Page 1

1276024-T01-D

KOHLER CHINA INVESTMENT CO., LTD NO.158, JIANG CHANG SAN ROAD,

JING'AN DISTRICT, SHANGHAI, PRC POST CODE: 200436

( ) 158 200436

Installation Guide

Kitchen WaterFiltration SystemCarafe Series

K-80021T-KP040-01R/K-80021T-KP050-01R

©©Copyright Kohler China Investment Co., Ltd. 2016

2016

Page 2

-1-

1276024-T01-D

Note: Note is used to emphasize installation, operation or

maintenance information which is important, but does not

present any hazard.

!

!

!

!

!

!

!

!

CAUTION!

CAUTION!

CAUTION!

CAUTION!

CAUTION!

CAUTION!

CAUTION!

CAUTION!

Make certain that installation and

connectors must comply with all state and local

plumbing codes.

Installation and maintenance must be done

by qualified plumbing professionals designated by

dealers authorized by Kohler.

For cold water use only (Temperature

Range: 5-38 C); This filter must be protected from

freezing, which can cause cracking of the filter and

water leakage. Drain filter when room temperature

drops below 5 C.

Inlet Pressure Range: 150-400 kPa, If

water pressure exceeds 400kPa, please install

pressure limiting valve. (Please consult plumbing

professionals or dealers authorized by Kohler for water

pressure measurement).

Do not install where water hammer

conditions may occur. If water hammer conditions

exist you must install a water hammer arrester.

Do not install in direct sunlight outdoors

or where blowtorch or other high temperature sources

are nearby.

The filter must be installed with the inlet,

outlet and drain ports as labeled. Make sure not to

reverse connections.

Water filtration faucet is not supplied with

the product. you will need to purchase a water filtration

faucet with a G1/2" connector or with a 1/4" adapter.

°

°

! Note: Do not use filtered water for the water exchange

of an aquarium or a fishbowl.

CAUTION! Caution is used when failuretofollow

directions could result in damageto

equipment orproperty.

!

!

!

!

!

!

!

!

( 5-38

)5

150-400

400 (

)

(

)

G1/2 2

!

WARNING!Warning is used to indicate a hazard

which could cause injury or death if

ignored.

This document contains important information and details

concerning product installation, operation and maintenance.

Please read it carefully prior to installation and obey all the

instructions during operation.

BEFORE YOU BEGIN

WARNING! Do not use with water that is

microbiologically unsafe or of unknown

quality without adequate disinfection

before or after the system.

WARNING! Unplug the unit before your installation,

make sure cold water valve is turned off

under the sink.

WARNING! Do not repair, disassemble, or modify.

Children should be supervised to ensure

that they do not play with the appliance.

Page 3

-2-

1276024-T01-D

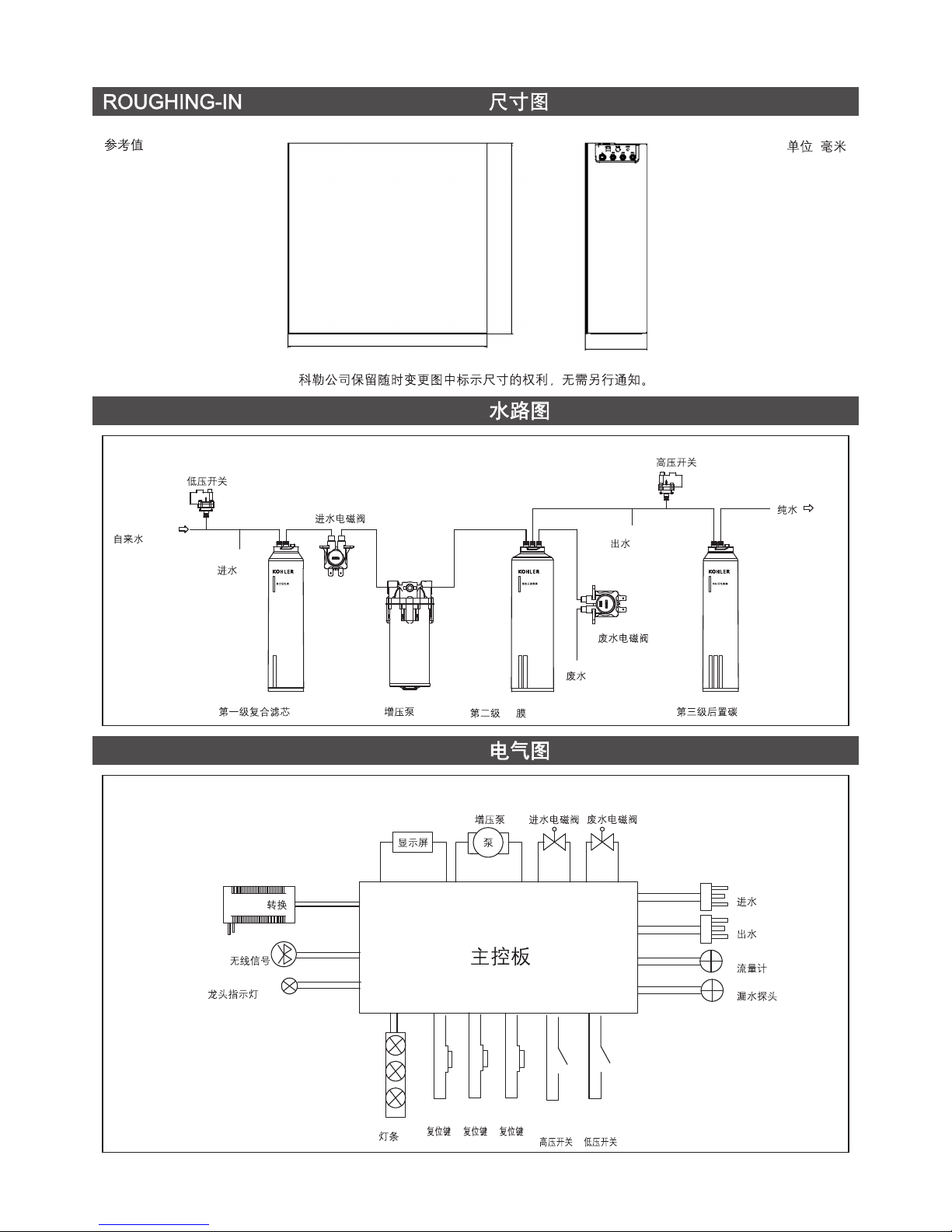

Unit: mm

:

Reference Value

Kohler reserves the right to change marked dimensions without prior notice.

482.5

462.2

149.4

Water Supply

Low Pressure Switch

Inlet TDS

TDS

Inlet Solenoid Valve

Drain Solenoid Valve

Drain

Outlet TDS

TDS

High Pressure Switch

Pure Water

Odor-Free Carbon FilterHigh Efficacy Reverse Osmosis Filter

RO

Composite Actived Carbon Filter

WATERWAY FIGURE

ELECTRICAL DIAQRAM

CompositeActivated

CarbonFilter

80031T-R1-01R

HighEfficacy Reverse

OsmosisFilter

80031T-R2-01R

Odor-Free

CarbonFilter

80031T-R3-01R

Booster Pump

AC/DC

24VDC

220VAC/50HZ

WIFI

Faucet Indicator

Led Bar

High

Pressure

Switch

Low

Pressure

Switch

Booster

Pump

Water-in

Solenoid

Valve

Drain

Solenoid

Valve

Inlet TDS

TDS

Outlet TDS

TDS

Flow Meter

Water Leak Detector

Display

Main Control Circuit Board

Reset

Button 3

3

Reset

Button 2

2

Reset

Button 1

1

Page 4

1276024-T01-D

-3-

PERFORMANCE DATA SHEETPERFORMANCE DATA SHEET

Model

Production Rate

1

1

Ratio of Product to Flush Flow

2

2

Capacity (gallon)

80021T-KP040-01R( )KP040

400 gpd (1500 / )

Standard Applications

1:1

Composite Activated Carbon Filter

80021T-KP050-01R( )KP050

INFLUENT WATER CHARACTERISTICINFLUENT WATER CHARACTERISTIC

Total Dissolved Solids

500 gpd (1900 / )

Standard Applications

1:1

1400gal (Chlorine reduction)

Total product water & drain

()

1600gal (Chlorine reduction)

Total product water & drain

()

High Efficacy Reverse Osmosis Filter

Recommendation: about 2 years

2

3

3

Recommendation: about 2 years

2

3

3

Odor-Free Carbon Filter

800gal (Chlorine reduction)

()

700gal (Chlorine reduction)

()

1 Production Rating at 40 psi, 25 C, 250 mg/L Nacl solution influent.

2 Ratio of Product to Flush Flow may vary with pressure.

3 The RO Filter performance varies depending on local water quality and product water Consumption.

1 40PSI, 250 mg/L Nacl

2

3Ro

°

1 0 - 1500 ppm(10 - 1500 mg/L)

pH

6-9

Chlorine

0 - 1 ppm (0 - 1 mg/L)

Turbidity

0-5NTU

Hardness

Limits of local standards of drinking water quality

Iron

0 - 0.5 ppm (0 - 0.5 mg/L)

Page 5

-4-

1276024-T01-D

Water Supply

Adapter

3/8" PE Tubing

3/8" PE

1/4" PE Tubing

1/4" PE

GETTING STARTEDGETTING STARTED

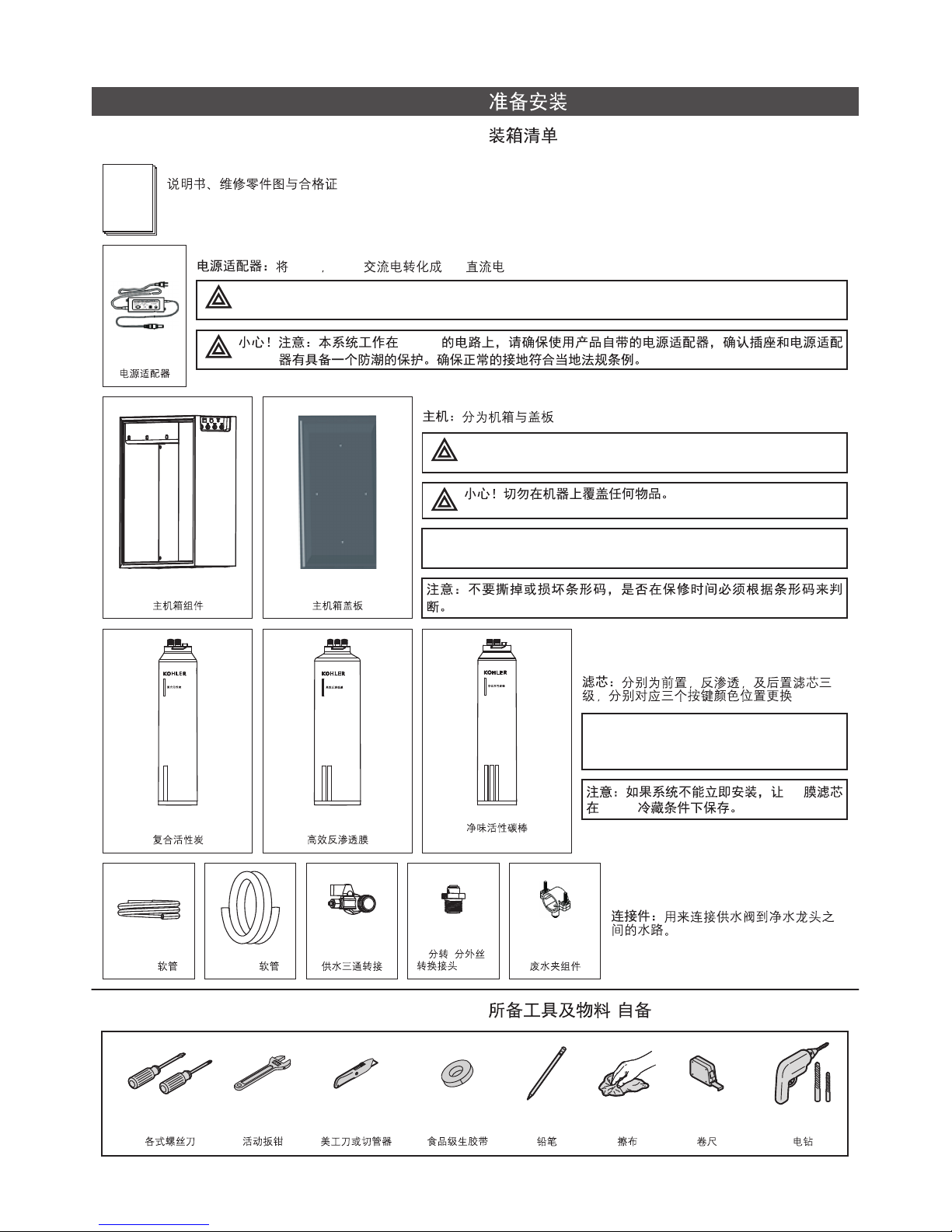

PackagingList

Assorted

Screwdrivers

Adjustable

Wrench

Drill

Pencil

Towels

Thread

Sealant Tape

Utility Knife or

Tube cutter

Measure Tape

Tools &Materiel required (not included)

()

Installation Guide & Service Parts Page & Compliance Certification

Power Adaper

Main Body Assembly Main Body Cover Assembly

CompositeActivated

CarbonFilter

80031T-R1-01R

HighEfficacy Reverse

OsmosisFilter

80031T-R2-01R

Composite Activated

Carbon Filter

High Efficacy Reverse

Osmosis Filter

Odor-Free Carbon Filter

Connect Fittings: Function is used to

connect the water supply valve to the

water filtration faucet.

Filter: including Pre-filter, RO, and the Postfilter 3 level, change this filters matched the

button colour

NOTE: If thesystemwill not be installed

immediately, refrigerate the RO

membrane element at 35 /40 F (2 /5 C).°° °°

RO

2/5C°°

1/4 *1/2" Male

Adapter(BSTP)

24

(BSTP)

Drain Saddle

Clamp Kit

PowerAdaper: Transform 220VAC, 50Hz into 24VDC

220V 50Hz 24V

CAUTION! Thesystemworkson24VDC electrical power only. Besure to use theincluded Power

Adapter.

24VDC

System: including Main body and Cover

CAUTION! Makesurethat the unit is not covered with

anything.

Note: DO NOT removeor destroy theserial number. It must be

referenced on request forwarrantyrepair orreplacement.

Odor-Free

CarbonFilter

80031T-R3-01R

Page 6

-5-

1276024-T01-D

Note: Please pre-install Water filtration faucet of Kohler

brand or other brands on the sink. (Refer to Water filtration

Faucet Installation Manual for tools and detailed installation

steps of water filtration faucet. For water filtration faucet

other than Kohler brand, please make sure the inlet

dimension is G1/2" or with a 1/4" adapter).

(

G1/2" 2 )

Step1 Pre-install WaterFiltration Faucet

(Refer to Figure 1- Figure 4)

(1-4)

INSTALLATION

1. Make sure cold water supply line under the sink is turned

off; (Figure 1)

(1)

2. Disconnect cold water line from threaded stub on bottom

of tap faucet; (Figure 2)

(2)

Cold Water Supply Valve

Cold Water Supply Valve

Fig.#1

1

Fig.#2

2

Stub of Tap Faucet

3. Screw the water supply adapter - female threaded stub

to the cold water supply valve male threads as shown.

Hand it tighten and snug with wrench. Screw the female

threaded tap faucet stub to the water supply adapter;

(Figure 3)

(3)

Fig.#3

3

Stub of Tap Faucet

Water Supply Adapter

4. Screw 1/4" x 1/2" Male Thread Faucet Adapter to the

female threaded Water filtration faucet stub, Hand it

tighten and snug with wrench. (Figure 4)

24

(4)

Fig.#4

4

Note: When using a wrench tight the plastic adapter, be

sure softly, if overexert, the adapter would be damaged.

,

Water Filtration Faucet Stub

1/4" X 1/2" Male Thread Faucet Adapter

24

Page 7

-6-

1276024-T01-D

Note: Cut tubing straight with a utility knife, make sure there

are no cuts, nicks, flat spots or sharp edges as figure 5, If

any of these are present, cut the tubing again; Do not kink

tubing. ( Figure 6)

(6)

Step2:Makingconnections

! Refer to Figure 5, insert the 3/8" Plastic tubing into the

filter inlet port and the water supply adapter, insert the

1/4" Plastic tubing into the filter outlet port and the end of

the Water filtration faucet; Then insert the a 1/4" Plastic

tubing into the Drain port of RO system and the Drain line

under the sink. (Figure 5)

TubingConnectors

! 53 2

RO

(5)

Fig.#5

5

Fig.#6

6

Tap Faucet

Water Filtration Faucet

Drain Saddle Clamp Kit

1/4" x 1/2" Male Thread Faucet Adapter

24

1/4" Plastic Tubing-Product Water

2

Water Supply Adapter

Cold Water Supply Valve

1/4" Plastic Tubing-Drain Water

2

3/8" Plastic

Tubing-Raw Water

3

Hot Water Supply Valve

Not Apply In This System

Not Apply In This System

Electronic Faucet Signals

(Only with Matchable Faucet)

()

Power

Drain Water (1/4")

(2 )

Product Water (1/4")

(2 )

Raw Inlet (3/8")

(3 )

Connections to undersink plumbing can be

made with a saddle clamp designed to

accept the drain tubing from the RO

system. Kohler offers a saddle kit, PN

1275904, designed for 40mm undersink

drain plumbing (Figure 13).

RO

1275904 40mm

Besuretocheck and follow local

plumbingcodes prior to installation.

Correct Cut

Incorrect Cut

Note: It may be difficult to release the tubing due to water

pressure when replacing service parts. In this case, please

shut off the cold water supply valve, turn on the Water

filtration faucet to depressurize and then try to release the

tubing again.

Fig.#7

7

To Attach Tubing

Push tubing in as

far as it can go

Tubing must be inserted

past O-ring and hit

backstop

O

Insert the locking clip

1

2

3

Fig.#8

8

To Release Tubing

Pull out locking clip Push in collect to release tubing.

With collect held, pull tubing straight out.

1

2

3

The Carafe system features reliable and convenient push-to-connect tubing connectors. Tubing is easily connected and

disconnected from these fittings as follows. (Figure 7 and 8)

(7 8)

Figure

Page 8

-7-

1276024-T01-D

NOTE: Before changing the filter, please make sure the cold

water valve is turned off.

NOTE: After the filter is replaced, the corresponding button

can be reset only. If not, the filter life indicator can't be

accurate. No need to reset after the first installation.

NOTE: Filtration performance varies depending on local

water quality.

Step3: InstallingFilterCartridge &ReplacingFilter

Cartridges

Fig.#9

9

!

!

!

Remove and discard the dustproof cap (sanitary

protective cap) from the cartridge;

Verify both O-rings are present and positioned correctly in

the grooves;

Push the filter cartridge into the filter base align the hollow

icon of the cartridge with the hollow icon on the filter base,

then turn cartridge clockwise until the hollow icon of the

cartridge were aligned the color filled icon on the filter

base, it will be fully installed. (Figure 9)

!

!

!

O

90

(9)

Rotate 90 degree & Pull out the old filter.

90

Change new filter matched the button colour.

Aim at the dot, rotate 90 degrees to fix.

90

Fig.#10

10

! When filters replaced remember to push and hold the

corresponding reset button to the filter for 5 seconds until

the indicator automatically with 2 short beep, then

corresponding orange LED light turn to white. (Figure 10)

! Please replace filter when prompted by the indicator.

!

5

( 10)

!

System Model

K-80021T-KP040-01R K-80021T-KP050-01R

First Stage

80031T-R1-01R 80041T-R1-01R

Second Stage

80031T-R2-01R 80041T-R2-01R

Third Stage

80031T-R3-01R 80041T-R3-01R

Press RESET button

for 5 seconds to reset

RESET 5

Page 9

-8-

1276024-T01-D

Fig.#11

11

Step4:Start-Up

CAUTION! If the powercord from thetransformer

to the unit looksorbecomes damaged,

the cord and transformer should be

replaced by a KohlerService Agent or

similarlyqualified person in order

to

avoid a hazard.

CAUTION! Do not touch the powerplugwith a wet

hand.

CAUTION! Do not connect and pull out the power

plugrepeatedly.

CAUTION! If ourproduct producesastrange

noise or odd smell, immediately

unplugfrom the electrical outlet and

call ourService Center.

1. Connect all electrical power;

2. When the first stage filter is brand new / replaced (must be

reset first), the system will do washout 5 minutes to get it

ready for making clean water. And the indicator light will

be waterfall effect. Make sure the filtration faucet be

turned off. (Figure 11)

1.

2.

5

( 11)

Note:Please confirm supplywater inlet

pipe & drain pipeisalreadyconnected,

thesystemwill automatically start

washing and drainingbefore

connectingpowerwhen thesystem is

brand new.

3. When the second stage RO-filter or the third stage carbon

block filter is brand new / replaced open the waterfiltrion

faucet , then run product water for a minimum 30 minutes

through the waterfiltration faucet to flush out any

remaining impurity & carbon dust from the RO & post filter.

3. 30

RO ,

Note: The initial product water can't be used as drinking or

cooking water.

Step5:Test System

!

!

Turn off the water filtration faucet, Keep the cold water

supply valve turned on. Check all fittings and tubings for

leaks. If it leaks, see Troubleshooting.

Complete the installation and cleanup.

!

!

Page 10

1276024-T01-D

-9-

TDS In

TDS

TDS Out

TDS

The first stage filter

pertormance indicator

The second stage filter

performance indicator

The third stage filter

performance indicator

PERFORMANCE INDICATOR

PRODUCE: When first time Start-up procedure is finished,

each time open the water filtration faucet to get the pure

water in&out water TDS value will light on shut off the

faucet, all lights black out

When filter life is running low or out each time open the

filtration faucet filter LEDs will change to orange with

normally lighting on or blinking.

TDS

LED

()

Plug in

!

!

!

!

Plug ICSelf-test Status:

Diagnosis Succeeded When

the user plug power into the

device, the IC self-test will be

automatically conducted. When

it is processing the self-test, the

LED displays looped "single

dash" with one short beep.

IC

IC

,

!

!

!

!

Status:Produce well

When produce the pure water

with performance well filters,

the filter indicator will be white

&the TDS value be displayed.

/

,

TDS

!

!

!

!

!

!

Washout

When the first stage filter is

brand new/replaced or the

system after every 24 hours

working, the system will do

washout to get it ready for

making clean water.

If power cut during the

washout, it will continue

washout until time over when

plug the power again.

/

24

515

,

!

!

!

!

FilterStatus:Filter lifeis

running low/ less than 10%

Filter LEDs will change to

orange with 3 short beep as

the filtration faucet is ON

when its life is running low/

less than 10% left. (Users

need to replace filters and

reset the indicator, and then

the LED turns white right after

the reset.)

10%

10%

!

!

!

!

FilterStatus: Immediate

change needed

Note:

Orange LED starts blinking

when the filter run out and

needs to be change

immediately when users turn

the filtration faucet ON, it

comes with 0.2 sec repeating

short beeps. (Users need to

replace filters and reset the

indicator, and then the LED

turns white right after the reset.)

TDS reduction problem

will blink orange LED with 3

short beep.

/

,

0.2 0.2

RO

Washout Normal

Expiration notice Expiration notice

Page 11

1276024-T01-D

-10-

ERROR: When system error is detected, the influent water

TDS value LED change to display an "Err" symbol, and the

effluent water TDS value LED will display an error code to

show a type of errors.

TDS LED "Err"

TDS

System Alarm (One long beep)

!

!

!

!

Error 02: EEPROM

02

The TDS indicator displays "Err

02" with System Alarm (One

long beep)when the system

self-diagnosis failed.

Err

02

EEPROM

!

!

!

!

Error 04: Disconnected TDS

outlet

04 TDS

Display "ERR" before "TDS IN"

and "04" before "TDS OUT"

when users turn the filtration

faucet on, it comes with 3

repeating short beeps. It means

the TDS outlet is not connected.

Err

04

TDS

!

!

!

!

Error 03:Disconnected TDS

inlet

03 TDS

Display "ERR" before "TDS

IN" and "03" before "TDS

OUT" when users turn the

filtration faucet on, it comes

with 3 repeating short beeps.

It means the TDS inlet is not

connected.

Err

03

TDS

!

!

!

!

Error 01: Leaking issue

01

When the leaking issue

occurs, system will shut down,

the TDS indicator will display

"Err 01" on your machine

when users turn the filtration

faucet on, it comes with a

repeating long beeps. Please

eliminate the leaking issue

follow the Troubleshooting.

Err

01

!

!

!

!

Error 05: Insufficient feed

waterpressure.

05

Display "ERR" before "TDS

IN" and "05" before "TDS

OUT" when feed water

pressure is Insufficient.

Err

05

!

!

!

!

Error 06:Pump Overused >40

Mins

06

40

Display "ERR" before "TDS IN"

and "06" before "TDS OUT" . It

means the pump is overused

more than 40 Mins.

Err

06

System Alarm (3 short beeps)

System Alarm (3 short beeps)

Page 12

1276024-T01-D

-11-

!

!

!

!

Error 08: Displaypanel is not

connected with PCB.

08

Display "ERR" before "TDS IN"

and "08" before "TDS OUT" . It

means the display panel have

communication problem with

PCB.

Err

08

!

!

!

!

Error 07: Pump malfunction

Display "ERR" before "TDS

IN" and "07" before "TDS

OUT". It means the pump

malfunction.

07

Err

07

!

!

!

!

Error 09: Unusual Pump

Start

09

Display "ERR" before "TDS

IN" and "09" before "TDS

OUT". It means unusual

pump start.

Err

09

System Alarm (3 short beeps)

System Alarm (3 short beeps)

Important Information in Using the System:

A period of time after the system shutoff, the product

water TDS value will be higher in less time, this is a

normal condition, just to discharge a small amount of

product water;

(System Alarm is a natural concomitant of this condition ,

if the alarm disappeared after producing the water a

minute later , system do not need any treatment;)

Before prolonged periods of non-use (such as during a

vacation) it is recommended that the cold water supply

valve be turned off. If it is more than one week, please

flush the filter thoroughly for at least 5 minutes before

reusing it;

If leaks occur and persist on system, please first turn off

the water supply valve. Call Kohler -Free Technical

Support line directly or your local distributor authorized by

Kohler;

Local water conditions and actual volume of water can

affect filter life. Be sure to replace the cartridge when

prompted by the performance LED indicator.

!

!

!

!

!

!

!

!

!

!

TDS

(RO

1)

()

15

OPERATION INSTRUCTIONS

Page 13

1276024-T01-D

WARING!Electrical shock hazard!Unplug the unit before maintaining.

-12-

TROUBLESHOOTINGGUIDE

Problem

Possible Cause

Remedy

"Err1"

"Err2"

"Err3"

"Err4"

"Err5"

"Err6"

"Err7"

"Err8"

"Err9"

Filter LEDs will change

to orange with beeps

Unit fails to initiate

Low or No faucet flow

Tubing not fully seated in fitting.

Self-diagnosis failed, EEPROM error.

TDS inlet not connected.

TDS outlet not connected.

Insufficient feed water pressure.

Pump Overused >40 Mins.

Pump malfunction.

Display panel is not connected with PCB.

Unusual Pump Start.

Filter life is running low or out.

No power supply.

Filter blockage caused by poor water quality.

Power adapter failure.

Pump or Solenoid Valve failure.

The Inlet TDS led indicator show waterfall effect,

and the system do washout.

Check all fittings for tightness.

Contact Kohler service.

Contact Kohler service.

Contact Kohler service.

Change in line pressure.

Repeat unplug and plug once.

Contact Kohler service.

Contact Kohler service.

Check all fittings tiny leakage or not.

Change in line pressure; or wait for the water

pressure change to normal.

Check the filtration faucet closed tightly or not.

Replace filter element.

Plug in again.

Check and Replace filter.

Contact Kohler service.

Contact Kohler service.

Turn off the faucet, wait for the washout finished.

Tubing abraded in seal area. Recut tubing and redo connection.

System inside leakage. Contact Kohler service.

Note: all the leakage (including not the system

leakage) could be detected and system will force

shutdown.

Note: after above steps, please unplug the

power first ,then wipe & dry the water leakage

protector sensor, plug in the power again.

"Err1"

"Err2"

"Err3"

"Err4"

TDS

TDS

"Err5"

"Err6"

"Err7"

"Err8"

40

"Err9"

,

NOTE: Should service, adjustment or trouble-shooting information be needed which is not covered in the Use Guide,call

yourKohlerDealer.

Page 14

1276024-T01-D

-

-

80021T-KP040-01R( )KP040 80021T-KP050-01R( )KP050

220V/50Hz

70W

1.05L/min

3800L

75W

1.31L/min

3900L

5-38

0.15-0.4Mpa

Q31/0108000050C001

(2015) 0123

()

302-303 307-308

Loading...

Loading...