Page 1

{PeriodicPrevMaint}{Producti on} {HealthImaging}

Publication No. 7C8289

28JAN98

HEALTH IMAGING

PREVENTIVE MAINTENANCE

Kodak X-Omat

in a

Kodak X-Omat

for the

3000 RA INTEGRATED PROCESSOR

MULTILOADER 300 PLUS

© Eastman Kodak Company, 1999

Page 2

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be liable

for any loss or damage, including consequential or special damages, resulting from any use of

this information, even if loss or damage is caused by Kodak’s negligence or other fault.

Table of Contents

Description Page

Weekly Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Monthly Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Month Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preventive Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 28JAN98 – 7C8289

Page 3

Weekly Preventive Maintenance

Section 1: Weekl y Preventive Maintenance

Important

The operator of the PROCESSOR should do the weekly preventive maintenance procedures in this section.

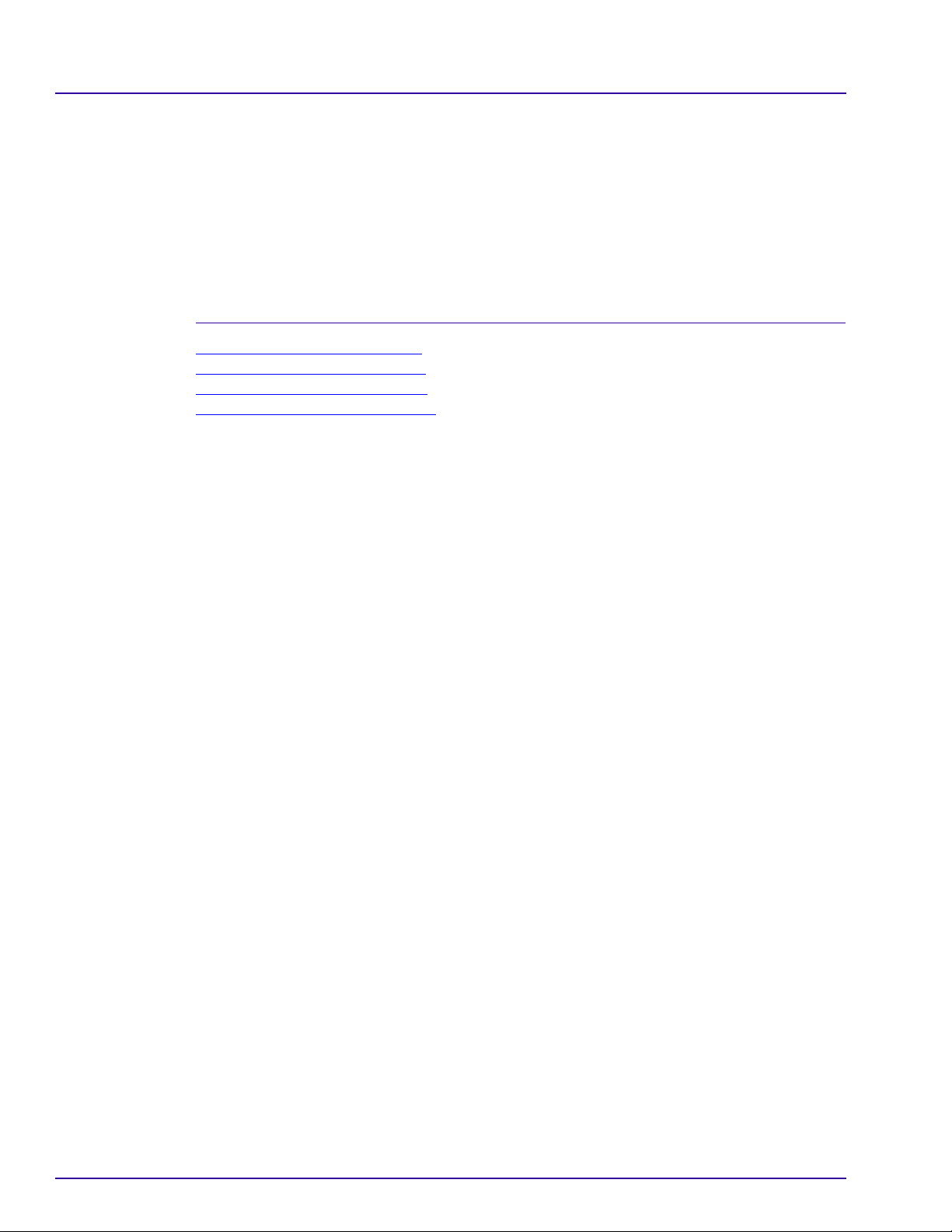

WET SECTION

COVER

ENTRANCE

CROSSOVER

WATER

RESERVOIR

2 EVAPORATION

COVERS

DEVELOPER

FILTER

DEVELOPER

RACK

DEVELOPER/FIXER

WATER DISCONNECT

H166_0003HCA

H166_0003HA

DRYER RACK

WASH

RACK

FIXER/

WASH

CROSSOVER

CROSSOVER

FIXER

RACK

Warning

Dangerous Voltage.

[1] De-energize the PROCESSOR.

[2] Remove the WET SECTION COVER.

[3] Disconnect the WATER RESERVOIR from the CROSSOVERS.

[4] Remove:

• EVAPORATION COVERS

• all CROSSOVERS

• WASH RACK

Important

Do not use abrasive cleaning materials on the ROLLERS.

[5] Rinse the 3 CROSSOVERS and the WASH RACK with warm water, 44C (110F) or less. Clean the ROLLERS

and the GUIDE SHOES with a damp, soft, synthetic sponge.

[6] Allow the ENTRANCE CROSSOVER to air dry before you install it in the PROCESSOR.

[7] Check that all the ROLLERS on all the CROSSOVERS and on the WASH RACK rotate freely.

[8] Check the squareness of the CROSSOVERS and the WASH RACK. See the procedures in the

ADJUSTMENTS AND REPLACEMENTS, Publication No. 7C8285.

7C8289 – 28JAN98 3

Page 4

PERIODIC PREVENTIVE MAINTENANCE

[9] Check that the CROSSOVER TROUGHS are clean, are not cracked or broken.

[10] Wipe any deposits from the processing section of the PROCESSOR.

[11] Install the following parts. Check that each assembly seats correctly:

• WASH RACK

• all CROSSOVERS

[12] Connect the WATER RESERVOIR to the CROSSOVERS.

[13] Check that the WATER DISCONNECT is positioned correctly.

[14] Install the following parts. Check that each assembly seats firmly:

• EVAPORATION COVERS

• WET SECTION COVER

[15] Engage the PROCESSOR in the MULTILOADER.

[16] Energize the PROCESSOR.

[17] Process a test film and check for correct operation of the PROCESSOR.

4 28JAN98 – 7C8289

Page 5

Monthly Preventive Maintenance

Section 2: Monthly Preventive Maintenance

Important

Completion of themonthly preventive maintenance procedures is recommended toensure the optimum reliability of

the PROCESSOR.

Warning

Dangerous Voltage.

[1] De-energize the PROCESSOR.

[2] Remove:

• WET SECTION COVER

• WATER DISCONNECT and WATER RESERVOIR

• EVAPORATION COVERS

• all CROSSOVERS

• DRYER RACK

• WASH RACK

Caution

To prevent contamination of the developer and fixer solutions when you remove the FIXER RACK and the

DEVELOPER RACK, placethe SPLASH GUARD between the DEVELOPER TANKand the FIXER TANK. Use the

DRIP TRAY when you remove or install the RACKS.

[3] Install the SPLASH GUARD between the DEVELOPER TANK and the FIXER TANK.

[4] Remove:

• DEVELOPER RACK

• FIXER RACK

• SPLASH GUARD

Important

Do not use abrasive cleaning materials on the ROLLERS.

[5] Rinse all the RACKS and the CROSSOVERS with warm water, 44C (110F) or less. Wipe the ROLLERS and

the GUIDE SHOES with a soft, synthetic sponge.

[6] Remove and clean the CROSSOVER TROUGHS. Check that the holes in the CROSSOVER TROUGHS are

free from biological growth or other obstructions.

[7] Install the CROSSOVER TROUGHS.

[8] On all RACKS, check:

(a) all ROLLERS rotate freely

(b) the ROLLERS are clean and smooth

(c) the GEARS do not have excessive wear

(d) the BEARINGS do not have excessive wear

(e) the SPROCKETS are engaged in the CHAINS

(f) the E-RINGS and SPRINGS are not broken, missing, or corroded

[9] If necessary, install new parts.

[10] Check the RACKS for squareness. See the procedures in the ADJUSTMENTS AND REPLACEMENTS,

Publication No. 7C8285.

7C8289 – 28JAN98 5

Page 6

PERIODIC PREVENTIVE MAINTENANCE

[11] Check that the SLOTS in the AIR TUBES are clean. If the parts are dirty:

(a) Remove the BAFFLES from the AIR TUBES.

(b) Rinse the BAFFLES with water.

(c) Clean the AIR TUBES with a BOTTLE BRUSH and rinse with water.

[12] Wipe any deposits from the processing section of the PROCESSOR.

[13] Change the DEVELOPER FILTER.

[14] Allow the ENTRANCE CROSSOVER to air dry before you install it in the PROCESSOR.

[15] Clean the WATER RESERVOIR.Checkthat the holes intheWATER RESERVOIRarefree of biological growth

and other obstructions.

[16] Install the RACKS.

[17] Install the following parts. Check that each part seats firmly.

• CROSSOVERS

• WATER RESERVOIR and WATER DISCONNECT

• EVAPORATION COVERS

• WET SECTION COVER

[18] Clean the REPLENISHMENT STRAINERS that are between the REPLENISHMENT TANKS and the

REPLENISHMENT PUMPS.

[19] Check the water supply FILTER. If necessary, change the FILTER.

Caution

• Any obstruction such as biological growth, tight bends, or an upward sloping WASH DRAIN HOSE can cause

wash water to return to the WASH TANK causing an overflow of water.

• Concentrationsofchlorinebleachhigherthan10%orallowingthechlorinebleach to remain in the PROCESSOR

for longer than 30 minutes can cause damage to the PROCESSOR.

[20] Check the WASH DRAIN for biological growth, tight bends, or other obstructions. To remove biological growth

do the following steps:

(a) Fill the WASH TANK and DRAIN with a 10% solution of chlorine bleach.

(b) Wait a minimum of 20 minutes and a maximum of 30 minutes.

(c) Drain the chlorine bleach solution and rinsethe TANK and DRAIN thoroughly with water before you return

the PROCESSOR to normal use.

Warning

• Drains at the site must be made of chemically resistant, non-corrosive material. Use PVC or the equivalent.

• The drain must have a minimum diameter of 7.6 cm (3.0 in.) and be free of obstruction.

• Drain service must comply with local codes.

[21] Correctly route the WASH DRAIN HOSE to slope down toward the floor DRAIN. If necessary, use

REINFORCED HOSES that resist making tight bends. Right angle ELBOW FITTINGS are also available. The

Part Numbers are:

• 696442 - Reinforced HOSE, 5/8-in. I.D. Order by the foot.

• 1C4521 - ELBOW FITTING, 5/8-in.

• 696441 - Reinforced HOSE, 1-in. I.D. Order by the foot.

• 1C4524 - ELBOW FITTING, 1-in.

[22] Energize the PROCESSOR.

[23] Process a test film and check for correct operation of the PROCESSOR.

6 28JAN98 – 7C8289

Page 7

3 Month Preventive Maintenance

Section 3: 3 Month Preventive Maintenance

Warning

Dangerous Voltage.

[1] De-energize the PROCESSOR.

[2] Open the FIXER and DEVELOPER DRAIN VALVES to drain the solutions from the PROCESSOR.

[3] Remove:

• WET SECTION COVER

• WATER DISCONNECT and WATER RESERVOIR

• EVAPORATION COVERS

• all CROSSOVERS

• DRYER RACK

• WASH RACK

Caution

To prevent contamination of the developer and fixer solutions when you remove the FIXER RACK and the

DEVELOPER RACK, place the SPLASH GUARD between the DEVELOPER TANK and the FIXER TANK. Use the

DRIP TRAY when you remove or install the RACKS.

[4] Install the SPLASH GUARD between the DEVELOPER TANK and the FIXER TANK.

[5] Remove:

• DEVELOPER RACK

• FIXER RACK

• SPLASH GUARD

Warning

• Carefullyfollowallsafety precautions and directions included with the

and

Kodak

DEVELOPER SYSTEM CLEANER AND NEUTRALIZER.

• The RACKS in the PROCESSOR have hollow ROLLERS. Use the instructions for cleaningRACKS with hollow

ROLLERS. Do not immerse RACKS with hollow ROLLERS in SYSTEM CLEANER. SYSTEM CLEANER that

remains inside the ROLLERS will contaminate the processing solutions.

• When circulating SYSTEM CLEANER or water through the recirculation system, energize the developer

COOLING SOLENOID and the RECIRCULATION PUMP using the PORTABLE COMPUTER. Otherwise the

following may occur:

– The effectiveness of the DEVELOPER SYSTEM CLEANER AND NEUTRALIZER will be greatly reduced

because of the developer remaining in the HEAT EXCHANGER.

– The DEVELOPER SYSTEM CLEANER AND NEUTRALIZER remaining in the HEAT EXCHANGER will

contaminate the new developer when the PROCESSOR is returned to operation.

[6] Clean the DEVELOPER RACK and the DEVELOPER TANK with

AND NEUTRALIZER, CATALOG No. 843 4615.

[7] Clean the FIXER RACK, the WASH RACK, and the FIXER TANK with

CLEANER, CATALOG No. 139 5110.

[8] Cleanthe WASHTANKwith

solution of chlorine bleach.

[9] If necessary, clean the LEVEL SENSOR PROBES with the correct SYSTEM CLEANER.

Kodak

FIXER/WASHSYSTEM CLEANERor, ifbiological growth exists,with a 10%

Kodak

Kodak

FIXER/WASHSYSTEMCLEANER

DEVELOPER SYSTEM CLEANER

Kodak

FIXER/WASH SYSTEM

7C8289 – 28JAN98 7

Page 8

PERIODIC PREVENTIVE MAINTENANCE

Important

Do not use abrasive cleaning materials on the ROLLERS.

[10] Rinse the following parts with warm water, 44C (110F) or less. Wipe the ROLLERS and the GUIDE SHOES

with a soft, synthetic sponge:

• CROSSOVERS

• EVAPORATION COVERS

• WET SECTION COVER

Note

If necessary, you may use DEVELOPER SYSTEM CLEANER AND NEUTRALIZER on the DEVELOPER/FIXER

CROSSOVER and FIXER/WASH SYSTEM CLEANER on the FIXER/WASH CROSSOVER.

[11] Remove and clean the CROSSOVER TROUGHS. Check that the holes in the CROSSOVER TROUGHS are

free from biological growth or other obstructions.

[12] Install the CROSSOVER TROUGHS.

[13] On all RACKS, check that:

(a) all ROLLERS rotate freely

(b) the ROLLERS are clean and smooth

(c) the GEARS do not have excessive wear

(d) the BEARINGS do not have excessive wear

(e) the SPROCKETS are engaged in the CHAINS

(f) the E-RINGS and SPRINGS are not broken, missing, or corroded

(g) the CHAIN is not worn or out of adjustment

[14] If necessary, install new parts.

[15] Check the RACKS for squareness. See the procedures in the ADJUSTMENTS AND REPLACEMENTS,

Publication No. 7C8285.

[16] Check that the SLOTS in the AIR TUBES are clean. If dirty:

(a) Remove the BAFFLES from the AIR TUBES.

(b) Rinse the BAFFLES with water.

(c) Clean the AIR TUBES with a BOTTLE BRUSH and rinse with water.

[17] Wipe any chemical deposits from the processing section of the PROCESSOR.

[18] Install a new DEVELOPER FILTER.

[19] Allow the ENTRANCE CROSSOVER to air dry before you install it in the PROCESSOR.

[20] Clean the WATER RESERVOIR.Check that theholes inthe WATER RESERVOIRare freeof biologicalgrowth

and other obstructions.

[21] Install the following parts. Check that each part seats firmly:

• RACKS

• CROSSOVERS

• WATER RESERVOIR and WATER DISCONNECT

• EVAPORATION COVERS

• WET SECTION COVER

[22] Clean the REPLENISHMENT STRAINERS located between the REPLENISHMENT TANKS and the

REPLENISHMENT PUMPS.

[23] Check the water supply FILTER. If necessary, change the FILTER.

8 28JAN98 – 7C8289

Page 9

3 Month Preventive Maintenance

Caution

• Any obstruction such as biological growth, tight bends, or an upward sloping WASH DRAIN HOSE can cause

wash water to return to the WASH TANK causing an overflow of water and damage to the ELECTRICAL BOX.

• Concentrationsof chlorine bleach higher than 10% or allowing the chlorinebleach to remain in the PROCESSOR

for longer than 30 minutes can cause damage to the PROCESSOR.

[24] Check the WASH DRAIN for biological growth, tight bends, or other obstructions. To remove biological growth

do:

(a) Fill the WASH TANK and DRAIN with a 10% solution of chlorine bleach.

(b) Wait a minimum of 20 minutes and a maximum of 30 minutes.

(c) Drain the chlorine bleachsolution, andrinse theTANK andDRAIN thoroughlywith waterbefore returning

the PROCESSOR to normal use.

Warning

• Drains at the site must be made of chemically resistant, non-corrosive material. Use PVC or the equivalent.

• The drain must have a minimum diameter of 7.6 cm (3.0 in.) and be free of obstruction.

• Drain service must comply with local codes.

[25] Correctly route the WASH DRAIN HOSE to slope down toward the WASH DRAIN. If necessary, use

REINFORCED HOSES that resist making tight bends. Right angle ELBOW FITTINGS are also available. The

Part Numbers are:

• 696442 - Reinforced HOSE, 5/8-in. I.D. Order by the foot.

• 1C4521 - ELBOW FITTING, 5/8-in.

• 696441 - Reinforced HOSE, 1-in. I.D. Order by the foot.

• 1C4524 - ELBOW FITTING, 1-in.

[26] Check the DRIVE CHAIN.

(a) If the DRIVE CHAIN is dry, apply lubricant to the DRIVE CHAIN. Use NLG1 - No. 2 LITHIUM BALL and

ROLLER BEARING GREASE TL-2324.

(b) If the DRIVE CHAIN is rusty, remove it and install a new DRIVE CHAIN.

(c) Adjust the tension of the DRIVE CHAIN. See the procedures in the ADJUSTMENTS AND

REPLACEMENTS, Publication No. 7C8285.

7C8289 – 28JAN98 9

Page 10

PERIODIC PREVENTIVE MAINTENANCE

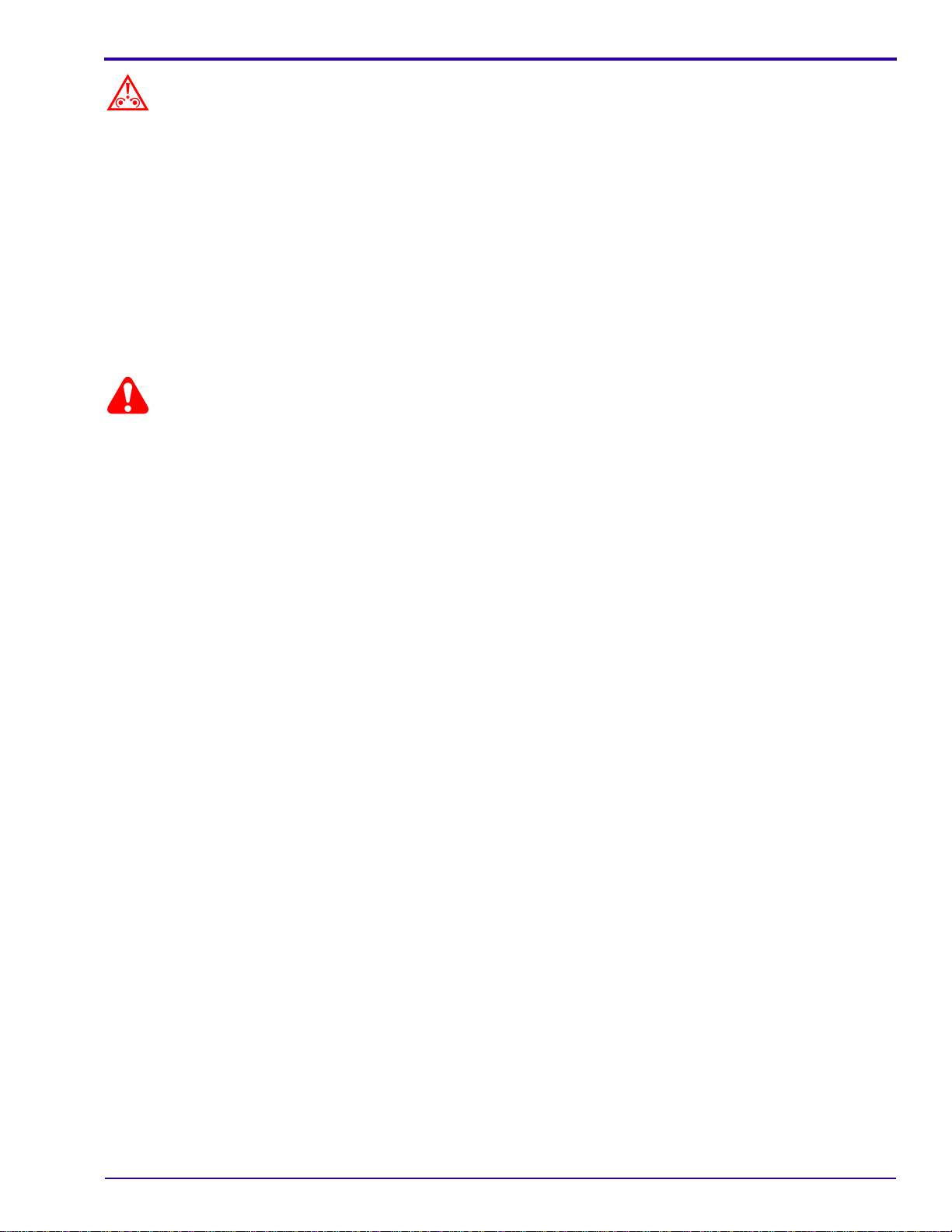

SPRING

SPADE

H104_0383BCB

H104_0383BA

[27] Check the SPRING SPADES on the LEVELSENSOR PROBES for corrosion. If necessary, cleanor install new

SPRING SPADES.

[28] Close the DRAIN VALVES and fill the processing TANKS with processing solutions and starter where

necessary.

[29] Energize the PROCESSOR.

[30] Process a test film and check the PROCESSOR for correct operation.

[31] Check the negative pressure at the EXHAUST VENT for the DRYER. See the MULTILOADER 300 PLUS

INSTALLATION INSTRUCTIONS.

[32] Calibrate the REPLENISHMENT PUMPS. See the section “Calibrating the Replenishment System” in the

OPERATOR'S MANUAL for the

Kodak X-Omat

MULTILOADER 300 PLUS.

10 28JAN98 – 7C8289

Page 11

Preventive Maintenance Schedule

Section 4: Preventive Maintenance Schedule

Part or Assembly Weekly* Monthly** 3 Month Schedule***

ENTRANCE CROSSOVER C

DEVELOPER/FIXER CROSSOVER C

FIXER/WASH CROSSOVER C

WASH RACK C C(2)

DEVELOPER RACK I,C C(1)

FIXER RACK I,C C(2)

DRYER RACK I,C

RACK BEARINGS, CHAINS, and DRIVE GEARS I

Squareness of RACKS I

DRYER AIR TUBES I,C

DEVELOPER FILTER R

REPLENISHMENT STRAINERS and FILTERS C

Water Supply FILTER R

DRAIN HOSES I,R

Ventilation Exhaust T

DRIVE MOTOR CHAIN I,L

LEVEL SENSOR PROBES C

SPRING SPADES on the LEVEL SENSOR PROBES C(3)

DEVELOPER PROCESSOR TANK C(1)

FIXER and WASH PROCESSOR TANKS C(2)

Calibration of the REPLENISHMENT PUMPS T

WATER RESERVOIR C

I = Inspect for condition and adjust or install

new parts, if necessary.

L = Apply recommended lubricant.

R = Replace, if necessary.

T = Test and adjust, if necessary.

* The weekly preventive maintenance

procedures can be performed by the operator of

the PROCESSOR or by the trained service

provider.

** Completion of the monthly preventive

maintenance procedures is recommended to

ensure the optimum reliability of the

PROCESSOR.

Publication History

Print Date Pub. No. ECO No. Affected Pages File Name Notes

January 1998 7C8289 All pm3488_1_28jan98 First Printing

C = Rinse and clean carefully and completely

using warm water and a soft synthetic

sponge.

C(1) = Clean with

CLEANER AND NEUTRALIZER.

C(2) = Clean with

CLEANER.

C(3) = Clean any corrosion from the SPRING

SPADES.

*** The 3 month schedule is a guideline for sites

adhering to the site specifications issued by

Kodak. Actual usage and site characteristics may

require shorter intervals between maintenance.

Kodak

Kodak

DEVELOPER SYSTEM

FIXER/WASH SYSTEM

7C8289 – 28JAN98 11

Page 12

Printed in U.S.A. • pm3488_1.fm

EASTMAN KODAK COMPANY

Rochester, NY 14650

Kodak

and

X-Omat

are trademarks.

HEALTH IMAGING

Loading...

Loading...