Page 1

Publication No. 981900

Supersedes September 1992

INSTALLATION INSTRUCTIONS

for the

September 1996

Kodak

M35-M and M35A-M

X-Omat

H112_0008AC

PROCESSORS

© Eastman Kodak Company

Page 2

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be liable

for any loss or damage, including consequential or special damages, resulting fromany useof

this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Warning

To avoid hazardous conditions, keep floors and floor coverings around your

associated drains clean and dry at all times. Any accumulation of fluids from mixing tanks, drain lines, etc, should

be cleaned upimmediately. In the eventof an accumulationof liquid dueto backup, overflow, or other malfunctions

of the drain associated with your

Kodak X-Omat

PROCESSOR, call a plumber or other contractor to correct any

problem with the drain. Kodak accepts no responsibility or liability whatsoever for the serviceability of any drain

connected to or associated with a

Kodak X-Omat

PROCESSOR. Such drains are the sole responsibility of the

customer.

Kodak X-Omat

PROCESSOR and

Related Publications for the M35-M and M35A-M PROCESSORS

This publication is part of a series of instruction books that provides technical support information on the

M35-M and M35A-M

X-Omat

PROCESSORS. If you need an adiitionalor replacement publication,order it through

your Eastman Kodak Representative using the Publication Part Numbers below.

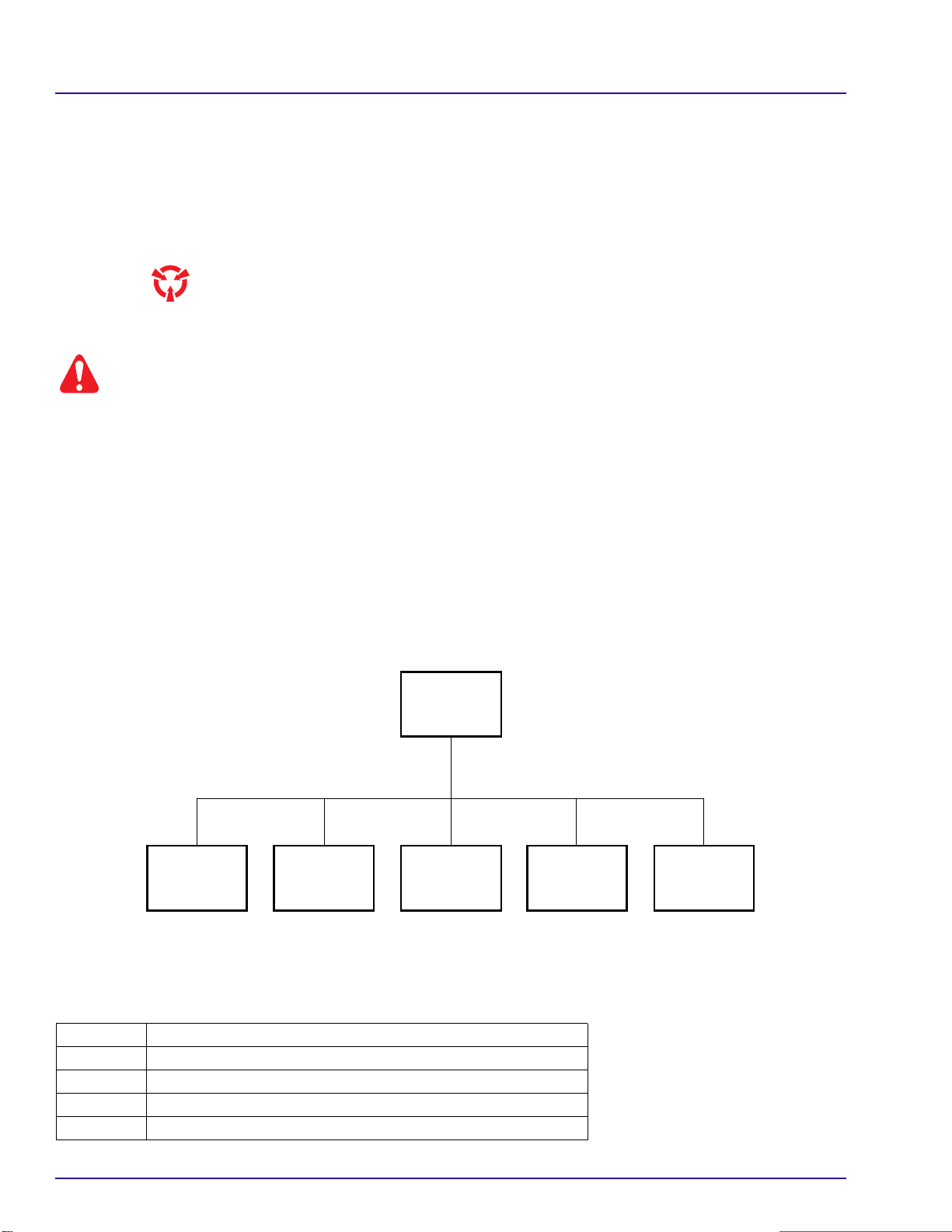

COMPLETE

BINDER

981903

OPERATOR

MANUAL

SITE SPECS

981157

INSTALLATION

INSTRUCTIONS

981900

SERVICE

MANUAL

981901981799

PARTS LIST

981902

H112_9003BC

Special Tools Required

Only qualified personnel should install this PROCESSOR. The following tools are required:

Kodak

Part No. Description

TL-2431 Air Meter

TL-1434 Level - approximately 30 cm (12 in.)

TL-1481 Potentiometer Adjusting Tool

1C7639 For M35A-M Processors only, Turnaround Adjustment Tool

2 September 1996 – 981900

Page 3

Table of Contents

Description Page

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpacking the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Preparing the PROCESSOR for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connecting the Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connecting the REPLENISHMENT TANKSto the REPLENISHMENT PUMPSandthe SILVER

RECOVERY UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting the Main Power for an M35A-M PROCESSOR, 120 Volts Only . . . . . . . . . . 22

Connecting the POWER CORD on an M35-M PROCESSOR, 220 Volts Only . . . . . . . . . 23

Circuit Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Preparing the PROCESSOR for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Publication History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Installing the FEED SHELF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Adjusting the FEED SHELF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing the DEVELOPER RACK and the DETECTOR CROSSOVER AY . . . 10

Installing the PROCESSOR onto a Flat Surface . . . . . . . . . . . . . . . . . . . . . . . 11

Installing the PROCESSOR Through a Wall . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Leveling the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing SEISMIC BRACKETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connecting the EXHAUST HOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Checking the Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Checking the Tubing CLAMPS, TANKS, and RACKS . . . . . . . . . . . . . . . . . . . . 26

Filling the TANKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Removing the REPLENISHMENT PUMP TIMER, for Very Low Volume Use Only 28

Checking the Replenishment Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Adjusting the REPLENISHMENT PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Installing the RACKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Checking the Operation of the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Adjusting the Speed of the MAIN DRIVE MOTOR . . . . . . . . . . . . . . . . . . . . . . 36

981900 – September 1996 3

Page 4

INSTALLATION INSTRUCTIONS

Section 1: Electrostatic Discharge

Overview

ESD - electrostatic discharge - is a primary source of:

• product downtime

• lost productivity

• costly repairs

While one cannot feel a static charge of less than 3,500 volts, as few as 30 volts can damage or destroy

essential components in electronic equipment.

Preventive Measures

• Always look for an ESD warning label before doing any procedure involving static-sensitive

components such as CIRCUIT BOARDS. All static-sensitive components are marked with bright

graphic labels, which frequently include instructions. Follow all label instructions.

• Wearagrounding strap when handling static-sensitivecomponents. Always make certainthatthe

clip remains attached to a properly grounded, unpainted, clean surface.

• Repairstatic-sensitive components at an ESD-protected work station oruse a portable grounding

mat. For help in setting up an ESD-protected work station, contact your Kodak representative.

• When moving static-sensitive components from one area to another, insert and transport the

components in ESD-protective packaging. Transparent antistatic bags are availablefromavariety

of manufacturers and will help shield components from ESD damage.

4 September 1996 – 981900

Page 5

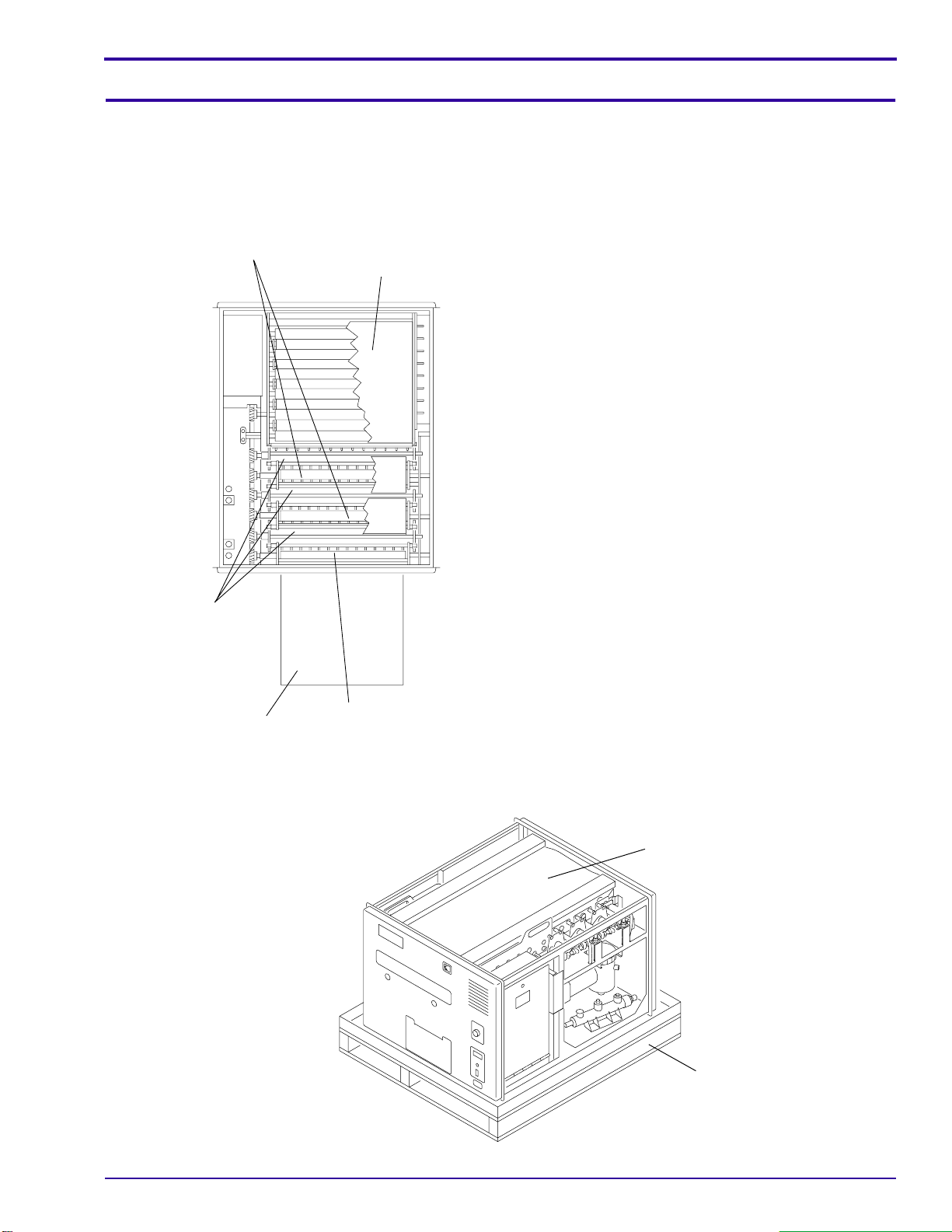

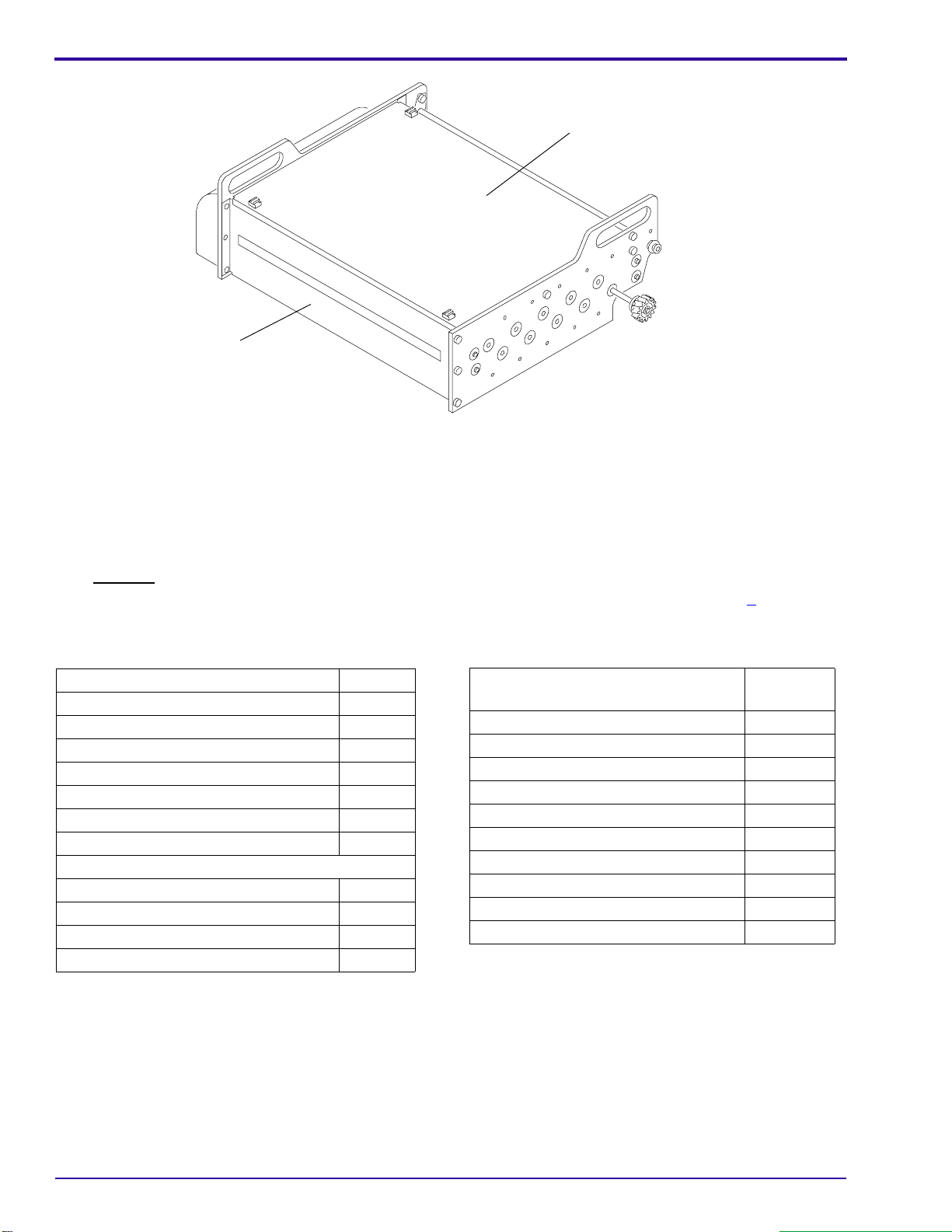

Section 2: Unpacking the PROCESSOR

[1] Remove the PACKING CARTON.

[2] Remove and keep the bags of parts, loose parts,

[3] During the unpacking, check the parts with the

CROSSOVER

ASSEMBLY (2)

DRYER

ASSEMBLY

[4] Remove:

Unpacking the PROCESSOR

and wrapped parts.

Packing List.

• TOP COVER

• 2 SIDE PANELS

• PACKING MATERIAL

• DETECTOR CROSSOVER ASSEMBLY

• 2 CROSSOVER ASSEMBLIES

• DRYER ASSEMBLY

• 3 RACKS

• installation and operator publications

RACK (3)

FEED SHELF

DETECTOR

CROSSOVER

ASSEMBLY

H112_0066CCA

H112_0066CC

PACKING MATERIAL

SHIPPING

BASE

H112_0186BCA

H112_0186BA

981900 – September 1996 5

Page 6

INSTALLATION INSTRUCTIONS

COVER

DRYER ASSEMBLY

H112_0064BCB

H112_0064BA

[5] From the DRYER ASSEMBLY, remove the:

• top and bottom COVERS

• PACKING MATERIAL

[6] Install the top and bottom COVERS on the DRYER ASSEMBLY.

[7] Carefully remove the PACKING MATERIAL from the TANKS.

[8] Before you start the PROCESSOR installation, check that you have all the parts listed on Page 6.

[9] Remove dust from the TANKS, the RACKS, the CROSSOVER ASSEMBLIES, and the DRYER SECTION by

rinsing with water. Wipe dry with a soft, clean cloth.

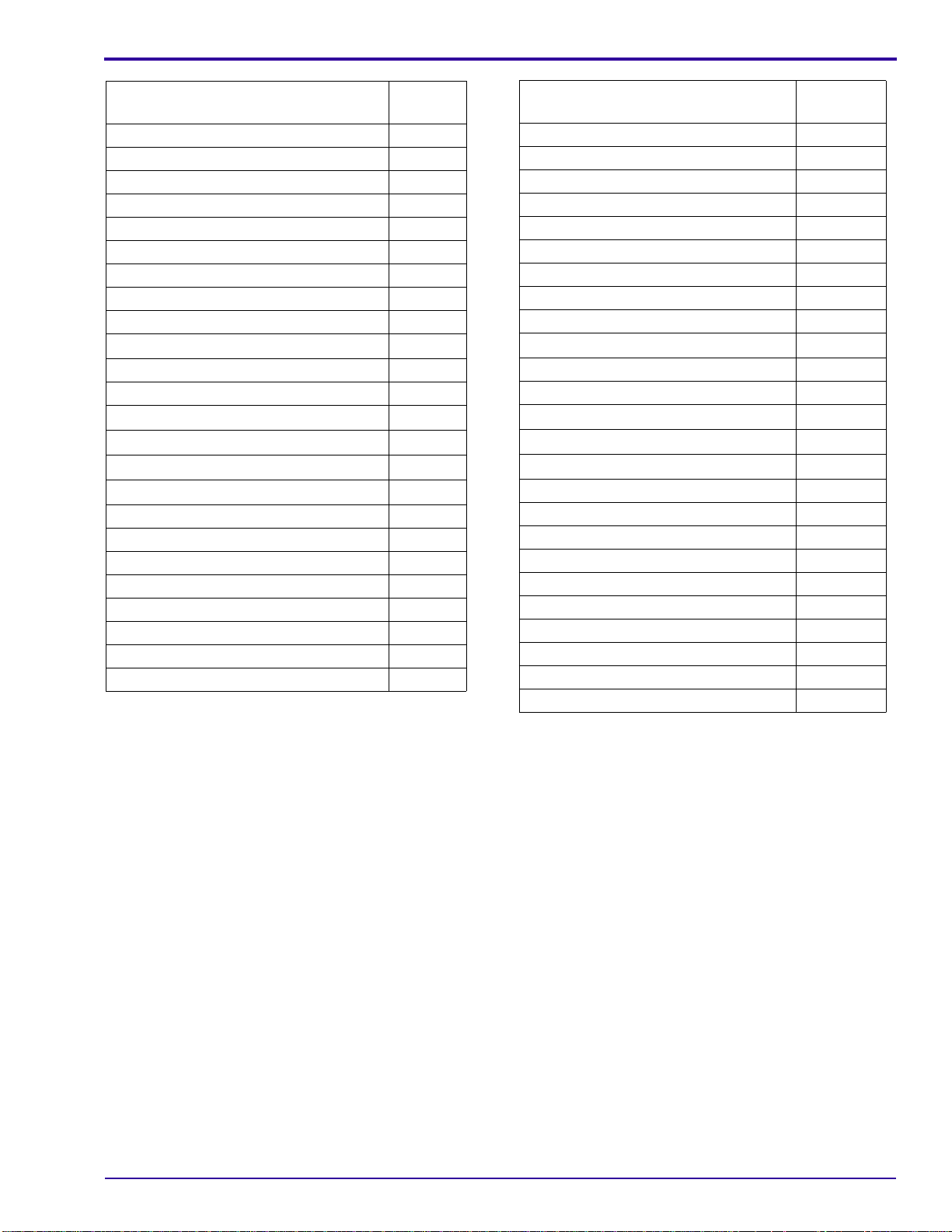

Packed In Top of Packing Carton Quantity

Bin - Receiving 1

Deflector - Bin 1

Feed Shelf Assembly 1

Gasket - Light Lock 1

Weir - Developer, red 1

Weir - Fixer, blue 1

Weir - Wash, beige 1

Wrapped in Paper Quantity

Cover - Evaporation 2

Guard - Splash 1

Tray - Drip 1

Packed In or Is Already On the

Processor Quantity

Cover Assembly 1

Side Panel Assembly 2

Detector Crossover Assembly 1

Fixer/Wash Crossover Assembly 1

Developer/Fixer Crossover Assembly 1

Developer Rack Assembly 1

Fixer Rack Assembly 1

Wash Rack Assembly 1

Dryer Rack Assembly 1

Installation and Operator Publications 2

6 September 1996 – 981900

Page 7

Unpacking the PROCESSOR

Prepack Plastic Bag for an M35A-M

Processor Quantity

Bolt - Hook 2

Cartridge - Filter 1

Clamp - Hose, large 2

Clamp - Hose, small 6

Elbow - Exhaust 1

Elbow - Hose 1

Fastener - Bin 2

Guide - Film, right 1

Nut - No. 8-32 3

Nut - No.1⁄4 -20

Plate - Floor 4

Receptacle - Polarized 1

Screw - No. 8-32 x5⁄

Screw - No. 8-32 x3⁄

Screw - No. 10-32 x3⁄

Screw - No. 10-32 x1⁄

16

8

8

2

Sprocket - 19-Tooth, 50 Hz 1

Strainer Assembly 2

Washer - Flat 4

Washer - Hook 2

Washer - Lock, No. 8 3

Washer - Lock, No. 10 6

Washer - No. 8 3

Washer - No. 10 6

Prepack Plastic Bag for an M35-M

Processor Quantity

Bolt - Hook 2

Bracket - Strain Relief, 220 volt only 1

Cartridge - Filter 1

Clamp - Hose, large 3

Clamp - Hose, small 6

Elbow - Hose 1

Fastener - Bin 2

Guide - Film, right 1

Nut - No. 8-32 3

4

Nut - No.1⁄4 -20

4

Plate - Floor 4

Relief - Strain, 220 volt only 1

1

3

2

4

Screw - No. 8-32 x3⁄

Screw - No. 10-32 x3⁄

Screw - No. 10-32 x1⁄

8

8

2

Sprocket - 19-Tooth, 50 Hz 1

3

3

4

Strainer Assembly 2

Strip - Data 1

Tie - Wire 2

Washer - Flat 4

Washer - Hook 2

Washer - Lock, No. 8 3

Washer - Lock, No. 10 7

Washer - No. 8 3

Washer - No. 10 7

981900 – September 1996 7

Page 8

INSTALLATION INSTRUCTIONS

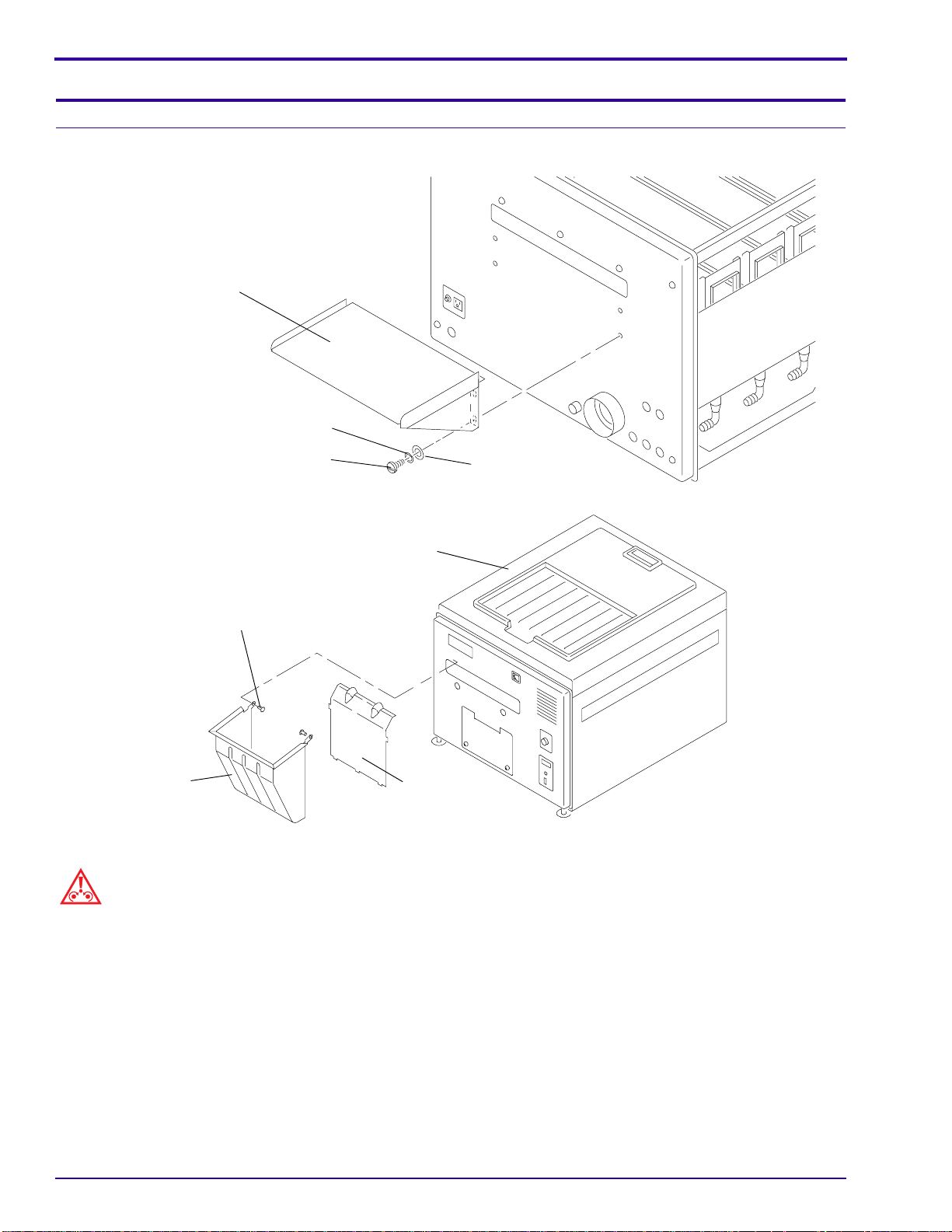

Section 3: Preparing the PROCESSOR for Installation

Installing the FEED SHELF

FEED SHELF

LOCK WASHER (4)

SCREW (4)

BIN FASTENER (2)

RECEIVING

BIN

Caution

Do not overtighten the SCREWS.

[1] Install the:

• FEED SHELF

• 4 WASHERS - No. 10

• 4 LOCK WASHERS - No. 10

TOP COVER

DEFLECTOR

WASHER (4)

H112_0193BCA

H112_0193BA

H112_0174BCA

H112_0174BC

• 4 SCREWS - No. 10-32 x1⁄

2

[2] Install the DEFLECTOR in the RECEIVING BIN.

[3] Install the RECEIVING BIN on the PROCESSOR using the 2 BIN FASTENERS.

8 September 1996 – 981900

Page 9

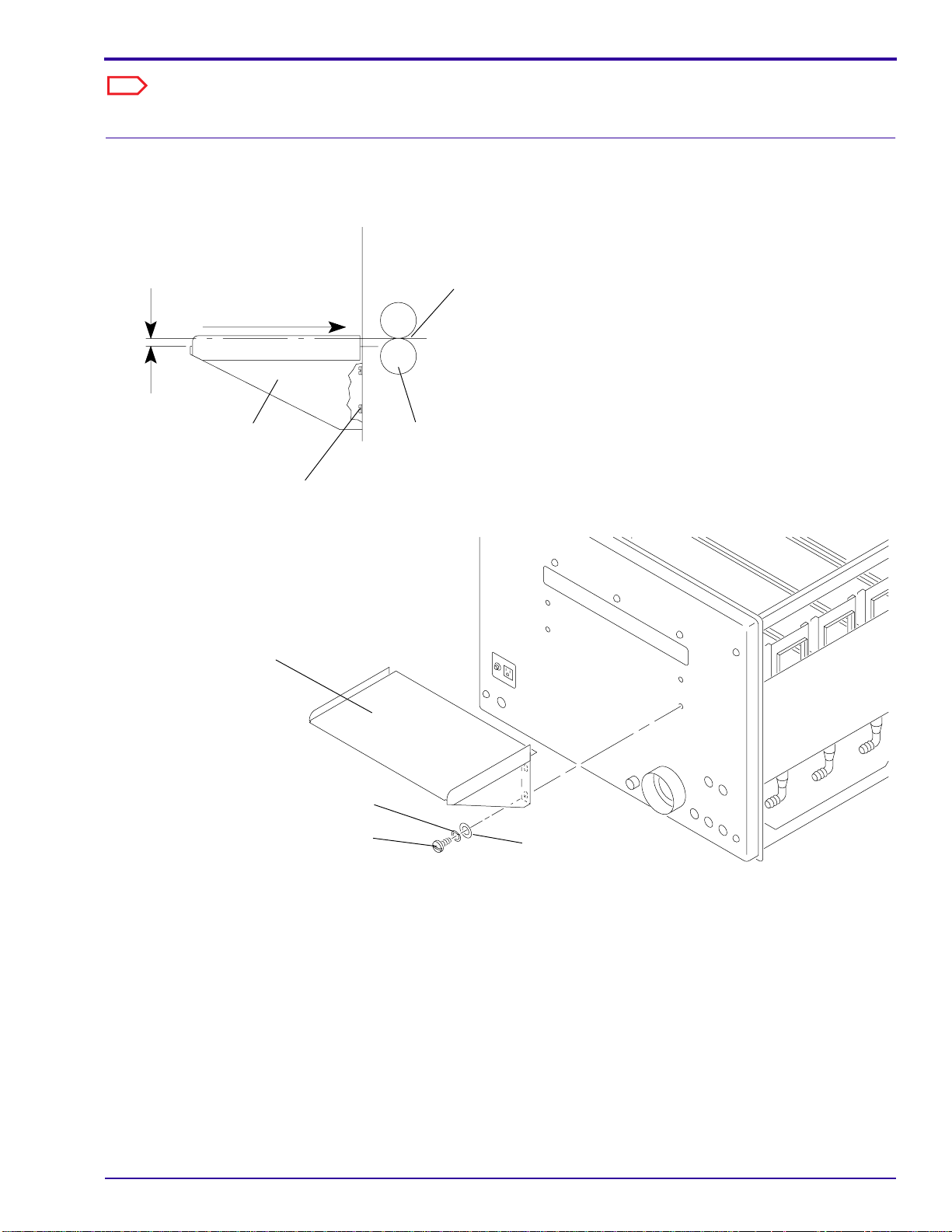

Preparing the PROCESSOR for Installation

Note

If you are using a LIGHTTIGHT FEED TRAY, you cannot feed 2 sheets of 18 x 24 cm film side-by-side.

Adjusting the FEED SHELF

[1] Adjust the height of the FEED SHELF to

approximately1.5 mm (0.06 or 1/16in.)belowthe

NIP of theDETECTORCROSSOVER ROLLERS.

1.5 mm

(0.06 in.)

film entry path

FEED

SHELF

SCREW (4)

NIP

DETECTOR

CROSSOVER

ROLLERS

H112_0090ACB

H112_0090AA

(a) Loosen the 4 SCREWS.

(b) Adjust the FEED SHELF for the correct

height by moving the FEED SHELF up or

down.

(c) Inserta sheet of 35 x43cmfilm into the NIP

of the DETECTOR CROSSOVER

ROLLERS.

[2] Use the edges of the film to align the FEED

SHELF with the DETECTOR CROSSOVER

ROLLERS for squareness.

[3] Tighten the 4 SCREWS.

FEED SHELF

LOCK WASHER (4)

SCREW (4)

WASHER (4)

H112_0193BCA

H112_0193BA

981900 – September 1996 9

Page 10

INSTALLATION INSTRUCTIONS

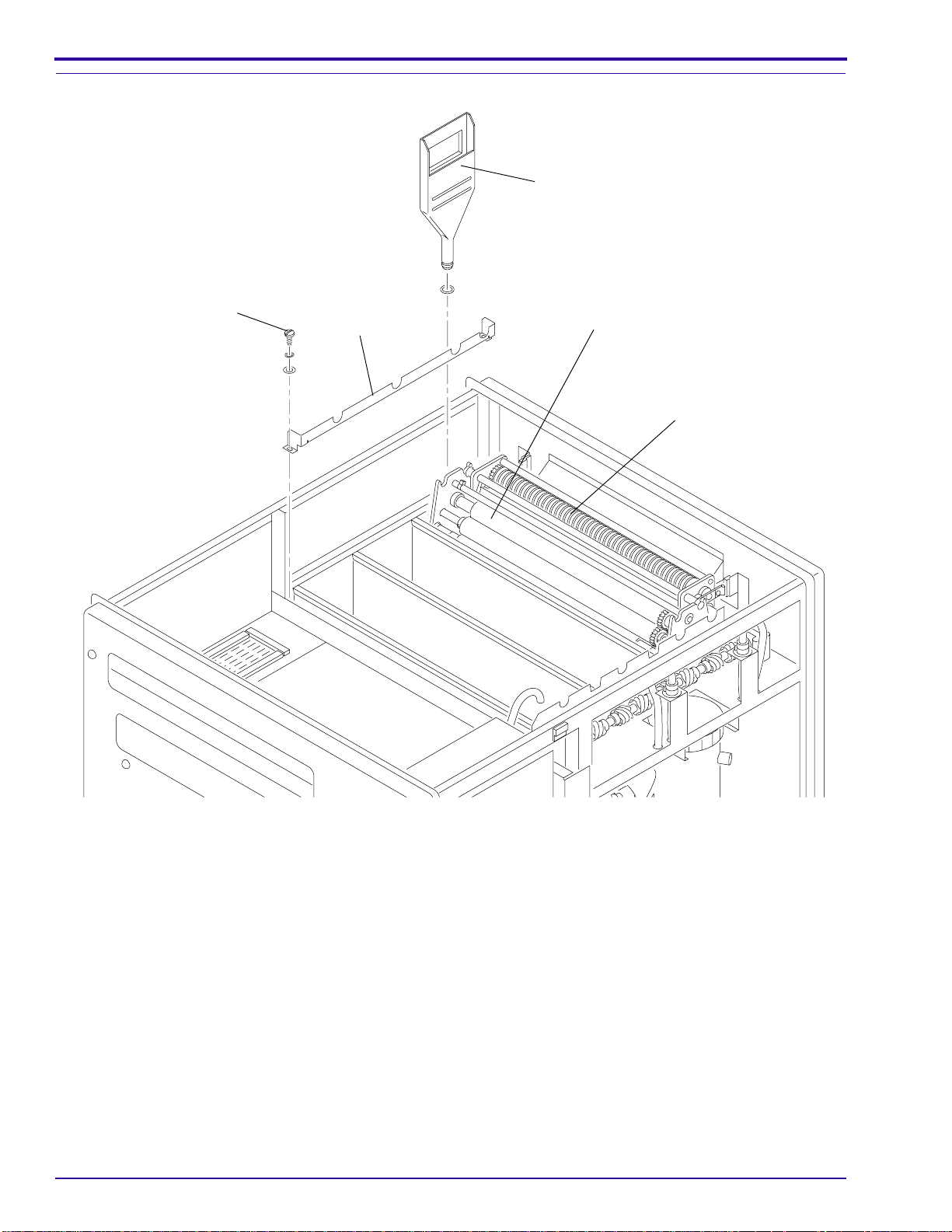

Installing the DEVELOPER RACK and the DETECTOR CROSSOVER AY

WEIR (3)

SCREW (2)

RACK

SUPPORT

DEVELOPER RACK

DETECTOR

CROSSOVER

ASSEMBLY

H112_0150DCA

H112_0150DA

[1] Install the 3 WEIRS.

[2] Install the DEVELOPER RACK.

[3] Loosen the 2 SCREWS and pull the RACK SUPPORT to the nondrive side of the PROCESSOR.

[4] Check the clearance by removing the WEIRS and the DEVELOPER RACK.

[5] If necessary, move the RACK SUPPORT.

[6] Tighten the 2 SCREWS on the RACK SUPPORT.

[7] Install:

• DEVELOPER RACK

• WEIRS

• DETECTOR CROSSOVER ASSEMBLY

10 September 1996 – 981900

Page 11

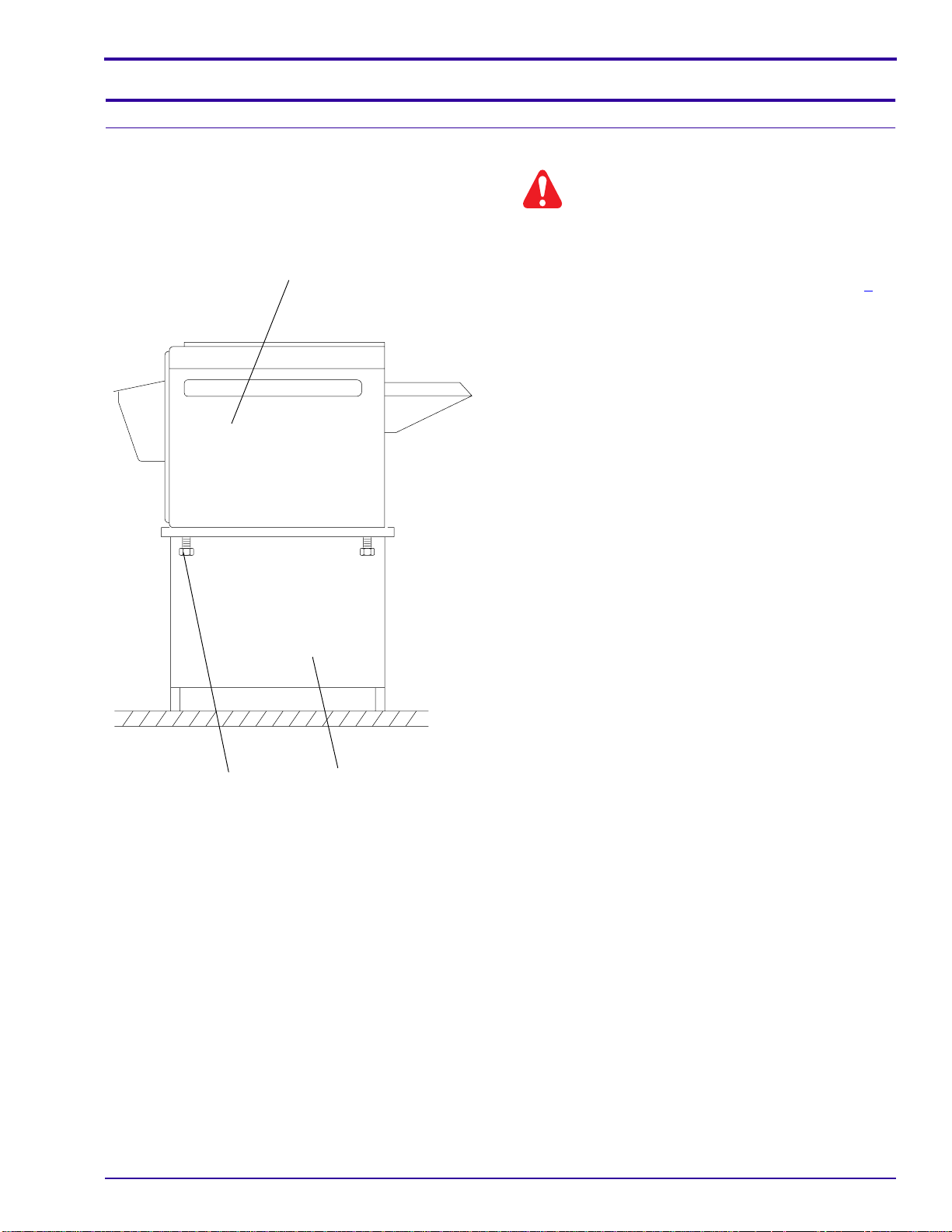

Section 4: Installing the PROCESSOR

Installing the PROCESSOR onto a Flat Surface

PROCESSOR

Installing the PROCESSOR

Warning

ThePROCESSORweighs90kg(200 lb). Usequalified

personnel to install this PROCESSOR.

[1] Remove the PROCESSOR from the SHIPPING

BASE. See the figure at the bottom of Page 5.

[2] Remove the 4 LEVELING SCREWS from the

PROCESSOR.

[3] Install the PROCESSOR on a stable, flat surface

or on a

STAND, CAT No. 808 1176.

[4] Install the LEVELING SCREWS through the

MOUNTING STAND or the stable, flat surface.

Kodak

M35/M43

X-Omat

MOUNTING

LEVELING

SCREW

(4)

981900 – September 1996 11

MOUNTING

STAND

H112_0148CCA

H112_0148CA

Page 12

INSTALLATION INSTRUCTIONS

H112_0129CA

Dark Room

5 cm

(2 in.)

Offset

56 cm

(22 in.)

Opening

in wall

46 cm

(18 in.)

Plywood

opening

Leave flexibility

in this dimension

to allow for

leveling

of processor

H112_0129CCA

GASKET

LIGHT LOCK

cover wall opening

frame, large enough to

20 mm (0.75 in.) plywood

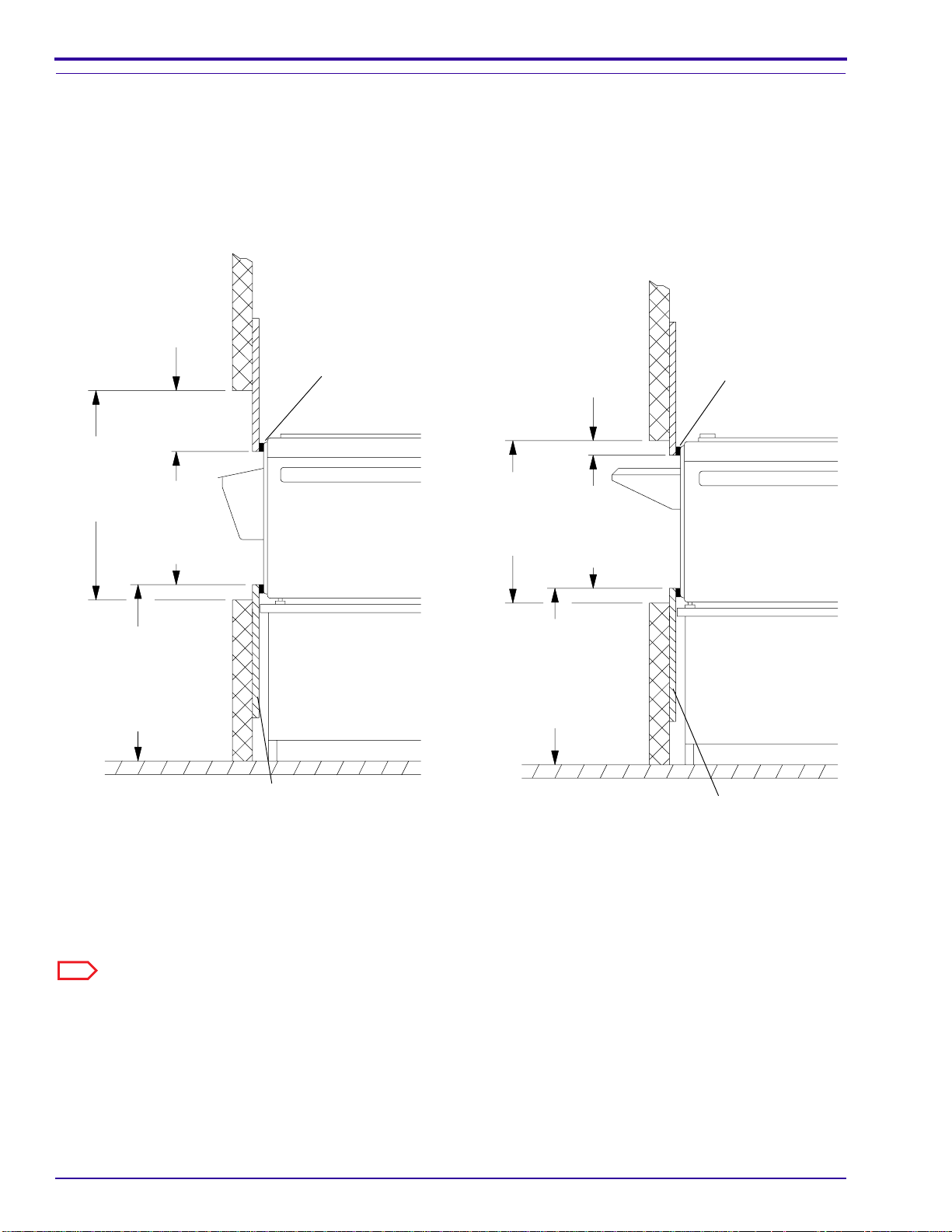

Installing the PROCESSOR Through a Wall

Wall Installation with the RECEIVING BIN through

the Wall

Dark Room

20 cm

(8 in.)

Offset

LIGHT LOCK

GASKET

71 cm

(28 in.)

Opening

in wall

46 cm

(18 in.)

Plywood

opening

Wall Installation with the FEED SHELF through the

Wall

Leave flexibility

in this dimension

to allow for

leveling

of processor

Note

The PROCESSOR may be installed with either the FEED SHELF or the RECEIVING BIN through the wall.

20 mm (0.75 in.)

plywood frame,

large enough to

cover wall opening

H112_0128CCA

H112_0128CA

12 September 1996 – 981900

Page 13

20 mm

(0.75 in.)

plywood

frame to

cover wall

opening

46 cm

(18 in.)

Installing the PROCESSOR

LIGHT LOCK GASKET

around opening

and attached to

plywood frame

61 cm (24 in.)

HOOK BOLT (2)

LEVELING

SCREW (4)

HOOK

FLOOR PLATE (4)

WASHER (2)

HOOK

NUT (4)

48.7 cm

(19.18 in.)

2.5 cm (1.0 in.)

1.4 cm (.56 in.)

Warning

• The PROCESSOR weighs 90 kg (200 lb). Use qualified personnel to install this PROCESSOR.

• Do not pull the LIGHT LOCK GASKET too tightly.

H112_0130DCA

H112_0130DA

[1] Install the LIGHT LOCK GASKET to the PLYWOOD FRAME. Do not stretch the LIGHT LOCK GASKET.

981900 – September 1996 13

Page 14

INSTALLATION INSTRUCTIONS

Leveling the PROCESSOR

FLOOR PLATE (4)

LEVELING

SCREW

(4)

2.5 cm

(1.00 in.)

H112_0133ACA

H112_0133AA

[1] Move the PROCESSOR into position.

[2] Install the 4 FLOOR PLATES under the

LEVELING SCREWS or under the MOUNTING

STAND.

Note

If using an M35/M43 MOUNTING STAND, bolt the

PROCESSORto the MOUNTING STAND and level the

MOUNTING STAND.

[3] Install the other RACKS and the CROSSOVER

ASSEMBLIES.

[4] Place the LEVEL on the CROSSOVER

ASSEMBLIES, not on the walls of the

PROCESSOR.

[5] Level the PROCESSOR side-to-side and then

end-to-end.

[6] Install the 2 HOOK BOLTS around the front 2

LEVELING SCREWS and through the wall. See

the figure on Page 13.

[7] Install the 4 HOOK NUTS and the 2 HOOK

WASHERS on the 2 HOOK BOLTS.

LEVEL

H112_0126BCA

H112_0126BA

14 September 1996 – 981900

Page 15

Installing SEISMIC BRACKETS

Installing the PROCESSOR

LEVELING

SCREW

(4)

FLOOR

PLATE

(4)

SEISMIC BRACKET KIT

H112_0189DCA

H112_0189DA

Important

Local building codes may require that SEISMIC BRACKETS be used.

[1] Install SEISMIC BRACKETS to the PROCESSOR or to the MOUNTING STAND if required by local codes. A

Seismic Bracket Kit, Part No. 261413, is available.

981900 – September 1996 15

Page 16

INSTALLATION INSTRUCTIONS

16 September 1996 – 981900

Page 17

Connecting the Plumbing

Section 5: Connecting the Plumbing

Warning

• Drains must be made of chemically resistant, non-corrosive material. Use PVC or the equivalent.

• The drain must have a minimum diameter of 7.6 cm (3 in.) and be free of obstruction.

• Drain service must comply with all local codes.

• Donot makea solid connection to the FLOOR DRAIN. Use anopen FLOOR DRAINwith a minimum clearance

of 2.5 cm (1 in.) between the tubing from the PROCESSOR and the FLOOR DRAIN.

[1] Check that the developer and fixer WEIRS are installed correctly.

[2] Use1⁄2 -in. (1.27 cm) ID tubing, Part No. 760476, to connect the developer, fixer, and wash DRAINS to the

FLOOR DRAIN. See the figure on Page 18. Order the tubing by the foot.

[3] Connect the incoming water supply to the WATER INLET of the PROCESSOR.

WEIRS

wash

WATER INLET

wash

fixer

DRAIN (3)

981900 – September 1996 17

developer

fixer

developer

H112_0160DCB

H112_0160DA

Page 18

INSTALLATION INSTRUCTIONS

Section 6: Connecting the REPLENISHMENT TANKS to the

REPLENISHMENT PUMPS and the SILVER RECOVERY UNIT

Caution

• Do not allow water in the tubing from the REPLENISHMENT TANKS.

• The highest solution level in the REPLENISHMENT TANKS must be below the solution level in the processing

TANKS.

• Maximum solution level is 97 cm (38 in.) with the PROCESSOR installed on an M35/M43 MOUNTING STAND.

[1] Check that the connections in the tubing are tight.

[2] Install the 2 STRAINERS in the tubing between the REPLENISHMENT PUMP and the REPLENISHMENT

TANKS. Use the3⁄8 -in. (9.5 mm) TUBING supplied.

[3] Connect the TUBING from the PUMPS to the processing TANKS.

[4] Check that the REPLENISHMENT TANKS are connected to the correct processing TANKS.

OUT

IN

REPLENISHMENT TANKS

STRAINERS

[5] Connect the SILVER RECOVERY UNIT to the

fixer DRAIN with1⁄2 -in. (1.27 cm) ID tubing.

FLOOR DRAIN

H104_0026BCB

SILVER RECOVERY UNIT

H112_0118AC

18 September 1996 – 981900

Page 19

Section 7: Environmental Requirements

Connecting the EXHAUST HOSE

The building ventilation system must draw air to the

outside of the building, so that no air is reused.

EXHAUST

DUCT

EXHAUST

HOSE

5 cm (2 in.)

maximum

Clearance for

Exhaust Duct

H104_0005ACA

H104_0005AA

[1] Connect a 7.6 cm (3 in.) EXHAUST HOSE, not

[2] Connect the EXHAUST HOSE to the EXHAUST

[3] Leave a 5 cm (2 in.) air gap between the

Environmental Requirements

Caution

supplied, to the EXHAUST ADAPTER.

DUCT from the building ventilation system.

EXHAUST HOSE and the EXHAUST DUCT.

Important

• Ifthe venting is not correct, fumes will corrode equipment andcause artifacts. Donot install the PROCESSOR

or accessories if the venting is not correct.

• The building ventilation system must draw air to the outside of the building, so that no air is reused.

• The AIR FLOW is correct when the fumes are flowing out of the PROCESSOR through the EXHAUST HOSE.

Before installing the PROCESSOR, or at the next service call, do the following to check that the AIR FLOW is

correct.

EXHAUST ADAPTER

981900 – September 1996 19

H112_0166BCA

H112_0166BA

Page 20

INSTALLATION INSTRUCTIONS

Checking the Ventilation

Important

• If the venting is not correct, fumes will corrode the equipment. Do not install the PROCESSOR or accessories

if the venting is not correct. Check local codes for venting requirements.

• Theair flow is correct whenthe fumes are flowing fromthe PROCESSOR through the EXHAUSTHOSE. Before

installing the PROCESSOR, orwhen checking thestatic pressurelater, do thefollowing procedureto checkthat

the air flow is correct.

AIR FLOW

30 cm

(12 in.)

AIR METER

EXHAUST HOSE

RUBBER HOSE or

MODIFIED J TUBE

TAPE (3 places)

HOSE SUPPORT

CENTER CONNECTOR

H048_0118BCA

H048_0118BA

Use an AIR METER TL-2431, to check that the venting is correct.

[1] If the PROCESSOR is installed, de-energize the PROCESSOR.

[2] Disconnect the EXHAUST HOSE from the EXHAUST ADAPTER on the PROCESSOR.

[3] Place the RUBBER HOSE on the CENTER CONNECTOR of the AIR METER.

[4] If a replenishment J TUBE, Part No. 592380, is available, do the following. If not, advance to Step 5.

(a) Cut off and discard the curved portion of the replenishment J TUBE.

(b) Install the tapered end of the replenishment J TUBE into the RUBBER HOSE.

(c) Advance to Step 7.

[5] Ifa replenishment J TUBE is not available, align a HOSE SUPPORT, such as a straightened coat hanger, next

to the RUBBER HOSE. The ends of the HOSE SUPPORT and the RUBBER HOSE must be together.

[6] Place tape around the HOSE SUPPORT and the RUBBER HOSE at 3 points. See the figure.

Important

The tape should not inhibit the air flow through the RUBBER HOSE.

[7] Insert the replenishment J TUBE or the RUBBER HOSE into the EXHAUST HOSE until the end is 30 cm

(12 in.) from the end of the EXHAUST HOSE.

20 September 1996 – 981900

Page 21

Measuring the Static Pressure

Negative Static Pressure, Water Head

Duct Diameter MIN MAX

76 mm (3 in.) 0.76 mm (0.03 in.) 1.02 mm (0.04 in.)

102 mm (4 in.) 0.25 mm (0.01 in.) 0.51 mm (0.02 in.)

5 cm (2 in.)

Exhaust

Duct

Exhaust

Hose

maximum

Clearance for

Exhaust Duct

Environmental Requirements

Important

The RUBBER HOSE or J TUBE must be in the center

of the EXHAUST DUCT.

[8] Hold the AIR METER vertical, and record the

average of several readings.

[9] Compare the average reading with the table:

[10] Adjust one of the following to obtain the required

reading:

(a) thedamper(orfan) in the buildingventilation

system or

(b) theclearance betweenthe EXHAUSTDUCT

andthe EXHAUSTHOSE to 5cm(2 in.); see

the figure.

[11] Ifthe air flowreadingis still not correct,contactthe

sales representative and the customer to correct

the venting.

[12] When the air flow reading is the same as the

measurements in the table, connect all the hoses.

[13] Ifthe PROCESSOR has been installed, install the

COVERS and PANELS on the PROCESSOR.

H104_0005ACB

H104_0005AA

Important

• Inform the customer that all COVERS and PANELS must be installed while the PROCESSOR is energized.

• The darkroom should have 10 room air exchanges per hour.

• If the PROCESSOR is installed through the darkroom wall, it is most important that the air pressure in the

darkroom is greater than the air pressure of the area surrounding the darkroom.

[14] Do the following to check the air flow at the FEED SHELF:

(a) If the PROCESSOR is installed, de-energize the PROCESSOR.

(b) Hold a piece of tissue paper in front of the FEED SHELF.

Note

The air flow should be toward the PROCESSOR.

(c) If the tissue paper moves away from the PROCESSOR, call Customer Service for Health Imaging,

Monday through Friday from 8:00 a.m. to 5:00 p.m. (Rochester, New York, time) at (800) 336-4722.

981900 – September 1996 21

Page 22

INSTALLATION INSTRUCTIONS

Section8: ConnectingtheMainPowerforanM35A-MPROCESSOR,120

Volts Only

TOP COVER

MAIN POWER SWITCH

H112_0043ACE

H112_0043AC

Connecting the Main Power to an M35A-M PROCESSOR

Warning

• Dangerous voltage.

• Possible damage from electrostatic discharge.

[1] Check and use the Local Electrical Codes.

[2] Consult with the customer about installing the

POLARIZED RECEPTACLE.

[3] Turn off the power to the wall outlet where the

POLARIZED RECEPTACLE will be installed.

[4] Install, or have the customer install, the

POLARIZED RECEPTACLE.

Note

The COVER PLATE is not supplied.

[5] Move the MAIN POWER SWITCH on the

PROCESSOR to the “OFF” position.

[6] Plug the POWER CORD into the POLARIZED

RECEPTACLE.

POLARIZED

RECEPTACLE,

M35A-M Processor

only

POWER

CORD

H112_0122BCC

H112_0122BA

22 September 1996 – 981900

Page 23

Connecting the POWER CORD on an M35-M PROCESSOR, 220 Volts Only

Section9: Connecting thePOWERCORDonanM35-MPROCESSOR,

220 Volts Only

Warning

• Dangerous voltage.

• Possible damage from electrostatic discharge.

[1] Check and use the Local Electrical Codes.

[2] Disconnect the main power at the wall.

[3] Move the MAIN POWER SWITCH to the “OFF” position.

[4] Remove the TOP COVER and the drive SIDE PANEL, not shown.

[5] Open the DOOR to the ELECTRICAL BOX.

[6] Move wire No. 8A to the correct terminal on TB5. See the figure on Page 24.

[7] Move JUMPER 8:

Volts Position of Jumper 8

200 or 208 TB5-2

220 TB5-3

240 TB5-4

[8] Apply the correct DATA STRIP inside the ELECTRICAL BOX DOOR to indicate the correct supply voltage.

[9] Install the STRAIN RELIEF BRACKET inside the PROCESSOR. See the figure below.

[10] Feed the CABLE through the FRONT PANEL.

[11] Insert the CABLE through the STRAIN RELIEF.

[12] Install the STRAIN RELIEF to the STRAIN RELIEF BRACKET with the NUT.

[13] Feed the CABLE into the ELECTRICAL BOX.

[14] Connect the incoming wires to L1, L2, and N of TB1. See the connection charts on the circuit diagrams that

start on Page 25.

[15] Connect the ground wire to the GROUND LUG, not shown.

[16] Install the 2 WIRE TIES to the CABLE and the STRAIN RELIEF.

[17] Close the DOOR to the ELECTRICAL BOX, and install the drive SIDE PANEL and the TOP COVER.

FRONT PANEL

CABLE

STRAIN RELIEF

NUT

ELECTRICAL BOX

981900 – September 1996 23

STRAIN

RELIEF

BRACKET

H112_0173BCA

H112_0173BA

Page 24

INSTALLATION INSTRUCTIONS

Connecting the 220 Volt POWER CORD

TB5

TB1

DATA

STRIP

DOOR

ELECTRICAL

BOX

H112_0187ECD

H112_0187EC

24 September 1996 – 981900

Page 25

Section 10: Circuit Diagrams

Processor Diagram See Page

M35-M Circuit Diagram, Sheet 1 of 2 25

M35-M Circuit Diagram, Sheet 2 of 2 25

M35A-M Circuit Diagram 25

Circuit Diagrams

Page 26 - Circuit Diagram, M35-M Processor, Sheet 1 of 2

Circuit Diagram, M35-M Processor, Sheet 2 of 2 - Page 27

Page 28 - Circuit Diagram, M35A-M Processor

981900 – September 1996 25

Page 26

INSTALLATION INSTRUCTIONS

Section 11: Preparing the PROCESSOR for Use

Checking the Tubing CLAMPS, TANKS, and RACKS

[1] Tighten and check all CLAMPS.

Caution

Check all CLAMPS 2 - 4 weeks after installing any new tubing. Tighten the CLAMPS if necessary. Although a

CLAMP may be tight when tubing is installed, temperature changes or shrinkage of the plastic tubingwill cause the

CLAMP to loosen.

[2] Check that the 3 WEIRS are installed and fully seated:

red in the developer TANK

blue in the fixer TANK

beige in the wash TANK

[3] Fill the 3 TANKS with water.

[4] Operate the PROCESSOR for a few minutes, and check for leakage.

[5] Drain the PROCESSOR completely.

TANK (3)

WEIR (3)

FILL TUBE

H112_0154DCB

H112_0154DA

26 September 1996 – 981900

Page 27

[6] Rinse the DEVELOPER, FIXER, and WASH RACKS with warm water.

H112_0117AC

GUARD

SPLASH

H112_0117ACA

[7] Rotate the ROLLERS manually to check that the ROLLERS rotate fully.

[8] Check that all the moving parts engage correctly.

[9] Wait to install the RACKS until Page 32.

Filling the TANKS

[1] Soakthe DEVELOPERFILTER for 30 secondsin

warm water.

[2] Insert the DEVELOPER FILTER into the FILTER

HOUSING.

[3] Check that the O-RING is seated correctly, or

leakage may occur.

[4] Tighten the CAP and install the FILTER

HOUSING in the PROCESSOR.

[5] Check that the tubing is not kinked.

Caution

To avoid contamination of the solutions:

• Rinsethe mixingand fillingequipment beforeeach

CAP

O-RING

use.

• Mix the developer first, then the fixer.

• Fill the FIXER TANK first.

• Wash the mixing equipment thoroughly between

solutions.

[6] Install the SPLASH GUARD between the

DEVELOPER TANK and the FIXER TANK.

Preparing the PROCESSOR for Use

DEVELOPER

FILTER

FILTER

HOUSING

H112_0169CCA

H112_0169CA

981900 – September 1996 27

Page 28

INSTALLATION INSTRUCTIONS

WEIRS

FIXER

TANK

H112_0014ACC

H112_0014AC

WASH

TANK

DEVELOPER

TANK

FILL

LINES

[7] To fill the FIXER TANK, add FIXER

REPLENISHER until the solution is at the higher

FILL LINE on the blue WEIR.

[8] Remove and rinse the SPLASH GUARD.

[9] Install the SPLASH GUARD over the FIXER

TANK.

[10] To fill the DEVELOPER TANK:

(a) Fill the DEVELOPER TANK half full of

DEVELOPER REPLENISHER from the

REPLENISHMENT TANK.

(b) Add190 mL(6.5 fl oz) of

KodakRPX-Omat

DEVELOPER STARTER.

(c) Fill the DEVELOPER TANK to the higher

FILL LINE on the red WEIR with

DEVELOPER REPLENISHER.

[11] Remove the SPLASH GUARD and rinse it

thoroughly.

[12] Allow the developer to reach the operating

temperature before processing any film.

Removing the REPLENISHMENT PUMP TIMER, for Very Low Volume Use Only

Important

The PROCESSOR is shipped with the

REPLENISHMENT PUMP TIMER installed.

[1] Skip this procedure if processing less than 30

sheets of film per 8 hours in this PROCESSOR.

Advance to Page 29.

[2] Remove the drive SIDE PANEL.

[3] Open the ELECTRICAL BOX by loosening the

SCREW.

[4] Remove the REPLENISHMENT PUMP TIMER.

[5] Close the ELECTRICAL BOX.

H112_0042ACC

H112_0042AC

SIDE

PANEL

ELECTRICAL

BOX

28 September 1996 – 981900

Page 29

REPLENISHMENT

PUMP TIMER

Preparing the PROCESSOR for Use

SCREW

Checking the Replenishment Flow Rates

METAL

LATCH

H112_0114ACA

H112_0114AC

DEVELOPER TUBING

QUICK

DISCONNECT

GRADUATED

CYLINDER

FIXER TUBING

H112_0041BCC

H112_0041BC

[1] Remove the TOP COVER if installed.

[2] Lift the top ROLLER of the DETECTOR

CROSSOVER ASSEMBLY.

[3] Check that the replenisher solutions flow freely

through the TUBING along the drive side of the

PROCESSOR.

[4] Press the METAL LATCH on the red QUICK

DISCONNECT to disconnect the developer

TUBING.

[5] Pull the TUBING slightly by rotating the TUBING

over the edge of the frame.

[6] Insert the TUBING into a GRADUATED

CYLINDER.

[7] Lift the top ROLLER of the DETECTOR

CROSSOVER ASSEMBLY for the correct time.

See the table on the next page.

Note

The REPLENISHMENT PUMP will operate 3 seconds

after you release the ROLLER.

[8] Check that the amount of developer in the

GRADUATED CYLINDER is the same as in the

table.

[9] If necessary, adjust the REPLENISHMENT

PUMP. See Page 31.

[10] If necessary, do Steps 7 - 9 again.

[11] Connect the QUICK DISCONNECT.

[12] Dothis procedure again with the fixer TUBING to

check the flow rate of the fixer.

981900 – September 1996 29

Page 30

INSTALLATION INSTRUCTIONS

Use

Film Size Processed

Only 35 x 35 cm

(14 x 14 in.) film

Average size film

intermix

Only 35 x 43 cm

(14 x 17 in.) film

Film Size Processed

Only 18 x 24 cm

Kodak Min-R

Only 18 x 24 cm

Kodak Min-R

Only 18 x 24 cm

Kodak Min-R

Only 18 x 24 cm

Kodak Min-R

Film

E Film

M Film

H Film

2000

Condition

High

Medium

Low

High

Medium

Low

High

Medium

Low

Use

Condition

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

Average Amount of

Film per 8 Hours of

Processor Operation

90 sheets or more

31 - 89 sheets

30 sheets or less

115 sheets or more

41 - 114 sheets

40 sheets or less

75 sheets or more

26 - 74 sheets

25 sheets or less

Average Amount of

Film per 8 Hours of

Processor Operation

150 sheets or more

60 - 149 sheets

59 sheets or less

150 sheets or more

60 - 149 sheets

59 sheets or less

150 sheets or more

60 - 149 sheets

59 sheets or less

150 sheets or more

60 - 149 sheets

59 sheets or less

Replenishment Flow Rate

mL per 35 cm(14 in.)

28 sec

of Film Travel

Developer Fixer

50 70

65 85

80 100

50 70

65 85

80 100

- - 60 85

Replenishment Flow Rate

mL per 24 cm

26 sec

of Film Travel in

Standard Mode

Developer Fixer

- - 20 30

30 30

30 35

35 40

50 30

50 35

50 40

20 30

20 35

20 40

mL per 43 cm (17 in.)

Developer Fixer

of Film Travel in

Extended Mode

Developer Fixer

34 sec

of Film Travel

- -

- -

80 100

100 120

mL per 24 cm

36 sec

27 35

35 40

- -

- -

- -

Note

•

Kodak

RP

X-Omat

• Replenishmentrates are based on one sheet of 18 x 24 cm film. If feeding two sheets, double the replenishment

rates.

• For best results, feed film consistently.

• Slight sensitometric changes will occur as subsequent films are processed through a freshly started process.

This is known as “seasoning” and is normal with any photographic process. Process control targets may have

to be adjusted slightly to compensate.

• For 30 sheets of film or less per day, flooded replenishment is recommended.

• Film travel time includes feed time plus an approximate 3-second delay.

30 September 1996 – 981900

Chemicals are recommended.

Page 31

Adjusting the REPLENISHMENT PUMP

Preparing the PROCESSOR for Use

BRACKET

HOLE

[2] Loosen the 2 SCREWS and remove the PUMP

COVER.

[3] Actuatethe DETECTORSWITCHbyliftingthetop

ROLLER of the DETECTOR CROSSOVER

ASSEMBLY until the ADJUSTMENT SCREW is

visible through the hole in the BRACKET.

[4] Loosen the SETSCREW.

Caution

Do not adjust the LOCKNUT on the other end of the

ADJUSTMENT SCREW.

[1] Remove the TOP COVER.

PUMP

COVER

SCREW (2)

H112_0005ACB

H112_0005AC

[7] Check theflowratesand, ifnecessary,do Steps 2 - 6 again. See the table on Page 30 forvarious replenishment

rates.

[8] Install the TOP COVER and the PUMP COVER.

[9] Feed a sheet of film into the PROCESSOR to check that the REPLENISHMENT PUMPS operate correctly. If

necessary, see the adjustment procedure for the DETECTOR SWITCHES in the Service Manual, Part No.

981901.

[5] Rotate the ADJUSTMENT SCREW to adjust the

flow rate.

clockwise

counterclockwise

increases the flow rate

decreases the flow rate

[6] Tighten the SETSCREW.

SETSCREW

Do not

adjust!

LOCKNUT

H112_0030BCB

H112_0030BC

ADJUSTMENT

SCREW

REPLENISHMENT PUMP

BRACKET

HOLE

ADJUSTMENT SCREW

DECREASE INCREASE

OUTPUT

981900 – September 1996 31

Page 32

INSTALLATION INSTRUCTIONS

H112_0015AC

DRIP TRAY

SPLASH GUARD

H112_0015ACA

Installing the RACKS

DEVELOPER/FIXER

CROSSOVER ASSEMBLY

FIXER/WASH

CROSSOVER

ASSEMBLY

FIXER

WASH

RACK

DRYER

ASSEMBLY

RACK

DETECTOR

CROSSOVER

ASSEMBLY

DEVELOPER

RACK

Caution

Use the DRIP TRAY and SPLASH GUARD when you

install or remove the RACKS. Lower the RACKS

slowly.

[1] Install the RACKS in the correct TANKS. Seat

them firmly.

H112_0171CCA

H112_0171CC

Note

The WASHER on the top of the drive side of the

DEVELOPER RACK has a “D” on it. The one on the

FIXER RACK has an “F”. The RACKS may also have

red, blue, and white wire ties for easy identification.

red DEVELOPER RACK

blue FIXER RACK

white WASH RACK

[2] Install the:

• DEVELOPER/FIXER CROSSOVER

ASSEMBLY

• FIXER/WASH CROSSOVER ASSEMBLY

• DETECTOR CROSSOVER ASSEMBLY

• DRYER ASSEMBLY

• EVAPORATION COVERS, not shown

[3] Check that the gap in the developer RACK

between the the GUIDE SHOES and the

MASTER ROLLER is:

Gap between Shoes and Master Roller

0.020 in.

If necessary, adjust the GUIDE SHOES. See the

procedure in the Service Manual, Publication Part

No. 981901.

32 September 1996 – 981900

Page 33

Checking the Operation of the PROCESSOR

Preparing the PROCESSOR for Use

[1] Turn on the water supply.

[2] Energize the PROCESSOR.

[3] Check that the:

• Developer and fixer have agitation

DRYER

TEMPERATURE

CONTROL

KNOB

TOP COVER

SIDE

PANEL

(2)

• No leakage occurs

• Solutions overflow into the WEIRS

• Water flows into the PROCESSOR

[4] Install the 2 SIDE PANELS and the TOP COVER.

[5] Check the operation of the RUN/STANDBY

SWITCH.

[6] Set the DRYER TEMPERATURE CONTROL

KNOB to the minimum temperature necessary to

provide dry film.

[7] Check that warm air comes out of the exhaust.

RUN/STANDBY

SWITCH

DIGITAL

TEMPERATURE

DISPLAY

H112_0043ACD

H112_0043AC

Note

• The PROCESSOR is now in the run mode.

• If checking both the Standard developer temperature and the Extended developer temperature, check for

Standard Mode first. The correct temperatures are:

Standard: 33.3˚C 0.3˚C (92.0˚F 0.5˚F)

Extended: 35˚C 0.3˚C (95.0˚F 0.5˚F)

[8] Insert a THERMOMETER of known accuracy, such as Part No. 761217, into the nondrive side of the

DEVELOPER TANK between the SIDE PLATE of the DEVELOPER RACK and the RACK SUPPORT.

Insert THERMOMETER

here

Caution

• Possible damage from electrostatic discharge. Use an ESD WRIST STRAP.

• Use the POTENTIOMETER ADJUSTING TOOL TL-1481 to adjust R301 and R302.

H112_0121BCA

H112_0121BA

981900 – September 1996 33

Page 34

INSTALLATION INSTRUCTIONS

[9] If a developer temperature adjustment is necessary, adjust R301 and R302 on the 300 CIRCUIT BOARD.

(a) Remove the drive SIDE PANEL from the PROCESSOR.

(b) Open the ELECTRICAL BOX.

(c) Usethe POTENTIOMETERADJUSTINGTOOLTL-1481 toadjust thedevelopertemperature byrotating

R302 for Standard Mode or R301 for Extended Mode.

clockwise

counterclockwise

increases the temperature

decreases the temperature

(d) Check the developer temperature in the DEVELOPER TANK with a THERMOMETER.

(e) If the developer temperature is not correct, do Steps (c) and (d) again.

Important

• Afterchanging from Extended Modeto Standard Mode,set the DRYERTEMPERATURE CONTROL

KNOB to “0” and remove the TOP COVER for venting. Check that the METER displays the correct

temperature before adjusting R302 or processing film.

•Donot process film until the METER shows that the developer is at the correct temperature.

Adjusting the Developer Temperature on the 300 CIRCUIT BOARD by Rotating R302 for Standard Mode or

R301 for Extended Mode

R302

R301

300 CIRCUIT

BOARD

100 CIRCUIT BOARD

34 September 1996 – 981900

H112_0041BCB

H112_0041BC

Page 35

Preparing the PROCESSOR for Use

Adjusting the Potentiometer on the Developer

Temperature METER

METER

HOLES

H112_0184ACB

H112_0184AC

[10] If the METER does not display the same

temperature as the THERMOMETER, adjust the

METER.

(a) Remove the drive SIDE PANEL.

(b) Open the ELECTRICAL BOX.

(c) Check that CR10 on the 100 CIRCUIT

BOARD is blinking.

(d) AfterCR10 has blinked for 2 minutes,insert

the POTENTIOMETER ADJUSTING TOOL

TL-1481 through the holes in the frame of

the ELECTRICAL BOX.

(e) Rotate TL-1481 to adjust the METER.

clockwise

increases the

temperature display

counterclockwise

decreases the

temperature display

(f) Check the developer temperature with the

THERMOMETER. If the temperature is not

the same as on the METER, adjust the

METER again.

[11] Close the ELECTRICAL BOX.

[12] Install the SIDE PANELS and the TOP COVER.

[13] Check the operation of the DETECTOR

SWITCHES by feeding a sheet of filmthrough the

PROCESSOR to check that the

REPLENISHMENT PUMP is operating.

981900 – September 1996 35

Page 36

INSTALLATION INSTRUCTIONS

Adjusting the Speed of the MAIN DRIVE MOTOR

R202

R201

STD/EXT SWITCH

200 CIRCUIT BOARD

REPLENISHMENT

PUMP TIMER

ELECTRICAL

BOX

H112_0187ECE

H112_0187EC

36 September 1996 – 981900

Page 37

Preparing the PROCESSOR for Use

[1] Determine the speed of the MAIN DRIVE

MOTOR.

(a) Process sheets of 24 cm (10 in.) film in

Extended and Standard Modes.

(b) Record the dry-to-dry processing times.

SIDE

PANEL

The correct time for a 24 cm (10 in.) film is:

Extended: 3 minutes and 23 seconds

Standard: 2 minutes and 15 seconds

ELECTRICAL

BOX

H112_0042ACC

H112_0042AC

[2] If the dry-to-dry processing times are not correct, adjust the speed of the MAIN DRIVE MOTOR.

(a) Remove the TOP COVER and drive SIDE PANEL from the PROCESSOR.

ESD

Possible damage from electrostatic discharge.

(b) Open the ELECTRICAL BOX.

(c) Set the STD/EXT SWITCH to “STD”.

(d) Feed 24 cm (10in.) of film into the PROCESSOR. Measure the time for each 24 cm(10 in.) of film to enter

the PROCESSOR. The correct time is: Standard: 19 seconds

(e) Set the STD/EXT SWITCH to “EXT”.

(f) Feed 24 cm (10in.) of film into the PROCESSOR. Measure the time for each 24 cm(10 in.) of film to enter

the PROCESSOR. The correct time is: Extended: 29 seconds

(g) Ifthe transport time is not correct, adjust R201for theExtended Modeor R202 for the Standard Modeon

the 200 CIRCUIT BOARD. See the figure on Page 36.

Important

It is important to check the speed of both modes, especially if an adjustment is necessary for one mode.

(h) DoSteps (a)-(g) again to check the processing times. Continue the procedure until the processingtimes

are correct.

(i) Close the ELECTRICAL BOX.

[3] Install the SIDE PANEL and the TOP COVER.

981900 – September 1996 37

Page 38

Publication History

Section 12: Publication History

Affected

Print Date Pub. No. ECO No.

Sept 1992 981900 4014-318 All 3133ii_f.txt Original Printing in caps

Sept 1996 981900 4014-432 All ii3133_1_432.doc Revisedto reflect the new sizeFeed Shelf,

Pages File Name Notes

update the replenishment flow rate table,

and add warnings on drain construction.

Converted to FrameBuilder.

ii313301.fm

Printed In USA

Kodak, Min-R,

and

X-Omat

are trademarks.

Health Imaging

EASTMAN KODAK COMPANY ● ROCHESTER, N.Y. 14650

Loading...

Loading...