Page 1

COURAGE SV710-740

COURAGE PRO SV810-840

VERTICAL CRANKSHAFT

OWNER'S MANUAL

Page 2

Safety Precautions

To ensure safe operation please read the following statements and understand their meaning. Also refer

to your equipment owner's manual for other important safety information. This manual contains safety

precautions which are explained below. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that can cause severe personal injury, death, or

substantial property damage if the warning is ignored.

CAUTION

Caution is used to indicate the presence of a hazard that will or can cause minor personal injury or

property damage if the caution is ignored.

NOTE

Note is used to notify people of installation, operation, or maintenance information that is important but

not hazard-related.

For Y our Safety!

These precautions should be followed at all times. Failure to follow these precautions could result in injury

to yourself and others.

WARNING

Explosive Fuel can cause fires and

severe burns.

Do not fill the fuel tank while the

engine is hot or running.

Explosive Fuel!

Gasoline is extremely flammable and

its vapors can explode if ignited. Store

gasoline only in approved containers,

in well ventilated, unoccupied

buildings, away from sparks or flames.

Do not fill the fuel tank while the

engine is hot or running, since spilled

fuel could ignite if it comes in contact

with hot parts or sparks from ignition.

Do not start the engine near spilled

fuel. Never use gasoline as a cleaning

agent.

WARNING

Rotating Parts can cause severe

injury.

Stay away while engine is in

operation.

Rotating Parts!

Keep hands, feet, hair, and clothing

away from all moving parts to prevent

injury. Never operate the engine with

covers, shrouds, or guards removed.

CAUTION

Electrical Shock can cause injury.

Do not touch wires while engine is

running.

WARNING

Hot Parts can cause severe burns.

Do not touch engine while operating

or just aer stopping.

Hot Parts!

Engine components can get extremely

hot from operation. To prevent severe

burns, do not touch these areas while

the engine is running, or immediately

aer it is turned off. Never operate

the engine with heat shields or guards

removed.

California

Proposition 65 Warning

Engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects, or other reproductive harm.

Electrical Shock!

Never touch electrical wires or

components while the engine is

running. They can be sources of

electrical shock.

2

Page 3

Safety Precautions (Cont.)

WARNING

Accidental Starts can cause severe

injury or death.

Disconnect and ground spark plug

leads before servicing.

Accidental Starts!

Disabling engine. Accidental

starting can cause severe injury or

death. Before working on the engine

or equipment, disable the engine as

follows: 1) Disconnect the spark plug

lead(s). 2) Disconnect negative (-)

baery cable from baery.

WARNING

Carbon Monoxide can cause severe

nausea, fainting or death.

Avoid inhaling exhaust fumes, and

never run the engine in a closed

building or confined area.

Lethal Exhaust Gases!

Engine exhaust gases contain

poisonous carbon monoxide. Carbon

monoxide is odorless, colorless, and can

cause death if inhaled. Avoid inhaling

exhaust fumes, and never run the

engine in a closed building or confined

area.

WARNING

Explosive Gas can cause fires and

severe acid burns.

Charge baery only in a well

ventilated area. Keep sources of

ignition away.

Explosive Gas!

Baeries produce explosive hydrogen

gas while being charged. To prevent a

fire or explosion, charge baeries only

in well ventilated areas. Keep sparks,

open flames, and other sources of

ignition away from the baery at all

times. Keep baeries out of the reach

of children. Remove all jewelry when

servicing baeries.

Before disconnecting the negative

(-) ground cable, make sure all switches

are OFF. If ON, a spark will occur at

the ground cable terminal which could

cause an explosion if hydrogen gas or

gasoline vapors are present.

Congratulations – You have selected a fine four-cycle, twin cylinder, air-cooled engine. Kohler designs long life

strength and on-the-job durability into each engine...making a Kohler engine dependable...dependability you

can count on. Here are some reasons why:

• Efficient overhead valve design, and pressure lubrication provide maximum power, torque, and reliability

under all operating conditions.

• Dependable, maintenance-free electronic ignition ensures fast, easy starts time aer time.

• Kohler engines are easy to service. All routine service areas (like the dipstick and oil fill, air cleaner, spark

plugs, and carburetor) are easily and quickly accessible.

• Parts subject to the most wear and tear (like the cylinder liner and camsha) are made from precision

formulated cast iron.

• Every Kohler engine is backed by a worldwide network of over 10,000 distributors and dealers. Service

support is just a phone call away. Call 1-800-544-2444 (U.S. & Canada) for Sales & Service assistance. Or

visit www.KohlerEngines.com.

To keep your engine in top operating condition, follow the maintenance procedures in this manual.

3

Page 4

SAE

10W-30

A

P

I

S

E

R

V

I

C

E

S

J

Courage

5W-20, 5W-30

RECOMMENDED SAE VISCOSITY GRADES

°F

-20 0 20 32 40 6050 80 100

°C

-30 -20

-10 0

10 20 30

40

TEMPERATURE RANGE EXPECTED BEFORE NEXT OIL CHANGE

10W-30

Kohler 10W-30

SAE 30

®

Courage PRO

™

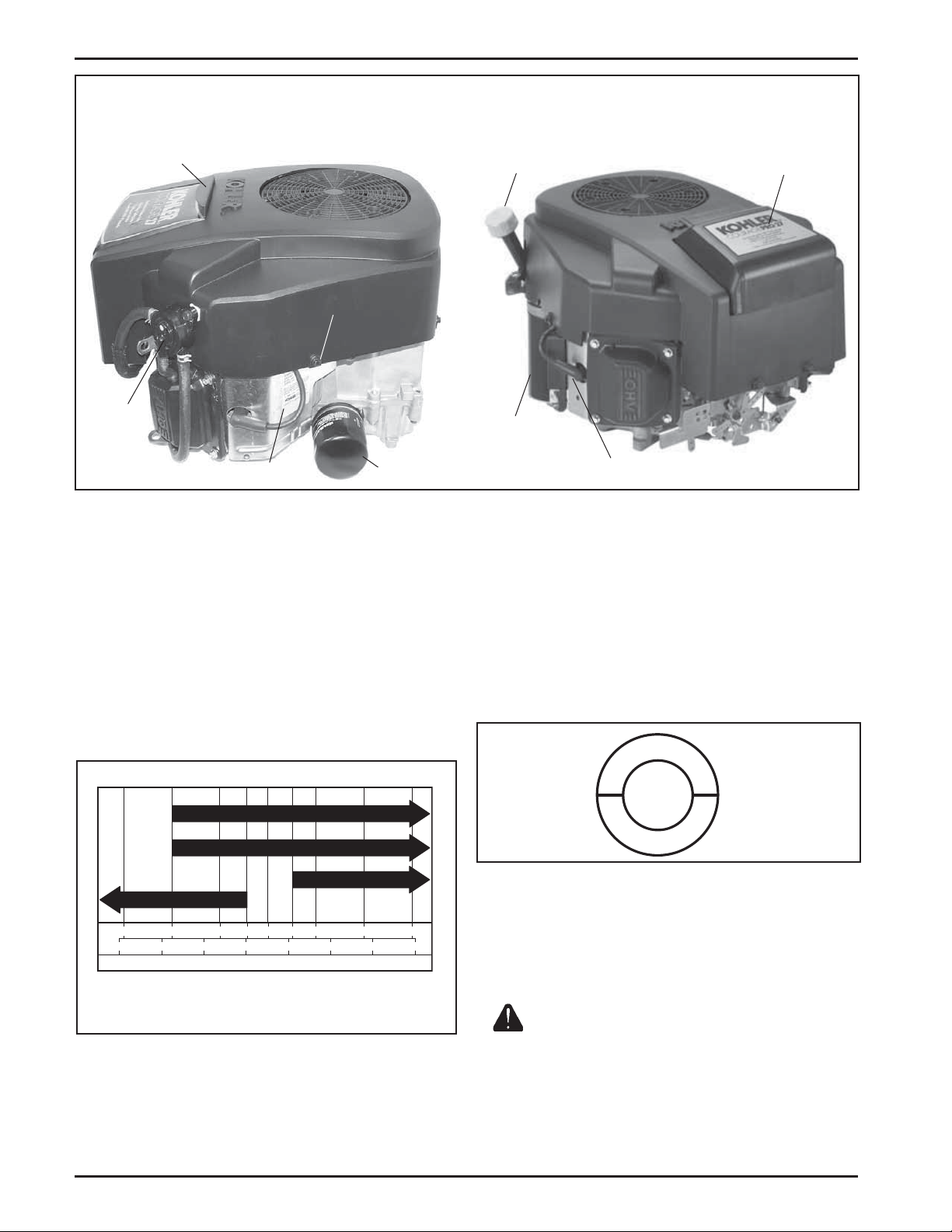

Air Cleaner Access

Door Handle

Dipstick

Rectifier-Regulator

Fuel

Pump

Electric

Starter

Identification Plate

Oil Filter

Spark Plug

Figure 1. Typical Courage® and Courage PRO™ Series Vertical Shaft Engines.

Oil Recommendations

Using the proper type and weight of oil in the

crankcase is extremely important. So is checking oil

daily and changing oil regularly. Failure to use the

correct oil, or using dirty oil, causes premature engine

wear and failure.

NOTE: Synthetic oils meeting the listed classifications

may be used with oil changes performed at

the recommended intervals. However to allow

piston rings to properly seat, a new or rebuilt

engine should be operated for at least 50 hours

using standard petroleum based oil before

switching to synthetic oil.

Oil Type

Use high quality detergent oil of API (American

Petroleum Institute) service class SG, SH, SJ or higher.

A logo or symbol on oil containers identifies the API

service class and SAE viscosity grade. See Figure 3.

Select the viscosity based on the air temperature at the

time of operation as shown in the following table.

Raised Air Cleaner

Access Door

**

*

*Use of synthetic oil having 5W-20 or 5W-30 rating is acceptable,

up to 4°C (40°F).

**Synthetic oils will provide better starting in extreme cold below

23°C (-10°F).

Figure 2. Viscosity Grades Table.

NOTE: Using other than service class SG, SH, SJ or

higher oil or extending oil change intervals

4

longer than recommended can cause engine

damage.

Figure 3. Oil Container Logo.

Refer to Maintenance Instructions beginning on

page 7 for detailed oil check, oil change, and oil filter

change procedures.

Fuel Recommendations

WARNING: Explosive Fuel!

Gasoline is extremely flammable and its vapors can explode

if ignited. Store gasoline only in approved containers, in well

ventilated, unoccupied buildings, away from sparks or flames.

Do not fill the fuel tank while the engine is hot or running,

since spilled fuel could ignite if it comes in contact with hot

parts or sparks from ignition. Do not start the engine near

spilled fuel. Never use gasoline as a cleaning agent.

Page 5

General Recommendations

Purchase gasoline in small quantities and store in clean,

approved containers. A container with a capacity of 2

gallons or less with a pouring spout is recommended.

Such a container is easier to handle and helps eliminate

spillage during refueling.

Do not use gasoline le over from the previous season,

to minimize gum deposits in your fuel system and to

ensure easy starting.

Do not add oil to the gasoline.

Do not overfill the fuel tank. Leave room for the fuel to

expand.

Fuel Type

For best results use only clean, fresh, unleaded gasoline

with the pump sticker octane rating of 87 or higher. In

countries using the Research method, it should be 90

octane minimum.

IMPORTANT ENGINE INFORMATION

THIS ENGINE MEETS U.S. EPA PH2 AND EC STAGE II

(SN:4) EMISSION REGS FOR SI SORE. NOT FOR SALE IN

CALIFORNIA UNLESS PREEMPT PER SEC. 209 (e) (1) OF CAA.

FAMILY

TYPE APP

DISPL. (CC)

MODEL NO.

SPEC. NO.

SERIAL NO.

BUILD DATE

OEM PROD. NO.

EMISSION COMPLIANCE PERIOD:

EPA: CARB:

CERTIFIED ON:

REFER TO OWNER'S MANUAL FOR HP RATING, SAFETY,

MAINTENANCE AND ADJUSTMENTS

1-800-544-2444 KohlerEngines.com

KOHLER CO. KOHLER, WISCONSIN USA

N11236

Unleaded gasoline is recommended as it leaves

less combustion chamber deposits and reduces

harmful exhaust emissions. Leaded gasoline is not

recommended.

Gasoline/Alcohol blends

Gasohol (up to 10% ethyl alcohol, 90% unleaded

gasoline by volume) is approved as a fuel for Kohler

engines. Other gasoline/alcohol blends including E20

and E85 are not to be used and not approved. Any

failures resulting from use of these fuels will not be

warranted.

Gasoline/Ether blends

Methyl Tertiary Butyl Ether (MTBE) and unleaded

gasoline blends (up to a maximum of 15% MTBE by

volume) are approved as a fuel for Kohler engine.

Other gasoline/ether blends are not approved.

Engine Identification Numbers

When ordering parts, or in any communication

involving an engine, always give the Model,

Specification, and Serial Numbers of the engine.

The engine identification numbers appear on a decal

(or decals) affixed to the engine shrouding. Include

leer suffixes, if there are any.

Record your engine identification numbers on the

identification label (Figure 4) for future reference.

IMPORTANT ENGINE INFORMATION

THIS ENGINE MEETS U.S. EPA PH2 AND CA 2008 AND

LATER EXH EMISSION REGS FOR SI SORE. USING

DELEGATED ASSEMBLY FOR AFTERTREATMENT .

FAMILY

TYPE APP

DISPL. (CC)

MODEL NO.

SPEC. NO.

SERIAL NO.

BUILD DATE

OEM PROD. NO.

EMISSION COMPLIANCE PERIOD:

EPA: CARB:

CERTIFIED ON:

REFER TO OWNER'S MANUAL FOR HP RATING, SAFETY,

MAINTENANCE AND ADJUSTMENTS

1-800-544-2444 KohlerEngines.com

KOHLER CO. KOHLER, WISCONSIN USA

N11236

Figure 4. Engine Identification Label.

The Emission Compliance Period referred to on the

Emission Control or Air Index label indicates the

number of operating hours for which the engine has

been shown to meet Federal and CARB emission

requirements. The following table provides the Engine

Compliance Period (in hours) associated with the

category descriptor found on the certification label.

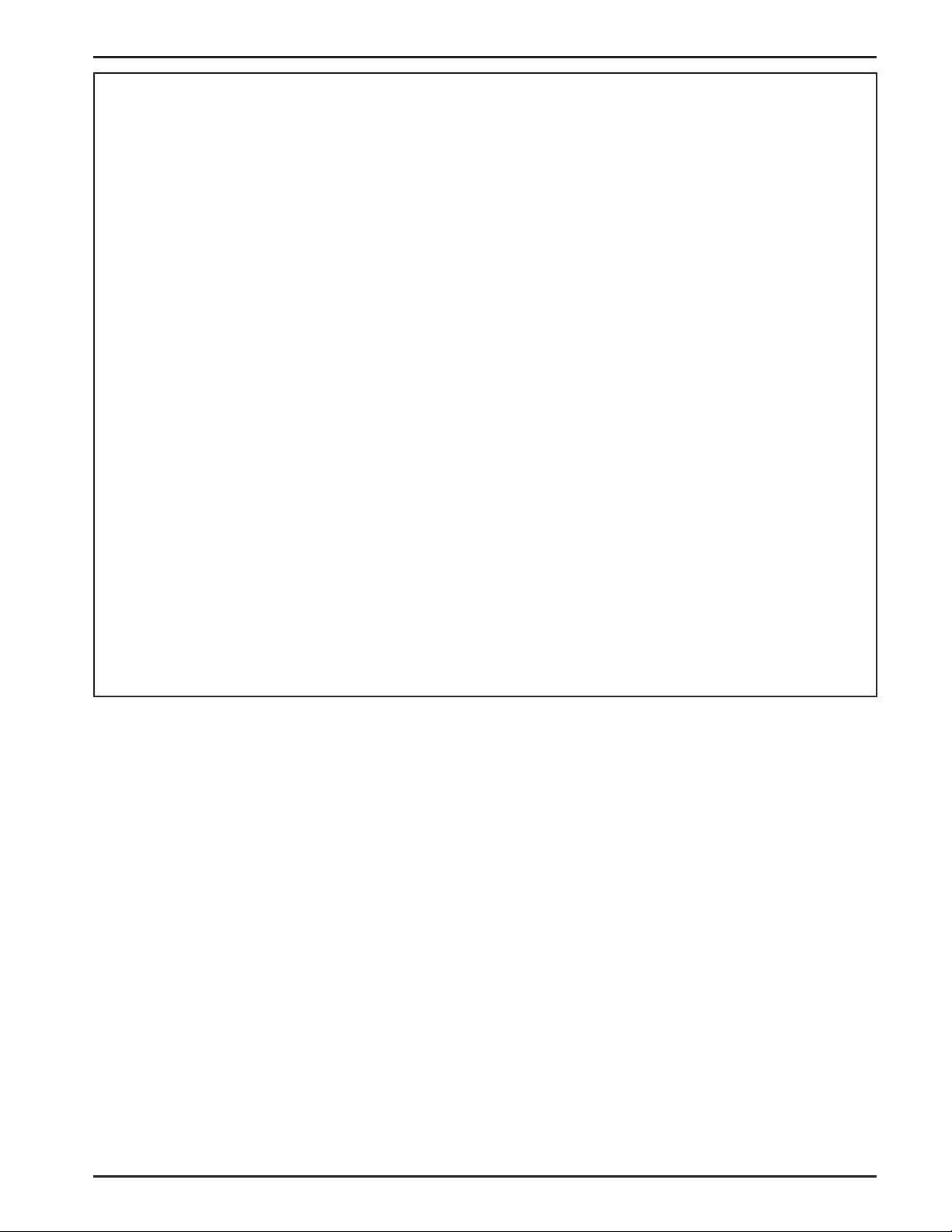

Emission Compliance Period (Hours)

EPA

Category C

250 hours

Category B

500 hours

Category A

1000 hours

CARB

Moderate

125 hours

Intermediate

250 hours

Extended

500 hours

Refer to certification label for engine displacement.

Exhaust Emission Control System for models SV710-SV840 is

EM for U.S. EPA and Europe; PAIR for California Tier III.

5

Page 6

Operating Instructions

Also read the operating instructions of the equipment this

engine powers.

Pre-Start Checklist

• Check oil level. Add oil if low. Do not overfill.

• Check fuel level. Add fuel if low.

• Check cooling air intake areas and external

surfaces of engine. Make sure they are clean and

unobstructed.

• Check that the air cleaner components and all

shrouds, equipment covers, and guards are in

place and securely fastened.

NOTE: If the engine develops sufficient speed to

disengage the starter but does not keep

running (a false start), engine rotation must

be allowed to come to a complete stop before

aempting to restart the engine.

If the starter is engaged while the flywheel is rotating,

the starter pinion and flywheel ring gear may clash,

resulting in damage to the starter.

If the starter does not turn the engine over, shut off

starter immediately. Do not make further aempts to

start the engine until the condition is corrected. Do

not jump start using another baery (refer to Baery).

See your Kohler Engine Service Dealer for service

assistance.

• Check that any clutches or transmissions are

disengaged or placed in neutral. This is especially

important on equipment with hydrostatic drive.

The shi lever must be exactly in neutral to

prevent resistance which could keep the engine

from starting.

WARNING: Lethal Exhaust Gases!

Engine exhaust gases contain poisonous carbon monoxide.

Carbon monoxide is odorless, colorless, and can cause death

if inhaled. Avoid inhaling exhaust fumes, and never run the

engine in a closed building or confined area.

Cold Weather Starting Hints

1. Be sure to use the proper oil for the temperature

expected. See Figure 2 on page 4.

2. Declutch all possible external loads.

3. Be sure the baery is in good condition. A warm

baery has much more starting capacity than a

cold baery.

4. Use fresh winter grade fuel. NOTE: Winter grade

gasoline has higher volatility to improve starting.

Do not use gasoline le over from summer.

Starting

1. Place the throle control midway between the

slow and fast positions. Place the choke control

into the on position.

2. Start the engine by activating the key switch.

Release the switch as soon as the engine starts.

NOTE: Do not crank the engine continuously for

more than 10 seconds at a time. If the engine

does not start, allow a 60 second cool down

period between starting aempts. Failure

to follow these guidelines can burn out the

starter motor.

3. For a Cold Engine – Gradually return the choke

control to the off position aer the engine starts

and warms up.

The engine/equipment may be operated during

the warm-up period, but it may be necessary

to leave the choke partially on until the engine

warms up.

4. For a Warm Engine – Return choke to off position

as soon as engine starts.

Stopping

1. Remove the load by disengaging all PTO driven

aachments.

2. For Engines without a Shutdown Solenoid:

Move the throle to the slow or low idle position.

Allow the engine to run at idle for 30-60 seconds;

then stop the engine.

For Engines Equipped with a Shutdown

Solenoid: Position the throle control between

half and full throle; then stop the engine.

Battery

A 12 volt baery is normally used. Refer to the

operating instructions of the equipment this engine

powers for specific baery requirements.

If the baery charge is not sufficient to crank the

engine, recharge the baery.

Operating

Angle of Operation

This engine will operate continuously at angles up to

25°. Check oil level to assure crankcase oil level is at

the FULL or “F” mark on the dipstick.

6

Page 7

Refer to the operating instructions of the equipment

this engine powers. Because of equipment design or

application, there may be more stringent restrictions

regarding the angle of operation.

WARNING: Hot Parts!

Engine components can get extremely hot from operation.

To prevent severe burns, do not touch these areas while

the engine is running, or immediately aer it is turned

off. Never operate the engine with heat shields or guards

NOTE: Do not operate this engine continuously

removed.

at angles exceeding 25° in any direction.

Engine damage could result from insufficient

lubrication.

Engine Speed

NOTE: Do not tamper with the governor seing

to increase the maximum engine speed.

Cooling

NOTE: If debris builds up on the grass screen or other

cooling areas, stop the engine immediately

and clean. Operating the engine with blocked

Overspeed is hazardous and will void the

engine warranty. The maximum allowable

high idle speed for these engines is 3675 RPM,

no load.

or dirty air intake and cooling areas can cause

extensive damage due to overheating. See

Clean Air Intake/Cooling Area.

Maintenance Instructions

Maintenance, repair, or replacement of the emission control devices and systems, which are being done at the

customers expense, may be performed by any non-road engine repair establishment or individual. Warranty

repairs must be performed by an authorized Kohler service outlet.

WARNING: Accidental Starts!

Disabling engine. Accidental starting can cause severe injury or death. Before working on the engine or

equipment, disable the engine as follows: 1) Disconnect the spark plug lead(s). 2) Disconnect negative (-) baery

cable from baery.

Maintenance Schedule

These required maintenance procedures should be performed at the frequency stated in the table. They should

also be included as part of any seasonal tune-up.

Frequency Maintenance Required

• Fill fuel tank.

Daily Or Before

Starting Engine

• Check oil level.

• Check air cleaner for dirty1, loose, or damaged parts.

• Check air intake and cooling areas, clean as necessary1.

Every 25 Hours

Every 50 Hours

• Service precleaner element1.

• Check air cleaner element, clean or replace as necessary¹.

• Replace air cleaner element and precleaner¹.

Annually or

Every 100 Hours

• Change oil and oil filter (more frequently under severe conditions).

• Remove cooling shrouds and clean cooling areas¹.

• Replace fuel filter.

• Check spark plug condition and gap.

Every 200 Hours

Every 500 Hours

1

Perform these maintenance procedures more frequently under extremely dusty, dirty conditions.

2

Have a Kohler Engine Service Dealer perform these services.

Check Oil Level

The importance of checking and maintaining

• Have valve lash checked/adjusted2.

• Have bendix starter drive serviced2.

• Have solenoid shi starter disassembled and cleaned2.

1. Make sure the engine is stopped, level, and is cool

so the oil has had time to drain into the sump.

the proper oil level in the crankcase cannot be

overemphasized. Check oil BEFORE EACH USE as

follows:

2. Clean the area around and the underside of the

oil fill cap/dipstick before removing it. This will

help keep dirt, debris, and other foreign maer

out of the engine.

7

Page 8

3. Remove the oil fill cap/dipstick; wipe oil off.

For engines with a press-on style dipstick:

Reinsert the dipstick into the tube and press all

the way down. See Figure 5.

For engines with a thread-on style dipstick:

Reinsert the dipstick into the oil fill tube and

thread the dipstick in completely. See Figures 5

and 6.

Press-On

Figure 5. Dipstick Styles.

Incorrect Correct

Oil Fill

Cap/

Dipstick

Thread-On

Oil Sentry™

Some engines are equipped with an optional Oil

Sentry™ oil pressure switch. If the oil pressure drops

below an acceptable level, the Oil Sentry™ will either

shut off the engine or activate a warning signal,

depending on the application.

NOTE: Make sure the oil level is checked BEFORE

EACH USE and is maintained up to the FULL

or “F” mark on the dipstick. This includes

engines equipped with Oil Sentry™.

Change Oil and Oil Filter

Change the oil and oil filter annually or every 100

hours of operation (more frequently under severe

conditions). Refill with service class SG, SH, SJ, or

higher oil as specified in the Viscosity Grades table

(Figure 2) on page 4. Always use a genuine Kohler oil

filter. Use chart below to determine part number to

order.

Oil Filter Part No.

12 050 01-S

52 050 02-S

Change the oil while the engine is still warm. The oil

will flow more freely and carry away more impurities.

Make sure the engine is level when filling, checking, or

changing the oil.

Length

2-1/2"

3-3/8"

Oil Fill

Tube

Figure 6. Thread-on Oil Fill Cap/Dipstick.

4. Remove the oil fill cap/dipstick and check

oil level. The oil level needs to be within the

operating range. See Figure 7. If low, add oil of

the proper type, up to the full mark. If oil is above

the "F" or FULL mark, drain oil to reach proper

level. Reinstall the oil fill cap/dipstick.

NOTE: To prevent extensive engine wear or damage,

always maintain the proper oil level in the

crankcase. Never operate the engine with

the oil level above the “F” or FULL mark, or

below the “L” or LOW mark on the dipstick.

Operating

Range

Starter

Oil Drain Plug

Figure 8. Oil Drain Plug.

Figure 7. Oil Level Marks on Dipstick (Typical).

8

Oil Filter

Figure 9. Oil Filter Location.

Page 9

Change the oil and oil filter as follows.

1. The drain plug is located on the starter side of the

oil pan. See Figure 8. Clean the area around the

oil drain plug and the oil fill cap/dipstick.

Check the air cleaner daily or before starting the

engine. Check for a buildup of dirt and debris around

the air cleaner system. Keep this area clean. Also check

for loose or damaged components. Replace all bent or

damaged air cleaner components.

2. Remove the drain plug and the oil fill cap/

dipstick.

3. Allow the oil to drain and then reinstall the drain

plug. Tighten 13.6 N·m (10 . lb.).

4. Remove the old filter and wipe off the filter

adapter with a clean cloth.

5. Place a new replacement filter in a shallow pan

with the open end up. Pour new oil, of the proper

type, in through the threaded center hole. Stop

pouring when the oil reaches the boom of the

threads. Allow a minute or two for the oil to be

absorbed by the filter material.

6. Apply a thin film of clean oil to the rubber gasket

on the new oil filter.

7. Install the new oil filter to the filter adapter. Hand

tighten the filter until the rubber gasket contacts

the adapter, then tighten the filter an additional

3/4-1 turn.

8. Fill the engine with the proper oil to the FULL or

“F” mark on the dipstick. Always check the oil

level with the dipstick before adding more oil.

NOTE: Operating the engine with loose or damaged

air cleaner components could allow unfiltered

air into the engine causing premature wear

and failure.

Precleaner (Some Models)

Latch

Air Cleaner Element

Figure 10. Courage Air Cleaner System.

Element (Taller)

Latch

Door

Door

9. Reinstall the oil fill cap/dipstick and tighten

securely.

10. Start the engine and check for oil leaks. Recheck

oil level before placing the engine into service.

Stop the engine, correct any leaks, and allow a

minute for the oil to drain down, then recheck the

level on the dipstick.

NOTE: To prevent extensive engine wear or damage,

always maintain the proper oil level in the

crankcase. Never operate the engine with

the oil level above the “F” or FULL mark, or

below the “L” or LOW mark on the dipstick.

Service Precleaner and Air Cleaner

Element

These engines are equipped with a replaceable, high

density paper air cleaner element. Some engines are

also equipped with an oiled, foam precleaner which

surrounds the paper element. See Figures 10 and

11. Two different capacity air cleaner systems are

available.

Precleaner (Some Models)

Figure 11. Courage PRO Air Cleaner System.

Precleaner (Some Models)

Door

Latch

Air Cleaner

Element

Figure 12. Unhooking Latch (Courage).

9

Page 10

Latch

Service Paper Element

Check the paper element every 50 hours of operation,

(more oen under extremely dusty or dirty

conditions). Clean or replace the element as necessary.

Replace the air cleaner element annually, or every 100

hours.

1. Open the door on the blower housing to access

the air cleaner element. See Figures 9 and 10.

2. Unhook the latch and remove the air cleaner

element and precleaner (if equipped). See Figure

12 and 13.

Figure 13. Unhooking Latch (Courage PRO).

Service Precleaner

If so equipped, wash and reoil the precleaner every 25

hours of operation (more oen under extremely dusty

or dirty conditions). Replace the precleaner annually

or every 100 hours.

1. Open the door on the blower housing to access

the air cleaner element and precleaner. See

Figures 10 and 11.

2. Unhook the latch and remove the precleaner from

the air cleaner element, or remove as an assembly

for servicing. Make sure the base and the sealing

area is clean before reassembly is performed. See

Figures 12 and 13.

3. Wash the precleaner in warm water with

detergent. Rinse the precleaner thoroughly until

all traces of detergent are eliminated. Squeeze out

excess water (do not wring). Allow the precleaner

to air dry.

4. Saturate the precleaner with new engine oil.

Squeeze out all excess oil.

5. Reinstall the precleaner over the paper element

and secure with the latch.

3. Remove the precleaner (if so equipped) from the

paper element. Service the precleaner as described

in Precleaner Service.

4. Gently tap the paper element to dislodge dirt. Do

not wash the paper element or use pressurized

air, as this will damage the element. Replace a

dirty, bent, or damaged element with a genuine

Kohler part. Handle the new element carefully;

do not use if the sealing surfaces are bent or

damaged.

32 083 03-S Element 44 mm (1.73 in.) high

32 083 06-S Element (PRO) 78 mm (3.07 in.) high

5. Clean the air cleaner base as required and check

condition.

6. Reinstall the precleaner (if equipped) over the

paper air cleaner element and install on the base.

Secure with the latch.

7. Close and latch the door.

Clean Air Intake/Cooling Areas

To ensure proper cooling, make sure the grass screen,

cooling fins, and other external surfaces of the engine

are kept clean at all times.

6. Close and latch the door.

7. When precleaner replacement is necessary order

genuine Kohler Parts.

32 083 05-S Precleaner 37 mm (1.45 in.) high

32 083 08-S Precleaner (PRO) 71 mm (2.79 in.) high

10

Every 100 hours of operation (more oen under

extremely dusty, dirty conditions), remove the blower

housing and other cooling shrouds. Clean the cooling

fins and external surfaces as necessary. Make sure the

cooling shrouds are reinstalled.

Page 11

NOTE: Operating the engine with a blocked grass

screen, dirty or plugged cooling fins, and/or

cooling shrouds removed, will cause engine

damage due to overheating.

Ignition System

These engines use an electronic Capacitive Discharge

(CD) ignition system. Other than periodically

checking/replacing the spark plugs, no maintenance,

timing, or adjustments are necessary or possible with

this system.

Check Spark Plugs

Every 100 hours of operation, remove the spark plugs,

check condition, and reset the gap or replace with new

plugs as necessary. The standard Courage spark plug

is a Champion® RC12YC (Kohler Part No.

12 132 02-S). RFI compliant engines use a Champion®

XC12YC (Kohler Part No. 25 132 14-S) spark plug. A

high-performance spark plug, Champion® Platinum

3071 (Kohler Part No. 25 132 12-S) is standard on

Courage PRO models. Equivalent alternate brand

plugs can also be used.

1. Before removing the spark plug, clean the area

around the base of the plug to keep dirt and

debris out of the engine.

2. Remove the plug and check its condition. Replace

the plug if worn or reuse is questionable.

Battery Charging

WARNING: Explosive Gas!

Baeries produce explosive hydrogen gas while being

charged. To prevent a fire or explosion, charge baeries only

in well ventilated areas. Keep sparks, open flames, and other

sources of ignition away from the baery at all times. Keep

baeries out of the reach of children. Remove all jewelry

when servicing baeries.

Before disconnecting the negative (-) ground cable, make

sure all switches are OFF. If ON, a spark will occur at the

ground cable terminal which could cause an explosion if

hydrogen gas or gasoline vapors are present.

Fuel System

Fuel Filter

Some engines are equipped with an in-line fuel filter.

Periodically inspect the filter and replace with a

genuine Kohler filter every 100 operating hours.

Fuel Line

In compliance with CARB Tier III Emission

Regulations, these engines use Low Permeation

SAE 30 R7 rated fuel line; certified to meet CARB

requirements. Standard fuel line may not be used.

Order replacement hose by part number through a

Kohler Engine Service Dealer.

NOTE: Do not clean the spark plug in a machine

using abrasive grit. Some grit could remain in

the spark plug and enter the engine causing

extensive wear and damage.

3. Check the gap using a wire feeler gauge. Adjust

the gap to 0.76 mm (0.030 in.) by carefully

bending the ground electrode. See Figure 14.

4. Reinstall the spark plug into the cylinder head.

Torque the spark plug to 24.4-29.8 N·m

(18-22 . lb.).

Wire Gauge

Spark Plug

Ground

Electrode

Figure 14. Servicing Spark Plug.

0.76 mm

(0.030 in.) Gap

Figure 15. Low Permeation Fuel Line.

Carburetor Troubleshooting and

Adjustments

In compliance with government emission standards,

the carburetor is calibrated to deliver the correct

fuel-to-air mixture to the engine under all operating

conditions. The high speed mixture is set at the factory

and cannot be adjusted. The low idle fuel adjustment

screw (if equipped) is also set at the factory and

normally does not require adjustment. See Figure 16.

Engines in this series depending on the model and

application, may also be equipped with a Governed

Idle System.

If the engine is equipped with a Governed Idle

System, refer to Models with Governed Idle System

when performing any carburetor adjustment, as an

additional step to the listed procedure(s) is required.

11

Page 12

Low Idle

Mixture Screw

If, aer checking the items listed above, the engine is

hard to start, runs roughly, or stalls at low idle speed, it

may be necessary to adjust or service the carburetor.

Idle Speed

(RPM)

Adjustment

Screw

Fuel Solenoid

Figure 16. Carburetor Details.

Low Idle Mixture Screw

Idle Speed (RPM)

Adjustment Screw

Element

Figure 17. Carburetor Adjustment Access

Locations (Latch Removed For Clarity).

Troubleshooting

If engine troubles are experienced that appear to be

fuel system related, check the following areas before

adjusting the carburetor.

Adjust Carburetor

NOTE: Some engines may have a fixed (capped)

idle fuel adjusting screw or limiter cap. On

these engines, do not aempt steps 1 and 2

below. Proceed directly to Step 3. On limiter

equipped models, adjustment can only be

performed within the limits allowed by the

cap.

1. Idle Fuel Adjustment: with the engine stopped,

turn the low idle fuel adjusting screw in

(clockwise) until it booms lightly. See Figures 16

and 17.

NOTE: The tip of the low idle fuel adjusting screw is

tapered to critical dimensions. Damage to the

needle tip and the seat in carburetor body will

result if the needle is forced.

2. Preliminary Seings: Turn the adjusting screw

out (counterclockwise) from lightly boomed

2-1/4 turns.

3. Start the engine and run at half throle for 5 to 10

minutes to warm up. The engine must be warm

before making final seings (step 4).

4. Low Idle Speed (RPM) Seing: Place the throle

control into the idle or slow position. Set the low

idle speed to 1200 RPM* (± 75 RPM) by turning the

low idle speed adjusting screw in or out. Check

the speed using a tachometer.

• Make sure the fuel tank is filled with clean, fresh

gasoline.

• Make sure the fuel tank cap vent is not blocked

and that it is operating properly.

• If the fuel tank is equipped with a shut-off valve,

make sure it is open.

• If the engine is equipped with an in-line fuel filter,

make sure it is clean and unobstructed. Replace

the filter if necessary.

• Make sure fuel is reaching the carburetor. This

includes checking the fuel lines and fuel pump

for restrictions or faulty components, replace as

necessary.

• Make sure the air cleaner element is clean and

all air cleaner element components are fastened

securely.

12

*NOTE: The actual low idle speed depends on

the application – refer to equipment

manufacturer’s recommendations. The

recommended low idle speed for basic engines

is 1200 RPM. To ensure best results when

seing the low idle fuel needle, the low idle

speed must not exceed 1200 RPM

(± 75 RPM).

5. If proper operation is not restored aer adjusting,

carburetor servicing by an authorized Kohler

Engine Service Dealer may be required.

Models with Governed Idle System

An optional governed idle control system is supplied

on some engines. The purpose of this system is to

maintain a desired idle speed regardless of ambient

conditions (temperature, parasitic load, etc.) that may

change. Engines with this feature contain a small

secondary spring connected between the governor

lever and the lower adjustment tab of the main bracket.

See Figure 18.

Page 13

The system requires an additional procedure for seing

the idle speed. If speed adjustments are required

proceed as follows.

1. Make any necessary speed or control adjustments

following the appropriate instructions covered in

this section.

2. Move the throle control to the idle position. Hold

the governor lever away from the carburetor, or

hold the throle lever so it is tight against the idle

speed adjusting screw, to negate the governor

activation. See Figure 19. Check the speed with a

tachometer and adjust it to 1500 RPM.

3. Release the governor lever and allow the engine to

return to the governed idle speed. Check it with a

tachometer against the equipment manufacturers

recommended idle speed. Governed Idle Speed

(RPM) is typically 300 RPM (approximate)

higher than the low idle speed. If adjustment is

necessary, bend the adjusting tab on the speed

control assembly to set. See Figure 18.

Governed

Idle Spring

Tab

Figure 18. Governed Idle Spring Location.

Hold

Throttle

Lever

Against

Screw

Figure 19. Holding Throttle Lever Against Idle Stop

Screw.

Troubleshooting

When troubles occur, be sure to check the simple causes which, at first, may seem too obvious to be considered.

For example, a starting problem could be caused by an empty fuel tank. Some common causes of engine troubles

are listed in the following table.

Do not aempt to service or replace major engine components, or any items that require special timing or

adjustment procedures. Have your Kohler Engine Service Dealer do this work.

Possible Cause No Improper Dirt In Dirty Incorrect Engine Dirty Air Faulty

Problem Fuel Fuel Fuel Line Grass Screen Oil Level Overloaded Cleaner Spark Plug

/System

Will Not Start • • • • • • •

Hard Starting • • • • •

Stops Suddenly • • • • • • •

Lacks Power • • • • • • •

Operates Erratically • • • • • •

Knocks or Pings • • • •

Skips or Misfires • • • • •

Backfires • • • • •

Overheats • • • • • •

High Fuel Consumption • • •

Storage

If the engine will be out of service for two months or

more, use the following storage procedure:

1. Clean the exterior surfaces of the engine.

2. Change the oil and filter while the engine is still

warm from operation. See Change Oil and Oil

Filter on page 8.

13

Page 14

3. The fuel system must be completely emptied,

or the gasoline must be treated with a stabilizer

to prevent deterioration. If you choose to

use a stabilizer, follow the manufacturer’s

recommendations, and add the correct amount for

the capacity of the fuel system. Fill the fuel tank

with clean, fresh gasoline. Run the engine for 2-3

minutes to get stabilized fuel into the carburetor.

Close fuel shut off valve when unit is being stored

or transported.

To empty the system, run the engine until the tank

and system are empty.

4. Remove the spark plugs. Add one tablespoon of

engine oil into each spark plug hole. Install plugs,

but do not connect the plug leads. Crank the

engine two or three revolutions.

5. Store the engine in a clean, dry place.

Parts Ordering

The engine Specification, Model, and Serial Numbers

are required when ordering replacement parts from

your Kohler Engine Service Dealer. These numbers are

found on the identification plate which is affixed to the

engine shrouding. Include leer suffixes if there are

any. See Engine Identification Numbers on page 5.

Always insist on genuine Kohler parts. All genuine Kohler

parts meet strict standards for fit, reliability, and

performance.

Major Repair

Major repair information is available in Kohler Engine

Service Manuals. This type of repair generally requires

the services of a trained mechanic and the use of

special tools and equipment. Kohler Engine Service

Dealers have the facilities, training, and genuine Kohler

replacement parts necessary to perform this service.

For the nearest Sales & Service location:

• visit our website www.kohlerengines.com

• call 1-800-544-2444 (U.S. & Canada)

• look in the yellow pages under Engines-Gasoline

Model Designation

Model SV730 for example: S designates Courage

engine, V designates vertical cranksha, and 730

indicates the numerical model designation. A leer

suffix designates a specific version as follows:

Suffix Designates

S Electric Start

Courage® SV710-740 Specifications

Model: ...................................................................................SV710 .................................SV715 ...........................SV720

Bore: ................................................ mm (in.)......................83 (3.27) .............................83 (3.27) .......................83 (3.27)

Stroke: ............................................. mm (in.)......................67 (2.64) .............................67 (2.64) .......................67 (2.64)

Displacement: ................................. cm3 (in3)......................725 (44.2) ...........................725 (44.2) .....................725 (44.2)

Power (@ 3600 RPM): ....................kW (HP)......................14.9 (20*) ...........................16.4 (22*) .....................17.2 (23*)

Compression Ratio: .............................................................9:1.......................................9:1.................................9:1

Weight: ...............................................kg (lb.)......................41.2 (91) .............................41.2 (91) .......................41.2 (91)

Oil Capacity (w/filter) - approximate,

determined by oil filter used: ---------------------------------------- 1.6-1.8 L (1.7-1.9 U.S. qt.) --------------------------------------Lubrication: -------------------------------------------- Combination Pressure/Splash Lube w/full Flow Filter -------------------

Model: ...................................................................................SV725/SV730 ....................SV735 ...........................SV740

Bore: ................................................ mm (in.)......................83 (3.27) .............................83 (3.27) .......................83 (3.27)

Stroke: ............................................. mm (in.)......................67 (2.64) .............................67 (2.64) .......................67 (2.64)

Displacement: ................................. cm3 (in3)......................725 (44.2) ...........................725 (44.2) .....................725 (44.2)

Power (@ 3600 RPM): ....................kW (HP)......................17.9(24*)/18.6 (25*) ...........19.3 (26*) .....................20.1(27*)

Compression Ratio: .............................................................9:1.......................................9:1.................................9:1

Weight: ...............................................kg (lb.)......................41.2 (91) .............................41.2 (91) .......................41.2 (91)

Oil Capacity (w/filter) - approximate,

determined by oil filter used: ---------------------------------------- 1.6-1.8 L (1.7-1.9 U.S. qt.) ---------------------------------------Lubrication: -------------------------------------------- Combination Pressure/Splash Lube w/full Flow Filter --------------------

Exhaust Emission Control System for models SV710-SV740 is EM for U.S. EPA and Europe; PAIR for California Tier III.

* Horsepower ratings exceed Society of Automotive Engineers Small Engine Test Code J1940. Actual engine

horsepower is lower and affected by, but not limited to, accessories (air cleaner, exhaust, charging, cooling, fuel

pump, etc.), application, engine speed and ambient operating conditions (temperature, humidity, and altitude).

Kohler reserves the right to change product specifications, design, and standard equipment without notice and

without incurring obligation.

14

Page 15

COURAGE® SV710-740 ENGINE LIMITED WARRANTY

Kohler Co. warrants to the original retail consumer that each new COURAGE® engine sold by Kohler Co. will be free from manufacturing

defects in materials or workmanship in normal residential homeowner service for a period of two (2) years from date of purchase, provided

it is operated and maintained in accordance with Kohler Co.’s instructions and manuals. If used commercially the COURAGE® engine is

covered by a 90 day* limited warranty.

The warranty period begins on the date of purchase by the original retail consumer or commercial end user. “Residential homeowner

service” means residential use by a retail consumer. “Commercial use” means all other uses, including use for commercial, or rental

purposes. Once in commercial use, the engine will thereaer be considered a commercial use engine for the purposes of this warranty.

Our obligation under this warranty is expressly limited, at our option, to the replacement or repair at Kohler Co., Kohler, Wisconsin 53044,

or at a service facility designated by us of such parts as inspection shall disclose to have been defective.

EXCLUSIONS:

Mufflers on engines used commercially (non-residential) are warranted for 90 days from date of purchase.

This warranty does not apply to defects caused by casualty or unreasonable use, including faulty repairs by others and failure to provide

reasonable and necessary maintenance.

The following items are not covered by this warranty:

Engine accessories such as fuel tanks, clutches, transmissions, power-drive assemblies, and baeries, unless supplied or installed by Kohler

Co. These are subject to the warranties, if any, of their manufacturers.

KOHLER CO. AND/OR THE SELLER SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES OF ANY KIND, including but not limited to labor costs or transportation charges in connection with the repair or replacement

of defective parts.

IMPLIED OR STATUTORY WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSLY LIMITED TO THE DURATION OF THIS WRITTEN WARRANTY. We make no other express warranty, nor is

any one authorized to make any on our behalf.

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

TO OBTAIN WARRANTY SERVICE:

Purchaser must bring the engine to an authorized Kohler service facility. To locate the nearest facility, visit our website, www.kohlerengines.

com and use the locator function, consult your Yellow Pages or telephone 1-800-544-2444.

ENGINE DIVISION, KOHLER CO., KOHLER, WISCONSIN 53044

*With the exception of countries governed by the European Union (EU), where a one (1) year warranty is required for commercial/professional use.

15

Page 16

Courage PRO™ SV810-840 Specifications

Model: ...................................................................................SV810 .......................................................................SV820

Bore: ................................................ mm (in.)......................83 (3.27) ...................................................................83 (3.27)

Stroke: ............................................. mm (in.)......................67 (2.64) ...................................................................67 (2.64)

Displacement: ................................. cm

Power (@ 3600 RPM): ....................kW (HP)......................14.9 (20*) .................................................................17.2 (23*)

Compression Ratio: .............................................................9:1.............................................................................9:1

Weight: ............................................... kg (lb.)......................41.2 (91) ...................................................................41.2 (91)

Oil Capacity (w/filter) - approximate,

determined by oil filter used: ------------------------------------------ 1.6-1.8 L (1.7-1.9 U.S. qt.) --------------------------------------Lubrication: ------------------------------------------- Combination Pressure/Splash Lube w/full Flow Filter ---------------------

Model: ...................................................................................SV830 .......................................................................SV840

Bore: ................................................ mm (in.)......................83 (3.27) ...................................................................83 (3.27)

Stroke: ............................................. mm (in.)......................67 (2.64) ...................................................................67 (2.64)

Displacement: ................................. cm

Power (@ 3600 RPM): ....................kW (HP)......................18.6 (25*) .................................................................20.1(27*)

Compression Ratio: .............................................................9:1.............................................................................9:1

Weight: ............................................... kg (lb.)......................41.2 (91) ...................................................................41.2 (91)

Oil Capacity (w/filter) - approximate,

determined by oil filter used: ------------------------------------------ 1.6-1.8 L (1.7-1.9 U.S. qt.) ---------------------------------------Lubrication: ------------------------------------------- Combination Pressure/Splash Lube w/full Flow Filter ----------------------

Exhaust Emission Control System for models SV810-SV840 is EM for U.S. EPA and Europe; PAIR for California Tier III.

* Horsepower ratings exceed Society of Automotive Engineers Small Engine Test Code J1940. Actual engine

horsepower is lower and affected by, but not limited to, accessories (air cleaner, exhaust, charging, cooling, fuel

pump, etc.), application, engine speed and ambient operating conditions (temperature, humidity, and altitude).

Kohler reserves the right to change product specifications, design, and standard equipment without notice and

without incurring obligation.

3

(in3)......................725 (44.2) .................................................................725 (44.2)

3

(in3)......................725 (44.2) .................................................................725 (44.2)

16

Page 17

COURAGE PROTM SV810-840 ENGINE LIMITED WARRANTY

Kohler Co. warrants to the original retail consumer that each new COURAGE PRO™ engine sold by Kohler Co. will be free from

manufacturing defects in materials or workmanship in normal residential homeowner service for a period of two (2) years from date of

purchase, provided it is operated and maintained in accordance with Kohler Co.’s instructions and manuals. If used commercially the

COURAGE PRO

The warranty period begins on the date of purchase by the original retail consumer or commercial end user. “Residential homeowner service”

means residential use by a retail consumer. “Commercial use” means all other uses, including use for commercial, or rental purposes. Once in

commercial use, the engine will thereaer be considered a commercial use engine for the purposes of this warranty.

Our obligation under this warranty is expressly limited, at our option, to the replacement or repair at Kohler Co., Kohler, Wisconsin 53044, or

at a service facility designated by us of such parts as inspection shall disclose to have been defective.

EXCLUSIONS:

Mufflers on engines used commercially (non-residential) are warranted for one (1) year from date of purchase.

This warranty does not apply to defects caused by casualty or unreasonable use, including faulty repairs by others and failure to provide

reasonable and necessary maintenance.

The following items are not covered by this warranty:

Engine accessories such as fuel tanks, clutches, transmissions, power-drive assemblies, and baeries, unless supplied or installed by Kohler

Co. These are subject to the warranties, if any, of their manufacturers.

KOHLER CO. AND/OR THE SELLER SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES OF ANY KIND, including but not limited to labor costs or transportation charges in connection with the repair or replacement of

defective parts.

IMPLIED OR STATUTORY WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSLY LIMITED TO THE DURATION OF THIS WRITTEN WARRANTY. We make no other express warranty, nor is

any one authorized to make any on our behalf.

engine is covered by a one (1) year limited warranty.

™

Some states do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

TO OBTAIN WARRANTY SERVICE:

Purchaser must bring the engine to an authorized Kohler service facility. To locate the nearest facility, visit our website, www.kohlerengines.

com and use the locator function, consult your Yellow Pages or telephone 1-800-544-2444.

ENGINE DIVISION, KOHLER CO., KOHLER, WISCONSIN 53044

17

Page 18

KOHLER CO.

FEDERAL AND CALIFORNIA EMISSION CONTROL SYSTEMS

LIMITED WARRANTY

SMALL OFF-ROAD ENGINES

The U.S. Environmental Protection Agency (EPA), the California Air Resources Board (CARB), and Kohler Co. are pleased to explain the Federal

and California Emission Control Systems Warranty on your small off-road equipment engine. In California beginning in 2006 "emissions"

means both exhaust and evaporative emissions. For California, engines produced in 2006 and later must be designed, built and equipped

to meet the state’s stringent anti-smog standards. In other states, 1997 and later model year engines must be designed, built and equipped,

to meet the U.S. EPA regulations for small non-road engines. The engine must be free from defects in materials and workmanship which cause

it to fail to conform with U.S. EPA standards for the first two years of engine use from the date of sale to the ultimate purchaser. Kohler Co. must

warrant the emission control system on the engine for the period of time listed above, provided there has been no abuse, neglect or improper

maintenance.

The emission control system may include parts such as the carburetor or fuel injection system, the ignition system, and catalytic converter.

Also included are the hoses, belts and connectors and other emission related assemblies.

Where a warrantable condition exists, Kohler Co. will repair the engine at no cost, including diagnosis (if the diagnostic work is performed at

an authorized dealer), parts and labor.

MANUFACTURER’S WARRANTY COVERAGE

Engines produced in 2006 or later are warranted for two years in California. In other states, 1997 and later model year engines are warranted

for two years. If any emission related part on the engine is defective, the part will be repaired or replaced by Kohler Co. free of charge.

OWNER’S WARRANTY RESPONSIBILITIES

(a) The engine owner is responsible for the performance of the required maintenance listed in the owner’s manual. Kohler Co. recommends that

you retain all receipts covering maintenance on the engine, but Kohler Co. cannot deny warranty solely for the lack of receipts or for

your failure to assure that all scheduled maintenance was performed.

(b) Be aware, however, that Kohler Co. may deny warranty coverage if the engine or a part has failed due to abuse, neglect, improper

maintenance or unapproved modifications.

(c) For warranty repairs, the engine must be presented to a Kohler Co. service center as soon as a problem exists. Call 1-800-544-2444 or

access our website at: www.kohlerengines.com, for the names of the nearest service centers. The warranty repairs should be completed

in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding warranty rights and responsibilities, you should contact Kohler Co. at 1-920-457-4441 and ask for an Engine

Service representative.

COVERAGE

Kohler Co. warrants to the ultimate purchaser and each subsequent purchaser that the engine will be designed, built and equipped, at the

time of sale, to meet all applicable regulations. Kohler Co. also warrants to the initial purchaser and each subsequent purchaser, that the

engine is free from defects in materials and workmanship which cause the engine to fail to conform with applicable regulations for a period

of two years.

Engines produced in 2006 or later are warranted for two years in California. For 1997 and later model years, EPA requires manufacturers

to warrant engines for two years in all other states. These warranty periods will begin on the date the engine is purchased by the initial

purchaser. If any emission related part on the engine is defective, the part will be replaced by Kohler Co. at no cost to the owner. Kohler Co. is

liable for damages to other engine components caused by the failure of a warranted part still under warranty.

Kohler Co. shall remedy warranty defects at any authorized Kohler Co. engine dealer or warranty station. Warranty repair work done at an

authorized dealer or warranty station shall be free of charge to the owner if such work determines that a warranted part is defective.

Listed below are the parts covered by the Federal and California Emission Control Systems Warranty. Some parts listed below may require

scheduled maintenance and are warranted up to the first scheduled replacement point for that part. The warranted parts include the

following if they were present in the engine purchased:

• Oxygen sensor (if equipped) • Ignition module(s) with high tension lead

• Intake manifold (if equipped) • Gaseous fuel regulator (if equipped)

• Exhaust manifold (if equipped) • Electronic control unit (if equipped)

• Catalytic muffler (if equipped) • Carburetor or fuel injection system

• Thermal reactor muffler (if equipped) • Fuel metering valve (if equipped)

Continued on next page.

18

Page 19

• Fuel lines, fuel line fiings and clamps (if equipped) • Air filter, fuel filter, and spark plugs (only

• Spark advance module (if equipped) to first scheduled replacement point)

• Crankcase breather • Evaporative System (if equipped)

• Air Injection System (if equipped) - Canister (if equipped)

- Air pump or pulse valve assembly (if equipped) - Canister filter (if equipped)

- Control/distribution valve (if equipped) - Vapor hose (if equipped)

- Distribution manifold (if equipped) - Orifice connector (if equipped)

- Air hoses (if equipped) - Fuel tank (if equipped)

- Vacuum lines (if equipped) - Fuel cap (if equipped)

- Primer bulb canister (if equipped)

LIMITATIONS

This Emission Control Systems Warranty shall not cover any of the following:

(a) repair or replacement required because of misuse or neglect, improper maintenance, repairs improperly performed or replacements

not conforming to Kohler Co. specifications that adversely affect performance and/or durability and alterations or modifications not

recommended or approved in writing by Kohler Co.,

(b) replacement of parts and other services and adjustments necessary for required maintenance at and aer the first scheduled replacement point,

(c) consequential damages such as loss of time, inconvenience, loss of use of the engine or equipment, etc.,

(d) diagnosis and inspection fees that do not result in eligible warranty service being performed, and

(e) any add-on or modified part, or malfunction of authorized parts due to the use of add-on or modified parts.

MAINTENANCE AND REPAIR REQUIREMENTS

The owner is responsible for the proper use and maintenance of the engine. Kohler Co. recommends that all receipts and records covering

the performance of regular maintenance be retained in case questions arise. If the engine is resold during the warranty period, the maintenance

records should be transferred to each subsequent owner. Kohler Co. reserves the right to deny warranty coverage if the engine has not been

properly maintained; however, Kohler Co. may not deny warranty repairs solely because of the lack of repair maintenance or failure to keep

maintenance records.

Normal maintenance, replacement or repair of emission control devices and systems may be performed by any repair establishment or

individual; however, warranty repairs must be performed by a Kohler authorized service center. Any replacement part or service that

is equivalent in performance and durability may be used in non-warranty maintenance or repairs, and shall not reduce the warranty obligations of the

engine manufacturer.

19

Page 20

FOR SALES AND SERVICE INFORMATION

IN U.S. AND CANADA, CALL 1-800-544-2444

KohlerEngines.com

ENGINE DIVISION, KOHLER CO., KOHLER, WISCONSIN 53044

FORM NO.: 32 590 01-B

ISSUED: 9/05

REVISED: 6/09

LITHO IN U.S.A.

Loading...

Loading...