komatsu PC300LC-8 SPECIFICATIONS

SPECIAL PURPOSE BUCKET

OPTIONAL EQUIPMENT

STANDARD EQUIPMENT

• Alternator, 60 Ampere, 24V

• Anti-slip plates

• Auto-decel

• Automatic engine warm-up system

• Batteries, 126 Ah/2 x 12V

• Boom holding valve

• Cab, capable OPG with optional bolt-on

top guard

• Corrosion resistor

• Counterweight

• Dry type air cleaner, double element

• Electric horn

• Engine, Komatsu SAA6D114E-3

• Engine overheat prevention system

• Fan guard structure

• Hydraulic track adjusters (each side)

• Multi-function color monitor

• Power maximizing system

• PPC hydraulic control system

• Radiator & oil cooler dust proof net

• Rear reflector

• Rear view mirror, RH, LH, rear,

sidewise

• Seat belt, retractable

• Starting motor, 7.5 kW/24 v x 1

• Suction fan

• Track guiding guard, center section

• Track roller

—PC300-8, 7 each side

—PC300LC-8, 8 each side

• Track shoe

—PC300-8, 600 mm 24" triple grouser

—PC300LC-8, 700 mm 28" triple grouser

• Travel alarm

• Two settings for boom

• Working light, 2 (boom and RH)

• Working mode selection system

• Additional filter system for poor-quality

fuel

• Air conditioner with defroster

•Arms

—2220 mm 7'3" arm assembly

—2550 mm 8'4" arm assembly

—3185 mm 10'5" arm assembly

—4020 mm 13'2" arm assembly

• Batteries, 140 Ah/2 x 12 V

• Bolt-on top guard, (Operator Protective

Guards level 2 (OPG))

• Boom, 6470 mm 21'3"

• Cab accessories

—Rain visor

—Sun visor

• Cab front guard

—Full height guard

—Half height guard

• Heater with defroster

• Long lubricating intervals for implement

bushing

• Rear view monitoring system

• Seat, suspension with heater

• Seat, suspension

• Service valve

• Shoes, triple grouser shoes

—PC300-8

700 mm 28", 800 mm 31.5"

—PC300LC-8

600 mm 24", 800 mm 31.5"

• Track roller guards (full length)

• Track frame undercover

• Working lights (2 on cab)

• Ripper bucket for hard and rock ground

—Capacity

SAE heaped 0.9 m31.18 yd

3

CECE heaped 0.8 m31.05 yd

3

Width 1200 mm 47.2"

www.Komatsu.com

CEN00219-04 Materials and specifications are subject to change without notice.

is a trademark of Komatsu Ltd. Japan.

Printed in Japan 200911 IP.As(15)

Photo may include optional equipment.

PC300-8

PC300LC-8

PC

300

FLYWHEEL HORSEPOWER

Gross: 194 kW 260 HP @ 1950 rpm

Net: 184 kW 246 HP @ 1950 rpm

OPERATING WEIGHT

PC300-8: 31100– 32010 kg

68,560– 70,570 lb

PC300LC-8: 31600– 32580 kg

69,670– 71,830 lb

HYDRAULIC EXCAVATOR

3

Photo may include optional equipment.

2

Easy Maintenance

• Long replacement interval of engine oil,

engine oil filter, hydraulic oil and

hydraulic filter.

• Equipped with fuel pre-filter as standard

(with water separator)

• Side-by-side radiator and oil cooler

configuration enables independent removal

and installation of those two components.

• Equipped with the EMMS monitoring

system.

• Easy access to engine oil filter and fuel

drain valve

• Large fuel tank capacity

See page 9.

Ecology and Economy Features

• Low emission engine

A powerful turbocharged and air to air aftercooled Komatsu SAA6D114E-3

engine provides 184 kW 246 HP. This engine meets

EPA Tier 3 and EU Stage 3A

emissions certified, without sacrificing power or machine productivity.

• Economy mode saves fuel consumption.

• Low operation noise

See pages 4 and 5.

● High Production and

Low Fuel Consumption

High power, working performance

and fuel efficiency improve

production and fuel costs.

● Large Drawbar Pull

provides superb steering and slope

climbing performance.

● Large Digging Force

Pressing the Power Max function

button temporarily increases the

digging force 7%.

● Two-mode Setting for Boom

Switch selection allows either

powerful digging or smooth boom

operation.

See page 5.

Productivity Features

Safety Design

• Cab dedicated to hydraulic excavator for protecting the operator in the event of

a roll over accident.

• Anti-slip plates for safe work on machine

• Safety enhancement with large side-view, sidewise, and rear mirrors added.

• Rear view monitoring system for easy checking behind the machine (optional)

See page 7.

WALK-AROUND

H YDRAULIC E XCAVATOR

HYDRAULIC EXCAVATOR

PC300-8

PC300-8 0

Large Comfortable Cab

• Low-noise cab

• Low vibration with cab damper mounting

• Highly pressurized cab with optional air conditioner

• Operator seat and console with armrest that enables

operations in the appropriate operational posture.

See page 6.

HORSEPOWER

Gross: 194 kW 260 HP @ 1950 rpm

Net: 184 kW 246 HP @ 1950 rpm

OPERATING WEIGHT

PC300-8: 31100 – 32010 kg

68,560 – 70,570 lb

PC300LC-8: 31600 – 32580 kg

69,670 – 71,830 lb

BUCKET CAPACITY

0.52 – 1.80 m

3

0.68 – 2.35 yd

3

Large TFT LCD Monitor

• Easy-to-see and use 7" large multi-function

color monitor

• Can be displayed in 12 languages for

global support.

TFT : Thin Film Transistor

LCD : Liquid Crystal Display

See page 8.

5

Larger Maximum

Drawbar Pull

Larger maximum draw-

bar pull provides superb

steering and slope

climbing performance.

Maximum drawbar pull:

264 kN 26900 kgf

59,300 lb

4

Smooth Loading Operation

Two return hoses improve

hydraulic performance. In the arm

out function, a portion of the oil is

returned directly to the tank

providing smooth operation.

Boom floats upward, reducing

lifting of machine front. This

facilitates gathering blasted rock

and scraping down operations.

Boom pushing force is

increased, ditch digging and

box digging operation on hard

ground are improved.

Two-mode Setting for Boom

Smooth mode provides easy operation for gathering blasted

rock or scraping down operation. When maximum digging

force is needed, switch to Power mode for more effective

excavating.

PRODUCTIVITY & ECOLOGY FEATURES

HYDRAULIC EXCAVATOR

Environment-friendly Clean Engine

The PC300-8 gets its exceptional power and work capacity

from a Komatsu SAA6D114E-3 engine. Output is 184 kW

246 HP, providing increased hydraulic power and improved

fuel efficiency.

Komatsu SAA6D114E-3 engine meets EPA Tier 3 and EU

Stage 3A emissions certified and reduced NOx emission by

40%.

The SAA6D114E-3 engine adopts the electronically con-

trolled Heavy Duty HPCR* fuel injection system.

*HPCR : High Pressure Common Rail

Hydraulics

Unique two-pump system ensures smooth compound

movement of the work equipment. HydrauMind controls

both pumps for efficient engine power use. This system

also reduces hydraulic loss during operation.

Low Operation Noise

Enables a low noise operation using the low-noise engine

and methods to cut noise at source. Ambient noise meets

the EU Stage 2 noise regulation.

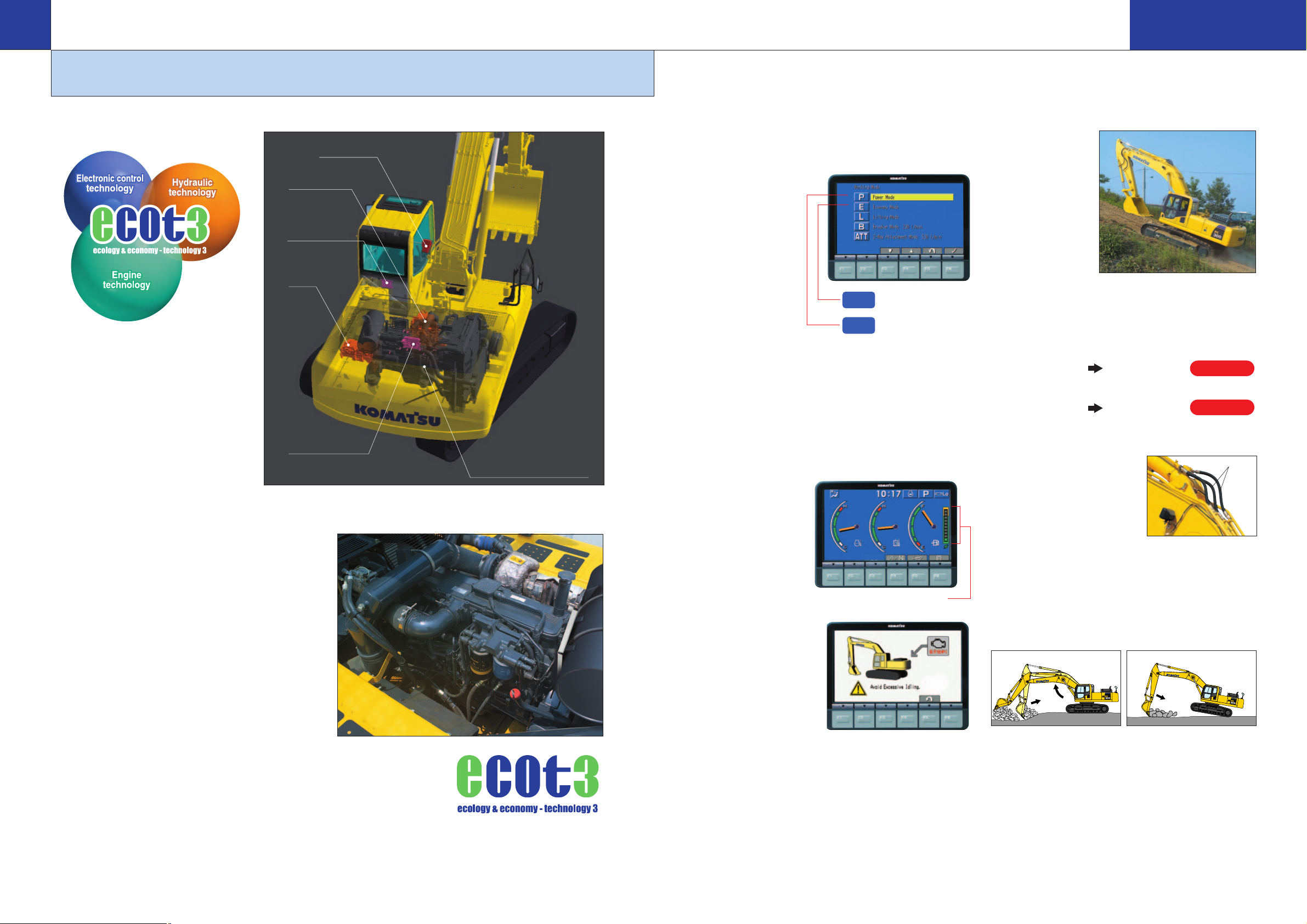

Komatsu Technology

Komatsu develops and produces all major

components, such as engines, electronics

and hydraulic components, in house.

With this “Komatsu Technology,” and adding

customer feedback, Komatsu is achieving

great advancements in technology.

To achieve both high levels of productivity

and economical performance, Komatsu has

developed the main components with a total

control system. The result is a new genera-

tion of high performance and environment

friendly excavators.

Return hoses

Large Digging Force

With the one-touch Power Max. function digging force has

been further increased. (8.5 seconds of operation)

Maximum arm crowd force (ISO):

160 kN (16.3t) 171 kN (17.4t)

(with Power Max.)

Maximum bucket digging force (ISO):

212 kN (21.6t) 227 kN (23.1t)

(with Power Max.)

*Measured with Power Max function, 3185 mm 10'5" arm and ISO rating

7%

UP

7%

UP

H YDRAULIC E XCAVATOR

PC300-8

PC300-8 0

Working Modes Selectable

Two established work modes are further improved.

P mode – Power or

work priority mode has

low fuel consumption,

but fast equipment

speed and maximum

production and power

are maintained.

E mode – Economy or

fuel priority mode

further reduces fuel

consumption, but

maintains the P-mode-like working equipment speed for light

duty work.

You can select Power or Economy modes using a one-touch

operation on the monitor panel depending on workloads.

E

P

Fuel priority

E mode

Work priority

P mode

Idling Caution

To prevent unnecessary

fuel consumption, an idling

caution is displayed on the

monitor, if the engine idles

for 5 minutes or more.

Eco-gauge that Assists Energy-saving Operations

Equipped with the Eco-gauge that can be recognized at a

glance on the right of the multi-function color monitor for

environment-friendly

energy-saving opera-

tions. Allows focus on

operation in the green

range with reduced CO

2

emissions and efficient

fuel consumption.

Eco-gauge

Hydraulic control valve

Hydraulic system

controller

Main pump

Electronic control

unit for engine

Seven-inch TFT

liquid crystal display

Engine

Heavy duty HPCR (High Pressure

Common Rail) system

Smooth mode Power mode

Loading...

Loading...