Page 1

Installation and Care Guide

Steam Control Kit

K-5557 K-5558

M product numbers are for Mexico (i.e. K-12345M)

Los números de productos seguidos de M corresponden a México

(Ej. K-12345M)

Français, page “Français-1”

Español, página “Español-1”

1230489-2-C

Page 2

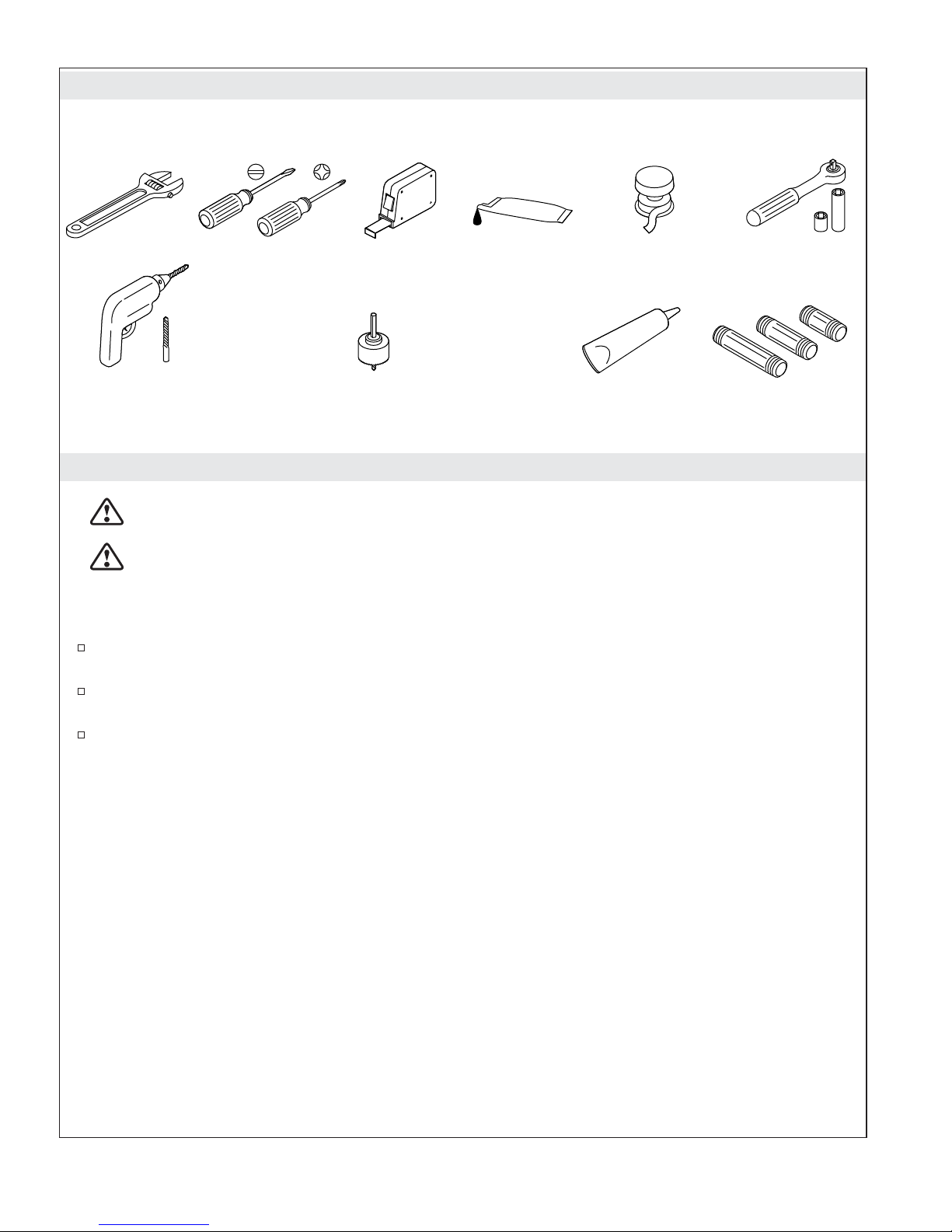

Tools and Materials

Socket Wrench

with 1" Socket

Pipe Nipples

Drill w/

1/4" Drill Bit

1-1/4" & 2-1/2" Hole Bit

(match bit to wall material)

Silicone

Lubricant

Silicone Sealant

Sealant

Tape

Before You Begin

CAUTION: Risk of electrocution. Disconnect the electricity to the working area at the main

breaker panel before performing these installation steps.

CAUTION: Risk of allergic reaction. Before adding any oils, aromatic therapies, or skin care

products to the aromatherapy well, make sure they will not cause an allergic reaction to the user.

NOTICE: Use this unit only for its intended use as specified in this manual. DO NOT use attachments

not recommended by Kohler Co.

Inspect the product for any shipping damage. Do not install the unit if it is damaged. Contact the

Kohler Co. Customer Care Center using the information on the back of this guide.

Follow all local plumbing and electrical codes. All electrical work should be done by a qualified

electrician.

Disconnect all power before making any electrical connections.

1230489-2-C 2 Kohler Co.

Page 3

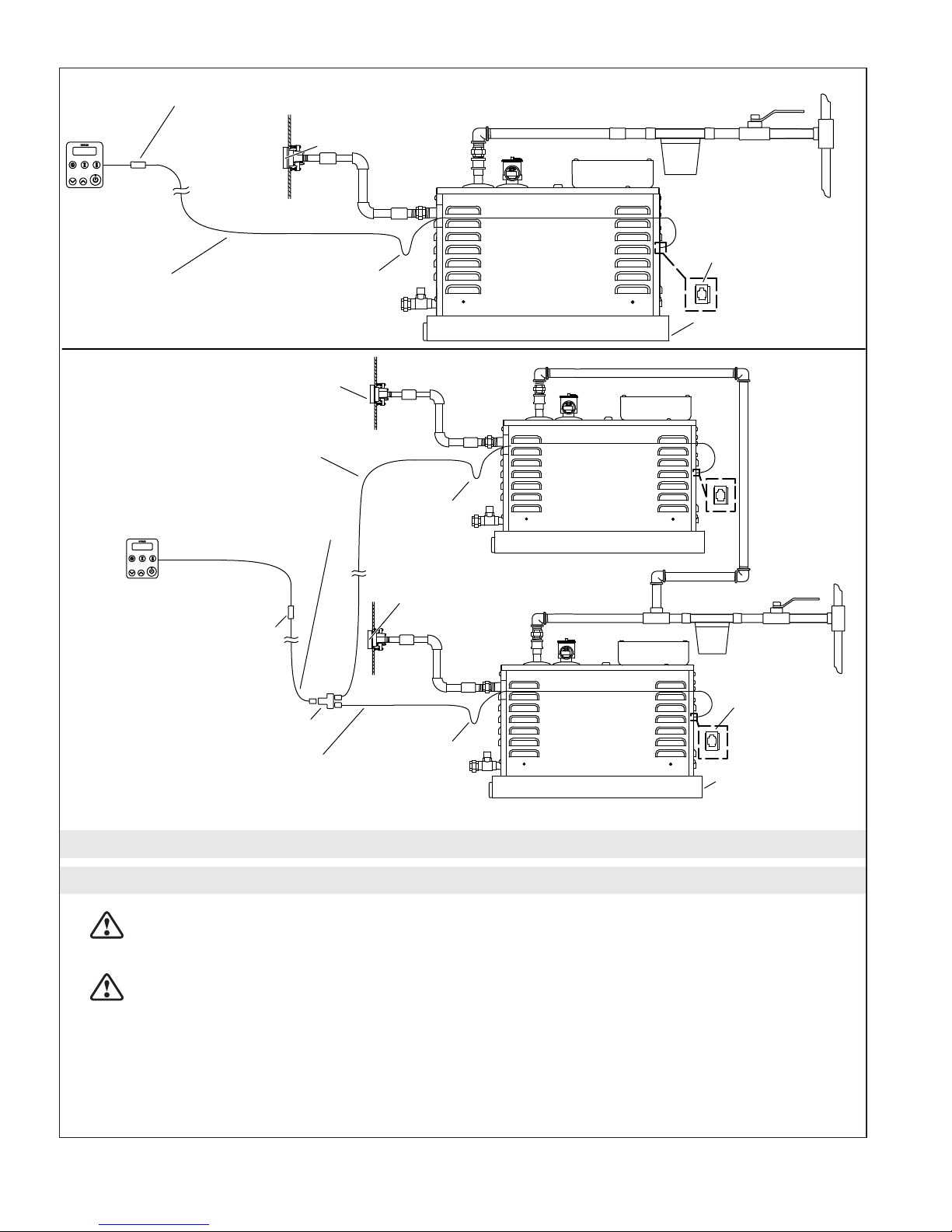

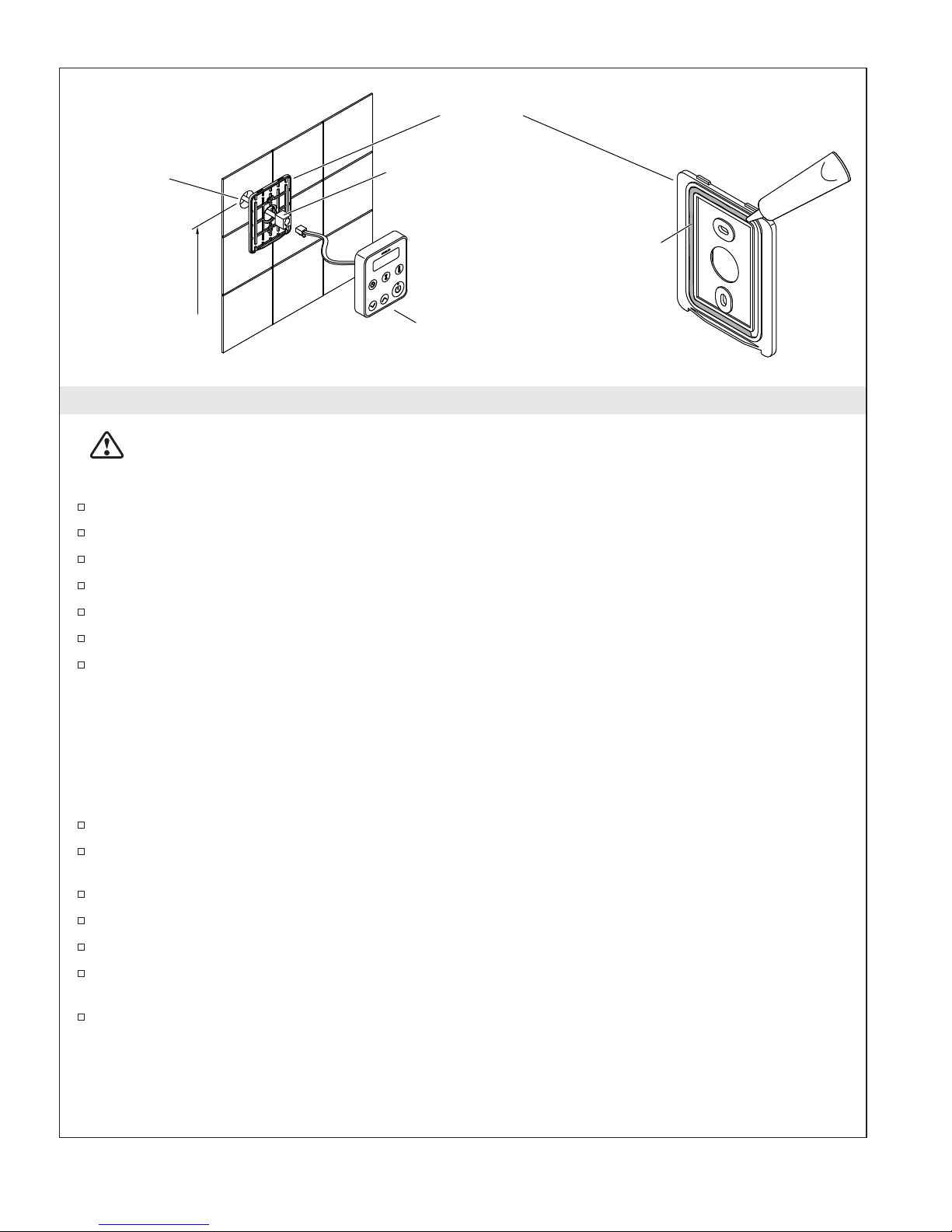

Connector, RJ12 Double Female (Assembled to Control Cable)

UIC

Control Cable

50' (15.2 m) White, Crossover

Steam Head and

Housing Assembly

Cable Data 6P/6C

78" (1981 mm)

Black, Straight Through

Steam Head and

Housing Assembly

Steam Generator

Control Cable Input

Drip Loop

Drain/Spill Pan

Control Cable

50' (15.2 m)

White, Crossover

UIC

Connector, RJ12 Double

Female(Assembled to

Control Cable)

Coupler 3-Way Straight

Cable Data 6P/6C

10" (254 mm)

Black, Straight Through

Layout Options

1. Review the Layout

CAUTION: Risk of personal injury. Do not install the Steam Control User Interface outside the

steam enclosure. The User Interface must be installed within the enclosure to allow the sensors to

regulate the temperature and control the flow of steam.

Drip Loop

Steam Head and

Housing Assembly

Drip Loop

Steam Generator

Control Cable

Input

Drain/Spill Pan

CAUTION: Risk of scalding. Do not locate the steam head near a seat or bench, as the steam head

is hot during operation and may scald the user if touched.

NOTICE: The user interface should be mounted on the wall opposite the steam head. The steam head

should always be located as far away from the seating area as possible.

NOTICE: Locate the steam head 6″ (152 mm) above the floor and a minimum of 4-1/2″ (114 mm) from

the threshold.

Kohler Co. 3 1230489-2-C

Page 4

Review the Layout (cont.)

Review the layout determined during the steam generator installation. See the steam generator installation

guide for more information.

Install the steam control user interface inside the steam enclosure.

Determine the steam head location or locations (for dual steam generator installations).

Ensure clearance between the steam line and any surrounding surfaces.

1230489-2-C 4 Kohler Co.

Page 5

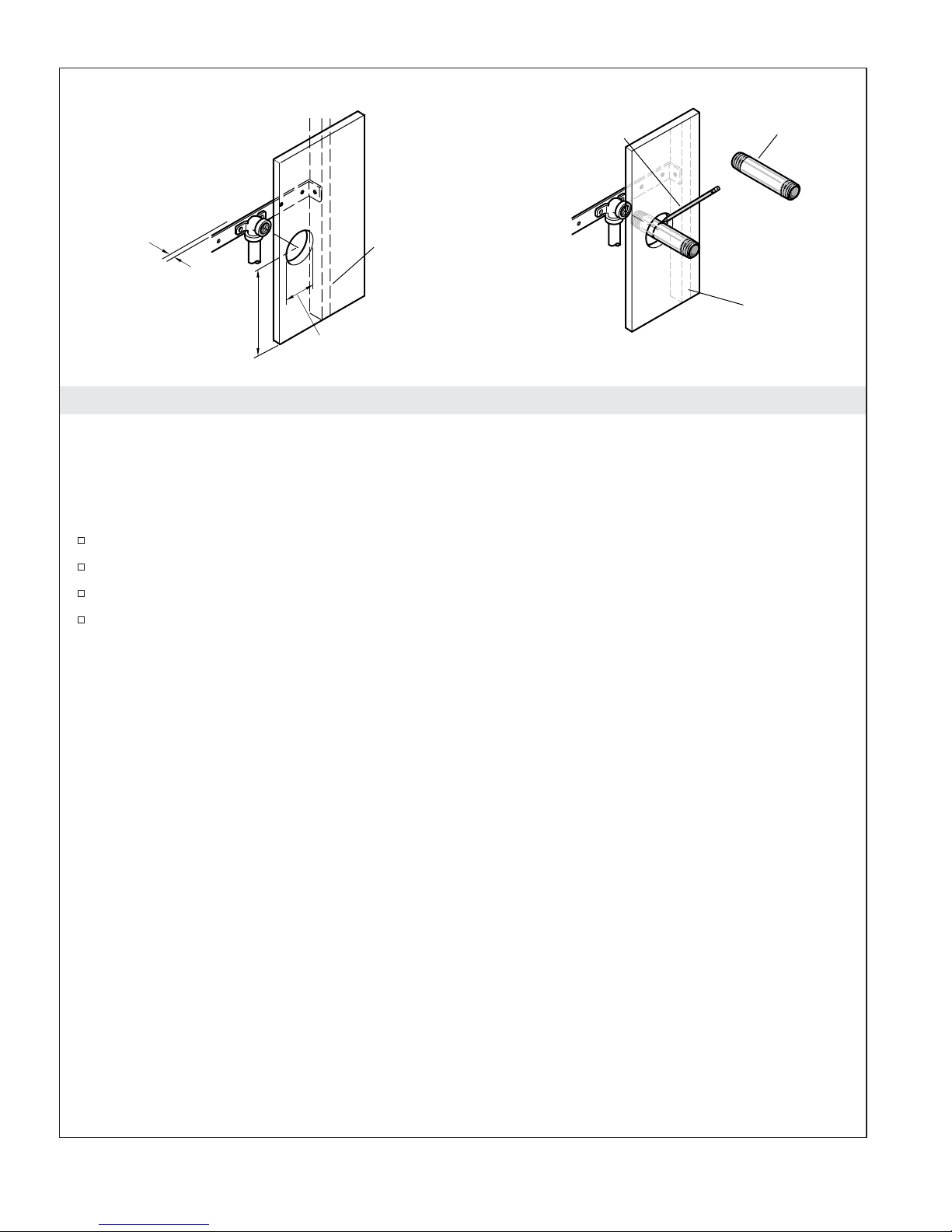

Provide clearance

from wall.

Wall Stud

Mark the nipple even

with finished wall.

Temporary

Nipple

6" (152 mm) from Floor

2-1/2" (64 mm)

Wall Stud

2. Prepare the Site

NOTE: This section continues the installation described in the steam generator installation instructions.

Refer to the steam generator installation instructions for more information, if needed.

NOTE: If two steam heads are used, there must be at least 12-1/2″ (318 mm) between the center of each

hole. The steam heads do not need to be located on the same wall. Two steam heads can be mounted on

different walls to improve steam distribution.

Install the finished wall.

Drill or cut a 2-1/2″ (64 mm) hole centered around the elbow in the wall.

Mark the temporary pipe nipple at the finished wall surface.

Remove the temporary pipe nipple from the elbow.

Kohler Co. 5 1230489-2-C

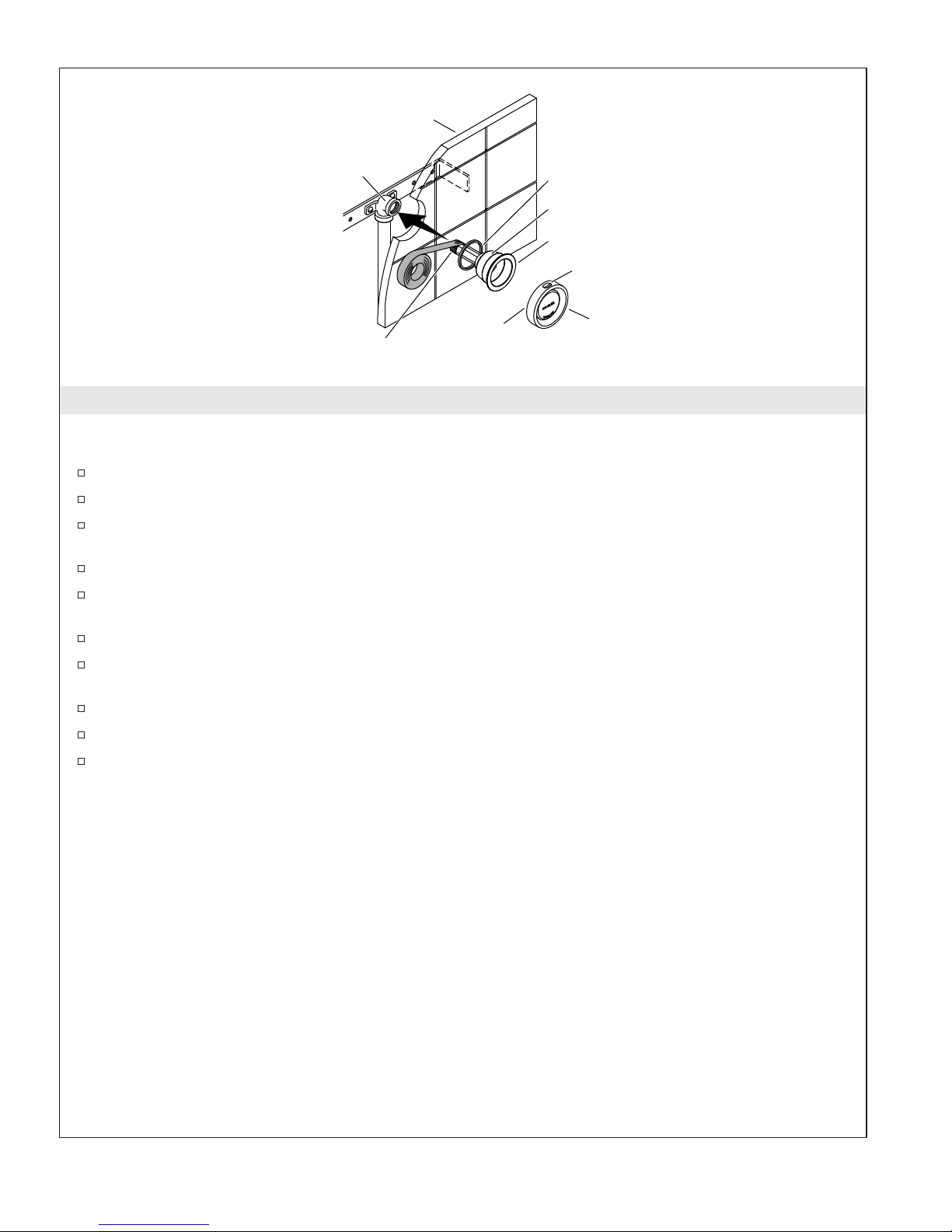

Page 6

Wall

1/2" Elbow

Nipple

Lubricate

O-rings.

Gasket

Steam Head Housing

Lip

Aromatherapy Well

Steam Head

3. Install the Steam Head(s)

NOTICE: Do not obstruct the steam head with shut-off valves, plugs, or caps.

Subtract 1-1/4″ (32 mm) from the marked length to determine the appropriate nipple size.

Choose a nipple length within 1/8″ (3 mm) of the appropriate nipple size.

Apply thread sealant to one end of the nipple and thread that end into the steam head housing

until hand-tight.

Apply thread sealant to the other end of the nipple.

Position the gasket around the steam head housing so that it will be between the finished wall and

the steam head housing flange.

Usea1″ socket to thread the steam head housing assembly into the elbow in the wall.

Make sure the gasket is compressed and a good seal has been achieved around the edges of the

steam head housing.

Use an appropriate sealant to achieve a watertight seal if needed.

Apply silicone lubricant to the steam head O-rings.

Carefully press the steam head assembly into the steam head housing with the aromatherapy well

positioned on the top of the steam head.

1230489-2-C 6 Kohler Co.

Page 7

Wall Mount

Back View

Ø 1-1/4"

(32 mm)

Control Connector

Apply silicone sealant

to groove.

60" (1524 mm)

to Floor

Control Pad

4. Install the Steam Control

WARNING: Risk of personal injury. Do not install the Steam Control User Interface outside the

steam enclosure. The User Interface must be installed within the enclosure to allow the sensors to

regulate the temperature and control the flow of steam.

Make sure that the power is turned off at the main breaker panel before proceeding.

Locate the control pad on the wall 60″ (1524 mm) from the floor.

At the selected location, drill a hole 1-1/4″ (32 mm) in diameter.

Center the wall mount on the 1-1/4″ (32 mm) hole, and mark the screw hole locations.

Use a 1/4″ drill bit to drill holes for the wall anchors at the marked locations.

Insert the wall anchors into the holes.

Apply a continuous bead of silicone sealant in the groove on the back side of the wall mount, and

secure the wall mount with the screws provided.

NOTICE: Do not pinch, nail, wedge, or use undue force when handling the control connector and the

control pad wire. Any damage may result in control kit failure. If the control pad is not installed

immediately, protect the control connector with tape or other shielding material.

NOTICE: When installing the control kit, allow room in the control cable for a drip loop. The drip loop

will discourage moisture from following the control cable to the steam generator.

Pull the steam control connector and cable from the steam generator through the drilled hole.

Carefully plug the control connector to the control pad wire using the double-end female connector

(provided).

Snap the control pad onto the wall mount.

Restore the power at the main breaker panel.

Turn on both water and power to the steam generator.

Test the control pad to ensure it is functioning properly. Refer to the ″Operating the Steam Control″

section.

Allow the silicone sealant to cure for 24 hours before use.

Kohler Co. 7 1230489-2-C

Page 8

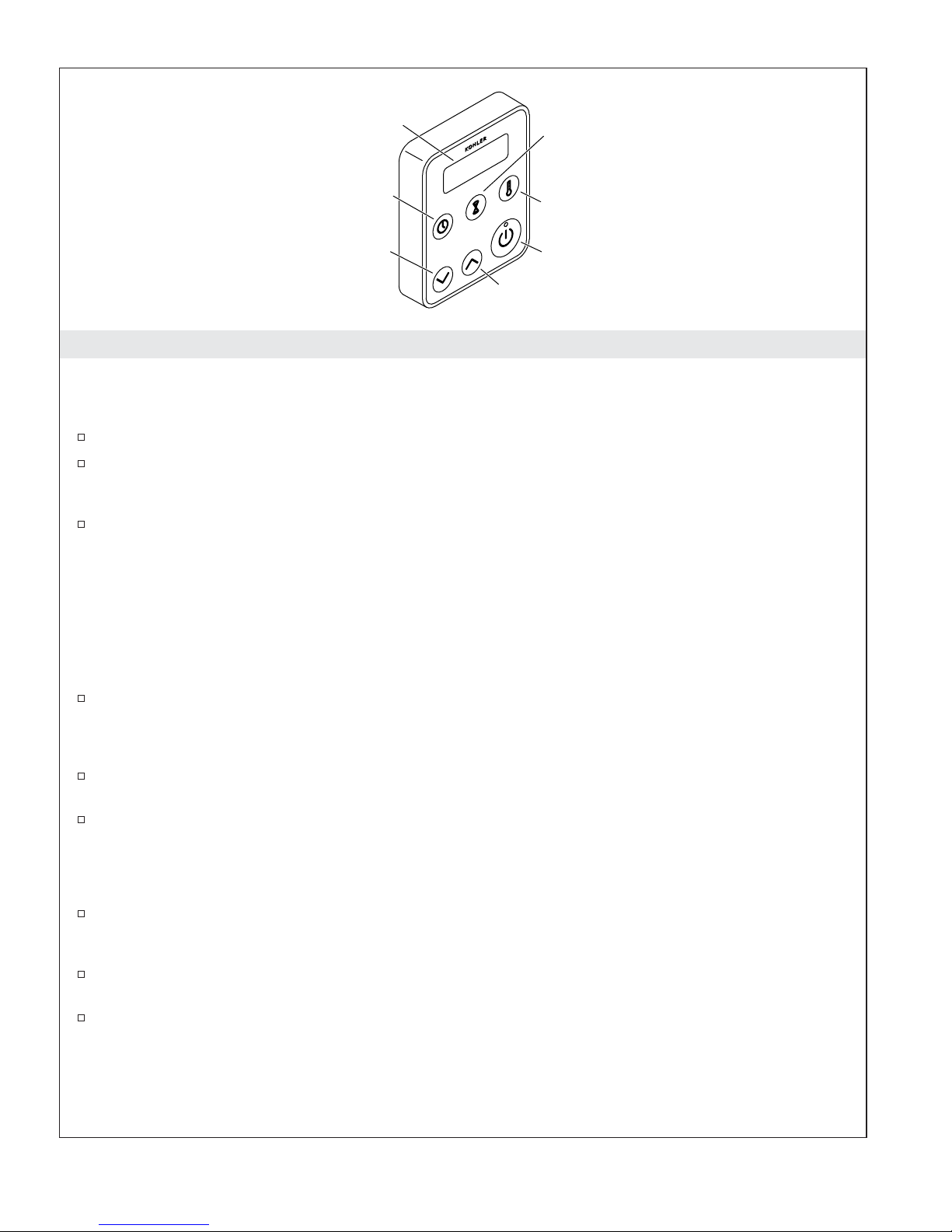

Display

Clock

Timer

Temperature

Decrease

Power

Increase

5. Operate the Steam Control

Steam Control Operation

NOTE: The clock is always displayed when the steam generator is not in use.

Press the ″Power″ button to start the steam generator.

When the ″Power″ button is pressed the green light on the button turns on. The light remains on

until the unit is turned off. The display reads ″On″ for the first 3 minutes of operation if the settings

are not changed.

Press the ″Power″ button again to turn off the steam generator. The green light on the ″Power″

button will turn off and the display will read ″Off″ for 5 seconds, and will then return to display the

clock.

NOTE: When the unit is turned on, the steam duration and temperature settings will be those of the

previous user’s settings. A new steam control unit comes pre-set to operate at 113°F (45°C) for 15 minutes.

Steam Control Operation

NOTE: Make sure the steam control unit is turned on before making any of the following adjustments.

Press the ″Temperature″ button and the display will flash the previous temperature setting. To

adjust the steam room temperature, press the ″Increase″ or ″Decrease″ buttons to raise or lower the

steam room temperature. The maximum allowable temperature is 125°F (52°C), and the minimum

operating temperature is 90°F (32°C).

After 5 seconds, the flashing will stop and the room temperature will be displayed as it changes to

the target temperature.

Press the ″Timer″ button and the display will flash the previous run time setting. Press the

″Increase″ or ″Decrease″ buttons to adjust the time setting higher or lower. After 5 seconds the

flashing will stop and the timer setting will be displayed. If the ″Increase″ or ″Decrease″ buttons are

not pressed the time will continue to count down. The minimum operating time is 10 minutes, and

the maximum time allowed is 20 minutes.

Press the ″Clock″ button and the display will flash the currently set time of day. Press the ″Increase″

or ″Decrease″ buttons to adjust the time of day. After 5 seconds the display will stop flashing and

the set time will be displayed.

Press the ″Power″ button to stop the steam generator and exit the steam room at any time. The

display will read ″Off″ for 5 seconds and then default to the set clock time.

Change the temperature reading between Fahrenheit and Celsius by pressing and holding the

″Temperature″ button for 3 seconds.

Power Clean Function

1230489-2-C 8 Kohler Co.

Page 9

Operate the Steam Control (cont.)

WARNING: Risk of personal injury. Steam room temperatures will be extremely high when the

power clean function is activated. Do not enter the steam room while the power clean function is in

progress.

IMPORTANT! The user will be automatically instructed to activate the power clean function after 600

minutes of steam generator use. The display will read ″run″″PCLn.″ The steam generator may be used

three times after the ″run″″PLCn″ message is delivered and then the steam generator will not operate

until the power clean cycle has been completed.

NOTE: Water will typically discharge from the steam head when the power clean function is activated.

This is normal operation during the power clean cycle.

NOTE: The power clean cycle must be entirely completed before normal steam generator operation can be

resumed.

To activate the power clean function, simultaneously press the ″Timer,″″Increase,″ and ″Decrease″

buttons and hold them down for 5 seconds. The display will read ″PCLn,″″On,″ and then count

down the power clean function cycle time until the cleaning process is complete. The cleaning cycle

may last up to 45 minutes and will shut off automatically when complete.

NOTE: If electrical power to the steam generator is interrupted during the power clean function, the

power clean cycle will need to be restarted after electrical power has been restored.

Care and Cleaning

For best results, keep the following in mind when caring for your KOHLER product:

•

Always test your cleaning solution on an inconspicuous area before applying to the entire surface.

•

Wipe surfaces clean and rinse completely with water immediately after applying cleaner. Rinse and

dry any overspray that lands on nearby surfaces.

•

Do not allow cleaners to soak on surfaces.

•

Use a soft, dampened sponge or cloth. Never use an abrasive material such as a brush or scouring

pad to clean surfaces.

For detailed cleaning information and products to consider, visit www.kohler.com/clean. To order Care &

Cleaning information, call 1-800-456-4537.

Warranty

KOHLER Steam Generator

THREE-YEAR LIMITED WARRANTY

Kohler steam generator units manufactured after September 15, 2001, are warranted to the original consumer

purchaser to be free of manufacturing defects in material and workmanship during normal residential usage

for three (3) years from the date of installation. This warranty only applies to KOHLER steam generator units

installed in the United States of America, Canada or Mexico (″North America″).

If a defect is found in normal residential usage, Kohler Co. will, at its election, repair or replace the unit, or

make appropriate adjustment. Damage caused by accident, misuse or abuse is not covered by this warranty.

Proof of purchase (original sales receipt) must be provided to Kohler Co. with all warranty claims. Kohler

Co. is not responsible for labor charges, removal charges, installation, or other consequential costs. In no

event shall the liability of Kohler Co. exceed the purchase price of the unit.

If this unit is used commercially or installed outside of North America, Kohler Co. warrants the unit to be

free from defects in material and workmanship for one (1) year from the date of installation with all other

terms of this warranty applying except duration.

To obtain warranty service contact Kohler Co., either through your Dealer, Plumbing Contractor, Home

Center or E-tailer or by writing Kohler Co., Attn: Customer Care Center, 444 Highland Drive, Kohler, WI

53044, USA, or by calling 1-800-4-KOHLER (1-800-456-4537) from within the USA and Canada, and

Kohler Co. 9 1230489-2-C

Page 10

Warranty (cont.)

001-800-456-4537 from within Mexico, or visit www.kohler.com within the USA, www.ca.kohler.com from

within Canada, or www.mx.kohler.com in Mexico.

KOHLER CO. AND/OR SELLER ARE PROVIDING THESE WARRANTIES IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. KOHLER CO.

AND/OR SELLER DISCLAIM ANY LIABILITY FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES. Some states/provinces do not allow limitations on how long an implied warranty lasts, or the

exclusion or limitation of special, incidental or consequential damages, so these limitations and exclusions

may not apply to you. This warranty gives you specific legal rights. You may also have other rights, which

vary from state/providence to state/providence.

This is Kohler Co.’s exclusive written warranty.

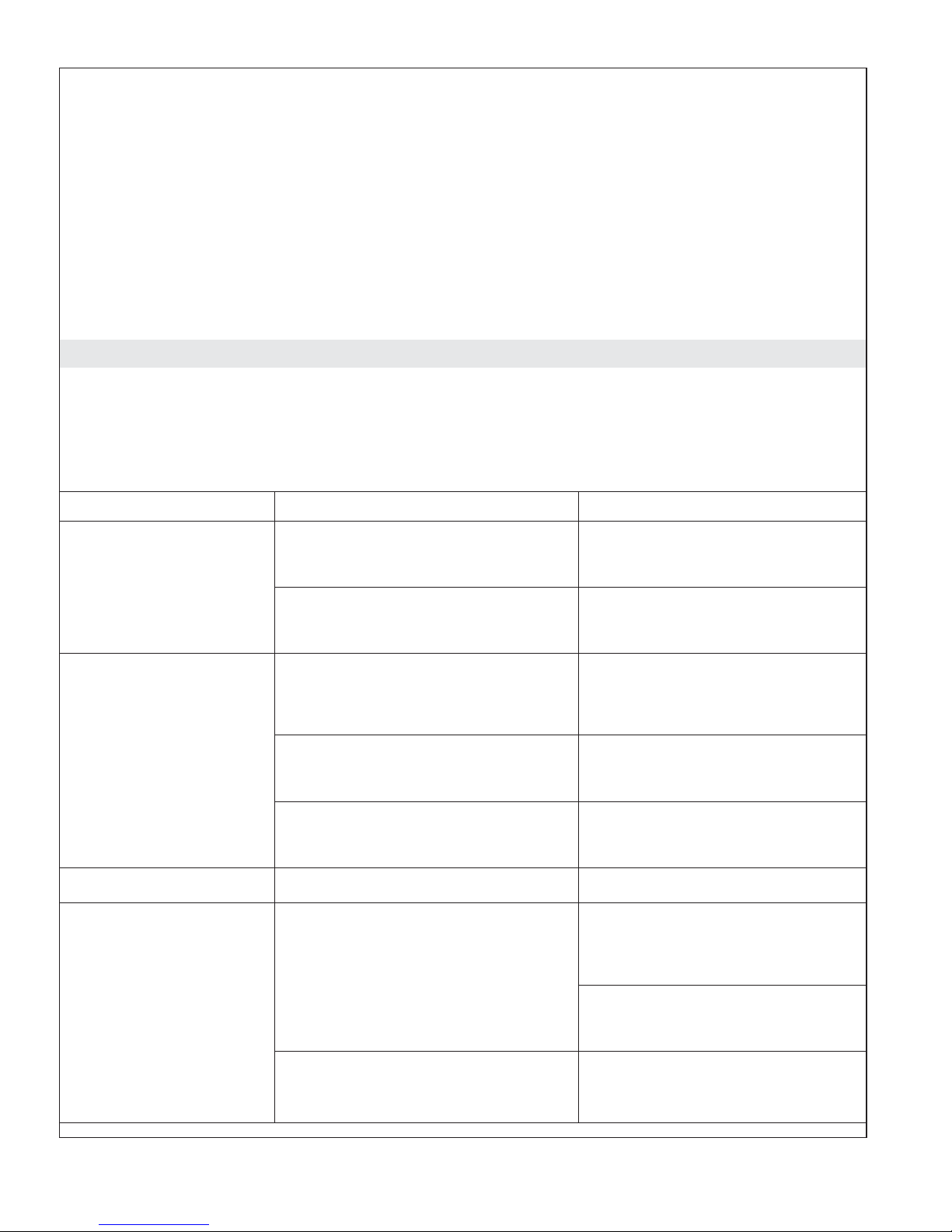

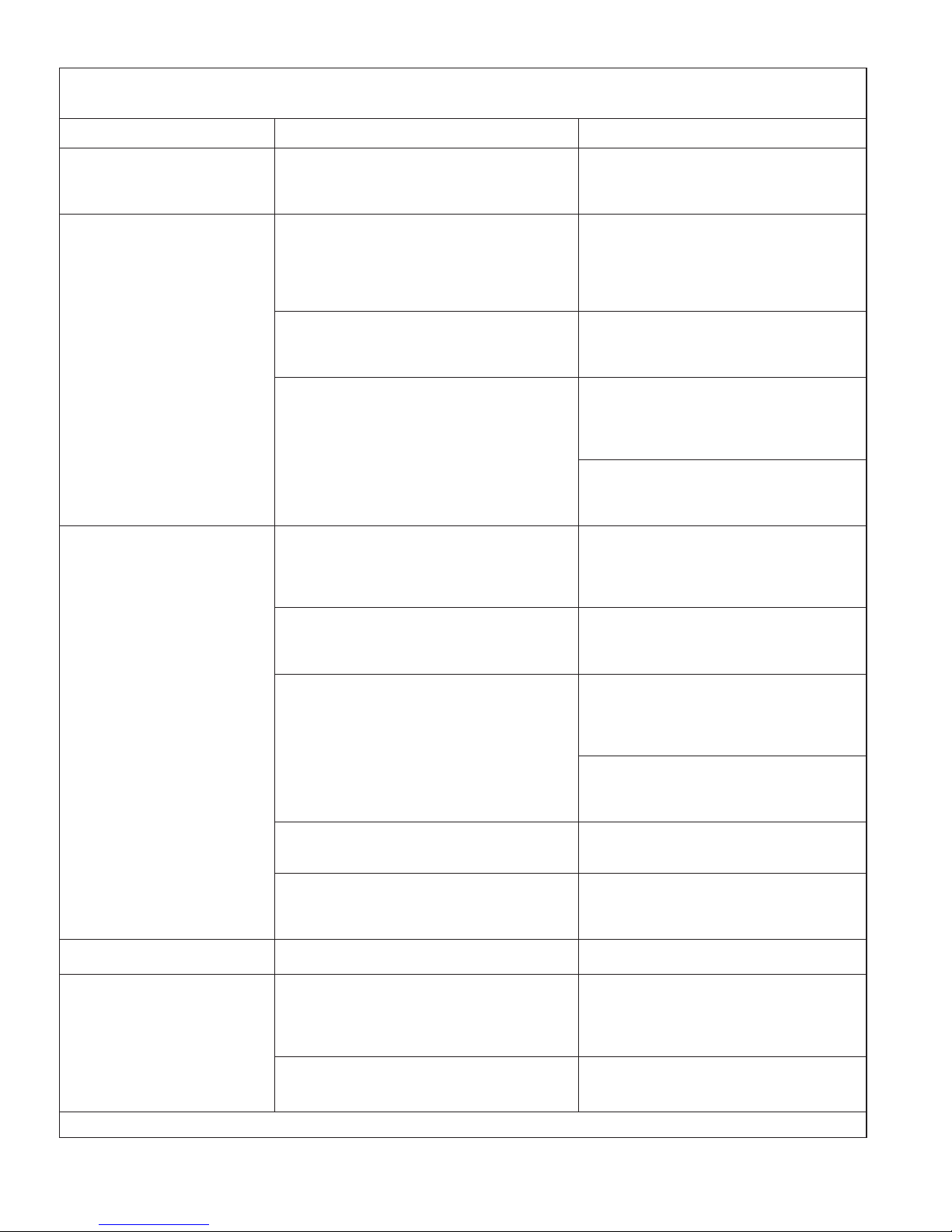

Troubleshooting

NOTE: The troubleshooting steps primarily apply to the steam control. For steam generator issues refer to

the ″Troubleshooting″ section in the steam generator installation instructions.

NOTE: For service parts information, visit your product page at www.kohler.com/serviceparts.

This troubleshooting guide is for general aid only. For service and installation issues and concerns, call

1-800-4KOHLER.

Symptoms Probable Causes Recommended Action

1. Error 1, 2, 3, 4, 7, or 8

is displayed.

2. Error 5 is displayed. A. Tank water level is too low (green

3. Error 6 is displayed. A. The user interface is installed too

4. Display is blank. A. Inadequate power is supplied to the

A. A button on the user interface is

stuck.

B. The user interface is damaged. B. Contact the Customer Care

status light on the steam generator is

on).

B. Tank temperature limit has been

exceeded (green status light on the

steam generator is on).

C. Internal steam generator components

are not functioning properly.

close to the steam head.

steam generator (green status light

on steam generator is off).

B. The user interface is not receiving

power from the steam generator

(green status light on the steam

generator is on).

A. Turn off power to the steam

generator and attempt to free the

stuck button. Restore power to

the steam generator.

Center using the information

provided on the back page of this

manual.

A. Inspect the water inlet screen and

clean if necessary. Ensure the

water supply valve is on and that

water is being supplied to the

steam generator.

B. Contact the Customer Care

Center using the information

provided on the back page of this

manual.

C. Contact the Customer Care

Center using the information

provided on the back page of this

manual.

A. Relocate the user interface away

from the steam head.

A1. Provide proper power to the

steam generator. If necessary, use

the provided test kit to ensure the

steam generator is working

properly.

A2. Contact the Customer Care

Center using the information

provided on the back page of this

manual.

B. Use the provided test kit and

instructions to identify the source

of the problem.

1230489-2-C 10 Kohler Co.

Page 11

Troubleshooting (cont.)

Symptoms Probable Causes Recommended Action

C. The user interface is damaged (green

status light on the steam generator is

on).

C. Contact the Customer Care

Center using the information

provided on the back page of this

manual.

5. Water is discharged

from the steam head.

A. Normal operation. A. A small amount of water is

normally discharged from the

steam head just before, during,

and after steam generator use, as

well as when the power clean

function is activated.

B. Water supply lines are connected

improperly.

B. Review the steam generator

installation guide and reinstall

the water supply lines at the

proper locations.

C. Internal steam generator components

are not functioning properly.

C1. Turn off the water supply to the

steam generator. If possible, drain

the tank. Slowly open the water

supply valve to refill the steam

generator.

C2. Contact the Customer Care

Center using the information

provided on the back page of this

manual.

6. No steam following 5

minutes of having

turned on the steam

generator.

A. An error has occurred. A. Check the user interface for error

messages. If an error message

appears, troubleshoot the

appropriate error message listed

above.

B. The temperature setpoint has already

been reached.

B. Confirm the temperature setpoint

is greater than the current steam

room temperature. Increase the

temperature setpoint if desired.

C. Inadequate power is being supplied

to the steam generator (green status

light on the steam generator is off).

C1. Provide adequate power to the

steam generator. Use the

provided test kit, if necessary, to

ensure the steam generator is

working properly.

C2. Contact the Customer Care

Center using the information

provided on the back page of this

manual.

D. Steam line or steam head is blocked. D. Check the steam line and steam

head for blockage. Remove any

blockage.

E. Steam generator is damaged. E. Contact the Customer Care

Center using the information

provided on the back page of this

manual.

7. Cannot set the clock or

change the settings.

A. The ″Power″ button has been turned

off.

A. Press the ″Power″ button on the

user interface.

8. Steam stopped. A. An error has occurred. A1. Check the user interface for error

messages. If an error message

appears, troubleshoot the

appropriate error message listed

above.

B. The session time limit or the

temperature setpoint were met.

B. Restart the session timer or

increase the temperature setpoint

to start another steam cycle.

Kohler Co. 11 1230489-2-C

Page 12

Troubleshooting (cont.)

Symptoms Probable Causes Recommended Action

C. The power provided to the steam

generator was intermittent or

C. Provide constant power to the

steam generator.

stopped.

9. Display reads ″run″

″PCLn.″

A. The power clean function must be

activated to maintain the steam

generator system.

A. Press and hold the ″Timer,″″Up,″

and ″Down″ buttons for 5

seconds to activate the power

clean cycle. See the instructions in

this guide.

1230489-2-C 12 Kohler Co.

Page 13

Guide d’installation et d’entretien

Kit de commande de vapeur

Outils et matériel

Clé à douille

avec douille de 1"

Mamelons de tuyau

Perceuse avec mèche

de 1/4"

Lubrifiant à la

silicone

Mèche pour trous 1-1/4" et 2-1/2"

(assortir la mèche au matériau du mur)

Ruban

d'étanchéité

Mastic à la silicone

Avant de commencer

ATTENTION: Risque d’électrocution. Déconnecter l’alimentation électrique pour la zone de travail

au niveau du disjoncteur principal avant d’exécuter ces étapes d’installation.

ATTENTION: Risque de réaction allergique. Avant d’ajouter des huiles, des traitements

aromathérapiques ou des produits de soins de la peau au puits d’aromathérapie, s’assurer qu’ils ne

causeront pas de réaction allergique pour l’utilisateur.

AVIS: Utiliser cette unité uniquement pour l’usage pour lequel elle est destinée, tel que spécifié dans ce

manuel. NE PAS utiliser de dispositifs accessoires non recommandés par Kohler Co.

Inspecter le produit pour y rechercher des dommages d’expédition. Ne pas installer l’unité si elle est

endommagée. Appeler le service après-vente de Kohler Co. en utilisant les informations fournies au

dos de ce guide.

Respecter tous les codes de plomberie et électriques locaux. Tout le travail électrique doit être

effectué par un électricien qualifié.

Déconnecter toute l’alimentation électrique avant d’effectuer des connexions électriques.

Kohler Co. Français-1 1230489-2-C

Page 14

Connecteur, Double femelle RJ12 (Assemblé sur le câble de commande)

UIC

Câble de commande

50' (15,2 m)

Blanc, Croisement

Ensemble tête de diffusion

de vapeur et logement

Ensemble tête de diffusion de

vapeur et logement

Entrée de câble de

commande de

générateur de vapeur

Boucle

d'égouttement

Bac de récupération/

collecteur

Câble données 6P/6C

78" (1981 mm)

Noir, Transit

Câble de commande

50' (15,2 m)

Blanc, Croisement

UIC

Connecteur, RJ12 Double

femelle (Assemblé sur le

câble de commande)

Coupleur droit 3 voies

Câble données 6P/6C

10" (254 mm)

Noir, Transit

Options de disposition

1. Étudier la disposition

ATTENTION: Risque de blessures. Ne pas installer l’interface utilisateur de commande de vapeur

à l’extérieur de l’enceinte de vapeur. L’interface utilisateur doit être installée dans l’enceinte afin de

permettre aux capteurs de régler la température et de commander le débit de vapeur.

Boucle

d'égouttement

Ensemble tête de diffusion de

vapeur et logement

Boucle

d'égouttement

Entrée de câble

de commande de

générateur de

vapeur

Bac de récupération/

collecteur

ATTENTION: Risque de brûlures. Ne pas positionner la tête de diffusion de vapeur à proximité

d’un siège ou d’un banc, étant donné que la tête de diffusion de vapeur est chaude pendant le

fonctionnement et qu’elle pourrait brûler l’utilisateur si celui-ci la touchait.

AVIS: L’interface utilisateur doit être montée sur le mur à l’opposé de la tête de diffusion de vapeur. La

tête de diffusion de vapeur doit toujours être placée aussi loin que possible de la zone où l’on s’assoit.

AVIS: Positionner la tête de diffusion de vapeur à 6″ (152 mm) au-dessus du sol et à un minimum de

4-1/2″ (114 mm) du seuil.

1230489-2-C Français-2 Kohler Co.

Page 15

Étudier la disposition (cont.)

Étudier la disposition déterminée pendant l’installation du générateur de vapeur. Se reporter au guide

d’installation du générateur de vapeur pour obtenir de l’information supplémentaire.

Installer l’interface utilisateur de commande de vapeur à l’intérieur de l’enceinte de vapeur.

Déterminer l’emplacement ou les emplacements des têtes de diffusion de vapeur (pour des

installations de générateurs de vapeur doubles).

S’assurer du dégagement entre la conduite de vapeur et toutes les surfaces alentour.

Kohler Co. Français-3 1230489-2-C

Page 16

Fournir un dégagement

à partir du mur.

Marquer le mamelon au

même niveau avec le mur fini.

Poteau mural

Mamelon

temporaire

6" (152 mm) à partir du sol

2-1/2" (64 mm)

Poteau mural

2. Préparer le site

REMARQUE: Cette section continue l’installation décrite dans les instructions d’installation du générateur

de vapeur. Se reporter aux instructions d’installation du générateur de vapeur pour obtenir de

l’information supplémentaire, le cas échéant.

REMARQUE: Si deux têtes de diffusion de vapeur sont utilisées, il doit y avoir un espace de 12-1/2 (318

mm) au moins entre le centre de chaque trou. Les têtes de diffusion de vapeur n’ont pas besoin d’être

placées sur le même mur. Deux têtes de diffusion de vapeur peuvent être montées sur des murs différents

pour améliorer la distribution de vapeur.

Poser la finition murale.

Percer ou couper un trou de 2-1/2″ (64 mm) centré autour du coude dans le mur.

Marquer le mamelon de tuyau temporaire et la surface du mur fini.

Retirer le mamelon de la conduite temporaire du coude.

1230489-2-C Français-4 Kohler Co.

Page 17

Mur

Coude 1/2"

Mamelon

Lubrifier

les joints toriques.

Joint statique

Logement de tête de vapeur

Lèvre

Puits d'aromathérapie

Tête de diffusion de vapeur

3. Installer la ou les têtes de diffusion de vapeur

AVIS: Ne pas obstruer la tête de diffusion de vapeur avec des robinets d’arrêt, des bouchons ou des

capuchons.

Soustraire 1-1/4″ (32 mm) de la longueur marquée pour déterminer la taille appropriée du

mamelon.

Choisir une longueur de mamelon comprise dans les 1/8″ (3 mm) de la taille de mamelon

appropriée.

Appliquer du mastic pour filets sur une extrémité du mamelon, et enfiler cette extrémité dans la tête

de diffusion de vapeur jusqu’à ce qu’elle soit serrée à la main.

Appliquer du mastic pour filets sur l’autre extrémité du mamelon.

Placer le joint statique autour du logement de la tête de vapeur de manière à ce qu’il soit assis entre

le mur fini et la bride du logement de la tête de diffusion de vapeur.

Utiliser une douille de 1″ pour enfiler le logement de la tête de diffusion de vapeur dans le coude se

trouvant dans le mur.

S’assurer que le joint torique est comprimé et qu’un bon joint a été obtenu autour des bords du

logement de la tête de diffusion de vapeur.

Utiliser un mastic approprié pour obtenir un joint étanche à l’eau, si nécessaire.

Appliquer du lubrifiant à la silicone sur les joints toriques de la tête de diffusion de vapeur.

Enfoncer avec précaution l’ensemble de tête de diffusion de vapeur dans le logement de la tête de

diffusion de vapeur avec l’aromathérapie bien placée sur le dessus de la tête de diffusion de

vapeur.

Kohler Co. Français-5 1230489-2-C

Page 18

Montage mural

Vue arrière

Ø 1-1/4"

(32 mm)

Connecteur de commande

Appliquer du mastic à la

60" (1524 mm)

vers sol

Boîtier de commande

silicone sur la rainure

4. Installer la commande de vapeur

AVERTISSEMENT: Risque de blessures. Ne pas installer l’interface utilisateur de commande de

vapeur à l’extérieur de l’enceinte de vapeur. L’interface utilisateur doit être installée dans l’enceinte

afin de permettre aux capteurs de régler la température et de commander le débit de vapeur.

S’assurer que l’alimentation électrique est coupée au niveau du panneau du disjoncteur principal

avant de continuer.

Placer le boîtier de commande sur le mur à 60″ (1524 mm) du sol.

Percer un trou de 1-1/4″ (32 mm) de diamètre à l’emplacement choisi.

Centrer le montage mural sur le trou de 1-1/4″ (32 mm) et marquer les emplacements des trous de

vis.

Utiliser une mèche de 1/4″ pour percer des trous pour les dispositifs d’ancrage aux emplacements

marqués.

Insérer les dispositifs d’ancrage au mur dans les trous.

Appliquer un boudin continu de mastic à la silicone dans la rainure sur le côté arrière du montage

mural et fixer le montage mural avec les vis fournies.

AVIS: Ne pas pincer, clouer, biseauter ou utiliser une force non nécessaire lors de la manipulation du

connecteur de commande et du fil du boîtier de commande. Tous dommages peuvent entraîner une

défaillance du kit de commande. Si le boîtier de commande n’est pas installé immédiatement, protéger le

connecteur de commande avec du ruban ou un autre matériau de blindage.

AVIS: Lors de l’installation du kit de commande, laisser de l’espace pour une boucle d’égouttement dans

le câble de commande. La boucle d’égouttement dissuade l’humidité de suivre le câble de commande vers

le générateur de vapeur.

Tirer sur le connecteur et le câble de commande de vapeur pour le retirer du générateur de vapeur

à travers le trou percé.

Brancher avec précaution le connecteur de commande sur le fil du boîtier de commande en utilisant

le connecteur femelle à deux têtes (fourni).

Enclencher le boîtier de commande sur le montage mural.

Restaurer l’alimentation au niveau du panneau du disjoncteur principal.

Ouvrir l’eau et l’alimentation électrique vers le générateur de vapeur.

Tester le boîtier de commande pour assurer qu’il fonctionne correctement. Se référer à la section

″Fonctionnement de la commande de vapeur″.

Laisser prendre le mastic à la silicone pendant 24 heures avant utilisation.

1230489-2-C Français-6 Kohler Co.

Page 19

Affichage

Horloge

Minuterie

Température

Diminuer

Marche/Arrêt

Augmenter

5. Faire fonctionner la commande de vapeur

Fonctionnement de la commande de vapeur

REMARQUE: L’horloge est toujours affichée lorsque le générateur de vapeur est utilisé.

Appuyer sur le bouton ″Marche/Arrêt″ pour faire démarrer le générateur de vapeur.

Lorsque l’on appuie sur le bouton ″Marche/Arrêt″, le voyant vert s’allume sur le bouton. Le voyant

reste allumé jusqu’à ce que l’unité soit éteinte. L’affichage indique ″On″ pendant les 3 premières

minutes de fonctionnement si les réglages ne sont pas modifiés.

Appuyer de nouveau sur le bouton ″Marche/Arrêt″ pour arrêter le générateur de vapeur. Le voyant

vert du bouton ″Marche/Arrêt″ s’éteint et l’affichage indique ″Off″ pendant 5 secondes, puis

retourne à l’affichage de l’horloge.

REMARQUE: Lorsque l’unité est mise en marche, les réglages de la durée et de la température de vapeur

seront ceux des réglages de l’utilisateur précédent. Une nouvelle unité de commande de vapeur est fournie

préréglée pour fonctionner à 113°F (45°C) pendant 15 minutes.

Fonctionnement de la commande de vapeur

REMARQUE: S’assurer que l’unité de commande de vapeur est en marche avant d’effectuer l’un des

réglages suivants.

Appuyer sur le bouton ″Température″ et l’affichage fait clignoter le réglage de température

précédent. Pour ajuster la température de la chambre de vapeur, appuyer sur les boutons

″Augmenter″ ou ″Diminuer″ pour élever ou abaisser la température de la chambre de vapeur. La

température maximale permise est de 125°F (52°C) et la température de fonctionnement minimum

est de 90°F (32°C).

Au bout de 5 secondes, le clignotement s’arrête et la température de la chambre de vapeur est

affichée au fur et à mesure des changements de la température cible.

Appuyer sur le bouton ″Minuterie″ et l’affichage fait clignoter le réglage du temps de

fonctionnement précédent. Appuyer sur les boutons ″Augmenter″ ou ″Diminuer pour régler la

configuration de minuterie plus haut ou plus bas. Le clignotement s’arrête au bout de 5 secondes et

la configuration de la minuterie s’affiche. Si l’on n’appuie pas sur les boutons ″Augmenter″ ou

″Diminuer″, la minuterie continue à compter à rebours. Le temps de fonctionnement minimum est

10 minutes, et le temps maximum permis est 20 minutes.

Appuyer sur le bouton ″Horloge″ et l’affichage fait clignoter l’heure du jour configurée actuellement.

Appuyer sur les boutons ″Augmenter″ ou ″Diminuer″ pour régler l’heure du jour. Le clignotement

s’arrête au bout de 5 secondes et l’heure configurée s’affiche.

Appuyer sur le bouton ″Marche/Arrêt″ pour arrêter le générateur de vapeur et quitter la chambre

de vapeur n’importe quand. L’affichage indique ″Off″ pendant 5 secondes puis se met à défaut à

l’heure de l’horloge configurée.

Modifier la lecture de la température entre les degrés Fahrenheit et Celsius en appuyant et en

continuant à appuyer sur le bouton ″Température″ pendant 3 secondes.

Kohler Co. Français-7 1230489-2-C

Page 20

Faire fonctionner la commande de vapeur (cont.)

Fonction de nettoyage sous pression

AVERTISSEMENT: Risque de blessures. Les températures de la chambre de vapeur seront

extrêmement élevées lorsque la fonction de nettoyage sous pression est activée. Ne pas entrer dans

la chambre de vapeur pendant que la fonction de nettoyage sous pression est en cours.

IMPORTANT! L’utilisateur recevra automatiquement l’instruction d’activer la fonction de nettoyage sous

pression au bout de 600 minutes d’utilisation du générateur de vapeur. L’affichage indique ″run″″PCLn.″

Le générateur de vapeur peut être utilisé trois fois après l’affichage du message ″run″″PLCn″, puis le

générateur de vapeur ne fonctionnera pas avant que le cycle de nettoyage sous pression ne soit terminé.

REMARQUE: De l’eau s’écoule généralement de la tête de diffusion de vapeur lorsque la fonction de

nettoyage sous pression est activée. Ceci est un fonctionnement normal pendant le cycle de nettoyage sous

pression.

REMARQUE: Le cycle de nettoyage sous pression doit être entièrement terminé avant que le

fonctionnement normal du générateur de vapeur puisse recommencer.

Pour activer la fonction de nettoyage sous pression, appuyer simultanément sur les boutons

″Minuterie,″″Augmenter″ et ″Diminuer″ et continuer à appuyer pendant 5 secondes. L’affichage

indique ″PCLn,″″On,″ puis compte le temps du cycle de la fonction de nettoyage sous pression à

rebours jusqu’à ce que le processus de nettoyage soit terminé. Le cycle de nettoyage peut durer

jusqu’à 45 minutes et s’arrête automatiquement lorsqu’il est terminé.

REMARQUE: Si l’alimentation électrique vers le générateur de vapeur est interrompue pendant la

fonction de nettoyage sous pression, le cycle de nettoyage sous pression doit être redémarré une fois que

l’alimentation électrique a été restaurée.

Entretien et nettoyage

Pour obtenir les meilleurs résultats possibles, prendre ce qui suit en considération lors de l’entretien de votre

produit KOHLER:

•

Toujours tester la solution de nettoyage sur une surface non visible avant de l’appliquer sur

l’ensemble de la surface.

•

Essuyer les surfaces et rincer complètement avec de l’eau immédiatement après l’application du

nettoyant. Rincer et sécher tout éclaboussement sur les surfaces avoisinantes.

•

Ne pas laisser les nettoyants tremper sur les surfaces.

•

Utiliser une éponge ou un chiffon doux et humide. Ne jamais utiliser de matériau abrasif tel qu’une

brosse ou une éponge à récurer pour nettoyer les surfaces.

Pour obtenir des informations détaillées sur le nettoyage et les produits à considérer, consulter le site

www.kohler.com/clean. Pour commander des informations sur l’entretien & le nettoyage, appeler le

1-800-456-4537.

Garantie

GARANTIE LIMITÉE DE TROIS ANS

pour le générateur de vapeur KOHLER

Kohler garantit les appareils générateurs de vapeur fabriqués après le 15 Septembre 2001, à l’acquéreur

d’origine contre tout vice de matériau et de fabrication lors d’une utilisation domestique normale pendant

trois (3) ans à partir de la date d’installation. Cette garantie s’applique uniquement aux générateurs de

vapeur KOHLER installés aux États-Unis, au Canada ou au Mexique (″Amérique du Nord″).

Si un vice est décelé lors d’une utilisation domestique normale, Kohler Co. choisira, à sa discrétion, la

réparation, le remplacement ou la correction appropriée. Tout dommage dû à un accident, un mauvais usage

ou un mauvais traitement n’est pas couvert par la présente garantie. Une preuve d’achat (ticket de caisse

d’origine) doit être présentée à Kohler Co. avec toutes les réclamations au titre de la garantie. Kohler Co.

n’est pas responsable des frais de main-d’œuvre, d’enlèvement, d’installation ou de tout autre frais indirect.

1230489-2-C Français-8 Kohler Co.

Page 21

Garantie (cont.)

La responsabilité de Kohler Co. ne dépassera en aucun cas le prix d’achat de l’appareil.

Si cet appareil est utilisé commercialement ou en dehors d’Amérique du Nord, Kohler Co. garantit l’appareil

contre tout vice de matériau et de fabrication pour un (1) an à partir de la date d’installation dudit appareil,

et toutes les autres modalités de la présente garantie s’appliquent à l’exception de sa durée.

Pour obtenir le service de garantie, contacter Kohler Co., par l’intermédiaire du vendeur, plombier, centre de

rénovation ou revendeur par internet, ou bien par écrit à l’adresse suivante Kohler Co., Attn.: Customer Care

Center, 444 Highland Drive, Kohler, WI 53044, USA, ou appeler le 1-800-4-KOHLER (1-800-456-4537) à partir

des É.-U. et du Canada, et le 001-800-456-4537 à partir du Mexique, ou consulter le site www.kohler.com aux

É.-U., www.ca.kohler.com à partir du Canada, ou www.mx.kohler.com au Mexique.

KOHLER CO. ET/OU LE REVENDEUR FOURNISSENT CES GARANTIES AU LIEU ET PLACE DE

TOUTES AUTRES GARANTIES, EXPRESSES OU TACITES, Y COMPRIS LES GARANTIES TACITES

DE COMMERCIALITÉ ET D’ADAPTATION À UN USAGE PARTICULIER. KOHLER CO. ET/OU LE

REVENDEUR DÉCLINENT TOUTE RESPONSABILITÉ CONTRE LES DOMMAGES PARTICULIERS,

ACCESSOIRES OU INDIRECTS. Certains états et provinces ne permettent pas de limite sur la durée de

la garantie tacite, ni l’exclusion ou la limite des dommages particuliers, accessoires ou indirects, et, par

conséquent, lesdites limites et exclusions peuvent ne pas s’appliquer à votre cas. Cette garantie vous

donne des droits juridiques particuliers. Vous pouvez également avoir d’autres droits qui varient d’un état

ou d’une providence à l’autre.

Ceci constitue la garantie écrite exclusive de Kohler Co.

Dépannage

REMARQUE: Les étapes de dépannage ci-dessous s’appliquent principalement à la commande de vapeur.

Pour des problèmes de générateur de vapeur, se reporter à la section ″Dépannage″ dans les instructions

d’installation du générateur de vapeur.

REMARQUE: Pour tout renseignement sur les pièces de rechange, visiter la page du produit sur le site

www.kohler.com/serviceparts.

Ce guide de dépannage est seulement destiné à fournir une aide d’ordre général. Pour des problèmes ou

questions concernant l’entretien et l’installation, composer le 1-800-4KOHLER.

Symptômes Causes probables Action recommandée

1. L’erreur 1, 2, 3, 4, 7, ou

8 est affichée.

2. L’erreur 5 est affichée. A. Le niveau d’eau du réservoir est trop

A. Un bouton est coincé sur l’interface

utilisateur.

B. L’interface utilisateur est

endommagée.

bas (le voyant d’état vert sur le

générateur de vapeur est allumé).

B. La limite de température du

réservoir est dépassée (le voyant

d’état vert du générateur de vapeur

est allumé).

C. Les composants internes du

générateur de vapeur ne

fonctionnent pas correctement.

A. Couper l’alimentation électrique

vers le générateur de vapeur et

essayer de libérer le bouton

coincé. Restaurer l’alimentation

électrique pour le générateur de

vapeur.

B. Appeler le service après-vente en

utilisant les informations fournies

sur la page arrière de ce manuel.

A. Inspecter la grille d’entrée d’eau

et la nettoyer si nécessaire.

S’assurer que la vanne d’arrivée

d’eau est en marche et que de

l’eau est fournie au générateur de

vapeur.

B. Appeler le service après-vente en

utilisant les informations fournies

sur la page arrière de ce manuel.

C. S’adresser au service après-vente

en utilisant les informations

fournies sur la page arrière de ce

manuel.

Kohler Co. Français-9 1230489-2-C

Page 22

Dépannage (cont.)

Symptômes Causes probables Action recommandée

3. L’erreur 6 est affichée. A. L’interface utilisateur est installée

trop près de la tête de diffusion de

vapeur.

4. L’affichage est vide. A. Une alimentation non adéquate est

fournie au générateur de vapeur (le

voyant d’état vert du générateur de

vapeur est éteint).

A. Déplacer l’interface utilisateur

pour la mettre loin de la tête de

diffusion de vapeur.

A1. Fournir une alimentation

adéquate au générateur de

vapeur. Si nécessaire, utiliser le

kit d’essai fourni pour assurer

que le générateur de vapeur

fonctionne correctement.

A2. S’adresser au service après-vente

en utilisant les informations

fournies sur la page arrière de ce

manuel.

B. L’interface utilisateur ne reçoit pas

d’alimentation en provenance du

générateur de vapeur (le voyant

B. Utiliser le kit d’essai et les

instructions fournis pour

identifier la source du problème.

d’état vert du générateur de vapeur

est allumé).

C. L’interface utilisateur est

endommagée (le voyant d’état vert

du générateur de vapeur est allumé).

C. S’adresser au service après-vente

en utilisant les informations

fournies sur la page arrière de ce

manuel.

5. De l’eau s’écoule de la

tête de diffusion de

vapeur.

A. Fonctionnement normal. A. Une petite quantité d’eau s’écoule

généralement de la tête de

diffusion de vapeur juste avant,

pendant et après l’utilisation du

générateur de vapeur, et

également lorsque la fonction de

nettoyage sous pression est

activée.

B. Les conduites d’arrivée d’eau sont

connectées incorrectement.

B. Examiner le guide d’installation

du générateur de vapeur et

réinstaller les conduites d’arrivée

d’eau aux emplacements

appropriés.

C. Les composants internes du

générateur de vapeur ne

fonctionnent pas correctement.

C1. Couper l’arrivée d’eau vers le

générateur de vapeur. Si possible,

vidanger le réservoir. Ouvrir

lentement la vanne d’arrivée

d’eau pour remplir le générateur

de vapeur.

C2. S’adresser au service après-vente

en utilisant les informations

fournies sur la page arrière de ce

manuel.

6. Aucune vapeur au

bout de 5 minutes

après avoir mis le

générateur de vapeur

en marche.

A. Une erreur s’est produite. A. Examiner l’interface utilisateur

pour y rechercher des messages

d’erreur. Si un message d’erreur

apparaît, faire un dépannage du

message d’erreur approprié de la

liste ci-dessus.

B. Le point de consigne de température

a déjà été atteint.

B. Confirmer que le point de

consigne de la température est

supérieur à la température

actuelle de la chambre de vapeur.

Augmenter le point de consigne

de la température si souhaité.

1230489-2-C Français-10 Kohler Co.

Page 23

Dépannage (cont.)

Symptômes Causes probables Action recommandée

C. Une alimentation non adéquate est

fournie au générateur de vapeur (le

voyant d’état vert du générateur de

vapeur est éteint).

C1. Fournir une alimentation

adéquate au générateur de

vapeur. Utiliser le kit d’essai

fourni, si nécessaire, pour assurer

que le générateur de vapeur

fonctionne correctement.

C2. S’adresser au service après-vente

en utilisant les informations

fournies sur la page arrière de ce

manuel.

D. La conduite de vapeur ou la tête de

diffusion de vapeur est bloquée.

D. Examiner la conduite de vapeur

et la tête de diffusion de vapeur

pour y rechercher une

obstruction. Éliminer toute

obstruction.

E. Le générateur de vapeur est

endommagé.

E. S’adresser au service après-vente

en utilisant les informations

fournies sur la page arrière de ce

manuel.

7. Impossible de voir

l’horloge ou le

changement de

A. Le bouton ″Marche/Arrêt″ a été mis

en position d’arrêt.

A. Appuyer sur le bouton

″Marche/Arrêt″ sur l’interface

utilisateur.

réglages.

8. La vapeur s’est arrêtée. A. Une erreur s’est produite. A1. Examiner l’interface utilisateur

pour y rechercher des messages

d’erreur. Si un message d’erreur

apparaît, faire un dépannage du

message d’erreur approprié de la

liste ci-dessus.

B. La limite du temps de session est

atteinte ou le point de consigne de

température est atteint.

B. Redémarrer la minuterie de la

session ou augmenter le point de

consigne de température pour

démarrer un autre cycle de

vapeur.

9. L’affichage indique

″run″″PCLn.″

C. L’alimentation fournie au générateur

de vapeur était intermittente ou a été

arrêtée.

A. La fonction de nettoyage sous

pression doit être activée pour

maintenir le système de générateur

de vapeur.

C. Fournir une alimentation

constante au générateur de

vapeur.

A. Appuyer sur les boutons

″Minuterie,″″Vers le haut,″ et

″Vers le bas″ pendant 5 secondes

pour activer le cycle de nettoyage

sous pression. Consulter les

instructions de ce guide.

Kohler Co. Français-11 1230489-2-C

Page 24

Guía de instalación y cuidado

Kit de control de vapor

Herramientas y materiales

Llave de dados

con dados de 1 pulg

Niples

Taladro c/

broca de 1/4"

Lubricante de

silicona

Broca de 1-1/4" y de 2-1/2"

(elija la broca para el material

de la pared)

Cinta

selladora

Sellador de silicona

Antes de comenzar

PRECAUCIÓN: Riesgo de electrocución. Antes de realizar estos pasos de instalación, desconecte

el suministro eléctrico al área de trabajo en el panel principal de interruptores de circuito.

PRECAUCIÓN: Riesgo de reacción alérgica. Antes de agregar aceites, terapias aromáticas o

productos para la piel en el depósito para aromaterapia, asegúrese de que no causen reacciones

alérgicas al usuario.

AVISO: Use esta unidad únicamente con el fin para el que ha sido fabricada, tal como se especifica en

este manual. NO use accesorios que no recomiende Kohler Co.

Revise el producto en busca de daños durante el transporte. No instale la unidad si está dañada.

Comuníquese con el Centro de Atención al Cliente de Kohler Co. mediante la información de la

página posterior de este manual.

Cumpla todos los códigos locales de electricidad y de plomería. Todo el trabajo eléctrico debe

hacerlo un electricista capacitado.

Desconecte todo el suministro eléctrico antes de hacer conexiones eléctricas.

Kohler Co. Español-1 1230489-2-C

Page 25

UIC

Cable de control

50' (15,2 m)

Blanco, cruzado

Cable de datos 6P/6C

78" (1981 mm)

Negro, recto a través

Conector, hembra doble RJ12 (ensamblado al cable de control)

Cabezal de vapor y montaje

del alojamiento

Entrada del cable de

control al generador

de vapor

Lazo de goteo

Bandeja de desagüe/

derrames

Cabezal de vapor y

montaje del alojamiento

Cable de control

50' (15,2 m)

Blanco, cruzado

UIC

Conector, hembra doble RJ12

(ensamblado al cable de

control)

Acoplador recto de 3 vías

Cable de datos 6P/6C

10" (254 mm)

Negro, recto a través

Opciones de distribución

1. Revise la distribución

PRECAUCIÓN: Riesgo de lesiones personales. No instale la interface del usuario para control de

vapor fuera del recinto de vapor. La interface del usuario debe instalarse dentro del recinto para

que los sensores regulen la temperatura y controlen el flujo de vapor.

Lazo de

goteo

Cabezal de vapor y

montaje del alojamiento

Lazo de goteo

Entrada del cable

de control al

generador de

vapor

Bandeja de desagüe/

derrames

PRECAUCIÓN: Riesgo de quemaduras. No ubique el cabezal de vapor cerca de un asiento o de

una banca, ya que el cabezal de vapor está caliente cuando está funcionando y puede quemar al

usuario si lo toca.

AVISO: La interface del usuario debe instalarse en la pared opuesta al cabezal de vapor. El cabezal de

vapor siempre debe ubicarse lo más lejos posible del área para sentarse.

AVISO: Coloque el cabezal de vapor 6″ (152 mm) arriba del pisoyaunmínimo de 4-1/2″ (114 mm) del

umbral.

Kohler Co. Español-2 1230489-2-C

Page 26

Revise la distribución (cont.)

Revise la distribución que haya sido determinada durante la instalación del generador de vapor. Consulte

más información en la guía de instalación del generador de vapor.

Instale la interface del usuario para control de vapor dentro del recinto de vapor.

Determine la ubicación del cabezal de vapor o de los cabezales de vapor (en el caso de instalaciones

de generadores de vapor dobles).

Asegúrese de que haya espacio libre entre la línea de vapor y todas las superficies alrededor.

1230489-2-C Español-3 Kohler Co.

Page 27

Deje espacio libre

de la pared.

Poste de pared

Marque el niple al ras

con la pared acabada.

Niple

temporal

6" (152 mm) del piso

2-1/2" (64 mm)

Poste de pared

2. Prepare el sitio

NOTA: Esta sección continúa la instalación descrita en las instrucciones de instalación del generador de

vapor. Si es necesario, consulte más información en las instrucciones de instalación del generador de

vapor.

NOTA: Si se usan dos cabezales de vapor, debe haber una distancia de por lo menos 12-1/2″ (318 mm)

entre los centros de los orificios. No es necesario que los cabezales de vapor estén ubicados en la misma

pared. Los cabezales de vapor dobles se pueden instalar en distintas paredes para mejorar la distribución

del vapor.

Instale la pared acabada.

Taladre o corte un orificio de 2-1/2″ (64 mm) centrado alrededor del codo en la pared.

Marque el niple temporal en la pared acabada.

Retire el niple temporal del codo.

Kohler Co. Español-4 1230489-2-C

Page 28

Pared

Codo de 1/2"

Niple

Lubricar

arosellos.

Empaque

Alojamiento del cabezal de vapor

Labio

Depósito para aromaterapia

Cabezal de vapor

3. Instale los cabezales de vapor

AVISO: No obstruya el cabezal de vapor con llaves de paso, tapones o tapas.

Reste 1-1/4″ (32 mm) de la longitud marcada para determinar el tamaño adecuado del niple.

Escoja un niple con una longitud más o menos 1/8″ (3 mm) del tamaño apropiado.

Aplique sellador de roscas en un extremo del niple y enrosque ese extremo en el alojamiento del

cabezal de vapor hasta que quede apretado con la fuerza de la mano.

Aplique sellador de roscas al otro extremo del niple.

Coloque el empaque alrededor del alojamiento del cabezal de vapor de tal forma que quede entre la

pared acabada y la brida del alojamiento del cabezal de vapor.

Use un dado de 1 pulg. para enroscar el montaje de alojamiento del cabezal de vapor en el codo en

la pared.

Asegúrese de que el empaque esté comprimido y de que se haya logrado un buen sello alrededor

de los bordes del alojamiento del cabezal de vapor.

De ser necesario, use un sellador apropiado para que el sello sea hermético.

Aplique lubricante de silicona a los arosellos del cabezal de vapor.

Oprima con cuidado el montaje del cabezal de vapor en el alojamiento del cabezal de vapor, con el

depósito para aromaterapia colocado en la parte superior del cabezal de vapor.

1230489-2-C Español-5 Kohler Co.

Page 29

Montaje a la pared

Vista posterior

Ø 1-1/4"

(32 mm)

Conector del control

Aplique sellador de

60" (1524 mm)

al piso

Cuadro de control

silicona a la ranura.

4. Instale el control de vapor

ADVERTENCIA: Riesgo de lesiones personales. No instale la interface del usuario para control

de vapor fuera del recinto de vapor. La interface del usuario debe instalarse dentro del recinto para

que los sensores regulen la temperatura y controlen el flujo de vapor.

Antes de seguir adelante, asegúrese de apagar la corriente eléctrica en el panel principal de

interruptores de circuito.

Ubique el cuadro de control en la pared a 60″ (1524 mm) del piso.

En el lugar elegido, taladre un orificio de 1-1/4″ (32 mm) de diámetro.

Centre el montaje a la pared en el orificio de 1-1/4″ (32 mm), y marque los lugares de los orificios

para tornillos.

Taladre orificios para los anclajes de pared en los lugares marcados con una broca de 1/4″.

Introduzca los anclajes de pared en los orificios.

Aplique un hilo continuo de sellador de silicona en la ranura en el lado posterior del montaje a la

pared, y fije el montaje a la pared con los tornillos provistos.

AVISO: No pellizque, clave, atore, ni use demasiada fuerza al maniobrar el conector del control y el cable

del cuadro de control. Cualquier daño podría ocasionar una falla en el kit de control. Si el cuadro de

control no se va a instalar de inmediato, proteja el conector del control con cinta de enmascarar o con

algún otro material protector.

AVISO: Al instalar el kit de control, deje lugar en el cable de control para un lazo de goteo. El lazo de

goteo evita que la humedad siga el cable de control hasta el generador de vapor.

Pase el conector y el cable del control de vapor del generador de vapor a través del orificio

taladrado.

Enchufe con cuidado el conector del control al cable del cuadro de control con el conector hembra

de doble extremo (provisto).

Meta a presión el cuadro de control en el montaje a la pared.

Restaure el suministro eléctrico al panel principal de interruptores de circuito.

Abra el suministro de agua y encienda la corriente al generador de vapor.

Pruebe el cuadro de control para asegurarse de que esté funcionando correctamente. Consulte la

sección ″Haga funcionar el control de vapor″.

Deje que el sellador de silicona se cure durante 24 horas antes de usar la unidad.

Kohler Co. Español-6 1230489-2-C

Page 30

Indicador

Reloj

Temporizador

Temperatura

Disminuir

Encendido

Aumentar

5. Haga funcionar el control de vapor

Funcionamiento del control de vapor

NOTA: El reloj siempre aparece cuando el generador de vapor no está en uso.

Oprima el botón de ″encendido″ para activar el generador de vapor.

Cuando se oprime el botón de ″encendido″ se ilumina la luz verde en el botón. La luz permanece

iluminada hasta que se apaga la unidad. En el indicador aparece ″On″ durante los primeros 3

minutos de funcionamiento si no se han cambiado las selecciones.

Oprima el botón de ″encendido″ de nuevo para apagar el generador de vapor. Se apaga la luz verde

en el botón de encendido y en el indicador aparece ″Off″ durante 5 segundos, y luego vuelve a

aparecer el reloj.

NOTA: Cuando se enciende la unidad, las selecciones de duración y temperatura del vapor serán las

selecciones del usuario anterior. Las unidades de control de vapor nuevas vienen establecidas con

anticipación a 113°F (45°C) para 15 minutos.

Funcionamiento del control de vapor

NOTA: Asegúrese de que la unidad de control de vapor esté encendida antes de hacer cualquiera de los

siguientes ajustes.

Oprima el botón de ″temperatura″, y en el indicador centellea la selección previa de temperatura.

Para ajustar la temperatura del cuarto de vapor, oprima los botones para ″aumentar″ o para

″disminuir″ la temperatura del cuarto de vapor. La temperatura máxima permisible es de 125°F

(52°C) y la temperatura mínima de funcionamiento es de 90°F (32°C).

Después de 5 segundos, la luz centelleante se apaga y la temperatura del cuarto aparece a medida

que cambia a la temperatura meta.

Oprima el botón de ″temporizador″, y en el indicador centellea la selección previa. Oprima los

botones de ″aumentar″ ode″disminuir″ para ajustar la selección de tiempo. Después de 5 segundos,

la luz centelleante se apaga y aparece la selección de tiempo. Si no se oprimen los botones de

″aumentar″ o ″disminuir″, el tiempo continúa la cuenta regresiva. El mínimo tiempo de

funcionamiento es 10 minutos, y el máximo tiempo permitido es 20 minutos.

Oprima el botón de ″reloj″, y en el indicador centellea la hora actual. Oprima los botones de

″aumentar″ ode″disminuir″ para ajustar la hora. Después de 5 segundos, la luz centelleante se

apaga y aparece la hora.

Oprima el botón de ″encendido″ para apagar el generador de vapor en cualquier momento y salir

del cuarto de vapor. En el indicador aparece ″Off″ durante 5 segundos y luego vuelve por diseño a

la hora.

Para cambiar la indicación de temperatura entre grados Fahrenheit y Celsius oprima y sostenga

oprimido el botón de ″temperatura″ durante 3 segundos.

Función de autolimpieza

1230489-2-C Español-7 Kohler Co.

Page 31

Haga funcionar el control de vapor (cont.)

ADVERTENCIA: Riesgo de lesiones personales. La temperatura del cuarto de vapor será

demasiado alta cuando se activa la función de autolimpieza. No entre al cuarto de vapor mientras

la función de autolimpieza esté activada.

¡IMPORTANTE! El usuario recibe un aviso automático para que active la función de autolimpieza

después de 600 minutos de uso del generador de vapor. En el indicador aparece ″run″″PCLn″.El

generador de vapor puede usarse tres veces después de que aparece el mensaje ″run″″PLCn″, y entonces

el generador de vapor no funciona mientras no haya terminado el ciclo de autolimpieza.

NOTA: Es típico que salga agua del cabezal de vapor cuando la función de autolimpieza está activa. Este

es el funcionamiento normal durante el ciclo de autolimpieza.

NOTA: El ciclo de autolimpieza debe terminar por completo antes de que pueda reiniciarse el

funcionamiento del generador de vapor.

Para activar la función de autolimpieza, oprima simultáneamente los botones de ″temporizador″,

″aumentar″ y ″disminuir″, y sosténgalos oprimidos durante 5 segundos. En el indicador aparece

″PCLn″, ″On″, y luego aparece la cuenta regresiva del tiempo de la función de autolimpieza hasta

que termina el proceso de limpieza. El ciclo de limpieza puede durar hasta 45 minutos, y se apaga

automáticamente al terminar.

NOTA: Si se interrumpe la corriente eléctrica al generador de vapor durante la función de autolimpieza,

es necesario reiniciar el ciclo de autolimpieza una vez que la corriente eléctrica se restaura.

Cuidado y limpieza

Para obtener los mejores resultados, tenga presente lo siguiente al limpiar su producto KOHLER:

•

Siempre pruebe la solución de limpieza en un área oculta antes de aplicarla a toda la superficie.

•

Limpie con un paño las superficies, y enjuague completa e inmediatamente con agua después de

haber aplicado el limpiador. Enjuague y seque las superficies cercanas que hayan sido rociadas.

•

No deje mucho tiempo los limpiadores en las superficies.

•

Utilice una esponja o un paño suave y húmedo. Para limpiar las superficies nunca utilice materiales

abrasivos, como cepillos o estropajos de tallar.

Para obtener información detallada de limpieza y de productos a considerar, visite www.kohler.com/clean.

Para solicitar información sobre el cuidado y la limpieza, llame al 1-800-456-4537.

Garantía

Generador de vapor KOHLER

GARANTÍA LIMITADA DE TRES AÑOS

Se garantizan al comprador consumidor original las unidades generadoras de vapor de Kohler fabricadas

después del 15 de septiembre del 2001 contra defectos de fabricación en material y mano de obra durante el

uso residencial normal durante (3) tres años a partir de la fecha de instalación. Esta garantía se aplica solo a

las unidades generadoras de vapor KOHLER instaladas en Estados Unidos de América, Canadá o México

(″Norteamérica″).

Si se encuentra algún defecto durante el uso residencial normal, Kohler Co., a su criterio, reparará o

reemplazará la unidad o realizará los ajustes pertinentes. Esta garantía no cubre daños causados por

accidente, abuso o uso indebido. Al presentar las reclamaciones de garantía a Kohler Co., es necesario incluir

el comprobante de compra (recibo de venta original). Kohler Co. no se hace responsable de costos de mano

de obra, desinstalación, instalación u otros costos indirectos. En ningún caso la responsabilidad de Kohler Co.

excederá el precio de compra de la unidad.

Si esta unidad se utiliza comercialmente o si se instala fuera del territorio de Norteamérica, Kohler Co.

garantiza la unidad contra defectos de material y de mano de obra durante un (1) año a partir de la fecha de

instalación, estando en efecto todas las demás condiciones de esta garantía, excepto la duración.

Kohler Co. Español-8 1230489-2-C

Page 32

Garantía (cont.)

Para obtener el servicio de garantía comuníquese con Kohler Co. a través de su distribuidor, contratista de

plomería, centro de remodelación o distribuidor por Internet, o escriba a Kohler Co., Atención: Customer

Care Center, 444 Highland Drive, Kohler, WI 53044, EE.UU., o llame al 1-800-4-KOHLER (1-800-456-4537)

desde los EE.UU. y Canadá, o al 001-800-456-4537 desde México, o visite www.kohler.com desde los EE.UU.,

www.ca.kohler.com desde Canadá, o www.mx.kohler.com en México.

KOHLER CO. Y/O EL VENDEDOR OFRECEN ESTAS GARANTÍAS QUE SUSTITUYEN A TODAS LAS

DEMÁS GARANTÍAS, EXPRESAS O IMPLÍCITAS, INCLUIDAS, ENTRE OTRAS, LAS GARANTÍAS

IMPLÍCITAS DE COMERCIALIZACIÓN E IDONEIDAD PARA UN USO DETERMINADO. KOHLER

CO. Y/O EL VENDEDOR DESCARGAN TODA RESPONSABILIDAD POR CONCEPTO DE DAÑOS

PARTICULARES, INCIDENTALES O INDIRECTOS. Algunos estados/provincias no permiten limitaciones

en cuanto a la duración de una garantía implícitaoalaexclusión o limitación de daños particulares,

incidentales o indirectos, por lo que estas limitaciones y exclusiones pueden no aplicar a su caso. Esta

garantía le otorga ciertos derechos legales específicos. Además, usted puede tener otros derechos que

varían de estado a estado y provincia a provincia.

Esta es la garantía exclusiva por escrito de Kohler Co.

Resolución de problemas

NOTA: Los pasos de resolución de problemas solo se aplican al control de vapor. En el caso de asuntos

del generador de vapor consulte la sección ″Resolución de problemas″ en las instrucciones de instalación

del generador de vapor.

NOTA: Para consultar información sobre piezas de repuesto, visite la página de su producto en

www.kohler.com/serviceparts.

Esta guía de resolución de problemas está diseñada únicamente como ayuda general. Si tiene preguntas con

respecto al servicioyalainstalación, llame a 1-800-4KOHLER.

Síntomas Causas probables Acción recomendada

1. Aparece Error 1, 2, 3, 4,

7u8.

2. Aparece Error 5. A. El nivel del tanque de agua está

3. Aparece Error 6. A. La interface del usuario está

A. Un botón en la interface del usuario

está atorado.

B. La interface del usuario está dañada. B. Comuníquese con el Centro de

demasiado bajo (la luz verde de

estado en el generador de vapor está

iluminada).

B. El límite de temperatura del tanque

ha sido excedido (la luz de estado

verde en el generador de vapor está

iluminada).

C. Los componentes internos del

generador de vapor no están

funcionando correctamente.

instalada demasiado cerca al cabezal

de vapor.

A. Apague la corriente eléctrica al

generador de vapor y trate de

soltar el botón atorado. Restaure

la corriente eléctrica al generador

de vapor.

Atención al Cliente mediante la

información en la página

posterior de este manual.

A. Revise el tamiz de la entrada de

agua y límpielo si es necesario.

Asegúrese de que la válvula de

suministro de agua esté abierta y

de que se esté suministrando

agua al generador de vapor.

B. Comuníquese con el Centro de

Atención al Cliente mediante la

información en la página

posterior de este manual.

C. Comuníquese con el Centro de

Atención al Cliente mediante la

información en la página

posterior de este manual.

A. Cambie de lugar la interface del

usuario lo más lejos posible del

cabezal de vapor.

1230489-2-C Español-9 Kohler Co.

Page 33

Resolución de problemas (cont.)

Síntomas Causas probables Acción recomendada

4. El indicador está en

blanco.

A. El suministro eléctrico al generador

de vapor es inadecuado (la luz verde

de estado en el generador de vapor

está apagada).

A1. Aplique el suministro eléctrico

adecuado al generador de vapor.

De ser necesario, use el kit de

prueba que se incluye para

asegurar que el generador de

vapor esté funcionando

correctamente.

A2. Comuníquese con el Centro de

Atención al Cliente mediante la

información en la página

posterior de este manual.

B. La interface del usuario no está

recibiendo suministro eléctrico del

generador de vapor (la luz verde de

B. Use el kit de prueba incluido y

las instrucciones para identificar

el origen del problema.

estado en el generador de vapor está

iluminada).

C. La interface del usuario está dañada

(la luz verde de estado en el

generador está iluminada).

C. Comuníquese con el Centro de

Atención al Cliente mediante la

información en la página

posterior de este manual.

5. Sale agua del cabezal

de vapor.

A. Funcionamiento normal. A. Normalmente sale una pequeña

cantidad de agua del cabezal de

vapor justo antes, durante, y

después del uso del generador de

vapor, así como cuando se activa

la función de autolimpieza.

B. Las líneas de suministro de agua

están conectadas incorrectamente.

B. Revise la guía de instalación del

generador de vapor y vuelva a

instalar las líneas de suministro

de agua en los lugares

apropiados.

C. Los componentes internos del

generador de vapor no están

funcionando correctamente.

C1. Cierre el suministro de agua al

generador de vapor. Si es posible,

vacíe el tanque. Abra lentamente

la válvula de suministro de agua

para rellenar el generador de

vapor.

C2. Comuníquese con el Centro de

Atención al Cliente mediante la

información en la página

posterior de este manual.

6. No hay vapor después

de 5 minutos de haber

encendido el generador

de vapor.

A. Ha ocurrido un error. A. Vea si hay mensajes de error en la

interface del usuario. Si aparece

un mensaje de error, consulte la

resolución de problemas para el

mensaje de error.

B. Ya se ha alcanzado la temperatura

preseleccionada.

B. Confirme que la temperatura

preseleccionada sea más alta que

la temperatura actual del cuarto

de vapor. Si lo desea, aumente la

temperatura preseleccionada.

C. El suministro eléctrico al generador

de vapor es inadecuado (la luz verde

de estado en el generador de vapor

está apagada).

C1. Aplique el suministro eléctrico

adecuado al generador de vapor.

Use el kit de prueba incluido, si

es necesario, para asegurar que el

generador de vapor esté

funcionando correctamente.

Kohler Co. Español-10 1230489-2-C

Page 34

Resolución de problemas (cont.)

Síntomas Causas probables Acción recomendada

C2. Comuníquese con el Centro de

Atención al Cliente mediante la

información en la página

posterior de este manual.

D. La línea de vapor o el cabezal de

vapor están bloqueados.

D. Revise que no haya obstrucciones

en el cabezal de vapor o en la

línea de vapor. Elimine todas las

obstrucciones.

E. El generador de vapor está dañado. E. Comuníquese con el Centro de

Atención al Cliente mediante la

información en la página

posterior de este manual.

7. No se puede poner la

hora del reloj ni se

A. El botón de ″encendido″ ha sido

apagado.

A. Oprima el botón de ″encendido″

en la interface del usuario.

pueden cambiar las

selecciones.

8. El vapor dejó de salir. A. Ha ocurrido un error. A1. Vea si hay mensajes de error en la

interface del usuario. Si aparece

un mensaje de error, consulte la

resolución de problemas para el

mensaje de error.

B. Se llegó al límite de tiempo de la

sesión o se llegó a la temperatura

preseleccionada.

B. Vuelva a iniciar el temporizador

de la sesión o aumente la

temperatura preseleccionada para

iniciar otro ciclo de vapor.

C. El suministro eléctrico provisto al

generador de vapor fue intermitente

C. Aplique suministro eléctrico

constante al generador de vapor.

o se detuvo.

9. En el indicador aparece

″run″″PCLn″.

A. Es necesario activar la función de

autolimpieza para mantener el

sistema del generador de vapor.

A. Oprima y sostenga oprimidos los

botones de ″temporizador″,

″arriba″ y ″abajo″ durante 5

segundos para activar el ciclo de

autolimpieza. Vea las

instrucciones en esta guía.

1230489-2-C Español-11 Kohler Co.

Page 35

1230489-2-C

Page 36

USA/Canada: 1-800-4KOHLER

México: 001-800-456-4537

kohler.com

©2015 Kohler Co.

1230489-2-C

Loading...

Loading...