Page 1

Installation Guide

Single Threshold Acrylic Shower Receptors

K-9531, K-9532, K-9533,

K-9534, K-9535, K-9536,

K-9538, K-9852, K-9858,

K-9861, K-9866

M product numbers are for Mexico (i.e. K-12345M)

Los números de productos seguidos de M corresponden a México

(Ej. K-12345M)

Français, page “Français-1”

Español, página “Español-1”

1030520-2-A

Page 2

Thank You For Choosing Kohler Company

We appreciate your commitment to Kohler quality. Please take a few minutes to review this manual before

you start installation. If you encounter any installation or performance problems, please don’t hesitate to

contact us. Our phone numbers and website are listed on the back cover. Thanks again for choosing Kohler

Company.

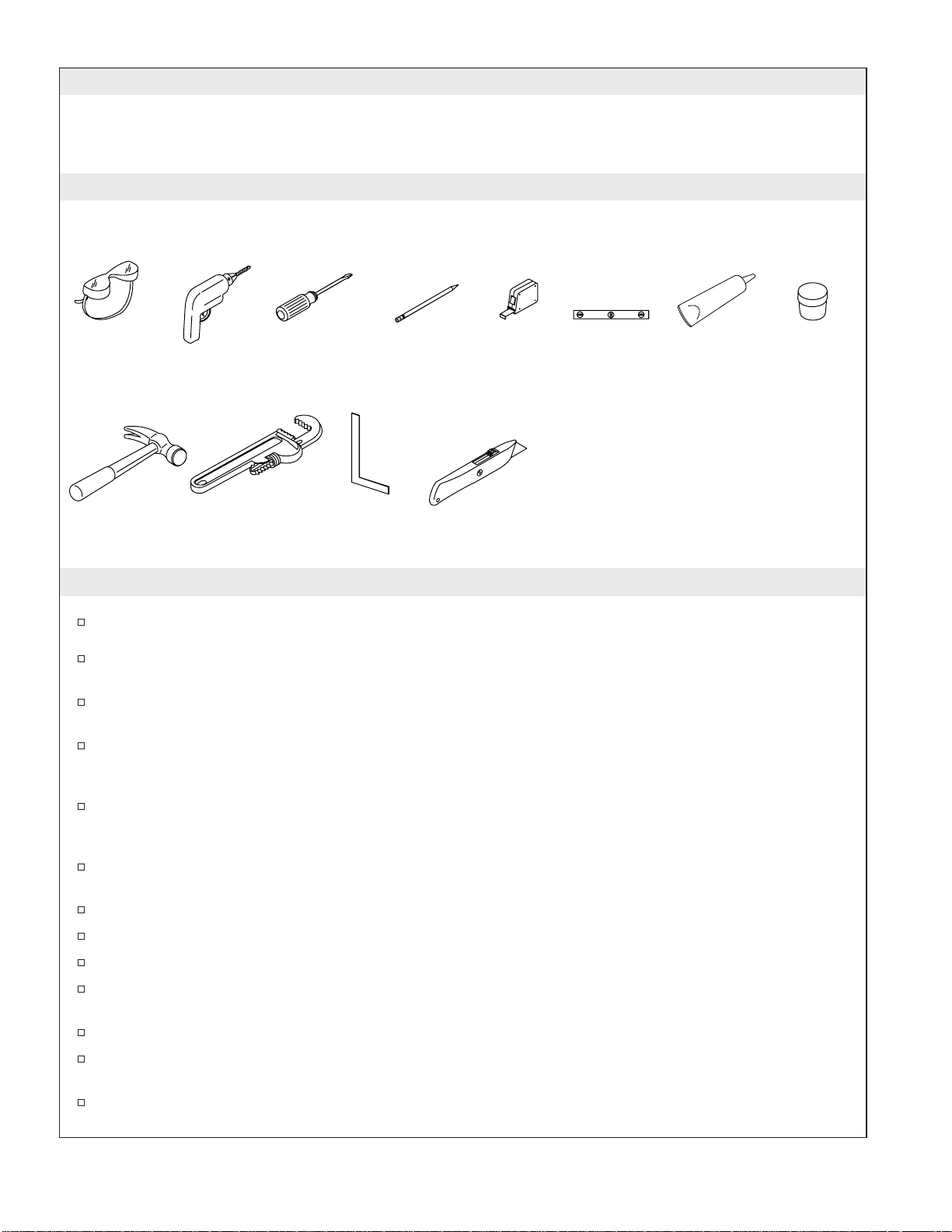

Tools and Materials

Safety

Glasses

Claw

Hammer

Drill

Pipe

Wrench

Screwdriver

Square

Pencil

Knife

Tape

Measure

Level

Plus:

• Common Woodworking

Tools and Materials

• Nails/Drywall Screws

• Drop Cloth

• 2 x 4s or 2 x 6s

• Water Resistant Wall Material

• Furring Strips

Sealant

Before You Begin

Observe all local plumbing and building codes.

Locate the rough plumbing for the drain in accordance with the roughing-in dimensions for your

particular model.

A variety of installations are possible. These instructions show suggested installation procedures,

your particular installation may require other construction techniques.

Please read these instructions carefully to familiarize yourself with the required tools, materials, and

installation sequences. Follow the sections that pertain to your particular installation. This will help

you to avoid costly mistakes.

Your shower receptor comes packaged in a single carton containing a one-piece shower receptor.

This carton will fit through any standard door. You should not remove the receptor from the

package until you are ready to install it.

Unpack and inspect the shower receptor for damage. If you find any damage, do not install the

receptor. Report the specific problem to your dealer immediately.

After inspection, return the receptor to the carton until you are ready to install it.

You must install this shower receptor to an adequately supported, level subfloor.

Be sure that you have enough access to move the receptor into the construction area.

Make sure the installation area is clean and free of all debris. If remodeling, remove all finished wall

material to expose the framing and remove all floor coverings to expose the subfloor.

Provide properly dimensioned framing.

Alcove installation is recommended for this receptor. A drop-in installation is also an option for this

receptor.

Corner or alcove installation is dependent upon the receptor model.

Plumbers

Putty

1030520-2-A 2 Kohler Co.

Page 3

Before You Begin (cont.)

Exact location of the end studs will depend on the thickness of the finished wall material.

If installing this unit adjacent to vertical ducts or chases, surround the unit with fire-rated

water-resistant wall material.

When fire-rated wall is specified, stud-opening dimensions are toward the exposed side of the wall

material.

Place the receptor within the installation area prior to completion of the framing.

The basin area requires no additional support when the subfloor is level and square with respect to

the framing. Consider using shims for additional support if the subfloor is uneven.

Consult all applicable instructions for options and accessories before beginning this installation.

Fixture conforms to ANSI Standard Z124.2. All dimensions are nominal. All models meet IAPMO

requirements with the exception of K-9531.

1. Prepare the Site

Ensure that the installation area is clean and free of all debris. If remodeling, remove all finished

wall material to expose the framing and remove all floor coverings to expose the subfloor.

Inspect the flooring at the installation site. Repair as necessary.

Make sure the sub and finished floors are flat and level.

Kohler Co. 3 1030520-2-A

Page 4

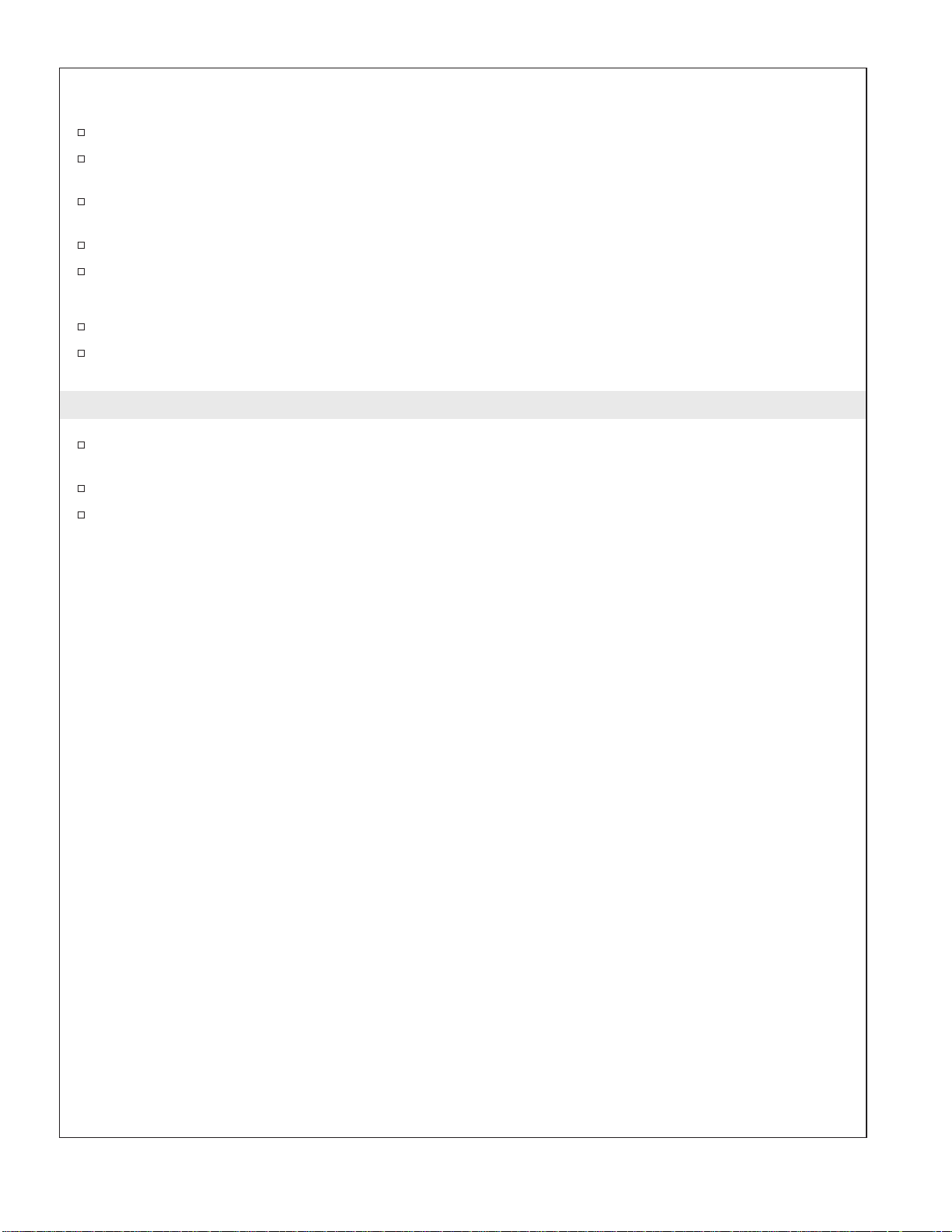

C

C

D

D

B

A

E

F

K-9531, K-9532, K-9533,

K-9534, K-9535, K-9538,

K-9852, K-9861, K-9858

A

B

A

E

F

K-9536

K-9866

Diagrams shown are representative and for use with the table only.

Your fixture may appear different from the illustrations.

2. Roughing-In Dimensions

ABCDE

K-9531 32″ (81.3cm) 16″ (40.6cm) 31-3/4″ 80.6cm) 15-7/8″ (40.3cm) 6-1/8″ (15.6cm)

K-9532 36″ (91.4cm) 18″ (45.7cm) 35-5/8″ (90.5cm) 17-13/16″

K-9533 42″ (106.7cm) 21″ 53.3cm) 41.75″ (106cm) 21″ (53.3cm) 6-1/8″ (15.6cm)

K-9534 47-7/8″

(121.6cm)

K-9535 60″ (152.4cm) 30″ (76.2cm) 34″ (86.4cm) 16-7/8″ (42.9cm) 6-1/8″ (15.6cm)

K-9536 37-7/8″ (96.2cm) 18-13/16″

K-9538 42″ (106.7cm) 21″ (53.3cm) 34″ (86.4cm) 17″ (43.2cm) 6-1/8″ (15.6cm)

K-9852 60″ (152.4cm) 30″ (76.2cm) 36″ (91.4cm) 27-1/8″ (68.9cm) 6-1/8″ (15.6cm)

K-9858 36″ (91.4cm) 8-7/8″ (22.5cm) 36″ (91.4cm) 27″ (68.6cm) 6-1/8″ (15.6cm)

K-9861 48″ (121.9cm) 24″ (61cm) 36″ (91.4cm) 27″ (68.6cm) 6-1/8″ (15.6cm)

K-9866 38″ (96.5cm) 21-7/8″ (55.6cm) 38″ (96.5cm) 18-5/8″ (47.3cm) 6-1/8″ (15.6cm)

23-15/16″

(60.8cm)

(47.8cm)

34″ (86.4cm) 17″ (43.2cm) 6-1/8″ (15.6cm)

37-7/8″ (96.2cm) 18-13/16″

(45.2cm)

(47.8cm)

6-1/8″ (15.6cm)

6-1/8″ (15.6cm)

IMPORTANT! All dimensions are nominal. The stud opening tolerance is plus 1/4″ (6mm) and minus 0.

Carefully measure your fixture before determining enclosure size. When a fire rated wall is specified,

dimensions are to the inside of the wall board. Some shimming between the stud frame and the fixture

may be required. Dimensions given in the roughing-in information are crucial for proper installation.

Construct the framing and plumbing accurately.

NOTE: If a firewall is required, roughing-in dimensions will have to increase according to the thickness of

the firewall material. Stud opening dimensions must be measured toward the exposed side of the wall

material.

NOTE: If installing this unit to a masonry wall, make provisions for plumbing connections. Construct a

separate frame wall a minimum of 6” (15.2cm) from the masonry wall.

1030520-2-A 4 Kohler Co.

Page 5

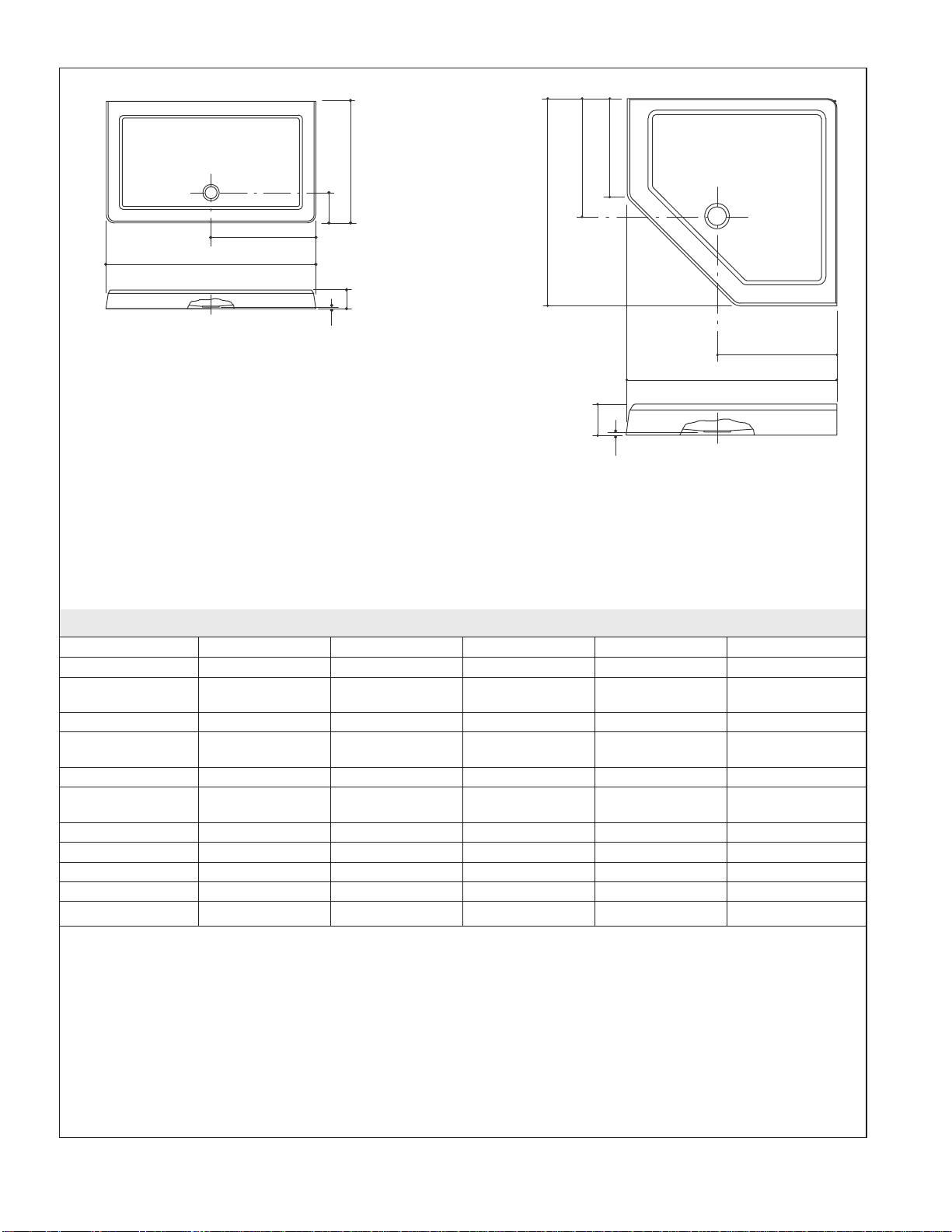

Construct 2 x 4

stud framing

according to the

roughing-in

information

Position

the rough

plumbing

Verify that the

subfloor offers

adequate support,

and is flat and level

Masonry Wall

2 x 4 Stud Framing

6" (15.2cm) MIN.

3. Construct the Stud Framing

If you will be installing a shower door with this unit, refer to the shower door installation

instructions for any special framing considerations.

Construct 2x4 or 2x6 stud framing according to the roughing-in information for your particular

model.

Verify that the framing is square and plumb.

If grab bars are to be installed, provide 2x6 bridging or attachment at specified positions. Refer to

the grab bar manufacturer’s instructions.

The basin area requires no additional support when the subfloor is plumb and level with respect to

the stud framing. If the subfloor is not level, shimming may be required to level the unit.

Kohler Co. 5 1030520-2-A

Page 6

2" (5cm) Drain Pipe

4-1/2" (11.4cm) D. MIN.

3/8" (1cm)

Wood Sub-Floor

2" (5cm) Drain Pipe

1-1/2" (3.8cm)

MIN.

4-1/2" (11.4cm) D. MIN.

3/8" (1cm)

Concrete Sub-Floor

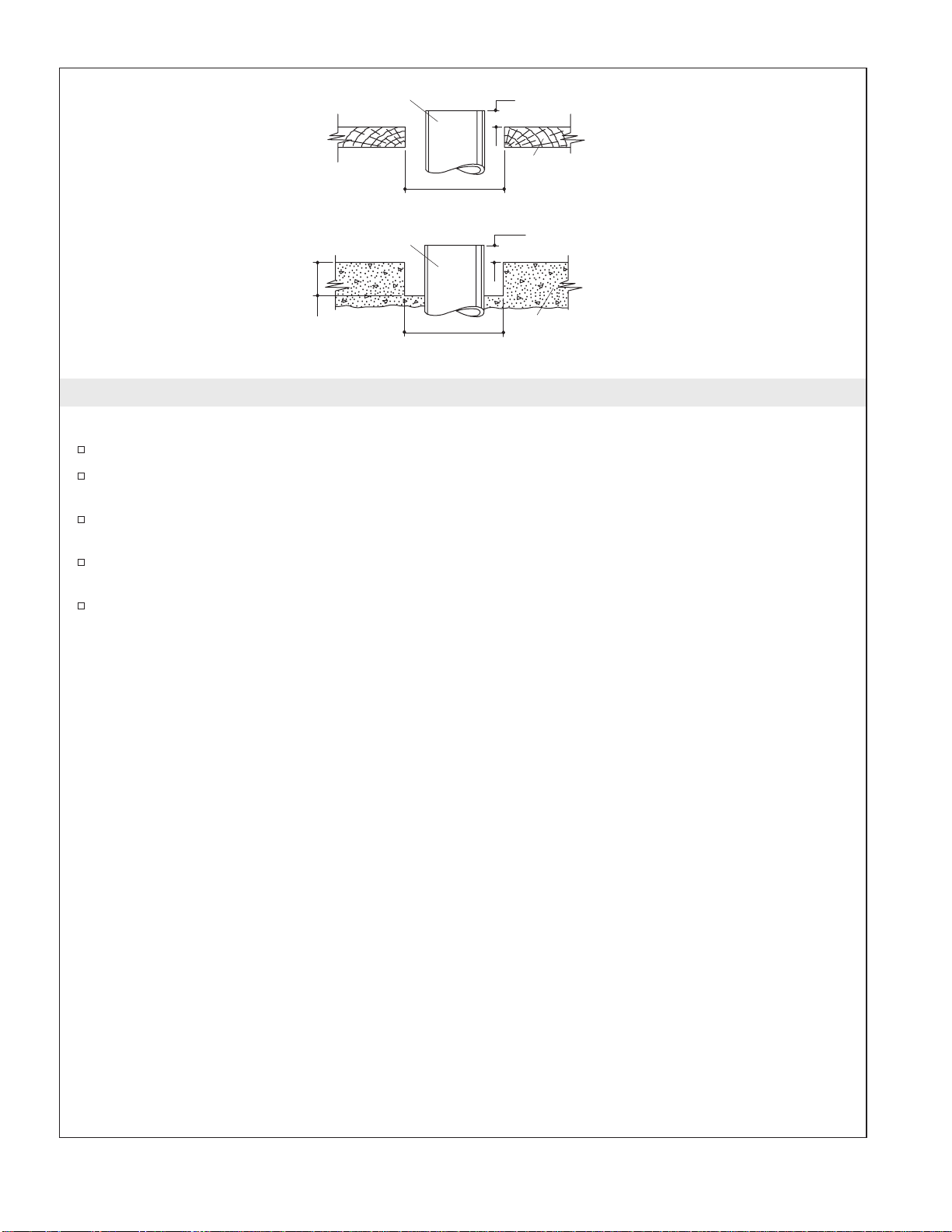

4. Install the Plumbing

NOTE: Provide access to all plumbing connections to simplify future maintenance.

Locate rough plumbing for the drain according to the correct model’s roughing-in dimensions.

Position the plumbing according to the roughing-in information. Cap the supplies and check for

leaks.

Install a 2” (5cm) drain pipe to extend 3/8” (1cm) above the subfloor or slab. A pocket is required in

a slab construction to accommodate the drain fitting.

If possible, provide an access at the back of the plumbing wall for servicing the supply and waste

piping.

Install the shower valving according to the manufacturer’s instructions. Do not install the trim at

this time.

1030520-2-A 6 Kohler Co.

Page 7

Water-Resistant

Wall Material

Unfinished Wall

Vinyl Tiling-In

Bead

Finished Wall

Water-Resistant

Sealer

Pressure-Sensitive

Tape

Receptor Rim

Sub-Floor

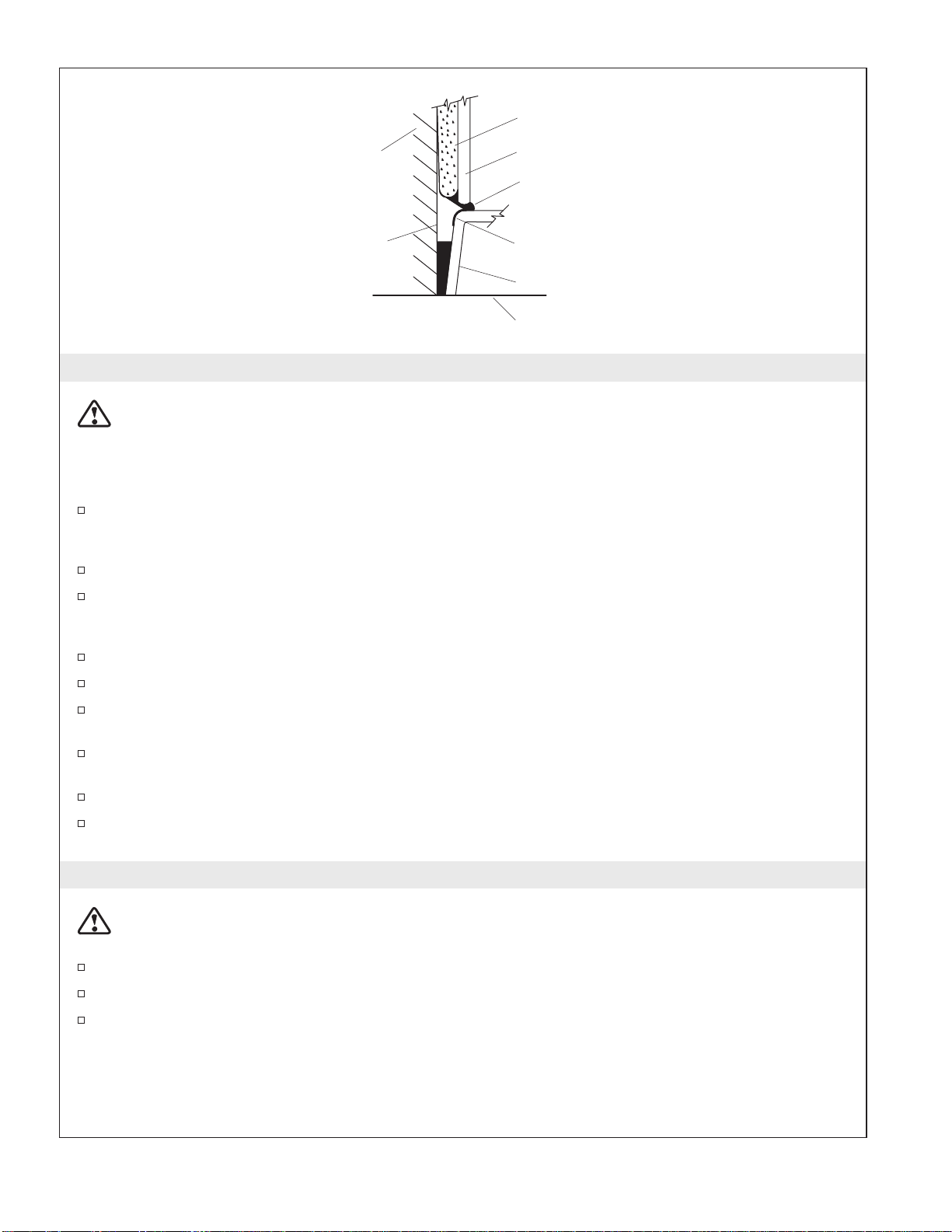

5. Install the Vinyl Tiling-in Bead

CAUTION: Risk of product damage. Do not apply the vinyl tiling-in bead or pressure-sensitive tape

in temperatures below 40°F (4.4°C).

NOTE: The K-1182 vinyl tiling-in bead is used for the corner installations of the K-9852 and K-9861 shower

receptors. There is enough vinyl tiling-in bead supplied for either receptor. Some cutting will be required.

The vinyl bead takes the place of the flange on the side(s) of the receptor and is necessary to

prevent water from seeping into the framing. The installation kit contains a 7’ (2.1 m) vinyl bead

and a 12’ (3.7 m) strip of pressure-sensitive sealing tape.

Clean the receptor rim of all dust, grease and foreign matter.

Temporarily position the tiling-in bead on the receptor to measure. Do not use the sealing tape at

this time. The bead should start 3/4” (1.9cm) back from the front corner and extend along the rim

all the way to the integral tiling-in flange at the rear of the receptor. Cut the length to fit.

Cut the same length(s) of pressure-sensitive tape, also starting from the front edge of the rim.

Apply the vinyl tiling-in bead just before moving the receptor into position.

Remove the paper backing from the pressure-sensitive tape and carefully apply the tape to the

corner radius of the receptor.

Start applying the vinyl bead 3/4” (1.9cm) back from the front corner. Press the bead firmly against

the sealing tape for proper sealing.

Repeat procedure working toward the opposite end.

After the bead is in place, start at the area where the bead was first applied and rub firmly with the

heel of your hand to ensure a continuous seal.

6. Prepare the Receptor

CAUTION: Risk of product or property damage. If a watertight seal on the drain is not obtained,

water damage to the receptor bottom and the subfloor may occur.

Install the drain to the shower receptor according to the drain manufacturer’s instructions.

Clean the receptor to reduce the risk of surface damage.

Place a clean drop cloth or other similar material into the bottom of the receptor. Be careful not to

scratch the surface of the unit.

Kohler Co. 7 1030520-2-A

Page 8

7. Position the Receptor

Move the receptor into position. Verify proper fit.

Fit the drain into the trap. Do not connect the trap at this time.

CAUTION: Risk of product damage. If shimming is required, shim between the subfloor or slab and

the wood block feet on the underside of the receptor. All wood block feet must be supported when the

receptor is leveled and nailed to the framing.

Check that the receptor is level in both directions and resting on all feet. Shim if necessary.

Concrete, gypsum cement or other similar materials can be used to level the base.

1030520-2-A 8 Kohler Co.

Page 9

Drill a small

hole through the

nailing-in flange

at each stud

Stud

Furring Strip

Nailing-In Flange

Stud

Use #6 large-head

galvanized nails or

screws to secure

the nailing-in flange

to the studs

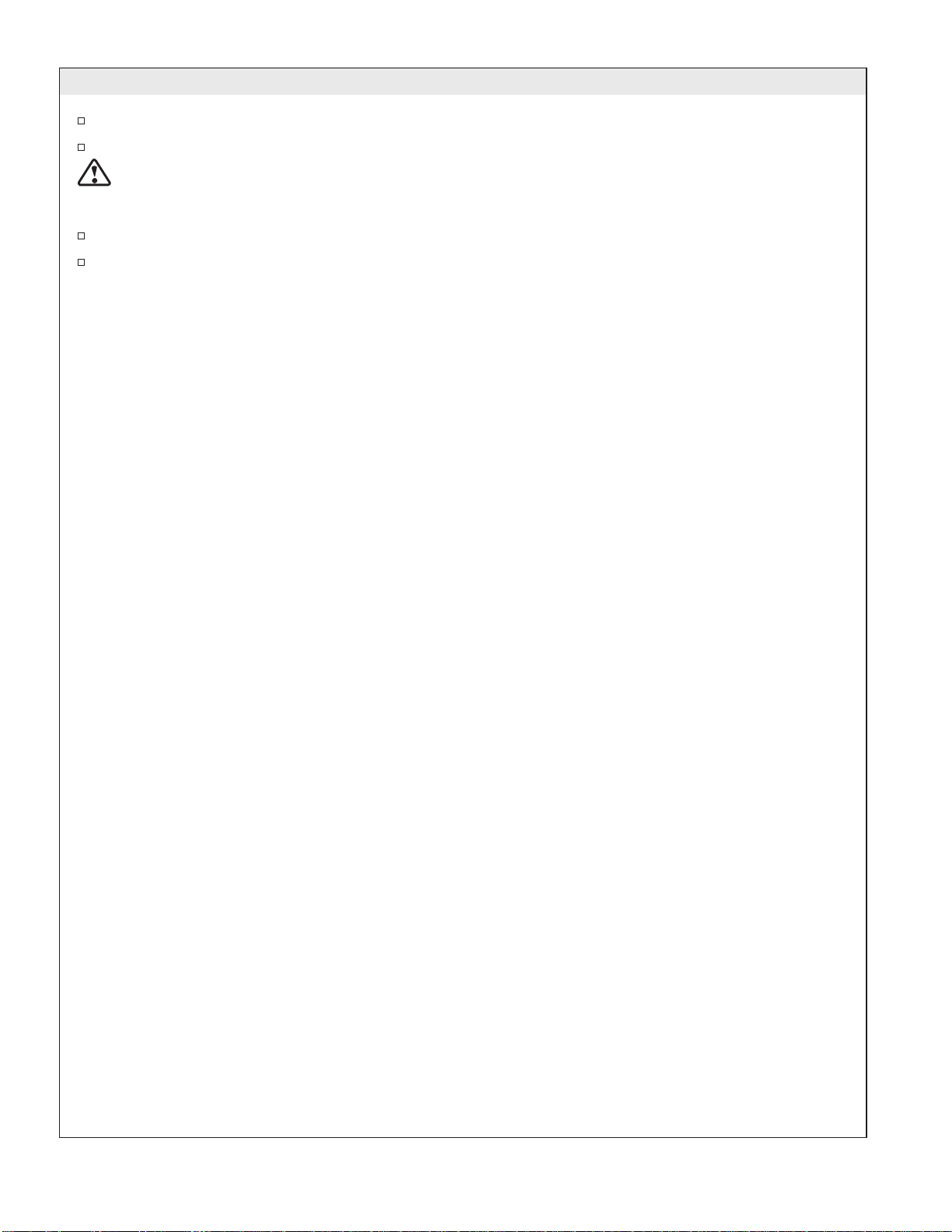

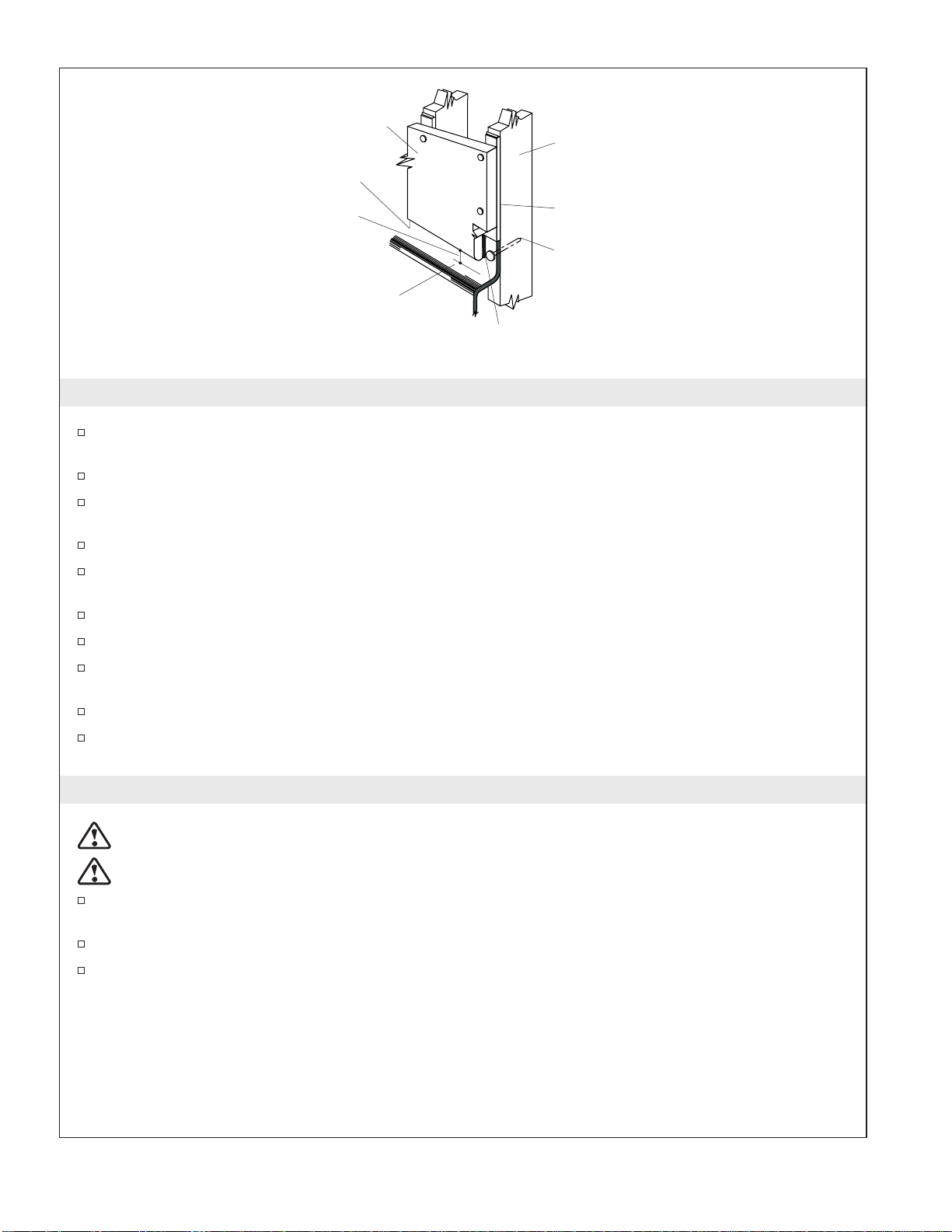

8. Secure the Receptor to the Stud Framing

CAUTION: Risk of property damage. Make sure a watertight seal exists on all drain connections.

Drill 1/8” (3mm) pilot holes through the nailing–in flange at each stud location. If needed, shim

between the nailing-in flange and the studs to prevent cracking the flange when drilling.

Complete the drain installation according to the instructions packed with the drain.

Open the water supplies and check all the connections for leaks.

Run water into the receptor and check the drain connections for leaks.

Use #6 large-head galvanized nails or screws to secure the nailing-in flange to the studs.

Nail 1/8” (3mm) thick furring strips to the studs to shim out to the edge of the nailing-in flange.

Kohler Co. 9 1030520-2-A

Page 10

1/2" (1.3cm)

Water-Resistant

Wall Material

Edge

(Paperboard)

Down

1/4" (6mm)

Concave Surface

Water Resistant Sealer Between Nailing-in Flange And

Paperbound Edge Of Water-Resistant Wall Material

2 x 4 Framing

1/8" (3mm)

Furring

Galvanized

Nail

9. Complete the Installation

Apply silicone sealant to the upper portion of the nailing-in flange/vinyl bead where it will meet

the water-resistant wall material.

Cover the framing, walls and nailing-in flange with water-resistant wall material.

Install the water-resistant wall material to the framing with the paperbound edge a maximum of

1/4” (6mm) above the finished concave surface of the receptor.

Tape and mud the wall material.

Install the finished wall. Seal the joints between the receptor rim and the finished wall with silicone

sealant. RTV (Room Temperature Vulcanizing) sealant is recommended.

Seal around the valving and outlets with silicone sealant or plumbers putty.

Install the faucet and drain trim according to the manufacturer’s instructions.

If used, install the grab bars or towel bars to the backing in the stud wall (previously installed).

Follow the manufacturer’s installation instructions.

If used, install the shower door according to the manufacturer’s instructions.

Install the finished floor. Apply silicone sealant along the front edge of the receptor where it meets

the floor.

10. Clean-Up

CAUTION: Risk of product damage. Do not allow cleaners containing petroleum distillates to remain

in contact with module surfaces for any length of time.

CAUTION: Risk of product damage. Do not use abrasive cleaners.

When cleaning up after installation, use warm water and an approved liquid cleanser to clean the

surface.

Stubborn stains, paint or tar can be removed with turpentine or paint thinner.

Plaster can be removed by scraping with a wood edge. Do not use metal scrapers, wire brushes, or

other metal tools. Use warm water and an approved liquid cleanser to provide mild abrasive action

to remove residual plaster.

1030520-2-A 10 Kohler Co.

Page 11

Guide de l’Installation

Receveur de Douche en Acrylique Avec Mono Seuil

Outils et Matériaux

Lunettes de

Protection

Marteau à

Griffes

Perceuse

Clé à

Griffes

Tournevis

Crayon à Papier

Équerre

Mètre

Ruban

Couteau

Niveau à Bulles

Plus :

• Travaille du Bois Commun

Outils et Matériaux

• Clous/Vis pour Cloison Sèche

• Chiffon

• 2 x 4 or 2 x 6

• Matériau Hydrofuge pour le Mur

• Tasseaux

Matériau

d'Étanchéité

Mastic de

Plomberie

Merci d’avoir choisi la Société KOHLER

Nous apprécions votre engagement envers la qualité KOHLER. S’il vous plait, prenez quelques minutes et

lisez attentivement ce guide avant de commencer votre installation. N’hésitez pas à nous contacter en cas de

problème d’installation ou de fonctionnement. Nos numéros de téléphone et adresse Internet sont au verso.

Merci encore d’avoir choisi un produit KOHLER.

Avant De Commencer

Respectez tous les codes locaux de plomberie et de bâtiment.

Déterminez l’emplacement de la plomberie brute servant au drain, selon les dimensions du plan de

raccordement.

Multiples installations sont possibles. Ces instructions montrent les procédures d’installation, il se

pourrait que vous ayez à utiliser d’autres techniques pour votre installation.

Veuillez lire avec attention cette notice pour connaître les outils et matériaux requis, ainsi que les

étapes d’installation. Suivez les étapes qui s’appliquent particulièrement à votre installation. Ceci

vous évitera des erreures coûteuses.

Les receveurs de douche sont emballés dans un seul carton contenant un receveur d’une seule pièce.

Ce carton passera par une porte standard quelconque. Ne retirez-pas le receveur de son carton

jusqu’au moment de sa pose.

Déballez le receveur de douche et examinez le soigneusement pour en déceler tout dommage. Si

vous notez des dommages, n’installez pas ce receveur. Veuillez informer votre Distributeur du

problème immédiatement.

Après l’inspection, remettre le receveur dans son emballage de protection en attendant de

commencer l’installation.

Vous devez installer ce receveur de douche sur un sol muni d’un support nécessaire, et de niveau.

Kohler Co. Français-1 1030520-2-A

Page 12

Avant De Commencer (cont.)

Assurez-vous de pouvoir déplacer le receveur dans son aire d’installation.

Assurez-vous que l’aire d’installation soit propre et sans débris. Dans le cas d’une rénovation, retirez

tous les matériaux du mur terminé pour exposer le cadre, et retirez le revêtement du sol pour

exposer le sol brut.

Prévoyez un cadre aux dimensions appropriées.

Une installation dans une alcôve et requise pour ce receveur. Une installation encastrée est en option

pour ce receveur.

L’installation dans une encoignure ou dans une alcôve dépendra du modèle de receveur.

L’emplacement exact des montants d’extrémité dépendra de l’épaisseur du matériau du mur

terminé.

Si le receveur doit être installé à coté de conduites pour caniveau ou de tuyauteries verticales,

entourez l’appareil d’un mur classé ignifugé et hydrofuge.

Dans le cas d’un mur ignifugé, les dimensions sont entre les montants et les cotés des murs latéraux

exposés.

Déplacez le receveur dans l’aire d’installation avant de compléter son cadre.

L’espace de la cuve ne nécessite pas de support additionnel si le sol est de niveau et d’aplomb avec

le cadre. Utilisez des cales pour un support additionnel si le sol brut n’est pas de niveau.

Avant de procéder à l’installation des accessoires, consultez toutes les directives à cet effet.

Les dimensions de l’appareil sont nominales et conformes aux tolérances données par les normes

Standard ANSI Z124.2. Tous les modèles satisfont aux exigences des normes IAPMO, avec

l’exception de K-9531.

1. Préparez le Site

Assurez-vous que l’espace réservé pour l’installation soit propre et sans débris. Dans le cas d’une

rénovation, retirez tous les matériaux du mur terminé pour exposer le cadre, et retirez le revêtement

du sol pour exposer le sol brut.

Vérifiez le sol du site de l’installation. Remplacez le au besoin.

Assurez-vous que le sol brut et le sol terminé soient de niveau.

1030520-2-A Français-2 Kohler Co.

Page 13

2. Dimensions du plan de raccordement

ABCDE

K-9531 32″ (81,3 cm) 16″ (40,6 cm) 31-3/4″ 80,6 cm) 15-7/8″ (40,3

K-9532 36″ (91,4 cm) 18″ (45,7 cm) 35-5/8″ (90,5

K-9533 42″ (106,7 cm) 21″ (53,3 cm) 41.75″ (106 cm) 21″ (53,3 cm) 6-1/8″ (15,6 cm)

K-9534 47-7/8″ (121,6

cm)

K-9535 60″ (152,4 cm) 30″ (76,2 cm) 34″ (86,4 cm) 16-7/8″ (42,9

K-9536 37-7/8″ (96,2

cm)

K-9538 42″ (106,7 cm) 21″ (53,3 cm) 34″ (86,4 cm) 17″ (43,2 cm) 6-1/8″ (15,6 cm)

K-9852 60″ (152,4 cm) 30″ (76,2 cm) 36″ (91,4 cm) 27-1/8″ (68,9

K-9858 36″ (91,4 cm) 8-7/8″ (22,5 cm) 36″ (91,4 cm) 27″ (68,6 cm) 6-1/8″ (15,6 cm)

K-9861 48″ (121,9 cm) 24″ (61 cm) 36″ (91,4 cm) 27″ (68,6 cm) 6-1/8″ (15,6 cm)

K-9866 38″ (96,5 cm) 21-7/8″ (55,6

IMPORTANT ! Toutes les dimensions sont nominales. L’espacement des montants ne doit pas être de plus

de 1/4″ (6 mm) et de moins de 0. Mesurez soigneusement votre appareil avant d’en déterminer la taille de

son logement. Dans le cas d’un mur ignifugé, les dimensions sont celles de l’intérieur du mur. Il se peut

que vous ayez à glisser des cales entre le cadre et l’appareil. Les dimensions fournies par le plan sont

cruciales pour une bonne installation. Construisez le cadre et installation de la plomberie très

soigneusement.

23-15/16″ (60,8

cm)

18-13/16″ (47,8

cm)

cm)

cm)

34″ (86,4 cm) 17″ (43,2 cm) 6-1/8″ (15,6 cm)

37-7/8″ (96,2

cm)

38″ (96,5 cm) 18-5/8″ (47,3

cm)

17-13/16″ (45,2

cm)

cm)

18-13/16″ (47,8

cm)

cm)

cm)

6-1/8″ (15,6 cm)

6-1/8″ (15,6 cm)

6-1/8″ (15,6 cm)

6-1/8″ (15,6 cm)

6-1/8″ (15,6 cm)

6-1/8″ (15,6 cm)

Kohler Co. Français-3 1030520-2-A

Page 14

Dimensions du plan de raccordement (cont.)

REMARQUE : Dans le cas d’un mur ignifugé, les dimensions brutes devront changer tenant compte de

l’épaisseur du mur ignifugé. Les dimensions de l’écartement des montants doivent être mesurées vers le

coté du mur exposé.

REMARQUE : Si vous installez cet appareil sur un mur en maçonnerie, prévoyez l’accès nécessaire pour

les raccordements de la plomberie. Construisez un mur séparé, à un minimum de 6″ (15,2 cm) du mur en

maçonnerie.

1030520-2-A Français-4 Kohler Co.

Page 15

Construisez le cadre

avec des 2 x 4 tout en

suivant l'information

du plan de

raccordement

Positionnez la

Plomberie

Cadre de 2 x 4

Vérifiez que le sol

peut supporter le

poids nécessaire et

qu'il soit plat et de

niveau.

Mur en Maçonnerie

6" (15,2 cm) MINI.

3. Construire le Cadre

Si vous installez une porte de douche à cet appareil, consultez la notice de l’installation de la porte

de douche pour toutes spécifications particulières de l’encadrement.

Construisez le cadre avec des montants de2x4oude2x6tout en suivant le plan de construction

de votre modèle.

Vérifiez que le cadre soit d’équerre et d’aplomb.

Si des barres d’appuis doivent être installées, prévoyez une liaisons ou des attaches avec des2x6

et aux emplacements spécifiés. Reportez-vous aux directives du Fabricant des barres d’appuis.

L’espace de la cuve ne nécessite pas de support additionnel si le sol est de niveau et d’aplomb avec

le cadre. Si le sol n’est pas de niveau, il faudra placer des cales au-dessous du receveur.

Kohler Co. Français-5 1030520-2-A

Page 16

2" (5 cm) Tuyau du Drain

4-1/2" (11,4 cm) Ø MINI.

2" (5 cm)

Tuyau du Drain

3/8" (1 cm)

Sol brut en bois

3/8" (1 cm)

1-1/2" (3,8 cm)

MINI.

4-1/2" (11,4 cm) Ø MINI.

Sol brut

en béton

4. Installez la Plomberie

REMARQUE : Prévoyez l’accès à toutes les connections de la plomberie pour un entretien future.

Déterminez l’emplacement de la plomberie, selon le plan de raccordement.

Positionnez la plomberie, selon le plan du raccordement. Bouchez les arrivées et vérifiez s’ilyades

fuites.

Installez un tuyau d’évacuation de 2″ (5 cm) de manière à ce qu’il se prolonge de 3/8″ (1 cm) au

dessus du sol. Il faut prévoir un logement dans la dalle de construction pour le tuyau d’évacuation.

Si possible, prévoyez un accès à l’arrière du mur de la plomberie pour l’entretien des conduites des

arrivées d’eau et de l’évacuation.

Assemblez la robinetterie de la douche conformément à la notice du fabricant. Ne pas installer les

rosaces à ce moment.

1030520-2-A Français-6 Kohler Co.

Page 17

Matériau

Hydrofuge Mural

Mur Non Fini

Couche de Vinyle

Pour l'Installation

Des Carreaux

Mur Terminé

Mastic

Hydrofuge

Ruban Ahésif

Sensible à la Pression

Rebord du Receveur

Sol brute

5. Installez la bande de vinyle

ATTENTION : Risque d’endommagement du produit. Ne pas exposer la bande de vinyle ou le ruban

adhésif sensible à la pression, à des tempèratures inférieures aux 40°F (4.4°C)

REMARQUE : La bande de vinyle K-1182 est utilisée pour une installation en encoignure avec les

receveurs K-9852 et K-9861. Il y a suffisamment de bande de vinyle fourni avec ce receveur. Quelques

découpes peuvent être nécessaires.

La bande de vinyle prend place sur la collerette carrelée du (des) côté(s) du receveur et elle sert de

joint étanche pour éviter que l’eau ne coule dans le cadre. Le jeu d’installation contient 7 pi (2,1 m)

de bande de vinyle et 12 pi (3,6 m) de ruban adhésif sensible à la pression.

Nettoyez le rebord du receveur de toutes poussières ou corps étrangers.

Positionnez temporairement la bande de vinyle sur le receveur et prenez la mesure. Ne pas serrer

les vis à ce moment. La bande devrait commencer à 3/4″ (1,9 cm) depuis la partie avant du coin, et

s’étendre le long du rebord jusqu’à la collerette carrelée, sur l’extrémité arrière du receveur. Coupez

à la distance requise.

Coupez la (les) bande(s) de rubans) adhésif(s) sensible(s) sur la même longueur, commençant aussi

depuis le rebord.

Appliquez la bande de vinyle juste avant d’installer le receveur en place.

Retirez le papier protecteur du ruban adhésif sensible à la pression et posez la bande soigneusement

sur le rayon de bec du receveur.

Positionnez le cordon de vinyle de 3/4″ (2 cm) depuis l’arrière à l’avant du coin avant. Appuyez

fermement sur la bande pour une bonne étanchéité.

Faire de même pour l’autre côté.

Après que la bande soit en place, commencez par le commencement de sa pose, et appuyez dessus

avec votre paume pour vous assurer de la continuité du joint.

6. Préparez le Receveur

ATTENTION : Risque de dommage matériel ou du produit. Si le joint d’échantéité du drain n’est pas

performant, des dommages causés par l’eau se produiront sur le sol et sous le receveur.

Installez le drain au receveur de la douche et selon la notice du Fabricant qui accompagne ce

produit.

Nettoyez le receveur pour réduire le risque d’endommagement de la surface.

Placez un linge ou une matière similaire sur le fond du receveur. Travaillez soigneusement pour ne

pas égratigner la surface de l’appareil.

Kohler Co. Français-7 1030520-2-A

Page 18

7. Positionnez le Receveur

Posez le receveur en place. Vérifiez le bon ajustage.

Introduire l’about dans le siphon. Ne pas brancher le siphon à ce moment.

ATTENTION : Risque d’endommagement du produit. Le cas échéant, placez les cales entre le sol ou

la dalle et les blocks en bois sous le receveur. Tous les blocks en bois doivent être supportés quand le

receveur est de niveau et cloué au cadre

Vérifiez que le receveur soit de niveau sur chaque coté et qu’il repose sur ses pied. Calez si besoin.

Il est possible d’utiliser du ciment, du plâtre ou des matières similaires pour mettre la base de

niveau.

1030520-2-A Français-8 Kohler Co.

Page 19

Percez un trou

pilote sur la

collerette à

chaque montant

Montant

Tasseau

Colerette de Cloutage

Montant

Utilisez des clous

galvanisés Nº 6 à large

tête pour fixer la

collerette de cloutage

aux montants.

8. Fixez le Receveur aux Montants du Cadre.

ATTENTION : Risque de dommage matériel. Assurez un joint étanche sur tous les raccords du drain.

Percez des trous de Ø 1/8″ (3 mm) au travers de la collerette de cloutage sur chaque montants.

Ajoutez des cales entre la bride de cloutage et les montants au besoin, pour empêcher l’éclatement

de la collerette pendant le perçage.

Complétez l’installation du drain suivant la notice d’installation correspondante.

Ouvrez les robinets des arrivées d’eau et vérifiez s’il y a des fuites.

Laissez couler l’eau dans le receveur et vérifiez s’il y a des fuites dans les raccords du drain.

Utilisez des clous galvanisés Nº 6 à tête large pour fixer la collerette de cloutage aux montants.

Clouez des planchettes de 1/8″ (3 mm) sur les montants de façon à ce qu’elles soient en contact

avec la collerette.

Kohler Co. Français-9 1030520-2-A

Page 20

1/2" (1,3 cm)

Matériau

Hydrofuge Mural

Rebord en

Papier Vers le

Bas

1/4" (6 mm)

Surface Concave

Materiel Hydrofuge entre la Colerette de Clouage et le

Papier du Mur de la Cloison Sèche

Cadre de 2 x 4

1/8" (3 mm)

Tasseaux

Clou Galvanisé

9. Complétez l’Installation

Posez du mastic d’étanchéité sur la partie supérieure de la collerette de cloutage, là où elle se

connecte avec la partie murale hydrofuge.

Recouvrez le cadre, le mur et la collerette de cloutage avec du matériau résistant à l’eau.

Installez le panneau mural avec l’arête (en papier broché) à un minimum de 1/4″ (6 mm) au-dessus

de la surface terminée et concave du receveur.

Collez et fixez le matériel mural.

Installez le mur terminé. Fixez les joints entre le rebord du receveur et le mur fini à l’aide de mastic

silicone. Le silicone RTV (Vulcanisation à Température Ambiante) d’étanchéité est conseillé.

Imperméabilisez autour des valves et des sorties avec du mastic ou du silicone.

Assemblez le robinet et le drain conformément à la notice du fabricant.

Si besoin, installez les barres d’appui ou les porte serviettes sur l’entretoisement (préalablement

installé). Suivez les instructions du Fabricant.

Si besoin, assemblez la porte de douche conformément à la notice du Fabricant.

Installez le sol terminé. Appliquez du mastic silicone d’étanchéité le long du rebord de la partie

avant du receveur là où il se connecte avec le sol.

10. Nettoyage

ATTENTION : Risque d’endommagement du produit. Ne jamais laisser des produits à base de

distillat de pétrole sur la surface de l’appareil pour une longue période de temps.

ATTENTION : Risque d’endommagement du produit. Ne pas utiliser de produits abrasifs.

Lors du nettoyage après l’installation, utilisez de l’eau tiède et un nettoyant liquide approuvé.

Les taches rebelles, la peinture ou le goudron peuvent être nettoyés au moyen de la térébenthine ou

d’un solvant pour peinture.

Les résidus de plâtre peuvent être nettoyés au moyen d’une spatule en bois. Ne pas utiliser un

grattoir en métal, une brosse en fer ou d’autres outils en métal. Utilisez de l’eau tiède avec un

nettoyant liquide approuvé pour une action abrasive douce.

1030520-2-A Français-10 Kohler Co.

Page 21

Guía de Instalación

Bases de ducha acrílicas con un umbral

Herramientas y materiales

Gafas

protectoras

Llave para

tubo

Taladro

Destornillador

Martillo de

uña

Escuadra

Lápiz

Cinta

métrica

Cuchillo

Nivel

Más:

• Herramientas y materiales comunes

para carpintería

• Clavos/tornillos para paneles de yeso

• Lona para el piso

• Listones de 2 x 4 ó 2 x 6

• Material de pared resistente al agua

• Listones de empotrar

Sellador

Masilla de

plomería

Gracias por elegir los productos de Kohler

Apreciamos su elección por la calidad de Kohler. Por favor, tome unos minutos para leer este manual antes

de comenzar la instalación. En caso de problemas de instalación o de funcionamiento, no dude en

contactarnos. Nuestros números de teléfono y nuestra página web se encuentran en la solapa posterior.

Gracias nuevamente por escoger a Kohler.

Antes de comenzar

Cumpla con todos los códigos locales de plomería y de construcción.

Emplace las tuberías para el desagüe conforme al diagrama de instalación de su modelo en

particular.

Es posible realizar varios tipos de instalaciones. En estas instrucciones encontrará procedimientos de

instalación recomendados, es posible que su instalación en particular requiera otras técnicas de

construcción.

Lea estas instrucciones atentamente para familiarizarse con la secuencia de instalación, las

herramientas y los materiales requeridos. Siga las secciones correspondientes a su instalación en

particular. Esto le ayudará a evitar errores costosos.

Su base de ducha viene empaquetada en una caja individual que contiene una base de ducha de

una pieza. Esta caja pasa a través de cualquier puerta de tamaño estándar. No debe sacar la base de

la caja hasta que vaya a instalarla.

Desembale la base de ducha y revise que no esté dañada. Si observa daños, no instale la base.

Informe inmediatamente a su distribuidor del problema específico.

Tras revisarla, vuelva a colocar la base en la caja hasta el momento de la instalación.

Es necesario instalar la base en un subpiso nivelado y con suficiente soporte.

Asegúrese de tener acceso suficiente para desplazar la base al área de construcción.

Kohler Co. Español-1 1030520-2-A

Page 22

Antes de comenzar (cont.)

Verifique que el área de instalación esté limpia y sin desechos. En caso de remodelación, retire todo

el material de la pared acabada para dejar expuesta la estructura, así como el revestimiento del piso

a fin de dejar el subpiso al descubierto.

Facilite una estructura que tenga las medidas correctas.

Se recomienda instalar esta base en espacios huecos. La instalación empotrada es otra opción para

esta base.

La instalación en esquina o en espacio hueco depende del modelo de la base.

La ubicación exacta de los travesaños extremos depende del espesor del material de la pared

acabada.

Si la unidad se va a instalar al lado de conductos o canales verticales, coloque un material de pared

resistente al agua y fuego alrededor de la unidad.

Cuando se especifique que la pared sea resistente al fuego, las dimensiones de las aberturas de los

travesaños deben tomarse por el lado expuesto del material de la pared.

Coloque la base dentro del área de instalación antes de completar la estructura.

El área interior de la pileta no requiere ningún soporte adicional cuando el subpiso esté a plomo y

nivelado con respecto a la estructura. Considere el uso de cuñas como soporte adicional en caso de

que el subpiso no esté nivelado.

Consulte todas las instrucciones correspondientes a las opciones y accesorios, antes de comenzar la

instalación.

El aparato sanitario cumple con la norma Z124.2 del ANSI. Todas las dimensiones son nominales.

Todos los modelos cumplen con los requisitos de IAPMO, con la excepción de K-9531.

1. Preparación del sitio

Verifique que el área de instalación esté limpia y sin desechos. En caso de remodelación, retire todo

el material de la pared acabada para dejar expuesta la estructura, así como el revestimiento del piso

a fin de dejar el subpiso al descubierto.

Inspeccione el piso en el lugar de instalación. Repare de ser necesario.

Verifique que el subpiso y el piso acabado estén planos y nivelados.

1030520-2-A Español-2 Kohler Co.

Page 23

2. Dimensiones de instalación

ABCDE

K-9531 32″ (81,3 cm) 16″ (40,6 cm) 31-3/4″ (80,6

K-9532 36″ (91,4 cm) 18″ (45,7 cm) 35-5/8″ (90,5

K-9533 42″ (106,7 cm) 21″ (53,3 cm) 41.75″ (106 cm) 21″ (53,3 cm) 6-1/8″ (15,6 cm)

K-9534 47-7/8″ (121,6

cm)

K-9535 60″ (152,4 cm) 30″ (76,2 cm) 34″ (86,4 cm) 16-7/8″ (42,9

K-9536 37-7/8″ (96,2

cm)

K-9538 42″ (106,7 cm) 21″ (53,3 cm) 34″ (86,4 cm) 17″ (43,2 cm) 6-1/8″ (15,6 cm)

K-9852 60″ (152,4 cm) 30″ (76,2 cm) 36″ (91,4 cm) 27-1/8″ (68,9

K-9858 36″ (91,4 cm) 8-7/8″ (22,5 cm) 36″ (91,4 cm) 27″ (68,6 cm) 6-1/8″ (15,6 cm)

K-9861 48″ (121,9 cm) 24″ (61 cm) 36″ (91,4 cm) 27″ (68,6 cm) 6-1/8″ (15,6 cm)

K-9866 38″ (96,5 cm) 21-7/8″ (55,6

¡IMPORTANTE! Todas las dimensiones son nominales. La tolerancia de la abertura de los travesaños es

más 1/4″ (6 mm) y menos 0. Mida con cuidado su aparato sanitario antes de determinar el tamaño del

recinto. Cuando se especifique que la pared sea resistente al fuego, las dimensiones deben tomarse en la

parte interior de la pared. Puede que sea necesario colocar cuñas entre la estructura de travesaños y el

aparato sanitario. Las medidas proporcionadas en la sección de dimensiones de instalación son cruciales

para una buena instalación. Construya la estructura y realice la instalación de plomería con precisión.

23-15/16″ (60,8

cm)

18-13/16″ (47,8

cm)

cm)

cm)

cm)

34″ (86,4 cm) 17″ (43,2 cm) 6-1/8″ (15,6 cm)

37-7/8″ (96,2

cm)

38″ (96,5 cm) 18-5/8″ (47,3

15-7/8″ (40,3

cm)

17-13/16″ (45,2

cm)

cm)

18-13/16″ (47,8

cm)

cm)

cm)

6-1/8″ (15,6 cm)

6-1/8″ (15,6 cm)

6-1/8″ (15,6 cm)

6-1/8″ (15,6 cm)

6-1/8″ (15,6 cm)

6-1/8″ (15,6 cm)

Kohler Co. Español-3 1030520-2-A

Page 24

Dimensiones de instalación (cont.)

NOTA: Si es necesario que se instale una pared resistente al fuego, las dimensiones deberán aumentar

conforme al espesor del material resistente al fuego. Las dimensiones de las aberturas entre los travesaños

se deben tomar por el lado expuesto del material de la pared.

NOTA: Si la unidad se instala junto a una pared de mampostería, haga provisiones para las conexiones de

plomería. Construya una pared separada a 6″ (15,2 cm) como mínimo de la pared de mampostería.

1030520-2-A Español-4 Kohler Co.

Page 25

Construya una estructura

de travesaños de 2 x 4

conforme al diagrama de

instalación incluido con el

producto

Realice el tendido

de la plomería

Estructura de

travesaños de 2 x 4

Verifique que el subpiso

proporcione el soporte

adecuado, y que esté

Muro de

mampostería

6" (15,2 cm) MÍN.

plano y nivelado

3. Construya la estructura de travesaños

Si va a instalar una puerta de ducha con esta unidad, consulte las instrucciones de instalación de la

puerta de ducha para cualquier consideración especial de la estructura.

Construya una estructura de travesaños de 2x4 o de 2x6, conforme al diagrama de instalación de su

modelo en particular.

Verifique que la estructura esté a escuadra y a plomo.

Si se van a instalar agarraderas, suministre un refuerzo de 2x6 en la posición especificada. Consulte

las instrucciones del fabricante de la agarradera.

El área de la pileta no requiere soporte adicional cuando el subpiso está a plomo y nivelado con la

estructura de travesaños. Si el subpiso no está nivelado, puede que necesite colocar cuñas para

nivelar la unidad.

Kohler Co. Español-5 1030520-2-A

Page 26

2" (5 cm) Tubería de desagüe

4-1/2" (11,4 cm) D. MÍN.

2" (5 cm)

Tubería de desagüe

3/8" (1 cm)

Subpiso de

madera

3/8" (1 cm)

1-1/2" (3,8 cm)

MÍN.

4-1/2" (11,4 cm) D. MÍN.

Subpiso

de concreto

4. Instalación de plomería

NOTA: Proporcione acceso a todas las conexiones de plomería para facilitar el mantenimiento futuro.

Ubique las tuberías de desagüe conforme a la dimensiones de instalación del modelo correcto.

Instale las tuberías según el diagrama de instalación. Cierre el suministro y verifique que no haya

fugas.

Instale una tubería de desagüe de 2″ (5 cm), que se extienda 3/8″ (1 cm) por encima del subpiso o

losa. En las construcciones de losa es necesario hacer una cavidad para alojar las conexiones de

desagüe.

De ser posible, provea un acceso en la parte posterior de la pared que tenga las conexiones de

plomería para poder realizar el mantenimiento de las tuberías de suministro y desagüe.

Instale la válvula de la ducha según las instrucciones del fabricante. No instale la guarnición en este

momento.

1030520-2-A Español-6 Kohler Co.

Page 27

Material de pared

resistente al agua

Pared no

acabada

Tira selladora

de vinilo

Pared acabada

Sellador

resistente al agua

Cinta autoadhesiva

Borde de la base

Subpiso

5. Instale la tira selladora de vinilo

PRECAUCIÓN: Riesgo de daños al producto. No aplique la tira selladora de vinilo ni la cinta

autoadhesiva a temperaturas inferiores a los 40°F (4,4°C).

NOTA: La tira selladora de vinilo K-1182 se utiliza en las instalaciones en esquina de las bases de ducha

K-9852 y K-9861. Se ha suministrado suficiente tira selladora de vinilo para cualquier base. Será necesario

cortar un poco.

La tira de vinilo sustituye al reborde en los lados de la base, y es necesaria para impedir que

penetre agua en la estructura. El juego de instalación contiene 7’ (2,1 m) de tira de vinilo y 12’ (3,7

m) de cinta autoadhesiva de sellado.

Limpie el polvo, la grasa y la suciedad de los bordes de la base de ducha.

Coloque la tira selladora temporalmente en la base para medir. No utilice la cinta selladora en este

momento. Coloque el principio de la tira a 3/4″ (1,9 cm) de la esquina frontal, hacia el interior, y

extiéndala a lo largo del borde, hasta llegar al reborde integral que se cubrirá de azulejos en la parte

posterior de la base. Corte la longitud necesaria.

Corte la(s) misma(s) longitud(es) de cinta autoadhesiva, partiendo igualmente desde la parte frontal

del borde.

Aplique la tira de vinilo justo antes de instalar la base en su lugar.

Retire el papel de la cinta autoadhesiva y aplíquelo con cuidado en el radio de la esquina de la

base.

Empiece por aplicar la tira de vinilo a 3/4” (1,9 cm) de la esquina frontal, hacia el interior. Presione

firmemente la tira sobre la cinta selladora para que se adhiera bien.

Repita el procedimiento en el lado contrario.

Después de colocar la tira, trabaje en el área donde se aplicó primero la tira presionando con la

palma de la mano para asegurar un sello continuo.

6. Prepare la base

PRECAUCIÓN: Riesgo de daños al productooalapropiedad. Si no se obtiene un sello hermético en

el desagüe, se pueden producir daños causados por el agua en el subpiso y la parte inferior de la base.

Instale el desagüe en la base de ducha según las instrucciones del fabricante del desagüe.

Limpie la base para reducir el riesgo de daños a la superficie.

Coloque una lona limpia u otro material similar en el fondo de la base. Tenga cuidado de no rayar

la superficie de la unidad.

Kohler Co. Español-7 1030520-2-A

Page 28

7. Coloque la base

Coloque la base en su lugar. Verifique que encaje correctamente.

Encaje el desagüe en el sifón. No conecte el sifón en este momento.

PRECAUCIÓN: Riesgo de daños al producto. Si es necesario acuñar, coloque cuñas entre el subpiso o

losas y los pies de los bloques de madera por debajo de la base. Todos los pies de los bloques de

madera deben estar apoyados cuando se nivele y clave la base a la estructura.

Compruebe que la base esté nivelada en ambas direcciones y quede apoyada sobre todos los pies.

Utilice cuñas de ser necesario.

Es posible utilizar concreto, yeso duro o materiales similares para nivelar la base.

1030520-2-A Español-8 Kohler Co.

Page 29

Perfore un pequeño

orificio a través del

reborde de clavado a la

altura de cada travesaño

Travesaño

Listón de empotrar

Reborde de clavado

Travesaño

Utilice clavos o

tornillos galvanizados

del nº 6 para fijar el

reborde de clavado a

los travesaños

8. Fije la base a la estructura de travesaños

PRECAUCIÓN: Riesgo de daños a la propiedad. Asegúrese de que todas las conexiones del desagüe

tengan un sello hermético.

Perfore orificios de guía de 1/8” (3 mm) a través del reborde de clavado a la altura de cada

travesaño. De ser necesario, utilice cuñas entre el reborde de clavado y los travesaños para evitar

agrietar el reborde mientras se taladra.

Termine de instalar el desagüe según las instrucciones incluidas con el mismo.

Abra los suministros de agua y verifique que no haya ninguna fuga en las conexiones.

Deje correr el agua en la base y verifique que no haya fugas en las conexiones del desagüe.

Utilice clavos o tornillos grandes galvanizados del nº 6 para fijar el reborde de clavado a los

travesaños.

Clave los listones de empotrar de 1/8″ (3 mm) de espesor en los travesaños para eliminar el filo del

reborde de clavado.

Kohler Co. Español-9 1030520-2-A

Page 30

1/2" (1,3 cm) Material

de pared resistente

al agua

Borde (de papel)

hacia abajo

1/4" (6 mm)

Superficie cóncava

Sellador resistente al agua entre el reborde de clavado y el

borde de papel del material de pared resistente al agua

Estructura de 2 x 4

1/8" (3 mm)

Listón

Clavo

galvanizado

9. Termine la instalación

Aplique sellador de silicona en la parte superior del reborde de clavado/tira de vinilo donde se

junta con el material de pared resistente al agua.

Cubra la estructura, las paredes y el reborde de clavado con material de pared resistente al agua.

Instale el material de pared resistente al agua en la estructura con el borde de papel a 1/4″ (6 mm)

como máximo por encima de la superficie acabada cóncava de la base.

Aplique cinta sobre el material de la pared y cúbrala con masilla.

Instale la pared acabada. Selle las juntas entre el borde de la base y la pared acabada utilizando

sellador de silicona. Se recomienda utilizar sellador RTV (Vulcanizado a temperatura ambiente).

Selle alrededor de las válvulas y de las salidas con sellador de silicona o masilla de plomería.

Instale la guarnición de la grifería y del desagüe según las instrucciones del fabricante.

Si es pertinente, instale las agarraderas o los toalleros en el soporte de la pared de travesaños

(previamente instalado). Siga las instrucciones de instalación del fabricante.

Si es pertinente, instale la puerta de ducha según las instrucciones del fabricante.

Instale el piso acabado. Aplique sellador de silicona por el borde frontal de la base donde se junta

con el piso.

10. Limpieza

PRECAUCIÓN: Riesgo de daños al producto. No permita que los limpiadores que contengan

destilados de petróleo entren en contacto con las superficies del módulo por ningún periodo de

tiempo.

PRECAUCIÓN: Riesgo de daños al producto. No utilice limpiadores abrasivos.

Al limpiar después de la instalación, utilice agua tibia y un detergente líquido aprobado para

limpiar la superficie.

Las manchas difíciles de quitar, la pintura y el alquitrán se pueden limpiar con aguarrás y diluyente

de pintura.

El yeso se puede eliminar raspando con un canto de madera. No utilice raspadores de metal,

cepillos de alambre ni otras herramientas metálicas. Utilice agua tibia y un detergente líquido

aprobado para crear una acción abrasiva suave y eliminar los residuos de yeso.

1030520-2-A Español-10 Kohler Co.

Page 31

1030520-2-A

Page 32

USA: 1-800-4-KOHLER

Canada: 1-800-964-5590

México: 001-877-680-1310

kohler.com

©2004 Kohler Co.

1030520-2-A

Loading...

Loading...