Page 1

Chapter 7 Electricity

7-1. Main control circuits ................................... 7-1

7-1-1. Toner density control .............................. 7-1

7-1-2. Fusing temperature control .................... 7-2

7-1-3. JAM detection .......................................... 7-3

7-1-4. Safety circuit ............................................ 7-4

7-2. Timing chart ................................................ 7-5

7-2-1. A4, TWO COPIES, CASSETTE PAPER

FEED (UPPER) .......................................... 7-5

7-2-2. A4, TWO COPIES, CASSETTE PAPER

FEED (LOWER) ......................................... 7-5

7-3. Connector list .............................................. 7-6

7-3-1. Main CB (UNIT MAIN) .............................. 7-6

7-3-2. High voltage unit (UNIT HV) .................... 7-9

7-3-3. Power supply board (UNIT PSU) .......... 7-12

7-4. IC list .......................................................... 7-13

7-5. Test points and VR list ............................. 7-14

7-6. Electrical parts layout drawing ................ 7-14

7-6-1. PCB, lamp (heater), fuse (rating) .......... 7-14

7-6-2. Clutches (solenoid) and motors ........... 7-15

7-6-3. Sensors and switches ........................... 7-15

Page 2

Chapter 7 Electricity

7-1. Main control circuits

7-1-1. Toner density control

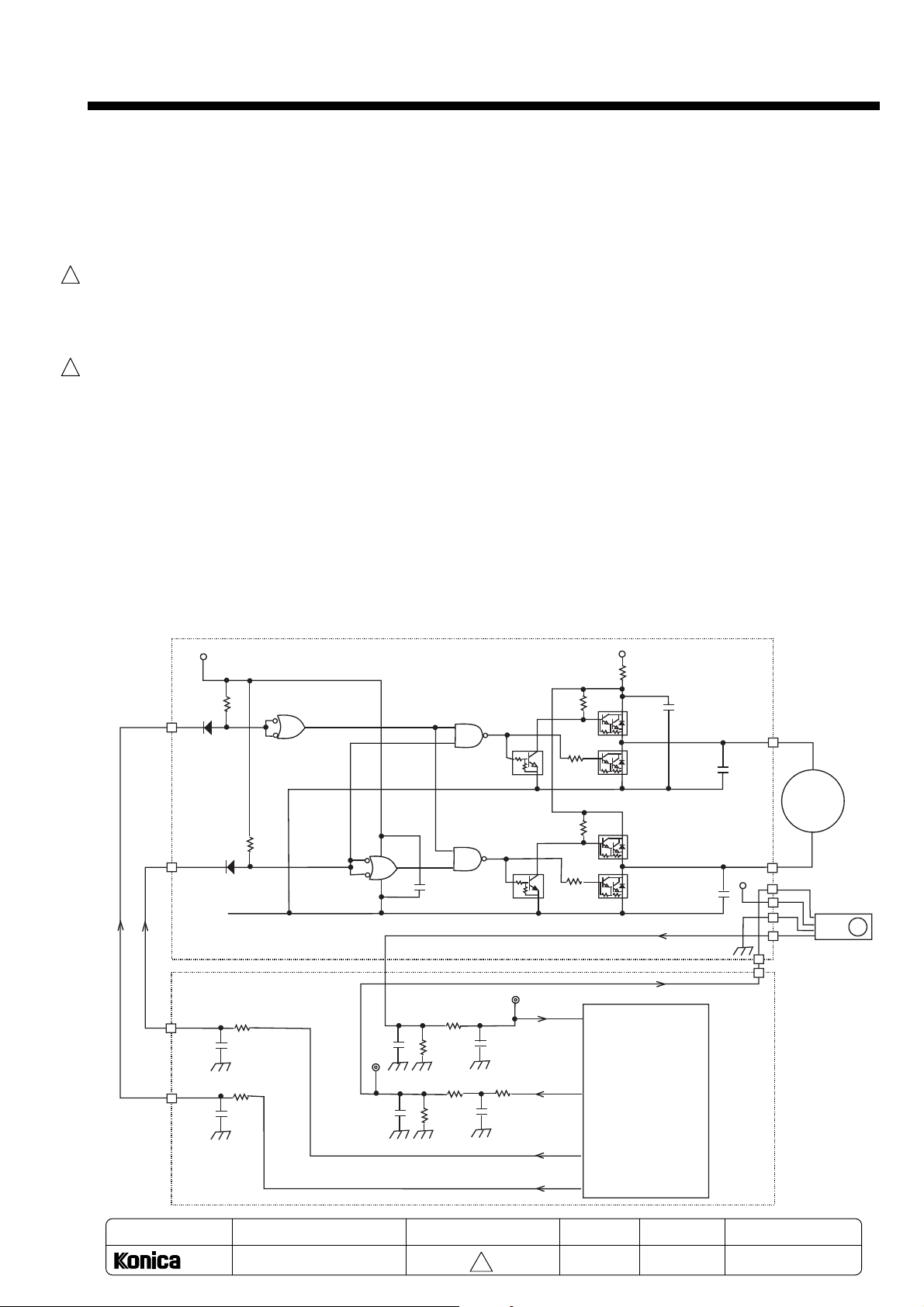

1. Toner density detection

The TNS signal detected by the toner sensor is relayed by the high voltage unit (UNIT HV) and connected to

CN191-20 on the main CB (UNIT MAIN). After the TNS signal is changed to a partial voltage (TNS! signal) by the

registance in the main CB, it is input into the IC121 (CPU) pin No. 77. The TNS! signal can be measured with the

test point (TP103).

2. Toner motor drive control

1

As the toner is consumed and the toner density becomes lighter than the optimum density, the TSM signal is

output (HIGH -> LOW) from the IC121 No. 23 pin. The drive circuit in the high voltage PCB (UNIT HV) is activated to rotate the toner motor (pulse motor) and supply the toner.

Supply time: 3.5 sec.

1

3. Forced toner supply mode

If the toner sensor detects a light density 1% less than the optimum density three times in succession, this unit

will stop the copy operation, and forcibly supply toner. During this mode’s operation, P25 will display (forcibly

supplying toner).time: Max. 250 sec.

When the toner density is recovered (6.5%), the stopped copy job will automatically resume. However, if the

density is not recovered, P25 will blink (toner empty), and after 30 copies, the copy operation will stop.

4. Initialization of developing unit

When the unit’s power is turned on in the unused state (when installed), P26 will light (developer not initialized),

and the standby state will not be entered. This is so that the compensation voltage TNSC signal (analog voltage)

applied on the toner sensor can be calculated beforehand so that the TNS signal will become the reference

voltage in the new developer (unused) state. When the initialization operation (user mode C-51) is carried out,

the detected compensation data will be saved in the main PCB’s EEPROM (IC123). (Note: The developing unit

must be initialized also when it has been replaced.)

Initialization time: 6 min. (3 min. agitation + 3 min. reading & compensation data registration)

+5V

UNIT HV

+24V

CN1261-5

CN191-18

CN191-17

/TSM

TSMCLK

GND24

TSMCLK

/TSM

UNIT MAIN

CI1251B

CI1251A

TP104

CI1251C

CI1251D

Q1255

Q1256

TP103

TNS!

TNSC!

TSMCLK

TSM

77

45

23

+24V

CN1251

1

Toner supply

motor

2

3

4

5

6

CN1261-4

CN191-19

Toner sensor

Q1251

Q1252

Q1253

Q1254

IC121

5

TNM0

TNM1

TNS

TNSC

MODEL

1312

MANUAL

SERVICE HANDBOOK

REVISED EDITION

7-1

1

DATA

May.1999

PAGE

7-1

METHOD

REPLACEMENT

Page 3

Chapter 7 Electricity

7-1-2 Fusing temperature control

The surface temperature of the heat roller is detected with a thermistor, and is kept to a constant optimum temperature (188ºC) by turning the fusing heater ON and OFF with the SSR circuit on the power supply PCB (UNIT

PSU).

1. Temperature detection

1

The temperature detection thermistor is contacted against the surface of the heat roller. The resistance value

changes according to the temperature.

Low temperature (20ºC) : 95KΩ~145KΩ

Optimum temperature (188ºC) : 0.9KΩ~1.0KΩ

The FUTHM signal detected by the thermistor is relayed by the power supply PCB (UNIT PSU), and connected to

CN151-B12 in the main PCB (UNIT MAIN). The signal is changed to a partial pressure (TEMP signal) by the

registance in the main PCB. The TEMP signal is changed into a further partial voltage(FU TEMP signal) by the

registance, and input into the IC121 (CPU) pin No. 76. The TEMP signal is approx. 4.14V at the optimum temperature (standard 188ºC), and can be measured with the test point (TP102).

2. Error detection

The TEMP signal is used also to monitor for thermistor errors. If an overheat (FUOVH) or thermistor open

(FUTHOPN) is detected, the heater power is cut off by the safety circuit. If a fault (hardware circuit fault or software hang up) that causes the fusing heater to remain lit occurs, the thermostat connected in series to the fusing

heater operates and cuts off the heater power.

(F34: High temperature error, F35: Low temperature error, F36: Thermistor error -> Must be released with service

mode 25-47)

3. SSR circuit

If the fusing temperature drops below the optimum temperature (188ºC), the SSR signal (LOW-> HIGH) is output

from the IC121 (CPU) pin No. 32, and reversed (HIGH->LOW) by the IC124. Then, the SSR circuit in the power

supply PCB (UNIT PSU) is driven to light the fusing heater.

MODEL

1312

MANUAL

SERVICE HANDBOOK

REVISED EDITION

7-2

1

DATA

May.1999

PAGE

7-2

METHOD

REPLACEMENT

Page 4

Chapter 7 Electricity

7-1-3. JAM detection

Paper jams are detected with the JAM1 sensor (photo coupler) installed at the paper feed section and the JAM2

sensor (switch) installed at the paper exit section. The JAM1 sensor is set before the slip roller, and also acts as

the manual feed detection sensor.

1. JAM1 sensor

The JAM1 signal (HIGH->LOW when there is paper) output from the JAM1 sensor is relayed by the power supply

PCB (UNIT PSU), and is connected to the main PCB (UNIT MAIN) CN151-B1. It is then input into the IC121

(CPU) pin No. 63.

2. JAM2 sensor

The JAM2 signal (HIGH->LOW when there is paper) output from the JAM2 sensor is relayed by the power supply

PCB (UNIT PSU), and is connected to the main PCB (UNIT MAIN) CN151-B13. It is then input into the IC121

(CPU) pin No. 64.

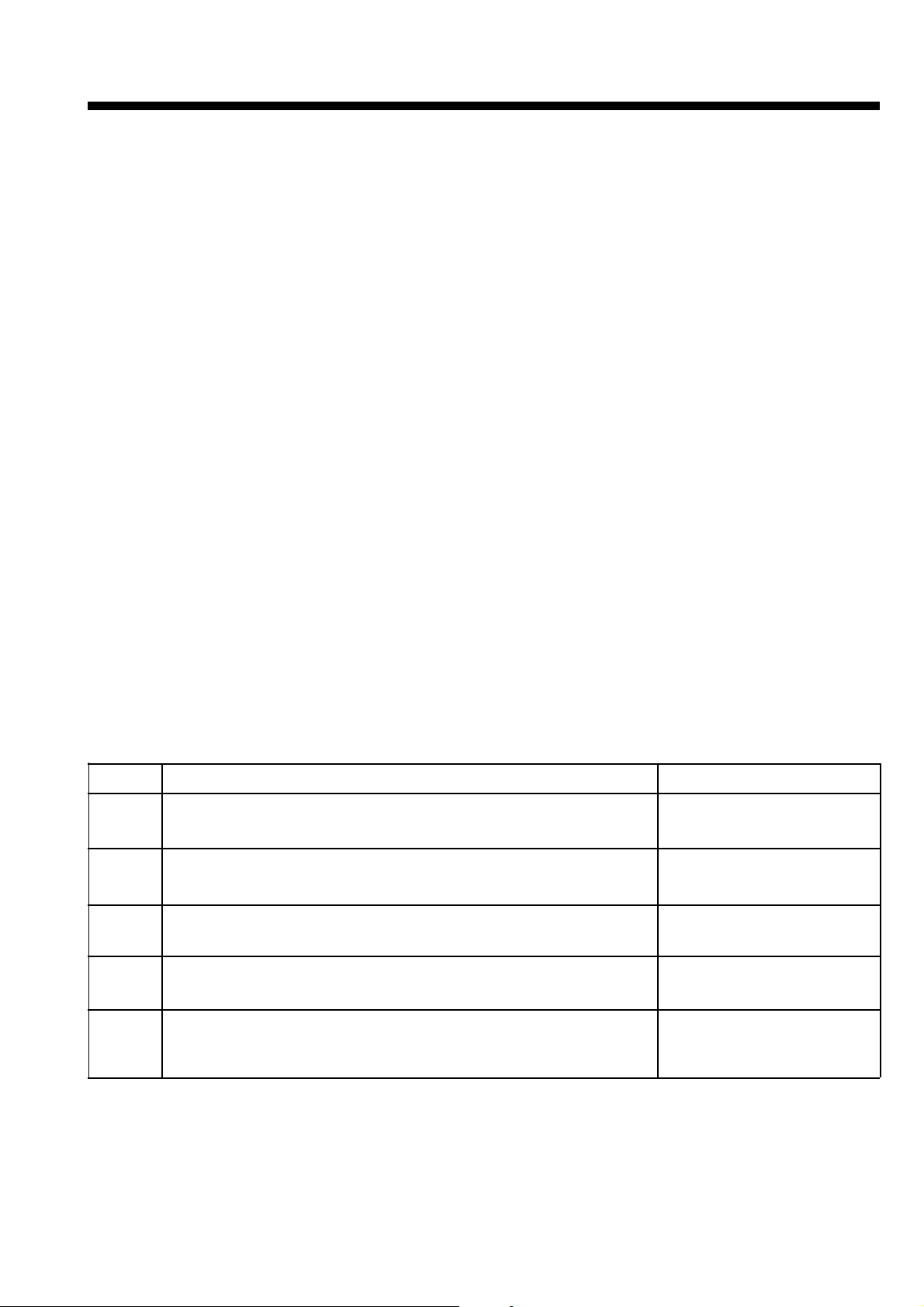

3. JAM detection conditions

Display code

J11

J12

J16

J31

J32

JAM releasing method: Remove the jammed paper, and then open and close the upper cover.

* After the jam releasing procedure was carried out, J16 may occur again when the paper which was at the paper

feed path was fed. In this case, release the jam again.

* Paper was incorrectly fed from unit standard cassette (upper cassette).

* Paper did not reach the JAM1 sensor within 1.3 sec. after the upper

cassette paper feed solenoid turned ON.

* Paper was incorrectly fed from option cassette feeder (lower cassette).

* Paper did not reach the JAM1 sensor within 3.21 sec. after the lower

cassette paper feed solenoid turned ON.

* There was paper on the JAM1 sensor when the power was turned

ON or the upper cover closed.

* The JAM2 sensor did not turn ON within 2.85 to 3.54 sec. after the

regist clutch turned ON.

* The JAM2 sensor did not turn OFF within 2.85 to 3.54 sec. after the

JAM1 sensor turned OFF.

* There was paper on the JAM2 sensor while waiting.

Detection conditions

Unit operation

* Operation stops after the

previous paper is exited.

* Operation stops after the

previous paper is exited.

* Instantaneous stop

* Fusing heater turns OFF.

* Instantaneous stop

* Fusing heater turns OFF.

* Instantaneous stop

* Fusing heater turns OFF.

7-3

Page 5

Chapter 7 Electricity

7-1-4. Safety circuit

With this unit, the interlock switch and upper cover open switch are turned OFF when the user opens the upper

cover. The AC power for the fusing lamp and exposure lamp, and the DC power (+24) for the high voltage circuit

shown in the circuit diagram and that for the main motor are cut off. The main relay is cut off in the same manner

when an error signal is detected on the main PCB (UNIT MAIN).

1. Exposure lamp error

The exposure lamp lighting signal (AVRERR: this is not an error signal) is detected and regulated its waveform by

the exposure lamp lighting detection circuit on the power supply PCB. The AVRERR signal is connected to the

main PCB (UNIT MAIN) by the CN1031-B16, and monitors whether the lamp is continuously lit (approx. 15 sec.).

If it is detected that the lamp is continuously lit for 15 sec. or more, the main relay is cut off by the AVRERR signal

(LOW-> HIGH).

2. Fusing heater error

When an error signal (FUTHOPN: thermistor open, FUOVH: fusing overheat) is detected with the fusing temperature control circuit, the AVRERR signal (LOW->HIGH) is generated in the same manner as the exposure lamp

error, and the main relay is cut off.

(F34: High temperature error, F35: Low temperature error, F36: Thermistor error -> Must be released with service

mode 25-47)

7-4

Page 6

7-2. Timing chart

7-2-1. A4, TWO COPIES, CASSETTE PAPER FEED (UPPER)

1

Chapter 7 Electricity

Main motor

Main erase lamp

Mirror feed

Mirror return

Mirror HP sensor

Exposure lamp

Side erase lamp

Developer bias

Charging

Transfer

Transfer polarity

Paper feed solenoid(U)

Regist clutch

JAM1 sensor

JAM2 sensor

Fan high-speed

Fan low-speed

Toner supply motor

Total counter

9190

10220

10000

10400

10420

10390

10290

10610

LastMultiFirst

12850

12850

11490

11400

12850

13350

12850

12850

10890

12730

13350

13350

12850 13350

5260

200

200

6610

1650

1670

300

1810

100

200

200

1400

770

300

1880

970

1880

0123456789101112131415161718192021

5440

5460 6530

6630

6510

5430

6390

6550

5330

5930

7280

5260 5730

5650

6840

5930

5040

4230

5130 10090

7770

6840

7-2-2. A4, TWO COPIES, CASSETTE PAPER FEED (LOWER)

1

5630

6440

6840

6860 7930

6830

6730

6440 6910

7050

6440

7330

7910

6860

8910

8450

Main motor

Main erase lamp

Mirror feed

Mirror return

Mirror HP sensor

Exposure lamp

Side erase lamp

Developer bias

Charging

Transfer

Transfer polarity

CF motor

Paper feed solenoid(L)

Regist clutch

JAM1 sensor

JAM2 sensor

200

3050

3070

300

3210

100

200

200

3720

300 3030 3280 9170

300

770

3280

1400

Fan high-speed

Fan low-speed

Toner supply motor

3280

6530 12670

Total counter

11440

9190

9350

9860 13470

9420 15430

9420

9170

9420

LastMultiFirst

12980

12960 14030

13900

12790

12870

13190

12580

11770

15430

15430

15930

15430

15430

15310

15930

15930

15430 15930

MODEL

1312

0123456789101112131415161718192021

MANUAL

REVISED EDITION

DATA

PAGE

METHOD

7-5

SERVICE HANDBOOK

1

May.1999

7-5

REPLACEMENT

Page 7

Chapter 7 Electricity

7-3. Connector list

7-3-1. Main CB (UNIT MAIN)

CN - No.

CN131

CN131

CN131

CN131

CN131

CN131

CN131

CN131

CN131

CN131

CN131

CN131

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

CN151

Pin

1

2

3

4

5

6

7

8

9

10

11

12

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

Symbol

STBLED

/E2000

VRGND

EXPVR

KEY2

KEY1

VR5V

/LEDLD

LEDCKL

LEDDO

DGND

+5V

/PRC

/PSC

STB5

S24V

GND24

GND24

+24V

DGND

DGND

+5V

+5V

+5V

+5V

/PWR

/EXP

EXPCONT

JAM1

/PE

S24V

S24V

GND24

+24V

+24V

DGND

DGND

+5V

/CSOPNU

FUTHM

JAM2

/MRL

Details

Not used

Not used

Exposure density adjustment VR, analog ground for each key

Exposure density adjustment VR signal

Key switch No. 2 group

Key switch No. 1 group

Exposure density adjustment VR, +5V for each key

LED serial data load signal

LED serial data transfer clock

LED lighting serial data

Digital ground

+5V power supply

Paper regist clutch drive signal

Paper feed solenoid(U) drive signal (Drive at Lo)

Not used

+24V power supply via cover open switch

+24V drive system ground

+24V drive system ground

+24V power supply

Digital ground

Digital ground

+5V power supply

+5V power supply

+5V power supply

+5V power supply

Not used

Exposure lamp lighting signal (Lights at Lo)

Exposure lamp lighting voltage control signal (analog)

JAM1 sensor signal

Upper cassette out of paper signal

+24V power supply via cover open switch

+24V power supply via cover open switch

+24V drive system ground

+24V power supply

+24V power supply

Digital ground

Digital ground

+5V power supply

Not used

Fusing temperature (thermistor) detection signal

JAM2 sensor signal

Main relay ON/OFF signal

IN/OUT

IN

IN

IN

OUT

OUT

OUT

OUT

OUT

OUT

OUT

IN

IN

IN

IN

OUT

Analog signal

Analog signal

Analog signal

Load at LOW

Clock signal

LED lights at HIGH

Drive at LOW

Drive at LOW

Lights at LOW

Analog signal

Paper detected at LOW

HIGH when out of paper

Analog signal

Paper detected at LOW

Relay drive at LOW

Active

Remarks

Measurement not possible

Upper cover open: OFF

Upper cover open: OFF

7-6

Page 8

Chapter 7 Electricity

CN - No.

CN151

CN151

CN152

CN152

CN152

CN152

CN152

CN152

CN152

CN152

CN152

CN152

CN152

CN152

CN152

CN152

CN152

CN161

CN161

CN161

CN161

CN162

CN162

Pin

B15

B16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

1

2

Symbol

/SSR

EXPERR

S24V

GND24

GND24

GND24

+24V

+24V

+24V

SDHFAN

FSLOCK

FOLOCK1

FAN24

MHP

DGND

DRV5V

SDHTHM

/MMLOCK

/MMST

DRV24V

GND24

/TPC

+24V

Details

SSR ON/OFF signal

Exposure lamp lighting monitor signal

IN/OUT

OUT

IN

S24V with ON/OFF control

(+24V except power save mode)

+24V drive system ground

+24V drive system ground

+24V drive system ground

+24V power supply

+24V power supply

+24V power supply

SDH fan ON/OFF signal

SDH fan lock signal

OP fan lock signal

OP fan drive signal

Mirror home position sensor signal

OUT

IN

IN

OUT

IN

Digital ground

+5V with ON/OFF control

SDH temperature detection (thermistor) signal

Main motor speed control lock signal

24/ Main motor drive signal

Power supply (24V) with ON/FF control and safety circuit

OUT

IN

IN

OUT

OUT

+24V drive system ground

Total paper counter drive signal

OUT

+24V power supply

Active

Fusing heater drive at LOW

Remarks

HIGH when exposure lamp is lit

Upper cover open: OFF

Drive at HIGH

HIGH when locked

(8P, 9P, 15P:

factory option)

HIGH when locked

OP fan drive at +24V

HIGH at set position

+5V when not in power save mode

Analog signal

LOW when locked

Drive at LOW

0V during power save

Upper cover open: OFF

Count up at LOW

CN171

CN171

CN171

CN171

CN171

CN171

CN171

CN171

CN171

CN171

CN171

CN171

CN171

CN171

CN191

CN191

CN191

CN191

CN191

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

2

3

4

5

/CSOPNL

DGND

+5V

/LPE

DGND

DGND

+5V

PTM

/LMST

GND24

+24V

+24V

/LPSC

NC

/DRUM

/TSE

/GRID

/HVCC

/HVTP

Lower cassette not mounted signal

Digital ground

+5V power supply

Lower cassette out of paper signal

Digital ground

Digital ground

+5V power supply

Cassette feeder paper feed motor clock

Cassette feeder paper feed motor ON/OFF signal

OUT

OUT

+24V drive system ground

+24V power supply

+24V power supply

Paper feed solenoid (L)

OUT

Not connected

Drum unit not mounted detection signal

IN

Not used

GRID terminal ON/OFF signal

CC terminal ON/OFF signal

TC polarity changeover signal

OUT

OUT

OUT

HIGH when no cassette is mounted

HIGH when out of paper

Clock signal

Measurement not possible

Drive at HIGH

Drive at LOW

HIGH when on mounted

GRID output at LOW

CC output at LOW

TC + polarity at LOW

7-7

Page 9

Chapter 7 Electricity

CN - No.

CN191

CN191

CN191

CN191

CN191

CN191

CN191

CN191

CN191

CN191

CN191

CN191

CN191

CN191

CN191

CN191

CN191

Pin

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Symbol

/HVTC

/LMB

/LMA

LMB

LMA

/SMB

/SMA

SMB

SMA

LHP

TRAYS

/TSM

TSMCLK

TNSC

TNS

DGND

AE

Details

TC terminal ON/OFF signal

Lens motor drive excitation signal (/B phase)

Lens motor drive excitation signal (/A phase)

Lens motor drive excitation signal (/B phase)

Lens motor drive excitation signal (/A phase)

Mirror motor drive excitation signal (/B phase)

Mirror motor drive excitation signal (/A phase)

Mirror motor drive excitation signal (/B phase)

Mirror motor drive excitation signal (/A phase)

Lens home position sensor signal

IN/OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

IN

Not used

Toner motor drive signal

Toner motor drive clock

Signal for toner sensor output adjustment

Toner sensor output signal

OUT

OUT

OUT

IN

Digital ground

Not used

Active

TC output at LOW

Clock signal

Clock signal

Clock signal

Clock signal

Clock signal

Clock signal

Clock signal

Clock signal

HIGH at set position

ON at LOW

60Hz pulse

Analog signal

Analog signal

Remarks

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

Voltage rises at

low density

CN192

CN192

CN192

CN192

CN192

CN192

CN192

CN192

CN192

CN192

CN192

CN192

CN192

CN192

CN192

CN192

CN192

CN192

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

CCL

/SER6

/SER5

/SER4

/SER3

/SER2

/SER1

/SER0

/AMB

/AMA

AMB

AMA

MRM

SDHPC

SDHOPN

/CS3

/CS2

/CS1

Main erase lamp drive signal

Side erase lamp drive signal(D56,D66)

Side erase lamp drive signal(D55,D65)

Side erase lamp drive signal(D54,D64)

Side erase lamp drive signal(D53,D63)

Side erase lamp drive signal(D52,D62)

Side erase lamp drive signal(D51,D61)

Side erase lamp drive signal

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

(D71 to D78,D81 to D88)

SDH motor drive excitation signal (/B phase)

SDH motor drive excitation signal (/A phase)

SDH motor drive excitation signal (/B phase)

SDH motor drive excitation signal (/A phase)

Mirror motor, SDH motor exciting current changeover signal

SDH paper feed clutch drive signal

SDH open detection sensor signal

SDH B4 size detection sensor signal

SDH document regist sensor signal

SDH no original detection sensor signal

OUT

OUT

OUT

OUT

OUT

OUT

IN

IN

IN

IN

Drive at +24V

Lights at LOW

Lights at LOW

Lights at LOW

Lights at LOW

Lights at LOW

Lights at LOW

Lights at LOW

(9 to 12P, 14 to 18P

: factory option)

Clock signal

Clock signal

Clock signal

Clock signal

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

Low current at HIGH

Clutch ON at HIGH

HIGH at open

LOW at B4 detection

LOW when original feed

LOW when original is detected

7-8

Page 10

7-3-2. High voltage unit (UNIT HV)

Chapter 7 Electricity

CN - No.

CN1201

CN1201

CN1201

CN1201

CN1201

CN1201

CN1211

CN1211

CN1211

CN1211

CN1211

CN1231

CN1231

CN1231

CN1231

CN1231

CN1231

CN1231

CN1231

CN1231

CN1231

CN1251

CN1251

CN1251

CN1251

CN1251

CN1251

CN1261

CN1261

CN1261

CN1261

CN1261

CN1261

CN1261

CN1261

CN1261

CN1261

CN1261

CN1261

CN1261

CN1261

Pin Symbol Details

1

2

3

4

5

6

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

LMOA

LMOB

/LMOA

/LMOB

LM24V

LM24V

SMOA

SMOB

/SMOA

/SMOB

SM24V

+24V

/SDHPC

+24V

/SDHPC

AMOA

AMOB

/AMOA

/AMOB

AM24V

AM24V

TNM0

TNM1

TNSC

+24V

DGND

TNS

AE

DGND

TNS

TNSC

TSMCLK

/TSM

TRAYS

LHP

SMA

SMB

/SMA

/SMB

LMA

LMB

Lens motor drive excitation signal (/A phase)Output

Lens motor drive excitation signal (/B phase)Output

Lens motor drive excitation signal (/A phase)Output

Lens motor drive excitation signal (/B phase)Output

Lens motor power supply

Lens motor power supply

Mirror motor drive excitation signal (/A phase)Output

Mirror motor drive excitation signal (/B phase)Output

Mirror motor drive excitation signal (/A phase)Output

Mirror motor drive excitation signal (/B phase)Output

Scanner motor power supply

+24V power supply

SDH shutter solenoid output

+24V power supply

SDH paper feed clutch output

SDH motor drive excitation signal (/A phase)Output

SDH motor drive excitation signal (/B phase)Output

SDH motor drive excitation signal (/A phase)Output

SDH motor drive excitation signal (/B phase)Output

SDH motor power supply

SDH motor power supply

Toner motor drive power supply output

Toner motor drive power supply output

Signal for toner sensor output adjustment

+24V power supply

Digital ground

Toner sensor output signal

Not used

Not used

Toner sensor output signal

Signal for toner sensor output adjustment

Toner motor drive clock

Toner motor drive signal

Not used

Lens home position sensor signal

Mirror motor drive excitation signal (/A phase)

Mirror motor drive excitation signal (/B phase)

Mirror motor drive excitation signal (/A phase)

Mirror motor drive excitation signal (/B phase)

Lens motor drive excitation signal (/A phase)

Lens motor drive excitation signal (/B phase)

IN/OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

IN

IN

OUT

OUT

OUT

IN

OUT

OUT

OUT

OUT

OUT

OUT

Active Remarks

Clock signal

Clock signal

Clock signal

Clock signal

Clock signal

Clock signal

Clock signal

Clock signal

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

(factory option)

ON at LOW

ON at LOW

Clock signal

Clock signal

Clock signal

Clock signal

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

60Hz pulse

60Hz pulse

Analog signal

Analog signal

Voltage rises at

low density

Analog signal

Voltage rises at

low density

Analog signal

60Hz pulse

Measurement not possible

ON at LOW

HIGH at set position

Clock signal

Clock signal

Clock signal

Clock signal

Clock signal

Clock signal

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

Measurement not possible

7-9

Page 11

Chapter 7 Electricity

CN - No.

CN1261

CN1261

CN1261

CN1261

CN1261

CN1261

CN1261

CN1261

CN1262

CN1262

CN1262

CN1262

CN1262

CN1262

CN1262

CN1262

CN1262

CN1262

CN1262

CN1262

CN1262

CN1262

CN1262

CN1262

CN1262

CN1262

CN1263

CN1263

CN1263

CN1263

CN1263

CN1263

CN1263

CN1263

CN1263

CN1263

CN1263

CN1263

CN1263

CN1263

CN1263

Pin Symbol

/LMA

15

/LMB

16

/HVTC

17

/HVTP

18

/HVCC

19

/GRID

20

/TSE

21

/DRUM

22

/CS1

1

/CS2

2

/CS3

3

SDHOPN

4

SDHPC

5

MRM

6

AMA

7

AMB

8

/AMA

9

/AMB

10

/SER0

11

/SER1

12

/SER2

13

/SER3

14

/SER4

15

/SER5

16

/SER6

17

CCL

18

SDHTHM

1

DRV5V

2

DGND

3

MHP

4

FAN24

5

FOLOCK1

6

FSLOCK

7

SDHFAN

8

+24V

9

+24V

10

+24V

11

GND24

12

GND24

13

GND24

14

S24V

15

Details

Lens motor drive excitation signal (/A phase)

Lens motor drive excitation signal (/B phase)

TC terminal ON/OF signal

TC polarity changeover signal

CC terminal ON/OF signal

GRID terminal ON/OF signal

IN/OUT

OUT

OUT

OUT

OUT

OUT

OUT

Not used

Drum unit not mounted detection signal

SDH no original detection sensor signal

SDH document regist sensor signal

SDH B4 size detection sensor signal

SDH open detection sensor signal

SDH paper feed clutch drive signal

Mirror motor, SDH motor exciting current changeover signal

SDH motor drive excitation signal (/A phase)

SDH motor drive excitation signal (/B phase)

SDH motor drive excitation signal (/A phase)

SDH motor drive excitation signal (/B phase)

Side erase lamp drive signal

IN

IN

IN

IN

IN

OUT

OUT

OUT

OUT

OUT

OUT

OUT

(D71 to D78,D81 to D88)

Side erase lamp drive signal(D56,D66)

Side erase lamp drive signal(D55,D65)

Side erase lamp drive signal(D54,D64)

Side erase lamp drive signal(D53,D63)

Side erase lamp drive signal(D52,D62)

Side erase lamp drive signal(D51,D61)

Main erase lamp drive signal

SDH temperature detection (thermistor) signal

+5V with ON/OFF control

OUT

OUT

OUT

OUT

OUT

OUT

OUT

IN

OUT

Digital ground

Mirror home position sensor signal

IN

OP fan drive signal

OP fan lock signal

SDH fan lock signal

SDH fan ON/OFF signal

IN

IN

OUT

+24V power supply

+24V power supply

+24V power supply

+24V drive system ground

+24V drive system ground

+24V drive system ground

+24V power supply via cover open switch

Active

Clock signal

Clock signal

Measurement not possible

Measurement not possible

TC output at LOW

TC + polarity at LOW

TC output at LOW

TC output at LOW

HIGH when not mounted

LOW when original is

detected

LOW when original feed

(1 to 5P: factory

option)

LOW at B4 detection

HIGH when open

Clutch ON at HIGH

Small current at HIGH

Clock signal

Clock signal

Clock signal

Clock signal

Measurement not possible (pulse wave)

Measurement not possible (pulse wave)

Measurement not possible (pulse wave)

Measurement not possible (pulse wave)

Lights at LOW

Lights at LOW

Lights at LOW

Lights at LOW

Lights at LOW

Lights at LOW

Lights at LOW

Analog signal

+5V when not in

(1 to 5P: factory

option)

power save mode

HIGH at set position

OP fan drive at +24V

HIGH when locked

HIGH when locked

Drive at HIGH

Upper cover open: OFF

Remarks

7-10

Page 12

CN - No.

Symbol Active

Pin

Details

IN/OUT

Chapter 7 Electricity

Remarks

CN1271

CN1271

CN1271

CN1271

CN1272

CN1272

CN1272

CN1273

CN1273

CN1273

CN1274

CN1274

CN1275

CN1275

CN1275

CN1276

CN1276

CN1276

CN1276

CN1276

CN1276

CN1276

CN1276

CN1277

CN1277

CN1277

CN1278

CN1278

CN1281

CN1281

CN1281

CN1281

CN1281

CN1281

CN1281

CN1281

CN1281

CN1282

CN1282

CN1282

1

2

3

4

1

2

3

1

2

3

1

2

1

2

3

1

2

3

4

5

6

7

8

1

2

3

1

2

1

2

3

4

5

6

7

8

9

1

2

3

+5V

LHP

DGND

NC

+5V

MHP

DGND

GND24

FOLOCK1

FAN24

+5V

SDHTHM

+5V

AE

DGND

+24V

SER0

SER1

SER2

SER3

SER4

SER5

SER6

GND24

FSLOCK

SFAN24

+24V

/CCL

/CS1

DGND

+5V

/CS2

DGND

/CS3

DGND

SDHOPN

DGND

GND24

FOLOCK2

FAN24

+5V power supply

Lens home position sensor signal

IN

Digital ground

Not connected

+5V power supply

Mirror home position sensor signal

IN

Digital ground

Ground

OP fan 1 lock signal

OP fan drive signal

IN

OUT

+5V power supply

SDH temperature detection (thermistor) signal

IN

Not used

Not used

Not used

+24V power supply

Side erase lamp drive signal

OUT

(D71~D78,D81~D88)

Side erase lamp drive signal(D51,D61)

Side erase lamp drive signal(D52,D62)

Side erase lamp drive signal(D53,D63)

Side erase lamp drive signal(D54,D64)

Side erase lamp drive signal(D55,D65)

Side erase lamp drive signal(D56,D66)

OUT

OUT

OUT

OUT

OUT

OUT

+24V drive system ground

SDH fan lock signal

IN

SDH fan power supply output

+24V power supply

Main erase lamp drive signal

SDH no original detection sensor signal

OUT

IN

Digital ground

+5V power supply

SDH document regist sensor signal

IN

Digital ground

SDH B4 size detection sensor signal

IN

Digital ground

SDH open detection sensor signal

IN

Digital ground

Ground

OP fan 2 lock signal

IN

OP fan 2 power supply output

HIGH at set position

HIGH at set position

HIGH when locked

OP fan drive at +24V

(Factory option)

Analog signal

Lights at LOW

Lights at LOW

Lights at LOW

Lights at LOW

Lights at LOW

Lights at LOW

Lights at LOW

(Factory option)

HIGH when locked

SDH fan drive at +24V

Lights at LOW

LOW when original is detected

(Factory option)

Detected when LOW

LOW when original feed

LOW at B4 detection

HIGH when open

HIGH when locked

7-11

Page 13

Chapter 7 Electricity

7-3-3. Power supply board (UNIT PSU)

CN - No.

CN1001

CN1001

CN1001

CN1002

CN1002

CN1011

CN1011

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1031

CN1032

CN1032

CN1032

CN1032

Pin

1

2

3

1

2

1

2

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

1

2

1

2

Symbol

AC-L

NC

AC-N

FU-L

FU-N

EXP-L

EXP-N

/PRC

/PSC

STB5

S24V

GND24

GND24

+24V

DGND

DGND

+5V

+5V

+5V

+5V

/PWR

/EXP

EXPCONT

JAM1

/PE

S24V

S24V

GND24

+24V

+24V

DGND

DGND

+5V

/CSOPNU

FUTHM

JAM2

/MRL

/SSR

EXPERR

+24V

/PSC

+24V

/PRC

Details

Power supply input(L)

IN/OUT

IN

AC primary circuit

Not connected

Power supply input(N)

Fusing heater output(L)

Fusing heater output(N)

Exposure lamp output(L)

Exposure lamp output(N)

Paper regist clutch drive signal

Paper feed solenoid(U) drive signal (Drive at Lo)

IN

OUT

OUT

OUT

OUT

OUT

OUT

AC primary circuit

AC primary circuit

AC primary circuit

AC primary circuit

AC primary circuit

Drive at LOW

Drive at LOW

Not used

+24V power supply via cover open switch

+24V drive system ground

+24V drive system ground

+24V power supply

Digital ground

Digital ground

+5V power supply

+5V power supply

+5V power supply

+5V power supply

Not used

Exposure lamp lighting signal (Lights at Lo)

Exposure lamp lighting voltage control signal (analog)

JAM1 sensor signal

OUT

OUT

IN

Lights at LOW

Analog signal

Paper detected at LOW

Not used

+24V power supply via cover open switch

+24V power supply via cover open switch

+24V power supply

+24V power supply

+24V power supply

Digital ground

Digital ground

+5V power supply

Standard cassette not mounted signal

Fusing temperature (thermistor) detection signal

JAM1 sensor signal

Main relay ON/OFF signal

SSR ON/OFF signal

Exposure lamp lighting monitor signal

IN

IN

IN

OUT

OUT

IN

No cassette mounted at HIGH

Analog signal

Paper detected at LOW

Relay drive at LOW

Fusing heater drive at LOW

HIGH when exposure lamp is lit

+24V power supply

Paper feed solenoid(U) drive signal

OUT

Drive at LOW

+24V power supply

Regist clutch drive signal

OUT

Drive at LOW

Active

Remarks

Upper cover open: OFF

Upper cover open: OFF

7-12

Page 14

Chapter 7 Electricity

CN - No.

CN1034

CN1034

CN1034

CN1035

CN1035

CN1035

CN1036

CN1036

CN1037

CN1037

CN1038

CN1038

CN1038

Pin Symbol Details

1

2

3

1

2

3

1

2

1

2

1

2

3

LEDJ1

JAM1

DGND

LEDPE

/PE

DGND

+24V

S24V

+5V

FUTHM

NC

JAM2

DGND

7-4. IC list

PCB Location No.

IN/OUT

+5V power supply for JAM1 sensor

JAM1 sensor signal

Digital ground

+5V power supply for PE sensor

Upper cassette out of paper signal

Digital ground

+24V power supply

+24V power supply via cover open switch

+5V power supply

Fusing temperature (thermistor) detection signal

Not connected

JAM2 sensor signal

Digital ground

Part name/type

IN

OUT

IN

IN

IN

Active Remarks

Paper detected at LOW

HIGH when out of paper

Upper cover open: OFF

1Analog signal

Paper detected at LOW

Application

UNIT PSU

UNIT PSU

UNIT PSU

UNIT PSU

UNIT OP

UNIT OP

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT HV

UNIT HV

UNIT HV

UNIT HV

UNIT HV

IC1031

IC1051

IC1071

IC1081

IC751

IC770 IC780

IC121

IC122

IC123

IC124

IC125

IC126

IC141

IC151

IC152

IC181 IC182

IC191

IC192 IC193

IC194

IC195

IC1121

IC1122

IC1171

IC1211

IC1251

LA6358NM-TP-T1

MC33262P

UPC1093T-T1

MC34063AP1

LC7932M-TE-R

LC7933M-TE-R

UPD78054FGC

M51953BFP-600C

S-29130AFJ-TB

TD62503F-TP1

TD62003AF-TP1

TC7W02F-TE12L

LA6393M-TP-T1

HD74HC132FP-TR

TC7W02F-TE12L

HD74HC244FP-TR

HD74HC244FP-TR

HD74HC175FP-T

HD74HC175FP-T

TD62503F-TP1

MC33262P

TA78L012AP

LA6082M-TP-T1

MTD1120F

HD74HC00FP-TR

Operation amplifier (for exposure lamp lighting control (AVR))

Switching power control

Reference voltage IC (switching power section)

DC-DC converter IC (+5V power supply)

Serial-parallel driver (for each LED lighting)

Serial driver (for 7-segment LED lighting)

CPU

Reset IC

EEPROM (for electronic counter, setting, adjustment data storage)

Transistor array (for high voltage, exposure and fusing drive)

Transistor array (clutch, solenoid main relay drive)

NOR gate (for main relay control signal)

Comparator (for fusing temperature error detection)

NAND gate (for exposure lamp lighting error detection)

OR gate (for exposure lamp lighting error detection)

Line buffer (stepping motor exciting output)

Line buffer (optical section sensor input selector)

D-TYPE FF (Side erase lamp, mirror motor control output)

D-TYPE FF (SDH clutch, SDH fan control output)

Transistor array (for side erase lamp drive)

Switching power control IC (charge, bias output)

12V 3-terminal regulator

Operation amplifier (for transfer output control)

Stepping motor set current drive driver (mirror scanner)

NAND gate (toner motor section)

7-13

Page 15

Chapter 7 Electricity

7-5. Test points and VR list

Location

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT MAIN

UNIT PSU

UNIT OP

Test point

TP101

TP102

TP103

TP104

TP105

TP106

TP107

TP108

TP109

VR1031

VR723

Symbol

DGND

TEMP

TNS!

TNSC

EXPCNT

EXRVR

KEY1

KEY2

AE!

-

-

7-6. Electrical parts layout drawing

7-6-1. PCB, lamp (heater), fuse (rating)

High voltage unit

(UNIT HV)

Main CB

(UNIT MAIN)

Power supply board

(UNIT PSU)

Fuse PCB

(UNIT FUSE)

Side erase lamp

Details

Remarks

Digital ground

Fusing temperature detection signal

Toner sensor output voltage

Toner sensor control voltage

Exposure lamp lighting voltage control signal (analog)

Exposure lamp lighting voltage adjustment input (analog)

Key switches No. 1 group (analog)

Key switches No. 2 group (analog)

Not used

For exposure voltage output adjustment

For exposure voltage output adjustment

Temperature fuse 128 C

Main erase lamp

1

Refer to page 7-2.

Refer to page 7-1.

Refer to page 7-1.

For factory use

For factory use

For factory use

For factory use

-

For factory adjustment (cannot be used)

For user operations (operation panel)

(For 120V machine is one fuse at front side)

Exposure lamp

80V 220W (for 120V)

160V 220W (for 220V to 240V)

Operation PCB

(UNIT OP)

Cassette heater

fuse

250V 4A

Main fuse

125V 10A(for 120V)

250V 6.3A

(for 220 to 240V)

Main cassette

dehumidification heater

fuse 250V 1.6A

Power supply board main fuse

125V 3.15A(for 120V)

250V 1.6A(for 220 to 240V)

Cassette feeder (option)

Dehumidification heater

Fuse 250V 1.6A

MODEL

1312

SERVICE HANDBOOK

MANUAL

Cassette feeder motor driver PCB

(UNIT MOTOR DRIVER)

REVISED EDITION

DATA

7-14

1

May.1999

1

Thermostat

150 C(For 120V

machine is one

thermostat at rear

side)

Fusing heater

120V 800W (for 120V)

230V 800W

(for 220 to 240V)

Main cassette

dehumidification heater

Cassette feeder (option)

dehumidification heater

PAGE

7-14

METHOD

REPLACEMENT

Page 16

Chapter 7 Electricity

7-6-2. Clutches (solenoid) and motors

SDH paper feed clutch

Lens drive motor

Mirror scan motor

Main motor

Toner supply motor

Regist clutch

Paper feed

solenoid(U)

Cassette feeder

paper feed motor

Paper feed solenoid(L)

SDH shutter solenoid

SDH paper feed motor

SDH cooling fan

OP cooling fan

7-6-3. Sensors and switches

1

SDH original detection sensor

Mirror home position sensor

Interlock switch

Main switch

JAM1 sensor

SDH original read

detection sensor

SDH thermistor

SDH cover open

detection sensor

Operation keys

Lens home

position sensor

JAM2 sensor

MODEL

PE sensor

1312

MANUAL

SERVICE HANDBOOK

Toner sensor

REVISED EDITION

7-15

1

Recycle switch

DATA

May.1999

Thermistor

PAGE

7-15

METHOD

REPLACEMENT

Loading...

Loading...