Page 1

PowerWAVE 9000DPA

S2 (30-250 kVA)

User Manual

Page 2

TS_619_00 PW9000DPA S2 User Manual 13/3/17

Page 3

TS_619_00 PW9000DPA S2 User Manual 13/3/17

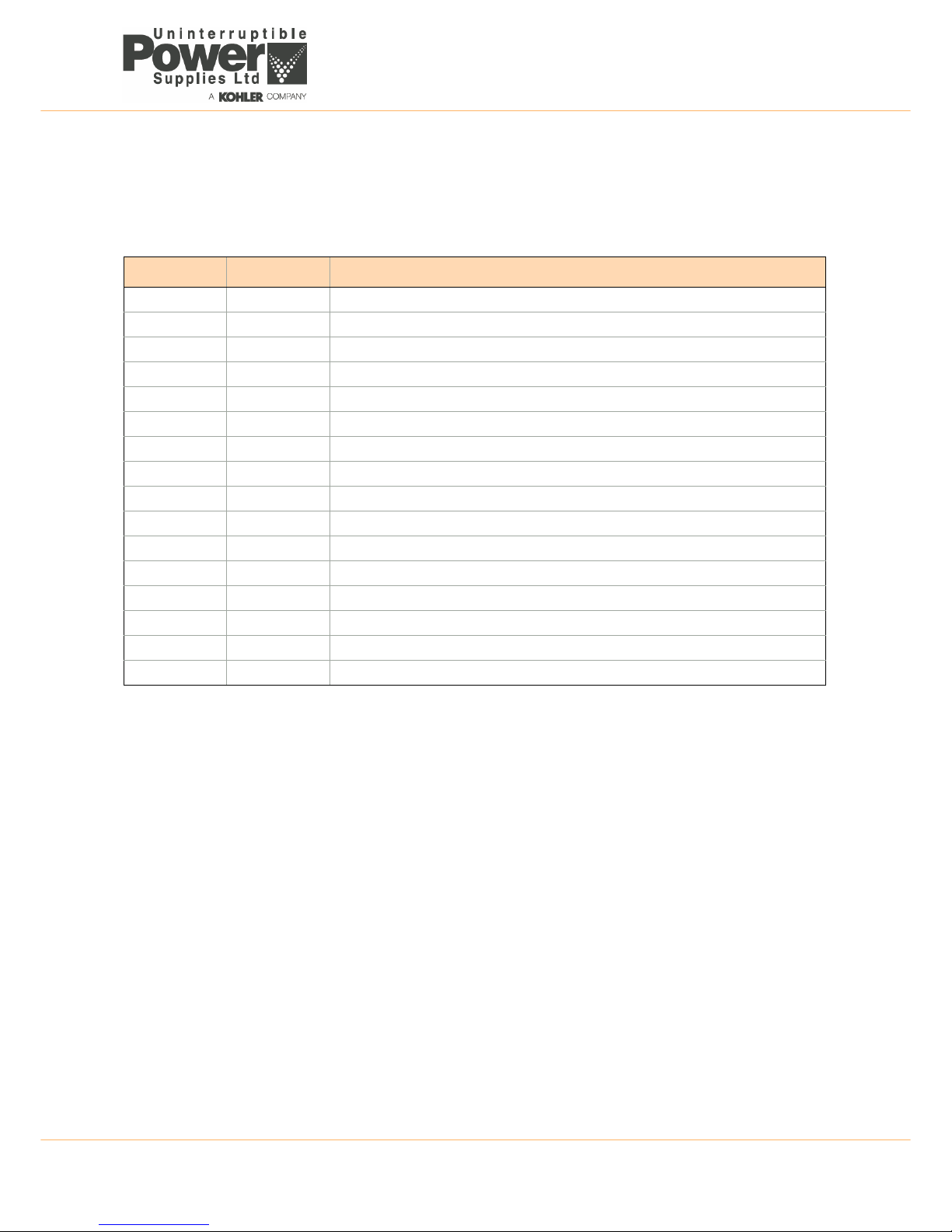

Document Control

PDF ISSUE DATE REVISION SUMMARY

TS_619_00B 19/01/17 Second draft copy

TS_619_00C 27/01/17 Third draft copy

TS_619_00D 09/03/17 Fourth draft copy

TS_619_00 13/03/17 First Issue

Page 4

TS_619_00 PW9000DPA S2 User Manual 13/3/17

Uninterruptible Power Supplies Ltd has taken every precaution to

produce an accurate, complete and easy to understand manual and will

therefore assume no responsibility nor liability for direct, indirect or

accidental personal or material damage due to any misinterpretation of or

accidental mistakes in this manual.

© 2017 Uninterruptible Power Supplies Ltd

This manual may not be copied or reproduced without written permission

of Uninterruptible Power Supplies Ltd.

USEFUL CONTACTS

www.upspower.co.uk UPS Limited web site

service@upspower.co.uk Service department – booking service, fault reporting etc.

technical@upspower.co.uk Technical queries

sales@upspower.co.uk Hardware sales

servicesales@upspower.co.uk Extended warranty agreements etc

Page 5

TS_619_00 PW9000DPA S2 User Manual 13/3/17 I

Table of Contents

Safety 1

1.1 Description of symbols used in this manual 1-1

1.2 User precautions 1-1

General Description 2

2.1 General introduction 2-2

2.1.1 Reliability and quality standards 2-2

2.1.2 Advanced design features 2-2

2.2 PW9000DPA S2 Model range 2-4

2.3 Functional description of operation 2-5

2.3.1 PW9000DPA S2 module block diagram 2-5

2.3.2 UPS Module operating modes 2-7

2.3.3 UPS System operating modes 2-9

2.3.4 Parallel system operation 2-10

2.4 PW9000DPA S2 User controls 2-11

2.4.1 DPA-50 Component identification 2-12

2.4.2 DPA-150 Component identification 2-13

2.4.3 DPA-250 Component identification 2-14

2.5 UPS Interface facilities 2-15

2.5.1 Customer Interface Board 2-15

2.5.2 Parallel Interface Board 2-16

2.6 Module control panel 2-16

2.6.1 Module control panel buttons 2-16

2.6.2 Module mimic LEDs 2-17

2.6.3 Power Management Display (PMD) 2-17

2.7 Warranty 2-21

2.8 Extended Warranty 2-21

2.9 Additional Service/Maintenance Support 2-21

Installation 22

3.1 Introduction 3-22

3.2 Taking receipt of the UPS 3-22

3.2.1 Reporting transportation damage 3-22

3.2.2 Weight and dimensions 3-23

3.2.3 Local transportation 3-23

3.2.4 Storage 3-24

3.2.5 Unpacking 3-24

3.3 Installation planning (environmental & mechanical) 3-25

3.3.1 Environmental considerations 3-25

3.3.2 Clearances 3-25

3.4 Installation planning (electrical) 3-27

3.4.1 General requirements 3-27

3.4.2 External maintenance bypass switches 3-29

3.4.3 Cable sizing 3-30

Page 6

:

II TS_619_00 PW9000DPA S2 User Manual 13/3/17

3.4.4 UPS Power connections 3-32

3.4.5 Battery configuration 3-33

External battery enclosure with separate battery configuration 35

External battery enclosure with common battery configuration 36

3.5 UPS Cabling procedure 3-37

3.5.1 Safety notes 3-37

3.5.2 Preparing the UPS power cabling 3-37

3.5.3 Connecting the UPS AC power cables 3-37

3.5.4 Connecting the battery cables 3-38

3.6 Customer Interface Board 3-38

3.6.1 Customer dry-port interface terminal block – X1 3-38

3.6.2 Customer interface output terminals – X2, X3, X4 3-39

3.7 Parallel-cabinet control and configuration 3-40

3.7.1 Parallel control bus 3-40

3.7.2 Multidrop 3-40

Operating Procedures 41

4.1 Introduction 4-41

4.1.1 Commissioning 4-41

4.1.2 Operating procedure summary 4-41

4.1.3 General warnings 4-42

4.2 Operating instructions 4-42

4.3 How to start the UPS system from a fully powered-down condition 4-42

4.4 How to start the UPS system from the maintenance bypass 4-44

4.5 How to transfer the load to maintenance bypass 4-45

4.6 How to shut down the complete UPS system 4-46

4.7 Operating in ‘on bypass’ mode 4-47

4.7.1 How to Turn ON the UPS in ‘on bypass’ mode 4-47

4.7.2 How to Turn OFF the UPS in ‘on bypass’ mode 4-47

4.7.3 How to transfer between ‘on bypass’ and ‘on inverter’ mode 4-47

Maintenance 48

5.1 Introduction 5-48

5.2 Scheduled maintenance 5-48

5.2.1 Preventative maintenance inspection 5-48

5.2.2 System calibration 5-48

5.2.3 Battery maintenance and testing 5-49

Troubleshooting 50

6.1 Alarms 6-50

6.2 Menu, Commands, Event Log, Measurements, 6-50

6.3 Fault identification messages and alarms 6-51

6.4 Contacting service 6-51

Options 52

7.1 Introduction 7-52

7.2 Customer interface board 7-53

7.2.1 Remote shut down customer input 7-53

7.2.2 Generator ON customer input 7-53

7.2.3 Battery temperature sensor 7-54

7.2.4 RS232 Computer serial interface – JD11 & USB 7-54

7.2.5 RS232 Interface for multidrop – JD12 7-54

7.2.6 SNMP/ CS141 slots – SLOT 1/ SLOT 2 7-55

Page 7

TS_619_00 PW9000DPA S2 User Manual 13/3/17 III

:

Specification 56

8.1 Mechanical Characteristics 8-56

8.2 Input Characteristics 8-57

8.3 Battery 8-57

8.4 Output 8-58

8.5 Standards 8-58

8.6 Environmental 8-59

Page 8

:

IV TS_619_00 PW9000DPA S2 User Manual 13/3/17

Page 9

TS_619_00 PW9000DPA S2 User Manual 13/3/17 1

1

Safety

1.1 Description of symbols used in this manual

1.2 User precautions

WARNING: The warning symbol is used where there is danger of an electrical shock, equipment damage or

personal-injury.

CAUTION: The caution symbol is used to highlight important information to avoid possible equipment

malfunction or damage.

WARNING: Keep this manual with the UPS for future reference.

WARNING: The UPS and peripheral equipment must be installed and commissioned by suitably qualified and

trained personnel who are aware of the potential shock hazards.

WARNING: Do not attempt to install this UPS system until you are satisfied that ALL the safety instructions and

hazard warnings contained in this manual are read and fully understood.

WARNING: High leakage current!

Ensure that the UPS has been correctly earthed before you connect the mains power supply!

WARNING: This UPS must not be started-up or put into use without having first been commissioned by a fully

trained engineer authorised by the manufacturer.

WARNING: All servicing must be performed by qualified personnel. Do not attempt to service the UPS

yourself.

You run risk of exposure to dangerous voltages by opening or removing the UPS-covers! Uninterruptible

Power Supplies Ltd will assume no responsibility nor liability due to incorrect operation or manipulation of the

UPS.

WARNING: The PW9000DPA S2 is a Class A UPS product (according to EN 62040-3). In a domestic

environment the UPS may cause radio interference. In such an environment the user may be required to

undertake additional measures.

Page 10

2 TS_619_00 PW9000DPA S2 User Manual 13/3/17

2

General Description

2.1 General introduction

Congratulations on your purchase of the PW9000DPA S2 UPS.

Continuous power availability is essential in today’s dynamic IT and process-related work environments. It is equally

important that any installed power protection system is sufficiently resilient and adaptable to handle any changes brought

about by the introduction of new server technologies, migration and centralization.

Such demands are well met by the PW9000DPA S2 UPS system which provides the foundation for continuous power

availability of network-critical infrastructures both in enterprise data centres, where business continuity has paramount

importance, and in process control environments where manufacturing continuity is essential.

The PW9000DPA S2 is a second generation high-power-density (HPD), leading-edge, double-conversion power

protection technology that has standardised on a modular component approach which helps speed deployment, improve

adaptability and increase system availability, while reducing total cost of ownership. It is a unique on-demand architecture

that integrates the power rack, power distribution unit, back-up battery and monitoring and management solutions to allow

easy selection of optimised configurations.

2.1.1 Reliability and quality standards

High reliability, upgrade ability, low operating cost and excellent electrical performance are just some of the highlights of

this innovative UPS solution.

By using a unique modular construction, and incorporating the latest technological developments in power engineering,

the PW9000DPA S2 represents a completely new generation of transformerless 3 phase UPS-System. Its advanced

double conversion VFI (Voltage and Frequency Independent) topology responds fully to both the highest availability and

environmentally friendly requirements compliant with IEC 62040-3 (VFI-SS-111) standards. The criteria and methods

which are used in the design, manufacture, and maintenance of Uninterruptible Power Supply systems are certified to

International Standard ISO 9001/EN 29001 and ISO 14001. A full UPS Specification is given in Chapter 8 of this manual.

Uninterruptible Power Supplies Ltd. specialises in the installation and maintenance of Uninterruptible Power Systems; and

this powerful UPS is just one example of our wide range of state-of-the-art power protection devices that will provide your

critical equipment with a steady and reliable power supply for many years.

2.1.2 Advanced design features

Key features

The highlights of this innovative UPS solution include:

• Decentralised Parallel Architecture (DPA) – Highest availability, with near zero down time.

• Truly modular design – The PW9000DPA S2 is designed around 30kVA, 40kVA,or 50kVA UPS modules.

• Hot-swappable modules – Enables system expansion and module replacement in a live system.

• Compact size, small foot print – Up to 342kW/m² saving on expensive floor space.

• Flexible battery management – Advanced management of battery charging and preventive-failure diagnostics.

• High ac-ac efficiency (up to 95.5%) even with partial loads – Results in energy and operational cost savings (TCO)

• Full power available from 0.9 lead to 0.8 lag – No de-rating required with leading power factor loads.

• Very low input current distortion – THDi = <3% @ 100% load leads to savings in generator-set power and

installation costs.

Page 11

TS_619_00 PW9000DPA S2 User Manual 13/3/17 3

2: General Description

Hot-swappable modules

In a redundant module system the unique ‘hot-swappable’ feature enables a UPS module to be added or removed from its

cabinet whilst the system is still powered. This can be done without disturbing the load or transferring it to the bypass

supply.

Note: In a non-redundant system the load will unavoidably have to be transferred to the bypass supply while a module is

shut down or removed from the system.

Advanced booster technology

The UPS module’s inbuilt advanced booster technology results in a perfect sinusoidal input power quality at 0.99 input

power factor with a harmonic content of less than 3-4% THDi. This leads to a more reliable system operation together with

savings in generator and transformer sizing due to reduced winding losses. It also means that the traditional input

harmonic filters, still used by some systems, are not required.

The high power factor presented by the UPS on the incoming mains supply minimises cabling and fusing costs due to the

reduced reactive power consumption which, together with the accompanying low harmonic currents, provides the

following benefits:

• No additional losses in wires and cables

• No extra heating of transformers and generators

• No over sizing of generators

• No false circuit breaker tripping and malfunction

• No erratic operation of computers, telecommunications, monitors, electronic test equipment etc.

• No resonance with power factor correction capacitors

Decentralised Parallel Architecture (DPA)

The PW9000DPA S2 system features DPA paralleling technology that provides n+x redundancy without introducing a

single-point-of-failure. Each module contains its individual charger and inverter power units, bypasses, CPUs, control

panels and separate battery configuration, and thereby offers completely autonomous operation.

This unique decentralized design:

• Enables a parallel redundant system providing 100% conditioned power at all time.

• Eliminates the system-level single point of failure inherent in traditional parallel UPS systems.

• Exponentially increases the reliability of the overall system.

Flexible battery management (FBM)

This equipment employs flexible battery charging management which avoids premature deterioration of battery life and

provides preventive failure diagnostics. The major benefits are:

• AC-ripple-free battery charging due to a dedicated dc-dc charger independent from the rectifier and inverter.

• Wide range of number of battery blocks (42-50 x 12V blocks, depending autonomy times).

• Wide UPS input voltage operating window extends the battery life due to fewer discharge cycles.

• Battery discharge protection caused by load jumps.

• Proactive battery protection from false manipulations and inadequate charging voltages.

• Proactive battery failure detection thanks to the Advanced Battery Diagnosis (ABD) algorithm.

• User-selectable battery tests to ascertain the battery state.

• Optional temperature compensated charging regime to enhance battery life.

Page 12

2: General Description

4 TS_619_00 PW9000DPA S2 User Manual 13/3/17

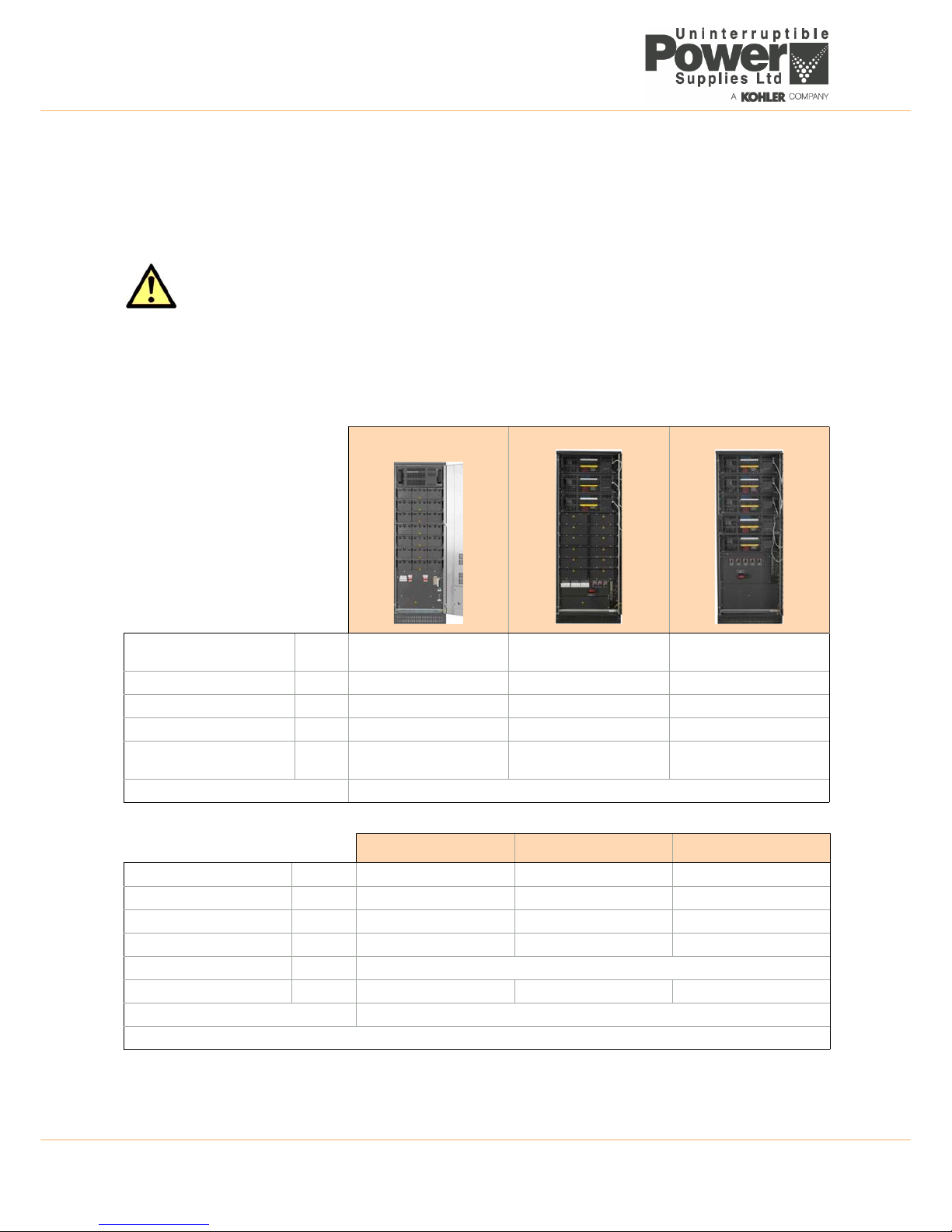

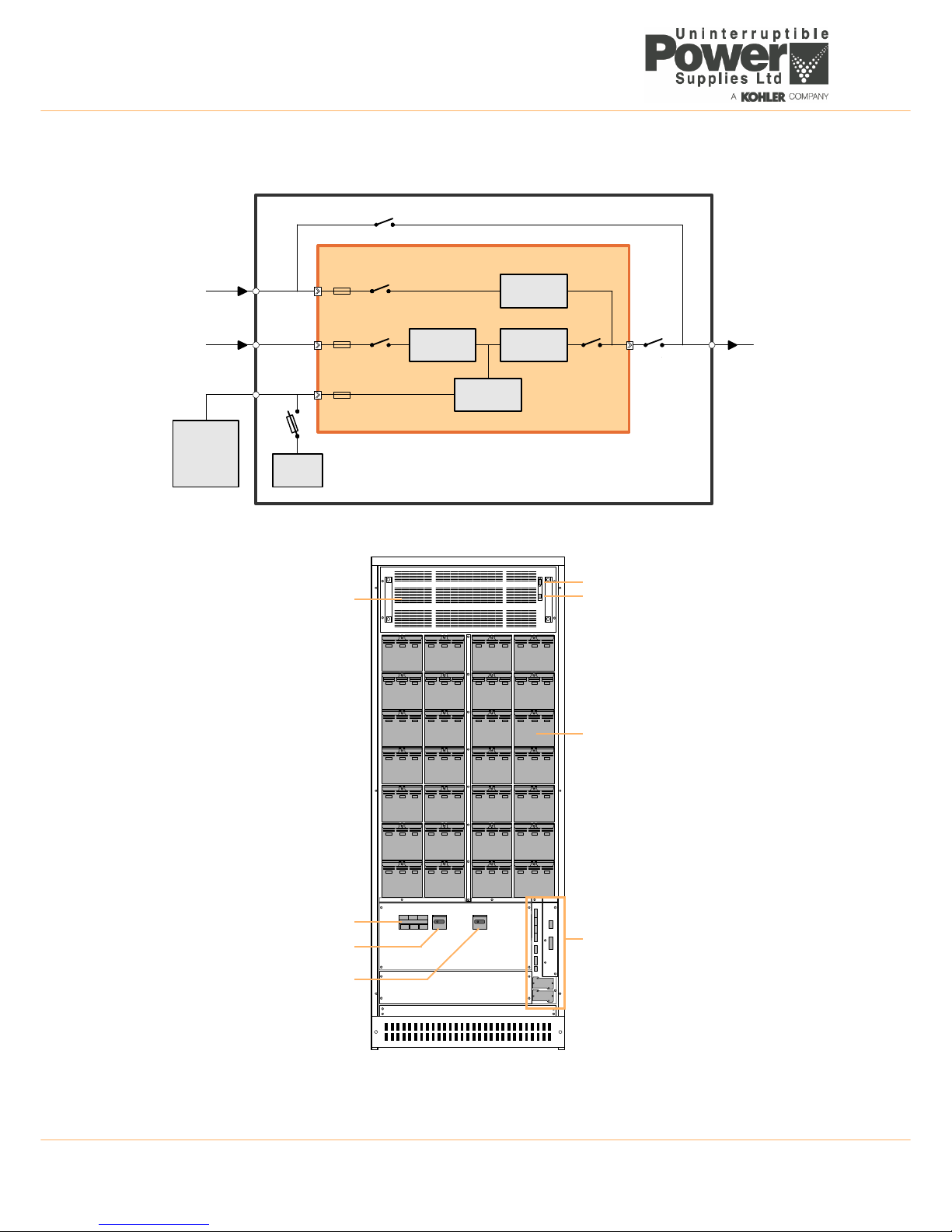

2.2 PW9000DPA S2 Model range

The PW9000DPA S2 UPS incorporates a rack-mountable design based on 30kVA, 40kVA and 50kVA plug-in UPS

modules fitted into one of three purpose-built cabinets. Each module is a self-contained UPS comprising a rectifier, battery

charger, inverter and static switch; and when two or more modules are fitted into a cabinet they effectively operate as a

parallel UPS system. The available cabinets are shown below in Figure 2.1.

The PW9000DPA S2 cabinets are identified as CLASSIC DPA-50, TRIPLE DPA-150 and UPGRADE DPA-250 – where

the model number represents the maximum kVA output when the cabinet is fully populated with 50 kVA UPS modules.

Figure 2.1 shows that the DPA-50 and DPA-150 cabinets also contain the UPS batteries; however the DPA-250 cabinet

requires an external battery cabinet, or battery rack. Uninterruptible Power Supplies Ltd. can supply a matching battery

cabinet which can installed adjacent to the DPA-250 cabinet in the majority of installations. An external battery cabinet can

also be added to the DPA-50 and DPA-150 models to extended the system’s autonomy time if desired.

Figure 2.1 PW9000DPA S2 Cabinets (frames)

Figure 2.2 PW9000DPA S2 UPS Modules

CAUTION: All the modules fitted within a cabinet must be of the same ra ting – for example, it is not possible to

mix 30kVA and 50kVA modules in the same cabinet.

CLASSIC DPA-50 TRIPLE DPA-150 UPGRADE DPA-250

UPS module capacity

Battery capacity

Max 1 module (30-50kVA)

280 x 7/9Ah batteries

3 modules (30-50kVA) 240x

7/9Ah batteries

5 modules (30-50kVA)

External batteries

Maximum power connection kVA 50 150 250

Dimensions (WxHxD) mm 730x1650x800 730x1975x800 730x1975x800

Weight of empty frame kg 262 239 205

Weight of frame with modules

fitted (but without batteries)

kg 305 - 309

(with 1 Module)

368 - 379

(with 3 Modules)

420 - 439

(with 5 Modules)

Colours Front: RAL 9007 + black (inlets). Sidewalls: Graphite grey

DPA 30 S2 Module DPA 40 S2 Module DPA 50 S2 Module

Output Apparent Power KVA 30 40 50*

Output Active Power KW 24 32 40

Output Power (PF=1) KVA / KW 24 / 24 32 / 32 40 /40

Number of 12V Battery Blocks No. 42-50 42-50 42-50

Dimensions (WxHxD) mm 663 x 225 x 720

Weight kg 43.1 45.3 46.8

Colours Front: Graphite grey

* On Inverter mode 50 KVA/40kW on Bypass mode 45 KVA/40kW

Page 13

TS_619_00 PW9000DPA S2 User Manual 13/3/17 5

2: General Description

2.3 Functional description of operation

This section describes:

• The internal operation of an individual UPS module at block-diagram level (see paragraph 2.3.1)

• The various operational modes of an individual UPS module (see paragraph 2.3.2)

• UPS system operational modes – ‘On-line’ versus ‘Off-line’ system operation (see paragraph 2.3.3)

• Multi-module system operation and paralleling considerations (see paragraph 2.3.4)

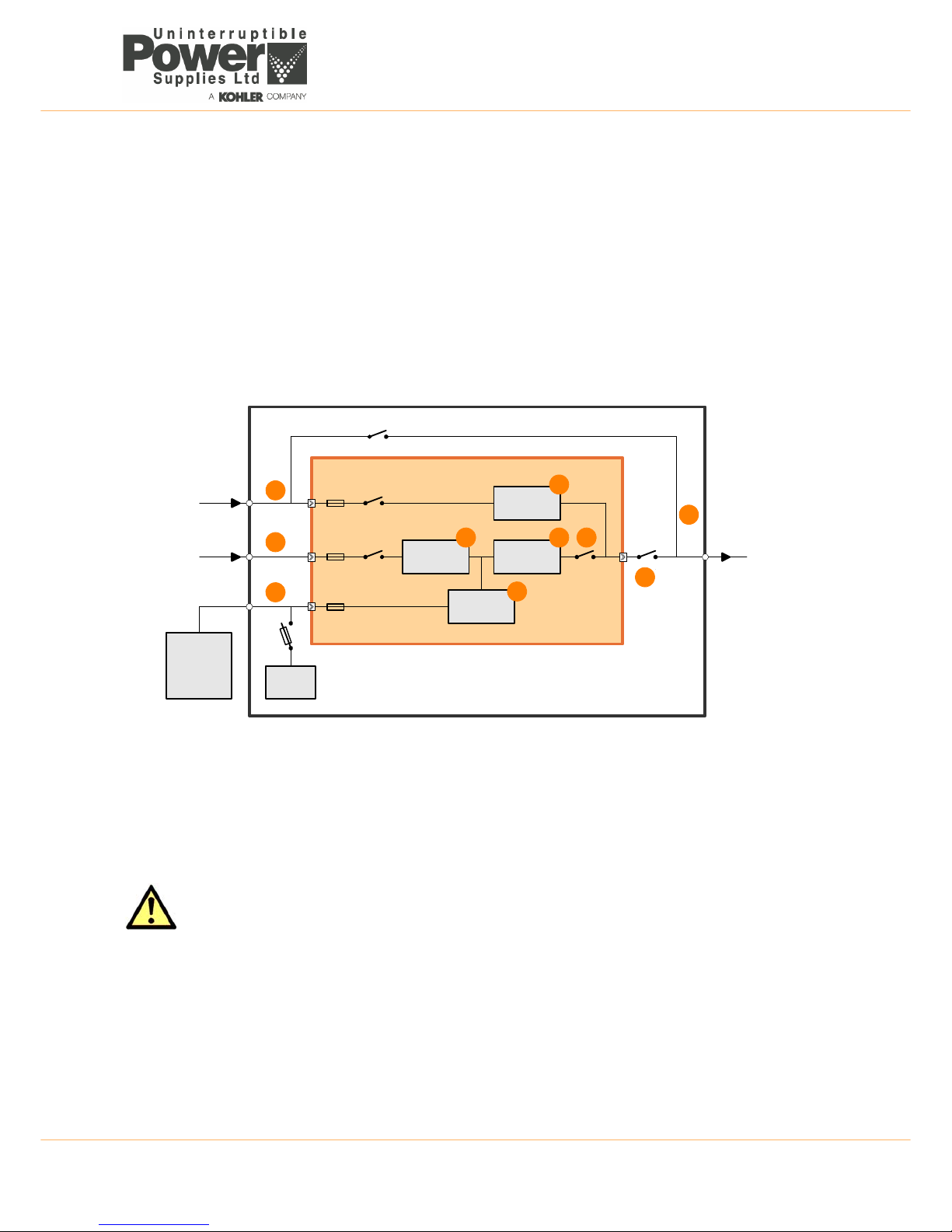

2.3.1 PW9000DPA S2 module block diagram

The PW9000DPA S2 UPS module is rack-mounted within the cabinet, and when the module is inserted into its rack it

plugs into a heavy-duty connector fitted to the back of the rack which carries all the module’s power connections – i.e.

input mains, bypass mains, battery and module power output.

Figure 2.3 PW9000DPA S2 module

Input power connections (1) / (2)

The UPS input mains and bypass mains are connected to an input power terminal block located in the lower part of the

UPS cabinet. Both inputs require a 3ph+N feed but, although the two inputs are shown as being separate in Figure 2.3, in

a standard installation the input mains terminals (1) and bypass mains terminals (2) are usually linked at the cabinet’s

input power terminal blocks so only one mains supply feed is required.

The input supplies are unswitched within the UPS cabinet and connected directly to each fitted module.

Both input supplies are fused within the module (F1/F2), however the fuses are internal to the module and not accessible

to the operator. In the event of a fuse failure the module must be removed and repaired by an authorised service agent. A

fuse failure event is shown on the module control panel to identify a faulty fuse.

Within the UPS module, the input supplies are connected to the module’s power blocks through individual supply

contactors which are driven by the module’s control logic and operate as part of the module’s start/stop sequences. They

are also used by the control system to isolate the input power within the module following certain fault conditions.

CAUTION: As the mains power supplies are unswitched within the UPS cabinet, the module(s) will be live at all

times unless the input/bypass supply is isolated at the external mains switchboard panel.

RECTIFIER

BATTERY

EXTERNAL

BATTERY

CABINET

INVERTER

STATIC

SWITCH

BOOSTER /

CHARGER

Bypass

Contactor

Inv. Output

Contactor

Input

Contactor

Bypass Mains

IA-2

IA-1

F4

F1

F2

F3

UPS MODULE

UPS CABINET

Static bypass line

Maintenance bypass line

UPS Input Mains

UPS Output

to critical load

3

4

1

2

5

6

7

8910

Page 14

2: General Description

6 TS_619_00 PW9000DPA S2 User Manual 13/3/17

Battery connections (3)

Each UPS module is connected to a battery string via a dedicated fused isolator. Ideally, each module is connected to an

individual battery but in some installations a common battery is shared between two (or more) modules.

The battery fuse (F3) is fitted inside the module and is not accessible to the operator. If the fuse ruptures, the module must

be removed and repaired by an authorised service agent. A fuse failure message is shown on the module control panel.

• DPA-50 (1 module) – The batteries are housed internally in the UPS cabinet and connected to the module through

a fused isolator (F4) located on the cabinet’s power panel.

• DPA-150 (3 modules) – The batteries are housed internally in the UPS cabinet and connected to the module

through three fused isolators annotated F4/ F5/ F6 (for modules 1, 2, and 3 respectively).

• DPA-250 (5 modules) – The batteries are housed in a separate battery cabinet (or rack) which must also contain

the fused isolators. There are no battery isolators within the UPS cabinet itself.

Output power connection (4)

A ‘parallel isolator’ switch (IA-2) is connected between the UPS module output and the cabinet’s output (load) terminal

block. IA-2 is used to disconnect the module from the UPS output; for example, when replacing a module in a redundant

parallel system, or when operating on maintenance bypass.

In the DPA-150 and DPA-250 cabinets, a dedicated ‘parallel isolator’ switch (IA-2) is provided for each UPS module. The

isolators are located on the cabinet’s power panel and identified as IA2-1, IA2-2, IA2-3.... (for modules 1, 2, and 3

respectively)

Maintenance bypass (5)

The maintenance bypass switch (IA-1) is external to the UPS module(s) and located on the cabinet’s power panel. This

switch connects the UPS cabinet output (load) terminals directly to the bypass mains terminals and is used to connect the

load to the (unprotected) bypass supply if the UPS modules have to be shut down due for service repair etc. See also

paragraph 3.4.2.

Rectifier (6)

The rectifier converts the UPS input mains supply into a regulated DC power source which provides the operating power

for the inverter. It uses leading-edge switched-mode techniques which results in a UPS module input power factor of

almost unity over its operating range (0.99 at full rated linear load). The rectifier can provide 100% inverter power demand

over an input voltage range of -20% to +15%. This wide input voltage operating range means that the battery is not called

upon during substantial power dips (brown outs), which in turn maximises the battery life and availability.

Battery booster/charger (7)

This block has bi-directional functions. When the input mains supply is available, and the rectifier is turned on, the booster/

charger acts as a multi-stage battery charger. The charger uses an intelligent charging profile to optimise the battery life

and at the same time ensure the battery recharges quickly following a deep discharge cycle.

If the input mains supply fails, or the rectifier is unable to provide a sufficient output to satisfy the prevailing inverter load,

the battery provides the inverter’s DC operating power source. The booster/charger circuit boosts the battery voltage as

the battery discharges and regulates it at a suitable level to allow the inverter to operate correctly.

Inverter (8)

The inverter converts the DC voltage produced by the rectifier (or the battery via the DC boost converter) into a sinusoidal

AC output voltage suitable to connect to the load. In addition to providing output voltage regulation, the inverter control

logic also provides various levels of overload protection, freq

uency regulation and synchronisation, and output voltage

error detection.

Static switch (9)

The static switch provides a means of connecting the UPS module output to the static bypass line – which is in turn

connected to the UPS bypass mains supply. Working in conjunction with the output contactor, the static switch control

logic is used to transfer the UPS output between the inverter and bypass mains without a break in the load supply.

Note: A brief load break will occur if transferring from bypass to inverter following a bypass supply failure. (See ‘Off Line

Mode’ in paragraph 2.3.3).

Page 15

TS_619_00 PW9000DPA S2 User Manual 13/3/17 7

2: General Description

Inverter output contactor (10)

The inverter output contactor is driven by the UPS module’s control logic and operates in conjunction with the static switch

as part of the bypass/inverter load transfer process. The contactor is also used to isolate the inverter from the UPS output

within the module following certain overload or fault conditions.

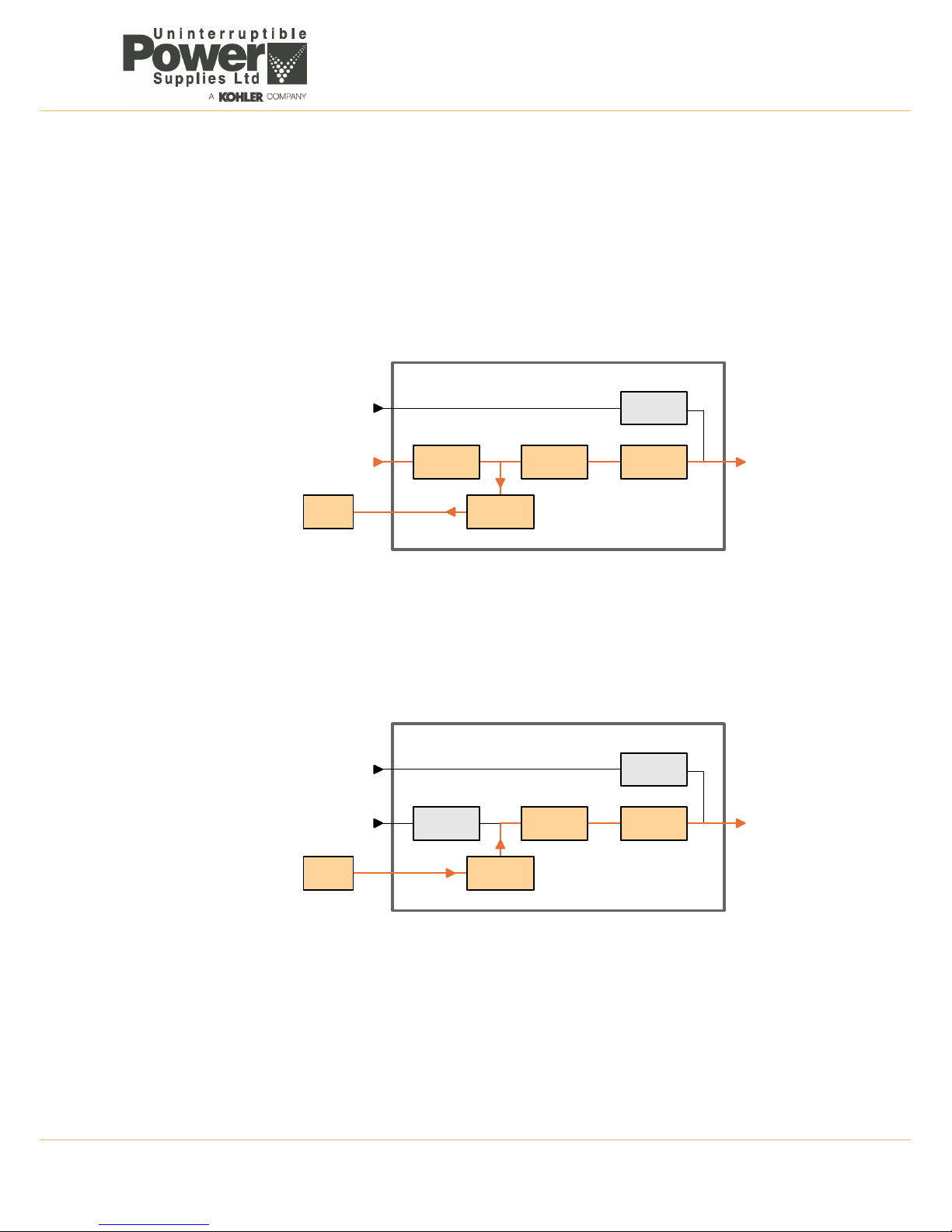

2.3.2 UPS Module operating modes

Simplified block diagrams are used in this section to illustrate the various UPS module operating modes. Note that where

two or more UPS modules are installed in a DPA-150 or DPA-250 cabinet they will always adopt the same operating mode

due to their parallel control signals.

Load on inverter

This is the only operating

mode that provides the

load with continuously

processed and backedup power: and in the

majority of installations

can be considered as

the ‘normal’ operating

mode.

In this mode, the input

mains AC supply is

converted to DC by the

rectifier which then

charges the battery and

provides the operating power for the inverter.

The inverter converts the DC produced by the rectifier back to an AC power source which is then connected to the load via

the inverter output contactor. The inverter frequency is synchronised to the bypass supply provided the bypass frequency

remains within preset limits. If these limits are exceeded, or if the bypass supply fails altogether, the inverter frequency

control reverts to a free-running oscillator which produces a constant 50Hz or 60Hz UPS output.

Load on battery

If the mains supply fails,

the rectifier shuts down

and the battery provides

the DC power source for

the inverter. The battery

voltage is regulated by

the booster circuit to

ensure the inverter

receives a suitable DC

input as the battery

discharges. On the

module control panel the

BATTERY LED will flash

green to indicate that it is

on load.

In the case of a dual feed input – if the bypass supply is still live when the input mains supply fails, the inverter frequency

remains synchronised to the bypass mains provided it is within its preset limits.

In the case of a single feed input – the bypass supply will fail at the same time as the input mains supply and the inverter

frequency control reverts to its free-running oscillator and will provide a constant 50Hz or 60Hz UPS output.

Battery discharge operation

When the battery is placed on load, and begins to discharge, the BATTERY mimic LED flashes green on the module

control panel accompanied by an audible alarm. The LED continues flashing green until the remaining autonomy time falls

RECTIFIER

BATTERY

INVERTER

STATIC

SWITCH

BOOSTER /

CHARGER

INV. Output

Contactor

Bypass Mains

UPS MODULE

Static bypass line

UPS Input Mains

UPS Output

to critical load

Figure 2.4 Load on inverter

RECTIFIER

BATTERY

INVERTER

STATIC

SWITCH

BOOSTER /

CHARGER

INV. Output

Contactor

Bypass Mains

UPS MODULE

Static bypass line

UPS Input Mains

UPS Output

to critical load

Figure 2.5 Load on battery

Page 16

2: General Description

8 TS_619_00 PW9000DPA S2 User Manual 13/3/17

to three minutes, whereupon it begins flashing red. This allows the operator to gauge the remaining autonomy time and,

where necessary, shut down the load in an orderly manner (e.g. save data) before the battery is fully discharged. Various

options are available to automate the load shut down process and if an automated data protection application is installed it

usually begins its automatic shut down routine at this point.

The initial audible alarm can be cancelled but it will reappear when the battery voltage falls to its LOW BATTERY alarm

threshold, whereupon the audible alarm sounds once again to warn the operator that the battery is nearing its end-ofdischarge.

Eventually, the BATTERY LED changes to solid red when the battery reaches its fully discharged voltage, and the UPS will

attempt to transfer the load to the bypass supply if the supply is present.

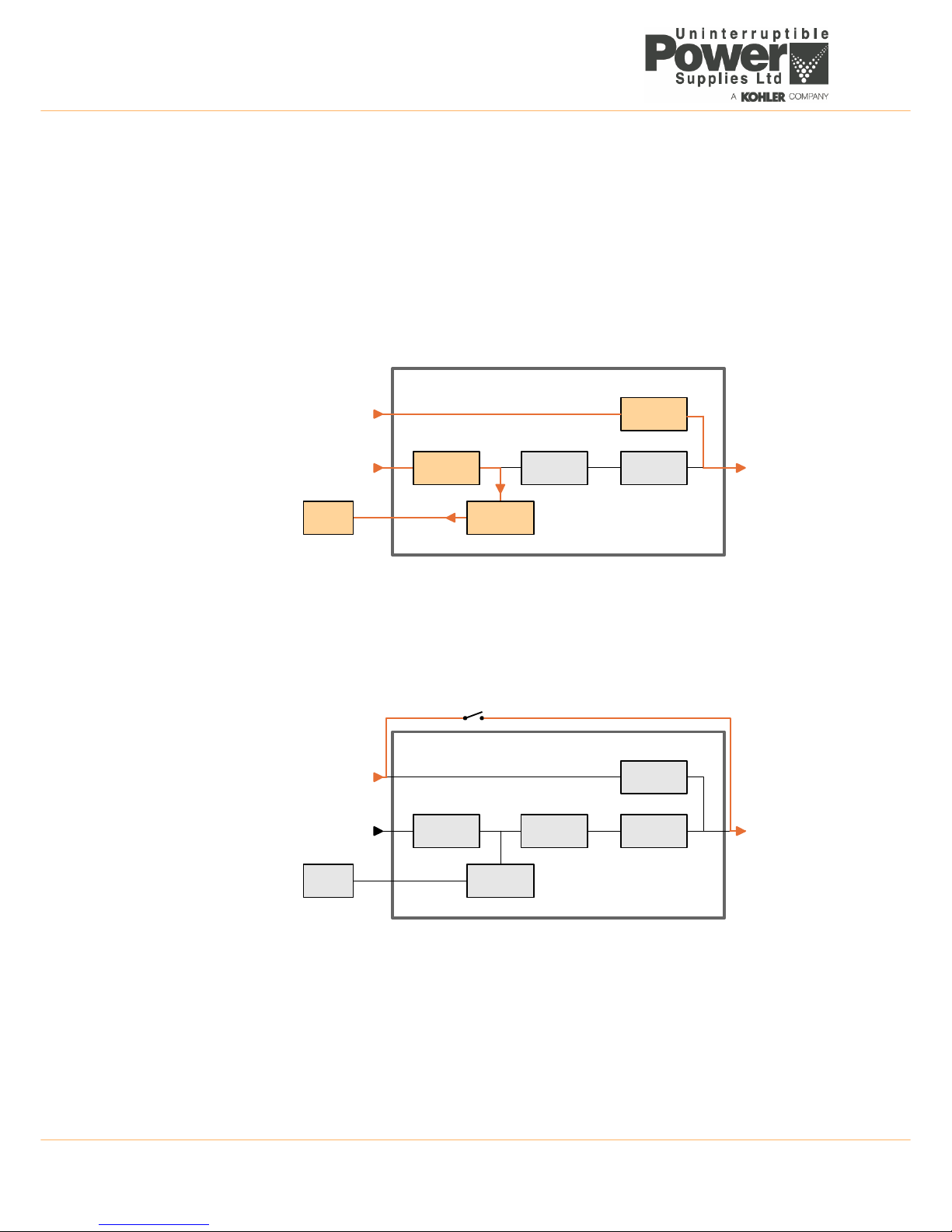

Load on bypass

In the ‘load on bypass’

mode the static switch

connects the load to the

unprotected static

bypass line.

This mode can be

selected manually (see

‘ECO Mode’ below) or

entered as the result of a

UPS fault (or overload)

condition which transfers

the load to bypass

because the inverter is

unable to support it.

Depending on the reason for entering the ‘load on bypass’ mode, the rectifier and charger sections might be turned off

entirely or remain operational and continue to provide battery charging (as shown above). Similarly, the inverter may have

been manually turned OFF or shutdown due to a fault, and the INVERTER LED on the module control panel may be either

OFF or solid RED.

Module OFF (Maintenance bypass)

When the UPS module

is turned OFF, all of its

internal power blocks

are effectively shut down

but the module input

power terminals remain

live unless the UPS

input/bypass mains are

externally isolated.

The maintenance

bypass switch (IA-1) can

be closed to maintain the

load supply, but in a

single UPS cabinet

installation this requires

the bypass mains supply

to remain live and

thereby prevents the bypass supply from being externally isolated.

Only one maintenance bypass switch is fitted per UPS cabinet and if the cabinet contains several modules (DPA-150,

DPA-250) the maintenance bypass switch (IA-1) bypass them all.

When operating a multi-cabinet system, the internal cabinet maintenance bypass switch (IA-1) should not be used, and an

external maintenance bypass installation that wraps-around the complete multi-cabinet system is required – usually

installed in a dedicated maintenance bypass cabinet, or wall-mounted as described in paragraph 3.4.2.

RECTIFIER

BATTERY

INVERTER

STATIC

SWITCH

BOOSTER /

CHARGER

INV. Output

Contactor

Bypass Mains

UPS MODULE

Static bypass line

UPS Input Mains

UPS Output

to critical load

Figure 2.6 Load on bypass

RECTIFIER

BATTERY

INVERTER

BOOSTER /

CHARGER

INV. Output

Contactor

Bypass Mains

UPS MODULE

Static bypass line

UPS Input Mains

UPS Output

to critical load

IA-1

Maintenance bypass line

STATIC

SWITCH

Figure 2.7 Module OFF (Load on maintenance bypass)

Page 17

TS_619_00 PW9000DPA S2 User Manual 13/3/17 9

2: General Description

2.3.3 UPS System operating modes

Section 2.3.2 described the operating modes for the individual UPS modules: but UPS systems are also categorised

according to the way in which they operate at a ‘system’ level, and are typically described as being either an ‘on-line’, or

‘off-line’ (‘line interactive’) system.

The PW9000DPA S2 can be operated in either of these categories.

ON-LINE UPS system

An ‘on-line’ system provides the highest degree of load protection, especially if the utility mains supply suffers a

disturbance or complete failure, and we always recommended this mode of operation if the critical load will not tolerate

even a very brief supply interruption – e.g. in the case of a computer system.

When the PW9000DPA S2 is used as an ‘on-line’ system, the UPS modules normally operate in their ‘on inverter’ mode

(Figure 2.4), and switch to the ‘on battery’ mode if the input mains supply fails (Figure 2.5). The changeover to battery

operation is totally transparent at the UPS output and an audible and visual alarm warns the operator that the battery is

discharging to enable any intervention to be taken to protect the load integrity.

The UPS then continues to provide its rated output until the battery discharges to a low cut-off point at which time the UPS

attempts to switch to its ‘on bypass’ mode. If the bypass is unavailable the UPS shuts down in a controlled manner.

It is usual, especially in larger installations, to provide the UPS with an alternative input supply from a standby generator

which starts automatically following a UPS input mains failure; and where this is implemented the batteries only discharge

for a short period, until the generator comes on-line. This not only avoids the UPS shutting down due to a fully discharged

battery but also helps maximise the battery life cycle.

If the UPS experiences an internal fault during ‘on-line’ operation, the inverter turns off and the static switch transfers the

load to bypass mains automatically and without interruption – provided the inverter is synchronised to the bypass. If there

is an output overload, the inverter can supply the overload for a limited time, depending on its severity, and if the permitted

time is exceeded the load transfers to bypass. The additional power available from the bypass supply will attempt to clear

the overload but if it persists it will ultimately rupture the bypass mains supply fuses. If the overload condition clears while

operating on bypass it re-transfers the load to the inverter and the UPS returns to its normal ‘on-line’ mode of operation.

OFF-LINE (On stand-by) UPS system operation

When the PW9000DPA S2 is used as an ‘off-line’ system, the UPS modules are normally operated in their ‘on bypass’

mode (Figure 2.6) with the load supplied via the static bypass line. However the rectifier and battery charger are still

powered up and maintain battery charging, and the inverter section is turned on and operating on standby.

Operating in this mode is slightly more energy efficient than operating in the ‘on-line’ mode due to the reduced rectifier and

inverter losses during normal system operation; and it is sometimes referred to as the “ECO” (economy) mode. However,

this mode is recommended only if the connected load equipment can tolerate power interruptions of up to 3~5 ms during

the transfer period.

If the bypass supply fails, the inverter is immediately brought on line and the load is transferred from the bypass line to the

inverter within 3 to 5 milliseconds. If the UPS bypass mains and input mains are connected to separate sources (dual

feed) and the input mains is still live when the load is transferred, the UPS modules will operate in their ‘on inverter’ mode

(Figure 2.4). However, if the input/bypass mains supplies are c

onnected to a common feed, or the input mains is

unavailable in a dual feed system, the modules immediately revert to the ‘on battery’ mode (Figure 2.5).

When the bypass supply returns to normal, the load re-transfers to the static bypass line (without a break) and the inverter

returns to its standby operation.

Note: if the bypass is unavailable it is unable to take over the load supply if the inverter fails, or assist the inverter han dle

an output overload. It is therefore important that the cause of the load transfer from bypass to inverter is quickly rectified.

WARNING: The ON-LINE mode should always be used for critical load protection.

Page 18

2: General Description

10 TS_619_00 PW9000DPA S2 User Manual 13/3/17

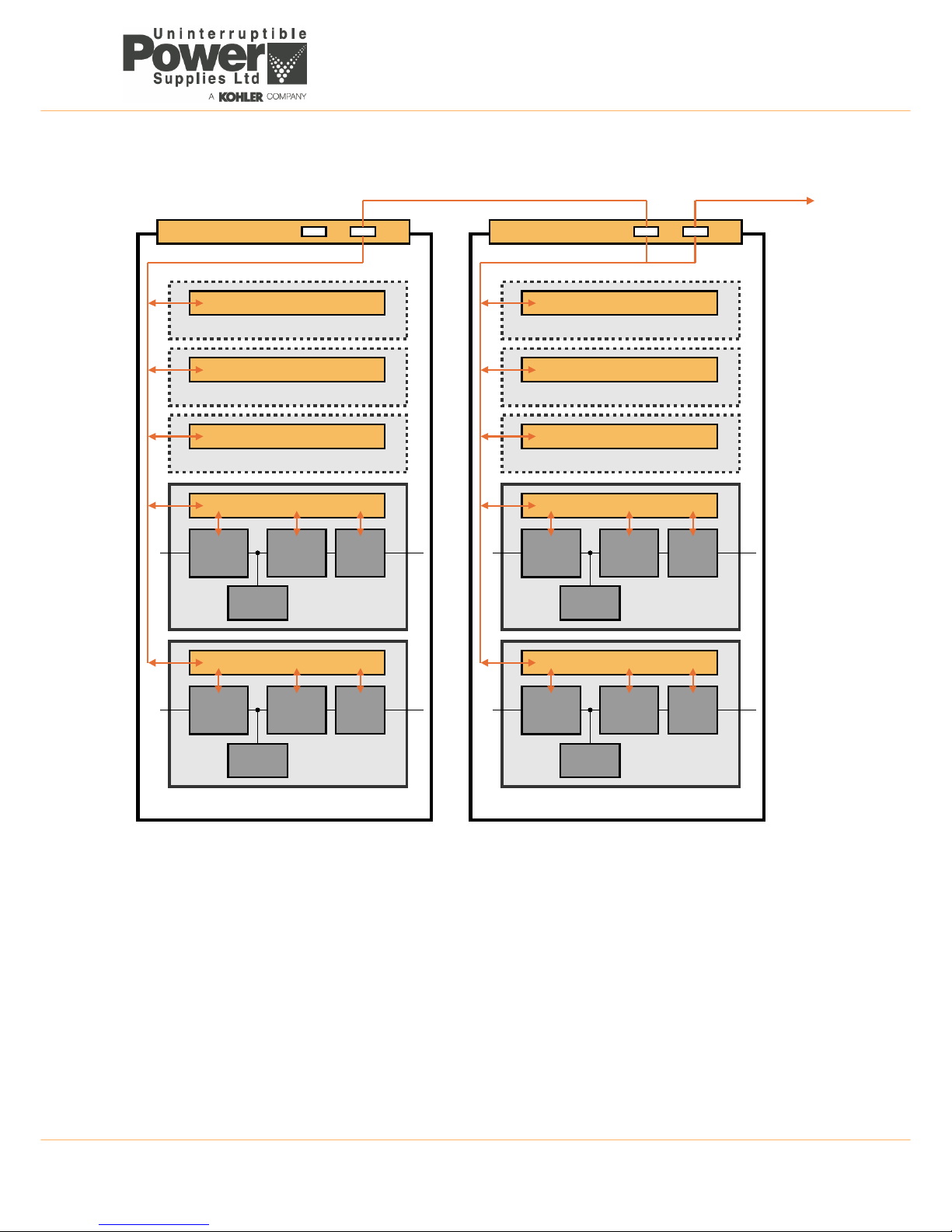

2.3.4 Parallel system operation

All the modules fitted in a UPS cabinet inherently operate as a parallel system as their outputs are connected in parallel at

the cabinet’s output terminals. The electronic control system built into each module ensures that:

• The modules are always frequency-synchronised to each other – and to the bypass mains (when present).

• The modules equally share the load current.

• The modules’ load transfer operation is synchronised such they ALL transfer their output between inverter and

bypass simultaneously when commanded from any one module.

The PW9000DPA S2 UPS system can be expanded by connecting up to six PW9000DPA S2 UPS cabinets in parallel;

and when two or more cabinets are connected in this way, all the UPS modules within them are effectively paralleled

together. For example: a maximum system capacity is obtained by connecting together six DPA-250 cabinets, each fully

populated with DPA-50 modules, which results in a total of thirty (50kVA) modules operating in parallel to provide a system

capacity of 1500kVA.

System expansion

Some UPS applications present a low initial power requirement which increases over time as the application grows; and it

is therefore essential that the installed UPS system can be expanded to meet the growing demand without compromising

the existing load. This requirement is well met with the ‘hot swappable’ feature of the PW9000DPA S2 UPS modules,

whereby an additional module can be inserted into a vacant slot in an existing cabinet without disturbing the load.

Note: If the expansion requires an additional cabinet the system will have to be shut down while the cabinet is installed.

‘Capacity’ versus ‘redundant module’ system

A parallel UPS system can be operated as either a ‘capacity’ or ‘redundant’ module system.

A ‘capacity’ system is rated such that ALL the UPS modules are required to furnish the specified full load power and the

loss of one module will automatically transfer the load to the bypass supply.

In a ‘redundant-module’ system, the system contains at least one UPS module over and above that required to supply the

full load and it is possible to lose a module without transferring the load to the bypass supply or in any way disrupt the UPS

output. A system operating with a redundant module is inherently the most reliable.

A parallel system operating with one redundant module is known as an ‘N+1’ system.

Parallel control bus

All the UPS modules within a cabinet, and between cabinets, are connected to a parallel control bus which carries several

control signals used for frequency synchronisation, load sharing etc. Each UPS module can electronically compare its own

frequency and output current with that of its neighbouring module and make any necessary fine adjustments to its control

logic to achieve balanced conditions across the system.

The parallel control logic observes one UPS module as being the ‘master’ and the others as ‘slaves’. However if the

‘master’ module goes faulty at any time the next module in the chain (a former ‘slave’) will immediately take over the role

of ‘master’ and the former ‘master’ module will turn off. The ‘master/slave’ configuration is set during commissioning.

During commissioning, the UPS modules are also assigned a numerical ID according to their position in the cabinet, with

the bottom module being given the lowest number. Figure 2.8 shows two DPA-250 cabinets with the modules in cabinet 1

assigned an ID of ‘P01’ to ‘P05’ and those in cabinet 2 an ID of ‘P06’ to ‘P10’ (‘P’ indicates that the modules are part of a

Parallel system). The module ID is used by the control and monitoring logic.

Key Point: When planning a multi-cabinet system, it is not necessary to fully populate one cabinet with UPS

modules before installing the next cabinet. For example, if it is known at the outset that a 200kVA initial load

requirement is likely to increase to 400kVA, it makes sense to install and cable-up two DPA-250 cabinets and

distribute the initial requirement of four UPS modules between them.

Page 19

TS_619_00 PW9000DPA S2 User Manual 13/3/17 11

2: General Description

Figure 2.8 PW9000DPA S2 – Parallel cabinet system

2.4 PW9000DPA S2 User controls

The following illustrations show the location of the PW9000DPA S2 power switches and fused isolators that are used

when operating the equipment. The module control panel (one per UPS module) is described in paragraph 2.6.

STATIC

SWITCH

INVERTERRECTIFIER

Parallel Control Logic

UPS Module P06

CHARGER

STATIC

SWITCH

INVERTERRECTIFIER

Parallel Control Logic

UPS Module P07

CHARGER

Parallel Control Logic

UPS Module P08

Parallel Control Logic

UPS Module P09

Parallel Control Logic

UPS Module P10

UPS CABINET 2

STATIC

SWITCH

INVERTERRECTIFIER

Parallel Control Logic

UPS Module P01

CHARGER

STATIC

SWITCH

INVERTERRECTIFIER

Parallel Control Logic

UPS Module P02

CHARGER

Parallel Control Logic

UPS Module P03

Parallel Control Logic

UPS Module P04

Parallel Control Logic

UPS Module P05

UPS CABINET 1

Parallel Adapter Board

To JD5 in UPS CABINET 3

JD5 JD6

ParallelAdapter Board

JD5 JD6

Page 20

2: General Description

12 TS_619_00 PW9000DPA S2 User Manual 13/3/17

2.4.1 DPA-50 Component identification

Figure 2.9 DPA-50 Cabinet details

Battery trays

UPS Customer Interface connections

(described in the Options chapter).

[F4] Battery fuse

[IA2] Parallel Isolator

[IA1] Maintenance Bypass Isolator

UPS Module

JD1 Smart Port – RS232 (Sub-D9P)

JD7 Module control panel connector

RECTIFIER

BATTERY

EXTERNAL

BATTERY

CABINET

INVERTER

STATIC

SWITCH

BOOSTER /

CHARGER

Bypass

Contactor

Inv. Output

Contactor

Input

Contactor

Bypass Mains

IA-2

IA-1

F4

F1

F2

F3

UPS MODULE

UPS CABINET

Static bypass line

Maintenance bypass line

UPS Input Mains

UPS Output

to critical load

Page 21

TS_619_00 PW9000DPA S2 User Manual 13/3/17 13

2: General Description

2.4.2 DPA-150 Component identification

Up to three UPS modules can be fitted, with the lower-most module identified as module 1.

The battery fuses are identified F4 to F6. F4 is associated with module 1, F5 with module 2 and F6 with module 3.

The parallel isolator switches (IA2) are labelled to identify their associated UPS module – e.g. IA2-2 pertains to module 2.

Figure 2.10 DPA-150 Cabinet details

Battery trays

UPS Customer Interface connections

(described in the Options chapter).

Parallel Isolator (1 per module)

[IA1] Maintenance Bypass Isolator

UPS Module P03

UPS Module P02

UPS Module P01

[IA2-1] [IA2-2] [IA2-3]

Battery fuse (1 per module)

[F4] [F5] [F6]

JD1 Smart Port – RS232 (Sub-D9P)

JD7 Module control panel connector

JD1 Smart Port – RS232 (Sub-D9P)

JD7 Control Panel connector

JD1 Smart Port – RS232 (Sub-D9P)

JD7 Control Panel connector

Page 22

2: General Description

14 TS_619_00 PW9000DPA S2 User Manual 13/3/17

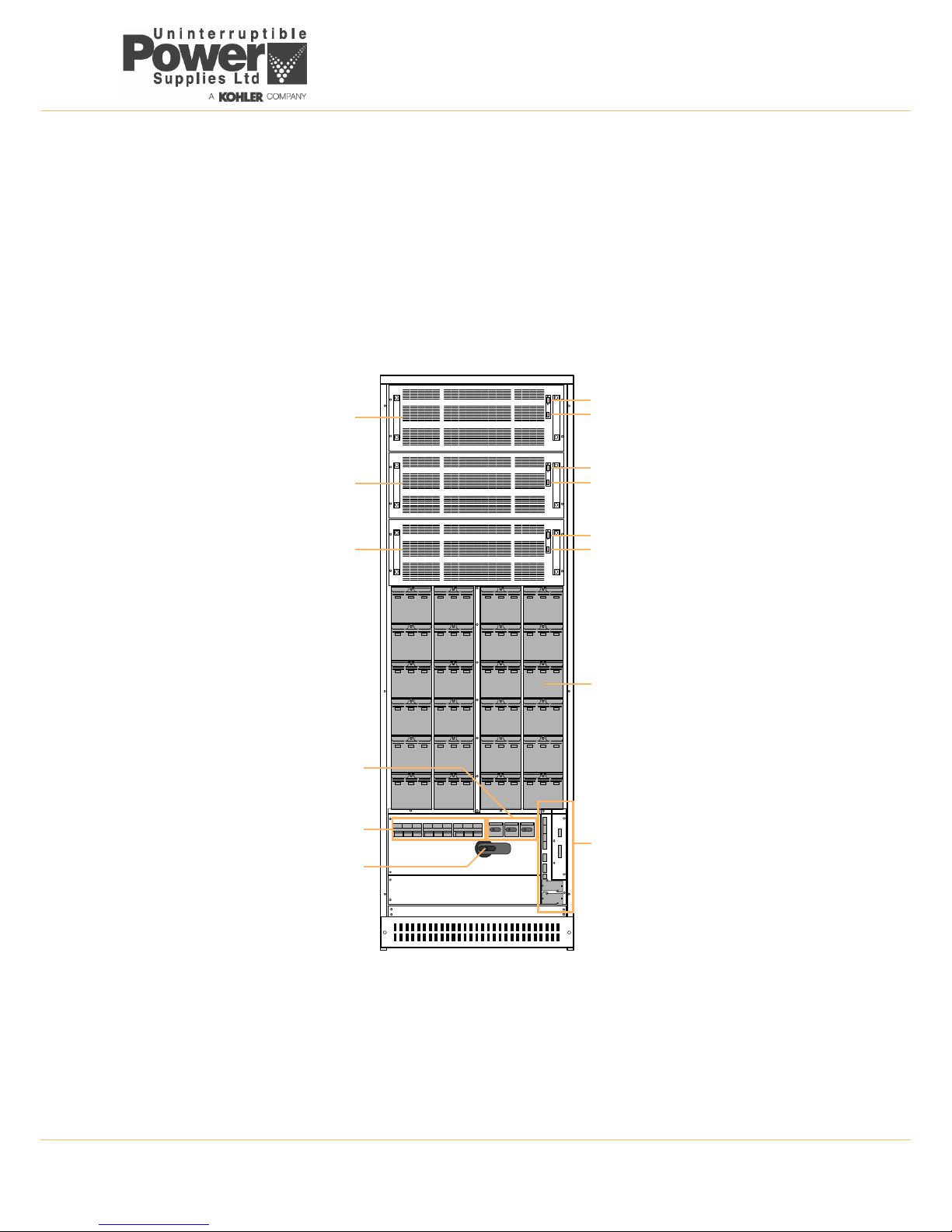

2.4.3 DPA-250 Component identification

The DPA-250 contains no batteries and can be fitted with up to five UPS modules, with the lower-most module identified

as module 1.

The module parallel isolator switches (IA2) are labelled to identify their associated UPS module – e.g. IA2-2 pertains to

power module 2.

Figure 2.11 DPA-250 Cabinet details

UPS Customer Interface connections

(described in the Options chapter).

Parallel Isolator (1 per module)

[IA1] Maintenance Bypass Isolator

UPS Module P05

UPS Module P04

UPS Module P03

[IA2-1] [IA2-2] [IA2-3] [IA2-4] [IA2-5]

UPS Module P02

UPS Module P01

JD1 Smart Port – RS232 (Sub-D9P)

JD7 Module control panel connector

JD1 Smart Port – RS232 (Sub-D9P)

JD7 Control Panel connector

JD1 Smart Port – RS232 (Sub-D9P)

JD7 Control Panel connector

JD1 Smart Port – RS232 (Sub-D9P)

JD7 Control Panel connector

JD1 Smart Port – RS232 (Sub-D9P)

JD7 Control Panel connector

Page 23

TS_619_00 PW9000DPA S2 User Manual 13/3/17 15

2: General Description

2.5 UPS Interface facilities

Figure 2.12 UPS Interface Boards

Two interface boards are fitted in the lower right-hand side of the UPS cabinet, adjacent to the UPS power switches. One

is the Customer Interface Board and the other is the Parallel Interface Board.

2.5.1 Customer Interface Board

The customer interface board provides a number of input/output connections that can be used by the customer to

interface the UPS cabinet with a range of external monitoring and control systems – e.g. as part as a building

management system (BMS). The available interfaces are shown in Figure 2.12:

The dry-port I/O connection details are shown in the Installation chapter of this manual (see Paragraph 3.6).

Multidrop

The optional ‘Multidrop’ feature, which is available only in a parallel system, allows the customer interface board in the

‘master’ cabinet to collect data/messages from the other system cabinets. The received data is then processed at a

centralised point on the ‘master’ customer interface board and made available to the user directly on the RS232 port

(JD1). It is also transmitted to the CS141 card if inserted in the relevant slot.

Key Point: The Parallel Interface Board is part of the factory-fitted ‘paralleling kit’ and is installed only in UPS

cabinets used in a parallel system.

Key Point: When the UPS cabinet is installed as part of a parallel system the customer interface board I/O is

disabled in the ‘slave’ cabinets if the system ‘Multidrop’ application is enabled.

2

3

4

6

8

9

5

7

1

Customer Interface Board

1 X1 Customer inputs (terminal block)

2 X2-X4 Customer dry port output (terminal blocks)

3 JD11 RS232 PC interface (Sub D-9 Female)

4 JD12 RS232 Multidrop (Sub D-9 Male)

5 USB PC Interface

6 SLOT 1 Slot for SNMP (CS141 adapter)

7 SLOT 2 Slot for optional Modem/Ethernet card

Parallel Interface Board (fitted in a parallel UPS cabinet only)

8 SW1-9 Parallel cabinet configuration DIP switch

9 JD8 Parallel bus connector via Parallel Adapter Board

Page 24

2: General Description

16 TS_619_00 PW9000DPA S2 User Manual 13/3/17

This facility requires a purpose designed ‘Multidrop’ cable to be connected between each module’s customer interface

board JD12.

Note that when the multidrop feature is used, the I/O facilities of customer interface board in the ‘slave’ cabinets are all

disabled, but the customer interface board fitted to the ‘master’ cabinet remains fully functional.

2.5.2 Parallel Interface Board

The parallel interface board facilitates the connection of the parallel control bus cables between the cabinets in a parallel

cabinet system. These cables are connected to a ‘Parallel Adapter’ board which is fitted to JD8.

2.6 Module control panel

A door-mounted module control panel is provided for each UPS module. The control panel is used to start and stop the

module, command a load transfer between inverter and bypass, and monitor the module’s operating parameters. It is also

used to configure and interrogate the module during commissioning and troubleshooting.

Figure 2.13 Module control panel

2.6.1 Module control panel buttons

The module control panel buttons allow you to:

• Start-up and shut down the UPS and transfer the load between inverter and bypass.

• Monitor and display the UPS operating voltages, currents, frequencies and other values on the LCD display.

• Reset/cancel an alarm.

Button function summary

ON/OFF Buttons

You can switch the UPS ON or OFF by simultaneously pressing both ON/OFF buttons (for less than 1s). The requirement

to press both buttons is to help prevent accidental operation.

BUTTON FUNCTION

ON/OFF Used to switch-on or switch-off the UPS by pressing both buttons simultaneously

UP

)

Scroll upwards through a displayed menu

DOWN

()

Scroll downwards through a displayed menu

ENTER Selects a chosen menu item

RESET Cancels an audible alarm. If the alarm condition is transient the ALARM LED will turn OFF, otherwise it will remain ON

Power Management Display (PMD)Mimic LED Indicators

Menu navigation &

Alarm & Reset

selection buttons

Module ON/OFF

control buttons

Page 25

TS_619_00 PW9000DPA S2 User Manual 13/3/17 17

2: General Description

Pressing the two ON/OFF buttons during normal operation will immediately shut down the UPS module.

• In a single module system (e.g. DPA-50) this disconnects the UPS from the load unless the load is first transferred

to the maintenance bypass.

• In a parallel module system the UPS module shuts down and is disconnected from the load: however the load may

or may-not transfer to the static bypass, depending on whether or not the number of remaining on-line UPS

modules satisfies the system’s redundancy – i.e. if there is a sufficient number of modules remaining to support the

system’s load then the load is not transferred.

Note: To shut down all the UPS modules in a parallel system you must press both ON/OFF buttons on every module.

2.6.2 Module mimic LEDs

The mimic diagram LEDs indicate the general power flow through the UPS module and changes colour between Green

and Red (and OFF) to indicate the prevailing UPS module operating conditions.

LED Indication summary

* The ALARM LED is a visual indication of an internal or external alarm condition. When activated, it is accompanied by an

audible warning which can be cancelled by pressing the RESET button.

2.6.3 Power Management Display (PMD)

A 2 x 20 character LCD Display simplifies communication with the UPS module and provides monitoring information.

The menu driven LCD provides:

• access to an ‘event’ register

• input and output voltage, current, frequency & power monitoring

• battery run time monitoring

• access to commands such as module load transfer between INVERTER and BYPASS

• access to the module’s diagnostics registers (service mode only)

• access to module adjustments and testing (service mode only)

INDICATOR INDICATOR STATUS INTERPRETATION

LINE 1 GREEN

RED

OFF

Input (rectifier) mains available

Input (rectifier) mains unavailable

No bypass supply (UPS Turned off)

LINE 2 GREEN

RED

OFF

Bypass mains available (bypass OK)

Bypass mains unavailable (bypass supply error)

No bypass supply (UPS Turned off)

ALARM* OFF

Flashing RED + buzzer

RED

No alarm condition

Alarm condition

Alarm condition present (audio has been reset)

INVERTER GREEN

RED

OFF

Load on inverter

Inverter fault or load transfer to inverter inhibited

Inverter not operating (switched off)

BY-PASS GREEN

OFF

Load on bypass (or in ECO mode)

Bypass not operating (turned off)

BATTERY GREEN

RED

Flashing GREEN

Battery OK

Battery faulty or discharged

Battery on load (discharging) or battery fuse open

Page 26

2: General Description

18 TS_619_00 PW9000DPA S2 User Manual 13/3/17

Status screens

The two-digit number on the right hand side of the LCD indicates the power module ID number (see Figure 2.8).

Main menu screen

Event log menu screen

DESCRIPTION LCD-DISPLAY

1. Load is protected and being supplied by UPS inverter

(Normal Operation).

LOAD

PROTECTED

01

2. Load is not protected by UPS. It is either connected to the bypass (load on bypass) or

connected to the inverter but with a battery problem.

LOAD

NOT PROTECTED

01

3. Load supply completely powered-down.

UPS has been switched off by “ON/OFF” buttons.

LOAD OFF

SUPPLY FAILURE

01

4. UPS/module is not supplying load.

The UPS output switch is open.

LOAD DISCONNECTED

PARALLEL SWITCH OPEN

01

DESCRIPTION LCD-DISPLAY

1. Single Systems. SYSTEM CONFIGURATION

SINGLE

S

2. Parallel System – e.g. DPA-250 bottom module in cabinet 2: SYSTEM CONFIGURATION

PARALLEL

P06

3. Parallel System – e.g. DPA-250 top module in cabinet 3: LOAD OFF

SUPPLY FAILURE

P15

DESCRIPTION LCD-DISPLAY

1. Provides access to a log of the last 64 stored events. EVENT LOG

MEASUREMENTS

2. Provides access to voltages, power, frequencies, currents, autonomy monitor screens. MEASUREMENTS

COMMANDS

3. Provides access to the ‘Load to inverter’, ‘Load to bypass’ and ‘battery test’ commands. COMMANDS

UPS DATA

4. Allows personalised UPS data (such as serial number) to be entered. UPS DATA

SET-UP USER

5. Allows the user to set up Date/Time, automatic battery test, etc. SET-UP USER

SET-UP SERVICE

6. This is a password-protected area for service engineer use only. SET-UP SERVICE

DESCRIPTION LCD-DISPLAY

1. Logging Control; a log of the last stored 64 events. 01 05-10-08 14-38-56

LOAD TO INV.

2. Every stored event is identified with a sequential number and time stamp. 02 05-10-08 14-38-59

LOAD TO BYP.

3. By pressing ENTER the code of the event will be displayed. 03 05-10-08 14-39-14

LOAD OFF

Page 27

TS_619_00 PW9000DPA S2 User Manual 13/3/17 19

2: General Description

Measurements menu screen

Commands menu screen

DESCRIPTION LCD-DISPLAY

1. Battery Runtime BATT. RUN TIME (MIN)

00h 00mm

2. UPS-Output Frequency OUTPUT FREQUENCY (HZ)

50.00

3. Bypass Frequency. BYPASS FREQUENCY (HZ)

50.00

4. Battery Voltage BATTERY VOLTAGE (V)

+0.0 - 0.0

5. Battery Charger Current BATT. CHARGE CUR. (A)

+ 0.0 - 0.0

6. Battery Discharge Current. DISCHARGE CURRENT (A)

00.00

7. Rectifier Voltage (all three phases) RECTIFIER VOLTAGE (V)

00.00 00.00 00.00

8. Bypass Voltage (all three phases) BYPASS VOLTAGE (V)

00.00 00.00 00.00

9. Output Voltage (all three phases) OUTPUT VOLTAGE (V)0

0.00 00.00 00.00

10.Output Current (all three phases) OUTPUT CURRENT (A)0

0.00 00.00 00.00

11.Active Output Power (all three phases) ACTIVE POWER (KW)

00.00 00.00 00.00

12.Reactive Output Power (all three phases) REACTIVE POWER (kVAr)

00.00 00.00 00.00

13.Apparent Output Power (all three phases) APPARENT POWER (KVA)

00.00 00.00 00.00

14.Output Power (all three phases) OUTPUT POWER (%)

00.00 00.00 00.00

15.Battery capacity BATT. CAPACITY (%)

00.00

DESCRIPTION LCD-DISPLAY

1. Transfer Load to inverter LOAD TO INVERTER

LOAD TO BYPASS

2. Transfer Load to bypass. LOAD TO BYPASS

PERFORM BATT.TEST

3. Battery Test PERFORM BATT.TEST

Page 28

2: General Description

20 TS_619_00 PW9000DPA S2 User Manual 13/3/17

UPS Data menu screen

Set-up User menu screen

Set-Up Service menu screen

DESCRIPTION LCD-DISPLAY

1. These general UPS Data are installed at the manufacturing plant. UPS SERIAL NUMBER

nn-nnnnn

2. Manufacturing date DATE OF MANUFACTURE

15-03-16

3. EPROM Version EPROM VERSION

V-000

4. Actual Date and Time DATE TIME

dd-mm-yyyy hh:mm:ss

DESCRIPTION LCD-DISPLAY

1. Set-up language SET LANGUAGE

SET DATE AND TIME

ENGLISH

FRANCAIS

POLISH

2. Set-up Date and Time SET-UP DATE/TIME

SET-UP BATT. TEST

DD-MM-YY HH-MM-SS

3. Set-up battery test SET-UP BATT. TEST

SET-UP GEN-SET OPER.

DAY OF MONTH

(1-31)

HOUR OF DAY

(0-23)

REPETITIVE (Y/N)

000

4. Set-up operation with Gen-Set SET GENERATOR OP.

BATT.CHARGE LOCK

(Y/N)

BYPASS LOCK

(Y/N)

Key Point: This area is password protected and access is restricted to approved Service Engineers only.

Page 29

TS_619_00 PW9000DPA S2 User Manual 13/3/17 21

2: General Description

2.7 Warranty

The PW9000DPA S2 UPS is supplied with a limited warranty that the UPS and its component parts are free from defects

in materials and workmanship for a period of one year from the date of original commissioning or fifteen months from the

date of original delivery, whichever is the sooner. This warranty is the only warranty given and no other warranty, express

or implied, is provided.

This warranty is invalidated if the UPS is used without having first been commissioned by a fully trained and authorised

person. This warranty does not apply to any losses or damages caused by misuse, abuse, negligence, neglect,

unauthorised repair or modification, incorrect installation, inappropriate environment, accident, act of God or inappropriate

application.

If the UPS fails to conform to the above within the warranty period then Uninterruptible Power Supplies Ltd. will, at its sole

option, repair or replace the UPS. All repaired or replaced parts will remain the property of Uninterruptible Power Supplies

Ltd.

As a general policy, Uninterruptible Power Supplies Ltd. does not recommend the use of any of its products in life support

applications where failure or malfunction of the product can be reasonably expected to cause failure of the life support

device or to significantly affect it’s safety or effectiveness. Uninterruptible Power Supplies Ltd. does not recommend the

use of any of its products in direct patient care. Uninterruptible Power Supplies Ltd. will not knowingly sell its products for

use in such applications unless it receives in writing assurances satisfactory to Uninterruptible Power Supplies Ltd. that

the risks of injury or damage have been minimized, the customer assumes all such risks and the liability of Uninterruptible

Power Supplies Ltd. is adequately protected under the circumstances

2.8 Extended Warranty

The Standard Warranty may be enhanced by protecting the UPS with an Extended Warranty Agreement (maintenance

contract). An Extended Warranty Agreement enhances the standard warranty by providing the following:-

• Regular preventative maintenance inspections.

• Guaranteed speed of response to operational problems.

• 24 hour telephone support.

• Fully comprehensive (excluding batteries) cover.

Contact the Service Support Hotline on 0800 731 3269 for further details.

2.9 Additional Service/Maintenance Support

In addition to providing support for the PW9000DPA S2, Uninterruptible Power Supplies Ltd. can provide maintenance

and support of a wide range of different UPS products.

If you are interested in an extended warranty for your PW9000DPA S2, or any other UPS you may have, please contact

Uninterruptible Power Supplies Ltd. at the address shown below:

CAUTION: The UPS system may contain batteries which must be re-charged for a minimum of 2 4 hours every

six months to prevent deep-discharging. Batteries that have been, for whatever reason, dee ply-discharged are

not covered by the warranty.

Uninterruptible Power Supplies Ltd..

Woodgate

Bartley Wood Business Park

Hook

Hampshire

RG27 9XA

Tel: 01256 386700

0800 731 3269 (24 Hr.)

Fax: 01256 386701

Email: service@upspower.co.uk

Page 30

22 TS_619_00 PW9000DPA S2 User Manual 13/3/17

3

Installation

3.1 Introduction

This chapter contains essential information concerning the unpacking, installation planning and cabling of the

PW9000DPA S2 UPS system.

3.2 Taking receipt of the UPS

The UPS and accessories are delivered on a purpose-designed pallet that is easy to move with a forklift or a pallet jack.

Depending on the method of shipping, the UPS is packed in a cardboard or wooden container designed to protect it from

mechanical and environmental damage. Further protection is provided by wrapping the equipment with a plastic sheet.

Before you accept the shipment ensure that the received package(s) correspond to the description shown in the delivery

documentation. Note that some ordered optional equipment packages might be shipped inside the UPS cabinet.

Carefully examine the packing container for signs of physical damage. The external 'Tip&Tel' (“FRAGILE” and “ARROW”)

indicators should be intact if the equipment has been transported in an upright position.

3.2.1 Reporting transportation damage

If the 'Tip&Tel' indicators are ruptured or there are other signs of suspected transportation damage you must inform the

carrier and Uninterruptible Power Supplies Ltd. immediately.

Other claims for shipping damage must be filed immediately when found, and the carrier must be informed of ALL claims

within seven days of receipt of the equipment. If the equipment is to be stored for longer than seven days before it is

installed, you should unpack it and inspect it for signs of internal damage before you put it into storage. Note that some

optional equipment packages might be shipped inside the UPS cabinet and these too should be checked for damage.

If the equipment is damaged you should store the packing materials for further investigation

Key Point: If you are installing an external battery cabinet supplied by Uninterruptible Power Supplies Ltd. you

should refer to the manual that is provided with the cabinet for installation instructions.

WARNING: All the operations described in this chapter must be supervised by suitably qualified personnel and

all aspects of the electrical installation must be carried out by an authorised electrician.

Uninterruptible Power Supplies Ltd. will take no responsibility for any personal injury or material damage

caused by incorrect cabling or operation, or activities which are not carried out in strict accordance with the

instructions contained in this manual.

WARNING: Once the UPS equipment is installed it must be commissioned by an engineer approved by

Uninterruptible Power Supplies Ltd., or one of its service agents, before it is powered-up. Uninterruptible Power

Supplies Ltd. will take no responsibility for any personal injury or material damage caused by the application of

electrical power to this equipment before it has been fully commissioned.

CAUTION: Observe the following precautions when off-loading and moving the UPS:

• Always keep the packages in an upright position.

• Do not drop the equipment.

• Do not stack the pallets.

WARNING: If the Tip&Tell indicators indicate that the UPS has been tilted in transit DO NOT connect the

UPS to the mains electricity supply.

Page 31

TS_619_00 PW9000DPA S2 User Manual 13/3/17 23

3: Installation

3.2.2 Weight and dimensions

Packed weight and dimensions

Unpacked weight and dimensions

3.2.3 Local transportation

When you transport the UPS equipment after it has been off-loaded please observe the following precautions.

Model

Number

of

Modules

30kVA Modules

w/o Batt (kg.)

40kVA Modules

w/o Batt (kg.)

50kVA Modules

w/o Batt (kg.)

Packed

Dimensions

UPS Module 43.1 45.3 46.8 WxHxD

DPA 50 1 328 330 332 890 x 1800 x 920

DPA150 1 307 309 311 890 x 2120 x 920

2 350 355 358 890 x 2120 x 920

3 393 400 404 890 x 2120 x 920

DPA250 1 273 275 277 890 x 2120 x 920

2 316 321 324 890 x 2120 x 920

3 359 366 370 890 x 2120 x 920

4 402 411 417 890 x 2120 x 920

5 446 457 464 890 x 2120 x 920

Model

Number

of

Modules.

30kVA Modules

w/o Batt (kg.)

40kVA Modules

w/o Batt (kg.)

50kVA Modules

w/o Batt (kg.)

Unpacked

Dimensions

Module 43.1 45.3 46.8 WxHxD

DPA 50 1 305 307 309 730 x 1650 x 800

DPA150 1 282 284 286 730 x 1975 x 800

2 325 330 333 730 x 1975 x 800

3 368 375 379 730 x 1975 x 800

DPA250 1 248 250 252 730 x 1975 x 800

2 291 296 299 730 x 1975 x 800

3 334 341 345 730 x 1975 x 800

4 377 386 392 730 x 1975 x 800

5 421 432 439 730 x 1975 x 800

CAUTION: Local transportation:

• When movin g the UPS cabinet using a forklift or pallet jack, insert the lifti ng equipment forks into the

front and rear shipping brackets to lift the cabinet securely and prevent it from toppling over.

• Do not at any time tilt the cabinet by more than 10° from vertical.

WARNING: Potential dangers:

• If the equipment cabinet is til ted by more than 10° it could cause inte rnal damage. If tilting occurs do

not connect the UPS to the mains electrical supply.

• The weight cabinet can ca use serious personal injury and/or structural damage to the surrounding

area if dropped in transit. Always take extreme care when moving the equipment.

Page 32

3: Installation

24 TS_619_00 PW9000DPA S2 User Manual 13/3/17

3.2.4 Storage

If you plan to store the UPS prior to its installation it should be kept (preferably in its shipping packaging) in a clean, dry

environment with a temperature between -25°C to +70°C and RH <90%. If the storage period is likely to exceed seven

days the packaging should be removed and the UPS inspected for shipping damage before it is placed into storage. If

there is no apparent damage you should refit the packaging or cover the UPS with a dust-cover to prevent the ingress of

dust and dirt.

Depending on the UPS model, the batteries can be housed within the UPS cabinet or an external battery cabinet/battery

rack. In the case of internally-mounted batteries, the batteries can be shipped already installed within a cabinet. Batteries

that are intended for external rack-mounting will be shipped in a separate package and should be stored under the

environmental conditions stipulated above.

3.2.5 Unpacking

If the shipment is received in good order (i.e. the ‘tip & tell’ “FRAGILE” and “ARROW” indicators on the packing container

are intact) then unpack the UPS as follows:

1. If the cabinet is shipped inside a wooden case, remove the screws at the base and sides of the case then carefully

remove the case from the from the package.

2. Remove the plastic sheeting covering the UPS.

3. Remove the external cabinet protection pieces (strengthened cardboard fillets, polystyrene foam etc.).

4. Remove the anchor bolts securing the cabinet to the pallet then lift and remove the cabinet from the pallet.

5. Retain the packaging materials for future shipment of the UPS.

6. Examine the cabinet for any sign of damage and notify your supplier immediately if any damage is found.

7. Open the cabinet door and verify that the UPS rating specifications on the nameplate located inside the door match

the order specification.

8. Remove any accessories packages that are shipped inside the cabinet.

9. Remove any internal protective packaging.

10. Ensure that all the UPS modules are correctly and securely fitted in their rack compartments.

11. Ensure that a protection cover is fitted to the front of any unpopulated UPS module rack compartment.

Batteries

If the batteries are shipped in a separate package they should remain in their packing until required by the Uninterruptible

Power Supplies Ltd. service engineer when the system is commissioned.

Battery life depends very much on the ambient temperature, and optimum battery life will be obtained if the batteries are

stored and operated at a temperature of 20°C.

WARNING: The UPS cabinet, battery cabinet (optional) and battery packages are heavy and may tip during

unpacking unless the unpacking instructions are not followed closely.

CAUTION: The UPS batteries must ALWAYS be installed by the commissioning engineer.

WARNING: If the UPS is delivered without batteries, Uninterruptible Power Supplies Ltd. will not accept

responsibility for any damage or malfunctioning caused to the UPS by the incorrect storage, installation or

connection of batteries carried out by third parties.

Page 33

TS_619_00 PW9000DPA S2 User Manual 13/3/17 25

3: Installation

3.3 Installation planning (environmental & mechanical)

3.3.1 Environmental considerations

A certain amount of pre-planning will help provide a trouble-free installation process. You should consider the following

guidelines when planning a suitable UPS location and operating environment.

1. The route to the installation location must allow the equipment to be transported in an upright position.

2. The floor at the proposed installation site and en-route from the off-loading point must be able to safely support the

weight of the UPS and battery equipment, plus fork lift or trolley jack during transit.

3. The UPS cabinet requires space to bottom/front, top and back to enable cooling airflow (see below).

4. A minimum clearance of 200mm must be provided at the back of the cabinet to provide adequate ventilation. A

clearance of 400mm should also be provided at the top of the cabinet if the passage of cooling airflow at the back of

the cabinet is insufficient to dissipate the generated heat – see figure 3.1.

5. All parts of the UPS required for maintenance, servicing and user operation are accessible from the front of the

cabinet and require a minimum front clearance of 1000mm.

Note: The cabinet door must be opened by 115° in order to remove/fit the UPS modules, so the right-hand side of the

cabinet cannot be positioned directly against a projecting wall – see figures 3.1.

6. An ambient temperature of 20°C is necessary to achieve the recommended battery life span. The cooling air entering

the UPS modules must not exceed +40°C.

7. The floor material should be non-flammable and strong enough to support the heavy load.

8. In summary, the UPS should be located where:

a) Humidity (< 90%) and temperature is ideally 20°C.

b) Fire protection standards are respected.

c) Cabling can be performed easily.

d) A minimum 1000mm front accessibility is available for service or periodic maintenance.

e) Adequate cooling air flow is available.

f) The air conditioning system can provide a sufficient amount of air cooling to keep the room at, or below, the

maximum desired temperature.

g) No dust or corrosive/explosive gases are present.

h) The location is vibration free.

i) If the UPS will be installed in bayed enclosures, partition walls must be installed.

3.3.2 Clearances

Cooling air enters the front and bottom of the UPS cabinet and is extracted by ventilation fans mounted on the cabinet

rear. If the UPS cabinet is installed immediately adjacent to another cabinet, battery enclosure or wall, a minimum

clearance of 300mm is required at the rear of the cabinet to permit sufficient cooling air flow. This can be reduced to

200mm if the cabinet is installed as a stand-alone unit with at least 400mm combined side clearance (see Figure 3.1).

The UPS cabinet does not require any side clearance for ventilation or service access, so it can be installed immediately

alongside other UPS cabinets or battery cabinets to form an equipment suite. If an external battery cabinet is used you

should install it as close as possible to the UPS cabinet, ideally immediately adjacent to it.

If you install the recommended external battery cabinet or battery rack supplied by Uninterruptible Power Supplies Ltd. the

battery cabinet itself does not require any side or rear clearance.

All UPS cabling, maintenance and servicing procedures can be carried out from the front of the cabinet, and a front

clearance of at least 1000mm should be provided to enable component replacement.

Key Point: When installing the UPS cabinet next to an external battery cabinet or battery rack, the battery

cabinet/rack might require more than 1000mm front clearance which must be taken into consideration when

installing a cabinet suite.

Key Point: The UPS door must be fully opened (to approximately 115°) to enable some major component to be

extracted from the cabinet. If the right side of the cabinet is positioned against a wall that protrudes in front of the

cabinet you must allow adequate, additional side clearance. See the clearance diagrams above for details.

Page 34

3: Installation

26 TS_619_00 PW9000DPA S2 User Manual 13/3/17

Figure 3.1 PW9000DPA S2 clearances

PW9000DPAS 2

(DPA‐50)

(DPA‐150)

(DPA‐250)

REARFANS

D

B

1

A

C1

C2

C1

Itisnecessarytoopenthedoorfullytoremovesomeinternalassembliesduringmaintenance

procedures.Ifthecabinetisplacedagainstawallensuresufficientspaceisprovided(C2).

Ifthecabinetisnotpositionedimmediatelyadjacenttoanyothercabinetorbatte ryenclosur e,the

clearancebehindtheunitcanbereducedfrom300mm(B1)to200mm(B2)ifthetotalcombinedside

clearance(E+F)isatleast400mm.

*ATOPclearanceof400mmisonlyrequiredifthereisnootherrouteattherearofthe UP Sto

dissipatethecoolingairflow .

PW9000DPAS 2

(DPA‐50)

(DPA‐150)

(DPA‐250)

REARFANS

B

2

E F

D

C2

1000mm

300mm

0mm

A

B1

C1

Min.Clearance

315mmC2

200mmB2

400mmE+F

115D

*400mmTOP

1000mm

300mm

0mm

A

B1

C1

Min.Clearance

315mmC2

200mmB2

400mmE+F

115D

*400mmTOP

Page 35

TS_619_00 PW9000DPA S2 User Manual 13/3/17 27

3: Installation

3.4 Installation planning (electrical)

3.4.1 General requirements

Figure 3.2 Input/output power connections for single feed and dual feed installations

It is the customer’s responsibility to design and install the UPS supply and distribution circuits and provide the external

fuses, isolators and cables required to connect the UPS input and output power supplies, and external battery (where

used). The information provided in this section should assist in the planning and preparation of the UPS power cabling.

As shown in Figure 3.2, the UPS input mains and bypass mains inputs should be connected to the utility mains supply

through an LV-switchgear panel and protected by a circuit breaker or fused isolator. These, not only provide overload

protection for the UPS cabinet but also serve as the primary means of isolating the UPS from the mains supply as the UPS

cabinet itself does not contain an internal mains isolator switch.

Similarly, the UPS output should be connected to the load equipment via a suitably fused load switchgear panel.

Figure 3.2 shows an external battery cabinet used with the DPA 250 (and DPA 50 or DPA150 if long autonomy times are

required). Suitable battery isolators must be fitted inside the external battery cabinet. This requires a three-pole breaker,

connected to the battery positive, negative, and mid-point (neutral), as shown. Uninterruptible Power Supplies Ltd. can

supply a matching battery cabinet containing the necessary fuses and switchgear.

UPS

CABINET

Rectifier

Inverter

StaticSwitch

3L3 3N PE3L1 3L2

StaticBypassLine

UPSModule

1L3 1N1L1 1L2

EXTERNAL

BATTERY

UPS

CABINET

EXTERNAL

BATTERY

FUSES

Re ctifie r

Inverter

StaticSwitch

MAINT.

BYP(IA1 )

3L3 3N PE3L1 3L2

StaticBypassLine

UPSModule

1L3 1N PE1L1 1L2

Parallel

Isolator

(IA2)

UPSINPUT

MAINSDEVICE

UPSOUTPUT

DEVICE

2L32L1 2L2PE

MAINT.

BYP(IA1 )

Parallel

Isolator

(IA2)

NN

UPSSYSTEMINPUTSUPPLY UPSSYSTEMINPUTSUPPLY

UPSINPUT

MAINSDEVICE

UPSBYPASS

MAINSDEVICE

UPSOUTPUT

DEVICE

UPSSYSTEM OUTPUT UPSSYSTEMO UTPUT

EXTER NAL

BATTERY

EXTERNAL

BATTERY

FUSES

NN

Page 36

3: Installation

28 TS_619_00 PW9000DPA S2 User Manual 13/3/17

Single feed / dual feed inputs

The UPS input mains and bypass mains terminals can be linked inside the UPS cabinet in what is known as a ‘single feed’

configuration. This configuration, which is used in the majority of installations, only requires one mains supply as illustrated

in the left illustration of Figure 3.2.

When the ‘single feed’ links are removed, the bypass mains terminals must be connected to a mains supply source via a