Page 1

SERVICE MANUAL

for the

Publication No. 981901

September 1996

Supersedes September 1992

Kodak

M35-M and M35A-M

X-Omat

H112_0008AC

PROCESSORS

© Eastman Kodak Company

Page 2

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be liable

for any loss or damage, including consequential or special damages, resulting from any use of

this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Warning

To avoid hazardous conditions, keep floors and floor coverings around your

associated drains clean and dry at all times. Any accumulation of fluids from mixing tanks, drain lines, etc, should

be cleaned upimmediately. Inthe event of an accumulation of liquiddue to backup, overflow, or other malfunctions

of the drain associated with your

Kodak X-Omat

PROCESSOR, call a plumber or other contractor to correct any

problem with the drain. Kodak accepts no responsibility or liability whatsoever for the serviceability of any drain

connected to or associated with a

Kodak X-Omat

PROCESSOR. Such drains are the sole responsibility of the

customer.

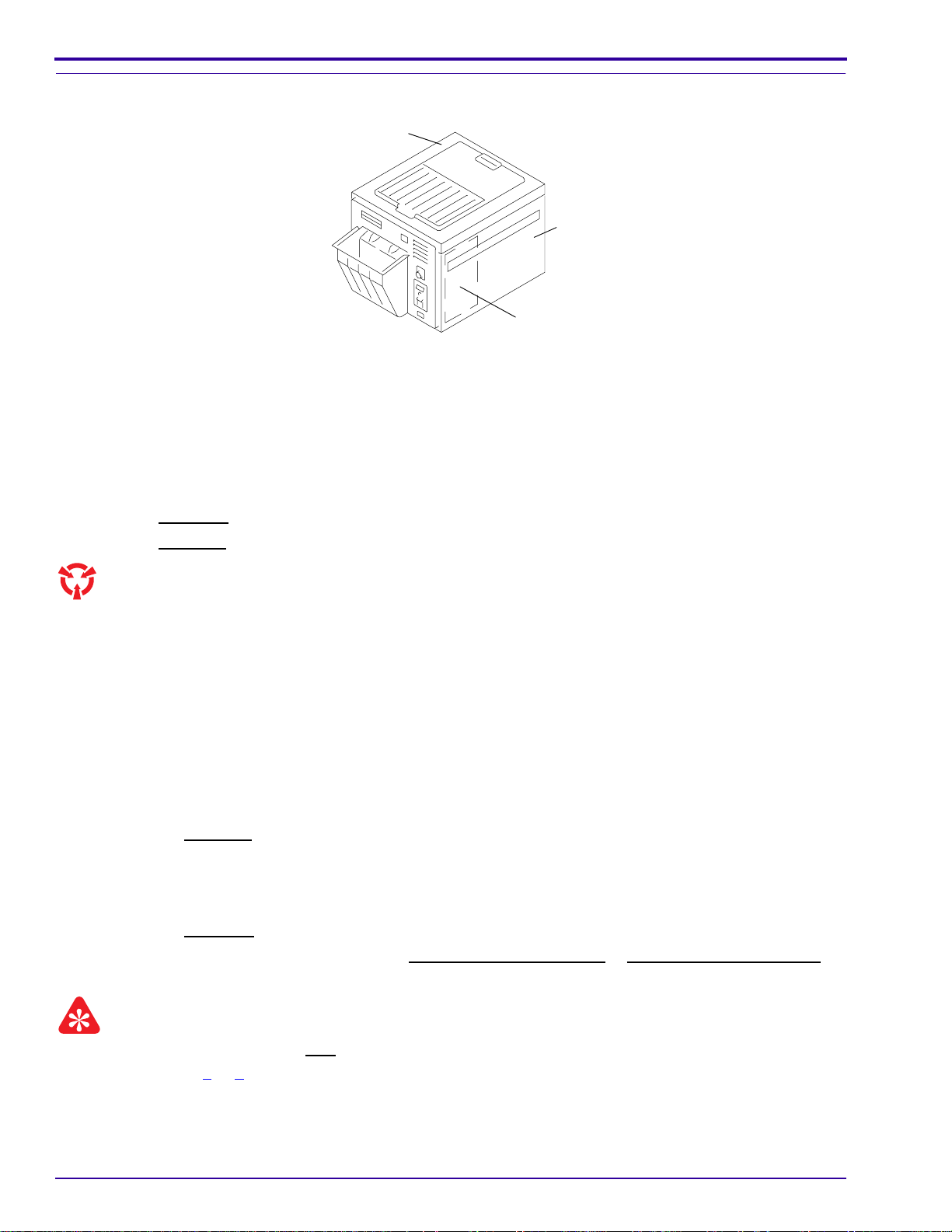

Kodak X-Omat

PROCESSOR and

Related Publications for the M35-M and M35A-M PROCESSORS

This publication is part of a series of instruction books that provides technical support information on the

Kodak

M35-M and M35A-M

X-Omat

PROCESSORS. Ifyou need anadditional or replacementpublication, order it

through your Eastman Kodak Representative using the Publication Part Numbers below.

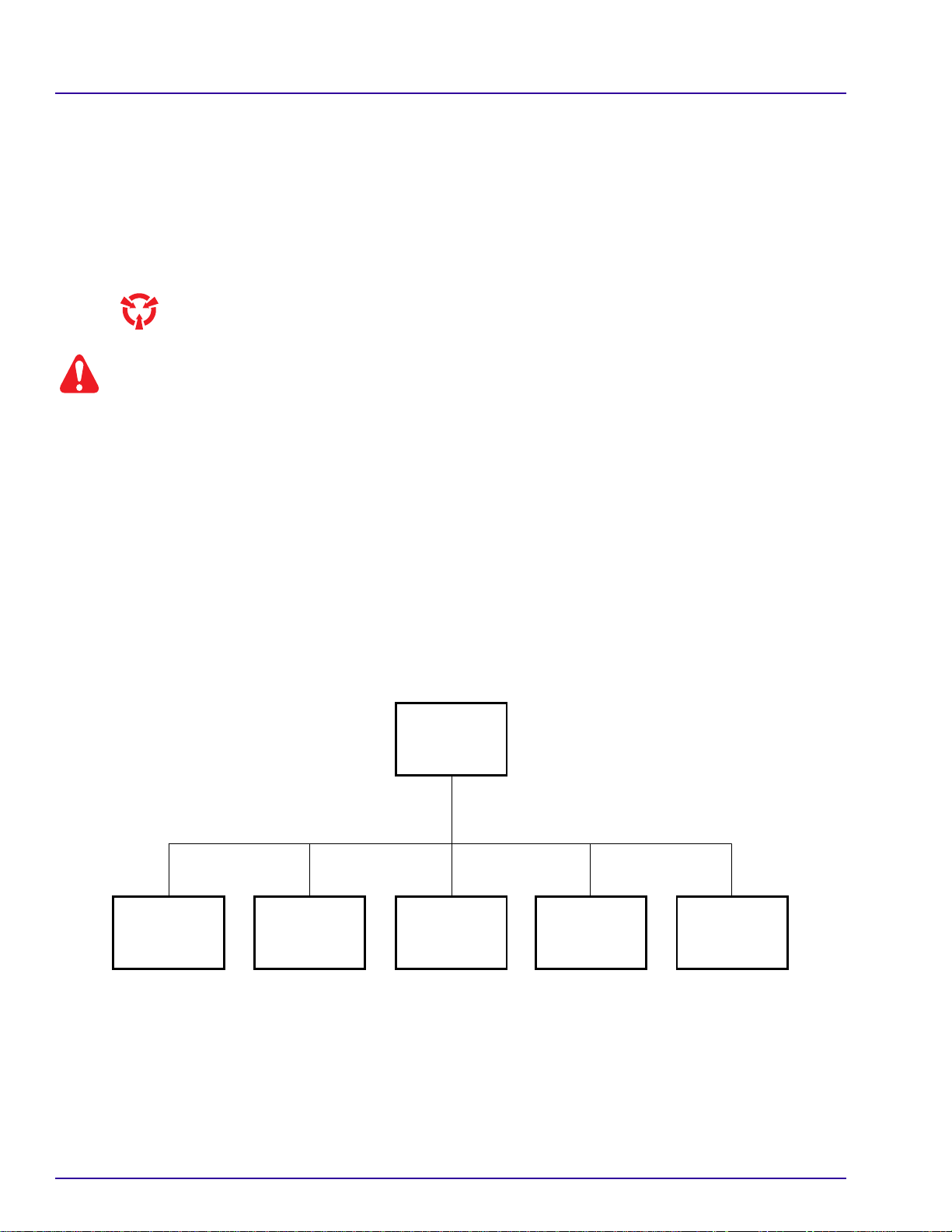

COMPLETE

BINDER

981903

OPERATOR

MANUAL

SITE SPECS

981157

INSTALLATION

INSTRUCTIONS

981900

SERVICE

MANUAL

981901981799

PARTS LIST

981902

H112_9003BC

2 September 1996 – 981901

Page 3

Table of Contents

Description Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Special Tools Needed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Specifications and Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Adjustments and Replacements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

FEED SHELF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

DETECTOR SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

CROSSOVER ASSEMBLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

RACKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Main Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

DRYER HEATER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Preventive Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Film Sizes and Direction of Film Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Speed of the PROCESSOR and Developer Temperature . . . . . . . . . . . . . . . . 1-2

Basic Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Wash Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

DRYER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Films and Chemicals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

REPLENISHMENT PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

MAIN DRIVE MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

BLOWER MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Capacity of the TANKS with the RACKS Installed . . . . . . . . . . . . . . . . . . . . . . . 1-3

Adjustment of the FEED SHELF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Replacement of the PROTECTIVE MATERIAL . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Adjustment of the DETECTOR SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Replacement of the DETECTOR SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Adjustment for Squareness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Adjustment for Squareness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Adjustment of the Tension on the DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . 2-6

Replacement of the DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Adjustment of the GUIDE SHOES in the DEVELOPER RACK . . . . . . . . . . . . . 2-7

Adjustment of the SMOOTH GUIDE SHOES in the DEVELOPER RACK . . . . 2-9

Adjustment of a TURNAROUND ASSEMBLY for Squareness . . . . . . . . . . . . 2-11

Replacement of a ROLLER in a TURNAROUND ASSEMBLY . . . . . . . . . . . . . 2-12

Replacement of the DRIVE ROLLER in the Developer RACK . . . . . . . . . . . . . 2-14

Replacement of the Resilient ROLLERS in the Fixer and Wash RACKS . . . . . 2-15

Adjustment of the DRYER RACK for Squareness . . . . . . . . . . . . . . . . . . . . . . 2-16

Replacement of the DRIVE ROLLER in the DRYER RACK . . . . . . . . . . . . . . . 2-17

Adjustment of the Main DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Alignment of the MAIN DRIVE MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Replacement of the Main DRIVE SHAFT, WORM GEARS, or

BEARING BLOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Adjustment of the Speed of the MAIN DRIVE MOTOR . . . . . . . . . . . . . . . . . . . 2-22

Adjustment of the Temperature of the DRYER . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Replacement of the BLOWER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Replacement of the DRYER HEATER or the HEATER CORE . . . . . . . . . . . . . 2-27

Adjustment of the Developer Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Adjustment of the Developer Temperature METER . . . . . . . . . . . . . . . . . . . . . 2-31

Removal of the Developer Temperature METER . . . . . . . . . . . . . . . . . . . . . . . 2-33

Installation of the Developer Temperature METER . . . . . . . . . . . . . . . . . . . . . . 2-34

Replacement of the DEVELOPER HEATER . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

981901 – September 1996 3

Page 4

Replacement of the DEVELOPER OVER-TEMPERATURE THERMOSTAT . . 2-37

Replacement of the DEVELOPER THERMISTOR . . . . . . . . . . . . . . . . . . . . . . 2-38

Replacement of the HEAT EXCHANGERS . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Replacement of the RECIRCULATION PUMP . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Replacement of the O-RING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

Replacement of a REPLENISHMENT PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

Adjustment of the REPLENISHMENT PUMPS . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

Adjustment of the Replenishment Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Roller Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

DETECTOR SWITCHES and DETECTOR CROSSOVER ASSEMBLY . . . . . 3-3

CROSSOVER ASSEMBLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

RACK ASSEMBLIES and ROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

TURNAROUND ASSEMBLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

DRIVE CHAIN and SPRINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

DRYER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Main Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

RECIRCULATION PUMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

DEVELOPER FILTER and Temperataure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Chemical Replenishment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

INTERLOCK SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Correcting Difficulties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Publication History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

4 September 1996 – 981901

Page 5

Section 1: Introduction

Electrostatic Discharge

Overview

ESD - electrostatic discharge - is a primary source of:

• product downtime

• lost productivity

• costly repairs

While one cannotfeelastaticchargeoflessthan3,500volts,asfewas30voltscandamageordestroy

essential components in electronic equipment.

Preventive Measures

• Always look for an ESD warning label before doing any procedure involving static-sensitive

components such as CIRCUIT BOARDS. All static-sensitive components are marked with bright

graphic labels, which frequently include instructions. Follow all label instructions.

• Wear agroundingstrap when handling static-sensitive components. Always make certain that the

clip remains attached to a properly grounded, unpainted, clean surface.

• Repair static-sensitive components at an ESD-protected work station or use a portablegrounding

mat. For help in setting up an ESD-protected work station, contact your Kodak representative.

• When moving static-sensitive components from one area to another, insert and transport the

components in ESD-protective packaging. Transparent antistatic bags are available from avariety

of manufacturers and will help shield components from ESD damage.

Introduction

Description

The

Kodak

mammography. This self-threading roller-transport processor has a replenishment system, a developer solution

filter, recirculation of the developer and fixer solutions, and an automatic standby feature.

M35-M and M35A-M

X-Omat

PROCESSORS are designed to process medical x-ray sheet film used for

Special Tools Needed

The following special tools are necessary for some of the service procedures in this manual.

• TL-2244 Motor Oil, 1-oz Tube

• TL-2324 Motor Oil, 12-oz Tube

• TL-1481 Potentiometer Adjusting Tool

• TL-3230 Sealant

• TL-4802 Thermometer

• 1C7639 Turnaround Adjustment Tool

Specifications and Data

Note

Publication No. 981157 contains the site specifications forthe

Kodak

M35-M and M35A-M

X-Omat

PROCESSORS.

981901 – September 1996 1–1

Page 6

SERVICE MANUAL

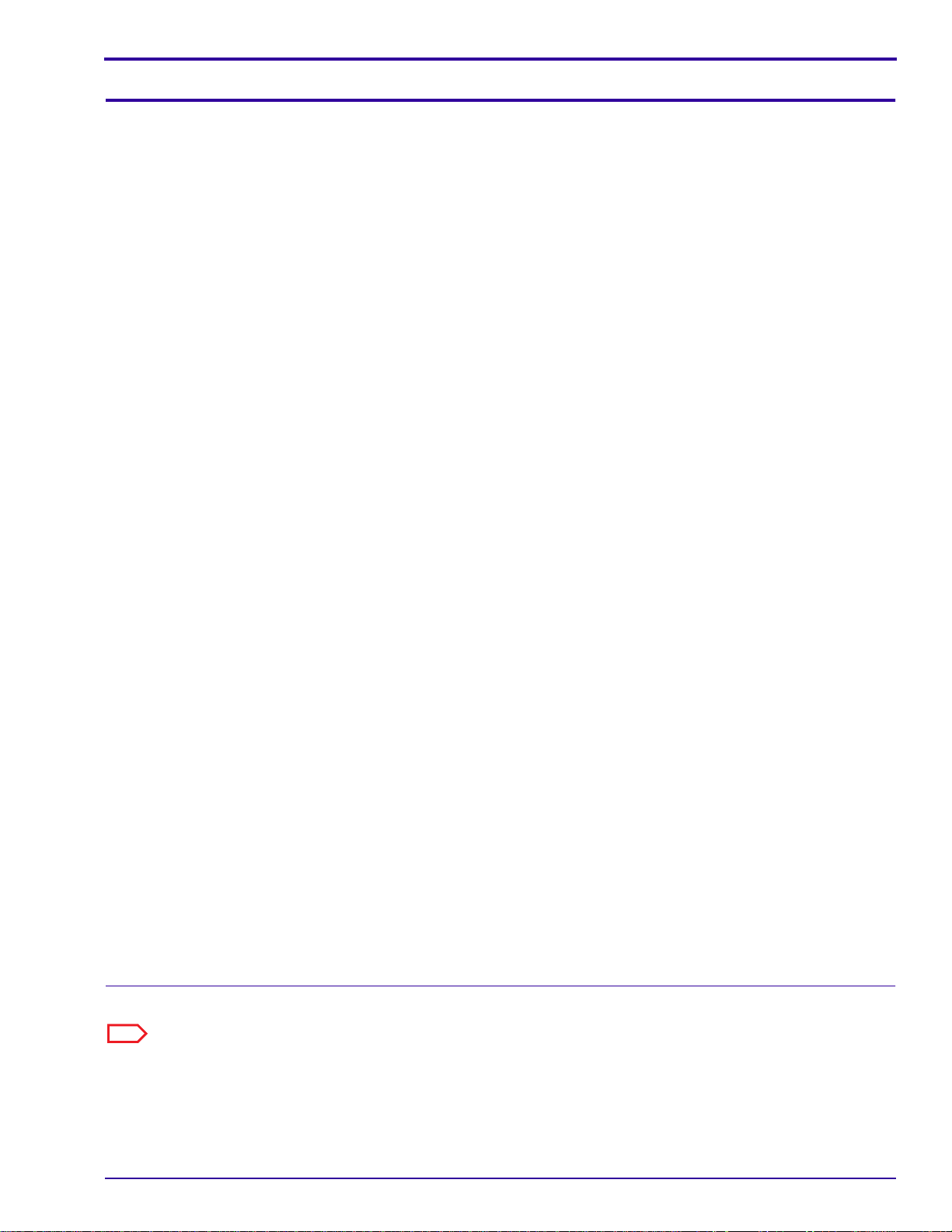

Film Sizes and Direction of Film Feed

1 each

35 x 43 cm

or

14 x 17 in.

1 each

24 x 30 cm

or

10 x 12 in.

2 each

1 each

35 x 35 cm

or

14 x 14 in.

1 each

24 x 24 cm

1 each

Caution

• Process only sheet film in the

M35A-M

X-Omat

PROCESSORS.

• Feeding other than sheet film may result in

transport failures and damage to the processing

RACKS.

The illustration shows the correct sizes of film to use.

Feed mammography film into the PROCESSOR with

the emulsion up and in the direction of the arrows. A

film feed signal will sound 8 seconds after the trailing

edge of the sheet of film leaves the DETECTOR

ROLLERS.

Kodak

M35-M and

2 each

10 x 10 cm

18 x 24 cm

or

4 x 4 in.

18 x 43 cm

1 each

11 x 14 in.

H112_9004CC

Speed of the PROCESSOR and Developer Temperature

Extended Mode: Use this mode for mammography films that the manufacturer has specified are suitable for

extended cycle processing. The transport speed for this mode is 50 cm (191⁄2) in.) per minute or 3 minutes and

23 seconds ± 2 sec drop time (dry to dry) for a 24 cm (10 in.) sheet of film. The developer temperature is 35˚C ±

0.3˚C (95.0˚F ± 0.5˚F). The development time is approximately 50 seconds and is based on using

Film.

Standard Mode: The Standard Mode is suitable for all mammography films. The transport speed for this mode is

76 cm (30 in.) per minute or 2 minutes and 15 seconds ± 2 sec drop time (dry to dry) for a 24 cm (10 in.) sheet of

film. The developer temperature is 33.3˚C ± 0.3˚C (92.0˚F ± 0.5˚F). The development time is approximately 33

seconds and is based on using

Kodak Min-R

M Film.

The temperature of the fixer is not adjustable.

Kodak Min-R

E

1–2 September 1996 – 981901

Page 7

Basic Theory of Operation

Wash Water

Thewaterforwashingthe film comes from thecustomer'swatersupply. The FLOW CONTROLVALVE

regulates the usage at approximately 1 litre (1⁄4 gallon) per minute.

DRYER

The PROCESSOR has a roller transportdryerwithslotted AIR TUBES. A THERMOSTATcontrolsthe

temperature from 46 - 65˚C (115 - 150˚F).

Films and Chemicals

The KODAK

Kodak

RP

The RECIRCULATION PUMPforthedeveloperandthefixerconsistsofathermallyprotectedMOTOR

that operates two magnetic, centrifugal pumps.

REPLENISHMENT PUMP

The replenishment system uses a positive displacement BELLOWS PUMP, designed for accurate

delivery of replenishment solutions regardless of the solution level in the REPLENISHMENT TANKS.

M35-M and M35A-M

X-Omat

Introduction

X-OMAT PROCESSORS accept film that can be processed in

Chemicals.

MAIN DRIVE MOTOR

The MAIN DRIVE MOTOR is an enclosed gearhead motor with an automatic thermal overload

protector.

BLOWER MOTOR

The BLOWER MOTOR is equipped with an automatic thermal overload protector.

Capacity of the TANKS with the RACKS Installed

The developer, fixer, and wash TANKS each contain 7.8 litres (2.07 gallons).

981901 – September 1996 1–3

Page 8

SERVICE MANUAL

1–4 September 1996 – 981901

Page 9

Section 2: Adjustments and Replacements

FEED SHELF

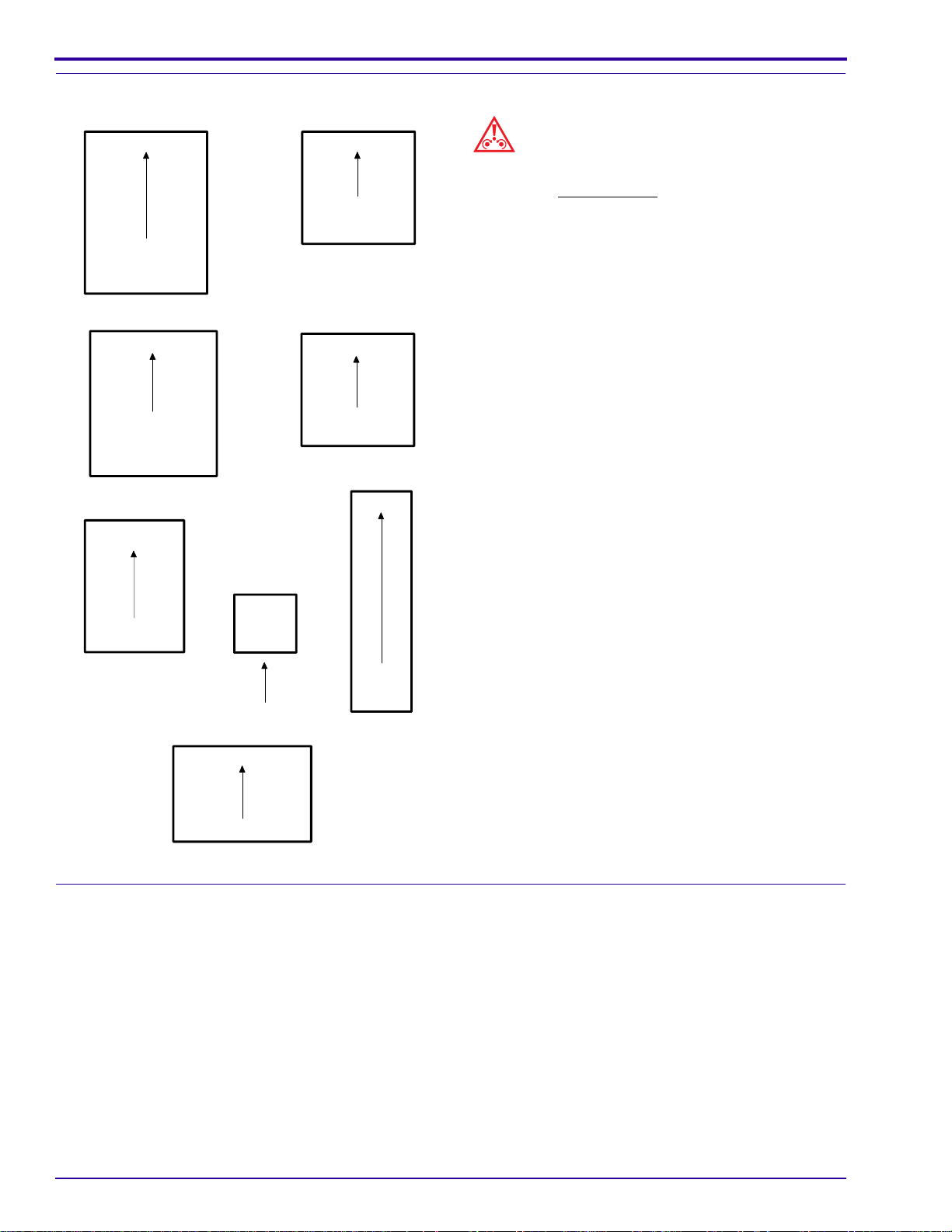

Adjustment of the FEED SHELF

[1] Adjust the height of the FEED SHELF to

approximately1.5 mm (0.06 or 1/16 in.)belowthe

NIPoftheDETECTORCROSSOVERROLLERS.

1.5 mm

(0.06 in.)

film entry path

FEED

SHELF

SCREW (4)

NIP

DETECTOR

CROSSOVER

ROLLERS

H112_0090ACB

H112_0090AA

(a) Loosen the 4 SCREWS.

(b) Adjust the FEED SHELF for the correct

(c) Insert a sheet of35 x 43 cm(14 x17 in.) film

[2] Use the edges of the film to align the FILM SHELF

withtheDETECTORCROSSOVERROLLERSfor

squareness.

[3] Tighten the 4 SCREWS.

Adjustments and Replacements

height by moving the FEED SHELF up or

down.

into the NIP of the DETECTOR

CROSSOVER ROLLERS.

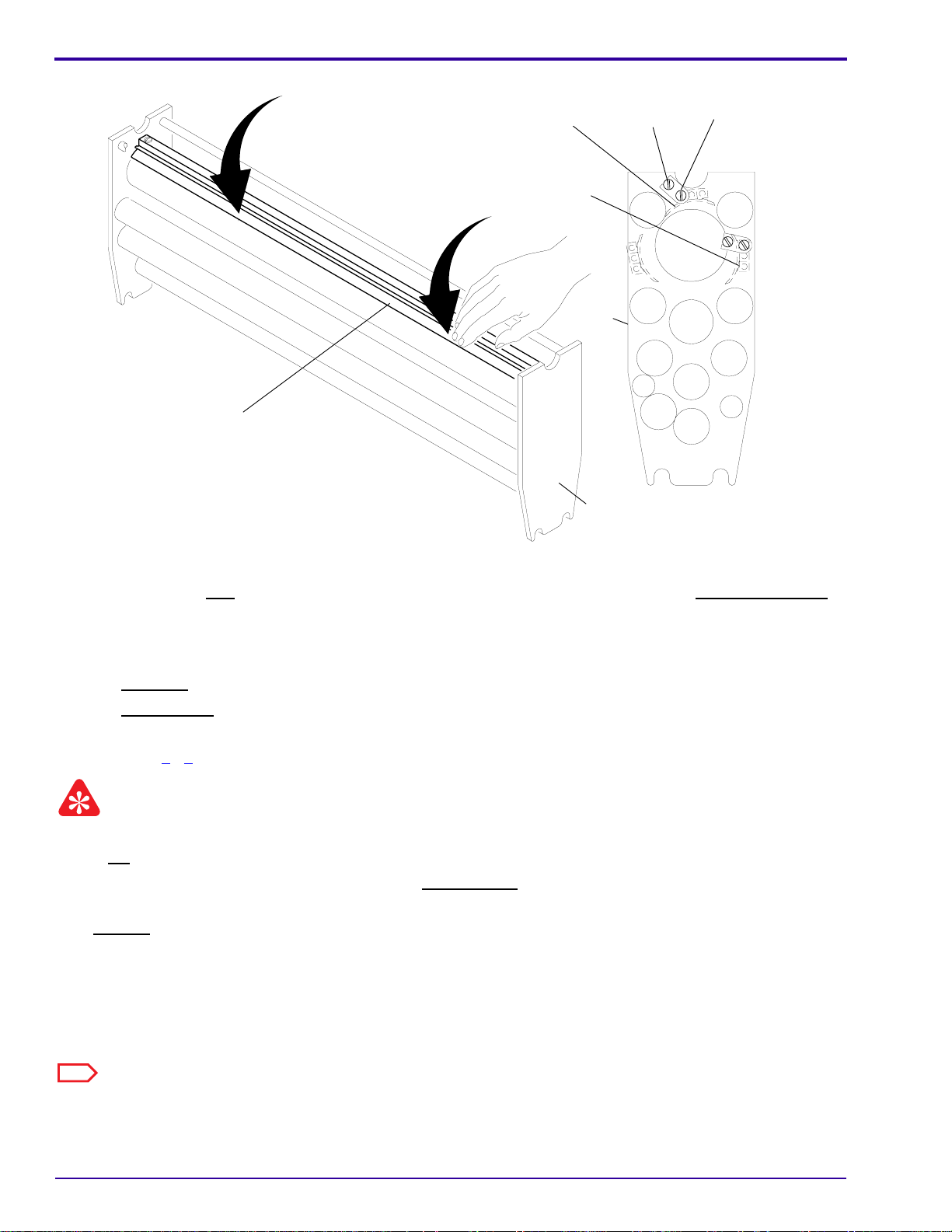

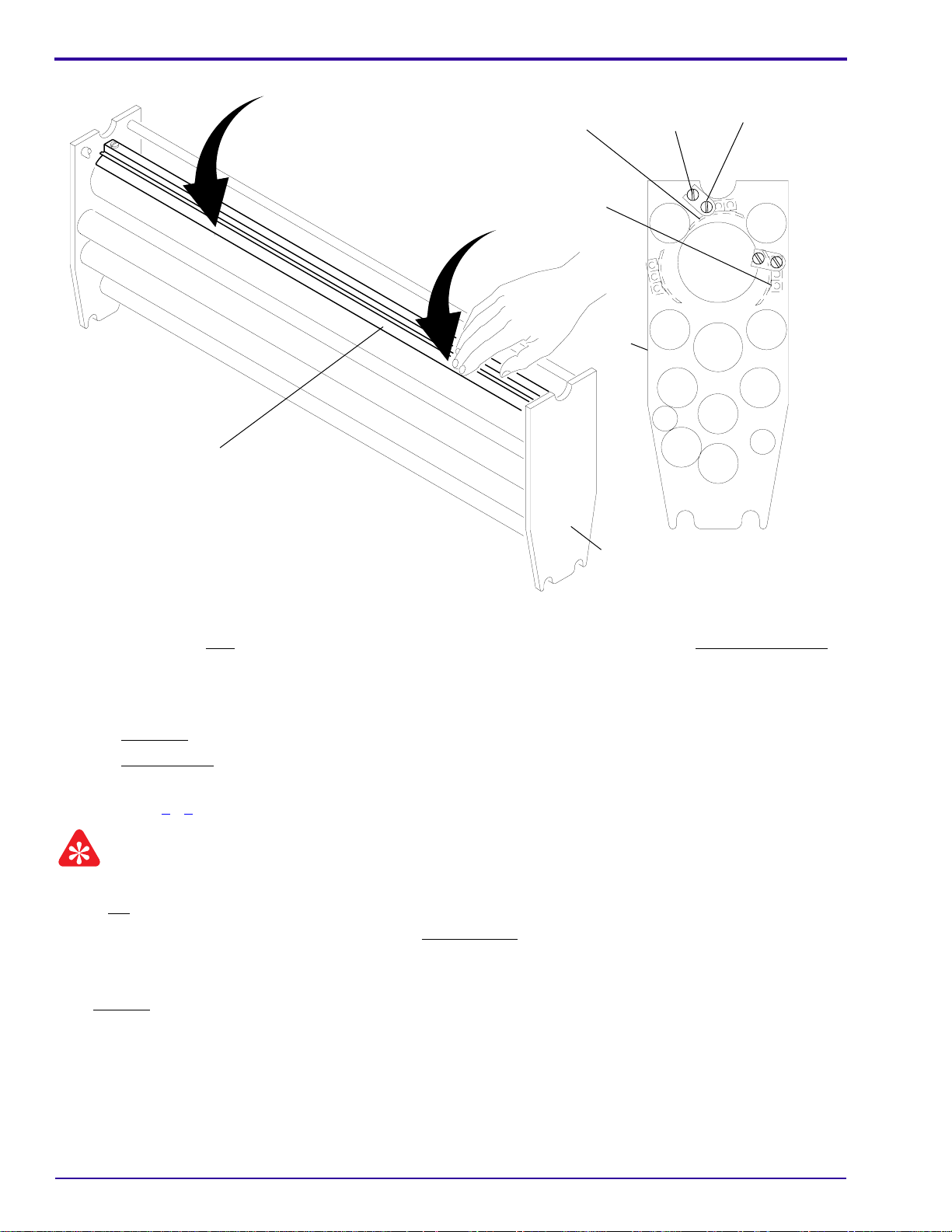

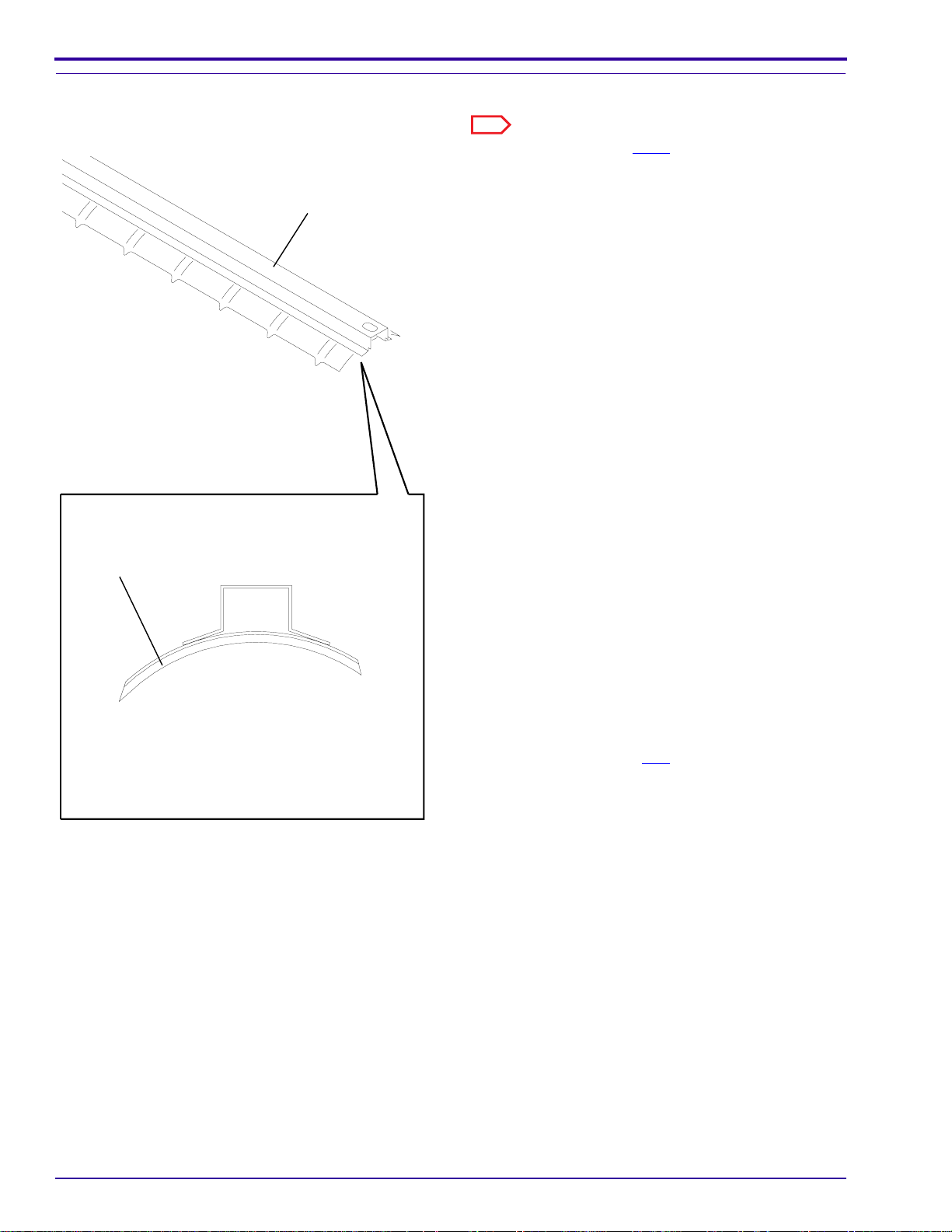

Replacement of the PROTECTIVE MATERIAL

PROTECTIVE

H112_0113BCA

H112_0113BA

MATERIAL

SCREW (4)

[1] Remove the 4 SCREWS and the FEED SHELF.

[2] Remove all of the existing PROTECTIVE MATERIAL and adhesive from the FEED SHELF.

[3] Clean the FEED SHELF with a damp sponge.

[4] Check that the FEED SHELF is dry before installing the PROTECTIVE MATERIAL.

[5] Install the new PROTECTIVE MATERIAL.

[6] Install the FEED SHELF and adjust if necessary. See the above procedure.

FEED SHELF

981901 – September 1996 2–1

Page 10

SERVICE MANUAL

DETECTOR SWITCHES

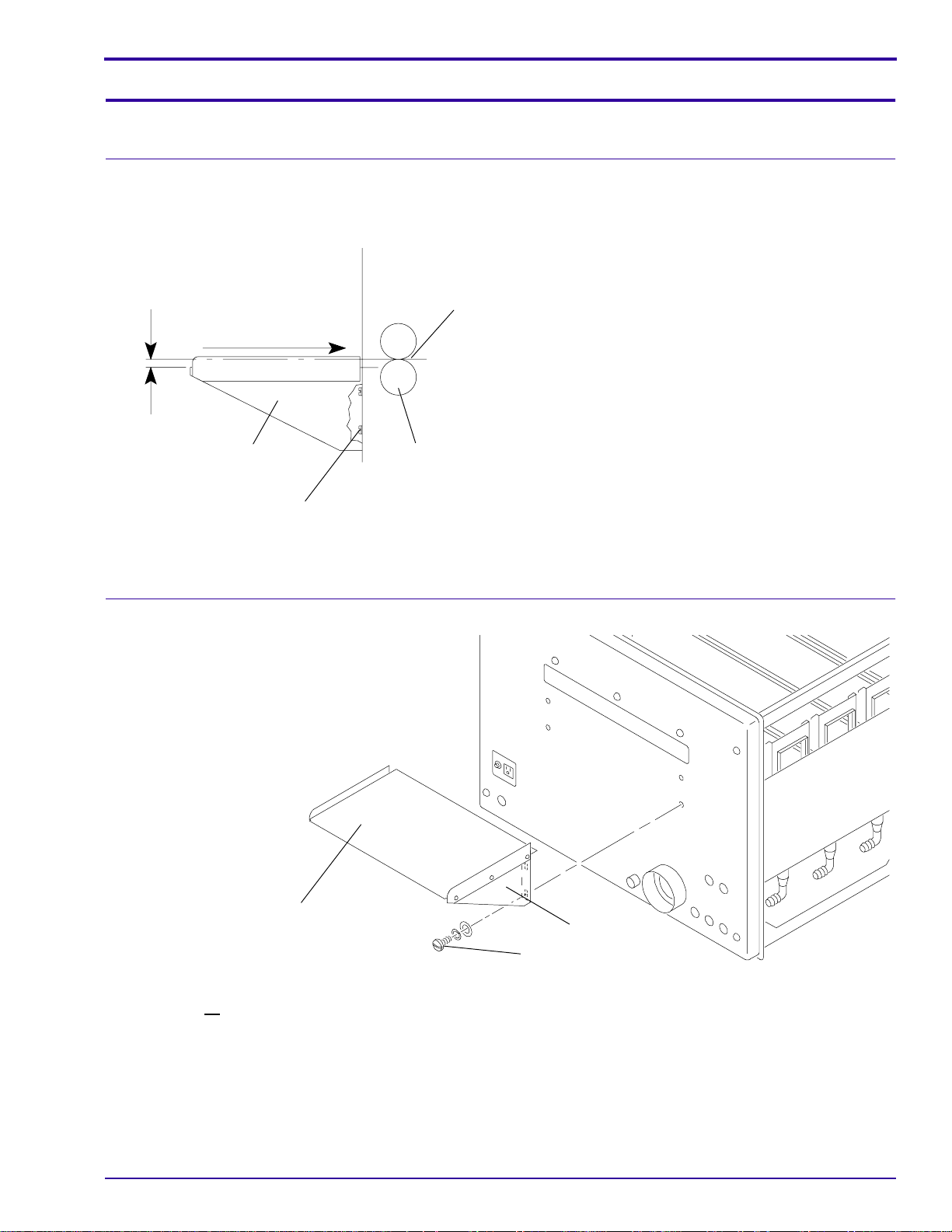

Adjustment of the DETECTOR SWITCHES

DETECTOR

ROLLER

DETECTOR

SWITCH (2)

SCREW

ROCKER

ARM

1.6 mm

(0.06 in.)

MAGNET (2)

ROCKER ARM

DETECTOR

SWITCH (2)

H112_0112BCA

H112_0112BA

Caution

Moving parts.

[1] Remove the TOP COVER.

[2] Check the DEVELOPER RACK and the DETECTOR CROSSOVER ASSEMBLY for squareness. See

Pages 2–4 and 2–5.

[3] Install the DEVELOPER RACK and the DETECTOR CROSSOVER ASSEMBLY.

[4] Set the clearance between the MAGNET and theDETECTORSWITCH on the drive side to 1.6 mm (0.06 or 1/

16 in.).

[5] Check the clearance between the MAGNET and the DETECTOR SWITCH:

(a) Energize the PROCESSOR.

(b) Lift the top DETECTOR ROLLER.

(c) Insert a 5 x 7 in. sheet of film.

(d) Move the drive side DETECTOR SWITCH until the REPLENISHMENT PUMP activates.

(e) Check that the REPLENISHMENT PUMP stops within 3 seconds after you remove the sheet of film.

[6] If necessary, adjust the clearance between the MAGNET and the DETECTOR SWITCH.

(a) Loosen the SCREW.

(b) Move the ROCKER ARM.

(c) Tighten the SCREW.

[7] Do Steps 4 - 6 to adjust the DETECTOR SWITCH on the nondrive side.

[8] Install the TOP COVER.

[9] Check that the REPLENISHMENT PUMP does not operate unless you feed film.

2–2 September 1996 – 981901

Page 11

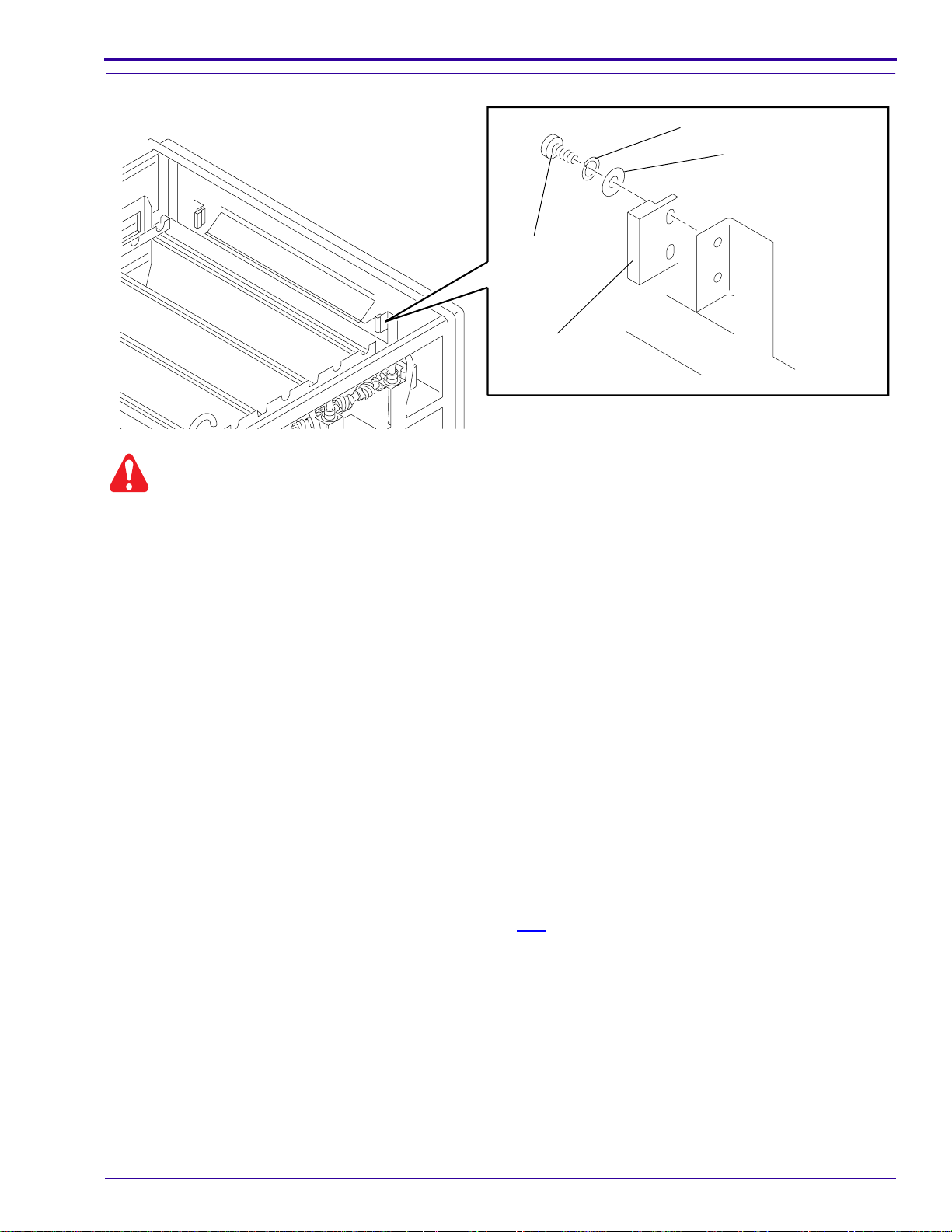

Replacement of the DETECTOR SWITCHES

Warning

Dangerous voltage.

SCREW (2)

DETECTOR

SWITCH

Adjustments and Replacements

LOCK WASHER (2)

WASHER (2)

H112_0067BCA

H112_0067BA

[1] Disconnect the main power.

[2] Remove:

• 2 SCREWS

• 2 LOCK WASHERS

• 2 WASHERS

• WIRE TIES, not shown

[3] Disconnect the SWITCH CABLE from the ELECTRICAL BOX.

[4] Connect the new SWITCH CABLE.

[5] Install:

• new DETECTOR SWITCH

• 2 WASHERS

• 2 LOCK WASHERS

• 2 SCREWS

• new WIRE TIES

[6] Connect the main power.

[7] If necessary, do the adjustment procedure. See Page 2–2.

981901 – September 1996 2–3

Page 12

SERVICE MANUAL

CROSSOVER ASSEMBLIES

Adjustment for Squareness

TIE ROD

SIDE

PLATE

GUIDE SHOE

SCREW (2)

TIE ROD

long edge

GUIDE

SHOE

NUT

SIDE PLATE

NUT

H112_0056BCC

H112_0056BA

Note

Use this procedure to check the squareness of any of

the CROSSOVER ASSEMBLIES.

[1] Remove the CROSSOVER ASSEMBLY from the

PROCESSOR.

[2] Place the CROSSOVER ASSEMBLY on a

smooth, flat surface.

[3] Loosen the 2 NUTS on the 2 TIE RODS.

[4] Check that the 2 SIDE PLATES touch the flat

surface evenly.

[5] Tighten the 2 NUTS.

Installation of a New GUIDE SHOE

[6] Removetheexisting GUIDESHOESCREWSand

the GUIDE SHOE.

[7] Install the new GUIDE SHOE, with the long edge

long edge

in the direction of film travel.

[8] Install the 2 GUIDE SHOE SCREWS.

Note

The GUIDE SHOES have no adjustment procedures.

H112_0220CCA

H112_0220CA

2–4 September 1996 – 981901

Page 13

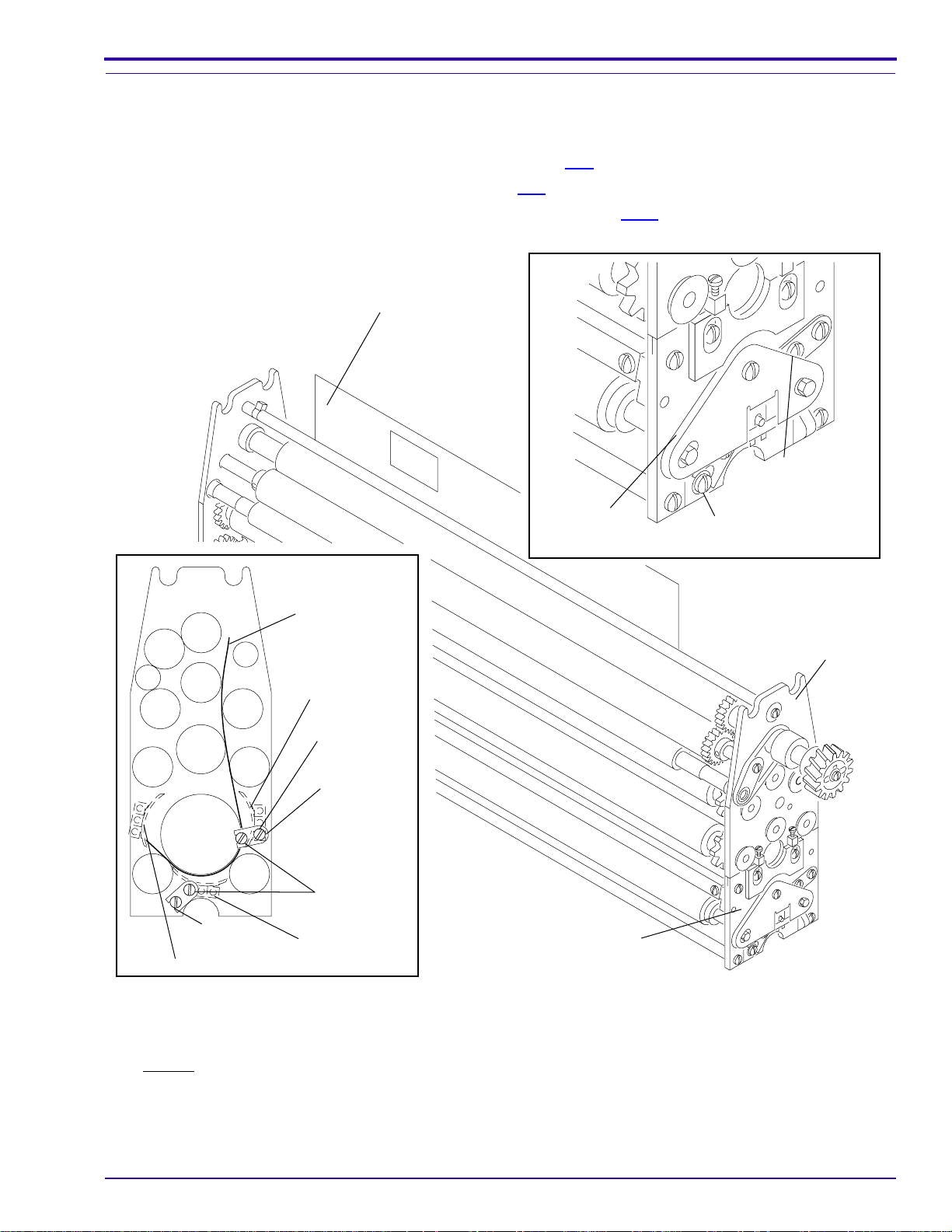

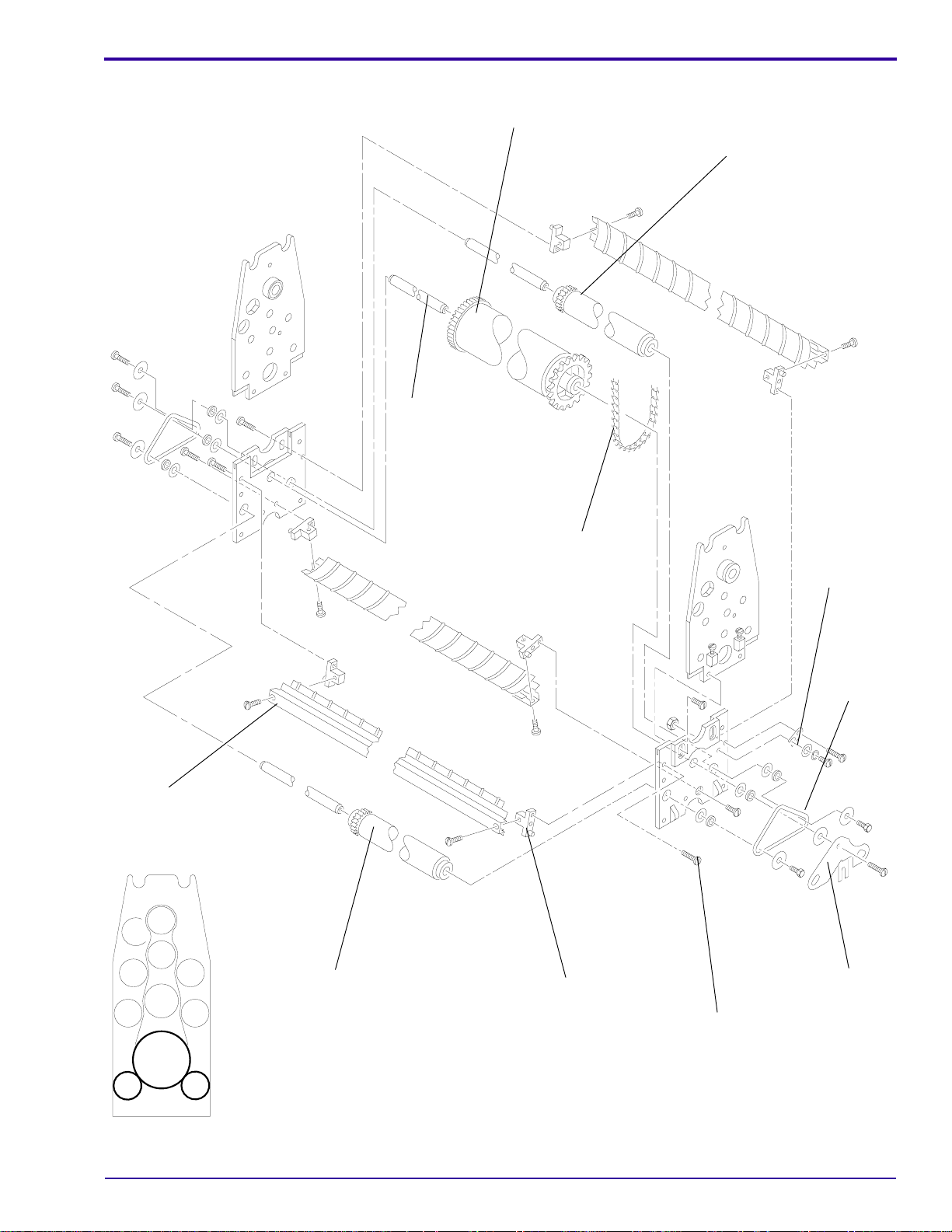

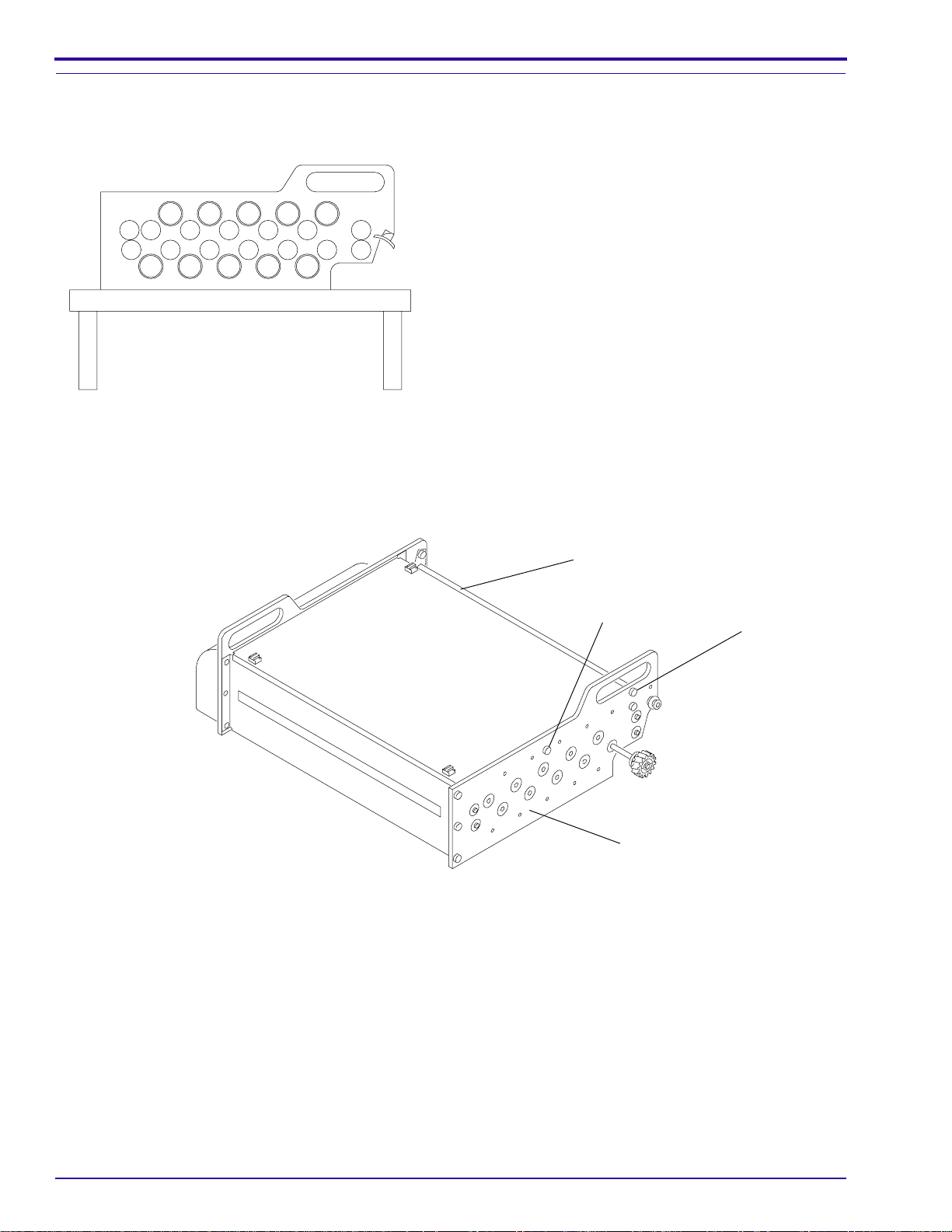

RACKS

H112_0017AC

H112_0017ACB

SCREWS

2 TIE RODS

SIDE PLATE

TIE ROD

SCREW (2)

SIDE PLATE

Adjustment for Squareness

smooth, flat surface

Adjustments and Replacements

Note

Use this procedure to check the squareness of any of

the RACKS.

[1] Remove the RACK from the PROCESSOR.

[2] Place the RACK on a smooth, flat surface.

[3] Loosen the SCREWS on the ends of the 3 TIE

RODS.

[4] Check that the 2 SIDE PLATES touch the flat

surface evenly.

[5] Tighten the SCREWS.

H112_0110AA

981901 – September 1996 2–5

Page 14

SERVICE MANUAL

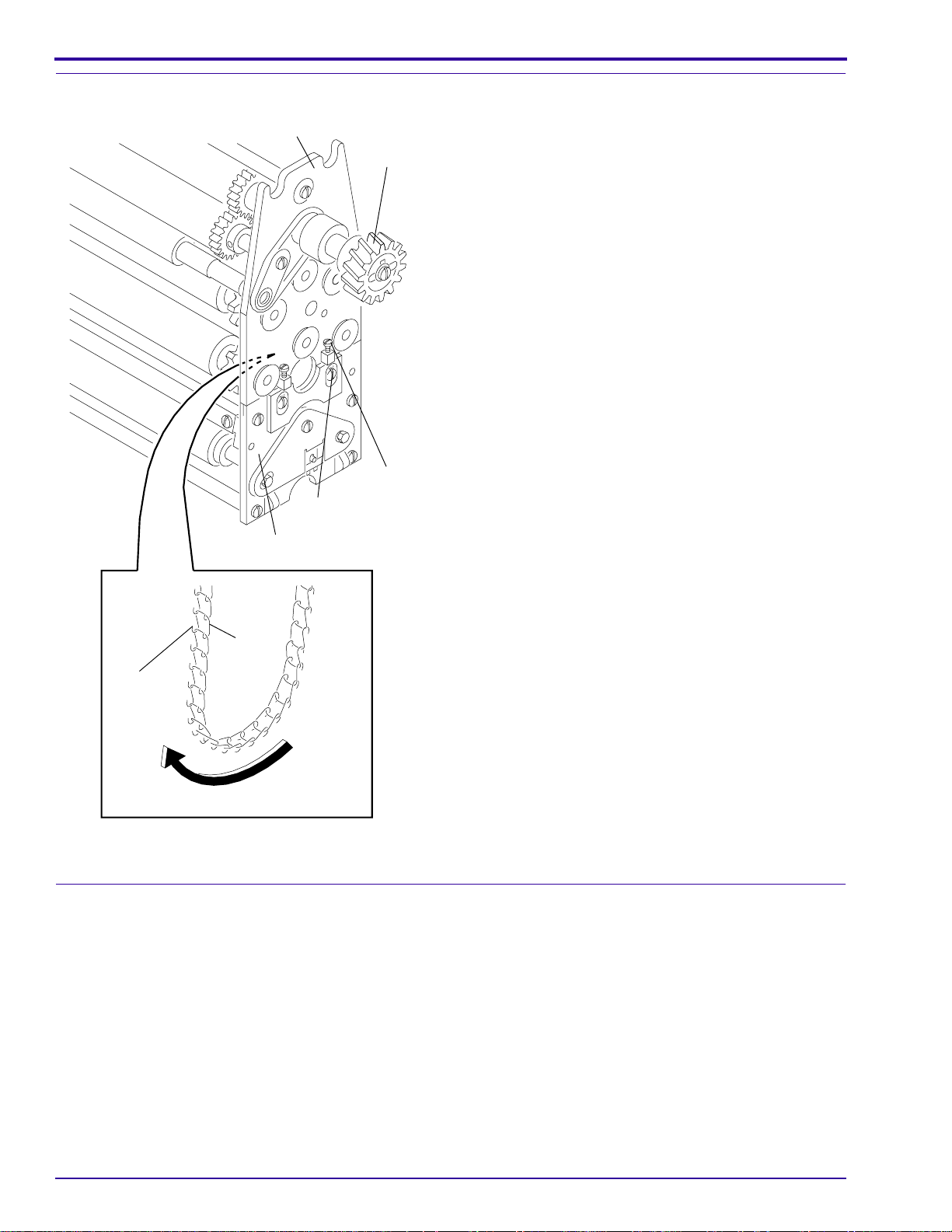

Adjustment of the Tension on the DRIVE CHAIN

HOOK

SIDE PLATE

HOLDING

SCREW (4)

TURNAROUND

ASSEMBLY

LINK

DRIVE

GEAR

ADJUSTING

SCREW (4)

[1] Check that the DRIVE CHAIN iswet with solution.

[2] To assure that the DRIVE CHAIN is the correct

length, check that the RACK is at approximately

the same temperature as the solutions in the

tanks.

[3] Loosen the 4 HOLDING SCREWS.

[4] Allow gravity to provide full tension on the

TURNAROUNDASSEMBLY byholding theRACK

above the work surface.

[5] Rotate the DRIVE GEAR one full rotation.

[6] Tighten the 2 HOLDING SCREWS on the drive

side first.

[7] Place the RACK on the work surface.

[8] On the drive side of the RACK, tighten the

2 ADJUSTING SCREWS until both SCREWS

make contact with the SIDE PLATE of the

TURNAROUND ASSEMBLY.

[9] Loosen the 2 HOLDING SCREWS on the drive

side.

[10] Rotate the 2 ADJUSTING SCREWS on the drive

side counterclockwise one full rotation.

[11] Rotate the DRIVE GEAR one full rotation.

[12] Tighten the 2 HOLDING SCREWS on the drive

side.

[13] On the nondrive side of the RACK, rotate the

2 ADJUSTING SCREWS until the distance

betweenthe2 SIDE PLATES onthenondriveside

is the same distance as the distance betweenthe

2 SIDE PLATES on the drive side.

[14] Assemble the PROCESSOR and check that it

operates correctly.

DRIVE CHAIN

H112_0109CCA

H112_0109CA

Replacement of the DRIVE CHAIN

[1] To open the existing DRIVE CHAIN, insert a screwdriver under theHOOKS of aLINK. Ifnecessary, rotatethe

screwdriver.

[2] Attach the new DRIVE CHAIN to the existing DRIVE CHAIN with the HOOKS in the direction of travel and the

openings of the LINKS outward. See the figure above.

[3] Pull the existing DRIVE CHAIN through the RACK until the new DRIVE CHAIN is in the correct position.

[4] Disconnect the existing DRIVE CHAIN from the new DRIVE CHAIN.

[5] Connect the ends of the new DRIVE CHAIN.

[6] Adjust the DRIVE CHAIN. See the procedure above.

2–6 September 1996 – 981901

Page 15

Adjustments and Replacements

Adjustment of the GUIDE SHOES in the DEVELOPER RACK

Important

Dothisadjustmentonlyifthecustomerprocesses double-emulsion film. The GUIDE SHOES are presetatthefactory

for a gap of 0.020 in. for single-emulsion film. For a gap of 0.040 in. necessary for double-emulsion film, feed

2 TURNAROUND ADJUSTMENT TOOLS together through the DEVELOPER RACK.

[1] Remove the DEVELOPER RACK from the PROCESSOR.

[2] Do these procedures before you adjust the GUIDE SHOES:

a. Adjust the DEVELOPER RACK for squareness, on Page 2–5

b. Adjust the tension on the DRIVE CHAIN, on Page 2–6

c. Adjust the TURNAROUND ASSEMBLY for squareness, on Page 2–11

[3] For access to the GUIDE SHOE BRACKET SCREWS, release the SPRING on the drive side of the

DEVELOPER RACK.

[4] Loosen the 4 GUIDE SHOE BRACKET SCREWS and the 4 LOCKING SCREWS for the ENTRANCE GUIDE

SHOE and the BOTTOM GUIDE SHOE in the TURNAROUND ASSEMBLY.

[5] Feed 2 TURNAROUND ADJUSTMENT TOOLS 1C7639 into the DEVELOPER RACK until the leading edges

of the TOOLS are in the EXIT GUIDE SHOE. See the figure below.

LOCKING

EXIT

GUIDE SHOE

SCREW (4)

TURNAROUND

ADJUSTMENT

TOOL

1C7639

TURNAROUND

ADJUSTMENT

TOOL

1C7639

ENTRANCE

GUIDE

SHOE

LOCKING

SCREW

DOUBLE

LOCK

MOUNTING

PLATE

1C7632

GUIDE SHOE

BRACKET

SCREW (4)

BOTTOM GUIDE

SHOE ASSY

1C7635

SPRING

TURNAROUND

ASSEMBLY

GUIDE SHOE

BRACKET SCREW

(4)

LOCKING SCREW

(4)

H112_0198DCA

drive

side

H112_0198DA

981901 – September 1996 2–7

Page 16

SERVICE MANUAL

Aligning the Edges of the GUIDE SHOES in the DEVELOPER RACK

press here

long edge

of GUIDE SHOE

BOTTOM

GUIDE

SHOE

ENTRANCE

press here

GUIDE

SHOE

exit

side

LOCKING

SCREW

GUIDE SHOE

BRACKET

SCREW

nondrive

side

H112_0218HCA

H112_0218HA

[6] Place the DEVELOPER RACK with the exit side on the work surface.

[7] Pressing on the long edge of the ENTRANCE GUIDE SHOE approximately 6 cm (3 in.) from the drive side,

tighten the drive side GUIDE SHOE BRACKET SCREW.

[8] Press on the nondrive side of the long edge, and tighten the nondrive GUIDE SHOE BRACKET SCREW.

[9] Tighten:

a. drive side LOCKING SCREW

b. nondrive side LOCKING SCREW

[10] Turn the DEVELOPER RACK upside down on the work surface. See the figure above.

[11] Do Steps 7 - 9 for the BOTTOM GUIDE SHOE.

Important

•Donot continue feeding the TURNAROUND ADJUSTMENT TOOL to remove it from the DEVELOPER RACK.

• The EXIT GUIDE SHOE is preset at the factory. Do not adjust.

[12] Reverse the DRIVE GEAR to remove the TURNAROUND ADJUSTMENT TOOL from the DEVELOPER RACK.

[13] Install the SPRING.

[14] Check the DEVELOPER RACK and the TURNAROUND ASSEMBLY for squareness.

[15] Install the DEVELOPER RACK in the PROCESSOR.

[16] Energize the PROCESSOR and check for correct operation.

Note

Adjusting the GUIDE SHOES in the WASH and FIXER RACKS is not necessary.

2–8 September 1996 – 981901

Page 17

Adjustments and Replacements

Adjustment of the SMOOTH GUIDE SHOES in the DEVELOPER RACK

[1] Remove the DEVELOPER RACK from the PROCESSOR.

[2] Do these 3 procedures before you adjust the GUIDE SHOES:

a. Adjust the DEVELOPER RACK for squareness, on Page 2–5

b. Adjust the tension on the DRIVE CHAIN, on Page 2–6

c. Adjust the TURNAROUND ASSEMBLY for squareness, on Page 2–11

TURNAROUND

ADJUSTMENT

TOOL

1C7639

SPRING

4 LOCKING SCREWS

4 GUIDE SHOE

BRACKET SCREWS

TURNAROUND

ADJUSTMENT

4 LOCKING

EXIT

GUIDE SHOE

SCREWS

TOOL

1C7639

ENTRANCE

GUIDE

SHOE

LOCKING

SCREW

DOUBLE

LOCK

MOUNTING

PLATE

4 GUIDE SHOE

BRACKET

SCREWS

BOTTOM GUIDE

SHOE ASSY

TURNAROUND

ASSEMBLY

drive

side

H112_0198DCB

H112_0198DA

[3] For access to the GUIDE SHOE BRACKET SCREWS, release the SPRING on the drive side of the

DEVELOPER RACK.

[4] Loosen the 4 GUIDE SHOE BRACKET SCREWS and the 4 LOCKING SCREWS for the ENTRANCE GUIDE

SHOE and the BOTTOM GUIDE SHOE in the TURNAROUND ASSEMBLY.

[5] Feed the TURNAROUND ADJUSTMENT TOOL 1C7639 into the DEVELOPERRACK until theleadingedgeof

the TOOL is in the EXIT GUIDE SHOE. See the figure.

981901 – September 1996 2–9

Page 18

SERVICE MANUAL

Aligning the Edges of the New GUIDE SHOES

press here

long edge

of GUIDE SHOE

BOTTOM

ENTRANCE

press here

GUIDE

SHOE

GUIDE

SHOE

exit

side

LOCKING

SCREW

GUIDE SHOE

BRACKET

SCREW

nondrive

side

H112_0218HCA

H112_0218HA

[6] Place the DEVELOPER RACK with the exit side on the work surface.

[7] Pressing on the long edge of the ENTRANCE GUIDE SHOE approximately 6 cm (3 in.) from the drive side,

tighten the drive side GUIDE SHOE BRACKET SCREW.

[8] Press on the nondrive side of the long edge, and tighten the nondrive GUIDE SHOE BRACKET SCREW.

[9] Tighten:

a. drive side LOCKING SCREW

b. nondrive side LOCKING SCREW

[10] Turn the DEVELOPER RACK upside down on the work surface. See the figure.

[11] Do Steps 7 - 9 for the BOTTOM GUIDE SHOE.

Important

•Donot continue feeding the TURNAROUND ADJUSTMENT TOOL to remove it from the DEVELOPER RACK.

• The EXIT GUIDE SHOE is preset at the factory. Do not adjust.

• Adjusting the GUIDE SHOES in the WASH and FIXER RACKS is not necessary.

[12] Reverse the DRIVE GEAR to remove the TURNAROUND ADJUSTMENT TOOL from the DEVELOPER RACK.

[13] Install the SPRING.

[14] Install the DEVELOPER RACK in the PROCESSOR.

[15] Energize the PROCESSOR and check for correct operation.

2–10 September 1996 – 981901

Page 19

Adjustments and Replacements

Adjustment of a TURNAROUND ASSEMBLY for Squareness

Note

This procedure is the same for disassembling all the RACKS.

[1] Place the RACK on a smooth, flat surface.

[2] Loosen the 4 HOLDING SCREWS.

[3] Rotate the 4 ADJUSTING SCREWS the same amounts to move the TURNAROUND ASSEMBLY up or down.

[4] Check that the 2 SIDE PLATES of the TURNAROUND ASSEMBLY touch the flat surface evenly.

[5] Tighten the 4 HOLDING SCREWS.

Upper Rack Assembly

Turnaround

Assembly

ADJUSTING

SCREW (4)

SIDE PLATE (2)

HOLDING

SCREW (4)

981901 – September 1996 2–11

H112_0096DCA

H112_0096DA

Page 20

SERVICE MANUAL

Replacement of a ROLLER in a TURNAROUND ASSEMBLY

Note

See the figure on Page 2–13 for this procedure.

[1] To remove an A ROLLER, remove:

• 2 SPRINGS

• LOCKING PLATE

• SCREW

• A ROLLER from the SHAFT

[2] To install a new A ROLLER, install:

• new A ROLLER on the SHAFT

• A ROLLER in the TURNAROUND

ASSEMBLY

• LOCKING PLATE

• 2 SPRINGS

[3] To remove the B ROLLER, remove:

• TURNAROUND ASSEMBLY from the RACK

• 2 SPRINGS

• LOCKING PLATE

• 2 A ROLLER ASSEMBLIES

• 2 SCREWS

• 2 BRACKETS

• EXIT GUIDE SHOE

• SHAFT, THRUST WASHERS, and the

BEARING from the B ROLLER

[4] Install the new B ROLLER and the other existing

parts.

[5] Check that the DRIVE CHAIN has the correct

tension. See Page 2–6 if adjustment of the

DRIVE CHAIN is necessary.

[6] Check that the long edges of the GUIDE SHOES

are in the directionof film travel. See the figureat

the left.

[7] Check that all GEARS in the TURNAROUND

ASSEMBLY engage.

long edge

GUIDE

SHOE

H112_0220CCA

H112_0220CA

2–12 September 1996 – 981901

Page 21

Disassembling a TURNAROUND ASSEMBLY

SHAFT

Adjustments and Replacements

B ROLLER

A ROLLER

EXIT

GUIDE

SHOE

A ROLLER

CHAIN

BRACKET (2)

HOLDING

SCREW (4)

SPRING

(2)

LOCKING

PLATE

SCREW (2)

H112_0075ECA

H112_0075EA

981901 – September 1996 2–13

Page 22

SERVICE MANUAL

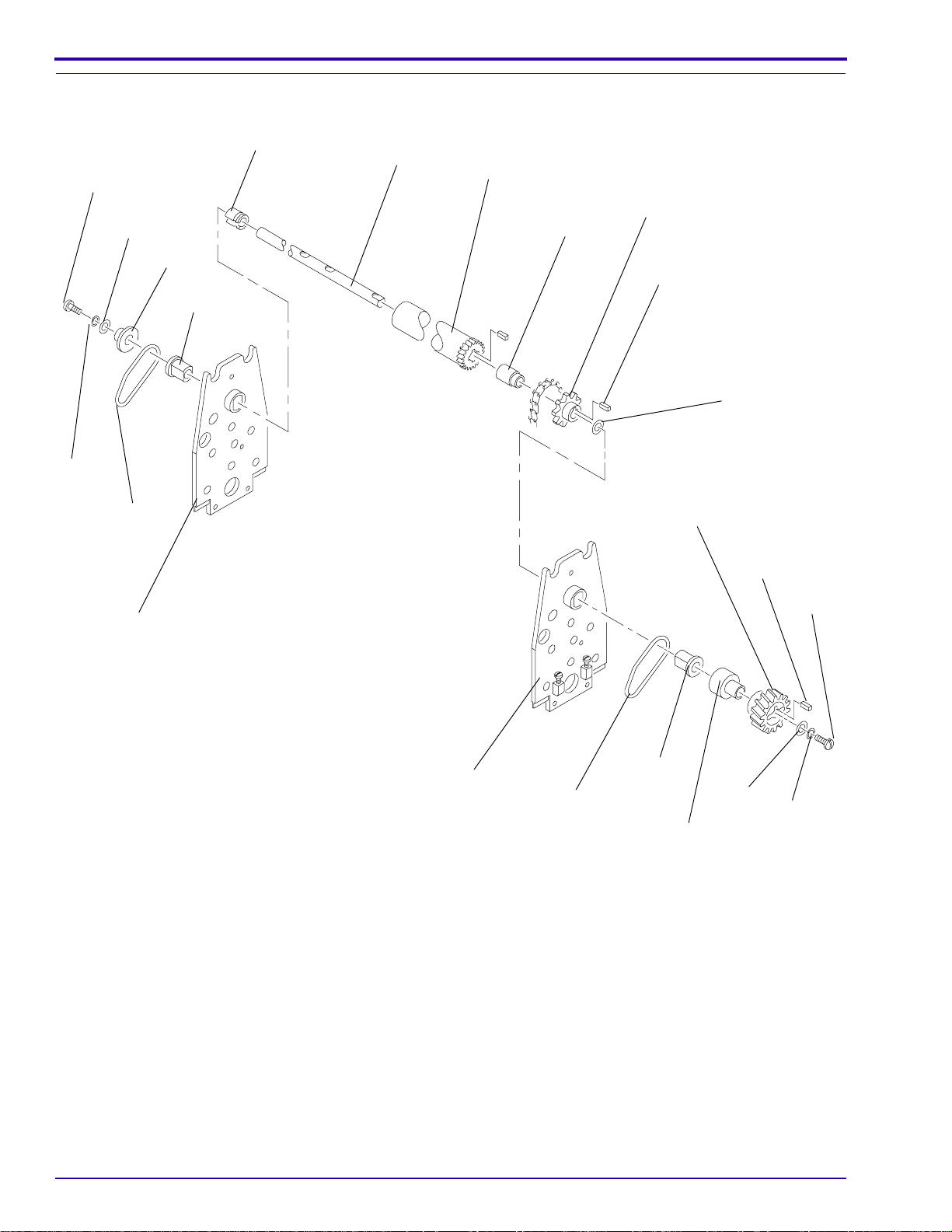

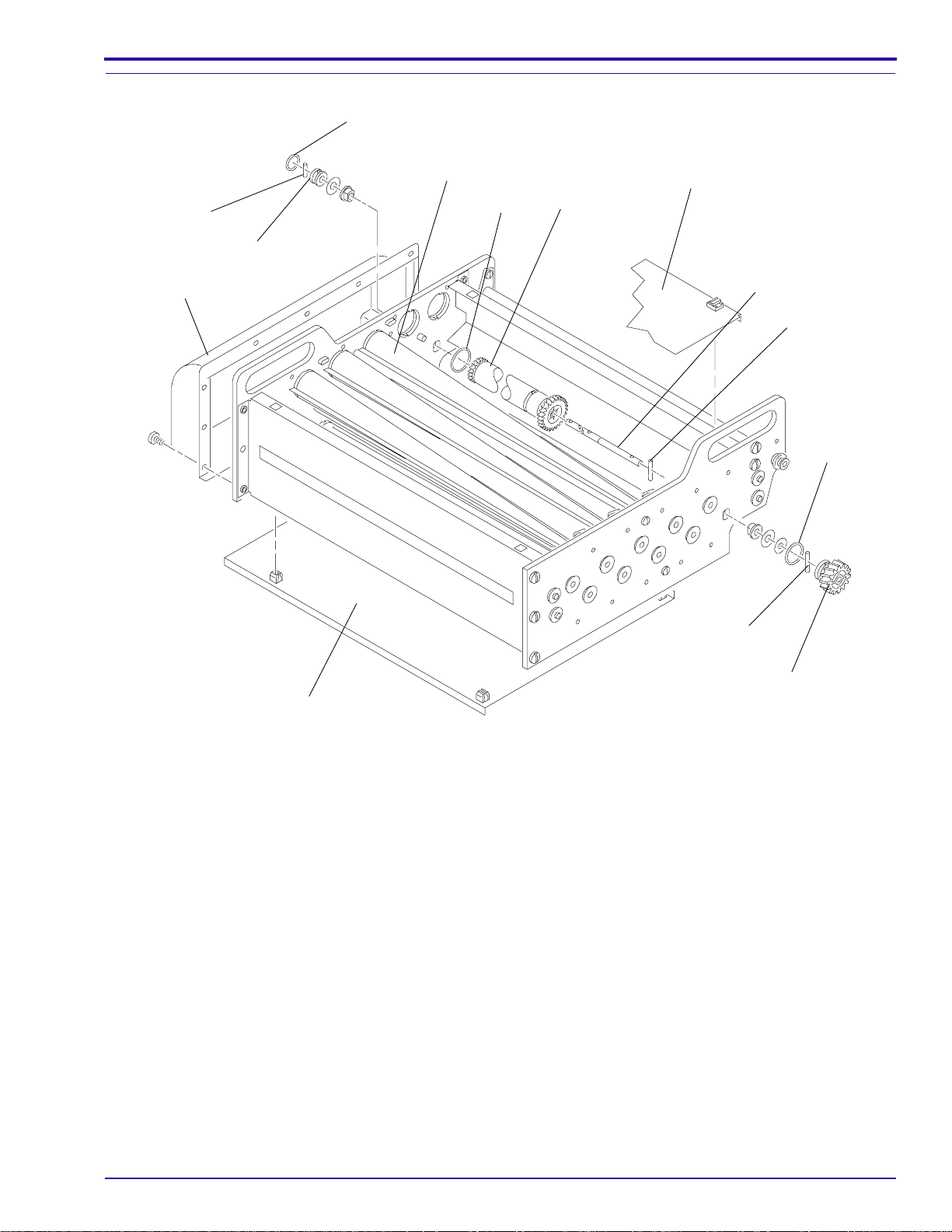

R

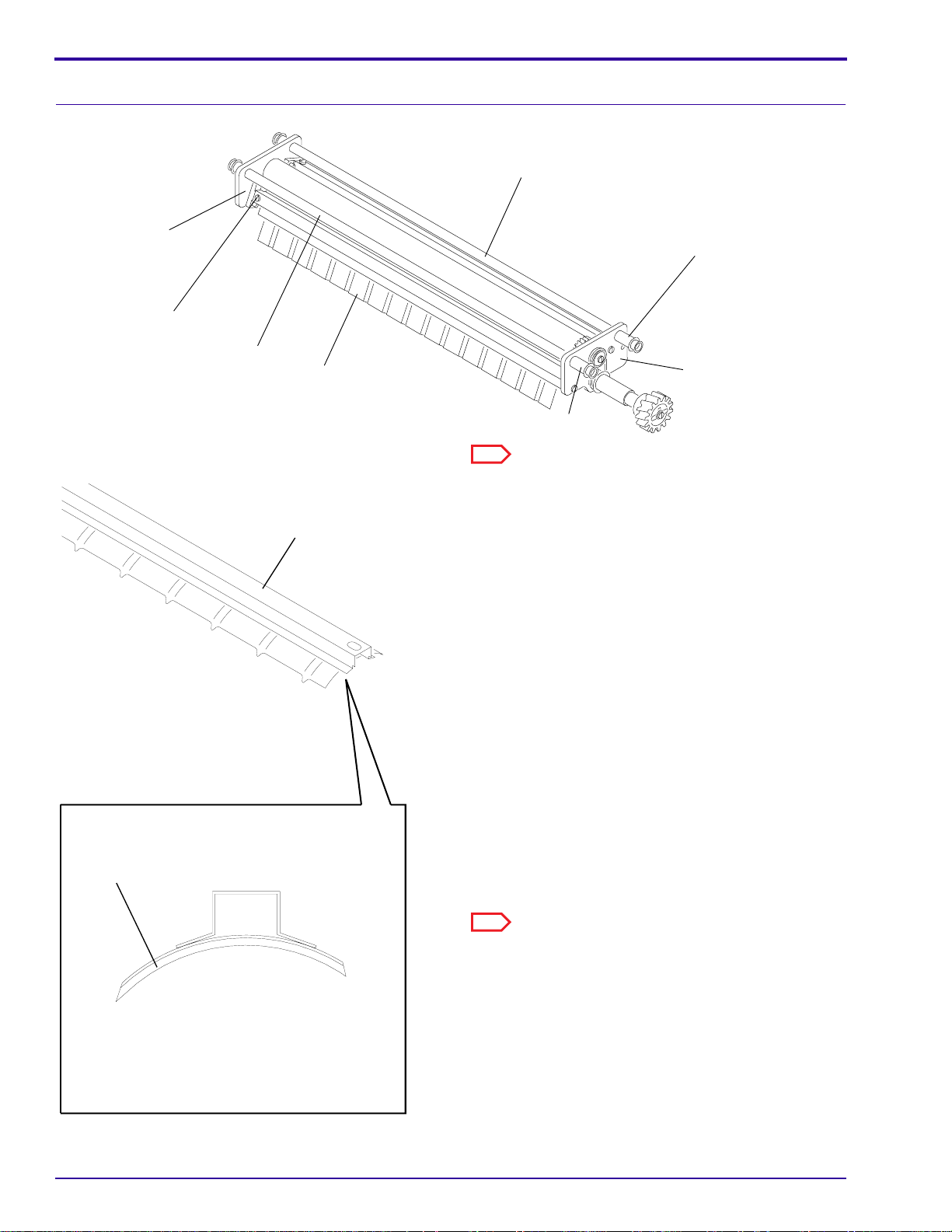

Replacement of the DRIVE ROLLER in the Developer RACK

SCREW

WASHER

LOCK

WASHER

SPRING

BEARING

SPACER

SPACER

SHAFT

DRIVE

ROLLER

SPROCKET

SPACER

KEY

THRUST

WASHER

DRIVE

GEAR

KEY

SCREW

non-drive

SIDE PLATE

drive

SIDE PLATE

SPRING

BEARING

SPACER

WASHER

H112_0106DCA

LOCK

WASHE

H112_0106DA

[1] Remove the 2 SPRINGS from the top of the RACK.

[2] Remove the SCREWS, WASHERS, LOCK WASHERS, GEAR, SPACERS, and BEARINGS from the DRIVE

ROLLER on the outside of both SIDE PLATES.

[3] Rotate the flat part of the SHAFT to the up position.

[4] Move the DRIVE ROLLER to the nondrive side and remove the KEY from the SPROCKET.

[5] Pull the SHAFT to the drive side to remove it from the nondrive SIDE PLATE.

[6] Remove the THRUST WASHER, SPROCKET, and SPACER.

[7] Continue to pull the SHAFT to the nondrive side.

[8] Remove the DRIVE ROLLER.

[9] Reverse the procedure to install the new DRIVE ROLLER.

2–14 September 1996 – 981901

Page 23

Adjustments and Replacements

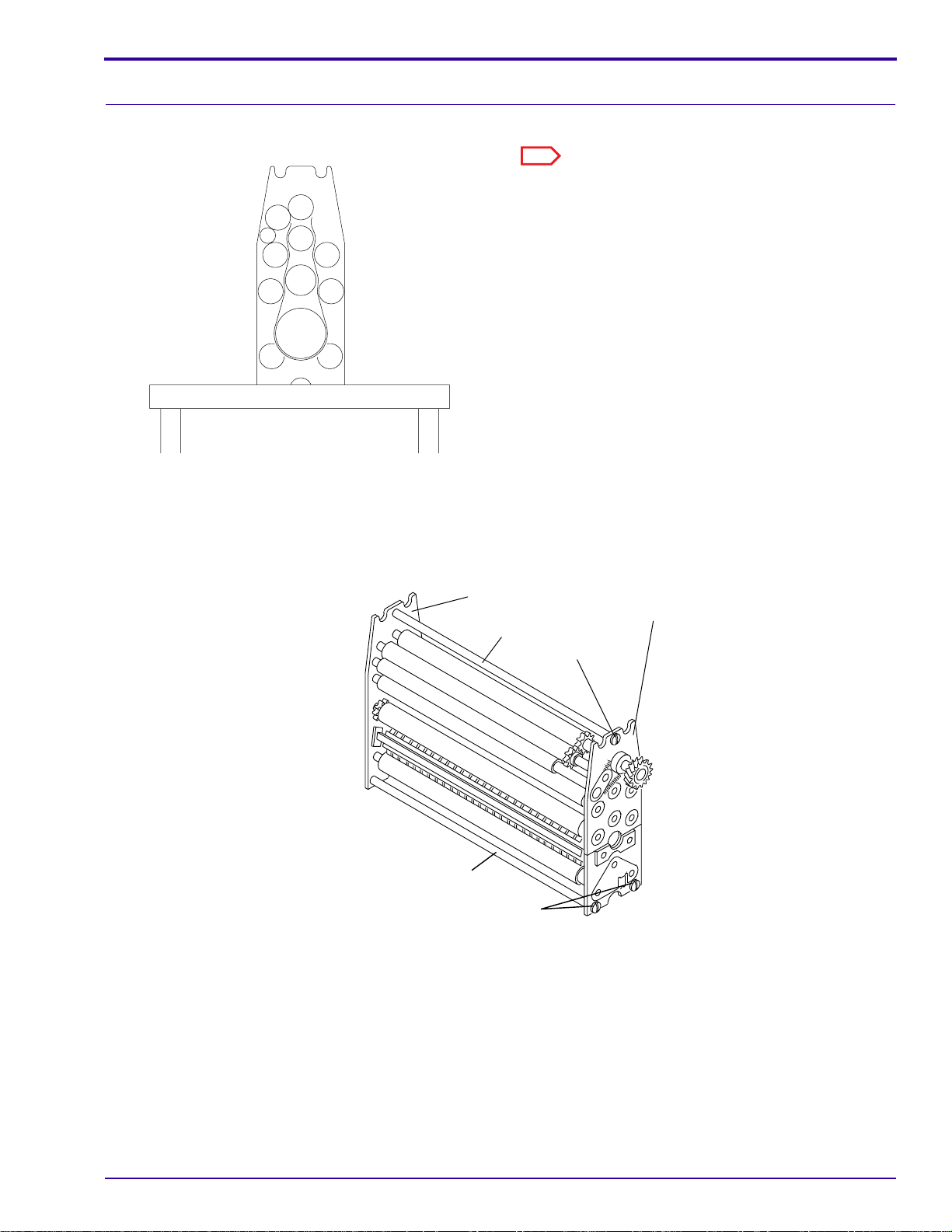

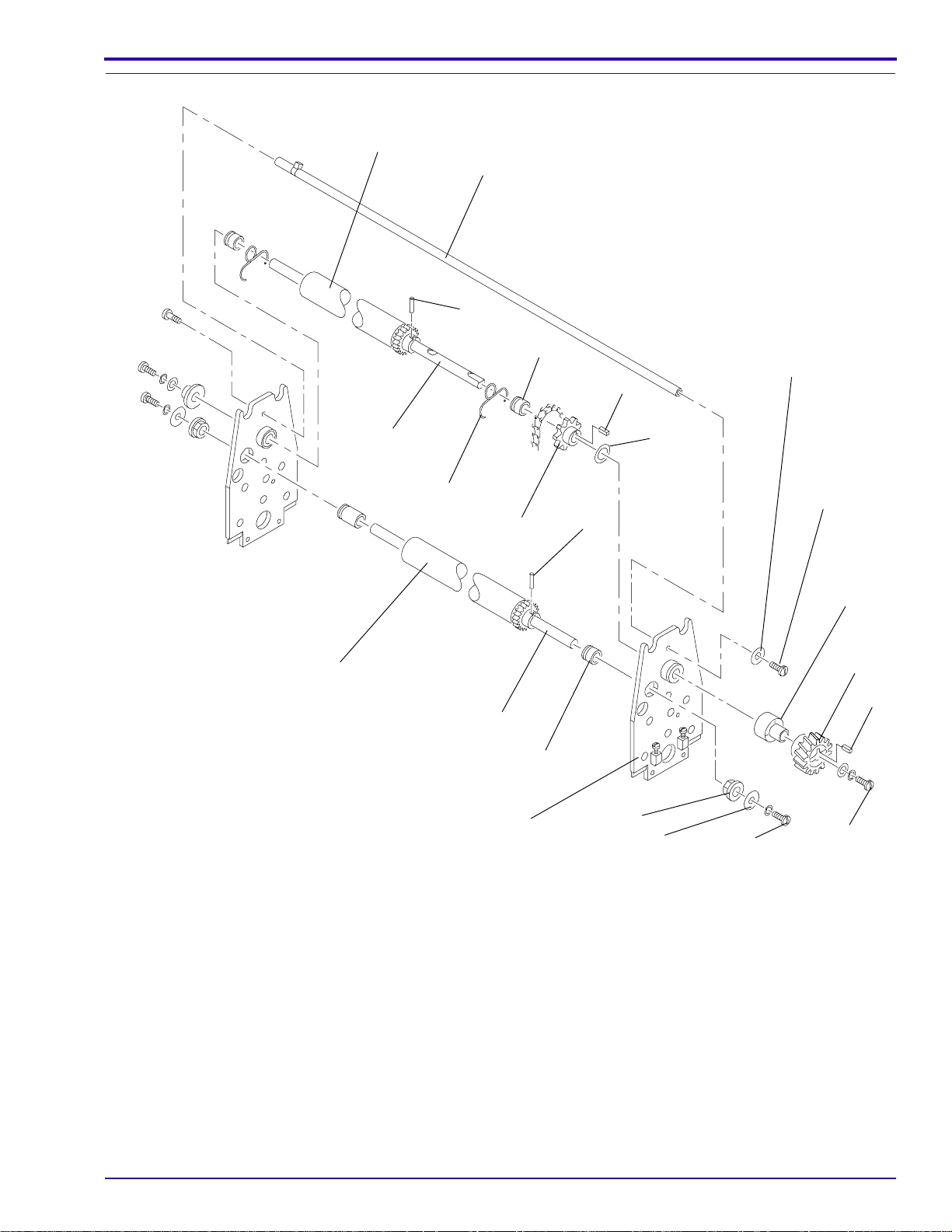

Replacement of the Resilient ROLLERS in the Fixer and Wash RACKS

DRIVE

ROLLER

TIE

ROD

PIN

SPACER

KEY

ID WASHER

SHAFT

THRUST

WASHER

SPRING

(2)

SPROCKET

PIN

SCREW (2)

SPACER

DRIVE

GEAR

DRIVEN

ROLLER

KEY

SHAFT

SPACER

H112_0105DCA

H112_0105DA

SIDE PLATE

BEARING

WASHER

SCREW

SCREW

[1] Remove:

• 2 SCREWS and the ID WASHER from the TIE ROD

• SCREWS, WASHERS, DRIVE GEAR, SPACERS, and BEARINGS from the DRIVE and DRIVEN

ROLLERS on the outside of both SIDE PLATES

[2] Rotate the flat part of the SHAFT of the DRIVE ROLLER to the up position.

[3] Move the DRIVE ROLLER to the nondrive side and remove the KEY from the SPROCKET.

[4] Remove the 2 SPRINGS.

[5] Pull the 2 SHAFTS of the DRIVE ROLLERand the DRIVENROLLER to the drive side to remove the SHAFTS

from the nondrive SIDE PLATE.

[6] Bend the SIDE PLATE slightly to allow removal of the DRIVE ROLLER.

[7] Remove the THRUST WASHER, SPROCKET, and SPACERS.

[8] Reverse the procedure to install new resilient ROLLERS.

981901 – September 1996 2–15

Page 24

SERVICE MANUAL

Adjustment of the DRYER RACK for Squareness

smooth, flat surface

H112_0104AA

[1] Remove the DRYER RACK from the

PROCESSOR and place it on a smooth, flat

surface.

[2] Loosen the 2 SCREWS and 2 NUTS from the

2 TIE RODS.

[3] Check that the SIDE PLATES touch the flat

surface evenly.

[4] Tighten the 2 SCREWS and 2 NUTS.

TIE ROD

TIE ROD

SCREW (2)

SIDE PLATE (2)

NUT (2)

H112_0064BCA

H112_0064BA

2–16 September 1996 – 981901

Page 25

Replacement of the DRIVE ROLLER in the DRYER RACK

O-RING

Adjustments and Replacements

PIN

COLLAR

PLENUM

AIR TUBE

O-RING

DRIVE

ROLLER

COVER

SHAFT

PIN

O-RING

COVER

[1] Remove:

• top and bottom COVERS from the DRYER RACK

• PLENUM

• first 3 AIR TUBES

• O-RING from the DRIVE GEAR

• PIN

• DRIVE GEAR

[2] On the nondrive side, remove:

• O-RING from the COLLAR

• PIN

• COLLAR

[3] On the drive side, remove the O-RING from the DRIVE ROLLER.

[4] Remove the PIN from the DRIVE ROLLER.

[5] Remove the SHAFT from the DRIVE ROLLER.

[6] Reverse the procedure to install the new DRIVE ROLLER.

PIN

DRIVE GEAR

H112_0103DCA

H112_0103DA

981901 – September 1996 2–17

Page 26

SERVICE MANUAL

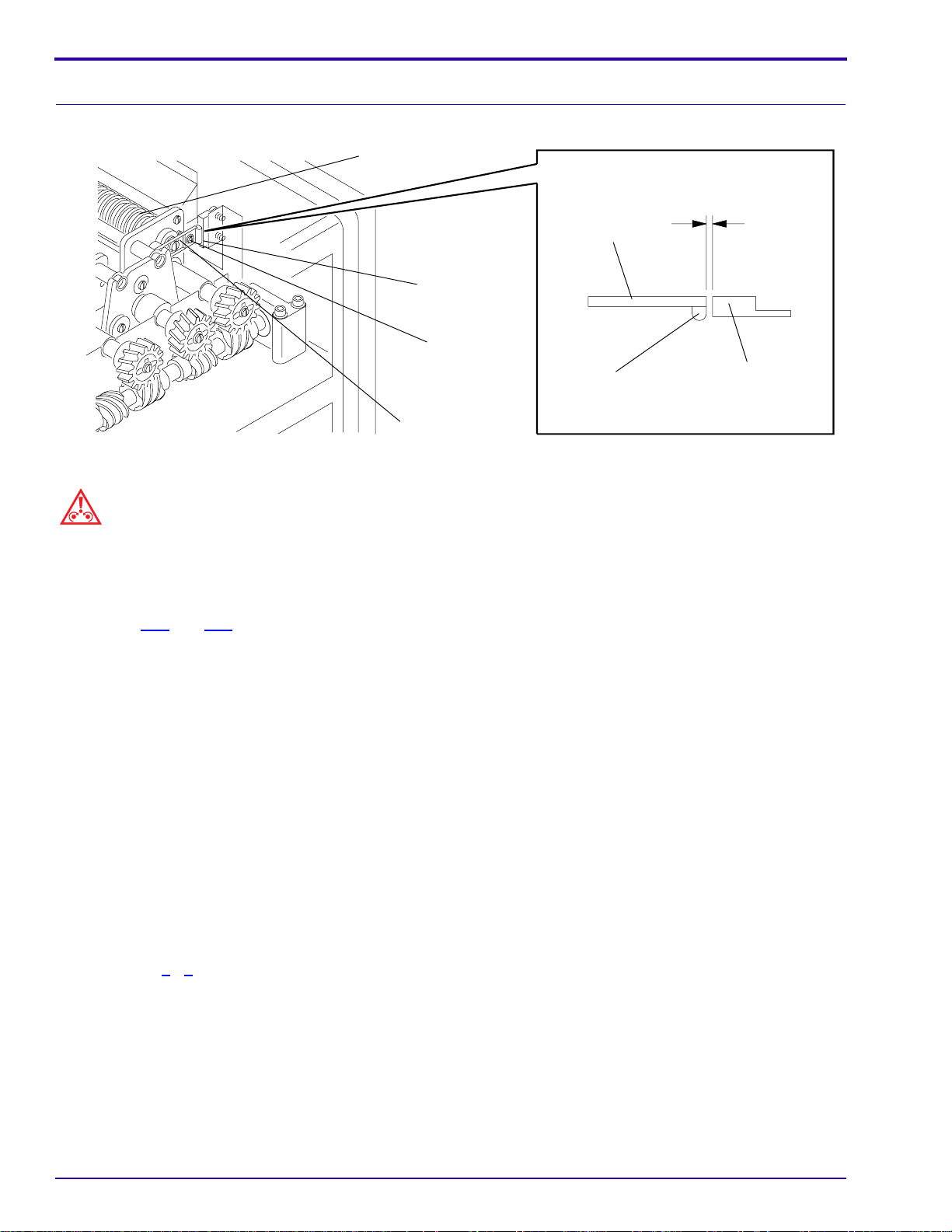

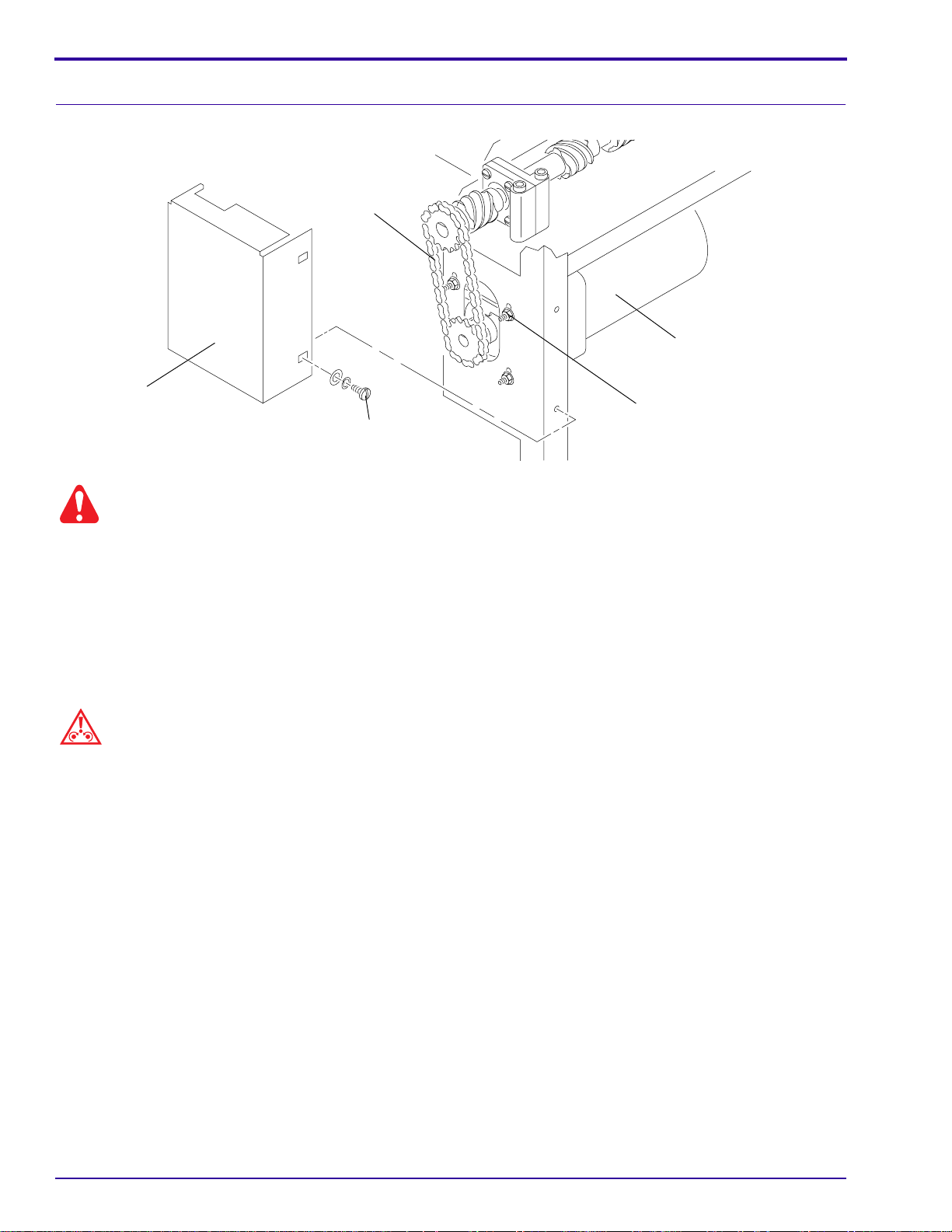

Main Drive

Adjustment of the Main DRIVE CHAIN

DRIVE

CHAIN

MAIN DRIVE MOTOR

CHAIN

GUARD

GUARD SCREW (2)

MOUNTING SCREWS (4)

H112_0181BCA

H112_0181BA

Warning

Moving parts.

[1] Disconnect the main power.

[2] Remove:

• drive SIDE PANEL

• 2 GUARD SCREWS

• CHAIN GUARD

[3] Loosen the 4 MOUNTING SCREWS.

Caution

Do not overtighten the DRIVE CHAIN.

[4] Move the MAIN DRIVE MOTOR up or down until the DRIVE CHAIN is tight. Do not overtighten the DRIVE

CHAIN.

[5] Tighten the 4 MOUNTING SCREWS.

[6] Install:

• CHAIN GUARD

• 2 GUARD SCREWS

• SIDE PANEL

2–18 September 1996 – 981901

Page 27

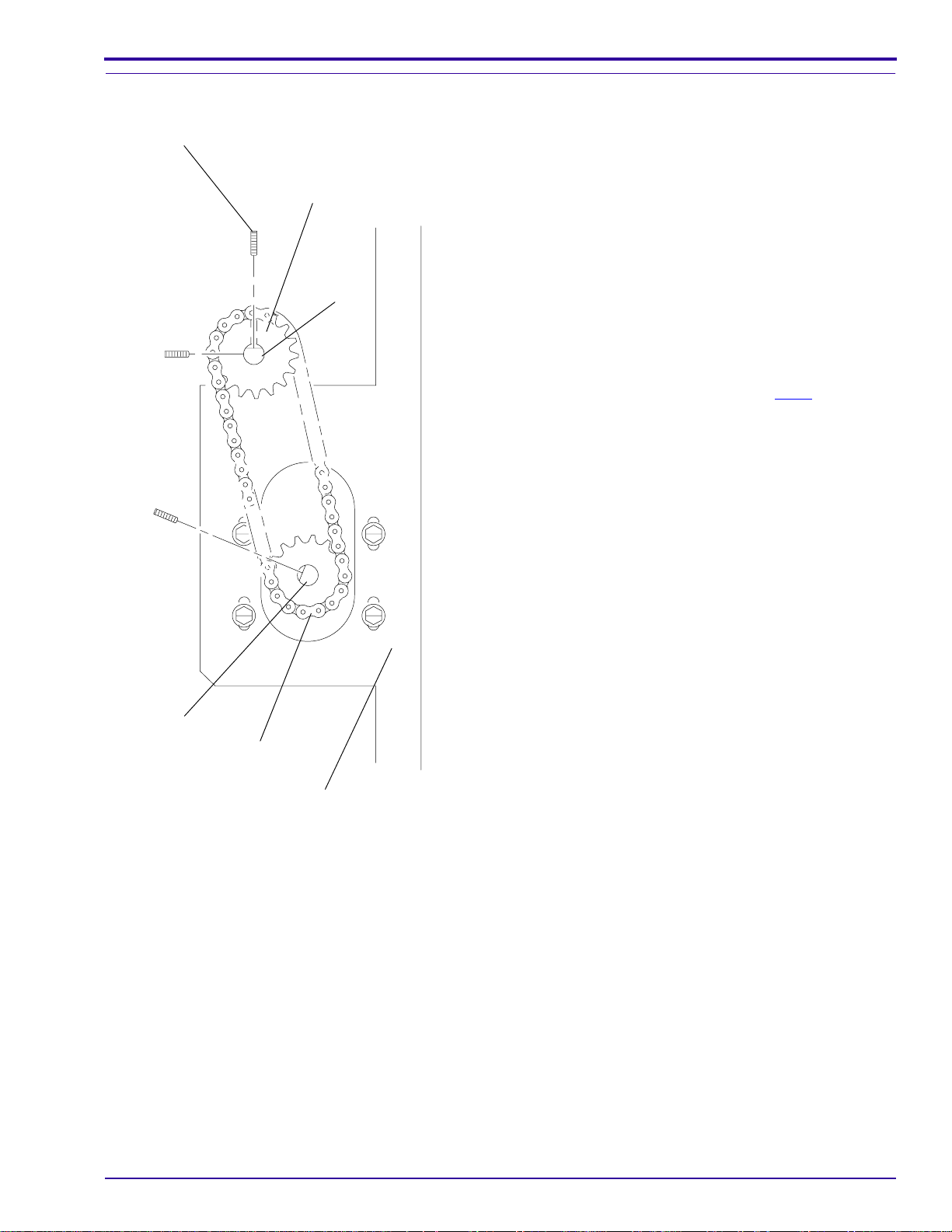

Alignment of the MAIN DRIVE MOTOR

SETSCREW (3)

SPROCKET (2)

DRIVE

SHAFT

Adjustments and Replacements

[1] Remove:

• drive SIDE PANEL

• 2 GUARD SCREWS

• CHAIN GUARD

[2] Loosen the 3 SETSCREWS.

[3] Align the SPROCKETS with the ends of the

DRIVE SHAFT and the MOTOR SHAFT.

[4] Tighten the 3 SETSCREWS.

[5] Check that the DRIVE CHAIN does not touch the

MOUNTING PLATE.

[6] Check that theSPROCKETontheDRIVE SHAFT

does not touch the DRIVE GEAR on the DRYER

RACK. See the figure on Page 2–17.

[7] Install:

• CHAIN GUARD

• 2 GUARD SCREWS

• SIDE PANEL

MOTOR

SHAFT

DRIVE

CHAIN

MOUNTING

PLATE

H112_0088CCA

H112_0088CC

981901 – September 1996 2–19

Page 28

SERVICE MANUAL

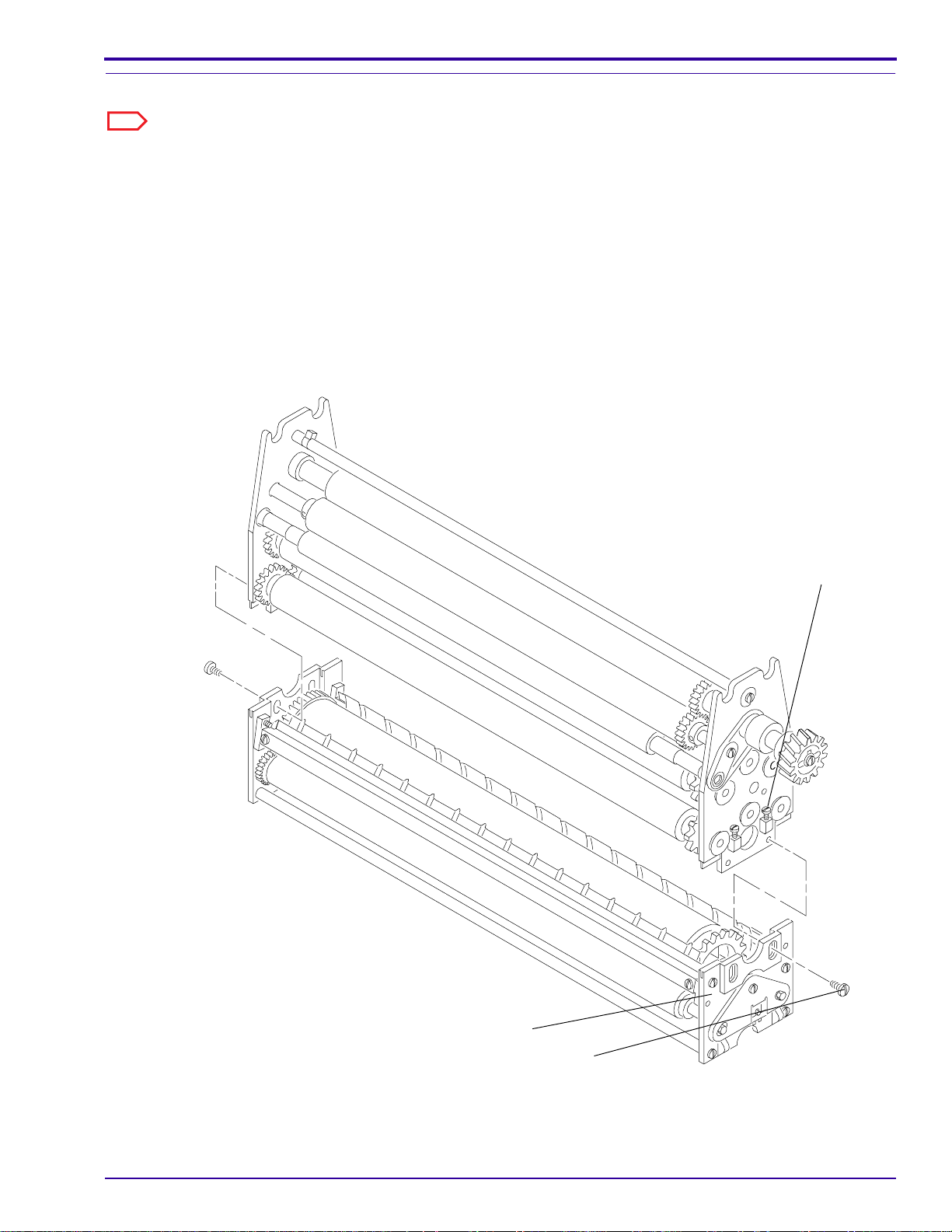

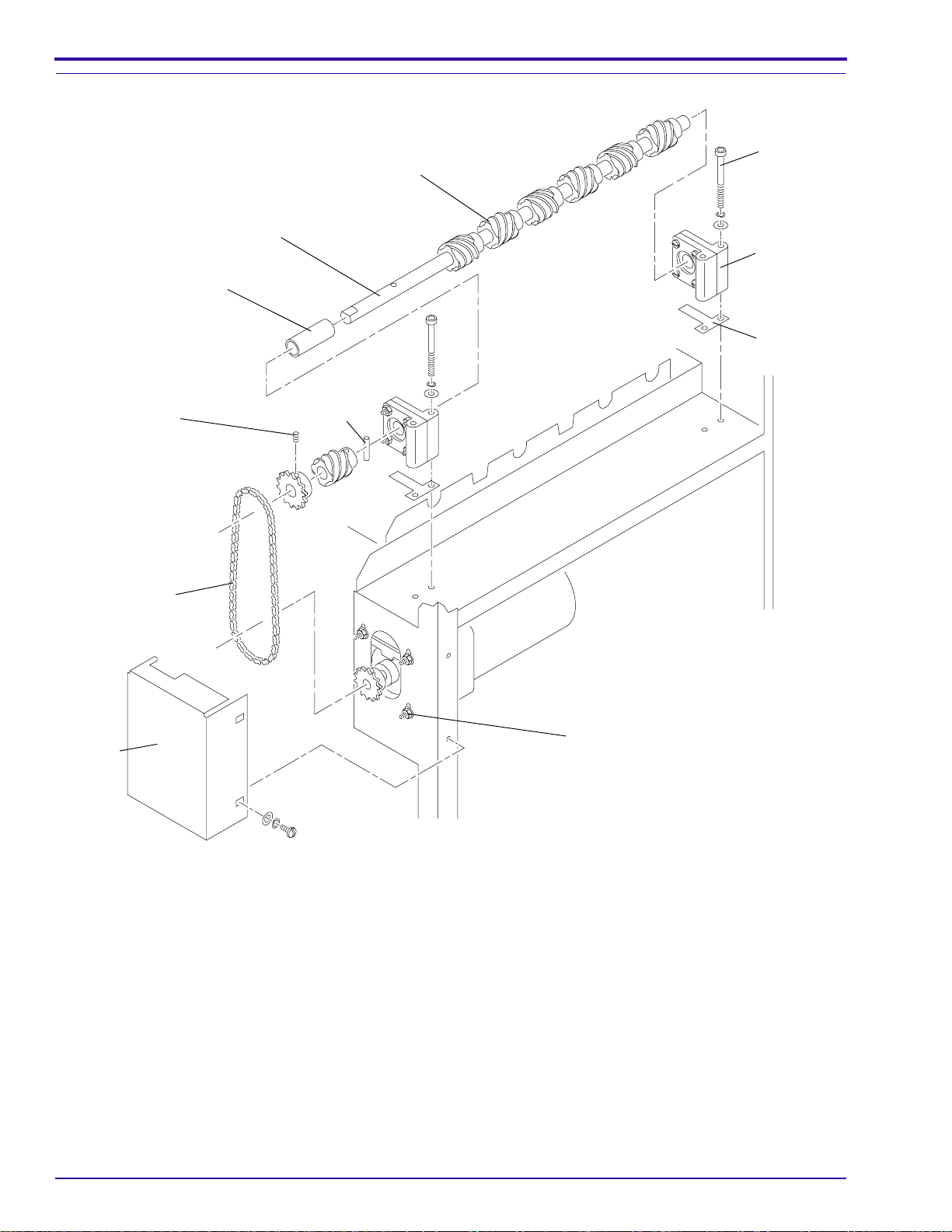

Replacement of the Main DRIVE SHAFT, WORM GEARS, or BEARING BLOCKS

SPACER

SETSCREW

DRIVE

SHAFT

PIN

WORM

GEAR

SCREW

(4)

BEARING

BLOCK

(2)

SHIM

(2)

DRIVE

CHAIN

MOUNTING SCREW (4)

CHAIN

GUARD

[1] Remove the CHAIN GUARD.

[2] Loosen the 4 MOUNTING SCREWS.

[3] Remove:

• DRIVE CHAIN

• 4 SCREWS from the 2 BEARING BLOCKS

• DRIVE SHAFT ASSEMBLY from the PROCESSOR

[4] If the PROCESSOR has SHIMS under the BEARING BLOCKS, save the SHIMS.

[5] Align the SHIMS with the holes for the SCREWS.

[6] Install:

• if necessary, new WORM GEARS or BEARING BLOCKS

• DRIVE SHAFT ASSEMBLY

H112_0182DCA

H112_0182DA

2–20 September 1996 – 981901

Page 29

Caution

Do not overtighten the 4 SCREWS.

[7] Install the 4 SCREWS in the BEARING BLOCKS.

[8] Adjust the position of the BEARING BLOCKS until the DRIVE SHAFT moves freely.

[9] Install the DRIVE CHAIN.

[10] Adjust the DRIVE CHAIN. See Page 2–6.

[11] Tighten the 4 MOUNTING SCREWS.

[12] Install the CHAIN GUARD.

Adjustments and Replacements

981901 – September 1996 2–21

Page 30

SERVICE MANUAL

Adjustment of the Speed of the MAIN DRIVE MOTOR

TOP COVER

ELECTRICAL

BOX

H112_0042ACB

H112_0042AC

[1] Determine the speed of the MAIN DRIVE MOTOR.

(a) Process sheets of 24 cm (10 in.) film in Extended and Standard Modes.

(b) Record the processing times. The correct time for a 24 cm (10 in.) film is:

Extended: 3 minutes and 23 seconds, ±2 sec

Standard: 2 minutes and 15 seconds, ±2 sec

SIDE

PANEL

ESD

Possible damage from electrostatic discharge.

[2] If the dry to dry processing times are not correct, adjust the speed of the MAIN DRIVE MOTOR.

(a) Remove the TOP COVER and the drive SIDE PANEL from the PROCESSOR.

(b) Open the ELECTRICAL BOX.

(c) Measure 24 cm (10 in.) on several new sheets of film.

(d) Set the STD/EXT SWITCH to “STD”.

(e) Feed half of the sheetsof film into the PROCESSOR. Measure the timefor each 24 cm (10 in.) of filmto

enter the PROCESSOR. The correct time is:

Standard: 20 seconds

(f) Set the STD/EXT SWITCH to “EXT”.

(g) Feed the other sheets of film into the PROCESSOR. Measure the time for each 24 cm (10 in.) of film to

enter the PROCESSOR. The correct time is:

Extended: 31 seconds

(h) If thetransport time is not correct, adjustR201 for the Extended Mode or R202 for theStandard Mode on

200 CIRCUIT BOARD. See the figure on the next page.

Important

It is important to check the speed of both modes, especially if an adjustment is necessary for one mode.

(i) Do Steps (a)-(h) again to check the processing times. Continue the procedure until theprocessingtimes

are correct.

(j) Close the ELECTRICAL BOX.

[3] Install the SIDE PANEL and the TOP COVER.

2–22 September 1996 – 981901

Page 31

Adjusting the Speed of the MAIN DRIVE MOTOR

R202

R201

Adjustments and Replacements

STD/EXT SWITCH

200 CIRCUIT BOARD

REPLENISHMENT

PUMP TIMER

ELECTRICAL

BOX

H112_0187ECE

H112_0187EC

981901 – September 1996 2–23

Page 32

SERVICE MANUAL

DRYER HEATER

Adjustment of the Temperature of the DRYER

DRYER

TEMPERATURE

CONTROL

KNOB

Insert

THERMOMETER

here

H112_0089ACC

H112_0089AC

[1] To check the temperature of the DRYER, insert a

THERMOMETER, Part No. 761217, under the

DRYER on the drive side of the PROCESSOR.

See the figure.

Important

The correct temperature for the DRYER depends on

the condition of the air and on the amount and type of

film fed into the PROCESSOR. Use the lowest

temperature possible for good drying.

[2] If necessary, adjust the temperature of the

DRYER,byrotating the DRYER TEMPERATURE

CONTROL KNOB:

clockwise

counterclockwise

increases the

temperature

decreases the

temperature

H112_0040AC

2–24 September 1996 – 981901

Page 33

Adjustments and Replacements

Replacement of the BLOWER ASSEMBLY

Warning

Dangerous voltage.

[1] Disconnect the main power.

[2] Remove:

• TOP COVER

• DRYER RACK

TOP COVER

Possible damage from electrostatic discharge.

H112_0028ACB

H112_0028AC

[3] Disconnect CONNECTORS 801 and 802, not shown, from the 800 CIRCUIT BOARD. See the figure on

Page 2–26 for the position of the 800 CIRCUIT BOARD.

[4] Disconnect the CABLE ASSEMBLY from the ELECTRICAL BOX.

[5] See the figure on Page 2–26. Remove:

• 2 MOUNTING SCREWS from the BRACKET

• 4 MOUNTING SCREWS from the DRYER HEATER

• BLOWER MOTOR and BRACKET

• BLOWER MOTOR from the BRACKET

[6] Install the new BLOWER MOTOR and the 4 MOUNTING SCREWS on the BRACKET.

• RECEIVING END COVER

• SIDE PANELS

ESD

Note

Do not tighten the 4 MOUNTING SCREWS on the BLOWER MOTOR until Step 9.

[7] Install the BRACKET on the DRYER HEATER.

[8] Install the 6 MOUNTING SCREWS.

[9] Tighten the MOUNTING SCREWS.

[10] Connect the CABLE ASSEMBLY to the ELECTRICAL BOX.

[11] Install:

• SIDE PANELS

• RECEIVING END COVER

• DRYER RACK

• TOP COVER

981901 – September 1996 2–25

Page 34

SERVICE MANUAL

Replacement of the BLOWER ASSEMBLY

MOUNTING

SCREW (4)

ELECTRICAL

BOX

RECEIVING

END

COVER

BLOWER

MOTOR

MOUNTING

SCREW (2)

800

CIRCUIT

BOARD

DRYER

HEATER

BRACKET

H112_0100DCA

H112_0100DA

2–26 September 1996 – 981901

Page 35

Adjustments and Replacements

Replacement of the DRYER HEATER or the HEATER CORE

Warning

Dangerous voltage.

[1] Disconnect the main power.

[2] Remove:

• TOP COVER

• DRYER RACK

TOP COVER

Possible damage from electrostatic discharge.

H112_0028ACB

H112_0028AC

[3] Disconnect CONNECTORS 801 and 802, not shown, from the 800 CIRCUIT BOARD. See the figure on

Page 2–28 for the position of the 800 CIRCUIT BOARD.

[4] Disconnect TB2-1, TB2-3, TB2-5, and the ground wire from the ELECTRICAL BOX.

[5] See the figure on Page 2–28. Remove:

• EXHAUST HOSE

• 4 SCREWS under the foam strips

• 6 MOUNTING SCREWS

• DRYER HEATER

[6] Do Steps 7 - 10 to install only a new HEATER CORE inside the DRYER HEATER. To install an entire new

DRYER HEATER, reverse the above procedure.

[7] Loosen the 2 SCREWS.

[8] Remove the HEATER TOP COVER.

[9] Remove the HEATER CORE from the DRYER HEATER:

(a) Remove the 4 HEX NUTS, not shown.

(b) Loosen the 4 MOUNTING SCREWS, not shown.

(c) Remove the HEATER CORE.

[10] Reverse the procedure to install the new HEATER CORE in the DRYER HEATER.

[11] Reverse Steps 2 - 5 to install the DRYER HEATER in the PROCESSOR.

• RECEIVING END COVER

• SIDE PANELS

ESD

981901 – September 1996 2–27

Page 36

SERVICE MANUAL

Replacement of the DRYER HEATER or the HEATER CORE

MOUNTING

SCREW (4)

ELECTRICAL

BOX

RECEIVING

END

COVER

800

CIRCUIT

BOARD

HEATER

TOP COVER

SCREW (2)

HEATER

CORE

MOUNTING

SCREW (2)

SCREW (2)

EXHAUST

HOSE

H112_0100DCB

H112_0100DA

2–28 September 1996 – 981901

Page 37

Adjustments and Replacements

Plumbing

Adjustment of the Developer Temperature

[1] Remove the TOP COVER.

[2] Insert a THERMOMETER of known accuracy, such as Part No. 761217, into the nondrive side of the

DEVELOPER TANK between the SIDE PLATE of the DEVELOPER RACK and the RACK SUPPORT.

Note

If checking both the Standard developer temperature and the Extended developer temperature, check for Standard

Mode first.

The correct temperatures are:

Standard: 33.3˚C ± 0.3˚C (92.0˚F 0.5˚F)

Extended: 35˚C ± 0.3˚C (95.0˚F 0.5˚F)

Insert THERMOMETER

here

H112_0121BCA

H112_0121BA

Caution

• Possible damage from electrostatic discharge. Use an ESD wrist strap.

• Use the POTENTIOMETER ADJUSTING TOOL TL-1481 to adjust R301 and R302.

[3] If a developer temperature adjustment is necessary, adjust R301 and R302 on the 300 CIRCUIT BOARD.

(a) Remove the drive SIDE PANEL from the PROCESSOR.

(b) Open the ELECTRICAL BOX.

(c) Use thePOTENTIOMETERADJUSTINGTOOLTL-1481toadjustthe developertemperaturebyrotating

R302 for Standard Mode or R301 for Extended Mode.

clockwise

counterclockwise

(d) Allow the developer to reach the new, adjusted temperature.

(e) Check the developer temperature in the DEVELOPER TANK with the THERMOMETER.

(f) If the developer temperature is not correct, do Steps (c) - (e) again.

(g) Close the ELECTRICAL BOX and install the SIDE PANEL.

[4] If the METER does not display the same temperature as the THERMOMETER, adjust the METER. See

Page 2–31.

increases the temperature

decreases the temperature

981901 – September 1996 2–29

Page 38

SERVICE MANUAL

Important

• After changing from Extended Mode to Standard Mode, set the DRYER TEMPERATURE CONTROL KNOB to

“0” and remove the TOP COVER for venting. Check that the METER displays the correct temperature before

adjusting R302 or processing film.

•Donot process films until the METER shows that the developer is at the correct temperature.

[5] Install the TOP COVER.

R302

R301

300 CIRCUIT

BOARD

100 CIRCUIT BOARD

H112_0041BCB

H112_0041BC

2–30 September 1996 – 981901

Page 39

Adjustment of the Developer Temperature METER

[1] Check:

TOP COVER

SIDE

PANEL

[2] Remove the TOP COVER.

[3] Check the temperature of the developer.

H112_0042ACB

H112_0042AC

ELECTRICAL

BOX

Adjustments and Replacements

• that the water to the PROCESSOR is on

• that the PROCESSOR is energized

• that the temperaturedisplayedonthe METER

has stablized

• for agitation of the developer in the

DEVELOPER TANK

• that the level of the developer is correct

(a) Insert a THERMOMETER of known

accuracy, such as Part No. 761217, into the

nondrive side of the DEVELOPER TANK

between the SIDE PLATE of the

DEVELOPER RACK and the RACK

SUPPORT. See the figure on Page 2–29.

(b) Compare the temperatures on the

THERMOMETER and on the METER.

Note

The correct temperature is:

METER

Standard: 33.3˚C ± 0.3˚C (92.0˚F ± 0.5˚F)

Extended: 35˚C ± 0.3˚C (95.0˚F ± 0.5˚F)

HOLES

H112_0184ACB

H112_0184AC

[4] If the temperatures are not the same, adjust the METER.

(a) Remove the drive SIDE PANEL from the PROCESSOR.

Caution

Possible damage from electrostatic discharge. Use an ESD wrist strap and a POTENTIOMETER ADJUSTING

TOOL TL-1481.

(b) Open the ELECTRICAL BOX.

(c) Check that CR10 on the 100 CIRCUIT BOARD is blinking.

(d) After CR10 hasblinked for 2 minutes,insert the POTENTIOMETER ADJUSTING TOOL TL-1481 through

the holes in the edge of the ELECTRICAL BOX. See the figure above.

(e) Rotate TL-1481 to adjust the POTENTIOMETER, not shown, on the METER.

clockwise

counterclockwise

increases the temperature

decreases the temperature display

(f) Check the developertemperaturewith the THERMOMETER. If the temperature is notthesameasonthe

METER, adjust the METER again.

981901 – September 1996 2–31

Page 40

SERVICE MANUAL

[5] Close the ELECTRICAL BOX.

[6] Check for correct operation of the PROCESSOR.

(a) Check that the DRYER and developer are at the correct temperatures.

(b) Feed 3 or 4 test sheets of film through the PROCESSOR.

[7] Install the drive SIDE PANEL and the TOP COVER.

2–32 September 1996 – 981901

Page 41

Removal of the Developer Temperature METER

METER

Adjustments and Replacements

[1] De-energize the PROCESSOR.

[2] Remove the TOP COVER and the drive SIDE

PANEL.

ESD

Possible damage from electrostatic discharge.

[3] Open the ELECTRICAL BOX.

[4] Remove from the METER:

• NUTS

• STAR WASHERS

• ground wire

• LOCK WASHER

• WASHER

• wire No. 27

• wire No. 13

• the red wire

• the black wire

• SHIELD

• 2 STANDOFFS

[5] Remove the CIRCUIT BOARD and the PLASTIC

COVER.

H112_0188CCA

H112_0188CC

MOUNTING STUD

PLASTIC COVER

CIRCUIT BOARD

SHIELD

STAR

WASHERS

NUT

WASHER

MOUNTING

STUD

2 STANDOFFS

981901 – September 1996 2–33

GROUND LUG

LOCK WASHER

NUT

ground wire

H112_0179BCA

H112_0179BA

Page 42

SERVICE MANUAL

Installation of the Developer Temperature METER

MOUNTING STUD

PLASTIC COVER

CIRCUIT BOARD

MOUNTING

STUD

2 STANDOFFS

ESD

Possible damage from electrostatic discharge.

GROUND LUG

SHIELD

WASHER

LOCK WASHER

NUT

STAR

WASHERS

ground wire

NUT

H112_0179BCA

H112_0179BA

[1] Align the holes of the PLASTIC COVER and the CIRCUIT BOARD.

[2] Install the PLASTIC COVER and the CIRCUIT BOARD on the MOUNTING STUDS inside the ELECTRICAL

BOX.

[3] Install the 2 STANDOFFS on the front and back MOUNTING STUDS.

Note

The center MOUNTING STUD is not used.

[4] Install the SHIELD on the 2 STANDOFFS.

[5] Install on each STANDOFF:

• WASHER

• LOCK WASHER

• NUT

[6] Connect:

• the red wire to the top TERMINAL

• the black wire to the second TERMINAL

• wire No. 27 to the third TERMINAL

• wire No. 13 to the bottom TERMINAL

[7] Install on the GROUND LUG:

• a STAR WASHER

• the ground wire

• another STAR WASHER

• a NUT

[8] Check that the METER operates correctly.

(a) Energize the PROCESSOR.

(b) Insert a THERMOMETER of known accuracy in the DEVELOPER TANK.

(c) Check that the temperature on the THERMOMETER and on the METER are the same.

2–34 September 1996 – 981901

Page 43

Adjustments and Replacements

H112_0184AC

HOLES

METER

H112_0184ACB

Note

The METER is operating correctly if the temperatures are the same. The correct developer temperature is:

Standard: 33.3˚C 0.3˚C (92.0˚F 0.5˚F)

Extended: 35˚C ± 0.3˚C (95.0°F ± 0.5°F)

(d) If the temperatures are the same, advance to Step 9 .

If the METER does not display the correct temperature, do Steps (e) to (g) below until the METER

displays the correct temperature.

ESD

Possible damage from electrostatic discharge.

(e) Insert the POTENTIOMETER ADJUSTING TOOL TL-1481 through the holes in the edge of the

ELECTRICAL BOX and rotate the POTENTIOMETER, not shown, on the CIRCUIT BOARD.

clockwise

counterclockwise

increase the temperature

decrease the temperature

Important

If decreasing the developer temperature, wait a few minutes before checking the developer temperature.

(f) Check that the developer temperature on the THERMOMETER in the DEVELOPER TANK and on the

METER are the same. If necessary, adjust the POTENTIOMETER again.

(g) Feed 3 sheets of test film to check the operation of the PROCESSOR.

[9] Close the ELECTRICAL BOX

[10] Install the SIDE PANEL and the TOP COVER.

981901 – September 1996 2–35

Page 44

SERVICE MANUAL

Replacement of the DEVELOPER HEATER

H112_0170BCB

H112_0170BA

DEVELOPER

TANK

TUBE

DEVELOPER

HEATER

2 SCREWS

[1] Disconnect the main power.

[2] Drain the DEVELOPER TANK, or install CLAMPS on the 2 TUBES to the THERMOWELL.

[3] Disconnect the wires to the DEVELOPER HEATER at TB2-9 and TB2-10.

TUBE

Caution

When you remove the DEVELOPER HEATER from the THERMOWELL, a small amount of developer may spill.

Clean any spilled solution.

[4] Remove:

• 2 SCREWS

• THERMOWELL

• DEVELOPER HEATER from the THERMOWELL

Caution

• Use only SEALANT TL-3230. AnyotherSEALANTwillcausedamage to the plastic. See the instructionspacked

with the SEALANT.

• Overtightening the DEVELOPER HEATER may cause damage to the THERMOWELL.

[5] Apply SEALANT TL-3230 to the threads of the new DEVELOPER HEATER.

(a) Cut the tube of SEALANT on an angle.

(b) Apply a small amount of SEALANT to the threads.

(c) Use the end of the tube of SEALANT to press the SEALANT into the threads.

[6] Insert the new DEVELOPER HEATER into the THERMOWELL.

[7] Check that the DEVELOPER HEATER isinthecorrectpositionthroughtheHEATER LOCATOR. See the figure

below.

[8] Hand tighten the DEVELOPER HEATER plus1⁄2 turn.

[9] Install the THERMOWELL and 2 SCREWS.

[10] Connect the wires to TB2-9 and TB2-10.

2–36 September 1996 – 981901

Page 45

[11] Remove the CLAMPS from the 2 TUBES, or fill the DEVELOPER TANK.

Adjustments and Replacements

5 mm

(13/64 in.)

13.9 cm

(5.500 .060 in.)

THERMOWELL

HEATER

HEATER LOCATOR

Replacement of the DEVELOPER OVER-TEMPERATURE THERMOSTAT

DEVELOPER

DEVELOPER

THERMISTOR

5 mm

(13/64 in.)

DEVELOPER

OVER-TEMPERATURE

THERMOSTAT

60

HEATER

LOCATOR

H048_0153BCA

H048_0153BA

13.9 cm

(5.500 + .060 in.)

-

THERMOWELL

H048_0162BCA

H048_0162BA

[1] Disconnect the main power.

[2] Drain the DEVELOPER TANK, or install CLAMPS on the 2 TUBES to the THERMOWELL. See the figure on

Page 2–36.

[3] Disconnect the OVER-TEMPERATURE THERMOSTAT at TB4-15, TB4-16, TB4-8, and TB4-9.

Caution

When you remove the OVER-TEMPERATURE THERMOSTAT from the THERMOWELL, a small amount of

developer may spill. Clean any spilled solution.

[4] Remove the OVER-TEMPERATURE THERMOSTAT from the THERMOWELL.

981901 – September 1996 2–37

Page 46

SERVICE MANUAL

Caution

Use only SEALANT TL-3230. Any other SEALANT will cause damage to the plastic. See the instructions packed

with the SEALANT.

[5] Apply SEALANT TL-3230 to the threads of the new OVER-TEMPERATURE THERMOSTAT.

(a) Cut the tube of SEALANT on an angle.

(b) Apply a small amount of SEALANT to the threads.

(c) Use the end of the tube of SEALANT to press the SEALANT into the threads.

Caution

Do not install the new OVER-TEMPERATURE THERMOSTAT below the position shown in the figure.

[6] Install the new OVER-TEMPERATURE THERMOSTAT 5 mm (13/64 in.) from the THERMOWELL. See the

figure above.

[7] Connect TB4-15, TB4-16, TB4-8, and TB4-9 to the new OVER-TEMPERATURE THERMOSTAT.

[8] Remove the CLAMPS from the 2 TUBES, or fill the DEVELOPER TANK.

Replacement of the DEVELOPER THERMISTOR

DEVELOPER

THERMISTOR

[1] Disconnect the main power.

[2] Drain the DEVELOPER TANK, or install CLAMPS on the 2 TUBES to the THERMOWELL. See the figure on

Page 2–36.

[3] Disconnect the DEVELOPER THERMISTOR at TB4-13 and TB4-14.

4 mm

(5/32 in.)

THERMOWELL

H112_0180BCA

H112_0180BA

Caution

When you remove the DEVELOPER THERMISTOR from the THERMOWELL, a small amount of liquid may spill.

Clean any spilled solution.

[4] Remove the DEVELOPER THERMISTOR from the THERMOWELL.

2–38 September 1996 – 981901

Page 47

Adjustments and Replacements

Caution

Use only SEALANT TL-3230. Any other SEALANT will cause damage to the plastic. See the instructions packed

with the SEALANT.

[5] Apply SEALANT TL-3230 to the threads of the new DEVELOPER THERMISTOR.

(a) Cut the tube of SEALANT on an angle.

(b) Apply a small amount of SEALANT to the threads.

(c) Use the end of the tube of SEALANT to press the SEALANT into the threads.

Caution

Do not install the new DEVELOPER THERMISTOR lower than shown in the figure.

[6] Install the new DEVELOPER THERMISTOR 4 mm (5/32 in.) from the DEVELOPER THERMOWELL.

[7] Connect TB4-13 and TB4-14 to the new DEVELOPER THERMISTOR.

[8] Remove the CLAMPS from the 2 TUBES, or fill the DEVELOPER TANK.

981901 – September 1996 2–39

Page 48

SERVICE MANUAL

Replacement of the HEAT EXCHANGERS

RACK

SUPPORT

SCREW (2)

TANK

CLIP (2)

Warning

Dangerous voltage.

[1] Disconnect the main power.

[2] Disconnect the water supply.

[3] Drain the 3 TANKS.

[4] Remove:

• 2 SCREWS from the RACK SUPPORT

• RACK SUPPORT

• TANK SEALS

• TANK CLIPS

[5] Disconnect all tubing from the TANK.

[6] If necessary, remove the 2 FITTINGS and the

WATER INLET TUBE. See the figure on

Page 2–42.

[7] Lift the nondrive side of the TANK, and then

remove the TANK from the PROCESSOR.

TANK

SEALS

(2)

H112_0146CCA

H112_0146CA

2–40 September 1996 – 981901

Page 49

GASKET (2)

FITTING (2)

O-RING (2)

WATER INLET

TUBE

TANK

HEATER

EXCHANGER

WASHER (2)

GLAND NUT (2)

Adjustments and Replacements

[8] Remove:

• 2 GLAND NUTS

• 2 O-RINGS

• 2 WASHERS

• HEAT EXCHANGER from the TANK

[9] Install:

• new HEAT EXCHANGER

• 2 O-RINGS

• 2 WASHERS

• 2 GLAND NUTS

• TANK in the PROCESSOR

• 2 FITTINGS, withnewGASKETSif in thefixer

TANK

• WATER INLET TUBE, wash TANK only

• TANK SEALS

• TANK CLIPS

• tubing

• RACK SUPPORT

[10] Pull the RACK SUPPORT toward the nondrive

side of the PROCESSOR and install the

2 SCREWS.

[11] Connect the water and fillthe3 TANKS with water.

[12] Check for leakage.

[13] Drain the water from the developer and fixer

TANKS. Fill the 2 TANKS with developer and fixer.

[14] Connect the main power.

H112_0098CCA

H112_0098CA

981901 – September 1996 2–41

Page 50

SERVICE MANUAL

Replacement of the RECIRCULATION PUMP

RECIRCULATION PUMP

Warning

Dangerous voltage.

[1] Disconnect the main power.

[2] Disconnect the water supply.

[3] Remove the TOP COVER and 2 SIDE PANELS.

[4] Drain the 3 TANKS.

[5] Use PINCH CLAMPS on the tubing to prevent leakage.

[6] Disconnect the tubing to the RECIRCULATION PUMP.

[7] Remove the MOUNTING SCREWS.

[8] Remove the RECIRCULATION PUMP.

[9] Reverse the above procedure to install a new RECIRCULATION PUMP.

[10] Connect the water supply.

[11] Remove the PINCH CLAMPS.

[12] Fill the 3 TANKS with water.

[13] Connect the main power.

MOUNTING

SCREW

H112_0166BCC

H112_0166BA

Caution

Never operate the RECIRCULATION PUMPS if the TANKS are empty.

[14] Actuate the RECIRCULATION PUMPS.

[15] Check for agitation on the surface of the solutions.

[16] Check for leakage.

[17] Drain the water thoroughly from the developer and fixer TANKS and fill the TANKS with developer and fixer.

2–42 September 1996 – 981901

Page 51

Replacement of the O-RING

Adjustments and Replacements

O-RING

WING

NUT

(4)

OUTER

PUMP

HOUSING

SCREW

WASHER

IMPELLER

SHAFT

H112_0084DCA

H112_0084DA

Warning

Dangerous voltage.

[1] Disconnect the main power.

[2] Remove the TOP COVER and the 2 SIDE PANELS.

[3] Install PINCH CLAMPS on the tubing of the RECIRCULATION PUMP to prevent leakage.

[4] Remove:

• 4 WING NUTS

• OUTER PUMP HOUSING

• O-RING

[5] Check that the O-RING is correctly seated.

[6] Install the OUTER PUMP HOUSING and the 4 WING NUTS.

[7] Remove the PINCH CLAMPS.

981901 – September 1996 2–43

Page 52

SERVICE MANUAL

[8] Connect the main power.

Caution

Never operate the RECIRCULATION PUMPS if the TANKS are empty.

[9] Actuate the RECIRCULATION PUMPS.

[10] Check for agitation on the surface of the solutions.

[11] Check for leakage.

Replacement of a REPLENISHMENT PUMP

EXIT PANEL

TOP COVER

SIDE

PANEL

(2)

Warning

Dangerous voltage.

[1] Disconnect the main power.

[2] Disconnect the water supply.

PUMP

COVER

[3] Remove:

• TOP COVER

• 2 SIDE PANELS

• RECEIVING BIN

• DRYER TEMPERATURE CONTROL KNOB

• PUMP COVER

DRYER

TEMPERATURE

CONTROL KNOB

H112_0005ACC

H112_0005AC

• EXIT PANEL

[4] Disconnect the 2 MOTOR LEADS TB3-6 and

TB3-2 and the ground wire.

[5] Install a CLAMP on the REPLENISHER TUBE.

[6] Remove the REPLENISHER TUBE LINES from the REPLENISHMENT PUMP.

[7] Remove and keep the 2 SCREWS, the 2 WASHERS, and the 2 LOCK WASHERS.

[8] Remove the REPLENISHMENT PUMP.

[9] Reverse the above procedure to install a new REPLENISHMENT PUMP.

REPLENISHER

TUBE LINES

REPLENISHMENT

PUMP (2)

WASHER (2)

LOCK

WASHER (2)

H112_0097BCA

SCREW (2)

2–44 September 1996 – 981901

H112_0097BA

Page 53

Adjustment of the REPLENISHMENT PUMPS

Adjustments and Replacements

BRACKET

HOLE

BIN.

[2] Loosen the 2 SCREWS and remove the PUMP

COVER.

[3] Actuate the DETECTOR SWITCH, by lifting the

top DETECTOR ROLLER of the DETECTOR

CROSSOVER ASSEMBLY, until the

ADJUSTMENT SCREW is visible through the

hole in the BRACKET.

[4] Loosen the SETSCREW.

Caution

[1] Remove the TOP COVER and the RECEIVING

PUMP

COVER

SCREW (2)

H112_0005ACB

H112_0005AC

[7] See Page 2–46 and check theflow rates. If necessary, do Steps 2 - 6 again. See the table on Page 2–46 for

various replenishment rates.

[8] Install the TOP COVER, the PUMP COVER, and the RECEIVING BIN.

[9] Check that theREPLENISHMENTPUMPS operate correctly by feeding a sheet offilm into the PROCESSOR.

See Page 2–2.

Do not adjust the LOCKNUT on the other end of the

ADJUSTMENT SCREW.

[5] Rotate the ADJUSTMENT SCREW:

clockwise

counterclockwise

increases the flow rate

decreases the flowrate

[6] Tighten the SETSCREW.

SETSCREW

Do not

adjust!

LOCKNUT

H112_0030BCB

H112_0030BC

ADJUSTMENT

SCREW

REPLENISHMENT PUMP

BRACKET

HOLE

ADJUSTMENT SCREW

DECREASE INCREASE

OUTPUT

981901 – September 1996 2–45

Page 54

SERVICE MANUAL

Adjustment of the Replenishment Flow Rates

[1] Remove the TOP COVER.

[2] Lift the top DETECTOR ROLLER of the

DETECTOR CROSSOVER ASSEMBLY.

[3] Check that the replenisher solutions flow freely

through the TUBING along the drive side of the

PROCESSOR.

METAL

LATCH

DEVELOPER TUBING

QUICK

DISCONNECT

GRADUATED

CYLINDER

FIXER TUBING

[4] Press the METAL LATCH on the red QUICK

DISCONNECT to disconnect the DEVELOPER

TUBING.

[5] Pull the DEVELOPER TUBING slightly byrotating

the DEVELOPER TUBING over the edge of the

PROCESSOR.

[6] Insert the DEVELOPER TUBING into a

GRADUATED CYLINDER.

H112_0114ACA

H112_0114AC

[7] Lift the top DETECTOR ROLLER of the

DETECTOR CROSSOVER ASSEMBLY for the

correct time. See the table on the next page.

Note

The REPLENISHMENT PUMP will operate 3 seconds after you release the DETECTOR ROLLER.

[8] Check that the amount of developer in the GRADUATED CYLINDER is the same as in the table.

[9] If necessary, adjust the REPLENISHMENT PUMP. See Page 2–45 for the adjustment procedure.

[10] If necessary, so Steps 7 - 9 again.

[11] Connect the QUICK DISCONNECT.

[12] Do this procedure again to check the flow rate of the fixer.

Film Size

Processed

Only 35 x 35 cm

(14 x 14 in.) film

Average size

film intermix

Only 35 x 43 cm

(14 x 17 in.) film

Use

Condition

High

Medium

Low

High

Medium

Low

High

Medium

Low

Average Amount

of Film

per 8 Hours of

Processor Operation

90 sheets or more

31 - 89 sheets

30 sheets or less

115 sheets or more

41 - 114 sheets

40 sheets or less

75 sheets or more

26 - 74 sheets

25 sheets or less

Replenishment Flow Rate

mL per 35 cm (14 in.)

28 sec

of Film Travel

Developer Fixer

50 70

65 85

80 100

50 70

65 85

80 100

— —

mL per 43 cm (17 in.)

34 sec

of Film Travel

Developer Fixer

— —

— —

60 85

80 100

100 120

2–46 September 1996 – 981901

Page 55

Film Size

Processed

Only 18 x 24 cm

Kodak Min-R

E Film

Only 18 x 24 cm

Kodak Min-R

M Film

Only 18 x 24 cm

Kodak Min-R

H Film

Only 18 x 24 cm

Kodak Min-R

2000 Film

Use

Condition

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

Average Amount

of Film

per 8 Hours of

Processor Operation

150 sheets or more

60 - 149 sheets

59 sheets or less

150 sheets or more

60 - 149 sheets

59 sheets or less

150 sheets or more

60 - 149 sheets

59 sheets or less

150 sheets or more

60 - 149 sheets

59 sheets or less

Replenishment Flow Rate

mL per 24 cm

26 sec

of Film Travel

in Standard Mode

Developer Fixer

— —

30 30

30 35

35 40

50 30

50 35

50 40

20 30

20 35

20 40

Adjustments and Replacements

mL per 24 cm

36 sec

of Film Travel

in Extended Mode

Developer Fixer

20 30

27 35

35 40

— —

— —

— —

Note

• Kodak

• Replenishment rates are based on one sheet of 18 x 24 cmfilm. Iffeedingtwosheets,doublethereplenishment

• For best results, feed film consistently.

• Slight sensitometric changes will occur as subsequent films are processed through a freshly started process.

• For 30 sheets of film or less per day, flooded replenishment is recommended.

• Film travel time includes feed time plus an approximate 3-second delay.

RP

X-Omat

Chemicals are recommended.

rates.

This is known as “seasoning” and is normal with any photographic process. Process control targets may have

to be adjusted slightly to compensate.

981901 – September 1996 2–47

Page 56

SERVICE MANUAL

2–48 September 1996 – 981901

Page 57

Periodic Maintenance

Section 3: Periodic Maintenance

General Information

Note

• This section includes additional procedures that are not in the Operator Manual, Publication No. 981799.

• To provide for optimum operation of the PROCESSOR, it is important to use the following procedures.

[1] Process 5 sheets of unprocessed film before you begin the periodic maintenance. Check for artifacts.

[2] Check for:

• cleanliness

• broken parts

• wear of parts

• leakage

• site specifications

[3] Install new parts for the broken parts and parts that have wear.

Warning

Dangerous Voltage

• Disconnect the main power before lubricating the parts.

• Do not allow anyoil or grease to touchthe CROSSOVERS and RACK ASSEMBLIES or to drip into the TANKS.

[4] If necessary, provide lubrication.

[5] Use the correct procedure to clean parts.

[6] Make the necessary adjustments.

[7] Process 5 sheets of unprocessed film in the PROCESSOR after you have performed any service. Check for

artifacts.

Periodic Maintenance Schedule

See Service

ITEM TO CHECK WEEKLY MONTHLY

Feed Shelf Alignment X 2–1

Detector and Crossover Assemblies X 3–3 and 3–4

Rollers

Gears

Guide Shoes

Bearings

Brackets

Nuts

Rack Assemblies X 3–5

Rollers

Gears

Guide Shoes

Procedure on Page:

981901 – September 1996 3–1

Page 58

SERVICE MANUAL

ITEM TO CHECK WEEKLY MONTHLY

Procedure on Page:

Bearings

Chain

Springs

Rewet Rollers

Turnaround Assemblies X 3–6

Rollers

Springs

Main Drive Assembly X 3–7

Plumbing X 3–11

Connections

Tubing

Recirculation System X 3–11

Developer Filter Or after 1000 films 3–12

Developer Temperature X 3–12

Water Flow to the Processor X

Chemical Replenishment X 3–12

Strainer Assemblies X 3–12

Dryer Sections 3–8

Bearings X

Air Tubes X

Rollers X

O-Rings X

Dryer Temperature X

Processor Speeds X

EXT

STD

See Service

Lubrication Table

Part Lubricant Frequency Procedure

Main DRIVE CHAIN NLGI - No. 2 Lithium Ball

andRollerBearingGrease,

As necessary.

Check each month.

Apply to surface of Chain.

TL-2324

RECIRCULATION PUMPS Light oil, such as SAE

No. 20 Motor Oil, TL-2244

Every 6 months. Several drops in the oil

holes.

Main DRIVE MOTOR No lubrication necessary ---- ---GEAR HOUSING of the

No lubrication necessary ---- ----

Main Drive Motor

BEARINGS in the Dryer

Blower Motor

3–2 September 1996 – 981901

Light oil, such as SAE

No. 20 Motor Oil, TL-2244

Every 6 months. Several drops in the oil

holes.

Page 59

Roller Transport

DETECTOR SWITCHES and DETECTOR CROSSOVER ASSEMBLY

DETECTOR

ROLLER

ROCKER

ARM

DETECTOR

SWITCH (2)

SCREW

Periodic Maintenance

1.6 mm

(0.06 in.)

MAGNET (2)

ROCKER ARM

DETECTOR

SWITCH (2)

H112_0112BCA

H112_0112BA

[1] Check that theDETECTOR SWITCHES operatetheREPLENISHMENT PUMP. SeePage 2–2foradjustment.

[2] Clean the DETECTOR ROLLERS with a damp, lint-free cloth or natural sponge.

[3] Check:

• That the ROCKER ARM moves freely. If not, remove the ROCKER ARM and BUSHING and clean with

warm water.

• For corrosion of the ROCKER ARM. If necessary, install a new ROCKER ARM.

• For squareness of the DETECTOR CROSSOVER ASSEMBLY. See Page 2–4.

• That the DETECTOR CROSSOVER ASSEMBLY is seated correctly.

981901 – September 1996 3–3

Page 60

SERVICE MANUAL

CROSSOVER ASSEMBLIES

BRACKET

ROLLER

ROLLER

GEAR

NUT

DRIVE

GEAR

GUIDE

SHOE

BEARING

H112_0056BCB

H112_0056BA

[1] Remove the CROSSOVER ASSEMBLIES from the PROCESSOR.

[2] Rinse the CROSSOVER ASSEMBLIES with running water.

[3] If necessary, use a soft brush and warm water or:

Developer/Fixer Crossover Assembly Kodak Liquid Developer System Cleaner

Fixer/Wash Crossover Assembly Kodak Fixer/Wash System Cleaner

[4] Check the ROLLER GEARS for broken or worn teeth. If necessary, install new ROLLERS.

[5] Check that the RESILIENT ROLLER is smooth. If necessary, install a new RESILIENT ROLLER.

[6] Check the BEARING, BRACKETS, and NUTS for wear or broken parts. If necessary, install new parts.

[7] Check the DRIVE GEAR for wear or burrs. If necessary, install a new DRIVE GEAR.

[8] Place the CROSSOVER ASSEMBLIES on a flat surface with the GUIDE SHOES up.

[9] Check for squareness. See Page 2–5 of this manual.

3–4 September 1996 – 981901

Page 61

RACK ASSEMBLIES and ROLLERS

DRIP TRAY

SPLASH GUARD

H112_0015ACA

H112_0015AC

Periodic Maintenance

Caution

When you remove the FIXER RACK ASSEMBLY,

install a SPLASH GUARD between the DEVELOPER

TANK and the FIXER TANK to prevent contamination

of the developer. Usea DRIP TRAY when youremove

the RACK ASSEMBLIES. Install the RACK

ASSEMBLIES slowly into the TANKS.

[1] Remove the RACK ASSEMBLIES from the

PROCESSOR.

[2] Rinse the RACK ASSEMBLIES with warm water,

approximately 44°C (110°F).

Note

Discoloration of the ROLLERS is normal.

[3] If necessary, use a soft brush or:

Assembly Use:

Developer Rack

Assembly

Fixer Rack Assembly

or Wash Rack

Assembly

Kodak Liquid

Developer System

Cleaner

Kodak Fixer/Wash

System Cleaner

smooth, flat surface

H112_0110AA

[4] Remove the STUDS from the drive side.

[5] Remove all the OUTER ROLLERS on the entrance side except the bottom OUTER ROLLER.

[6] Clean the INNER and OUTER ROLLERS.

[7] Check all SPROCKETS and GEARS for wear.

[8] Check that all ROLLERS are straight.

[9] Install the ROLLERS in the RACK ASSEMBLY.

[10] Check:

• That the ROLLERS are installed correctly.

• The REWET ROLLER for wear.

• That the REWET ROLLER is smooth.

• That the REWET ROLLER touches the ROLLERS above and below it.

• The RACK ASSEMBLY for squareness. See Page 2–4.

981901 – September 1996 3–5

Page 62

SERVICE MANUAL

TURNAROUND ASSEMBLIES

bottom view

BEARING

SHAFT

SPRING

ROLLER

top view

LOCKING

PLATE

BEARING

[1] Remove the TURNAROUND ASSEMBLIES from the RACK ASSEMBLIES.

[2] Clean the DEVELOPER TURNAROUND ASSEMBLY with

[3] Clean the FIXER TURNAROUND ASSEMBLY with

Kodak

Kodak

Liquid Developer System Cleaner.

Liquid Fixer/Wash System Cleaner.

[4] Check the tension of the SPRINGS. If necessary, install new SPRINGS.