Page 1

UEBM001201

PW130ES-6K

MACHINE MODEL

PW130ES-6K PW130ES-6K

• This shop manual may contain attachments and optional equipment that are not available in your area.

Please consult your local Komatsu distributor for those items you may require. Materials and specifications

are subject to change without notice.

SERIAL NUMBER

K32001 and up

K34001 and up

© 2001

All Rights Reserved

Printed in Belgium 09-01

00-1

햲

Page 2

CONTENTS

No. of page

10 STRUCTURE AND FUNCTION......................................................... 10-1

20 TESTING AND ADJUSTING ............................................................. 20-1

30 DISASSEMBLY AND ASSEMBLY .................................................... 30-1

40 MAINTENANCE STANDARD............................................................ 40-1

00-2

햲

Page 3

CONTENTS

No. of page

01 GENERAL.......................................................................................... 01-1

10 STRUCTURE AND FUNCTION.............................................. 10-1

20 TESTING AND ADJUSTING .................................................... 20-1

30 DISASSEMBL Y AND ASSEMBLY........................................ 30-1

40 MAINTENANCE STANDARD.................................................. 40-1

00-2

햲

Page 4

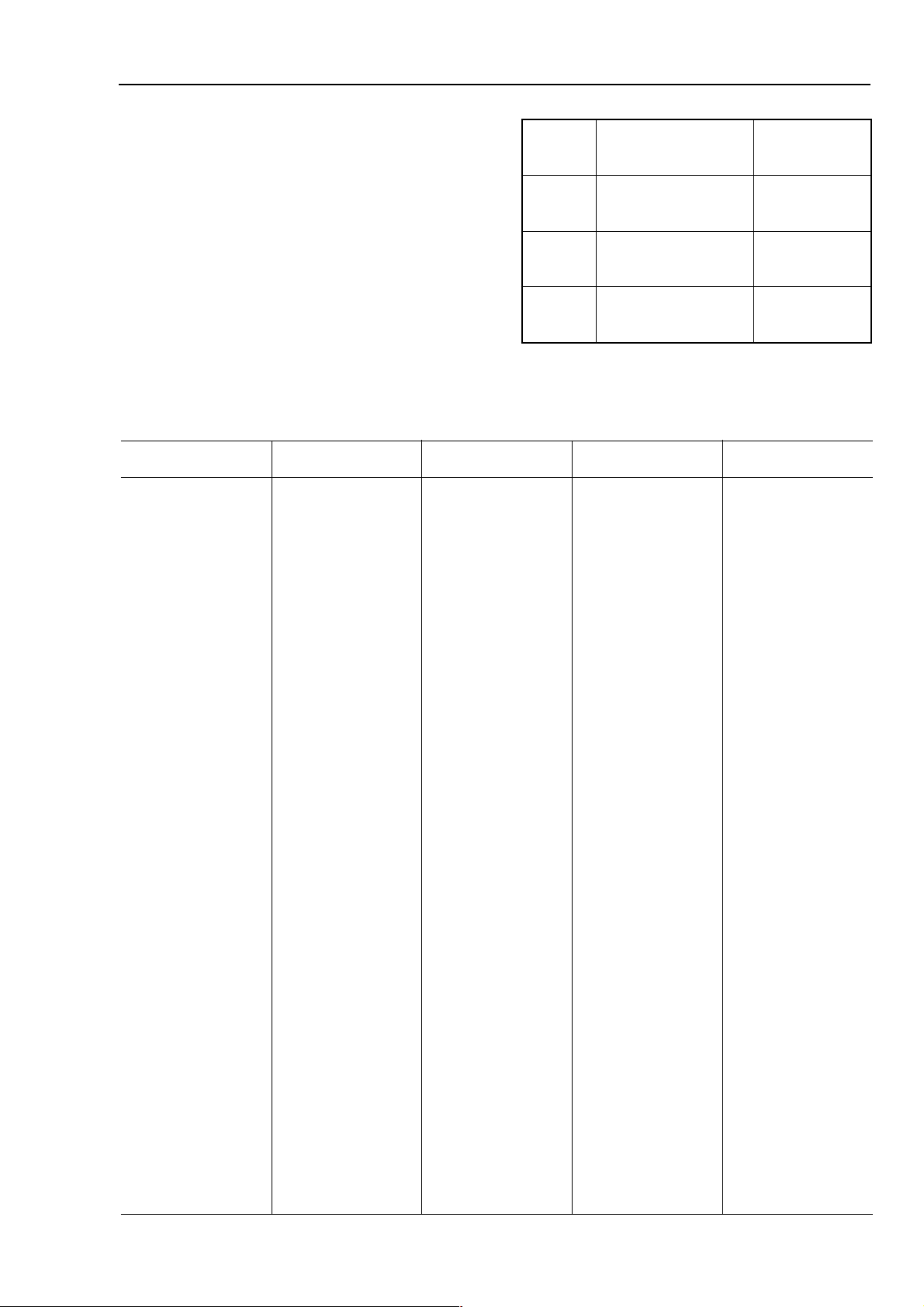

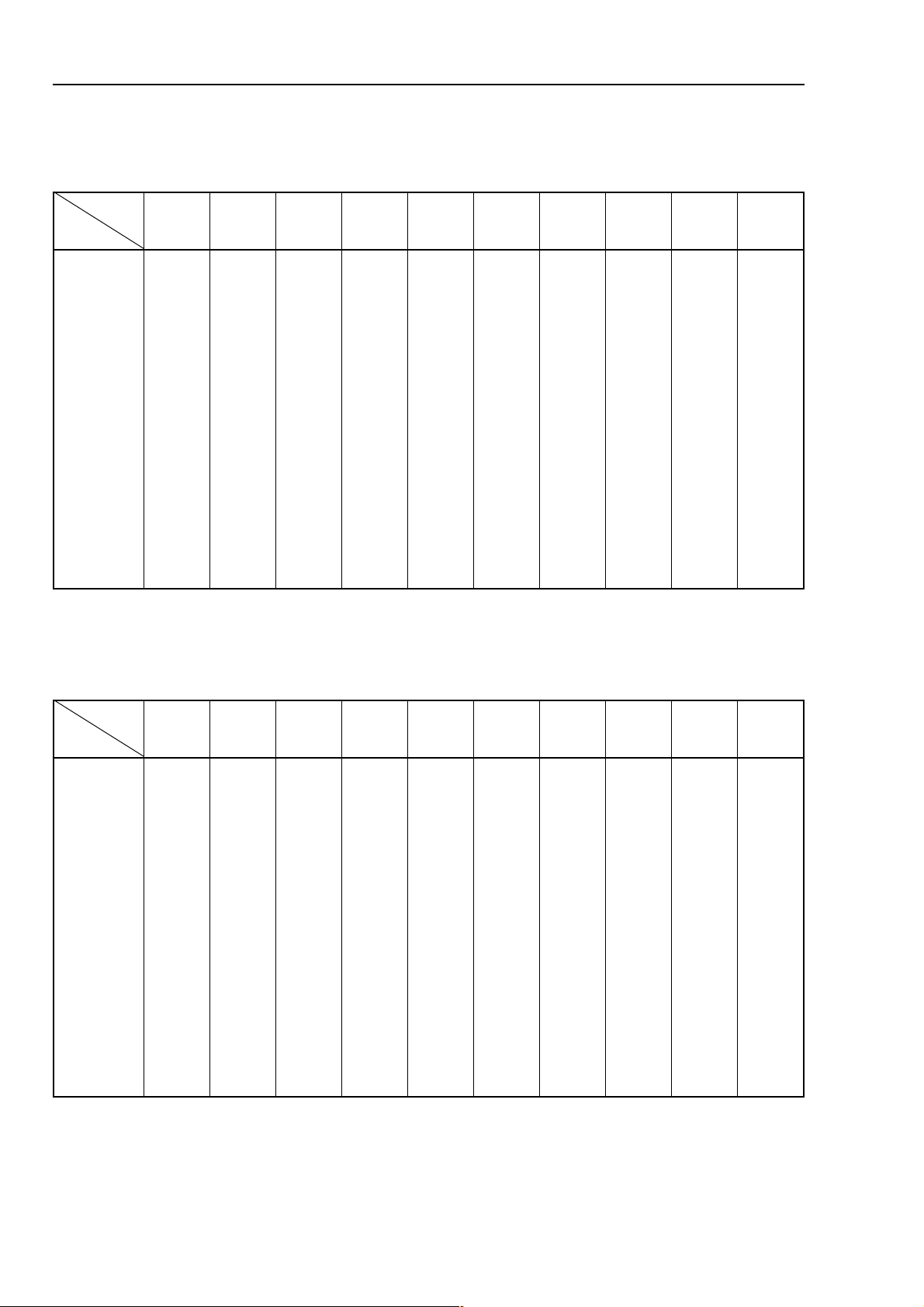

The affected pages are indicated by the use of the

following marks. It is requested that necessary actions be taken to these pages according to the table

below.

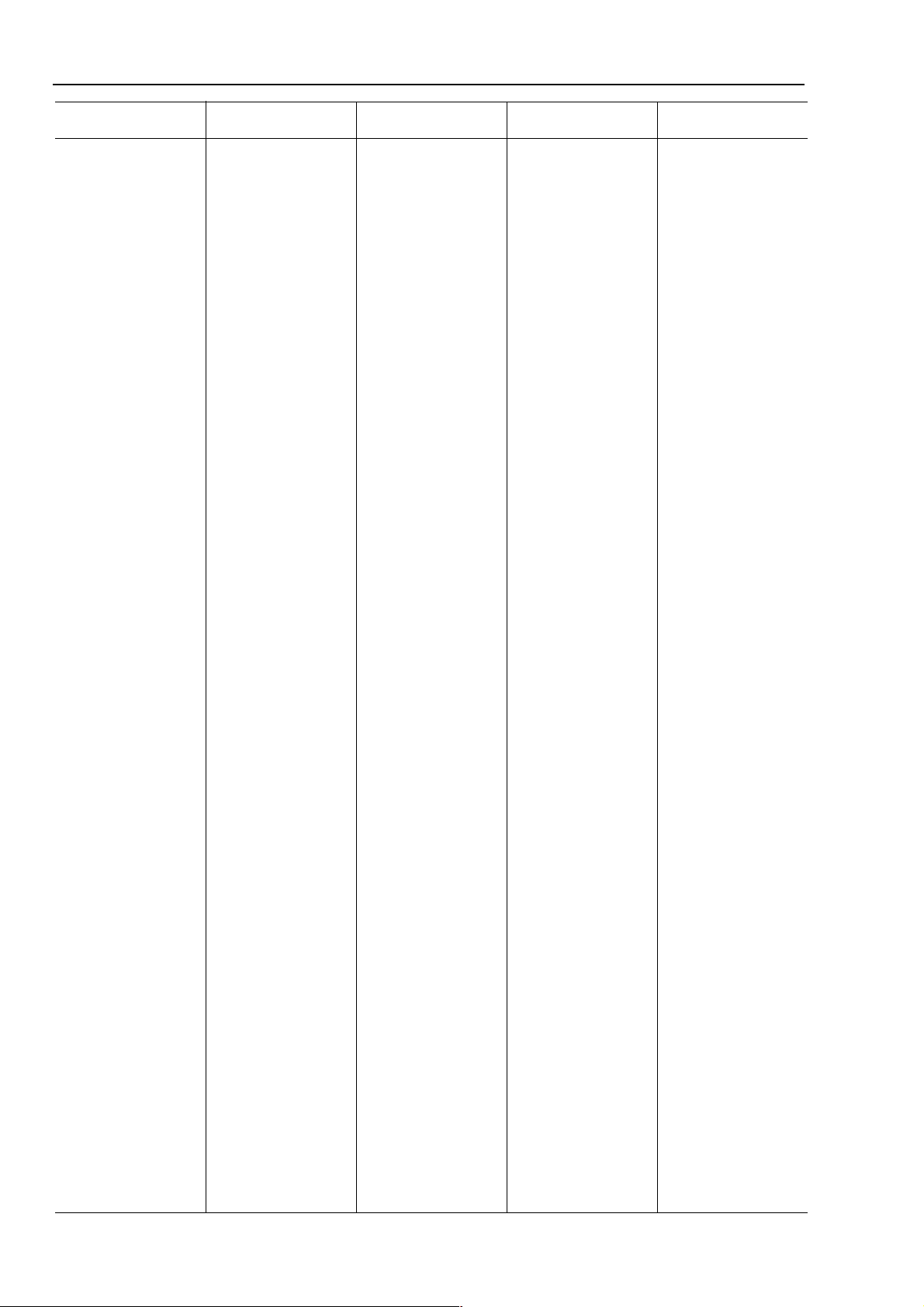

kraMnoitacidnIderiuqernoitcA

왌

dedda

ylwenebotegaP

ddA

Mark

Page

• 00-1 햲

• 00-2 햲

• 00-2-1 햲

• 00-2-2 햲

• 00-2-3 햲

• 00-2-4 햲

• 00-3 햲

• 00-4 햲

• 00-5 햲

• 00-6 햲

• 00-7 햲

• 00-8 햲

• 00-9 햲

• 00-10 햲

• 00-11 햲

• 00-12 햲

• 00-13 햲

• 00-14 햲

• 00-15 햲

• 00-16 햲

• 00-17 햲

• 00-18 햲

10-1

10-2

10-3

10-4

10-5

10-6

10-7

10-8

10-9

10-10

10-11

10-12

10-13

10-14

10-15

10-16

Time of

revision

Mark

Page

10-17

10-18

10-19

10-20

10-21

10-22

10-23

10-24

10-25

10-26

10-27

10-28

10-29

10-30

10-31

10-32

10-33

10-34

10-35

10-36

10-37

10-38

• 10-39 햲

• 10-39-1 햲

• 10-39-2 햲

10-40

10-41

10-42

10-43

10-44

10-45

10-46

10-47

10-47A

10-47B

10-47C

10-47D

10-47E

10-47F

쐌

)(deteledebotegaPdracsiD

Pages having no marks are those previously revised

or made additions.

LIST OF REVISED PAGES

Time of

revision

Mark

Page

10-47G

10-47H

10-47I

10-47J

10-48

10-49

10-50

10-51

10-52

10-53

10-54

10-55

10-56

10-57

10-58

10-59

10-60

10-61

10-62

10-63

10-64

10-65

10-66

10-67

10-68

10-69

10-70

10-71

10-72

10-73

10-74

10-76

10-77

10-78

10-79

10-80

10-81

10-82

10-83

Time of

revision

Mark

Page

10-84

10-85

10-86

10-87

10-88

10-89

10-90

10-91

10-92

10-93

10-94

10-95

10-96

10-97

10-98

10-99

10-100

10-101

10-102

10-103

10-104

10-105

10-106

10-107

10-108

10-109

10-110

10-111

10-112

10-113

10-114

10-115

10-116

10-117

10-118

10-119

10-120

10-121

10-122

Time of

revision

decalperebotegaPecalpeR

Mark

Page

10-123

10-124

10-125

10-126

10-127

10-128

10-129

10-130

10-130-1

10-130-2

10-130-3

10-131

10-132

10-133

10-134

10-135

10-136

10-137

10-138

10-139

10-140

10-141

10-142

10-143

10-144

10-145

10-146

10-147

10-148

10-149

10-150

10-151

10-152

10-153

10-154

10-155

10-156

10-157

10-158

Time of

revision

00-2-1

00-3

햲

햲

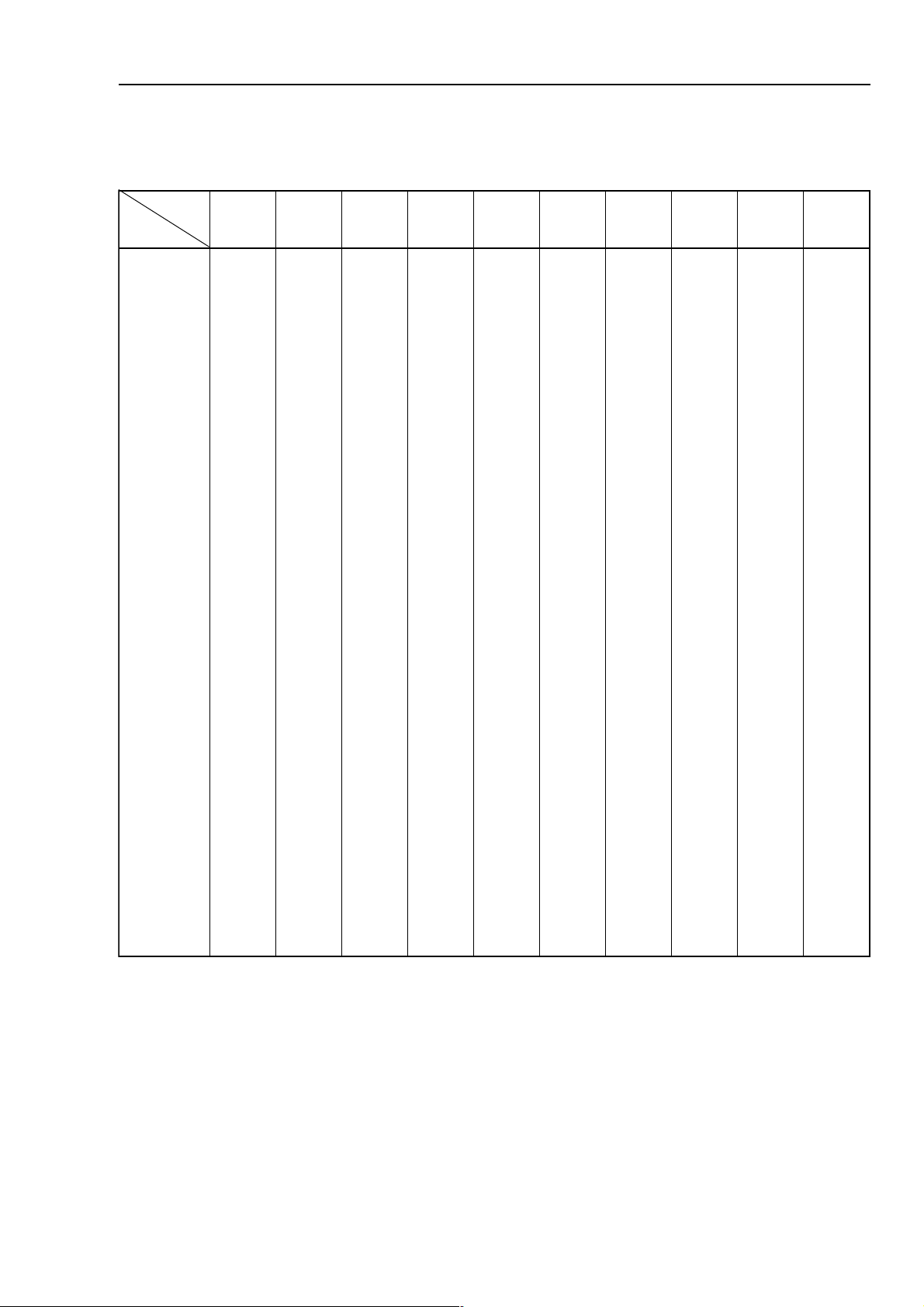

Page 5

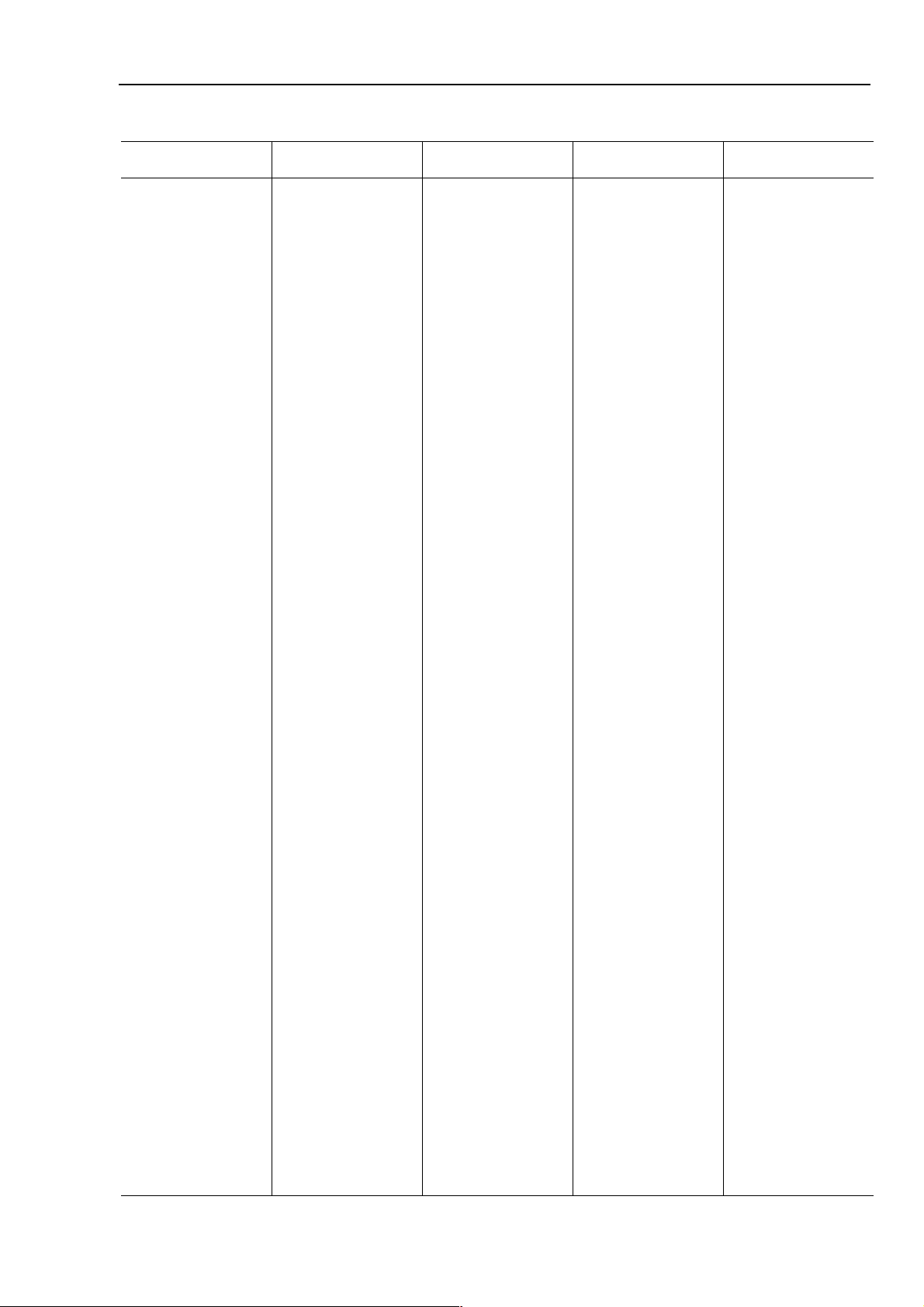

Mark

Page

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

10-159

10-160

10-161

10-162

10-163

10-164

10-165

10-166

10-167

10-168

10-169

10-170

10-171

10-172

10-173

10-174

10-175

20-1

20-2

• 20-3 햲

20-4

20-5

20-6

20-7

20-8

20-9

20-10

20-11

20-12

20-13

20-14

20-15

20-16

20-17

20-18

20-19

20-20

20-21

20-22

20-23

20-24

20-25

20-26

20-27

20-28

20-29

20-30

20-31

20-32

20-33

20-34

20-35

20-36

20-37

20-38

20-39

20-40

20-41

20-42

20-43

20-44

20-45

20-46

20-47

20-48

20-49

20-50

20-51

20-52

20-53

20-54

20-55

20-56

20-57

20-58

20-59

20-60

20-61

20-62

20-63

20-64

20-65

20-66

20-67

20-68

• 20-69 햲

• 20-69-1 햲

• 20-69-2 햲

• 20-70 햲

• 20-71 햲

20-72

20-73

20-74

20-75

20-76

20-77

20-78

20-79

20-80

20-81

20-82

20-83

20-84

20-85

20-86

20-87

20-88

20-89

20-90

20-91

20-92

20-93

20-94

20-95

20-96

20-97

20-98

20-99

20-100

20-101

20-102

20-103

20-104

20-105

20-106

20-107

20-108

20-109

20-110

20-111

20-112

20-113

20-114

20-115

20-116

20-117

20-118

20-119

20-120

20-121

20-122

20-123

20-124

20-125

20-126

20-127

20-128

20-129

20-130

20-131

20-132

20-133

20-134

20-135

20-136

20-137

20-138

20-139

20-140

20-141

20-142

20-143

20-144

20-145

20-146

20-147

20-148

20-149

20-150

20-151

20-152

20-153

20-154

20-155

20-156

20-157

20-158

20-159

20-160

20-161

20-162

20-163

20-164

20-165

20-166

20-167

20-168

20-169

20-170

20-171

20-172

20-173

20-174

20-175

20-176

20-177

20-178

20-179

20-180

20-181

20-182

20-183

20-184

20-185

20-186

20-187

20-188

20-189

20-190

20-191

20-192

20-193

20-194

20-195

20-196

20-197

20-198

20-199

20-200

20-201

20-202

20-203

20-204

20-205

20-206

20-207

20-208

20-209

20-210

20-211

20-212

20-213

20-214

20-215

20-216

20-217

20-218

20-219

20-220

20-221

20-222

20-223

20-224

20-225

20-226

20-227

20-228

20-229

20-230

20-231

20-232

20-233

20-234

20-235

20-236

20-237

20-238

20-239

20-240

20-241

20-242

20-243

20-244

20-245

20-246

20-247

20-248

20-249

20-250

20-251

20-252

20-253

20-254

20-255

20-256

20-257

20-258

20-259

20-260

20-261

20-262

20-263

20-264

00-2-2

00-4

햲

햲

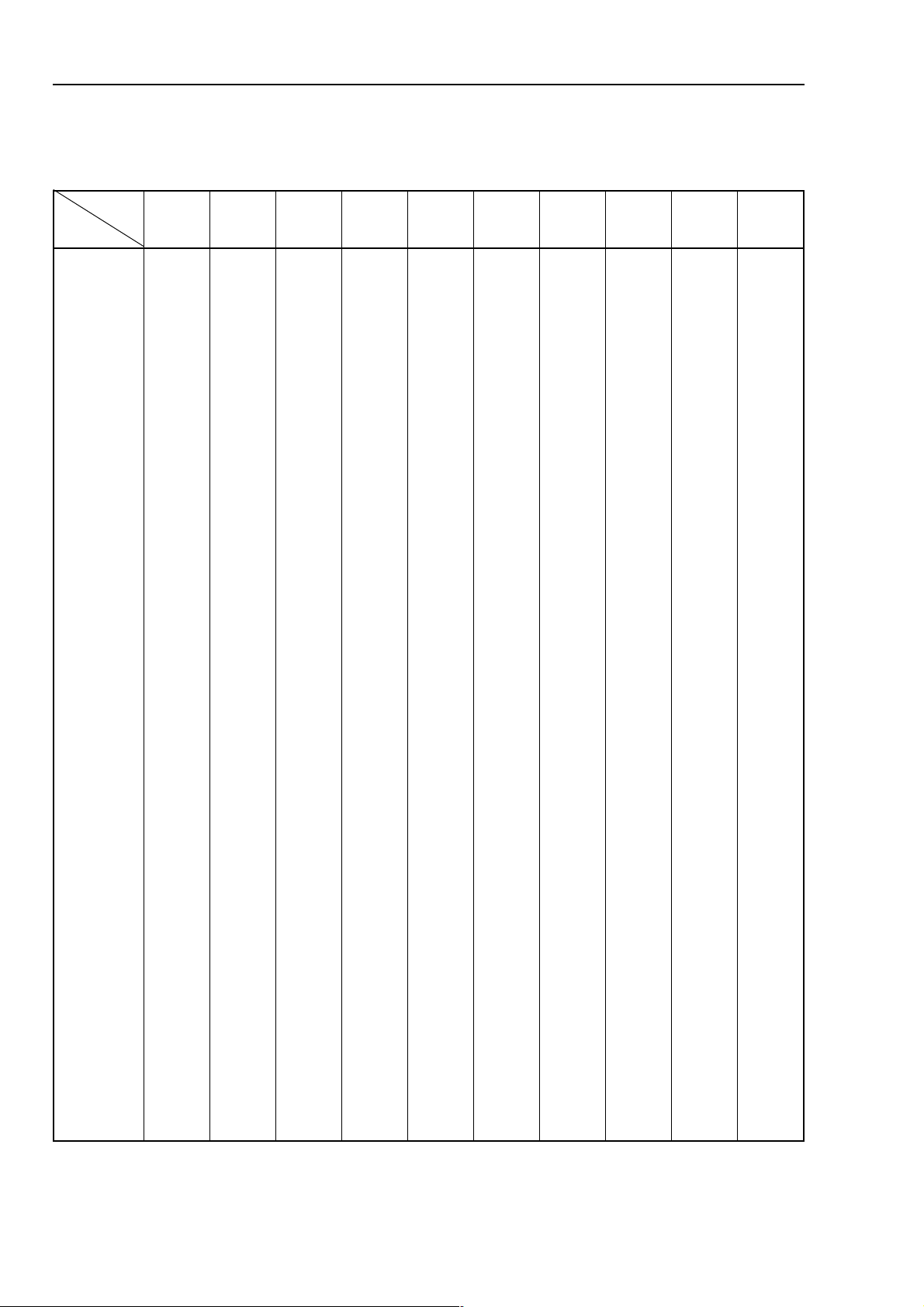

Page 6

Mark

Page

Time of

revision

Mark

Page

Time of

revision

Mark

Page

Time of

revision

Mark

Page

Time of

revision

Mark

Page

Time of

revision

20-265

20-266

20-267

20-268

20-269

20-270

20-271

20-272

20-273

20-274

20-275

20-276

20-277

20-278

20-279

20-280

20-281

20-282

20-283

20-284

20-285

20-286

30-1

30-2

30-3

30-4

30-5

30-6

30-7

30-8

30-9

30-10

30-11

30-12

30-13

30-14

30-15

30-16

30-17

30-18

30-19

30-20

30-21

30-22

30-23

30-24

30-25

30-26

30-27

30-28

30-29

30-30

30-31

30-32

30-33

30-34

30-35

30-36

30-37

30-38

30-39

30-40

30-41

30-42

30-43

30-44

30-45

30-46

30-47

30-48

30-49

30-50

30-51

30-52

30-53

30-54

30-55

30-56

30-57

30-58

30-59

30-60

30-61

30-62

30-63

30-64

30-65

30-66

30-67

30-68

30-69

30-70

30-71

30-72

30-73

30-74

30-75

30-76

30-77

30-78

30-79

30-80

30-81

30-82

30-83

30-84

30-85

30-86

30-87

30-88

30-89

30-90

30-91

30-92

30-93

30-94

30-95

30-96

30-97

30-98

30-99

30-100

30-101

30-102

30-103

30-104

30-105

30-106

30-107

30-108

30-109

30-110

30-111

30-112

30-113

30-114

30-115

30-116

30-117

30-118

30-119

30-120

30-121

30-122

30-123

30-124

30-125

30-126

30-127

30-128

30-129

30-130

30-131

30-132

30-133

30-134

30-135

30-136

30-137

30-138

30-139

30-140

30-141

30-142

30-143

30-144

30-145

30-146

30-147

30-148

30-149

30-150

30-151

30-152

30-153

30-154

30-155

30-156

30-157

30-158

30-159

30-160

30-161

30-162

30-163

30-164

40-1

40-2

40-3

40-4

40-5

40-6

40-7

40-8

40-9

40-10

40-11

40-12

40-13

40-14

40-15

40-16

40-17

40-18

40-19

40-20

40-21

40-22

40-23

40-24

40-25

40-26

40-27

40-28

40-29

40-30

40-31

40-32

40-33

40-34

00-2-3

00-5

햲

햲

Page 7

SAFETY SAFETY NOTICE

SAFETY

SAFETY NOTICE

IMPORT ANT SAFETY NOTICE

Proper service and repairs extremely important for safe machine operation. The service and

repair techniques recommended by Komatsu and described in this manual are both sepcially

designed by Komatsu for the specific purpose.

To prevent injury to workers, the symbol is used to mark safety precautions in this

manual. The cautions accompaning these symbols should always be followed carefully . If any

dangerous situation arises or may possibly arise, first consider safety , and take the necessary

actions to deal with the situation.

GENERAL PRECAUTIONS

Mistakes in operation are extremely dangerous.

Read the Operation and Maintenance carefully BEFORE operating the machine.

1. Before carrying out any greasing or re-

pairs, read all the precautions given on the

decals which are fixed to the machine.

2. When carrying out any operation, always

wear safety shoes and helmet. Do not wear

loose work clothes, or clothes with buttons

missing.

• Always wear safety glasses when hitting parts with a hammer.

• Always wear safety glasses when

grinding parts with a grinder, etc.

3. If welding repairs are needed, always have

a trained, experienced welder carry out the

work. When carrying out welding work, always wear welding gloves, apron, glasses,

cap and other clothes suited for welding

work.

6. Decide a place in the repair workshop to keep

tools and removed parts. Always keep the tools

and parts in their correct places. Always keep

the work area clean and make sure that there is

no dirt or oil on the floor. Smoke only in the areas provided for smoking. Never smoke while

working.

PREP ARA TIONS FOR WORK.

7. Before adding the oil or making any repairs

park the machine on hard, level ground, and

block the wheels or tracks to prevent the machine from moving.

8. Before starting work, lower blade, ripper, bucket

or any other work equipment to the ground. If

this is not possible, insert the safety pin or use

blocks to prevent the wrok equipment from falling. In addition, be sure to lock all the control

levers and hang warning signs on them.

9. When disassembling or assembling, support

the machine with blocks, jacks or stands before

starting work.

4. When carrying out any operation with two

or more workers, always agree on the operating procedure before starting. Always

inform your fellow workers before starting

any step of the operation. Before starting

work, hang UNDER REPAIR signs on the

controls in the operator's compartment.

5. Keep all tools in good condition and learn

the correct way to use them.

10. Remove all mud and oil from the steps or other

paces used to get on and off the machine. Always use the handrails, ladders or steps when

getting on or off the machine. Never jump on or

off the machine. If it is impossible to use the

handrails, ladders or steps, use a stand to provide safe footing.

00-3

햲

Page 8

SAFETY SAFETY NOTICE

PRECAUTIONS DURING WORK

11. When removing the oil filter cap, drain plug or

hydraulic pressure measuring plugs, loosen

them slowly to prevent the oil from spurting out.

Before disconnecting or removing components

of the oil, water or air circuits, first remove the

pressure completely from the circuit.

12. The water and oil in the circuits are hot when

the engine is stopped, so be careful not to get

burned.

Wait for the oil and water to cool before carrying

out any work on the oil or water circuits.

13. Before starting work, remove the leads from the

battery . Always remove the lead from the negative (-) terminal first.

14. When raising heavy components, use a hoist or

crane.

Check that the wire rope, chains and hooks are

free from damage.

Always use lifting equipment which has ample

capacity .

Install the lifting equipment at he correct places.

Use a hoist of crane and operate slowly to prevent the component from hitting any other part.

Do not work with any part still raised by the

hoist or crane.

20. When installing high pressure hoses, make

sure that they are not twisted. Damaged tubes

are dangerous, so be extremely careful when

installing tubes for high pressure circuits. Also,

check that connecting parts are correctly installed.

21. When assembling or installing parts, always

use the specified tightening torques. When installing protective parts such as guards. or

parts which vibrate violently or rotate at high

speed, be particulary careful to check that they

are installed correctly .

22. When aligning two holes, never insert your fingers or hand. Be careful not to get your fingers

caught in a hole.

23. When messuring hydraulic pressure, check that

the messuring tool is correctly assembled for

taking any measurements.

24. Take care when removing or installing the

tracks of track-type machines. When removing

the track, the track separates suddenly, so

never let anyone stand at either end of the

track.

15. When removing covers which are under internal pressure or under pressure from a spring,

always leave two bolts in position on opposite

sides. Slowly release the pressure, then slowly

loosen the bolts to remove.

16. When removing components, be careful not to

break or damage the wiring. Damaged wiring

may cause electrical fires.

17. When removing piping, stop the fuel or oil from

spilling out. If any oil or fuel drops onto the floor,

wipe it up immediately. Fuel or oil on the floor

can cause you to slip, or can even start fires.

18. As a general rule, do not use gasoline to wash

parts. In particular, only use the minimum of

gasoline when washing electrical parts.

19. Be sure to assemble all parts again in their

original places.

Replace any damaged parts with new parts.

• When installing hoses and wires, be sure

that the will not be damaged by contact

with oter parts when the machine is being

operated.

00-4

햲

Page 9

FOREWORD FOREWORD GENERAL

FOREWORD

GENERAL

This shop manual has been prepared as an aid to improve the quality of repairs by giving the serviceman an

accurate understanding of the product and by showing him the correct way to perform repairs and make judgements. Make sure you understand the contents of this manual and use it to full effect at every opportunity.

This shop manual mainly contains the necessary technical information for operations performed in a service

workshop. For ease of understanding, the manual is divided into the following chapters: these chapters are

further divided into the each main group of components.

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting.

TESTING AND ADJUSTING

This section explains checks to be made before and after performing repairs , as well as adjustments to be

made at completion of the checks and repairs. Troubleshooting charts correlating "problems" to "Causes"

are also included in this section.

DISASSEMBL Y AND ASSEMBLY

This section explains the order to be followed when removing, installing, disassembling or assembling

eachr component, as well as precautions to be taken for these operations.

MAINTENANCE ST ANDARD

This section gives the judgement standards when inspecting disassembled parts.

NOTICE

The specifiactions contained in this shop manual are subject to change at any time and without any

advance notice. Use the specifications given in the book with the latest date.

00-5

햲

Page 10

FOREWORD HOW TO READ THE SHOP MANUAL

HOW TO READ THE SHOP MANUAL

VOLUMES

Shop manuals are issued as a guide to carrying out

repairs. They are devided as follows:

Chassis volume: Issued for every machine model

Engine model: Issued for each engine series

Electrical volume:

Attachments volume:

These various volumes are designed to avoid duplicating the same information. Therefore, to deal with

all repairs for any model, it is necessary that chassis, engine , electrical and attachement volumes be

available.

DISTRIBUTION AND UPDATING

Any additions, amendments or other changes will be

sent to KOMATSU distributors. Get the most up-todate information before you start any work.

FILING METHOD

1. See the page number on the bottom of the

page. File the pages in correct order.

2. Following examples show how to read the page

number

Example 1 (Chassis volume:)

10 - 3

Example 2 (Engine Volume:)

1 2 - 5

3. Additional pages: Additional pages are indicated by a hyphen (-) and number after the

page number. File as in the example.

Example:

10-4 12-203

10-4-1 12-203-1

10-4-2 12-203-2

10-5 12-204

Added pages

Each issued as one

volume to cover all

}

models

Item number (10. Structure

and Function)

Consecutive page number

for each item

Unit number (1. Engine)

Item number (2. Testing and

Adjusting)

Consecutive page number

for each item

REVISED EDITION MARK

When a manual is revised, an edition mark (1,2,3,...)

is recorded on the bottom of the pages.

REVISIONS

Revised pages are shown in the LIST OF REVISED

P AGES next to the CONTENTS page.

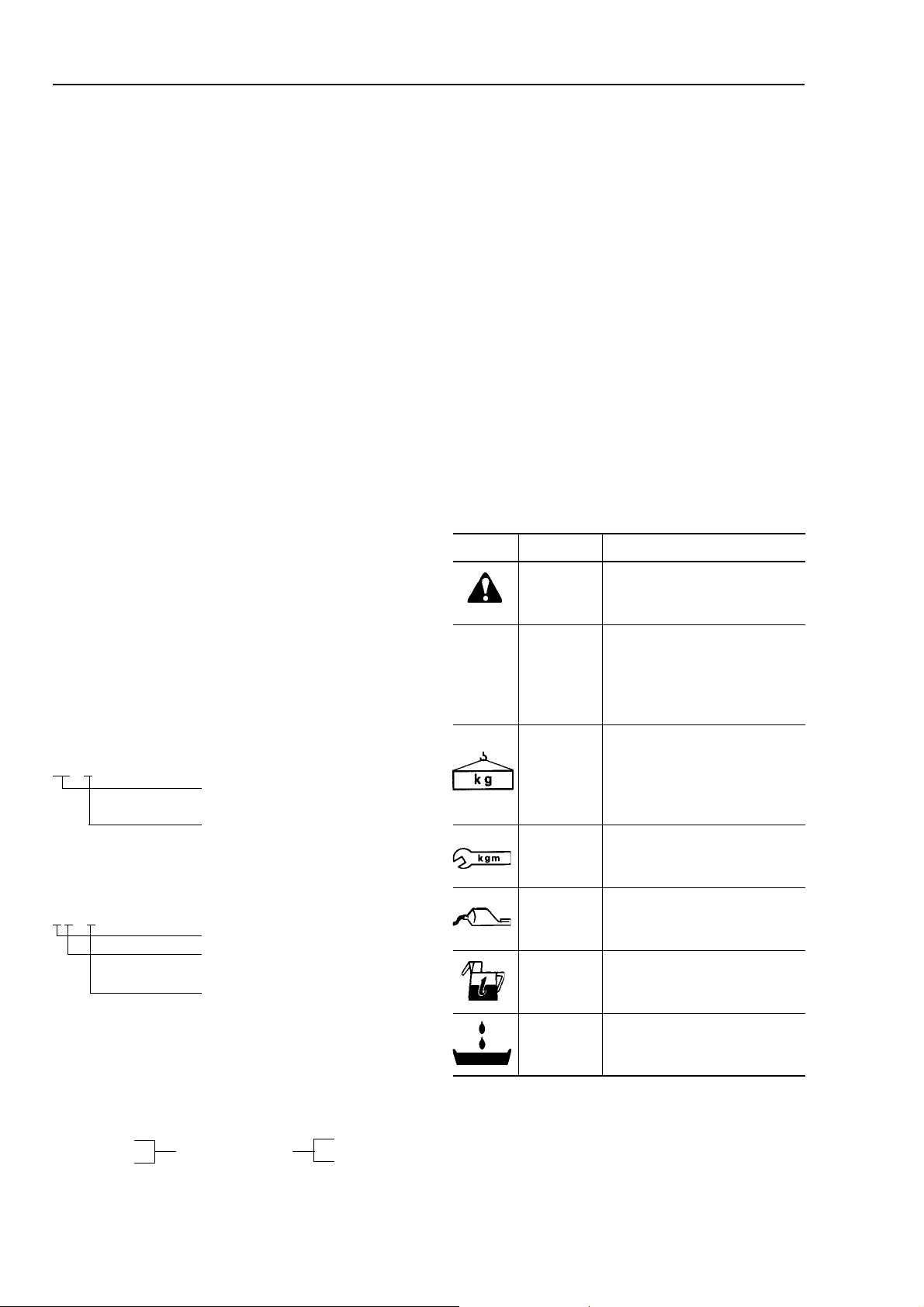

SYMBOLS

So that the shop manual can be of ample practical

use, important safety and quality portions are

marked with the following symbols.

lobmySmetIskrameR

snoituacerpytefaslaicepS

★

ytefaS

noituaC

thgieW

gninethgiT

euqrot

taoC

.cte

retaw,liO

.yticapac

niarD

nehwyrassecenera

.krowehtgnimrofrep

lacinhcetlaicepS

rehtorosnoituacerp

gnivreserprofsnoituacerp

yrassecenerasdradnats

.krowehtgnimrofrepnehw

.smetsysfostrapfothgieW

nehwyrassecennoituaC

ro,eriwgnitsiohgnitceles

sierutsopgnikrownehw

.tce,tnatropmi

laicepseriuqertahtsecalP

gninethgitehtrofnoitnetta

.ylbmessagnirudeuqrot

htiwdetaocebotsecalP

,stnacirbuldnasevisehda

roretaw,lioerehwsecalP

ehtdna,deddaebtsumleuf

retawrolioerehwsecalP

dna,deniardebtsum

.deniardebotytitnauq

00-6

햲

Page 11

FOREWORD HOISTING INSTRUCTIONS

HOISTING INSTRUCTIONS

HOISTING

Heavy parts (25 kg or more) must be

lifted with a hoist, etc. In the DISASSEM-

BLY AND ASSEMBLY section, every

part weighing 25 kg op mroe is indicated

with the symbol

• If a part cannot be smootlhy removed from the

machine by hoisting, the following checks

should be made:

1) Check for removal of all bolts fastening the

part to the relative parts.

2) Check for existence of another part caus-

ing interference with the part to be removed.

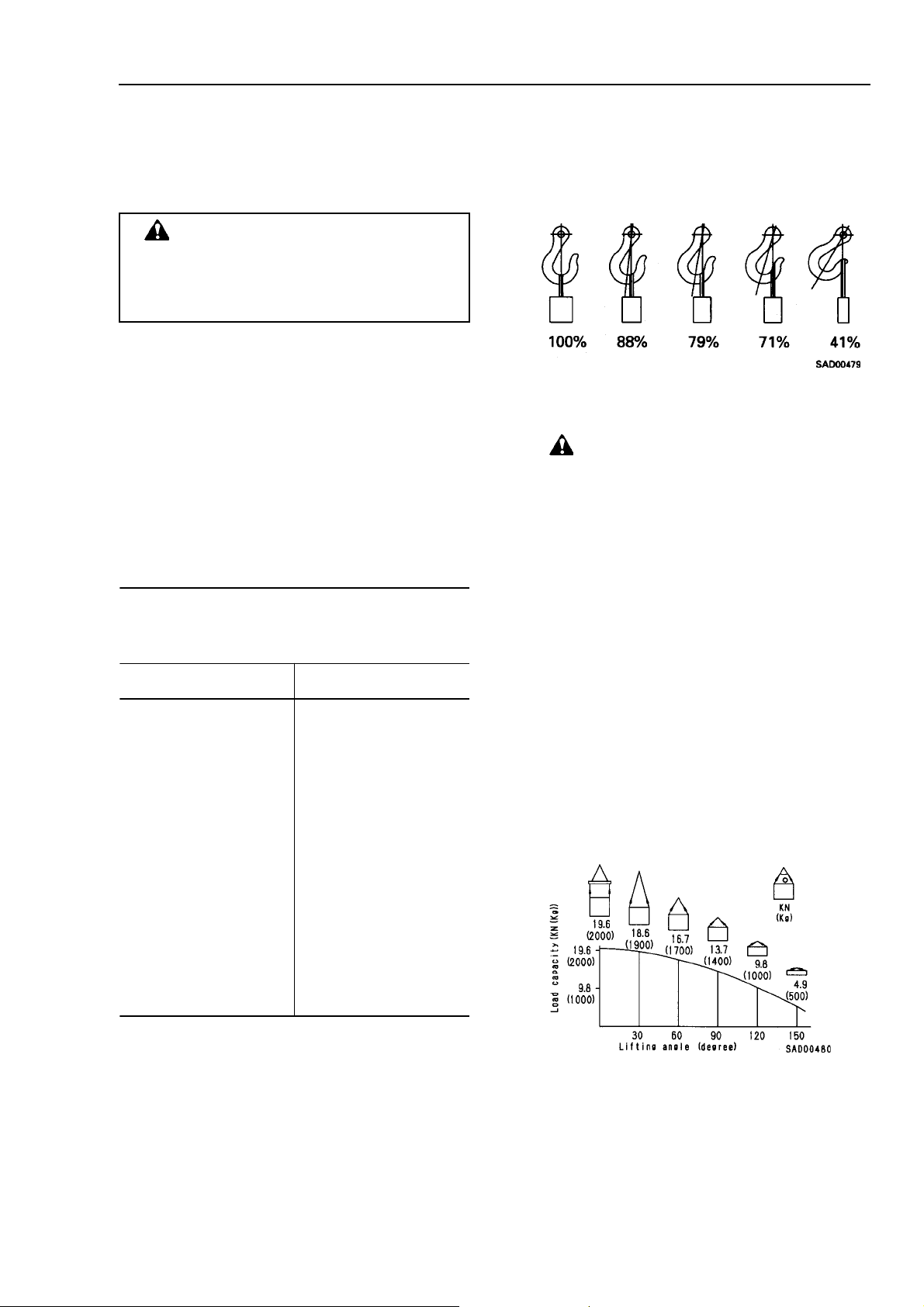

WIRE ROPES

1) Use adequate ropes depending on the

weight of parts to be hoisted, referring to

the table below:

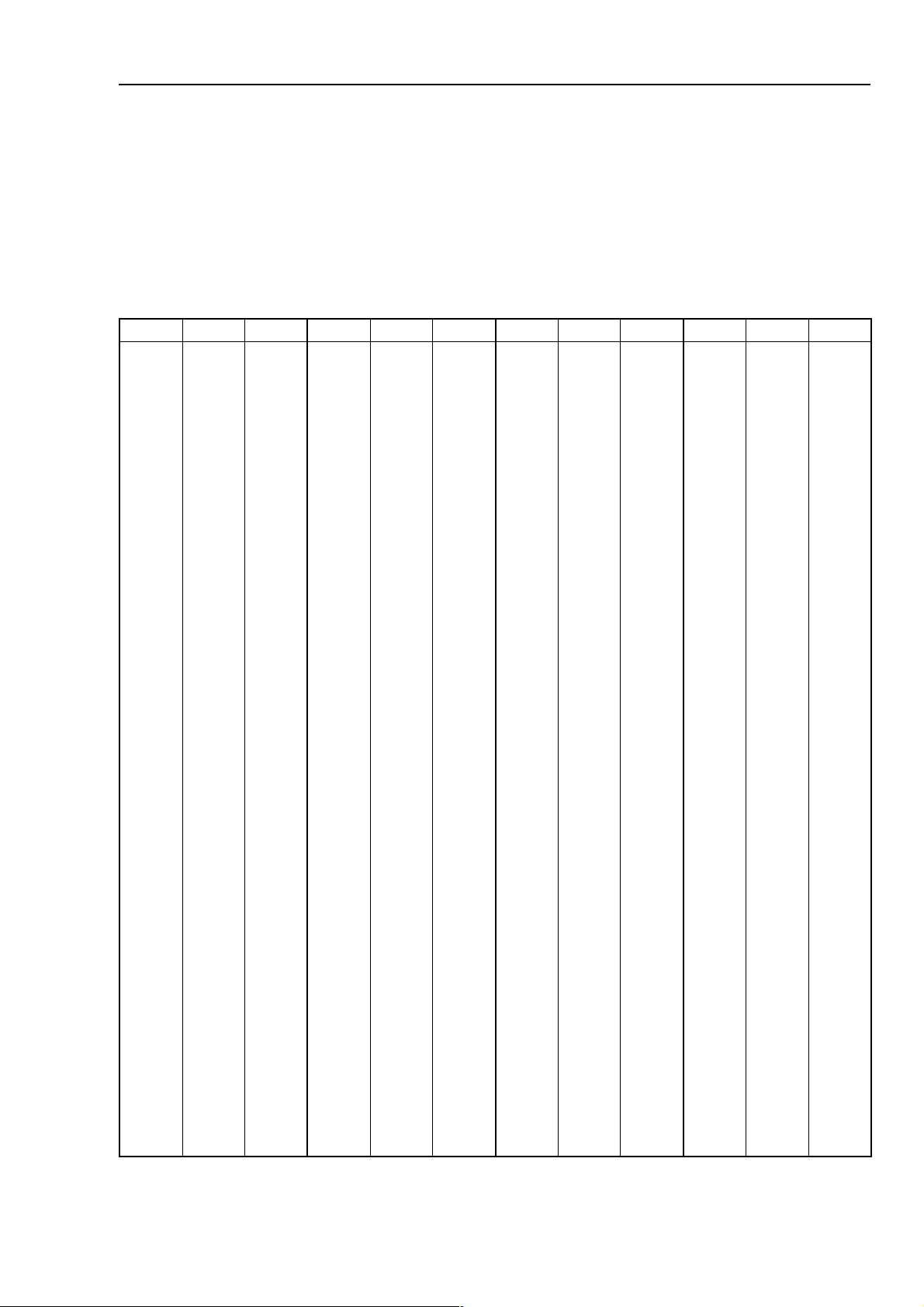

seporeriW

seportsiwt"S"ro"Z"dradnatS(

gnizinavlagtuohtiw

)mm(retemaidepoR)snot(daolelbawollA

010.1

2.114.1

5.216.1

412.2

618..2

816.3

Slinging near the edge of the hook may cause the

rope to slip off the hook during hoisting, and a serious accident can result. Hooks have a maximum

strength at the middle portion.

3) Do not sling a heavy load with one rope alone,

but sling with two or more ropes symmetrically

wound onto the load.

Slinging with one rope may cause turning

of the load during hoisting, untwisting of

the rope, or slipping of the rope from its

original winding position on the load, which

can result in a dangerous accident.

4) Do not sling a heavy load with ropes forming a

wide hanging angle from the hook. When hoisting a load with two or more ropes, the force subjected to each rope will increase with the

nahging angles. The table below shows the

variation of allowable load (kg) when hoisting is

made with two ropes, each of which is allowed

to sling up to 1000 kg vertically , at various hanging angles.

When two ropes sling a load vertically, up to

2000 kg of total weight can be suspended. This

weight becomes 1000 kg when two ropes make

a 120° hanging angle. On the other hand, two

ropes are subjected to an excessive force as

large as 4000 kg if they sling a 2000 kg load at a

lifting angle of 150°.

024.4

4.226.5

030.01

040.81

050.82

060.04

★ The allowable load value is estimated to be

one-sixth or one-seventh of the breaking

strength of the rope used.

2) Sling wire ropes from the middle portion of the

hook.

00-7

햲

Page 12

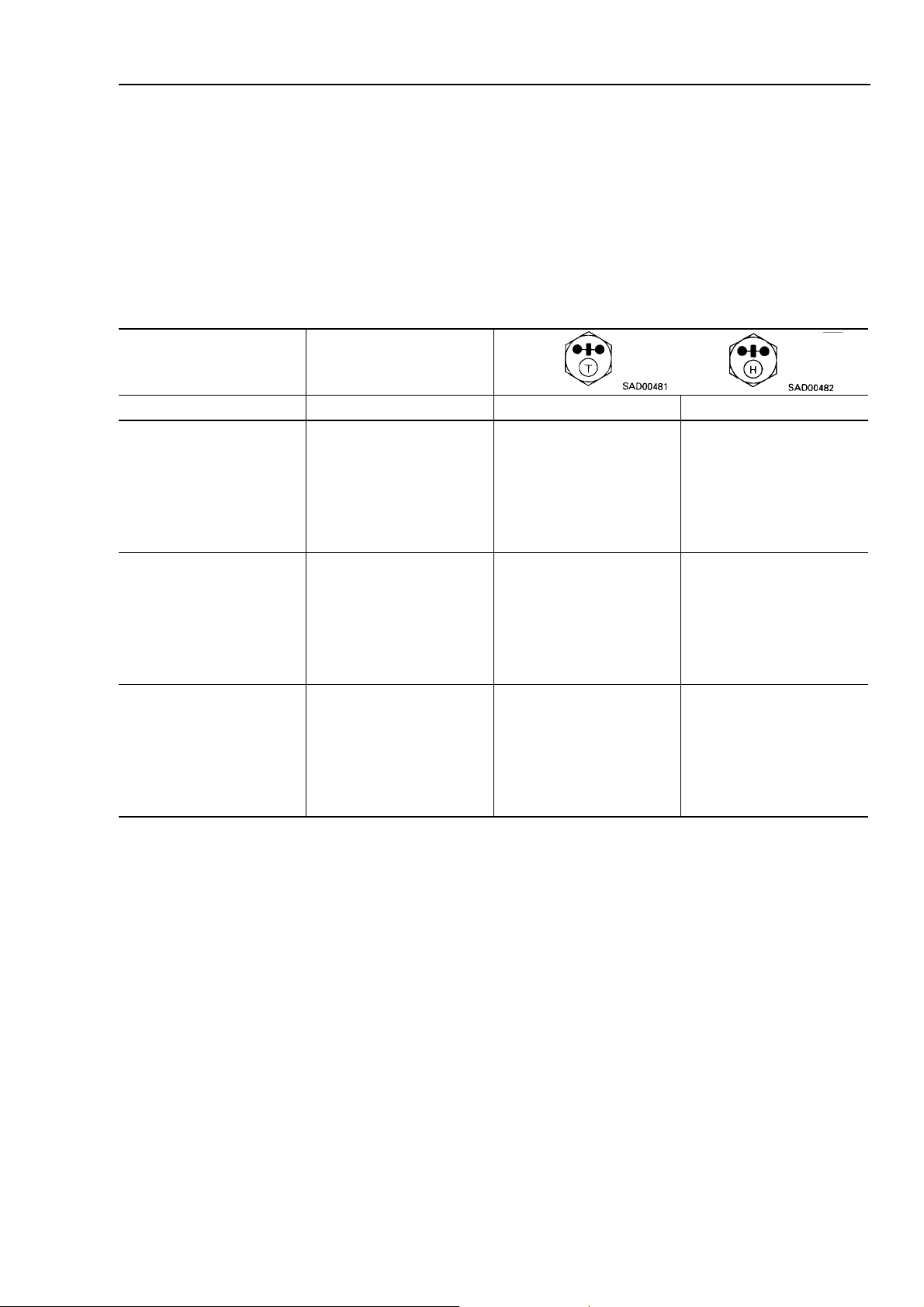

FOREWROD COA TING MA TERIALS

COA TING MA TERIALS

The recommended coating materials prescribed in Komatsu Shop Manuals are listed below.

Category

Adhesive

Gasket sealant

Rust prevention

lubricant

Molybdenum

disulphide

lubricant

Lithium grease

Calcium grease

Molybdenum

disulphide

grease

Komatsu code

LT-1A

LT-1B

LT-2

LT-3

LT-4

(Loctite 648-50)

LG-1

LG-3

LG-4

LG-5

LG-6

LG-7

-

-

G2-LI

G2-CA

-

Part No.

790-129-9030

790-129-9050

09940-00030

790-129-9060

(Set of adhesive

and hardening

agent)

790-129-9040

79A-129-9110

790-129-9070

790-120-9020

790-129-9080

09940-00011

09920-00150

09940-00051

09940-00040

SYG350LI

SYG-400LI

SYG-400LI-A

SYG-160LI

SYGA-160CNLI

SSG2-400CA

SYG2-350CA

SYG2-400CA-A

SYG2-160CA

SYGA-16NCA

SYG2-400M

Q'ty

150 g

20 g

(x2)

50 g

Adhesive

: 1 kg

Hardening

agent

: 500 g

250 g

50 cc

200 g

1kg

200 g

1 kg

250 g

150 g

60 g

200 g

Various

Various

400 g (10

per case)

Container

Tube

Plastic

container

Plastic

container

Can

Plastic

container

-

Tube

Can

Tube

Plastic

container

Tube

Tube

Can

Tube

Various

Various

Bellows type

Main applications, features

• Used to prevent rubber gaskets, rubber cushions, and

cork plugs from coming out

• Used in places requiring an immediately effective, strong

adhesive. Used for plastics (except polyethylene,

polyprpylene, tetrafluoroethylene and vinyl chloride),

rubber, metal, and non-metal.

• Features: resistance to heat, chemicals

• Used for anti-lossening and sealant purposes for bolts

and plugs

• Used as adhesive or sealant for metal, glass, plastic

• Used as sealant for machined holes

• Features: Resistance to heat, chemicals

• Used at joint portions subject to high temperature

• Used as adhesive or sealant for gaskets and packings of

power train case, etc.

• Features: Resistance to heat

• Used as sealant for flange surfaces and bolts at high

temperature locations, used te prevent seizure

• Used as sealant for heat resistant gasket for high

temperature locations such as engine precombustion

chamber, exhaust pipe

• Features: Resistance to water, oil

• Used as sealant for flange surface, thread

• Aiso possible to use as sealant for flanges with large

clearance

• Used as sealant for mating surfaces of final drive case,

transmission case.

• Used as sealant for various threads, pipe joints, flanges

• Used as sealant for tapered plugs, elbows, nipples of

hydraulic piping

• Features: Silicon based, resistance to heat, cold

• Used as sealant for flange surface, thread

• Used as sealant for oil pan, final drive case, etc.

• Features: Silicon based, quick hardening type

• Used as sealant fo rflywheel housing, intake manifold, oil

pan, thermostat housing, etc.

• Used as lubricant for sliding parts (to prevent squeaking)

• Used to prevent seizure or scuffing of the thread when

presss fitting or shrink fitting

• Used as lubricant for linkage, bearings, etc.

• General purpose type

• Used for normal temperature, light load bearing at places

in contact with water or steam

• Used for places with heavy load

00-8

햲

Page 13

FOREWORD ST ANDARD TIGHTENING TORQUE

ST ANDARD TIGHTENING TORQUE

ST ANDARD TIGHTENING TORQUES OF BOLTS AND NUTS

The following charts give the standard tightening torques of bolts and nuts. Exceptions are given in section of

DISASSEMBL Y AND ASSEMBLY.

1 Kgm = 9.806 Nm

retemaiddaerhT

tlobfo

mmmmmgkmN

60153.1 ± 51.02.31 ± 4.1

8312.3 ± 3.04.13 ± 9.2

01717.6 ± 7.07.56 ± 8.6

21915.11 ± 0.1211 ± 8.9

41220.81 ± 0.2771 ± 91

61425.82 ± 3972 ± 92

817293 ± 4383 ± 93

020365 ± 6945 ± 85

222367 ± 8547 ± 87

42635.49 ± 01729 ± 89

7214531 ± 510231 ± 041

0364571 ± 020271 ± 091

3305522 ± 520122 ± 042

6355082 ± 030572 ± 092

htdiW

stalfssorca

9306533 ± 520823 ± 043

★ This torque table does not apply to the bolts with nylon packaging or other nonferrous metal wash-

ers are to be used, or which require tightening to otherwise specified torque.

00-9

햲

Page 14

FOREWORD ST ANDARD TIGHTENING TORQUE

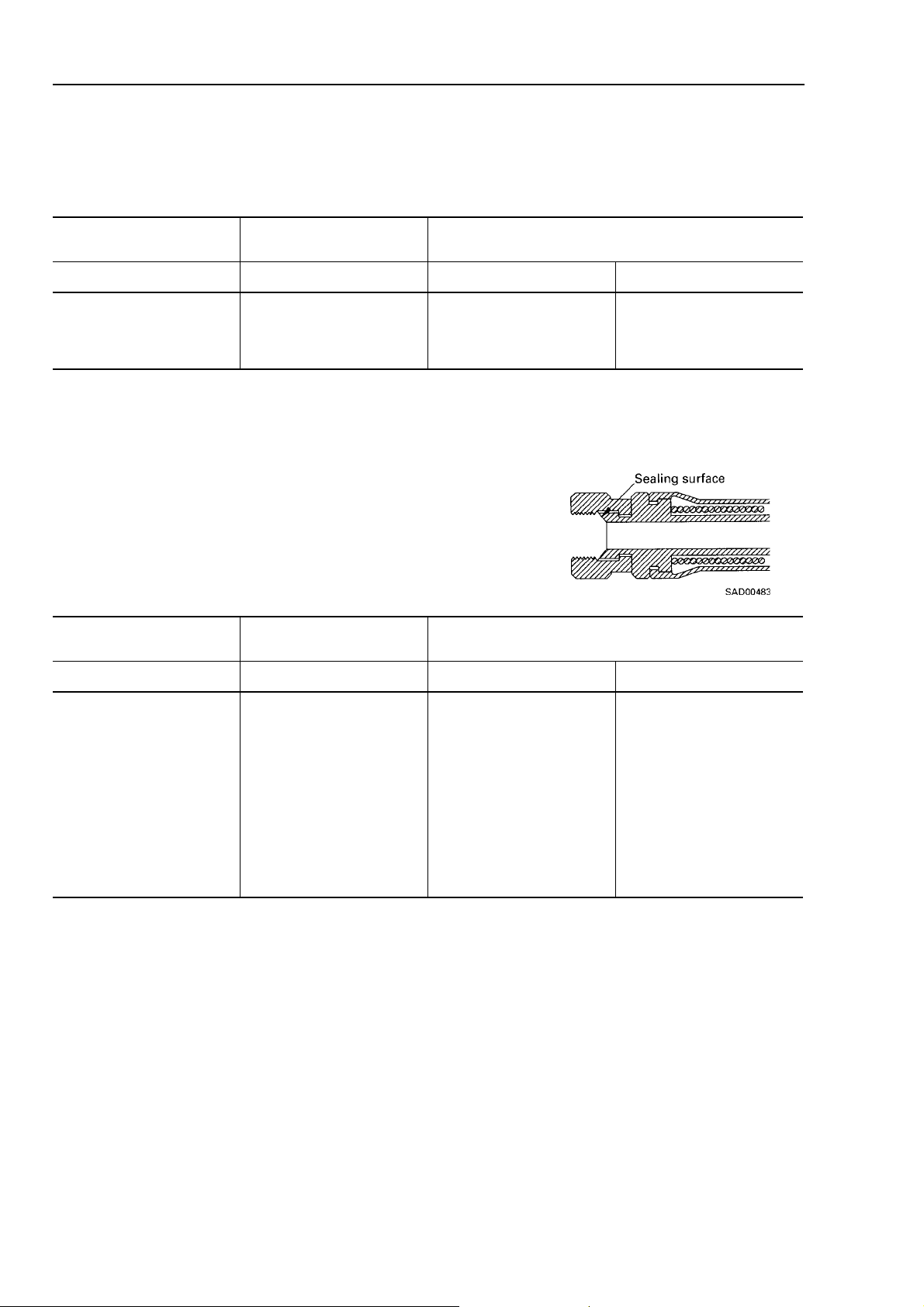

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS

Use these torques for split flange bolts.

retemiaddaerhT

tlobfo

mmmmmgkmN

01417.6 ± 7.07.56 ± 8.6

21715.11 ± 1211 ± 8.9

61225.82 ± 3972 ± 92

TIGHTENING TORQUE FOR FLRED NUTS

Use these torques for flared part of nut.

retemiaddaerhT

tlobfo

mmmmmgkmN

htdiW

stalfssorca

htdiW

stalfssorca

euqrotgninethgiT

euqrotgninethgiT

41915.2 ± 5.05.42 ± 9.4

81425± 294 ± 6.91

22728± 25.87 ± 6.91

422341 ± 33.731 ± 4.92

036381 ± 35.671 ± 4.92

331402 ± 51.691 ± 94

636452 ± 52.542 ± 94

245503 ± 52.492 ± 94

00-10

햲

Page 15

FOREWORD ELECTRIC WIRE CODE

ELECTRIC WIRE CODE

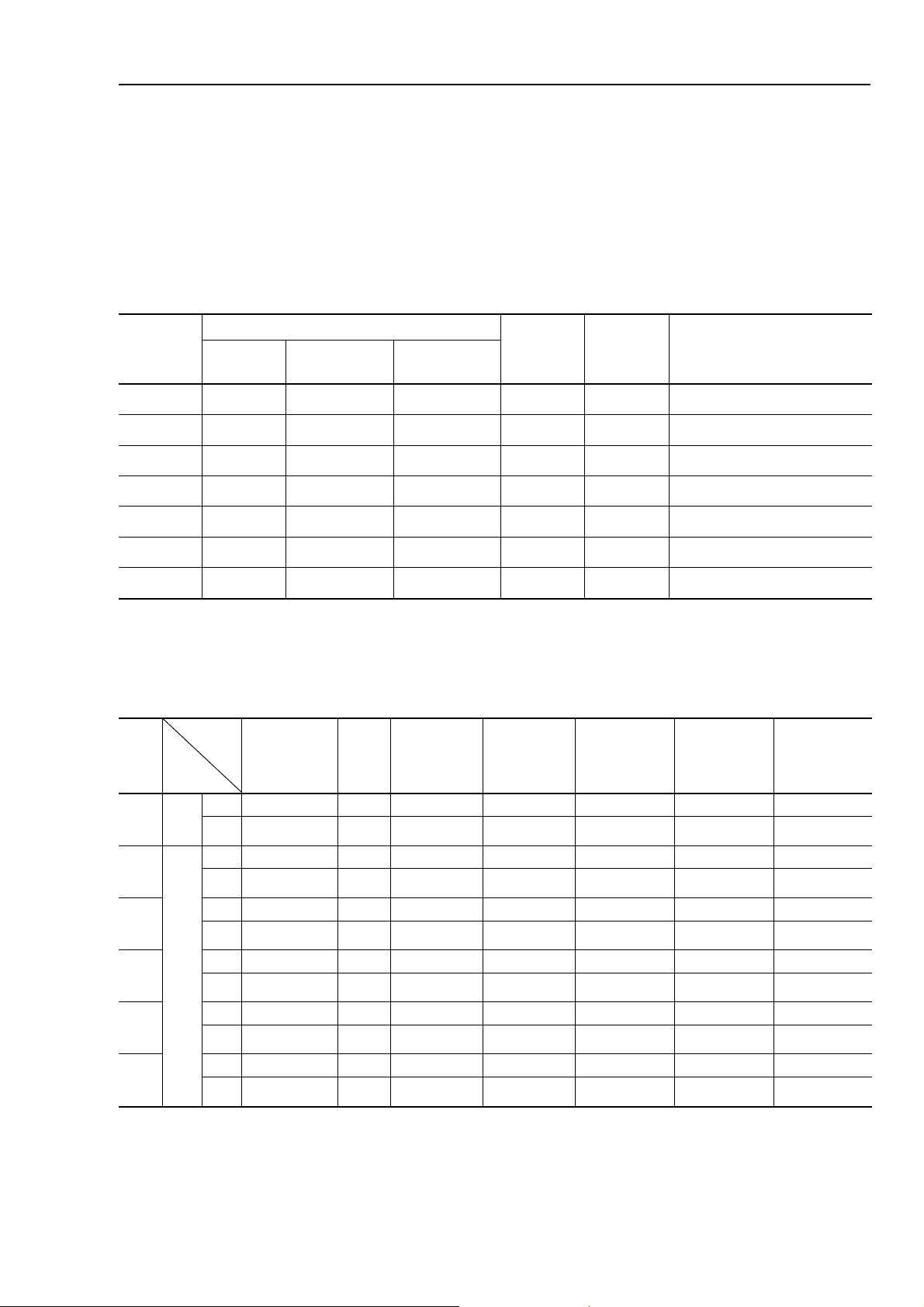

In the wiring diagrams, various colors and symbols are employed to indicate the thickness of wires. This

wire code table will help you understand WIRING DIAGRAMS.

Example: 5WB indicates a cable having a nominale number 5 and white coating with black stripe.

CLASSIFICA TION BY THICKNESS

lanimoN

rebmun

forebmuN

sdnarts

fo.aiD

)mm(sdnarts

noitcesssorC

)2mm(

elbaC

)mm(.D.O

58.01123.088.04.221.ctelangis,gnithgil,gnitratS

26223.090.21.302.ctelangis,gnithgiL

55623.032.56.473langisdnagnigrah

514854.063.310.795)gulpwolG(gnitratS

045808.037.244.11531gnitratS

0672108.048.366.31871gnitratS

00171208.01.9016.71032gnitratS

CLASSIFICATION BY COLOR AND CODE

stiucriC

eriwreppoC

-roirP

yti

1

2

3

4

5

6

-salC

noitacifis

-irP

yrail

edoCWBB R Y G L

yram

roloCetihWkcalBkcalBdeRwolleYneerGeulB

edoCRW-WBWRRYWGWL

roloCdeR&etihW- etihW&kcalBetihW&deRdeR&wolleYetihW&neerGetihW&eulB

edoCBW-YBBRBYRGRL

roloCkcalB&etihW- wolleY&kcalBkcalB&deRkcalB&wolleYdeR&neerGdeR&eulB

edoCLW-RBYRGYYGYL

-ixuA

roloCeulB&etihW-deR&kcalBwolleY&deRneerG&wolleYwolleY&neerGwolleY&eulB

edoCGW-- GRLYBGBBL

roloCneerG&etihW-- neerG&deReulB&wolleYkcalB&neerGkcalB&eulB

edoC--- LRWYLG-

roloC--- eulB&deRetihW&wolleYeulB&neerG-

gnigrahCdnuorGgnitratSgnithgiLtnemurtsnIlangiSrehtO

tnerruC

)A(gnitar

tiucricelbacilppA

00-11

햲

Page 16

FOREWORD CONVERSION T ABLE

CONVERSION T ABLE

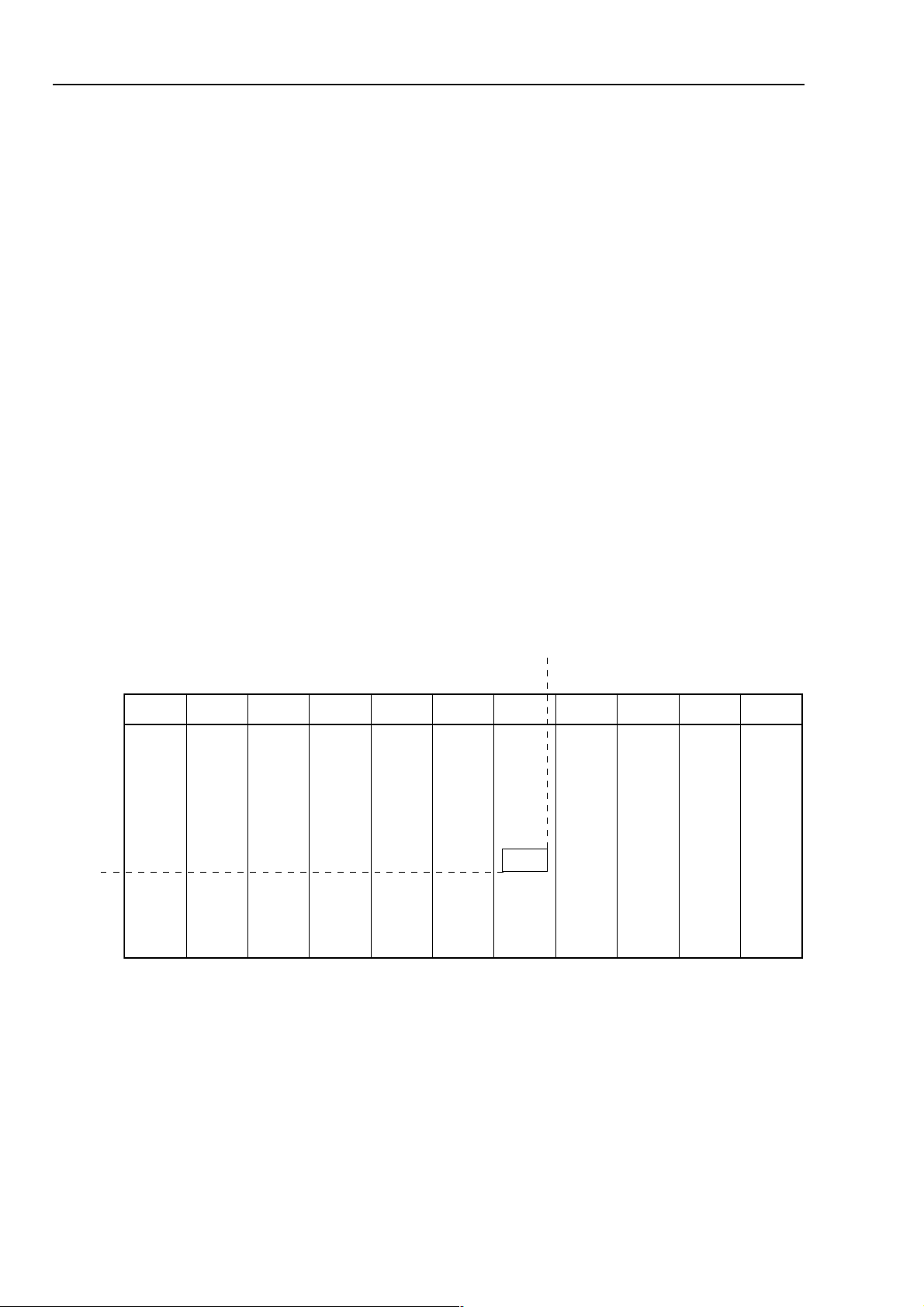

METHOD OF USING THE CONVERSION T ABLE

The Conversion T able in this section is provided to enable simple conversion of figures. For details of the method

of using the Conversion Table, see the example given below.

EXAMPLE

• Method of using the Conversion Table to convert from millimeters to inches

1. Convert 55 mm to inches

(1) Locate the number 50 in the vertical column at the left side, take this as 훽, then draw a horizontal line

from 훽.

(2) Locate the number 5 in the row across the top, take this as 훾, then draw a perpendicular line down

from 훾.

(3) Take the point where the two lines cross as 훿. This pint 훿 gives the value when converting from

millimeters to inches. Therefore, 55mm = 2.165 inches.

2. Convert 550 mm into inches.

(1) The nuber 550 does not appear in the table, so divide by 10 (move the decimal point one place to the

left) to convert it to 55 mm.

(2) Carry out the same procedure as above to convert 55 mm to 2.165 inches.

(3) The original value (550 mm) was divided by 10, so multiply 2.165 inches by 10 (move the decimal point

one place to the right) to return to the orginal value. This gives 550 mm = 21.65 inches.

훾

Millimeters to inches 1 mm = 0.03937 in

0123456789

00 930.0970.0811.0751.0791.0632.0672.0513.0453.0

01493.0334.0274.0215.0155.0195.0036.0966.0907.0847.0

02787.0728.0668.0609.0549.0489.0420.1360.1201.1241.1

03181.1022.1062.1992.1933.1873.1714.1754.1694.1635.1

04575.1416.1456.1396.1237.1277.1118.1058.1098.1929.1

훿

훽

05969.1800.2740.2780.2621.2561.2502.2442.2382.2323.2

06263.2204.2144.2084.2025.2955.2895.2836.2776.2717.2

07657.2597.2583.2478.2319.2359.2299.2230.3170.3011.3

08051.3981.3822.3862.3703.3643.3683.3524.3564.3405.3

09345.3385.3226.3166.3107.3047.3087.3918.3858.3898.3

00-12

햲

Page 17

FORWORD CONVERSION T ABLE

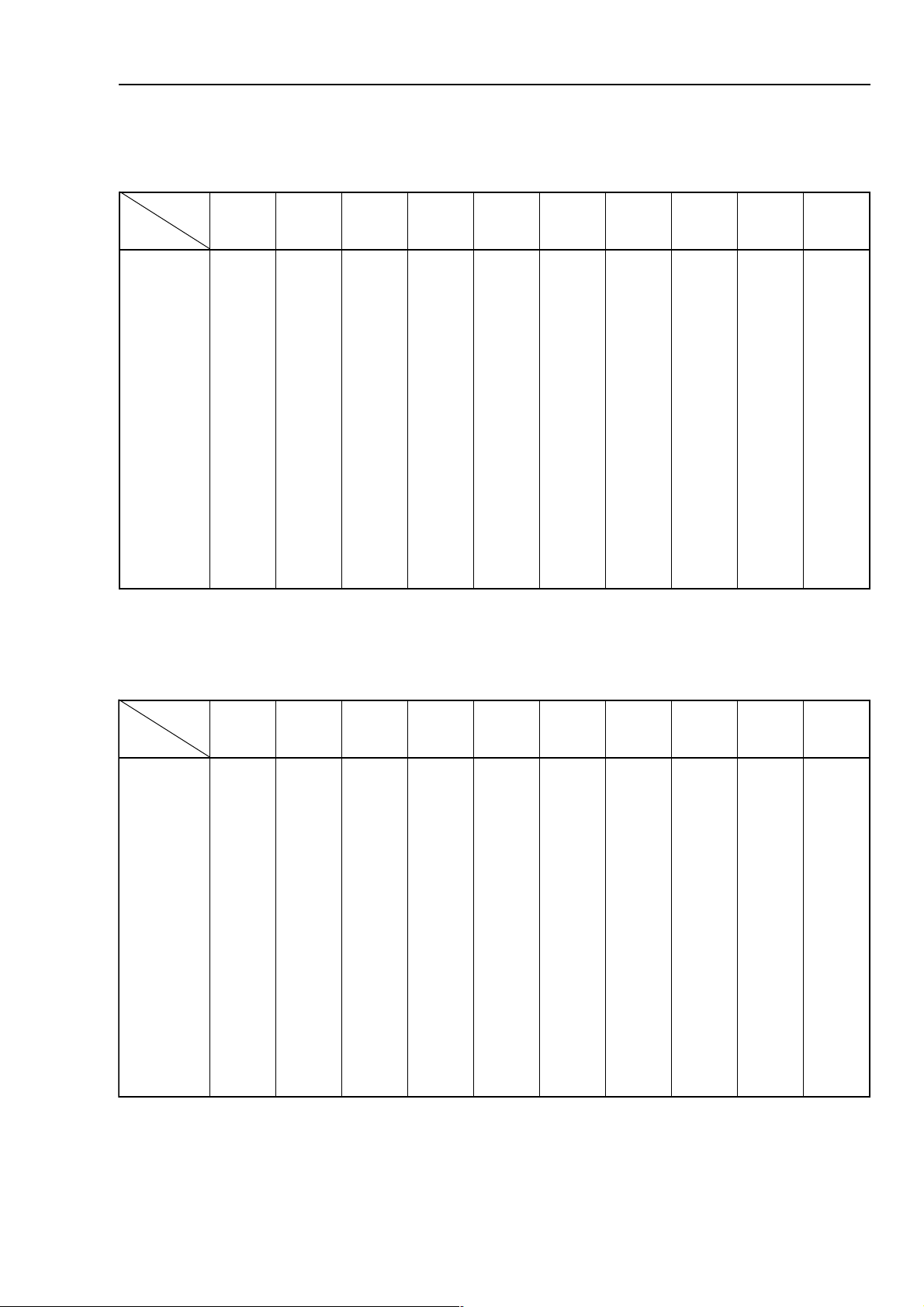

Millimeters to Inches

1 mm = 0.03937 in

0123456789

00930.0970.0811.0751.0791.0632.0672.0513.0453.0

01493.0334.0274.0215.0155.0195.0036.0966.0907.0847.0

02787.0728.0668.0609.0549.0489.0420.1360.1201.1241.1

03181.1022.1062.1992.1933.1873.1714.1754.1694.1635.1

04575.1416.1456.1396.1237.1277.1118.1058.1098.1929.1

05969.1800.2740.2780.2621.2561.2502.2442.2382.2323.2

06263.2204.2144.2084.2025.2955.2895.2836.2776.2217.2

07657.2597.2538.2478.2319.2359.2299.2230.3170.3011.3

08051.3981.3822.3862.370.33643.3683.3524.3564.3405.3

09345.3385.3226.3166.3107.3047.3087.3918.3858.3898.3

Kilogram to Pound

0123456789

0002.214.416.628.820.1132.3134.5146.7148.91

0150.2252.4264.6266.8268.0370.3372.5384.7386.9398.14

0290.4403.6405.8417.0519.1521.5523.7535.9537.1639.36

0341.6643.8655.0757.2769.4761.7773.9775.1887.3889.58

0481.8893.0995.2908.4900.7912.9914.10126.30128.50130.801

0532.01144.21146.41158.61150.91152.12164.32166.53178.72170.031

0682.23184.43196.63198.83101.14103.34115.54117.74119.94121.251

1kg = 2.2046 lb

0723.45135.65137.85149.06141.36153.56155.76167.96169.17171.471

0873.67175.87187.08189.28191.58193.78106.98108.19110.49112.691

0924.89126.00230.20230.50242.70244.90246.11258.31250.61262.812

00-13

햲

Page 18

FORWORD CONVERSION T ABLE

Litre to U.S. Gallon

1l = 0.2642 U.S. Gal

0123456789

00462.0825.0397.0750.1123.1585.1948.1311.2873.2

01246.2609.2071.3434.3896.3369.3722.4194.4557.4910.5

02382.5845.5218.5670.60433.6406.6968.6331.7793.7166.7

03529.7981.8454.8817.8289.8642.9015.9477.9930.01303.01

04765.01138.01590.11953.11426.11888.11251.21614.21086.21449.21

05902.31374.31737.31100.41562.41925.41597.41850.51223.51685.51

06058.51511.61973.61346.61709.61171.71534.71007.71469.71822.81

07294.81657.81020.91582.91945.91318.91770.02143.02506.02078.02

08431.12893.12266.12629.12091.22554.22917.22389.22742.32115.32

09577.32040.42403.42865.42238.42690.52163.52526.52988.52351.62

Litre to U.K. Gallon

1l = 0.21997 U.K. Gal

0123456789

00022.0044.0066.0088.0001.1023.1045.1067.1089.1

01002.2024.2046.2068.2080.3003.302.53047.3059.3971.4

02993.4916.4938.4950.5972.5994.5917.5939.5951.69736

03995.6918.6930.7952.7974.7969.7919.7931.8953.8975.8

04997.8910.9932.9954.9976.9998.9911.01933.01955.01877.01

05899.01182.11834.11856.11878.11890.21813.21825.21857.21879.21

06891.31814.31836.31858.31870.41892.41815.41837.41859.41871.51

07893.51816.51838.51850.61872.61894.61817.61839.61851.71873.71

08895.71818.71730.81752.81774.81796.81719.81731.91753.91775.91

09797.91710.02732.02754.02776.02798.02711.12733.12755.12777.12

00-14

햲

Page 19

FORWORD CONVERSION T ABLE

kgm to ft. lb

1 kgm = 7.233 ft. lb

0123456789

002.75.417.129.822.634.346.059.751.56

013.276.978.680.493.1015.8017.5110.3212.0314.731

027.4419.1511.9514.6616.3718.0811.8813.5915.2028.902

030.7122.4225.1327.8329.5422.3524.0626.7629.4721.282

043.9826.6928.3030.1133.8135.5237.2330.0432.7434.453

057.1639.8631.6734.3836.0938.7931.5043.2145.9148.624

060.4342.1445.8447.5549.2642.0744.7746.4848.1941.994

073.6055.3158.0250.8252.5355.2457.9459.6552.4654.175

086.8759.5851.3953.0066.7068.4160.2263.9265.6367.346

090.1562.8564.5667.2769.9761.7864.4966.1078.8071.617

0013.3275.0378.7370.5472.2575.9577.6679.3772.1874.887

0116.5979.2081.0183.7186.4288.1380.9383.6485.3587.068

0210.8682.5784.2887.9889.6981.4094.1196.8198.5291.339

0313.0495.7498.4590.2692.9695.6797.3899.0992.8994.5001

0416.21019.91011.72013.43015.14018.84010.65012.36015.07017.7701

0519.48012.29014.99016.60119.31111.12113.82116.53118.24110.0511

0613.75115.46117.17110.97112.68114.39117.00219.70211.51214.2221

0716.92118.63211.44213.15215.85218.56210.37211.08215.78217.4921

0819.10312.90314.61316.32319.03311.83313.54216.25318.95310.7631

0913.47315.18317.88310.69312.30414.01417.71419.42411.23414.9341

00-15

햲

Page 20

FORWORD CONVERSION T ABLE

kg/cm

2

to lb/in

2

1 kg/cm2 = 14.2233 lb/in

0123456789

002.414.827.249.651.173.586.998.3110.821

012.2415.6517.0719.4811.9914.3126.7228.1420.6522.072

025.4827.8929.2131.7234.1436.5538.9630.4833.8935.214

037.6249.0441.5544.9646.3848.7940.2153.6255.0457.455

049.8652.3854.7956.1168.5261.0463.4565.8667.2869.696

052.1174.5276.9378.3571.8673.2875.6977.0180.5282.938

064.3586.7688.1881.6983.0195.4297.8390.3592.7694.189

076.599010142018301350176011801590190114211

088311251166111811591190213221732125216621

090821492190313231733115315631083149318041

2

0012241734115415641974139418051225163510551

0115651975139517061126163610561466187613961

0217071127153719471467187712971608112815381

0319481368177812981609102914391949136917791

0411991500202024302840226027702190250129112

0514312841226126712091250229122332274222622

0616722092240328132333274321632573298324042

0718142234264420642574298423052815223526452

0810652475298523062716113626462066247628862

0912072717213725472957237728872208261820382

0025482958237827882109261920392449285923792

0127892100351030303440385032703680310135113

0229213341385132713681300234123922334237523

00-16

햲

0321723682300334133823334337533174458339933

0424143824324436543074358439943315372532453

Page 21

FORWORD CONVERSION T ABLE

Temperature

Fahrenheit-Centigrade Conversion; a simple way to convert a Fahrenheit temperature reading into a Centigrade

temperature reading or vice is to enter the accompanying table in the center or boldface column of figures.

These figures refer to the temperature in either Fahrenheit or Centigrade degrees.

If it desired to convert from Fahrenheit to Centigrade degrees, consider the center column as a table of Fahrenheit temperatures and read the corresponding Centigrade temperature in the column at the left.

If it is desired to convert from Centigrade to Fahrenheit degrees, consider the center column as a table of

Centigrade values, and read the corresponding Fahrenheit temperature on the right.

1°C = 33.8°F

°C °F °C °F °C °F °C °F

4.04-04-0.04-7.11-118.158.7648.4112.72188.711

2.73-53-0.13-1.11-216.353.8746.6118.72286.971

4.43-03-0.22-6.01-314.559.8844.8113.82384.181

7.13-52-0.31-0.01-412.754.9942.0219.82482.381

9.82-02-0.4-4.9-510.950.01050.2214.92580.581

3.82-91-2.2-9.8-618.066.01158.3210.03688.681

8.72-81-4.0-3.8-716.261.11256.5216.03786.881

2.72-71-4.18.7-814.467.11354.7211.13884.091

7.62-61-2.32.7-912.662.21452.9217.13982.291

1.62-51-0.57.6-020.868.21550.1312.23090.491

6.52-41-8.61.6-128.963.31658.2318.23198.591

0.52-31-6.86.5-226.179.31756.4313.33296.791

4.42-21-4.010.5-324.374.41854.6319.33304.991

9.32-11-2.214.4-424.370.51952.8314.43492.102

3.32-01-0.419.3-522.576.51060.0410.53590.302

8.22-9-8.513.3-620.771.61168.1416.53698.402

2.22-8-6.718.2-728.877.61266.3411.63796.602

7.12-7-4.912.2-826.082.71364.5417.63894.802

1.12-6-2.127.1-924.288.71462.7412.73992.012

6.02-5-0.321.1-030.683.81560.9418.730010.212

0.02-4-8.426.0-138.789.81668.0516.045010.122

4.91-3-6.620236.984.91766.2513.340110.032

9.81-2-4.826.0334.190.02864.4511.645110.932

3.81-1-2.031.1432.396.02962.6519.840210.842

8.71-00.237.1530.591.12070.8517.155210.752

2.71-18.332.2638.697.12178.9514.450310.662

7.61-26.538.2736.892.22276.1612.755310.572

1.61-34.733.3834.0018.22374.3610.060410.482

6.51-42.939.3932.2013.32472.5617.265410.392

0.51-50.144.4040.4019.32570.7616.560510.203

4.41-68.240.5148.5014.42678.8613.865510.113

9.31-76.446.5246.7010.52776.0711.170610.023

3.31-84.641.6344.9016.52874.2719.375610.923

8.21-92.847.6442.1111.62972.4717.670710.833

2.21-010.052.7540.3117.62080.6714.975710.743

00-17

햲

Page 22

00-18

햲

Page 23

STRUCTURE AND FUNCTION

10 STRUCTURE AND FUNCTION

ENGINE RELATED PARTS ...................... 10-2

RADIATOR & OIL COOLER...................... 10-3

PTO........................................................... 10-4

POWER TRAIN......................................... 10-5

SWING CIRCLE........................................ 10-7

SWING MACHINERY ............................... 10-8

UNDERCARRIAGE................................... 10-9

TRANSMISSION....................................... 10-11

CLUTCH CONTROL ................................. 10-13

AXLE ......................................................... 10-15

SUSPENSION LOCK CYLINDER............. 10-19

BRAKING TRAIN ...................................... 10-21

BRAKE & STEERING CIRCUIT................ 10-22

BRAKE/STEERING PUMP ....................... 10-25

BRAKE PEDAL/BRAKE VALVE................ 10-26

PRIORITY VALVE ..................................... 10-27

ACCUMULATOR FOR BRAKE SYSTEM . 10-28

STEERING TRAIN .................................... 10-29

STEERING COLUMN ............................... 10-31

ORBITROL VALVE.................................... 10-32

HYDRAULIC CIRCUIT DIAGRAM ............ 10-33

FUEL/HYDRAULIC T ANK......................... 10-35

HYDRAULIC PUMP .................................. 10-36

LS VALVE/PC VALVE................................ 10-42

PPC PUMPLESS SYSTEM ...................... 10-56

CONTROL VALVE..................................... 10-58

CLSS......................................................... 10-68

SWING MOTOR........................................ 10-98

CENTER SWIVEL JOINT ......................... 10-103

TRAVEL MOTORS.................................... 10-104

WORK EQUIPMENT -

SWING PPC VALVE ................................. 10-110

TRAVEL PPC PEDAL ............................... 10-114

SERVICE PPC PEDAL ............................. 10-113

SAFETY LOCK SWITCH .......................... 10-117

PPC MANIFOLD BLOCK .......................... 10-118

PPC MANIFOLD BLOCK

PRESSURE SWITCHES .......................... 10-119

SOLENOID VALVE ................................... 10-120

TRAVEL SPEED - SWING BRAKE 2-STAGE RELIEF SUSPENSION

SOLENOID VALVE ................................... 10-121

BOOM SAFETY VALVE ............................ 10-122

HYDRAULIC CYLINDERS

(BOOM, ARM & BUCKET)........................ 10-125

OUTRIGGER CYLINDER ......................... 10-127

DOZER BLADE CYLINDER...................... 10-128

WORK EQUIPMENT................................. 10-129

ELECTRICAL WIRING DIAGRAM............ 10-130-1

ENGINE CONTROL SYSTEM .................. 10-131

MACHINE MONITOR SYSTEM................ 10-160

OVERLOAD WARNING DEVICE ............. 10-167

BREAKER MODE HYDRAULIC

PERFORMANCE ...................................... 10-168

10-1

Page 24

STRUCTURE AND FUNCTION

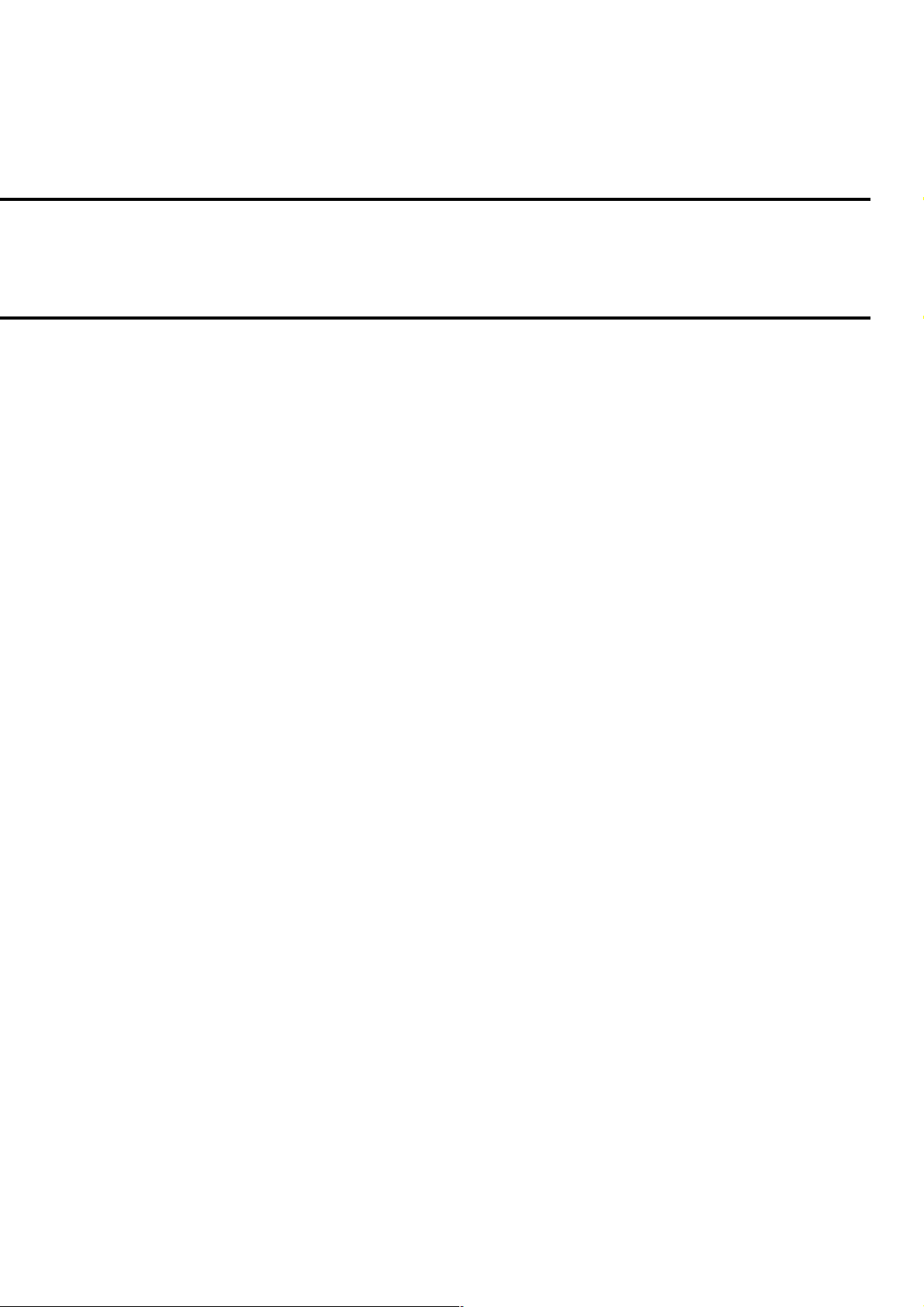

ENIGNE RELATED PARTS

ENGINE RELATED PARTS

1. Air cleaner

2. Intake hose

3. Muffler

4. Rear engine mount

5. Front engine mount

10-2

Page 25

STRUCTURE AND FUNCTION

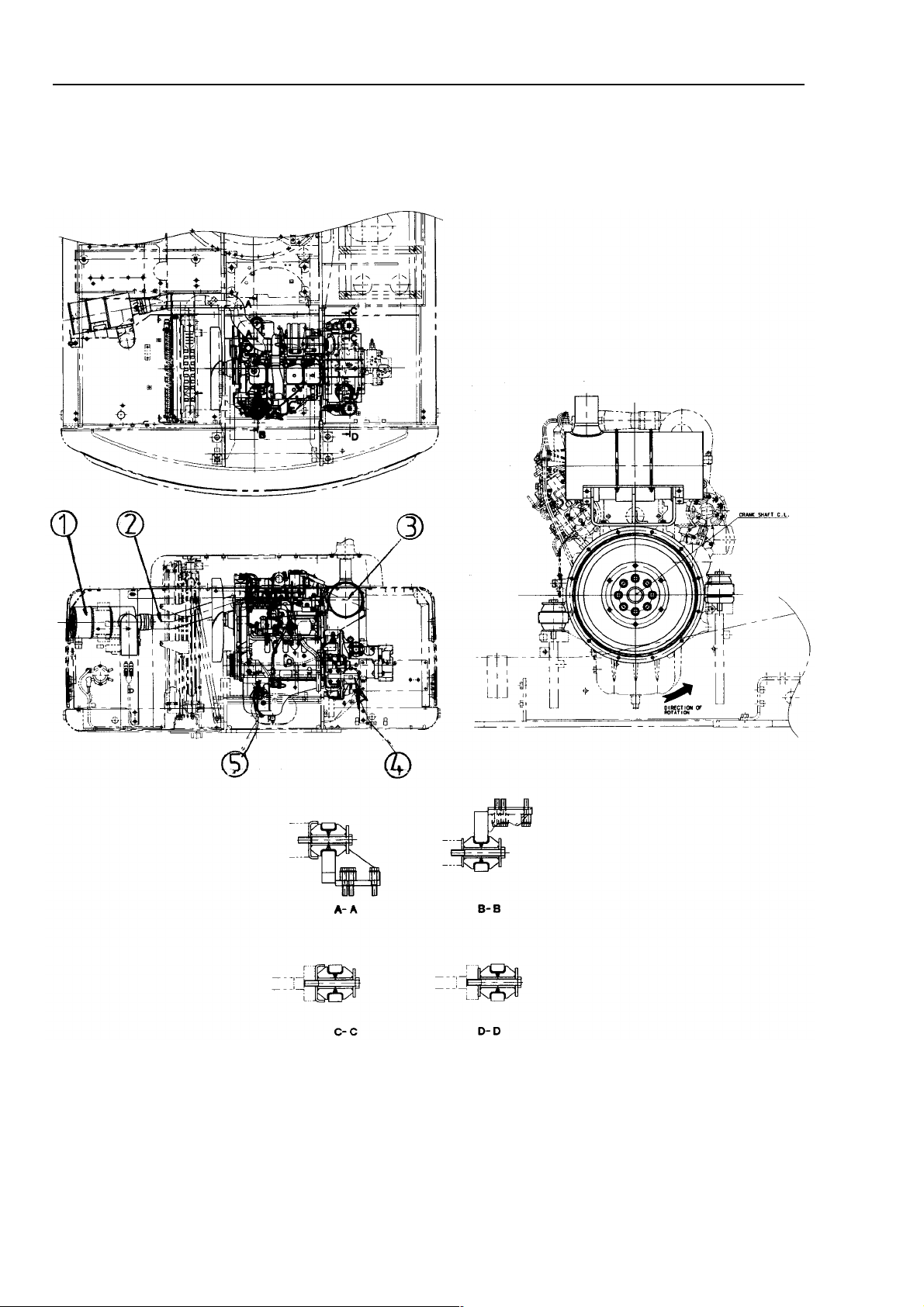

RADIATOR AND OIL COOLER

RADIATOR AND OIL COOLER

SPECIFICATIONS

RADIATOR

- Core type: CWX-4

- Fin pitch: 3.5/2 mm

- Total radiation area: 40.37 m

- Pressure valve cracking pressure:

0.05 MPa (0.5 kg/cm2)

- Vacuum valve cracking pressure:

-0.005 MPa (-0.05 kg/cm2)

OIL COOLER

- Core Type: CF40-1

- Fin pitch: 4.5/2 mm

- Total radiation area 10.41 m

2

2

1. Radiator outlet hose

2. Radiator cap

3. Radiator

4. Radiator inlet hose

5. Fan guard

6. Fan

7. Drain valve

8. Shroud

9. Oil cooler

10. Reservoirtank

10-3

Page 26

STRUCTURE AND FUNCTION

PTO (COUPLING)

PTO (COUPLING)

1. Shaft

2. Coupling

3. Breather

4. Cage

5. Hydraulic pump

6. Oil filler plug

7. Level plug

10-4

Page 27

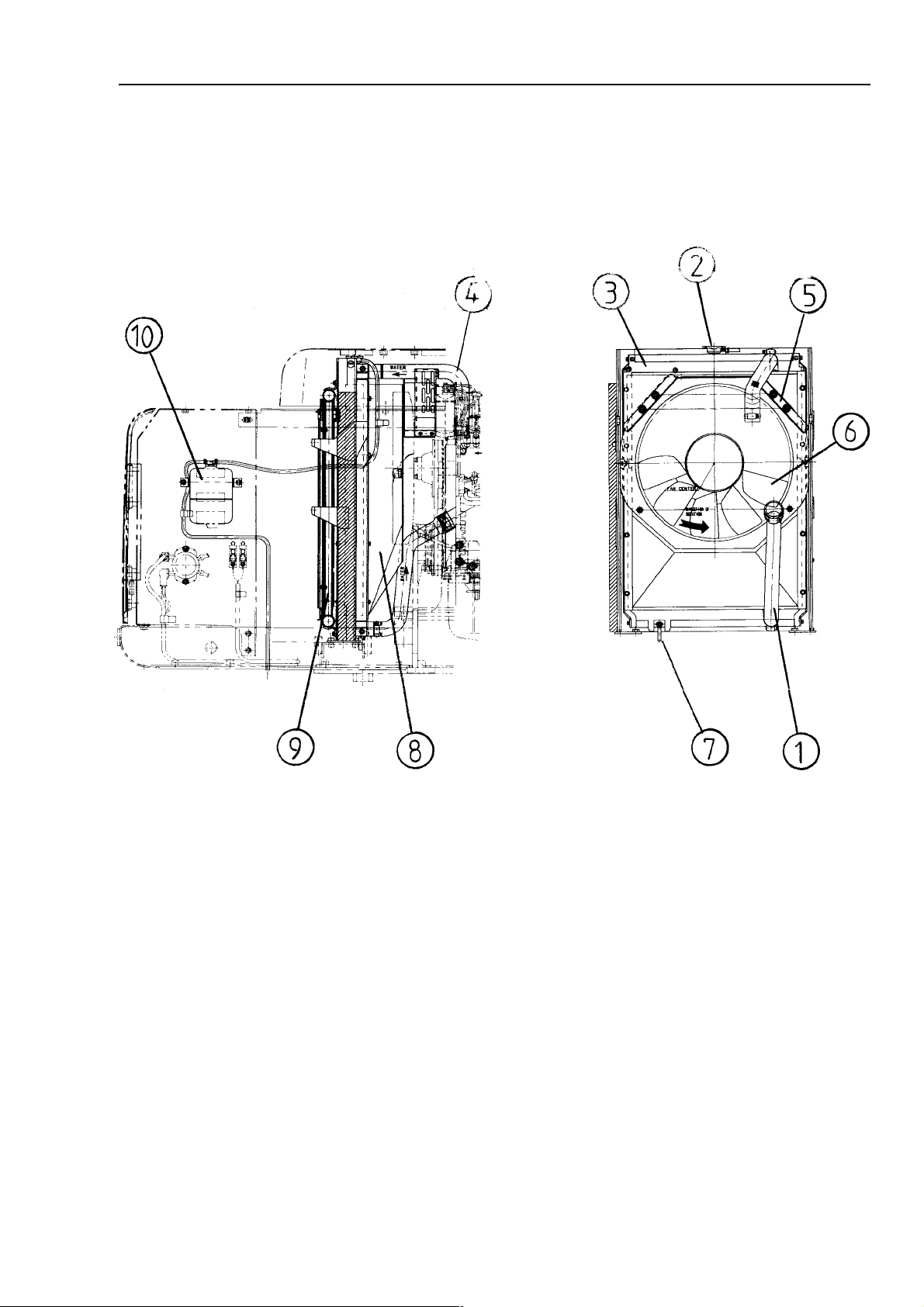

STRUCTURE AND FUNCTION

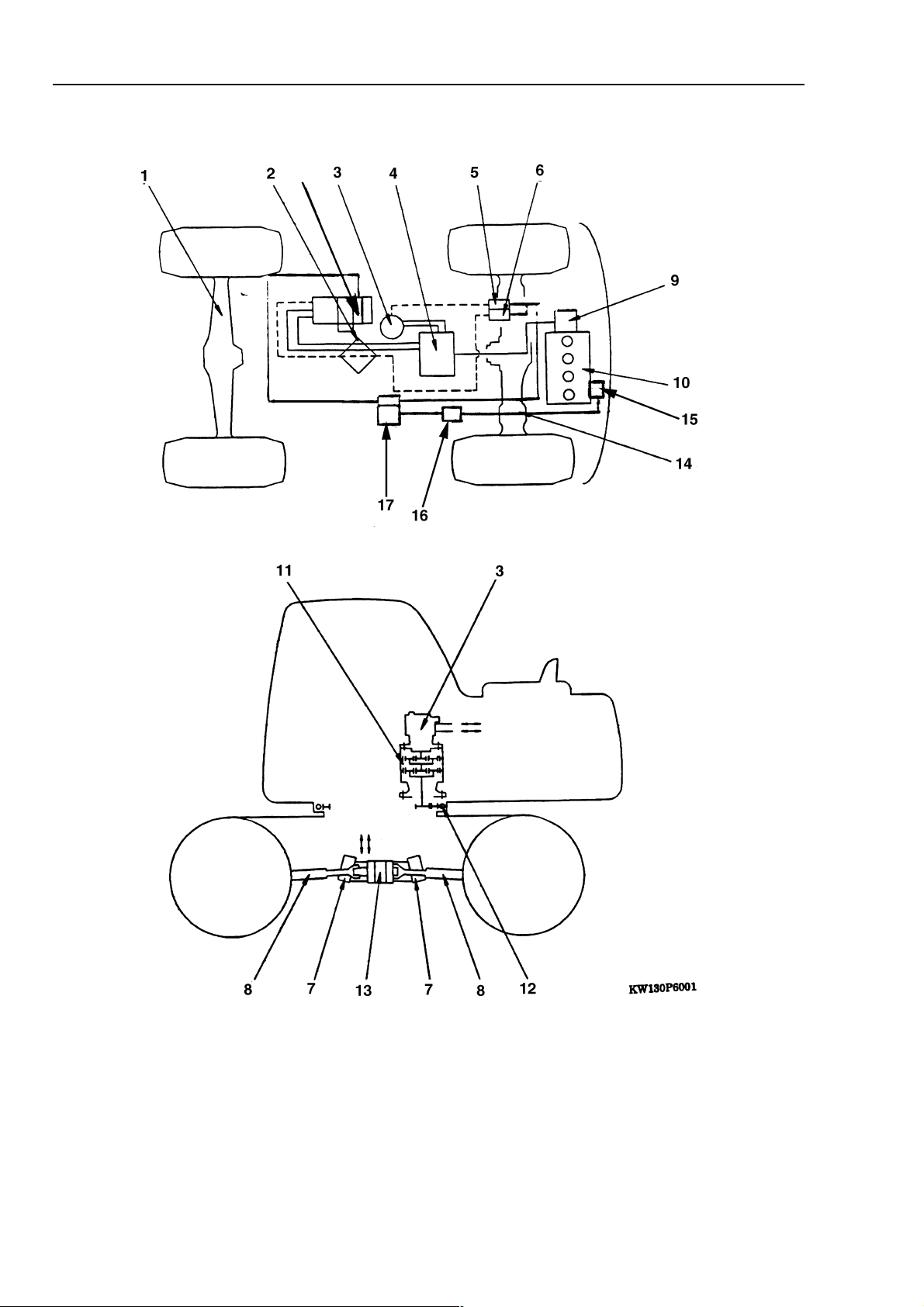

POWER TRAIN - 20 Km/h TRAVEL SPEED SPEC.

POWER TRAIN

1. Front axle

2. Center swivel joint

3. Swing motor

4. Control valve

5. Swing brake solenoid valve

6. Travel speed solenoid valve

7. Travel motor

8. Propshaft

9. Hydraulic pump

10. Engine

11. Swing machinery

12. Swing circle

13. Transmission

14. Rear axle

10-5

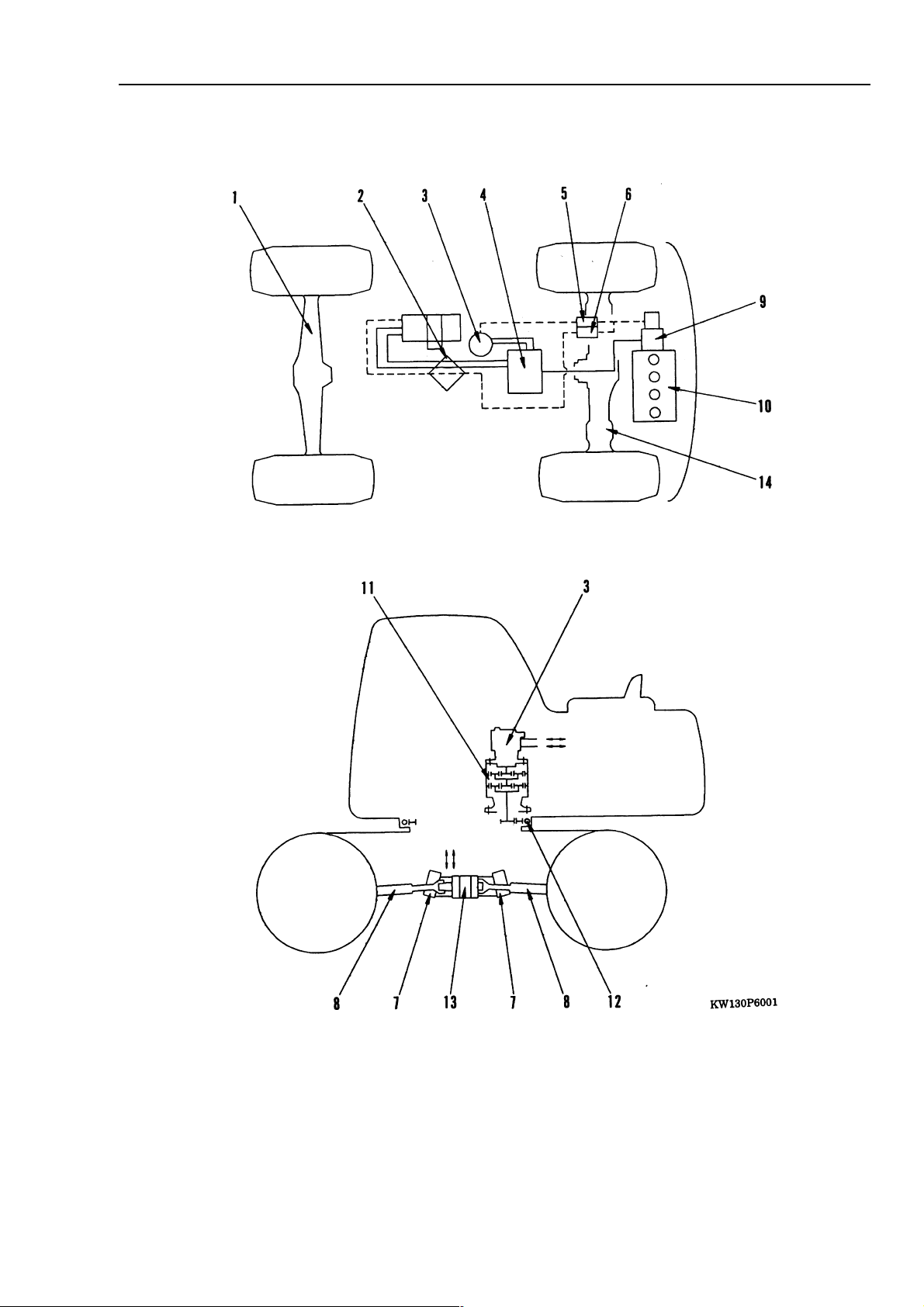

Page 28

STRUCTURE AND FUNCTION

POWER TRAIN - 30 Km/h TRAVEL SPEED SPEC.

18

POWER TRAIN

1. Front axle

2. Center swivel joint

3. Swing motor

4. Control valve

5. Swing brake solenoid valve

6. Travel speed solenoid valve

7. Travel motor

8. Propshaft

9. Hydraulic pump

10-6

10. Engine

11. Swing machinery

12. Swing circle

13. Transmission

14. Rear axle

15. Gear pump

16. Priority valve

17. Power brake valve

18. Clutch

Page 29

STRUCTURE AND FUNCTION

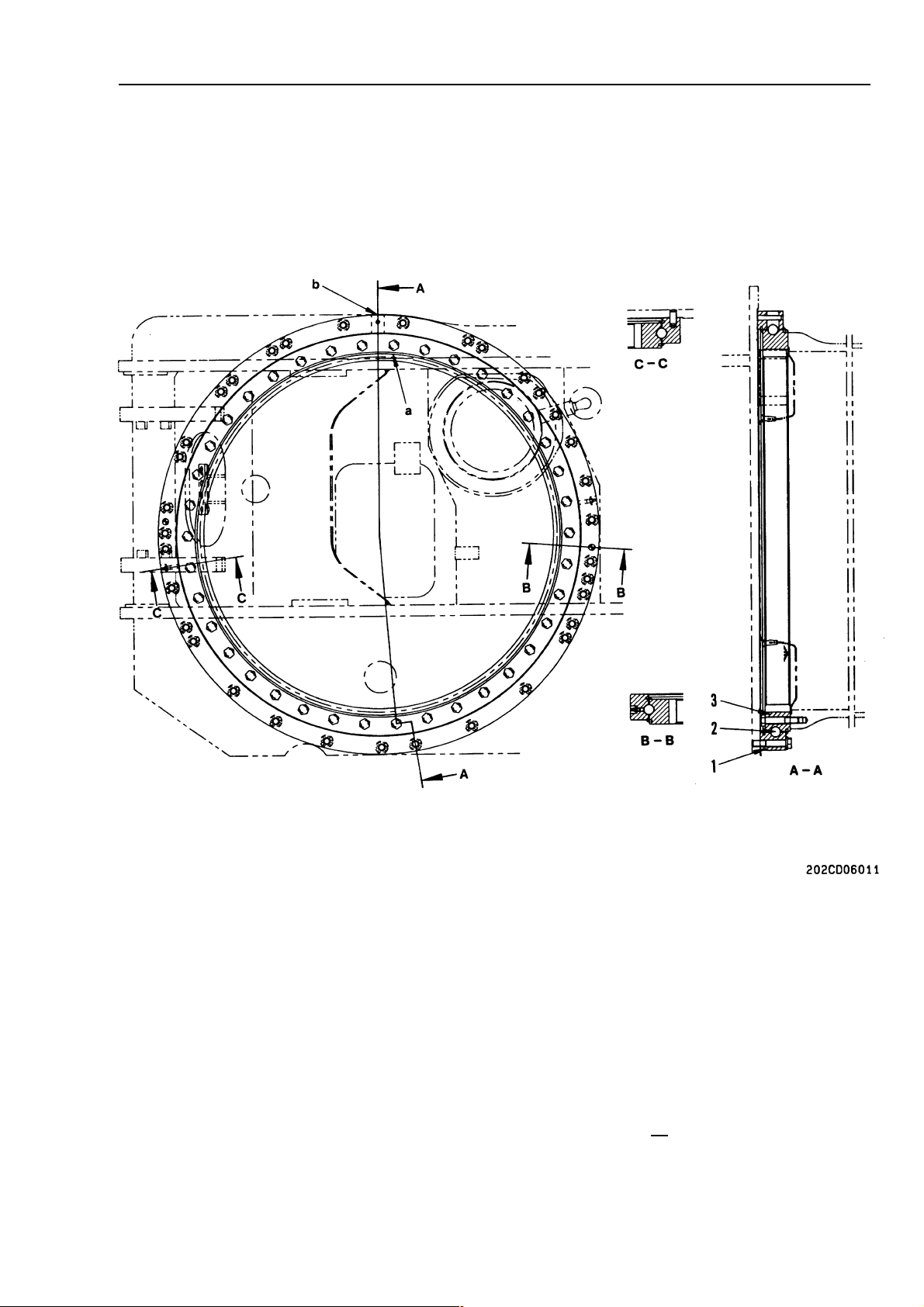

SWING CIRCLE

SWING CIRCLE

1. Outer race

2. Ball

3. Inner race

a. Inner race soft zone "S" position

b. Outer race soft zone "S" position

Specifications

Reduction ratio:

Amount of grease: 10 l (Grease: (G2-LI)

90

= 8.182

11

10-7

Page 30

STRUCTURE AND FUNCTION

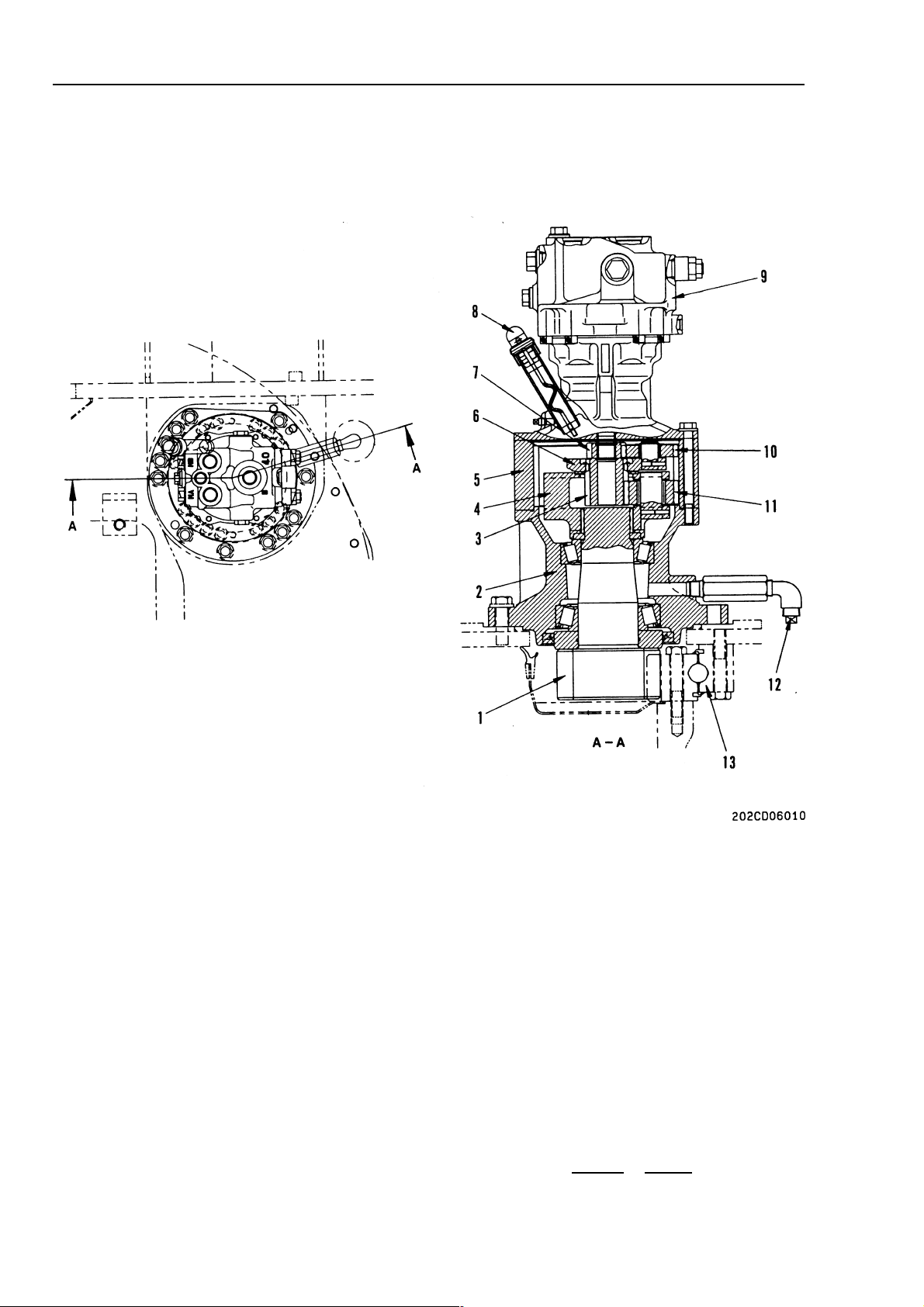

SWING MACHINERY

SWING MACHINERY

1. Swing pinion (No. of teeth:11)

2. Case

3. No. 2 sun gear (No. of teeth: 17)

4. No. 2 planetary carrier (No. of teeth: 17)

5. Ring gear (No. of teeth:61)

6. No. 1 planetary carrier (No. of teeth: 17)

7. No. 1 sun gear (No. of teeth: 14)

8. Oil level gauge/oil filler port

9. Swing motor

10-8

10. No. 1 planetary gear (No. of teeth: 24)

11. No. 2 planetary gear (No. of teeth: 22)

12. Drain plug

13. Swing circle

Specification

Reduction ratio

14 + 61 x 17 +61

14 17

= 24.586

Page 31

UNDERCARRIAGE

UNDERCARRIAGESTRUCTURE AND FUNCTION

1. Undercarriage

2. Step

3. Wheel chock

4. Front oscillating steering axle

5. Rear axle

6. Propshaft

7. Travel motor

8. Transmission

9. Double wheel ass'y

10. Single wheel ass'y

10-9

Page 32

STRUCTURE AND FUNCTION

10-10

Page 33

STRUCTURE AND FUNCTION

TRANSMISSION - 20 Km/h TRAVEL SPEED SPEC.

TRANSMISSION

1. Screw-fork to shaft

2. Flange

3. Brake cylinder

4. Brake drum

5. Friction disk

6. Flange

7. Gear

8. Cover

9. Output shaft

10. Bearing

11. Gear

Specification

Reduction ratio: 2.265 : 1

10-11

Page 34

TRANSMISSIONSTRUCTURE AND FUNCTION

TRANSMISSION - 30 Km/h TRAVEL SPEED SPEC.

CLUTCH ASS'Y - 30 Km/h TRAVEL SPEED SPEC.

1. Screw-fork to shaft

2. Flange

3. Brake cylinder

4. Brake drum

5. Friction disk

6. Flange

7. Gear

8. Cover

9. Output shaft

10. Bearing

11. Gear

12. Clutch ass'y

Specification

Reduction ratio: 1.846 : 1

1. Casing

2. Drive shaft

3. Friction plates

4. Spring discs

5. Gear

6. Clutch control gear pump

7. Plug

8. Plug

10-12

Page 35

STRUCTURE AND FUNCTION

CLUTCH CONTROL CIRCUIT (30 Km/h SPEC. ONLY)

CLUTCH

STRUCTURE

1. Clutch control pump

2. Clutch control valve

10-13

Page 36

STRUCTURE AND FUNCTION

FUNCTION

The clutch is a device which automatically disengages the drive between the large diplacement

(Rear) travel motor and the transmission. This occurs when the machine is accelerating and the disengagement occurs at 11 Kph. The transmission

system becomes more efficient (by reducing losses

caused by the unnecessary rotation of the rear

travel motor) providing better acceleration and enabling a maximum speed of 30 Kph.

When the machine decelerates from a high speed

the clutch will re-engage automatically at 9 Kph and

will remain engaged until the speed is increased

above 11 Kpm again.

CLUTCH

10-14

Page 37

STRUCTURE AND FUNCTION

AXLE

OUTLINE

• Each axle consists of an axle housing supporting the chassis weight, a differential set in the

axle housing, a final drive, and a brake provided

at each end.

• A trunnion-type axle shaft with a king pin at the

final drive end is used to enable the direction of

travel of the machine to be changed.

FRONT AXLE

AXLE

10-15

Page 38

STRUCTURE AND FUNCTION

REAR AXLE

AXLE

10-16

Page 39

STRUCTURE AND FUNCTION

FRONT AXLE

AXLE

Axle reduction ratio = 17,73 : 1

1. Planetary carrier

2. Washer

3. Brake drum

4. Pin

5. Seal ring

6. Grease nipple

7. Seal ring

8. Seal ring

9. Bushing

10. Axle tube

11. Ring nut

12. Ball bearing

13. Ring nut

14. Ball bearing

15. Seal ring

16. Roller bearing

17. Roller bearing

18. Hexagon head screw

19. Shaft

20. Joint

21. Bushing

22. Grease nipple

23. Seal ring

24. Cylinder head screw

25. Roller bearing

26. Washer

27. Ring

28. Hexagon head screw

29. Sun gear

10-17

Page 40

STRUCTURE AND FUNCTION

REAR AXLE

AXLE

1. Planetary gear

2. Bolt

3. Planetary carrier

4. Stud

5. Wheel Hub

6. Bushing

7. Socket

8. Shaft

9. Axle tube

10. Ring nut

11. Roller bearing

12. Roller bearing

10-18

13. Shim

14. Bolt

15. Cover

16. Seal ring

17. Roller bearing

18. Roller bearing

19. Bevel gear

20. Cylinder head screw

21. Bearing

22. Ring gear plate

23. Sun gear

Page 41

STRUCTURE AND FUNCTION

SUSPENSION LOCK CYLINDER

SUSPENSION LOCK CYLINDER

1. Barrel

2. Plunger

Specifications

Piston: ø 85 mm

Stoke: 160 mm

Operating pressure: 40.0 MPa (408 kg/cm

Pilot pressure: 3.0 MPa (30.6 kg/cm2)

Max 5.0 MPa (51.0 kg/cm2)

2

)

10-19

Page 42

STRUCTURE AND FUNCTION

CIRCUIT

SUSPENSION LOCK CYLINDER

Purpose

The undercarriages of wheeled hydraulic excavators have one of the two driven axles oscillating

mounted. This makes it possible to fully utilize the

excavator's rimpull in rough terrain - all of the

wheels being constantly in contact with the ground.

An oscillation blocking ram is fitted on each side of

the undercarriage to block the axle during digging or

lifting work.

Blocking the axle increases the excavator's stability .

1. Ram

2. Axle oscillation point

3. Oscillating axle

4. Oscillation lock solenoid valve

5. Pilot pressure reducing valve

6. Hydraulic tank

7. Swivel joint

8. Check valve

Function

The oscillating axle (3) is mounted in bearing (2) in

the middle of the excavator. The two rams (1) which

are full of hydraulic oil are connected through pipelines to the oscillation lock solenoid valve (4).

When the excavator is being moved, the oscillation

lock solenoid valve should be de-energized so that

the hydraulic oil in the ram can be returned to tank

as the axle is oscillating up and down. Before commencing excavating operations, the oscillation lock

solenoid valve should be energized to pressurize

the oil in the rams. This will lock the axle in the position it is in.

10-20

Page 43

STRUCTURE AND FUNCTION BRAKING TRAIN

1. Hydraulic oil filter

2. Hydraulic oil pump (shared with steering system)

3. Priority valve

4. Brake control valve

5. Accumulator - service brake

6. Accumulator - service brake

7. Accumulator - parking brake

8. Pressure switch - stop light

9. Pressure switch - accumulator

10. Pressure switch - parking brake

11. Pressure switch - service brake

12. Brake pedal

13. Swivel joint

14. Service brake cylinder

15. Service brake cylinder

16. Parking brake cylinder

Structure and function

The brake system is fully hydraulic. Oil is supplied at high pressure by a pump to a priority valve. The priority valve gives

priority to the steering circuit. When braking, oil is sent to the brake valve which provides braking pressure to two separate

braking circuits (service brakes). In the event of a failure of the power supply, the accumulators provide brake pressure to

allow the machine to be safety stopped.

A parking brake is provided which is operated by energizing a solenoid valve in the brake valve which sends pressure to the

park brake in the transmission. Park brake on solenoid off.

10-21

Page 44

STRUCTURE AND FUNCTION BRAKE & STEERING CIRCUIT

BRAKE & STEERING CIRCUIT (ITALIAN SPECIFICATION)

10-22

Page 45

STRUCTURE AND FUNCTION

Function

The function of the steer/brake circuit (Italian specification) is identical to the standard circuit except for the

tandem gear pump.

The tandem pump consists of two gear pumps, one for each circuit. The priority value is maintened in the

steering circuit to provide a load sensing output for emergency steering when required.

BRAKE AND STEERING CIRCUIT

10-23

Page 46

STRUCTURE AND FUNCTION BRAKE AND STEERING CIRCUIT

GEAR PUMP (ITALIAN SPECIFICATION)

10-24-1

Page 47

STRUCTURE AND FUNCTION BRAKING TRAIN

BRAKING TRAIN

10-24-2

Page 48

STRUCTURE AND FUNCTION

BRAKE/STEER PUMP

BRAKE/STEER PUMP

1. Delivery port

2. Suction port

Specifications

Rated peed: 2,400 RPM

Displacement: 19 cc/REV

Rated pressure: 250 bar

Type: gear pump

10-25

Page 49

STRUCTURE AND FUNCTION

BRAKE PEDAL INCORPORATING BRAKE VALVE

BRAKE PEDAL

F = Accumulator pressure switch

R = Accumulator (parking brake)

R

= Accumulator (service brake)

1

r

= Accumulator (service brake)

2

T

= Service brake

1

1

T

= Service brake pressure switch

1

T

= Service brake

2

1

T

= Stop light pressure switch

2

X = Parking brake

X

= Parking brake pressure switch

1

P = Delivery

B = Return

N = Tank

10-26

Specifications

Accumulator charge pressure (cut in) = 122 bar

(cut out) = 150 bar

+6

-2

+8

-4

Page 50

STRUCTURE AND FUNCTION

PRIORITY V AL VE

PRIORITY V AL VE

P = Pressure port (from pump)

EF = Output port to brake system

CF = Output port to steering system

LS = Load sensing port from steering valve

Specification

Control spring pressure: 7 bar

10-27

Page 51

STRUCTURE AND FUNCTION

ACCUMULATOR FOR BRAKE SYSTEM

ACCUMULATOR FOR BRAKE SYSTEM

Specifications

Volume: 0.75 l

Max working pressure: 210 bar

10-28

Page 52

STRUCTURE AND FUNCTION

STEERING TRAIN

STEERING TRAIN

Structure and function

• The steering is fully hydraulic. The oil sent by

the brake/steer pump (2) mounted on the PTO

at the front of the engine (1) flows via the priority valve (3) to the steering valve (4). From here

it is passed through swivel joint (7) to steering

cylinder (5). The steering cylinder then extends

or retracts to move the tie-rod and steer the machine.

• In the event of failure of the power supply the

machine can be steered by emergency steering. The steering valve acts as a pump to send

oil to the steering cylinder.

10-29

Page 53

STRUCTURE AND FUNCTION

STEERING TRAIN

ITEM

POSITIONS

1. ENGINE

2. HYDRAULIC OIL PUMP (SHARED WITH BRAKING CIRCUIT) .................................................... 19cc/rev

3. PRIORITY VALVE

CONTROL SPRING PRESSURE ........................................................................................................ 7 bar

4. STEERING VALVE.................................................................................................. OSPD 70/195 LS DYN.

5. STEERING CYLINDER ............................................................................... D=ø90, d=ø50, STROKE=170

STEERING CYLINDER VOLUME = (9 -5) x π x17 = 748 cmm

2

4

6. STEERING WHEEL .............................................................................................................................Ø352

7. SWIVEL JOINT

QUANTITIY OF STEERING TURNS

NORMAL

1 = CYL. VOL = 748 cm3= 3.8 TURNS

PUMP.VOL 195 cm

EMERGENCY

1 = CYL. VOL = 748 cm3= 10.7 TURNS

PUMP.VOL 70 cm

3

3

0

-1

10-30

Page 54

STRUCTURE AND FUNCTION BRAKING TRAIN

10-30-2

햲

Page 55

STRUCTURE AND FUNCTION

STEERING COLUMN

STEERING COLUMN

1. Steering wheel

2. Steering column

3. Gaiter

4. Pedal

5. Hose

6. Orbitroll valve

7. Mounting bracket

10-31

Page 56

STRUCTURE AND FUNCTION

ORBITROL V ALVE

ORBITROL V AL VE

P = Pressure port (from priority valve)

T = Tank port

L = Left turn port

R = Right turn port

LS = Load sensing port (to priority valve)

Specifications

Nominal displacement (normal operation):

195 cc/REV

Nominal displacement (emergency operation):

70cc/REV

Relief valve setting:

150 +5 bar

10-32

Page 57

STRUCTURE AND FUNCTION

(

)

(

)

8

B

02

02

02

02

02

02

02

02

02

02

#02

02

05#05

05

05

05

05

05

05

05

05

05

05

05

02

SOR

04

04

ÿ

05X

ÿ

990

ÿ

05X

ÿ

0

02

02

02

02

S

OR

0.2

/

ЗнЗЦЗс

.1

S

05

05

R

(

ÿ

0X

ÿ

)

R

(

95X

ÿ

)

S.

R

(

ÿ

05X

ÿ

)

05

1

08021

(2)

05

05

05

0

05

8

8

0

05

0

05

05

05

Y

05

.

300

Çç

G

G

B

E

8

/

ÇÉÇç

CF

S

O

L

O

D

C

ON

02

ÿ

t3

ÿ

t3

ÿ

t3

9

S

Y

Ç

.1

05

ÿ

t3

ÿ

t3

05

t3

t3

05

05

ÿ

t3

C

L

O

ON

ï™ó£ïŸ

S

S1

5

6

8

0

6

S

ÇÉ

3

3

9

5

5

5

8

8

S

CK

COO

SS

S

ON

OOM

SAFETY SET

S

T

p

S

CE

E

T

E

CHEC

T

p

ÇÉÇç

6

SAFETY SET

S

T

p

ÇÉÇç

T

6

3

p

ÇÉÇç

SECO

OOM

S

R

CRAC

E

2

M

M

ÿ

t3

ÿ

t3

ÿ

t3

ÿ

t3

ÿ

t3

ÿ

t3

ÿ

t3

ÿ

t3

ÿ

t3

m

B

E

92

35.8

p

05

05

ÿ

t3

ÿ

t3

0.75l

04

04

ÿ

.0

S

T

C

CY

Y

C

CY

0.75l

0.75l

T

OOM

P

G

P

N

S

G

B

E

P

OOM

S

G

DIGGING

P

T

D

CT

SO

Y

E

3

SUS

OCK

E

02

02

02

02

02

02

02

02

02

02

02

02

02

02

02

02

02

3

02

02

02

04

03

5

3

91

06

0

0

0

R

5

µ

)

O

COOLER

µ

)

CAP

A

P

v

(

G

)

E

K

C

l

8

(

)

S

Y

OCK

SE

D

02

02

02

R

0

3

35

E

03

03

03

03

02

E

0

0

S

O

ON

3

3

B

S

SW

S

SW

S

SW

E

S

SW

E

16

32

62

52

82

O

O

B

S

3

B

3

3

02

04

0#04

O

03

OCK

0

3

0

3

(

)

D

pc

s

C

C

E

E

g

b

d2ad3

d1

s

T

S

T

CLOC

SE

ON

P

v

S

T

04

04

06

06

v

/M

S

E

(

)

E

S

E

(

)

SUS LOCK C

R

(

ÿ

)

(

90X

ÿ

)

04

02

04

02

04

0

02

03

03

03

03

03

03

03

03

03

B

04

C

D

ÿ

.5

ph

(

)

2

03

03

ÿ

0.80

.8

0

3

50

n

BAR

0

0

8

R

ÿ

0.7

ÿ

.1

C

OL

04

ph

ÿ

.0

0

0

W

B

B

S

G

B

G

C

CH

2

0.45

0.2

0.2

2

v

v

v

ph

ph

v

(

)

(

)

OR

)(

)

(

B

#

#1

#1

#1

LENOID

ASSEMBL

#

PPC VALV

PPC VALV

FROM BRAKE VALVE

PPC VALV

#

#

ENGINE 4BT

GEAR PUM

19.0cc/re

FOR STEERIN

AND BRAKE

m

HYDRAULIC TAN

APACITY 145

#

#

22X

22X

BREAKER / CLAMSHELL

#

#

#

#

#

VER LOA

7861-

AUTI

#

#

RBITROL

RAK

1

#

#

ADJUST CYLINDE

14

70-507.5

#

#

2X

LEFT

22X

2X

LAMSHEL

PTI

BUCKET CYLINDE

65-885

1

1PB BOOM CYLINDER

1

70-95

70-

ARM CYLINDE

1

75-1175

22X

RIGHT

22X

WING MOT

4

=201

WING MACHINER

â=201

10-33

#

PUMP PRESSUR

PRESSURE SEN

ï™ó£ïŸ

1

#

1

#

KING POR

LS1 + 25kg/c

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

L

4

2

#

#

LS PRESSURE CHECKING POR

-

1l/mi

2

LUTCH CONTR

#1

#

2

285Kg/cm

PARKING BRAK

T

YLINDE

85-160 STROKE

BA

2

-

TRAVEL MOT

20 k

107cc/re

7

U

M

#

ERVICE BRAK

REAR

M1

U

1

315-325Kg/cm

LUT

#0

TRAVEL MOTOR 80cc/re

20/30k

20 k

30 k

MIN 39cc/re

MIN 32cc/re

50-170

MIN 26cc/re

#

#

FORWARD

REVERSE

WIVEL JOIN

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

2

1

#

1

1

2

2

ERVICE BRAK

FRONT

#

TO 'T' BLOCK

#

#

PPC MANIFOL

BYPASS STRAINE

150 MESH (10

#

#

1

#

#

#

#

#

WING RH

WING LH

#

#

#

#

P

T

#

#

#1

PC VALV

LS VALV

l

si

T

m

IL

1

T

TAB UP

P

ERVICE

ROTAT

ROTAT

LS-EP

e

PC-EP

MAIN PUM

MAX = 105cc/re

MIN = 13cc/rev

#1

BREAKER

#

#

L

BA

-

T

P

T

L

A

A

WIN

RAK

2 STE

AFET

L

P

P

PTI

T-BL

RIGHT PPC VALV

BUCKE

DIGGIN

LEFT PPC VALV

RETRA

2ND B

EXTEN

REVER

FORWAR

#

#

#

DUM

#

#

U

B

DOW

#

#

#

#

#

DUM

#

RIGH

WIN

#

#

#

#

#

#

#

#

#

#

2

KWI

INPU

ROTATI

HAF

#1

Ë

AFETY SE

BUCKE

AFETY SE

TABILIZE

WING MOTI

CA1

UNLOADING VALV

ERVI

ND B

ÇÉÇç

ÇÉÇç

B

KING PRESSUR

7Kg/cm

LER BYPA

LIFT CHE

CRACK 2.5KG/C

RELIEF 12KG/C

W

L

22X

22X

BOOM SAFET

#

22X

22X

A

B

#

#

22X

22X

#

22X

22X

#

#

22X

#

22X

22X

22X

702-2

#

#

RAK

RIGHT SWIN

1

ËÇÉ

LEFT SWIN

Page 58

STRUCTURE AND FUNCTION

10-34

Page 59

STRUCTURE AND FUNCTION

FUEL / HYDRAULIC TANK

K32001 and up

FUEL / HYDRAULIC TANK

1. Suction strainer

2. Drain plug

3. Filter element

4. Bypass valve

5. Bypass strainer

6. Sight gauge

7. Vacuum valve

8. Pressure valve

Specifications

Fuel capacity: 246 l

Oil capacity: 145 l

Pressure valve cracking pressure:

38 ± 3.14.7 kPa (0.39 ± 0.15 kg/cm

Vacuum valve cracking pressure:

-4.5 - 0 Pa (-0.046 -0 kg/cm2)

Bypass valve cracking pressure

1.05 ± 0.2 kg/cm

10-35

햲

2

)

2

Page 60

STRUCTURE AND FUNCTION

FUEL / HYDRAULIC TANK

K34001 and up

HYDRAULIC T ANK

1. Suction strainer

2. Drain plug

3. Filter element

4. Bypass valve

5. Bypass strainer

6. Sight gauge

7. Vacuum valve

8. Pressure valve

10-35-1

10-36

햲

Specifications

Fuel capacity: 246 l

Oil capacity: 145 l

Pressure valve cracking pressure:

38 ± 3.14.7 kPa (0.39 ± 0.15 kg/cm2)

V acuum valve cracking pressure:

-4.5 - 0 Pa (-0.046 -0 kg/cm2)

Bypass valve cracking pressure

1.05 ± 0.2 kg/cm

2

Page 61

STRUCTURE AND FUNCTION

10-35-2

10-37

햲

Page 62

STRUCTURE AND FUNCTION

HYDRAULIC PUMP

HYDRAULIC PUMP

a. Port PS (suction)

b. Port PA (delivery)

c. Port PLS (load pressure input port)

d. Port PEPC (EPC basis pressure port)

e. Breather mounting port

f. Port Pd3 (Air bleeder plug)

g. Port Pd1 (case drain)

h. Port im (PC mode selector current)

j. Port isig (LS set selector current)

10-36

1. Main pump

2. LS valve

3. PC valve

4. Fixed throttle valve

5. PC-EPC valve (for PC mode selector)

6. LS-EPC valve (for LS set selector)

Page 63

STRUCTURE AND FUNCTION

MAIN PUMP

HPV 105

HYDRAULIC PUMP

a. Port Pd (drain)

b. Port PA (discharge)

c. Port PS (suction)

10-37

Page 64

STRUCTURE AND FUNCTION

HYDRAULIC PUMP

1. Shaft

2. Cradle

3. Case

4. Rocker cam

5. Shoe

6. Piston

10-38

7. Cylinder block

8. Valve plate

9. End cap

10. Spring

11. Servo piston

12. Slider

Page 65

STRUCTURE AND FUNCTION

Function

• The engine rotation and torque transmitted to

the pump shaft is converted into hydraulic energy, and pressurized oil is discharged according to the load.

• It is possible to change the delivery amount by

changing the swash plate angle.

HYDRAULIC PUMP

Structure

• Cylinder block (7) is supported to shaft (1) by

spline a, and shaft (1) is supported by the front

and rear bearings.

• The tip of piston (6) is a concave ball, and shoe

(5) is caulked to it to from one unit. Piston (6)

and shoe (5) form a spherical bearing.

• Locker cam (4) has flat surface A, and shoe (5)

is always pressed against this surface while

sliding in a circular movement. Rocker cam (4)

brings high pressure oil at cylindrical surface B

with cradle (2), which is secured to the case,

and forms a static pressure bearing when it

slides.

• Piston (6) carries out relative movement in the

axial direction inside each cylinder chamber of

cylinder block (7).

• Cylinder block (7) seals the pressure oil to valve

plate (8) and carries out relative rotation. This

surface is designed so that the oil pressure balance is maintained at a suitable level. The oil

inside each cylinder chamber of cylinder block

(7) is sucked in and discharged through valve

plate (8).

10-39

Page 66

STRUCTURE AND FUNCTION

OPERATION

1. Operation of pump

1) Cylinder block (7) rotates together with shaft

(1), and shoe (5) slides on flat surface A. When

this happens, rocker cam (4) moves along cylindrical surface B, so angle ( between center

liner X of rocker cam (4) and the axial direction

of cylinder block (7) changes. (Angle ( is called

the swash plate angle.)

2) Center line X of rocker cam (4) maintains

swash plate angle α in relation to the axial direction of cylinder block (7), and flat surface A

moves as a cam in relation to shoe (5). In this

way, piston (6) slides on the inside of cylinder

block (7), so a difference between volume E

and F is created inside cylinder block (7). The

suction and discharge is carried out by this difference F - E.

In other words, when cylinder block (7) rotates

and the volume of chamber E becomes smaller ,

the oil is discharged during that stroke. On the

other hand, the volume of chamber F becomes

larger, so in that stroke, the oil is sucked in.

HYDRAULIC PUMP

3) If center line X of rocker cam (4) is in line with

the axial direction of cylinder block (7) (swash

plate angle = 0), the difference between volumes E and F inside cylinder block (7) becomes 0, so the pump does not carry out any

suction or discharge of oil. (In actual fact, the

swash plate angle never becomes 0.)

10-40

Page 67

STRUCTURE AND FUNCTION

2) Control of discharge amount

• If swash plate angle α becomes larger, the difference in volumes E and F becomes larger

and discharge volume Q increases. Swash

plate angle α is changed by servo piston (11).

• Servo piston (11) moves in a reciprocal movement () under the signal pressure of the PC

and LS valves. This straight line movement is

transmitted through rod (12) to rocker cam (4),

and rocker cam (4), which is supported by the

cylindrical surface to cradle (2), slides in a rotating movement in direction ().

• With servo piston (11), the area receiving the

pressure is different on the left and right, so

main pump discharge pressure (self pressure)

PP is always brought to the pressure chamber

on the small diameter piston side (front).

Output pressure Pen of the LS valve is brought

to the pressure chamber at the large diameter

piston end (rear). The relationship in the size of

pressure PP at the small diameter piston end

and pressure Pen at the large diameter piston

end, and the ratio between the area receiving

the pressure of the small diameter piston and

the large diameter piston controls the movement of servo piston (11).

HYDRAULIC PUMP

10-41

Page 68

STRUCTURE AND FUNCTION

LS V AL VE

HYDRAULIC PUMP

a. Port PLS (Control valve LS pressure inlet port)

b. Port PA (Pump delivery pressure inlet port)

c. Port PLP (LS valve signal pressure outlet port)

d. Port PPL (PC valve signal pressure inlet port)

e. Port Pa (Drain pressure outlet port)

f. Port PSIG (LS control EPC valve pressure inlet port)

g. Port PA (Pump delivery pressure inlet port)

PC V AL VE

1. Plug

2. Locknut

3. Sleeve

4. Spring

5. Seat

6. Spool

7. Piston

8. Sleeve

a. Port Pa (Drain pressure outlet port)

b. Port PPL (PC valve signal pressure outlet port)

c. Port PA (Pump delivery pressure inlet port)

d. Port PA2 (Pump delivery pressure inlet port)

e. Port PM (PC mode select pressure inlet port)

10-42

1. Piston

2. Spring

3. Seat

4. Spring

5. Seat

6. Spool

7. Piston

8. Sleeve

9. Locknut

10. Plug

11. Locknut

Page 69

STRUCTURE AND FUNCTION

FIXED THRO TTLE V AL VE

HYDRAULIC PUMP