Page 1

Chapter 9 Troubleshooting

9-1. Defective image and diagnosis flow .........9-1

9-1-1. Both sides and trailing edge is black

when making a reduced copy ................9-1

9-1-2. Background fogging

(White background fogging) ...................9-2

9-1-3. Black lines ................................................9-3

9-1-4. Center deviation.......................................9-4

9-1-5. Smearing .................................................. 9-5

9-1-6. Light copy.................................................9-6

9-1-7. Dark copy ................................................. 9-7

9-1-8. Partial skipping of transfer .....................9-8

9-1-9. Copy is black............................................9-9

9-1-10. No image...............................................9-10

9-1-11. Distorted image.................................... 9-11

9-1-12. White band ........................................... 9-12

9-1-13. Black band............................................9-13

9-1-14. Density balance deviation...................9-14

9-1-15. Leading position deviation .................9-15

9-1-16. Contamination......................................9-16

9-1-17. Jittering.................................................9-17

9-1-18. White dots on black matte section.....9-18

9-1-19. Extremely light copy............................9-19

9-2. Operation defects ..................................... 9-20

9-2-1. Power does not turn ON........................9-20

9-2-2. Copying operation is not possible ....... 9-20

9-2-3. Paper feed or conveyance defect.........9-20

9-2-4. Abnormal noise ......................................9-21

9-2-5. Special symptoms .................................9-22

9-2-6. Malfunction.............................................9-22

Page 2

9-1. Defective image and diagnosis flow

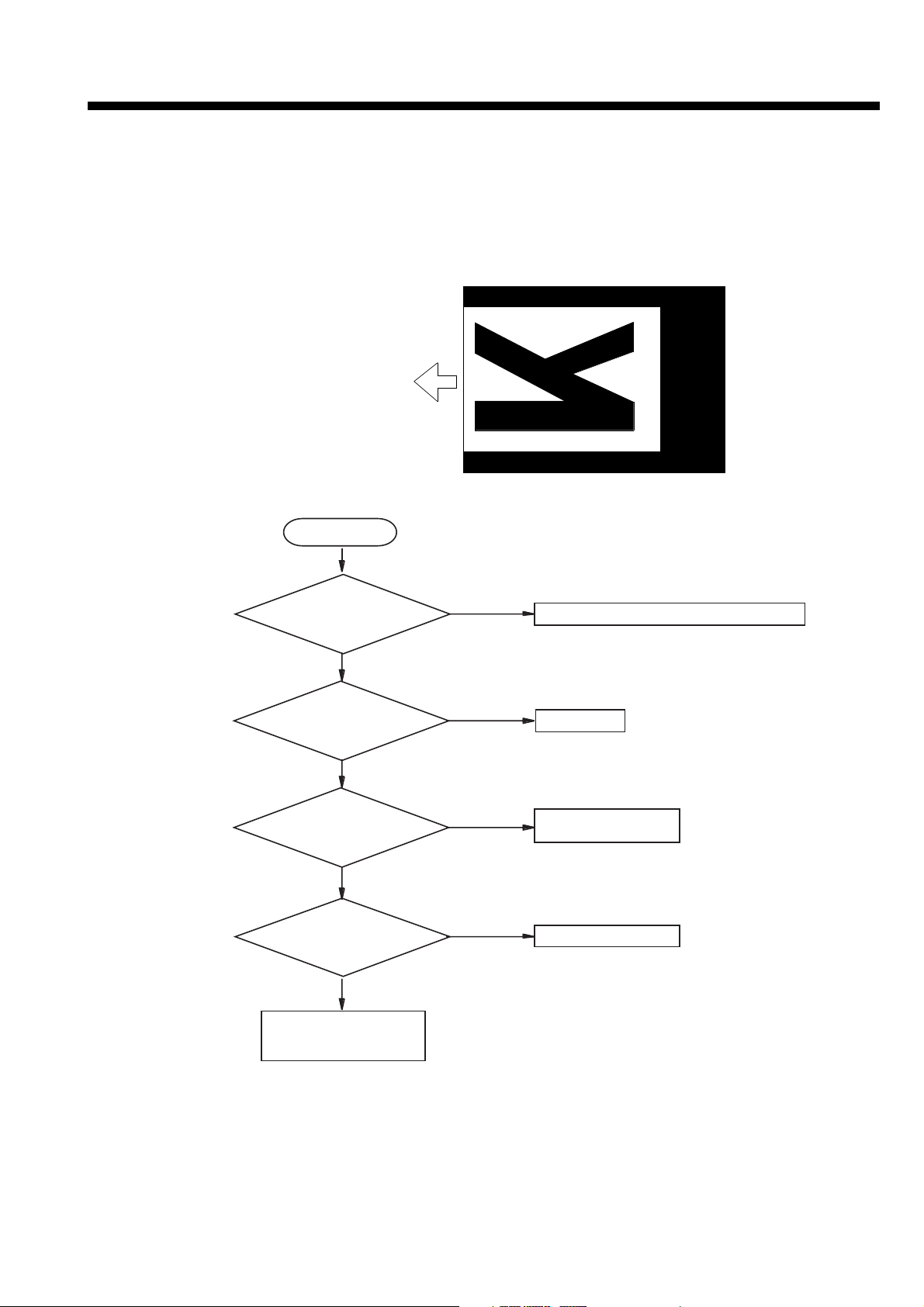

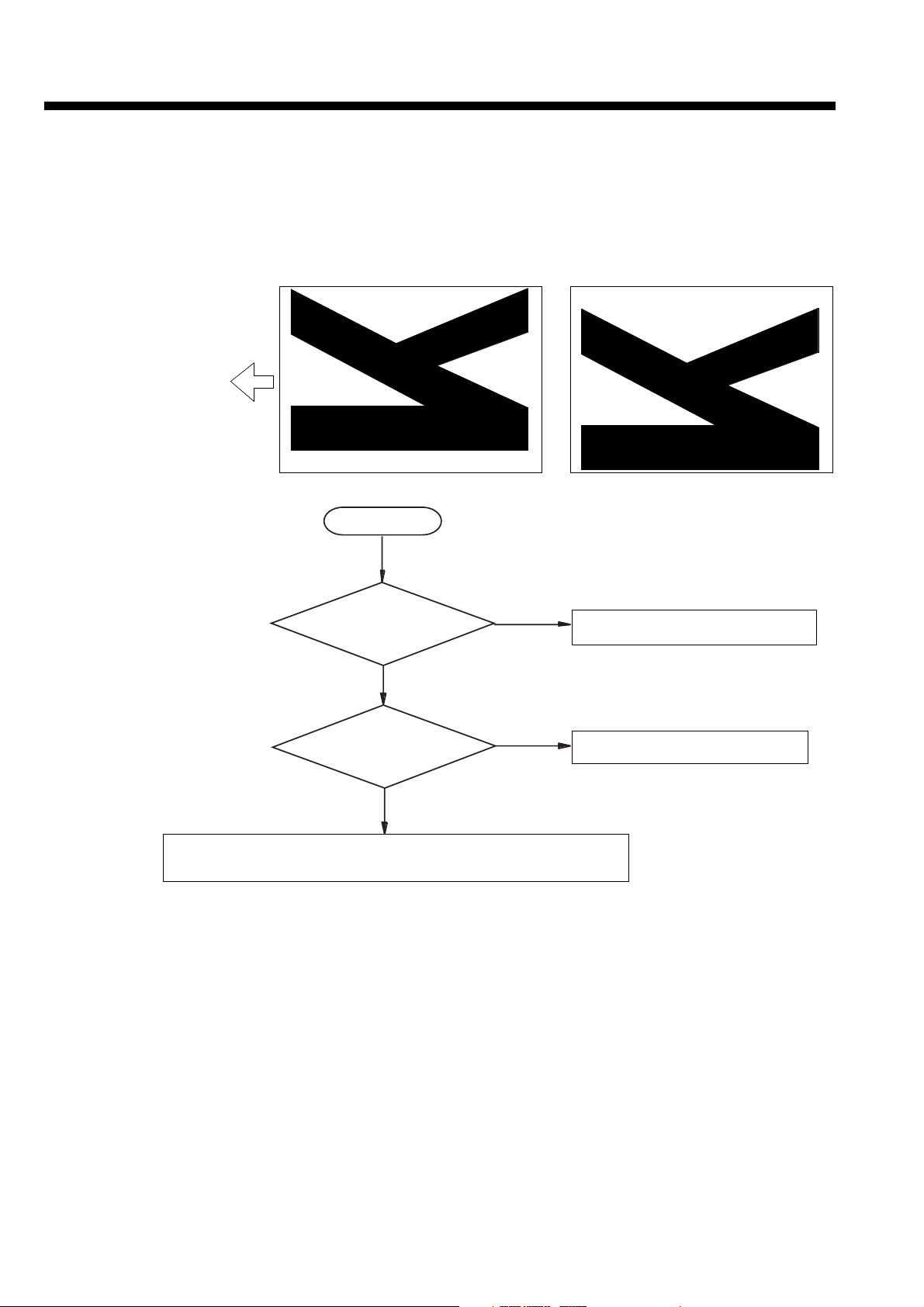

9-1-1. Both sides and trailing edge is black when making a reduced copy

Paper feeding direction

Chapter 9 Troubleshooting

START

Was copy made with platen

cover opened?

NO

Is the side erase lamp surface dirty?

NO

Is the side erase lamp lit?

NO

Is the connector disconnected?

YES

YES

YES

YES

Close the platen cover, make a copy, and reconfirm.

Clean or replace.

Check the side erase lamp

installation state.

Securely insert the connector.

NO

Control PCB defect -> Replace.

Wire harness defect -> Replace.

Side erase lanp defect -Replace.

9-1

Page 3

Chapter 9 Troubleshooting

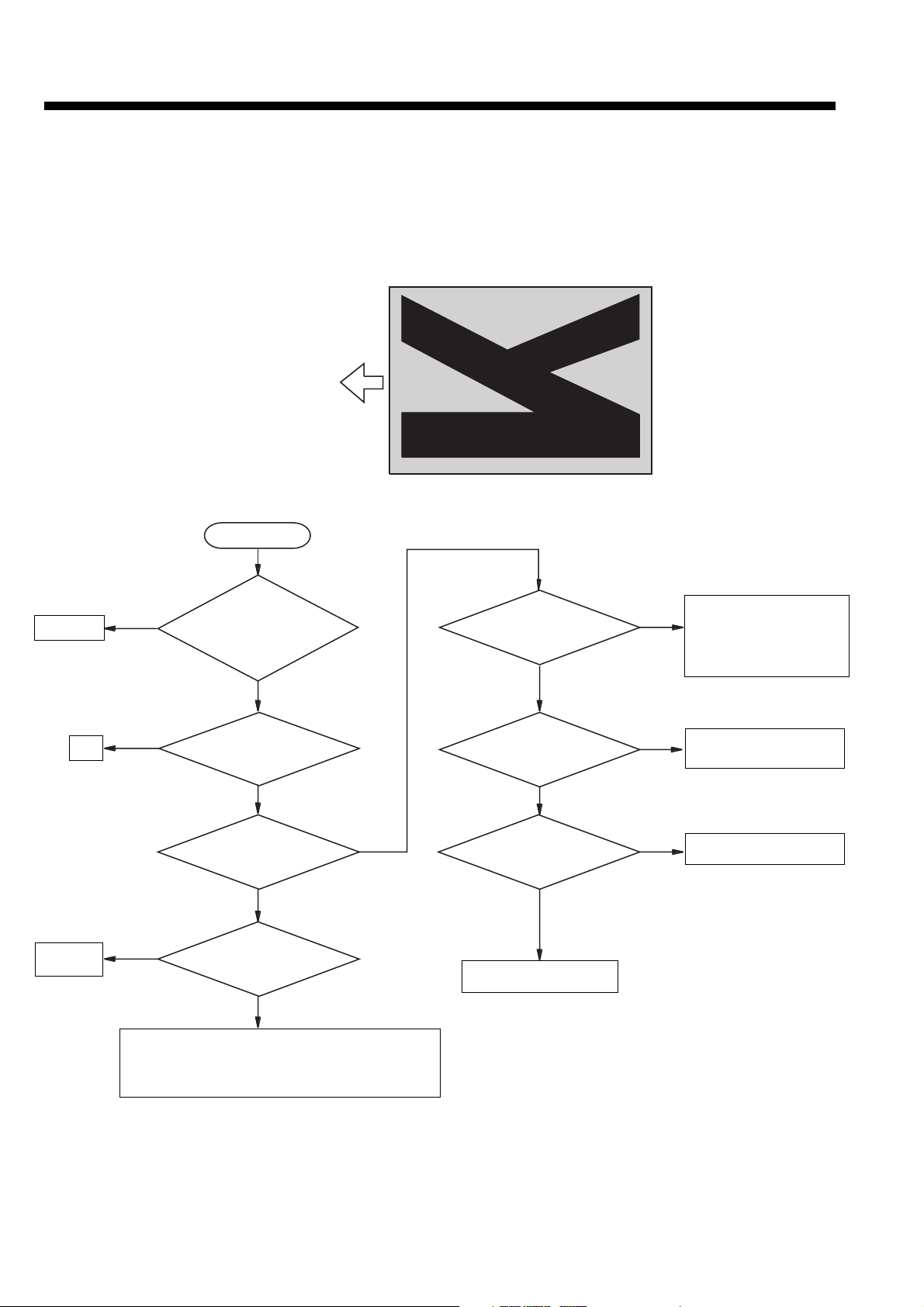

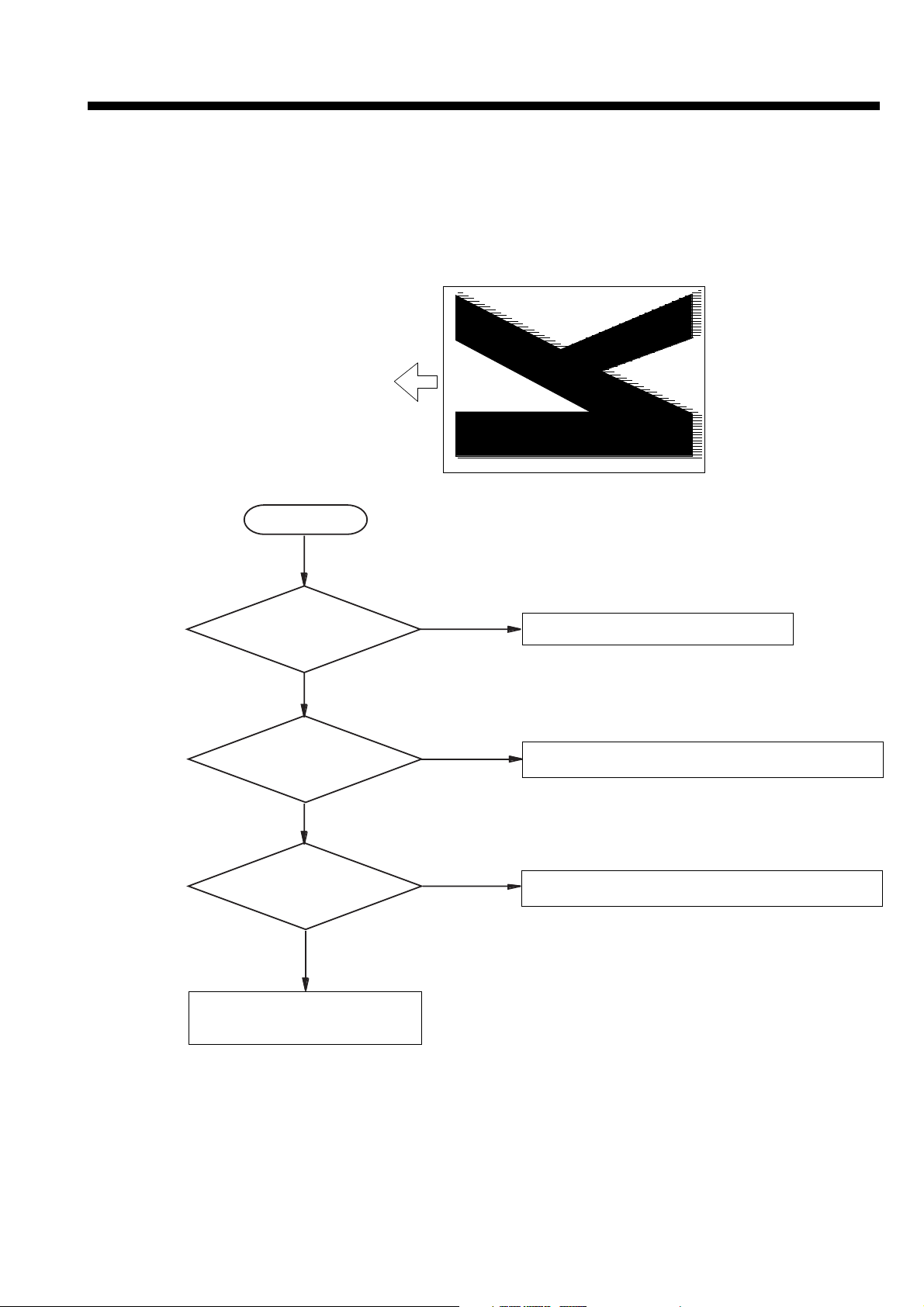

9-1-2. Background fogging (White background fogging)

Paper feeding direction

Replace or clean.

Clean.

Replace developer

material.

YES

YES

YES

START

Is the designated rating

exposure lamp installed?

Is the platen glass surface

dirty?

NO

Is the platen, glass,

mirror or lens dirty?

NO

Is the toner control correct?

NO

Was a non-designated

developer material used?

YES

Is main erase lamp lit?

YES

Is the developing bias

voltage correct?

(170±10V)

YES

Are the gaps for the drum gap

and doctor blade gap correct?

(0.6±0.05mm)

YES

Cleaning defect -> Replace.

NO

Main erase lamp defect ->

Replace.

Connector contact defect ->

Repair or replace.

Main PCB defect -> Replace.

NO

NO

High voltage PCB defect -> Replace.

Re-adjust. Replace defective

parts.

NO

Toner supply mechanism defect -> Replace corresponding part.

Toner sensor defect -> Replace.

Control circuit defect -> Replace main PCB.

Developer unit defect -> Replace.

9-2

Page 4

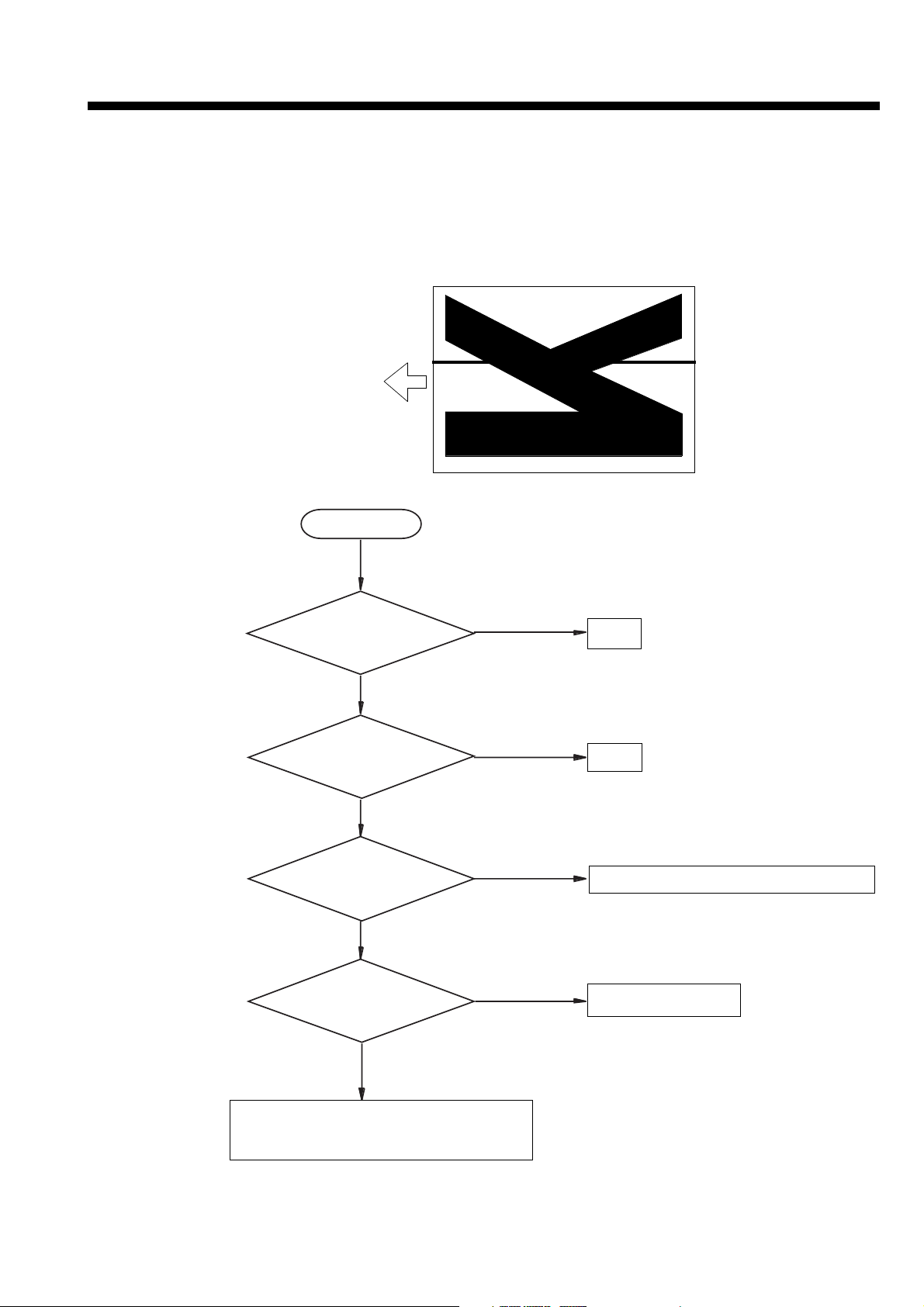

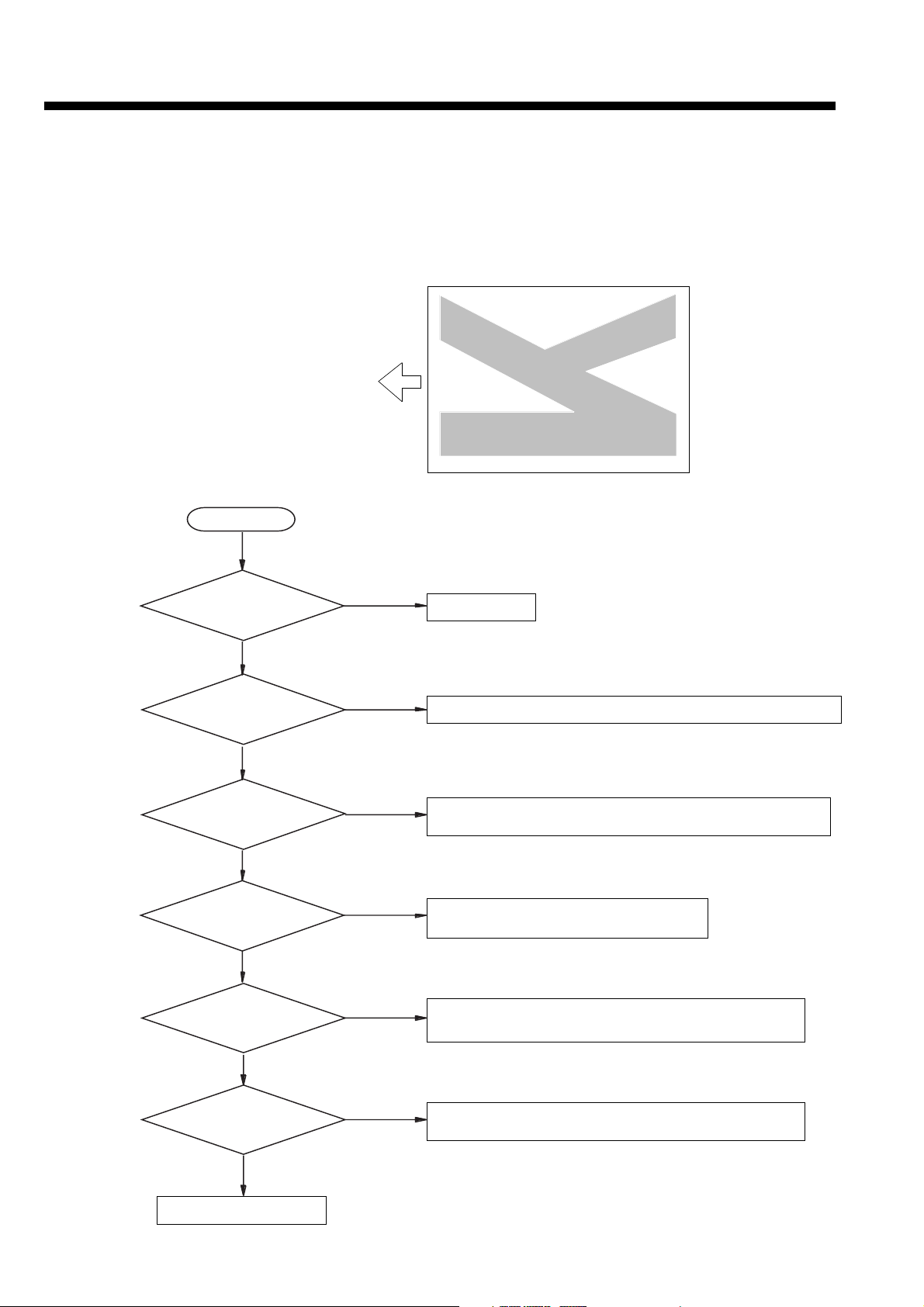

9-1-3. Black lines

Paper feeding direction

Chapter 9 Troubleshooting

START

Is the OPC drum scratched?

NO

Is the edge of the cleaning

blade

scratched?

NO

Are there any foreign matter

contacting the OPC drum surface

before the developing process?

NO

Is there anything

(lead wire of side erase, etc.)

shielding the exposure axis?

NO

YES

YES

YES

YES

Replace.

Replace.

Correct the installation of the corresponding part, or

replace.

Correct the harness fairing.

Heat roller scratch -> Replace.

Charge wire scratch or contamination -> Replace or clean.

Grid mesh deformation or contamination -> Replace or clean.

9-3

Page 5

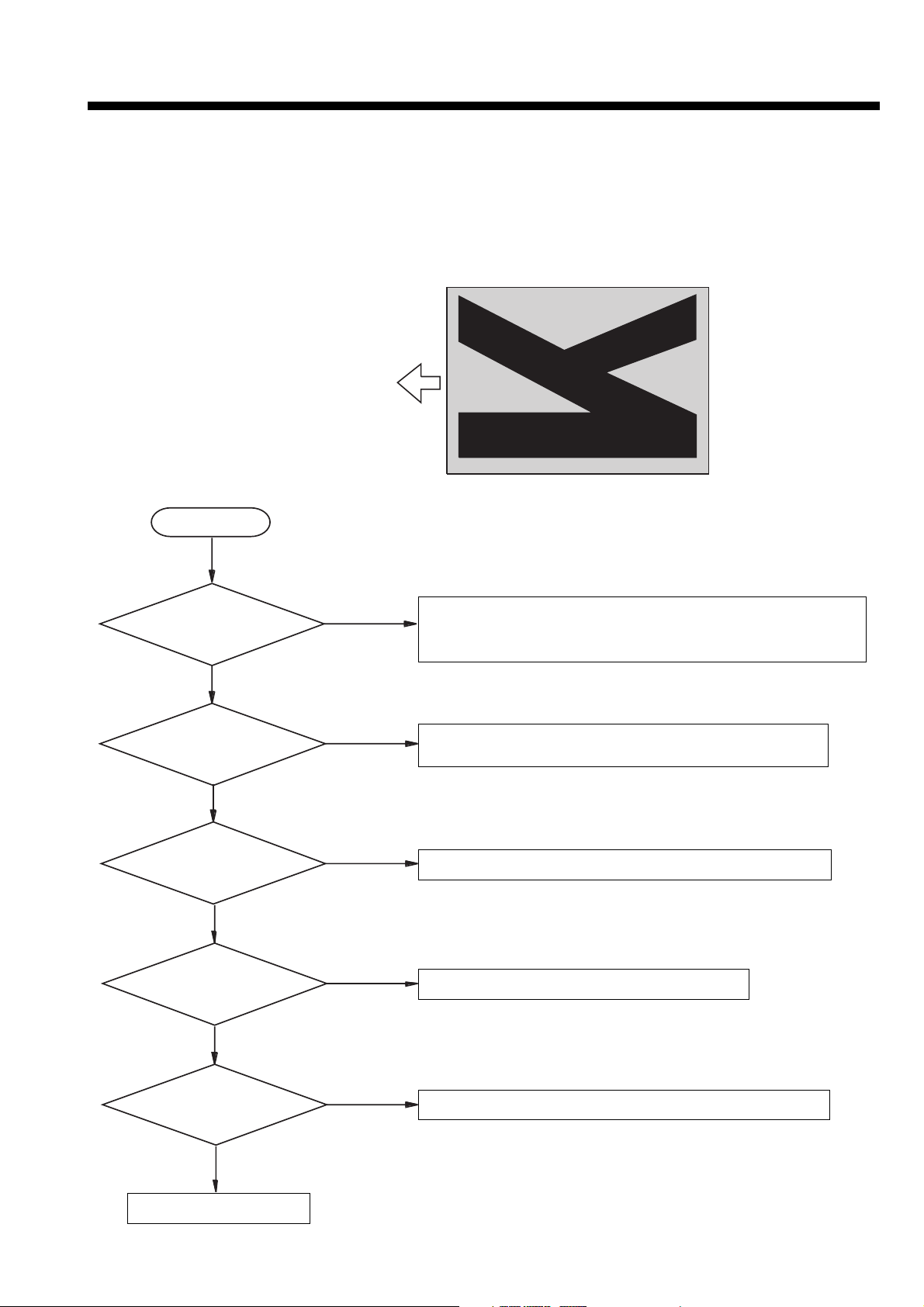

Chapter 9 Troubleshooting

9-1-4. Center deviation

Paper feeding direction

START

Is the document set in alignment

with the platen scale?

YES

Is the platen scale installation

position correct?

YES

Paper feed cassette fixing position deviation -> Install so that the center position is

aligned. (Refer to Chapter 4)

NO

NO

Correctly set the document, and confirm.

Install so that the center position is aligned.

9-4

Page 6

9-1-5. Smearing

Chapter 9 Troubleshooting

Paper feeding direction

START

Is there any part, etc., contacting

the OPC drum surface after the

developing process?

NO

Is the paper slipping during

the image transfer?

NO

Is the trailing edge of the

paper rising to the top before

fusing?

NO

Fusing defect -> Confirm the main parts

Fuser lamp, pressurized spring, heat

roller, fuse roller, etc.

If the fusing is insufficient, the image will smear

when the surface of the copied image is

rubbed.

YES

YES

YES

Correct the installation position of contacting

parts.

Confirm the drive state of the transfer roller, etc. Repair or replace the

part.

Use of paper that curls easily -> Replace the paper.

Fuser roller or heat roller defect -> Replace.

9-5

Page 7

Chapter 9 Troubleshooting

9-1-6. Light copy

Paper feeding direction

START

Has the paper absorbed moisture?

NO

Is the toner density abnormally low?

NO

Has the charging or transfer

voltage dropped?

NO

Does the developer brush sufficiently

contact the OPC drum?

YES

Is the exposure voltage too high?

YES

YES

YES

YES

Replace the paper.

Inspect the toner control mechanism (Refer to 7-1) -> Adjust or replace defective part.

Inspect charge corona unit and transfer roller -> Repair or replace defective part

Confirm charging and transfer voltage -> Replace high voltage PCB.

NO

Inspect the doctor blade gap (0.6±0.05mm)-> Adjust

Inspect the drum gap -> Replace defective part.

Confirm voltage -> Re-adjust (Refer to 4-3) or replace PCB. (power supply

PCB, main PCB)

NO

Is the developing bias circuit

open?

NO

OPC drum defect -> Replace.

YES

Inspect bias circuit (170±10V)-> Repair or replace defective part.

(developing unit, high voltage PCB, etc.)

9-6

Page 8

9-1-7. Dark copy

START

Chapter 9 Troubleshooting

Paper feeding direction

Has the exposure lamp’s light

amount dropped?

Is the developing bias abnormally low?

Is the toner density abnormally high?

Is the charging grid circuit open?

Inspect the lamp rating, and surface contamination -> Replace or clean.

Inspect mirror, lens and reflector for contamination -> Clean or replace.

Inspect exposure voltage -> Adjust (Refer to 4-3) or replace PCB. (power supply PCB,

main PCB)

Inspect developing bias circuit -> Repair, or replace high voltage PCB or wire

harness, etc.

Inspect the control mechanism (Refer to 4-1) -> Adjust or replace defective part.

Inspect high voltage circuit -> Repair or replace defective part.

Is the main erase lamp lit?

OPC drum defect -> Replace.

Inspect the lamp, connector and drive power -> Repair or replace defective part.

9-7

Page 9

Chapter 9 Troubleshooting

9-1-8. Partial skipping of transfer

Paper feeding direction

START

Has the paper absorbed moisture?

NO

Is the developer brush

poor?

NO

Is the developer brush position

correct?

YES

Is the toner density correct?

YES

YES

NO

NO

Replace the paper.

Insufficient developer material -> Replace.

Foreign matter in developer material -> Remove or replace.

Developer unit defect -> Repair or replace.

Adjust the developer brush height.

Inspect the toner density control and mechanism -> Re-adjust

or replace defective part.

YES

Inspect charging process -> Repair or replace defective part

OPC drum defect -> Replace.

9-8

Page 10

9-1-9. Copy is black

Chapter 9 Troubleshooting

START

Is the exposure lamp lit?

NO

Is the voltage applied on the

exposure lamp?

NO

Temperature fuse blown -> Replace.

AVR circuit defect -> Replace PCB.

Control signal defect -> Main PCB defect.

Wire harness, CN defect -> Repair or replace.

YES

YES

Mirror or lens installation defect or deviation -> Repair.

Lamp wire breakage -> Replace.

9-9

Page 11

Chapter 9 Troubleshooting

9-1-10. No image

START

Is the document set?

Is the charge corona unit set?

Are the OPC drum and developer’s

MG roller rotating?

Is the developer brush correct and

contacting the OPC drum?

Set the document.

Accurately set.

Inspect the drive mechanism-> Repair or replace

defective parts.

Inspect -> Repair or replace defective parts.

High voltage is not applied on charge corona unit or transfer roller -> Replace

defective parts. (PCB, wire harness, etc.)

9-10

Page 12

9-1-11. Distorted image

Paper feeding direction

Chapter 9 Troubleshooting

START

Is the distortion caused by the

beam axis deviation?

Paper is

oblique.

Is image distorted during

manual feed copying?

Is image distorted

during image transfer?

Is image distorted after paper

trailing end separates from resist

roller?

Reference: To check whether the paper is oblique, make a dark reduced copy of the section where

there is white base, and check the side erase section’s linearity.

Beam axis deviation -> Adjust the mirror height and parallelism.

(Refer to 4-6)

Inspect the cassette mounting state, corner claw, paper feed roller, and

pressure balance, etc. -> Repair or replace defective parts.

Resist roller or intermediate roller oblique (inspect thrust play,

pressurizing balance) -> Repair or replace defective parts.

Fusing roller oblique (inspect fusing unit installation position,

pressurized spring balance, etc.) -> Repair or replace defective

parts.

Others: Catching of paper in conveyance path (inspect paper guide, etc.) ->

Repair or replace defective parts.

9-11

Page 13

Chapter 9 Troubleshooting

9-1-12. White band

Paper feeding direction

START

Does the white band occur

in the paper feeding

direction?

NO

(Crosswise direction)

Does the developer’s MG roller

rotation stop sometimes?

NO

Is charge corona unit or

transfer roller contact

defective?

NO

Is there a contact defect sometimes

in the developer’s bias circuit?

NO

OPC drum defect -> Replace.

(Paper feeding direction)

YES

YES

Inspect drive mechanism ->

Repair or replace defective parts.

YES

Inspect high voltage circuit ->

Repair or replace defective parts.

YES

Is any foreign matter adhered

on charge corona unit?

NO

Is part of the side

erase lamp lit?

NO

I

s the developer brush

even?

NO

YES

YES

YES

Clean or replace.

Inspect lighting control circuit

-> Replace defective parts.

Remove the foreign matter or

replace developer material.

9-12

Page 14

9-1-13. Black band

START

Chapter 9 Troubleshooting

Paper feeding direction

Does the black band occur

in the paper feeding?

NO

(Crosswise direction)

Is there a cleaning defect?

NO

Is the developer’s bias

contact defective?

NO

Is the platen glass dirty?

(Black band always

occurs at same place)

NO

(Paper feeding direction)

YES

YES

YES

Replace the cleaning blade.

Inspect bias circuit (170±10V)-> Repair or

replace defective parts.

YES

NO

Clean.

Is there filming on the OPC

drum?

Is the lens or mirror dirty?

NO

Is the charge corona unit’s

grid mesh dirty?

NO

Is the exposure lamp or

main erase lamp partially

dirty?

NO

Is the cleaning blade’s edge

partially defective?

YES

YES

YES

YES

Clean.

Clean.

Clean.

Replace.

OPC drum grounding contact defect ->

Repair OPC drum defect -> Replace.

YES

Clean with alcohol (IPA), and dry.

9-13

NO

Is the heat roller

surface scratched?

NO

YES

Clean.

Page 15

Chapter 9 Troubleshooting

9-1-14. Density balance deviation

Paper feeding direction

START

Does the density balance

deviation occur in the paper

feeding direction?

(Crosswise direction)

NO

Is the balance deviated

even with a black matte

copy?

YES

Is the gap between the

charging grid mesh and OPC

drum even?

YES

Is the developer brush even?

YES

(Paper feeding direction)

YES

NO

NO

NO

Inspect the grid mesh fixing state ->

Repair or replace.

Adjust the doctor blade.(0.6±0.05mm)

A

Is the lens, mirror, reflector or

exposure lamp dirty?

NO

Light distribution adjustment defect -> Adjust the No. 1 scanner light

distribution adjustment plate. (Refer to 4-6)

YES

Clean.

Is the gap between the drum

and MG roller even?

YES

Other causes:

OPC drum defect -> Replace.

Paper moisture absorption -> Replace.

Developer defect -> Replace.

NO

Repair or replace defective parts.

A

9-14

Page 16

9-1-15. Leading position deviation

Paper feeding direction

START

Chapter 9 Troubleshooting

Is the position always deviated

by the same amount?

Is the regist clutch operation

defective?

The amount of paper fed into the regist roller is unstable, so inspect

the paper feed and conveyance roller operation state -> Repair or

replace defective parts.

Re-adjust with the leading edge position adjustment . (Refer to

4-4)

Repair or replace the regist clutch.

9-15

Page 17

Chapter 9 Troubleshooting

9-1-16. Contamination

Paper feeding direction

START

Is the image periphery smeared and

dirty?

NO

Does the contamination seem

as though toner has spilled?

NO

1

Other cause

(Platen contamination, use of differing brands of

developer material, etc.)

Is back side of paper dirty?

NO

YES

YES

YES

Paper slipping during transfer -> Inspect the transfer process

Fusing defect -> Inspect the fusing temperature, pressure and heat

roller surface, etc.

Spilling of toner from developer -> Inspect developer rotation state,

and clean.

1

The pressure (rubber) roller is dirty -> Clean.

More than 50 copy papers on the paper exit

tray -> Eliminate the copy papers

MODEL

1312

MANUAL

SERVICE HANDBOOK

REVISED EDITION

9-16

1

DATA

May.1999

PAGE

9-16

METHOD

REPLACEMENT

Page 18

9-1-17. Jittering

Chapter 9 Troubleshooting

Paper feeding direction

START

Does the jittering occur with the

image (before transfer) on the OPC

drum?

YES

Is the OPC drum rotation smooth?

YES

Inspect the scanner drive mechanism.

NO

NO

Inspect the paper feed conveyance mechanism.

Inspect the main drive, developing drive and drum drive

mechanism.

9-17

Page 19

Chapter 9 Troubleshooting

9-1-18. White dots on black matte section

START

Has the paper absorbed

moisture?

NO

Is the paper curled or wrinkled?

NO

Is there dew condensation or

filming on the OPC drum

surface?

NO

Is the transfer roller dirty?

Has the transfer voltage dropped?

YES

YES

YES

YES

Replace the paper, and confirm.

Replace the paper, and confirm.

Wipe off the filming with alcohol (IPA), completely dry the OPC

drum surface, and then reconfirm.

Inspect the transfer roller and application voltage -> Clean or replace

defective parts.

NO

OPC drum defect -> Replace.

9-18

Page 20

9-1-19. Extremely light copy

START

Chapter 9 Troubleshooting

Does almost none of the

image on the OPC drum

appear?

YES

Is the exposure lamp voltage

abnormally high?

NO

Is the developer’s MG roller

rotating?

YES

Other causes

Use of differing brands of developer

material, etc.

NO

YES

NO

Inspect the transfer roller -> Repair or replace defective parts

Inspect the AVR circuit -> Repair or replace defective parts.

NO

Inspect the drive mechanism -> Repair or replace defective parts.

9-19

Page 21

Chapter 9 Troubleshooting

9-2. Operation defects

9-2-1. Power does not turn ON

Symptom

* The power is not supplied to the power supply

PCB.

The power is supplied to the power supply PCB.

* Power (+5V) is supplied to the main PCB.

* The fusing heater is correct controlled, but

nothing displays.

9-2-2. Copying operation is not possible

Symptom

* Key operations are not accepted

Estimated cause

* Power plug contact defect, or

wire breakage

* The main breaker of the

power socket is shut off.

* Fuse is blown

* The power PCB is defective

* Main PCB defect

* Operation PCB connector

contact defect, or operation

PCB defect

Estimated cause

* The operation key is pressed

down

* The connector connection is

incomplete

* The operation PCB is defective

Remedy

* Repair or replace

* Turn the breaker ON.

* Replace

* Replace

* Replace

* Repair the connector, or

replace the defective parts

Remedy

* Repair or replace the ornament

* Securely connect

* Replace

* P** error displays

* F** error displays

* J** error displays

9-2-3. Paper feed or conveyance defect

Symptom

* Paper is not fed (Incorrect feeding)

* Several sheets are feed at once (overlapping

supply)

* The paper is fed at an inclination

* Consumable unit is not

mounted or not set

* Service call error

Paper jam detection

Estimated cause

* Paper feed roller surface

contamination

* Use of non-designated paper

* Use of curled paper

* Use of paper that has absorbed moisture

* The paper was replenished

without separation

* The cassette's spring pressure is too high

* The cassette fixing position is

deviated

* The paper feed roller's

conveyance force is unbalanced

* Refer to 8-1

* Refer to 8-1

* Refer to 8-1,8-3-4

Remedy

* Clean or replace

* Replace with designated paper

* Replace

* Replace

* Loosen the paper well

* Inspect the spring -> Repair

or replace

* Adjust (Refer to 4-4)

* Repair or replace defective

parts

* Corners are folded after feda

* Corner claw catching force is

high

9-20

* Repair or replace

Page 22

Chapter 9 Troubleshooting

Symptom

* The paper is fed, but it does not reach the resist

roller

* The paper reaches the resist roller, but jams

* The paper jams or is oblique up to the fusing

process

* Paper jams at heat roller

Estimated cause

* The intermediate roller feed is

defective

* JAM1 sensor detection defect

* The paper feed or intermediate roller does not stop

*Use of curled paper

* Catching on paper guide

* Resist roller pressure

unbalance (Spring dislocation,

etc.)

* The separation claw does not

contact the roller (Spring

dislocation, etc.)

* Roller surface contamination

* The fuser roller is not rotating

(metal burning, etc.)

Remedy

*

Inspect the drive mechanism ->

Repair or replace defective parts

* Inspect the sensor operation

(Refer to 8-3-4) -> Repair or

replace

*

Inspect the clutch operation ->

Repair or replace defective parts

* Replace

* Inspect -> Repair or replace

defective parts

* Adjust, install spring again

* Inspect, install spring again

* Clean or replace

* Oil or replace defective parts

* The paper is fed slightly from the fusing roller,

and jams on the tray side, or JAM is displayed

when paper has been completely exited to the

tray.

* The paper exited to the tray is wrinkled or curled

9-2-4. Abnormal noise

Symptom

* A high pitch metallic noise is generated periodically

* JAM2 sensor detection defect

* Mounting of very curled paper,

moist paper, non-designated

paper, etc., in cassette

* Fusing pressure unbalance

Estimated cause

* Metal burning noise

* OPC drum resonance

* Recycle screw drive noise

* Inspect sensor operation

(Refer to 8-3-4) -> Repair or

replace

* Replace paper

* Inspect -> Repair or replace

Remedy

* Inspect corresponding place

-> Oil or replace defective part

(Note: Do not apply oil on the

photosensitive surface)

* Clean or replace

* Abnormal noise generated in synchronization

with main motor rotation

* Abnormal noise in OPC drum

drive system

9-21

* Inspect corresponding place > Repair

(Note: Do not apply oil on the

photosensitive surface)

Page 23

Chapter 9 Troubleshooting

Symptom

* Abnormal noise generated in synchronization

with main motor rotation

* Abnormal noise generated in synchronization

with exposure process

* Abnormal noise generated when magnification

ratio is changed

* Lens motor stepping-out noise

Reference: The place where the abnormal noise is coming from can be pinpointed easily by separating the drive system

into drive blocks and confirming the operation. Note that the symptom may not appear unless there is a normal load.

Estimated cause

* Abnormal noise in developing

drive system

* Abnormal noise in fusing

drive system

* Abnormal noise in scanner

drive system

* Abnormal noise in zoom lens

drive system

* Lens motor stepping-out

noise

* Oil or replace defective part

* Oil or replace defective part

* Inspect corresponding place

-> Repair, oil or replace

defective part

* Inspect corresponding place

-> Repair, oil or replace

defective part

Remedy

9-2-5. Special symptoms

Symptom

* Image is out of focus when the magnification ratio changed.

* Paper size error is happen.

Estimated cause

* Lens drive error

* 4-5 mirror drive error

* JAM1 sensor operation

defect

* Inspect drive mechanism ->

Repair, oil or replace defective

parts

* Repair or replace (Refer to 83-4)

Remedy

* Out of focus

* Out of focus partly

9-2-6. Malfunction

Symptom

* Display LEDs flicker.

* Main motor starts moving suddenly

* Power turns OFF when Copy button is pressed

* Mirror or lens positional

deviation

* OPC drum defect (dew

condensation, filming)

Estimated cause

* High voltage leak

* Power supply PCB defect

(unstable voltage)

* Obstructive noise

* Catching of JAM1 sensor

actuator

* Obstructive noise

* Power voltage is too low.

* 24V system electronic part

or PCB is short circuited.

* Inspect -> Repair or replace

defective parts

* Inspect -> Clean with alcohol

(IPA), or replace

Remedy

* Inspect -> Repair or replace

defective parts

* Inspect -> Replace

* Inspect -> Remove cause

* Repair

* Inspect -> Remove cause

* Change supply power

* Inspect -> Repair or replace

defective part

9-22

Page 24

Chapter 9 Troubleshooting

Symptom

* Returns to default state during copying

(Jams when there is still appear inside.)

Note: Obstructive noise includes internal noise and external noise. The internal noise includes noise from the high

voltage circuit system, static electricity noise and power noise. Thus, confirm whether there are any leaks or

grounding defects. The external noise includes nose that enters on the power supply line, and obstructive wave

noise that enters through the air. If there are any devices that are noise sources near the unit, the unit could be

affected.

Estimated cause

* High voltage leak

* Power voltage is too low

* Obstructive noise

Remedy

* Inspect -> Repair or replace

defective part

* Change supply power

* Inspect -> Remove cause

9-23

Loading...

Loading...