Page 1

Installation and Care Guide

In-Wall Tank and Carriage

K-18829

M product numbers are for Mexico (i.e. K-12345M)

Los números de productos seguidos de

M corresponden a México (Ej.

K-12345M)

Français, page “Français-1”

Español, página “Español-1”

1246750-2-B

Page 2

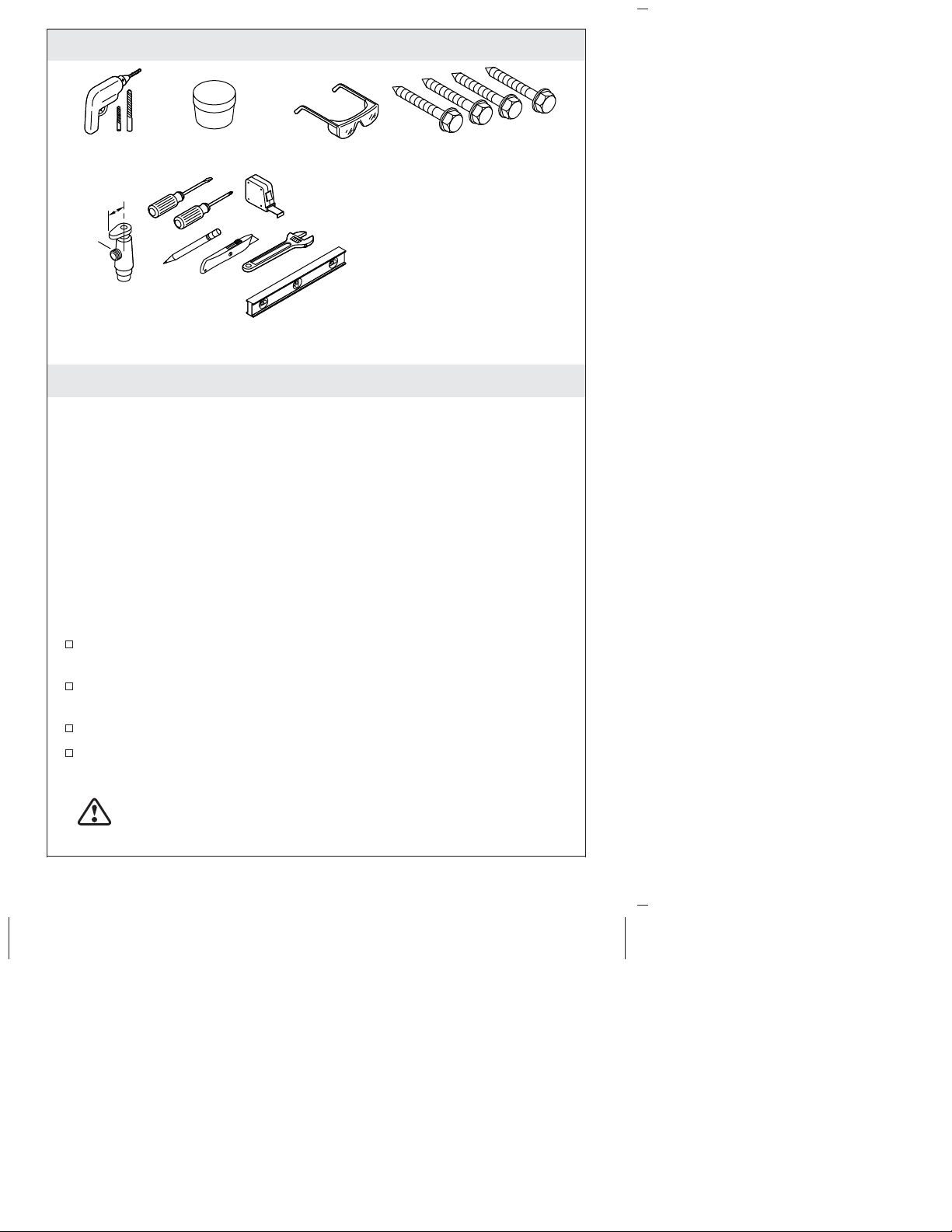

Tools and Materials

Assorted Drill Bits

5/8"

(16 mm)

1/2"

1/4 turn, 1/2" NPT

Supply Shut-off with

5/8" or Shorter Handle

Silicone Plumbers

Grease

1/4" x 2" (51 mm) Min

Lag Bolts

Plus:

• Conventional woodworking

tools and materials

• 1/4" x 2" (51 mm) Min

Concrete Expansion Bolts

(for concrete subflooring)

Optional:

• Assorted electrical tools

Before You Begin

IMPORTANT! 2x4 framing is required for this product.

IMPORTANT! In areas with freezing temperatures, install on an

interior wall. If installed on an exterior wall, provide adequate

insulation to prevent the possibility of freezing.

NOTE: If 2x6 framing is used, the drain outlet may be angled 45

degrees in either direction.

NOTE: This device is not intended to be used as a retrofit device

for 1.28 gpf (4.8 lpf) water closets.

NOTE: Performance may vary. This product was tested with toilets

that are listed as compatible.

Only bowl numbers K-6299 and K-6300 are compatible with the

carriage.

During installation, make sure the inlet tube connections and

gaskets remain fully engaged to ensure a watertight seal.

Carefully inspect the carriage and tank for damage.

Observe all local plumbing and building codes.

For Installations with a Bidet Seat

1246750-2-B 2 Kohler Co.

CAUTION: Risk of personal injury. If the optional electrical

outlet will be installed, it must be connected to a GFCI or

RCD protected circuit.

Page 3

Before You Begin (cont.)

If the optional electrical outlet will be installed, observe all local

electrical codes.

Kohler Co. 3 1246750-2-B

Page 4

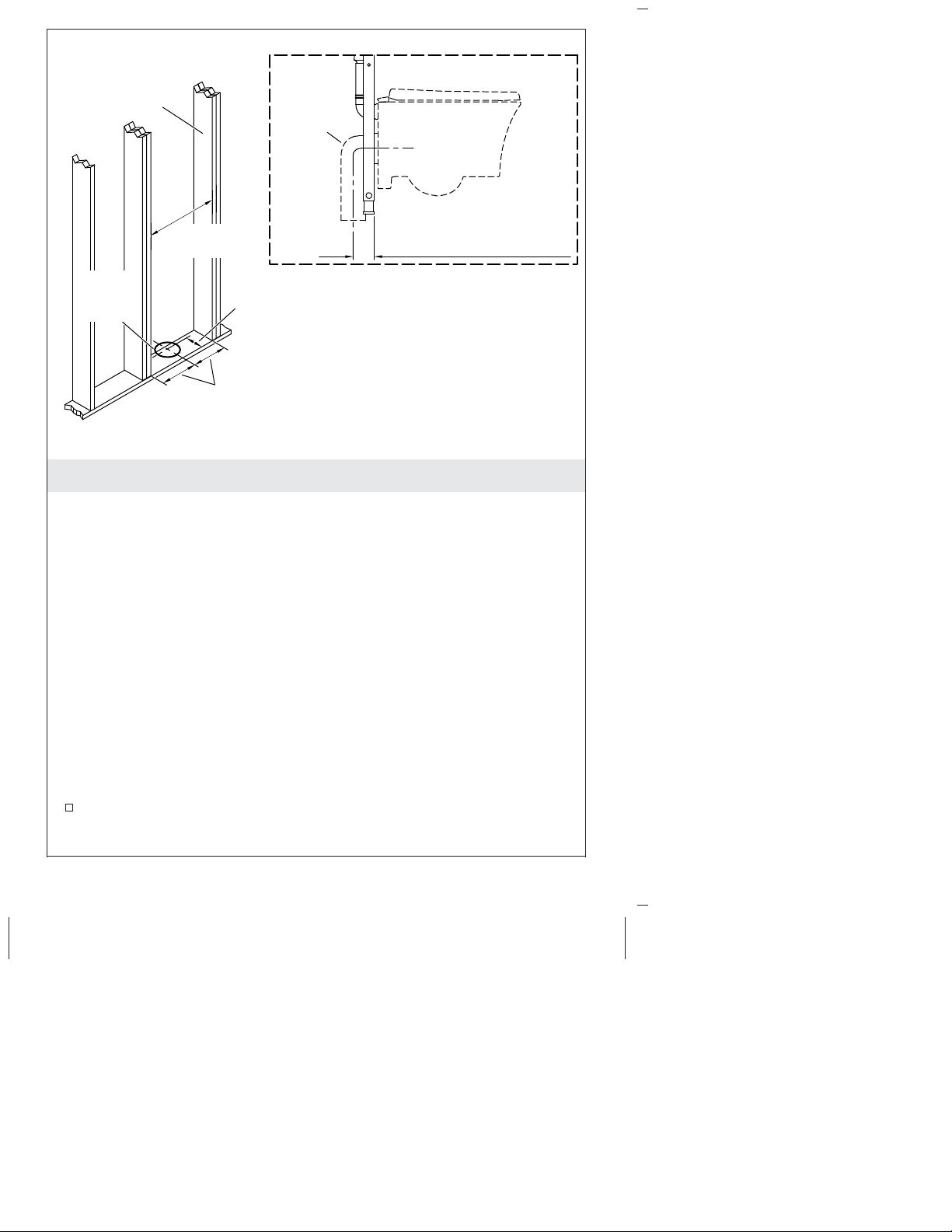

2x4 Studs or

2x6 Studs

PVC

Elbow

1-3/4" (44 mm) [2x4 Studs]

3-1/4" (83 mm) [2x6 Studs]

Waste

Outlet

Pipe

23-1/4"

(591 mm)

1-3/4" (44 mm) [2x4 Studs]

3-1/4" (83 mm) [2x6 Studs]

8" (203 mm) [Plywood Subfloor]

9-1/8" (232 mm) [Concrete Subfloor]

1. Install the Framing

IMPORTANT! Note the 1-3/4″ (44 mm) or 3-1/4″ (83 mm)

dimension from the front edge of the framing to the center of the

outlet pipe depending on your installation. This dimension is critical

for the installation.

NOTE: Refer to the specification sheet for more details and

dimensions for roughing-in.

NOTE: The waste outlet pipe may need to be relocated for this

installation.

NOTE: A PVC elbow is supplied with this product. A cast iron

elbow may be required by codes in some areas. The height of the

toilet drain pipe may need to be adjusted if the cast iron elbow is

used.

NOTE: Double studs must be used on either side of the stud

pocket.

Construct the stud pocket using the dimensions shown.

1246750-2-B 4 Kohler Co.

Page 5

Install the Framing (cont.)

The center of the waste outlet should be 1-3/4″ (44 mm) or 3-1/4″

(83 mm) from the front edge of the framing.

Kohler Co. 5 1246750-2-B

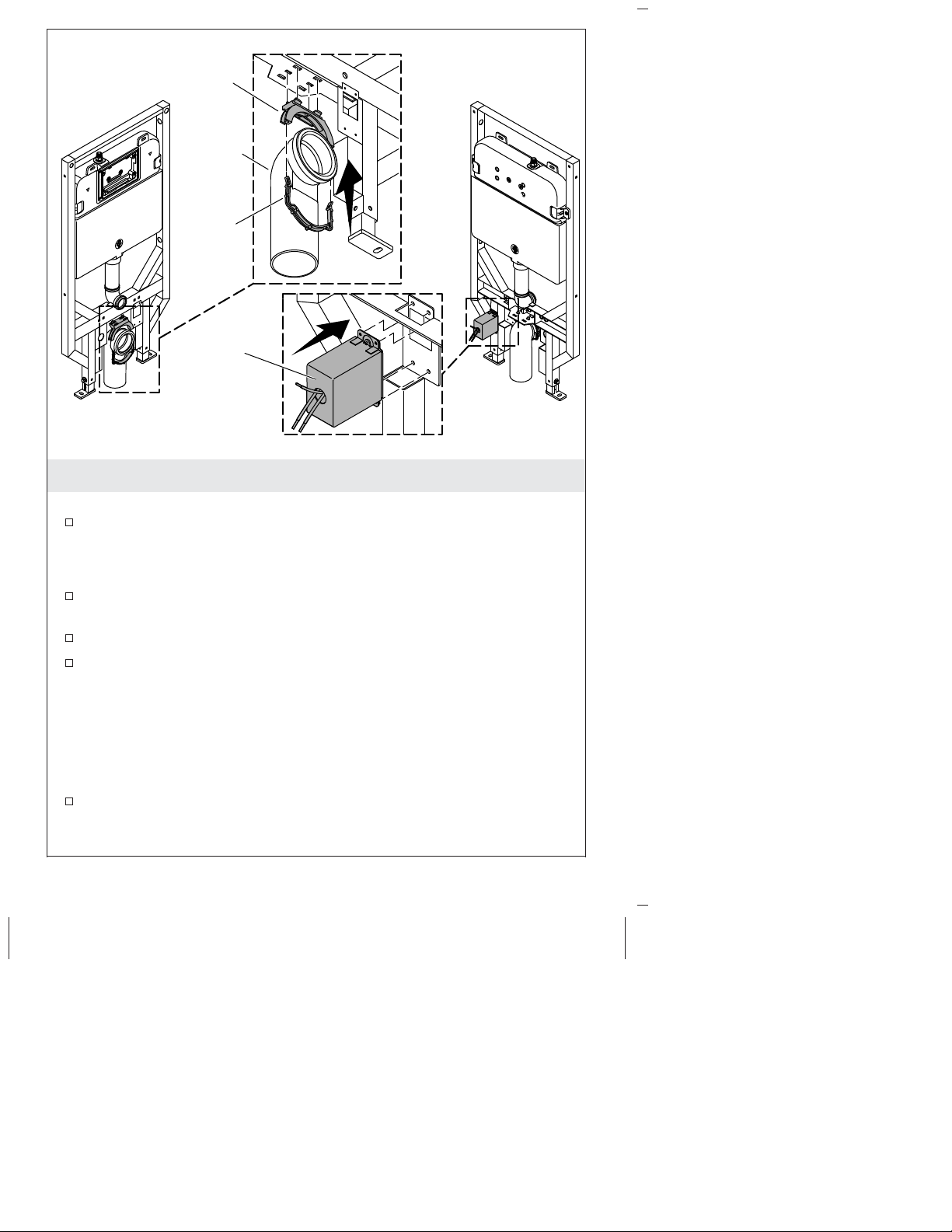

Page 6

Mounting

Front View

Frame

PVC

Elbow

Drain

Clamp

Electrical

Box

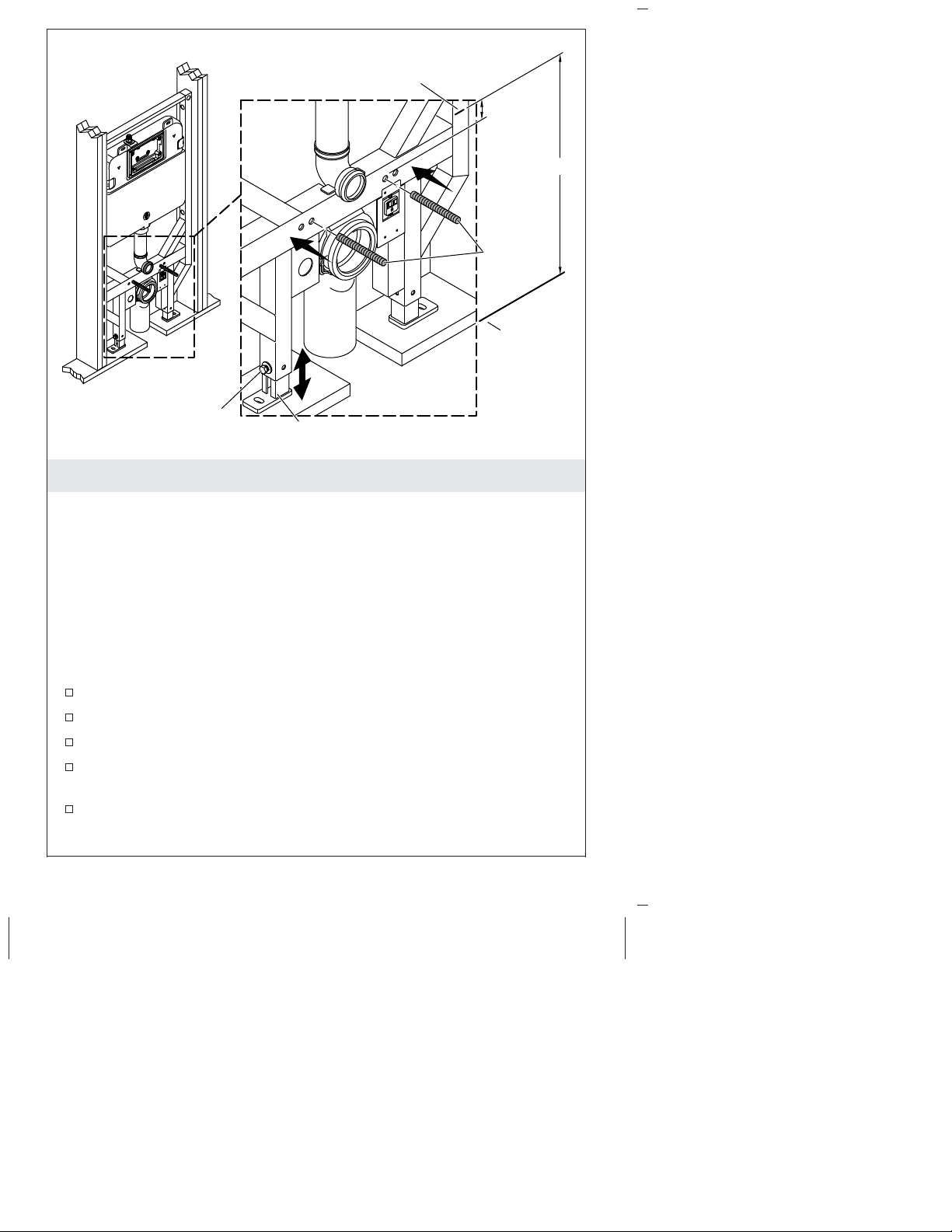

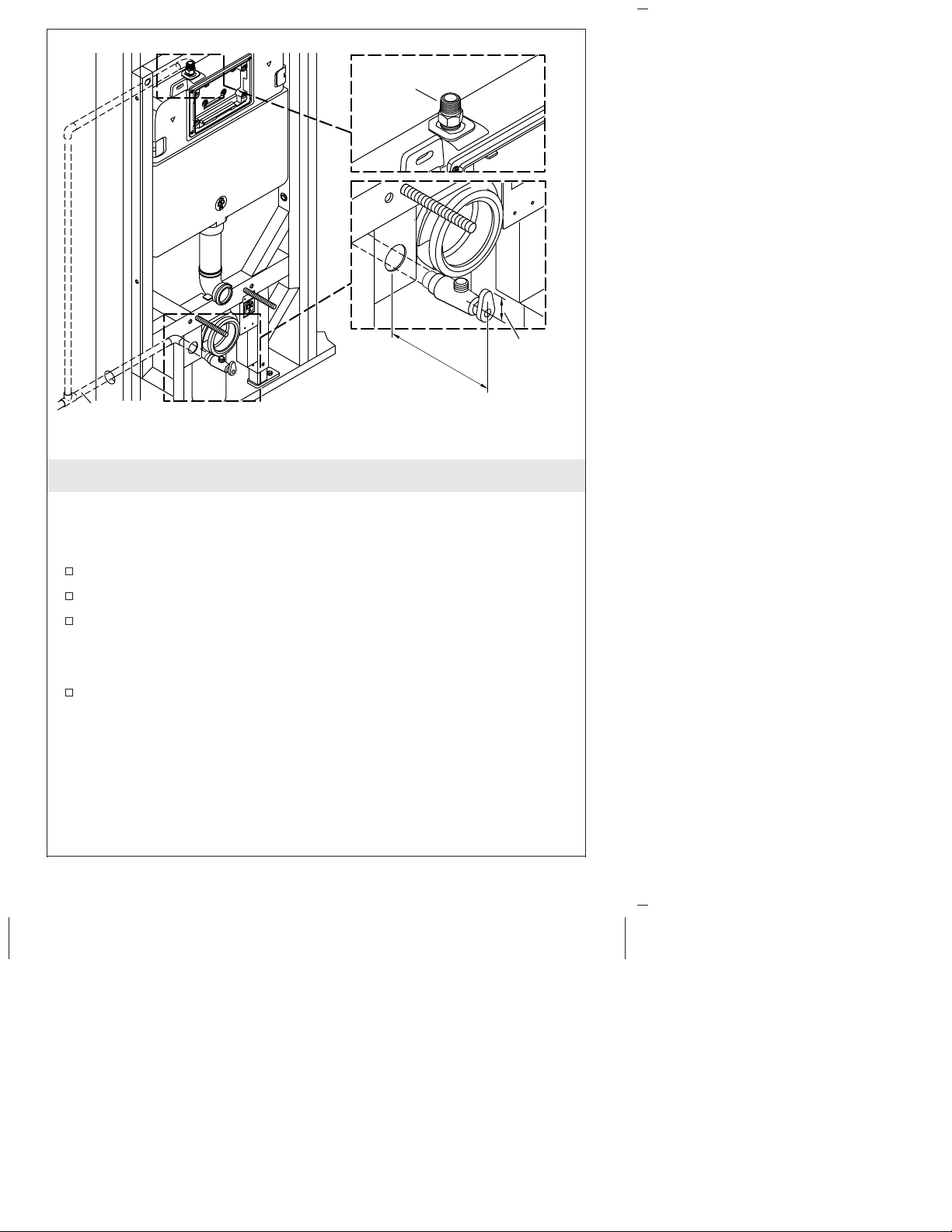

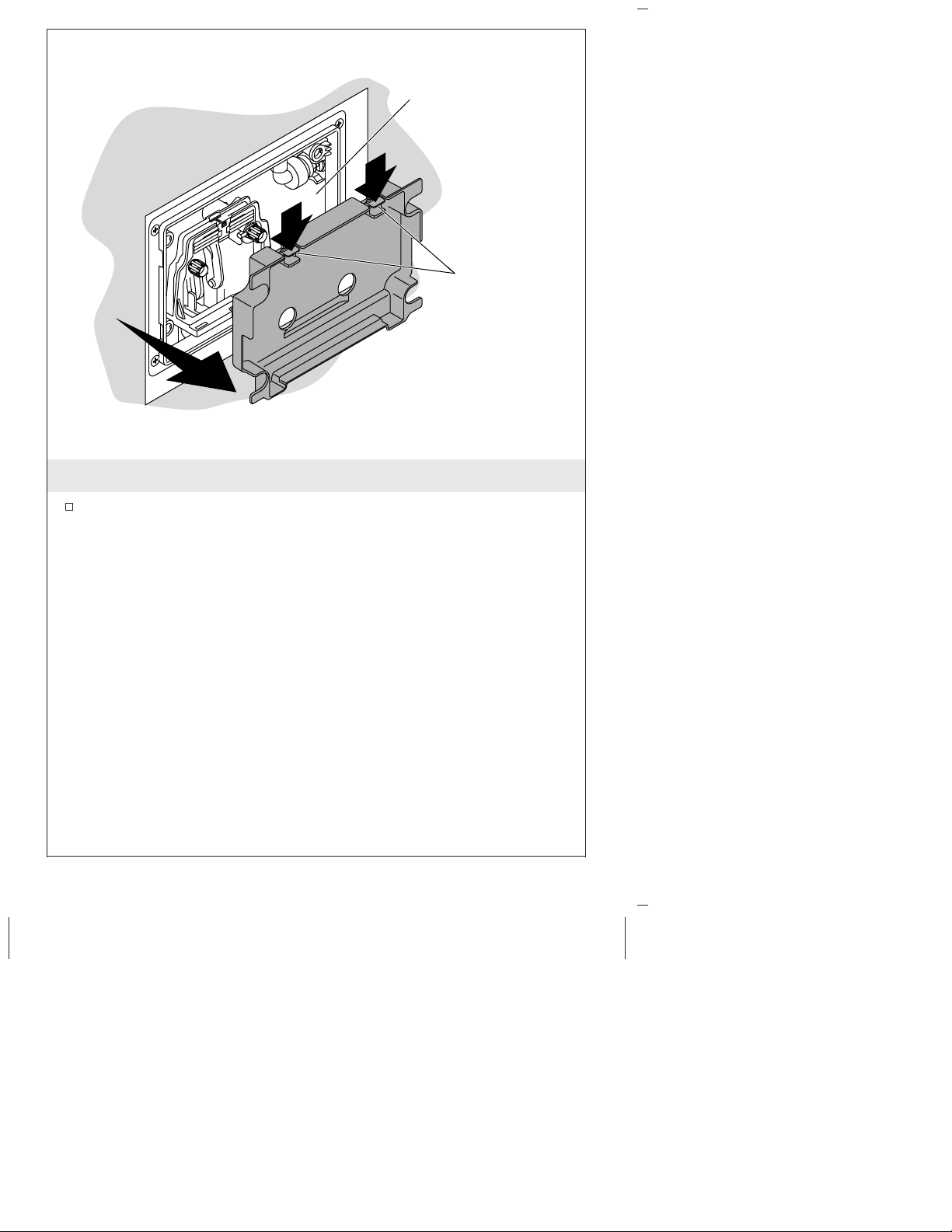

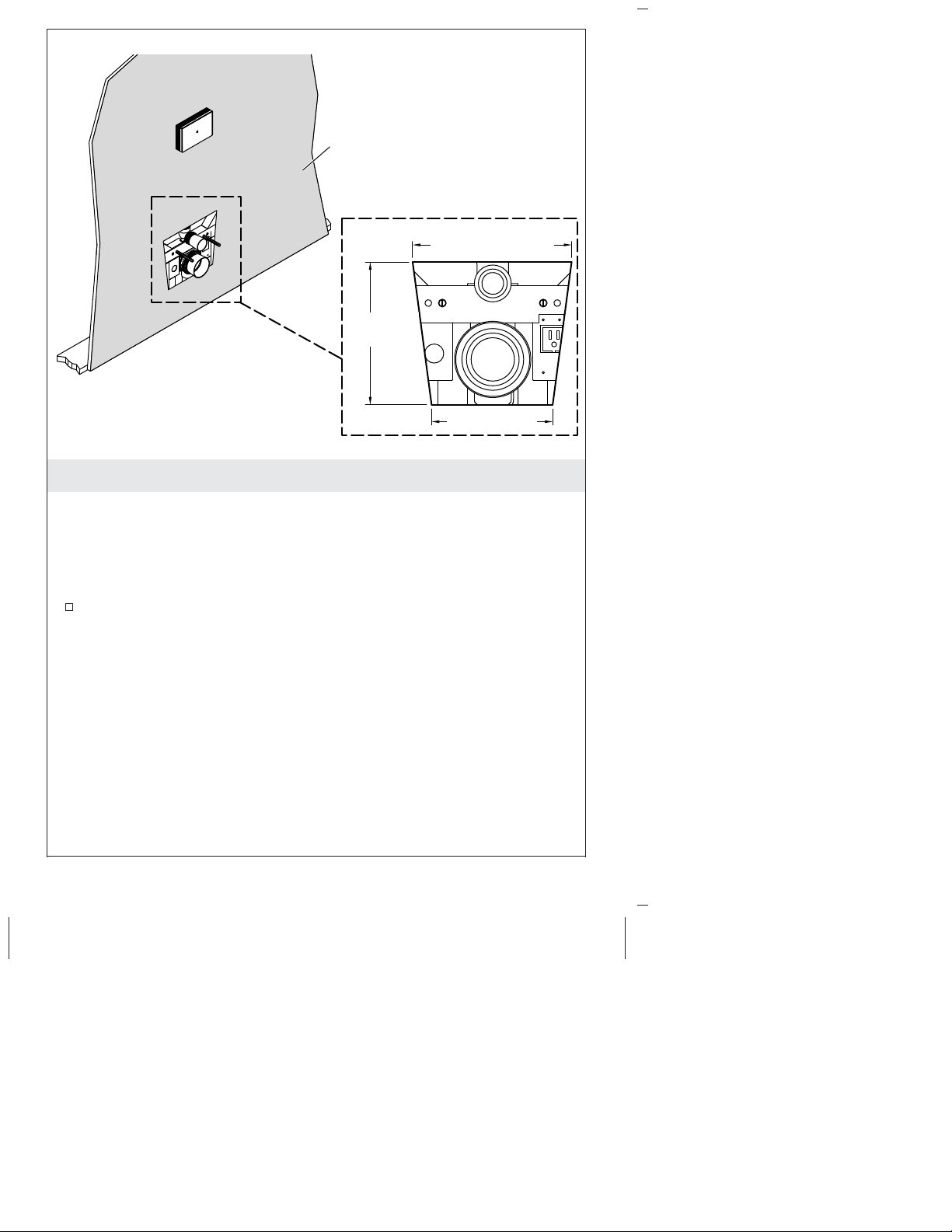

2. Prepare the Carriage

Install the Drain Clamp

Unpack and inspect the carriage.

Back View

NOTE: If using 2x6 studs, install the mounting frame reversed into

the back notches.

Install the mounting frame into the front notches on the bottom

of the carriage.

Insert the PVC elbow into the mounting frame.

Secure the elbow in place with the drain clamp. Push the clamp

into the frame until it locks into place.

Install the Electrical Box - Bidet Installations

NOTE: The 1201721 electrical box kit is required when the K-4744

bidet seat will be paired with the bowl. Skip this step for standard

installations.

Connect the electrical box to the carriage at the location shown.

1246750-2-B 6 Kohler Co.

Page 7

Mark the carriage.

2-5/8"

(67 mm)

A

Threaded

Rods

Finished

Floor

Nut

Leg

3. Adjust the Carriage Height

IMPORTANT! If the carriage is not correctly adjusted, the bowl rim

height may not be compliant with applicable codes. The finished

wall would need to be removed to make the correct adjustments if

the bowl height is not correct.

NOTE: For the K-6299 and K-6300 bowls, the minimum rim height

is 15″ (381 mm) when the finished floor is even with the bottom of

the carriage legs. The maximum rim height is 23″ (584 mm) when

the legs are fully raised. The carriage can be adjusted up to 8″ (203

mm), with 6″ (152 mm) or less of adjustment sufficient in most

installations.

Move the carriage into place in the stud pocket.

Temporarily secure the carriage in place so it will not fall.

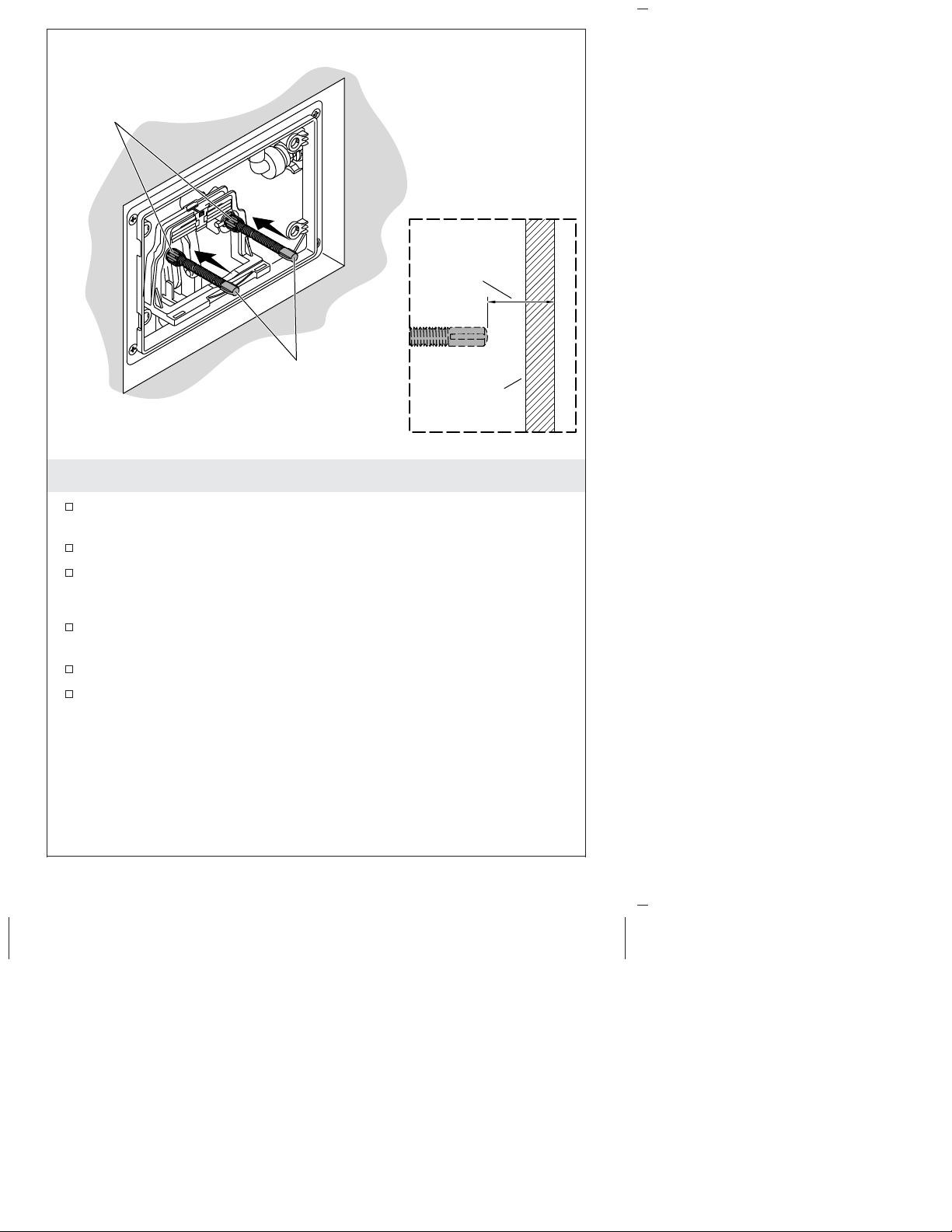

Install the threaded rods several turns into the carriage.

Make a mark on the carriage 2-5/8″ (67 mm) above the top of the

threaded rod.

Measure from the finished floor to the mark (A) to determine the

rim height of the bowl.

Kohler Co. 7 1246750-2-B

Page 8

Adjust the Carriage Height (cont.)

Loosen the nuts securing the legs to the carriage.

NOTE: As the carriage is lowered, make sure the elbow aligns with

the toilet drain pipe.

NOTE: If applicable, confirm the gasket on the elbow stays

correctly positioned as it enters the toilet drain pipe.

Adjust the carriage until the desired height is reached. Securely

tighten the nuts using a wrench to secure the legs in place.

NOTE: If a cast iron elbow is required, make the connections

following all applicable codes.

1246750-2-B 8 Kohler Co.

Page 9

Lag Bolts

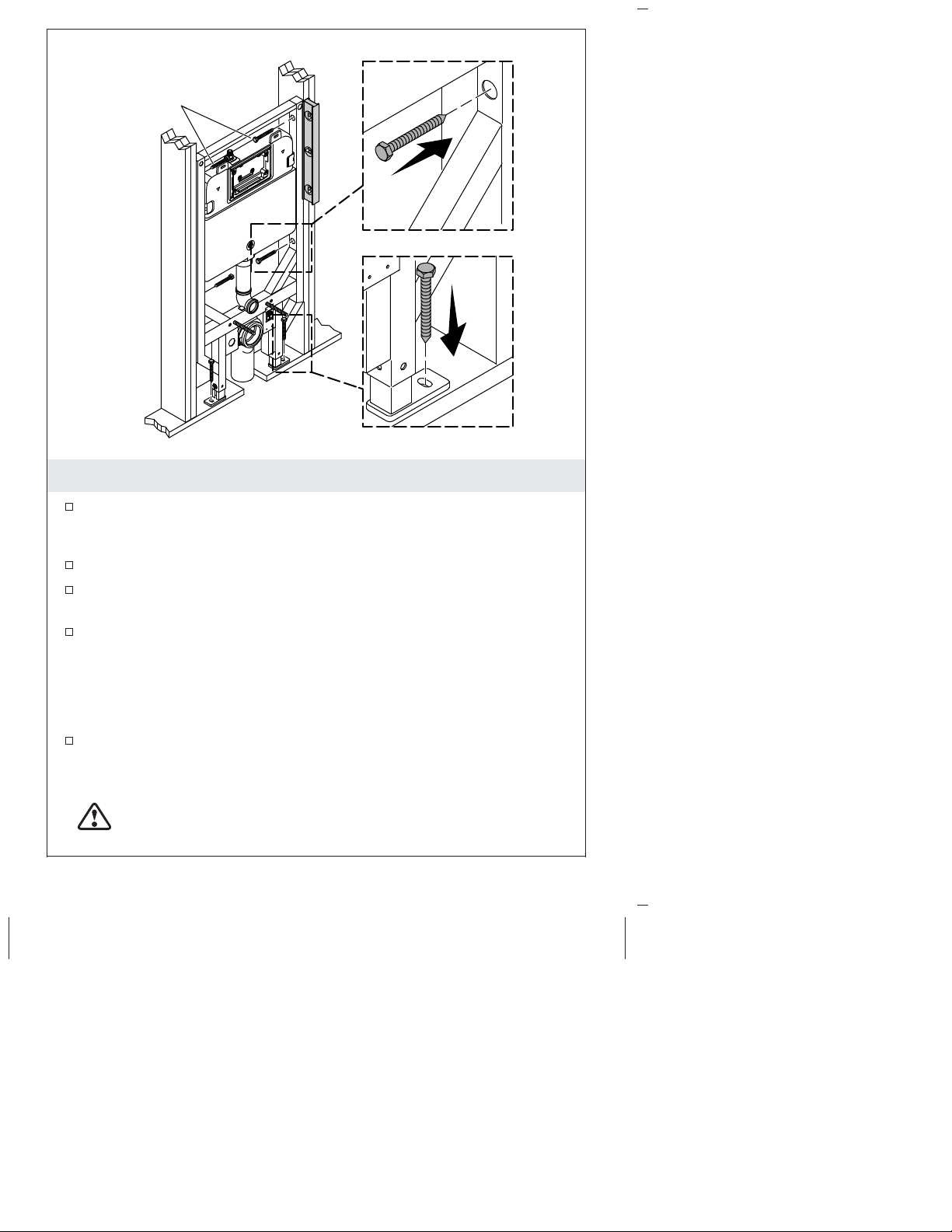

4. Install the Carriage

Align the carriage flush with the front edge of the studs. The

front of the carriage should be flush with the front edge of the

studs or set back slightly for finished wall installation.

Check the front of the carriage for plumb.

Mark the hole locations for the six lag bolts, one for each foot and

two on either side of the carriage.

Drill pilot holes (remove the carriage if needed) to reduce the risk

of the lag bolts causing the studs to split or crack.

NOTE: If the carriage is installed onto a concrete sub-floor use

concrete expansion bolts (not supplied) when securing the feet of

the carriage.

Secure the carriage to the support studs using 2″ (51 mm) long

(minimum) lag bolts (not supplied), one at each location.

Connect the Power - Bidet Seat Installations

Kohler Co. 9 1246750-2-B

WARNING: Risk of personal injury. Disconnect the power

before connecting the wires.

Page 10

Install the Carriage (cont.)

CAUTION: Risk of personal injury. The electrical outlet

must be connected to a GFCI or RCD protected circuit or an

accessible Ground-Fault Circuit-Interrupter (GFCI) or

Residual-Current Device (RCD) must be installed.

NOTE: This step is only needed if the electrical box was installed in

the ″Prepare the Carriage″ section.

Connect the power following all applicable codes.

1246750-2-B 10 Kohler Co.

Page 11

Bidet Water Supply

(Optional)

5. Install the Water Supply

All Installations

1/2" NTP

Adapter

4" (102 mm)

Maximum Clearance

from the Front of

the Finished Wall

5/8"

(16 mm)

Max

IMPORTANT! Optional bidet water supply is shown. Do not install

a second water supply unless a bidet seat will be installed.

Install the water supply pipes, following all local codes.

Connect the waste pipe following all applicable local codes.

If using a G 1/2 connection, remove the 1/2″ NTP adapter and

discard.

Installations With a Bidet Seat

Optional: Install the bidet water supply and a quarter turn, 1/2″

NPT supply shut-off.

IMPORTANT! The bidet supply shut-off must extend 3″ (76 mm)

minimum to 4″ (102 mm) maximum from the finished wall to allow

access to the handle. The supply shut-off handle should be no

higher than 5/8″ (16 mm) from the center of the water supply.

Kohler Co. 11 1246750-2-B

Page 12

Inlet

Hole

Flush Shield

Outlet

Hole

Plaster Guard

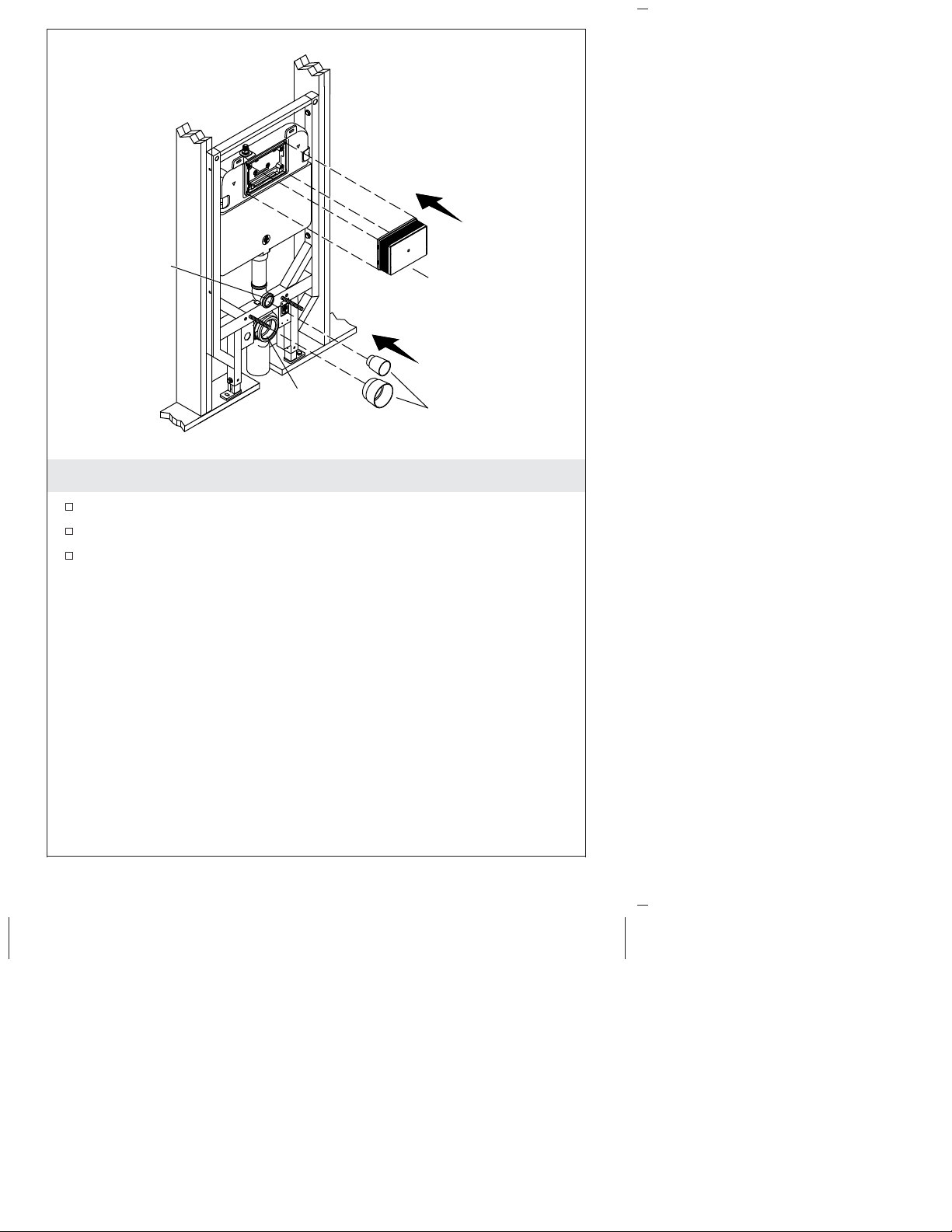

6. Install the Plaster Guards

Insert a plaster guard into the inlet hole in the carriage.

Install a plaster guard into the outlet hole in the carriage.

Install the flush shield in the flush valve opening by snapping it

into place.

1246750-2-B 12 Kohler Co.

Page 13

Finished Wall

Front View

10-1/2" (267 mm)

9-1/4"

(235 mm)

8" (203 mm)

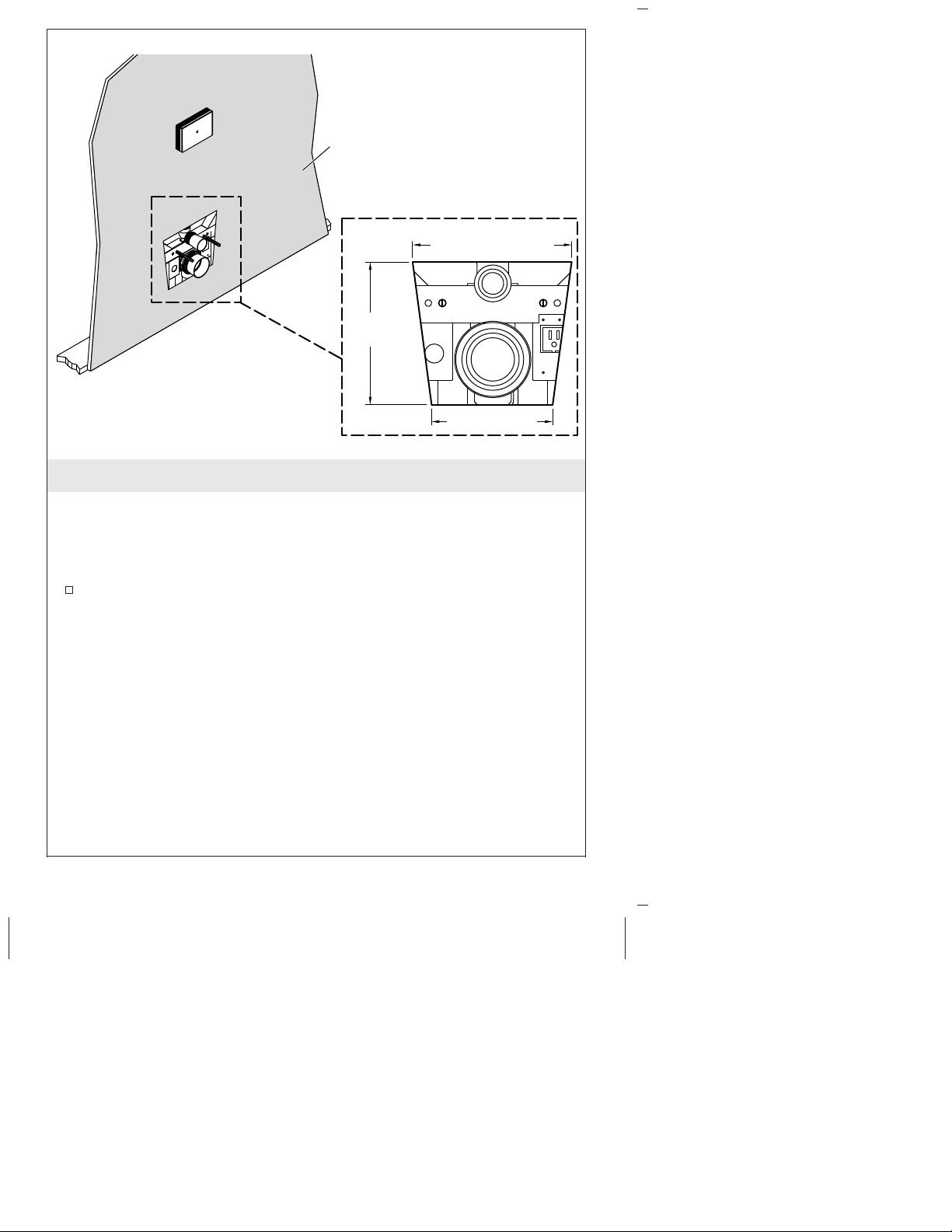

7. Install the Finished Wall

NOTE: It is recommended to use cement board or tile backer board

for the wallboard backing. Gypsum board can also be used but it

may affect the toilet loading strength.

NOTE: The wall thickness should not exceed 2-3/4″ (70 mm).

Install the finished wall.

Kohler Co. 13 1246750-2-B

Page 14

Utility Knife

Finished Wall

Flush Shield

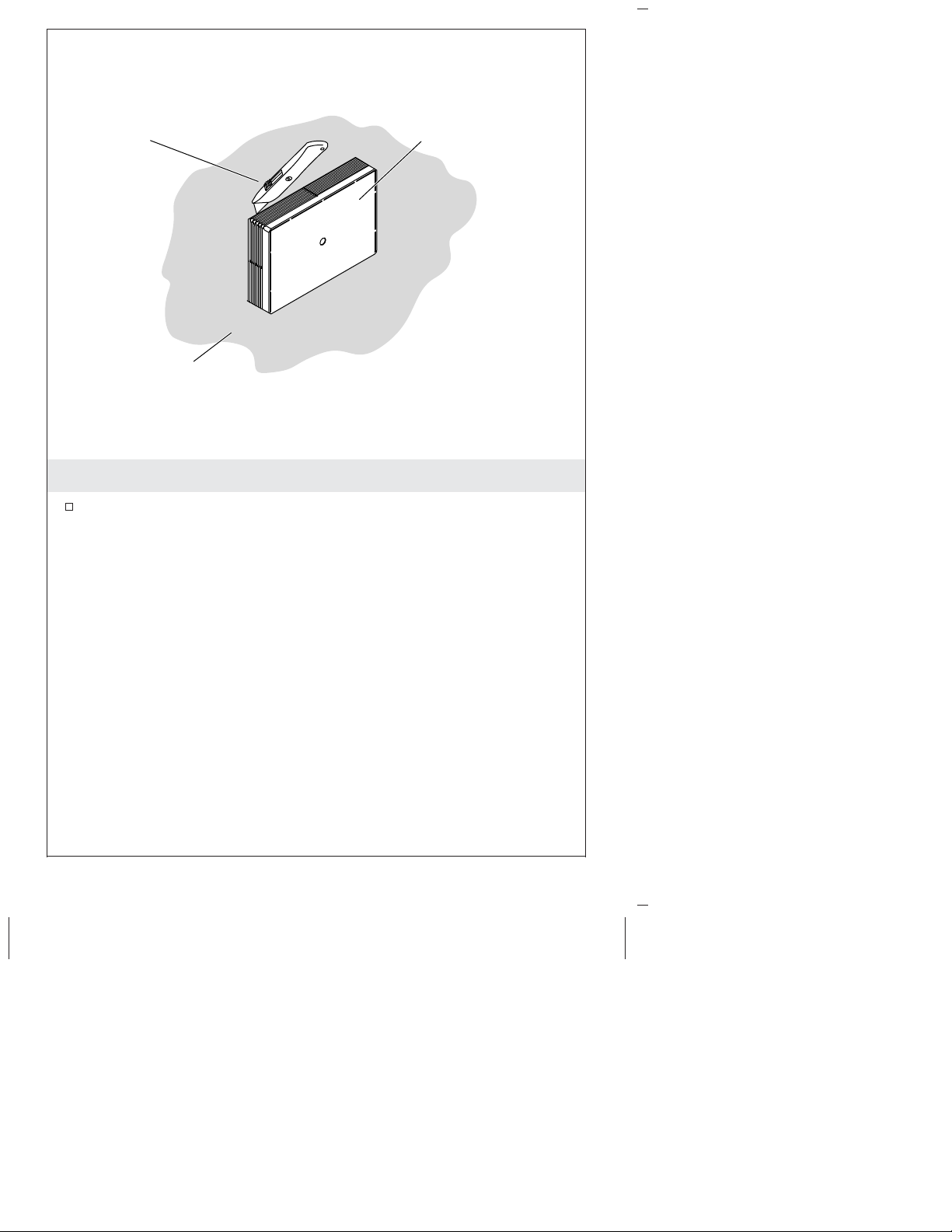

8. Trim the Flush Shield

Use a utility knife to carefully trim the flush shield even with the

finished wall.

1246750-2-B 14 Kohler Co.

Page 15

Flush Valve Opening

Service Cover

Tabs

9. Remove the Service Cover

Remove and discard the service cover by pressing down on the

tabs and pulling forward.

Kohler Co. 15 1246750-2-B

Page 16

Push Rod

Nuts

Side View

1/2"

(13 mm)

Min

Push Rods

Finished

Wall

10. Install the Actuator

Thread the push rods into the actuator assembly 1/2″ (13 mm)

behind the finished wall.

If needed, trim the threaded end of the push rods.

Secure the push rods in place with the push rod nuts.

K-4177, K-8857 and K-5413

Thread the push rods into the actuator assembly flush with the

finished wall.

If needed, trim the threaded end of the push rods.

Secure the push rods in place with the push rod nuts.

1246750-2-B 16 Kohler Co.

Page 17

Mounting Frame

Faceplate

Open Position

Lock Position

Finished

Wall

11. Install the Faceplate

Install the locking pins into the mounting frame.

Turn the locking pins to the ″Open″ position.

Align the mounting frame with the tank mounting opening and

install the frame.

If needed, trim the locking pins.

Turn the locking pins to the ″Lock″ position.

Position the faceplate over the lift rod assembly and press into

place.

Care and Cleaning

WARNING: Risk of property or product damage. Do not

use in-tank cleaners in your toilet. Products containing

chlorine (calcium hypochlorite) can seriously damage fittings

in the tank. This damage can cause leakage and property

damage.

Kohler Co. shall not be responsible or liable for any tank fitting

Kohler Co. 17 1246750-2-B

Page 18

Care and Cleaning (cont.)

damage caused by the use of cleaners containing chlorine (calcium

hypochlorite).

For best results, keep the following in mind when caring for your

KOHLER product:

•

Always test your cleaning solution on an inconspicuous area

before applying to the entire surface.

•

Wipe surfaces clean and rinse completely with water immediately

after applying cleaner. Rinse and dry any overspray that lands on

nearby surfaces.

•

Do not allow cleaners to soak on surfaces.

•

Use a soft, dampened sponge or cloth. Never use an abrasive

material such as a brush or scouring pad to clean surfaces.

•

For Artist Edition Toilets: Treat your decorative product just as

you would treat your fine china. DO NOT use bristle brushes or

abrasive-backed sponges. They will scratch decorative surfaces.

Use only warm water to clean. Dry with a cotton cloth or soft

sponge.

For detailed cleaning information and products to consider, visit

www.kohler.com/clean. To order Care & Cleaning information, call

1-800-456-4537.

Troubleshooting

For service parts information, visit www.kohler.com/serviceparts.

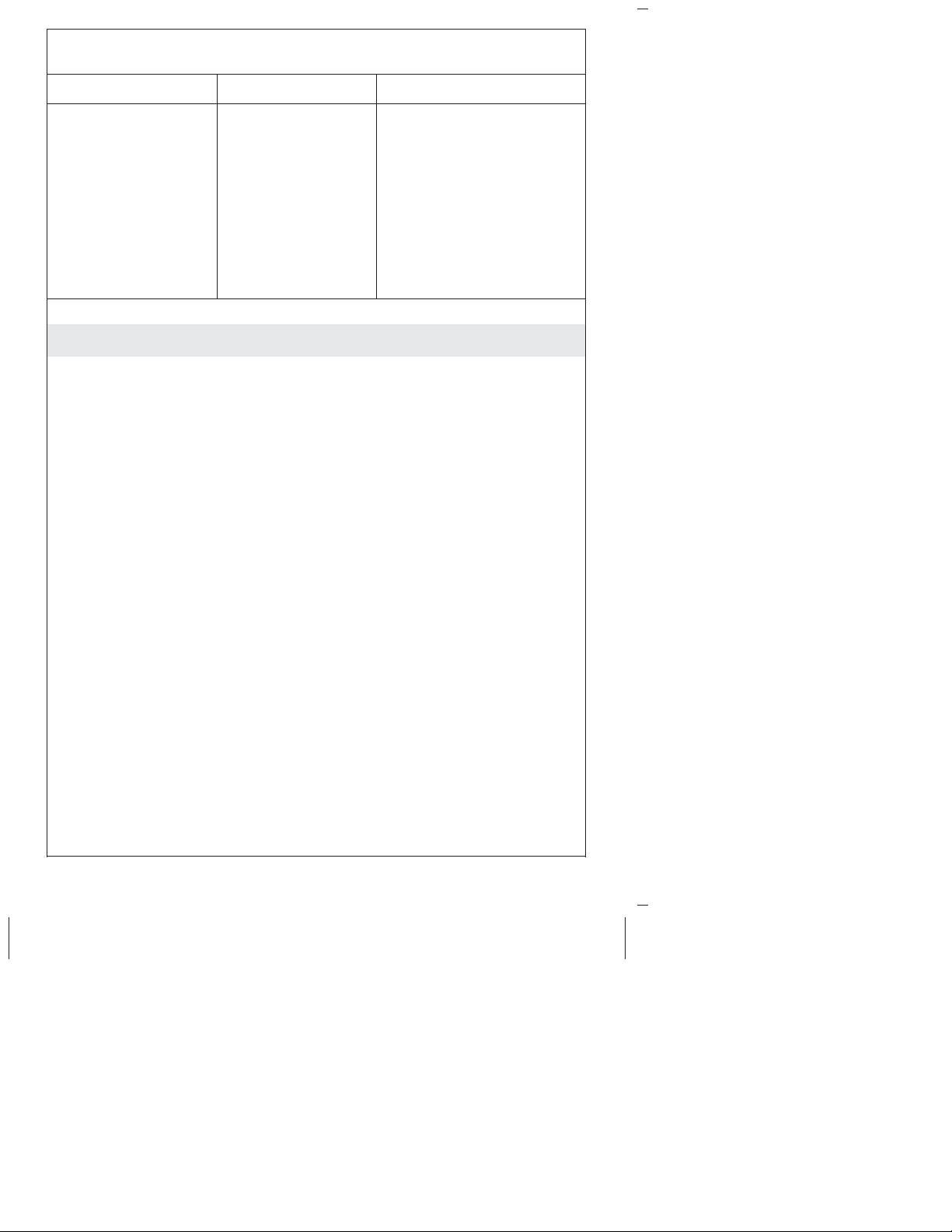

Symptoms Cause Recommended Action

1. Poor flush. A. Water level is

too low.

B. Improper waste

line venting.

1246750-2-B 18 Kohler Co.

A. The water line should

be about 8″ (203 mm)

above the bottom of

the tank. Raise the

water level in the tank

to the marked

waterline by turning

the white knob

clockwise until the

water level reaches the

waterline marked in

the tank.

B. Install venting to code.

Page 19

Troubleshooting (cont.)

Symptoms Cause Recommended Action

2. Running fill

valve.

A. Water level is

too high.

A. Lower the water level

in the tank by turning

the knob at the top of

the threaded rod

counterclockwise until

the fill valve shuts off

when the water level

reaches the marked

waterline in the tank.

B. Flush valve

gasket or flush

valve are

B. Replace gasket or

flush valve as

necessary.

damaged.

C. Flush valve is

sticking open.

C. Check flush valve and

actuating mechanisms

for free movement.

Push button actuators

should raise levers

then spring back

without force. Replace

components as

necessary.

3. Leaks from

behind the bowl.

A. Gaskets not

positioned

correctly.

A. Remove the bowl and

inspect all the gaskets.

Reposition the gaskets

if needed. Lubricate

the gaskets so they

slide over the mating

part they seal.

Reinstall the bowl,

making sure the

gaskets stay in the

correct positions.

4. Carriage and

bowl flex when

used.

A. Insufficient

support for

frame.

A. Add additional

support members, and

mount the frame with

1/4″ or larger lag

screws.

5. No water flow. A. Supply stop

located in tank

is closed.

A. Open the supply stop

(located on the left

side).

Kohler Co. 19 1246750-2-B

Page 20

Troubleshooting (cont.)

Symptoms Cause Recommended Action

B. There is an

obstruction in

the water line.

B. Close the external

supply stop,

disconnect the braided

hose where it attaches

to the fill valve. Turn

on the water supply

and check the flow

through the hose.

Continue to

investigate water path

for obstructions. Clear

any blockages.

Warranty

ONE-YEAR LIMITED WARRANTY

KOHLER plumbing products are warranted to be free of defects in

material and workmanship for one year from date of installation.

Kohler Co. will, at its election, repair, replace or make appropriate

adjustment where Kohler Co. inspection discloses any such defects

occurring in normal usage within one (1) year after installation. Kohler

Co. is not responsible for removal or installation costs. Use of in-tank

toilet cleaners will void the warranty.

To obtain warranty service contact Kohler Co. either through your

Dealer, Plumbing Contractor, Home Center or E-tailer, or by writing

Kohler Co., Attn.: Customer Care Center, 444 Highland Drive, Kohler,

WI 53044, USA, or by calling 1-800-4-KOHLER (1-800-456-4537) from

within the USA and Canada, and 001-800-456-4537 from within Mexico,

or visit www.kohler.com within the USA, www.ca.kohler.com from

within Canada, or www.mx.kohler.com in Mexico.

IMPLIED WARRANTIES INCLUDING THAT OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE EXPRESSLY LIMITED IN DURATION TO THE

DURATION OF THIS WARRANTY. KOHLER CO. AND/OR

SELLER DISCLAIM ANY LIABILITY FOR SPECIAL, INCIDENTAL

OR CONSEQUENTIAL DAMAGES. Some states/provinces do not

allow limitations on how long an implied warranty lasts, or the

exclusion or limitation of special, incidental or consequential damages,

so these limitations and exclusions may not apply to you. This

warranty gives you specific legal rights. You may also have other

rights which vary from state/province to state/province.

1246750-2-B 20 Kohler Co.

Page 21

Warranty (cont.)

This is Kohler Co.’s exclusive written warranty.

Kohler Co. 21 1246750-2-B

Page 22

Guide d’installation et d’entretien

Bâti-support et réservoir encastrés

Outils et matériel

Assortiment

de mèches

5/8"

(16 mm)

1/2"

Robinet d'arrêt 1/4 de

tour de 1/2" NPT avec

poignée de 5/8" ou moins

Graisse de plombier

à la silicone

Plus:

• Outils et matériel de menuiserie

classiques

• 1/4" x 2" (51 mm) Min

Boulons à expansion pour

béton (pour les sous-planchers

en béton)

Optionnel:

Outils d'électricien assortis

Tire-fonds de

1/4" x 2" (51 mm) min.

Avant de commencer

IMPORTANT! Une ossature de 2x4 est requise pour ce produit.

IMPORTANT! Dans les régions sujettes au gel, effectuer

l’installation sur une cloison intérieure. Pour les installations sur un

mur extérieur, prévoir une isolation suffisante pour écarter tout

risque de gel.

REMARQUE: Si l’on utilise une ossature 2x6, l’évacuation du drain

peut être placée à un angle de 45 degrés dans n’importe quelle

direction.

REMARQUE: Cet appareil n’est pas destiné à être utilisé en tant

que remplacement de toilettes de 1,28 gpc (4,8 lpc).

REMARQUE: Les résultats peuvent varier. Ce produit a été testé

avec des toilettes figurant sur la liste des modèles compatibles.

Seules les cuvettes K-6299 et K-6300 sont compatibles avec le

bâti-support.

Kohler Co. Français-1 1246750-2-B

Page 23

Avant de commencer (cont.)

Durant l’installation, s’assurer que les raccordements et les joints

du tube d’arrivée restent complètement engagés afin préserver

leur étanchéité.

Contrôler soigneusement l’état du bâti-support et du réservoir.

Respecter tous les codes de plomberie et de bâtiment locaux.

Pour les installations avec un siège-bidet

Si la prise électrique en option doit être installée, respecter tous

les codes électriques locaux.

ATTENTION: Risque de blessures. Si la prise électrique en

option doit être installée, elle doit être raccordée à un circuit

protégé par un disjoncteur de type GFCI ou RCD.

Kohler Co. Français-2 1246750-2-B

Page 24

Montants 2x4 ou

montants 2x6

23-1/4"

(591 mm)

Coude

en PVC

1-3/4" (44 mm)

[Montants 2x4]

3-1/4" (83 mm)

[Montants 2x6]

Conduite

d'évacuation

1-3/4" (44 mm) [Montants 2x4]

3-1/4" (83 mm) [Montants 2x6]

8" (203 mm) [Sous-plancher en contreplaqué]

9-1/8" (232 mm) [Sous-plancher en béton]

1. Monter l’ossature

IMPORTANT! Noter la dimension 1-3/4″ (44 mm) ou 3-1/4″ (83

mm) entre le bord avant de l’ossature et le centre de la conduite

d’évacuation, en fonction de l’installation en question. Cette

dimension est d’une importance essentielle pour l’installation.

REMARQUE: Voir les détails et les dimensions de raccordement

dans la fiche technique.

REMARQUE: Il peut être nécessaire de déplacer la canalisation

d’évacuation pour cette installation.

REMARQUE: Un coude en PVC est fourni avec ce produit. Dans

certains endroits, la réglementation peut exiger un coude en fonte. Il

peut être nécessaire d’ajuster la hauteur du tuyau d’écoulement du

W.C. si le coude en fonte est utilisé.

REMARQUE: Des montants doubles doivent être utilisés sur

n’importe quel côté du cadre porteur.

Construire le cadre porteur en utilisant les dimensions indiquées.

1246750-2-B Français-3 Kohler Co.

Page 25

Monter l’ossature (cont.)

Le centre de l’orifice d’évacuation doit se trouver à 1-3/4″ (44

mm) ou 3-1/4″ (83 mm) du bord avant de l’ossature.

Kohler Co. Français-4 1246750-2-B

Page 26

Cadre

Vue avant

de montage

Coude

en PVC

Bride de

drain

Boîtier

électrique

2. Préparer le bâti-support

Installer la bride d’évacuation

Déballer et inspecter le bâti-support.

Vue arrière

REMARQUE: Si l’on utilise des montant 2x6, installer le cadre de

montage en sens inverse dans les encoches arrière.

Installer le cadre de montage dans les encoches avant sur le bas

du bâti-support.

Insérer le coude en PVC dans le cadre de montage.

Fixer le coude en place avec la bride du drain. Pousser la bride

dans le cadre jusqu’à ce qu’elle se verrouille en place.

Installer le boîtier électrique - Installations avec bidet

REMARQUE: Le kit du boîtier électrique 1201721 est nécessaire si

le siège-bidet K-4744 sera utilisé avec la cuvette. Ignorer cette étape

lors d’une installation standard.

Raccorder le boîtier électrique au bâti-support à l’emplacement

indiqué.

1246750-2-B Français-5 Kohler Co.

Page 27

Marquer le bâti-support.

2-5/8"

(67 mm)

A

Tiges

filetées

Plancher

fini

Écrou

Pied

3. Ajuster la hauteur du bâti-support

IMPORTANT! Si le bâti-support n’est pas correctement ajusté, la

hauteur du rebord de cuvette peut ne pas être conforme aux codes

en vigueur. La finition murale doit être enlevée pour effectuer les

ajustements si la hauteur de la cuvette n’est pas correcte.

REMARQUE: Pour les cuvettes K-6299 et K-6300, la hauteur

minimale du rebord est de 15″ (381 mm) lorsque le sol fini est au

niveau du dessous des pieds du bâti-support. La hauteur maximale

du rebord est de 23″ (584 mm) lorsque les pieds sont complètement

déployés. Le bâti-support peut être ajusté sur une hauteur totale de

8″ (203 mm), mais un ajustement de 6″ (152 mm) ou moins suffit

dans la majorité des cas.

Mettre le bâti-support en place dans le cadre porteur.

Fixer le bâti-support provisoirement pour l’empêcher de tomber.

Visser les tiges filetées de plusieurs tours dans le bâti-support.

Tracer un repère sur le bâti-support à 2-5/8″ (67 mm) au-dessus

du haut de la tige filetée.

Kohler Co. Français-6 1246750-2-B

Page 28

Ajuster la hauteur du bâti-support (cont.)

Mesurer la distance entre le sol fini et le repère (A) pour

déterminer la hauteur du rebord de cuvette.

Desserrer les écrous de blocage des pieds dans le bâti.

REMARQUE: Lorsque le bâti-support est abaissé, s’assurer que le

coude s’aligne avec tuyau d’écoulement du W.C.

REMARQUE: Le cas échéant, vérifier que le joint sur le coude reste

en position correcte lorsqu’il s’engage dans le tuyau d’écoulement

du W.C.

Ajuster le bâti-support jusqu’à la hauteur souhaitée. Bien serrer

les écrous à l’aide d’une clé pour fixer les pieds en place.

REMARQUE: Si un coude en fonte est requis, effectuer le

raccordement en conformité avec tous les codes en vigueur.

1246750-2-B Français-7 Kohler Co.

Page 29

Tire-fonds

4. Installer le bâti-support

Placer le bâti-support au ras du bord avant des montants

d’ossature. L’avant du bâti-support doit être au ras du bord avant

des montants ou légèrement en retrait pour la pose de la finition

murale.

Vérifier que l’avant du bâti-support est d’aplomb.

Marquer les emplacements des trous pour les six tire-fonds, un

pour chaque pied et deux sur chaque côté du bâti-support.

Percer des avant-trous (retirer le bâti-support au besoin) afin

d’éviter que les tire-fonds fendent ou fissurent les montants.

REMARQUE: Si le bâti-support est installé sur un plancher en

béton, utiliser des boulons à expansion pour béton (non fournis) lors

de la fixation des pieds sur le bâti-support.

Fixer le bâti-support sur les montants de support avec des

tire-fonds de 2″ (51 mm) de long (minimum) (non fournis), un à

chaque emplacement.

Raccorder l’alimentation électrique - Installations à siège-bidet

Kohler Co. Français-8 1246750-2-B

Page 30

Installer le bâti-support (cont.)

AVERTISSEMENT: Risque de blessures. Débrancher

l’alimentation électrique avant de raccorder les fils.

ATTENTION: Risque de blessures. La prise électrique doit

être raccordée à un circuit protégé par un disjoncteur de type

GFCI ou RCD ou alors un disjoncteur de fuite de terre (GFCI)

ou un appareil à courant résiduel (RCD) doit être installé de

façon accessible.

REMARQUE: Cette étape est nécessaire uniquement si le boîtier

électrique a été installé à la section ″Préparer le bâti-support″.

Raccorder l’alimentation électrique conformément à tous les codes

en vigueur.

1246750-2-B Français-9 Kohler Co.

Page 31

Dégagement maximal

de 4" (102 mm)

Arrivée d'eau du bidet

(optionnel)

à partir de l'avant

du mur fini

5. Installer l’alimentation d’eau

Toutes les installations

Adaptateur NTP de

1/2"

5/8"

(16 mm)

Max

IMPORTANT! L’arrivée d’eau du bidet en option est représentée.

Ne pas poser de deuxième arrivée d’eau sauf si le siège-bidet doit

être installé.

Poser les tuyaux d’arrivée d’eau conformément à tous les codes

locaux.

Raccorder le conduit d’évacuation conformément à tous les codes

en vigueur.

Si l’on utilise un raccord G 1/2, retirer l’adaptateur NTP 1/2″ et

le jeter.

Installations avec un siège-bidet

Optionnel: Installer l’arrivée d’eau de bidet et un robinet d’arrêt

quart de tour de 1/2″ NPT.

IMPORTANT! Le robinet d’arrêt d’arrivée du bidet doit dépasser

de 3″ (76 mm) minimum à 4″ (102 mm) maximum au-delà du mur

fini pour permettre l’accès à la poignée. La poignée du robinet

Kohler Co. Français-10 1246750-2-B

Page 32

Installer l’alimentation d’eau (cont.)

d’arrêt ne doit pas dépasser de plus de 5/8″ (16 mm) en hauteur par

rapport au centre de l’arrivée d’eau.

1246750-2-B Français-11 Kohler Co.

Page 33

Orifice

d'entrée

Protège-chasse

Orifice

de sortie

Protecteur de plâtre

6. Poser les protège-plâtres

Insérer un protège-plâtre dans l’orifice d’entrée du bâti-support.

Insérer un protège-plâtre dans l’orifice de sortie du bâti-support.

Installer le protège-chasse dans l’ouverture de la vanne de chasse

en l’enclenchant en place.

Kohler Co. Français-12 1246750-2-B

Page 34

Mur fini

Vue avant

10-1/2" (267 mm)

9-1/4"

(235 mm)

8" (203 mm)

7. Installer la finition murale

REMARQUE: Il est recommandé d’utiliser une planche en ciment

ou un panneau d’appui pour tuiles pour le support du panneau

mural. Une plaque de plâtre peut également être utilisée, mais ceci

peut affecter la force de charge de la toilette.

REMARQUE: L’épaisseur du mur ne doit pas dépasser 2-3/4″ (70

mm).

Poser la finition murale.

1246750-2-B Français-13 Kohler Co.

Page 35

Couteau

utilitaire

Mur fini

Protège-chasse

8. Raccourcir le protège-chasse

À l’aide d’un couteau utilitaire, couper le protège-chasse avec

précaution au ras du mur fini.

Kohler Co. Français-14 1246750-2-B

Page 36

Ouverture de

vanne de chasse

9. Retirer le couvercle d’entretien

Retirer et jeter le couvercle d’entretien en appuyant sur les

languettes et en tirant vers l’avant.

Pattes de

couvercle

d'entretien

1246750-2-B Français-15 Kohler Co.

Page 37

Écrous de

tiges-poussoirs

Vue latérale

1/2"

(13 mm)

Min

Tiges-poussoirs

10. Installer l’actionneur

Enfiler les tiges-poussoirs dans l’ensemble de l’actionneur à 1/2″

(13 mm) à l’arrière du mur fini.

Si nécessaire, couper l’extrémité filetée des tiges-poussoirs.

Fixer les tiges-poussoirs en place avec les écrous des

tiges-poussoirs.

Mur

fini

K-4177, K-8857 et K-5413

Enfiler les tiges-poussoirs dans l’ensemble de l’actionneur à ras

du mur fini.

Si nécessaire, couper l’extrémité filetée des tiges-poussoirs.

Fixer les tiges-poussoirs en place avec les écrous des

tiges-poussoirs.

Kohler Co. Français-16 1246750-2-B

Page 38

Cadre de montage

Plateau de garniture

Position ouverte

Position verrouillée

Mur

fini

11. Installer le plateau de garniture

Installer les goupilles de fixation dans le cadre de montage.

Tourner les goupilles de fixation à la position ″Ouvrir″.

Aligner le cadre de montage sur l’ouverture de montage du

réservoir et installer le cadre.

Si nécessaire, couper les goupilles de fixation.

Tourner les goupilles de fixation à la position ″Verrouiller″.

Positionner le plateau de garniture par-dessus l’ensemble de la

tige de levage et appuyer pour le mettre en place.

Entretien et nettoyage

AVERTISSEMENT: Risque de dommages matériel ou

d’endommagement du produit. Ne pas utiliser de détergents

faits pour le réservoir dans la toilette. Les produits contenant

du chlore (hypochlorite de calcium) peuvent sérieusement

endommager les raccords du réservoir. Ceci peut créer des

fuites et des dommages matériels.

1246750-2-B Français-17 Kohler Co.

Page 39

Entretien et nettoyage (cont.)

La société Kohler Co. décline toute responsabilité et ne pourra être

responsable pour des dommages de raccords de réservoir dus à

l’utilisation de nettoyants contenant du chlore (hypochlorite de

calcium).

Pour obtenir les meilleurs résultats possibles, prendre ce qui suit en

considération lors de l’entretien de votre produit KOHLER:

•

Toujours tester la solution de nettoyage sur une surface non

visible avant de l’appliquer sur l’ensemble de la surface.

•

Essuyer les surfaces et rincer complètement avec de l’eau

immédiatement après l’application du nettoyant. Rincer et sécher

tout éclaboussement sur les surfaces avoisinantes.

•

Ne pas laisser les nettoyants tremper sur les surfaces.

•

Utiliser une éponge ou un chiffon doux et humide. Ne jamais

utiliser de matériau abrasif tel qu’une brosse ou une éponge à

récurer pour nettoyer les surfaces.

•

Pour la toilette Artist Edition: Traiter le produit décoratif comme

s’il s’agissait d’une porcelaine fine. NE PAS utiliser de brosses en

soies ni d’éponges abrasives. Cela rayerait les surfaces

décoratives. Utiliser uniquement de l’eau chaude pour le

nettoyage. Sécher avec un chiffon en coton ou une éponge douce.

Pour obtenir des informations détaillées sur le nettoyage et les produits

à considérer, consulter le site www.kohler.com/clean. Pour commander

des informations sur l’entretien & le nettoyage, appeler le

1-800-456-4537.

Dépannage

Pour tout renseignement sur les pièces de rechange, visiter

www.kohler.com/serviceparts.

Kohler Co. Français-18 1246750-2-B

Page 40

Dépannage (cont.)

Symptômes Cause Action recommandée

1. Chasse médiocre. A. Niveau d’eau

trop bas.

A. Le niveau de l’eau

doit être à 8″ (203

mm) environ

au-dessus du fond du

réservoir. Relever le

niveau d’eau dans le

réservoir en tournant

le bouton blanc dans

le sens des aiguilles

d’une montre jusqu’à

ce que l’eau atteigne

le repère de niveau

dans le réservoir.

B. Ventilation

insuffisante de la

conduite

B. Installer une

ventilation conforme

au code.

d’évacuation.

2. Fuite de la vanne

de remplissage.

A. Niveau d’eau

trop haut.

A. Abaisser le niveau

d’eau dans le réservoir

en tournant le bouton

au-dessus de la tige

filetée dans le sens

contraire des aiguilles

d’une montre jusqu’à

ce que la vanne de

remplissage se ferme

lorsque l’eau atteint le

repère de niveau dans

le réservoir.

B. Le robinet de

chasse ou son

joint sont

endommagés.

C. La vanne de

remplissage

coince en

position ouverte.

B. Remplacer le joint ou

le robinet de

remplissage selon les

besoins.

C. Vérifier que le robinet

de chasse et les

mécanismes

d’actionnement

bougent librement. Les

actionneurs à bouton

poussoir doivent

soulever les leviers

puis revenir sans

effort. Changer les

pièces comme il se

doit.

1246750-2-B Français-19 Kohler Co.

Page 41

Dépannage (cont.)

Symptômes Cause Action recommandée

3. Fuites derrière la

cuvette.

4. Le bâti-support

et la cuvette

fléchissent

durant

l’utilisation.

5. Pas

d’écoulement

d’eau.

A. Joints par

correctement en

place.

A. Support

insuffisant pour

le bâti.

A. Le robinet

d’arrêt d’arrivée

situé dans le

réservoir est

fermé.

B. La conduite

d’eau est

obstruée.

A. Retirer la cuvette et

inspecter tous les

joints. Rectifier la

position des joints

comme il se doit.

Lubrifier les joints afin

qu’ils glissent

par-dessus la pièce

appariée qu’ils

rendent étanches.

Remonter la cuvette,

en vérifier que les

joints restent dans la

bonne position.

A. Poser des éléments de

support

supplémentaires et

fixer le bâti avec des

tire-fonds de 1/4″ ou

plus.

A. Ouvrir le robinet

d’arrêt d’arrivée (situé

du côté gauche).

B. Fermer le robinet

d’arrêt d’arrivée

externe, débrancher le

tuyau tressé de la

vanne de remplissage.

Ouvrir l’arrivée d’eau

et vérifier que l’eau

s’écoule à travers le

tuyau. Poursuivre la

recherche

d’obstruction sur le

circuit d’eau. Éliminer

tout blocage.

Garantie

GARANTIE LIMITÉE D’UN AN

Les produits de plomberie KOHLER sont garantis contre tout vice de

matériau et de fabrication pendant un an à partir de la date de

Kohler Co. Français-20 1246750-2-B

Page 42

Garantie (cont.)

l’installation.

Si un vice est découvert au cours d’une utilisation normale, Kohler Co.

choisira, à sa discrétion, la réparation, le remplacement ou la

rectification appropriée après inspection desdits vices par Kohler Co.

pendant un (1) an à partir de la date d’installation. Kohler Co. n’est

pas responsable des frais d’enlèvement ou d’installation. L’utilisation

de nettoyants à l’intérieur du réservoir annule la garantie.

Pour obtenir le service de garantie, contacter Kohler Co., par

l’intermédiaire du vendeur, plombier, centre de rénovation ou

revendeur par internet, ou bien par écrit à l’adresse suivante Kohler

Co., Attn.: Customer Care Center, 444 Highland Drive, Kohler, WI

53044, USA, ou appeler le 1-800-4-KOHLER (1-800-456-4537) à partir

des É.-U. et du Canada, et le 001-800-456-4537 à partir du Mexique, ou

consulter le site www.kohler.com aux É.-U., www.ca.kohler.com à

partir du Canada, ou www.mx.kohler.com au Mexique.

LES GARANTIES TACITES, Y COMPRIS CELLES DE

COMMERCIALITÉ ET D’ADAPTATION À UN USAGE

PARTICULIER, SONT EXPRESSÉMENT LIMITÉE À LA DURÉE DE

LA PRÉSENTE GARANTIE. KOHLER CO. ET/OU LE REVENDEUR

DÉCLINENT TOUTE RESPONSABILITÉ CONTRE LES

DOMMAGES PARTICULIERS, ACCESSOIRES OU INDIRECTS.

Certains états et provinces ne permettent pas de limite sur la durée de

la garantie tacite, ni l’exclusion ou la limite des dommages particuliers,

accessoires ou indirects, et, par conséquent, lesdites limites et

exclusions peuvent ne pas s’appliquer à votre cas. Cette garantie vous

donne des droits juridiques particuliers. Vous pouvez également avoir

d’autres droits qui varient d’un état ou d’une province à l’autre.

Ceci constitue la garantie écrite exclusive de Kohler Co.

1246750-2-B Français-21 Kohler Co.

Page 43

Guía de instalación y cuidado

Tanque y armazón dentro de la pared

Herramientas y materiales

Brocas para

taladro, surtidas

5/8"

(16 mm)

1/2"

Llave de paso de suministro

de 1/2" NPT de 1/4 de

vuelta con manija de 5/8" o más corta

Grasa de silicona

para plomería

Más:

• Herramientas y materiales

normales para trabajar madera

• Pernos expansores para

concreto de 1/4" x 2" (51 mm)

mín. (en subpisos de concreto)

Opcional:

• Herramientas eléctricas

diversas

Pernos de fijación de

1/4" x 2" (51 mm) mín.

Antes de comenzar

¡IMPORTANTE! Este producto requiere una estructura de postes de

2x4.

¡IMPORTANTE! En zonas con temperaturas de congelación, instale

en una pared interior. Si se instala en una pared exterior, provea

aislamiento adecuado para evitar la posibilidad de congelación.

NOTA: Si se usa una estructura de postes de 2x6, la salida del

desagüe puede quedar a un ángulo de 45 grados en cualquier

dirección.

NOTA: Este dispositivo no está diseñado para utilizarse como

dispositivo de modernización para inodoros de 1,28

galones/descarga (4,8 litros/descarga).

NOTA: Los resultados pueden variar. Este producto fue probado

con inodoros que están identificados en la lista como compatibles.

Solo las tazas K-6299 y K-6300 son compatibles con el armazón.

Durante la instalación, asegúrese de que los empaques y las

conexiones del tubo de entrada permanezcan completamente

embonados para asegurar el sello hermético.

1246750-2-B

Page 44

Antes de comenzar (cont.)

Revise atentamente el armazón y el tanque para cerciorarse de

que no estén dañados.

Cumpla todos los códigos locales de plomería y de construcción.

Para instalaciones con asiento bidet

Si va a instalar el tomacorriente opcional, observe todos los

códigos eléctricos locales.

PRECAUCIÓN: Riesgo de lesiones personales. Si se va a

instalar el tomacorriente eléctrico opcional, se debe conectar a

un circuito protegido mediante un interruptor GFCI o RCD.

1246750-2-B 2 Kohler Co.

Page 45

Postes de 2x4 o

postes de 2x6

23-1/4"

(591 mm)

Codo de

PVC

1-3/4" (44 mm)

[postes de 2x4]

3-1/4" (83 mm)

[postes de 2x6]

Tubo de

salida de

desechos

1-3/4" (44 mm) [postes de 2x4]

3-1/4" (83 mm) [postes de 2x6]

8" (203 mm) [subpiso de madera contrachapada]

9-1/8" (232 mm) [subpiso de concreto]

1. Instale la estructura de postes

¡IMPORTANTE! Tome en cuenta la dimensión de 1-3/4″ (44 mm) o

de 3-1/4″ (83 mm) desde el borde delantero de la estructura de

postes hasta el centro del tubo de salida, de acuerdo a su

instalación. Esta dimensión es crítica para la instalación.

NOTA: Consulte la hoja de especificaciones para obtener más

detalles y las dimensiones de instalación.

NOTA: Es posible cambiar la ubicación del tubo de salida de

desechos en esta instalación.

NOTA: Se incluye un codo de PVC con este producto. En ciertas

zonas es posible que el código requiera un codo de hierro fundido.

Tal vez sea necesario ajustar la altura del tubo de desagüe del

inodoro si se utiliza un codo de hierro fundido.

NOTA: Se deben usar dobles postes de madera a cada lado del

encajonado de postes.

Construya el encajonado de postes de acuerdo a las dimensiones

que se muestran.

Kohler Co. 3 1246750-2-B

Page 46

Instale la estructura de postes (cont.)

El centro de la salida de desechos debe estar a 1-3/4″ (44 mm) o a

3-1/4″ (83 mm) del borde delantero de la estructura de postes.

1246750-2-B 4 Kohler Co.

Page 47

Marco

Vista frontal

de montaje

Codo de

PVC

Abrazadera

del

desagüe

Caja

eléctrica

2. Prepare el armazón

Instale la abrazadera del desagüe

Desempaque y revise el armazón.

Vista posterior

NOTA: Si va a usar postes de 2x6, instale el marco de montaje

invertido en las muescas posteriores.

Instale el marco de montaje en las muescas delanteras en la parte

inferior del armazón.

Introduzca el codo de PVC en el marco de montaje.

Fije el codo en su lugar con la abrazadera del desagüe. Empuje la

abrazadera hacia dentro del marco hasta que quede fija en su

lugar.

Instale la caja eléctrica - Instalaciones de bidet

NOTA: Se requiere el kit de caja eléctrica 1201721 cuando se va a

usar el asiento de bidet K-4744 con la taza. En instalaciones estándar

sáltese este paso.

Conecte la caja eléctrica al armazón en el lugar que se muestra.

Kohler Co. 5 1246750-2-B

Page 48

Marque el armazón.

2-5/8"

(67 mm)

A

Varillas

roscadas

Piso

acabado

Tuerca

Pata

3. Ajuste la altura del armazón

¡IMPORTANTE! Si el armazón no se ajusta correctamente, es

posible que la altura del reborde de la taza no cumpla los códigos

pertinentes. Si la altura de la taza no es correcta, será necesario

retirar la pared acabada para hacer ajustes.

NOTA: Con las tazas K-6299 y K-6300, la altura mínima del reborde

es 15″ (381 mm) cuando el piso acabado está parejo con con la parte

inferior de las patas del armazón. La altura máxima del reborde es

23″ (584 mm) cuando las patas están completamente elevadas. El

armazón se puede ajustar hasta 8″ (203 mm), siendo 6″ (152 mm) o

menos el ajuste suficiente en la mayoría de las instalaciones.

Mueva el armazón a su lugar en el encajonado de postes.

Fije temporalmente el armazón en su lugar, de manera que no se

caiga.

Instale las varillas roscadas al armazón, dándoles varias vueltas.

Haga una marca en el armazón 2-5/8″ (67 mm) arriba de la parte

superior de la varilla roscada.

1246750-2-B 6 Kohler Co.

Page 49

Ajuste la altura del armazón (cont.)

Mida desde el piso acabado hasta la marca (A) para determinar la

altura del reborde de la taza.

Afloje las tuercas que fijan las patas al armazón.

NOTA: Al ir bajando el armazón, asegúrese de que el codo quede

alineado con el tubo de desagüe del inodoro.

NOTA: Si aplica, verifique que el empaque del codo quede

correctamente instalado al ir entrando en el tubo de desagüe del

inodoro.

Ajuste el armazón hasta que quede a la altura deseada. Apriete

bien las tuercas con una llave de tuercas para fijar las patas en su

lugar.

NOTA: Si se requiere un codo de hierro fundido, haga las

conexiones de acuerdo a los códigos pertinentes.

Kohler Co. 7 1246750-2-B

Page 50

Pernos de fijación

4. Instale el armazón

Alinee el armazón al ras con el borde delantero de los postes de

madera. El frente del armazón debe quedar al ras con el borde

frontal de los postes de madera o ligeramente detrás en

instalaciones con la pared acabada.

Verifique que el frente del armazón esté a plomo.

Marque los lugares de los orificios para los seis tornillos de rosca

para madera, uno para cada pata y dos a cada lado del armazón.

Taladre orificios guía (retire el armazón si es necesario) para

reducir el riesgo de que los tornillos de rosca para madera hagan

que los postes se rajen o se fisuren.

NOTA: Si el armazón se instala en un subpiso de concreto, use

pernos expansores para concreto (no se incluyen) al fijar las patas

del armazón.

Fije el armazón a los postes de soporte con tornillos de rosca para

madera de 2″ (51 mm) de largo (mínimo) (no se incluyen), uno en

cada lugar.

Conecte la energía eléctrica - Instalaciones de asiento bidet

1246750-2-B 8 Kohler Co.

Page 51

Instale el armazón (cont.)

ADVERTENCIA: Riesgo de lesiones personales. Desconecte

el suministro eléctrico antes de conectar los cables.

PRECAUCIÓN: Riesgo de lesiones personales. El

tomacorriente eléctrico tiene que estar conectado a un circuito

protegido mediante un interruptor GFCI o RCD, o se tiene

que instalar un interruptor de circuito con pérdida a tierra

(GFCI) o dispositivo de corriente residual (RCD).

NOTA: Este paso solo es necesario si se instaló una caja eléctrica en

la sección ″Prepare el armazón″.

Conecte el suministro eléctrico de acuerdo a los códigos

pertinentes.

Kohler Co. 9 1246750-2-B

Page 52

Espacio libre máximo

de 4" (102 mm)

Suministro de agua para el bidet

(opcional)

desde el frente

de la pared acabada

5. Instale el suministro de agua

Todas las instalaciones

Adaptador de

1/2" NTP

5/8"

(16 mm)

máx.

¡IMPORTANTE! Se muestra el suministro de agua al bidet

opcional. No instale un segundo suministro de agua a menos que

vaya a instalar un asiento bidet.

Instale los tubos de suministro de agua, de acuerdo a todos los

códigos locales.

Conecte la tubería de desechos de acuerdo a todos los códigos

locales pertinentes.

Si usa una conexión G 1/2 retire el adaptador de 1/2″ NTP y

deséchelo.

Instalaciones con asiento bidet

Opcional: Instale el suministro de agua de bidet y una llave de

paso de 1/2″ NPT de un cuarto de vuelta.

¡IMPORTANTE! La llave de paso del suministro del bidet debe

sobresalir de 3″ (76 mm) como mínimo a 4″ (102 mm) como máximo

a partir de la pared acabada, para permitir acceso a la manija. La

1246750-2-B 10 Kohler Co.

Page 53

Instale el suministro de agua (cont.)

manija de la llave de paso del suministro no debe estar más arriba

de 5/8″ (16 mm) a partir del centro del suministro de agua.

Kohler Co. 11 1246750-2-B

Page 54

Orificio

de entrada

Pantalla de la

descarga

Orificio

de salida

Protector de yeso

6. Instale los protectores de yeso

Introduzca un protector de yeso en el orificio de entrada en el

armazón.

Instale un protector de yeso en el orificio de salida en el armazón.

Instale la pantalla de la descarga en la abertura para la válvula de

descarga, metiéndola a presión a su lugar.

1246750-2-B 12 Kohler Co.

Page 55

Pared acabada

Vista frontal

10-1/2" (267 mm)

9-1/4"

(235 mm)

8" (203 mm)

7. Instale la pared acabada

NOTA: Recomendamos usar panel de cemento o tabla de refuerzo

para azulejo como refuerzo para el panel de yeso. También se puede

usar tablarroca, pero puede afectar la resistencia a la carga del

inodoro.

NOTA: El espesor de la pared no debe exceder 2-3/4″ (70 mm).

Instale la pared acabada.

Kohler Co. 13 1246750-2-B

Page 56

Pantalla de la

Navaja

Pared acabada

descarga

8. Recorte la pantalla de la descarga

Con una navaja recorte con cuidado la pantalla de la descarga

pareja con la pared acabada.

1246750-2-B 14 Kohler Co.

Page 57

Abertura para

la válvula de descarga

Lengüetas de la

cubierta de

servicio

9. Retire la cubierta de servicio

Oprima las lengüetas y jale hacia adelante para retirar la cubierta

de servicio, luego deséchela.

Kohler Co. 15 1246750-2-B

Page 58

Tuercas de

varillas de empuje

Vista lateral

1/2"

(13 mm)

mín.

Varillas de

empuje

Pared

acabada

10. Instale el accionador

Enrosque las varillas de empuje en el montaje del accionador 1/2″

(13 mm) detrás de la pared acabada.

De ser necesario, recorte el extremo roscado de las varillas de

empuje.

Empuje las varillas de empuje en su lugar con las tuercas de las

varillas de empuje.

K-4177, K-8857 y K-5413

Enrosque las varillas de empuje en el montaje del accionador al

ras con la pared acabada.

De ser necesario, recorte el extremo roscado de las varillas de

empuje.

Empuje las varillas de empuje en su lugar con las tuercas de las

varillas de empuje.

1246750-2-B 16 Kohler Co.

Page 59

Marco de montaje

Placa frontal

Posición abierta

Posición cerrada

Pared

acabada

11. Instale la placa frontal

Instale las clavijas de bloqueo en el marco de montaje.

Gire las clavijas de bloqueo a la posición abierta ″Open″.

Alinee el marco de montaje con la abertura de montaje del

tanque, e instale el marco.

De ser necesario, recorte las clavijas de bloqueo.

Gire las clavijas de bloqueo a la posición cerrada ″Lock″.

Coloque la placa frontal sobre el montaje del tirador y presiónela

en su lugar.

Cuidado y limpieza

ADVERTENCIA: Riesgo de daños al productooala

propiedad. No utilice productos para limpiar el inodoro que

se colocan dentro del tanque. Los productos que contienen

cloro (hipoclorito de calcio) pueden dañar las piezas del

tanque. Esto puede causar fugas y daños a la propiedad.

Kohler Co. no se hará responsable de daños a las conexiones del

Kohler Co. 17 1246750-2-B

Page 60

Cuidado y limpieza (cont.)

tanque causados por el uso de limpiadores que contengan cloro

(hipoclorito de calcio).

Para obtener los mejores resultados, tenga presente lo siguiente al

limpiar su producto KOHLER:

•

Siempre pruebe la solución de limpieza en un área oculta antes

de aplicarla a toda la superficie.

•

Limpie con un paño las superficies, y enjuague completa e

inmediatamente con agua después de haber aplicado el limpiador.

Enjuague y seque las superficies cercanas que hayan recibido

salpicaduras.

•

No deje mucho tiempo los limpiadores en las superficies.

•

Utilice una esponja humedecida o un paño suave y húmedo. Para

limpiar las superficies nunca utilice materiales abrasivos, como

cepillos o estropajos de tallar.

•

Para los inodoros Artist Edition: Cuide su producto decorativo

tal como lo haría con su porcelana más fina. NO utilice cepillos

de cerdas o esponjas con un lado abrasivo. Podrían rayar las

superficies decoradas. Limpie estos acabados solamente con agua

tibia. Seque con un trapo de algodón o con una esponja suave.

Para obtener información detallada de limpieza y de productos a

considerar, visite www.kohler.com/clean. Para solicitar información

sobre el cuidado y la limpieza, llame al 1-800-456-4537.

Resolución de problemas

Para consultar información sobre piezas de repuesto, visite

www.kohler.com/serviceparts.

1246750-2-B 18 Kohler Co.

Page 61

Resolución de problemas (cont.)

Síntomas Causa Acción recomendada

1. Descarga

deficiente.

A. El nivel de agua

es demasiado

bajo.

A. La línea de agua debe

estar

aproximadamente 8″

(203 mm) arriba del

fondo del tanque. Para

subir el nivel de agua

en el tanque hasta la

línea de agua

marcada, gire hacia la

derecha la perilla

blanca hasta que el

nivel de agua alcance

la línea de agua

marcada en el tanque.

B. Venteo

inadecuado de

B. Instale venteo de

acuerdo al código.

la línea de

desechos.

2. Válvula de

llenado en

funcionamiento

constante.

A. El nivel de agua

es demasiado

alto.

A. Baje el nivel de agua

en el tanque girando

hacia la izquierda la

perilla de la parte

superior de la varilla

roscada hasta que se

cierre la válvula de

llenado cuando el

nivel de agua alcance

la línea de agua

marcada en el tanque.

B. El empaque de

la válvula de

descarga o la

B. Cambie el empaque o

la válvula de descarga

según sea necesario.

válvula de

descarga están

dañados.

Kohler Co. 19 1246750-2-B

Page 62

Resolución de problemas (cont.)

Síntomas Causa Acción recomendada

C. La válvula de

descarga se

atora en la

posición abierta.

C. Revise que la válvula

de descarga y que los

mecanismos de

activación se puedan

mover con libertad.

Los accionadores de

los botones deben

elevar las palancas y

luego regresar

elásticamente sin

fuerza. Cambie los

componentes que sea

necesario.

3. Hay fugas detrás

de la taza.

A. Los empaques

no están bien

colocados.

A. Retire la taza y revise

todos los empaques.

Cambie la posición de

los empaques si es

necesario. Lubrique

los empaques de

manera que se

deslicen sobre la pieza

de embone que sellan.

Vuelva a instalar la

taza, asegurándose de

que los empaques

permanezcan en las

posiciones correctas.

4. El armazón y la

taza se flexionan

durante el uso.

A. Soporte

insuficiente para

la estructura.

A. Agregue piezas de

soporte adicionales y

monte la estructura

con tornillos de rosca

para madera de 1/4″ o

más grandes.

5. No hay flujo de

agua.

A. La llave de paso

de suministro en

el tanque está

A. Abra la llave de paso

de suministro (en el

lado izquierdo).

cerrada.

1246750-2-B 20 Kohler Co.

Page 63

Resolución de problemas (cont.)

Síntomas Causa Acción recomendada

B. Hay una

obstrucción en

la línea de agua.

B. Cierre la llave de paso

de suministro externa,

desconecte la

manguera trenzada

donde se fija a la

válvula de llenado.

Abra el suministro de

agua y verifique el

flujo a través de la

manguera. Continúe

investigando si hay

obstrucciones en la

ruta de agua. Elimine

las obstrucciones que

haya.

Garantía

GARANTÍA LIMITADA DE UN AÑO

Se garantizan los productos de plomería KOHLER contra defectos de

material y mano de obra durante un año a partir de la fecha de

instalación.

Kohler Co., a su criterio, reparará, reemplazará o realizará los ajustes

pertinentes en los casos en que la inspección realizada por Kohler Co.

determine que dichos defectos hayan ocurrido durante el uso normal

en el transcurso de un (1) año a partir de la fecha de instalación.

Kohler Co. no se hace responsable de costos de desinstalación o de

instalación. El uso de limpiadores de inodoro que se colocan dentro

del tanque anula la garantía.

Para obtener el servicio de garantía, comuníquese con Kohler Co. a

través de su distribuidor, contratista de plomería, centro de

remodelación o distribuidor por Internet, o escriba a Kohler Co.,

Atención: Customer Care Center, 444 Highland Drive, Kohler, WI

53044, EE.UU., o llame al 1-800-4-KOHLER (1-800-456-4537) desde los

EE.UU. y Canadá, o al 001-800-456-4537 desde México, o visite

www.kohler.com desde los EE.UU., www.ca.kohler.com desde Canadá,

o www.mx.kohler.com en México.

TODA GARANTÍA IMPLÍCITA, INCLUIDA LA DE

COMERCIALIZACIÓN E IDONEIDAD DEL PRODUCTO PARA UN

USO DETERMINADO, SE LIMITA EXPRESAMENTE A LA

DURACIÓN DE ESTA GARANTÍA. KOHLER CO. Y/O EL

Kohler Co. 21 1246750-2-B

Page 64

Garantía (cont.)

VENDEDOR DESCARGAN TODA RESPONSABILIDAD POR

CONCEPTO DE DAÑOS PARTICULARES, INCIDENTALES O

INDIRECTOS. Algunos estados/provincias no permiten limitaciones

en cuanto a la duración de una garantía implícitaoalaexclusión o

limitación de daños particulares, incidentales o indirectos, por lo que es

posible que estas limitaciones y exclusiones no se apliquen a su caso.

Esta garantía le otorga ciertos derechos legales específicos. Además,

usted también puede tener otros derechos que varían de estado a

estado y de provincia a provincia.

Esta es la garantía exclusiva por escrito de Kohler Co.

1246750-2-B 22 Kohler Co.

Page 65

1246750-2-B

Page 66

1246750-2-B

Page 67

1246750-2-B

Page 68

USA/Canada: 1-800-4KOHLER

México: 001-800-456-4537

kohler.com

©2016 Kohler Co.

1246750-2-B

Loading...

Loading...