Komatsu WA430-5 User Manual

Photo may include optional equipment.

WA430-5

BUCKET CAPACITY

3.1–4.6 m

3

4.1– 6.0 yd

3

WHEEL LOADER

WA

430

3

NET HORSEPOWER

162 kW 217 HP @ 2000 rpm

OPERATING WEIGHT

18275– 18585 kg

40,290– 40,970 lb

BUCKET CAPACITY

3.1 – 4.6 m

3

4.1 – 6.0 yd

3

WA430-5

WHEEL LOADER

Increased Reliability

● Reliable Komatsu designed and

manufactured components

● Sturdy main frame

● Maintenance-free, fully hydraulic,

wet disc service and parking brakes

● All hydraulic hoses use flat face

O-ring seals

See page 6.

● Cathion electrodeposition process

is used to apply primer paint

● Powder coating process is used to

apply on main structure

● Sealed DT connectors for electrical

connections

Easy Maintenance

● “EMMS” (Equipment Management

Monitoring System)

● Reversible radiator fan

● Swing-out aftercooler and

oil coolers

See page 7.

● Prolonged engine oil change interval

● Ground check for windshield washer

tank and coolant tank

● Easy access, gull-wing type engine

side doors

Photo may include optional equipment.

2

WA430-5 Wheel Loader

W

ALK

-A

ROUND

W

ALK

-A

ROUND

High Productivity

& Low Fuel Consumption

● Powerful engine

● Ultra-low fuel consumption

● Dual-mode engine power select system

● Transmission mode select system

● Dual speed hydraulic system

● Superior dumping clearance and reach

● Long wheelbase and 40 degree articulation

See page 4.

Excellent Operator Environment

● Automatic transmission with selectable modes

● Low-noise designed cab (option)

● Electrically controlled transmission lever

● Fingertip control levers

● Pillar-less large ROPS/FOPS cab (option)

● Easy entry/exit, rear-hinged doors

● Telescopic/tilt steering column

See pages 8 and 9.

Harmony with Environment

● Low spectator noise

● Low fuel consumption

5

WA430-5

WHEEL LOADER

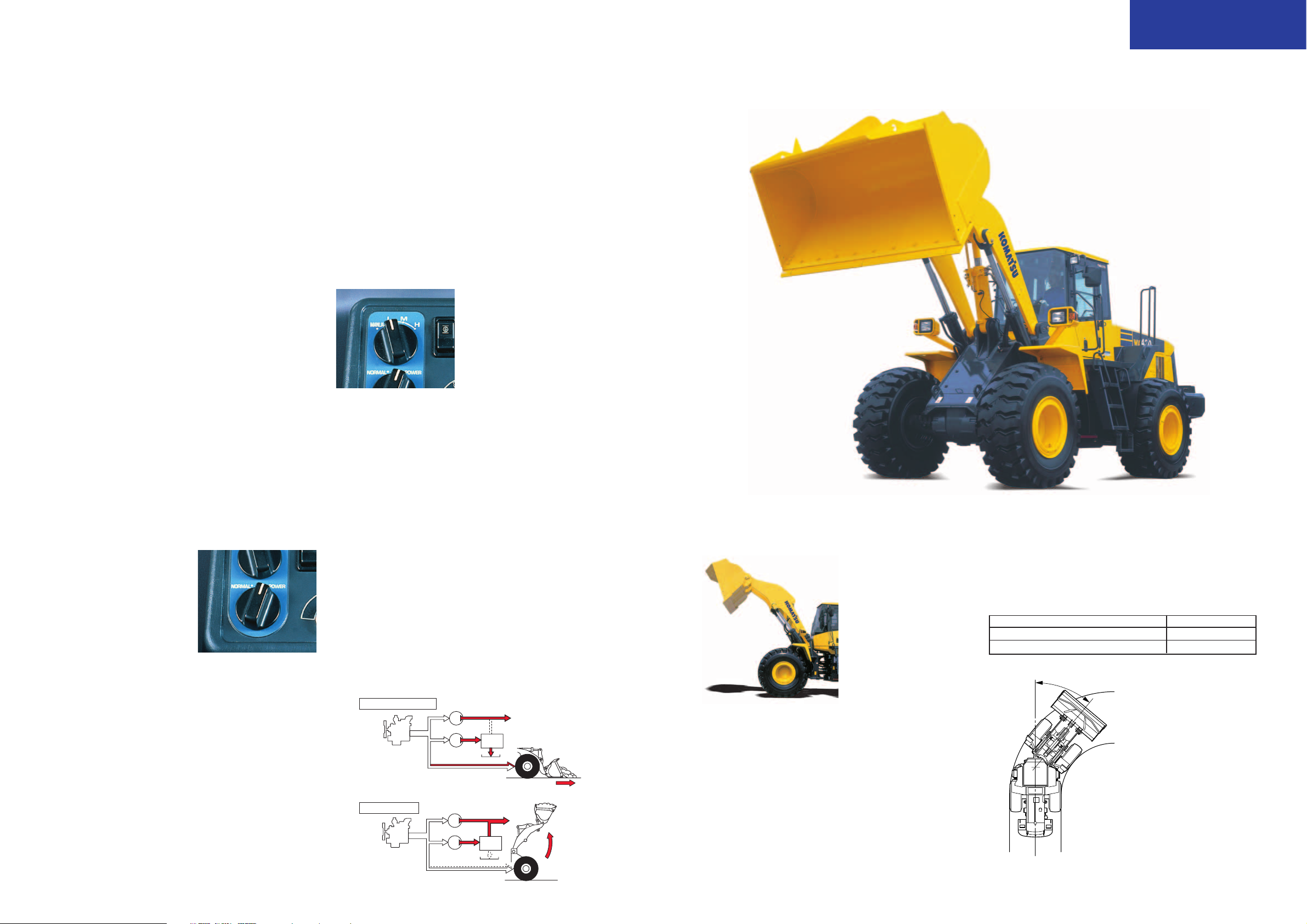

Maximum Dumping Clearance and Reach

The long lift arms provide

high dumping clearances

and maximum dumping

reach. The operator can

even level loads on the

body of a dump truck

easily and efficiently.

Dumping Clearance: 3125 mm 10'3"

Dumping Reach: 1110 mm 3'8"

(3.7 m

3

4.8 yd3bucket with B.O.C.)

Long Wheelbase/Articulation Angle of 40˚

The widest tread in class and the long wheelbase provide

improved machine stability in both longitudinal and lateral

directions. Since the articulation angle is 40

˚

, the operator

can work efficiently even in the tightest job sites.

Tread 2200 mm 7'3"

Wheelbase 3350 mm 11'0"

Minimum turning radius (center of outside tire) 5700 mm 18'8"

4

P

RODUCTIVITY

F

EATURES

P

RODUCTIVITY

F

EATURES

Powerful Engine

The high pressure fuel injection in the SAA6D125E-3

engine provides optimum combustion of fuel

at both low and high speed/power applications. This engine

also provides fast throttle response to match the machine’s

powerful rim pull and fast hydraulic response.

162 kW, 217 HP

Low Fuel Consumption

The fuel consumption is reduced greatly because of the

low-noise, high-torque engine and the large-capacity torque

converter with maximum efficiency in the low-speed range.

Reduction of Fuel Consumption: 15% (compared with

Dash 3 technology).

Dual-Mode Select System

This wheel loader offers two selectable operating modes—

Normal and Power. The operator can adjust the machine’s

performance by flipping a switch.

● Normal Mode: This mode

provides maximum fuel

efficiency for most of

general loading.

● Power Mode: This mode

provides maximum power

output for hard digging

operation or hill climb.

Transmission Mode Select System

This operator controlled system allows the operator to

select manual shifting or three levels of automatic shifting

(low, medium, and high).

● Manual: Transmission is

fixed to gear speed selected

with gear shift lever.

● Auto. L: This mode

provides smooth gear

change and low fuel

consumption since gear

shifting is performed at relatively low engine speeds,

suitable for general excavating and loading.

● Auto. M: Gear is shifted at medium engine speeds

between those of L and H modes.

● Auto. H: This mode provides large rim pull and short

cycle time since gear shifting is performed at relatively

high engine speeds, suitable for load and carry operation

on uphill.

New Dual-Speed Hydraulic System

Komatsu’s dual-speed hydraulic system increases

operational efficiency by matching the hydraulic demands

to work conditions.

Oil from the switch pump is completely returned to the tank

when digging and breaking out, therefore, hydraulic flow

to the loader is reduced and pressure is increased. This

reduces horsepower demand from the engine and makes

the operation more efficient. Kick-down switch signal also

controls the oil flow. This new technology is greater

productivity at the lowest operating cost.

Loader pump

Switching pump

Cut-off

valve

Tank

Cut-off

valve

Tank

Loader pump

Switching pump

When digging / scooping

All the oil from the switching pump returns to the tank.

Hydraulic load is reduced and large power flows to the tires.

All the oil from the switching pump flows to the work equipment.

The raising speed of the lift arm is increased.

When raising lift arm

High Productivity and Low Fuel Consumption

40˚

Loading...

Loading...