Page 1

Chapter 6 Mechanism

6-1. Copy process ....................................................... 6-1

6-2. Front cross-section (Main mechanism

parts layout drawing) .......................................... 6-3

6-3. Drive conveyance system diagram .................... 6-4

Page 2

6-1. Copy process

Chapter 6 Mechanism

2. Side erase

1. Charging

3. Exposure

4. Development

Photosensitive

OPC drum

5.Transfer

5.Separation 5.Conveyance

8.Paper feed cassette

1. Charging

A high voltage of -4 to -5.5KV, output from the high

voltage PCB (UNITHV), is applied on the charge

corona unit. The grid mesh between the

photosensitive OPC drum and charger is grounded via

a 780V Zenner diode, keeping the surface of the

photosensitive drum constant at -720V.

7.Main erase

7.Cleaning

7.Toner collection

6.Fixing

4. Development

1) The toner contained in the developer is positively

charged when agitated. The charged toner is

developed (magnetic brush method) when contacted against the OPC drum by the carrier (ferrite)

and magnet roller. The toner adheres only at the

sections of the OPC drum where there is an image,

and creates a visible image. There is a slight

negative charge even at the sections with no image

(white sections), and some toner will adhere. The

bias voltage -170V, output from the high voltage

PCB (UNITHV) is applied on the magnet roller to

prevent this adhesion.

2. Side erase

The non-image area such as the edges during reduction copy, of the OPC drum surface after charging is

discharged with the side erase lamp.

Side erase lamp

Reduction

image area

Non-image area

3. Exposure

The light irradiated from the exposure lamp exposes the

photosensitive surface via the six mirrors and lens.

Document table glass

No. 4 mirror

No. 5 mirror

No. 6 mirror

Slit

OPC drum

Erase light

OPC drum

Document (back side is image)

Exposure

No. 1 mirror

lamp

No. 1 scanner

No. 2 scanner

No. 2 mirror

No. 3 mirror

Magnet roller

Toner

OPC drum

Carrier

2) The density of the toner contained in the developer

is kept constant by the toner sensor (magnetic

sensor). When the toner sensor detects a low

density, the supply screw provided at the bottom of

the toner box rotates, and the toner is supplied into

the developer.

Toner

Developer

Supply screw

Toner sensor

6-1

Page 3

Chapter 6 Mechanism

5. Transfer, separation and conveyance

1) Transfer

The paper fed from the paper cassette is conveyed

between the OPC drum and TC roller. A transfer

voltage of -1 to -2KV, output from the high voltage

PCB (UNIT HV) is applied on the TC roller, and the

paper is negatively charge. As the toner on the

OPC drum is positively charged, the toner image is

transferred onto the paper. At areas other than the

transfer area, the transfer voltage is changed to a

positive voltage (600V), so the toner adhered on

the transfer roller surface is returned to the OPC

drum.

OPC drum

Toner image

Transfer roller

2) Separation

As the diameter of the OPC is small at 30mm, the

paper after transfer is naturally separated (curvature separation) by the firmness of the paper.

Copy paper

1

7. Cleaning

1) Blade cleaning, toner recycle

The toner left on the OPC drum after the transfer

process is scraped off by the cleaning blade

(urethane rubber).

The toner scraped off is returned to the developing

unit by the screw conveyor, and is reused.

Cleaning blade

OPC drum

Screw conveyor

2) Main erase lamp

A slight residual potential is left on the OPC drum

surface after the toner is scraped off. As the OPC

drum is repeatedly used, the residual potential is

completed erased by the main erase lamp.

Main erase lamp

Drum diameter

large

Copy paper

Winds up

Drum diameter small

Curvature separation

3) Conveyance

As the distance between the transfer process and

fusing process in this machine is short, the paper is

conveyed to the fusing process by the regist roller

and transfer roller.

Regist roller

Transfer roller

6. Fixing

The toner image transferred onto the paper is fixed by

the heat roller’s heat and pressure roller’s pressure.

The fixed paper is peeled off by the separation claws,

and is exited.

Heat roller

Separation claw

Copy paper

8. Paper feed

The paper in the paper feed cassette is separated by

the claws on both edges, and only one sheet is

conveyed into the unit by the paper feed roller (segment roller). When the paper feed is completed, the

segment roller stops at a position where it does not

contact the paper, so the paper pressing load is

reduced.

Segment roller during paper feed

Pressue roller

MODEL

1312

Exit tray

Pressue spring

MANUAL

SERVICE HANDBOOK

REVISED EDITION

6-2

1

DATA

May.1999

Segment roller stop position after paper feed

PAGE

6-2

METHOD

REPLACEMENT

Page 4

1

6-2. Front cross-section (Main mechanism parts layout drawing)

SDH

Chapter 6 Mechanism

No. 4 mirror

No. 5 mirror

Developer unit

JAM1 sensor

No.6 mirror

Side erase lamp

Shield glass

Lens

Charge corona unit

Main erase (cleaning) lamp

Paper feed roller

S1 sensor

Separation roller

Reflector (reflection mirror)

Exposure lamp

Cleaning blade

Heat roller

S2 sensor

Conveyance

roller

No. 1 mirror

JAM2 sensor

Turn roller

Paper exit roller

No. 2 mirror

No. 3 mirror

Relay roller

Paper feed roller

Slip roller

Transfer roller

Regist roller

Paper feed roller

OPC drum

Pressure (rubber) roller

Cassette feeder (option)

MODEL

1312

MANUAL

SERVICE HANDBOOK

REVISED EDITION

6-3

1

DATA

May.1999

PAGE

6-3

METHOD

REPLACEMENT

Page 5

Chapter 6 Mechanism

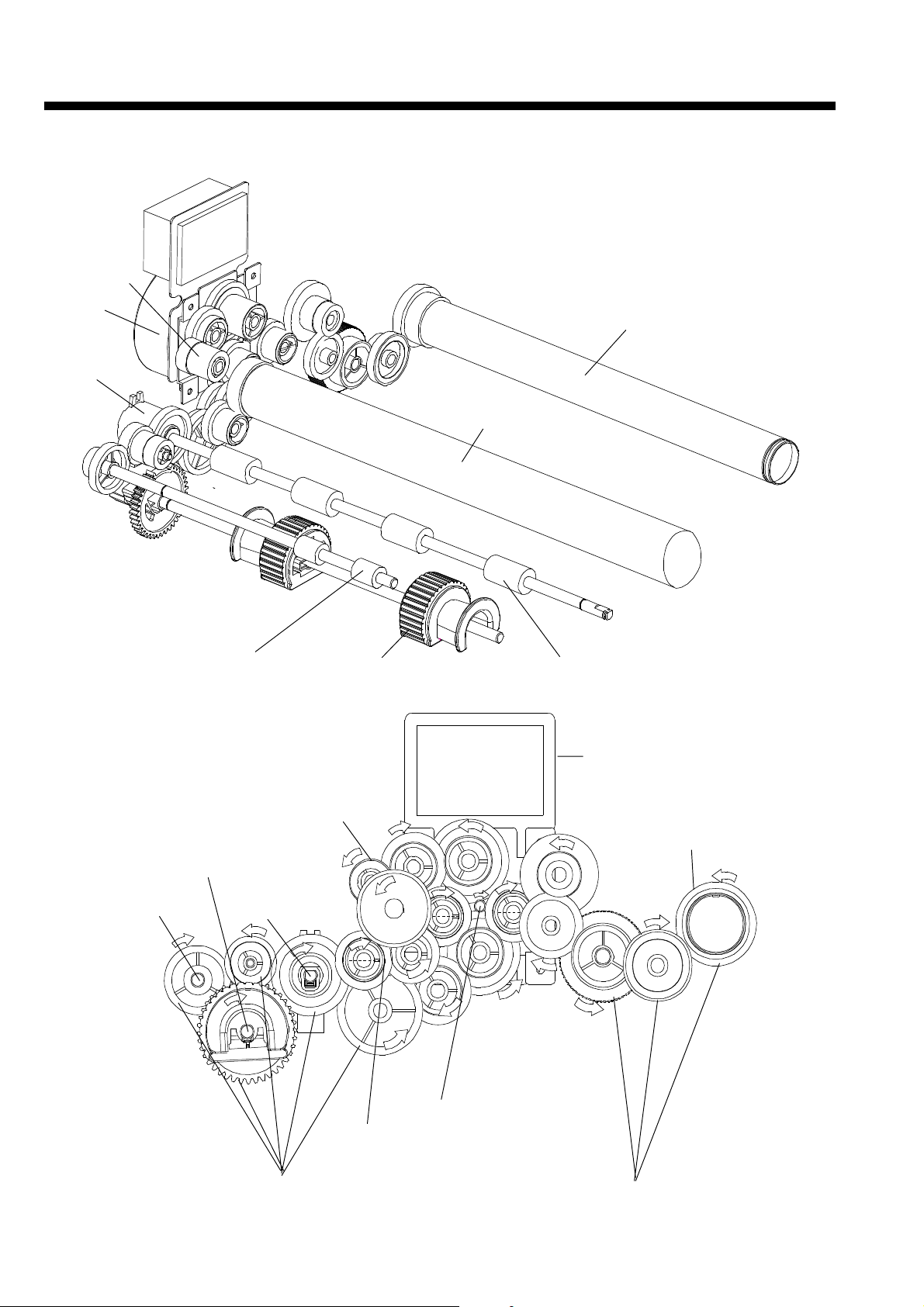

6-3. Drive conveyance system diagram

Developing unit drive gear

Main motor

Regist clutch

Slip roller Paper feed (segment) roller

Heat roller

OPC drum

Regist roller

Main motor

Paper feed (segment) roller

Slip roller

Paper feed unit gear

Developing unit drive gear

Heat roller

Resist roller

Main motor shaft (gear)

OPC drum

Fixing unit gear

6-4

Loading...

Loading...