SEBM033000

MACHINE MODEL SERIAL No.

PC400-7 50001 and up

PC400LC-7 50001 and up

PC450-7 20001 and up

PC450LC-7 20001 and up

• This shop manual may contain attachments and optional equipment that are not available

in your area. Please consult your local Komatsu distributor for those items you may

require. Materials and specifications are subject to change without notice.

• PC400, 400LC, PC450, 450LC-7 mount the SAA6D125E-3 engine.

For details of the engine, see the 125-3 Series Engine Shop Manual.

© 2003

All Rights Reserved

Printed in Japan 10-03 (01)

00-1

GENERAL

CONTENTS

No. of page

01 GENERAL

............................................................................................................................ 01-1

10 STRUCTURE, FUNCTION AND

MAINTENANCE STANDARD

20 TESTING AND ADJUSTING

............................................. To be issued next time

30 DISASSEMBLY AND ASSEMBLY

90 OTHERS

................................................................................................................................ 90-1

............................................ 10-1

......................... To be issued next time

00-2

(1)

PC400/450(LC)-7

01 GENERAL

SPECIFICATION DRAWINGS ......................................................................................................................01- 2

SPECIFICATIONS ........................................................................................................................................01- 4

WEIGHT TABLE............................................................................................................................................01- 8

FUEL, COOLANT AND LUBRICANTS .........................................................................................................01- 12

PC400/450(LC)-7

01-1

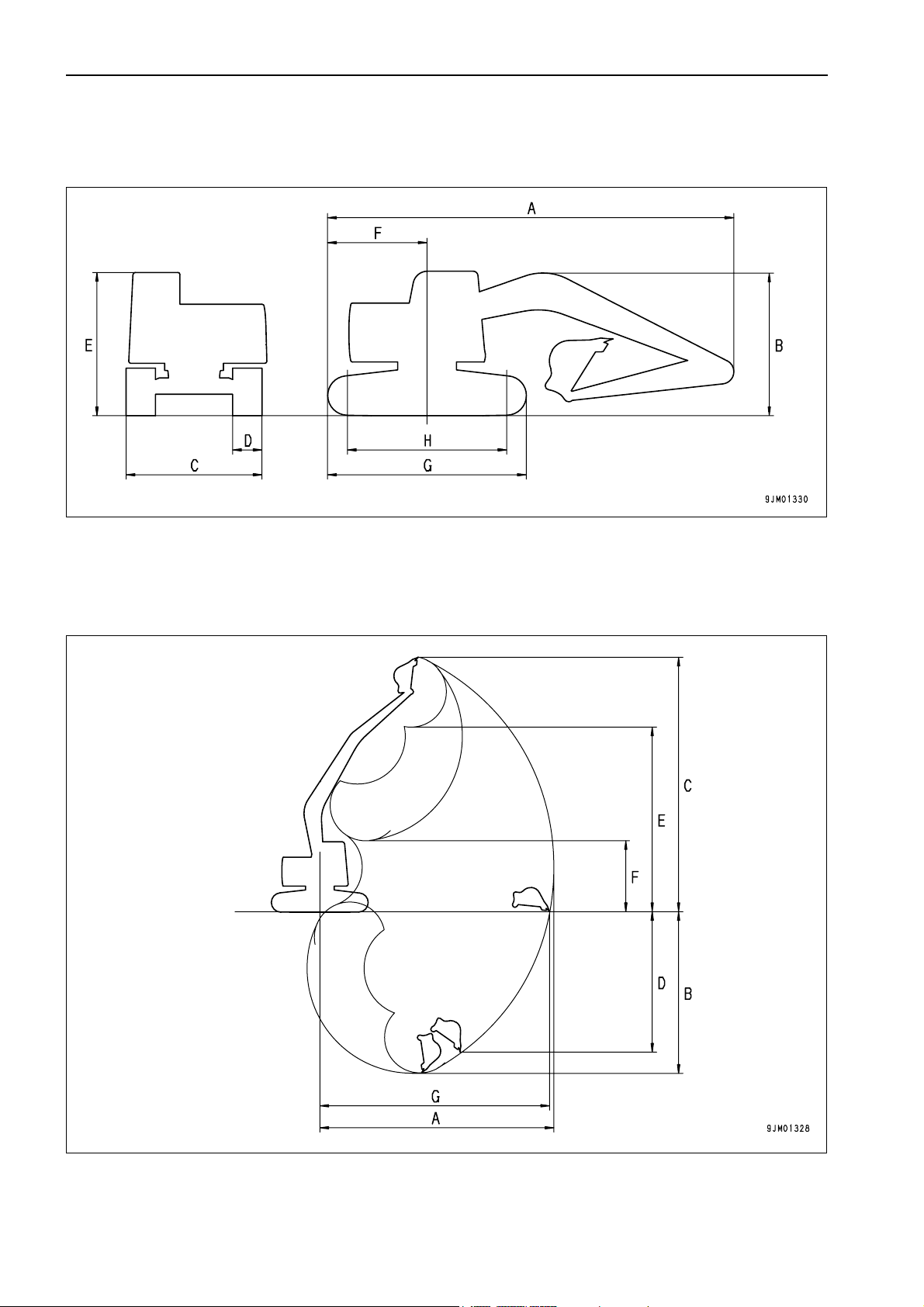

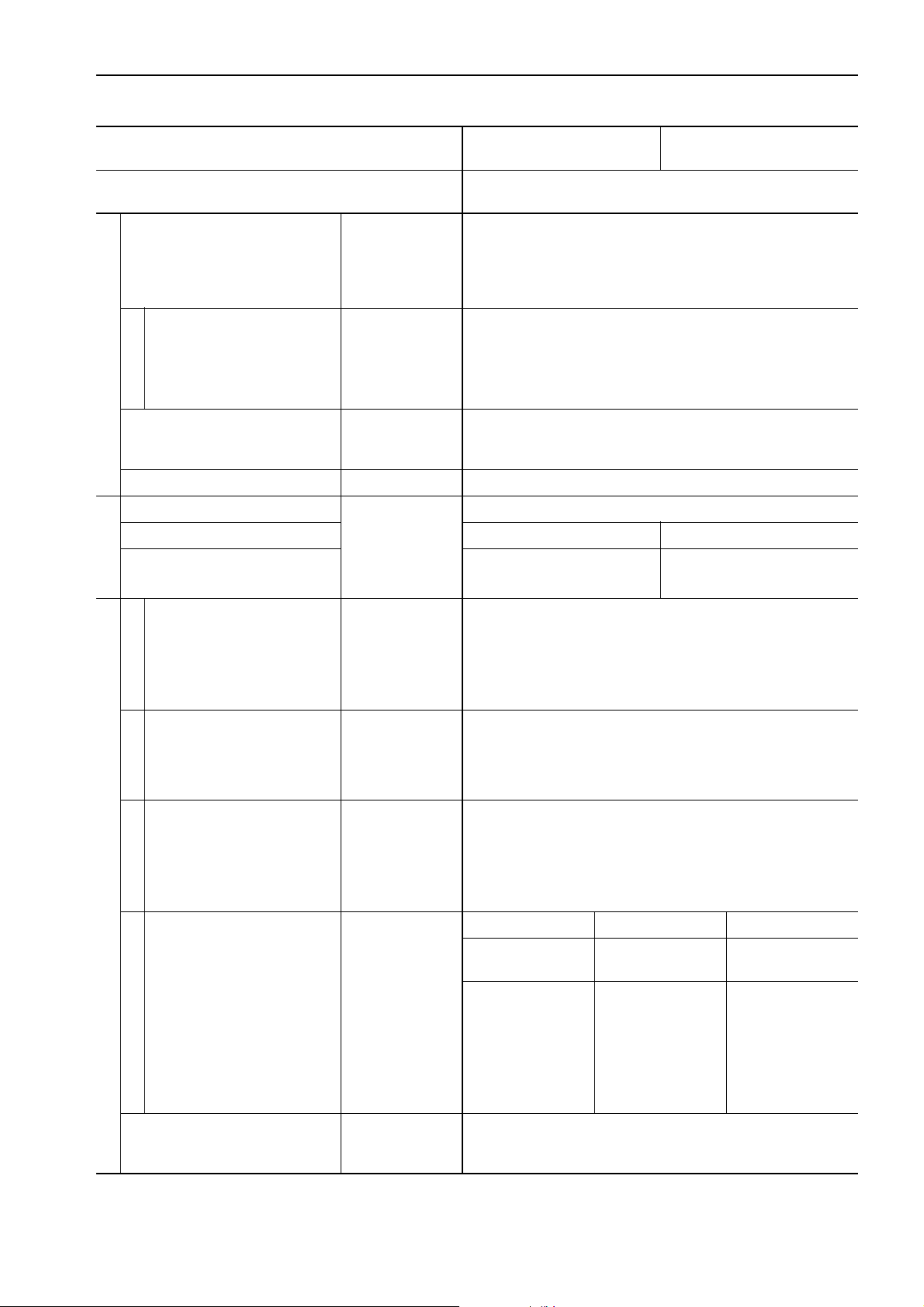

GENERAL SPECIFICATION DRAWINGS

SPECIFICATION DRAWINGS

DIMENSIONS

WORKING RANGES

01-2

PC400/450(LC)-7

GENERAL SPECIFICATION DRAWINGS

DIMENSIONS

Fixed gauge specification

Item Unit PC400-7 PC400LC-7 PC450-7 PC450LC-7

A Overall length mm 11,940 11,940 12,040 12,040

B Overall height mm 3,635 3,635 3,660 3,660

C Overall width mm 3,340 3,440 3,340 3,340

D Track shoe width mm 600 700 600 600

E Height of machine cab mm 3,265 3,265 3,265 3,265

F Tail swing radius mm 3,645 3,645 3,645 3,645

G Track overall length mm 5,055 5,355 5,055 5,355

H Length of track on ground mm 4,020 4,350 4,020 4,350

Min. ground clearance mm 555 550 555 550

Variable gauge specification

Item Unit PC400-7 PC400LC-7 PC450-7 PC450LC-7

A Overall length mm 11,940 11,940 12,040 12,040

B Overall height mm 3,635 3,635 3,660 3,660

C Overall width mm 3,490 3,490 3,490 3,490

D Track shoe width mm 600 600 600 600

E Height of machine cab mm 3,265 3,265 3,265 3,265

F Tail swing radius mm 3,645 3,645 3,645 3,645

G Track overall length mm 5,055 5,355 5,055 5,355

H Length of track on ground mm 4,020 4,350 4,020 4,350

Min. ground clearance mm 685 685 685 685

WORKING RANGES

Working range Unit PC400-7 PC400LC-7 PC450-7 PC450LC-7

A Max. digging reach mm 12,025 12,025 12,005 12,005

B Max. digging depth mm 7,820 7,820 7,790 7,790

C Max. digging height mm 10,915 10,915 10,925 10,925

D Max. vertical wall depth mm 6,870 6,870 6,600 6,600

E Max. dumping height mm 7,565 7,565 7,625 7,625

F Min. dumping height mm — — — —

Max. reach at ground

G

level

mm 11, 820 11,8 20 11,8 00 11,800

PC400/450(LC)-7

01-3

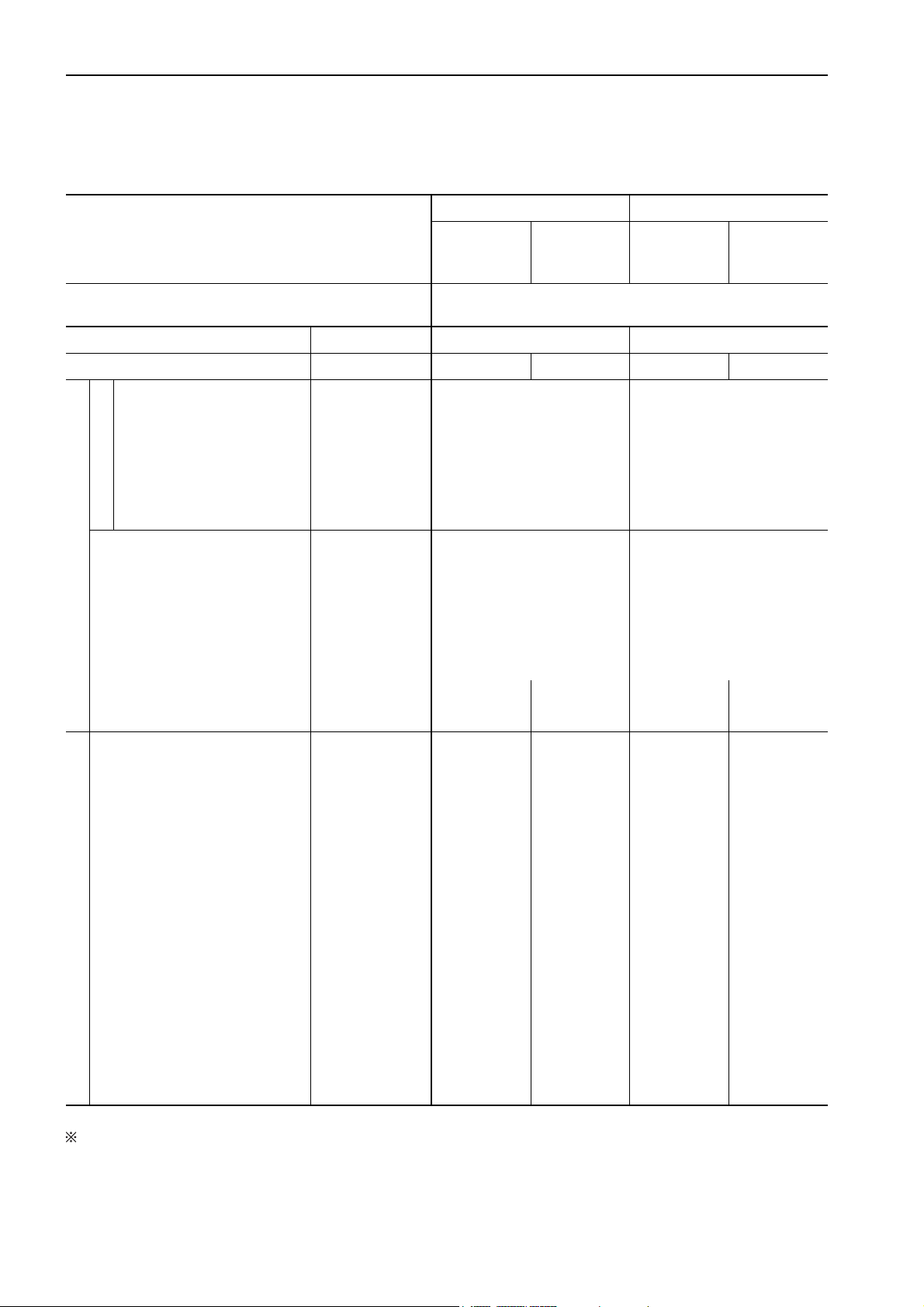

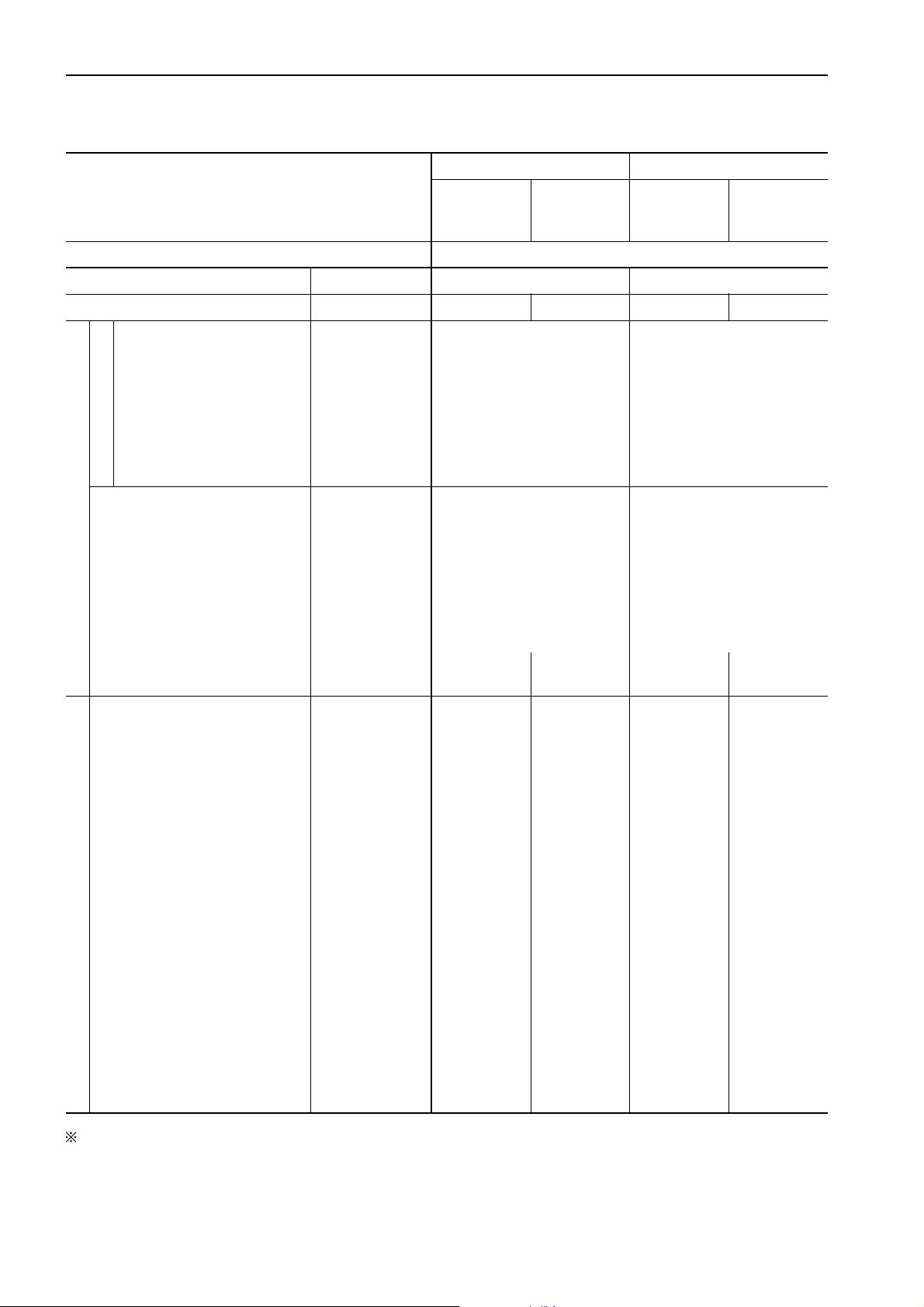

GENERAL SPECIFICATIONS

SPECIFICATIONS

PC400-7, PC400LC-7

PC400-7 PC400LC-7

Machine model

Serial Number 50001 and up

Bucket capacity m

Weight of machine kg 41,200 42,400 42,200 43,500

Max. digging depth

Max. vertical wall depth

Max. digging reach

Max. reach at ground level

Max. digging height

Working ranges

Max. dumping height

Max. digging force

(using power max. function)

Performance

Swing speed

Swing max. slope angle

Travel speed

Gradeability

Ground pressure

[standard shoe width]

Overall length (for transport)

Overall width

Overall width of track

Overall width of track when extended

Overall height (for transport)

Overall height to top of machine

Ground clearance of upper structure

Min. ground clearance

Tail swing radius

Dimensions

Min. swing radius of work equipment

Height of work equipment

at min. swing radius

Length of track on ground

Track gauge

Height of machine cab

3

mm

mm

mm

mm

mm

mm

kN {kg}

kN {kg}

rpm

deg.

km/h

deg.

kPa {kg/cm

[mm]

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

2

}

Fixed gauge

spec.

256.0 {26,100}

(274.6 {28,000})

Lo: 3.0, Mi: 4.4, Hi: 5.5

77.7{0.79}

[600]

11, 940

3,340

3,340

—

3,635

3,265

1,320

555

3,645

4,735

9,210

4,020

2,740

3,265

Variable

gauge spec

1.4 1.4

7,820

6,870

12,025

11,8 20

10,915

7,565

9.1

20

35

79.9 {0.82}

[600]

11,940

3,490

2,990

3,490

3,635

3,265

1,320

685

3,645

4,735

9,210

4,020

2,890

3,265

Fixed gauge

spec.

.

256.0 {26,100}

(274.6 {28,000})

Lo: 3.0, Mi: 4.4, Hi: 5.5

73.9 {0.75}

[700]

11, 940

3,440

3,440

—

3,635

3,265

1,320

555

3,645

4,735

9,210

4,020

2,740

3,265

gauge spec

7,820

6,870

12,025

11,8 20

10,915

7,565

9.1

20

35

65.3 {0.67}

Variable

.

[700]

11,9 40

3,490

2,990

3,490

3,635

3,265

1,320

685

3,645

4,735

9,210

4,020

2,890

3,265

: The “Mi” mode is on the multi-monitor specification machine only

01-4

PC400/450(LC)-7

GENERAL SPECIFICATIONS

Machine model PC400-7 PC400LC-7

Serial Number 50001 and up

Model

Typ e

No. of cylinders – bore × stroke

Piston displacement

Flywheel horsepower

Max. torque

Max. speed at no load

Engine

Min. speed at no load

Min. fuel consumption

Performance

Starting motor

Alternator

Battery

Radiator core type ALW-4

Carrier roller 2 on each side

Track roller 7 on each side 8 on each side

Track shoe

Undercarriage

Type × No .

Delivery

Set pressure

Hydraulic pump

Type × No .

mm

l {cc}

kW/rpm {HP/rpm}

Nm/rpm {kgm/rpm}

rpm

rpm

g/kWh {g/HPh}

l /min

MPa {kg/cm

2

}

4-cycle, water-cooled, in-line, vertical, direct injection,

with turbocharger and aftercooler

Assembly-type triple grouser,

45 on each side

HPV190+190, variable displacement, piston type x2

6-spool type + 1-spool type × 1

SAA6D125E-3

6 – 125 × 150

11.045 {11,045}

246.4/1,850 {330/1,850}

1,334/1,400 {136/1,400}

1,930

1,000

203 {151}

24V, 7.5 kW

24V, 35A

12V, 110 Ah × 2

Assembly-type triple grouser,

48 on each side

345 × 2

37.8 {380}

Control method

Control valve

Travel motor

Swing motor

Hydraulic motor

Hydraulic system

Type

Inside diameter of cylinder mm 160 185 160

Diameter of piston rod mm 110 120 110

Stroke mm 1,570 1,820 1,270

Hydraulic cylinder

Max. distance between pins mm 3,830 4,325 3,140

Min. distance between pins mm 2,260 2,505 1,870

Hydraulic tank

Hydraulic filter

Hydraulic cooler

KMV200ADT-2, Variable displacement, piston type

(with brake valve, parking brake): × 2

KMF230ABE-5, Fixed displacement piston type

(with safety valve, holding brake, reverse rotation preventive valve): × 1

Boom Arm Bucket

Double-acting

piston

Hydraulic

Double-acting

piston

Closed box type

Tank return side

CF40-1 (Air cooled)

Double-acting

piston

PC400/450(LC)-7

01-5

GENERAL SPECIFICATIONS

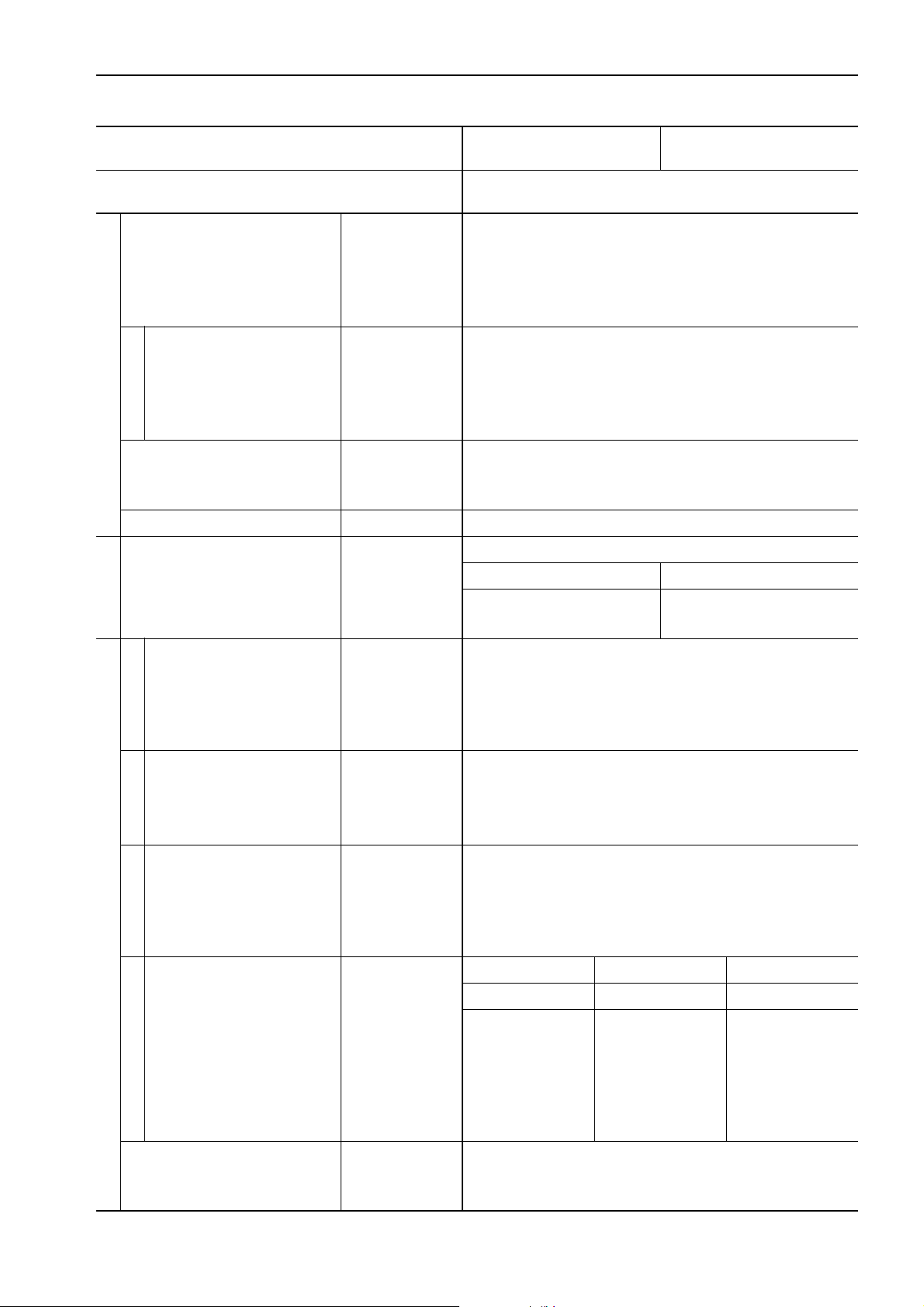

PC450-7, PC450LC-7

PC450LC-7 PC450LC-7

Machine model

Serial Number 20001 and up

Bucket capacity m

Operating weight kg 42,700 44,000 43,700 44,600

Max. digging depth

Max. vertical wall depth

Max. digging reach

Max. reach at ground level

Max. digging height

Working ranges

Max. dumping height

Max. digging force

(using power max. function)

Performance

Swing speed

Swing max. slope angle

Travel speed

Gradeability

Ground pressure

[standard shoe width]

3

mm

mm

mm

mm

mm

mm

kN {kg}

rpm

deg.

km/h

deg.

kPa {kg/cm

[mm]

2

}

Fixed gauge

spec.

258.9 {26,400}

(275.5 {28,300})

Lo: 3.0, Mi: 4.4, Hi: 5.5

80.5 {0.82}

[600]

gauge spec

1.4 1.4

7,790

6,600

12,005

11,8 00

10,925

7,625

9.1

17

35

82.9 {0.85}

Var iable

[600]

Fixed gauge

spec.

.

258.9 {26,400}

(275.5 {28,300})

Lo: 3.0, Mi: 4.4, Hi: 5.5

76.5 {0.78}

[600]

gauge spec

7,790

6,600

12,005

11,8 00

10,925

7,625

9.1

17

35

Var iable

.

78.1 {0.80}

[600]

Overall length (for transport)

Overall width

Overall width of track

Overall width of track when extended

Overall height (for transport)

Overall height to top of machine

Ground clearance of upper structure

Min. ground clearance

Tail swing radius

Dimensions

Min. swing radius of work equipment

Height of work equipment

at min. swing radius

Length of track on ground

Track gauge

Height of machine cab

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

12,040

3,340

3,340

—

3,660

3,265

1,320

555

3,645

4,805

9,230

4,020

2,740

3,265

: The “Mi” mode is on the multi-monitor specification machine only

12,040

3,490

2,990

3,490

3,660

3,265

1,320

685

3,645

4,805

9,230

4,020

2,890

3,265

12,040

3,340

3,340

—

3,660

3,265

1,320

555

3,645

4,805

9,230

4,350

2,740

3,265

12,040

3,490

2,990

3,490

3,660

3,265

1,320

685

3,645

4,805

9,230

4,350

2,890

3,265

01-6

PC400/450(LC)-7

GENERAL SPECIFICATIONS

Machine model PC450-7

Serial Number 20001 and up

Model

Typ e

No. of cylinders – bore × stroke

Piston displacement

Flywheel horsepower

Max. torque

Max. speed at no load

Engine

Min. speed at no load

Performance

Min. fuel consumption

Starting motor

Alternator

Battery

Radiator core type ALW-4

Carrier roller 2 on each side

Track roller 7 on each side 8 on each side

mm

l {cc}

kW/rpm {HP/rpm}

Nm/rpm {kgm/rpm}

rpm

rpm

g/kWh {g/HPh}

4-cycle, water-cooled, in-line, vertical, direct injection,

with turbocharger and aftercooler

SAA6D125E-3

6 – 125 × 150

11.045 {11,045}

246.4/1,850 {330/1,850}

1,334/1,400 {136/1,400}

1,930

4,000

203 {151}

24V, 7.5 kW

24 V, 35 A

12V, 110 Ah × 2

PC450LC-7

Track shoe

Undercarriage

Type × No .

Delivery

Set pressure

Hydraulic pump

Type × No .

Control method

Control valve

Travel motor

Swing motor

Hydraulic motor

Hydraulic system

Cylinder type

Inside diameter of cylinder

Outside diameter of piston rod

Stroke

Hydraulic cylinder

Max. distance between pins

Min. distance between pins

Hydraulic tank

Hydraulic filter

Hydraulic cooler

l /min

MPa {kg/cm

mm

mm

mm

mm

mm

Assembly-type triple grouser,

45 on each side

HPV190+190, ariable displacement, piston type × 2

2

}

6-spool type + 1-spool type × 1

KMV200ADT-2, Variable displacement, piston type

(with brake valve, parking brake): × 2

KMF230ABE-5, Fixed displacement piston type × 2

(with safety valve, holding brake, reverse rotation preventive valve): × 1

Boom Arm Bucket

Double-acting piston Double-acting piston Double-acting piston

160 185 160

110 130 110

1,570 1,985 1,270

3,830 4,325 3,140

2,260 2,505 1,870

Closed box type

Tank return side

CF40-1 (Air cooled)

Assembly-type triple grouser,

48 on each side

345 × 2

37.8 {380}

Hydraulic

PC400/450(LC)-7

01-7

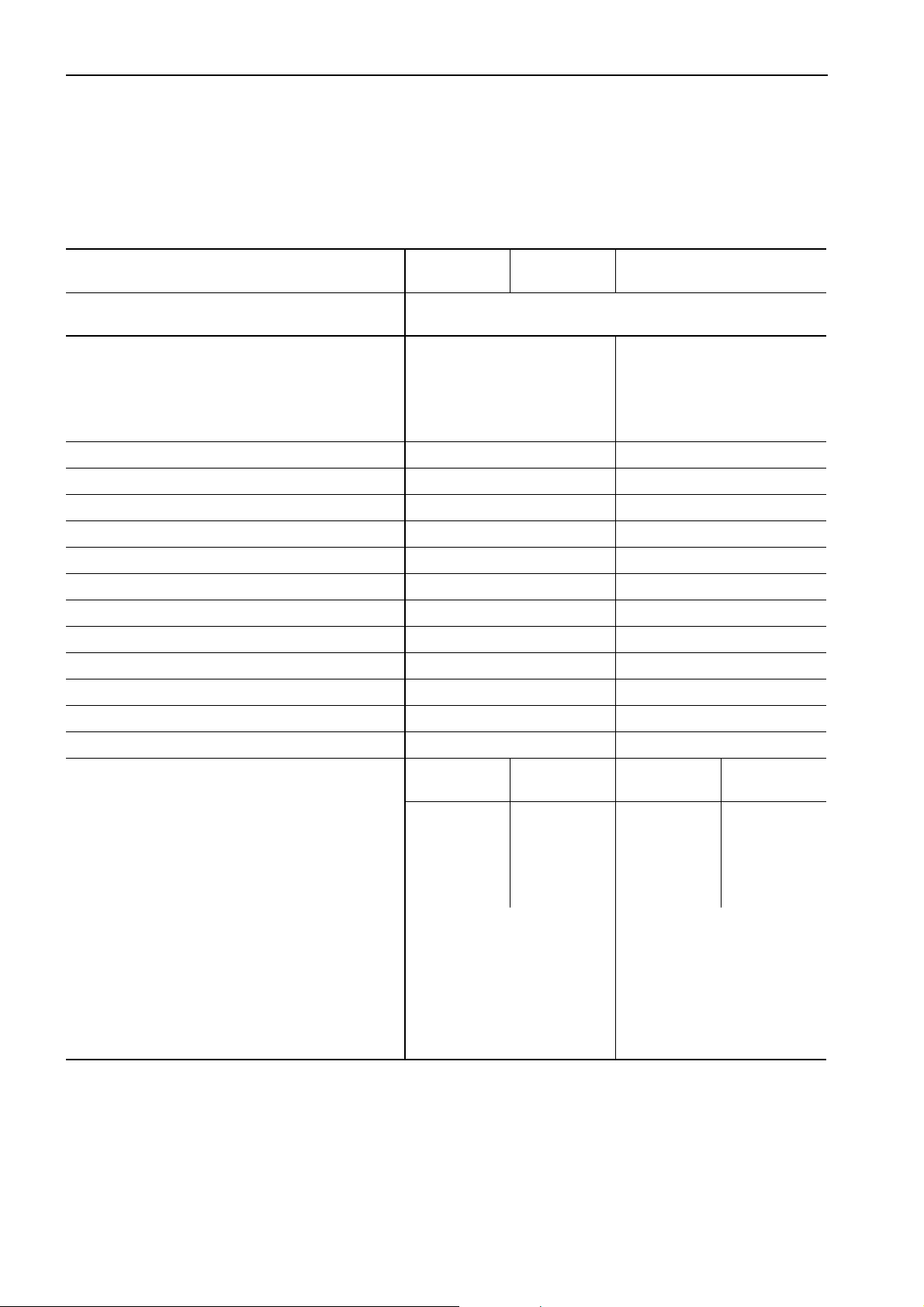

GENERAL WEIGHT TABLE

WEIGHT TABLE

PC400-7, PC400LC-7

k This weight table is for use when handling components or when transporting the machine.

Unit: kg

Machine model PC400-7 PC400LC-7

Serial Number 50001 and up

Engine assembly

•Engine

• Damper

• Hydraulic pump

Radiator, oil cooler assembly 195 195

Hydraulic tank, filter assembly (excluding hydraulic oil) 198 198

Fuel tank (excluding fuel) 251 251

Revolving frame 3,297 3,297

Operator's cab 279 279

Operator's seat 35 35

Counterweight 9,220 9,500

Swing machinery (including swing motor) 526 526

Control valve (with service valve) 257 257

Swing motor 105 105

Travel motor 208 × 2 208 × 2

Center swivel joint 40 40

Fixed gauge

specification

• Track frame assembly

• Track frame

• • Center frame

• • Crawler frame

•Swing circle

•Idler

•Idler cushion

• Carrier roller

• Track roller

• Final drive (including travel motor)

10,173 11,367 10,965 11,934

5,506 6,766 6,077 7,096

1,500

1,150

14.7

210

Variable gauge

specification

—3,229—3,229

— 1,754 × 2 — 1,921 × 2

605 × 2

230 × 2

338 × 2

32 × 4

72 × 14

722 × 2

Fixed gauge

specification

1,500

1,150

14.7

210

Variable gauge

605 × 2

230 × 2

338 × 2

32 × 4

72 × 16

722 × 2

specification

01-8

PC400/450(LC)-7

GENERAL WEIGHT TABLE

Unit: kg

Machine model PC400-7 PC400LC-7

Serial Number 50001 and up

Track shoe assembly

• Standard triple grouser shoe (600 mm)

• Standard triple grouser shoe (700 mm)

• Wide triple grouser shoe (800 mm)

• Wide triple grouser shoe (900 mm)

Boom assembly 3,290 3,290

Arm assembly 1,374 1,374

Bucket assembly 1,366 1,366

4,470

4,890

5,320

—

4,760

5,210

5,670

6,130

Boom cylinder assembly 355 × 2 355 × 2

Arm cylinder assembly 510 510

Bucket cylinder assembly 280 280

Link assembly 258 258

Boom pin 92 + 20 × 2 + 73 + 27 + 54 92 + 20 × 2 + 73 + 27 + 54

Arm pin 17 + 23 17 + 23

Bucket pin 38 × 2 38 × 2

Link pin 34 × 2 34 × 2

PC400/450(LC)-7

01-9

GENERAL WEIGHT TABLE

PC450-7, PC450LC-7

Unit: kg

Machine model PC450-7 PC450LC-7

Serial Number 20001 and up

Engine assembly

•Engine

• Damper

• Hydraulic pump

Radiator oil cooler assembly 195 195

Hydraulic tank, filter assembly (excluding hydraulic oil) 198 198

Fuel tank (excluding fuel) 251 251

Revolving frame 3,402 3,402

Operator’s cab 279 279

Operator’s seat 35 35

Counterweight 9,220 9,220

Swing machinery 526 526

Control valve 257 257

Swing motor 105 105

Travel motor 208 × 2 208 × 2

Center swivel joint 40 40

Fixed gauge

specification

• Track frame assembly

• Track frame

• • Center frame

• • Crawler frame

•Swing circle

•Idler

•Idler cushion

• Carrier roller

• Track roller

• Final drive (including travel motor)

10,462 11,697 11,269 12,244

5,506 6,766 6,077 7,096

1,500

1,150

14.7

210

Variable gauge

specification

—3,229—3,229

— 1,754 × 2 — 1,921 × 2

605

230 × 2

338 × 2

32 × 4

81 × 6, 72 × 8

722 × 2

Fixed gauge

specification

1,500

1,150

14.7

210

Variable gauge

605

230 × 2

338 × 2

32 × 4

81 × 8, 72 × 8

722 × 2

specification

01-10

PC400/450(LC)-7

GENERAL WEIGHT TABLE

Unit: kg

Machine model PC450-7 PC450LC-7

Serial Number 20001 and up

Track shoe assembly

• Standard triple grouser shoe (600 mm)

• Standard triple grouser shoe (700 mm)

• Wide triple grouser shoe (800 mm)

Boom assembly 3,380 3,380

Arm assembly 1,622 1,622

Bucket assembly 1,941 1,941

Boom cylinder assembly 355 × 2 355 × 2

Arm cylinder assembly 580 580

Bucket cylinder assembly 280 280

4,470

4,890

—

4,760

5,210

—

Link assembly 258 258

Boom pin 92 + 20 × 2 + 73 + 27 + 54 92 + 20 × 2 + 73 + 27 + 54

Arm pin 17 + 23 17 + 23

Bucket pin 38 × 2 38 × 2

Link pin 34 × 2 34 × 2

PC400/450(LC)-7

01-11

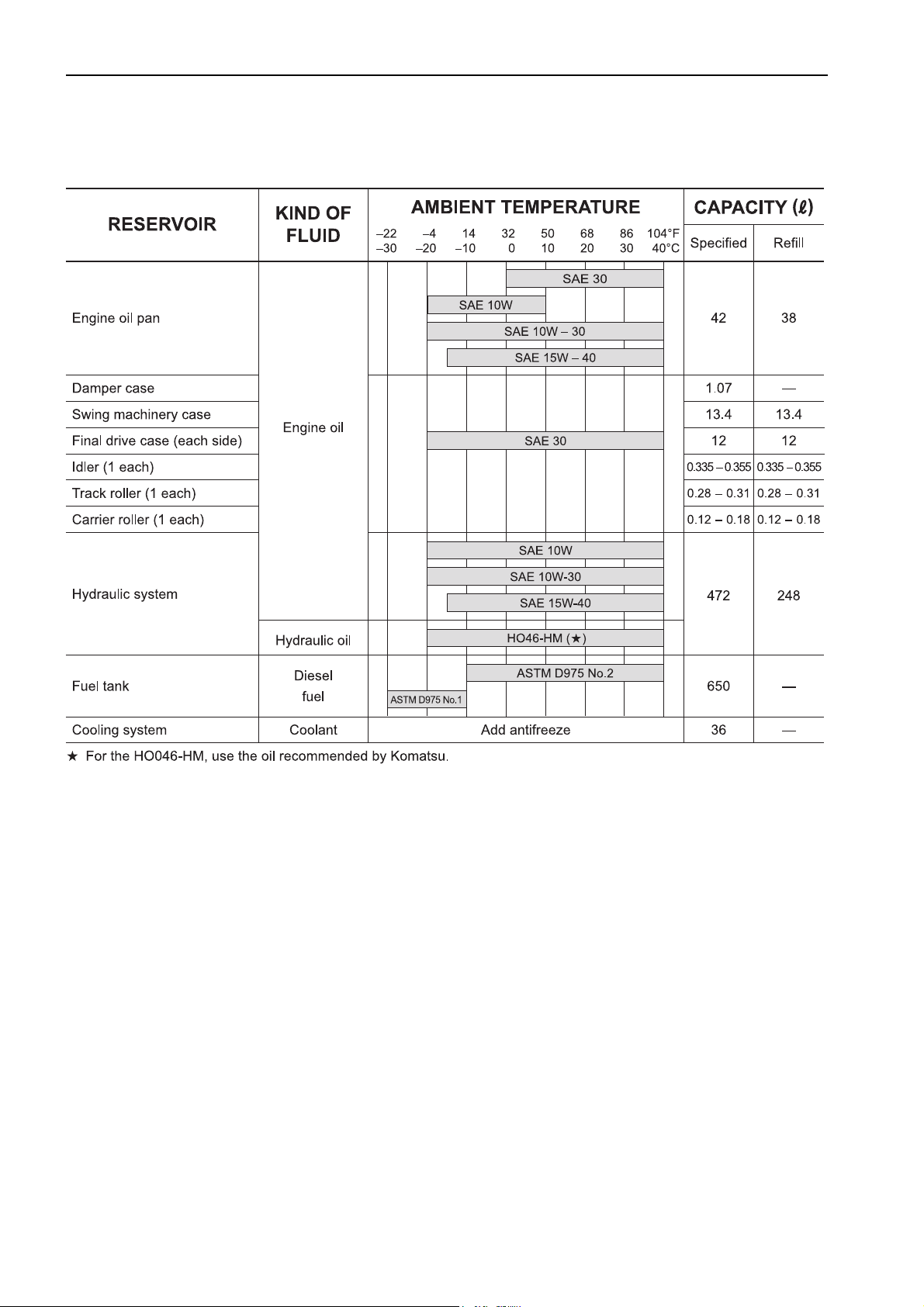

GENERAL FUEL, COOLANT AND LUBRICANTS

FUEL, COOLANT AND LUBRICANTS

01-12

PC400/450(LC)-7

10 STRUCTURE, FUNCTION AND

MAINTENANCE STANDARD

ENGINE RELATED PARTS..................... 10- 2

RADIATOR • OIL COOLER •

AFTERCOOLER ................................ 10- 3

POWER TRAIN ....................................... 10- 4

FINAL DRIVE .......................................... 10- 6

SWING MACHINERY .............................. 10- 8

SWING CIRCLE ...................................... 10- 10

TRACK FRAME AND RECOIL SPRING . 10- 12

IDLER ...................................................... 10- 14

CARRIER ROLLER ................................. 10- 16

TRACK ROLLER ..................................... 10- 17

TRACK SHOE ......................................... 10- 18

HYDRAULIC PIPING DRAWING ............ 10- 22

HYDRAULIC TANK.................................. 10- 24

HYDRAULIC PUMP ................................ 10- 26

LS(PC)-EPC VALVE ................................ 10- 44

VARIABLE VOLUME VALVE .................. 10- 47

CONTROL VALVE ................................... 10- 50

MAIN RELIEF VALVE .............................. 10- 64

CLSS ....................................................... 10- 66

SELF PRESSURE REDUCING VALVE... 10- 69

SWING MOTOR ...................................... 10- 72

CENTER SWIVEL JOINT ........................ 10- 80

TRAVEL MOTOR..................................... 10- 82

TRAVEL JUNCTION VALVE .................... 10- 93

VALVE CONTROL ................................... 10- 95

TRAVEL PPC SHUTTLE VALVE ............. 10- 96

WORK EQUIPMENT • SWING PPC

VALVE ................................................ 10-100

TRAVEL PPC VALVE .............................. 10-104

SERVICE PPC VALVE ............................ 10- 111

SOLENOID VALVE .................................. 10-112

PPC ACCUMULATOR............................. 10-114

RETURN OIL FILTER ............................. 10-115

BOOM HYDRAULIC DRIFT

PREVENTION VALVE........................ 10-116

ARM HYDRAULIC DRIFT PREVENTION

VALVE ................................................ 10-121

QUICK RETURN VALVE......................... 10-125

LIFT CHECK VALVE................................ 10-127

ATTACHMENT CIRCUIT SELECTOR

VALVE................................................ 10-128

HOLDING VALVE .................................... 10-130

HYDRAULIC CYLINDER......................... 10-136

WORK EQUIPMENT ............................... 10-138

AIR CONDITIONER ................................ 10-144

ENGINE CONTROL .................................10-145

ELECTRONIC CONTROL SYSTEM........10-151

MONITOR SYSTEM.................................10-178

SENSOR ..................................................10-198

PC400/450(LC)-7

10-1

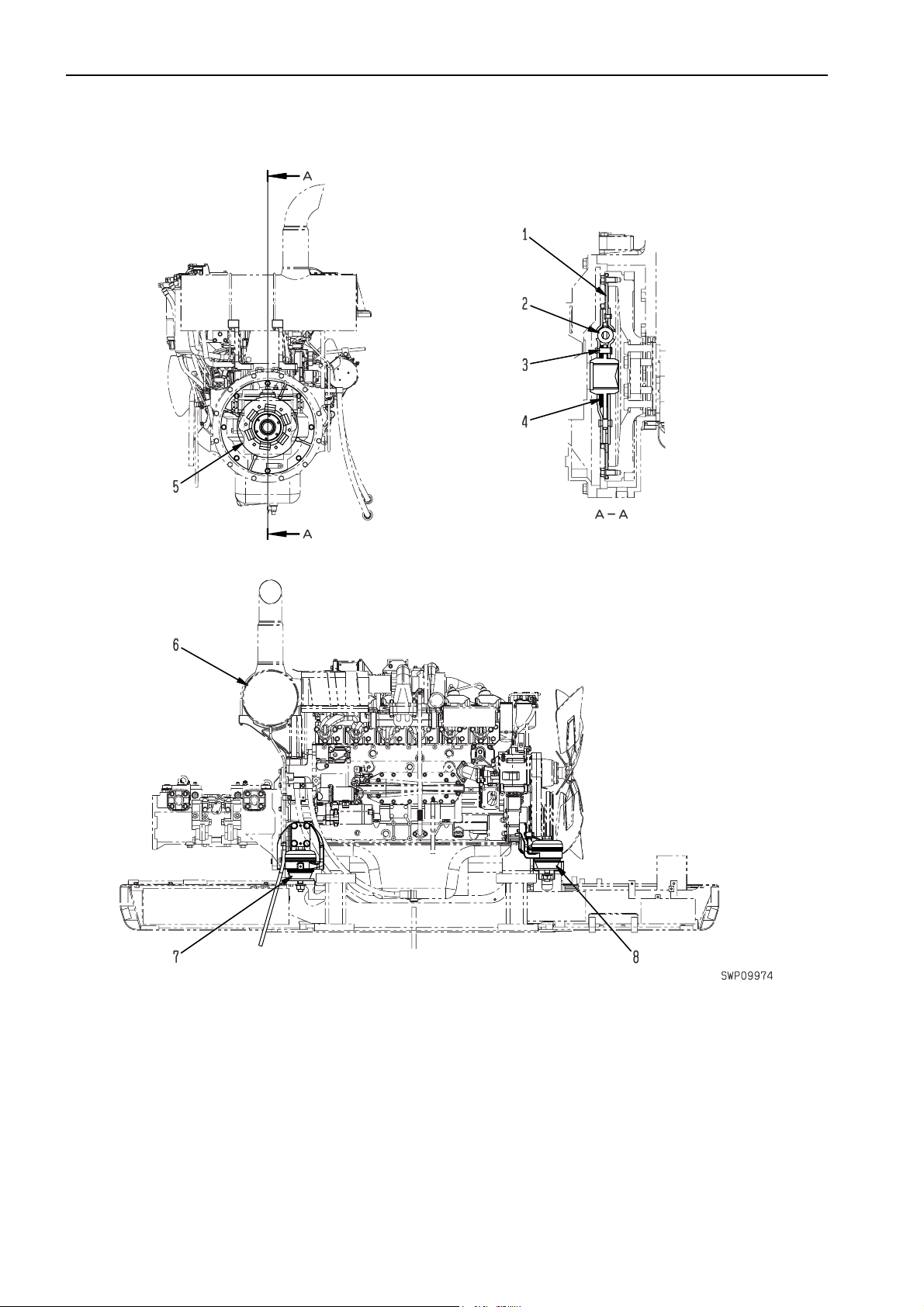

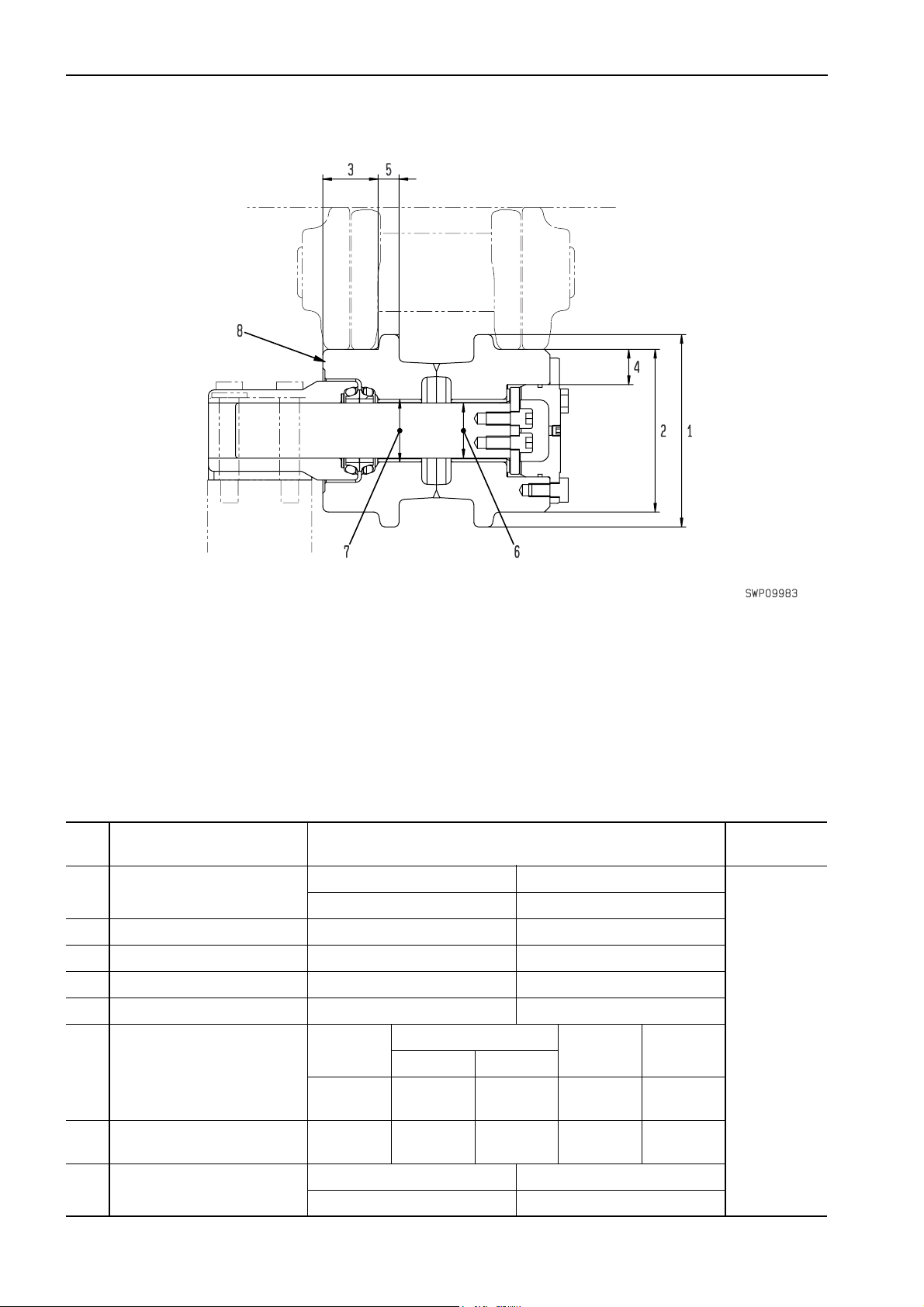

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD ENGINE RELATED PARTS

ENGINE RELATED PARTS

1. Drive plate 5. Damper assembly

2. Torsion spring 6. Muffler

3. Stopper pin 7. Rear engine mount

4. Friction plate 8. Front engine mount

10-2

Outline

• The damper assembly is a wet type.

Oil capacity: 1.3 l

PC400/450(LC)-7

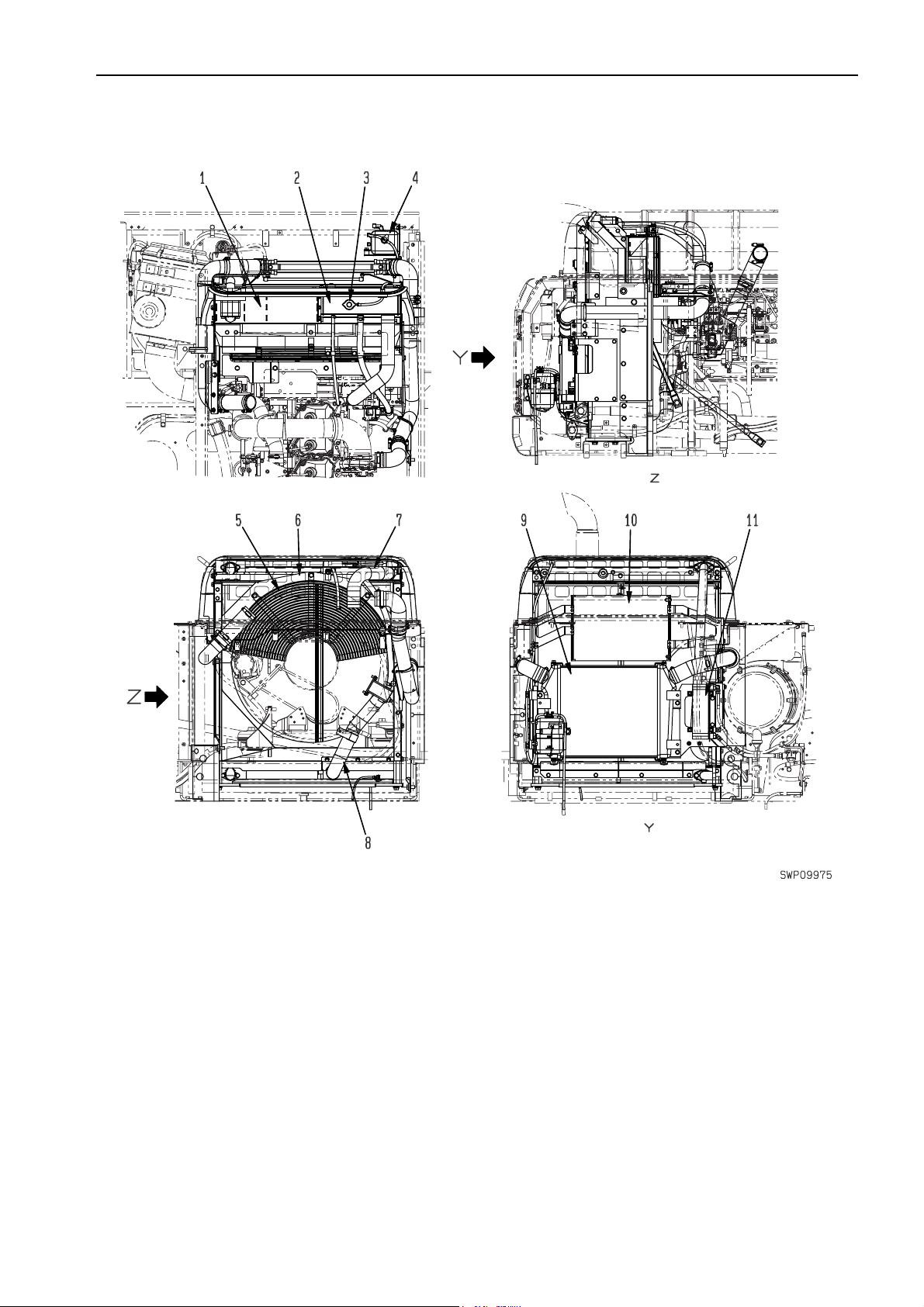

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD RADIATOR • OIL COOLER • AFTERCOOLER

RADIATOR • OIL COOLER • AFTERCOOLER

1. Oil cooler 10. Condenser

2. Radiator 11. Fuel cooler

3. Radiator cap

4. Reservoir tank

5. Net

6. Shroud

7. Radiator inlet hose

8. Radiator outlet hose

9. Aftercooler

PC400/450(LC)-7

Specifications

Radiator : ALW-4

Oil cooler : CF40-1

10-3

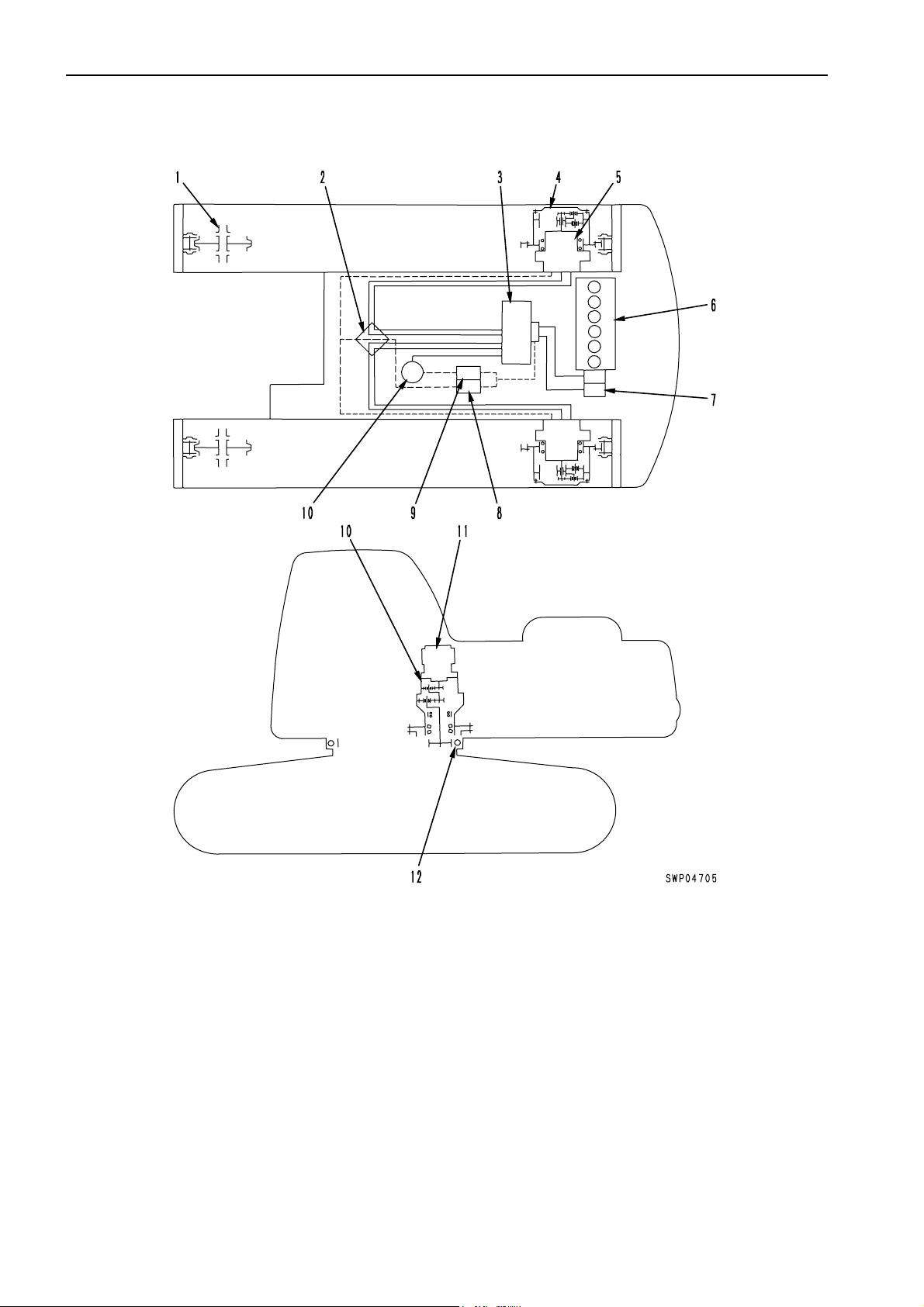

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD POWER TRAIN

POWER TRAIN

1. Idler 7. Hydraulic pump (HPV190+190)

2. Center swivel joint 8. Travel speed solenoid valve

3. Control valve 9. Swing brake solenoid valve

4. Final drive 10. Swing machinery

5. Travel motor (KMV 200ADT-2) 11. Swing motor (KMF230ABE-5)

6. Engine (SAA6D125-3E) 12. Swing circle

10-4

PC400/450(LC)-7

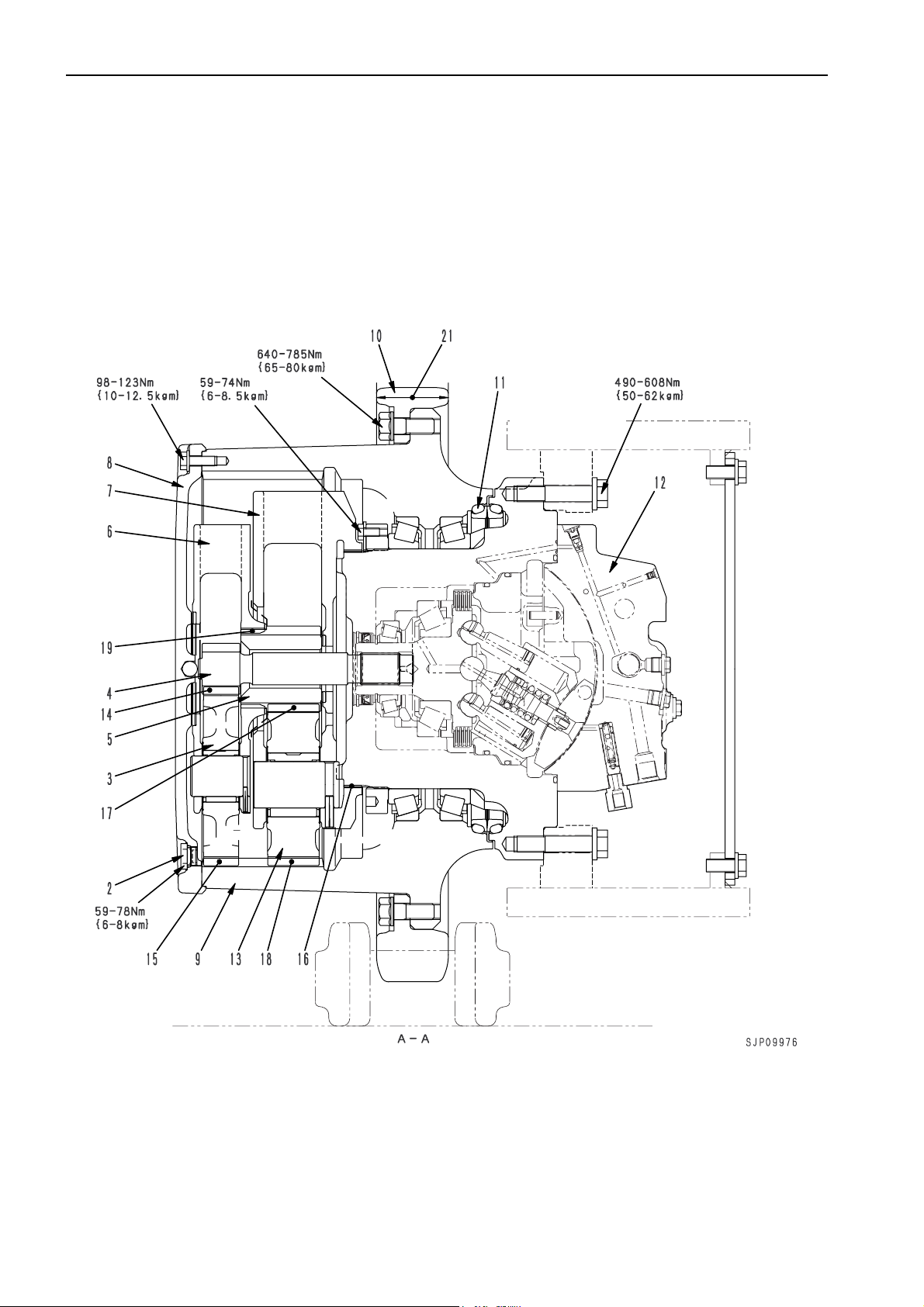

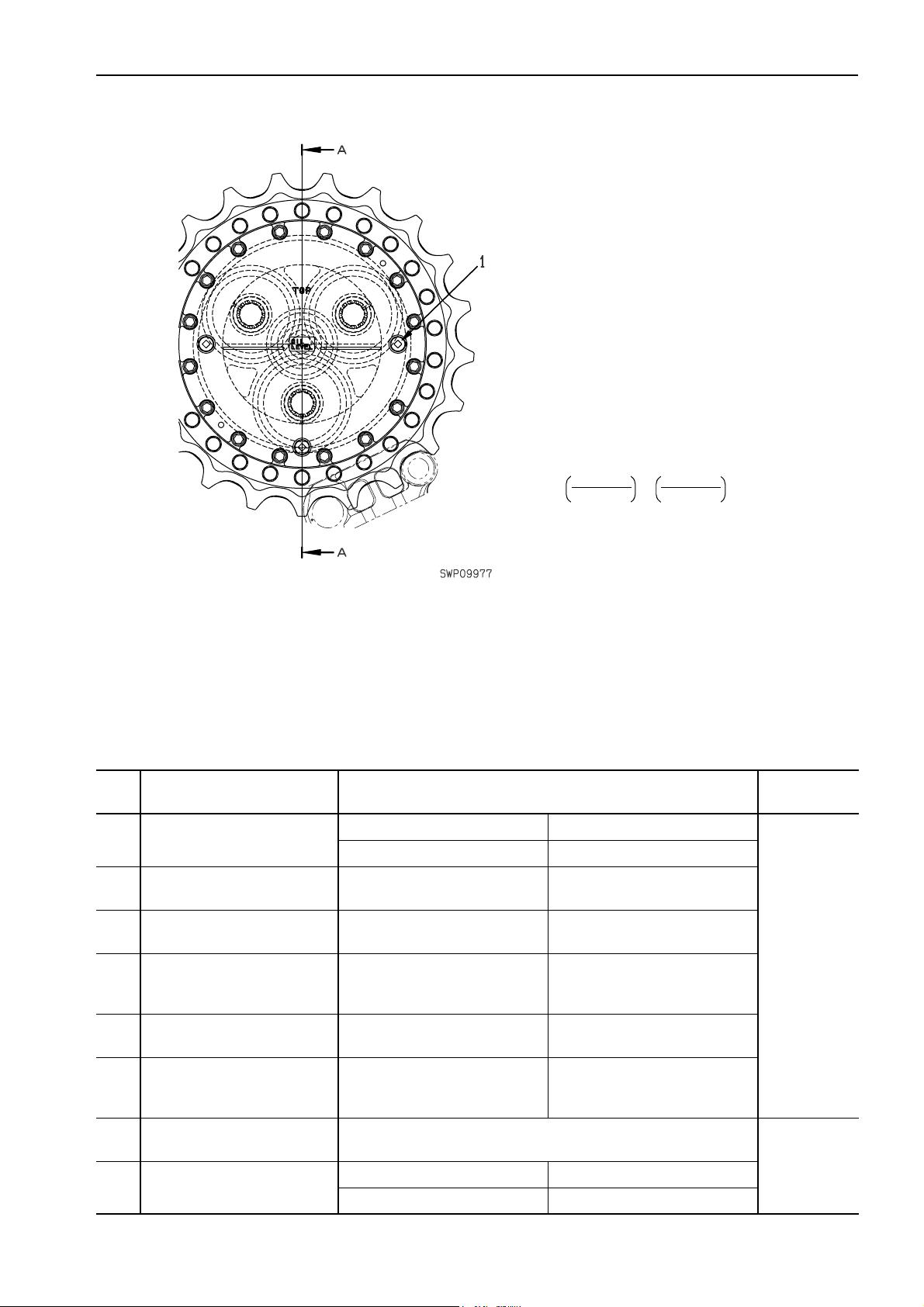

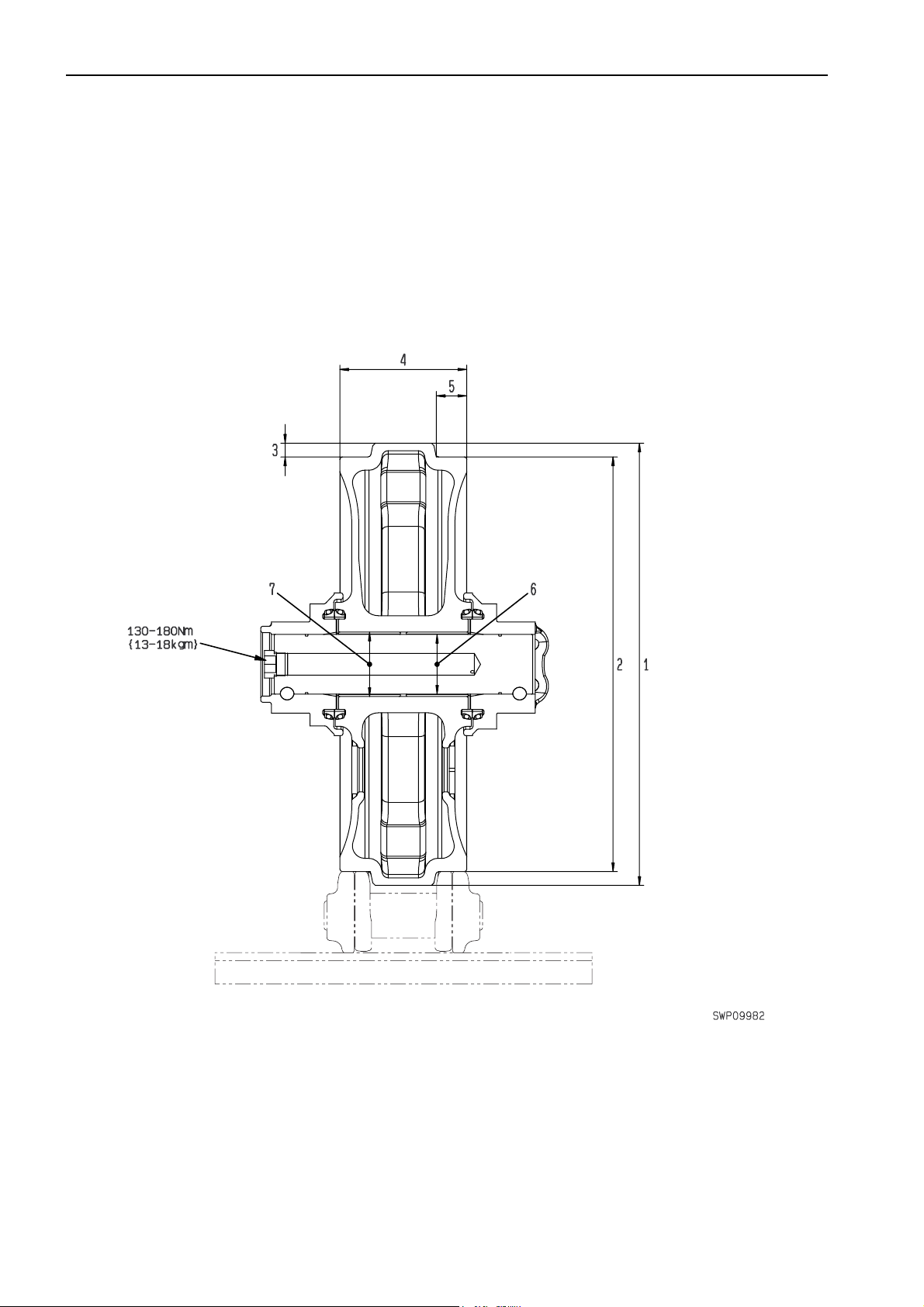

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD FINAL DRIVE

FINAL DRIVE

10-6

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD FINAL DRIVE

1. Level plug

2. Drain plug

3. No. 1 planetary gear (No. of teeth: 43)

4. No. 1 sun gear (No. of teeth: 10)

5. No. 2 sun gear (No. of teeth: 18)

6. No. 1 planetary carrier

7. No. 2 planetary carrier

8. Cover

9. Ring gear (No. of teeth: 98)

10. Sprocket

11. Floating seal

12. Travel motor

13. No. 2 planetary gear (No. of teeth: 38)

Specification

Reduction ratio:

10 + 98

– × = –68.600

10

18 + 98

18

Unit: mm

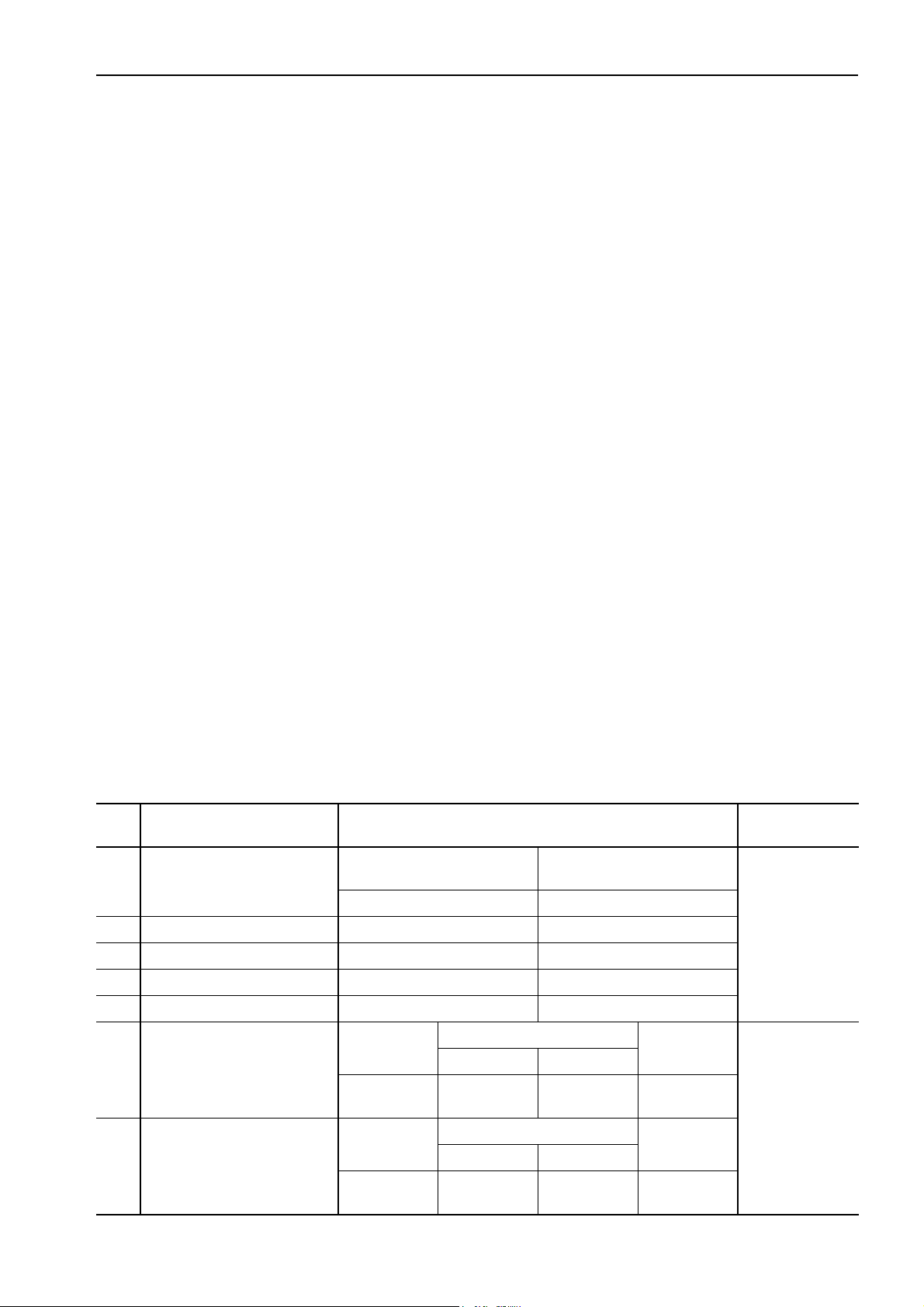

No. Check item Criteria Remedy

Backlash between No. 1 sun

14

gear and No. 1 planetary gear

Backlash between No. 1

15

planetary gear and ring gear

Backlash between No. 2

16

planetary carrier and motor

Backlash between No. 2 sun

17

gear and No. 2 planetary

gear

Backlash between No. 2 plan-

18

etary gear and ring gear

Backlash between No. 2

19

planetary carrier and No. 2

sun gear

Amount of wear on sprocket

20

tooth

21 Width of sprocket tooth

Standard clearance Clearance limit

0.15 – 0.54 1.10

0.18 – 0.66 1.30

0.06 – 0.24 —

0.15 – 0.51 1.00

0.17 – 0.60 1.20

0.15 – 0.54 —

Repair limit: 6

Standard size Repair limit

90 87

Replace

Rebuild or

replace

PC400/450(LC)-7

10-7

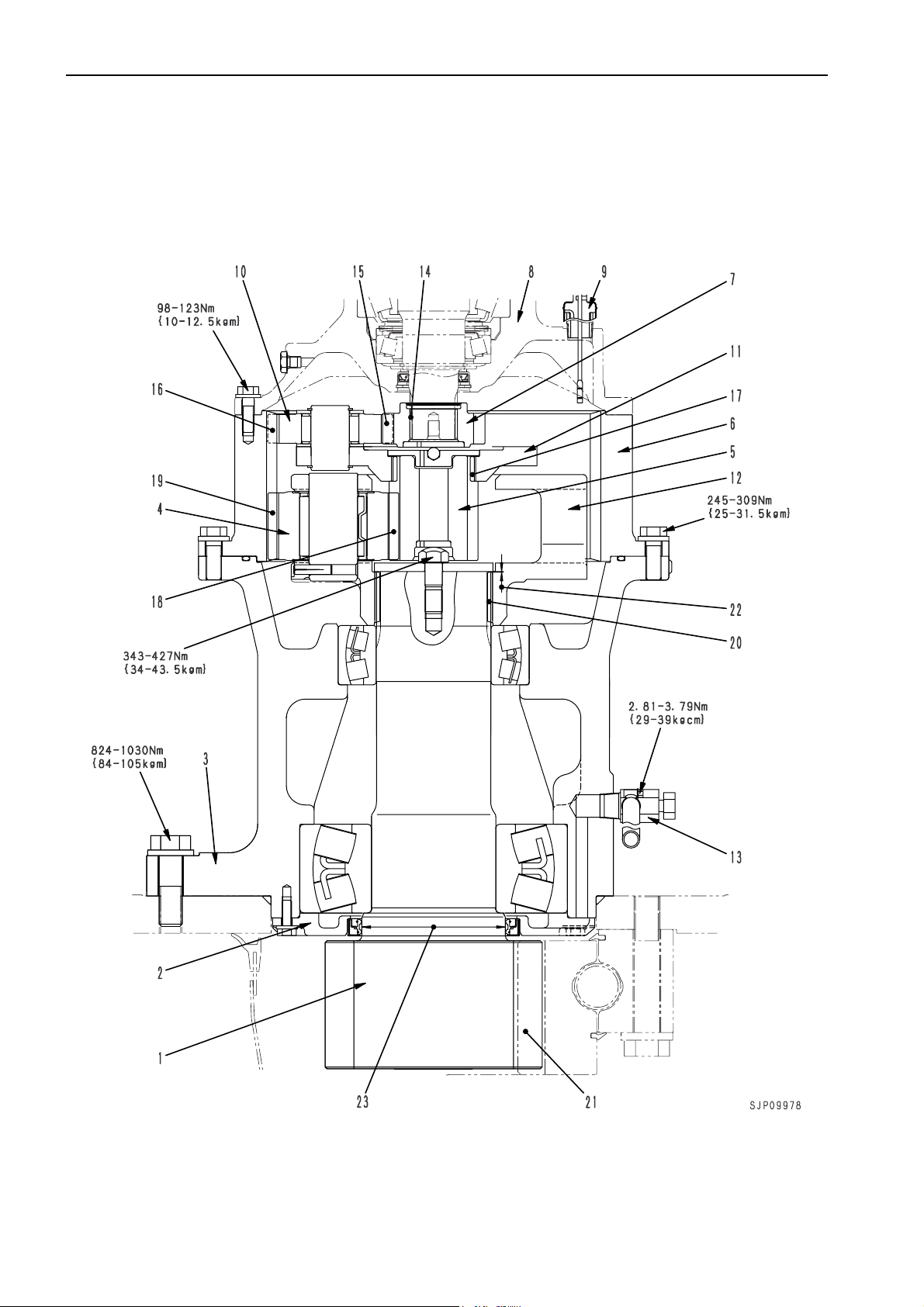

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD SWING MACHINERY

SWING MACHINERY

10-8

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD SWING MACHINERY

1. Swing pinion (No. of teeth: 13)

2. Cover

3. Case

4. No. 2 planetary gear

5. No. 2 sun gear

6. Ring gear

7. No. 1 sun gear

8. Swing motor

9. Oil level gauge

10. No. 1 planetary gear

11. No. 1 planetary carrier

12. No. 2 planetary carrier

13. Drain plug

Specification

Reduction ratio:

19 + 68

19

16 + 68

× = 24.039

16

Unit: mm

No. Check item Criteria Remedy

Backlash between swing

14

motor shaft and No. 1 sun gear

Backlash between No. 1 sun

15

gear and No. 1 planetary

gear

Backlash between No. 1

16

planetary gear and ring gear

Backlash between No. 1

17

planetary carrier and No. 2

sun gear

Backlash between No. 2 sun

18

gear and No. 2 planetary gear

Backlash between No. 2

19

planetary gear and ring gear

Backlash between coupling

20

and swing pinion

Backlash between swing pin-

21

ion and swing circle

Standard clearance Clearance limit

0.18 – 0.28 —

0.15 – 0.51 1.00

0.17 – 0.60 1.10

0.40 – 0.75 1.20

Replace

0.16 – 0.55 1.00

0.17 – 0.60 1.10

0.08 – 0.25 —

0.00 – 1.21 2.00

Clearance between plate

22

and coupling

Wear of swing pinion surface

23

contacting with oil seal

PC400/450(LC)-7

0.57 – 1.09 —

Standard size Repair limit Apply hard

chrome plat-

150

0

–0.100

—

ing, recondition, or

replace

10-9

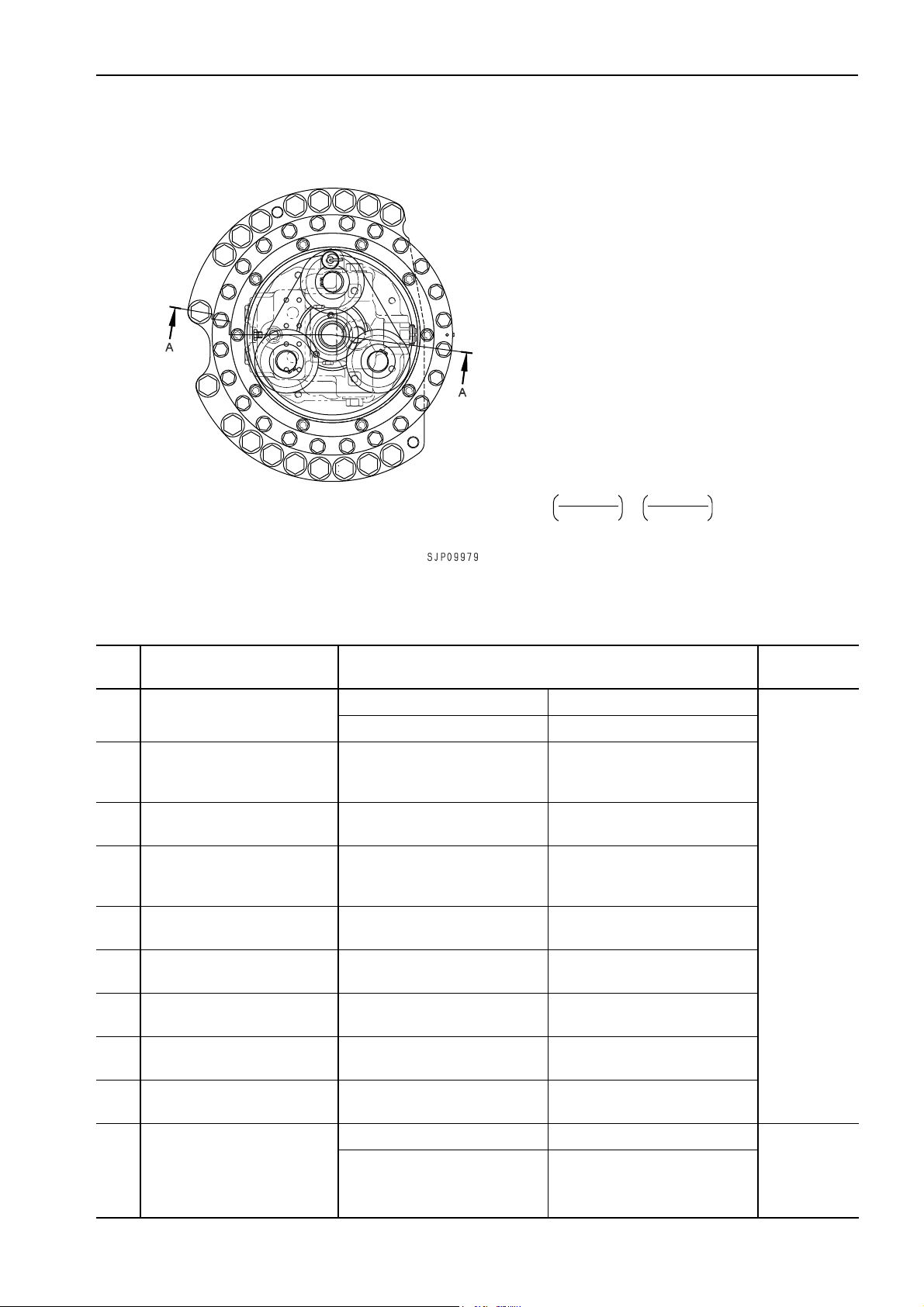

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD SWING CIRCLE

SWING CIRCLE

1. Swing circle inner race (No. of teeth: 84)

2. Ball

3. Swing circle outer race

a. Inner race soft zone “S” position

b. Outer race soft zone “S” position

No. Check item Criteria Remedy

Axial clearance of bearing

4

(when mounted on chassis)

Standard clearance Repair limit

0.5 – 1.6 3.2

10-10

Specifications

Reduction ratio: – =

Amount of grease: 33 l (G2-LI)

84

13

6.462

–

Unit: mm

Replace

PC400/450(LC)-7

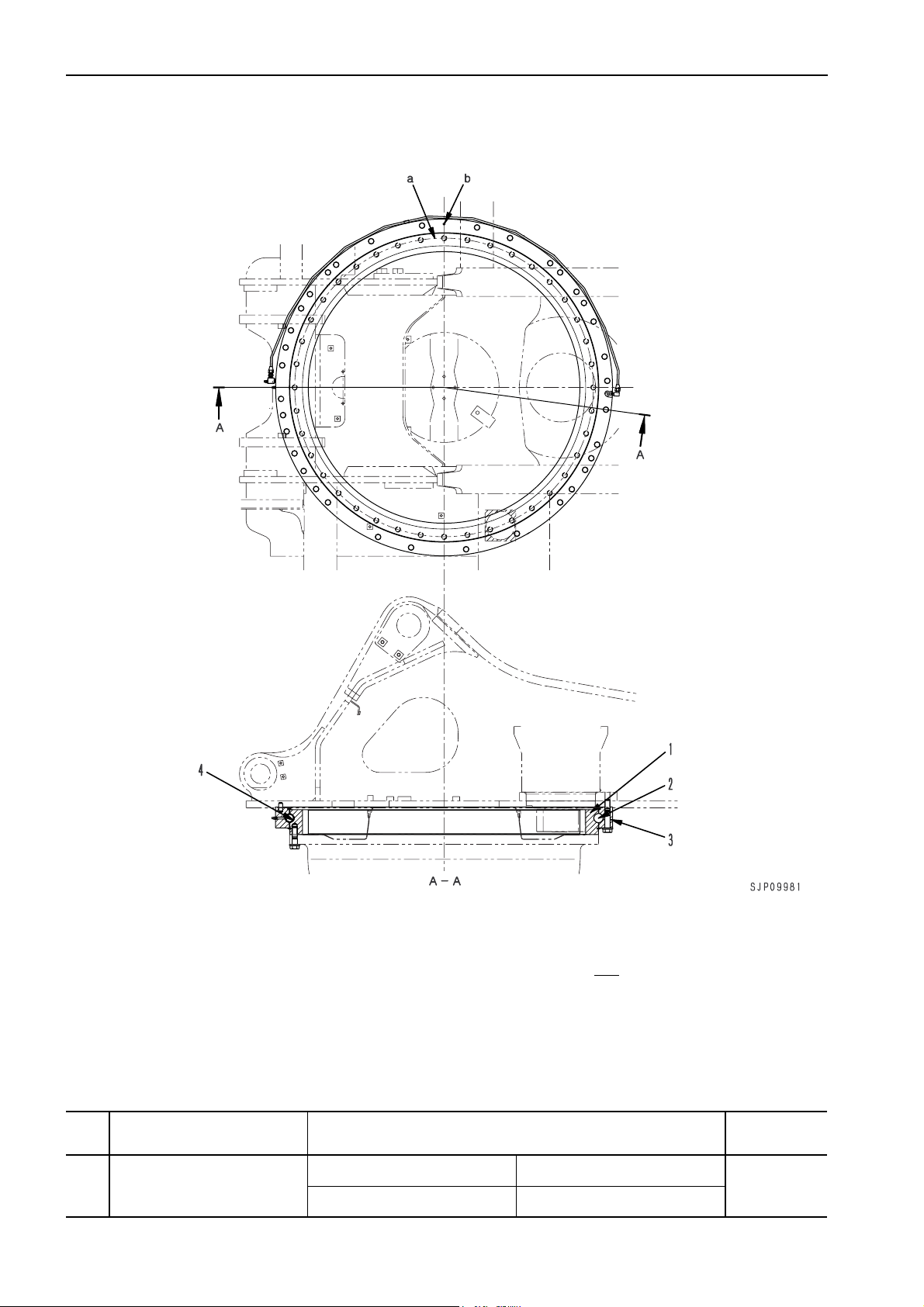

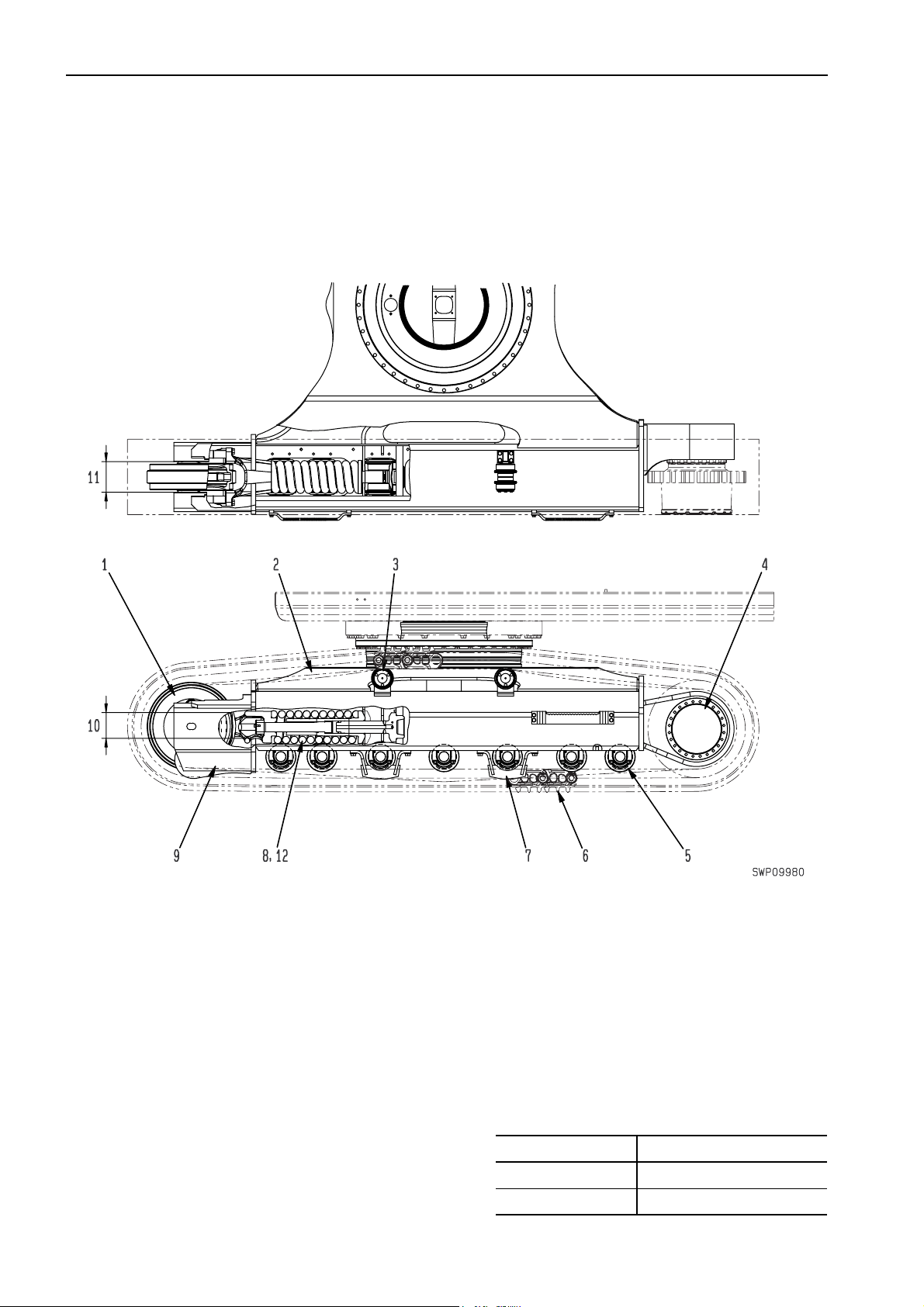

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD TRACK FRAME AND RECOIL SPRING

TRACK FRAME AND RECOIL SPRING

1. Idler

2. Track frame

3. Carrier roller

4. Final drive

5. Track roller

6. Track shoe

7. Center guard

8. Recoil spring

9. Front guard

10-12

• The dimensions and the number of track rollers

depend on the model, but the basic structure is

not different.

• Number of track rollers

Model Q’ty

PC400-7, 450-7 7

PC400LC-7, 450LC-7

8

PC400/450(LC)-7

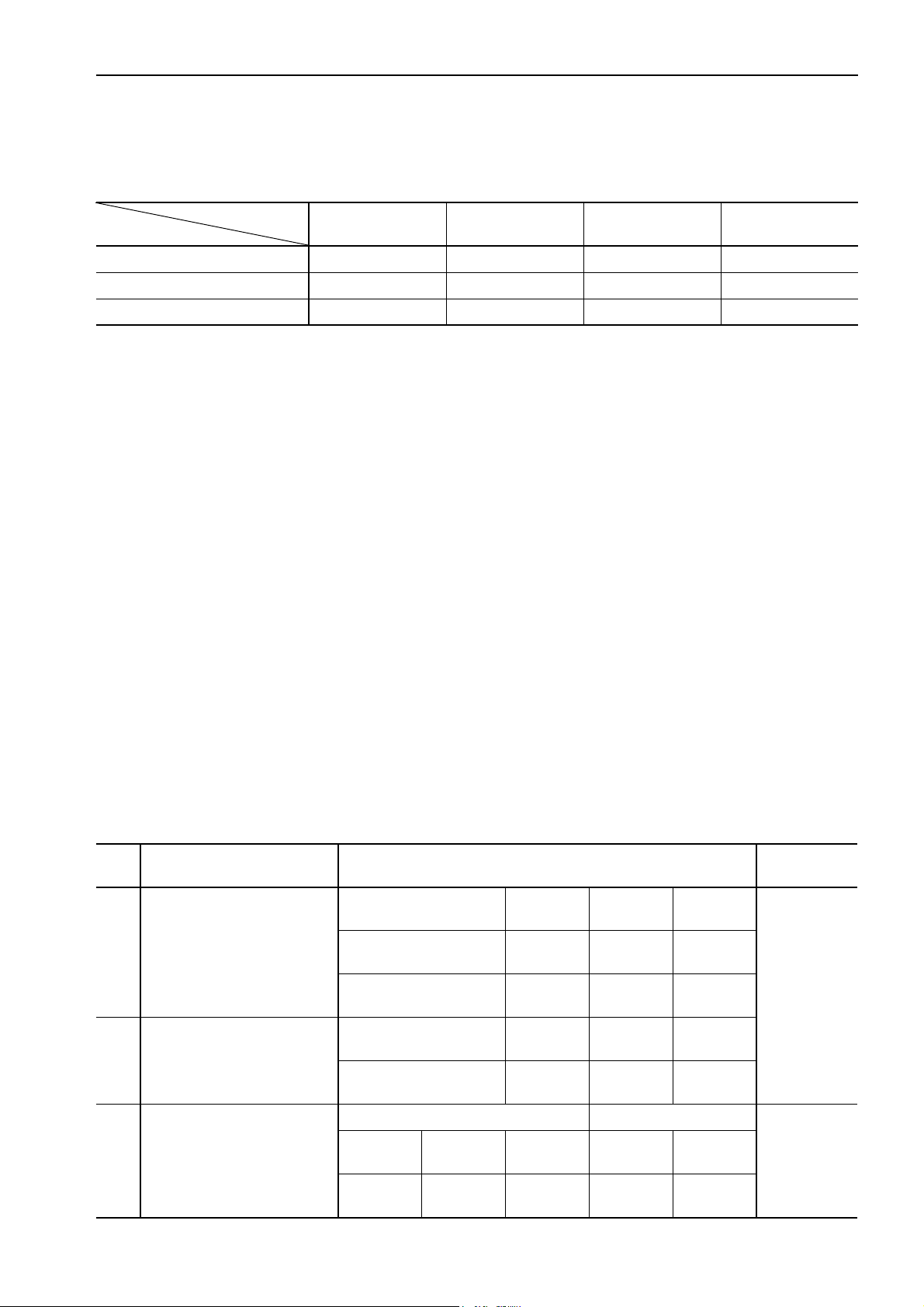

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD TRACK FRAME AND RECOIL SPRING

Standard shoe

Model

Item

Shoe width 600 mm 700 mm 600 mm 600 mm

Link pitch 228 mm 228 mm 228 mm 228 mm

No. on track (one side) 46 (Pieces) 46 (Pieces) 49 (Pieces) 49 (Pieces)

PC400-7 PC400LC-7 PC450-7 PC450LC-7

Unit: mm

No. Check item Criteria Remedy

10 Vertical width of idler guide

11 Horizontal width of idler guide

12 Recoil spring

Standard

size

Track frame 123 127

Idler support 120 ±0.5 118

Track frame 266 271

Idler support 261 — 259

Standard size Repair limit

Free length

× OD

795 × 241 648

Installation

length

Installation

load

173.3 kN

{17,680 kg}

Tolerance Repair limit

+2

–1

+3

–1

Free length

—

Installation

load

138.56 kN

{14,140 kg}

Rebuild or

replace

Replace

PC400/450(LC)-7

10-13

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD IDLER

IDLER

10-14

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

Unit: mm

No. Check item Criteria Remedy

+0.360

+0.220

–0.027

–0.079

Repair limit

Rebuild or

replace

Standard

clearance

0.340 –0.507

Replace bushing

Standard

interference

0.064 –0.149

Outside diameter of protrud-

1

ing

2 Outside diameter of tread 660 648

3 Depth of tread 22 28

4 Total width 202 —

5 Width of tread 48.5 —

Clearance between shaft and

6

bushing

Interference between idler

7

and bushing

Standard size

Standard size

Standard size

95

102.6

704 —

To le ra n c e

Shaft Hole

–0.120

–0.207

To le ra n c e

Shaft Hole

+0.087

+0.037

PC400/450(LC)-7

10-15

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CARRIER ROLLER

CARRIER ROLLER

Unit: mm

No. Check item Criteria Remedy

1 Outside diameter of flange

2 Outside diameter of tread 148 134

3 Width of tread 50.3 —

4 Thickness of tread 32 25

5 Width of flange 19 —

Standard

Interference between shaft

6

and bushing

Interference between roller

7

and bushing

8 Axial clearance of roller

10-16

Standard size Repair limit

175 —

To le r a nc e

size

50

57

Standard clearance Clearance limit

Shaft Hole

–0.250

–0.270

+0.117

+0.087

0.5 – 0.7 —

+0.099

–0.032

+0.040

0

Standard

interference

0.218 –

0.369

0.047 –

0.177

Interference

limit

—

—

PC400/450(LC)-7

Replace

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD TRACK ROLLER

TRACK ROLLER

Unit: mm

No. Check item Criteria Remedy

Outside diameter of outer

1

flange

Outside diameter of inner flange

2

(double flange)

3 Outside diameter of tread 200 188

4 Thickness of tread 56.2 50.2

5 Overall width 278 —

6 Width of tread

Width of outer

7

flange

Width of inner flange

8

(Double flange)

9 Axial play 0.4 – 1.0 —

Clearance between shaft and

10

bushing

Interference between roller

11

and bushing

Singe flange 54.6 —

Double flange

Singe flange 32.6 —

Double flange

Standard

Standard

Standard size Repair limit

240 —

237 —

51.6 —

32.6 —

23.0 —

size

80

size

87.6

Tolerance

Shaft Hole

–0.250

–0.350

Tolerance

Shaft Hole

+0.108

+0.008

+0.174

+0.029

–0.006

–0.036

Standard

clearance

Standard

interference

0.279 –

0.524

0.014 –

0.144

Clearance

limit

1.5

Interference

limit

—

Rebuild or

replace

Replace

bushing

PC400/450(LC)-7

10-17

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD TRACK SHOE

TRACK SHOE

TRACK SHOE

a P portion shows the link of bushing press-fitting end.

10-18

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD TRACK SHOE

Unit: mm

No. Check item Criteria Remedy

1Link pitch

2 Bushing outside diameter

3 Thickness of bushing metal 12 7

4Link height

Thickness of link metal

5

(bushing press-fitting portion)

6

Shoe bolt pitch

876.2

Inside

width

Overall

width

Tread

width

10

11

9

Link

Standard size Repair limit

228.9 231.9

Standard size When turned

71.5 66.5

Standard size Repair limit

129 119

34.5 24.5

184

106

51.6

44.8

Reverse or

replace

Adjust or

replace

Repair or

replace

Replace7 144

Repair or

replace

12 Protrusion of pin 4.4

13 Protrusion of regular bushing 5.25

14 Overall length of pin 252

15 Overall length of bushing 164.5

16 Thickness of spacer —

17

Press-fitting

force

19

Bushing 118 – 304 kN {12 – 31 ton}

Regular

pin

Master

pin

176 – 451 kN {18 – 46 ton}

137 – 284 kN {14 – 29 ton}

: Dry type track link

PC400/450(LC)-7

Adjust or

replace

—18

10-19

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD TRACK SHOE

Unit: mm

No. Check item Criteria Remedy

Shoe bolt

20

No. of shoes (each side)

Interference between

21

bushing and link

Interference between regular

22

pin and link

Clearance between regular

23

pin and bushing

a. Regular

link

b. Master

link

Tightening torque

(Nm {kgm})

Triple shoe 393±39 {40±4} 120±10

Tightening torque

(Nm {kgm})

———

Standard size

71

47

Standard size

47

Additinal tightening

angle (deg.)

PC400-7, PC450-7: 46

PC400LC-7, PC450LC-7: 49

Tolerance

Shaft Hole

+0.494

+0.454

+0.235

+0.085

Tolerance

Shaft Hole

+0.235

+0.085

Additinal tightening

angle (deg.)

Lower limit torque

(Nm {kgm})

+0.074

0

–0.218

–0.280

+0.915

+0.415

0.380 – 0.494

0.303 – 0.515

0.180 – 0.830

Retighten

—

Standard

interference

Standard

clearance

Adjust or

replace

24

25

10-20

Interference between master

pin and bushing

Clearance between master

pin and bushing

Standard size

47

Standard size

47

Tolerance

Shaft Hole

+0.03

0

Tolerance

Shaft Hole

–0.2

–0.4

–0.218

–0.280

+0.915

+0.415

Standard

interference

0.218 – 0.310

Standard

clearance

0.615 – 1.315

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD TRACK SHOE

TRIPLE GROUSER SHOE

Unit: mm

No. Check item Criteria Remedy

1Height

2 Thickness 13

3

Length at of base

427

5

Length at tip

617.5

723.5

PC400/450(LC)-7

Standard size Repair limit

37 22

33

25.5

Rebuild or

replace

10-21

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PIPING DRAWING

HYDRAULIC PIPING DRAWING

1. Bucket cylinder

2. Arm cylinder

3. Boom cylinder

4. Swing motor

5. Control valve

6. Oil cooler

7. Hydraulic filter

8. Hydraulic pump

9. L.H. travel motor

10. Hydraulic tank

11. Multi-pattern selector valve

12. L.H. PPC valve

13. Safety lever (electric type)

14. Center swivel joint

15. R.H. PPC valve

16. Travel PPC valve

17. Attachment circuit selector valve

18. Holding valve

19. Accumulator

20. Solenoid valve assembly 20A. PPC lock solenoid 20B. Travel junction solenoid 20C. Pump merge/divider solenoid 20D. Travel speed solenoid 20E. Swing brake solenoid 20F. Machine push-up solenoid 20G. 2-stage relief solenoid

10-22

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PIPING DRAWING

PC400/450(LC)-7

10-23

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC TANK

HYDRAULIC TANK

1. Oil filler cap

2. Breather

3. Hydraulic tank

4. Sight gauge

5. Strainer

6. Filter element

7. Strainer

8. Bypass valve

10-24

Specifications

Tank capacity: 335 l

Amount of oil inside tank: 248 l

Pressure valve

• Relief cracking pressure: 16.7 ± 6.9 kPa

{0.17 ± 0.07 kg/cm

• Suction cracking pressure: 0 – 0.49 kPa

{0 – 0.005 kg/cm

• Bypass valve set pressure: 150 ± 30 kPa

{1.5 ± 0.3 kg/cm

Breather

• Intake valve set pressure: 2.0 ± 0.3 kPa

{0.02 ± 0.003 kg/cm

• Exhaust valve set pressure: 98 ± 14.7 kPa

{1.0 ± 0.15 kg/cm

PC400/450(LC)-7

2

}

2

}

2

}

2

}

2

}

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

HYDRAULIC PUMP

HPV160+160(190)

1. Front main pump

2. Rear main pump

3. LS valve

4. PC valve

5. LS-EPC valve

6. PC-EPC valve

7. Variable volume valve

IM : PC mode selector current

ISIG : LS set selector current

PAF : Front pump delivery

PFC : Front pump delivery

pressure detection

PAR : Rear pump delivery

PRC : Rear pump delivery

pressure detection

PBF : Front pump pressure input

PD1F : Case drain port

PENF : Front pump control

pressure detection

PBR : Rear pump pressure input

PD2F : Drain plug

PD2R : Drain plug

PENR : Rear pump control

pressure detection port

PLSF : Front load pressure input

PLSFC: Front load pressure

detection port

PLSR : Rear load pressure input

PLSRC: Rear load pressure

detection port

PS : Pump suction

PLSCR: LS set selector pressure

detection port

PM : PC set selector pressure

detection port

PEPC : EPC basic pressure input

PDIR : Air bleeder

PEPB : EPC basic pressure

detection port

Outline

• This pump consists of 2 variable capacity swash plate piston pumps, PC valve, LS valve, and EPC valve.

10-26

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

1. Shaft (Front) 7. Cylinder block

2. Cradle 8. Valve plate

3. Case (Front) 9. End cap

4. Rocker cam 10. Shaft (Rear)

5. Shoe 11. Case (Rear)

6. Piston 12. Servo piston

PC400/450(LC)-7

10-27

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

Function

• The rotation and torque transmitted to the pump

shaft are converted into hydraulic energy, and

pressurized oil is discharged according to the

load.

• It is possible to change the discharge amount by

changing the swash plate angle.

Structure

• Cylinder block (7) is supported to shaft (1) by a

spline, and shaft (1) is supported by the front and

rear bearings.

• The tip of piston (6) is a concave ball, and shoe

(5) is caulked to it to form one unit. Piston (6) and

shoe (5) form a spherical bearing.

• Rocker cam (4) has flat surface A, and shoe (5) is

always pressed against this surface while sliding

in a circular movement.

Rocker cam (4) brings high pressure oil at cylinder surface B with cradle (2), which is secured to

the case, and forms a static pressure bearing

when it slides.

• Piston (6) carries out relative movement in the axial direction inside each cylinder chamber of cylinder block (7).

• The cylinder block seals the pressure oil to valve

plate (8) and carries out relative rotation. This surface is designed so that the oil pressure balance is

maintained at a suitable level. The oil inside each

cylinder chamber of cylinder block (7) is sucked in

and discharged through valve plate (8).

10-28

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

Operation

1) Operation of pump

i Cylinder block (7) rotates together with shaft

(1), and shoe (5) slides on flat surface A.

When this happens, rocker cam (4) moves

along cylindrical surface B, so angle a

between center line X of rocker cam (4) and

the axial direction of cylinder block (7)

changes. (Angle is called the swash plate

angle.)

ii Center line X of rocker cam (4) maintains

swash plate angle in relation to the axial

direction of cylinder block (7), and flat surface

moves as a cam in relation to shoe (5).

A

In this way, piston (6) slides on the inside of

cylinder block (7), so a difference between

volumes E and F is created inside cylinder

block (7). The suction and discharge is carried out by this difference F – E.

In other words, when cylinder block (7)

rotates and the volume of chamber

becomes smaller, the oil is discharged during

that stroke. On the other hand, the volume of

chamber F becomes larger, and as the volume becomes bigger, the oil is sucked in.

iii If center line X of rocker cam (4) is in line with

the axial direction of cylinder block (7) (swash

plate angle = 0), the difference between volumes E and F inside cylinder block (7)

becomes 0, so the pump does not carry out

any suction or discharge of oil.

(In actual fact, the swash plate angle never

becomes 0.)

E

PC400/450(LC)-7

10-29

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

2) Control of discharge amount

• If the swash plate angle becomes larger,

the difference between volumes E and F becomes larger and discharge amount Q increases.

• Swash plate angle is changed by servo

piston (12).

• Servo piston (12) moves in a reciprocal

movement ( ) according to the signal pressure from the PC and LS valves. This

straight line movement is transmitted

through rod (13) to rocker cam (4), and rocker cam (4), which is supported by the cylindrical surface to cradle (2), slides in a

rotating movement in direction of arrow.

• With servo piston (12), the area receiving the

pressure is different on the left and the right,

so main pump discharge pressure (self pressure) PP is always brought to the chamber

receiving the pressure at the small diameter

piston end.

• Output pressure

brought to the chamber receiving the pressure at the large diameter end. The relationship in the size of pressure PP at the small

diameter piston end and pressure

large diameter end, and the ratio between

the area receiving the pressure of the small

diameter piston and the large diameter piston controls the movement of servo piston

(12).

of the LS valve is

Pen

Pen

at the

10-30

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

LS VALVE

1. Plug

2. Locknut

3. Sleeve

4. Spring

5. Seat

6. Spool

7. Piston

8. Sleeve

PC VALVE

: Pump port

PA

PP

PDP

PLP

PLS

PPL

PSIG

Pump port

:

: Drain port

: LS control pressure output port

: LS pressure input port

: PC control pressure input port

: LS mode selection pilot port

1. Servo piston assembly

2. Plug

3. Pin

4. Spool

5. Retainer

6. Seat

7. Cover

8. Wiring

PC400/450(LC)-7

: Pump port

PA

PA2 : Pump pressure pilot port

: Drain port

PDP

: PC mode selector pressure pilot port

PM

: PC control pressure output port

PPL

10-31

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

Function

(1) LS valve

The LS valve detects the load and controls the

discharge amount.

This valve controls main pump discharge

amount Q according to differential pressure

PLS

(=PP –

) [called the LS differential

PLS

pressure] (the difference between main pump

pressure PP and control valve outlet port pressure

Main pump pressure PP, pressure

PLS

).

{called

PLS

the LS pressure} coming from the control valve

output, and pressure

{called the LS selec-

Psig

tor pressure} from the proportional solenoid

valve enter this valve. The relationship between

discharge amount Q and differential pressure

, (the difference between main pump

PLS

pressure PP and LS pressure

) changes as shown in the diagram at the

PLS

PLS

) (= PP –

right according to LS pressure selector current

of the LS-EPC valve.

isig

When isig changes between 0 and 1A, the set

pressure of the spring changes according to this,

and the selector point for the pump discharge

amount changes at the rated central valve

between 1.2 2.6 MPa {12 27 kg/cm

2

}.

(2) PC valve

When the pump discharge pressure

pressure) and

(other pump pressure) are

PP2

PP1

high, the PC valve controls the pump so that no

more oil than the constant flow (in accordance

with the discharge pressure) flows even if the

stroke of the control valve becomes larger. In

this way, it carries out equal horsepower control

so that the horsepower absorbed by the pump

does not exceed the engine horsepower.

In other words, If the load during the operation

becomes larger and the pump discharge pressure rises, it reduces the discharge amount from

the pump; and if the pump discharge pressure

drops, it increases the discharge amount from

the pump. The relationship between the average

of the front and rear pump discharge pressures

(average discharge amount of F, R pumps (

+ PP2)/2

) and pump discharge amount Q is

shown on the right, with the current given to the

PC-EPC valve solenoid shown as a parameter.

The controller senses the actual speed of the

engine, and if the speed drops because of an

increase in the load, it reduces the pump discharge amount to allow the speed to recover. In

other words, when the load increases and the

engine speed drops below

the set value, the command current to the PCEPC valve solenoid from the controller

increases according to the drop in the engine

speed to reduce the pump swash plate angle.

(self-

PP1

10-32

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

OPERATION

(1) LS valve

1) When control valve is at neutral position

• The LS valve is a three-way selector valve, with

pressure

(LS pressure) from the inlet port of

PLS

the control valve brought to spring chamber B,

and main pump discharge pressure PP brought

to port H of sleeve (8). The size of this LS pressure

+ force Z of spring (4) and the main

PLS

pump pressure (self pressure) PP determines

the position of spool (6). However, the size of the

output pressure

(the LS selection pres-

PSIG

sure) of the EPC valve for the LS valve entering

port G also changes the position of spool (6).

(The set pressure of the spring changes).

• Before the engine is started, servo piston (12) is

pushed to the right. (See the diagram on the

right)

• When the engine is started and the control lever

is at the neutral position, LS pressure

MPa {0 kg/cm

2

}. (It is interconnected with the

PLS

is 0

drain circuit through the control valve spool.)

At this point, spool (6) is pushed to the right, and

port C and port D are connected. Pump pressure PP enters the large diameter end of the

piston from port K and the same pump pressure

also enters port J at the small diameter end

PP

of the piston, so the swash plate is moved to the

minimum angle by the difference in the area of

the piston (12).

PC400/450(LC)-7

10-33

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

2) Operation in increase direction for pump discharge amount

• When the difference between the main pump

pressure PP and LS pressure

words, LS differential pressure

smaller (for example, when the area of opening

of the control valve becomes larger and pump

drops), spool (6) is pushed to the left by the

PP

combined force of LS pressure

force of spring (4).

• When spool (6) moves, port D and port E are

joined and connected to the PC valve. When this

happens, the PC valve is connected to the drain

port, so circuit D – K becomes drain pressure PT.

(The operation of the PC valve is explained later).

PLS

, becomes

PLS

PLS

, in other

and the

10-34

• For this reason, the pressure at the large diameter end of servo piston (12) becomes drain pressure PT, and pump pressure PP enters port J at

the small diameter end, so servo piston (12) is

pushed to the right. Therefore, the swash plate

moves in the direction to make the discharge

amount larger. If the output pressure of the EPC

valve for the LS valve enters port G, this pressure creates a force to move piston (7) to the

right. If piston (7) is pushed to the right, it acts to

make the set pressure of spring (4) weaker, and

the difference between

when ports D and E of spool (6) are connected.

and PP changes

PLS

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

3) Operation in decrease direction for pump discharge amount

• The following explains the situation if the servo

piston (12) moves to the right (the discharge

amount becomes smaller). When LS differential

pressure

when the area of opening of the control valve becomes smaller and pump pressure PP rises),

pump pressure PP pushes spool (6) to the right.

• When spool (6) moves, main port pressure

flows from port C and port D and from port K, it

enters the large diameter end of the piston.

• Main pump pressure PP also enters port J at the

small diameter end of the piston, but because of

the difference in area between the large diameter

end and the small diameter end of servo piston

(12), servo piston (12) is pushed to the right.

PC400/450(LC)-7

becomes larger (for example,

PLS

PP

• As a result, the swash plate moves in the direction to make angle smaller.

• If LS selection pressure

acts to make the set pressure of spring (4) weaker.

enters port G, it

PSIG

10-35

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

4) When servo piston is balanced

• Let us take the area receiving the pressure at the

large diameter end of the piston as A1, the area

receiving the pressure at the small diameter end

as A0, and the pressure flowing into the large diameter end of the piston as

. If the main

Pen

pump pressure PP of the LS valve and the combined force of force Z of spring (4) and LS pressure

A0

are balanced, and the relationship is

PLS

PP = A1 ×

×

, servo piston (11) will stop

Pen

in that position, and the swash plate will be kept

at an intermediate position. (It will stop at a position where the opening of the throttle from port

to port E and from port C to port D of spool (6) is

approximately the same.)

10-36

• At this point, the relationship between the area

receiving the pressure at both ends of piston (12)

is A0 : A1 = 1:2, so the pressure applied to both

ends of the piston when it is balanced becomes

:

Pen

= 2:1.

PP

• The position where spool (6) is balanced and

stopped is the standard center, and the force of

spring (4) is adjusted so that it is determined when

PP

–

PLS

= 2.6 MPa {27 kg/cm

2

}. However, if

PSIG (the output pressure of 0 2.9 MPa {0

30 kg/cm

D

plied to port G, the balance stop position will

change in proportion to pressure

PP

2

} of the EPC valve of the LS valve) is ap-

PLS

–

= 2.6 1.2 MPa {27 12 kg/cm

PSIG

between

2

}.

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

(2) PC Valve

1) When pump controller is normal a. When the load on the actuator is small

and pump pressures PP1 and PP2 are

low

i) Movement of PC-EPC solenoid (1)

• The command current from the pump controller flows to PC-EPC solenoid (1).This

command current acts on the PC-EPC valve

and outputs the signal pressure. When this

signal pressure is received, the force pushing piston (2) is changed.

• On the opposite side to the force pushing this

piston (2) is the spring set pressure of

springs (4) and (6) and pump pressure

(self pressure) and

sure) pushing spool (3). Piston (2) stops at a

position where the combined force pushing

spool (3) is balanced, and the pressure

(pressure of port C) output from the PC valve

changes according to this position.

PC400/450(LC)-7

(other pump pres-

PP2

PP1

• The size of command current X is determined by the nature of the operation (lever

operation), the selection of the working

mode, and the set value and actual value for

the engine speed.

a Other pump pressure

This is the pressure of the pump at the opposite end.

For the F pump, it is the R pump pressure

For the R pump, it is the F pump pressure

10-37

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

ii) Action of spring

• The spring load of springs (4) and (6) in the

PC valve is determined by the swash plate

position.

• If piston (9) moves to the right, spring (6) is

compressed, and if it moves further to the

right, spring (6) contacts seat (5) and is fixed

in position. In other words, the spring load is

changed by piston (9) extending or compressing springs (4) and (6).

10-38

• If the command circuit input to PC-EPC

valve solenoid (1) changes further, the force

pushing piston (2) changes, and the spring

load of springs (4) and (6) also changes according to the valve of the PC-EPC valve solenoid command current.

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

•Port C of the PC valve is connected to port

of the LS valve (see (1) LS valve). Self pressure

ter end of servo piston (9), and other pump

pressure

• When pump pressures

small, spool (3) is on the left. At this point,

port C and D are connected, and the pressure entering the LS valve becomes drain

pressure PT. If port E and port G of the LS

valve are connected (see (1) LS valve), the

pressure entering the large diameter end of

the piston from port J becomes drain pressure PT, and servo piston (9) moves to the

left. In this way, the pump discharge amount

moves in the direction of increase.

• As servo piston (9) moves further, springs

(4) and (6) expand and the spring force becomes weaker. When the spring force becomes weaker, spool (3) moves to the right,

so the connection between port C and port

is cut, and the pump discharge pressure

ports B and C are connected. As a result, the

pressure at port C rises, and the pressure at

the large diameter end of the piston also rises, so the movement of piston (9) to the left

is stopped.

• In other words, the stop position for piston (9)

(= pump discharge amount) is decided at the

point where the force of springs (4) and (6)

and the pushing force from the PC-EPC

valve solenoid and the pushing force created

by the pressures

spool (3) are in balance.

enters port B and the small diame-

PP1

enters port A.

PP2

and

PP1

PP1

and

acting on the

PP2

PP2

are

E

D

PC400/450(LC)-7

10-39

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

b. When load on actuator is large and pump

discharge pressure is high

• When the load is large and pump discharge

pressures

pushing spool (3) to the right becomes larger

and spool (3) moves to the position in the diagram above. When this happens, as shown

in the diagram above, part of the pressurized

oil from port B flows out through port

where the LS valve is actuated to port D, and

the pressurized oil flowing from port C to the

LS valve becomes approximately half of

main pump pressure PP.

• When port E and port G of the LS valve are

connected (see (1) LS valve), the pressure

from port J enters the large diameter end of

servo piston (9), and servo piston (9) stops.

PP1

and

are high, the force

PP2

10-40

• If pump discharge pressure PP and

creases further and spool (3) moves further

to the right, main pump pressure

to port C and acts to make the discharge

amount the minimum. When piston (9)

moves to the right, springs (4) and (6) are

C

compressed and push back spool (3). When

spool (3) moves to the left, port C and port

are disconnected and port C and port D are

interconnected. As a result, the pressure at

port C (= J) drops, and piston (9) stops moving to the right.

• The position in which piston (9) stops when

this happens is further to the right than the

position when pump pressures

are low.

PC400/450(LC)-7

PP1

PP1

PP2

and

in-

flows

B

PP2

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

• The relation of average pump pressure

+ PP2)/2

forms a bent line because of the doublespring effect of springs (4) and (6). The relationship between average pump pressure

(PP1 + PP2)/2

is shown in the figure at the right.

Q

• If command voltage X sent to PC-EPC valve

solenoid (1) increases further, the relationship between average pump pressure

+ PP2)/2

proportional to the pushing force of the PCEPC valve solenoid and moves in parallel. In

other words, the pushing force of PC-EPC

solenoid (1) is added to the force pushing to

the left because of the pump pressure applied to the spool (3), so the relationship between the average pump pressure

PP2)/2

ance with the increase in X.

and the position of servo piston (9)

and pump discharge amount

, and pump discharge amount Q is

and Q moves from to in accord-

(PP1

(PP1

(PP1 +

PC400/450(LC)-7

10-41

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

2) When pump controller is abnormal and emergency pump drive switch is ON

a. When load on main pump is light

• If there is a failure in the pump controller, turn

emergency pump drive switch ON to switch

to the resistor side. In this case, the power

source is taken directly from the battery. But

if the current is used as it is, it is too large, so

use the resistor to control the current flowing

to PC-EPC valve solenoid (1).

• When this is done, the current becomes con-

stant, so the force pushing piston (2) is also

constant.

• If the main pump pressure

low, the combined force of the pump pressure and the force of PC-EPC valve solenoid

(1) is weaker than the spring set force, so

spool (3) is balanced at a position to the left.

PP1

and

PP2

10-42

• At this point, port C is connected to the drain

pressure of port D, and the large diameter

end of the piston of servo piston (9) also becomes the drain pressure PT through the LS

valve. When this happens, the pressure at

the small diameter end of the piston is large,

so servo piston (9) moves in the direction to

make the discharge amount larger.

are

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

b. When main pump load is heavy

• In the same way as in the previous item,

when the emergency pump drive switch is

, the command current sent to PC-EPC

ON

valve solenoid (1) becomes constant. For

this reason, the force of piston (2) pushing

spool (3) is constant.

• If main pump pressures

crease, spool (3) moves further to the right

than when the main pump load is light, and is

balanced at the position in the diagram

above (See Fig. P).

• In this case, the pressure from port B flows

to port C, so servo piston (9) moves to the

right (to make the discharge amount smaller)

by the same mechanism as explained in item

2)-b, and stops at a position to the right of the

position when the load on the pump is light

(See Fig. Q). In other words, even when the

emergency pump drive switch is ON, the

curve for the pump pressure PP and discharge amount Q is determined as shown in

PC400/450(LC)-7

PP1

and

PP2

in-

the diagram for the valve of the current sent

to the PC-EPC valve solenoid through the

resistor.

The curve when the emergency pump drive

switch is ON is curve , which is to the left

of curve for when the pump controller is

normal.

10-43

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD LS(PC)-EPC VALVE

LS(PC)-EPC VALVE

1. Body 5. Coil

2. Spool 6. Plunger

3. Spring 7. Connector

10-44

:To LS(PC) valve

PSIG

: To tank

PT

:From self-reducing pressure

PEPC

valve4. Rod

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD LS(PC)-EPC VALVE

Function

• The EPC valve consists of the proportional solenoid portion and the hydraulic valve portion.

• When it receives signal current i from the pump

controller, it generates the EPC output pressure

in proportion to the size of the signal, and outputs

it to the LS valve.

Operation

1. When signal current is 0 (coil de-energized)

• When there is no signal current flowing from the

controller to coil (5), coil (5) is de-energized.

• For this reason, spool (2) is pushed to the left in

the direction of the arrow by spring (3).

• As a result, port

rized oil from the main pump does not flow to the

LS valve.

At the same time, the pressurized oil from the LS

valve passes from port

and is drained to the tank.

PT

closes and the pressu-

PEPC

PSIG(PM)

through port

PC400/450(LC)-7

10-45

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD LS(PC)-EPC VALVE

2. When signal current is very small (coil energized)

• When a very small signal current flows to coil (5),

coil (5) is energized, and a propulsion force is

generated which pushes plunger (6) to the left.

• Push pin (4) pushes spool (2) to the left, and

pressurized oil flows from port

PSIG(PM)

• When the pressure at port

the load of spring (3) + the force acting on surface a of spool (2) becomes greater than the propulsion force of plunger (6), spool (2) is pushed

to the right. The circuit between port

port

port

• As a result, spool (2) is moved up or down until

the propulsion force of plunger (6) is balanced

with the load of spring (3) + pressure of port

PSIG(PM)

• Therefore, the circuit pressure between the EPC

valve and the LS valve is controlled in proportion

to the size of the signal current.

.

PSIG(PM)

PSIG(PM)

.

PSIG(PM)

is shut off, and at the same time,

and port PT are connected.

PEPC

rises and

PEPC

to port

and

3. When signal current is maximum (coil energized)

• When the signal current flows to coil (5), coil (5)

is energized.

• When this happens, the signal current is at its

maximum, so the propulsion force of plunger (6)

is also at its maximum.

• For this reason, spool (2) is pushed fully to the

left by push pin (4).

• As a result, the maximum flow of pressurized oil

from port

circuit pressure between the EPC valve and LS

valve becomes the maximum.

At the same time, port PT closes and stops the

oil from flowing to the tank.

PEPC

flows to port

PSIG(PM)

, and the

10-46

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD VARIABLE VOLUME VALVE

VARIABLE VOLUME VALVE

1. Block

2. Plug

3. Spring

4. Piston

:To PC valve

PM

:To tank

PT

:From self-reducing pressure valve

PEPC

PC400/450(LC)-7

10-47

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD VARIABLE VOLUME VALVE

Function

• This stabilizes the EPC output pressure.

Operation

• The output pressure from EPC flows to port PM,

and when the propulsion force of piston (4) becomes larger than the load of spring (3), piston

(4) is pushed to the left and the volume at port

increases.

PM

When the propulsion force of piston (4) becomes

less than the load on spring (3), piston (4) is

pushed to the right and the volume at port

goes down.

PM

10-48

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CONTROL VALVE

CONTROL VALVE

Outline

1. 6-spool valve

2. Cover 1

3. Cover 2

4. Pump merge-divider valve

5. Back pressure valve

6. Boom lock valve

7. Boom, arm Hi valve

8. Quick return valve

9. Boom Hi check valve

• This control valve consists of a 7-spool valve (6

spool valve + boom • arm Hi valve). A merge-divider valve, back-pressure valve, boom hydraulic

drift prevention valve, quick return valve, and Hi

valve check valve are installed to it.

• Since all the valves are assembled together with

connecting bolts and their passes are connected

to each other inside the assembly, the assembly

is small in size and easy to maintain.

• Since one spool of this control valve is used for

one work equipment unit, its structure is simple.

A1

A2

A3

A4

A5

A6

A-1

A-2

B1

B3

B4

B5

B6

B-1

P1

P2

P3

P4

P5

P6

P7

P8

P9

P10

: To bucket cylinder bottom

: o left travel motor

: To boom cylinder bottom

: To swing motor

: To right travel motor

: To arm cylinder head

: To boom cylinder bottom

: To attachment

: To bucket cylinder head

: To bottom cylinder head

: To swing motor

: To right travel motor

: To arm cylinder bottom

: To arm cylinder bottom

: From bucket PPC valve

: From bucket PPC valve

: From left travel PPC valve

: From left travel PPC valve

: From boom PPC valve

: From boom PPC valve

: From swing PPC valve

: From swing PPC valve

: From right travel PPC valve

: From right travel PPC valve

P11

P12

BP1

PB5

PLS1

PLS2

PP1

PP2

PPS1

PPS2

PR

PS

PST

PX1

PX2

SA

SB

T

T1

TS

TSW

:From arm PPC valve

:From arm PPC valve

: Boom RAISE PPC output pressure

: From 2-stage safety valve solenoid valve

: To rear pump control

: To front pump control

: To rear pump control

: To front pump control

: From rear main pump

: From front main pump

: To solenoid valve, PPC valve, EPC valve

: From pump merge-divider solenoid valve

: From travel junction valve

: From 2-stage solenoid valve

: From 2-stage solenoid valve

: Pressure sensor fitting port

: Pressure sensor fitting port

: To tank

: To tank

: To tank

: To swing motor

10-50

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CONTROL VALVE

7-spool valve

(1/9)

PC400/450(LC)-7

10-51

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CONTROL VALVE

(2/9)

10-52

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CONTROL VALVE

(3/9)

1. Unload valve 9. Pressure compensation valve (Arm IN)

2. Pressure compensation valve (Arm OUT) 10. Pressure compensation valve (Bucket DUMP)

3. Pressure compensation valve (Right travel reverse)

4. Pressure compensation valve (Left swing) 13. Pressure compensation valve (Right swing)

5. Pressure compensation valve (Boom RAISE) 14. Pressure compensation valve (Right travel for-

7. Pressure compensation valve (Bucket CURL) 15. Pressure compensation valve (Arm IN)

8. Pressure compensation valve (Boom RAISE) 16. Main relief valve

PC400/450(LC)-7

11. Pressure compensation valve (Left travel forward)

12. Pressure compensation valve (Boom LOWER)

ward)6. Pressure compensation valve (Left travel reverse)

10-53

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CONTROL VALVE

(4/9)

1. Spool (Arm) 6. Spool (Bucket)

2. Spool (Right travel) 7. Spool (Boom Hi)

3. Spool (Swing) 8. Spool (Arm Hi)

4. Spool (Boom) 9. Unload valve

5. Spool (Left travel) 10. Main relief valve

No. Check item

Standard size Repair limit

Free length

OD

11 Spool return spring

12 Spool return spring 54.6 × 34.8 51.2

13 Spool return spring 54.5 × 34.8 51.2

14 Spool return spring 54.9 × 24.2 51.2

15 Spool return spring 57.2 × 32.8 51

×

54.2 × 34.8 51.2

Installed

length

Criteria

Installed

load

416.5 N

{42.5 kg}

429.9 N

{42.9 kg}

393 N

{40.1 kg}

251 N

{25.1 kg}

416 N

{42.5 kg}

Free

length

—

—

—

—

—

Installed

load

333.2 N

{34 kg}

336.1 N

{34.3 kg}

314.6 N

{32.1 kg}

201.0 N

{20.5 kg}

333.2 N

{34.0 kg}

Unit: mm

Remedy

If damaged or

deformed,

replace spring

10-54

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CONTROL VALVE

(5/9)

1. Safety-suction valve (Arm OUT) 9. Safety-suction valve (2-stage) (Boom LOWER)

2. Suction valve (Right travel reverse) 10. Suction valve (Right travel forward)

3. Suction valve (Boom RAISE) 11. Safety-suction valve (Arm IN)

4. Suction valve (Left travel reverse) 12. LS shuttle valve (Arm, right travel)

5. Safety-suction valve (Boom Hi) 13. LS select valve

6. Safety-suction valve (Arm IN) 14. LS shuttle valve (Boom, left travel, bucket)

7. Safety-suction valve (Bucket DUMP) 15. LS check valve

8. Suction valve (Left travel forward) 16. Pressure relief plug

No. Check item

17 Check valve spring

Standard size Repair limit

Free length

OD

×

11.5 × 4.6 8.5

Installed

length

Criteria

Installed

load

1.5 N

{0.15 kg}

Free

length

—

Installed

load

1.2 N

{0.12 kg}

Remedy

If damaged or

deformed,

replace spring

PC400/450(LC)-7

Unit: mm

10-55

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CONTROL VALVE

(6/9)

ARM CONTROL VALVE R. H. TRAVEL CONTROL VALVE

1. Unload valve 5. Safety-suction valve 12. Suction valve

2. Main relief valve 6. Spool 13. Spool

3. Safety valve (Boom RAISE) 7. Pressure compensation valve (OUT)

8. LS shuttle valve 15. LS shuttle valve

9. Pressure compensation valve (IN)

10. Safety-suction valve 17. Suction valve

11. Check valve for regeneration circuit

14. Pressure compensation valve (Reverse)4. Lift check valve

16. Pressure compensation valve (Forward)

10-56

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CONTROL VALVE

Unit: mm

No. Check item

Standard size Repair limit

Free length

OD

18 Regeneration valve spring

19 Piston return spring 36.9 × 11.1 28

20 Piston return spring 36.9 × 11.1 28

×

31.5 × 10.3 19.5

Installed

length

Criteria

Installed

load

6.2 N

{0.6 kg}

29.4 N

{3 kg}

29.4 N

{3 kg}

Free

length

—

—

—

Installed

load

4.9 N

{0.5 kg}

23.5 N

{2.4 kg}

23.5 N

{2.4 kg}

Remedy

If damaged or

deformed,

replace spring

PC400/450(LC)-7

10-57

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CONTROL VALVE

(7/9)

SWING CONTROL VALVE

1. Spool

2. Pressure compensation valve (Left)

3. LS select valve

4. Pressure compensation valve (Right)

10-58

ARM CONTROL VALVE

5. Suction valve

6. Spool

7. Pressure compensation valve (RAISE)

8. Hydraulic drift prevention valve

9. LS shuttle valve

10. Pressure compensation valve (Lower)

11. Safety-suction valve

12. Check valve for regeneration circuit

L. H. TRAVEL CONTROL VALVE

13. Pump merge-divider valve (Travel junction valve)

14. Return spring

15. Suction valve

16. Spool

17. Pressure compensation valve (Reverse)

18. LS shuttle valve

19. Pressure compensation valve (Forward)

20. Suction valve

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CONTROL VALVE

Unit: mm

No. Check item

Standard size Repair limit

Free length

OD

21 Regeneration valve spring

22 Piston return spring 48.1 × 10.8 28

23 Piston return spring 36.9 × 11.1 28

24 Spool return spring 30.7 × 20.5 23

×

31.5 × 10.3 19.5

Installed

length

Criteria

Installed

load

6.2 N

{0.6 kg}

17.5 N

{1.8 kg}

29.4 N

{3 kg}

50.0 N

{5.1 kg}

Free

length

—

—

—

—

Installed

load

4.9 N

{0.5 kg}

14.0 N

{1.4 kg}

23.5 N

{2.4 kg}

40.0 N

{4.1 kg}

Remedy

If damaged or

deformed,

replace spring

PC400/450(LC)-7

10-59

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CONTROL VALVE

(8/9)

BUCKET CONTROL VALVE

1. Safety-suction valve

2. Spool

3. Pressure compensation valve (CURL)

4. LS shuttle valve

5. Pressure compensation valve (DUMP)

6. Safety-suction valve

No. Check item

Standard size Repair limit

Free length

OD

14 Piston return spring

15 Piston return spring 36.9 × 11.1 28

×

48.1 × 10.8 28

10-60

BOOM, ARM HI VALVE

7. Boom Hi spool

8. Pressure compensation valve (Boom RAISE)

9. Boom Hi check valve

10. Quick-return valve

11. Pressure compensation valve (Arm IN)

12. Arm Hi spool

13. Safety-suction valve

Criteria

Installed

length

Installed

load

17.5 N

{1.8 kg}

29.4 N

{3 kg}

Free

length

—

—

Installed

load

14.0 N

{1.4 kg}

23.5 N

{2.4 kg}

Unit: mm

Remedy

If damaged or

deformed,

replace spring

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CONTROL VALVE

(9/9)

1. Unload valve 9. LS bypass plug

2. Main relief valve 10. Screw

3. Pump merge-divider valve (Main) 11. Poppet

4. Return spring 12. Spring (Pressure reducing valve pilot)

5. Pump merge-divider valve (For LS) 13. Spring (Pressure reducing valve main)

6. Return spring 14. Valve (Pressure reducing valve)

7. Valve (Sequence valve) 15. Spring (Safety valve)

8. Spring (Sequence valve) 16. Ball

10-62

PC400/450(LC)-7

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD CONTROL VALVE

Unit: mm

No. Check item

Standard size Repair limit