Page 1

Chapter 8 Service Functions

8-1. Error codes ................................................. 8-1

8-2. User setting mode...................................... 8-4

8-2-1. Setting procedure ................................... 8-4

8-2-2. Setting item list ....................................... 8-4

8-3. Service mode.............................................. 8-6

8-3-1. Entering the service mode ..................... 8-6

8-3-2. 25 mode ................................................... 8-7

8-3-3. 36 mode ................................................... 8-9

8-3-4. 47 mode ..................................................8-11

8-4. Backup data.............................................. 8-13

8-5. Automatic paper size detection .............. 8-13

8-6. General operation mode.......................... 8-14

Page 2

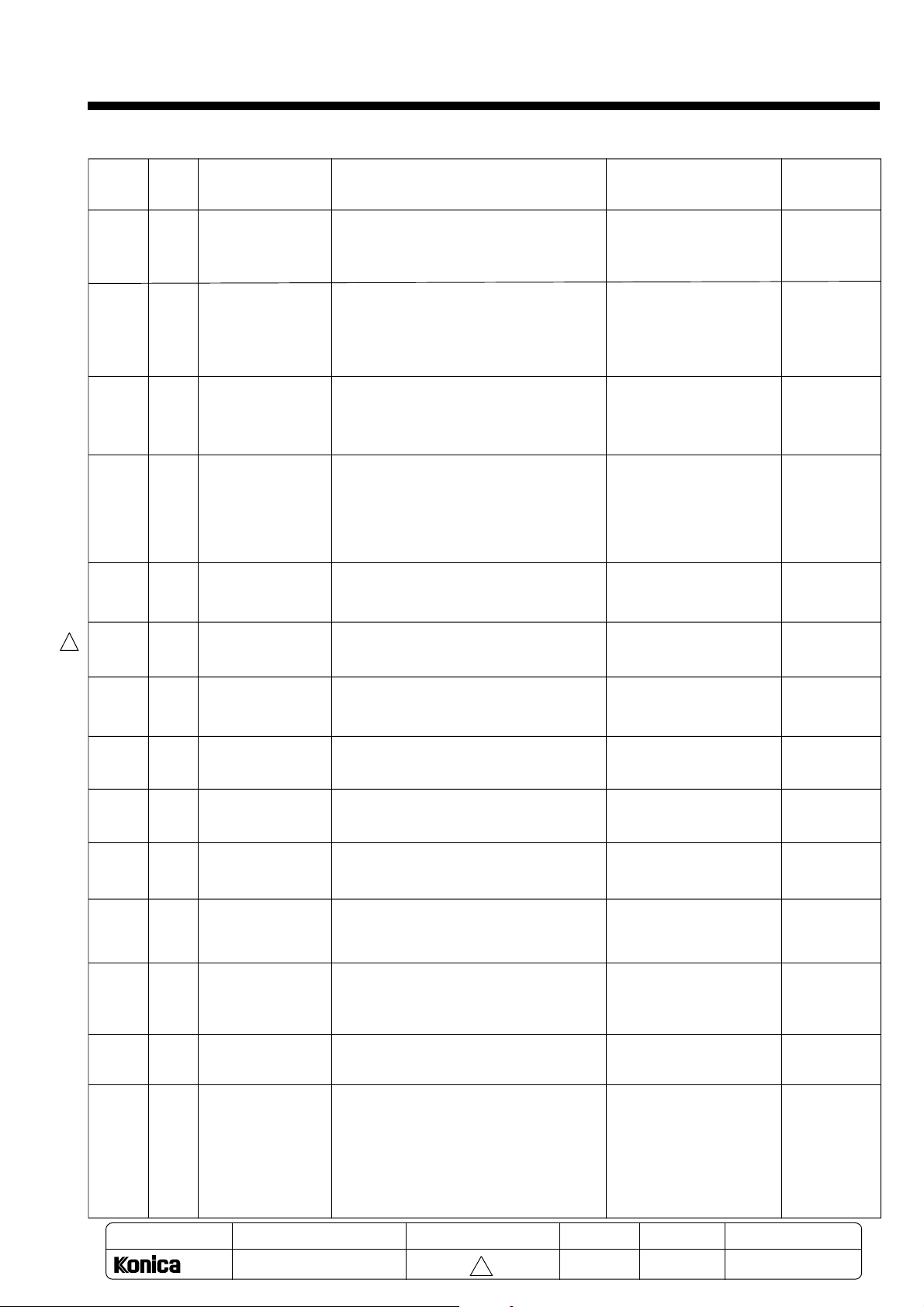

8-1. Error codes

Chapter 8 Service Functions

Order of

display

priority

1

2

3

4

5

Code

F34

F35

F36

F43

F54

Symptom

Fusing high

temperature

abnormality

Fusing low

temperature

abnormality

Fusing sensor

abnormality

AVR abnormality

Fan motor lock

Cause

* The fusing temperature exceeds the

specified temperature. (Detection

temperature = 225°C)

* The unit does not warm up even after

the set time (60 sec.) has passed from

the warm up start.

* After warming up, the fusing lamp does

not turn OFF for the specified time (30

sec.) or more.

* Fusing low temperature/thermistor

open/wire breakage.

* The temperature does not exceed -5

even after 10 sec. from the warm up

start.

* The exposure lamp error signal is ON

continuously for 15 sec. or more.

(The lamp is continuously lit, or the lamp

or temperature fuse is blown.)

* The exposure lamp does not light. (For

two seconds)

* The fan's unlock signal is detected for

two continuous seconds while the fan is

operating.

°C

Unit operation

* Copy operation impossi-

ble.

* Main unit instantaneously

stops.

* Main relay turns OFF.

* Copy operation impossi-

ble.

* Main unit instantaneously

stops.

* Main relay turns OFF.

* Copy operation impossi-

ble.

* Main unit instantaneously

stops.

* Main relay turns OFF.

* Copy operation impossi-

ble.

* Main unit instantaneously

stops.

* Main relay turns OFF.

*

Copy operation impossible.

*

Main unit instantaneously stops.

* Main relay turns OFF.

* 25-47

* Power ON/

* 25-47

* Power ON/

* 25-47

* Power ON/

* Power ON/

* Power ON/

Releasing

method

OFF

OFF

OFF

OFF

OFF

1

6

7

8

9

10

F49

F41

F42

F52

F45

SDH temperature

abnormality

Scanner return

abnormality

Scanner feeding

abnormality

Main motor drive

abnormality

Lens

drive abnormality

Developer

11

F26

initialization

abnormality

Engine section

12

F50

EEPROM

abnormality

13

P51

Upper cover

open

* When using the SDH, the platen

temperature rises to the specified

temperature.

* The Scanner HP sensor does not turn

ON even after a set time passed from

the return drive ON.

* The Scanner HP sensor does not turn

OFF even after a set time passed from

the feed drive ON.

* The unlock signal is detected for one

continuous second during the main

motor drive.

* The initialization is not completed within

a set time during the lens drive motor

drive.

* Developing unit initialization error

* Engine section EEPROM access error

* The upper cover is open.

* Instantaneous stop.

Copy operation impossible.

*

*

Main unit instantaneously stops

* Main relay turns OFF.

Copy operation impossible.

*

*

Main unit instantaneously stops

* Main relay turns OFF.

*

Copy operation impossible..

*

Main unit instantaneously stops

* Main relay turns OFF.

*

Copy operation impossible.

*

Main unit instantaneously stops

* Main relay turns OFF.

Copy operation impossible.

*

* Main unit instantaneously

stops.

* Main unit instantaneously

stops.

Copy operation impossible.

*

*

Main unit instantaneously stops.

* Power ON/

* Power ON/

* Power ON/

* Power ON/

* Power ON/

* Insialize of

Developing

unit

* Power ON/

* Close the

OFF

OFF

OFF

OFF

OFF

OFF

upper cover.

14

J32

MODEL

Fusing paper

exit jam

1312

SERVICE HANDBOOK

MANUAL

* The JAM2 sensor does not turn OFF

within 2.85 to 3.13 seconds after JAM1

sensor turned OFF. (During copying)

* Paper on the JAM2 sensor. (When

stationary)

REVISED EDITION

8-1

1

* Instantaneous stop

* The fusing heater turns

OFF.

DATA

May.1999

PAGE

8-1

* Open the

upper cover

and remove

the jammed

paper.

METHOD

REPLACEMENT

Page 3

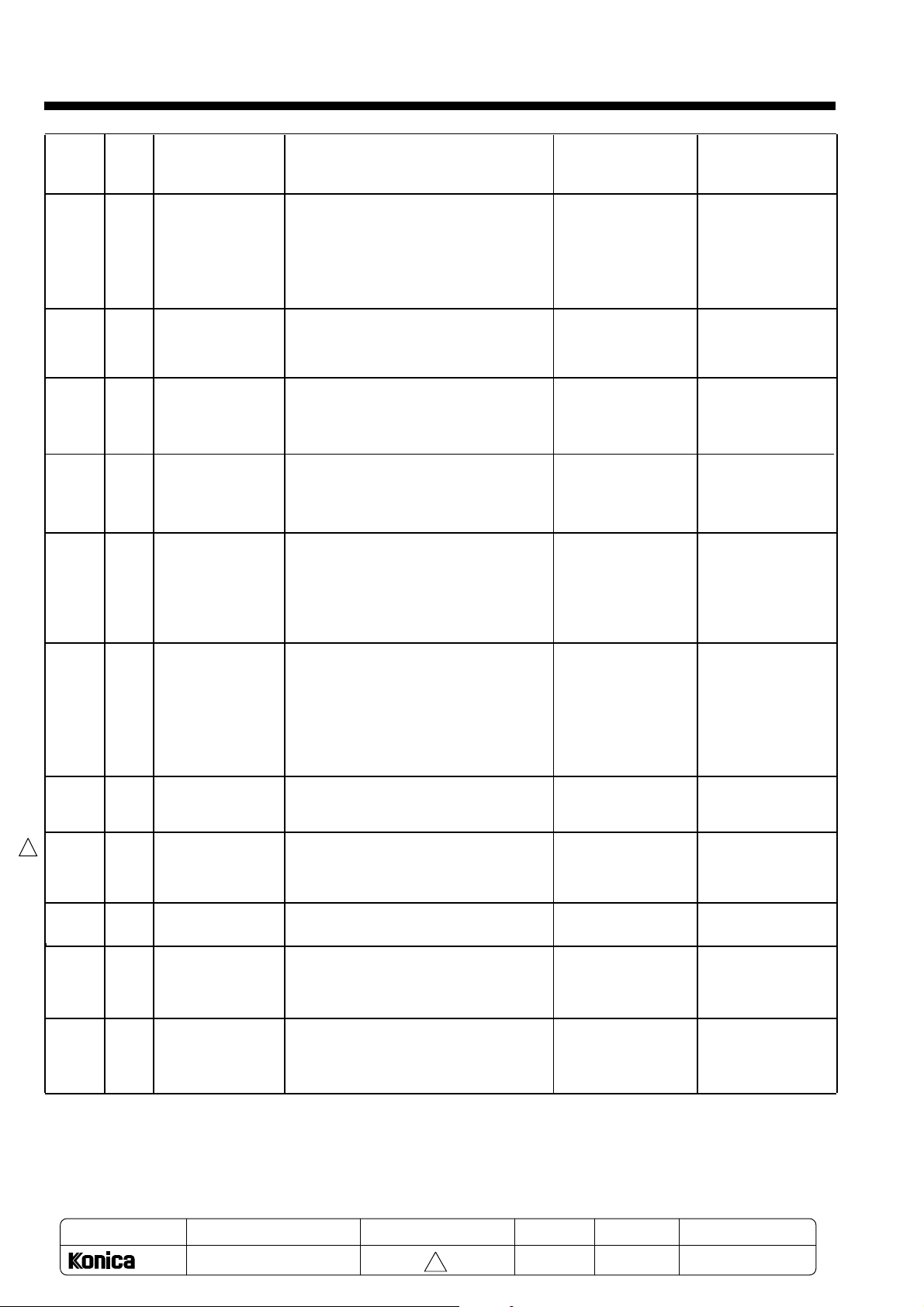

Chapter 8 Service Functions

Order of

display

priority

Code

Symptom

Cause

Unit operation

Releasing method

15

16

17

18

19

20

J16

J31

J61

J62

J11

J12

Paper feed jam

Conveyance

jam

SDH open

SDH jam

Paper feed jam

Paper feed jam

* Paper on the JAM1 sensor. (Only when

stationary)

* The JAM2 sensor (fusing paper exit

sensor) does not turn OFF within 2.85 to

3.54 sec. after the regist clutch turned

ON.

* The SDH is open while SDH is driven.

* Jam during the SDH document feed,

conveyance or exit.

* Paper is incorrectly supplied from the

unit standard cassette (upper cassette).

* The paper does not reach the JAM1

sensor within 1.30 sec. after the upper

cassette paper feed solenoid turned

ON.

* Paper is incorrectly supplied from the

operation cassette feeder (lower level).

* The paper does not reach the JAM1

sensor within 3.21 sec. after the lower

level paper feed solenoid turned ON.

* Maintains the stop

state.

* The fusing heater

turns OFF.

* Instantaneous stop

* The fusing heater

turns OFF.

* The SDH instanta-

neously stops.

* Operation stops

after the previous

paper exits.

* The SDH instanta-

neously stops.

* Operation stops

after the previous

paper exits.

*Operation stops

after the previous

paper exits.

* Operation stops

after the previous

paper exits.

* Open the jam lid on

the side of the unit,

and remove the jam

paper.

* Then, open and

close the upper

cover.

* Open the upper

cover and remove

the jam paper.

Close the SDH cover

* Remove all docu-

ments from the

SDH once.

* Open the jam lid on

the side of the unit,

and remove the jam

paper.

* Then, open and

close the upper

cover.

* Open the cassette

feeder or jam lid on

the side of the unit,

and remove the jam

paper.

* Then open and

close the upper

cover.

21

22

1

23

24

P20

P20

P26

P24

(Blink)

25

P29

(Blink)

MODEL

Drum cartridge

not mounted

Developing unit

not mounted

Developing unit

initialization

Change drum

Change

developer

MANUAL

* The drum cartridge is not installed.

* The developing unit is not installed.

* The recycle pipe is not set.

* The developing unit is not initialized.

*

This appears to indicate that the drum must

be replaced when 500 sheets have been

copied after the check drum display.

* This appears to indicate that the

developing unit must be replaced when

the toner is emptied after the check

developer display.

REVISED EDITION

DATA

* Copy operation

impossible.

* Copy operation

impossible.

* Copy operation

impossible.

* Copy operation

stops after the

previous paper

exits.

* Copy operation

stops after the

previous paper

exits.

PAGE

* Mount the drum

cartridge.

* Mount the devel-

oping unit.

* Set the recycle

pipe.

* Initialize the

developing unit.

* Replace and

initialize the drum.

* Replace and

initialize the

developing unit.

METHOD

8-2

1312

SERVICE HANDBOOK

1

May.1999

8-2

REPLACEMENT

Page 4

Chapter 8 Service Functions

Order of

display

priority

26 P25

1

27 P49

28

(Note 1)

29 P25

(Note 3) (Blink)

30 P27

(Note 2)

Code

Symptom

Supplying toner

Cooling SDH

Out of paper

Toner empty

Check developer/

drum

Cause

* The toner level is low.

* A document with a high black ratio was

continuously copied.

* When using the SDH, the platen section

rose to the specified temperature.

* No paper in the selected cassette.

* Toner empty

* This appears when check drum and

check developer occur simultaneously.

Unit operation

* The copy operation

is suspended. After

forced supply, the

remaining copies

are automatically

made.

* The copy operation

is suspended to cool

the unit.

* The copy operation

will resume when

the unit cools to the

specified temperature.

* Copy operation

stops after the

previous paper exits.

* After copying 30

sheets, copy

operation stops

according to the

toner empty.

* This is only a

display. The copy

operation will

continue.

Resetting

method

* Automatically

reset.

Note when there

is no toner left in

the core, Toner

empty (P25 blink)

will appear.

* Automatically

reset.

* Supply paper.

* Supply toner.

* If the change

developer or

change drum

display appears,

follow the instructions.

31 P24

(Note 2)

32 P29

(Note 2)

33 P11

(Note 3)

34 P12

(Note 3)

Check drum

Check developer

Upper cassette

paper size error

Lower cassette

paper size error

* This indicates that the No. of copies

made by the drum has reached 24500

sheets, and the drum replacement

interval is nearing.

* This indicates that the No. of copies

made with the developer has reached

25000 sheets, and the developer

replacement interval is nearing.

* The size setting for the upper cassette is

incorrect.

* The size setting for the lower cassette

is incorrect.

* This is only a

display. The copy

operation will

continue.

* This is only a

display. The copy

operation will

continue.

*

After the copy

operation is completed, a warning will

appear. However, the

copy operation is not

be prohibited.

*

After the copy

operation is completed, a warning will

appear. However, the

copy operation is not

be prohibited.

* When the change

drum display

appears, replace

and initialize the

drum.

* When the change

developer display

appears, replace

and initialize the

developing unit.

* Set the correct

size for the upper

cassette.

* Set the correct

size for the lower

cassette.

(Note 1) This is not displayed by the code.The cassette LED will blink.

(Note 2) This appears at Auto Clear or when the power is turned ON. The error display will go out when the nu-

meric keys, Stop key or Copy key are pressed.

(Note 3)

This is displayed again at Auto Clear or when the power is turned ON after the copy operation is completed.

The error display will go out when the numeric keys, Stop key or Start Print key are pressed.

MODEL

1312

MANUAL

SERVICE HANDBOOK

REVISED EDITION

8-3

1

DATA

May.1999

PAGE

8-3

METHOD

REPLACEMENT

Page 5

Chapter 8 Service Functions

8-2. User setting mode

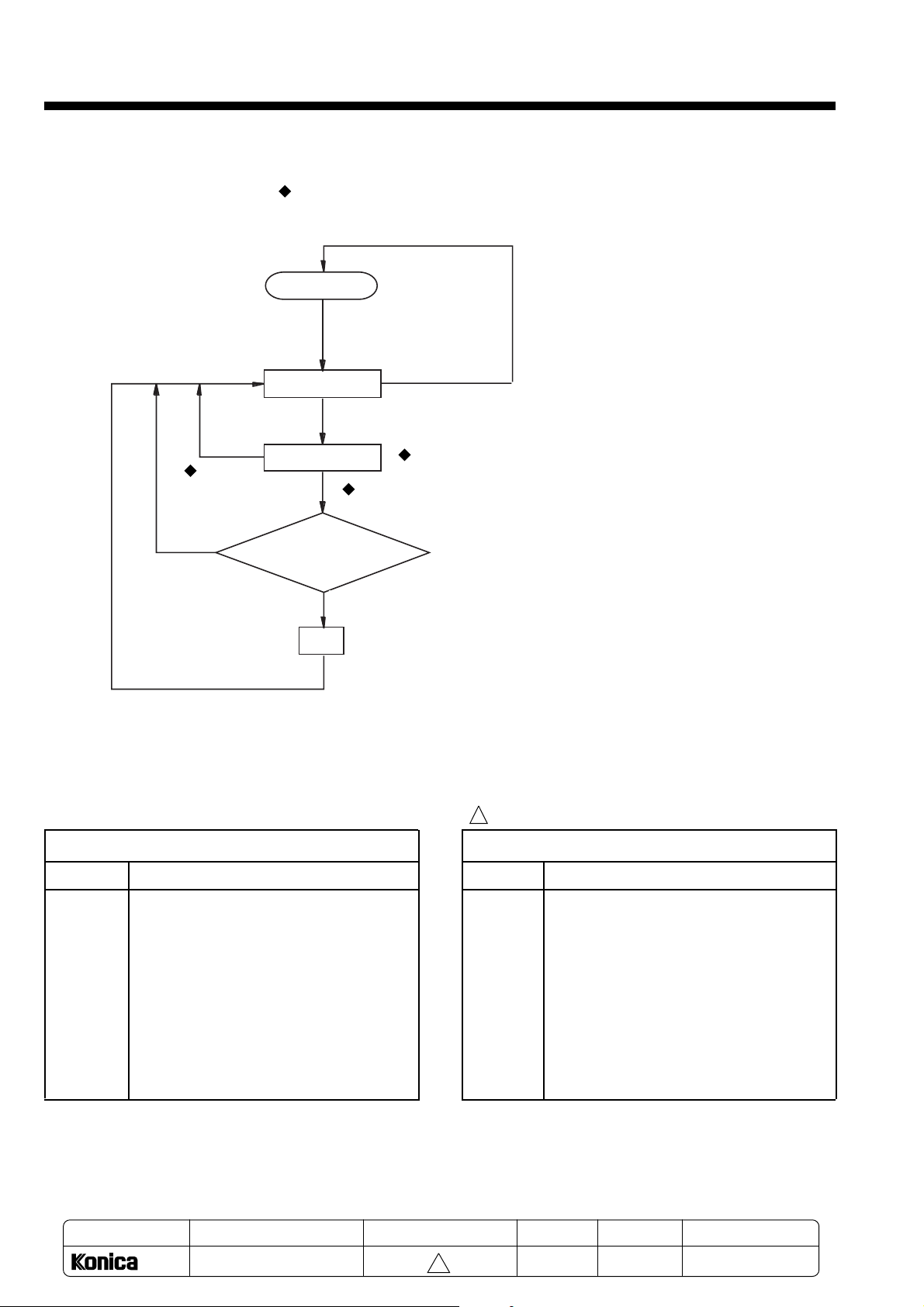

8-2-1. Setting procedure

: Indicates key operation.

Return to Auto Clear state

Standby

Press the

"Select Paper"

key for 5 sec.

Setting default

state

Stop key

Input the

Stop key

NO

setting values

Start Print

Valid number?

YES

Set

Setting completed.

Note 2: The “Magnification”, “Enlarge”, “Reduce” and “Select Paper” keys are invalid in this mode.

Note 3: Auto Clear and Power Save operations are invalid in this mode.

8-2-2. Setting item list

C-00 to C-09: Standard cassette paper size setting

Item No.

Details

Input a 2-digit number with

the numeric keys.

Note 1:The key operation is ignored if press the "Start

Print" key after the input of the 1-digit number.

1

Option cassette paper size setting

Item No.

Details

C-00 LT

C-01 LG

C-02 A4

C-03 B5

C-04 A5

C-05 F4-1: 8X13"(203X330mm)

C-06 F4-2: 8.5X13"(216X330mm)

C-07 F4-3: 8.25X13"(210X330mm)

C-08 F4-4: 206X337mm

C-09 -

MODEL

1312

SERVICE HANDBOOK

MANUAL

C-10 LT

C-11 LG

C-12 A4

C-13 B5

C-14 A5

C-15 F4-1: 8X13"(203X330mm)

C-16 F4-2: 8.5X13"(216X330mm)

C-17 F4-3: 8.25X13"(210X330mm)

C-18 F4-4: 206X337mm

C-19 -

REVISED EDITION

8-4

1

DATA

May.1999

PAGE

8-4

METHOD

REPLACEMENT

Page 6

Chapter 8 Service Functions

C-20 to C29:

Item No.

C-20

C-21

C-22

C-23

C-24

C-25

C-26

C-27

C-28

C-29

1

C-30 to 33: Auto reset time

Item No.

C-30

C-31

C-32

C-33

30 sec.

60 sec.

90 sec.

120 sec.

C-34

C-35

C-36

C-37

C-38

C-39

Details

Details

(Default)

C-50 to C51: Initialization

Item No.

C-50

C-51

Drum initialization (Note 1)

Developer initialization (Note 2)

Details

C-52

C-53

C-54

C-55

C-56

C-57

C-58

C-59

C-60 to C62: Automatic paper length check

Item No.

C-60

C-61

C-62

OFF (Note 3)

ON (Note 4)

ON (Default) (Note 5)

Details

C-63

C-64

C-65

C-66

C-67

C-68

C-69

C-40 to C-42: Counter read

1

Item No.

C-40

C-41

C-42

Total counter read

Drum counter read

Developer counter read

Details

C-43

C-44

C-45

C-46

C-47

C-48

C-49

The display for each counter is displayed in the order

of 3 high-order digits (3 sec.), blank (1 sec.) and 3

low-order digits (3 sec.)

(Note 1) Aging the drum and reset the drum counter.

(Note 2) Adjust the L detection data and reset the

developer counter.

(Note 3) The side erase lamp is controlled with the

user registered paper size.

(Note 4) The side erase lamp at the first copy is

controlled with the user registered paper size

during continuous copies. From the second

copy, it is controlled with the detected paper

size at the first copy. The paper size is detected with the paper passing time on JAM1

sensor.

(Note 5) The side erase lamp at the first copy is

controlled with LT size during the continuous

copies. From the second copy, it is controlled

with the detected paper size at the first copy.

The paper size is detected with the paper

passing time on JAM1 sensor.

MODEL

1312

MANUAL

SERVICE HANDBOOK

REVISED EDITION

8-5

1

DATA

May.1999

PAGE

8-5

METHOD

REPLACEMENT

Page 7

Chapter 8 Service Functions

8-3. Service mode

8-3-1. Entering the service mode

The destination display appears during and after transition to the service mode.

Standby state display

Note 1: The “Magnification”, “Enlarge” and “Select Paper” keys are

US destination display

Japan destination display

Europe destination display

Input the numeric key “0”

within 2 sec.

invalid during transition to the service mode. (These are valid after

the service mode is entered.)

Note 2: Auto Clear and Power Save operations are invalid in this

mode.

Standby state

Press the "Enlarge" key and "Reduce" key for 5

sec. in the Scale 1: 1 mode, the local distination is

displayed.

NO

Includes an input other

than “0”.

YES

: Indicates key operation.

Stop key

Stop key

25 Mode default

setting state

Data setting

25 Mode

operation

Enter operation

Stop key

NO

25

Stop key

Service mode default state

Select service mode

Start Print key

Valid No.

YES

What is the input

value?

36

36 Mode default

setting state

Test/adjustment

setting

36 Mode

operation

36

Enter operation

Stop key

Input a valid mode No. using the numeric keys.

(The valid mode Nos. are 25, 36, 47.)

47

47 Mode default

setting state

Input/output

control setting

Stop key

47 Mode

operation

Enter operation

Operation completed

Operation completed

8-6

Operation completed

Page 8

8-3-2. 25 mode

25 mode is used to change the data written in the involute memory.

Operation example: To change the address 35 data. (Example: 6 ->5)

Standby state display

Chapter 8 Service Functions

: Indicates key operation.

Destination display

State with 25 mode elected

25 Mode address input wait

Example: State with address

35 selected

Example: Data already registered

Example: State with data changed

Stop key

Standby state

Service mode default state

Select service mode

Stop key

25 Mode

Select non-volatile

memory address

Return to Auto Clear state.

Press the "Enlarge" key and "Reduce" key for 5 sec.

in the Scale 1: 1 mode, and press the 0 key within 2

sec. after the local destination displayed.

Stop key

Input 25 with the numeric keys

Start Print key

Stop key

Input 2-digit address with the numeric keys

Start Print key

Non-volute data display

Non-volatile data change

Input 5 with the numeric keys

Start Print key

8-7

Page 9

Chapter 8 Service Functions

25 mode list

1

1

1

Address

20

30

32

33

34

35

36

37

39

40

41

42

43

44

47

Details

Setting for time to enter power save mode (spare)

1: Address 62 setting takes precedence

2: OFF

3: 60 min.

4: 120 min.

5: 240 min.

Destination setting (Note 1)

1:Japan (Fixed scale: Japan, paper size default setting: A4)

2: US (Fixed scale: US, paper size default setting: LT)

3: Europe (Fixed scale: Europe, paper size default setting: A4)

Total counter setting (105)

Total counter setting (104)

Total counter setting (103)

Total counter setting (102)

Total counter setting (101)

Total counter setting (100)

Drum counter setting (105)

Drum counter setting (104)

Drum counter setting (103)

Drum counter setting (102)

Drum counter setting (101)

Drum counter setting (100)

Reset fusing error (Reset by inputting "0", and turning power ON/OFF.)

Fusing high temperature error (F34) detection (hardware)

Fusing sensor error (F36) detection (hardware)

Fusing high temperature error (F34) detection (software)

Fusing low temperature error (F35) detection (software)

Fusing sensor error (F36) detection (software)

Setting value

1 to 5 (default: 1)

1 too 3 (default:3)

0 to 9

0 to 9

0 to 9

0 to 9

0 to 9

0 to 9

0 to 9

0 to 9

0 to 9

0 to 9

0 to 9

0 to 9

0 (default)

1

3

4

5

6

62

1

Setting for time to enter power save mode (normal use)

1: 30 min.

1 to 3 (default: 1)

2: 2 min.

3: 5 min.

80

Fusing temperature control setting 1: 182 ˚C

1 to 5 (default: 3)

2: 185 ˚C

3: 188 ˚C

4: 190 ˚C

5: 193 ˚C

81

User/service selection setting for drum initialization and developer

1 to 2 (default: 1)

initialization

1: Released to user

2: Only service mode (47 mode) valid

84

1

Toner density control setting 1: 5.5%

1 to 5 (default: 3)

2: 6.0%

3: 6.5%

4: 7.0%

5: 7.5%

85

86

87

1

88

89

90

Developer count setting (105)

Developer count setting (104)

Developer count setting (103)

Developer count setting (102)

Developer count setting (101)

Developer count setting (100)

0 to 9

0 to 9

0 to 9

0 to 9

0 to 9

0 to 9

(Note 1) Fixed scale Japan: B5>A4(115%), B4>A4(82%), B4>B5(71%)

US: 5.5

x

8.5>8.5

x

11(129%), 8.5

x

14>8.5

x

11(77%)

Europe: A5>A4(141%), B4>A4(82%), A4>A5(71%)

MODEL

MANUAL

REVISED EDITION

8-8

1312

SERVICE HANDBOOK

1

May.1999

DATA

PAGE

8-8

METHOD

REPLACEMENT

Page 10

Chapter 8 Service Functions

8-3-3. 36 mode

36 mode is used to carry out the running test and to make various adjustments.

(Note) When doing the running test, close the upper cover. If the upper cover is open, the developing unit will be

locked, or the scanner operation failure will occur.

Operation example: To carry out AVR adjustment (address 90) of the equal magnification MIN. position.

Standby state display

Destination display

State with 36 mode selected

36 mode code input wait

Example: State with code

90 selected

Example: The data already

registered brinks

Stop key

Stop key

Return to Auto Clear state.

Standby state

Press the "Enlarge" key and "Reduce" key for 5 sec.

in the Scale 1: 1 mode, and press the 0 key within 2

sec. after the local destination displayed.

Service mode default state

Select service mode

Start Print key

36 Mode

Select adjustment mode

: Indicates key operation.

Stop key

Input 25 with the numeric keys

Input code (example: 90) with numeric keys

Example: The changed data blinks

Example: State with changed

data entered

Adjustment data change mode

Adjustment data change

Adjustment data enter

Copy operation

8-9

Page 11

Chapter 8 Service Functions

36 mode list

Code

01

02

10

11

12

13

14

40

1

1

41

86

87

88

89

90

Details

No paper copy running (Mechanical counter: No count up)

Copy running test (Mechanical counter: No count up)

x100 copy running test (Mechanical counter: Count up)

No paper copy running test (Mechanical counter: Count up)

x100 no paper copy running test (Mechanical counter: Count up)

Intermittent copy running test (Mechanical counter: Count up)

Intermittent copy + no paper copy running test (Mechanical counter: Count up)

Paper leading edge transfer start timing adjustment

Adjustment range: Approx. +9 ~ -13mm

Paper trailing edge transfer end timing adjustment

Adjustment range: Approx. +15 ~ -7mm

AVR adjustment 1 Enlargement center (Light amount adjustment)

Adjustment range: Approx. 43V ~ 67V

AVR adjustment 2 Reduction center (Light amount adjustment)

Adjustment range: Approx. 43V ~ 67V

AVR adjustment 3 Life size Max. (Light amount adjustment)

Adjustment range: Approx. 55V ~ 80V

AVR adjustment 4 Life size Center (Light amount adjustment)

Adjustment range: Approx. 43V ~ 67V

AVR adjustment 5 Life size Min. (Light amount adjustment)

Adjustment range: Approx. 30V ~ 55V

1

Adjustment range

01 to 64

01 to 64

01 to 64

01 to 64

01 to 64

01 to 64

01 to 64

91

Copy leading edge timing (Paper feed timing adjustment)

01 to 64

Adjustment range: Approx. ±5mm

1

92

Image leading edge erase

01 to 64

Adjustment range: Approx. ±10mm

93

Scanner speed adjustment (Vertical magnification adjustment)

01 to 64

Adjustment range: Approx. ±6 mm in respect to A4 length

95

Lens home position adjustment (Horizontal magnification adjustment)

01 to 64

Adjustment range: Approx. ±6mm in respect to A4 width

96

SDH copy leading edge timing(Document feed timing adjustment)

01 to 64

Adjustment range: Approx. ±5mm

97

SDH scanner speed adjustment (Vertical magnification adjustment)

01 to 64

Adjustment range: Approx. ±6mm in respect to A4 length

1

98

Image trailing edge erase

01 to 64

Adjustment range: Approx. ±10mm in respect to default setting

Note 1: The Enlarge, Scale and Reduce mode is apply for codes 91 and 96.

Note 2: For codes 02 and 10, if the original is set to theSDH and operation is started, the SDH copy operation

will take place. (No. of copies setting is invalid.)

Note 3: For codes 01, 11 and 12, if the SDH original sensor is turned ON and operation is started, no paper

operation will also take place with the SDH.

MODEL

1312

MANUAL

SERVICE HANDBOOK

REVISED EDITION

8-10

1

DATA

May.1999

PAGE

8-10

METHOD

REPLACEMENT

Page 12

Chapter 8 Service Functions

8-3-4. 47 mode

47 mode is used to check the input and output. The operation of each electrical part can be confirmed. This mode

is also used to initialize the drum, developer and settings.

Operation example: To carry out the JAM2 sensor check (code 22).

: Indicates key operation.

Standby state display

Return to Auto Clear state.

Destination display

Standby state

47 Mode code input wait

Example: State with code

22 selected

JAM2 sensor

"OFF"

JAM2 sensor

"ON"

Stop key

Stop key

Press the "Enlarge" key and "Reduce" key for 5 sec.

in the Scale 1: 1 mode, and press the 0 key within 2

sec. after the local destination displayed.

Service mode default state

Select service mode

Start Print key

47 Mode

Input code (example: 22) with numeric keys.

Input the input/output code

Start Print key

Output

operation

Input 47 with the numeric keys

Stop key

Stop key or end of operation

8-11

Page 13

Chapter 8 Service Functions

Mode 47 list

Code

00

01

1

02

1

03

1

04

1

20

22

30

JAM1 sensor input

JAM2 sensor input

Mirror HP sensor input

31

32

Lens HP sensor input

41

Input details

Output details

Exposure lamp continuous lighting (Mirror moves to shipping

position after lit for 6 sec.)

Toner motor forced rotation mode (Stops after 4 sec. )

High voltage output (Adjustment not possible) (Charging) (Stops

after 1 min. output)

High voltage output (Adjustment not possible) (Transfer +)

(Stops after 1 min. output)

High voltage output (Adjustment not possible) (Transfer -) (Stops

after 1 min. output)

Scanner running mode (Optical reciprocation drive) (Stops with

Stop key)

Developing unit running mode (Steps after 1 min.)

42

43

Cooling fan high-speed rotation (5 sec.)

Mechanical counter, count up (Counts one with each press of

Start Print key)

48

49

69

91

92

93

ROM version read (After once Start

Print key press)

All LEDs on the operation panel light (After two Start Print key

presses) (Note 1)

All side erase lamps light (Goes out after 3 sec. or Stop key)

SDH scanner running mode

Drum initialization(Aging the drum and reset the drum counter)

Setting initialization (initial reset) (Note 2)

Developer initialization(Adjust the L detection data and reset the

developer counter)

Note 1: When the Start Print key is pressed after inputting code 48, first the ROM version displays. When the Copy

key is pressed again, the 7-segment LED and all LEDS on the other operation panels light.

ROM version display

Example: Ver. 1.07

All light

Start Print Key

Note 2: Initializied data

"Cassette paper size data", "Time data to enter Power save mode", "Auto clear time data", "Counter value",

Drum counter value", "Developer counter value"," Developer initialization data","Fusing temperature selection data" are initializied.

MODEL

MANUAL

REVISED EDITION

DATA

PAGE

METHOD

8-12

1312

SERVICE HANDBOOK

1

May.1999

8-12

REPLACEMENT

Page 14

Chapter 8 Service Functions

8-4. Backup data

The following data is backed up in the non-volatile

memory (EEPROM) on the main CB(unit main).

1

Data item

Cassette paper size(U)

Cassette paper size(L)

Time to enter power save mode

Auto clear time

Total counter value

Drum counter value

Developer counter value

Image leading edge timing value

Image leading edge erase

amount adjustment value

Image trailing edge erase amount

adjustment value

AVR adjustment value

Developer initialization data

(L detection data)

Toner density control selection

value

Fusing temperature control

selection value

Scanner speed adjustment value

Lens unit home position adjustment value

SDH copy leading edge timing

value

SDH speed adjustment value

Destination setting value

Setting method

User setting mode

C-00~08

User setting mode

C-10~18

25 mode: 20

User setting mode

C-30~33

25 mode: 32 to 37

25 mode: 39 to 44

25 mode: 85 to 90

36 mode: 91

36 mode: 92

36 mode: 98

36 mode: 86 to 90

Re-initialization

25 mode: 84

25 mode: 80

36 mode: 93

36 mode: 95

36 mode: 96

36 mode: 97

25 mode: 30

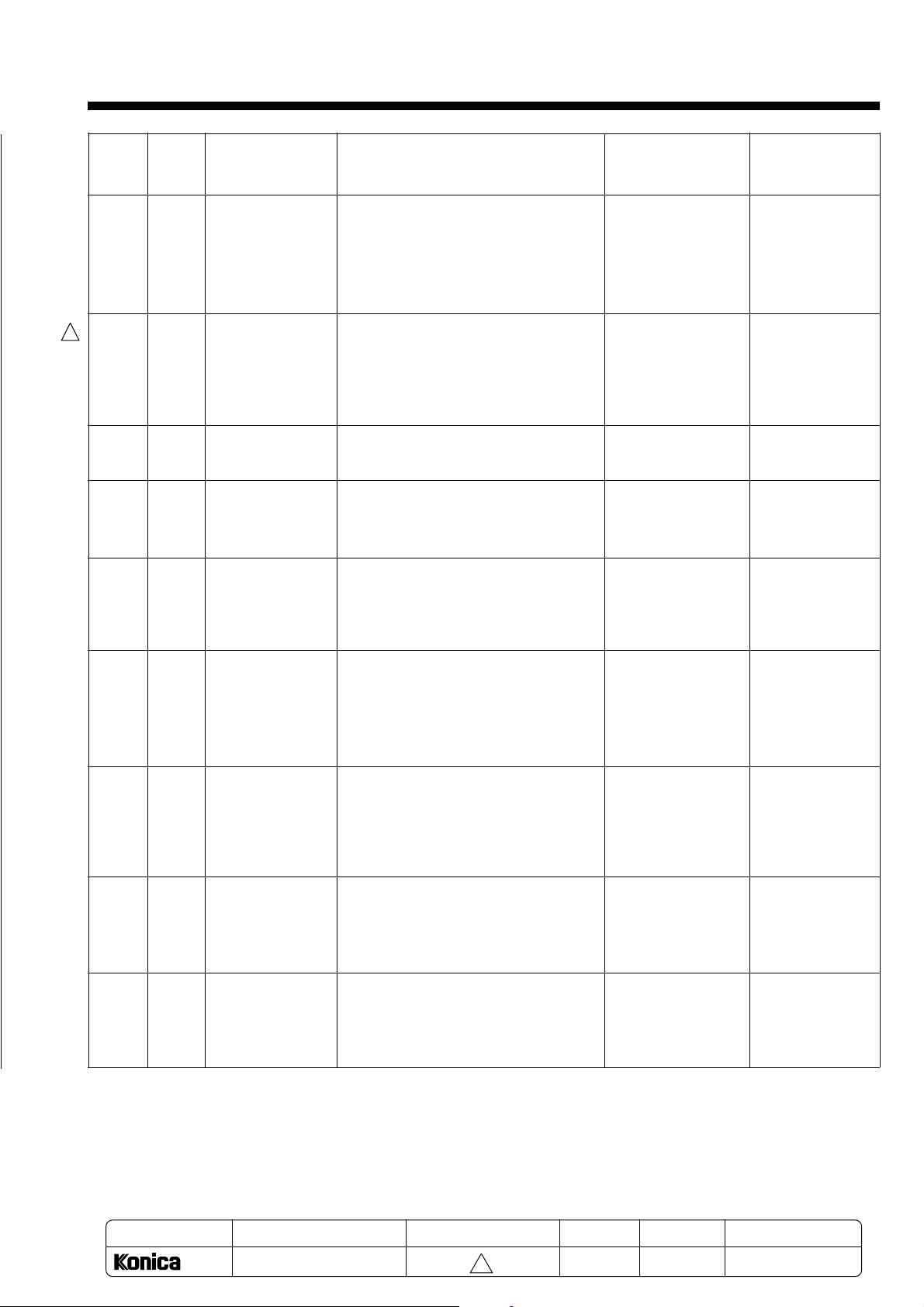

Note 2: When the paper length is from 314mm to 347

mm, if the paper size set with the cassette

paper setting and the detected paper size

differ, an error code (P11, P12) will appear.

Note 3: When the paper size error code does not

appear, the detected paper size will be detected. (The cassette paper setting’s paper

size will be reset.)

1st copy operation

Determine as

jam

Standby state

Set the document

Set the No. of copies, and start copying

Paper length is

automatically detected

Paper length 234mm?

Paper length 268mm?

Paper length 288mm?

Paper length 314mm?

Paper length 347mm?

NO

Paper length 370mm?

2nd and following copy operation

End of copy operation

Example: To make 18 copies

<

=

NO

<

=

NO

<

=

NO

<

=

NO

<

=

NO

<

=

YES

YES

YES

YES

YES

YES

Input 18 with the numeric keys,

and press the Copy key

Determine as A5, and copy.

Determine as B5, and copy.

Determine as LT, and copy.

Determine as A4, and copy.

Determine as F4 size, and copy.

Determine as LG, and copy.

8-5. Automatic paper size detection

When the automatic paper size detection is selected

with the user setting mode (C-61, 62), the paper

length will be automatically checked by JAM 1 sensor.

Note 1: The paper length is detected during the first

copy operation, so the 1st copy time will not

satisfy 12CPM.

(When feeding from lower cassette.)

MODEL

1312

MANUAL

SERVICE HANDBOOK

REVISED EDITION

8-13

1

DATA

May.1999

PAGE

8-13

METHOD

REPLACEMENT

Page 15

Chapter 8 Service Functions

8-6. General operation mode

Power ON

Warming up

Key input

Power save mode

Press the "Enlarge" key and "Reduce" key for 5 sec. in the Scale 1: 1

mode, and press the 0 key within 2 sec. after the local destination

displayed.

2, 5, "Start Print" key

3, 6, "Start Print" key

25 mode

* Writing of

non-volatile memory

Service mode

Stop key Stop key

Stop key

36 mode

* Running test

* Adjustment

Stop key

4, 7, "Start Print" key

47 mode

* Input check

* Output check

Standby mode

(User mode)

Press "Select Paper"

key for 5 sec.

User setting mode

* Cassette paper size setting

* Clear timer setting

* Counter value read

Power save timeout

Setting end

8-14

Loading...

Loading...