Page 1

supersedes SM 3058-5 from 12/97

SERVICE MANUAL

for the

Publication No. SM 3058-6

9/98

SM 3058-4 from 1/96

SM 3058-2 from 7/93

SM 3058 from 3/93

SM 3058 from 2/91

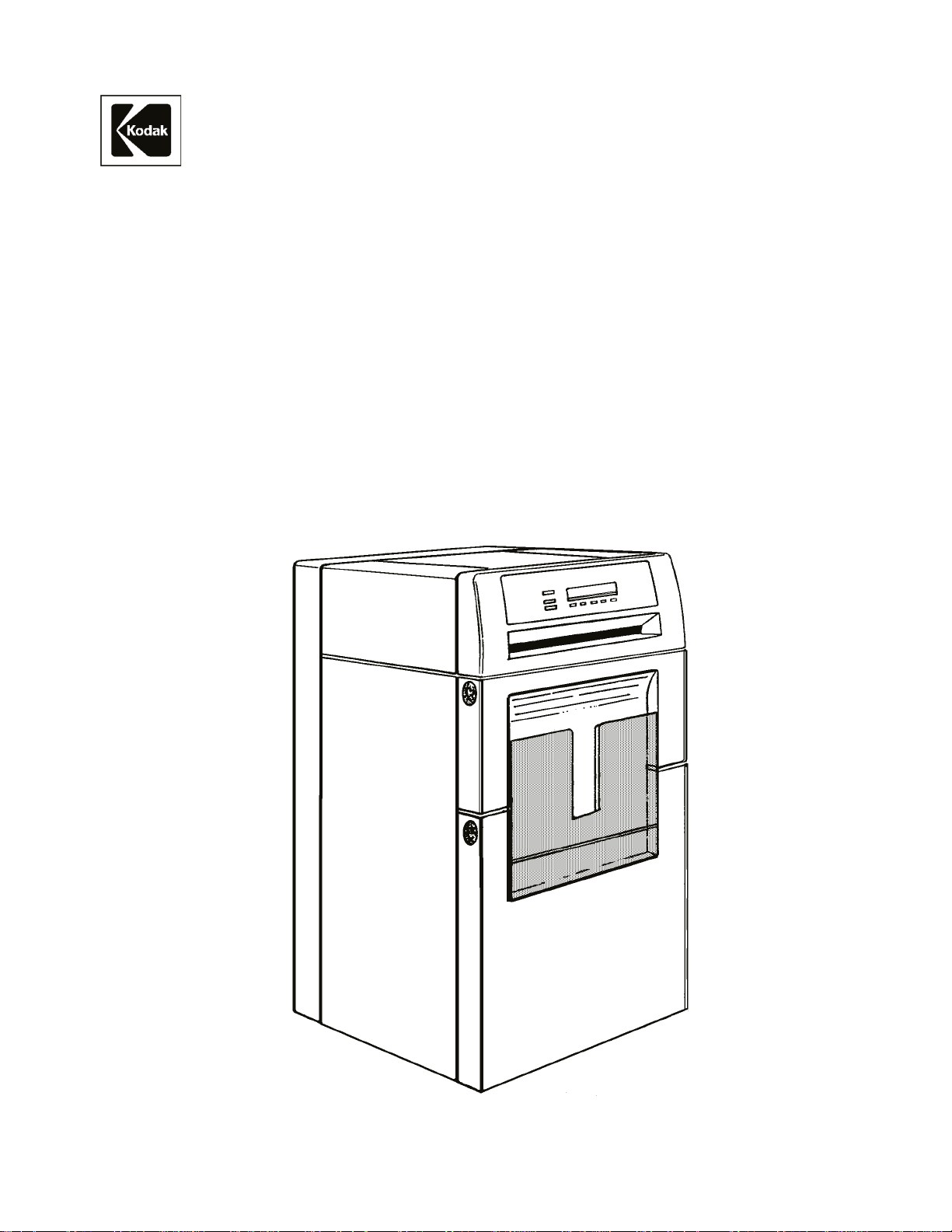

Kodak X-Omat

MULTILOADER 300 / 300 Plus

© KODAK AG STUTTGART, 1993, 1998

Page 2

PLEASE NOTE

The information contained herein is based on the experience and knowledge

relating to the subject matter gained by Kodak prior to publication.No patent license

is granted by this information.Kodak reserves the right to change this information

without notice, and makes no warranty, express or implied, with respect to this

information. Kodak shall not be liable for any loss or damage, including

consequential or special damages, resulting from the use of this information, even if

loss or damage is caused by Kodak’s negligence or other fault.

Page 3

SERVICEMANUAL SM3058-6

TABLEOFCONTENTS

ELECTROSTATICDISCHARGE.................................................................................................V

SAFETYWARNINGS......................................................................................VI

1.SPECIALTOOLS...................................................................................................................1-1

2.REPLACEMENTS..................................................................................................................2-1

INTRODUCTION...................................................................................................................2-1

CASSETTETRANSPORT....................................................................................................2-1

REPLACEMENTOFCASSETTEINPUTFLAPMOTOR.....................................................2-1

REPLACEMENTOFTHESHORTTRANSPORTROLLERS..............................................2-3

REPLACEMENTOFTHELONGTRANSPORTROLLER...................................................2-7

REPLACEMENTOFTHECASSETTEWIDTHTIMINGBELT.............................................2-9

REPLACEMENTOFTHECASSETTETRANSPORTMOTORM2...................................2-13

REPLACEMENTOFTHECASSETTEOPENERMOTORM5..........................................2-16

REPLACEMENTOFTHECASSETTEOPENERSOLENOIDY4......................................2-23

MAGAZINE OPENER.........................................................................................................2-26

REPLACEMENTOFTHEMAGAZINEOPENERMOTORM14.........................................2-26

FILM POCKET....................................................................................................................2-28

REPLACEMENTOFTHEFILMPOCKETSTEPPERMOTORM10..................................2-28

REPLACEMENTOFTHEFILMPOCKETSUCKERBARMOTORM15...........................2-30

REPLACEMENTOFFILMPOCKETTORSIONSPRING(SN<2000).............................2-32

REPLACEMENTOFFILMPOCKETTORSIONSPRING(SN>2000).............................2-35

REPLACEMENTOFTHEFILMPOCKETCLUTCHSPRING(SN>2000).......................2-37

REPLACEMENTOFTHE FILMREJECTERSPRING.......................................................2-40

PROCESSORINTERFACE................................................................................................2-42

REPLACEMENTOFPROCESSORINTERFACEMOTORM13.......................................2-42

PROCESSORINTERFACECLUTCHES............................................................................2-43

CONVEYOR.......................................................................................................................2-44

KodakAGStuttgart I 9/98

Page 4

SM 3058-6 SERVICE MANUAL

REMOVAL OF THE CONVEYOR ......................................................................................2-44

DISASSEMBLY OF THE CONVEYOR............................................................................... 2-47

REPLACEMENT OF THE FILM PICK UP MOTOR BELT (CARRIAGE)............................2-50

REPLACEMENT OF FILM PICK UP MOTOR (CARRIAGE) M6 ........................................ 2-51

REPLACEMENT OF CARRIAGE ASSEMBLY DRIVE BELTS...........................................2-52

REPLACEMENT OF SOLENOID CASSETTE SUCKER BAR TILTING Y7.......................2-54

REPLACEMENT OF THE SENSOR SUCKER BAR TILT B19........................................... 2-56

3. ADJUSTMENTS.....................................................................................................................3-1

INTRODUCTION...................................................................................................................3-1

SENSORS and DAYLIGHT................................................................................................... 3-1

FRAME LEVELLING .............................................................................................................3-2

CASSETTE AREA.................................................................................................................3-4

INPUT FLAP..........................................................................................................................3-4

CASSETTE REGISTRATION SENSOR B2..........................................................................3-5

CASSETTE OPENER GUIDE SHOE POSITION ................................................................. 3-7

CASSETTE OPENER MECHANISM.................................................................................... 3-8

CASSETTE BLOW PIPE HOLDER.....................................................................................3-12

CASSETTE BLOW PIPE POSITION .................................................................................. 3-13

CASSETTE SUCKER BAR.................................................................................................3-14

CASSETTE TYPE 2 SENSORS. (B21 and B22)................................................................3-22

CASSETTE LENGTH .........................................................................................................3-25

SENSOR B20 VACUUM OFF ............................................................................................3-27

DRIVE BELT TENSION ......................................................................................................3-34

FILM POCKET ...................................................................................................................3-35

HOW TO CLEAN THE SUCKERS...................................................................................... 3-35

FILM POCKET CHAIN ........................................................................................................3-35

FILM POCKET ADJUSTMENT ........................................................................................... 3-39

MAGAZINE EMPTY SENSOR............................................................................................3-60

9/98 II Kodak AG Stuttgart

Page 5

SERVICE MANUAL SM 3058-6

DOUBLE SHEET SENSOR SN < 3000 .............................................................................. 3-62

DOUBLE SHEET SENSOR SN > 3000 .............................................................................. 3-63

MAGAZINE LEVELS...........................................................................................................3-69

NEARLY EMPTY ADJUSTMENT ....................................................................................... 3-71

SCAN RUN.......................................................................................................................... 3-72

MAGAZINE AREA............................................................................................................... 3-73

MAGAZINE OPENER ......................................................................................................... 3-73

STEPPER MOTOR FILM POCKET M10/M_PO.................................................................3-75

FILM CHUTE ...................................................................................................................... 3-78

INTERFACE FLAP ............................................................................................................ 3-78

INTERFACE FLAP CAM and SENSOR B33 ...................................................................... 3-79

FILM RELEASE .................................................................................................................. 3-82

FILM CHUTE GUIDE ..........................................................................................................3-85

STEPPER MOTOR PROCESSOR INTERFACE M13/M_PI ..............................................3-86

SENSOR B35 FILM IN INTERFACE BOTTOM ..................................................................3-88

ADJUSTMENT SENSOR B25 / B26 ML300 Plus...............................................................3-92

ADJUSTMENT SENSOR B24............................................................................................. 3-94

ADJUSTMENT PCB A10 .................................................................................................... 3-96

4. PARAMETER......................................................................................................................... 4-1

INTRODUCTION...................................................................................................................4-1

HOW TO SET A PARAMETER............................................................................................. 4-1

CASSETTE UNIT..................................................................................................................4-2

VACUUM OFF TIME.............................................................................................................4-2

BLOW TIME .......................................................................................................................... 4-3

CASSETTE OFFSET ............................................................................................................4-3

DISABLE OPENER............................................................................................................... 4-4

CASSETTE OPEN / RETURN.............................................................................................. 4-5

DISABLE INTERFACE..........................................................................................................4-5

Kodak AG Stuttgart III 9/98

Page 6

SM 3058-6 SERVICE MANUAL

MAGAZINE UNIT ..................................................................................................................4-6

TILT POSITION.....................................................................................................................4-6

ADDITIONAL STEPS............................................................................................................ 4-7

LOWER POCKET .................................................................................................................4-7

MAGAZINE LEVELS............................................................................................................. 4-8

NEARLY EMPTY................................................................................................................... 4-9

DOUBLE FILM DETECTION................................................................................................. 4-9

CONVERSION TABLES ..................................................................................................... 4-10

5. RESIZING MAGAZINES ....................................................................................................... 5-1

6. X-OMATIC CASSETTES .......................................................................................................6-1

LATCH ADJUSTMENTS.......................................................................................................6-1

TYPE2 CODING OF CASSETTES.......................................................................................6-1

7. Changes for XML300 with SN > 2000..................................................................................7-1

CASSETTE OPENER ........................................................................................................... 7-1

FILM TYPE 2 SENSOR MOUNT .......................................................................................... 7-4

NEW CASSETTE TRANSPORT ROLLERS.........................................................................7-5

NEW FILM PICK UP MOTOR M6.........................................................................................7-6

IMPROVED FILM POCKET .................................................................................................. 7-7

NEW PROCESSOR INTERFACE.......................................................................................7-12

MOUNTING BRACKET INTERFACE FLAP MOTOR M11................................................. 7-13

MAGAZINE HOLDERS ....................................................................................................... 7-13

MAGAZINE DOOR PIVOTS................................................................................................7-14

SOFTWARE VERSION 3.23 and above.............................................................................7-15

DFF FEATURES .................................................................................................................7-15

SERVICE CALLS................................................................................................................7-17

NEW CASSETTE OPENER SEQUENCE .......................................................................... 7-18

PARAMETERS AND SOFTWARE UPDATE......................................................................7-18

8. Changes for XML300 with SN > 3000..................................................................................8-1

9/98 IV Kodak AG Stuttgart

Page 7

SERVICE MANUAL SM 3058-6

OPERATING SOFTWARE version 3.31. .............................................................................. 8-1

HARDWARE CHANGES.......................................................................................................8-3

9. Changes for XML300 Plus.................................................................................................... 9-1

10. PREVENTIVE MAINTENANCE ......................................................................................... 10-1

Preparation:......................................................................................................................... 10-1

General Activities:................................................................................................................10-1

CASSETTE AREA:..............................................................................................................10-3

AIR FILTER.........................................................................................................................10-5

HUMIDIFIER (MOD 14)....................................................................................................... 10-6

HUMIDIFIER (MOD 42)....................................................................................................... 10-7

VENTING ............................................................................................................................10-8

FINAL CHECK-OUT:.........................................................................................................10-10

11. COMPONENT LOCATOR ................................................................................................. 11-1

CONNECTORS................................................................................................................... 11-1

MOTORS............................................................................................................................. 11-1

PRINTED CIRCUIT BOARDS.............................................................................................11-1

SENSORS .......................................................................................................................... 11-2

SOLENOID VALVES...........................................................................................................11-3

SOLENOIDS ...................................................................................................................... 11-3

SWITCHES .........................................................................................................................11-3

POWER SUPPLY................................................................................................................ 11-3

Kodak AG Stuttgart V 9/98

Page 8

SM 3058-6 SERVICE MANUAL

9/98 VI Kodak AG Stuttgart

Page 9

ESD SM 3058-6

ELECTROSTATIC DISCHARGE

OVERVIEW

ESD—electrostatic discharge—is a primary source of:

· product downtime

· lost productivity

· costly repairs.

While we cannot even feel a static charge of less than 3,500 volts, a s few as 30 volts can

damage or destroy essential components in t he electronic eq uipment upon which you rely. As

technology continues to advance, these advanced components will be even more vulnerable

to ESD destruction. The conclusion is clear. To tak e charge of p roductivity and p rofitability,

you must take care of ESD, now. Effective ESD control requires the following things.

AWARENESS

Everyone in your organisa tion needs to b e aware of ESD , because p artial ESD control is no

ESD control at all. Ev eryone needs to remember that:

· ESD is a primary source of frustrating equipment failures and intermittent malfunc tions.

ESD affects productivity and profitability.

ESD can be co ntrolled.

ACTION

To take charge of ESD , you must take action. And that mean s everyone from senior

management to the evening security crew.

If you repair and maintain electronic equipment, it means always w earing grounding straps

and working at ESD- protected sites.

If you ever work around electronic eq uipment, it means keeping static gener ators like plas tic

trash bags away from sensitive components.

For everyone, taking charge of ESD means maling the simple ESD controls a way of life.

(See the following sec tions for sp ecial tips).

EFFECTIVE ESD CONTROL IS EVERYONE’S RESPONSIBILITY.

EVERY DAY

1. Put trash in its place. A nd that place is away from static-sensitive equipment. Plastic

materials, like trashcan liners and plastic foam cups, generate t he static elec tricity that

damages or destroys e lectronic components .

2. Look for the label. Static-sensitive components are marked with bright graphic labels. Look

for these labels. Follow label directions.

3. Sp ray the carpe t. ESD that is generated when yo u walk over ca rpet is a ma jor culprit in

component destruction. In some cases, especially in low-humidity environments, you may

need to periodically spray carpets with an anti-static preparation, available at loca l stores.

KODAK AG, Stuttgart V 9/98

Page 10

SM 3058-6 ESD

DURING MAINTENANCE AND REPAIR

· Wear a grounding strap when you deal with static -sensitive components . Always mak e

certain that the clip is attached to a properly grounded, unpainted surface.

· Use a portable grounding mat if you cannot r epair components at an ESD-protected

workstation. (Kodak’s Customer Equipment Services Division can assist you in setting up

ESD-protected workstations .)

· Use protective pack aging when y ou transport components from one area to another.

Transparent anti static bags , available from a variety of manufactures , shield your

just-repaired components from further damage.

SAFETY WARNINGS

· BE CAREFUL WHEN WORKING IN THE CASSETTE OPENER AREA. THE OPENER

MOTOR AND THE OPENER MECHANISM ARE VERY STRONG. THEY CANNOT BE

MOVED MANUALLY. THEY MAY SQUEEZE YOUR HAND AND TRAP YOU IF YOU TRY

TO STOP THEM MANUALLY. NEVER START THE CASSETTE OPENER MOTOR WHEN

SOMEONE’S HANDS ARE IN THE CASSETTE AREA.

· DISCONNECT THE POWER WHEN TAKING OUT OR INSTALLING THE POWER

SUPPLY. IT IS POSSIBLE TO TOUCH THE MAINS VOLTAGE.

· IF YOU TAKE OUT SAFETY COVERS OR WIRE TIES TO HAVE EASIER ACCESS TO

PARTS, INSTALL THEM B EFORE YOU MOUNT THE SIDE PANELS WHEN THE

SERVICE CALL OR THE PM IS FINISHED.

· BE CAREFUL WHEN WORKING ON CIRCUIT BOARDS A4 AND A8. THERE ARE 120

VAC ON THOSE BOARDS. BE ESPECIALLY CARE FUL WHEN MEASURING ON THE

REAR SIDE OF THE CIRCUIT BOARDS OR WHE N A4 IS PIVOTED OUT OR A8 IS

PIVOTED UP. AN ELECTRIC SHOCK MAY RESULT.

· WHEN WORKING IN THE AREA OF PCB A4, COVER THE VENTING HOLE AT THE

TOP OF THE POWER SUPPLY SO THAT NOTHING MAY FALL INTO IT. TAKE THIS

COVER OFF BEFORE MOUNTING THE SIDE PANELS TO AVOID OVERHEATING OF

THE SYSTEM.

9/98 VI KODAK AG, Stuttgart

Page 11

TOOLS SM 3058-6

1. SPECIAL TOOLS

VERNIER CALIPER ......................................................................................................TL 1727

GREASE...........................................................................................................................TL 2247

TEMPLATE CASSETTE TYPE 2 ................................................................................9194501

METRIC ALLEN SET.....................................................................................................TL 2764

METRIC ALLEN SET BALL ENDED...........................................................................TL 3789

METRIC OPEN END WRENCH SET ..........................................................................TL 2765

METRIC OPEN END WRENCH 5.5mm......................................................................TL 1936

ESD KIT ...........................................................................................................................TL 3346

DENTIST MIRROR.........................................................................................................TL 2753

LOGIC PEN.....................................................................................................................TL 3008

EXTRACTION TOOL ......................................................................................................TL 1580

EXTRACTION TOOL ......................................................................................................TL 1654

THICKNESS GAUGE .....................................................................................................TL 2372

LAPTOP DATA CABLE .................................................................................................TL 4391

TORX WRENCH SET ....................................................................................................TL 3261

BLOW PIPE POSITIONER CASSETTE ......................................................................TL 4830

BLOW PIPE POSITIONER MAGAZINE......................................................................TL 4582

CES SERVICE SOFTWARE..............................................................G9904537 / TL4462 ***

LAPTOP COMPUTER, has to be bought locally.

*** Always use the lates t software vers ion available.

KODAK AG, Stuttgart 1-1 9/98

Page 12

SM 3058-6 TOOLS

9/98 1-2 KODAK AG, Stuttgart

Page 13

REPLACEMENTS SM 3058-6

2. REPLACEMENTS

INTRODUCTION

In this section it is very often explained how to use the CES SERVICE SOFTWARE. The first

line tells always what should be performed. In the next lines it is explained how to reach this

goal. These additional explanations are printed italic and can be skipped if you are

experienced w ith the CES SERVICE SOFTW ARE.

EXAMPLE:

1. Start the CASSETTE INPUT FLAP MOTOR M1

Start the SERVICE PROGRAM.

Select SERVICE MODE from the GLOBAL MENU....................................... press ENTER

ENTER SERVICE MODE MESSAGE is displayed............................................press ENTER

UNIT DATA are displayed ...............................................................................press ENTER

Select COMPONENT TEST from the MAIN MENU.......................................press ENTER

Select CASSETTE MOTORS ...............................................................................press ENTER

Select INPUT FLAP MOT M1.............................................................................press ENTER

Select CLOSE/OPEN.......................................................................................... press ENTER

CASSETTE TRANSPORT

REPLACEMENT OF CASSETTE INPUT FLAP MOTOR.

1. Switch off the ML300.

2. Take off the PANELS.

3. Take off the MOTOR CAM.

MOUNTING SCREW (4)

MOUNTING SCREW (4)

GUIDE BRACKET

NUT

CAM

figure 2-1

KODAK AG, Stuttgart 2-1 9/98

Page 14

SM 3058-6 REPLACEMENTS

4. Take out the 2 MOUNTING SCREWS of the GUIDE BRACKET.

5. Remove the NUT.

6. Take off the GUIDE BRACKET.

7. Take off the INPUT FLAP.

8. Take out the 4 MOUNTING SCREWS of the MOTOR INPUT FLAP.

9. Install the new MOTOR.

FUNCTION TEST

1. Start the CASSETTE INPUT FLAP MOTOR M1

Start the SERVICE PROGRAM.

Select SERVICE MODE from the GLOBAL MENU....................................... press ENTER

ENTER SERVICE MODE MESSAGE is displayed............................................press ENTER

UNIT DATA are displayed ...............................................................................press ENTER

Select COMPONENT TEST from the MAIN MENU.......................................press ENTER

Select CASSETTE MOTORS ...............................................................................press ENTER

Select INPUT FLAP MOT M1.............................................................................press ENTER

Select CLOSE/OPEN.......................................................................................... press ENTER

2. Make sure that the MOTOR CAM turns clockwise. If it turns counter-clockwise

interchange PIN 1 and 3 at the MOTOR C ONNECTOR.

3. Exit the SERVICE PROGRAM

Press 3 times BACKSPACE.

Select LEAVE COMPONENT TEST ...................................................................press ENTER

Select QUIT ML300 SERVICE MODE............................................................... press ENTER

Select Quit the program................................................................................. press ENTER

9/98 2-2 KODAK AG, Stuttgart

Page 15

REPLACEMENTS SM 3058-6

REPLACEMENT OF THE SHORT TRANSPORT ROLLERS.

1. Switch off ML300.

2. Take off the PANELS.

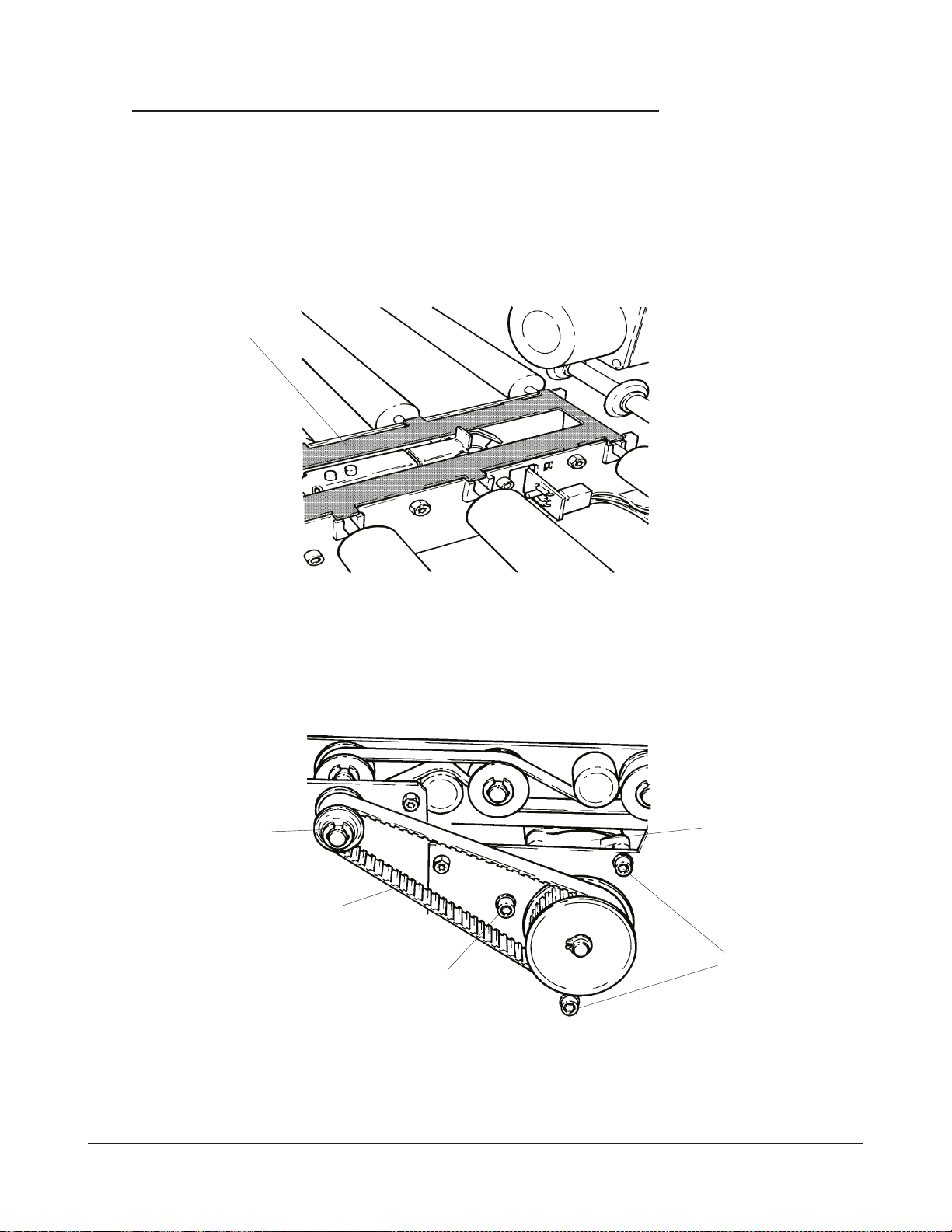

3. Remove the COVE R PLATE .

REAR

COVER PLATE

MOTOR INPUT FLAP

FRONT

MOUNTING SCREW (6)

figure 2-2

KODAK AG, Stuttgart 2-3 9/98

Page 16

SM 3058-6 REPLACEMENTS

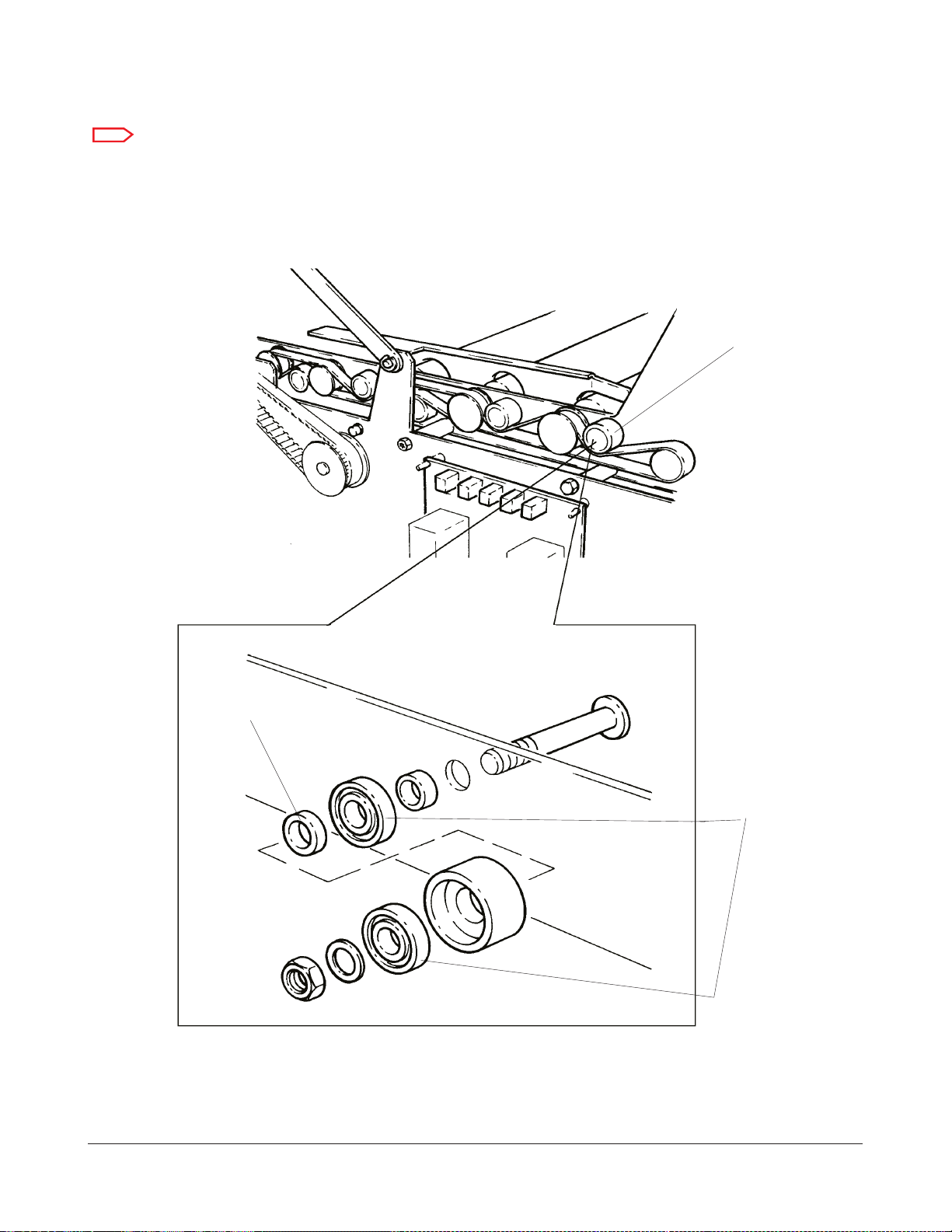

Note

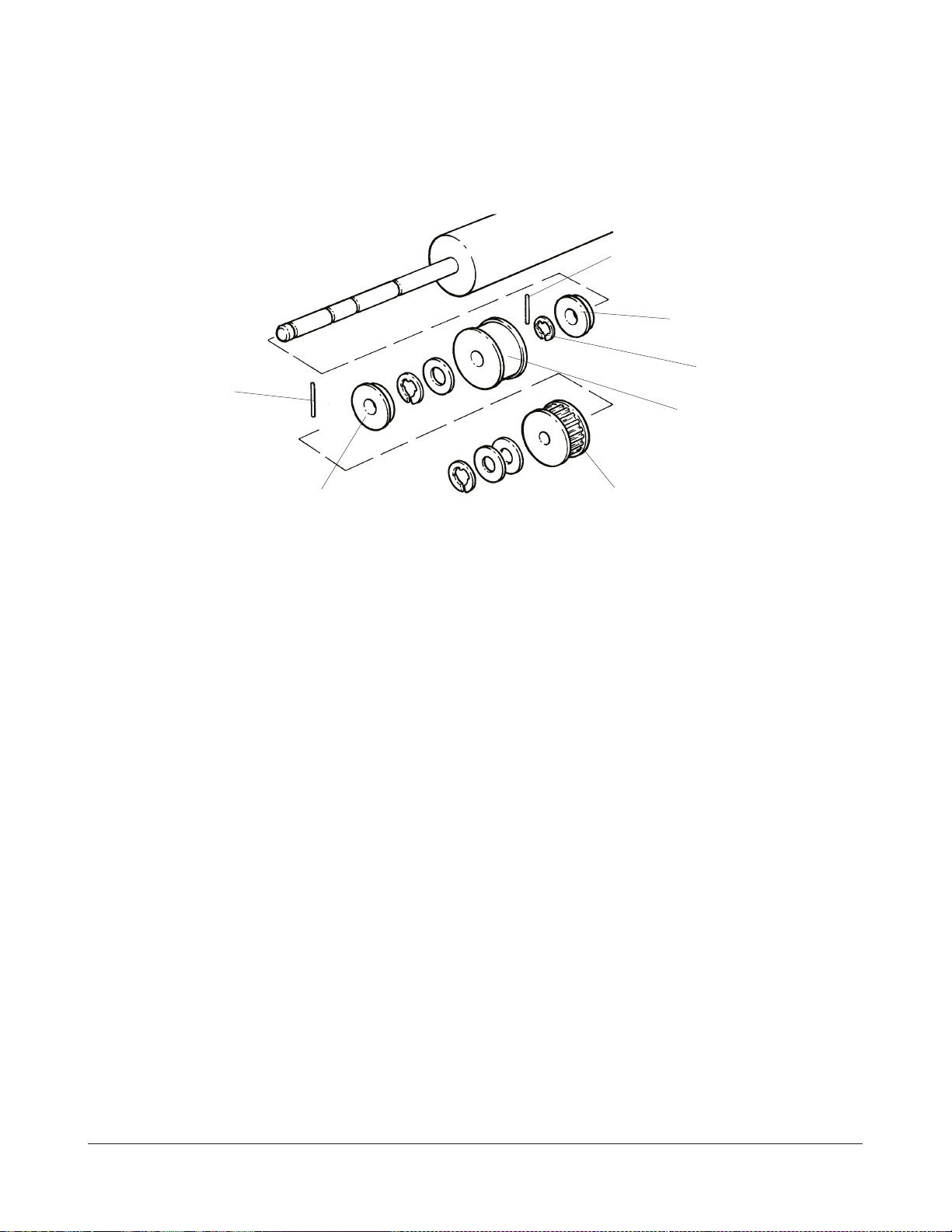

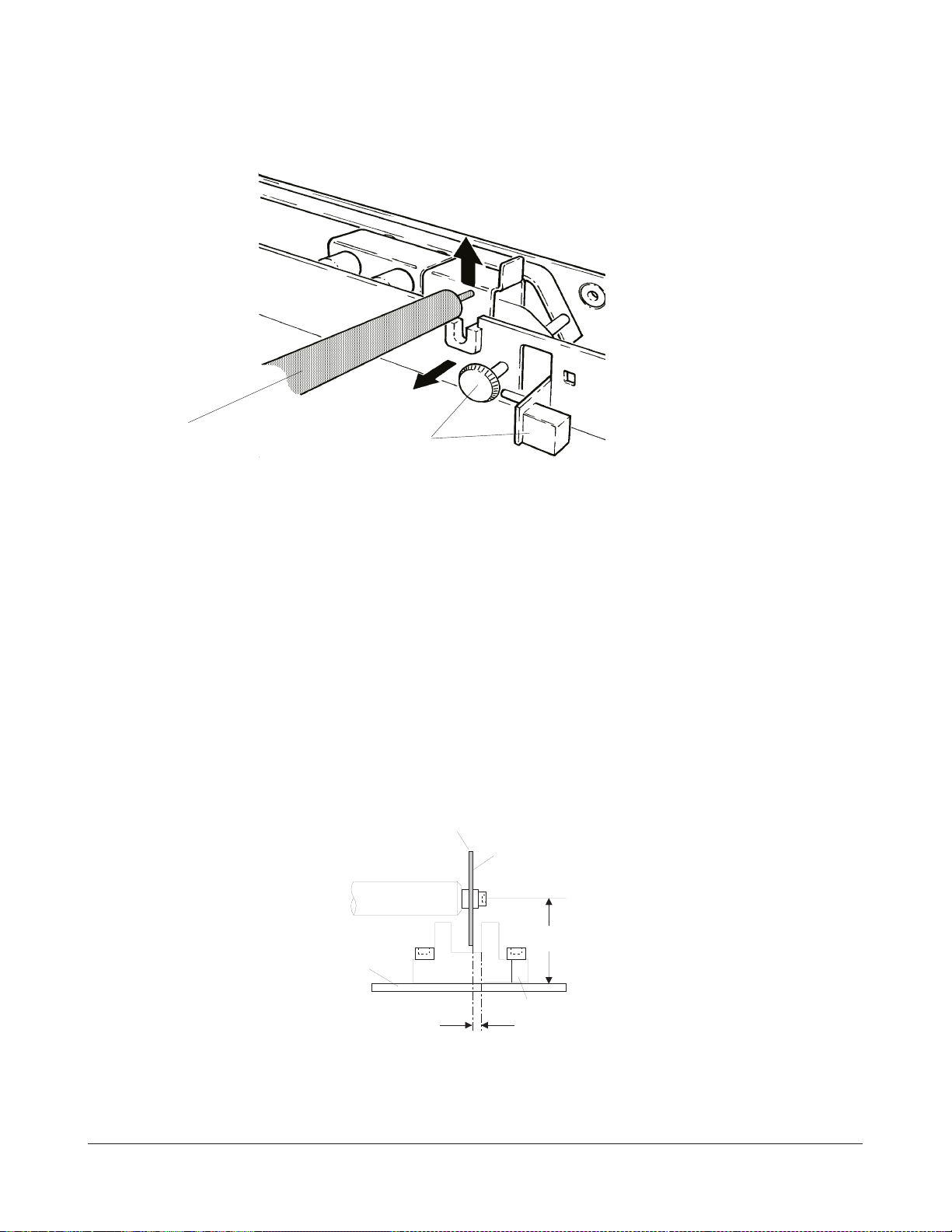

There is a SPACER between the 2 BALL B EARINGS of the BELT TENS IONER.

4. Remove the FRONT BELT TENSIONER and take off the DRIVE BELT.

BELT

TENSIONER

SPACER

BALL

BEARING

figure 2-3

9/98 2-4 KODAK AG, Stuttgart

Page 17

REPLACEMENTS SM 3058-6

5. Take off the C-RING at the DRIVE PULLEY.

C-RING

C-RING DRIVE PULLEY DOWEL PIN C-RING BALL BEARING

figure 2-4

KODAK AG, Stuttgart 2-5 9/98

Page 18

SM 3058-6 REPLACEMENTS

6. Take out the DRIVE PU LLEY with the DOW EL PIN.

7. Take off the C-RING of the BALL BEARING.

8. Take off the BALL BEARING.

9. Lift the ROLLER END with the PLASTIC BEARING and pull out the TRANSPORT

ROLLER.

Note

Make sure that all PLASTIC BEARINGS are installed as shown in the figure below.

10. Install the new TRANS PORT ROLLER.

This side of all PLASTIC BEAR-

INGS must show up

figure 2-5

FUNCTION TEST

1. Check that a CASSETTE is transported correctly forward and backward.

9/98 2-6 KODAK AG, Stuttgart

Page 19

REPLACEMENTS SM 3058-6

REPLACEMENT OF THE LONG TRANSPORT ROLLER.

1. Switch off the ML300.

2. Take off the PANELS.

3. Remove the COVER PLATE of the HOLDING FINGER ASSEMBLY.

COVER PLATE

REAR

figure 2-6

FRONT

4. Loosen the MOUNTING SCREWS of the CASSETTE TRANSPORT MOTOR to take

off the TIMING BELT tension.

REAR

SMALL DRIVE

PULLEY

TRANSPORT MOTOR

FRONT

CASSETTE

TIMING BELT

MOUNTING

MOUNTING SCREW

figure 2-7

SCREWS

5. Take off the small DRIVE PULLEY with the TIMING BELT.

KODAK AG, Stuttgart 2-7 9/98

Page 20

SM 3058-6 REPLACEMENTS

6. Take off the DOWEL PIN and the BEARING.

DOWEL PIN

BEARING

C-RING

DOWEL PIN

PLASTIC DRIVE

PULLEY

BEARING

figure 2-8

SMALL DRIVE PULLEY

7. TakeofftheleftsideDRIVEBELT.

8. Take off the C-RING, WASHER and the DOWEL PIN of the PLASTIC DRIVE

PULLEY.

9. Take off the TRANSPORT ROLLER DRIVE BELT on the right side.

10. Remove the right-hand CENTRING BAR from the MOUNTING BRACKET. To do

so take out the 2 MOUNTING SCREW S and lift up the right-hand TRANS PORT

ROLLERS with their BEARING SIDE.

11. Take off the right-hand PLASTIC PULLEY and BEARING of the TRANSPORT

ROLLER.

12. Shift the TRANSPORT ROLLER fully to the left until it stops.

13. Lift the right end of the TRAN SPORT ROLLER up and slide it out to the right.

14. Install new the TRANSPORT ROLLER.

9/98 2-8 KODAK AG, Stuttgart

Page 21

REPLACEMENTS SM 3058-6

FUNCTION TEST.

1. Check that a CASSETTE is transported correctly forward and backward.

REPLACEMENT OF THE CASSETTE WIDTH TIMING BELT.

1. Switch off the ML300.

2. Open the TOP COVER.

3. Remove the COVE R PLATE .

COVER PLATE

REAR

4. Take out the left GUID E.

FRONT

FRONT

figure 2-9

REAR

MOUNTING

LEFT GUIDE

figure 2-10

KODAK AG, Stuttgart 2-9 9/98

SCREWS

HOLDING

FINGER

Page 22

SM 3058-6 REPLACEMENTS

5. Loosen the MOUNTING SCREWS of the HOLDING FINGER.

6. Take out the HOLDING FINGER.

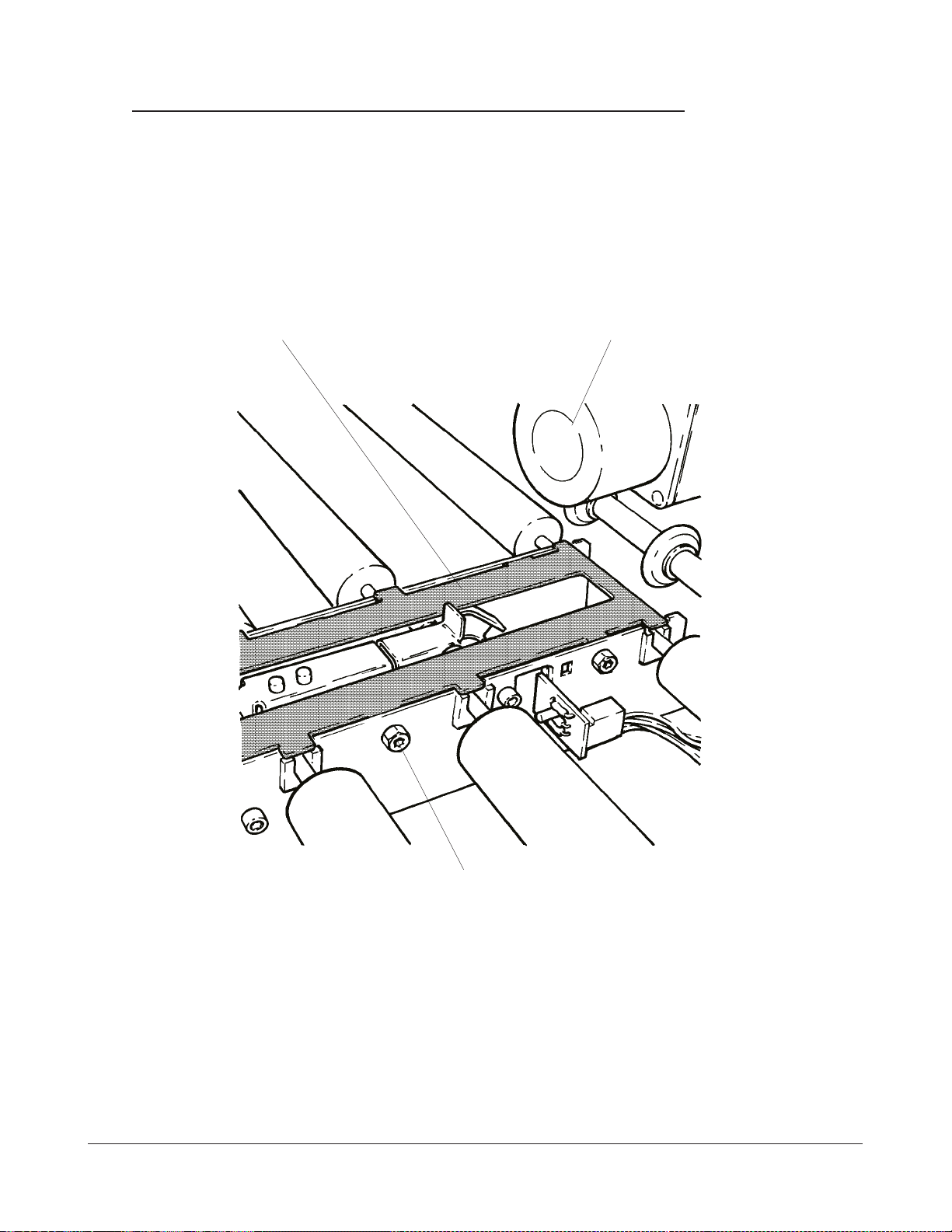

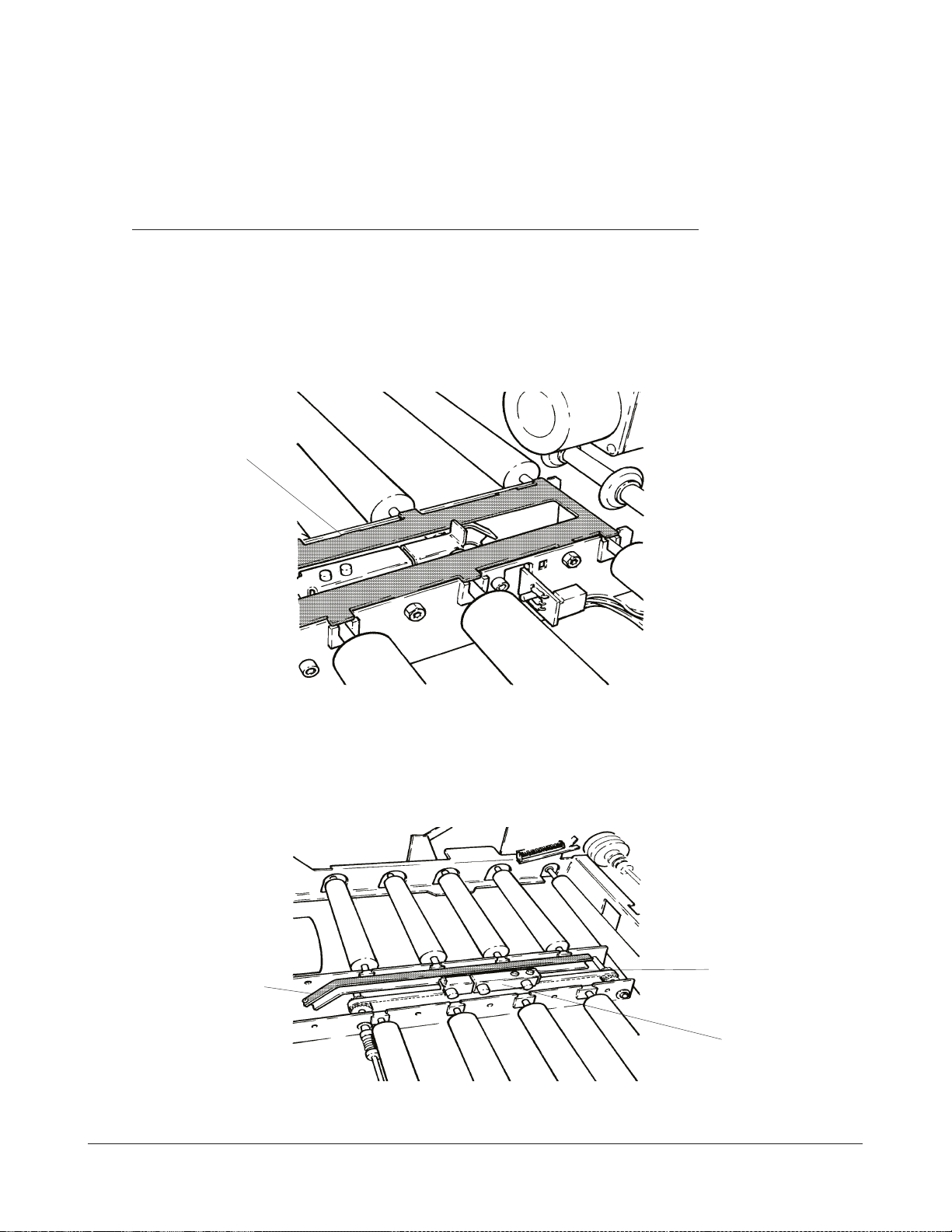

7. Take out BOARD A10 (ODOMETER CASSETTE WIDTH).

PCB A10

figure 2-11

8. Take out the right C-RINGS of the 2 CASSE TTE TIMING BELT SHAFTS.

FRONT

TIMING BELT

SHAFT

C-RING

SET SCREW

PIN

CLUTCH

figure 2-12

REAR

C-RING

TIMING BELT

SHAFT

9. Loosen the CLUTCH SE T SCREWS and take out the PIN.

9/98 2-10 KODAK AG, Stuttgart

Page 23

REPLACEMENTS SM 3058-6

10. Lift out the short TRANSPORT ROLLER near to the ODOMETER.

short TRANSPORT

ODOMETER

ROLLER

figure 2-13

11. Shift both CA SSETTE TIMING BELT SHAFTS to the left.

12. Replace the TIMING BELT.

13. When installing the HOLDING FINGER, make sure that the TIMING BELT is

centred before you tighten the MOUNTING SCREWS.

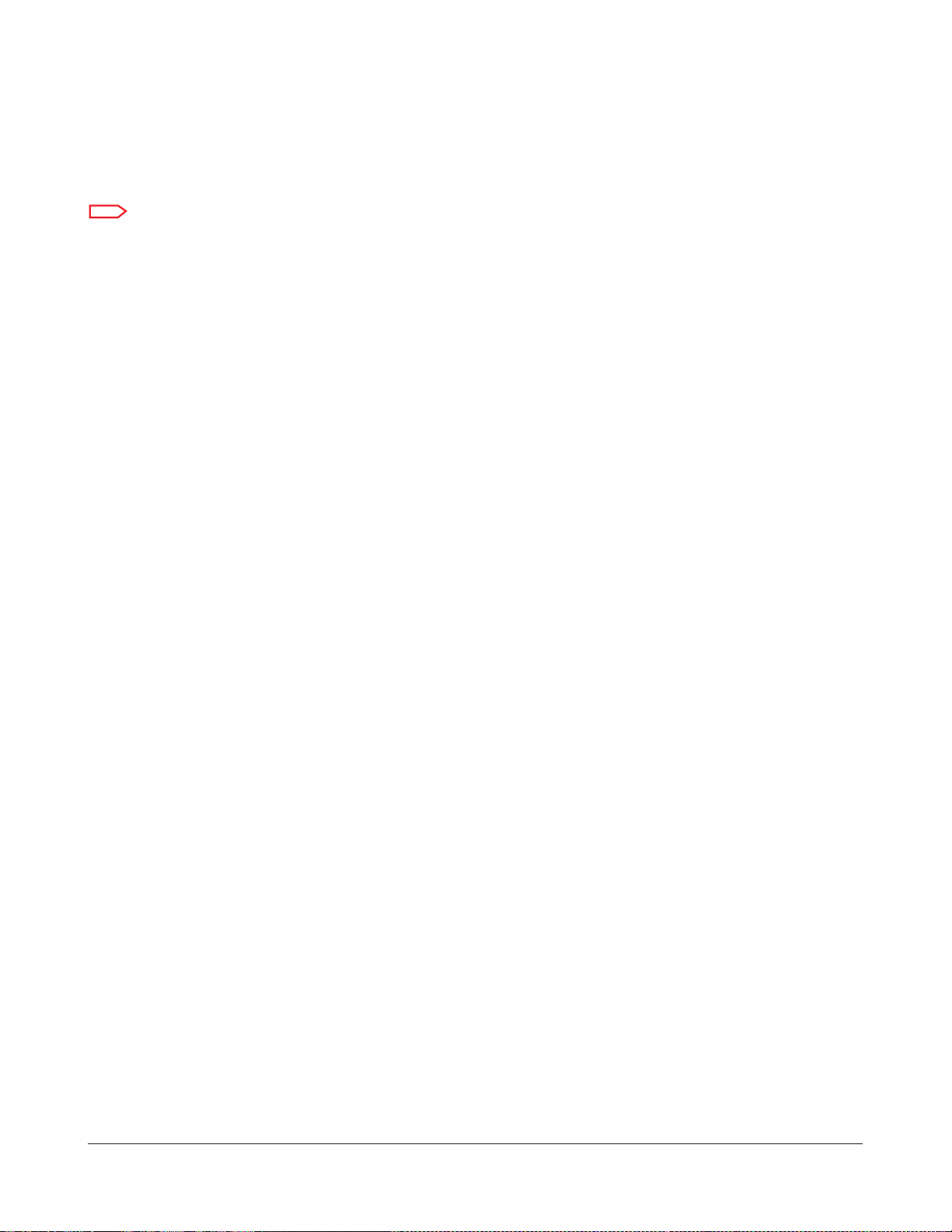

14. The ODOMETER (PCB A10) has to be positioned as shown.

CODE DISC

On this side of the CODE DISC

is an imprinted number

21.3 ± 0.5 mm

PCB A10

This corner is cut at an angle

1.2 mm max. for new style PCBs

0.5 mm max. for old style PCBs

0.1 mm min. for both styles.

figure 2-14

KODAK AG, Stuttgart 2-11 9/98

Page 24

SM 3058-6 REPLACEMENTS

15. If the distance of 21.3mm is not correct, loosen the MOUNTING SCREW of the

PCB HOLDER and move it as required.

Note

Not all PCB A10 are working correctly when the gap is set to 1 .2 mm. Espec ially with the

old style PCBs the g ap should not be bigger than 0.5 mm.

16. If the distance of 1mm is not correct, loosen the MOUNTING SCREWS of PCBA10

and move it as re quired.

17. If the PCB cannot be moved fa r enough, take it out and elongate the MOUNTING

SCREW HOLES with a small file.

FUNCTION TEST

1. FeedinaCASSETTE.

2. Check that the HOLDING FINGER transports the CASSETTE up to the CASSETTE

END STOP.

3. Check that the correct CASSETTE SIZE is detected.

9/98 2-12 KODAK AG, Stuttgart

Page 25

REPLACEMENTS SM 3058-6

REPLACEMENT OF THE CASSETTE TRANSPORT MOTOR M2.

Note

Always order MOTOR PN 9228010 and RETAINING RING PN 450016

1. Switch off the ML300.

2. Take off the PANELS.

Note

THE DOWEL PIN MAY FALL DOWN

3. Take off the DRIVE PULLEY with the D OWEL PIN and the TIMING B ELT.

SCREW 3

SCREW 1 SCREW 2 TIMING BELT SCREW 4 SCREW 5

PCB A9

MOUNTING

SCREW (3)

DRIVE PULLEY WITH

DOWEL PIN

RETAINING RING

figure 2-15

KODAK AG, Stuttgart 2-13 9/98

Page 26

SM 3058-6 REPLACEMENTS

4. Loosen SCREWS 1, 2 and 3. Se e figure 2-15.

5. Take out SCREWS 4 and 5. See figures 2-15.

Note

The SPACERS between the MOTOR and the MOUNTING BRACKET may fall down.

6. Take out the MOUNTING SCREWS of the CA SSETTE TRANSPORT MOTOR.

MOUNTING SCREW

MOUNTING

SCREW

figure 2-16

7. Take out the CASSETTE TRANSPORT MOTOR.

8. Install the new MOTOR.

9/98 2-14 KODAK AG, Stuttgart

Page 27

REPLACEMENTS SM 3058-6

FUNCTION TEST.

1. Start the CASSETTE TRANSPORT MOTOR M2

Start the SERVICE PROGRAM

Select SERVICE MODE from the GLOBAL MENU....................................... press ENTER

ENTER SERVICE MODE MESSAGE is displayed............................................press ENTER

UNIT Data are displayed ...............................................................................press ENTER

Select COMPONENT TEST from the MAIN MENU.......................................press ENTER

Select CASSETTE MOTORS ...............................................................................press ENTER

Select CASSETTE TRANSPORT M2 ...................................................................press ENTER

2. Check that the MOTOR is running forward/backward.

Select FORWARD/BACKWARD

3. Exit the SERVICE PROGRAM

Press 3 times BACKSPACE

Select LEAVE COMPONENT TEST ...................................................................press ENTER

Select QUIT ML300 SERVICE MODE............................................................... press ENTER

Select Quit the program................................................................................. press ENTER

KODAK AG, Stuttgart 2-15 9/98

Page 28

SM 3058-6 REPLACEMENTS

REPLACEMENT OF THE CASSETTE OPENER MOTOR M5

1. Switch off the ML300.

2. Remove the PANE LS.

3. Take off the ACTUATOR

MOUNTING

SCREW (3)

CASSETTE

OPENER

MOTOR

OPENER

STOP PLATE

MOUNTING

SCREW (3)

OPENER STOP

PLATE

PCB A9

SENSOR B15

DRIVE GEAR

ACTUATOR

figure 2-17

4. Take out MOUNTING SCREWS of CASSETTE OPENER MOTOR.

5. Mark the position of the OPENER STOP PLATE.

6. Take out the MOUNTING SCREWS of the OPENER STOP PLATE.

7. Take out the DOWEL PIN of the MOTOR SHAFT.

8. Take out the STOP PLATE .

9/98 2-16 KODAK AG, Stuttgart

Page 29

REPLACEMENTS SM 3058-6

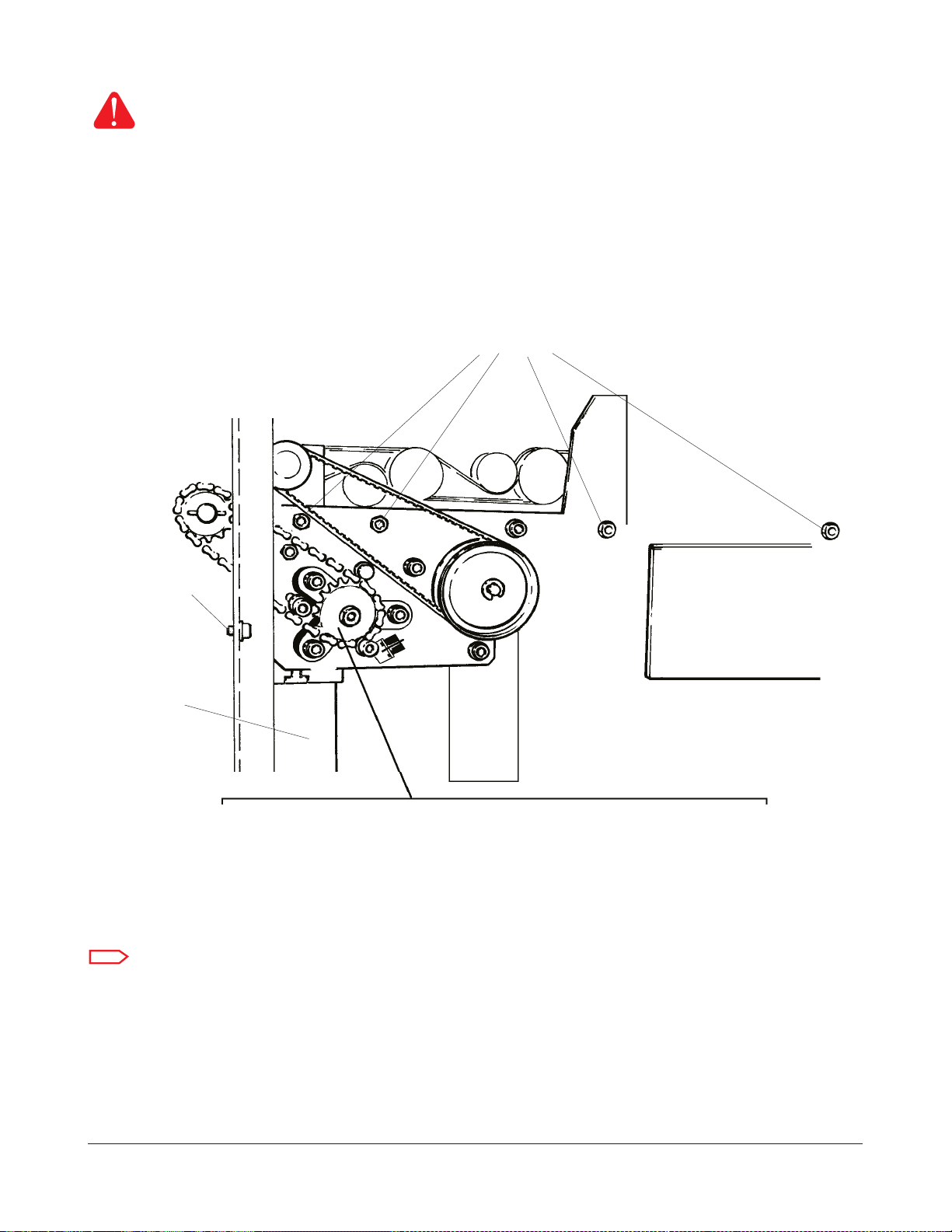

Warning

Hold with one hand the CASSETTE OPENER MECHANISM. As soon as you take off the

CHAIN, the mechanism moves down and may squeeze in your fingers . When the t he GEAR

is off lower the CASSETTE OPENER MECHANISM to its bottom position.

9. Take off the DRIVE GEAR with the CHAIN.

10. TakeoutSCREW1to5.

SCREW 1 2 3 4

SCREW 5

PCB A9

CASSETTE

OPENER

MOTOR

figure 2-18

11. Pull the MOUNTING PLATE forward a s far as possible.

Note

The MOTOR comes off with a THREAD P LATE. This THREAD PLATE must be inserted again

with the new MOTOR. It holds the OP ENER STOP PLA TE.

12. Take out the CASSETTE OPENER MOTOR.

13. Insert the new CASSETTE OPENER MOTOR together with the THREAD PLATE.

KODAK AG, Stuttgart 2-17 9/98

Page 30

SM 3058-6 REPLACEMENTS

14. Insert and fasten SCREW 1 to 5.

15. Insert the 3 MOTOR MOUNTING SCRE WS. Do not fasten them. Mount SENSOR

B15/C_OP_EO.

16. Mount the OPENER STOP PLATE. Use the marks made in step 5 as reference.

Tighten the MOUNTING SCREWS just a bit, that the STOP PLATE can s till be moved.

Warning

BE CAREFUL WHEN WORKING IN THE CASSETTE OPENER AREA. THE OPENER MOTOR

AND THE OPENER MECHANISM ARE VERY STRONG. THEY CANNOT BE MOVED

MANUALLY. THEY MAY SQUEEZE YOUR HAND AND TRAP YOU IF YOU TRY TO STOP

THEM MANUALLY. NEVER START THE CASSETTE OPE NER MOTOR WHEN SOMEONE’S

HANDS ARE IN THE CASSETTE AREA.

17. Switch on the ML300

DOWEL PIN should be

in a horizontal position

DOWEL PIN GROOVE

figure 2-19

18. To mount the MOTOR D RIVE GEAR the D OWEL PIN has to be in the correct

position in relation to the STOP BOLTS of the STOP PLATE.

To rotate the MOTOR SHAFT use the SERVICE PROGRAM. Switch on the CASSETTE

OPENER MOTOR M5 until the DOWEL PIN is in a horizontal position.

9/98 2-18 KODAK AG, Stuttgart

Page 31

REPLACEMENTS SM 3058-6

Select SERVICE MODE from the GLOBAL MENU....................................... press ENTER

ENTER SERVICE MODE MESSAGE is displayed............................................press ENTER

UNIT DATA are displayed ................................................................................ press ENTER

Select COMPONENT TEST from the MAIN MENU.......................................press ENTER

Select CASSETTE MOTORS ...............................................................................press ENTER

Select CASSETTE OPENING M5.......................................................................press ENTER

Select DOWN or UP unti l the DOWEL PIN is in a horizontal position.

Note

The STOP PIN of the DRIVE GEAR has to be to the left of the bottom STOP BOLT. If it is to

the right, the CASSETTE OPENER cannot mo ve for the co rrect distance.

19. Mount the DRIVE GE AR onto the MOTOR SHAFT. Ensure that it is seated properly

ontheDOWELPIN.MounttheACTUATORremovedinstep3toholdtheDRIVEGEAR

on the SHAFT. Do not tighten the ACTUATOR SCREW at this time.

OPENER STOP PLATE

DRIVE GEAR

bottom STOP BOLT

STOP PIN

figure 2-20

20. To mount the CHAIN is the next step. To do this the CASSETTE OPENER

MECHANISMandtheMOTORDRIVEGEARhavetobeinthecorrectposition.

a. The CASSETTE OPENER MECHANISM must be in its bottom position.

b. The STOP PIN of the DRIVE GEAR should just touch the bottom STOP BOLT of

the STOP PLATE.

Select DOWN until the STOP PIN just touches the STOP BOLT.

KODAK AG, Stuttgart 2-19 9/98

Page 32

SM 3058-6 REPLACEMENTS

21. Take off the SMALL GEAR.

SMALL GEAR

C-RING

figure 2-21

22. Mount the CHAIN onto the MOTOR DRIVE GEAR and onto the SMALL GEAR.

23. Put the small GEAR onto its SHAFT and secure it with the C-RING.

24. Tension the CHAIN by moving the CASSETTE OPENER MOTOR to the right.

25. Tighten the MOTOR MOUNTING SCREW S.

26. Move the CASSETTE OP ENER to its fully up position.

Select UP until the OPENER BRACKET is vertical.

9/98 2-20 KODAK AG, Stuttgart

Page 33

REPLACEMENTS SM 3058-6

The OPENER

BRACKET must

be vertical

figure 2-22

27. Adjust the ACTUATOR that SENSOR B 15 is actuated. Tighten its MOUNTING

SCREW.

SENSOR B15

ACTUATOR

2-23

KODAK AG, Stuttgart 2-21 9/98

Page 34

SM 3058-6 REPLACEMENTS

28. The ACTUATOR must now be set to a position that the CA SSETTE OPENER

MOTOR is switched off as soon as the OPENER B RACKET is vertical.

Select DOWN until the OPENER is fully down

Select UP until the OPENER stops

29. If the OPE NER BRAC KET is vertical p roceed with step 30. If not proceed here.

Reposition the ACTUATOR as required and proceed with step 28.

30. SENSOR B15 is now adjusted correct ly. The next s tep is to adjust the OPENER

STOP PLATE.

Note

It is not possible to s ee this gap. You have to set it by feeling.

31. The OPENER is still in the upper position. Turn the STOP PLATE

counter-clockwise until the STOP BOLT touches the STOP PIN of the DRIVE GEAR.

Turn the STOP PLATE clockwise until there is a gap of approximately 1mm between

the STOP PIN and the STOP BOLT.

32. Tighten the MOUNTING SCREW S of the STOP PLA TE.

33. Check the position of the STOP PLATE.

-Disconnect SEN SOR B15(CONNECTOR X9)

-Select U P. The MOTOR M5 must turn for a short distance and is stopped then.

A high pitched tone can be heard at the same time.

-Connect SENSOR B15.

-Select DOWN until the CASSETTE OPENER stops in its bottom position.

-Manually actuate SENSOR B15. Do not break its thin PLASTIC ACTUATOR.

-Select DOWN again. MOTOR M5 should turn for a short distance and is

stopped then. A high pitched tone can be heard at the same time.

-Select UP until the CASSETTE OPENER stops in its uppermost position.

If the UP and DOW N positions are correct, proceed with s tep 34. Otherwise

reposition the STOP PLATE and repeat step 33.

34. Exit the SERVICE MODE.

Press 3 times BACKSPACE

Select LEAVE THE COMPONENT TEST .......................................................... press ENTER

Select QUIT ML300 SERVICE MODE............................................................... press ENTER

Select Quit the program................................................................................. press ENTER

9/98 2-22 KODAK AG, Stuttgart

Page 35

REPLACEMENTS SM 3058-6

FUNCTION TEST.

Warning

BE CAREFUL WHEN WORKING IN THE CASSETTE OPENER AREA. THE OPENER MOTOR

AND THE OPENER MECHANISM ARE VERY STRONG. THEY CANNOT BE MOVED

MANUALLY. THEY MAY SQUEEZE YOUR HAND AND TRAP YOU IF YOU TRY TO STOP

THEM MANUALLY. NEVER START THE CASSETTE OPE NER MOTOR WHEN SOMEONE’S

HANDS ARE IN THE CASSETTE AREA.

1. Take out the MAGAZINES loaded with CUSTOMER FILMS to avoid film fogging.

2. Run several cycles with test films.

3. Check that the OPENER BRACKET is vertical when the CASSETTE is open.

4. Check that the CASSETTE is correctly c losed.

REPLACEMENT OF THE CASSETTE OPENER SOLENOID Y4.

1. Switch off the ML300.

2. Take off the PANELS.

3. Unplug the CASSETTE OPENER SOLENOID (Connector X40).

4. Take out the 2 NUTS from the CASSETTE OPENER SOLENOID.

CONNECTOR X40

NUT

figure 2-24

KODAK AG, Stuttgart 2-23 9/98

Page 36

SM 3058-6 REPLACEMENTS

5. Install the new CASSETTE OPENER SOLENOID.

6. Adjust the CAS SETTE OPENER SOLENOID.

Start the SERVICE PROGRAM

Select SERVICE MODE from the GLOBAL MENU .................................... press ENTER

ENTER SERVICE MODE MESSAGE is displayed............................................press ENTER

UNIT DATA are displayed ................................................................................ press ENTER

Select COMPONENT TEST from the MAIN MENU.......................................press ENTER

Select SOLENOIDS .............................................................................................press ENTER

Select CASSETTE OPENER Y4...........................................................................press ENTER

Select SOLENOID ON

7. If the OPENER SHOVEL is only just touching the OPENER PLATE, proceed with

step 9, else proceed with step 8.

NUTS

touching slightly

OPENER

PLATE

OPENER SHOVEL

figure 2-25

Do not turn the SOLENOID too far, the BLOCK LEVE R may slide under the LEVER STOP.

See the drawing on th e next page.

8. Loosen the NUTS and turn the OPENER SOLENOID Y4 until the OPENER SHOVEL

is just touching the OPENER PLATE. Tighten the NUTS.

9/98 2-24 KODAK AG, Stuttgart

Page 37

REPLACEMENTS SM 3058-6

OPENER

SOLENOID

OPENER PLATE

LEVER STOP

NUT

CLUTCH

OPENER SHOVEL

figure 2-26

BLOCK LEVER

9. Make sure that the C LUTCH can be moved slightly to left and right using low force

only.

10. Exit the SERVICE PROGRA M.

Press 3 times BACKSPACE

Select LEAVE COMPONENT TEST ...................................................................press ENTER

Select QUIT ML300 SERVICE MODE............................................................... press ENTER

Select Quit the program................................................................................. press ENTER

FUNCTION TEST.

1. To avoid fogging CUSTOMER FILMS load the MAGAZINES with TEST FILMS.

2. Run several cycles with different CASSETTES. Check that they are opened correctly.

3. Reload the MAGAZINES with CUSTOMER FILMS.

KODAK AG, Stuttgart 2-25 9/98

Page 38

SM 3058-6 REPLACEMENTS

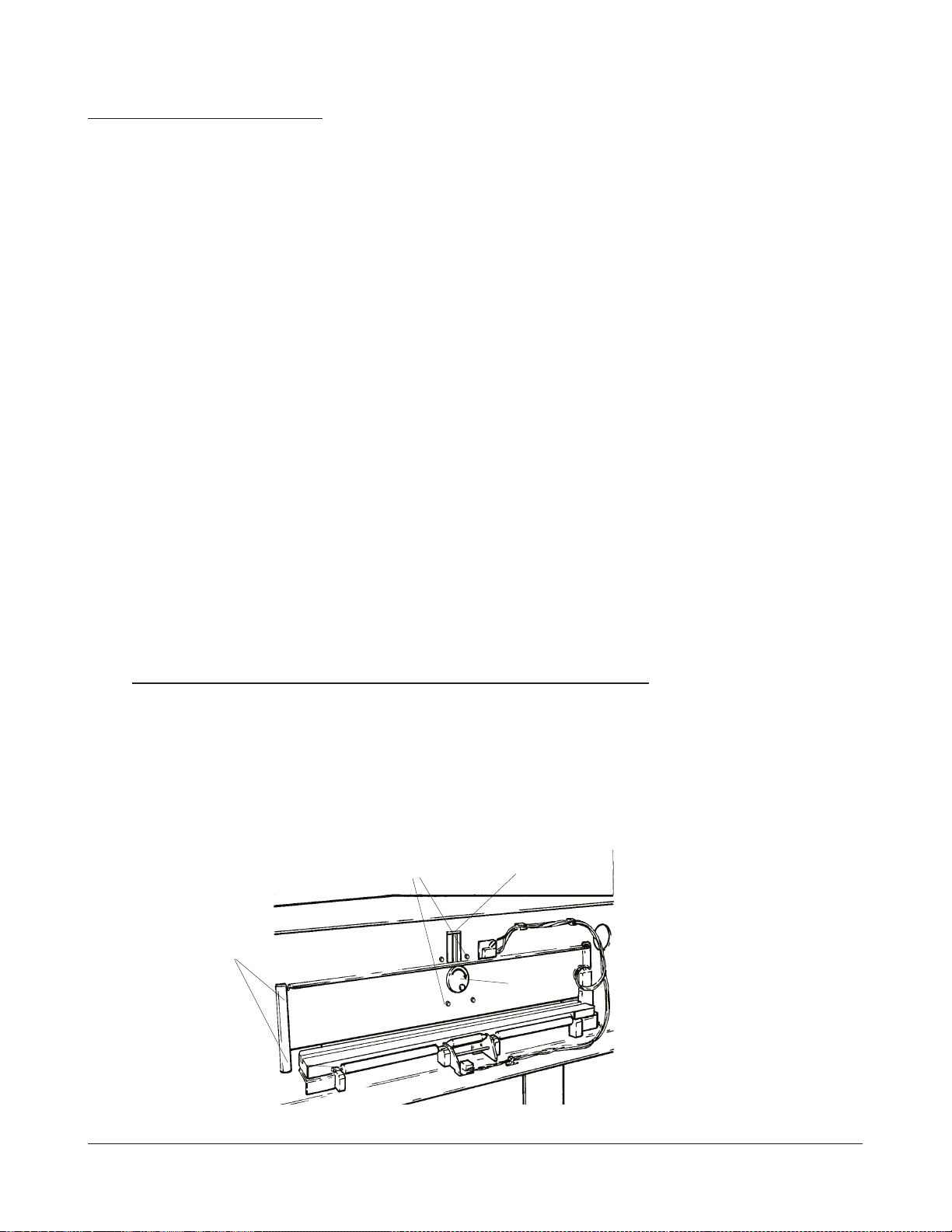

MAGAZINE OPENER

REPLACEMENT OF THE MAGAZINE OPENER MOTOR M 14.

1. Switch off the ML300.

2. Take off the Panels.

3. Move the MAGAZINE OPEN ER to the “CLO SED” position.

4. Take out all MAGAZINES.

5. Move the MAGAZINE OPENER to the “OPENED” position.

6. Take out the 2 BRACKET MOUNTING SCREWS.

7. Take out the MOTOR CONNECTOR from the FRAME.

8. Take out the OPENER ASSEMBLY.

REAR

BRACKET

MOUNTING

SCREWS

FRONT

MOTOR MOUNTING SCREW (4)

CONNECTOR

GEAR

figure 2-27

9/98 2-26 KODAK AG, Stuttgart

Page 39

REPLACEMENTS SM 3058-6

9. Take off the GEAR.

10. Take o ut the MOTOR MOUNTING SCREWS.

11. Install the new MAGAZINE OPENER MOTOR.

12. Move the MAGAZINE OPENER MOTOR to the “CLOSED” position.

13. Fasten the MOUNTING SCREWS.

14. Do the MAGAZINE OPENER MOTOR ADJUSTMENT as described in the section

ADJUSTMENT PROCEDURE S.

FUNCTION TEST.

No special FUNCTION TEST is necessary. The function of MOTOR M14 was tested during

the adjustments.

KODAK AG, Stuttgart 2-27 9/98

Page 40

SM 3058-6 REPLACEMENTS

FILM POCKET

REPLACEMENT OF THE FILM POCKET STEPPER MOTOR M10.

1. Switch off the ML300.

2. Take off the PANELS.

3. Take out the FILM CONVEYOR. See procedure REMOVAL OF CONVEYOR.

4. Loosen the STEPPER MOTOR MOUNTING SCREWS.

MOUNTING SCREW (4)

THREAD PLATE

CHAIN

STEPPER MOTOR

DOWEL PIN

C-RING

SPROCKET

figure 2-28

5. Take off theCHAIN from the SPROCKET.

9/98 2-28 KODAK AG, Stuttgart

Page 41

REPLACEMENTS SM 3058-6

Note

Take care of the DOWEL PIN it may fall down.

6. Take off the C-RING and take out the SPRO CKET.

7. Take out the STEPPER MOTOR MOUNTING SCREW S.

8. Install new the STEPPER MOTOR.

9. Move the STEPPER MOTOR up to tension the CHAIN.

10. Tighten the MOUNTING SCREWS.

FUNCTION TEST

1. To test the function of the FILM POCKET STEPPER MOTOR do a SCAN RUN.

Start the SERVICE PROGRAM.

Select SERVICE MODE from the GLOBAL MENU....................................... press ENTER

ENTER SERVICE MODE MESSAGE is displayed............................................press ENTER

UNIT DATA are displayed ................................................................................ press ENTER

Select CHANGE ML300 DATA from the MAIN MENU ............................... press ENTER

Select CHANGE PARAMETER.......................................................................... press ENTER

Select SCAN RUN ..............................................................................................press ENTER

Select STORE PARAMETERS .............................................................................press ENTER

2. Exit the SERVICE PROGRAM

Press BACKSPACE twice

Select QUIT ML300 SERVICE MODE............................................................... press ENTER

Select Quit the program................................................................................. press ENTER

KODAK AG, Stuttgart 2-29 9/98

Page 42

SM 3058-6 REPLACEMENTS

REPLACEMENT OF THE FILM POCKET SUCKER BAR MOTOR M15.

1. Switch off the ML300.

2. Take off the PANELS.

3. Take out the FILM CHUTE.

4. Cut the WIRE TIE and unplug the FILM POCKET MOTOR.

!

Caution

HOLD THE MOTOR. IT MIGHT FALL DOWN.

5. Take out the 4 MOUNTING SCREWS.

GEAR FILM POCKET DRIVE SHAFT

CHAIN

FILM POCKET MOTOR

DOWEL PIN

MOUNTING

SCREW (4)

FILM POCKET

DRIVE SHAFT

WIRE TIE

figure 2-29

9/98 2-30 KODAK AG, Stuttgart

Page 43

REPLACEMENTS SM 3058-6

Note

Use the DOWEL PIN and the GEAR from the old MOTOR.

6. Install the new FILM POCKET MOTOR.

FUNCTION TEST.

1. Take out all MAGAZINES.

2. Check that the FILM POCKET SUCKER BAR ARM m oves forward and backward.

Start the SERVICE PROGRAM

Select SERVICE MODE from the GLOBAL MENU....................................... press ENTER

ENTER SERVICE MODE MESSAGE is displayed............................................press ENTER

UNIT DATA are displayed ................................................................................ press ENTER

Select COMPONENT TEST ................................................................................press ENTER

Select MAGAZINE MOTORS ............................................................................press ENTER

Select FILM PICK UP MAGAZINE M15...........................................................press ENTER

Select f orward and backward

3. Exit the SERVICE PROGRAM

Press 3 times BACKSPACE

Select LEAVE COMPONENT TEST ...................................................................press ENTER

Select QUIT ML300 SERVICE MODE............................................................... press ENTER

Select Quit the program................................................................................. press ENTER

KODAK AG, Stuttgart 2-31 9/98

Page 44

SM 3058-6 REPLACEMENTS

REPLACEMENT OF FILM POCKET TORSION SPRING (SN < 2000).

Note

· If modification 34 is installed proceed with page 2-35

· AFTER THE TORSION SPRING IS REPLACED DO ALL THE FILM POCKET

ADJUSTMENTS.

1. Switch off the ML300.

2. Take off the PANELS.

RIGHT FILM GUIDE

TIMING DISKS

FILM POCKET

MOTOR

COLLAR WITH

SET SCREW

PCB A5

SCREW (2)

LEFT FILM GUIDE

MOUNTING

figure 2-30

3. Rotate out the FILM CHU TE.

4. Take out BOARD A5 together with the MOUNTING BRACKET.

Note

DETENT ASSY

SCREW (2)

DETENT ARM

BRACKET

Starting with SN 1422 a DOU BLE DETENT is use d. See the figure on the next page.

5. Take out the DETENT ASSEMBLY.

9/98 2-32 KODAK AG, Stuttgart

Page 45

REPLACEMENTS SM 3058-6

FILM REJECTER ASSY

right-hand NUT

TORSION

6. Take out the right FILM GUIDE.

DETENT

ASSY

PCB A5

SPRING

figure 2-31

7. Remove the right-hand NUT of the FILM REJECTER AS SEMBLY

8. Take of the TIMING DISKS.

9. Slide out the right-hand side FILM REJECTER ASSEMBLY and the C AMS with the

TORSION SPRING.

KODAK AG, Stuttgart 2-33 9/98

Page 46

SM 3058-6 REPLACEMENTS

Note

The TORSION SPRING is installed correctly if the FILM REJECTER ASSEMBLY rests at the

rear MAGAZINE WALL after the FILM P OCKET SUCKER BAR ARM is rotated in the upright

(vertical ) position.

10. Install the new SPRING.

11. Do the FILM POCKET ADJUSTMENTS.

FUNCTION TEST.

1. Chec k that s mall and large FIL MS are pick ed up corre ctly from the magazines.

9/98 2-34 KODAK AG, Stuttgart

Page 47

REPLACEMENTS SM 3058-6

REPLACEMENT OF FILM POCKET TORSION SPRING (SN > 2000).

Note

AFTER THE TORSION SPRING IS REPLACED, NO FILM POCKET ADJUSTMENTS is

required.

1. Switch off the ML300.

2. Take off the PANELS.

3. Rotate out the FILM CHU TE.

4. Loosen the SET SCREW of the COLLAR at the right-hand FILM REJECTER.

SET SCREW

figure 2-32

KODAK AG, Stuttgart 2-35 9/98

Page 48

SM 3058-6 REPLACEMENTS

5. Slide the right-hand CLUTC H DISK to the right and take out the defective CLUTCH

SPRING.

6. Lubricate the RING an d the right-hand CLUTCH DISK as sh own to avoid wear and

install the new CLUTCH DISK.

lubricate this surface

right-hand

CLUTCH DISK

lubricate this surface

RING

figure 2-33

7. Slide the right-hand CLUTCH D ISK, the right-hand FILM REJECTER and the

COLLAR to the left. Tighten the SET SCREW.

8. Ensure that the CLUTCH SPRING is mounted as shown.

CLUTCH SPRING

figure 2-34

9/98 2-36 KODAK AG, Stuttgart

Page 49

REPLACEMENTS SM 3058-6

FUNCTION TEST.

1. Chec k that s mall and large FIL MS are pick ed up corre ctly from the magazines.

REPLACEMENT OF THE FILM POCKET CLUTCH SPRING (SN > 2000)

Note

After the replacement of this SPRING no adjustment is necessar y.

1. Switch off the ML300.

2. Remove the REAR PANEL.

3. Take out the 6 FILM CHUTE MOUNTING SCREW S. With SN > 3000 there is just 1

MOUNTING SCREW.

MOUNTING

SCREW

SN < 3000

MOUNTING SCREW

SN < 3000

figure 2-35

MOUNTING

SCREW

SN < 3000

MOUNTING

SCREW

SN > 3000

MOUNTING

SCREW

SN < 3000

FILM CHUTE

KODAK AG, Stuttgart 2-37 9/98

Page 50

SM 3058-6 REPLACEMENTS

4. Rotate out the FILM CHU TE.

5. Loosen the SET SCREW of the COLLAR and shift the COLLAR to the right.

SET SCREW

figure 2-36

9/98 2-38 KODAK AG, Stuttgart

Page 51

REPLACEMENTS SM 3058-6

Note

It is not necessary to unhook the REJECTER SPR ING (SPRING between REJECTER and

PCB A5).

6. Loosen the SPRING HOOK NUTS on the right-hand REJECTER, so that the

REJECTERcanbeshiftedafewmillimetrestotheright.

7. Shift the CLUTCH DISK 2 to the right. If necessary push the STOP PLATE a little

forward. Do not loosen the STOP PLATE. This would alter the end positions of

the REJECTER.

8. Take out the old CLUTCH SPRING.

9. Install the new SPRING.

10. Shift CLUTCH DISK 2 fully to the left. Ensure that CLUTCH DISK 1 is engaged

with the FILM POCKET ARM.

11. Move the COLLAR fully to the left and tighten its SET SCRE W.

12. Tighten the SPRING HOOK NUTS on the right-hand REJECTER.

13. Rotate in the FILM CHUTE and fix it with the 6 MOUNTING SCREWS

(or1forSN>3000)fromstep3.

14. Mount the REAR PANEL

FUNCTION TEST

1. Switch on the ML300.

2. Run a few cycles with different film sizes to check for correct operation.

KODAK AG, Stuttgart 2-39 9/98

Page 52

SM 3058-6 REPLACEMENTS

REPLACEMENT OF THE FILM REJECTER SPRING

1. Switch off the ML300.

2. Remove the REAR PANEL.

3. Take out the 6 FILM CHUTE MOUNTING SCREW S. With SN > 3000 there is just 1

MOUNTING SCREW.

4. Rotate out the FILM CHU TE.

MOUNTING

SCREW

SN < 3000

MOUNTING SCREW

SN < 3000

figure 2-37

MOUNTING

SCREW

SN < 3000

MOUNTING

SCREW

SN > 3000

MOUNTING

SCREW

SN < 3000

FILM CHUTE

9/98 2-40 KODAK AG, Stuttgart

Page 53

REPLACEMENTS SM 3058-6

5. Unhook the old REJECTER SPRING.

6. Install the new REJECTER SPRING.

REJECTER SPRING

figure 2-38

KODAK AG, Stuttgart 2-41 9/98

Page 54

SM 3058-6 REPLACEMENTS

7. Manually rotate in and out the FILM POCKET SUCKER BAR ARM and check that

the REJECTER moves correctly forward and backward.

8. Rotate in the FILM CHUTE and fix it with the 6 MOUNTING SCREWS

(or1forSN>3000)fromstep3.

9. Mount the REAR PANEL.

PROCESSOR INTERFACE

REPLACEMENT OF PROCESSOR INTERFACE MOTOR M13

1. Switch off the ML300.

2. Take off the PANELS.

3. Take off the MOTOR CONNECTOR on BOARD A5 X25.

4. Take out the INTERFACE ASSEMBLY.

5. Take off the DRIVE BELT.

6. Take off the MOTOR MOUNTING SCREWS.

7. Install the new MOTOR.

DRIVE BELT

INTERFACE MOTOR

(mounted to the inner side

of the interface)

figure 2-39

9/98 2-42 KODAK AG, Stuttgart

Page 55

REPLACEMENTS SM 3058-6

FUNCTION TEST.

1. Check that the PROCESSOR INTERFACE MOTOR is running.

Start the SERVICE PROGRAM

Select SERVICE MODE from the GLOBAL MENU....................................... press ENTER

ENTER SERVICE MODE MESSAGE is displayed............................................press ENTER

UNIT DATA are displayed ................................................................................ press ENTER

Select COMPONENT TEST ................................................................................press ENTER

Select INTERFACE/FILM MOT........................................................................... press ENTER

Select MAGAZINE ROLLER MOTOR M13 ...................................................... press ENTER

Select ON /OFF

2. Exit the SERVICE PROGRAM

Press 3 times BACKSPACE

Select LEAVE COMPONENT TEST..................................................................press ENTER

Select QUIT ML300 SERVICE MODE............................................................... press ENTER

Select Quit the program................................................................................. press ENTER.

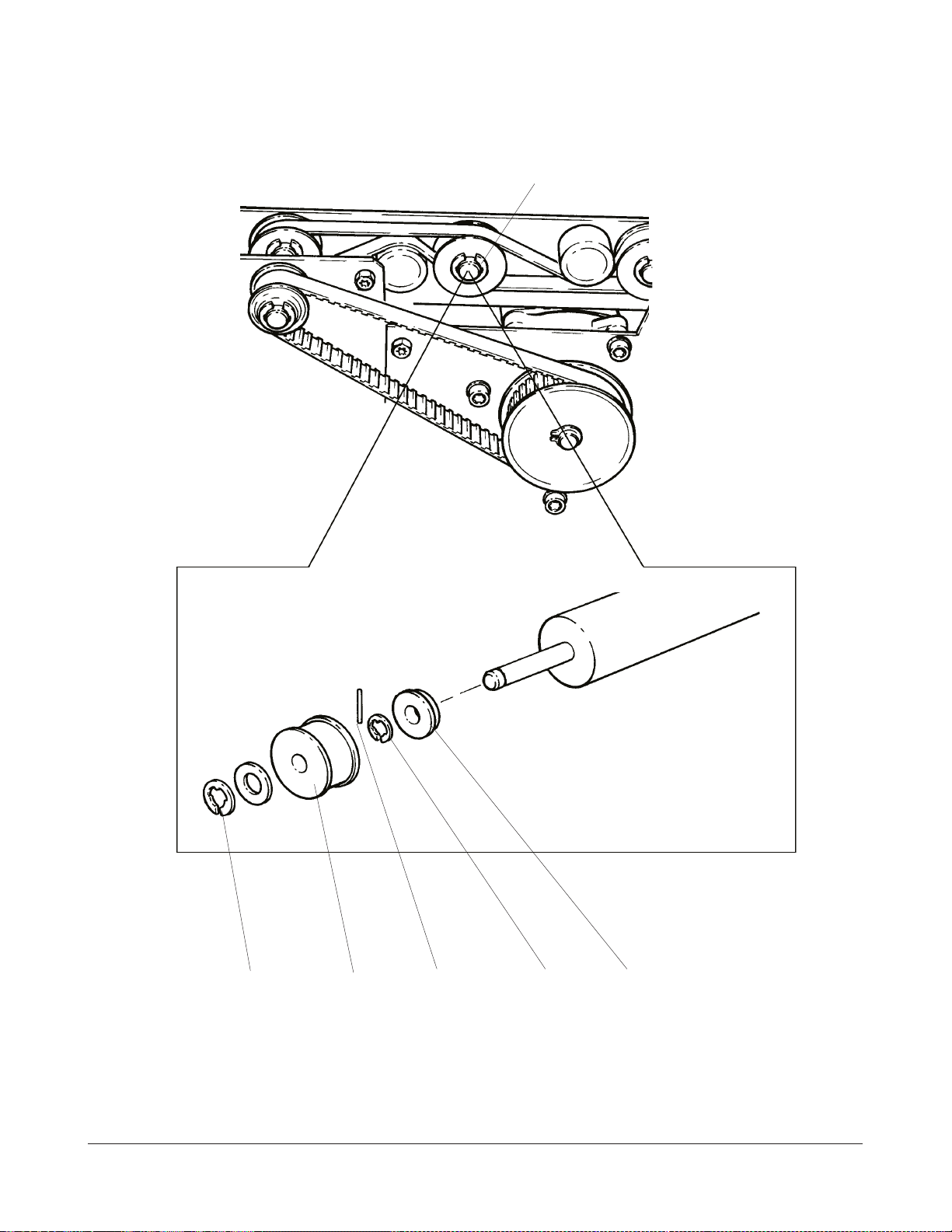

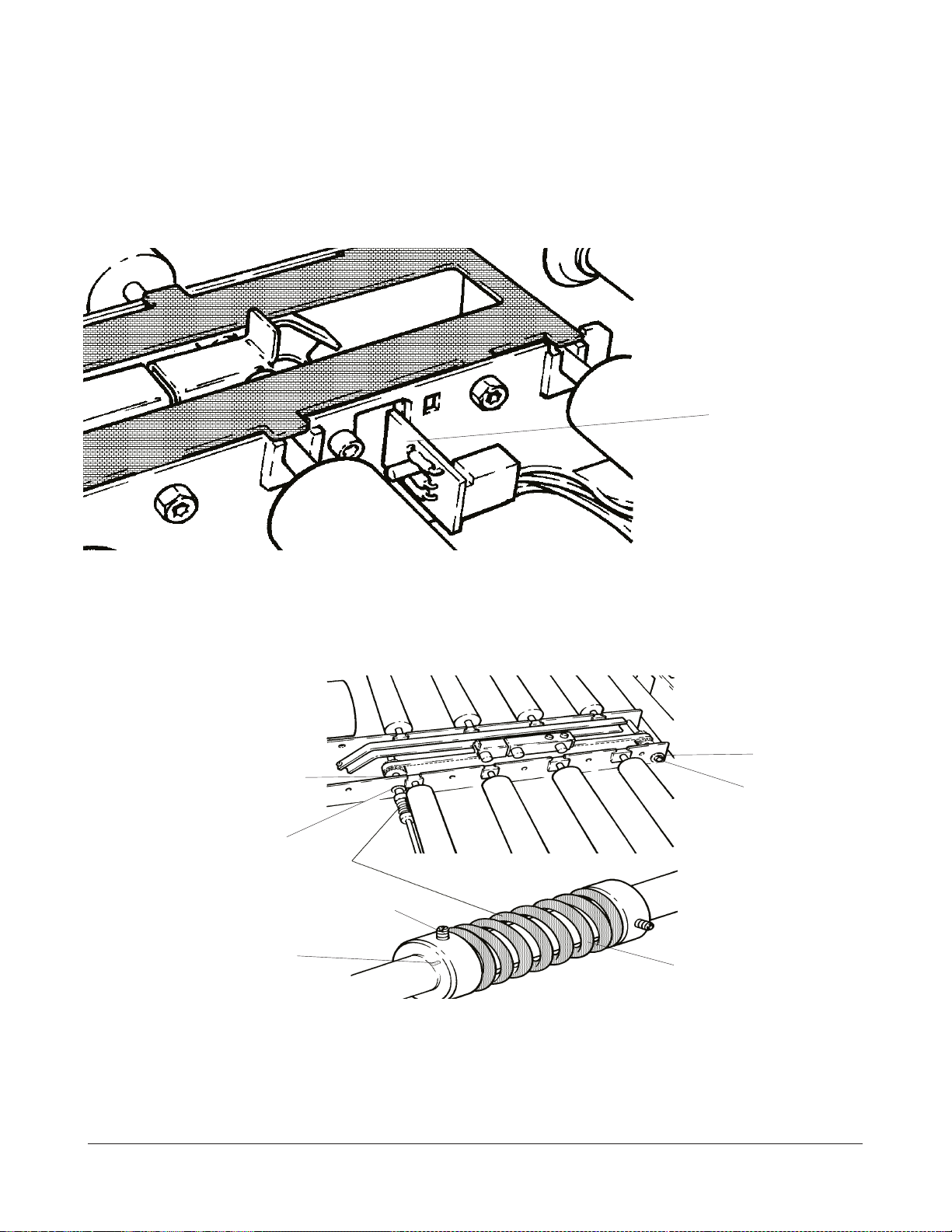

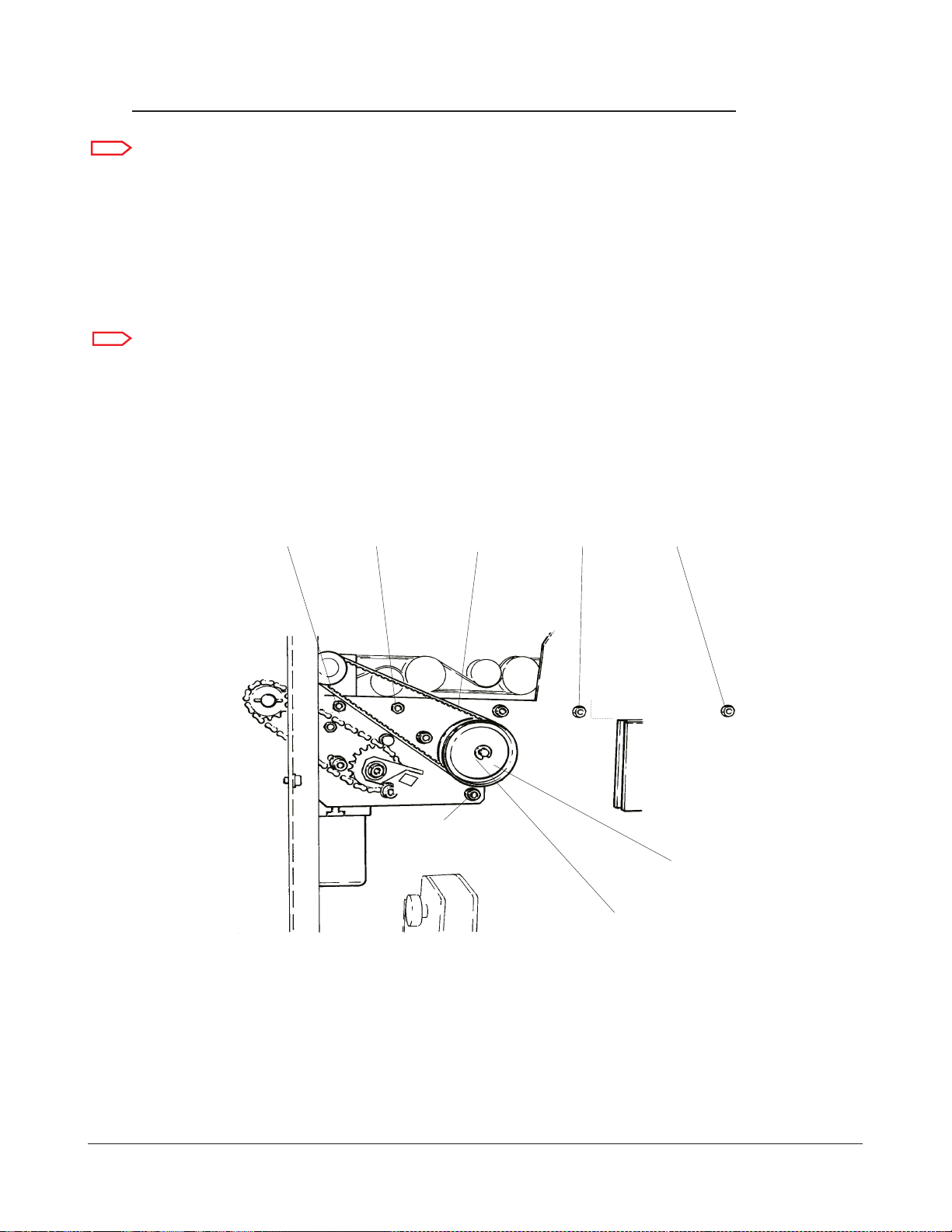

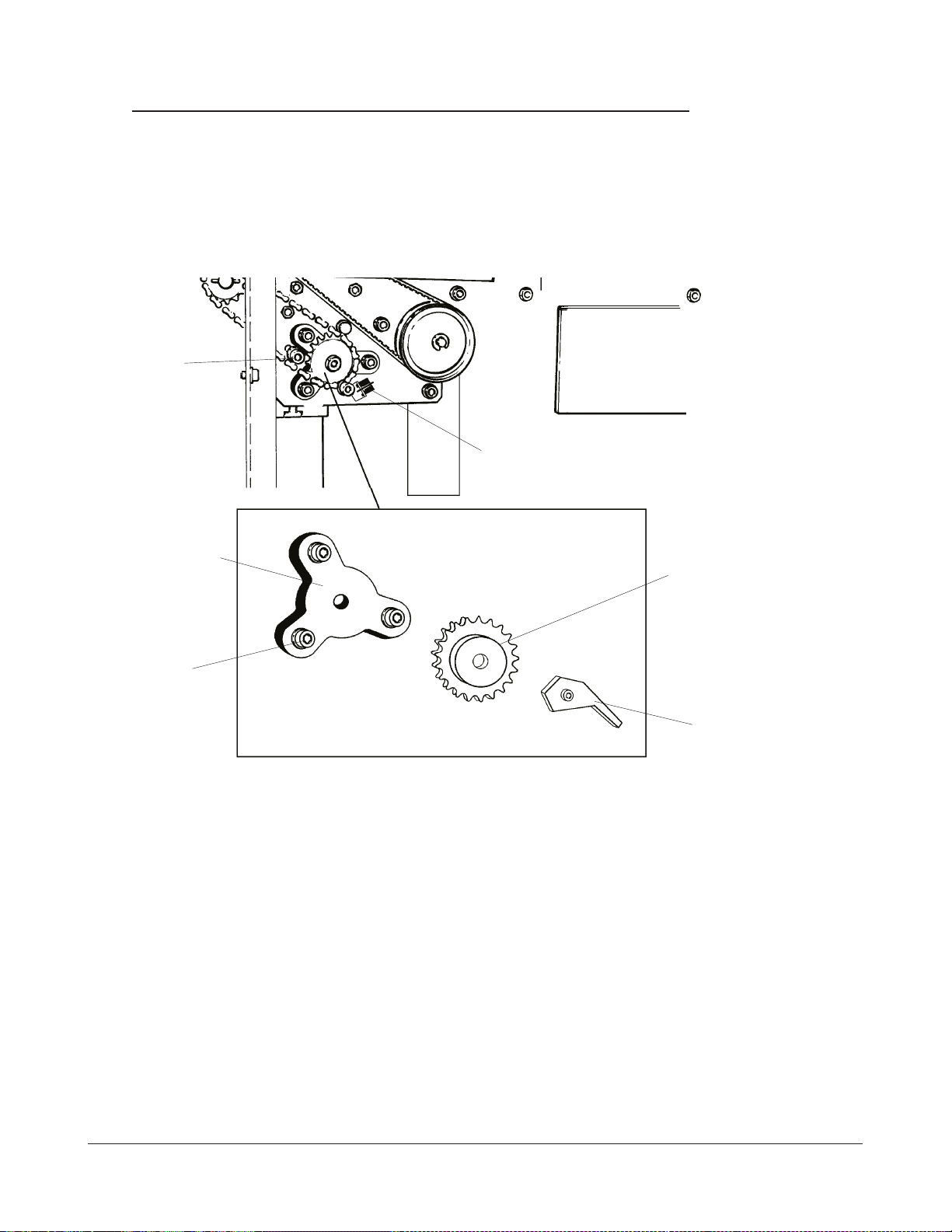

PROCESSOR INTERFACE CLUTCHES

There are 2 free running ONE_WAY CLUTCHES in the PROCESSOR INTERFACE PULLEYS.

If you pull a FILM through the PROCESSOR INTERFACE in direction of the PROCESSOR

the toothed BELT must not move. If it moves as you pull, one of the free running ONE-WA Y

CLUTCHES is assembled wrong.

This ARROW must be on the visible side of the

CLUTCH and must point into the indicated direction. It

is possible that the ARROW is covered by the C-RING

figure 2-40

KODAK AG, Stuttgart 2-43 9/98

Page 56

SM 3058-6 REPLACEMENTS

CONVEYOR

REMOVAL OF THE CONVEYOR

1. Switch off the ML300.

2. Take off the PANELS.

3. Disconnect CONNEC TOR X55 and CON NECTOR X60.

CONNECTOR X60

CONNECTOR X55

figure 41

9/98 2-44 KODAK AG, Stuttgart

Page 57

REPLACEMENTS SM 3058-6

4. Cut the WIRE TIE and mark the position of it.

WIRE TIE

figure 2-42

5. Disconnect the HOSE and carefully pull it out o ff the CABLE DUCT.

Disconnect the

HOSE here

CABLE DUCT

figure 2-43

KODAK AG, Stuttgart 2-45 9/98

Page 58

SM 3058-6 REPLACEMENTS

6. Remove the SCREW S from each of the RETAINERS on each side of the

CONVEYOR.

RETAINER

RETAINER

RETAINER

7. Takeoffthe2SUPPORTS.

figure 2-44

SUPPORT

figure 2-45

9/98 2-46 KODAK AG, Stuttgart

SUPPORT

Page 59

REPLACEMENTS SM 3058-6

8. Lift out the CONVEY OR.

FUNCTION TEST

1. Check that the CON VEYOR is seat ed properly. It must be as far as possible to the

front (e.g. to the INPUT F LAP).

2. Check that the HOS E is connec ted again and th at it is routed through the CABLE

DUCT.

3. Check that the HARNESS is fixed with a WIRE TIE at the correct place. Use the

mark from step 4 as reference.

4. Check that CONNECTOR S X55 and X60 are seated properly .

5. Run TEST CYCLES with different film sizes and check that the FILM is picked up

from the CASSETTE.

6. Check that the FILM is transported correctly into the FILM CHUTE.

DISASSEMBLY OF THE CONVEYOR

Disassembly of the CONVEYOR is needed for removing the following:

· DRIVE SHAFTS

· CARRIAGE ASSEMBLY

· DRIVE BELTS

1. Do PROCEDURE “REMOVAL OF CONVEYOR”.

2. Cut the WIRE TIES along the upper TIERODS. Mark the position of the WIRE TIES.

See the top drawing on the next page.

3. Take out the 4 NUTS at the TIERODS.

4. Remove the 12 C-R INGS from the upper 2 TIERODS.

5. Remove the CARRIAGE STOP.

6. Slide out both upper TIE RODS.

KODAK AG, Stuttgart 2-47 9/98

Page 60

SM 3058-6 REPLACEMENTS

NUT

CARRIAGE

STOP

NUT

upper TIEROD

figure 2-46

7. Take out C-RINGS at both PRESSURE ROLLER SHAFTS and slide SHAFTS

outwards.

SPRING

PRESSURE ROLLER SHAFT

C-RING

figure 2-47

9/98 2-48 KODAK AG, Stuttgart

Page 61

REPLACEMENTS SM 3058-6

8. Take out SPRINGS.

9. Disconnect the VACUUM SOLENOID CONNECTOR.

10. Disconnect the GROUND WIRE at the ROLLER MOTOR.

11. Disconnect the CONNECTORS of both CARRIAGE POSITION SENSORS.

12. Disconnect the CONNECTOR of the SENSOR VACUUM OFF.

Note

Do not lose the SPACER of the PRESSURE ROLLER SHAFT located on the ROLLER

MOTOR side.

13. Carefully lift out the CARRIAGE ASSEMBLY.

FUNCTION TEST

1. Check that the WIRE TIES are at the correct position. Use the marks from step 4 as

reference.

2. Check that the CON VEYOR is seat ed properly. It must be as far as possible to the

front (e.g. to the INPUT F LAP).

3. Run a TEST CYCLE.

4. Check that the FILM is picked up from the CASSETTE.

5. Check that the FILM is transported correctly into the FILM CHUTE.

6. Use various FILM SIZES.

KODAK AG, Stuttgart 2-49 9/98

Page 62

SM 3058-6 REPLACEMENTS

REPLACEMENT OF THE FILM PICK UP MOTOR BELT (CARRIAGE)

1. Do Procedure “REMOVAL OF CONVEYOR”.

2. Remove the 3 MOUNTING SCREWS of the FILM PICK UP MOTOR.

MOUNTING SCREW

(3)

BELT

MOTOR M6

figure 2-48

3. Replace the BELT with a new one.

FUNCTION TEST

1. Check that the CON VEYOR is seat ed properly. It must be as far as possible to the

front (e.g. to the INPUT F LAP).

2. Run a TEST CYCLE.

3. Check that the FILM is picked up from the CASSETTE.

4. Check that the FILM is transported correctly into the FILM CHUTE.

5. Use various FILM SIZES.

9/98 2-50 KODAK AG, Stuttgart

Page 63

REPLACEMENTS SM 3058-6

REPLACEMENT OF FILM PICK UP MOTOR (CARRIAGE ) M6

1. Do PROCEDURE “REMOVAL OF CONVEYOR”.

2. Remove the 3 MOUNTING SCREWS.

3. Take out the 3 MOTOR WIRES from the CONNECTOR X60. Extraction Tool TL1580.

4. Take out the MOTOR.

CONNECTOR X60

figure 2-49

MOUNTING SCREW

(3)

MOTOR M6

figure 2-50

5. Install the new MOTOR.

KODAK AG, Stuttgart 2-51 9/98

Page 64

SM 3058-6 REPLACEMENTS

FUNCTION TEST

1. Check that the FILM PICK UP MOTOR M6 is running.

Start the SERVICE PROGRAM

Select SERVICE MODE from the GLOBAL MENU....................................... press ENTER

ENTER SERVICE MODE MESSAGE IS DISPLAYED.......................................... press ENTER

UNIT DATA are displayed ................................................................................ press ENTER

Select COMPONENT TEST ................................................................................press ENTER

Select CASSETTE MOTORS ...............................................................................press ENTER

Select FILM PICK UP M6...................................................................................press ENTER

Select forward ................................................................................................... press ENTER

Select backward ............................................................................................... press ENTER

2. Exit the SERVICE PROGRAM

Press 3 times BACKSPACE

Select LEAVE COMPONENT TEST ...................................................................press ENTER

Select Quit ML300 SERVICE MODE ............................................................... press ENTER

Select Quit the program................................................................................. press ENTER.

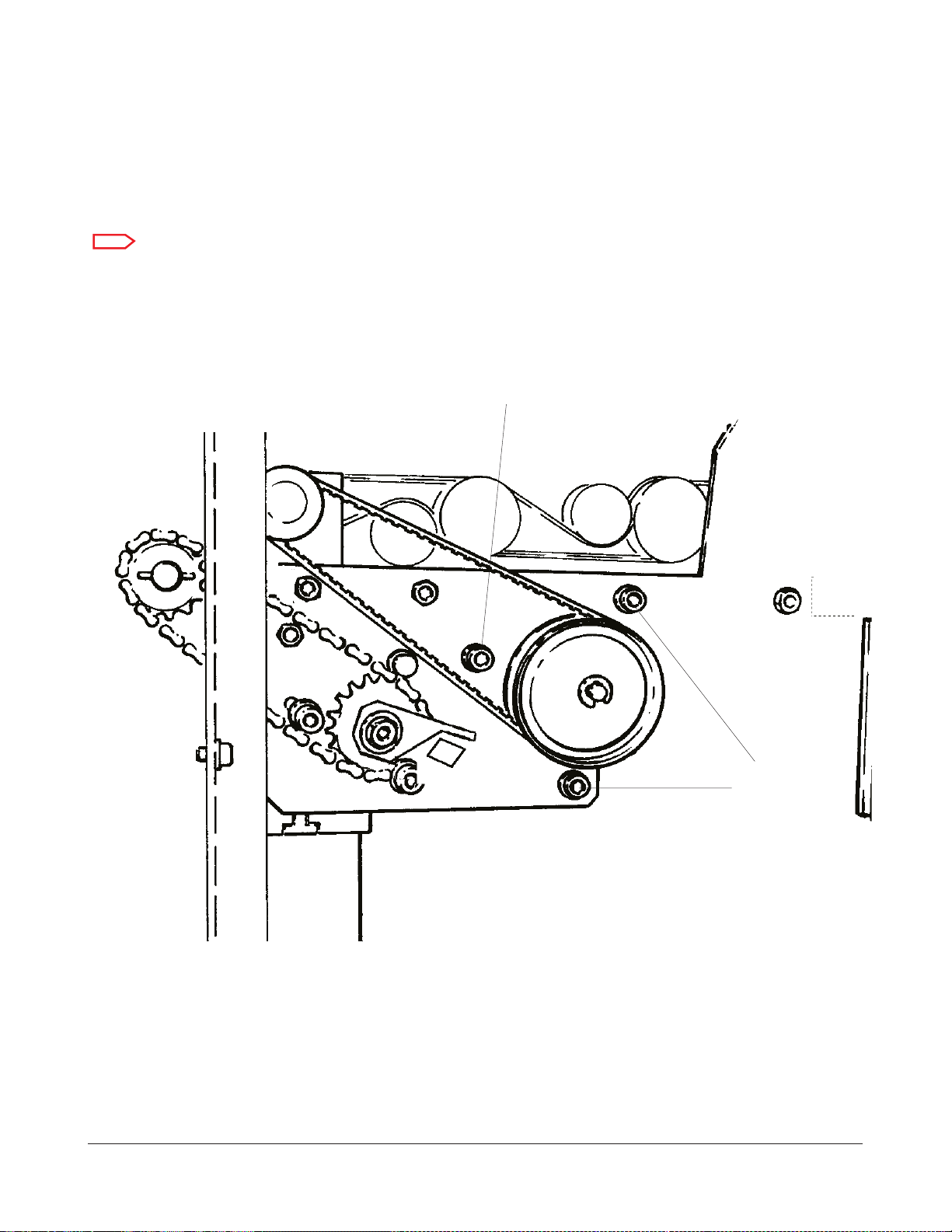

REPLACEMENT OF CARRIAGE ASS EMBLY DRIVE BELTS

Note

Replace both Drive Belts at the same time.

1. Do PROCEDURE “REMOVAL OF CONVEYOR”.

2. Do PROCEDURE “REPLACEMENT OF FILM PICK UP MOTOR” step 1 to 3.

3. Mark the position of the BEL T-LINKS on the MECHANISM PLATES. These m arks

areusedasareferencewheninstallingthenewDRIVEBELTS.

4. Remove the IDLER ROLLERS.

5. Remove the small C-RINGS at the BELT LINKS.

6. SlidetheGEARtotherightandremovetheDOWELPIN.

7. Slide the FILM PICK UP DRIV E SHAFT to the left.

9/98 2-52 KODAK AG, Stuttgart

Page 65

REPLACEMENTS SM 3058-6

Note

A CARRIAGE JAM OCCURS IF THE BELT LINKS ARE NOT ALIGNED WITH THE

REFERENCE MARKS FROM STEP 3.

8. Replace the BELTS.

IDLER ROLLER (2)

C-RING and

BELT LINK

FILM PICK UP DRIVE SHAFT

DOWEL PIN

figure 2-51

KODAK AG, Stuttgart 2-53 9/98

C-RING

Page 66

SM 3058-6 REPLACEMENTS

FUNCTION TEST

1. Check that the CON VEYOR is seat ed properly. It must be as far as possible to the

front (e.g. to the INPUT F LAP).

2. Run a TEST CYCLE.

3. Check that the FILM is picked up from the CASSETTE.

4. Check that the CASSETTE SUCKER BAR CARRIA GE moves freely forward and

backward.

5. Check that the FILM is transported correctly into the FILM CHUTE.

6. Use various FILM SIZES.

REPLACEMENT OF SOLENOID CASSETTE SUCKER BAR TILTING Y7

1. Do PROCEDURE “REMOVAL OF CONVEYOR”.

2. Put CARRIAGE ASSEMBLY upside down.

3. Pull CASSETTE SUCKER BAR carefully forward to get access to the SOLENOID

CASSETTE SUCKER BAR TILTING Y7.

OLD VERSION

PIN

NUT

SOLENOID

figure 2-52

9/98 2-54 KODAK AG, Stuttgart

Page 67

REPLACEMENTS SM 3058-6

NEW VERSION

NUT

PIN

figure 2-53

4. Remove the PIN to dis connect the ARMATU RE from the AC TUATOR.

5. Undo the NUT.

6. Cut the WIRE TIES.

7. Replace the SOLENOID.

FUNCTION TEST

1. Check that the SOLENOID CASSETTE SUCKER BAR TILTING Y7 tilts the

CASSETTE SUCKER BAR.

Start the SERVICE PROGRAM

Select SERVICE MODE from the GLOBAL MENU....................................... press ENTER

ENTER SERVICE MODE MESSAGE is displayed............................................press ENTER

UNIT DATA are displayed ................................................................................ press ENTER

Select COMPONENT TEST ................................................................................press ENTER

Select SOLENOIDS .............................................................................................press ENTER

Select SOLENOID ON........................................................................................press ENTER

Select SOLENOID OFF....................................................................................... press ENTER

KODAK AG, Stuttgart 2-55 9/98

Page 68

SM 3058-6 REPLACEMENTS

2. Exit the SERVICE PROGRAM

Press 3 times BACKSPACE

Select LEAVE COMPONENT TEST ...................................................................press ENTER

Select QUIT ML300 SERVICE MODE............................................................... press ENTER

Select Quit the program................................................................................. press ENTER.

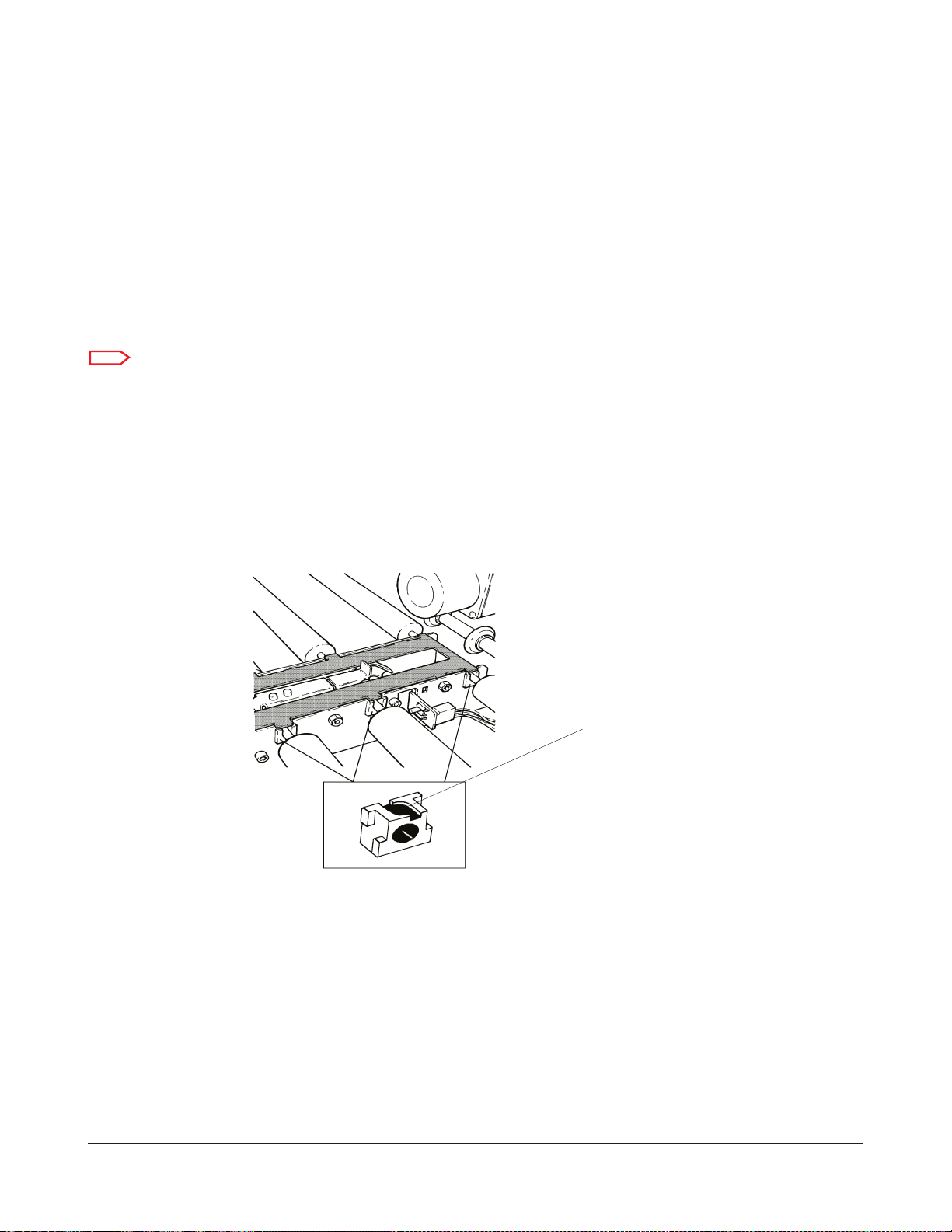

REPLACEMENT OF THE SENSOR SUCKER BAR TILT B19

1. Switch off the ML300.

2. Take off the TOP COVER, the REAR and the RIGHT-HAND PANEL.

3. Manually move the CASSETTE SUCKER BA R to the front.

4. Take out SENSOR B19. Mark the position of the WIRE TIES.

SENSOR B19

For XML300 without the additional SEN-

SOR MOUNTING BRACKET. Make the

front of the MOUNTING CLIPS

0.8 to 1.0 mm shorter, as indicated

by the dark area. Use a file for it.

This SENSOR MOUNTING BRACKET is

used in XML300 with SN > 1260

figure 2-54

9/98 2-56 KODAK AG, Stuttgart

Page 69

REPLACEMENTS SM 3058-6

5. If you have a X ML300 without th e additional SENS OR MOUNTING B RACKET

proceedwithstep6.Otherwiseproceedwithstep9.

6. Make the front of the SENSOR MOUNTING CLIPS (B19) 0.8 to 1mm smaller and

mount it into the CARRIAGE ASSEMBLY. See the drawing on the previous page.

7. Move the SENSOR B1 9 forward in direction of the CASSETTE as far as possible

and fix it in this position with glue.

8. Proceed with s tep 10.

9. Install the new SENSOR into the SENSOR MOUNTING BRACKET.

10. Fix the harness with WIRE TIES. Use the marks from step 4 as reference.

FUNCTION TEST

1. Sw itch on the ML300.

2. Test the function of SENSOR B19 with the SENSOR TEST.

Start the SERVICE PROGRAM.

Select SERVICE MODE from the GLOBAL MENU....................................... press ENTER

ENTER SERVICE MODE MESSAGE is displayed............................................press ENTER

UNIT DATA are displayed ................................................................................ press ENTER

Select COMPONENT TEST ................................................................................press ENTER

Select SENSORS.................................................................................................. press ENTER

Select WITH/WITHOUT SOUND ........................................................................press ENTER

3. Manually tilt the CASSETTE SUCKER BAR. B19 must now be indicated ON.

4. Exit the SERVICE PROGRAM.

Press 3 time BACKSPACE

Select LEAVE COMPONENT TEST ...................................................................press ENTER

Select QUIT ML300 SERVICE MODE............................................................... press ENTER

Select Quit the program................................................................................. press ENTER.

KODAK AG, Stuttgart 2-57 9/98

Page 70

SM 3058-6 REPLACEMENTS

9/98 2-58 KODAK AG, Stuttgart

Page 71

ADJUSTMENTS SM 3058-6

3. ADJUSTMENTS

INTRODUCTION

In this section it is very often explained how to use the CES SERVICE SOFTWARE. The first

line tells always what should be performed. In the next lines it is explained how to reach this

goal. These additional explanations are printed italic and can be skipped if you are

experienced w ith the CES SERVICE SOFTW ARE.

EXAMPLE:

1. Start the CASSETTE INPUT FLAP MOTOR M1

Start the SERVICE PROGRAM.

Select SERVICE MODE from the GLOBAL MENU....................................... press ENTER

ENTER SERVICE MODE MESSAGE is displayed............................................press ENTER

UNIT DATA are displayed ...............................................................................press ENTER

Select COMPONENT TEST from the MAIN MENU.......................................press ENTER

Select CASSETTE MOTORS ...............................................................................press ENTER

Select INPUT FLAP MOT M1.............................................................................press ENTER

Select CLOSE/OPEN.......................................................................................... press ENTER

SENSORS and DAYLIGHT

The SENSORS are s ensitive to daylight and to room light. This can result in wrong

measurements when you do an adjustment, or a SENSOR becomes triggered and the ML300

tries to bring the various units to HOME POSITION. For this reason dim the light or cover the

SENSORS when yo u do the a djustments. Th is is espec ially important whe n you meas ure the

output voltage of a SENSOR.

KODAK AG, Stuttgart 3-1 9/98

Page 72

SM 3058-6 ADJUSTMENTS

FRAME LEVELLING

PURPOSE:

This adjustment makes s ure, the PROCE SSOR will roll out smoothly. If the FRAM E is not

levelled it may be possible that the MAGAZINE SUCKER BAR is n o longer parallel to the

MAGAZINES. This may result in FILM PICKUP problems. Also it is possible that a

MAGAZINE stays open.

1. Take out all MAGAZINES.

Note

TheoldstyleFILMCHUTEhasalwaystobefixedwith4SCREWS.ThenewstyleFILM

CHUTE is only fixed with one SCREW and can be rotated out.

2. Make sure that the FIL M CHUTE is in the correct place an d that it is fixed with all 4

MOUNTING SCREWS to the FRAME.

3. Place the LEVEL onto the BASE PLATE of the MAGAZINE CHAMBER.

MOUNTING

SCREW

FILM CHUTE

old style

FILM

CHUTE

MOUNTING

SCREW

MOUNTING

SCREW

MOUNTING

SCREW

MOUNTING SCREW

figure 3-1

9/98 3-2 KODAK AG, Stuttgart

Page 73

ADJUSTMENTS SM 3058-6

4. Adjust the 4 LEVELLING FEET until the FRAME is horizontal in the X and Y

direction.

figure 3-2

KODAK AG, Stuttgart 3-3 9/98

Page 74

SM 3058-6 ADJUSTMENTS

CASSETTE AREA

INPUT FLAP

PURPOSE:

This adjustment ensures that the INPUT FLAP is closed light-tight when a C ASSETTE is fed

into the MULTILOADER 300.

1. Take off the PANEL.

2. TakeofftheFRONTPANELwiththeDISPLAY.

3. Close the INPUT FLAP.

Start the SERVICE PROGRAM

Select SERVICE MODE from the GLOBAL MENU....................................... press ENTER

ENTER SERVICE MODE MESSAGE is displayed............................................press ENTER

Select COMPONENT TEST from the MAIN MENU.......................................press ENTER

Select CASSETTE MOTORS ...............................................................................press ENTER

Select CASSETTE INPUT FLAP M1.................................................................... press ENTER

Select CLOSE

4. Adjust SENSOR B4/C_IF_EC INPUT FLAP CLOSED until the INPUT FLAP rests

properly in the BLOCK GROOVE.

SENSOR B3/C_IF_EO

SENSOR

B4/C_IF_EC

BLOCK GROOVE

figure 3-3

9/98 3-4 KODAK AG, Stuttgart

Page 75

ADJUSTMENTS SM 3058-6

5. Open the INPUT FLAP.

Select OPEN

6. Adjust SENSOR B3/C_IF_EO INPUT FLAP OPEN that the FLAP is fully open.

7. Exit the SERVICE MODE.

Press 3 times BACKSPACE

Select LEAVE COMPONENT TEST ...................................................................press ENTER

Select QUIT ML300 SERVICE MODE............................................................... press ENTER

Select Quit the program................................................................................. press ENTER.

CASSETTE REGISTRATION SENSOR B2.

Purpose:

To make sure that the SENSOR B2 is not deactuated by a curved CASSETTE before it is

removed from the ML300.

1. Take out the MAGAZINES to avoid FILM FOGGING.

2. Take off the PANELS.

3. Check that the distance between the CASSETTE REGISTRATION ROLLER level

and the TRANSPORT ROLLER level is ≥ 3mm.

figure 3-4

KODAK AG, Stuttgart 3-5 9/98

Page 76

SM 3058-6 ADJUSTMENTS

4. If the distance is not correct, do the following:

5. Remove the DISPLAY PANEL.

6. Remove the CASSETTE REGISTRATION MECHANISM.

CASSETTE REGISTRATION

MECHANISM

NOTE

ThePANELmayblockthe

function of the CASSETTE

REGISTRATION MECHANISM, if the MECHANISM

is mounted too high.

Elongate these 2 holes with a small file

figure 3-5

7. Elongatethe2MOUNTINGHOLESwithasmallfile.Thisallowstomovethe

complete CASSETTE REGISTRATION MECHANISM up or down to adjust it to the

correct level.

8. Install the CASSETTE REGISTRATION MECHANISM. Make sure that the level of

the CASSETTE REGISTRATION ROLLER is ≥ 3mm above the level of the

TRANSPORT ROLLER.

9. Check that no cycle is started, when a C ASSETTE is pulled out of the ML300.

10. Check that the CASSETTE REGIS TRATION SENSOR B2 is working correctly with

all PANELS mounted.

9/98 3-6 KODAK AG, Stuttgart

Page 77

ADJUSTMENTS SM 3058-6

CASSETTE OPENER GUIDE SHOE POSITION

PURPOSE:

To ensure that the CASSETTE is opened correctly.

Note