KOMATSU wa150pz5 loaders op manuals

VEAM420100

Operation & Maintenance

Manual

WA150PZ-5

WHEEL LOADER

SERIAL NUMBERS

WARNING

Unsafe use of this machine may cause serious injury or

death. Operators and maintenance personnel must read

this manual before operating or maintaining this

machine. This manual should be kept near the machine

for reference and periodically reviewed by all personnel

who will come into contact with it.

NOTICE

Komatsu has had the operating and maintenance instructions translated into all the languages of the member states in the European Union. Should you wish to

have a version of the operating instructions in another

language, please don’t hesitate to ask at your local

dealer’s.

H50051

and up

© 2005 Komatsu Hanomag GmbH

All Rights Reserved

Printed in Europe 06-05

Foreword

1. Foreword

WA150PZ-5 – VEAM420100 1-1

1.1 Foreword Foreword

1.1 Foreword

This manual provides rules and guidelines which will help you

use this machine safely and effectively. The precautions in this

manual must be followed at all times when performing operation

and maintenance. Most accidents are caused by the failure to

follow fundamental safety rules for the operation and maintenance of machines. Accidents can be prevented by knowing

beforehand conditions that may cause a hazard when performing operation and maintenance.

CAUTION

z Operators and maintenance personnel must always do

as follows before beginning operation or maintenance.

z Always be sure to read and understand this manual

thoroughly before performing operation and maintenance.

z Read the safety messages given in this manual and the

safety labels affixed to the machine thoroughly and be

sure that you understand them fully.

z Keep this manual at the storage location for the Opera-

tion and Maintenance Manual given below, and have all

personnel read it periodically.

z If this manual has been lost or has become dirty and

cannot be read, request a replacement manual immediately from KOMATSU or your KOMATSU distributor.

z If you sell the machine, be sure to give this manual to

the new owners together with the machine.

z KOMATSU delivers machines that comply with all appli-

cable regulations and standards of the country to which

it has been shipped. If this machine has been purchased

in another country or purchased from someone in

another country, it may lack certain safety devices and

specifications that are necessary for use in your country. If there is any question about whether your product

complies with the applicable standards and regulations

of your country, consult KOMATSU or your KOMATSU

distributor before operating the machine.

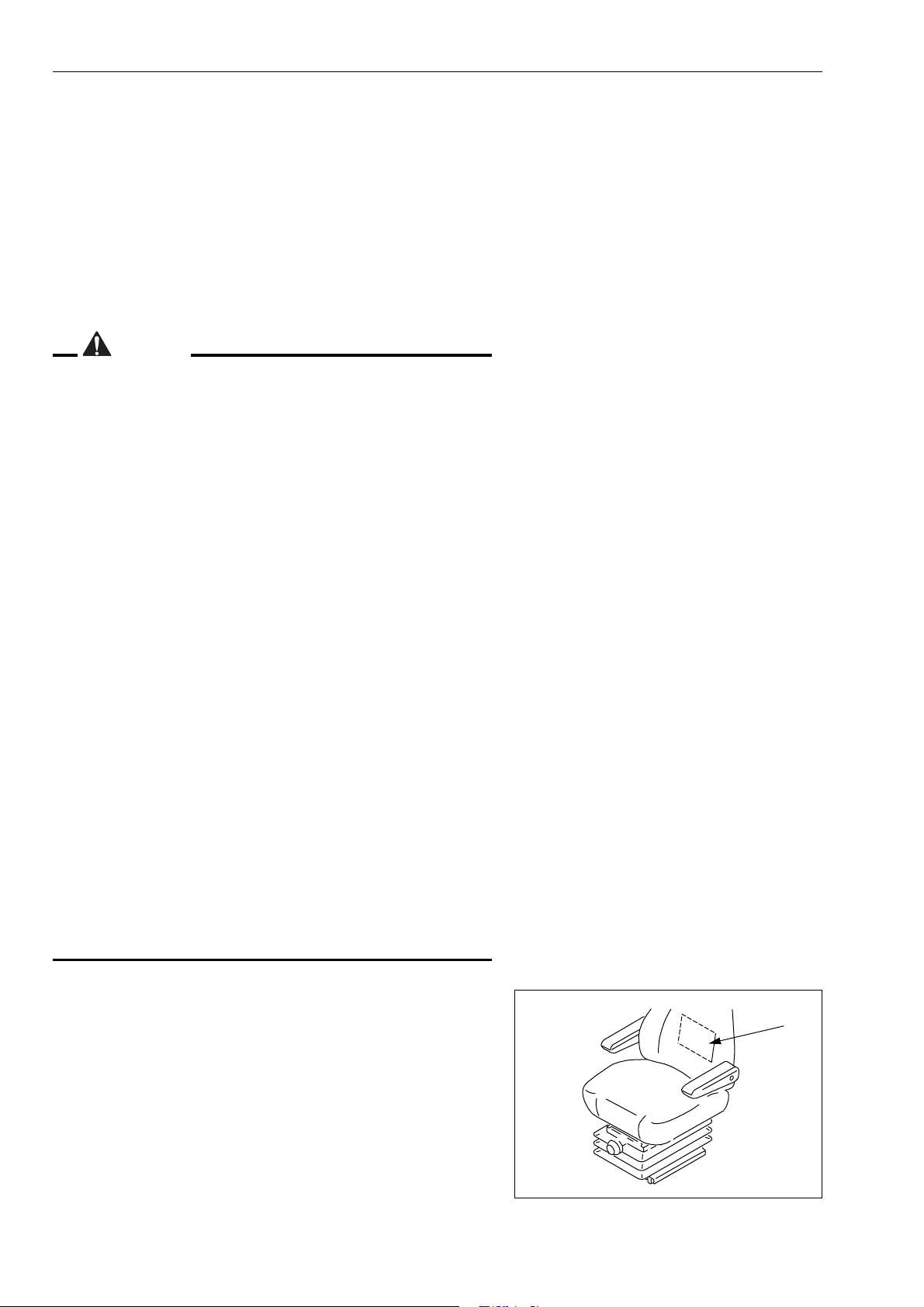

Storage location for the Operation and Maintenance Manual:

Pocket (1) at rear of operator's seat

1

GK032001

1-2 WA150PZ-5 – VEAM420100

Foreword 1.1 Foreword

1.1.1 EU Directives

Machines supplied by us fulfil the Directive for Machinery 89/

392/EEC and all supplements. If the machine is being used in

another country, it is possible that certain safety regulations and

specifications may not be fulfilled for use in that country. For

example, priority vehicle warning lamps may be used in some

countries, but are forbidden in others.

Please contact our dealer before using the machine if you have

any questions regarding the fulfilment of standards and regulations in a specific country.

Notes on subsequent installation of electrical and electronic equipment and components

Electrical and electronic equipment and/or components which

have been installed subsequently, emit electromagnetic radiation which can influence the function of the electronic components and sections of the machine. This can have an influence

on the safety of the machine and endanger persons. For this

reason, please ensure that the following safety instructions are

observed.

If you are installing electrical or electronic equipment and/or

components in the machine and connect them to the vehicle

electrical system, you must check at own responsibility that the

installations do not cause any disturbance to the vehicle’s electronic system or other components. Above all, you must ensure

that any subsequently installed electrical and electronic components comply with the EMV Directive 89/336/EEC in its current

edition and bear the CE mark.

The following requirements also have to be met for subsequent

installation of mobile communication systems (e.g. radio, telephone):

z Only equipment approved by national legislation may be

used

z The unit must be fixed in position

z Portable or mobile units may only be used inside the vehi-

cles if they are connected to a fixed outside antenna

z The transmitter unit must be spatially separated from the

vehicle’s electronic system

z Make sure when installing the antenna that this is installed

correctly with good earth connection between antenna and

vehicle mass

Also observe KOMATSU and manufacturer’s installation instructions for wiring, installation and maximum permitted power consumption.

WA150PZ-5 – VEAM420100 1-3

1.2 Safety information Foreword

1.2 Safety information

To enable you to use this machine safely, safety precautions

and labels are given in this manual and affixed to the machine to

give explanations of situations involving potential hazards and of

the methods of avoiding such situations.

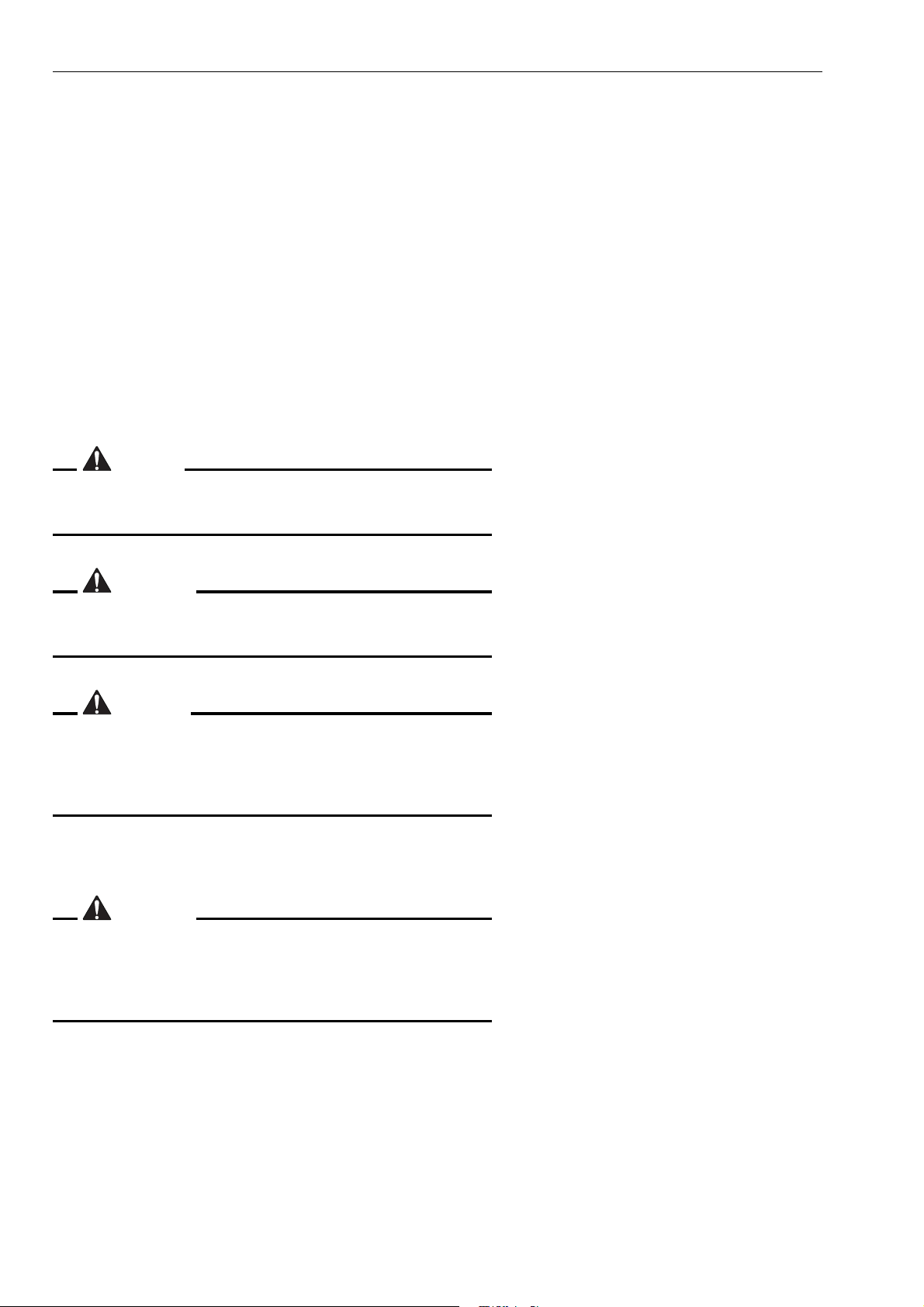

1.2.1 Signal words

The following signal words are used to inform you that there is a

potential hazardous situation that may lead to personal injury or

damage.

In this manual and on machine labels, the following signal words

are used to express the potential level of hazard.

DANGER

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. This word

is used also to alert against unsafe practices that may

cause property damage.

Example of safety message using signal word

WARNING

When standing up from the operator's seat, always place

the safety lock lever in the LOCK position.

If you accidentally touch the control levers when they are

not locked, this may cause a serious injury or death.

1-4 WA150PZ-5 – VEAM420100

Foreword 1.2 Safety information

Other signal words

In addition to the above, the following signal words are used to

indicate precautions that should be followed to protect the

machine or to give information that is useful to know.

NOTE

This word is used for precautions that must be taken to

avoid actions which could shorten the life of the machine.

REMARK

This word is used for information that is useful to know.

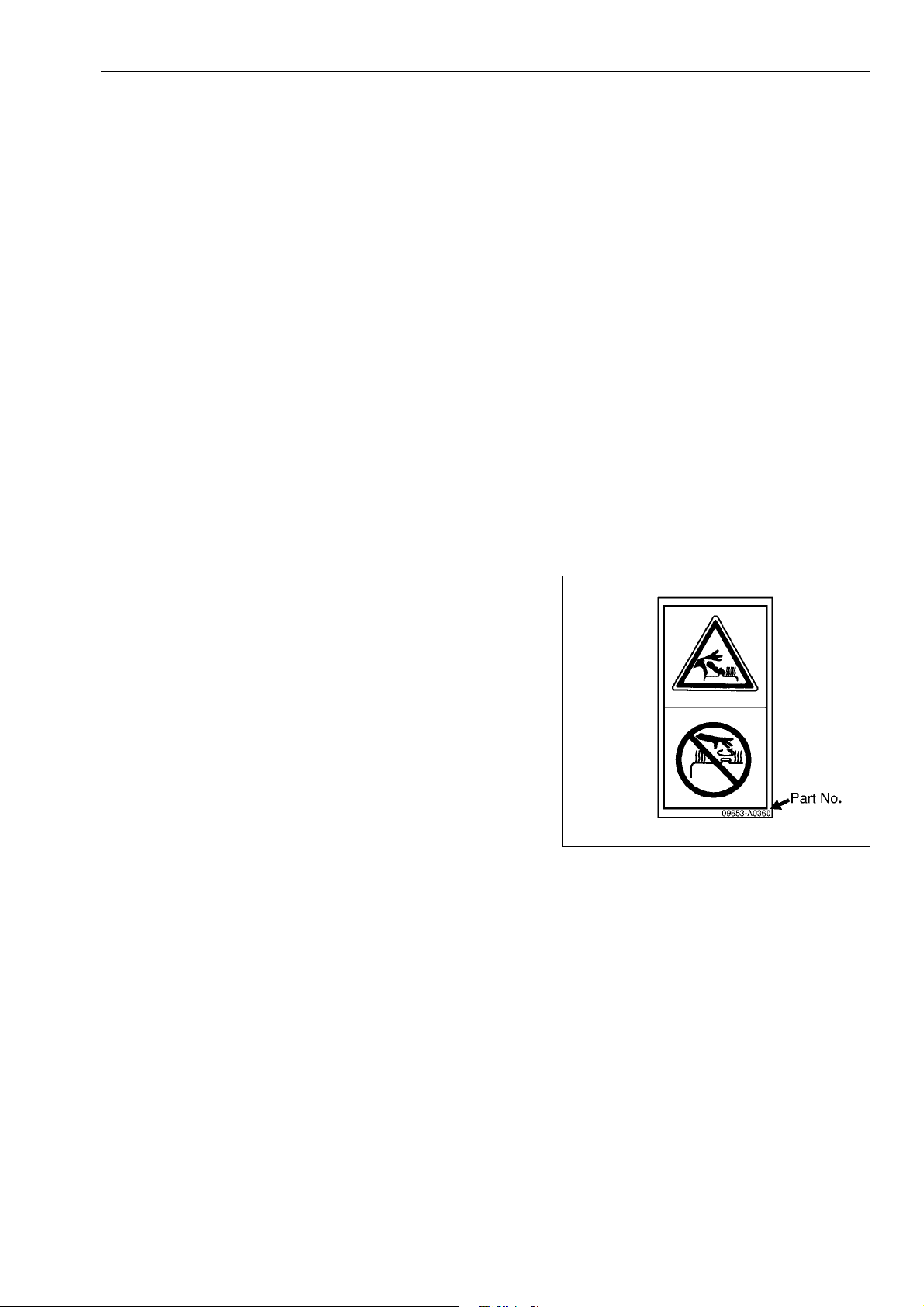

1.2.2 Safety labels

Safety labels are affixed to the machine to inform the operator or

maintenance worker on the spot when carrying out operation or

maintenance of the machine that may involve hazard.

For details of safety labels, see "Safety labels (2-2)".

Safety labels using pictogram

Safety pictograms use a picture to express a level of hazardous

condition equivalent to the signal word. These safety pictograms

use pictures in order to let the operator or maintenance worker

understand the level and type of hazardous condition at all

times. Safety pictograms show the type of hazardous condition

at the top or left side, and the method of avoiding the hazardous

condition at the bottom or right side. In addition, the type of hazardous condition is displayed inside a triangle and the method of

avoiding the hazardous condition is shown inside a circle.

KOMATSU cannot predict every circumstance that might involve

a potential hazard in operation and maintenance. Therefore, the

safety messages in this manual and on the machine may not

include all possible safety precautions.

If any procedures or actions not specifically recommended or

allowed in this manual are used, it is your responsibility to take

the necessary steps to ensure safety.

In no event should you engage in prohibited uses or actions

described in this manual.

The explanations, values, and illustrations in this manual were

prepared based on the latest information available at that time.

Continuing improvements in the design of this machine can

lead to changes in detail which may not be reflected in this manual. Consult KOMATSU or your KOMATSU distributor for the

latest available information of your machine or for questions

regarding information in this manual.

GK032002

WA150PZ-5 – VEAM420100 1-5

1.3 Introduction Foreword

1.3 Introduction

This loader is a machine with independent transmission, moving

on chains or wheels. Driving in forward direction, the loader can

load or dig material using its attachments intended for loading

operations (i.e. bucket).

The standard operation cycle of a loader includes filling up and

loading of the bucket, transporting the material and emptying the

bucket.

1.3.1 Intended use

If you use the machine for any other purpose than specified

above, we will not accept any responsibility for safety. All considerations concerning safety will then be up to the owner or the

operating and maintenance personnel. In any case, neither you

nor any other person are/is authorised to perform work and functions explicitly prohibited in these operating instructions.

The transport of persons in the work equipment is strictly

forbidden!

For details of the operating procedure, see "Work possible using

wheel loader (3-88)"

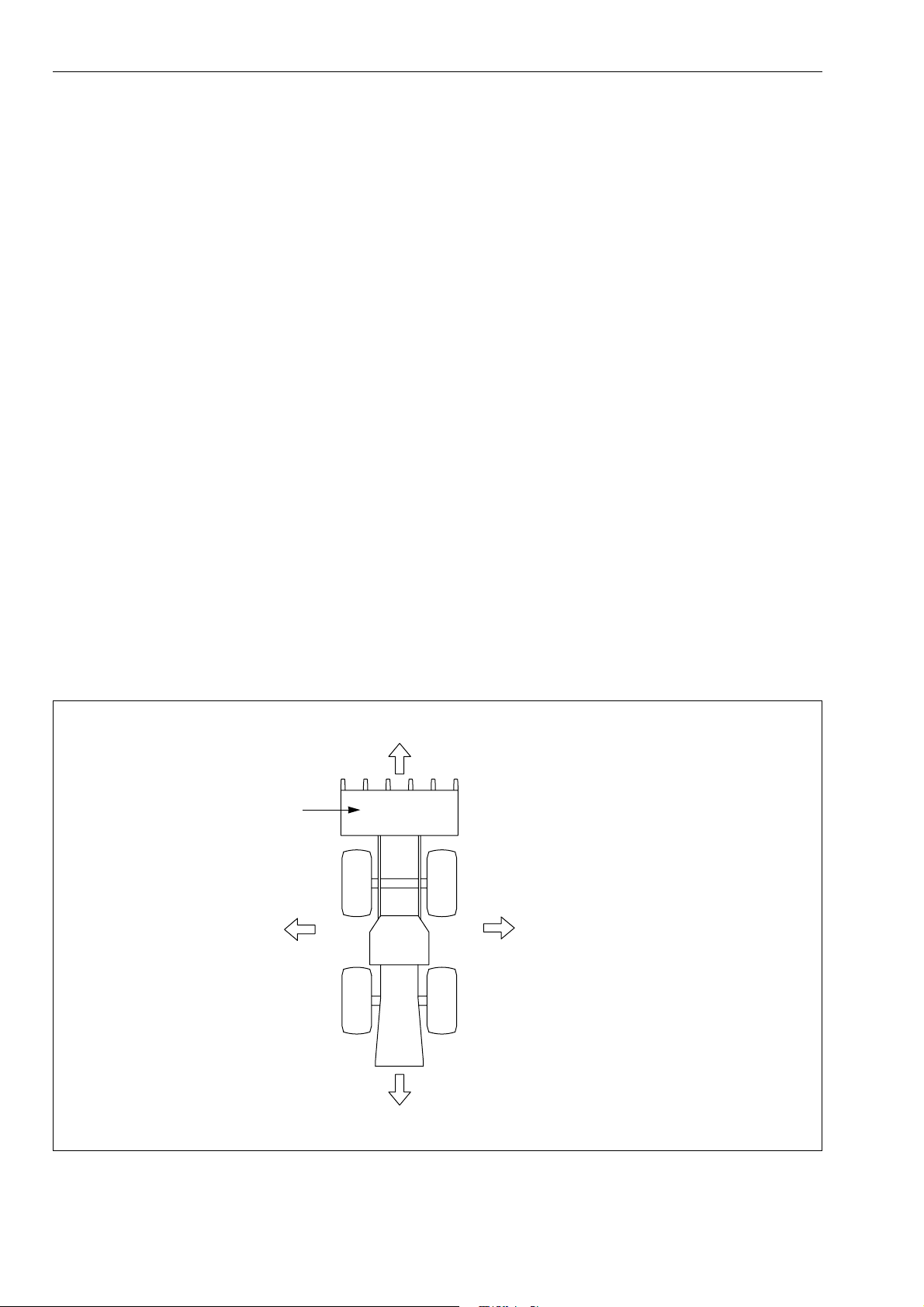

1.3.2 Directions of machine

Front

Bucket

RightLeft

Rear

GK032003

In this manual, the directions of the machine (front, rear, left,

right) are determined according to the view from the operator's

seat in the direction of travel (front) of the machine.

1-6 WA150PZ-5 – VEAM420100

Foreword 1.4 Necessary information

1.4 Necessary information

When requesting service or ordering replacement parts, please

inform your KOMATSU distributor of the following items.

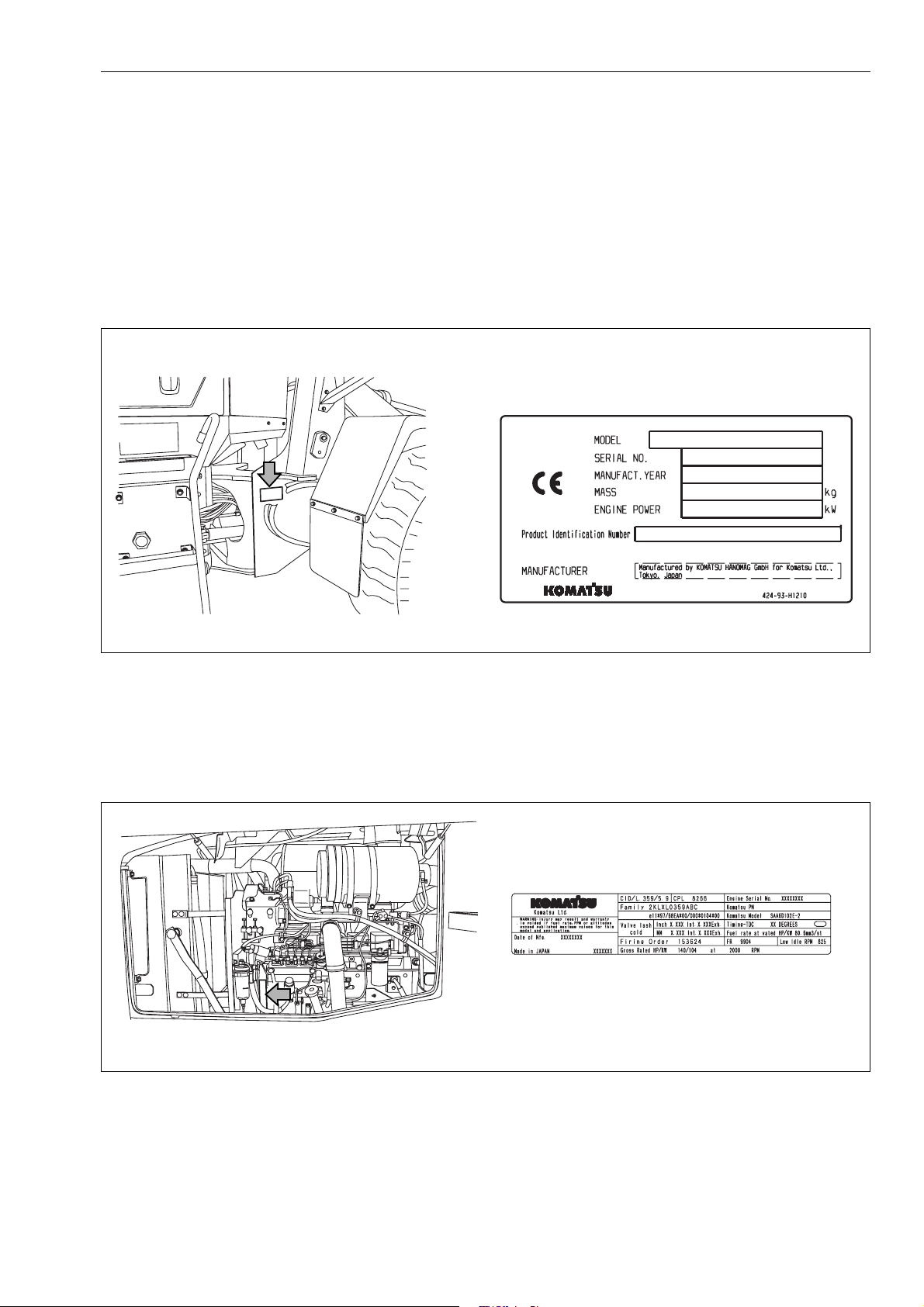

1.4.1 PIN/Machine serial no. plate and position

On the center right of the front frame.

1.4.2 Engine serial no. plate and position

This is on the side face of the engine cover on the right side of

the machine.

GK015035GB

GK020002

EPA: Environmental Protection Agency, U.S.A.

WA150PZ-5 – VEAM420100 1-7

1.4 Necessary information Foreword

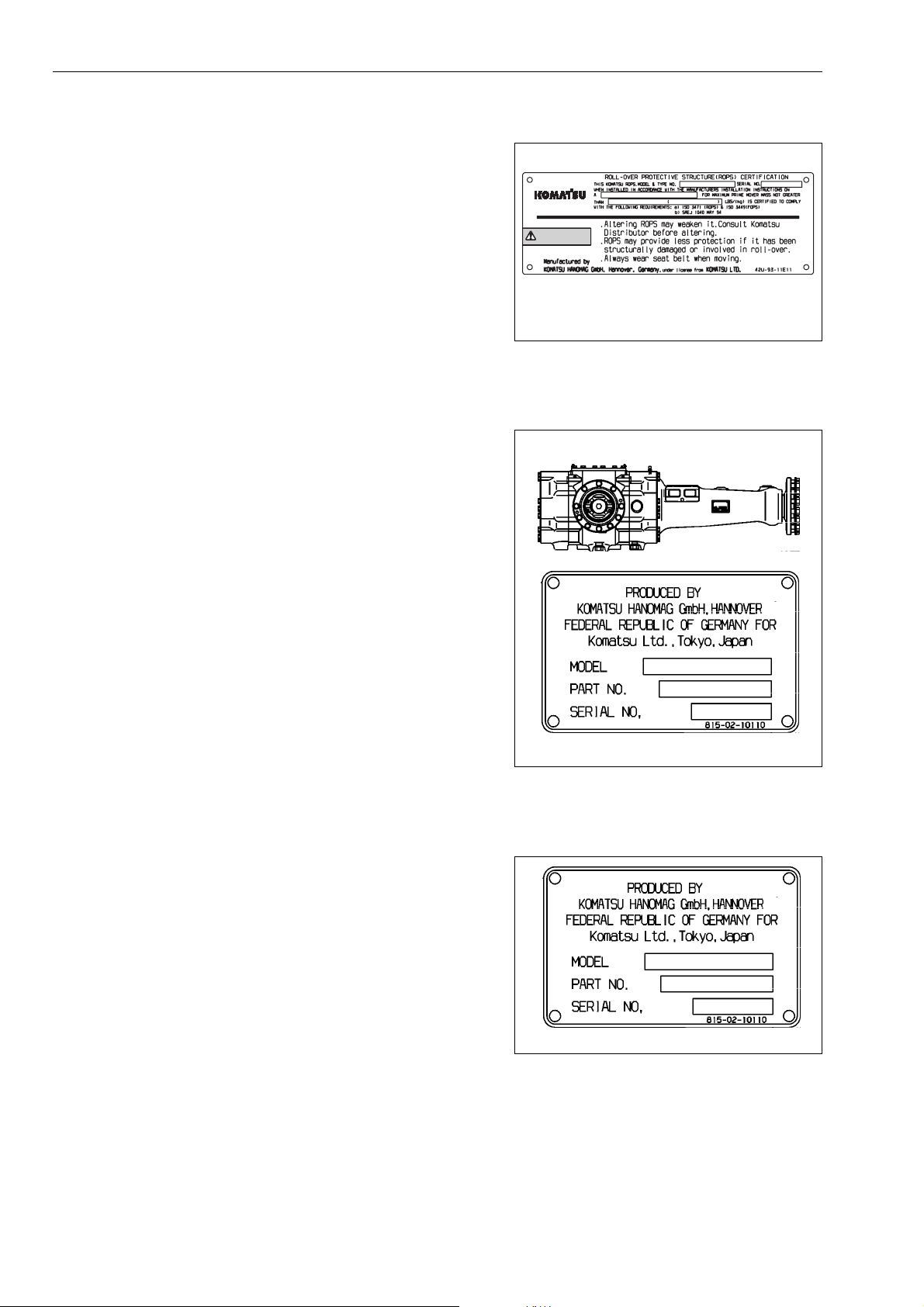

1.4.3 ROPS/FOPS-Cab serial no. plate

This plate is located on the right inside cab on the rear beam.

WARNING

GK032006

1.4.4 Axle serial no. plate

This plate is located on the right of front axle and on the left of

rear axle.

1.4.5 Transmission serial no. plate

This plate is located in travel direction front, above the

transmission output.

GK032007

GK032008

1-8 WA150PZ-5 – VEAM420100

Foreword 1.4 Necessary information

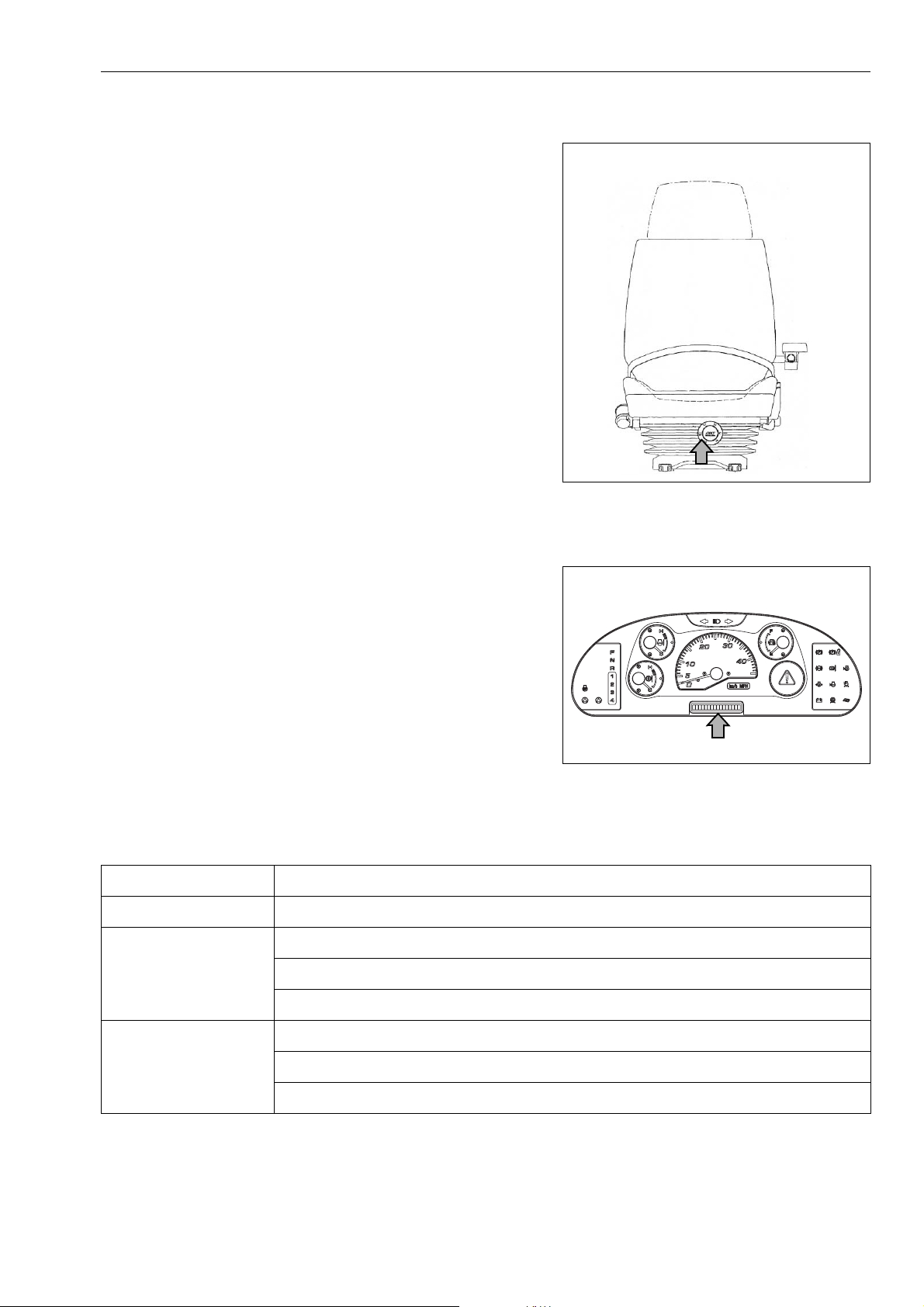

1.4.6 Seat operator serial no. plate

This plate is located in front of seat, covered by the bellows.

GK032009

1.4.7 Position of service meter

It is at the center bottom of the machine monitor.

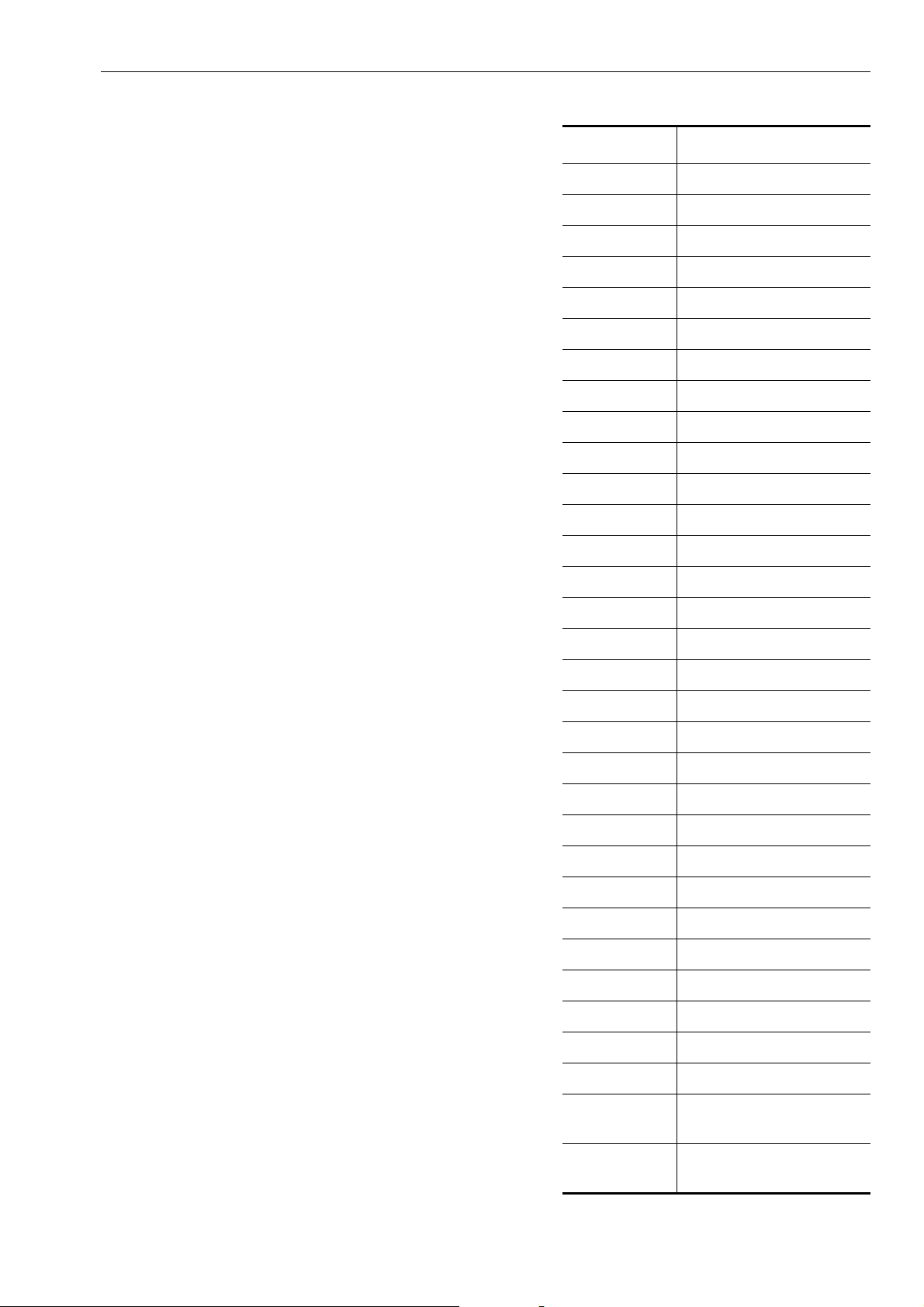

1.4.8 Table to enter serial no. and distributor

Machine serial No.

Engine serial No.

Distributor name

Address

GK032010

Service Personnel

Phone/Fax

WA150PZ-5 – VEAM420100 1-9

1.5 Contents Foreword

1.5 Contents

1. Foreword. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.1 EU Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.2.1 Signal words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.2.2 Safety labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.3 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.3.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.3.2 Directions of machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.4 Necessary information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.4.1 PIN/Machine serial no. plate and position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.4.2 Engine serial no. plate and position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.4.3 ROPS/FOPS-Cab serial no. plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.4.4 Axle serial no. plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.4.5 Transmission serial no. plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.4.6 Seat operator serial no. plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4.7 Position of service meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4.8 Table to enter serial no. and distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.5 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.6 Dimensions, weights and operating data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.6.1 WA150PZ-5: Dimensions, weights and operating data . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.7 CE-Conforming equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.7.1 CE-Conforming equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.7.2 Manufacturer-supplied CE-Conforming equipment, according to

document 419-93-H1250. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

2. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Safety labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.1 Location of safety labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.1.2 Presentation of safety labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 General precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3 Precautions for operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.3.1 Starting engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.3.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.3.3 Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.3.4 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.3.5 Towing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.4 Precautions for maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2.5 Precautions with tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

1-10 WA150PZ-5 – VEAM420100

Foreword 1.5 Contents

3. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 General view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.1 General view of machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.2 General view of controls and gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2 Explanation of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.2.1 Machine monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Monitor system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Types of warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Central warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Character display portion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Emergency stop item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Caution items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Warning/Limit functions for travel speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Inspection and maintenance item. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Pilot display portion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Meter display portion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Other functions of machine monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

3.2.2 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

3.2.3 Control levers, pedals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

3.2.4 Steering tilt lock lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

3.2.5 Cap and cover with lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

3.2.6 Safety bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

3.2.7 Towing pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

3.2.8 Grease pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

3.2.9 Cab door inner lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

3.2.10 Cab door open lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

3.2.11 Cab window open lock cancel knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

3.2.12 Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

Fuse capacity and name of circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

3.2.13 Slow blow fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

3.2.14 Power outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

3.2.15 Storage box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

3.2.16 Air conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

General locations and function of control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

Method of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

Precautions when using . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

3.2.17 Handling cab wiper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

Preventing damage to wiper arm bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

3.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

3.3.1 Check before starting engine, adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

Walk-around check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

Check before starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-63

Safety belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-64

Operations and checks before starting engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-66

3.3.2 Starting engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-68

Normal starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-68

WA150PZ-5 – VEAM420100 1-11

1.5 Contents Foreword

Starting in cold weather. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-70

3.3.3 Operations and checks after starting engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-72

Breaking-in the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-72

Normal operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-73

3.3.4 Stopping engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-74

3.3.5 Moving the machine (directional, speed), stopping the machine. . . . . . . . . . . . . . . . . . 3-75

Moving the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-75

Changing direction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-77

Using switch to change between forward and reverse . . . . . . . . . . . . . . . . . . . . . . . . . 3-78

Stopping the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-80

3.3.6 Turning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-81

Emergency steering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-82

3.3.7 Operation of work equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-83

3.3.8 Handling hydraulic quick coupler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-85

3.3.9 Work possible using wheel loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-88

Digging operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-88

Leveling operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-90

Pushing operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-90

Load and carry operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-91

Loading operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-91

3.3.10 Precautions for operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-93

Permissible water depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-93

If wheel brake does not work. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-93

Precautions when driving up or down slopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-93

3.3.11 Adjusting work equipment posture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-95

Adjusting boom kickout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-95

Adjusting bucket positioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-96

Bucket level indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-96

3.3.12 Parking machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-97

3.3.13 Check after stopping engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-99

3.3.14 Checks after completion of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-99

3.3.15 Locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-99

3.3.16 Handling the tires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-100

Precautions when handling tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-100

Tire pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-100

Precautions for using load and carry method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-101

3.4 Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-102

3.4.1 Transportation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-102

3.4.2 Loading, unloading work with trailers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-102

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-103

Securing machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-103

Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-105

3.4.3 Lifting machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-106

Location of lifting position mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-107

Weight table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-107

Lifting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-108

3.5 Cold weather operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-109

3.5.1 Precautions for low temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-109

1-12 WA150PZ-5 – VEAM420100

Foreword 1.5 Contents

Fuel and lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-109

Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-109

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-110

3.5.2 Precautions after completion of work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-111

3.5.3 After cold weather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-111

3.5.4 Warming-up operation for steering hydraulic circuit in cold weather . . . . . . . . . . . . . 3-111

3.6 Long-term storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-112

3.6.1 Before storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-112

3.6.2 During storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-112

3.6.3 After storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-112

3.7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-114

3.7.1 When machine runs out of fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-114

3.7.2 Towing the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-114

When engine can be used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-115

When engine cannot be used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-116

Emergency travel operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-116

3.7.3 If battery is discharged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-117

Removal and installation of battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-117

Precautions for charging battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-118

Starting engine with booster cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-119

3.7.4 Other trouble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-121

Electrical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-121

Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-122

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-124

4. Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Guides to maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Outlines of service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.1 Handling oil, fuel, coolant, grease and carrying out KOWA

(KOMATSU Oil Wear Analysis) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Carrying out KOWA (KOMATSU Oil Wear Analysis) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Storing oil and fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Biodegradable hydraulic oil and lubricants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.2.2 Outline of electric system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3 Wear parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.3.1 Wear parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.4 Fuel, coolant and lubricants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.4.1 Lubrication chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.4.2 Proper selection of fuel, coolant and lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.5 Standard tightening torques for bolts and nuts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.5.1 Torque list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

WA150PZ-5 – VEAM420100 1-13

1.5 Contents Foreword

4.6 Periodic replacement of safety critical parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.7 Maintenance schedule chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.7.1 Maintenance schedule chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.8 Service procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.8.1 Initial 250 hours service (only after the first 250 hours). . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.8.2 When required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Check, clean, or replace air cleaner element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Dust pre-cleaner "Turbo II": Check, clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Clean inside of cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Check oil level in transfer case, add oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Check axle oil level, add oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Clean axle case breather. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Clean slack adjuster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Clean air conditioner condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Check window washing fluid level, add fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Clean radiator fins and cooler fins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Check electrical intake air heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Replace bolt on cutting edge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Replace bucket teeth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Check air conditioner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Replace slow blow fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Selection and inspection of tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

4.8.3 Check before starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Check before starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

4.8.4 Every 50 hours service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Drain water, sediment from fuel tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

4.8.5 Every 100 hours service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

Lubricate rear axle pivot pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

Clean element in air conditioner fresh air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

Check oil level in hydraulic tank, add oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Lubricating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-43

4.8.6 Every 250 hours service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Check battery electrolyte level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Check parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Check air conditioner compressor belt tension, adjust . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Check for loose wheel hub bolts, tighten. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Clean element in air conditioner recirculation filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Lubricating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-49

4.8.7 Every 500 hours service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

Change oil in engine oil pan, replace engine oil filter cartridge . . . . . . . . . . . . . . . . . . . 4-50

Replace fuel filter cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Replacement of filter cartridge for poor-quality fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Clean water separator strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Lubricating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-55

4.8.8 Every 1000 hours service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

Change oil in transfer case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

Clean transfer case breather. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

Replace HST oil filter element. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

1-14 WA150PZ-5 – VEAM420100

Foreword 1.5 Contents

Lubricating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

Check tightening parts of turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

Check play of turbocharger rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

Check alternator driving belt tension and replacement . . . . . . . . . . . . . . . . . . . . . . . . 4-59

4.8.9 Every 2000 hours service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

Change oil in hydraulic tank, replace hydraulic filter element . . . . . . . . . . . . . . . . . . . 4-60

Replace hydraulic tank breather element. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

Cleaning the strainer of the brake filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

Change axle oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

Replace element in air conditioner recirculation air filter, fresh air filter. . . . . . . . . . . . 4-64

Check alternator, starting motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

Check engine valve clearance, adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

Check brake disc wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

Clean and check turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

Check accumulator gas pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

Check vibration damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

4.8.10 Every 4000 hours service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

Lubricating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

Check water pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-67

5. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 Noise emission levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3 Vibration level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

6. Attachments, Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Selecting bucket and tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2 Method of using 2 levers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.2.1 Explanation of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.2.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Using switch to change between forward and reverse. . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.3 Handling fork tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.3.1 Explanation of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Work equipment lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.3.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Loading operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Loading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.4 Method of using 3 levers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.4.1 Explanation of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.4.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Using switch to change between forward and reverse. . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.5 Central lubrication system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.5.1 Operating the central lubrication system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

WA150PZ-5 – VEAM420100 1-15

1.5 Contents Foreword

6.5.2 Display and control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

LED-display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Pushbuttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.5.3 Changing the lubrication interval times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

7. Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

8. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

1-16 WA150PZ-5 – VEAM420100

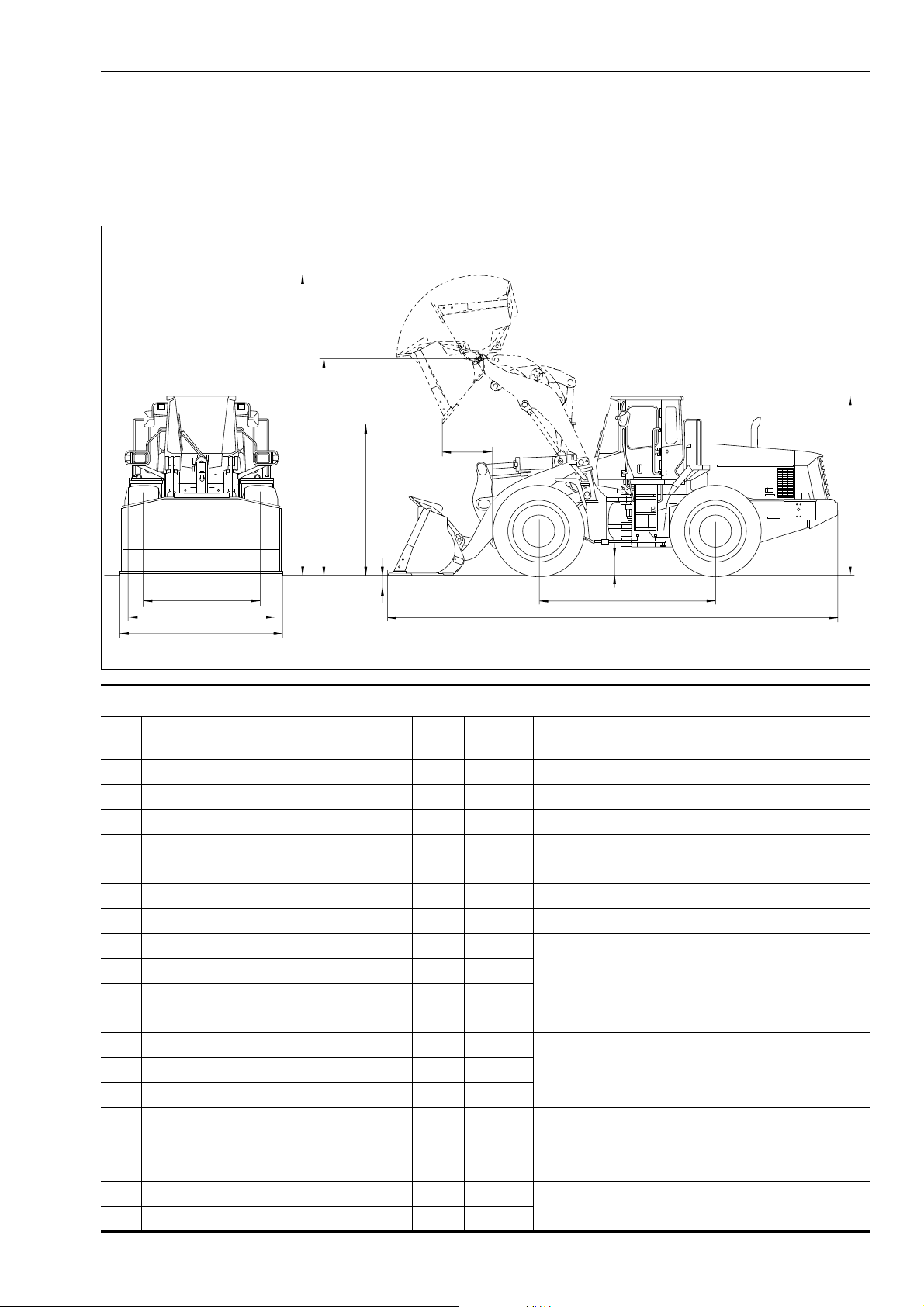

Foreword 1.6 Dimensions, weights and operating data

1.6 Dimensions, weights and operating data

1.6.1 WA150PZ-5: Dimensions, weights and operating data

d

a

c

b

H

F

E

D

C

e

B

A

Measurements, operating data

Bucket capacity to ISO 7546 m³ 1.5

without teeth and without BOC,

without Quick coupler)

Material density t/m³ 1.8

Bucket weight without teeth kg 645

Static tipping load, straight kg 6,740

Static tipping load, 40° angle kg 5,960

Breakout force, hydraulic kN 80,9 with QC (Quick coupler)

Lifting capacity, hydraulic, on ground kN 98,4 with QC (Quick coupler)

Operating weight kg 8,590

a Reach at 45° discharge mm 824

b Dumping height at 45° discharge mm 2,891

c Lift height, hinge pin mm 3,697

d Height to upper edge of bucket mm 4,979

e Digging depth mm 60

A Overall length, bucket on ground mm 6,400

B Wheel base mm 2,600

C Bucket width mm 2,400

These values refer to machines with 17,5R25 D Width over tyres mm 2,228

E Gauge mm 1,872

F Ground clearance mm 420

H Overall height mm 3,063

GK032011

WA150PZ-5 – VEAM420100 1-17

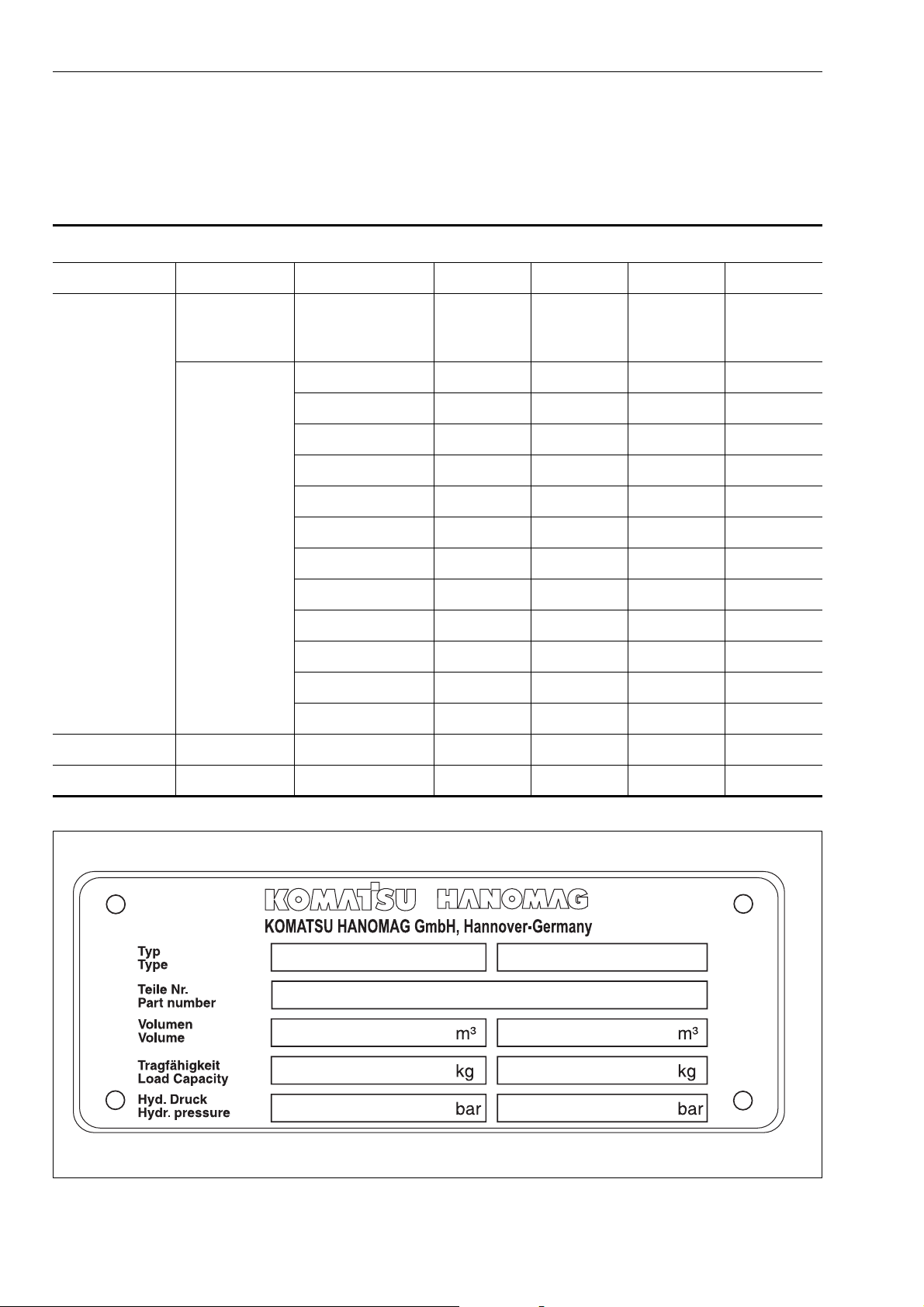

1.7 CE-Conforming equipment Foreword

1.7 CE-Conforming equipment

1.7.1 CE-Conforming equipment

CE-Conforming equipment

1 2 345–

Type Part No.

416-71-H2C00 1.5 2,700 --- 700

416-71-H2C10 1.5 2,700 --- 650

416-71-H2C20 1.6 2,880 --- 740

416-71-H2C30 1.5 2,700 --- 750

416-71-H2C40 1.5 2,700 --- 700

416-71-H2C50 1.6 2,880 --- 750

Bucket WA150PZ-5

416-71-H2C60 1.6 2,880 --- 790

416-71-H2C70 1.6 2,880 --- 740

416-71-H2C80 1.7 3,060 --- 830

416-71-H2D30 1.6 2,880 --- 770

416-71-H2D20 1.6 2,880 --- 728

416-71-H2D40 1.7 3,060 --- 821

Fork 416-71-H2B00 --- 3,400 --- 422

Volume

m³

Load

Capacity

kg

Hydraulic

pressure

bar

Weight

kg

Quick coupler 416-71-H2A90 --- 4,000 --- 270

1

2

3

4

5

GK032012

1-18 WA150PZ-5 – VEAM420100

Foreword 1.7 CE-Conforming equipment

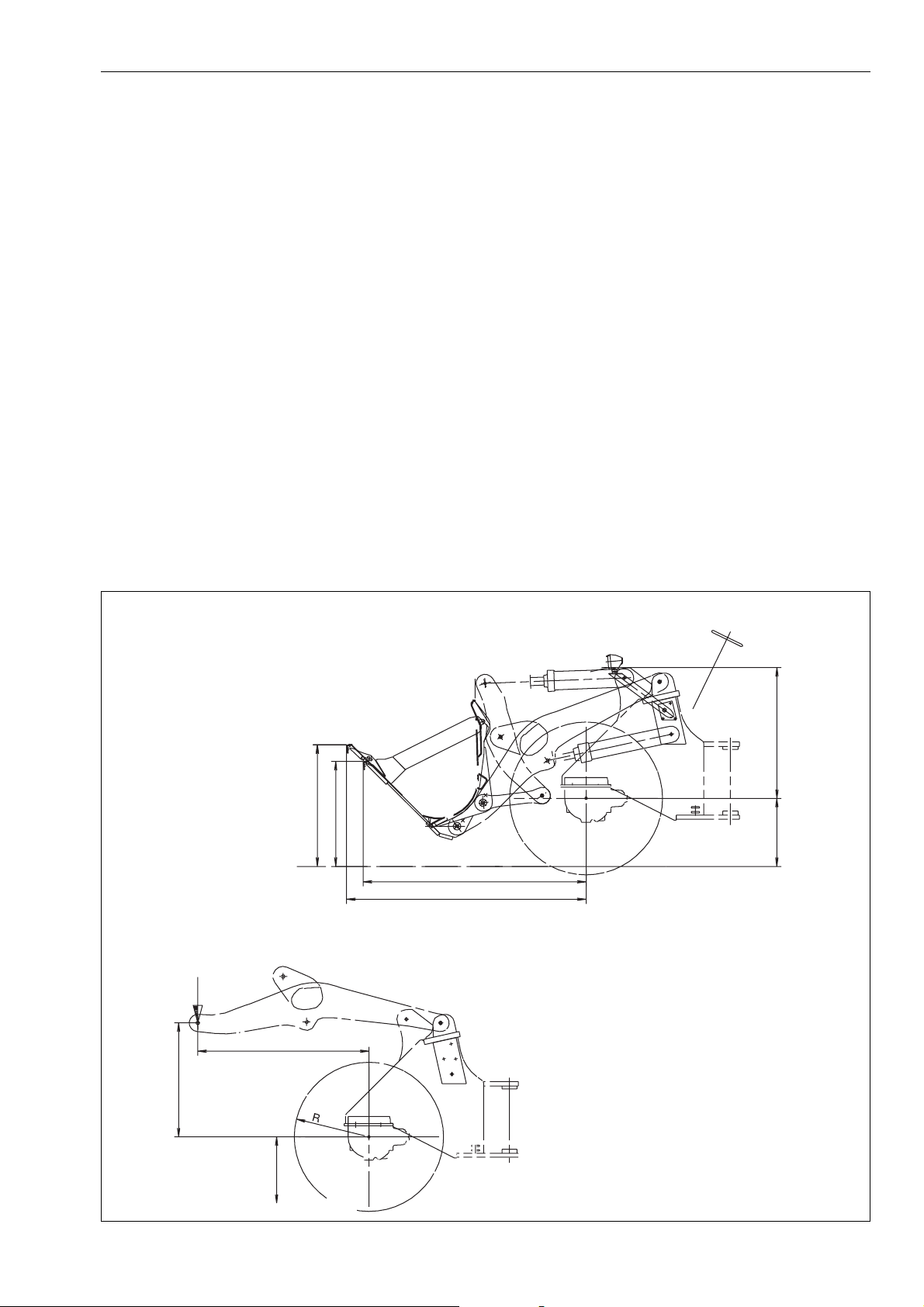

1.7.2 Manufacturer-supplied CE-Conforming equipment, according to document 419-93-H1250

The responsibility for observing valid regulations in the case of

wheel loaders with "interchangeable equipment" (e.g. bucket or

fork-lift) which was not supplied from works lies with the customer which was subsequently fitted to the machine.

The directives for CE conformity and road-traffic registration are

deemed to have been fulfilled when the manufacturer of the

equipment confirms fulfilment of the form 419-93-H1250 alongside.

The certification must be sent to the customer and the wheel

loader manufacturer. The CE conformity declaration for a specific wheel loader is only legally valid once this has taken place.

The dimensions X1, X2, Y1 and Y2 must be provided by the customer for approval for use on public roads.

The dimension Sh (smallest tyre radius) must be added to the

dimension D2.

The figure G (in kg) represents the maximum load (equipment

and operating load) which may act upon this point.

Y2

X2

X1

Y1

G

D2

Sh

A1

A2

Sh

GK032013

WA150PZ-5 – VEAM420100 1-19

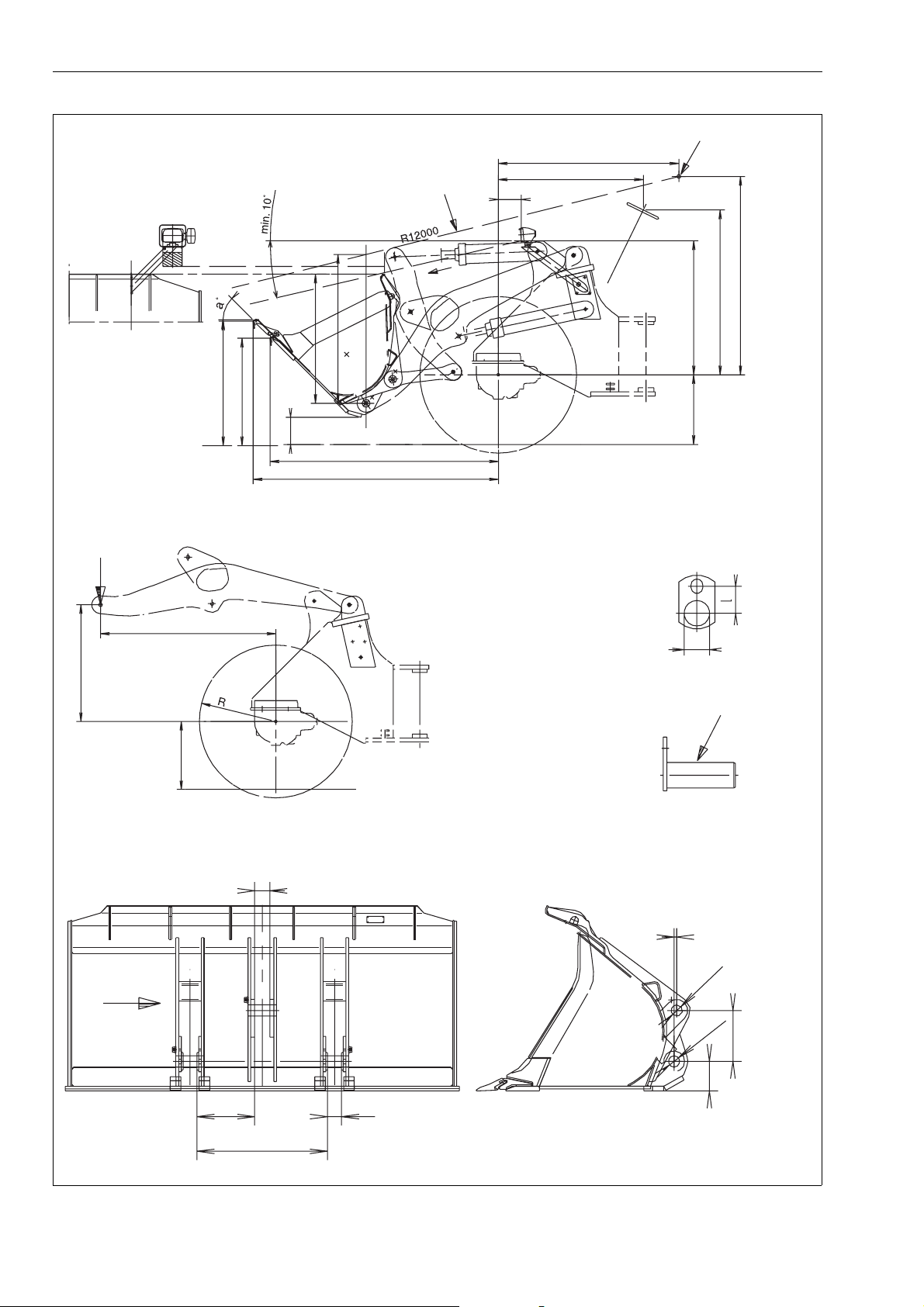

1.7 CE-Conforming equipment Foreword

1

B1

C1

D2

Sh

B2

C2

Y2

X2

2

H2

H1

J

X1

Y1

D1

A2

G

A1

d1=d2

3

Sh

b3

e

d2

3

d1

c

h

b4

b1

b2

GK032014

1-20 WA150PZ-5 – VEAM420100

Foreword 1.7 CE-Conforming equipment

Manufacturer- supplied CE-Conforming equipment, according to document 419-93-H1250

WA150PZ-5 419-93-H1250

A1 Distance: bucket pivoting point - front axle, horizontal

A1 1,805

A2 Distance: bucket pivoting point - front axle, vertical

A2 1,196

Sh Distance: road level - front axle

Sh 630

B1 Distance: driver's eye (1) - front axle, horizontal

B1 1,812

B2 Distance: driver's eye (1) - front axle, vertical

B2 2,027

C1 Distance: centre steering wheel - centre front axle,

horizontal

C2 Distance: center steering wheel - centre front axle,

vertical

D1 Distance: headlight - centre front axle, horizontal

D2 Distance: headlight - centre front axle, vertical

G Weight of equipment and working load

H1 Distance: bucket pivoting point - bucket upper edge,

C1 1,336

C2 1,686

D1 461

D2 1,238

G 3,400

H1 1,277

H2 1,543

vertical (carrying position)

H2 Distance: bucket pivoting point - vision line, vertical

(carrying position)

J270

X1 -

J Distance: road level - bucket bottom edge (carrying

position)

X1 Distance: cutter protection - front axle, horizontal

X2 Distance: cutter protection - road level, vertical

Y1 Distance: teeth protection - front axle, horizontal

Y2 Distance: teeth protection - road level, vertical

b1 Bucket connection dimension, boom width inside

b2 Bucket connection dimension, boom arm

b3 Bucket connection dimension, tilt rod

b4 Bucket connection dimension, temporary size

c Bucket connection dimension between d1 and d2, verti-

cal

d1 Bucket connection dimension, bolt (3) for boom

d2 Bucket connection dimension, bolt (3) for tilt rod

e Bucket connection dimension d1 - d2, horizontally dis-

placed

h Distance: bucket bottom edge - boom bolt hole

l Distance: centre of bolt - centre of fastening screw

X2 -

Y1 -

Y2 -

b1 884

b2 88

b3 88

b4 398

c330

d1 50

d2 50

e0

h163

l60

1 Driver’s eye

2 Vision line

3Bolts

Tyres

MICHELIN

17.5R25XHA

Bucket

WA150PZ-5 – VEAM420100 1-21

1,5 m³

416-71-H2C00

1.7 CE-Conforming equipment Foreword

1-22 WA150PZ-5 – VEAM420100

Safety

2. Safety

WARNING

Please read and make sure that you fully understand the precautions

described in this manual and the safety labels on the machine. When operating or servicing the machine, always follow these precautions strictly.

WA150PZ-5 – VEAM420100 2-1

2.1 Safety labels Safety

2.1 Safety labels

The following safety labels are used on this machine. Be sure

that you fully understand the correct position and content of

these safety labels.

Always keep all safety labels clean. When cleaning them, use

soap and water. Do not use organic solvents or gasoline. These

may cause the safety labels to peel off.

Missing or damaged safety labels must be replaced. Order the

new part from your KOMATSU distributor.

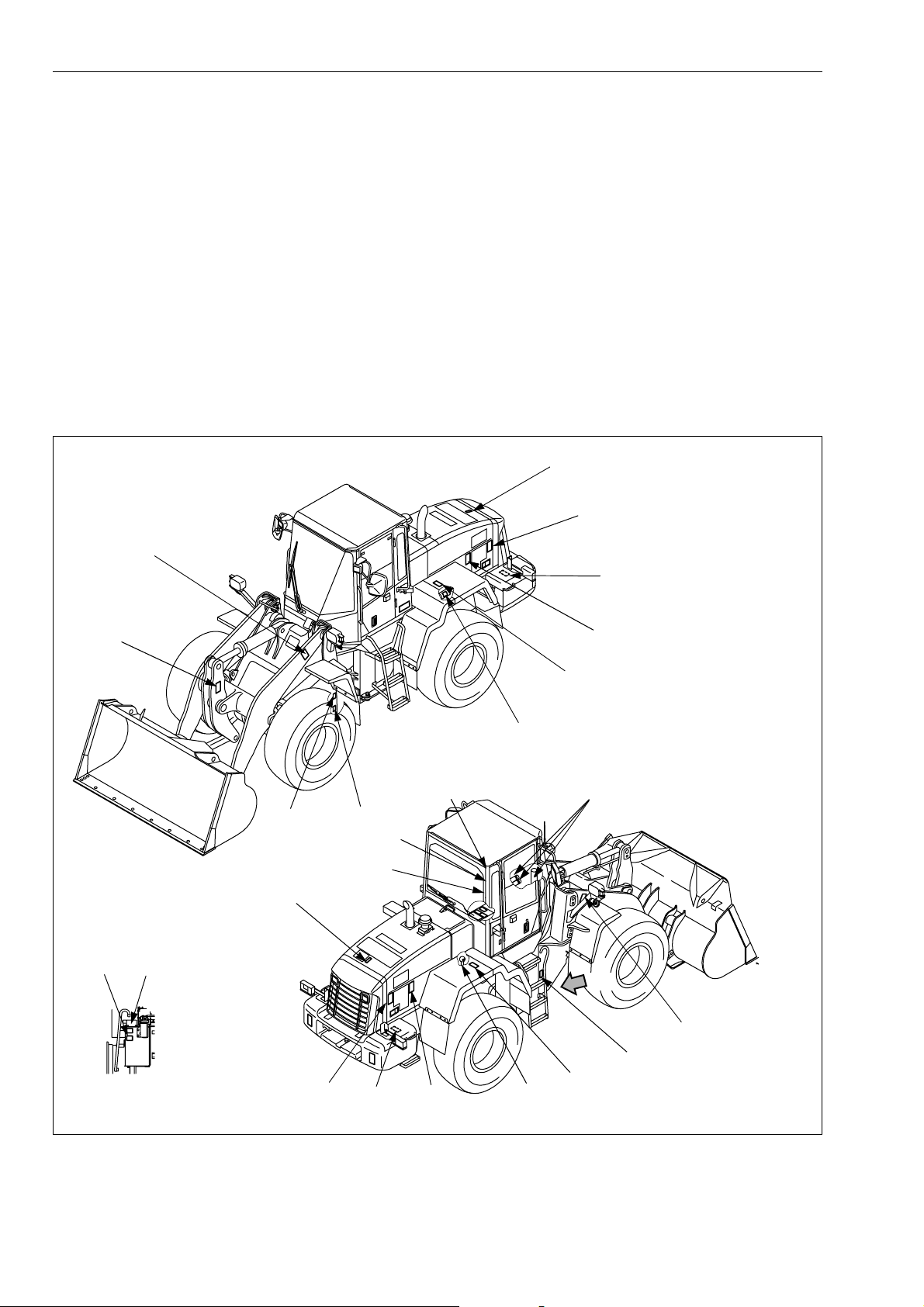

2.1.1 Location of safety labels

7

13

14

3

9

12

11

16

1

5

7

6

2

17

10

4

8

"Z"

2-2 WA150PZ-5 – VEAM420100

3

912

10

11

"Z"

14

5

GK032015

Safety 2.1 Safety labels

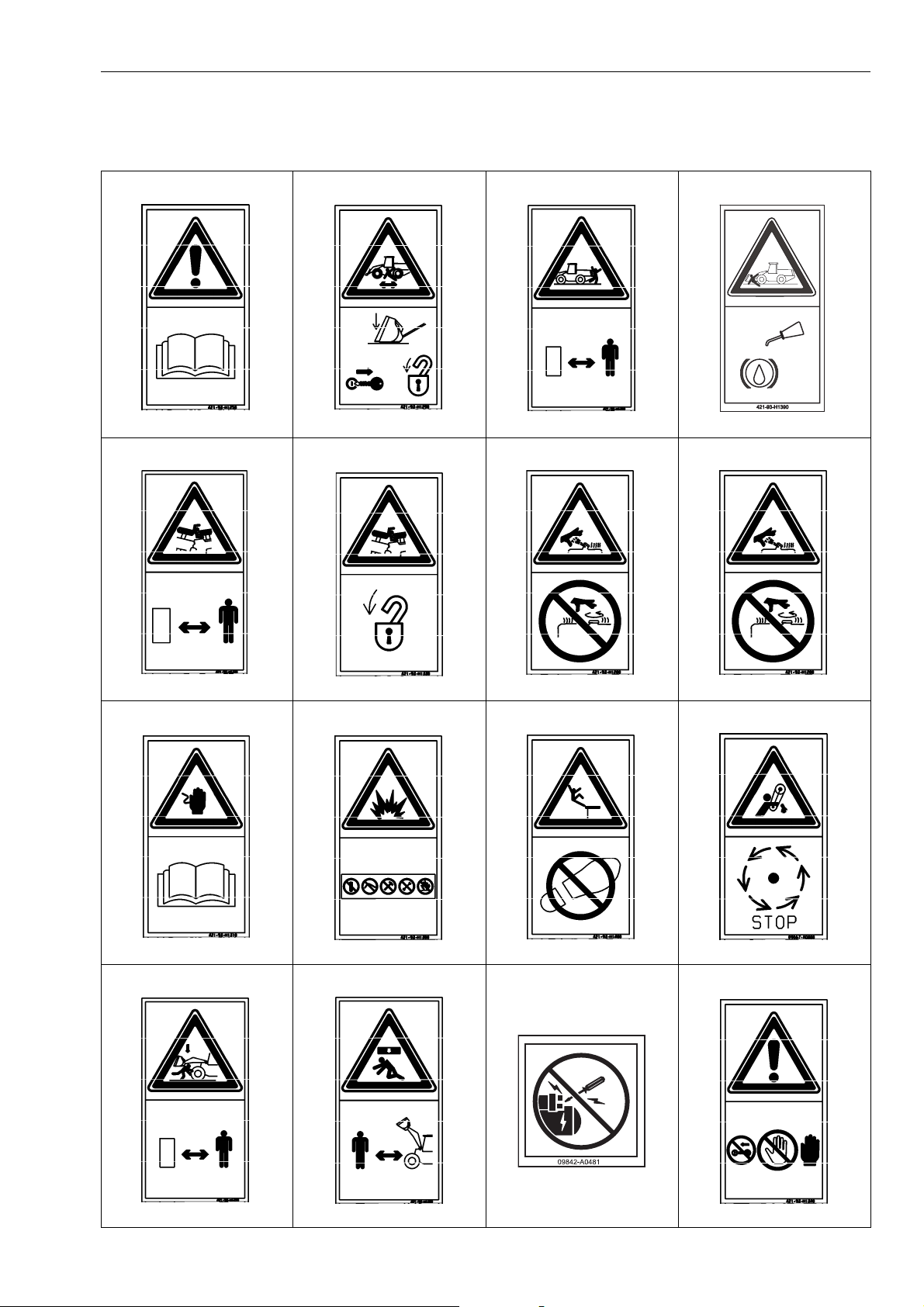

2.1.2 Presentation of safety labels

1

GK032016

2

GK032017

3

GK032018

4

GK032019

5678

GK032020

GK032021

GK032022 GK032022

9101112

GK032023 GK032024

GK032025

GK032026

13 14 16 17

GK032027 GK032028

WA150PZ-5 – VEAM420100 2-3

GK032029

GK032030

2.1 Safety labels Safety

1

GK032016

2

GK032017

3

GK032018

4

GK032019

5678

GK032020

GK032021

GK032022 GK032022

9101112

GK032023 GK032024

GK032025

GK032026

13 14 16 17

GK032027 GK032028

GK032029

GK032030

2-4 WA150PZ-5 – VEAM420100

Safety 2.1 Safety labels

Precautions before starting operation, inspection and maintenance (421-93-H1250)

1

WARNING

Read the Operator’s Manual before starting operation, inspection, maintenance or transportation.

Precautions before leaving the machine (421-93-H1290)

Sign indicates a hazard of unexpected moving of stopped machine.

2

Lower working device to ground, move safety lever to lock position and take engine key with you before

leaving machine.

Precautions when traveling in reverse (421-93-H1360)

3

Sign indicates to prevere severe injury or death

Honk to alert people nearby. Be sure no one is on or near machine. Use spotter if view is obstructed.

4 Use KOMATSU oil only (421-93-H1390)

Do not enter (421-93-H1320)

5

Sign indicates a crush hazard between the articulating parts of the vehicle.

Keep away from the vehicle when it is move.

Precautions for safety bar (421-93-H1330)

6

Sign indicates a crush hazard between the articulating parts of vehicle.

Lock vehicle with lock bar to avoid movement during maintenance, inspection and transportation.

Precautions when coolant is at high temperature (421-93-H1280)

7

Sign indicates a burn hazard from spurting hot water if radiator is uncapped while hot.

Allow coolant to cool before removing cap.

Precautions when oil is at high temperature (421-93-H1280)

8

Sign indicates a burn hazard from spurting hot oil if hydraulic oil tank is uncapped while hot.

Allow hydraulic oil to cool before removing cap.

Precautions when handling battery cable (421-93-H1310)

9

Sign indicates an electric hazard from handling the cable.

Read manual for safe and proper handling.

High pressure warning (421-93-H1300)

10

There is a hazard of explosion injury.

Do not disassembly the accumulator, make holes in it, weld it cut it, hit it, roll it or bring it near flame.

Do not climb on fender (421-93-H1400)

11

Sign indicates a hazard of falling.

Do not stand on this place here.

Do not open when engine is running (09667-A0880)

12

Sign indicates a hazard of rotating parts, such as belt.

Turn off engine before inspection and maintenance.

“Do not come under machine“ sign (421-93-H1370)

13

Sign indicates a hazard of being run over by moving vehicle.

Keep a safe distance from vehicle when it is moving.

“Do not go under work equipment“ sign (421-93-H1380)

14

Sign indicate a crush hazard from falling off of working device.

Keep away when the working device is raised.

16 Only start machine from driver's seat (09842-A0481)

17 Safety measures before starting work (421-93-H1340)

WA150PZ-5 – VEAM420100 2-5

2.2 General precautions Safety

2.2 General precautions

Safety rules

z Only trained and authorized personnel can operate and

maintain the machine.

z Follow all safety rules, precautions and instructions when

operating or performing maintenance on the machine.

z If you are under the influence of alcohol or medication, your

ability to safely operate or repair your machine may be severly impaired putting yourself and everyone else on your jobsite in danger.

z When working with another operator or with a person on

worksite traffic duty, be sure that all personnel understand all

hand signals that are to be used.

If abnormalities are found

If you find any abnormality in the machine during operation or

maintenance (noise, vibration, smell, incorrect gauges, smoke,

oil leakage, etc., or any abnormal display on the warning devices

or monitor), report to the person in charge and have the necessary action taken. Do not operate the machine until the abnormality has been corrected.

Clothing and personal protective items

z Do not wear loose clothing and accessories. There is a haz-

ard that they may catch on control levers or other protruding

parts.

z If you have long hair and it hangs out from your hard hat,

there is a hazard that it may get caught up in the machine,

so tie your hair up and be careful not to let it get caught.

z Always wear a hard hat and safety shoes. If the nature of

the work requires it, wear safety glasses, mask, gloves, ear

plugs, and safety belt when operating or maintaining the

machine.

z Check that all protective equipment functions properly

before using it.

GK032031

2-6 WA150PZ-5 – VEAM420100

Safety 2.2 General precautions

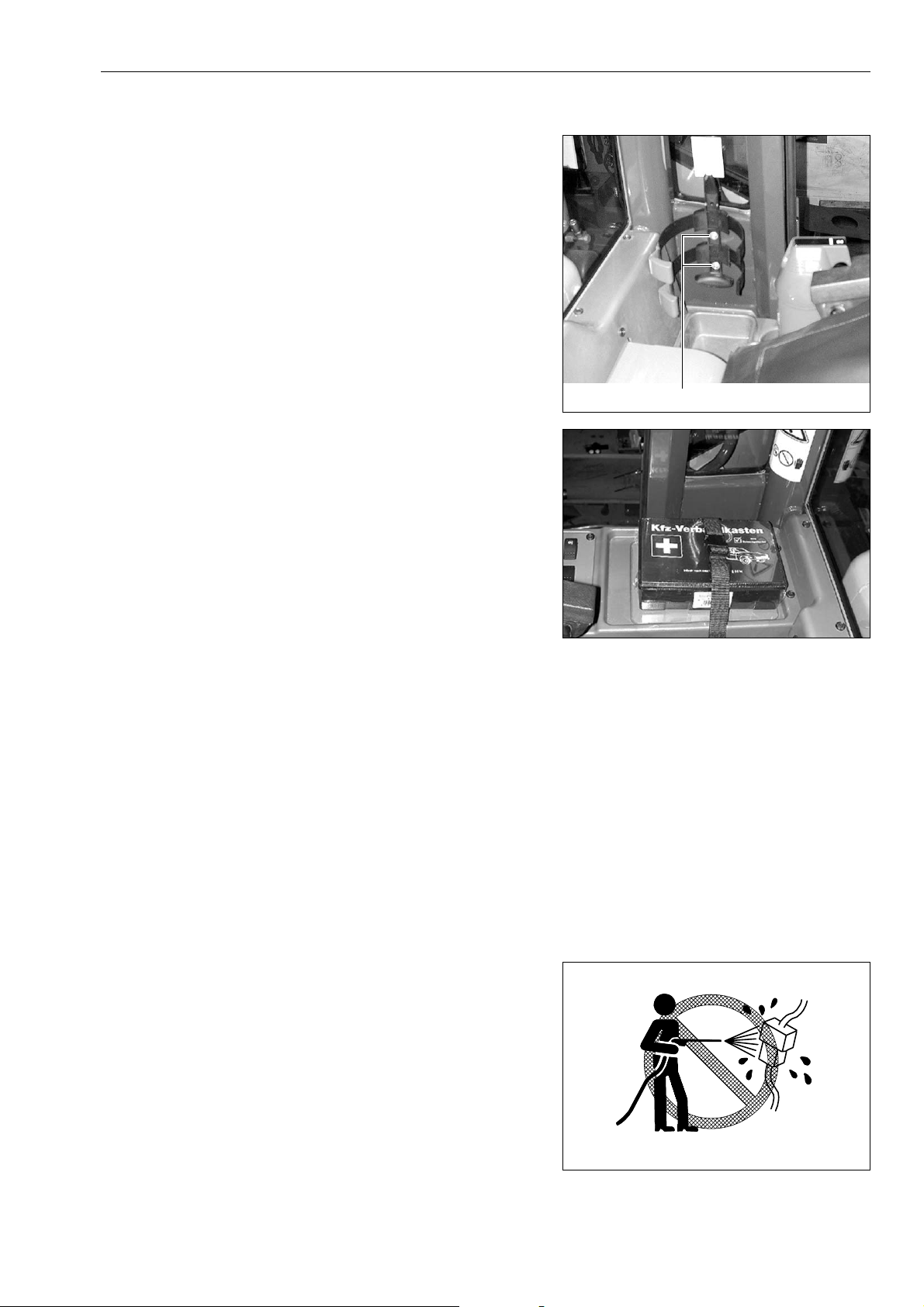

Fire extinguisher and first aid kit

Always follow the precautions below to prepare for action if any

injury or fire should occur.

z The fire extinguisher can be fastened to the inside cabin wall

on the left.

z If, in the course of certain operations, there is danger of fire,

fire extinguishers must be at hand. Familiarise with the use

of the fire extinguishers.

z Inform yourself on measures to be taken in the event of a

fire.

z The first-aid kit can be positioned on the right of the cabin's

interior.

z Make sure that you know all telephone numbers of the per-

sons that you need to contact in an emergency.

Safety features

z Be sure that all guards and covers are in their proper posi-

tion. Have guards and covers repaired immediately if they

are damaged.

z Understand the method of use of safety features and use

them properly.

GK032032

Fastening points

GK032033

z Never remove any safety features. Always keep them in

good operating condition.

Keep machine clean

z If water gets into the electrical system, there is a hazard that

it will cause malfunctions or misoperation. Do not use water

or steam to wash the electrical system (sensors, connectors).

z If inspection and maintenance is carried out when the

machine is still dirty with mud or oil, there is a hazard that

you will slip and fall, or that dirt or mud will get into your

eyes. Always keep the machine clean.

GK032034

WA150PZ-5 – VEAM420100 2-7

Loading...

Loading...