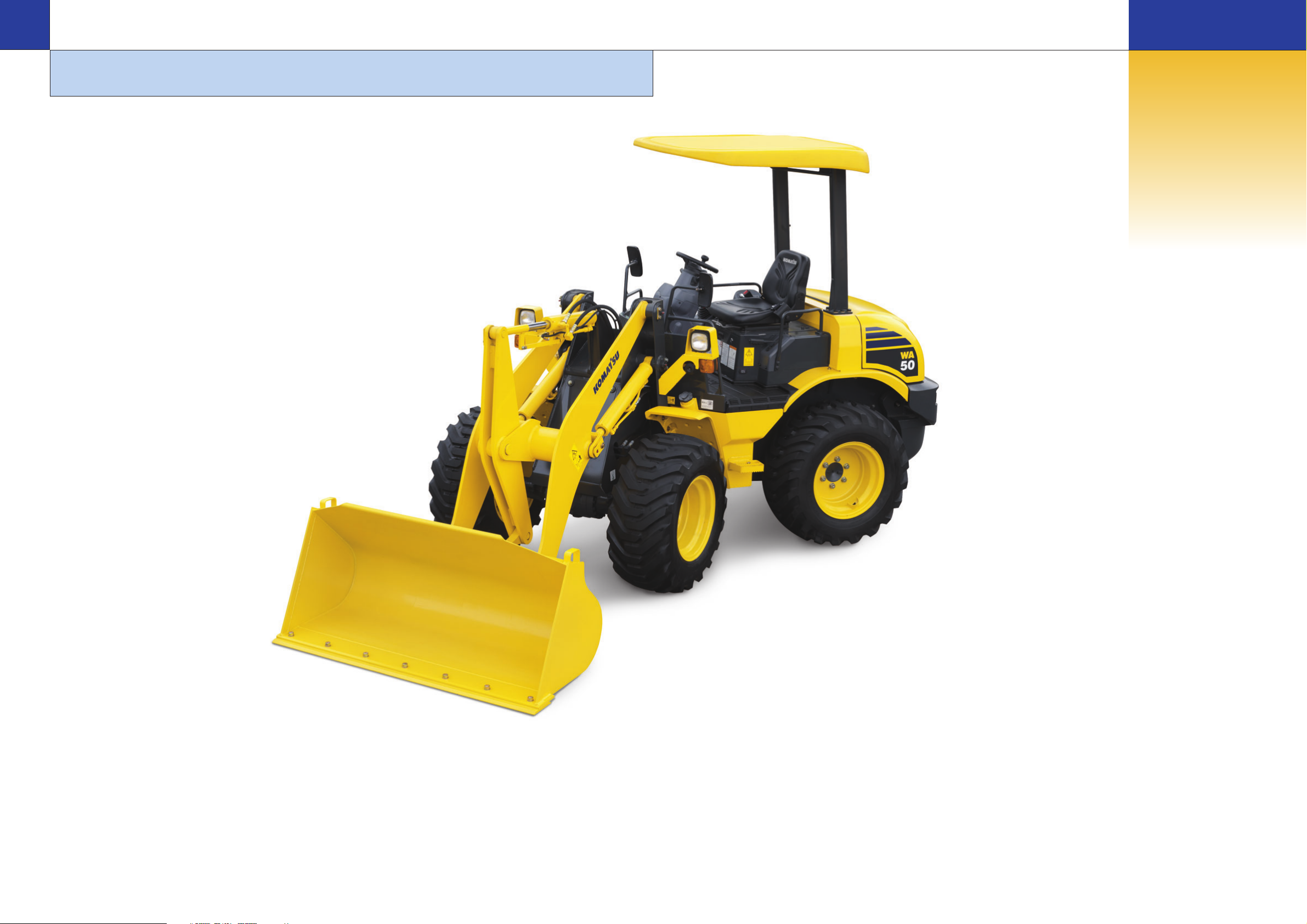

Komatsu WA50-6 User Manual

WA50-6

HORSEPOWER

Gross: 29.7 kW 39.8 HP @ 2400 rpm

Net: 28.7 kW 38.6 HP @ 2400 rpm

OPERATING WEIGHT

3675 – 3825 kg 8,100 –8,430 lb

BUCKET CAPACITY

0.5 –0.6 m

3

0.7 –0.8 yd

3

Photo may include optional equipment.

MINI WHEEL LOADER

WA

50

WALK-AROUND

MINI WHEEL LOADER

HORSEPOWER

Gross: 29.7 kW 39.8 HP @ 2400 rpm

Net: 28.7 kW 38.6 HP @ 2400 rpm

OPERATING WEIGHT

3675 – 3825 kg

8,100 – 8,430 lb

BUCKET CAPACITY

0.5 – 0.6 m

3

0.7 – 0.8 yd

3

WA50-6 M INI W HEEL L OADER

WA50-6

32

Environmental Features

• Low emission engine

• Low operation noise

See page 9.

Productivity Features

• New high-power engine allows any operation to be carried out with minimal effort.

• Allows easy operation even in narrow spaces. Excellent machine operability and stability.

• Short overhang structure and increased articulation angle

• Rear axle oscillation system

• Long wheelbase and wide tread

• Electronic-control HST allows operation of the machine as you desire.

• Speed control function

• Traction control function

• Floor-mounted inching pedal allows easy machine maneuvering for loading.

• Electric auto leveler allows easy operation of the bucket.

• Good dumping clearance and reach

See pages 4 and 5.

Operator Comfort

• Comfortable operator's compartment

featuring increased legroom

• Easy operation by simple lever control

• Electric forward/reverse selector lever

• Single-lever bucket control

• Very comfortable operator's seat

• Small-diameter steering wheel allows you to

operate the machine as you would drive

a passenger car.

• Easy-to-clean floor mat flush with the entrance

frame

Additional Features

• ROPS and canopy

• Excellent visibility for secure and reliable operations

• Safe and easy-to-use access ladder

• Anti-slip floor mat

• Large counterweight to protect the rear and rear side

sections of the machine

• New boom design permitting excellent front visibility

• High braking performance assures reliable operation.

• HST dynamic braking

• Sealed wet-type disc brakes featuring high

braking performance and long service life

• Hand operated parking brake

• Overrun control system

• Bucket leveler plates allow you to quickly check the

angle of bucket.

See page 8.

Increased Reliability & Serviceability

• Easy-to-maintain designs allow quick and

easy daily checks and maintenance.

• Single-touch full-open hood

• Remote and collective arrangement of filters

• Side-by-side cooling system

• Automatic air bleeding system

• Pre-cleaner (optional)

• Components that prevent machine failure and

improve machine reliability

• Face-seal type hydraulic hose/tube connectors

• DT connectors

• Tapered roller bearings

See page 9.

• Newly designed large operator's cab (optional) with wide

visibility and comfortable seating

• Pillar-less front cab glass for excellent visibility

• Wide operating space

• Walk through cab

• Fresh air type heater and defroster as standard equipment

• Fresh air type air conditioner (optional)

See pages 6 and 7.

Photo may include optional equipment.

5

MINI WHEEL LOADER

WA50-6

New high-power engine allows

any operation to be carried out

with minimal effort.

Featuring a new high-power and flexi-

ble Komatsu engine. Combined with

electronic control HST with minimum

power loss, Komatsu engine allows the

machine to perform any operation with

minimal effort.

Allows easy operation even in

narrow spaces. Excellent

machine operability and stability.

Short overhang structure and

increased articulation angle

Maneuverability has been increased

through a redesign of the chassis lay-

out. The machines prove their worth

when operated in narrow spaces.

PRODUCTIVITY FEATURES

4

WA50-6 M INI W HEEL L OADER

Passageway width

at right angles

Short

overhang

Min. turning radius

Articulation

angle: 42.5°

Min. turning radius (outer):

3825 mm 12'7"

Passageway width at right angles:

2460 mm 8'1"

(Machine with standard specifications)

Rear axle oscillation system

Following the uneven ground surface,

the rear axle oscillates to keep the

machine horizontal and stable. When

operated on rough roads, the swing

and vibration are minimized and you

can smoothly complete your work

while positioned on the comfortable

operator's seat.

Note: The photo at right was taken for advertising purposes only.

Do not leave your machine on a slope for security reasons.

Wheelbase Tread

Long wheelbase and wide tread

In addition to the short overhang struc-

ture, the machines feature long wheel-

base and wide tread providing excel-

lent stability both in operation and trav-

eling.

Wheelbase:

1900 mm 6'3"

Tread: 1250 mm 4'1"

Electronic control

HST

(Hydrostatic Transmission)

Electronic-control HST allows operation of the

machine as you desire.

The electronic-control HST allows any operator to start,

accelerate and stop the machine by using accelerator con-

trol only. Also, you can adjust the maximum travel speed

using the stepless speed control switch according to the

work you are engaged in.

The maximum rim pull

can be set to any of 3

stages using the traction

control switch to tailor the

machine to operating

conditions.

Speed control function

The maximum travel

speed can easily be set

from 3 to 15 km/h using

the speed control switch.

Max speed is infinitely,

variable up to 15 km/h to

give the operator option-

al control at all times.

Speed control switch

Traction control switch

Traction control function

The maximum rim pull can be set to any of 3 levels

according to the work you are engaged in.

P mode

Appropriate for operations

requiring an extra burst of rim

pull on demand such as ground

leveling, grading, excavating

and piling.

N mode

Appropriate for loading opera-

tions such as V-shape loading,

aggregate loading and load-

and-carry operation.

S mode

Appropriate for operations car-

ried out on soft and slippery

ground such as snow clearance

and livestock farming.

ATT mode

Reserved mode

Floor-mounted inching pedal allows easy machine

maneuvering for loading.

The floor-mount inching pedal puts the operator in full time

control of his machine. As the trav-

el speed is easy to control, you

can easily stop the machine at the

precise loading position.

Electric auto leveler allows

easy operation of the bucket.

When the bucket is lowered to the

ground, the bucket bottom becomes

level automatically.

Good dumping clearance and reach

The dumping clearance and reach of the machine allow for

efficient loading in to a dump truck or a hopper, and for

stockpiling work.

Dumping clearance:

2475 mm 8'1"

Dumping reach: 900 mm 2'11"

Dumping

clearance

Dumping

reach

Rim pull (kg)

Travel speed (km/h)

Can be limited

to any speed.

Rim pull (kg)

Travel speed (km/h)

Rim pull (kg)

Travel speed (km/h)

Rim pull (kg)

Travel speed (km/h)

Loading...

Loading...