Page 1

UEAM003700

Operation &

Maintenance Manual

PW200-7K

PW220-7K

WHEELED EXCAVATOR

SERIAL NUMBER

PW200-7K - K40146

PW220-7K - K40146

and up

and up

WARNING

Unsafe use of this machine may cause serious injury or

death. Operators and maintenance personnel must read

this manual before operating or maintaining this

machine. This manual should be kept inside the cab for

reference and periodically reviewed by all personnel who

will come into contact with the machine.

Page 2

Page 3

FOREWORD

FOREWORD

This manual provides rules and guidelines which will help you use this machine safely and effectively. Keep this

manual handy and have all personnel read it periodically. If this manual has been lost or has become dirty and can

not be read, request a replacement manual from Komatsu or your Komatsu distributor.

If you sell the machine, be sure to give this manual to the new owners.

Continuing improvements in the design of this machine can lead to changes in detail which may not be reflected in

this manual. Consult Komatsu or your Komatsu distributor for the latest available information for your machine or

for questions regarding information in this manual.

WARNING

q This operation & maintenance manual may contain

attachments and optional equipment that are not available in your area. Please consult your local Komatsu distributor for those items you require.

q This machine complies with EC directive (89/392/EEC).

Machines complying with this directive display the CE

mark

q Improper operation and maintenance of this machine can

be hazardous and could result in serious injury or death.

q Operators and maintenance personnel should read this

manual thoroughly before beginning operation or maintenance.

q Some actions involved in operation and maintenance of

the machine can cause a serious accident, if they are not

done in a manner described in this manual.

q The procedures and precautions given in this manual

apply only to intended uses of the machine. If you use

your machine for any unintended uses that are not specifically prohibited, you must be sure that it is safe for

you and others. In no event should you or others engage

in prohibited uses or actions as described in this manual.

q Komatsu delivers machines that comply with all applica-

ble regulations and standards of the country to which it

has been shipped. If this machine has been purchased in

another country or purchased from someone in another

country, it may lack certain safety devices and specifications that are necessary for use in your country. If there

is any question about whether your product complies

with the applicable standards and regulations of your

country, consult Komatsu or your Komatsu distributor

before operating the machine.

q The description of safety is given, see "SAFETY INFOR-

MATION (4)" and in "SAFETY" from page 19.

3

Page 4

SAFETY INFORMATION

SAFETY INFORMATION

SAFETY MESSAGES

Most accidents are caused by the failure to follow fundamental

safety rules for the operation and maintenance of machines.

To avoid accidents, read, understand and follow all precautions

and warnings in this manual and on the machine before performing operation and maintenance.

To identify hazards on the machine pictorial decals are used (see

POSITION FOR ATTACHING SAFETY LABELS).

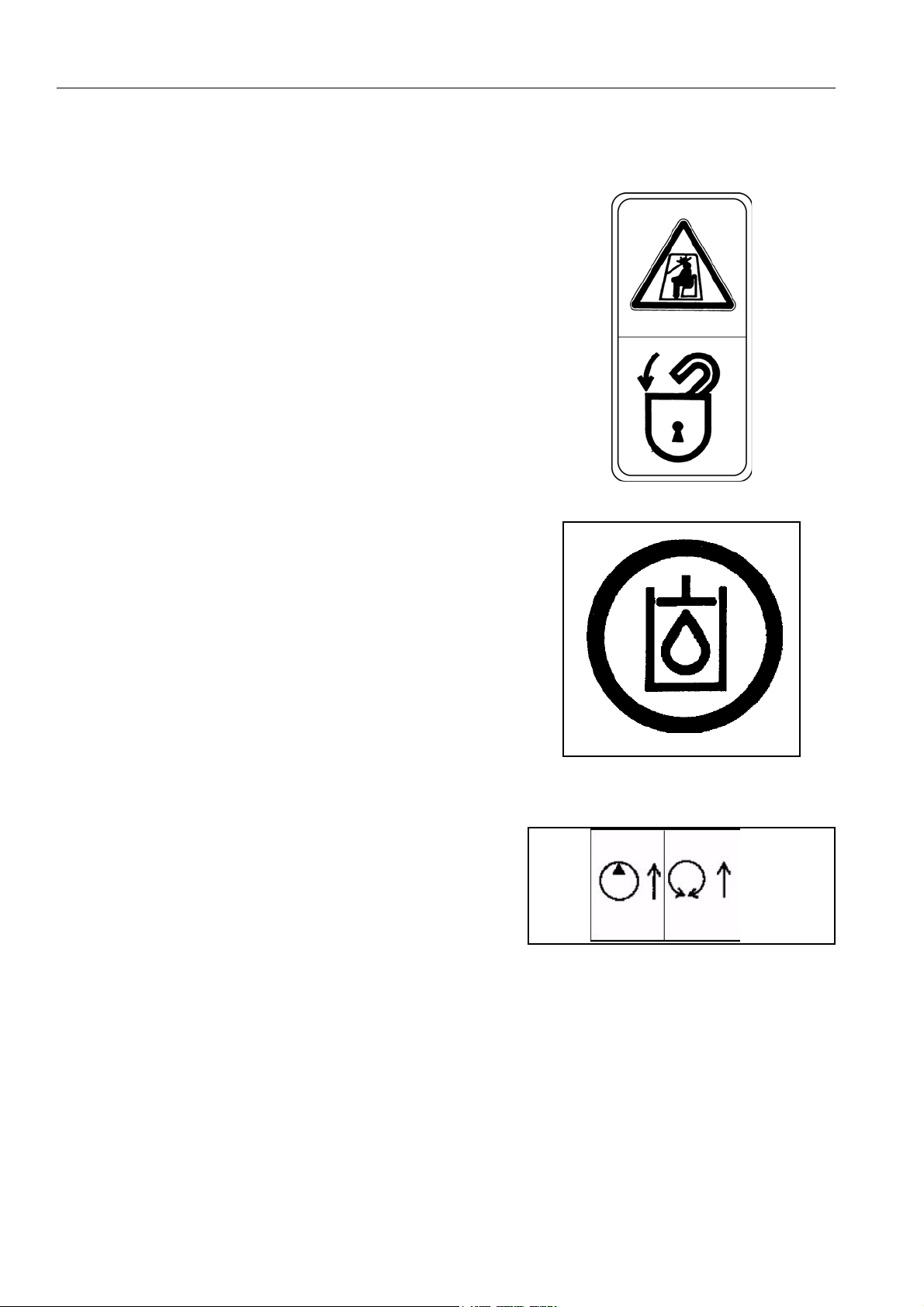

RED WARNING TRIANGLE - This is used on safety

labels where there is a high probability of serious injury or death if

the hazard is not avoided. These safety messages or labels usually describe precautions that must be taken to avoid the hazard.

Failure to avoid this hazard may also result in serious damage to

the machine.

ORANGE WARNING TRIANGLE - This is used on

safety labels where there is a potentially dangerous situation

which could result in serious injury or death if the hazard is not

avoided. These safety messages or labels usually describe precautions that must be taken to avoid the hazard. Failure to avoid

this hazard may also result in serious damage of the machine

YELLOW SAFETY TRIANGLE - This is used on

safety labels for hazards which could result in minor or moderate

injury if the hazard is not avoided. This word might also be used

for a hazard where the only result could be damage to the

machine.

NOTICE - This word is used for precautions that must be taken to

avoid actions which could shorten the life of the machine.

Safety precautions are described in SAFETY from page 19.

Komatsu cannot predict every circumstance that might involve a

potential hazard in operation and maintenance. Therefore the

safety message in this manual and on the machine may not

include all possible safety precautions. If any procedures or

actions not specifically recommended or allowed in this manual

are used, you must be sure that you and others can do such procedures and actions safely and without damaging the machine. If

you are unsure about the safety of some procedures, contact

Komatsu or your Komatsu distributor.

4

Page 5

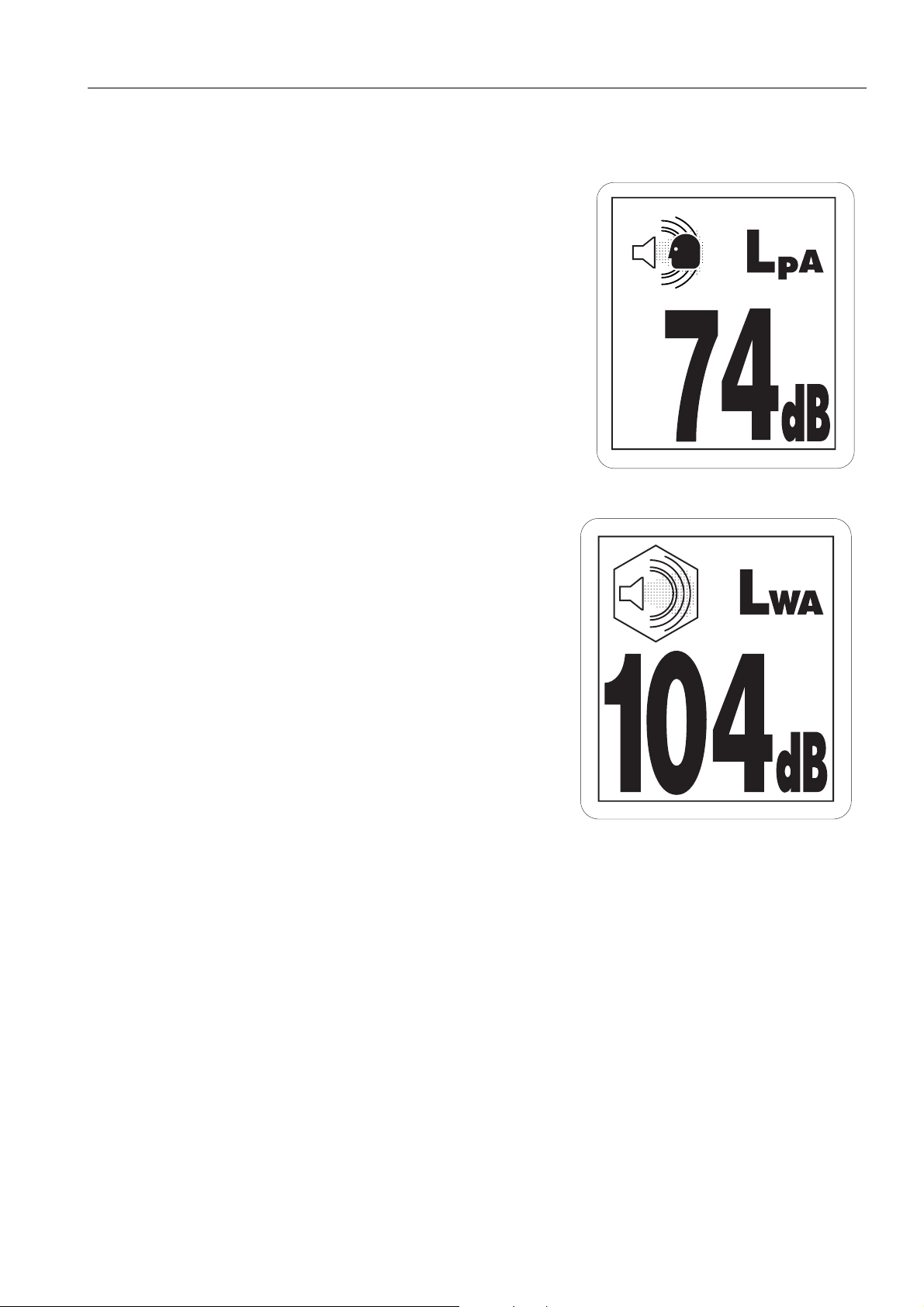

NOISE

q Sound pressure level at the operator’s station, measured

according to ISO6396 (Dynamic test method, simulated working cycle).

q Sound power level emitted. This is the guaranteed value as

specified in the European directive 2000/14/EC

SAFETY INFORMATION

VIBRATION

q The weighted root mean square acceleration value to which

the operator’s arms are subjected does not exceed 2.5 m/s²

q The weighted root mean square acceleration value to which

the operator’s body is subjected was measured at 0.64 m/s²

These results were obtained by accelerometers during trench digging.

5

Page 6

SAFETY INFORMATION

EMERGENCY STEERING

This machine is equipped with an emergency steering system

and complies to ISO 5010 (BSEN 12643). In the advent of failure

of the source of power for the steering system (engine failure)

whilst travelling, the machine can be steered allowing the

machine to be safely stopped.

In such a case, the effort required at the steering wheel and the

number of turns to steer the machine will increase. To confirm

function of emergency steering system, raise the front wheels off

the ground (using the work equipment) and with the engine off,

turn the steering wheel and check movement of the wheels.

EMERGENCY BRAKING

This machine is equipped with an emergency braking system and

complies to ISO 3450. In the advent of failure of the source of

power for the braking system (engine failure) whilst travelling, the

brakes can be actuated from stored energy in the accumulators to

bring the machine safely to a stop.

In such a case, seven brake applications can be made before

exhausting the energy in the accumulators. In the advent of service brake failure, the park brake can be used as an emergency

brake to bring the machine to a stop.

6

Page 7

INTRODUCTION

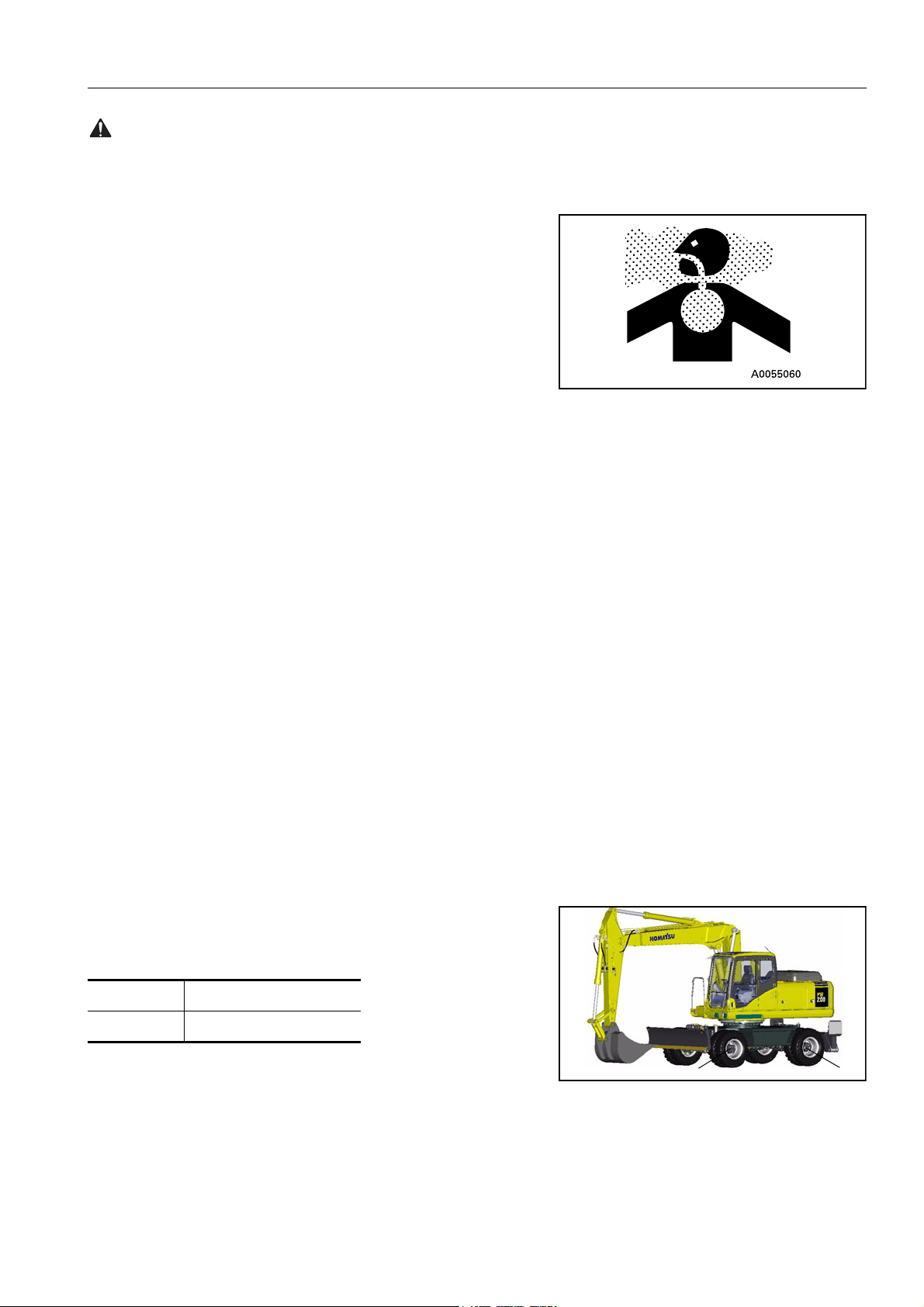

INTENDED USE

This Komatsu HYDRA U L I C E X CAVATO R i s designed to be used

mainly for the following work:

q Digging

q Smoothing work

q Ditching work

q Loading work

See the section see "WORK POSSIBLE USING HYDRAULIC EXCAVATOR (226)" for further details

FEATURES

INTRODUCTION

q This Komatsu HYDRAULIC EXCAVATOR is equip p e d w i t h

various controls based on an advanced electronics system.

q The monitor panel greatly facilitates daily maintenance and

self-diagnosis.

q Working mode & travel speed are selectable.

q Digging and lifting force can be increased by light-touch con-

trol. (For details, see operation section.)

q Adjustable wrist control levers make operations smooth and

easy.

q Fresh filtered air conditioner assures comfortable operation.

q Low noise level and smart urban style design and colouring.

q Superb operation performance provided by powerful engine

and high-performance hydraulic pump.

q Low fuel consumption controlled by an electronic control sys-

tem provides an environment-friendly machine.

q Sophisticated drive train provides fast and smooth travelling

on the highway and off road.

7

Page 8

INTRODUCTION

BREAKING IN YOUR NEW MACHINE

Your Komatsu machine has been thoroughly adjusted and tested

before shipment.

However, operating the machine under severe conditions at the

beginning can adversely affect the performance and shorten the

machine life.

Be sure to break in the machine for the initial 100 hours (as indicated by the hour meter.)

During breaking in:

q Idle the engine for 5 minutes after starting it up.

q Avoid operation with heavy loads or at high speeds.

q Sudden starting or acceleration, unnecessarily abrupt braking

and sharp turning should be avoided except in cases of emergency.

Additionally for the first 20 hours

q Avoid operating engine for prolonged periods at constant

speed (including idle.)

q Avoid high speed travelling for periods of more than 5 min-

utes.

Pay particular attention to oil pressure and temperature indicators

& check coolant and oil levels frequently during breaking in.

The precautions given in this manual for operating, maintenance,

and safety procedures are only those that apply when this product

is used for the specified purpose. If the machine is used for a purpose that is not listed in this manual, Komatsu cannot bear any

responsibility for safety. All consideration of safety in such operations is the responsibility of the user.

Operations that are prohibited in this manual must never be carried out under any circumstances.

8

Page 9

LOCATIONS OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

LOCATIONS OF PLATES, TABLE TO ENTER SERIAL NO.

AND DISTRIBUTOR

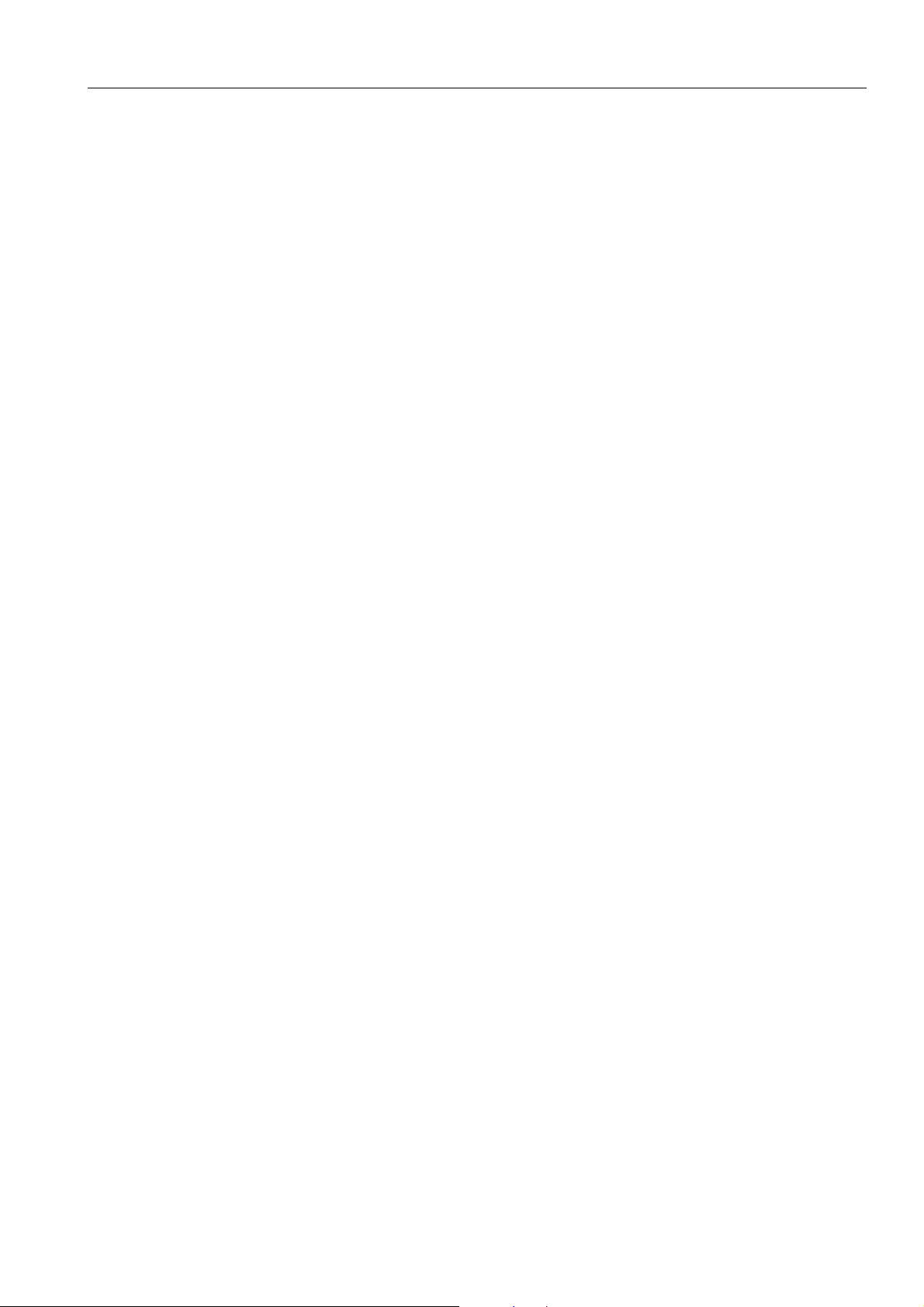

MACHINE SERIAL NO. PLATE POSITION

On the front left of the undercarriage

ENGINE SERIAL NO. PLATE POSITION

On the gear case front corner.

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

Machine serial No.:

Engine Serial No.:

Product Identificaiton Number :

Manufacturer’s name: Komatsu UK Ltd.

Address

Durham Road

Birtley

Chester-Le-Street

County Durham DH32QX

United Kingdom

Distributor

Address

Phone

9

Page 10

LOCATIONS OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

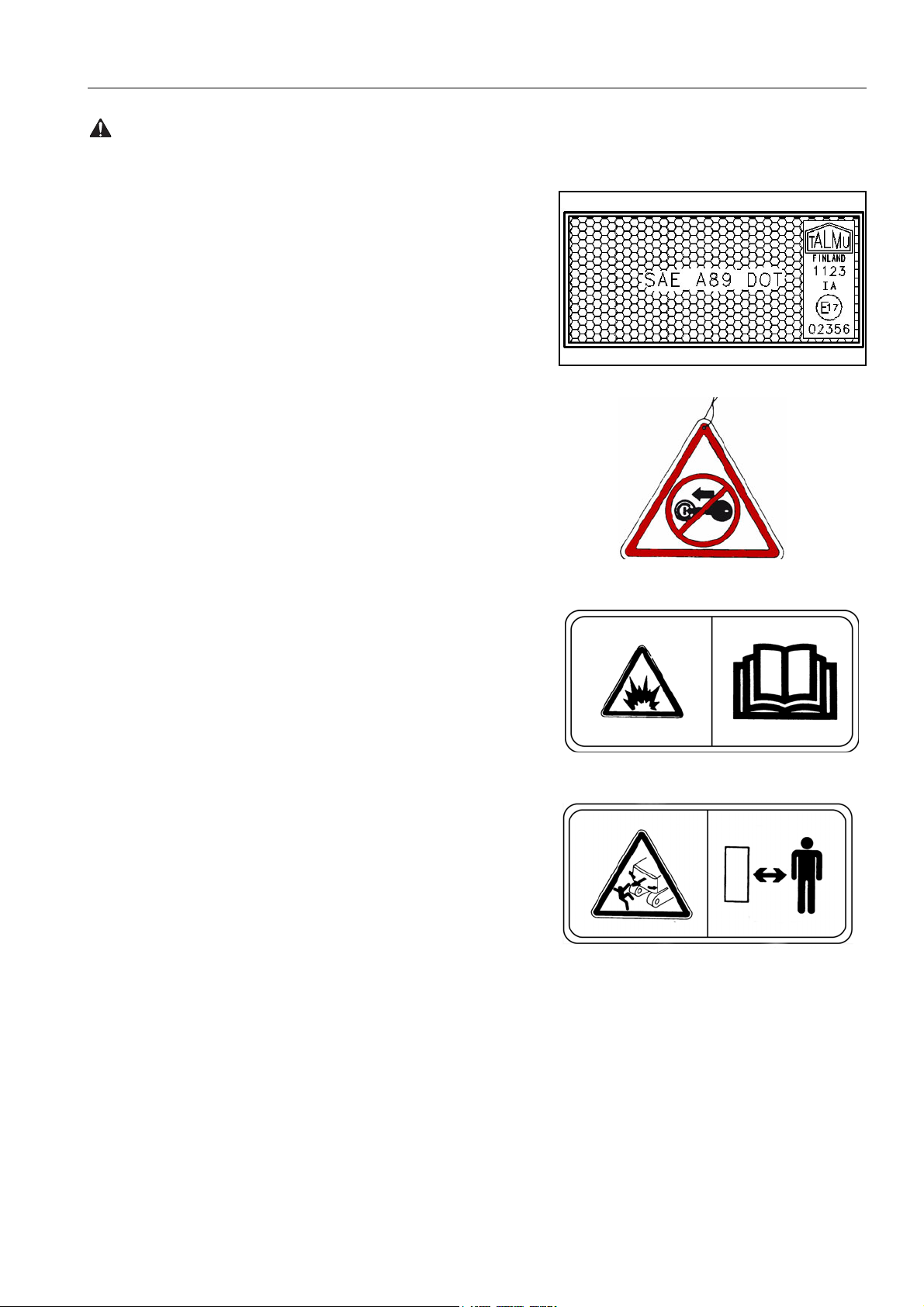

MACHINE SERIAL PLATES

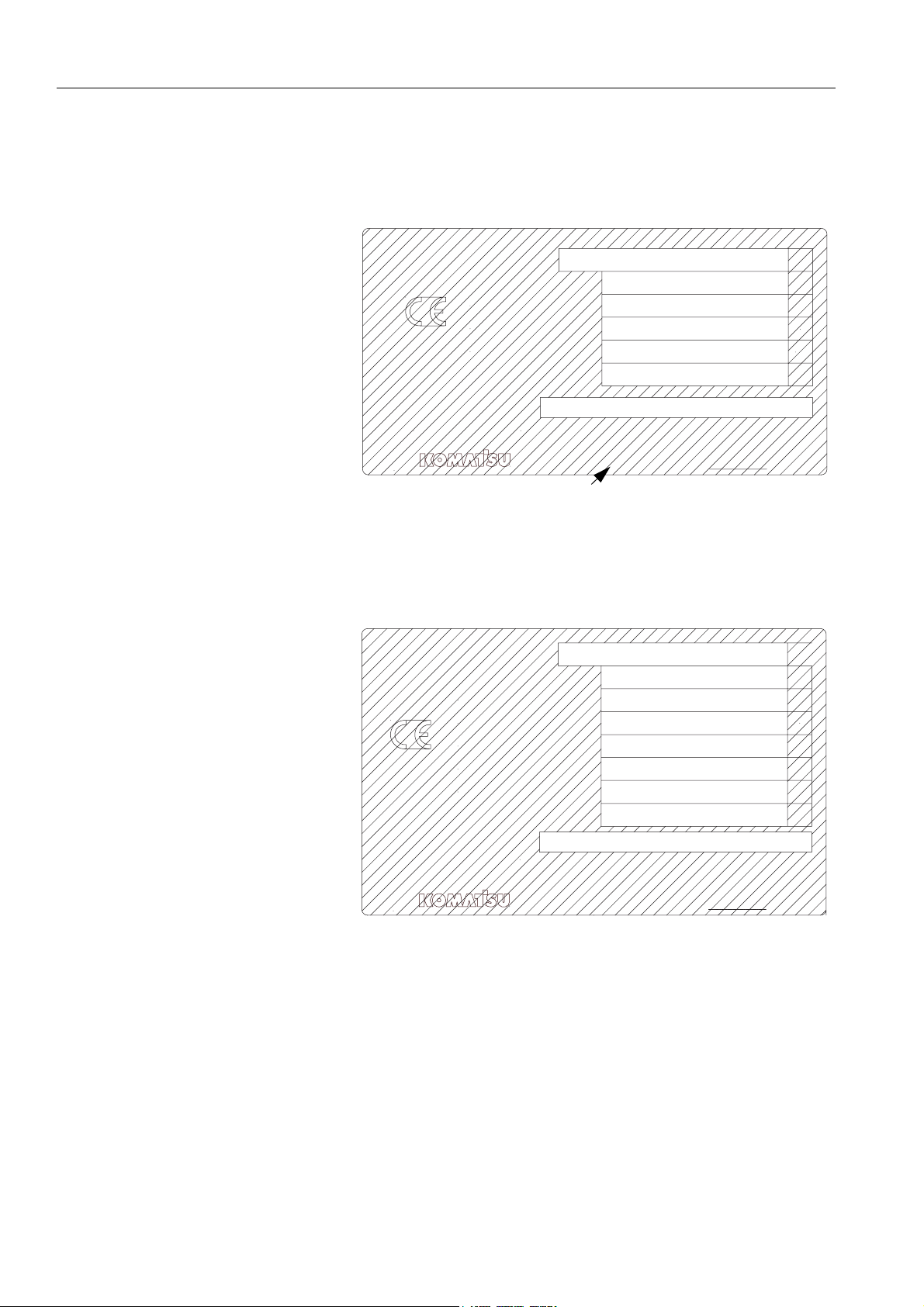

STANDARD SERIAL PLATE

MODEL

SERIAL No.

MANUFACT. YEAR

MAX. DRAWBAR PULL

MASS

ENGINE POWER

Product Identification Number

MANUFACTURER

Manufactured by Komatsu UK Ltd.

for Komatsu Ltd., Tokyo, Japan

Manufactured by Komatsu UK Ltd.

for Komatsu Ltd.,Tokyo,Japan

N

kg

kW

20G-00-K2382

GERMANY SERIAL PLATE

TYP

FABR. NR.

BAUJAHR

ZUL. ZUGKRAFT

ZUL.GESAMTGEWICHT

LEISTUNG

ZUL.ACHSLAST VORN

ZUL.ACHSLAST HINTEN

Produkt Identifizierung Nummer

HERSTELLER

Hergestellt vom Komatsu UK Ltd. Birtley Co Durham,

United Kingdom unter lizenz der Komatsu Ltd.

N

kg

kW

kg

kg

20G-00-K2392

10

Page 11

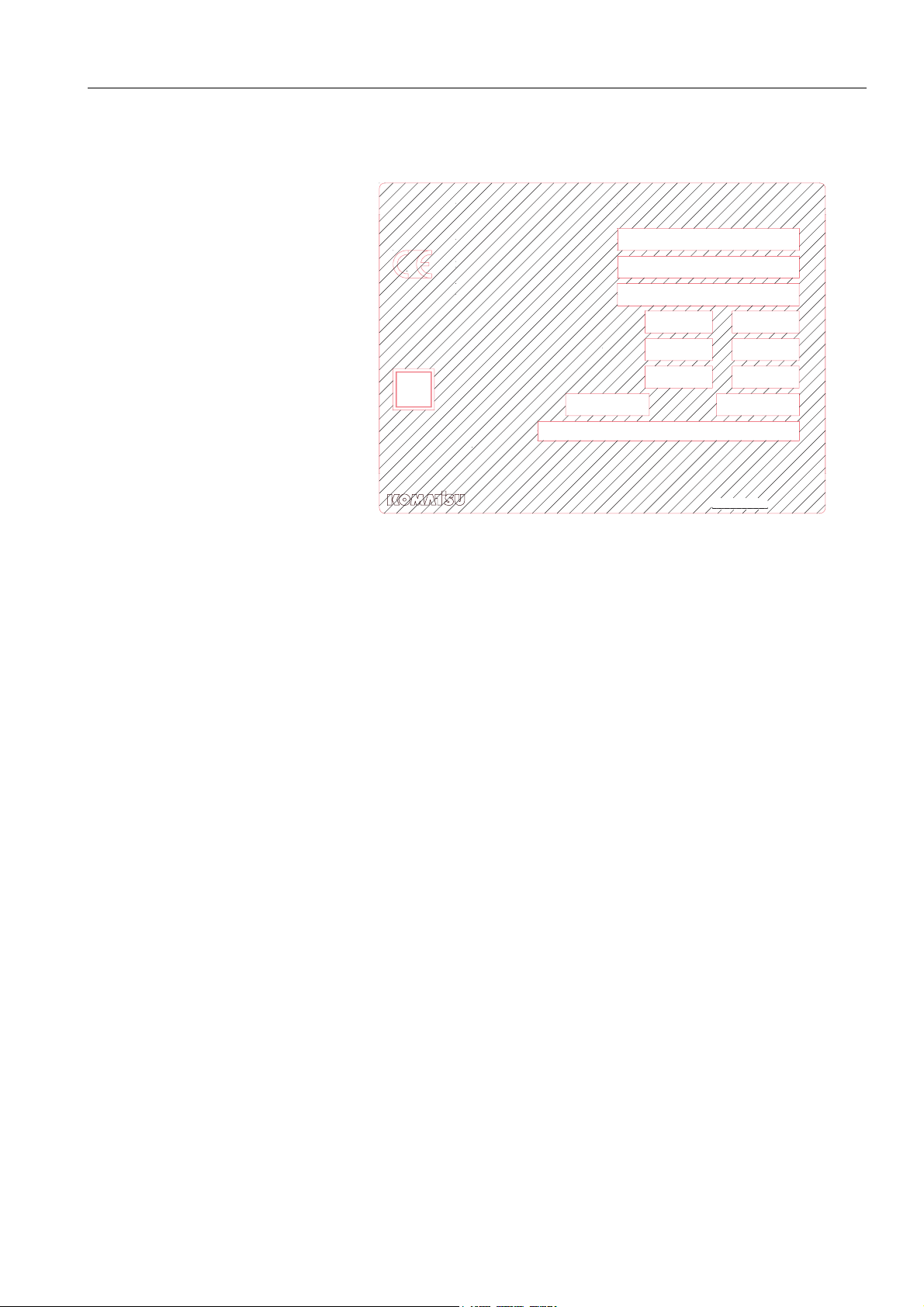

ITALIAN SERIAL PLATE

LOCATIONS OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

MANUFACTURER

TIPO

TYPE-MODEL

NUMERO DI OMOLOGAZIONE

HOMOLOGATION NUMBER

MATRICOLA

SERIAL NUMBER

MASSA TOTALE AMMISSIBILE

TOTAL MAX WEIGHT

CARICO AMMISSIBILE ASSE ANT.

WEIGHT FRONT AXLE

CARICO AMMISSIBILE ASSE POST.

WEIGHT REAR AXLE

POTENZA MOTORE

ENGINE POWER

Numero di Identificazione del Prodotto.

Product Identification Number

Massa rimorchiabile ammissibile:

- Massa rimorchiabile con frenata: non atto

- Massa rimorchiabile con frenatura indipendente: non atto

- Massa rimorchiabile con frenatura ad inerzia: non atto

- Massa rimorchiabile con frenatura assistita: non atto

Manufactured by Komatsu UK Ltd.

for Komatsu Ltd.,Tokyo,Japan.

DA

FROM

DA

FROM

DA

FROM

kW

kg

kg

kg

ANNO

YEAR

A

TO

A

TO

A

TO

20E-00-K1932

kg

kg

kg

11

Page 12

LOCATIONS OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

12

Page 13

CONTENTS

FOREWORD ........................................................................................................................................................... 3

SAFETY INFORMATION ........................................................................................................................................ 4

SAFETY MESSAGES ................................................................................................................................... 4

NOISE ........................................................................................................................................................... 5

VIBRATION ................................................................................................................................................... 5

EMERGENCY STEERING ........................................................................................................................... 6

INTRODUCTION ..................................................................................................................................................... 7

INTENDED USE ........................................................................................................................................... 7

FEATURES ................................................................................................................................................... 7

BREAKING IN YOUR NEW MACHINE ........................................................................................................ 8

LOCATIONS OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR ............................................. 9

MACHINE SERIAL NO. PLATE POSITION .................................................................................................. 9

ENGINE SERIAL NO. PLATE POSITION .................................................................................................... 9

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR ................................................................................ 9

MACHINE SERIAL PLATES ....................................................................................................................... 10

SAFETY............................................................................................................. 19

GENERAL PRECAUTIONS ................................................................................................................................. 20

PRECAUTION DURING OPERATION ................................................................................................................. 26

BEFORE STARTING ENGINE ................................................................................................................... 26

OPERATING MACHINE ............................................................................................................................. 27

TRANSPORTATION ................................................................................................................................... 33

BATTERY ................................................................................................................................................... 34

TOWING ..................................................................................................................................................... 35

BUCKET WITH HOOK OR BUCKET LINK WITH LIFTING EYE ............................................................... 36

PRECAUTIONS FOR MAINTENANCE ................................................................................................................ 39

BEFORE CARRYING OUT MAINTENANCE ............................................................................................. 39

DURING MAINTENANCE ........................................................................................................................... 42

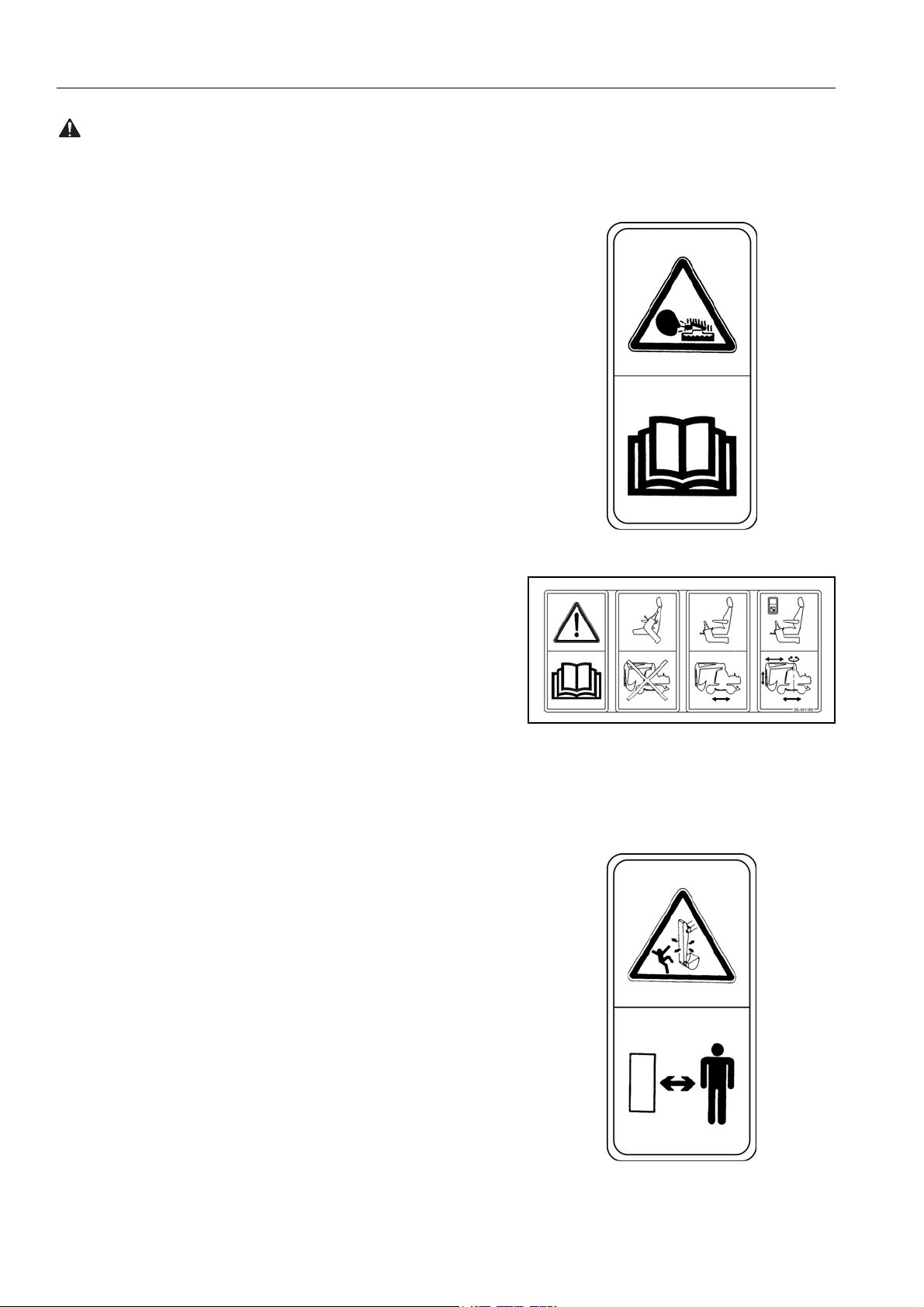

POSITION FOR ATTACHING SAFETY LABELS ................................................................................................ 45

POSITION FOR ATTACHING SAFETY LABELS ....................................................................................... 45

LIFTING CAPACITY CHART PW200-7K ............................................................................................................. 53

ONE PIECE BOOM Lift capacity tables for 2.5 metre undercarriage ......................................................... 53

ONE PIECE BOOM Lift capacity tables for 2.75 metre undercarriage ....................................................... 60

TWO PIECE BOOM Lift capacity tables for 2.5 metre undercarriage ......................................................... 67

TWO PIECE BOOM Lift capacity tables for 2.75 metre undercarriage ....................................................... 74

LIFTING CAPACITY CHART PW220-7K ............................................................................................................. 81

ONE PIECE BOOM Lift capacity tables for 2.75 metre undercarriage and heavy duty counterweight. ..... 81

13

Page 14

ONE PIECE BOOM Lift capacity tables for 2.75 metre undercarriage ....................................................... 88

TWO PIECE BOOM Lift capacity tables for 2.75 metre undercarriage and heavy duty counterweight ...... 95

TWO PIECE BOOM Lift capacity tables for 2.75 metre undercarriage ..................................................... 102

OPERATION..................................................................................................... 111

GENERAL VIEW ................................................................................................................................................ 112

GENERAL VIEW OF MACHINE ............................................................................................................... 112

GENERAL VIEW OF CONTROLS AND GAUGES ................................................................................... 113

EXPLANATION OF COMPONENTS .................................................................................................................. 114

1. MACHINE MONITOR ........................................................................................................................... 114

BASIC CHECK ITEMS .............................................................................................................................. 117

SWITCHES ......................................................................................................................................................... 146

CONTROL LEVERS, PEDALS .......................................................................................................................... 154

FRONT WINDOW ..................................................................................................................................... 159

EMERGENCY EXIT FROM OPERATOR'S CAB ...................................................................................... 163

DOOR LOCK ............................................................................................................................................ 164

CAP, COVER WITH LOCK ....................................................................................................................... 165

FUSE ........................................................................................................................................................ 166

LUGGAGE TRAY ...................................................................................................................................... 167

ASHTRAY ................................................................................................................................................. 167

CUP HOLDER .......................................................................................................................................... 167

HOT AND COOL BOX .............................................................................................................................. 167

CAB RADIO .............................................................................................................................................. 168

POWER PICK-UP PORT .......................................................................................................................... 168

HANDLING AIR CONDITIONER .............................................................................................................. 169

FUSIBLE LINK .......................................................................................................................................... 182

CONTROLLER ......................................................................................................................................... 182

TOOL BOX ................................................................................................................................................ 183

REFUELLING PUMP ................................................................................................................................ 183

WARNING LAMPS ................................................................................................................................... 185

HANDLING ACCUMULATORS ................................................................................................................ 186

OPERATION ....................................................................................................................................................... 187

CHECK BEFORE STARTING ENGINE .................................................................................................... 187

OPERATIONS AND CHECKS BEFORE STARTING ENGINE ......................................................................... 199

STARTING ENGINE ................................................................................................................................. 201

MOVING MACHINE OFF .......................................................................................................................... 210

STEERING ................................................................................................................................................ 213

TRAVELLING ON PUBLIC HIGHWAY ..................................................................................................... 214

STOPPING & PARKING ........................................................................................................................... 215

SWINGING (Slewing the upper carriage) ................................................................................................. 217

OPERATION OF WORK EQUIPMENT ....................................................................................................218

WORKING MODE SELECTION ............................................................................................................... 221

14

Page 15

PROHIBITIONS FOR OPERATION ......................................................................................................... 222

PRECAUTIONS FOR OPERATION ......................................................................................................... 223

PRECAUTIONS WHEN TRAVELLING UP OR DOWN HILLS ................................................................. 225

HOW TO ESCAPE FROM MUD ............................................................................................................... 226

WORK POSSIBLE USING HYDRAULIC EXCAVATOR ........................................................................... 226

REPLACEMENT AND INVERSION OF BUCKET .................................................................................... 228

STOPPING ENGINE ................................................................................................................................. 230

CHECK AFTER FINISHING WORK ......................................................................................................... 230

CHECK AFTER STOPPING ENGINE ................................................................................................................ 231

LOCKING .................................................................................................................................................. 231

OVERLOAD WARNING DEVICE ............................................................................................................. 231

HANDLING THE WHEELS ....................................................................................................................... 231

TRANSPORTATION ........................................................................................................................................... 235

LOADING, UNLOADING WORK .............................................................................................................. 235

PRECAUTIONS FOR LOADING .............................................................................................................. 237

PRECAUTIONS FOR TRANSPORTATION ............................................................................................. 239

TRAVELLING POSTURE ......................................................................................................................... 240

COLD WEATHER OPERATION ........................................................................................................................ 241

PRECAUTIONS FOR LOW TEMPERATURE .......................................................................................... 241

PRECAUTIONS AFTER COMPLETION OF WORK ................................................................................ 243

AFTER COLD WEATHER ........................................................................................................................ 243

LONG-TERM STORAGE .................................................................................................................................... 244

BEFORE STORAGE ................................................................................................................................. 244

DURING STORAGE ................................................................................................................................. 244

AFTER STORAGE .................................................................................................................................... 245

STARTING MACHINE AFTER LONG-TERM STORAGE ........................................................................ 245

TROUBLESHOOTING ........................................................................................................................................ 246

PHENOMENA THAT ARE NOT FAILURES ............................................................................................. 246

METHOD OF TOWING MACHINE ........................................................................................................... 247

PRECAUTIONS ON PARTICULAR JOBSITES ....................................................................................... 247

DISCHARGED BATTERY ........................................................................................................................ 248

OTHER TROUBLE ................................................................................................................................... 252

MAINTENANCE. .............................................................................................. 257

GUIDES TO MAINTENANCE ............................................................................................................................. 258

OUTLINE OF SERVICE ...................................................................................................................................... 261

USE OF BIO-DEGRADEABLE OIL .......................................................................................................... 261

If an abnormality is found in the characteristics of the oil, change the oil immediately. ............................ 261

OUTLINE OF OIL, FUEL, COOLANT ....................................................................................................... 262

OUTLINE OF ELECTRIC SYSTEM .......................................................................................................... 266

OUTLINE OF HYDRAULIC SYSTEM ....................................................................................................... 266

15

Page 16

WEAR PARTS LIST ........................................................................................................................................... 268

USE FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE ........................... 269

PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS ......................................................... 269

USE FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE CONT. .............. 271

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS ..................................................................... 273

INTRODUCTION OF NECESSARY TOOLS ............................................................................................ 273

TIGHTENING TORQUE SPECIFICATIONS ...................................................................................................... 274

TIGHTENING TORQUE LIST ................................................................................................................... 274

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS .......................................................................... 275

SAFETY CRITICAL PARTS ...................................................................................................................... 276

MAINTENANCE SCHEDULE CHART ............................................................................................................... 277

KEY TO LUBRICATION POINTS ............................................................................................................. 281

SERVICE PROCEDURE .................................................................................................................................... 283

INITIAL 250 HOURS SERVICE ................................................................................................................ 283

WHEN REQUIRED ................................................................................................................................... 284

CHECKING COOLANT LEVEL ................................................................................................................ 292

CHECK AND TIGHTEN WHEEL NUTS ...................................................................................................295

CHECK ELECTRICAL INTAKE AIR HEATER .......................................................................................... 295

CHECK ALTERNATOR ............................................................................................................................ 295

REPLACE BUCKET SIDE CUTTERS ...................................................................................................... 296

REPLACE BUCKET TEETH ..................................................................................................................... 297

ADJUST BUCKET CLEARANCE ............................................................................................................. 301

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID ....................................................................... 302

CHECK AND ADJUST AIR CONDITIONER ............................................................................................. 303

DRAIN ENGINE BREATHER OIL CATCHER .......................................................................................... 304

CHECK BEFORE STARTING .................................................................................................................. 305

CHECK COOLANT LEVEL, ADD WATER ............................................................................................... 305

EVERY 50 HOURS ................................................................................................................................... 309

EVERY 100 HOURS SERVICE ................................................................................................................ 309

EVERY 250 HOURS MAINTENANCE ...................................................................................................... 315

EVERY 500 HOURS SERVICE ................................................................................................................ 320

EVERY 1000 HOURS SERVICE .............................................................................................................. 328

EVERY 2000 HOURS SERVICE .............................................................................................................. 334

EVERY 4000 HOURS SERVICE .............................................................................................................. 335

EVERY 5000 HOURS SERVICE .............................................................................................................. 336

SPECIFICATIONS............................................................................................ 339

SPECIFICATIONS .............................................................................................................................................. 340

1 - PIECE BOOM ...................................................................................................................................... 341

2 - PIECE BOOM ...................................................................................................................................... 343

16

Page 17

WORKING RANGE: ONE PIECE BOOM ................................................................................................. 345

WORKING RANGE: TWO PIECE BOOM ................................................................................................ 346

OPTIONS, ATTACHMENTS ............................................................................ 347

GENERAL PRECAUTIONS ............................................................................................................................... 348

PRECAUTIONS RELATED TO SAFETY ................................................................................................. 348

PRECAUTIONS WHEN INSTALLING ATTACHMENTS ................................................................................... 349

HANDLING BUCKET WITH HOOK ................................................................................................................... 351

CHECKING FOR DAMAGE TO BUCKET WITH HOOK .......................................................................... 351

PROHIBITED OPERATIONS ................................................................................................................... 351

PRECAUTIONS DURING OPERATIONS ................................................................................................ 351

MACHINES READY FOR ATTACHMENTS ...................................................................................................... 352

GENERAL LOCATIONS ........................................................................................................................... 352

HANDLING THE CLAMSHELL BUCKET ................................................................................................. 354

OPERATION ............................................................................................................................................. 355

METHOD FOR RELEASING PRESSURE IN CONTROL CIRCUIT OF MACHINES EQUIPPED WITH

ACCUMULATOR ...................................................................................................................................... 357

LONG-TERM STORAGE .......................................................................................................................... 357

INTRODUCTION OF ATTACHMENTS AND EXTENDING MACHINE SERVICE LIFE .................................... 358

HYDRAULIC BREAKER ........................................................................................................................... 358

POWER RIPPER ...................................................................................................................................... 361

FORK GRAB ............................................................................................................................................. 362

GRAPPLE BUCKET ................................................................................................................................. 363

SCRAP GRAPPLE .................................................................................................................................... 364

CRUSHER & SMASHER .......................................................................................................................... 366

HYDRAULIC PILE DRIVER ...................................................................................................................... 367

HYDRAULIC EXCAVATOR WITH MULTIPURPOSE CRANE ................................................................. 368

17

Page 18

18

Page 19

SAFETY

WARNING

Read and follow all safety precautions. Failure to do so may

result in serious injury or death.

This safety section also contains precautions for optional equipment and attachments.

19

Page 20

GENERAL PRECAUTIONS SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

GENERAL PRECAUTIONS

SAFETY RULES

q ONLY trained and authorised personnel can operate and

maintain the machine.

q Follow all safety rules, precautions and instructions when

operating or performing maintenance on the machine.

q When working with another operator or a person on work site

traffic duty, be sure all personnel understand all hand signals

that are to be used.

SAFETY FEATURES

q Be sure all guards and covers are in their proper position.

Have guards and covers repaired if damaged.

q Use safety features such as safety lock lever at all times.

q NEVER remove any safety features. ALWAYS keep them in

good operating condition.

q Always wear safety belt when operating machine.

q Improper use of safety features could result in serious bodily

injury or death.

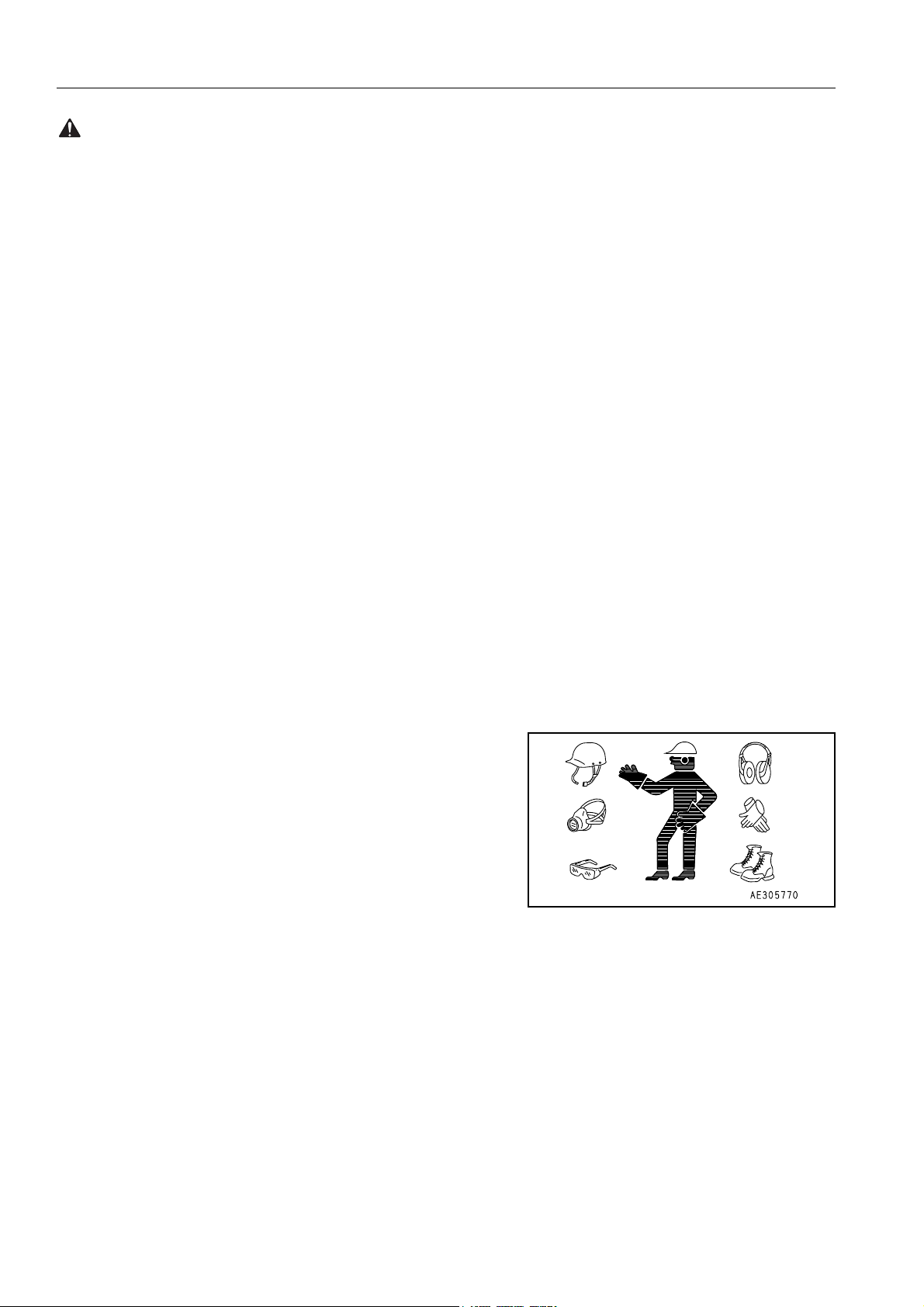

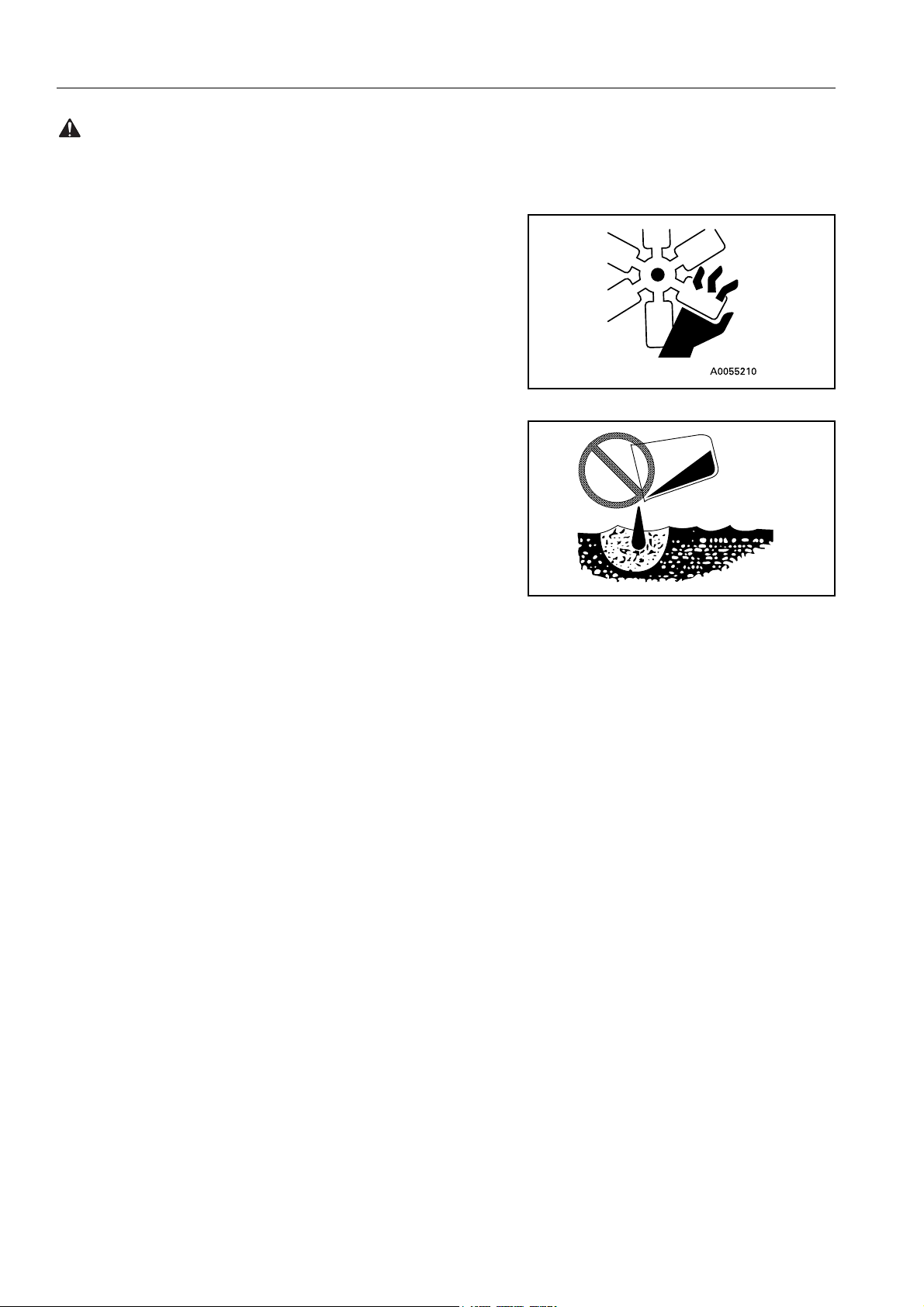

CLOTHING AND PERSONAL PROTECTIVE ITEMS

q Avoid loose clothing, jewellery, and loose long hair. They can

catch on controls or in moving parts and cause serious injury

or death. Also, do not wear oily cloths because they are flammable.

q Wear a hard hat, safety glasses, safety shoes, mask or

gloves when operating or maintaining the machine. Always

wear safety goggles, hard hat and heavy gloves if your job

involves scattering metal chips or minute materials, this is so

particularly when driving pins with a hammer and when cleaning the air cleaner element with compressed air.

Check also that there is no one near the machine.

Driving in pins, see"REPLACEMENT AND INVERSION OF

BUCKET (228)"

Cleaning of air cleaner element, see "WHEN REQUIRED

(284)" in service procedure.

UNAUTHORISED MODIFICATION

q Any modification made without authorisation from Komatsu

can create hazards.

q Before making a modification, consult your Komatsu distribu-

tor. Komatsu will not be responsible for any injury or damage

caused by any unauthorised modification.

20

Page 21

SAFETY GENERAL PRECAUTIONS

WARNING: Failure to follow these safety precautions may lead to a serious accident.

ALWAYS APPLY (RAISE) SAFETY LOCK LEVER WHEN

LEAVING OPERATOR’S SEAT

q When standing up from the operator’s seat, always raise the

safety lock lever to the LOCK position. If you accidentally

touch the travel, attachment or swing lever when they are not

locked, the machine may suddenly move and cause serious

injury or damage.

q When leaving the machine, lower the work equipment com-

pletely to the ground, set the safety lock lever to the LOCK

position, then stop the engine and use the key to lock the

machine. Always take the key with you.

LOCK

UNLOCK

WARNING

If the control lever is touched by accident, the work equipment or the machine may move suddenly, and this may lead

to a serious accident. Before leaving the operator’s compartment, always raise the safety lock lever to lock the work

equipment controls.

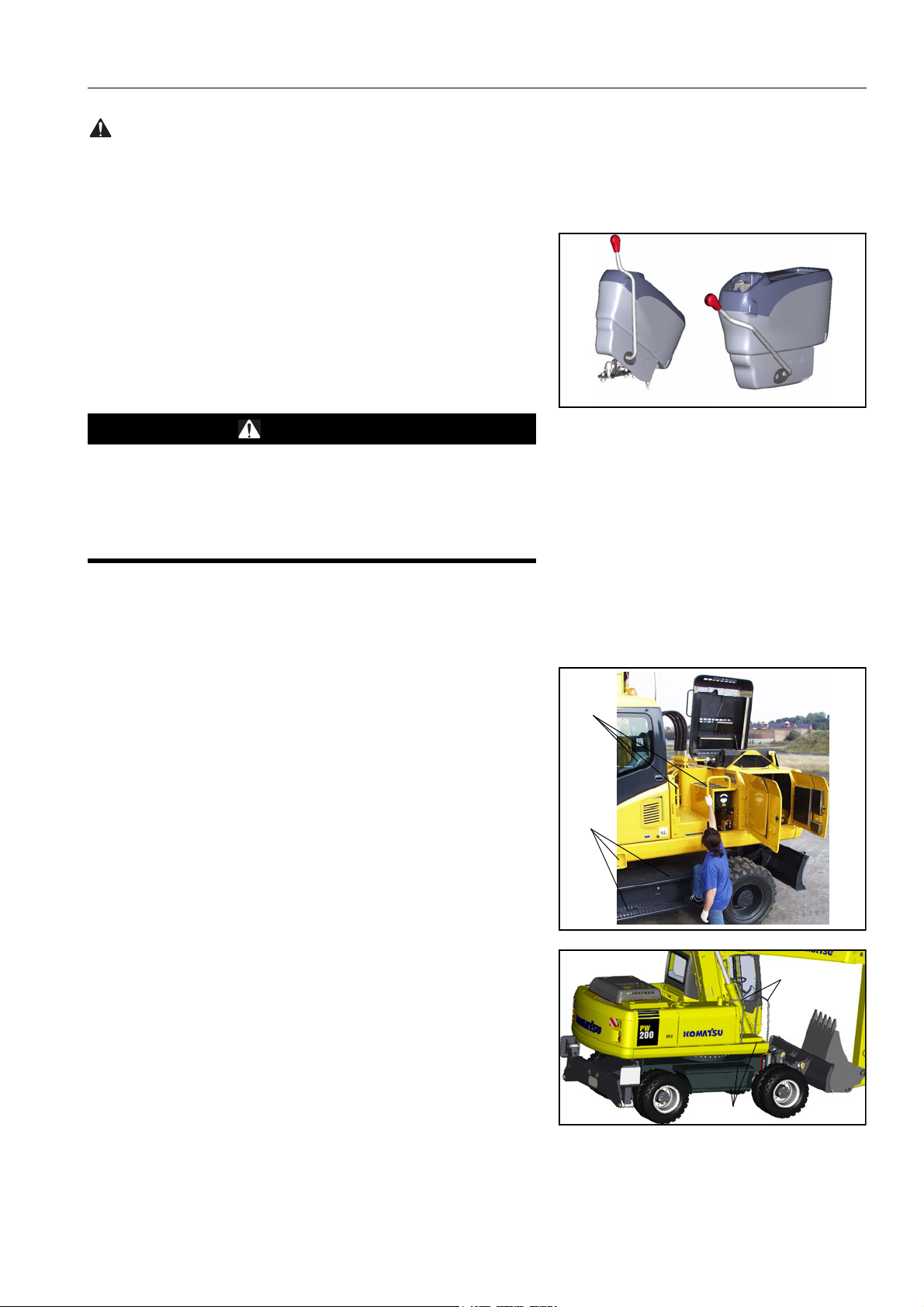

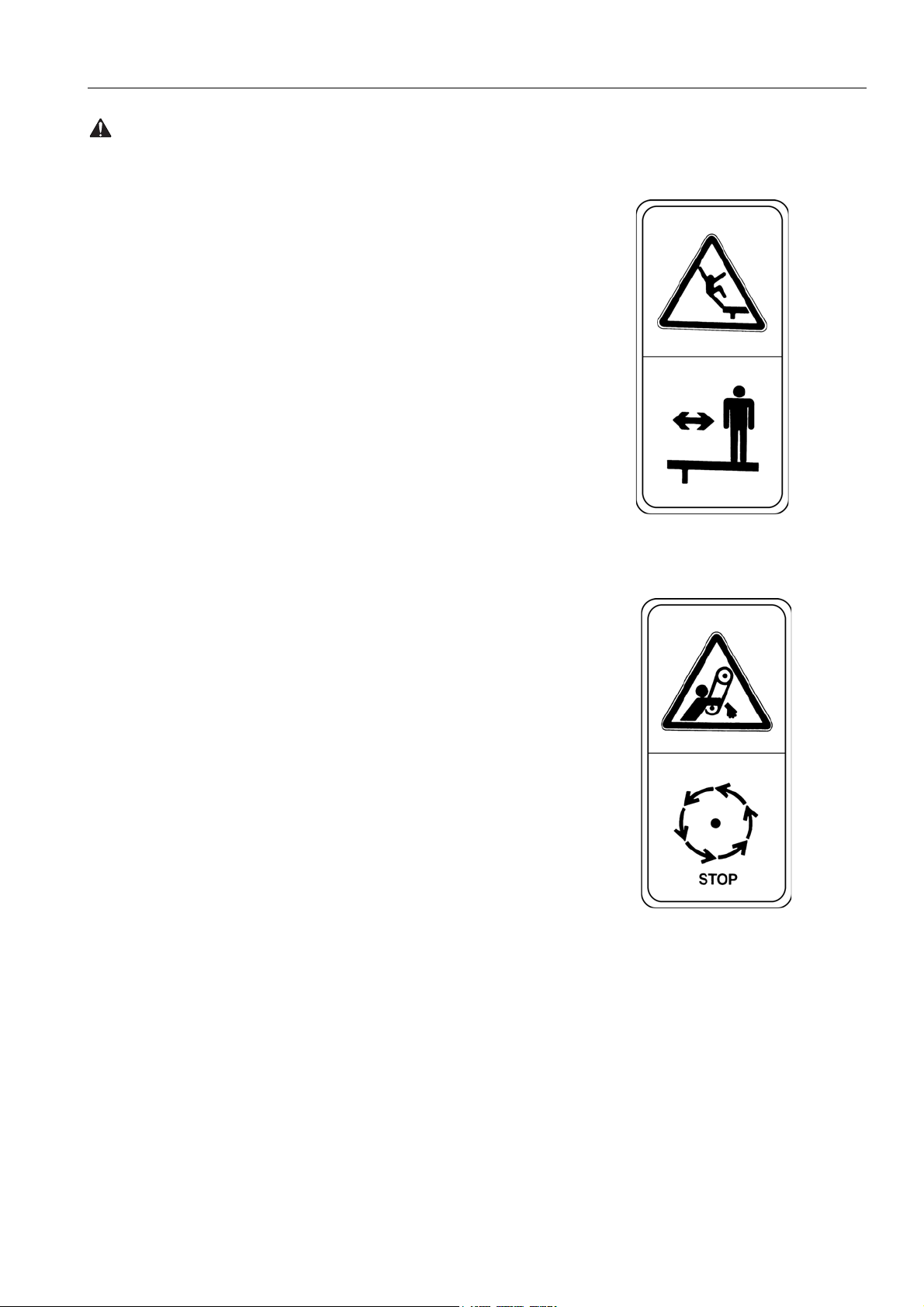

MOUNTING AND DISMOUNTING

q NEVER jump on or off the machine. NEVER get on or off a

moving machine.

q When mounting or dismounting, always face the machine and

use the handrails (A), machine or chassis steps (B).

q Do not hold any control levers when getting on or off the

machine.

q Ensure safety by always maintaining at least three-point con-

tact of hands and feet with the handrails, steps or wheels.

q Always remove any oil or mud from the handrails, steps and

track shoes. If they are damaged, repair them and tighten any

loose bolts.

q If grasping the door handrail when mounting or dismounting

or moving on the chassis steps, open and lock the door

securely in the open position. Otherwise, the door may move

suddenly, causing you to lose balance and fall.

A

B

A

B

21

Page 22

GENERAL PRECAUTIONS SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

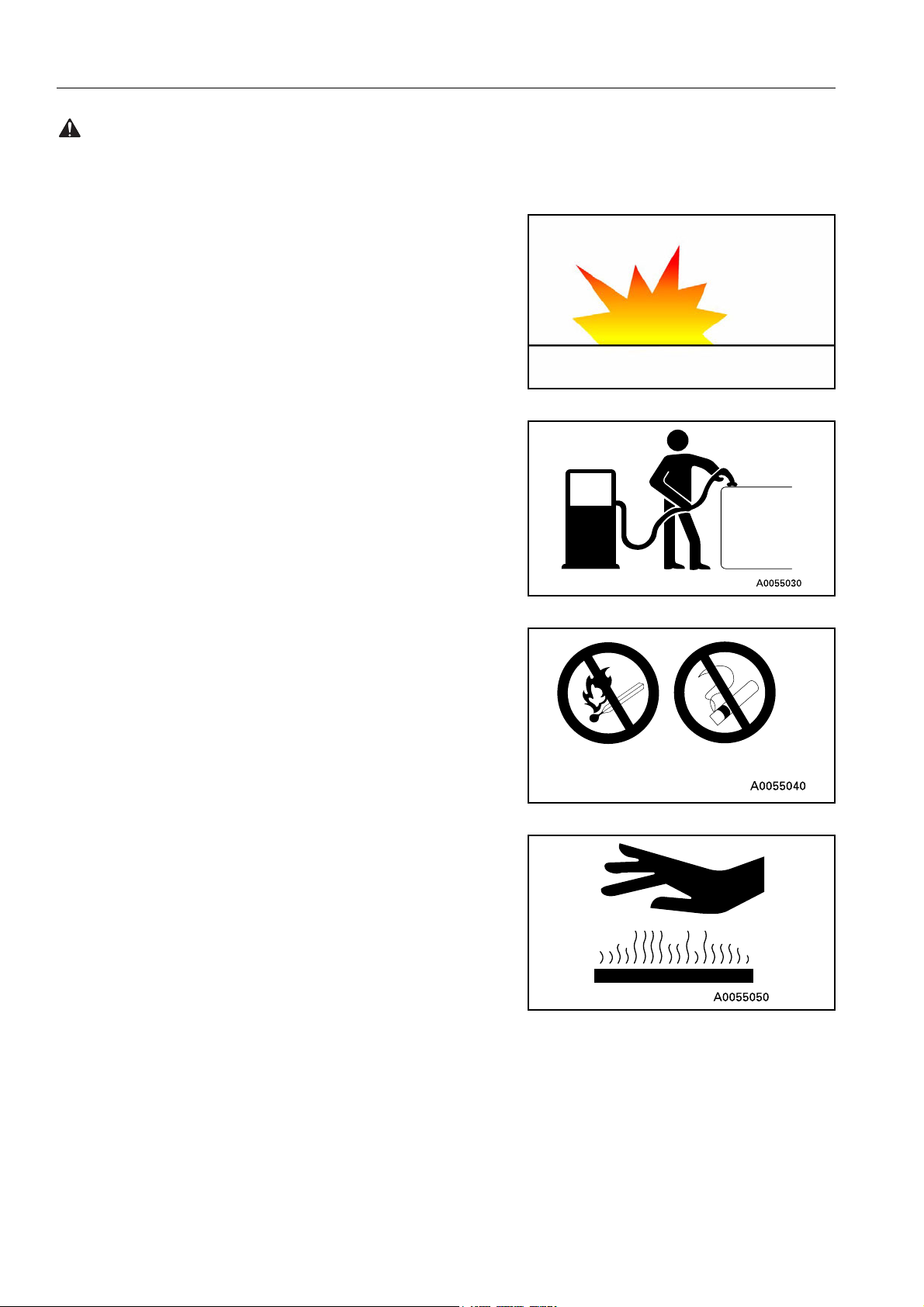

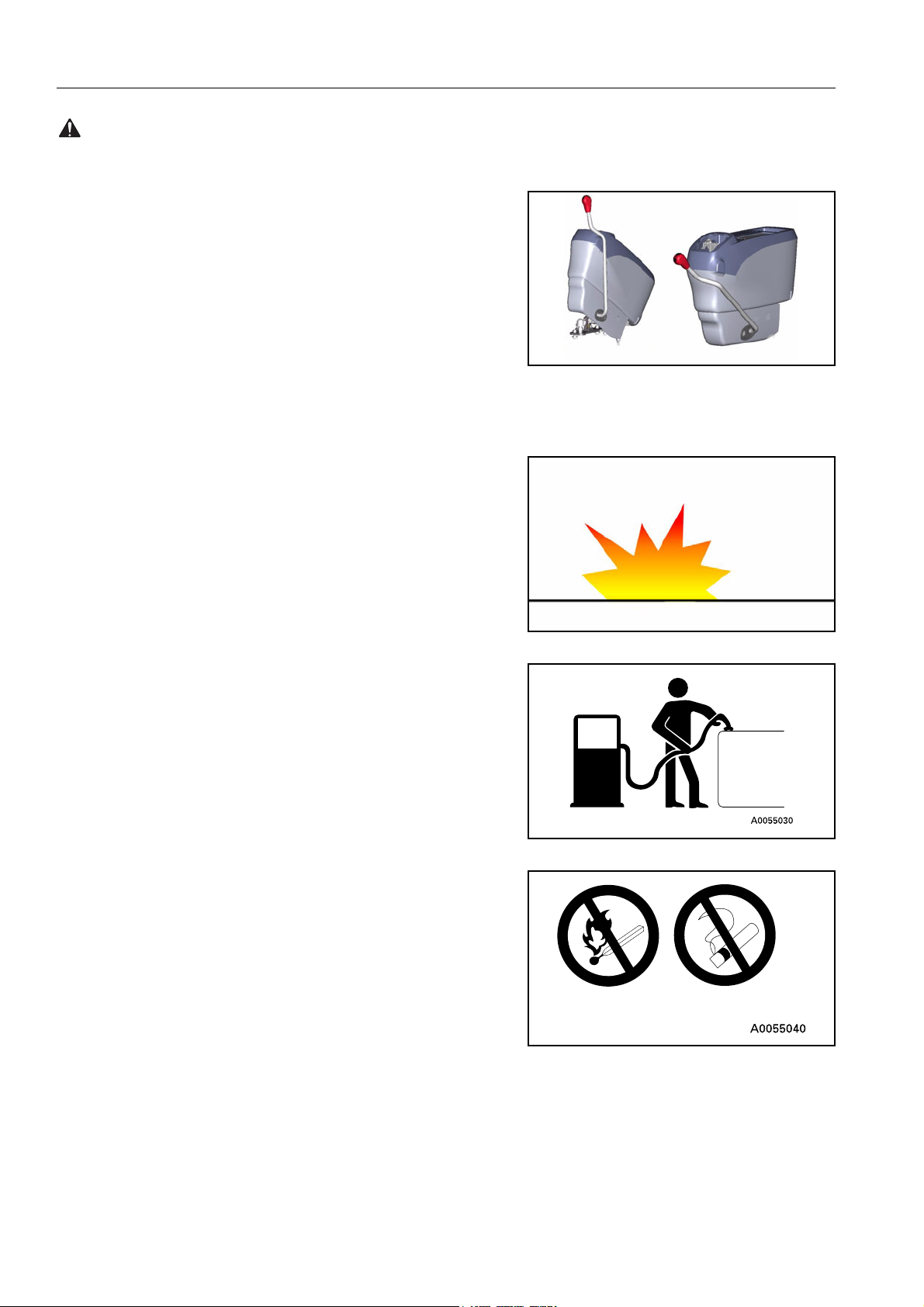

FIRE PREVENTION FOR FUEL AND OIL

Fuel, oil, and antifreeze can be ignited by a flame. Fuel is particularly FLAMMABLE and can be HAZARDOUS.

q Keep flames away from flammable fluids.

q Stop the engine and do not smoke when refuelling.

q Tighten all fuel and oil caps securely.

q Refuelling and oiling should be carried out in well ventilated

areas.

q Keep oil and fuel in a secure place and do not allow unautho-

rised persons to enter.

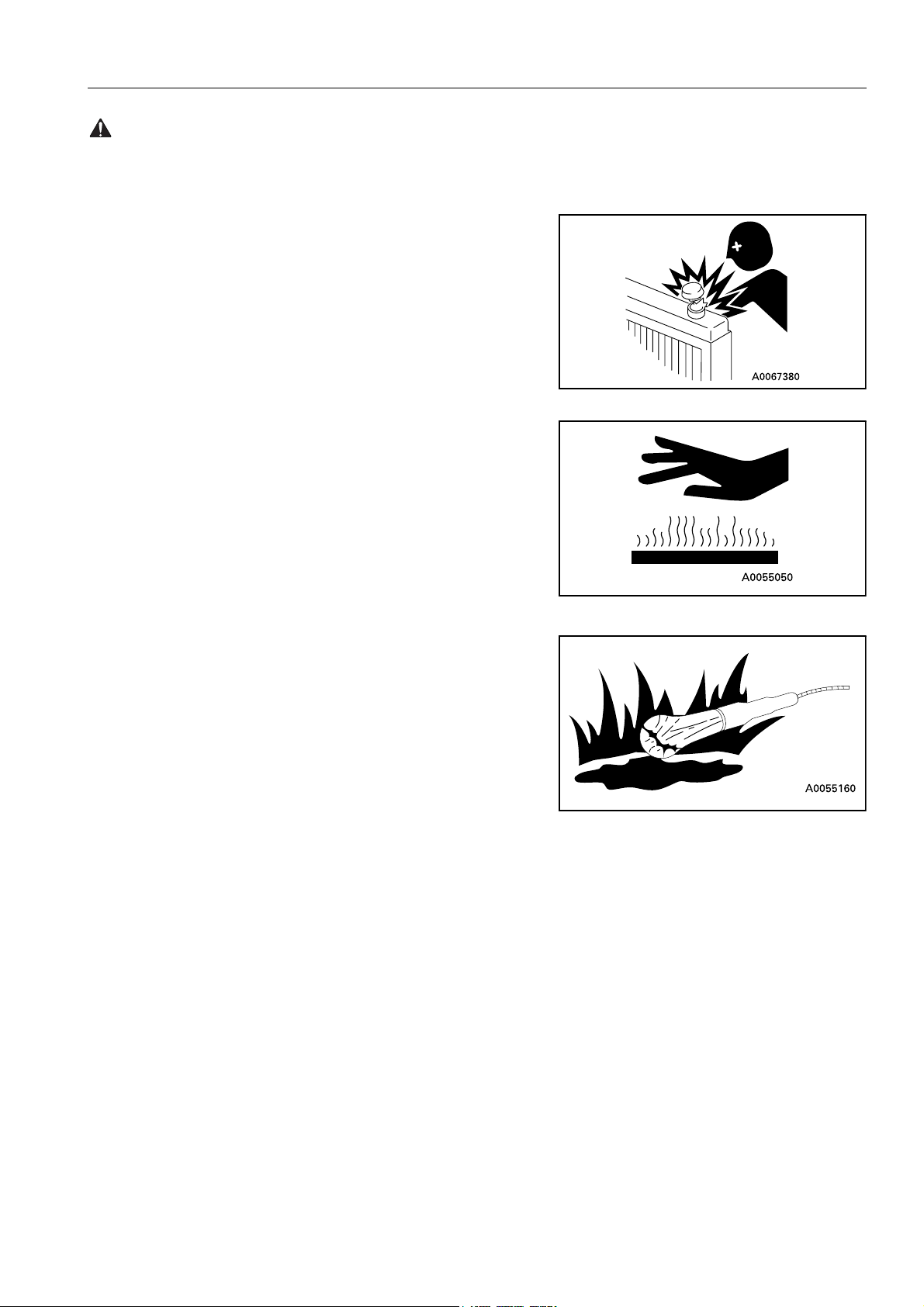

PRECAUTIONS WHEN HANDLING AT HIGH TEMPERATURES

q Immediately after operations are stopped, the engine coolant,

engine oil, and hydraulic oil are at high temperatures, and are

still under pressure. Attempting to remove the cap, drain the

oil or water, or replace the filters may lead to serious burns.

Always wait for the temperature to go down, and follow the

specified procedures when carrying out these operations.

q To prevent hot water from spurting out:

1. Turn engine off.

2. Allow water to cool.

3. Slowly loosen cap to relieve pressure before removing.

q To prevent hot oil from spurting out:

1. Turn engine off.

2. Allow oil to cool.

3. Slowly loosen cap to relieve pressure before removing.

22

Page 23

SAFETY GENERAL PRECAUTIONS

WARNING: Failure to follow these safety precautions may lead to a serious accident.

MACHINES FITTED WITH WHEELS

Never perform any repair work or modifications to wheel rims

while the tyres are fitted, and never apply heat in the vicinity of the

tyres.

ASBESTOS DUST HAZARD PREVENTION

Asbestos dust can be HAZARDOUS to your health if it is inhaled.

Your Komatsu machine and genuine Komatsu spare parts do not

contain any asbestos. Use only genuine Komatsu spare parts. If

spare parts containing asbestos are used, the following precautions must be observed:

q NEVER use compressed air for cleaning.

q Use water for cleaning to keep down the dust.

q Operate the machine with the wind to your back, whenever

possible.

q Use an approved respirator if necessary.

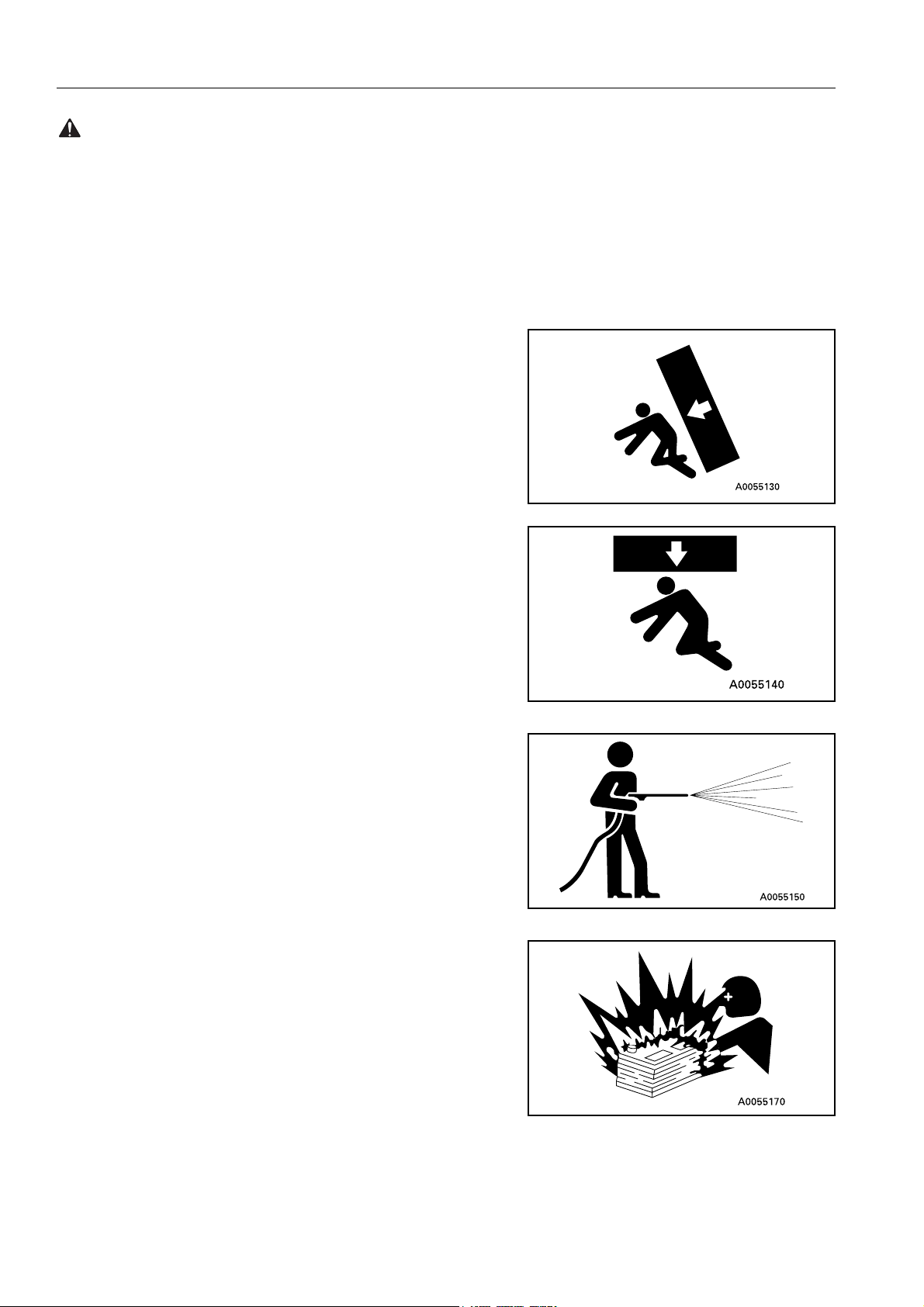

CRUSHING OR CUTTING PREVENTION

Do not enter, or put your hand or arm or any other part of your

body between movable parts such as between the work equipment and cylinders, or between the machine and work equipment.

If the work equipment is operated, the clearance will change and

this may lead to serious damage or personal injury.

FIRE EXTINGUISHER AND FIRST AID KIT

q Know how to use fire extinguisher (if installed).

q Provide a first aid kit at the storage point.

q Know what to do in the event of a fire.

q Be sure you know the phone numbers of persons you should

contact in case of an emergency.

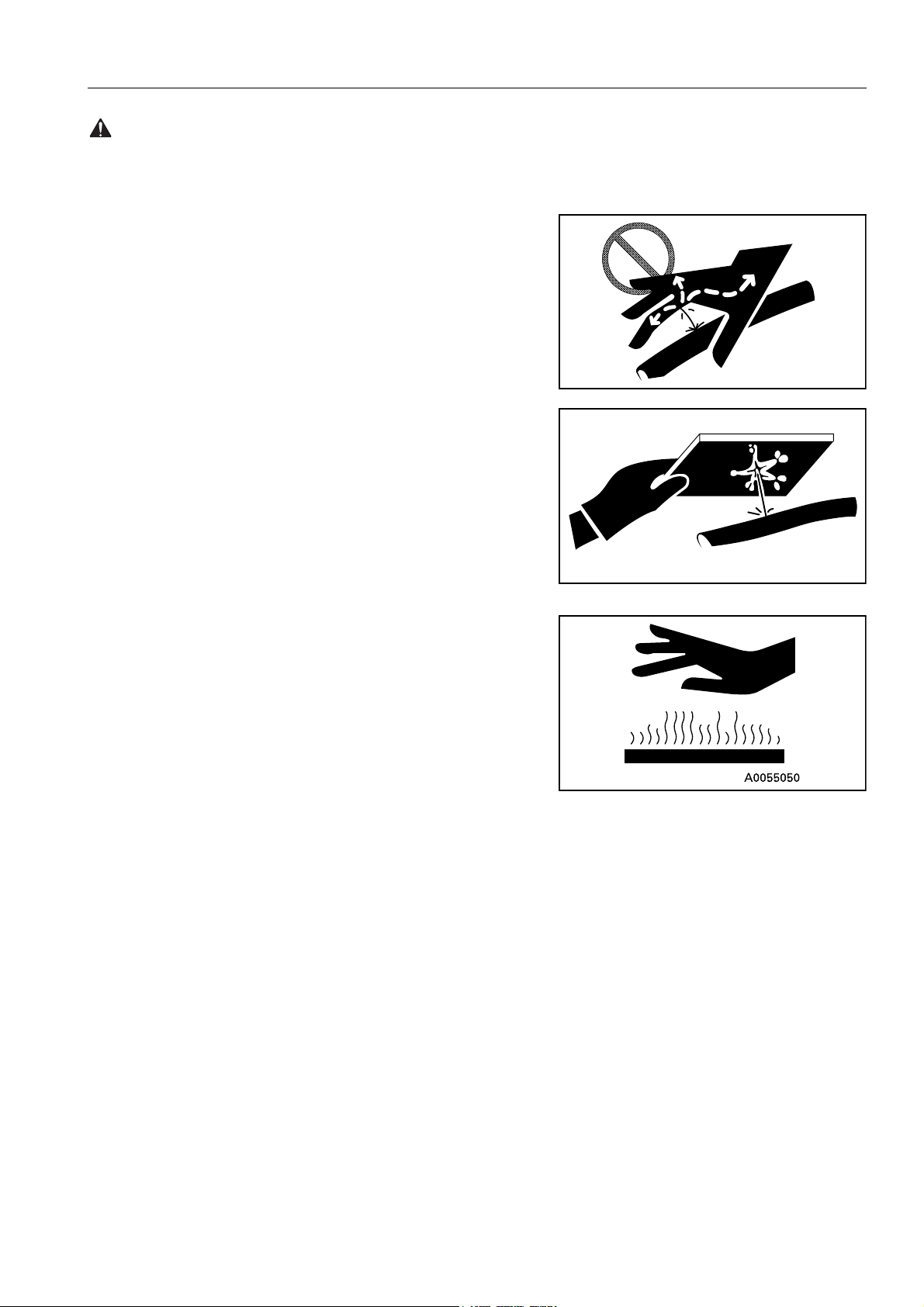

PROTECTION AGAINST FALLING OR FLYING OBJECTS

If there is any danger of falling or flying objects hitting the operator, install protective guards to protect the operator as required for

each particular situation.

q For work with breakers, install a front guard on the wind-

shield. Also, place a laminate coating sheet over the windshield.

q For demolition or shear work, install a front guard on the

windshield and a top guard on the cab. Also, place a laminate

coating sheet over the windshield.

23

Page 24

GENERAL PRECAUTIONS SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

q For work in mines, quarries, demolition, tunnels or other

places where there is danger of falling rocks, put FOPS (falling object protective structure) in place. Also, place a laminate coating sheet over the windshield.

The above comments are made with regards to typical working

conditions. By all means you should put on other guards if

required by conditions at your particular site.

For details of safety guards, please contact your Komatsu distributor.

Also, even for other types of work, if there is any danger of being

hit by falling or flying objects or of objects entering the operator’s

(B)

cab, select and install a guard that matches the working conditions.

(C)

(B): Top guard (C): Front guard

Be sure to close the front window before commencing work.

When carrying out the above operations, make sure to keep all

persons other than the operator outside the range of falling or flying objects. Be particularly sure to maintain a proper distance

when carrying out shear operations.

PRECAUTIONS FOR ATTACHMENTS

q When installing and using an optional attachment, read the

instruction manual for the attachment and the information

related to attachments in this manual.

q Do not use attachments that are not authorised by Komatsu

or your Komatsu distributor. Use of unauthorised attachments

could create a safety problem and adversely affect the proper

operation and useful life of the machine.

q Any injuries, accidents, product failures resulting from the use

of unauthorised attachments will not be the responsibility of

Komatsu.

MACHINES WITH ACCUMULATOR

On machines equipped with an accumulator, for a short time after

the engine is stopped, the work equipment will lower under its

own weight when the work equipment control lever is shifted to

LOWER. After the engine is stopped, raise safety lock lever to the

LOCK position.

AB30052C

When releasing the pressure inside the work equipment circuit on

machines equipped with an accumulator, follow the procedure

given in the inspection and maintenance section.

Method of releasing pressure, see "HANDLING ACCUMULATORS (186)"

The accumulator is filled with high-pressure nitrogen gas, and it is

extremely dangerous if it is handled in the wrong way. Always

observe the following precautions.

24

Page 25

SAFETY GENERAL PRECAUTIONS

WARNING: Failure to follow these safety precautions may lead to a serious accident.

q Never make any hole in the accumulator or expose it to flame

or fire.

q Do not weld anything to the accumulator.

q When carrying out disassembly or maintenance of the accu-

mulator, or when disposing of the accumulator, it is necessary

to release the gas from the accumulator. A special bleed

valve is necessary for this operation, so please contact your

Komatsu distributor.

Gas in accumulator, see "HANDLING ACCUMULATORS

(186)"

EMERGENCY EXIT

q When exit by normal means is prevented in an emergency

you can get out through the emergency exit (rear window).

q Pull the ring at the bottom of the window and remove strip.

This will allow you to push out glass.

ROTATING BEACON (Option)

q When the machine is operated on or beside a road, a rotating

beacon is required to avoid a traffic accident.

q Contact your Komatsu distributor to install beacon lamp.

ELECTROMAGNETIC INTERFERENCE

When this machine is operating close to a source of high electromagnetic interference, such as a radar station, some abnormal

phenomena may be observed.

q The display on the monitor panel may behave erratically.

q The warning buzzer may sound.

These effects do not signify a malfunction and the machine will

return to normal as soon as the source of interference is removed.

25

Page 26

PRECAUTION DURING OPERATION SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

PRECAUTION DURING OPERATION

BEFORE STARTING ENGINE

SAFETY AT WORKSITE

q Before starting the engine, thoroughly check the area for any

unusual conditions that could be dangerous.

q Before starting the engine, examine the terrain and soil condi-

tions of the work site. Determine the best and safest method

of operation.

q Make the slope as horizontal as possible before continuing

operations.

q If you need to operate on a street, protect pedestrians and

cars by designating a person for work site traffic duty or by

installing fences around the work site.

q If water lines, gas lines, and high-voltage electrical lines may

be buried under the work site, contact each utility and identify

their locations. Be careful not to sever or cut any of these

lines.

q Check the depth and flow of water before operating in water

or crossing a river. NEVER be in water which is in excess of

the permissible water depth.

Permissible water depth, see "PRECAUTIONS FOR

OPERATION (223)"

FIRE PREVENTION

q Thoroughly remove wood chips, leaves, paper and other

flammable things accumulated in the engine compartment.

They could cause a fire.

q Check fuel, lubrication, and hydraulic systems for leaks. Have

any leaks repaired. Wipe up any excess oil, fuel or other flammable fluids.

Check point, see "WALK-AROUND CHECK (187)"

q Be sure a fire extinguisher is present and working.

IN OPERATOR’S CAB

q Do not leave tools or spare parts lying around in the opera-

tor’s compartment. They may damage or break the control

levers or switches. Always put them in the tool box on the

front right side of the revolving frame or in the tool boxes on

the undercarriage.

q Keep the cab floor, controls, steps and handrails free of oil,

grease, snow, and excess dirt.

26

Page 27

SAFETY PRECAUTION DURING OPERATION

WARNING: Failure to follow these safety precautions may lead to a serious accident.

VENTILATION FOR ENCLOSED AREAS

If it is necessary to start the engine within an enclosed area, provide adequate ventilation. Exhaust fumes from the engine can

KILL.

PRECAUTIONS FOR MIRRORS, WINDOWS AND LIGHTS

q Remove all dirt from the surface of the windows and lights to

ensure that you can see well.

q Adjust the rear view mirrors so that you can see clearly from

the operator’s seat, and always keep the surface of the mirrors clean. If any glass is broken, replace it with a new part.

q Check that the head lamps and working lamps are installed to

match the operating conditions. Check also that they light up

properly.

OPERATING MACHINE

WHEN STARTING THE ENGINE

q Walk around for machine again just before mounting it, to

check for people and objects that might be in the way.

q NEVER start the engine if a warning tag has been attached to

the wrist control.

q Before starting the engine, sound the horn as an alert.

q Start and operate the machine only while seated.

q Do not allow anyone other than the operator to ride in the cab

or on the machine body.

q For machines equipped with a reverse alarm buzzer, check

that the warning device operates correctly.

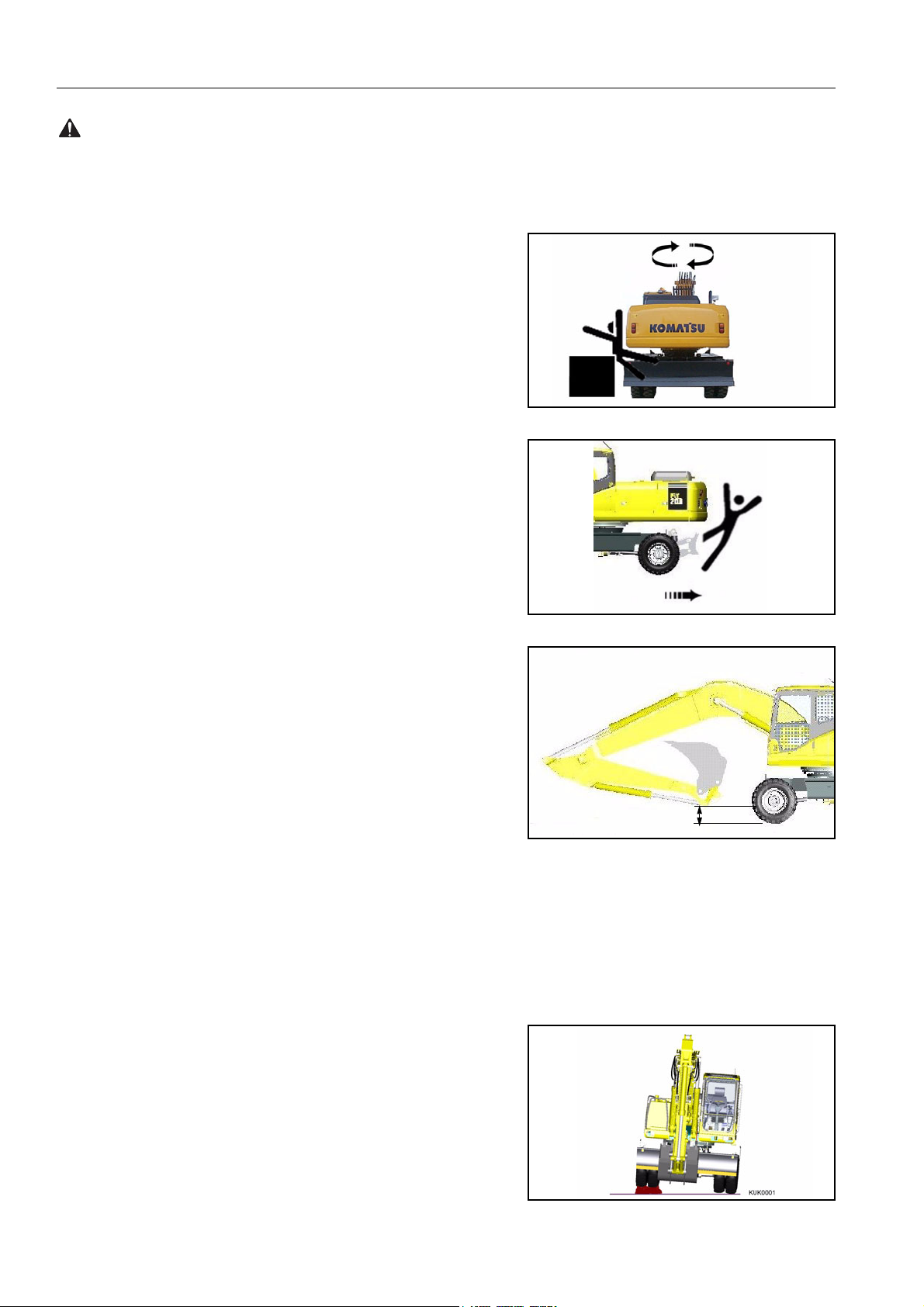

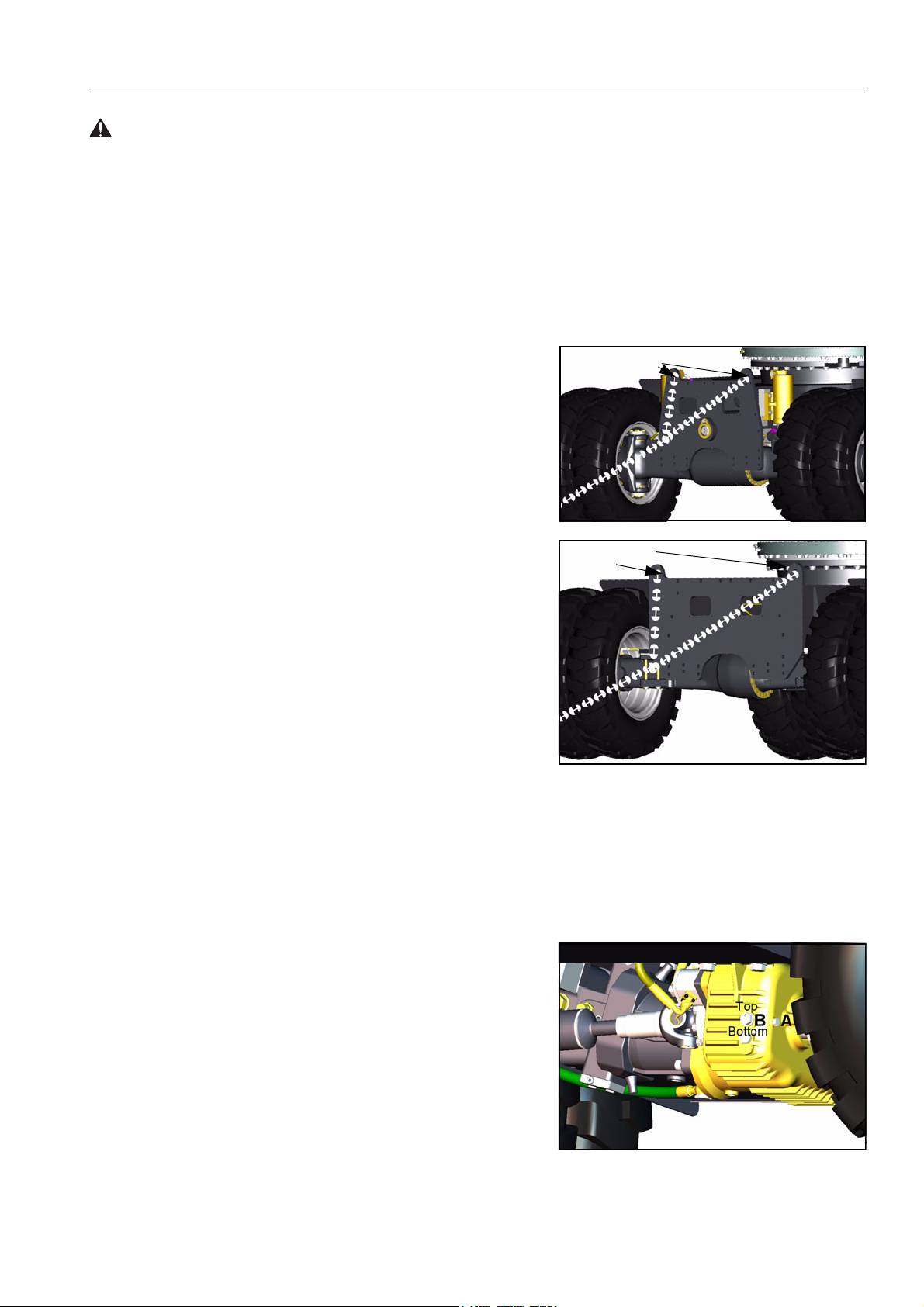

CHECK DIRECTION BEFORE STARTING MACHINE

Before operating the travel pedal, check the direction of the under

carriage.

If the fixed axle is at the front, the forward/neutral/reverse lever

and steering will function in the opposite direction.

A Fixed axle

B Oscillating axle

Travel operations, see "MOVING MACHINE OFF (210)"

B

A

27

Page 28

PRECAUTION DURING OPERATION SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

CHECK THAT NO ONE IS IN THE AREA BEFORE SWINGING

OR TRAVELLING IN REVERSE

q Always position a signalman when operating in dangerous

places or places where the view is not clear.

q Make sure that no one comes inside the swing radius or

direction of travel.

q Before starting to move, sound the horn or give a signal to

warn people not to come close to the machine.

q There are blind spots behind the machine, so if necessary,

swing the upper structure to check that there is no one behind

the machine before travelling in reverse.

PRECAUTIONS WHEN TRAVELLING

q Fold in the work equipment as shown in the diagram, and

keep it at a height of 40-50 cm from the ground level before

starting to travel.

q Before travelling on public roads, fully raise dozer blade and

outriggers, lock the outriggers in position with the safety pin,

lock the bucket and arm cylinder with isolation valves, and

insert swing lock pin.

For details, see "TRAVELLING ON PUBLIC HIGHWAY

(214)"

q When travelling on public roads the safety lock lever should

be down (UNLOCKED) and lock lever switch engaged. This

prevents operation of the control levers and activates the rear

facing brake lamp circuit.

q When travelling on rough ground, travel at low speed, and

avoid sudden changes in direction.

q Avoid travelling over obstacles as far as possible. If the

machine has to travel over an obstacle, keep the work equipment as close to the ground as possible and travel at low

speed. Never travel over obstacles which make the machine

tilt strongly (10° or more).

40 - 50cm

INCORRECT

28

Page 29

SAFETY PRECAUTION DURING OPERATION

WARNING: Failure to follow these safety precautions may lead to a serious accident.

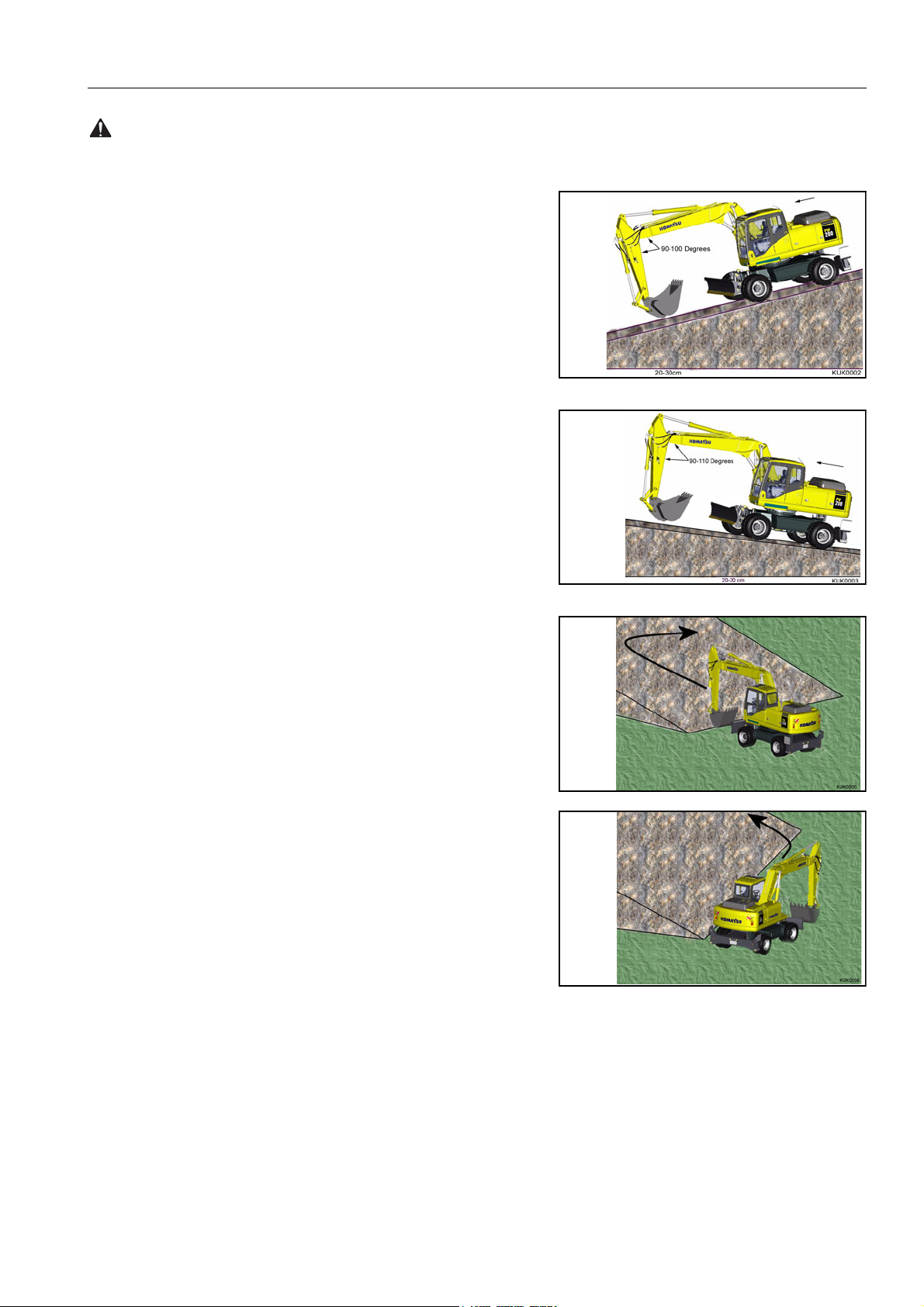

TRAVELLING ON SLOPES

q Travelling on hills, banks or slopes that are steep could result

Downhill

in the machine tipping over or slipping.

q On hills, banks or slopes, carry the bucket closer to the

ground, approximately 20 to 30 cm above the ground. In case

of emergency, quickly lower the bucket to the ground to help

the machine stop and prevent it from tipping over.

q Do not turn on slopes or travel across slopes. Always go

down to a flat place to perform these operations.

Uphill

Method of travelling on slopes, see "PRECAUTIONS

WHEN TRAVELLING UP OR DOWN HILLS (225)"

Do not travel up and down on grass, fallen leaves, and wet steel

plates. These materials may allow the machine to slip, if it is travelling sideways. Keep travel speed very low.

INCORRECT

CORRECT

29

Page 30

PRECAUTION DURING OPERATION SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

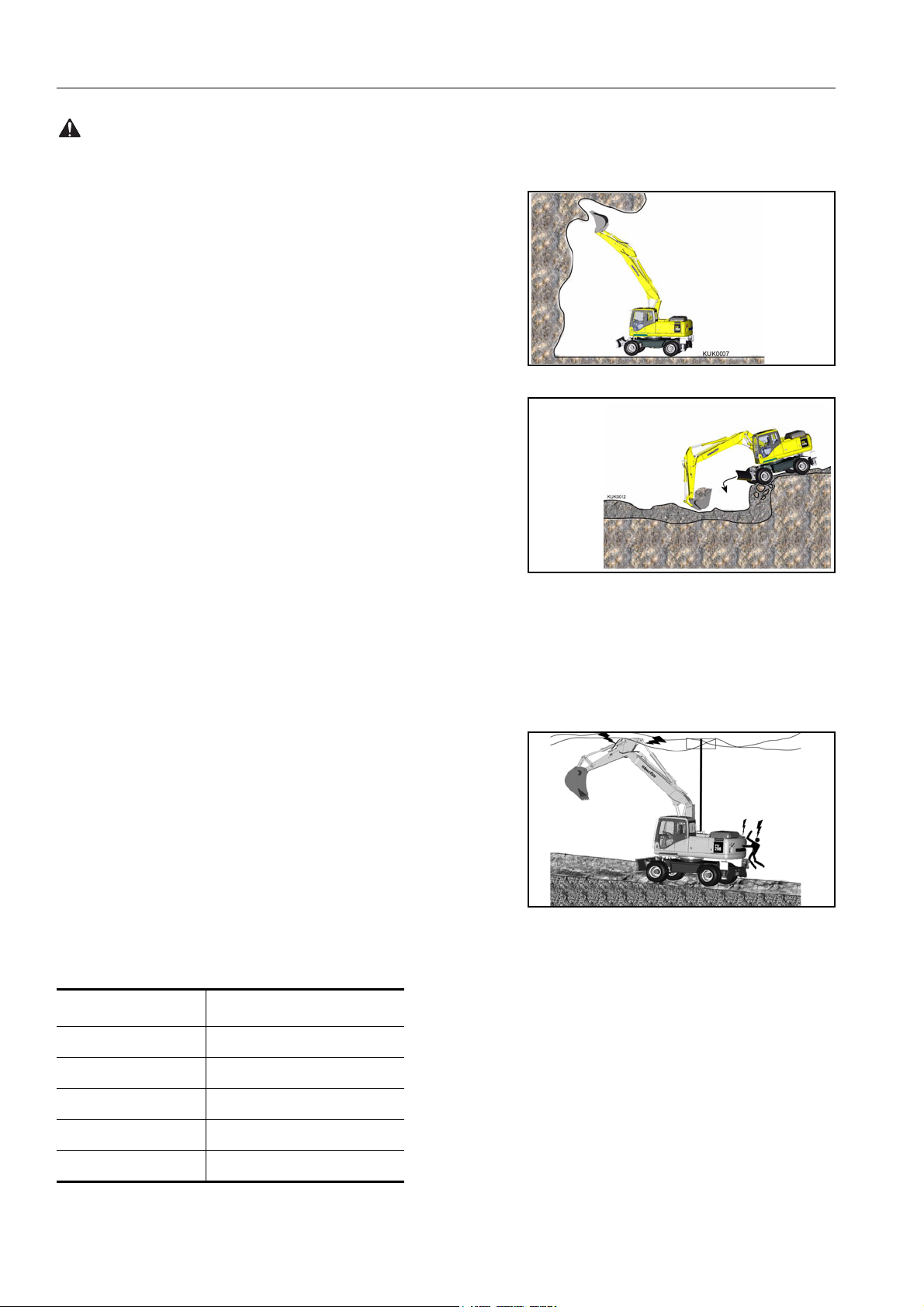

PROHIBITED OPERATIONS

q Do not dig the work face under an overhang. This may cause

INCORRECT

the overhang to collapse and fall on top of the machine.

.q Do not carry out deep digging under the front of the machine.

The ground under the machine may collapse and cause the

INCORRECT

machine to fall.

DO NOT GO CLOSE TO HIGH-VOLTAGE CABLES

Going close to high-voltage cables can cause electric shock.

Always maintain the safe distance given below, between the

machine and the electric cable.

q The following actions are effective in preventing accidents.

1) Wear shoes with rubber or leather soles.

2) Use a signalman to give warning if the machine

approaches too close to the electric cable.

q If the work equipment should touch the electric cable, the

operator should not leave the operator’s compartment.

q When carrying out operations near high voltage cables, do

not let anyone come close to the machine.

q Check with the electricity company about the voltage of the

cables before starting operations.

Voltage Min. safety distance

6.6 kV 3 m

33.0 kV 4 m

66.0 kV 5 m

154.0 kV 8 m

275.0 kV 10 m

30

Page 31

SAFETY PRECAUTION DURING OPERATION

WARNING: Failure to follow these safety precautions may lead to a serious accident.

DO NOT HIT WORK EQUIPMENT

q When working in places where there are height limits, such as

in tunnels, under bridges, under electric cables, or in garages,

be extremely careful not to hit the boom or arm.

ENSURE GOOD VISIBILITY

q When working in dark places, install working lamps, and set

up lighting in the work area if necessary.

q Stop operations if the visibility is poor, such as in mist, snow,

or rain, and wait for the weather to improve to a condition that

allows the operation to be carried out safely.

OPERATE CAREFULLY ON SNOW

q When working on snow or icy roads, even a slight slope may

cause the machine to slip to the side, so always travel at low

speed and avoid sudden starting, stopping, or turning.

q When there has been heavy snow, the road shoulder and

objects placed beside the road are buried in the snow and

cannot be seen, so always carry out snow-clearing operations

carefully.

WORKING ON LOOSE GROUND

q Avoid operating your machine too close to the edge of cliffs,

overhangs, and deep ditches. If these areas collapse, your

machine could fall or tip over and result in serious injury or

death. Remember that the soil after heavy rain or blasting is

weakened in these areas.

q Earth laid on the ground and the soil near ditches are loose.

They can collapse under the weight or vibration of your

machine.

q Install the HEAD GUARD (FOPS) if working in areas where

there is danger of falling rocks and dirt.

DO NOT HIT THE OPERATOR CAB (for two piece boom only)

q When the second boom cylinder is retracted, the bucket or

the attachment can hit the operator cab or chassis.

q Operate work equipment slowly and carefully to avoid any

injury and damage.

31

Page 32

PRECAUTION DURING OPERATION SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

OPERATIONS ON SLOPES

q When working on slopes, there is danger that the machine

may lose its balance and turn over when the swing or work

equipment are operated. Always carry out these operations

carefully.

q Do not swing the work equipment from the uphill side to the

downhill side when the bucket is loaded. This operation is

dangerous.

(See the upper diagram on the right.)

q If the machine has to be used on a slope, pile the soil to make

a platform that will keep the machine as horizontal as possible.

(See the lower diagram on the right.)

Piled soil on slope, see "PRECAUTIONS WHEN TRAVELLING UP OR DOWN HILLS (225)"

CORRECT

INCORRECT

PARKING THE MACHINE

Park on level ground whenever possible. If not possible, chock

the wheels, lower the bucket to the ground and thrust the bucket

in the ground.

q When parking on public roads, provide fences and signs,

such as flags or lights, on the machine to warn passersby to

be careful. Be sure that the machine, flags or lights do not

obstruct traffic.

q When leaving the machine, lower the work equipment com-

pletely to the ground, raise the safety lock lever to the LOCK

position, then stop the engine and use the key to lock the

machine. Always take the key with you.

WARNING

if the control lever is touched by accident, the work equipment or the machine may move suddenly, and this may lead

to a serious accident. Before leaving the operator’s compartment, always raise the safety lock lever to lock the work

equipment controls.

CORRECT

LOCK

Platform

UNLOCK

Places to lock, see "LOCKING (231)"

32

Page 33

SAFETY PRECAUTION DURING OPERATION

WARNING: Failure to follow these safety precautions may lead to a serious accident.

TRANSPORTATION

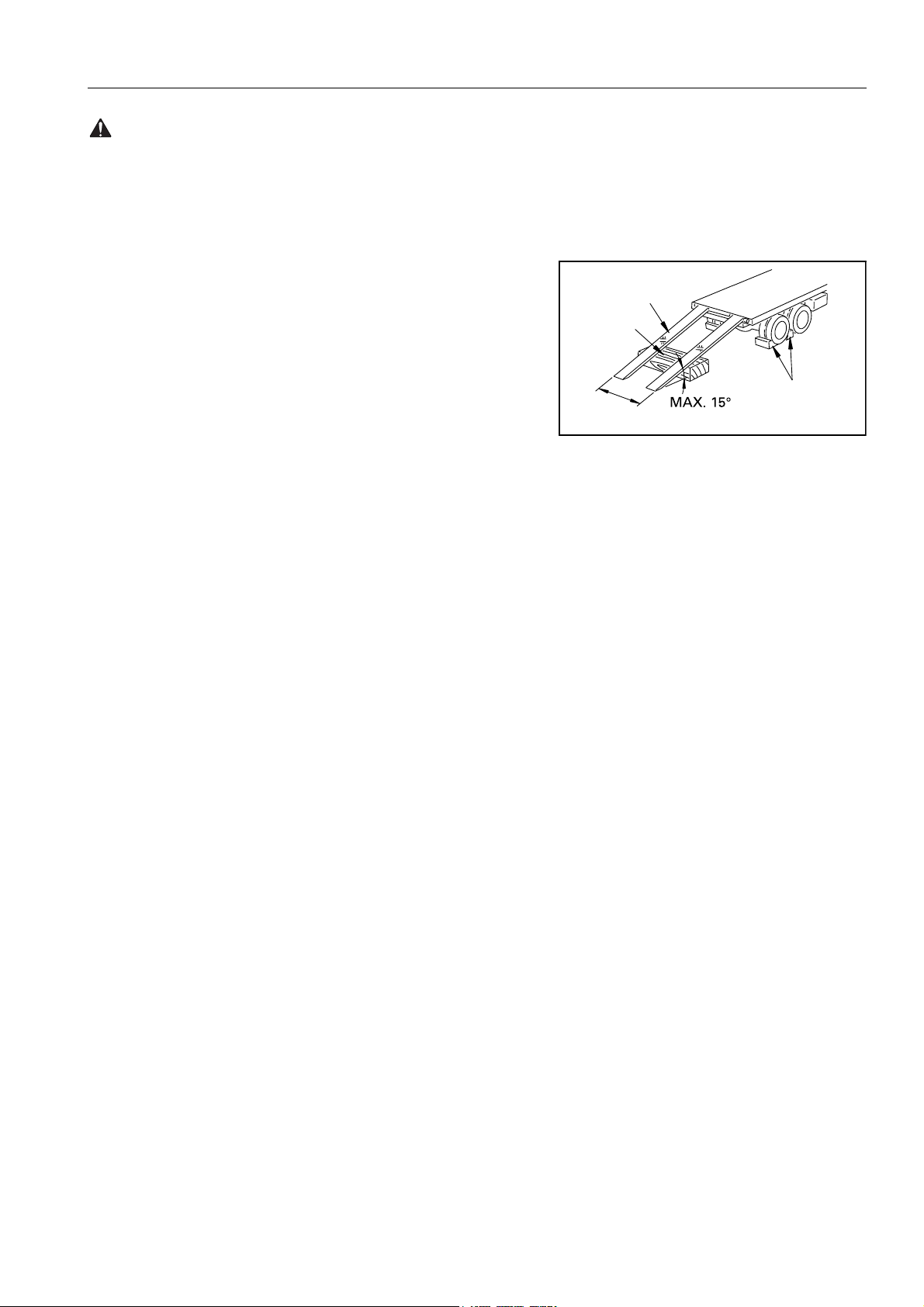

LOADING AND UNLOADING

q Loading and unloading the machine always involves potential

hazards. EXTREME CAUTION SHOULD BE USED.

When loading or unloading the machine, run the engine at

low idling and travel at low speed.

q Perform loading and unloading on firm, level ground only.

Maintain a safe distance from the edge of a road.

q ALWAYS block the wheels of the hauling vehicle and place

blocks under both ramps before loading and unloading.

q ALWAYS use ramps of adequate strength. Be sure the ramps

are wide and long enough to provide a safe loading slope.

q Be sure that the ramps are securely positioned and fastened,

and that the two sides are at the same level as one another.

Ramp

Block

Distance between ramps

Blocks

AD052900B

q Be sure the ramp surface is clean and free of grease, oil, ice

and loose materials. Remove dirt from the machine wheels.

q NEVER correct your steering on the ramps. If necessary,

drive away from the ramps and climb again.

q Swing the upper structure with extreme care on the trailer to

avoid a possible accident caused by body instability.

q After loading, block the machine wheels and secure the

machine with tie-downs.

Loading and unloading, see "TRANSPORTATION (235)"

SHIPPING

q When shipping the machine on a hauling vehicle, obey all

state and local laws governing the weight, width, and length

of a load. Also obey all applicable traffic regulations.

q Determine the shipping route while taking into account the

width, height and weight of the load.

33

Page 34

PRECAUTION DURING OPERATION SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

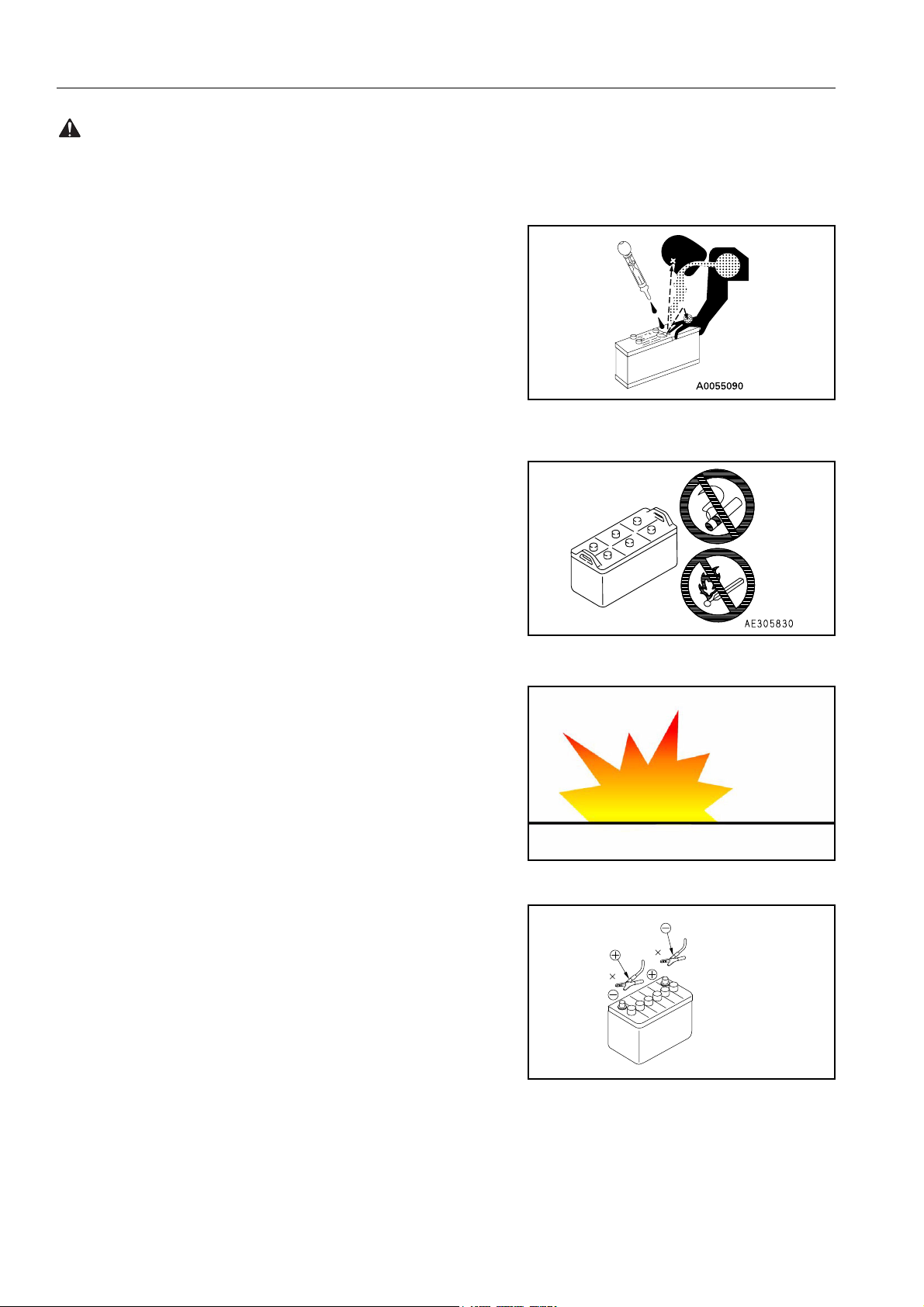

BATTERY

BATTERY HAZARD PREVENTION

q Battery electrolyte contains sulphuric acid and can quickly

burn the skin and eat holes in clothing. If you spill acid on

yourself, immediately flush the area with water.

q Battery acid could cause blindness if splashed into the eyes.

If acid gets into the eyes, flush them immediately with large

quantities of water and see a doctor at once.

q If you accidentally drink acid, drink a large quantity of water or

milk, beaten egg or vegetable oil. Call a doctor or poison prevention centre immediately.

q When working with batteries. ALWAYS wear safety glasses or

goggles.

q Batteries generate hydrogen gas. Hydrogen gas is very

EXPLOSIVE, and is easily ignited with a small spark or flame.

q Before working with batteries, stop the engine and turn the

starting switch to the OFF position.

q Avoid short-circuiting the battery terminals through accidental

contact with metallic objects, such as tools, across the terminals.

q When removing or installing, check which is the positive (+)

terminal and negative (-) terminal.

q Tighten the battery cap securely.

q Tighten the battery terminals securely. Loosened terminals

can generate sparks and lead to an explosion.

q When removing battery cap wear rubber groves to prevent

electrolyte contact with skin.

STARTING WITH BOOSTER CABLES

q ALWAYS wear safety glasses or goggles when starting the

machine with booster cables.

q When starting from another machine, do not allow the two

machines to touch.

q Be sure to connect the positive (+) cable first when installing

the booster cables. Disconnect the ground or negative (-)

cable first when removing them.

q If any tool touches between the positive (+) terminal and the

chassis, it will cause sparks. This is dangerous, so be sure to

work carefully.

INCORRECT

A0067320A

q Connect the batteries in parallel: positive to positive and neg-

ative to negative.

34

Page 35

SAFETY PRECAUTION DURING OPERATION

WARNING: Failure to follow these safety precautions may lead to a serious accident.

q When connecting the ground cable to the frame of the

machine to be started, be sure to connect it as far away as

possible from the battery.

Starting with booster cables, see "DISCHARGED BATTERY (248)"

TOWING

WHEN TOWING, ATTACH WIRE TO FRAME

q Injury or death could result if a disabled machine is towed

incorrectly.

q If your machine is towed by another machine, ALWAYS use a

wire rope with a sufficient towing capacity.

q NEVER allow a disabled machine to be towed on a slope.

Towing holes

on front

q Do not use a chinked or frayed wire rope.

q If towing on the highway, a rigid tow bar should be used and

not a tow rope of any kind.

q Do not straddle the towing cable or wire rope.

q When connecting up a towing machine, do not let anyone

enter the area between the towing machine and the equipment being towed.

q Set the towing machine and the towing connection of the

equipment being towed in a straight line when connecting it.

q Place pieces of wood between the wire ropes and chassis

body to protect them from wear of damage.

Towing method, see "METHOD OF TOWING MACHINE

(247)"

When towing the machine without the engine running or in the

advent of loss of hydraulic pressure, its is necessary to manually

release the park brake, as follows.

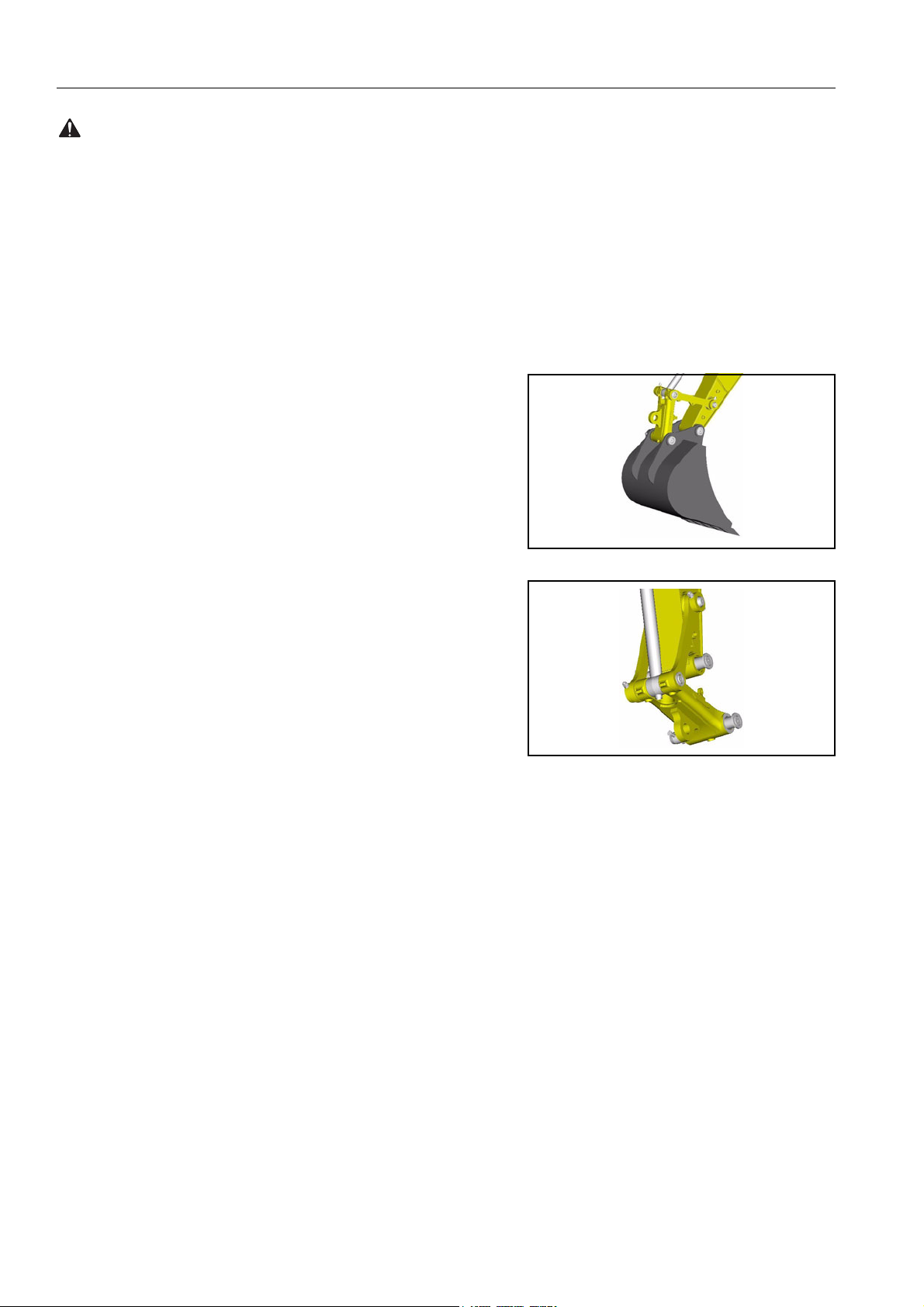

View on transmission

Releasing the park brake before towing:

Undercarriage

Towing holes

on rear

Undercarriage

1. Unscrew bolt (A) 2-3 turns which will allow bolt (B) to rotate

(DO NOT REMOVE BOLT ’A’).

2. Turn park brake release bolt (B) 180 degrees, the indicator

mark located at the top, moves to the bottom, which will disengage the park brake.

3. Re-tighten bolt (A) to lock the park brake in the disengaged

position for towing.

To reset the park brake:

1. Unscrew bolt (A) 2~3 turns, this allows bolt (B) to rotate.

(DO NOT REMOVE BOLT ’A’)

35

Page 36

PRECAUTION DURING OPERATION SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

2. Turn park brake release bolt (B) 180 degrees so that indicator

mark is located at the top position.

3. Re-tighten bolt (A)

BUCKET WITH HOOK OR BUCKET LINK WITH LIFTING EYE

GENERAL PRECAUTIONS

SPECIAL HOOK

q When carrying out lifting work, a special lifting hook or lifting

eye is necessary.

q The lifting hook must be fitted with a safety latch to prevent

accidental un-hooking of the load.

q The following operations are prohibited.

Q Lifting loads with a wire rope fitted around the bucket

teeth.

Q Lifting loads with the wire rope wrapped directly around

the boom or arm.

Q Check safe working load of lifting equipment.

CHECKING HOOK

q When lifting a load, carry out the following checks to confirm

that there is no abnormality before starting operations.

Q Check that there are no cracks or deformation in the lift-

ing equipment.

Q Check that there is no abnormality in the safety latch of

the hook.

HOOKING WIRE ROPE SECURELY TO HOOK

q When performing lifting operation, securely hook the wire

rope onto the special lifting hook or lifting eye.

PRECAUTIONS FOR MACHINE INSTALLATION

q After carrying out a preliminary inspection of ground condi-

tions, select a flat, solid location. Confirm that the machine

can be safely operated without toppling or rolling.

PROHIBITED OPERATIONS OTHER THAN MAIN APPLICATIONS

q When performing lifting operation, never raise or lower a per-

son.

36

Page 37

SAFETY PRECAUTION DURING OPERATION

WARNING: Failure to follow these safety precautions may lead to a serious accident.

NO PERSONS SHALL BE PERMITTED TO ENTER THE

WORKING AREA

q Due to the possible danger of the load falling or of collision

with the load, no persons shall be allowed in the working

area.

OPERATION SUPERVISOR

q Before performing lifting operation, designate an operation

supervisor.

Always execute operation according to his instructions.

Q Execute operating methods and procedures under his

direction.

Q Select a person responsible for signalling. Operate only

on signals given by such person.

HANDLING OF WIRE ROPES ETC.

q Wear leather gloves when handling wire ropes.

PROTECTING EYES

q Some oils and fluids can damage eyes. Refer to manufac-

tured data sheet for handling and storage instructions.

PRECAUTIONS FOR LIFTING OPERATION

GRADUAL LIFTING OPERATION

q When carrying out lifting operations, run the engine at low

idling and use the L (lifting operation mode).

q Avoid sudden lever shifting and acceleration.

q Swing speed is three to four times that of mobile cranes.

Therefore, be especially careful when performing swing operation.

37

Page 38

PRECAUTION DURING OPERATION SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

NEVER LEAVE THE OPERATOR’S SEAT

q Never leave the operator’s seat while lifting a load.

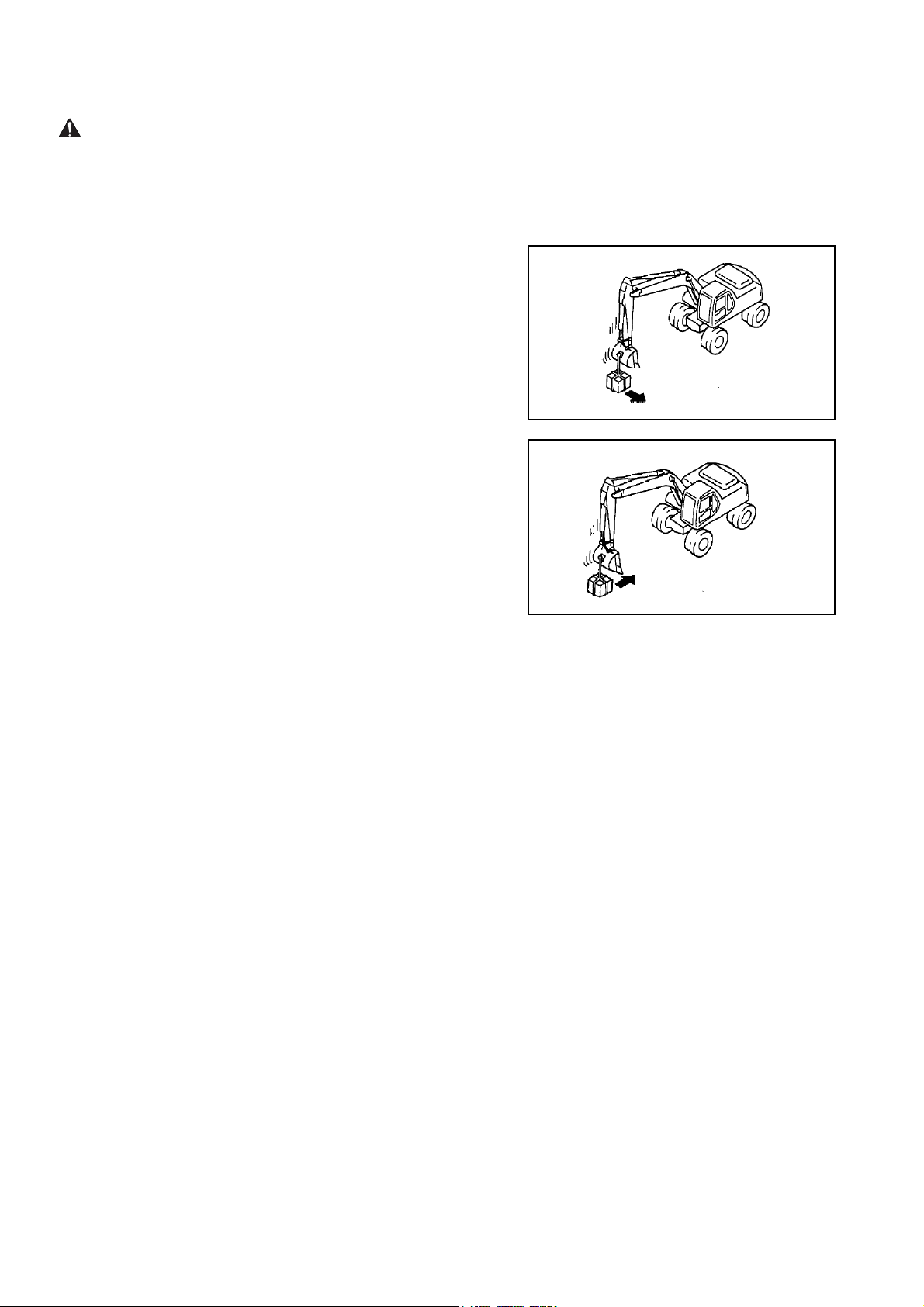

NEVER CARRY OUT EXCESSIVE OPERATIONS

q Operation exceeding machine performance may result in

INCORRECT

accident or failure.

q Carry out lifting operation within specified load limit of

machine and lifting equipment.

q Never carry out operations which may damage the machine

such as overload or over-impact-load.

q Never drag a load laterally or longitudinally, nor retract the

arm, otherwise, a dangerous situation may result.

INCORRECT

NEVER TRAVEL WHILE LIFTING A LOAD

q Never travel while carrying a load.

OPERATING POSTURE

q If the machine posture is not correct, the wire ropes or ring

may detach from the hook. Confirm that the hook angle is correct to avoid this.

HANDLING OF FLUIDS

q Some oils and other fluids, such as Antifreeze, can be harm-

ful to you and the environment, you should therefore always

follow the manufacturers instructions regarding storage, handling and disposal.

HANDLING OF USED ENGINE OILS

q Avoid contact with used engine oils.

q Refer to engine oils data sheet for handling and storage pre-

cautions.

HANDLING OF OILS

q For diesel oils, hydraulic oils and oils used in the swing

machinery, PTO, transmission axles and hubs avoid prolonged or frequent contact with skin.

q Refer to manufacturers data sheet for handling and storage

precautions.

HANDLING OF FLUIDS

q For antifreeze and grease refer to manufacturers data sheet

for handling and storage precautions.

38

Page 39

SAFETY PRECAUTIONS FOR MAINTENANCE

WARNING: Failure to follow these safety precautions may lead to a serious accident.

PRECAUTIONS FOR MAINTENANCE

BEFORE CARRYING OUT MAINTENANCE

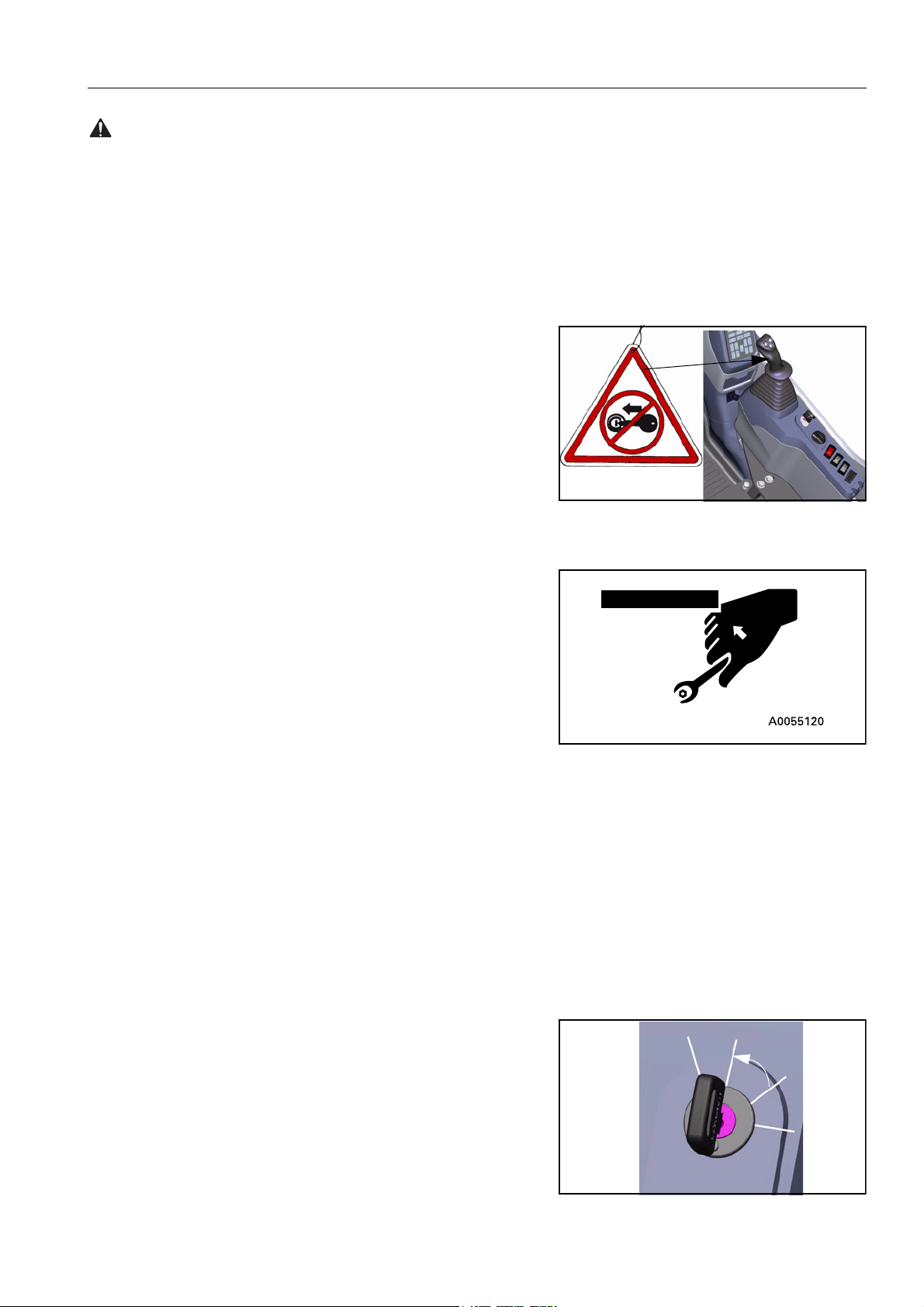

WARNING TAG

q If others start the engine or operate the controls while you are

performing service or lubrication, you could suffer serious

injury or death.

q ALWAYS attach the WARNING TAG to the control lever in the

operator’s cab to alert others that you are working on the

machine. Attach additional warning tags around the machine,

if necessary.

q These tags are available from your Komatsu distributor. (Part

no. 20E-00-K1340)

PROPER TOOLS

q Use only tools suited to the task. Using damaged, low quality,

faulty, or makeshift tools could cause personal injury.

Tools, see "INTRODUCTION OF NECESSARY TOOLS

(273)"

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

q Replace the following fire-related components periodically:

Fuel system: Fuel hose, spilling hose, and fuel tube cap.

Hydraulic system: Pump outlet hose.

q Replace these components periodically with new ones,

regardless of whether or not they appear to be defective.

These components deteriorate over time.

q Replace or repair any such components if any defect is found,

event though they have not reached the time specified.

Replacement of safety critical components, see "PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

(275)"

STOP THE ENGINE BEFORE CARRYING OUT INSPECTION

AND MAINTENANCE

q Always stop the machine on firm flat ground and stop the

engine before carrying out inspection and maintenance.

q If it is necessary to run the engine when carrying out mainte-

nance, such as when cleaning the inside of the radiator,

Raise the safety lock lever to the LOCK position and carry out

the operation with two workers.

Heat

Heat

Off

Off

On

Start

On

Start

39

Page 40

PRECAUTIONS FOR MAINTENANCE SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

q One worker should sit in the operator’s seat so that he can

stop the engine immediately if necessary. He should also be

extremely careful not to touch any lever by mistake. Touch the

levers only when they have to be operated.

q The worker carrying out the maintenance should be

extremely careful not to touch or get caught in the moving

parts.

RULES TO FOLLOW WHEN ADDING FUEL OR OIL

q Spilt fuel and oil may cause you to slip, so always wipe it up

immediately.

q Always tighten the cap of the fuel and oil fillers securely.

q Never use fuel for washing any parts.

LOCK

UNLOCK

q Always add fuel and oil in a well-ventilated place.

40

Page 41

SAFETY PRECAUTIONS FOR MAINTENANCE

WARNING: Failure to follow these safety precautions may lead to a serious accident.

RADIATOR WATER LEVEL

q If it is necessary to add water to the radiator, stop the engine

and allow the engine and radiator to cool down before adding

the water.

q Slowly loosen the caps to relieve pressure before removing

the caps.

USE OF LIGHTING

q When checking fuel, oil, coolant, or battery electrolyte, always

use lighting with anti-explosion specifications.

If such lighting equipment is not used, there is danger of

explosion.

41

Page 42

PRECAUTIONS FOR MAINTENANCE SAFETY

WARNING: For reasons of safety, always follow these safety precautions.

DURING MAINTENANCE

PERSONNEL

q Only authorised personnel can service and repair the

machine. Extra precaution should be used when grinding,

welding, and using a sledge-hammer.

ATTACHMENTS

q Place attachments that have been removed from the machine

in a safe place so that they do not fall. If they fall on you or

others, serious injury could result.

WORK UNDER THE MACHINE

q Always lower all movable work equipment to the ground or to

their lowest position before performing service or repairs

under the machine.

q Always chock the wheels of the machine securely.