Page 1

RV GENERATOR

SERVICE MANUAL

3.5KW-7.5KW

(with relay controller)

KOHLER -

GENERATORS ,.’

Page 2

Table of Contents

Page

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . .

i

Section 1. Introduction and Specifications

l-l.

l-2.

l-3.

l-4.

l-5.

1-6.

l-7.

1-8.

1-9.

Introduction

............................. l-l

Model 3.5 CM21-RV

...................... l-l

Model 4.5 CM21-RV (single)

.............. l-l

Model 4.5CKM21-RV (twin)

............... 1-I

Model 5.5 CM21-RV

......................

l-l

Model 7 CM21-RV

........................ l-l

Model 7.5 C21-RV

........................

1-2

Oil Specifications

........................ l-4

Fuel Specifications

.......................

l-5

Section 2. Operation

2-1. General.

......................... 2-1

2-2. Prestart Checklist

................... 2-1

2-3.

Operation

........................ 2-l

Section 3. Scheduled Maintenance

Governor

3-1.

General.

......................... 3-1

3-2.

Scheduled Maintenance

............... 3-I

Section 4. Troubleshooting

4-l. General.

........................ .4-l

4-2.

RV Systems Check

.................. 4-1

4-3. Troubleshooting

.................... 4-2

Section 5. Relay Controller

5-l.

5-2.

5-3.

5-4.

5-5.

Description

....................... 5-1

Sequence of Operation

............... 5-l

Fuses

........................... 5-4

REl Diode

....................... 5-5

Relays

.......................... 5-5

Page

Section 6. Generator

6-l. General

..........................

6-1

6-2. Troubleshooting .................... 6-1

6-3. Generator Disassembly ............... 6-l

6-4. Build-up Circuit

.................... 6-7

6-5. Brushes .......................... 6-8

6-6. Slip Rings

........................ 6-9

6-7. Exciter / Voltage Regulator ............ 6-9

6-8. Stator .......................... 6-I 1

6-9. Rotor. ......................... 6-11

6-10. Separate Field Excitation ............. 6-11

6-11. Voltage Sensing Relay ............... 6-12

6-l 2. Generator Reassembly ............... 6-12

Section 7. Choke, Shutdown Control and

7-1.

7-2.

7-3.

7-4.

7-5.

7-6

7-7.

7-8.

7-9.

Choke Testing and Adjustments

(3.5kW,4.5kW). . . . . . . . . . . . . . . . . . . . 7-1

Choke Testing and Adjustments

(4.5 twin, 5.5,7, 7.5kW) . . . . . . . . . . . . . 7-3

Positive Shutdown Control (3.5kW-7kW) . . . . 7-3

Crankcase Breather (3.5kW, 4.5kW) . . . . . . . 7-4

Governor (3.5kW, 4.5kW single). . . . . . . . . . 7-4

Governor Hunting Checks (4.5kW Only) . . . . 7-5

Governor (4.5kW twin). . . . . . . . . . . . . . . . 7-6

Governor (5.5kW, 7kW) . . . . . . . . . . . . . . . 7-6

Governor (7.5kW) . . . . . . . . . . . . . . . . . . . 7-7

Section 8. Wiring Diagrams

Appendix

Radio Frequency Interference Kit.. . . . . . . . . A-l

Page 3

Safety Precautions

A Generator Set, like any other electro-mechanical device

can pose potential dangers to life and limb if improperly

maintained or imprudently operated. The best safeguards

against accident are to be ever mindful of the potential

dangers and to always use good common sense. In the

interest of safety, some general precautions relating to

operating of a Generator Set are presented below. Keep

these in mind.

A

WARNING

LETHAL EXHAUST GAS! An engine discharges deadly

carbon monoxide as part of the exhaust when operating.

Carbon monoxide is particularly dangerous in that it is an

odorless, tasteless, and nonirritating gas, but be ever

mindful that it can cause death if inhaled for even a short

period of time. Have only qualified specialists install and

replace exhaust system components and have the system

inspected frequently. Be careful when parking your coach

to avoid obstructing the exhaust outlet. The exhaust

gasses must discharge freely, otherwise carbon monoxide

may deflect under and into the vehicle or enter through

open doors, windows, or vents. Also make sure that your

exhaust cannot be discharged toward neighboring RV’s,

campers, or any occupied building. Be especially watchful

for exhaust accumulation under calm, windless conditions.

A

WARNING

ELECTRICAL SHOCK! Battery can cause electrical burns

and shocks. Exercise reasonable care when working near

the battery to avoid electrical connections through tools.

Remove wristwatch, rings, and any other jewelry.

A

WARNING

HIGH VOLTAGE! Remember that the function of a genera-

tor set is to produce electricity and that wherever electricity is present, there is the potential danger of electrocution. Take the same precautions with electrical appliances

in your coach that you would observe in your home. Keep

away from electrical circuits and wiring while the set is

running and have electrical service performed only by

qualified electricians. Make sure unqualified persons,

especially children, cannot gain access to your set - keep

the compartment door locked or securely latched at all

times. Be sure that generator is properly grounded. Never

touch electrical leads or appliances with wet hands, when

standing in water, or on wet ground as the chance of

electrocution is especially prevalent under such conditions.

A

WARNING

UNIT STARTS WITHOUT NOTICE! To prevent accidental

starting on units with a remote start/stop switch, always

disconnect battery (remove negative lead first and reconnect it last) to disable generator set before working on any

equipment connected to generator.

A

WARNING

DANGEROUS ACID! Avoid contact with battery electro-

lyte. It contains acid which can eat holes in clothing, burn

skin, and cause permanent damage to eyes. Always wear

splash-proof safety goggles when working around the

battery. If battery electrolyte is splashed in the eyes or on

skin, immediately flush the affected area for 15 minutes

with large quantities of clean water. In the case of eye

contact, seek immediate medical aid. Never add acid to a

battery once the battery has been placed in service. Doing

so may result in dangerous spattering of electrolyte.

.A WARNING

EXPLOSIVE t3ATTERY GASES! The gases generated by a

battery being charged are highly explosive. Do not smoke

or permit flame or spark to occur near a battery at any

time, particularly when it is being charged. Avoid contacting terminals with tools, etc., to prevent burns and to

prevent sparks that could cause an explosion. Remove

wristwatch, rings, and any other jewelry before handling

battery. Any compartment containing batteries should be

...

well ventilated to prevent accumulation of explosive gases.

To avoid sparks, do not disturb battery charger connections while battery is being charged and always turn

charger off before disconnecting battery connections.

Turn automotive test equipment off when connecting or

removing battery clips. When removing or reconnecting

battery cables, make sure ignition switch and all accessories are turned off.

A

WARNING

EXCESSIVE NOISE! Never operate without adequate

muffler or with faulty exhaust system - exposure to

excessive noise is not only tiring but can lead to impairment of hearing.

A

WARNING

HOT PIPING! An engine gets hot while running and

exhaust system components get extremely hot. Do not

work on generator set until unit is allowed to cool.

A

WARNING

DANGEROUS FUELS! Use extreme caution when hand-

ling, storing, and using fuels - all fuels are highly

explosive in a vapor state. Store fuel in a well-ventilated

area away from spark producing equipment and out of the

reach of children. Never add fuel to the tank while the

engine is running to prevent spilled fuel from igniting on

contact with hot parts or from ignition spark. Keep fuel

lines and connections tight and in good condition - don’t

replace flexible fuel lines with rigid lines. Flexiblesections

are used to avoid breakage due to vibration. Should any

fuel leakage, fuel accumulation, or electrical sparks be

noted, DO NOT OPERATE GENERATOR SET. Have sys-

Page 4

terns repaired by qualified specialists before resuming

generator operation. Additional precautions should be

taken when using the following fuels:

Gasoline-Store gasoline only in approved red containers

clearly marked GASOLINE. Don’t store gasoline in .any

occupied building.

Propane (LP)-Adequate ventilation is mandatory. Pro-

pane is heavier than air; install gas detectors low in room.

Inspect detectors often.

A

WARNING

UNINTENTIONAL STARTING! To prevent accidental

starting when checking choke operation, remove spark

plug lead(s) at spark plug(s).

A

WARNING

FLASH FIRE! A sudden flash fire can cause serious burns.

To avoid the possibility of a flash fire, do not smoke or

permit flame or spark to occur near carburetor, fuel line,

fuel filter, fuel pump, or other potential sources of spilled

fuel or fuel vapors.

A

WARNING

ELECTROCUTION! Your RV generator set must not be

used to “backfeed” by connecting it to building/campground electrical circuits. Doing so can cause serious

injury or death to utility personnel working on utility

transmission lines and may also seriously injure persons in

your household. Unauthorized connection may be unlawful

in some states and/or localities. A transfer switch must be

installed in the RV to prevent interconnection of generator

and outside source of power.

A

WARNING

BACKFIRE! A sudden backfire can cause serious burns.

Keep hands and face away from the carburetor when the

air cleaner is removed.

A

WARNING

FIRE HAZARD! Keep the compartment and generator set

clean and free of debris to minimize chances of fire. Also

remember that hot exhaust gases and exhaust system

parts could start grass fires. Keep away from hot engine

and generator parts’to avoid burning yourself.

A

WARNING

MOVING PARTS! Do not open generator set compartment

door when unit is running, except for servicing by qualified specialists. Replace guards, covers, and screens (if

used) before operating generator set.

A

WARNING

HIGH VOLTAGE! When the power cord is plugged in

during voltage regulator test, the AC pins become “hot”

and there is danger of electrocution.

A

WARNING

EXPLOSION! Use generator sets specified for RV use in RV

installations only.

Page 5

Section 1.

Introduction and Specifications

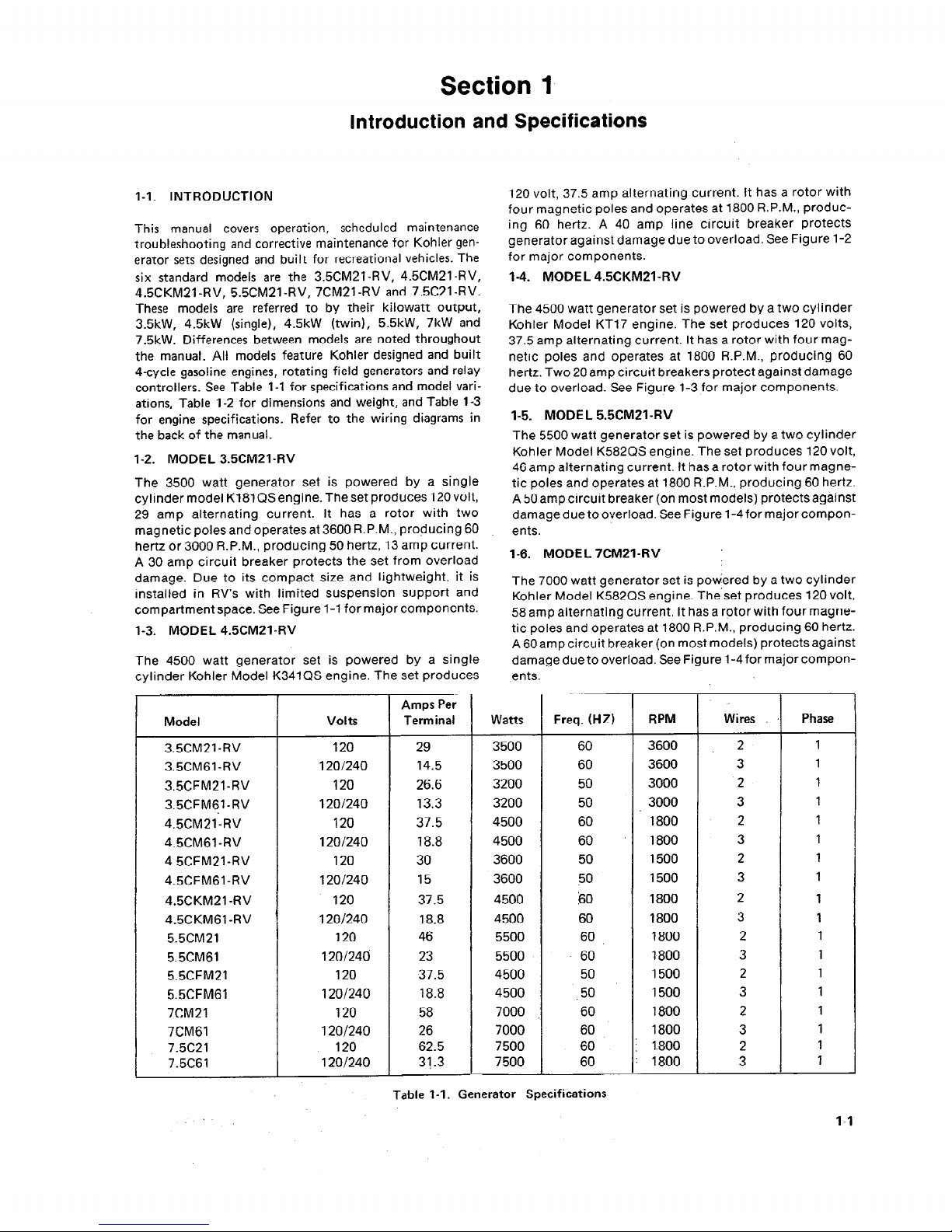

l-l. INTRODUCTION

This manual covers operation, scheduled maintenance

troubleshooting and corrective maintenance for Kohler generator sets designed and built for recreational vehicles. The

six standard models are the 3.5CM21 -RV, 4.5CM21-RV,

4.5CKM21 -RV, 5.5CM21 -RV, 7CM21 -RV and 7.5C21 -RV.

These models are referred to by their kilowatt output,

3.5kW, 4.5kW (single), 4.5kW (twin), 5.5kW, 7kW and

7.5kW. Differences between models are noted throughout

the manual. All models feature Kohler designed and built

4-cycle gasoline engines, rotating field generators and relay

controllers. See Table l-l for specifications and model variations, Table 1-2 for dimensions and weight, and Table l-3

for engine specifications. Refer to the wiring diagrams in

the back of the manual.

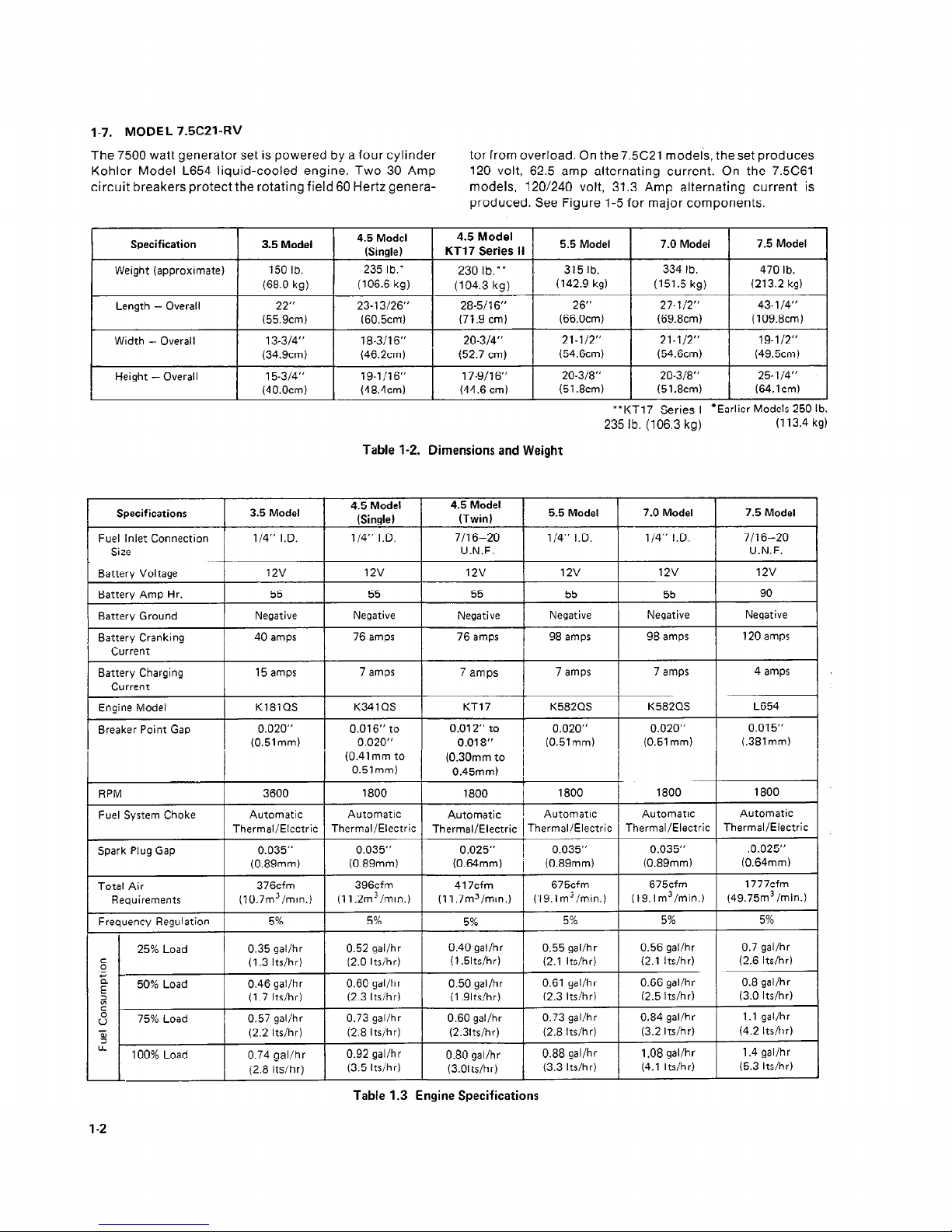

I-2. MODEL 3.5CM21-RV

The 3500 watt generator set is powered by a single

cylinder model K181 QS engine. The set produces 120 volt,

29 amp alternating current. It has a rotor with two

magnetic poles and operates at 3600 R.P.M., producing 60

hertz or 3000 R.P.M., producing 50 hertz, 13 amp current.

A 30 amp circuit breaker protects the set from overload

damage. Due to its compact size and lightweight, it is

installed in RV’s with limited suspension support and

compartment space. See Figure l-l for major components.

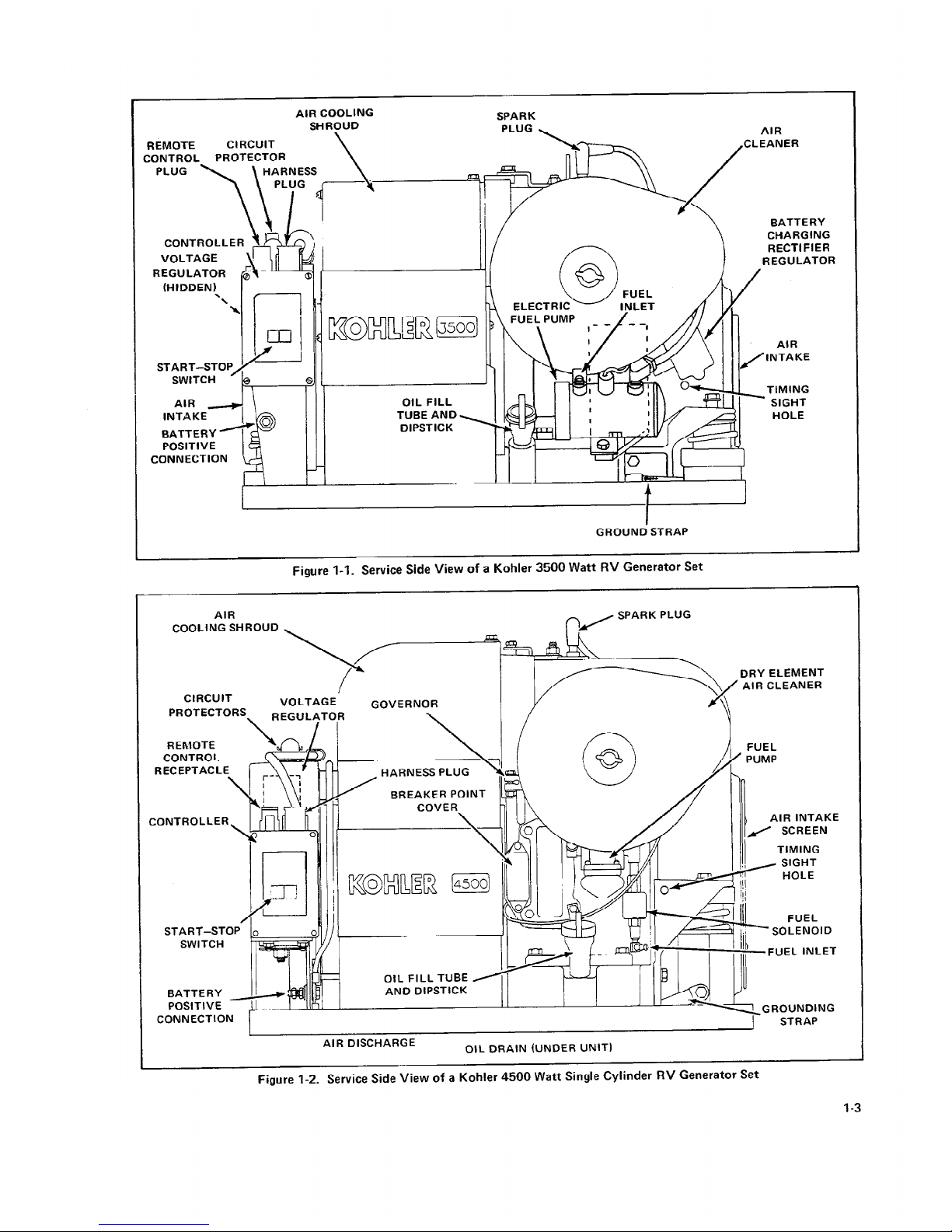

1-3. MODEL 4.5CM21-RV

The 4500 watt generator set is powered by a single

cylinder Kohler Model K341QS engine. The set produces

Model

3.5CM21-RV

3.5CM61-RV

3.5CFM21-RV

3.5CFM61-RV

4.5CM21:RV

4.5CM61 -RV

4.5CFM21-RV

4.5CFM61-RV

4.5CKM21 -RV

4.5CKM61 -RV

5.5CM21

5.5CM61

5.5CFM21

5.5CFM61

7CM21

7CM61

7.5C21

7.5C61

Volts

Amps Per

Term in al Watts Freq. (HZ) RPM

120

29

3500 60 3600

120/240

14.5 3500 60

3600

120

26.6

3200 50

3000

120/240

13.3

3200

50

3000

120

37.5 4500 60

1800

120/240 18.8

4500 60 *

1800

120

30

3600 50 1500

120/240

15

3600

SO

1500

120 37.5 4500 60

1800

1201240

18.8

4500 60

1800

120

46

5500 60

1800

120/246 23 5500 . 60 1800

120 37.5 4500 50 1500

120/240

18.8 4500 ,50 1500

120 58

7000 60 1800

120/240 26

7000

60 ’ 1800

120

62.5

7500

60 1.800

120/240

31.3 7500

60 1800

120 volt, 37.5 amp alternating current. It has a rotor with

four magnetic poles and operates at 1800 R.P.M., producing 60 hertz. A 40 amp line circuit breaker protects

generator against damage due to overload. See Figure l-2

for major components.

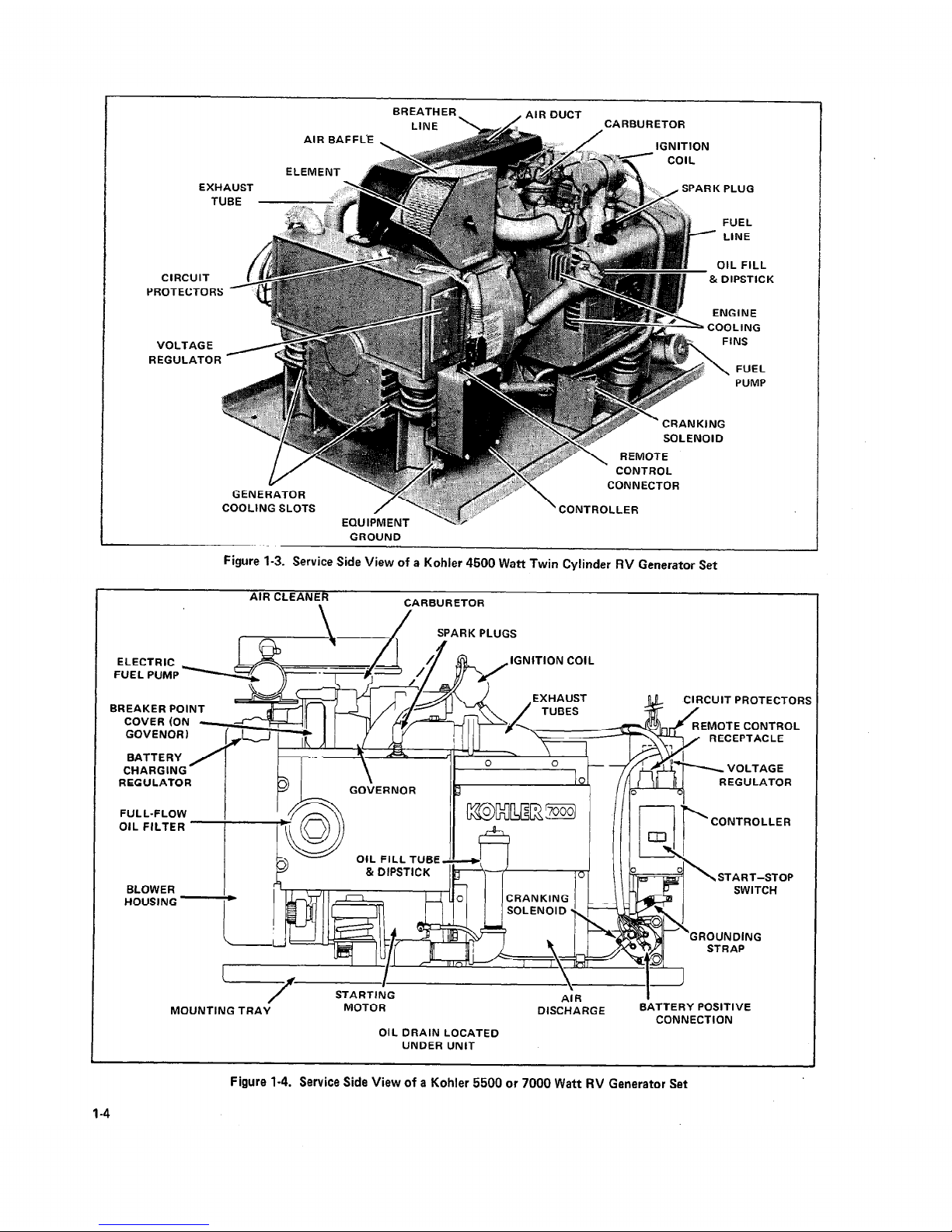

1-4. MODEL 4.5CKM21-RV

The 4500 watt generator set is powered by a two cylinder

Kohler Model KT17 engine. The set produces 120 volts,

37.5 amp alternating current. It has a rotor with four magnetic poles and operates at 1800 R.P.M., producing 60

hertz. Two 20 amp circuit breakers protect against damage

due to overload. See Figure l-3 for major components.

1-5. MODEL 5.5CM21-RV

The 5500 watt generator set is powered by a two cylinder

Kohler Model K582QS engine. The set produces 120 volt,

46 amp alternating current. It has a rotor with four magne-

tic poles and operates at 1800 R.P.M., producing 60 hertz.

A 50 amp circuit breaker (on most models) protects against

damage due to overload. See Figure I-4for major components.

1-6. MODEL 7CM21-RV

The 7000 watt generator set is powdered by a two cylinder

Kohler Model K582QS engine. The’set produces 120 volt,

58 amp alternating current. It has a rotor with four magnetic poles and operates at 1800 R.P.M., producing 60 hertz.

A 60amp circuit breaker (on most models) protects against

damage due to overload. See Figure I-4for major components.

. .

Wires, I

2

3

‘2

3

2

3

2

3

2

3

2

3

2

3

2

3

2

3

Phase

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Table l-l. Generator Specifications

l-l

Page 6

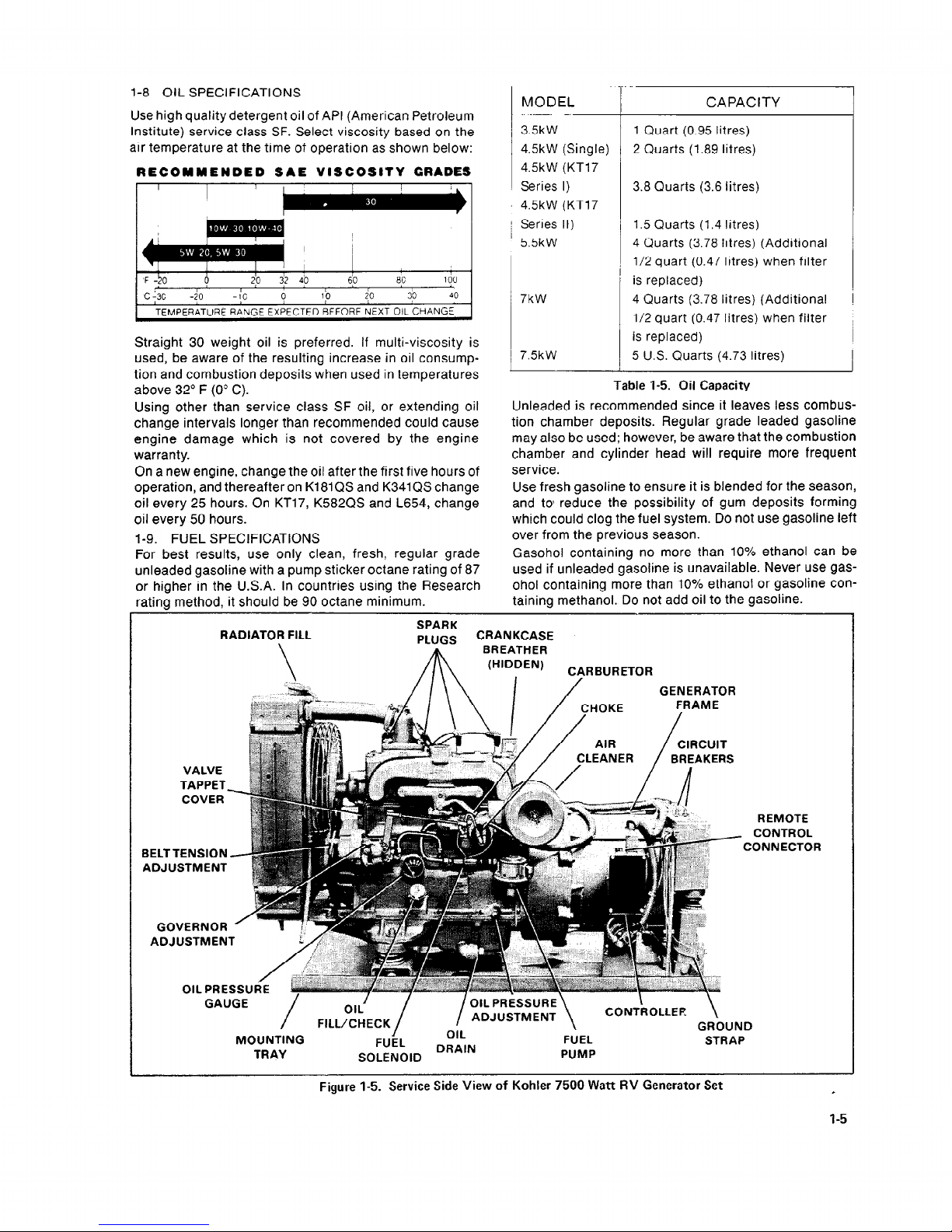

1-7. MODEL 7.5CZl-RV

The 7500 watt generator set is powered by a four cylinder

Kohler Model L654 liquid-cooled engine. Two 30 Amp

circuit breakers protect the rotating field 60 Hertz genera-

torfrom overload. On the 7.X21 model-s, the set produces

120 volt, 62.5 amp alternating current. On the 7.5661

models, 120/240 volt, 31.3 Amp alternating current is

produced. See Figure 1-5 for major components.

Specification

Weight (approximate)

3.5 Model

150 lb.

(68.0 kg)

4.5 Model

(Single)

235 lb.*

(106.6 kg)

,

4.5 Model

KT17

Series II

5.5 Model 7.0 Model

7.5 Model

4

230 lb.**

315 lb. 334 lb.

470 lb.

(104.3 kg)

(142.9 kg)

(151.5 kg) (213.2 kg)

Length - Overall 22” 23- 13/26”

28-5/l 6”

26”

27-l/2”

43-l /4”

(55.9cm)

(60.5cm) (71.9 cm)

(66.Ocm)

(69.8cm) (109.8cm)

Width - Overall 13-3/4” 18-3/l 6” 1 20-3/4” 21-l/2”

(34.9cm) (46.2cm) 1 (52.7 cm)

(54.6cm)

Height - Overall 15-314” 19-l /I 6” 17-9/l 6”

20-3/8”

20-3/8” 25-l /4”

(40.0cm) (48.4cm) (44.6 cm)

(51.8cm)

(51.8cm) (64.1cm)

A

A

**KT17 Series I

*Earlier Models 250 I b.

235 lb. (106.3 kg)

(113.4 kg)

Table l-2. Dimensions and Weight

Specifications

Fuel Inlet Connection

Size

Battery Voltage

Battery Amp Hr.

Battery Ground

Battery Cranking

Current

3.5 Model

l/4” I.D.

12v

55

Negative

40 amps

4.5 Model

(Single)

l/4” I.D.

12v

55

Negative

76 amps

4.5 Model

(Twin)

7/l 6-20

U.N.F.

12v

55

Negative

76 amps

5.5 Model 7.0 Model

l/4” I.D. l/4” I.D.

12v

12v

55

55

Negative Negative

98 amps 98 amps

.

7.5 Model

7/l 6-20

U.N.F.

12v

90

Negative

120 amps

Battery Charging

Current

15 amps

7 amps

7 amps

7 amps 7 amps 4 amps

Engine Model

K181QS K34 1 QS KTI 7 K582QS K582QS L654

Breaker Point Gap

0.020” 0.016” to 0.012” to

0.020” 0.020” 0.015”

(0.51 mm)

0.020”

0.018”

(0.51 mm) (0.51 mm)

(.381mm)

(0.41 mm to

(0.30mm to

0.51 mm)

0.45mm)

RPM

3600 1800

1800

1800

1800

1800

Fuel System Choke

Automatic

Automatic

Automatic

Automatic Automatic

Automatic

Thermal/Electric Thermal/Electric Thermal/Electric Thermal./Electric Thermal/Electric Thermal/Electric

Spark Plug Gap

0.035” 0.035”

0 -025”

0.035” 0.035” .0.025”

(0.89mm)

(0.89mm)

(0.64mm) (0.89mm) (0.89mm)

(0.64mm)

Total Air

376cfm

396cfm

417cfm

675cfm

675cfm 1777cfm

Requirements ( 10.7m3/min.)

(11 .2m3/min.) (11 .7m3/min.) (19.1m3/min.)

(19.1 m3/min.) (49.75m3/min.)

Frequency Regulation

5% 5%

5%

5%

5% 5%

25% Load 0.35 gal/hr

0.52 gal/hr

0.40 gal/hr

0.55 gal/hr 0.56 gal/hr

0.7 gal/hr

g

(1.3 lts/hr) (2.0 lts/hr)

(1.5lts/hr)

(2.1 lts/hr)

(2.1 lts/hr)

(2.6 lts/hr)

._

‘;

5

50% Load

0.46 gal/hr 0.60 gal/hr

0.50 gal/hr

0.61 gal/hr

0.66 gal/hr 0.8 gal/hr

(1.7 lts/hr) (2.3 lts/hr)

(1 .9lts/hr)

(2.3 lts/hr)

(2.5 lts/hr)

(3.0 lts/hr)

v)

c

s

75% Load 0.57 gal/hr

0.73 gal/hr

0.60 gal/hr

0.73 gal/hr 0.84 gal/hr

1.1 gal/hr

z

(2.2 lts/hr) (2.8 lts/hr) (2.3lts/hr)

(2.8 lts/hr)

(3.2 Its/h r)

(4.2 Its/hr)

l? .

100% Load

0.74 gal/hr

0.92 gal/hr

0.80 gal/hr

0.88 gal/hr 1.08 gal/hr

1.4 gal/hr

I I

(2.8 Itslhr) I

(3.5 Its/hr)

I

(3.0lts/hr) I

(3.3 lts/hr) ,

(4.1 lts/hr) ,

(5.3 lts/hr) ,

Table 1.3 Engine Specifications

1-2

Page 7

AIR COOLING

SPARK

SHROUD

REMOTE

CIRCUIT

CL

CONTROL PROTECTOR

CONTROLLER

(HIDDEN) I

INTAKE

BATTERY -+@ /

POSITIVE

CONNECTION

GROUND STRAP

AIR

EANER

BATTERY

CHARGING

RECTIFIER

REGULATOR

INTAKE

TIMING

SIGHT

HOLE

Figure 1-1. Service Side View of a Kohler 3500 Watt RV Generator Set

AIR

COOLING SHROUD

SPARK PLUG

DRY ELEMENT

AIR CLEANER

CIRCUIT

GOVERNOR

_

PROTECTORS\

REGULAT(

REMOTE

CONTROL

EC EPTAC L

iONTROLLER

START-STOP

SWITCH

BATTERY

POSITIVE

CONNECTION

I

STRAP

HARNESS PLUG

BREAKER POINT

FUEL

PUMP

AIR INTAKE

/ SCREEN

TIMING

SIGHT

HOLE

OIL FILL TUBE

AND DIPSTICK

,

AIR DISCHARGE

0lL DRAIN (UNDER UNIT)

Figure l-2. Service Side View of a Kohler 4500 Watt Single Cylinder RV Generator Set

Page 8

BREATHER_

AIR DUCT

/

IGNITION

thtMtNT

EXHAUST

.d

~.

TUBE

..”

FUEL

LINE

i OIL FILL

CIRCUIT

?OTECTOR

FINS

VOLTAGE /

EGULATOR

c

&j \ FUEL

PUMP

COOLING SLOTS

/

EQUIPMENT

GROUND

$p”

.:’ ,::. : ,, :.:::::,A~

:i:::::

,:*.

r

“’ :

./: >::: ;,.. 1’

,;:z>

. . .

..,,,,,.

’ CONTROLLER

Figure 1-3. Service Side View of a Kohler 4500 Watt Twin Cylinder RV Generator Set

AIR CLEANER

.

CARBURETOR

UST

ES

CIRCUIT PROTECTORS

/

b=AA9TE CONTROL

ICEPTACLE

BREAKER POINT

COVER (ON

GOVENOR)

BATTERY

CHARGING

VOLTAGE

REGULATOR

GOVERNOR

EGULATOR

FULL-FLOW

OIL FILTER

CONTROLLER

OIL FILL TUBE

& DIPSTICK

‘OP

BLOWER

, Ah I I

HOUSING

/

SWITCH

GROUNDING

AIR

I

“ISCHARGE

BATTERY POSITIVE

Y

CONNECTION

MOUNTI

OIL DRAIN LOCATED

UNDER UNIT

Figure I-4. Service Side View of a Kohler 5500 or 7000 Watt RV Generator Set

I-4

Page 9

l-8 OIL SPECIFICATIONS

Use high quality detergent oil of API (American Petroleum

Institute) service class SF. Select viscosity based on the

air temperature at the time of operation as shown below:

RECOMMENDED SAE VISCOSITY GRADES

!

I

I

I

I

I 1 I

'F -50 6

T 1 r I I

20

32 40 60 80 100

t

I I

T

I

I I

I

c-30 -20 -10

0 10 20 30 40

TEMPERATURE RANGE EXPECTED BEFORE NEXT OIL CHANGE

l

Straight 30 weight oil is preferred. If multi-viscosity is

used, be aware of the resulting increase in oil consumption and combustion deposits when used in temperatures

above 32’ F (0” C).

I

Using other than service class SF oil, or extending oil

change intervals longer than recommended could cause

engine damage which is not covered by the engine

warranty.

On a new engine, change the oil after the first five hours of

operation, and thereafter on K181QS and K341 QS change

oil every 25 hours. On KT17, K582QS and L654, change

oil every 50 hours.

I-9. FUEL SPECIFICATIONS

For best results, use only clean, fresh, regular grade

unleaded gasoline with a pump sticker octane rating of 87

or higher in the U.S.A. In countries using the Research

MODEL

CAPACITY

35kW

1 Quart (0.95 Iitres)

4.5kW (Single)

2 Quarts (1.89 litres)

4.5kW (KT17

Series I)

3.8 Quarts (3.6 litres)

4.5kW (KT17

Series II)

1.5 Quarts (1.4 litres)

5.5kW

4 Quarts (3.78 litres) (Additional

l/2 quart (0.47 litres) when filter

is replaced)

7kW

4 Quarts (3.78 litres) (Additional

l/2 quart (0.47 litres) when filter

is replaced)

7.5kW

5 U.S. Quarts (4.73 Iitres)

Unleaded is recommended since it leaves less combus-

tion chamber deposits. Regular grade leaded gasoline

may also be used; however, be aware that the combustion

chamber and cylinder head will require more frequent

service.

Use fresh gasoline to ensure it is blended for the season,

and to’ reduce the possibility of gum deposits forming

which could clog the fuel system. Do not use gasoline left

over from the previous season.

Gasohol containing no more than 10% ethanol can be

used if unleaded gasoline is unavailable. Never use gas-

ohol containing more than 10% ethanol or gasoline con-

Table 1-5. Oil Capacity

rating method, it should be 90 octane minimum.

taining methanol. Do not add oil to the gasoline.

RADIATOR FILL

\

SPARK

PLUGS

CRANKCASE

A

BREATHER

\ /I\\

(HIDDEN)

I

CIjRBURETOR

VALVE

TAPPET,

COVER

BELTTENSION

ADJUSTMENT

GOVERNOR

ADJUSTMEN

OIL PRE

GAUGE

/

/

OIL

FILL/CHECK

MOUNTING

I /

OIL PRESSURE

ADJUSTMENT

\

\

CONTROLLER

\

GROUN

FUEL

OIL

FUEL

DRAIN

STRAF

TRAY

SOLENOID

PUMP

C

REMO’

CONTR

:ONNEC

TE

OL

TOR

Figure 1-5. Service Side View of Kohler 7500 Watt RV Generator Set

c

l-5

Page 10

Section 2

Operation

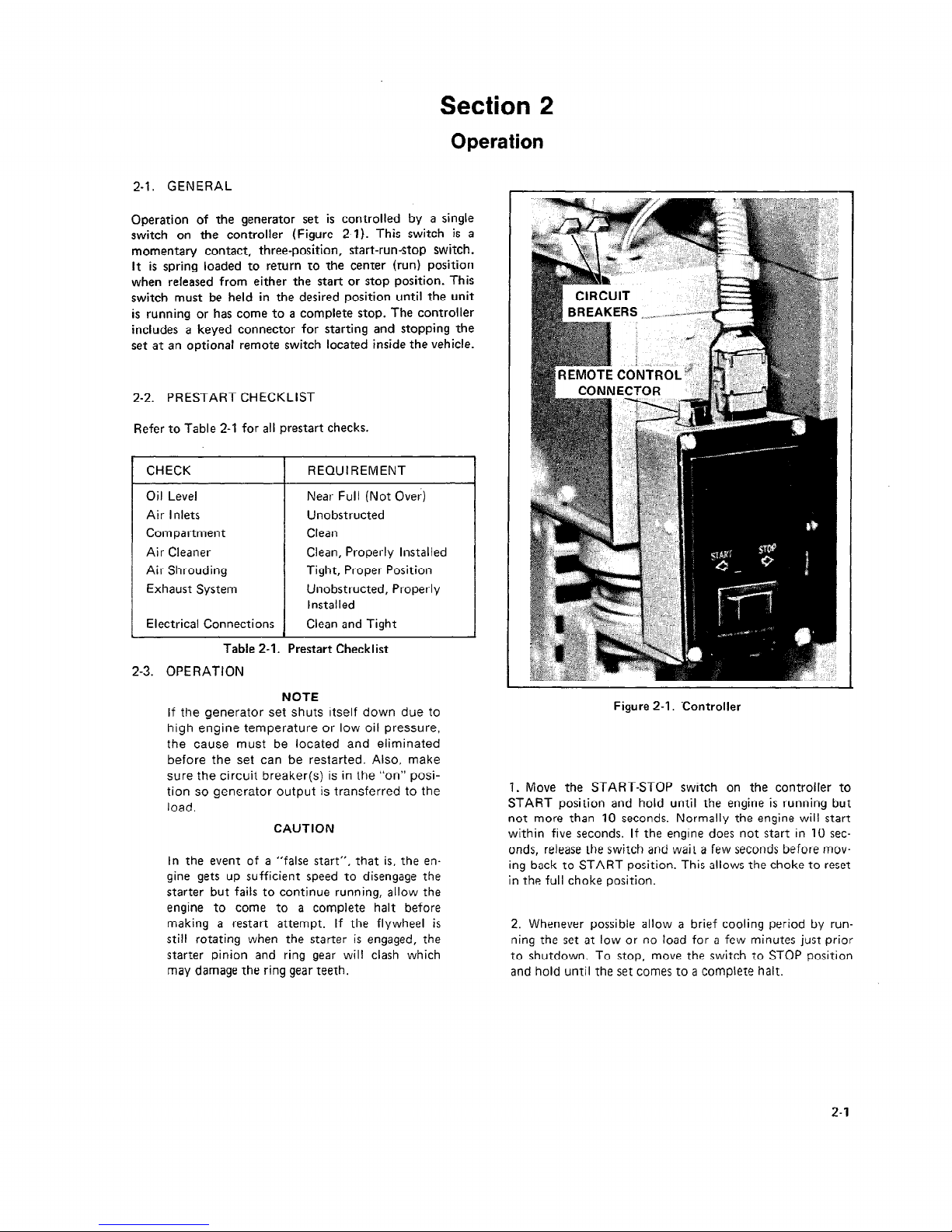

2-l. GENERAL

Operation of the generator set is controlled by a single

switch on the controller (Figure 2-l). This switch is a

momentary contact, three-position, start-run-stop switch.

It is spring loaded to return to the center (run) position

when released from either the start or stop position. This

switch must be held in the desired position until the unit

is running or has come to a complete stop. The controller

includes a keyed connector for starting and stopping the

set at an optional remote switch located inside the vehicle.

2-2. PRESTART CHECKLIST

Refer to Table 2-l for all prestart checks.

CHECK REQUIREMENT

Oil Level Near Full (Not Over)

Air Inlets Unobstructed

Compartment Clean

Air Cleaner Clean, Properly Installed

Air Shrouding

Tight, Proper Position

Exhaust System Unobstructed, Properly

lnstal led

Electrical Connections Clean and Tight

Table 2-I. Prestart Checklist

2-3. OPERATION

NOTE

If the generator set shuts itself down due to

high engine temperature or low oil pressure,

the cause must be located and eliminated

before the set can be restarted. Also, make

sure the circuit breaker(s) is in the “on” position so generator output is transferred to the

load.

CAUTION

In the event of a “false start”, that is, the engine gets up sufficient speed to disengage the

starter but fails to continue running, allow the

engine to come to a complete halt before

making a restart attempt. If the flywheel is

still rotating when the starter is engaged, the

starter pinion and ring gear will clash which

may damage the ring gear teeth.

Figure 2-I. Controller

‘I. Move the START-STOP switch on the controller to

START position and hold until the engine is running but

not more than 10 seconds. Normally the engine will start

within five seconds. If the engine does not start in 10 seconds, release the switch and wait a few seconds before moving back to START position. This allows the choke to reset

in the full choke position.

2. Whenever possible allow a brief cooling period by running the set at low or no load for a few minutes just prior

to shutdown. To stop, move the switch to STOP position

and hold until the set comes to a complete halt.

2-I

Page 11

Section 3

Scheduled Maintenance

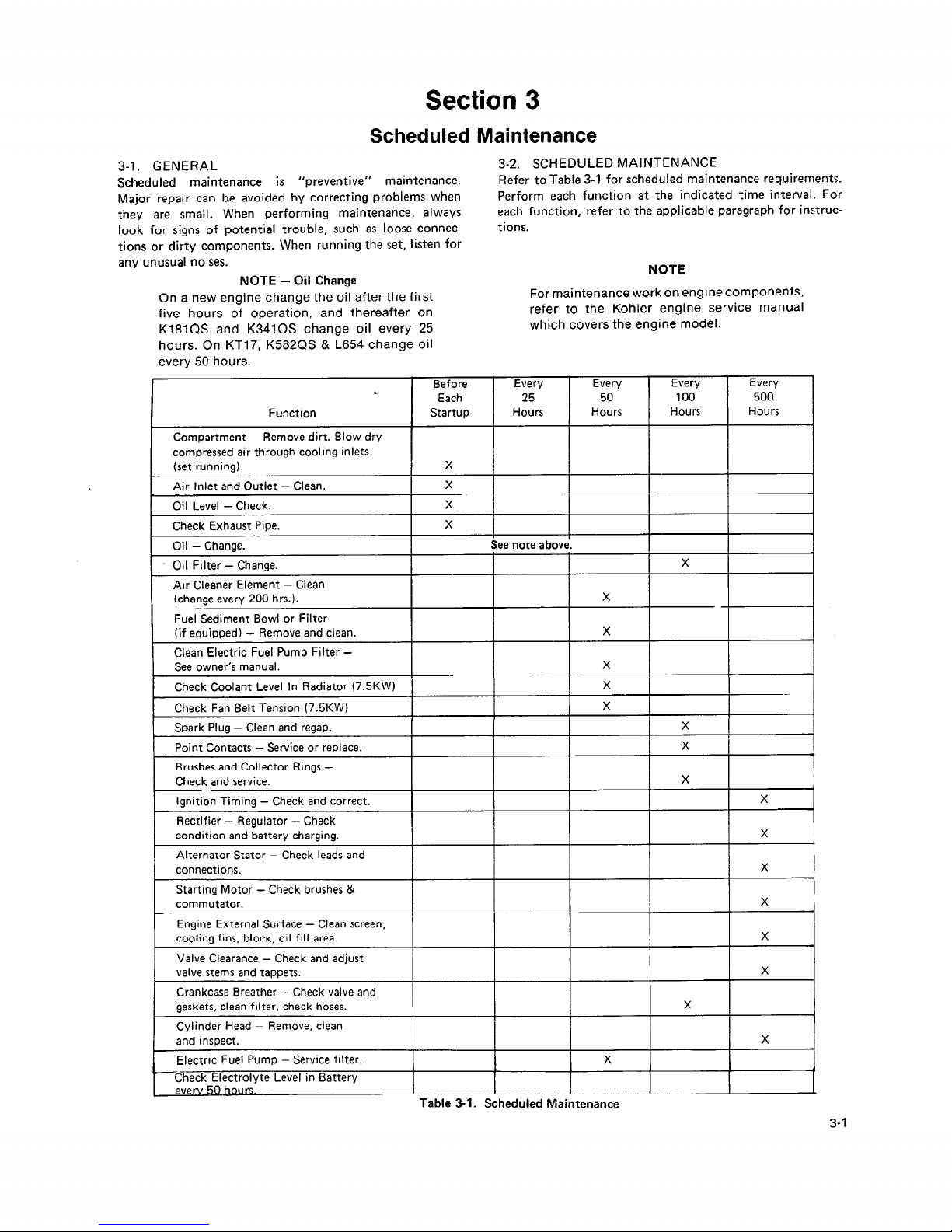

3-l. GENERAL

Scheduled maintenance is “preventive” maintenance.

Major repair can be avoided by correcting problems when

they are small. When performing maintenance, always

look for signs of potential trouble, such as loose connections or dirty components. When running the set, listen for

any unusual noises.

NOTE - Oil Change

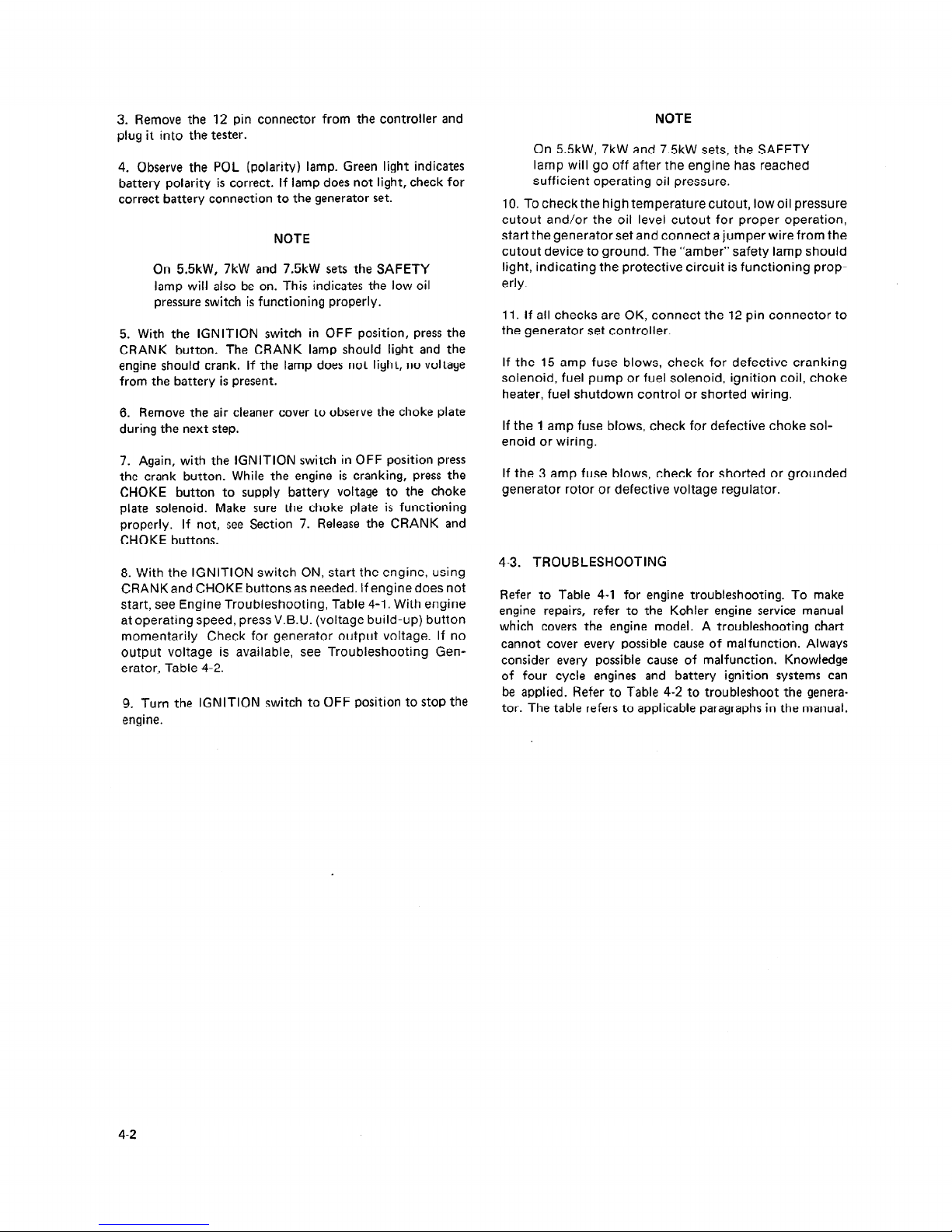

3-2. SCHEDULED MAINTENANCE

Refer to Table 3-1 for scheduled maintenance requirements.

Perform each function at the indicated time interval. For

each function, refer to the applicable paragraph for instructions.

NOTE

On a new engine change the oil after the first

five hours of operation, and thereafter on

K181QS and K341QS change oil every 25

hours. On KT17, K582QS & L654 change oil

every 50 hours.

For maintenance work on engine components,

refer to the Kohler engine service manual

which covers the engine model.

Every

1

Before Every Every Every

.

Each

25 50

100 500

Function Startup Hours

Hours Hours Hours

.

Compartment - Remove dirt. Blow dry

compressed air through cooling inlets

(set running).

X

I

Air Inlet and Outlet - Clean.

X

Oil Level - Check.

X

Check Exhaust Pipe. X

I

Oil - Change.

See note above.

. Oil Filter - Change.

X

Air Cleaner Element - Clean

(change every 200 hrs.).

X

Fuel Sediment Bowl or Filter

(if equipped) - Remove and clean.

X

Clean Electric Fuel Pump Filter See owner’s manual.

X

Check Coolant Level In Radiator (7.5KW) X

Check Fan Belt Tension (7.5KW)

X

Spark Plug - Clean and regap.

X

Point Contacts - Service or replace.

X

Brushes and Collector Rings Check and service.

X

Ignition Timing -

Check and correct.

X

Rectifier

- Regulator - Check

condition and battery charging.

X

Alternator Stator - Check leads and

connections. X

Starting Motor - Check brushes &

commutator.

X

Engine External Surface - Clean screen,

cooling fins, block, oil fill area.

X

Valve Clearance

- Check and adjust

valve stems and tappets. X

I

Crankcase Breather - Check valve and

gaskets, clean filter, check hoses.

X

Cylinder Head - Remove, clean

and inspect.

X

.

Electric Fuel Pump - Service filter.

X

1-i: 50 hours.

Check Electrolyte Level in Battery

---_--.-_ . ..-_ _

Table 3-1. Scheduled Maintenance

3-1

Page 12

Section 4

Troubleshooting

4-l. GENERAL

CAUTION

When troubleshooting a generator set, always consider the

simplest causes first. Narrow the problem down to a functional system, such as fuel or ignition. To operate efficiently, an engine must have sufficient fuel, a good ignition

spark and good compression. All adjustments must be

correct. For a generator to produce the required electricity,

all parts must be clean, all connections tight, and all components in working order. See Table 4-l for Engine Troubleshooting and Table 4-2 for Generator Troubleshooting.

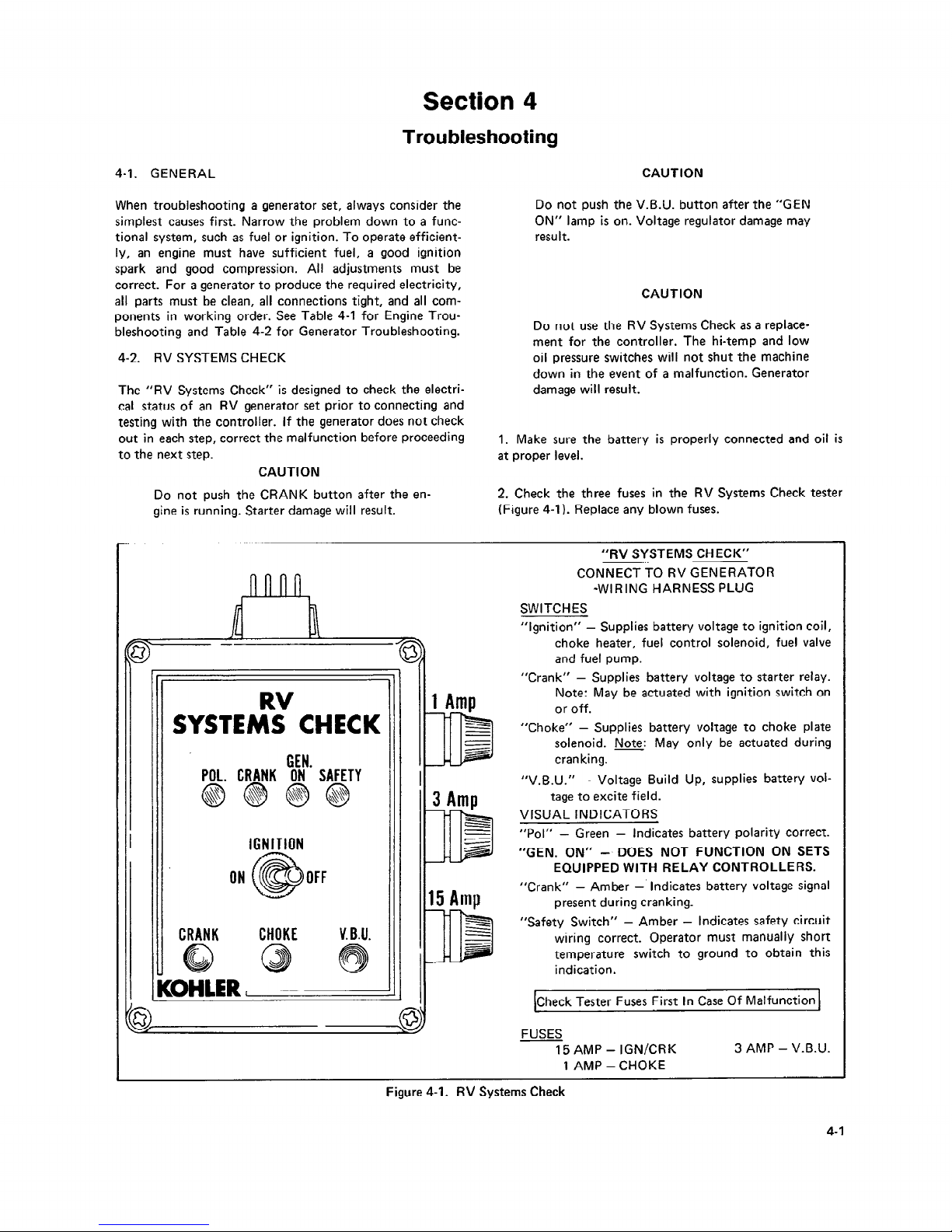

4-2. RV SYSTEMS CHECK

The “RV Systems Check” is designed to check the electrical status of an RV generator set prior to connecting and

testing with the controller. If the generator does not check

out in each step, correct the malfunction before proceeding

to the next step.

Do not push the V.B.U. button after the “GEN

ON” lamp is on. Voltage regulator damage may

resu It.

CAUTION

Do not use the RV Systems Check as a replacement for the controller. The hi-temp and low

oil pressure switches will not shut the machine

down in the event of a malfunction. Generator

damage will result.

1. Make sure the battery is properly connected and oil is

at proper level.

CAUTION

Do not push the CRANK button after the en-

2. Check the three fuses in the RV Systems Check tester

gine is running. Starter damage will result.

(Figure 4-l). Replace any blown fuses.

RV

‘II I

SYSTEMS CHECK

GEN

POL. CRANK ON’ SAFETY

IGNITION

ON OFF

CRANK CHOKE

V. B.U.

“RV SYSTEMS CHECK”

CONNECT TO RV GENERATOR

*WIRING HARNESS PLUG

SWITCHES

“Ignition” -

Supplies battery voltage to ignition coil,

choke heater, fuel control solenoid, fuel valve

and fuel pump.

“Crank” -

Supplies battery voltage to starter relay.

Note: May be actuated with ignition switch on

or off.

“Choke” - Supplies battery voltage to choke plate

solenoid. Note: May only be actuated during

cranking.

“V.B.U.” -

Voltage Build Up, supplies battery vol-

tage to excite field.

VISUAL INDICATORS

“Pol” - Green -

Indicates battery polarity correct.

“GEN. ON” -. DOES NOT FUNCTION ON SETS

EQUIPPED WITH RELAY CONTROLLERS.

“Crank” - Amber -’

Indicates battery voltage signal

present during cranking.

“Safety Switch” - Amber - Indicates safety circuit

wiring correct. Operator must manually short

temperature switch to ground to obtain this

indication.

[Check Tester Fuses First In Case Of Malfunction 1

FUSES

15 AMP - IGN/CRK

1 AMP -CHOKE

3 AMP - V.B.U.

Figure 4-1. RV Systems Check

4-1

Page 13

3. Remove the

12 pin connector

plug it into the

tester.

from the controller and NOTE

4. Observe the POL (polarity) lamp. Green light indicates

battery polarity is correct. If lamp does not light, check for

correct battery connection to the generator set.

NOTE

On 5.5kW, 7kW and 7.5kW sets the SAFETY

lamp will also be on. This indicates the low oil

pressure switch is functioning properly.

5. With the IGNITION switch in OFF position, press the

CRANK button. The CRANK lamp should light and the

engine should crank. If the lamp does not light, no voltage

from the battery is present.

On 5.5kW, 7kW and 7.5kW sets, the SAFETY

lamp will go off after the engine has reached

sufficient operating oil pressure.

IO. To check the high temperature cutout, low oil pressure

cutout and/or the oil level cutout for proper operation,

start the generator set and connect a jumper wire from the

cutout device to ground. The “amber” safety lamp should

light, indicating the protective circuit is functioning properly.

11. If all checks are OK, connect the 12 pin connector to

the generator set controller.

If the 15 amp fuse blows, check for defective cranking

solenoid, fuel pump or fuel solenoid, ignition coil, choke

heater, fuel shutdown control or shorted wiring.

6. Remove the air cleaner cover to observe the choke plate

during the next step.

If the 1 amp fuse blows, check for defective choke solenoid or wiring.

7. Again, with the IGNITION switch in OFF position press

the crank button. While the engine is cranking, press the

CHOKE button to supply battery voltage to the choke

plate solenoid. Make sure the choke plate is functioning

properly. If not, see Section 7. Release the CRANK and

CHOKE buttons.

If the 3 amp fuse blows, check for shorted or grounded

generator rotor or defective voltage regulator.

8. With the IGNITION switch ON, start the engine, using

CRANK and CHOKE buttons as needed. If engine does not

start, see Engine Troubleshooting, Table 4-l. With engine

at operating speed, press V.B.U. (voltage build-up) button

momentarily. Check for generator output voltage. If no

output voltage is available, see Troubleshooting Generator., Table 4-2.

9. Turn the IGNITION switch to OFF position to stop the

engine.

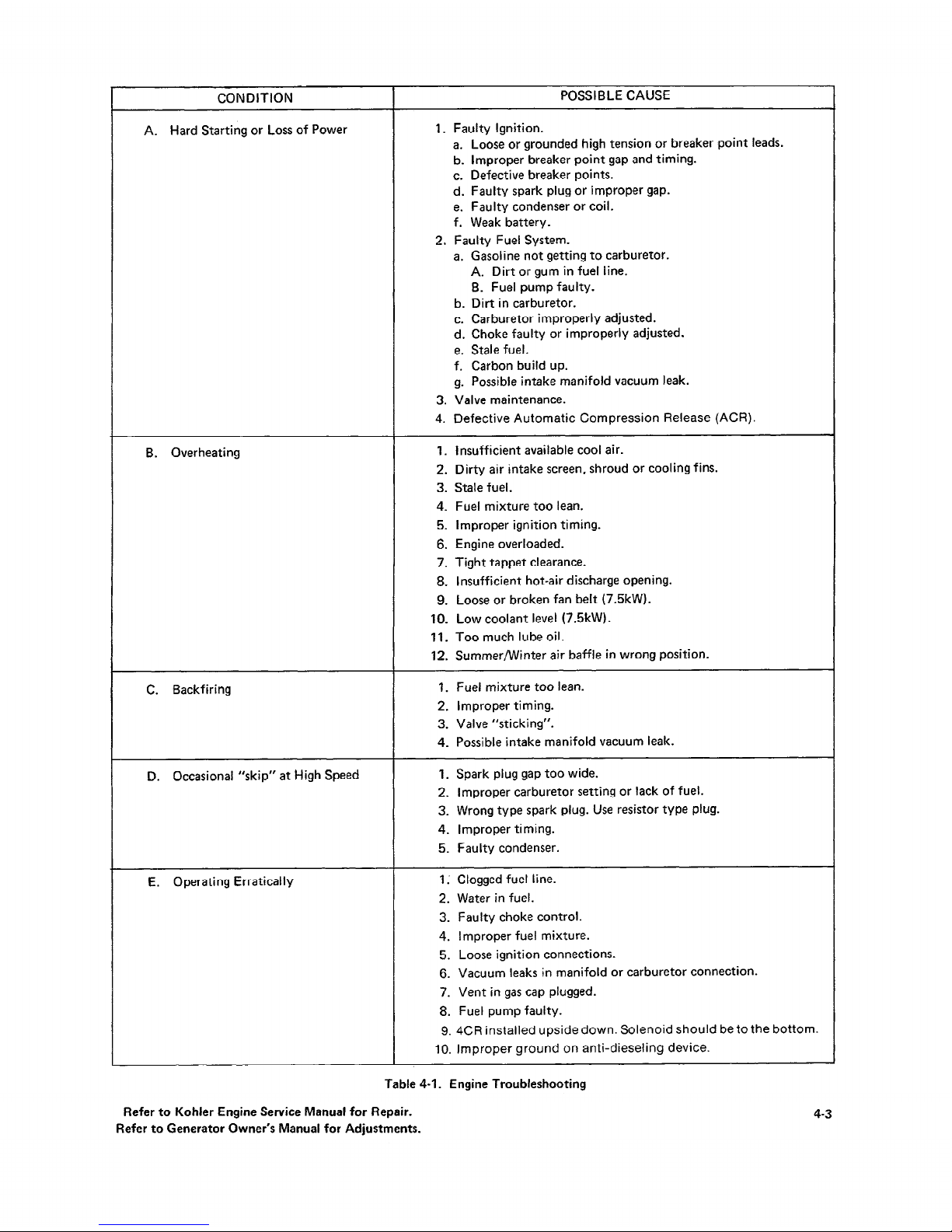

4-3. TROUBLESHOOTING

Refer to Table 4-l for engine troubleshooting. To make

engine repairs, refer to the Kohler engine service manual

which covers the engine model. A troubleshooting chart

cannot cover every possible cause of malfunction. Always

consider every possible cause of malfunction. Knowledge

of four cycle engines and battery ignition systems can

be applied. Refer to Table 4-2 to troubleshoot the generator. The table refers to applicable paragraphs in the manual.

4-2

Page 14

CONDITION

A. Hard Starting or Loss of Power

B. Overheating

C. Backfiring

D.

Occasional “skip” at High Speed

E. Operating Erratically

POSSIBLE CAUSE

1. Faulty Ignition.

a. Loose or grounded high tension or breaker point leads.

b. Improper breaker point gap and timing.

c. Defective breaker points.

d. Faulty spark plug or improper gap.

e. Faulty condenser or coil.

f. Weak battery.

2. Faulty Fuel System.

a. Gasoline not getting to carburetor.

A. Dirt or gum in fuel line.

B. Fuel pump faulty.

b. Dirt in carburetor.

c. Carburetor improperly adjusted.

d. Choke faulty or improperly adjusted.

e. Stale fuel.

f. Carbon build up.

g. Possible intake manifold vacuum leak.

3. Valve maintenance.

4. Defective Automatic Compression Release (ACR).

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Insufficient available cool air.

Dirty air intake screen, shroud or cooling fins.

Stale fuel.

Fuel mixture too lean.

Improper ignition timing.

Engine overloaded.

Tight tappet clearance.

Insufficient hot-air discharge opening.

Loose or broken fan belt (7.5kW).

Low coolant level (7.5kW).

Too much lube oil.

Summer/Winter air baffle in wrong position.

‘I. Fuel mixture too lean.

2. Improper timing.

3. Valve “sticking”.

4. Possible intake manifold vacuum leak.

1. Spark plug gap too wide.

2. Improper carburetor setting or lack of fuel.

3. Wrong type spark plug. Use resistor type plug.

4. Improper timing.

5. Faulty condenser.

1:

2.

3.

4.

5.

6.

7.

8.

9.

IO.

Clogged fuel line.

Water in fuel.

Faulty choke control.

Improper fuel mixture.

Loose ignition connections.

Vacuum leaks in manifold or carburetor connection.

Vent in gas cap plugged.

Fuel pump faulty.

4CR installed upside down. Solenoid should be to the bottom.

Improper ground on anti-dieseling device.

Table 4-1. Engine Troubleshooting

Refer to Kohler Engine Service Manual for Repair.

defer to Generator Owner’s Manual for Adjustments.

4-3

Page 15

CONDITION

1. Engine will not crank.

POSSIBLE CAUSE/CORRECTION (SECTION)

1. Battery cable connections reversed. (Must be negative ground.)

2. 10 amp fuse in controller blown (5-3).

3. Defective start switch or “C” relay (5-2).

4. Open circuit in wiring harness or connector.

5. Faulty starter motor.

6. Open circuit in REI diode (5-4).

7. Normally closed 3CR contacts, open (5-5).

8. Busted or loose ground strap.

2. Engine cranks but will not start.

1. Choke not operating or out of adjustment (7-1, 7-2).

2. Check fuel supply to carburetor.

3. Faulty fuel shut-down control (7-3).

4. Faulty fuel pump.

5. Dirty or stuck ignition points.

6. Faulty condenser.

7. Faulty spark plug.

3. Engine starts, then stops when

switch is closed.

8. 2CR relay not functioning. Must have battery voltage on positive

connection of ignition coil (5-5).

9. Fuel mixture. Replace.

1. No AC generator output.

2. Faulty 3CR interlock relay (5-5).

3. Faulty 4CR voltage sensing relay (5-5).

4. Faulty exciter voltage regulator (6-7).

4. No AC output.

1. Circuit breakers in the off position (2-3).

2. Generator brushes not making contact on slip rings (6-5).

3. Faulty build-up circuit. Battery voltage must be present at terminal

“B” of regulator during cranking (6-7).

4. Open connection in wiring harness or plug connector (5-2).

5. Faulty exciter voltage regulator (6-7).

6. Circuit protector tripping due to overload, reduce load.

5. Low output or excessive drop in

voltage (below 1 IO volts).

1. Generator set overloaded.

2. Engine rpm set too low (7-5 thru 7-9).

3. Faulty exciter voltage regulator (6-7).

4. Poor stator coil connections, use a clamp-on ammeter and check

each connection. .

6. High AC voltage (above 125 volts AC).

1. Faulty exciter voltage regulator.

2. Stator reconnected improperly.

7. Engine shuts down for no apparent

reason.

1. Generator set overheated

- improper installation. Refer to RV

installation manual or 75kW Owner’s Manual.

2. No fuel.

3. Oil level or oil pressure system failure.

4. Faulty shutdown solenoid.

8. Unit will not operate with remote

switch - OK at controller.

I. Incorrect wiring of remote switch to remote plug assembly. Center

pole of remote switch must connect to terminal 4 of remote harness

plug, Figure 5-2.

2. Open connection in wiring.

Table 4-2. Troubleshooting Generator

Page 16

Section 5

Relay Controller

5-I. DESCRIPTION

All generator set functions are dependent upon the control-

ler. See Figure 5-l for parts identification. For operation

instructions refer to Section 2. The controller includes a

keyed connector for installing a remote switch and hourmeter panel. This optional remote switch allows the operator to start and stop the generator set from another location in the vehicle. The hourmeter records the hours of

generator set operation (Figure 5-2). The controller can be

removed by removing the two snap connectors and two

capscrews underneath the controller. This section covers

sequence of operation, and fuse, diode, and relay replacement.

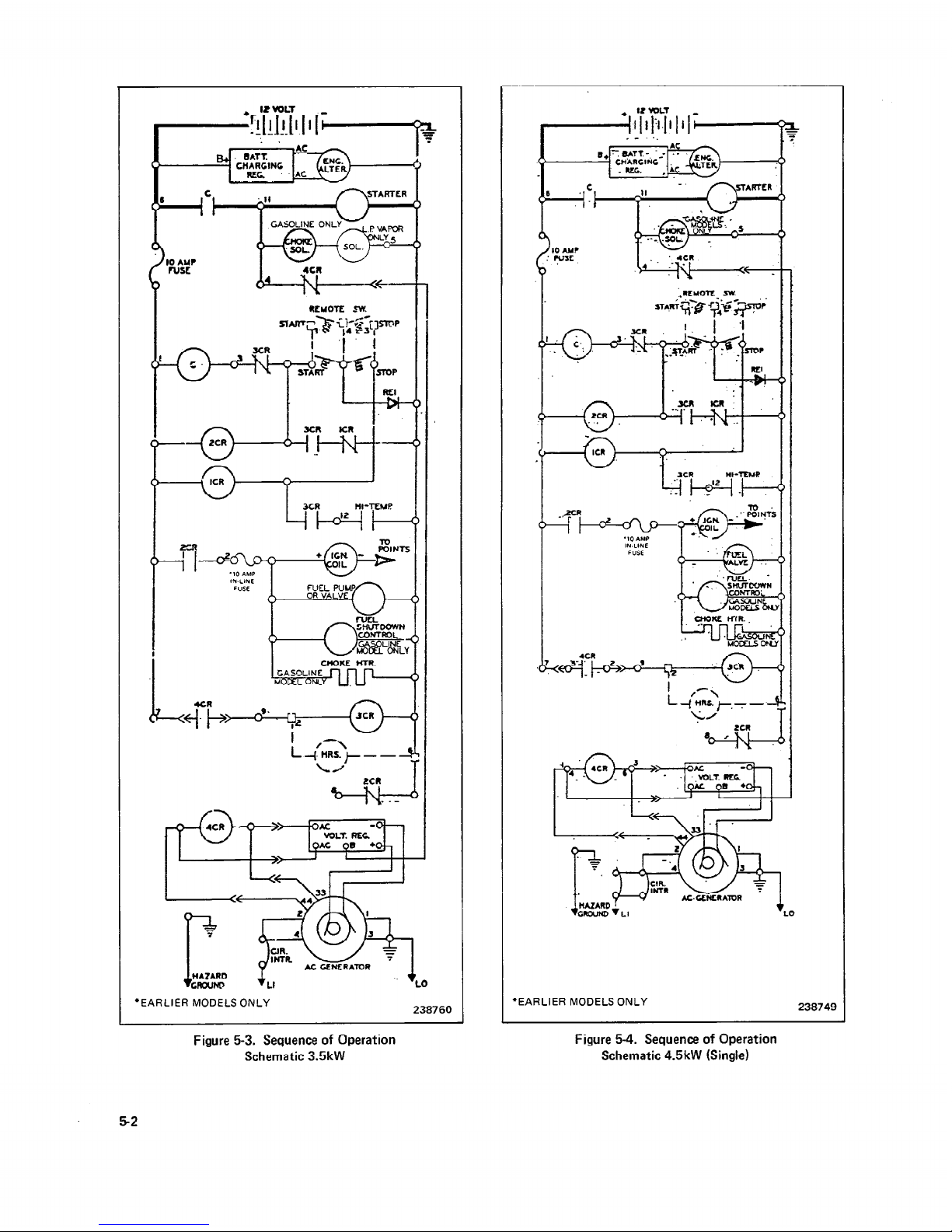

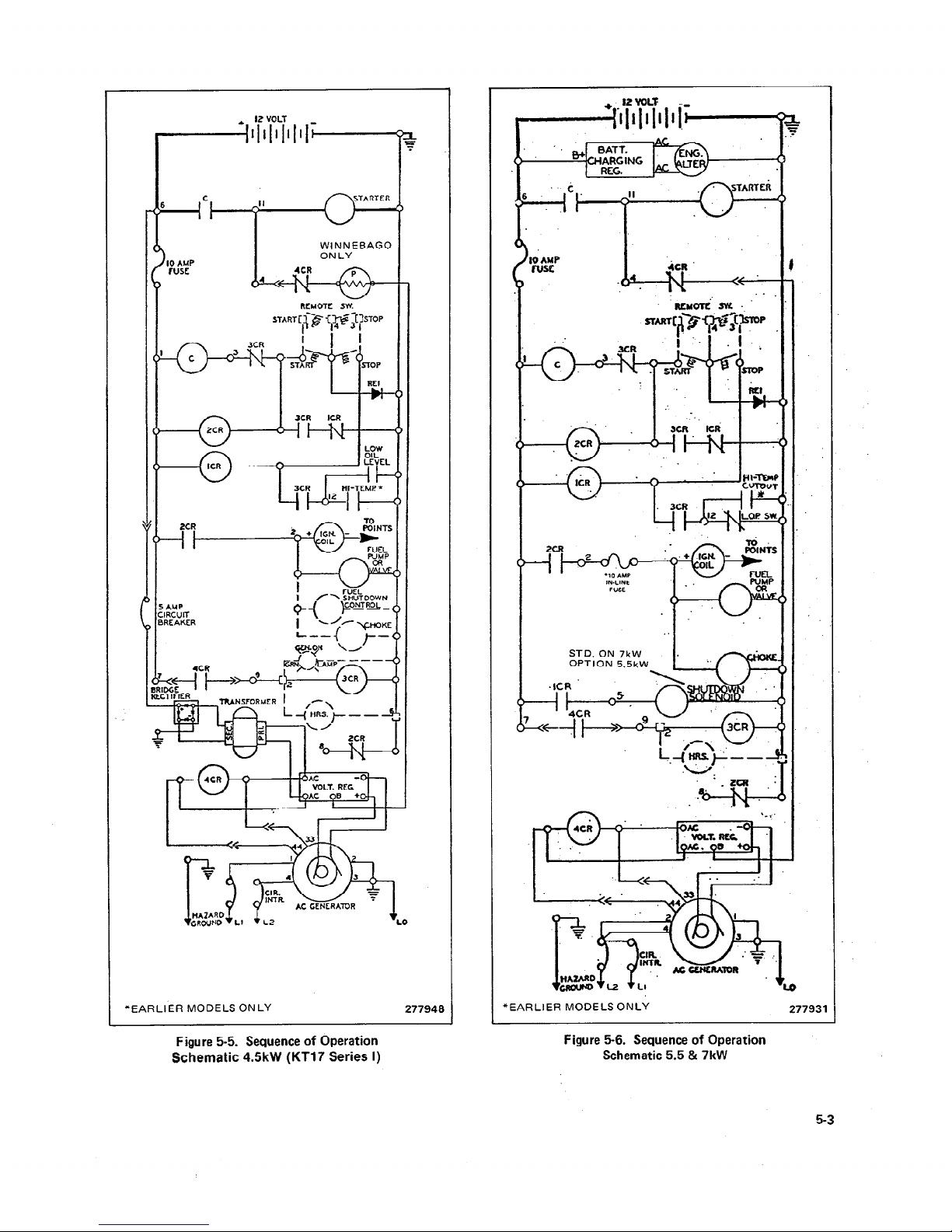

5-2. SEQUENCE OF OPERATION

The Relay Controller is the controlling point for generator

set operation. The following is the sequence of operations

controlled by the Relay Controller. See Figures 5-3

through 5-7.

.

REMOTE CONTROL

/

WIRING HARNESS

CONNECTOR

PLUG

IGNITION RELAY

REI

3CR

DIODE INTERLOCK RELAY

Figure 5-1. Controller

12 VOLT

GENERATOR

“ON” LIGHT

12 VOLT

HOURMETER

Lead Designation

. .

Pin No. Color Gauge of Wire

1 Red

18

2 White

22

3 Brown

22

4 Black

18

5

6 Blue

22

REMOTE CONTROL CONNECTOR

(ON CONTROLLER)

HARNESS

/

PLUG

SPRING LOADED

START-STOP

APPLIES TO SWITCH A-269299 ONLY

KOHLER PART NO. PA-269966

Figure 5-2. Remote Control Connections

5-l

Page 17

l lO AMP

lN.LINE

FUSE

I

CHOKE HTR.

ZCR

I I

*EARLIER MODELS ONLY

238760

\;/-

.

d

2CR

8 /

*EARLIER MODELS ONLY

238749

Figure 5-3. Sequence of Operation

Schematic 3.5kW

Figure 5-4. Sequence of Operation

Schematic 4.5kW (Single)

52

Page 18

5 II

-STARTER 1

REuOTE SW.

+

YLL

2CR

2 + ICN -

EINTS

OIL

e

II

LIITLUI I

BREAKER

4

“EARLIER MODELS ONLY

277948

STD. ON 7kW

OPTION 5.5kW

. :

Q%. Qb +O-.

.

I, 1

.

.

*EARLIER MODELS ONLY

277931

Figure 5-5. Sequence of Operation

Schematic 4SkW (KT17 Series I)

Figure 5-6. Sequence of Operation

Schematic 5.5 & 7kW

5-3

Page 19

I2 VOLT

3CRT

La?-

FUEL ‘PUMP

.

I

TRANSFORMER

Y

r

CEN:: ATOR

i t

L2 LI

LO

“EARLIER MODELS ONLY

241753

Figure 5-7. Sequence of Operation

Schematic 7.5kW

1. Pressing the start-stop switch to the start position energizes both the cranking contactor “C” and the 2CR relay.

(Diode REI will prevent this from happening if the battery

is connected in reverse.)

5-4

2. Energizing the 2CR relay will allow current to flow

through the 10 Amp in-line fuse to the ignition coil, choke

heater, carburetor shut-down solenoid and electric fuel

pump (if equipped).

3. Energizing cranking contactor “C” will allow current to

flow to the starter motor and crank the engine. The carburetor choke solenoid will also be energized and current

can flow through the normally closed 4CR contacts to the

“B” terminal of the aenerator voltage regulator for the

initial voltage build-up.

4. When the engine starts and the generator is producing

AC output, the 4CR relay (mounted in the generator end

bracket) will energize.

5. The normally CLOSED contacts in the V.B.U. (voltage

. .

bui,ld-up) circuit will then open and disconnect the battery

supply from the generator voltage regulator.

6. The normally OPEN 4CR contacts will close and allow

the 3CR relay to become energized. All the 3CR contacts

will then change positions, the normally open contacts

will close and the normally closed contacts will open.

7. The normally closed 3CR contacts in series with the

“C” cranking contactor will open deenergizing the “C”

contactor. This offers protection from engaging the starter

motor while the unit is operating.

8. The 3CR contacts in series with the 2CR relay coil will

close, maintaining current flow to the 2CR relay coil.

The 2CR relay controls current flow to the engine ignition

circuit.

9. The now closed 3CR contacts in series with the ICR

relay coil and engine safety cutouts will allow the ICR relay

to become energized if the safety cutout contacts close.

The ICR relay also energizes when the start-stop switch is

placed in the stop position.

10. Energizing the ICR relay, either by the engine safety

cutouts or by placing the start-stop switch to the stop position will disrupt current flow to the 2CR relay coil and in

turn prevent current flow to the ignition circuit when the

2CR contacts in this circuit open.

5-3. FUSES

A

WARNING

UNIT STARTS WITHOUT NOTICE! To prevent accidental

starting on units with a remote start/stop switch, always

disconnect battery (remove negative lead first and reconnect it last) to disable generator set before working on any

equipment connected to generator.

There is one IO Amp fuse inside the controller (Figure 5-l).

This fuse protects the controller against damage in the

event a short develops in the engine wiring. If this fuse

“blows” the set will stop. If the set has stopped due to

causes other than lack of fuel, engine malfunction, or low

oil pressure, remove the cover of the controller and check

the fuse. If blown, replace the fuse then attempt to restart

the generator set. If the set will not start, or if the fuse

blows again, locate and correct the cause.

Page 20

NOTE

On earlier models a 10 Amp fuse is mounted inline between the controller and ignition coil.

See the wiring diagram, It protects the control-

ler in the event of a shorted or failed ignition

coil, fuel pump, choke heater, shut-down control or engine wiring.

NOTE

If the 10 Amp in-line fuse is blown the engine

will not crank. If the 10 Amp fuse inside the

controller is blown the engine will crank but

not start. If either fuse blows while the engine

is running, the set will stop.

NOTE

On 4.5 (twin) & 7.5kW models, a self-resetting

circuit breaker located in the generator end

bracket protects the battery charging circuit.

The 7.5kW model uses an 8 Amp circuit breaker. The 4.5kW (twin) and early 7.5kW models

5-5. RELAYS

There are four relays in the generator set. One relay is lo-

cated in the generator end bracket (Figure 6-7). The other

three relays are mounted inside the controller. Refer to

Figure 5-8 when checking or replacing relays. The function

of each relay is described below.

. ICR (STOP RELAY)

- When energized, deenergizes

the 2CR relay.

l 2CR (IGNITION RELAY) - When energized, pro-

vides battery supply to the engine electrical system.

l 3CR (INTERLOCK RELAY) - When energized, de-

energizes the

“C” cranking contactor, and provides

current to energize the ICR relay upon closing of the

engine safety cutouts.

l 4CR (VOLTAGE SENSING RELAY) - When ener-

gized, disconnects excitation current from battery to

regulator and field (V.B.U.), and energizes the 3CR

relay. (The 4CR relay is located inside the generator

end bracket.)

use a 5 Amp circuit breaker.

5-4. REl DIODE

A diode is located in-line between

the start-stop switch and

the 2CR relay to protect against

reverse battery polarity.

When replacing the diode, make

certain connections are

made with the arrow on the diode directing away from the

start-stop switch (Figure 5-8).

STARTING 1 RUNNING 1 STOPPING

“C” contactor

energized

2CR relay

energized

4CR relay

energized

3CR relay

energized

2CR relay

energized

’ 1CR relay

energized

5-5

Page 21

THE SCHEMATIC BELOW SERVES AS

A GUIDE TO LOCATING PROPER

TERMINAL CONNECTIONS.

CONTROLLER

- COVER

0 0

TERMINAL CONNECTIONS AS

SHOWN ON WIRING DIAGRAM

0 0

I

START

STOP

SWITCH

CONNECTORS SHOWN

FROM PIN INSERTION

SIDE

-lr

r

I

c

I

I

I

IO AMP FUSE

I

I

I

I

I

I

I

I

I

I

---

l

I

I

I

I

!

I I

1

I

I

I

I

I

I

I

I

I

I

I

I

.I

I

-m-----

~~~~~~--~~-----~

LOCAL CONTROL BOX A-241752 COVER

(SHOW FROM RcAR)

277947

I

I

I

I

I

I

.I

I

~~~~,~~~ w-&-w------

- - - - - LOCAL CONTROL 801 A-241939

--e,u#

WUCR

&W@J fROu RUR)

277932

Figure 5-8. Relay Terminal Connections

Page 22

Section 6

Generator

6-1. GENERAL

This chapter covers disassembly, inspection, and testing of

the generator components. See Figures 6-l and 6-2 for

parts identification.

grounded. Never touch electrical leadi or appliances with

wet hands, when standing in water, or on wet ground as

the chance of electrocution is especially prevalent under

such conditions.

6-2. TROUBLESHOOTING

6-3. GENERATOR DISASSEMBLY

Refer to Table 4-2 to troubleshoot the generator. Follow

the disassembly procedure in Section 6-3 as far as necessary

to inspect a component, then start reassembly procedure in

Section 6-12 at the point the component is replaced, When

a fuse must be replaced, always inspect the related components and wiring to locate the cause. Refer to the wiring

diagrams in the back of the manual,

A

WARNING

HIGH VOLTAGE! Remember that the function of a generator set is to produce electricity and that wherever

electricity is present, there is the potential danger of

electrocution. Take the same precautions with electrical

appliances in your coach that you would observe in your

home. Keep away from electrical circuits and wiring while

the set is running and have electrical service performed

only by qualified electricians. Make sure unqualified

persons, especially children, cannot gain access to your

set-keep the compartment door locked or securely

latched at all times. Be sure that generator is properly

NOTE

Tag leads to ease re-installation. Scratch align-

ing marks on parts before removing to aid

reassembly.

7. Disconnect battery of generator set, negative lead first.

2. Disconnect the generator ground strap at the tray (Figgure 6-3 or 6-4). On the 3.5kW and 4.5kW (single), remove

the battery positive lead from the generator positive stud

and remove stud remove stud from the generator mounting.

3. Remove the center panel (4.5, 5.5, 7, 7.5kW), see Figure 6-5; or remove the end panel (3.5kW), see Figure 6-6.

4. Remove the plug from the voltage sensing relay Figure

6-7). The relay can now be removed.

‘j 12b

1. End Bracket

7. Panel, Center

12b. Voltage Regulator (7.5KW) 18. Ball Bearing

2. Stator 8.

Circuit Breaker(s)

13. Voltage Sensing Relay (VSR) 19. Washer

3. Rotor

9. Junction Panel

14. Thru Bolt 20. Tolerance Ring

4. Adapter

IO. Generator Fan

15. Over Bolt

21. Brush

5. Guard, Fan 11. Bearing Cap

16.

End Bracket

22. Brush Holder

6. Junction Panel

12a. Voltage Regulator (3.5kW-7kW)

17. Slip Ring

Figure 6-l.

Generator, Cross Sectional View

6-1

Page 23

3

2 \

13

1

I --.- /

16-

19’ i?y-

1.

2.

3.

4.

5.

6.

7.

8.

9. Ball Bearing

10.

Slip Ring

Voltage Sensing Relay

(VSR)

Wiring Harness

Spring

Brush

Brush Holder

Panel

Tolerance Ring

Rotor (2 Pole Shown)

11.

Fan

12.

Adapter

13.

Stator

14. End Bracket

15.

Exciter / Voltage Regulator

16.

Circuit Breaker

17. Transformer

18. Transformer Bracket

19. Circuit Breaker

20. Bridge Rectifier

Figure 6-2. Generator Pa

,:::; GROUND STRAF

Figure 6-3. Generator Ground Strap (3.5kW Shown)

Figure 6-4. Generator Ground Strap

(4.5 Twin, 5.5, 7, 7.5kW)

es Identification

Figure 6-5. Center Panel Removal (4.5, 5.5, 7, 7.5kW)

Figure 6-6. End Panel Removed (3.5kW)

6-2

Page 24

Figure 6-7. Removing Plug from Voltage

Sensing Relay (VSR) (4.5kW-7kW)

5. Remove the top housing (Figure 6-8) (3.5 and 4.5kW

single).

6. Remove the exhaust tube (Figure 6-9) (3.5kW-7kW).

7. Remove the side housings (3.5kW-7kW).

8. Remove the inside housings (Figure 6-10) (3.5 and 4.5

kW single).

9. Loosen the vibro-mounts (Figure 6-11) and lift the gen-

erator from the base.

10. Tilt the generator end up and place blocks under the

generator adapter.

Figure 6-9. Exhaust Tube

Figure 6-10. Inside Housing Removal

Figure 6-8. Top Housing Removal

Figure 6-l I. Vibro-Mounts

6-3

Page 25

Figure 6-13. Over Bolt Removal (Two Shown)

11. Lift the brushes by the leads and lock in this position

by inserting a retainer wire as shown in Figure 6-12.

12. Remove the end bracket by removing four long over

bolts. See Figure 6-13.

13. Disconnect the stator leads from the regulator.

NOTE

The voltage regulators on 4.5, 5.5, 7 and 7.5kW

generator sets are located inside the end bracket.

On the 3.5kW, the voltage regulator is located

outside the end bracket. See Figures 6-14 and

6-15. Terminal connections and testing will be

the same for all.

Figure 6-14. Exciter / Voltage Regulator

Figure 6-15. Exciter / Voltage Regulator (3.5KW)

14. The stator (Figure 6-16) can be tested at this time (Sec-

tion 6-8). Remove the stator by guiding it to the rear,

15.1 l Four-Pole Removal (4.5, 5.5,7,7.5kW). Remove thru

bolt and detach washers. Re-insert thru bolt leaving a l/8

6-4

Page 26

inch gap between bolt and rotor. Bump the thru bolt with

a lead mallet to break the rotor loose (4.5, 5.5, 7, 7.5kW

only) for removal (Figure 6-l 7). If the bearing turns freely

and has no sign of damage do not remove, the fan will be

removed with rotor (Figure 6-18).

NOTE

On 7.5kW, if the rotor seems loose but can not

be removed, see Section 6-3.2.

Figure 6-16. Stator

Figure 6-17. Rotor Thru Bolt

15.2. Two-Pole Removal (3.5kW). On the 3.5kW, the rotor

is held to the engine crankshaft by right-hand threads on

the crankshaft and in the rotor shaft (engine rotates counterclockwise when viewed from drive side). These threads

have been coated with antiseize compound to aid disassembly. To remove rotor, place a wood block in a trailing edge

of one rotor pole. A sharp, medium force hammer blow to

wood block’s end will free the rotor, allowing it to be

turned off by hand (Figure 6-19).

Figure 6-18. Removing Rotor (4.5,5.5, 7kW)

CAUTION

Do not attempt to remove rotor by blocking

engine cooling fan and turning rotor with any

kind of wrench. Damage to fan blades and rotor

may result.

Figure 6-19. Removing Rotor (3.5kW)

6-5

Page 27

Figure 6-20. Removing Oil Tank

Figure 6-21. Oil Tank Removed

6-3.1. Removal of Oil Tank 4.5kW (KT17 Series I only)

1. Drain oil from oil tank assembly.

2. Detach nut from eyebolt. Remove the bolt attaching the

oil tank to engine leg. Detach ventilation line (Figure 6-20).

3. Pull the tank off, making sure it is removed squarely

(Figure 6-21).

4. Oil Level Switch Replacement. (If the oil level switch

does not need replacement, omit Step 4.)

a. Remove oil tank cover by removing six screws. Be

careful not to damage gasket surface when prying

apart.

b. Remove switch at coupling connection. It will be

necessary to cutoff eyelet terminal and insulink to

remove switch.

c. Apply pipe thread compound to new switch, slide

leads through insulator sleeve and thread switch into

coupling. Tighten switch so that distance between

bottom of switch and inside of cover is 3.0 in. (76.2mm).

See Figure 6-22.

6-6

Insulator

Sleeve

YL-J

Notch Must Be

On Bottom

Figure 6-22. Oil Level Switch Mounting

d. With gasket surfaces clean, install oil tank cover

using a new gasket. Torque bolts to 70 in/lbs. (7.9Nm)

using torque sequence shown in Figure 6-23.

NOTE

Cut one wire from switch so that it reaches

screw shown in Figure 6-23, strip 250 in.

(6.4mm) of insulation and crimp-on l/4” eyelet term inal. Place terminal between lockwasher

and cover.

e. Plug end of ventilation fitting. Below compressed air,

about 30 psi (207kPa), into oil tank bore and check for

leaks at gasket surfaces, switch connection and ventilation fitting using a soap solution. Repair any leaks.

CAUTION

Any air leak in the ventilation line system could

cause the engine oil to be drawn from the reservoir into the crankcase, resulting in engine blowby and a low oil level shutdown.

f. Cut the other wire from switch so that it reaches #I2

(purple) lead, strip .250 in. (6.4mm) of insulation and

connect together using an insulink.

.+

w

\

Ground

Lead

Figure 6-23. Torque Sequence

Page 28

5. When installing the oil tank, make sure O-rings are not

damaged. Apply grease to the O-rings, fitting and the oil

tank bore. Push tank on squarely.

6-3.2 On the 7.5kW generator set, if the rotor seems loose

but cannot be removed, the flywheel has become free of

the crankshaft taper. To separate rotor from flywheel,

adapter, and stub shaft proceed as follows.

I. Remove eight bolts fastening generator adapter to bell

housing (Figure 6-24).

2. Pull rotor, adapter, and flywheel away from engine.

3. Slide adapter over generator fan as far as possible.

4. Remove four bolts fastening stub shaft to flywheel

(Figure 6-25).

Figure 6-24. Adapter Removal

Stub

Flywheel

Figure 6-25. Separating Stub Shaft and Flywheel

5. The flywheel and adapter can now be removed (Figure

6-26).

6. Strike downward on corner of stub shaft with a lead

mallet as shown in Figure 6-27.

7. The stub shaft can now be removed.

- .

Figure 6-26. Remove Flywheel and Adapter

Figure 6-27. Stub Shaft Removal

6-4. BUI LD-UP Cl RCUIT

This circuit magnetizes the rotor during cranking. When

the switch on the controller is moved to the start position,

6-7

Page 29

DC current flows from the battery to brushes and sl

on the rotor. See Figure 6-28.

ip rings

6-5. BRUSHES

6-5.1 General. The brushes transfer current from the voltage regulator to slip rings. The brushes carry a very low cur-

rent (approximately 2 Amps) and should last the life of the

generator set. Abrasive dust on the slip rings could, however, shorten the life of the brushes. Excessive arcing at the

brushes could damage the voltage regulator. Arcing could

be caused by weak springs, damaged slip rings, sticking

brushes, loose holder, or poor brush alignment.

6-5.2. Maintenance.

1. Remove the end bracket panel to gain access to the

brushes.

2. The brushes must be free to move within the holder and

held in proper contact by the springs. When properly

positioned, spring pressure on the brush surface will

cause the brush to wear evenly. Figure 6-29 shows normal

brush wear.

3. Replace the brushes if worn excessively or unevenly.

4. Replace the springs if damaged or discolored.

5. Be sure to use original or identical l/2 inch (12.7mm)

screws when reinstalling the brush holder. Longer screws

will break the holder when tightened.

6. To install the brushes and holder insert a wire as shown

in Figure 6-30, to hold the brushes in. Position the brushes

on the slip rings and install the two screws. Remove the

wire.

CAUTION

If the retainer wire is not removed, the voltage

regulator will be damaged when the generator

is started.

Figure 6-29. Brushes

WIRE

Figure 6-30. Brush Holder

STARTER

GENERATOR

ROTOR

/

BRUSHES &

SLIP RINGS

4CR

GENERATOR

REGULATOR

12 VOLT

BATTERY

Figure 6-28. Buildup Circuit

6-8

Page 30

6-6. SLIP RINGS

Slip rings acquire a glossy brown finish in normal operation.

Do not attempt to maintain a bright, newly-machined appearance. Ordinary cleaning with a dry, lint free cloth is

usually sufficient. Very fine sandpaper (#OO) may be used

to remove roughness. Use light pressure on the sandpaper.

Do not use emery or Carborundum‘ paper or cloth. Clean

out all carbon dust from the generator. If the rings are

black or pitted, remove the rotor and remove some of the

surface material by using a lathe.

6-7. EXCITER / VOLTAGE REGULATOR

6-7.1. General. The voltage regulator assembly (Figure

6-31) includes a bridge rectifier and a voltage regulating

circuit. AC from the stator is received at the “AC” terminals on the regulator. Thi’s current is rectified to DC by the

bridge rectifier and supplied to the rotor from terminals

(+) and (-) through the brushes and slip rings. This AC is

constantly monitored by the regulator to maintain +2%

variation of the stator output.

NOTE

Although the physical appearance of your

voltage regulator may differ from the one pictured, its fu tiction is identical.

NOTE

When replacing regulators apply a light coating

of thermal compound between the regulator

and end bracket. This compound aids in dissipating heat from regulator to end bracket. For

regulators with two mounting screws tighten to

20 in. Ibs. (2.3Nm) maximum. For center

mount-type regulators, tighten screw to 15 in.

Ibs. (1.7Nm) maximum.

67.2. Exciter / Voltage Regulator Test.

A

’ WARNING

HIGH VOLTAGE! Remember that the function of a gen-

erator set is to produce electricity and that wherever

electricity is present, there is the potential danger of

electrocution. Take the same precautions with electrical

appliances in your coach that you would observe in your

home. Keep away from electrical circuits and wiring while

the set is running and have electrical service performed

only by qualified electricians. Make sure unqualified

persons, especially children, cannot gain access to your

set-keep the compartment door Iock,ed or securely

latched at all times. Be sure that generator is properly

grounded. Never touch electrical leads or appliances with

wet hands, when standing in water, or on wet ground as

the chance of electrocution is especially prevalent under

such conditions.

Since this test is designed for use in the field, it only

checks regulator output when “cold” and does not check

voltage build-up.

Figure 6-31. Exciter / Voltage Regulator

To complete the test you’ll need the following equipment:

Two 12OV/lOO watt bulbs and sockets.

11 O/l 20V AC power source or variable transformer.

Switch, PST, 12OV, 2 Amp. minimum

Fuse, 2A (in holder)

Jumpers

Multimeter

Figure 6-32 shows the typical voltage regulator terminal

identification:

OR

AC

0

+

AC

Figure 6-32. Terminal Identification

6-9

Page 31

1. Connect two 100 watt light bulbs across “+” and ‘I-”

terminals of regulator. See Figure 6-33.

NOTE

2. Set multimeter range to 100 Volts DC. Connect meter

across light bulbs. Check for correct polarity (refer to

Figure 6-33).

A

WARNING

HIGH VOLTAGE! Remember that the function of a gen-

erator set is to produce electricity and that wherever

electricity is present, there is the potential danger of

electrocution. Take the same precautions with electrical

appliances in your coach that you would observe in your

home. Keep away from electrical circuits and wiring while

the set is running and have electrical service performed

only by qualified electricians. Make sure unqualified

persons, especially children, cannot gain access to your

set-keep the compartment door locked or securely

latched at all times. Be sure that generator is properly

grounded. Never touch electrical leads or appliances with

wet hands, when standing in water, or on wet ground as

the chance of electrocution is especially prevalent under

such conditions.

3. Completely disconnect IZOV AC source from primary

power source before connecting across regulator.

A

WARNING

HIGH VOLTAGE! When the power cord is plugged in

during voltage regulator test, the AC pins become “hot”

and there is danger of electrocution.

4. Connect one pole of (on-off) switch and the fuse to one

of the “AC” terminals on the regulator. Connect other pole

of switch to the 110/l 20 AC source (Figure 6-33). Connect

other “AC” terminal to 110/12OV AC source.

5. Turn on 1 IO/l 20V AC source.

6. With multimeter connected across light bulbs, turn on

switch. Bulbs should light immediately, DC voltmeter

should register 10 to 50V DC.

If bulbs flash momentarily and extinguish,

flicker dimly or glow steadily the regulator is

functioning properly.

These conditions are

caused by the amplitude of the “AC” supply

voltage used. A momentary flash results when

supply voltage is above the regulating voltage

or regulator under test. Flickering results when

supply voltage and regulating voltage are with-

in a few volts. If a variable transformer is

available, it should be used to adjust the AC

supply ‘until the bulbs glow steadily. The variable transformer will adjust the voltage to coincide with the approximate regulating voltage of

the regulator.

7. Test field build-up circuit by connecting one end of

jumper to either “AC” terminal. Touch the other end of

jumper to “B” terminal. Bulbs should glow brighter. Volt-

meter should indicate 50-75 Volts DC.

A

WARNING

HIGH VOLTAGE! When the power cord is plugged in

during voltage regulator test, the AC pins become “hot”

and there is danger of electrocution.

NOTE

If voltage readings coincide with above recom-

mended test results, regulator may be used in

generator set.

CAUTION

Completely disconnect IZOV AC source from

primary power

source before disconnecting

from regulator.

Fl

2A

110/120 AC B

+

VAC OR

VARIABLE

TRANSFORMER’+

* See Note After Step 7.

Figure 6-33. Wiring Diagram -Voltage Regulator Field Test

6-10

Page 32

Figure 6-34. Stator

6-8. STAT0 R

6-8.1. General. The stator (Figure 6-34) consists of a series

of coils of wire laid in a laminated steel frame. The stator

leads (see Generator Wiring Diagram) supply voltage to the

AC load and exciter / voltage regulator.

6-8.2. Testing. The stator should have 0.25 ohms resistance

across each winding. To test, connect an ohmmeter between

leads 1 and 2, 3 and 4, and then 33 and 44. The leads are

tagged with the lead number,

6-9. ROTOR

The function of the rotor is to create a magnetic field. The

3.5kW has a rotor with two electromagnetic field poles

(Figure 6-35). The +5kW, 55kW, 7kW and 7.5kW each

have a rotor with four electromagnetic field poles (Figure

6-36). Rotor resistance readings are given in Table 6-1.

Measure resistance (ohms) between the two slip rings.

c

s

l

MODEL

RESISTANCE

3.5KW 9 to 11 ohms

4.5KW 8 to 10 ohms

5.5KW 8 to 10 ohms

7KW 8 to 10 ohms.

Table 6-l. Rotor Resistance

6-10. SEPARATE FIELD EXCITATION

As a preliminary aid to troubleshooting, the generator field

(rotor) may be excited (magnetized) using an outside power

source and the following procedure:

1. Disconnect brush leads from voltage regulator.

Figure 6-35. Two Pole Rotor

.:

Figure 6-36. Four Pole Rotor

A

WARNING

DANGEROUS ACID! Avoid contact with battery electro-

lyte. It contains acid which can eat holes in clothing, burn

skin, and cause permanent damage to eyes. Always wear

splash-proof safety goggles when working around the

battery. If battery electrolyte is splashed in the eyes or on

skin, immediately flush the affected area for 15 minutes

with large quantities of clean water. In the case of eye

contact, seek immediate medical aid. Never add acid to a

battery once the battery has been placed in service. Doing

so may result in dangerous spattering of electrolyte.

A

WARNING

EXPLOSIVE BATTERY GASES! The gases generated by a

battery being charged are highly explosive. Do not smoke

or permit flame or spark to occur near a battery at any

time, particularly when it is being charged. Avoid contacting terminals with tools, etc., to prevent burns and to

prevent sparks that could cause an explosion. Remove

wristwatch, rings, and any other jewelry before handling

battery. Any compartment containing batteries should be

well ventilated to prevent accumulation of explosive gases.

To avoid sparks, do not disturb battery charger connections while battery is being charged and always turn

charger off before disconnecting battery connections.

Turn automotive test equipment off when connecting or

removing battery clips. When removing or reconnecting

battery cables, make sure ignition switch and all accessories are turned off.

6-11

Page 33

2. Connect brush leads in series with 12-Volt battery and

DC ammeter as shown in Figure 6-37.

3. Ammeter reading should approximate battery voltage

divided by specified rotor resistance (Table 6-1).

4. Record ammeter reading.

5. Start generator set and run at NO load.

6. Observe ammeter with unit running. If current increases

considerably, a running short in the rotor has been detected.

EXCITER /

VOLTAGE r 1

REGULATOR ,-‘&I;

DC

BATTERY

SLIP RINGS J BRUSHES

Figure 6-37. Separate Excitation Connections

6-l 1. VOLTAGE SENSING RELAY

erator output, and disconnect excitation current from the

battery to the regulator and field (V.B.U.), and energize the

3CR (interlock relay). If there is no AC output; the relay

will not energize, and the unit will shut down when the

start-stop switch is released from the start position.

6-12. GENERATOR REASSEMBLY

1. On the 3.5kW, apply antiseize compound to the rotor

threads (Figure 6-39). Thread the rotor onto the drive

shaft, and tighten by hand.

2. On the 4SkW, 55kW, 7kW or 7.5kW, apply antiseize

compound to the crankshaft stub (Figure 6-40). Install the

rotor onto the crankshaft with the thru bolt. See Table 6-2

for torque value.

I

SIZE

I

TORQUE

I

5116

3/8

l/2

100 to 125 in. Ibs. (11.3-14.1Nm)

175 to 200 in. Ibs. (19.8-22.6Nm)

40 to 55 ft. Ibs. (54.2-74.6Nm)

Table 6-2. Generator Thru Bolt Torque

3. Slide the stator into position making sure the leads are

at 12 o’clock position (Figure 6-41).

4. Install the end bracket with the four long over bolts.

5. Position the brush holder and install the two brush

holder screws. To install the brush holder, it will be

The voltage sensing relay (Figure 6-38) is located in the

necessary to retain the brushes with a wire (Figure 6-42).

end bracket assembly. Its function is to sense AC gen-

Remove the wire when the brushes are installed.

’ TO PIN “4” OF

PI CONNECTOR

TO LEAD FROM “B”

TERMINAL OF

VOLTAGE REGULATOR

I

I

COIL RESISTANCE = 4000 OHMS

COIL VOLTAGE = 120 VOLTS AC

Figure 6-38. Generator Voltage Sensing Relay (VSR)

6-12

Page 34

).A:::‘; ::,..:, :,<4y:.:

,. ..::

THREADS

Figure 6-39. Rotor (3.5kW)

6. Install the generator to the base.

Figure 6-41. Stator and Rotor

Figure 6-42. Brush Retaining Wire

Figure 6-40. Driveshaft (4.5kW Shown)

7. Install the exhaust tube. Install the side housings and

top housing.

8. Install the voltage sensing relay and plug. See Generator Wiring Diagram for connections.

9. Install the circuit breaker(s) and end panels (Figures

6-43 and 6-44).

10. Reconnect the generator ground strap to the tray, On

the 3.5kW and 4.5kW (single), reinstall the generator posi-

tive stud and reconnect battery positive lead to stud.

11. Reconnect battery of generator set, negative lead last.

6-13

Page 35

.A..

.: ,...

Figure 6-43. End Bracket, Panels Removed (4.5kW Single Shown)

BREAKER :

Figure 6-44. Lower End Bracket (4.5 Twin, 7SkW)

6-14

Page 36

Section 7

Choke, Shutdown Control and Governor

7-1. CHOKE TESTING AND ADJUSTMENTS (3.5kW,

4.5kW SINGLE)

A

WARNING

BACKFIRE! A sudden backfire can cause serious burns.

Keep hands and face away from the carburetor when the

air cleaner is removed.

7-1.1

General. When the engine start switch is activated,

battery current activates the rotary solenoid in the electric

choke unit (Figure 7-l). The choke lever pushes the choke

plate into the full choke position. The solenoid deenergizes

immediately after the switch is released from the start posi-

tion. When the solenoid deenergizes, the choke plate opens

to a position determined by a thermostatic spring and the

ambient temperature. As the engine warms and less choking

is needed, the thermistor circuit allows the choke plate to

gradually move to full open position.

A

WARNING

UNINTENTIONAL STARTING! To prevent accidental