Komatsu WA1200-3 User Manual

STANDARD EQUIPMENT

OPTIONAL EQUIPMENT

● Alternator, 140 A/24 V

● AM/FM radio with cassette

● Air conditioner, heater,

defroster, pressurizer

● Automatic greasing system

● Automatic transmission

● Auxiliary steering system

● Axles, full floating

● Backup alarm with light

● Batteries, 200 Ah/6 x 12 V

● Boarding stairs

● Boom kick-out, automatic

and adjustable

● Brakes:

—Service: wet, multiple-disc

—Parking: wet, multiple-disc

● Bucket positioner, automatic

● Cab with ROPS/FOPS canopy

● Converter, 2.5 amps 12 volt

● Counterweight, standard

● Electronic display/Multi Monitor

● Fenders, front and left rear

● Ground level shutdown

● Hitch

● Horn, electric

● High pressure filters

● Lights

—Backup light

—Headlights (4 front)

—Stop and tail

—Turn signal with hazard switch

(2 front, 2 rear)

—Working lights (6 front, 4 rear)

—Access stairs and service area

● Payload meter

● Proportional pressure hydraulic controls

● Rearview mirror and rear underview

mirror mounted to radiator guard

● Rims, 44.00-57

● Seat belt, 78 mm 3" with retractor

● Seat, air suspension

● Starting motor, direct electric

24 V with pre-lube

● Steering, full hydraulic power

(joystick steering control)

● Sun visor

● Tinted glass

● Tires, 55.5/80-57 68PR

● Tire saver (modulation clutch controlled)

● Vandalism protection kit

● Washer, front and rear

● Wiggins fast fuel fill

● Wiggins fast oil fill

● Wipers, front and rear, front intermittent

● Beacon lamp

● Buckets:

—20.0 m3 26.2 yd3spade nose rock

—18.0 m323.5 yd3spade nose rock

(both with ESCO loadmaster system

teeth and wear shrouds)

—35.0 m345.8 yd3coal

● Cold weather arrangement

● Fire extinguisher

● High lift arrangement

● Odometer

● Power train guard

● Radiator core protective grid

● Rear cab glass with internal heat element

● Retractable rear window shade

● Rims, 52.00-57

● Tires

—65/65-57 62PR

—53.5/85-57 76PR

● Tire chains

www.Komatsu.com Printed in Japan 200602 IP. AD (10)

CEN00041-01 Materials and specifications are subject to change without notice

is a trademark of Komatsu Ltd. Japan

WA1200-3

WA 1 2 0 0 - 3

BUCKET CAPACITIES

18.0 – 35.0 m

3

23.5 – 45.8 yd

3

WHEEL LOA D E R

WA1200-3

32

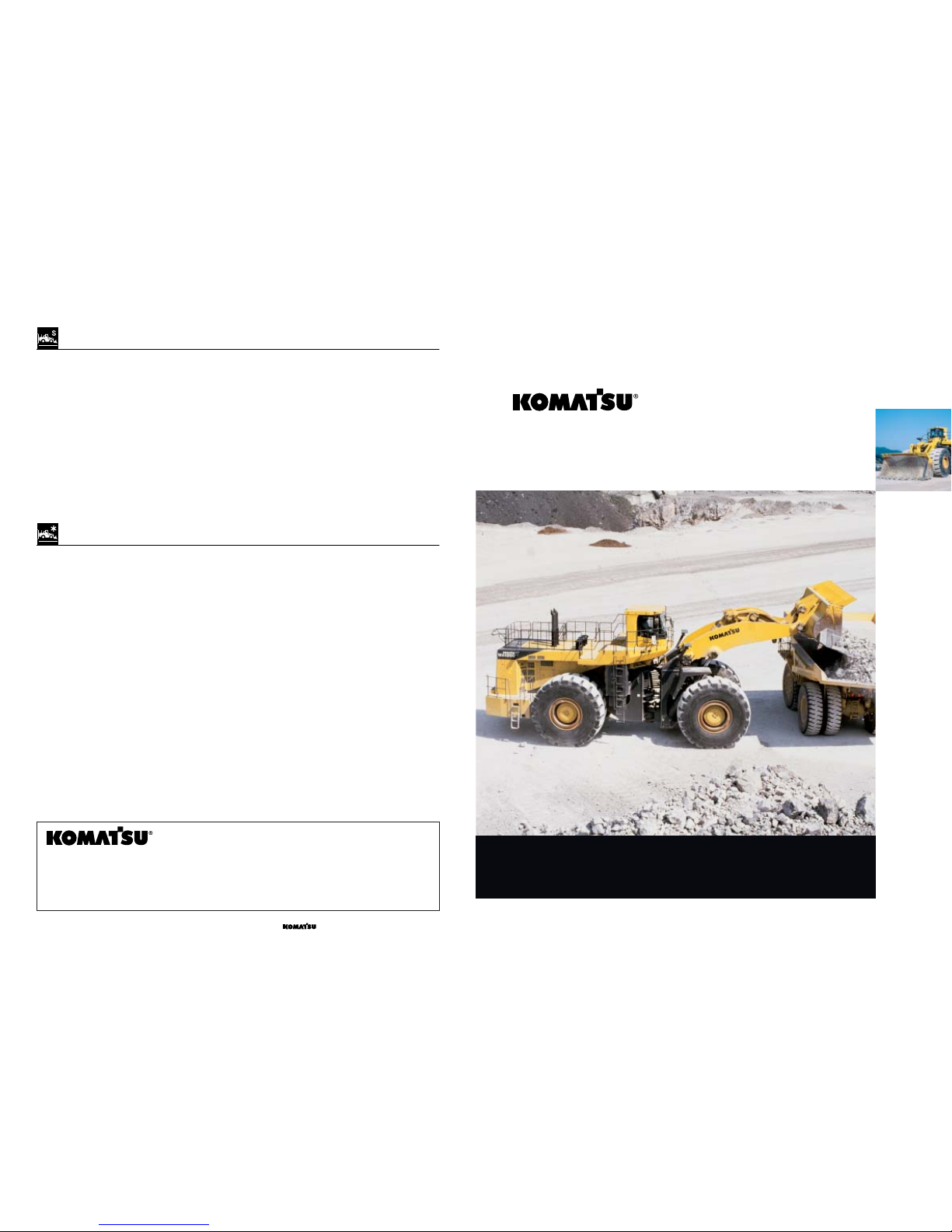

Today’s mines around the world need larger machines to provide

improved productivity and economy within their operation. Simple

size increases can’t achieve this. Komatsu has responded to this

need with larger, more productive machines which incorporate

leading edge technologies. In keeping with Komatsu’s motto “always

respond to customer needs with the most advanced equipment

available,” the

MOUNTAIN MOVER WA1200-3 was born.

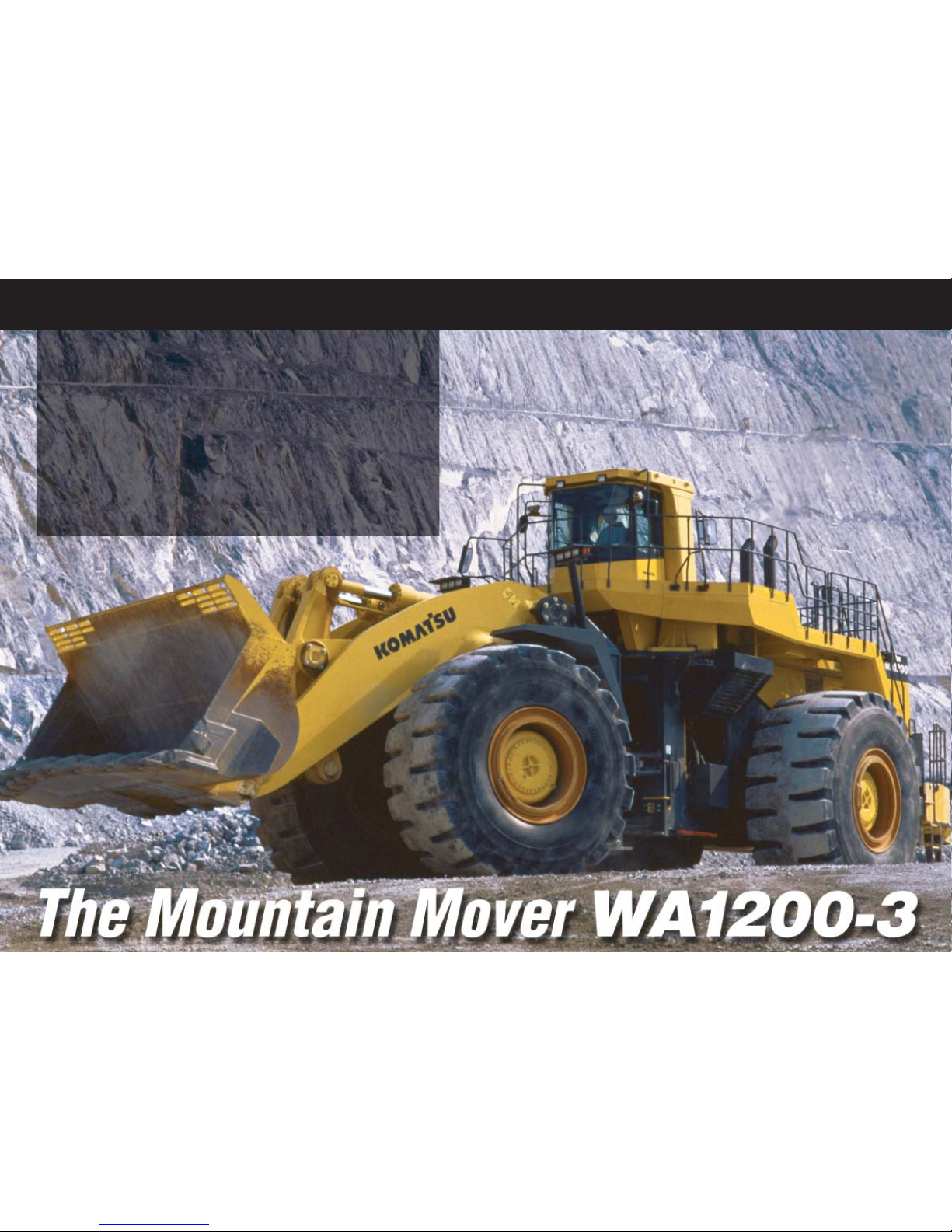

From the Leading Edge of Technology Comes

NET HORSEPOWER

1165 kW 1560 HP @ 1900 rpm

OPERATING WEIGHT

205200 kg 452,390 lb

BUCKET CAPACITY

18.0 – 35.0 m

3

23.5 – 45.8 yd

3

WA1200-3

WHEEL LOADER

The Most Advanced Technology

Safe boarding and exiting

machine. Boarding stairs are

equipped with safety handrail

and step lights for night operation.

The dream has come true.

Advanced Joystick Steering System

(AJSS) with light, short strokes

for perfect steering accuracy.

Remote boom positioner is easy to set up.

High and low bucket positions are easily set up

promoting smooth bucket movement stops

without shocks to machine components.

Hi-Cab is extra long and wide to

provide a comfortable work environment.

The seated operator has a better view

inside the body of a 240-ton haul truck.

Oversized, obstruction-free windshield,

side and rear windows provide a

panoramic view of the work site.

Overhead panel

for cassette/radio and

air conditioner controls.

Safe maintenance accessibility. All maintenance

points are equipped with a step and safety handrail.

Engine radiator grille pivots open for easy access.

Variable traction and hydraulic power. Variable Output

Hydraulic System (VOHS) is a self-adjusting hydraulic system

to meet system demand for high productivity.

Breakout force:

1274 kN 130000 kg 286,600 lb

Traction force:

1127 kN 115000 kg 253,500 lb

RPM set system

allows engine speed to

be easily set with a gentle

momentary touch.

Quick fluid change-out system:

hydraulic oil, transmission/

torque converter oil, engine

oil, engine coolant, and fuel.

Emergency

brakes/emergency

steering.

Selectable traction power.

● Maximum traction control for

adjusting the traction to suit the

conditions at various operations.

● Maximum speed control of 1st and

2nd travel speeds to help shorten

cycle times and extend tire lives.

Longer tire life. Tire Saver controls tire slip

and lengthens tire life. Optional wide base tires

(65/65-57 62PR) offer longer service life than

standard tires.

Multi Monitor

serves as a service information center.

It has gauge, maintenance, load meter,

and remote boom positioner and

service functions.

5

WA 1 2 0 0 - 3 W h eel Loader

W

ALK

-A

ROUND

W

ALK

-A

ROUND

Komatsu-integrated design offers the best value, reliability, and versatility. Hydraulics, power train,

frame, and all other major components are engineered by Komatsu. You get a machine whose components are

designed to work together for

higher production, greater reliability, and more versatility.

Main monitor shows travel condition

and has troubleshooting capability.

Cab air conditioner is a large capacity unit

with air ducts strategically located to offer

the most comfortable operator work space.

ROPS/FOPS cab protection.

Operator’s safety is built

into the cab with the use

of a ROPS/FOPS canopy,

a two-door system, and

an emergency ladder.

Rigid frame for superior

digging performance.

Single plate frame design

employing multiple castings is proven in both

lab and field tests.

Bucket/arm configurations

to match various haul trucks:

Standard arm with 20.0 m326.2 yd

3

bucket: 150–240 ton trucks

High lift arm with 18.0 m323.5 yd

3

bucket: 240–300 ton trucks

Low maintenance brake system.

Extra dumping clearance and reach.

Dumping clearance: 6285 mm 20'7"

Dumping reach: 2970 mm 9'9"

Special viscous mounts support cab to absorb

vibration and noise (interior levels of 73 dB(A)).

Automatic transmission for efficient

load and carry operations. Electronic

Controlled Modulation Valve (ECMV)

system provides smooth shifting in

all speeds.

Safe durable service brakes. Closed wet

disc brake system used. Oil cooler allows long

downhill travel with full bucket loads.

Centralized filter layout. Transmission/

torque converter oil, engine oil, fuel.

Extended oil change intervals

using hybrid filter and oversized

hydraulic tank.

Automatic greasing system.

Oil sealed pins offer 2,000 hour

maintenance intervals.

Largest bucket in its class—

20.0 m326.2 yd3.

4

Loading...

Loading...