Page 1

Chapter 4 Adjustment

4-1. Toner density.........................................................4-1

4-2. Fusing temperature .............................................. 4-1

4-3. Exposure voltage ..................................................4-2

4-4. Image position.......................................................4-2

4-4-1. Center position ..................................................4-2

4-4-2. Leading edge position.......................................4-3

4-4-3. Image skew.........................................................4-3

4-5. Magnification adjustment.....................................4-3

4-5-1. Feeding direction (Vertical magnification) ......4-3

4-5-2. Crosswise direction

(Horizontal magnification) ................................. 4-4

4-6. Optical section adjustment ..................................4-4

4-6-1. Light distribution ...............................................4-4

4-6-2. Scanner reference position .............................. 4-5

4-6-3. Lens reference position ....................................4-5

4-6-4. Diagonal distortion ............................................4-5

4-6-5. Image distortion ................................................. 4-5

4-6-6. Focus ..................................................................4-5

4-6-7. Image center position........................................4-6

4-6-8. Focus (Horizontal blurring)...............................4-6

4-6-9. Horizontal magnification ................................... 4-6

4-7. Leading and trailing edges erase width..............4-6

Page 2

Chapter 4 Adjustment

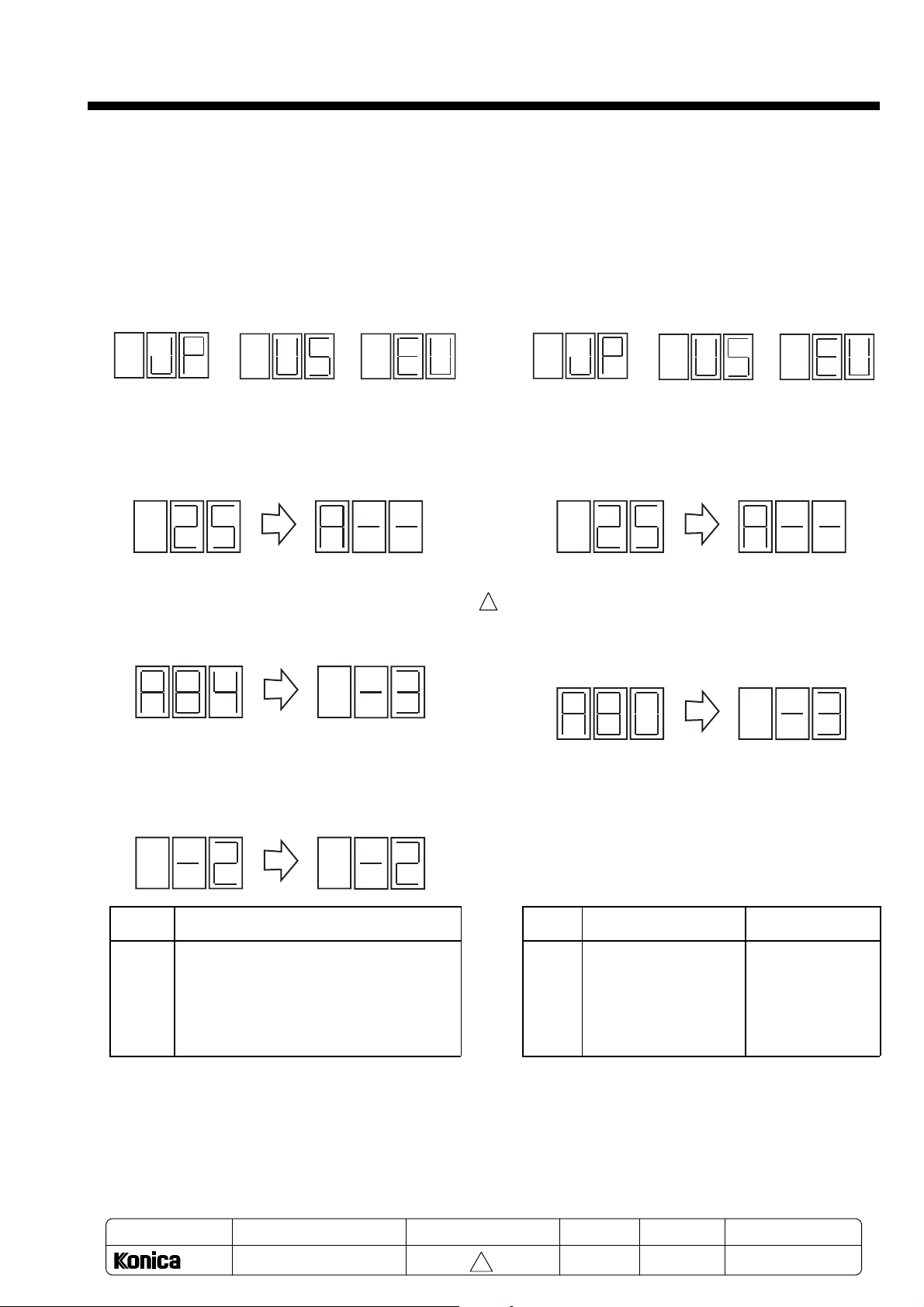

4-1. Toner density

The toner density adjustment procedure is used to

adjust the black matte section density or the toner

consumption amount, etc.

1) Procedure

1. Call out the service mode.

(Press the Enlarge key and Reduce key for 5 sec.

in the Scale 1: 1 mode, and press the 0 key within

2 sec. after the local destination displayed)

Japan

US

2. Select 25 mode.

(Input 25 with the numeric keypad, and then press

the Start Print key.)

Europe

4-2. Fusing temperature

The fusing temperature adjustment is carried out to

improve the fusing performance when copying onto

thick paper, and to uncurl thin paper, etc.

1) Procedure

1. Call out the service mode.

(Press the Enlarge key and Reduce key for 5 sec.

in the Scale 1: 1 mode, and press the 0 key within

2 sec. after the local destination displayed)

Japan

US

2. Select 25 mode.

(Input 25 with the numeric keypad, and then press

the Start Print key.)

Europe

3. Select address 84 (toner density control setting).

(Input 84 with the numeric keypad, and then press

the Start Print key.)

4. Change the setting data to the required data (1 to 5).

(Input the data with the numeric keypad, and then

press the Start Print key.)

Data Toner density

1 Lighter

2

↑

3 Default value

4

↓

5 Darker

3. Select address 80 (Fusing temperature control

1

setting).

(Input 80 with the numeric keypad, and then press

the Start Print key.)

4.

Change the setting data to the required data (1 to 5)

(Input the data with the numeric keypad, and then

Data Fusing temperature Remarks

1 182ºC Lower

2 185ºC

3 188ºC Default value

4 190ºC

5 193ºC Higher

.

↑

↓

5. Press the Clear/Stop key until the normal mode

appears (3 presses).

(When the Clear key is pressed once, the state

will return to the previous state.)

Note: After changing this setting, the changed

toner density will not be achieved immediately.

MODEL

1312

SERVICE HANDBOOK

MANUAL

REVISED EDITION

press the Start Print key.)

5. Press the Clear/Stop key until the normal mode

appears (3 presses).

(When the Clear key is pressed once, the state will

return to the previous state.)

DATA

PAGE

4-1

1

May.1999

4-1

REPLACEMENT

METHOD

Page 3

Chapter 4 Adjustment

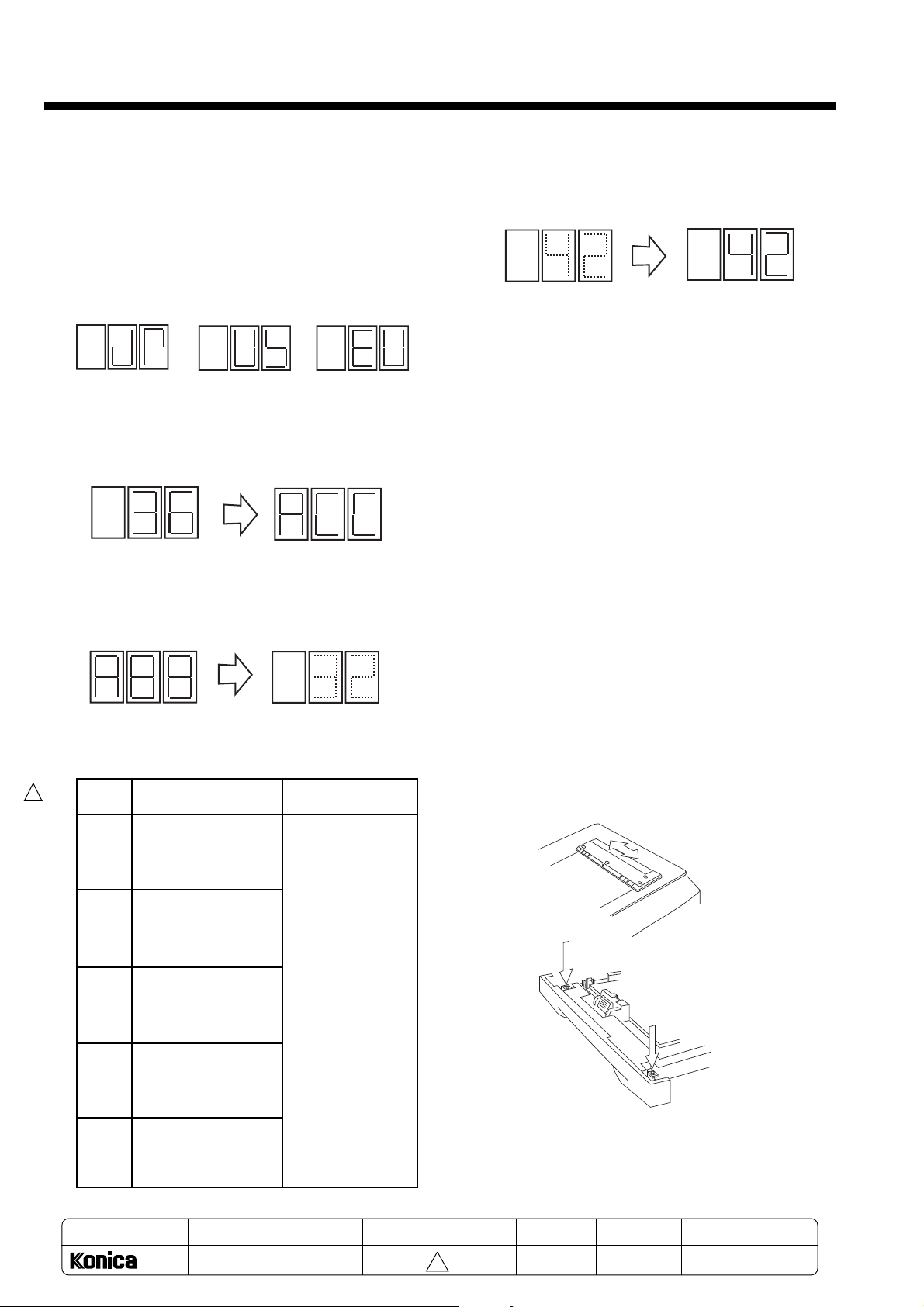

4-3. Exposure voltage

The exposure lamp voltage adjustment is carried out

to change the adjustment width of the density control

knob on the operation panel.

1) Procedure

1. Call out the service mode.

(Press the Enlarge key and Reduce key for 5

sec. in the Scale 1: 1 mode, and press the 0 key

within 2 sec. after the local destination displayed)

Japan

US

2. Select 36 mode.

(Input 36 with the numeric keypad, and then

press the Start Print key.)

3. Select the code to be changed (86 to 90: AVR

adjustment 1 to 5).

(Example: Input 88 with the numeric keypad, and

then press the Start Print key.)

Europe

4. Change the setting data to the required data (01 to

64).

(Input the data with the numeric keypad, and then

press the Start Print key.)

Changed data

(example: 42) blinks

Changed data is

set

5. When the Start Print key is pressed again, a test

copy of the settings after the changes can be

made.

6. After copying, the status will return to step 4. Thus,

if the density is not as required, repeat the procedure from step 4.

7. When completed with the adjustment, press the

Clear/Stop key until the normal mode appears (3

presses).

(When the Clear key is pressed once, the state

will return to the previous state.)

4-4. Image position

4-4-1. Center position

If the position of the copy is mis-centered, adjust the

fixing position (four screws) of the document scale or

the cassette fixing position (two screws).

Adjustment data

(example: 32) blinks

1

Code Adjustment details Adjustment range

86 Center density in

enlargement.

(Adjustment range:

Approx. 43V to 67V)

87 Center density in

reduction.

(Adjustment range:

Approx. 43V to 67V)

88 Max. density in 01 to 64

life size.

(Adjustment range:

Approx. 55V to 80V)

89 Center density in

life size.

(Adjustment range:

Approx. 43V to 67V)

90 Min. density in

life size.

(Adjustment range:

Approx. 30V to 55V)

Document

Copy

Copy

Note: When adjusting the center position of a manual

feed copy, since the manual feed guide is fixed,

align the document scale to the manual feed

side first, and then align the cassette’s fixing

position.

MODEL

MANUAL

REVISED EDITION

DATA

PAGE

METHOD

4-2

1312

SERVICE HANDBOOK

1

May.1999

4-2

REPLACEMENT

Page 4

Chapter 4 Adjustment

4-4-2. Leading edge position

If the leading edge position of the copy is miscentered, change the edge adjustment data.

o r

Document

Copy

1) Procedure

1. Call out the service mode.

(Press the Enlarge key and Reduce key for 5 sec.

in the Scale 1: 1 mode, and press the 0 key within

2 sec. after the local destination displayed)

Japan

US

2. Select 36 mode.

(Input 36 with the numeric keypad, and then press

the Start Print key.)

Copy

Europe

7. When completed with the adjustment, press the

Clear/Stop key until the normal mode appears (3

pushes).

(When the Clear key is pressed once, the state will

return to the previous state.)

8. To adjust the leading edge for an enlarged or reduced copy, press the Scale key and Arrow key

before step 4, and select the fixed scale enlargement or reduction.

Note: Enlargement or reduction can be carried out in

the zoom mode. However, as the scale 114% to

83% is a full size adjustment scale, set a scale

that exceeds this range.

4-4-3. Image skew

The image skew caused by the document inclination

when it is placed on the platen is adjusted by changing the position of the document scale’s fixed position (four screws).

o r

Document

Copy

Copy

3. Select address 91 (leading edge position setting).

(Example: Input 91 with the numeric keypad, and then

press the Start Print key.)

Adjustment data

(example: 32) blinks

4. Change the setting data to the required data (01 to

64:adjustment width 5mm).

(Input the data with the numeric keypad, and then

press the Start Print key.)

Changed data

(example: 42) blinks

Changed data is

set

5. When the Start Print key is pressed again, a test

copy of the settings after the changes can be

made.

6. After copying, the status will return to step 4. Thus,

if the density is not as required, repeat the procedure from step 4.

4-5. Magnification adjustment

If the length of the copy is deviated from that of the

original in the feeding direction or the crosswise

direction, perform the magnification adjustment.

4-5-1. Feeding direction (Vertical

magnification)

Document

1) Procedure

1. Call out the service mode.

(Press the Enlarge key and Reduce key for 5 sec.

in the Scale 1: 1 mode, and press the 0 key within

2 sec. after the local destination displayed)

Japan

Copy

US

Copy

Europe

4-3

Page 5

Chapter 4 Adjustment

2. Select 36 mode.

(Input 36 with the numeric keypad, and then press

the Start Print key.)

3. Select address 93 (Scanner speed adjustment).

(Example: Input 93 with the numeric keypad, and

then press the Start Print key.)

Adjustment data

(example: 32) blinks

4. Change the setting data to the required data (01 to

64:adjustment width 5mm).

(Input the data with the numeric keypad, and then

press the Start Print key.)

Changed data

(example: 42) blinks

Changed data is

set

5. When the Start Print key is pressed again, a test

copy of the settings after the changes can be

made.

6. When the copy is done, the status will return to

step 4. Thus, if the density is not as required,

repeat the procedure from step 4.

7. When completed with the adjustment, press the

Clear/Stop key until the normal mode appears (3

presses).

(When the Clear key is pressed once, the state

will return to the previous state.)

4-5-2. Crosswise direction (Horizontal

magnification)

1) Procedure

1. Call out the service mode.

(Press the Enlarge key and Reduce key for 5 sec.

in the Scale 1: 1 mode, and press the 0 key within

2 sec. after the local destination displayed)

3. Select address 95 (lens home position adjustment).

(Example: Input 95 with the numeric keypad, and

then press the Start Print key.)

Adjustment data

(example: 32) blinks

4. Change the setting data to the required data (01 to

64:adjustment width 5mm).

(Input the data with the numeric keypad, and then

press the Start Print key.)

Changed data

(example: 42) blinks

Changed data is

set

5. When the Start Print key is pressed again, a test

copy of the settings after the changes can be

made.

6. When the copy is done, the status will return to

step 4. Thus, if the density is not as required,

repeat the procedure from step 4.

7. When completed with the adjustment, press the

Clear/Stop key until the normal mode appears (3

presses).

(When the Clear key is pressed once, the state will

return to the previous state.)

4-6. Optical section adjustment

Note 1: As advanced adjustment skills are required

for adjusting the optical section, avoid

adjusting this section unless absolutely

necessary.

Note 2: Each of the adjustment places in the optical

section are marked with lock paint on screws,

so dissolve the lock paint using alcohol, etc.,

before starting the adjustment. (Some

screws are resin.) Always apply screw lock

after the adjustments.

4-6-1. Light distribution

If the light distribution of the exposure lamp is unbalanced, adjust the aperture plate, and even out the

half tone density.

Japan US Europe

2. Select 36 mode.

(Input 36 with the numeric keypad, and then press

the Start Print key.)

4-4

Page 6

Chapter 4 Adjustment

4-6-2. Scanner reference position

When the distance between the No. 2 scanner frame

side and optical base frame’s inner wall is 89.5mm,

fix (one screw, two places) the wire rope’s caulking

plate so that the distance between the No. 2 scanner’s reference slot and No. 1 scanner’s reference

surface is 73.5mm.

Reference: When replacing the wire ropes, it is easy

to adjust precisely leaving one wire rope intact

and keeping the No. 1 scanner and No. 2

scanner parallel.

Note: If this position deviates, the diagonal distortion

and focus adjustment will not be possible.

73.3

Reference slot

Base slot

Optical base frame

89.5

Caulking plate

4-6-4. Diagonal distortion

The slant caused by the optical section is adjusted

by the No. 2 scanner pulley’s fixing position.

Note: Confirm that the diagonal distortion is not

caused by the paper.

o r

Document

Copy

Fixing screw

Copy

4-6-5. Image distortion

The image distortion caused by the optical section is

adjusted by the No. 4 and No. 5 mirror height.

Note: Do not mistake this for that caused by placing

the document at a slant.

1

4-6-3. Lens reference position

Fix the timing belt (one screw) in the following state:

The lens height adjustment plate side being aligned

to the optical base frame reference position (marking

line), and No. 4 and No. 5 mirror drive cam’s reference hole and lens motor fixing frame reference hole

being in the same position (by inserting a fine pin).

Note: If this position is deviated, the horizontal

magnification (lens) and focus cannot be

adjusted.

Align the inner cam reference hole

positions and insert a pin

Lens hight

Timing belt fixing screw

adjustment plate

Marking line

Lens motor

fixing frame

o r

Document

Copy

Copy

4-6-6. Focus

Adjust the stop position of the No. 4 and No. 5

mirrors.

Note: If the focus adjustment is deviated, the magni-

fication will also be deviated. Thus, carry out

this adjustment before the magnification

adjustment.

Stop position adjustment screw

Height adjustment screw

MODEL

1312

Marking line

MANUAL

SERVICE HANDBOOK

REVISED EDITION

4-5

1

DATA

May.1999

PAGE

4-5

METHOD

REPLACEMENT

Page 7

Chapter 4 Adjustment

4-6-7. Image center position

Adjust the lens fixing position.

Note: This adjustment is carried out only when the

corresponding section is disassembled.

Normally, the adjustment is done with the

document scale.

o r

Document

4-6-8. Focus (Horizontal blurring)

1

Adjust the lens installation direction.

Note: This adjustment is carried out only when the

corresponding section is disassembled.

One-sided blurring

Copy

Fixing screw

Copy

4-7. Leading and trailing edges erase width

Adjust the leading and trailing edges erase width.

1) Procedure

1. Call out the service mode.

(Press the Enlarge key and Reduce key for 5 sec.

in the Scale 1: 1 mode, and press the 0 key within

2 sec. after the local destination displayed)

Japan

US

2. Select 36 mode.

(Input 36 with the numeric keypad, and then press

the Start Print key.)

3. Select address (92:leading edge, 98:trailing edge).

(Example: Input 92 with the numeric keypad, and

then press the Start Print key.)

Europe

Center

4-6-9. Horizontal magnification

Adjust the fixing position of the sensor plate, and

change the lens home position.

Note: This adjustment is carried out only when the

corresponding section is disassembled.

Normally, the adjustment is done with the

software (36-95).

o r

Document

Lens home position sensor

Sensor plate

MODEL

1312

SERVICE HANDBOOK

Copy

MANUAL

Copy

Fixing screw

1

4. Change the setting data to the required data (01 to

64:adjustment width 5mm).

(Input the data with the numeric keypad, and then

press the Start Print key.)

5. When the Start Print key is pressed again, a test

copy of the settings after the changes can be

made.

6. After copying, the status will return to step 4. Thus,

if the density is not as required, repeat the

rocedure from step 4.

REVISED EDITION

4-6

1

Adjustment data

(example: 32) blinks

Code Adjustment details Adjustment range

92 Adjustment width:

±3mm

Adjustment range:

DATA

±5mm

PAGE

98

Changed data

(example: 42) blinks

May.1999

4-6

01 to 64

Changed data is

set

METHOD

REPLACEMENT

Page 8

7. When completed with the adjustment, press the

Clear/Stop key until the normal mode appears (3

pushes).

(When the Clear key is pressed once, the state

will return to the previous state.)

Note: Refer to the Chapter 8 about other adjustment

items by using the service function.

Chapter 4 Adjustment

4-7

Loading...

Loading...