komatsu PC350LC-7 SPECIFICATIONS

FLYWHEEL HORSEPOWER

180 kW 242 HP @ 1900 rpm

OPERATING WEIGHT

PC350-7: 32300 kg 71,210 lb

PC350LC-7: 33400 kg 73,630 lb

Photo may include optional equipment.

PC350-7

PC350LC-7

PC

350

HYDRAULIC EXCAVATOR

Productivity Features

● High Production and

Low Fuel Consumption

Production is increased with

larger output during Active mode

while fuel efficiency

is further improved.

● Maximum

Drawbar Pull is

increased 17% offering

superb steering and slope

climbing performance.

See page 4

● Larger Arm Crowd Force and Bucket

Digging Force Provide Increased

Production

Bucket digging force and Arm crowd force are

increased 7% when the Power Max function is applied

(compared with PC350-6).

See page 4

● Higher Lifting Capacity

PC350-7’s lateral stability is

improved, lifting capacity also

increased.

Quarry Bucket

Large Comfortable Cab

New PC350-7’s cab volume is increased by 14%,

offering an exceptionally roomy operating

environment

● Highly pressurized cab with optional air

conditioner

● Low noise design

● Low vibration with cab damper mounting

● FOG capable with optional bolt-on top guard

FOG has been renamed to OPG (Operator Protective Guards)

top guard level 2 by ISO 10262

See page 6

H

e

avy-D

u

ty A

rm

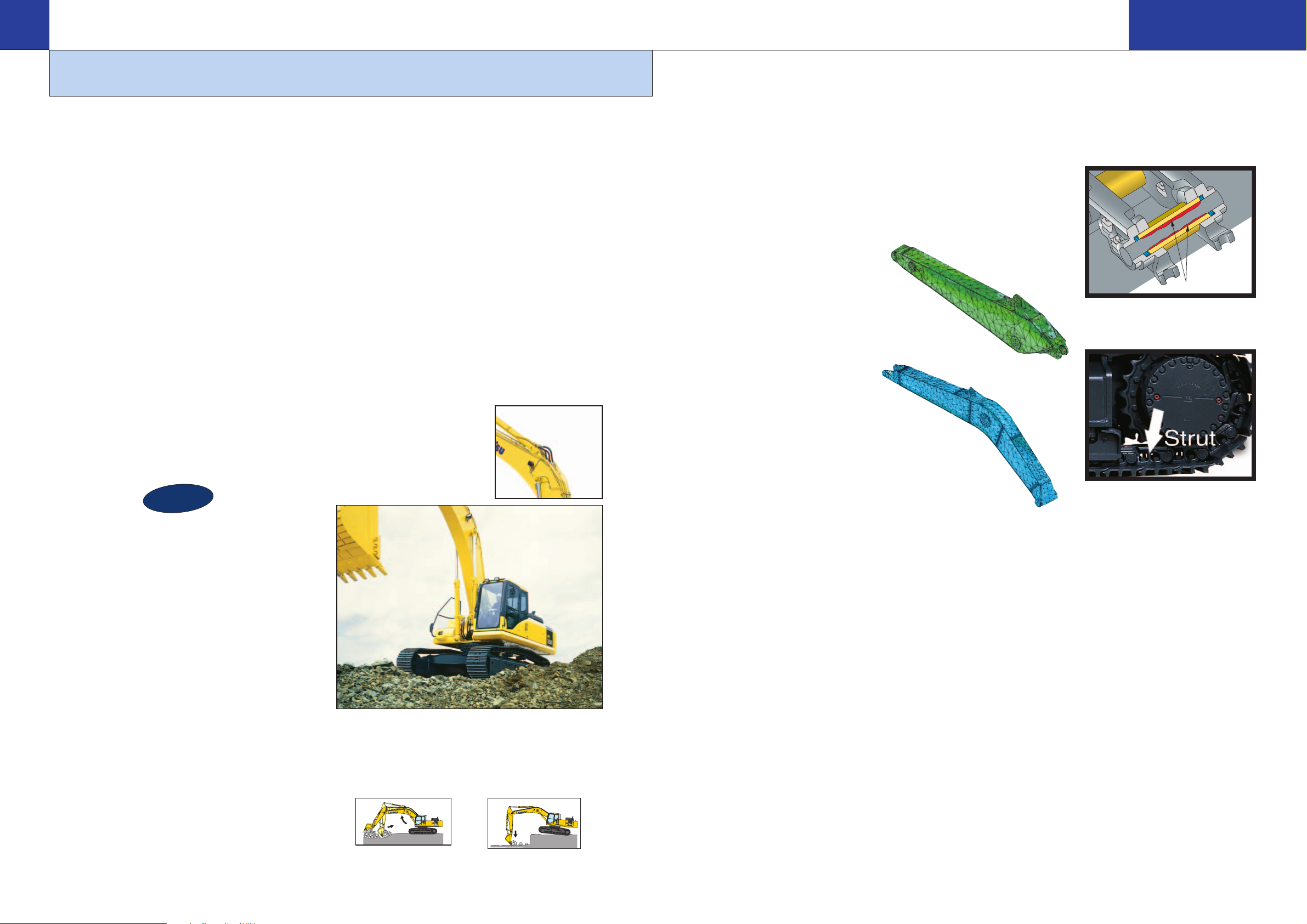

Heavy-Duty Boom

The PC350-7 is a further reinforced model of the

PC300-7 backhoe. It is equipped with special

applications for extremely tough assignments.

Excellent Reliability and Durability

● High rigidity work equipment

● Sturdy frame structure

● Reliable Komatsu manufactured major components

● Highly reliable electronic devices

See page 5

Harmony with Environment

● Low emission engine

A powerful turbocharged air to air aftercooled

Komatsu SAA6D114E provides 180 kW 242 HP.

● Economy mode saves fuel consumption

● Low operation noise

● Easily recycled design

See page 5

Additional Working Light (optional)

Large

Counterweight

Strengthened

Revolving Frame

Photo may include optional equipment.

Full Roller Guard

and Double-Flange

Track Roller

Easy Maintenance

● Replacement interval is extended for engine oil, engine oil filter and hydraulic filter

● Remote mounted engine oil filter and fuel drain valve for easy access

● Water separator and corrosion resistor are standard equipment

● Easier radiator cleaning

● Fuel tank capacity is increased

● BMRC bushings on work equipment extend lubricating interval

See page 8

FLYWHEEL HORSEPOWER

180 kW 242 HP @ 1900 rpm

OPERATING WEIGHT

PC350-7: 32300 kg 71,210 lb

PC350LC-7: 33400 kg 73,630 lb

BUCKET CAPACITY

1.40 m31.83 yd

3

32

WALK-AROUND

H YDRAULIC E XCAVATOR

HYDRAULIC EXCAVATOR

PC350-7

PC350-7 0

● High Rigidity Work Equipment

The arm and boom are strengthened to correspond to increasing bucket and arm

digging forces. The top and lower plate of the boom are changed from a three-

piece to a one-piece welded structure to improve durability. The arm plate thick-

ness is also increased (compared with PC300-7). The boom and arm have large

cross sectional dimensions as well

as continuous groove welding to improve

digging and side-contact strength.

● Sturdy Frame Structure

The revolving frame, center frame and undercarriage

are designed by using the most advanced three-dimensional

CAD and FEM analysis technology.

● Reliable Components

All of the major machine components,

such as engine, hydraulic pumps,

hydraulic motors and control valves, etc.,

are exclusively designed and manufactured by Komatsu.

● Highly Reliable Electronic Devices

Exclusively designed electronic devices have passed

severe testing.

● Controller ● Sensors

● Connectors ● Heat resistant wiring

● Metal guard rings protect all the hydraulic cylinders and improve reliability.

● Low Noise

Noise is reduced not only from the engine, but also

during swing and hydraulic relief. Dynamic noise level

is 104 dB.

● Environment Oriented Mode (Economy Mode)

Economy mode meets the needs of the 21st century.

Economy mode offers the user fuel savings, quiet opera-

tion and less CO

2

emission.

Fuel consumption is reduced 20% (compared with

Active mode).

Production is the same as the PC350-6

heavy duty mode.

● Easily Recycled

PC350-7 is designed with consideration of recycling and

uses natural resources effectively.

Sound suppressing material is made from PET (poly-

ethylene terephthalate) resin that is easy to recycle.

All exterior parts are made from steel.

Engine and hydraulic system oil and filter replacement

intervals are extended to save earth resources.

All resin-made parts are indicated by material code

symbol.

5

Excellent Reliability and Durability

Harmony with Environment

Grease Sealed Track

PC350-7 uses grease sealed tracks for

extended undercarriage life.

Track Link with Strut

PC350-7 uses track links with

strut providing superb durability

The increased output and fuel savings of the Komatsu

SAA6D114E engine result in increased production and

improved production per unit of fuel.

Engine

The PC350-7 gets its exceptional power and work capacity

from a Komatsu SAA6D114E engine. Output is 180 kW

242 HP, providing increased hydraulic power and improved

fuel efficiency.

Hydraulics

Unique two-pump system ensures smooth compound

movement of the work equipment. HydrauMind controls both

pumps for efficient engine power use. This system also

reduces hydraulic loss during operation.

Larger Maximum Drawbar Pull

PC350-7’s maximum drawbar pull is increased by 17% and

provides superb steering and slope climbing performance.

Maximum drawbar pull: 264 kN 26900 kgf 59,300 lb.

Drawbar pull/operating weight: 0.83

Drawbar pull

Hydraulic Pump Oil Flow Adjustment

When installing attachment (breaker, crusher, etc.) and B,

A or E mode is selected, it is possible to adjust engine and

hydraulic pump discharge flow to match attachment char-

acteristics. Selection is possible throught the LCD (Liquid

Crystal Display). This system also allows throttling of the

attachment side discharge flow to provide smooth work

equipment movement and compound operation with work

equipment and attachment.

Larger Digging Forces Provide Increased Production

Bucket digging force and arm crowd force when Power Max

is applied are increased 7% by improvement of hydraulic

system. The larger digging forces generate the largest pro-

duction in the 30 ton 33 U.S. ton class.

*Bucket Digging Force: 228 kN 23200 kgf 51,150 lb.

*Arm Crowd Force: 171 kN 17400 kgf 38,360 lb.

*Measured with Power Max function, 3185 mm 10'5" arm and ISO rating

Smooth Loading Operation

High Production and Low Fuel Consumption

4

17%

increase

Four Working Modes

Working Mode Selection

The PC350-7 excavator is equipped with four working

modes (A, E, L and B mode). Each mode is designed to

match engine speed, pump speed, and system pressure with

the current application. This provides the flexibility to match

equipment performance to the job at hand.

Economy Mode

Economy mode is environmentally friendly. Fuel consumption

is reduced 20% (compared with PC350-7 Active mode)

and production is equal to the PC350-6 heavy duty mode.

Two return hoses

Two return hoses improve

hydraulic performance. In the arm

out function, the oil is returned to

the tank smoothly.

Boom floats upward, reducing

lifting of machine front. This facilitates gathering blasted rock and

scraping down operations.

Boom pushing force is increased,

ditch digging and box digging

operation on hard ground are

improved.

Two Boom Settings

Smooth mode provides easy operation for gathering blasted

rock or scraping down operation. When maximum digging

force is needed, switch to Power mode for more effective

excavating.

Lifting Mode

When lifting mode is selected, lifting capacity is increased by

7% by raising hydraulic pressure.

Photo may include optional equipment.

PRODUCTIVITY FEATURES

H YDRAULIC E XCAVATOR

HYDRAULIC EXCAVATOR

PC350-7

PC350-7 0

Grease

Smooth mode

Power mode

Loading...

Loading...