Page 1

Publication No. 981095

September 1995

Supersedes 981095

October 1994

THEORY GUIDE for the

Kodak X-Omat M43 and M43A PROCESSORS

and the

Kodak X-Omat Clinic 1 PROCESSOR

HEALTH SCIENCES DIVISION

© Eastman Kodak Company

H130_0009DA

Page 2

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be

liable for any loss or damage, including consequential or special damages, resulting from any

use of this information, even if loss or damage is caused by Kodak’s negligence or other fault.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Model Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Optional Accessories and KITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Basic Principles of Film Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

The Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

The PROCESSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DEVELOPER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

FIXER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

WASH SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DRYER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Regulating the Temperature of the Developer Solution . . . . . . . . . . . . . . . . . . . . . . 16

Regulating the Temperature of the Fixer Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Regulating the Temperature of the DRYER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Control Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

AC and DC INTERLOCK SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

MAIN CIRCUIT BREAKER CB1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

100 CIRCUIT BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

System Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Sequence of Events after the Completion of the Initialization Routine . . . . . . . . . . . 32

Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Continuous Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

MAIN DRIVE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Detecting Film. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Replenishment of the Developer and Fixer Processing Solutions . . . . . . . . . . . . . . . 36

Replenishment of the Wash Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Wash Water Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Replenishment Check Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ALARM Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2 September 1995 – 981095

Page 3

Introduction

Section 1: Introduction

Product Description

The Kodak X-Omat M43, M43A, and Clinic 1 PROCESSORS are compact, table-top PROCESSORS used for

processing medical x-ray films. The Kodak X-Omat M43 and M43A PROCESSORS are designed to perform

primarily in the professional, hospital satellite market. The Kodak X-Omat Clinic 1 PROCESSOR is designed to

perform primarily in the professional, non-hospital market. The PROCESSOR uses ROLLER transport technology

to reliably process sheet film in sizes ranging from 10 x 10 cm to 43 x 137 cm (4 x 4 to 17 x 54 in.).

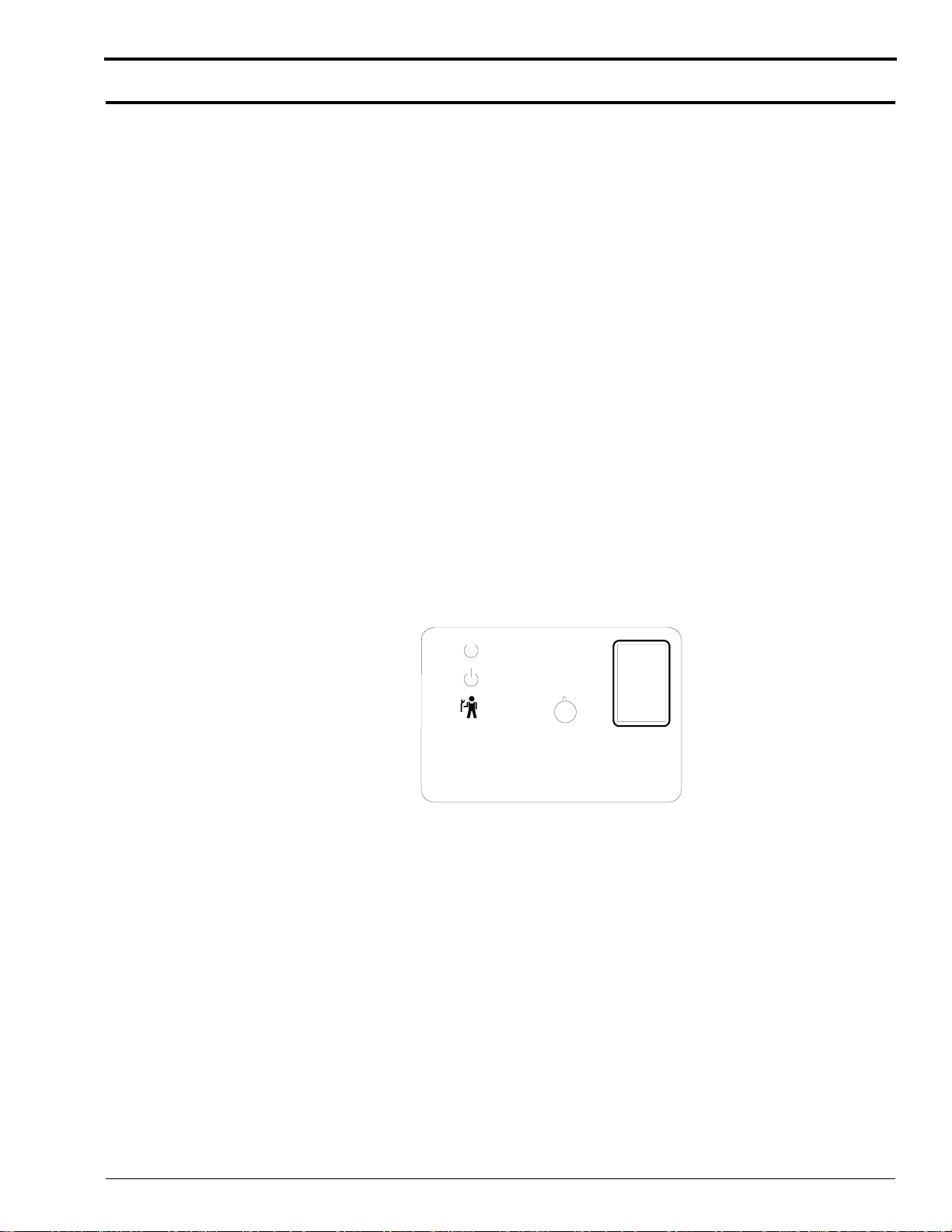

The PROCESSOR is simple and easy to use. It requires minimal operator intervention. Operator controls consist

solely of an ON/OFF POWER SWITCH and a DRYER TEMPERATURE CONTROL KNOB. The PROCESSOR

also has a DISPLAY PANEL that allows the operator to monitor the status of the PROCESSOR. Located on the

DISPLAY PANEL are 3 STATUS INDICATORS that provide additional operator information about the operating

status of the PROCESSOR.

READY The READY INDICATOR illuminates when the PROCESSOR is ready to

accept film.

WAIT The WAIT INDICATOR illuminates or blinks when the PROCESSOR is not at

its optimum operating condition. The WAIT INDICATOR illuminates and does

not blink when you feed film.

SERVICE The SERVICE INDICATOR illuminates or blinks when the PROCESSOR has a

more serious error. In this condition, the PROCESSOR may not accept film

depending on how serious the error is.

Figure 1 Identifying the STATUS INDICATORS

Ready

Wait

Service

Dryer

Temperature

+

-

ON

-1-

-0-

OFF

H130_0018AA

981095 – September 1995 3

Page 4

THEORY GUIDE

Product Features

The processing cycle of the Kodak X-Omat M43, M43A, and Clinic 1 PROCESSORS is short and efficient. The

“drop time” for a 35 x 43 cm (14 x 17 in.) sheet of film from “leading edge in” to the “trailing edge out” is just over

2 minutes (127 seconds) assuming that the film is fed 43 cm (17 in.) wide.

Features found on the PROCESSOR include:

• Replenishment Check Mode - which allows you to easily check and reconfigure the volumes of replenishment

solutions

• DEVELOPER TEMPERATURE DISPLAY (M43 and M43A Models) - which displays the temperature of the

developer solution

• Water Recirculation System - which reduces the amount of water consumed

• Automatic Exit from Standby Mode - which eliminates the need for the operator to press a RUN BUTTON before

the PROCESSOR will process films

• Flooded Replenishment Mode - which maintains the stability of the chemical solutions by automatically

replenishing the processing solutions for low film usage applications.

In addition to the benefits provided by the features listed above, the M43, M43A, and Clinic 1 PROCESSORS

provide further benefits to the installer. The M43, M43A, and Clinic 1 PROCESSORS are simple and easy to install.

If the installation site meets all the requirements outlined in the Site Specifications, Publication Number 981087, no

additional exhaust venting is required.

Model Information

Use the table below to determine which PROCESSOR model is right for your operating conditions.

Table 2 Selecting the Correct Model

Film

Model Voltage Amperage Frequency

M43A Nominal 115 volt 20 amp 50/60 Hz Medium

Clinic 1 Nominal 115 volt 20 amp 60 Hz Low

M43 Nominal 230 volt 10 amp 50/60 Hz Medium

Volume

4 September 1995 – 981095

Page 5

Optional Accessories and KITS

Introduction

MOUNTING STAND:

LIGHTTIGHT FEED TRAY: Order CAT No. 188 0355 for the optional LIGHTTIGHT FEED TRAY KIT.

TRANSFORMER KITS:

SEISMIC ANCHOR

BRACKET KIT:

VENT DUCT ADAPTER KIT:

Kodak AUXILIARY

VENTILATION FAN KIT

115 V AC:

Kodak X-Omat Clinic 1

Installation KIT:

Kodak X-Omat M43

PROCESSOR

Through-the-Wall KIT:

Order CAT No. 808 1176 for the Kodak M35, M43, Clinic 1 MOUNTING

STAND. The STAND offers the following benefits:

• provides a sturdy work surface for the PROCESSOR

• occupies a minimum of space

• positions the PROCESSOR at a convenient height for feeding films

• offers the convenience of a slide-out SHELF in the BASE for storing

replenishment SUPPLY TANKS

• simplifies through-the-wall PROCESSOR installations

The LIGHTTIGHT FEED TRAY allows you to turn on the darkroom lights

immediately upon feeding the last sheet of film.

Order CAT No. 167 4340 for the 115 V AC TRANSFORMER KIT, or CAT

No. 171 0292 for the 230 V AC TRANSFORMER KIT. The KIT is available

for sites that do not meet the voltage specifications as outlined in the Site

Specifications, Publication Number 981087. Use of this KIT brings the voltage

within the acceptable operating range.

• Clinic 1 and M43A voltage range is 115

• M43 voltage range is 230

Order Part No. 261413 for the SEISMIC ANCHOR BRACKET KIT. The KIT

is available for areas with high likelihood of seismic activity. The KIT allows

you to attach the MOUNTING STAND securely to the floor. You can also use

the KIT to anchor the PROCESSOR to a table top. Always install the KIT

according to local codes.

Order CAT No. 143 4943 for the VENT DUCT ADAPTER KIT. The KIT is

available for sites that do not meet the specifications outlined in the Site

Specifications, Publication Number 981087, and therefore require auxiliary

venting. The ADAPTER attaches to the PROCESSOR and provides a FLANGE

for connecting a 7.62 cm (3.0 in.) DUCT. The KIT facilitates the routing of an

EXHAUST DUCT to an external ventilation source to remove fumes from the

darkroom. If no exhaust is available, you can use this KIT with the Kodak

AUXILIARY VENTILATION FAN KIT.

Order Part No. 264503 for this KIT. The KIT is available for sites that do not

meet the specifications for room air changes as outlined in the Site

Specifications, Publication Number 981087. The KIT is available for 115 V AC

installations only.

Order CAT No. 863 2754 for all of the components necessary to properly install

a Clinic 1 PROCESSOR. The parts contained in this KIT are included with the

PROCESSOR when you purchase either the M43 or the M43A model.

Order CAT No. 871 3109 for the Through-the-Wall KIT. This KIT includes the

components and instructions necessary to install the PROCESSOR properly

through the darkroom wall. This KIT assumes the use of the Kodak M35, M43,

and ClinIc 1 MOUNTING STAND.

+22 V AC

+11.5 V AC

981095 – September 1995 5

Page 6

THEORY GUIDE

Section 2: Basic Principles of Film Processing

The Process

Film processing can be divided into 4 basic parts:

Developing In the developing stage of the process, developer solution converts the invisible

latent image on the film to a visible image.

Fixing In the fixing stage of the process, fixer solution stops the continued development

of the visible image by removing the unexposed silver halide crystals from the

film.

Washing In the washing stage of the process, wash water rinses both the developer and

fixer solutions from the film, which prepares the film for drying. Proper

washing of the film ensures a permanent image on the film.

Drying In the drying stage of the process, the film is dried so that the image can

withstand handling.

The PROCESSOR

TheKodak X-Omat M43, M43A, and Clinic 1 PROCESSORS are designed to contain 4 sections that correspond with

the 4 stages of the film processing:

1. DEVELOPER SECTION

2. FIXER SECTION

3. WASH SECTION

4. DRYER SECTION

6 September 1995 – 981095

Page 7

Figure 1 Identifying the Sections of the PROCESSOR

FILM EXIT

DRYER SECTION

Basic Principles of Film Processing

ENTRANCE ROLLERS

WASH

SECTION

FIXER TANK/RACK

FIXER

SECTION

DEVELOPER TANK/

DEVELOPER

SECTION

EXIT ROLLERS

RACK

FILM ENTRANCE

H130_0166DCA

H130_0166DA

Film Entrance

The operator begins to process a sheet of film by placing the film onto the FEED TRAY and feeding the film along

the left edge of the FEED TRAY. A set of 3 FILM SENSORS detects the film on the FEED TRAY and brings the

PROCESSOR out of Standby Mode, which then allows the ENTRANCE ROLLERS to transport the film into the

DEVELOPER SECTION of the PROCESSOR.

For optimum replenishment of the processing solutions, feed films along the left edge of the FEED TRAY. See the

section “Detecting Film” on Page 35 for more information.

981095 – September 1995 7

Page 8

THEORY GUIDE

DEVELOPER SECTION

Components

The DEVELOPER SECTION contains the following components:

• DEVELOPER RACK, which consists of:

– Series of GEARS and ROLLERS

– RACK COVER

– GUIDE SHOES

– MANIFOLD BOX

• DEVELOPER TANK, which consists of:

– 850 watt HEATER

– THERMISTOR

– HEAT EXCHANGER

• DEVELOPER RECIRCULATION PUMP

• DEVELOPER REPLENISHMENT PUMP

Process

The developing process consists of a few simple steps.

[1] The film enters the DEVELOPER RACK through the ENTRANCE ROLLERS.

[2] The DEVELOPER RACK immerses the film in the TANK full of developer solution for 17 seconds. The total

development time is approximately 28 seconds.

[3] The DEVELOPER RECIRCULATION PUMP continually recirculates the developer solution from the TANK

into the RACK. The pumping actions causes the gentle agitation of the developer solution surrounding the film

in the DEVELOPER RACK.

[4] The film exits the DEVELOPER RACK and enters into the FIXER SECTION.

[5] The amount of developer replenishment solution that the replenishment system delivers is based on the area of

the film fed.

8 September 1995 – 981095

Page 9

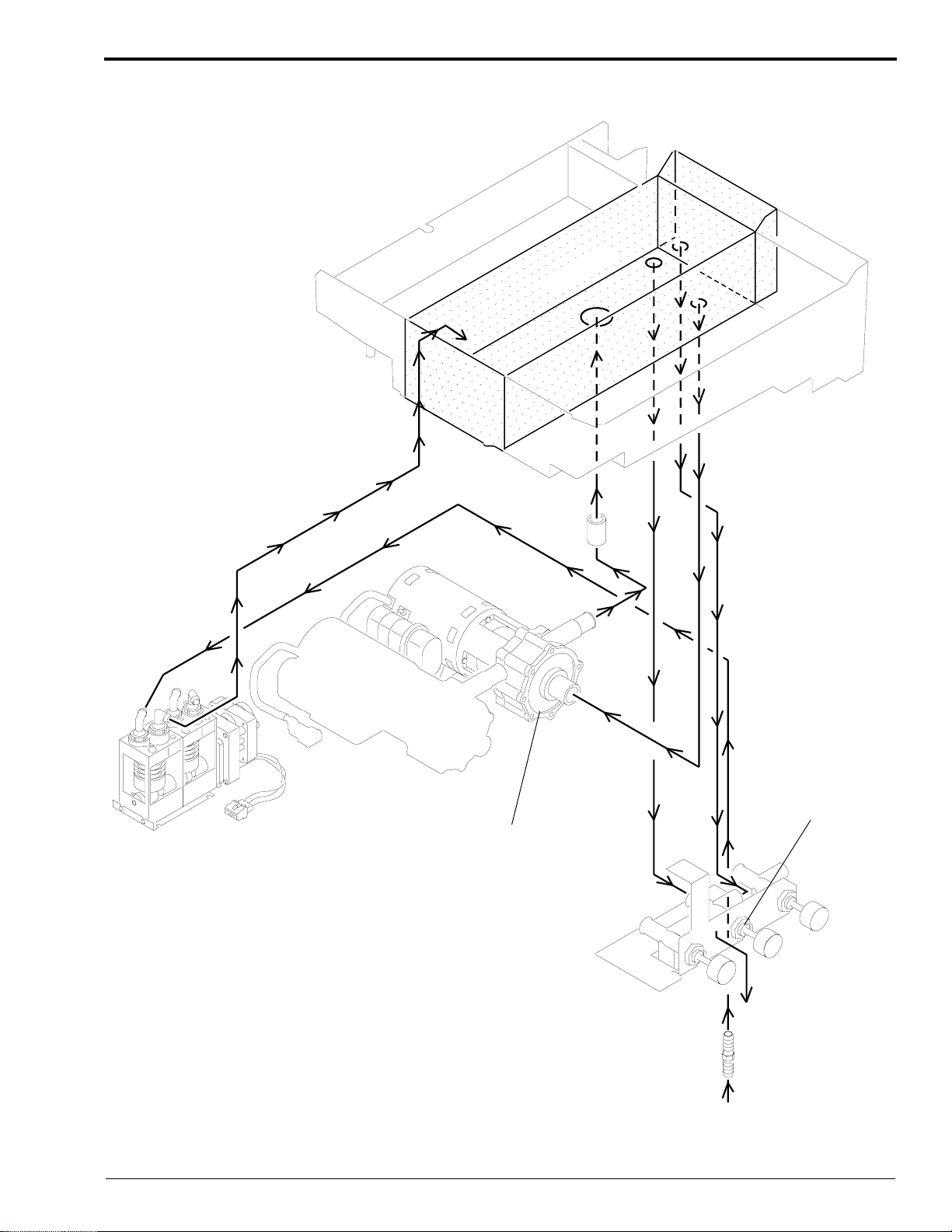

Figure 2 Solution Flow in the DEVELOPER TANK

WASH

FIXER

REPLENISHMENT

into

PROCESSOR

Basic Principles of Film Processing

DEVELOPER

V

E

D

FIX

REPLENISHMENT PUMP

RECIRCULATION PUMP

DRAIN

VALVE

H130_0123ECA

H130_0123EA

981095 – September 1995 9

Page 10

THEORY GUIDE

FIXER SECTION

Components

The FIXER SECTION contains the following components:

• FIXER RACK, which consists of:

– Series of GEARS and ROLLERS

– GUIDE SHOES

• FIXER TANK, which consists of:

– HEAT EXCHANGER - (M43 and M43A Models Only)

• FIXER RECIRCULATION PUMP

• FIXER REPLENISHMENT PUMP

Process

The fixing process consists of a few simple steps.

[1] The film enters the FIXER RACK from the DEVELOPER SECTION through a set of ENTRANCE

ROLLERS.

[2] The FIXER RACK immerses the film in the TANK full of fixer solution for 17 seconds.

[3] The FIXER RECIRCULATION PUMP continually recirculates the fixer solution from the TANK into the

RACK. The pumping action causes the gentle agitation of the fixer solution surrounding the film in the FIXER

RACK.

[4] The film exits the FIXER RACK and enters the WASH SECTION.

[5] The amount of fixer replenishment solution that the replenishment system delivers is based on the area of film

fed.

10 September 1995 – 981095

Page 11

Figure 3 Solution Flow in the FIXER TANK

Basic Principles of Film Processing

WASH

FIXER

DEVELOPER

EV

D

FIX

DRAIN

VALVE

RECIRCULATION

PUMP

H130_0124ECA

H130_0124EA

981095 – September 1995 11

Page 12

THEORY GUIDE

WASH SECTION

Components

The WASH SECTION contains the following components:

• WASH RACK, which consists of:

– set of ENTRANCE ROLLERS

– UPPER WASH TUBE

– LOWER WASH TUBE

– set of EXIT SQUEEGEE ROLLERS

– series of GEARS and ROLLERS

– MANIFOLD

• WATER SOLENOID

• WASH TANK

• WASH PUMP

• DIVERTER VALVE (M43 and M43A Models Only)

Process

The washing process consists of a few simple steps.

[1] The film enters the WASH RACK from the FIXER SECTION through a set of ENTRANCE ROLLERS.

[2] The WASH RECIRCULATION PUMP pumps wash water from the TANK, through the DIVERTER VALVE

(M43 and M43A Only), through the MANIFOLD, and into the LOWER and UPPER WASH TUBES.

[3] The WASH TUBES create a fluid suspension layer through which the film passes. This technique allows for

superior rinsing of the film without needing to immerse the film into the TANK.

[4] The EXIT SQUEEGEE ROLLERS eliminate any excess water from the film before the film enters the DRYER

RACK.

[5] The film exits the WASH RACK and enters setpointthe DRYER SECTION.

The wash stage is critical to the entire process because:

• Washing the film eliminates all residual chemicals and therefore:

– prevents artifacts on the film

– prevents the deterioration of the image over time

12 September 1995 – 981095

Page 13

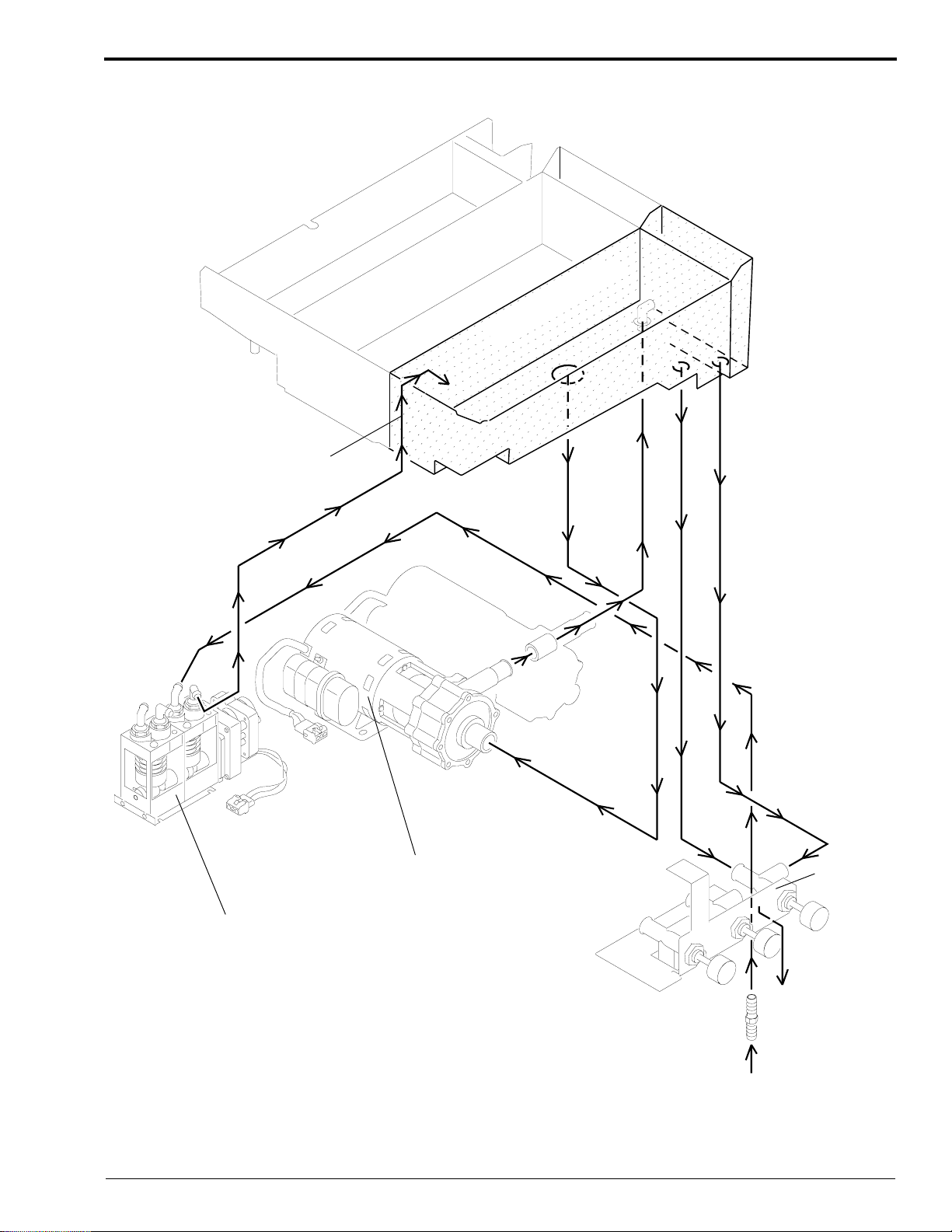

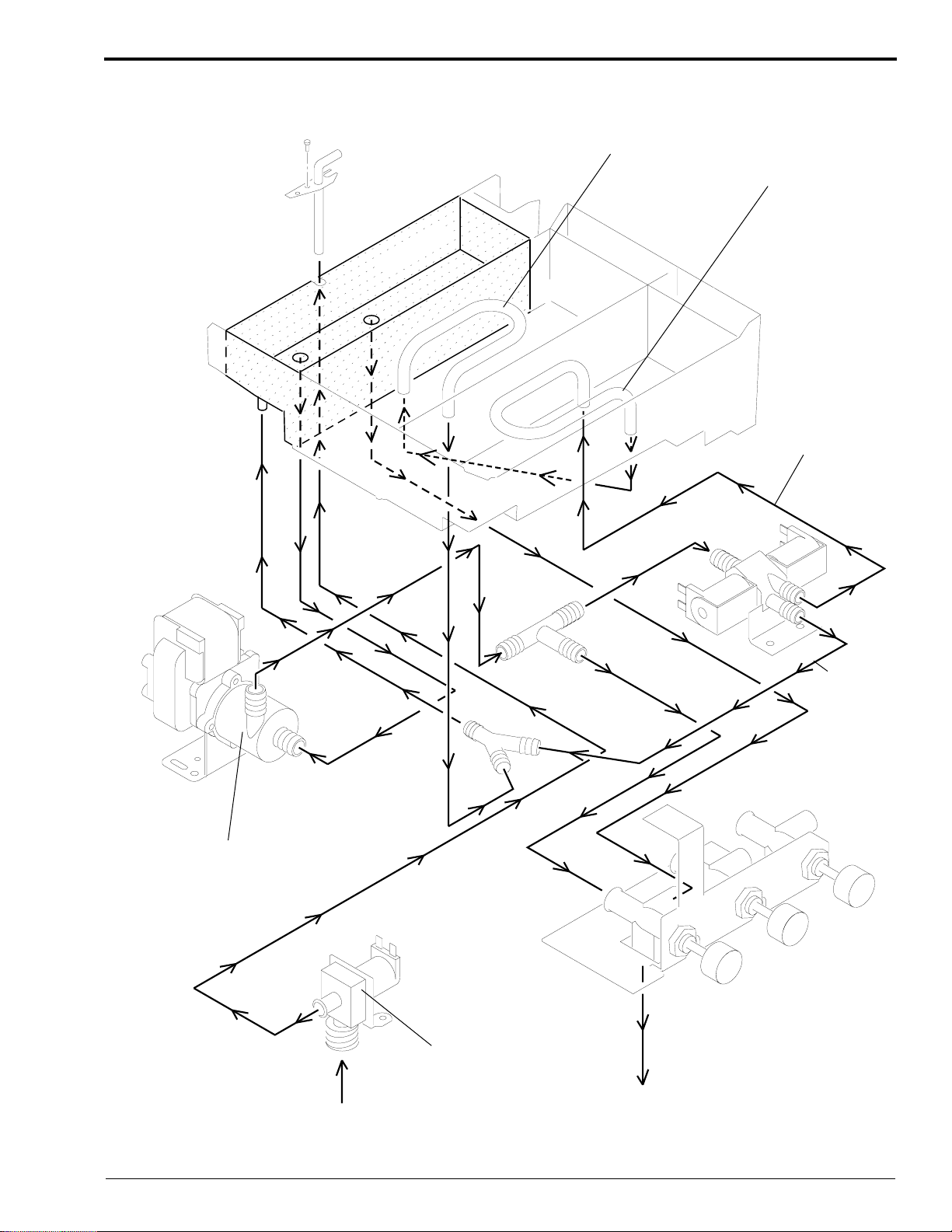

Figure 4 Wash Water Flow in the M43 and M43A PROCESSORS

Basic Principles of Film Processing

WASH

FIXER

HEAT

EXCHANGER

FIXER

DEVELOPER

DEVELOPER

HEAT

EXCHANGER

Path for

Developer

Cooling

Mode

WASH

PUMP

INPUT

WATER

SOLENOID

DRAIN

Path for

Normal

Mode

H130_0121ECA

H130_0121EA

981095 – September 1995 13

Page 14

THEORY GUIDE

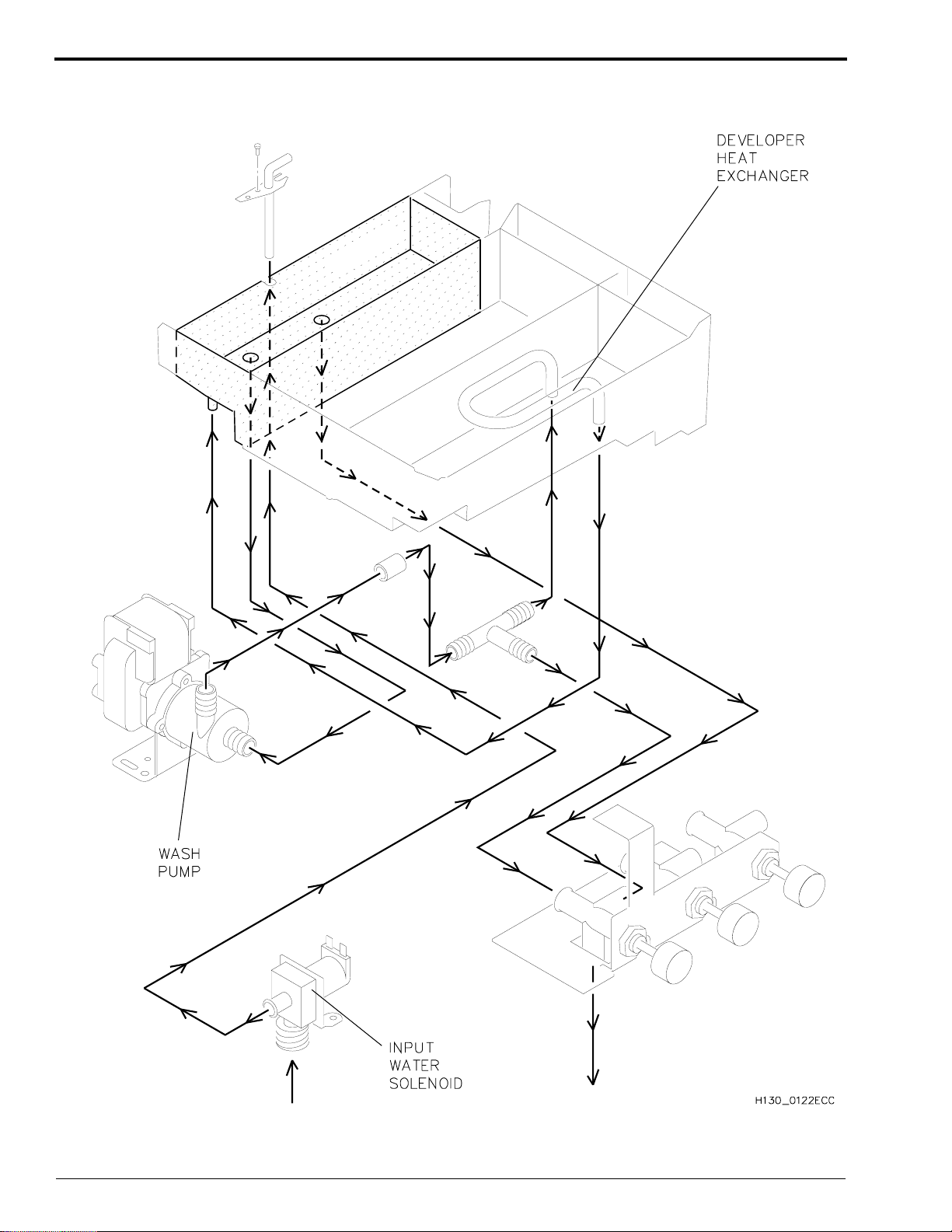

Figure 5 Wash Water Flow in the Clinic 1 PROCESSOR

WASH

FIXER

DEVELOPER

DRAIN

14 September 1995 – 981095

H130_0122EA

Page 15

Basic Principles of Film Processing

DRYER SECTION

Components

The DRYER SECTION contains the following components:

• DRYER RACK, which includes:

– AIR TUBES

– FILM TRANSPORT ROLLERS

• PLENUM, which includes:

– BAFFLE

– HEATER

– AIR VANE SWITCH

– THERMISTOR

• BLOWER

• TEMPERATURE CONTROL POTENTIOMETER

Process

The drying process consists of a few simple steps.

[1] The film enters the DRYER RACK from the WASH SECTION through a set of ENTRANCE ROLLERS.

[2] The film is transported through the RACK by a series of ROLLERS. AIR TUBES create 2 layers of hot air

through which the film passes. The method of drying allows hot air to be circulated across both sides of the

film as the film passes through the ROLLERS, and consequently allows for a more efficient dryer system.

[3] The film exits the DRYER RACK and enters into the RECEIVING BIN.

981095 – September 1995 15

Page 16

THEORY GUIDE

Section 3: Temperature Control

Regulating the Temperature of the Developer Solution

Components

The temperature of the developer solution is regulated by several different components:

• DEVELOPER RECIRCULATION PUMP (B5)

• DEVELOPER THERMISTOR (RT1)

• 100 CIRCUIT BOARD

• WASH RECIRCULATION PUMP (B2)

• SOLID STATE RELAY (U3) controlling DEVELOPER HEATER (HR1)

• SOLID STATE RELAY (U4) controlling WASH RECIRCULATION PUMP (B2)

– B2 recirculates water through a HEAT EXCHANGER in the DEVELOPER TANK

• DIVERTER VALVE ASSEMBLY (M43 and M43A Models Only)

• INCOMING WATER SOLENOID (L1)

• HEAT EXCHANGER in the DEVELOPER TANK

Process

The components listed above regulate and maintain the temperature of the developer solution to within ± 0.3°C

(±0.5°F) of the set-temperature through a series of steps:

Important

The DC INTERLOCK S6 is only found in PROCESSORS that either have a serial number of 350 or higher, or have

Mod 1 installed.

[1] The closing of the TOP COVER actuates the 2 INTERLOCK SWITCHES S5 and S6.

[2] CIRCUIT BREAKER (CB1) provides voltage to the DEVELOPER RECIRCULATION PUMP (B2).

[3] While the developer solution is recirculating, the DEVELOPER THERMISTOR (RT1) monitors the

temperature of the developer solution.

[4] The resistance of the DEVELOPER THERMISTOR (RT1) changes inversely with the temperature of the

developer solution.

[5] The 100 CIRCUIT BOARD reacts to variations in resistance that develop across the DEVELOPER

THERMISTOR (RT1) due to a change in temperature of the developer solution.

[6] The PROCESSOR compares the sensed temperature value to the set-temperature value. The PROCESSOR

maintains the set-temperature by the following series of steps.

(a) If necessary, the PROCESSOR supplies heat by energizing and de-energizing SSR U3 and the

DEVELOPER HEATER (HR1).

(b) If necessary, the PROCESSOR provides cooling by energizing and de-energizing several components:

• SSR U4

• WASH RECIRCULATION PUMP (B2)

• DIVERTER VALVE ASSEMBLY (M43 and M43A Only)

– L2 DEVELOPER COOLING SOLENOID (M43 and M43A Only)

– L3 WASH SOLENOID (M43 and M43A Only)

• INCOMING WATER SOLENOID (L1)

16 September 1995 – 981095

Page 17

Temperature Control

The Developer Heating System

Once the DEVELOPER THERMISTOR (RT1) senses a temperature change, the information is transmitted through

CONNECTOR P/J104 into the MICROPROCESSOR located on the 100 CIRCUIT BOARD. The

MICROPROCESSOR then determines when it needs to actuate the SOLID STATE RELAY (U3). Once actuated,

the SOLID STATE RELAY (U3) then applies line voltage to energize the DEVELOPER HEATER (R1). The

MICROPROCESSOR uses a proportional control algorithm to determine when to energize the components. The

algorithm determines the correct duty cycle for the DEVELOPER HEATER depending on how close the temperature

reading is to the setpoint temperature. The table below indicates the relationship between duty cycle and developer

temperature.

Table 3 DEVELOPER HEATER Duty Cycles

Current Developer Temperature

Duty Cycle

100% > 1.0° below setpoint temperature

75% <= 1.0°, > 0.7° below setpoint temperature

60% <= 0.7°, > 0.5° below setpoint temperature

40% <= 0.5°, > 0.3° below setpoint temperature

20% <= 0.3°, > 0.2° below setpoint temperature

0% <= 0.2° below setpoint temperature

Measured in °Fahrenheit*

* To convert degrees Fahrenheit to degrees Celsius, subtract 32 from the Fahrenheit temperature and divide the

resulting temperature by 1.8.

Kodak X-Omat Clinic 1 PROCESSOR Only:

The PROCESSOR energizes the DEVELOPER HEATER 100% to offset the cooling effect of the WASH PUMP

only when both conditions below exist:

1. The PROCESSOR energizes the WASH PUMP because an operator is feeding film.

2. The developer temperature is below the setpoint temperature.

Developer Temperature Control

Measuring the Temperature of the Developer Solution

Kodak X-Omat M43 and M43A PROCESSORS have a THERMISTOR, which measures the temperature of the

developer solution. The PROCESSOR averages 10 THERMISTOR readings in order to minimize the effect of

instantaneous changes of temperature at the THERMISTOR. The DEVELOPER TEMPERATURE DISPLAY,

located on the FRONT PANEL of the PROCESSOR, displays the temperature obtained from the averaging process,

and updates the DISPLAY every 2 seconds.

Controlling the Temperature of the Developer Solution (Heating Only)

The temperature control subsystem is responsible for maintaining the temperature of the developer solution to within

0.3°C (0.5°F) above or below the setpoint temperature under all operating conditions of the PROCESSOR.

The setpoint temperature for the developer solution may be set for any temperature between 32 − 39°C

(90 − 102.5°F). Only a qualified service provider should set or change the setpoint temperature by rotating

POTENTIOMETER (R25) on the 100 CIRCUIT BOARD. Normally, the service person sets up the PROCESSOR

to obtain optimum results for use with Kodak film and chemicals. The optimum setpoint temperature when using

Kodak film and chemicals is 33.9°C (93°F).

Calibrating the DEVELOPER TEMPERATURE DISPLAY

The DEVELOPER TEMPERATURE DISPLAY can be calibrated by rotating POTENTIOMETER (R42). Only a

qualified service provider should calibrate the DEVELOPER TEMPERATURE DISPLAY.

981095 – September 1995 17

Page 18

THEORY GUIDE

Figure 6 Control System for Developer Temperature

RT1

DEVELOPER

THERMISTOR

10 K

C@ 25

CB1

L1

R25

R42

+5 V DC

+5 V Return

-15 V DC

+15 V DC

100 PCB

DEVELOPER

TEMPERATURE

ADJUST

DEVELOPER DISPLAY

CALIBRATION

(M43,M43A)

DEVELOPER

TEMPERATURE DISPLAY

M43 AND M43A ONLY

DIVERTER VALVE ASSEMBLY

SOLENOIDS L2 AND L3

M43 AND M43A ONLY

WATER INPUT

SOLENOID

L1

L2

or N

DEVELOPER

RECIRCULATION

PUMP

B5

SSR

U3

A1

DC POWER

SUPPLY

DEVELOPER

HEATER

R1

DEVELOPER TEMPERATURE CONTROL

M43, M43A AND CLINIC 1 PROCESSORS

AC DC

SSR

U4

WASH RECIRCULATION

PUMP MOTOR

B3

H130_0003DC_

18 September 1995 – 981095

Page 19

Temperature Control

Operation of the Cooling System in the Kodak X-Omat Clinic 1 PROCESSOR Only:

During Standard Film Feeding:

Approximately 45 seconds after an operator feeds a sheet of film into the PROCESSOR, the WASH

RECIRCULATION PUMP actuates to circulate wash water through the HEAT EXCHANGER in the bottom of the

DEVELOPER TANK. Because the wash water is cold, the flow of the water through the HEAT EXCHANGER

tends to cool the temperature of the developer solution. If necessary to partially offset the decrease in temperature

of the developer solution, the DEVELOPER HEATER may energize. The cold wash water that is circulated through

the HEAT EXCHANGER in the DEVELOPER TANK eventually returns to the WASH TANK through the WASH

TUBES in the WASH RACK, thus completing the cycle. Because this cooling process takes time to work, you

should not feed more than 5 sheets of film consecutively, or else a wait condition may result.

When the Developer Temperature Rises Above the setpoint Temperature:

If the temperature of the developer solution increases and reaches 0.1°C (0.2°F) above the setpoint temperature, the

WASH RECIRCULATION PUMP energizes. The WASH RECIRCULATION PUMP circulates wash water from

the WASH TANK through the HEAT EXCHANGER in the DEVELOPER TANK and back into the WASH TANK.

This action helps to cool the developer solution.

When Additional Cooling is Required From the WATER INPUT SOLENOID in Low Water Usage Mode:

If however, the wash water becomes too warm to provide sufficient cooling for the developer solution, and the

temperature of the developer solution reaches 0.15°C (0.3°F) above the setpoint temperature, the WATER INPUT

SOLENOID energizes. The WATER INPUT SOLENOID provides cooler incoming water that reduces the

temperature of the water in the WASH TANK. The WATER INPUT SOLENOID remains energized and the cooling

process continues until the temperature of the developer solution decreases to 0.1°C (0.2°F) above the setpoint

temperature. Once the temperature of the developer solution decreases to just 0.1°C (0.2°F) above the setpoint

temperature, the WATER INPUT SOLENOID de-energizes, but the WASH PUMP remains energized circulating

wash water through the HEAT EXCHANGER until the temperature of the developer solution decreases to setpoint

temperature.

In Continuous Water Usage Mode, the WATER INPUT SOLENOID remains energized continuously after warm-up.

981095 – September 1995 19

Page 20

THEORY GUIDE

Operation of the Cooling System in the Kodak X-Omat M43 and M43A PROCESSORS

Only:

Because the M43 and M43A PROCESSORS contain a DIVERTER VALVE that the Clinic 1 PROCESSOR does

not have, the cooling system of the M43 and M43A PROCESSORS works differently from that of the Clinic 1

PROCESSOR.

During Standard Film Feeding

Approximately 45 seconds after an operator feeds a sheet of film into the PROCESSOR, the WASH

RECIRCULATION PUMP actuates to circulate wash water. Up to this point, the M43 and M43A PROCESSORS

operate similarly to the Clinic 1 PROCESSOR. In the Clinic 1 PROCESSOR, the WASH RECIRCULATION

PUMP pumps the cool wash water into the HEAT EXCHANGER in the DEVELOPER TANK. In the M43 and

M43A PROCESSORS, the wash water may or may not be pumped into the HEAT EXCHANGER depending upon

the temperature of the developer solution. If the temperature of the developer solution is within the acceptable range,

then the DIVERTER VALVE remains closed and the wash water is pumped only through the WASH SECTION of

the PROCESSOR. By not pumping the cool wash water through the HEAT EXCHANGER in the DEVELOPER

TANK, the PROCESSOR helps to maintain the setpoint temperature of the developer solution.

When the Developer Temperature Rises Above the setpoint Temperature:

If however the temperature of the developer solution reaches 0.1°C (0.2°F) above the setpoint temperature, the

PROCESSOR switches the DIVERTER VALVE to its cooling position. In this case, the WASH

RECIRCULATION PUMP circulates the cool wash water through the HEAT EXCHANGER in the DEVELOPER

TANK and then through the WASH SECTION of the PROCESSOR. The circulation of the cool wash water through

the HEAT EXCHANGER in the developer tank thereby helps to cool the developer solution.

When Additional Cooling is Required From the WATER INPUT SOLENOID in Low Water Usage Mode:

If however, the wash water becomes too warm to provide sufficient cooling for the developer solution, and the

temperature of the developer solution reaches 0.15°C (0.3°F) above the setpoint temperature, the WATER INPUT

SOLENOID energizes. The WATER INPUT SOLENOID provides cooler incoming water that reduces the

temperature of the water in the WASH TANK. The WATER INPUT SOLENOID remains energized and the cooling

process continues until the temperature of the developer solution decreases to 0.1°C (0.2°F) above the setpoint

temperature. Once the temperature of the developer solution decreases to just 0.1°C (0.2°F) above the setpoint

temperature, the WATER INPUT SOLENOID de-energizes, but the WASH PUMP remains energized circulating

wash water through the HEAT EXCHANGER until the temperature of the developer solution decreases to setpoint

temperature.

Operation of the Water Usage Mode

The PROCESSOR is factory set for Continuous Water Usage Mode. In this mode, water runs at one litre per minute.

This allows fresh water to circulate through the PROCESSOR and prevent biological growth. If biological growth is

not a concern, the PROCESSOR may be set to Low Water Usage Mode.

In Continuous Water Usage Mode, the WATER INPUT SOLENOID remains energized continuously after warm-up.

The WASH WATER DRAIN VALVE has an orifice that allows continuous draining of the WASH TANKS.

20 September 1995 – 981095

Page 21

Figure 7 Control Systems for Cooling the Developer Solution

RT1

DEVELOPER THERMISTOR

100 BOARD

Temperature Control

FILM SENSOR

U7

-

L1

L2

or N

CB1

10 K

@ 25 C

F2

+5 V Return

+5 V DC

DC POWER

SUPPLY

FILM SENSOR

U8

FILM SENSOR

U9

WATER INPUT

SOLENOID L1

DIVERTER VALVE

WASH SOLENOID L3

M43 & M43A ONLY

-15 V DC

+15 V DC

SSR

U4

A1

B2

DIVERTER VALVE

COOLING SOLENOID L2

M43 & M43A ONLY

WASH

RECIRCULATION

PUMP

CENTER

+

WASH WATER AND DEVELOPER COOLING CONTROL

DCAC

H130_0000DC_

981095 – September 1995 21

Page 22

THEORY GUIDE

Regulating the Temperature of the Fixer Solution

In the Kodak X-Omat M43 and M43A PROCESSORS Only:

The M43 and M43A PROCESSORS regulate the temperature of the fixer solution by pumping wash water through

the HEAT EXCHANGER in the bottom of the FIXER TANK. The wash water either absorbs or gives off heat

depending upon its temperature relative to the temperature of the fixer solution. The transfer of heat between the

wash water in the HEAT EXCHANGER and the fixer solution eventually cools or heats the fixer solution.

Unlike the DEVELOPER TANK, the FIXER TANK does not contain a HEATER or a THERMISTOR. Because the

temperature of the fixer solution is regulated through heat transfer and not regulated electronically, the HEATER and

THERMISTOR are not needed.

In the Kodak X-Omat Clinic 1 PROCESSOR Only:

Unlike the M43 and M43A PROCESSORS, the Clinic 1 PROCESSOR does not regulate the temperature of the fixer

solution. Therefore, the Clinic 1 PROCESSOR does not have a HEAT EXCHANGER in the FIXER TANK. The

temperature of the fixer solution depends primarily on the internal temperature of the PROCESSOR, which is

regulated by the DRYER temperature setting. However, the fixer temperature can also be affected by the ambient

temperature and room conditions. If the ambient temperature and humidity are not within the specifications outlined

in the Site Specifications, Publication Number 981087, correct “fixing” of the films cannot be ensured.

22 September 1995 – 981095

Page 23

Temperature Control

Regulating the Temperature of the DRYER

Adjusting the setpoint Temperature of the DRYER

The operator can select and adjust the setpoint temperature of the DRYER simply by rotating the DRYER

TEMPERATURE CONTROL KNOB located on the front DISPLAY PANEL of the PROCESSOR. By rotating the

DRYER TEMPERATURE CONTROL KNOB, the operator is actually rotating the DRYER HEATER

POTENTIOMETER (R3). The KNOB provides the operator with 11 detent positions to choose from. The detent

positions correspond to the setpoint temperatures outlined in the table below.

Table 4 DRYER setpoint Temperatures for the M43, M43A, and Clinic 1 PROCESSORS

Detent

Position A/D Range Celsius Fahrenheit

0 0 - 11 32° 90°

1 12 - 37 34.4° 94°

2 38 - 63 36.7° 98°

3 64 - 88 38.9° 102°

4 89 - 113 41.4° 106°

5 114 - 139 43.1° 110°

6 140 - 165 45.6° 114°

7 166 - 191 48.0° 118°

8 192 - 216 50.0° 122°

9 217 - 242 52.2° 126°

10 243 - 255 54.2° 130°

Once the operator has selected a setpoint temperature for the DRYER, the DRYER temperature control subsystem

is responsible for maintaining the temperature of the DRYER to within approximately 4°C (7°F) above or below the

setpoint temperature.

Components

The DRYER temperature control subsystem includes several components:

• DRYER THERMISTOR (RT2)

• 100 CIRCUIT BOARD

• SOLID STATE RELAY (U6) controlling DRYER BLOWER (B1) and DRIVE MOTOR (B4)

• DRYER AIR VANE SWITCH (S4)

• DRYER HEATER POTENTIOMETER (R3)

• SOLID STATE RELAY (U1) controlling DRYER HEATER (HR2)

981095 – September 1995 23

Page 24

THEORY GUIDE

Process

The components listed regulate and maintain the temperature of the DRYER through a series of steps:

[1] The 100 CIRCUIT BOARD senses air temperature changes in the DRYER when resistance variations develop

across DRYER THERMISTOR (RT2) due to temperature changes in the DRYER.

[2] RT2 varies inversely (decreasing in resistance) as DRYER air temperature increases.

[3] The 100 BOARD compares the DRYER setpoint temperature (R3) to the actual temperature (RT2) of the air

in the PLENUM.

[4] The 100 BOARD energizes SOLID STATE RELAY (U1) to control power and duty cycle to DRYER

HEATER (HR2).

[5] DRYER AIR VANE SWITCH (S4) monitors the BLOWER status and informs the 100 BOARD when it is safe

to apply power to DRYER HEATER (HR2).

Figure 8 DRYER Circuit for the M43A and Clinic 1 PROCESSORS

In M43 PROCESSORS, the HEATER COILS are Wired in Series

RT2

DRYER THERMISTOR

100 BOARD

L1

L2

or N

CB1

10 K

@ 25 C

R3

DRYER

HEATER

POTENTIOMETER

10 K

SSR

U6

S4

AIR VANE

SWITCH

F2

SSR

U1

DRYERDRIVE

BLOWERMOTOR

B3B3

MOTOR

DRYER

HEATER

+5 V DC

+5 V Return

-15 V DC

+15 V DC

A1

DC POWER

SUPPLY

DRYER TEMPERATURE CONTROL

AC DC

H130_0002DC_

24 September 1995 – 981095

Page 25

Temperature Control

DRYER Operation During PROCESSOR Start-Up

When the PROCESSOR is first energized, the DRYER HEATER energizes to 100% of its capacity until the

temperature of the DRYER reaches 4°C (7°F) above the setpoint temperature. If the temperature of the DRYER has

not reached at least 3°C (5°F) below the setpoint temperature within 45 minutes after the operator energized or reset

the PROCESSOR, the PROCESSOR indicates an error condition. The PROCESSOR may display either a DRYER

Under Range Error (E10) or a DRYER Under Temperature Warning (E13), depending upon how far the DRYER

temperature is below the setpoint temperature.

DRYER Operation During the Processing of Films

Located in the DRYER SECTION of the PROCESSOR, is a DRYER HEATER. The 100 CIRCUIT BOARD

controls the DRYER HEATER by sending an actuation command to SSR U1. SSR U1 then controls the current

necessary to energize the DRYER HEATER.

The PROCESSOR energizes the DRYER HEATER to 100% of its capacity in 2 operating conditions:

1. The temperature of the DRYER is more than 2.3°C (4°F) below the setpoint temperature, and the DRYER

TEMPERATURE CONTROL KNOB is set between 1 and 8.

2. The DRYER TEMPERATURE CONTROL KNOB is set at 9 or 10.

The DRYER HEATER remains energized at 100% of its capacity until one of the following conditions exists:

1. The temperature of the DRYER reaches 4°C (7°F) above the setpoint temperature with the DRYER

TEMPERATURE CONTROL KNOB set between 1 and 8.

2. The 2 Minute Film Clear TIMER expires and the DRYER TEMPERATURE CONTROL KNOB is set

at 9 or 10.

3. The temperature of the DRYER reaches 66°C (150°F).

4. The temperature of the developer reaches more than 3°C (5°F) above the setpoint temperature.

The DRYER HEATER energizes again if, during normal operation, the temperature of the DRYER falls to between

2.3 and 4°C (4 and 7°F) below the setpoint temperature. The DRYER HEATER remains energized until the

temperature of the DRYER is again within 2.3°C (4°F) of the setpoint temperature.

The PROCESSOR energizes the DRYER HEATER to only 60% of its capacity if the temperature of the DRYER

reaches 4°C (7°F) above the setpoint temperature and the DRYER TEMPERATURE CONTROL KNOB is set

between 1 and 8.

981095 – September 1995 25

Page 26

THEORY GUIDE

Explanation of Flowchart for DRYER Operation During the Feeding of Film

[1] The MICROPROCESSOR energizes the DRYER BLOWER.

[2] The MICROPROCESSOR sets a 2-minute DELAY TIMER and checks the status of the AIR VANE SWITCH.

(a) If the AIR VANE SWITCH is open and the 2-minute DELAY TIMER has expired, then Error 03 - Air

Vane Switch Error is displayed on the DISPLAY PANEL.

(b) If the AIR VANE SWITCH is closed, then the MICROPROCESSOR completes the following actions:

• energizes the DRYER HEATER

• checks the status of the AIR VANE SWITCH

• reads the DRYER HEATER POTENTIOMETER (R3) to determine the setpoint temperature of the

DRYER

• reads the THERMISTOR to determine the actual temperature of the DRYER

• The DRYER at this point, operates normally at 100% of its capacity until the temperature of the

DRYER reaches 4°C (7°F) above the setpoint temperature.

• If the 2-minute FILM CLEAR TIMER has expired and the temperature of the DRYER has increased

to 4°C (7°F) above the setpoint temperature, provided that no film has been sensed, then the

MICROPROCESSOR completes the following actions:

– de-energizes the DRYER HEATER

– de-energizes the DRYER BLOWER

– sets the 5-minute STANDBY TIMER

26 September 1995 – 981095

Page 27

Figure 9 DRYER Control Flowchart for PROCESSOR During the Processing of Films

Temperature Control

Exit Standby Mode,

Lead Edge of Film

Detected

N

Is Temperature

> 150 ?

Y

Dryer potentiometer

Position = 9 or 10 ?

Y

Energize

Heater 100%

Airflow Still

Present?

Y

Read Dryer

Potentiometer

Read

Thermistor

Y

N

N

Air Flow

Present?

N

2 Minute

Delay Timer

Expire?

Y

Air Vane

Switch Error

Displayed

Is Temperature > =

setpoint + 7 ?

Y

N

N

Error Mode

**

Is Temperature

Less Than

Setpoint - 4 ?

Energize

Blower

Start 2 Minute

Delay Timer

Error mode will de-energize

Dryer Heater.

**

Y

Energize

Heater 100%

N

Is Temperature < =

Setpoint + 7 ?

Y

Energize

Heater 100%

De-energize Heater

De-energize Blower

Standby Mode

N

Energize

Heater 60%

N

Y N

2 Minute

Film Clear Timer

**

Expired

Y

Is Temperature

> = Setpoint ?

Y

Airflow Still

Present?

N

Energize

Heater 60%

2 Minute Film Clear Timer is started

when the trail edge of film is detected.

Developer Over

Temperature ?

N

Energize

Heater 100%

Energize

Heater 60%

**

Set Air Vane

Switch Error

Y

*

Film Clear Timer

*

De-energize

Heater

Error Mode

2 Minute

Expired

Y

Error mode will de-energize

Dryer Heater.

*

Read

Thermistor

Read Dryer

Potentiometer

Y

Airflow Still

Present?

H130_9003EC

NN

981095 – September 1995 27

Page 28

THEORY GUIDE

DRYER Operation While the PROCESSOR is in Standby Mode

Both the DRYER HEATER and DRYER BLOWER energize on and off while the PROCESSOR is in Standby

Mode. The DRYER HEATER and DRYER BLOWER remain “off” for 5 minutes. However the length of time that

the DRYER HEATER and DRYER BLOWER remain “on” may change. The components can remain “on”

anywhere from 30 seconds to as long as is required for the DRYER to reach 4°C (7°F) above the setpoint temperature.

For example, if the input voltage to the PROCESSOR is low, the “ON” cycles may become longer.

DRYER Temperature Control Algorithm to Assist With the Cooling of the Developer

Solution

When the temperature of the developer solution reaches 0.3°C (0.5°F) over the setpoint temperature, the DRYER

BLOWER energizes to help remove hot air and draw in cooler air in order to assist with the cooling of the developer

solution. The DRYER BLOWER remains energized until the temperature of the developer is within 0.1°C (0.2°F)

of its setpoint temperature. Once the developer is within 0.1°C (0.2°F) of its setpoint temperature, the DRYER

HEATER energizes and remains energized until the temperature of the DRYER reaches the setpoint temperature.

Once the DRYER is at setpoint, the entire DRYER system enters the Standby Mode.

DRYER Operation During the Cooling of the Developer Solution

The DRYER HEATER de-energizes, and the DRYER BLOWER remains energized in order to vent hot air, thereby

helping to cool the developer solution when the following conditions exist:

• the FILM SENSORS do not detect film

• the temperature of the developer solution is more than 0.3°C (0.5°F) above the developer setpoint temperature

and Service Error 08 - Developer Over Temperature Range is displayed on the DISPLAY PANEL of the

PROCESSOR

If the conditions listed above exist, then the DRYER system initiates the following actions:

• the DRYER HEATER is de-energized if it is currently energized

• the DRYER HEATER remains de-energized until the temperature of the developer solution is 0.1°C (0.2°F)

above the developer setpoint temperature

• the DRYER HEATER is then energized until the air temperature in the DRYER reaches the setpoint temperature

– at this point, the DRYER enters Standby Mode

28 September 1995 – 981095

Page 29

Temperature Control

Explanation of Flowchart for DRYER Operation During Standby Mode

Every 5 minutes the PROCESSOR completes the standby cycle and exits Standby Mode for a minimum of

30 seconds. The MICROPROCESSOR first checks the status of the AIR VANE SWITCH.

[1] If the AIR VANE SWITCH is closed, the MICROPROCESSOR displays Error 03 - Air Vane Switch Error on

the DISPLAY PANEL of the PROCESSOR.

[2] If the AIR VANE SWITCH is open, the MICROPROCESSOR completes the following actions:

• energizes the DRYER BLOWER

• starts the 2-minute DELAY TIMER

• checks the status of the AIR VANE SWITCH continually until air flow is detected

(a) If the 2-minute DELAY TIMER has expired and no air flow has been detected, the MICROPROCESSOR

displays Service Error 02 - Loss of Air Flow Error on the DISPLAY PANEL of the PROCESSOR.

(b) If air flow is detected, the MICROPROCESSOR starts a 30-second TIMER and completes the following

actions repeatedly for as long as air flow is detected:

• checks for the presence of film

• reads the DRYER HEATER POTENTIOMETER (R3) to determine the setpoint temperature of the

DRYER

• reads the THERMISTOR to determine the actual temperature of the DRYER

• checks whether the temperature of the DRYER is more than 4°C (7°F) above the setpoint temperature

If the DRYER temperature is less than 4°C (7°F) above setpoint, the MICROPROCESSOR checks

whether the temperature of the developer solution is over the setpoint temperature.

• If the developer is over temperature, the DRYER HEATER de-energizes but the DRYER BLOWER

remains energized to assist with the cooling of the developer solution.

• If the developer is not over temperature, the DRYER HEATER energizes to 100% of its capacity until

the temperature of the DRYER reaches 4°C (7°F) above the setpoint temperature.

• Once the DRYER temperature reaches 4°C (7°F) above setpoint, the MICROPROCESSOR

completes the following actions:

– de-energizes the DRYER HEATER

– de-energizes the DRYER BLOWER, provided that the 30-second TIMER has expired

– starts the 5 minute Standby TIMER, provided that the 30-second TIMER has expired

• If the operator feeds film during this cycle, the PROCESSOR exits the Standby Mode and enters the

Film Run Mode.

• If the operator increases the setting of the DRYER TEMPERATURE CONTROL KNOB, the

PROCESSOR exits the Standby Mode in order to increase the DRYER temperature and cycles

through the steps outlined above.

981095 – September 1995 29

Page 30

THEORY GUIDE

Figure 10 DRYER Control Flowchart for PROCESSOR When Cycling Through Standby Mode

Energize

Processor

Start 30 sec.

Timer

Y

Energize

Blower

Start 2 Minute

Delay Timer

Air Flow

Present?

N

2 Minute

Delay Timer

Expire?

Y

N

Air Flow Still

Present?

Y

N

N

Air Vane

Switch

Stuck?

Y

Air Vane

Switch Error

Displayed

Error Mode

Set Loss of Air Flow

*

Error

Error mode will

*

turn OFF the

Dryer Heater.

Dryer Film

Run Mode

Y

Y

Y

5 Minute

Standby Timer

Expired?

N

Setpoint

Increased?

Read Dryer

Potentiometer

N

Film

Present?

Start 5 Minute

Standby Timer

De-energize

Blower

N

Energize

Heater

100%

N

De-energize

Y

Developer

Over

Temperature?

Heater

Film

Present?

N

Read Dryer

Potentiometer

Read

Thermistor

Y

Temperature

Below

Setpoint +7

Degrees F

N

De-energize

Heater

Y

Dryer Film

Run Mode

N

30 sec

Timer

Expire?

Y

H130_9004EC

30 September 1995 – 981095

Page 31

Control Systems

Section 4: Control Systems

AC and DC INTERLOCK SWITCHES

Note

The DC INTERLOCK SWITCH S6 is only found in PROCESSORS that either have a serial number of 350 or

higher, or have Mod 1 installed. PROCESSORS having a serial number below 350 or without Mod 1 installed have

a single SWITCH that incorporates both the AC and DC interlocks.

The INTERLOCK SWITCH(ES) serve(s) as safety feature(s) for the operator. The INTERLOCK SWITCH(ES)

prevent(s) the PROCESSOR from operating without the TOP COVER installed. Therefore, the operator cannot feed

films without the TOP COVER installed. Having the TOP COVER installed when the operator feeds films protects

the operator from possible harm from contact with moving parts.

The AC INTERLOCK SWITCH S5 is located on the drive side of the PROCESSOR near the DRYER SECTION.

The DC INTERLOCK SWITCH S6 is located on the non-drive side of the DRYER PLENUM and is actuated by a

MAGNET inside the TOP COVER.

MAIN CIRCUIT BREAKER CB1

The MAIN CIRCUIT BREAKER CB1 is located on the DISPLAY PANEL on the front of the PROCESSOR.

Moving the MAIN CIRCUIT BREAKER CB1 to the “ON” position, allows you to energize the PROCESSOR. The

PROCESSOR contains a built-in safety feature that will not allow the PROCESSOR to energize if the TOP COVER

is not installed correctly onto the PROCESSOR.

Once you actuate the MAIN CIRCUIT BREAKER CB1, each separate system of the PROCESSOR energizes.

• The DRIVE MOTOR rotates the MAIN DRIVE SHAFT and the DRIVE ROLLERS.

• The DEVELOPER and FIXER RECIRCULATION PUMPS recirculate the processing solutions in the

DEVELOPER and FIXER TANKS.

• the DC POWER SUPPLY (A1) and the low voltage TRANSFORMER (T1) provide power to the 100 CIRCUIT

BOARD.

100 CIRCUIT BOARD

The 100 CIRCUIT BOARD contains a MICROPROCESSOR, which monitors and controls the PROCESSOR as

shown.

Table 5 Monitor and Control Functions of the MICROPROCESSOR

Components Monitored Components Controlled

SENSORS STATUS INDICATORS

SWITCHES SOLID STATE RELAYS

981095 – September 1995 31

Page 32

THEORY GUIDE

System Initialization

The software initialization procedure occurs any time you:

• energize the PROCESSOR

• reset the PROCESSOR by:

– placing the TOP COVER on the PROCESSOR

– exiting from the Diagnostic Mode

The PROCESSOR performs the initialization routine using limited hardware on the 100 CIRCUIT BOARD.

The hardware completes the following basic self-checks on the 100 CIRCUIT BOARD to ensure that the

MICROPROCESSOR can execute its resident programs.

• RAM test

• PROM checksum test

• I/O PORT check

Sequence of Events after the Completion of the Initialization Routine

Once the 100 CIRCUIT BOARD completes these self-checks successfully, the PROCESSOR performs the actions

listed below:

• beeps 3 times

• energizes the WATER INPUT SOLENOID to fill the WASH TANK

• illuminates the WAIT INDICATOR

• checks the AIR VANE SWITCH for the absence of air flow

– if it detects air flow, it indicates an air flow error

– if it does not detect air flow, it energizes the DRYER BLOWER and DRIVE MOTOR

• checks the AIR VANE SWITCH again, for the presence of air flow

• energizes the DRYER HEATER and the BLOWER to achieve the correct operating conditions

• energizes the DEVELOPER HEATER

• energizes the DEVELOPER RECIRCULATION PUMP

• energizes the FIXER RECIRCULATION PUMP

• energizes the WASH RECIRCULATION PUMP

Note

If the operator energizes the PROCESSOR without the TOP COVER installed, the PROCESSOR beeps 3 times and

enters Replenishment Calibration Mode.

32 September 1995 – 981095

Page 33

Control Systems

Standby Mode

The PROCESSOR enters the Standby Mode when either of the following conditions exists:

1. the temperature of the DRYER reaches 2.5°C (7°F) above its setpoint temperature

2. approximately 2 minutes after the FILM SENSORS detect the trailing edge of a sheet of film on the FEED TRAY

unless the operator feeds a second sheet of film

While in the Standby Mode, the PROCESSOR de-energizes certain components or operates them intermittently in

order to conserve energy and wear on parts:

• de-energizes the WASH RECIRCULATION PUMP, unless the PUMP is needed for cooling

• maintains developer temperature at its setpoint temperature

• de-energizes the DRYER HEATER, DRYER BLOWER and the MAIN DRIVE MOTOR

– every 5 minutes, the PROCESSOR energizes the DRYER BLOWER, DRYER HEATER and MAIN DRIVE

MOTOR for a minimum of 30 seconds or until the temperature of the DRYER reaches 2.5°C (7°F) above its

setpoint temperature

The PROCESSOR, even though in Standby Mode, must occasionally energize the WASH RECIRCULATION

PUMP and the WATER INPUT SOLENOID (L1) to cool the developer solution (intermittently) if the temperature

of the developer solution is 0.1°C (0.2°F) above the setpoint temperature.

Once the FILM SENSORS detect a film on the FEED TRAY, the PROCESSOR automatically exits the Standby

Mode and begins processing films.

Continuous Mode

A qualified service provider can configure the PROCESSOR to operate in the Continuous Mode. The Continuous

Mode feature can be selected to help eliminate ROLLER artifacts from appearing on films. The Continuous Mode

should be selected for sites with extreme ambient and operating conditions. See the Site Specifications, Publication

Number 981087, for the recommended ambient conditions. The Continuous Mode can also be selected when

diagnosing errors with the PROCESSOR. All components of the MAIN DRIVE, FILM TRANSPORT, and DRYER

systems remain energized continuously for as long as the PROCESSOR is in the Continuous Mode.

981095 – September 1995 33

Page 34

THEORY GUIDE

MAIN DRIVE SYSTEM

Overview

Once the FILM SENSORS detect film, the PROCESSOR exits the Standby Mode and enters the Operating Mode.

When the PROCESSOR enters the Operating Mode, the MAIN DRIVE system energizes and is able to transport

film. If you operate the PROCESSOR in the Continuous Mode, the MAIN DRIVE system and all other systems

remain operational at all times. Continuous operation of the PROCESSOR can lead to wear on all the parts.

Sequence of Events for the Operating Mode

[1] When the PROCESSOR enters the Operating Mode, a series of actions occurs:

(a) The MAIN DRIVE MOTOR (B4) activates.

(b) The DRYER BLOWER (B1) activates.

(c) The DRYER HEATER (HR2) energizes.

(d) The WASH RECIRCULATION PUMP (B2) energizes, providing water to the WASH RACK.

[2] While the PROCESSOR is in the Operating Mode, the following series of actions occurs:

(a) The MAIN DRIVE MOTOR (B4) provides rotational energy for the DRIVE system, which is used to

transport film.

Note

The MAIN DRIVE MOTOR for the M43A and Clinic 1 PROCESSORS is a 115 V AC 50/60 Hz MOTOR. The

MAIN DRIVE MOTOR for the M43 PROCESSOR is a 230 V AC 50/60 Hz motor. The MAIN DRIVE MOTOR

has an internal GEAR reduction unit to decrease its RPM range (250 RPM on 50 hertz power and 300 RPM range at

60 hertz). An additional SPROCKET equalizes SHAFT rotation so that the MOTOR transports the film at

1.016 cm/sec (0.4 in./sec). In 1 minute the film travels 60.96 cm (24 in.).

(b) The MAIN DRIVE MOTOR rotates the MAIN DRIVE SHAFT with a DRIVE CHAIN.

(c) A series of WORMS located on the MAIN DRIVE SHAFT drives the DRIVE ROLLERS in the

DEVELOPER RACK, FIXER RACK, and WASH RACK.

(d) A GEAR on the DRIVE ROLLER of the WASH RACK drives the ROLLERS in the DRYER RACK.

(e) The PROCESSOR automatically de-energizes the MAIN DRIVE MOTOR while the PROCESSOR is in

the Standby Mode.

34 September 1995 – 981095

Page 35

Figure 11 The MAIN DRIVE System

60 Hz SPROCKET

16-TOOTH

Control Systems

WASH/DRYER

DRIVE GEAR

FIXER

DRIVE

GEAR

50 Hz SPROCKET

20-TOOTH

DRIVE

CHAIN

MAIN DRIVE

MOTOR

MAIN DRIVE

SHAFT

DEVELOPER DRIVE

GEAR

WORM

(1 of 5)

H130_0167HCC

H130_0167HA

Detecting Film

Overview

The operator should feed a sheet of film along the recommended left edge of the FEED TRAY and into the set of

ENTRANCE ROLLERS. The M43 and M43A PROCESSORS use 3 FILM SENSORS to determine the area of the

sheet of film being fed. The Clinic 1 PROCESSOR uses the same 3 FILM SENSORS, but in the Clinic 1

PROCESSOR the FILM SENSORS determine the length of the film, not the area of the film. The FILM SENSORS

must approximate the film area or length in order to determine the amount of replenishment solution needed to

maintain sensitometric control. The FILM SENSORS use LIGHT EMITTING DIODE (LED) technology to emit

infrared (IR) light energy. The FILM SENSORS pulse the IR light they produce to prevent film exposure. The FILM

SENSORS detect the leading edge of a sheet of film when the film reflects the IR light to a light sensitive receptor

built into the SENSOR. The FILM SENSORS detect the trailing edge of the film when the film no longer reflects

the IR light.

The 3 FILM SENSORS are in 3 different locations on the FEED TRAY:

(RIGHT) FILM SENSOR (U7) - 10.8 cm (4.3 in.) from the left edge of the FEED TRAY

(MIDDLE) FILM SENSOR (U8) - 26.0 cm (10.3 in.) from the left edge of the FEED TRAY

(LEFT) FILM SENSOR (U9) - 40.0 cm (15.8 in.) from the left edge of the FEED TRAY

Note

If the FILM SENSORS detect a film longer than 1.5 m (5 ft), the PROCESSOR indicates an error condition.

981095 – September 1995 35

Page 36

THEORY GUIDE

Film Approximation for the Kodak X-Omat Clinic 1 PROCESSOR Only:

The Kodak X-Omat Clinic 1 PROCESSOR detects only the length of film an operator feeds into the PROCESSOR.

The software always assumes the width of the film is 43.2 cm (17 in.) when the PROCESSOR calculates

replenishment volumes.

For example, the PROCESSOR calculates the area for a 28 x 35 cm (11 x 14 in.) film fed 35 cm (14 in.) wide to be

1204 cm2 (187 sq in.).

Film Approximation for the Kodak X-Omat M43 and M43A PROCESSORS Only:

The Kodak X-Omat M43 and M43A PROCESSORS detect the actual length of the film the operator feeds and

approximates the width by the use of the 3 FILM SENSORS. See the table below for the estimated dimensions that

the PROCESSOR uses in calculating film area.

Table 6 Film Area Approximations for the M43 and M43A PROCESSORS

SENSOR 1 Blocked SENSOR 2 Blocked SENSOR 3 Blocked Estimated Film Width

Yes No No 26 cm (10.25 in.)

No Yes No 29.2 cm (11.5 in.)

No No Yes 17.1 cm (6.75 in.)

Yes Yes No 40 cm (15.75 in.)

No Yes Yes 32.4 cm (12.8 in.)

Yes Yes Yes 43 cm (17 in.)

Yes No Yes 43 cm (17 in.)

Replenishment of the Developer and Fixer Processing Solutions

Overview

Note

For information about the recommended replenishment rates of the processing solutions, see either Publication

Number 1C0578 located in the pocket of your publications binder or Service Bulletin No. 30.

When the developer and fixer solutions process films, the active chemicals in the solutions react and eventually lose

potency. The PROCESSOR supplies the DEVELOPER and FIXER TANKS with a preset amount of developer and

fixer solutions as determined by either the area of film processed, or by time if the PROCESSOR is set for the

Flooded Replenishment Mode. By replenishing the solutions, the PROCESSOR maintains an effective level of

chemical activity in the solutions. The volume of developer and fixer solution to be delivered during replenishment

is set at the factory. However, the operator can alter the volumes added by doing the procedure in the section

“Replenishment Check Mode” on Page 40..

Replenishment Modes

The PROCESSOR can operate in either of 2 Replenishment Modes:

• Flooded Replenishment Mode

• Normal Replenishment Mode

The PROCESSOR is most commonly operated in the Normal Replenishment Mode. The Normal Replenishment

Mode will accommodate most installation sites and operating conditions. However, the Flooded Replenishment

Mode will ensure stable processing solutions in sites processing less than 20 sheets of 35 x 43 cm (14 x 17 in.) films

per 8 hours.

36 September 1995 – 981095

Page 37

Control Systems

Flooded Replenishment

If the operator configures the PROCESSOR for the Flooded Replenishment Mode, the PROCESSOR adds a volume

of solution equal to the replenishment volume required for 238 sq in. of film every 24 minutes. This maintains the

freshness and activity of the processing solutions, even if the operator feeds no additional films. This rate of

replenishment is equivalent to processing 20 sheets of 35 x 43 cm (14 x 17 in.) films in an 8-hour period. The

PROCESSOR also adds replenishment water whenever an operator feeds a sheet of film.

A qualified service provider can configure your PROCESSOR to operate in the Flooded Replenishment Mode by

moving the position of JUMPER (E1) on the 100 CIRCUIT BOARD.

Normal Replenishment

The replenishment control subsystem supplies developer and fixer solution to the DEVELOPER and FIXER

PROCESSING TANKS any time the REPLENISHMENT PUMPS energize. The subsystem delivers a volume of

processing solutions based on the approximate film area determined by the 3 FILM SENSORS. The PROCESSOR

calculates film area using the following formula:

Replenishment area of current film

volume for film = -------------------------- ( volume for 238 sq in. )

238 sq in. as set in Calibration

Mode

SI Units: 238 sq in. = 1505 cm(2)

The actual volume of replenishment solutions that the REPLENISHMENT system delivers depends on the actual

size of the film fed.

The list below describes in more detail the replenishment of the processing solutions.

• If the approximated film area is less than or equal to 238 sq in., the PROCESSOR replenishes the processing

solutions when the 3 FILM SENSORS detect the trailing edge of the film.

• If the approximated film area is greater than 238 sq in., the PROCESSOR replenishes the processing solutions

twice:

– when the FILM SENSORS detects 238 sq in.

– when the FILM SENSORS detect the trailing edge of the film

Examples:

If the area of a sheet of 14 x 36 in. tri-fold film (width of film is estimated to be 15.75 in.) is fed into the

PROCESSOR, and replenishment is set at 100 mL/238 sq in., the PROCESSOR would deliver the processing

solutions as outlined below:

• Approximately 100 mL after the FILM SENSORS detect 15.1 in. of film.

• Approximately 100 mL after the FILM SENSORS detect a total of 30.2 in. of film.

• Approximately 6 mL after the FILM SENSORS detect the trailing edge of the film.

If the operator feeds an 11 x 14 in. sheet of film into the PROCESSOR (14 in. wide), the replenishment system will

replenish the processing solutions only once: when the 3 FILM SENSORS detect the trailing edge of the film. Since

the approximate area of the film detected (173 sq in.) isless than 238 sq in., the replenishment system only delivers

processing solutions when the SENSORS detect the trailing edge of the film. Since the approximate area of the film

detected is about 73% of the 238 sq in. required in order to add 100 mL of processing solutions, the replenishment

system will deliver about 73% of the processing solutions, or approximately 73 mL.

981095 – September 1995 37

Page 38

THEORY GUIDE

Figure 12 The Replenishment Systems

AUDIO

ALARM

LS1

100 BOARD

FILM SENSOR

U7

-

L1

L2

or N

SERVICE

CB1

READY

DS1

WAIT

DS2

DS3

SSR

U5

DEVELOPER/

FIXER

B3

REPLENISHMENT

PUMP MOTOR

+5 V DC

+5 V Return

-15 V DC

+15 V DC

SSR

U4

B2

WASH

RECIRCULATION

PUMP MOTOR

FILM SENSOR

U8

FILM SENSOR

U9

CENTER

+

F2

A1

DC POWER

SUPPLY

FILM DETECTION AND REPLENISHMENT SYSTEMS

AC DC

H130_0001DC_

38 September 1995 – 981095

Page 39

Control Systems

Replenishment of the Wash Water

Overview

The PROCESSOR can be set in two modes for water replenishment:

• Continous Water Usage Mode

• Low Water Usage Mode

Continuous Water Usage Mode

The PROCESSOR is factory-set in this mode. The INPUT WATER SOLENOID is energized continuously, allowing

water to overflow and drain out through the DRAIN VALVE. In this mode, water drains continuously.

Low Water Usage Mode

The PROCESSOR replenishes wash water every time a sheet of film is fed. The PROCESSOR calculates the volume

of water to deliver based on 2 factors:

1. the approximate film area detected

2. the volume of water (if any) that the replenishment system delivered for cooling after the last film was fed

If the PROCESSOR needed to add wash water in order to help cool the temperature of the developer solution, the

PROCESSOR automatically decreases that amount of water from the total volume of water to deliver for

replenishment.

The PROCESSOR supplies 850 mL (28.7 fluid ounces) of water to the RECIRCULATION system whenever the 3

2

FILM SENSORS detect 1505 cm

sheet of film) of film passing by the FILM DETECTOR ASSEMBLY. If the operator feeds a sheet of film that has

2

an area less than 1505 cm

(238 sq in.), the PROCESSOR replenishes the wash water by supplying a percentage of

the 850 mL.

In this mode, you must rotate the DRAIN VALVE KNOBS

, the area for a 35 x 43 cm sheet of film, (238 sq in., the area for a 14 x 17 sq in.

1

⁄4 turn to drain the water.

Note

Low Water Usage Mode is only recommended in locations where biological growth is not a concern.

981095 – September 1995 39

Page 40

THEORY GUIDE

Wash Water Control

Wash Control

Any time the operator energizes the PROCESSOR, the WATER INPUT SOLENOID (L1) which controls the

incoming wash water, energizes. The WATER INPUT SOLENOID requires 8 minutes to fill the WASH TANK with

fresh water. During normal operation, the PROCESSOR adds additional water to aid in the cooling of the developer

solution.

45 Second Safety Delay

The WASH RECIRCULATION PUMP does not energize until 45 seconds after the operator energizes the

PROCESSOR, even if the operator has already fed a film, or even if the the PROCESSOR requires fresh water to aid

in the cooling of the developer solution. The 45 second delay prevents the WASH RECIRCULATION PUMP from

operating without water and therefore prevents damage to the PUMP.

Feeding a Film After the “Warm-Up” Period

When an operator feeds a film after the “warm-up” period, the PROCESSOR does not immediately energize the

WASH RECIRCULATION PUMP. The WASH RECIRCULATION PUMP does not energize until 55 seconds

after the FILM SENSORS detect the leading edge of the film.

• If the operator does not feed additional films, the PROCESSOR de-energizes the WASH RECIRCULATION

PUMP 70 seconds after the FILM SENSORS detect the trailing edge of the film.

• If the operator feeds multiple films consecutively, the PROCESSOR energizes the WASH RECIRCULATION

PUMP 55 seconds after it detects the first leading edge of film.

• The WASH RECIRCULATION PUMP remains energized until 70 seconds after the PROCESSOR detects the

last trailing edge of the film. This is done to limit the length of time that water is flowing through the HEAT

EXCHANGER in the DEVELOPER SECTION.

Removing Air from the TUBING

After the 8 minutes, required for the WASH TANK to fill, has elapsed, the PROCESSOR energizes the WASH

RECIRCULATION PUMP and the DEVELOPER COOLING SOLENOID (M43 and M43A only) for

approximately 20 seconds to remove any air from all TUBING including the HEAT EXCHANGER. During the 20

seconds that the cooling system removes air from the TUBING, the individual parts are operating as outlined:

• the WATER INPUT SOLENOID remains energized

• the DEVELOPER COOLING SOLENOID energizes (M43 and M43A Only)

• the WASH RECIRCULATION PUMP remains energized for an additional 20 seconds

Replenishment Check Mode

The operator can adjust the base replenishment volumes by blocking the FILM SENSORS with film to provide

information to the 100 CIRCUIT BOARD.

[1] With the PROCESSOR still energized, remove the TOP COVER of the PROCESSOR. The PROCESSOR will

enter the Replenishment Check Mode.

(a) If while the PROCESSOR is in the Replenishment Check Mode you block the middle FILM SENSOR,

the ALARM sounds twice and the PROCESSOR adds replenishment solution equal to the preset volume

2

that the PROCESSOR would deliver for a 35 x 43 cm sheet of film or for an area of 1505 cm

sheet of film or for an area of 238 sq in.).

(b) The PROCESSOR sounds the ALARM only once if you block either the LEFT or RIGHT FILM

SENSOR.

(c) If you block the left FILM SENSOR, the PROCESSOR decreases the base replenishment volume by

approximately 5 mL for each time you block the SENSOR.

(d) If you block the right FILM SENSOR, the PROCESSOR increases the base replenishment volume by

approximately 5 mL for each time you block the SENSOR.

(14 x 17 in.

40 September 1995 – 981095

Page 41

Control Systems

Note

For information about how to perform the replenishment check procedure, see the Operator Manual, Publication

Number 981089, or the Installation Instructions, Publication Number 981088.

[2] By installing the TOP COVER onto the PROCESSOR, you exit Replenishment Check Mode and return the

PROCESSOR to normal operation.

981095 – September 1995 41

Page 42

THEORY GUIDE

Section 5: ALARM Control

Overview

The AUDIO ALARM beeps to indicate various status conditions of the PROCESSOR.

• Normal Operating Conditions

– that the PROCESSOR successfully completed a “Power On Self Test” (POST) upon being energized

– that the PROCESSOR can accept a second sheet of film

– that a warning condition exists

• In Replenishment Check Mode

– that 1 of the FILM SENSORS detects a sheet of film

• Error Condition

– that the PROCESSOR has detected an error or warning condition that requires attention

ALARMS Heard During Normal Operating Conditions

The PROCESSOR’S AUDIO ALARM beeps 3 times when the operator first energizes the PROCESSOR.

The AUDIO ALARM then beeps as a film feeding signal to the operator whenever the FILM SENSORS have

detected the presence of film. The film feeding signal consisting of 1 beep that lasts for a full second, sounds

6 seconds after the FILM SENSORS detect the trailing edge of a sheet of film. The beep actually indicates a couple

of possible operator responses:

• that the operator may feed a second sheet of film into the PROCESSOR

• that the operator may turn on the darkroom lights if he or she does not have any more film to process

The 6 second delay allows sufficient distance between films to prevent the films from overlapping in the various

sections of the PROCESSOR. By not allowing the films to overlap, the operator is taking steps to avoid the under

development of those films and film transport problems.

ALARMS Heard During Warning Conditions

The AUDIO ALARM may also beep to indicate a warning condition or an error that the operator can correct. If the

operator attempts to feed a sheet of film into the PROCESSOR before correcting the warning or error condition, the

ALARM will beep twice when the PROCESSOR detects the leading edge of a sheet of film.

ALARMS Heard During Fatal Error Conditions

If the PROCESSOR detects a fatal error after an operator feeds a sheet of film, the ALARM beeps on for 2 seconds

and off for 2 seconds until the sheet of film exits into the RECEIVING BIN.

ALARMS Heard While the PROCESSOR Is In The Replenishment Check Mode

When the PROCESSOR is in the Replenishment Check Mode, the ALARM beeps on 2 occasions:

• when the PROCESSOR increments or decrements the replenishment rate, the ALARM beeps once

• when the PROCESSOR energizes the REPLENISHMENT PUMPS, the ALARM beeps twice

42 September 1995 – 981095

Page 43

ALARM Control

Publication History

Print Date Pub. No. ECO No. Affected Pages File Name Notes

Oct. 1994 981095 26622-117 All Pages 3229tg_a_117.txt 1st Printing

SEP95 981095 2622-157 All Pages tg3229_1_01sep95.doc Revision due to

product changes;

reprinted entire

manual due to

new publication

software used for

documentation

981095 – September 1995 43

Page 44

Kodakand X-Omatare trademarks.

tg3229_1_01sep95.doc

Printed In USA

HEALTH SCIENCES DIVISION

EASTMAN KODAK COMPANY

● ROCHESTER, N.Y. 14650

Loading...

Loading...