WEBM005500

WEBM005500

SK714-5 SK815-5 SK815-5 turbo

00-1

CONTENTS

CONTENTS

Page

10 STRUCTURE AND FUNCTION........................................................................................10-1

20 TESTING AND ADJUSTING.............................................................................................20-1

30 DISASSEMBLY AND ASSEMBLY..................................................................................30-1

40 MAINTENANCE STANDARD...........................................................................................40-1

00-2

SK714-5 SK815-5 SK815-5 turbo

The affected pages are indicated by the use of the

following marks. It is requested that necessary actions be taken to these pages according to table below.

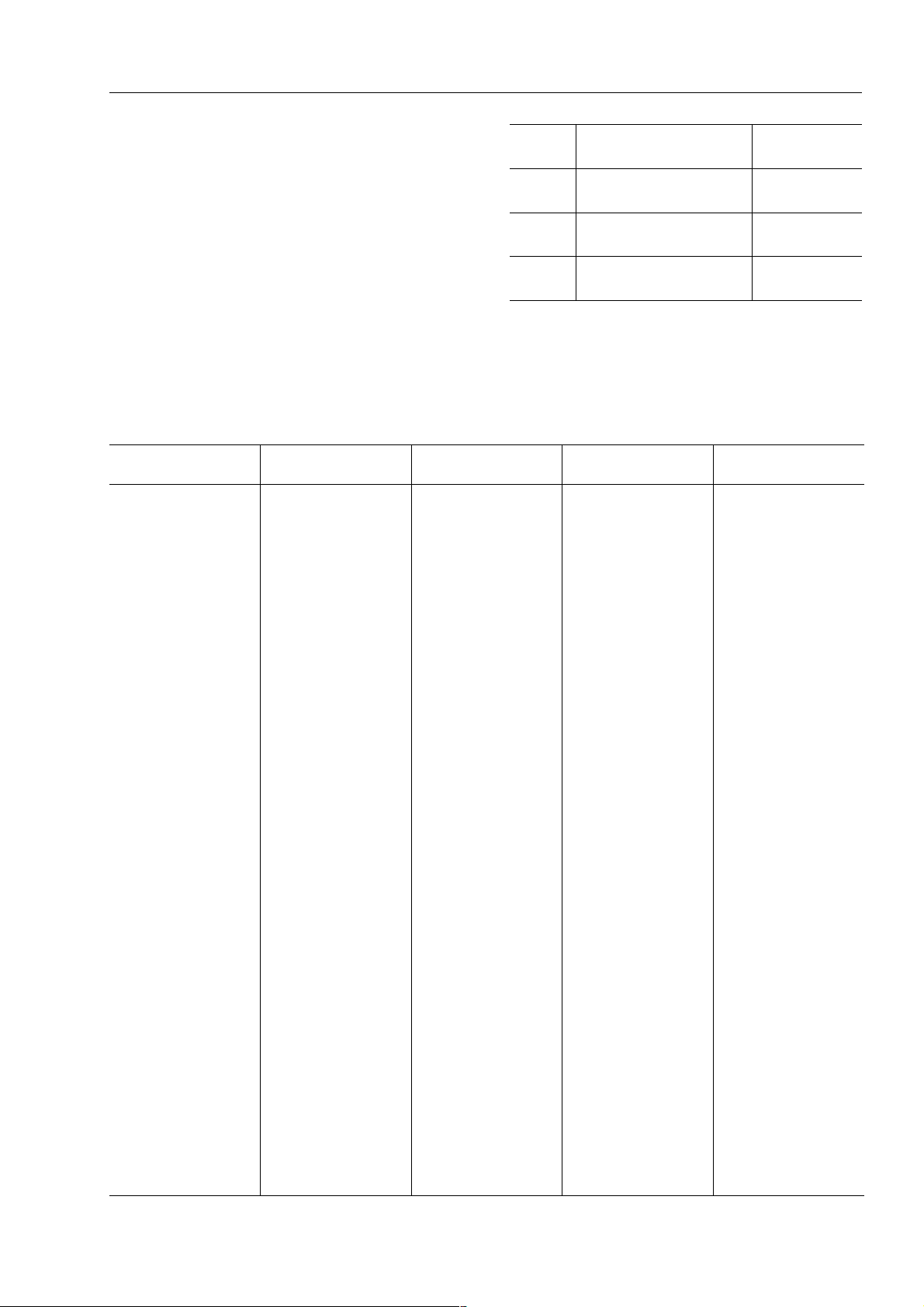

REVISED PAGES

Mark Indication Action required

❍

Page to be newly Add

Mark Page

00-1

00-2

00-2-1

00-2-2

00-3

00-4

00-5

00-6

00-7

00-8

00-9

00-10

00-11

00-12

00-13

00-14

00-15

00-16

00-17

00-18

00-19

00-20

00-21

00-22

10-1

10-2

10-3

10-4

10-5

10-6

10-7

10-8

10-9

10-10

10-11

10-12

10-13

10-14

10-15

10-16

Time of

revision

Mark Page

10-17

10-18

10-19

10-20

10-21

10-22

10-23

10-24

10-25

10-26

10-27

10-28

10-29

10-30

10-31

10-32

10-33

10-34

10-35

10-36

10-37

10-38

10-39

10-40

10-41

10-42

10-43

10-44

10-45

10-46

10-47

10-48

10-49

10-50

10-51

10-52

10-53

10-54

10-55

10-56

10-57

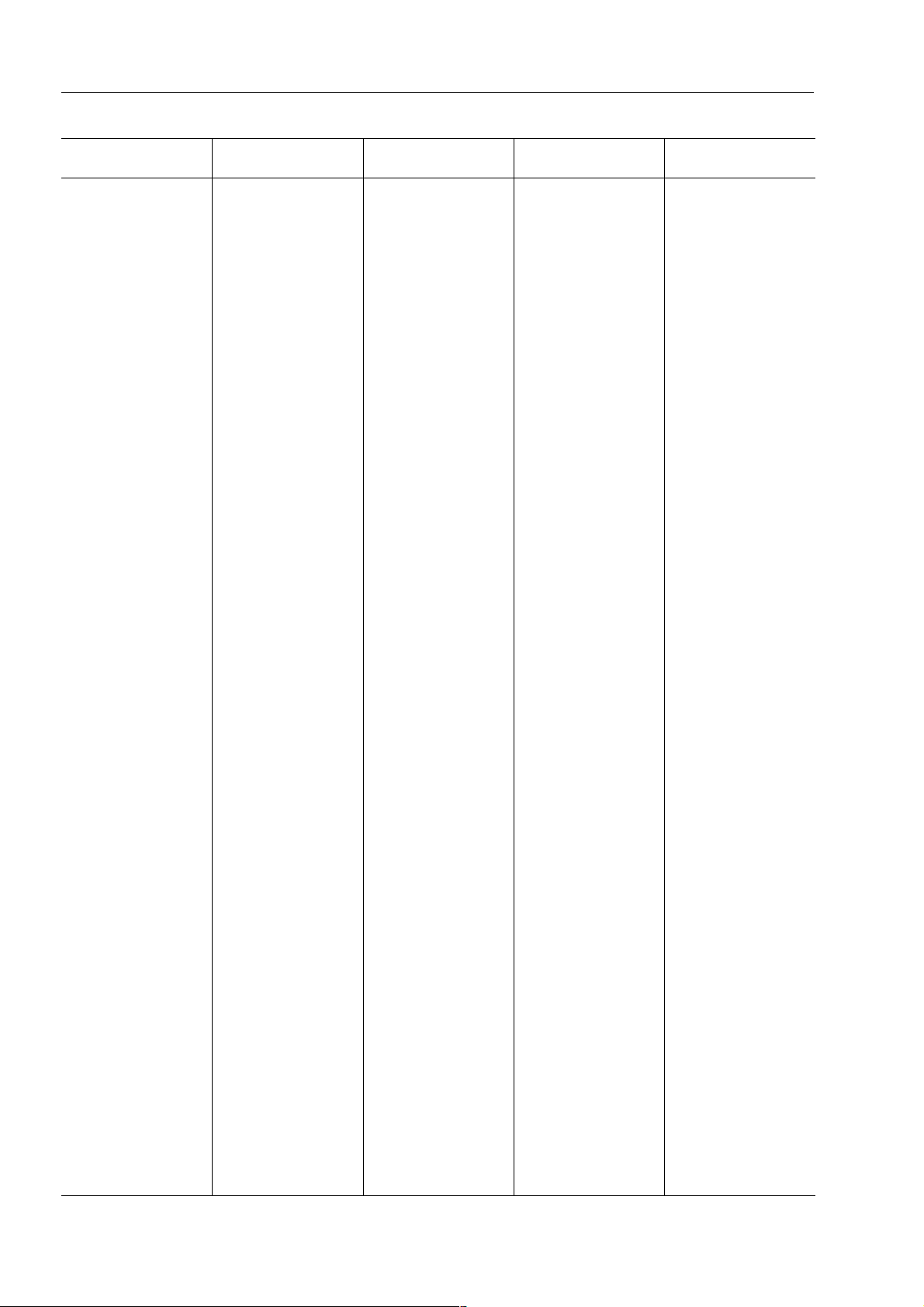

LIST OF REVISED PAGES

Time of

revision

Mark Page

10-58

10-59

10-60

10-61

10-62

10-63

10-64

10-65

10-66

10-67

10-68

10-69

10-70

10-71

10-72

10-73

10-74

10-75

10-76

10-77

10-78

10-79

10-80

10-81

10-82

10-83

10-84

10-85

10-86

10-87

10-88

10-89

10-90

10-91

10-92

10-93

10-94

10-95

10-96

10-97

10-98

●

Page to be replaced Replace

( ) Page to b e delete Discar d

Pages having no marks are those previously revised or

made additions.

Time of

revision

Mark Page

10-99

10-100

10-101

10-102

10-103

10-104

10-105

Time of

revision

Mark Page

20-32

20-34

20-35

20-36

20-37

20-38

20-39

Time of

revision

10-106

30-1

20-1

20-2

20-3

20-4

20-5

20-6

20-7

20-8

20-9

20-10

20-11

20-12

20-13

20-14

20-15

20-16

20-17

20-18

20-19

20-20

20-21

20-22

20-23

20-24

20-25

20-26

20-27

20-28

20-29

20-30

20-31

20-32

30-2

30-3

30-4

30-5

30-6

30-7

30-8

30-9

30-10

30-11

30-12

30-13

30-14

30-15

30-16

30-17

30-18

30-19

30-20

30-21

30-22

30-23

30-24

30-25

30-26

30-27

30-28

30-29

30-30

30-31

30-32

30-33

SK714-5 SK815-5 SK815-5 turbo

00-2-1

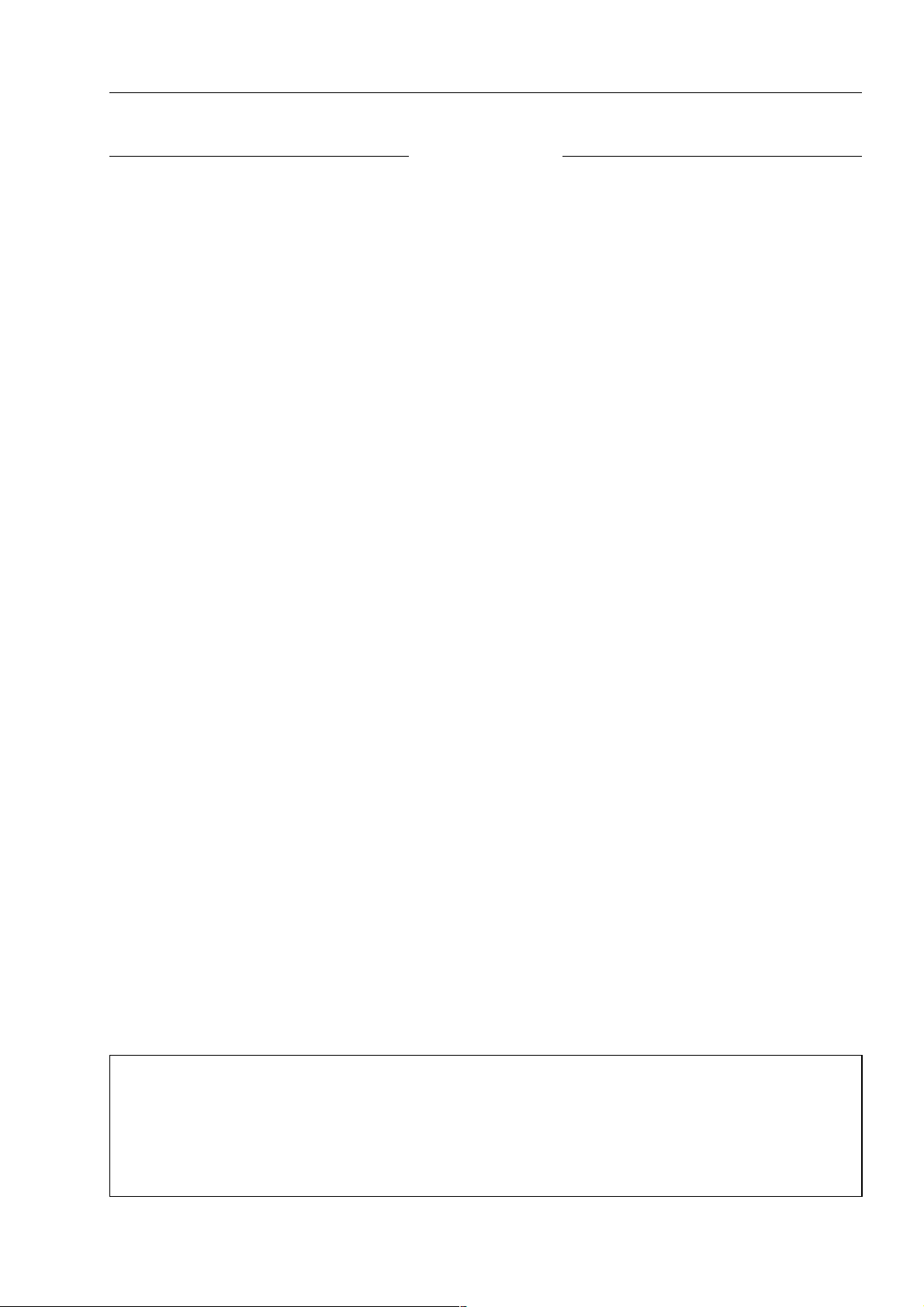

REVISED PAGES

Mark Page

30-34

30-35

30-36

30-37

30-38

30-39

30-40

30-41

30-42

30-43

30-44

30-45

30-46

30-47

30-48

30-49

30-50

30-51

30-52

30-53

30-54

30-55

30-56

30-57

30-58

30-59

30-60

30-61

30-62

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

40-1

40-2

40-3

40-4

40-5

40-6

40-7

40-8

40-9

40-10

40-11

40-12

40-13

40-14

40-15

40-16

40-17

40-18

40-19

40-20

40-21

40-22

00-2-2

SK714-5 SK815-5 SK815-5 turbo

IMPORTANT SAFETY NOTICE

Proper service and repair is extremely important for the safe operation of your machine.

The service and repair techniques recommended by Komatsu Utility and describe in this manual are both effective and safe methods of operation. Some of these operations require the use of tools specially designed

by Komatsu Utility for the purpose.

To prevent injury to workers, the symbols and are used to mark safety precautions in this manual.

The cautions accompanying these symbols should always be carefully followed. If any danger arises or may

possibly arise, first consider safety, and take necessary steps to face.

SAFETY

GENERAL PRECAUTIONS

Mistakes in operation extremely dangerous.

Read all the Operation and Maintenance Manual carefully BEFORE operating the machine.

1. Before carrying out any greasing or repairs, read all

the precautions written on the decals which are suck

on the machine.

2. When carrying out any operation, always wear safety shoes and helmet. Do not wear loose work

clothes, or clothes with buttons missing.

• Always wear safety glasses when hitting parts

with a hammer.

• Always wear safety glasses when grinding

parts with a grinder, etc.

3. If welding repairs are needed, always have a

trained, experienced welder carry out the work.

When carrying out welding work, always wear welding gloves, apron, glasses, cap and other clo thes

suited for welding work.

4. When carrying out any operation with two or more

workers, always agree on the operating procedure

before starting. Always inform your fellow workers

before starting any step of the operation. Before

starting work, hang UNDER REPAIR signs on the

controls in the operator’s compartment.

5. Keep all tools in good condition and learn the correct

way to use them.

6. Decide a place in the repair workshop to keep tools

and removed parts. Always keep the tools and parts

in their correct places. Always keep the work are a

clean and make sure that there is no dirt or oil on the

floor.

Smoke only in the areas provided for smoking. Never smoke while working.

PREPARATIONS FOR WORK

7. Before adding or making any repairs, park the machine on hard, level ground, and block the wheels to

prevent the machine from moving.

8. Before starting work, lower outrigger, bucket or any

other work equipment to the ground. If this is not

possible, use blocks to prevent the work equipment

from falling down. In addition, be sure to lock all the

control levers and hang warning sign on them.

9. When disassembling or assembling, support the

machine with blocks, jacks or stands before starting

work.

10. Remove all mud and oil from the steps or other places used to get on and off the machine. Always use

the handrails, ladders or steps when getting on or off

the machine.

Never jump on or off the machine.

If it is impossible to use the handrails, ladders or

steps, use a stand to provide safe footing.

PRECAUTIONS DURING WORK

11. When removing the oil filler cap, drain plug or hydraulic pressure measuring plugs, loosen them

slowly to prevent the oil from spurting out.

Before disconnecting or removing components of

the hydraulic circuit and engine cooling circuit, first

remove the pressure completely from the circuit.

12. The water and oil in the circuits are not hot when the

engine in stopped, so be careful not to get burned.

Wait for the oil water to cool before carrying out any

work on the cooling water circuits.

13. Before starting work, remove the leads from the battery. Always remove the lead from the negative ( – )

terminal first.

SAFETY

SK714-5 SK815-5 SK815-5 turbo

00-3

SAFETY

14. When raising heavy components, use a hoist or

crane. Check that the wire rope, chains and hooks

are free from damage.

Always use lifting equipment which has ample ca pacity. Install the lifting equipment at the correct

places.

Use a hoist or crane and operate slowly to prevent

the component from hitting any other part.

Do not work with any part still raised by the hoist or

crane.

15. When removing covers which are under internal

pressure or under pressure from a spring, always

leave two bolts in position on opposite sides. Slowly

release the pressure, then slowly loosen the bolts to

remove.

16. When removing components, be careful not to

break or damage the wiring.

Damage wiring may cause electrical fires.

17. When removing piping, stop the fuel or oil from spilling out. If any fuel or oil drips on to the floor, wipe it up

immediately.

Fuel or oil on the floor can cause you to slip, or can

even start fires.

18. As a general rule, do not use gasoline to wash parts.

In particular, use only the minimum of gasoline

when washing electrical parts.

19. Be sure to assemble all parts again in their original

places. Replace any damage parts with new parts.

When installing hoses and wires, be sure that they

will not be damaged by contact with other parts

when the machine is being operated.

20. When installing high pressure hoses, make sure

that they are not twisted. Damaged tubes are dangerous, so be extremely careful when installing

tubes for high pressure circuits. Also, check that

connecting parts are correctly tightened.

21. When assembling or installing parts, always use

specified tightening torques.

When installing the parts which vibrate violently or

rotate at high speed, be particulary careful to check

that they are correctly installed.

22. When aligning two holes, never insert your fingers

or hand.

23. When measuring hydraulic pressure, check that the

measuring tool is correctly assembled before taking

any measurement.

24. Take sure when removing or installing wheels.

00-4

SK714-5 SK815-5 SK815-5 turbo

FOREWORD

FOREWORD

This shop manual has been prepared as an aid to improve the quality of repairs by giving the operator an accurate

understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure

you understand the contents of this manual and use it to full effect at every opportunity.

This shop manual mainly contains the necessary technical information for operations performed in a service workshop.

The manual is divided into chapters on each main group of components; these chapters are further divided into the

following sections.

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give an u nderstanding

of the structure, but also serves as reference material for troubleshooting.

TESTING AND ADJUSTING

This sections explains checks to be made before and after performing repairs, as well as adjustments to be

made at completion of the checks and repairs.

Troubleshooting charts correlating «Problems» to «Causes» are also included in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the order to be followed when removing, installing, disassembling or assembling each

component, as well as precautions to be taken for these operations.

MAINTENANCE STANDARD

This section gives the judgement standards when inspecting disassembled parts.

NOTE

The specifications contained in this shop manual are subject to change at any time and without any notice.

Contact your Komatsu Utility distributor for the latest information.

SK714-5 SK815-5 SK815-5 turbo

00-5

HOW TO READ THE SHOP MANUAL

HOW TO READ THE SHOP MANUAL

VOLUMES

Shop manual are issued as a guide to carry out repairs.

These various volumes are designed to avoid duplicating the same information.

DISTRIBUTION AND UPDATING

Any additions, amendments or other changes will be

sent to Komatsu Utility distributors.

Get the most up-to-date information before you start any

work.

FILING METHOD

1. See the page number on the bottom of the page.

File the pages in correct order.

2. Following examples show you how to read the page

number.

Example:

10

-

3

Item number (10. Structure and

Function)

Consecutive page number for each

item

SYMBOLS

In order to make the shop manual greatly chelpful, important points about safety and q uality are marked with

the following symbols.

Symbol Item Remarks

Special safety precautions

are necessary when

performing the work.

★

Safety

Caution

Weight

Tightening

torque

Extra special safety precautions

are necessary when performing

the work because it is under internal pressure.

Special technical precautions or

other precautions for preserving

standards are necessary when

performing the work.

Weight of parts or systems.

Caution necessary when selecting hoisting wire, or when working posture is important, etc.

Parts that require special attention for the tightening torque during assembly.

3. Additional pages: additional pages are indicated by

a hyphen (–) and number after the page number.

Fle as in the example.

Example:

10-4

10-4-1

Added pages

10-4-2

10-5

REVISED EDITION MARK

(

➀ ➁ ➂ ....)

When a manual is revised, an edition mark is recorded

on the bottom outside corner of the pages.

REVISIONS

Revised pages are shown on the LIST OF REVISED

PAGES between the title page and SAFETY page.

Coat

Oil, water

Drain

Parts to be coated with adhesives and lubricants etc.

Places where oil, water or fuel

must be added, and their quantity.

Places where oil or water must

be drained, and quantity to be

drained.

00-6

SK714-5 SK815-5 SK815-5 turbo

HOISTING INSTRUCTIONS

Heavy parts (25 kg or more) must be lifted

with a hoist etc. In the

bly

section, every part weighing 25 kg or more is

clearly indicated with the symbol

1. If a part cannot be smoothly removed from the machine by hoisting, the following checks should be

made:

• Check for removal of all bolts fastening the part

to the relative parts.

• Check for any part causing interference with

the part to be removed.

2. Wire ropes

1) Use adequate ropes depending on the weight of

parts to be hoisted, referring to the table below:

(Standard «S» or «Z» twist ropes

without galvanizing)

Rope diameter (mm) Allowable load (tons)

10.0

11.2

12.5

14.0

16.0

18.0

Disassembly and Assem-

WIRE ROPES

1.0

1.4

1.6

2.2

2.8

3.6

HOISTING INSTRUCTIONS

Hooks have maximum strength at the middle portion.

3) Do not sling a heavy load with one rope alone, but

sling with two or more ropes symmetrically wound

on to the load.

Slinging with one rope may cause turning of the load

during hoisting, untwisting of the rope, or slipping of

the rope from its original winding position on the

load, which can cause dangerous accidents.

4) Do not sling a heavy load with ropes forming a wide

hanging angle from the hook.

When hoisting a load with two or more ropes, the

force subjected to each rope will increase with the

hanging angles.

The table below shows the va riation of a llowable

load (kg) when hoisting is made with two ropes,

each of which is allowed to sling up to 1000 kg vertically, at various handing angles.

When two ropes sling a load vertically, up to 2000 kg

of total weight can be suspended.

This weight becomes 1000 kg when two ropes

make a 120° hanging angle.

On the other hand, two ropes are subjected to an excessive force as large as 4000 kg if they sling a 2000

kg load at a lifting angle of 150°.

20.0

22.4

30.0

40.0

50.0

60.0

The allowable load value is estimated to be onesixth or one-seventh of the breaking strength of the

rope used.

2) Sling wire ropes from the middle portion of the hook.

Slinging near the edge of the hook may cause the

rope to slip off the hook during hoist

rious accident can result.

4.4

5.6

10.0

18.0

28.0

40.0

ing, and a se-

SK714-5 SK815-5 SK815-5 turbo

00-7

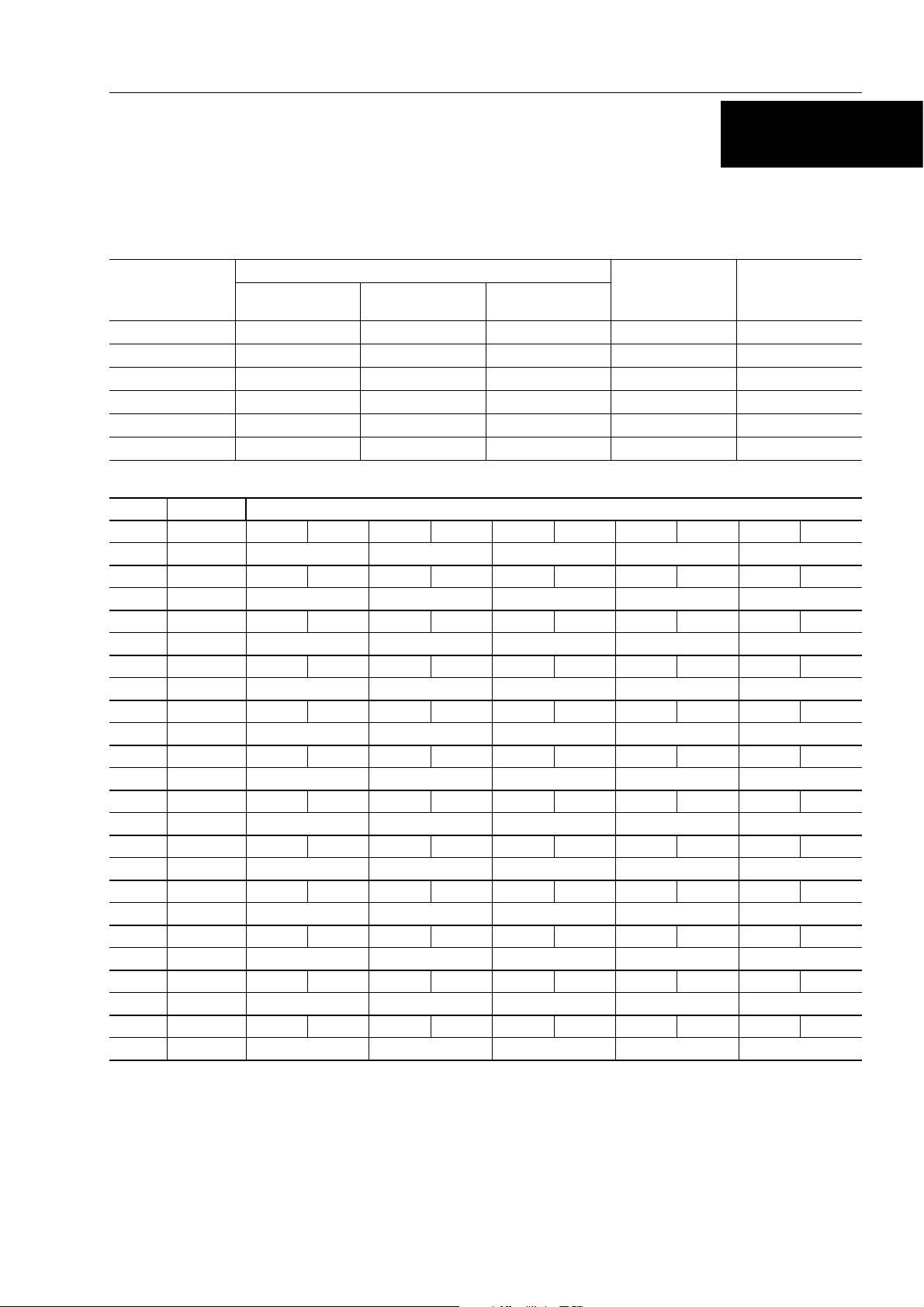

STANDARD TIGHTENING TORQUE

The following charts give the standard tightening torques of bolts and nuts.

Exceptions are given in section of «Disassembly and Assembly».

1. STANDARD TIGHTENING TORQUE OF BOLTS AND NUT

Width across flat

Thread

diameter of bolts

(mm)

Pitch of

bolts

(mm)

(mm)

kgmNmkgmNm

STANDARD TIGHTENING TORQUE

10

12

14

16

18

20

22

24

27

30

6

8

1

1.25

1.5

1.75

2

2

2.5

2.5

2.5

3

3

3.5

10

13

17

19

22

24

27

30

32

36

41

46

8

6

8

10

12

14

14

17

17

19

19

22

0.96

2.3

4.6

7.8

12.5

19.5

27

38

52

66

96±10

131

±0.1

±0.2

±0.5

±0.8

±1

±2

±3

±4

±6

±7

±14

9.5

23

45

77

122

191

262

372

511

644

945

1287

±1

±2

±4.9

±8

±13

±21

±28

±40

±57

±70

±100

±140

1.3

3.2

6.5

17.5

92

135

184

±0.15

±0.3

±0.6

11

27

37

53

73

±10

±1

±2

±3

±4

±6

±8

±15

±20

13.5

32.2

63

108

172

268

366

524

719

905

1329

1810

±1.5

±3.5

±6.5

±11

±18

±29

±36

±57

±80

±98

±140

±190

33

36

39

This torque table does not apply to bolts or nuts which have to fasten nylon or other parts non-ferrous metal washer.

3.5

4

4

50

55

60

24

27

----

177

±20

230±25

295

±33

1740

±200

2250±250

2900

±330

250

±27

320±35

410

±45

2455

±270

3150±350

4050

±450

★ Nm (newton meter): 1 Nm = 0.102 kgm

00-8

SK714-5 SK815-5 SK815-5 turbo

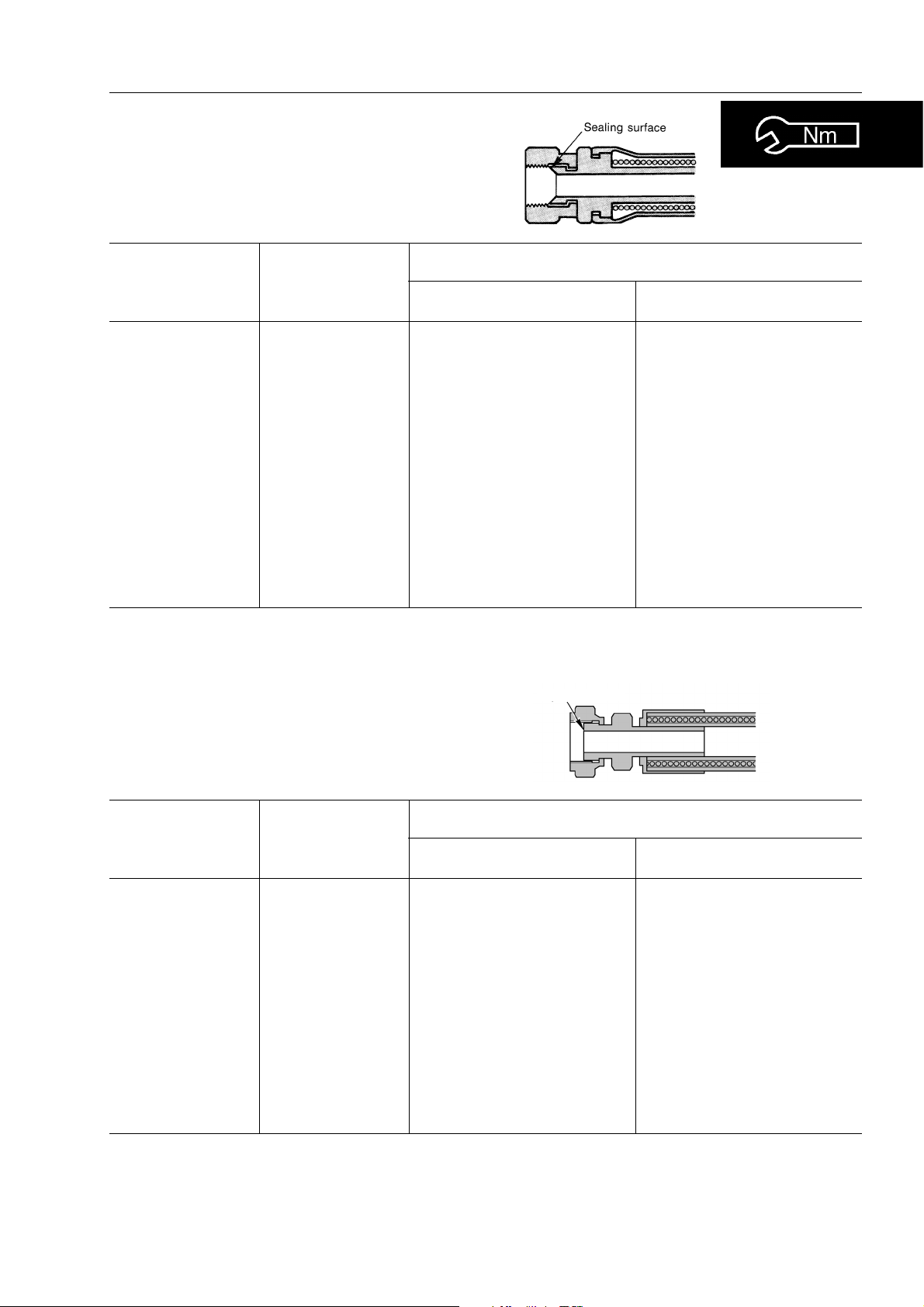

2. TIGHTENING TORQUE FOR NUTS OF FLARED

Use these torques for nut part of flared.

STANDARD TIGHTENING TORQUE

Thread diameter

of nut part

(mm)

1/2” - 20

9/16” - 18

3/4” - 16

7/8” - 14

1.1/16 - 12

1.5/16 - 12

1.5/8 - 12

22

33

Width across flats

of nut part

(mm)

17

17

22

27

32

38

50

27

41

TIGHTENING TORQUE

kgm Nm

±0.5

2.6

4

±0.5

±2

6.7

8

±2

9.7

±3

±3

17

20

±5

8

±2

±5

20

Sealing surface

25.5

39.2

65.7

78.5

95.15

166.7

196.2

78.5

196.2

±4.9

±4.9

±19.6

±19.6

±29.4

±29.4

±49

±19.6

±49

Thread diameter

of nut part

(mm)

9/16” - 18

11/16” - 16

13/16” - 16

1” - 14

1.3/16 - 12

1.7/16 - 12

1.11/16 - 12

2” - 12

Width across flats

of nut part

(mm)

17

22

24

30

36

41

50

57

TIGHTENING TORQUE

kgm Nm

2.3–2.5

3.4–3.9

5.2–5.8

8.2–9.2

12.2–13.3

15.3–17.3

18.4–20.4

20.4–24.4

23–25

33–38

51–57

80–90

120–130

150–170

180–200

200–240

SK714-5 SK815-5 SK815-5 turbo

00-9

COATING MATERIALS

COATING MATERIALS

The recommended coating materials prescribed in Komatsu Utility Shop Manuals are listed below:

Nomenclature Code Applications

Bostik 99 Used to apply rubber pads, rubber gaskets and cork plugs.

Adhesives

Gasket sealant

Loctite 406

Loctite 222 Used for low resistance locking of screws, check nuts and adjustment nuts.

Loctite 242

Loctite 262 Used for high resistant of threaded parts that can be removed with normal tools.

Loctite 270

Loctite 542 Used for sealing the union threads for hydraulic tubes.

Loctite 573

Loctite 601

Loctite 675

Loctite 542

Loctite 510

Used to apply resin, rubber, metallic and non-metallic parts when a fast, strong

seal is needed.

To prevent the loosening of bolts, nuts and plugs and the leakage of oil. Used for

medium resistance locking of screws and nuts of every type, and for loc king

keys and bearings.

Used for high resistant locking and for sealing threaded parts, bolts and stud

bolts.

Used for sealing rather exact plane surfaces when the option of possible future

dismantling is required.

Used for high resistant locking of mechanical components that can be removed

only after heating

Used to lock cylindrical couplings and for the permanent locking of threaded

parts, and also to lock shafts to bearings, gears, pulleys, pins, bushings, etc.

Used by itself to seal grease fittings, tapered screw fittings and tapered screw

fittings in hydraulic circuits of less than 50 mm in diameter.

Used by itself on mounting flat surface

(Clearance between surfaces within 0.2 mm)

Antifriction compound

(Lubricant including

Molybdenum disulfide)

Grease

(Lithium grease)

Vaseline

00-10

Loctite 518

Litio EP MS2

NLGI 2

Litio EP

NLGI 2

-----

Used by itself on mounting flat surface

(Clearance between surfaces within 0.5 mm

Applied to bearings and taper shaft to facilitate press-fitting and to prevent

sticking, burning or rusting.

Applied to bearings, sliding parts and oil seals for lubrication, rust prevention

and facilitation of assembling work.

Used for protecting battery electrode terminals from corrosion

SK714-5 SK815-5 SK815-5 turbo

ELECTRIC WIRE CODE

ELECTRIC

In the wiring diagrams various colour and symbols are employed to indicate the thickness of wires.

This wire code table will help you understand WIRING DIAGRAMS.

Example: R–N 1.5 indicates a cable having a nominal number 1.5 and red coating with black stripe.

CLASSIFICATION BY THICKNESS

Nominal

number

0.5 16 0.20 0.35 1.55 3.5

1 14 0.30 0.99 2.80 11

1.5 21 0.30 1.48 3.35 14

2.5 35 0.30 2.47 3.80 20

4 56 0.30 3.95 4.60 28

6 84 0.30 5.93 5.20 37

Number

strands

Copper wire

Ø of strands

(mm)

Cross section

(mm)

Cable O.D.

(mm)

Current rating

(A)

CLASSIFICATION BY COLOUR AND CODE

Primary Auxiliary

Code A A–B A/B A–G – A–N A/N A–R A–V A/V

Colour Light Blue Light Blue – White Light Blue–Yellow Light Blue–Black Light Blue–Red Light Blue–Green

Code B B–G – B–N B/N B–R B/R – – – –

Colour White White–Yellow White–Black White–Red – –

Code C C–B C/B C–L – C–N C/N – – – –

Colour Orange Orange–White Orange–Blue Orange–Black – –

Code G G–N G/N – G/R – – – – – –

Colour Yellow Yellow–Black Yellow–Red – – –

Code H H–L – H–N – H–R H/R – – – –

Colour Grey Grey–Blue Grey–Black Grey–Red – –

Code L – L/B L–G L/G L–N L/N L–R L/R – –

Colour Blue Blue–White Blue–Yellow Blue–Black Blue–Red –

Code M M–B M/B M–N – M–V – – – – –

Colour Brown Brown–White Brown–Black Brown–Green – –

CodeN ––––––––––

ColourBlack–––––

Code R R–G – R–N R/N R–V – – – – –

Colour Red Red–Yellow Red–Black Red–Green – –

Code S S–G – S–N S/N – – – – – –

Colour Pink Pink–Yellow Pink–Black – – –

Code V V–B V/B V–N V/N – – – – – –

Colour Green Green–White Green–Black – – –

Code Z Z–B – Z–N Z/N – – – – – –

Colour Violet Violet–White Violet–Black – – –

COMPOSITION OF THE COLOURS

The coloration of two-colour wires is indicated by the composition of the symbol listed.

Example: G–V = Yellow-Green with longitudinal colouring

G/V = Yellow-Green with transversal colouring

SK714-5 SK815-5 SK815-5 turbo

00-11

WEIGHT TABLE

WEIGHT TABLE

This weight table is a guide for use when transporting or handling components.

Unit: kg

Machine model SK714-5 SK815-5 SK815-5 turbo

Engine assembly - Muffler - Exhaust pipe 200 200 200

Radiator 22 22 22

Hydraulic oil tank (without oil) 21.5 21.5 21.5

Engine hood 14.5 14.5 14.5

Cabin (without seat) 215 215 215

Seat:

• standard

• witj suspension

Engine-pump group 278–285 283–290 283–290

Piston pump:

• standard

• High-Flow

10

16

78

84

10

16

82

88

10

16

82

88

Wheel, assy. (standard) 43 44 44

Control valve:

• 3-spool (standard)

• 4-spool (High-Flow)

Work equipment (without bucket)

• Arm

• Work equipment support

• Bucket (L=1460 mm)

• Tilt cylinder

• Dump cylinder

19

21.5

280

49

159

17,3

12

19

21.5

295

49

171,5

16,8

12

19

21.5

295

49

171,5

16,8

12

00-12

SK714-5 SK815-5 SK815-5 turbo

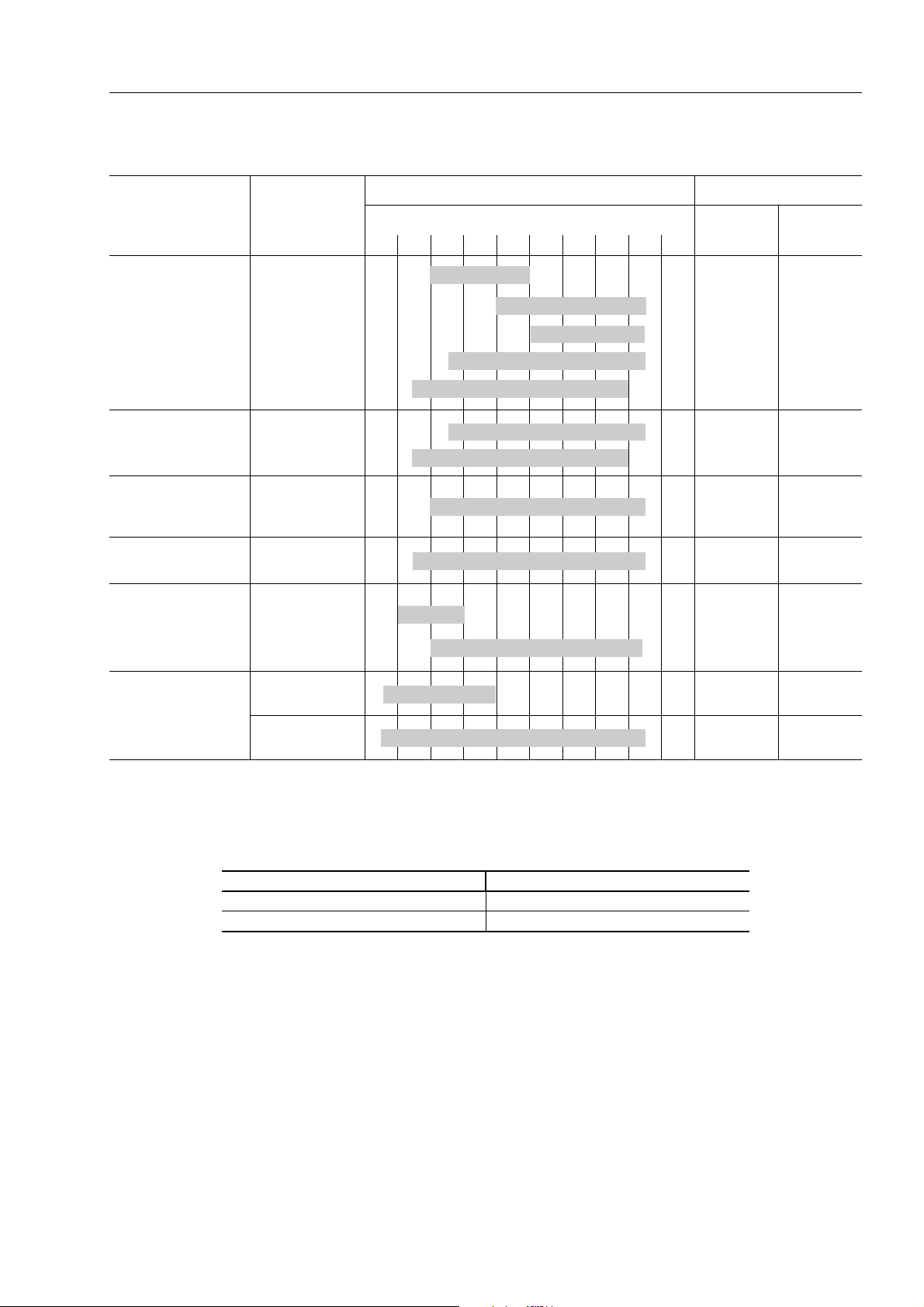

TABLE OF OIL AND COOLANT QUANTITIES

TABLE OF OIL AND COOLANT QUANTITIES

RESERVOIR

Engine oil pan

Hydraulic system

and hydrostatic

trasmissione

Hydraulic circuit

with biodegradable

oil

Final transmission

case (ea.)

Fuel tank DIESEL OIL

KIND OF

FLUID

OIL

• API CD

OIL

• API CD

OIL

• API CD

--

AMBIENT TEMPERATURE CAPACITY (

30 -- 20

✽

--

10 0 10 20 30 40 50°C

SAE 10W

SAE 30

SAE 40

SAE 10W-30

SAE 5W-30

SAE 10W

SAE 5W-30

SAE 10W-30

ASTM D975 N.2

Specified Refill

SK714-5

SK815-5:

SK815-5 turbo:

ᐉ)

88

38 27

38 27

15.5 15.5

38

50

–

Engine cooling

system

WATER +

ANTIFREEZE

PERMANENT

COOLANT

9–

9–

✽ ASTM D975 N.

IMPORTANT:

(1) When the diesel oil sulphur content is less then 0.5%, change the engine oil according to the periodic maintenance

intervals indicated in the operation and maintenance manual. In the diesel oil sulphur content exceeds 0.5% change

the engine oil according to the following table:

Sulphur content Engine oil change interval

from 0.5 to 1.0% 1/2

over 1.0% 1/4

of regular interval

of regular interval

(2) When starting the engine at temperatures below 0 °C, use engine oil SAE 10W, 20W-20 and 10W-30, even if during

the day the temperature increases by 10 °C.

(3) Use engine oil with CD classification; if oil with CD classification is used, reduce the engine oil change interval by a

half.

(4) Use original products, which have characteristics specifically formulated and approved for the engine, the hydraulic

circuit of equipment and for reductions.

First filling quantity:

total quantity of oil, including the oil for the components and pipes.

Oil change quantity:

quantity of oil necessary to fill the system or unit during the normal inspection and maintenance operations.

ASTM: American Society of Testing and Materials

SAE: Society of Automotive Engineers

API: American Petroleum Institute

SK714-5 SK815-5 SK815-5 turbo

00-13

PAGE INTENTIONALLY

LEFT BLANK

CONVERSION TABLE

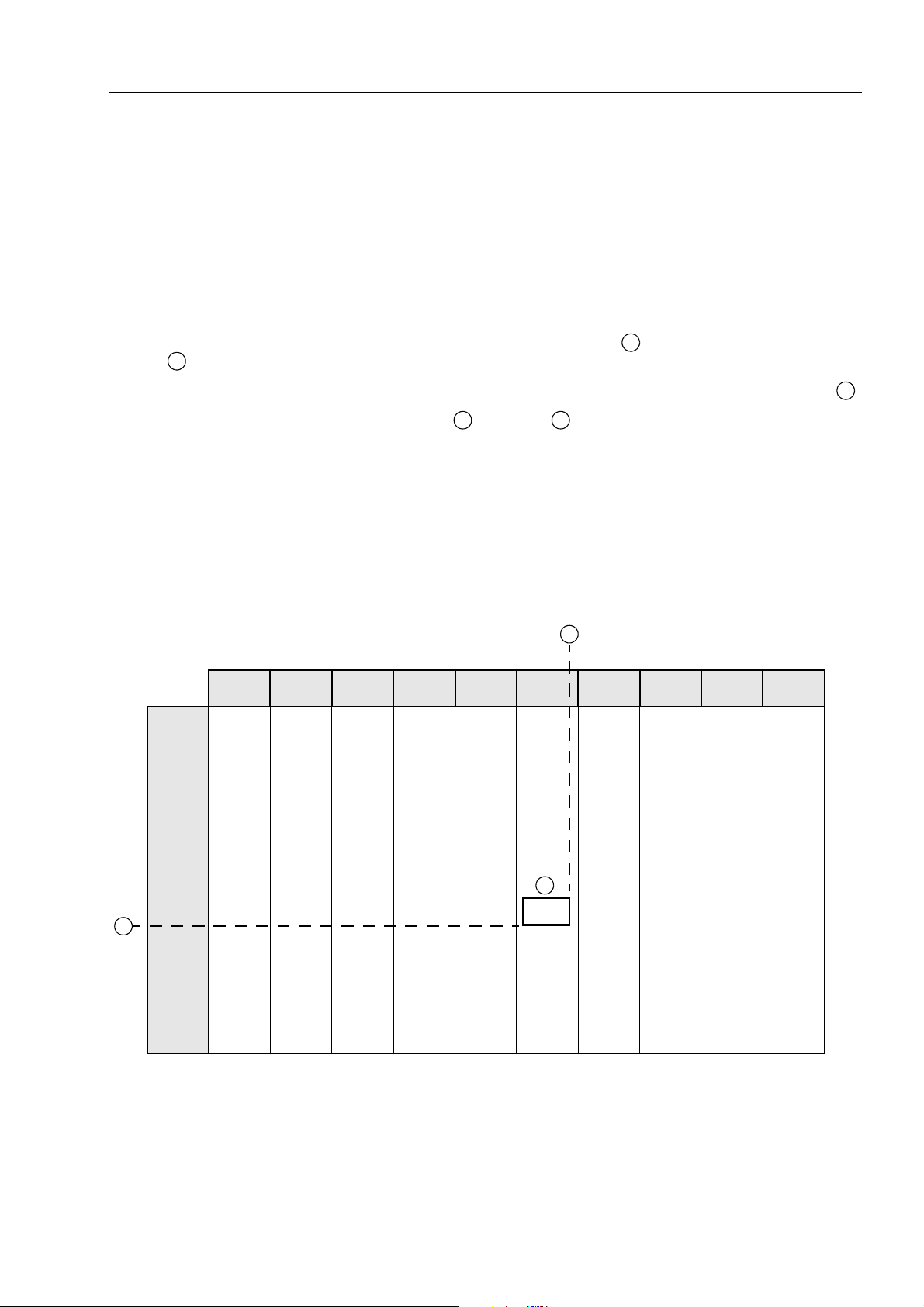

METHOD OF USING THE CONVERSION TABLE

The conversion table in this section is provided to enable simple conversion of figures.

For details of the method of using the conversion table, see the example given below.

EXAMPLE

• Method of using the conversion table to convert from millimeters to inches.

1. Convert 55 mm into inches.

CONVERSION TABLE

0.236

0.630

1.024

A

, then drow a horizontal line from

1 mm = 0.03937 in.

0.276

0.669

1.063

0.315

0.709

1.102

0.354

0.748

1.142

1 - Locate the number 50 in the vertical column at the left side, take this as

A

.

2 - Locate the number 5 in the row across the top, take this as , then draw a perpendicular line down from .

3 - Take the point where the two lines cross as . This point gives the value when converting from mil-

limeters to inches. Therefore,

2. Convert 550 mm into inches

1 - The number 550 does not appear in the table, so divide by 10 (move the decimal point one place to the left) to

convert it to 55 mm.

2 - Carry out the same procedure as above to convert 55 mm to 2.165 in.

3 - The original value (550 mm) was divided by 10, so multiply 2.165 in. by 10 (move the decimal point one place to

the right) to return to the original value. This gives 550 mm = 21.65 in.

From millimeters to inches

0 1 2 3 4 5 6 7 8 9

0.039

0.433

0.827

10

20

0

0

0.394

0.787

55 mm =2.165 in.

0.079

0.472

0.866

0.118

0.512

0.906

C C

0.157

0.551

0.945

0.197

0.591

0.984

B

B

30

40

50

1.181

1.575

1.969

1.220

1.614

2.008

A

60

70

80

90

2.362

2.756

3.150

3.543

2.402

2.795

3.189

3.583

SK714-5 SK815-5 SK815-5 turbo

1.260

1.654

2.047

2.441

2.835

3.228

3.622

1.299

1.693

2.087

2.480

2.874

3.268

3.661

1.339

1.732

2.126

2.520

2.913

3.307

3.701

1.378

1.772

C

2.165

2.559

2.953

3.346

3.740

1.417

1.811

2.205

2.598

2.992

3.386

3.780

1.457

1.850

2.244

2.638

3.032

3.425

3.819

1.496

1.890

2.283

2.677

3.071

3.465

3.858

1.536

1.929

2.323

2.717

3.110

3.504

3.898

00-15

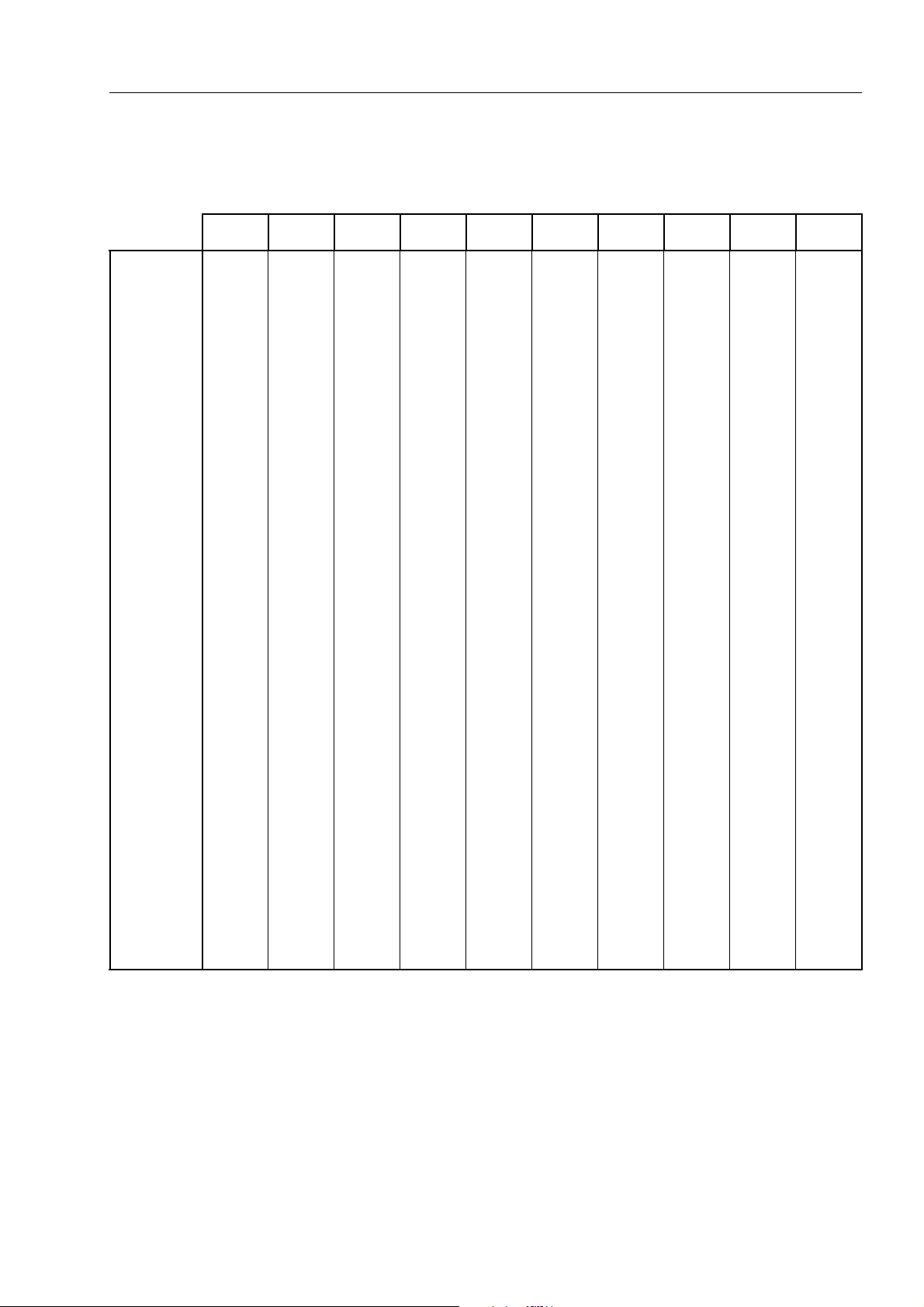

From mm to in.

CONVERSION TABLE

1 mm = 0.03937 in.

0123456789

0

10

20

30

40

50

60

70

80

90

From kg to lb.

0

0.394

0.787

1.181

1.575

1.969

2.362

2.756

3.150

3.543

0.039

0.433

0.827

1.220

1.614

2.008

2.402

2.795

3.189

3.583

0.079

0.472

0.866

1.260

1.654

2.047

2.441

2.835

3.228

3.622

0.118

0.512

0.906

1.299

1.693

2.087

2.480

2.874

3.268

3.661

0.157

0.551

0.945

1.339

1.732

2.126

2.520

2.913

3.307

3.701

0.197

0.591

0.984

1.378

1.772

2.165

2.559

2.953

3.346

3.740

0.236

0.630

1.024

1.417

1.811

2.205

2.598

2.992

3.386

3.780

0.276

0.669

1.063

1.457

1.850

2.244

2.638

3.032

3.425

3.819

0.315

0.709

1.102

1.496

1.890

2.283

2.677

3.071

3.465

3.858

1 kg = 2.2046 lb.

0.354

0.748

1.142

1.536

1.929

2.323

2.717

3.110

3.504

3.898

0

10

20

30

40

50

60

70

80

90

0123456789

0

22.05

44.09

66.14

88.18

110.23

132.28

154.32

176.37

198.42

2.20

24.25

46.30

68.34

90.39

112.44

134.48

156.53

178.57

200.62

4.41

26.46

48.50

70.55

92.59

114.64

136.69

158.73

180.78

202.83

6.61

28.66

50.71

72.75

94.80

116.85

138.89

160.94

182.98

205.03

8.82

30.86

51.91

74.96

97.00

119.05

141.10

163.14

185.19

207.24

11.02

33.07

55.12

77.16

99.21

121.24

143.30

165.35

187.39

209.44

13.23

35.27

57.32

79.37

101.41

123.46

145.51

167.55

189.60

211.64

15.43

37.48

59.53

81.57

103.62

125.66

147.71

169.76

191.80

213.85

17.64

39.68

61.73

83.78

105.82

127.87

149.91

171.96

194.01

216.05

19.84

41.89

63.93

85.98

108.03

130.07

152.12

174.17

196.21

218.26

00-16

SK714-5 SK815-5 SK815-5 turbo

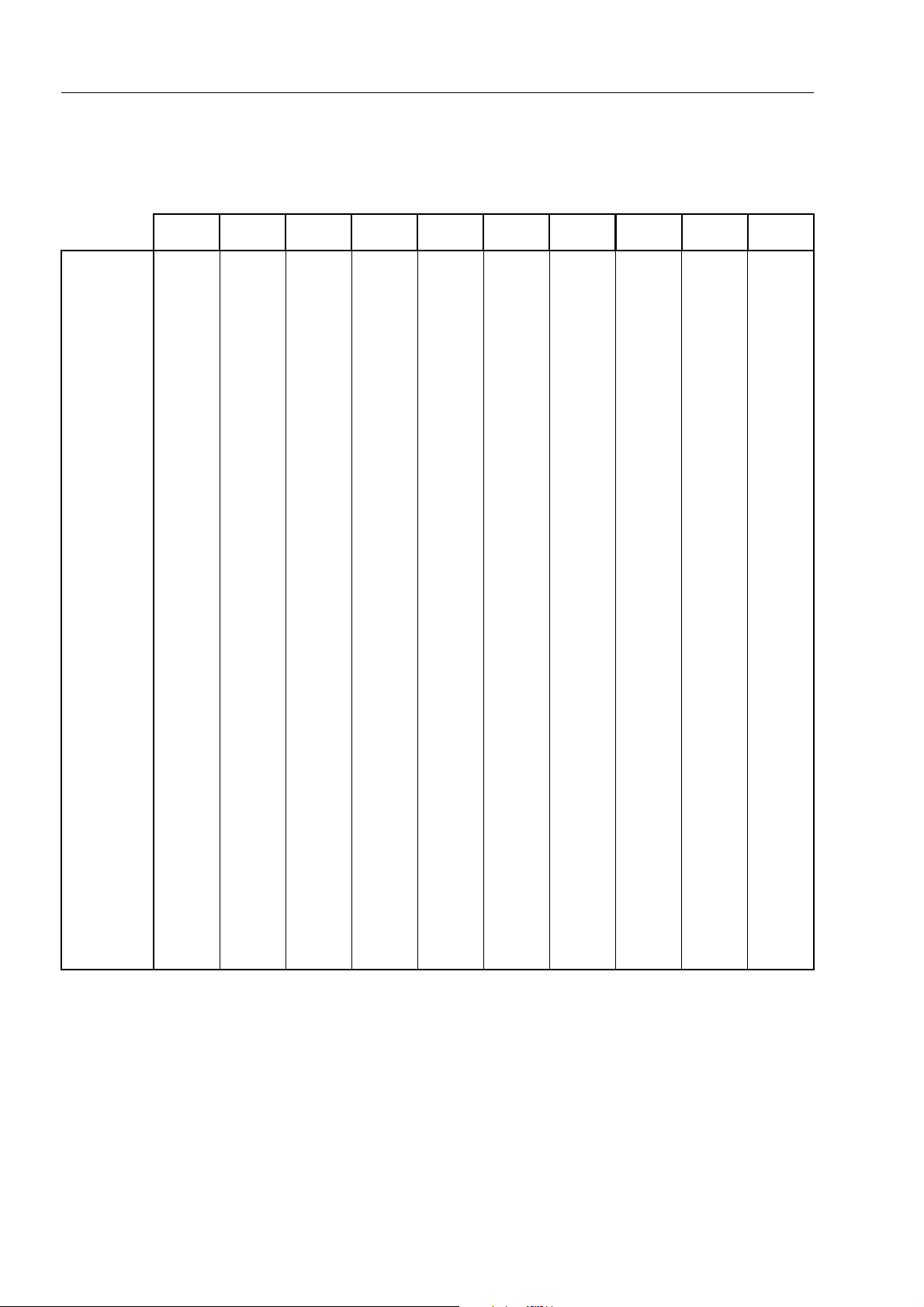

From liter to U.S. Gall.

0123456789

CONVERSION TABLE

1 ᐉ = 0.2642 U.S. Gall.

0

10

20

30

40

50

60

70

80

90

0

2.642

5.283

7.925

10.567

13.209

15.850

18.492

21.134

23.775

From liter to U.K. Gall.

0.264

2.906

5.548

8.189

10.831

13.473

16.115

18.756

21.398

24.040

0.528

3.170

5.812

8.454

11.095

13.737

16.379

19.020

21.662

24.304

0.793

3.434

6.076

8.718

11.359

14.001

16.643

19.285

21.926

24.568

1.057

3.698

6.340

8.982

11.624

14.265

16.907

19.549

22.190

24.832

1.321

3.963

6.604

9.246

11.888

14.529

17.171

19.813

22.455

25.096

1.585

4.227

6.869

9.510

12.152

14.795

17.435

20.077

22.719

25.361

1.849

4.491

7.133

9.774

12.416

15.058

17.700

20.341

22.983

25.625

2.113

4.755

7.397

10.039

12.680

15.322

17.964

20.605

23.247

25.889

1 ᐉ = 0.21997 U.K. Gall.

2.378

5.019

7.661

10.303

12.944

15.586

18.228

20.870

23.511

26.153

0

10

20

30

40

50

60

70

80

90

0123456789

0

2.200

4.399

6.599

8.799

10.998

13.198

15.398

17.598

19.797

0.220

2.420

4.619

6.819

9.019

11.281

13.418

15.618

17.818

20.017

0.440

2.640

4.839

7.039

9.239

11.438

13.638

15.838

18.037

20.237

0.660

2.860

5.059

7.259

9.459

11.658

13.858

16.058

12.257

20.457

0.880

3.080

5.279

7.479

9.679

11.878

14.078

16.278

18.477

20.677

1.100

3.300

5.499

7.969

9.899

12.098

14.298

16.498

18.697

20.897

1.320

3.520

5.719

7.919

10.119

12.318

14.518

16.718

18.917

21.117

1.540

3.740

5.939

8.139

10.339

12.528

14.738

16.938

19.137

21.337

1.760

3.950

6.159

8.359

10.559

12.758

14.958

17.158

19.357

21.557

1.980

4.179

6.379

8.579

10.778

12.978

15.178

17.378

19.577

21.777

SK714-5 SK815-5 SK815-5 turbo

00-17

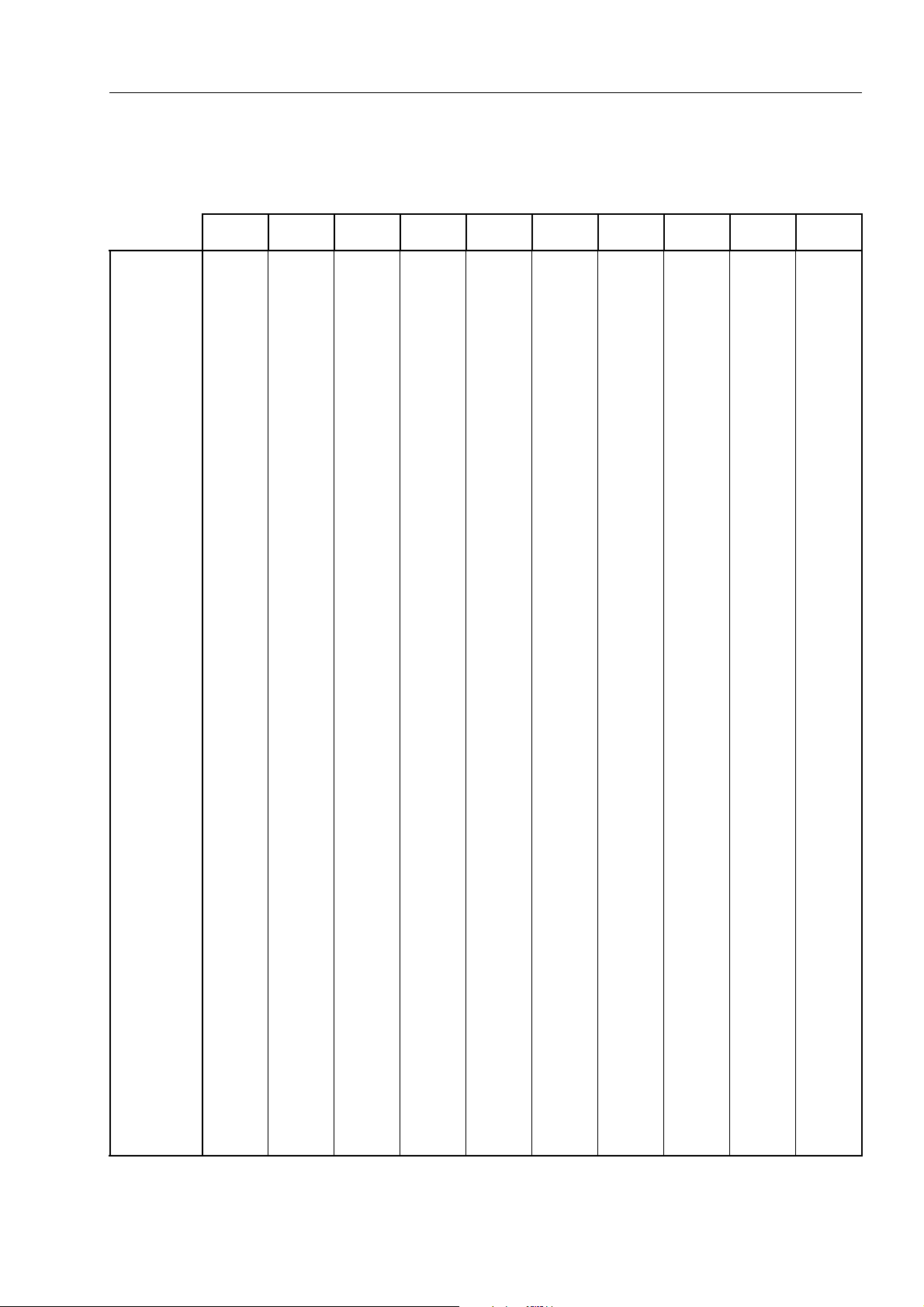

From Nm to lb.ft.

0123456789

CONVERSION TABLE

1 Nm = 0.737 lb.ft.

0

10

20

30

40

50

60

70

80

90

100

110

120

0

7.370

14.740

22.110

29.480

36.850

44.220

51.590

58.960

66.330

73.700

81.070

88.440

0.737

8.107

15.477

22.847

30.217

37.587

44.957

52.327

59.697

67.067

74.437

81.807

89.177

1.474

8.844

16.214

23.584

30.954

38.324

45.694

53.064

60.434

67.804

75.174

82.544

89.914

2.211

9.581

16.951

24.321

31.691

39.061

46.431

53.801

61.171

68.541

75.911

83.281

90.651

2.948

10.318

17.688

25.058

32.428

39.798

47.168

54.538

61.908

69.278

76.648

84.018

91.388

3.685

11.055

18.425

25.795

33.165

40.535

47.905

55.275

82.645

70.015

77.385

84.755

92.125

4.422

11.792

19.162

26.532

33.902

41.272

48.642

56.012

63.382

70.752

78.122

85.492

92.862

5.159

12.529

19.899

27.269

34.639

42.009

49.379

56.749

64.119

71.489

78.859

86.229

93.599

5.896

13.266

20.636

28.006

35.376

42.746

50.116

57.486

64.856

72.226

79.596

86.966

94.336

6.633

14.003

21.373

28.743

36.113

43.483

50.853

58.223

65.593

72.963

80.333

87.703

95.073

130

140

150

160

170

180

190

95.810

103.180

110.550

117.920

125.290

132.660

140.030

96.547

103.917

111.287

118.657

126.027

133.397

140.767

97.284

104.654

112.024

119.394

126.764

134.134

141.504

98.021

105.391

112.761

120.131

127.501

134.871

142.241

98.758

106.128

113.498

120.868

128.238

135.608

142.978

99.495

106.865

114.235

121.605

128.975

136.345

143.715

100.232

107.602

114.972

122.342

129.712

137.082

144.452

100.969

108.339

115.709

123.079

130.449

137.819

145.189

101.706

109.076

116.446

123.816

131.186

138.556

145.926

102.443

109.813

117.183

124.553

131.923

139.293

146.663

00-18

SK714-5 SK815-5 SK815-5 turbo

From Nm to kgm

0123456789

CONVERSION TABLE

1 Nm = 0.102 kgm

0

10

20

30

40

50

60

70

80

90

100

110

120

0

1.020

2.040

3.060

4.080

5.100

6.120

7.140

8.160

9.180

10.200

11.220

12.240

0.102

1.222

2.142

3.162

4.182

5.202

6.222

7.242

8.262

9.282

10.302

11.322

12.342

0.204

1.224

2.244

3.264

4.284

5.304

6.324

7.344

8.364

9.384

10.404

11.424

12.444

0.306

1.326

2.346

3.366

4.386

5.406

6.426

7.446

8.466

9.486

10.506

11.526

12.546

0.408

1.428

2.448

3.468

4.488

5.508

6.528

7.548

8.568

9.588

10.608

11.628

12.648

0.510

1.530

2.550

3.570

4.590

5.610

6.630

7.650

8.670

9.690

10.710

11.730

12.750

0.612

1.632

2.652

3.672

4.692

5.712

6.732

7.752

8.772

9.792

10.812

11.832

12.852

0.714

1.734

2.754

3.774

4.794

5.814

6.834

7.854

8.874

9.894

10.914

11.934

12.954

0.816

1.836

2.856

3.876

4.896

5.916

6.936

7.956

8.976

9.996

11.016

12.036

13.056

0.918

1.938

2.958

3.978

4.998

6.018

7.038

8.058

9.078

10.098

11.118

12.138

13.158

130

140

150

160

170

180

190

13.260

14.280

15.300

16.320

17.340

18.360

19.380

13.362

14.382

15.402

16.422

17.442

18.462

19.482

13.464

14.484

15.504

16.524

17.544

18.564

19.584

13.566

14.586

15.606

16.626

17.646

18.666

19.686

13.668

14.688

15.708

16.728

17.748

18.768

19.788

13.770

14.790

15.810

16.830

17.850

18.870

19.890

13.872

14.892

15.912

16.932

17.952

18.972

19.992

13.974

14.994

16.014

17.034

18.054

19.074

20.094

14.076

15.096

16.116

17.136

18.156

19.176

20.196

14.178

15.198

16.218

17.238

18.258

19.278

20.298

SK714-5 SK815-5 SK815-5 turbo

00-19

From kgm to lb.ft.

0123456789

CONVERSION TABLE

1 kgm = 7.233 lb.ft.

0

10

20

30

40

50

60

70

80

90

100

110

120

0

72.3

144.7

217.0

289.3

361.7

434.0

506.3

578.6

651.0

723.3

795.6

868.0

7.2

79.6

151.9

224.2

296.6

368.9

441.2

513.5

585.9

658.2

730.5

802.9

875.2

14.5

86.8

159.1

231.5

303.8

376.1

448.5

520.8

593.1

665.4

737.8

810.1

882.4

21.7

94.0

166.4

238.7

311.0

383.4

455.7

528.0

600.3

672.2

745.0

817.3

889.7

28.9

101.3

173.6

245.9

318.3

390.6

462.9

535.2

607.6

679.9

752.2

824.6

896.9

36.2

108.5

180.8

253.2

325.5

397.8

470.2

542.5

614.8

687.1

759.5

831.8

904.1

43.4

115.7

188.1

260.4

332.7

405.1

477.4

549.7

622.0

694.4

766.7

839.0

911.4

50.6

123.0

195.3

267.6

340.0

412.3

484.6

556.9

629.3

701.6

773.9

846.3

918.6

57.9

130.2

202.5

274.9

347.2

419.5

491.8

564.2

636.5

708.8

781.2

853.5

925.8

65.1

137.4

209.8

282.1

354.4

426.8

499.1

571.4

643.7

716.1

788.4

860.7

933.1

130

140

150

160

170

180

190

940.3

1012.6

1084.9

1157.3

1129.6

1301.9

1374.3

947.5

1019.9

1092.2

1164.5

1236.8

1309.2

1381.5

954.8

1027.1

1099.4

1171.7

1244.1

1316.4

1388.7

962.0

1034.3

1106.6

1179.0

1251.3

1323.6

1396.0

969.2

1041.5

1113.9

1186.2

1258.5

1330.9

1403.2

876.5

1048.8

1121.1

1193.4

1265.8

1338.1

1410.4

983.7

1056.0

1128.3

1200.7

1273.0

1345.3

1417.7

990.9

1063.2

1135.6

1207.9

1280.1

1352.6

1424.9

998.2

1070.5

1142.8

1215.1

1287.5

1359.8

1432.1

1005.4

1077.7

1150.0

1222.4

1294.7

1367.0

1439.4

00-20

SK714-5 SK815-5 SK815-5 turbo

From bar to psi (lb/in2)

0123456789

CONVERSION TABLE

1 bar = 14.503 psi

0

10

20

30

40

50

60

70

80

90

100

110

120

0

145.0

290.0

435.1

580.1

725.1

870.2

1015.2

1160.2

1305.3

1450.3

1595.3

1740.4

14.5

159.5

304.6

449.6

594.6

739.6

884.7

1029.7

1174.7

1319.8

1464.8

1609.8

1754.9

29.0

174.0

319.1

464.1

609.1

754.1

899.2

1044.2

1189.2

1334.3

1479.3

1624.3

1769.4

43.5

188.5

333.6

478.6

623.6

768.6

913.7

1058.7

1203.7

1348.8

1493.8

1638.8

1783.9

58.0

203.0

348.1

493.1

638.1

783.2

928.2

1073.2

1218.2

1363.3

1508.3

1653.3

1798.4

72.5

217.5

362.6

507.6

652.6

797.7

942.7

1087.7

1232.7

1377.8

1522.8

1667.8

1812.9

87.0

232.0

377.1

522.1

667.1

812.2

957.2

1102.2

1247.2

1392.3

1537.3

1682.3

1827.4

101.5

246.5

391.6

536.6

681.6

826.7

971.7

1116.7

1261.8

1406.8

1551.8

1696.8

1841.9

116.0

261.0

406.1

551.1

696.1

841.2

986.2

1131.2

1276.3

1421.3

1566.3

1711.3

1856.4

130.5

275.6

420.6

565.6

710.6

855.7

1000.7

1145.7

1290.8

1435.8

1580.8

1725.8

1870.8

130

140

150

160

170

180

190

200

210

220

230

240

1885.4

2030.4

2175.4

2320.5

2465.5

2610.5

2755.6

2900.6

3045.6

3190.7

3335.7

3480.7

1899.9

2044.9

2189.9

2335.0

2480.0

2625.0

2770.0

2915.1

3060.1

3205.2

3350.2

3495.2

1914.4

2059.4

2204.4

2349.5

2494.5

2639.5

2784.6

2929.6

3074.6

3219.7

3364.7

3509.7

1928.9

2073.9

2218.9

2364.0

2509.0

2654.0

2799.1

2944.1

3089.1

3234.2

3379.2

3524.2

1943.4

2088.4

2233.5

2378.5

2523.5

2668.5

2813.6

2958.6

3103.6

3248.7

3393.7

3538.7

1957.9

2102.9

2248.0

2393.0

2538.0

2683.0

2828.1

2973.1

3118.1

3263.2

3408.2

3553.2

1972.4

1217.4

2262.5

2407.5

2552.5

2697.7

2842.6

2987.6

3132.6

3277.7

3422.7

3567.7

1986.9

2131.9

2277.0

2422.0

2567.0

2712.1

2857.1

3002.1

3147.1

3192.2

3437.2

3582.2

2001.4

2146.4

2291.5

2436.5

2581.5

2726.6

2871.6

3016.6

3161.6

3306.7

3451.7

3596.7

2015.9

2160.9

2306.0

2451.0

2596.0

2641.1

2886.1

3031.1

3176.1

3321.2

3466.2

3611.2

SK714-5 SK815-5 SK815-5 turbo

00-21

CONVERSION TABLE

TEMPERATURE

Fahrenheit-Centigrade conversion; a simple way to convert a Fahrenhe it temperature reading int o a Centigrade temperature reading or vice versa is to enter the accompanying table in the center or boldface column of figures.

These figures refer to the temperature in either Fahrenheit or Centigrade degrees.

If it is desired to convert from Fahrenheit to Centigrade degrees, consider the center column as a table of Fahrenheit temperatures and read the corresponding Centigrade temperature in the column at the left.

If it is desired to convert from Centigrade to Fahrenheit degrees, consider the center column as a table of Centigrade values and read the corresponding Fahrenheit temperature on the right.

1 °C = 33.8°F

°C

–40.4

–37.2

–34.4

–31.7

–28.9

–28.3

–27.8

–27.2

–26.7

–26.1

–25.6

–25.0

–24.4

–23.9

–23.3

–22.8

–22.2

–21.7

–21.1

–20.6

–40

–35

–30

–25

–20

–19

–18

–17

–16

–15

–14

–13

–12

–11

–10

–9

–8

–7

–6

–5

°F °C °F °C °F °C °F

–40.0

–31.0

–22.0

–13.0

–4.0

–2.2

–0.4

1.4

3.2

5.0

6.8

8.6

10.4

12.2

14.0

15.8

17.6

19.4

21.2

23.0

–11.7

–11.1

–10.6

–10.0

–9.4

–8.9

–8.3

–7.8

–7.2

–6.7

–6.1

–5.6

–5.0

–4.4

–3.9

–3.3

–2.8

–2.2

–1.7

–1.1

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

51.8

53.6

55.4

57.2

59.0

60.8

62.6

64.4

66.2

68.0

69.8

71.6

73.4

75.2

77.0

78.8

80.6

72.4

84.2

86.0

7.8

8.3

8.9

9.4

10.0

10.6

11.1

11.7

12.2

12.8

13.3

13.9

14.4

15.0

15.6

16.1

16.7

17.2

17.8

18.3

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

144.8

116.6

118.4

120.2

122.0

123.8

125.6

127.4

129.2

131.0

132.8

134.6

136.4

138.2

140.0

141.8

143.6

145.4

147.2

149.0

27.2

27.8

28.3

28.9

29.4

30.0

30.6

31.1

31.7

32.2

32.8

33.3

33.9

34.4

35.0

35.6

36.1

36.7

37.2

37.8

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

117.8

179.6

181.4

183.2

185.0

186.8

188.6

190.4

192.2

194.0

195.8

197.6

199.4

201.2

203.0

204.8

206.6

208.4

210.2

212.0

–20.0

–19.4

–18.9

–18.3

–17.8

–17.2

–16.7

–16.1

–15.6

–15.0

–14.4

–13.9

–13.3

–12.8

–12.2

00-22

–4

–3

–2

–1

10

24.8

26.6

28.4

30.2

0

32.0

1

33.8

2

35.6

3

37.4

4

39.2

5

41.0

6

42.8

7

44.6

8

46.4

9

48.2

50.0

–0.6

0.0

0.6

1.1

1.7

2.2

2.8

3.3

3.9

4.4

5.0

5.6

6.1

6.7

7.2

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

87.8

89.6

91.4

93.2

95.0

96.8

98.6

100.4

102.2

104.0

105.8

107.6

109.4

111.2

113.0

18.9

19.4

20.0

20.6

21.1

21.7

22.2

22.8

23.3

23.9

24.4

25.0

25.6

26.1

26.7

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

150.8

152.6

154.4

156.2

158.0

159.8

161.6

163.4

165.2

167.0

168.8

170.6

172.4

174.2

176.0

40.6

43.3

46.1

48.9

51.7

54.4

57.2

60.0

62.7

65.6

68.3

71.1

73.9

76.7

79.4

105

110

115

120

125

130

135

140

145

150

155

160

165

170

175

221.0

230.0

239.0

248.0

257.0

266.0

275.0

284.0

2930

302.0

311.0

320.0

329.0

338.0

347.0

SK714-5 SK815-5 SK815-5 turbo

STRUCTURE AND FUNCTION

P.T.O......................................................................... 2

Power train ................................................................3

Transmission ............................................................. 4

Final drive.................................................................. 6

Hydraulic circuit

SK714-5 (Standard)................................................. 13

Hydraulic circuit

SK714-5 (Road homologation)................................ 14

Hydraulic circuit

SK815-5 - SK815-5 turbo (Standard)...................... 15

Hydraulic circuit

SK815-5 - SK815-5 turbo (Road homologation)...... 16

Hydraulic pump........................................................ 17

Control valve (3-Spool)............................................ 36

Control valve (4-Spool)............................................ 39

CLSS....................................................................... 43

Solenoid valve......................................................... 51

Accumulator............................................................. 53

Pattern change valve (Optional)...............................54

R.H. PPC Valve (Standard)......................................58

R.H. PPC Valve (Pattern Change) (Optional) ..........62

L.H. PPC Valve (Standard) ......................................66

L.H. PPC VALVE (Pattern Change) (Optional) ........70

Cylinders ..................................................................74

Electrical diagram (Engine line)................................75

Electrical diagram (Frame line standard) .................79

Electrical diagram (Frame line optional) ..................83

Electrical diagram (Cabin line standard) ..................87

Electrical diagram (Cabin line optional)....................93

Electrical diagram (Top-cabin light line standard)..101

Electrical diagram (Top-cabin light line omologation).103

Electrical diagram (Top-cabin light line optional)....105

SK714-5 SK815-5 SK815-5 turbo

10-1

STRUCTURE AND FUNCTION

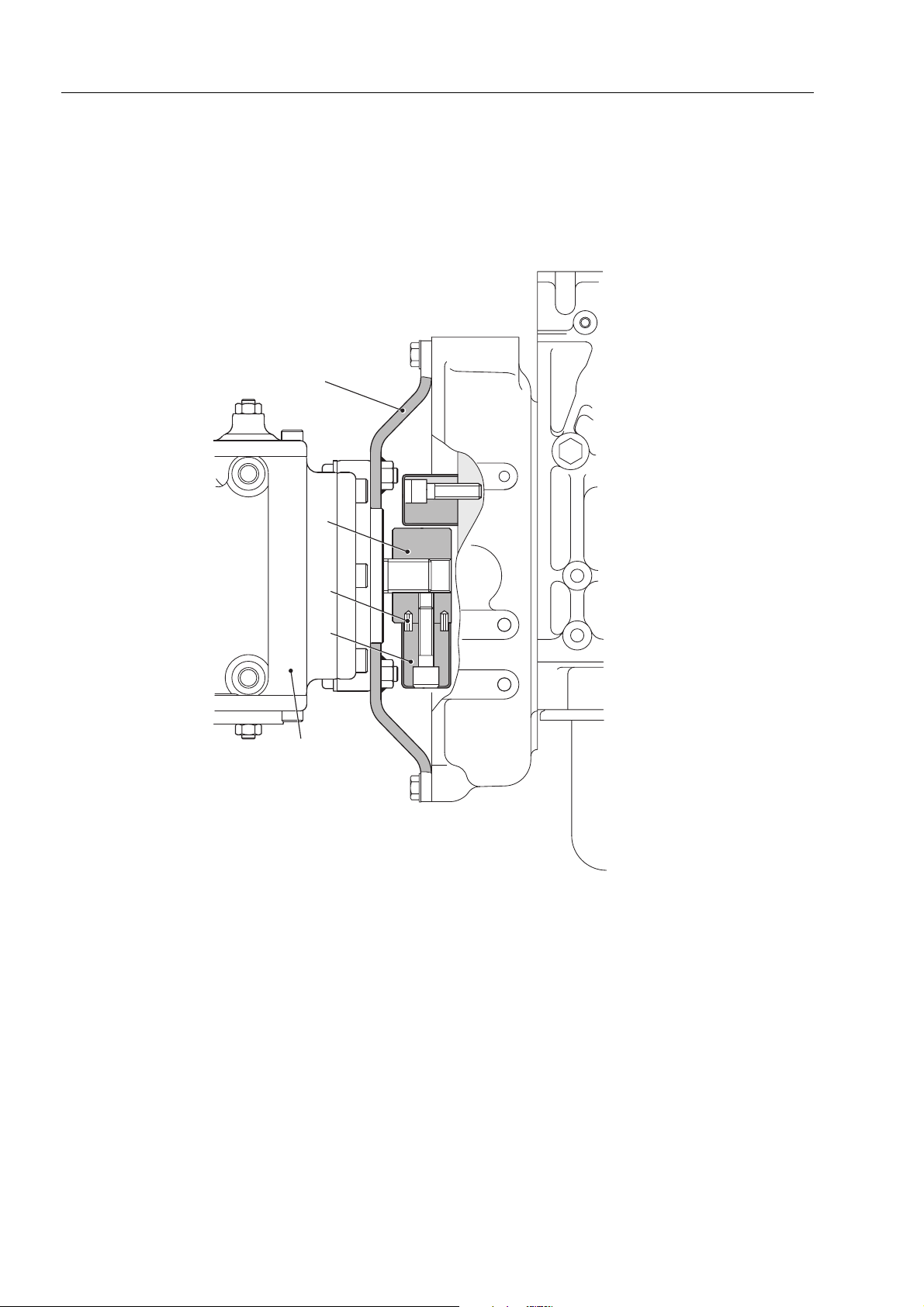

P.T.O.

P. T. O .

4

1

2

3

5

RKS01090

1. Joint

2. Spring pin

3. Dumper

4. Flywheel cover

5. Hydraulic pump

10-2

SK714-5 SK815-5 SK815-5 turbo

STRUCTURE AND FUNCTION

POWER TRAIN

POWER TRAIN

1. Engine

2. Hydraulic pump

3. Control valve

4. Solenoid valve

4a. Servocontrol

4b. Speed increment

4c. Parking brake

8

4

3

ABC

5

7

6

8

5. High-flow solenoid valve

6. L.H. final drive

7. R.H. final drive

8. Axle

8

1

2

8

RKS00990

SK714-5 SK815-5 SK815-5 turbo

10-3

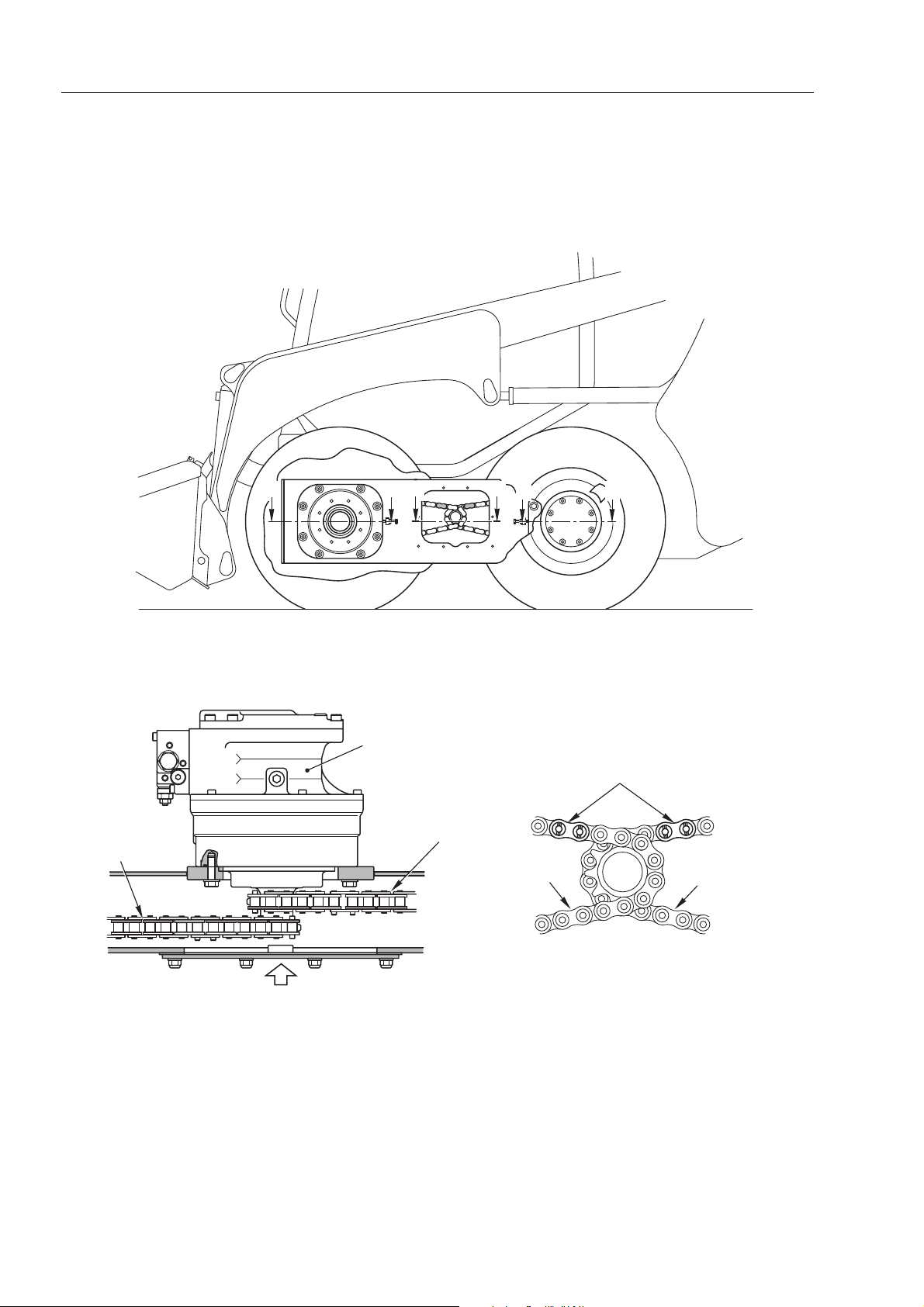

STRUCTURE AND FUNCTION

TRANSMISSION

B B

A

A

C C

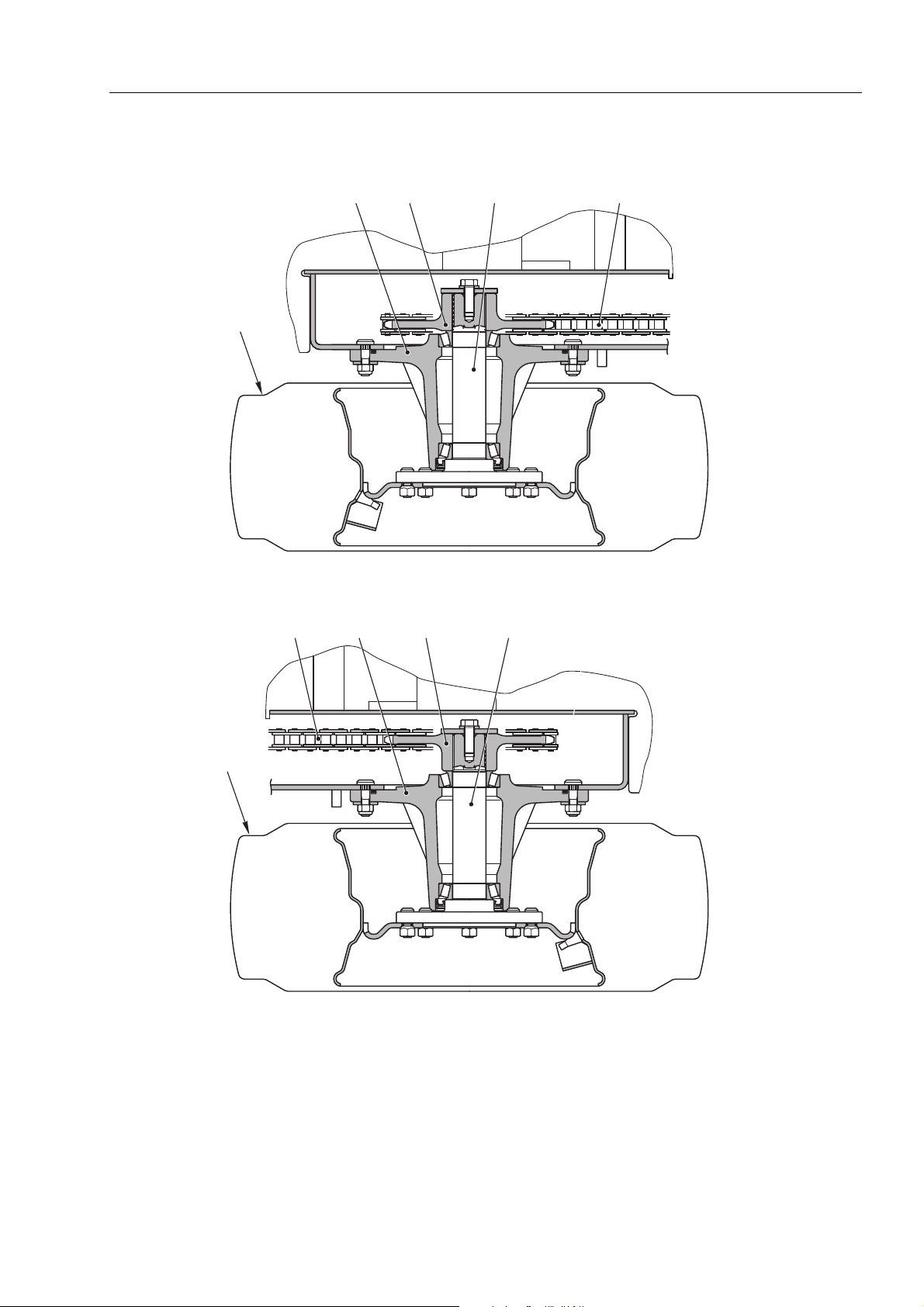

TRANSMISSION

3

Section A - A

1. L.H. final drive

2. Front trasmission chain

3. Rear trasmission chain

4. Master link

X

1

4

2

2

View X

3

RKS01001

10-4

SK714-5 SK815-5 SK815-5 turbo

STRUCTURE AND FUNCTION

1

TRANSMISSION

4532

Section B - B

4372

6

Section C -C

RKS01010

1. Front wheel

2. Axle housing

3. Sprocket

4. Shaft

5. Front trasmission chain

6. Rear wheel

7. Rear trasmission chain

SK714-5 SK815-5 SK815-5 turbo

10-5

STRUCTURE AND FUNCTION

FINAL DRIVE

FINAL DRIVE

Z

A

View Z

L.H. FINAL DRIVE

a. A Port – To hydraulic pump (PA2 port)

b. B Port – To hydraulic pump (PB2 port)

c. PP1 Port – From solenoid valve group ST1(A Port)

(2nd speed)

d. PP2 Port – From solenoid valve group ST1 (C Port)

(parking brake)

e. DR Port – To hydraulic tank

d

ce

b

A

a

RKS01020

R.H. FINAL DRIVE

a. A Port – To hydraulic pump (PB1 port)

b. B Port – To hydraulic pump (PA1 port)

c. PP1 Port – From solenoid valve group ST1(A Port)

(2nd speed)

d. PP2 Port – From solenoid valve group ST1 (C Port)

(parking brake)

e. DR Port – To hydraulic tank

10-6

SK714-5 SK815-5 SK815-5 turbo

STRUCTURE AND FUNCTION

FINAL DRIVE

B

B

45 6

7

1

23

22

8

9

10

11

12

13

14

15

16

17

18192021

Section A - A

1. Shaft

2. Bearing

3. Bearing

4. Body

5. Pin

6. Gear

7. Shoe

8. Brake piston

9. Plate

10. Cylinder block

11. Bearing

12. Spring

13. Piston

14. Brake spring

15. Bushing

16. Retainer plate

26

27

25

24

26

23

17. Swash plate

18. Plate

19. Shaft

20. Flange

21. Collar

22. Gasket

23. Plug

24. Spring

Section B - B

2928

RKS01031

25. Spool

26. Plug

27. Spool

28. Plug

29. Spring

SK714-5 SK815-5 SK815-5 turbo

10-7

STRUCTURE AND FUNCTION

DESCRIPTION

The final drive motor consists of:

1. 2-speed hydraulic motor

2. Selector valve

3. Reduction gearing

1. HYDRAULIC MOTOR

Function

The hydraulic motor is of the axial piston type, and converts hydraulic energy supplied by the pump into rotary motion.

Operation

The hydraulic oil arriving from the selector valve is sent on to the valve plate (1). When the oil is sent to port “A” of the

valve, it flows into the corresponding port on the cylinder block (2) and presses against the pistons (3).

This pressure is converted into rotary motion by a swash plate (4) and hence transmitted to the shaft (5). The shaft and

the cylinder block have been integrated into one piece by means of splined toothing.

The return oil is sent to the pump through port “B”.

Rotation in the opposite direction is achieved by sending the oil to port “B” instead of to port “A”..

FINAL DRIVE

5

4

2

1

3

B

A

RKS01050

Varying the displacement

The swash plate (4), which has two surfaces “A” and “B” on the side opposite the sliding side for the shoes (6), is supported by two bearings (7) attached to the body of the motor (8).

The position of the bearings is eccentric with respect to the axis of the shaft and when running at low speed the surface

“A” remains in contact with the body of the motor through the pressure exerted by the pistons (3) and by the force of a

spring (9) mounted in the cylinder block (2).

The angle of the swash plate is

When an increase in speed is demanded, the oil is sent under pressure to the command piston (10). The command piston (10) moves to the left ( ) until the surface “B” makes contact with the housing and the angle of the swash plate

becomes

β (the displacement of the motor is reduced).

α.

10-8

SK714-5 SK815-5 SK815-5 turbo

STRUCTURE AND FUNCTION

.

FINAL DRIVE

8

10

B

8

10

B

6

4

7

A

␣

23

9

Brake

The hydraulic motor is equipped with a negative brake.

• When the motor is at a standstill, or when the operator applies the brake, the braking piston (1) is pushed to the left

( ) by the force of the springs (2).

The friction disk (3), which has b een integrated with the cylinder block by means of semicircular groo ves, is compressed between steel disks (4) and (5), which are integrated with the housing, and is thus blocked. The drive shaft

(6) can therefore no longer turn.

• When the motor is running and the operator disengages the brake, oil is sent under pressure to the chamber “A”.

The force exerted by the oil is greater than the force of the springs (2) and the piston (1) is therefore pushed to the

right ( ) thus releasing the friction disk (3) and permitting rotation of the cylinder block (7) (and also of the drive

shaft).

4

3

3

7

A

923

RKS01040

5

3

4

7

6

SK714-5 SK815-5 SK815-5 turbo

A

1

2

5

3

1

2

4

7

A

6

RKS01060

10-9

STRUCTURE AND FUNCTION

FLUSHING RELIEF VALVE

2.

When the oil is sent under pressure to the “A” port, the oil that activated the motor returns to the pump through the “B”

port.

The pressurised oil sent to the “A” port is also introduced into the chamber “C”. It now pushes the selector valve (1) to

the right ( ). This opens communication between the “B” port and the oil gallery “D”, which is connected to the overpressure limitation valve (2).

If the pressure present at port “B” exceeds the calibration value of the overpressure limitation valve (2), this valve will

open and discharge the excess oil into the reduction gears.

The valve also functions in the same way when the pressurised oil is sent to the “B” port. The only difference is that the

selector valve moves to the left ( ), and the oil gallery “D” communicates with the “A” port.

.

FINAL DRIVE

C

2

D

1

AB

C

2

D

1

AB

RKS01070

10-10

SK714-5 SK815-5 SK815-5 turbo

STRUCTURE AND FUNCTION

REDUCTION GEARING

3.

Function

This final drive motor is equipped with a one-stage epicycloidal reduction gear that converts the high rotation speed and

low torque of the hydraulic motor into low speed and high torque at the swing pinion.

Operating principle

The rotary movement of the output shaft of the motor is transmitted to the gear (s1) and hence to the bevel gears (b1) which are integrated with the planetary gear (1).

Since the gear (a1) is fixed with respect to the output shaft of the hydraulic motor, the planeta ry gear is obliged to turn, moving with it the output shaft (2) of the reduction gearing (connected to the planetary gear by means of grooved toothing).

The reduction ratio of the rotation speed is described by the formula:

R= Zs1/(Zs1+Za1)

Zs1= number of sun gear teeth

Za1= number of ring gear teeth

FINAL DRIVE

b1

1

2

a1

s1

RKS01080

SK714-5 SK815-5 SK815-5 turbo

10-11

PAGE INTENTIONALLY

LEFT BLANK

STRUCTURE AND FUNCTION

HYDRAULIC CIRCUIT SK714-5 (STANDARD)

13

ø

12.7L=3450

(

/

-16Orfs)

12.7L=3450

16

13

(

/

-16Orfs)

16

P

Lift arm

raise

Lift arm cylinder L.H.

Lift arm cylinder R.H.

Bucket cylinder L.H.

ø

9.5L=530

ø

9.5L=530

13

(

ø

9.5L=1100

ø

9.5L=1750

ø

9.5L=1100

ø

9.5L=1750

/

-16Orfs)

16

ø

16 t=2

ø

16 t=2

13

(

/

-16Orfs)

16

13

(

/

-16Orfs)

16

13

(

/

-16Orfs)

16

13

(

/

-16Orfs)

16

13

(

/

-16Orfs)

16

ø

P

Bucket dump

HYDRAULIC CIRCUIT SK714-5 (STANDARD)

P2 P4 P3

P1

T

P

6.5L=400(1/2-20 Jic)

ø

A3

B3

PA3

6.5L=400(1/2-20 Jic)

ø

-18 Jic)

16

/

9

6.5L=600(

ø

-18 Jic)

16

/

9

6.5L=680(

ø

Pout 1 Pout 3 Pout 2 Pout 4

-20 Jic)

-20 Jic)

2

/

1

6.4L=435(

ø

-20 Jic)

2

/

1

6.4L=435(

ø

2

/

1

6.4L=435(

ø

A2

P

B2

ø6.

4L=1500(1/2-20 Jic)

PA2

A1

Unload

valve

B1

PA1

Lift arm lower

Relief valve

19.1MPa

(195kg/cm

2

)

ø

6.4L=1500(1/2-20 Jic)

ø6.

4L=950(1/2-20 Jic)

ø6.

4L=950(1/2-20 Jic)

-20 Jic)

2

/

1

6.4L=435(

ø

100 Mesh

-18 Jic)

16

/

9

10L=520(

ø

-18 Jic)

16

/

9

10L=520(

ø

-18 Jic)

16

10L=1050

/

9

ø

(

P1

-20 Jic)

2

/

1

6.4L=435(

ø

P2P4P3

-20 Jic)

2

/

1

6.4L=435(

ø

-20 Jic)

2

/

1

6.4L=435(

ø

-18 Jic)

16

10L=1050

/

9

ø

(

-20 Jic)

2

/

1

6.4L=435(

ø

100 Mesh

-18 Jic)

16

/

9

10L=520(

ø

-18 Jic)

16

/

9

10L=520(

ø

Bucket cylinder R.H.

Travel motor L.H.

DR

PP2

PP1

A

6.5L=600

ø

(9/16-18 JIC)

6.5L=500

ø

9

/16-18 JIC)

(

BA

RED

ø

9.5L=530

13

(

/

-16Orfs)

16

ø

9.5L=530

13

(

/

-16Orfs)

16

13

ø

12.7L=1800(

/

-16Orfs)

16

13

ø

12.7L=1800(

/

-16Orfs)

16

13

ø

12.7L=3450(

/

-16Orfs)

ø

16 t=2

ø

16 t=2

PP1

B

ø

ø

ø

ø

16

13

ø

12.7L=3450(

/

-16Orfs)

16

15.9L=950(1”3/16-12 Orfs)

15.9L=950(1”3/16-12 Orfs)

15.9L=950(1”3/16-12 Orfs)

15.9L=950(1”3/16-12 Orfs)

PP2

P

ø

19.1L=1100(1”3/16-12 Orfs)

ø

20L=1000

ø

9.5L=1050(9/16-18 JIC)

T

T

-20 Jic)

-20 Jic)

-20 Jic)

-20 Jic)

2

2

2

2

/

/

/

/

1

1

1

1

6.4L=950(

6.4L=850(

6.4L=650(

6.4L=650(

ø

ø

ø

ø

P4

S3 S4

Engine

4D88E-E1FD

34.7km/2800rpm

PA1 DA1 DB1 DB2 DA2 PA2

E

±40cm3/rev

PB1

E2

±40cm3/rev

T5

PB2

ABC

SV3SV2SV1

P

T

RED

DR

Travel motor R.H.

SK714-5 SK815-5 SK815-5 turbo

ø

9.5L=1300(9/16-18 Jic)

ø

9.5L=1300(9/16-18 Jic)

-12 JIC)

16

/

19.1L=800

1

ø

(1”

-12 JIC)

16

/

19.1L=850

1

ø

(1”

ø

(1”

19L=1650

1

/16-12 JIC)

-12 JIC)

16

/

25.4L=620

5

ø

(1”

ø

ø

16

t.2

19L=1450(1”5/16-12 JIC)

ø

20

-12 JIC)

16

/

25.4L=500

5

ø

(1”

ø

9.5L=1000(9/16-18 Jic)

ø

6.5L=350(9/16-18 Jic)

ø

6.5L=680(9/16-18 Jic)

10-13

STRUCTURE AND FUNCTION

HYDRAULIC CIRCUIT SK714-5 (ROAD HOMOLOGATION)

13

ø

12.7L=3450

(

/

-16Orfs)

12.7L=3450

16

13

(

/

-16Orfs)

16

P

P

Bucket dump

P

Lift arm

raise

Unload

valve

Lift arm cylinder L.H.

Lift arm cylinder R.H.

Bucket cylinder L.H.

ø

9.5L=530

ø

9.5L=530

13

(

ø

9.5L=1100

ø

9.5L=1750

ø

9.5L=1100

ø

9.5L=1750

/

-16Orfs)

16

ø

16 t=2

ø

16 t=2

13

(

/

-16Orfs)

16

13

(

/

-16Orfs)

16

13

(

/

-16Orfs)

16

13

(

/

-16Orfs)

16

13

(

/

-16Orfs)

16

ø

6.5L=400(1/2-20 Jic)

ø

A3

B3

PA3

A2

B2

PA2

A1

B1

PA1

Lift arm lower

Relief valve

19.1MPa

(195kg/cm

6.5L=400(1/2-20 Jic)

ø

2

)

ø6.

4L=1500(1/2-20 Jic)

ø

6.4L=1500(1/2-20 Jic)

ø6.

4L=950(1/2-20 Jic)

ø6.

4L=950(1/2-20 Jic)

T

P

-18 Jic)

16

/

9

6.5L=600(

ø

-18 Jic)

16

/

9

6.5L=680(

ø

P2 P4 P3

P1

Pout 1 Pout 3 Pout 2 Pout 4

-20 Jic)

-20 Jic)

2

/

1

6.4L=435(

ø

-20 Jic)

2

/

1

6.4L=435(

ø

2

/

1

6.4L=435(

ø

-20 Jic)

2

/

1

6.4L=435(

ø

100 Mesh

-18 Jic)

16

/

9

10L=520(

ø

HYDRAULIC CIRCUIT SK714-5 (ROAD HOMOLOGATION)

100 Mesh

-18 Jic)

16

/

9

10L=520(

ø

-18 Jic)

16

10L=1050

/

9

ø

(

P1

-20 Jic)

2

/

1

6.4L=435(

ø

P2P4P3

-20 Jic)

2

/

1

6.4L=435(

ø

-20 Jic)

2

/

1

6.4L=435(

ø

-20 Jic)

2

/

1

6.4L=435(

ø

-18 Jic)

16

/

9

10L=520(

ø

-18 Jic)

16

/

9.5L=1050

9

(

ø

-18 Jic)

16

/

9

10L=520(

ø

Bucket cylinder R.H.

Travel motor L.H.

DR

A

PP2

6.5L=600

ø

(9/16-18 JIC)

ø

6.5L=500

9

/16-18 JIC)

(

BA

PP1

RED

ø

9.5L=530

13

(

/

-16Orfs)

16

ø

9.5L=530

13

(

/

-16Orfs)

16

13

ø

12.7L=1800(

/

-16Orfs)

16

13

ø

12.7L=1800(

/

-16Orfs)

16

13

ø

12.7L=3450(

/

-16Orfs)

ø

16 t=2

ø

16 t=2

PP1

B

ø

ø

ø

ø

16

13

ø

12.7L=3450(

/

-16Orfs)

16

15.9L=950(1”3/16-12 Orfs)

15.9L=950(1”3/16-12 Orfs)

15.9L=950(1”3/16-12 Orfs)

15.9L=950(1”3/16-12 Orfs)

PP2

P

ø

19.1L=1100(1”3/16-12 Orfs)

ø

20L=1000

ø

9.5L=1050(9/16-18 JIC)

T

T

-20 Jic)

-20 Jic)

-20 Jic)

-20 Jic)

2

2

2

2

/

/

/

/

1

1

1

1

6.4L=950(

6.4L=850(

6.4L=650(

6.4L=650(

ø

ø

ø

ø

P4

S3 S4

Engine

4D88E-E1FD

34.7km/2800rpm

PA1 DA1 DB1 DB2 DA2 PA2

E

±40cm3/rev

PB1

E2

±40cm3/rev

T5

PB2

P

T

-18 Jic)

16

10L=470

/

ø

9

(

ø

(9/16-18 Jic)

A

9.5L=1000

BC

SV3SV2SV1

S

RED

Travel motor R.H.

-12 JIC)

16

/

25.4L=620

5

-12 JIC)

16

/

5

(1”

ø

(1”

-12 JIC)

16

/

19.1L=800

1

ø

(1”

ø

19L=1650

1

/16-12 JIC)

(1”

-12 JIC)

16

/

19.1L=850

DR

ø

9.5L=1300(9/16-18 Jic)

ø

9.5L=1300(9/16-18 Jic)

1

ø

(1”

ø

16

t.2

ø

19L=1450(1”5/16-12 JIC)

ø

20

25.4L=500

ø

10-14

ø

10L=470(9/16-18 Jic)

ø

10L=350(9/16-18 Jic)

ø

10L=680(9/16-18 Jic)

SK714-5 SK815-5 SK815-5 turbo

STRUCTURE AND FUNCTION

HYDRAULIC CIRCUIT SK815-5 - SK815-5 turbo (STANDARD)

13

ø

12.7L=3700

(

/

-16Orfs)

12.7L=3700

16

13

(

/

-16Orfs)

16

6.5L=400(1/2-20 Jic)

ø

P

P

Bucket dump

P

Lift arm

raise

Unload

valve

Lift arm cylinder L.H.

Lift arm cylinder R.H.

Bucket cylinder L.H.

ø

9.5L=530

ø

9.5L=530

(

ø

ø

13

/

9.5L=1100

ø

9.5L=1750

9.5L=1100

ø

9.5L=1750

(

-16Orfs)

16

ø