Page 1

Primary Precautions to be Observed During Maintenance

Powered by

Aleck Kholopov

Slash, Ltd

( 095 201 48 20

* slash@slash.ru

" http://www.slash.ru

SERVICE

1. Before troubleshooting a particular problem, consult the operator to obtain clues that may assist in

finding the problem. Who would be more familiar

with the symptom of the problem than the individual that constantly operates the machine.

2. Copy Samples

Always make copy samples before and after your

maintenance service to ensure proper machine

operation.

3. Drum

• Do not expose the drum to sunlight or room light.

When the drum is removed from the machine, place a

cover over it.

• When cleaning the photosensitive surface, use a

cleaning pad moistened with the specified drum

cleaner.

Never use solvents other than the drum cleaner;

otherwise the photosensitive material of the drum can

be dissolved.

4. After maintenance is completed, remember to

reset the PM counter. (47 mode, Code 90/See the

adjustment section for details.)

5. Always reset the drum counter when replacing the

drum. (47 mode, Code 91/See the adjustment

section for details.)

Caution

Be sure to turn the main switch OFF and pull the

plug before working on the machine.

7-1

Page 2

SERVICE

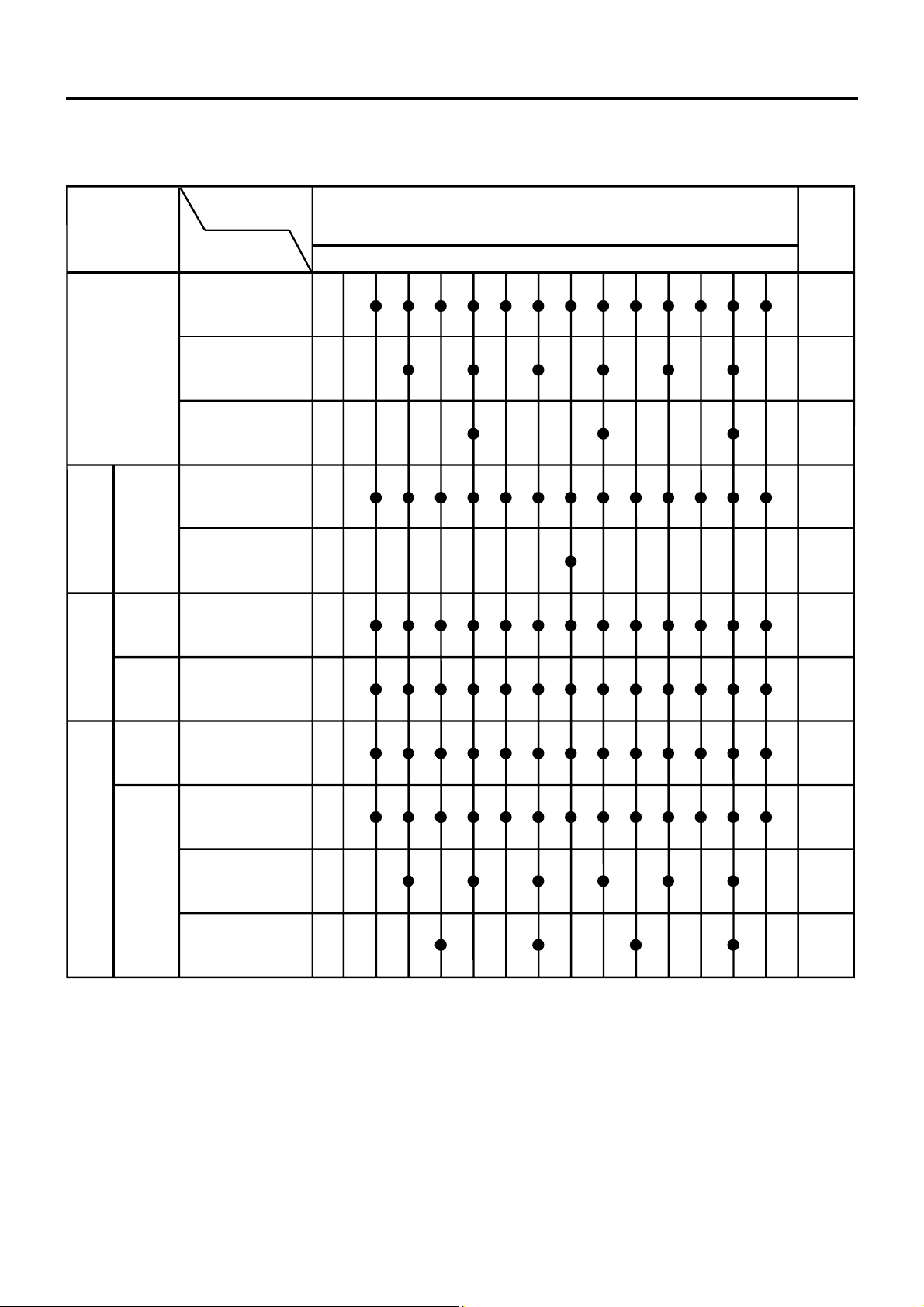

SERVICE SCHEDULE

[1] Service Schedule

ADF

DBU

Model

Main

body

DF-204

DB-607

Copy Q'ty

Service items

Maintenance

(Every 30,000cps)

Periodic check ( I )

(Every 60,000cps)

Periodic check ( II )

(Every 120,000cps)

Maintenance

(Every 30,000cps)

Periodic check ( I )

(Every 210,000cps)

Maintenance

(Every 30,000cps)

(Unit:1,000cps)

Guarantee period (5years or 400,000cps)

0 30 60 90 120 150 180 210 240 270 300 330 360 390

Number

of cycle

13

6

3

13

1

13

STR

DB-207A

ST-103

ST-104

Maintenance

(Every 30,000cps)

Maintenance

(Every 30,000cps)

Maintenance

(Every 30,000cps)

Periodic check ( I )

(Every 60,000cps)

Periodic check ( II )

(Every 90,000cps)

13

13

13

6

4

7-2

Page 3

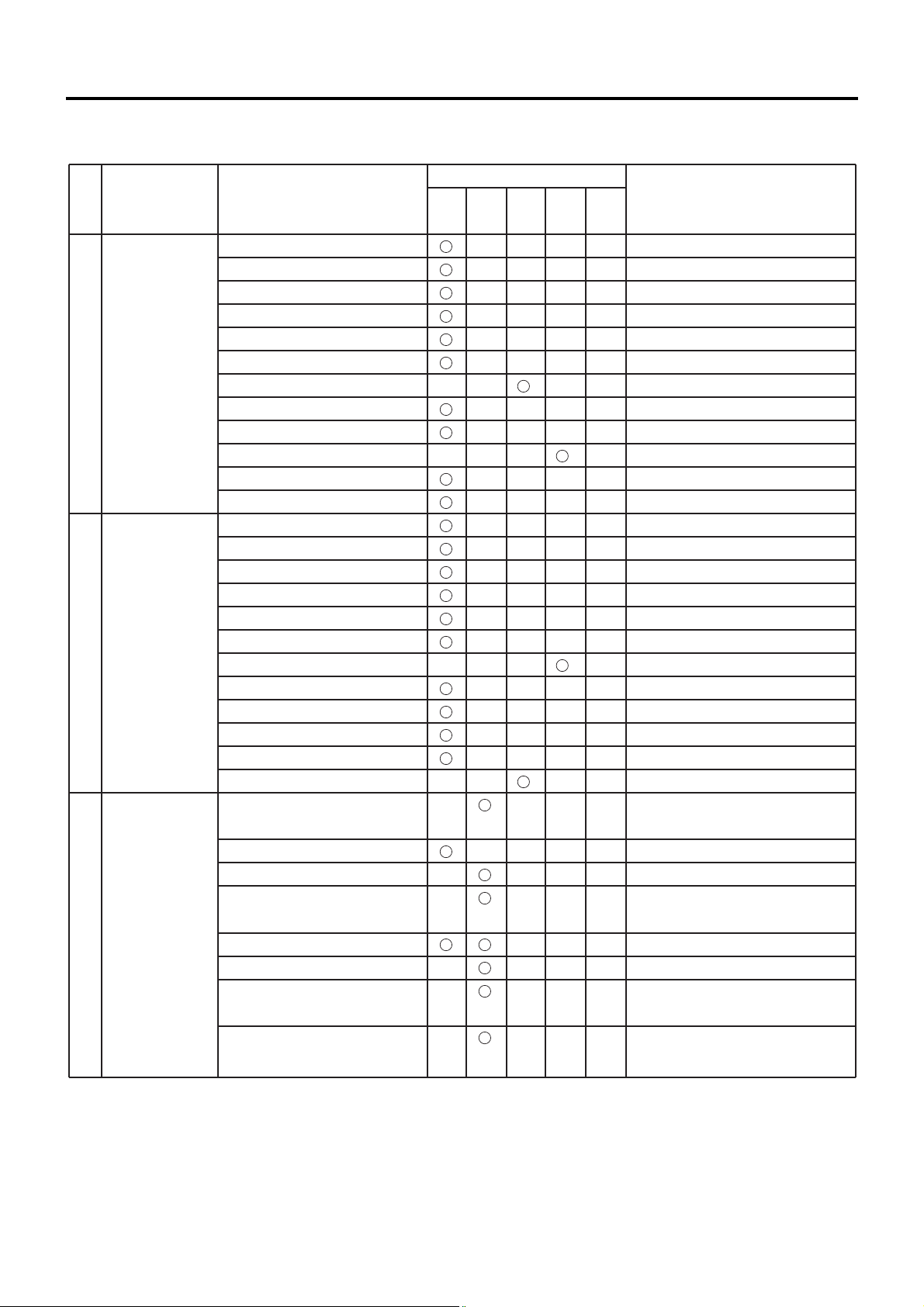

[2] Maintenance Items

1. Main body (Every 30,000 copies)

1

Preparation

2

Drum unit

3

Conveyance

section

4

Developing

section

5

Paper feed

section

Image check

Kit contents check

Drum cartridge

Cleaning blade (25HA-213*)

Separation claw (include separation claw position change)

PCL

CEL

Charging corona unit (wire)

Second paper feed driven roller

Third paper feed driven roller

Toner supply unit

Transfer/Separation corona unit

Paper conveyance guide plate

Paper conveyance section

(upper section)

Developer

Developing unit

Toner density sensor

Around the unit

Paper feed roller (Upper/Lower)

Paper drive roller (Upper/Lower)

Paper driven roller

Bypass roller

Sensor (PS1)

Paper feed guide plate

(Upper/Lower)

Implementation classification

Re-

Check

Lubrication

place-

ment

Clean-

ing

Supply

SERVICE

Service material and toolsService itemClassificationNo.

Setting powder

Drum cleaner/Cleaning pad

Blower brush/Cleaning pad

Blower brush/Cleaning pad

Cleaner knob/Blower brush

Blower brush/Cleaning pad

Blower brush/Cleaning pad

Blower brush/Cleaning pad

Blower brush/Cleaning pad

Blower brush/Cleaning pad

Blower brush/Cleaning pad

Blower brush

Blower brush/Cleaning pad

Towel/Blower brush

Towel/Blower brush

Towel/Blower brush

Towel/Blower brush

Blower brush

Blower brush/Cleaning pad

7-3

Page 4

SERVICE

6

Optics

section

7

Fixing unit

section

8

Final check

Exposure lamp

Reflection mirrors(main and aux.)

Lens

First to fourth mirrors

AE sensor

Photo sensors

Optics stopper felt

Platen glass

Platen cover

Ozone filter (26LA1001*)

Scale plate

APS sensor

Upper fixing roller

Lower fixing roller

Paper exit roller

Paper exit roller/A

Fixing claw

Upper fixing guide plate

Cleaning roller (35EA5305*)

Fixing temperature sensor 1

Fixing temperature sensor 2

Thermostat

Sensor cleaning blade (2 pcs)

Gears

L detection adjustment

(47 mode, Code 51) *1

Around the machine

W.U.T. check

Image check (light distribution

and intensity adjustments)

Unit external parts

Current leakage breaker

PM counter reset

(47 mode, Code 90) *2

Drum counter reset

(47 mode, Code 91) *3

Implementation classification

Re-

Check

Lubrication

place-

ment

Clean-

ing

Supply

Service material and toolsService itemClassificationNo.

Blower brush/Cleaning pad

Blower brush/Cleaning pad

Blower brush/Cleaning pad

Blower brush/Cleaning pad

Blower brush

Blower brush

Multi oil

Drum cleaner/Cleaning pad

Drum cleaner/Cleaning pad

Cleaning pad

Blower brush

Roller cleaner/Cleaning pad

Roller cleaner/Cleaning pad

Drum cleaner/Cleaning pad

Roller cleaner/Cleaning pad

Roller cleaner/Cleaning pad

Drum cleaner/Cleaning pad

Cleaning pad/Paper/Drum cleaner

Cleaning pad/Paper/Drum cleaner

Cleaning pad/Paper/Drum cleaner

Roller cleaner/Cleaning pad

Solvest 240

Plas guard No.2

Drum cleaner/Cleaning pad

Drum cleaner/Cleaning pad

* Every 2PM (60,000 cps) or drum

replacement

Note : *1 to*3 : Perform checking in this order.

7-4

Page 5

2. ADF [DF-204] (every 30,000 copies)

Preparation

1

Paper feed

2

section

Paper

3

conveyance

section

4

Reversal

paper exit

section

5

Final check

Paper feed check

(with enclosures removed)

Paper feed roller

Paper feed belt

Paper feed driven roller

Double feed prevention roller

Photo sensor

Paper conveyance belt

Photo sensor

Conveyance gear

Reversal roller

Paper exit roller

Around the unit

(with enclosures mounted)

Paper feed check

Implementation classification

Re-

Check

Lubrication

place-

ment

Clean-

ing

Supply

Service material and toolsService itemClassificationNo.

Drum cleaner/Cleaning pad

Drum cleaner/Cleaning pad

Drum cleaner/Cleaning pad

Drum cleaner/Cleaning pad

Blower brush

Drum cleaner/Cleaning pad

Blower brush

Plas guard No.2

Drum cleaner/Cleaning pad

Drum cleaner/Cleaning pad

Cleaning pad

SERVICE

3. DBU [DB-207A] (every 30,000 copies)

1

Preparation

2

Paper feed

section

3

Paper

conveyance

section

Final check

4

Paper feed check

(with enclosures removed)

Paper feed roller

Paper feed drive roller

Paper feed driven roller

Paper conveyance side door

Sensor

Paper feed check

(with enclosures mounted)

External section

Implementation classification

Clean-

ing

Check

Lubrication

Re-

place-

ment

Supply

Service material and toolsService itemClassificationNo.

Drum cleaner/Cleaning pad

Drum cleaner/Cleaning pad

Drum cleaner/Cleaning pad

Blower brush

Blower brush

Drum cleaner/Cleaning pad

7-5

Page 6

SERVICE

4. DBU [DB-607] (Every 30,000 copies)

1

Preparation

2

Paper feed

section

(LCT/PFU)

Paper

3

conveyance

section

(LCT/PFU)

Final check

4

Paper feed check

(with enclosures removed)

Paper feed roller

Paper feed drive roller

Paper feed driven roller

Paper conveyance side door

Sensor

Paper feed check

(with enclosures mounted)

External section

Implementation classification

Re-

Check

Lubrication

place-

ment

Clean-

ing

Supply

Service material and toolsService itemClassificationNo.

Drum cleaner/Cleaning pad

Drum cleaner/Cleaning pad

Drum cleaner/Cleaning pad

Blower brush

Blower brush

Drum cleaner/Cleaning pad

5. STR[ST-103] (Every 30,000 copies)

1

Preparation

2

Paper

conveyance

section

Stapler unit

3

Final check

4

Paper feed check

(with enclosures removed)

Conveyance belt

Feed belt

Gate switching gear

Conveyance roller

Conveyance guide plate

Paper detection sensor

Drive in a staple position

Paper feed check

(with enclosures mounted)

External section

Implementation classification

Re-

Check

Lubrication

place-

ment

Clean-

ing

Supply

Service material and toolsService itemClassificationNo.

Cleaning pad

Cleaning pad

Plas guard No.2

Drum cleaner/Cleaning pad

Drum cleaner/Cleaning pad

Blower brush

Blower brush

Drum cleaner/Cleaning pad

Drum cleaner/Cleaning pad

7-6

Page 7

6. STR[ST-104] (Every 30,000 copies)

Preparation

1

Conveyance

2

unit

3

Drive unit

4

Final check

Paper feed check

(with enclosures removed)

Static brush (L,S)

Feed roller

Sensor hole for paper remainder

Aligner

Tray pin slide groove

Carrier support slide groove

Inside of groove for transfer cam

Stapler slide groove

Shaft holder section

Gear section

Paper feed check

(with enclosures mounted)

External section

Implementation classification

Clean-

ing

Check

Lubrication

Re-

place-

ment

Supply

Service material and toolsService itemClassificationNo.

Drum cleaner/Cleaning pad

Cleaning pad/Cotton pad

Cleaning pad

Plas guard No.2 /Cotton pad

Plas guard No.2 /Cotton pad

Plas guard No.2 /Cotton pad

Plas guard No.2 /Cotton pad

Multi oil /Cotton pad

Plas guard No.2 /Cotton pad

Drum cleaner/Cleaning pad

SERVICE

7-7

Page 8

SERVICE

[3] Periodic Check Service Items

1. Main body

(1) Periodic check [ I ] (Every 60,000 copies)

No.

Drum unit

1

Fixing unit

2

Final check

3

(2) Periodic check [ II ] (Every 120,000 copies)

No.

Fixing unit2

Service item

Drum

Upper fixing roller

26AA5305*

Drum counter reset

(47 mode, Code 91)

Service item

Lower fixing roller

35EA5304*

Cleaning

Cleaning

Implementation classification

Check Supply

Lubrica-

tion

Replace-

ment

Implementation classification

Check Supply

Lubrica-

tion

Replace-

ment

Service material and toolsClassification

Service material and toolsClassification

2. ADF [DF-204]

(1) Periodic check [ I ] (Every 210,000 copies)

No.

1

Paper feed

section

Service item

Paper feed belt

04804027*

Double feed

prevention roller

19604021*

3. STR [ST-104]

(1) Periodic check [ I ] (Every 60,000 copies)

No.

Drive unit1

Service item

Tray pin slide groove

Carrier support slide

groove

Inside of groove for

transfer cam

Stapler slide groove

Shaft holder section

Gear section

Cleaning

Cleaning

Implementation classification

Check Supply

Lubrica-

tion

Replace-

ment

Implementation classification

Check Supply

Lubrica-

tion

Replace-

ment

Service material and toolsClassification

Service material and toolsClassification

Plas guard No.2/Cotton pad

Plas guard No.2/Cotton pad

Plas guard No.2/Cotton pad

Plas guard No.2/Cotton pad

Multi oil/Cotton pad

Plas guard No.2/Cotton pad

7-8

Page 9

(2) Periodic check [ II ] (every 90,000 copies)

No.

Paper

1

conveyance

section

Service item

Static brush (L)

12QA1019*

Static brush (S)

12QA4819*

Cleaning

Implementation classification

Check Supply

Lubrica-

tion

Replace-

ment

SERVICE

Service material and toolsClassification

7-9

Page 10

SERVICE

COPY MATERIALS

[1] Toner Kit

1. Configuration (1kit/8,000 copies)

Description Quantity

Toner 1 pc

Toner Cartridge

Dust bag 1 pc

[2] PM Parts Kit

1. Configuration (1 kit/30,000 copies)

Description Quantity

Drum cleaning blade 1 pc

Fixing cleaning roller 1 pc

Ozone filter 1 pc

Cleaning pad (10pcs) 1 pc

Polyethylene gloves 1 set

Developer collecting sheet 1 pc

and rubber band

Dust bag and rubber band 1 pc

Collecting hand bag 1 pc

7-10

Page 11

[3] Maintenance Kit

1. Configuration (1 kit/30,000 copies)

SERVICE

Description Quantity

Developer 1 pc

Drum cleaning blade 1 pc

Fixing cleaning roller 1 pc

Ozone filter 1 pc

Description Quantity

Polyethylene gloves 1 set

Developer collecting sheet 1 pc

and rubber band

Dust bag and rubber band 1 pc

Collecting hand bag 1 pc

Cleaning pad (10pcs) 1 pc

7-11

Page 12

SERVICE

SERVICE MATERIALS

Material No. Description Shape Remarks

000V-16-0 Drum cleaner

000V-17-0 Roller cleaner

00GR00020 Plas guard No.2

00GR00170 Multi-oil

00GR00210 Solvest 240

000V-19-0 Setting powder

000V-18-1 Cleaning pad

1 pack

7-12

Page 13

SPECIAL TOOLS

Tool No. Description Shape Quantity Remarks

LX15-0010 Optics pulley holding 1

jig (for replacing

optics wire)

SERVICE

25HA61651

00M6-2-00 Door switch jig 1

00V9-4-00 AE chart 1

00VD-2002 Potential chart 1

00VD-5000 New pyramid chart 1

Optics positioning plate (1) 1

00VC-2-00 Drum cover 1

00VD-1000 Blower brush 1

00VE-1002 Tester 1

or 00VE-1003

(00VE-1002) (00VE-1003)

7-13

Loading...

Loading...