Page 1

SERVICE MANUAL

SM208

TB45E(CARB2010)-BE1

CX50 Forklift Truck, EPA/CARB 2010 Compliant

Gasoline/LPG FG40ZTU/40TU/45TU/50ATU-10

FG40Z/35/40/45/50A-10

S/N 134756~

TB45 GASOLINE

ENGINE (ECU)

WARNING

Read and observe all warnings on this unit

before operating it.

DO NOT operate this equipment unless all

factory-installed guards and shields are properly

secured in place.

ISSUED: JUNE 2011

Page 2

PRECAUTIONS FOR SAFETY AND QUALITY

PRECAUTIONS FOR SAFETY AND QUALITY

Description

• Observe the following precautions for safe and proper maintenance.

• Only qualified and appointed persons shall inspect, repair, or

adjust the vehicle.

• Keep the workplace and tools clean.

Safe Work

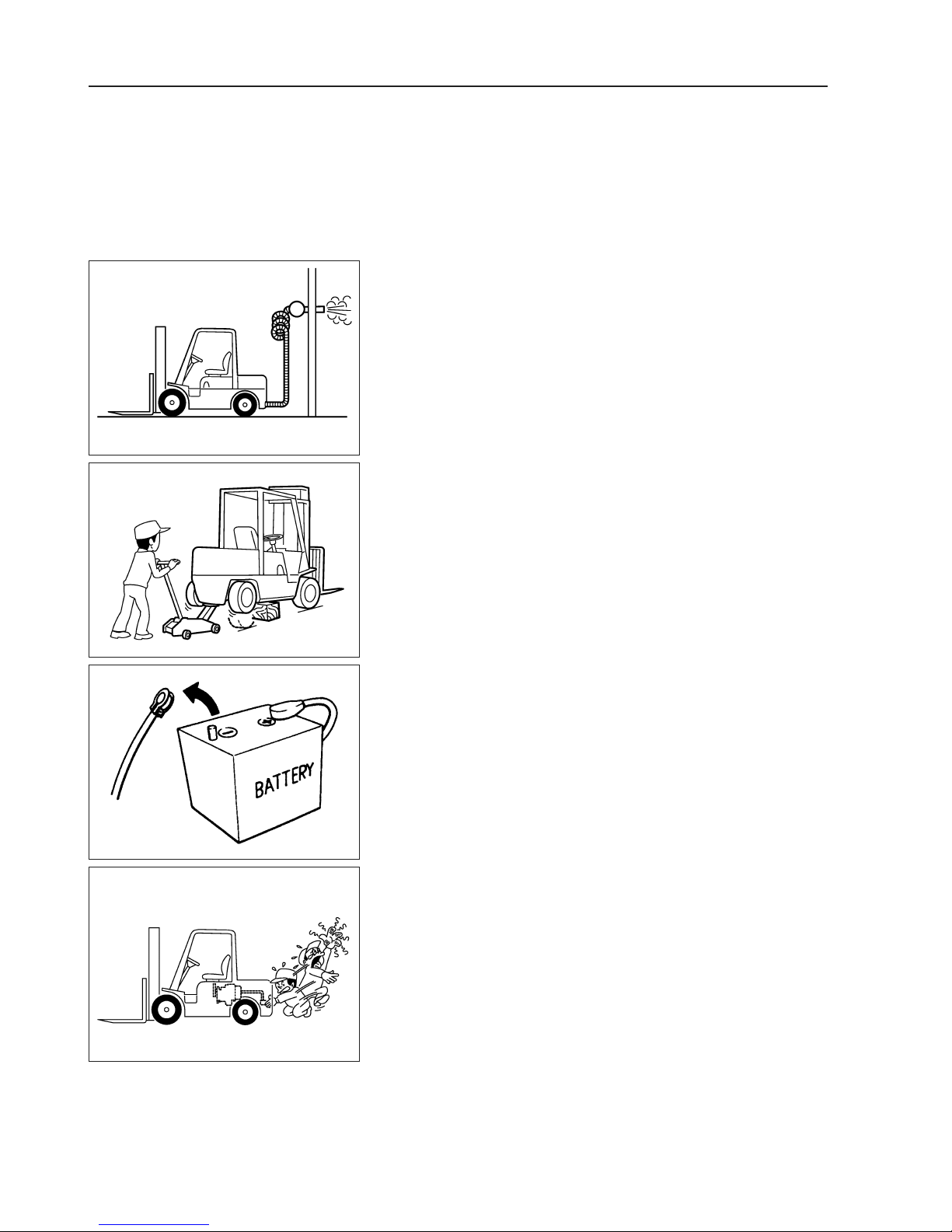

• Do not run the engine in a place which has no exhaust ducts

and which is poorly ventilated.

• Ventilate the workplace well and do not place a combustible

thing there. Take extreme care when handling a combustible

thing or a hazardous material such as gasoline.

• Dispose of the replaced oil, parts washing oil, etc. according to

laws.

• When working on parts which become hot, rotary parts, or

sliding parts, take care not to burn or injure yourself.

• When working in a pit or a closed place, ventilate it to discharge

EGM0043

harmful materials in advance.

• Do not work on the vehicle jacked up. When working on it,

support it by the specified parts on wood blocks, etc.

• When lifting up the vehicle, support it by the specified parts and

apply a safety device.

• When removing a heavy part such as the engine, vehicle body,

etc. take care not to drop it by unbalancing it.

• Do not smoke while maintaining the vehicle.

• When maintaining the vehicle, take off rings and necklace to

prevent a short circuit in the electrical system.

EGM0044

EGM0045

EGM0046

• Before starting repair which does not need the battery power,

turn the key switch OFF and disconnect the negative (–)

terminal of the battery.

• Take care not to touch the hot metal parts just after stopping the

engine. While the engine is still hot, do not remove the radiator

cap or another part of the coolant system.

• Use the specified proper common tools or special tools for safe

and efficient repair.

EG-2

Page 3

PRECAUTIONS FOR SAFETY AND QUALITY

Correct Work

• Grasp the contents of each trouble, and then troubleshoot and

work efficiently.

• When removing and disassembling parts, check their normal

assembly condition in advance. Make match marks on places

which do not affect the function, if necessary.

• If an oil seal, gasket, packing, O-ring, lock washer, cotter pin,

self-lock nut, etc. are removed, replace them according to the

directions in their sections (Parts which must not be reused).

• When a tapered roller bearing or a needle roller bearing needs

to be replaced, replace its inner race and outer race as a set.

• Arrange the removed parts in order so that they will not be

mixed up.

• Before checking or assembling the disassembled parts, clean

them.

• When replacing a part, install a NISSAN genuine part.

• Use the specified oil, grease, sealant, etc.

• Before removing a pressurized pipe, hose, etc., release the

pressure.

• After repairing the fuel, oil, coolant, exhaust, or vacuum system,

check it for leakage securely.

Precautions for Radio Equipment Installation

Check the following when installing a commercial/ham radio or

mobile phone. If mounting position is not chosen carefully, the unit

may interfere with the electronic control system.

• Separate the antenna as far from the ECM as possible.

• Route an antenna feeder line at least 20 cm (7.87 in) apart from

the control unit harness.

• Adjust an antenna and feeder line to eliminate radio wave

interference.

EG-3

Page 4

HOW TO READ THIS MANUAL

HOW TO READ THIS MANUAL

Outline

This chapter explains how to read the procedures of "removal,

disassembly, assembly, inspection, and adjustment" and "troubleshooting".

Definition of Terms

CAUTION:

• An item or a work procedure, neglect of which can cause a

death or a serious injury if neglected.

• An item or a work procedure to be observed especially

among those, neglect of which can cause an injury, an

accident, or a damage of the vehicle or component parts.

Reference : Supplementary explanation for the ease of work.

Standard value : Permissible deviation of a value at inspection or

adjustment.

Limit value : The maximum or minimum which a value must not

exceed at inspection or adjustment.

Definition of Units

In this manual, tightening torque, pressure, etc. are indicated by the

"SI unit" (International unit) first, then by the "metric unit) in { }.

Example) Tightening torque: 59 - 78 Nm {6.0 - 8.0 kgf•m}

SI unit {Metric unit}

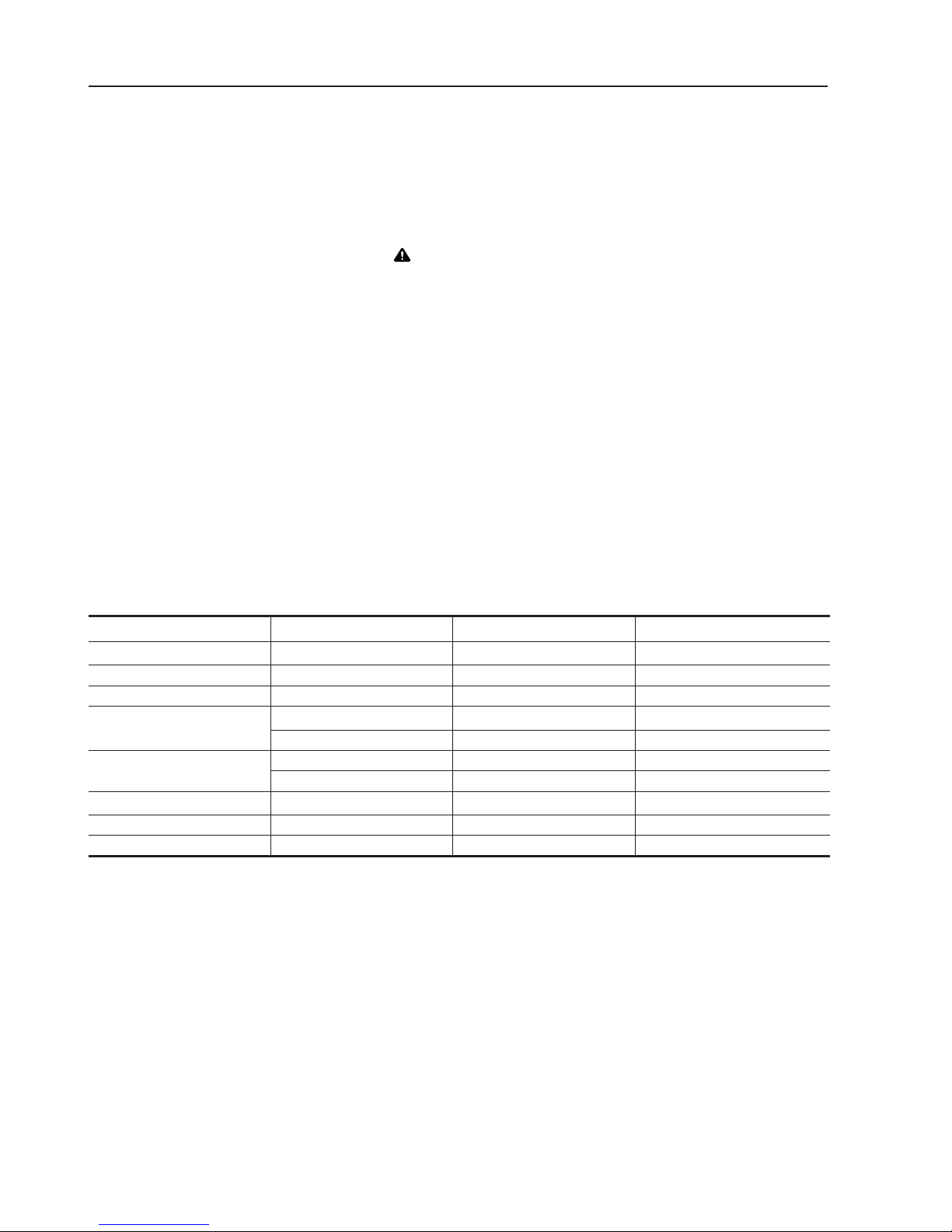

CONVERSION OF MAJOR UNITS

Quantity SI unit Conventional unit Coefficient of conversion into SI

Acceleration

Torque and moment Nm kgf•m 9.80665

Force N kgf 9.80665

Pressure MPa

Power/Power efficiency kW PS 0.735499

Vol um e

Spring constant N/mm kgf/mm 9.80665

Fuel consumption g/kW•h(*1) g/PS•h 1.3596

2

m/s

kPa mmHg 0.133322

W kcal/h 1.16279

3

cm

G 9.80665

2

kgf/cm

cc 1

*1. Conventional unit may be used in SI.

0.09809665

EG-4

Page 5

HOW TO READ THIS MANUAL

Description

CAUTION : At the beginning of each section, the precautions

exclusive to the section are described.

Preparation: At the beginning of each section and during the trouble

diagnosis items, the SSTs, gauges, and other tools to

be prepared before operation are described. Some

commercial service tools, assumed to be available in

any workshop, are omitted.

Description : To perform correct operations, operational procedures,

notes, SSTs, and other service information are

described.

CAUTION : Descriptions of visual inspections and cleaning of

removed parts are generally omitted. Please

remember that actual operations require these

processes.

Component Parts Location

The "Component Parts Location" diagram (refer to the figure)

includes information for removal, installation, disassembly, and

assembly (tightening torque, grease points, non-reusable parts) as

well as other information important for repair work.

EGM0097

EG-5

Page 6

HOW TO READ THIS MANUAL

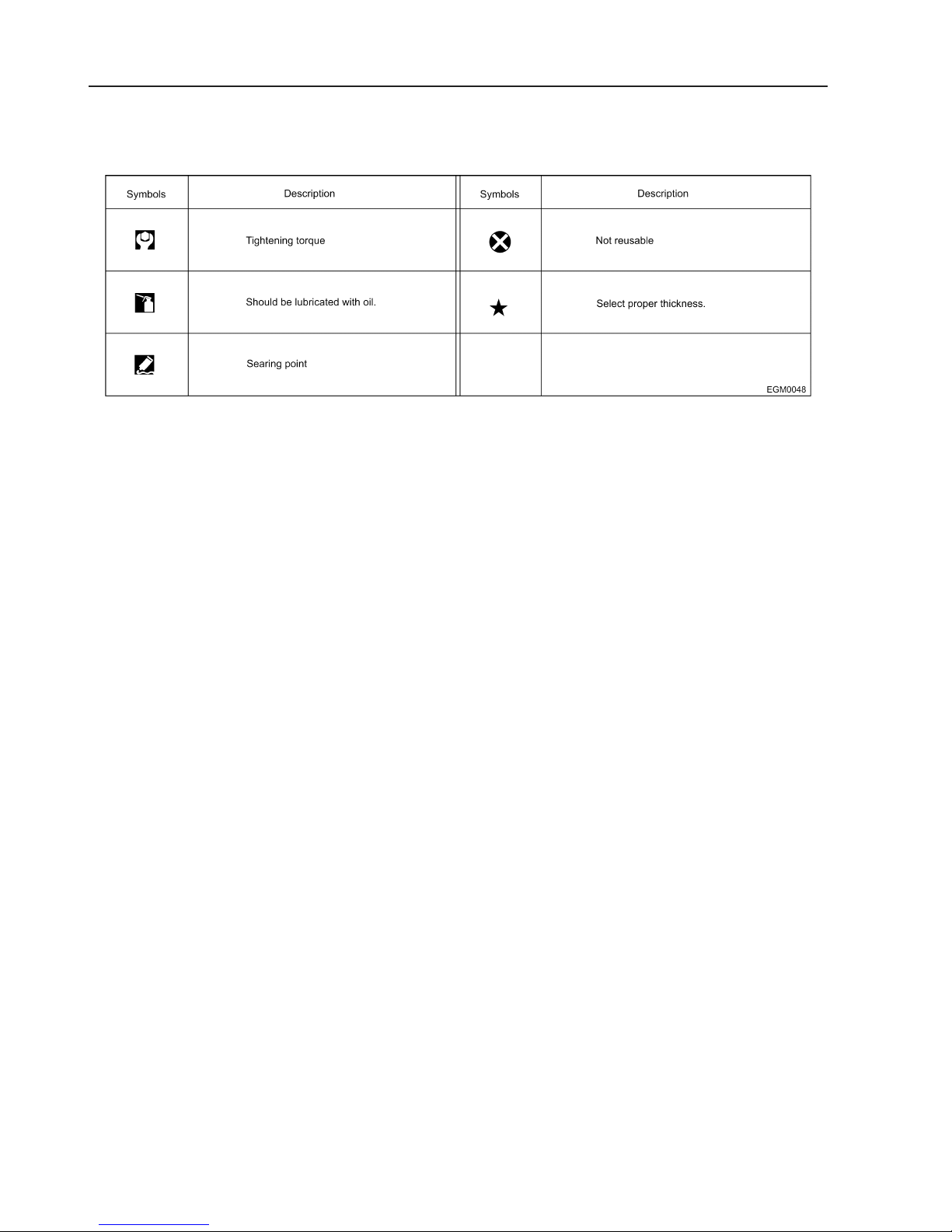

Component Parts Location (Cont'd)

COMPONENT SYMBOLS

EG-6

Page 7

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

ECM Trouble Diagnosis

CAUTION:

• The following trouble diagnosis procedures are designed

to identify the trouble causes efficiently. When performing

diagnoses, carefully observe the following instructions.

• Before starting a trouble diagnosis, carefully read and

understand the contents in "Basic Inspection", "Diagnosis

Chart by Symptom" and "Trouble Diagnosis Flowchart".

• After the repair work, always verify that the trouble is

eliminated.

• For the locations of the parts and harness connectors,

refer to "Component Parts Location" in the relevant

section.

• To perform a simple inspection, utilize the circuit diagrams.

To inspect the circuit for continuity in details including the

sub-harnesses, identify the relevant connectors and

harness layouts referring to the "Wiring Diagrams".

• Before inspecting a circuit for continuity, always turn the

ignition switch to OFF.

• Before measuring voltage at a connector, always measure

the battery voltage.

• After finishing diagnoses or inspections, always ensure

that all removed harness connectors are reconnected

correctly.

EG-7

Page 8

TROUBLE DIAGNOSIS

ECM Trouble Diagnosis (Cont'd)

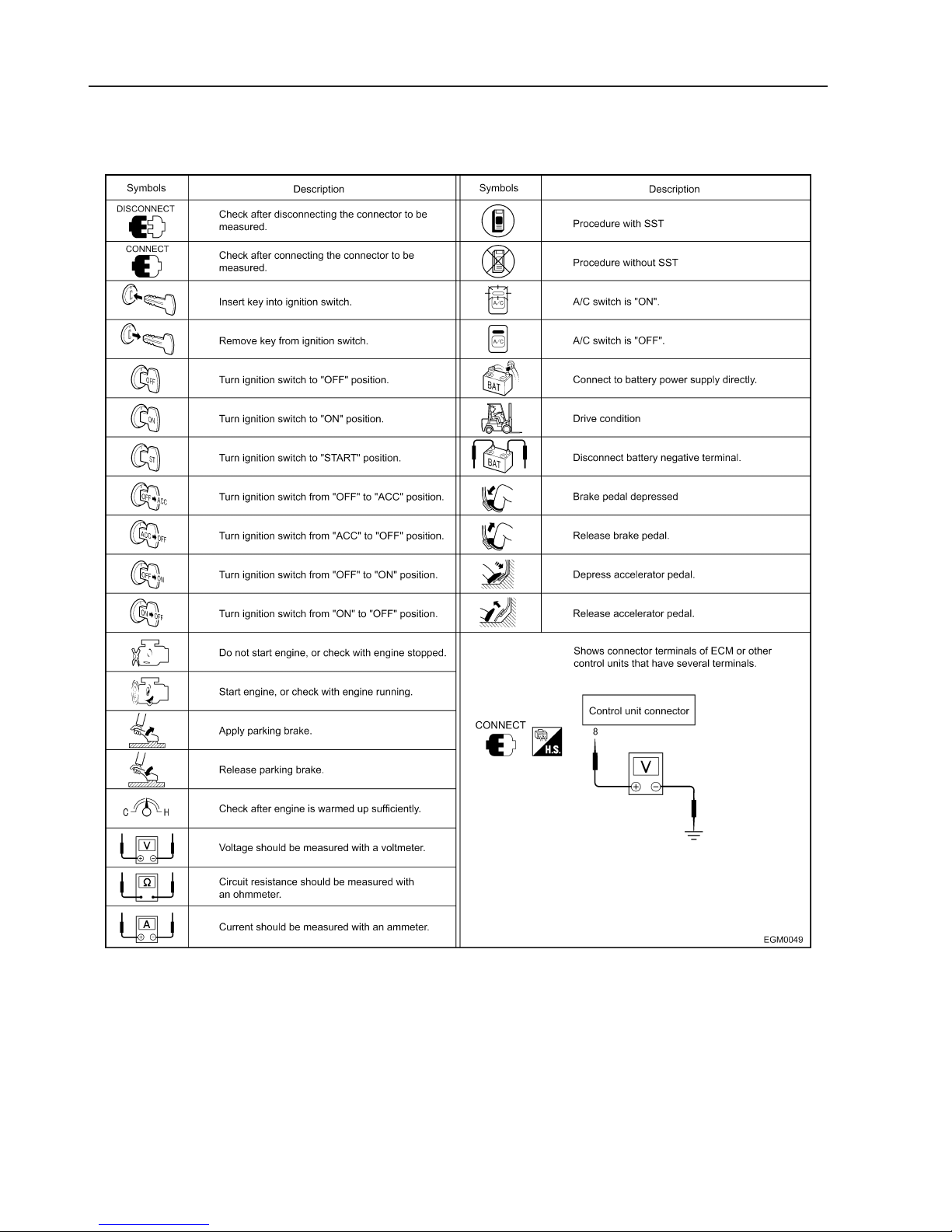

SYMBOLS

EG-8

Page 9

TROUBLE DIAGNOSIS

ECM Trouble Diagnosis (Cont'd)

SYMBOLS FOR HARNESS CONNECTOR

FEMALE CONNECTOR

• When a harness connector is viewed from A (terminal side), the

outer frame of the connector symbol is indicated with a single

line. In addition, the direction indicator shows "TS" (Terminal

Side) in description type font.

EGM0050

• When a harness connector is viewed from B (harness side), the

outer frame of the connector symbol is indicated with double

lines. In addition, the direction indicator shows "HS" (Harness

Side) in description type font.

• Terminal assignments of a connector viewed from A and B are

mirror images, indicating just as they are seen.

EGM0051

EGM0052

MALE CONNECTOR

The illustration method is the same as that for a female connector,

the black guide box, however, indicates a male connector (the white

guide box a female connector).

SINGLE UNIT (CONTROL UNIT)

A single control unit is viewed only from A, and the illustration is as

shown in the figure.

EGM0053

EG-9

Page 10

TROUBLE DIAGNOSIS

ECM Abbreviations List

Abbreviations Description Abbreviations Description

A/C Air conditioner INT Intake

A/T Automatic transmission LH Left

ALT Alternator LED Light emitting diode

ASSY Assembly LLC Long-life coolant

BAT Battery M/T Manual transmission

C/P Crankshaft pulley OHV Overhead valve

C/U Control unit OS Oversize

Cyl Cylinder P/S Power steering

ENG Engine PTO Power take-off

EXH Exhaust RH Right

F/L Fusible link RR Rear

FR Front TAS Throttle adjust screw

I/P Idler pulley Tr Transistor

IGN Ignition US Undersize

EG-10

Page 11

ECM GENERAL SERVICE INFORMATION

ECM GENERAL SERVICE INFORMATION

Connector Terminal Inspection

CONNECTOR INSPECTION PROCEDURE

In circuit inspection, inappropriate connector probing will cause

connector damages and/or poor connection. The probes provided

with the circuit tester may be too large to probe connector terminals

without damaging them. Always use alligator clips and "T" pins

according to following the procedure.

INSPECTION FROM HARNESS SIDE

For a standard connector without any waterproofing, use "T" pins

from the harness side.

CAUTION:

• For a connector with a rear cover, such as ECM

connectors, remove the rear cover before the inspection.

• For a waterproof connector, do not probe the terminals

from the harness side. Doing so may damage the seal.

EGM0054

INSPECTION FROM TERMINAL SIDE

1. Female terminal

• Female connector terminals have a small notch difference

inside. Insert a "T" pin along the step to inspect.

EGM0055

EGM0056

CAUTION:

Do not insert any objects to a female connector terminal other

than the corresponding male connector terminal.

• In case of a female connector terminal without any notches,

remove the retainer before probing.

EG-11

Page 12

ECM GENERAL SERVICE INFORMATION

Connector Terminal Inspection (Cont'd)

2. Male terminal

For a male connector terminal, apply a "T" pin to the surface of the

terminal.

CAUTION:

Do not bend terminals.

EGM0057

Inspection for Electrical System

DESCRIPTION

• If the malfunction can be traced directly to the electrical system,

first check for items such as burned-out fuses and fusible links,

broken wires or loose connectors, pulled-out terminals, and

improper connections.

• If a fuse or a fusible link is blown out, determine the possible

cause and restore it. Always replace it with a new fuse or fusible

link of the specified capacity.

• When removing a connector, do not apply excessive force to the

main body by grasping and twisting.

• Do not pull a connector off by tugging on the harness.

• For a lock-type connector, disengage its lock first, then

disconnect the connector by holding the main body of the

connector.

EGM0058

EGM0059

• Before connecting a connector, check terminals for bends or

breakage. Connect it securely.

• For a lock-type connector, press it until its lock is securely

engaged.

• When installing parts, prevent harnesses from being snagged

or overextended.

EG-12

Page 13

ECM GENERAL SERVICE INFORMATION

Control Unit and Electronic Component

PRECAUTIONS

• Never reverse polarity of battery terminals.

• Install only parts specified for each model.

• Before replacing a control unit, check input and output signals

to/from the control unit, and component functions.

• When disconnecting a connector, do not twist or apply

excessive force.

• For a bolt-type connector, loosen the bolt first, then hold the

main body of the connector to disconnect.

• Before connecting a connector, check terminals for bends or

breakage. Connect it securely. For a bolt-type connector, screw

in the bolt until the colored lug is flush with the surface to be

sure it is securely connected.

• Do not drop, hit, or subject control units to impact.

• Be sure to protect control units from condensation caused by a

sudden shift in temperature, or from raindrops or splashes. If

any water drops adhere to the unit, dry it well prior to

installation.

• Be sure to protect control unit connectors from oil.

• Avoid cleaning control units with benzine.

• Do not open a top or bottom cover on a control unit.

EGM0062

EGM0063

• When using a circuit tester, ensure the appropriate distance

between test probes. A longer distance is recommended,

because if the distance is too short, it may cause contact of the

test probes, resulting in a short circuit. A short circuit allows

battery voltage to be applied directly to the control unit, resulting

in damage to its internal power transistors.

• Use the specified check adapter to check input and output

signals to/from control units.

EG-13

Page 14

ECM GENERAL SERVICE INFORMATION

SST

DESCRIPTION

SST is a small, lightweight handheld tester. When connected to the

vehicle-side data link connector, it communicates with control units

installed on the vehicle and performs a variety of diagnostic tests.

FUNCTION AND APPLIED SYSTEM

Items Function

WORK SUPPORT Sends command to control unit to set status suitable for inspection and service.

FUNCTION SYSTEM Checks each system as ECM basic inspection.

SELF-DIAG RESULTS Receives self-diagnostic results from control unit and indicates DTCs and number of occurrences.

SELF-DIAG RESULTS

[MEMORY]

DATA MONITOR Receives input/output signals from control unit and indicates and stores them to facilitate locating cause of

DATA MONITOR [SPEC]

Active test Sends command to control unit to change output signals and check operation of output system.

DTC RECORD DISPLAY Indicates self-diagnostic results stored in ECM prior to the most recent "ERASE MEMORY".

Control unit part No. Displays control unit part number.

Control unit identification No. Displays control unit identification number.

DTCs (Diagnostic Trouble Codes) recorded in control unit's memory are displayed.

malfunctions.

Diagnostic systems Engine

WORK SUPPORT {

SELF-DIAG RESULTS {

SELF-DIAG RESULTS [MEMORY]

DATA MONITOR {

DATA MONITOR [SPEC] {

Active test {

DTC RECORD DISPLAY

Control unit part No. {

Control unit identification No.

EG-14

Page 15

PRECAUTIONS FOR WORK

PRECAUTIONS FOR WORK

Precautions for Draining Coolant

Drain the coolant after its temperature lowers sufficiently.

Precautions for Separating Fuel Piping

• Work in a place where there is nothing to start a fire.

• Release the fuel pressure in advance.

• After separating the fuel piping, plug it to prevent the fuel from

flowing out.

Precautions for Removal and Disassembly

• If specified, use correct special tools and pay attention. Do not

apply an excessive force.

• Take extreme care not to lower the accuracy of the mating

faces, sliding faces, etc.

• If necessary, cover the openings with tapes, etc. to prevent

foreign matter from entering the engine.

• Make marks on the removed parts and arrange them for secure

troubleshooting and assembly.

• As a rule, loosen the bolts and nuts from outside in the diagonal

direction. If the loosening order is specified, observe it.

Precautions for Checking, Repairing, and

Replacing Parts

Before repairing or replacing parts, check them sufficiently according

to the check procedure. Check the new parts similarly and replace

them if necessary.

Precautions for Assembling and Installing

Parts

• When tightening the bolts and nuts, be sure to use torque

wrenches.

• As a rule, tighten the bolts and nuts from inside to outside in the

diagonal direction in 2 – 3 times. If the tightening order is

specified, observe it.

• Replace the gaskets, packings, oil seal, and O-rings with new

ones.

• Clean each part and dry it by blowing compressed air against it.

In particular, take care that the oil passages and coolant

passages will not be clogged.

• Take care not to damage the sliding surfaces and mating faces,

and remove all dirt, lint, etc. from them. Apply sufficient oil to the

sliding surface before assembling.

• If the coolant is drained, bleed air from the coolant system.

• After repairing, run the engine at high speed and check for

leakage of the coolant, fuel, oil, grease, and exhaust gas.

EG-15

Page 16

PRECAUTIONS FOR WORK

Precautions for Using Power Tools

Use power tools such as an air runner for disassembly only. Do not

use them for assembly.

Precautions for Applying Gasket Sealant

SEPARATION OF PARTS COATED WITH GASKET

SEALANT

• After removing the mounting bolts and mounting nuts, cut and

remove the gasket sealant with seal cutter (special tool KV101-

11100) according tothe following procedure.

[1] Drive in the seal cutter in the direction of the arrow.

[2] Slide the seal cutter in the direction of the arrow.

[3] Slide the seal cutter in the direction of the arrow.

CAUTION:

• Take care not to damage the mating faces.

• If it is difficult to use the seal cutter, remove the gasket

EGM0066

sealant by hitting it lightly with a plastic hammer.

CAUTION:

If it is obliged to use a flat-head screwdriver, take extreme care

not to damage the mating faces.

EGM0067

EGM0068

PROCEDURE FOR APPLYING GASKET SEALANT

1. Remove the old gasket sealant sticking to the mating faces with

scraper.

• Remove all the gasket sealant from the grooves, mounting

bolts, and bolt holes, too.

2. Wipe the mating faces with isoparaffin, etc. to remove water, oil,

grease, and foreign matter.

3. Install the genuine gasket sealant to tube presser (common

tool).

4. Apply the gasket sealant to the specified parts and dimensions

without breaking it.

• Apply the gasket sealant to the grooves, too, if specified so.

• As a rule, apply the gasket sealant to the inside of the bolt

holes. The outside of the bolt holes may need to be coated

with the gasket sealant, however. Accordingly, refer to the

manual without fail.

• Install the parts within 5 minutes after applying the gasket

sealant.

• Wipe off the projected gasket sealant immediately.

• Do not retighten the bolts after installing the parts.

• After installing the parts, wait at least 30 minutes before

supplying engine oil or coolant.

CAUTION:

If a direction is given in the manual, observe it.

EG-16

Page 17

PRECAUTIONS FOR WORK

Parts Which Need to be Tightened by Angle

Tightening Method

• Use angle wrenches (special tools) to tighten the following

parts.

• Cylinder head bolt

Check that the cylinder head, cylinder block mounting face, and

cylinder head gasket are free from oil and dirt, and then coat the

threads and stem of the cylinder head bolt and tighten it.

EG-17

Page 18

Seal cutter

KV1011 11100

Ring gear stopper

KVl101 056S0

1 Adapter

KV101 05630

2 Stopper plate

KV101 05610

Oil seal drift

KV101 04900

Angle wrench

KV101 12100

PREPARATION

PREPARATION

Special Service Tools

Special Service Tools (Cont'd)

Description Application Remarks

Removing parts attached with

liquid gasket

EGM0069

Removing and installing

crankshaft pulley

EGM0070

Installing front oil seal

EGM0071

Checking tightening angle

1. Valve spring compressor

KV101 09210

2. Adapter

KV101 11200

Valve oil seal puller

KV101 07901

Valve oil seal drift

KV101 13000

Already established

EGM0072

Removing and installing valve

collet

EGM0073

Removing valve oil seal

EGM0074

Installing valve oil seal

EGM0075

EG-18

Page 19

Engine stand assembly

ST0501 S000

Engine attachment

KV101 06500

Engine sub-attachment

KV111 04800

Camshaft bushing tool set

KV111 045S0

1. Bar

KV111 04510

2. Guide plate

KV111 04520

3. Adapter

KV111 04530

4. Drift

ST1524 3000

Pulley puller

KV111 03000

PREPARATION

Special Service Tools (Cont'd)

Description Application Remarks

Overhauling engine

EGM0076

EGM0077

Already established

EGM0078

Removing and installing camshaft

bushing

EGM0079

Removing crankshaft pulley. Already established

Oil filter wrench

KV101 15801

EGI fuel pressure indicator

ST1959 0000

EGM0080

Removing oil filter Already established

EGM0081

For measuring fuel pressure

gauge

EGM0082

EG-19

Page 20

Heated oxygen sensor wrench

KV101 13700

Maintenance tool

1. DIAGNOSIS KIT

SKVEE GY010

2. SOFT WARE

SKVEE GY100

Check adapter V

EG1755 0000

(for SMJ 150-pin connector)

Harness adapter

EG1755 0200

(150-pin to 121-pin conversion adapter)

PREPARATION

Special Service Tools (Cont'd)

Description Application Remarks

Removing and installing heated

oxygen sensor

EGM0083

For system inspection and

diagnosis

For control unit input/output signal

inspection

EGM0084

For molding coil

Adapter harness

EG101 17500

EGM0085

Checking engine speed

EGM0086

Service Parts

Piston oversize

0.5 mm (0.020 in) OS [0.5 mm (0.020 in) oversize]

1.0 mm (0.039 in) OS [1.0 mm (0.039 in) oversize]

Main bearing undersize

Unit: mm (in)

Size Thickness

STD 2.000 (0.0787)

US 0.25 (0.0098) 2.125 (0.0837)

US 0.50 (0.0197) 2.250 (0.0886)

US 0.75 (0.0295) 2.375 (0.0935)

US 1.00 (0.0394) 2.500 (0.0984)

EG-20

Page 21

Refer to the following notes for values in ( ).

Engine system inspection (except LPG fuel systems)

No. Inspection items

1 Intake/exhaust valve clearance

Electronic controls

2 Engine drive belt tension Electronic

3 Engine oil Electronic

4 Oil filter Electronic

5 Engine coolant Electronic

6 Air cleaner element Electronic

7 Ignition timing Electronic

8 Spark plug Electronic

9 Distributor Electronic

10 PCV valve Electronic

11 PCV hose Electronic

Applicable

control

system

Electronic

controls

controls

controls

controls

controls

controls

controls

controls

controls

controls

controls

SERVICE DATA

SERVICE DATA

Periodical Inspection

To maintain the initial performance of the KOMATSU FORKLIFT,

make sure to perform appropriate maintenance and service work.

PERFORM INSPECTION

Make sure to perform the periodical inspections at the appropriate

times, according to the month basis or the operating hour basis,

whichever comes first.

Months of

use

Operation

hours

(x 100 hours)

(1) RRRRRRRRRRRR...R

(1) R R R R R ... R

(1) I I I I ... I

123456789101112...18

2 4 6 8 1012141618202224 ... 36

AAAAA...A

IIIIIIIIIIII...I

R...

CCCCCRCCCCCR...R

AAAAAAAAAAAA...A

IIIIIIIIIIII...R

C...

IIII...I

EG-21

Page 22

SERVICE DATA

Periodical Inspection (Cont'd)

No. Engine system inspection (LPG models)

1 Gas leakage from piping and piping

joints

2 Damage to piping and piping joints Electronic

3 Tar in vaporizer Electronic

4 Injection nozzle Electronic

5 LPG filter Electronic

CAUTION:

• If the vehicle is being used in dusty and dirty environments, the maintenance work should be performed

more frequently.

• After replacing the LPG tank, apply soapsuds to the piping joints to check for any gas leakage.

Meanings of symbols: I = Inspection. Repair or replace if necessary.

R = Replacement

A = Adjustment

C = Cleaning

D = Draining

T = Tightening (Retightening)

Electronic

controls

controls

controls

controls

controls

(2) IIIIIIIIIIII ...I

IIIIIIIIIIII ...I

DDDDDDDDDDDD ...D

IIIII...I

CCCR...C

EG-22

Page 23

SERVICE DATA

Standard, Repair Limit

Fuel in use Gasoline specification Lead-free regular gasoline with an octane value of 91 or more

LPG specification 20-100P

Engine weight (without water, with oil) kg (lb) Approx. GAS, LPG:301’, DUAL:302’

Firing order 1 - 5 - 3 - 6 - 2 - 4

Compression pressure

kPa (bar, kgf/cm

Distortion limit mm (in) Intake manifold 0.2 (0.008)

Engine oil amount l (Imp qt)

(SL class)

Spark plug Manufacturer/type/gap mm (in) NGK/BPR4ES-D/0.8 - 0.9 (0.031 - 0.035)

Resistance on high-tension cable (k:) #1: Approx. 2.7 #2: Approx. 2.8 #3: Approx. 4

Ignition advance device Electronically controlled ignition advance

Onboard idle speed (rpm) 750 r 50

Onboard idling pace speed (When feedback control is stopped) (rpm) 750

Density of CO at idle speed/Density of HC at idle speed (%/ppm) 0.1 or less/50 or less

Ignition timing (When feedback control is stopped) (BTDCq/rpm) 10 r 2/750

Valve clearance mm (in) INT/EXH Hot 0.35 (0.0138)/0.35 (0.0138)

Thermostat opening valve temperature (Start - Full open) qC (qF) 82 - 95 (180 - 203)

Engine drive belt deflection New belt After adjustment Limit

[Measured by pressing

with 98 N (10 kg, 22 lb)] mm (in)

2

, psi)/rpm

Standard 1,187 (11.87, 12.1, 172)/200

Repair limit 892 (8.92, 9.1, 129)/200

Difference limit among cylinders 98 (0.98, 1.0, 14)/200

Exhaust manifold

Cylinder head 0.2 (0.008)

Cylinder block 0.1 (0.004)

When replacing oil only Approx. 8.3 (7-1/4)

When replacing oil and filter Approx. 8.6 (6-5/8)

#4: Approx. 5 #5: Approx. 5.2 #6: Approx. 6.1

Alternator belt/Fan belt 10 - 12

(0.39 - 0.47)

0.3 (0.012)

13 - 15

(0.51 - 0.59)

16 (0.63)

EGM0098

EG-23

Page 24

SERVICE DATA

Tightening Torque

STANDARD BOLT TIGHTENING TORQUE

<Hexagon head> <No lubrication> Unit: N•m (kg-m, ft-lb)

N•m (kg-m, in-lb)*

Normal size

d

M3 0.5 0.6

M3.5 0.6 1.0

M4 0.7 1.5

M5 0.8 2.9

M6 1.0 5.0

M8 1.25 12.7

M10 1.5 24.5

M12 1.75 42.2

M14 1.5 73.6

M16 1.5 108

M18 1.5 167

M20 1.5 226

M22 1.5 304

Pitch

P

1.0 13.7

1.25 25.5

1.25 46.1

Non-flanged

bolt

(0.06, 5)*

(0.10, 9)*

(0.15, 13)*

(0.30, 26)*

(0.51, 44)*

(1.3, 9.4)

(1.4, 10)

(2.5, 18)

(2.6, 19)

(4.3, 31)

(4.7, 34)

(7.5, 54)

(11, 80)

(17, 123)

(23, 166)

(31, 224)

4T 7T 9T

Flanged bolt Non-flanged bolt Flanged bolt

0.7

(0.07, 6)*

1.2

(0.12, 10)*

1.7

(0.17, 15)*

3.5

(0.36, 31)*

6.0

(0.61, 53)*

14.7

(1.5, 10.8)

15.7

(1.6, 12)

29.4

(3.0, 22)

30.4

(3.1, 22)

51

(5.2, 38)

55.9

(5.7, 41)

87.3

(8.9, 64)

137

(14, 101)

196

(20, 145)

275

(28, 203)

363

(37, 268)

1.1

(0.11, 10)*

1.7

(0.17, 15)*

2.5

(0.25, 22)*

5.0

(0.51, 44)*

8.4

(0.86, 75)*

20.6

(2.1, 15)

21.6

(2.2, 16)

41.2

(4.2, 30)

43.1

(4.4, 32)

70.6

(7.2, 52)

77.5

(7.9, 57)

127

(13, 94)

186

(19, 137)

275

(28, 203)

382

(39, 282)

510

(52, 376)

1.3

(0.13, 11)*

2.1

(0.21, 18)*

2.9

(0.30, 26)*

5.9

(0.6, 52)*

10

(1.0, 87)*

24.5

(2.5, 18)

26.5

(2.7, 20)

49

5, 36)

(

51

(5.2, 38)

84.3

(8.6, 62)

92.2

(9.4, 68)

147

(15, 108)

226

(23, 166)

324

(33, 239)

451

(46, 333)

608

(62, 448)

Non-flanged

bolt

1.6

(0.16, 14)*

2.5

(0.25, 22)*

3.5

(0.36, 31)*

7.2

(0.73, 63)*

11.8

(1.2, 8.7)

29.4

(3.0, 22)

31.4

(3.2, 23)

58.8

(6.0, 43)

61.8

(6.3, 46)

98.1

(10, 72)

108

(11, 80)

177

(18, 130)

265

(27, 195)

392

(40, 289)

549

(56, 405)

736

(75, 542)

Flanged bolt

1.9

(0.19, 16)*

2.8

(0.29, 25)*

4.2

(0.43, 37)*

8.5

(0.87, 76)*

14.7

(1.5, 10.8)

35.3

(3.6, 26)

37.3

(3.8, 27)

69.6

(7

.1, 51)

73.6

(7.5, 54)

118

(12, 87)

137

(14, 101)

206

(21, 152)

324

(33, 239)

471

(48, 34)

657

(67, 485)

883

(90, 651)

CAUTION:

• Except special parts.

• The bolt applicable to the list has the following number embossed on the head.

Model Number

4T ... 4 or none

7T ... 7

9T ... 9

CAUTION FOR USE OF POWER TOOLS

Do not use any power tools (e.g. air ratchet, impact wrench) to

tighten the bolts and nuts. Use these tools only for loosening the

bolts and nuts. However, do not use power tools in any event and for

any purposes on the parts subject to heat (catalyst, muffler, and

other exhaust parts) and the tapping screws. These parts may also

be damaged when loosened with a power tool.

EG-24

Page 25

SERVICE DATA

Tightening Torque (Cont'd)

MAIN TIGHTENING TORQUE

* : Parts with tightening sequence

1) - :Tighten separately in several turns.

Unit :N•m (kg-m, ft-lb)

N•m (kg-m, in-lb)*

Parts name or location Tightening torque

Adjusting screw Lock nut 16 - 22 (1.6 - 2.2, 12 - 16)

AlternatorAdjusting bar side

Bracket side

Oil pan drain plug 54 - 59 (5.5 - 6.0, 40 - 43)

Spark plug 20 - 29 (2.04 - 2.96, 14 - 22)

* Intake manifold 15.7 - 18.6 (1.6 - 1.9, 12 - 14)

* Air horn 20.6 - 26.5 (2.1 - 2.7, 16 - 27)

Exhaust manifold cover 6.37 - 7.45 (0.65 - 0.76, 56 - 66)*

* Exhaust manifold 27 - 31 (2.8 - 3.2, 20 - 23)

Exhaust manifold connector 59 - 78 (6.0 - 8.0, 43 - 58)

* Oil pan [M6]

[M8]

Oil strainer 16 - 19 (1.6 - 1.9, 12 - 14)

* Rocker cover 1.0 - 2.9 (0.1 - 0.3, 9 - 26)*

Rocker shaft bracket 15.6 - 21.6 (1.6 - 2.2, 12 - 16)

* Cylinder head bolt 1) 29.4 (3, 22)

Cylinder head additional bolt 6.4 - 7.5 (0.65 - 0.76, 56 - 66)*

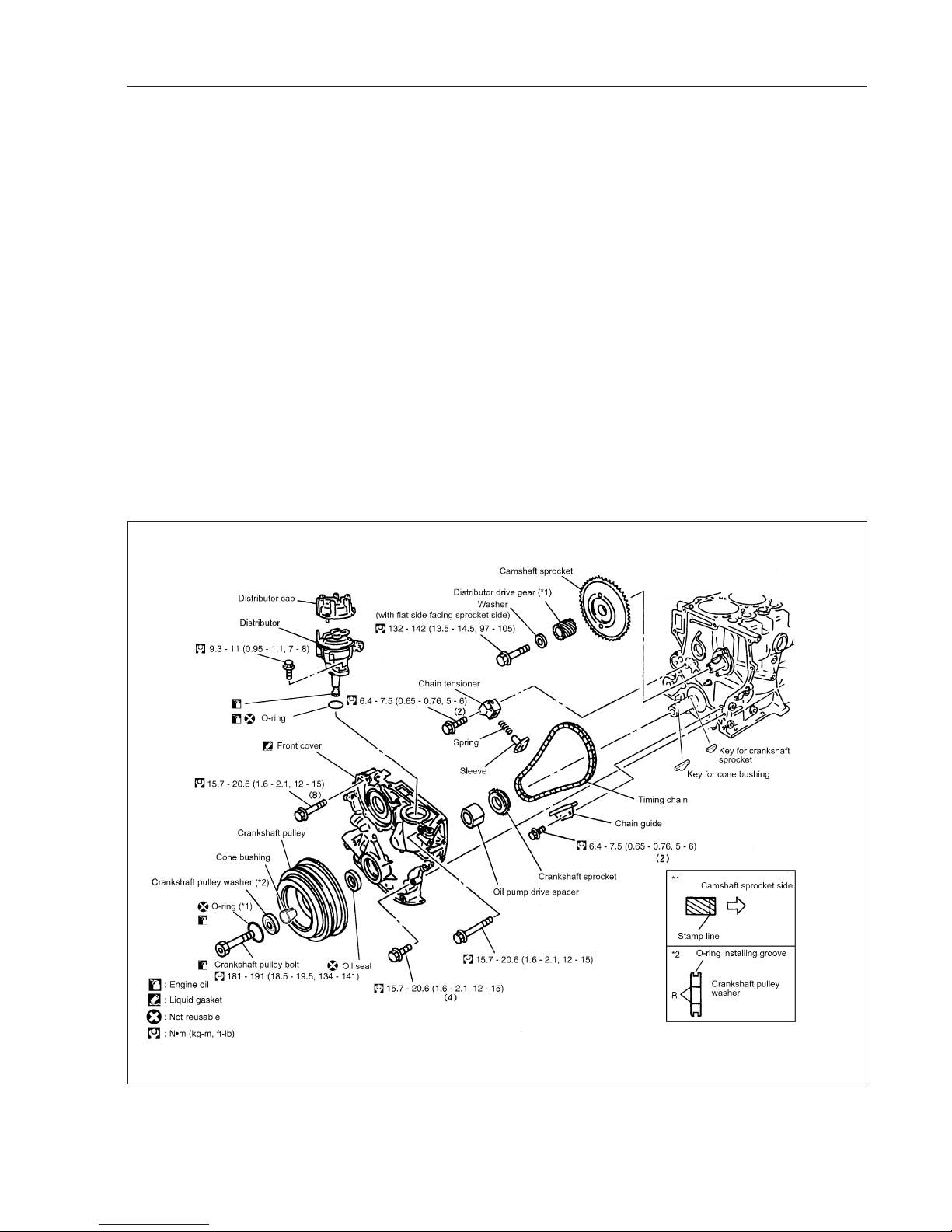

Crankshaft pulley 181 - 191 (18.5 - 19.5, 134 - 141)

* Front cover 15.7 - 20.6 (1.6 - 2.1, 12 - 15)

Camshaft sprocket 132.3 - 142.1 (13.5 - 14.5, 98 - 105)

Chain tensioner 5.6 - 8.4 (0.57 - 0.86, 49.5 - 74.7)

Distributor 9.35 - 11 (0.95 - 1.1, 82 - 95)*

Camshaft locating plate 5.6 - 8.4 (0.57 - 0.86, 49.5 - 74.7)

* Flywheel 146 - 167 (15 - 17, 108 - 123)

* Main bearing cap 162 - 172 (16.5 - 17.5, 119 - 127)

Connecting rod nut 1) 38 - 40 (3.9 - 4.1, 28 - 30)

Engine coolant drain plug 34 - 44 (3.5 - 4.5, 25 - 33)

Water pump 15.7 - 18.6 (1.6 - 1.9, 12 - 14)

Engine coolant temperature sensor 20 - 29 (2.0 - 3.0, 14 - 22)

PCV valve 20 - 29 (2.0 - 3.0, 14 - 22)

* Fuel tube 1) 9.3 - 20.6 (0.9 - 2.1, 78 - 182)*

Starter motor 41.2 - 52 (4.2 - 5.3, 30 - 38)

Heated oxygen sensor 1 40 - 60 (4.1 - 6.1, 30 - 44)

17.5 - 23.7 (1.8 - 2.4, 13 - 17)

50.0 - 67.6 (5.1 - 6.9, 37 - 50)

6.3 - 8.3 (0.64 - 0.85, 56 - 74)*

15.7 - 20.6 (1.6 - 2.1, 12 - 15)

2) 61.7 (6.3, 46)

3) 0 (0, 0)

4) 29.4 (3, 22)

5) 69q - 74q(Angle tightening)

2) 40q - 45q(Angle tightening)

2) 20.6 - 26.5 (2.1 - 2.7, 15 - 20)

EG-25

Loading...

Loading...