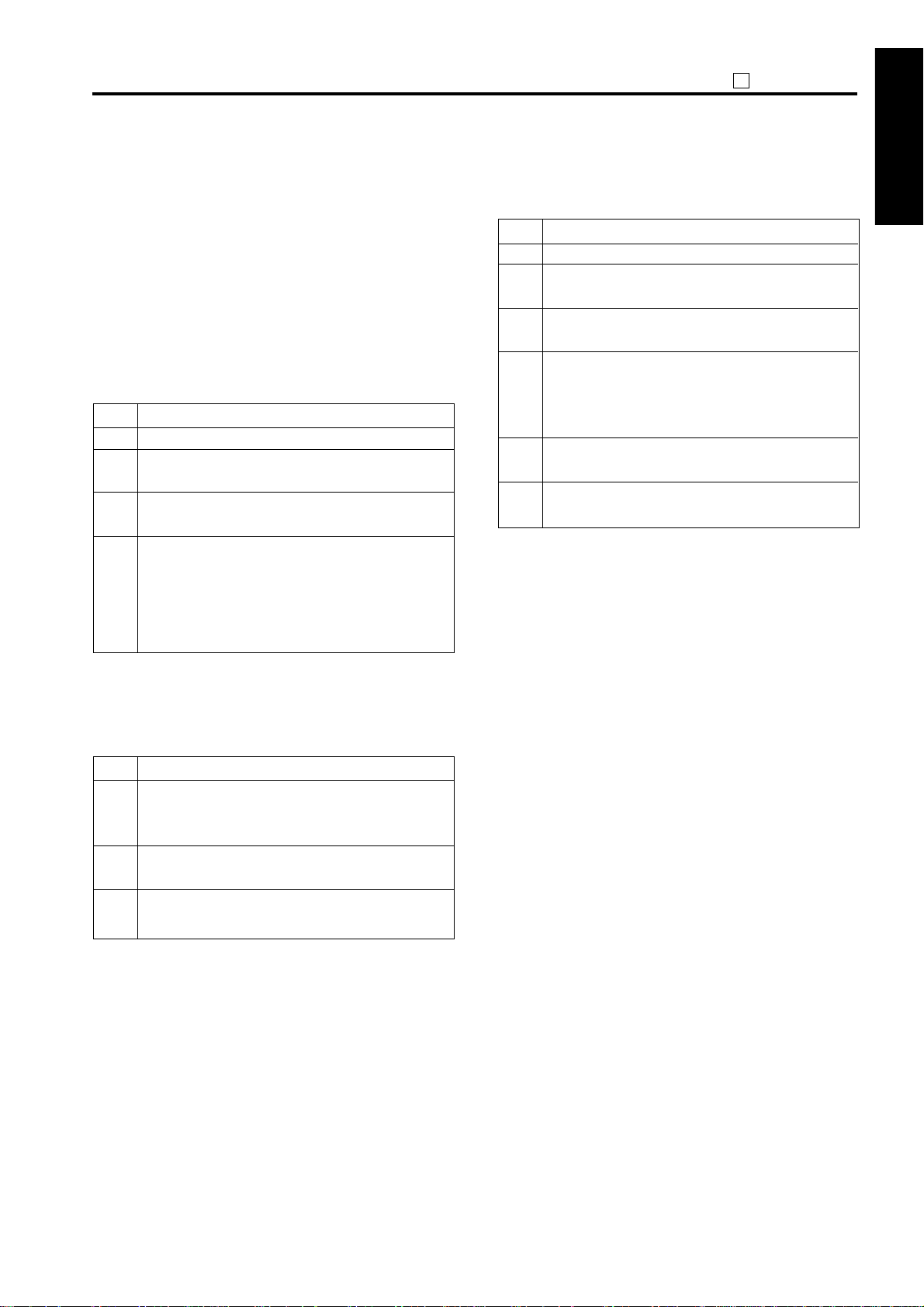

[4] Data collection

1 ADJUSTMENT

This function enables viewing of the various data recorded

in the machine.

Also, it is possible for the collected data to be checked by

KRDS and management listing.

Data collection menu

1. Count data collection

2. Area data collection start

2 ISW

Data collection list

Classification

Data collection

1

Data collection

2

3 SERVICE4 DIAGRAM

Data collection

3

Data collection

4

Contents

Count number of

copies by each size

Count RADF original

feed quantities

Count number of JAM

occurrence by each

point

Count number of

copies by each mode

Count number of SC

occurrence

Pre-peration

– (Note 1)

Enter the 25 mode

•

•

Select [1. Software

SW]

•

Set the address to

8-7:1 (

↓

↓

Note

1. Procedures for checking collected data

Step

Operation procedure

1

Enter the 25 mode.

2

[25 mode menu screen]

Press the [3. Collecting data] key.

3

[Data collection menu screen]

Press the [1. Count data] key.

4

[Data collection screen]

Change the data number with the [▲] or [▼] key.

5

Pressing [NEXT] or [FRONT] key enables display

of next data collection screen. (Note 3)

Data collection 1

↓

Data collection 2

↓

Data collection 3

↓

Data collection 4

Press the [RETURN] key to return to the data

2)

6

collection menu screen.

Note 1: Only data collection 1 can be checked in

default.

Note 2 : For the setting method, see "[2] Setting

software DIP SW" in 25 mode.

(1) The data is displayed at the line 2 in the message

display area as “Data number (No.): Count value

(000000)”.

(2) The data number can be changed by pressing the

[ ▲ ] or [ ▼ ] key.

(3) Press and hold the [ ▲ ] or [ ▼ ] key to display the

next items continuously.

Note 3 : In order to confirm collected data 2 to 4,

set DIP SW 8-7 to “1” beforehand.

1-18

Page 20

25

ADJUSTMENT

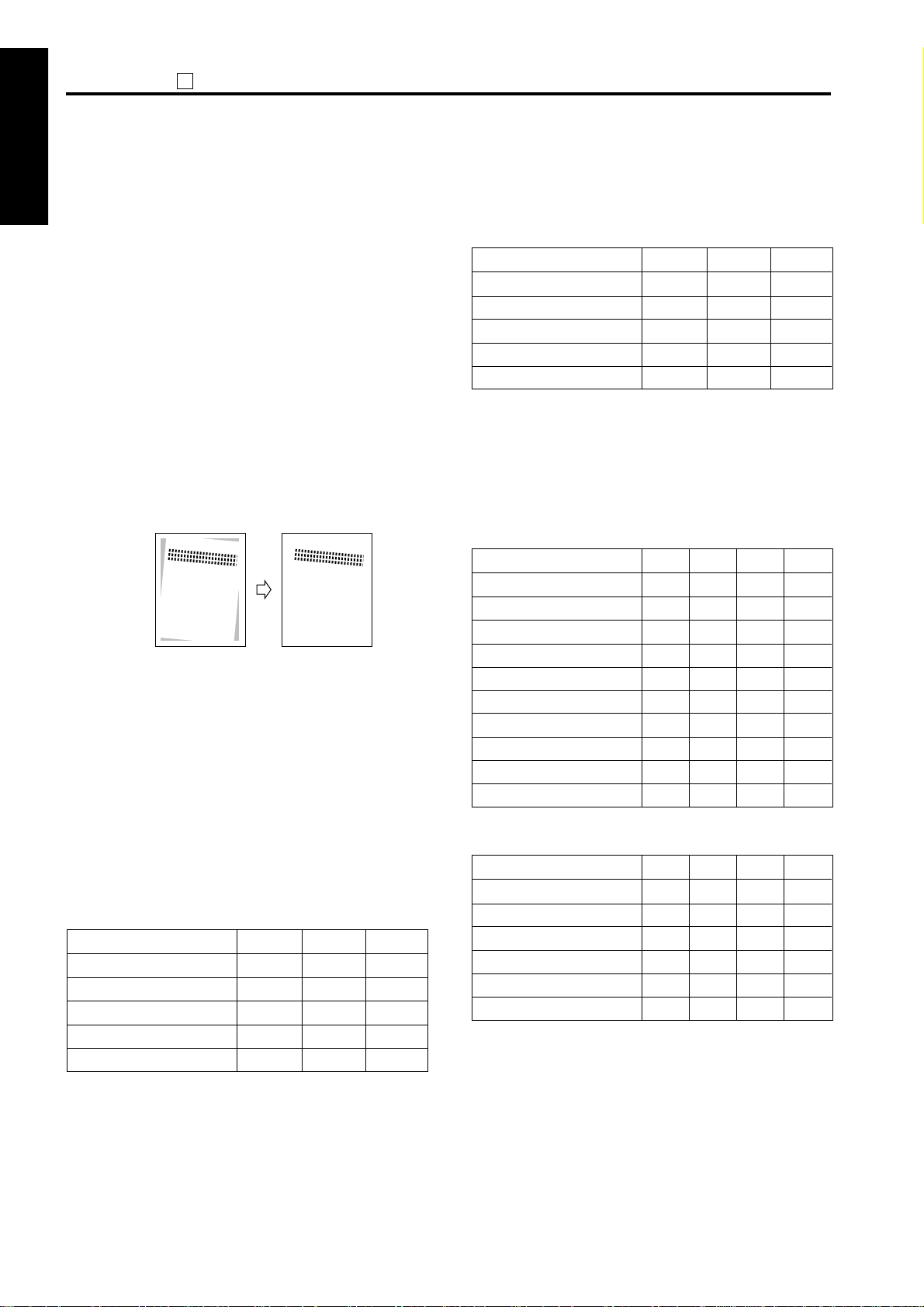

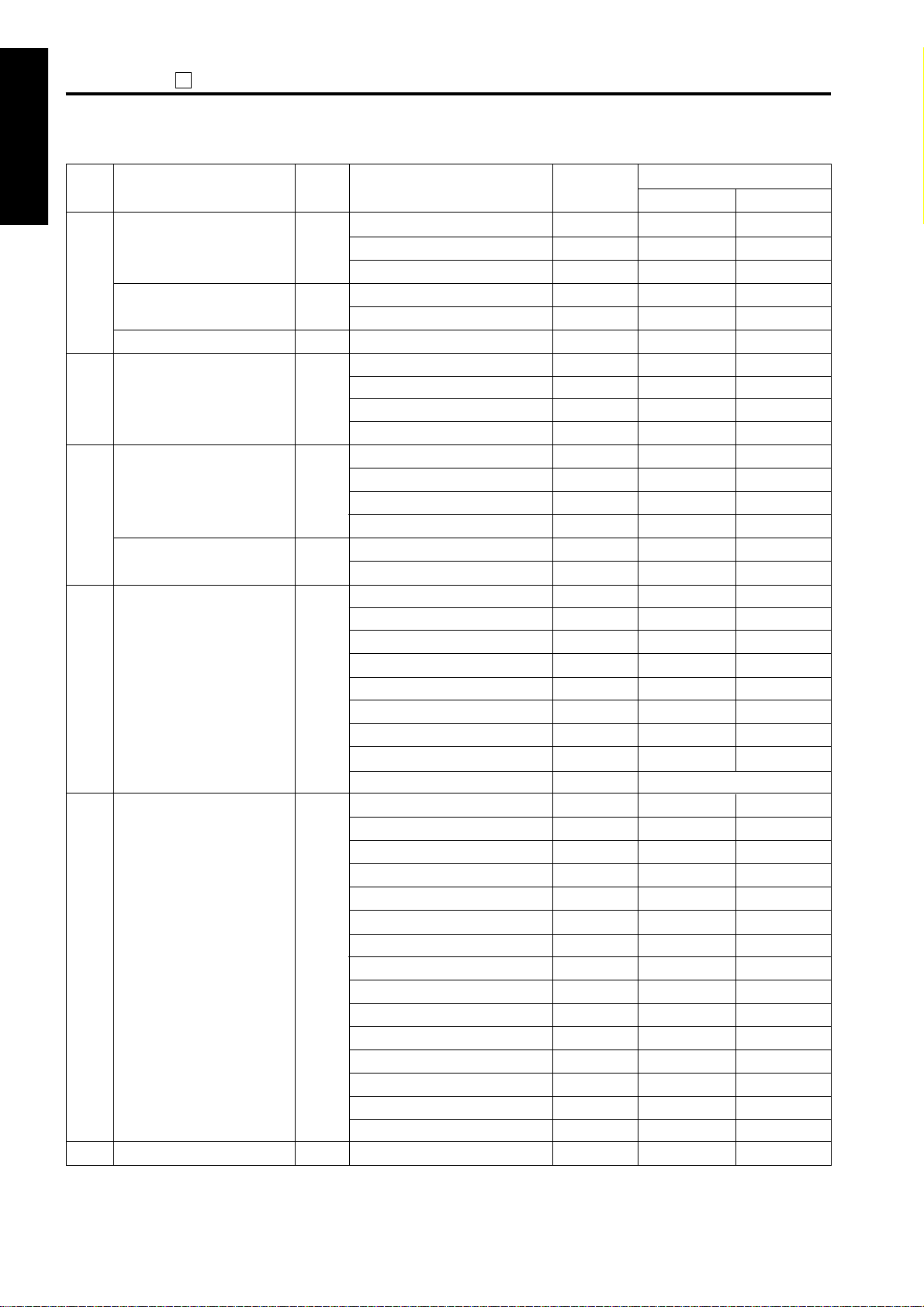

2. Data collection details

(1) Data collection 1

a. Count number of copies by each size

Type

Count

number of

copies

by each size

Size

No.

1 A4 + A4R A4 + A4R 8.5 x 11

2 B5 + B5R B5 + B5R 5.5 x 8.5

3 A5 + A5R A5 + A5R 4 8.5 x 11

5 AB series AB series Inch series

6 A3R A3R 11 x 17R

7 A4R A4R 8.5 x 14R

8 A5R A5R 8.5 x 11R

9 B4R B4R 5.5 x 8.5R

10 B5R B5R 11 B6R F4R 12 Postcard --

13 - - 14 8.5 x 11R - 15 - - -

Paper size for destination

Japan Europe

+8.5 x 11R

+5.5 x 8.5R

+8.5 x 11R

Special Special Special

Maximum count number : 99,999,999

b. Count RADF original feed quantities

Type

Count RADF

original feed

quantities

Size

No.

16 ADF mode original feed counter

17 RADF mode original feed counter

18 ADF mixed original mode original

feed counter

19 RADF mixed original mode original

feed counter

Maximum count number : 99,999,999

Feed mode

U.S.A.

--

(2) Data collection 2

<Jam occurrence count by factor>

No. Jam Point

1 10-0 By-pass

2 11-0 Upper tray (main body)

3 12-0 Lower tray (main body)

4 13-0 DB upper tray

5 14-0 DB lower tray

6 16-0 Paper feed jam

7- 8- -

9- 10 30-0 Conveyance jam

11 31-0 Conveyance jam

12 - 13 - 14 32-0 Conveyance jam

15 32-2 Conveyance jam

16 33-0 Conveyance jam

17 - 18 - 19 - 20 97-1 ADU conveyance jam

21 97-2 ADU conveyance jam

22 92-0 ADU conveyance jam

23 - 24 - 25 61-0 DF-314

26 61-1 DF-314

27 62-0 DF-314

28 62-1 DF-314

29 62-2 DF-314

30 62-3 DF-314

31 62-4 DF-314

32 62-5 DF-314

33 63-0 DF-314

34 63-1 DF-314

35 63-2 DF-314

36 63-3 DF-314

37 63-4 DF-314

1 ADJUSTMENT

2 ISW

3 SERVICE

4 DIAGRAMS

1-19

Page 21

ADJUSTMENT

25

No. Jam Classification

1 ADJUSTMENT

2 ISW

38 63-5 DF-314

39 63-6 DF-314

40 63-7 DF-314

41 - 42 - -

43 72-16 FS-107

44 72-17 FS-107

45 72-19 FS-107

46 72-21 FS-107

47 72-23 FS-107

48 - 49 - -

3 SERVICE4 DIAGRAM

Maximum count number : 999,999

(3) Data collection

<Count number of copies by each mode>

No. Contents

1 Platen single side → single side

2-

3 RADF double side → single side

4 RADF double side → double side

5 RADF single side → single side

6 RADF single side → double side

7 Finisher (Staple mode)

8 Finisher (Sort mode)

9 Finisher (Group mode)

10 Finisher (No. of stapling)

11 Life size mode

12 Fixed ratio (E3: 1.41/2.00)

13 Fixed ratio (E2: 1.22/1.55)

14 Fixed ratio (E1: 1.15/1.29)

15 Fixed ratio (R1: 0.86/0.77)

16 Fixed ratio (R2: 0.82/0.65)

17 Fixed ratio (R3: 0.71/0.50)

18 Arbitrary magnification

19 Zoom

20 2.00 magnification

21 0.45 magnification

22 AMS mode

23 APS mode

24 AE mode

25 Interrupt mode

26 By-pass feed mode

27 Book copy mode

28 Frame erase mode

29 Fold erase mode

30 Life size image shift mode

31 Reduction image shift mode

32 33 34

35 36 No. of paper feed quantities at OHP mode

37

38 Access number of the JOB memory call mode

No. of paper feed quantities at inter sheet mode

No. of paper feed quantities at mixed original mode

(Number of pressing the

button)

*

1-20

Page 22

25

ADJUSTMENT

No. Contents

39 Preheat mode

40 Copy quantity is set to 1.

41 Copy quantity is set between 2 and 5.

42 Copy quantity is set between 6 and 10.

43 Copy quantity is set to 11 or above.

44 Intersheet

45 -

46 Photo mode

47 48 Verti./Horiz. zoom mode

49 Book memory mode

50 Single step mode

51 Text/Photo mode

52 Text mode

53 Arbitrary density mode

54 No. of paper feed quantities at OHP mode 2

55 56 57 Image insert mode

58 Chapter management mode

59 Combination mode

60 Repeat mode

61 Reverse image mode

62 Non-image area erase mode

63 Increase contrast mode

64 Auto layout copy

65 66 67 Copy quantity of paper feed from tray 1

68 Copy quantity of paper feed from tray 2

69 Copy quantity of paper feed from tray 3

70 Copy quantity of paper feed from tray 4

71 72 73 Finisher, Number of stapling (front)

74 Finisher, Number of stapling (rear)

75 Booklet mode copying count

76

77 Z-fold mode copying count

78 Mixed mode copying count

79 Stamp mode copying count

80 Top/bottom correction mode copying count

OHP mode (without doubled sheet) copying count

Maximum count : 99,999,999

(4) Data collection 4

Count number of SC occurrence (F Code)

Error code (decimal number)

No. Classification

Main code Sub code

1 10-1 Communication

2 10-2 abnormality

3 10-9

4 18-1 Paper feed

5 18-2 lifting abnormality

6 18-3

7 18-4

8 26-1 High-voltage power

9 28-1 source abnormality

10 28-2

11 28-3

12 34-1 Fixing high-temperature

13 34-2 abnormality

14 35-1 Fixing low-temperature

15 35-2 abnormality

16 35-3

17 35-4

18 35-5

19 35-6

20 35-7

21 35-8

22 35-9

23 35-10

24 36-1 Broken fixing sensor

25 36-2

26 36-3

27 37-1

28 40-1 Scanning system

29 40-9 abnormality

30 41-1

31 46-1 Image processing

32 46-8 system

33 46-10

34 46-11

35 49-2

36 49-4

37 49-6

38 51-4 Motor speed

39 51-5 abnormality

Fixing web abnormality

1 ADJUSTMENT

2 ISW

3 SERVICE

4 DIAGRAMS

1-21

Page 23

ADJUSTMENT

25

Error code (decimal number)

No. Classification

1 ADJUSTMENT

2 ISW

3 SERVICE4 DIAGRAM

Main code Sub code

40 51-6

41 52-1 Fan lock abnormality

42 52-2

43 56-1 Image control

44 56-2 communication

45 56-3 abnormality

46 56-4

47 56-5

48 56-6 Operation control

49 56-7 section system error

50 56-8

51 56-9

52 56-10

53 56-11

54 60-1 RADF abnormality

55 60-9

56 60-11

57 67-3

58 70-1 Finisher abnormality

59 70-9

60 70-11

61 77-2

62 77-3

63 77-5

64 77-6

65 77-11

66 77-16

67 80-1 Non-volatile memory

68 80-2 abnormality

69 80-3

70 80-4

71 80-5

72 81-1 Flash ROM abnormality

73 81-2

74 81-3

75 88-1

76 89-1

77 89-2

78 89-3

79 89-4

80 89-5

Motor speed abnormality

Main body identification error

Image processing system

Overrall control board

communication error

Error code (decimal number)

No. Classification

Main code Sub code

81 89-6

82 87-00 Print controller error

83 52-5 Fan lock error

84 86-02 Fax board error

85 86-03

86 86-04

87 86-06 Fax error

88 86-88

89 86-89

90 86-90

91 86-91

92 86-10 Fax error

93 86-20 (Fax board side)

94 22-1

95 23-1 Drum periphery

96 26-2 High voltage

97 26-3 power supply

98 28-4

99 43-1 Scanning system error

100 52-3 Fan lock error

Overrall control board

communication error

(overrall control board side)

Machine internal temperature

Maximum count : 9,999

1-22

Page 24

25

ADJUSTMENT

3. Starting periodic date collection

Reset the periodic data from the setting periodic

collection start date. Make a date that this operation

is performed as a new periodic collection start date.

The periodic data can be checked with the KRDS and

management list.

Operation procedure

Step

Enter the 25 mode.

1

[25 mode menu screen]

2

Press the [3. Collecting data] key.

[Data collection menu screen]

3

Press the [2. Date count data] key.

[Starting periodic data collection screen]

4

Press the [YES] key to start the periodic data

collection.

Press the [NO] or [RETURN] key, then data

collection start date is not reset and returns to

the data colleciton menu screen.

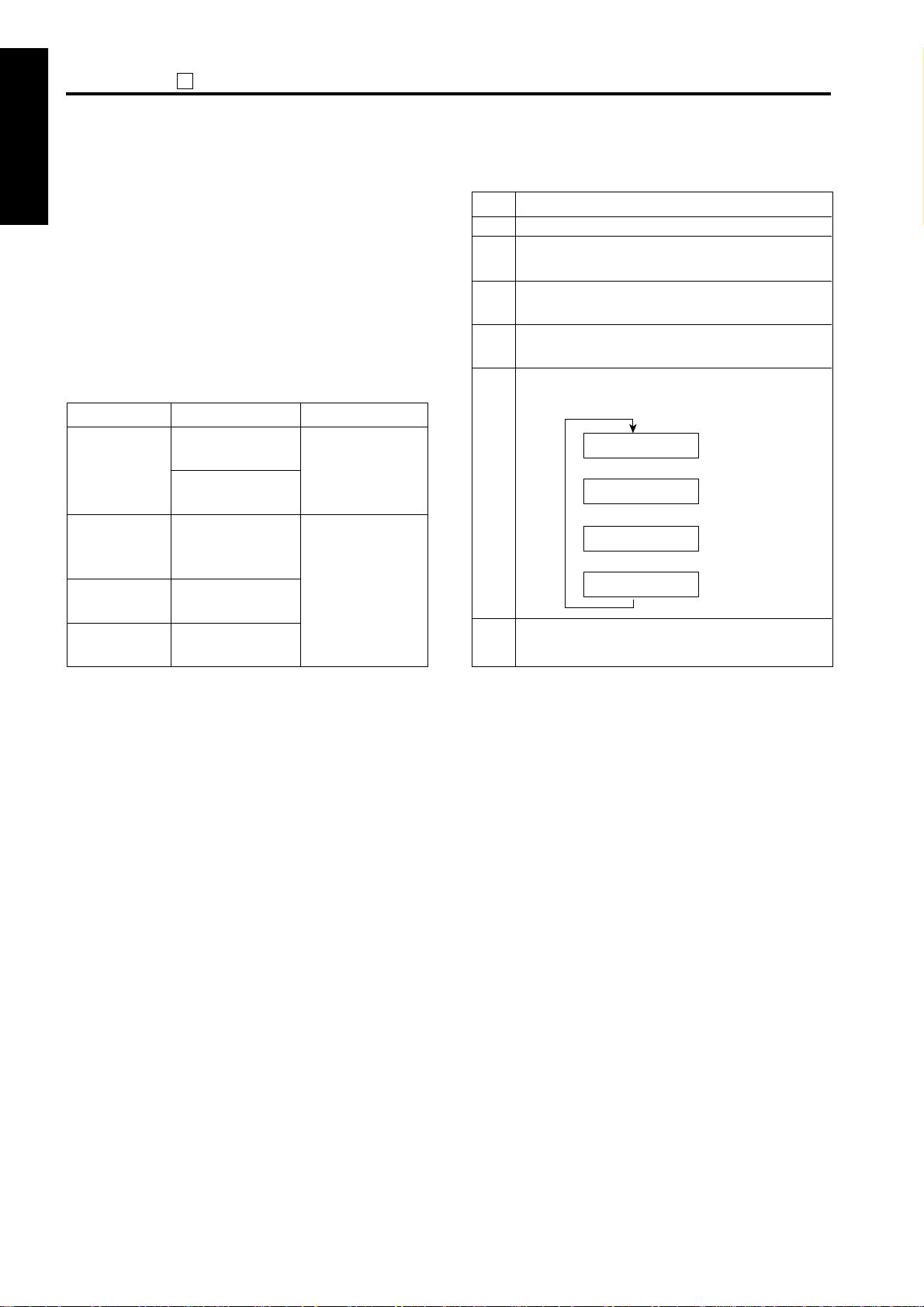

[5] Copy count for each part to be

replaced

Perform the copy count display, count clear, limit value

setting and arbitrarily parts to be replaced setting to the

data of the parts to be replaced (fixed/arbitrarily).

Each count value can be check with the management list

of 36 Mode and the KRDS.

Parts counter menu

1. Copy Count for each fixed replacement part

2. Copy Count for each arbitrarily replacement part

1. Copy count display and count reset by

parts to be replaced (fixed)

Set the parts name of the fixed parts to be replaced

(fixed), parts No. and copy count display, and count

reset.

Step

Operation procedure

1

Enter the 25 mode.

2

[25 mode menu screen]

Press the [4. Parts counter] key.

3

[Parts counter menu screen]

Press the [1. Count of parts (Fixed)] key.

4

[Copy count screen by parts to be replaced (fixed)]

Press [▲] , [▼] keys to select the data.

5

Press the [Count reset] key.

6

[Count reset screen by parts to be replaced (fixed)]

Press the [YES] key to clear the copy count.

Press the [NO] or [RETURN] key, then the copy

count is not reset and returns to the copy count

screen by parts to be replaced.

1 ADJUSTMENT

2 ISW

3 SERVICE

4 DIAGRAMS

1-23

Page 25

ADJUSTMENT

25

<List of parts to be replaced (fixed)>

1 ADJUSTMENT

1

2

3

4

5

6

2 ISW

7

8

9

10

11

12

13

14

3 SERVICE4 DIAGRAM

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

UnitNo. Parts name

Drum unit

(including charging

corona unit)

Transfer separation

corona unit

Developing unit

Main body

Main body paper

feed unit

DB (LCT or tray 3)

paper feed unit

DB Tray 4 paper

feed unit

By-pass feed unit

Fixing unit

DF-314

FS-107

Drum

Cleaning blade assembly

Drum unit

Transfer separation corona unit

Developer

Developing unit

Ozone filter

(Tray: 1) Feed rubber

(Tray: 1) Double feed prevention

rubber/Upper

(Tray: 1) Double feed prevention

rubber/Lower

(Tray: 2) Feed rubber

(Tray: 2) Double feed prevention

rubber/Upper

(Tray: 2) Double feed prevention

rubber/Lower

(Tray: 3 or LCT) Feed rubber

(Tray: 3 or LCT) Double feed

prevention rubber/Upper

(Tray: 3 or LCT) Double feed

prevention rubber/Lower

(Tray: 4) Feed rubber

(Tray: 4) Double feed prevention

rubber/Upper

(Tray: 4) Double feed prevention

rubber/Lower

By-pass feed reverse roller

By-pass feed pick up roller

By-pass feed conveyance roller

Fixing heat roller

Fixing pressure roller

Fixing web

Heat insulating sleeve/A

Heat insulating sleeve/B

Fixing cleaning roller

Cleaner assembly

Fixing claw

Fixing roller holder/Upper

Fixing roller holder/Lower

Fixing sensor

Fuse mounting plate assembly

Fixing heater lamp 1

Fixing heater lamp 2

Paper feed roller (A)

Double feed prevention roller (A assembly)

Paper exit roller (A)

2. Copy count display and count reset by

parts to be replaced (Named; arbitrarily)

Set the limit value for the parts to be replaced, parts

No., parts name setting, copy count display and

count reset.

Step

Operation procedure

1

Enter the 25 Mode.

2

[25 mode menu screen]

Press the [4. Parts counter ] key.

3

[Parts counter menu screen]

Press the [2. Count of parts (Named)] key.

[Copy count screen by parts to be replaced (named)]

4

Press the [▲] or [▼] key to select the data to be

set or changed.

The following items can be set below:

5

[COUNT RESET] : To clear the copy count.

[LIMIT SET] : To enter the limit value (6-digit).

[P/N SET] : To enter the parts number (9-digit).

[Parts name] : To enter the parts name.

6

Press the [RETURN] key, then return to copy

count screen by parts to be replaced.

1-24

Page 26

25

ADJUSTMENT

<List of parts to be replaced (arbitrarily)>

Count timingNo.

1

When copy count (at the paper exit is completed)

2

When copy count (at the paper exit is completed)

3

When copy count (at the paper exit is completed)

4

When copy count (at the paper exit is completed)

5

When copy count (at the paper exit is completed)

6

When copy count (at the paper exit is completed)

7

When copy count (at the paper exit is completed)

8

When copy count (at the paper exit is completed)

9

When copy count (at the paper exit is completed)

10

When copy count (at the paper exit is completed)

11

When copy count (at the paper exit is completed)

12

When copy count (at the paper exit is completed)

13

When copy count (at the paper exit is completed)

14

When copy count (at the paper exit is completed)

15

When copy count (at the paper exit is completed)

16

When copy count (at the paper exit is completed)

17

When copy count (at the paper exit is completed)

18

When copy count (at the paper exit is completed)

19

When copy count (at the paper exit is completed)

20

When copy count (at the paper exit is completed)

21

When paper is fed from by-pass tray

22

When paper is fed from tray 1

23

When paper is fed from tray 2

24

When paper is fed from tray 3

25

When paper is fed from tray 4

26

When paper is fed from ADU

27

When paper is exited from main body

28

When original is fed into RADF

29

When original is fed into RADF

30

When original is fed into RADF

(1) Count resetting method

Step

Operation procedure

1

Enter the 25 mode.

2

[25 mode menu screen]

Press the [4. Parts counter ] key.

3

[Parts counter menu screen]

Press the [2. Count of parts (Named)] key.

4

[Copy count screen by parts to be replaced (named)]

Press the [▲] or [▼] to select the data.

5

Press the [COUNT RESET] key.

6

[Count reset screen by parts to be replaced (named)]

Press the [YES] key to clear the copy count that

has been selected.

Press the [NO] or [RETURN] key, then the copy

count is not reset and returns to the copy count

screen by parts to be replaced (named).

1 ADJUSTMENT

2 ISW

3 SERVICE

4 DIAGRAMS

1-25

Page 27

ADJUSTMENT

25

(2) Count limit setting method

1 ADJUSTMENT

2 ISW

3 SERVICE4 DIAGRAM

Enter the new limit value from the numeric keys on

the screen.

Step

Operation procedure

1

Enter the 25 mode.

2

[25 mode menu screen]

Press the [4. Parts counter ] key.

3

[Parts counter menu screen]

Press the [2. Count of parts (Named)] key.

4

[Copy count screen by parts to be replaced (named)]

Press the [▲] or [▼] to select the data to be set

or changed.

5

Press the [LIMIT SET] key.

6

[Copy count limit setting screen by parts to

be replaced (named)]

Enter new value using the numeric keys.

7

Press the [SET] key to enter the limit value that

has been entered.

8

Press the [RETURN] key to return to the copy

count screen by parts to be replaced (named).

(3) Parts No. setting

Enter the new parts No. (8-digit) from the numeric

keys and alphabet keys on the screen.

Step

Operation procedure

1

Enter the 25 mode.

2

[25 mode menu screen]

Press the [4. Parts counter ] key.

3

[Parts counter menu screen]

Press the [2. Count of parts (Named)] key.

4

[Copy count screen by parts to be replaced (named)]

Press the [▲] or [▼] to select the data to be set

or changed.

5

Press the [P/N SET] key.

6

[Part No. setting screen by parts to be replaced (named)]

Enter new parts No. using the numeric and

alphabet keys.

7

Press the [SET] key to enter the parts No. that

has been entered.

8

Press the [RETURN] key to return to the copy

count screen by parts to be replaced (Named).

Note: When pressing the [RETURN] key without

pressing the [SET] key, the setting is

complete without changing a new limit

value and returns to the copy count screen

by parts to be replaced (Named).

Reference: The right side of the limit value will be

marked as

its limit value.

if the copy count exceeds

*

Note: When pressing the [RETURN] key without

pressing the [SET] key, the setting is

complete without changing a new parts

No. and returns to the copy count screen

by parts to be replaced (Named).

1-26

Page 28

25

ADJUSTMENT

(4) Parts name setting

Enter the new parts name from the keys on the

screen.

There are three screen in the input screen and are

changed with the [ ▼ ] or [ ▲ ] key:

• Alphabet (a capital letter), numeric number

• Alphabet (a small letter), numeric number

• Symbol, numeric number

Step

Operation procedure

1

Enter the 25 mode.

2

[25 mode menu screen]

Press the [4. Parts counter ] key.

[Parts counter menu screen]

3

Press the [2. Count of parts (Named)] key.

4

[Copy count screen by parts to be replaced (named)]

Press the [▲] or [▼] to select the data to be

set or changed.

5

Press the [P/N SET] key.

[Parts name setting screen by parts to be

6

replaced (named)]

Enter new parts name using the keys on the screen.

7

Press the [OK] key to enter the parts name that has

been entered.

8

Press the [CANCEL] key to return to the copy

count screen by parts to be replaced (Named).

Note: When pressing the [CANCEL] key without

pressing the [OK] key, the setting is

completed without setting a parts name

and returns to the copy count screen by

parts to be replaced (Named).

[6] Password setting

This function sets the password to enter each mode.

In the 25 mode menu screen, select the [6. Password

setting], then the password setting menu screen will

appear.

Select the password to be adjusted/entered in this screen.

Password setting menu

1. Key operator password set

2. E.K.C. master key code set

3. Weekly timer master key set

1. Setting key operator password

This function sets the password to enter the key

operator mode.

Step

Operation procedure

1

Enter the 25 mode.

2

[25 mode menu screen]

Press the [5. Password setting] key.

3

[Password setting menu screen]

Press the [1. Key operator password det] key.

4

[Key Operator Password Setting Screen]

Enter 4-digit new password from the numeric

keys.

5

Press the [SET] key to set the password that has

been entered.

6

Press the [RETURN] key to return to the

password setting menu screen.

Note: When pressing the [RETURN] key without

pressing the [SET] key, the setting is

complete. However the new password will

not be entered and the password setting

menu screen will return.

1 ADJUSTMENT

2 ISW

3 SERVICE

4 DIAGRAMS

1-27

Reference: When setting a password to “0000”,

the key operator mode can be used

without a password.

Page 29

ADJUSTMENT

25

2. Setting of EKC master key code

1 ADJUSTMENT

2 ISW

3 SERVICE4 DIAGRAM

This function sets the EKC master key code.

Operation procedure

Step

Enter the 25 mode.

1

[25 mode menu screen]

2

Press the [5. Password setting] key.

[Password setting menu screen]

3

Press the [2. E.K.C. master key code set] key.

[EKC master key code setting screen]

4

Enter 8-digit new EKC master key code using

the numeric keys.

Press the [SET] key to enter the EKC master

5

key code that has been entered.

Press the [RETURN] key to return to the

6

password setting menu screen.

Note: When pressing the [RETURN] key without

pressing the [SET] key, the setting is

complete without changing a new EKC

master key code and returns to the

password setting menu screen.

Reference: When “00000000” is set as the pass-

word, the EKC setting menu screen will

be displayed instead of the password

entry screen.

3. Setting the weekly timer master key

This function sets the weekly timer master key

required for entering the various weekly timer set

mode.

Step

Operation procedure

1

Enter the 25 mode.

2

[25 mode menu screen]

Press the [5. Password setting] key.

3

[Password setting menu screen]

Press the [3. Weekly timer master key set] key.

[Weekly timer master key setting screen]

4

Enter 4-digit new weekly timer master key

using the numeric keys.

Press the [SET] key to enter the weekly timer

5

master key that has been entered.

6

Press the [RETURN] key to return to the

password setting menu screen.

Note: When pressing the [RETURN] key without

pressing the [SET] key, the setting is

complete without changing a new weekly

timer master key and returns to the

password setting screen.

Reference: When setting the master key to “0000”,

the weekly timer mode can be used

without a password.

1-28

Page 30

25

ADJUSTMENT

[7] Setting phone number of the

service center

This function displays the phone and fax numbers of the

service center which is indicated on the screen if a service

call is required.

This function is not related to KRDS functions. It is

designed only for indicating the data on the screen.

1. Setting phone and fax number of the

service center

Select [6. Service TEL No.] in the 25 mode screen.

Service center number setting screen will appear.

Step

Operation procedure

1

Enter the 25 mode.

2

[25 mode menu screen]

Press the [6. Service TEL No.] key.

3

[Service center number setting screen]

Press the [TEL] key to set the phone number

and the [FAX] key to set the [FAX] number, and

input the number (Max. 16 digits) using the

numeric keys on the screen.

4

When input has been mistaken, rewrite it after

moving the cursor with [<<] or [>>] key, or delete

all with the Stop/clear button to input again.

5

Press the [SET] key to enter the number that has

been entered.

6

Press the [RETURN] key to return to the 25

mode menu screen.

Note: When pressing the [RETURN] key without

pressing the [SET] key, the setting is

complete. However the new phone

number will not be entered and the 25

mode menu screen will return.

[8] Setting the serial number

This function is used to display, set and change the serial

number of the main body and optional units.

The serial numbers can be read from KRDS.

1. Serial number display procedure

Select [7. Serial number] in the 25 mode screen. The

serial number setting screen will appear.

The item name and serial number are displayed on

the serial number setting menu screen. Each serial

number is displayed at the right side of each unit.

Press the [DESTINATION] key to select the machine

destination.

Press the [RETURN] key to end setting and return to

the 25 mode menu screen.

2. Setting and changing serial number

On the serial number setting screen, select the

desired item, then each serial number setting screen

will appear.

Step

Operation procedure

1

Enter the 25 mode.

2

[25 mode menu screen]

Press the [7. Serial number] key.

3

[Serial number setting menu screen]

Press the key corresponding to the desired item

on the screen.

4

[Serial number setting screen]

Enter the 9-digit serial number from the alphabet

and numeric keys on the screen and then press

the [SET] key to enter the number that has been

entered.

5

Press the [RETURN] key to return to the serial

number setting menu screen.

6

When changing the serial number of other item,

repeat steps 3 to 5.

7

Press the [RETURN] key to return to the 25

mode menu screen.

1 ADJUSTMENT

2 ISW

3 SERVICE

4 DIAGRAMS

1-29

Note: When pressing the [RETURN] key without

pressing the [SET] key, the setting is

complete. However the new serial number

will not be entered and the serial number

setting menu screen will return.

Page 31

ADJUSTMENT

25

3. Changing the destination setting for FAX

1 ADJUSTMENT

2 ISW

To change the destination setting, press the

"Destination" key on the serial-number setup menu.

The procedure is as follows.

Step

Operation procedure

1

Enter the 25 mode.

2

[25 mode menu screen]

Press the [7. Serial No.] key.

3

[Serial number setting screen]

Press the [Destination] key.

4

[Destination setting screen]

Use the [▲] or [▼] key to select the destination.

5

Press the [OK] key to register the setting and to

return to the serial number setting screen.

Note: If you press [CANCEL] key without first

pressing [OK] key, the copier will retain the

previous destination setting and return you

to the serial number setting screen.

<Destination codes>

3 SERVICE4 DIAGRAM

Code Destination Code Destination

JP Japan FI Finland

CA Canada SE Sweden

US U.S.A NO Norway

CN China AT Austria

SA Saudi Arabia BE Belgium

TW Taiwan NL Netherlands

ZA South Africa CH Switzerland

PL Poland FR France

PT Portugal GB Great Britain

ES Spain DE German

IT Italy NZ New Zealand

DK Denmark AU Australia

IE Ireland EU Europe

[9] Displaying the ROM version

Display ROM version mounted to the machine.

1. ROM version viewing method

In the 25 mode menu screen, select [8. ROM

version], then the ROM version display screen will

appear.

The item name and ROM version are displayed on

the ROM version display screen. Each serial number

is displayed at the right side of each item.

When there is no option not installed, the applicable

position is a blank.

ROM version display

1. System control

2. Image control

3. Panel

4. Optical control

5. RADF

6. Finisher

When the optional fax and printer are installed, their

ROM versions will also be displayed.

Press the [RETURN] key to end this screen and

return to the 25 mode screen.

1-30

Page 32

25

ADJUSTMENT

[10] Outline

If a FAX board is installed in this machine, it is not

necessary to connect a modem for KRDS. If a FAX board