Kohler KT3144MSN Installation Manual

FINIAL FUNDAMENTALS

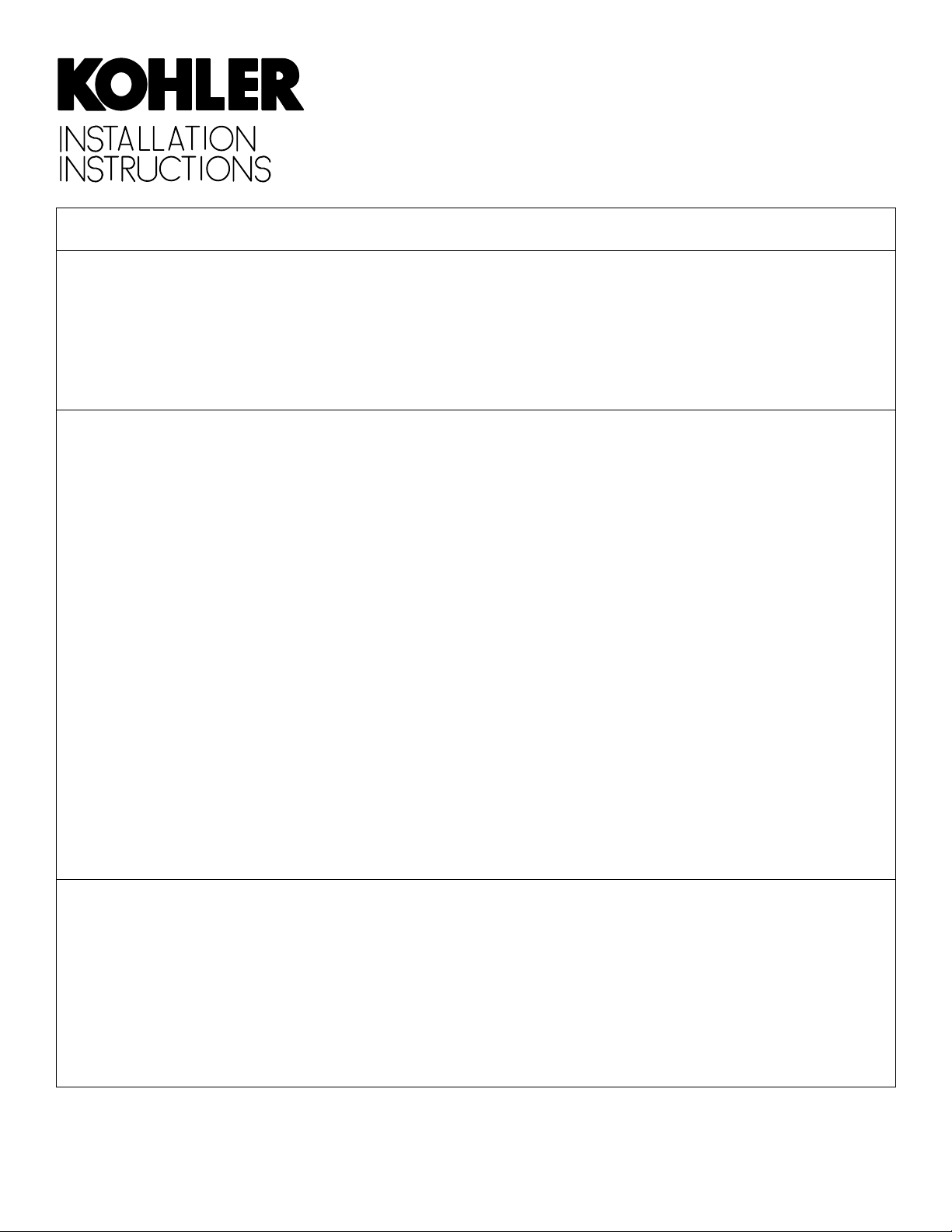

BATH/DECK-MOUNT BATH FAUCET

K-T314, K-T314M, K-T333, K-T333M

1. BEFORE YOU BEGIN

HOW TO USE THESE INSTRUCTIONS

Please read these instructions carefully to familiarize

yourself with the required tools, materials, and installation

sequences. Follow the sections that pertain to your

particular installation. This will help you avoid costly

mistakes. In addition to proper installation, read all

operating and safety instructions.

PRODUCT REQUIREMENTS

For roughing-in dimensions, see Fig. #1.

Ensure that any holes drilled in the deck are not

oversized. The spout requires adequate base

material strength. Spout and valve washers must

contact a maximum amount of deck surface. Spout

hole = 1” (2.5cm) maximum; and valve holes =

1-1/2” (3.8cm) maximum.

Finish deck material must fit closely to the

diameters of the plaster guards, especially the

spout plaster guard.

If holes are drilled in the sheet deck material before

placement on the deck, they must match the

plaster guard diameters.

Plaster guard diameters are approximately 1-5/8”

(4.1cm) for the valve, and 13/16” (2.1cm) for the

spout.

Installer-supplied copper tubing is to be 5/8” O.D.

(1/2” nominal).

Provide an access panel to the valves from the

underside of the deck.

Install water hammer arrestors in the supply lines

near the valves.

All information in these instructions is based on the latest

product information available at the time of publication.

Kohler Co. reserves the right to make changes in product

characteristics, packaging, or availability at any time

without notice.

INST ALLER INFORMA TION

Observe all local plumbing and building codes.

Products purchased separately may influence

valve placement and alignment.

Spout will require that the spout supply tube be cut

to the proper length.

Instructions are given for installation with 8”

(20.3cm) centers. For installations wider than 8”

(20.3cm) centers, adjust all roughing-in

dimensions and copper tubing lengths accordingly .

These instructions cover two methods of

installation: installation on finished deck or rim; and

installation on rough (unfinished) deck (to be

covered later with tile or other finish material).

Leave the protective sleeve on the spout supply

tube until the spout is installed. This is an O-ring

sealing surface, which may be damaged if

unprotected.

ORDERING INFORMA TION

Bath/Deck-mount bath faucet:

Cross handles K-T314-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Lever handles K-T314-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Tee handles K-T314-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cross handles K-T333-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Lever handles K-T333-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Tee handles K-T333-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1012557-2-A

TOOLS AND MA TERIALS REQUIRED

Open end/adjustable wrenches

Adjustable arc pliers

1/2” Nom. (5/8” O.D.) tubing

Tubing cutter

Hole cutting equipment

Soldering equipment and supplies

Phillips screwdriver

Español, Página 13

Français, Page 25

2001 Kohler Co.

ROUGHING-IN

Turn off the water supply.

Install or relocate the supplies as necessary to conform to

the roughing-in dimensions.

* Dashed lines indicate items to be supplied by the

installer.

Diameter of the spout hole in the deck = 1” (2.5cm).

2-3/8” (6cm)

1/4” (6mm) TO 1-1/4”

1/4” (6mm) TO 2-1/8”

(5.4cm) MAX. RIM OR

DECK MOUNT

1-5/16”

(3.3cm) D.

RIM OR DECK MOUNT

INSTALLATION

8” (20.3cm) Min.

3-3/8” (8.6cm)

(3.2cm) MAX.

FINISHED DECK

3/4” I.D.

3-3/8”

(8.6cm)

Diameter of valve hole in the deck = 1-1/2” (3.8cm).

NOTE: Reinforcing material may be required if the deck or

rim is thin. Install before proceeding.

NOTE: For installations on a rough (unfinished) deck to be

covered later with tile, the tile thickness must not exceed

1-1/4” (3.2cm).

9-1/2”

(24.1cm)

2-1/8” (5.4cm) MAX.

ROUGH DECK

ROUGH + FINISHED

DECK MOUNT INSTALLATION

1-1/4”

(3.2cm)

6-1/4”

(15.9cm)

3-3/4” (9.5cm)

7-1/2”

(19.1cm)

7/8”

(2.2cm) D.

4-1/2”

(11.4cm)

2-1/2” (6.4cm)

2-1/2” (6.4cm)

Fig. #1

4-1/2”

(11.4cm)

4-1/2”

(11.4cm)

2-1/2” (6.4cm)

TEECROSS LEVER

1012557-2-A

2

Kohler Co., Kohler, WI U.S.A.

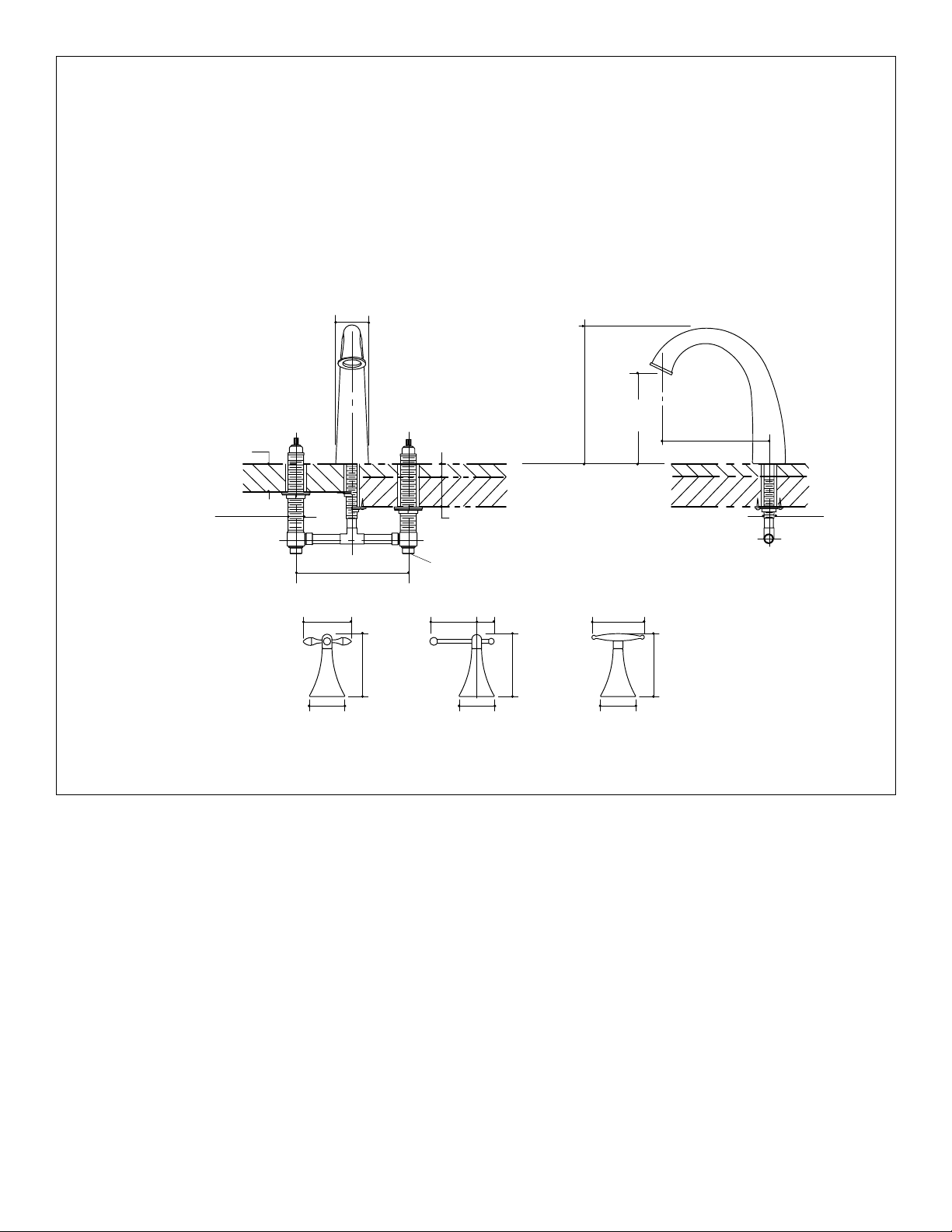

2. INSTALLATION ON FINISHED DECK OR RIM

NOTE: For installation on rough (unfinished) deck,

proceed to Section 3.

Preparation: For installations with 8” (20.3cm) centers

using copper tubing (1/2” nominal, 5/8” O.D.), cut the

tubing to the lengths as follows:

2 pieces: 2-7/8” (7.3cm) long

1 piece: 2-3/8” (6cm) long (for spout supply)

For non-8” (20.3cm) center installations, adjust the

tubing lengths as necessary.

NOTE: Leave the protective sleeve on the spout supply

tube until the spout is installed. This is an O-ring sealing

surface, which may be damaged if unprotected.

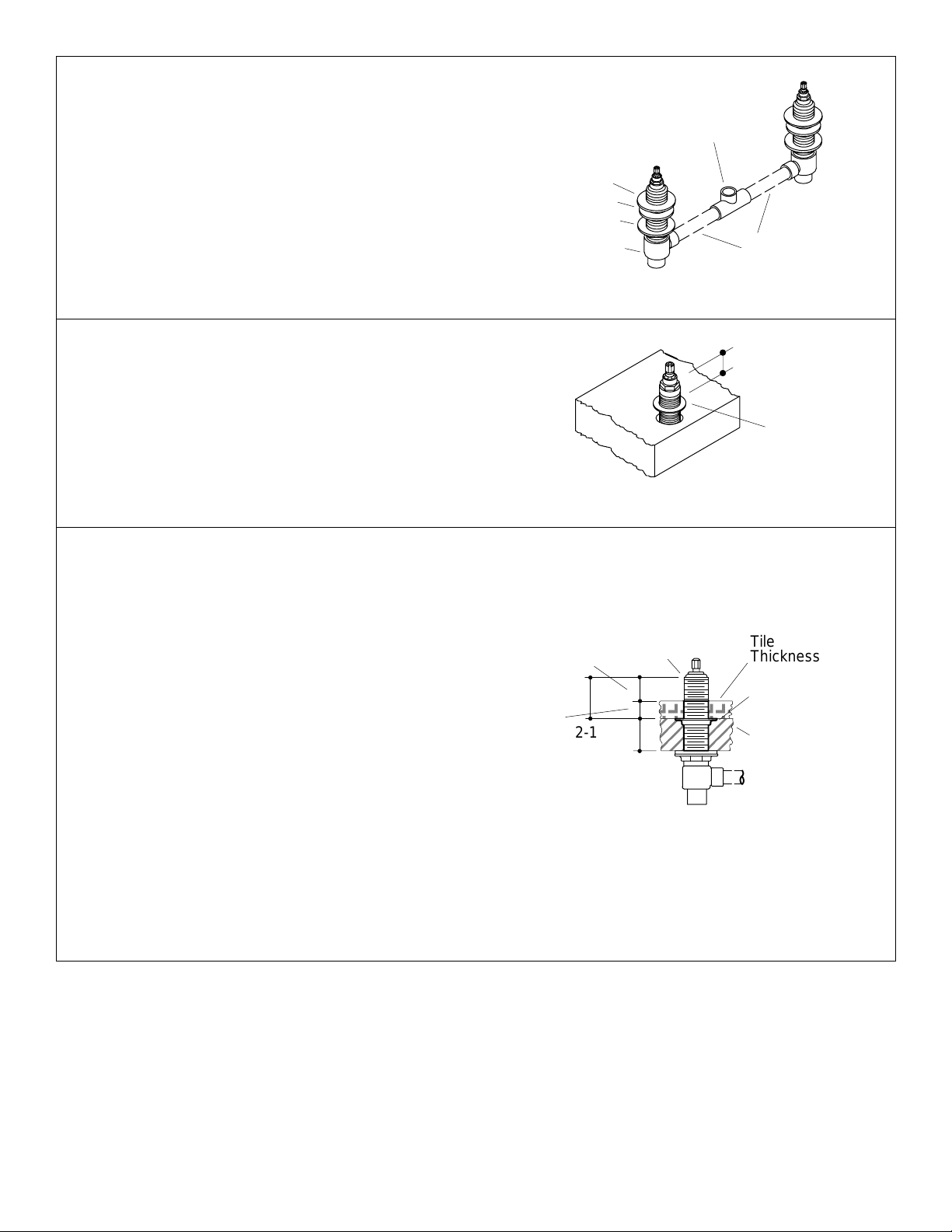

Install Spout Supply Tube: Slide a brass washer from

the bottom of the spout supply tube over the threads until

the washer reaches the supply tube shoulder.

Insert the spout supply tube through the mounting hole

from the top of the deck/rim. Ensure that the flat portion

of the washer faces forward. The supply tube will be

suspended by the washer.

Slide a brass washer onto the spout supply tube from the

bottom, and thread on the mounting nut. Tighten the nut.

NOTE: Do not use the supplied wood screws for

installation on finished deck or rim.

Install Valve Bodies: Thread one mounting nut, flange

side up, onto each valve body.

NOTE: Rims less than 1/4” (6mm) thick require two

rubber washers in the following step; other installations

require only one rubber washer.

Slide one fiber washer, followed by one or two rubber

washers, onto each valve body.

Insert the 2-7/8” (7.3cm) long copper tubes between the

valve bodies and the 1/2” tee. Then insert the 2-3/8” (6cm)

long copper tube into the top of the tee.

Spout Supply Tube

Supply Tube Shoulder

2-3/8” (6cm)

Copper Tube

Rubber Washer

or Washers

Fiber Washer

Mounting Nut

Valve Body

Brass Washer

Brass Washer

Nut

Fig. #2

1/2”

Tee

2-7/8” (7.3cm)

Copper Tubes

Fig. #3

DO NOT solder the connections yet.

Kohler Co., Kohler, WI U.S.A.

3

1012557-2-A

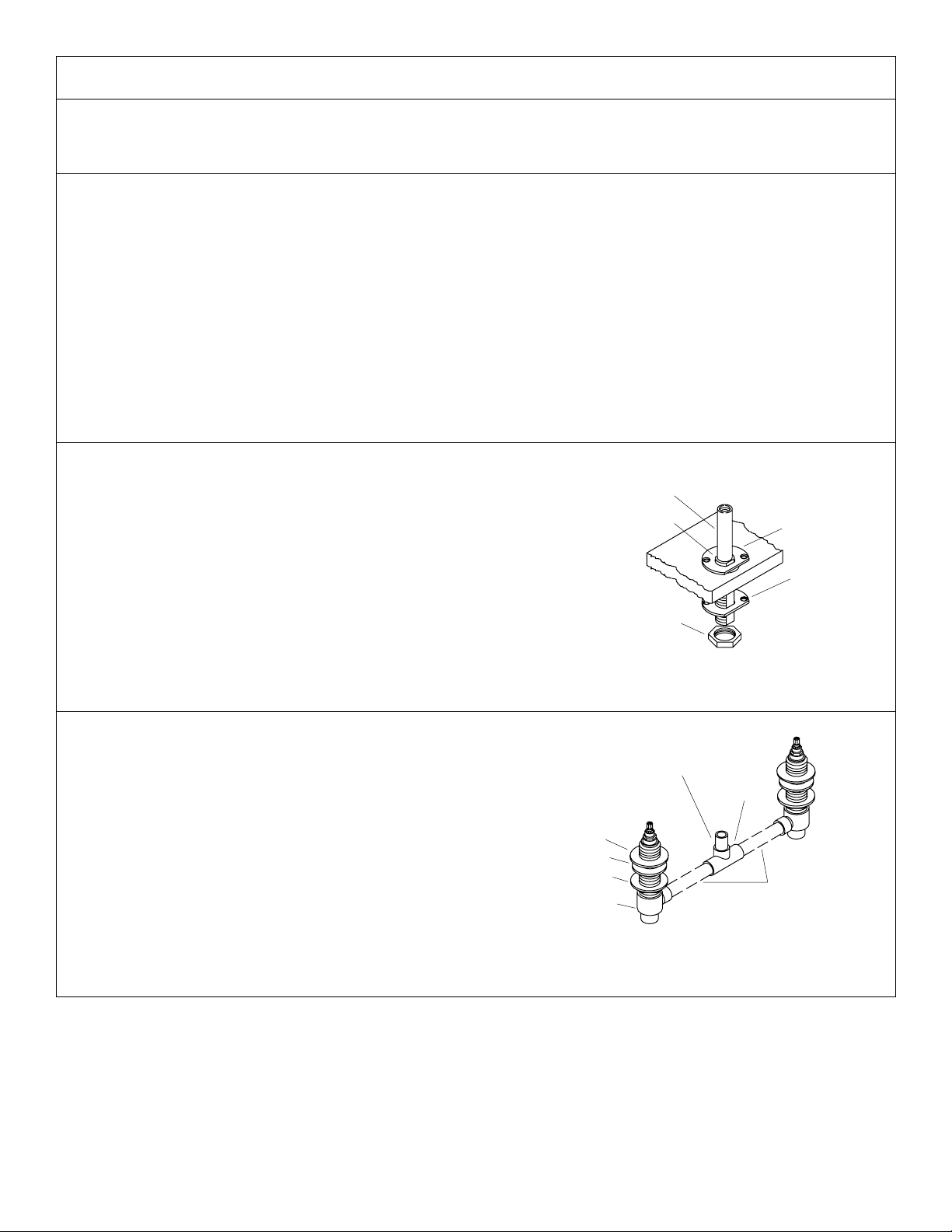

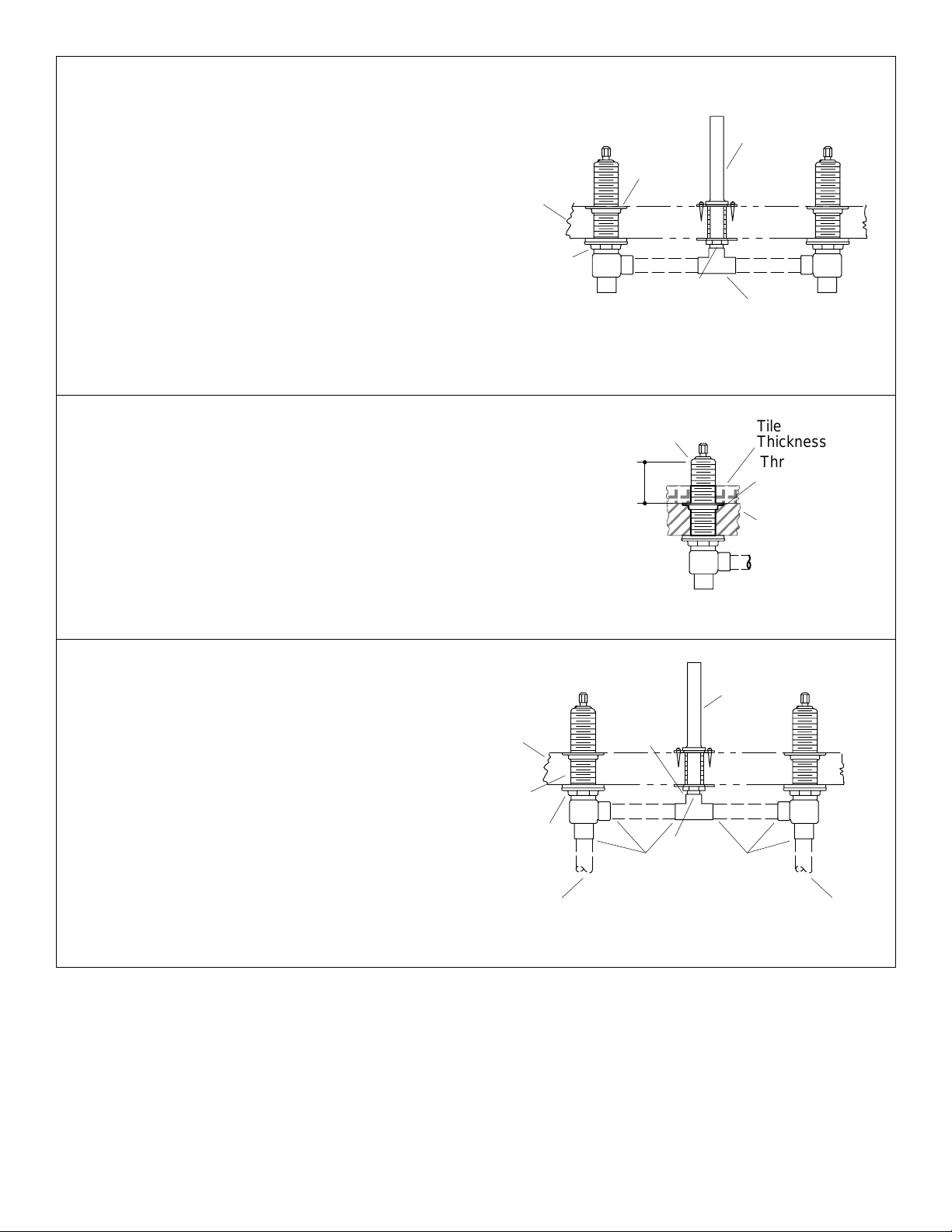

NOTE: Orient the valve body marked “COLD” so it is on

the right when you are facing the front of the faucet.

Insert the valve bodies through the mounting holes from

the bottom of the deck/rim. Mate the copper tube from the

tee with the spout supply tube. Hold in place.

Set a collar, with the flange side up, onto each valve body .

Thread down to at least 1” (2.5cm) from the top thread on

the valve body.

Tighten the mounting nuts on each valve body from

underneath the deck/rim.

Solder the copper tubes to the valve bodies, tee, and

spout supply tube.

Solder the hot and cold water tubes to the valve body

inlets. Ensure that the cold supply is on the right side.

NOTE: Proceed to Section 4.

1” (2.5cm)

Collar

Fig. #4

Cold

Supply

Solder

Solder

Hot

Supply

Solder

Fig. #5

3. INSTALLATION ON ROUGH (UNFINISHED) DECK

Preparation: For installations with 8” (20.3cm) centers

using copper tubing (1/2” nominal, 5/8” O.D.), cut two

pieces of tubing to 2-7/8” (7.3cm) in length.

For non-8” (20.3cm) center installations, adjust the tubing

lengths as necessary.

NOTE: Leave the protective sleeve on the spout supply

tube until the spout is installed. This is an O-ring sealing

surface which may be damaged if unprotected.

Install Spout Supply Tube: Slide a brass washer from

the bottom of the spout supply tube over the threads until

the washer reaches the supply tube shoulder . Ensure that

the countersunk holes in the washer are facing upward.

Insert the spout supply tube through the mounting hole

from the top of the deck. Ensure that the flat portion of

washer faces forward. The supply tube will be suspended

by the washer.

Brass

Washer

Spout Supply Tube

ScrewScrew

Supply Tube

Shoulder

Brass

Washer

Slide a brass washer onto the spout supply tube, and

thread on the mounting nut. Tighten the nut.

Secure the brass washer to the deck using the two

supplied wood screws.

1012557-2-A

Rough

Deck

Fig. #6

4

Nut

Kohler Co., Kohler, WI U.S.A.

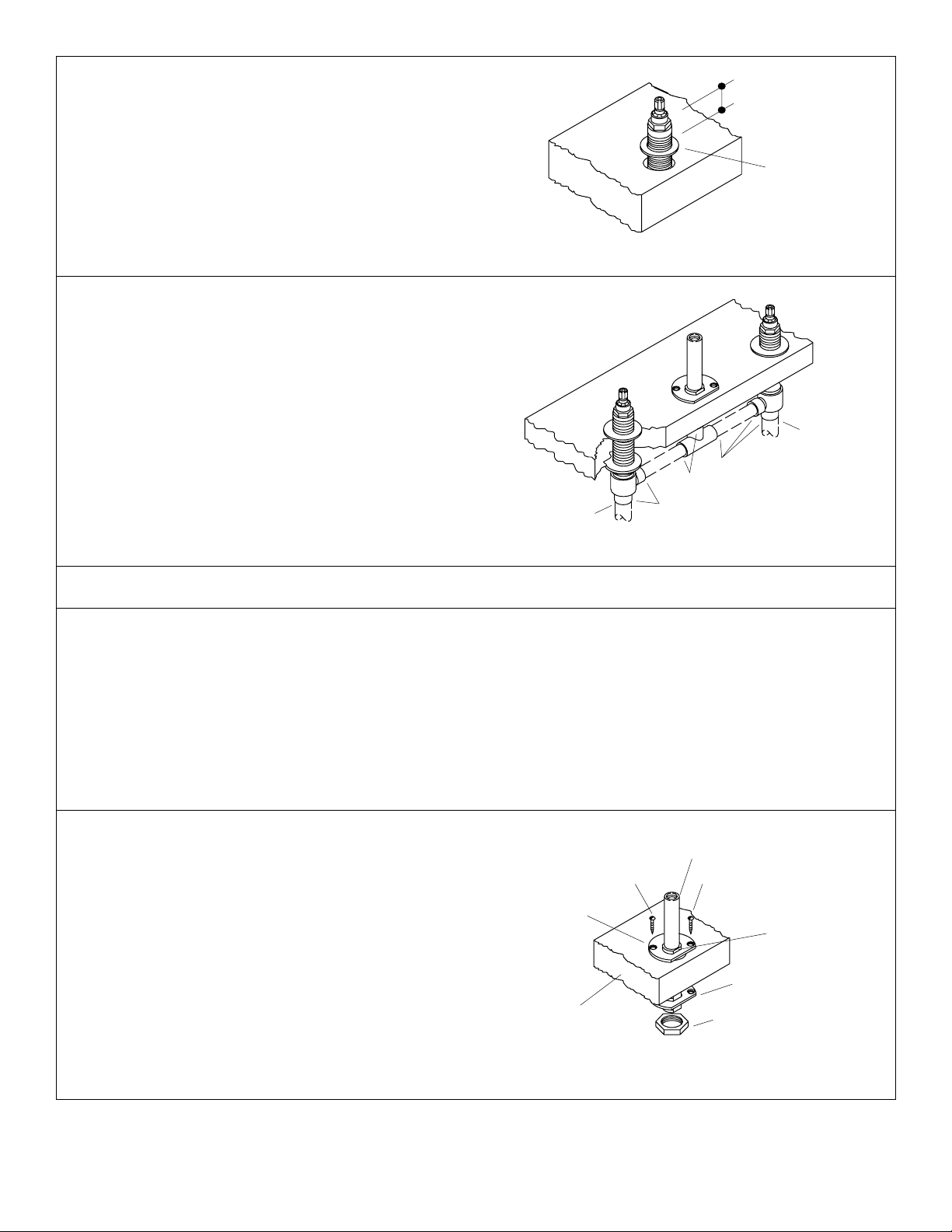

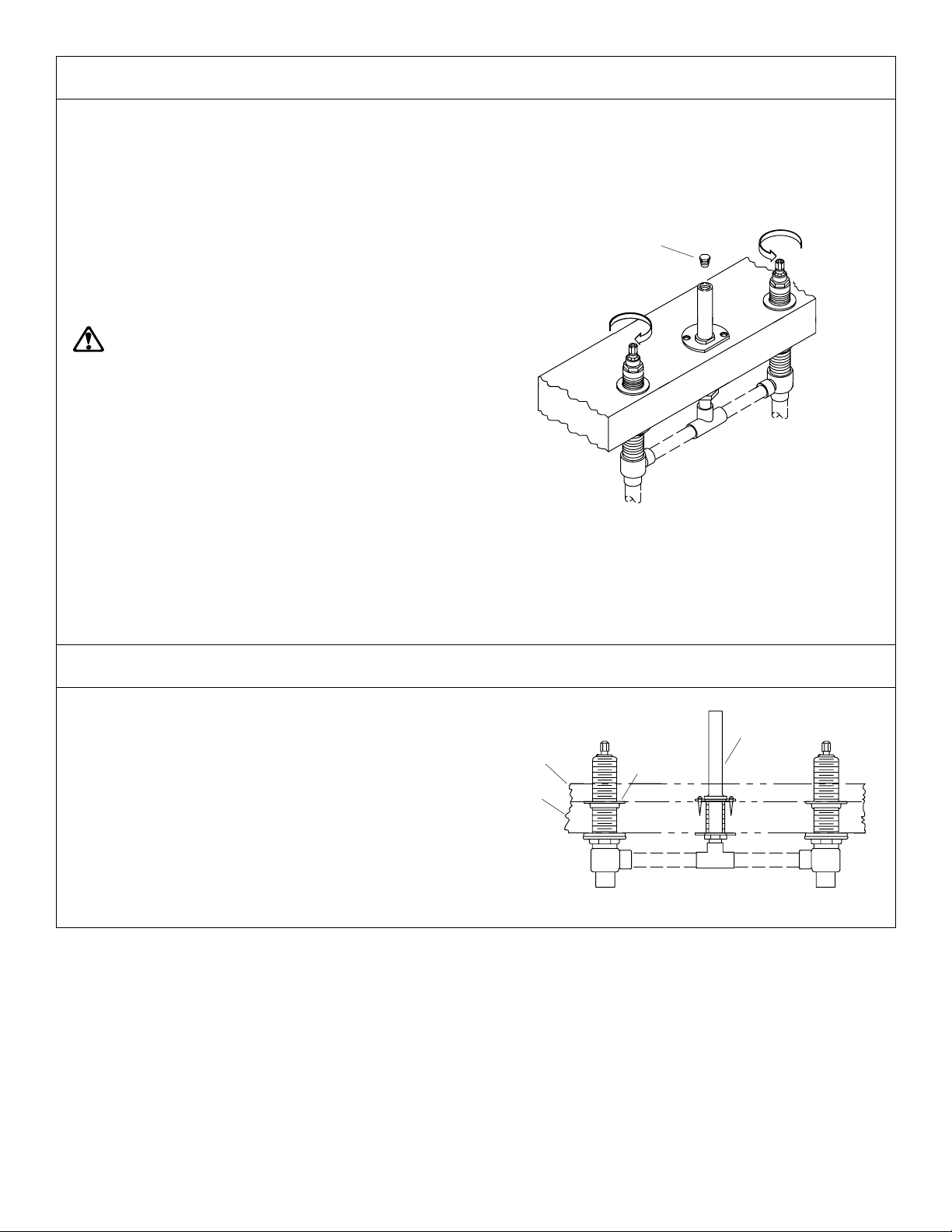

Install Valve Bodies: Thread one mounting nut, flange

side up, followed by one fiber washer and one rubber

washer onto each valve body.

Insert the 2-7/8” (7.3cm) long copper tubes between the

valve bodies and tee.

DO NOT solder the connections yet.

1/2” Tee

Rubber Washer

Fiber Washer

Mounting Nut

NOTE: Orient the valve body marked “COLD” so it is on

the right when facing the front of the faucet.

Insert the valve bodies through the mounting holes from

the bottom of the deck. Mate the copper tube from the tee

with the spout supply tube. Hold in place.

Set a collar, with the flange side up, onto each valve body .

Thread down to at least 1” (2.5cm) from the top thread on

the valve body.

Set Valve Body Height: Use one of the following two

formulas to calculate the valve body clearance required

for the finish material at your site.

Add the tile thickness to 1-1/4” (3.2cm) (distance required

from the finished deck to the top of the valve threads), if

the tile is less than 1” (2.5cm) thick.

Example #1: Tile thickness 3/4” (2cm) + 1-1/4” (3.2cm)

= 2” (5cm) clearance.

If the tile thickness is between 1” (2.5cm) and 1-1/4”

(3.2cm), add only 1” (2.5cm) to the 1-1/4” (3.2cm)

distance.

Valve Body

1-1/4” (3.2cm)

2” (5cm)

3/4” (2cm)

Top of Valve

Threads

2-1/8”

(5.4cm)

Max.

2-7/8” (7.3cm)

Copper Tubes

Fig. #7

1” (2.5cm)

Collar

Fig. #8

Tile

Thickness

Threaded

Collar

Rough

Deck

Example #2: Tile thickness 1” (2.5cm) + 1-1/4” (3.2cm)

= 2-1/4” (5.7cm) clearance.

Adjust the threaded collar until the dimension from the top

of the valve threads to the top of the rough deck surface

equals the clearance requirement you calculated.

Note this dimension. Y ou will need to use it again after

connecting the supply tube.

Kohler Co., Kohler, WI U.S.A.

EXAMPLE #1

Fig. #9

5

1012557-2-A

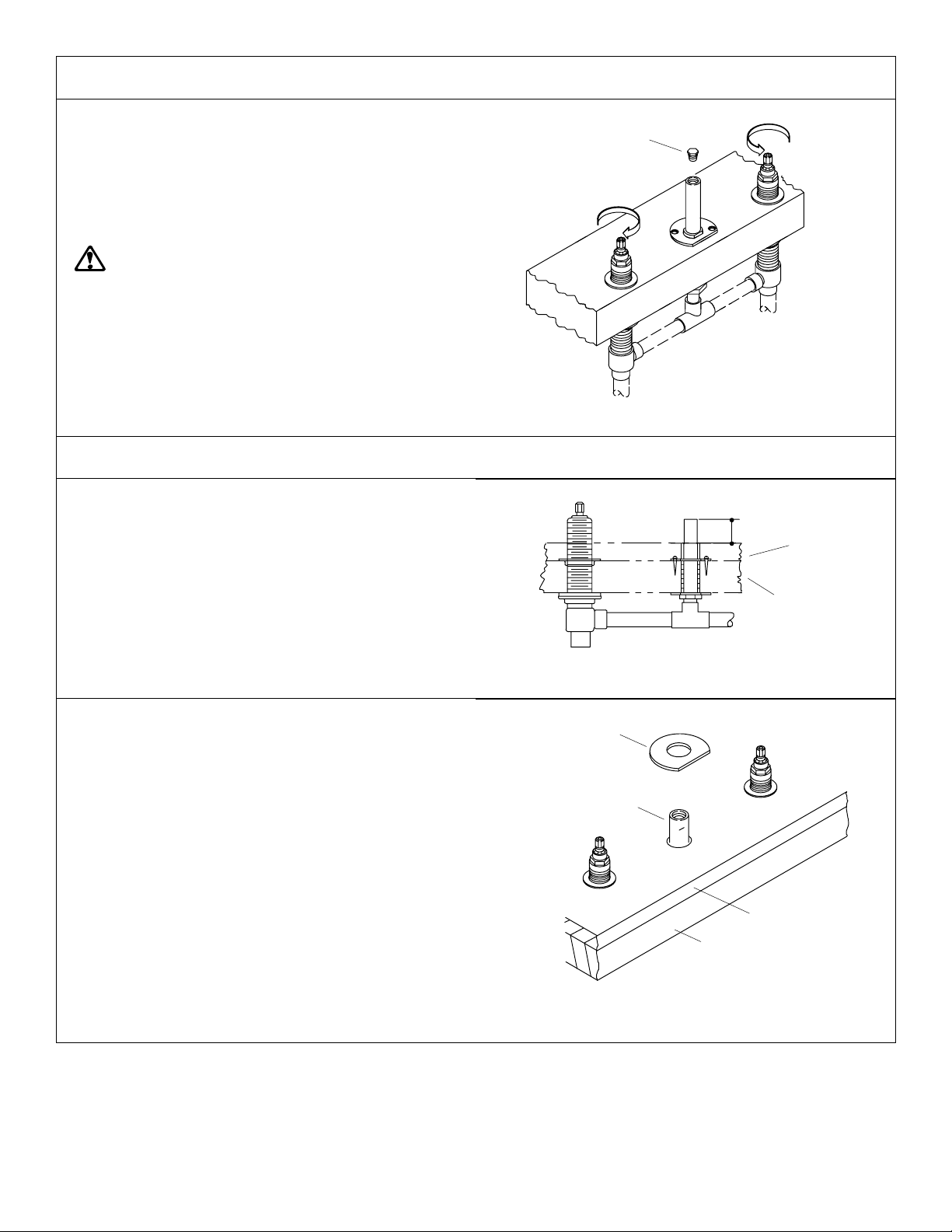

Supply Tube Connection: Measure the distance from

the bottom of the spout supply tube to the top of the tee.

Add 1” (2.5cm) to this measurement, and cut a piece of

1/2” nominal (5/8” O.D.) copper tubing to fit into the supply

tube and tee port.

Back off the threaded collars as far as possible without

removing them. Pivot the valve bodies enough to remove

the tee and two pieces of tubing. If the valve body holes

are smaller than recommended, it may be necessary to

remove the entire valve body assembly.

Install the tubing into the tee. Mate the copper tube from

the tee with the spout supply tube. Pivot the valve bodies

onto the two pieces of copper tubing.

DO NOT solder at this time.

Reset Valve Body Height: Adjust the threaded collars

until the dimension from the top of the valve threads to the

top of the rough deck surface equals the clearance

requirement you calculated in Fig. #9.

Rough

Deck

Mounting

Nut

Top of Valve Threads

Pre-determined

Clearance

Requirement

Threaded

Collar

Copper

Tube

Fig. #10

Spout

Supply

Tube

Tee

Tile

Thickness

Threaded

Collar

Rough

Deck

Tighten the mounting nuts on each valve body underneath

the deck.

Solder the copper tubes to the valve bodies, tee, and

spout supply tube.

Ensure that the cold supply is on the right side.

Solder the hot and cold water supply tubes to the valve

body inlets.

Rough

Deck

Valve

Body

Mounting

Nut

Hot

Supply

Copper

Tube

Solder

Fig. #11

Spout

Supply

Tube

Solder

Solder

Cold

Supply

Fig. #12

1012557-2-A

6

Kohler Co., Kohler, WI U.S.A.

4. VALVING CHECKOUT (ALL INSTALLATIONS)

Close

Thread a 1/4” pipe plug into the top of the spout supply

tube.

Ensure that the valves are closed (cold - fully

counterclockwise, hot - fully clockwise).

Turn on the main water supply, and check the complete

installation for leaks with the valves closed and open.

Repair leaks as required.

Close both valves. Turn off the main water supply.

WARNING:Risk of personal injury. Lines will be

pressurized. Do not lean over pipe plug when

turning or removing the plug.

Wrap a towel around the pipe plug to prevent water spray .

Water will purge from the supply tube when you remove

the plug.

Carefully back out the pipe plug to relieve pressure.

Thread the pipe plug back into the spout supply tube.

Leave the pipe plug installed until the spout and handle

are installed.

Install the cardboard plaster guards over both valves and

the spout supply tube. Leave in place until the spout and

handle are installed.

5. INSTALL TILE (IF APPLICABLE)

1/4” Pipe Plug

Close

Hot

Close

Cold

Fig. #13

Verify that there will be a 1-1/4” (3.2cm) distance from the

top of the sleeve to the top of the tile. If not, do not install

the tile due to improper valve installation.

If proper clearance exists, install tile up to the plaster

guards on the valves and the spout supply tube.

Tile

Rough

Deck

Threaded

Collar

Fig. #14

Spout

Supply

Tube

Kohler Co., Kohler, WI U.S.A.

7

1012557-2-A

6. BEFORE INSTALLING SPOUT AND HANDLES

REMOVE PIPE PLUG

Ensure that the valves are closed (cold - fully

counterclockwise, hot - fully clockwise).

Turn off the main water supply.

WARNING:Risk of personal injury . Lines may be

pressurized. Do not lean over pipe plug when

turning or removing the plug.

Wrap a towel around the pipe plug to prevent water spray .

Water may purge from the supply tube when you remove

the plug.

Carefully remove the pipe plug.

7. INSTALL SPOUT

Remove the plaster guard from the spout supply tube.

Cut off the spout supply tube 1-1/4” (3.2cm) above the rim,

finished deck, or tile.

1/4” Pipe Plug

Close

Hot

Close

Cold

Fig. #15

1-1/4” (3.2cm)

Tile

Finish

Ensure that all burrs are removed from the supply tube to

prevent damage to the O-ring seal on the sleeve.

NOTE: The following step is applicable to a tile covered

rough deck installation only.

Slide a brass washer, flat side facing forward, onto the

supply tube. The brass washer is furnished with the spout.

NOTE: The washer is not needed for rim/finished deck

installation.

Rough

Deck

Fig. #16

Washer

Spout

Supply

Tube

Finished

Deck

Rough

Deck

Fig. #17

1012557-2-A

8

Kohler Co., Kohler, WI U.S.A.

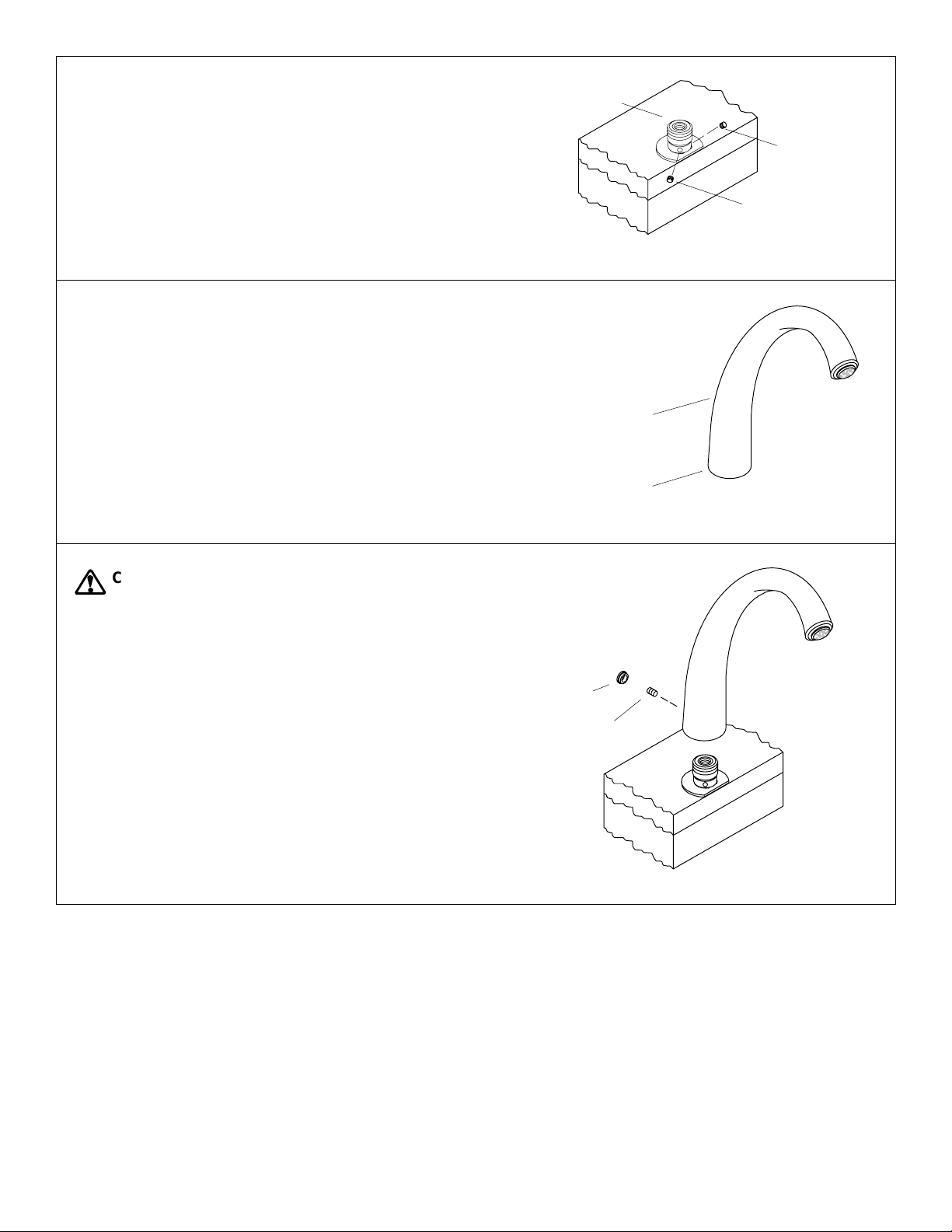

Back off the setscrews in the sleeve, and with a twisting

motion install the sleeve on the spout supply tube until it

contacts the washer surface.

Align the sleeve so the setscrews are not facing directly

forward or backward.

Sleeve

Setscrew

Tighten the setscrews.

When supplied, position the ring over the sleeve so it rests

upon the washer.

Apply a ring of plumbers putty or other sealant around the

underside of the spout according to the putty

manufacturer’s instructions.

CAUTION: Risk of product damage. Use care

when installing the spout assembly to prevent

damage to the O-ring seal on the sleeve.

Install the spout assembly onto the sleeve, and carefully

press down until the spout base contacts the deck, rim, or

tile.

Align the spout as desired, and tighten the setscrew.

If included, press the plug button into the setscrew hole.

Setscrew

Fig. #18

Spout

Apply Plumbers Putty

Fig. #19

Plug

Button

Setscrew

Kohler Co., Kohler, WI U.S.A.

Fig. #20

9

1012557-2-A

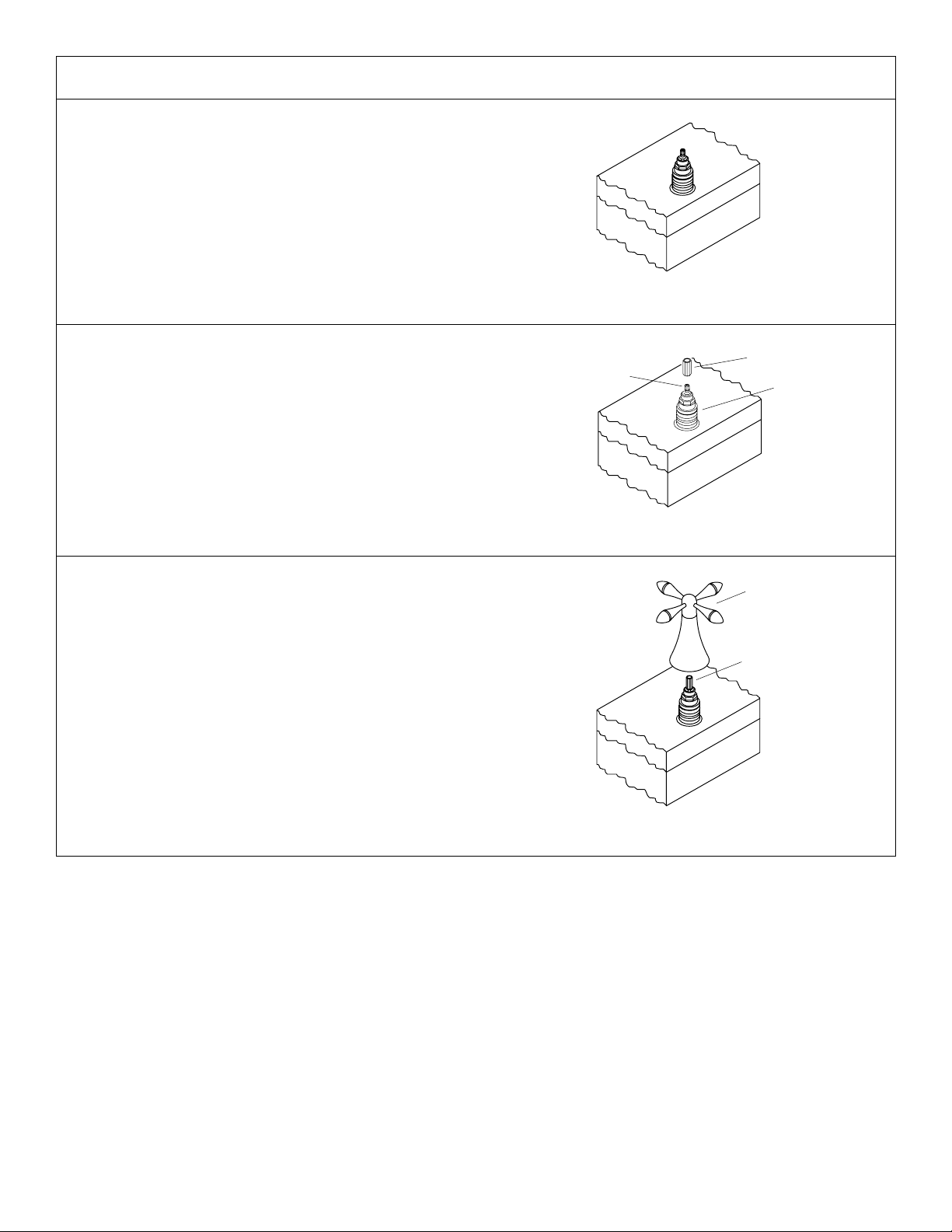

8. INSTALL HANDLES

Remove the plaster guards from the hot and cold valves.

Fig. #21

Install a stem extension onto each valve stem spline.

Ensure that the splines are properly aligned.

NOTE: There are several handle styles available for this

product. For illustrative purposes, only the Cross handle

is shown. Installation of the different handle styles is

identical.

Install the handle assembly by threading onto the valve

body . Take care that the splines inside the skirt and stem

extension are engaged. Adjust as required.

NOTE: The stem extension allows for fine adjustment of

handle alignment. To refine the alignment, unthread the

handle assembly, and reposition the stem extension on

the valve stem. Rethread the handle assembly , and check

the handle alignment. Repeat until the alignment is

satisfactory.

Valve Stem Spline

Stem Extension

Valve Body

Fig. #22

Handle

Assembly

Stem Extension

Fig. #23

1012557-2-A

10

Kohler Co., Kohler, WI U.S.A.

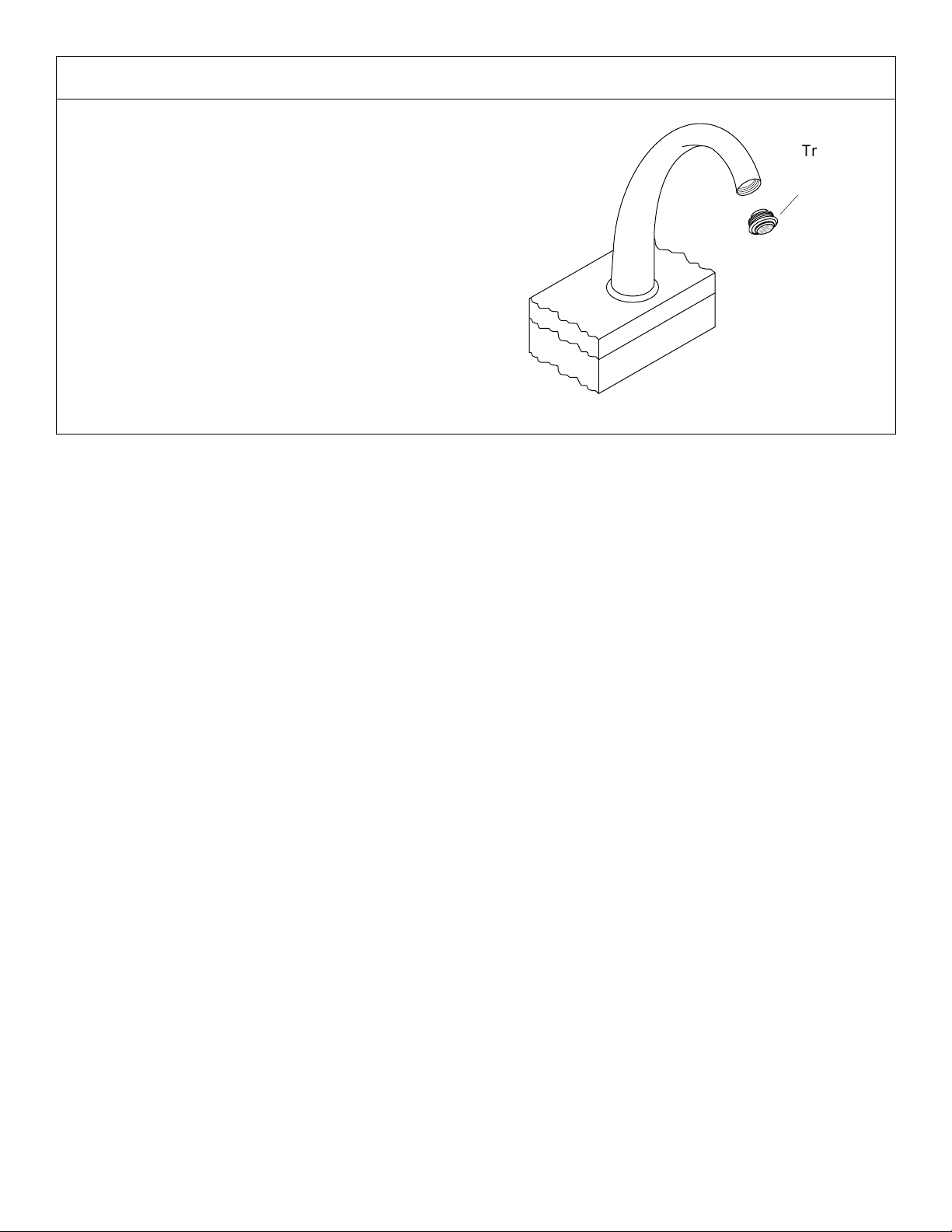

9. INSTALLATION COMPLETION

Ensure that both faucet handles are turned off (hot clockwise close, cold - counterclockwise close).

Turn on the main water supply, and check for leaks.

Repair as required.

Remove the trim ring/aerator assembly . Turn on both hot

and cold valves, and run water through the spout for about

a minute to remove any debris. Check for leaks.

Turn off both hot and cold valves. Reinstall the trim

ring/aerator assembly.

Trim Ring/

Aerator

Assembly

Fig. #24

Kohler Co., Kohler, WI U.S.A.

11

1012557-2-A

Loading...

Loading...